Patents

Literature

37results about How to "Low thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acoustical insulation material containing fine thermoplastic fibers

InactiveUS6893711B2Low thicknessHigh densityWallsSynthetic resin layered productsUltrasound attenuationPlastic property

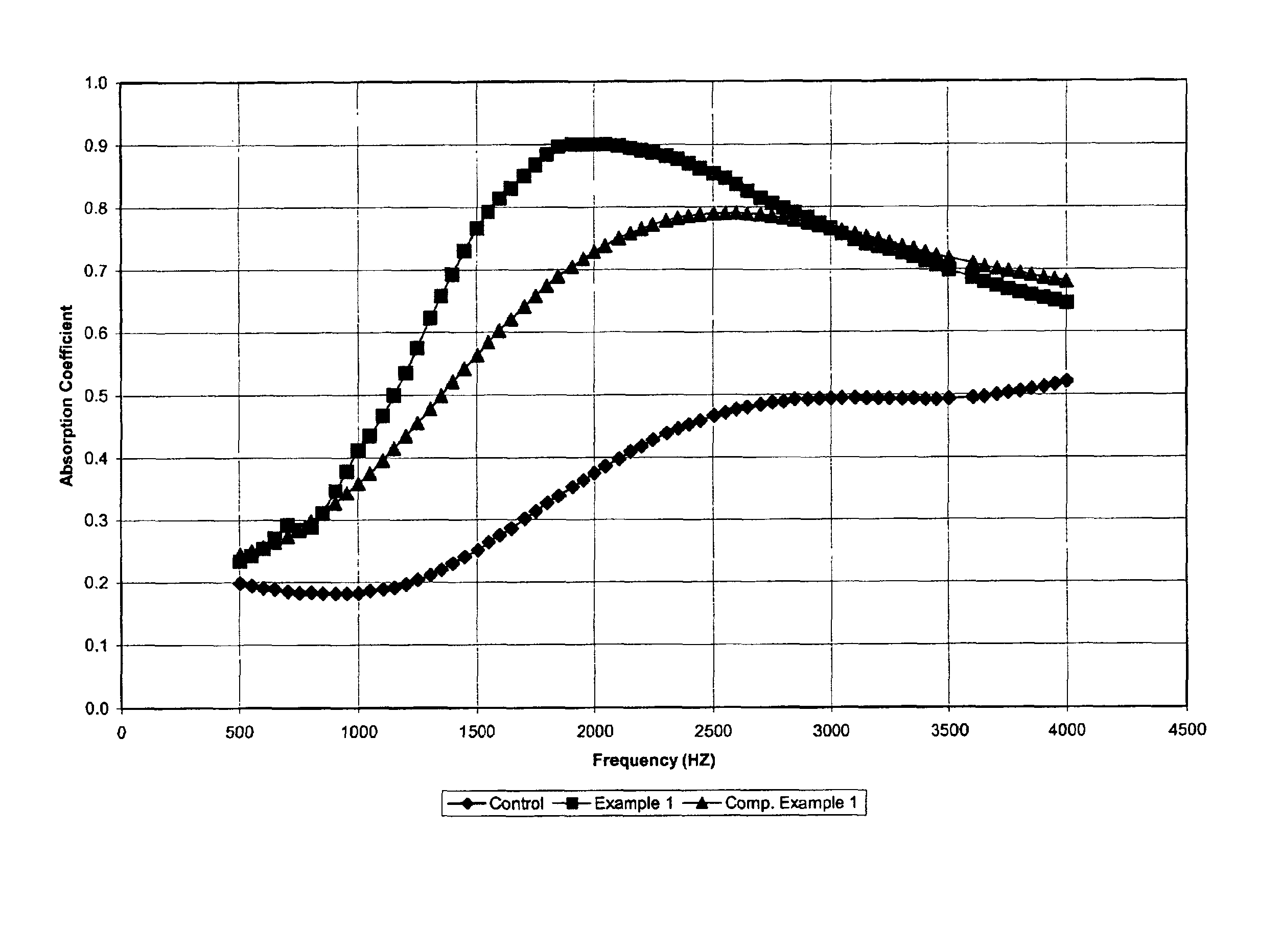

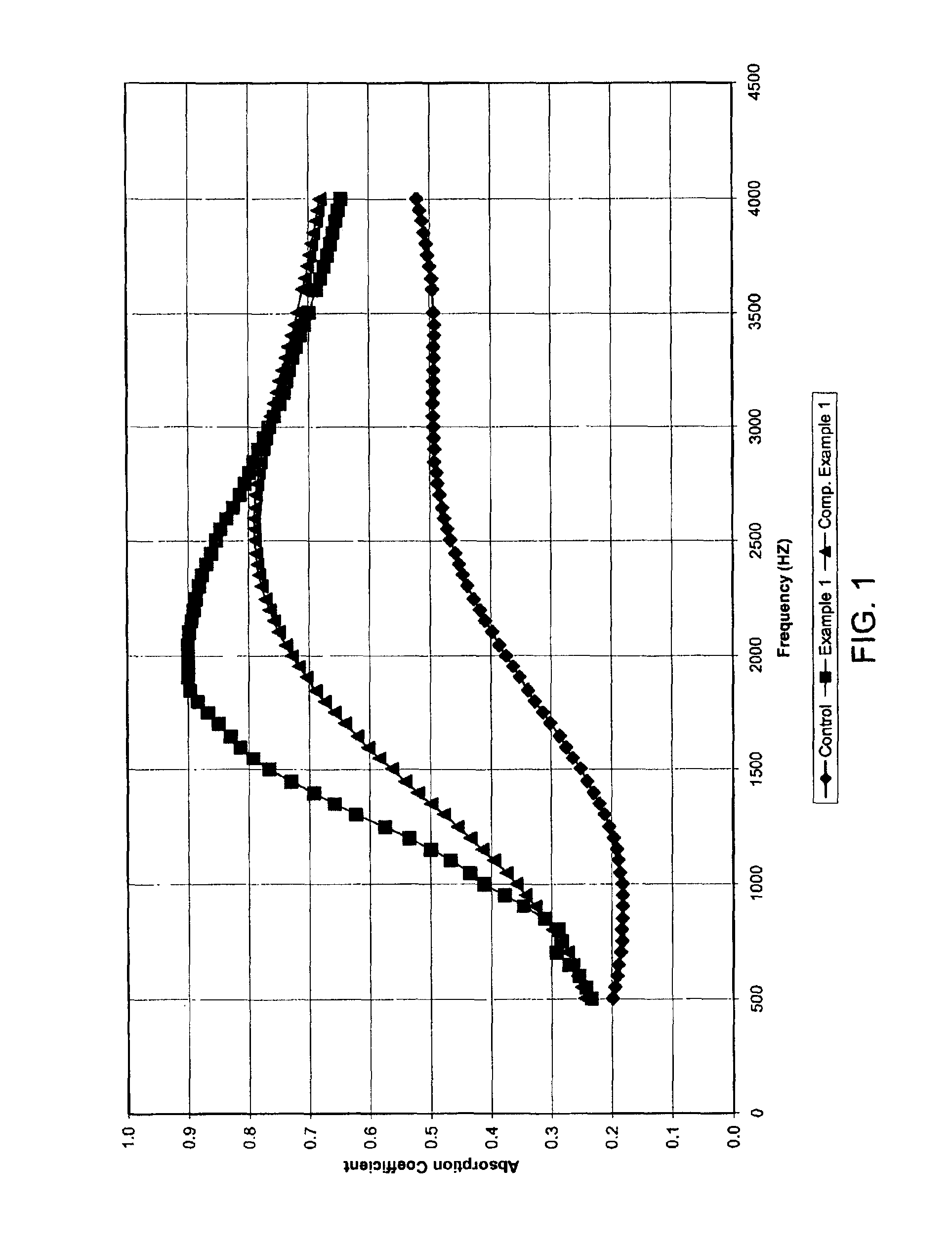

The present invention relates an acoustical insulation material for sound attenuation containing a nonwoven web. Surprisingly, it has been discovered that an acoustical insulation material made from a nonwoven web of thermoplastic fibers having an average fiber diameter of less than about 7 microns, wherein the acoustical insulation has a thickness less than about 3 mm and a density of greater than about 50 kg / m3 is effective as a sound insulation material. The acoustical insulation is very effective as an acoustical insulation material, despite the low thickness and high density of the acoustical insulation. A method of attenuating sound waves passing from a sound source area to a second area using the acoustical insulation material is also disclosed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

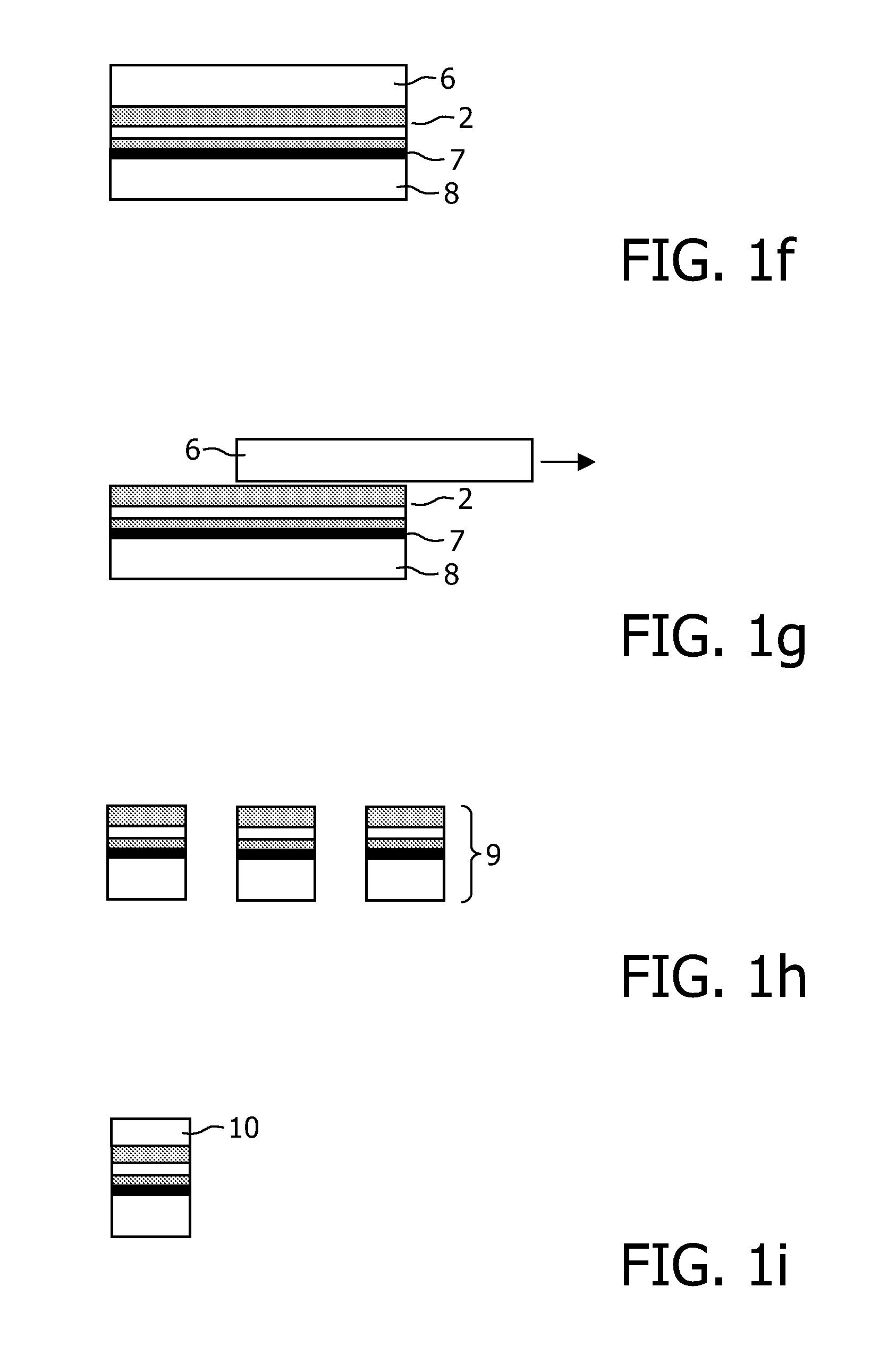

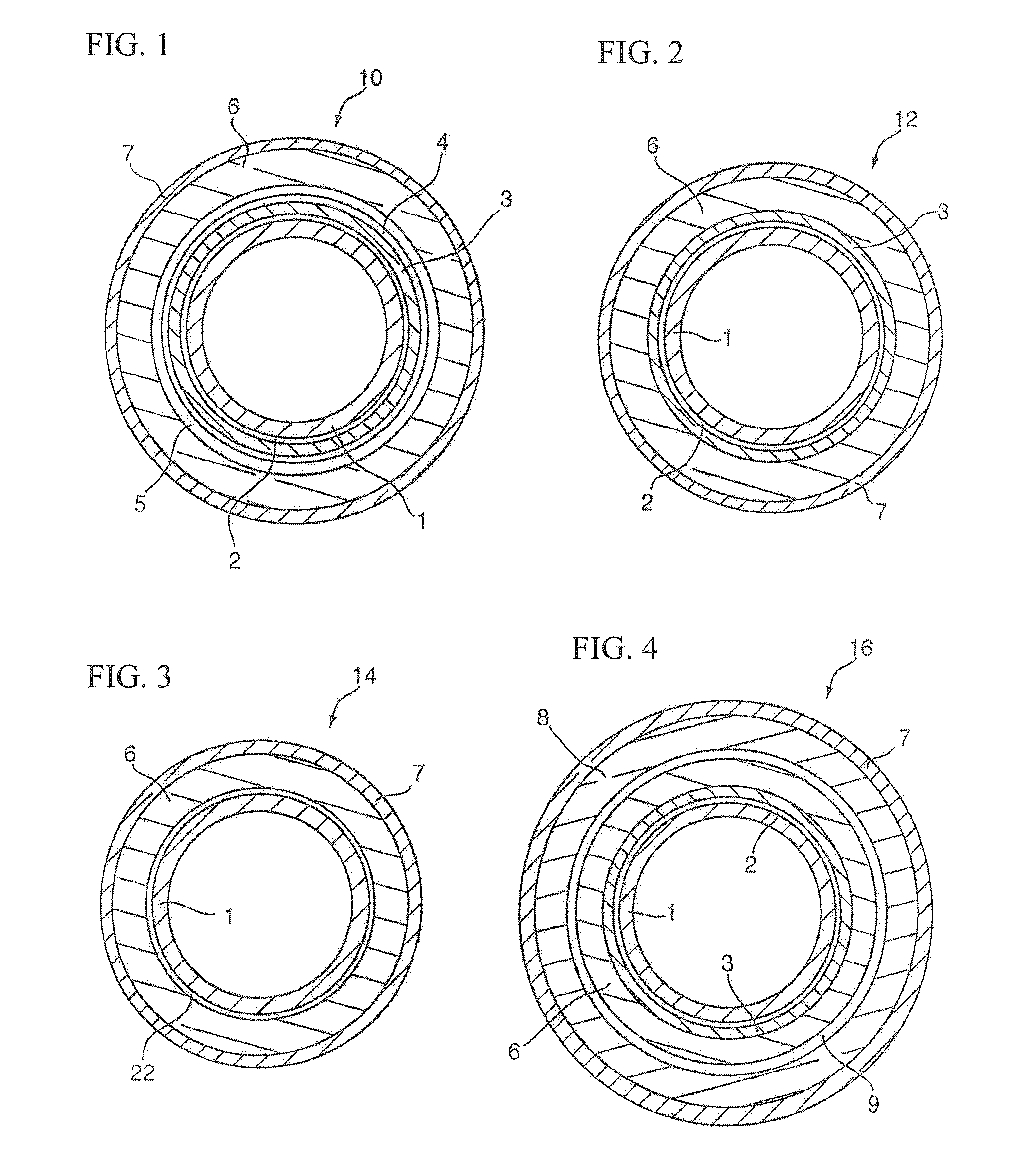

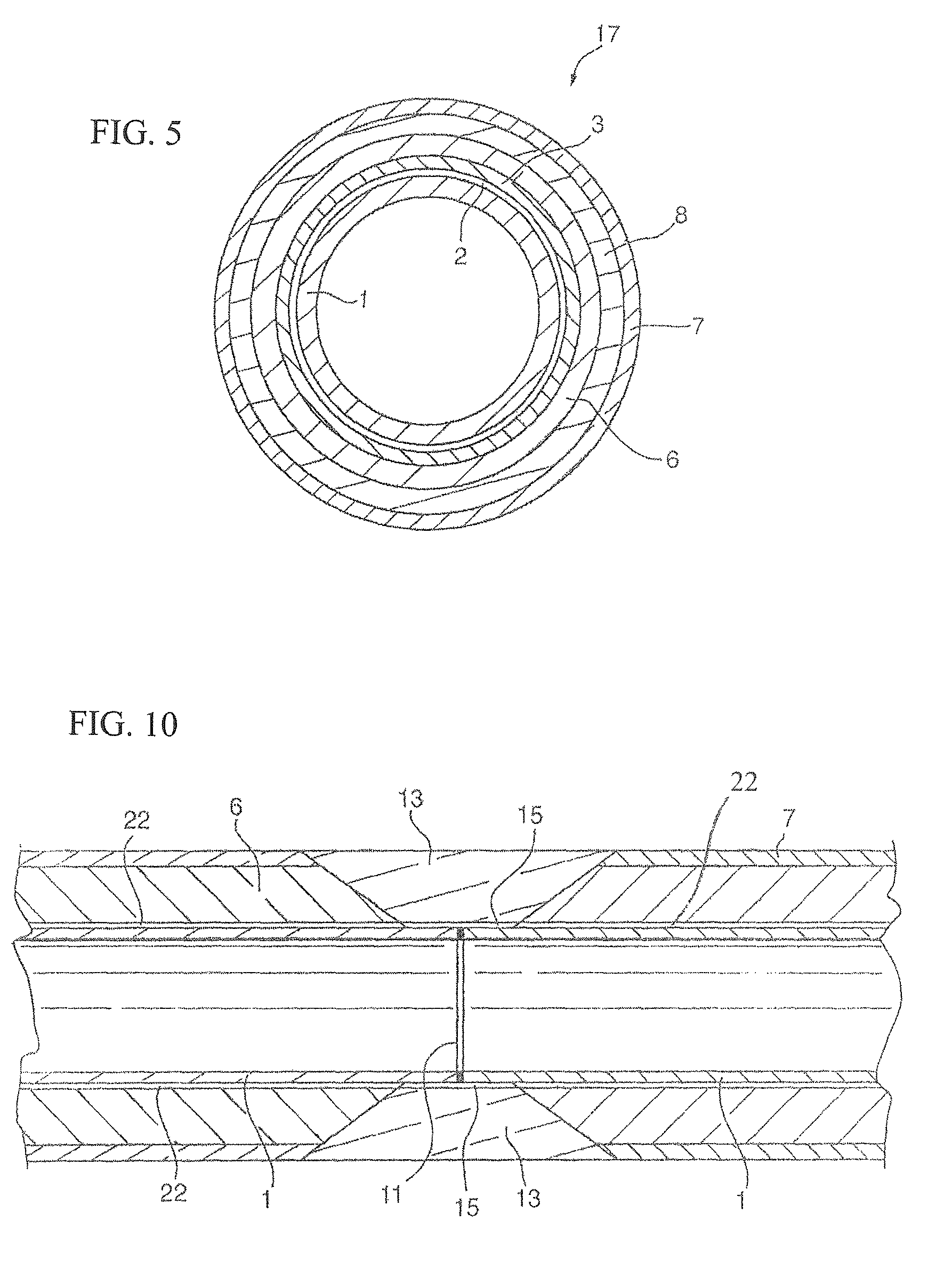

Vertical extended cavity surface emission laser and method for manufacturing a light emitting component of the same

ActiveUS20100195690A1Low thicknessSolve the low heat dissipation efficiencyLaser detailsLaser optical resonator constructionPhysicsSemiconductor

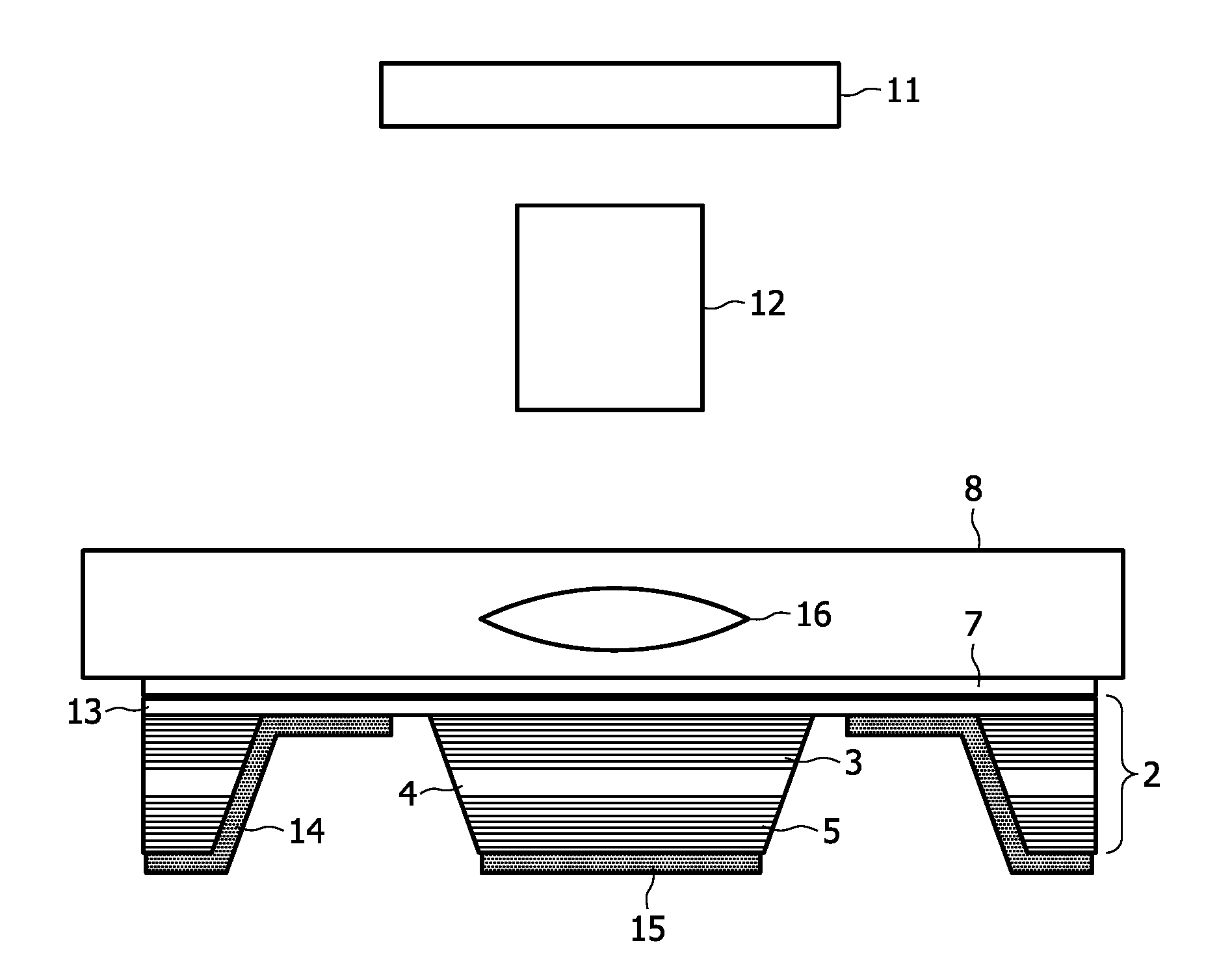

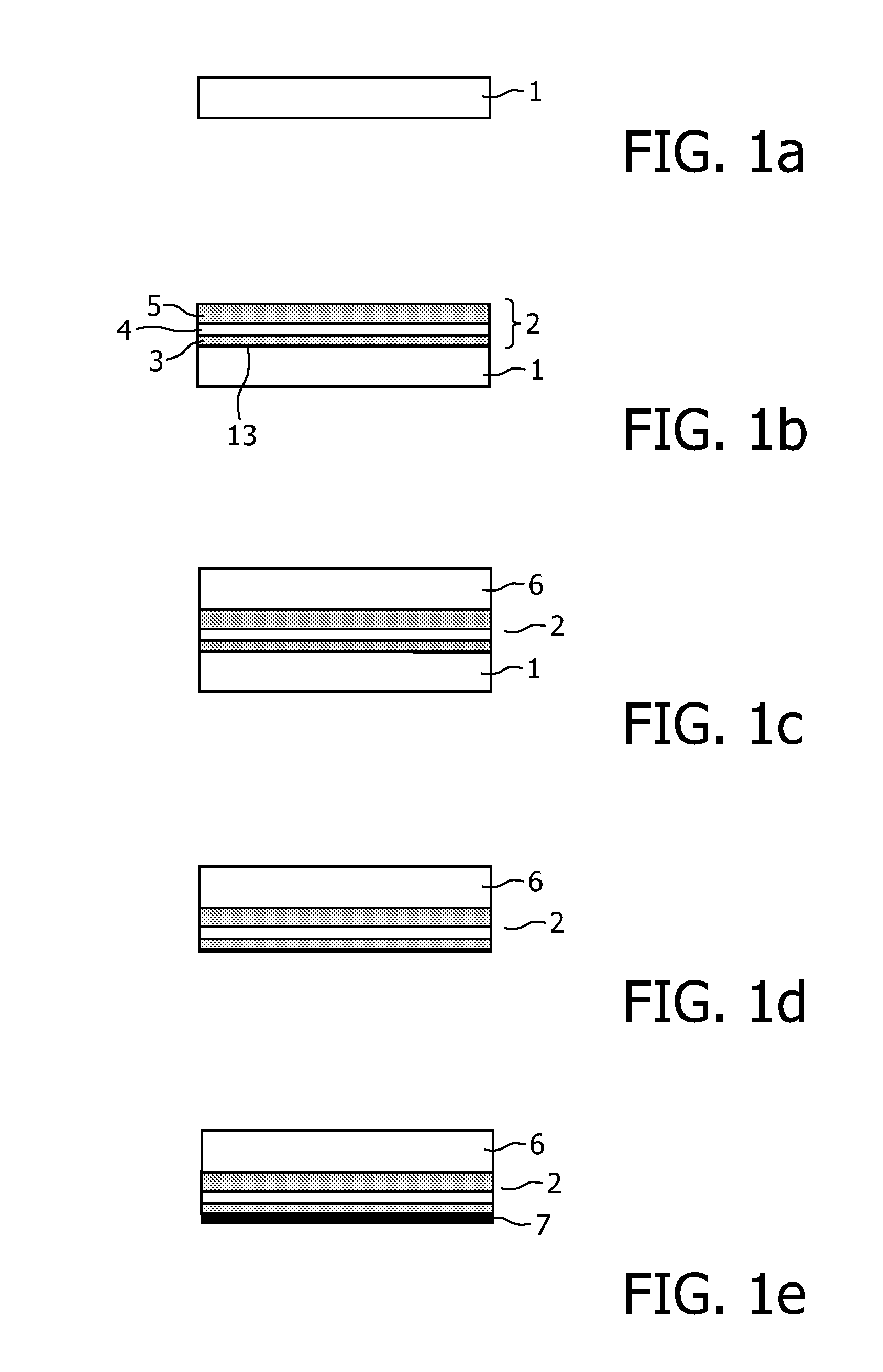

The present invention relates to a method of manufacturing the light emitting component of a VECSEL and the corresponding VECSEL. In the method a layer stack (2) is epitaxially grown on a semiconductor substrate (1). The layer stack comprises an active region (4), an upper distributed Bragg reflector (5) and a n- or p-doped current injection layer (13) arranged between the active region (4) and the semiconductor substrate (1). A mechanical support (6) or submount is bonded to an upper side of the layer stack (2) and the semiconductor substrate (1) is subsequently removed. A metallization layer (7) is optionally deposited on the lower side of the layer stack (2) and an optically transparent substrate (8) is bonded to this lower side. The proposed method allows the manufacturing of such a component in a standard manner and results in a VECSEL with a homogenous current injection and high efficiency of heat dissipation.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

