Patents

Literature

85results about How to "Avoid excessive absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

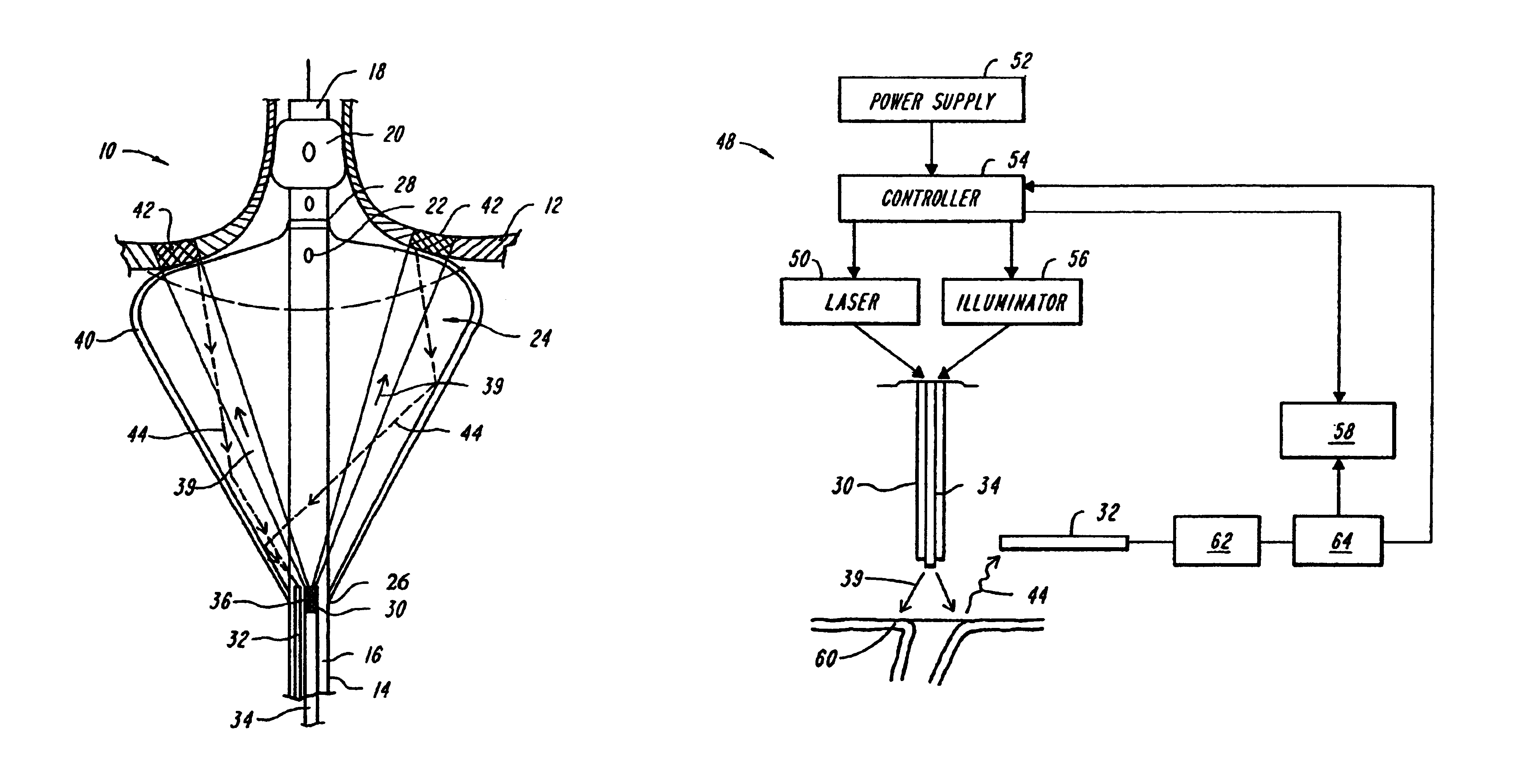

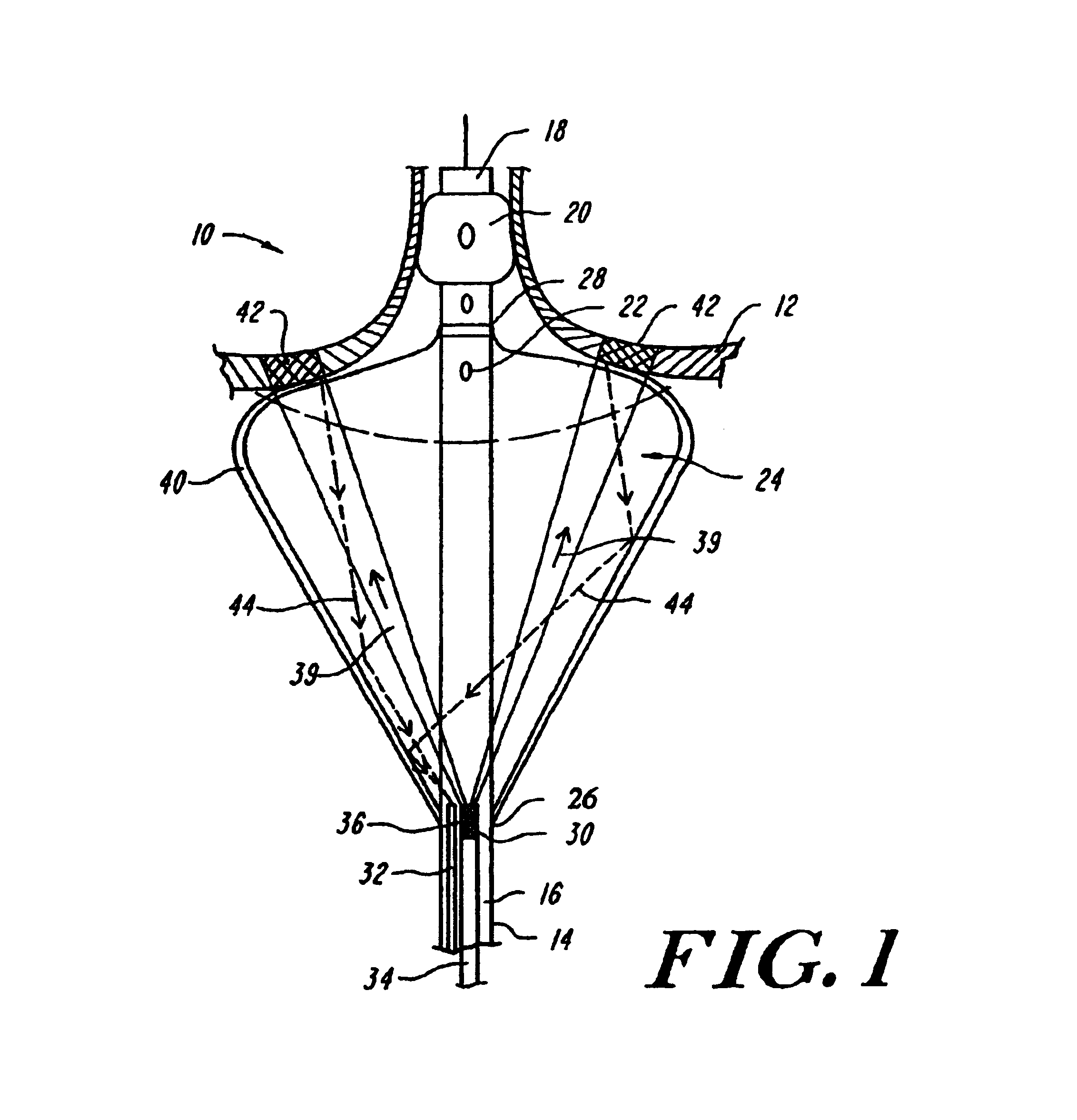

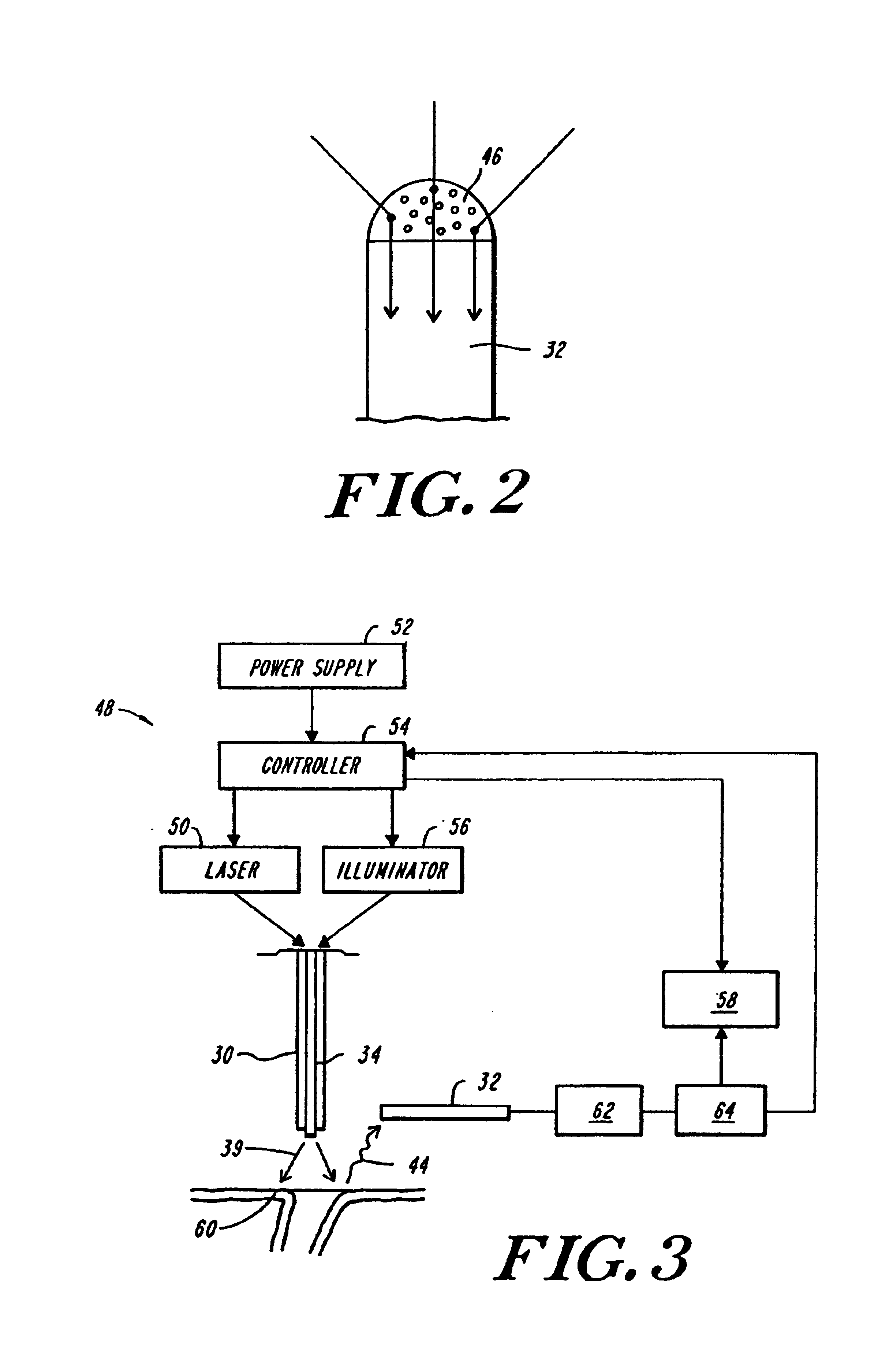

Intralumenal contact sensor

InactiveUS6942657B2Eliminate aberrant wave conductionReduce lossDiagnosticsCatheterLight treatmentLaser light

An apparatus and method for phototherapy are described in which laser light or other radiation is projected from within a catheter, through a balloon member, and toward the surface of tissue. The light reflected from body fluids or the tissue surface is captured by a collecting device located within the catheter, e.g., within the balloon member, and the intensity of the reflected light is ascertained. The apparatus and method provides for accurately positioning the apparatus against the tissue treatment site.

Owner:CARDIOFOCUS INC

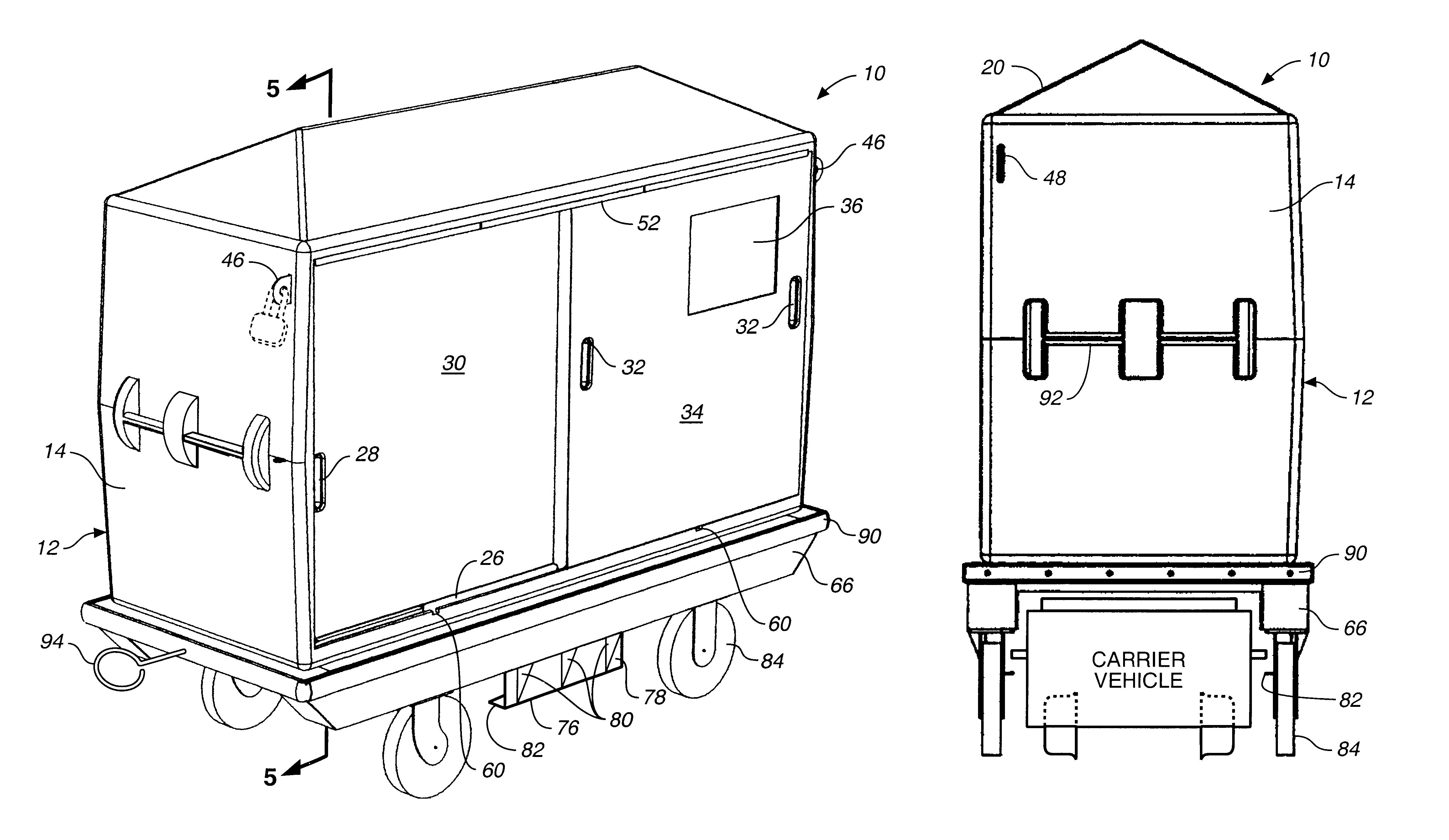

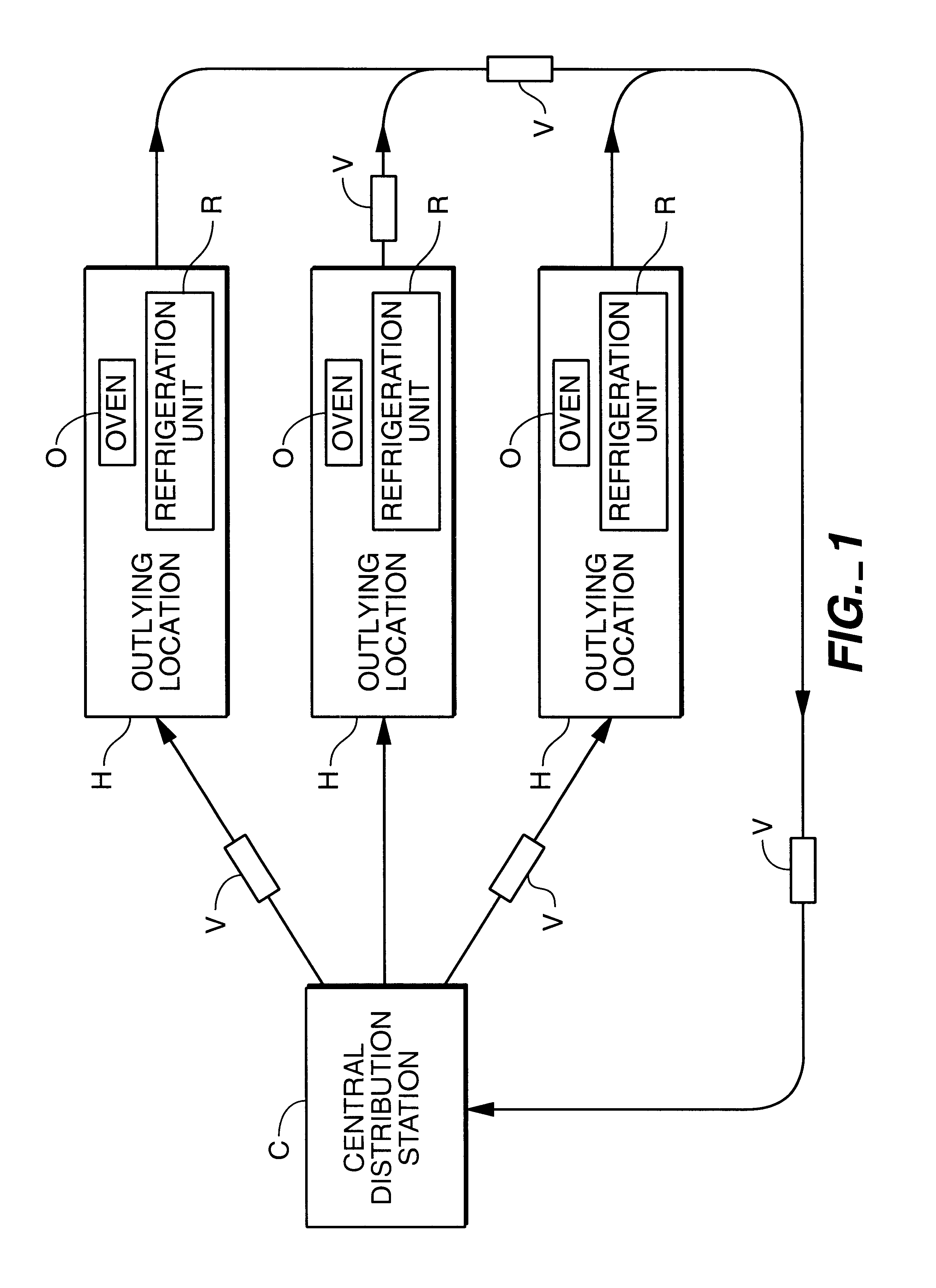

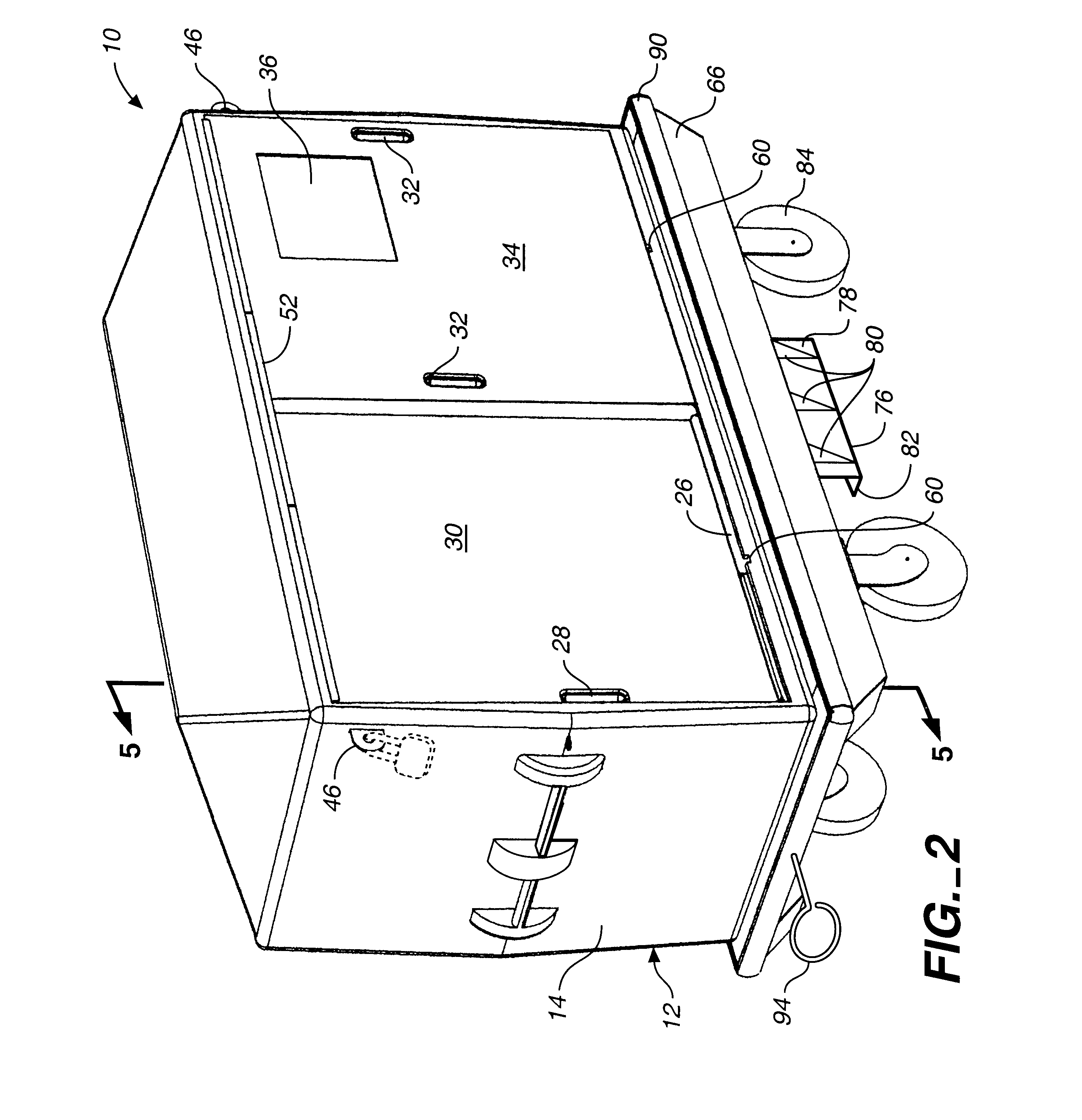

Meal delivery cart

InactiveUS6672601B1Durable and impervious to waterAvoid excessive absorptionVentilationService system furnitureDelivery vehicleAutomated guided vehicle

An improved meal delivery system and a method for delivery of pre-cooked, chilled meals from a central distribution station to a plurality of remote locations in cooperation with an Automatic Guided Vehicle system, and in particular a one-piece, molded, insulated meal-delivery cart for transportation of chilled meals.

Owner:COUNTY OF ALAMEDA THE A POLITICAL SUBDIV OF THE STATE OF CALIFORNIA

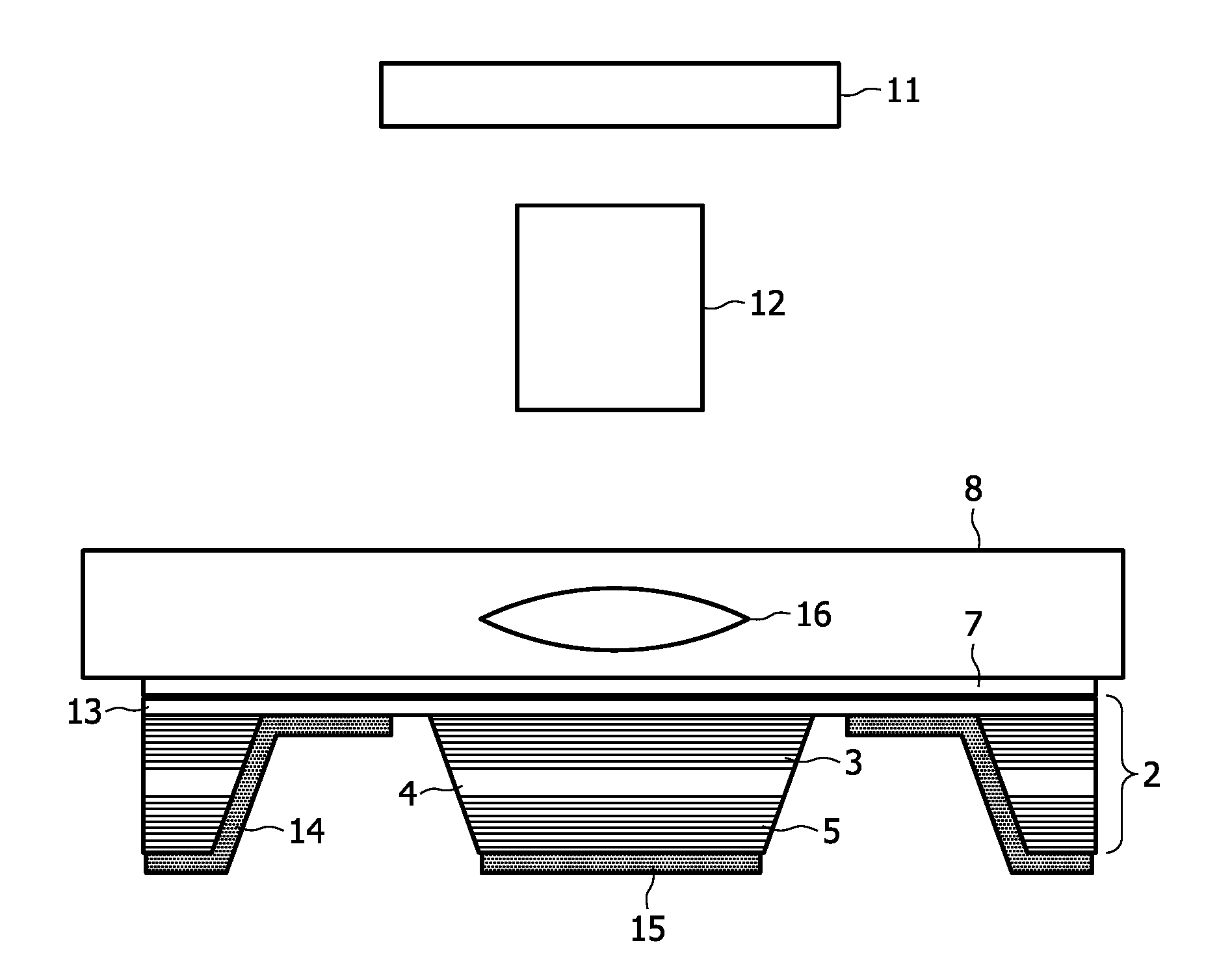

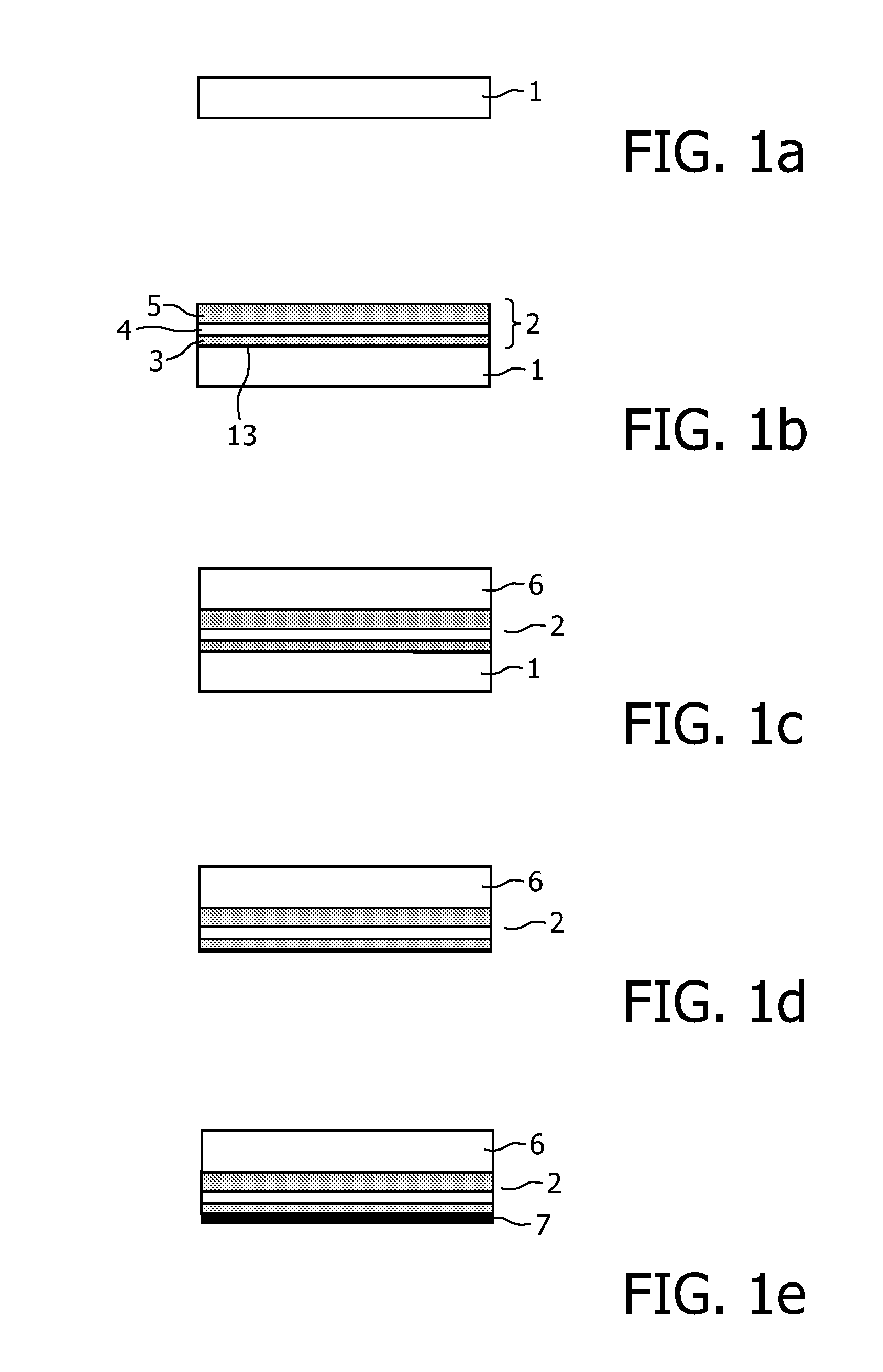

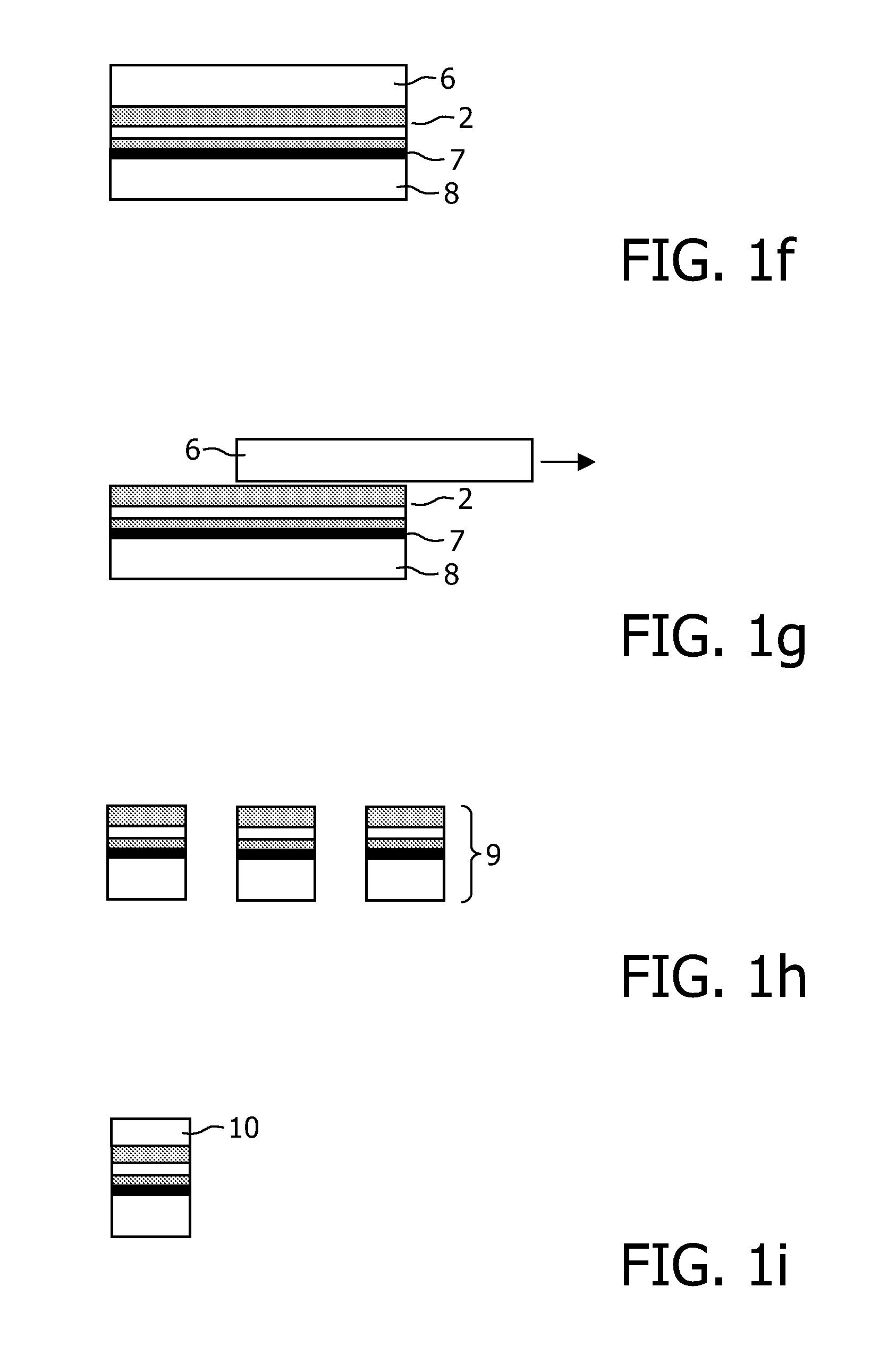

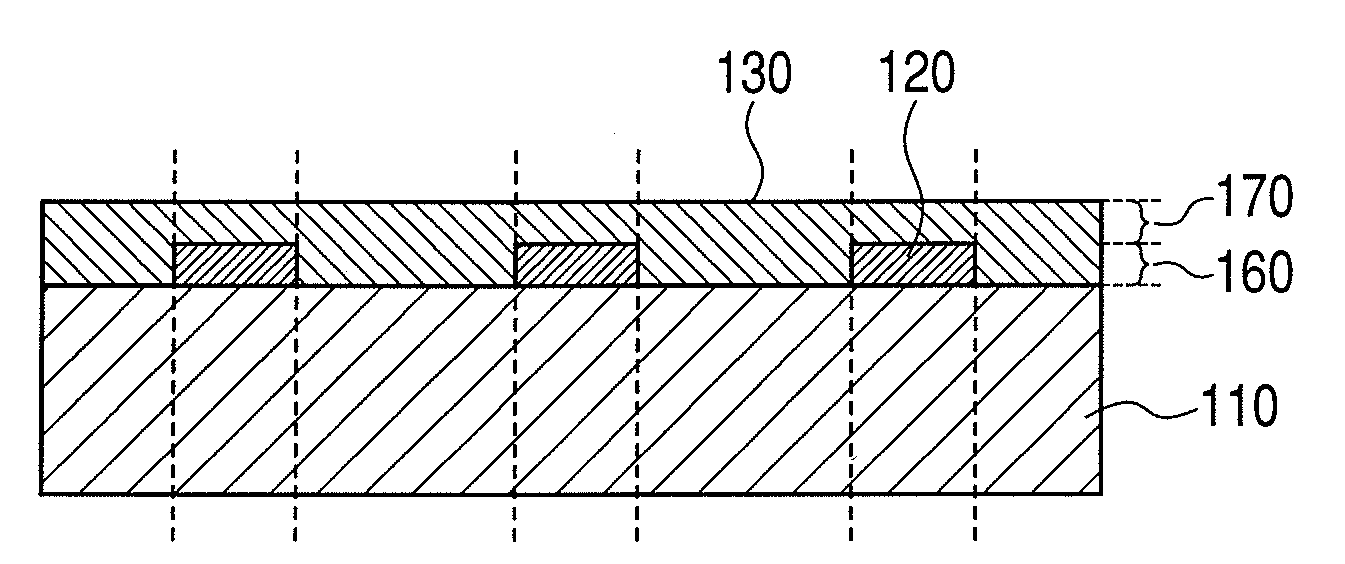

Vertical extended cavity surface emission laser and method for manufacturing a light emitting component of the same

ActiveUS20100195690A1Low thicknessSolve the low heat dissipation efficiencyLaser detailsLaser optical resonator constructionPhysicsSemiconductor

The present invention relates to a method of manufacturing the light emitting component of a VECSEL and the corresponding VECSEL. In the method a layer stack (2) is epitaxially grown on a semiconductor substrate (1). The layer stack comprises an active region (4), an upper distributed Bragg reflector (5) and a n- or p-doped current injection layer (13) arranged between the active region (4) and the semiconductor substrate (1). A mechanical support (6) or submount is bonded to an upper side of the layer stack (2) and the semiconductor substrate (1) is subsequently removed. A metallization layer (7) is optionally deposited on the lower side of the layer stack (2) and an optically transparent substrate (8) is bonded to this lower side. The proposed method allows the manufacturing of such a component in a standard manner and results in a VECSEL with a homogenous current injection and high efficiency of heat dissipation.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

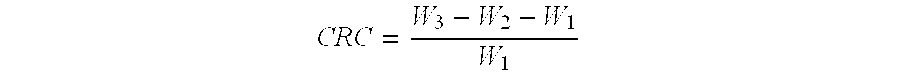

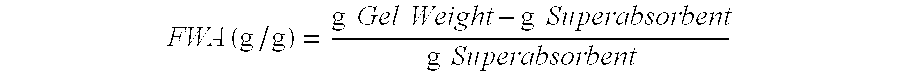

Superabsorbent polymers having delayed water absorption characteristics

InactiveUS6514615B1Shorten drying timeReduce removalNon-fibrous pulp additionPaper/cardboardMicrometerSuperabsorbent polymer

A superabsorbent polymer comprising a delayed absorption superabsorbent polymer having a free water absorbency property of absorbing less than about 3 grams of aqueous saline per gram of superabsorbent polymer in about 6 seconds, for a full particle size distribution of superabsorbent polymer ranging from about 40 micrometers to about 890 micrometers.

