Patents

Literature

615 results about "Ceramic heater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ceramic heater as a consumer product is a space heater that generates heat using a heating element of PTC (Positive Temperature Coefficient) ceramic. Ceramic heaters are usually portable and typically used for heating a room or small office, and are of similar utility to metal-element fan heaters.

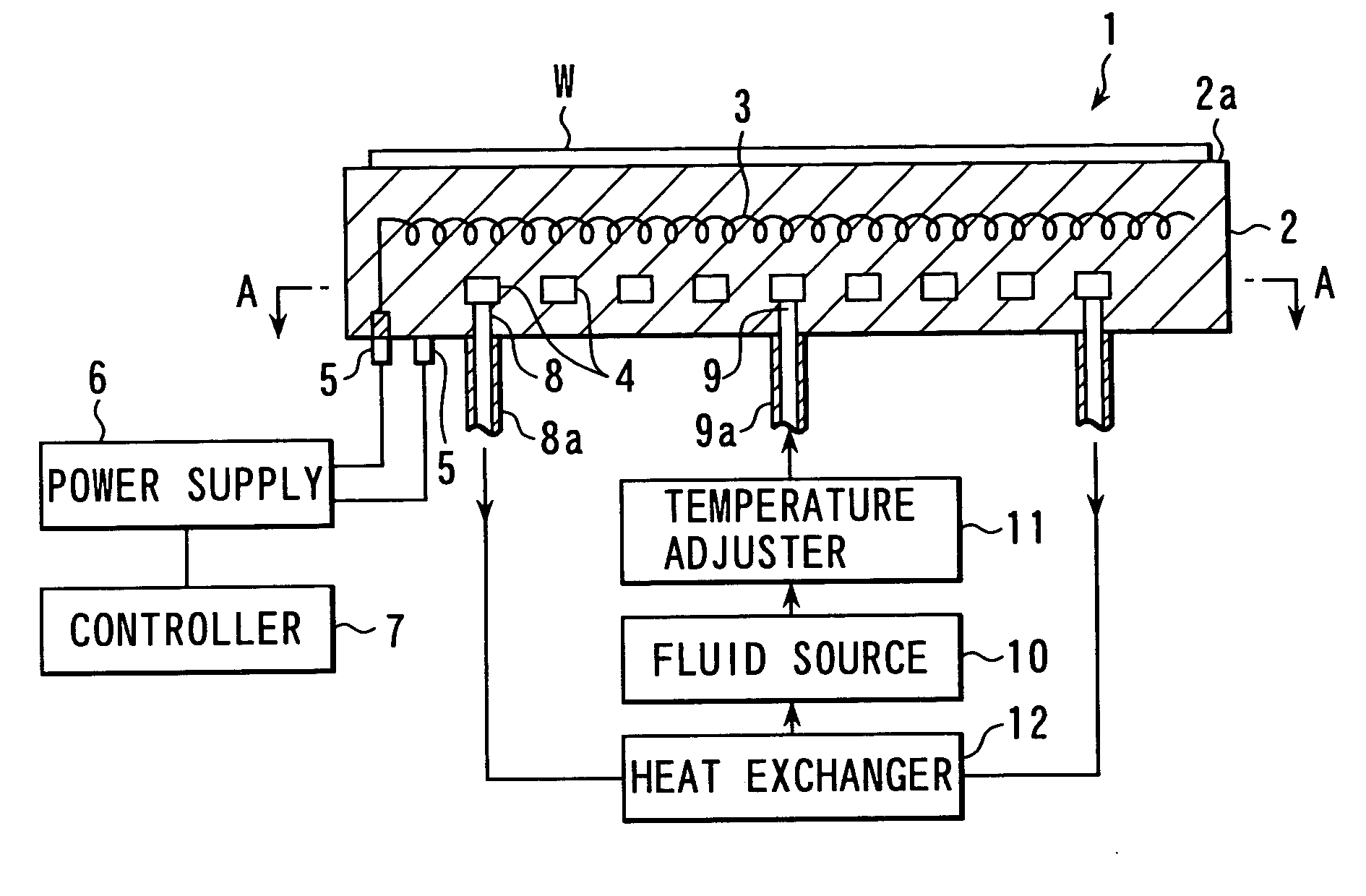

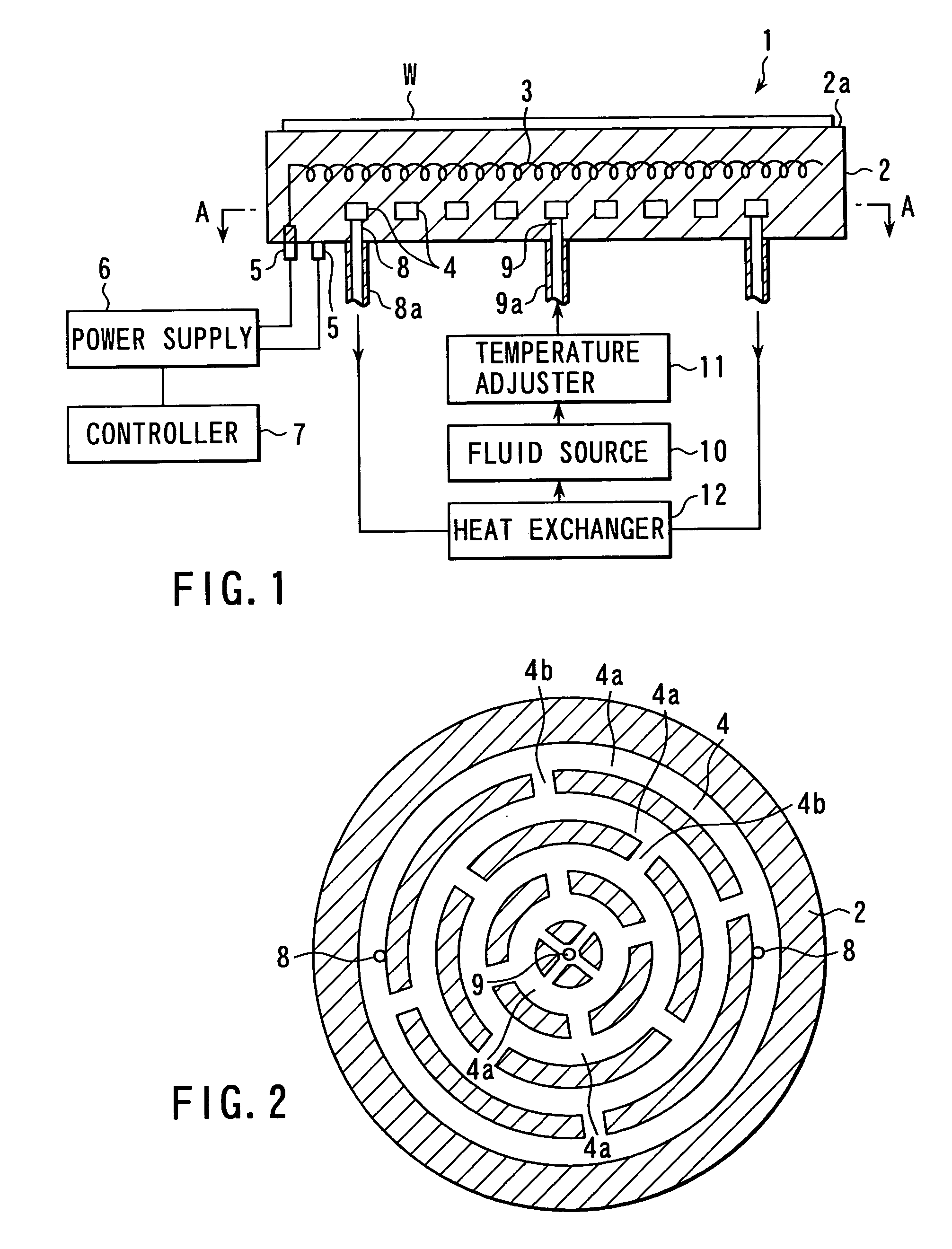

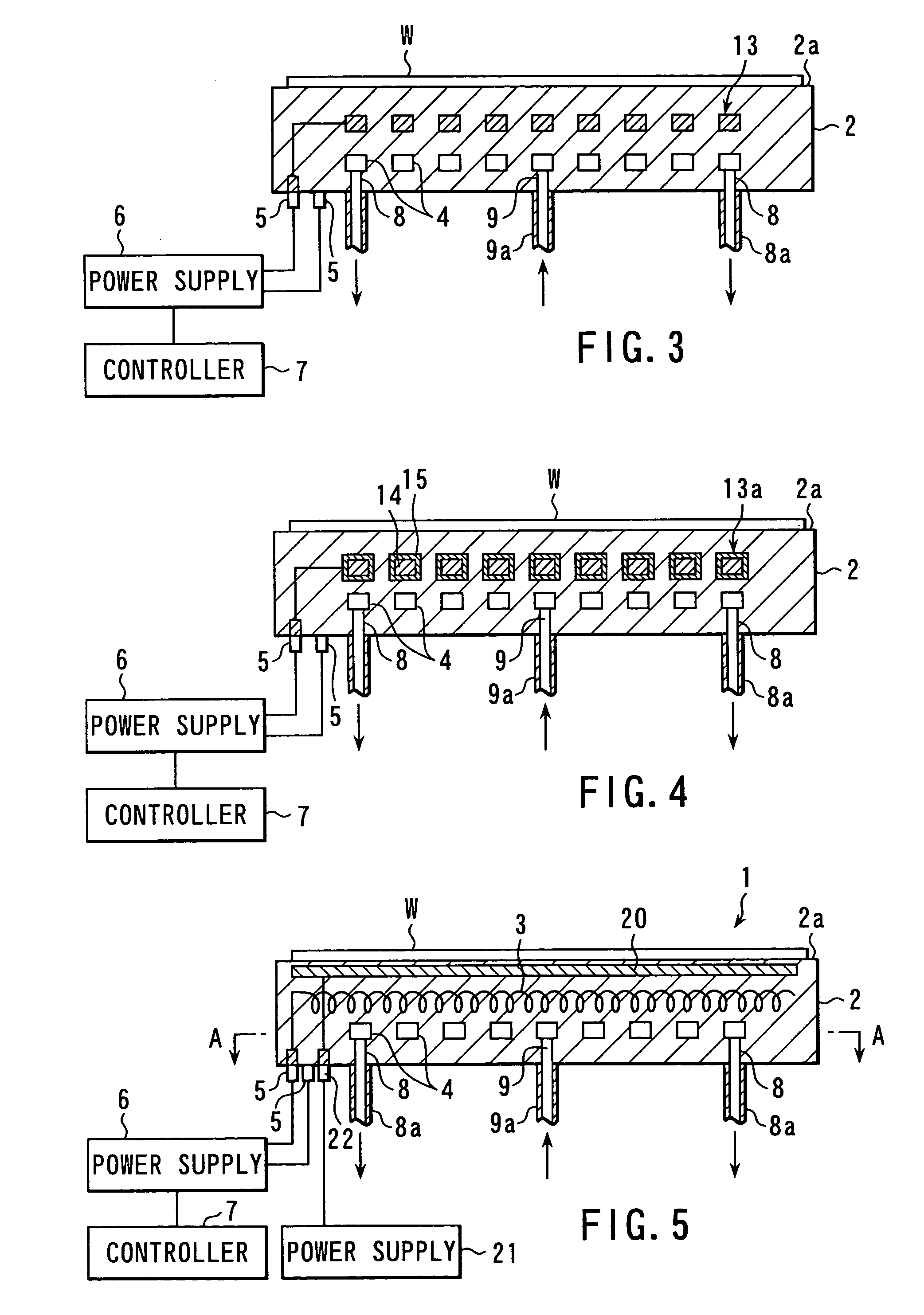

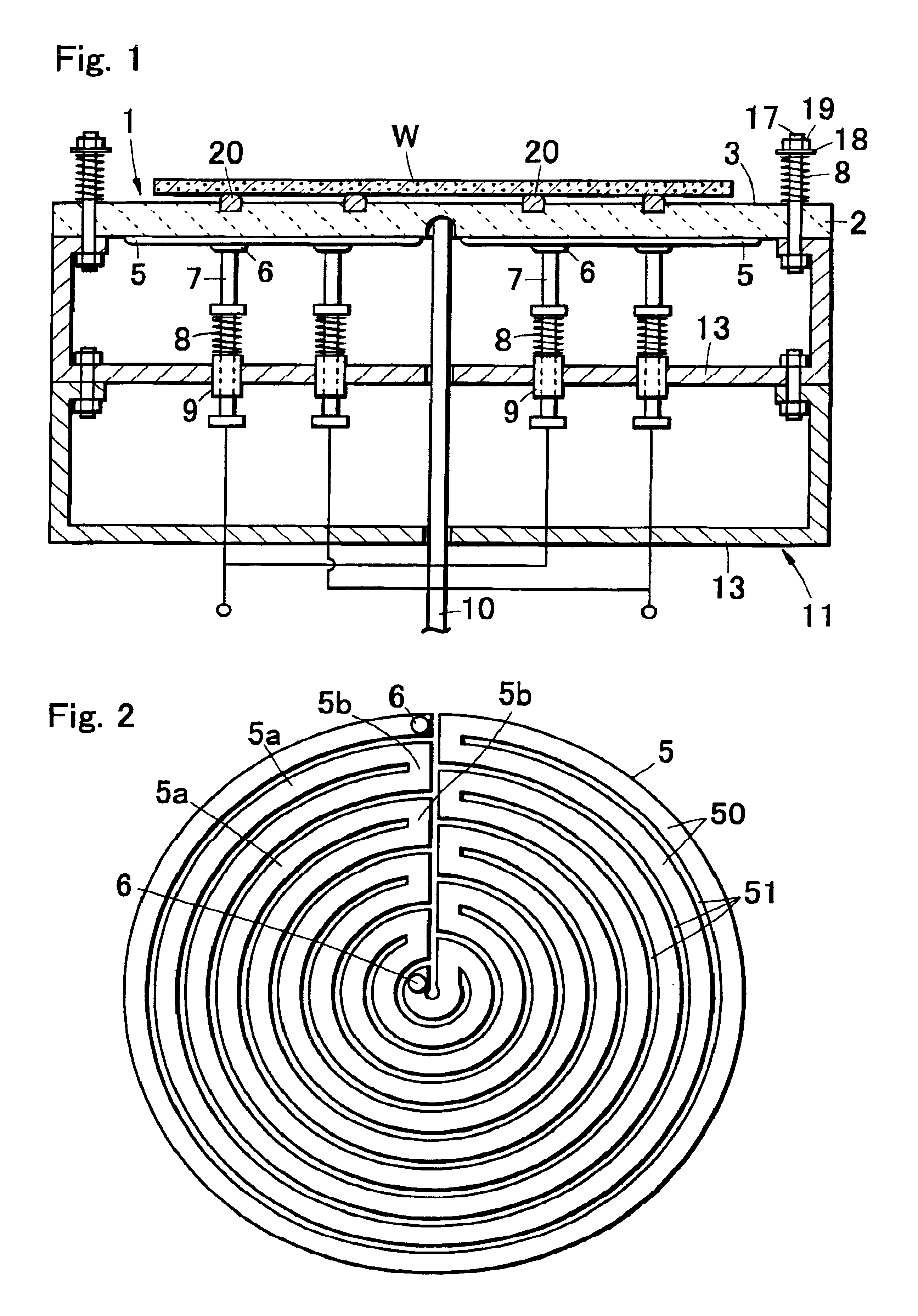

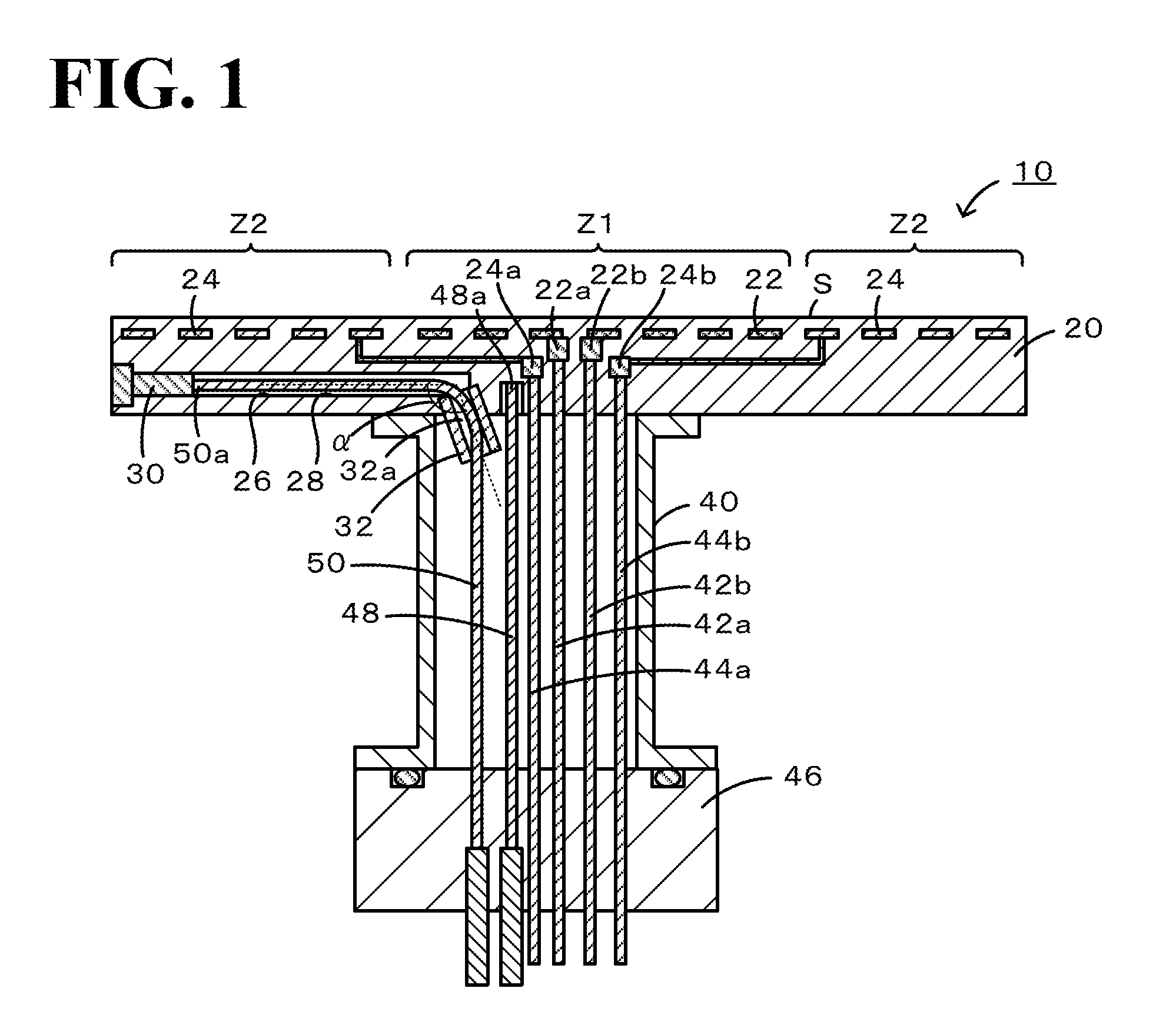

Ceramic heater system and substrate processing apparatus having the same installed therein

InactiveUS6951587B1Improve cooling efficiencyUniform heating effectSemiconductor/solid-state device manufacturingOhmic-resistance heatingMetallurgyGas supply

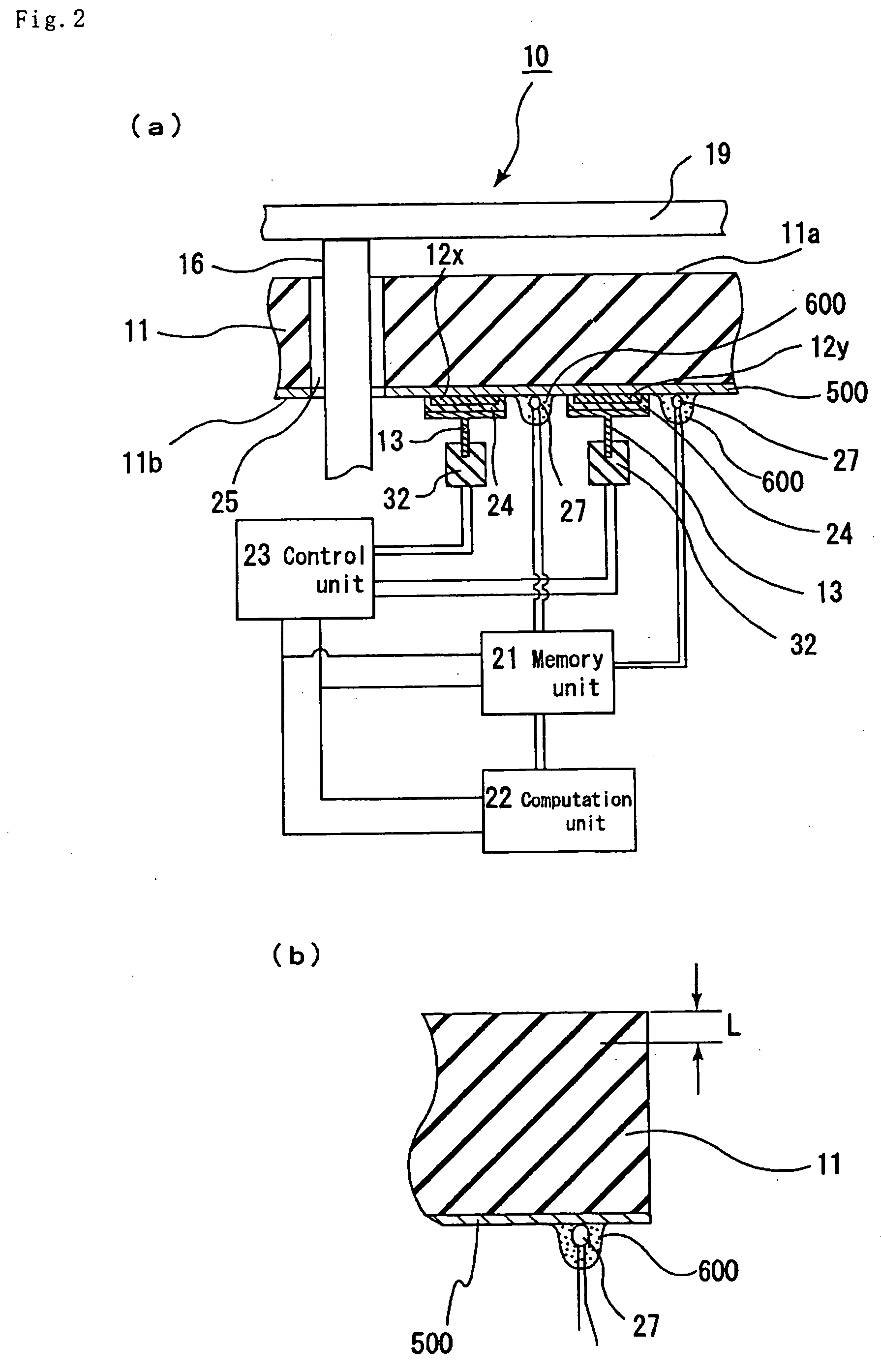

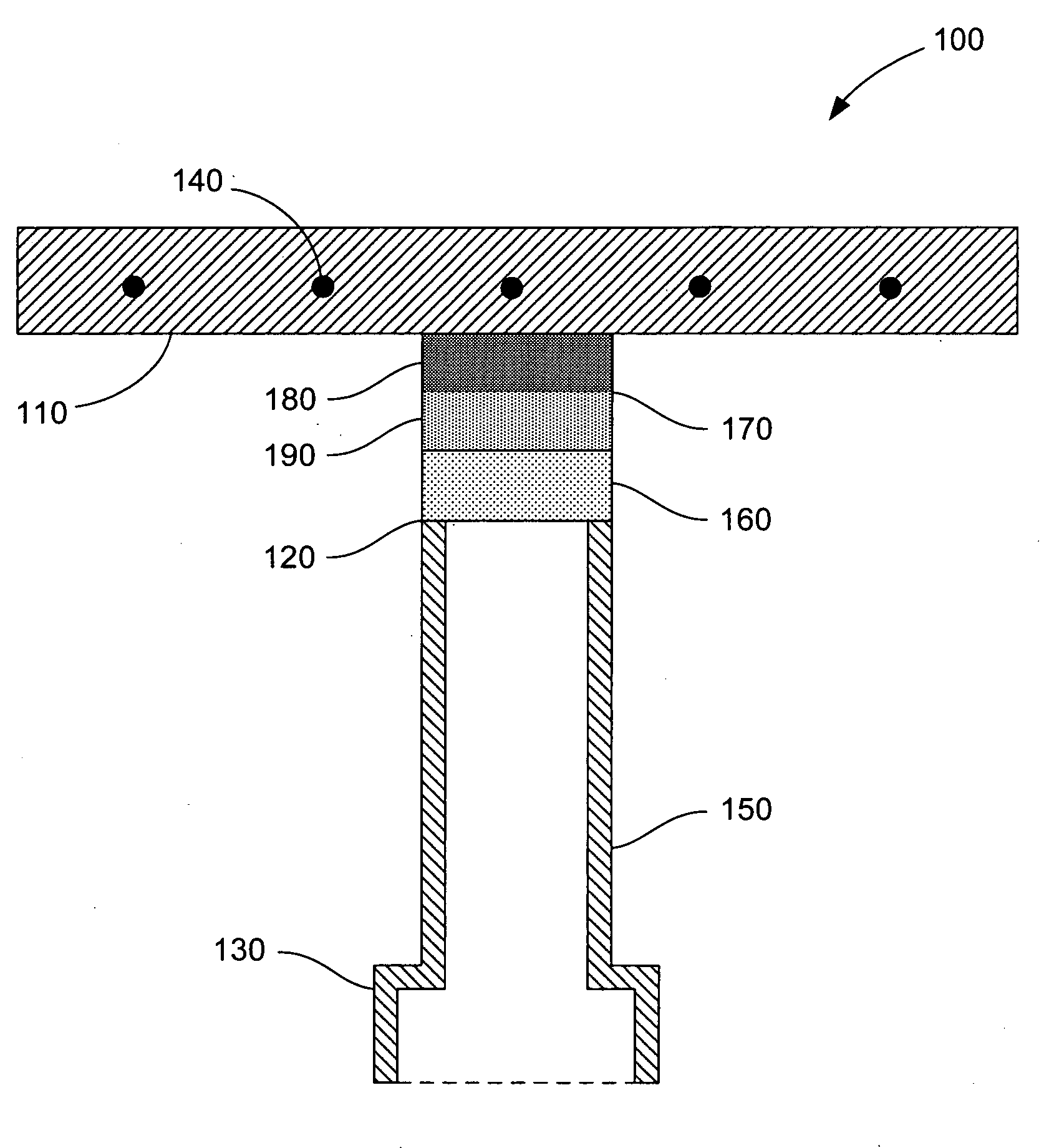

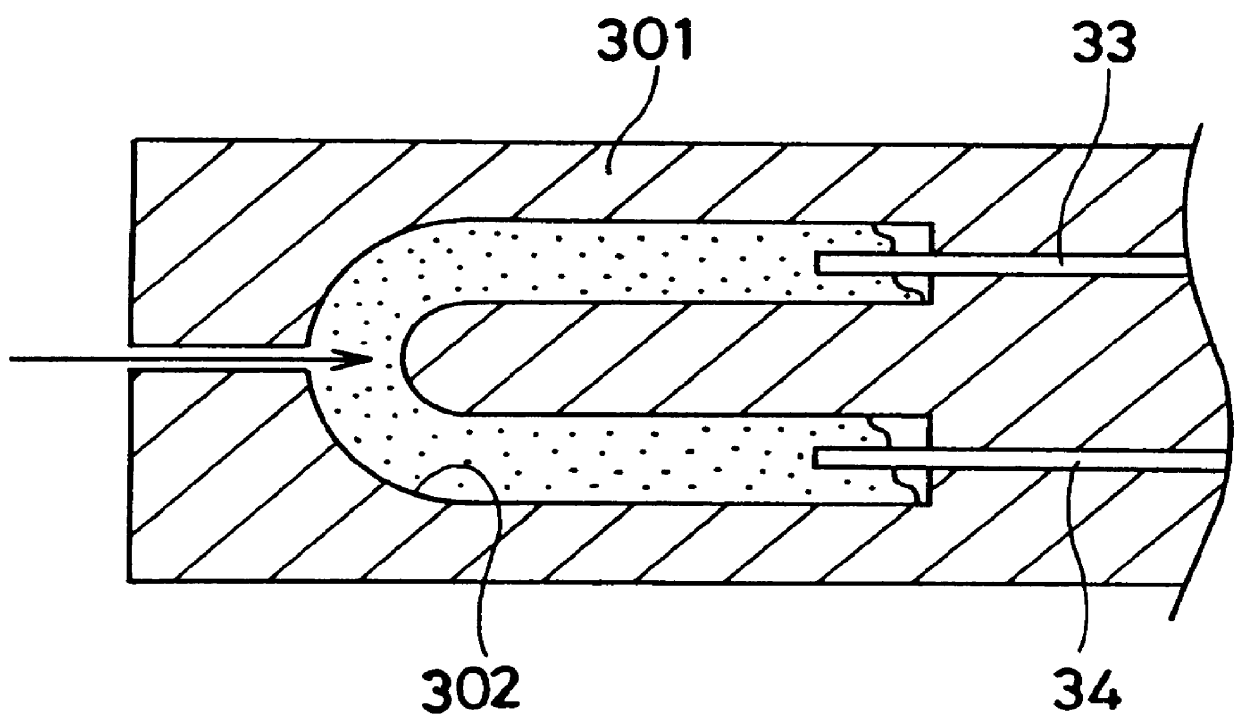

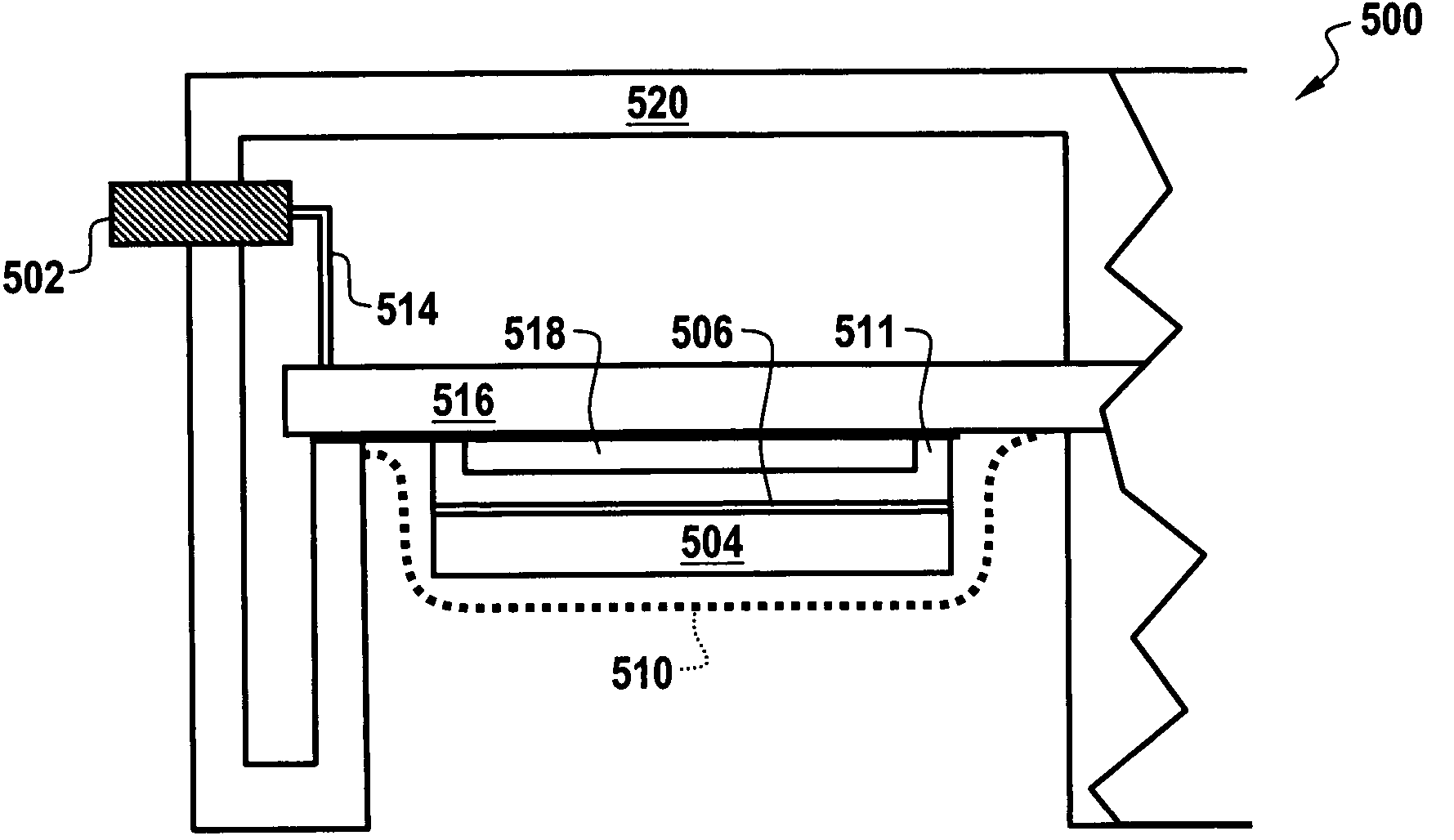

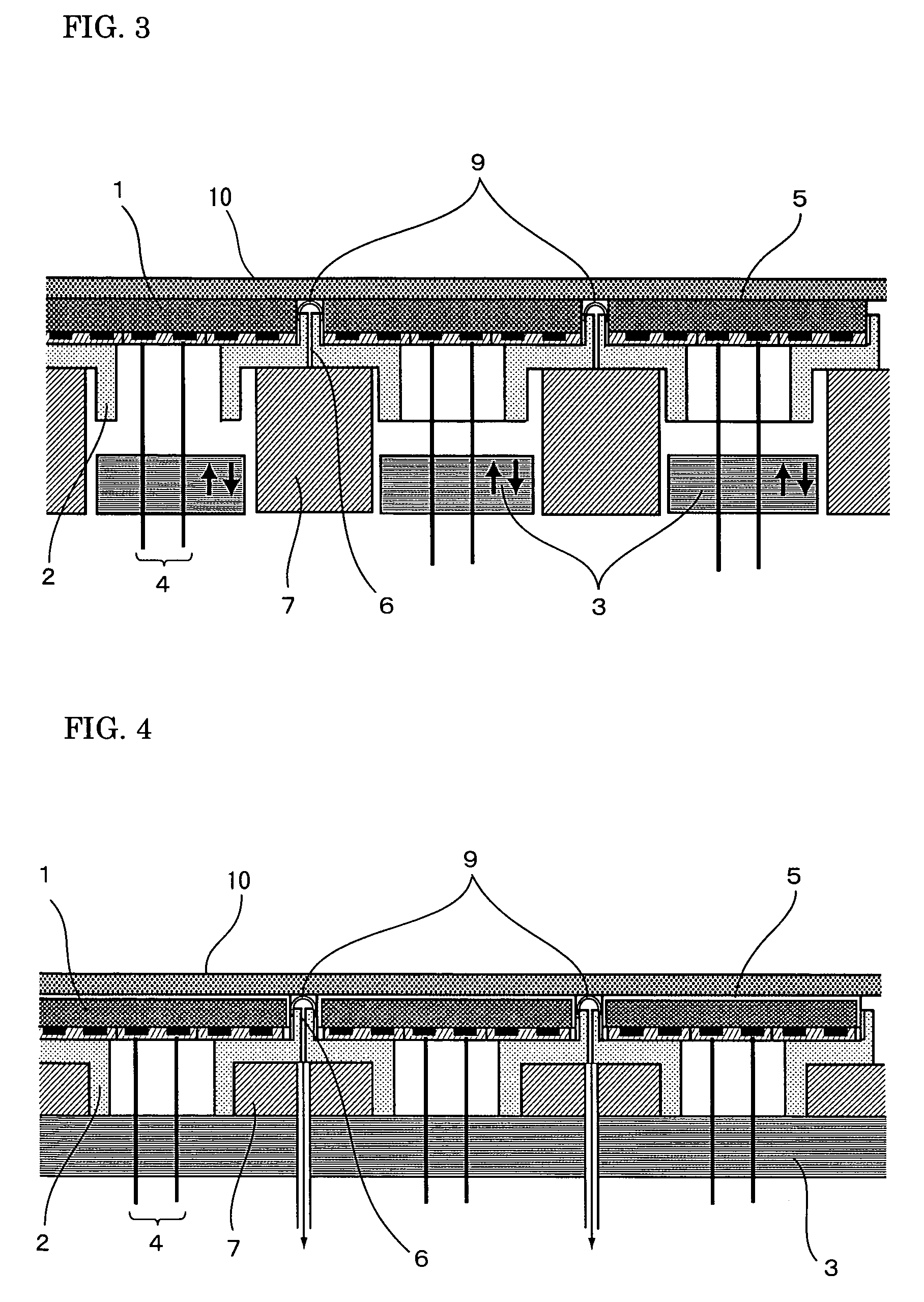

A ceramic heater system has a ceramic heater base having a substrate-mounting surface formed on the top surface thereof and a heater, buried in the heater base, for heating a substrate. A fluid passage is formed buried in the heater base below where the heater is buried. The heater base is cooled as a fluid whose temperature is lower than the temperature of the heater base is let flow in the fluid passage. A substrate processing apparatus has the ceramic heater system installed in a process chamber whose vacuum state can be maintained, a gas supply mechanism for feeding a gas into the process chamber, and a power supply. The substrate processing apparatus performs a heat treatment, etching and film deposition on a substrate placed in the process chamber.