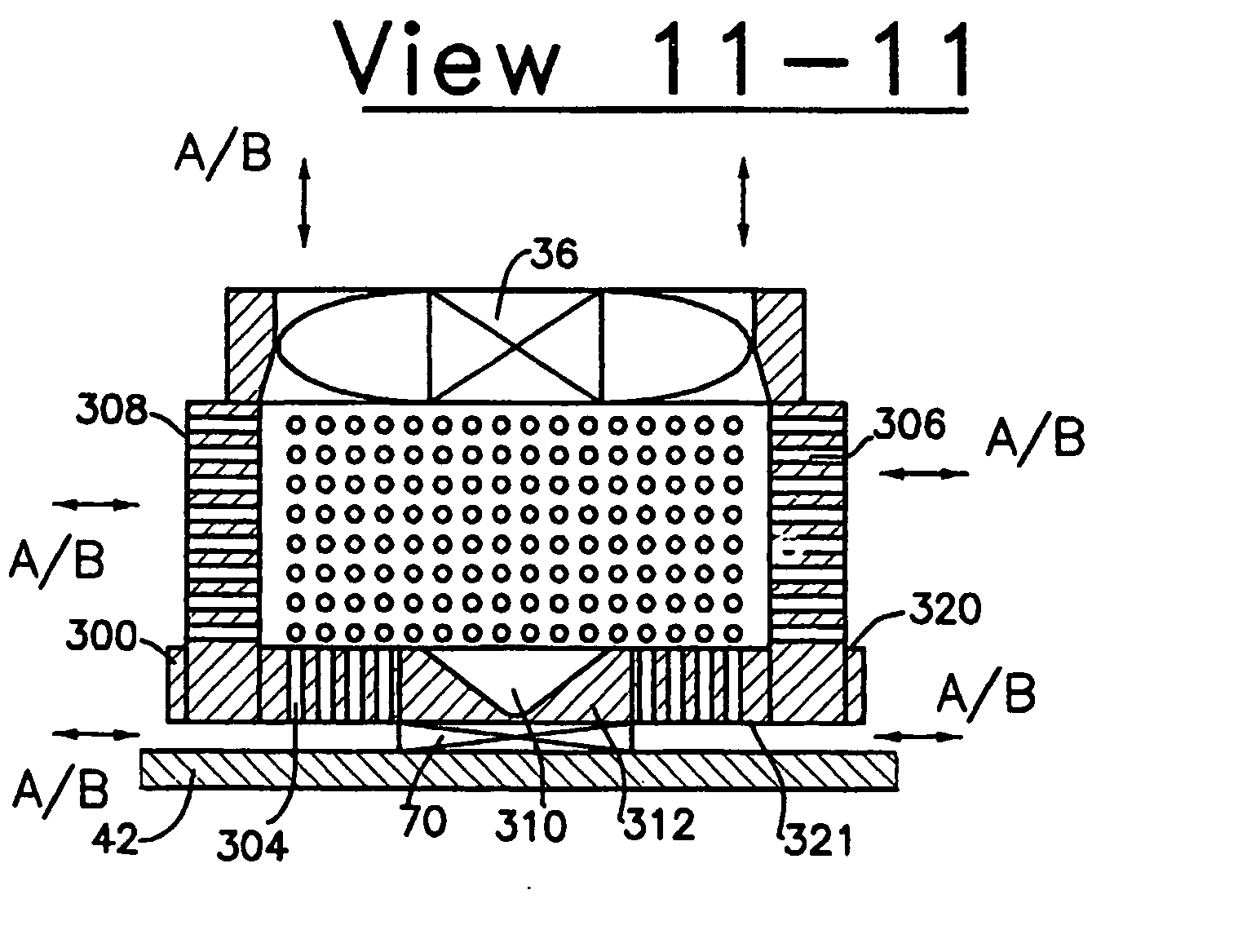

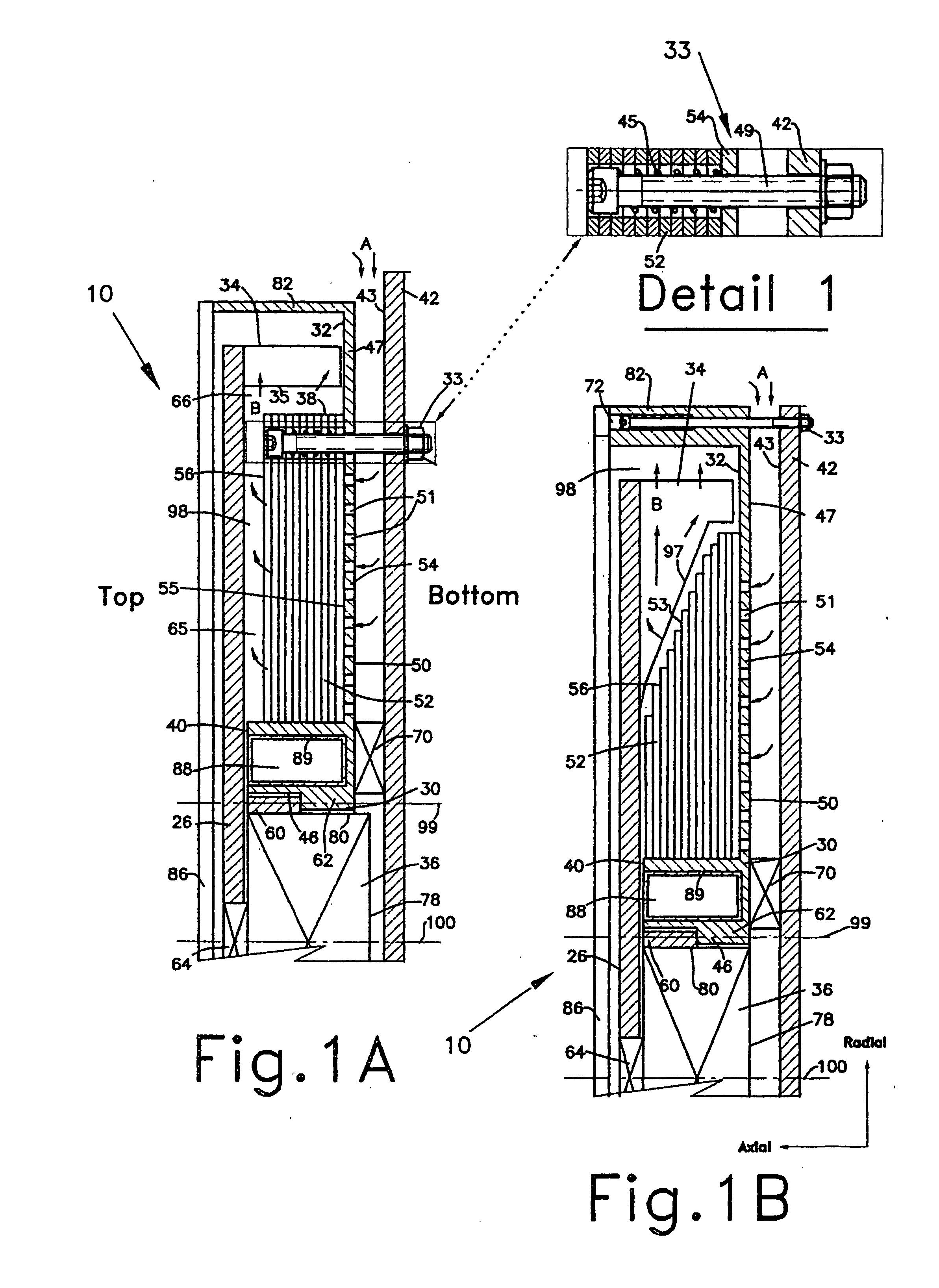

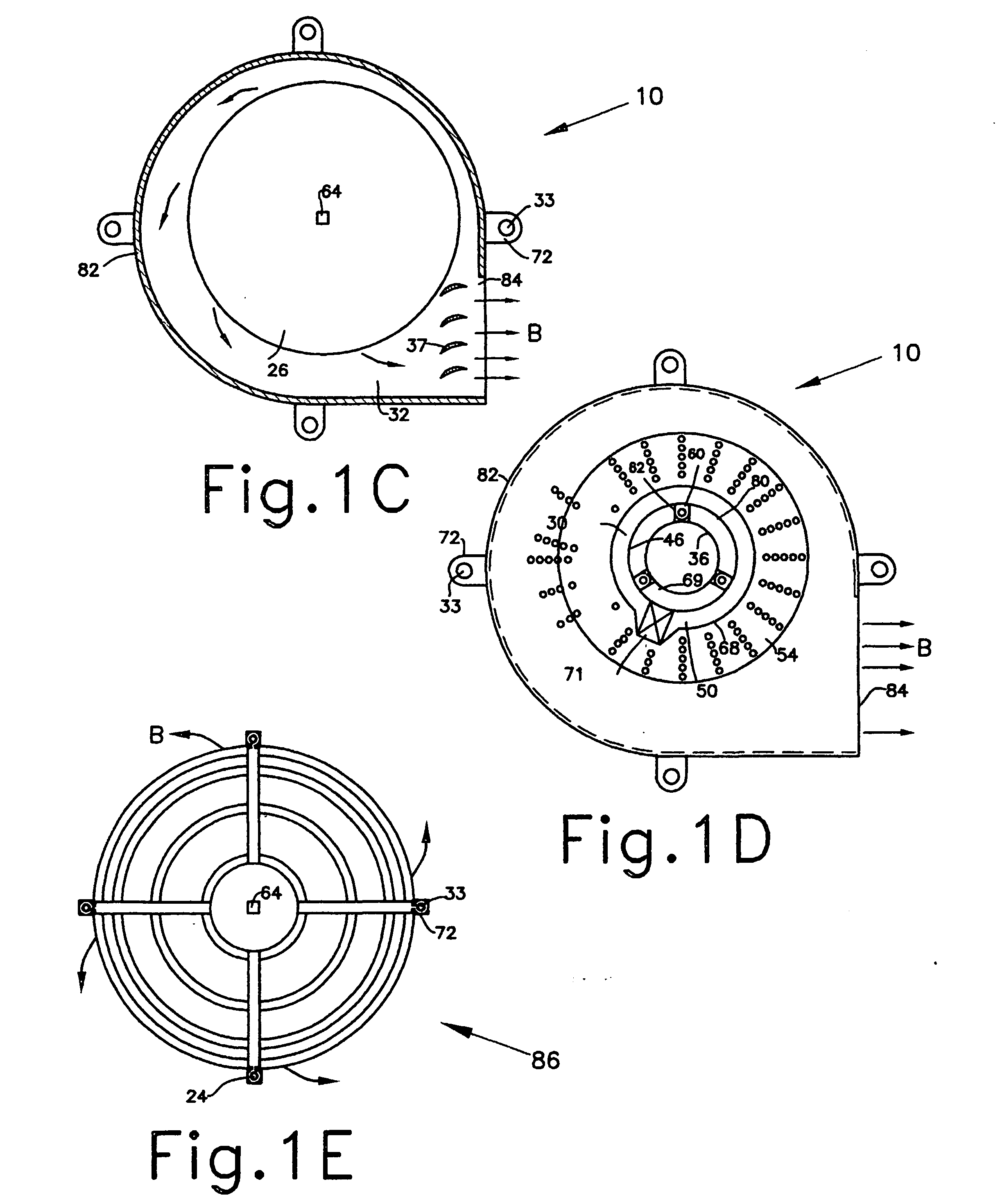

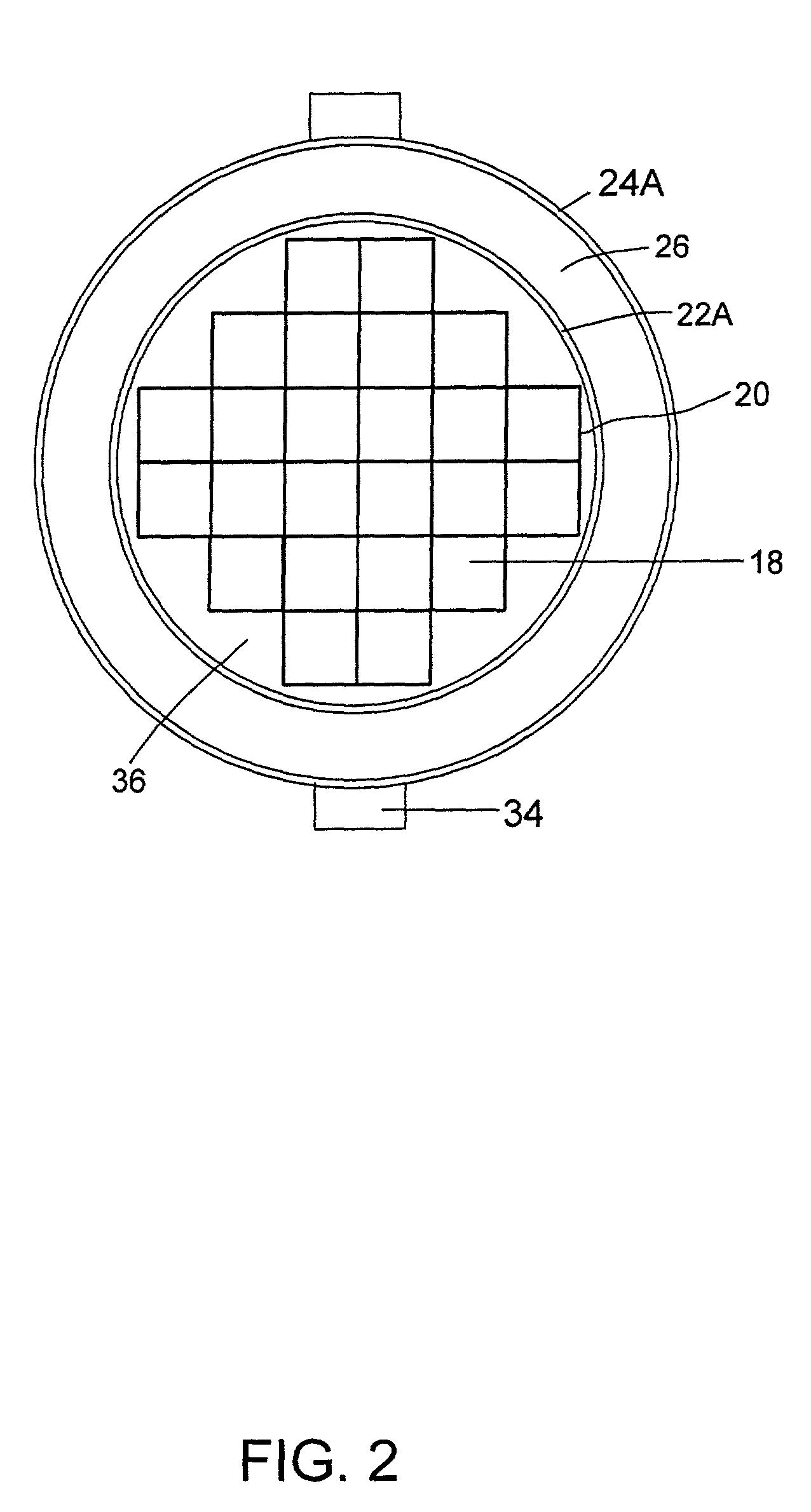

Heat-sink with large fins-to-air contact area

InactiveUS20050145366A1Improve cooling effectMinimal axial thicknessSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

A heat sink adapted for cooling a heat generating component, operative with an air moving means to generate airflow and remove the generated heat. The heat sink comprises a heat conducting element in thermal contact with the heat generating component, which is also in thermal contact with a plurality of fins having through fin-perforations defining free airflow passages and heat paths so as to spread the generated heat through the perforated fins. The structural configuration and relative spatial disposition of the perforated fins form airflow directing elements for the generated airflow, which flows via an air inlet and through inflow and outflow air passages which are in fluid communication via the fin-perforations, such that the airflow directing elements at least partially block the generated airflow, thus substantially directing all of it to flow via each of the fin-perforations, thereby developing cross-flow only once through the fin-perforations so as to exit via the air outlet.

Owner:EREL DAVID

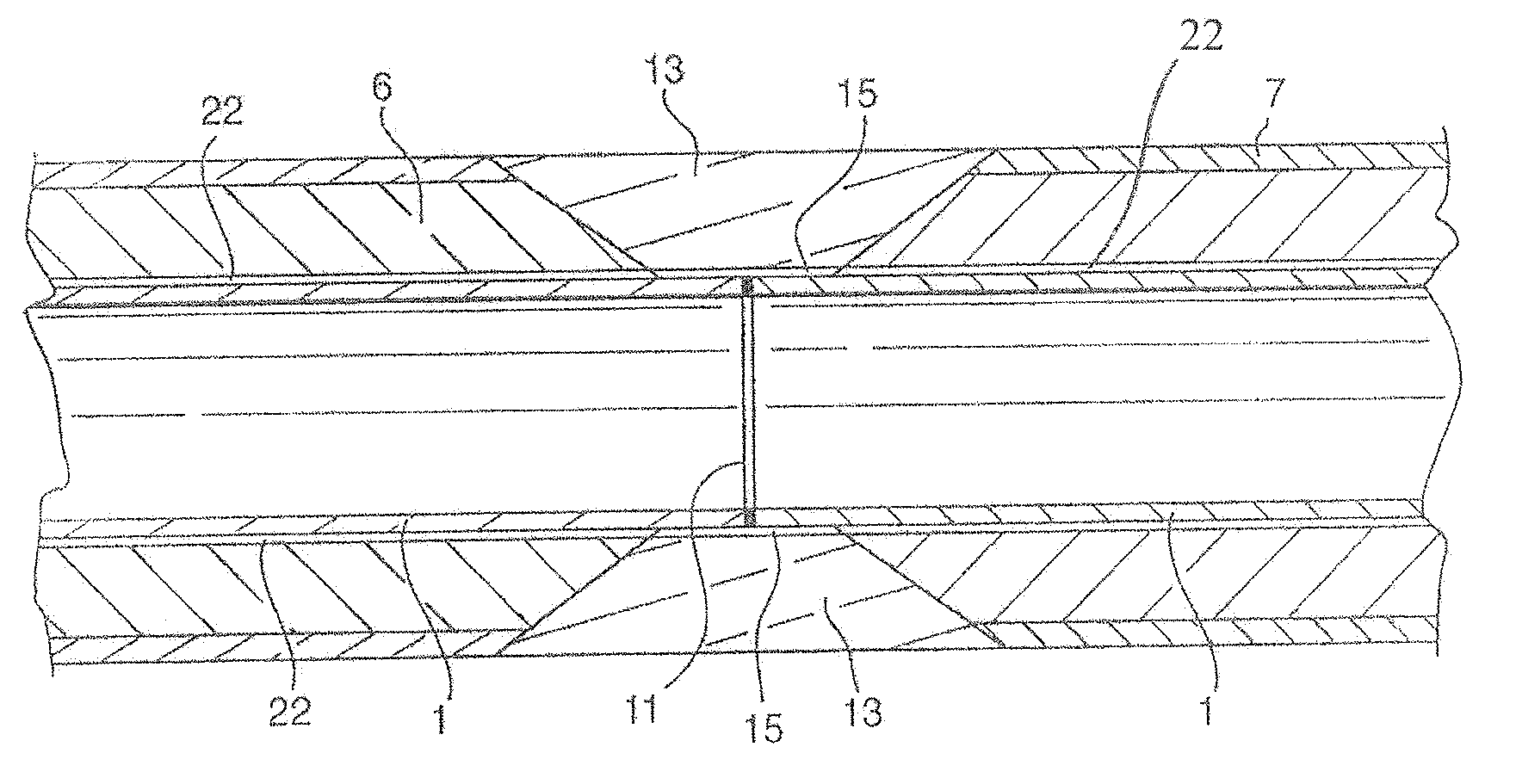

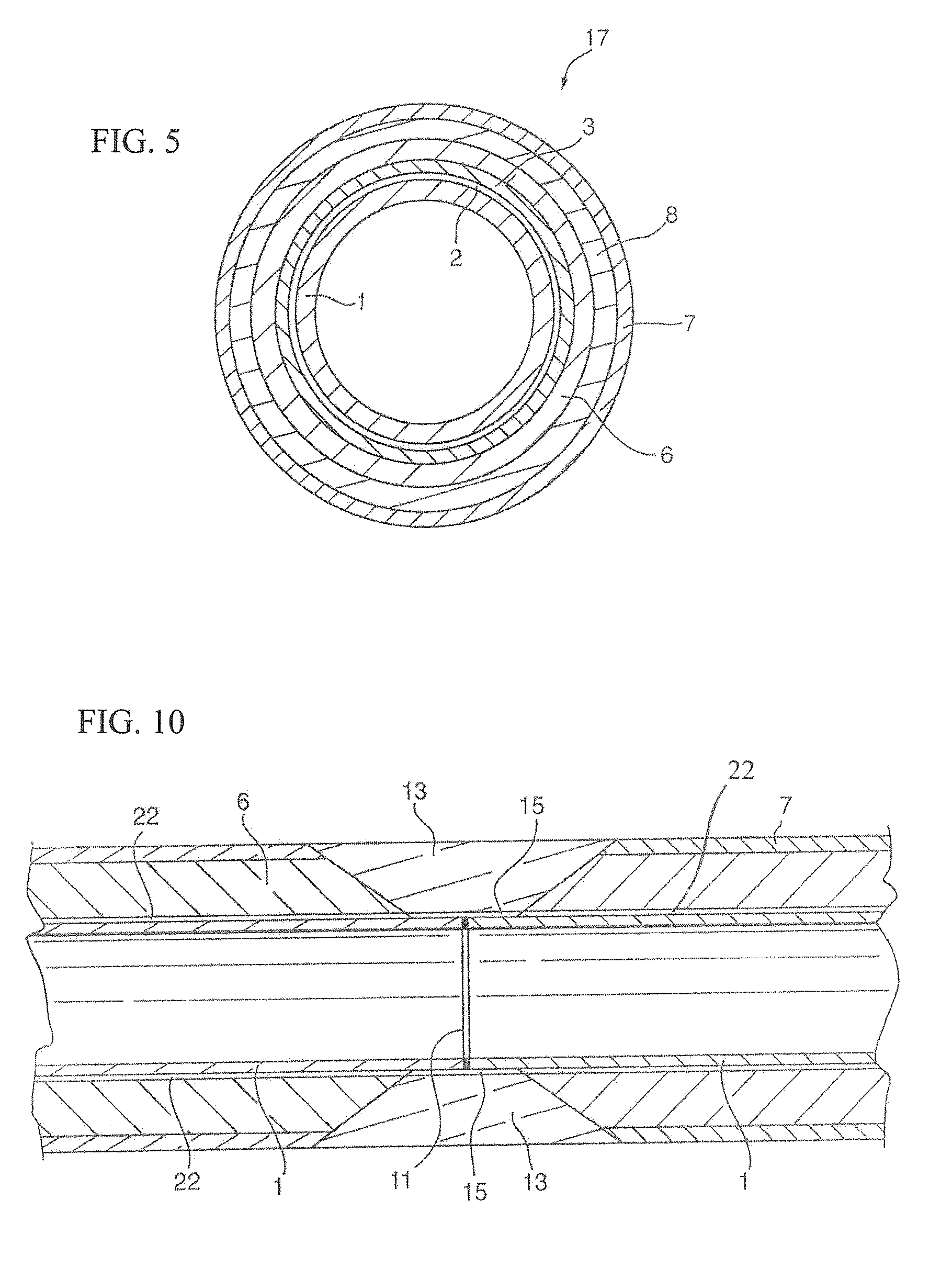

Styrenic insulation for pipe

ActiveUS20090159146A1Improve insulation effectReduce coating thicknessThermal insulationCorrosion preventionThermoplasticCompressive creep

Coatings for protecting and insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of up to 100° C. in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of thermal insulation comprising polystyrene or styrene-based thermoplastic, having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance.

Owner:SHAWCOR LTD

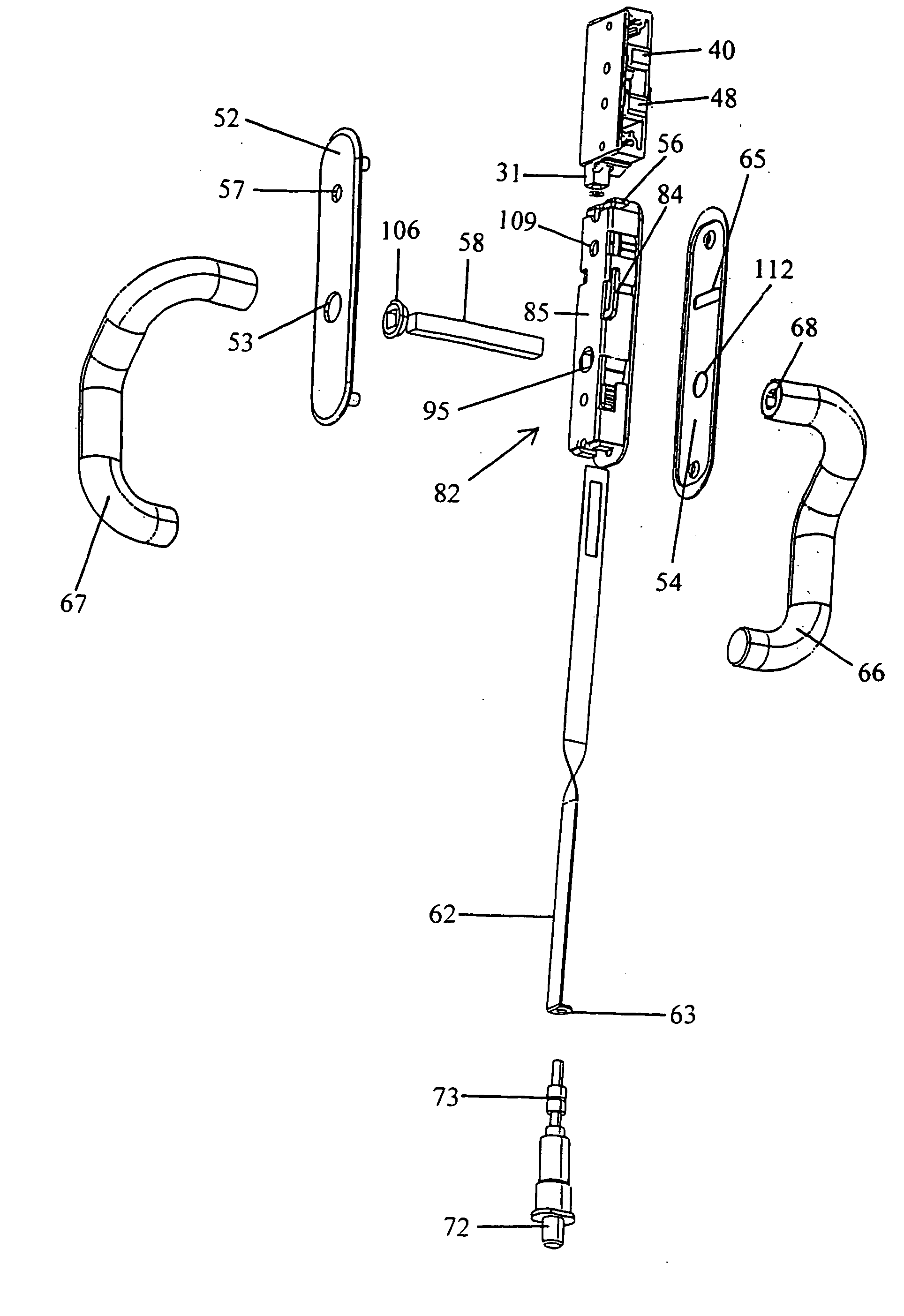

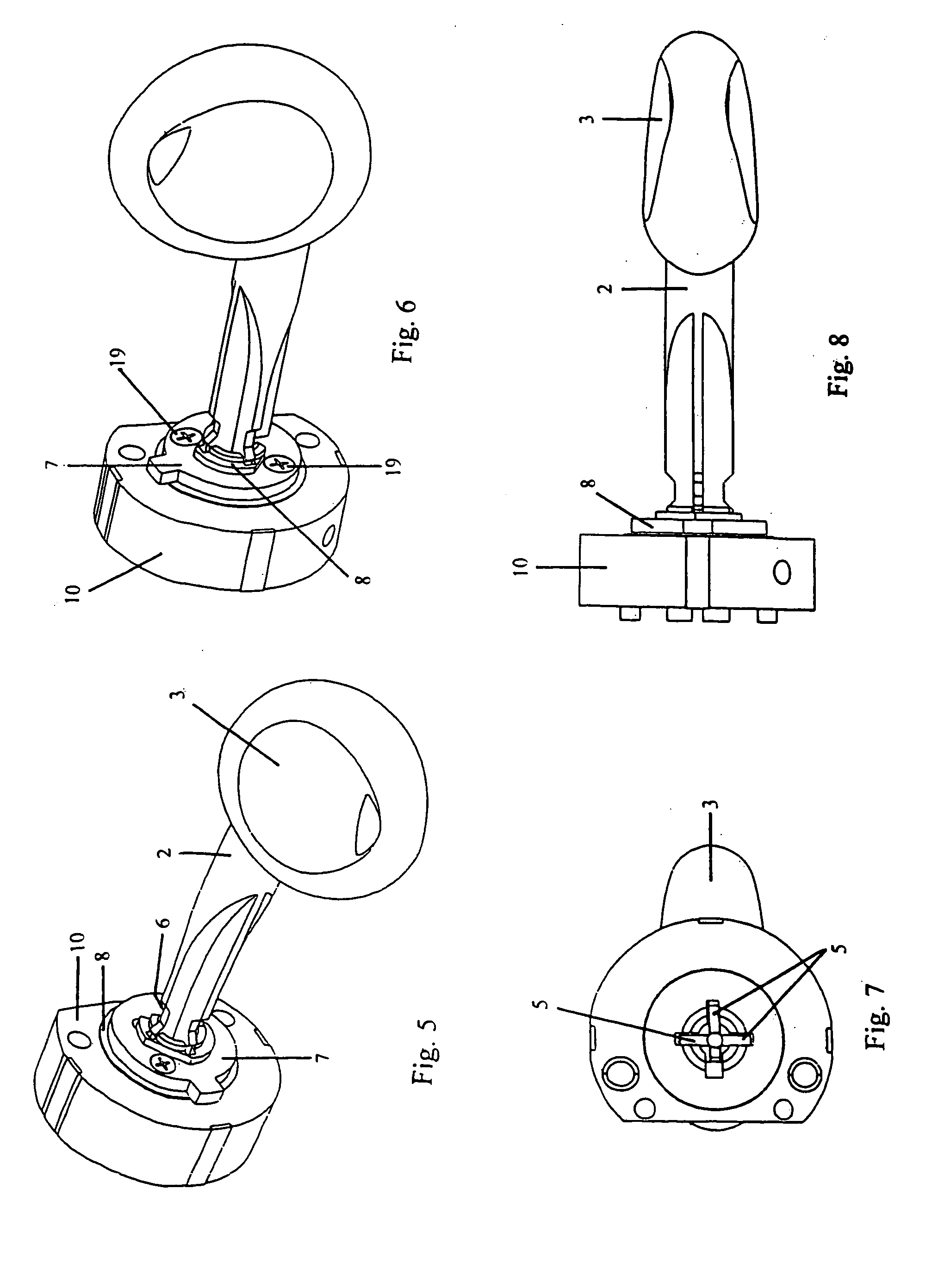

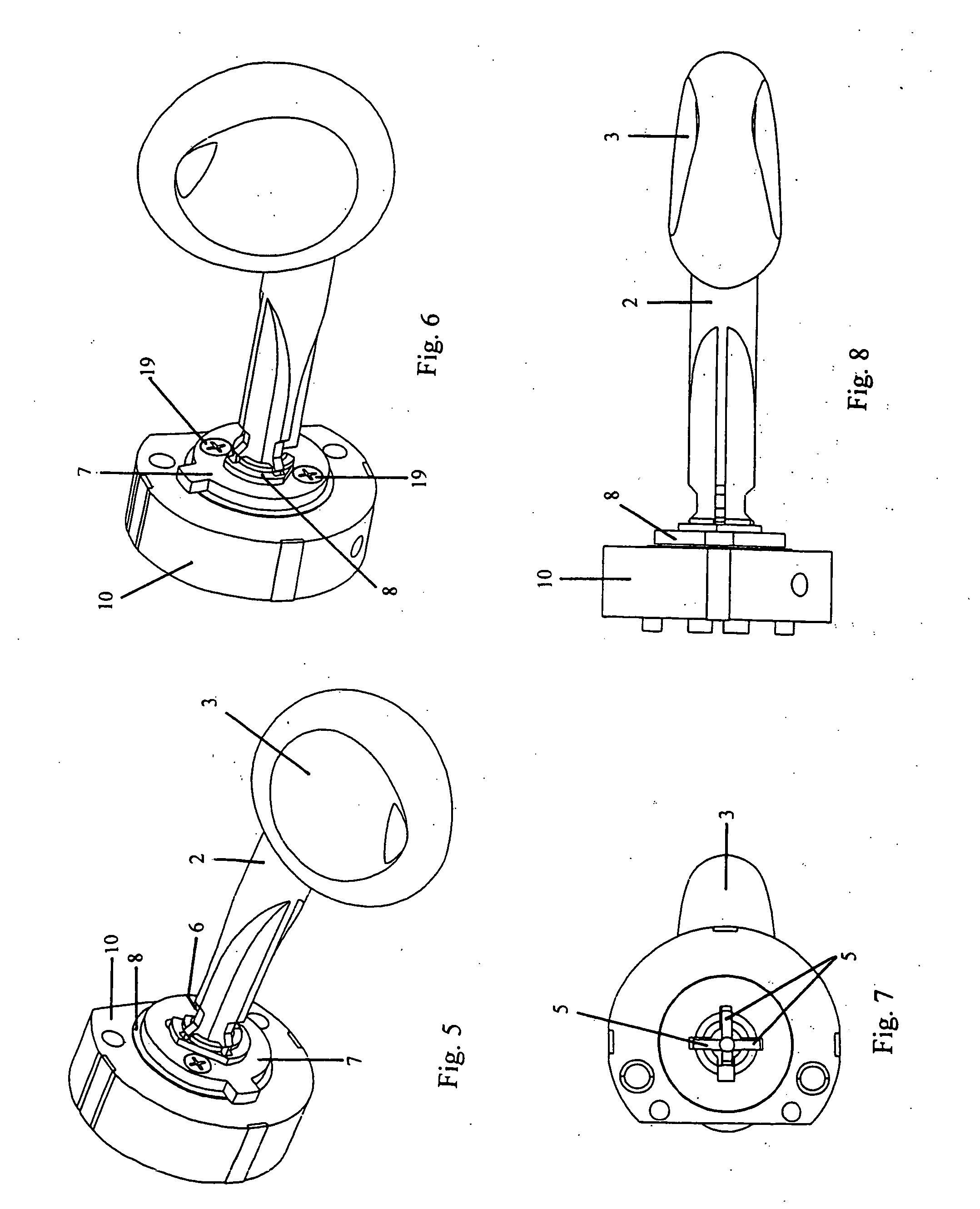

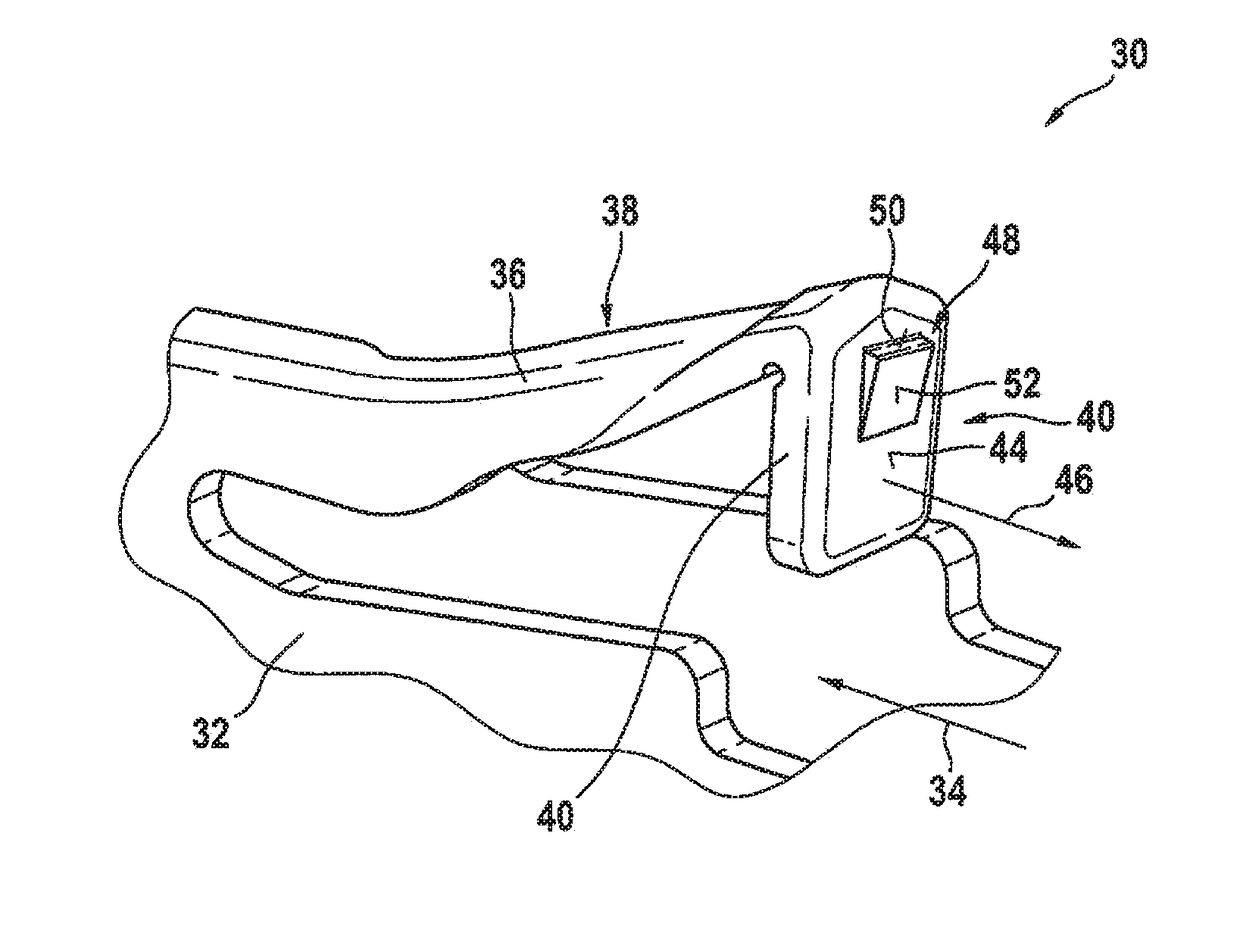

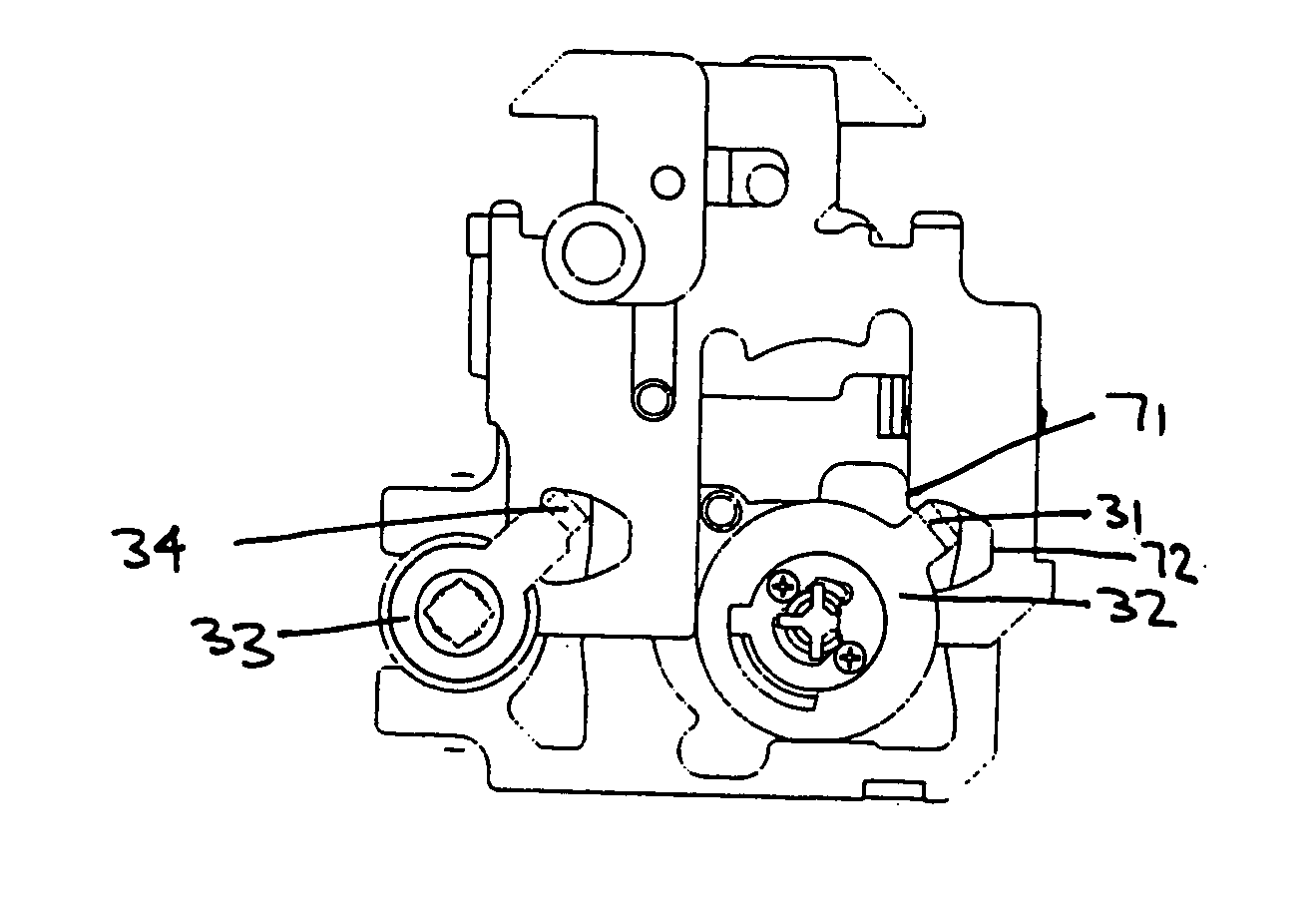

Latch assembly

ActiveUS20050229657A1Readily adaptable to different thicknessEasy to operateWing fastenersKeysEngineeringActuator

A latch assembly having a keyless toggle lock capability and capable of being unlocked by either a low level security key or a master key. When a user rotates the front handle or rear handle the actuator of the latch assembly provides for sliding movement of a sliding element so as to provide for actuation of a latching means.