Owner:EVONIK OPERATIONS GMBH

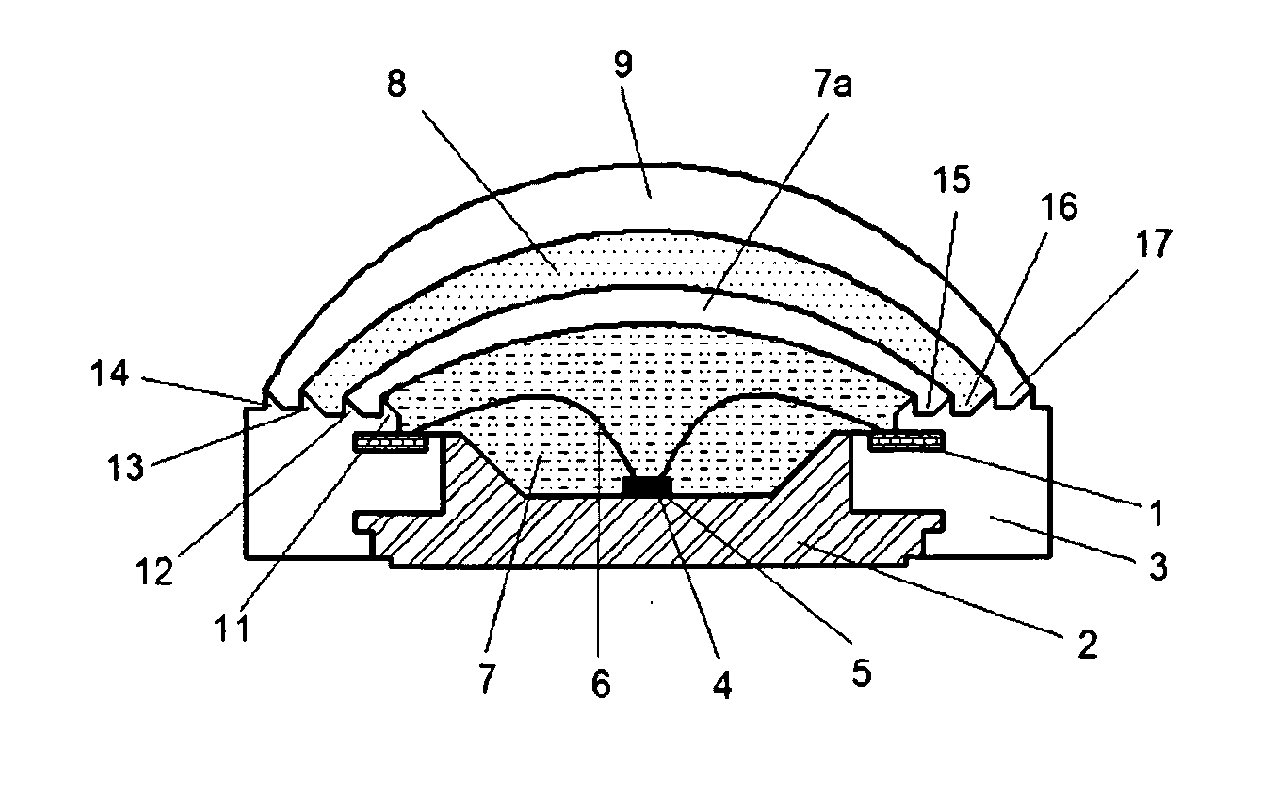

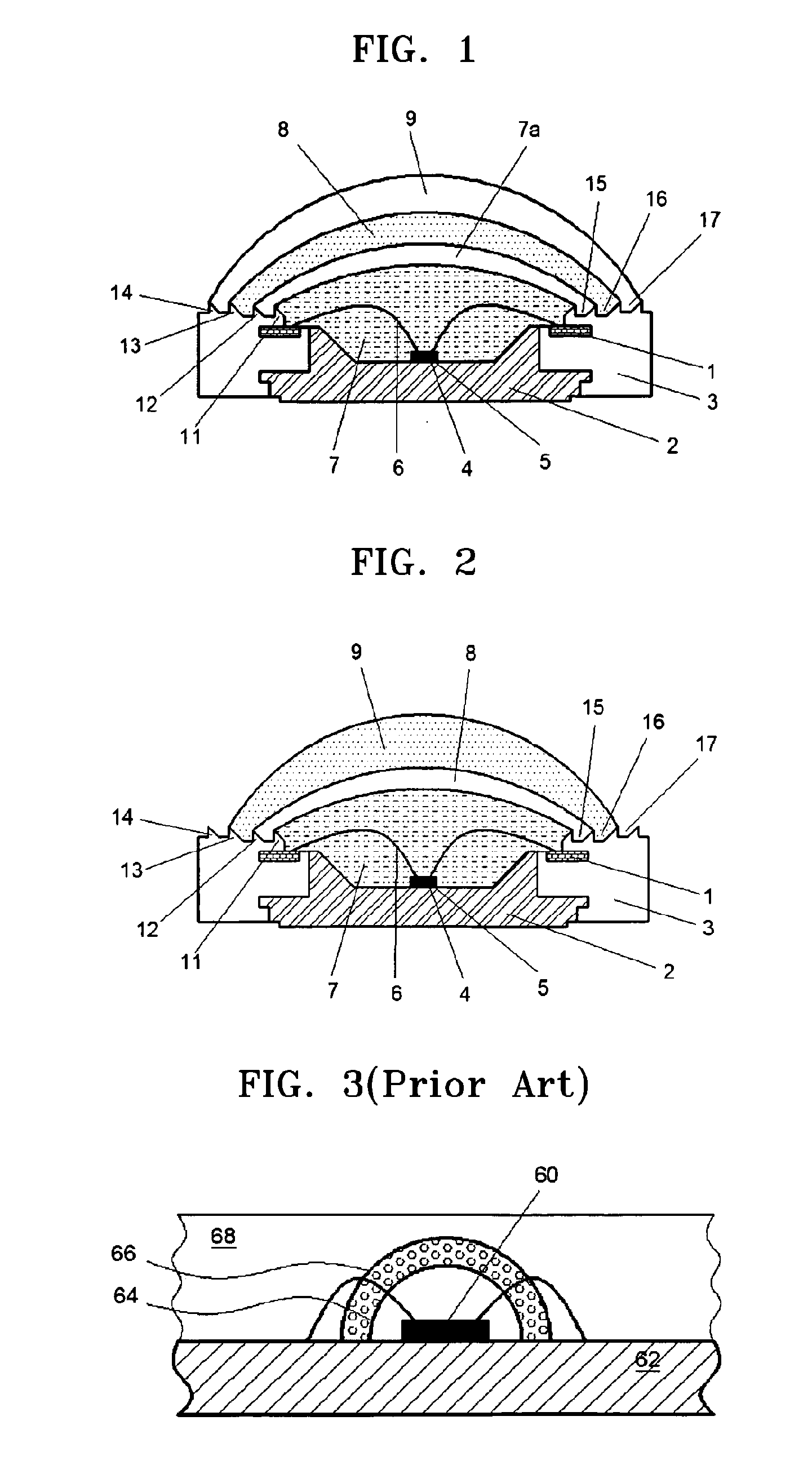

White light emitting diode package and method of making the same

InactiveUS20100230693A1Convenient lightingAvoid excessive absorptionSolid-state devicesSemiconductor devicesPhosphorRefractive index

A white light emitting diode (LED) package with multilayered encapsulation structure and the packaging methods are disclosed. The white LED package structure includes metal electrodes, a heat dissipation base, a PPA plastic for fixing the electrodes and the heat dissipation base together, at least one LED die, a die attaching material, gold wires for electrically connecting the LED die to the electrodes, a first type of silicone encapsulant, a second type of silicone encapsulant, and a phosphor containing layer. The invention utilizes a low-refractive index silicone (the second type of silicone encapsulant) to separate the phosphor containing layer away from the first type of silicone, which covers the LED die, to prevent / reduce emitted light going backward and hitting the LED die.

Owner:NEPES LED CORP

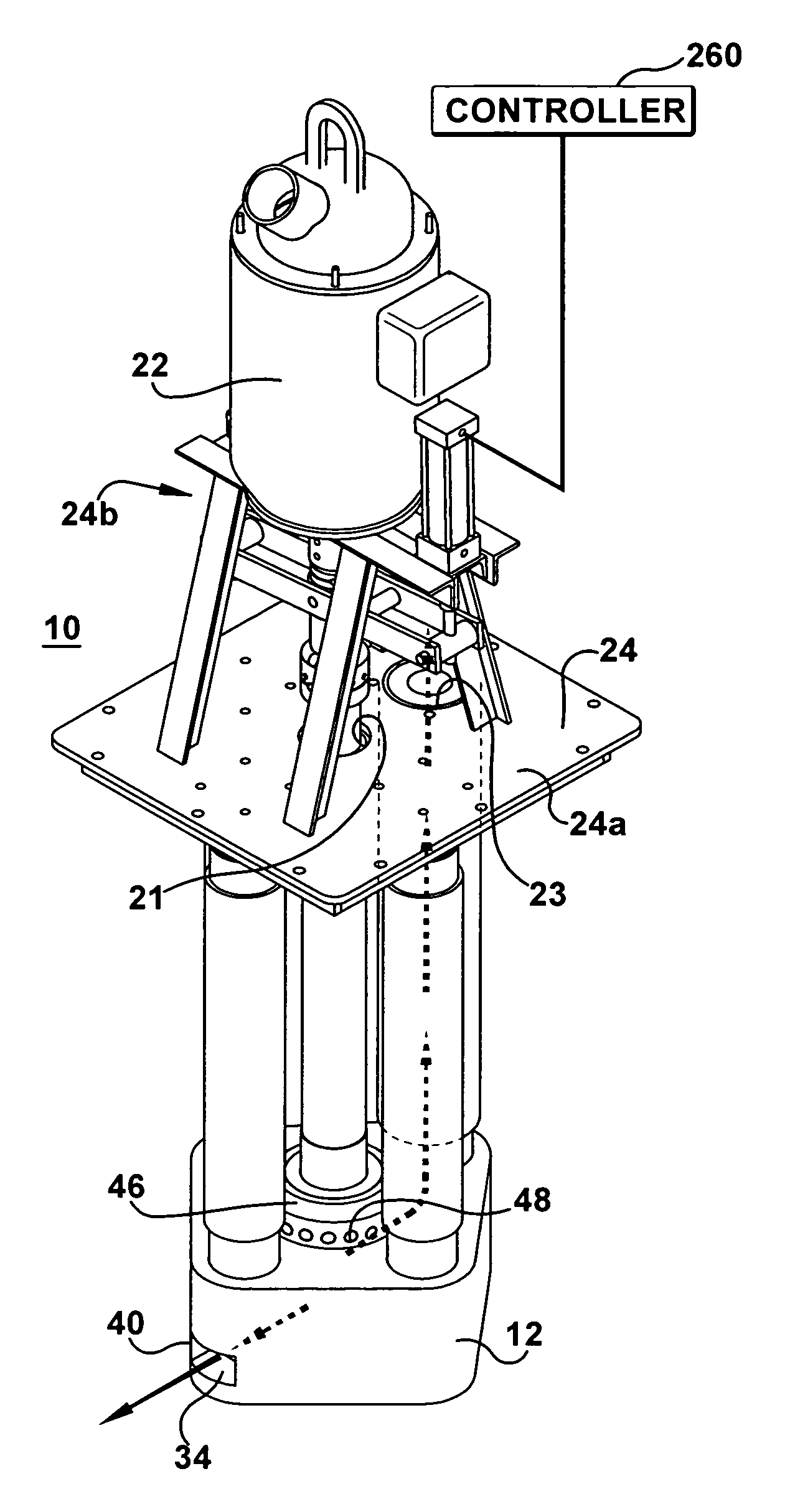

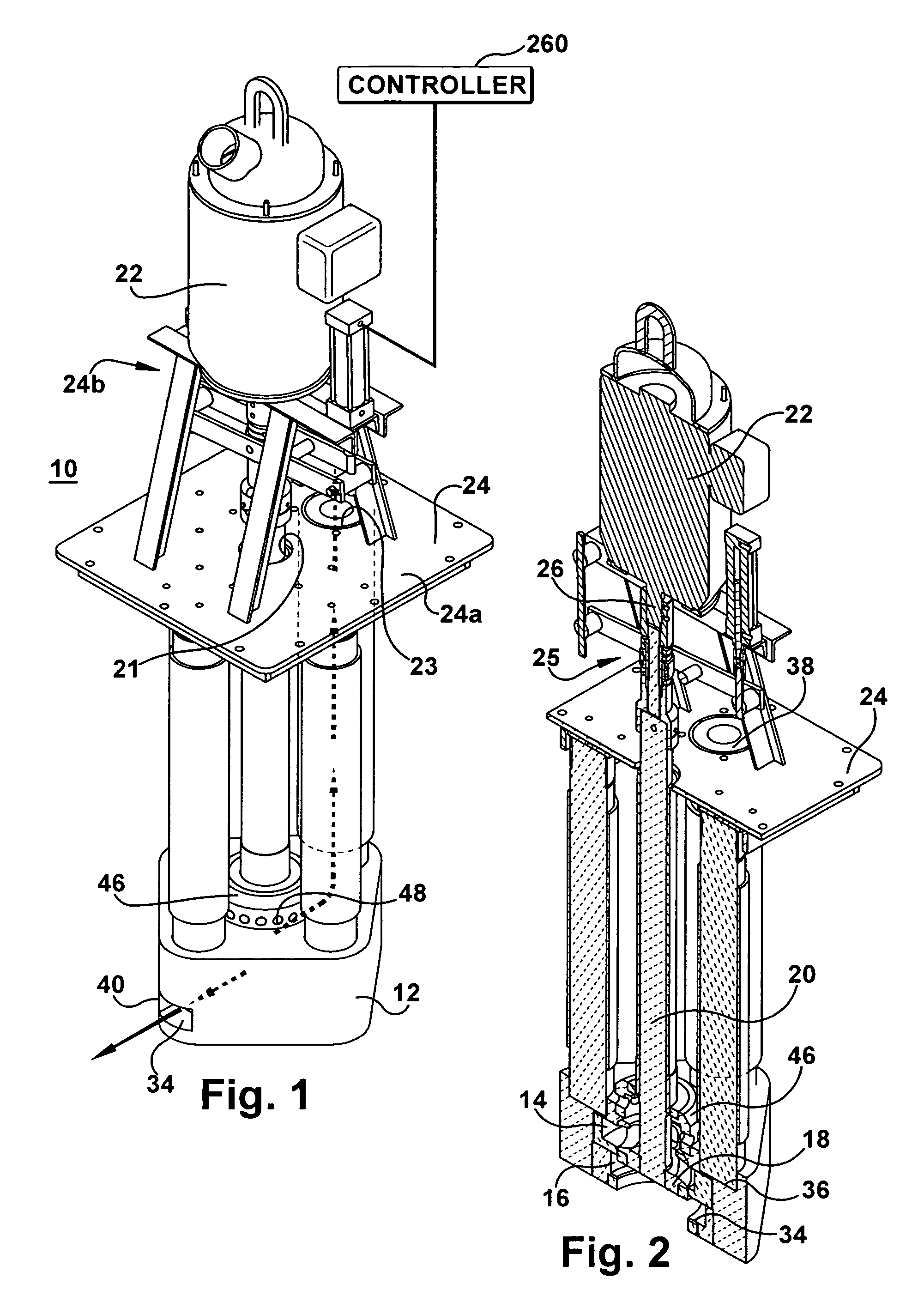

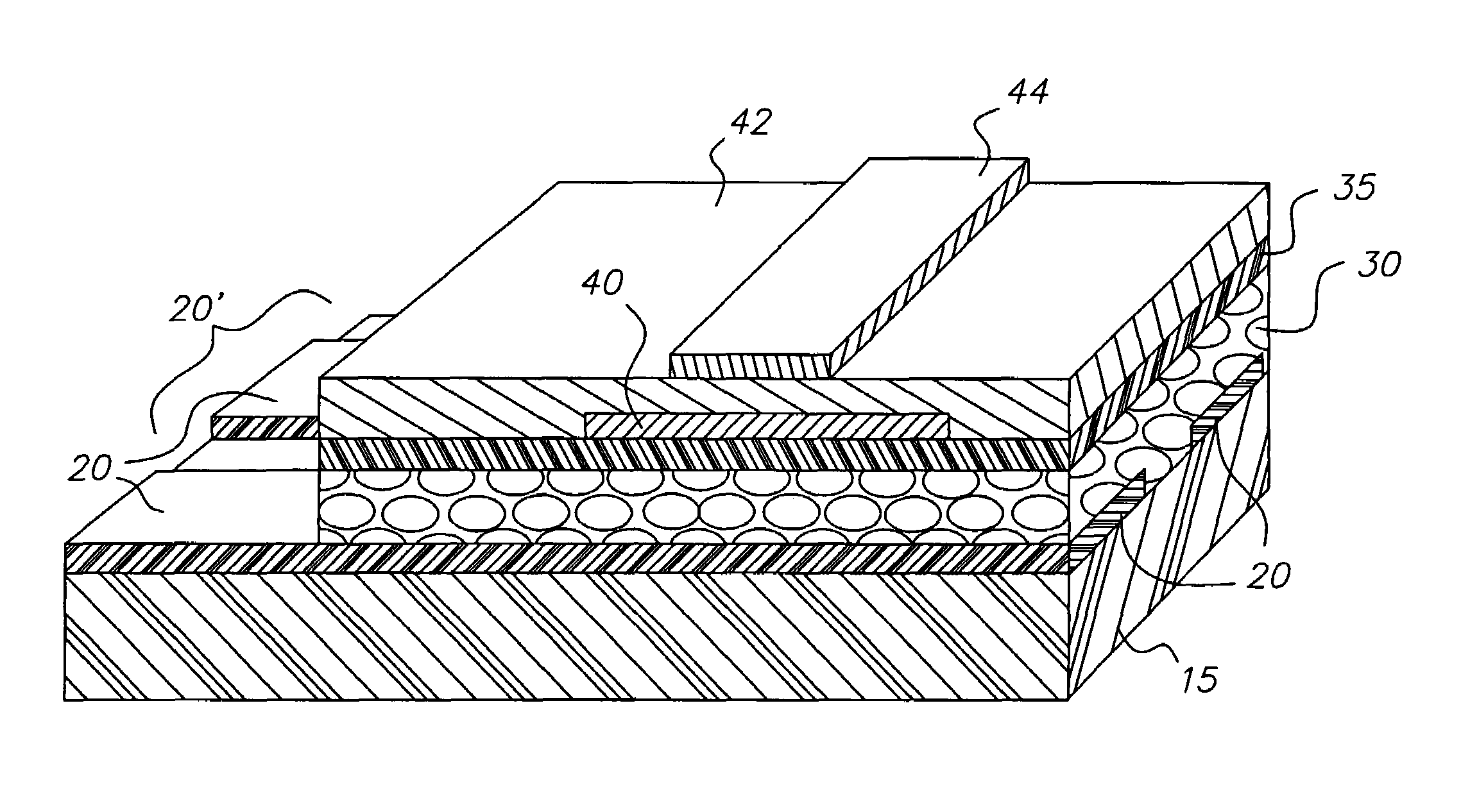

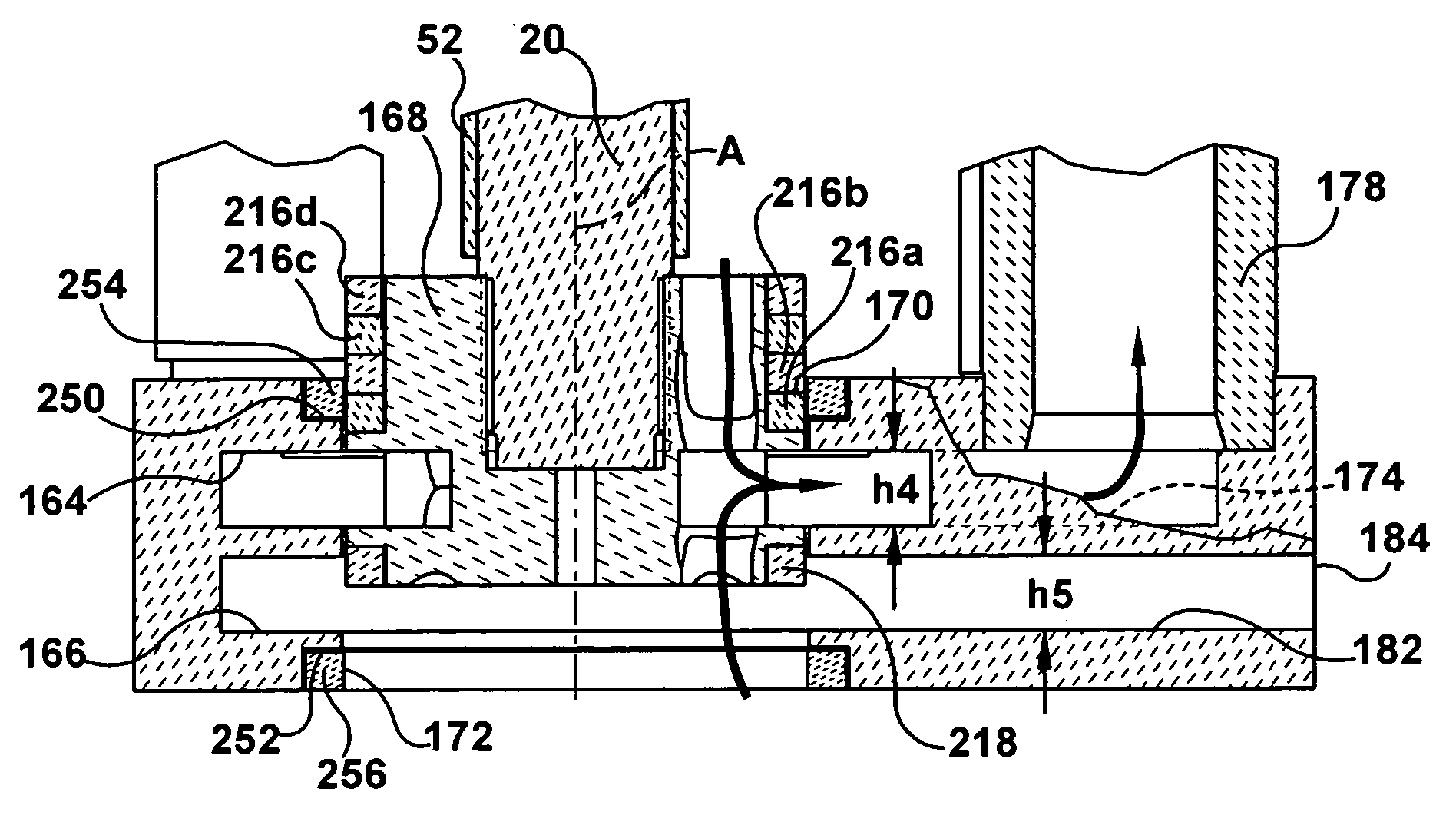

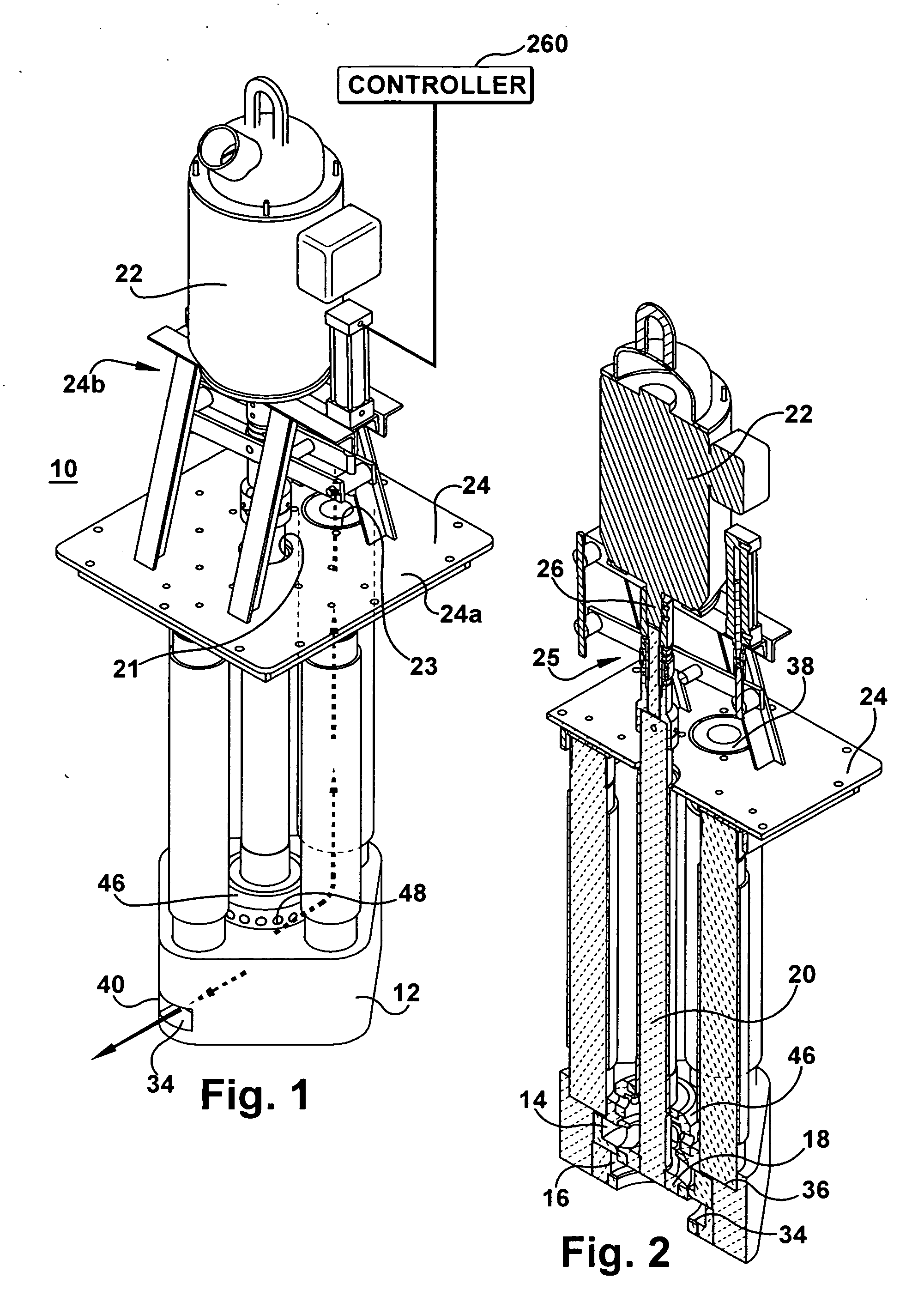

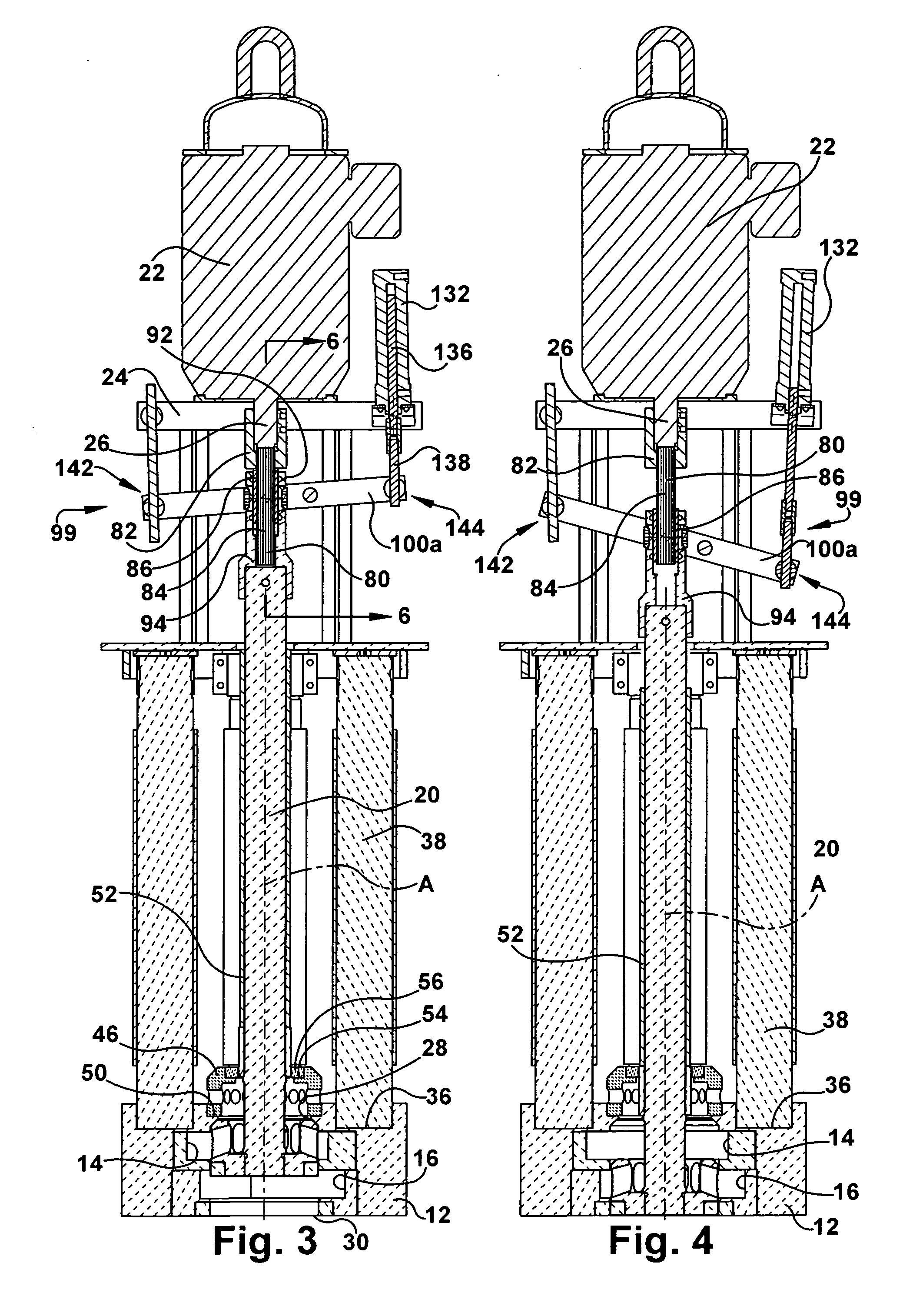

Multi functional pump for pumping molten metal

ActiveUS7507365B2Easy to pumpMaximize molten metal dischargeSpecific fluid pumpsPump componentsImpellerProgrammable logic controller

The present invention features a multi-functional pump for pumping molten metal, which includes a base that is submerged in molten metal having at least two impeller chambers. The base includes one or more inlet openings and one or more outlet openings. Each outlet opening leads from one of the impeller chambers. The invention enables the impeller to be moved to a position to rotate in either impeller chamber or while straddling impeller chambers. This enables the pump to have the versatility to operate in a circulation mode; a transfer mode; two or more circulation modes; two or more transfer modes; and a combination of transfer and circulation modes. The impeller chambers can be stacked over each other and the impeller can be moved vertically in and between impeller chambers. Inventive vaned or barrel type impellers can be used to facilitate pumping while straddling impeller chambers, in view of an elongated bearing member on the impeller that maintains position relative to a bearing ring attached to the base or an inlet protector sleeve. The multifunctional pump of the invention enables infinite adjustment of the impeller using a programmable logic controller that results in positioning of the impeller at any of various locations in the base to achieve any desired output. The inventive pump is ideally suited for use in die casting and scrap submergence applications. Also featured is a method of operating the multifunctional pump of the present invention.

