Patents

Literature

140results about How to "High durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-aqueous electrolyte solution for secondary battery and non-aqueous electrolyte secondary battery using the electrolyte solution

InactiveUS20070287071A1Excellent load characteristicHigh durabilityCell electrodesOrganic electrolyte cellsSolventCarboxylic ester

A non-aqueous electrolyte for a secondary battery includes a solvent and an electrolyte containing a lithium salt. The solvent contains 4-fluoroethylene carbonate and a chain carboxylic ester represented by the formula R1COOR2, where R1 and R2 are alkyl groups having 3 or less carbon atoms. The amount of the 4-fluoroethylene carbonate is 7 volume % or greater with respect to the total amount of the solvent.

Owner:SANYO ELECTRIC CO LTD

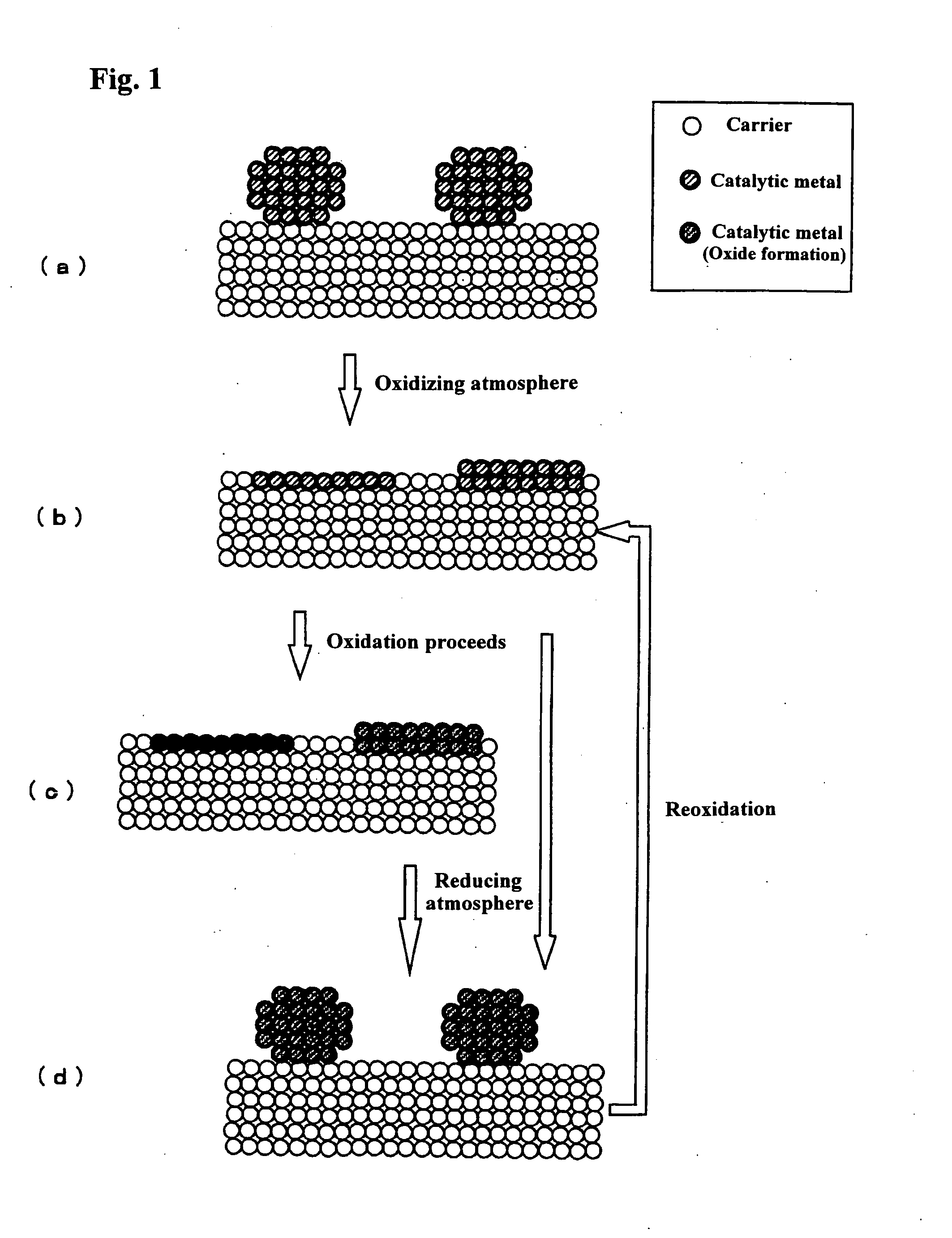

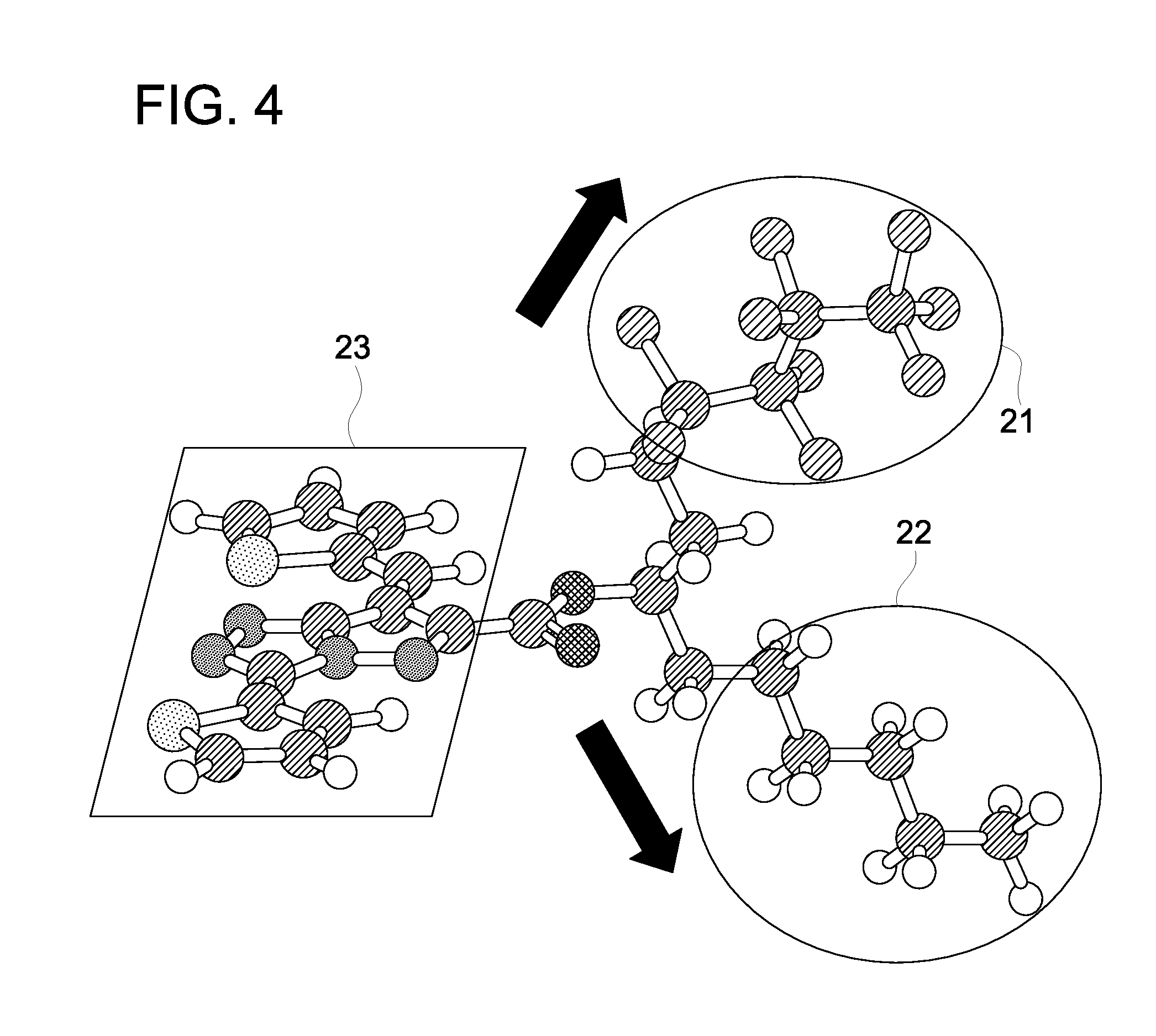

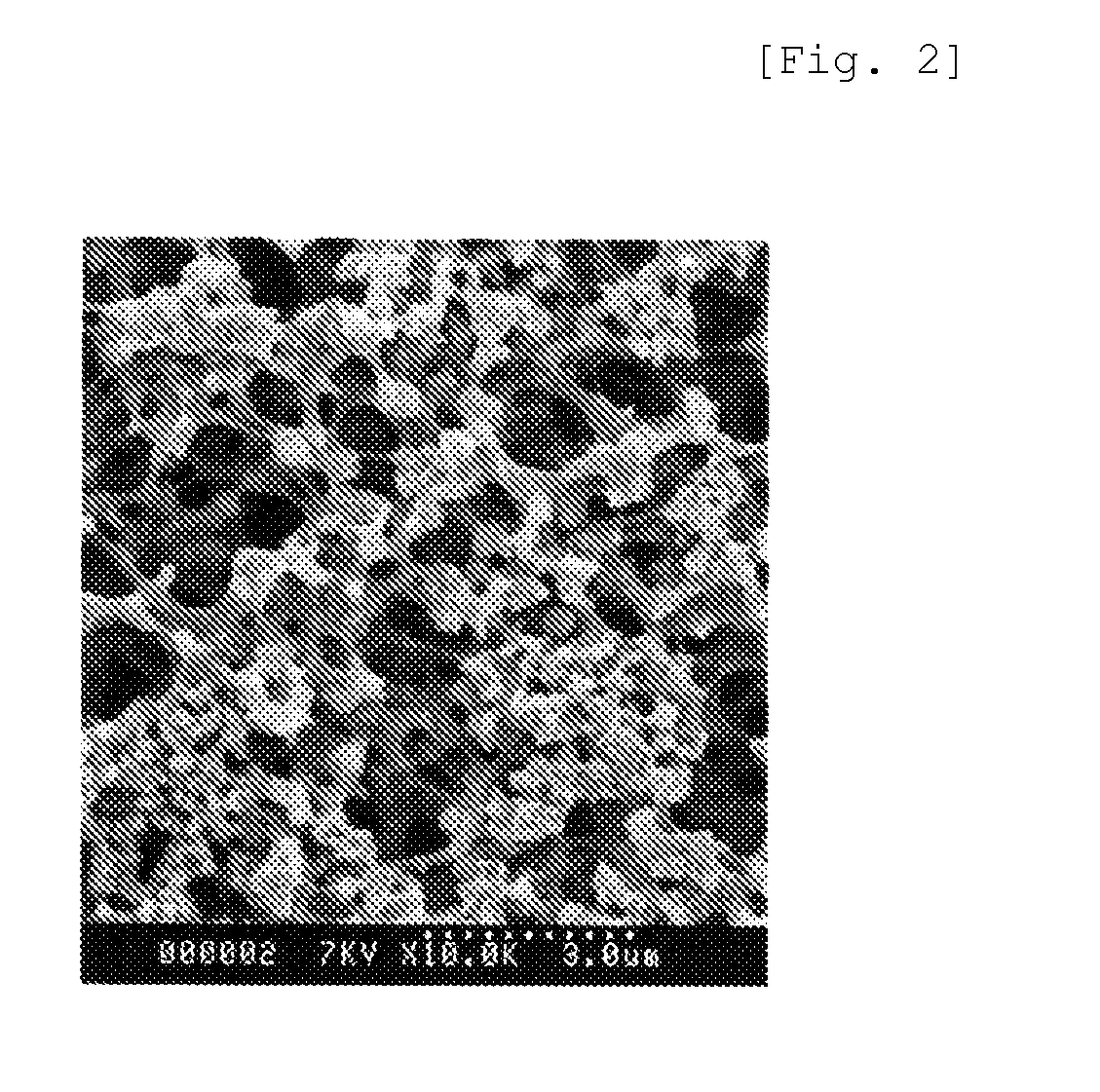

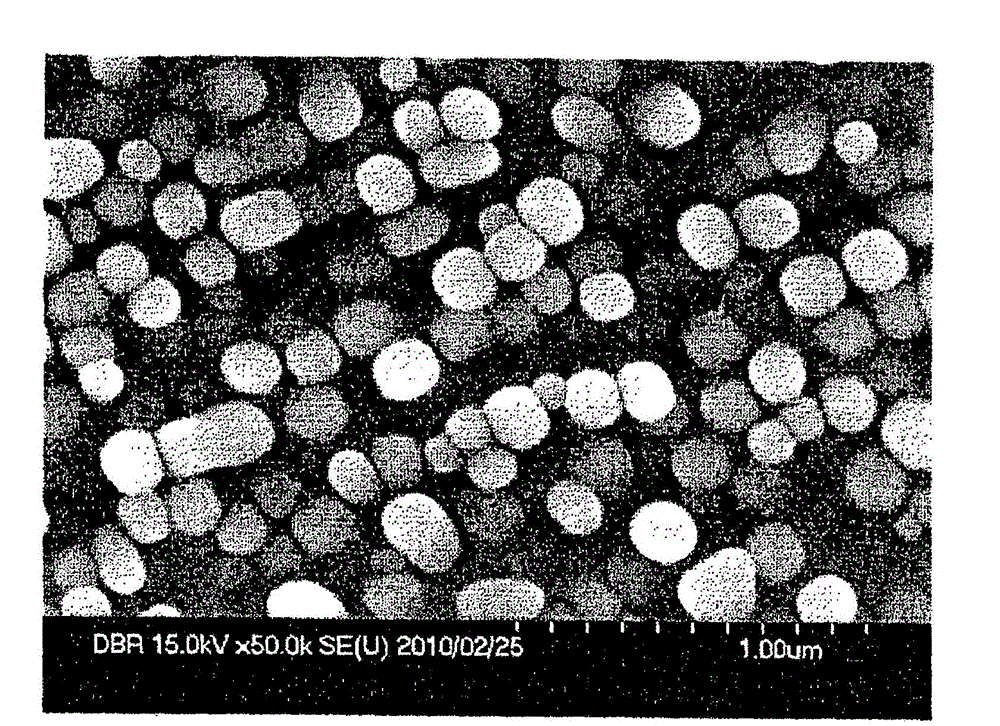

Catalyst

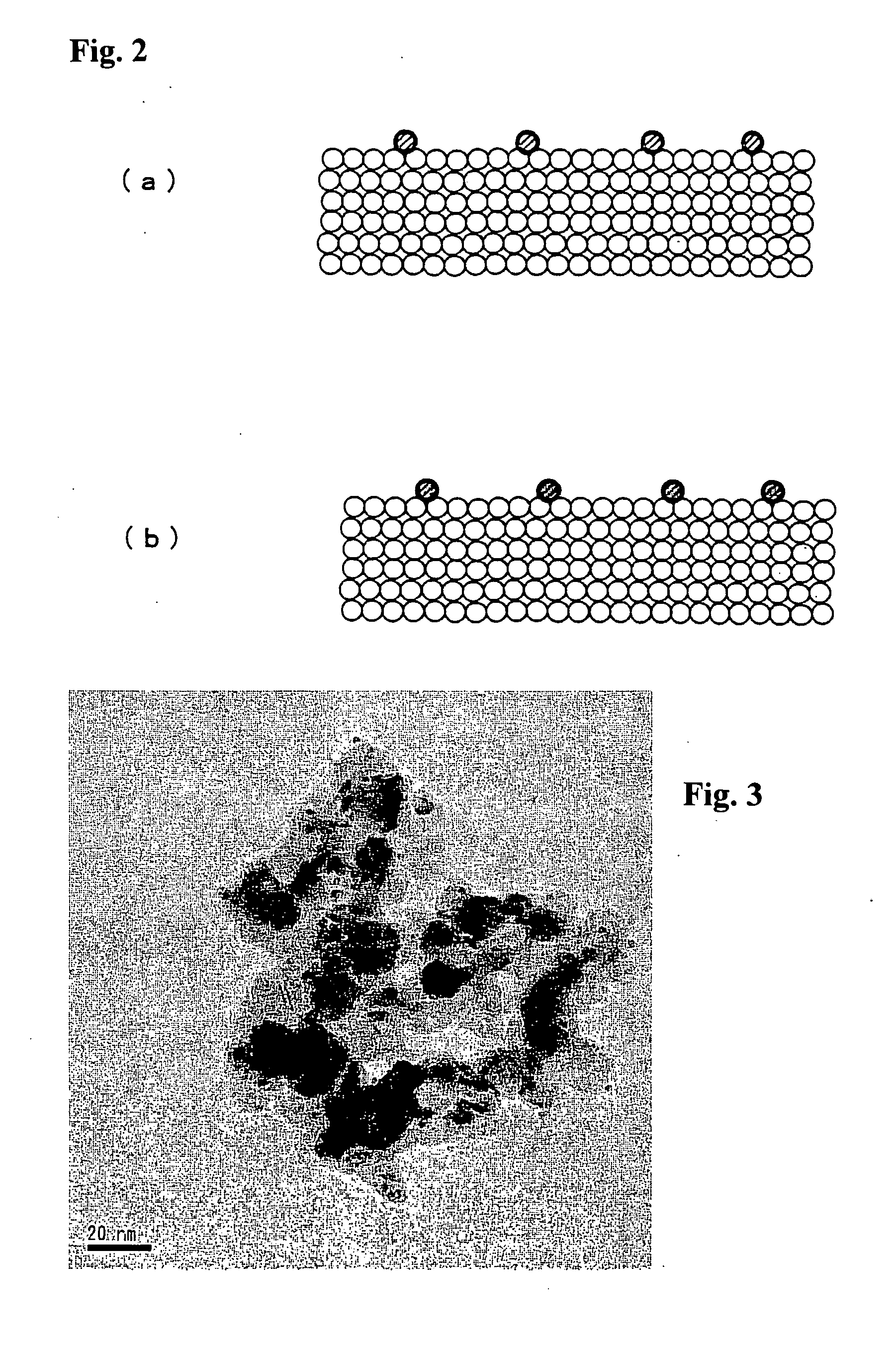

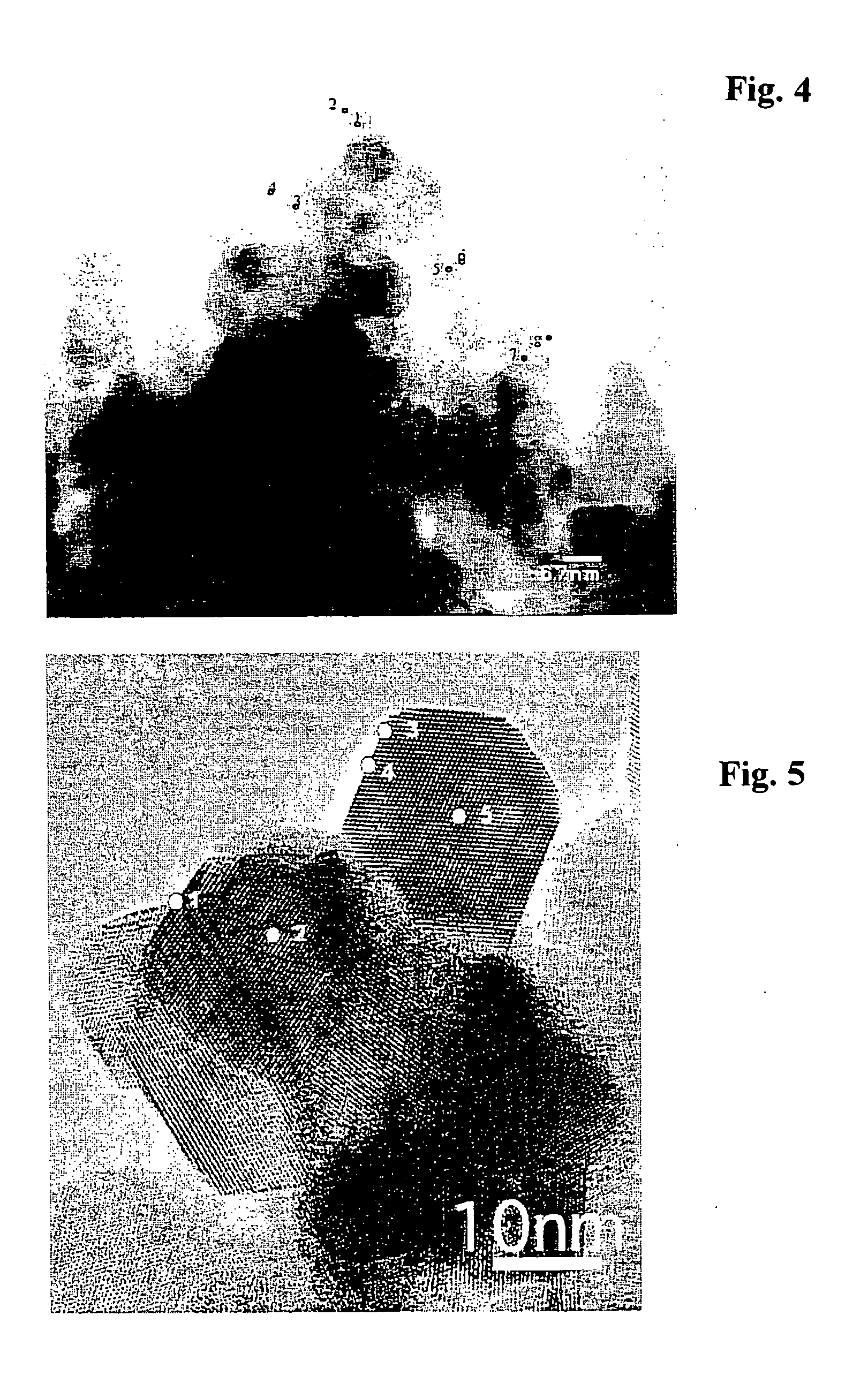

InactiveUS20070161506A1High reaction activityHigh durabilityGas treatmentInternal combustion piston enginesChemistryOxide

The present invention provides a catalyst comprising particles of one or more catalytic metals supported on a porous carrier made of one or more metal oxides, wherein the porous carrier is made of an oxide containing a rare earth oxide, and that the catalytic metal particles are made of one or more transition metals or transition metal oxides having 10 to 50000 atoms. In the present invention, cluster-like catalyst particles are supported on a specific carrier. The catalyst of the present invention maintains desirable activity while changing the morphology of catalyst particles by the atmosphere of the catalyst.

Owner:TANAKA PRECIOUS METAL IND

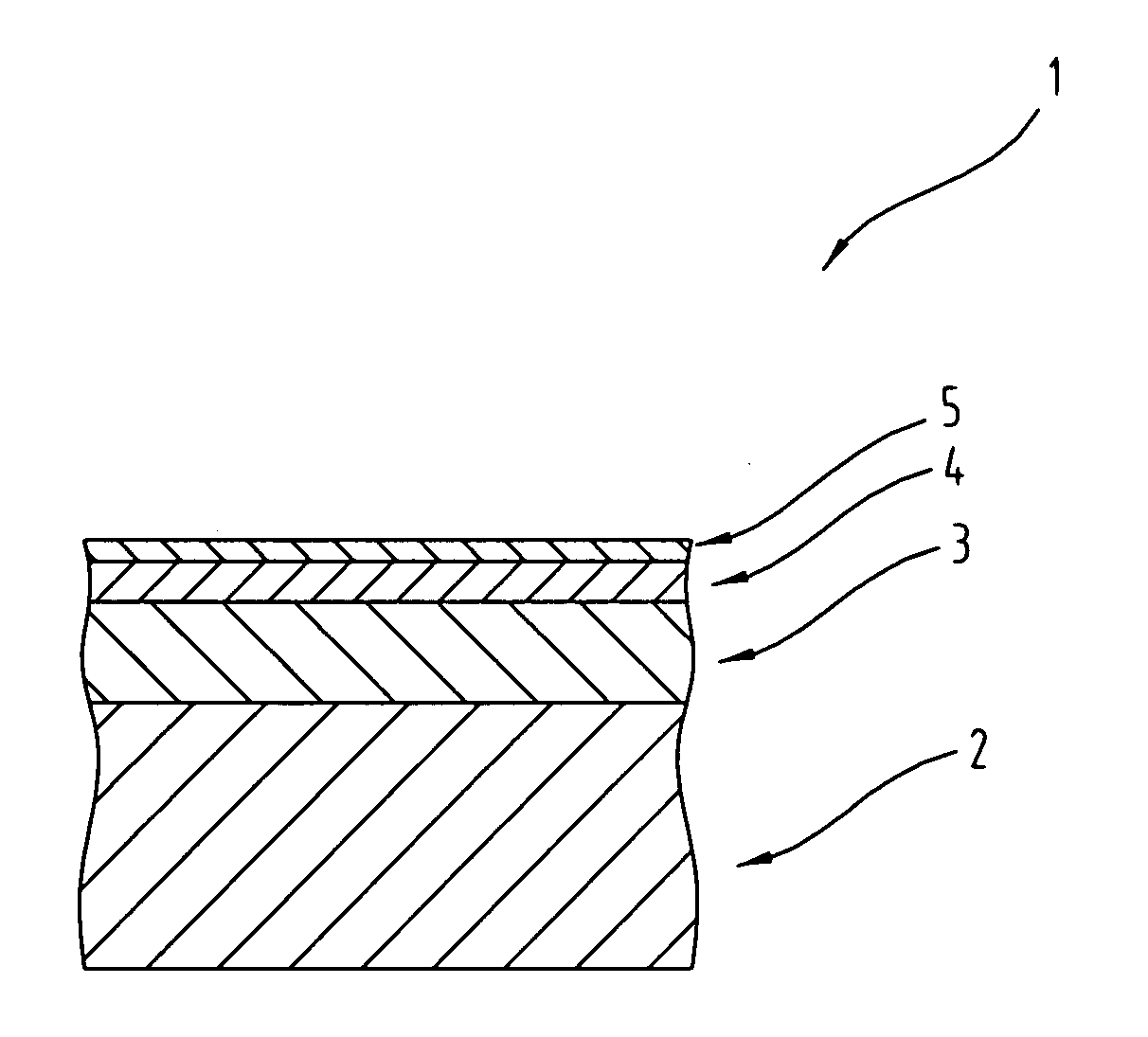

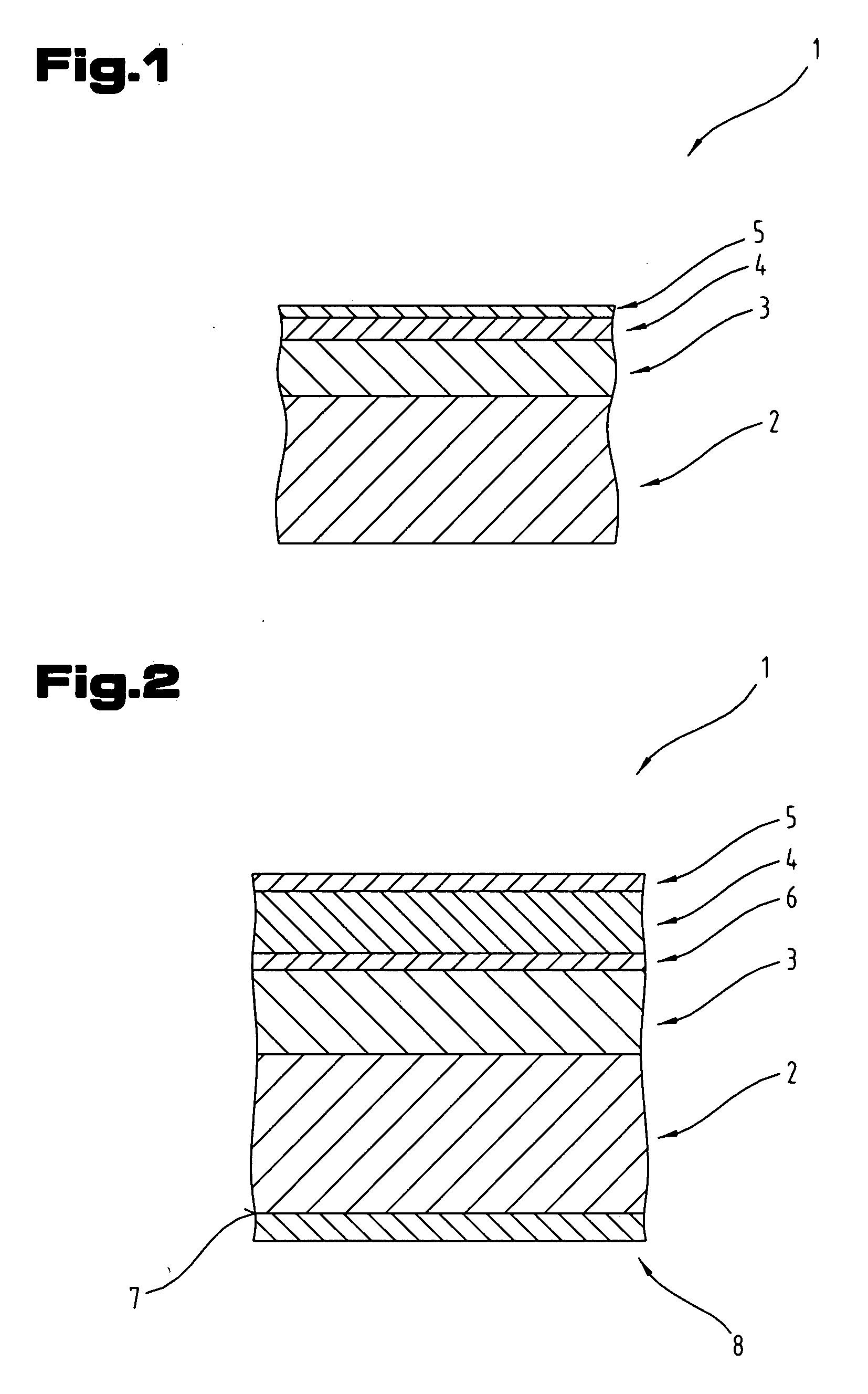

Multi-layered bearing

The invention describes a multi-layered bearing with a supporting metal layer, optionally a bearing metal layer disposed on top of it, an anti-friction layer on top of the latter as well as a wearing layer on top of it. The wearing layer is made from bismuth or a bismuth alloy and the anti-friction layer is made from a copper-bismuth or silver-bismuth alloy or silver.

Owner:MIBA SINTER AUSTRIA +1

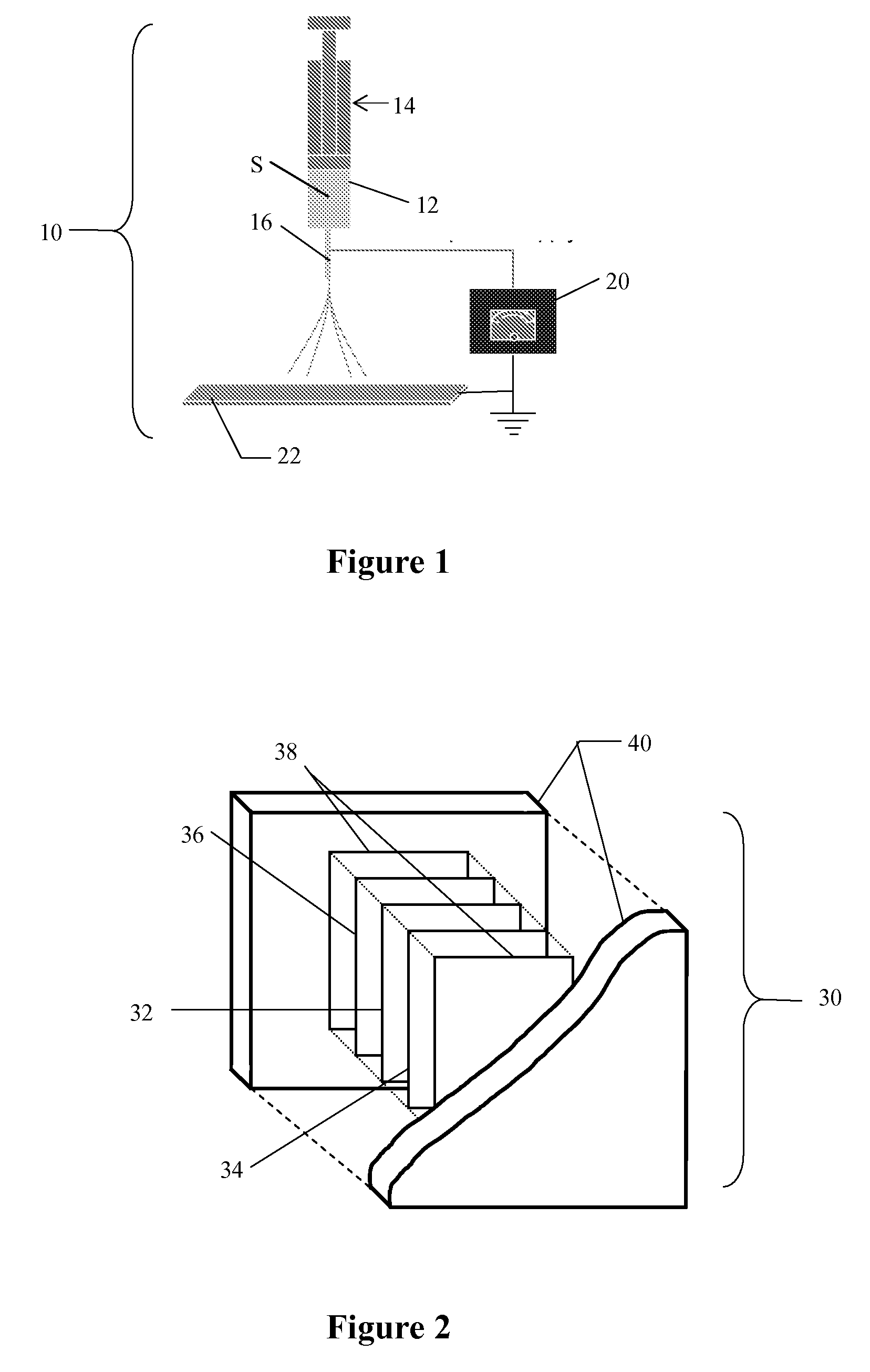

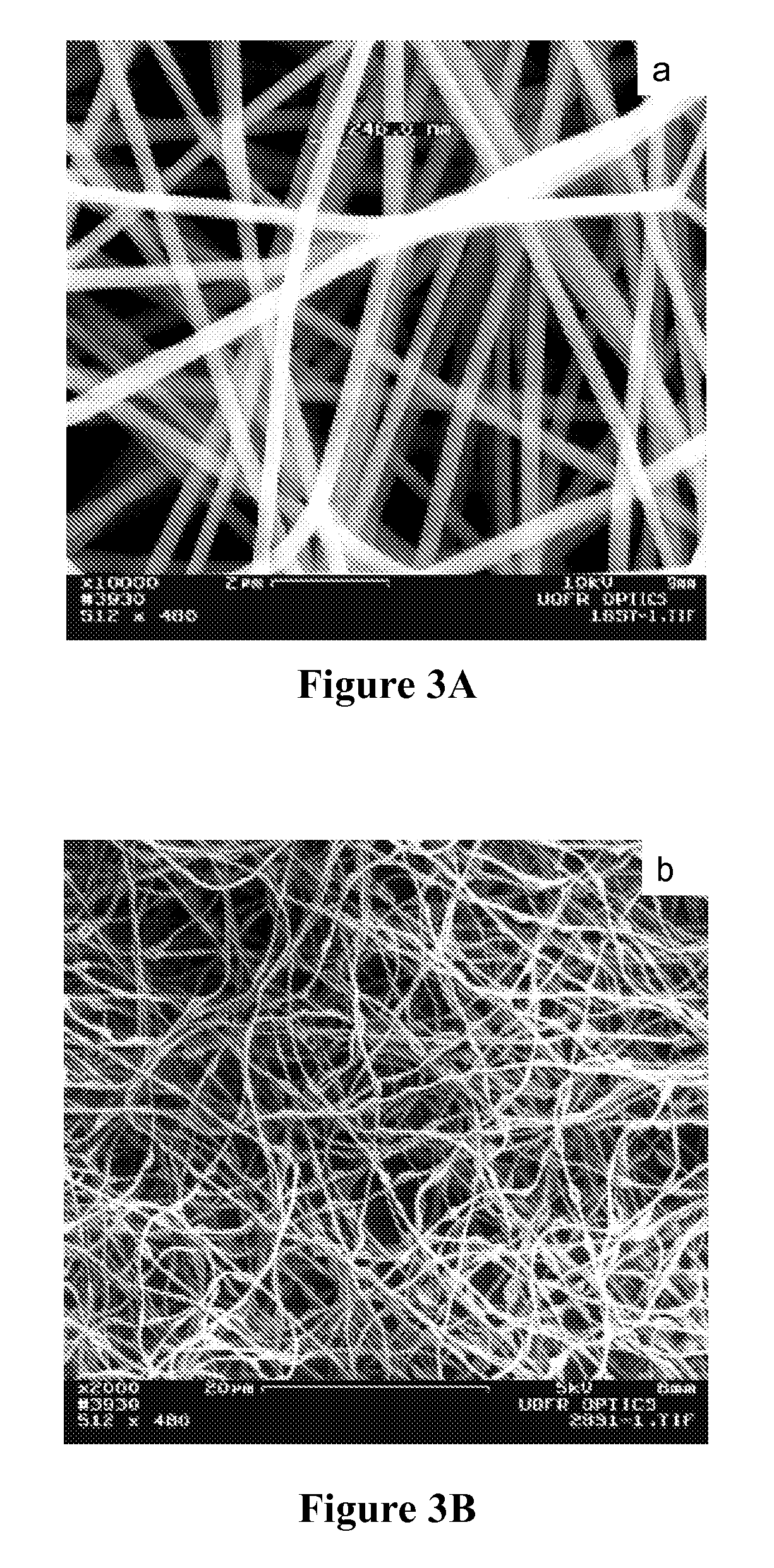

Long metallic nanowires, methods of making, and use thereof in proton exchange membrane fuel cell

InactiveUS20080305377A1High surface areaHigh durabilityMaterial nanotechnologyCell electrodesFiber structureNanofiber

A method and apparatus for making a metallic nanofiber structure are disclosed. The method includes the steps of: providing a first solution including a first material and a second material, wherein the second material includes at least one metal; forming the first solution into composite fibers including the first material and the second material; and removing the first material from the composite fibers under conditions effective to produce a metallic nanofiber structure that includes a plurality of metallic nanofibers. Also disclosed are metallic nanofiber structures prepared according to a process of the present invention, which can be used as fuel cell catalysts. Fuel cells containing electrodes that include these metallic nanofiber structures are also disclosed.