Owner:SOUTHCO

Radiation shielding materials and containers incorporating same

InactiveUS6960311B1Improve shielding effectMaximum flexibilityOther chemical processesTransuranic element compoundsMicrosphereUranium carbide

An improved radiation shielding material and storage systems for radioactive materials incorporating the same. The PYRolytic Uranium Compound (“PYRUC”) shielding material is preferably formed by heat and / or pressure treatment of a precursor material comprising microspheres of a uranium compound, such as uranium dioxide or uranium carbide, and a suitable binder. The PYRUC shielding material provides improved radiation shielding, thermal characteristic, cost and ease of use in comparison with other shielding materials. The shielding material can be used to form containment systems, container vessels, shielding structures, and containment storage areas, all of which can be used to house radioactive waste. The preferred shielding system is in the form of a container for storage, transportation, and disposal of radioactive waste. In addition, improved methods for preparing uranium dioxide and uranium carbide microspheres for use in the radiation shielding materials are also provided.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

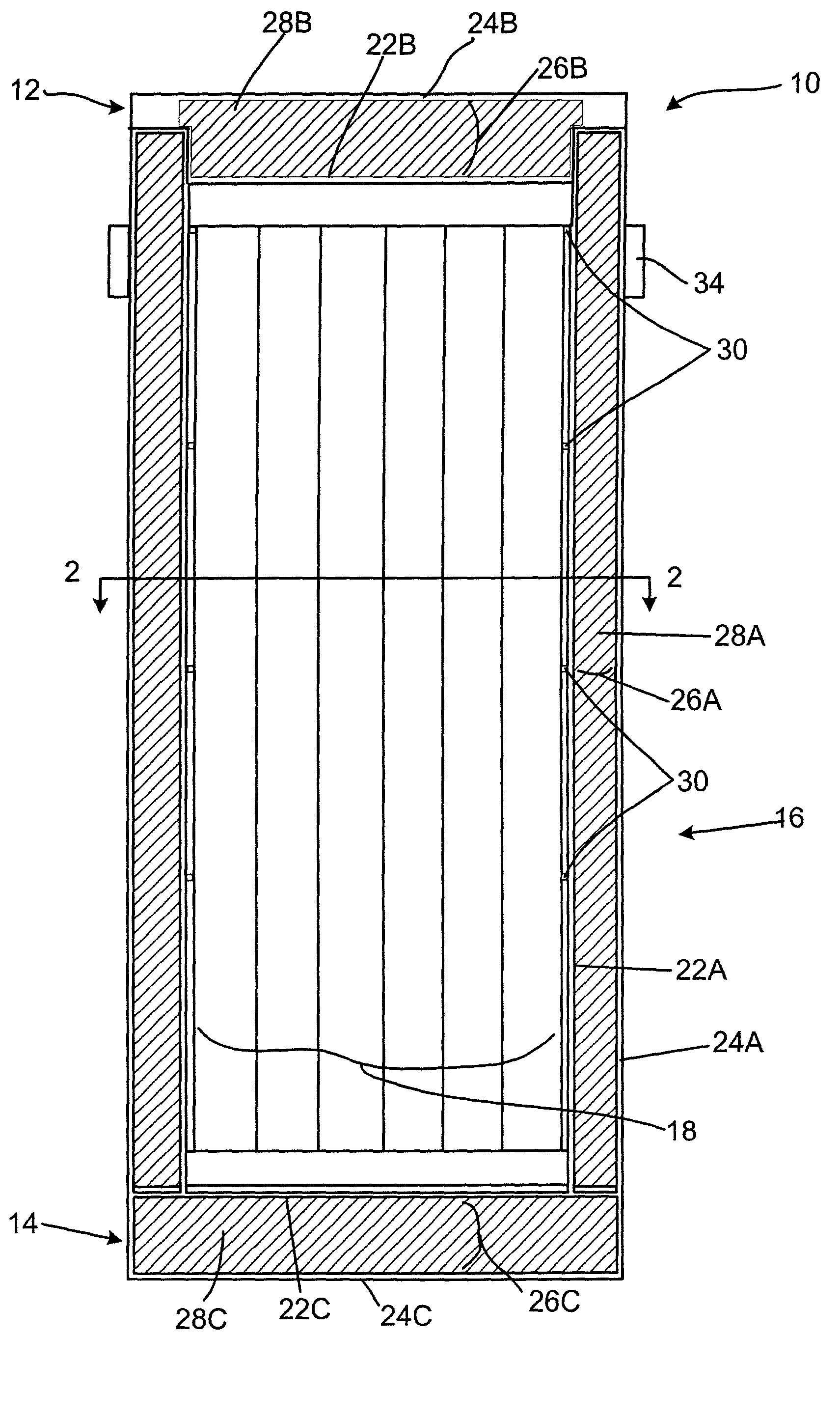

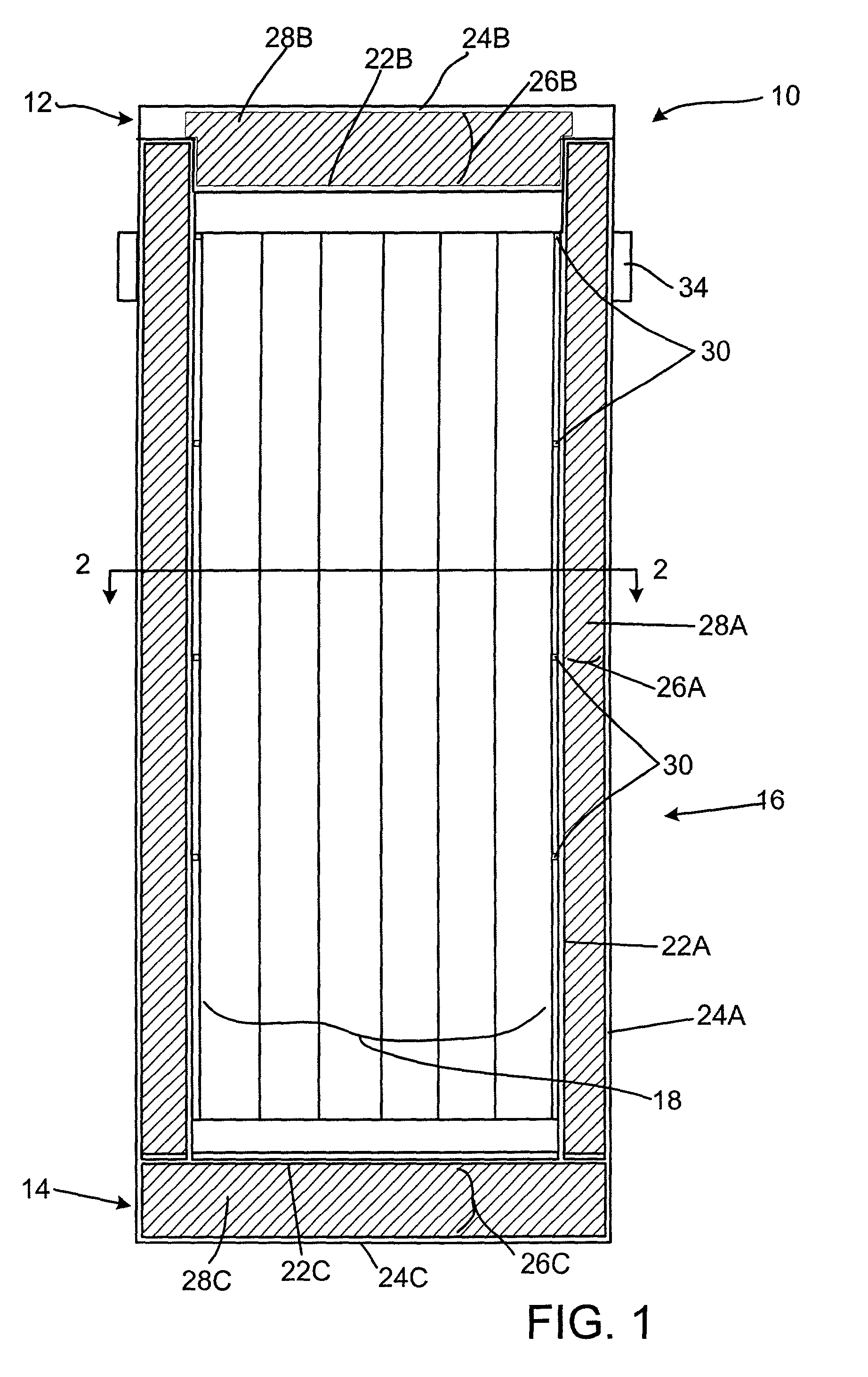

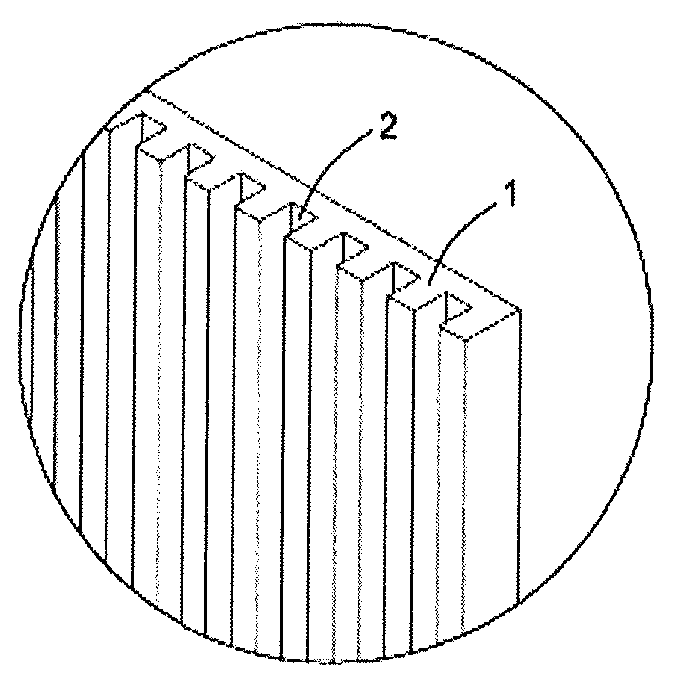

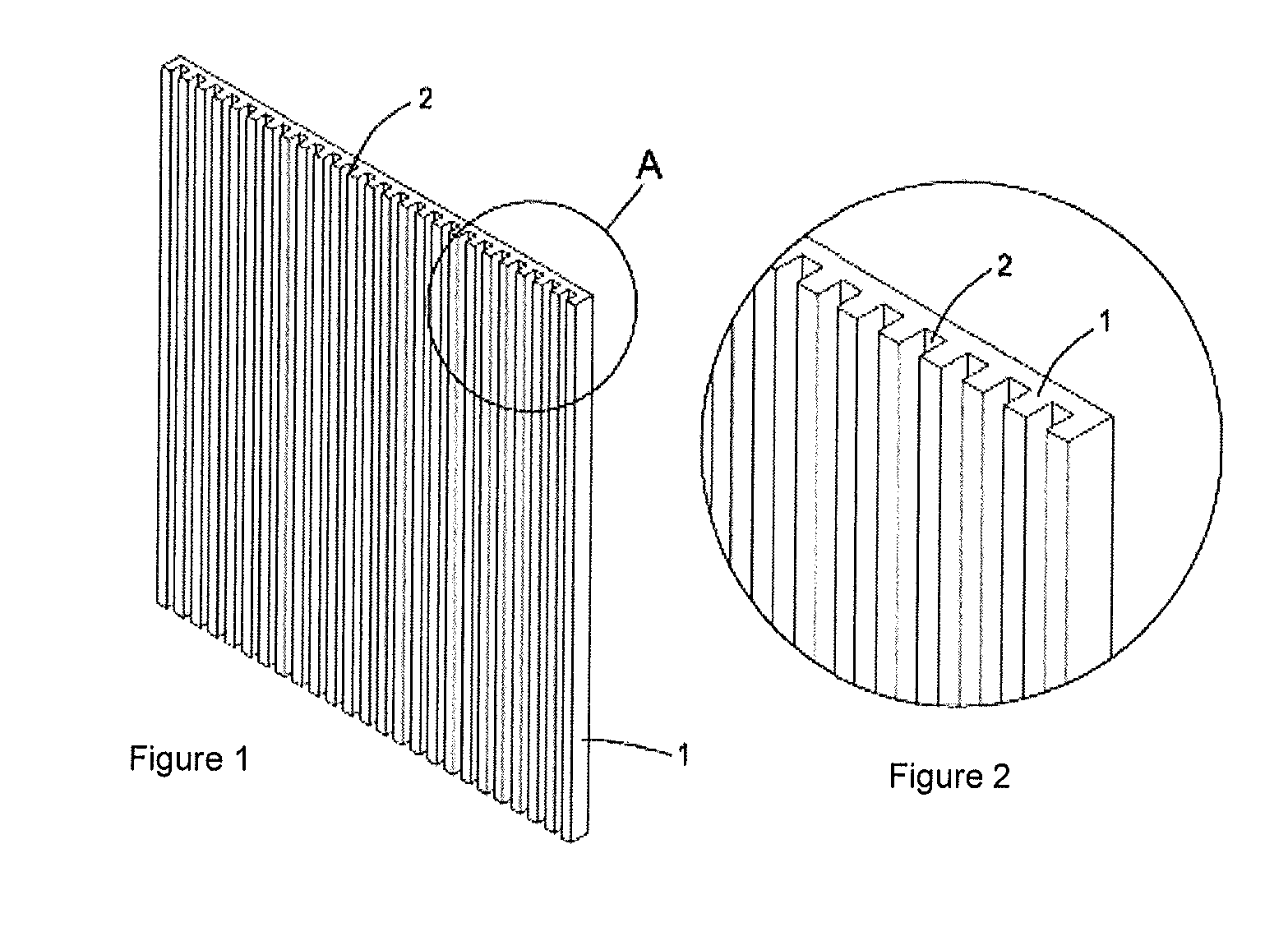

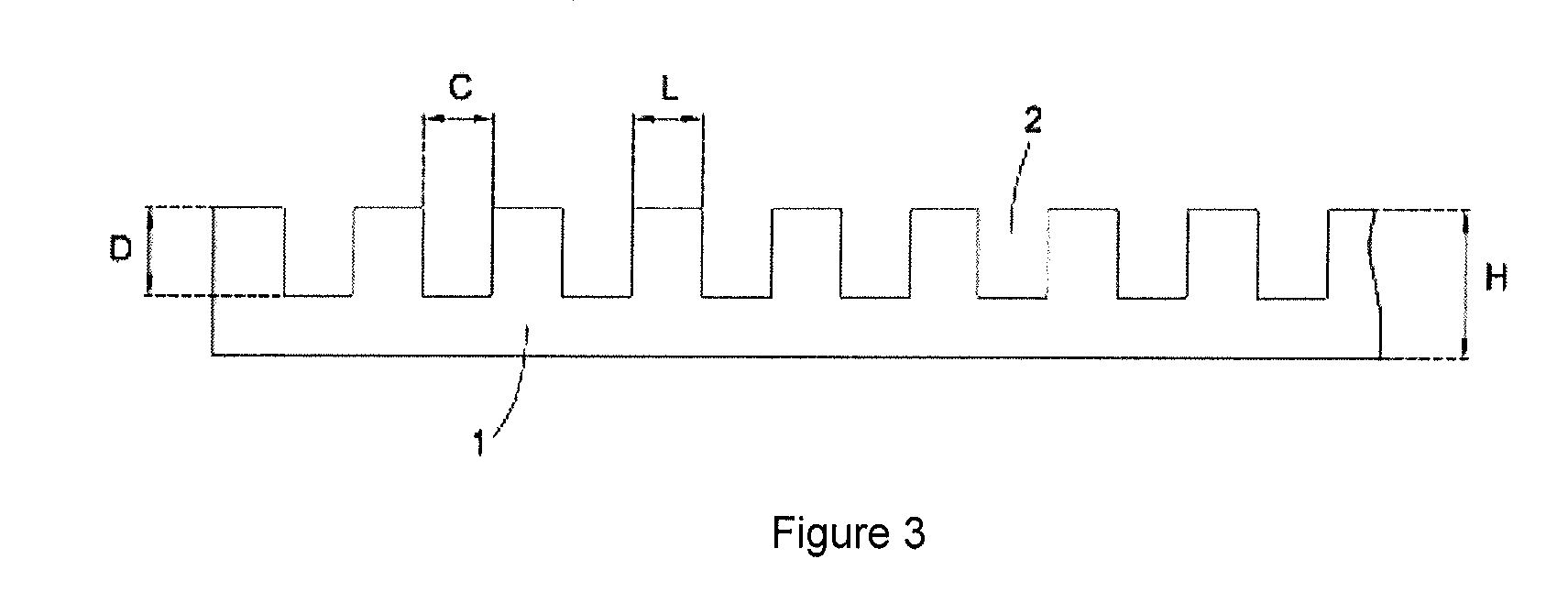

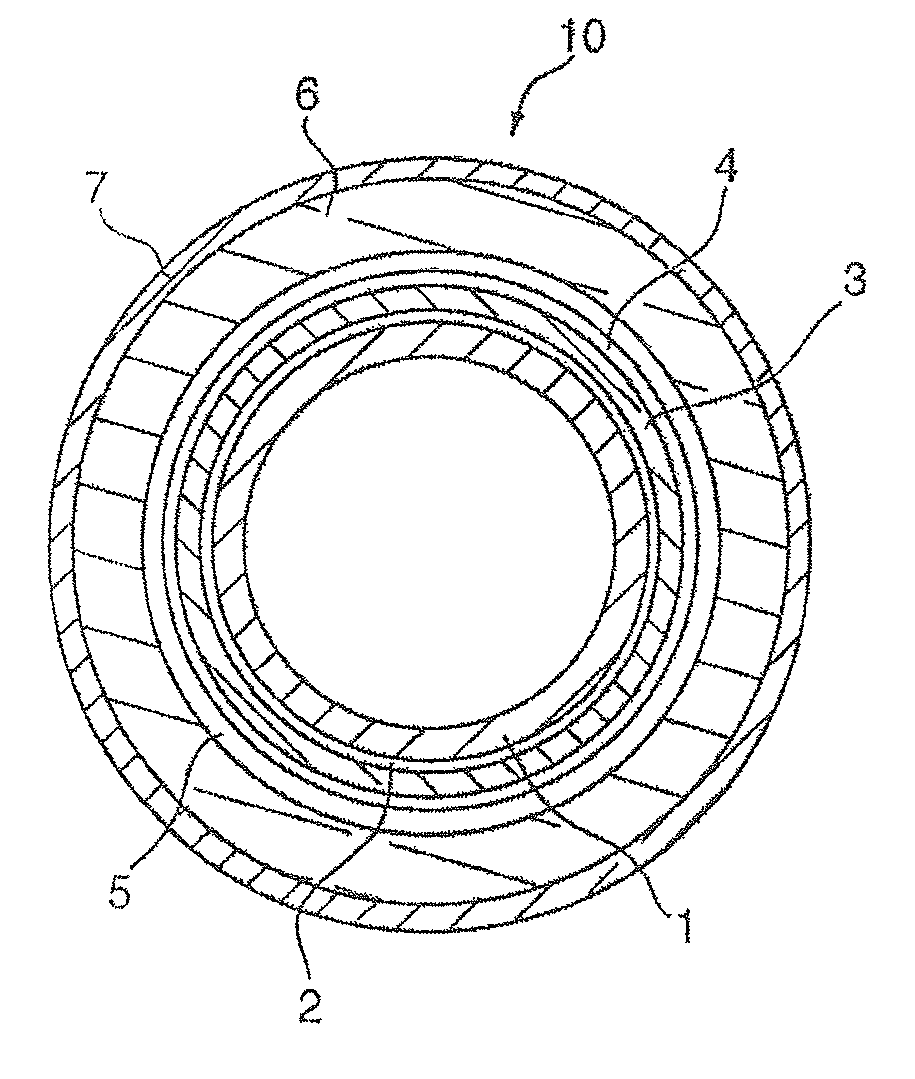

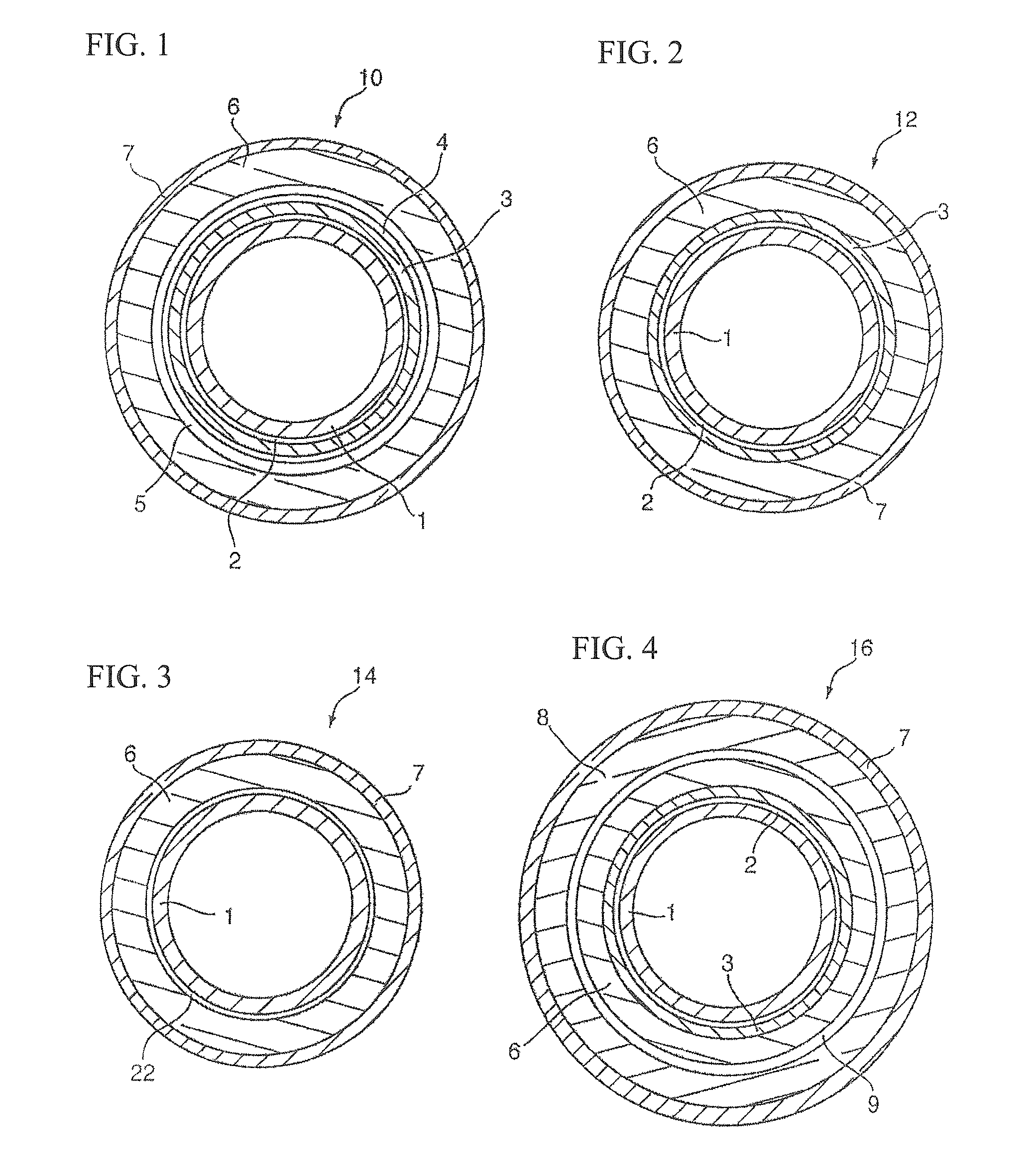

Electrode for a flow battery

InactiveUS20110281169A1Low flow areaLow of battery efficiencyRegenerative fuel cellsNon-aqueous electrolyte accumulator electrodesPower flowElectrical battery

Enclosed is an electrode for a flow battery, which comprises a graphite felt (1), wherein: said graphite felt includes multiple flow channels (2) for transmitting an electrolyte, said flow channels (2) are straight and distributed at equally spaced intervals, and the width and depth of said channels (2) and the interval between adjacent flow channels (2) are each half of the thickness of the graphite felt (1), which is a polyacrylonitrile graphite felt (1). Said flow battery electrolyte has a simple structure and is easily processed and assembled, the flow battery thickness and internal resistance are low, and transmission and dispersion of the electrolyte is highly effective. Flow batteries using said electrode enjoy high power density, high energy efficiency, long life, and can be made into high-power or even super-high-power flow batteries.