Owner:THUT BRUNO H

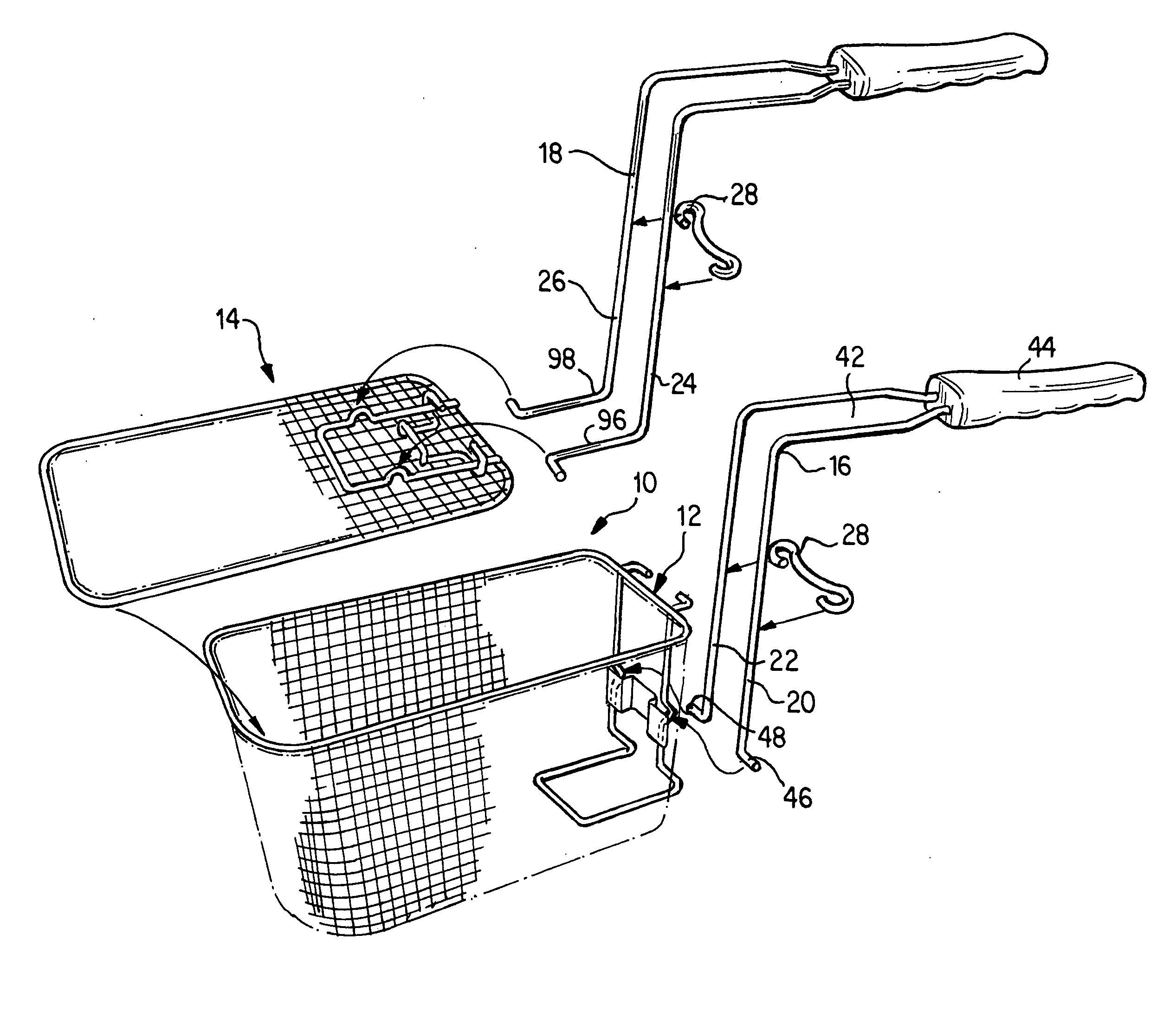

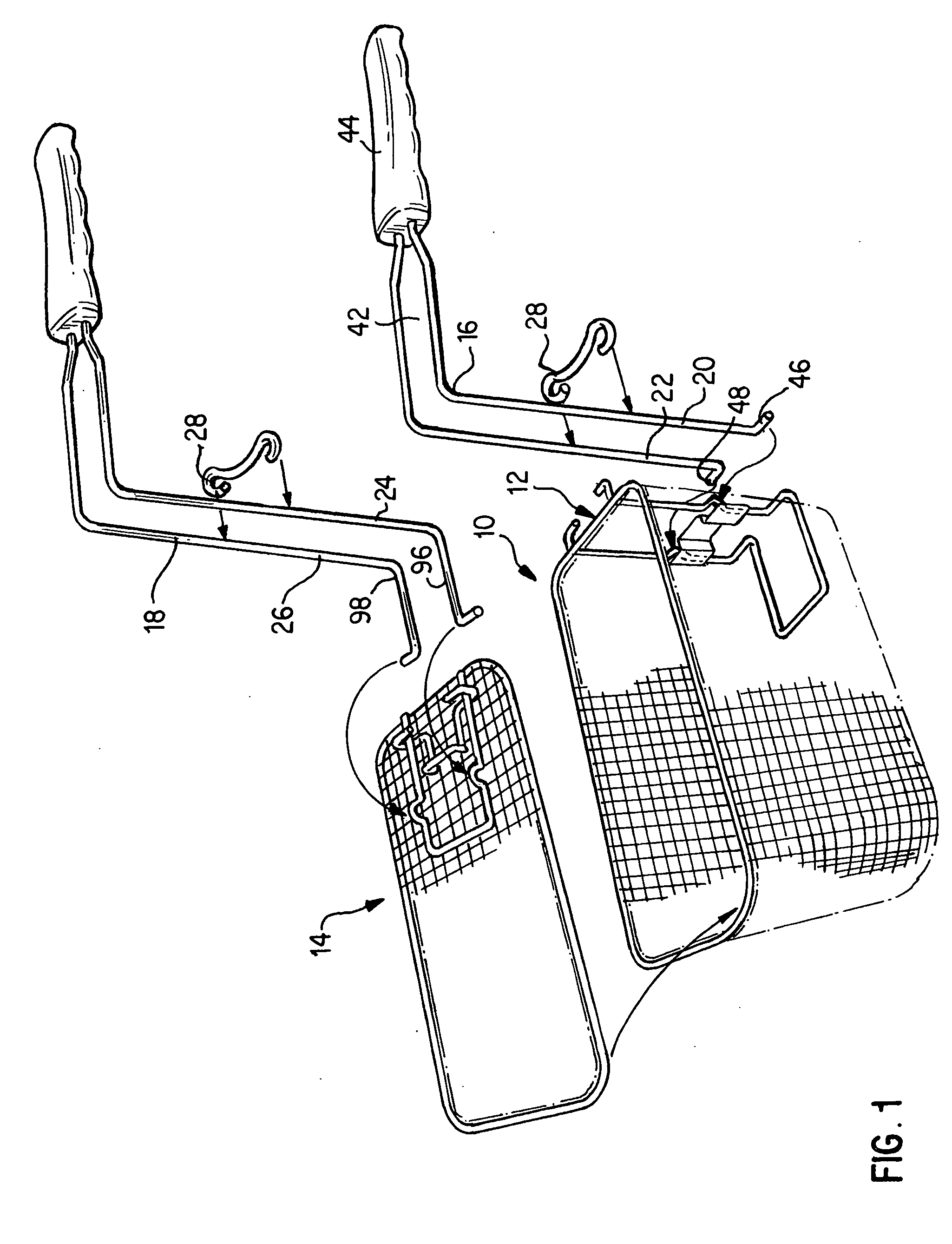

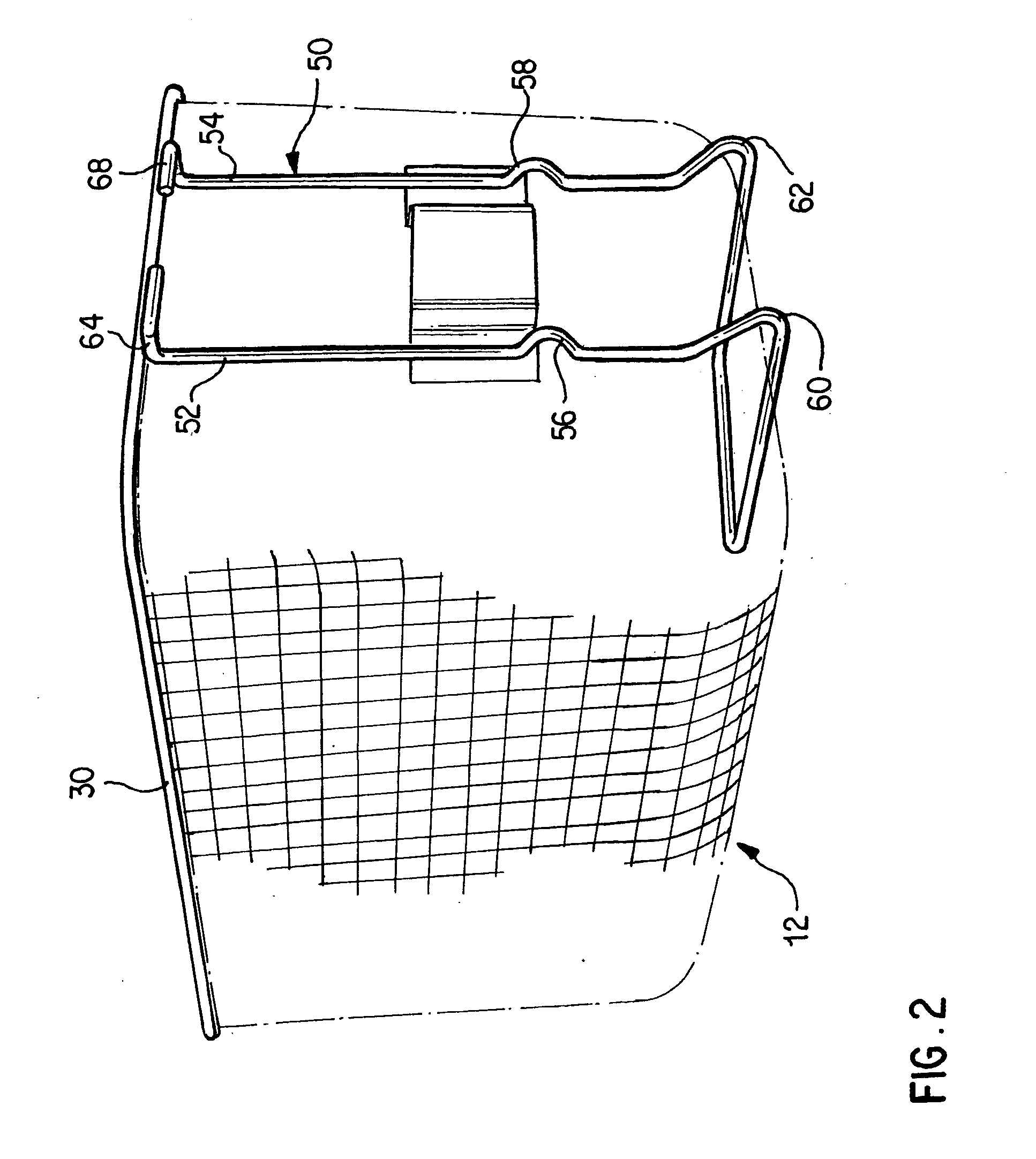

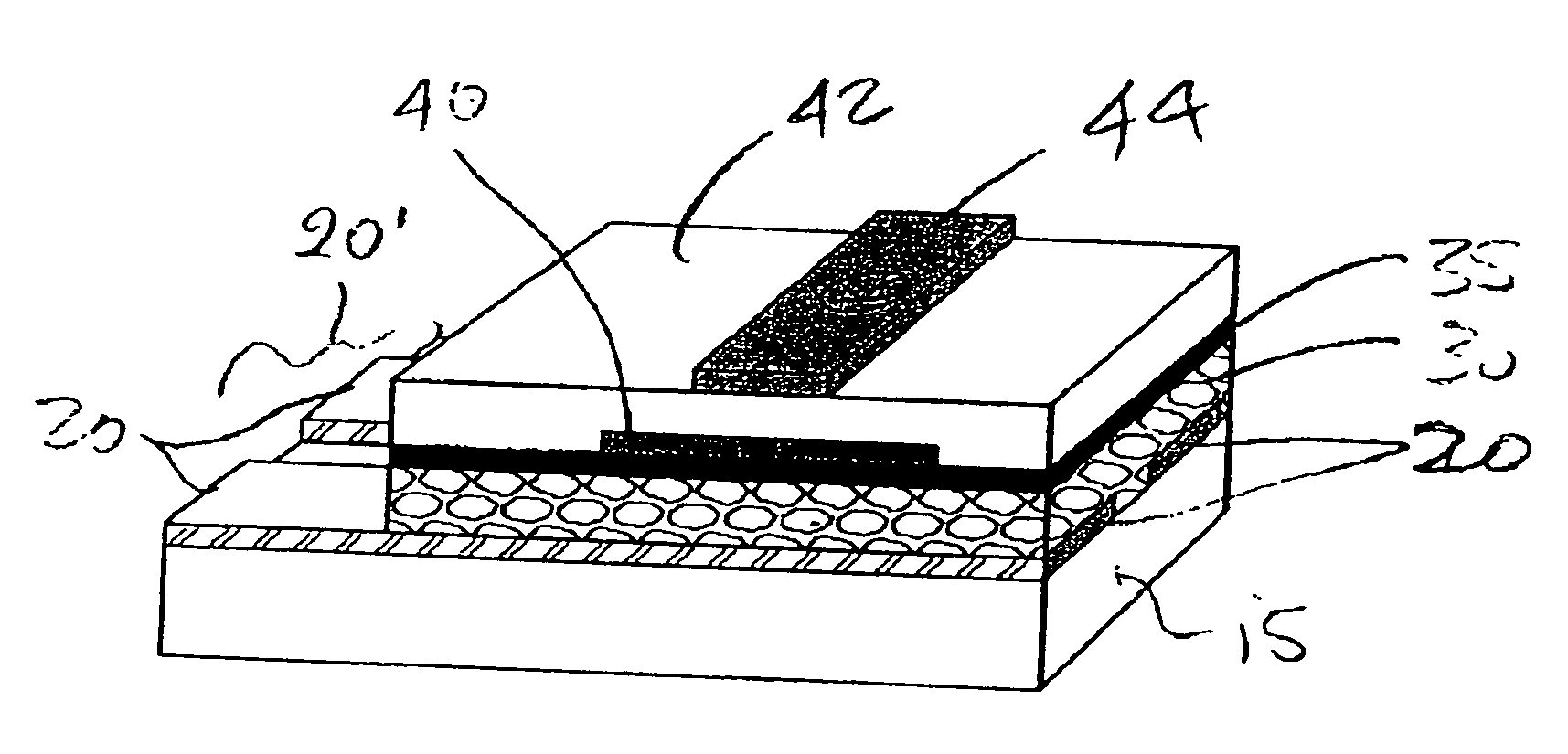

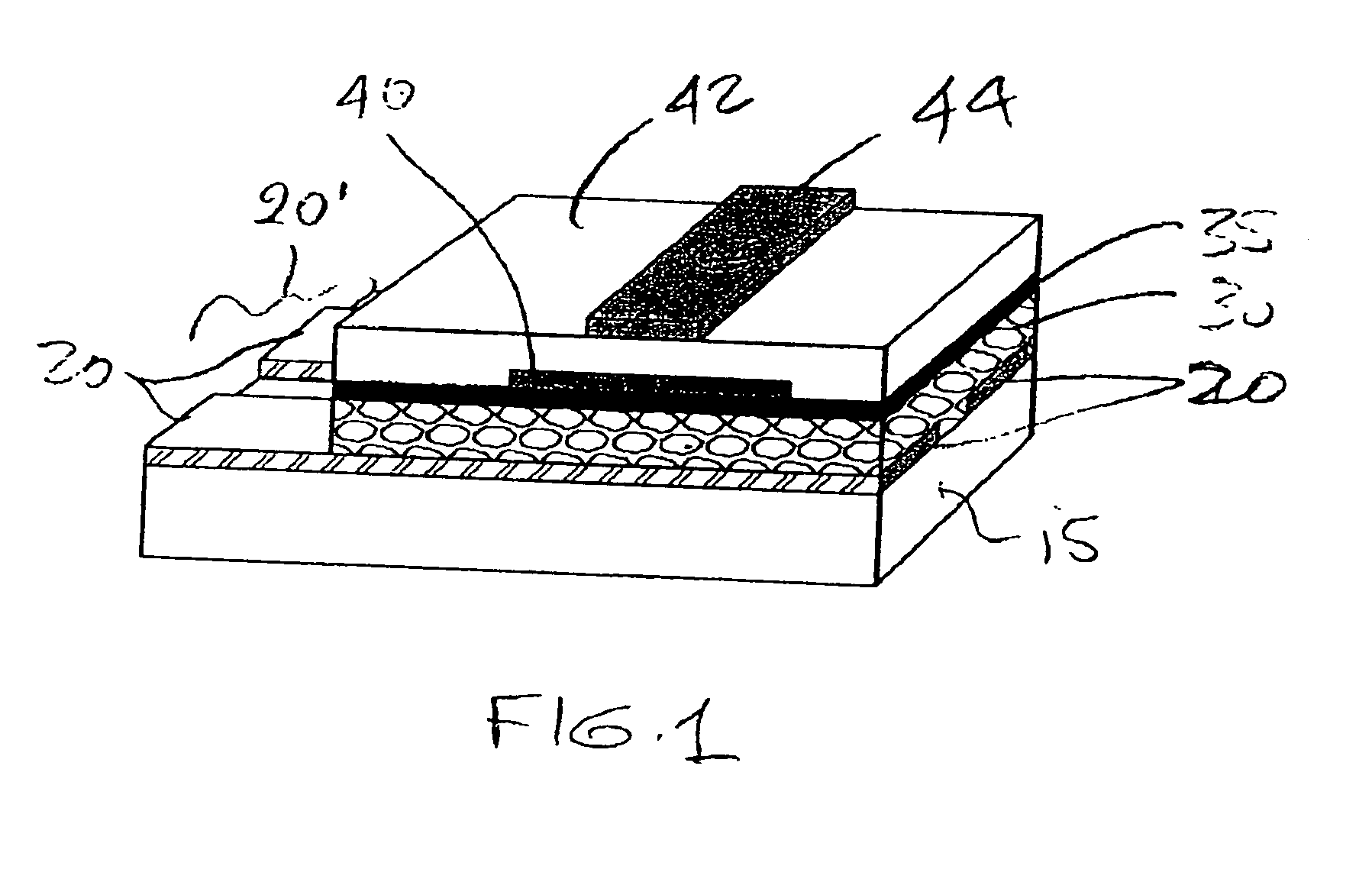

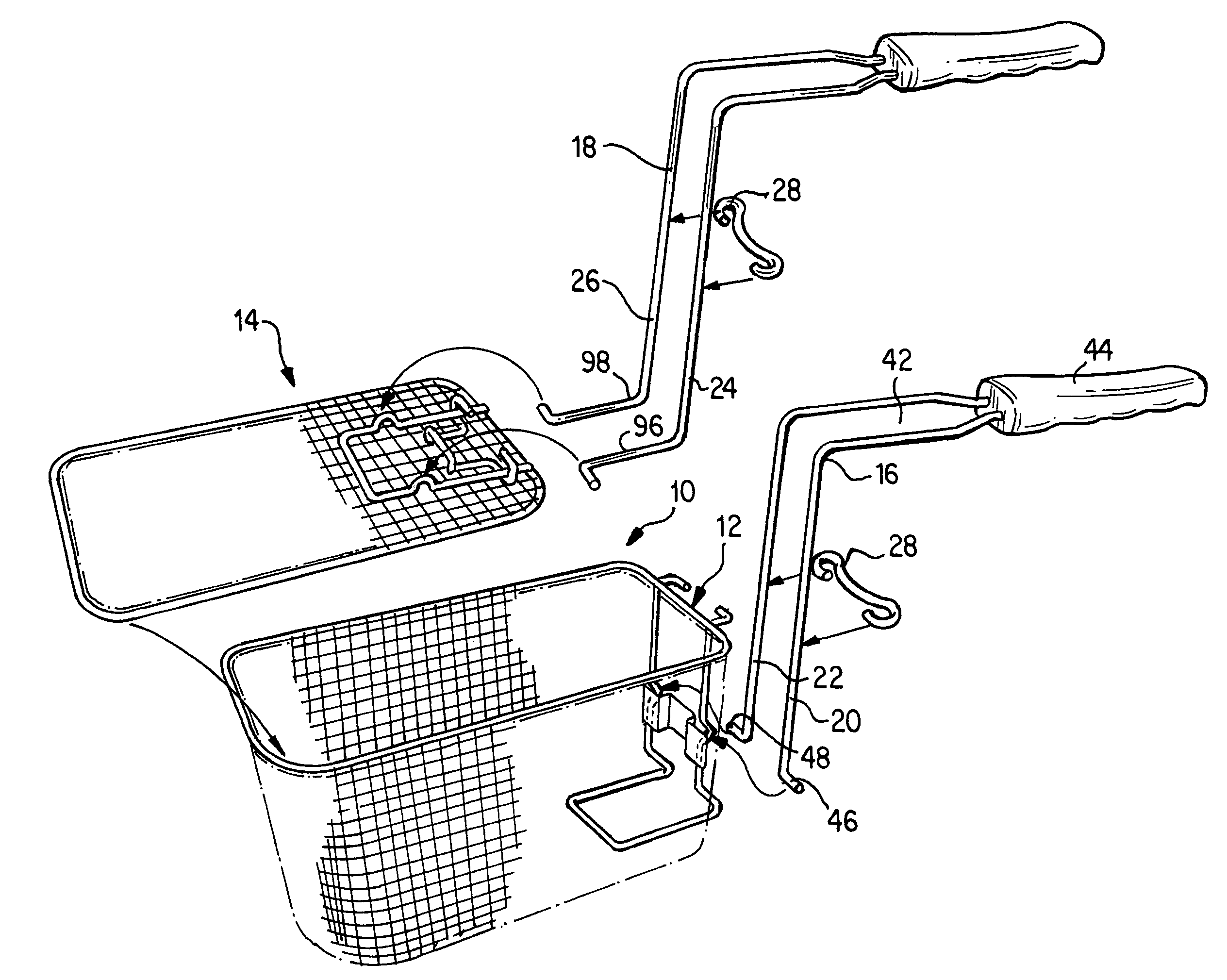

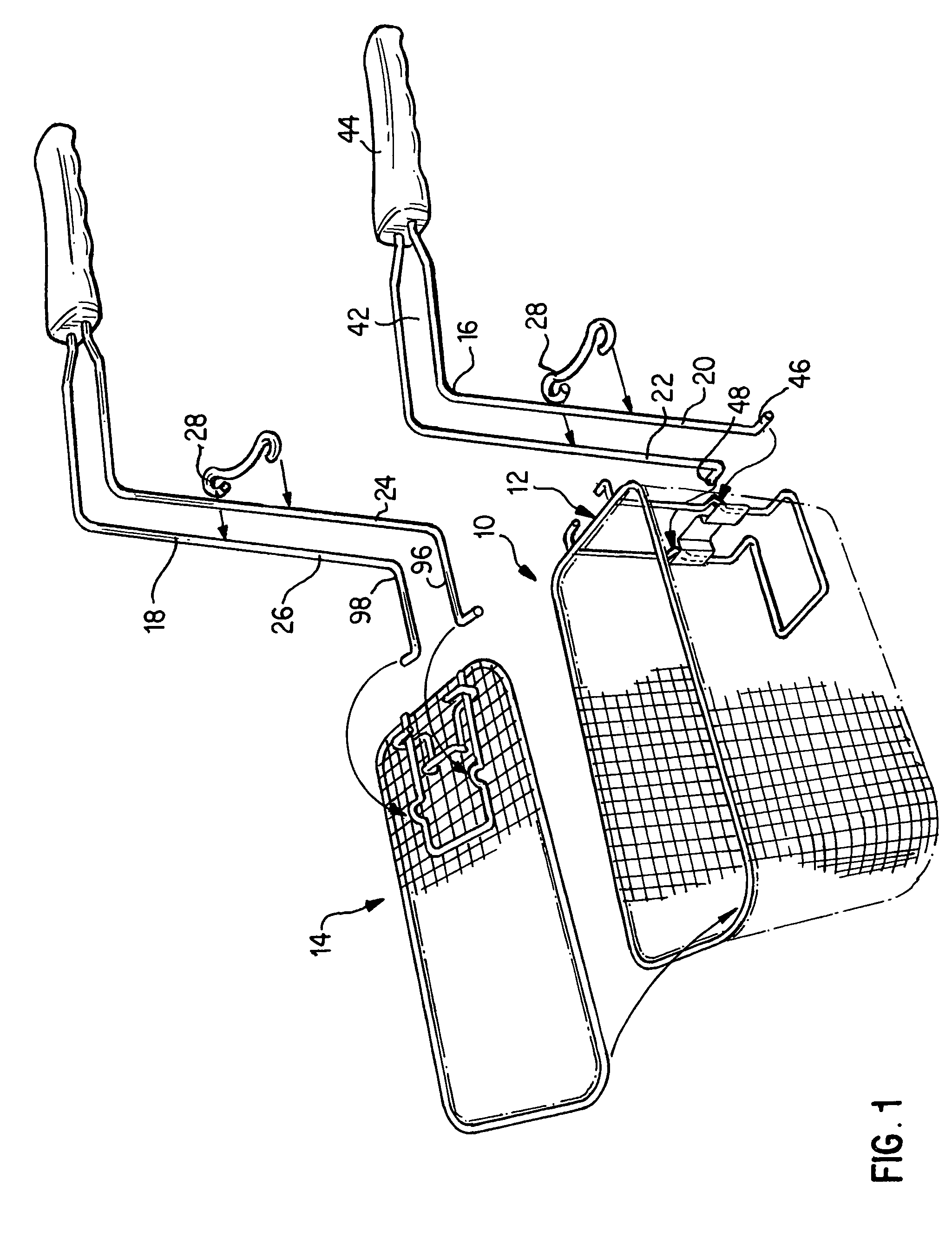

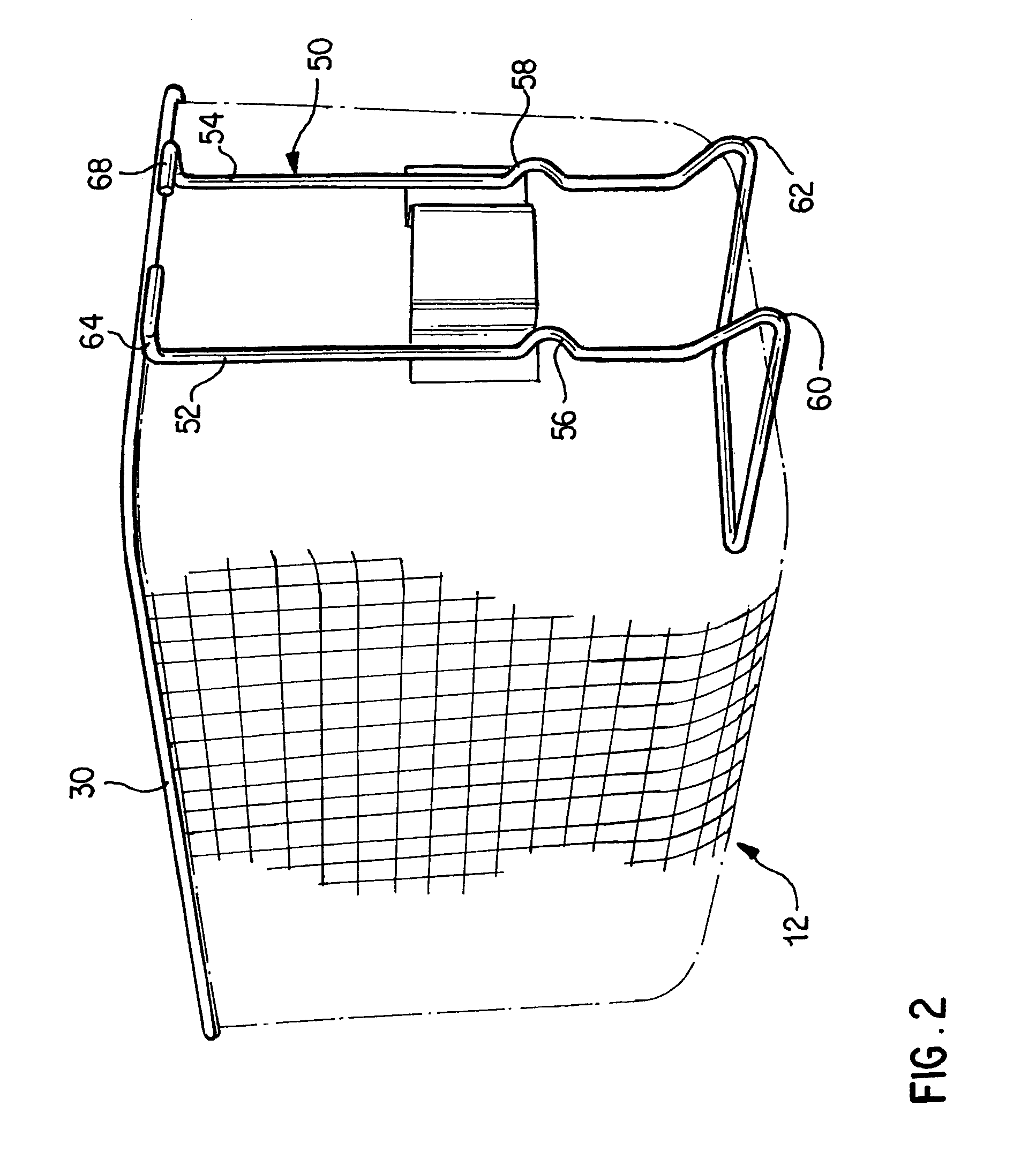

Basket for deep fryer and methods of cooking food products

ActiveUS20050204929A1The process is convenient and fastImprove efficiencyFood preparationDeep fat fryersEngineeringMechanical engineering

A basket assembly for use with a deep fryer having a lower foraminous basket and an upper foraminous insert which quickly and easily attaches to the lower basket at a predetermined location intermediate the top and bottom of the lower basket to thereby hold the food in place beneath the surface of a hot cooking liquid such as oil. Advantages of the assembly are that it forces foods down to increase the efficiency of flash frying, it provides the ability to cook more than one item at a time while keeping them separated, and it provides a food product which cooks faster because it is unnecessary to turn food which floats to the top, thereby resulting in less fat absorption.

Owner:SHARKNINJA OPERATING LLC

Polyolefin oil resistant film using high isotactic content polypropylene

InactiveUS6844078B2Fine surfaceImprove performanceSynthetic resin layered productsThin material handlingPolyolefinEthylene Homopolymers

A coextruded multilayer film, having of at least a high crystalline propylene homopolymer resin layer of isotactic content greater than about 95%; a discharge-treated surface on one side of said polyolefin resin layer; an amount of hydrocarbon resin up to 10% by weight of the high crystalline propylene homopolymer of greater than about 95% isotactic content; and on the high crystalline propylene homopolymer resin layer side opposite said discharge-treated surface, a heat sealable layer or winding layer having an antiblock is disclosed.