Owner:UNIVERSITY OF ROCHESTER

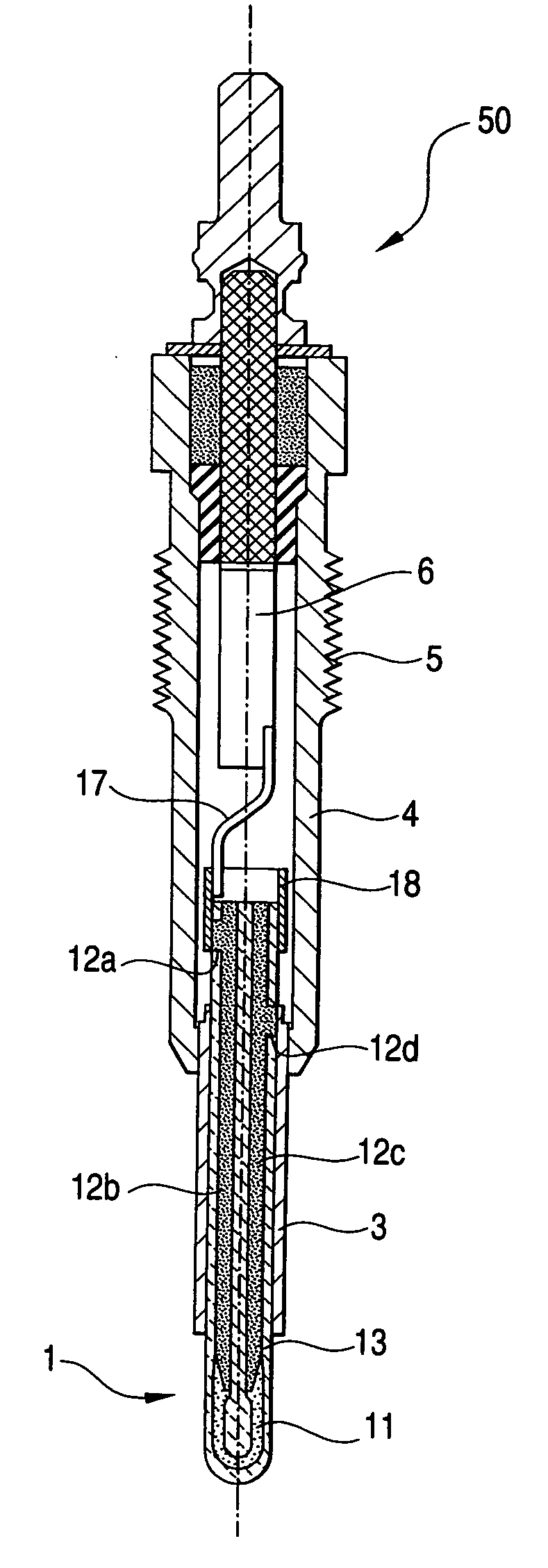

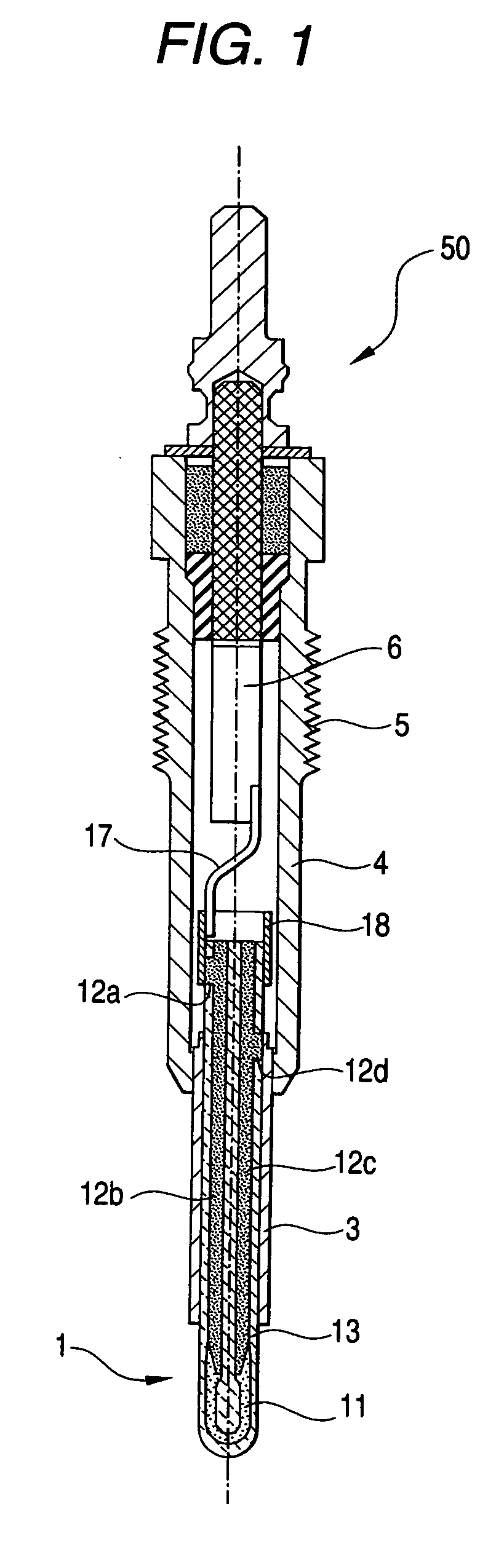

Ceramic heater, glow plug, and ceramic heater manufacturing method

ActiveUS20060011602A1High durabilityIncreased durabilityIncandescent ignitionMachines/enginesCeramic heaterMetallurgy

Owner:NGK SPARK PLUG CO LTD

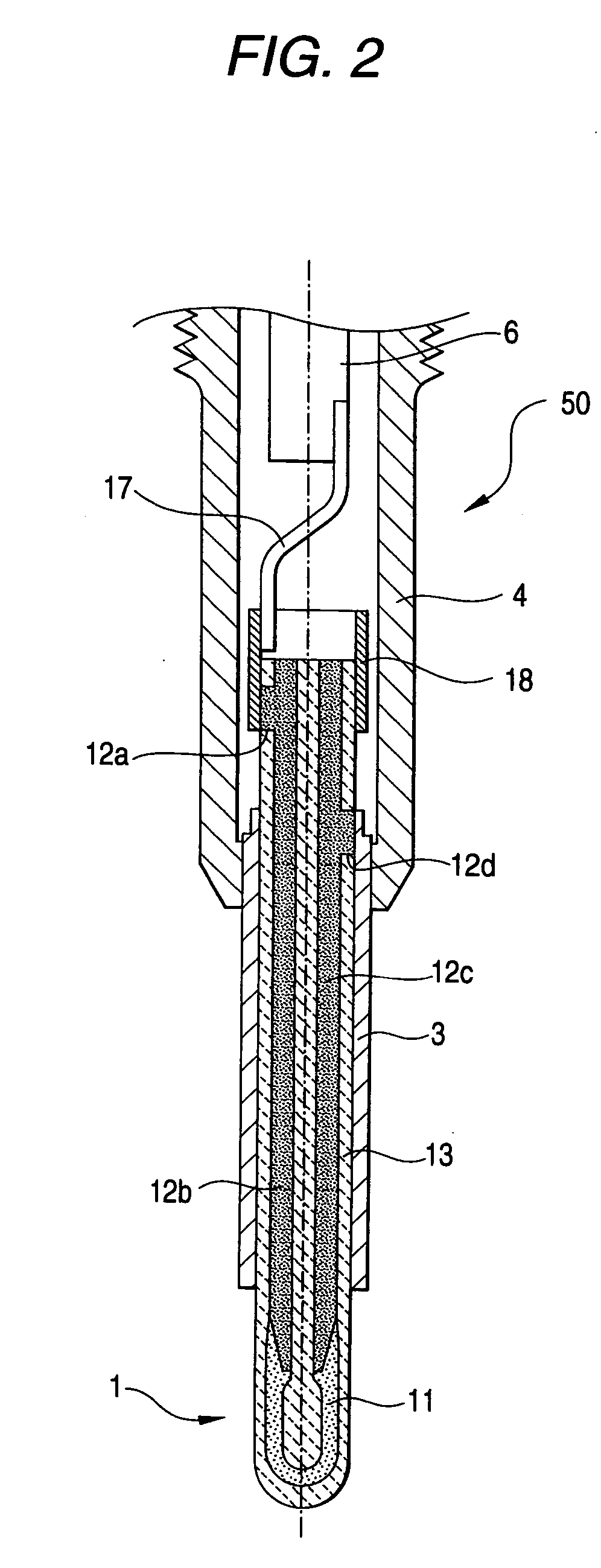

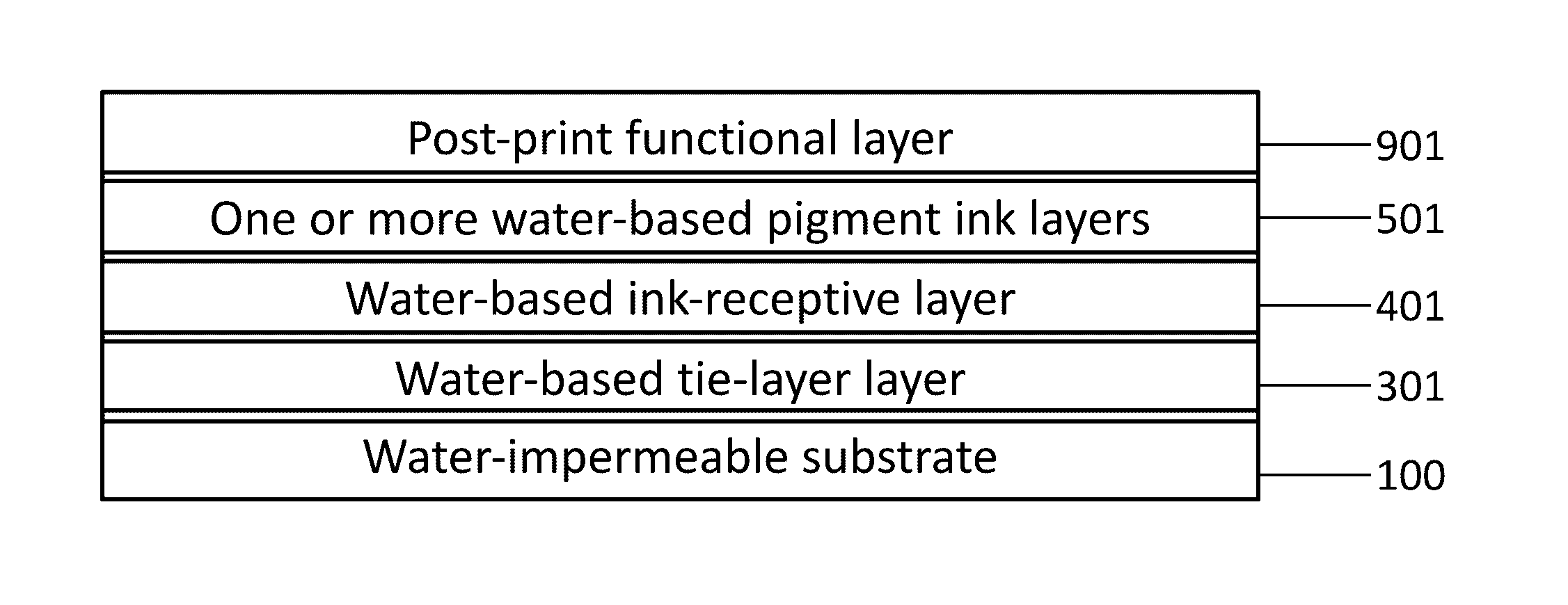

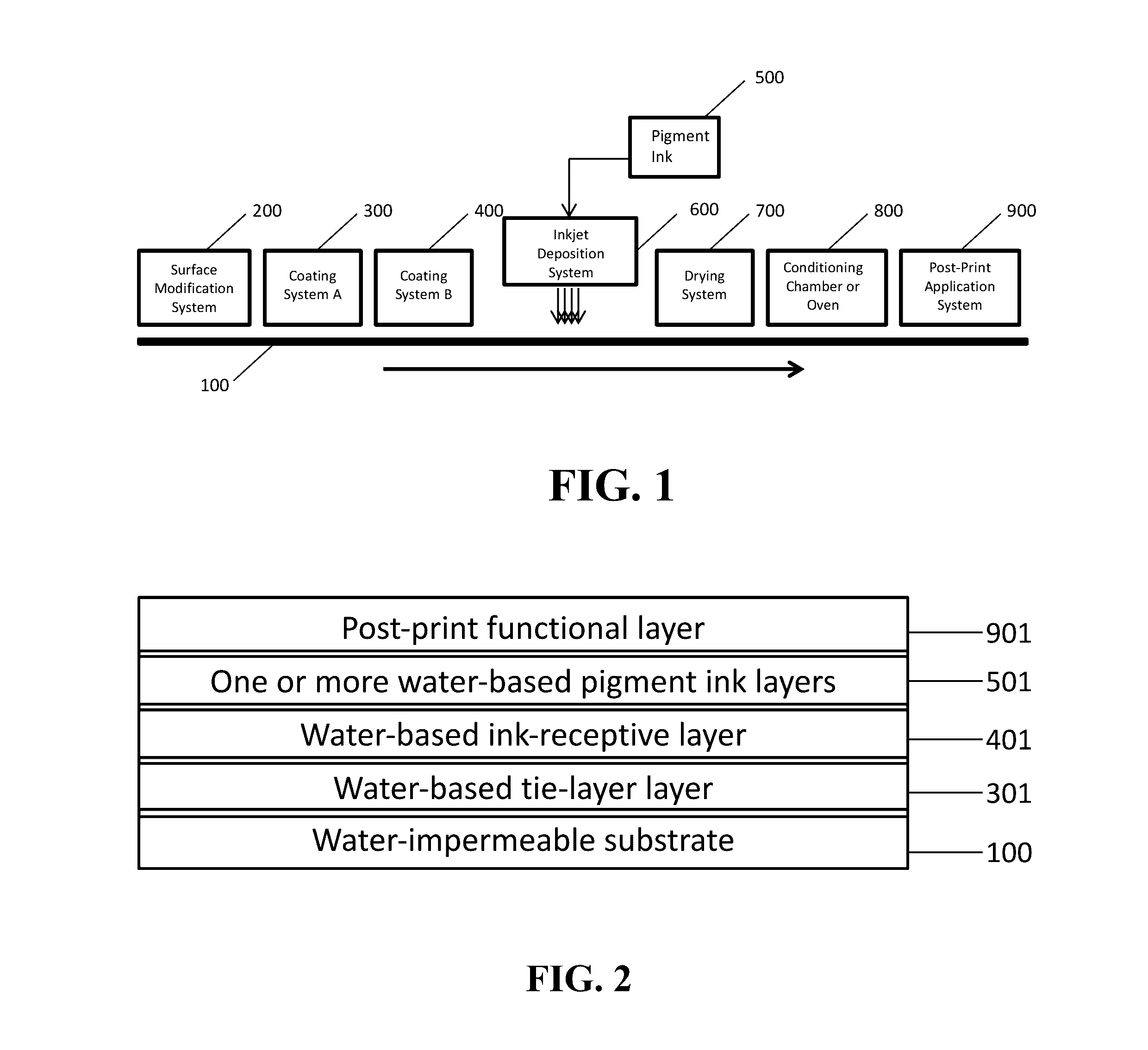

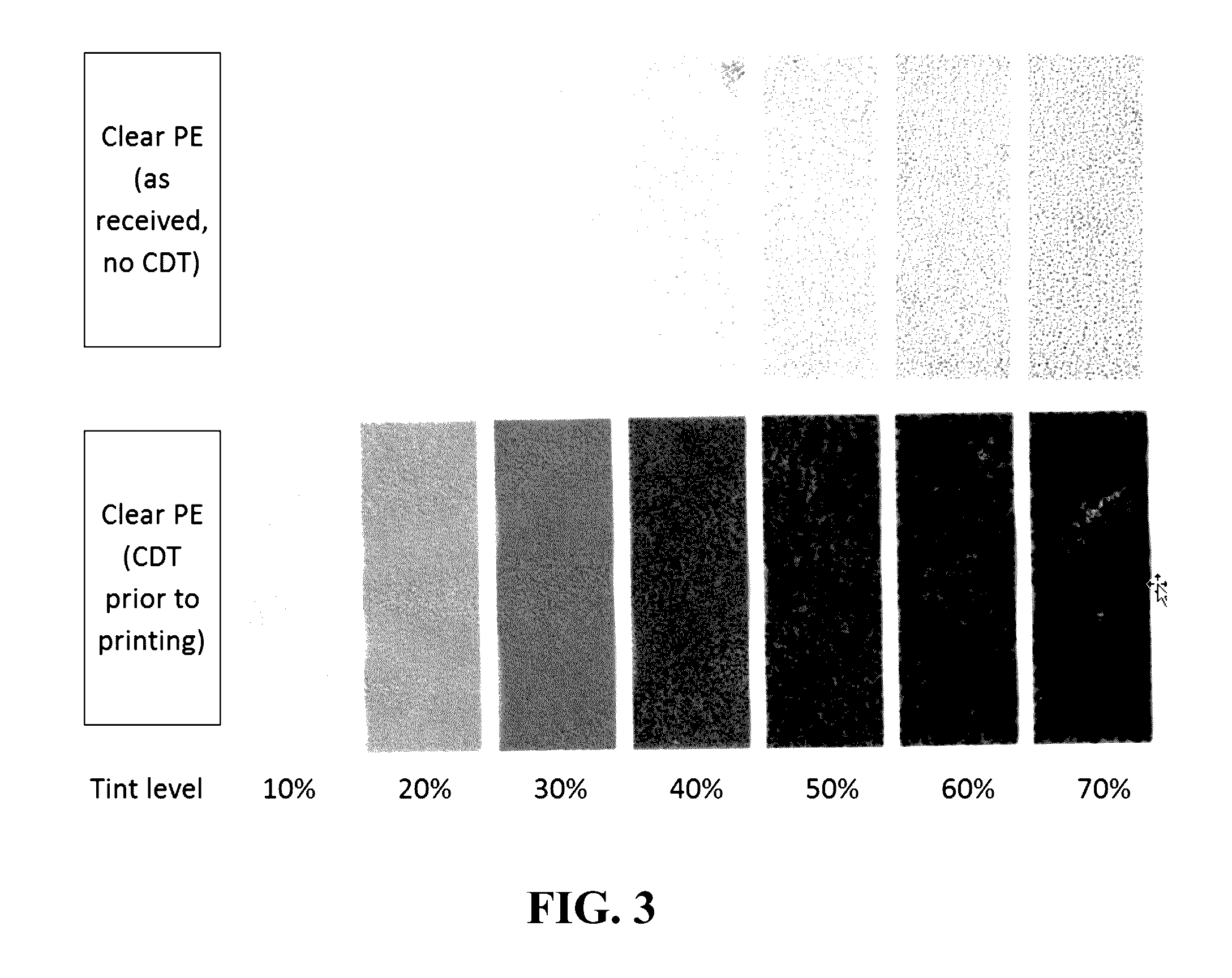

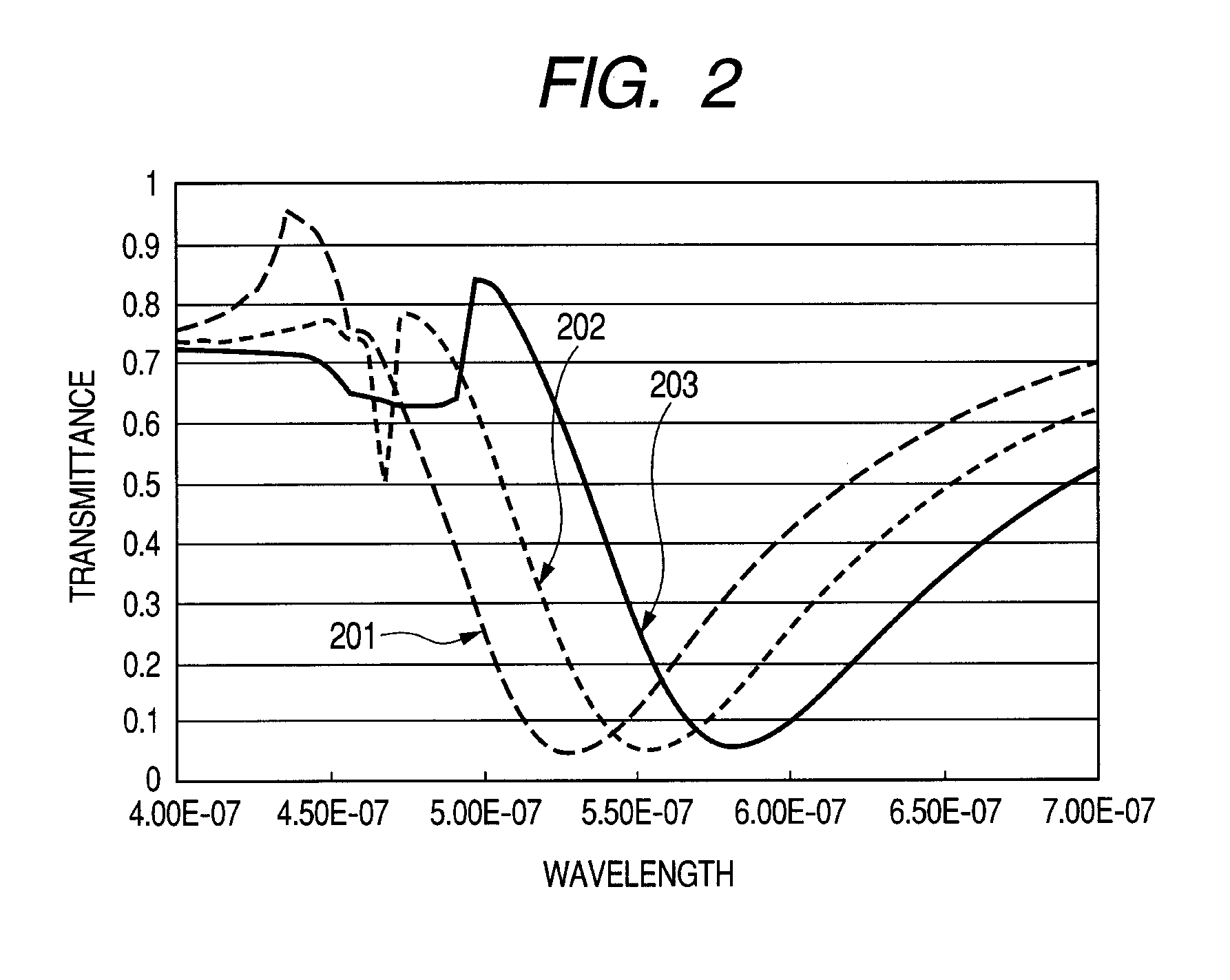

Multilayered structure with water-impermeable substrate

ActiveUS20170028688A1High print qualityHigh durabilityDuplicating/marking methodsPolyureas/polyurethane adhesivesLayered structureWater dispersible

In accordance with the present invention, there is provided a multi-layered structure includes:a) a water-impermeable substrate;b) a first layer on at least one surface of the substrate comprising a water-based tie-layer composition;c) a second layer formed over the first layer, wherein the second layer is a water-based ink-receptive composition includes:i) a multivalent metal salt; andii) a hydrophilic binder polymer;d) a third layer including at least one water-based ink composition deposited in a single pass by an inkjet printing process, wherein the water-based ink composition includes an anionically stabilized, water-dispersible pigment; ande) additional layers deposited over the one or more ink layers and exposed second layer, the additional layers selected from one or more of the following compositions:i) an opaque white layer;ii) a protective layer; andiii) an adhesive layer, further includes a continuous protective plastic or paper layer adhered thereto.

Owner:EASTMAN KODAK CO

Carbazole derivative and organic light emitting device using the same

InactiveUS20080131731A1High efficiencyHigh durabilityOrganic chemistryDischarge tube luminescnet screensHigh luminanceOrganic compound

Provided is an organic light emitting device including: a pair of electrodes including an anode and a cathode; and at least one layer formed of an organic compound interposed between the pair of electrodes, in which the at least one layer formed of the organic compound layer contains at least one kind of the carbazole derivative represented by the following general formula (I). The organic light emitting device has an optical output with extremely high efficiency and a high luminance and has an extremely high durability.