Owner:GOLDEN ENERGY FUEL CELL

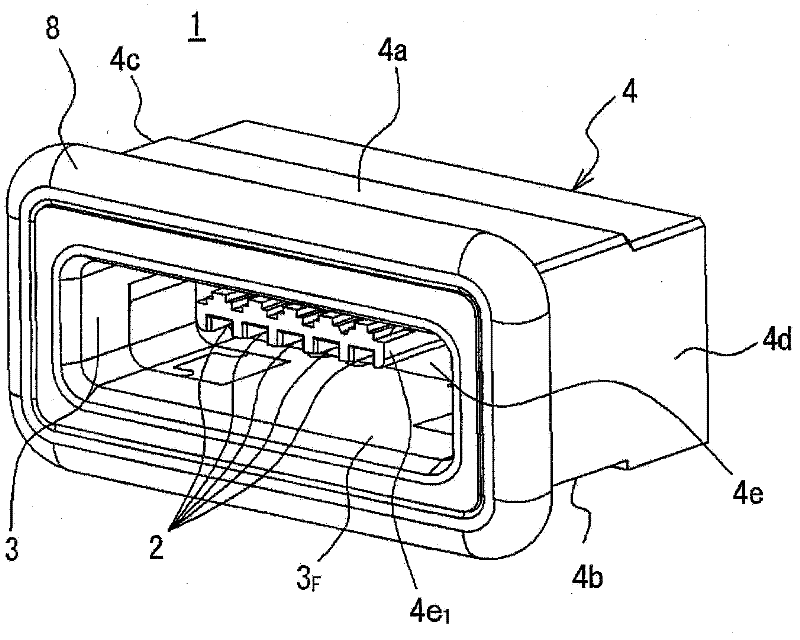

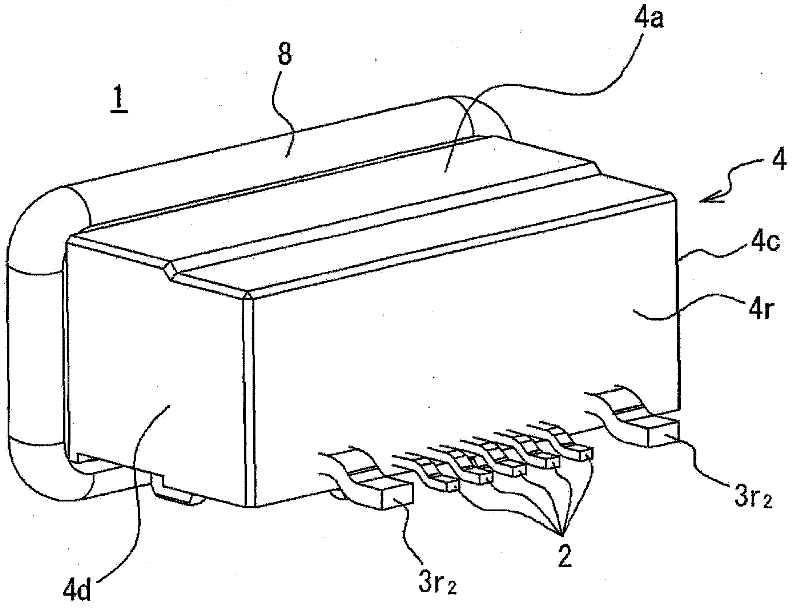

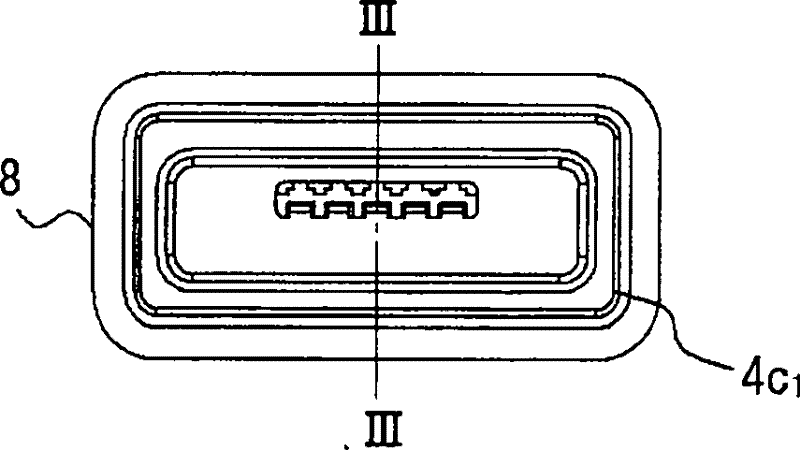

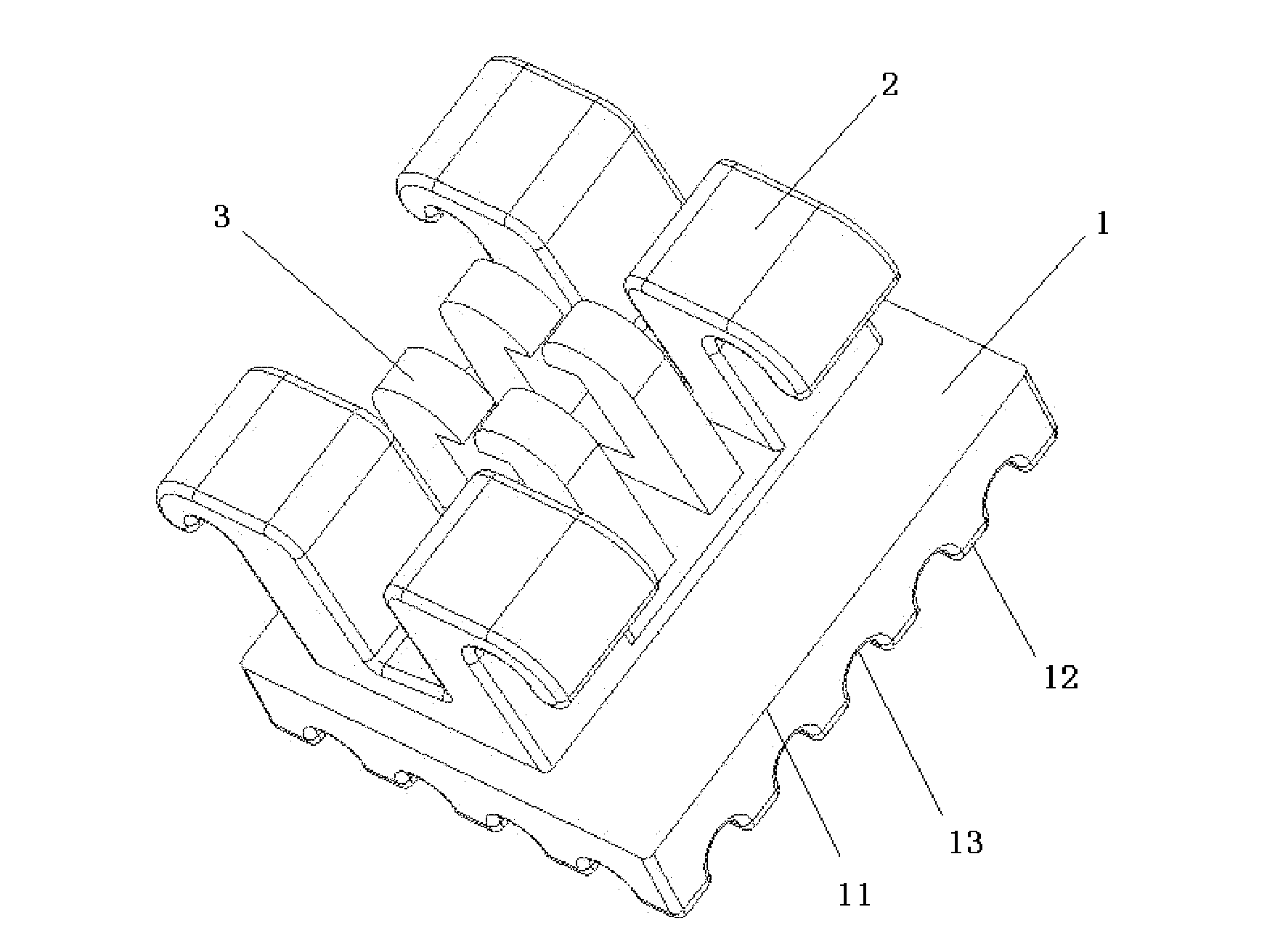

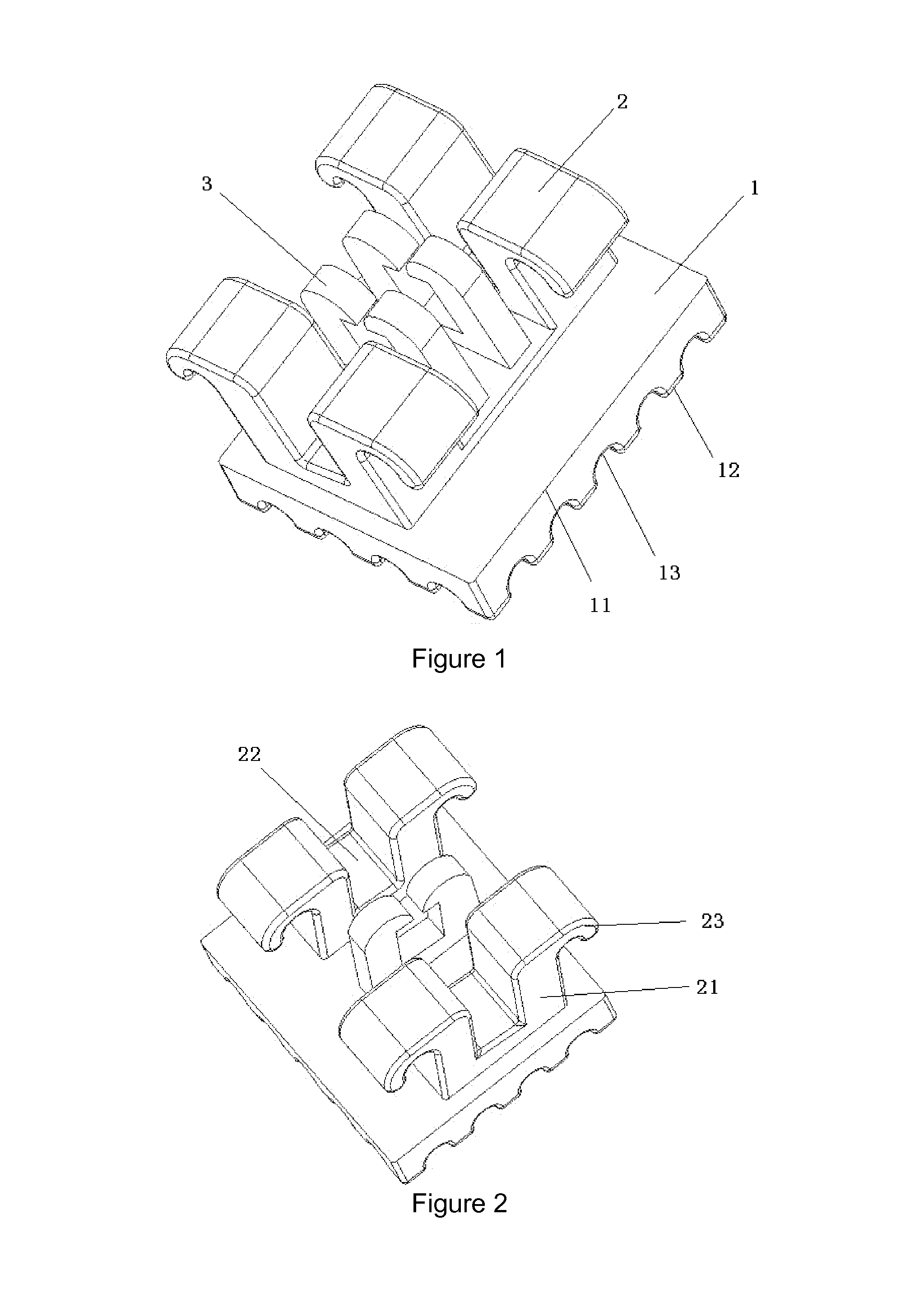

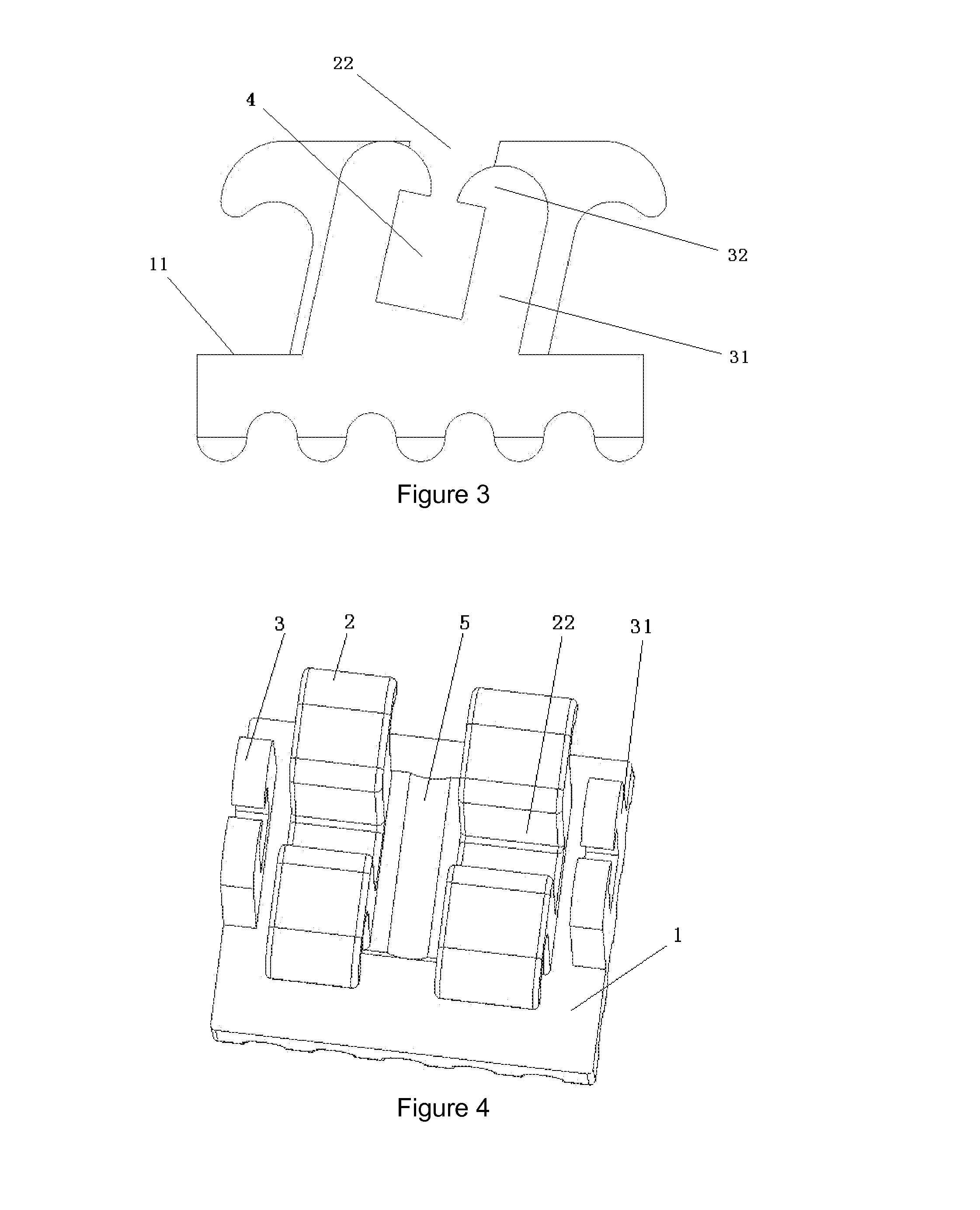

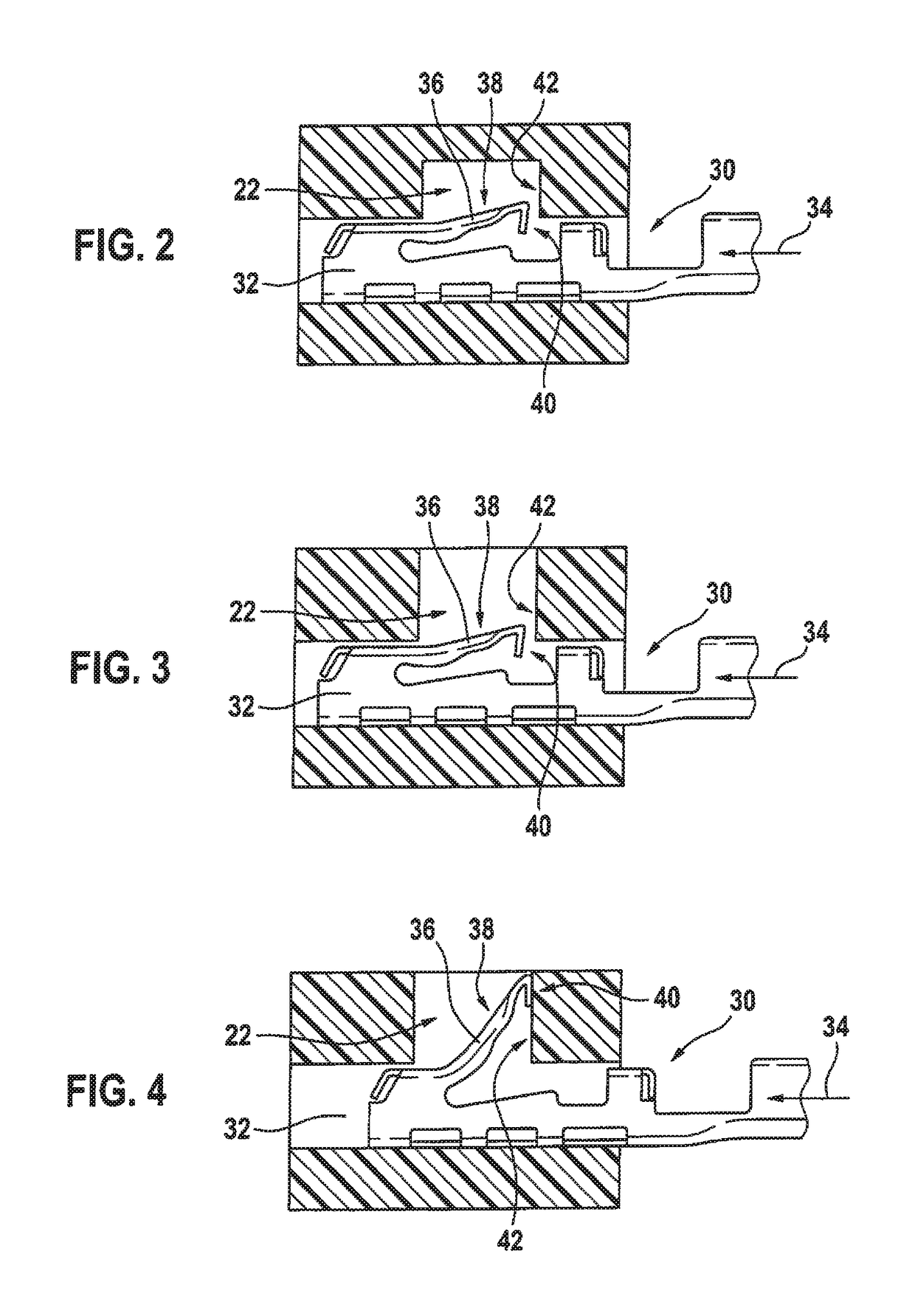

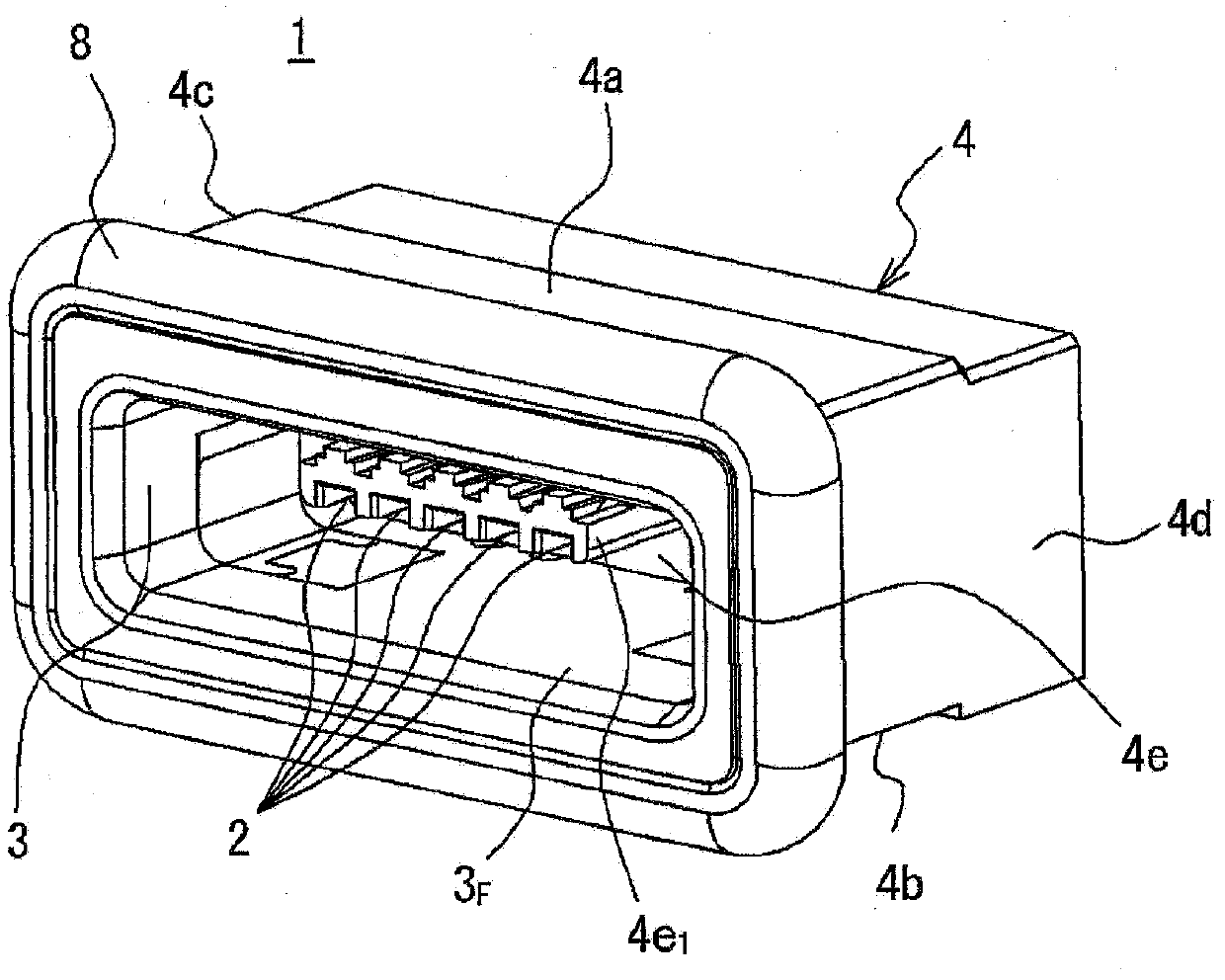

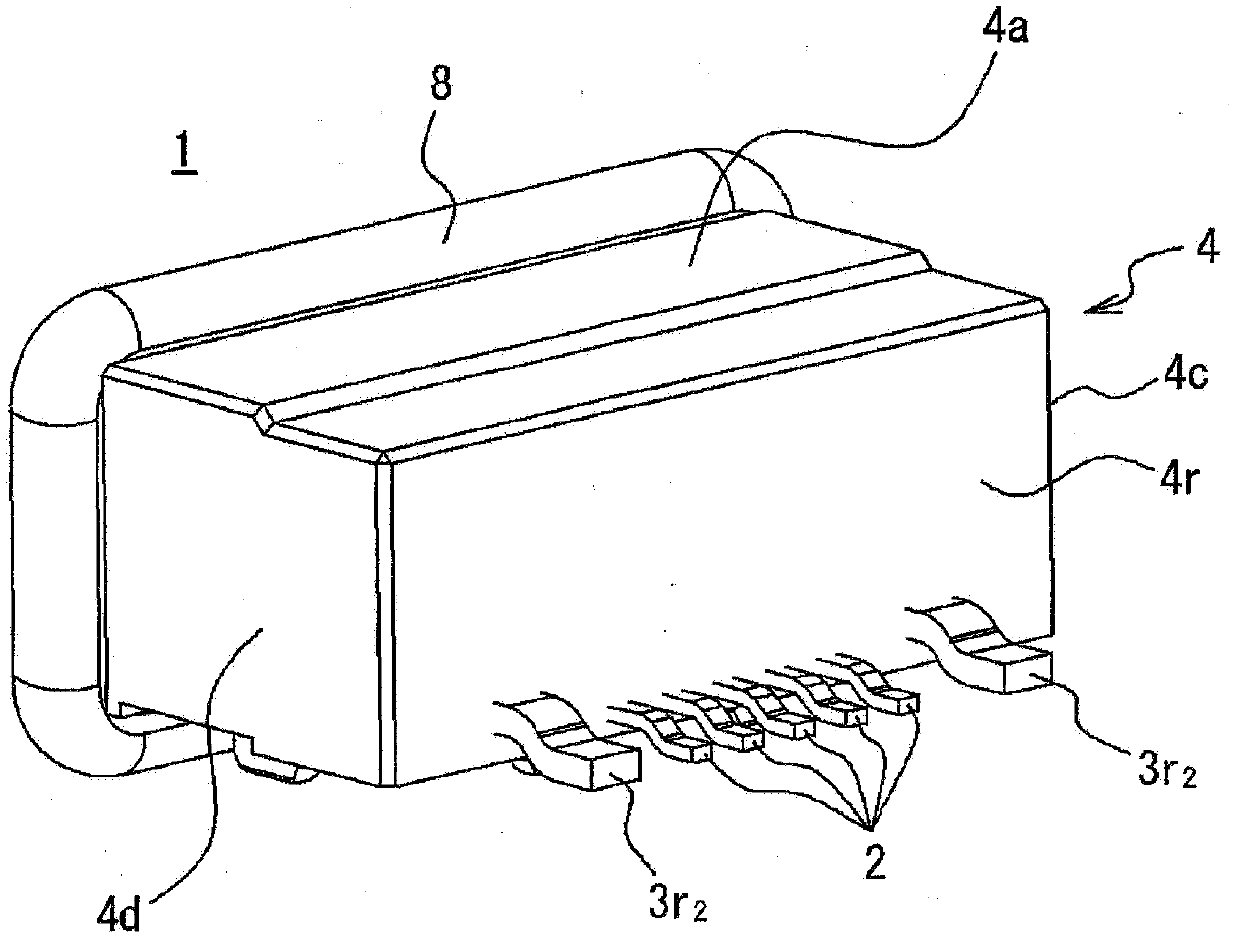

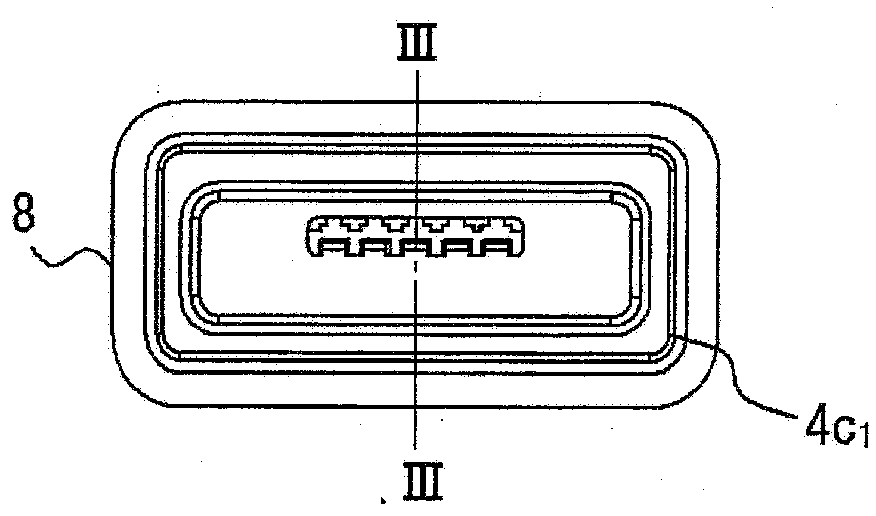

Water-proof connector and producing method thereof

InactiveCN102544888AImprove waterproof performancePrevent intrusionContact member cases/bases manufactureCouplings bases/casesEngineeringSealant

The invention provides a water-proof connector and a producing method thereof. The water-proof connector improves the waterproofness of a molded connector formed by inserting a metallic connector component in electrically insulating resin. The water-proof connector (1) is composed of a molded connector which is obtained in a manner that the metallic connector components forming the connector are inserted in the electrically insulating resin, enabling the electrically insulating resin to be a connector housing. The metallic connector components are a contact point (2) and a metallic cover (3), wherein the contact point (2) enables one end to electrically contact with the contact point of the connector; the metallic cover (3) is composed of metallic tube-shaped body which has an opening at at least one end and has a cavity hole communicated with the opening. The internal part of the opening is an insertion part for other connectors to insert. Water-proof sealants (Li1) for water resistance and sealing are filled in the contact point (2) and between the metallic cover (3) and the connector housing (4).

Owner:JST MFG CO LTD

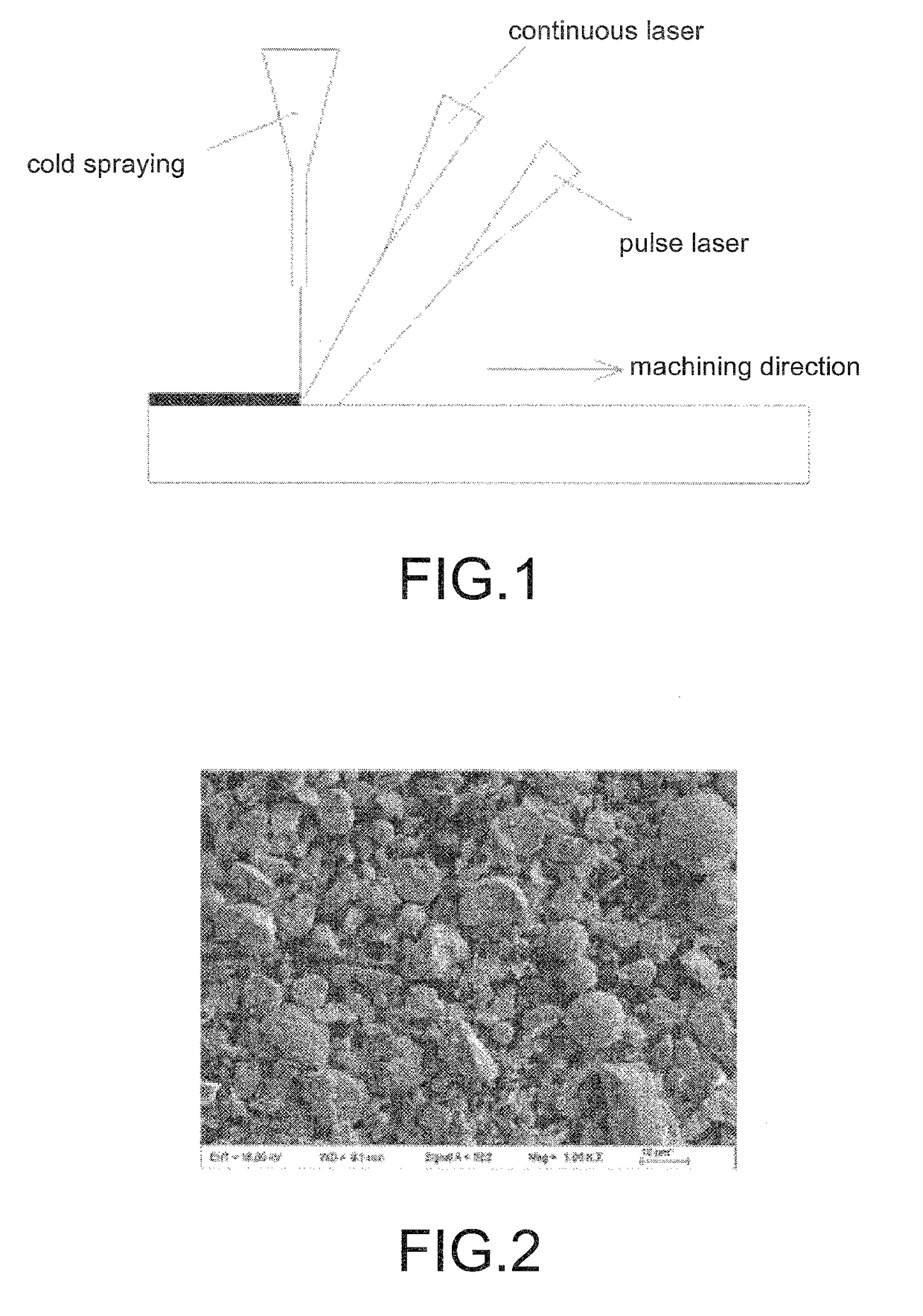

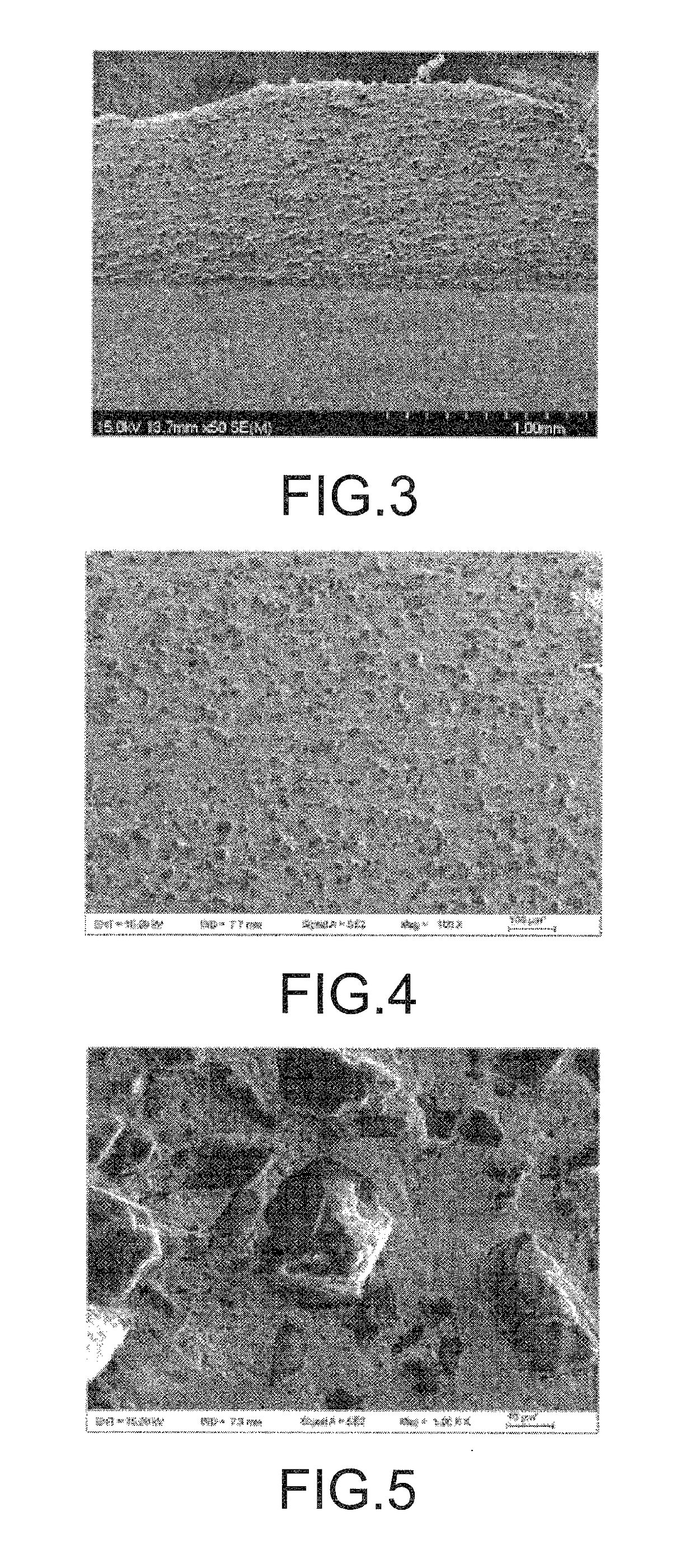

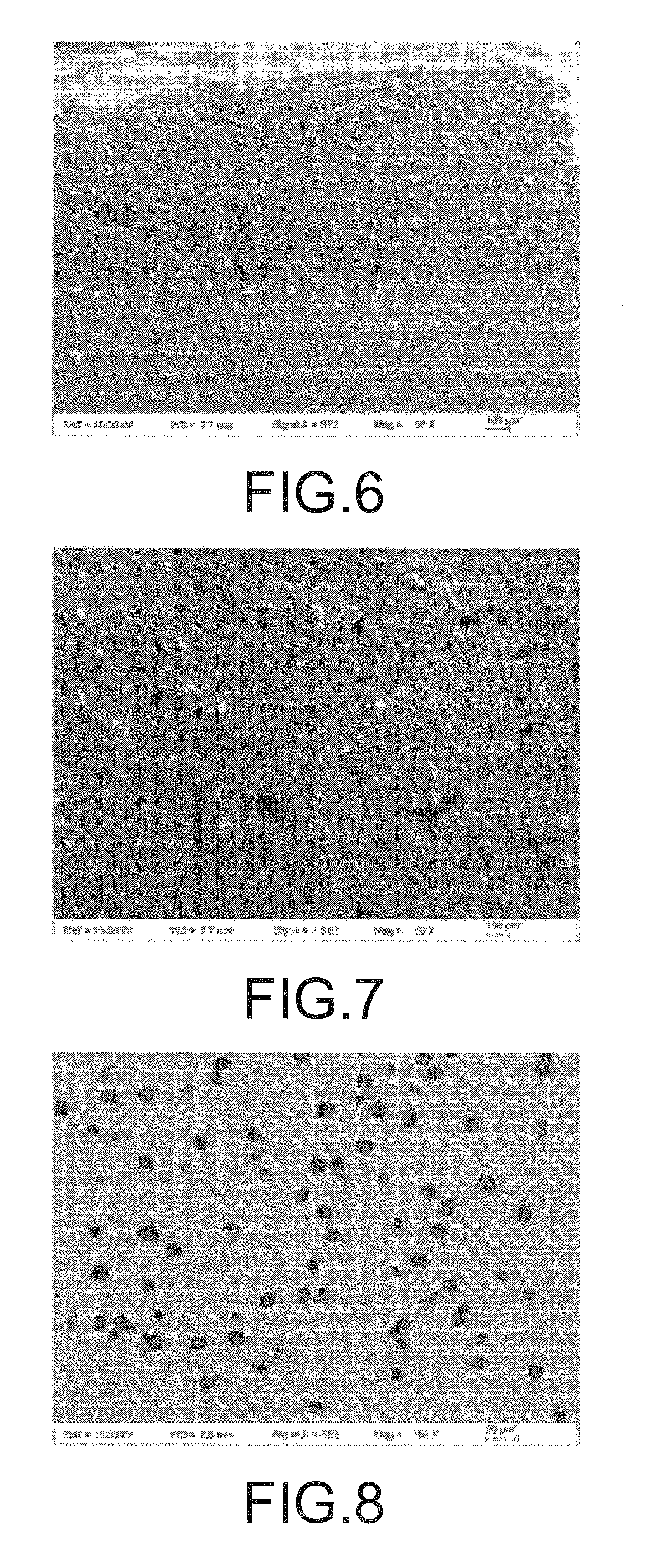

Metal-based/diamond laser composite coating and preparation method thereof

ActiveUS20170145568A1Raises content of diamondMaintain propertiesMovable spraying apparatusLaser beam welding apparatusMetal powderDiamond

A metal-based / diamond laser composite coating preparation method includes: first selecting high-hardness metal powder and diamond powder of a proper grain size and shape; then uniformly mixing the high-hardness metal powder and diamond powder via a ball-milling method; and finally preparing a composite coating on a substrate by synchronously combining laser texturing technology, laser thermal treatment technology and cold spraying technology. The thickness of the composite coating is greater than 1 mm, and the volume content of diamond in the coating is greater than 45%. A metal-based / diamond laser composite coating is also provided.

Owner:ZHEJIANG UNIV OF TECH +1

Styrenic insulation for pipe

ActiveUS8714206B2Improve insulation effectLow costThermal insulationCorrosion preventionThermoplasticCompressive creep

Owner:SHAWCOR LTD

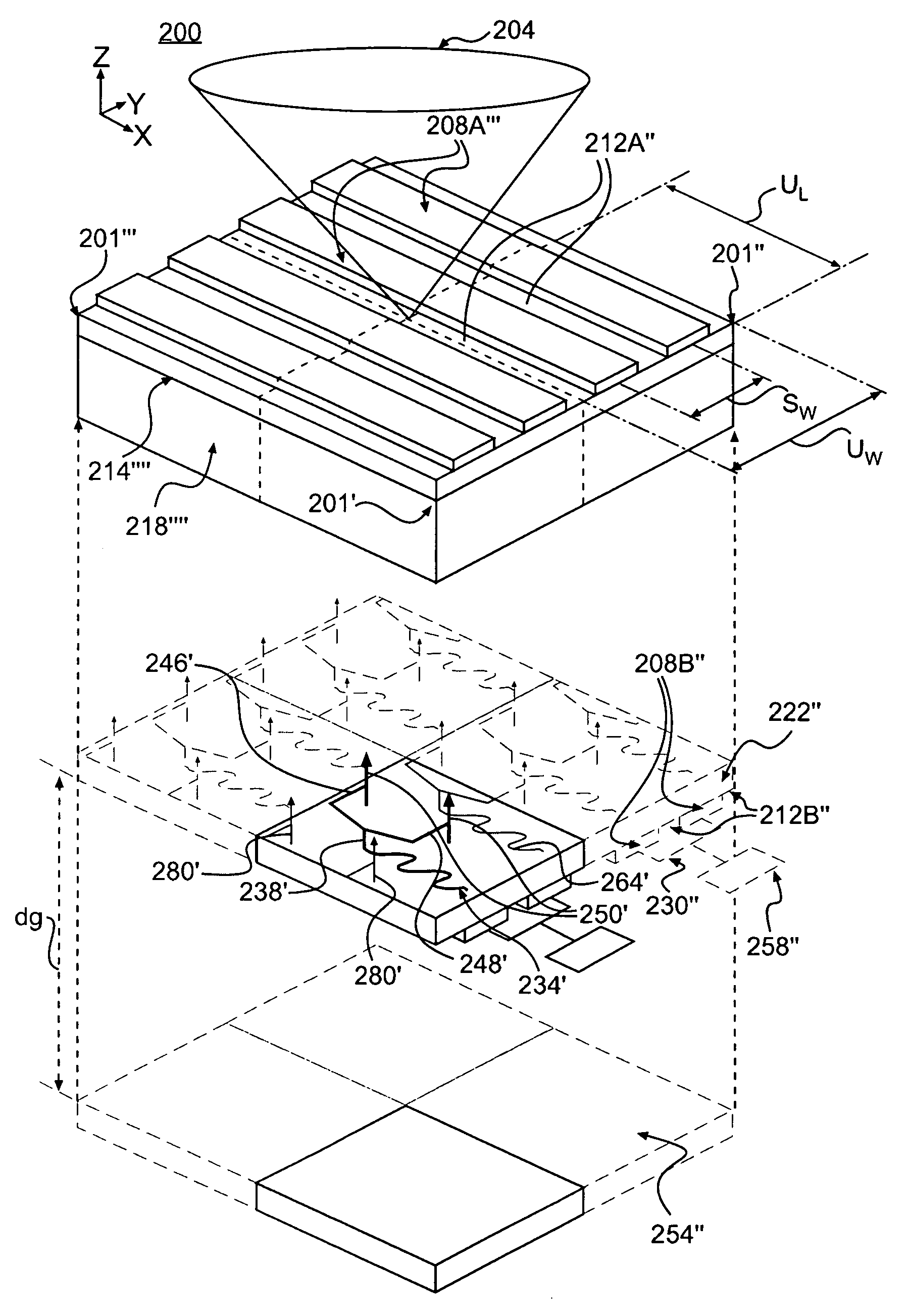

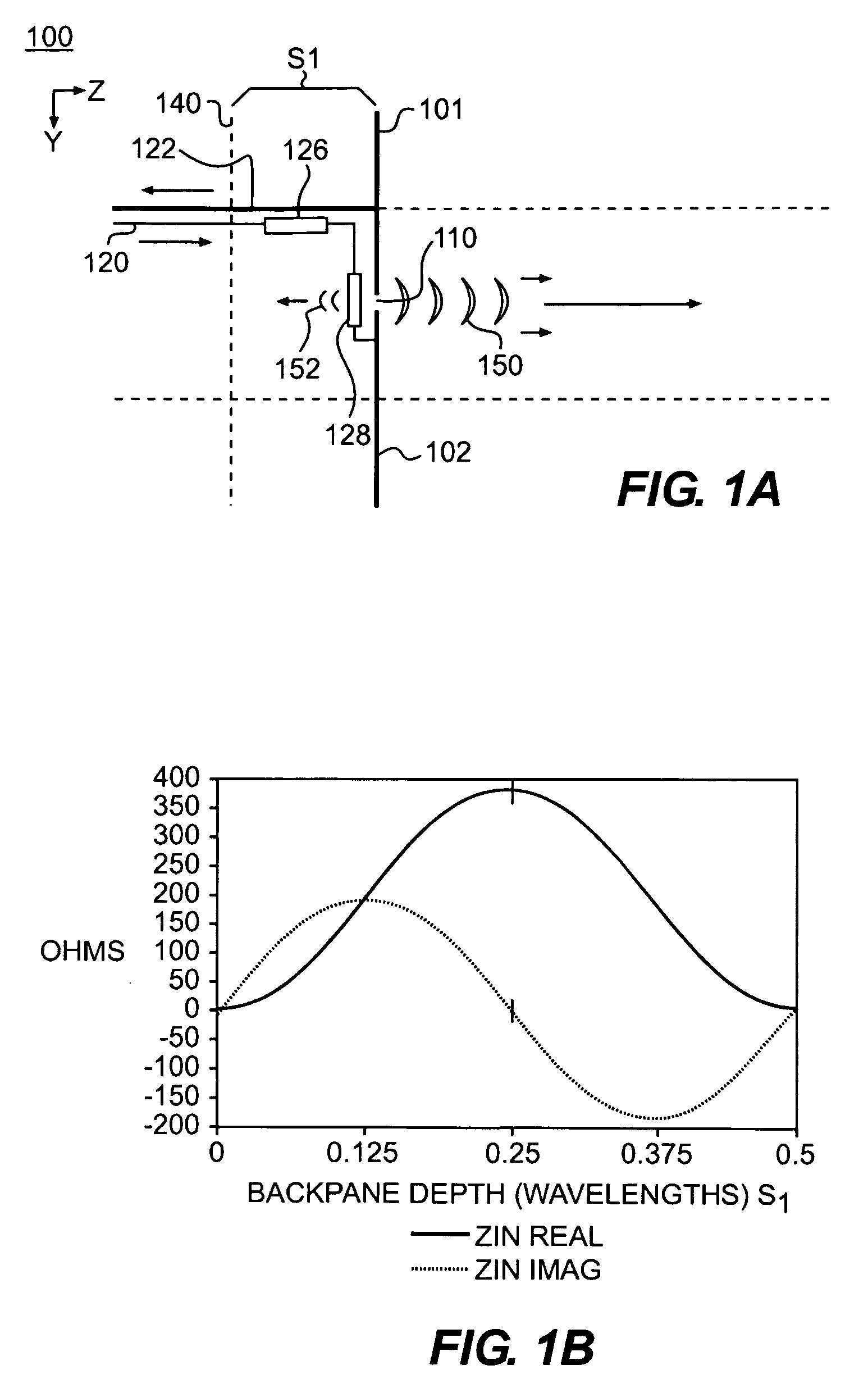

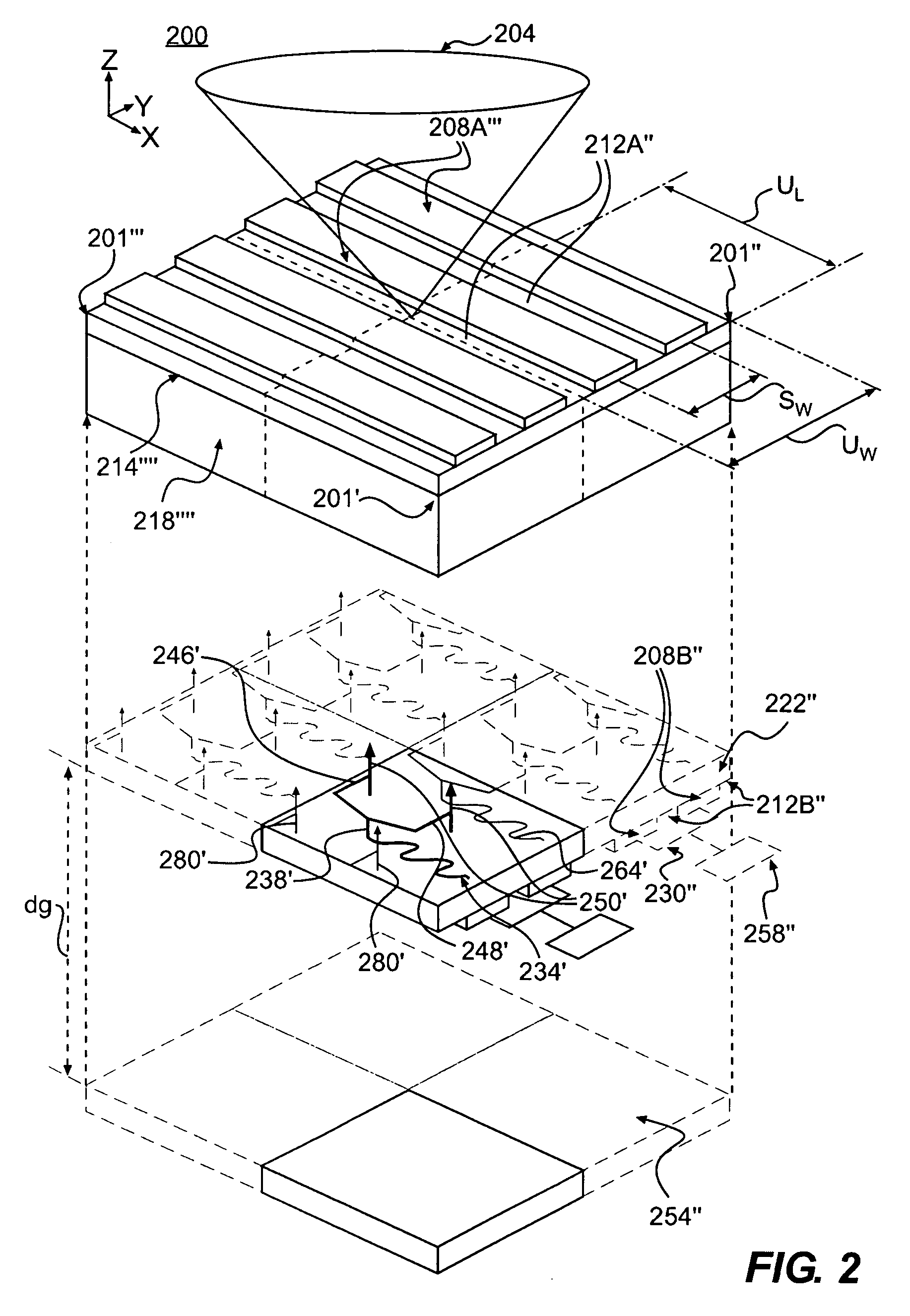

Wide band long slot array antenna using simple balun-less feed elements

ActiveUS20090322637A1Low costLow thicknessAntenna arraysSlot antennasTransceiverImpedance transformer