Owner:TOKYO ELECTRON LTD

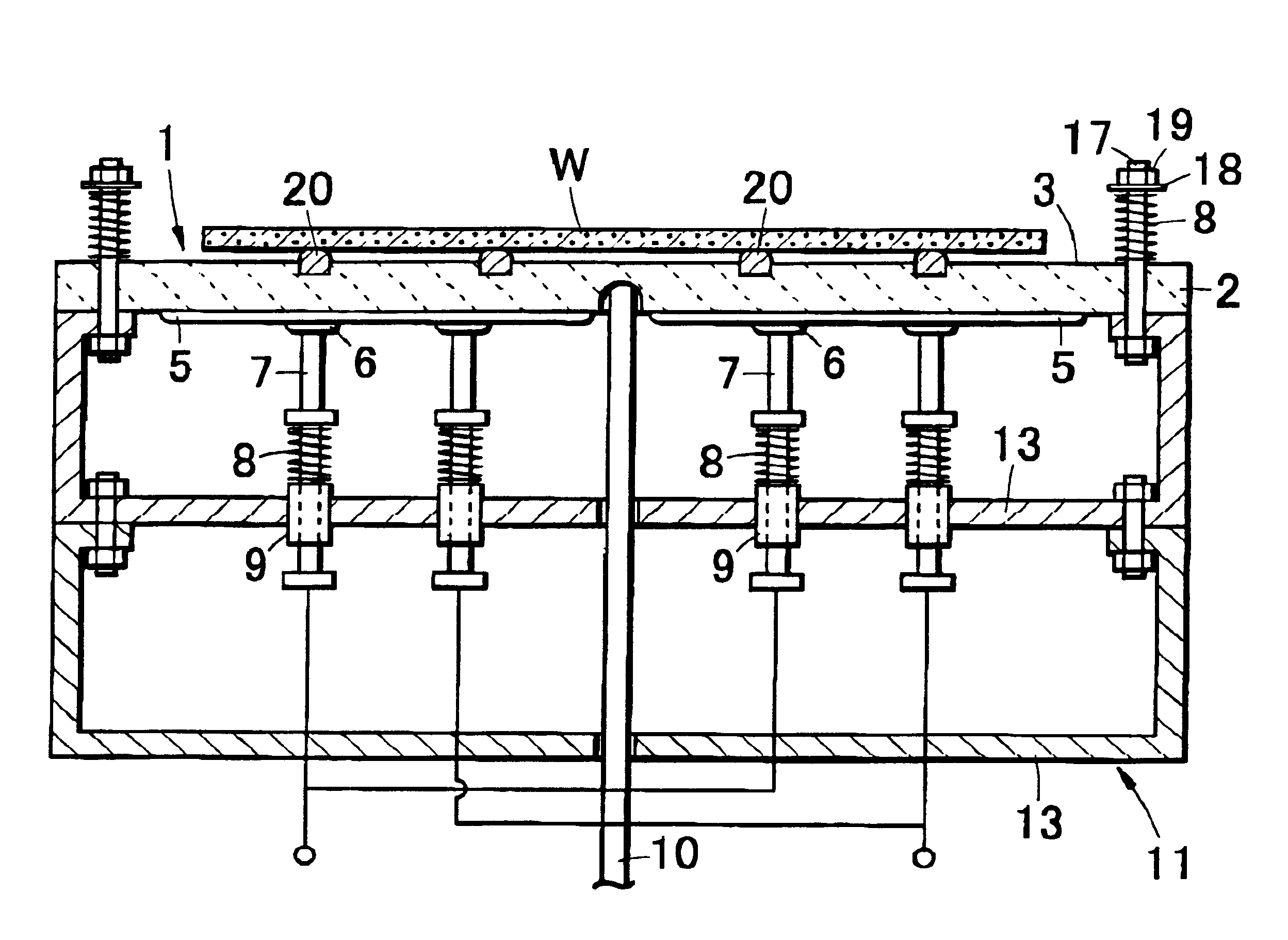

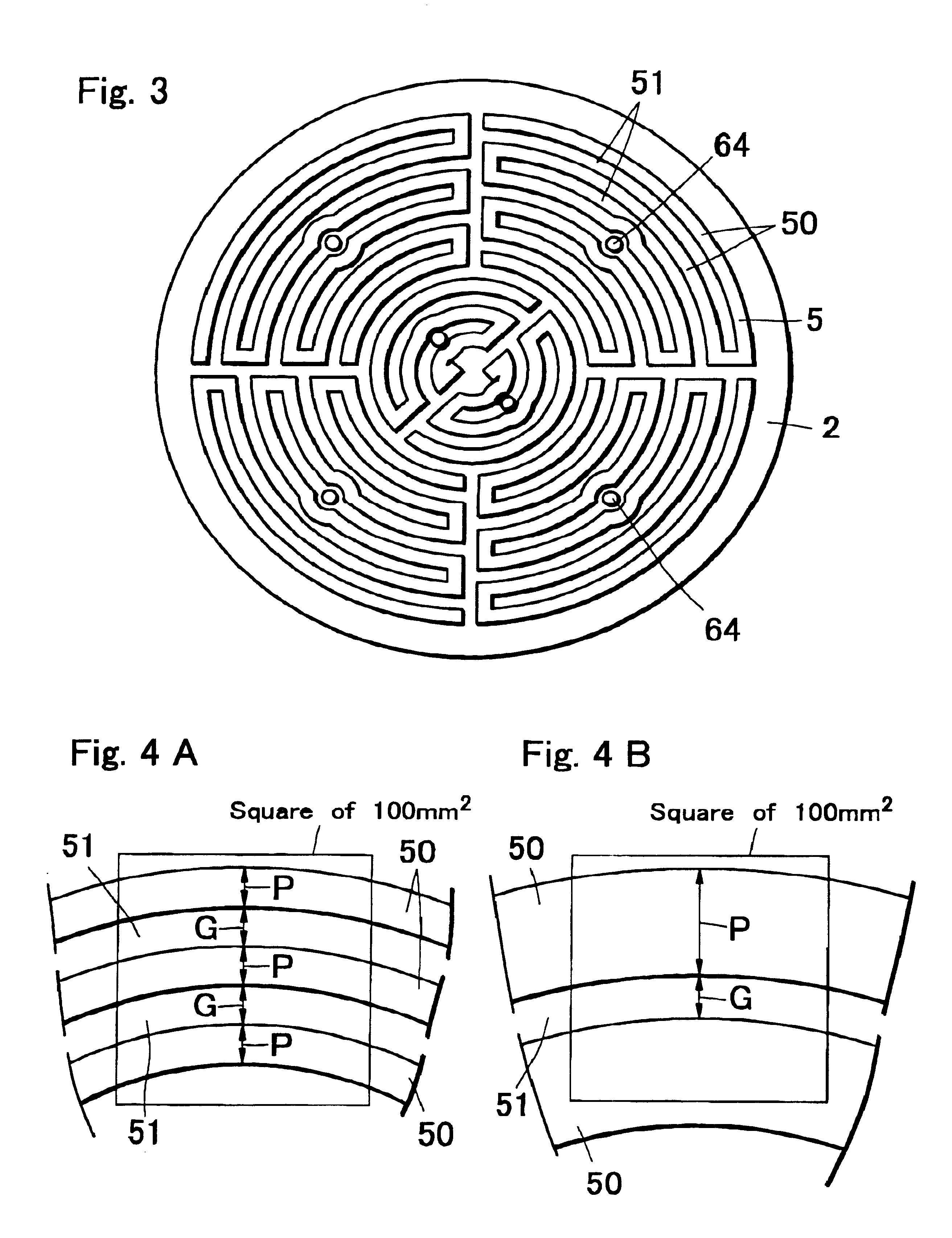

Wafer heating apparatus

InactiveUS6753507B2Semiconductor/solid-state device manufacturingHot plates heating arrangementsMetallurgyHeat generation

Owner:KYOCERA CORP

Ceramic heater for semiconductor manufacturing and inspecting equipment

InactiveUS20050092733A1Improve responseCausing temperature distributionMuffle furnacesSemiconductor/solid-state device manufacturingMetallurgySemiconductor

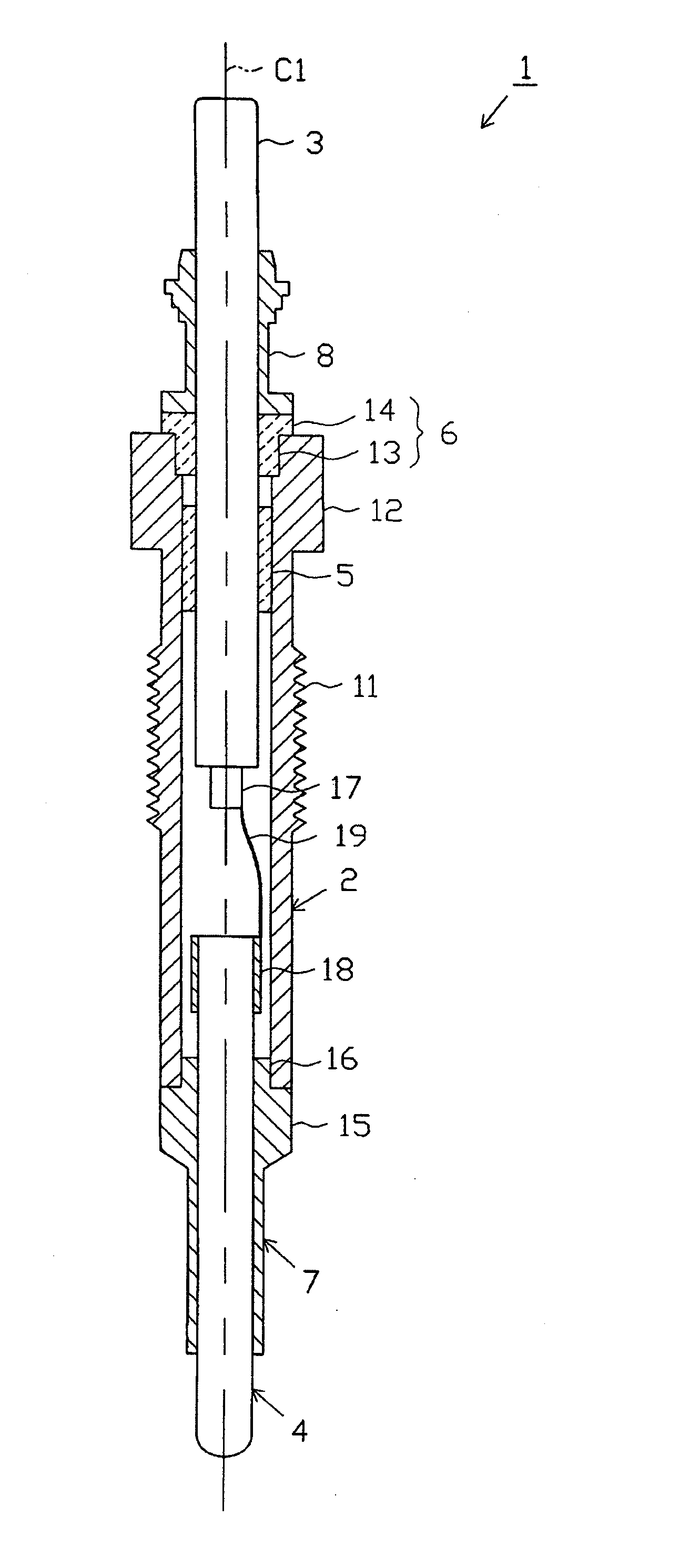

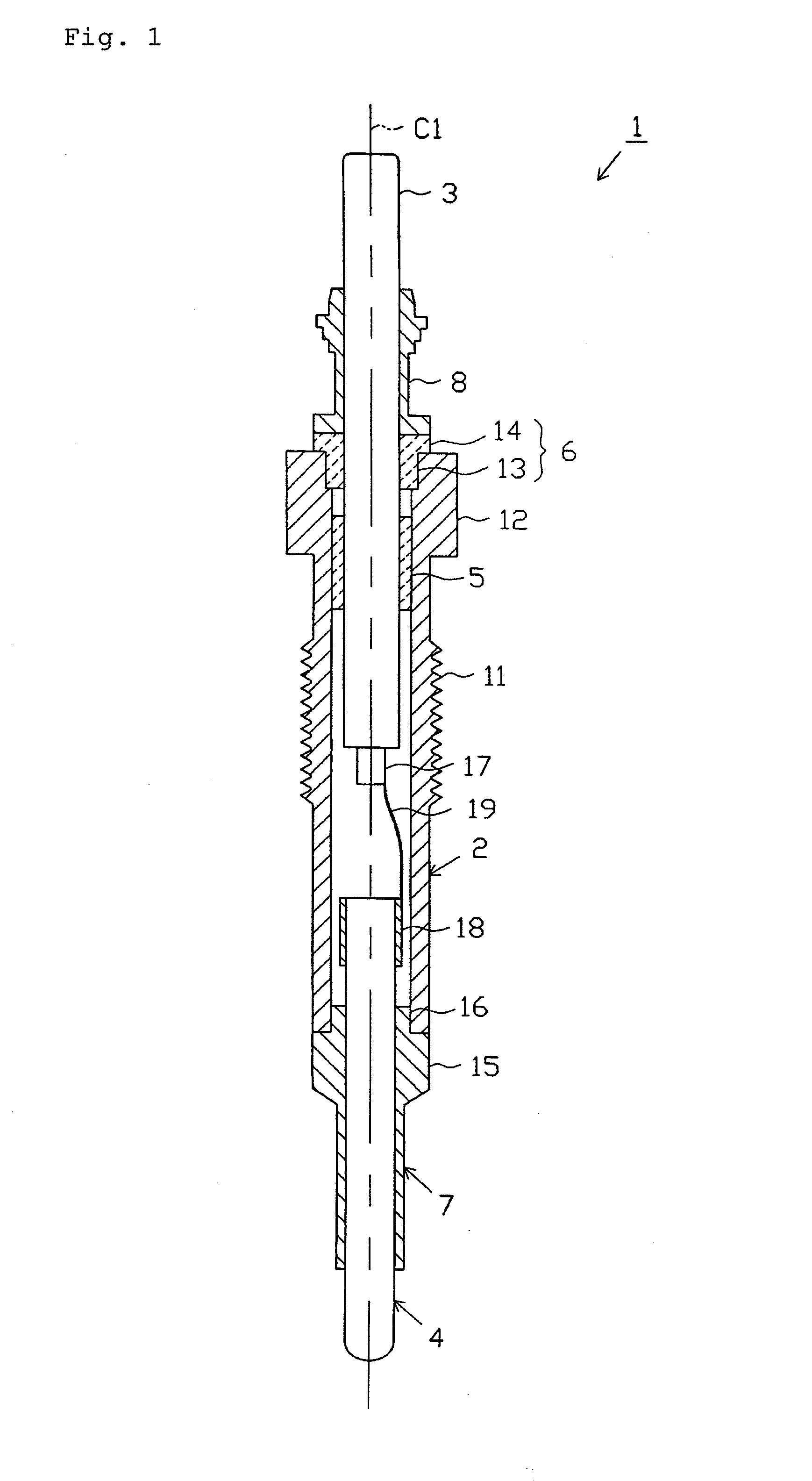

A ceramic heater for a semiconductor producing / examining device including a ceramic substrate having a heating surface for receiving a semiconductor wafer, a heating device for generating heat sufficient for producing / examining the semiconductor wafer and formed on the heating surface or inside the ceramic substrate, and a temperature measuring device for measuring a temperature of the heating surface and pressed against the ceramic substrate.

Owner:IBIDEN CO LTD

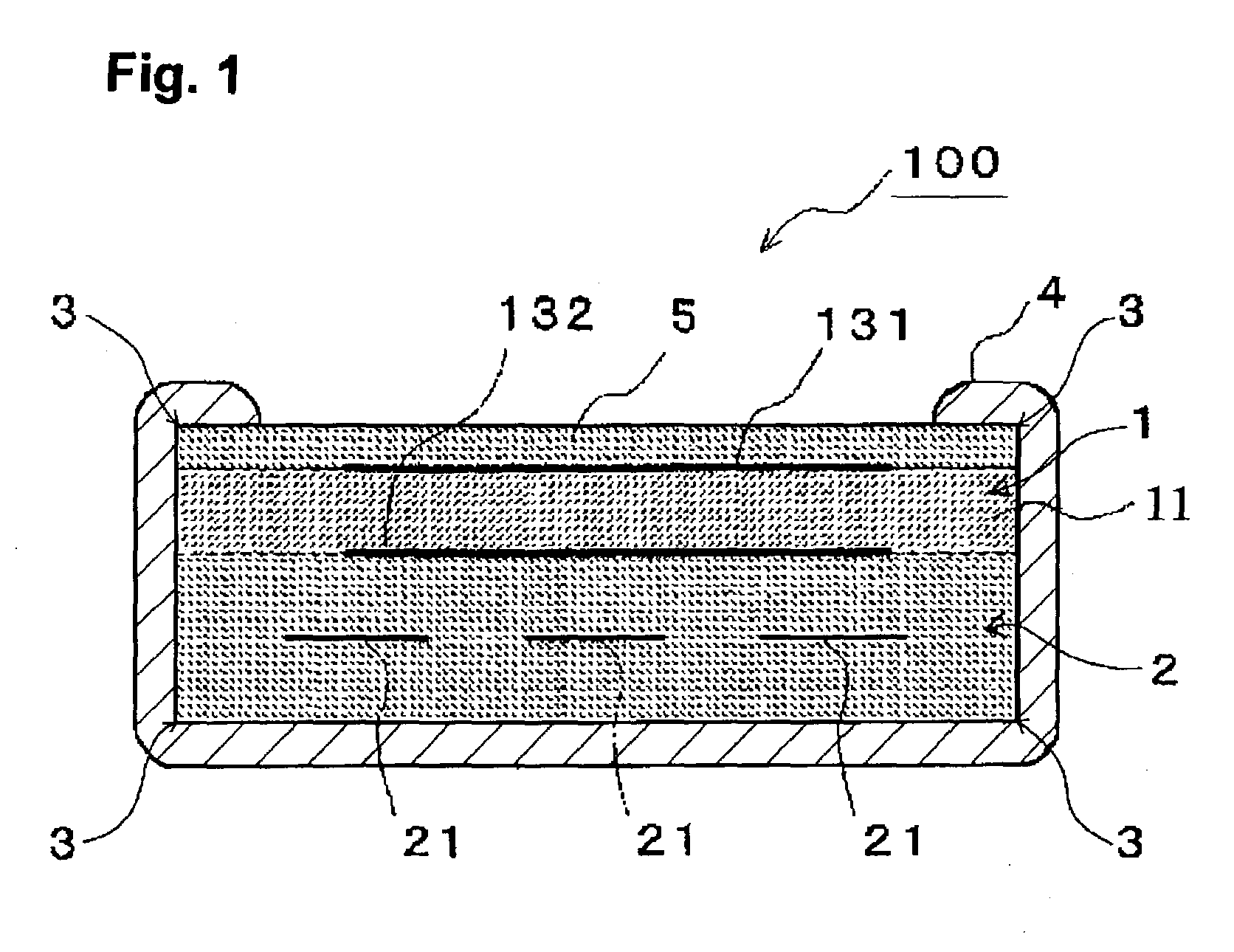

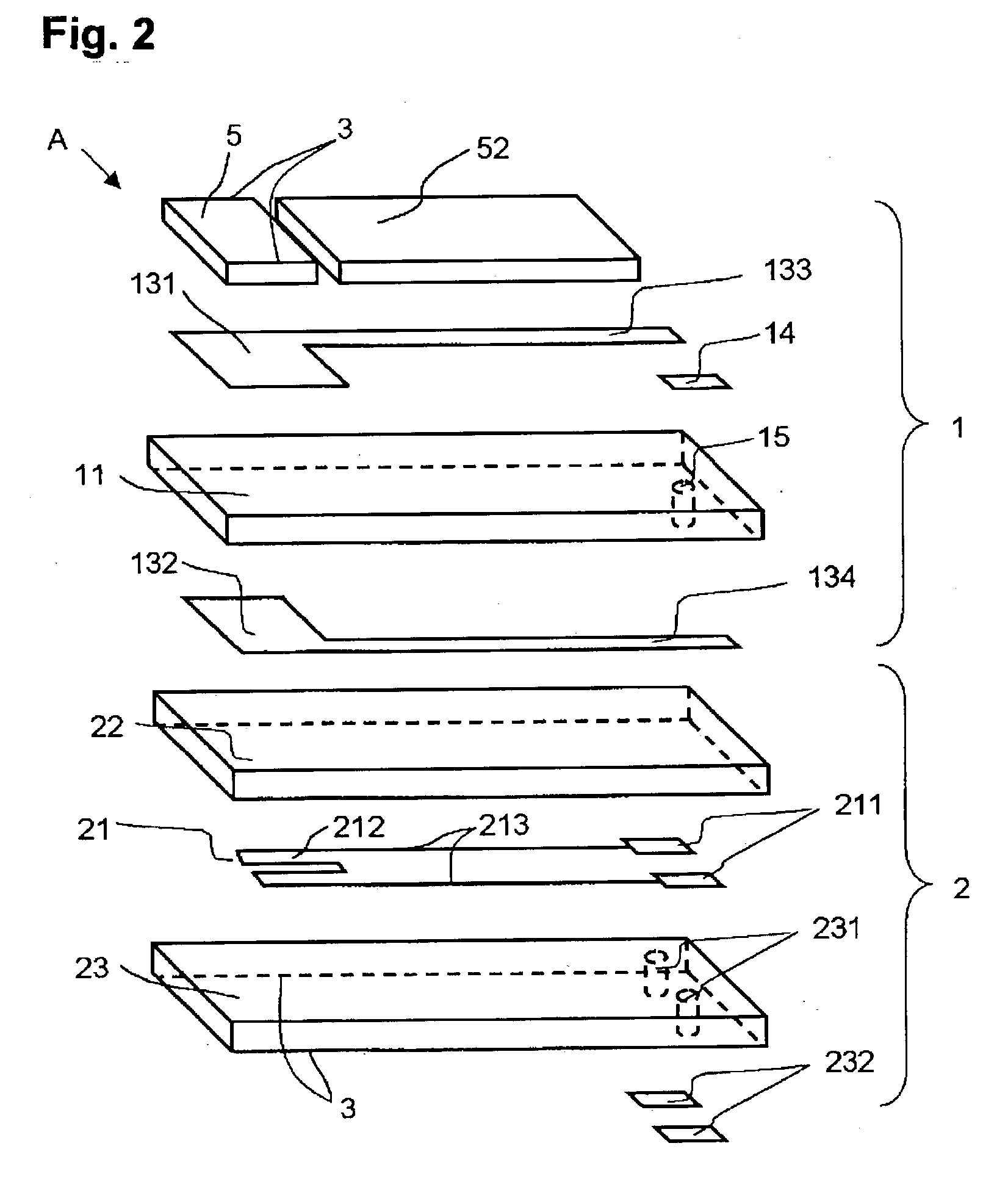

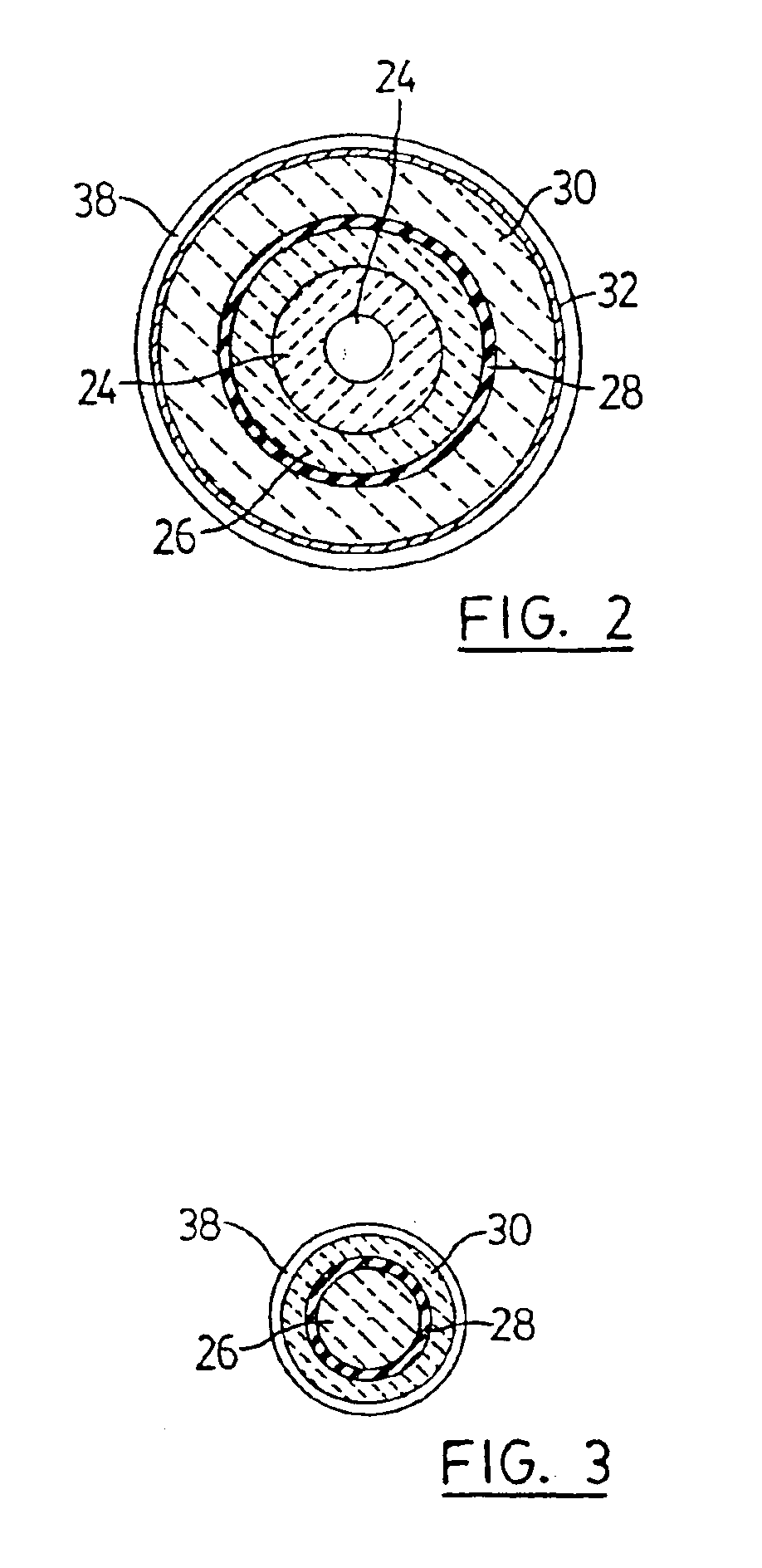

Ceramic heater

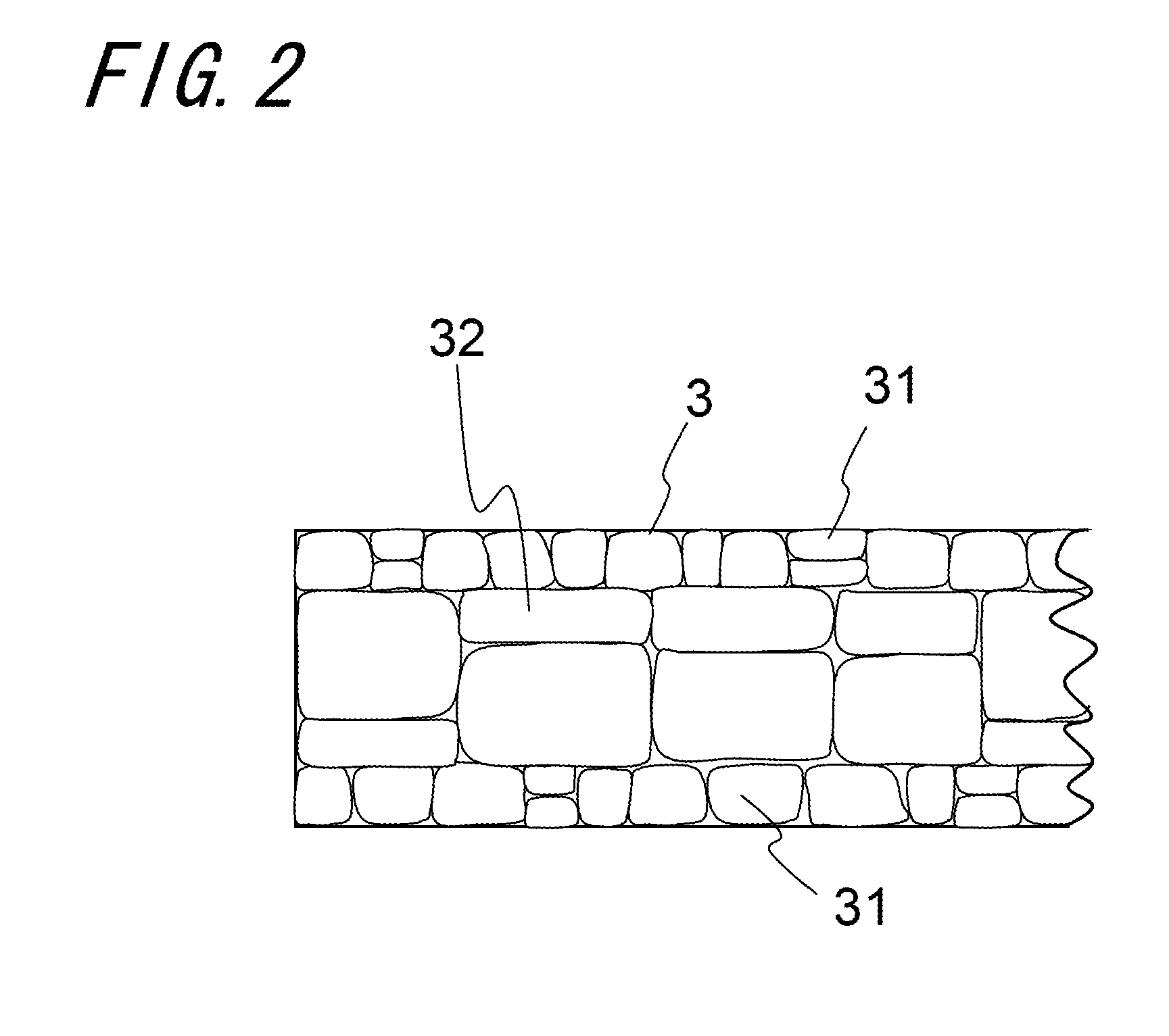

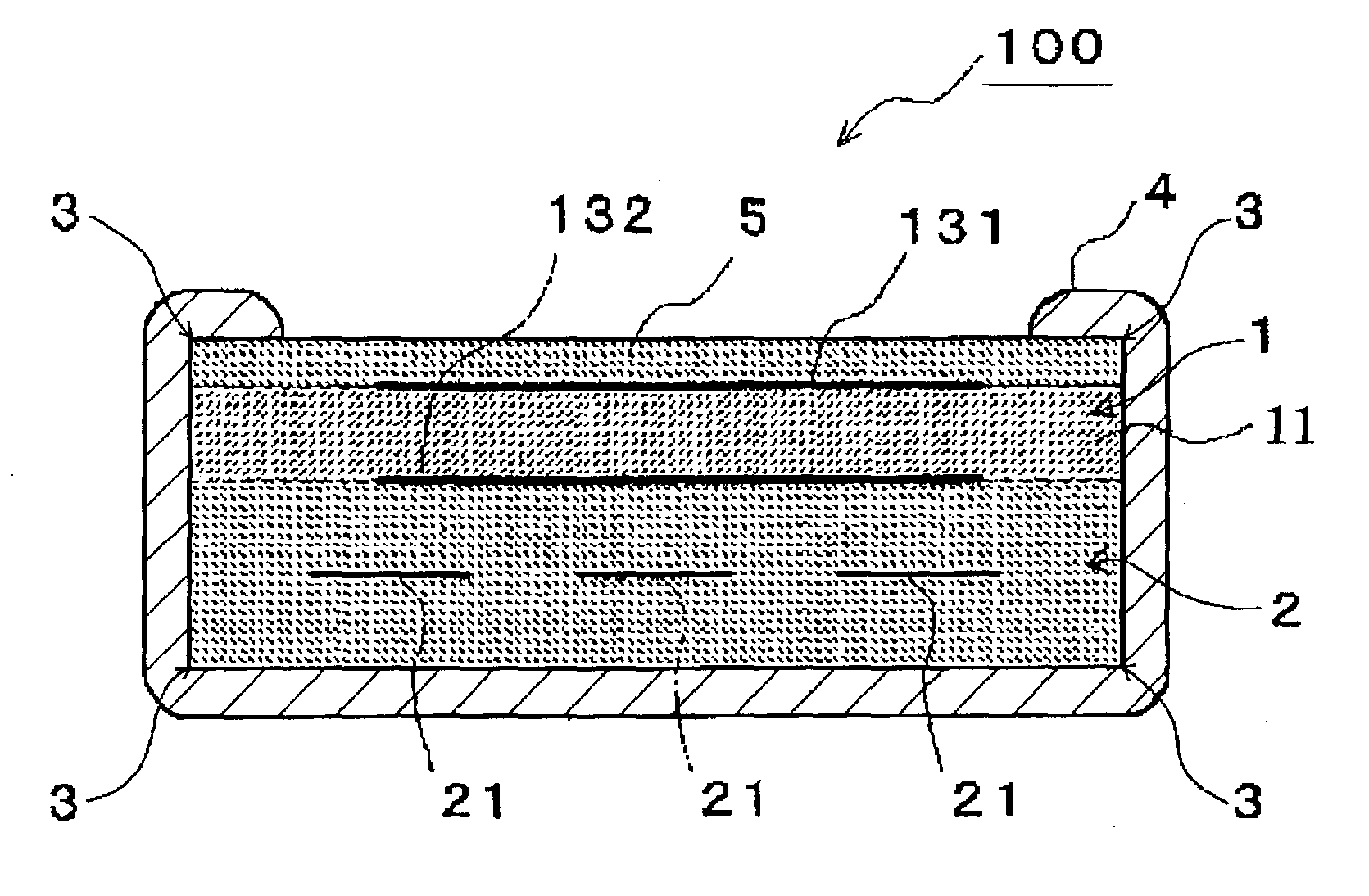

A ceramic heater of the invention includes a ceramic structure; a heat-generating resistor embedded in the ceramic structure; and a feeder line embedded in the ceramic structure so as to be connected, at one end thereof, to the heat-generating resistor. The feeder line is made of metal, and metal grains of a center region of the feeder line are greater in grain size than metal grains of an outer periphery region of the feeder line. Even if a crack developed in the outer periphery region of the feeder line propagates through grain boundaries in the outer periphery region and comes near the center region, propagation of the crack through the interior of the center region can be suppressed.

Owner:KYOCERA CORP

Advanced ceramic heater for substrate processing

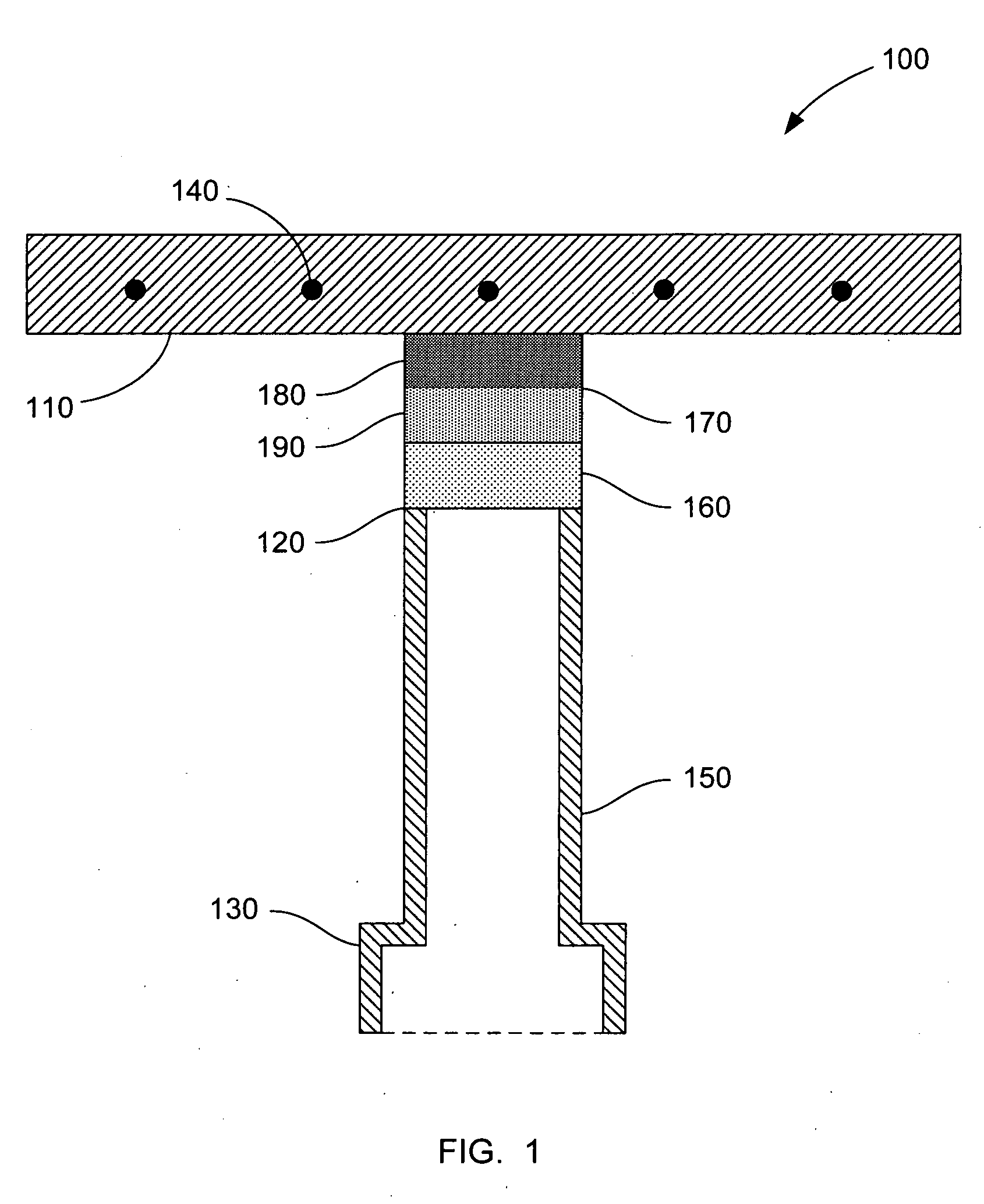

InactiveUS20070169703A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorMetal alloy

Susceptors are provided that employ layers of CTE-matching materials to reduce the stresses that otherwise lead to cracking and failure. Exemplary CTE-matching materials include metal alloys of aluminum and silicon that can be tailored to specific CTE values by adjusting the ratio of the elements. An exemplary susceptor comprises a CTE-matching material that accommodates the differences in the CTEs of a ceramic material and a thermal barrier layer disposed on opposite sides of the CTE-matching material. Methods are also provided for forming susceptors. These methods comprise assembling the components and bonding the assembly together, such as by diffusion bonding, to produce a susceptor that is a monolithic body.

Owner:COMPONENT RE ENGINEERING COMPANY INC +1

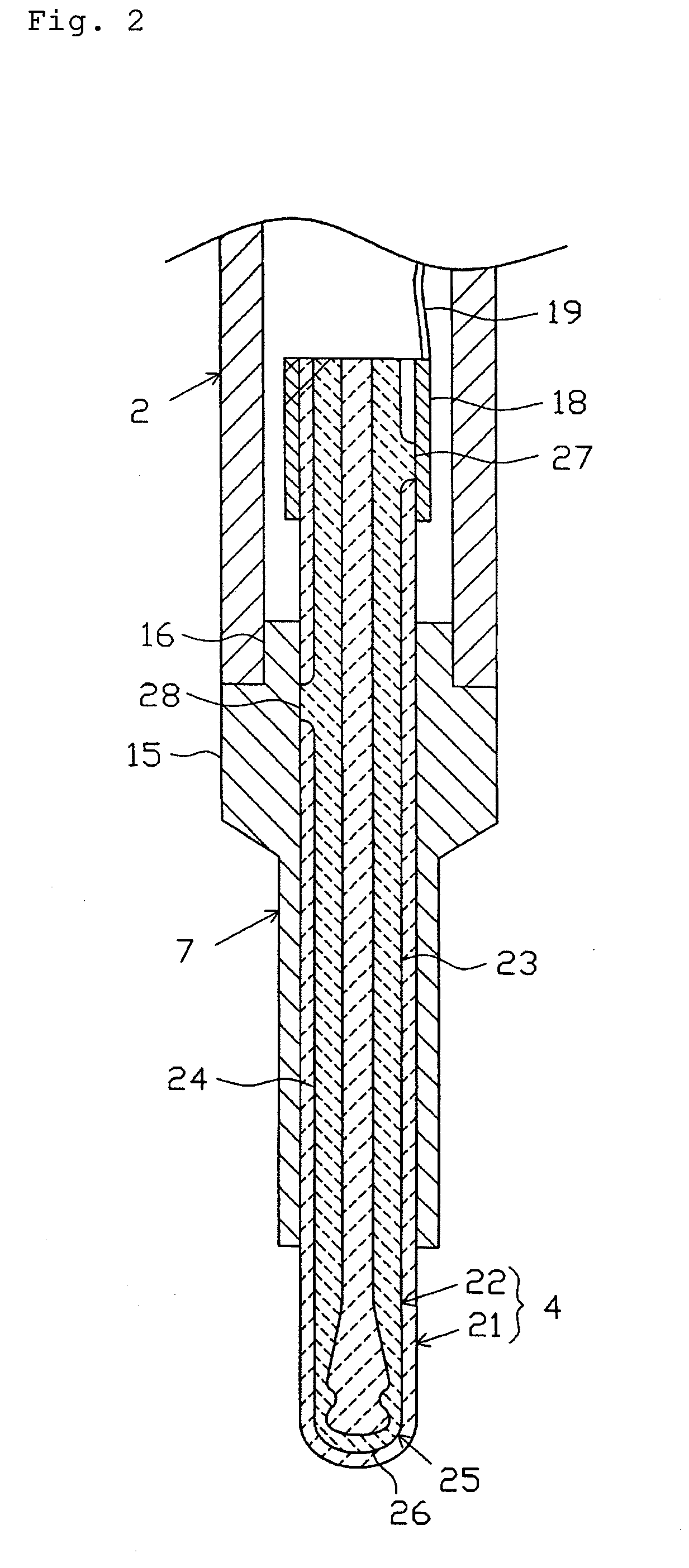

Prismatic ceramic heater for heating gas sensor element, prismatic gas sensor element in multilayered structure including the prismatic ceramic heater, and method for manufacturing the prismatic ceramic heater and prismatic gas sensor element

ActiveUS20030159928A1Heating element shapesMaterial electrochemical variablesMetallurgyProtection layer

A prismatic ceramic heater for heating a gas sensor element includes a heating resistor embedded in ceramic, and has a substantially rectangular cross section. At least part of a longitudinally extending edge portion of the prismatic ceramic heater is located in the vicinity of the heating resistor. This part of the longitudinally extending edge portion is coated with a porous protective layer. The protective layer has a thickness not less than 20 mum and a curved surface of a curvature radius not less than 10 mum. The protective layer prevents cracking induced by contact with water.

