Patents

Literature

72results about How to "Calorific value stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

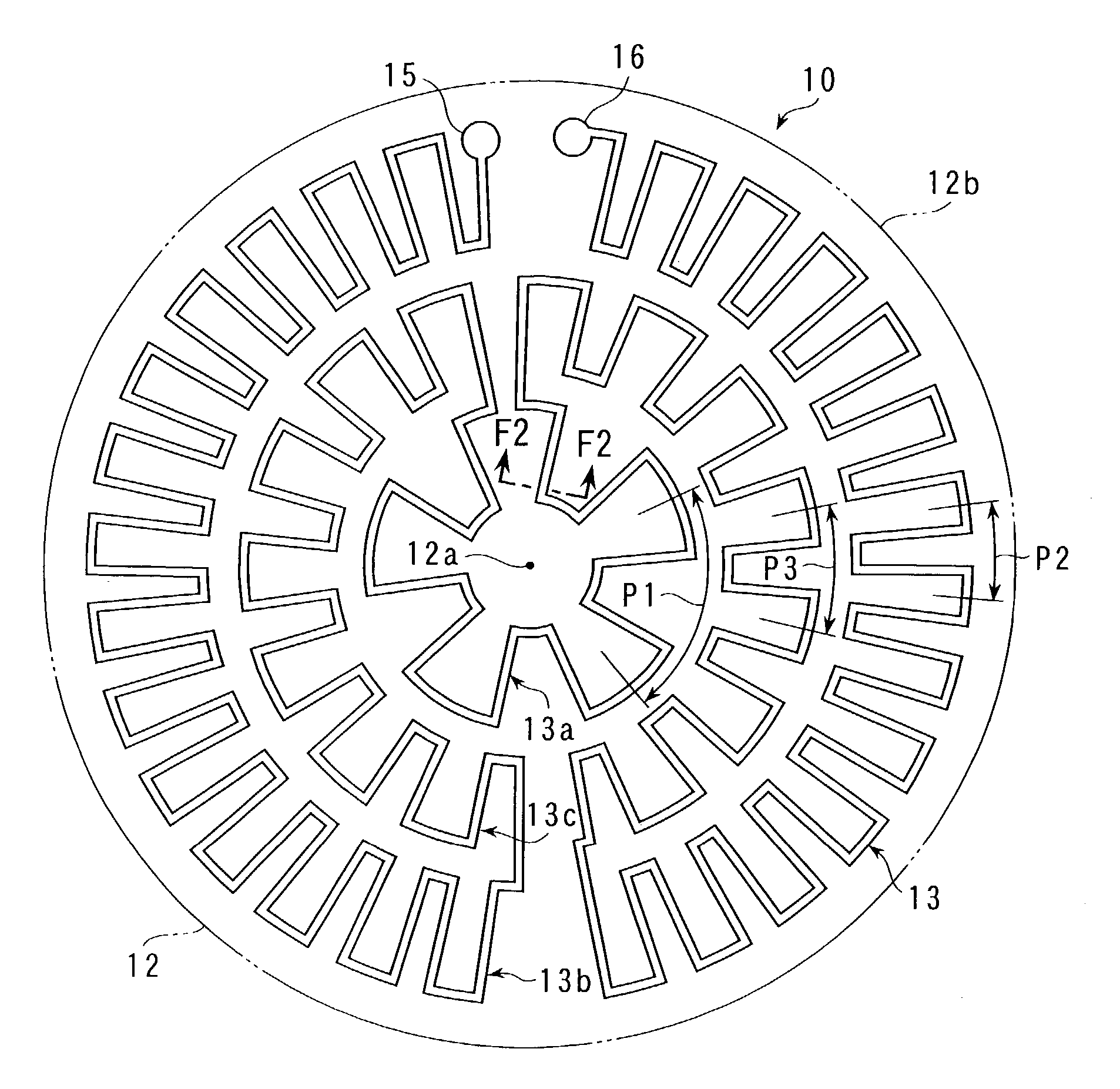

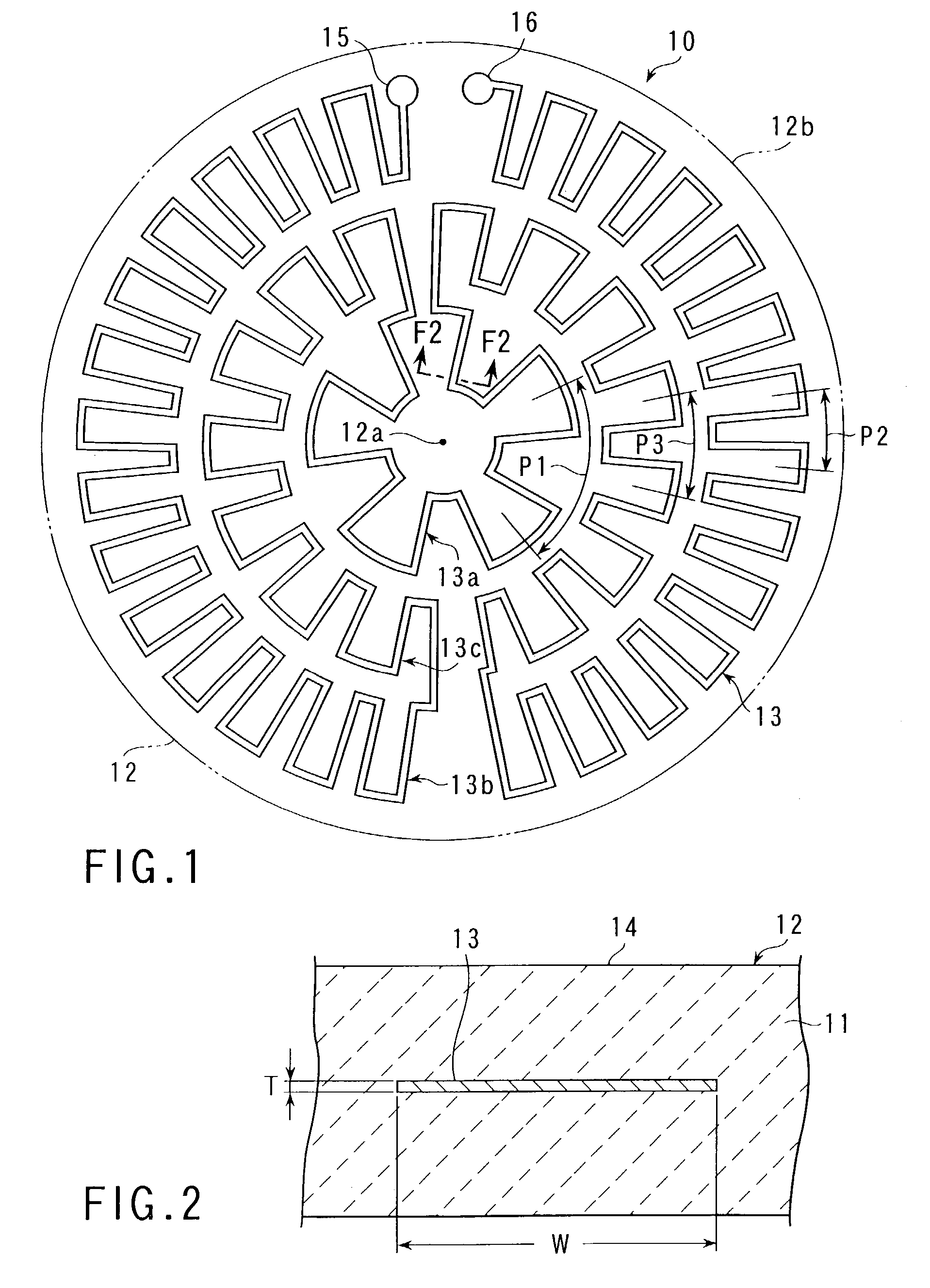

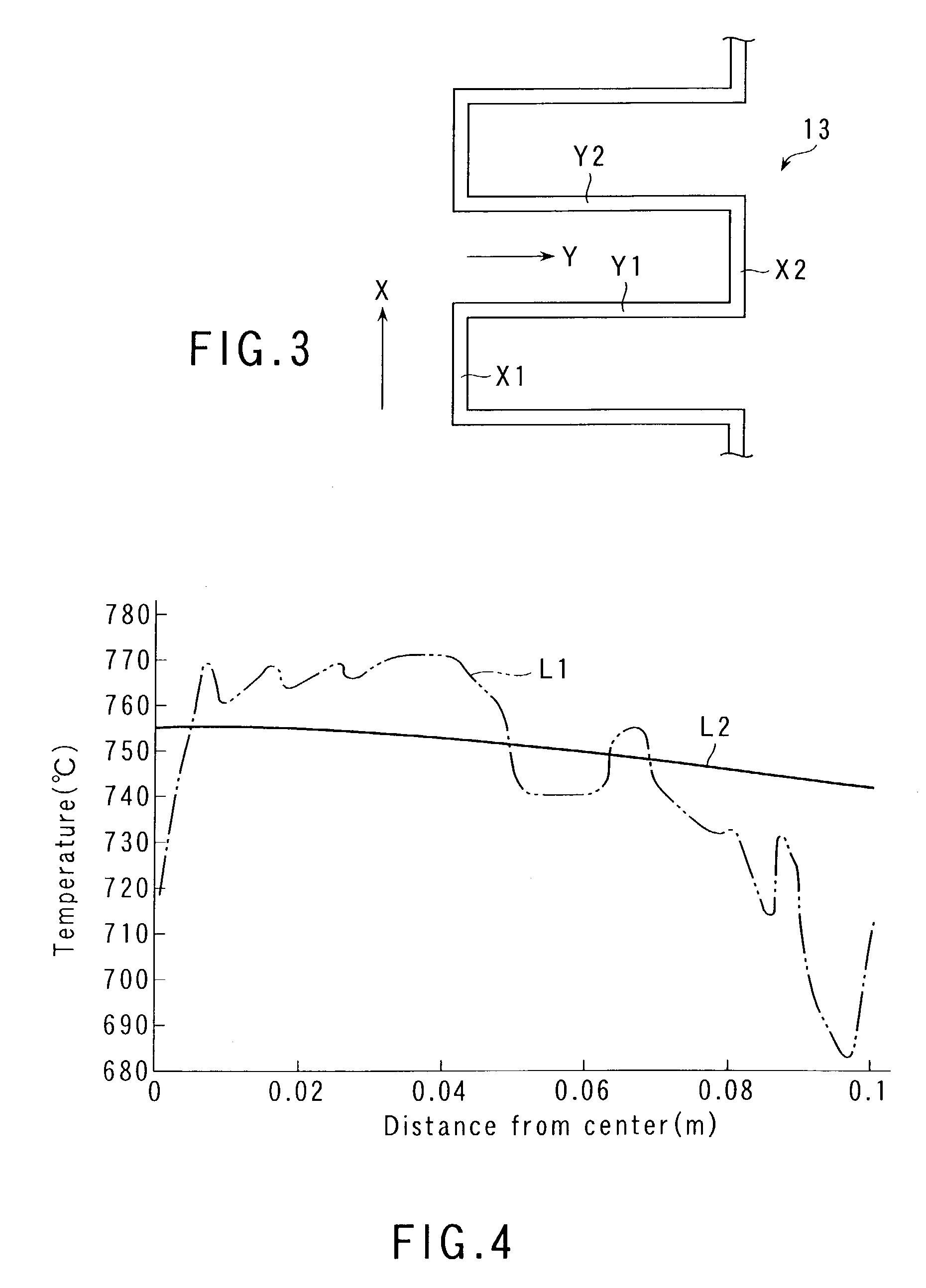

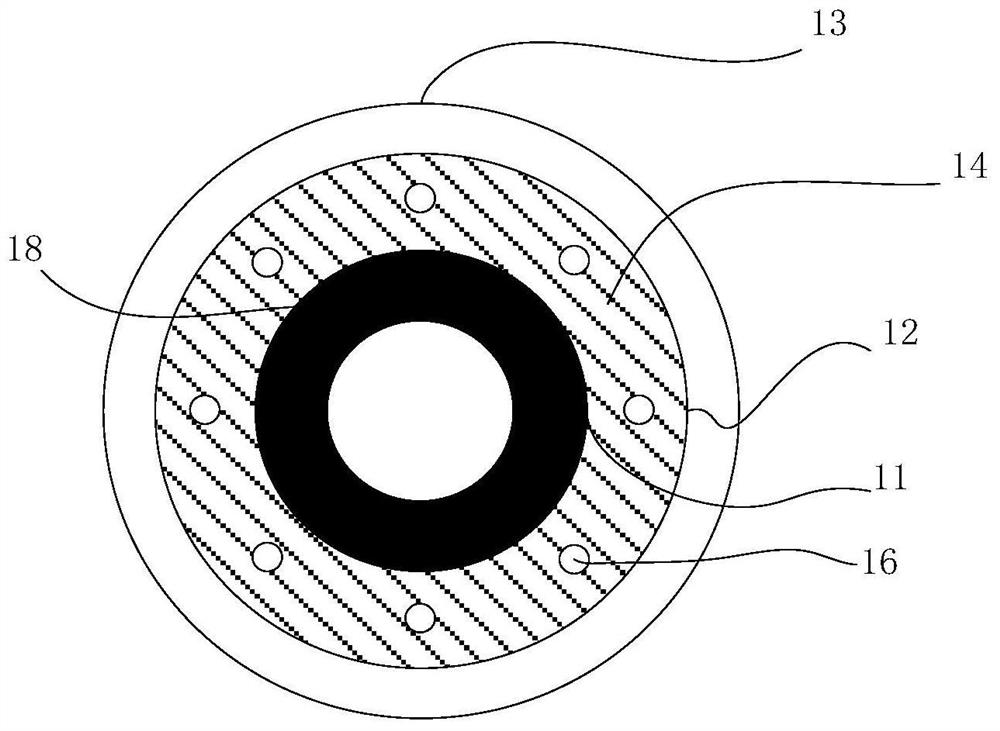

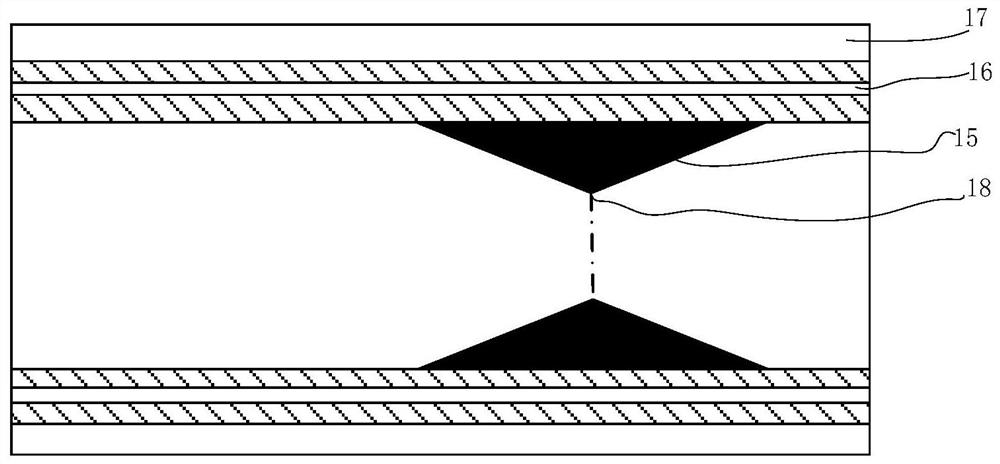

Ceramics heater

InactiveUS7372001B2Satisfactory temperature uniformityCalorific value stableHot plates heating arrangementsHeating element materialsMetal foilMechanical engineering

A ceramics heater comprises a circular heater plate formed of aluminum nitride and a metal foil heater wire formed of a high-melting metal and having a thickness of 100 μm to 175 μm. The heater wire is embedded in the heater plate. The heater wire has an inside portion located near the center of the heater plate and formed in zigzags at first pitches in the circumferential direction of the heater plate and an outside portion located near the outer periphery of the heater plate and formed in zigzags at second pitches in the circumferential direction of the heater plate. The second pitches are shorter than the first pitches.