Owner:TORAY PLASTICS (AMERICA) INC

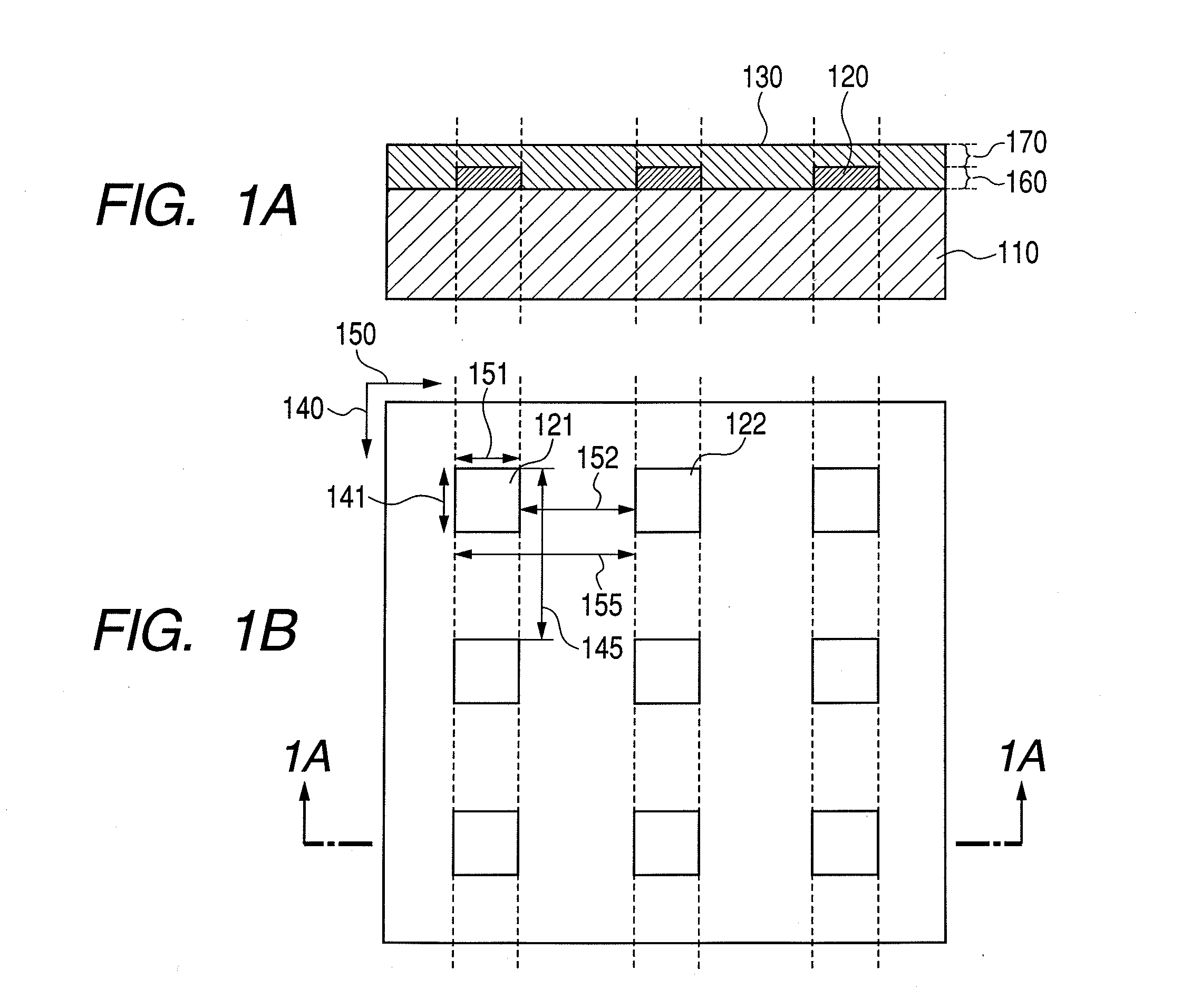

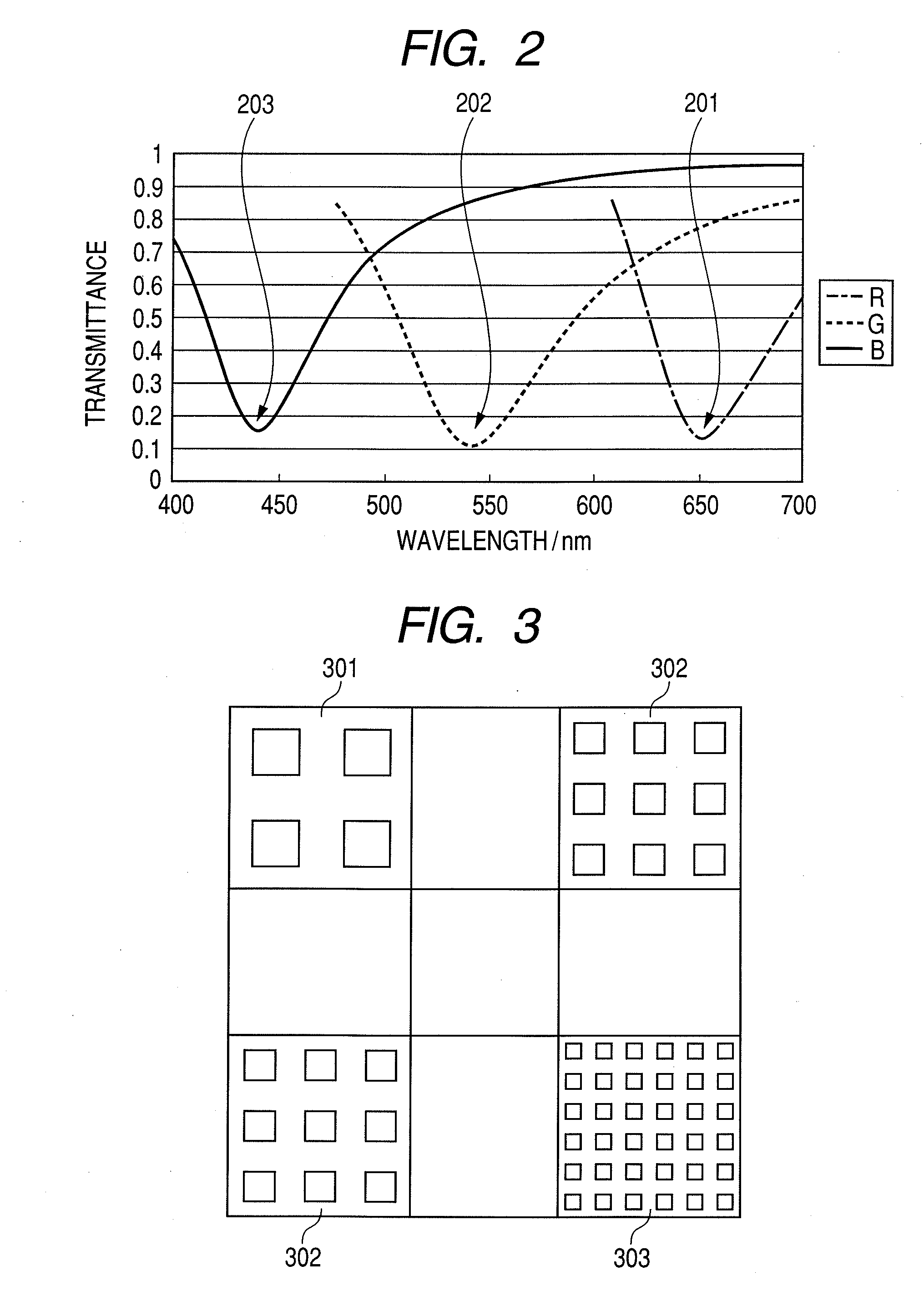

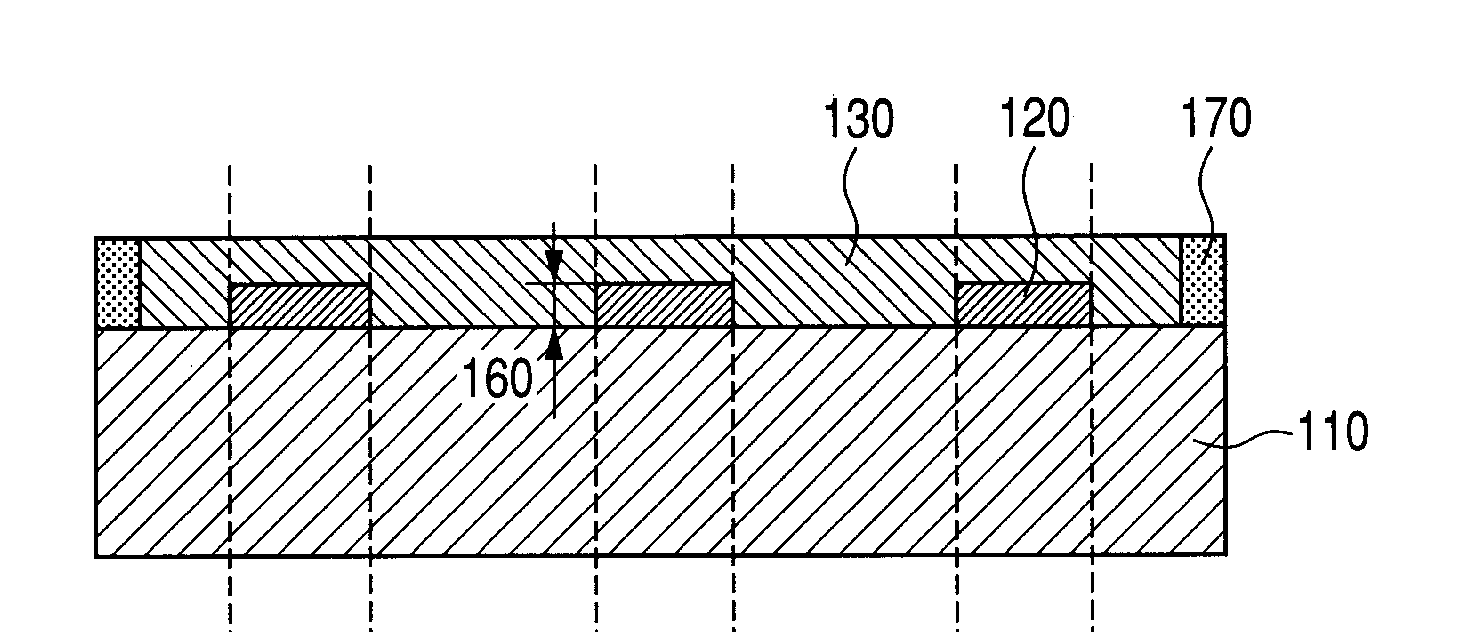

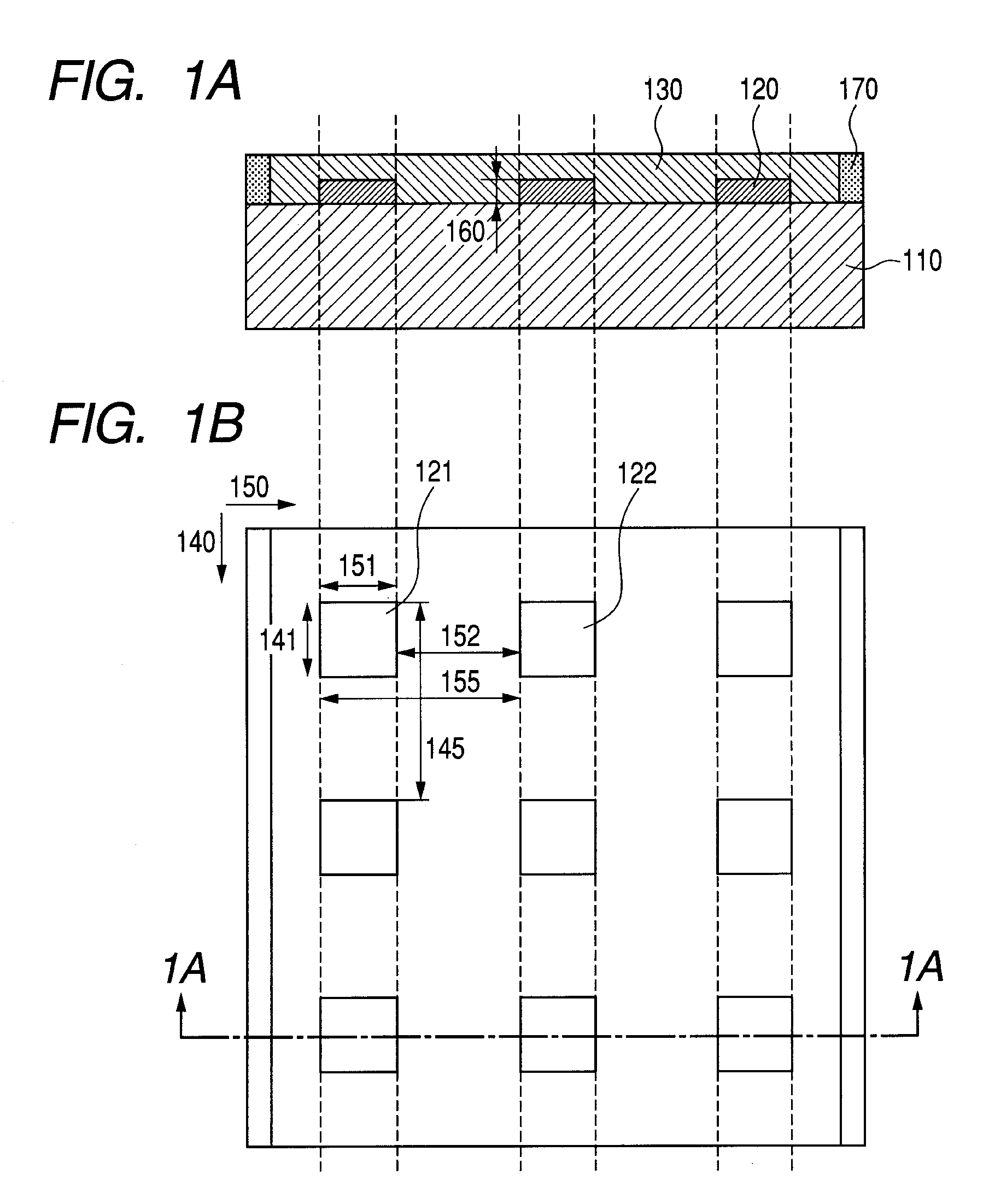

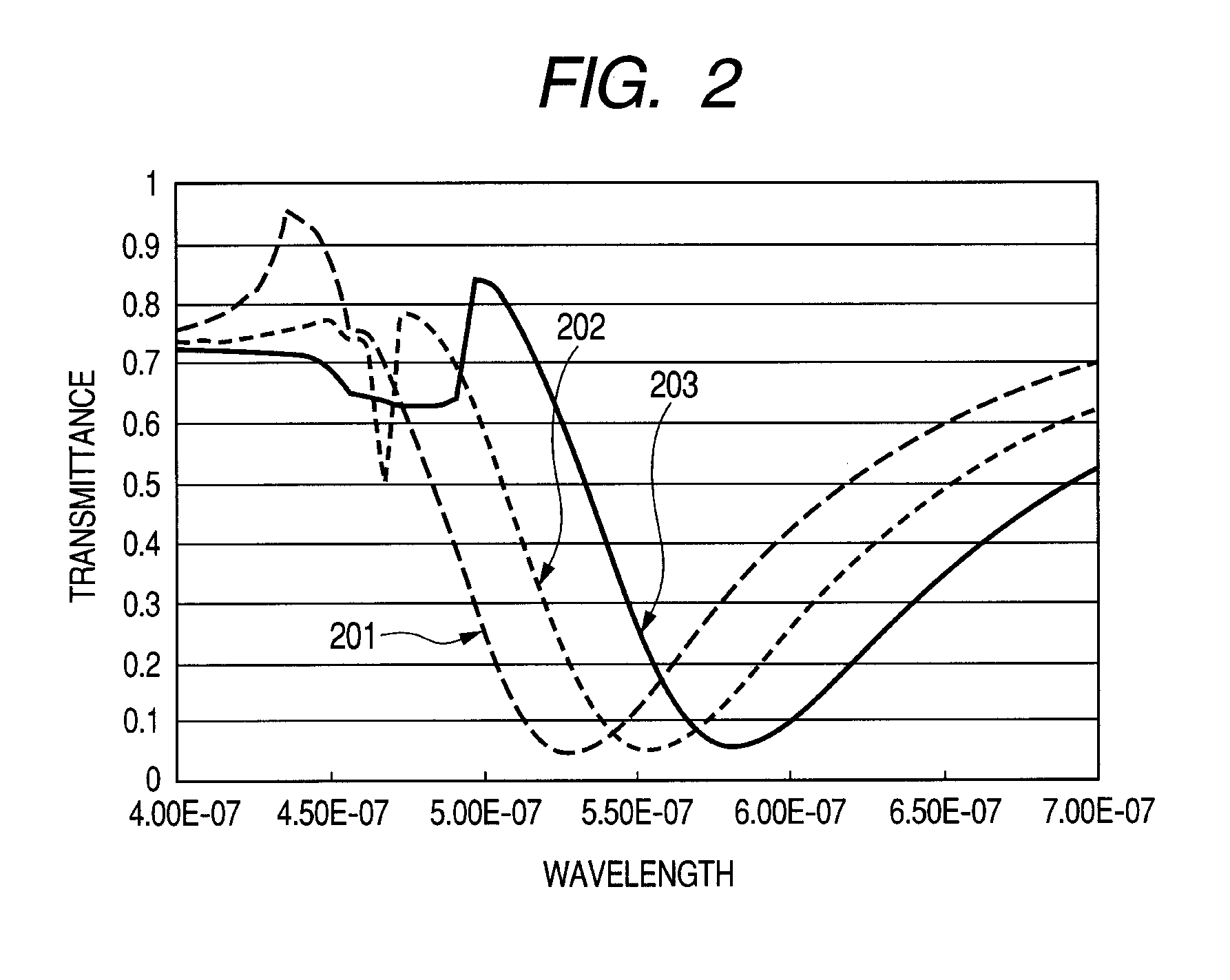

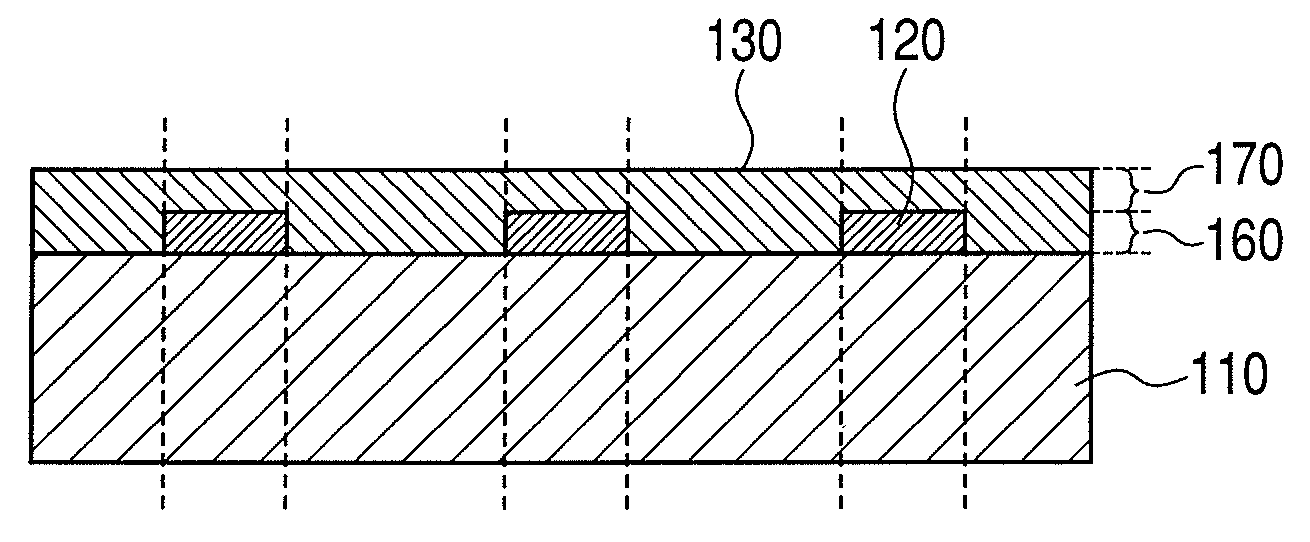

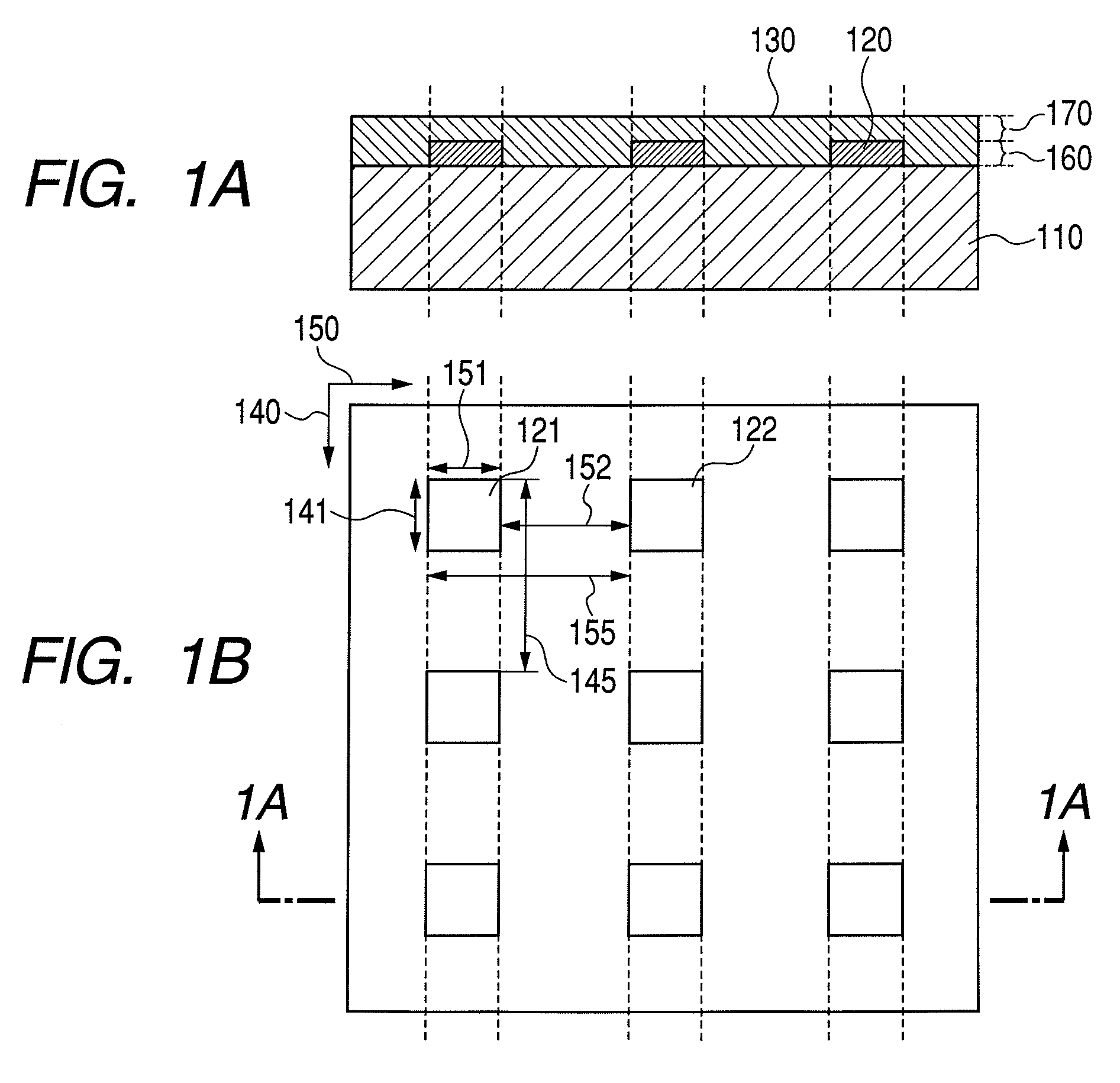

Optical filter

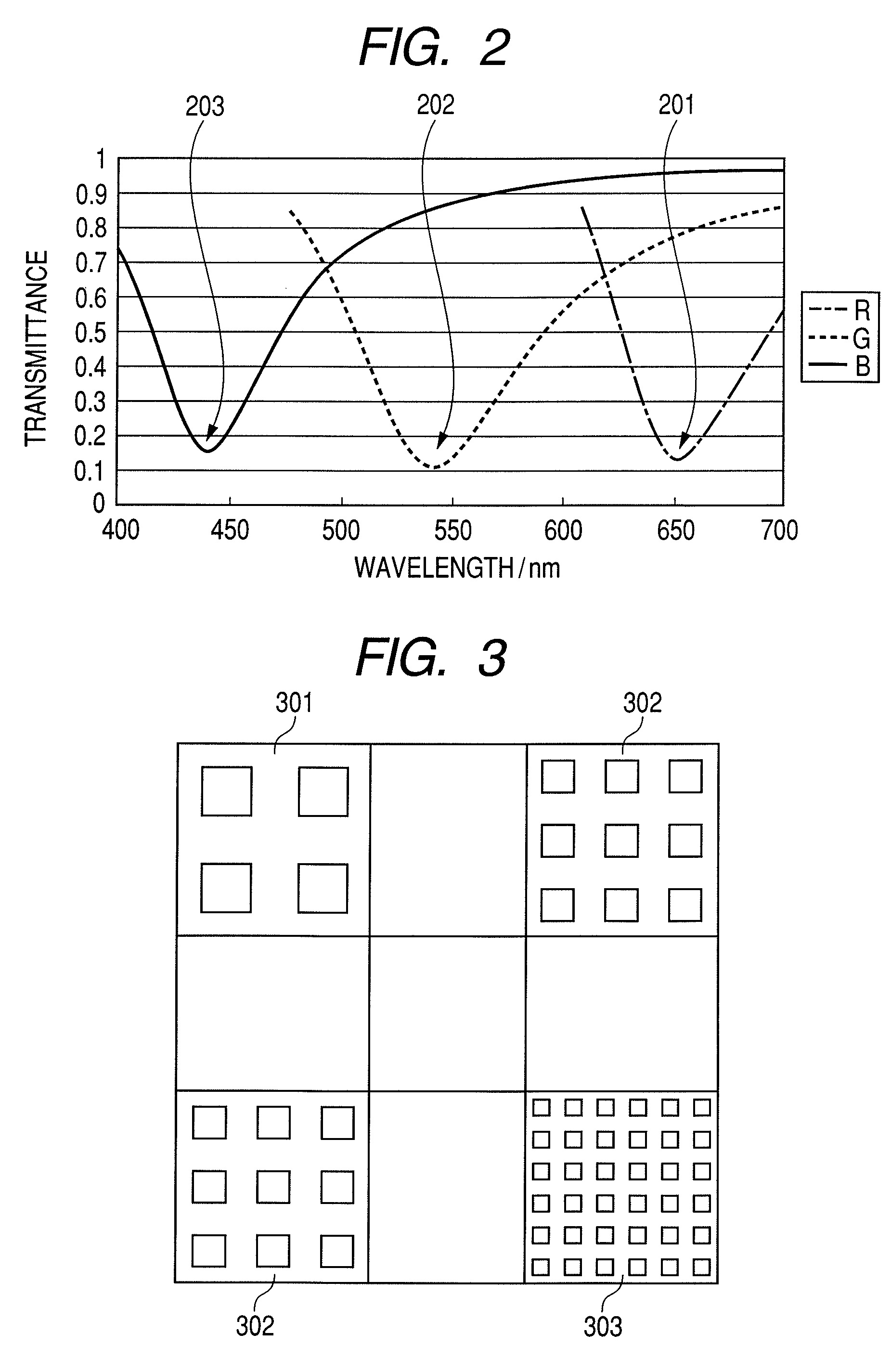

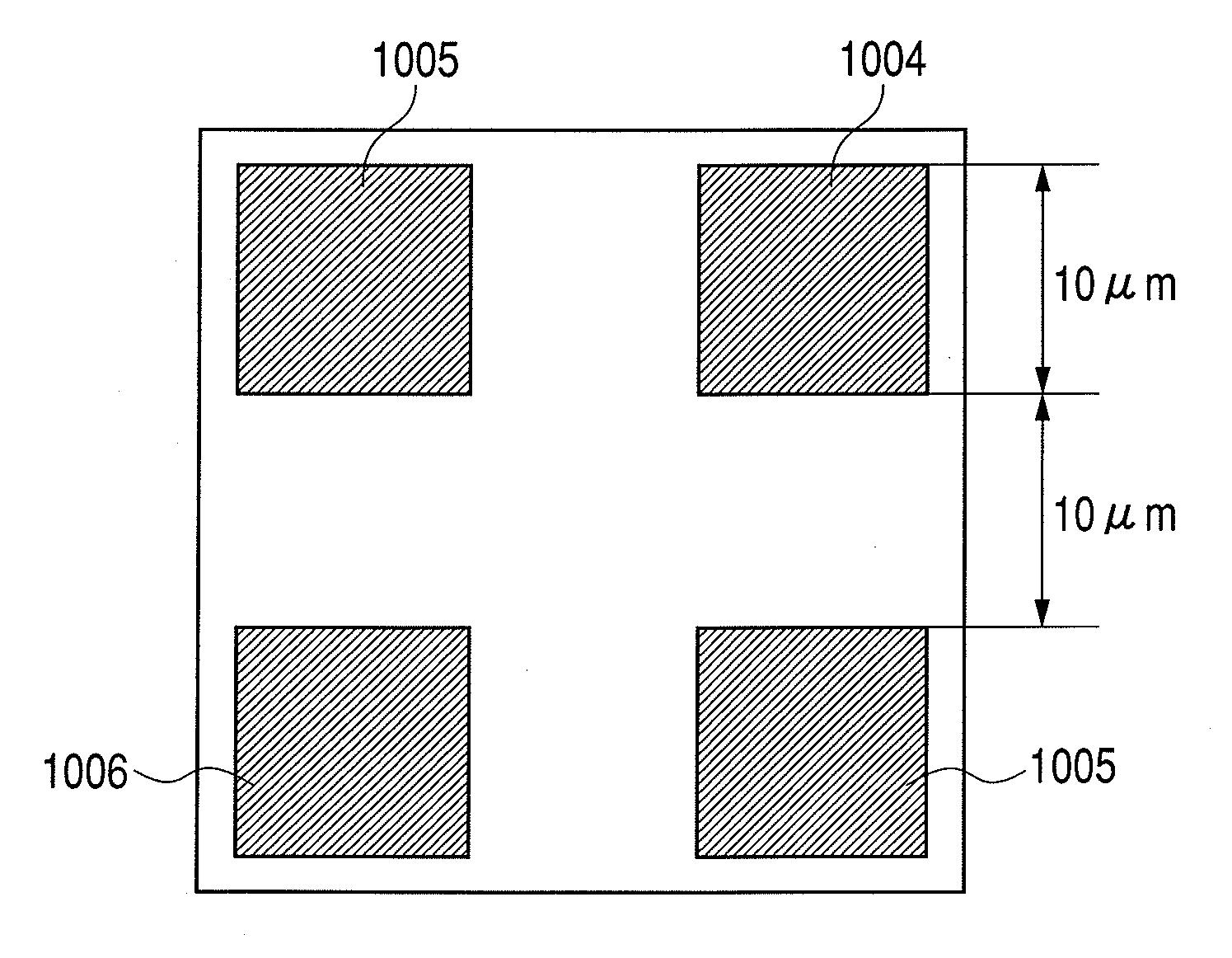

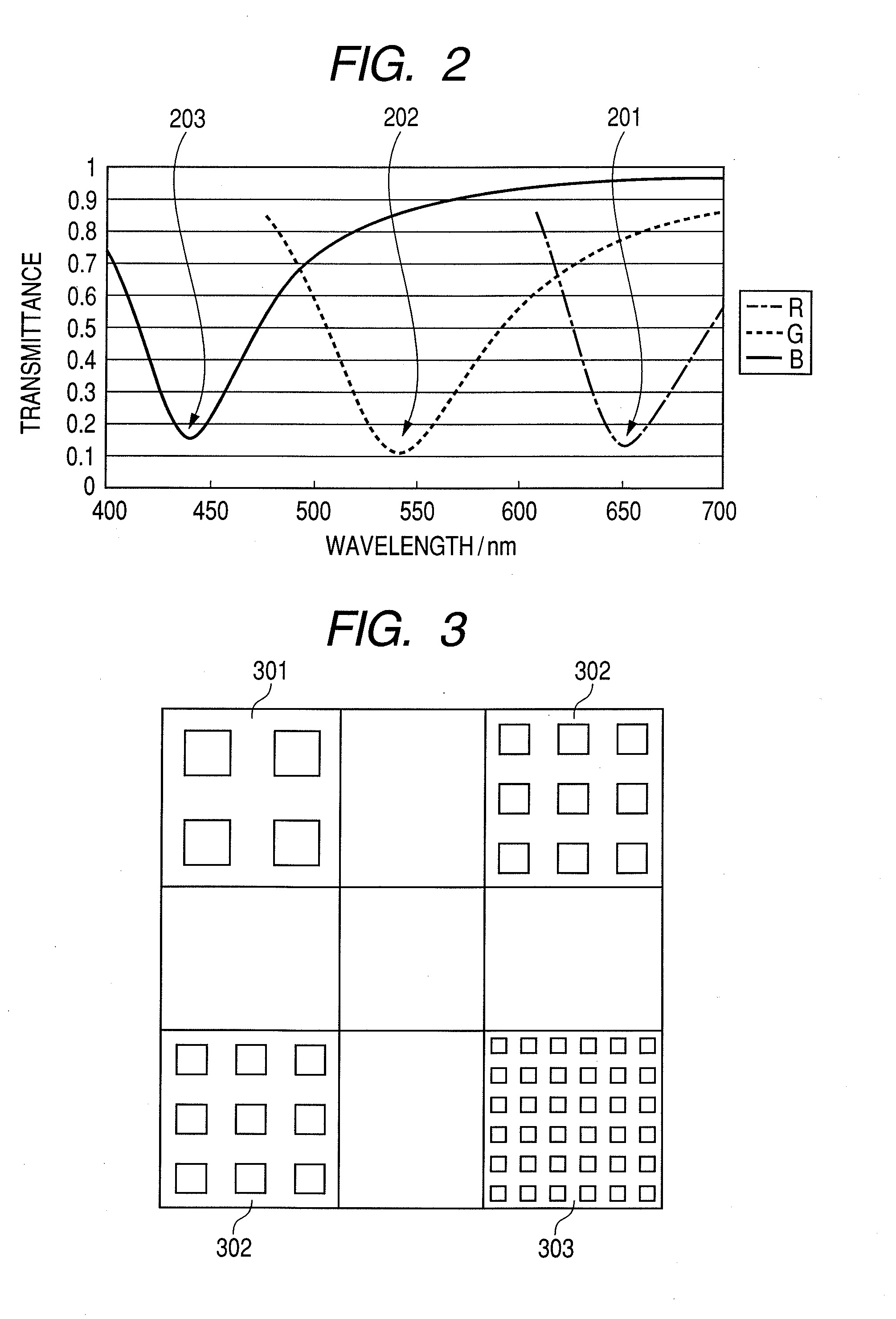

InactiveUS20100220377A1High strengthAvoid excessive absorptionSolid-state devicesNon-linear opticsIn planeDielectric substrate

An optical filter that transmits light of the visible light region includes a dielectric substrate; a dielectric layer that is formed on a surface of the dielectric substrate; and a first metal structure group in which a plurality of first metal structures are arranged two-dimensionally in an isolated state in the in-plane direction of the dielectric substrate, that is provided between the dielectric substrate and the dielectric layer, comprising: the first metal structures having first and second lengths in first and second directions orthogonal to each other, which lengths are equal to or less than a first wavelength in the visible light region; and a transmittance of the first wavelength being reduced or a reflectance being increased by surface plasmons induced on a surface of the first metal structures by resonance between light incident on the dielectric substrate or the dielectric layer and the first metal structures.

Owner:CANON KK

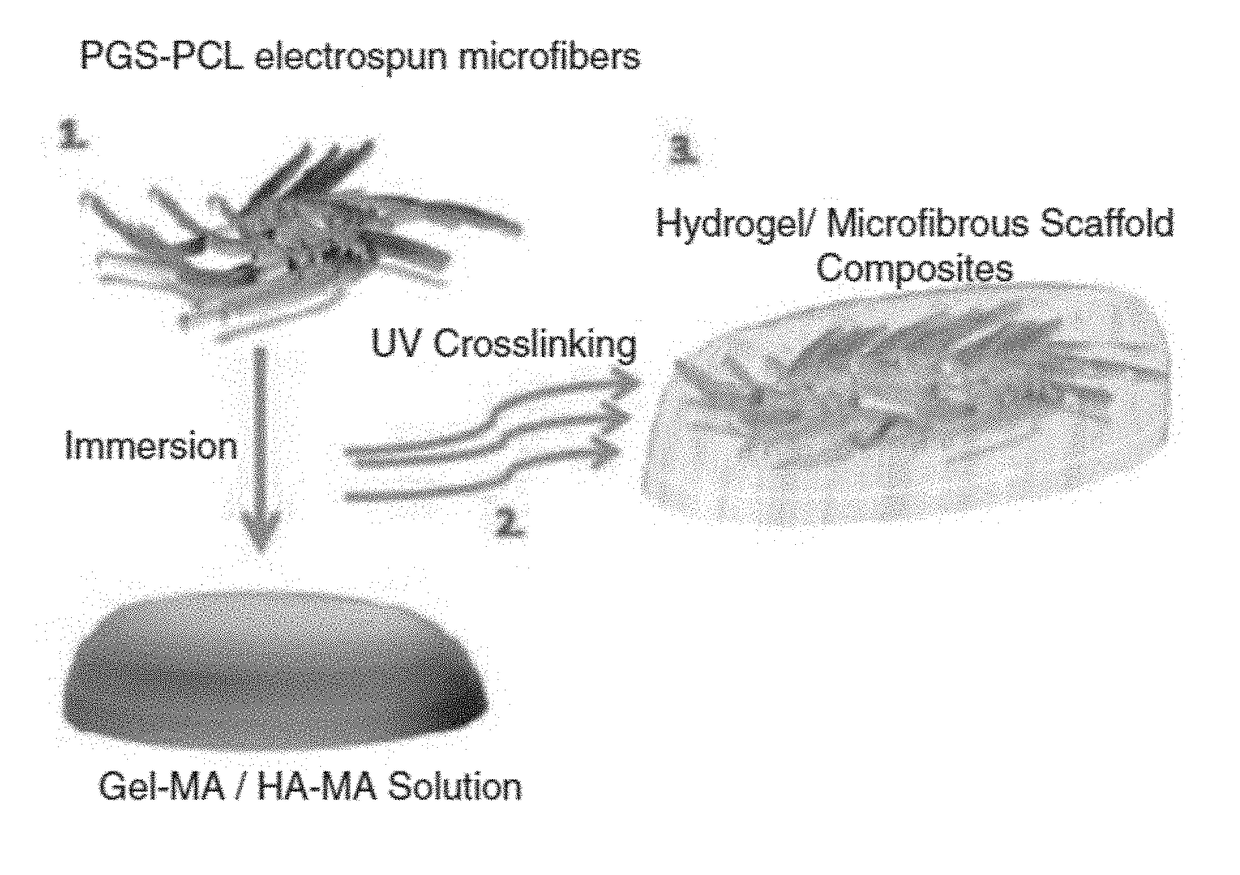

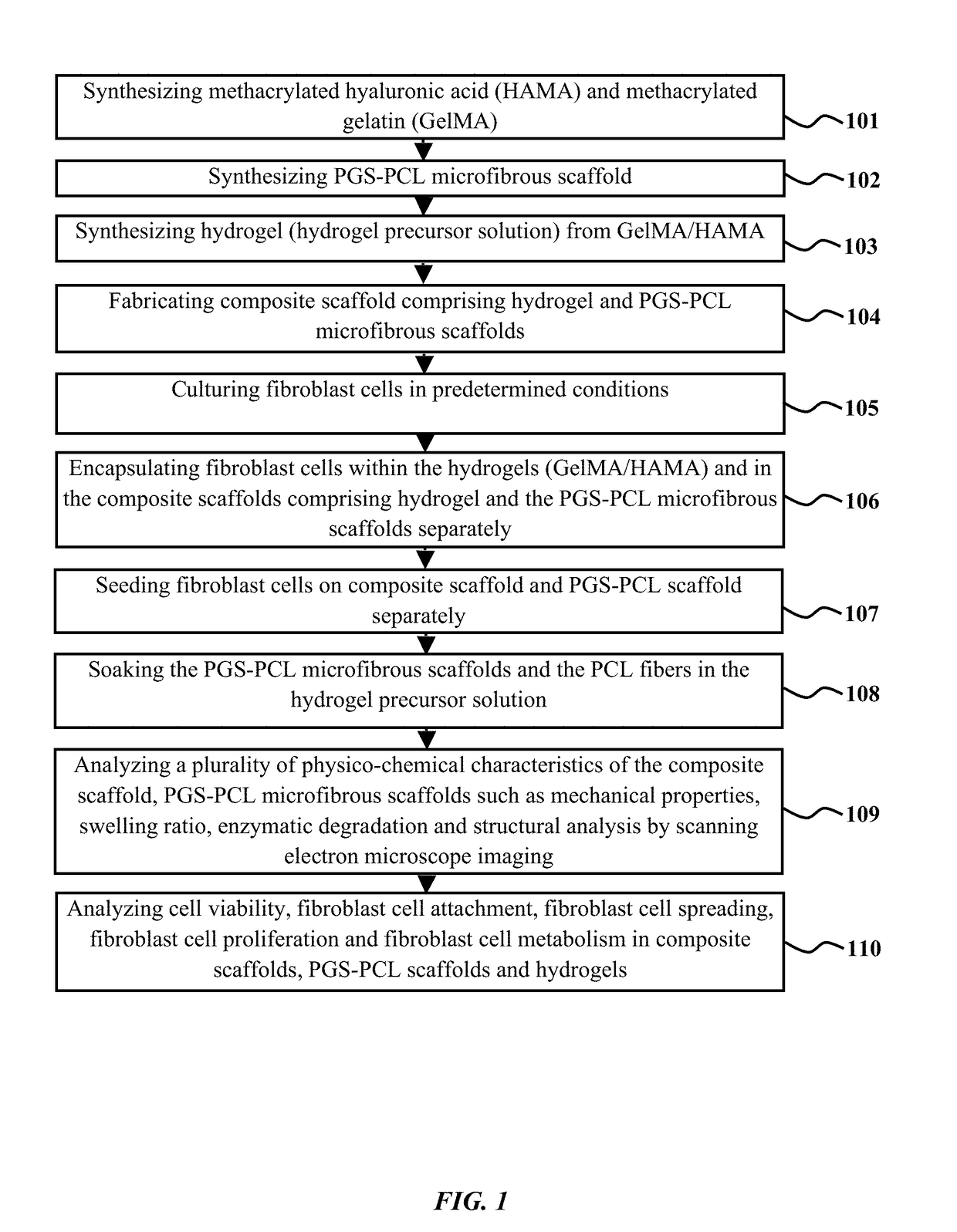

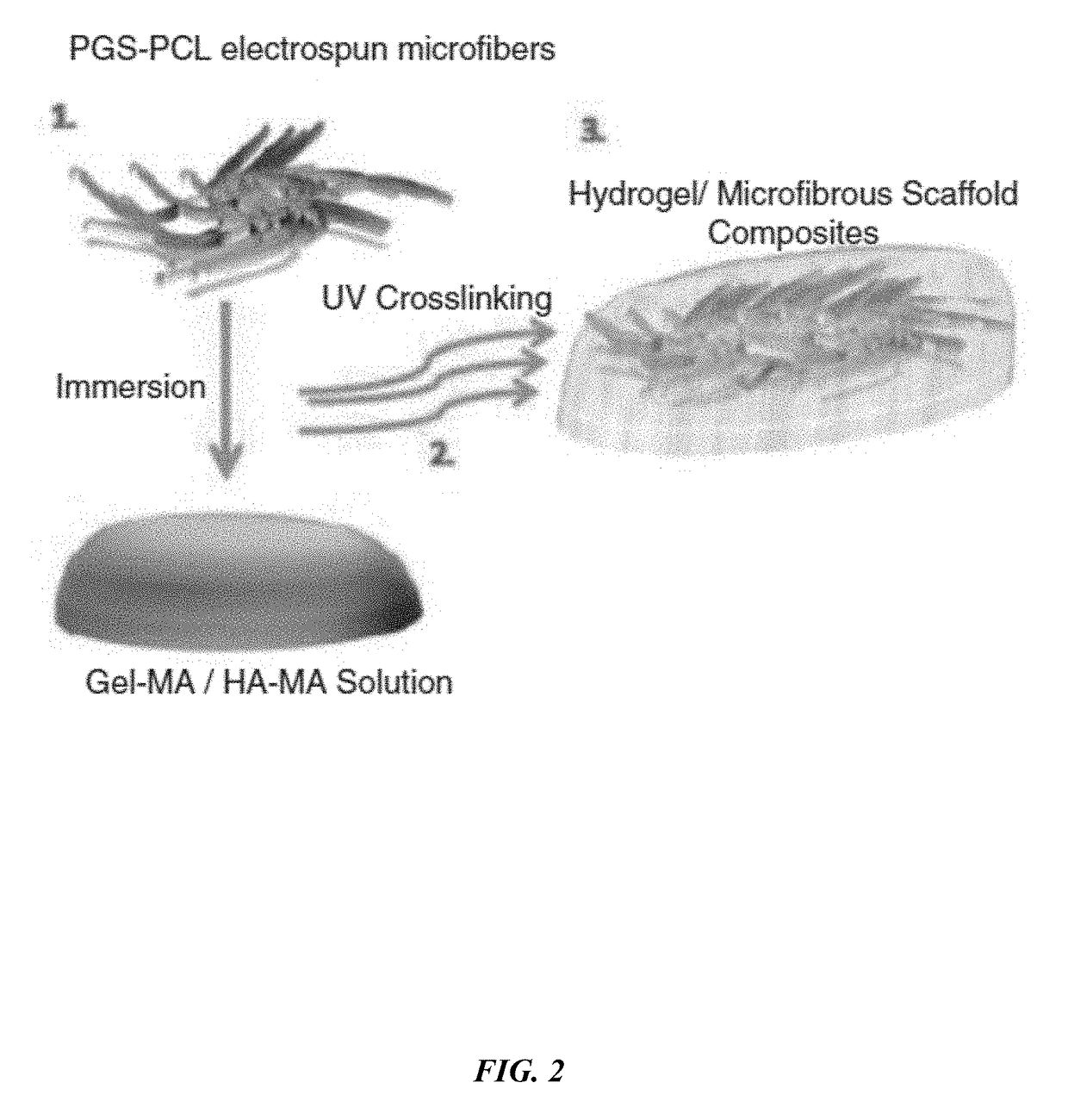

Scaffold for skin tissue engineering and a method of synthesizing thereof

ActiveUS20180117215A1Improve mechanical propertiesFacilitates penetration and imbibitionConnective tissue peptidesSkeletal/connective tissue cellsSwelling ratioGlycerol

The embodiments herein disclose a method of fabricating composite scaffolds for skin tissue regeneration. The methacrylated hyaluronic acid (HAMA) and methacrylated gelatin (GelMA) are synthesized. The poly (glycerol sebacate)-poly(ε-caprolactone) (PGS-PCL) microfibrous scaffolds are synthesized. The hydrogel is synthesized. The composite scaffold comprising hydrogel and poly (glycerol sebacate)-poly(ε-caprolactone) (PGS-PCL) microfibrous scaffolds is fabricated. A plurality of physico-chemical characteristics of the composite scaffold comprising hydrogel and poly (glycerol sebacate)-poly(ε-caprolactone) (PGS-PCL) microfibrous scaffolds are analysed. The physico-chemical characteristics comprises mechanical properties, swelling ratio and enzymatic degradation and scanning electron microscope imaging. The fibroblast cells are encapsulated within the composite scaffold comprising hydrogel and poly (glycerol sebacate)-poly(ε-caprolactone) (PGS-PCL) microfibrous scaffolds and hydrogels. The fibroblast cells are seeded on composite scaffold and PGS-PCL scaffold. The fibroblast cell viability, fibroblast cell attachment, fibroblast cell spreading, fibroblast cell proliferation and fibroblast cell metabolism are analysed in composite scaffolds, PGS-PCL scaffolds and hydrogels.