Owner:NGK SPARK PLUG CO LTD

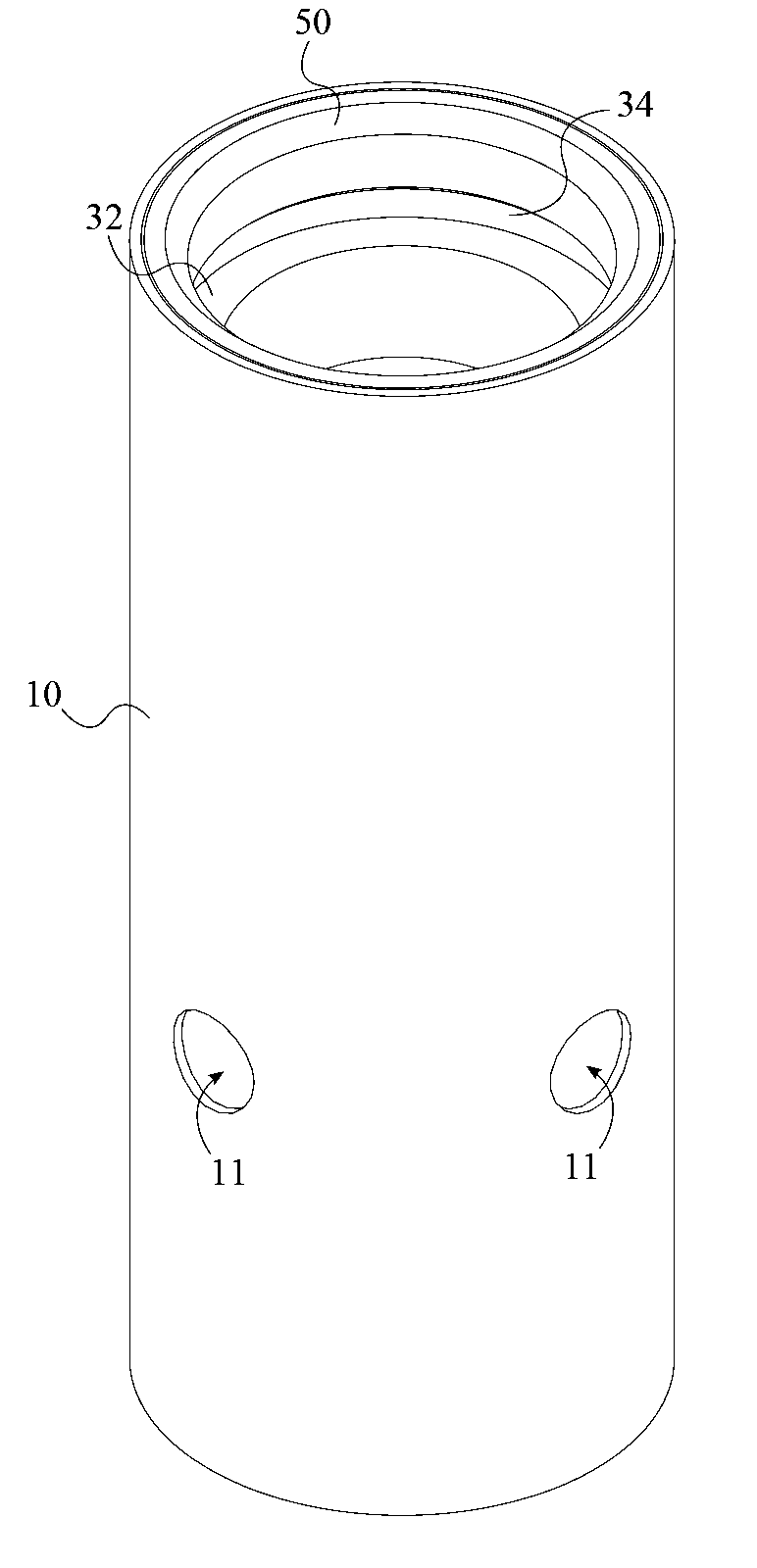

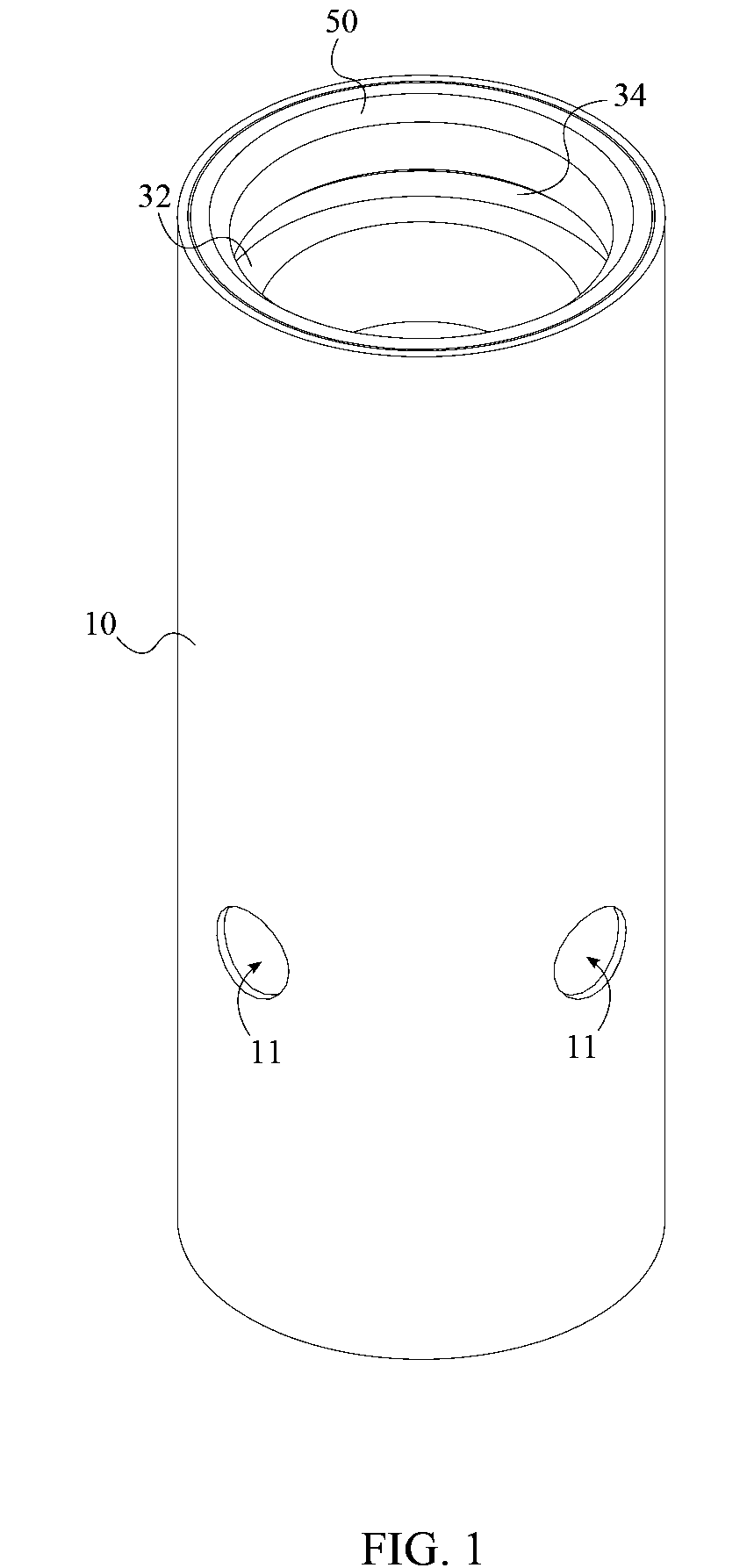

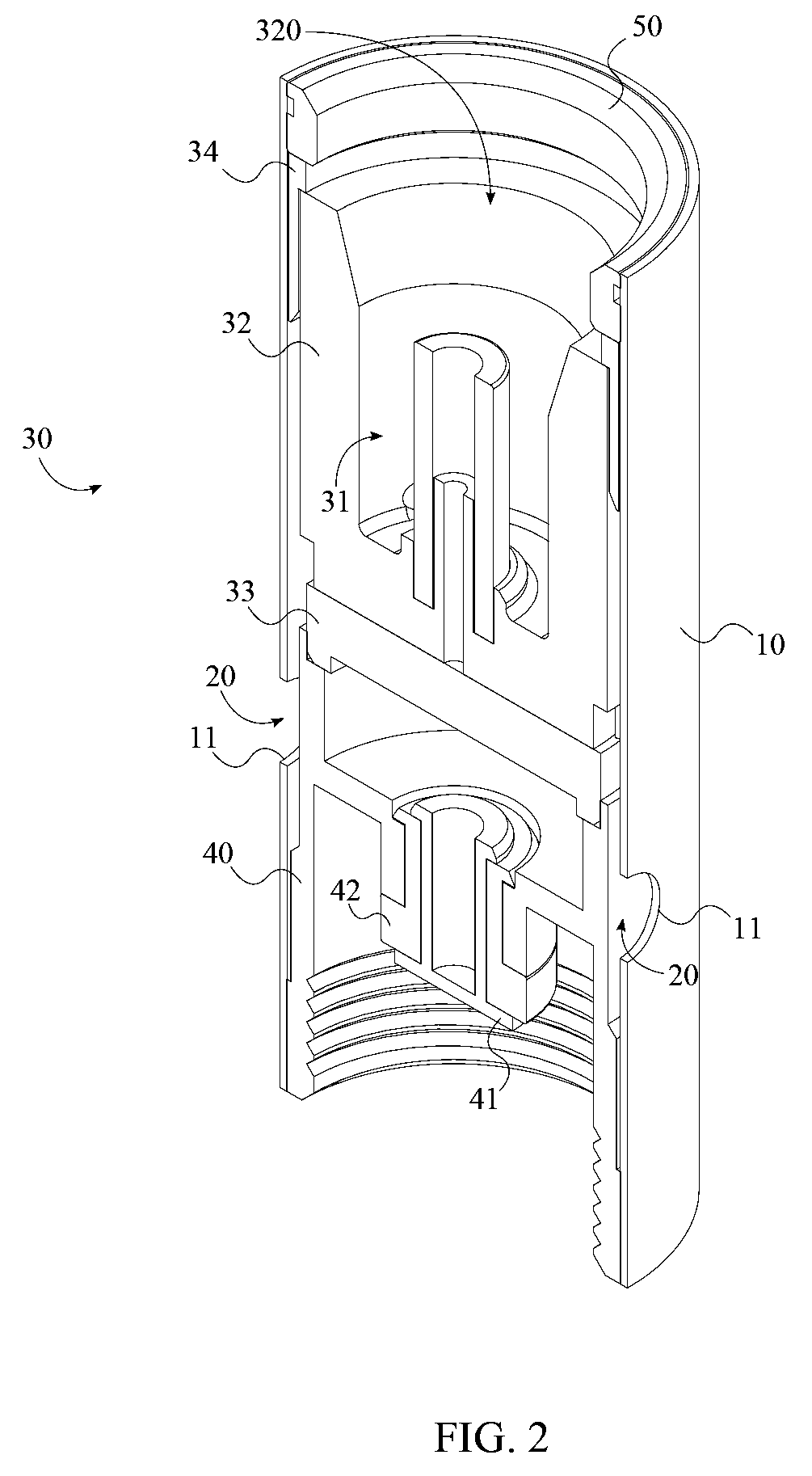

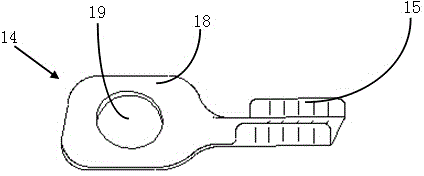

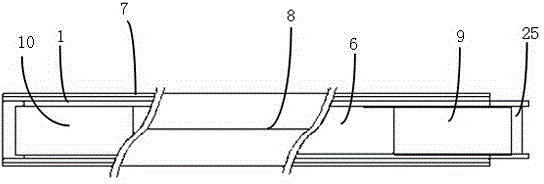

Electric Heating Cartridge for a Dry Herb Vaporizer

InactiveUS20160302486A1Improve operation and efficiencyLow thermal conductivityTobacco devicesHeating element shapesEngineeringEvaporator

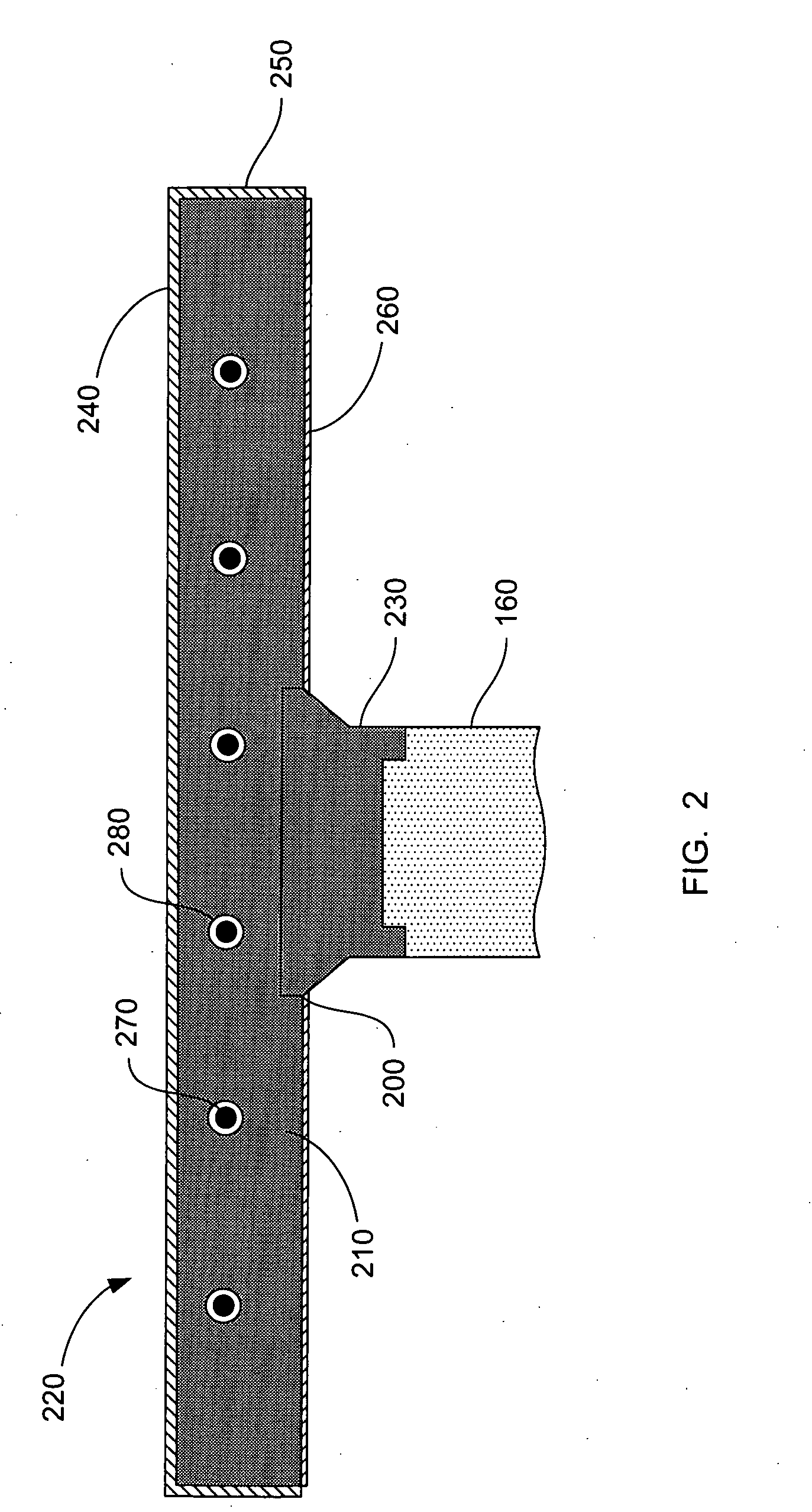

An electric heating cartridge for dry herb vaporizers has a heating assembly, a battery connector, and a connector insert enclosed by a cartridge sleeve. The battery connector provides a means for attaching the electric heating cartridge to a power source, while a mouthpiece is attached via the connector insert. The heating assembly includes a heating element, a heating chamber, a lower heat insulator, and an upper heat insulator. The heating element is positioned within the heating chamber and powered through the battery connector, wherein herbs are heated within the heating chamber. The heating chamber is positioned in between the lower heat insulator and the upper heat insulator, wherein the lower heat insulator and the upper heat insulator dissipate heat from the heating chamber and the heating element. Ideally, the heating element has a ceramic heater body with at least one heating coil embedded in the heater body.

Owner:ATMOS NATION

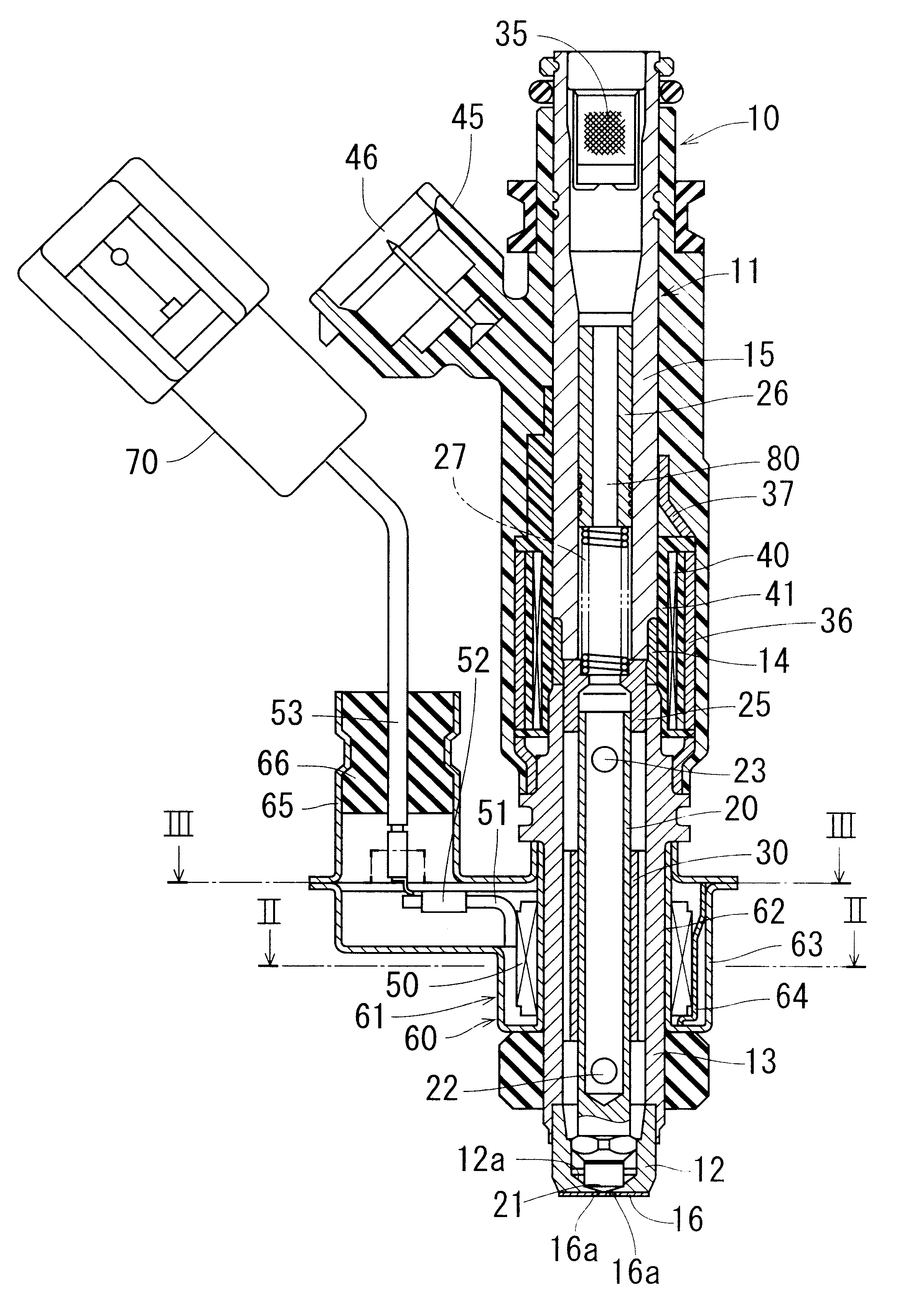

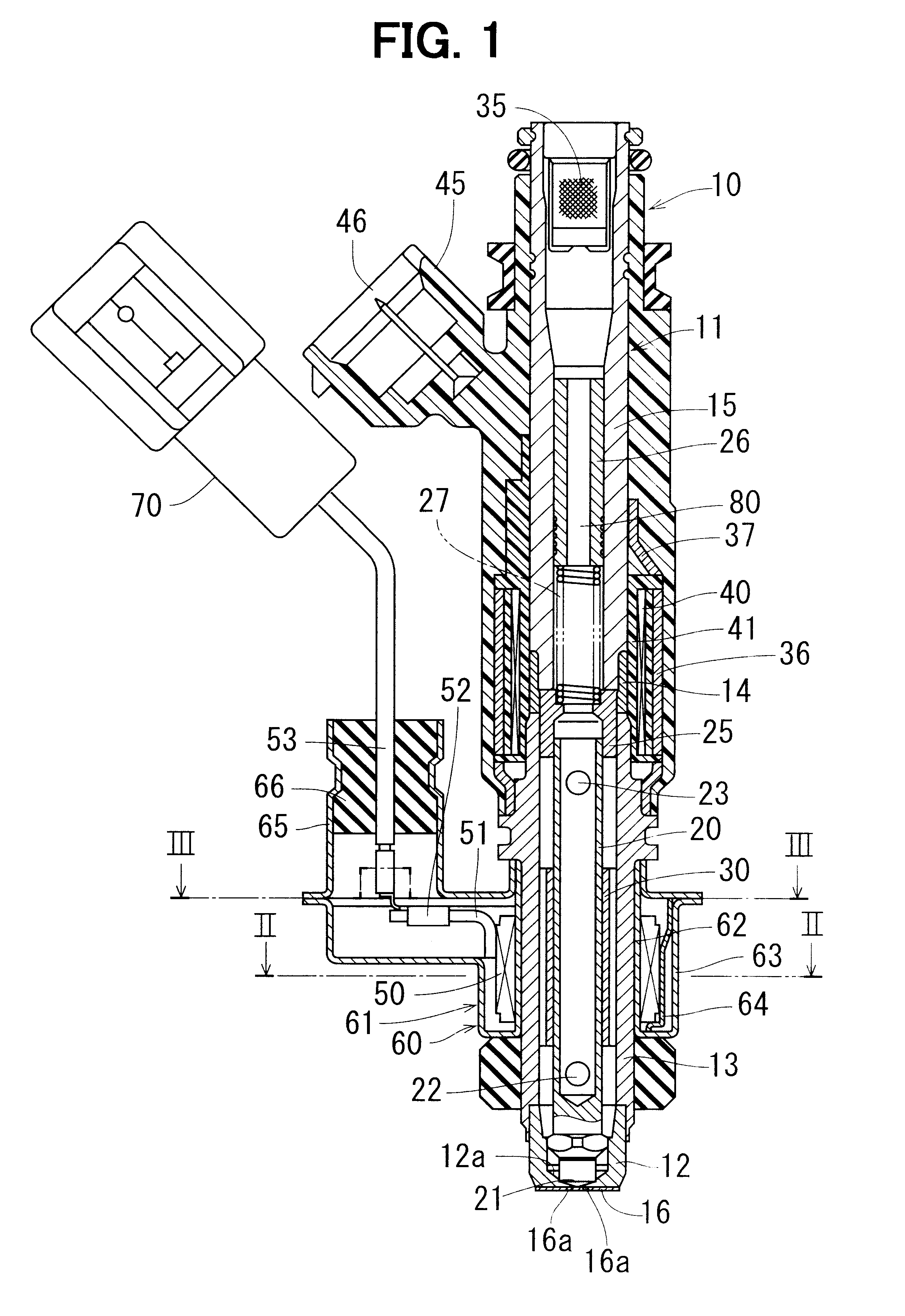

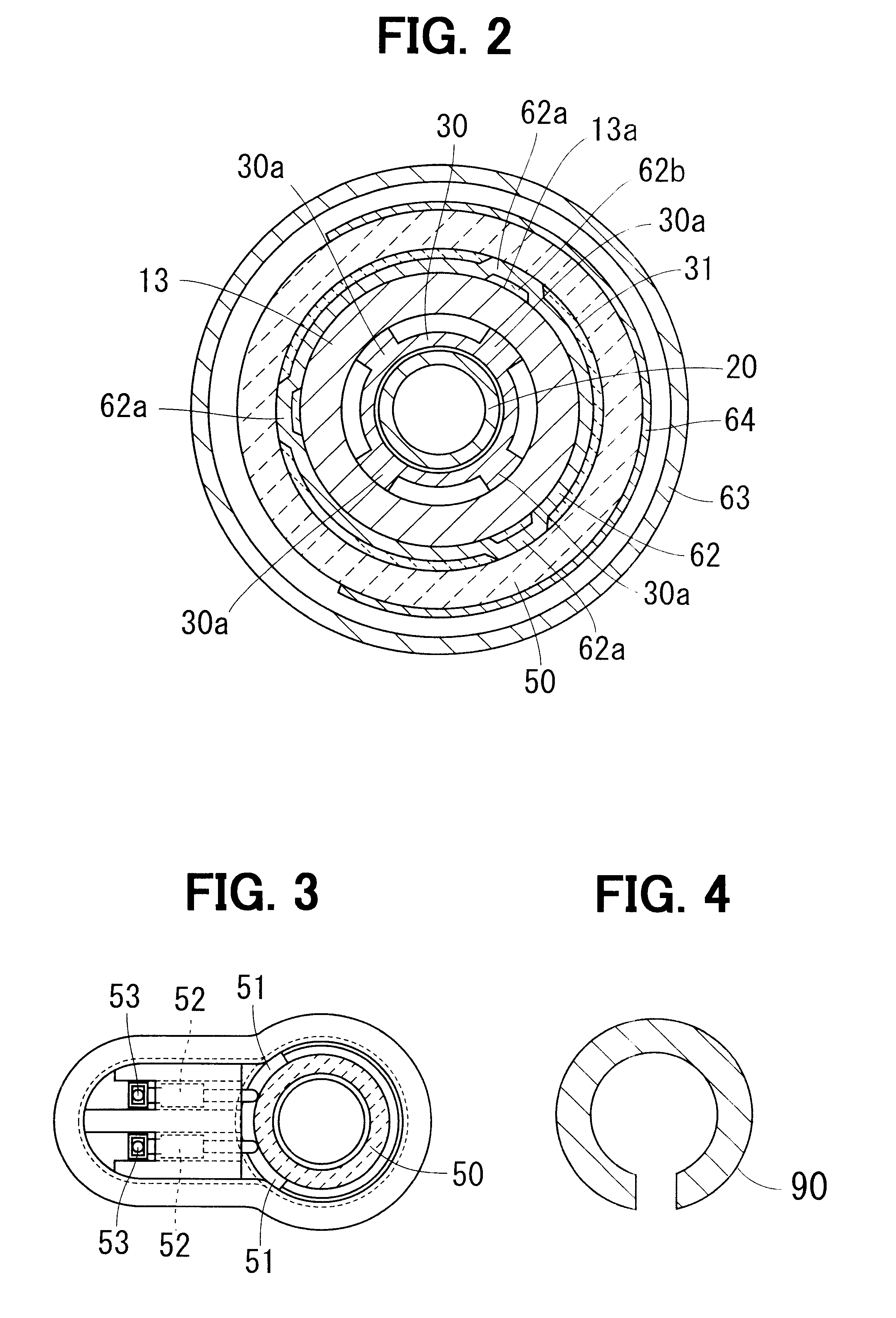

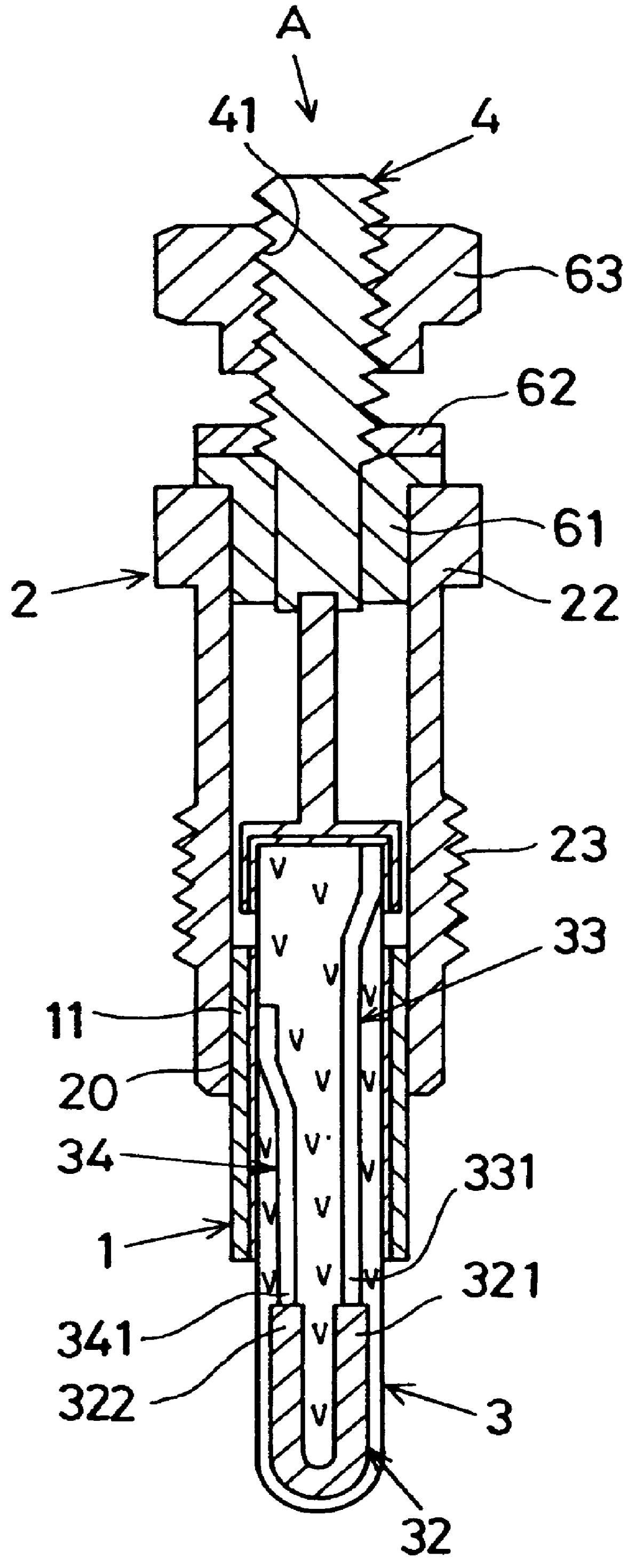

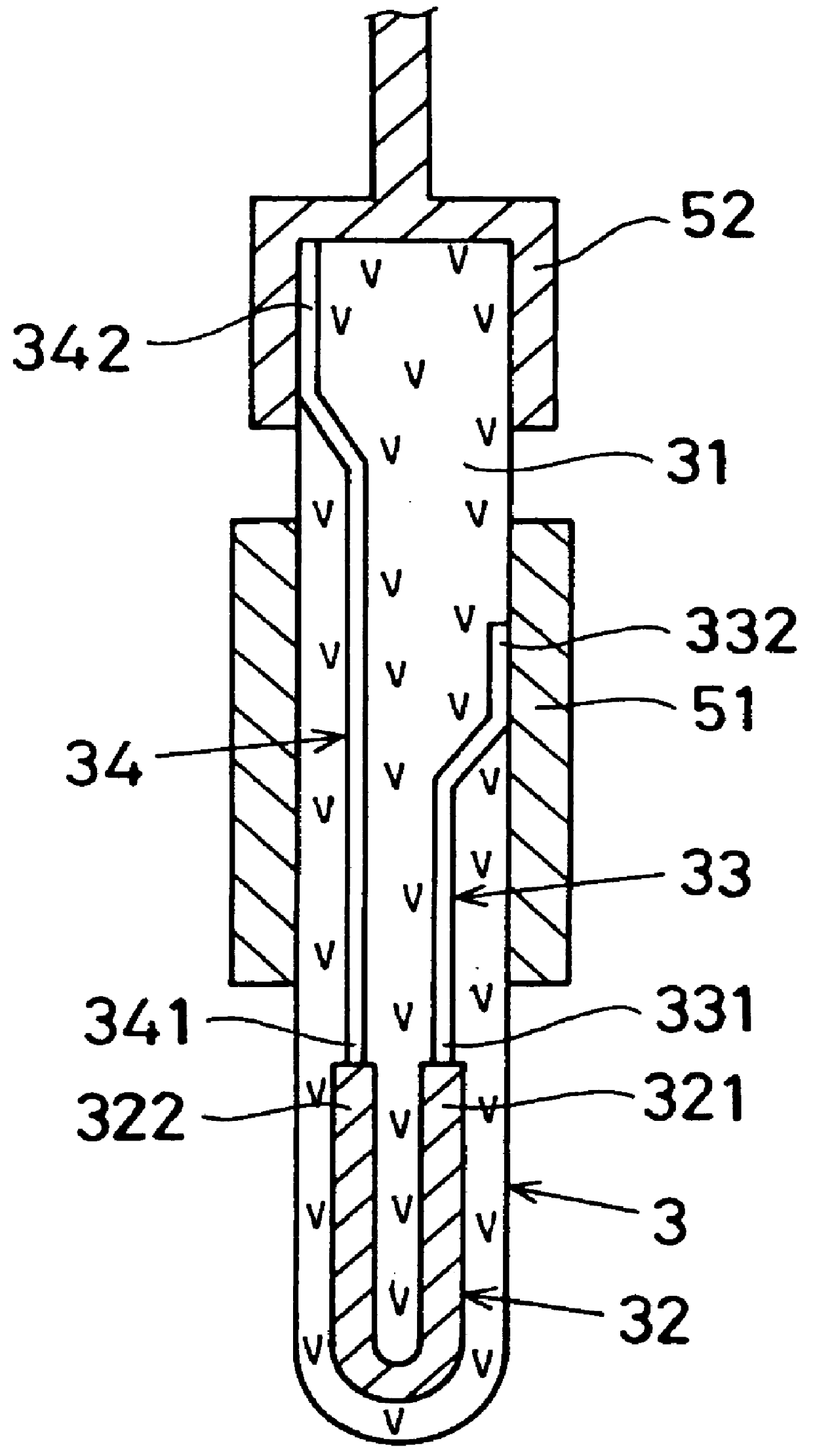

Fuel injection device having heater

InactiveUS6561168B2Liquid fuel feeder/distributionLiquid surface applicatorsEngineeringHeat transfer tube

A nozzle needle has a hollow tubular form having a closed base end. A heat transfer tube is press fitted into a first magnetic portion. The heat transfer tube surrounds an outer peripheral surface of the nozzle needle. A ceramic heater is formed as an integral cylindrical body by sintering a ceramic material together with a heat generating resistive element. A case covers the heater and protects the heater from externally applied water. An inner tube of the case is resiliently engaged with both the heater and the first magnetic portion. Heat of the heater is conducted to the nozzle needle through the inner tube, the first magnetic portion and the heat transfer tube to heat fuel inside the nozzle needle.