Owner:NHK SPRING CO LTD

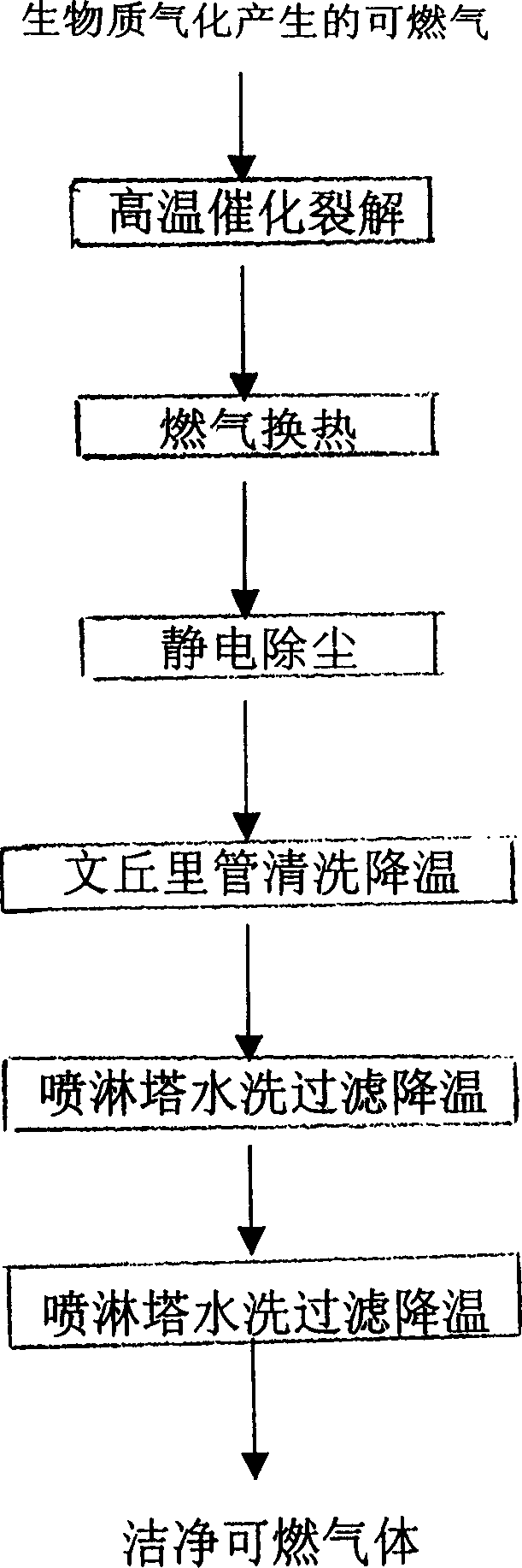

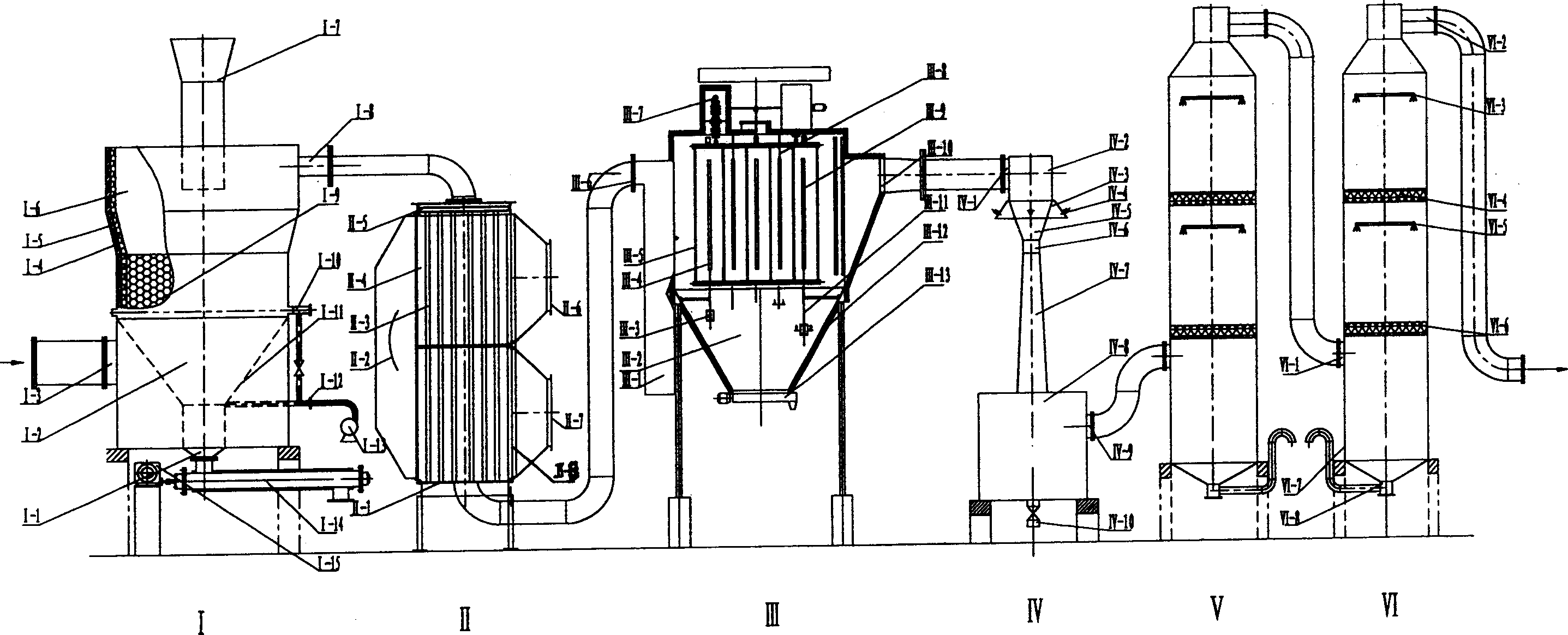

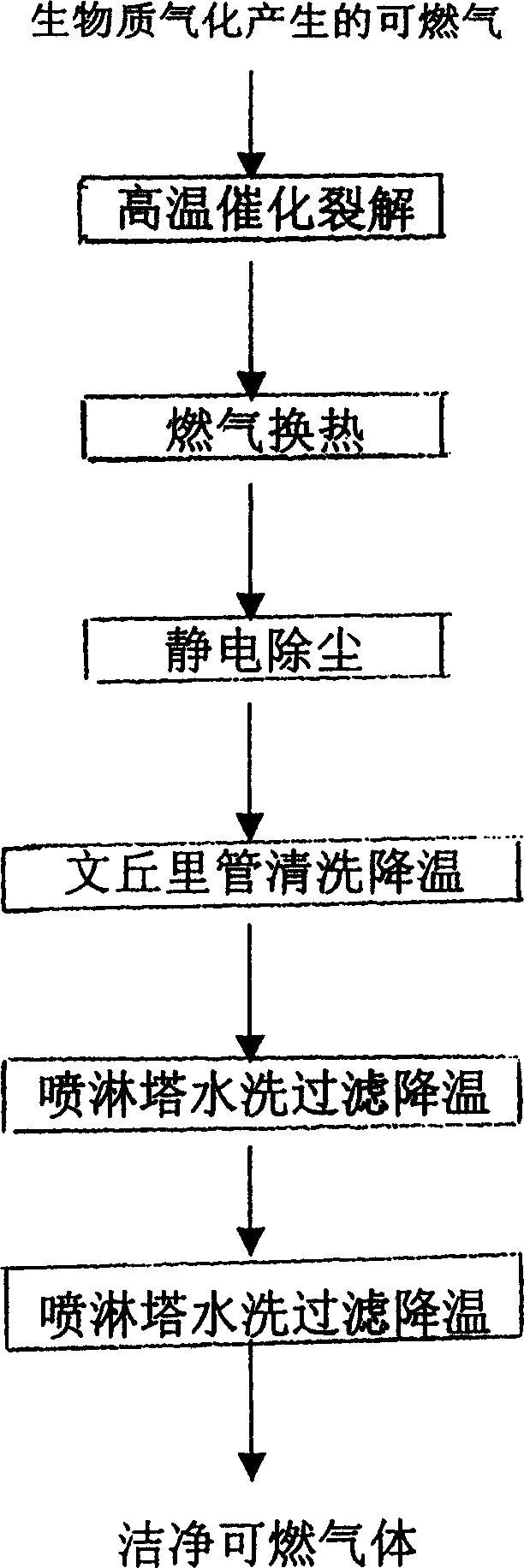

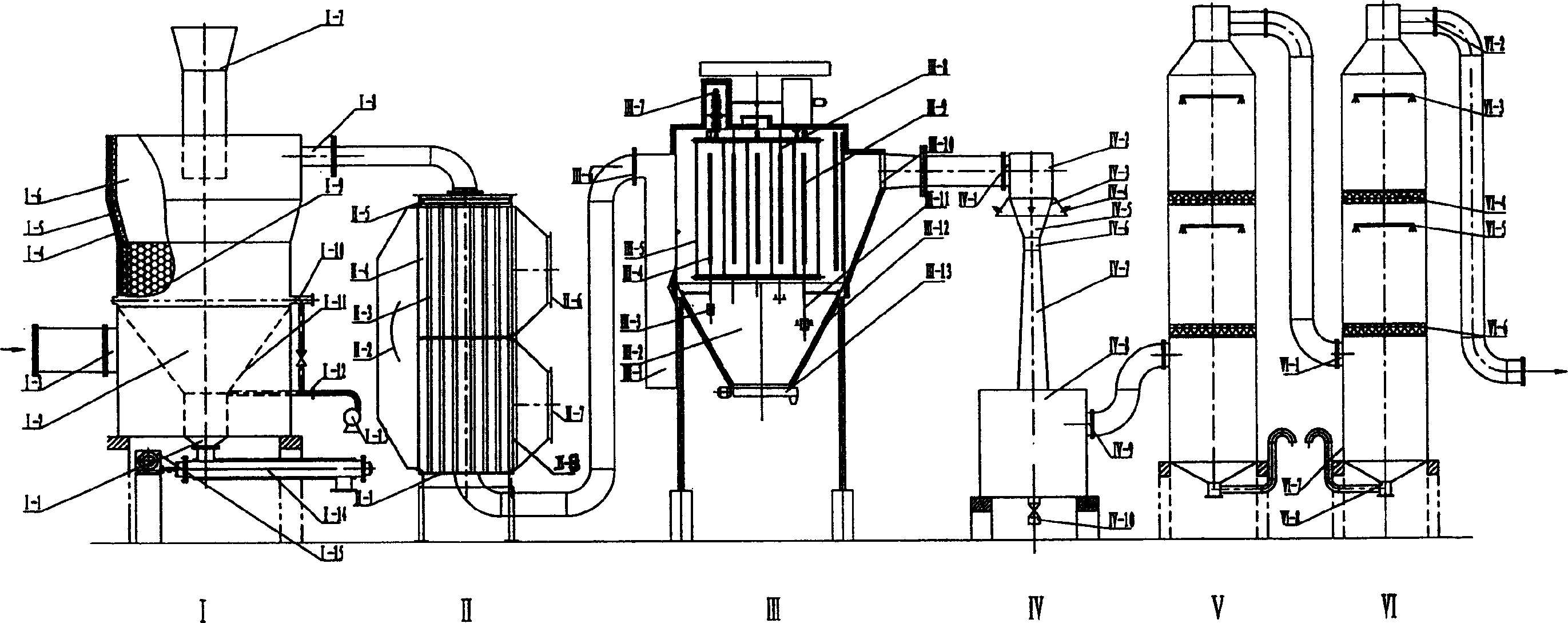

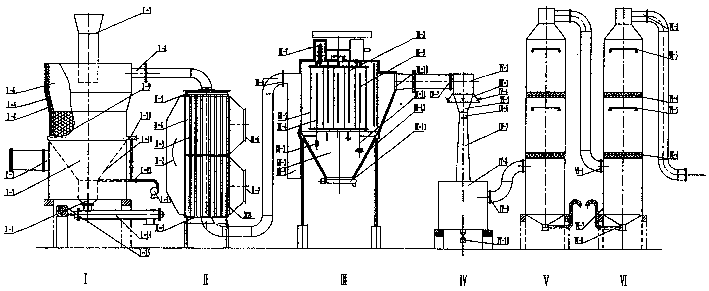

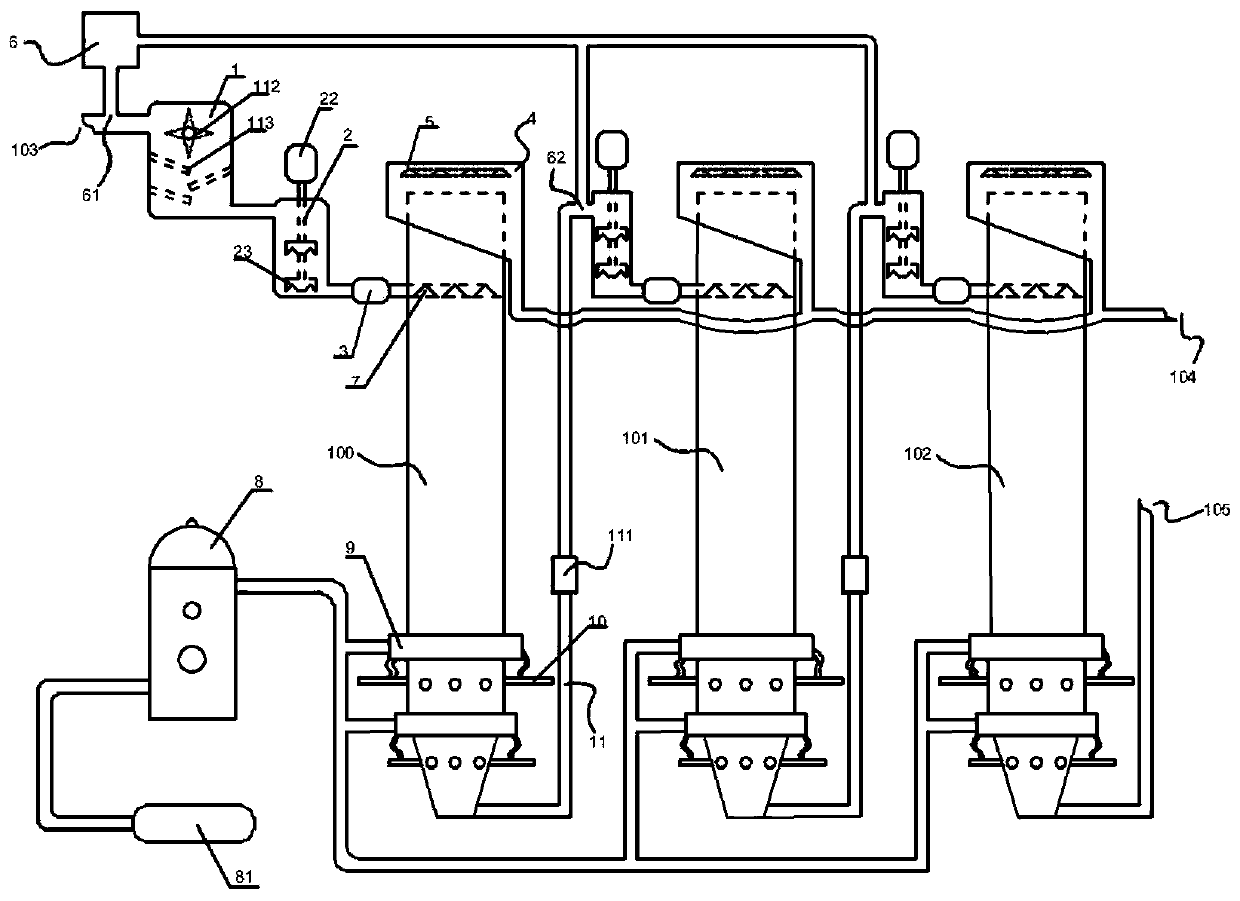

Cracking purification method for combustible gas produced by gasifying crude material

InactiveCN1485415AEfficient recyclingAffect operationCombustible gas catalytic treatmentPurification methodsHigh pressure

A method of degrading and cleansing combustible gases produced during gasifying biological matters. It comprises) passing a cracking machine with a moving bed, the combustible gases will be cracked by high-temperature and catalysis in the charcoal bed at 800-1200degree C, most of tar is removed; b)reducing the temperature of combustible gases from 800degree C to 300-350degree C; c) dedusting by static electricity at a high-voltage electric field of 80000 volts, reducing the temperature to 250-300degree Cú”(d) washed by water, debusting and detarring, reducing the temperature to 60-80degree Cú”(E) washing, filtering and reducing the temperature to below 40degree C, the contents of tar and dust in the combustible gases will be reduced below 50mg / Nm3. The invention could remove completely dust and tar in combustible gases.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

