Preparation and application of adsorbing agent of pseudo-boehmite and gamma-Al*O* hollow microspheres

A technology of pseudo-boehmite and hollow microspheres, which is applied in the preparation of microspheres, microcapsule preparation, adsorption water/sewage treatment, etc., to achieve low additive concentration, controllable grain size and good structure reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Sorbent provided by the invention, its preparation method comprises the following steps:

[0024] 1. Dissolve one of aluminum sulfate, aluminum ammonium sulfate and aluminum potassium sulfate or a mixture of any proportion in distilled water, then add urea and sodium tartrate respectively, and stir to form Al 3+ The concentration is 0.0005~0.5mol / L, urea and Al 3+ A solution with a molar ratio of 1.0 to 3.0:1.0 and a sodium tartrate concentration of 0.0005 to 0.03 mol / L, then transferred to a hydrothermal kettle, and reacted at 120 to 200°C for 5 minutes to 8 hours to obtain a hydrothermal product;

[0025] 2. After cooling and filtering the hydrothermal product, wash it with distilled water until it becomes neutral, then disperse and wash the neutral filter cake once with absolute ethanol and filter it, and then vacuum-dry the obtained filter cake at 60-100°C for 4-16 hours Obtain pseudo-boehmite (core-shell) hollow microsphere powder;

[0026] 3. Calcining the vacuu...

Embodiment 1

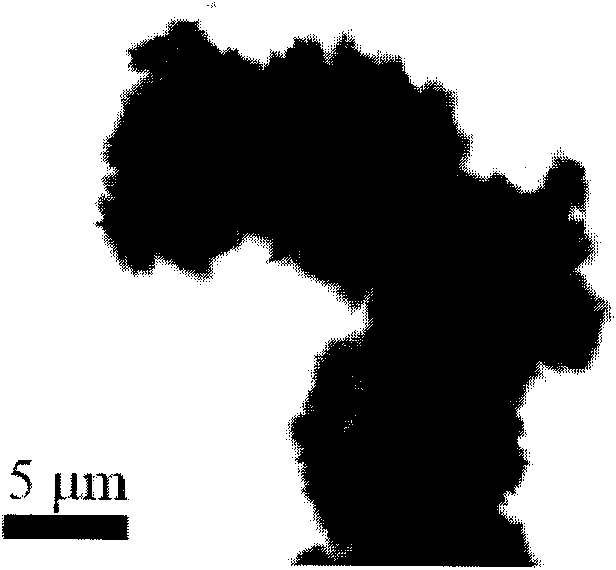

[0031] Weigh a certain amount of aluminum sulfate, urea and sodium tartrate respectively, mix and dissolve them in 70mL distilled water, stir well to form Al 3+ The concentration is 0.05mol / L, urea and Al 3+ A solution with a molar ratio of 2.0:1.0 and a sodium tartrate concentration of 0.01 mol / L was then transferred to a hydrothermal kettle and reacted at 165°C for 3 hours under closed hydrothermal conditions. The hydrothermal product is cooled, filtered, dispersed and washed with a small amount of absolute ethanol, filtered, and then vacuum-dried at 80°C for 6 hours to obtain alumina hydrate core-shell hollow microspheres with a particle size of 2-6 μm, see figure 1 , the XRD analysis is pseudo-boehmite phase, the average grain size is 6.4nm, and its specific surface area and pore volume are 269.1m 2 / g and 0.47cm 3 / g, the average pore diameter is 8.1nm.

[0032] Prepare 100mL and 95mg / L Congo red solution and phenol solution respectively, wherein the phenol solution is...

Embodiment 2

[0035] Weigh a certain amount of aluminum sulfate, aluminum potassium sulfate, aluminum ammonium sulfate, urea and sodium tartrate respectively, mix and dissolve them in 70ml of distilled water, and stir to form Al 3+ Concentration is 0.2mol / L (among them, aluminum sulfate, aluminum potassium sulfate and aluminum ammonium sulfate are to Al 3+ Concentration contributions were 0.1, 0.04 and 0.06mol / L), urea and Al 3+ A solution with a molar ratio of 2.5:1.0 and a sodium tartrate concentration of 0.03 mol / L was then transferred to a hydrothermal kettle and reacted at 180°C for 6 hours under closed hydrothermal conditions. The hydrothermal product was cooled, filtered, dispersed and washed with a small amount of absolute ethanol in sequence, and then dried in vacuum at 60°C for 16 hours to obtain alumina hydrate microspheres with a particle size of 1-3 μm, which were pseudoboehmite by XRD analysis. Stone phase. Then it was calcined in a static air atmosphere at 700°C for 0.5h to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com