Owner:DENSO CORP

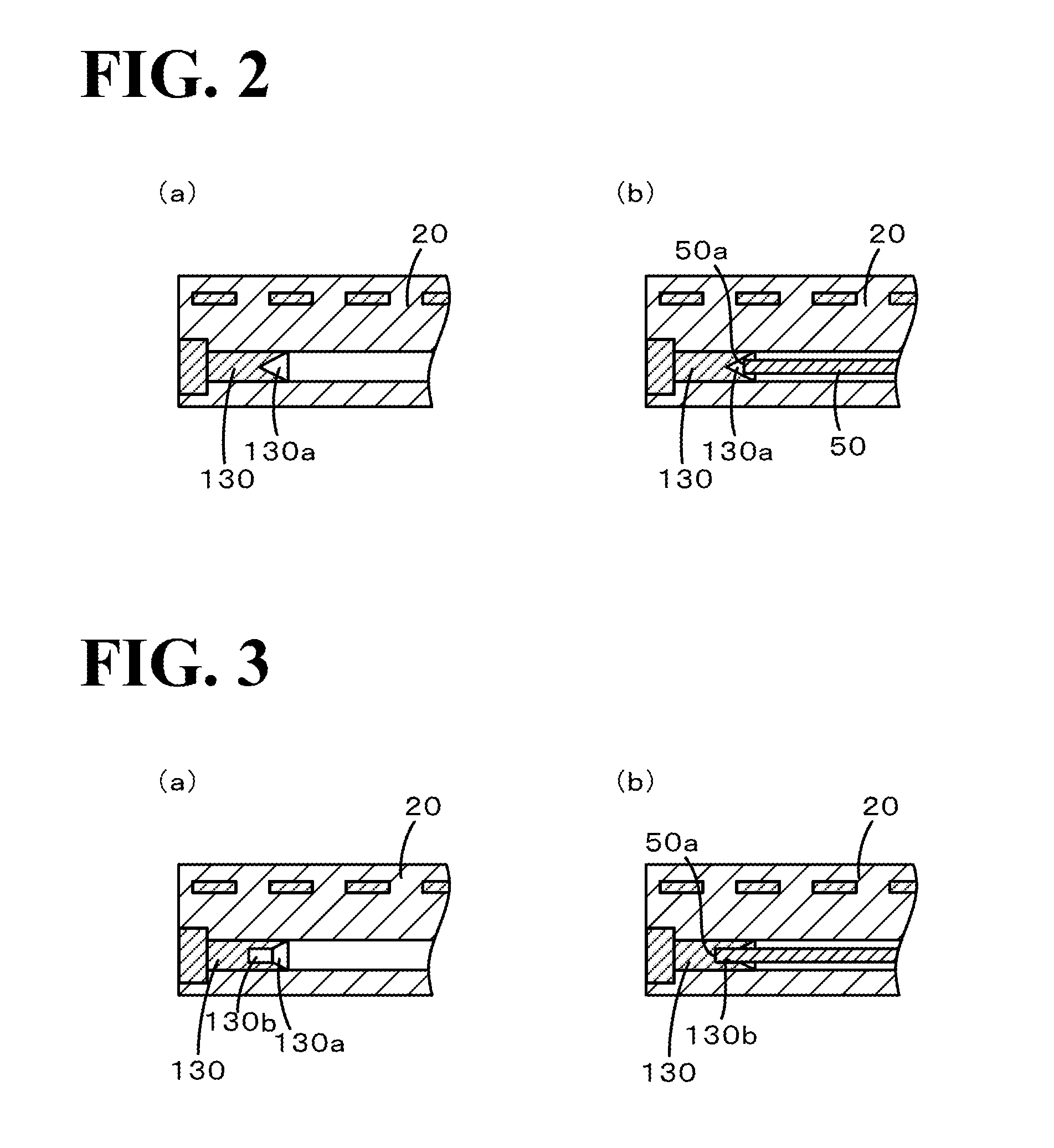

Ceramic heater

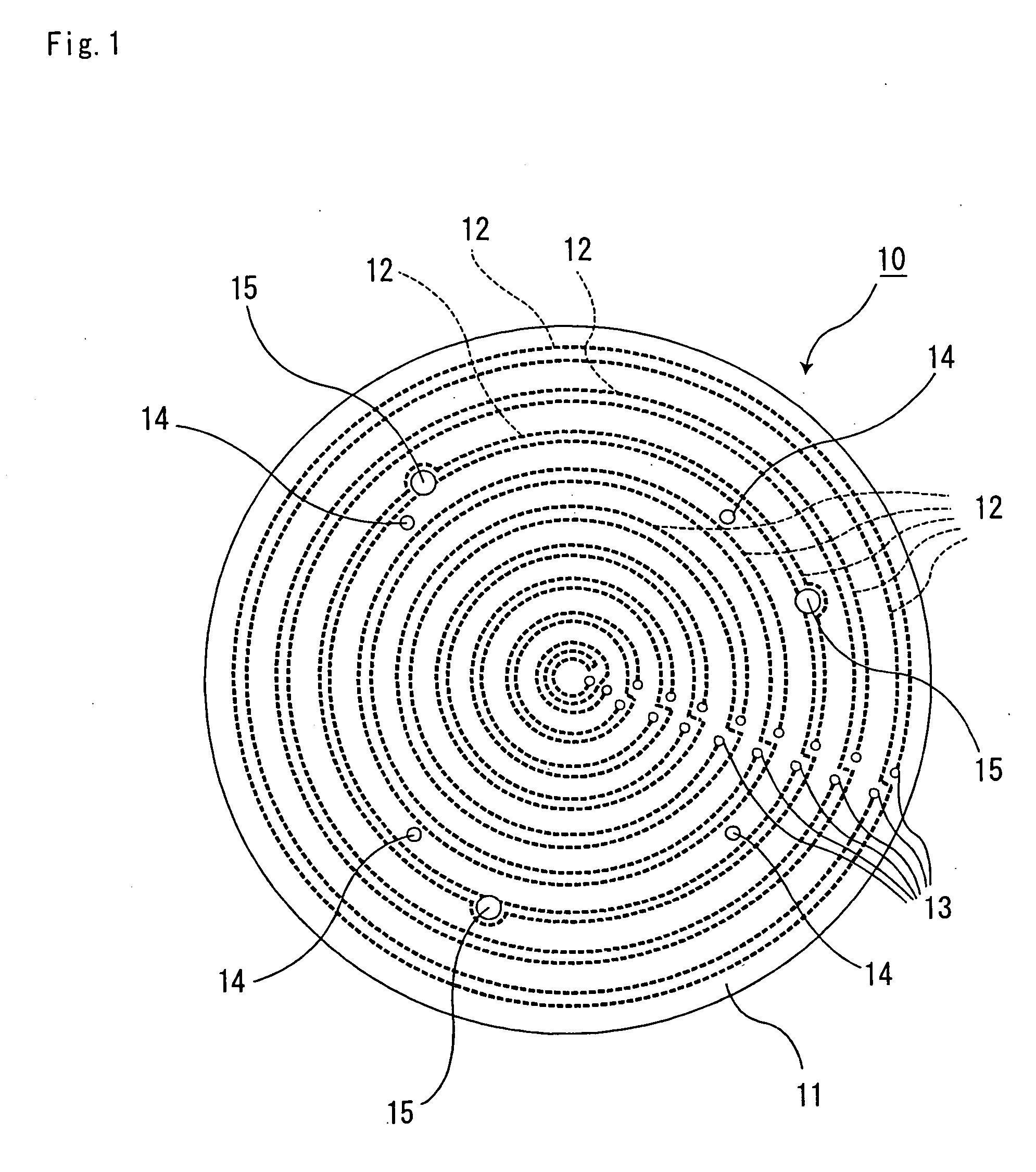

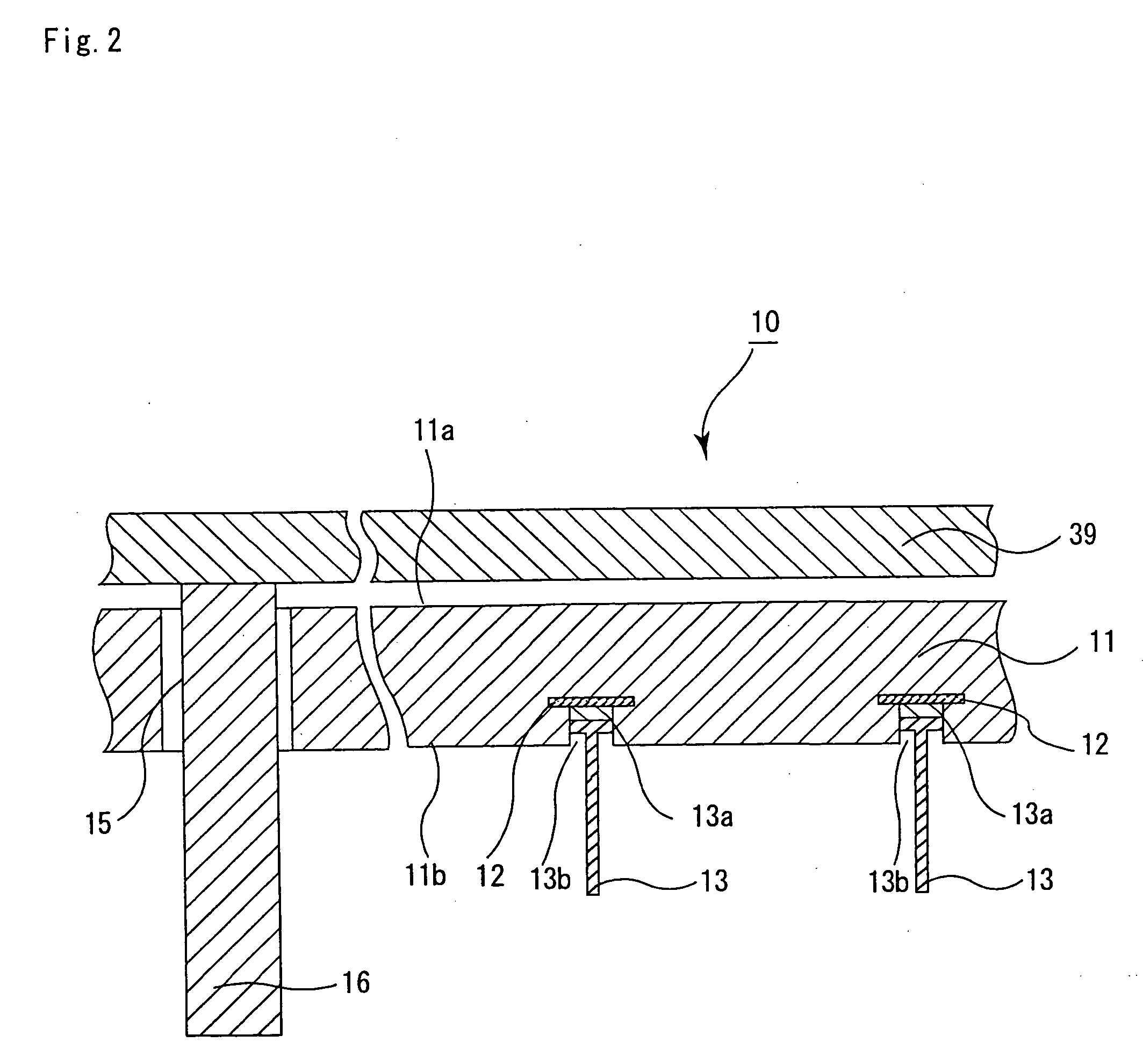

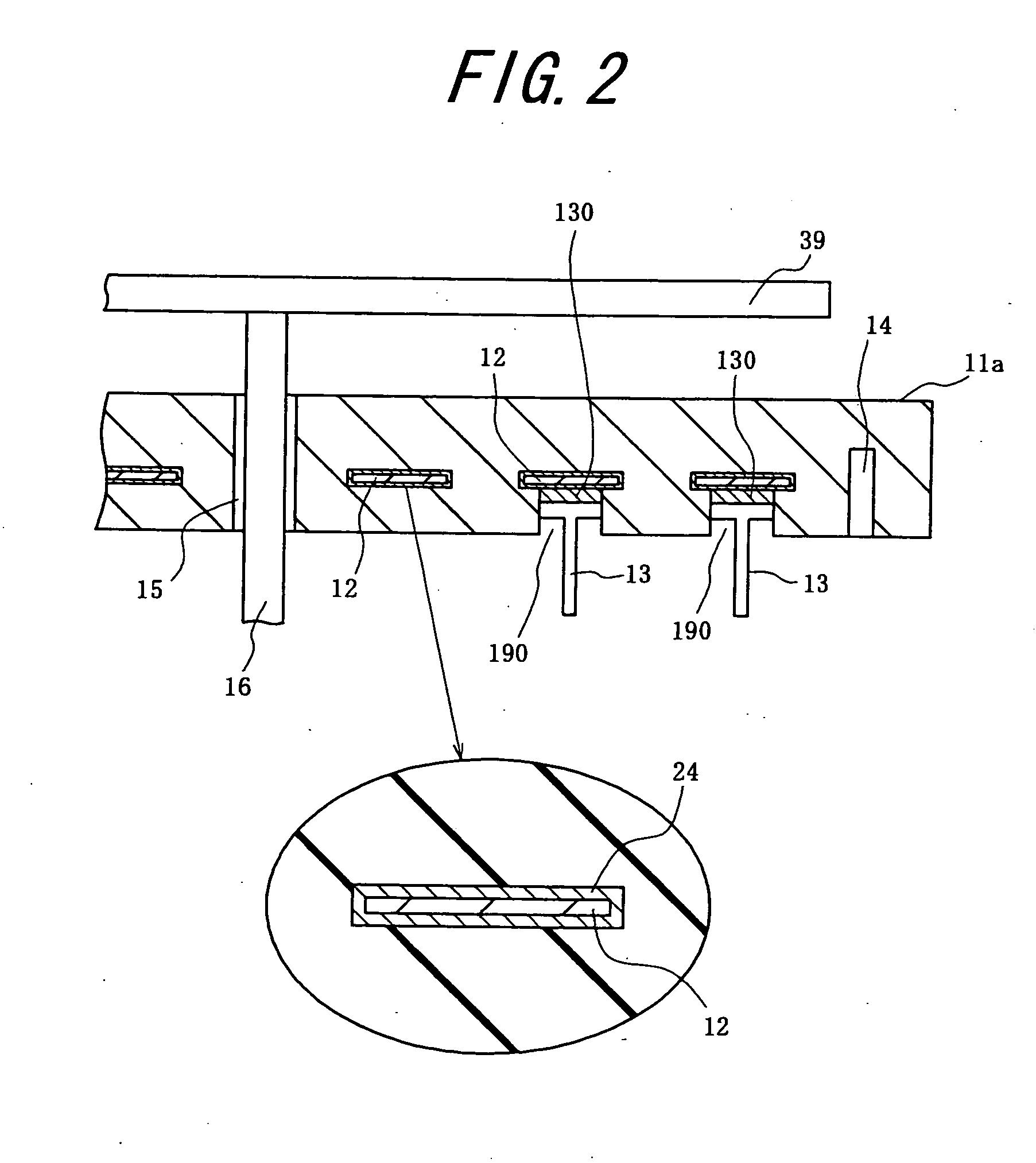

InactiveUS20030015521A1Maintain good propertiesLow costHot plates heating arrangementsHeating element shapesSlurryThermal shock

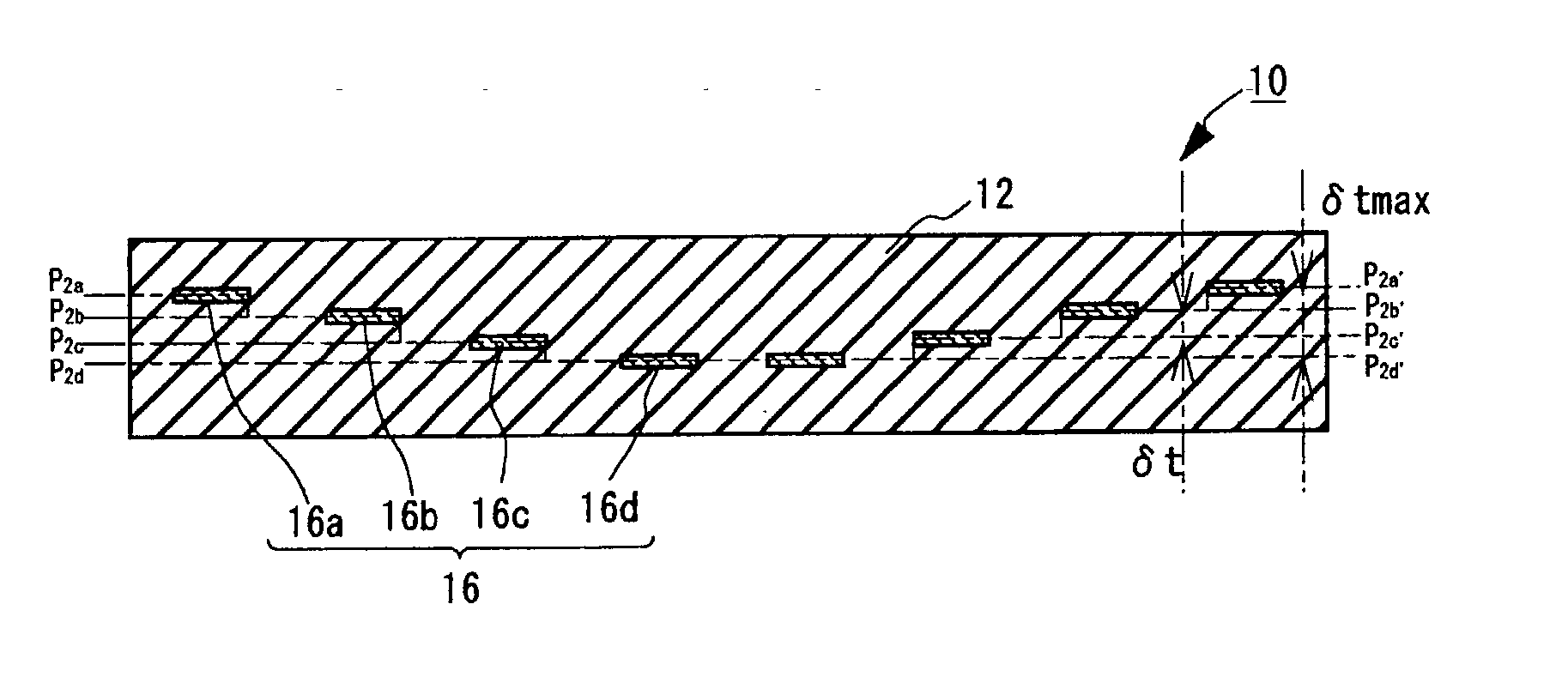

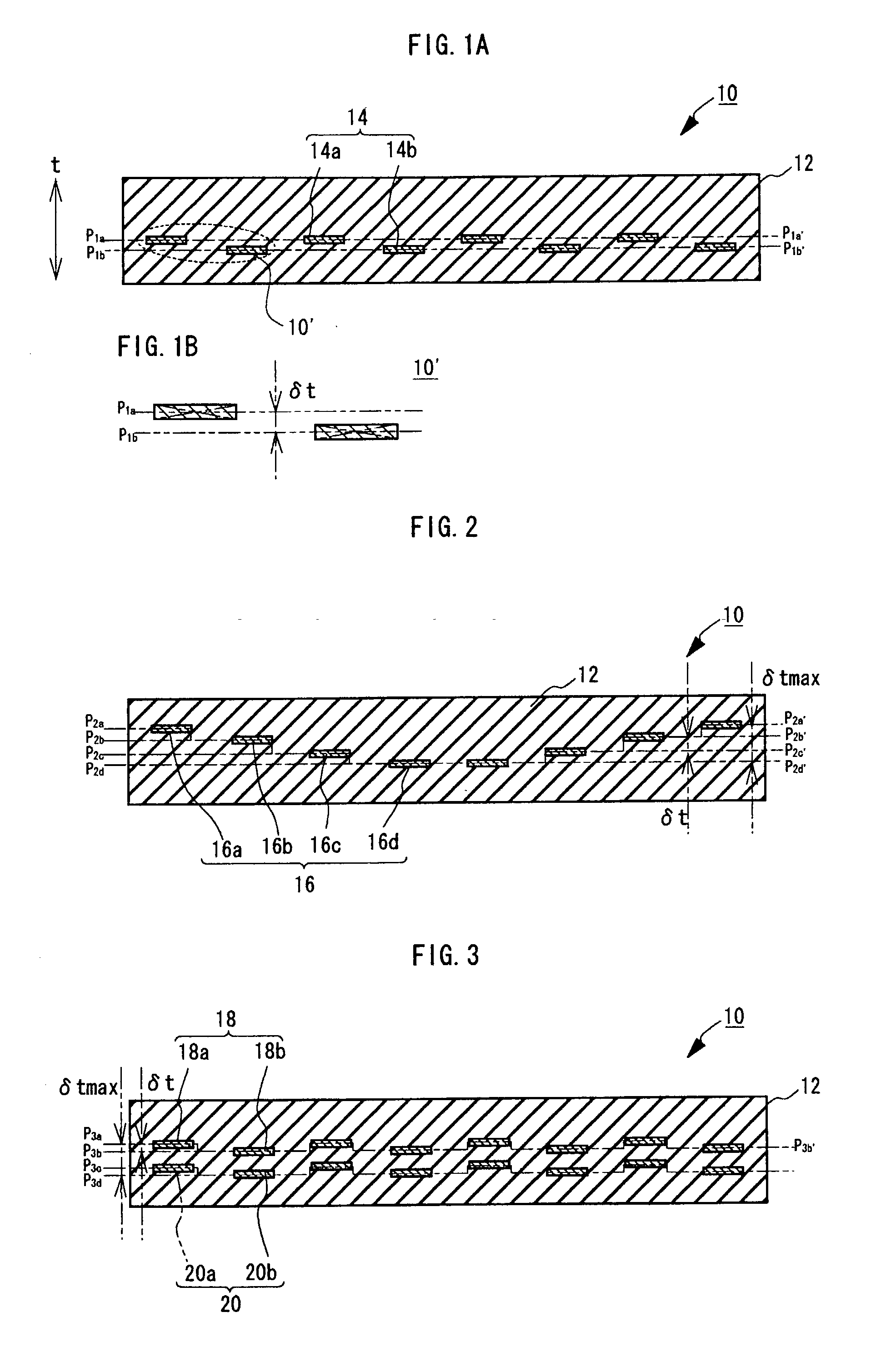

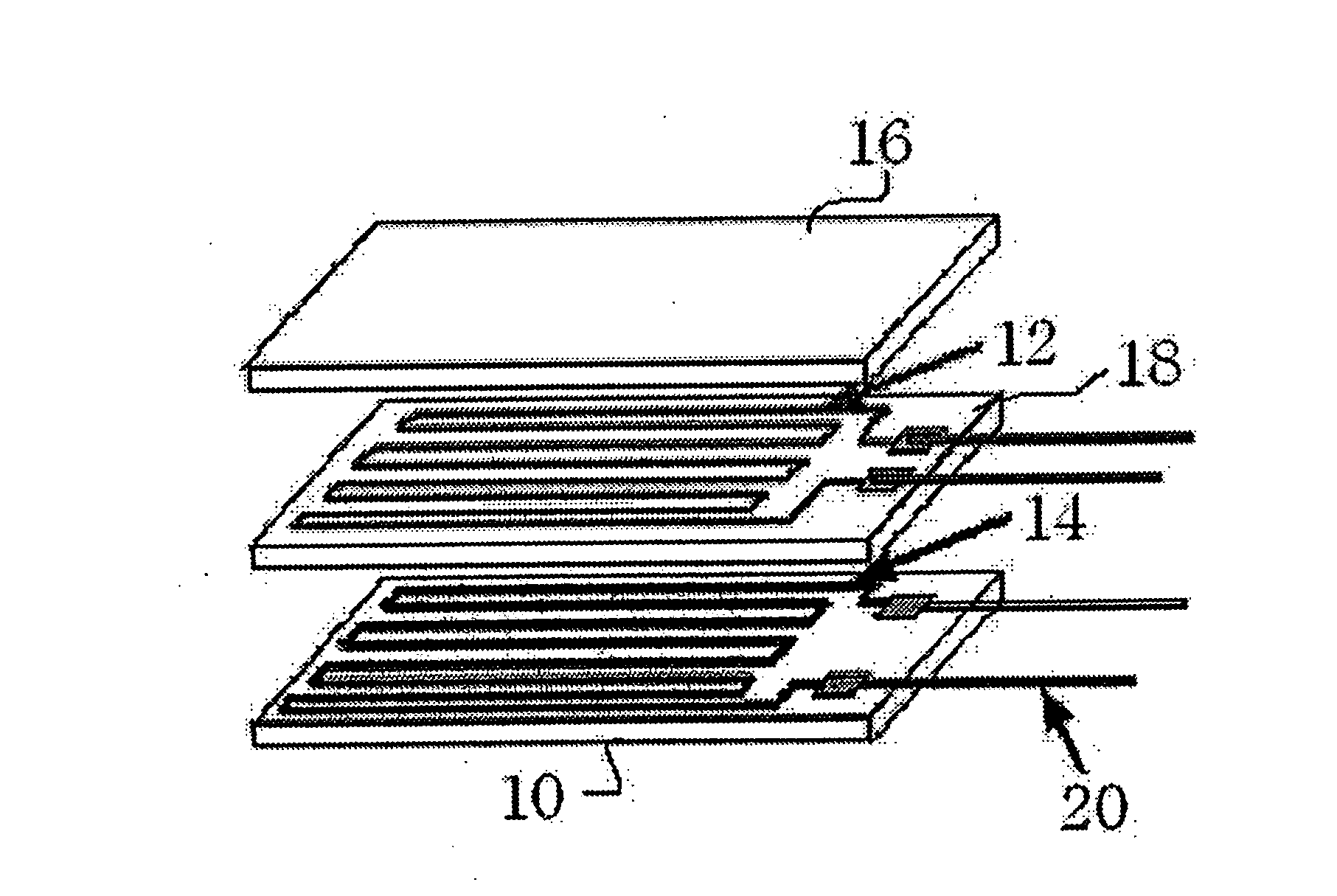

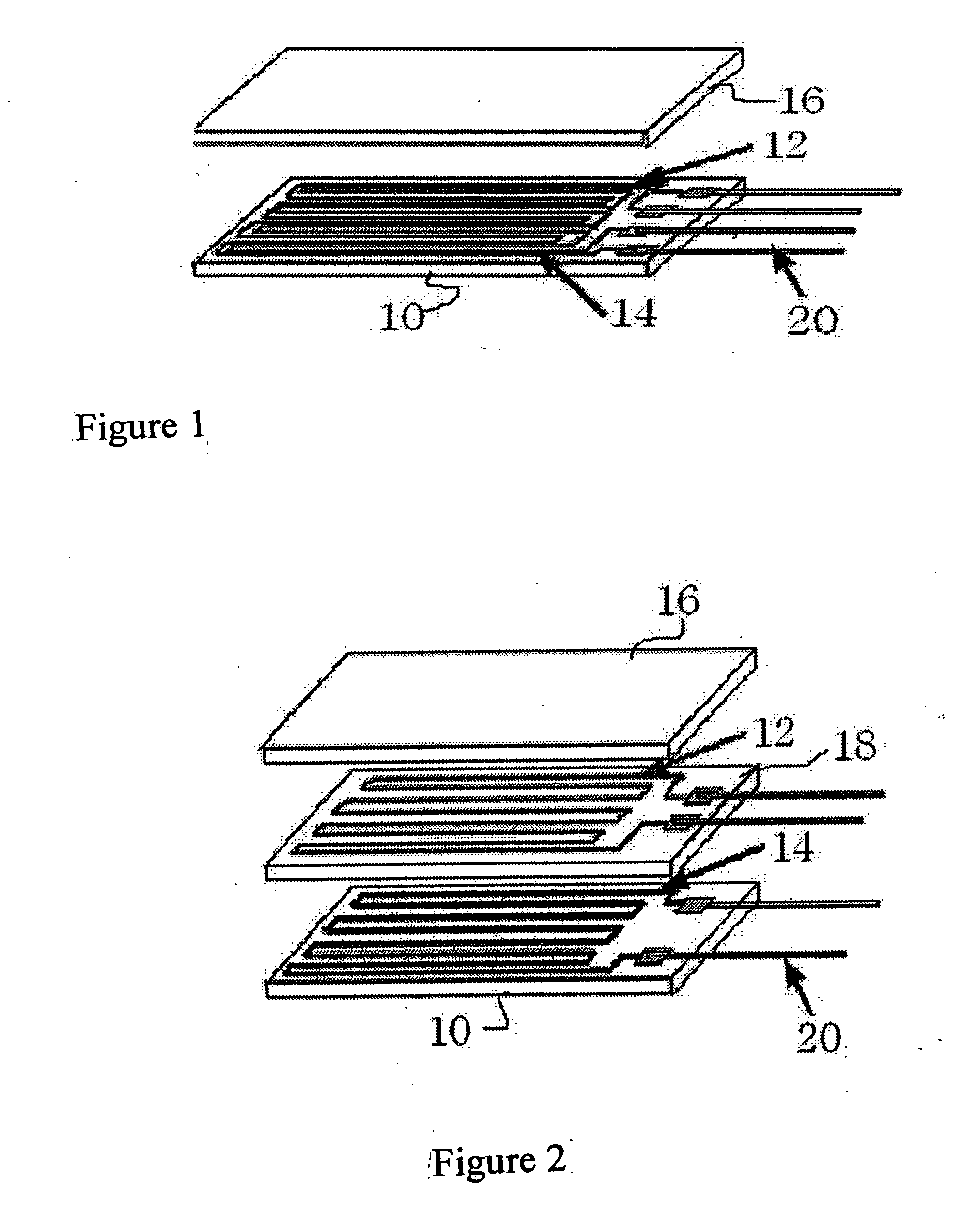

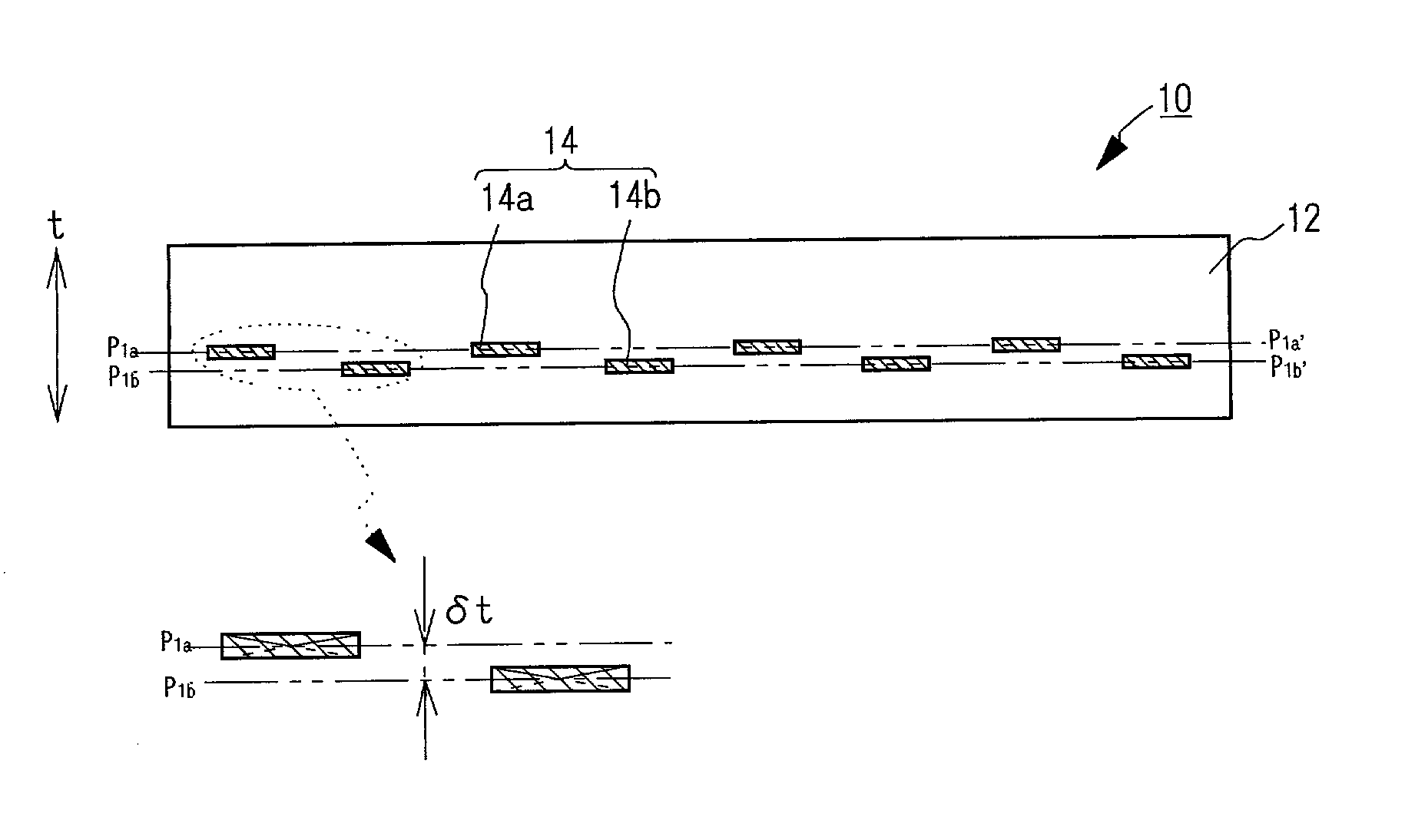

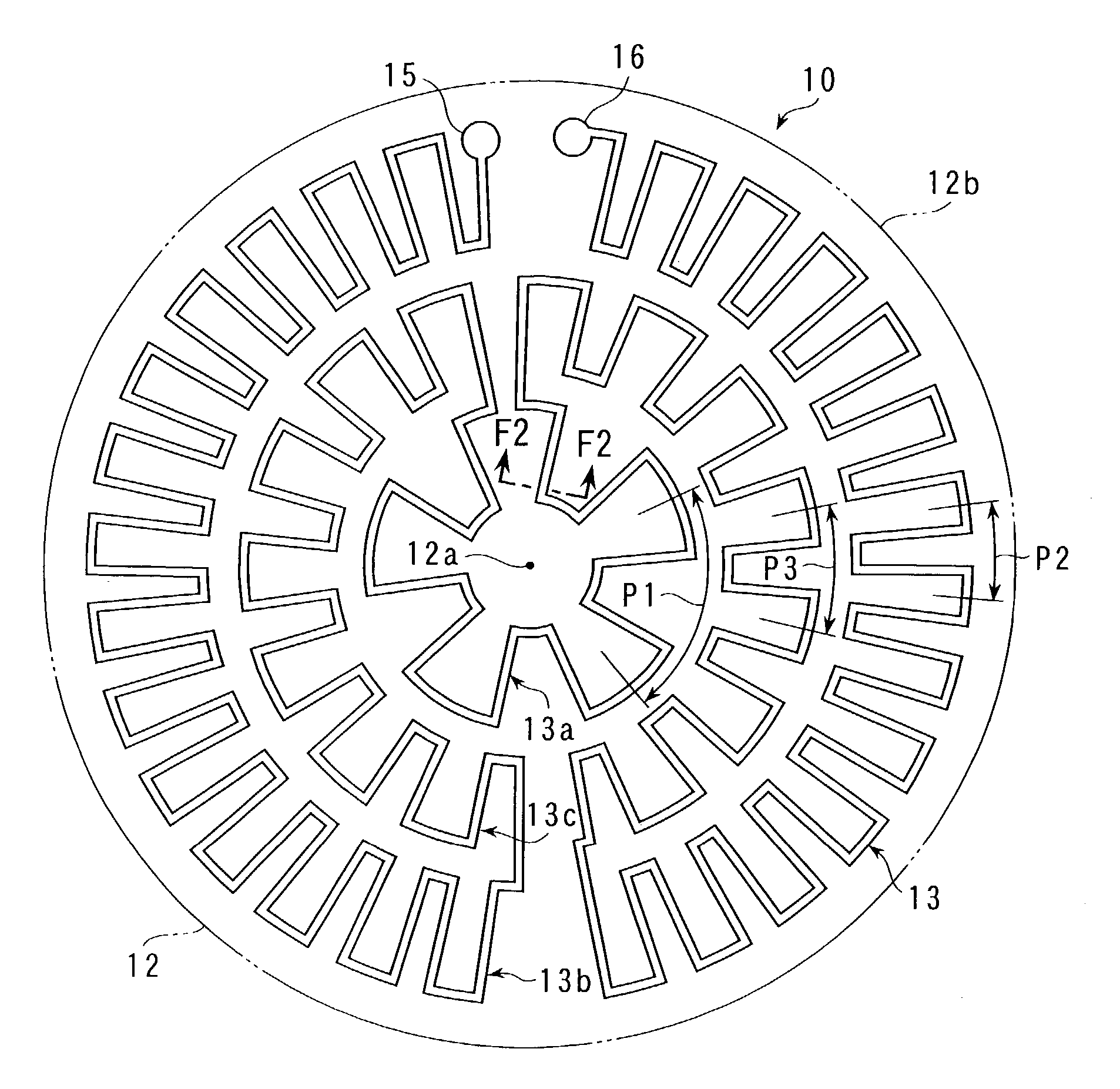

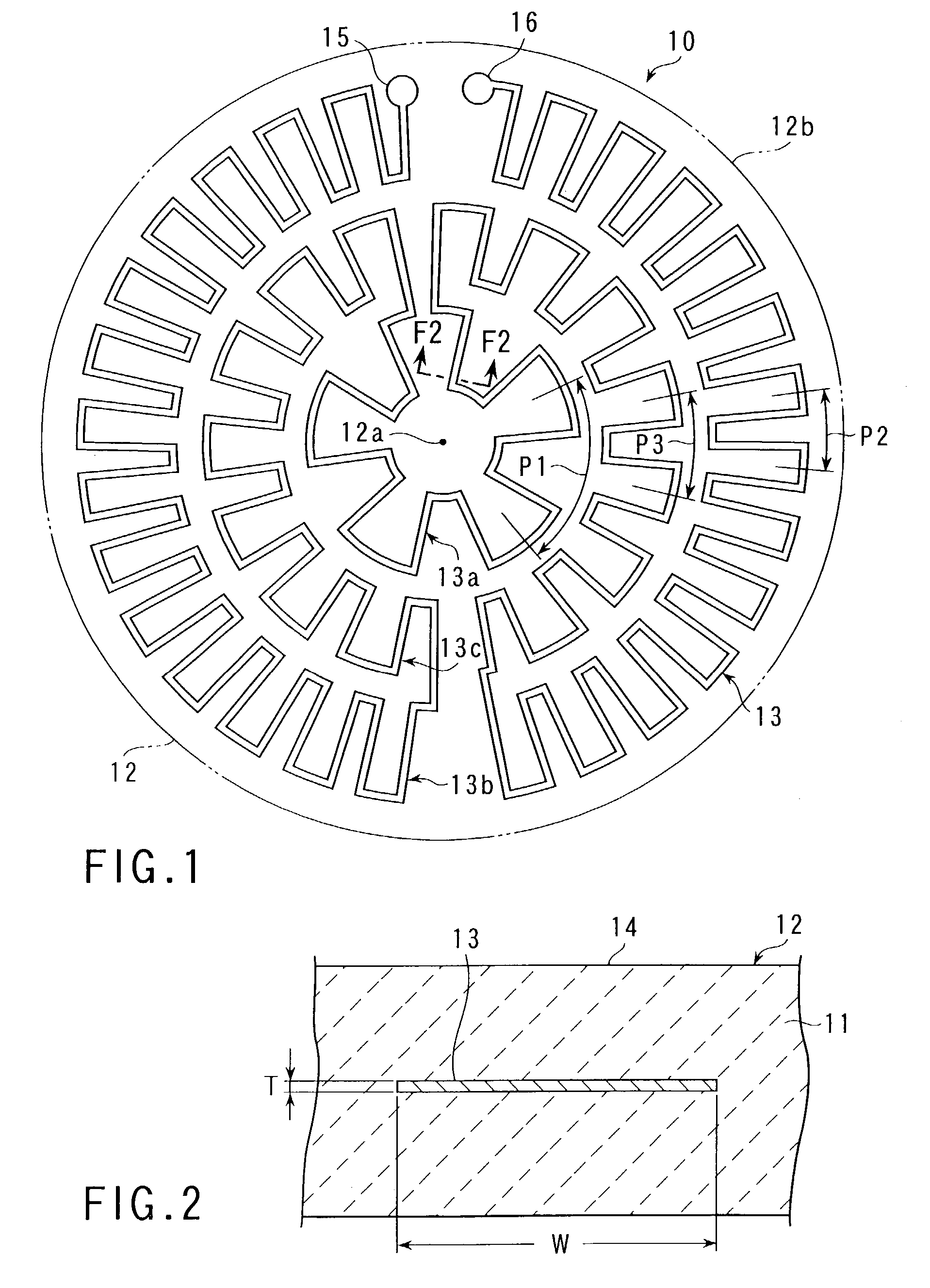

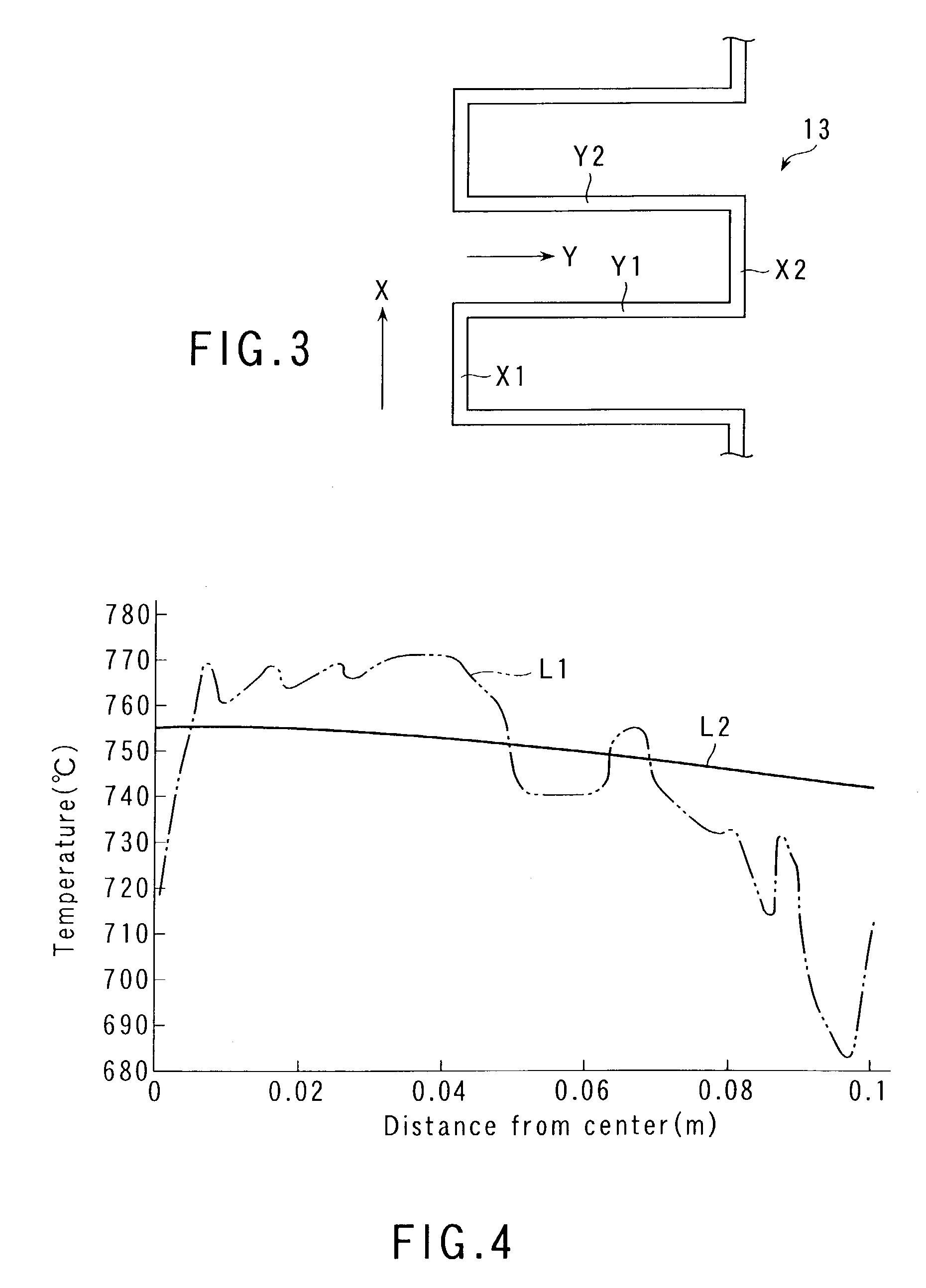

The present invention provides a ceramic heater having better anti thermal shock property. A ceramic substrate 12 is formed by providing heat generation bodies 14a and 14b on the surface of a green sheet made from a slurry containing powdered ceramics, sandwiching the green sheet with other green sheets from both upper and lower sides and then laminating and pressing the compiled green sheets. At least some of the heat generation bodies 14a and 14b are disposed on a level P1b offset from a level P1a of other heat generation bodies in the direction of thickness of the ceramic substrate 12.