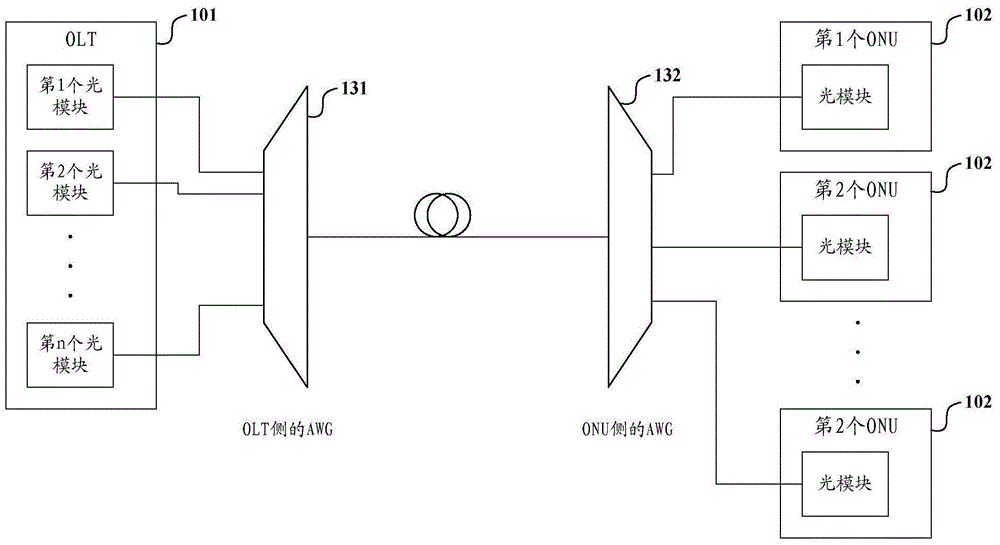

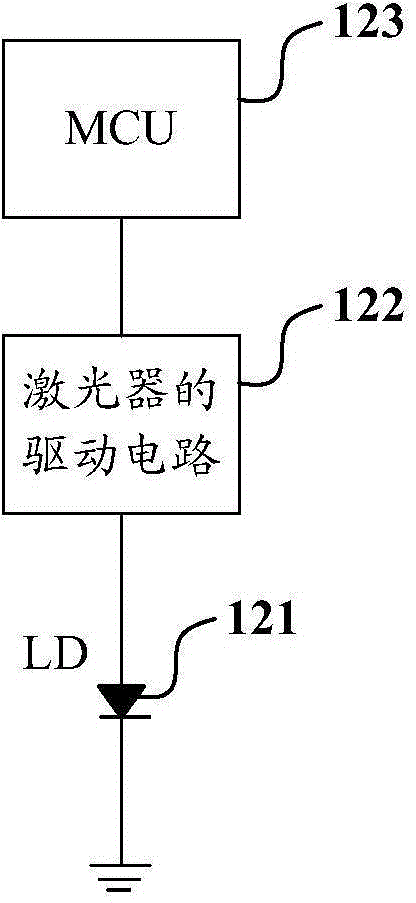

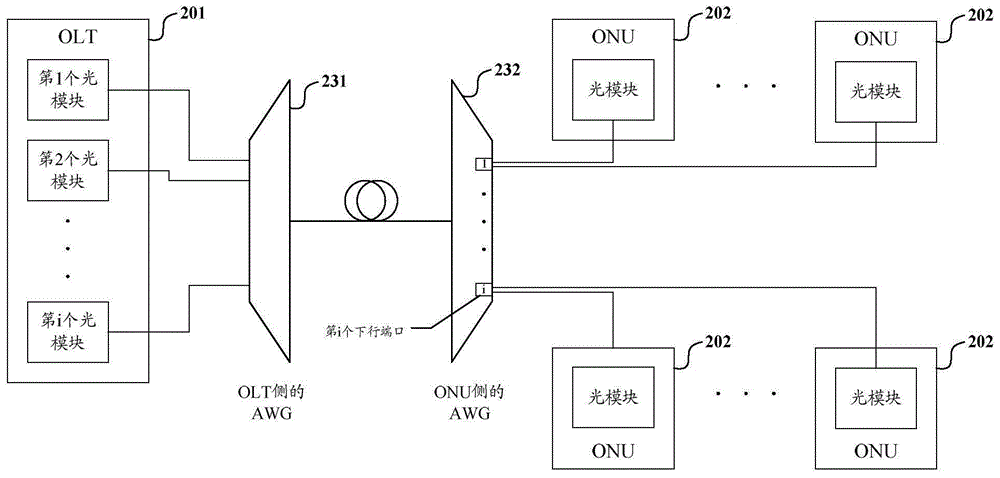

Optical module and optical signal output control method

ActiveCN106330328AStable stateCalorific value stableElectromagnetic transceiversCurrent sourceStop signal

An embodiment of the present invention provides an optical module and an optical signal output control method thereof. The optical module comprises a distributed Bragg reflective DBR laser, a driving circuit for supplying a driving current to the active region of the laser, a first current source, a second current source, and a circuit switching unit. The first and second current sources are used for outputting a first current and a second current. The two input ends of the circuit switching unit are respectively connected to the current output ends of the first and second current sources. The output end of the circuit switching unit is connected to the DBR area of the laser. The circuit switching unit is used for connecting the current output end of the first current source to the DBR area of the laser to output the first current to allow the laser to transmit an optical signal with operating wavelength, after an optical transmitting signal is received. The circuit switching unit is further used for connecting the DBR current output end of the second current source to the DBR area of the laser to output the second current to allow the laser to transmit an optical signal with non-operating wavelength, after an optical stopping signal is received. The optical module is operated in a burst mode and wavelength shift of the optical signal emitted by the laser is small.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