Owner:CANON KK

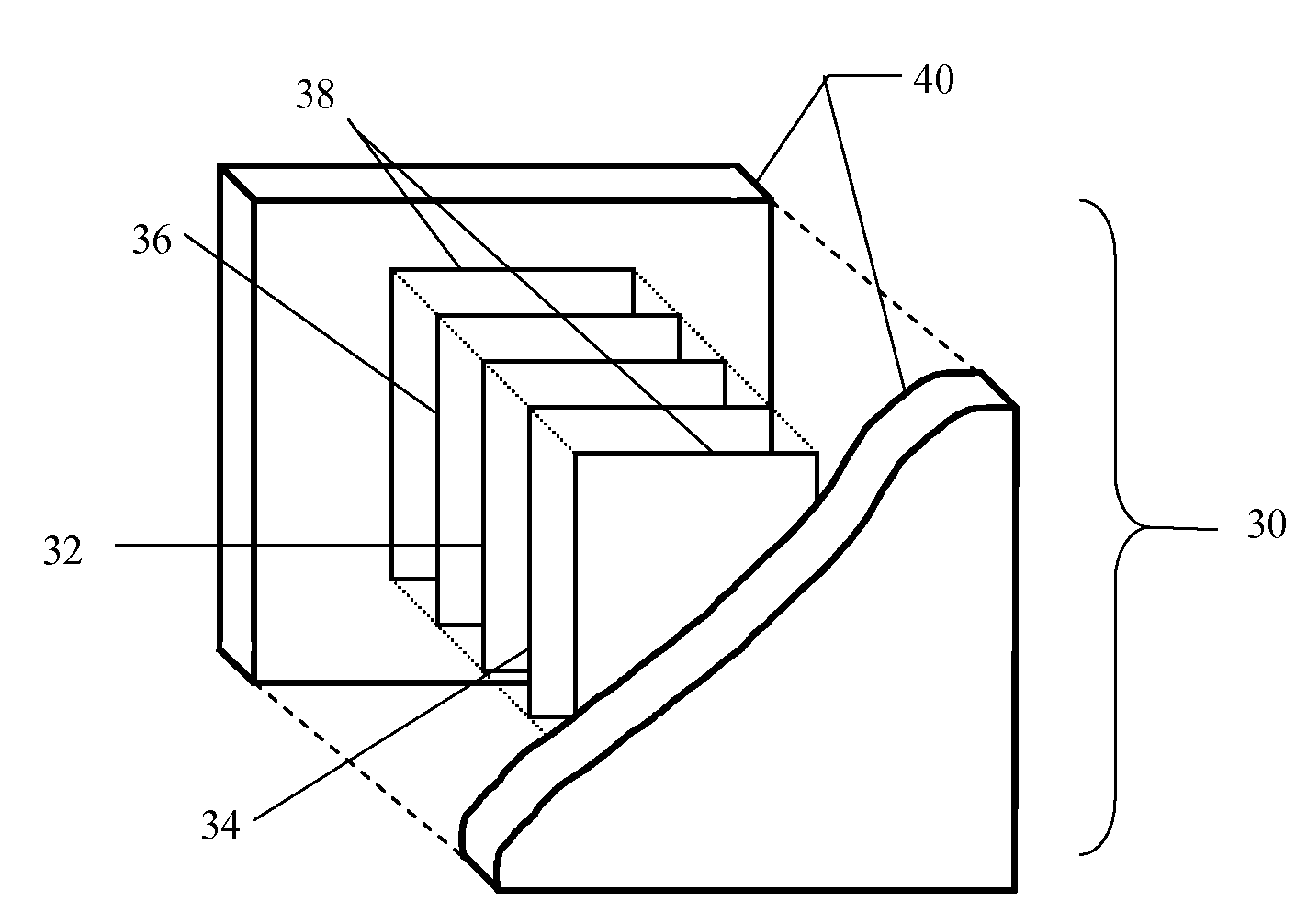

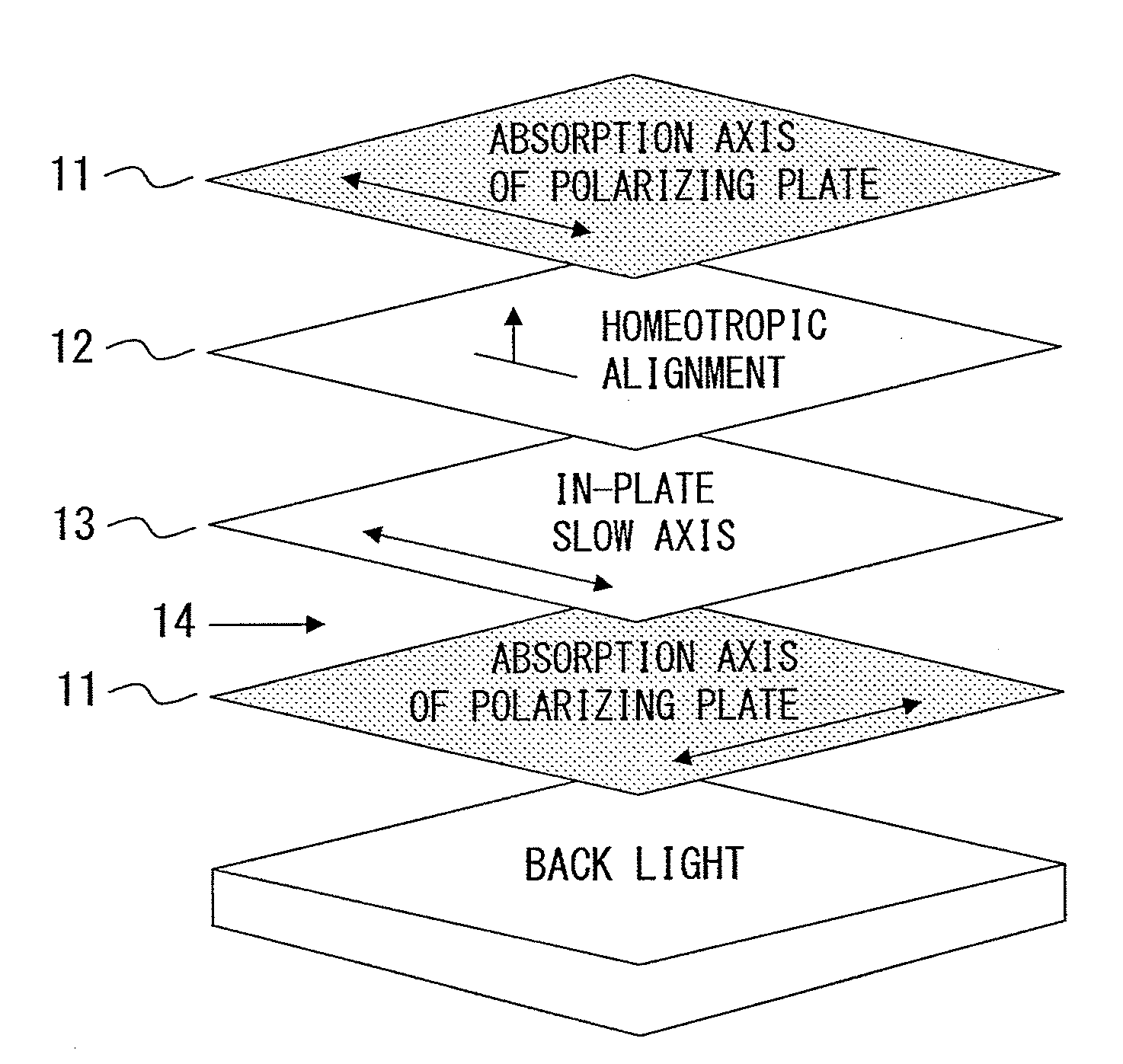

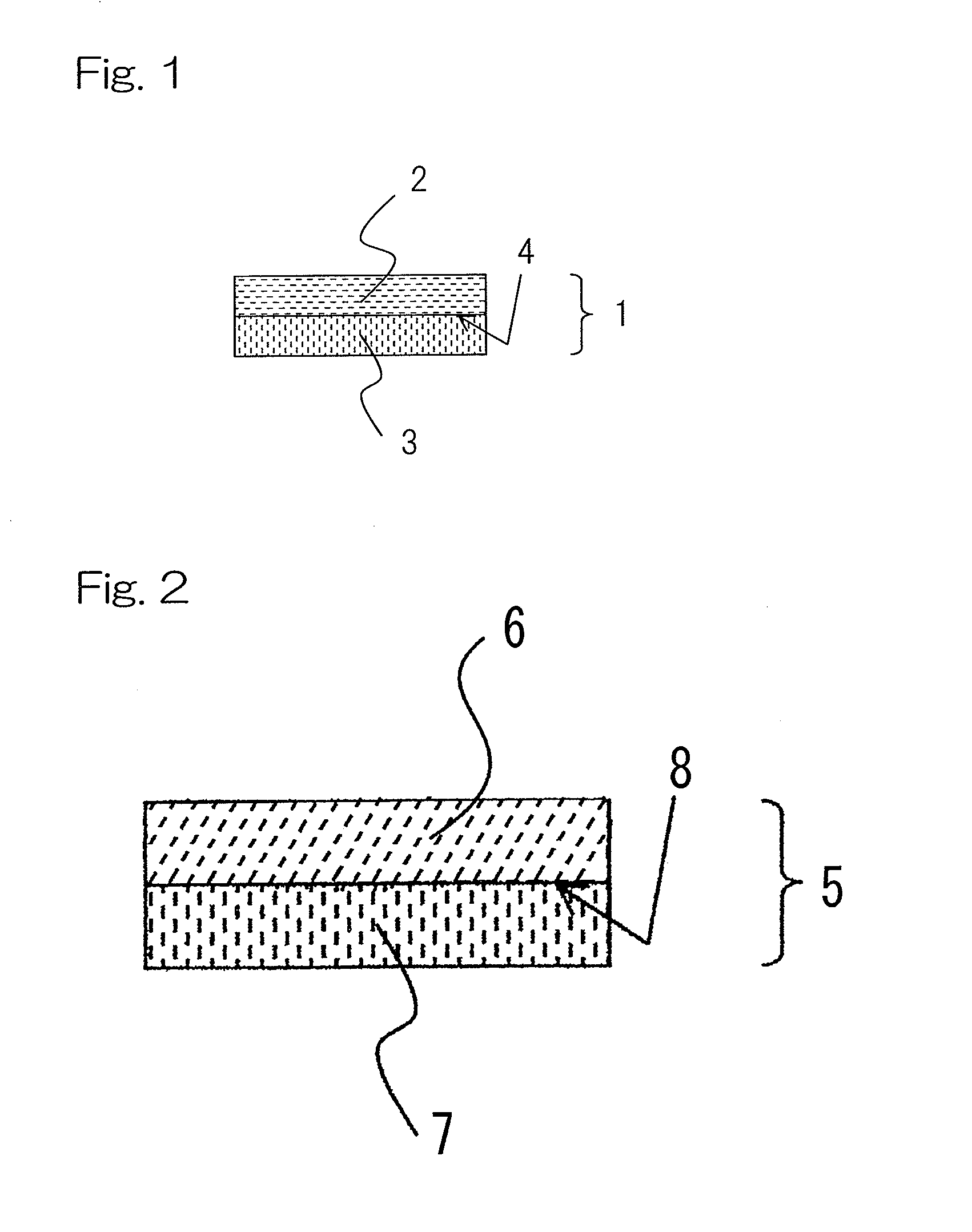

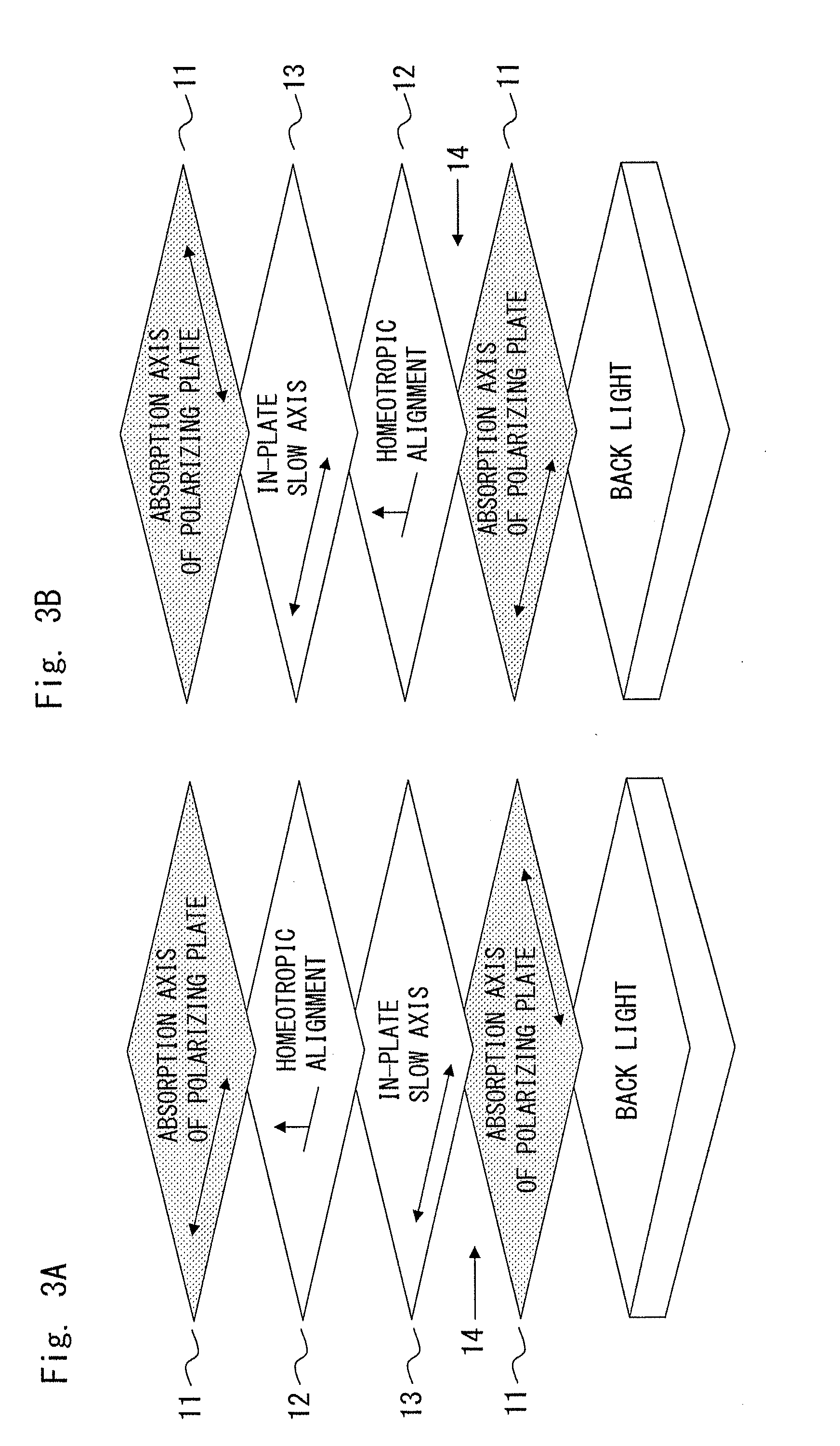

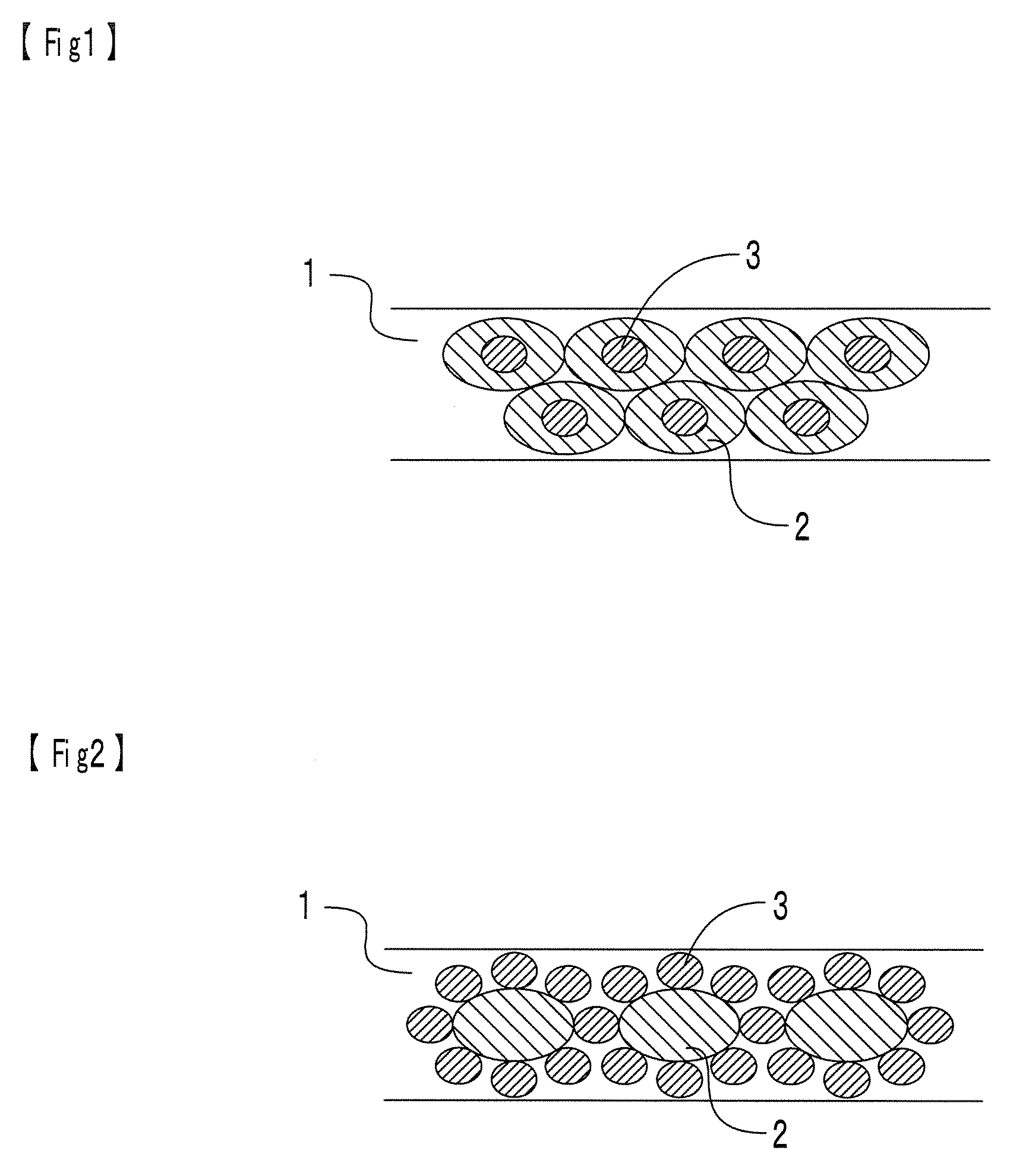

Optical film laminate, method for producing the same, and liquid crystal display panel using the same

InactiveUS20120314159A1High durabilityThinner optical compensationPretreated surfacesPolarising elementsLiquid-crystal displayLiquid crystal

Provided is an optical film laminate with a thinner thickness having an optical compensation function. According to the present invention is provided an optical film laminate comprising (i) a positive C plate comprising a liquid crystal material having a photosensitive group and (ii) a positive A plate, an optically biaxial plate, or an O plate, these plate comprising a liquid crystal material having a photosensitive group; wherein the both plates are directly bonded with each other to be firmly laminated without adhesive.

Owner:HAYASHI TELEMPU CO LTD

Sheet for solar cell encapsulant and solar cell module

ActiveUS20120048354A1High stabilityHigh durabilityOther chemical processesPV power plantsGLYCIDYL ACRYLATEMeth-

A sheet for solar cell encapsulant including (A) an ethylene copolymer selected from 1a to 5a; and (B) an ethylene copolymer selected from 1b to 3b, the copolymer (A) having a melting point of 90° C. or higher and containing constituent unit derived from ethylene [1a: ethylene-vinyl acetate (VA) copolymer, 2a: ethylene-acrylate copolymer, 3a: high-pressure method low-density polyethylene, 4a: ethylene-α-olefin copolymer, 5a: ethylene-G(M)A copolymer other than the below-described 1b, 1b: ethylene-G(M)A copolymer, 2b: ethylene-VA-G(M)A copolymer, 3b: ethylene-acrylate-G(M)A copolymer]. In the ethylene copolymer (B), the total ratio of the constituent unit derived from glycidyl(meth)acrylate (G(M)A) is preferably from 2% to 30% by mass. As a result of this, crosslinking treatment is substantially unnecessary, and practical adhesion and adhesion stability are achieved without heat treatment for crosslinking.

Owner:MITSUI LTD

Spring with high durability and method of coating the same

InactiveUS20070172665A1High durabilityIncreased durabilitySpringsSynthetic resin layered productsChemistryPowder coating

A spring with high durability has a coating film composed of an epoxy resin powder coating containing softening agent which contains an epoxy resin and a softening agent comprising a thermoplastic resin for improving impact resistance of the coating film. A method of coating a spring with high durability comprises a coating step of making an epoxy resin powder coating containing softening agent which contains an epoxy resin and a softening agent comprising a thermoplastic resin for improving impact resistance of a coating film adhere to a surface on which the coating film is formed, and a baking step of baking the epoxy resin powder coating containing softening agent adhered to the surface.

Owner:CHUO SPRING +1

Contact slidable structure with a high durability

ActiveUS6866517B2High electrical conductivityHigh durabilityElectrical controlNon-rotary current collectorMaterials scienceElectrode

A contact slidable structure is formed between a resilient terminal and a terminal electrode. The terminal electrodes and are disposed on the ceramic element. The resilient terminals and are resiliently deformed and forced to press the terminal electrodes and. The ceramic element has the ceramic body, inner leads and formed inside the ceramic body, terminal electrodes and disposed on the outer surfaces and, and conductive through holes and electrically connecting the inner leads and with the terminal electrodes and, respectively. In the ceramic element, the resilient terminals and are placed slidably on the outer surfaces and of the terminal electrodes and to form the contact slidable structure, and the conductive through holes and are not formed within the contact slidable areas and to the terminal electrodes and, respectively.

Owner:DENSO CORP

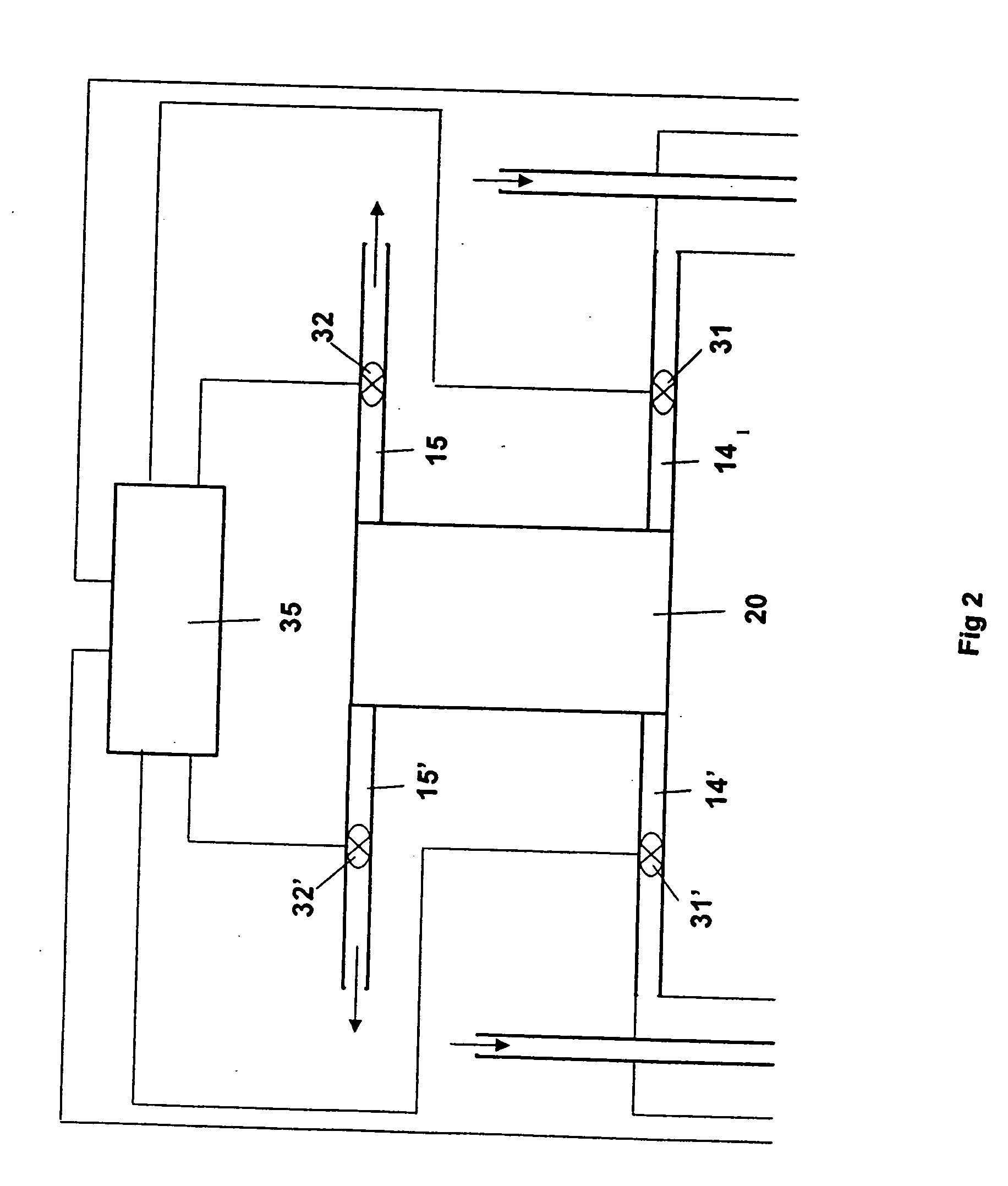

Method and apparatus for operating a fuel cell

InactiveUS20050221134A1High durabilityLong lifeSolid electrolytesFuel cell auxillariesOperating temperatureRelative humidity

A method of operating a fuel cell at an operating temperature below about 150 degrees Celsius, wherein the fuel cell has an anode and a cathode with an electrolyte interposed therebetween, the cathode having at least one surface in contact with a cathode chamber having a gas inlet and a gas outlet, and the anode in contact with an anode chamber having a gas inlet and a gas outlet, and the electrolyte containing less than about 500 ppm of a catalyst capable of enhancing the formation of radicals from hydrogen peroxide. The method includes the steps of applying a fuel to the anode chamber; applying an oxidant to the cathode chamber; and controlling the amount of water supplied to the anode chamber and the cathode chamber such that water vapor pressure is sub-saturated at the operating temperature at the gas outlet of the cathode chamber. Also disclosed is an apparatus comprising sensors to measure outlet relative humidity of the gas outlets of a fuel cell and a means to control the relative humidity on the gas inlets of a fuel cell, such that the apparatus can control the relative humidity of the gas inlets to maintain an average relative humidity in the fuel cell of less than 100%.

Owner:WL GORE & ASSOC INC

Welding rod for welding of martensite heat-resistant steel

ActiveCN106346167AImprove mechanical propertiesHigh strengthWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a welding rod for welding of martensite heat-resistant steel and belongs to the technical field of welding materials. The welding rod consists of a core wire and a coating, wherein the core wire is prepared from components in percentage by weight as follows: 0.07%-0.10% of C, less than or equal to 0.3% of Si, 0.3%-0.7% of Mn, less than or equal to 0.004% of P, less than or equal to 0.002% of S, 8.5%-9.5% of Cr, 2.8%-3.3% of W, 2.8%-3.5% of Co, 0.04%-0.08% of Nb, 0.15%-0.25% of V, 0.8%-1.0% of Cu, 0.007%-0.011% of N, 0.011%-0.020% of B and the balance of Fe; the coating is prepared from components as follows: 30%-45% of marble, 18%-25% of fluorite, 5%-10% of rutile, 10%-16% of barium carbonate, 5%-10% of ferrotitanium, 1.5%-3% of electrolytic manganese, 5%-10% of iron powder, 0.4%-0.8% of sodium carbonate, 0.4%-0.8% of carboxymethyl cellulose and 0.8%-3% of chromium metal powder. The welding rod has the advantages that the arc is stable during welding, few splashes are caused, the all-position operability is good, the slag detachability is good, formed welds are attractive in appearance, and deposited metal after welding has high strength and high toughness close to that of a parent metal, higher endurance strength and excellent crack sensitivity.

Owner:CENT IRON & STEEL RES INST

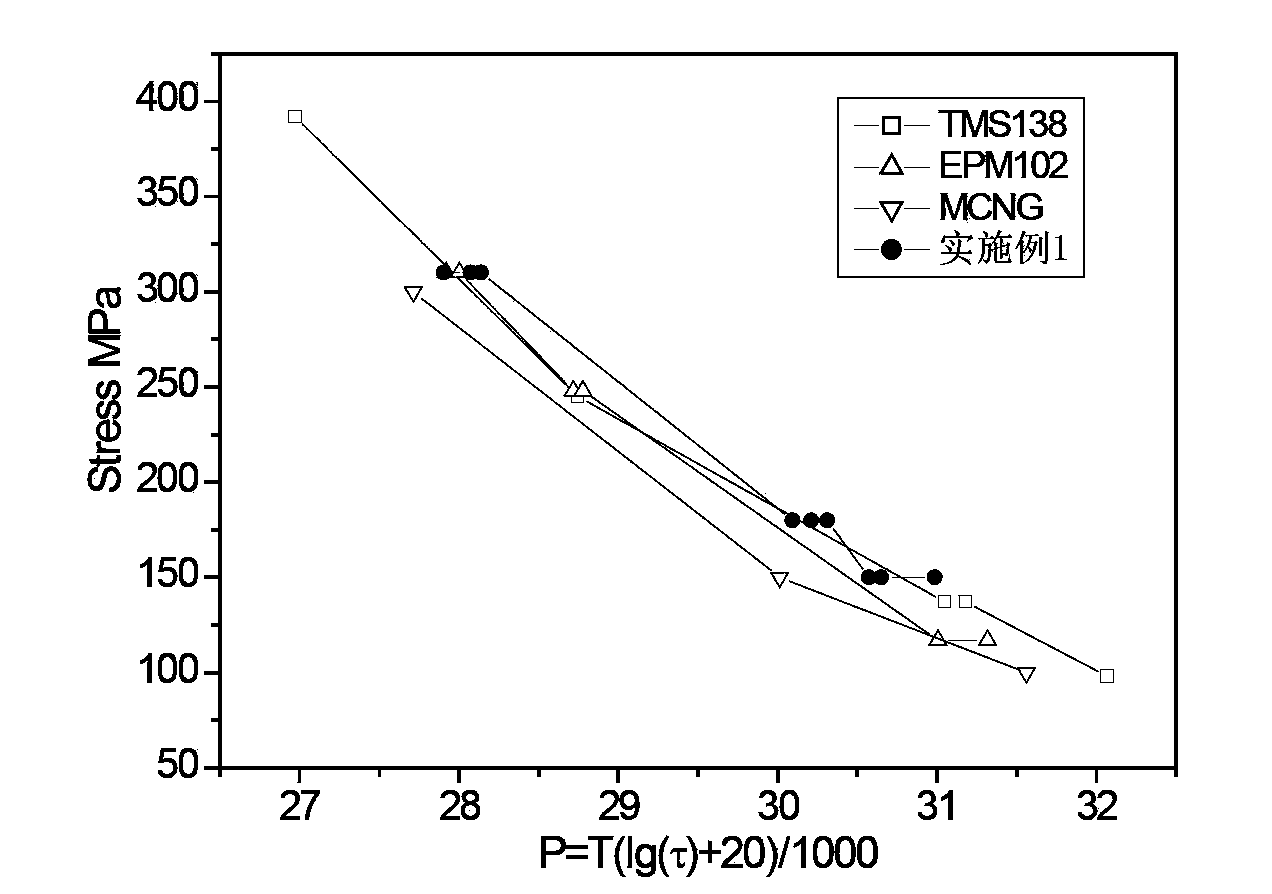

Fourth-generation single-crystal high temperature alloy with high strength and stable structure and preparation method thereof

InactiveCN103382536AHigh durabilityImprove organizational stabilityPolycrystalline material growthAfter-treatment detailsChemical compositionSingle crystal

The invention relates to the field of high-strength single-crystal high temperature alloys and especially provides a fourth-generation single-crystal high temperature alloy with high strength and a stable structure and a preparation method thereof. The alloy is mainly applicable to aero-engine blade materials used at a temperature higher than 1100 DEG C. Chemical components of the alloy comprise, by weight, 3 to 5% of Cr, 5 to 12% of Co, 6 to 8% of W, 0.1 to 2% of Mo, 4.5 to 6% of Re, 2 to 4% of Ru, 5.5 to 6.5% of Al and 6 to 10% of Ta, with the balance being Ni. The preparation method comprises the following steps: preparing a single-crystal blade or test rod under the conditions that temperature gradient of a single crystal growth furnace is in a range of 40 K / cm to 80 K / cm, casting temperature is 1480 to 1550 DEG C, shuttering temperature is consistent with the casting temperature and a growth rate is 4 to 8 mm / min; and then carrying out solid solution homogenization treatment, high temperature aging treatment and low temperature aging treatment so as to allow the alloy provided by the invention to have high endurance strength. The alloy has a life of no less than 100 h in endurance conditions of a temperature of 1140 DEG C and a pressure of 137 MPa and has endurance strength equivalent to the endurance strength of an EPM102 alloy; and the alloy has the advantages of good structure stability at a high temperature, a wide heat treatment window and easily controllable solid solution treatment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

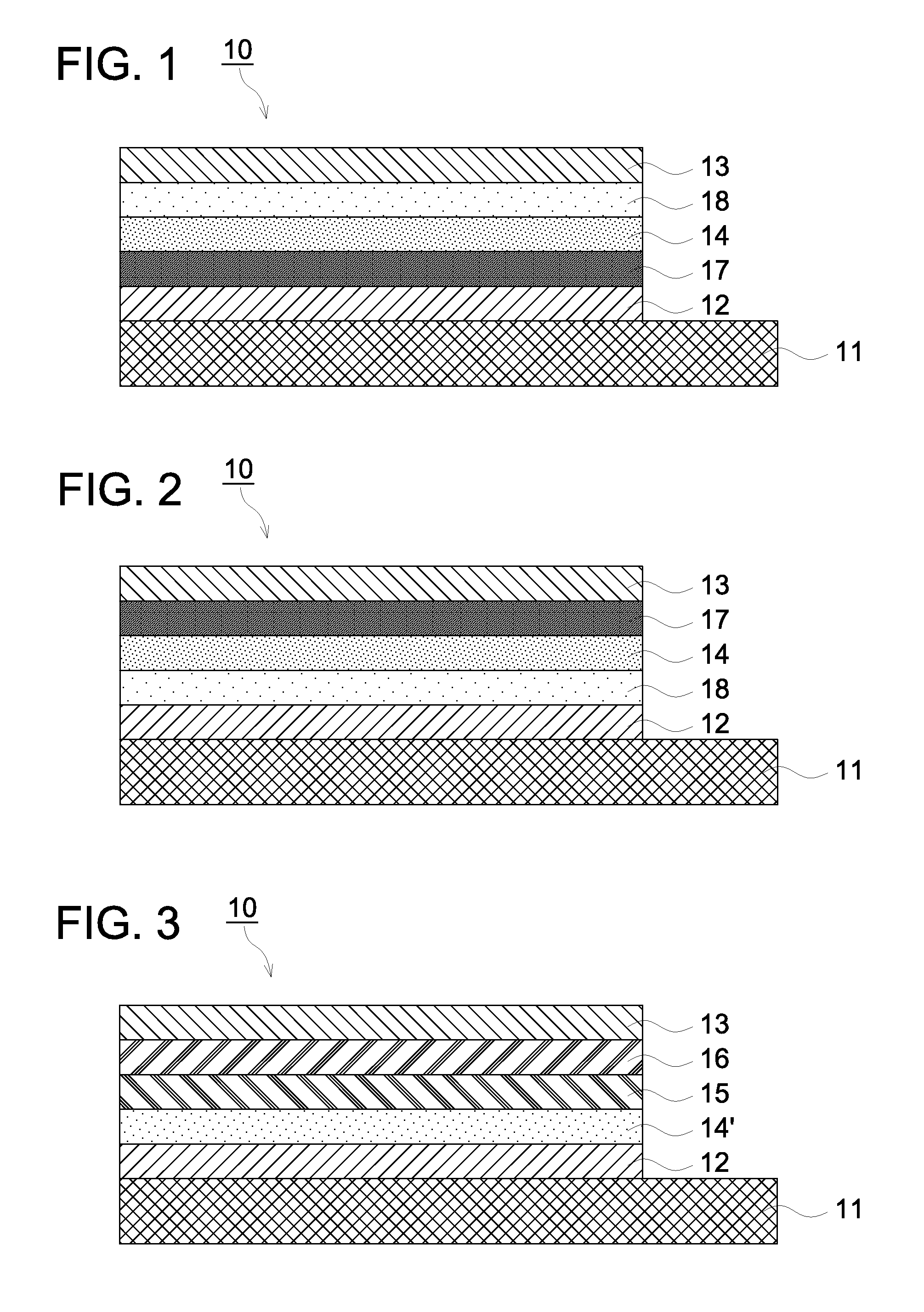

Organic photoelectric conversion element and solar cell using same

ActiveUS20130098449A1High durabilityImprove photoelectric conversion efficiencyNanoinformaticsSolid-state devicesChemistryOrganic semiconductor

Disclosed is an organic photoelectric conversion element which has a reverse layer structure wherein at least a first electrode, a photoelectric conversion layer and a second electrode are arranged on a substrate in this order. The organic photoelectric conversion element is characterized in that: the photoelectric conversion layer is a bulk heterojunction layer that is composed of a p-type organic semiconductor material and an n-type organic semiconductor material; and a compound that has a linear or branched fluorinated alkyl group having 6-20 carbon atoms is contained as the p-type organic semiconductor material.