Owner:IBIDEN CO LTD

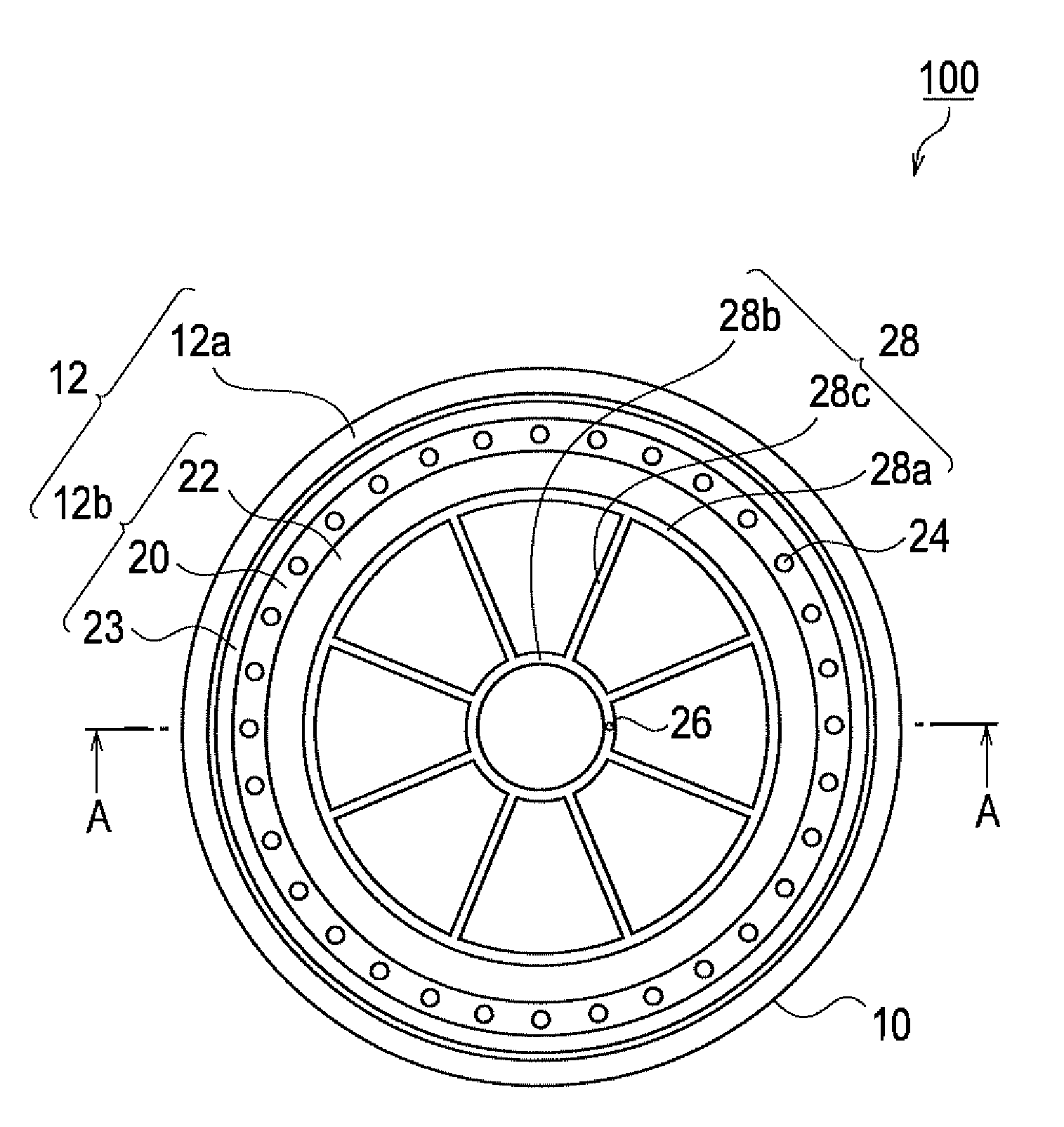

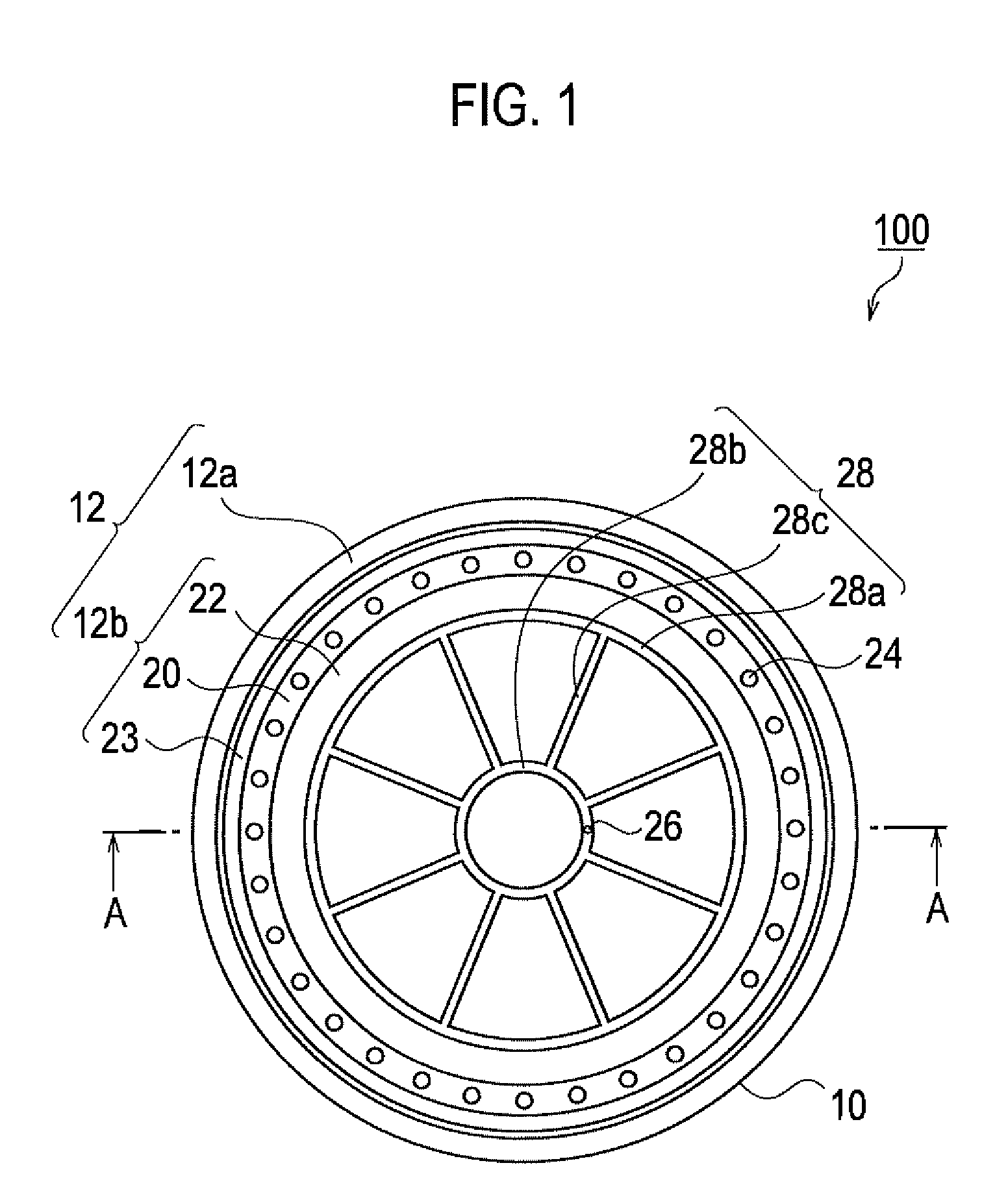

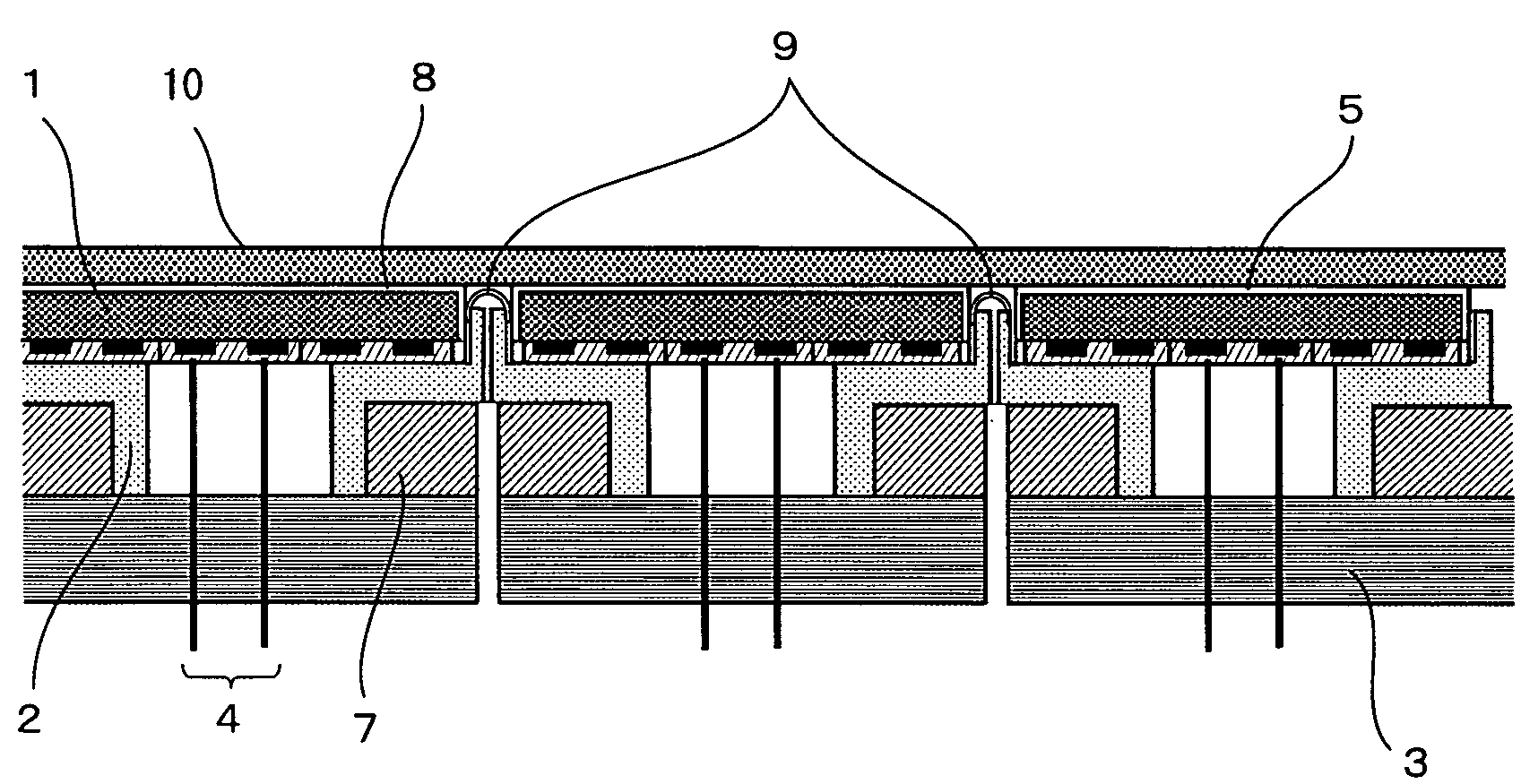

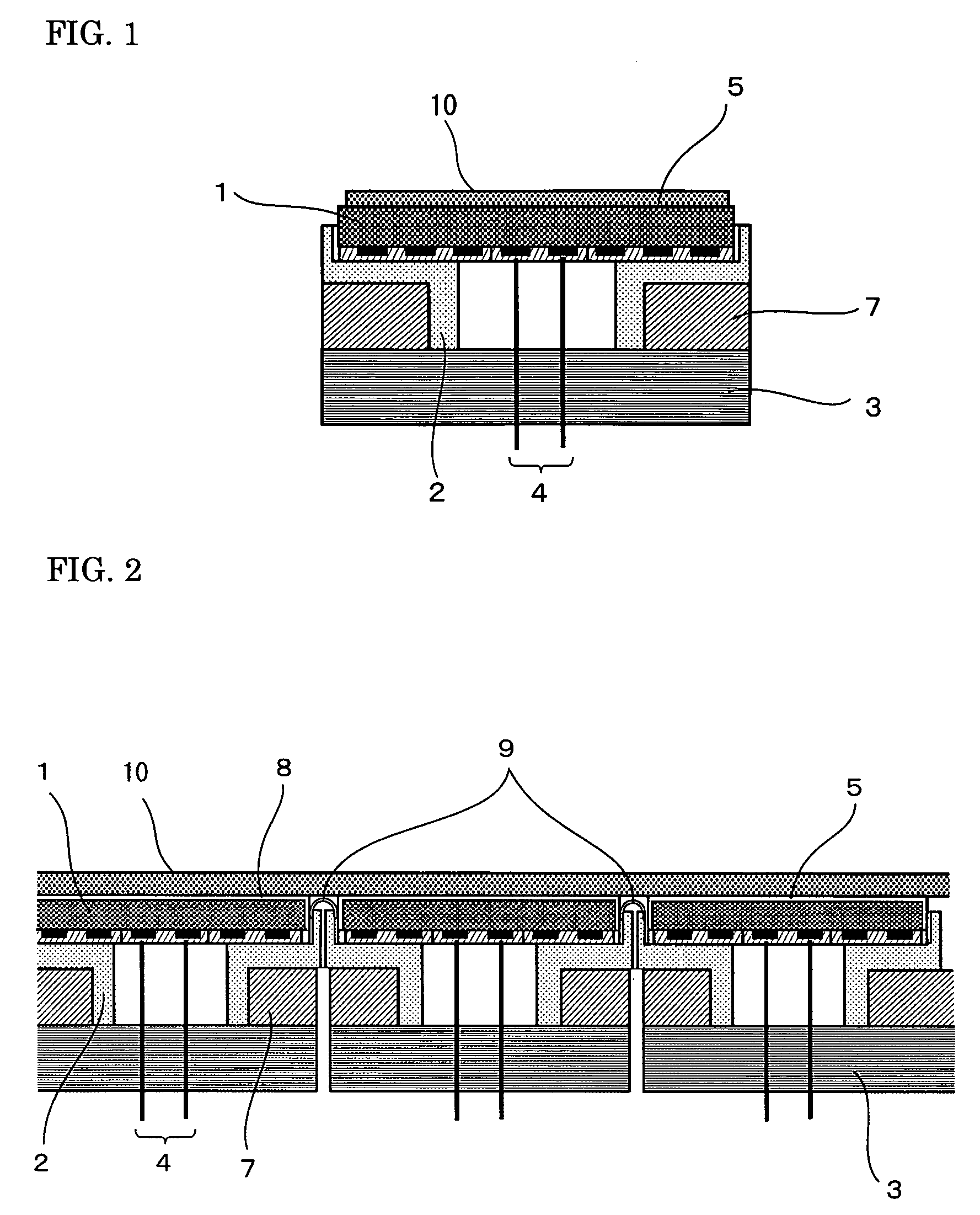

Ceramic heater and ceramic joined article

InactiveUS20050045618A1Inhibit the generation of cracksIncrease spawn rateLamination ancillary operationsLaminationMetallurgySemiconductor

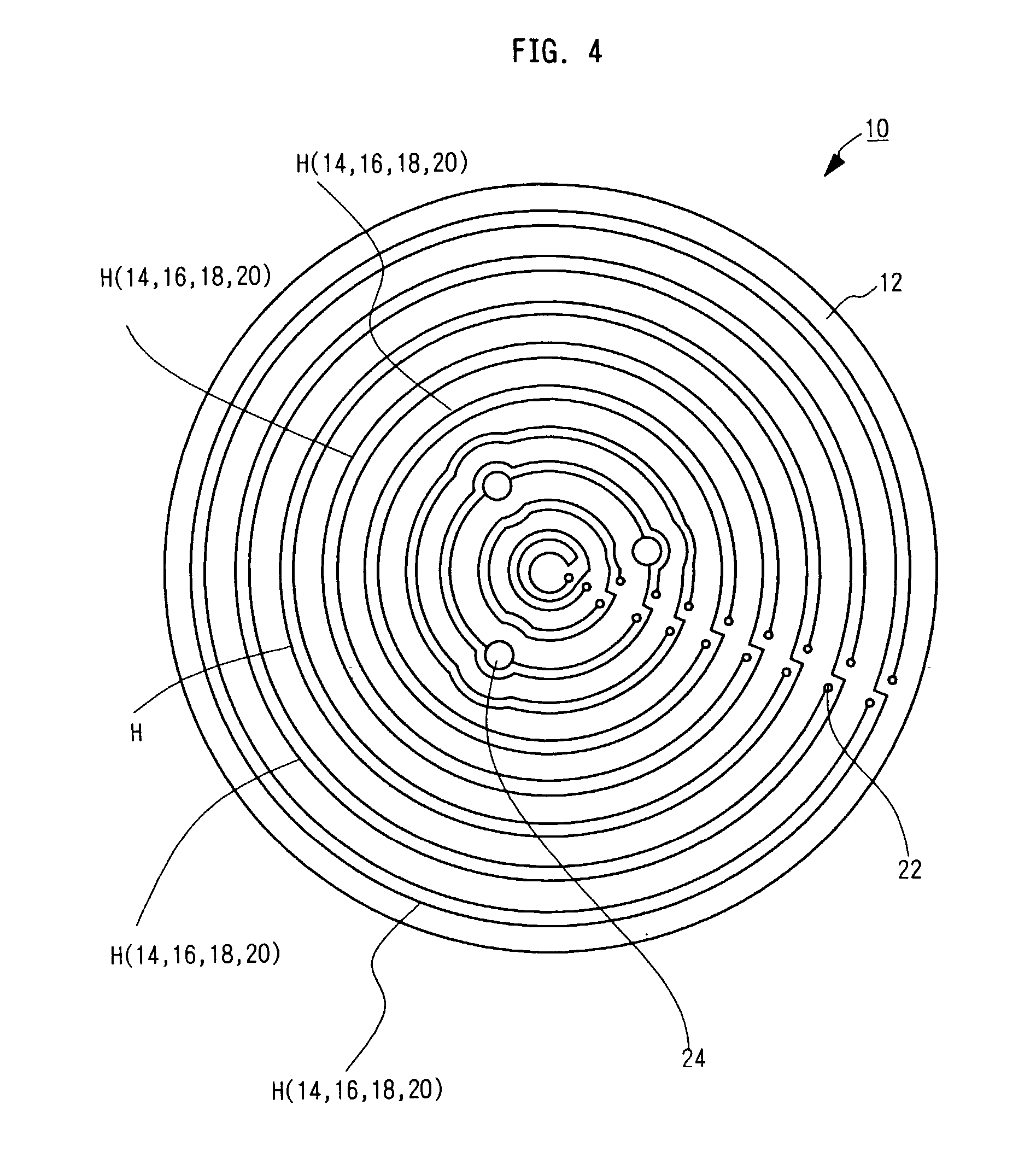

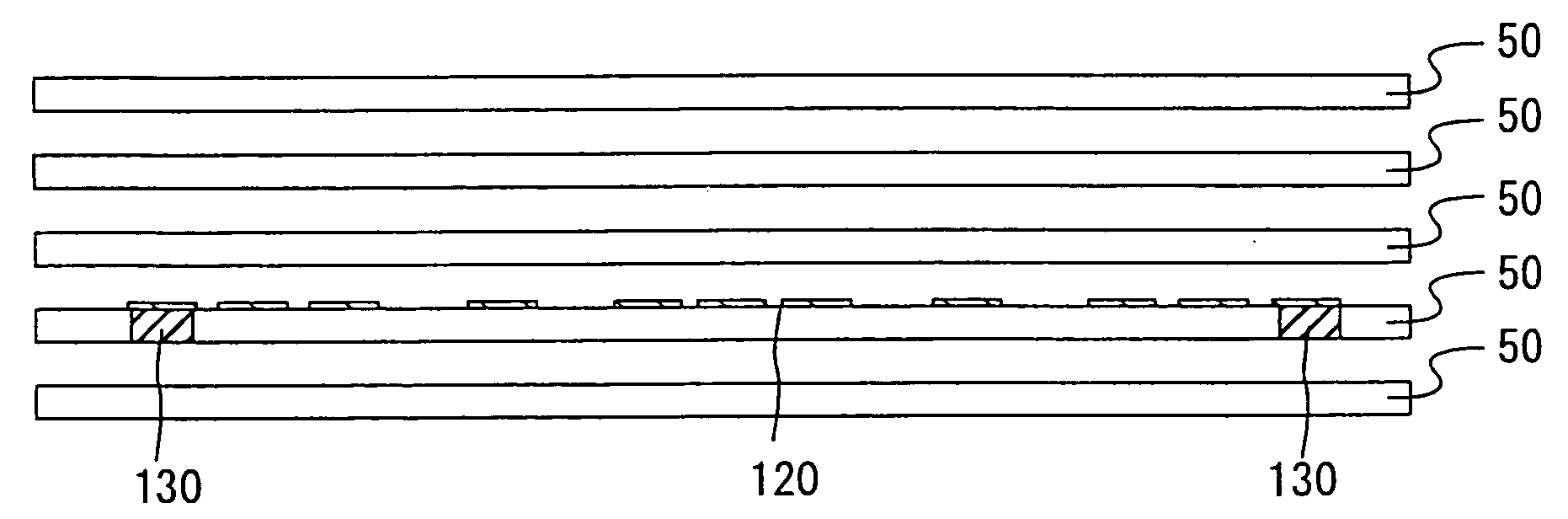

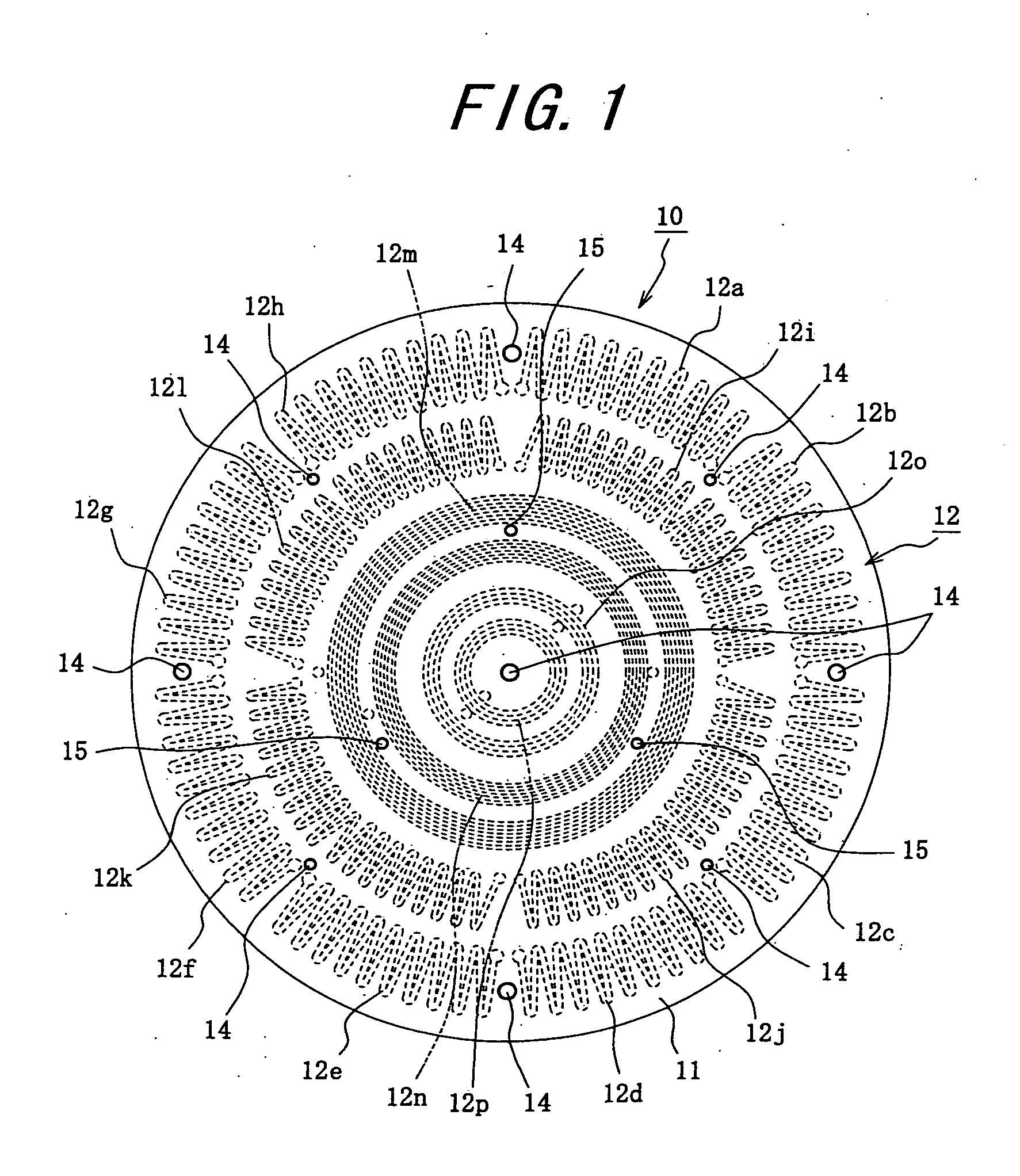

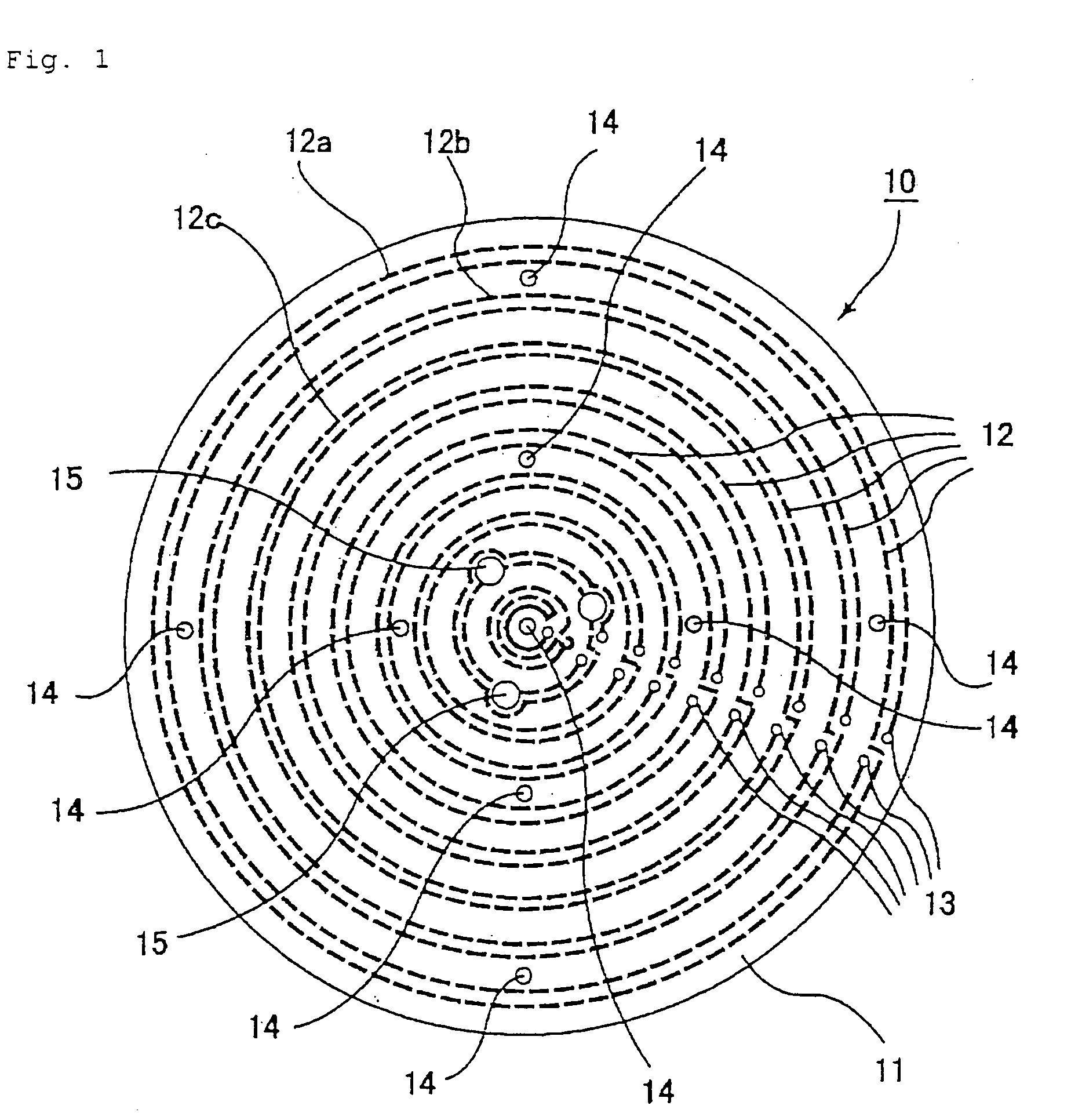

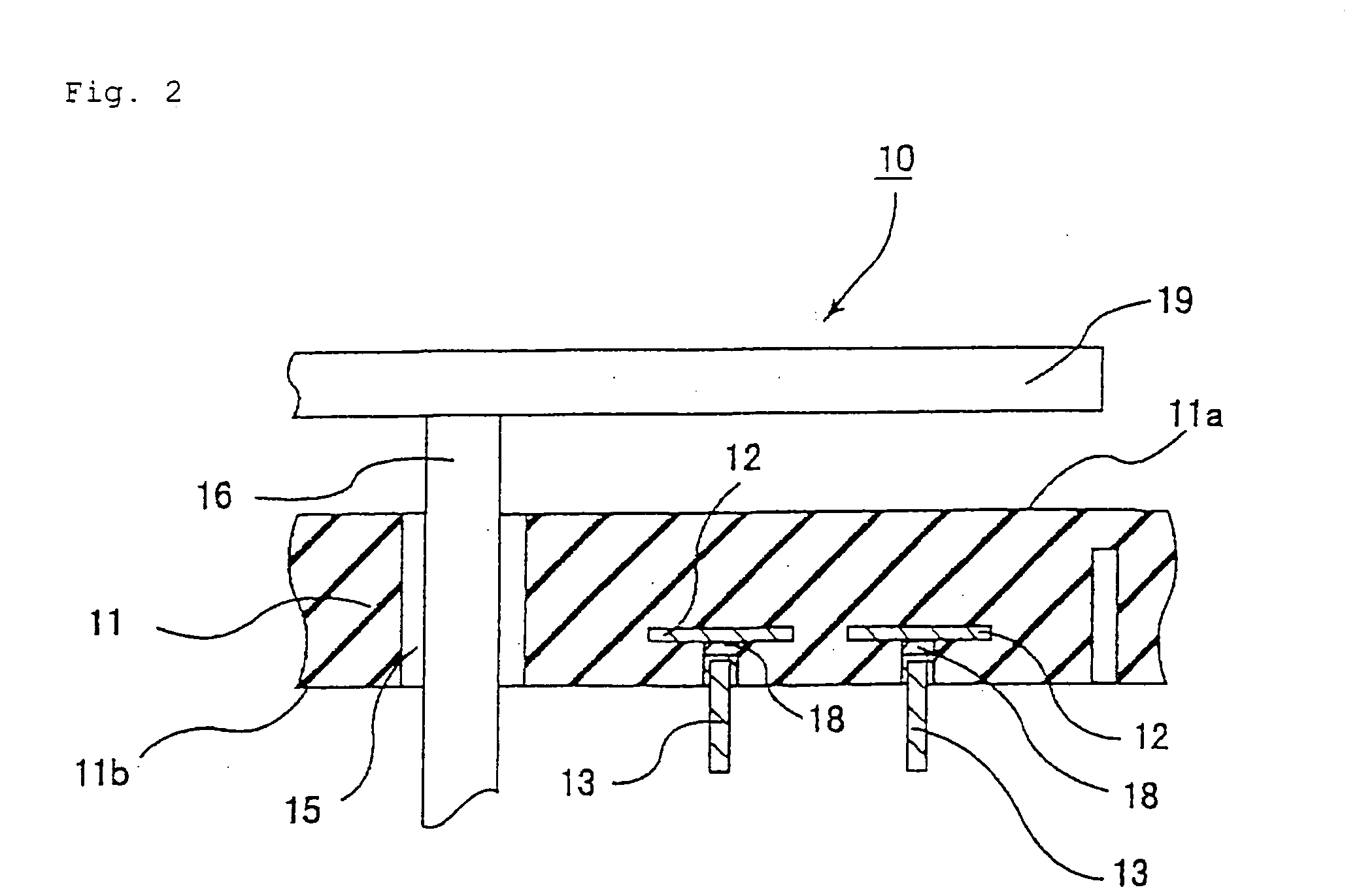

A ceramic heater capable of stably supporting a semiconductor safer and evenly heating the whole of a semiconductor wafer or the like without generating any warp in the semiconductor wafer or the like. The ceramic heater includes a disk-like ceramic substrate, a heating element formed on a surface of or inside the ceramic substrate, and through holes for letting lifter pins pass through the ceramic substrate. The number of the formed through holes is three or more, and the through holes are formed in an area whose distance from the center of the ceramic substrate is ½ or more of the distance from the center to the outer edge of the ceramic substrate.

Owner:IBIDEN CO LTD

Ceramic heater

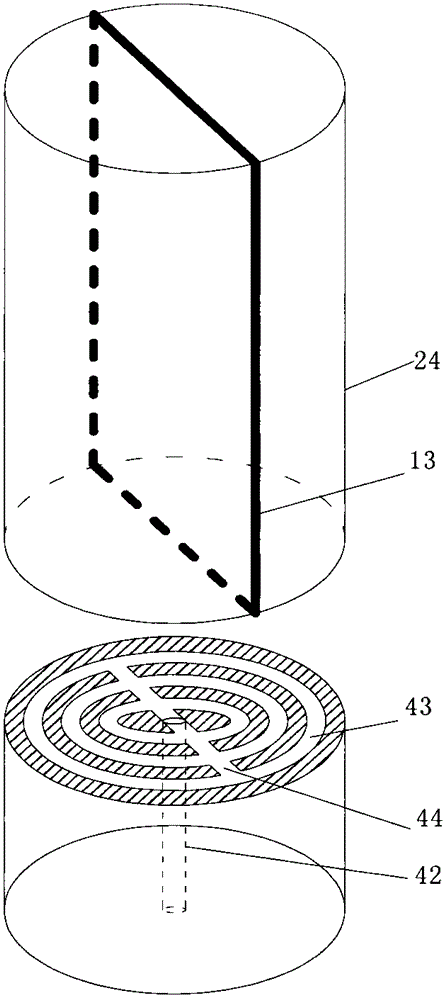

ActiveUS20090235866A1Deteriorates temperature uniformityIncrease volumeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringSemiconductor

A ceramic heater for a semiconductor substrate process includes a plate and a shaft. The plate includes a first base and a second base bonded to the first base. Defined on a mounting surface of the first base are: a first region having a surface contacting with a mounted substrate; a purge groove provided in the portion covered with the substrate and surrounds the first region; and a second region having a surface surrounding the purge groove. The first base has: an adsorber configured to adsorb the mounted substrate onto the surface of the first region; and multiple purge holes each penetrating from the bottom surface of the purge groove to the lower surface of the first base. The purge groove is supplied with a purge gas through the multiple purge holes. The surface of the second region is located lower than that of the first region.