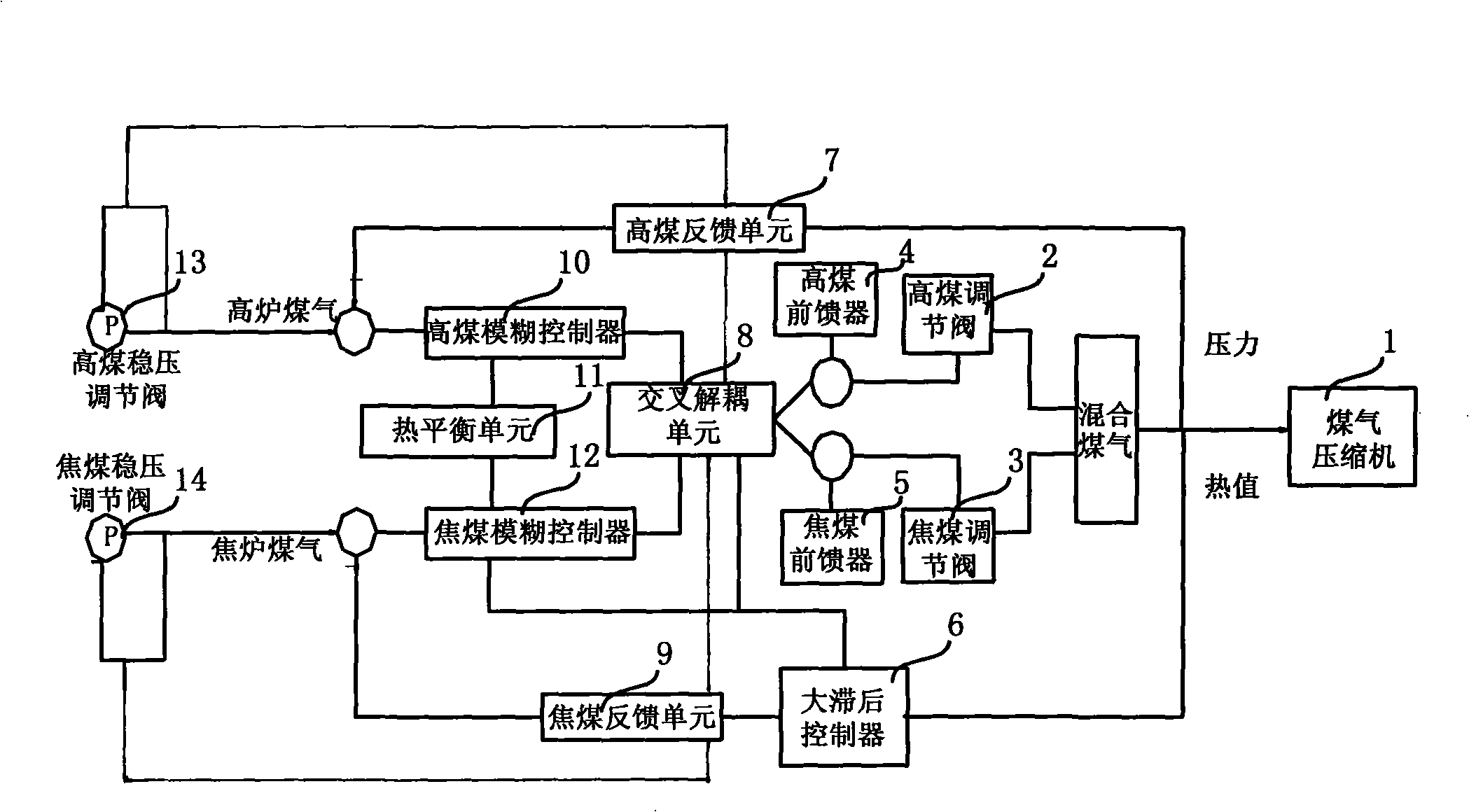

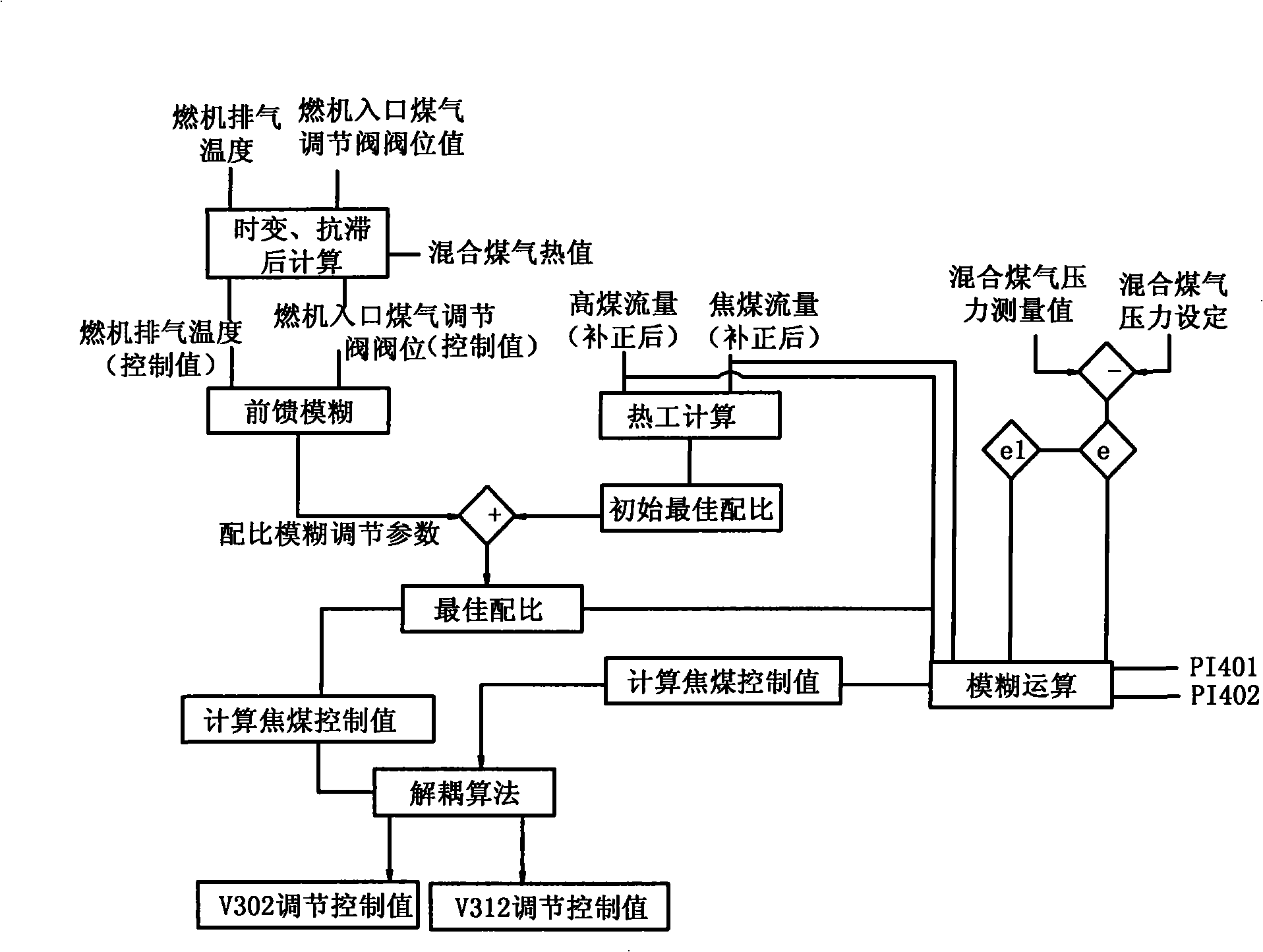

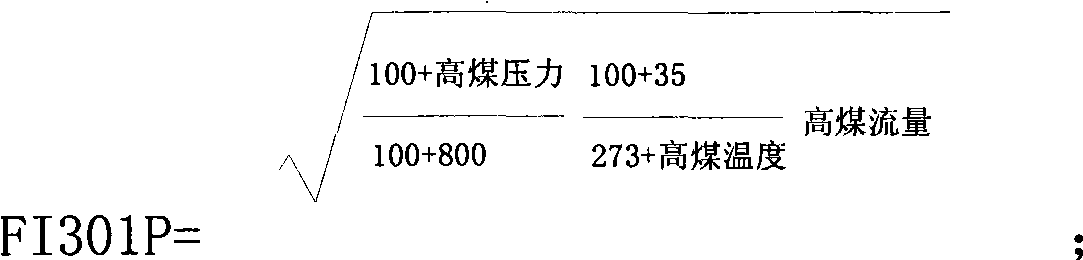

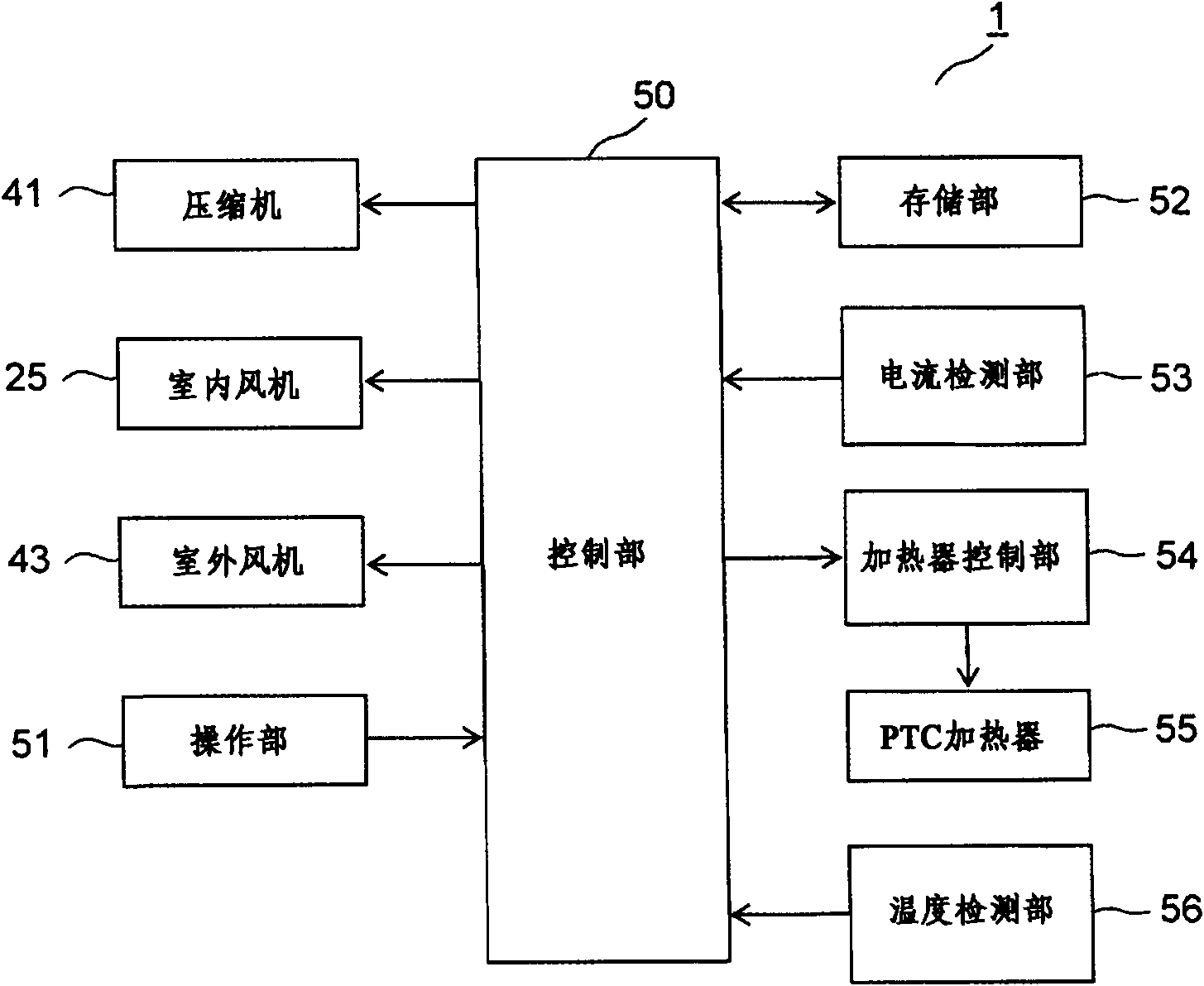

Mixed gas thermal value control system and method

InactiveCN101286042AEnsure inlet pressureAchieve normal operationElectric controllersAdaptive controlCaloric valuesControl system

The invention discloses a mixed gas heat value control system and a method. The system comprises a coking coal fuzzy controller which is used for calculating the control output quantity of a coking coal adjusting valve, carrying out heat value arrangement according to the data figured out by a heat balance unit, tracking and adjusting the feedback of a caloric value instrument and outputting the feedback to a cross decoupling unit for disposal; a high coal fuzzy controller which is used for calculating the control output quantity of a high coal adjusting valve, carrying out pressure arrangement according to the data figured out by the heat balance unit, tracking and adjusting the feedback of the mixed pressure and outputting the feedback to the cross decoupling unit for disposal; the heat balance unit which is used for calculating the given value of the heat value and the given value of the mixed pressure and providing process thermo-technical parameters and current conditions; the cross decoupling unit which is used for carrying out the cross decoupling to the output of the high coal fuzzy controller and the coking coal fuzzy controller and controlling the high coal adjusting valve and the coking coal adjusting valve. The mixed gas heat value control system achieves the stable heat value, ensures the inlet pressure, and realizes normal running of burning machines, thus sufficiently using the residual coal gas to generate the power.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Direct desulfurization method of high-sulfur coal by microwave radiation

The invention discloses a direct desulfurization method of high-sulfur coal by microwave radiation, which comprises the following steps: 1) putting high-sulfur coal in a reactor, and putting the reactor in a microwave radiation reaction furnace; and 2) introducing carrier gas, switching on the microwave radiation reaction furnace to perform microwave radiation on the high-sulfur coal after the gas flow is stable, and switching off the microwave radiation reaction furnace. The desulfurization percent is 50% or so, the microwave-radiation high-sulfur coal desulfurization process has small influence on the major structure of coal, the heating amount, binding property, intrinsic structure characteristic, crystallinity, stability, thermal chemical properties and the like of the coal are kept stable, and the loss rate of coal is very low; and the microwave-radiation high-sulfur coal direct desulfurization method has the advantages of short production cycle, low equipment investment, high reaction speed, low energy consumption and high controllability, and can implement continuous production.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Hybrid fuel and method for preparing the same

The invention discloses a composite fuel production method, which is characterized by the following: mixing the raw coal powder, vegetable fuel powder, sulfur-fixed agent, adhesive, hardener and oxygenation agent according to proportion with water; producing particle through particle moulding equipment; drying naturally into product. The invention reduces the environmental pollution, which is fit for industrial and civil fuel heat supply device.