Owner:KONICA MINOLTA INC

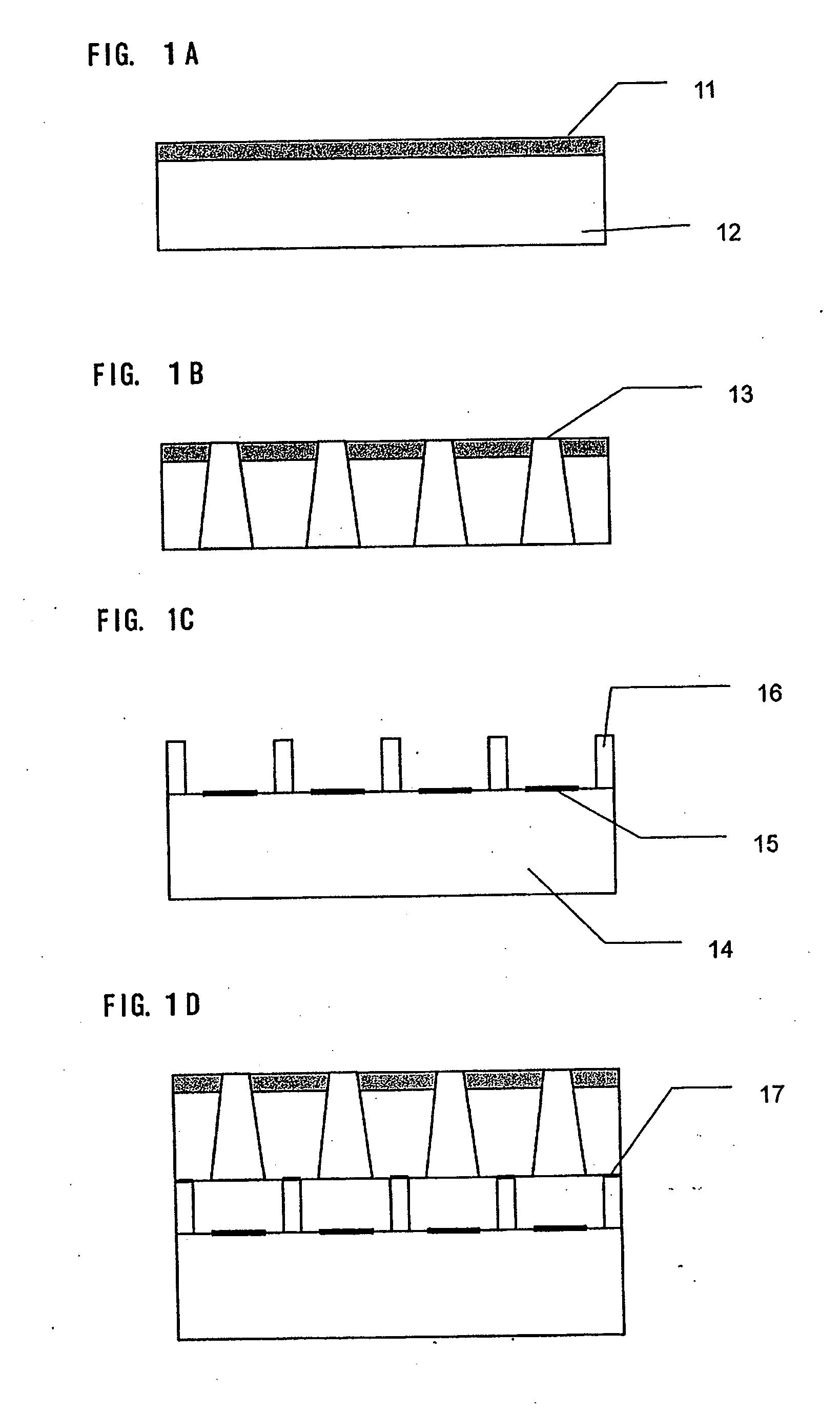

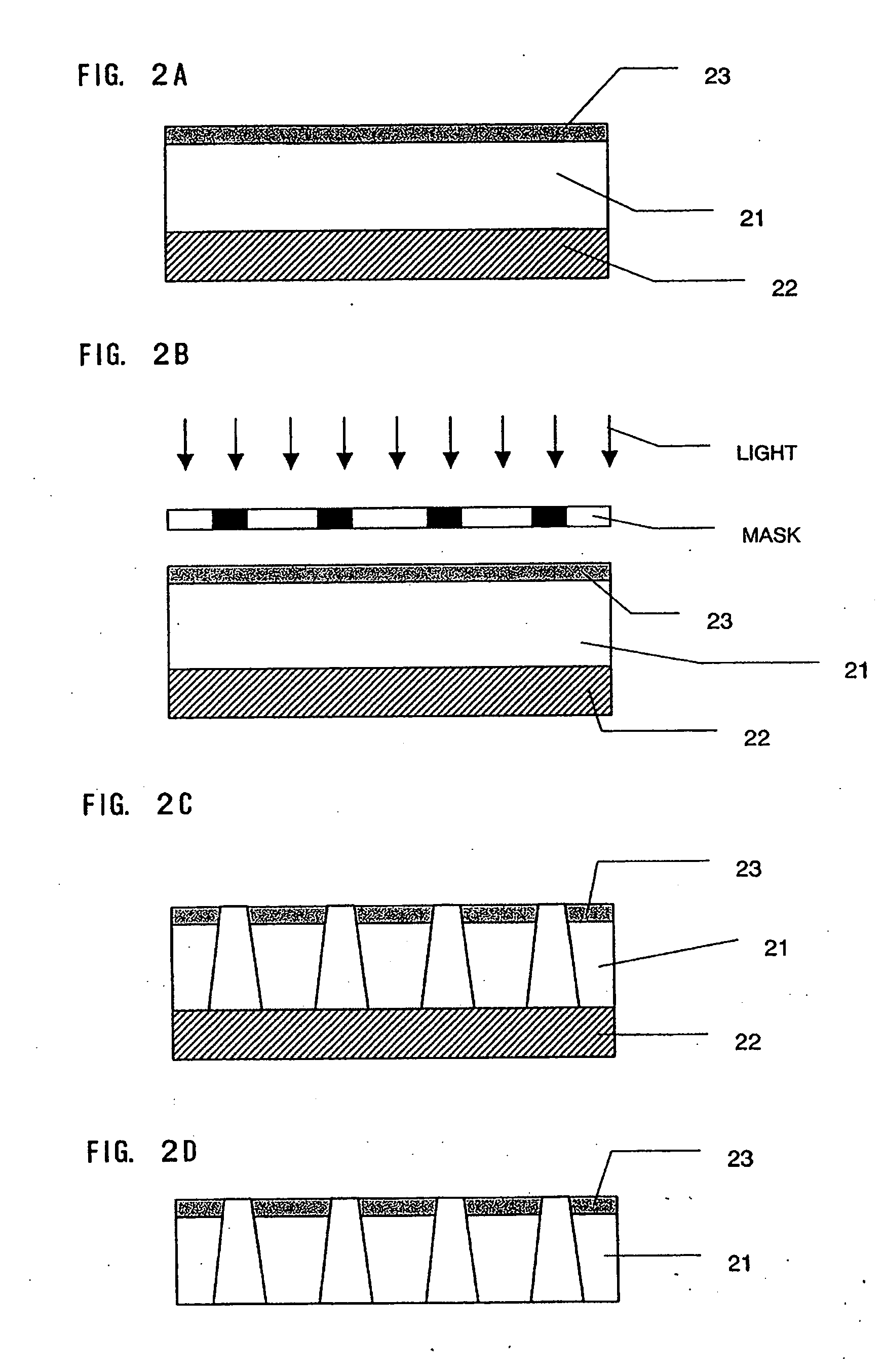

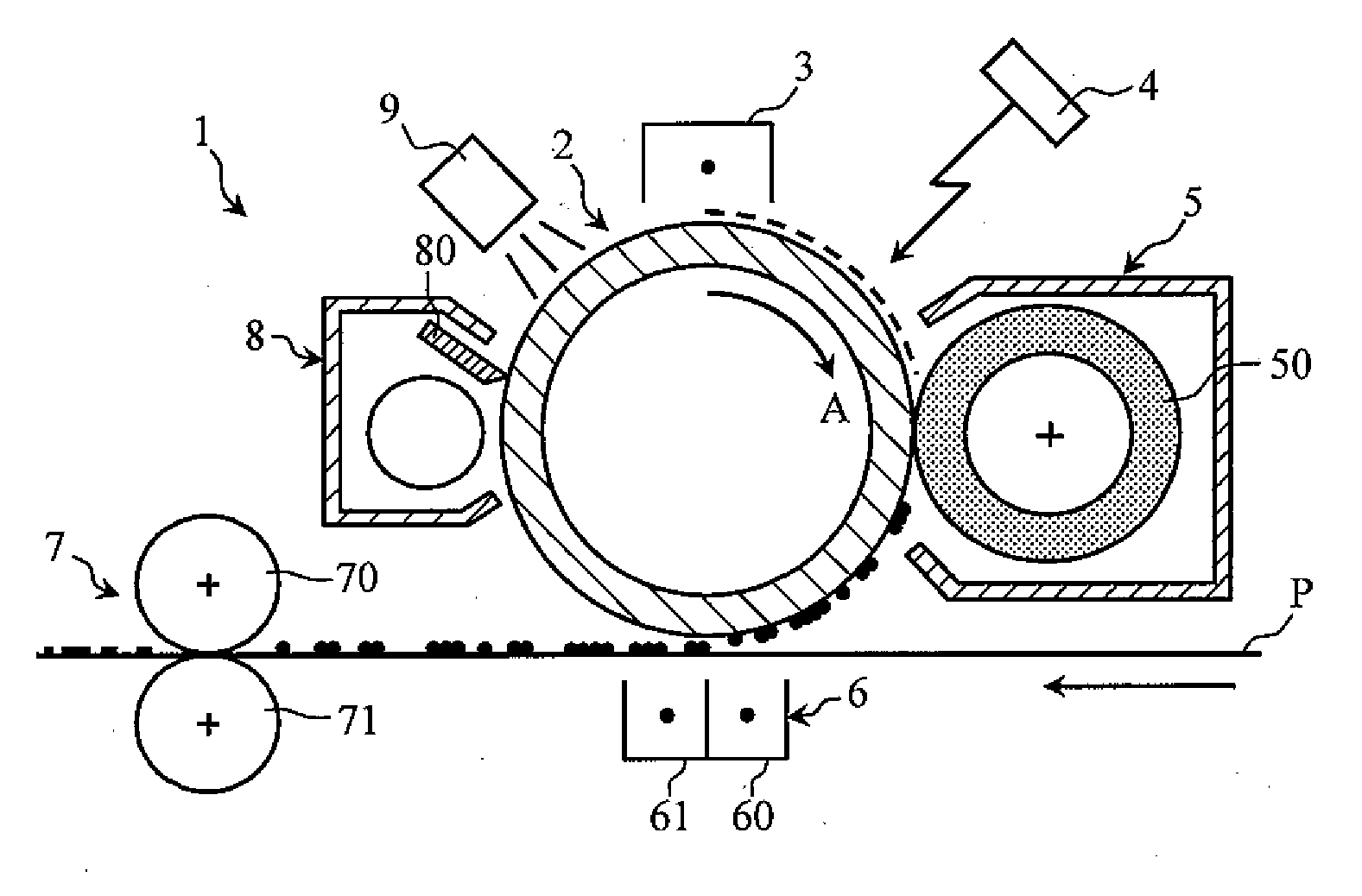

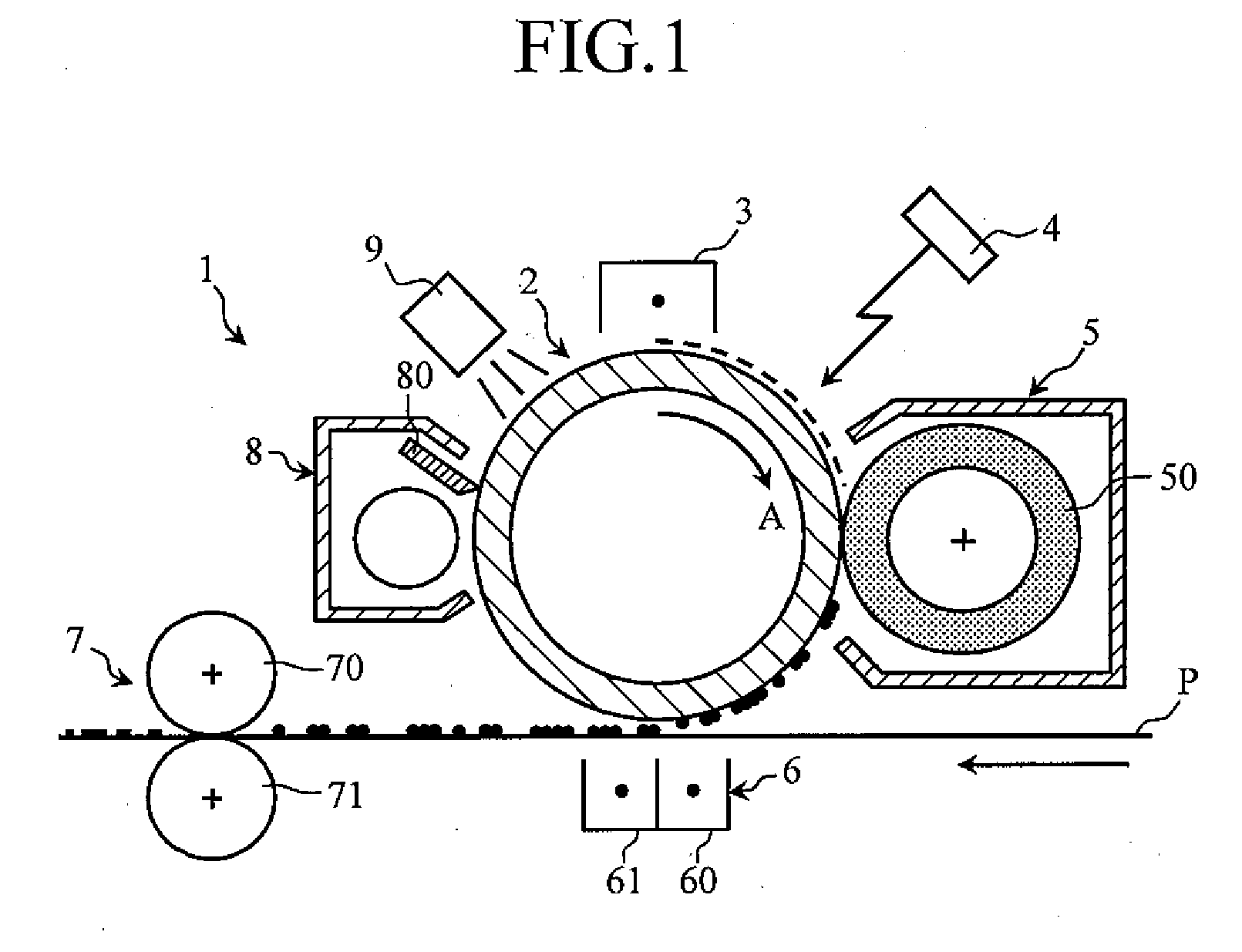

Electrophotographic Photosensitive Member and Image Forming Apparatus Provided with the Same

InactiveUS20100014888A1High durabilityHigh qualityElectrographic process apparatusCorona dischargeEngineeringSurface layer

The present invention relates to an electrophotographic photosensitive member 2 including a conductive body 20, a photoconductive layer 22 formed on the conductive body 20 using amorphous silicon, and a surface layer 23 formed on the photoconductive layer using amorphous silicon. The present invention further relates to an image forming apparatus provided with the electrophotographic photosensitive member 2. The photoconductive layer 22 has a mean roughness Ra of not more than 10 nm per 10 μm square. The surface layer 23, without undergoing grinding process, has a mean roughness Ra of not more than 10 nm per 10 μm square.

Owner:KYOCERA CORP

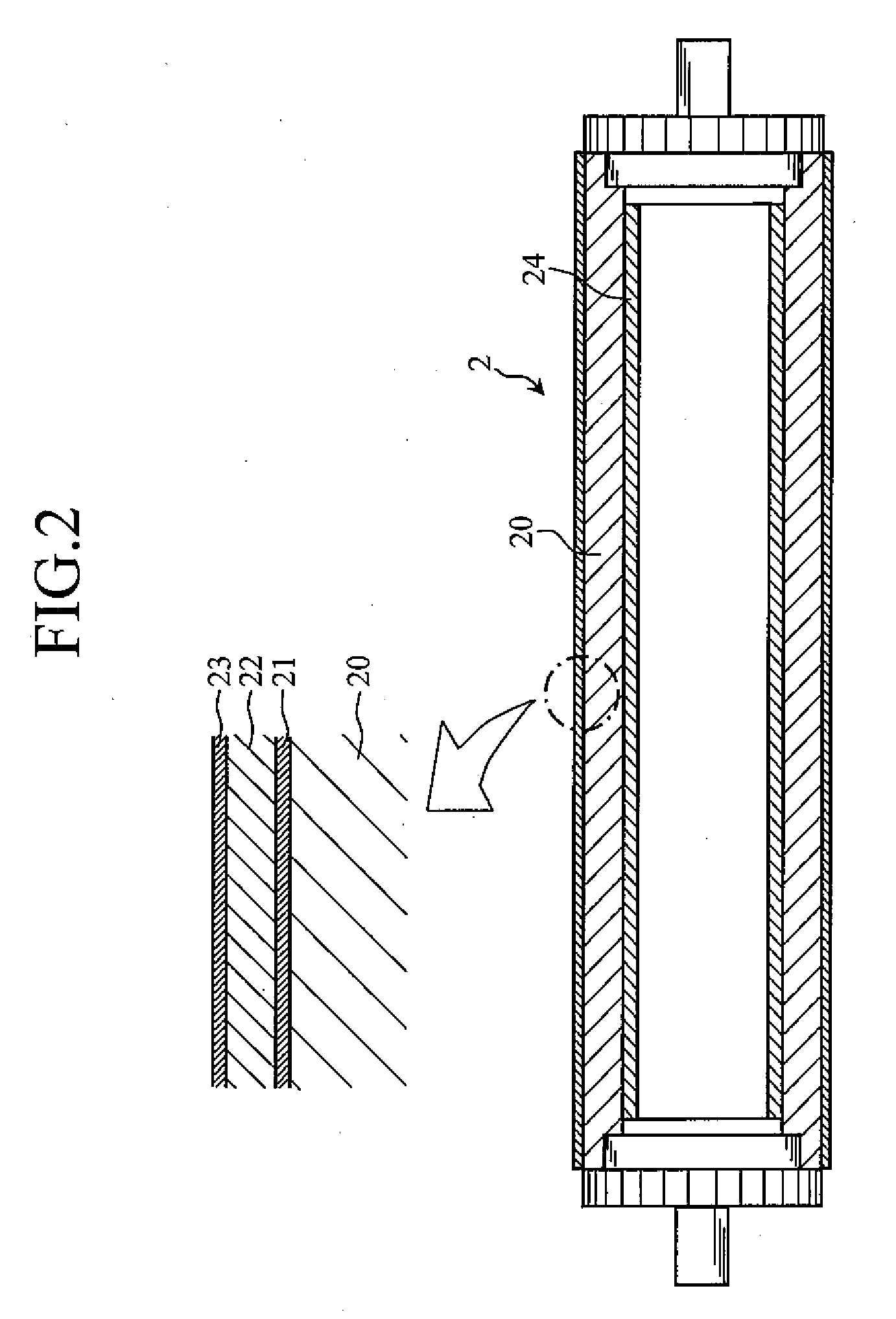

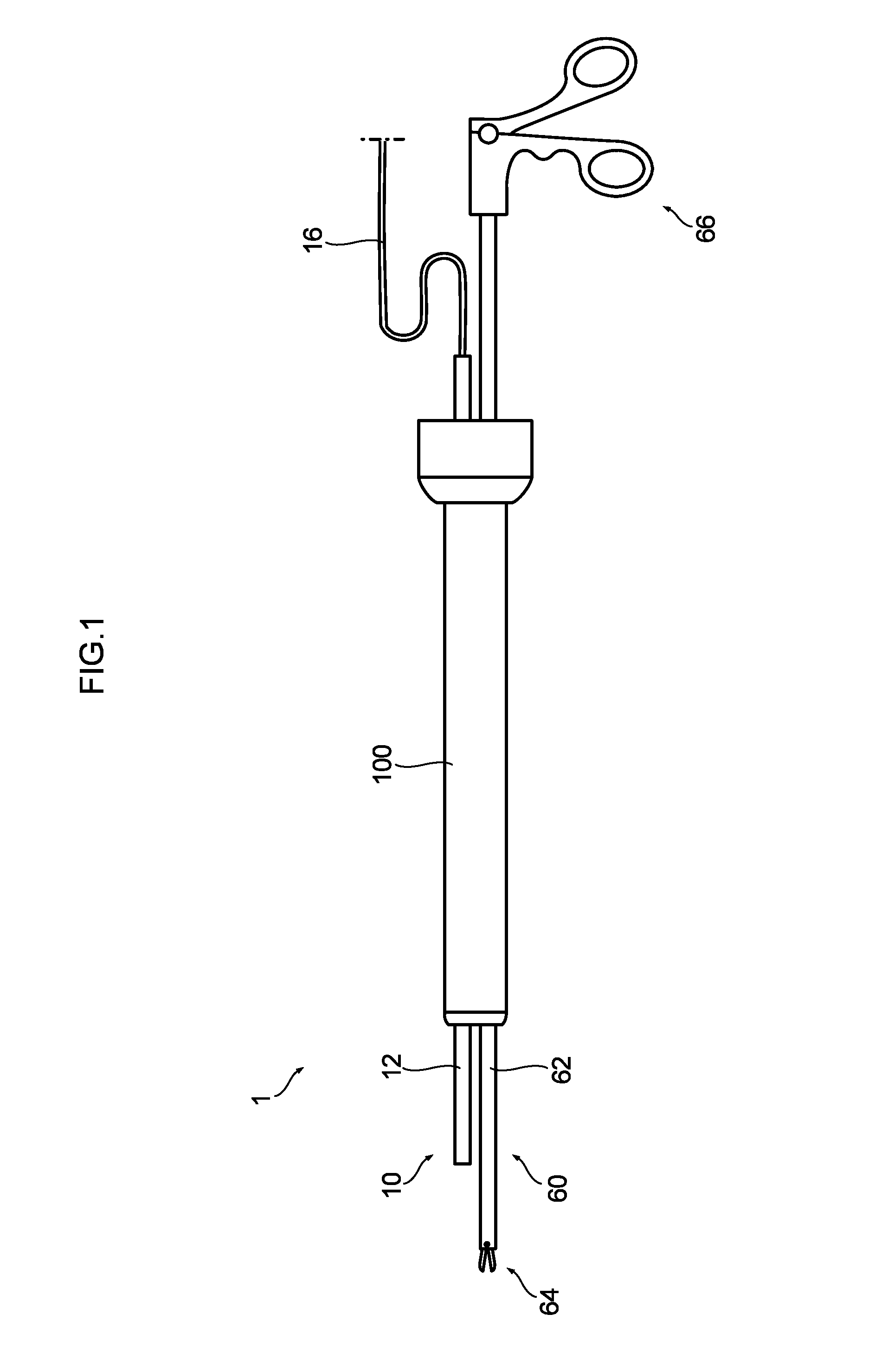

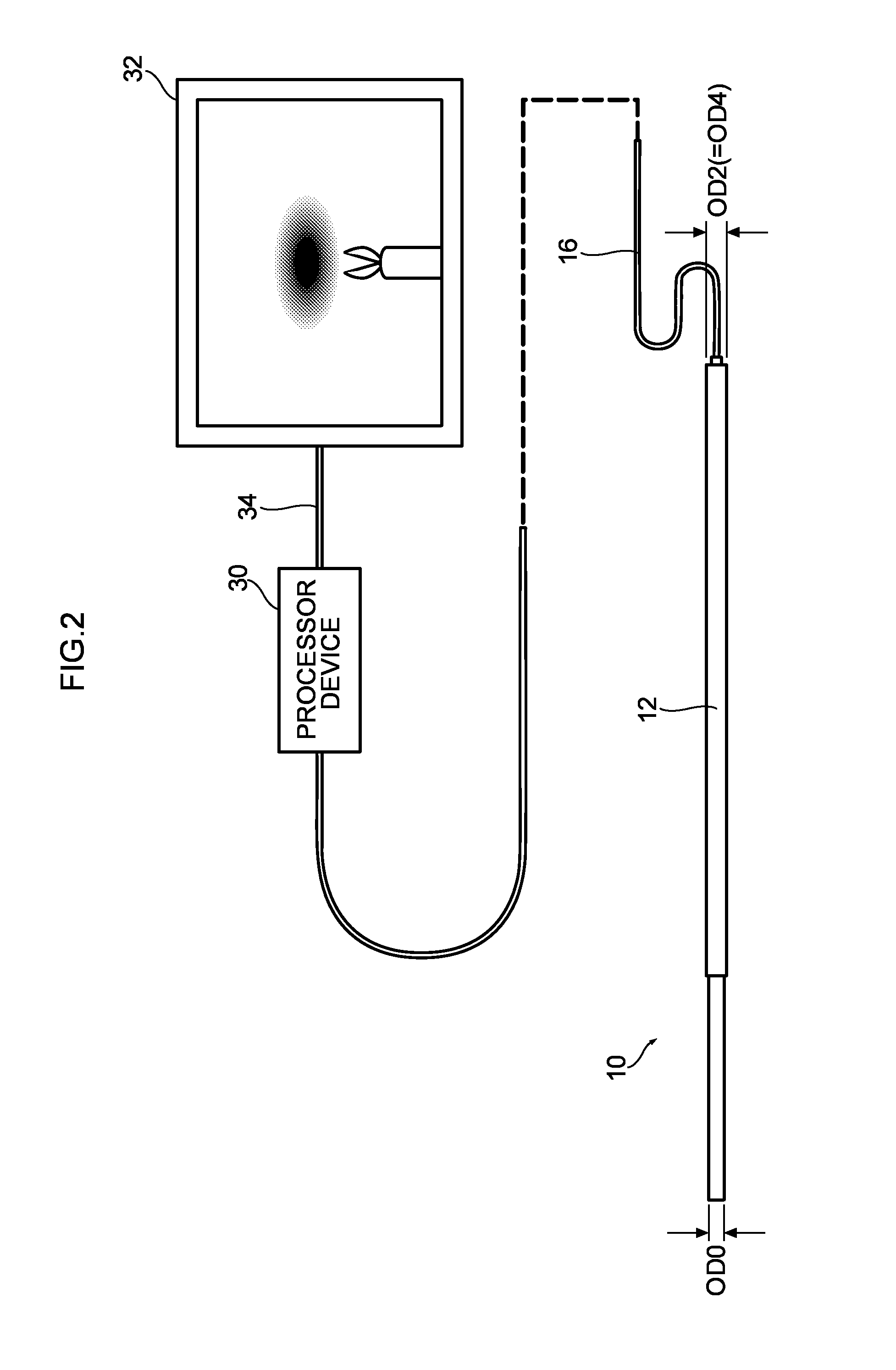

Surgical device, outer tube, endoscope, and treatment tool

A surgical device, an outer tube, an endoscope, and a treatment tool that have a compact configuration and achieve high durability are provided. The outer tube includes a slider in an outer tube body. When the endoscope and the treatment tool are inserted into the outer tube, and are held by an endoscope holding part and a treatment tool holding part each being provided in the slider, and are combined into a single unit. Consequently, when the treatment tool is moved in the axial direction, the endoscope is moved in the axial direction in interlock with the movement. Because the outer tube is configured such that the endoscope exit port has an inner diameter that is smaller than the inner diameter of the elastic member provided to hold the endoscope at the endoscope holding part, the strength of the endoscope can be secured while preventing interference with the treatment tool.