Owner:NGK INSULATORS LTD

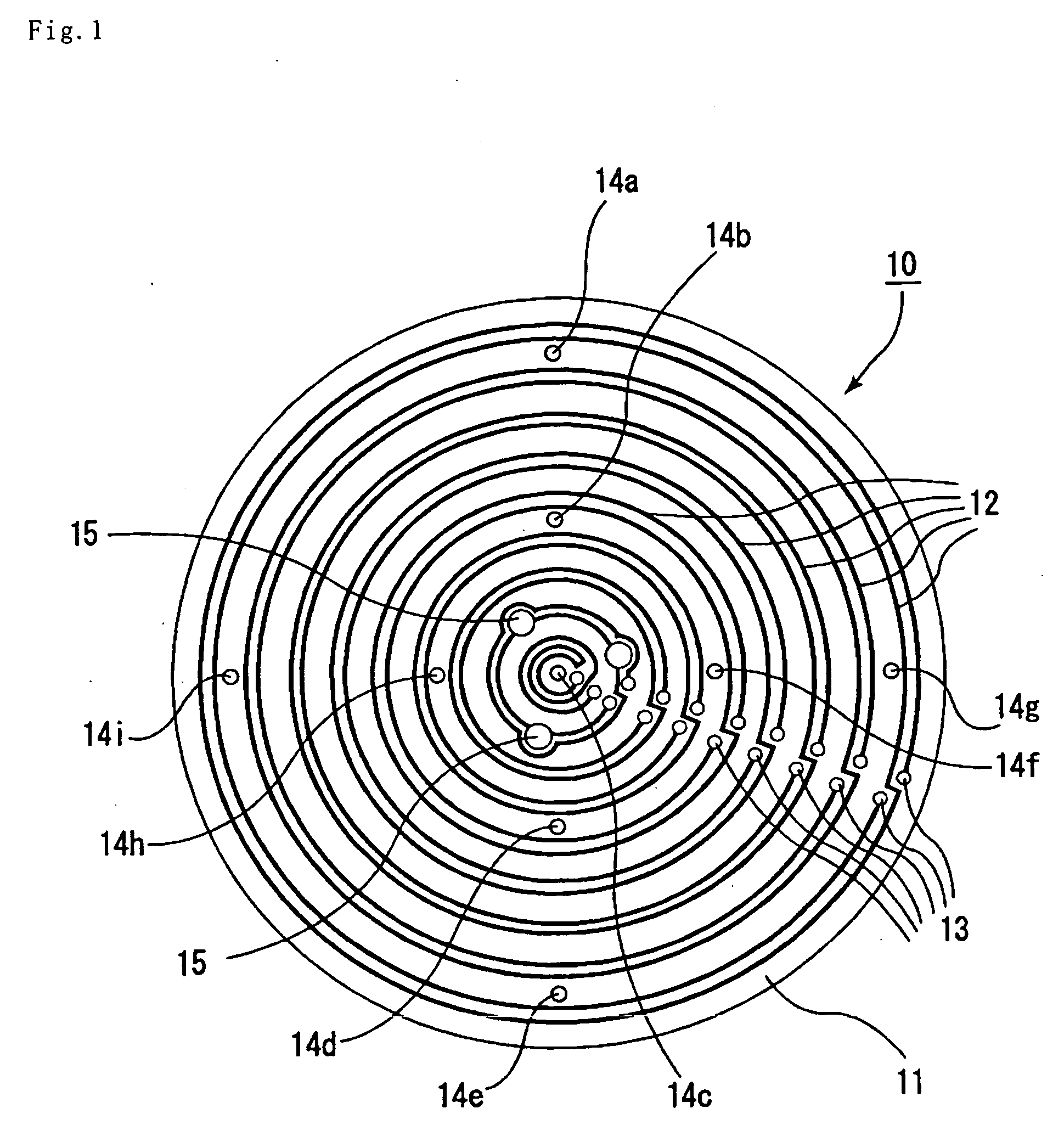

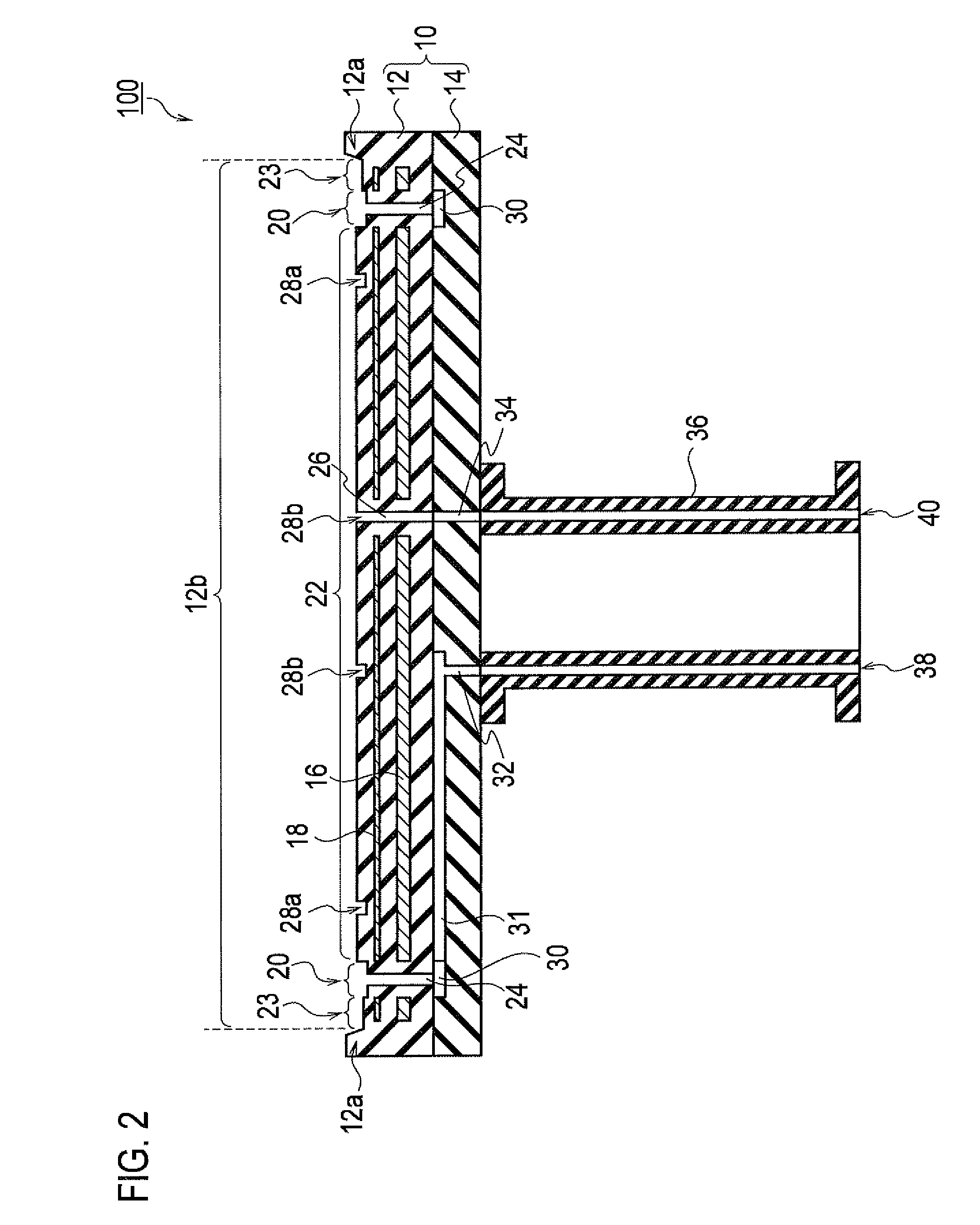

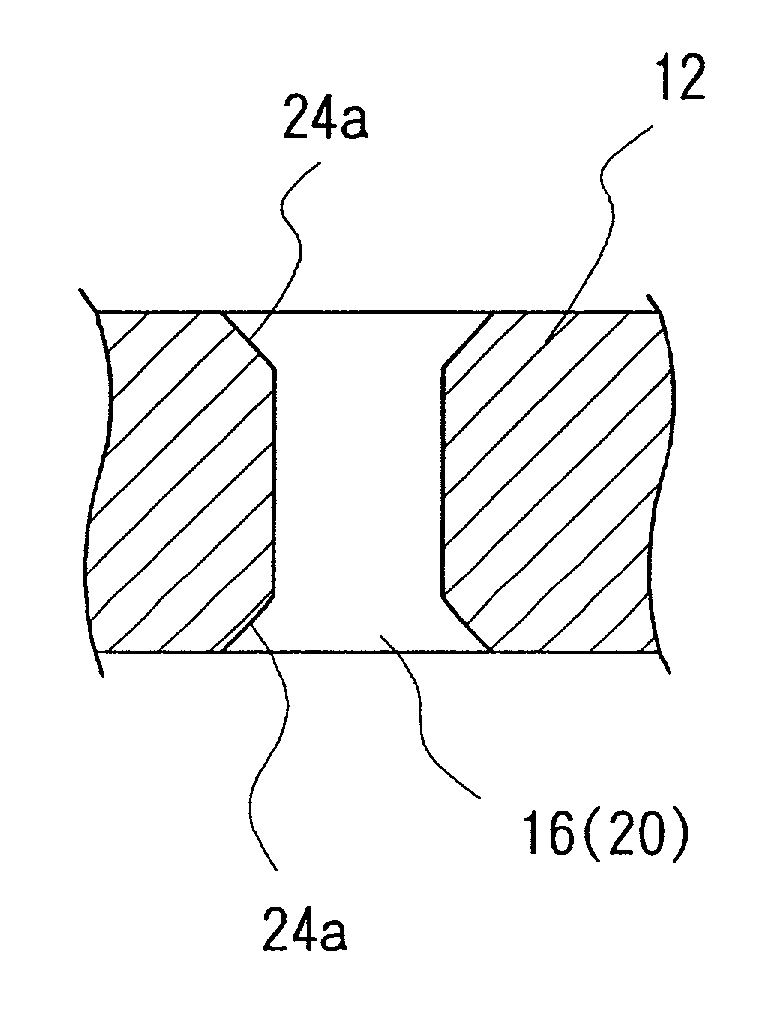

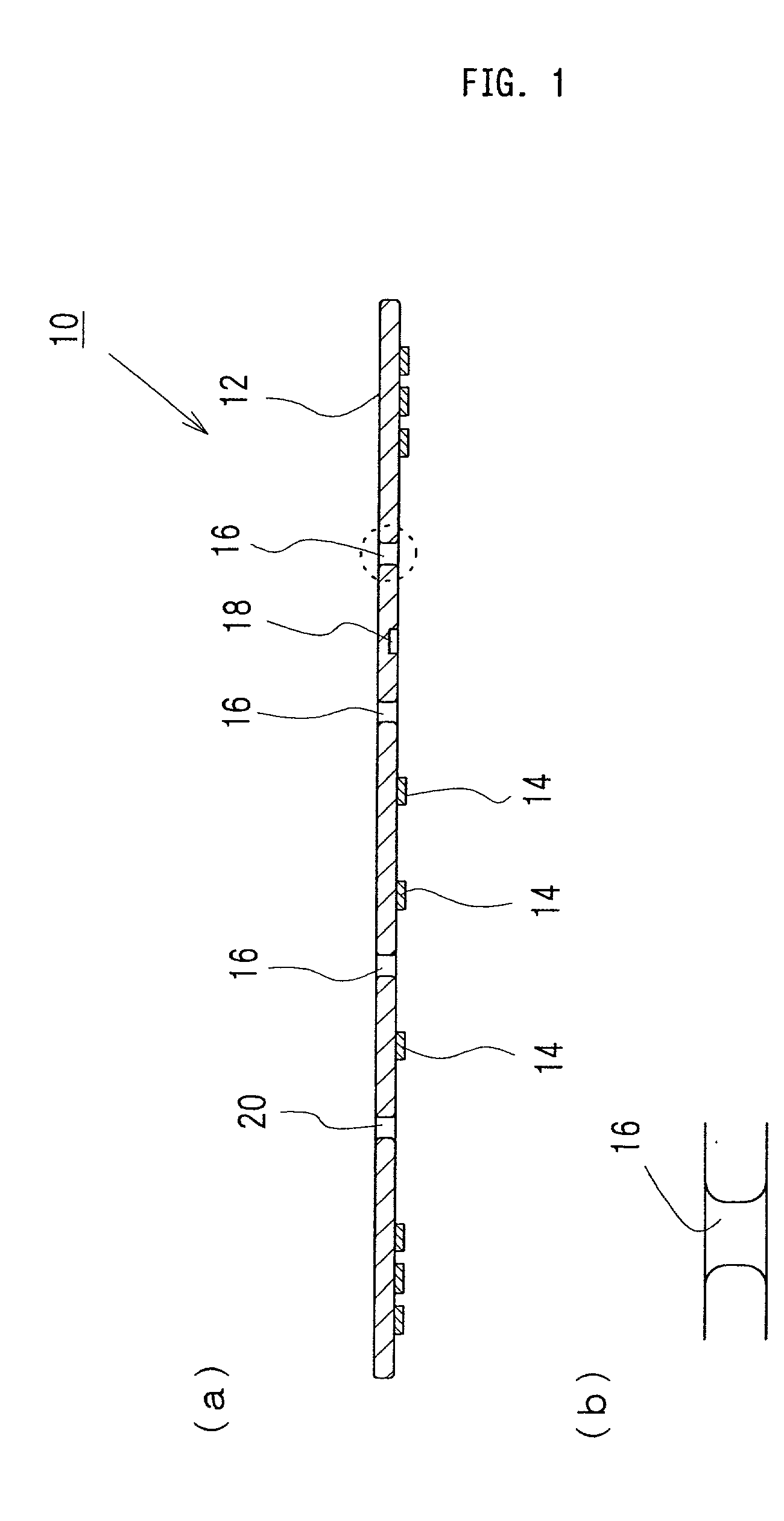

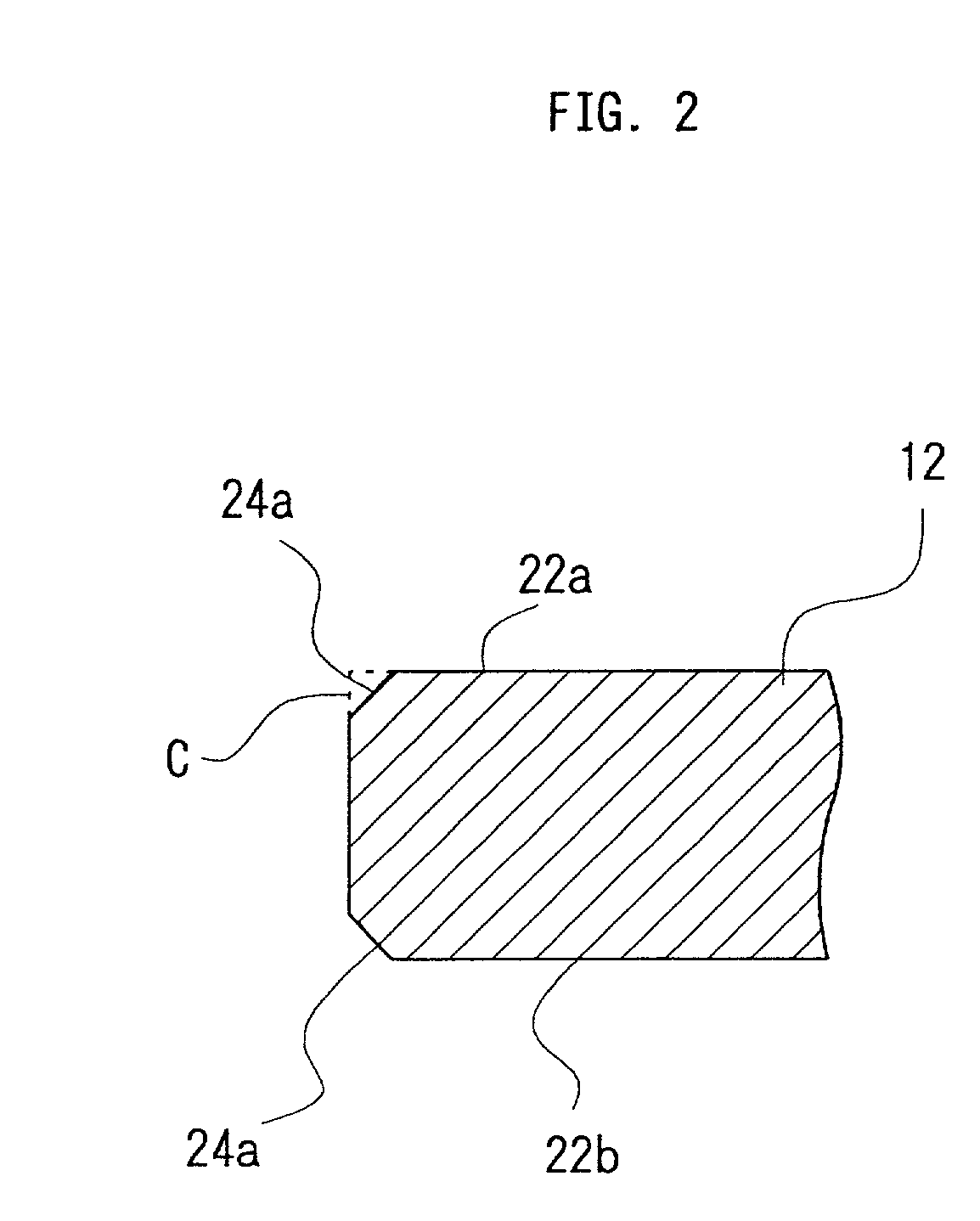

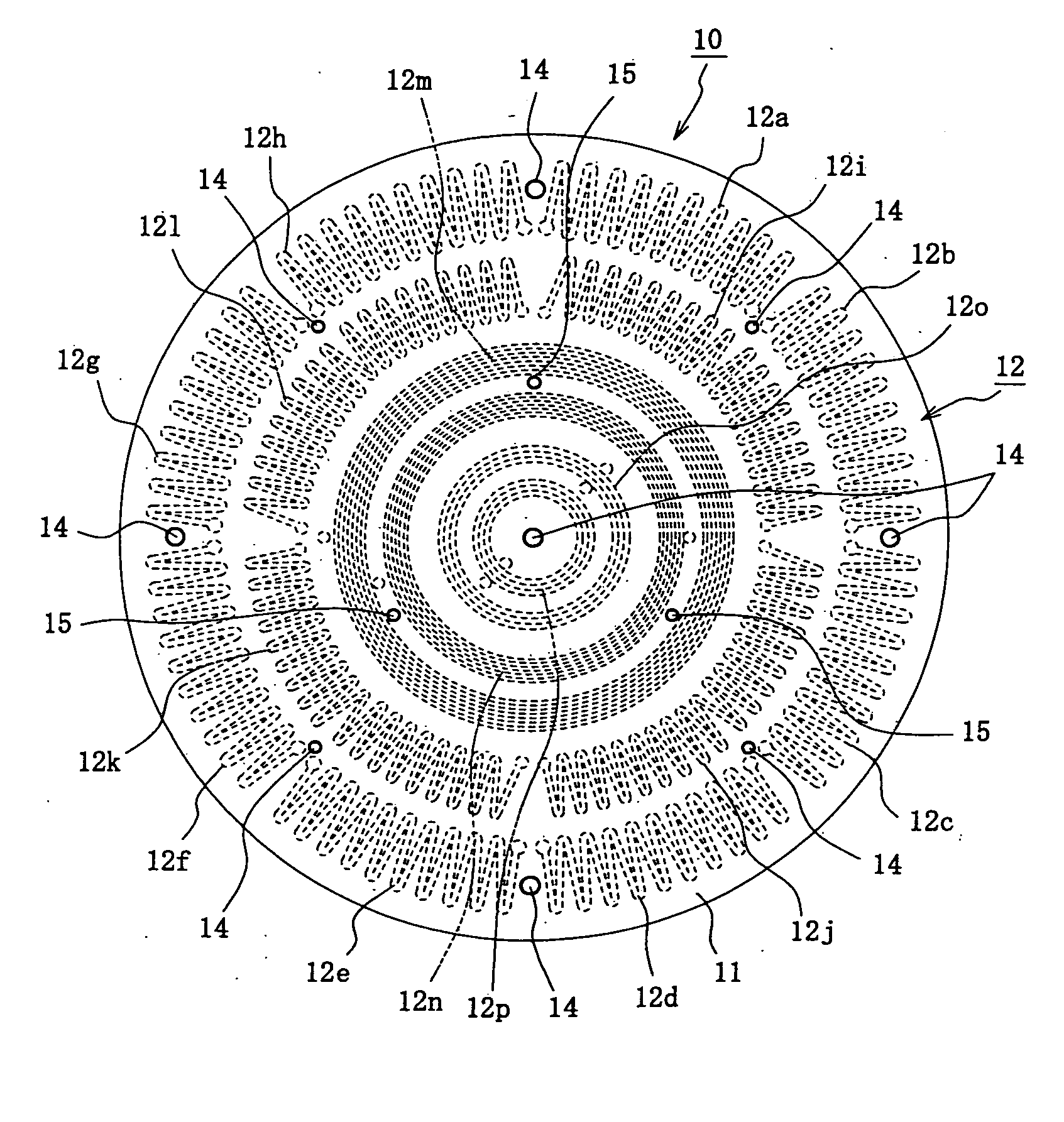

Ceramic heater

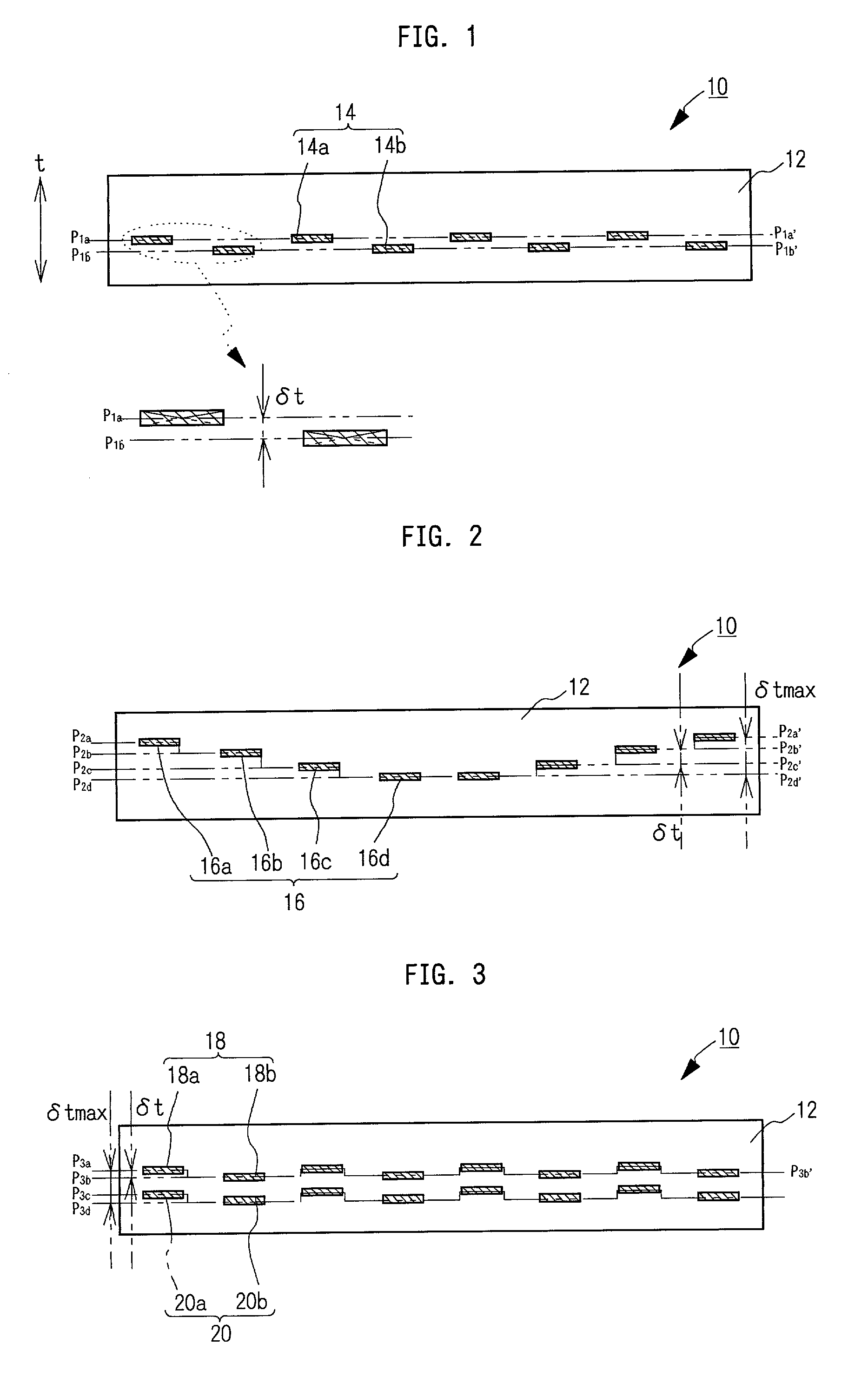

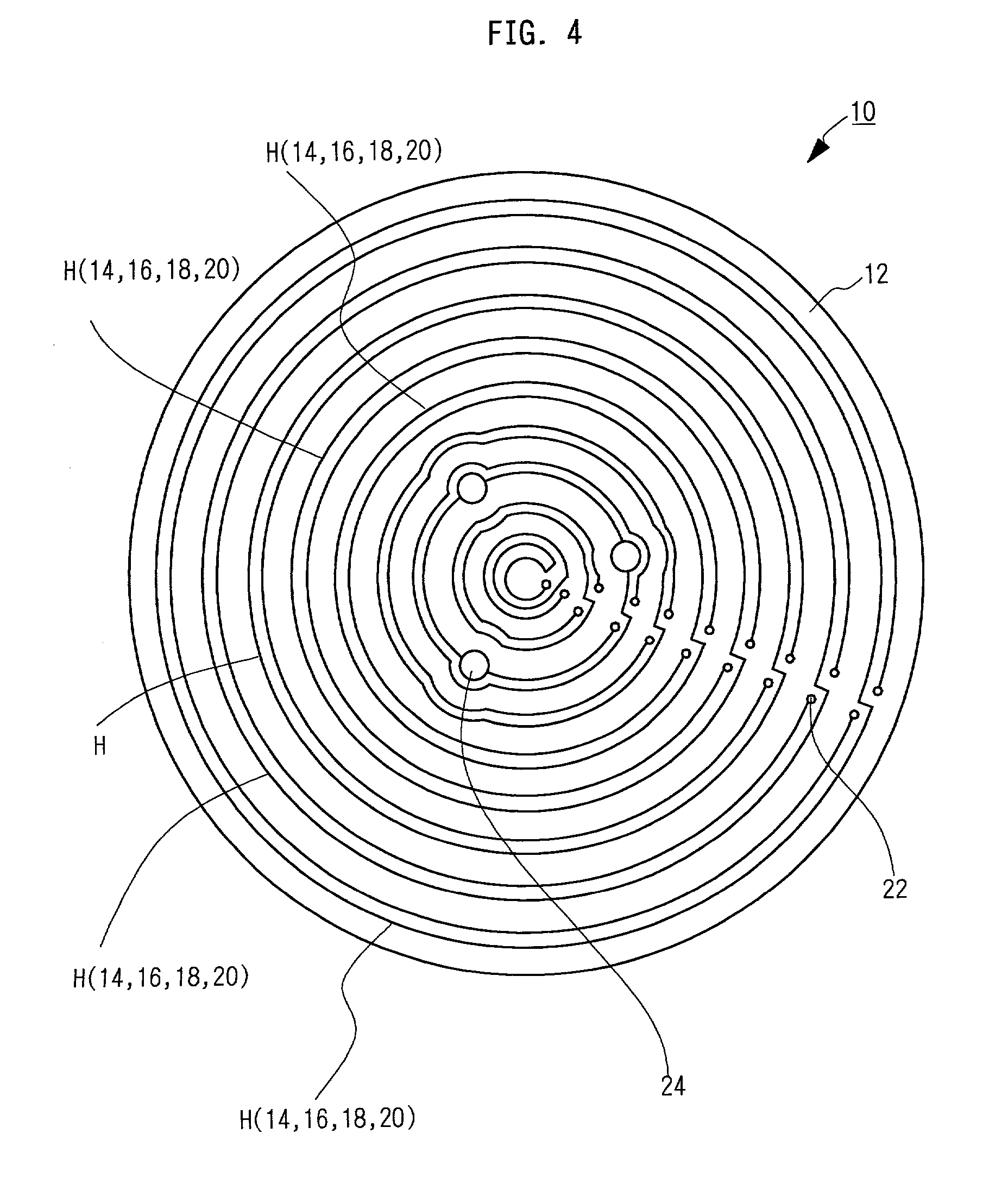

InactiveUS20020043527A1Improve unevennessSemiconductor/solid-state device manufacturingHot plates heating arrangementsTemperature controlThermocouple

To provide a ceramic heater capable of reducing temperature uniformity at the periphery of through holes such as insertion holes and vacuum suction holes, thereby protecting the wafer against thermal shocks and having improved controllability for temperature control parts such as thermocouples and temperature fuse. Further, a ceramic heater capable of uniform resin curing is provided. A heat generation body 14 is disposed on the surface or inside of the ceramic substrate 12. Further, corners for the insertion holes 16, the recesses 18 and the vacuum suction holes 20 of the ceramic substrate 12 are chamfered.

Owner:IBIDEN CO LTD

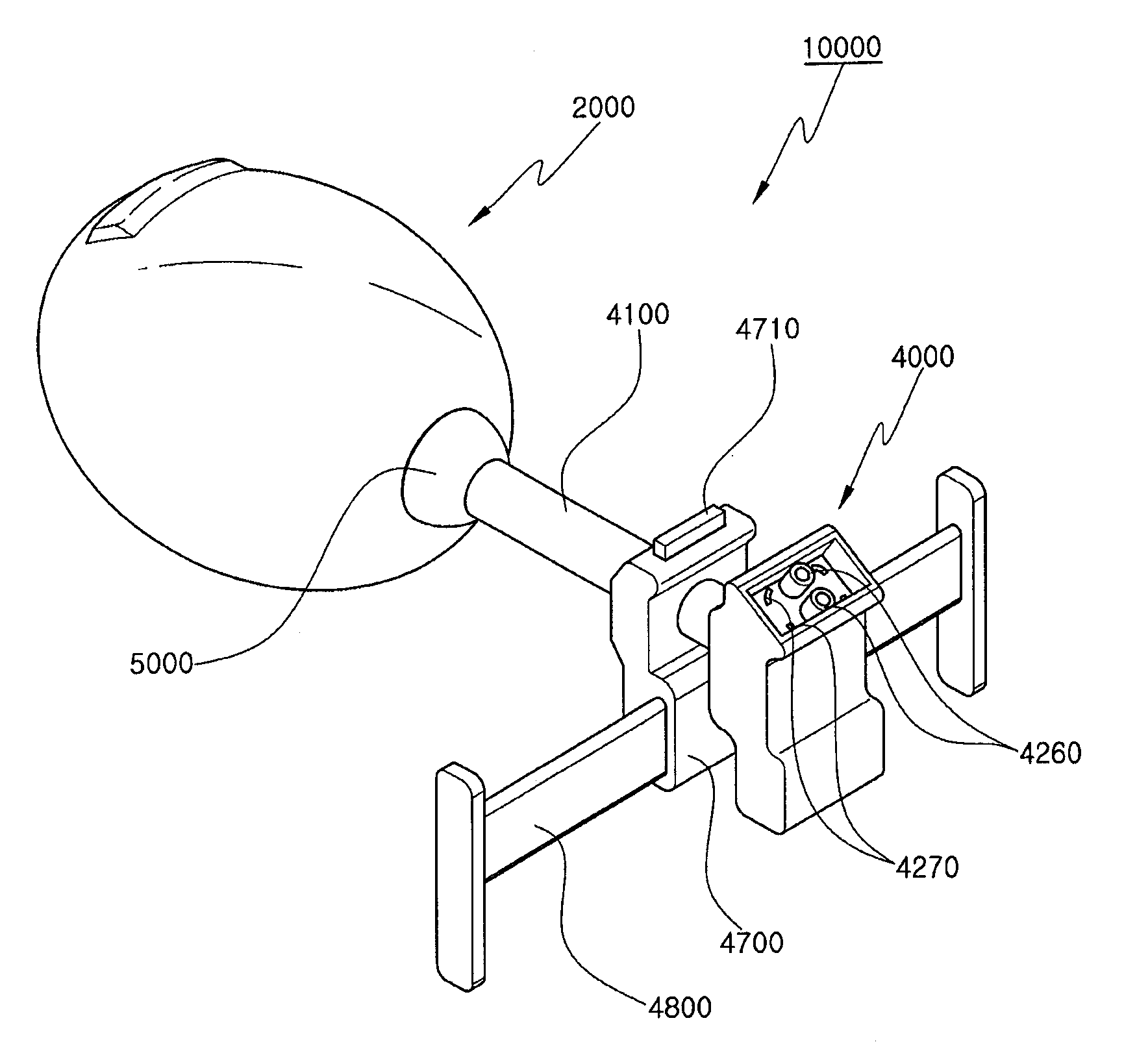

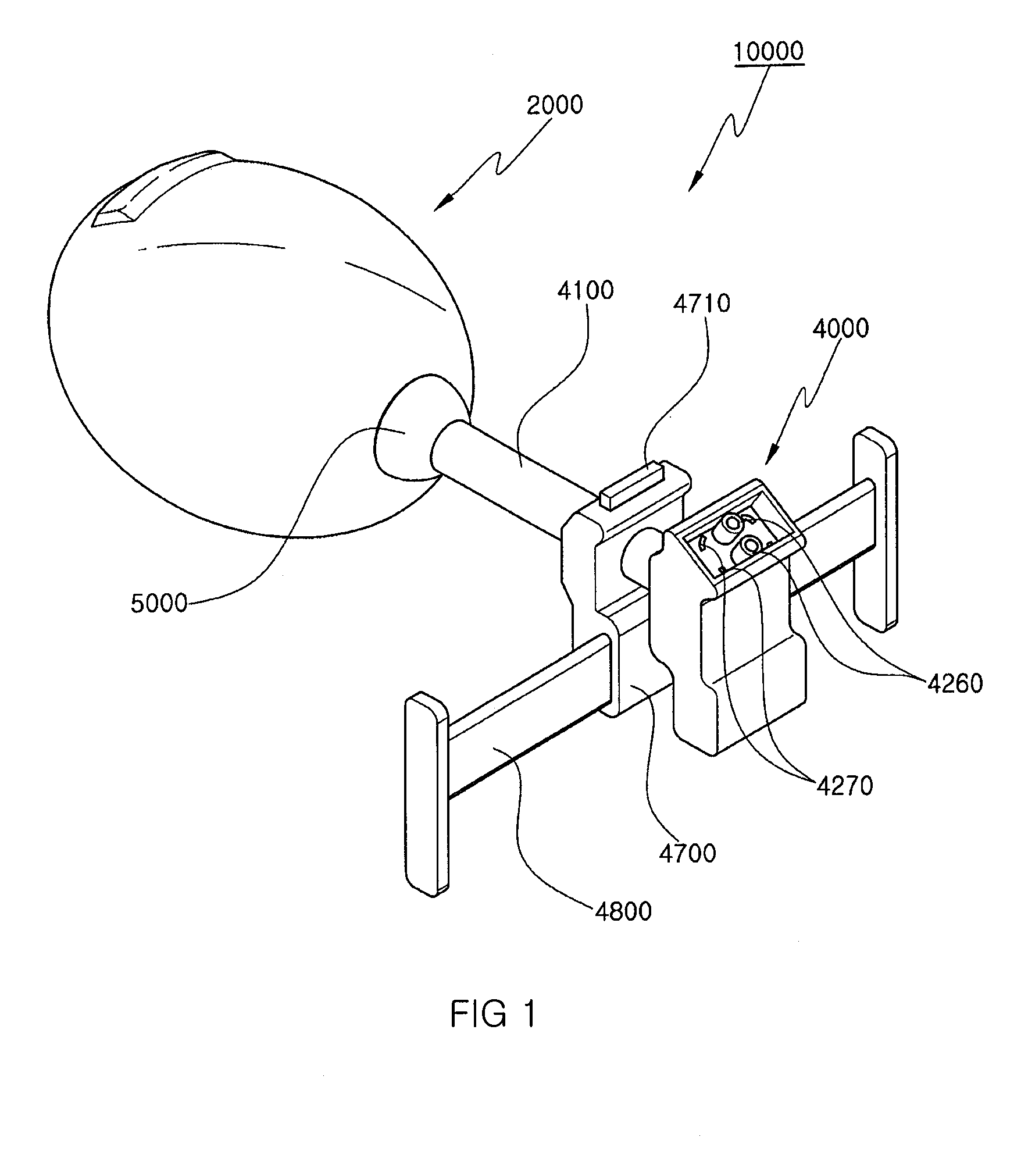

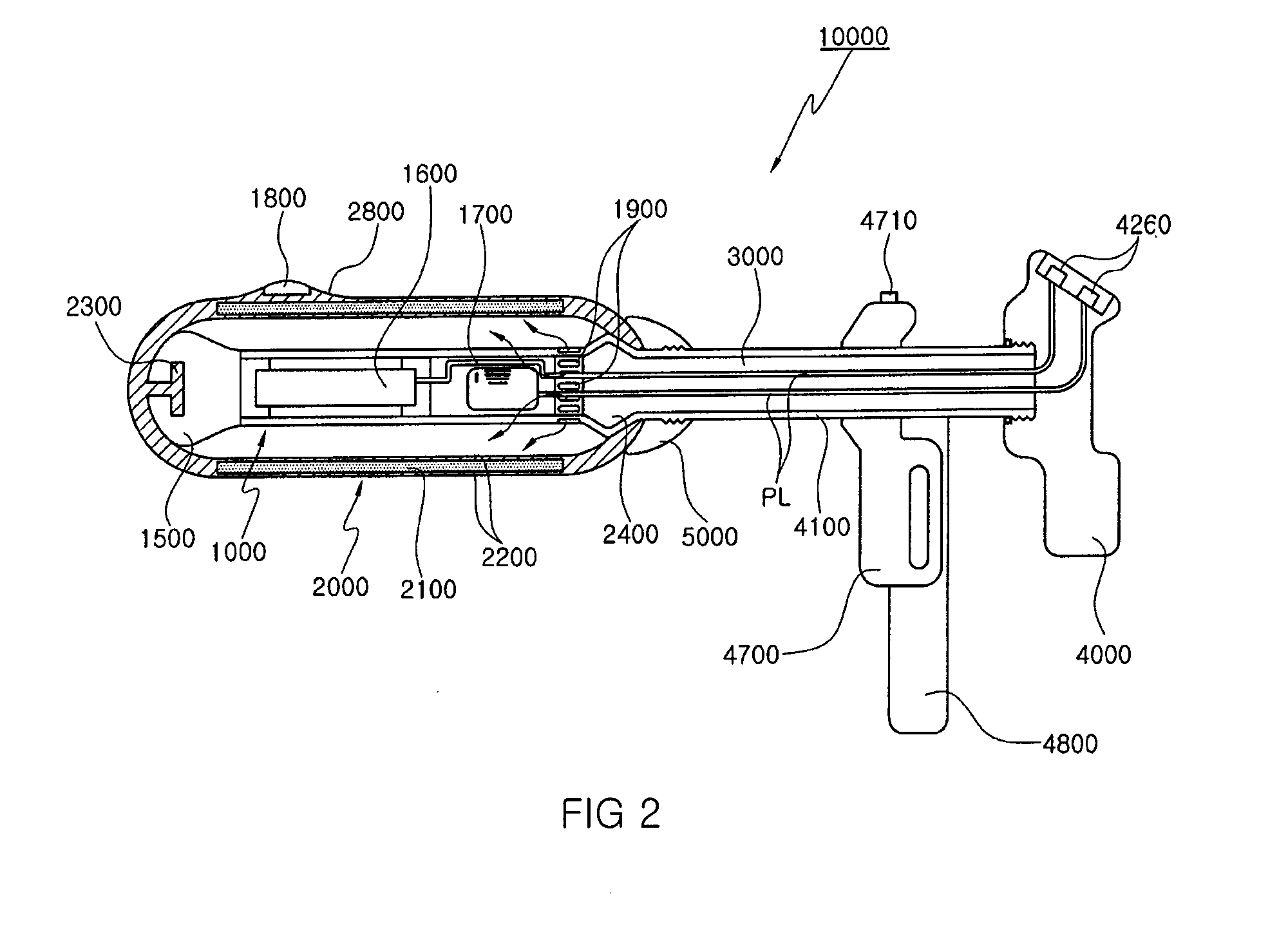

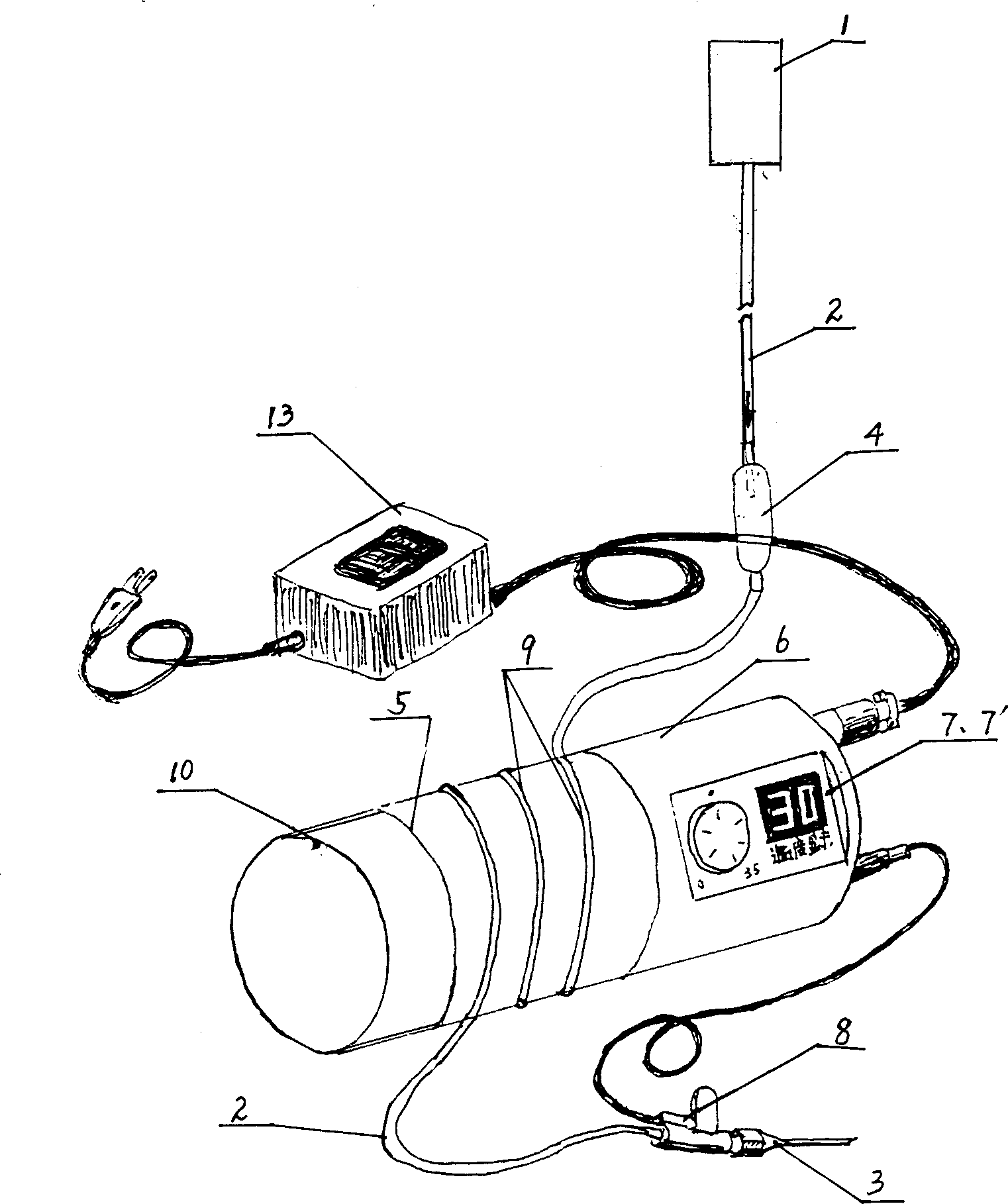

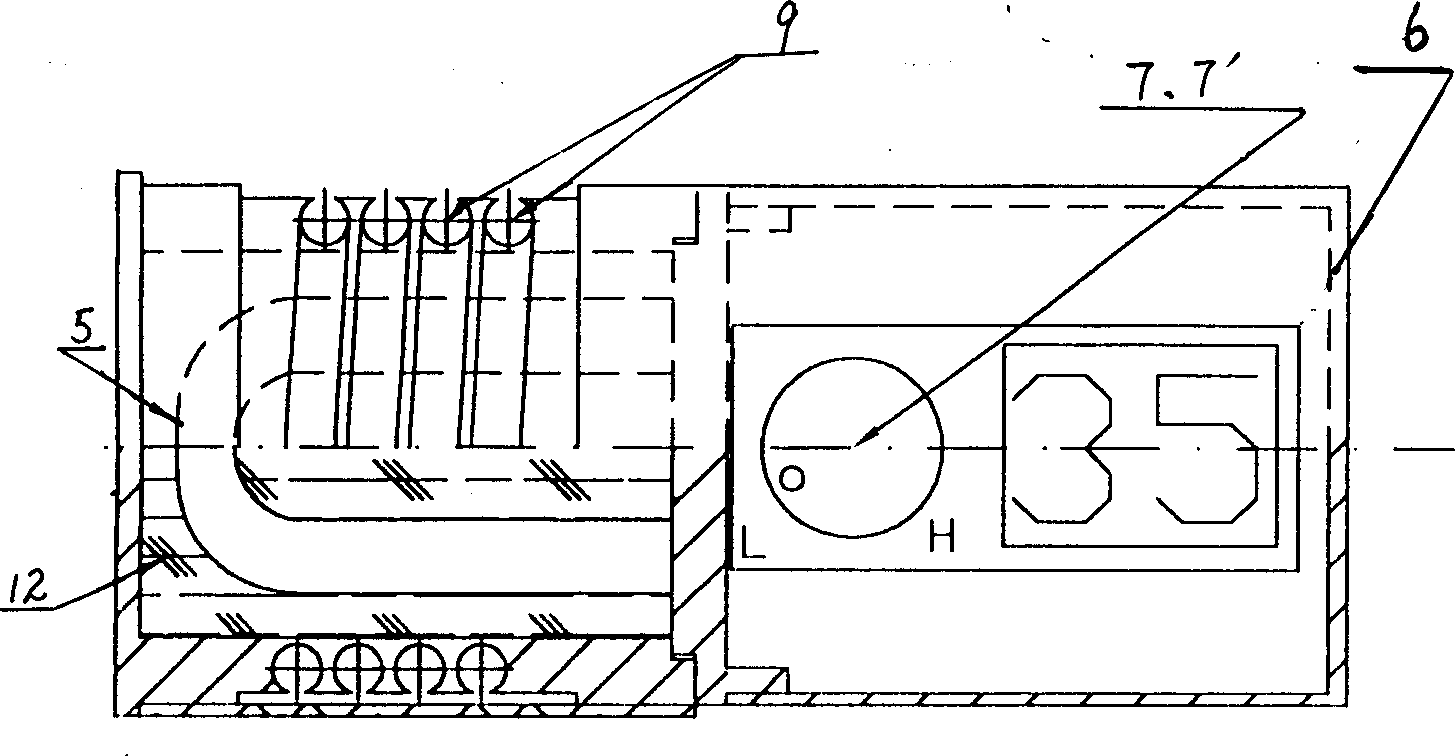

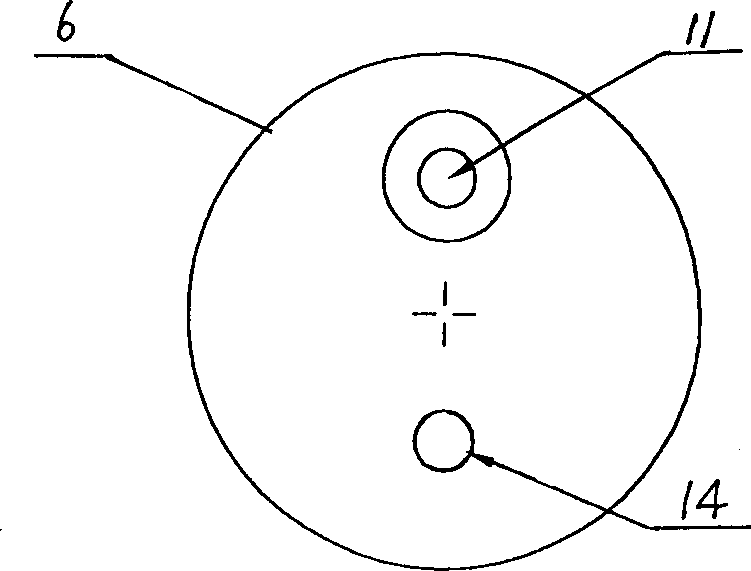

Apparatus For Examining and Curing Urinary Incontinence, and For Exercising Bio-Feedback of Women Vagina Muscles

ActiveUS20080139876A1Simple treatmentReadily treat urinaryPerson identificationGenitals massagePelvic diaphragm muscleAir pump

An apparatus for examining and curing urinary incontinence and exercising the pelvic floor muscles and vaginal muscles using bio-feedback including a controller main body, a probe, and a bio-feedback device. The probe includes: an insert frame extending in a longitudinal direction thereof, an insert expansion part surrounding adjacent to a front end of the insert frame and expandable therearound; an air supply path connected to the interior of the insert expansion part to supply air; a handle engaged with the insert frame; a fixing means for fixing the insert expansion part to the insert frame or the handle; a valve installed at the air supply path; and a PTC ceramic heater and a vibration motor installed at the insert frame. An elastic member includes a magnet, an insertion depth adjustment part, and leg support parts installed at the insertion depth adjustment part. The bio-feedback device includes a sound generating means, and an image display means. The main body includes a controller for controlling each component, a motorized air pump, an air flow detection sensor, a pressure detection sensor, a spring air cylinder, a solenoid air injection valve, an air tank, etc. Therefore, it is possible for a user to readily perform examination and treatment of urinary incontinence and pelvic floor muscle (vagina muscle) reinforcement exercise using bio-feedback.