Owner:魏文烃

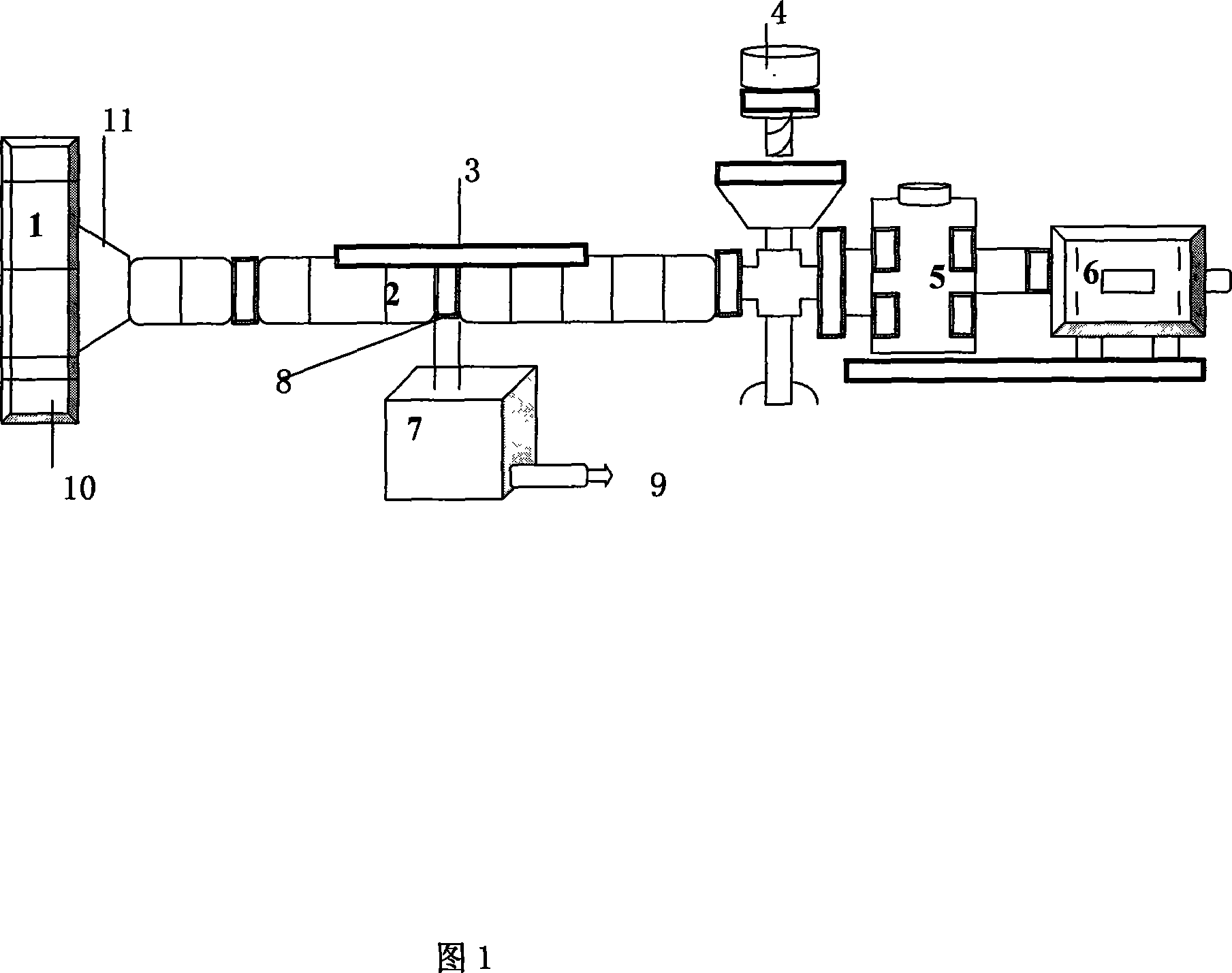

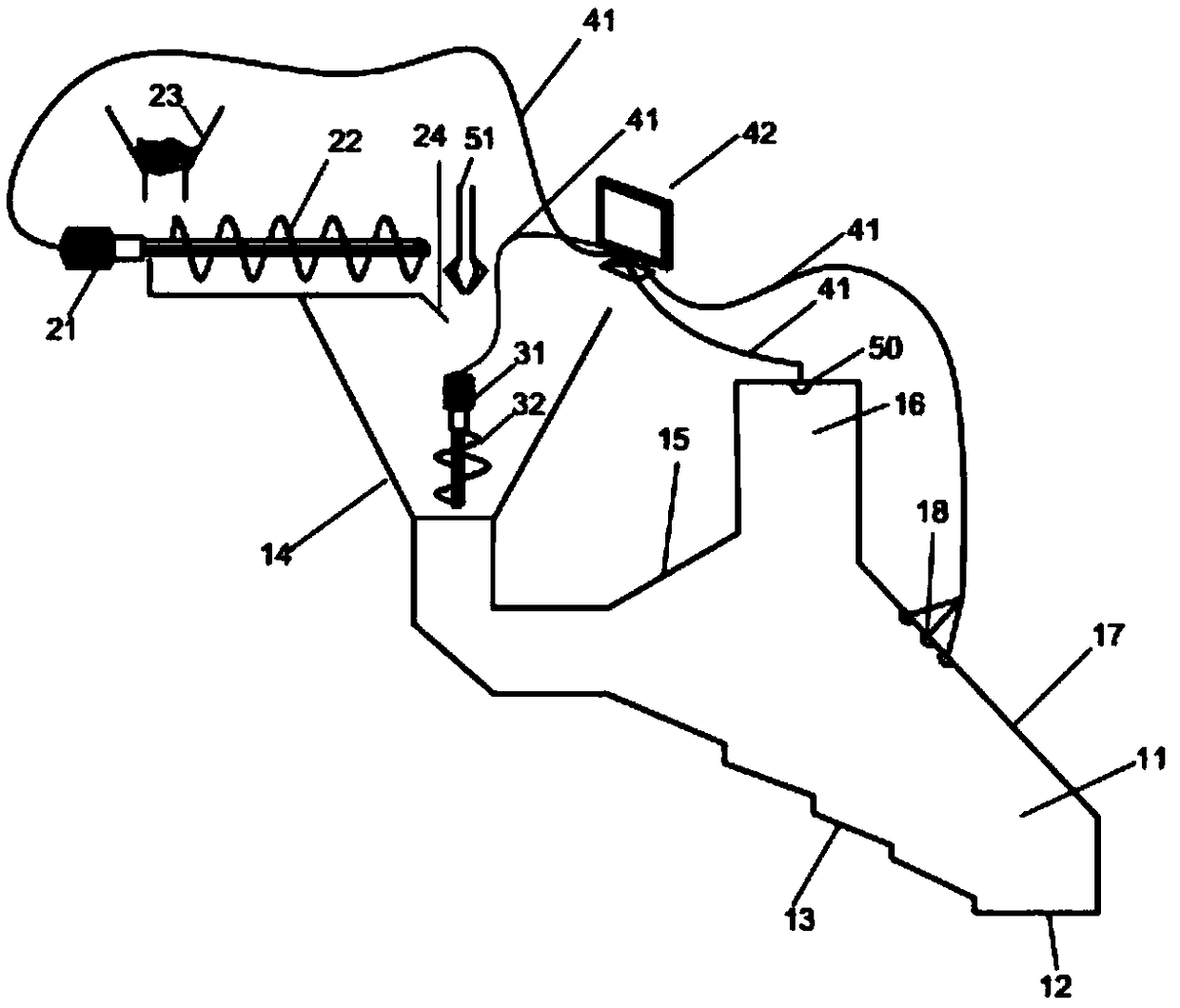

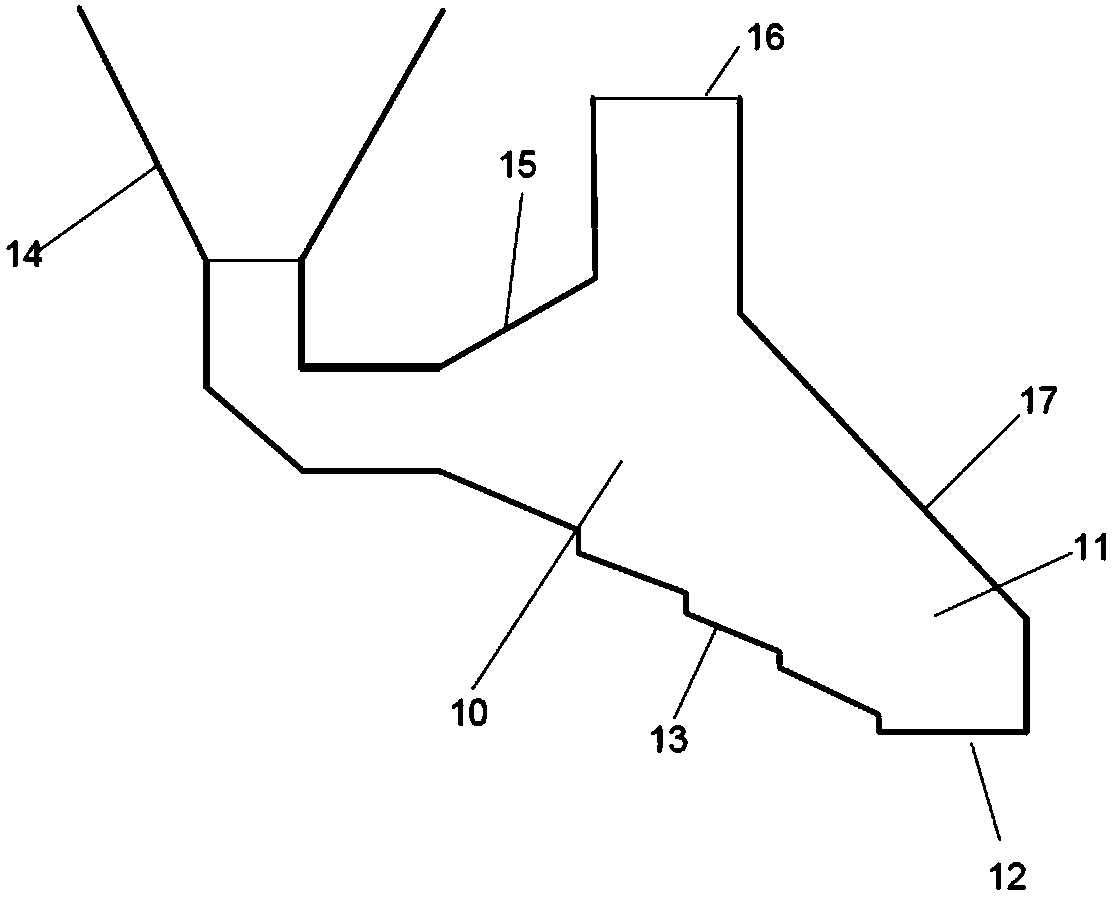

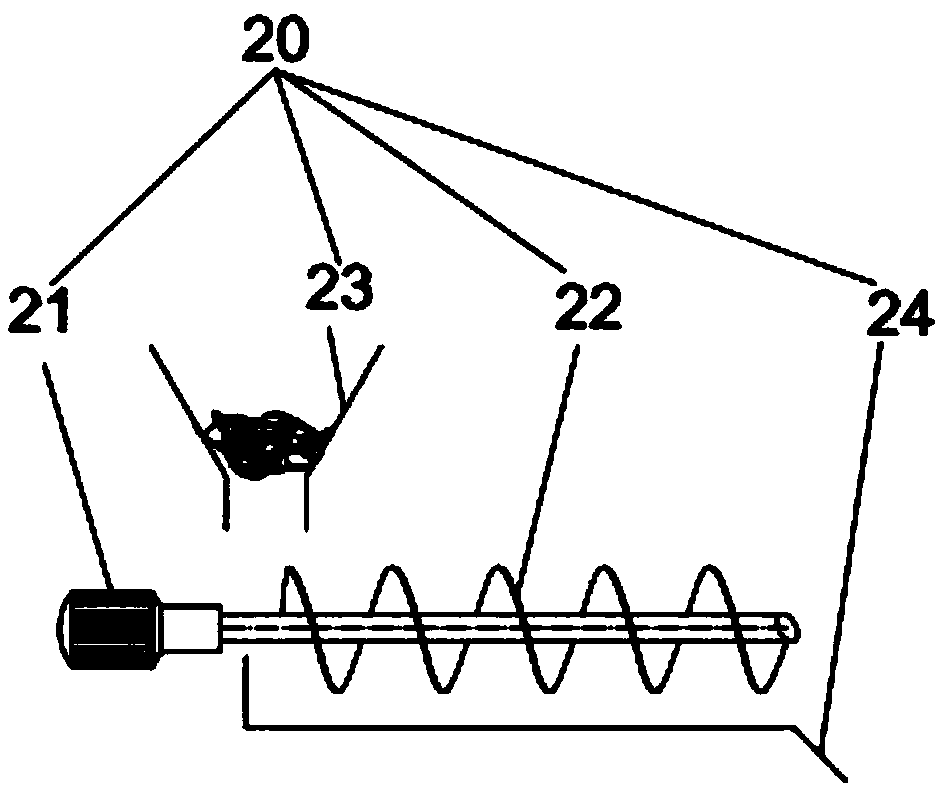

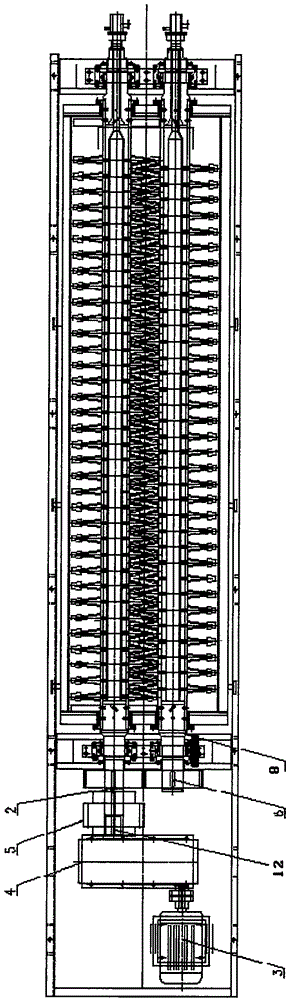

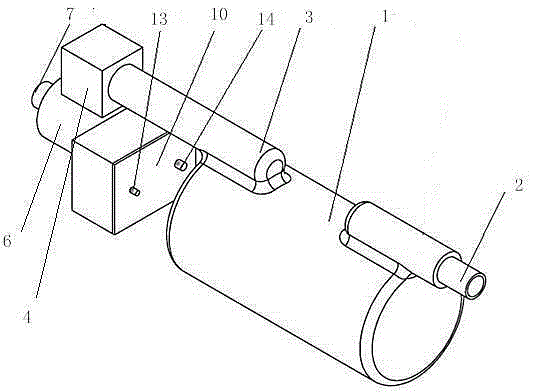

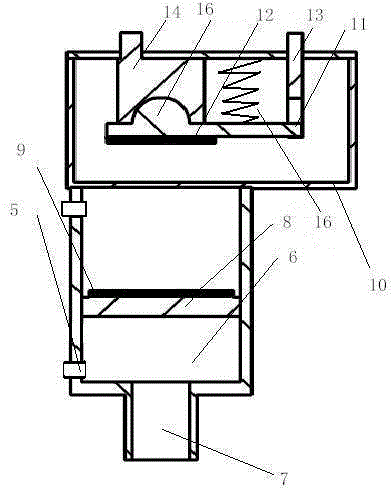

Special type sludge dewatering extrusion granulator

InactiveCN101121107AReduce energy consumptionSave energySludge treatment by de-watering/drying/thickeningGranulation by material expressionWater vaporScrew thread

The present invention provides a novel technical device of sludge dehydration and belongs to the solid waste disposal field. The device is applicable to the dehydration and granulation requirements of sludge with various components. A single screw and reverse screw threads and a peculiar structure arrangement are adopted to make the water of the sludge (a moisture content of which is about 80 percent) is dehydrated as a form of liquid, and make the sludge form a sludge dehydration and granulation process, the moisture content of which is 30 percent to 35 percent. A special sludge dehydration and granulation machine fills a blank that the sludge dehydration has to be dehydrated as the form of water vapor, which greatly reduces the energy cost of the sludge dehydration. With small size, low operation cost, high production efficiency, high mechanization degree and wide scope of application, the present invention is a novel and most energy-saving and cleanly-produced sludge dehydration device.