Owner:ESLAMI MARYAM +2

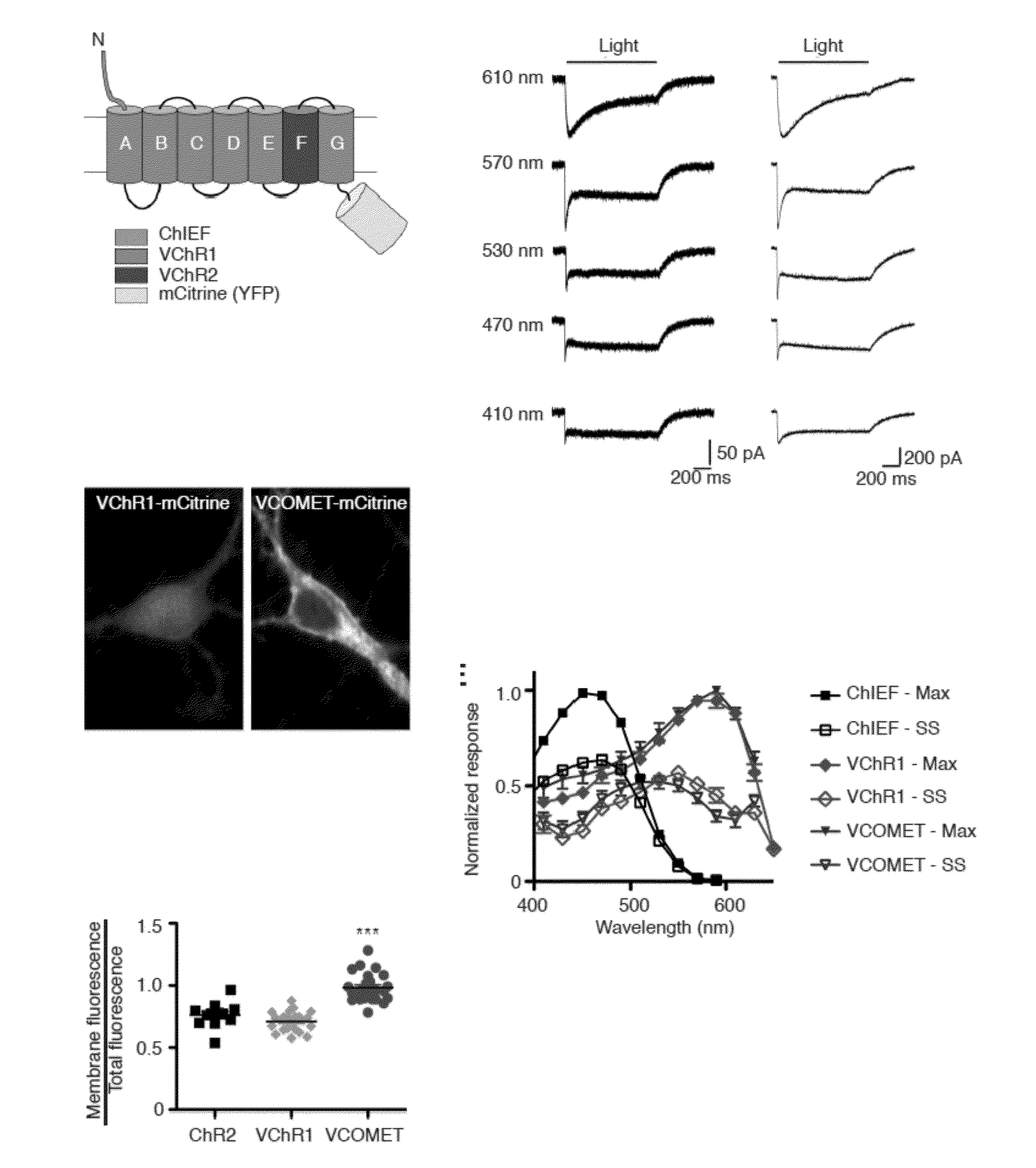

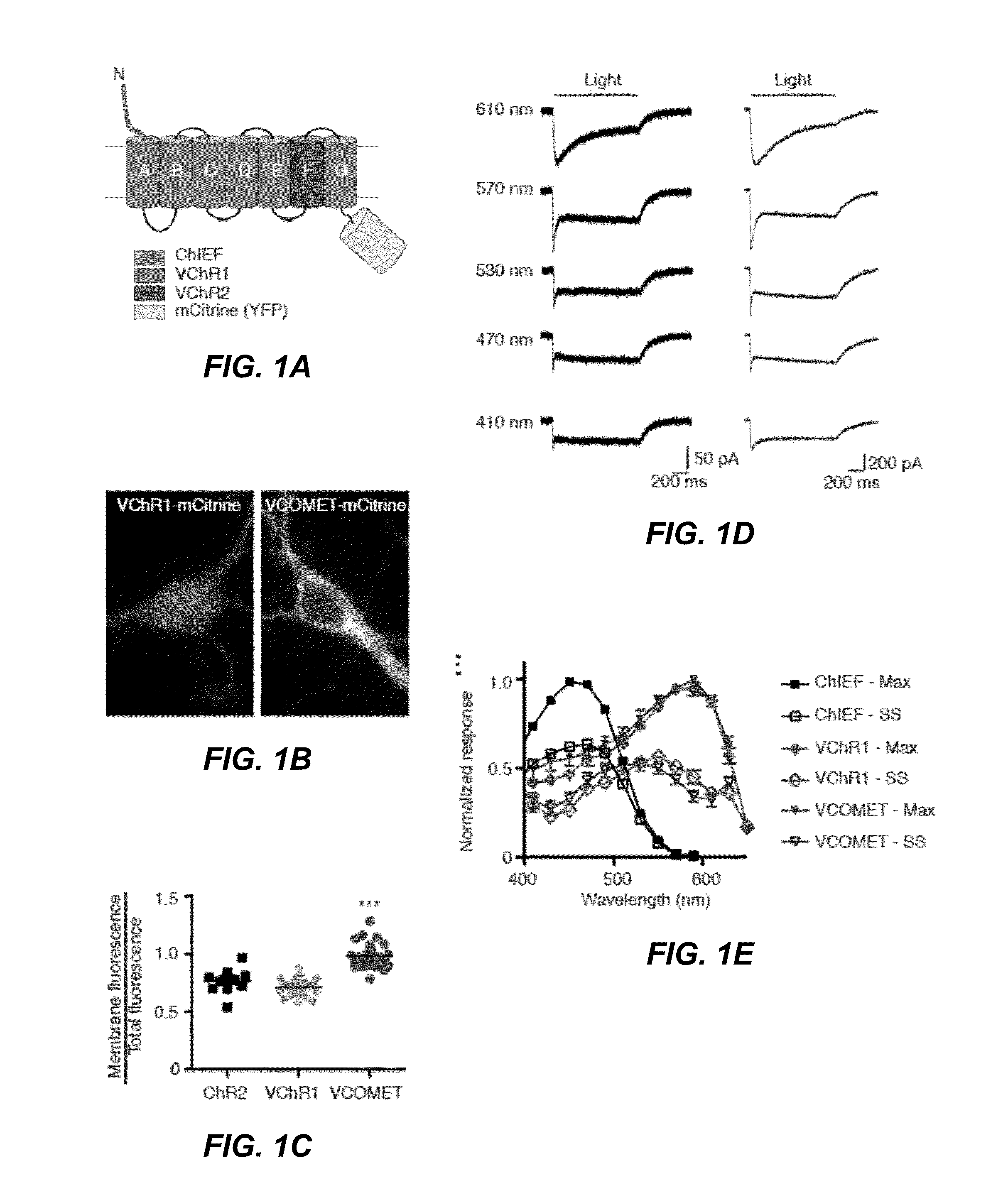

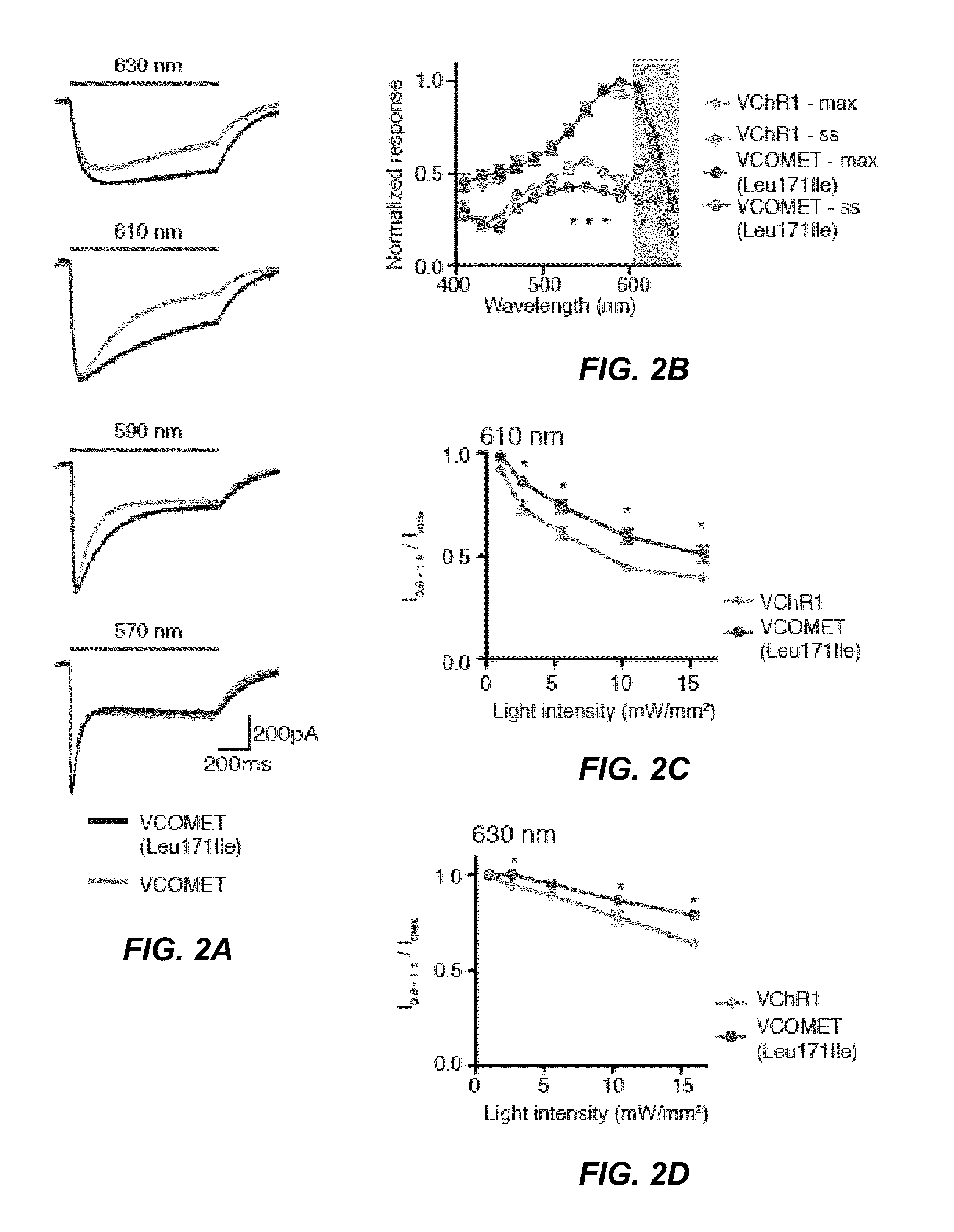

Engineered red-shifted channelrhodopsin variants

ActiveUS20130066402A1Reduce intrusionImproved channel kineticsAntibody mimetics/scaffoldsFermentationBiologyChannelrhodopsin

The invention provides engineered red-shifted channelrhodopsin variants. In some embodiments, the channelrhodopsin variants are characterized by improved membrane trafficking, expression, and / or unique spectral and kinetic properties.

Owner:RGT UNIV OF CALIFORNIA

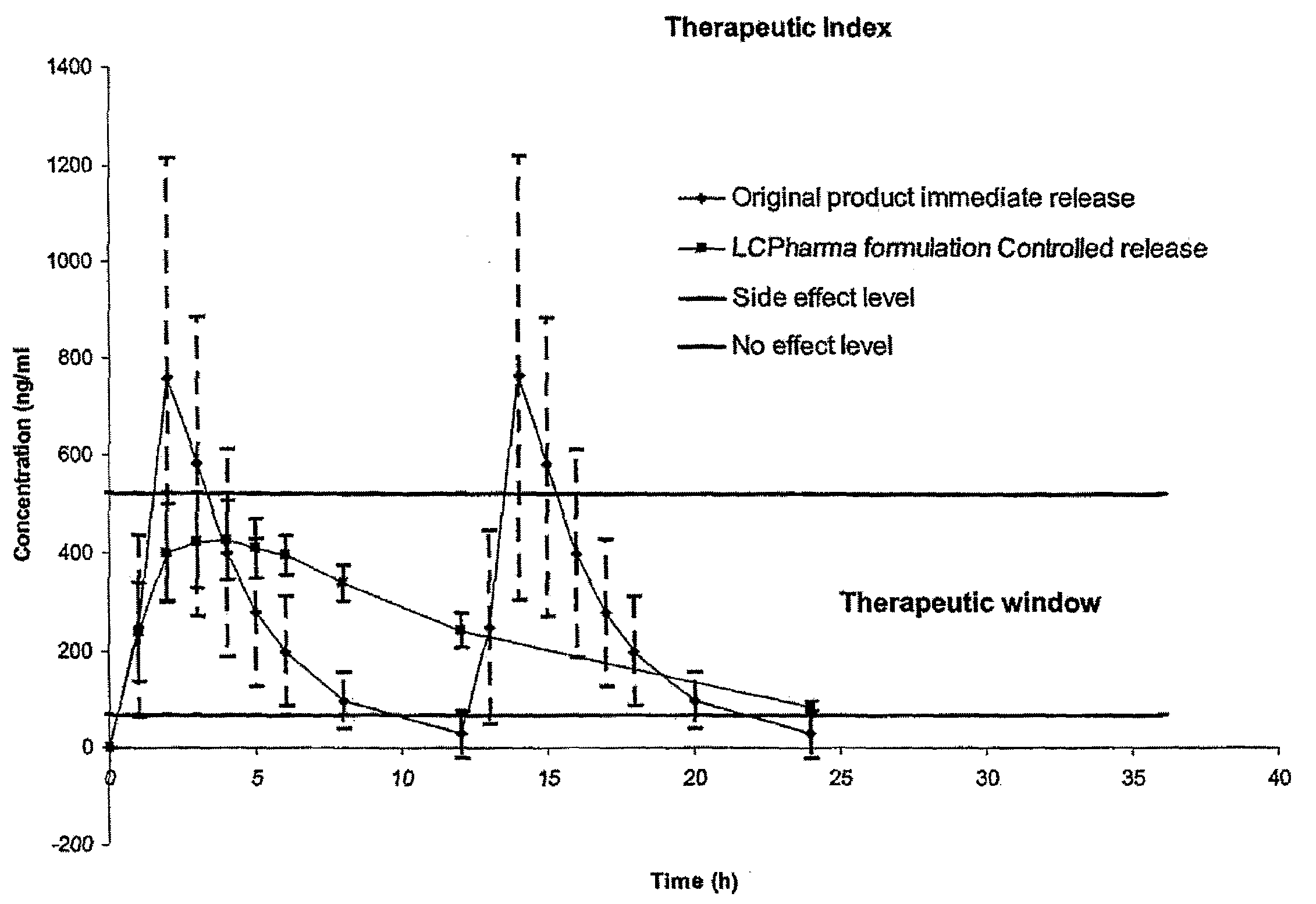

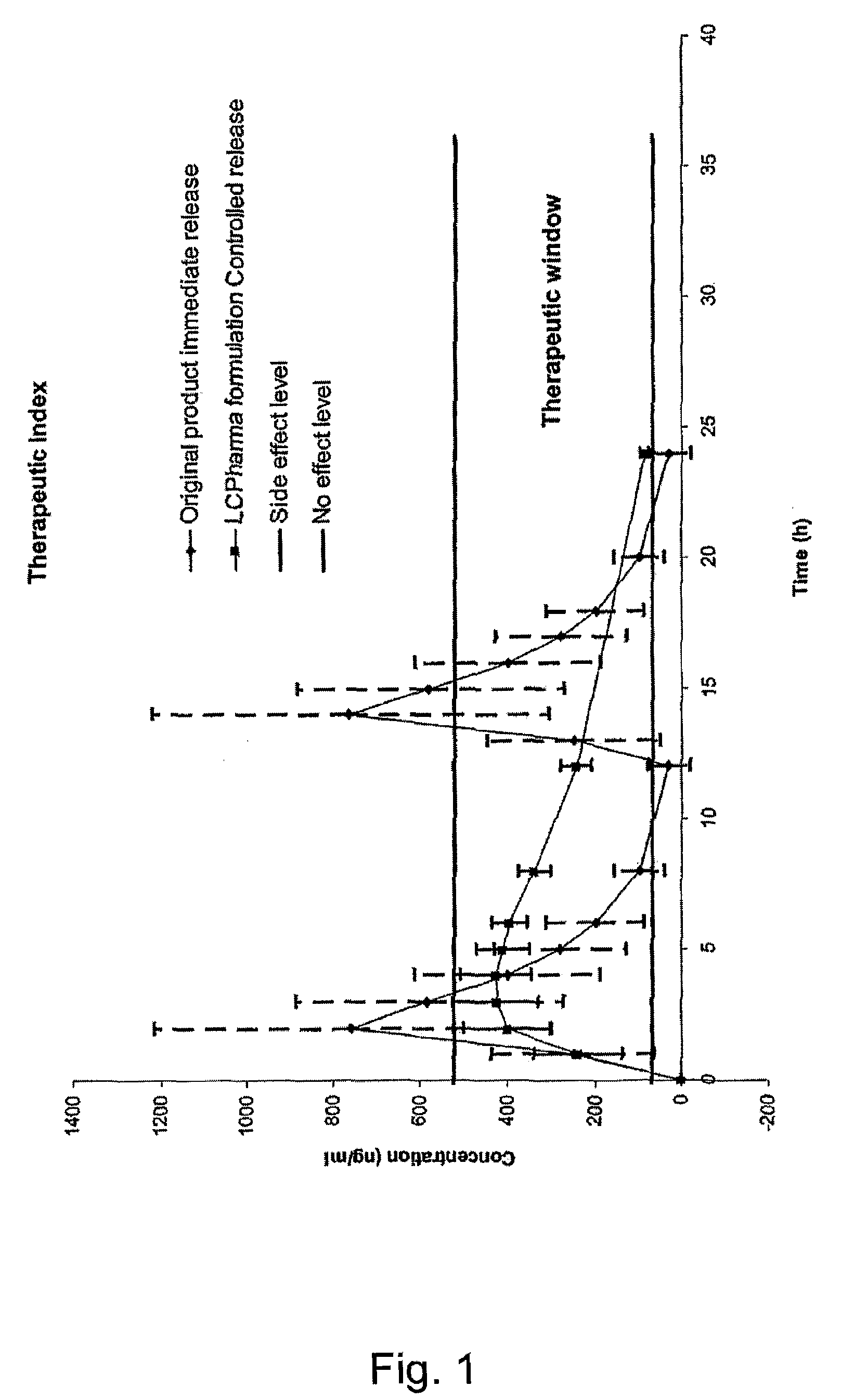

Pharmaceutical Compositions Comprising Sirolimus and/or an Analogue Thereof

InactiveUS20080275076A1Improve safety/efficacy ratioReduce impactAntibacterial agentsBiocideParticulatesSide effect

The present invention relates to pharmaceutical compositions in particulate form or in solid dosage forms comprising sirolimus (rapamycin) and / or derivatives and / or analogues thereof. Compositions of the invention exhibit an acceptable bioavailability of sirolimus and / or a derivative and / or an analogue thereof. The pharmaceutical compositions of the invention are designed to release sirolimus in a controlled manner so that the plasma levels stays within the narrow therapeutic window that exist for this class of substances. An extended release profile, where the peak concentration has been reduced without loosing significant bioavailability, together with less variable absorption, is expected to improve the safety / efficacy ratio of the drug. Furthermore, compositions according to the invention provide for a significant reduced food effect and a delayed release of sirolimus is expected to reduce the number of gastro-intestinal related side effects.

Owner:LIFECYCLE PHARMA AS

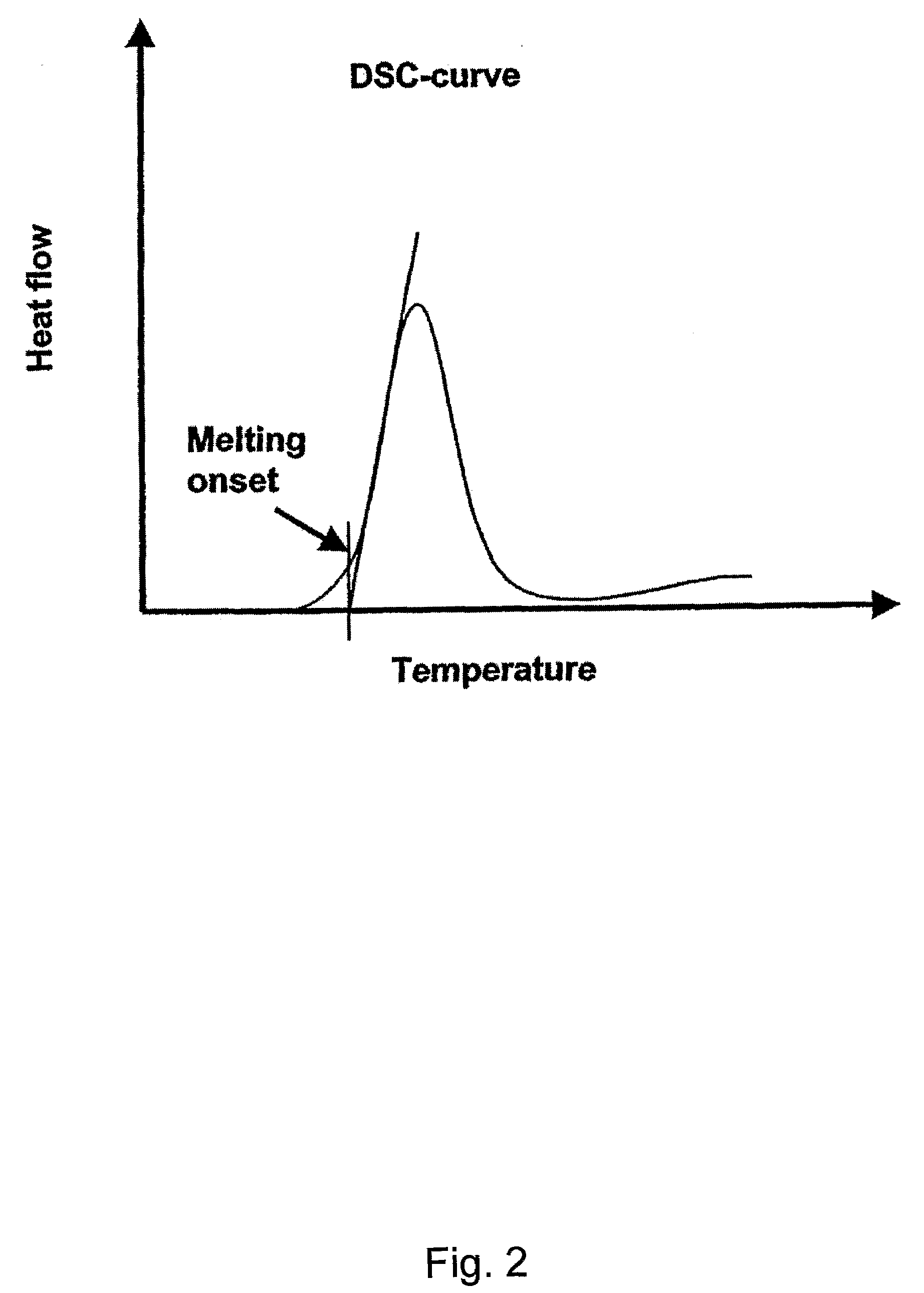

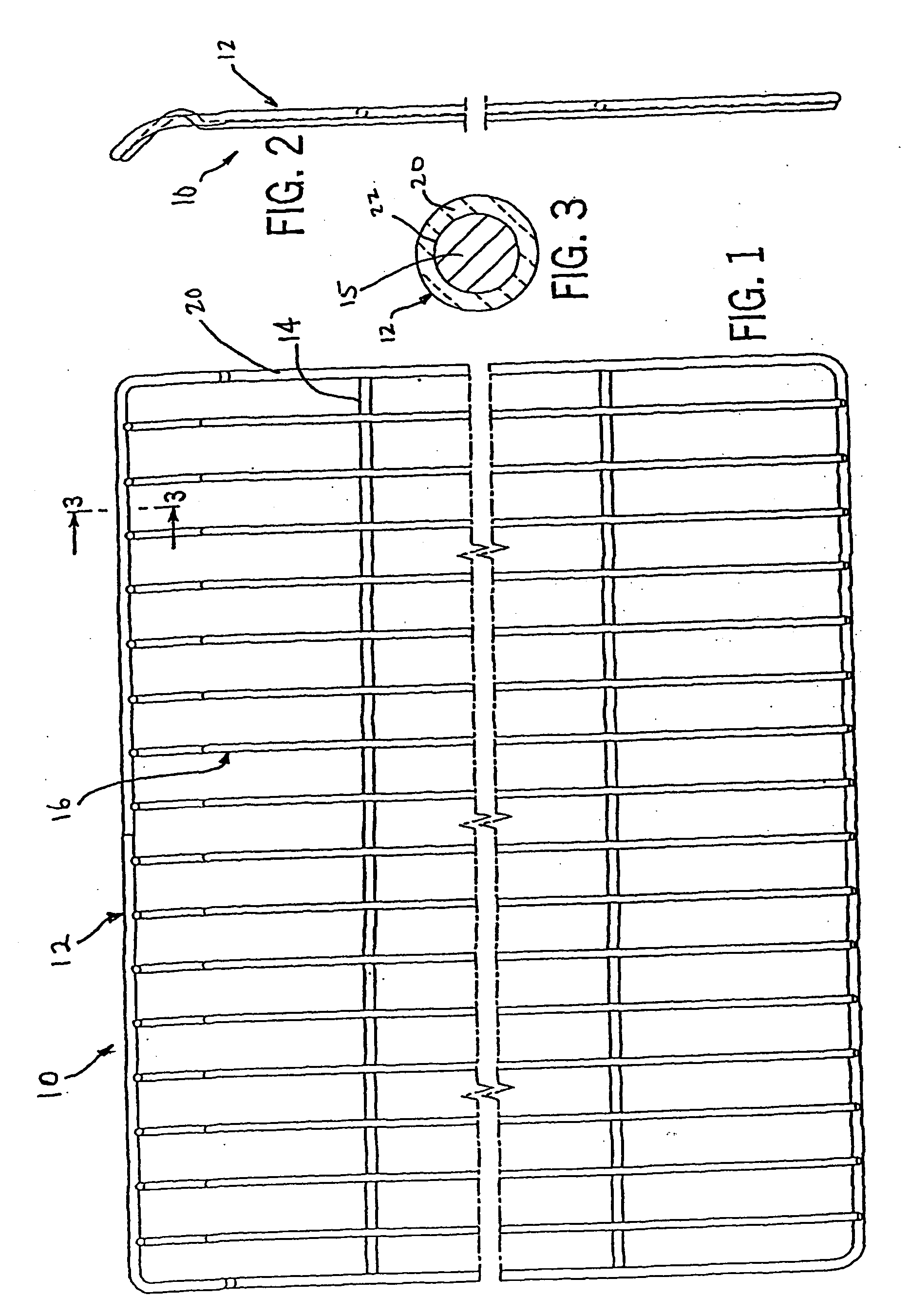

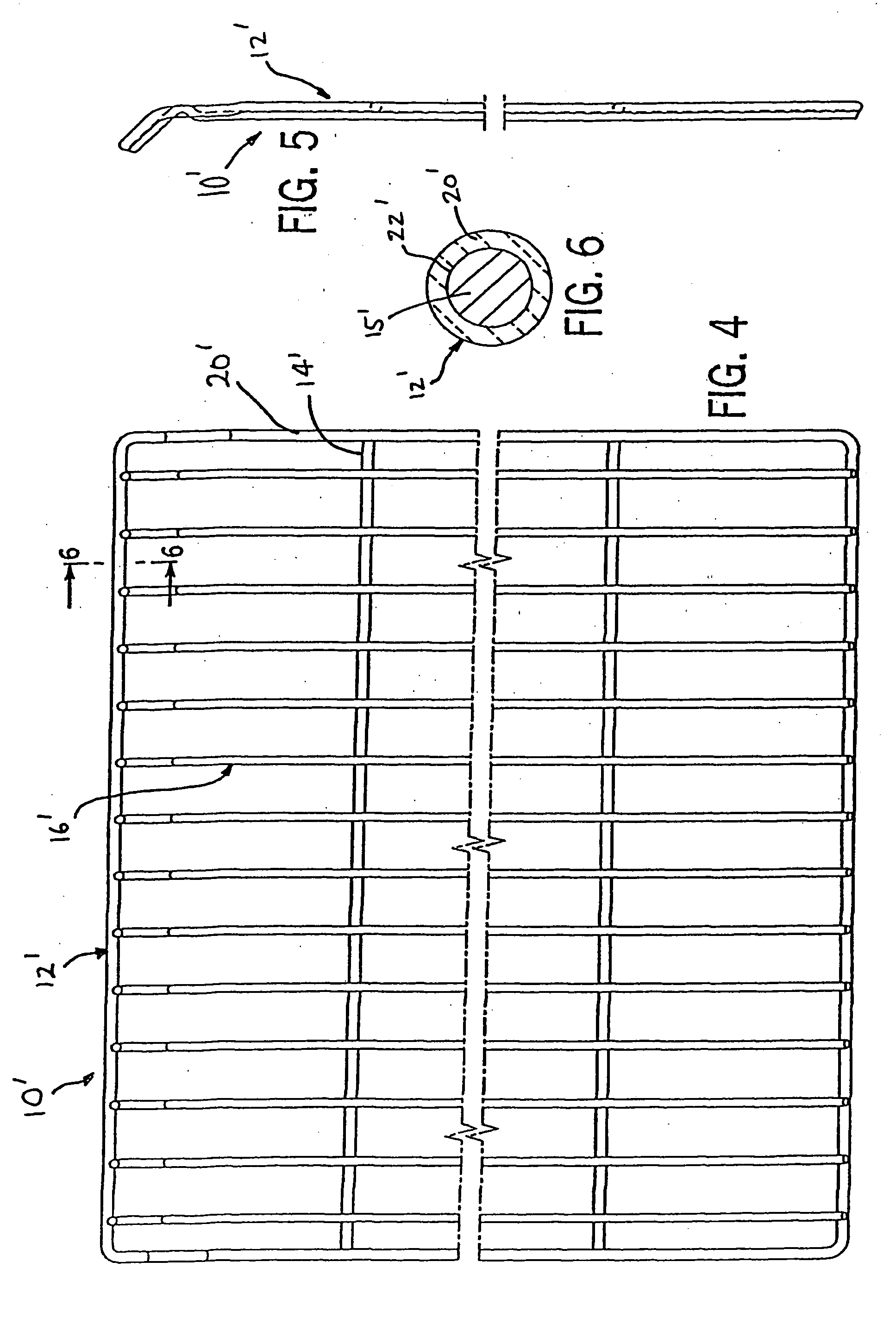

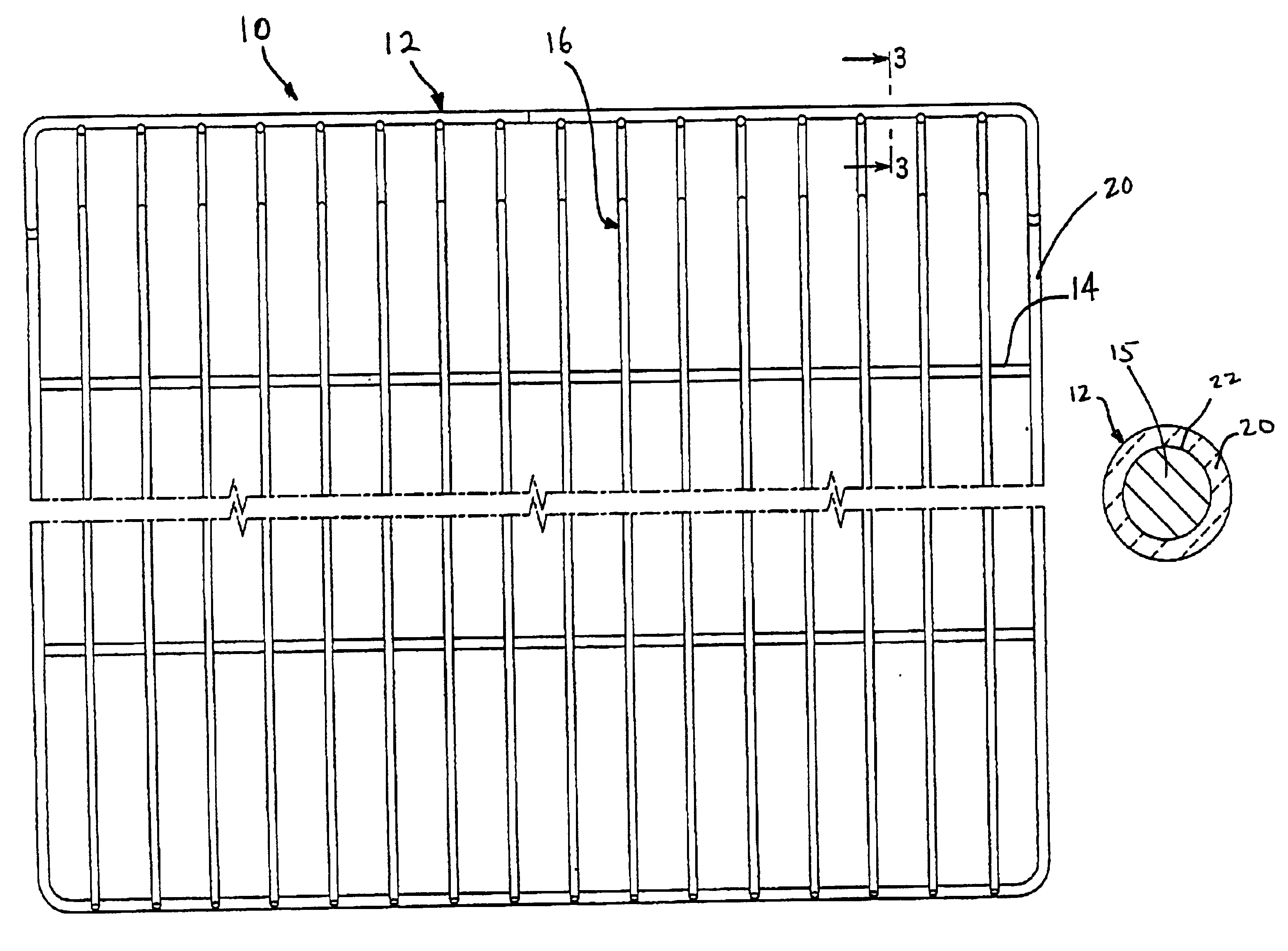

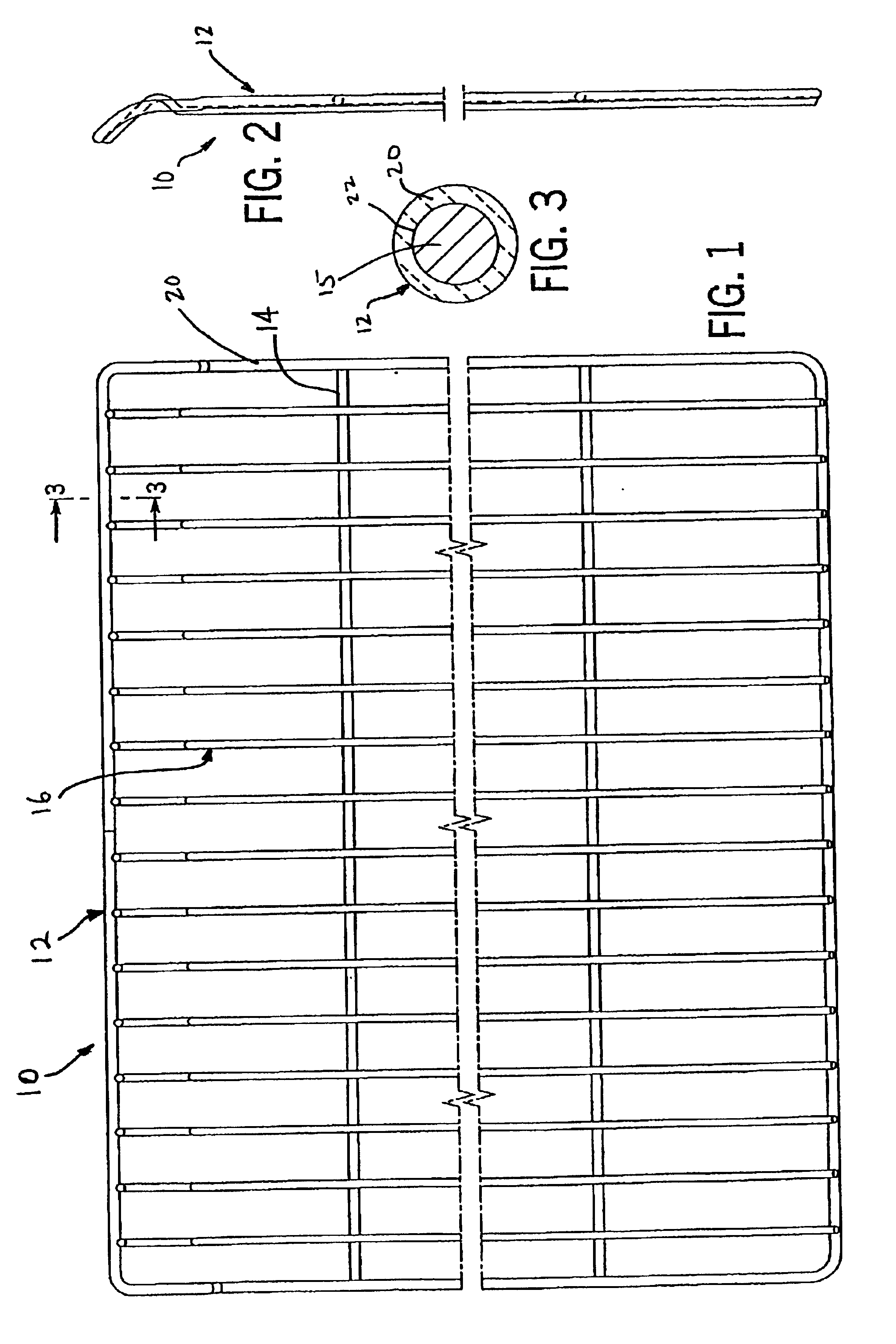

Oven rack having an integral lubricious, dry porcelain surface

InactiveUS20070272231A1Avoid chippingReduce the overall diameterDomestic stoves or rangesStoves/ranges shelves or racksDiamond-like carbonAntimony trioxide

A lubricious porcelain coated steel wire oven rack. The preferred coated steel wire oven rack includes a plurality of elongated steel wire members joined together to form an oven rack having an outer surface. The plurality of elongated steel wire members are made from a cold drawn steel rod material containing from about 80 to about 99.9% by weight of iron, up to about 0.08% by weight of carbon and from about 0.001 to about 0.2% by weight of a carbon stabilizing transition metal, preferably selected from the group consisting of Vanadium, Tantalum, Titanium and Niobium. In a preferred embodiment, the porcelain surface of the oven rack includes a dry lubricant selected from carbon; graphite; boron nitride; cubic boron nitride; molybdenum (IV) sulfide; molybdenum disulfide; molybdenum sulfide; molybdenum (IV) selenide; molybdenum selenide; tungsten (IV) sulfide; tungsten disulfide; tungsten sulfide; silicon nitride (Si3N4); TiN; TiC; TiCN; TiO2; TiAlN; CrN; SiC; diamond-like carbon; tungsten carbide (WC); zirconium oxide (ZrO2); zirconium oxide and 0.1 to 40 weight % aluminum oxide; alumina-zirconia; antimony; antimony oxide; antimony trioxide; and mixtures thereof.