Owner:FUJIFILM CORP

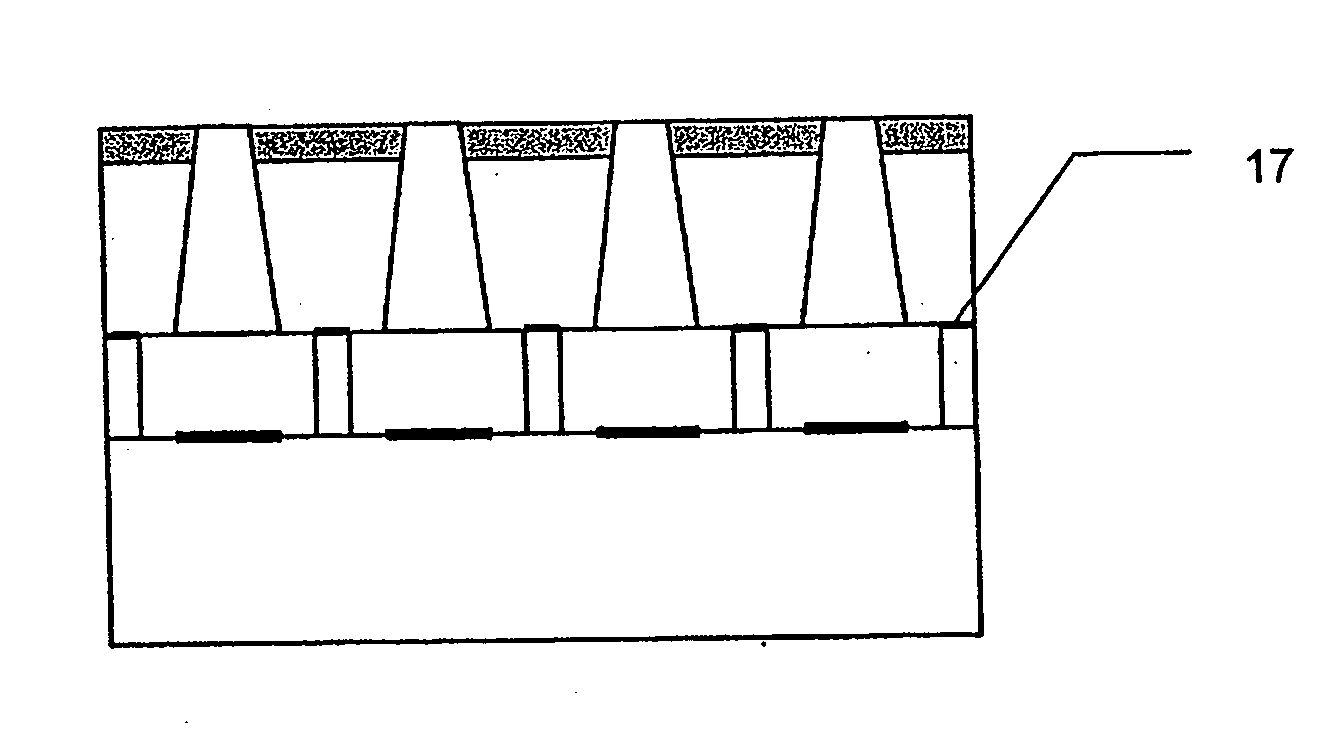

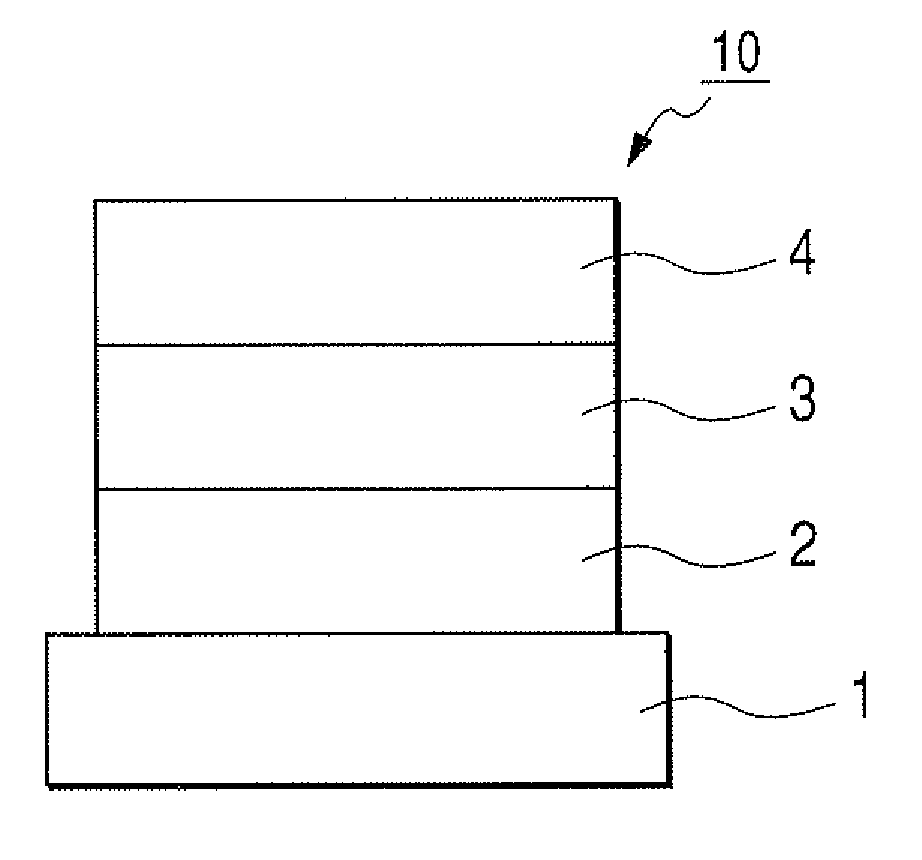

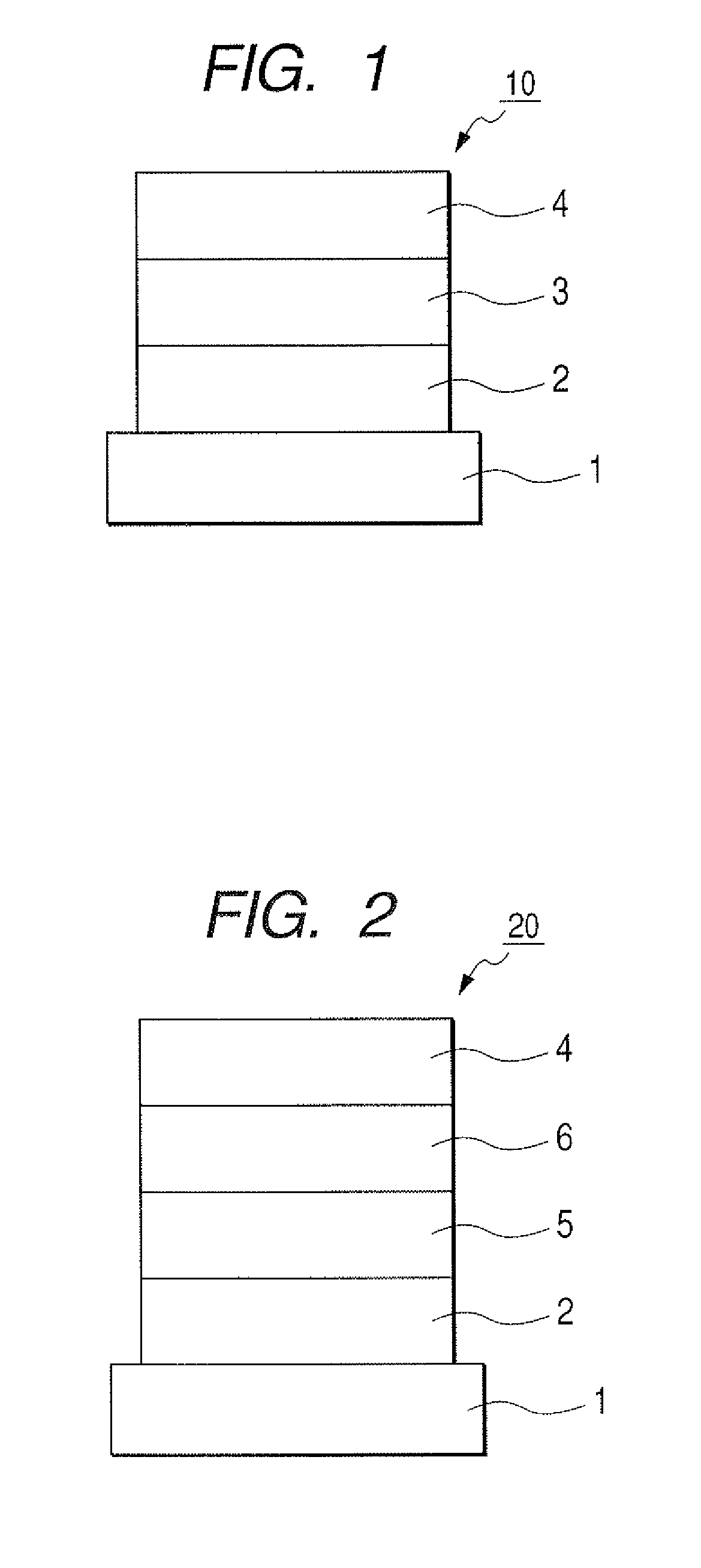

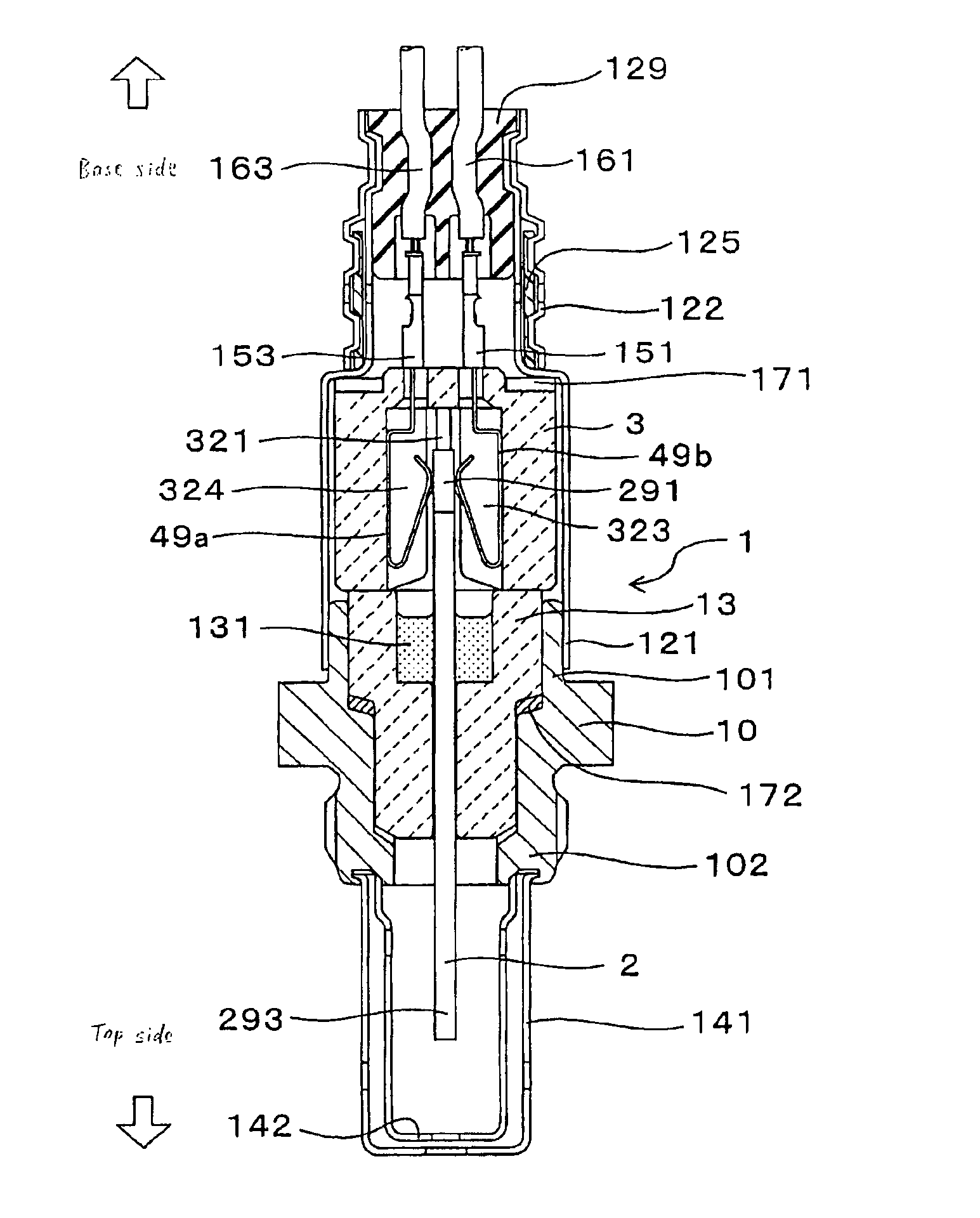

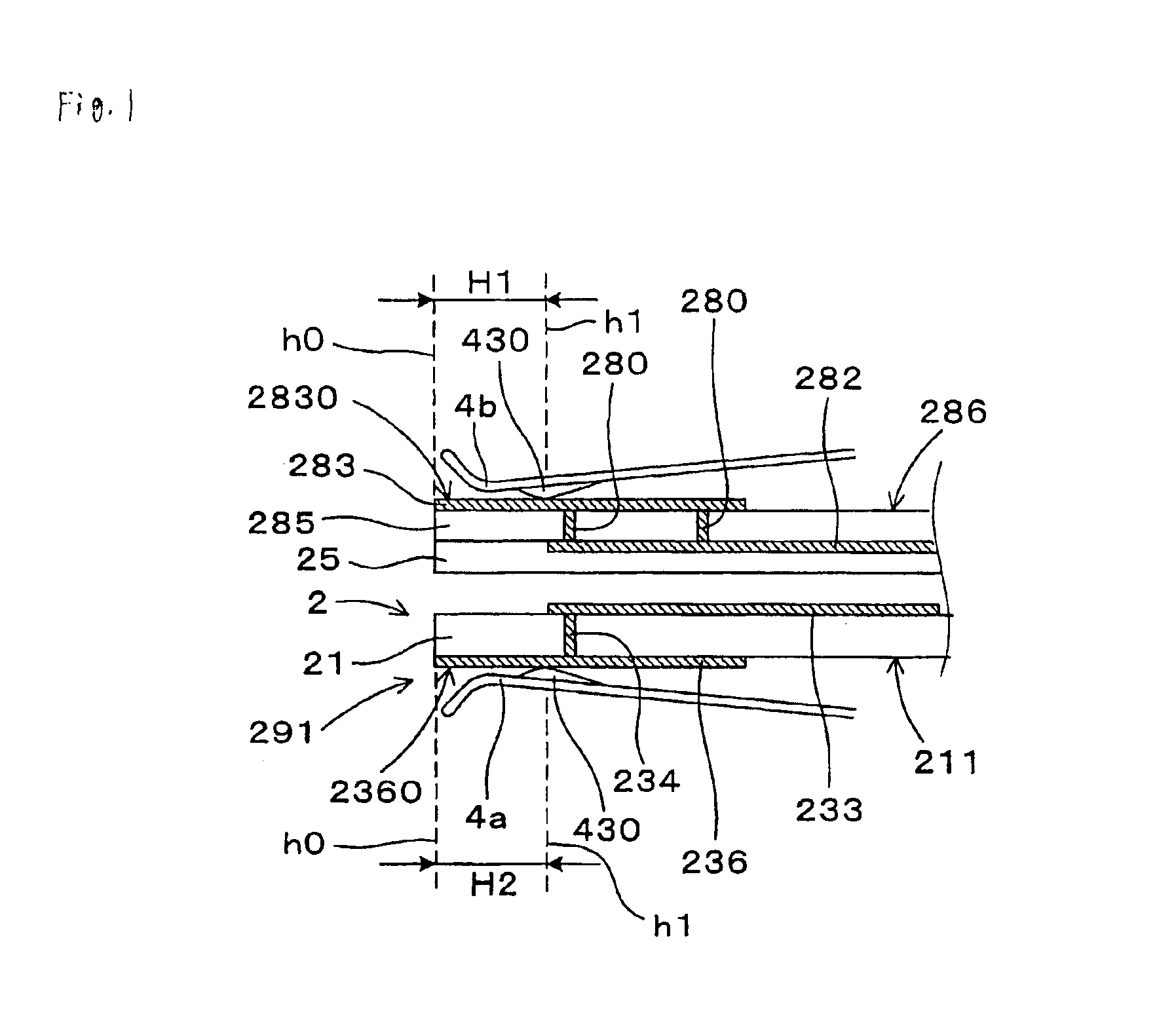

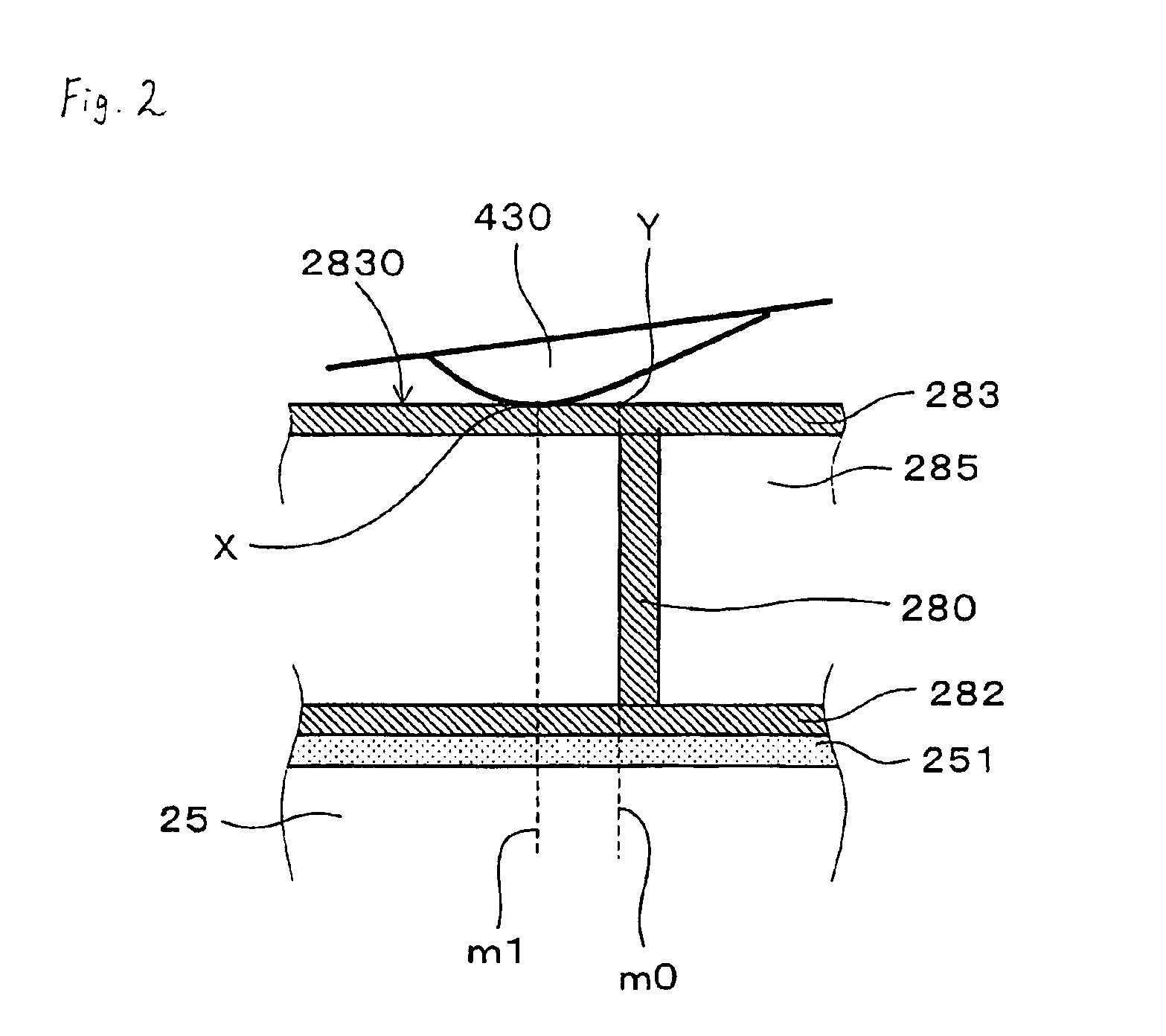

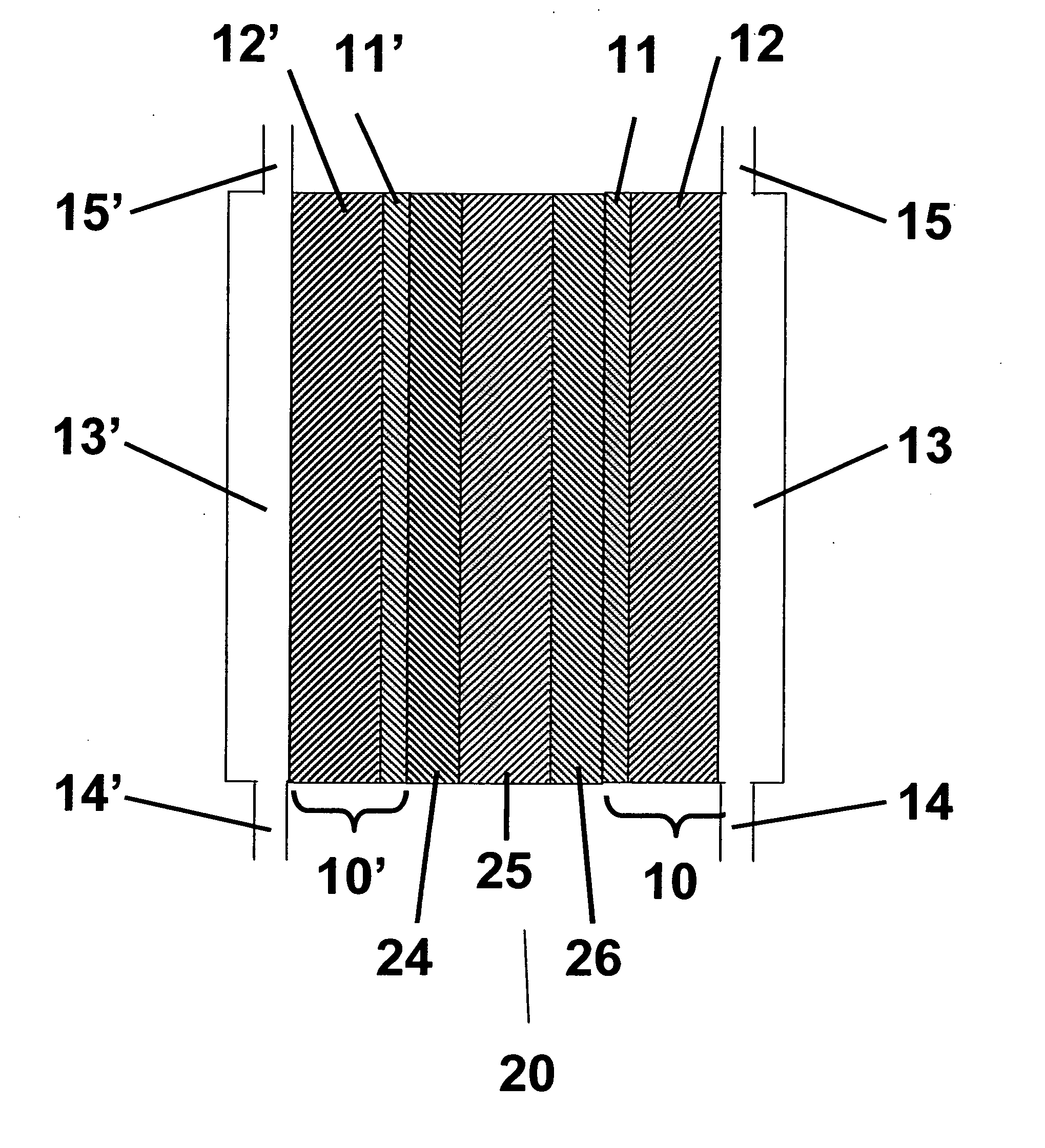

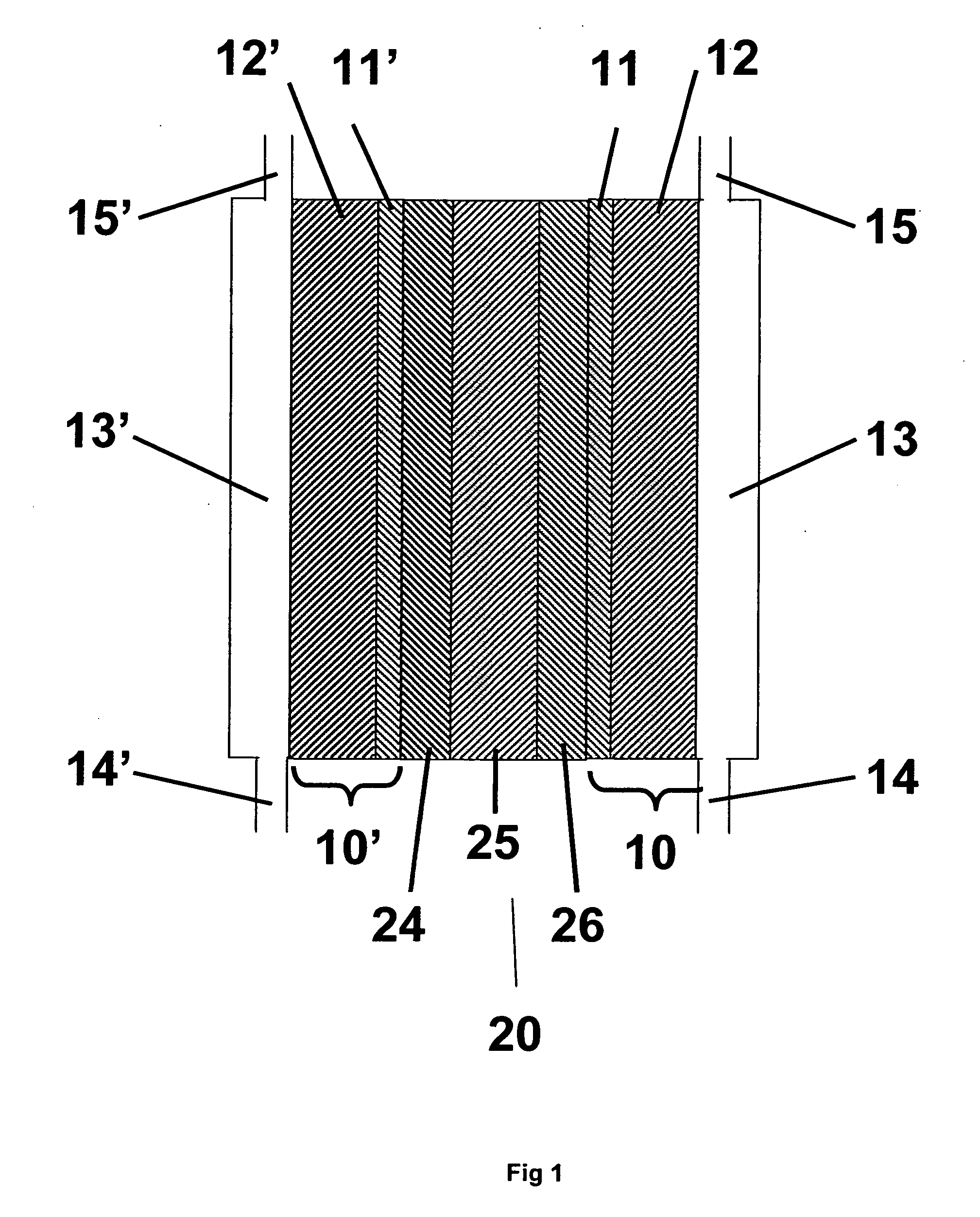

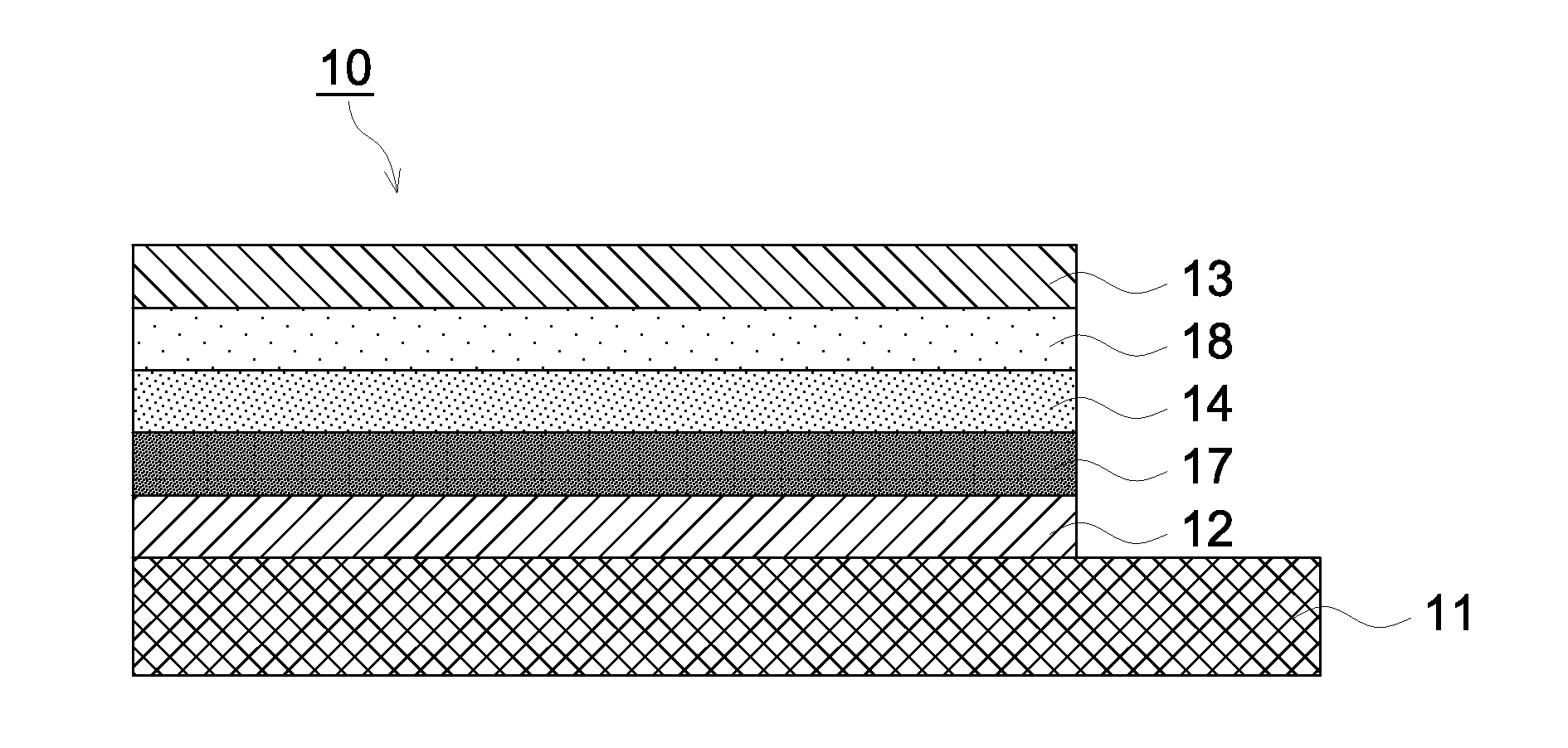

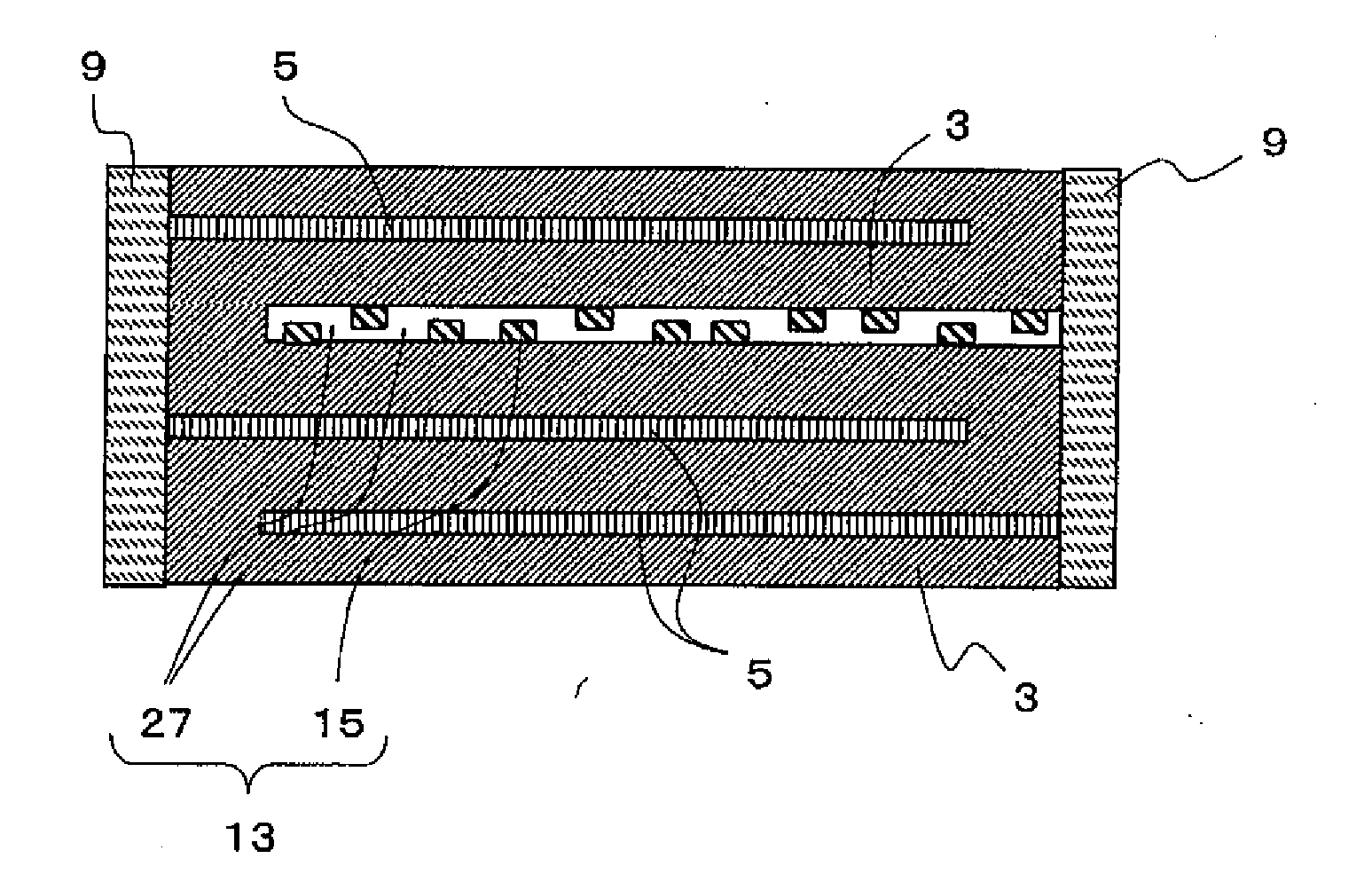

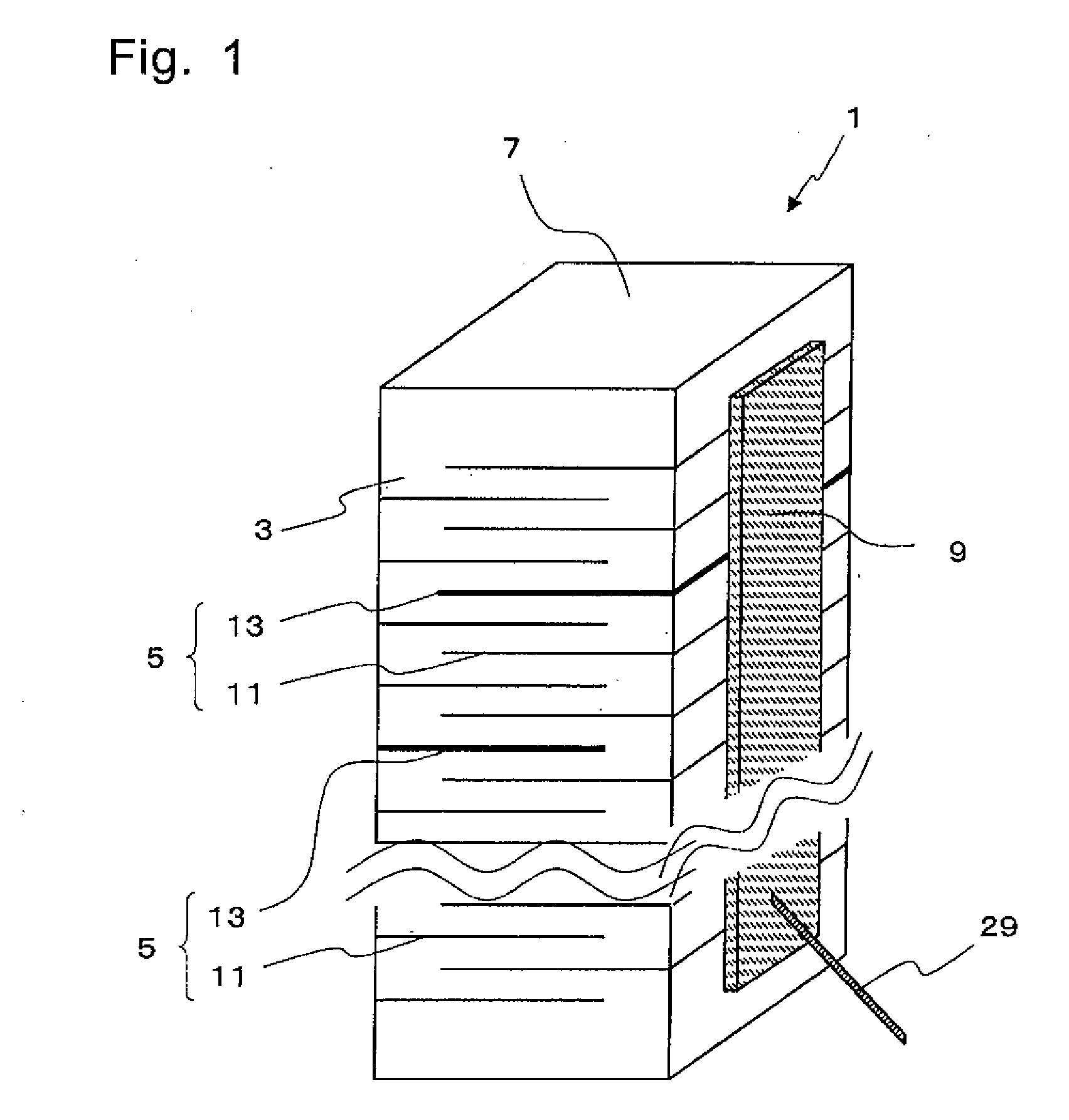

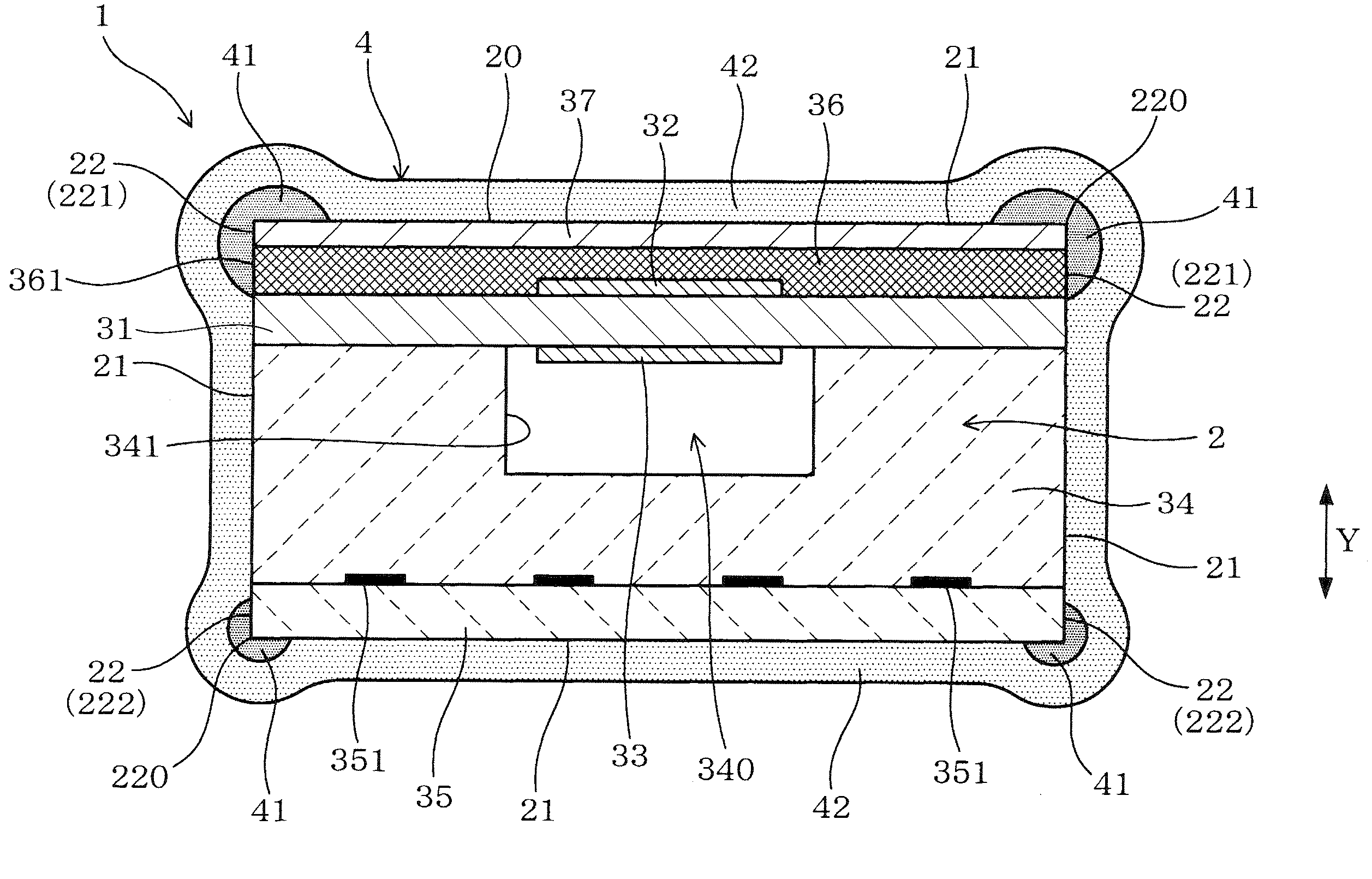

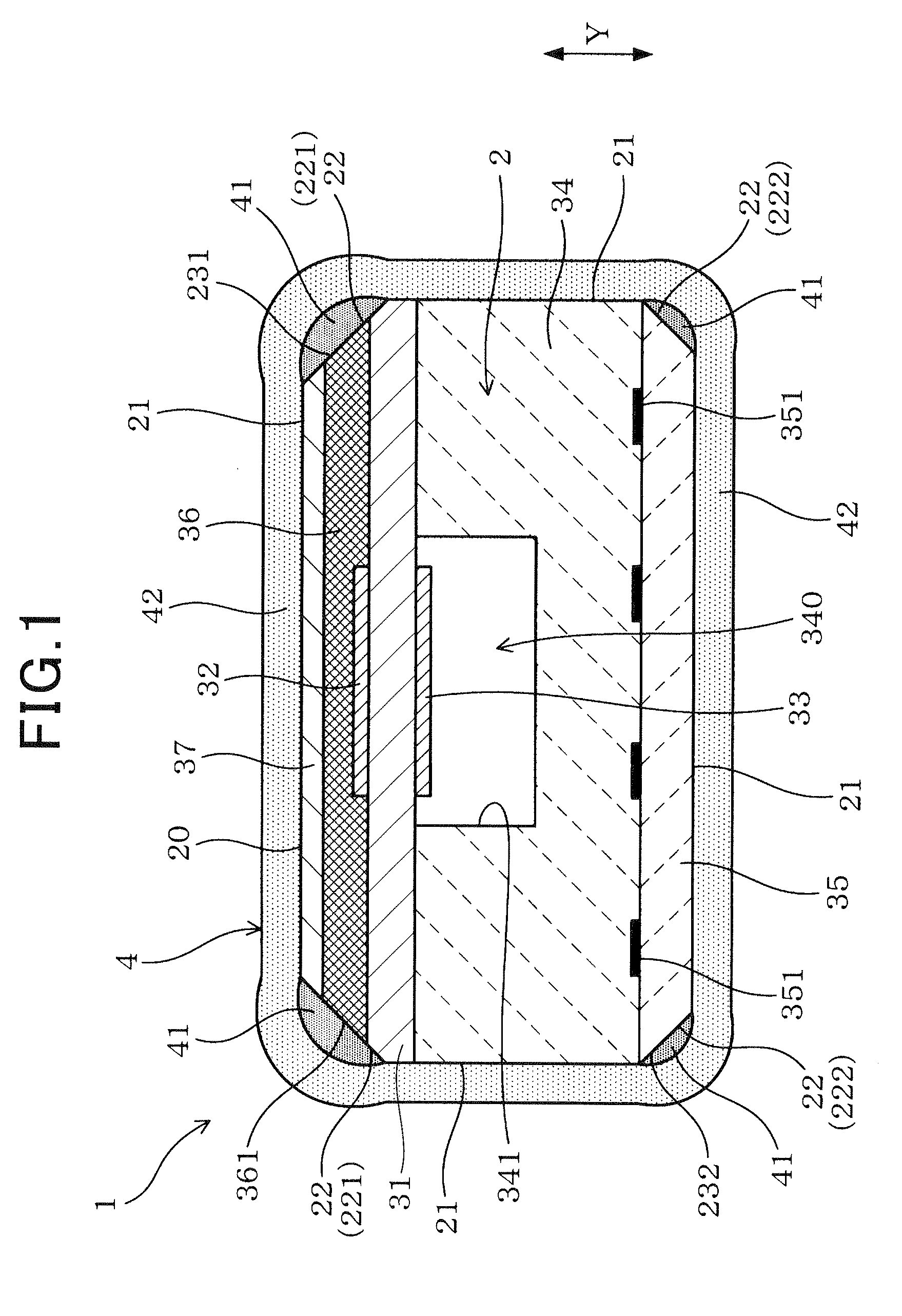

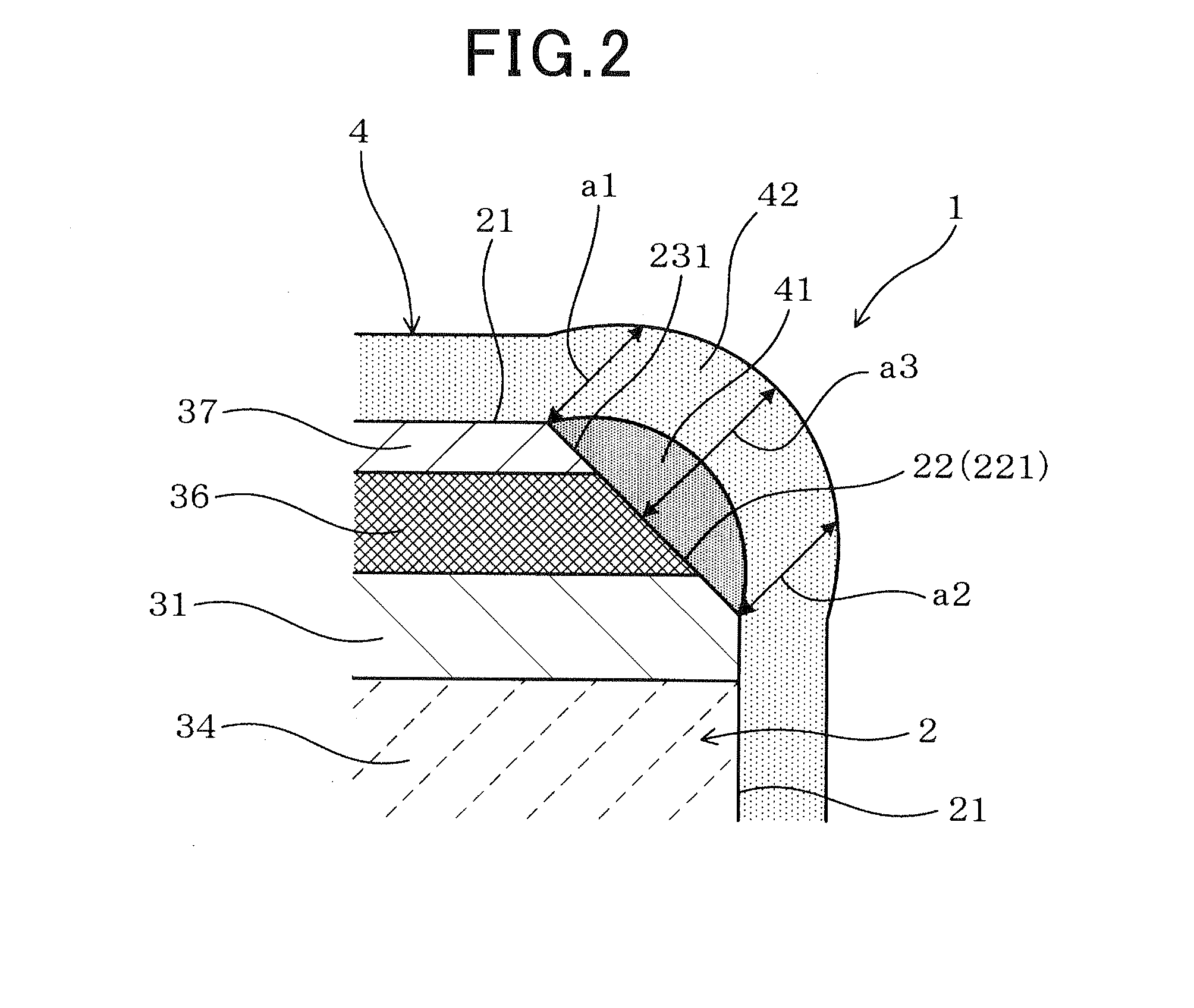

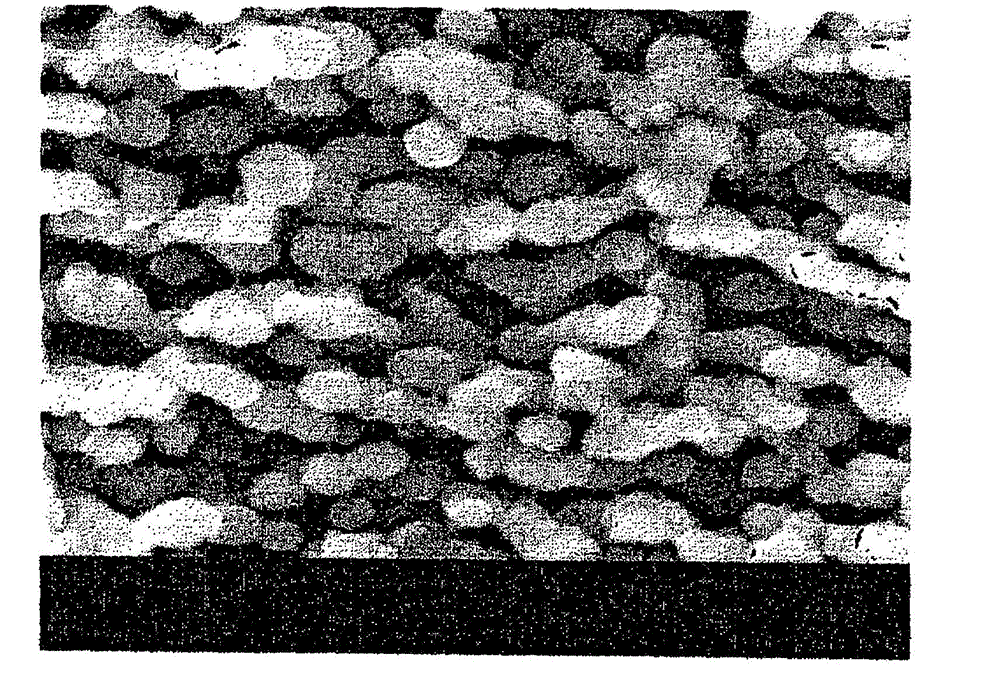

Multi-Layer Piezoelectric Element, and Ejection Apparatus and Fuel Ejection System That Employ the Same

ActiveUS20100276511A1High durabilityIncreased durabilityPiezoelectric/electrostriction/magnetostriction machinesMovable spraying apparatusElectric fieldEngineering

A multi-layer piezoelectric element having high durability of which amount of displacement is suppressed from varying even when operated continuously over a long period of time with a higher electric field under a high pressure is provided.The multi-layer piezoelectric element comprising a multi-layer structure in which a plurality of piezoelectric material layers and a plurality of metal layers are stacked alternately one on another, wherein the plurality of metal layers comprises internal electrodes and low-rigidity metal layer that has rigidity lower than those of the piezoelectric material layer and the internal electrode, wherein the low-rigidity metal layer comprises a plurality of metal parts that are separated from each other, and wherein at least one of the metal parts is bonded with only one piezoelectric material layer among the two piezoelectric material layers that adjoin in the stacking direction.

Owner:KYOCERA CORP

Gas sensor element and its manufacturing method, and gas sensor employing the gas sensor element

ActiveUS20120297861A1High durabilityHigh performanceMaterial analysis by electric/magnetic meansPretreated surfacesEngineeringMechanical engineering

A gas sensor element includes a main body and a protective layer. The main body has four plane portions and four corner portions each of which is formed between one adjacent pair of the plane portions. The four corner portions include a pair of first corner portions that are formed on a porous diffusion-resistant layer side in a lamination direction of the main body and a pair of second corner portions that are formed on a heater layer side in the lamination direction. The protective layer is comprised of an inner protective layer that covers at least the first corner portions of the main body and an outer protective layer that covers the entire outer periphery of the main body and the inner protective layer. The protective layer has a larger average thickness at the first corner portions than at the plane portions of the main body.

Owner:DENSO CORP

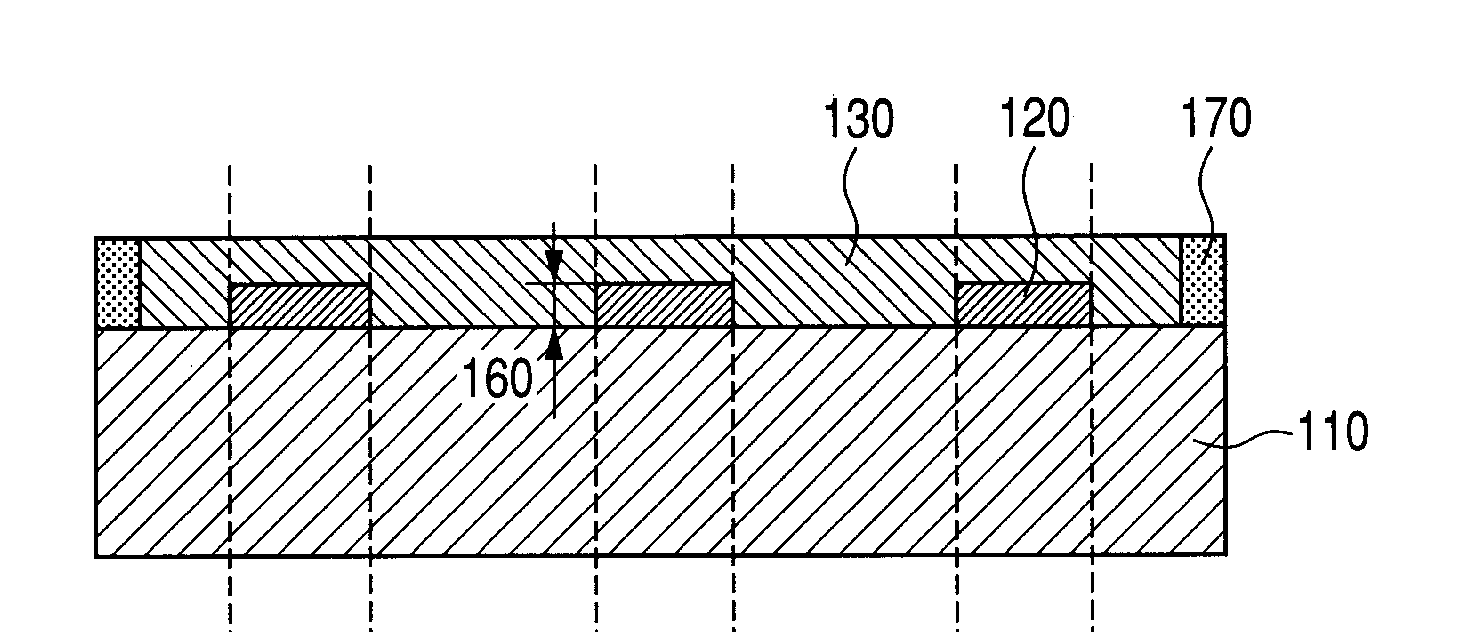