In one embodiment, a wide bandwidth, reduced depth transmit / receive antenna array includes unit cells having continuous slots, a transceiver, unbalanced feeds, impedance transformers, and exciters. The continuous slots are formed in a conductive antenna plane, and the transceiver generates and / or receives electrical signals. The unbalanced feeds may be electrically connected between the transceiver and impedance transformers which match the impedance between feed lines and the exciter. They may be located in a plane perpendicular to the direction of propagation of the radiation, and also may be arranged between the conductive antenna plane and a backplane. The exciter spans a continuous slot, and emits and / or receives radiation from the slot. The antenna array is capable of operating without a radome or balun.

Owner:RAYTHEON CO

Monolithic metallic self-ligating bracket with locking catch devices

InactiveUS20120052459A1Low thicknessEasy to cleanArch wiresBracketsEngineeringMechanical engineering

A monolithic metallic self-ligating bracket with a locking catch device is provided. The bracket includes a base, at least one tie wing and at least one locking catch device placed on one surface of the base. A slot in the middle of the tie wing extends in a generally mesial-distal direction. One end of a trailing arm connects with the base, and the other end of the trailing arm extends transversely toward the axis to form an arm tip, the inner edge of the trailing arm and arm tip towards the axis, together with the slot form an archwire concave. After the arch wire is inserted to the archwire concave, the locking catch device returns to its original shape, and the arm tip extending into the archwire concave of the locking catch device enclasps the arch wire, making the best use of the therapeutic force of the archwire.

Owner:BEIJING SMART TECH

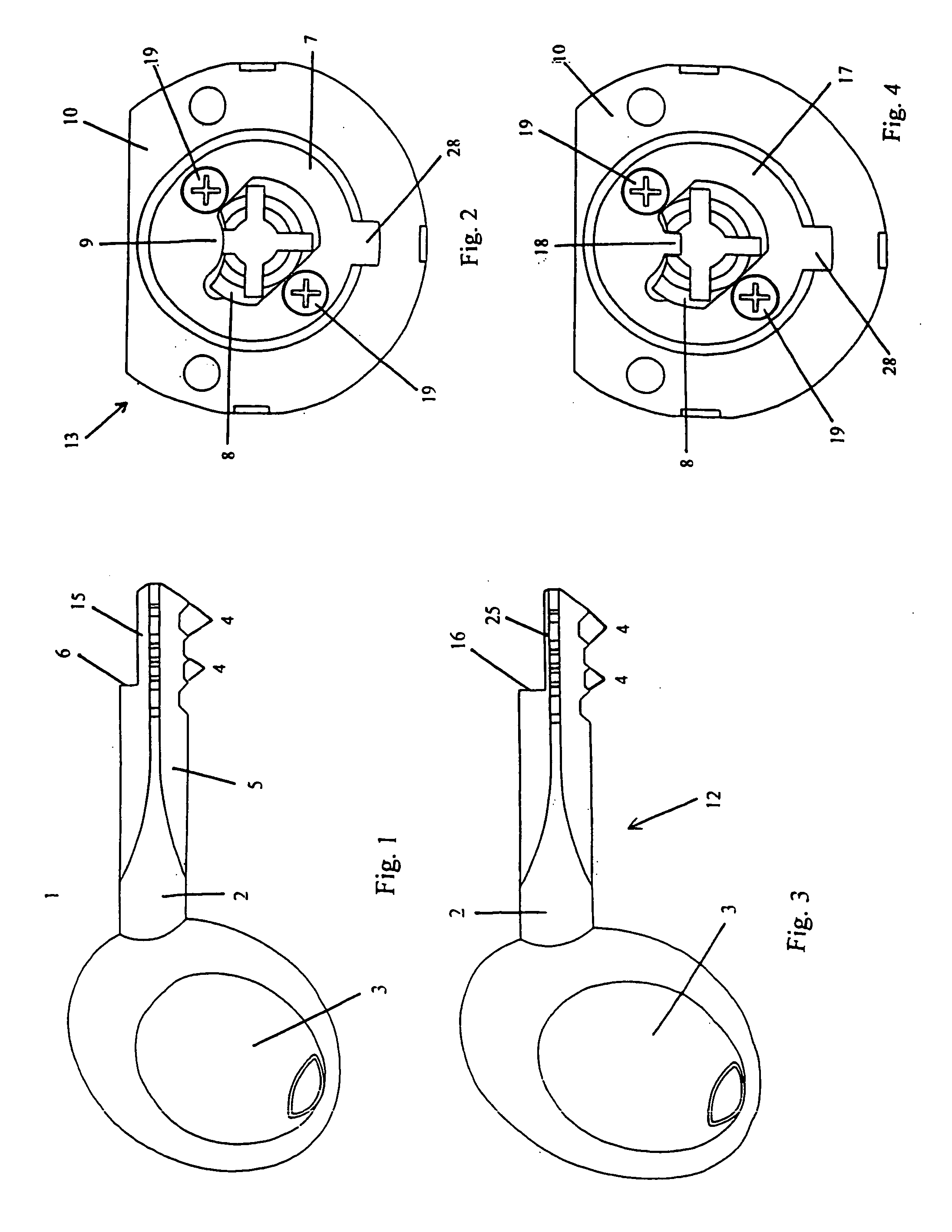

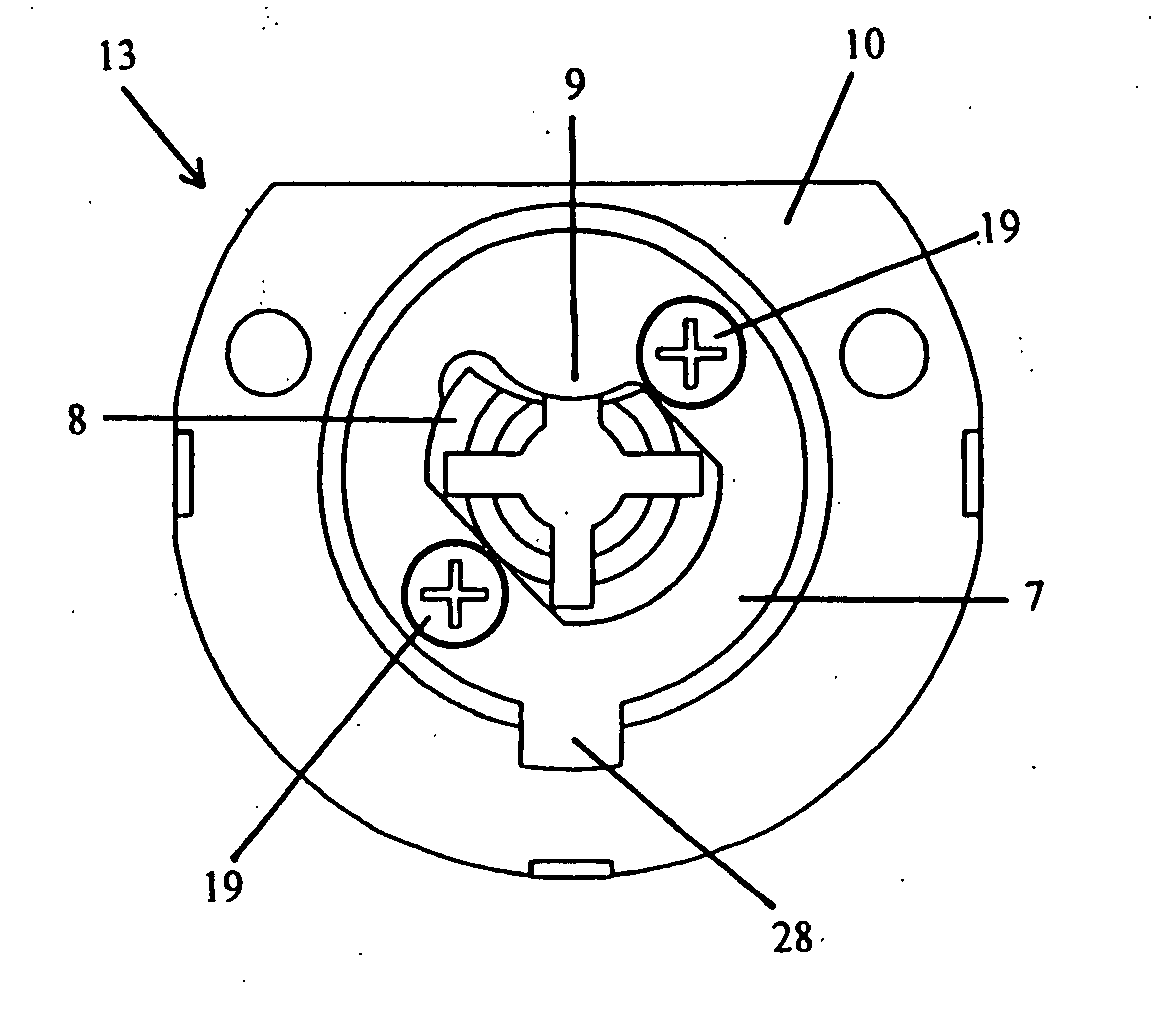

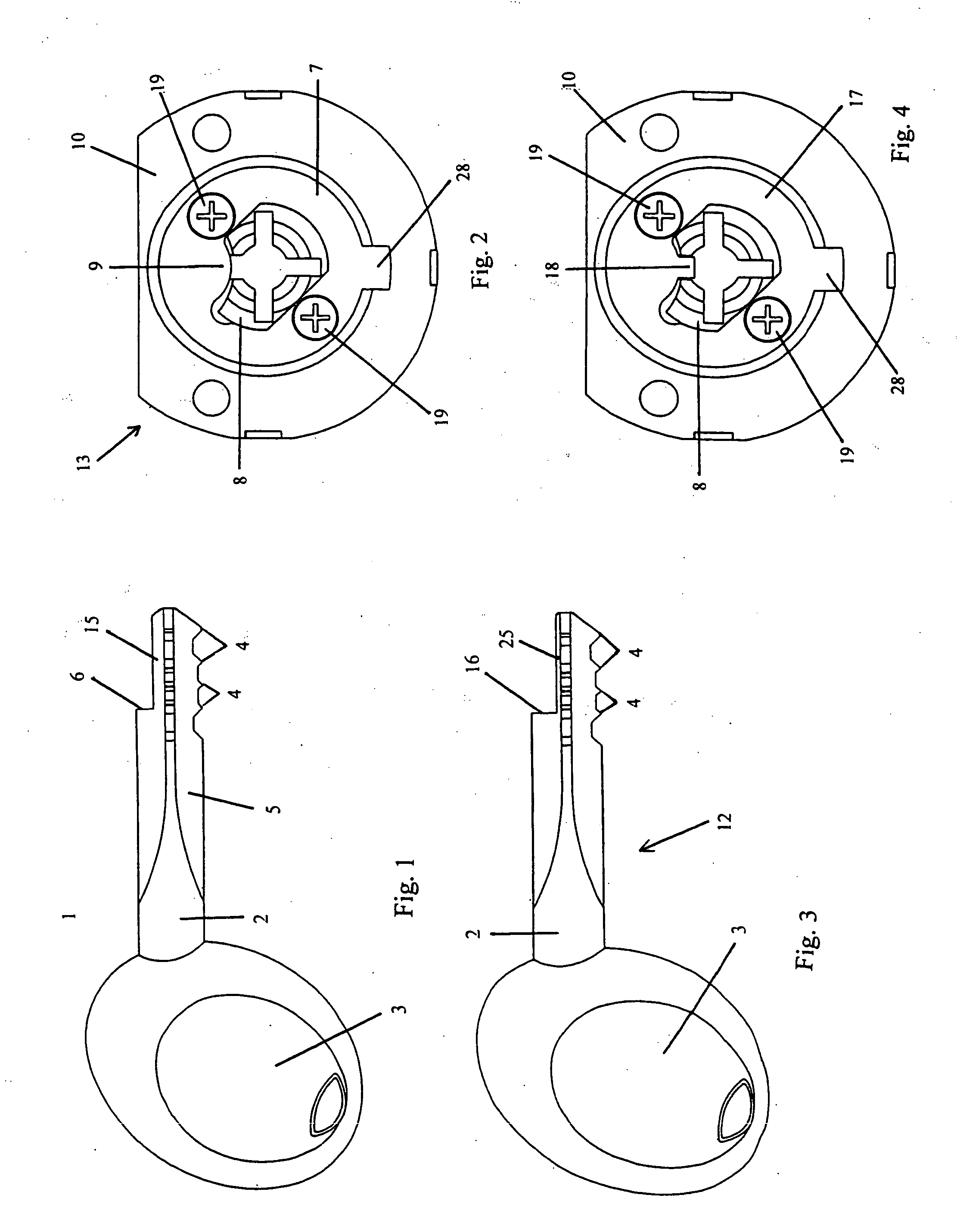

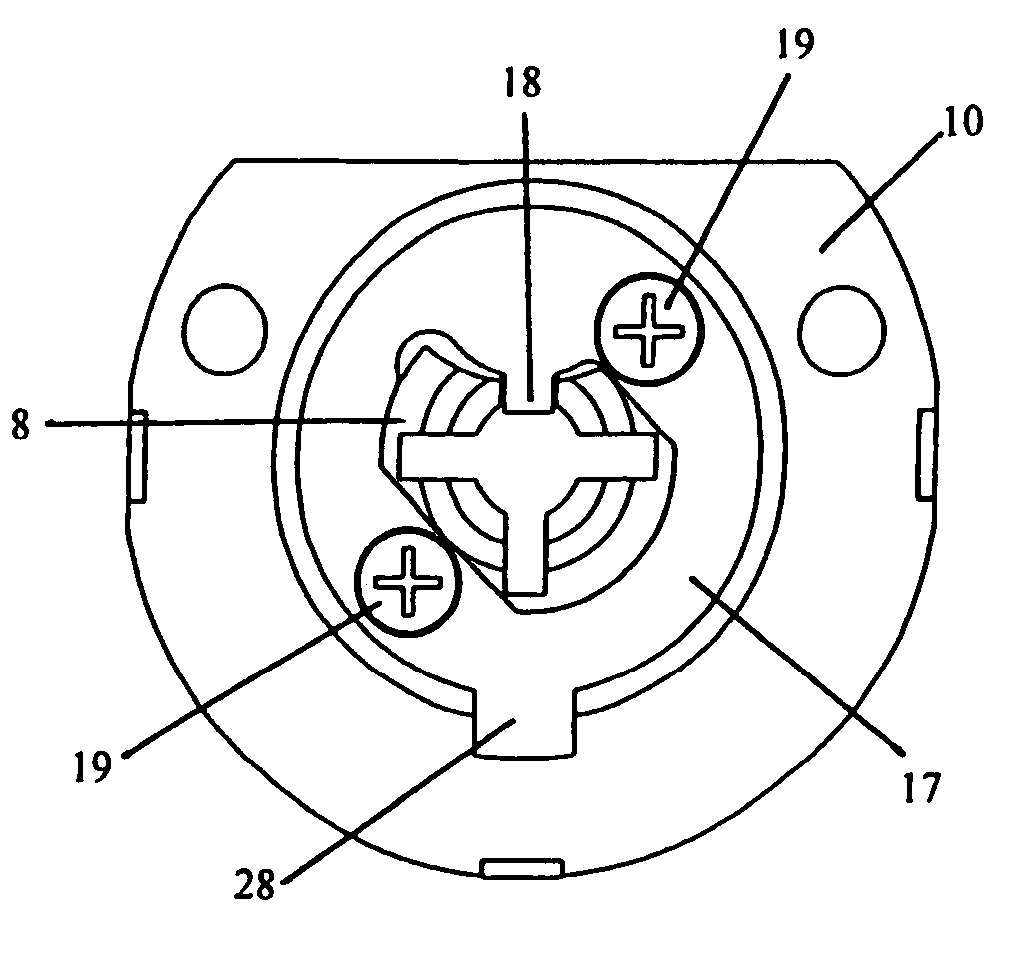

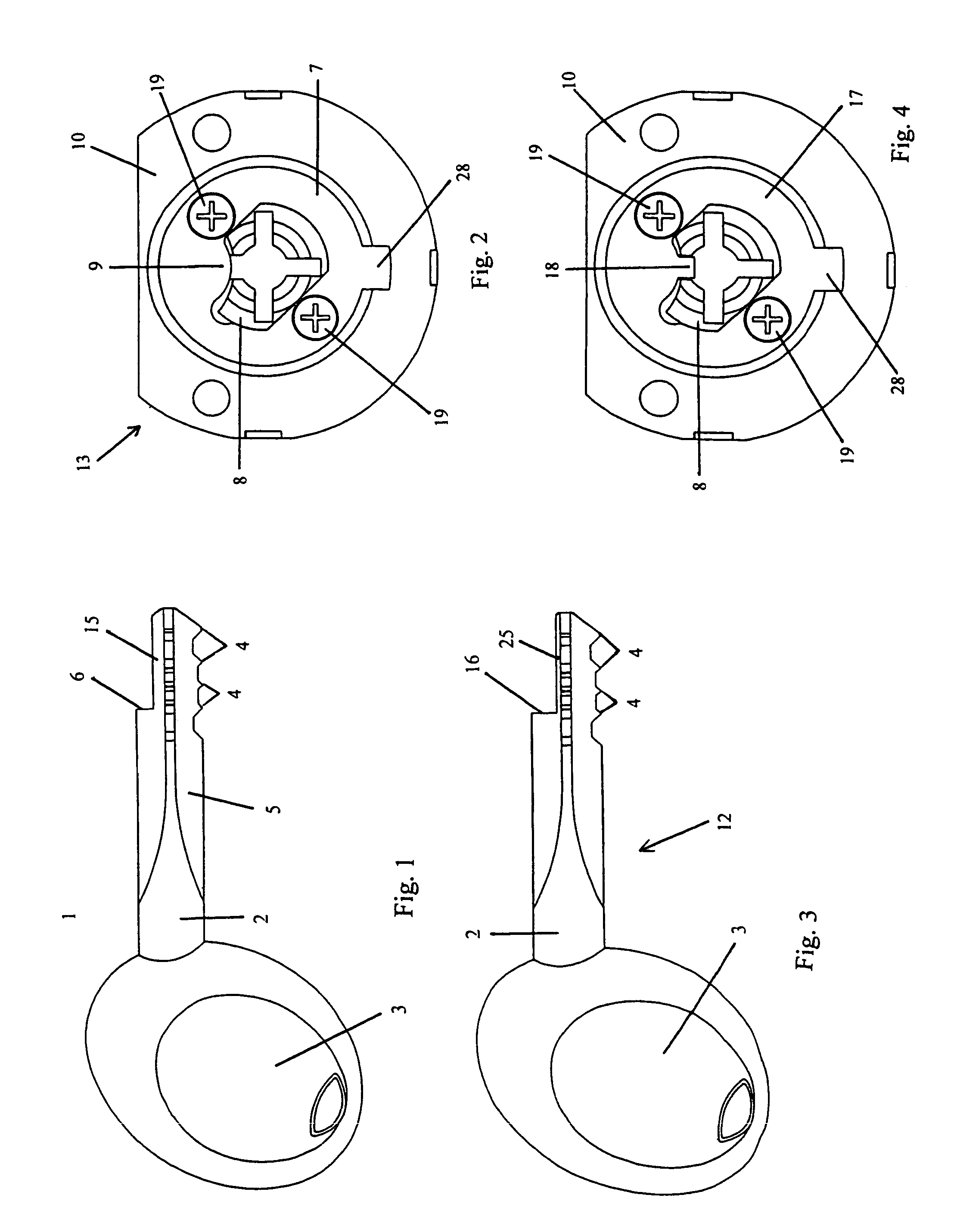

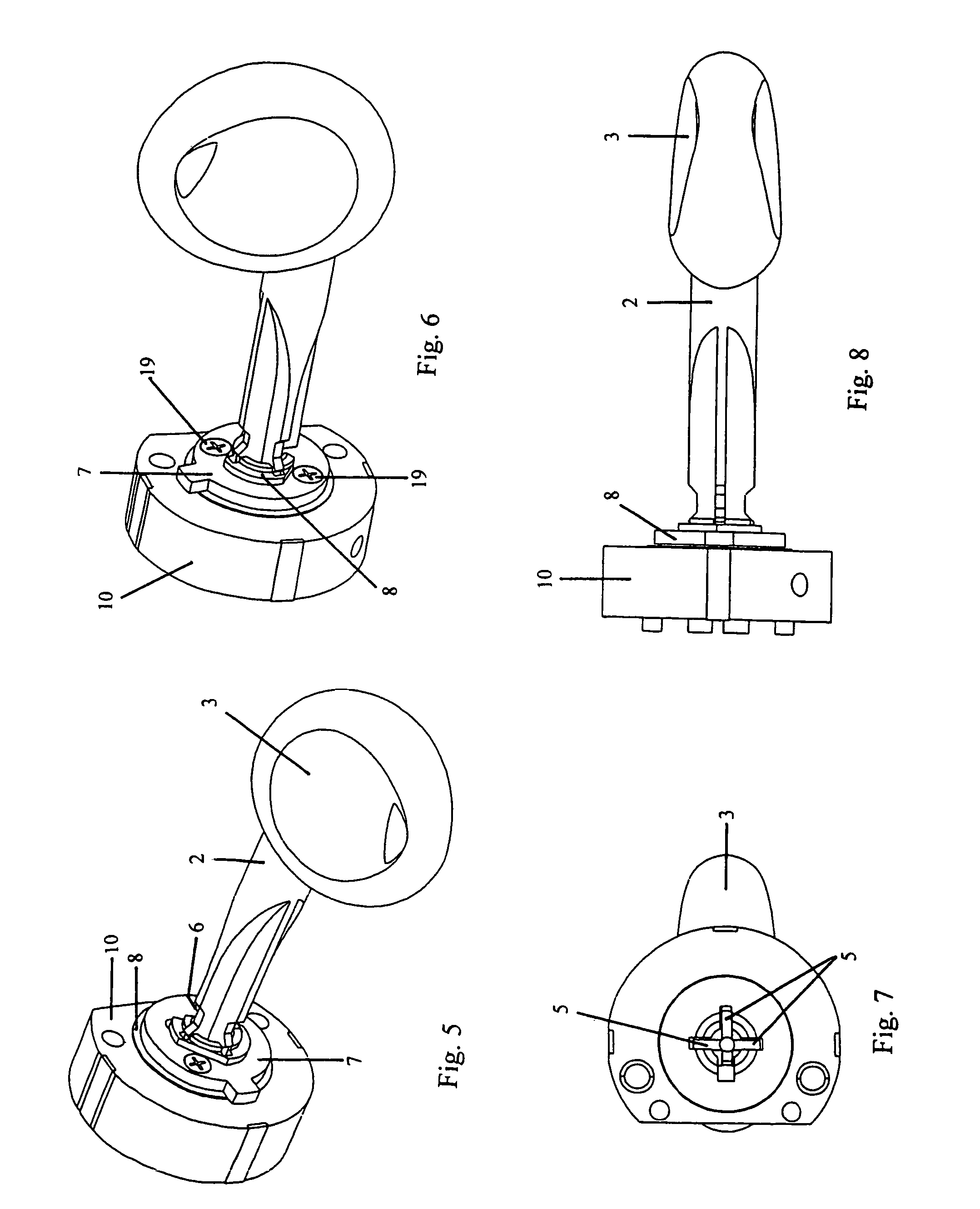

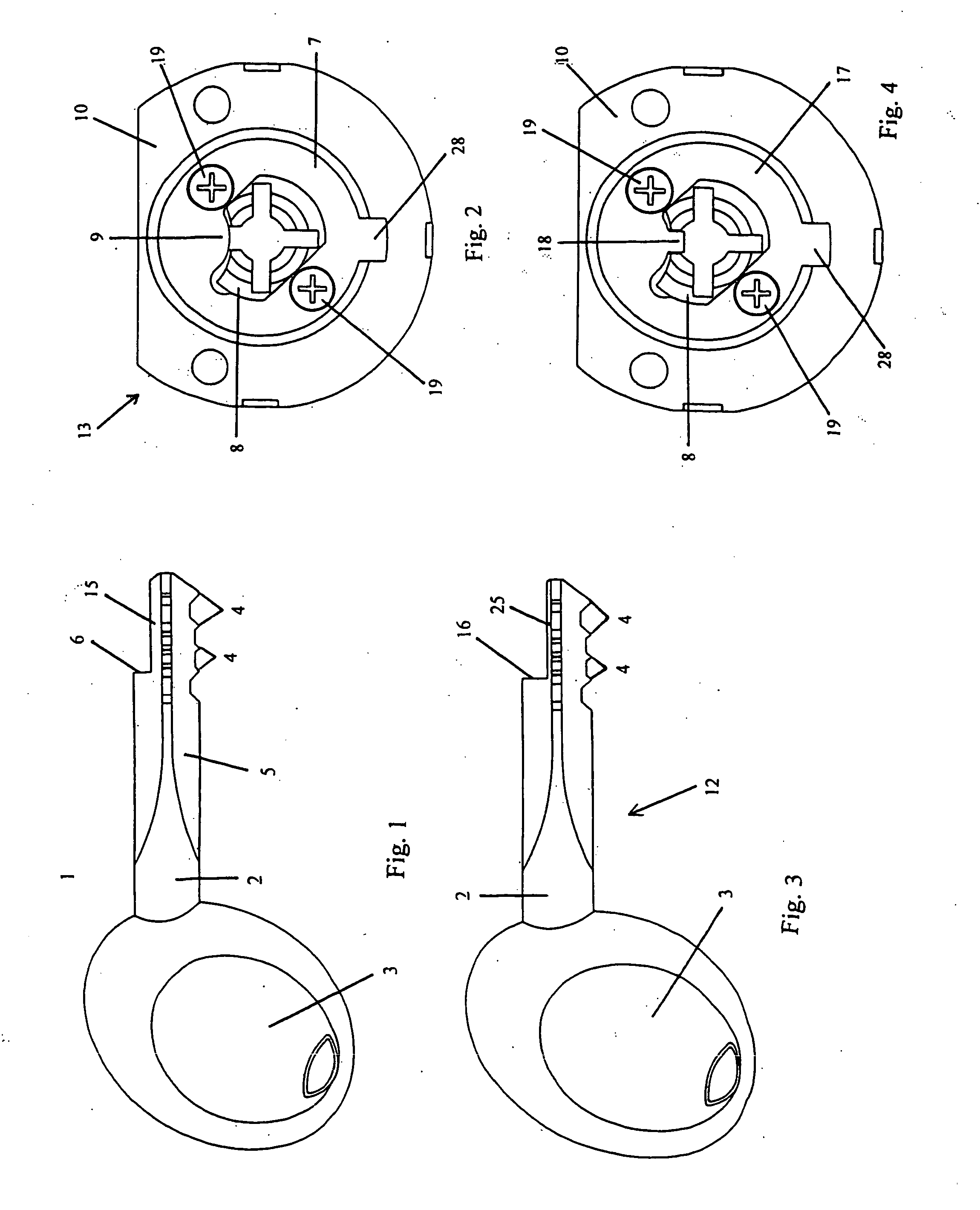

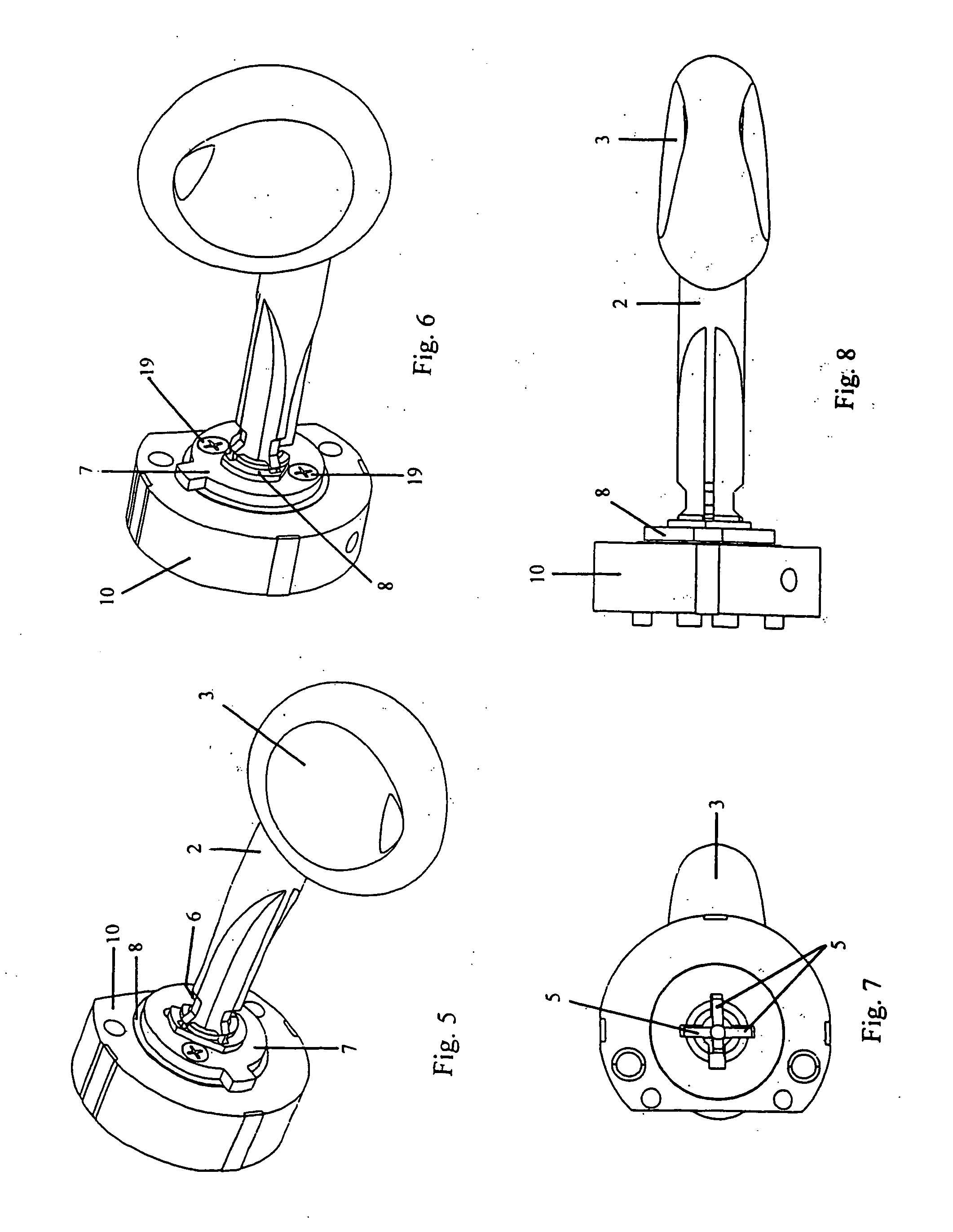

Lock cylinder

ActiveUS20050235713A1Readily adaptable to different thicknessEasy to operateKeysLock casingsEngineeringMaster key

A lock cylinder having a master key capability wherein the lock cylinder can be provided with either a master annular ring on the front of the lock plug which can only be opened by a master key or a low level security annular ring which permits the lock cylinder to be opened by either the master key or the low level security key.