Owner:SSW ADVANCED TECH LLC

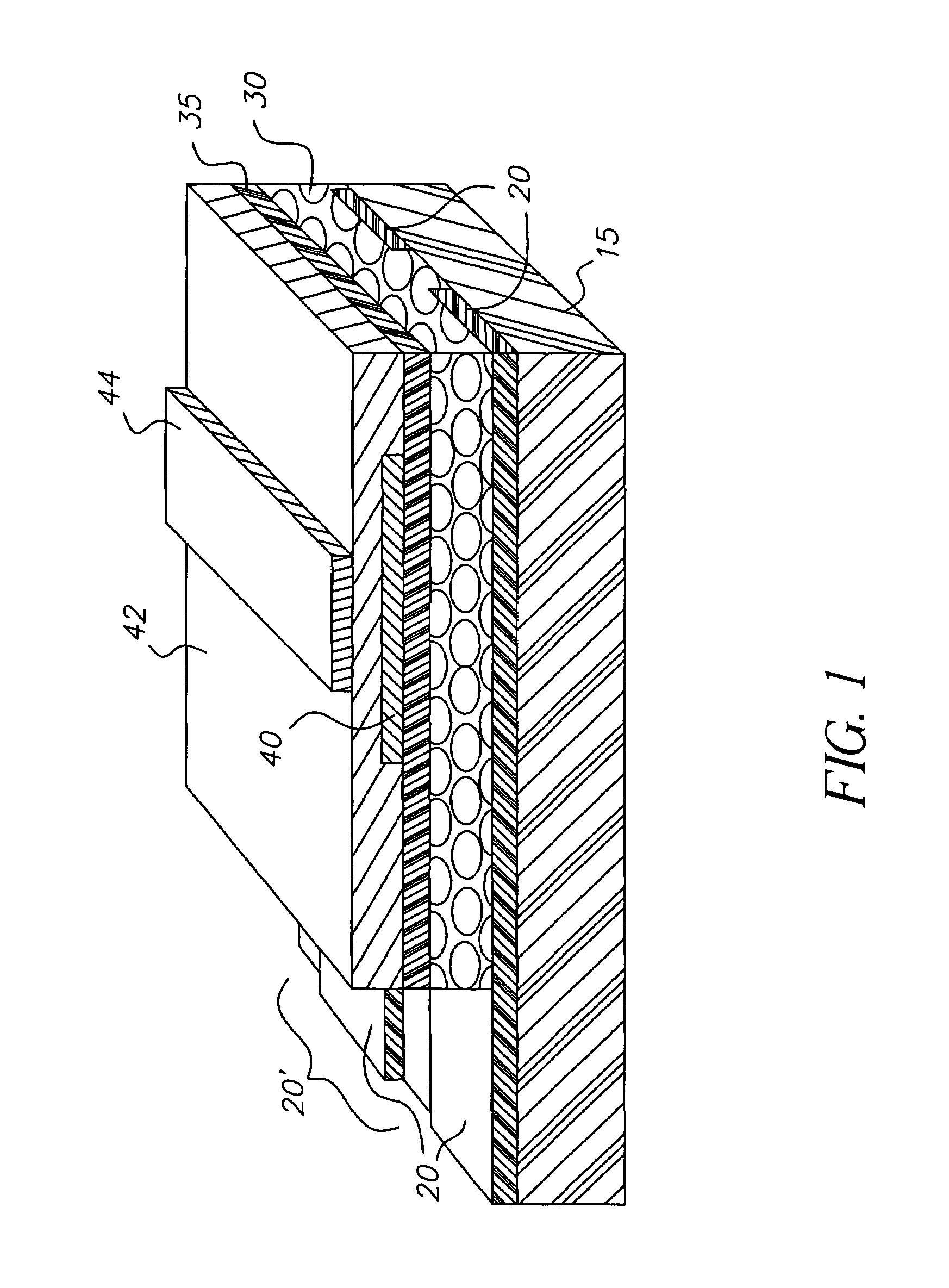

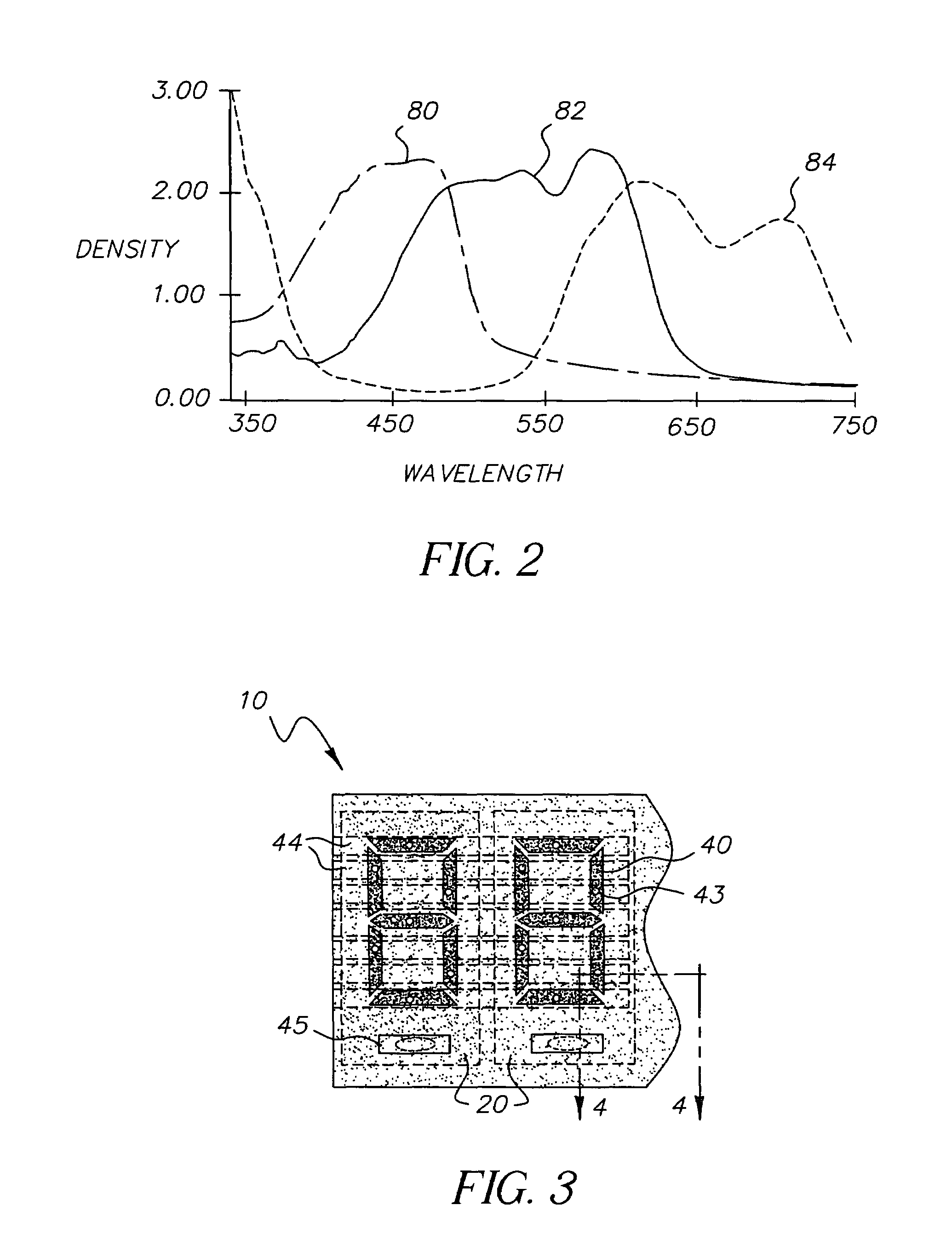

Mixed absorber layer for displays

ActiveUS20050259300A1Good blacknessAvoid excessive absorptionLiquid crystal compositionsLiquid surface applicatorsElectricityOptoelectronics

Owner:IRIS OPTRONICS CO LTD +1

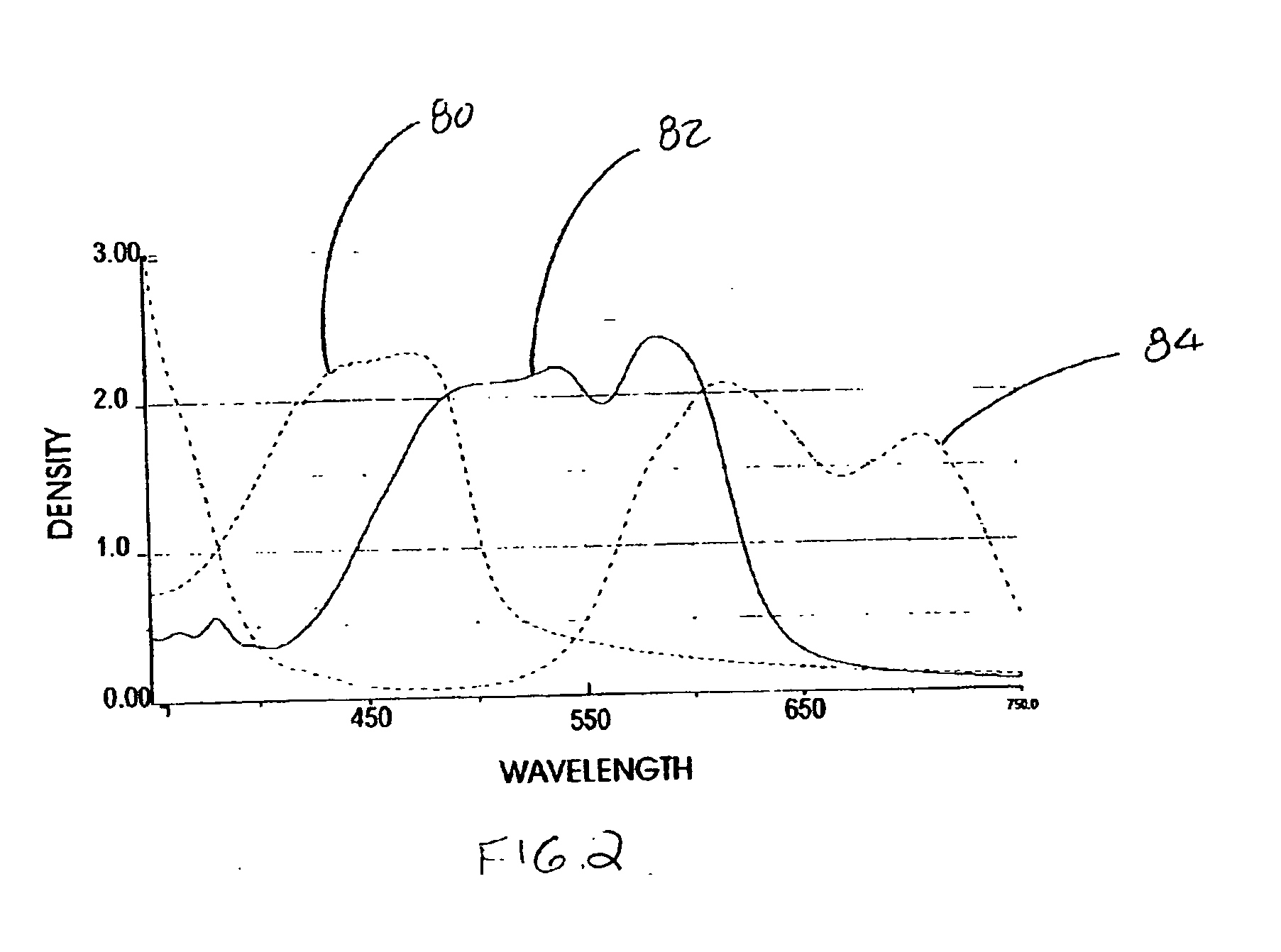

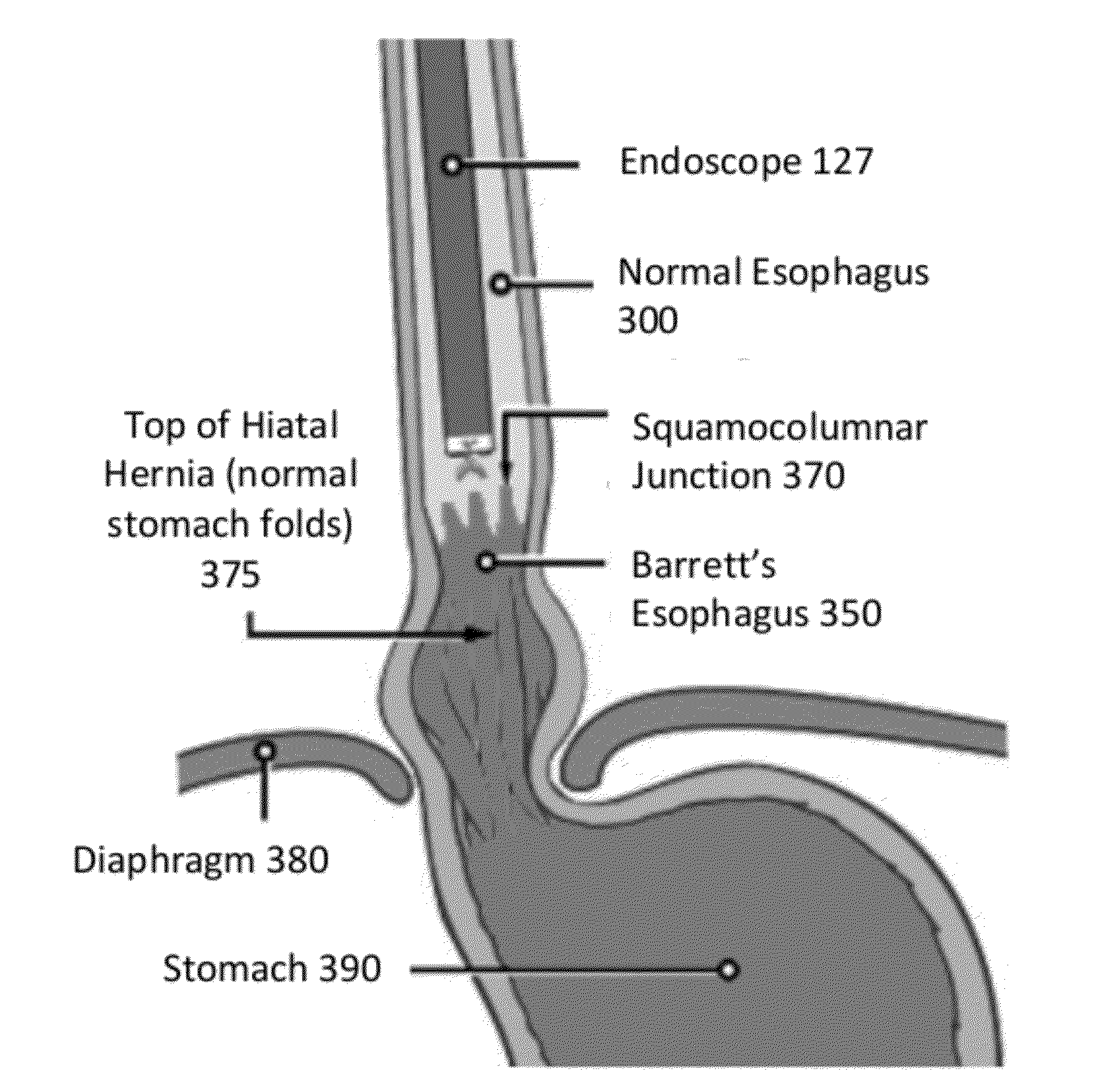

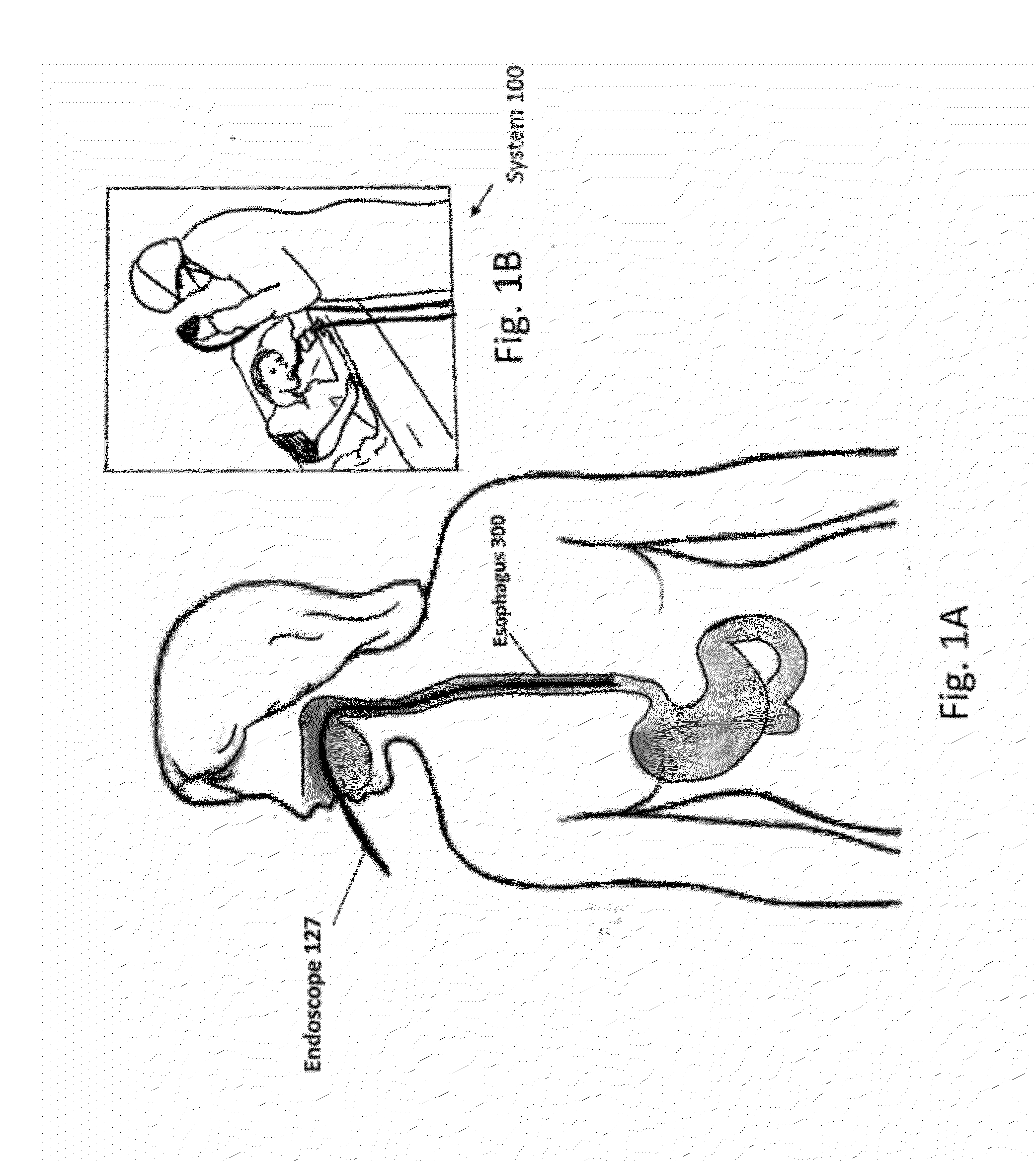

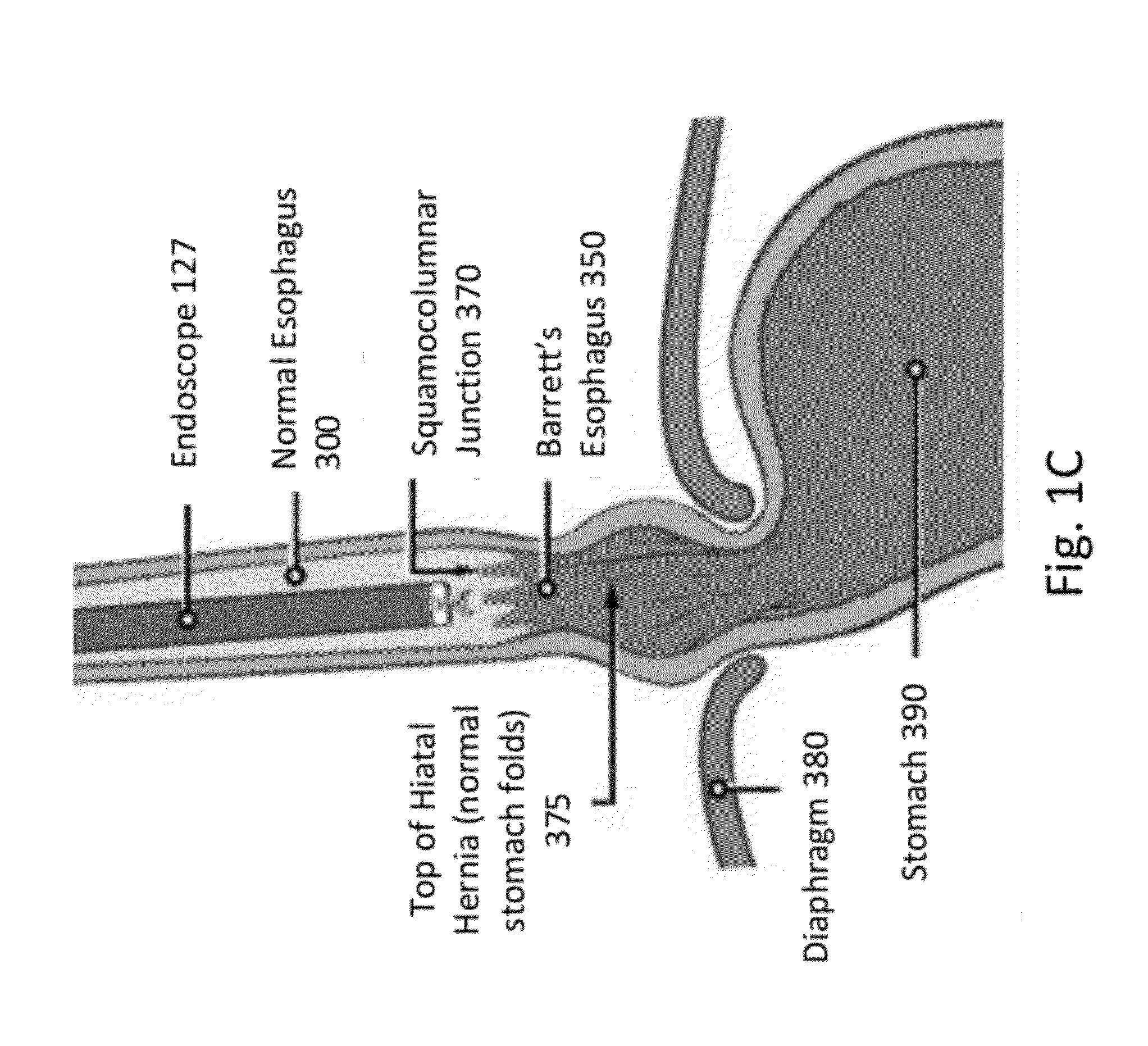

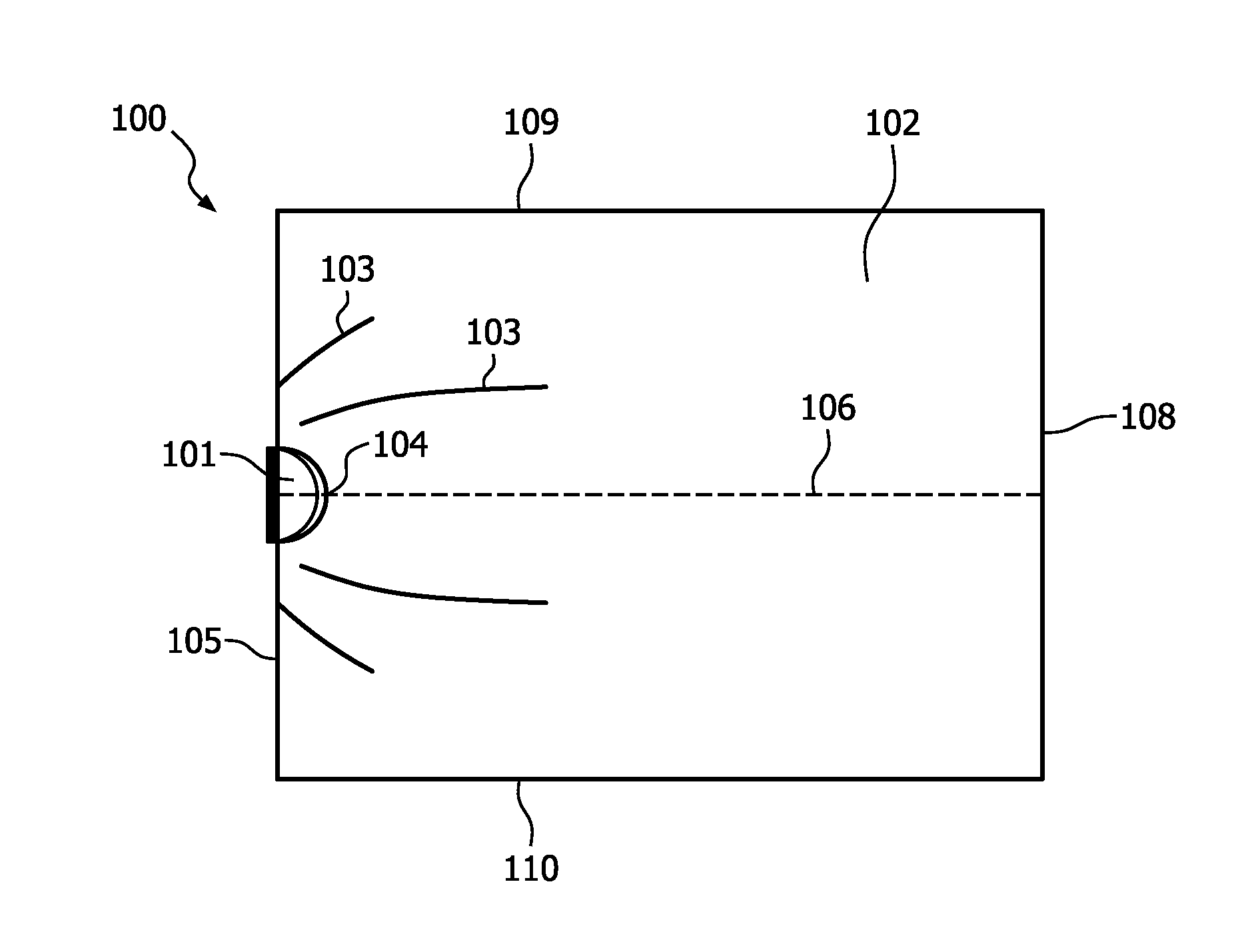

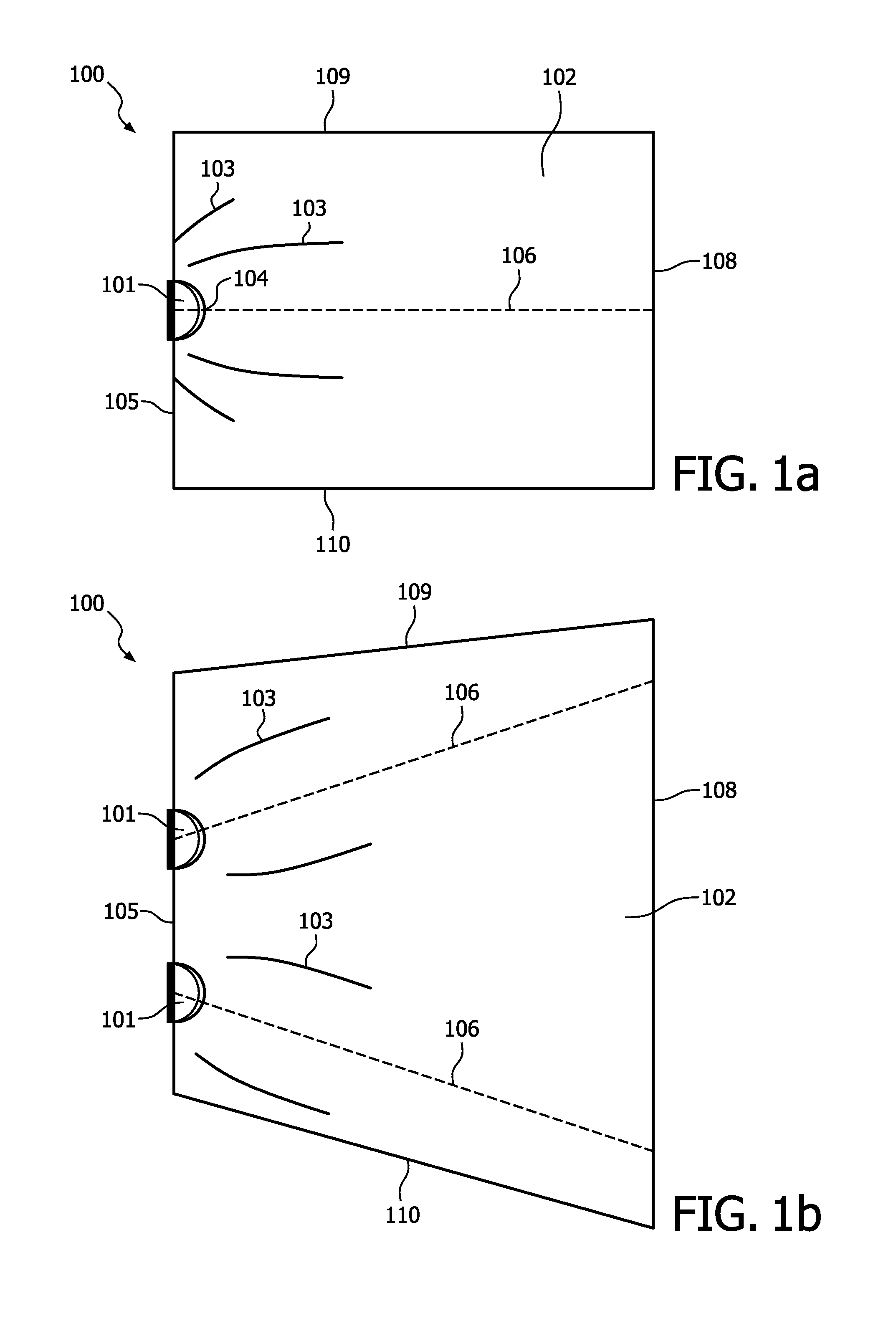

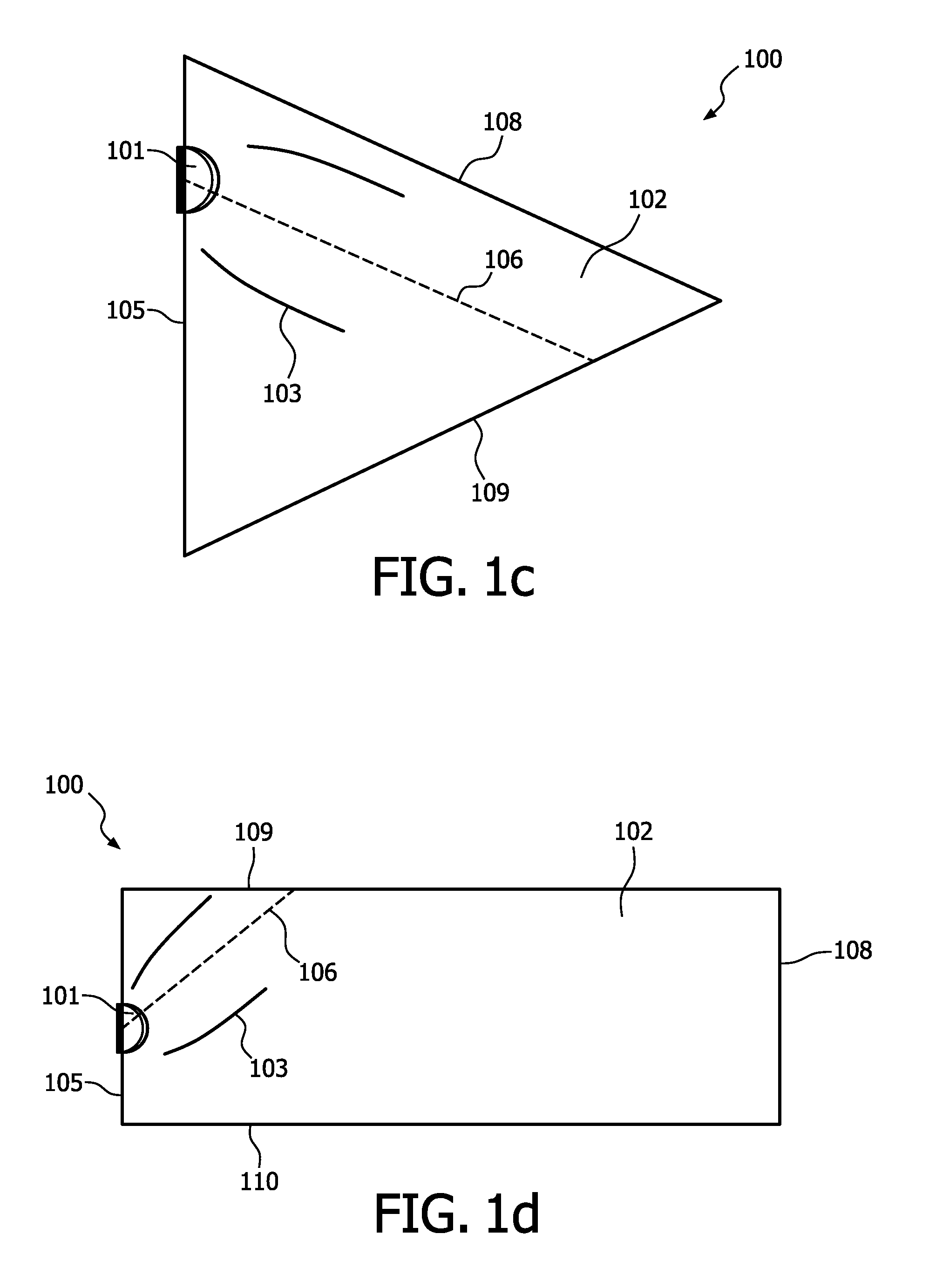

Diode laser systems and methods for endoscopic treatment of tissue

InactiveUS20120071867A1Improve methodMinimal damageEndoscopesSurgical instrument detailsDysplasiaEndoscope

Embodiments of the present invention provide improved laser systems and methods for endoscopic laser treatment of abnormal tissue such as abnormal mucosal tissue, for example esophageal dysplasia that is also referred to as Barrett's esophagus (BE). The systems and methods described here can also be used in many applications where treatment of shallow surface layers with minimal damage to the tissue beneath is desirable, for example BE tissue comprising hemoglobin. In many embodiments, the system is configured to emit light energy having an optical wavelength to treat tissue having oxygenated hemoglobin.

Owner:METALASE

Composition for amelioration of body lipid

InactiveUS20100190708A1Growth inhibitionPrevent and treat and ameliorate hyperlipemiaPeptide/protein ingredientsMetabolism disorderSecondary hyperlipidemiaAllergy

An object of the present invention is to obtain a composition, which is excellent in amelioration of a lipid metabolism disorder and has a preventive or ameliorating effect on hyperlipemia, obesity or type II diabetes induced by the lipid metabolism disorder, and is also economical and safe with respect to allergy, by extracting a rice bran extract containing a rice bran protein, followed by separation.Disclosed is a composition for amelioration of a lipid metabolism disorder, containing a rice bran protein.