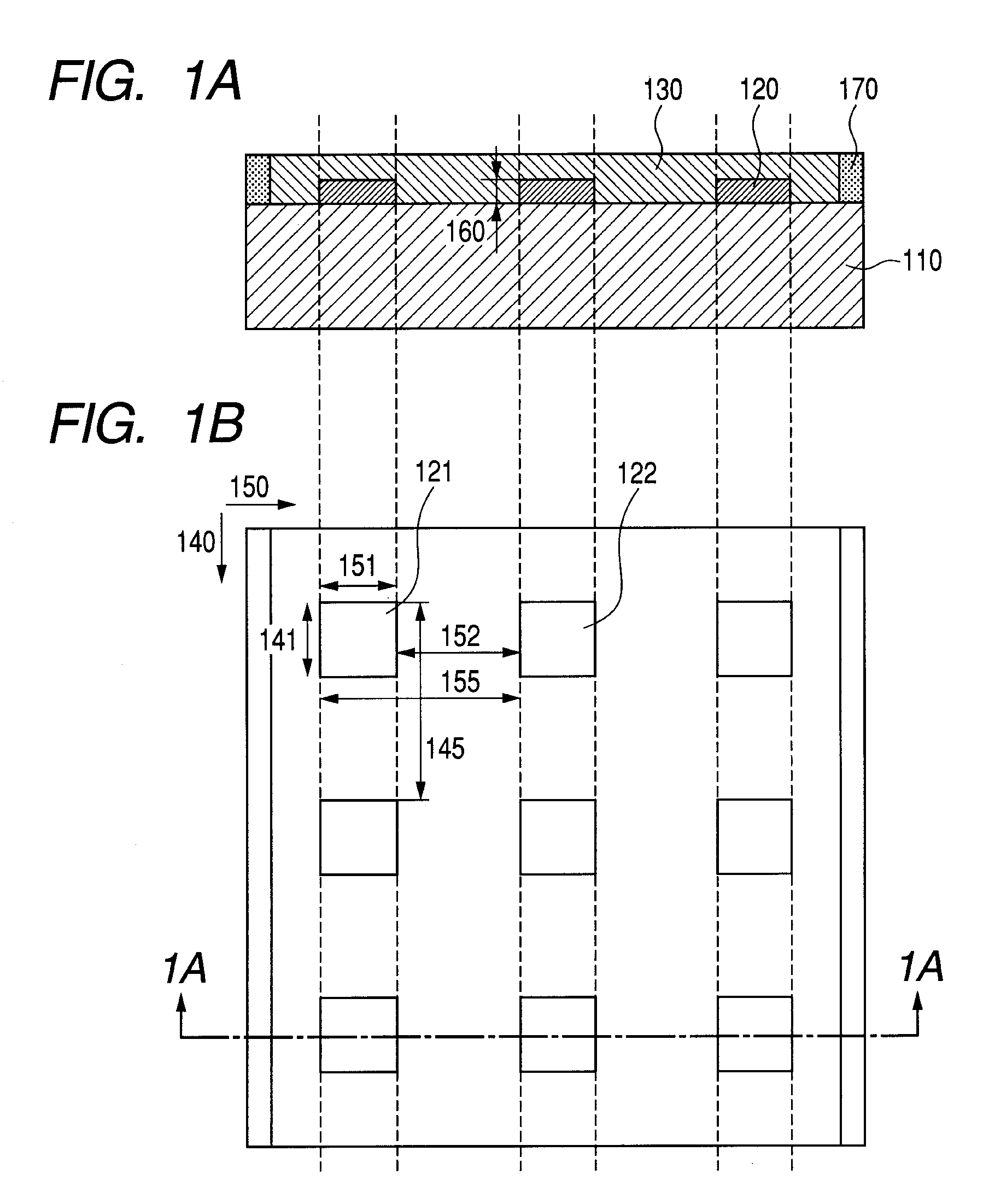

Optical apparatus, optical detector, optical modulator, imaging apparatus, and camera

InactiveUS20110043813A1High durabilityLess absorptionOptical filtersSolid-state devicesDielectric substrateType metal

Provided is an optical apparatus having high durability, less optical absorption than a hole-type metal thin film filter, high transmittance and high reflectance, and variable optical characteristics. The apparatus includes: a dielectric substrate; a metal structure group including multiple metal structures two-dimensionally and discretely disposed at regular intervals; and a dielectric layer covering the metal structure group, in which: the metal structures have a first length equal to or shorter than a predetermined wavelength in a visible light region in one direction, and a second length equal to or shorter than the wavelength in a perpendicular direction; and the metal structures resonates with light entering the dielectric substrate or the dielectric layer, having a variable dielectric constant, to generate localized surface plasmon resonance on a surface of the metal structures to have a minimum transmittance or a maximum reflectance of the light having the wavelength.

Owner:CANON KK

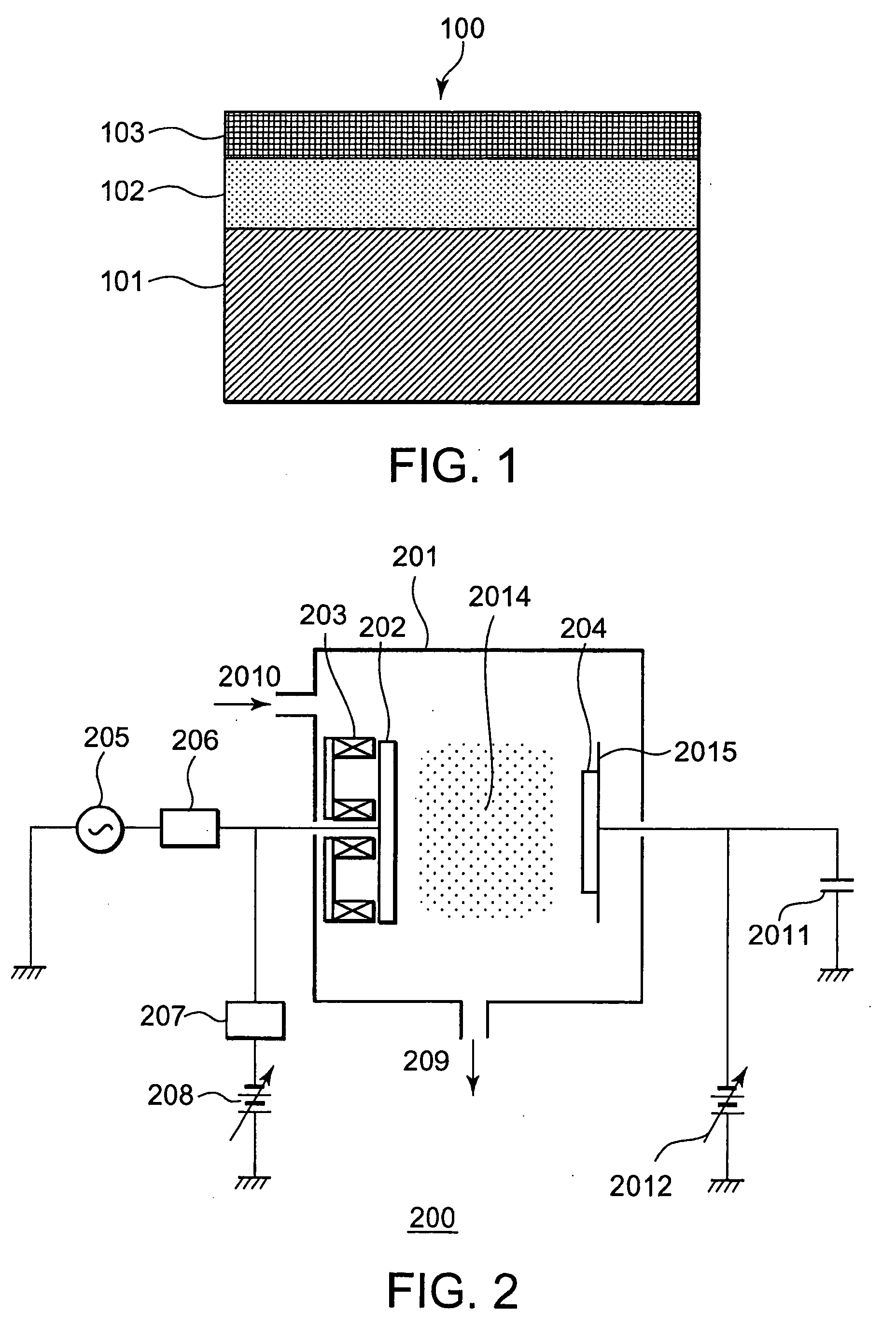

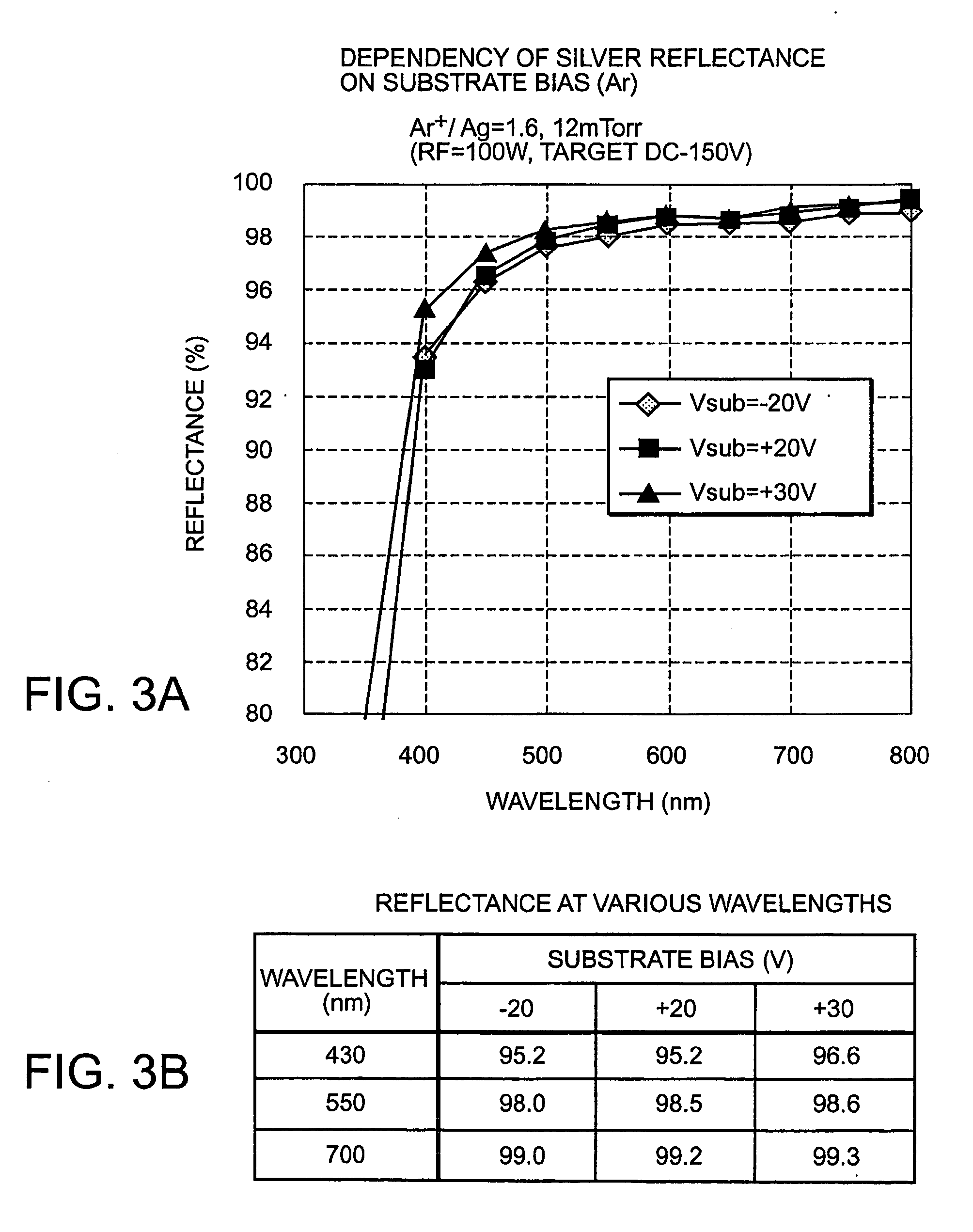

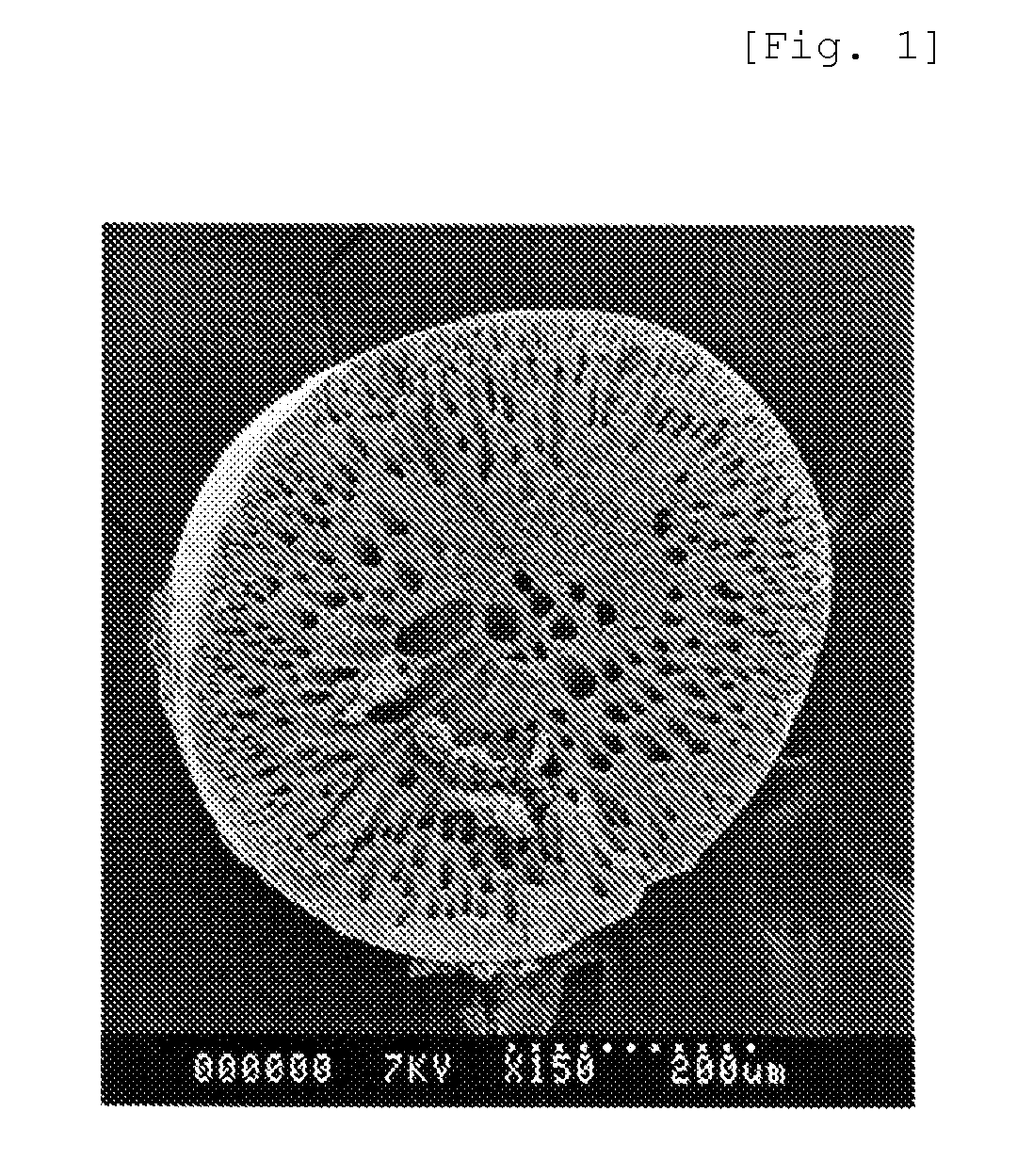

High-reflectance visible-light reflector member, liquid-crystal display backlight unit employing the same, and manufacture of the high-reflectance visible-light reflector member

InactiveUS20070030568A1High reflectanceHigh durabilityMirrorsOptical filtersReflectivitySilicon nitride

A reflector member of the present invention includes a silver thin film formed on a substrate and a silicon nitride protection film formed on the silver thin film. The silver thin film has the (111) orientation as the principal plane orientation. Preferably, 99% or more of the silver thin film has the (111) orientation as the principal plane orientation. The thickness of the silver thin film is in a range of 100 nm to 350 nm.

Owner:TOHOKU UNIV +1

Sliding bearing

ActiveUS20050157964A1Excellent initial conformability and seizure resistanceHigh durabilityShaftsSynthetic resin layered productsMaterials sciencePlain bearing

Owner:TAIHO INDUSTRIES CO LTD

Porous Molded Article, and Method for Manufacturing the Same

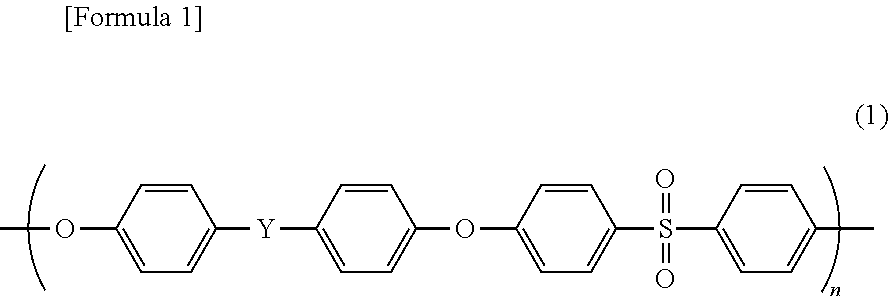

ActiveUS20120219799A1High adsorption capacityHigh durabilityOther chemical processesScale removal and water softeningSulfoneCompound (substance)

There is provided a porous formed article which can remove hazardous substances at a high speed, has a high adsorption capacity and has high durability to cleaning chemicals and further which is scarcely broken even if being repeatedly used, and which contains an organic polymeric resin and an inorganic ion-adsorbing material, wherein the organic polymeric resin is a polyether sulfone resin and / or a polysulfone resin, and is an organic polymeric resin having a hydroxyl group.