Owner:SOUTHCO

Lock cylinder

ActiveUS7073360B2Readily adaptable to different thicknessEasy to operateKeysLock casingsMaster keyMechanical engineering

A lock cylinder having a master key capability wherein the lock cylinder can be provided with either a master annular ring on the front of the lock plug which can only be opened by a master key or a low level security annular ring which permits the lock cylinder to be opened by either the master key or the low level security key.

Owner:SOUTHCO

Process for preparing a thermal insulation coating paint with flexibility and lightness properties

ActiveUS20100152366A1Improve the level ofFlexibility and lightness propertyLiquid surface applicatorsInksThermal insulationPliability

A process is described in which, through the combination of certain components, a thermal insulated coating paint is obtained having the properties of flexibility and lightness (low density) in a film of low thickness. This coating paint offers better thermal insulation properties with a low thickness film than other insulators having greater thickness, without requiring any additional protection. These properties are provided due to the internal structure of the coating paint wherein internal caverns are formed by the reaction of ramified chain polymers and additional materials. These characteristics are not present in traditional coating paints.

Owner:PEREZ HINOJOSA ULISES ELADIO

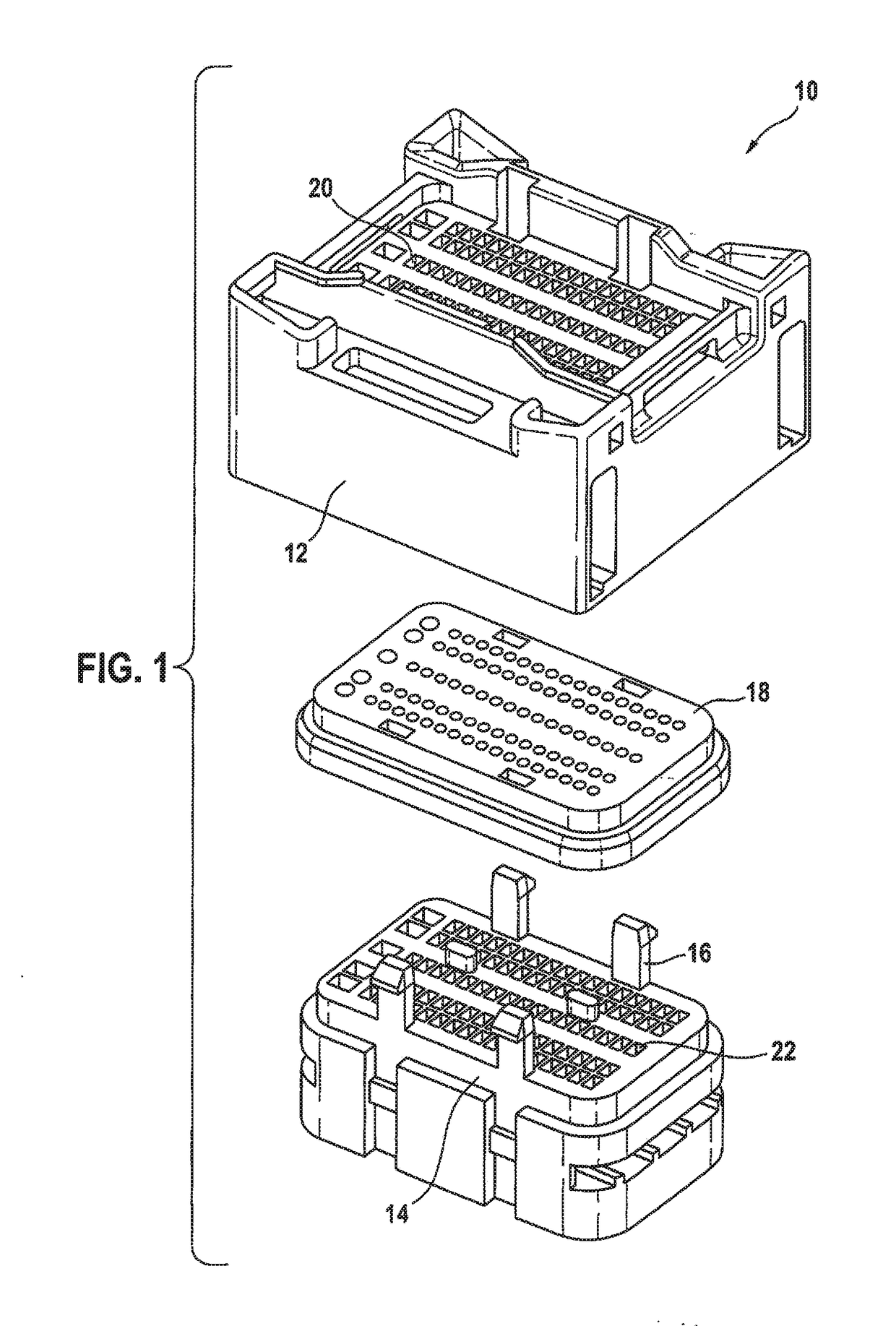

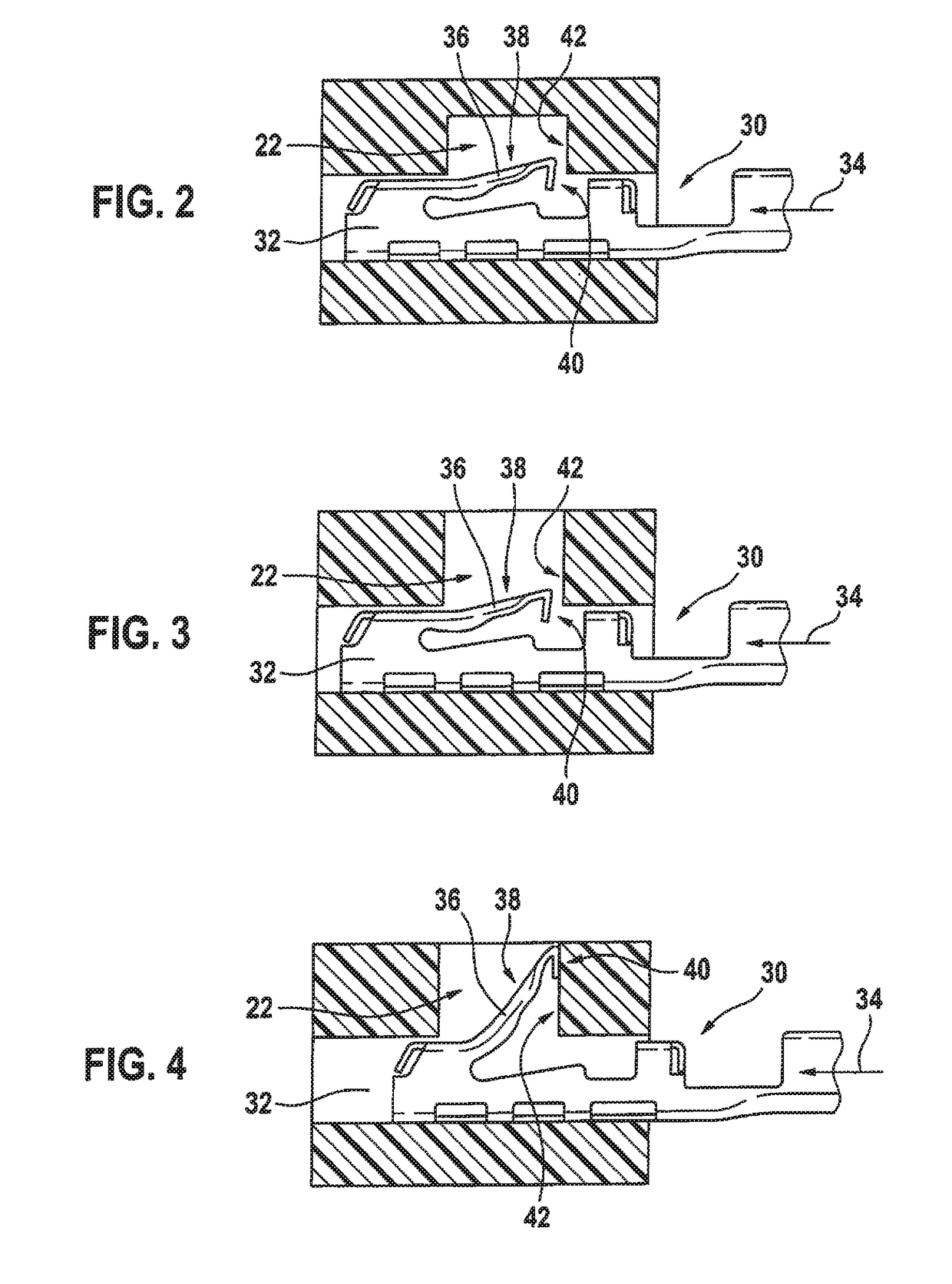

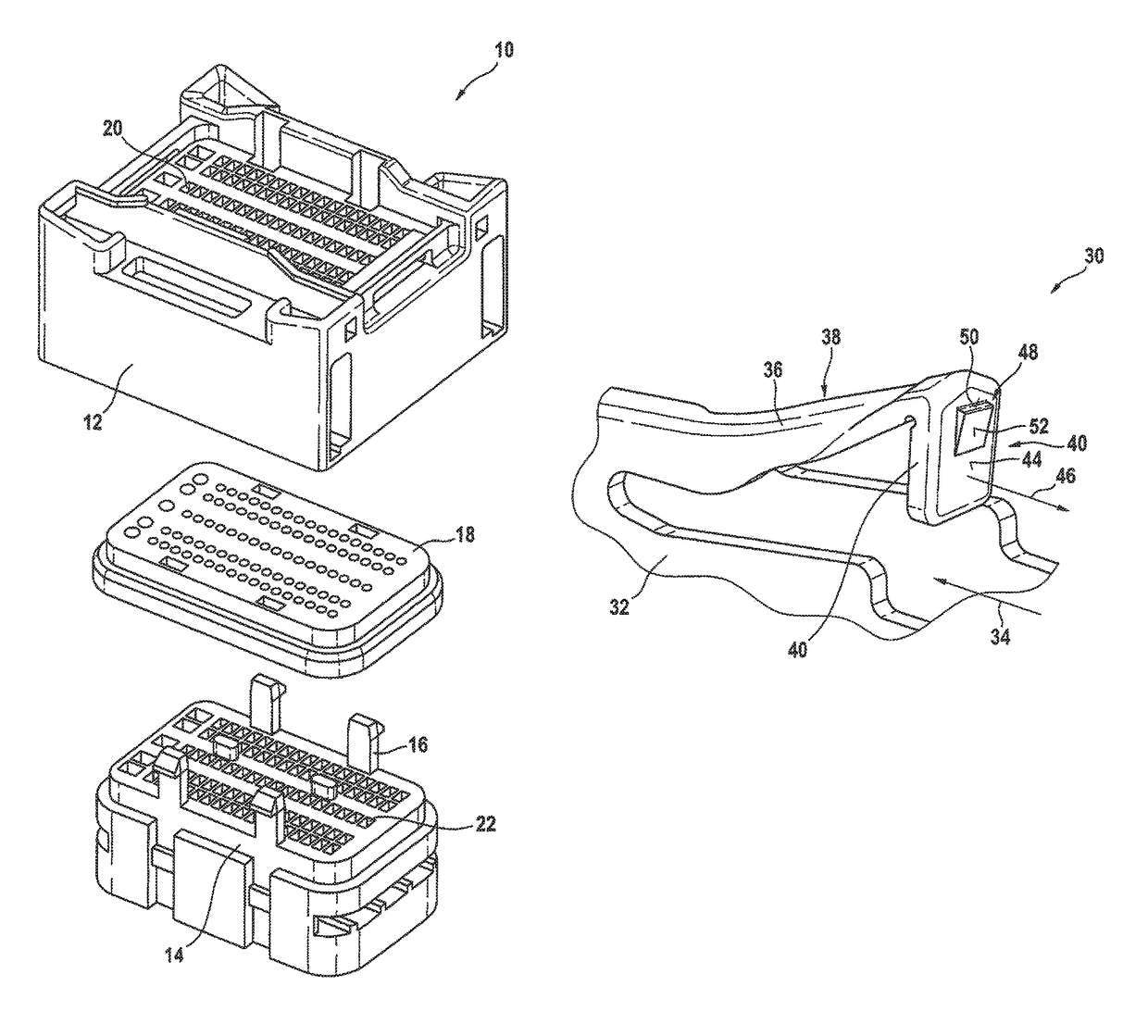

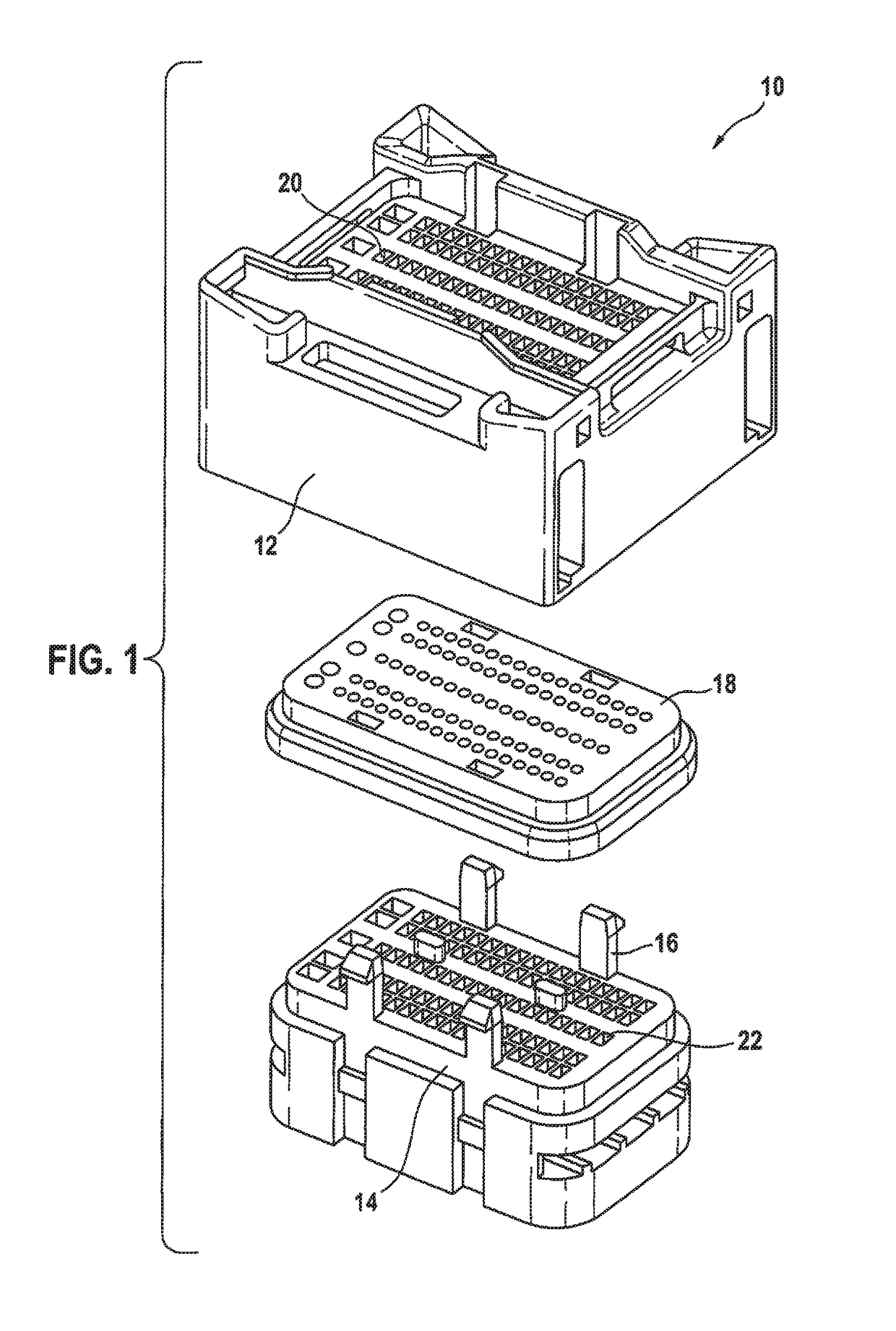

Catch element of a contact having a nose-shaped projection

ActiveUS20170133783A1Prevent movementLow elastic modulusCoupling device detailsEngineeringMechanical engineering

Owner:ROBERT BOSCH GMBH

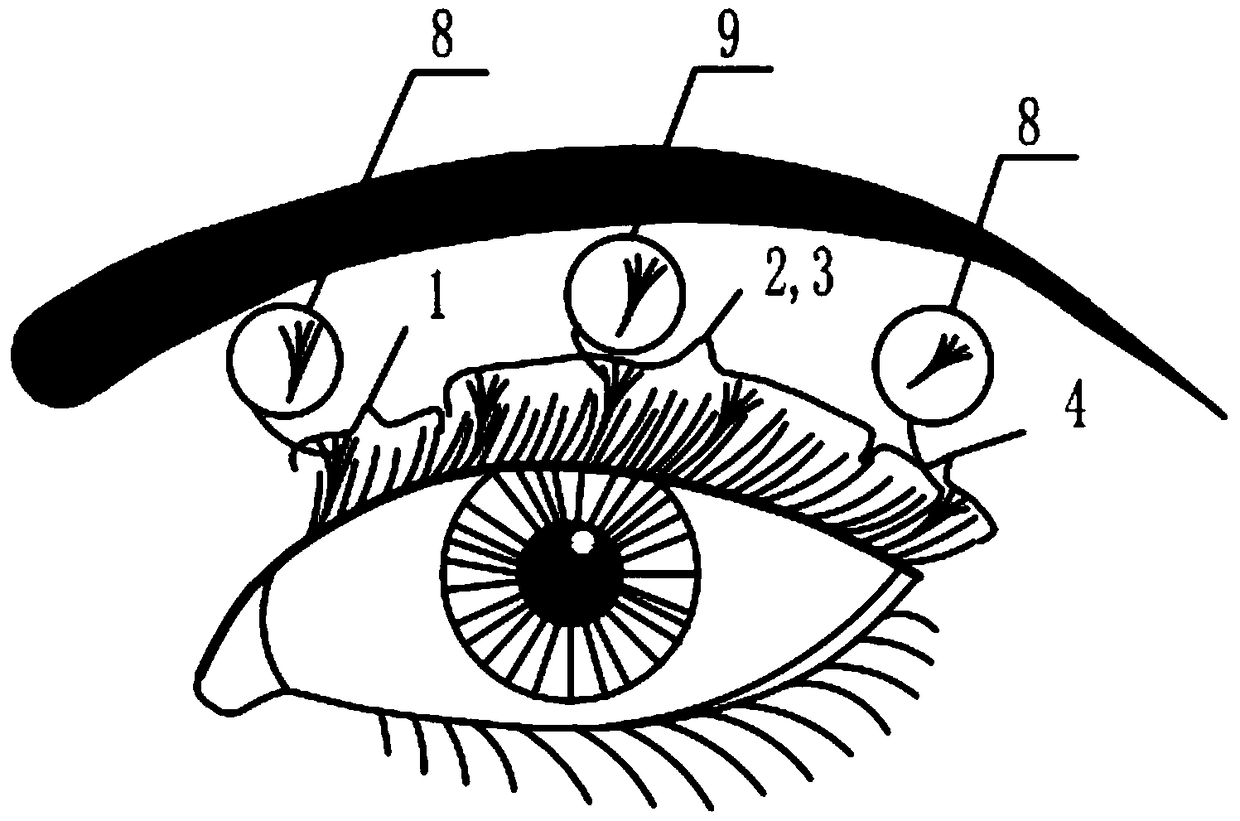

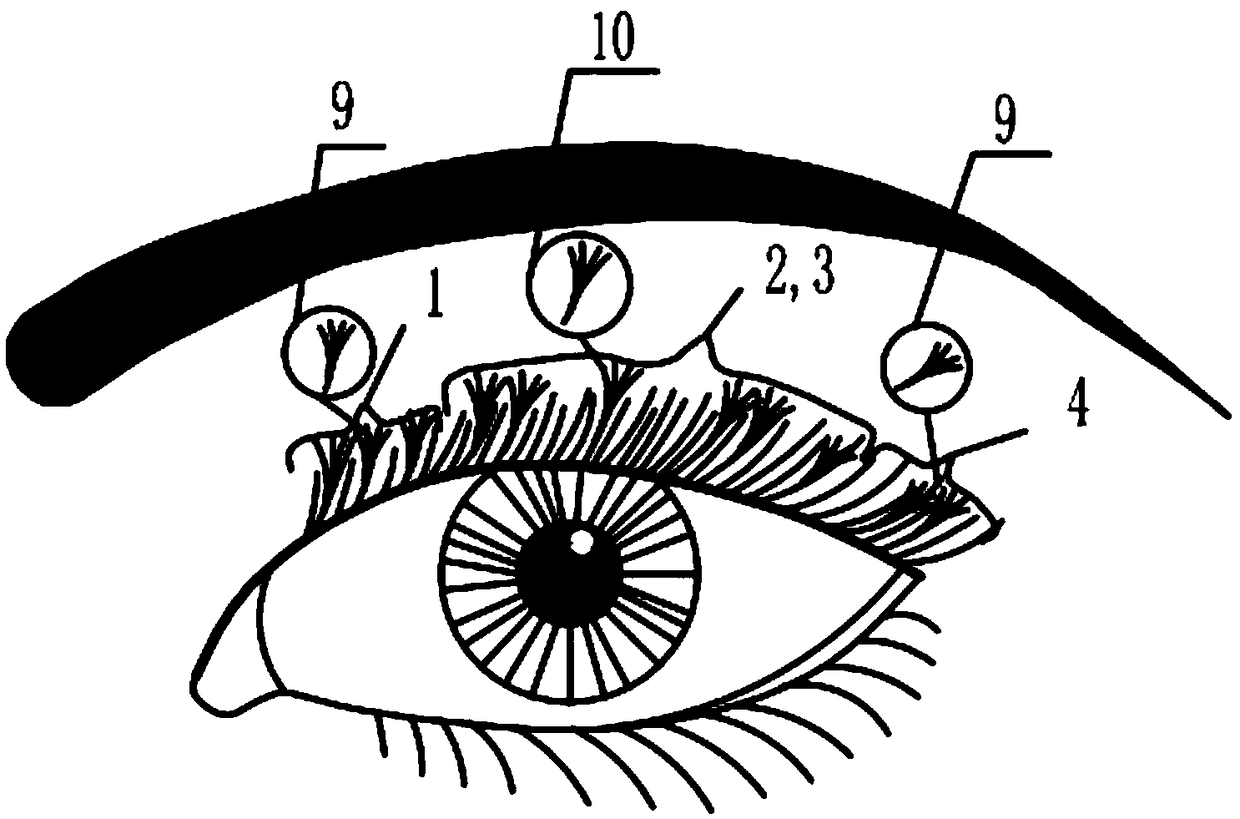

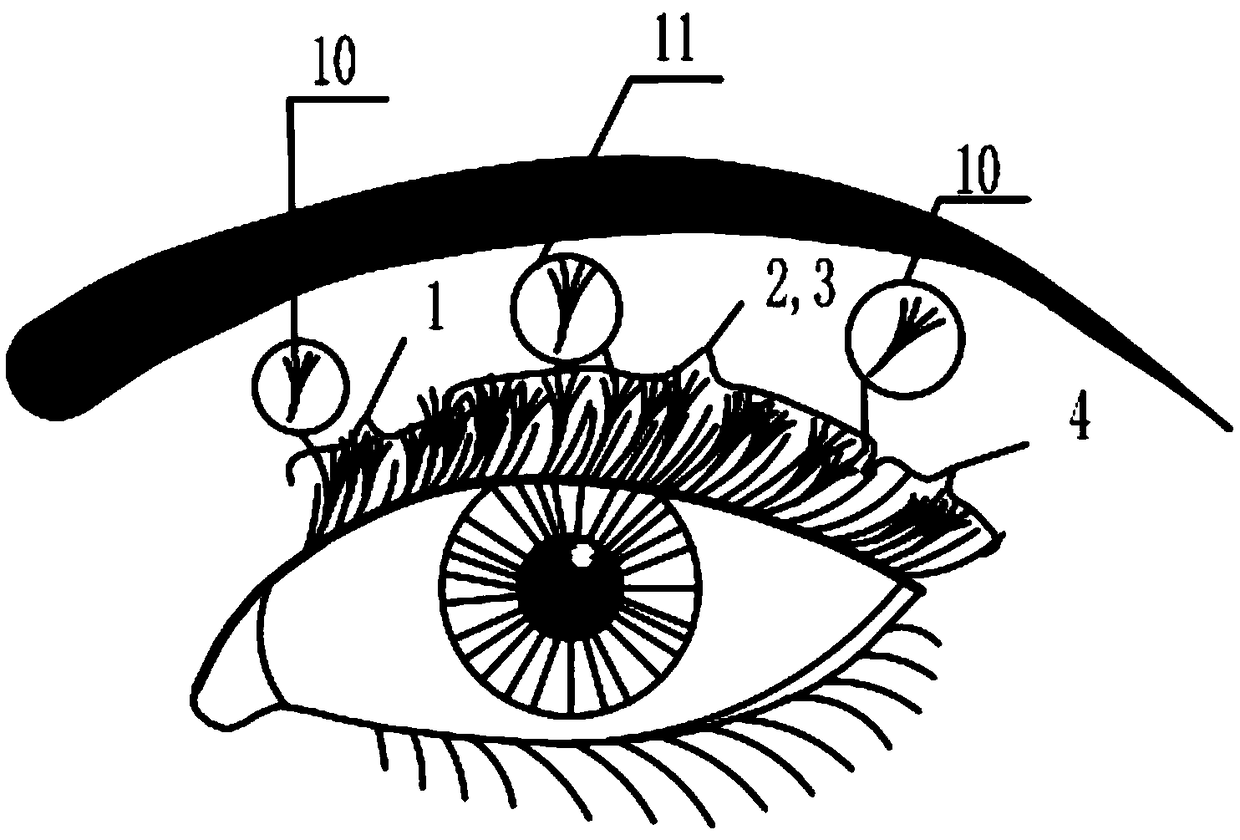

Method for multifarious eyelash grafting

The invention provides a method for multifarious eyelash grafting, which comprises a knitting method, a micro-warping method, a single grafting method, a camellia grafting method, an infantile interlacing method, a lower eyelash grafting method and an icicle grafting method. The method for multifarious eyelash grafting requires the following tools: cleaning fluid, surgical alcohol, medical cottonsheets, special magnetic glue for eyelashes, a flower clip, a straight clip, a dolphin clip, a crystal table, collagen eye pastes, eyelash, a mascara brush, a medical adhesive tape, and a small fan for grafting eyelashes. A dense and long-lasting eyelashes achieved by the method for multifarious eyelash grafting can make up for people who have defects with the eyelashes. The method for multifarious eyelash grafting has the advantages of being quick, meticulous, and long-lasting. 300 eyelashes can be grafted in 20 minutes. The minimum thickness of an eyelash is 0.05 millimeter. The duration ofeyelashes can be enhanced by 40%. The use of the unique 'flowering' technique and eyelash grafting products with certain characteristics can achieve natural eyelashes without burden and natural falling of eyelashes.

Owner:曹杰

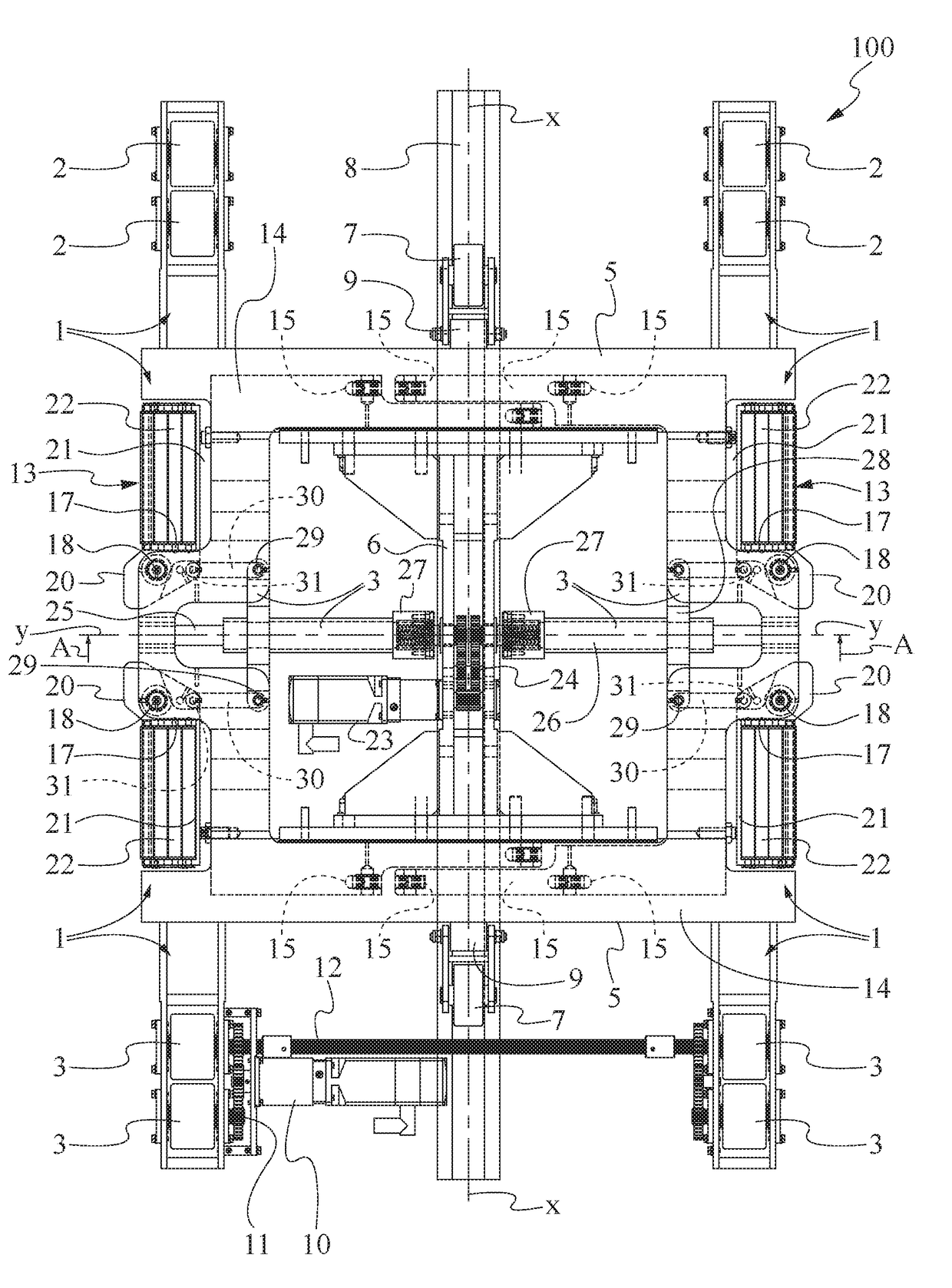

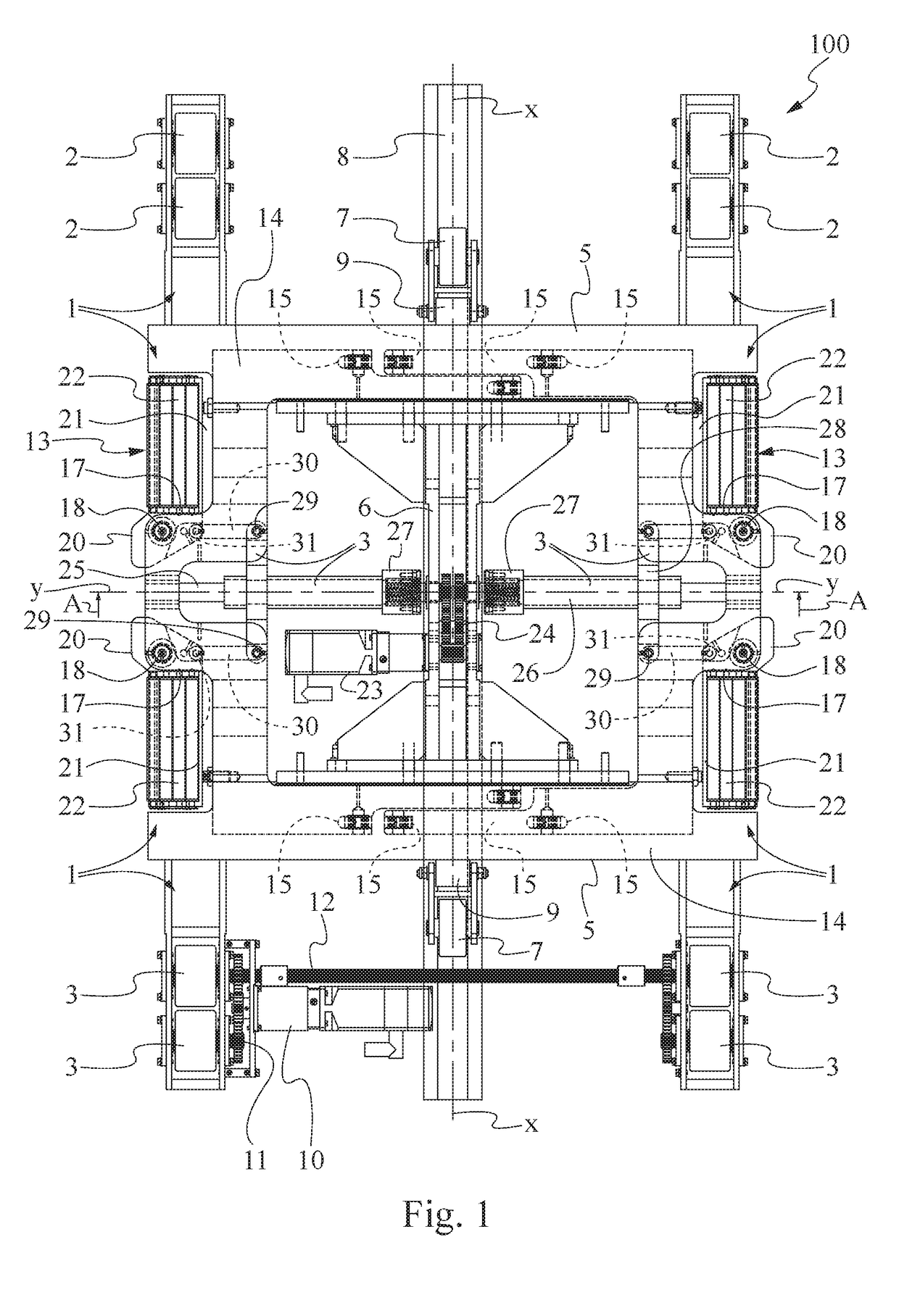

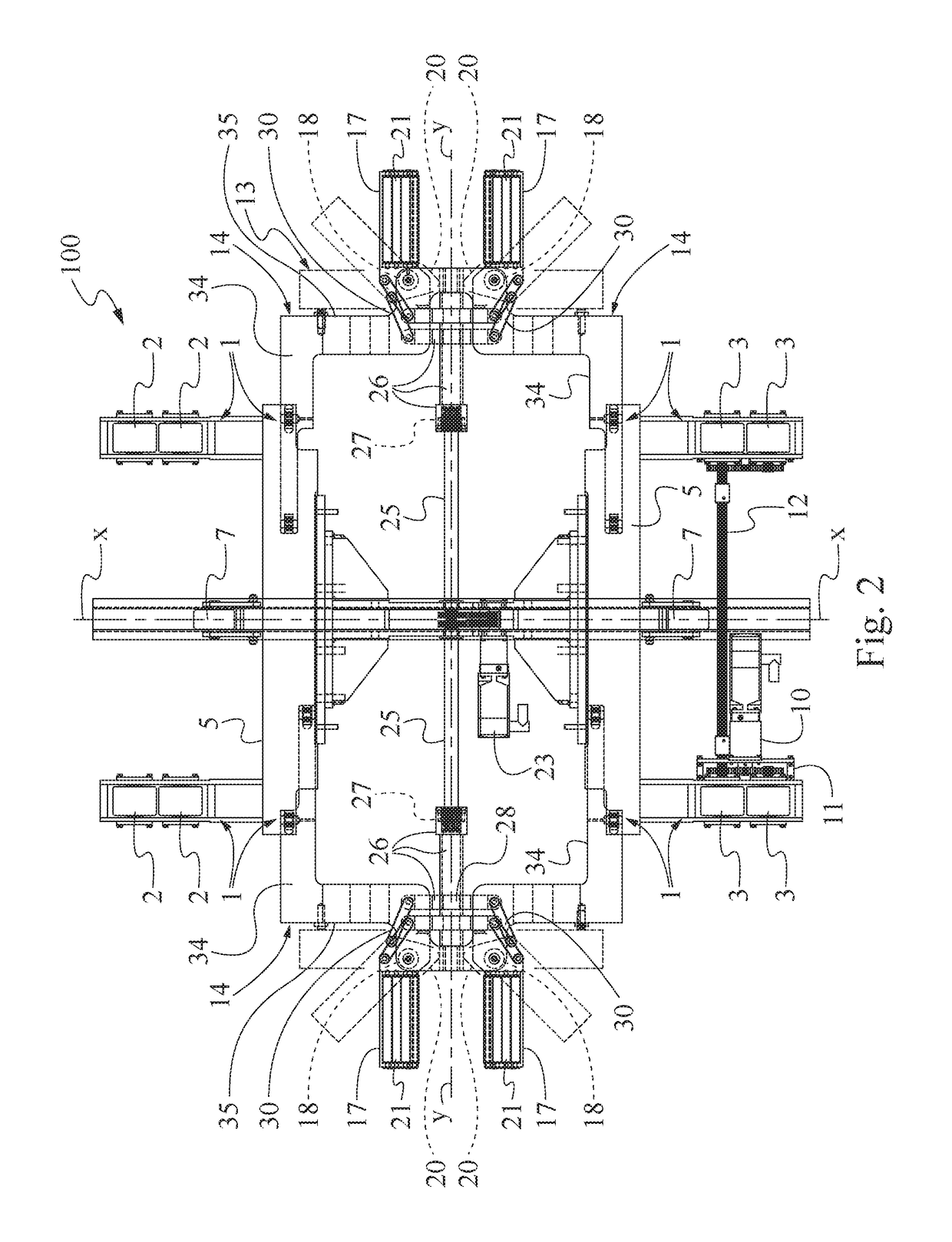

Transferring carriage of vehicles for an automatic mechanic parking system

Transferring carriage (100) of vehicles for automatic mechanic parking systems comprising at least a frame (1); means of handling of said carriage (100); and at least a device (13) of centering, raising and keeping up of the wheel (32) of a vehicle, said device (13) comprising at least a couple of clamp elements (17) and at least a movable support (14); each couple of clamp elements (17) being supported by said movable support (14); said movable support (14) being transversally translatable for positioning said clamp elements (17) of a same couple in proximity of a wheel (32) of an axle of a vehicle such that the centering, raising and keeping up of the two wheels (32) of an axle of a vehicle is achieved by means of a single transversal movement towards outside of the carriage of said at least one movable support (14) and of the couple of clamp elements (17) integral therewith.