Owner:CHIKUNO SHOKUHIN INDS

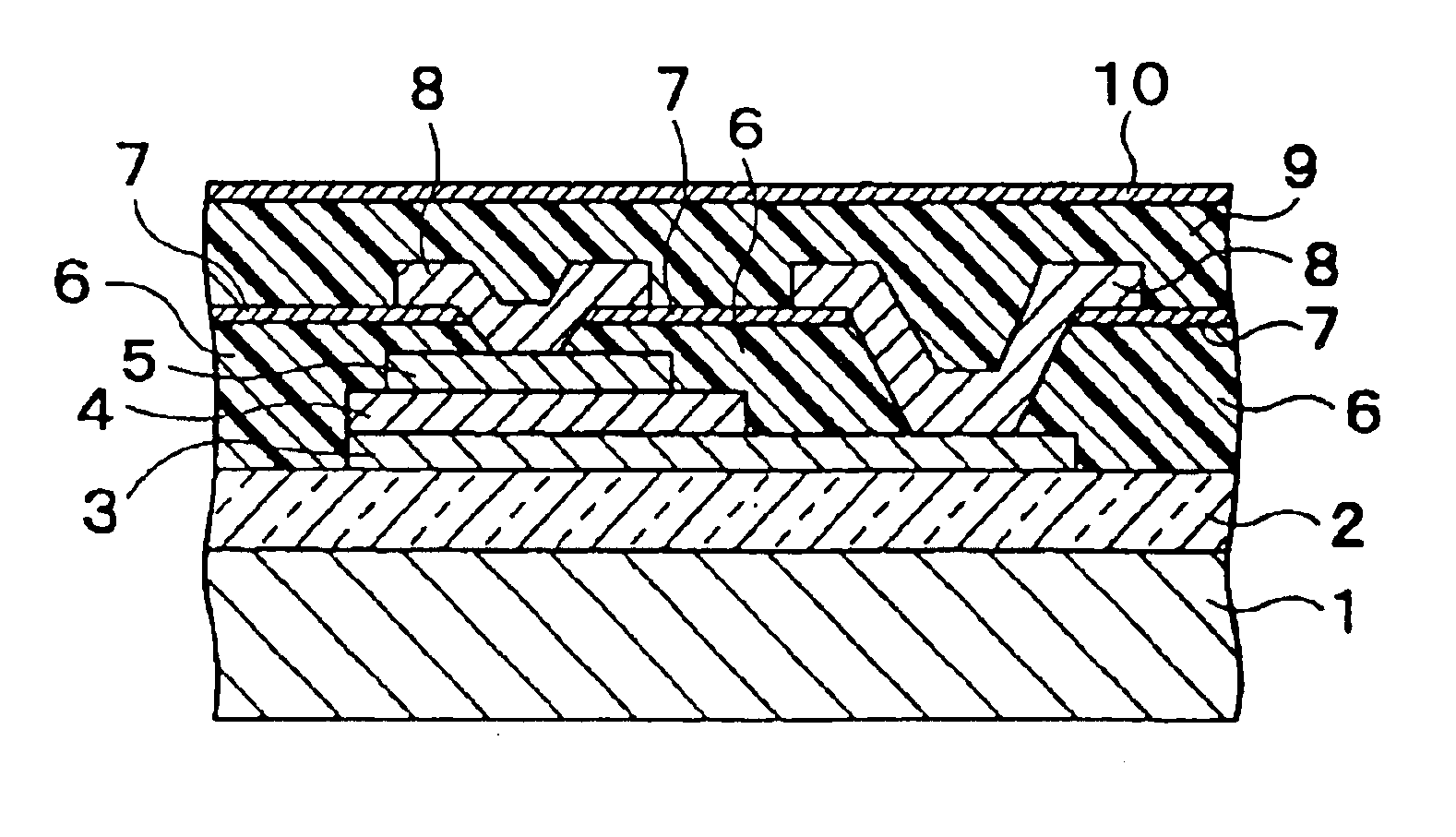

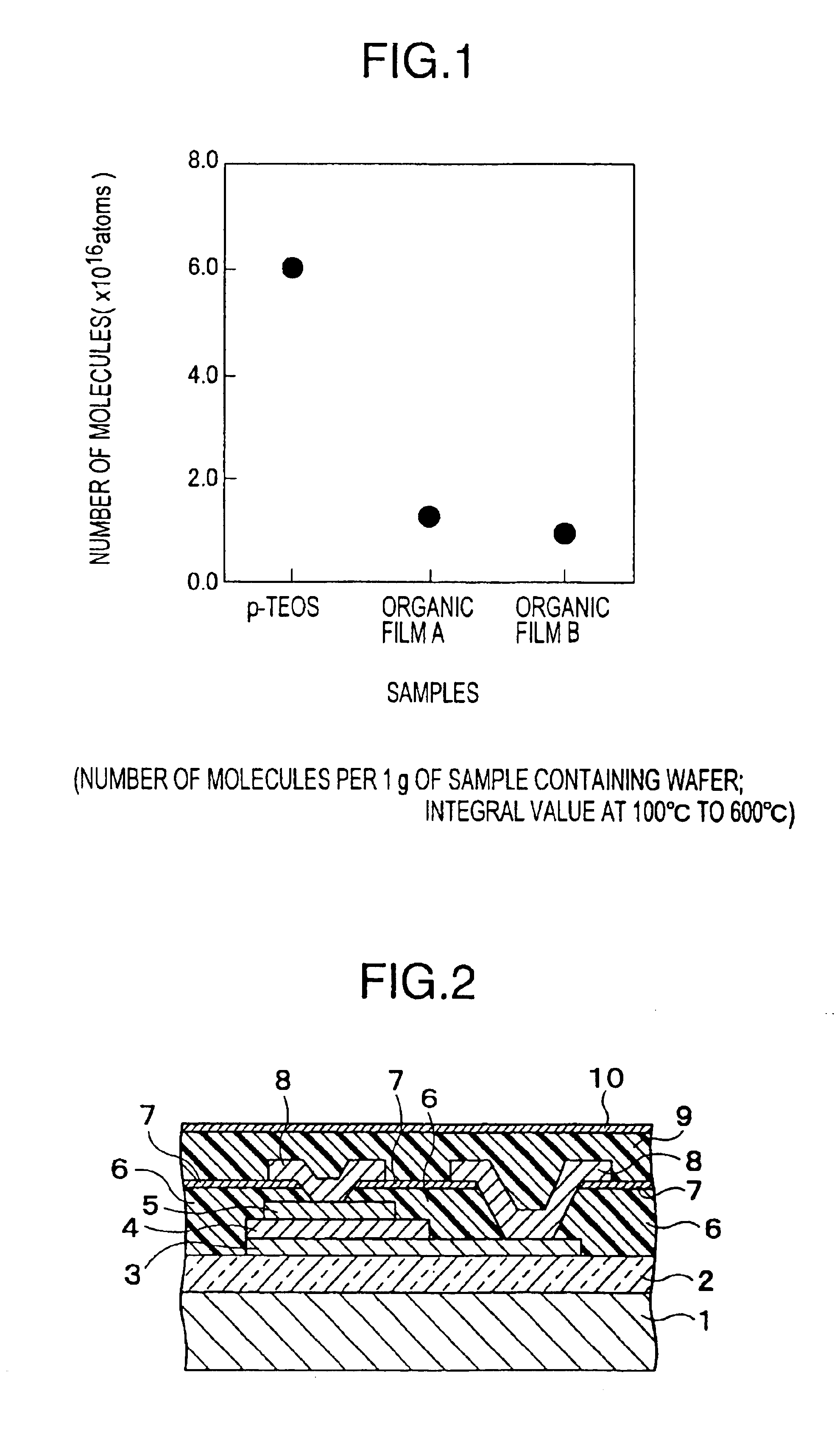

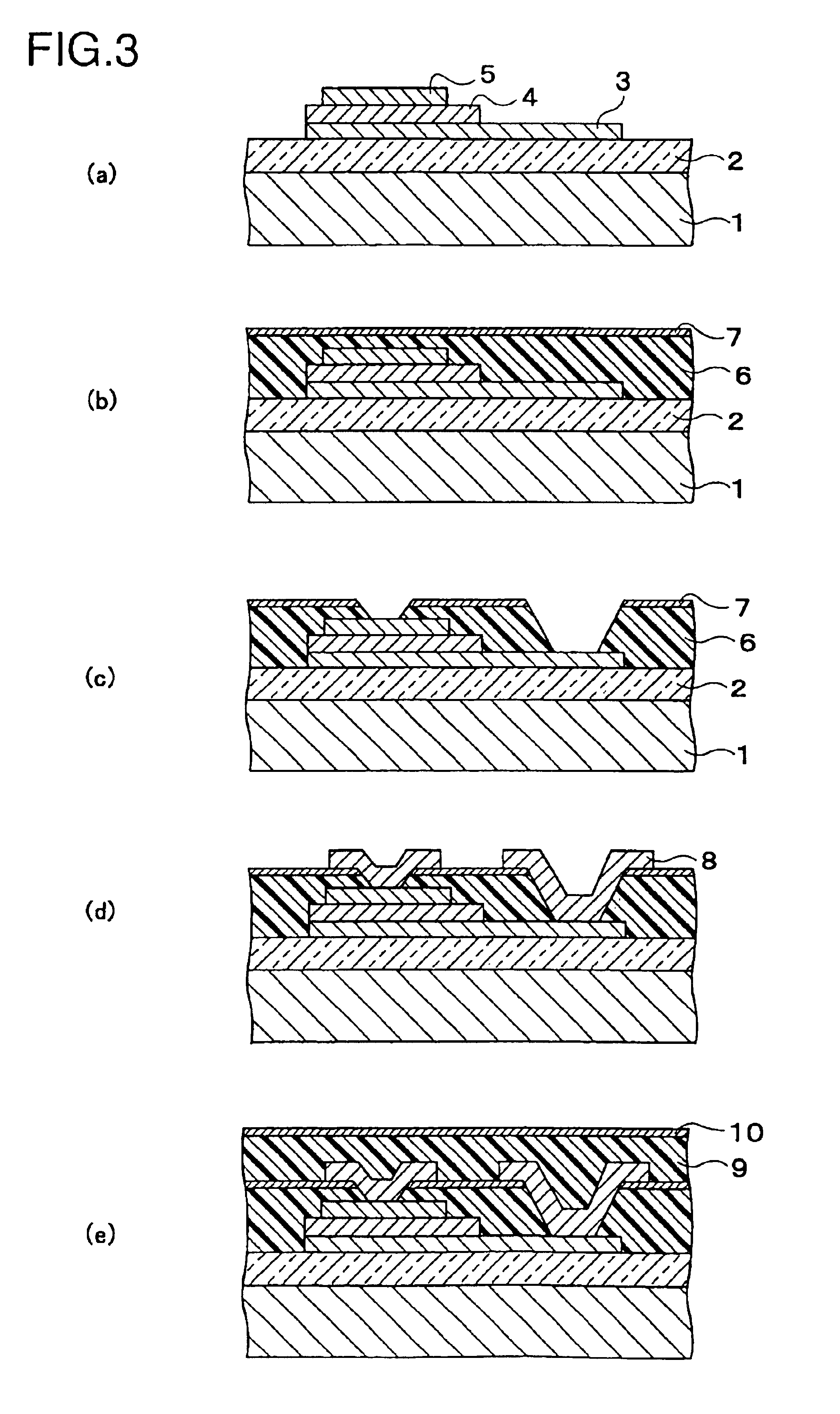

Semiconductor memory device and manufacturing process for the same

InactiveUS6897503B2Inhibit deteriorationImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesOrganic filmHydrogen

In a semiconductor memory device having a capacitor layer comprising a dielectric film or a ferroelectric film, as an interlayer insulation film formed between the capacitor and a wiring layer formed at the upper part thereof or an insulation film which covers the wiring layer, a multilayered film is used which consists of a first insulation film and a second insulation film laid upon the other; the former being a lower layer and being formed of an organic film, and the latter being an upper layer and being formed of a hard-mask material.This makes it possible to prevent thin films comprised of a dielectric material or a ferroelectric material from any deterioration caused by the hydrogen and water contained in the interlayer insulation film and passivation film of the semiconductor memory device and also by the stress of these films.

Owner:RENESAS ELECTRONICS CORP

Mixed absorber layer for displays

ActiveUS7195813B2Good blacknessAvoid excessive absorptionLiquid crystal compositionsLiquid surface applicatorsDisplay deviceOptoelectronics

Owner:IRIS OPTRONICS CO LTD +1

Multi functional pump for pumping molten metal

ActiveUS20060198725A1Easy to pumpMaximize molten metal dischargeSpecific fluid pumpsPump componentsImpellerProgrammable logic controller

The present invention features a multi-functional pump for pumping molten metal, which includes a base that is submerged in molten metal having at least two impeller chambers. The base includes one or more inlet openings and one or more outlet openings. Each outlet opening leads from one of the impeller chambers. The invention enables the impeller to be moved to a position to rotate in either impeller chamber or while straddling impeller chambers. This enables the pump to have the versatility to operate in a circulation mode; a transfer mode; two or more circulation modes; two or more transfer modes; and a combination of transfer and circulation modes. The impeller chambers can be stacked over each other and the impeller can be moved vertically in and between impeller chambers. Inventive vaned or barrel type impellers can be used to facilitate pumping while straddling impeller chambers, in view of an elongated bearing member on the impeller that maintains position relative to a bearing ring attached to the base or an inlet protector sleeve. The multifunctional pump of the invention enables infinite adjustment of the impeller using a programmable logic controller that results in positioning of the impeller at any of various locations in the base to achieve any desired output. The inventive pump is ideally suited for use in die casting and scrap submergence applications. Also featured is a method of operating the multifunctional pump of the present invention.

Owner:THUT BRUNO H

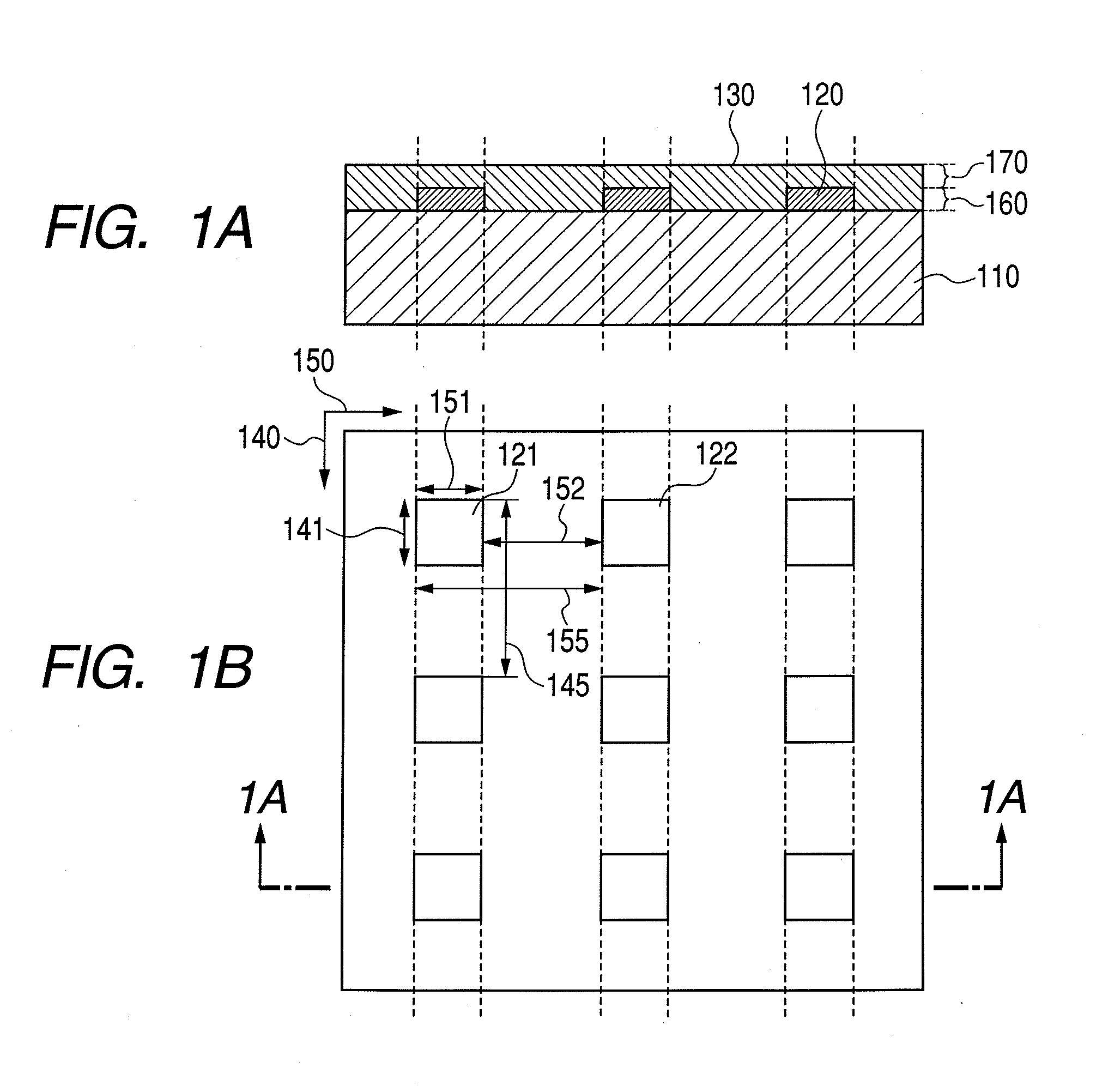

Optical apparatus, optical detector, optical modulator, imaging apparatus, and camera

InactiveUS20110043813A1High durabilityLess absorptionOptical filtersSolid-state devicesDielectric substrateType metal

Provided is an optical apparatus having high durability, less optical absorption than a hole-type metal thin film filter, high transmittance and high reflectance, and variable optical characteristics. The apparatus includes: a dielectric substrate; a metal structure group including multiple metal structures two-dimensionally and discretely disposed at regular intervals; and a dielectric layer covering the metal structure group, in which: the metal structures have a first length equal to or shorter than a predetermined wavelength in a visible light region in one direction, and a second length equal to or shorter than the wavelength in a perpendicular direction; and the metal structures resonates with light entering the dielectric substrate or the dielectric layer, having a variable dielectric constant, to generate localized surface plasmon resonance on a surface of the metal structures to have a minimum transmittance or a maximum reflectance of the light having the wavelength.

Owner:CANON KK

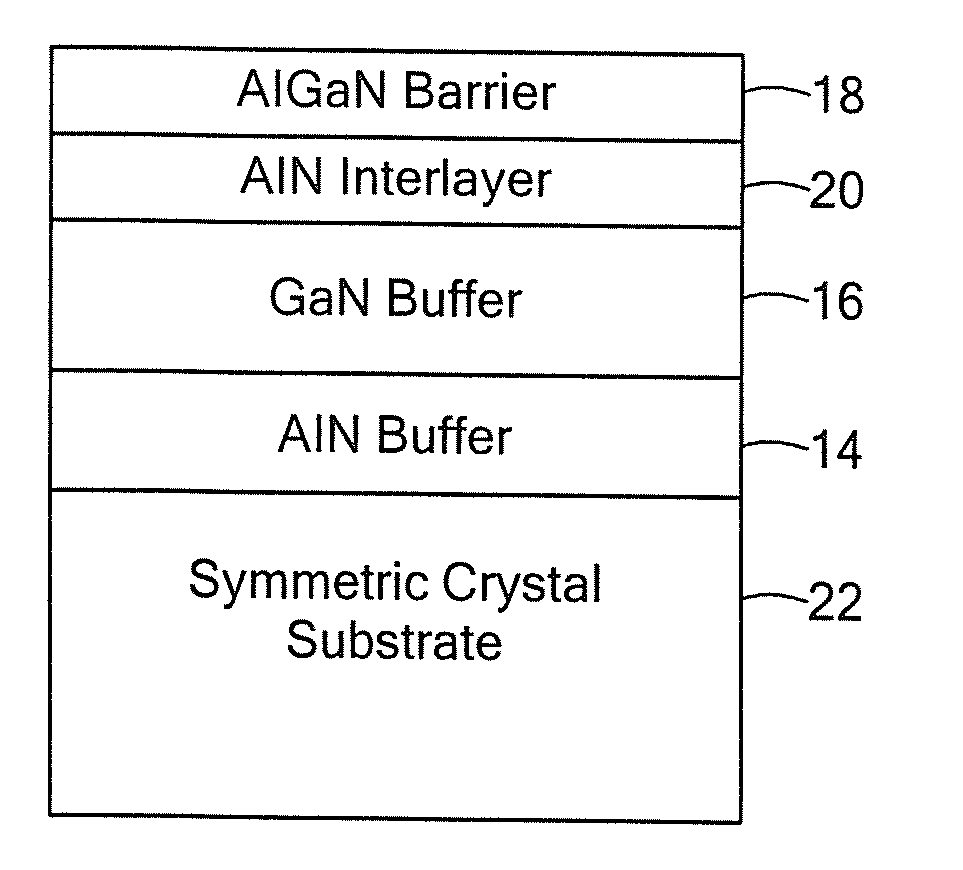

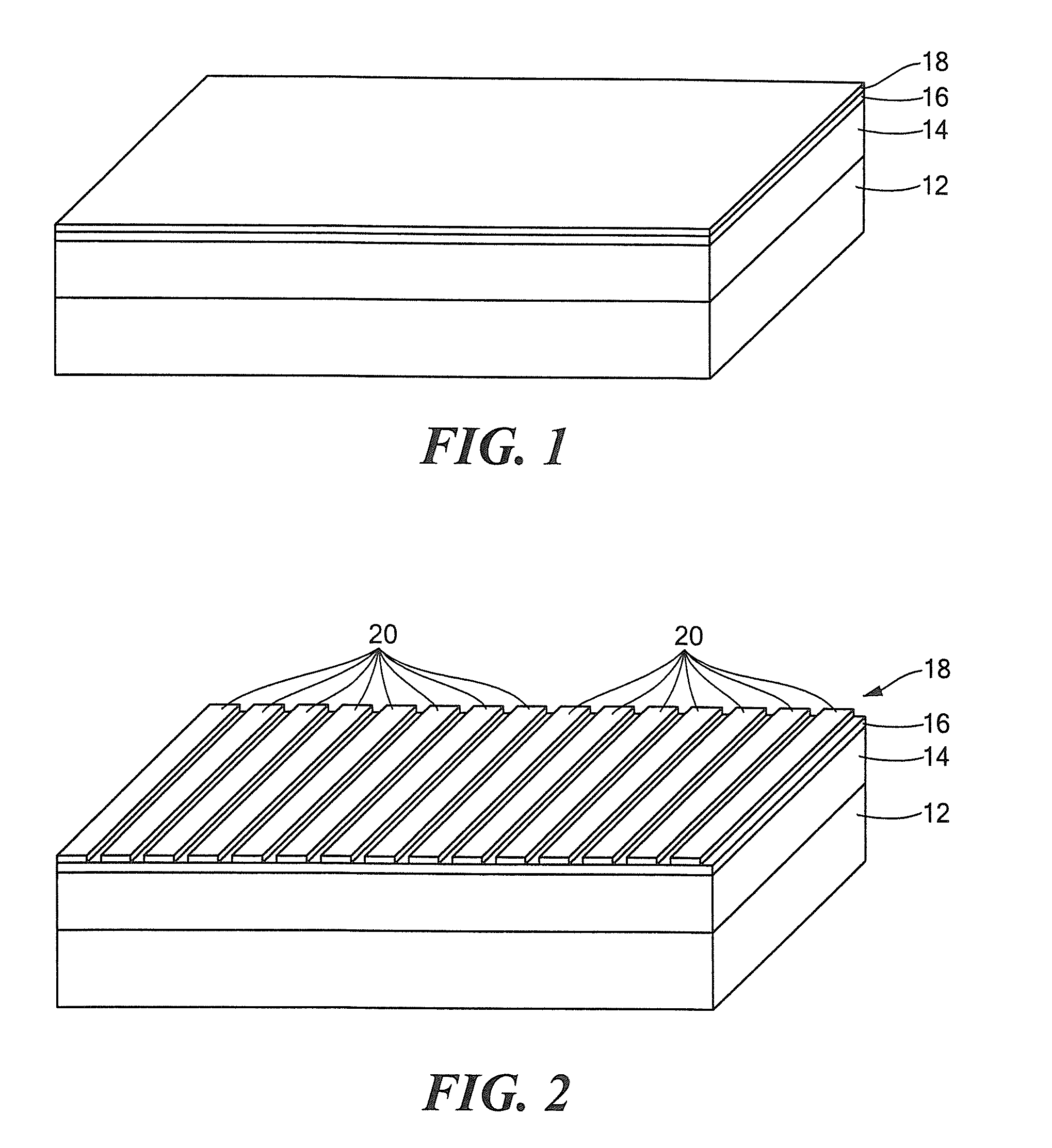

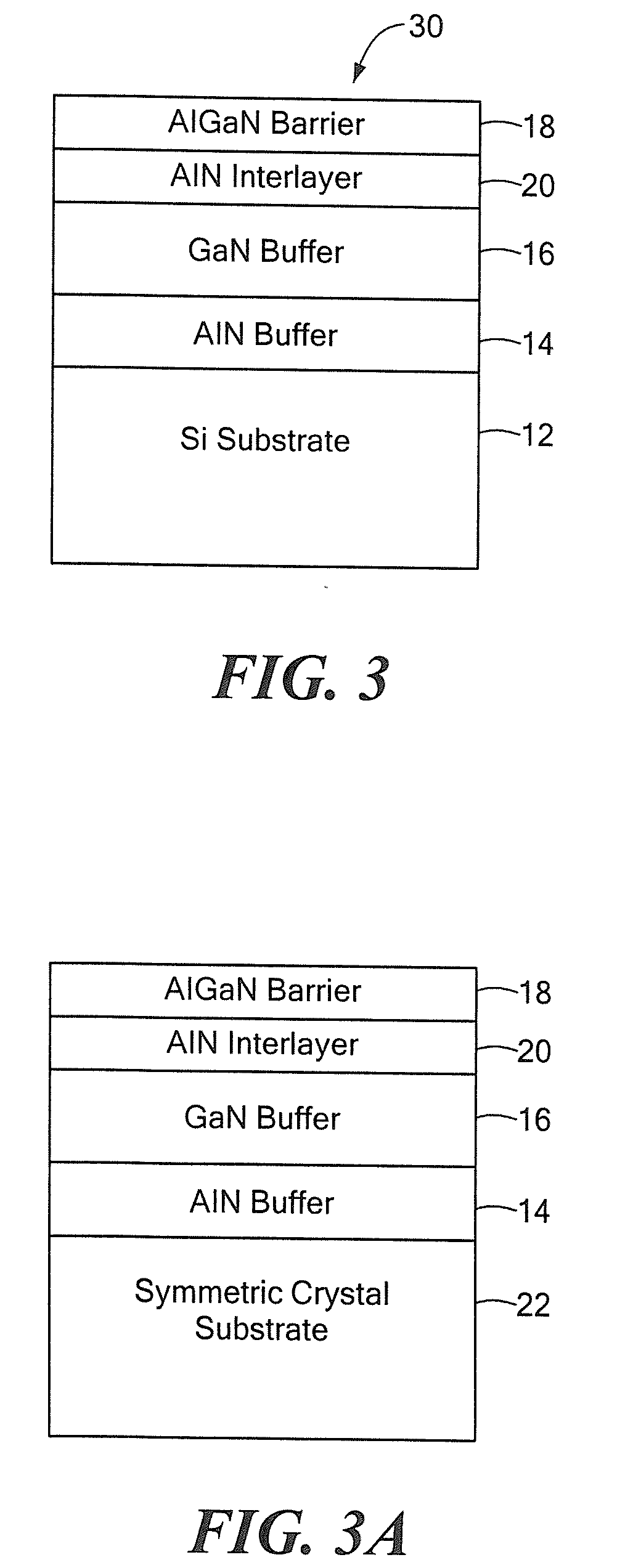

Gallium nitride for liquid crystal electrodes

ActiveUS20100320474A1High electron mobilityAvoid excessive absorptionSemiconductor/solid-state device manufacturingNon-linear opticsSpinelGallium nitride

Described herein is a liquid crystal (LC) device having Gallium Nitride HEMT electrodes. The Gallium Nitride HEMT electrodes can be grown on a variety of substrates, including but not limited to sapphire, silicon carbide, silicon, fused silica (using a calcium fluoride buffer layer), and spinel. Also described is a structure provided from GaN HEMT grown on large area silicon substrates and transferred to another substrate with appropriate properties for OPA devices. Such substrates include, but are not limited to sapphire, silicon carbide, silicon, fused silica (using a calcium fluoride buffer layer), and spinel. The GaN HEMT structure includes an AlN interlayer for improving the mobility of the structure.

Owner:RAYTHEON CO

Basket for deep fryer and methods of cooking food products

ActiveUS7500427B2The process is convenient and fastImprove flash efficiencyFood preparationDeep fat fryersEngineeringMechanical engineering

A basket assembly for use with a deep fryer having a lower foraminous basket and an upper foraminous insert which quickly and easily attaches to the lower basket at a predetermined location intermediate the top and bottom of the lower basket to thereby hold the food in place beneath the surface of a hot cooking liquid such as oil. Advantages of the assembly are that it forces foods down to increase the efficiency of flash frying, it provides the ability to cook more than one item at a time while keeping them separated, and it provides a food product which cooks faster because it is unnecessary to turn food which floats to the top, thereby resulting in less fat absorption.

Owner:SHARKNINJA OPERATING LLC

Optical filter

InactiveUS8094394B2High strengthAvoid excessive absorptionSolid-state devicesNon-linear opticsIn planeDielectric substrate

An optical filter that transmits light of the visible light region includes a dielectric substrate; a dielectric layer that is formed on a surface of the dielectric substrate; and a first metal structure group in which a plurality of first metal structures are arranged two-dimensionally in an isolated state in the in-plane direction of the dielectric substrate, that is provided between the dielectric substrate and the dielectric layer, comprising: the first metal structures having first and second lengths in first and second directions orthogonal to each other, which lengths are equal to or less than a first wavelength in the visible light region; and a transmittance of the first wavelength being reduced or a reflectance being increased by surface plasmons induced on a surface of the first metal structures by resonance between light incident on the dielectric substrate or the dielectric layer and the first metal structures.

Owner:CANON KK

Optical filter

ActiveUS20120075688A1High strengthAvoid excessive absorptionSolid-state devicesNon-linear opticsIn planeDielectric substrate

An optical filter that transmits light of the visible light region includes a dielectric substrate; a dielectric layer that is formed on a surface of the dielectric substrate; and a first metal structure group in which a plurality of first metal structures are arranged two-dimensionally in an isolated state in the in-plane direction of the dielectric substrate, that is provided between the dielectric substrate and the dielectric layer, comprising: the first metal structures having first and second lengths in first and second directions orthogonal to each other, which lengths are equal to or less than a first wavelength in the visible light region; and a transmittance of the first wavelength being reduced or a reflectance being increased by surface plasmons induced on a surface of the first metal structures by resonance between light incident on the dielectric substrate or the dielectric layer and the first metal structures.

Owner:CANON KK

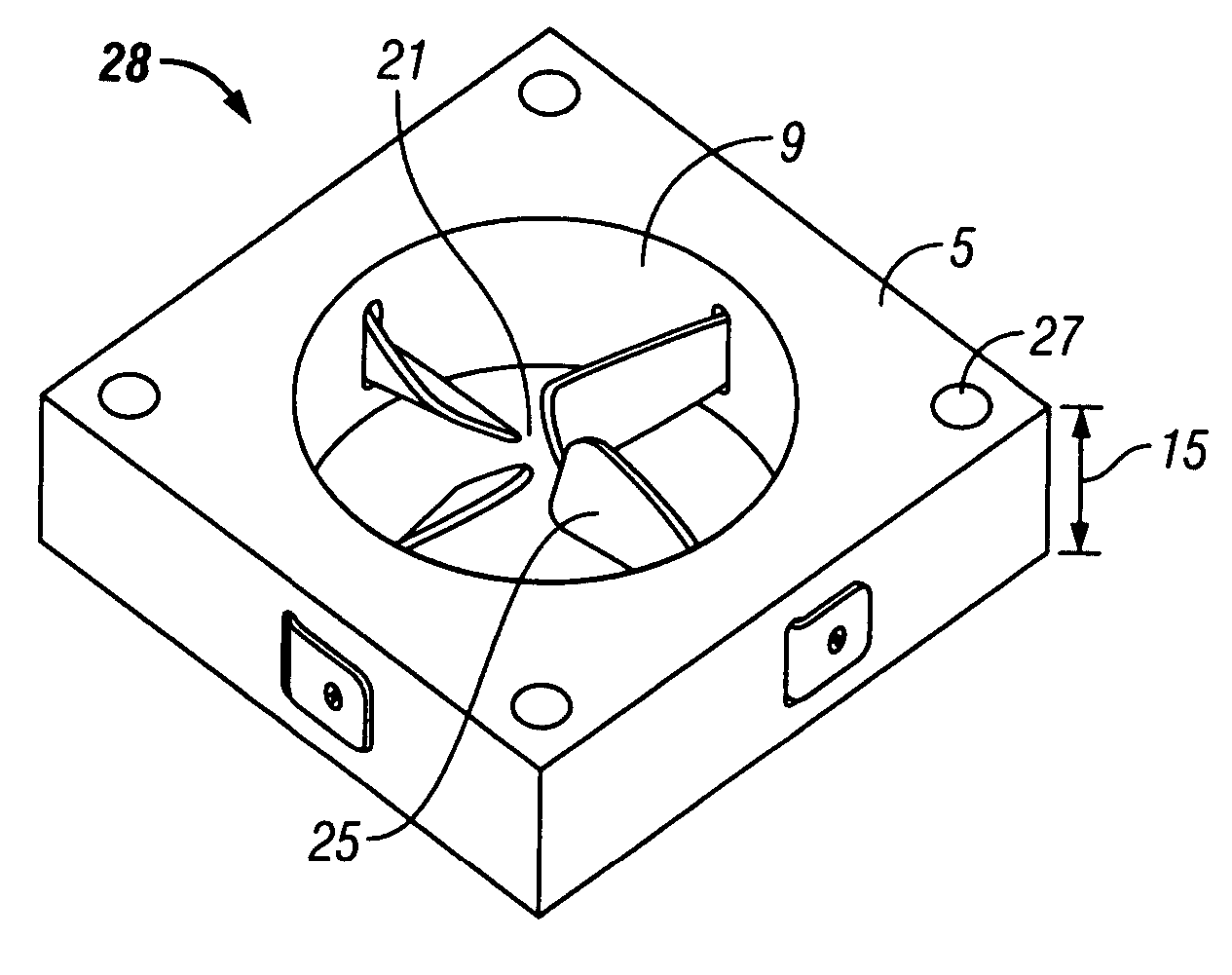

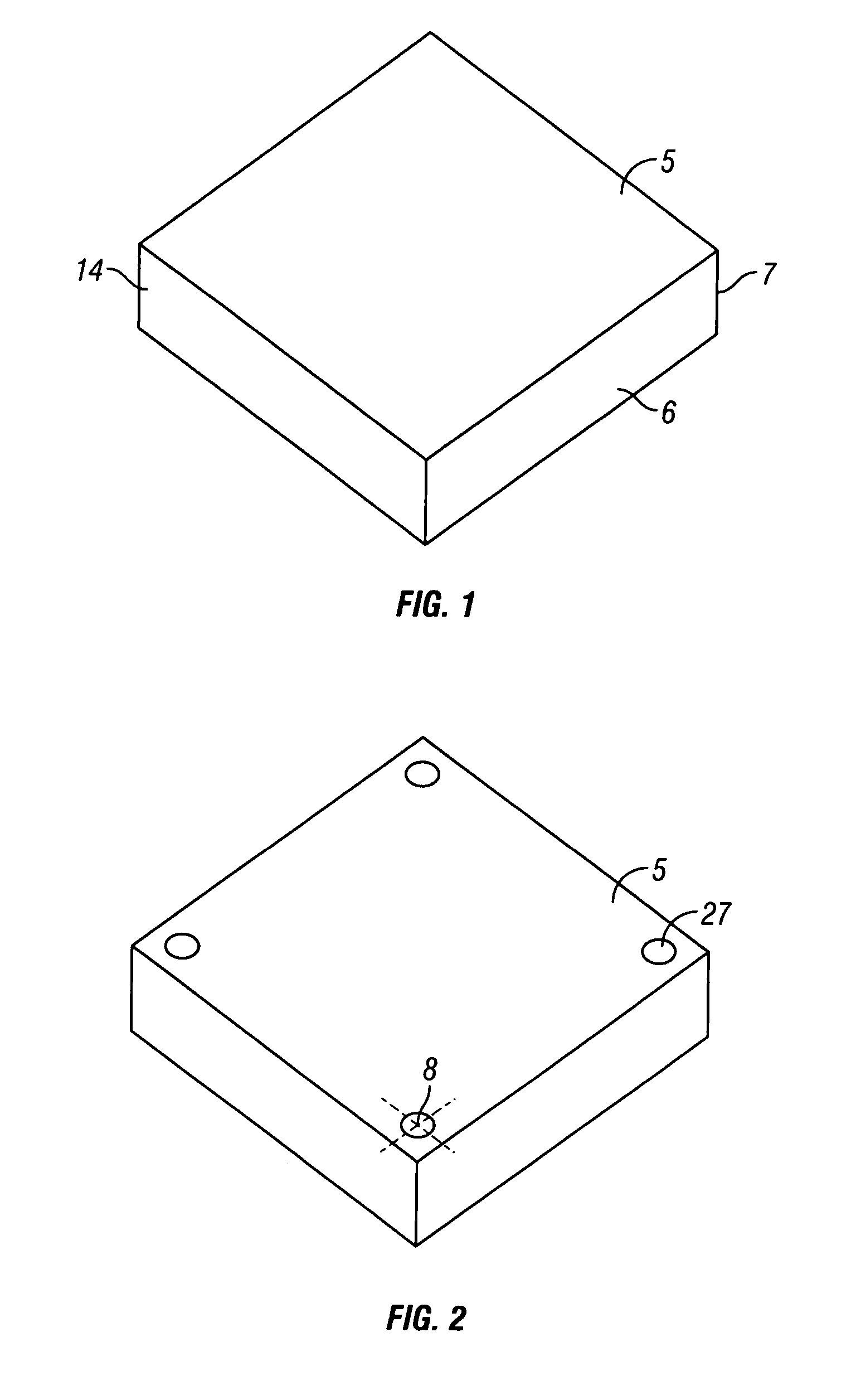

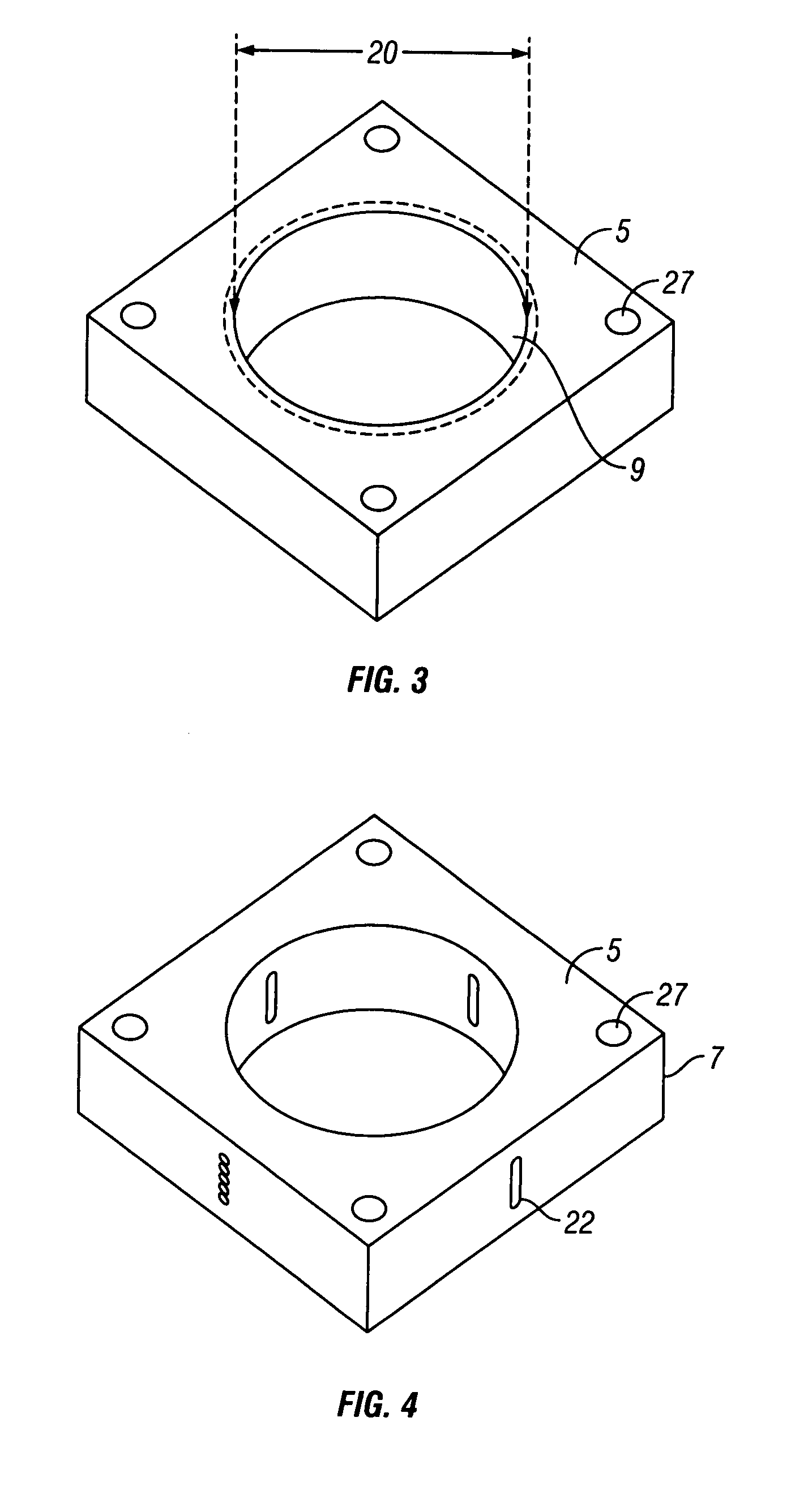

Throttle body spacer for use with internal combustion engines

InactiveUS7690349B2Improve efficiencyIncreases velocity and forceInternal combustion piston enginesFuel re-atomisation/homogenisationCombustionEngineering

A throttle body spacer for improving engine performance is provided. It comprises a spacer block with a smooth bore hole, a plurality of air fins, each air fin being connected at one end to the spacer block and the distal end extending to about the center of the bore hole, and a means for mounting the throttle spacer body to hold it in place. In one embodiment the spacer block forming the throttle spacer body is square with a single bore hole in the center. There are four air fins, one mounted from about the middle of each side of the spacer body, that extend to about the center of the hole. The air fins can be made from aluminum and are bent at a forty-five degree angle. In order to accomplish the goal of absorbing less heat, the spacer block forming the throttle body spacer is comprised of thermoset resin. The throttle body spacer has holes located near each corner where fastening elements can be inserted to hold the apparatus in place.