Owner:ASAHI KASEI CHEM CORP

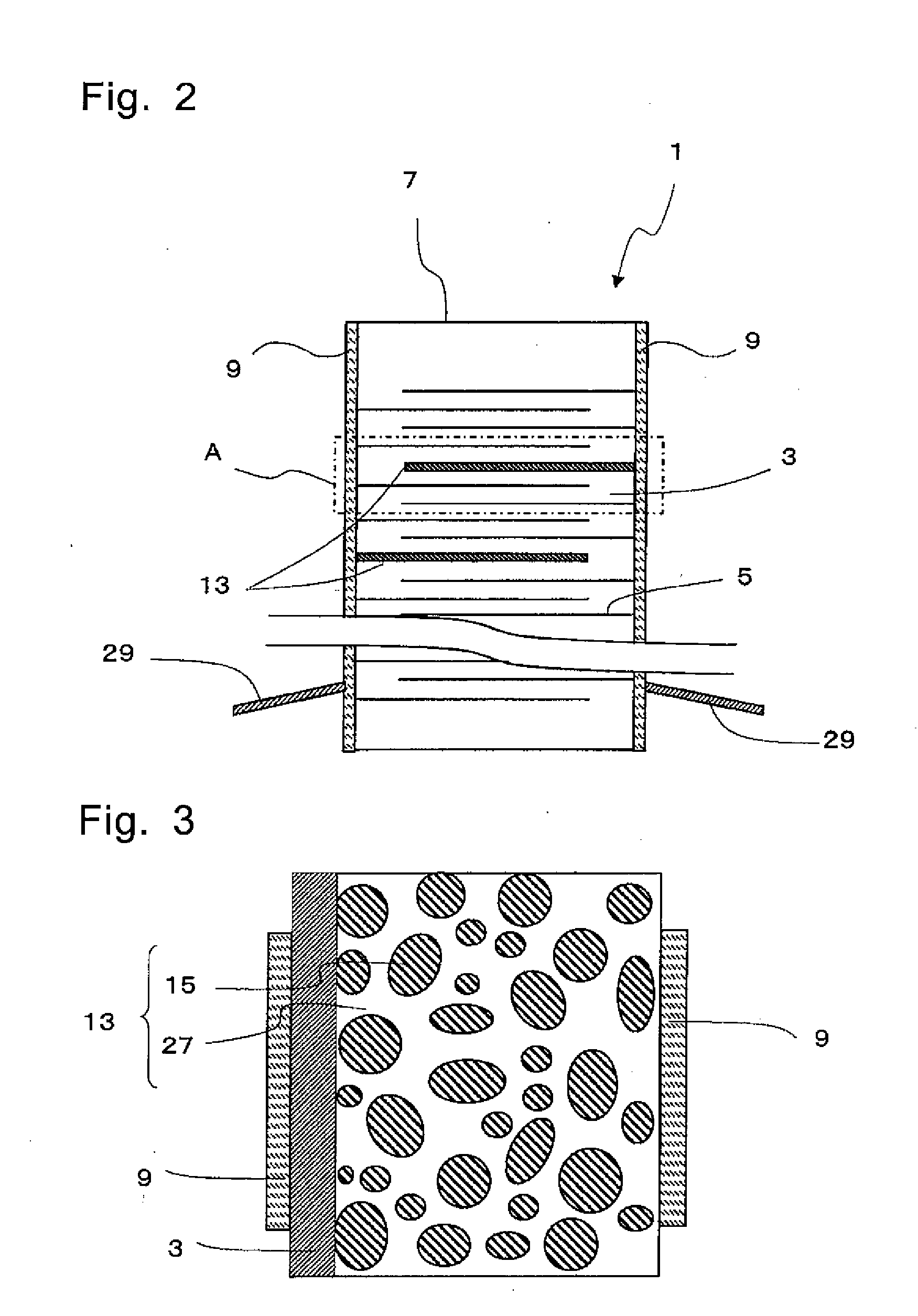

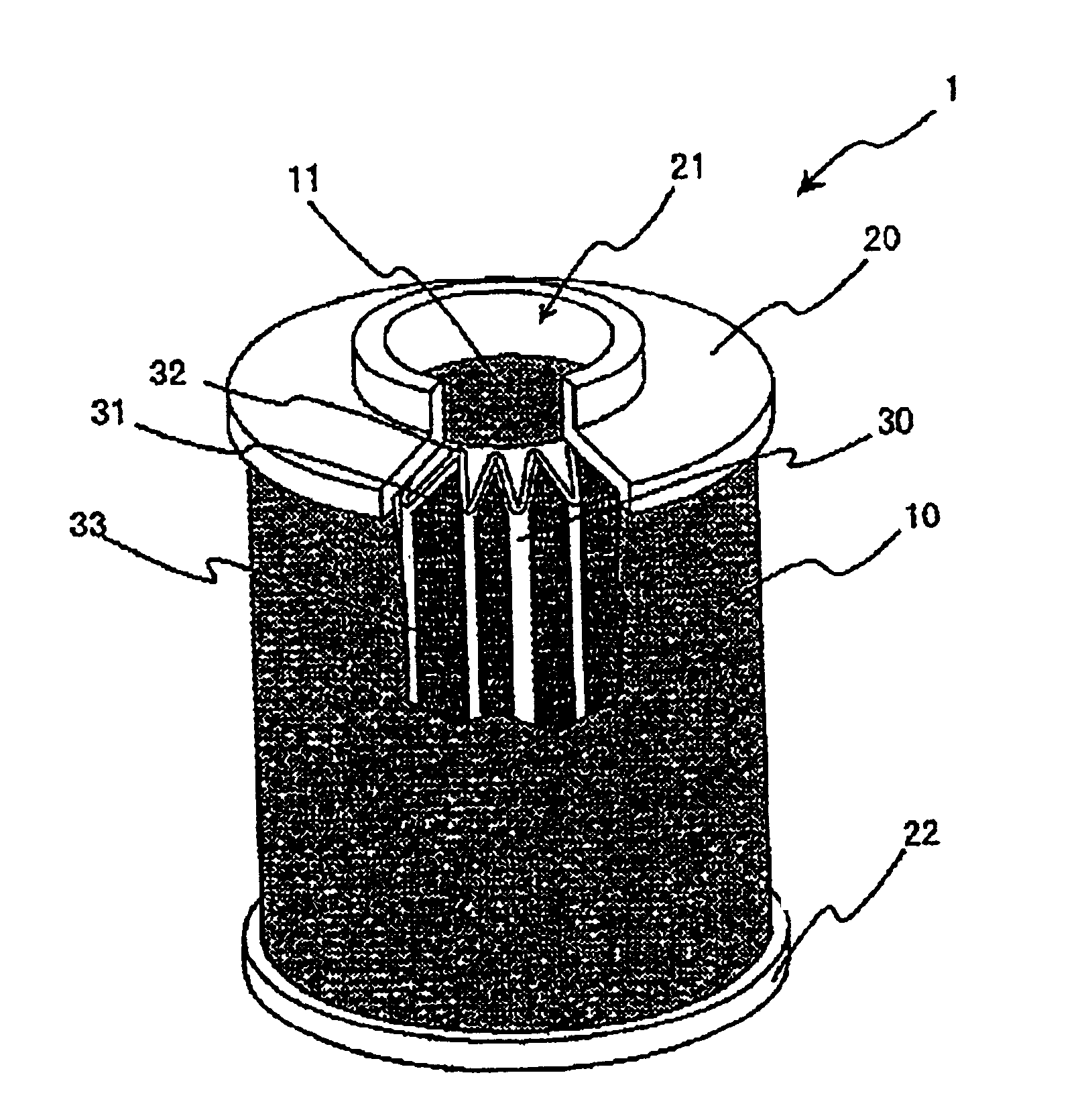

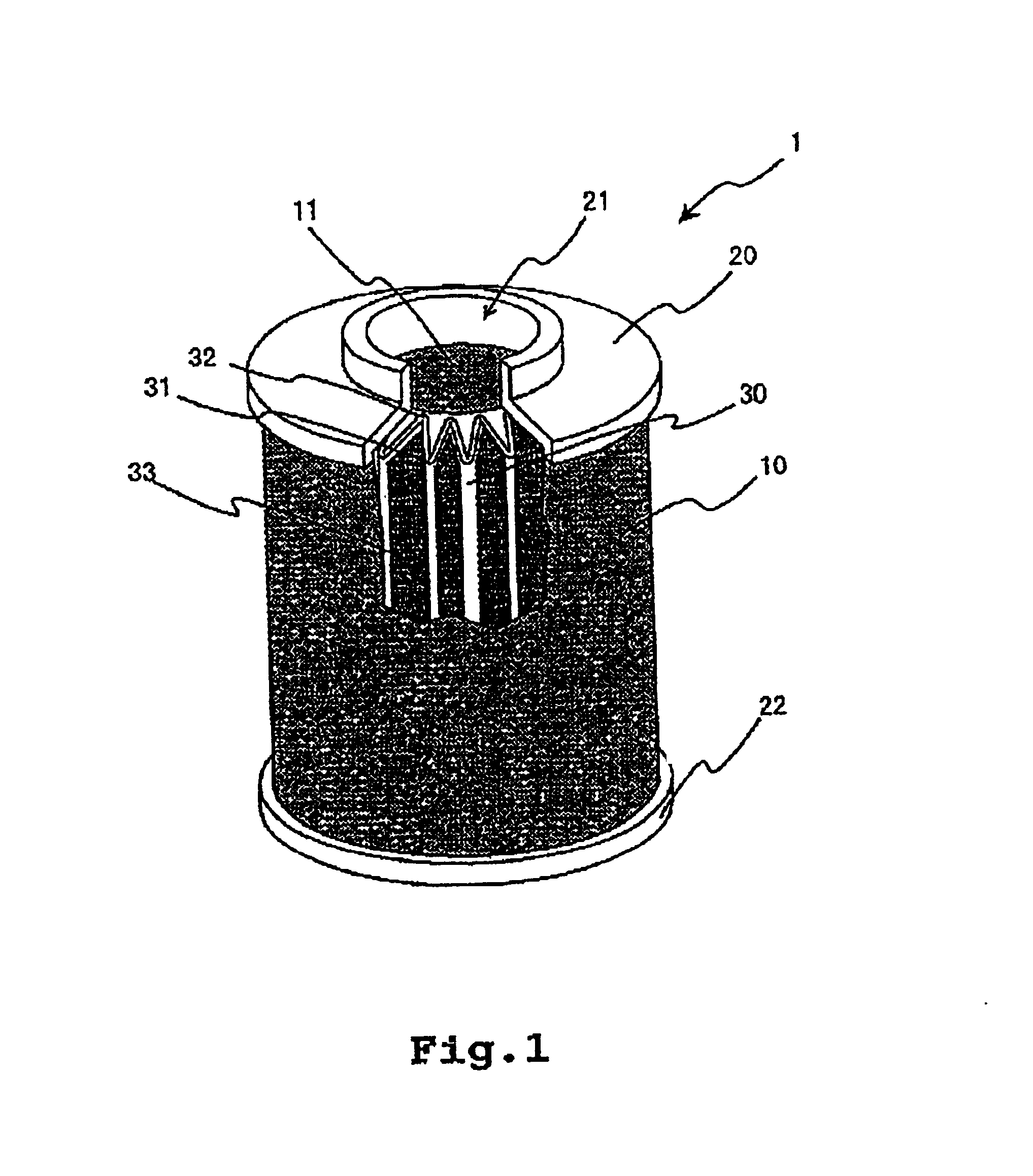

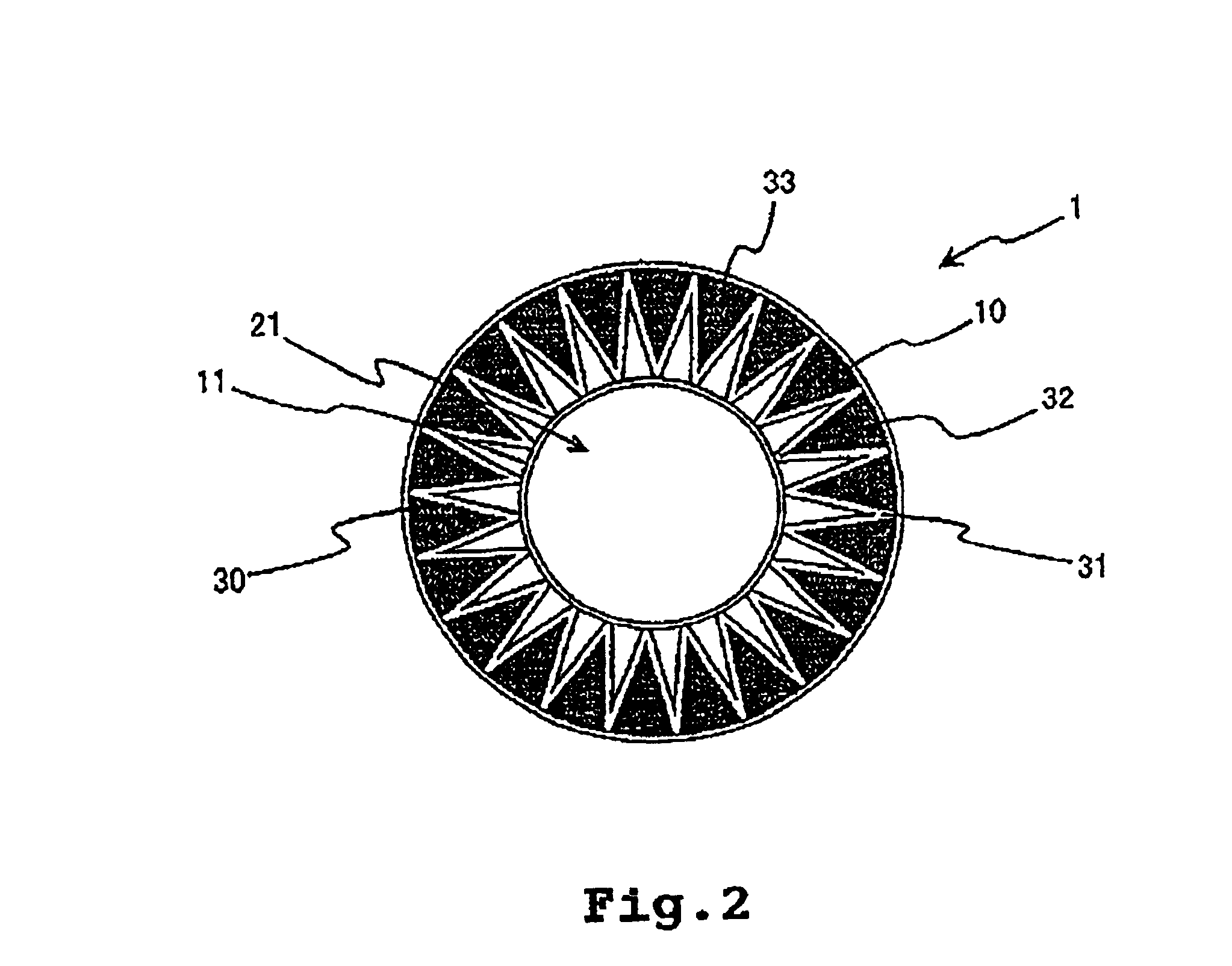

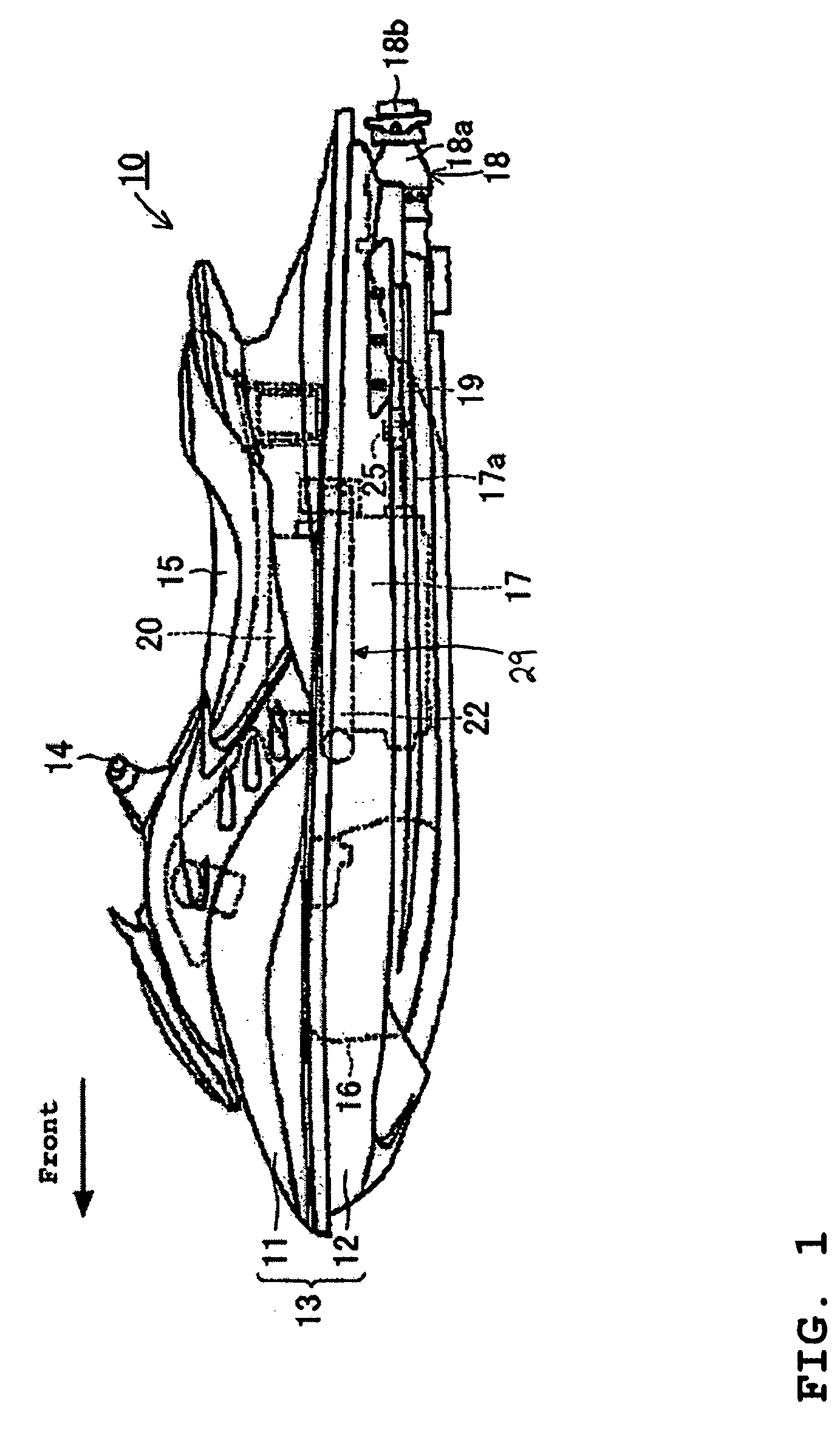

Washable air filter for internal combustion engine

InactiveUS6866693B2High durabilityWash with easeCombination devicesGas treatmentEngineeringDust particles

A washable air filter for an internal combustion engine which has high durability and can be washed with ease to reuse it is disclosed. The washable air filter includes an outer cylindrical member 10; an inner cylindrical member 11; a first filter element 30 formed from a stainless mesh sheet which is folded in a pleated-form having peaks and valleys arranged alternately and provided between the outer cylindrical member 10 and the inner cylindrical member 11; and a second filter element 33 provided between the outer cylindrical member 10 and the first tilter element 30. Since the washable air filter uses the filter element made from the stainless mesh sheet, it is possible to effectively remove dust particles from air. Further, the washable air filter can be reused because dust particles are removed off the filter element by washing after use.

Owner:SHUETSUTECHNICA

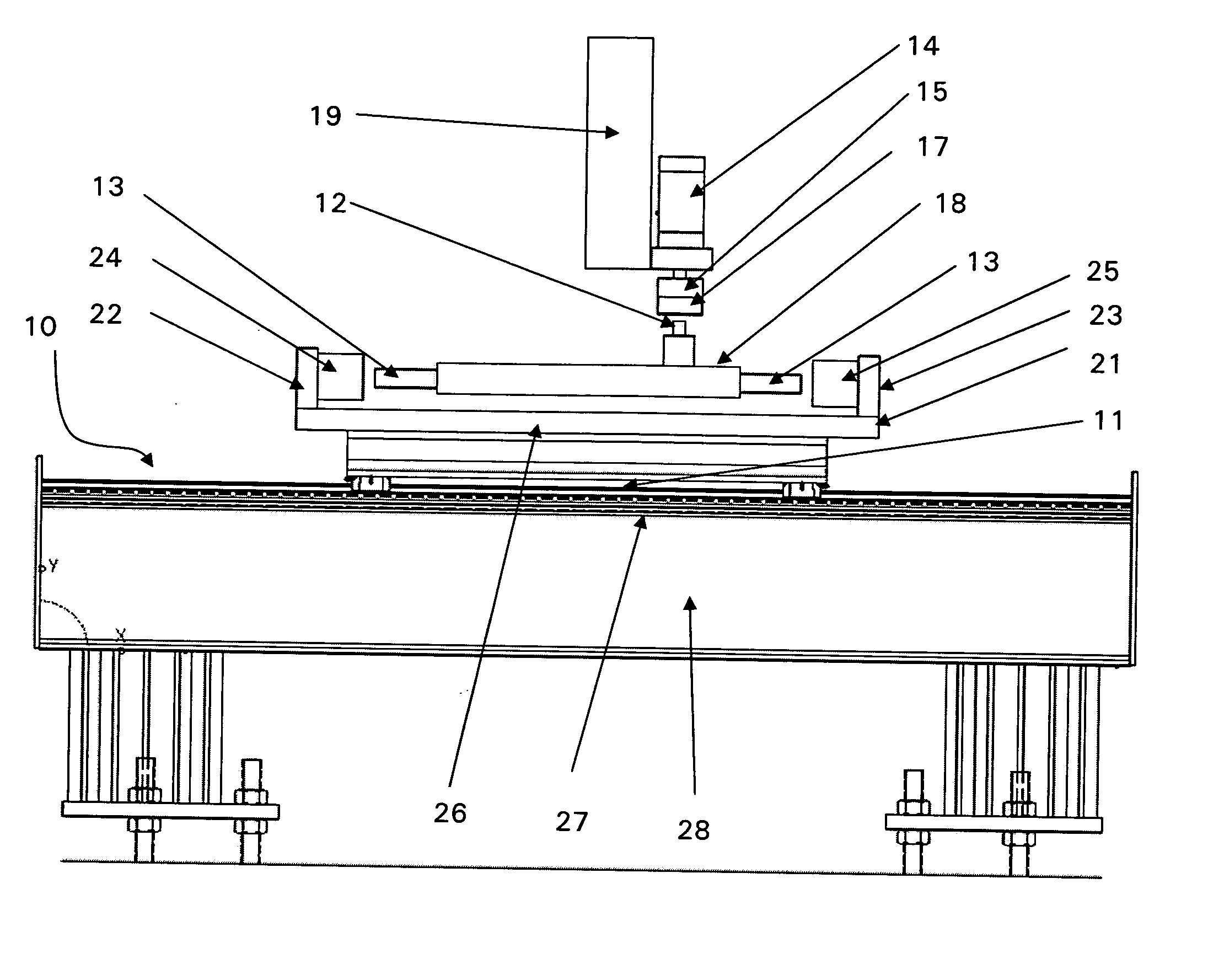

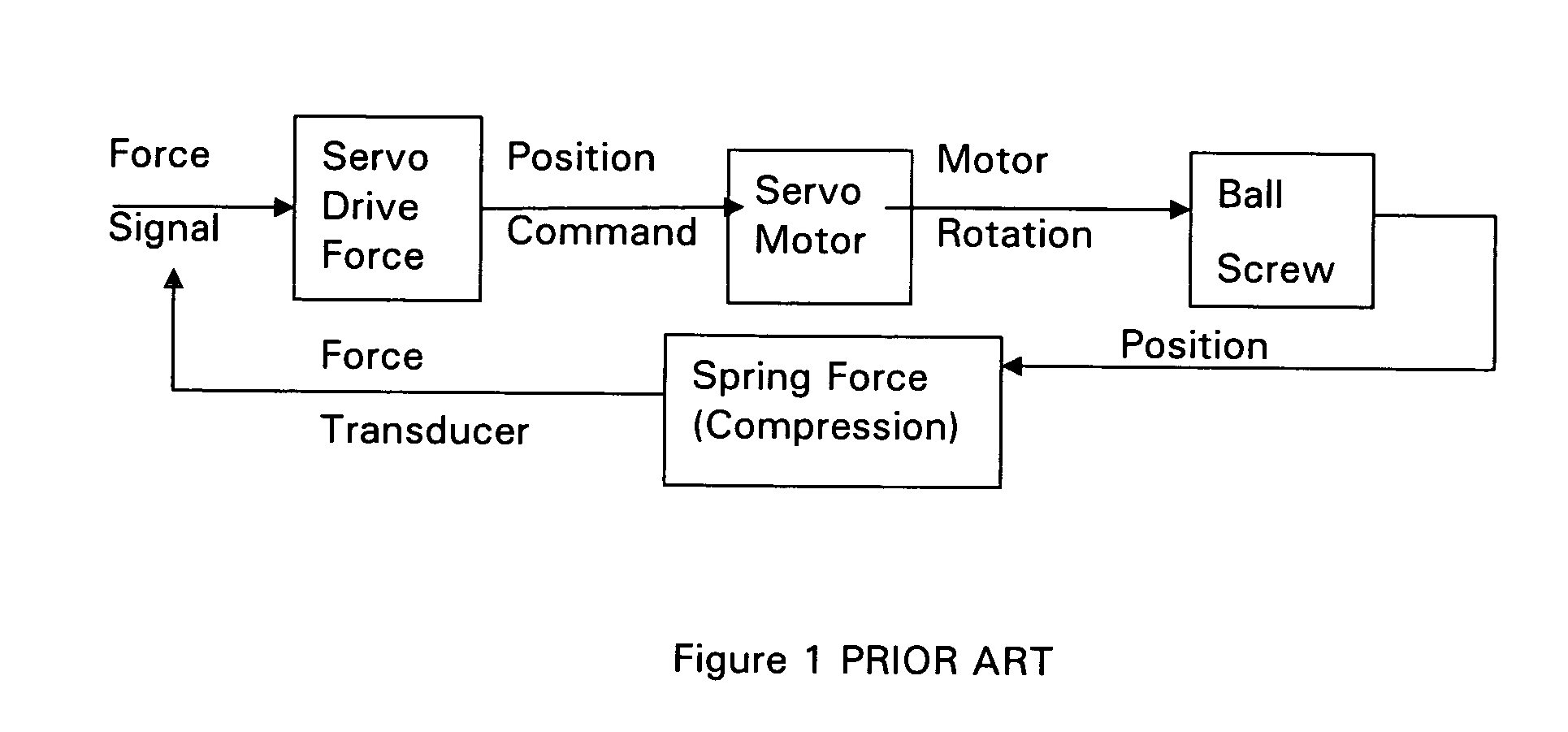

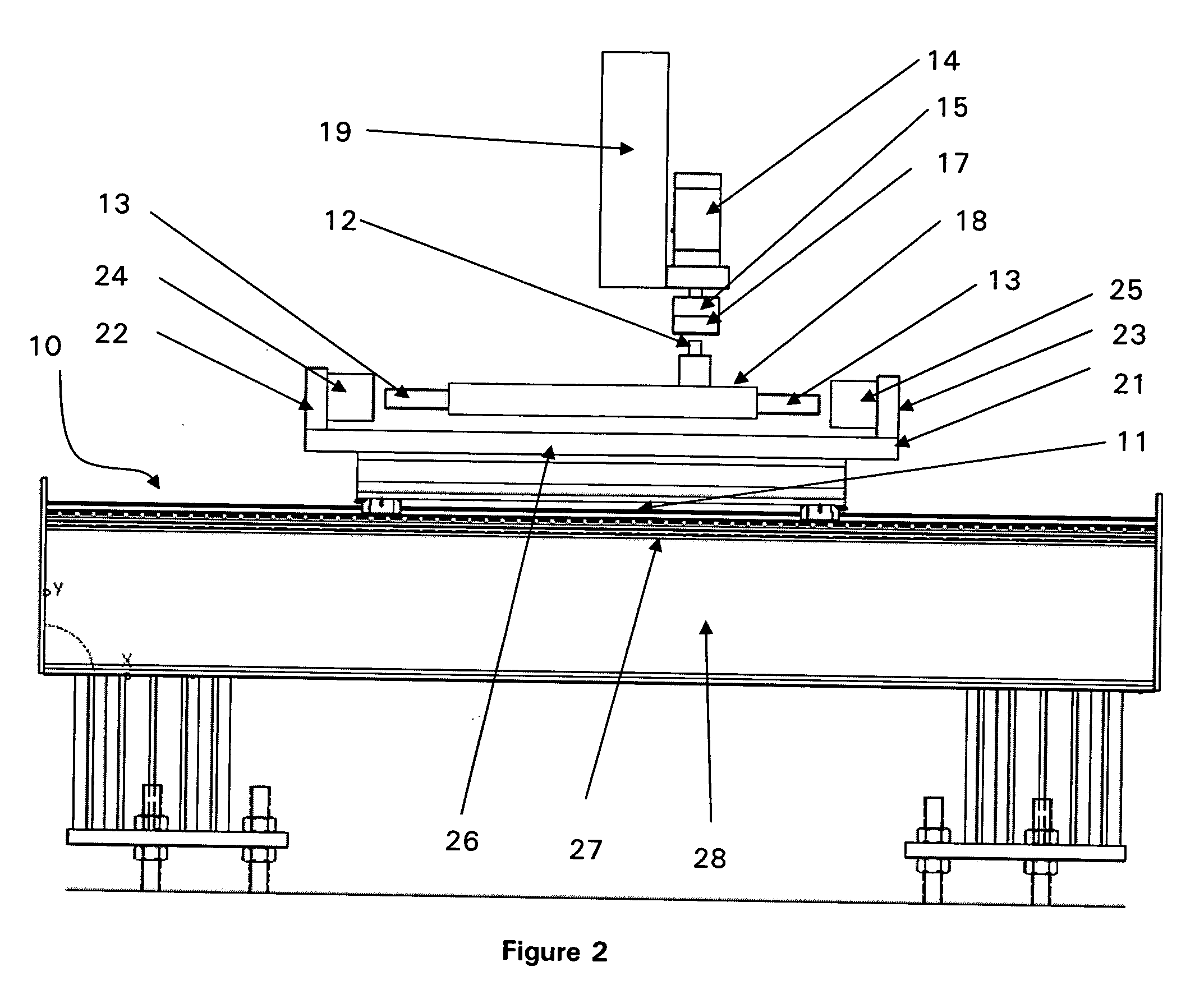

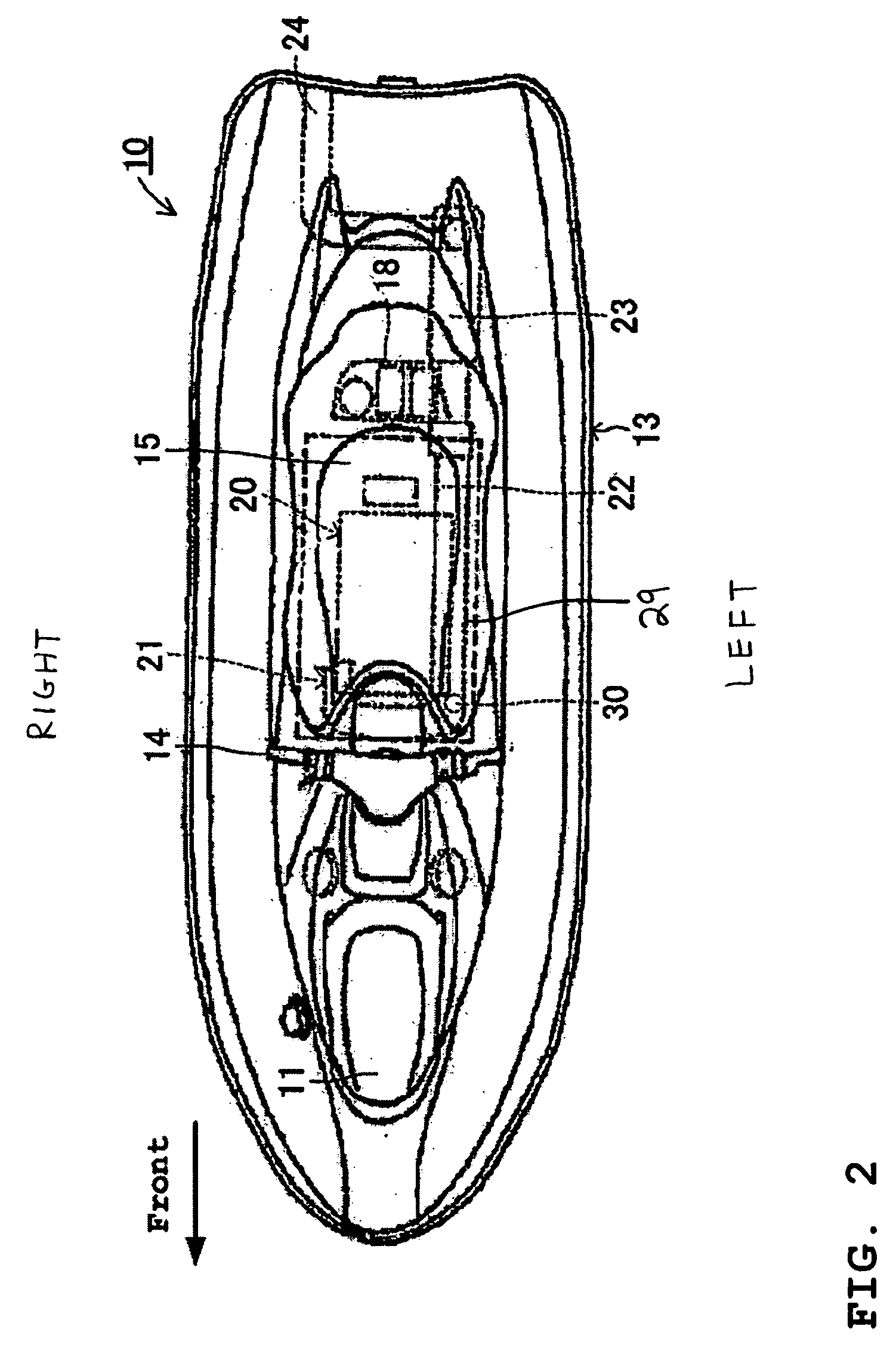

Apparatus and method for function testing

InactiveUS20050061065A1Low maintenanceHigh durabilityMachine gearing/transmission testingEngine testingForce transducerRack and pinion

An apparatus for function testing rack and pinion systems having a linear servo motor. A single actuator provides force to both ends of the rack and a linear motor to provide resistive force to the rack. The linear motor is used to apply the required forces. In a preferred embodiment, the actuator is a generally “U” shaped structure mounted onto a linear motor stage. A force transducer is placed at each end of the generally “U” shaped structure between the structure and the rack to monitor the force being applied to the rack.