Owner:APIMEDS

Ceramic heater

InactiveUS20050016986A1Efficient transferEliminate temperature differenceSemiconductor/solid-state device manufacturingHot plates heating arrangementsElectrical resistance and conductanceSemiconductor

The invention is a ceramic heater provided with a resistor heating body formed in an interior of a ceramic substrate, characterized in that the resistor heating body is made of an electrically conductive ceramic and a sintering aid containing layer is existent at least on the surface of the resistor heating body. This heater does not generate crack even in the rapid temperature rise, and has an effect of uniformizing the heating and rapidly increasing the temperature rising rate, and is used in an industrial field of semiconductor production-inspection apparatuses including an electrostatic chuck or plasma generating device, optical apparatuses and the like.

Owner:IBIDEN CO LTD

Test device for chemical solution seepage in rock single fracture at different temperatures

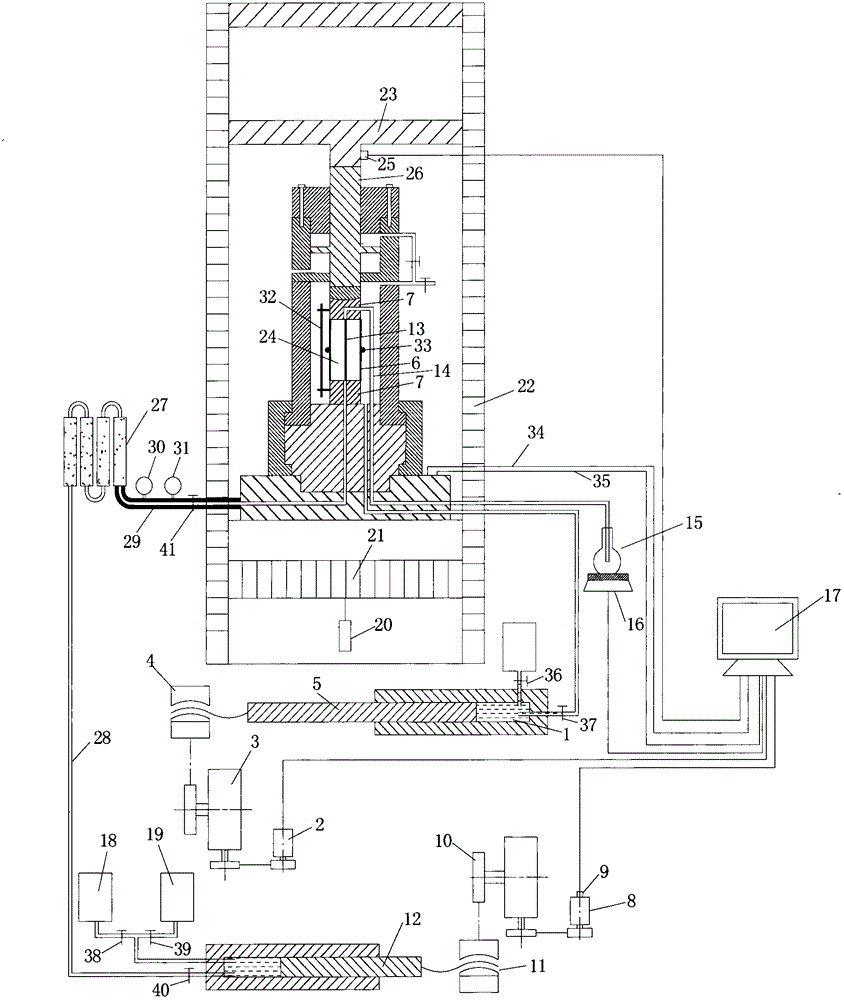

ActiveCN104007013ASolve corrosiveSolve the defects of crack deformation testWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesChemical solutionPressure system

The invention relates to a test device for chemical solution seepage in rock single fracture at different temperatures. The test device comprises a sample apparatus system, an axial compression system, a confining pressure system, a chemical solution pressure loading system, a servo control system and a data acquisition system. The sample apparatus system comprises a sample, a cylindrical heat-shrinkable tube and a cylindrical rigid spacer block; one end of the rigid spacer block is provided with a permeation hole, a circular permeation groove and a radial permeation groove; the chemical solution pressure loading system is provided with a heating device; the heating device comprises a heater and a temperature sensor; the heater is disposed on a solution pipe at one side of the sample apparatus system; and the solution pipe between the heater and the sample apparatus system is provided with the temperature sensor. To increase test precision, the wall of the solution pipe between the heater and the sample apparatus system is provided with a heat insulation material; and a ceramic heater is employed.

Owner:HUNAN UNIV OF SCI & TECH

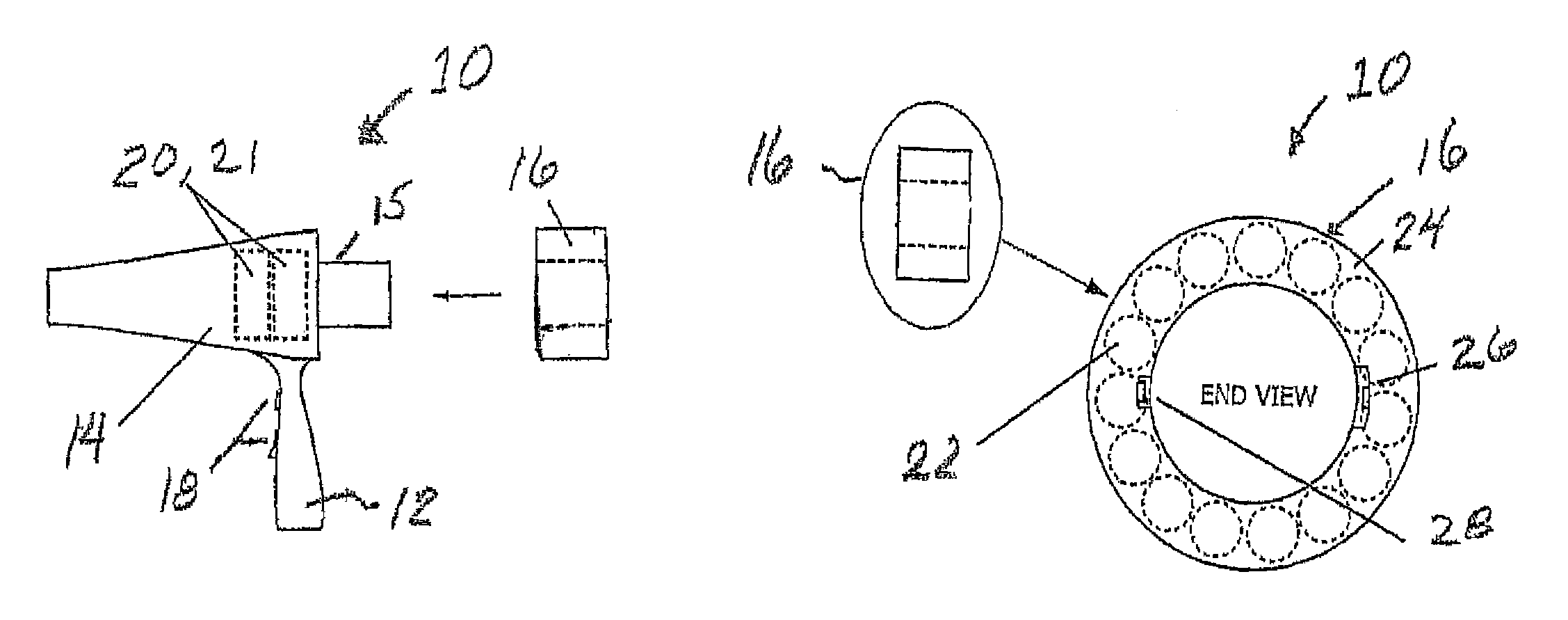

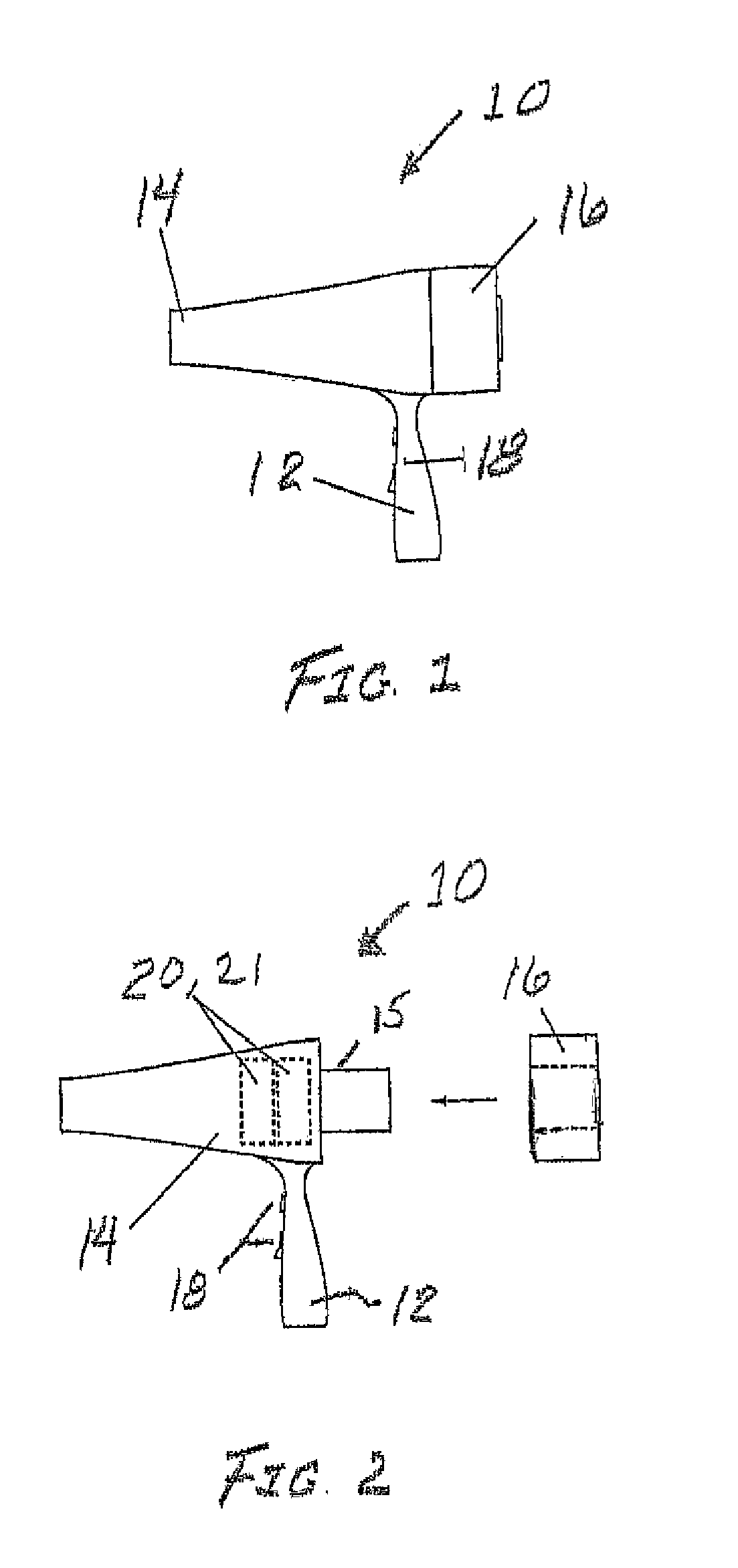

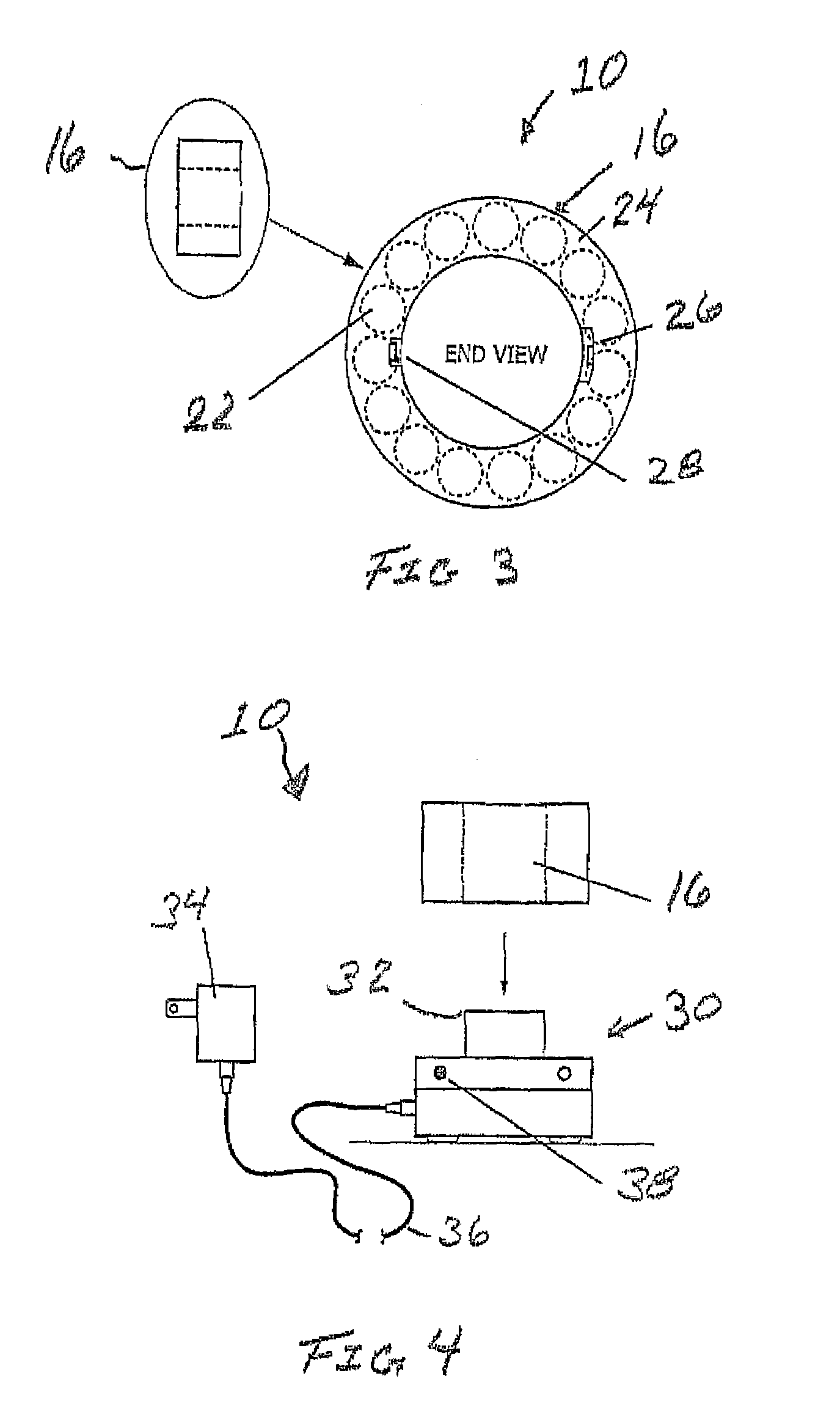

Cordless hair dryer device

A cordless hair dryer device comprising an ergonomically shaped handle, air cone, rechargeable lithium-type battery pack that releasably attaches to a battery mount on the back of the hair dryer, temperature controls, blower speed controls, DC motor, heater and battery pack charger. The handle is ergonomically designed for balance and comprises the heat and blower controls for convenient access and use. The heater comprises a tourmaline impregnated ceramic heater. Intake air flows over the tourmaline / ceramic heater producing negative ions so the hair does not become statically charged during the drying process. The air intake at the back of the hair dryer includes a removable filter to catch errant fibers and hair before they flow into the blower / heater area. The motor and tourmaline impregnated ceramic heater are mounted close to the battery pack in a manner that provides easier control.

Owner:STEFANO ROBERT +1

Ceramic substrate, ceramic heater, electrostatic chuck and wafer prober for use in semiconductor producing and inspecting devices

InactiveUS20050029244A1Remarkable effectReduce resistanceSemiconductor/solid-state device testing/measurementSolid-state devicesMetallurgySemiconductor

A ceramic substrate for semiconductor manufacture and / or inspection which is conducive to decrease in α-rays radiated, to prevent electrical errors, and to decrease an electrostatic chucking force such as heater or wafer prober, generation of particles, and circuit defects. The ceramic substrate is configured such that the level of α-rays radiated from the surface of the ceramic substrate is not higher than 0.250 c / cm2·hr.

Owner:IBIDEN CO LTD

Ceramic heater

InactiveUS20060267614A1Improve the heating effectGood temperature sensing performanceSemiconductor/solid-state device manufacturingFault location by increasing destruction at faultEngineeringElectrical and Electronics engineering

This invention is about a Ceramic Heater which comprises a built-in heating unit circuit and a built-in separate temperature sensor circuit, wherein precision circuit printing technology and layering technology are used, and which is manufactured by means of cofiring process. This invention is featured by a first circuit board, a heating circuit in certain patterns on the top side of the aforesaid first board, a sensor circuit positioned between the patterns of the heating circuit, and a second board which is layered over the aforesaid first board.

Owner:SMA TECH

Ceramic heater

InactiveUS20020043530A1The implementation process is simpleGood repeatabilityHot plates heating arrangementsHeating element shapesThermal shockCeramic heater

The present invention provides a ceramic heater having better anti thermal shock property. A ceramic substrate 12 is formed by providing heat generation bodies 14a and 14b on the surface of a green sheet made from a slurry containing powdered ceramics, sandwiching the green sheet with other green sheets from both upper and lower sides and then laminating and pressing the compiled green sheets. At least some of the heat generation bodies 14a and 14b are disposed on a level P1b offset from a level P1a of other heat generation bodies in the direction of thickness of the ceramic substrate 12.

Owner:IBIDEN CO LTD

Thermal sensitive ceramic heater and heating body and heating core applied to thermal sensitive ceramic heater

ActiveCN104797015AImprove insulation performanceIncrease productivityOhmic-resistance electrodesHeater elementsHeat conductingHeat sensitive

The invention discloses a thermal sensitive camera heater. The thermal sensitive camera heater comprises a heating portion, a connection wire harness and a mounting frame, the heating portion is formed by a heating body and a radiator, the heating body comprises a heat conducting tube and a heating core, the heating core comprises a heating slice, an electrode slice and insulation paper, and the connection wire harness comprises a connection slice. Not fewer than two semi-circular grooves are formed in the outer lateral side of the heat conducting tube. A heat conducting face of the heat conducting tube is 0-15mm wider than the radiator. The thermal sensitive camera heater has the advantages that by the aid of the connection slice added on the electrode slice, reliable connection point contact and stable connection between the heater and the wire harness and convenience in manufacturing are achieved; by the aid of the heat conducting tube and the radiator which are different in width, the radiator can be combined with the heat conducting tube more stably and more uniform in radiation; by the aid of the semi-circular grooves in the lateral side of the heat conducting tube, the inner wall of the heat conducting tube causes less damage to a heating core insulation film, combination of the heating core in the heat conducting tube is tighter, and safety and heat efficiency are improved greatly.

Owner:SUZHOU GUOWEI CERAMIC ELECTRICAL APPLIANCE CO LTD

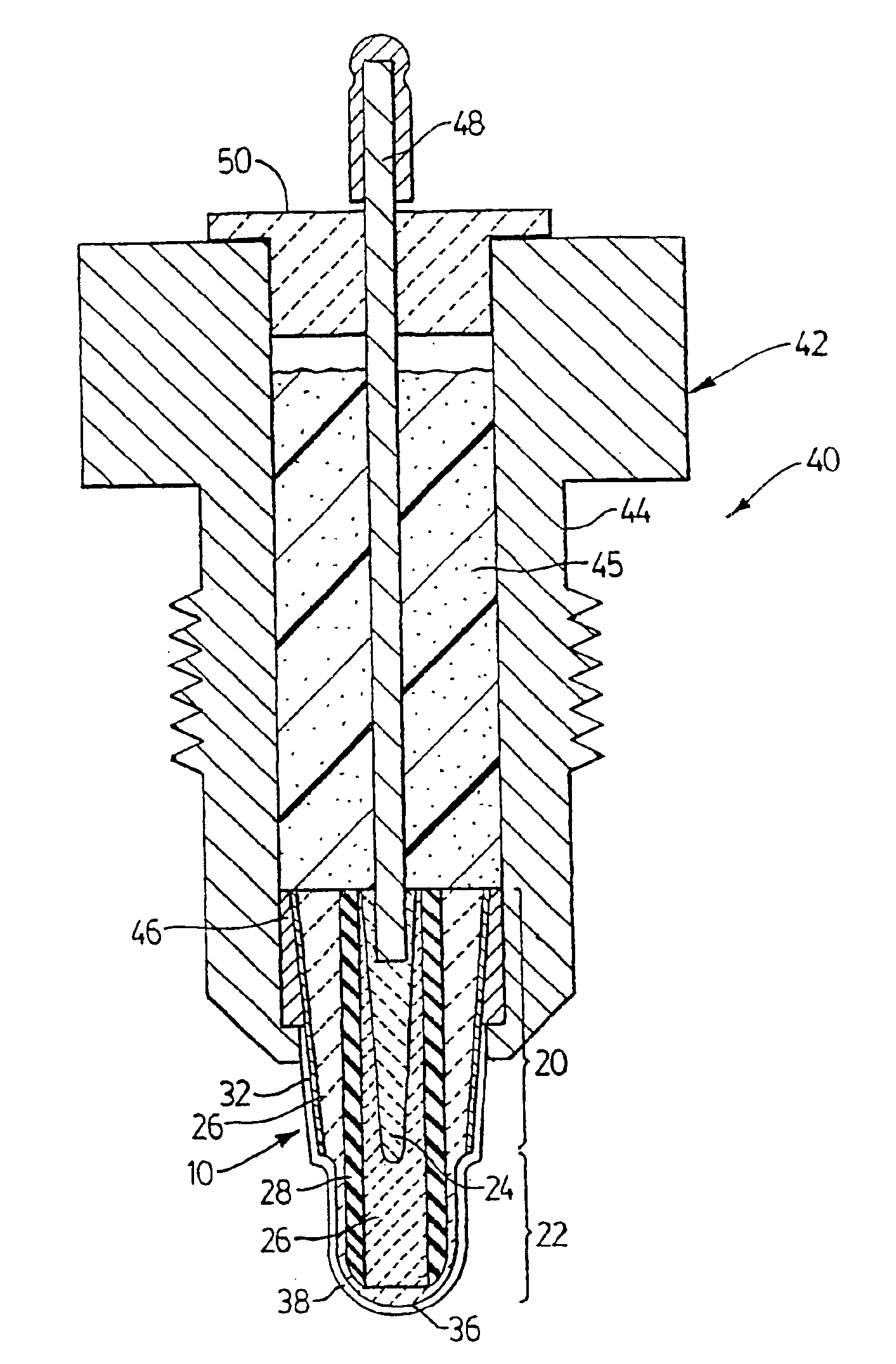

Ceramic heater, a method of making the same and a ceramic glow plug having the ceramic heater

InactiveUS6049065AReduce crackingIncandescent ignitionHeating element shapesMetallurgySilicon nitride

In a ceramic heater a heating element is embedded in a basal ceramic body which is prepared with silicon nitride as a main constituent. MoSi2 particles are dispersed throughout the basal ceramic body. The MoSi2 particles have a granular diameter ranging from 0.1 mu m up to but not including 3.0 mu m. The MoSi2 particles range from 1.0% to 5.0% by weight.

Owner:NGK SPARK PLUG CO LTD

Heating infusion device

InactiveCN1375338AElimination of transfusion reactionsLow costInfusion devicesAutomatic controlFluid infusion

The present invention relates to a medicinal transfusion system with heating body positioned under the Murphy's dropper, said heating body adopts electric resistance heating wire or electric heating tube or far infrared heater or ceramic heater or radio-frequency heater or semiconductor heater or other liquid heat source which can enure that the temp. of blood or liquid medicine for transfusion is approximate to body temp. so as to completely eliminate the blood transfusion and fluid infusion reaction due to infusion of low-temp fluid.

Owner:张浩 +1

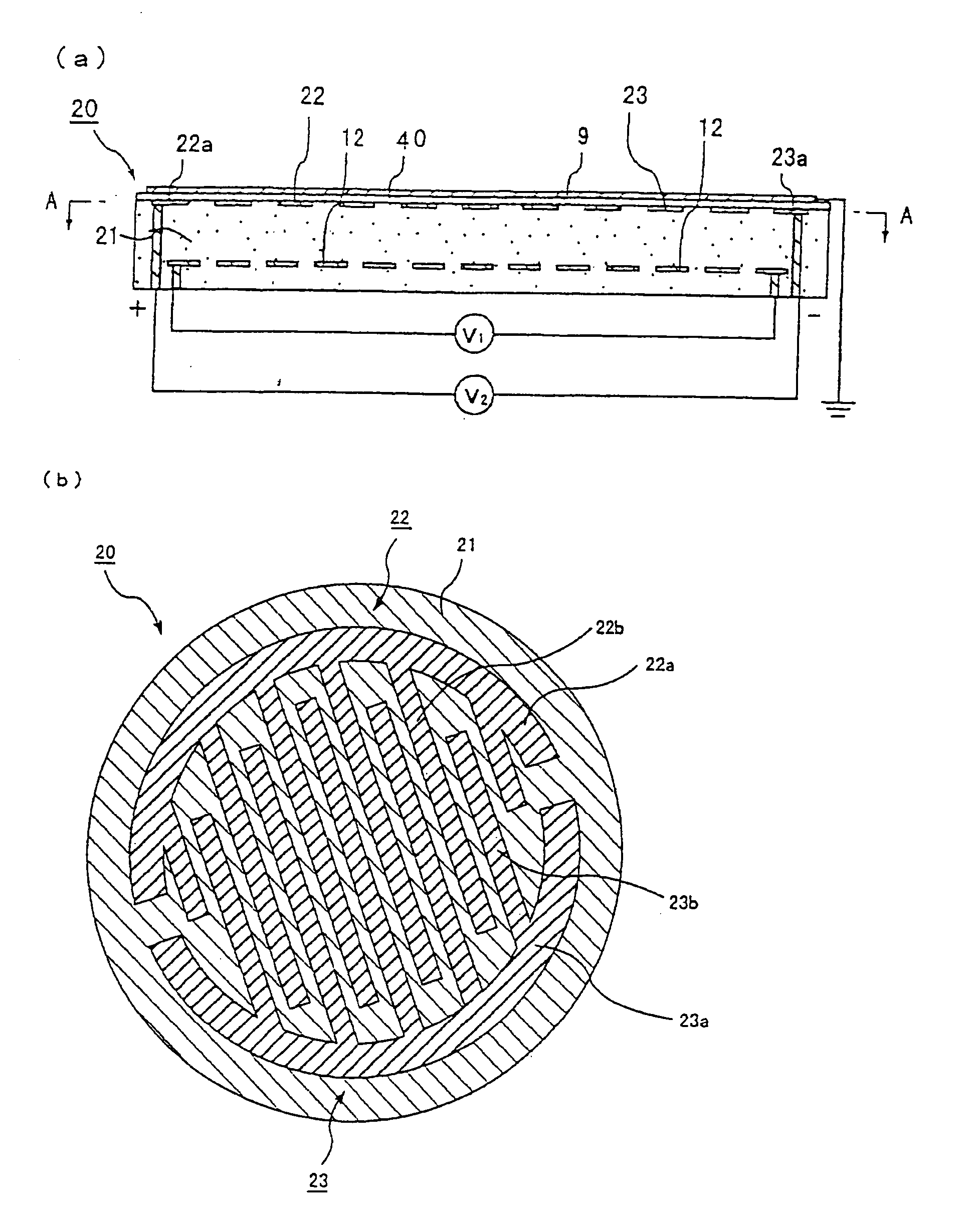

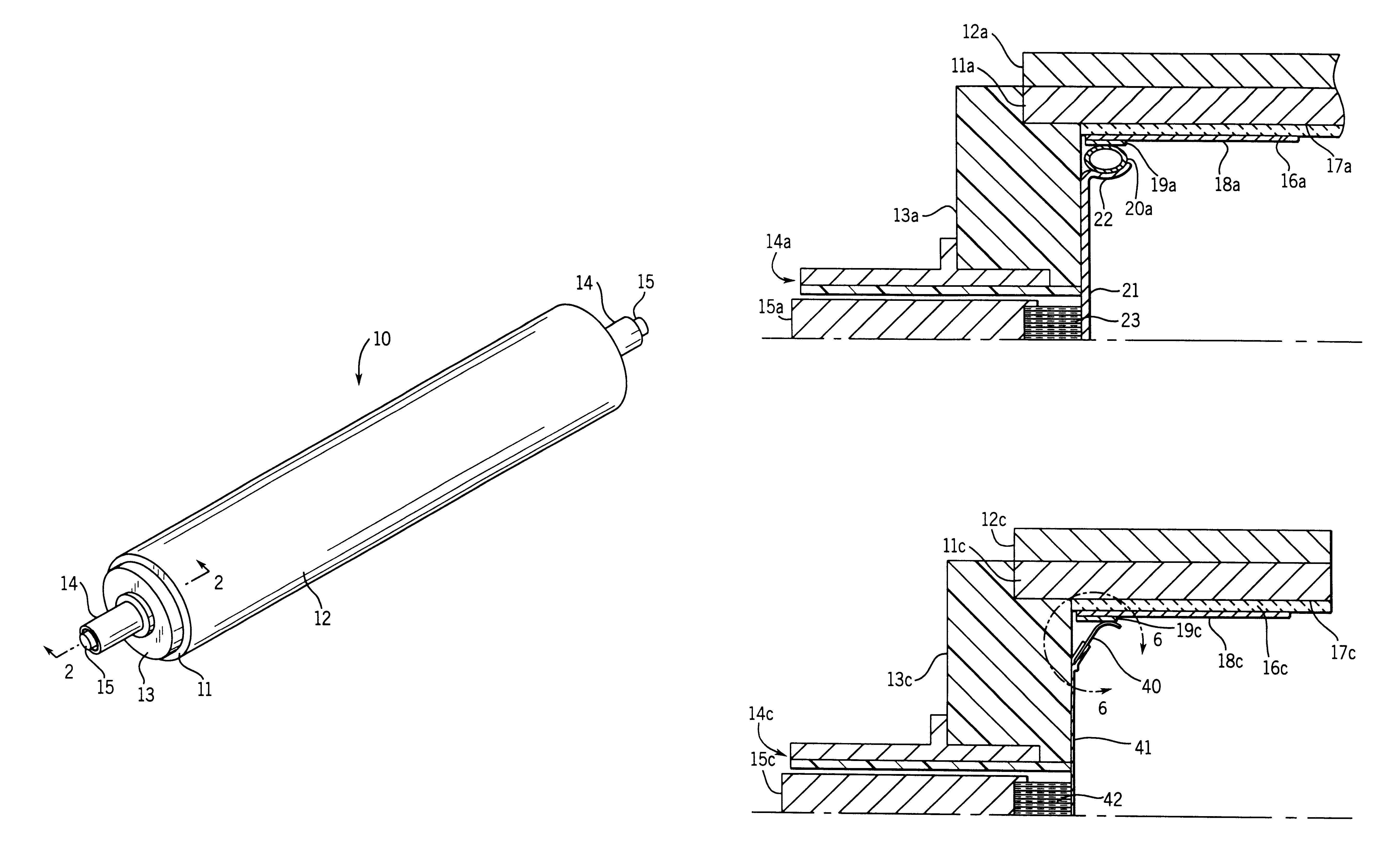

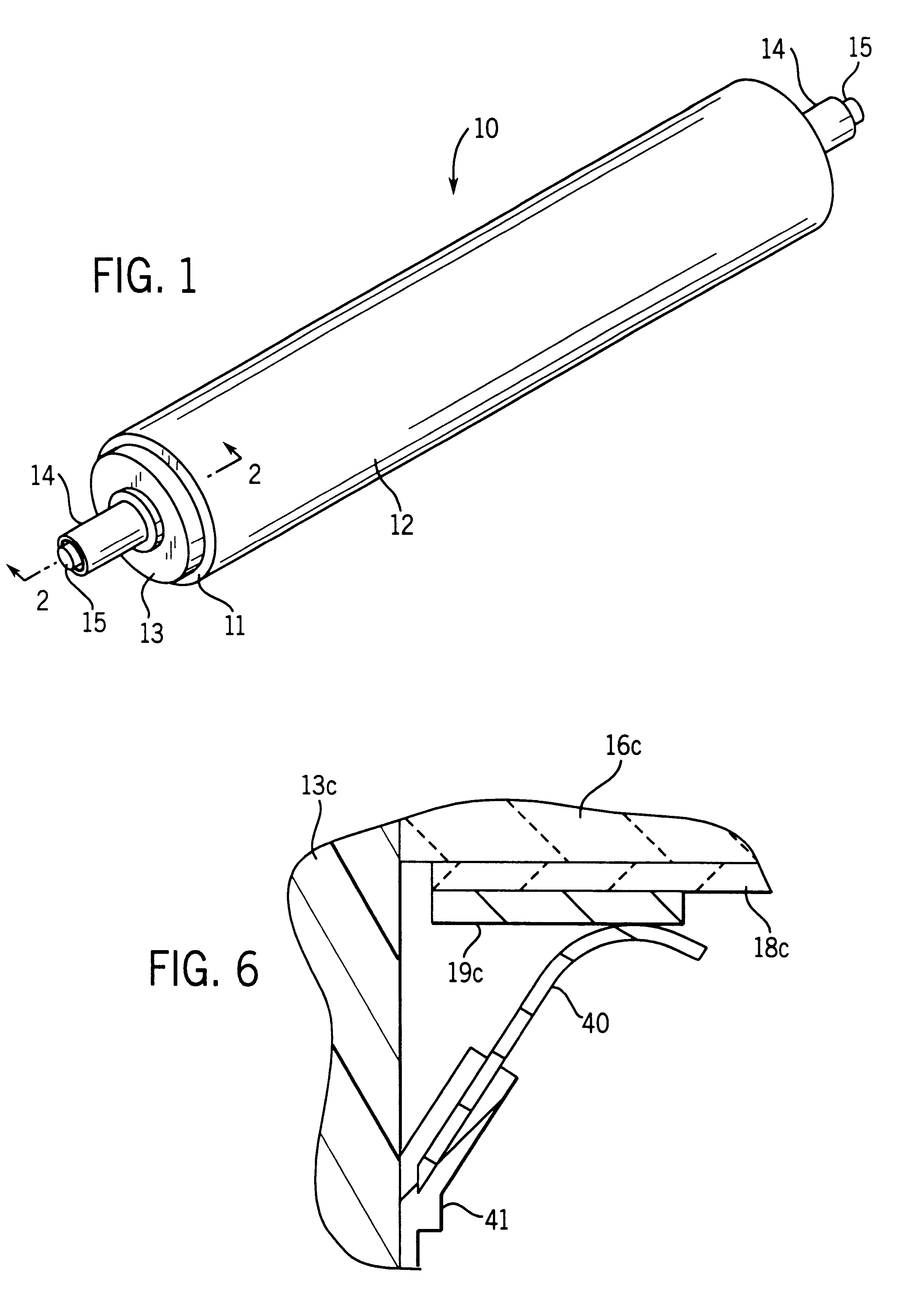

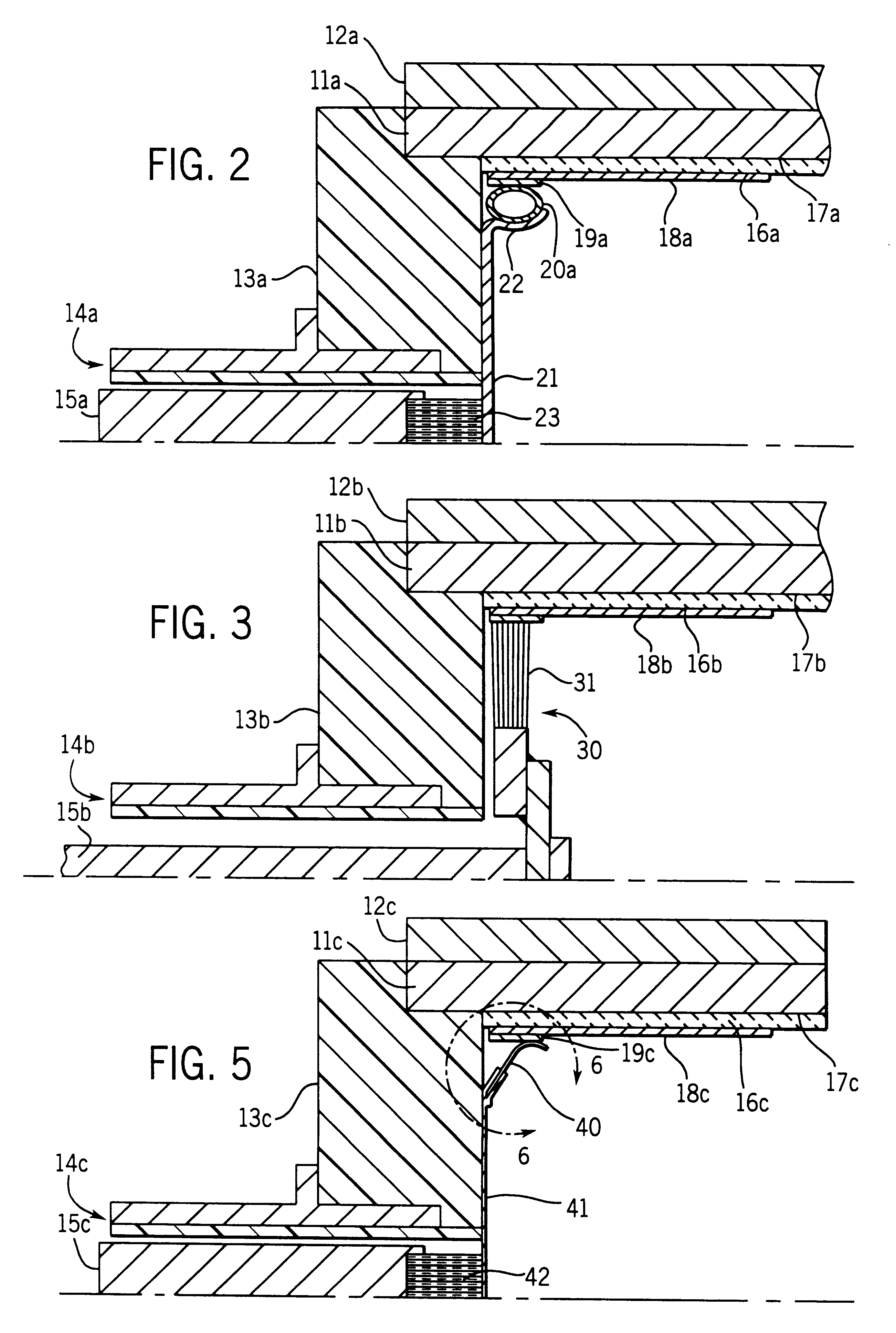

Ceramic heater/fuser roller with internal heater

InactiveUS6285006B1Easy and more straightforward to bondReduced risk of damageOhmic-resistance heating detailsRollsElectricityThree-phase

A thermal conduction roller (10) has a tubular roller core (11) with an inside surface; and an electrical insulator coat (16) primarily of zirconia on the inside surface, a heater coat (18) of titania or a titania blend is disposed over the insulator coat (16), and at least two electrical contact assemblies that are disposed inside the roller and electrically connect to the heater coat (18) as the roller (10) is being rotated. One embodiment utilizes an electrical insulator coat (16) in a range of thickness from about ten mils to about twenty mils. A thinner coat may not have sufficient dielectric strength, while a thicker coat decreases thermal conduction. A release material (12) is applied to the outside of the roller (10). Various contact structures according to the present invention are also described in detail, including one especially adapted to connect to a three-phase power supply.