Owner:SOTEFIN PATENTS

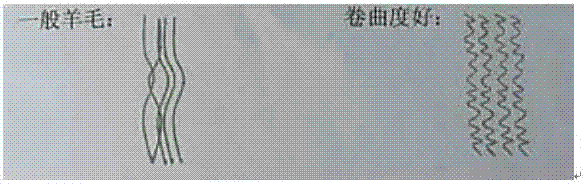

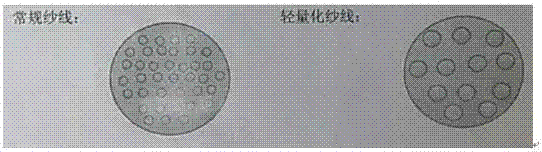

Preparing method of light weight wool yarn for roving

The invention discloses a preparing method of light weight wool yarn for roving. The method comprises the first step of adding oil water and an antistatic agent with a certain proportion into a wool mixed material of wool raw materials and chemical fiber, and conducting intensive mixing, wherein the length of the wool mixed material is 5cm or above, and the wool mixed material is in a wavy shape; the second step of carding the wool mixed material in which moisture is absorbed till a spinning requirement is accorded with, controlling the clip distance between roller cylinders to be in a relaxed state till the fiber is not straightened, and then making rove with no twisting degree through winding; the third step of firstly conducting unwinding on wound rove with no twisting degree to form wool yarn, and then lengthening shaft distances in the unwinding process till no tension exists; the fourth step of feeding and winding two ends of each of the wool yarn and filament with a twisting degree; the fifth step of winding two pieces of yarn prepared in the fourth step under the condition that airflow is blown to the yarn. According to the preparing method of the light weight wool yarn for roving, innovation is made in both material selection and technology, the design and manufacturing technology of the wool yarn are a breakthrough made in traditional design application of roving wool yarn, and thus the preparing method of the light weight wool yarn for roving is worthy of popularization.

Owner:江阴天而然纺织科技有限公司

Process for preparing a thermal insulation coating paint with flexibility and lightness properties

ActiveUS8242200B2Flexibility and lightness propertyThermal and flexibility and lightness propertyLiquid surface applicatorsInksThermal insulationEngineering

A process is described in which, through the combination of certain components, a thermal insulated coating paint is obtained having the properties of flexibility and lightness (low density) in a film of low thickness. This coating paint offers better thermal insulation properties with a low thickness film than other insulators having greater thickness, without requiring any additional protection. These properties are provided due to the internal structure of the coating paint wherein internal caverns are formed by the reaction of ramified chain polymers and additional materials. These characteristics are not present in traditional coating paints.

Owner:PEREZ HINOJOSA ULISES ELADIO

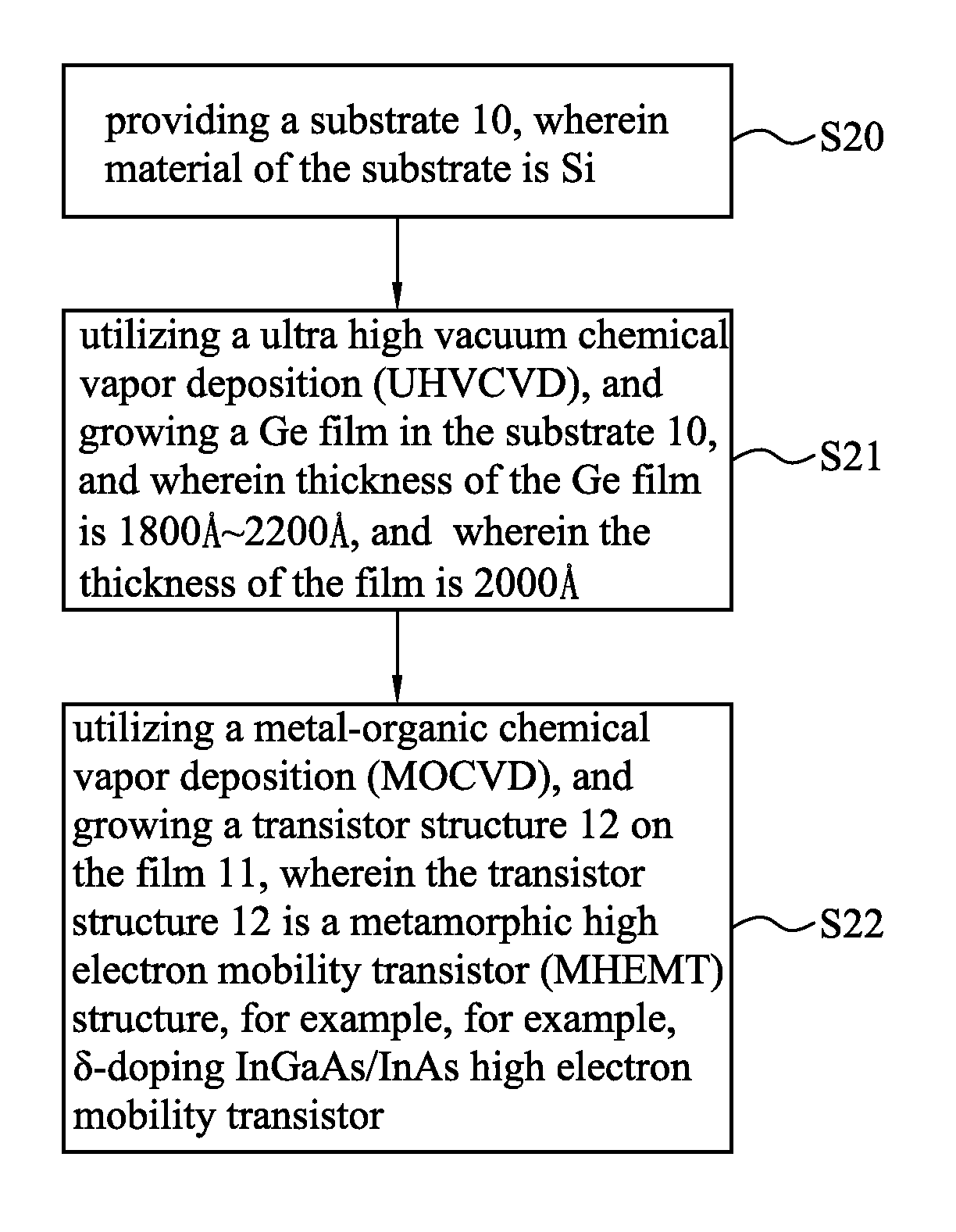

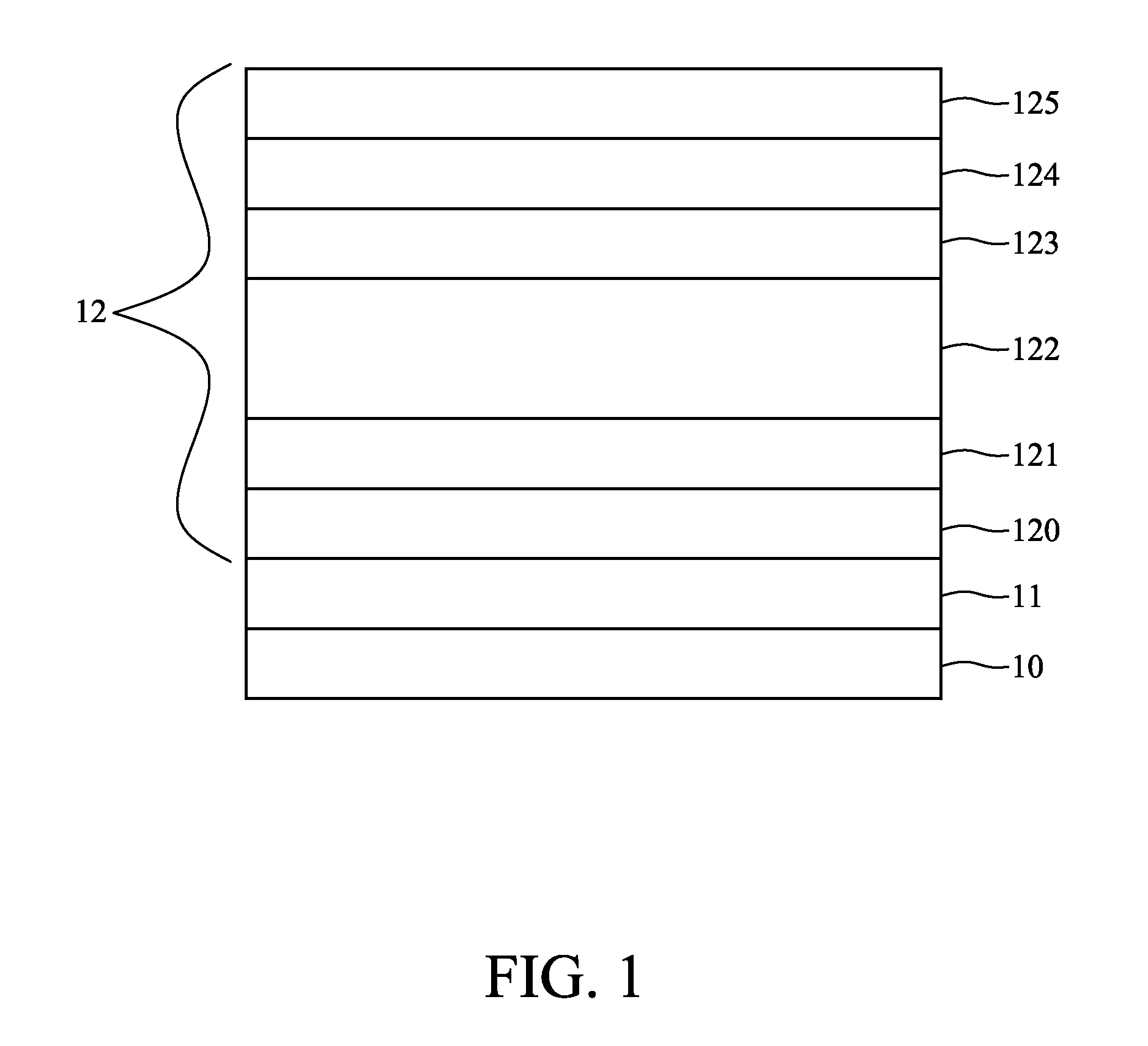

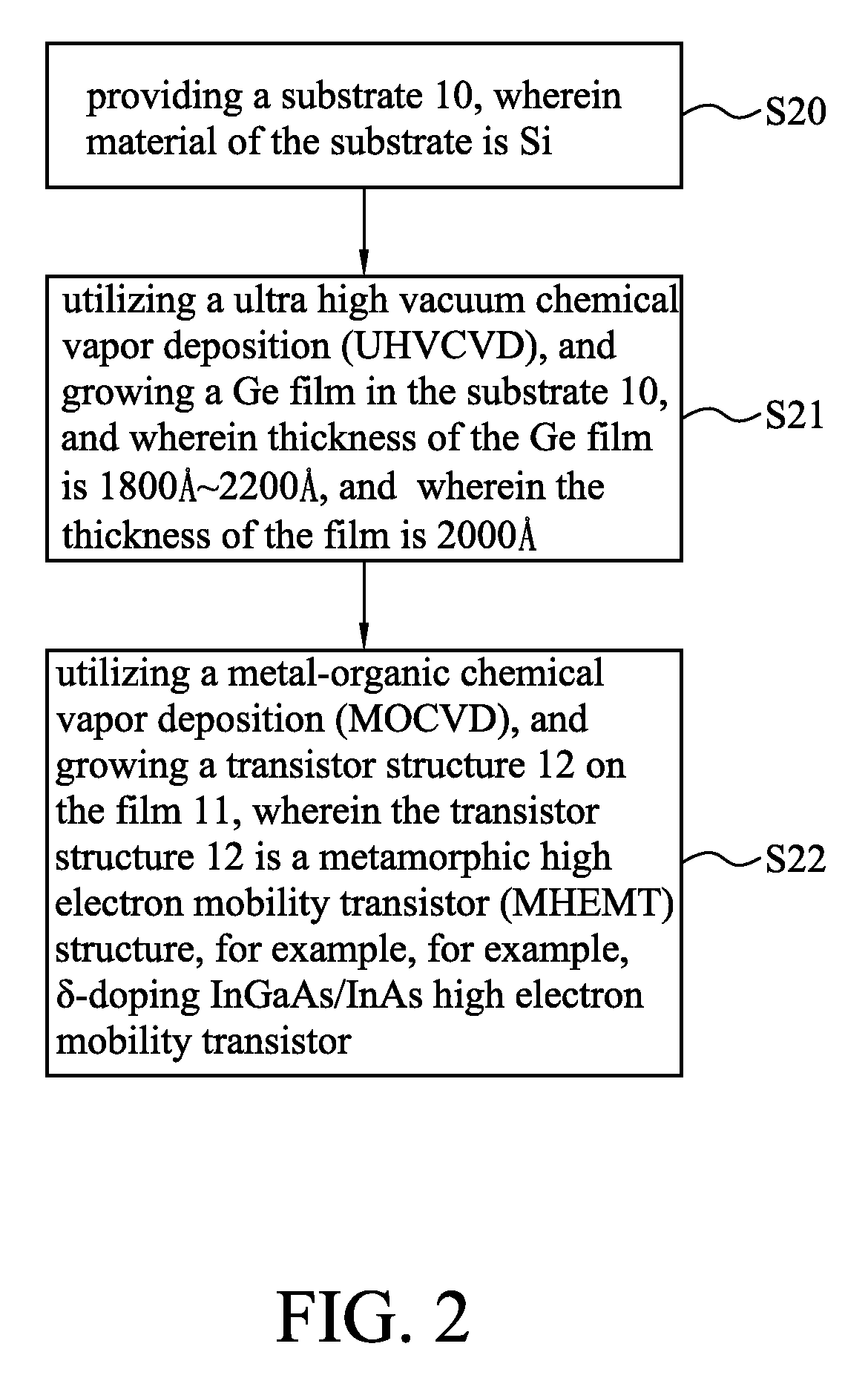

Structure of high electron mobility transistor growth on Si substrate and the method thereof

InactiveUS8796117B2Quality improvementLow costSemiconductor/solid-state device manufacturingSemiconductor devicesLattice mismatchSilicon oxide

A structure of high electron mobility transistor growth on Si substrate and the method thereof, in particular used for the semiconductor device manufacturing in the semiconductor industry. The UHVCVD system was used in the related invention to grow a Ge film on Si substrate then grow the high electron mobility transistor on the Ge film for the reduction of buffer layer thickness and cost. The function of the Ge film is preventing the formation of silicon oxide when growing III-V MHEMT structure in MOCVD system on Si substrate. The reason of using MHEMT in the invention is that the metamorphic buffer layer in MHEMT structure could block the penetration of dislocation which is formed because of the very large lattice mismatch (4.2%) between Ge and Si substrate.

Owner:NAT CHIAO TUNG UNIV

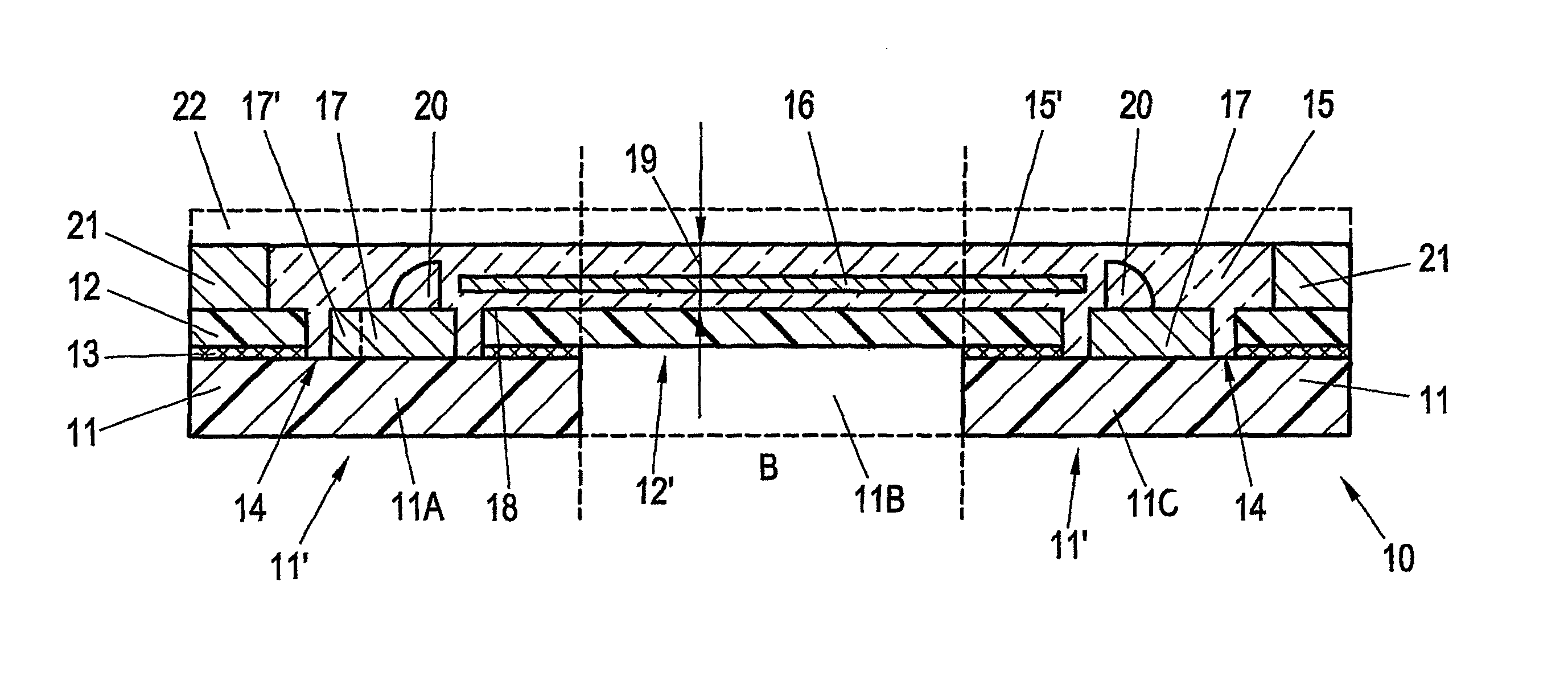

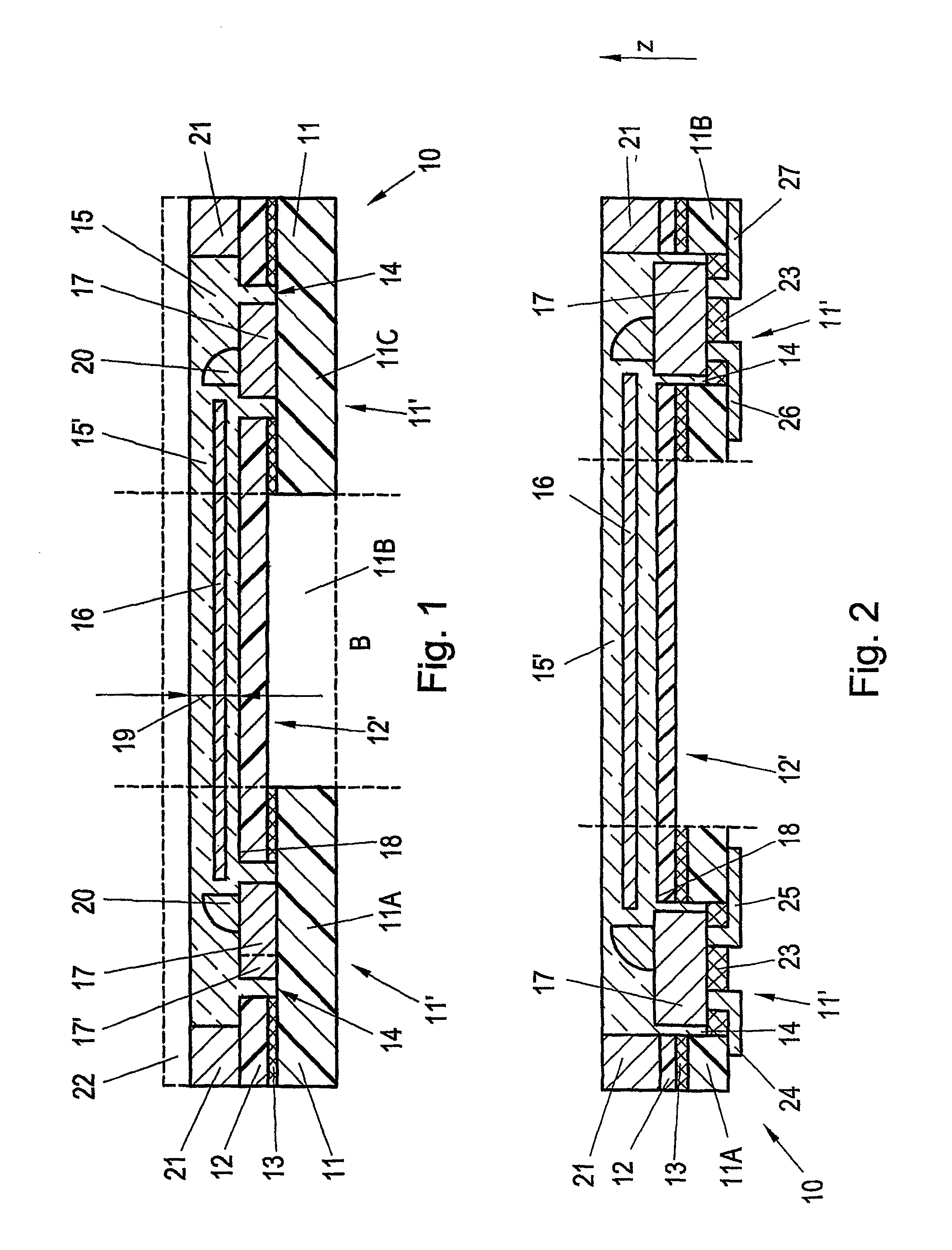

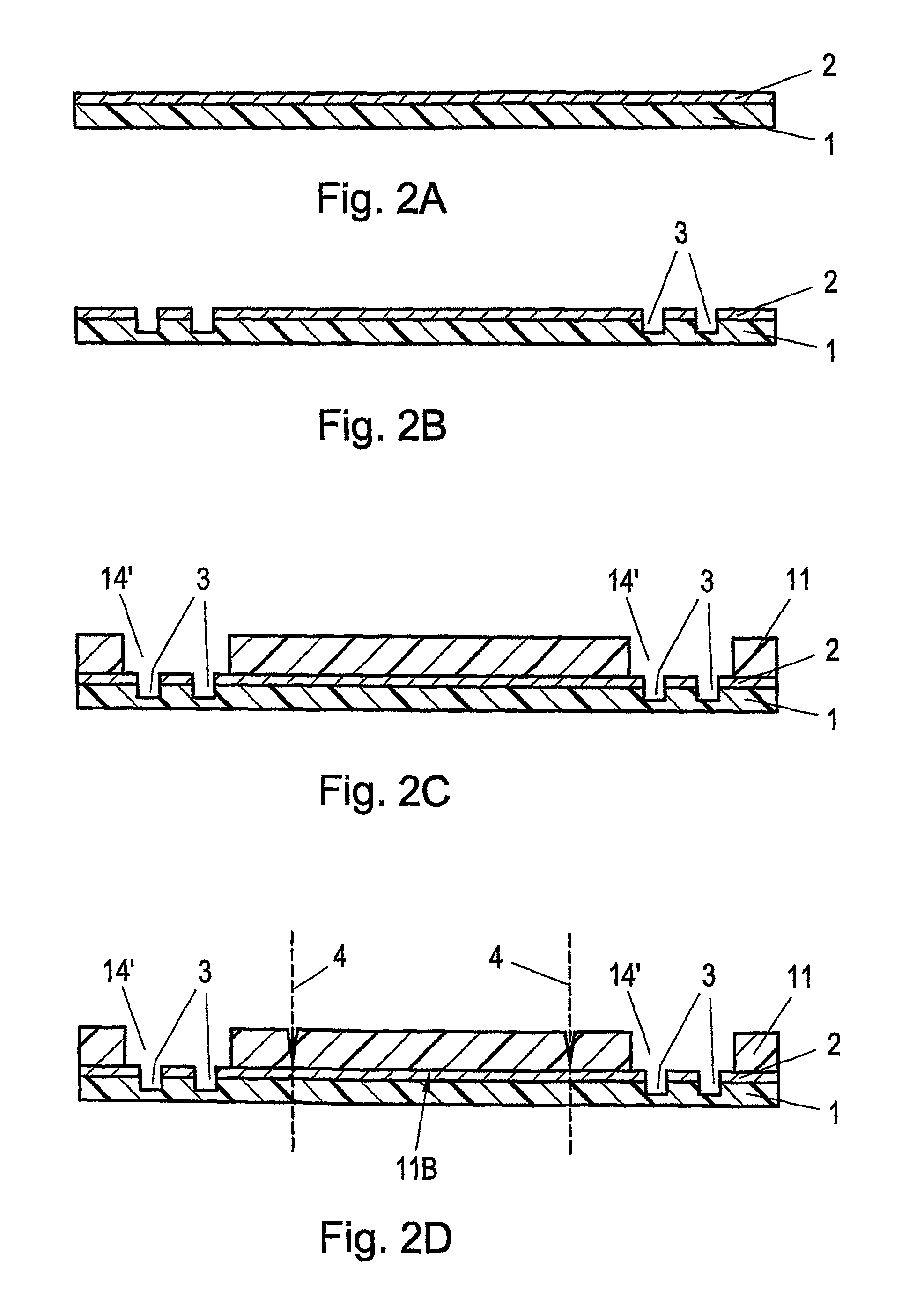

Printed circuit board element and method for the production thereof

ActiveUS8705905B2Signal connectionImprove data transfer rateCircuit optical detailsPrinted circuit aspectsEngineeringFlexible electronics

The invention relates to a printed circuit board element (10), comprising at least one flexible printed circuit board part (12) and at least one rigid printed circuit board part (11A, 11C; 34, 35; 37) having a component (17), which is accommodated in a cavity (14) and with a light-emitting or light-receiving part (17) projects over the edge (18) of the cavity (14), wherein the flexible printed circuit board part (12) has a flexible layer (15′) made of an optical, photo-polymerizable material (15), in which an optical fiber (15) is structured in alignment with the light-emitting or light-receiving part (17) of the optoelectronic component (17) by way of radiation.

Owner:AT & S AUSTRIA TECH & SYSTTECHN AG

Catch element of a contact having a nose-shaped projection

Owner:ROBERT BOSCH GMBH

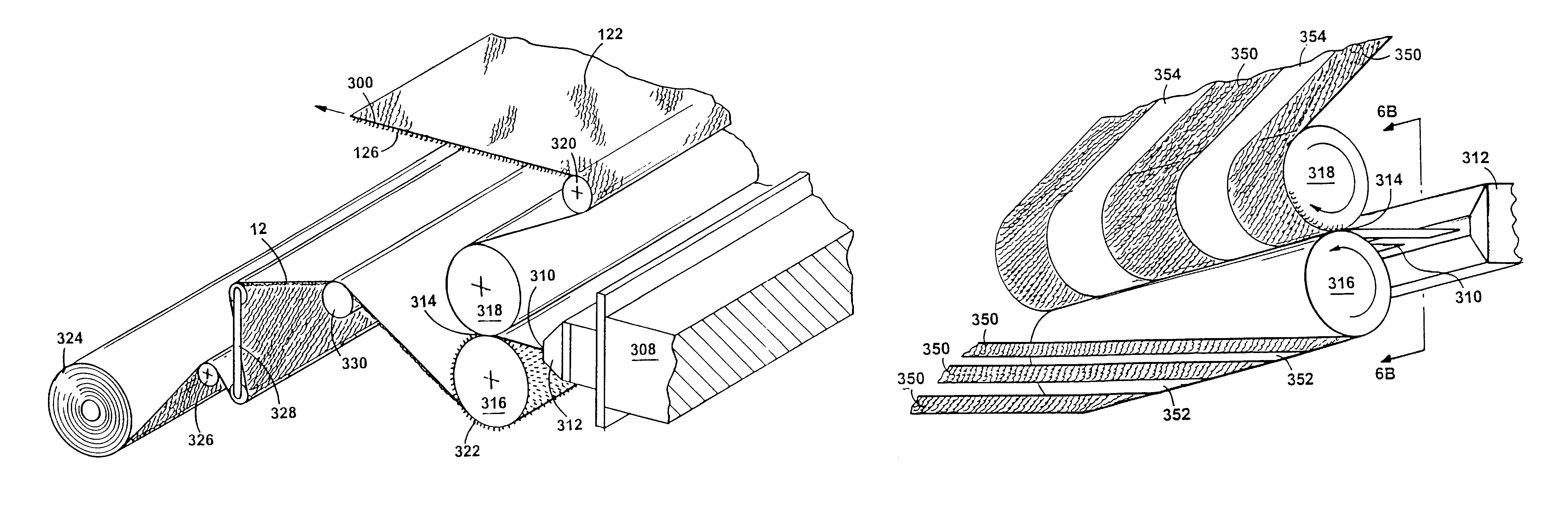

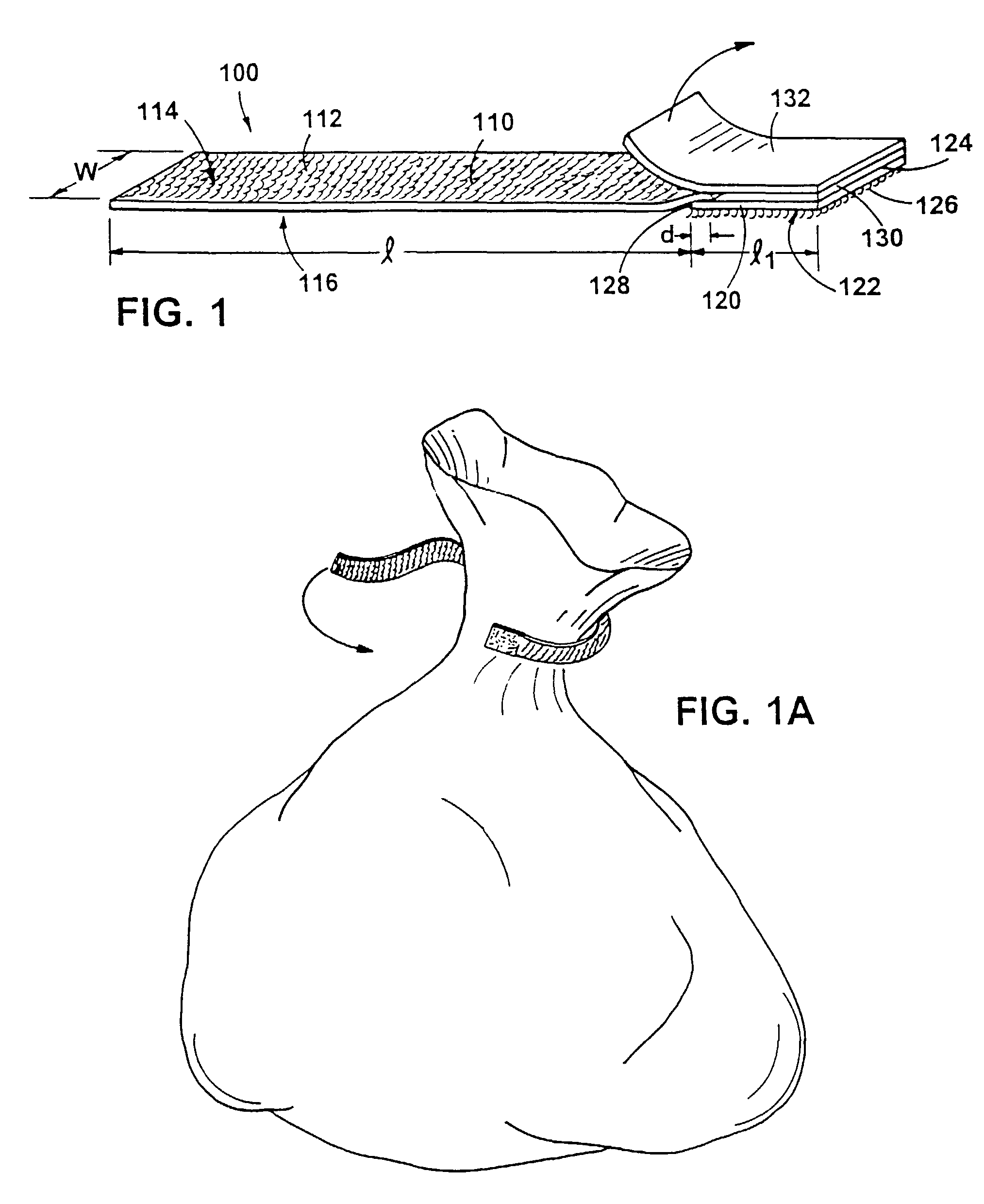

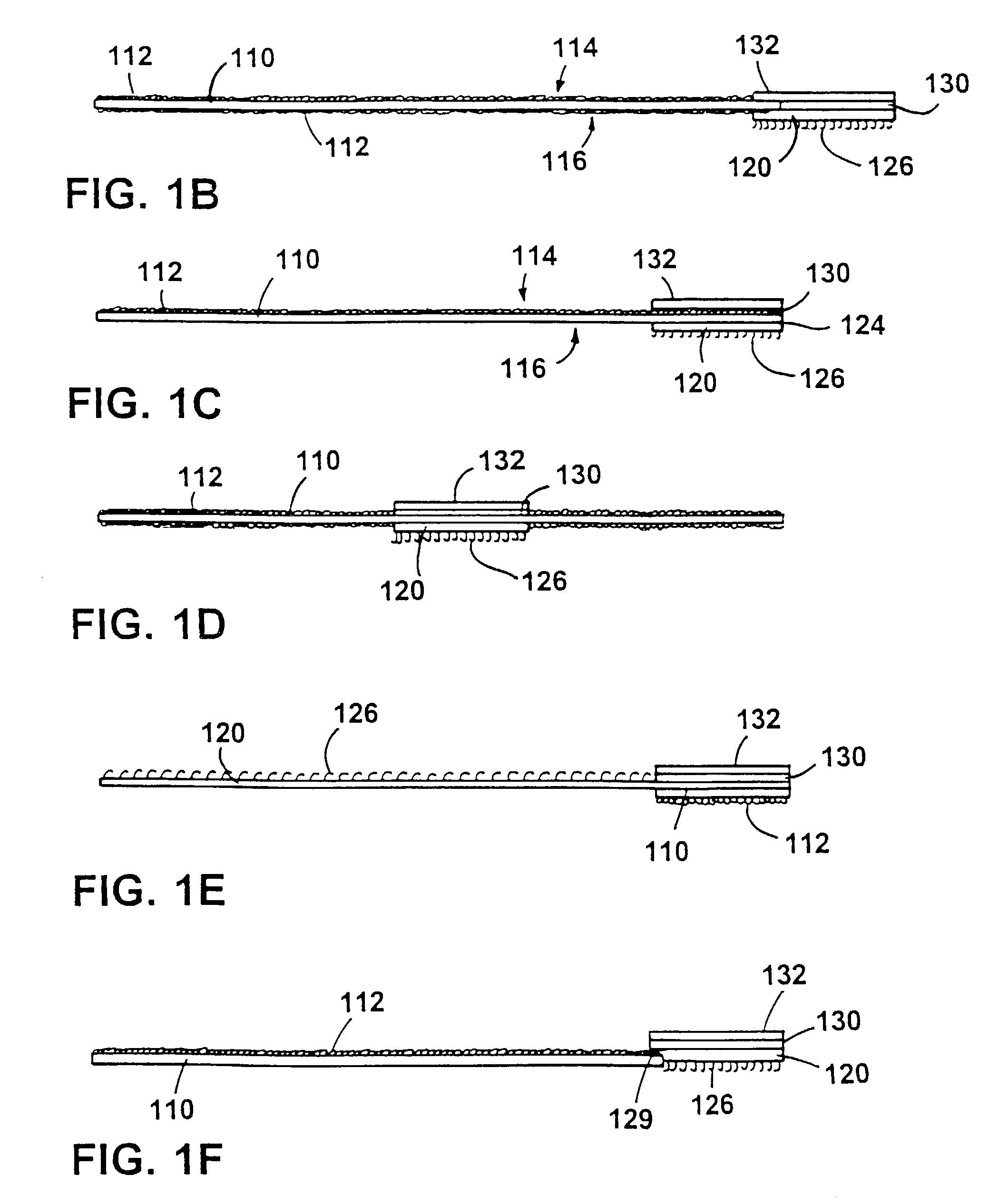

Composite hook and loop fasteners, methods of their manufacture, and products containing them