Owner:GILMAN ENG & MFG

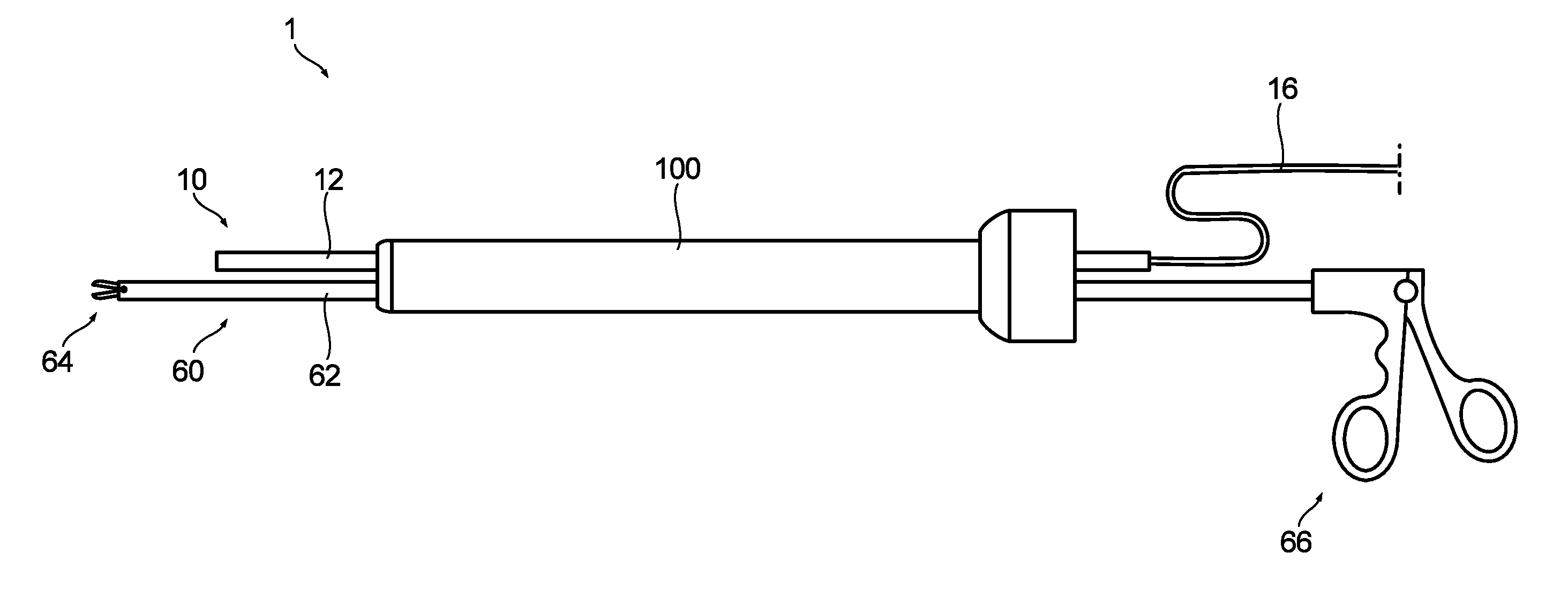

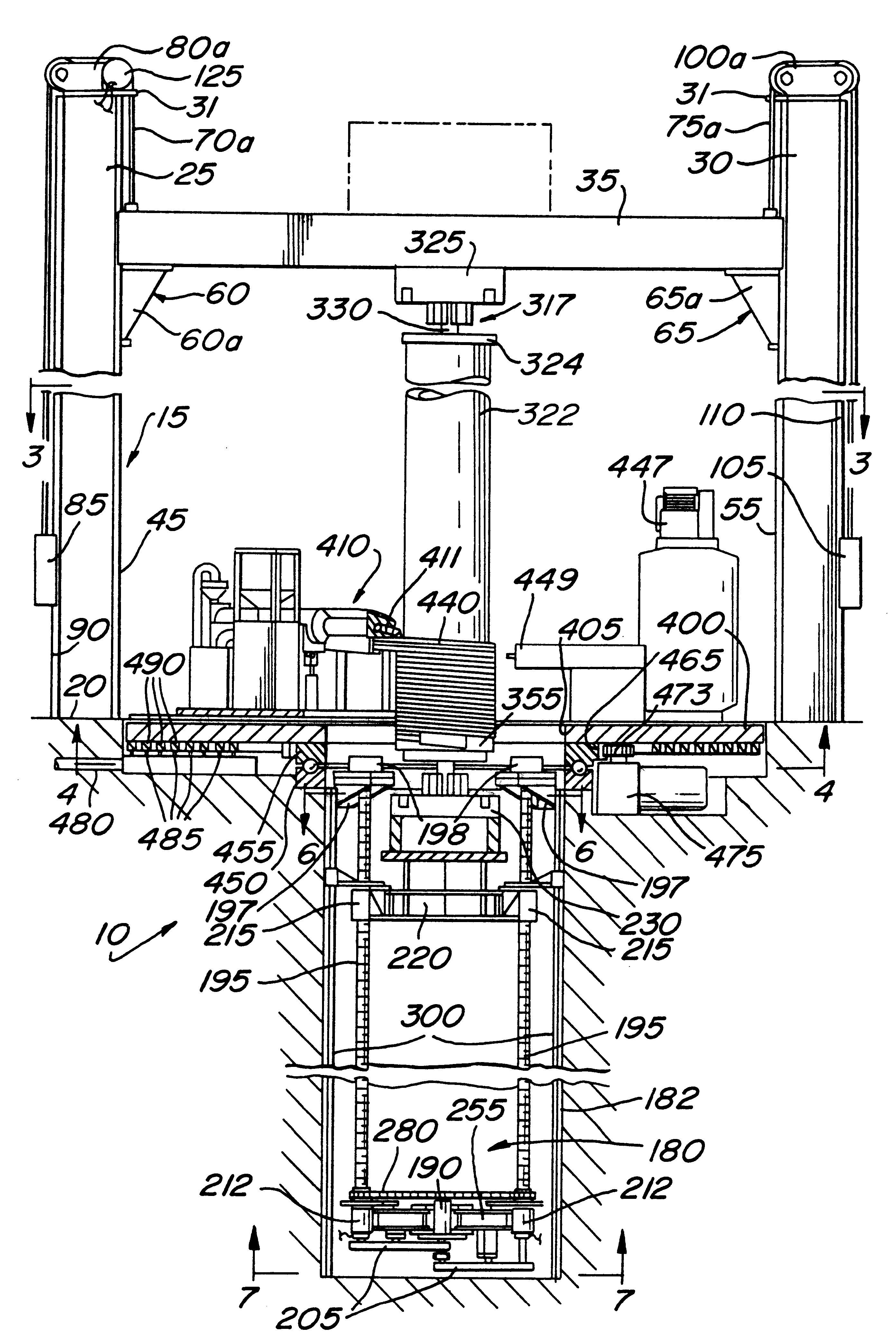

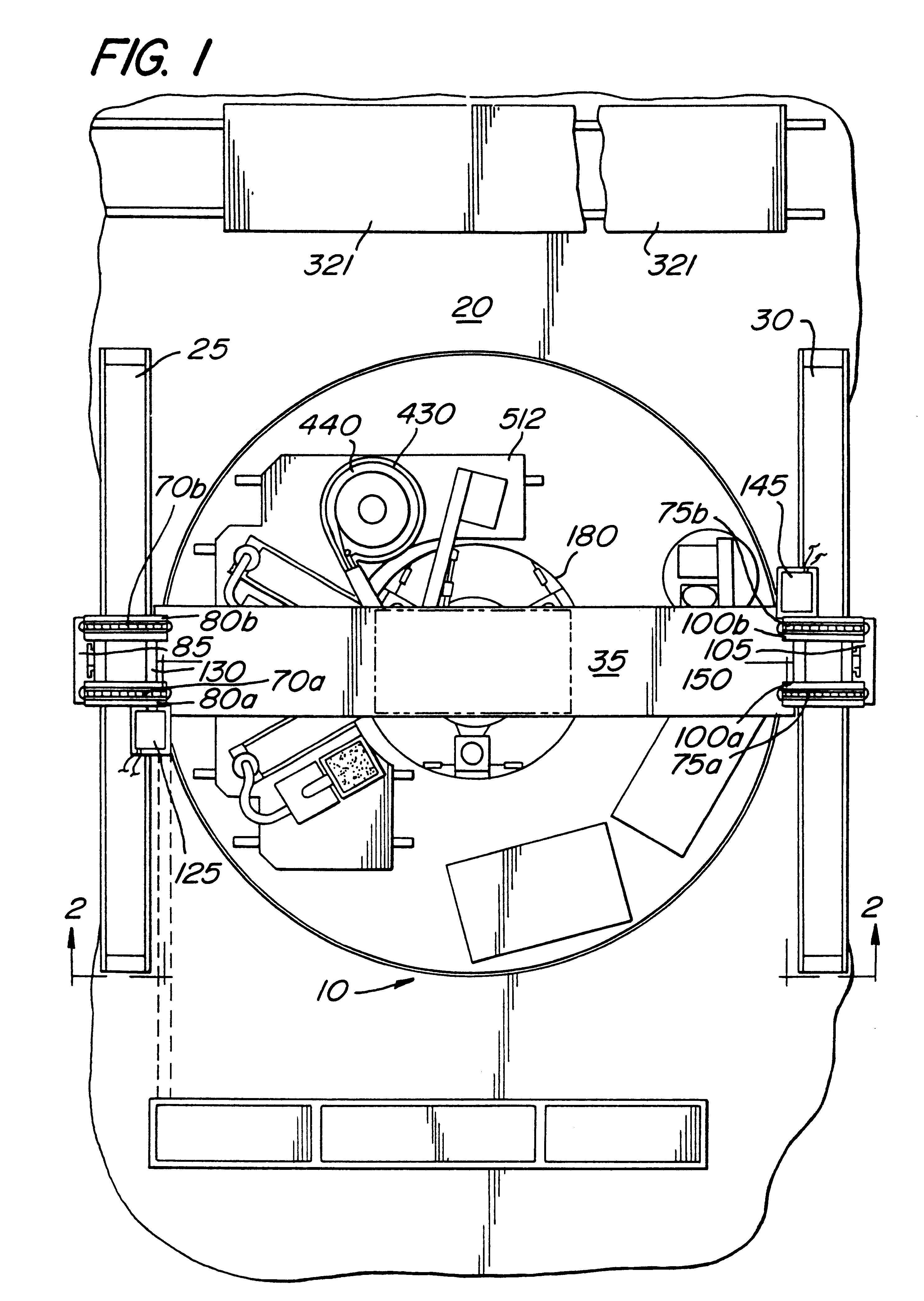

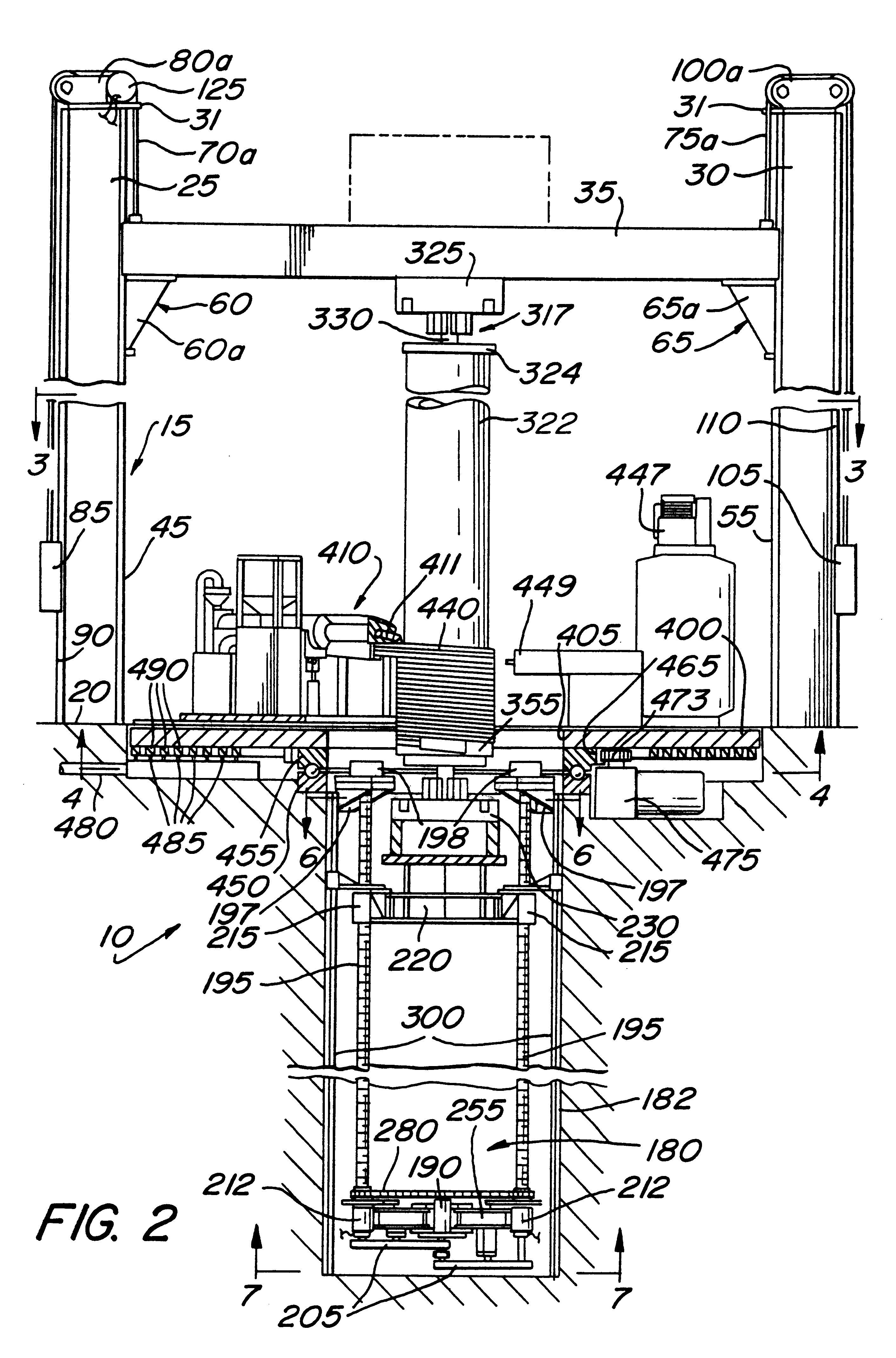

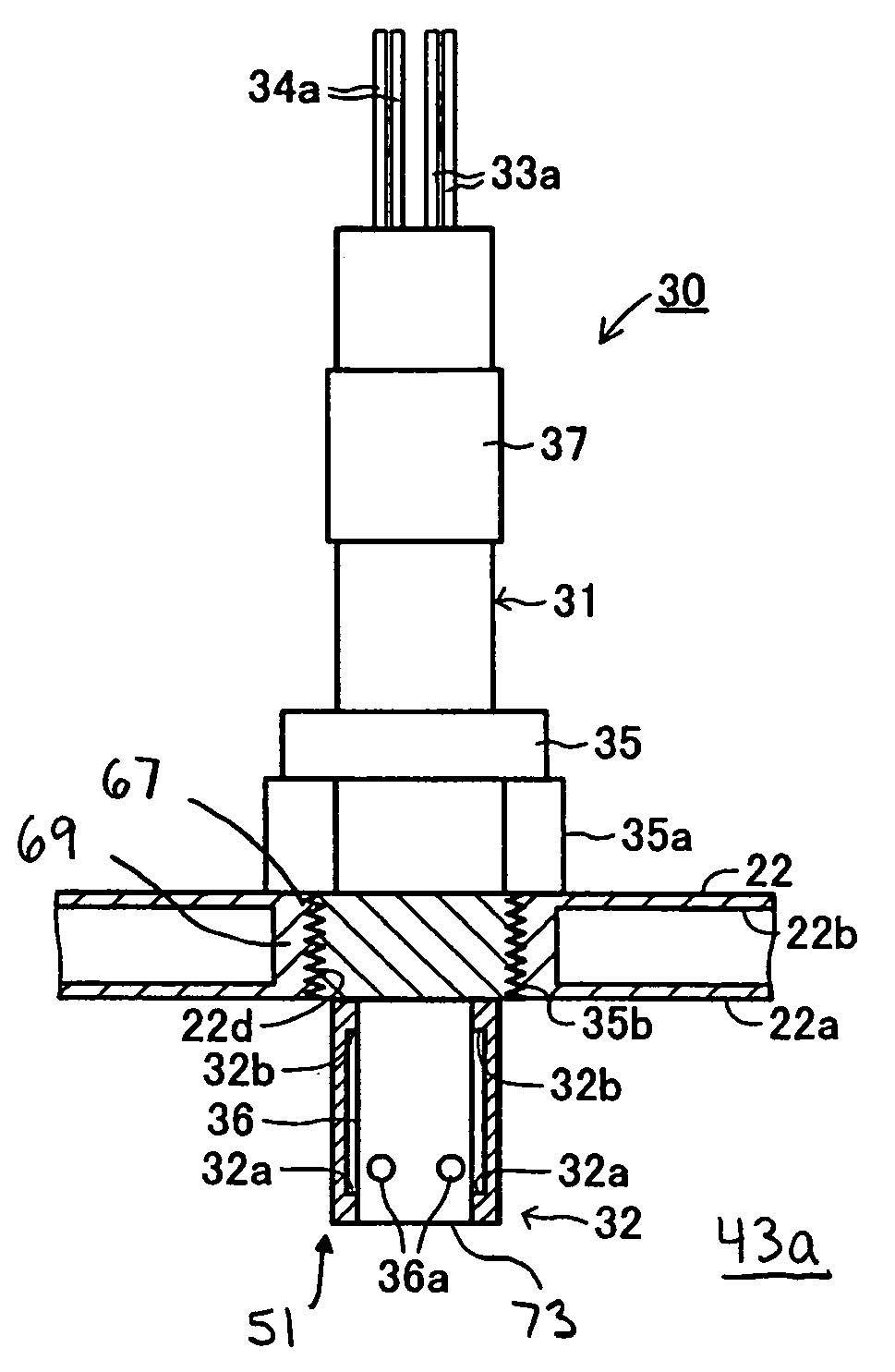

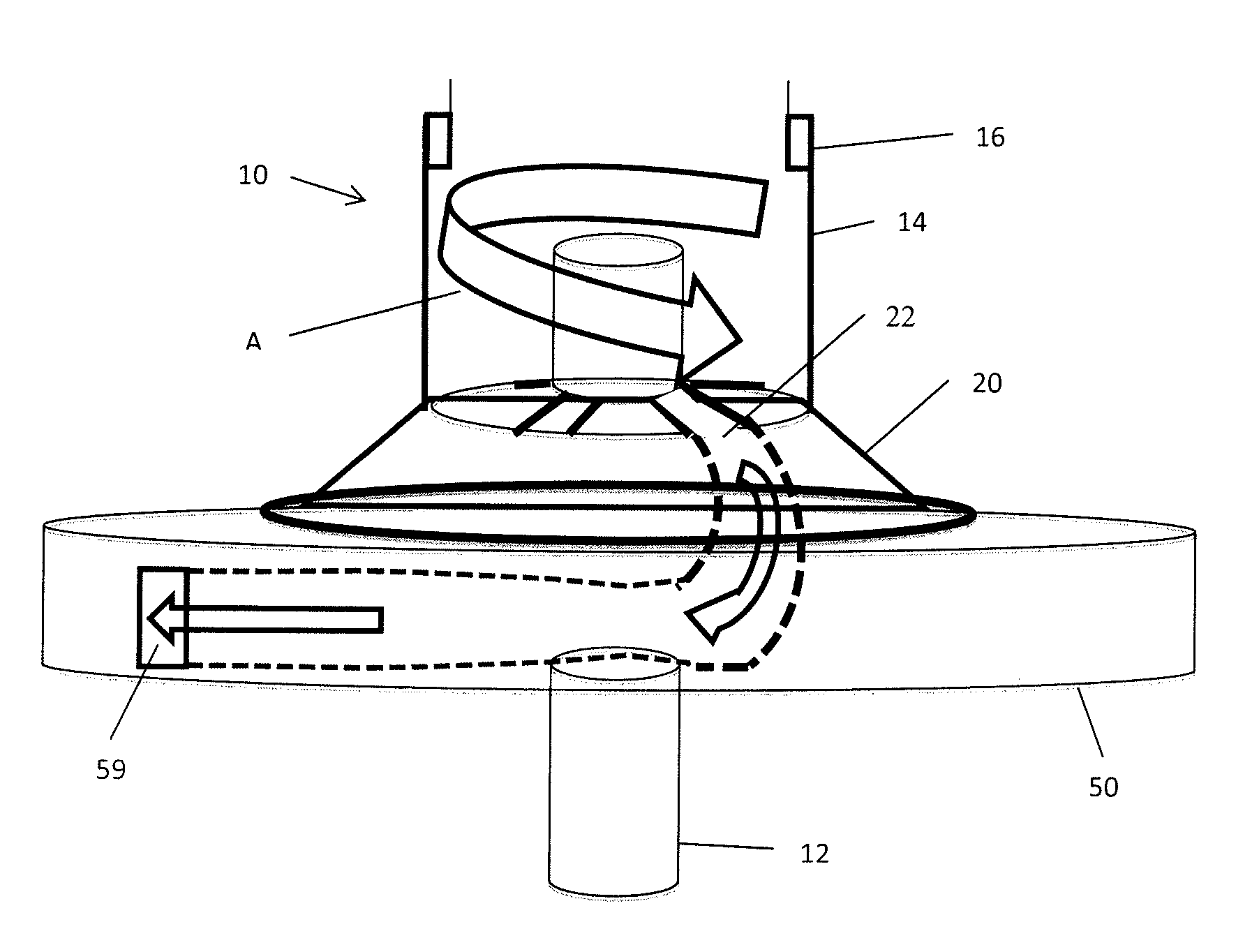

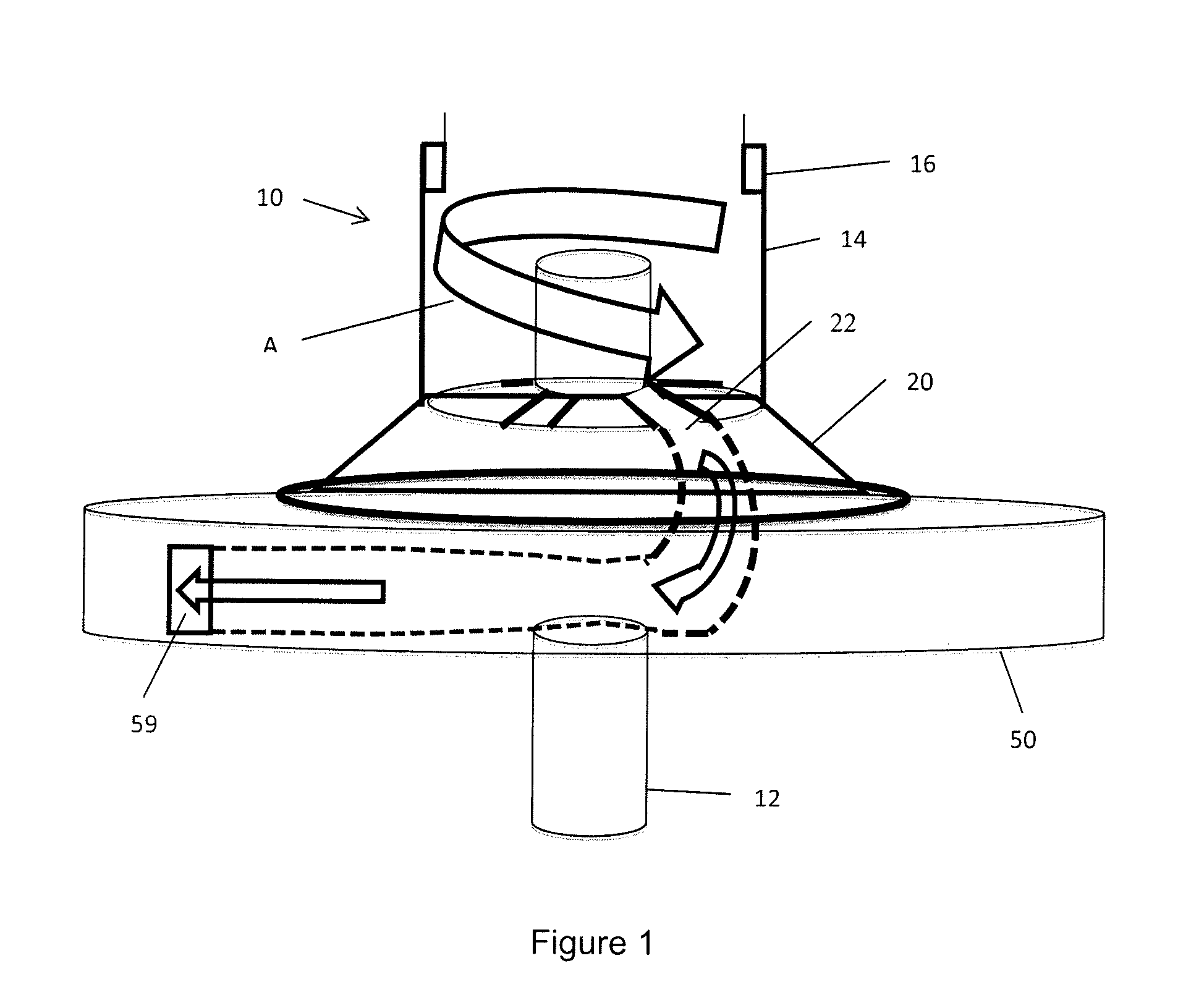

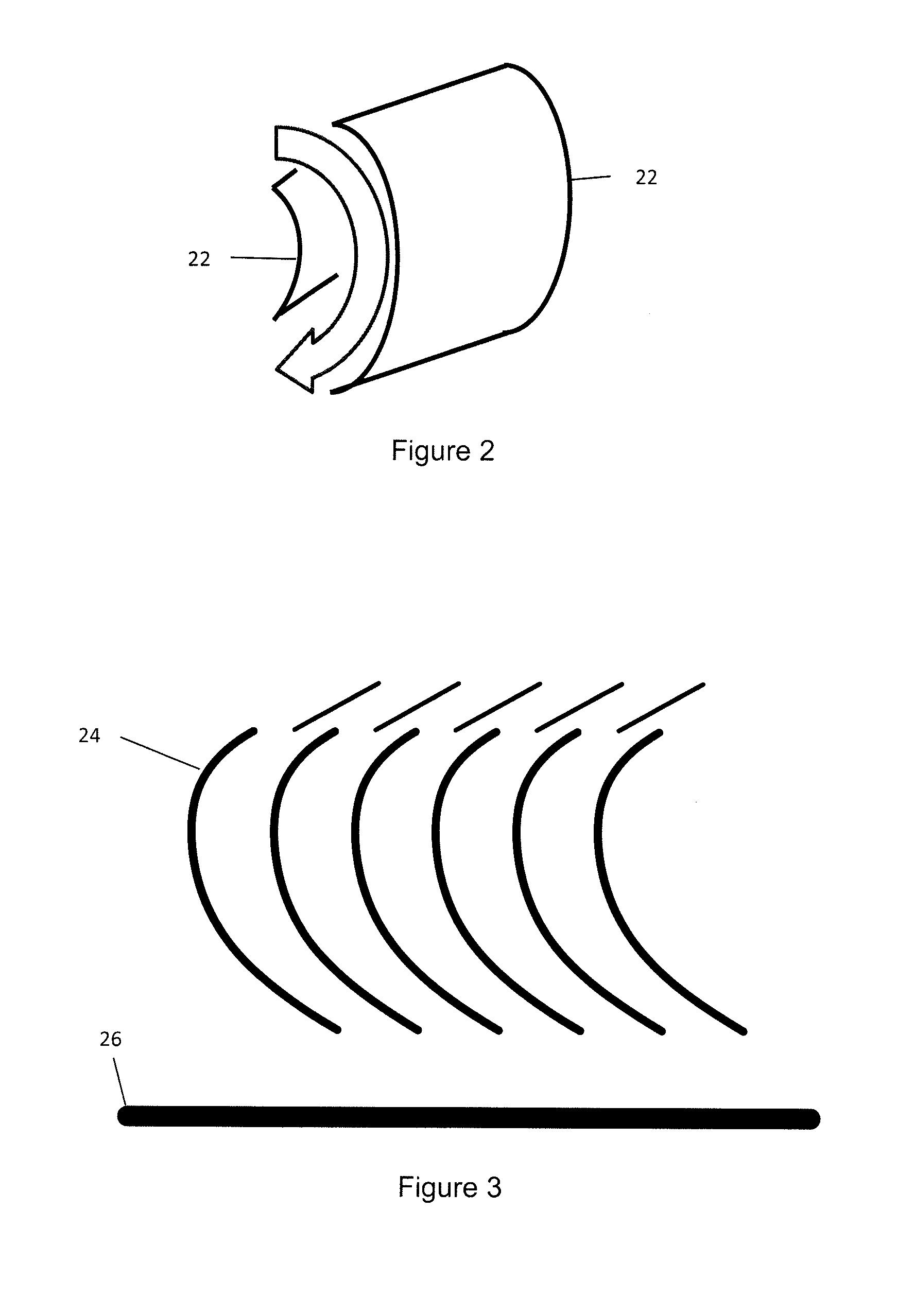

Method and apparatus for covering a metal roll core with a polymeric material preferable a high performance thermoplastic material

InactiveUS6206994B1High durabilityLong lifespanPaper/cardboard wound articlesShaft and bearingsPlastic propertyMetal

A method and apparatus for covering a roll core with a polymeric material, preferably a high performance thermoplastic material, is disclosed. The method includes first providing a cylindrical roll core having two ends, a length, and an outer surface. A spacer assembly is attached proximate one end of the roll core, the spacer assembly having a circumference greater than that of the roll core. After preheating to a desired temperature, the roll core is then placed within an apparatus in a substantially vertical orientation and held therein by suitable fixtures, e.g., opposed universal chucks. A length of mold tape is helically wound over the length of the roll core in a spaced-apart relationship therewith to define an application zone between the mold tape and the roll core outer surface. A filament formed of the polymeric material is extruded within the application zone and helically wound over the roll core outer surface so that the roll core is covered with the material. Localized heating is applied to the roll core surface just prior to the application of the filament to improve bonding to the roll core surface. The mold tape acts as a supportive form to prevent sagging of the extruded material prior to solidifying. The wound extruded material is allowed to solidify in a temperature controlled manner to be hardened to form a continuous layer over the length of the roll core. Finally, the mold tape is removed. The resulting covered roll fabricated in accordance with this method has minimal residual stresses and a has a higher tensile strength, compression strength and impact strength. The resulting covered roll also has a glass transition temperature, greater durability, more suitable Young's modulus, and a longer lifespan than prior art covered rolls. The covered roll fabricated in accordance with this method also performs consistently under extremely high pressures, high heating conditions and high speed conditions.

Owner:ROBERT H NEESE TRUST

Exhaust gas sensor

ActiveUS20060042946A1High detection accuracyHigh durabilityElectrical controlExhaust apparatusExhaust fumesEngineering

An exhaust gas sensor inhibits a detecting part of an exhaust gas sensor from being exposed to water and has high detection accuracy and high durability. The exhaust gas sensor has a sensor body and a protective cover. The sensor body has an outer housing. The outer housing has a plurality of gas inlets. A gas detection element for detecting a component of the exhaust gas (e.g., oxygen) disposed within the outer housing. The protective cover has a cylindrical shape and has a plurality of protrusions at its opposing ends. The protrusions provide a tight fit with the outer housing. The protective cover is attached to the outer periphery of the outer housing without closing gas inlets formed through the outer cylinder by press-fitting the outer cylinder into the protective cover.

Owner:YAMAHA MOTOR CO LTD

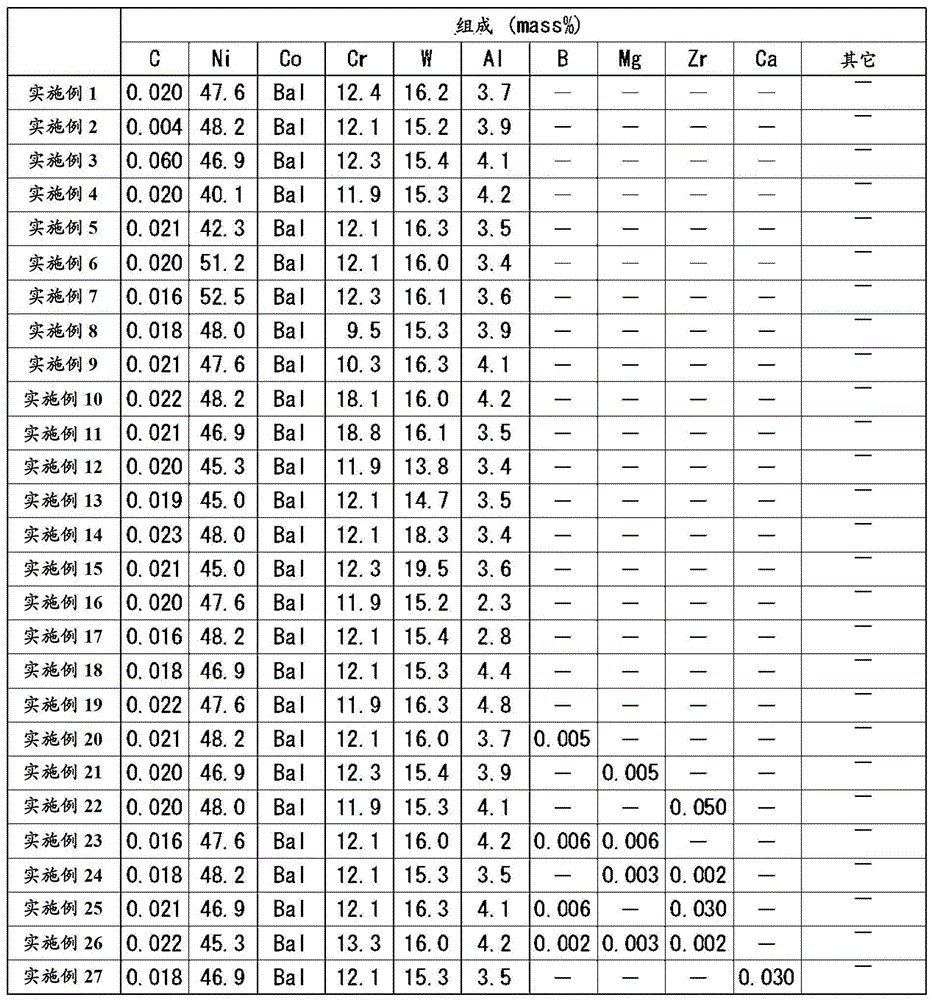

Co-based alloy

InactiveCN103069028AReduced hot workabilityHigh durabilityBlade accessoriesEfficient propulsion technologiesAlloyImpurity

A Co-based alloy containing not less than 0.001 mass% and less than 0.100 mass% of C, not less than 9.0 mass% and less than 20.0 mass% of Cr, not less than 2.0 mass% and less than 5.0 mass% of Al, not less than 13.0 mass% and less than 20.0 mass% of W, and not less than 39.0 mass% and less than 55.0 mass% of Ni, with the remainder being made up by Co and unavoidable impurities, wherein the contents of Mo, Nb, Ti and Ta which are included in the unavoidable impurities are as follows: Mo < 0.010 mass%, Nb < 0.010 mass%, Ti < 0.010 mass%, and Ta < 0.010 mass%.

Owner:MITSUBISHI HITACHIPOWER SYST LTD +1

Reaction turbine and hybrid impulse reaction turbine

ActiveUS20130101393A1High durabilityLess efficientCombination enginesGas turbine plantsMagnetCooling channel

A reaction turbine has channels formed in the top surface of a disc to create nozzles. The channels can be covered by a membrane sealed to the disc or by the housing extended from a combustor. Each channel may have a first section extending radially outwardly from an inlet of the reaction turbine and a second curved section extending from the first section to a periphery of the disc. A reaction turbine may also receive input from an impulse turbine. Fluid flows through the impulse turbine and fluid from the impulse turbine enters an inlet of the reaction turbine. The reaction turbine may have cooling channels and cooling fins to lower the temperature of the disc during operation. In addition, magnets may provide bearing support and electricity generation. In addition, the reaction turbine may have a dual shaft construction, with each shaft connected to a reaction turbine. One reaction turbine powers a compressor, while the second reaction turbine powers a load through the second shaft.

Owner:HYBRID TURBINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com