Owner:GSP POWERSPACER

Porcelain oven rack

InactiveUS6837235B2Avoid chippingReduce the cross-sectional areaLine/current collector detailsLiquid surface applicatorsTitaniumSteel bar

In one embodiment, the present invention provides a coated steel wire oven rack. The preferred coated steel wire oven rack includes a plurality of elongated steel wire members joined together to form an oven rack having an outer surface. The plurality of elongated steel wire members are made from a steel rod material containing from about 80 to about 99.9% by weight of iron, from about 0.001 to about 0.08% by weight of carbon and from about 0.001 to about 0.2% by weight of a carbon stabilizing transition metal, preferably selected from the group consisting of Vanadium, Tantalum, Titanium and Niobium. The plurality of elongated steel wire members are preferably made from the steel rod material by drawing the steel rod material to form steel wire; wherein the diameter of the cross-sectional area of the steel rod material is reduced by at least about 20% when the steel rod material is drawn to form the steel wire. The outer surface of the oven rack is coated by a glass material, preferably porcelain; wherein the amount of carbon in the steel rod material, the amount of carbon stabilizing transition metal in the steel rod material and the degree to which the diameter of the cross-sectional area of the steel rod material is reduced, when the steel wire is drawn from the steel rod material, is optimized so as to prevent chipping of the glass material from the outer surface due to the release of hydrogen gas from the steel wire members when the steel wire is either heated or cooled. In preferred embodiments, the glass material is coated onto the oven rack in two distinct coating steps. The present invention also includes a method of making a coated steel wire oven rack comprising the steps of providing steel rod material; drawing the steel rod material to form steel wire; forming a plurality of elongated steel wire members; joining the plurality of steel wire members to one another to form a steel wire oven rack; and coating the steel wire oven rack with a glass material, preferably porcelain.

Owner:AMERICAN APPLICANCE PROD INC

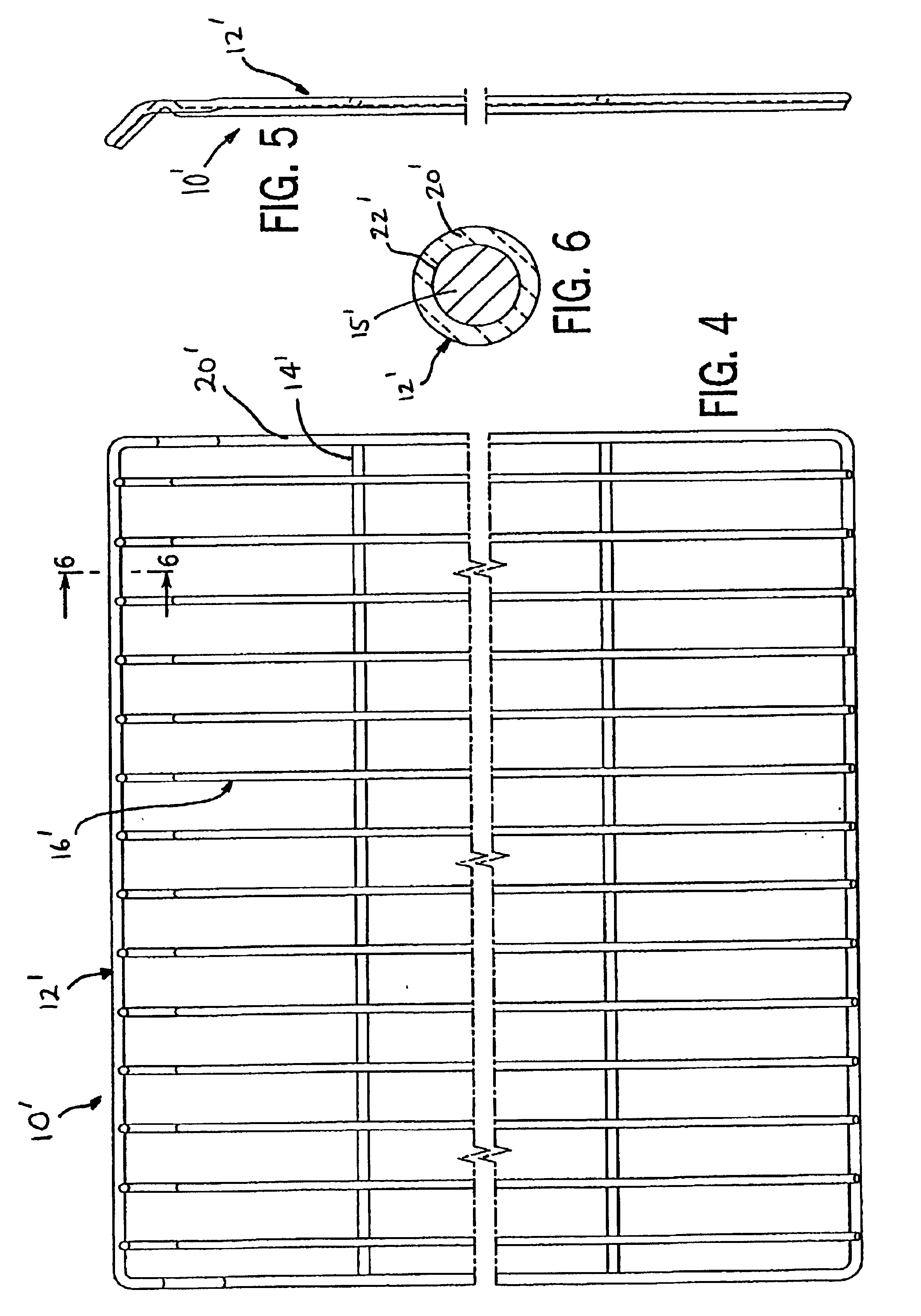

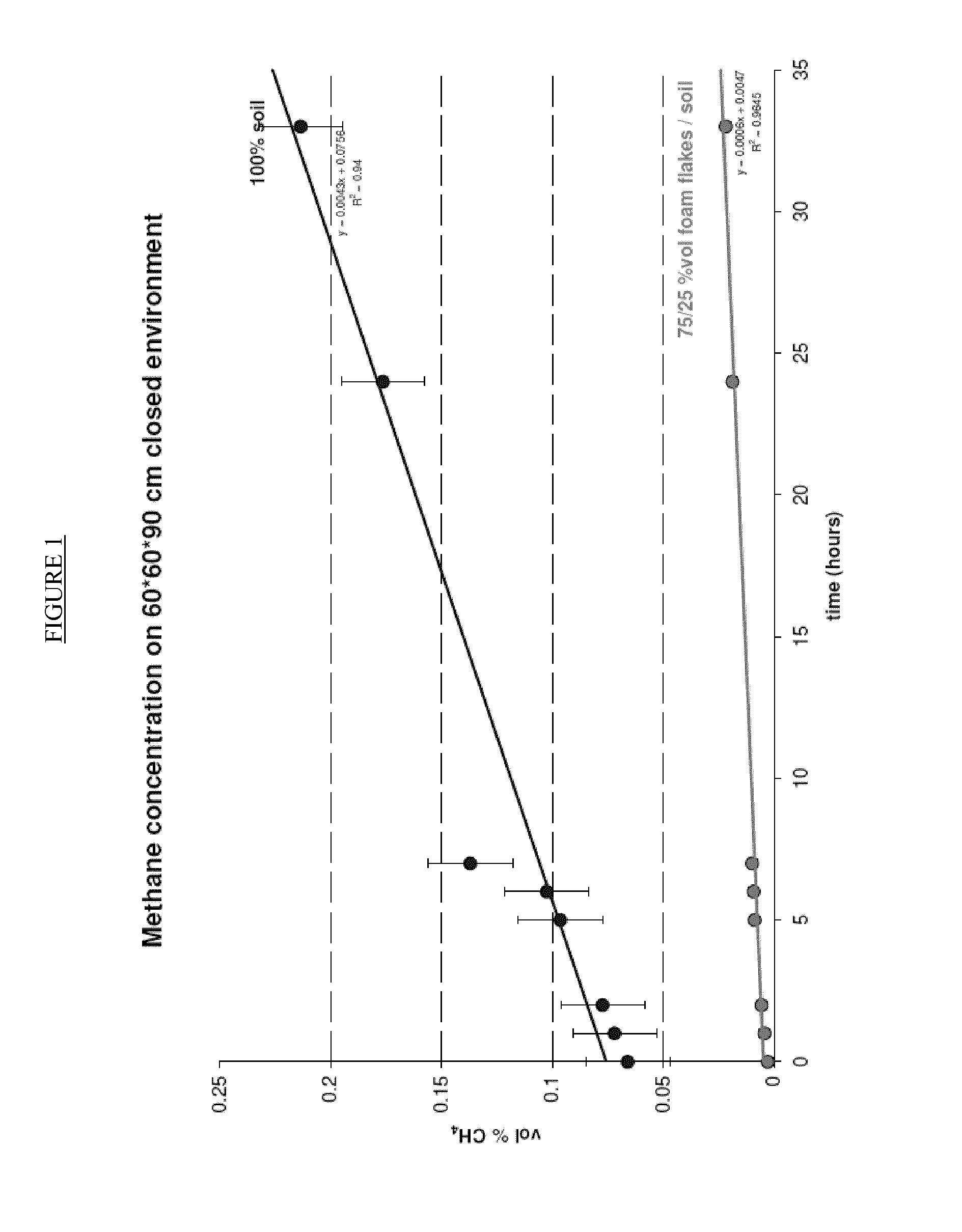

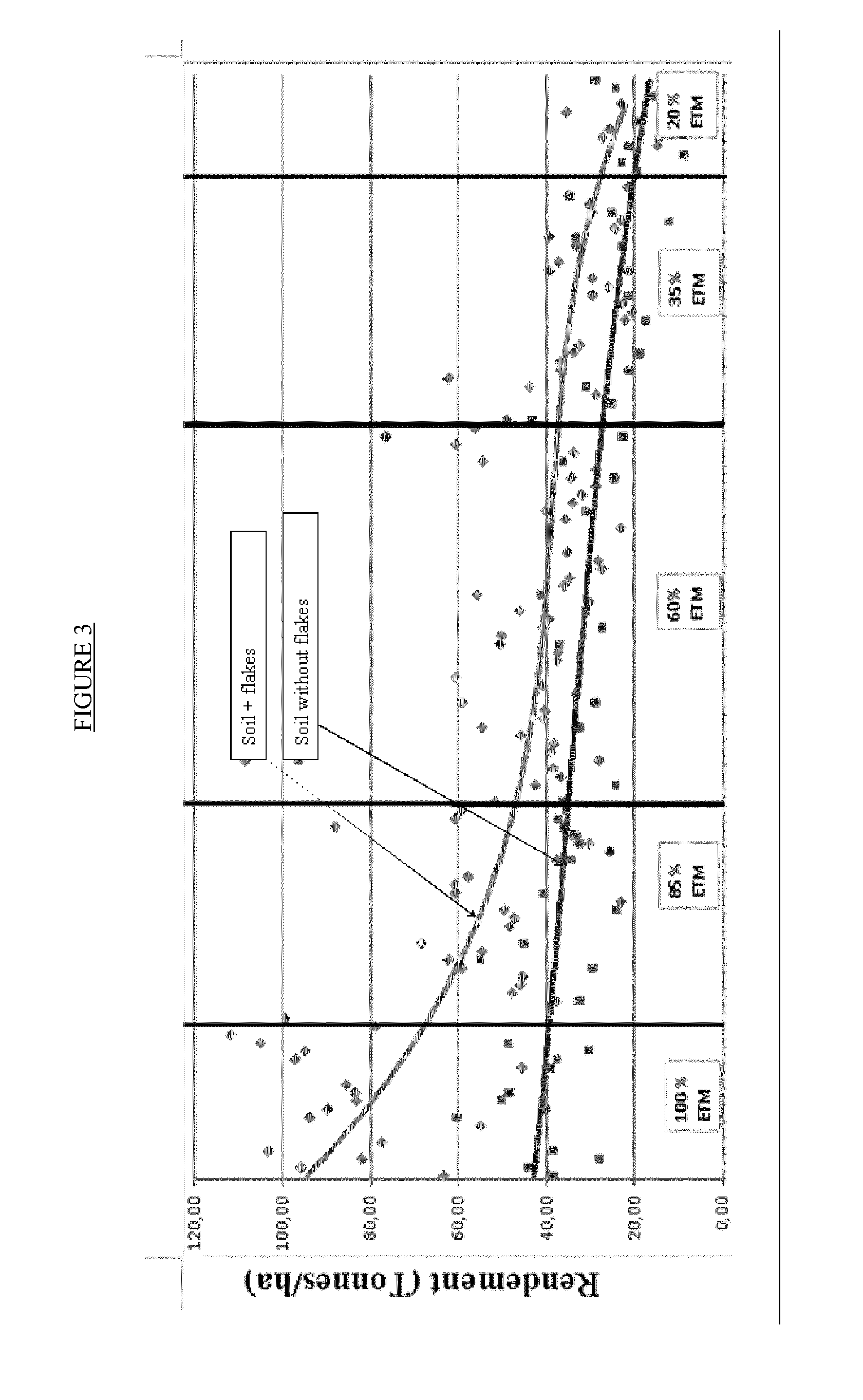

Polyurethane Foam For Use as Soil Improver

ActiveUS20160115387A1Emission reductionReduce the amount requiredBio-organic fraction processingGrowth substratesGrowth plantSoil conditioner

Polyurethane foam flakes for use as additive to soil and / or other natural plant growth media for improving the water retention and / or reduction of the methane emission.

Owner:HUNTSMAN INT LLC

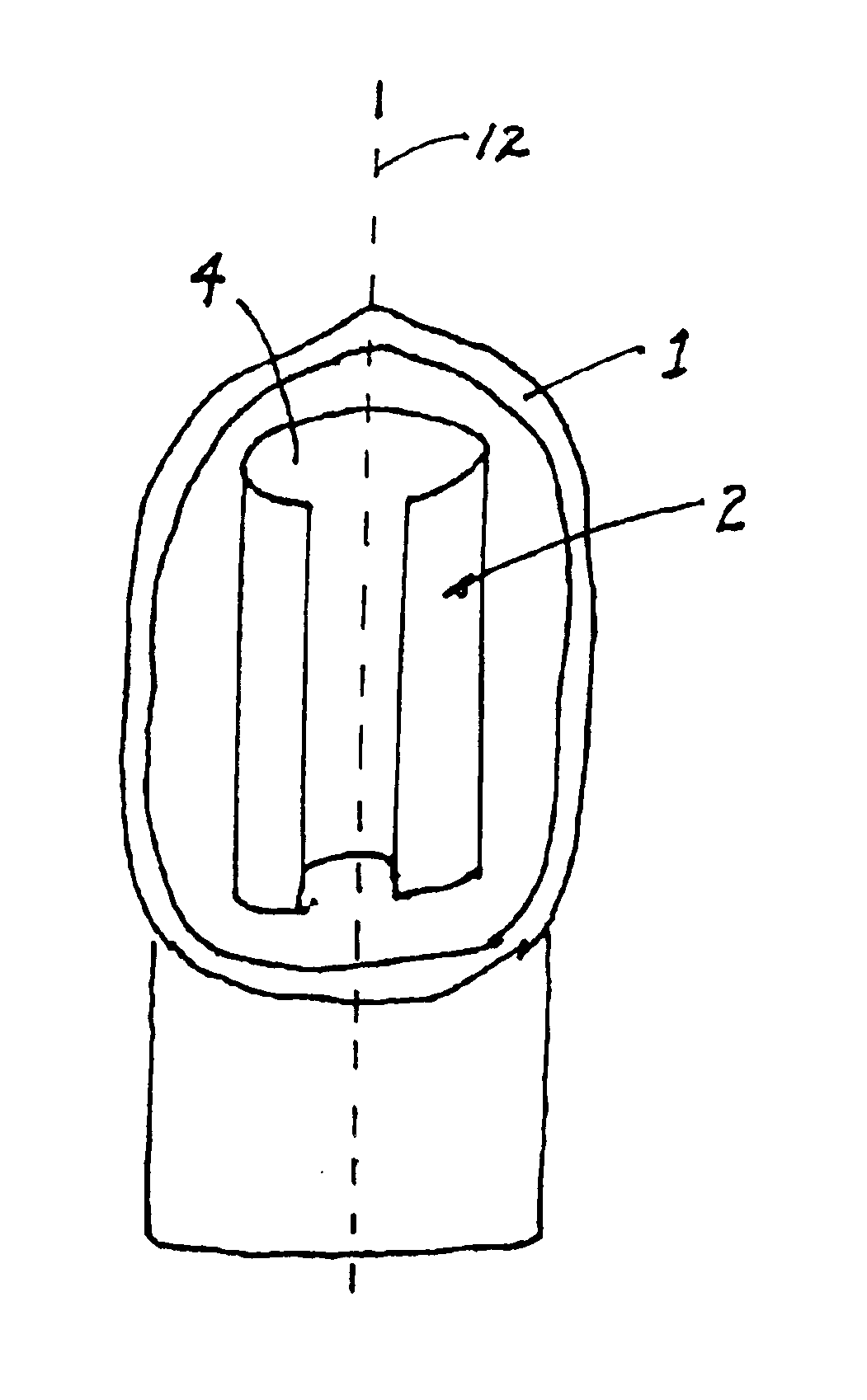

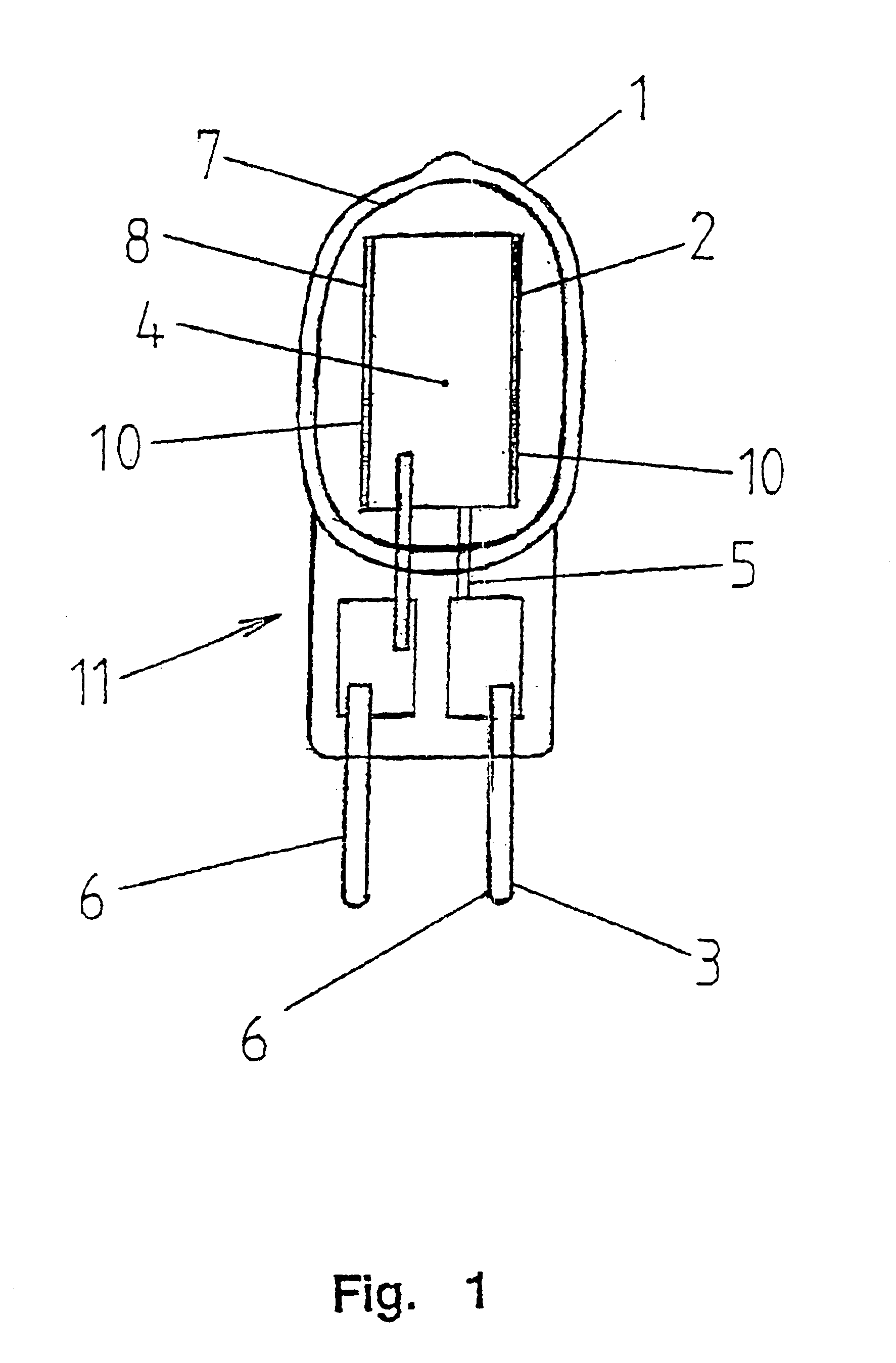

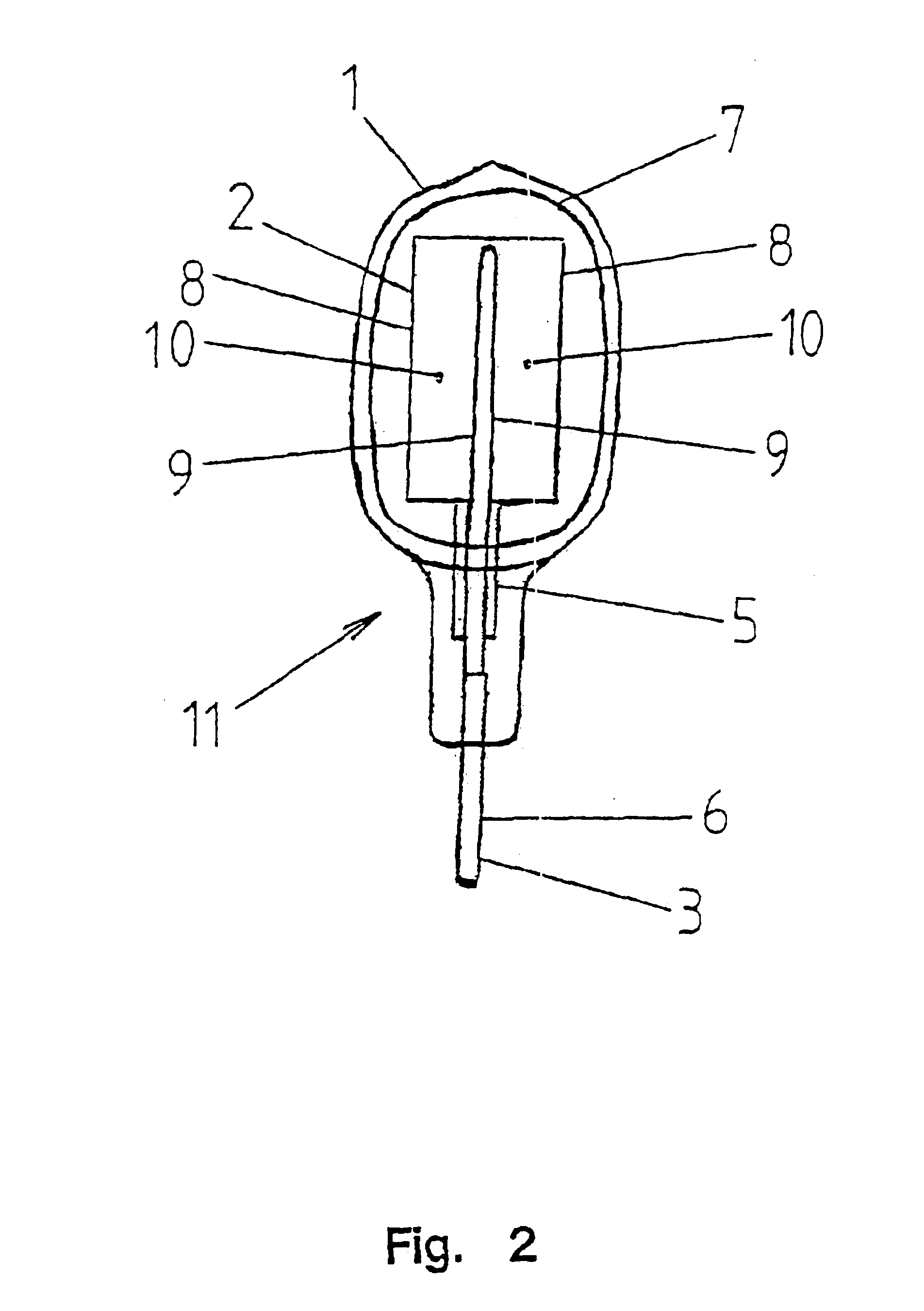

Light source and method for producing a light source

InactiveUS6903508B1Reliable productImprove conversion efficiencyDischarge tube luminescnet screensLamp incadescent bodiesCarbideThermal radiation

A light source, in particular incandescent lamp, with a bulb (1), a filament (2) arranged in the bulb (1), and a heating device (3) for the filament (2), the filament (2) emitting both visible light and heat radiation, is designed and constructed with respect to a high conversion efficiency between an electrical power input and emitted light output such that the filament (2) includes a flat section (4). A light source of this type may be produced by a method, wherein initially a filament (2) of a sintered metal powder is provided. Subsequently, the filament (2) is exposed to an atmosphere of carbon dioxide or of carbon dioxide and inert gas for forming a metal carbide. Finally, the filament (2) is sealed into the bulb (1).

Owner:IP2H AG

Illumination apparatus

InactiveUS20120163022A1Improve efficiencyReduce light lossMechanical apparatusPlanar/plate-like light guidesLight guideConcentrator

This invention relates to an illumination apparatus. The illumination apparatus comprises a light guide plate and a light source configured to emit light into the light guide plate through a first surface, and the light guide plate comprises a concentrator configured to direct incident light in the light guide plate so as to radiate in a direction substantially parallel to a preset plane. The preset plane is perpendicular to any one of the top surface and bottom surface of the light guide plate, and intersects the first surface and a second surface of the light guide plate or intersects the first surface and one of the side surfaces at an angle that is substantially larger than the critical angle of a total reflection. In this way, unwanted light loss in the light guide plate is reduced, and the distribution of the light intensity or luminance along the light guide plate is improved, i.e., a substantially uniform distribution of the light intensity can be achieved.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

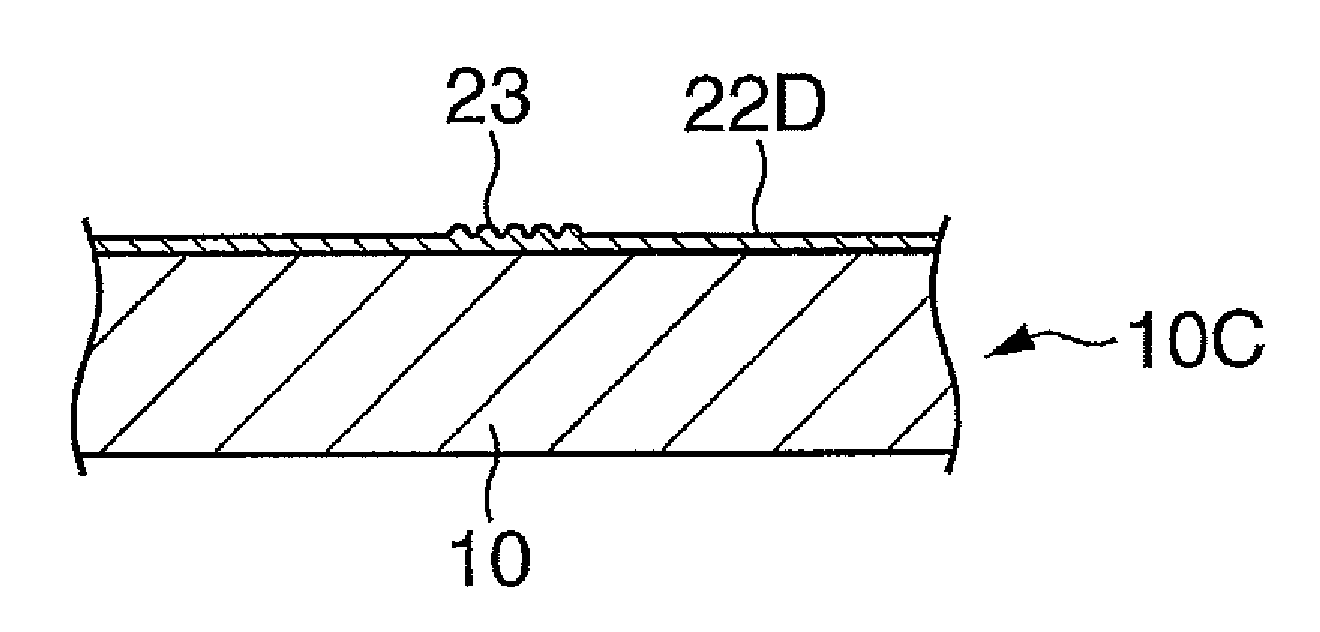

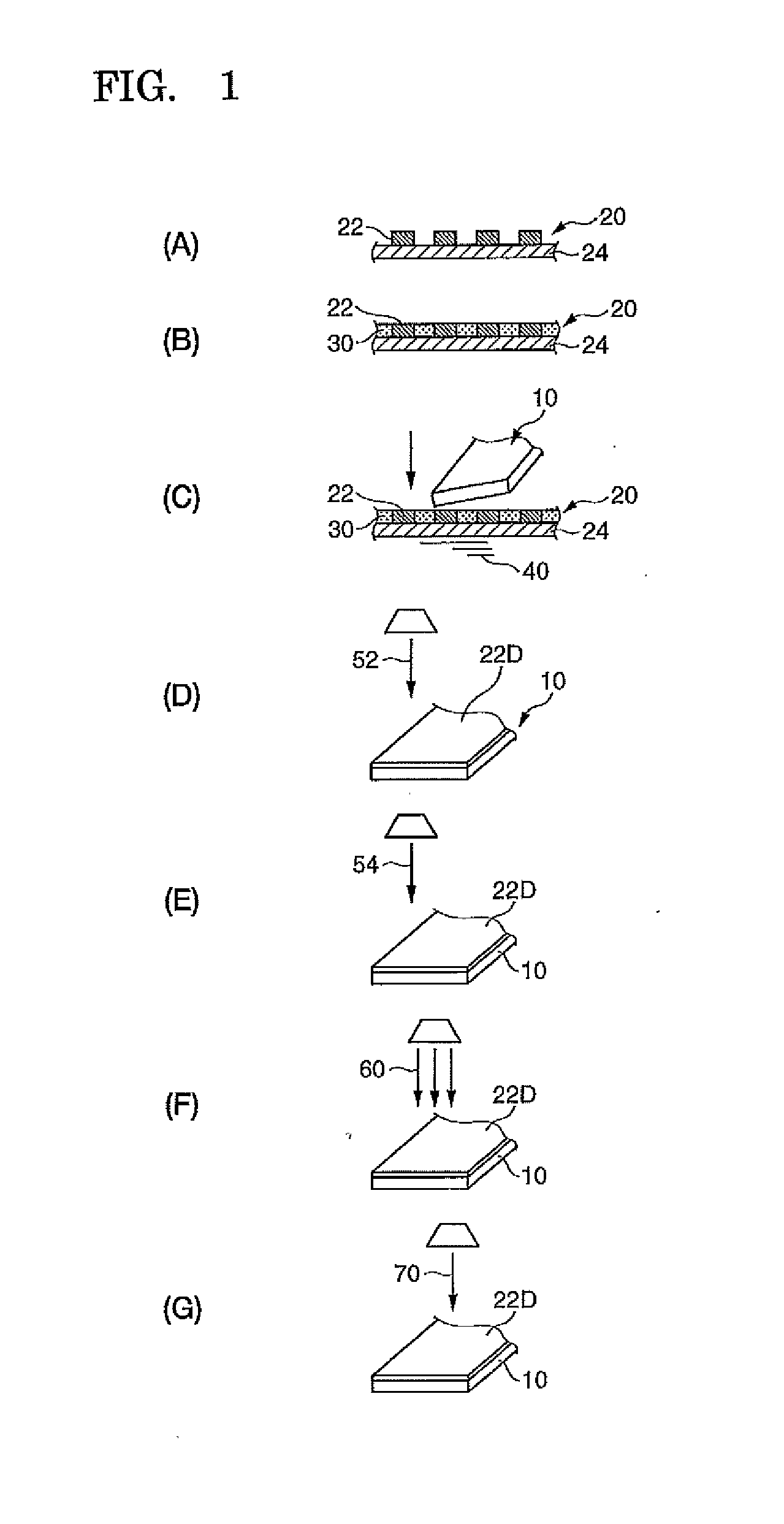

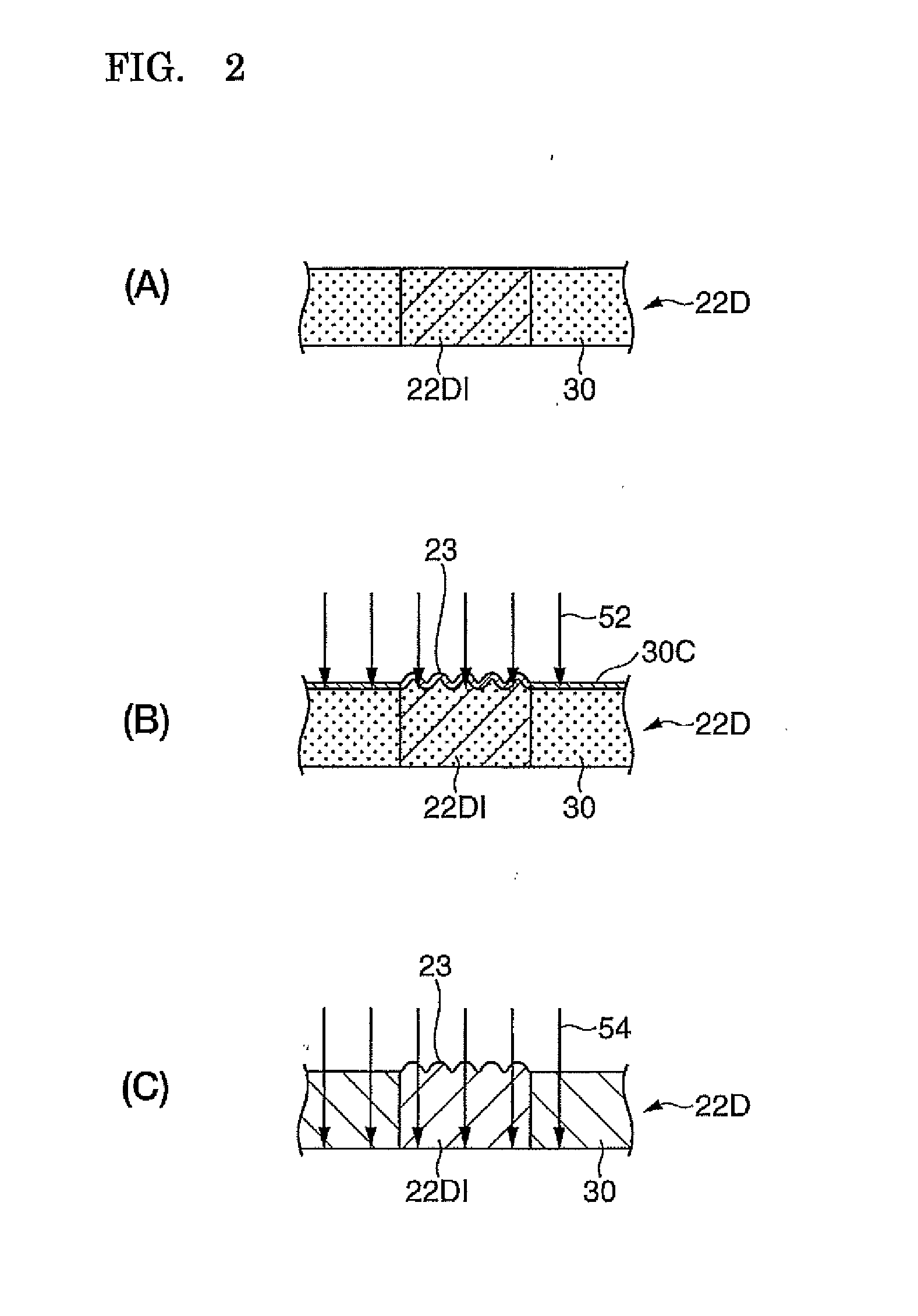

Method and product of hydraulic transfer

ActiveUS20120111951A1Gloss feeling be reduceFine unevennessDecorative surface effectsPrintingTotal thicknessResin composite

After applying an ultraviolet ray hardening resin composite 30 on a print pattern 22 of dry state and also permeating the resin composite through the print pattern to thereby reproduce the adhesion of the print pattern 22, the print pattern 22 is transferred under water pressure onto the surface of article 10 to form the decoration layer 22D on the surface of the article 10. Then, the preliminary irradiation of ultraviolet ray permeating only near the surface of this decoration layer 22D is performed to form a fine surface height variation portion 23 by shrinkage of ink in the surface of the ink printing portion of the decoration layer 22D. Thereafter, the complete irradiation of ultraviolet ray permeating through the total thickness of the decoration layer 22D is performed to completely harden the total thickness of the decoration layer 22D while maintaining the surface height variation portion 23. This enables the matting of the decoration layer in a controlled state without applying a topcoat.

Owner:TAICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com