Owner:朱清海

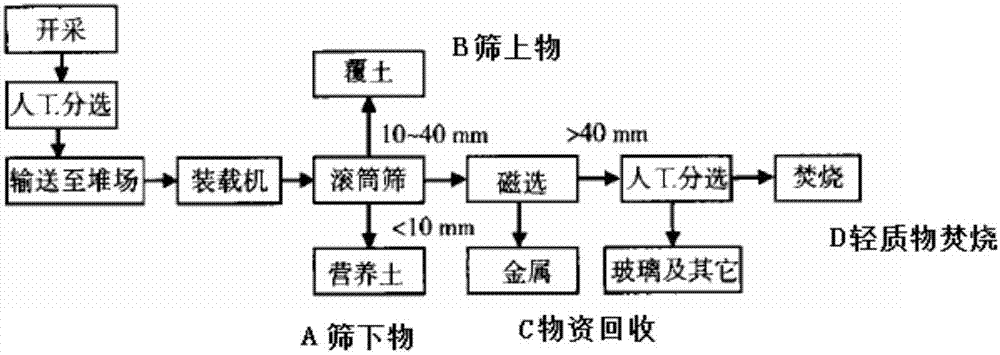

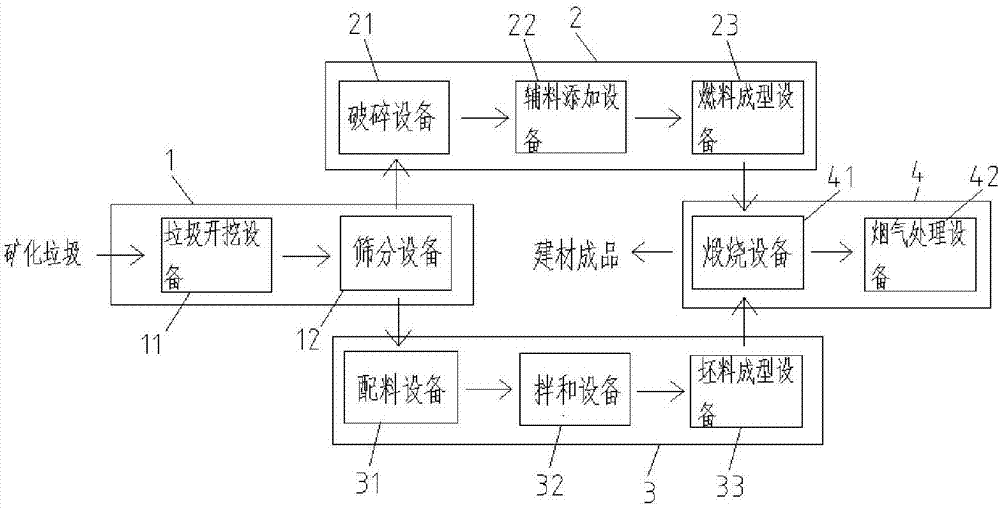

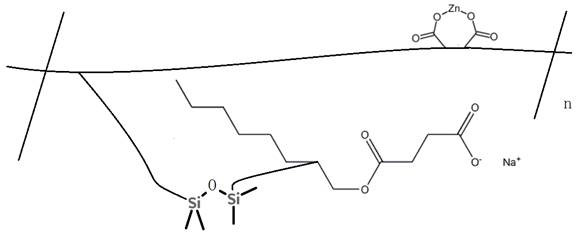

Stale garbage incineration and building material preparation system

ActiveCN107448944AStable placeImprove operational efficiencyIncinerator apparatusCeramic materials productionResource utilizationLitter

The invention discloses a stale garbage incineration and building material preparation system. The system comprises excavator screening equipment, a RDF preparation device, a humus soil blank production device and a finished product calcining device; the excavator screening equipment is used for dividing stale garbage into oversize products and undersize products; one part of the oversize products are light substances with a certain heat values; the undersize products are humus soil; the RDF preparation device is used for preparing oversize combustible matters as RDFs; the humus soil blank preparation device is used for preparing the undersize products as blanks; and the finished product calcining device uses the RDFs as fuels for calcining the blanks to prepare finished building materials. The blanks are prepared by the humus soil in the stale garbage; and the RDFs are prepared by the light substances with a certain heat values in the stale garbage as a heat source for burning the blanks, so that perfect combination of the environmental treatment and the resource utilization can be achieved. The stale garbage incineration and building material preparation system is higher in resource utilization rate and better in environmental protection.