Owner:AMERICAN ROLLER

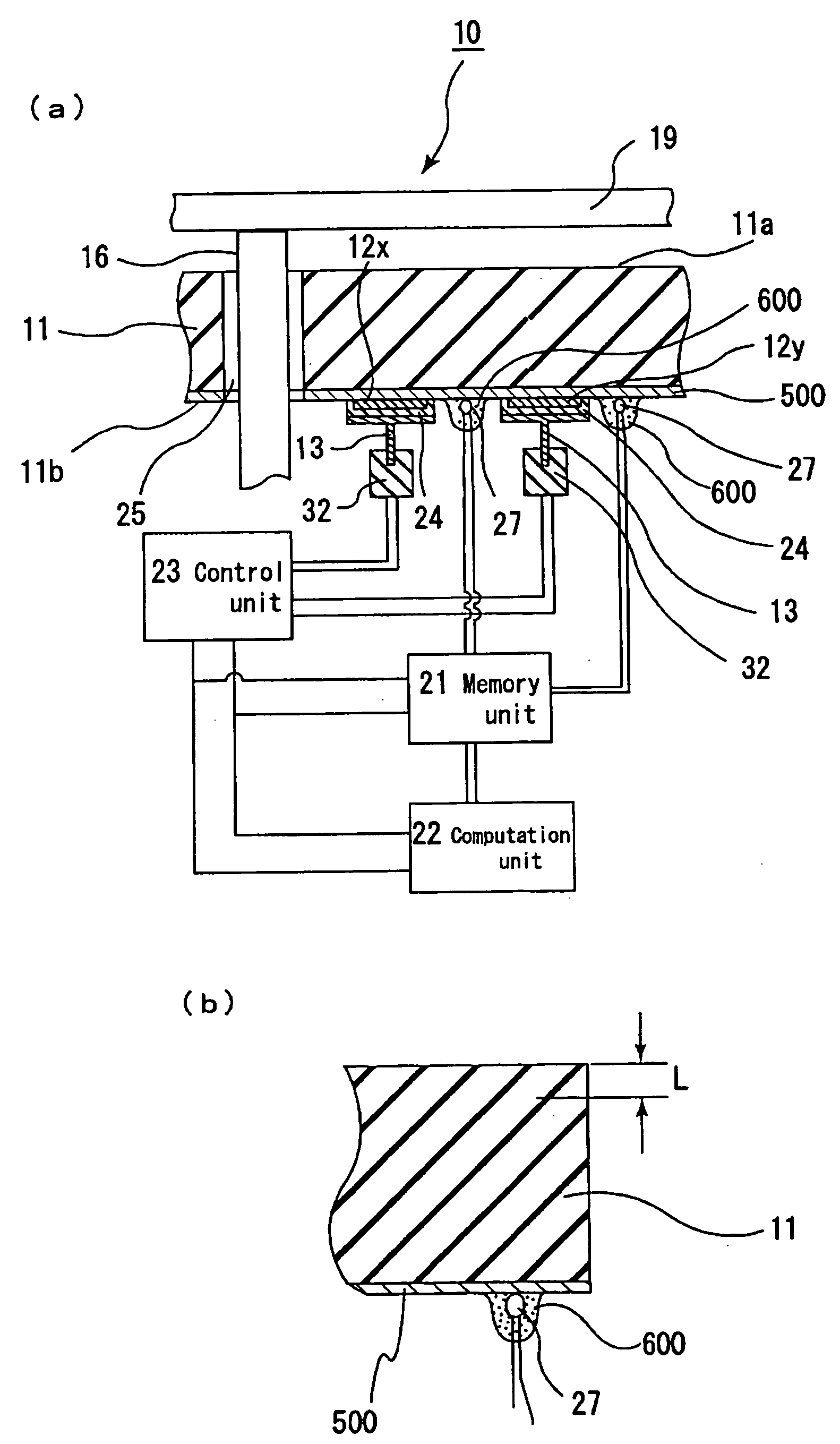

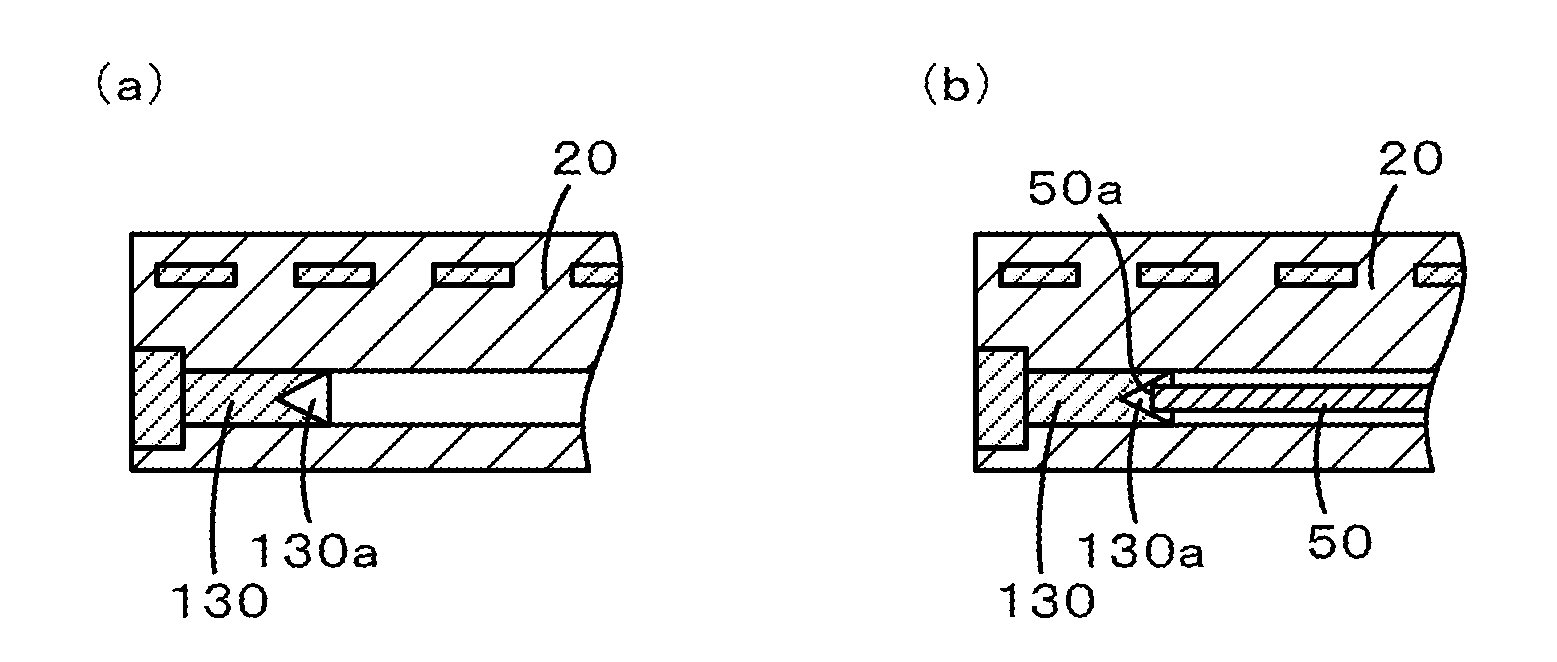

Semiconductor manufacturing apparatus member

ActiveUS20120211933A1Improve accuracyWell formedThermometers using electric/magnetic elementsSemiconductor/solid-state device manufacturingMetallurgyManufactured apparatus

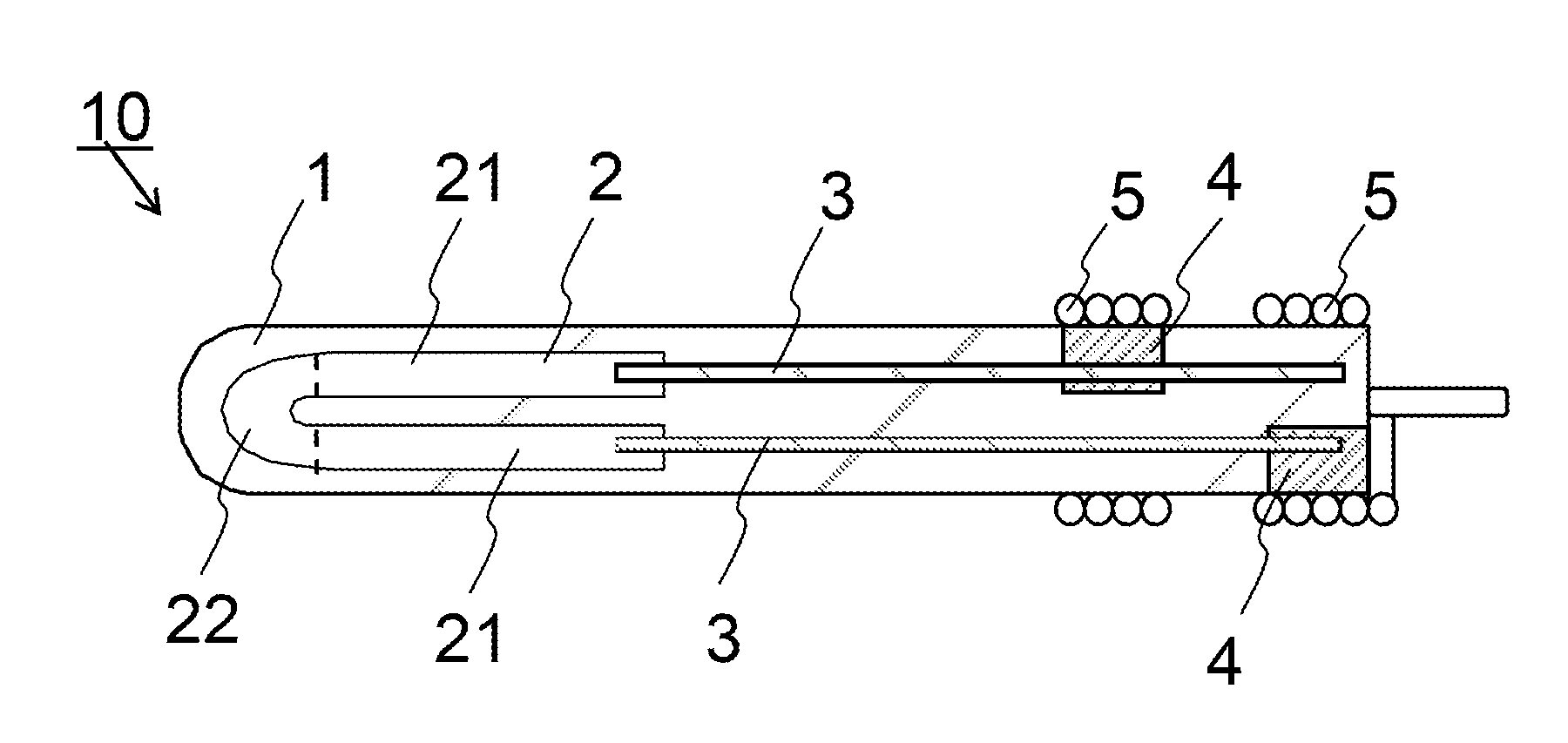

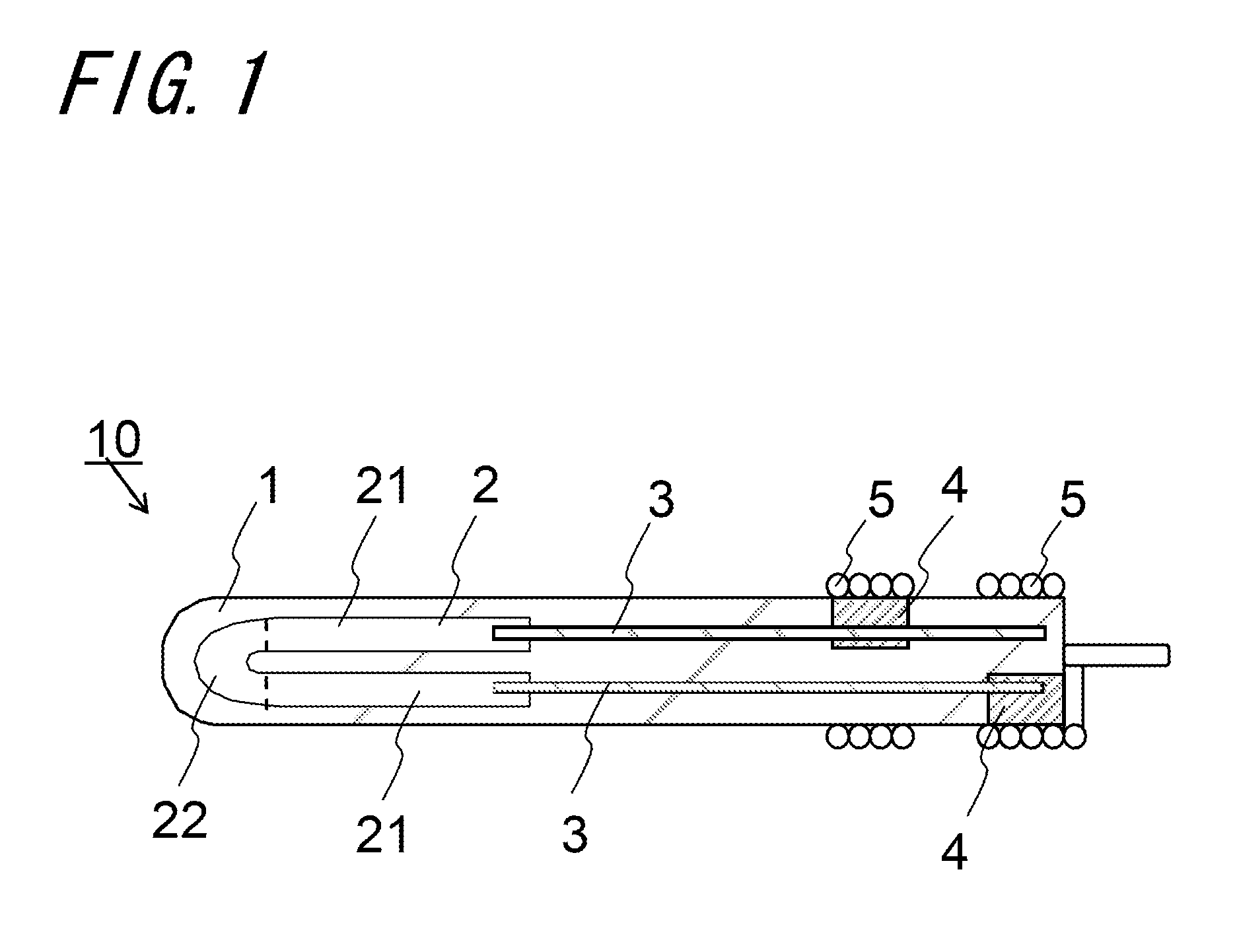

A ceramic heater includes a disk-shaped ceramic plate and a shaft. The ceramic plate includes a wafer-placing surface. The shaft has a hollow shape and is bonded to a surface of the ceramic plate opposite to the wafer-placing surface. A thermocouple conduit is formed in the ceramic plate so as to extend from a central portion of the ceramic plate to a position which is short of an outer peripheral surface of the ceramic plate. A thermocouple guide having a pipe-like shape is attached to the back surface of the ceramic plate. A guide hole in the thermocouple guide is connected to a portion of the thermocouple conduit at the central portion of the ceramic plate. The guide hole is disposed so as to be inclined with respect to the direction in which the thermocouple conduit extends.

Owner:NGK INSULATORS LTD

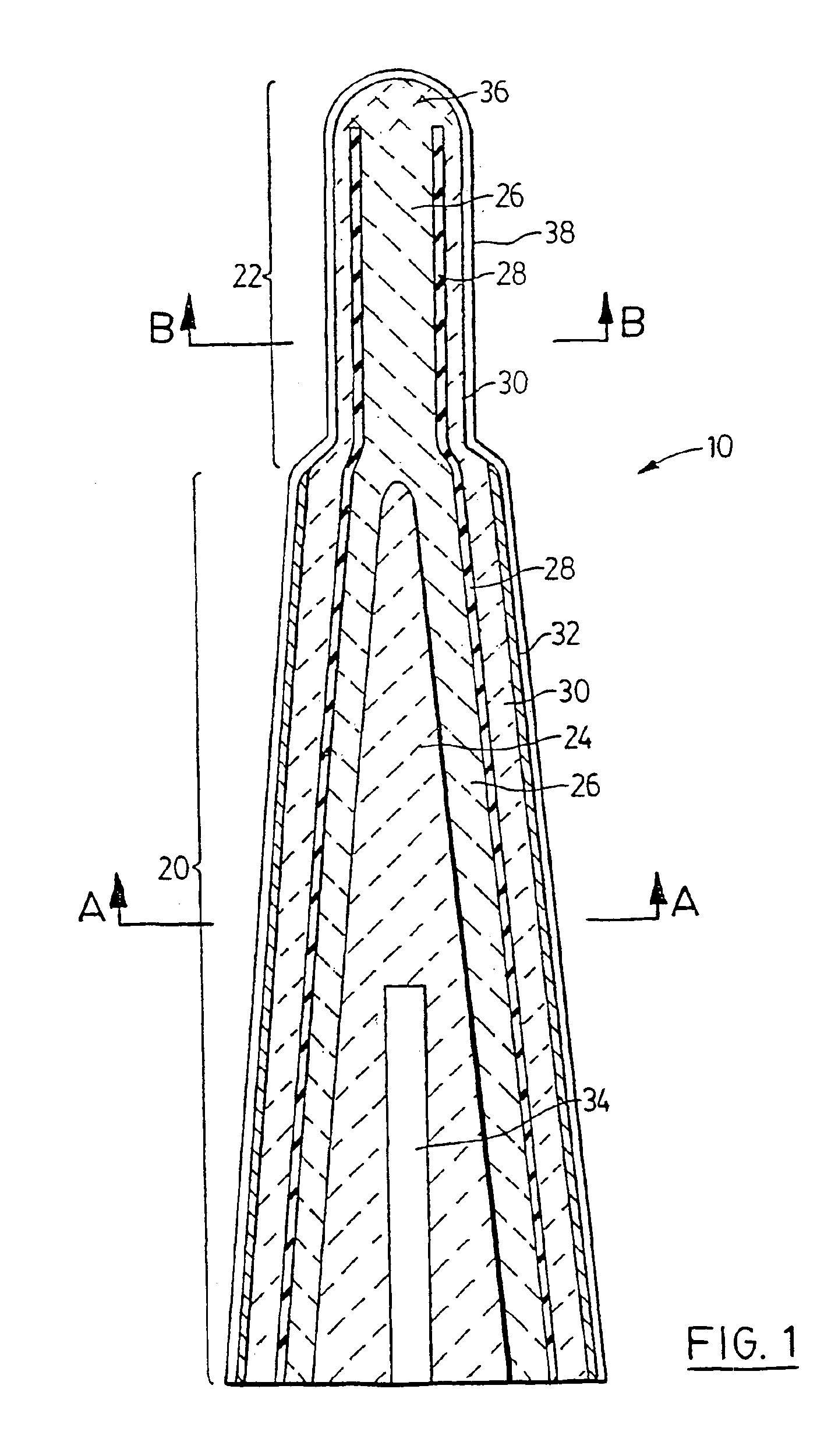

Multi-layer ceramic heater element and method of making same

InactiveUS6884967B1Heat resistanceReliable heat concentrationIncandescent ignitionCombustion enginesEngineeringDiesel engine

A ceramic heater element and a glow plug incorporating the novel heater element. The heater element has a base portion and a heater portion. Conductive, insulative and resistive layers extend through both the base and heater portions. An outer conductive layer is applied to the outside of the base portion to provide a highly conductive return path. This lends to limit the heating of the resistive layer in the base portion and results in better and more reliable heat concentration in the heater portion. The heater element is further provided with a waterproof non-electrically conductive outer layer. The heater element can be assembled to form a glow plug for a diesel engine.

Owner:CHONGGING LE MARK CERAMIC TECH

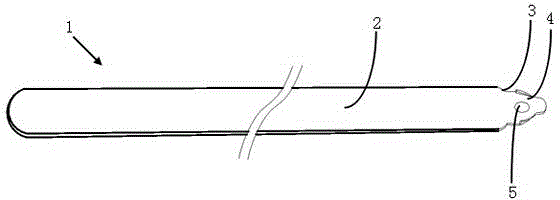

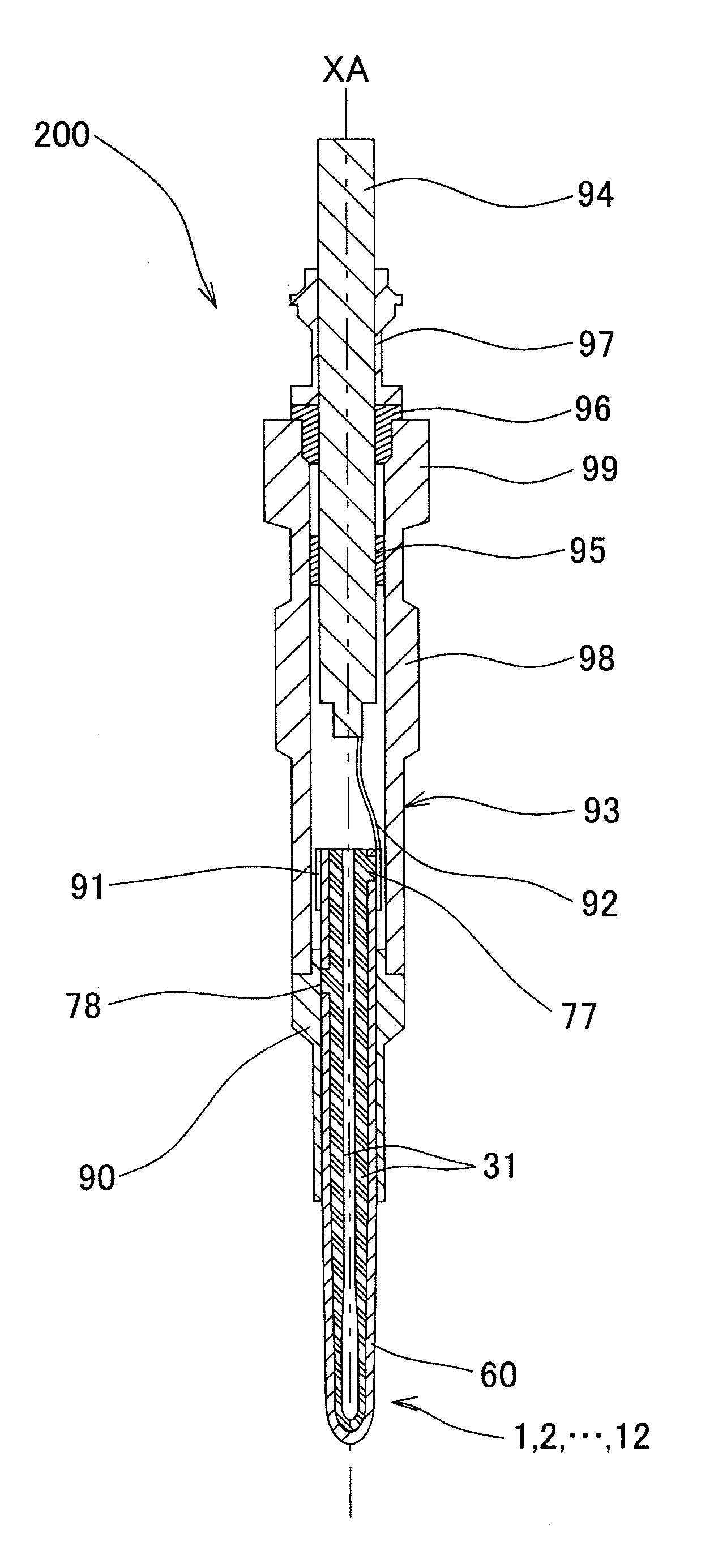

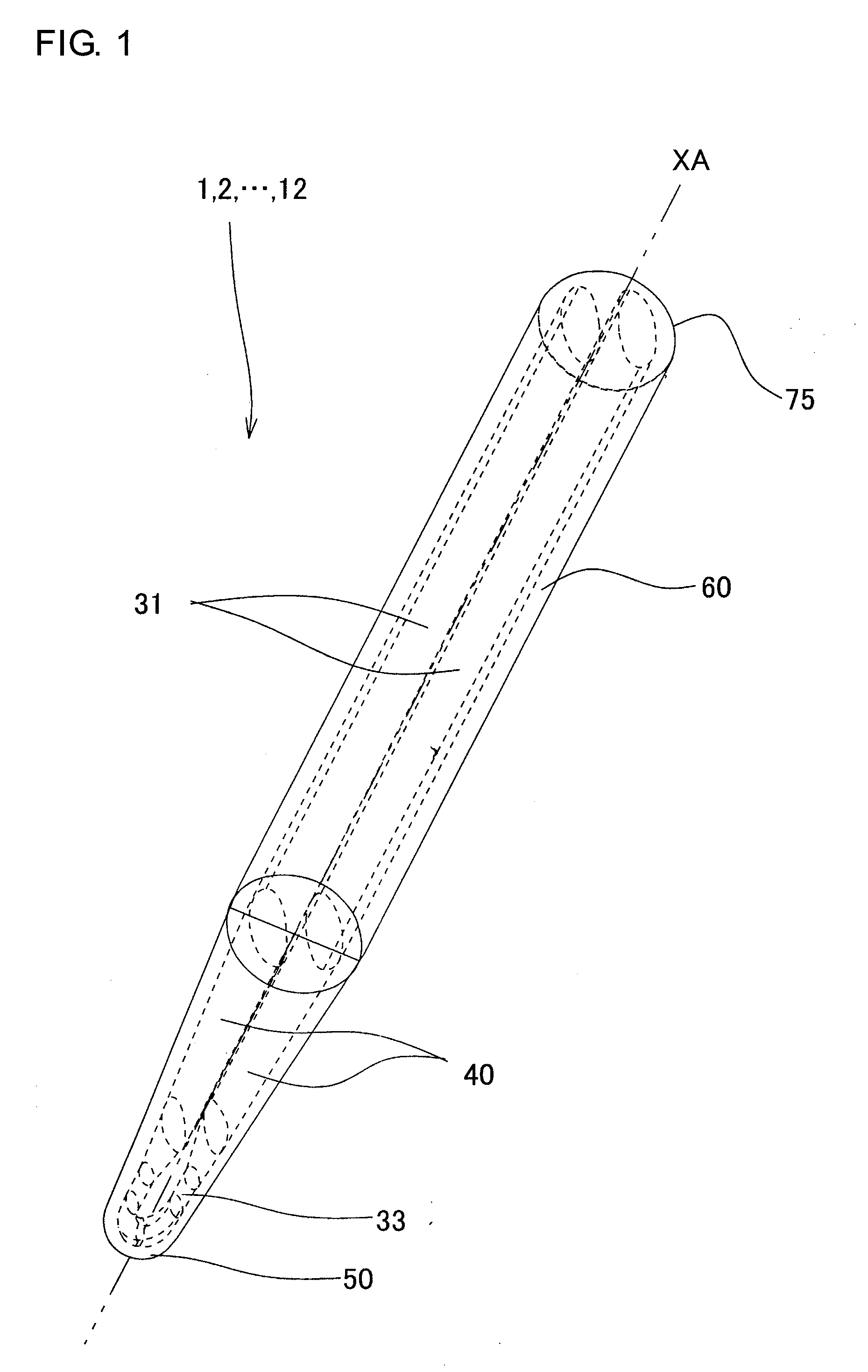

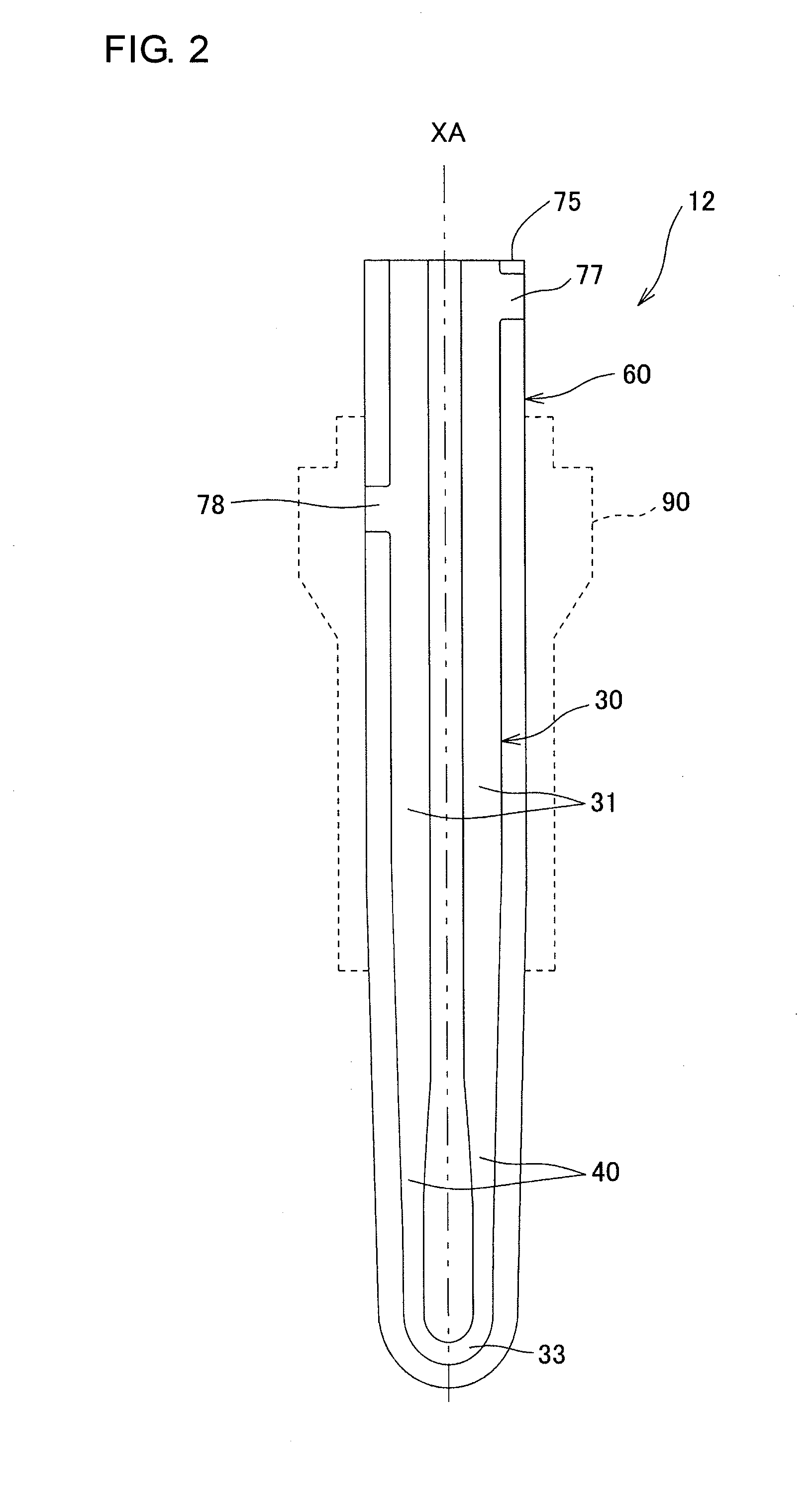

Ceramic heater and glow plug

ActiveUS20110114622A1Lower the volumeExcellent quick heating performanceIncandescent ignitionHeating element shapesEngineeringResistor

A ceramic heater (12) includes a substrate (60) and a resistor element (30) buried in the substrate (60). The resistor element (30) includes a heat-generating portion (33), lead portions (31), and intermediate portions (40) located between the heat-generating portions (33) and the lead portions (31). The intermediate portions (40) are formed such that, when cross sections at arbitrary two points P1 and P2 along the axis XA direction are compared, both the diameter CL of an imaginary circumscribed circle CG containing cross sections of the resistor element 30 and the total cross sectional area HS of the cross sections become small in the front end side cross section as compared with those in the rear end side cross section.

Owner:NGK SPARK PLUG CO LTD

Ceramics heater

InactiveUS7372001B2Satisfactory temperature uniformityCalorific value stableHot plates heating arrangementsHeating element materialsMetal foilMechanical engineering

A ceramics heater comprises a circular heater plate formed of aluminum nitride and a metal foil heater wire formed of a high-melting metal and having a thickness of 100 μm to 175 μm. The heater wire is embedded in the heater plate. The heater wire has an inside portion located near the center of the heater plate and formed in zigzags at first pitches in the circumferential direction of the heater plate and an outside portion located near the outer periphery of the heater plate and formed in zigzags at second pitches in the circumferential direction of the heater plate. The second pitches are shorter than the first pitches.

Owner:NHK SPRING CO LTD

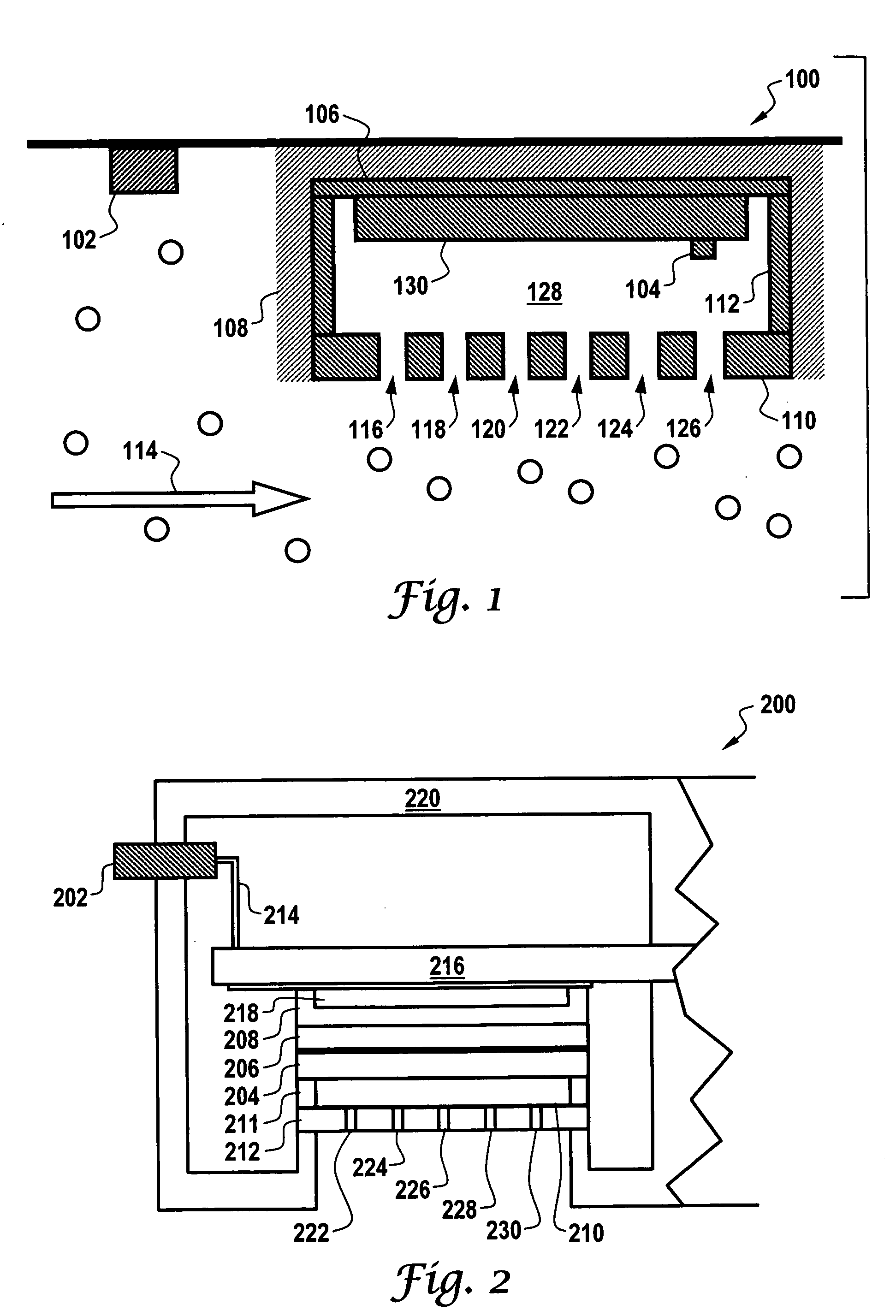

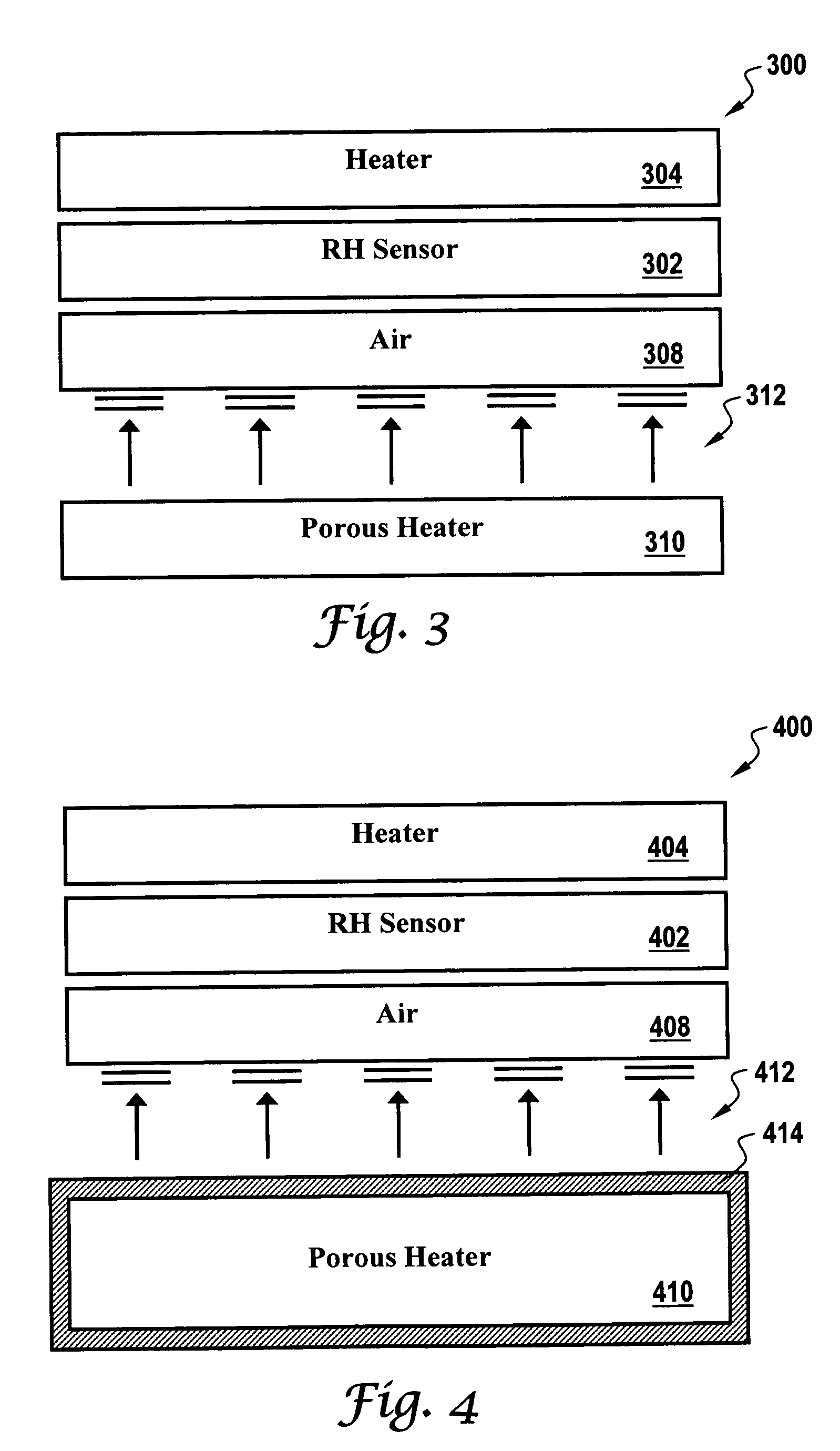

Relative humidity sensor enclosed with ceramic heater

InactiveUS20050247106A1Lower the volumeSmall sizeMaterial moisture contentMaterial resistancePorosityElectrical resistance and conductance

Sensor systems and methods are disclosed herein. A relative humidity sensor can be associated with one or more ceramic heating elements configured from a porous material. In general, a perimeter of the relative humidity sensor is surrounded with a relatively conductive material. A resistive material surrounds one or more of the ceramic heating elements, such that air that is saturated with water vapor passes through the porous material of the ceramic heating element(s). Water vapor can therefore be heated by the ceramic heating element(s) in order to evaporate water droplets associated with the water vapor and thereby reduce relative humidity to a measurable level. The porous material of the ceramic heating element(s) can be provided via a plurality of laser drilled holes to create such porosity.

Owner:HONEYWELL INT INC

Semiconductor heating apparatus

InactiveUS7268322B2Improve rigidityReduce capacitySemiconductor/solid-state device testing/measurementHeater elementsComputer moduleEngineering

Owner:SUMITOMO ELECTRIC IND LTD

Ceramic Heater and Glow Plug

ActiveUS20090194519A1Reduced strengthProcess controlIncandescent ignitionOhmic-resistance heatingRare-earth elementChromium silicide

Disclosed is a ceramic heater capable of preventing failures due to the thermal stress, such as cracks, and corrosion by a calcium component. The ceramic heater has a heating element including at least one substance selected from silicides, nitrides and carbides of molybdenum and silicides, nitrides and carbides of tungsten as a main component, and a base mainly containing silicon nitride in which the heating element is embedded, wherein the base includes: a rare earth element component in an amount from 4 to 25% by mass in terms of an oxide thereof; a silicide of chromium in an amount from 1 to 8% by mass in terms of chromium silicide; and an aluminum component in an amount from 0.02 to 1.0% by mass in terms of aluminum nitride.

Owner:NGK SPARK PLUG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com