InactiveUS8778243B2Opens and closes easilyLow stiffnessSnap fastenersFilament/thread formingFiberEngineering

Owner:VELCRO IND BV

Hook latch

ActiveUS20050262907A1Readily adaptable to different thicknessEasy to operateWing fastenersKeysEngineeringLocking plate

A hook latch for fastening and unfastening a closure member to a keeper in a latched position. The hook latch is moveable between the latched position and an open position. The hook latch comprises a rotation means which preferably comprises a knob connected to a cam shaped protuberance which acts upon an actuator plate and a locking plate. Upon rotation of either the knob or the key which is inserted in a lock cylinder which has a locking ring having a cam-shaped protuberance, the cam-shaped protuberances displace both the actuator plate and the locking plate.

Owner:SOUTHCO

Producing method of water-proof connector

InactiveCN102544888BImprove waterproof performancePrevent intrusionContact member cases/bases manufactureCouplings bases/casesEngineeringSealant

The invention provides a water-proof connector and a producing method thereof. The water-proof connector improves the waterproofness of a molded connector formed by inserting a metallic connector component in electrically insulating resin. The water-proof connector (1) is composed of a molded connector which is obtained in a manner that the metallic connector components forming the connector are inserted in the electrically insulating resin, enabling the electrically insulating resin to be a connector housing. The metallic connector components are a contact point (2) and a metallic cover (3), wherein the contact point (2) enables one end to electrically contact with the contact point of the connector; the metallic cover (3) is composed of metallic tube-shaped body which has an opening at at least one end and has a cavity hole communicated with the opening. The internal part of the opening is an insertion part for other connectors to insert. Water-proof sealants (Li1) for water resistance and sealing are filled in the contact point (2) and between the metallic cover (3) and the connector housing (4).

Owner:JST MFG CO LTD

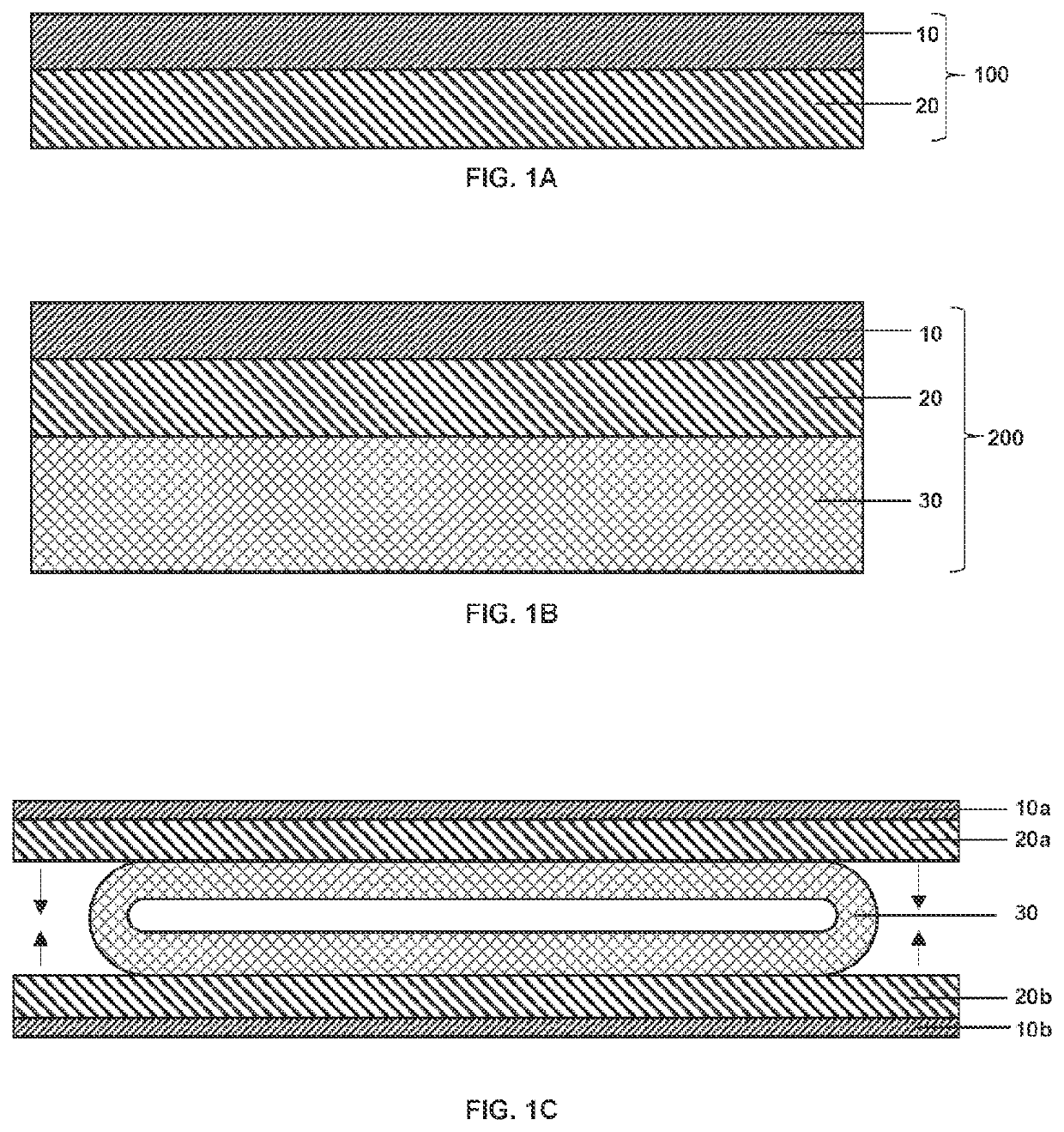

Multilayer films for airbag applications

PendingUS20220212624A1Low production costHigh peel strengthProtective equipmentAdhesive articlesMultilayer membranePolyolefin

A multilayer film is provided that includes a barrier layer, and an adhesive layer, which includes a maleic anhydride (MAH)-grafted polyolefin. The barrier layer has a melting point higher than the adhesive layer, and the melting point of the barrier layer is higher than 165° C. The multilayer film enables production of gas-tight multilayer laminates which exhibit a high peel resistance combined with a low weight and / or thickness. Further, a multilayer laminate and an inflatable airbag that include a fabric layer adhered to the multilayer film, as well as a method of its manufacturing are described.

Owner:ZF AUTOMOTIVE GERMANY GMBH

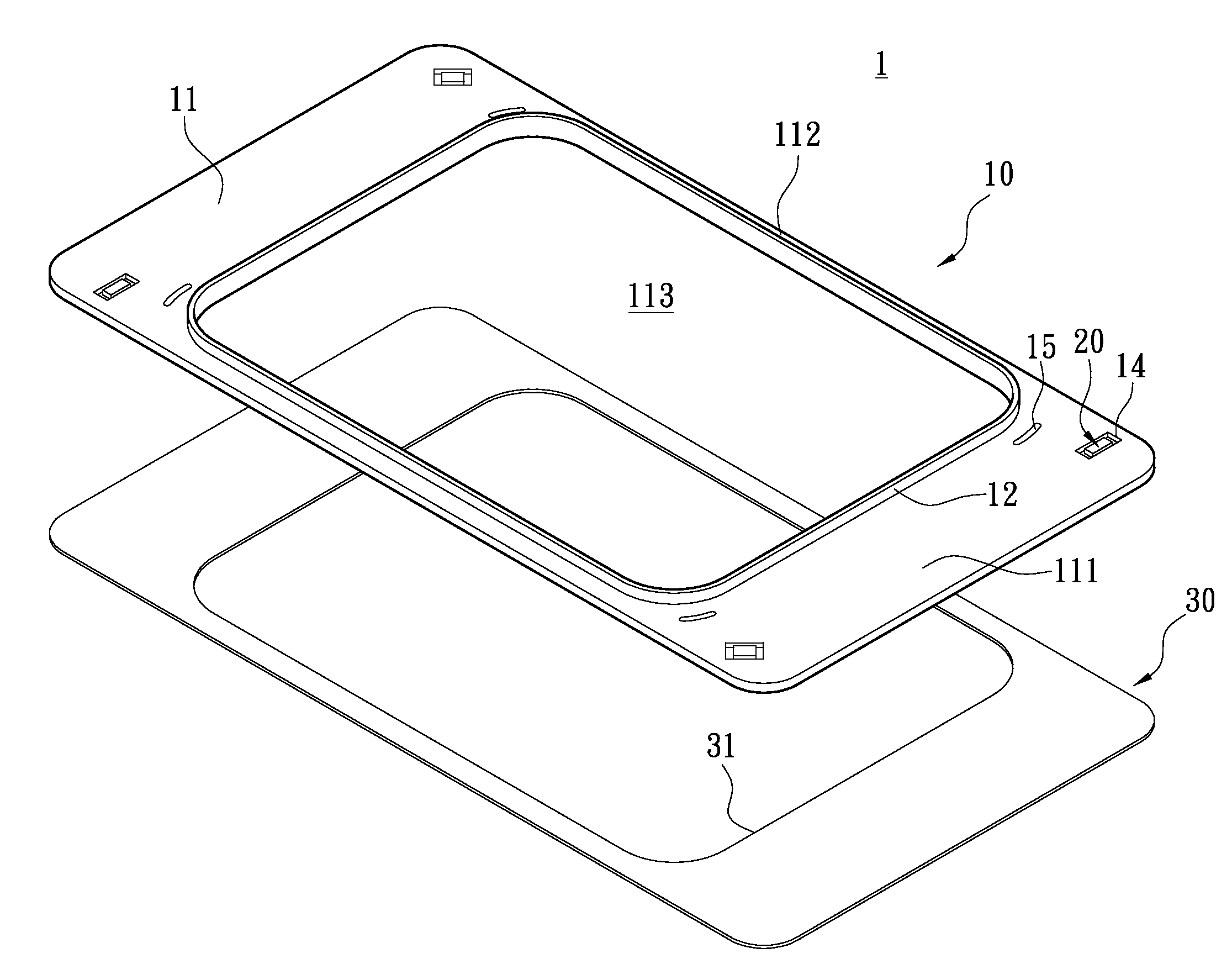

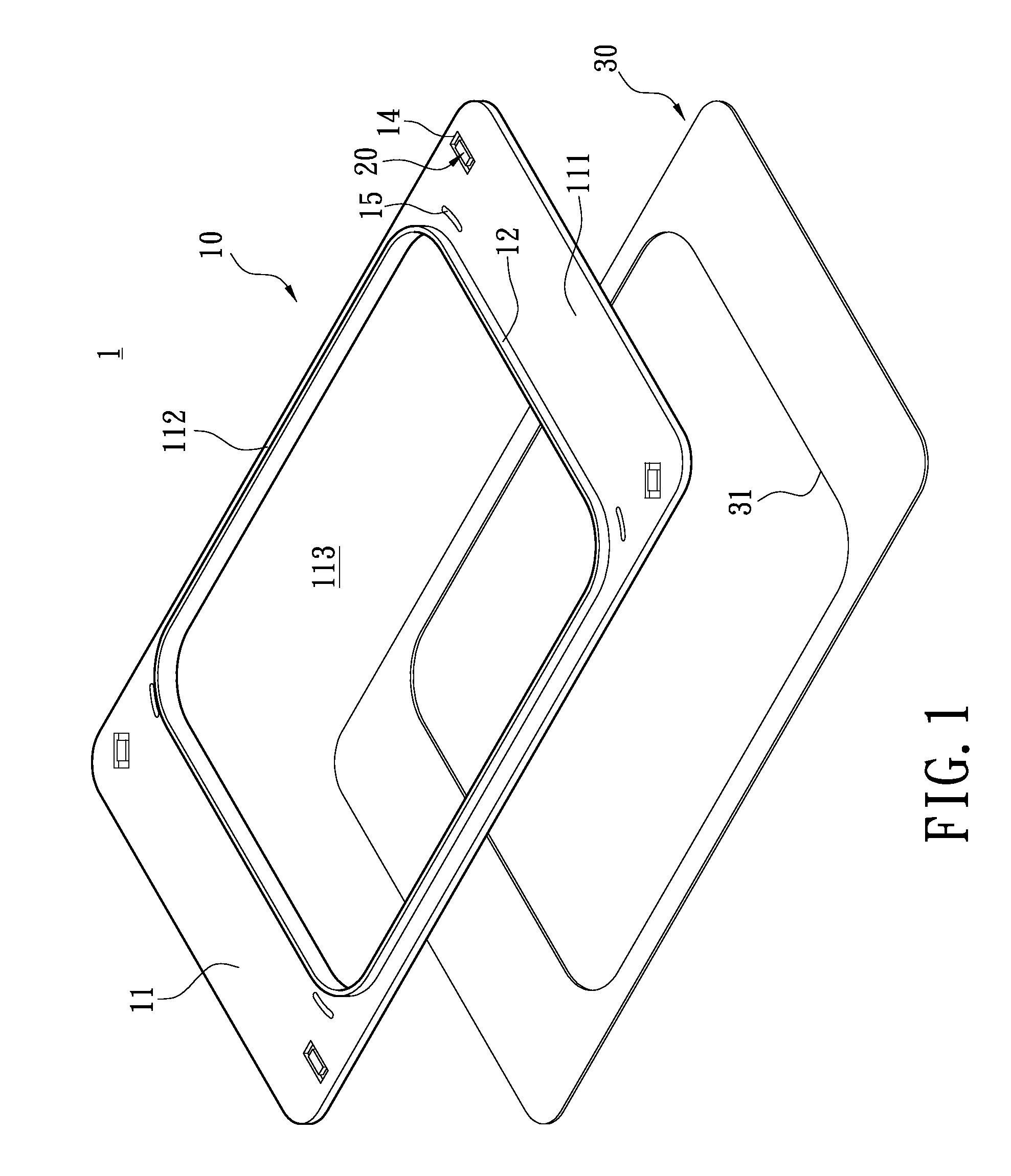

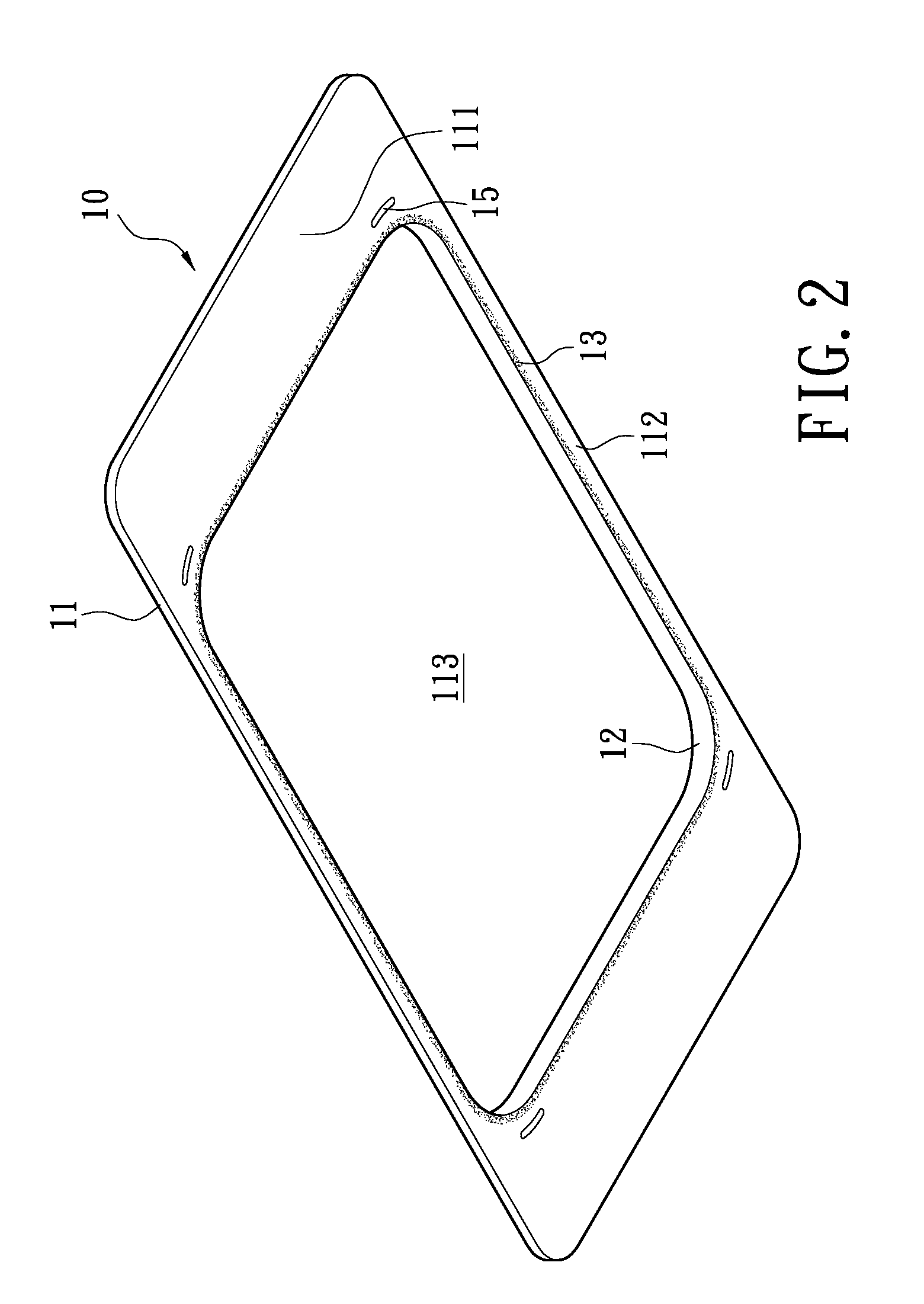

Electronic device and light-guiding structure thereof

ActiveUS20120218780A1Low thicknessReduce thicknessAircraft componentsMechanical apparatusEngineeringLight guide

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

Preparation method of lightweight woolen yarn for slubbing

The invention discloses a preparing method of light weight wool yarn for roving. The method comprises the first step of adding oil water and an antistatic agent with a certain proportion into a wool mixed material of wool raw materials and chemical fiber, and conducting intensive mixing, wherein the length of the wool mixed material is 5cm or above, and the wool mixed material is in a wavy shape; the second step of carding the wool mixed material in which moisture is absorbed till a spinning requirement is accorded with, controlling the clip distance between roller cylinders to be in a relaxed state till the fiber is not straightened, and then making rove with no twisting degree through winding; the third step of firstly conducting unwinding on wound rove with no twisting degree to form wool yarn, and then lengthening shaft distances in the unwinding process till no tension exists; the fourth step of feeding and winding two ends of each of the wool yarn and filament with a twisting degree; the fifth step of winding two pieces of yarn prepared in the fourth step under the condition that airflow is blown to the yarn. According to the preparing method of the light weight wool yarn for roving, innovation is made in both material selection and technology, the design and manufacturing technology of the wool yarn are a breakthrough made in traditional design application of roving wool yarn, and thus the preparing method of the light weight wool yarn for roving is worthy of popularization.

Owner:江阴天而然纺织科技有限公司

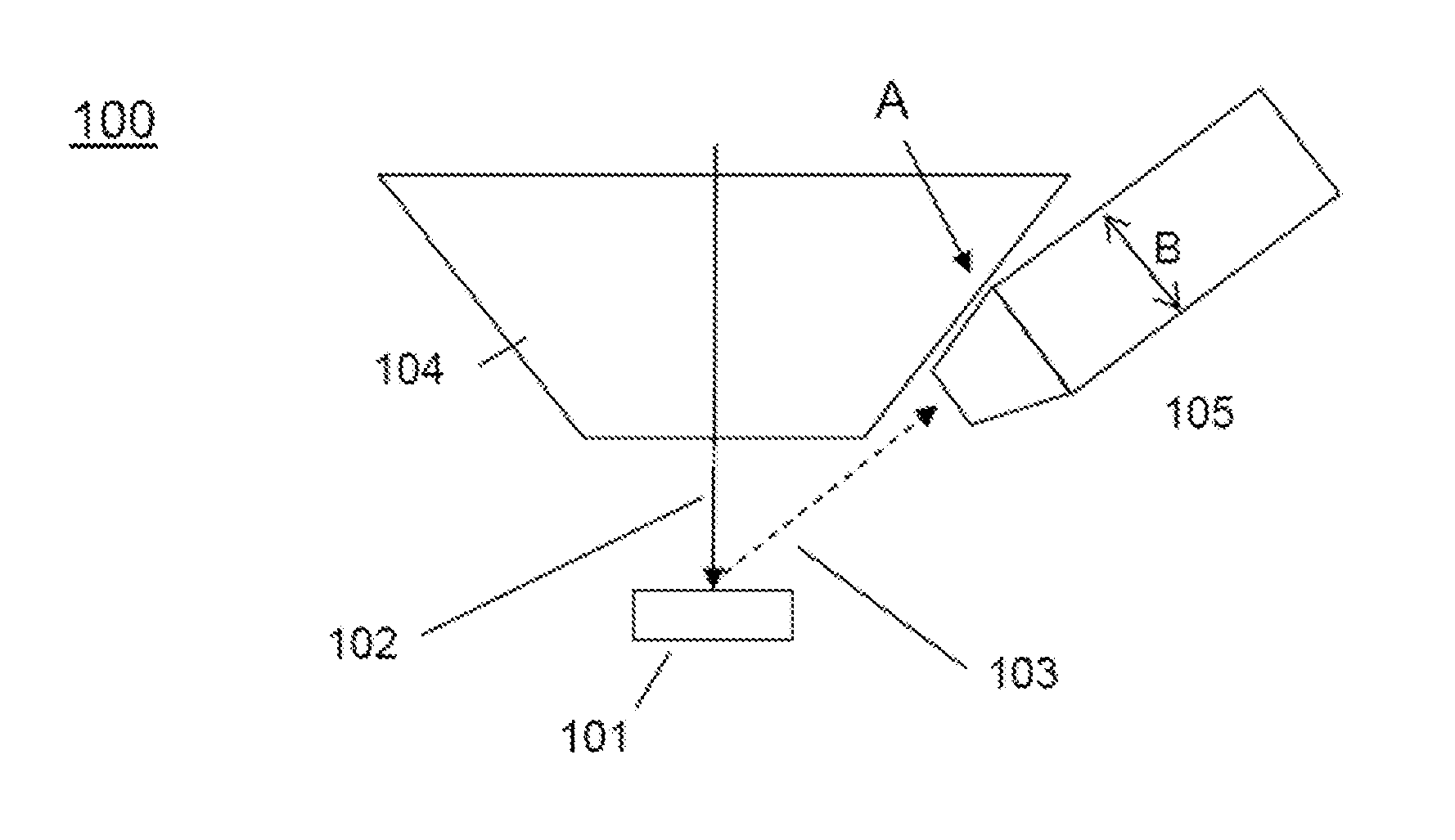

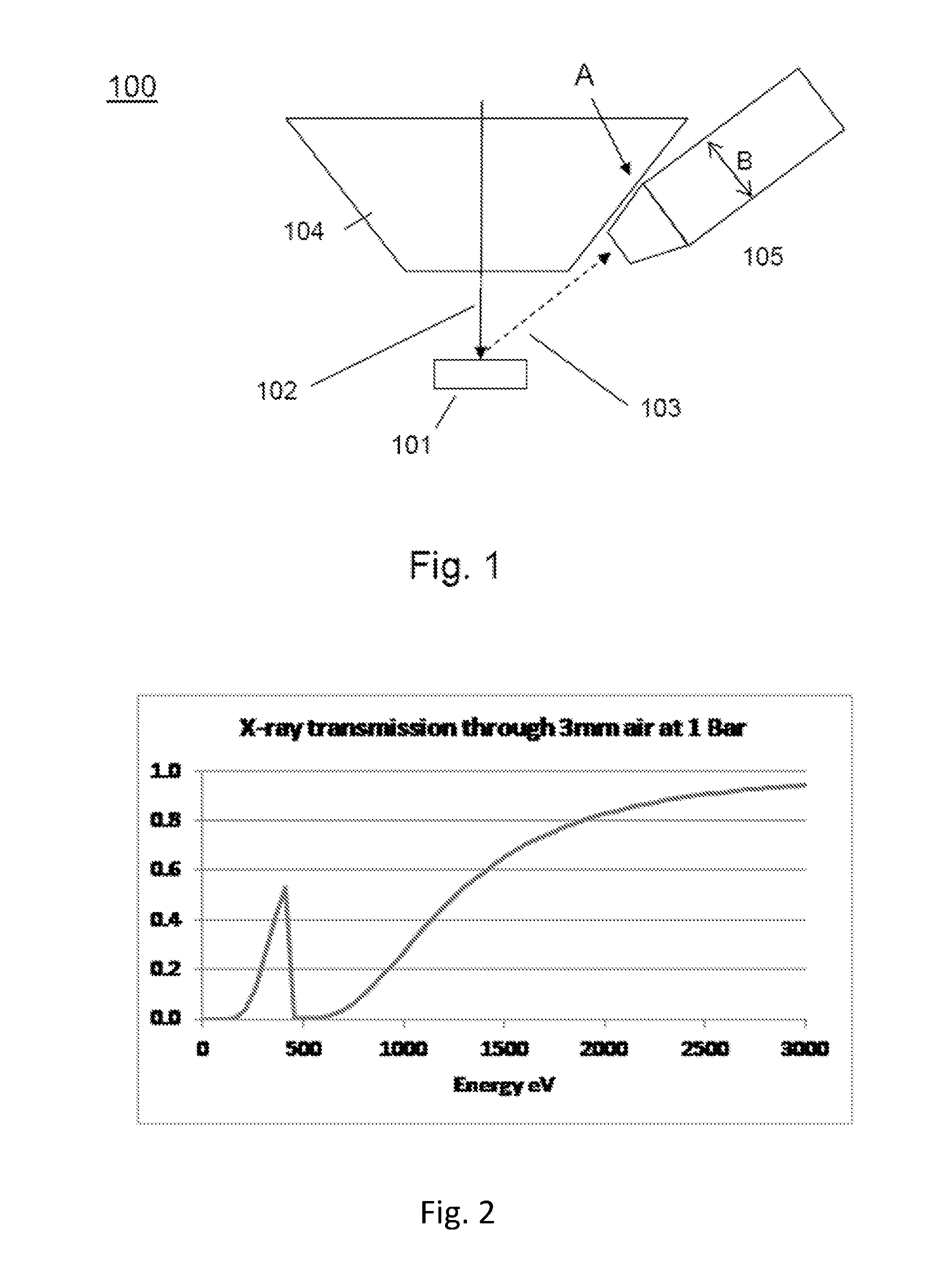

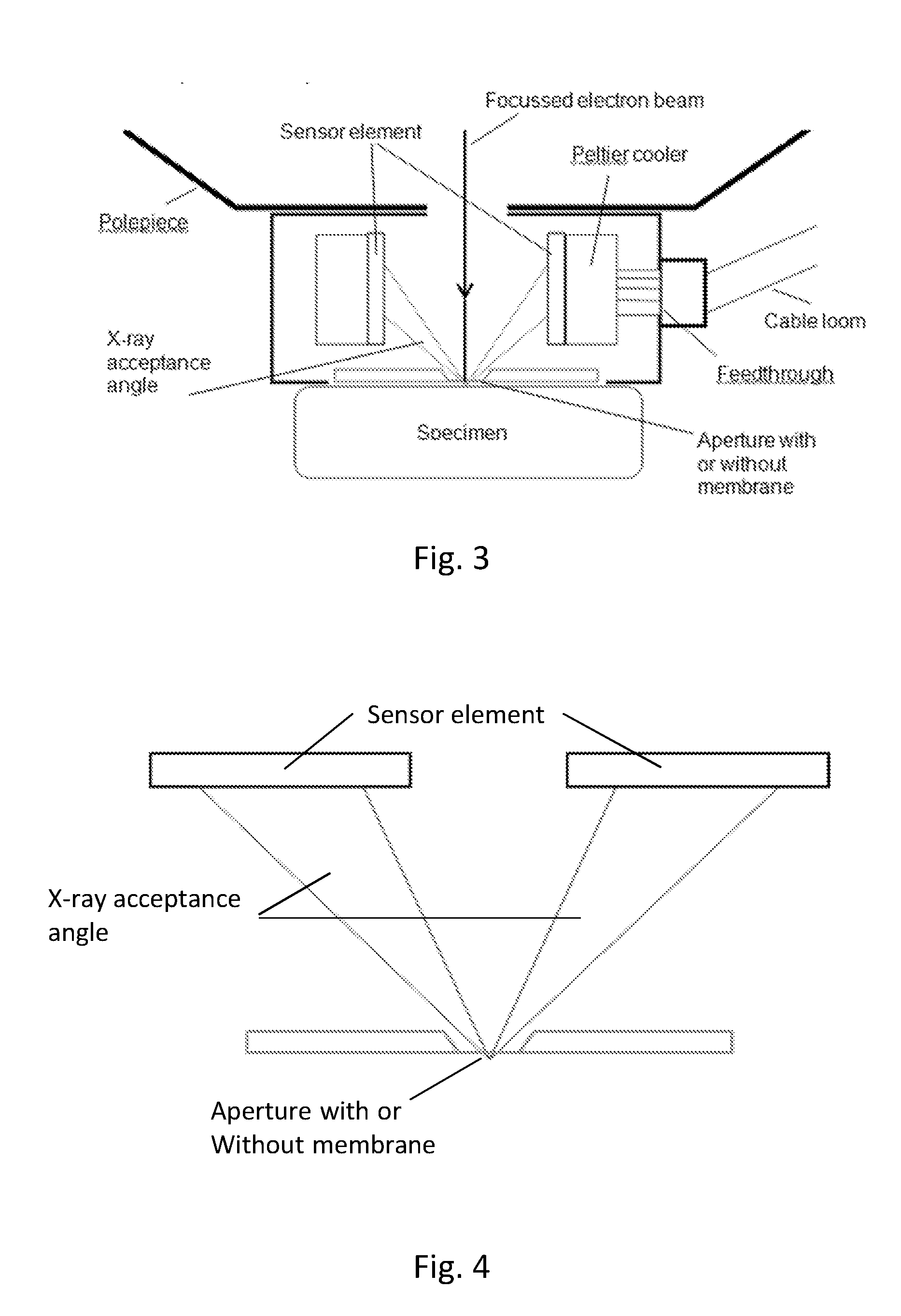

X-ray analysis in air

An x-ray analysis apparatus comprises an electron beam assembly for generating a focused electron beam within a first gas pressure environment. A sample assembly is used for retaining a sample within a second gas pressure environment such that the sample receives the electron beam from the electron beam assembly and such that the gas pressure in the second gas pressure environment is greater than the gas pressure within the first gas pressure environment. An x-ray detector is positioned so as to have at least one x-ray sensor element within the first gas pressure environment. The sensor element is mounted to a part of the electron beam assembly which is proximal to the sample assembly and further arranged in use to receive x-rays generated by the interaction between the electron beam and the sample.

Owner:OXFORD INSTR NANOTECH TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com