Owner:北京鸿洲兴业环保科技有限公司

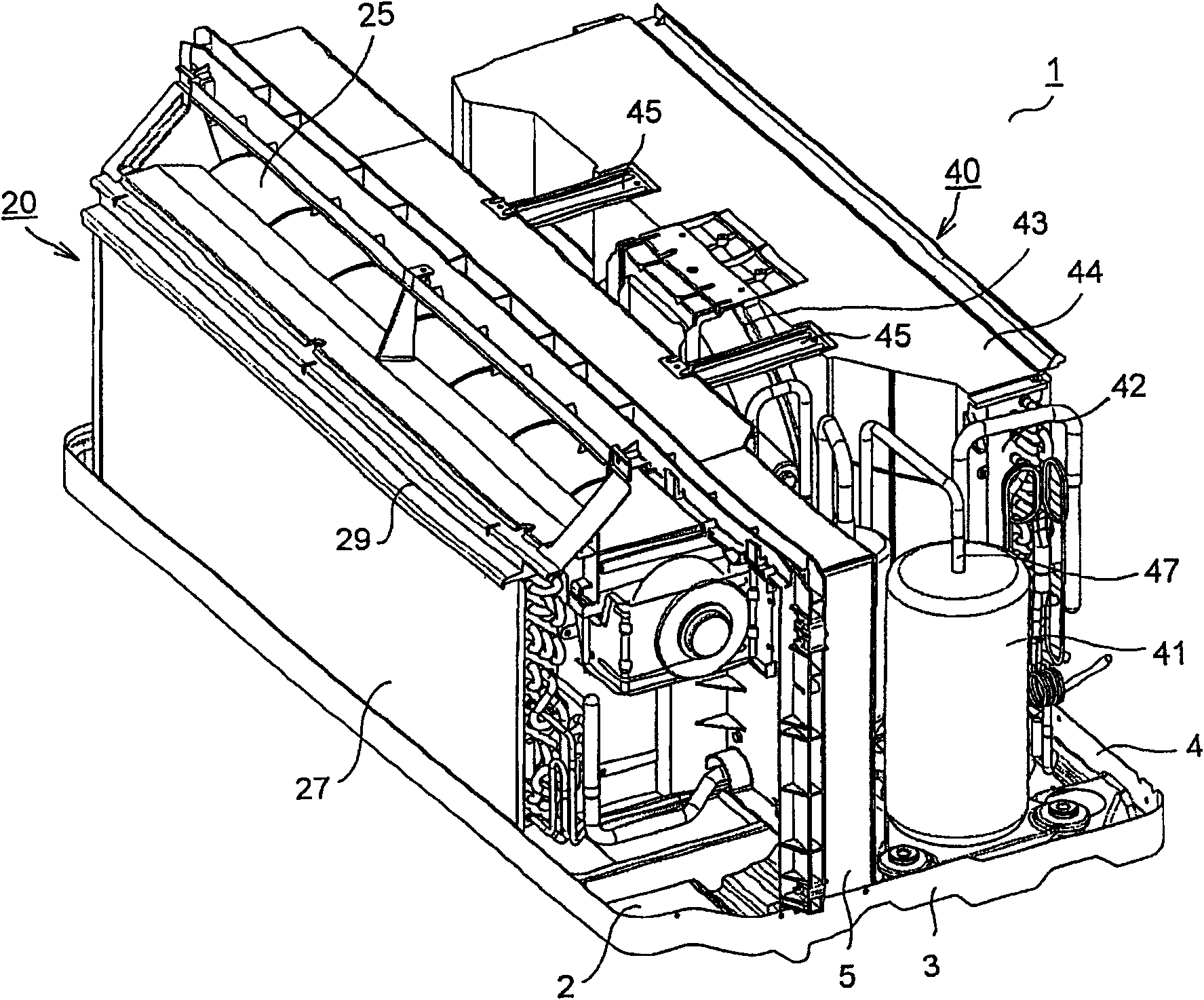

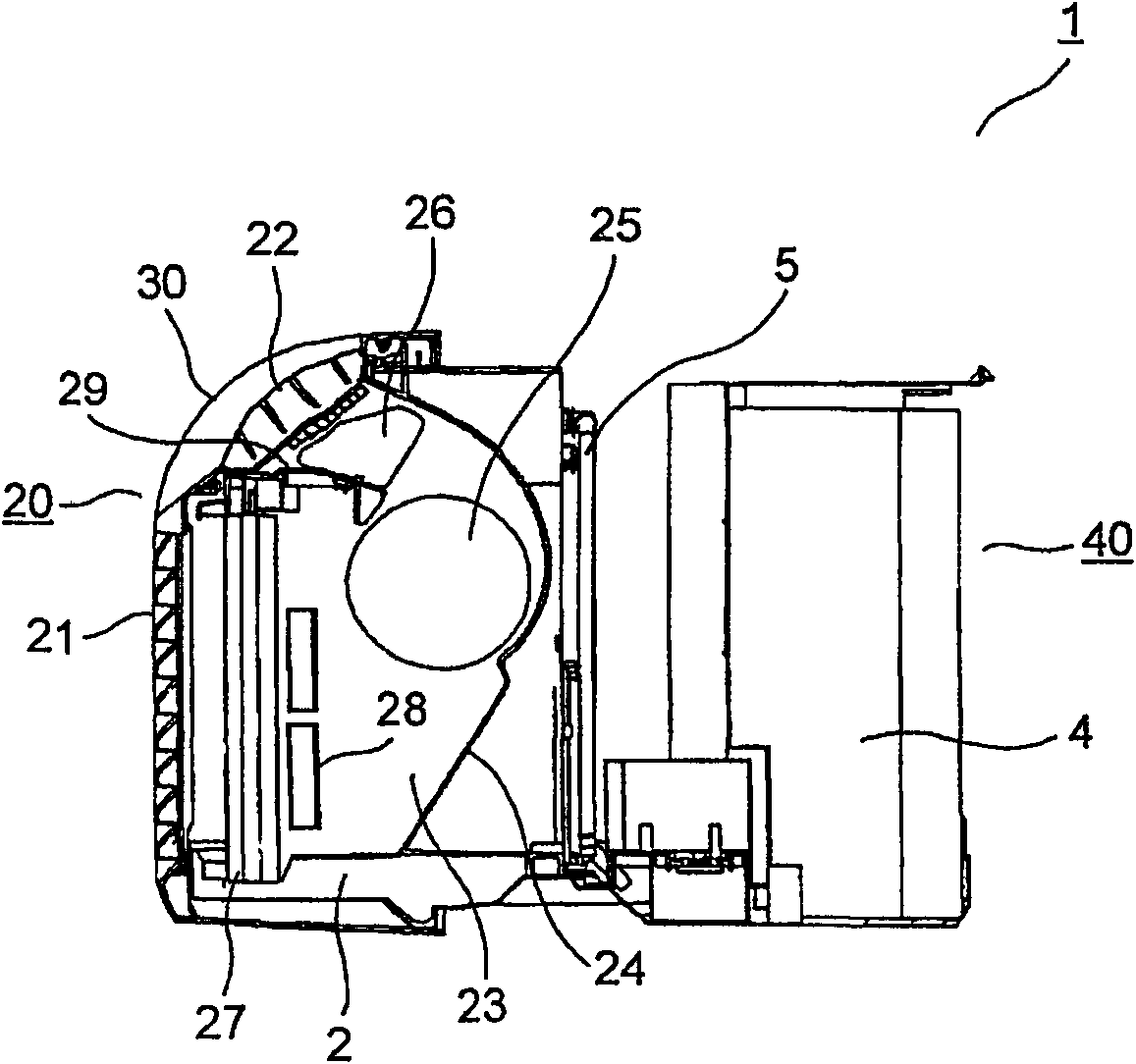

air conditioner

InactiveCN102278794AIncrease temperatureCalorific value stableMechanical apparatusSpace heating and ventilation safety systemsElectrical resistance and conductancePower flow

Disclosed is an air conditioning device (1) that includes: a PTC heater (55) in which, in a stable region (S1), when the temperature of the PTC heater (55) is increased, a resistance is decreased or is substantially constant whereas, in a rise region (S2), the resistance is rapidly increased when the temperature exceeds a rise temperature (T1); and an air blower (25) that generates an air current which exchanges heat with the PTC heater (55), and that performs a heating operation by discharging air heated by the PTC heater (55) into the room, when the temperature within the room is within a low temperature range including a region whose temperature is lower than a set temperature, the duty ratio is set at 100%, and the PTC heater (55) is driven in the rise region (S2), when the temperature within the room is within a high temperature range whose temperatures are higher than the set temperature, the PTC heater (55) is stopped, and when the temperature within the room is within an intermediate temperature range between the low temperature range and the high temperature range, the duty ratio is set at a predetermined duty ratio, and the PTC heater (55) is driven in the stable region (S1).

Owner:SHARP KK

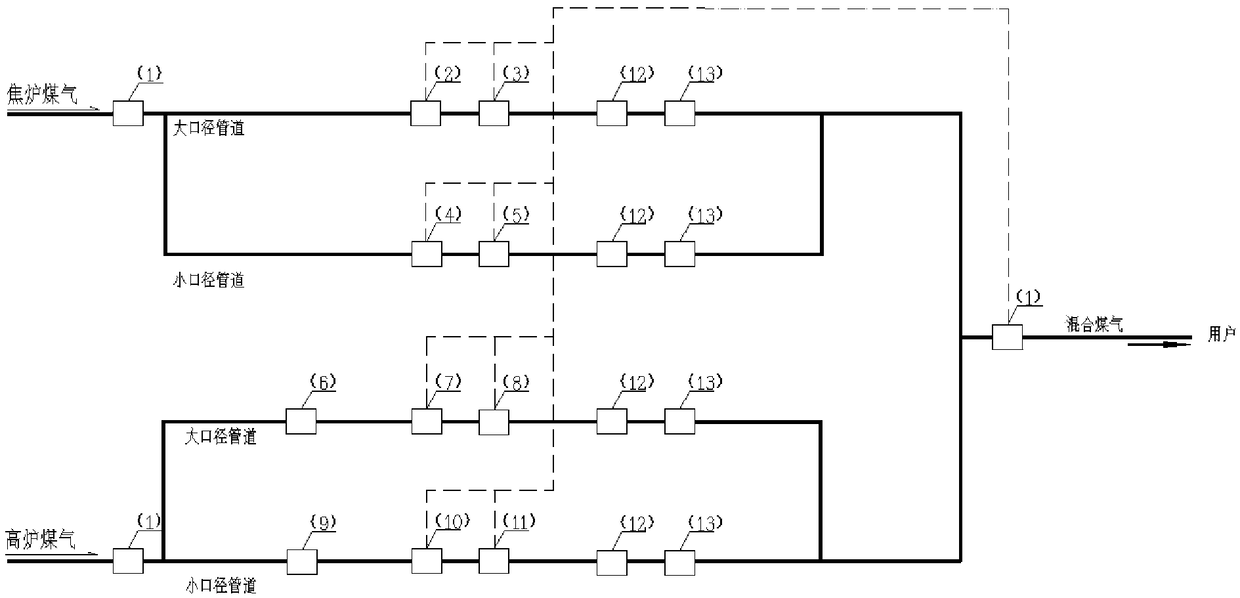

Control system and method for steady-value voltage stabilization of mixed gas

InactiveCN109028134AIncrease usageImprove the qualified rate of finished productsGaseous fuel feeder/distributionGaseous fuel pretreatmentControl systemClosed loop

The invention discloses a control system and a method for the steady-value voltage stabilization of the mixed gas. The control system comprises a coke oven gas source and a blast furnace gas source, the coke oven gas source and the blast furnace gas source are connected with a first caliber branch and a second caliber branch which are connected in parallel through corresponding supply branches, the first caliber branch and the second caliber branch are merged to form a mixed branch; flow meters and flow regulating valves are arranged on the first caliber branch and the second caliber branch, aheat value instrument is arranged on the coke oven gas source and the blast furnace gas source supply branch and the mixing branch. According to the control system, a given amount of a flow regulating valve on each caliber branch is controlled through a mode of combining feedforward control with a double-closed-loop ratio control system, so as to adjust the heat value and the pressure of the mixed gas.

Owner:BERIS ENG & RES CORP

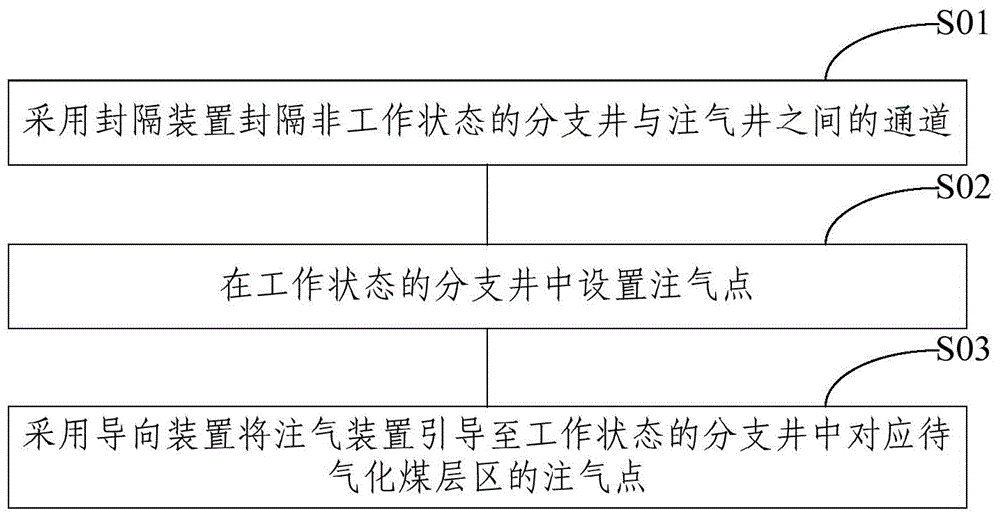

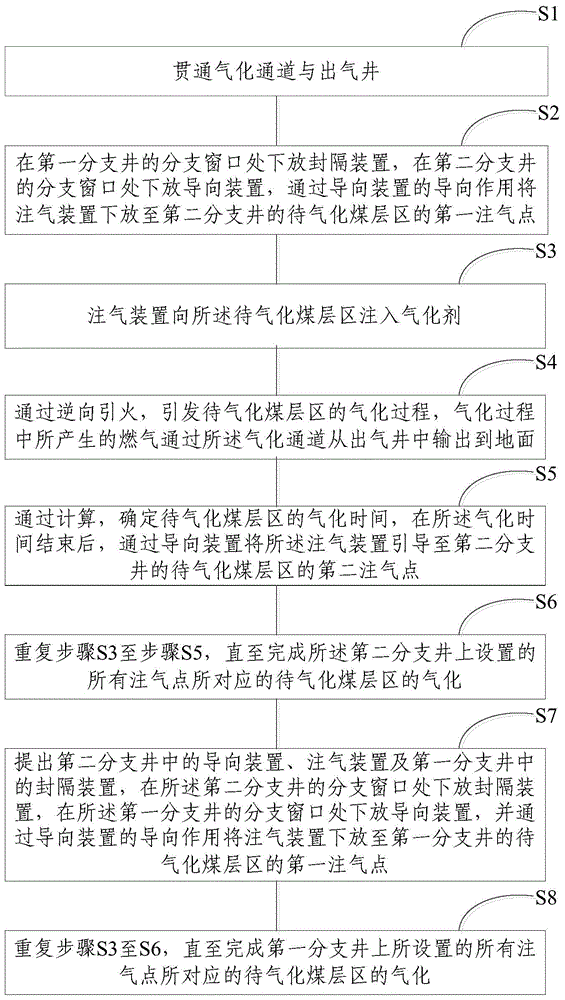

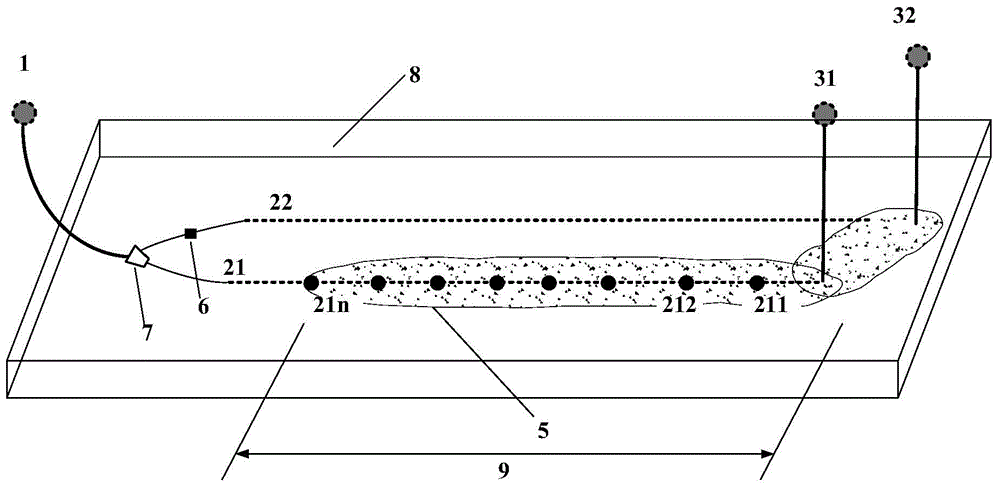

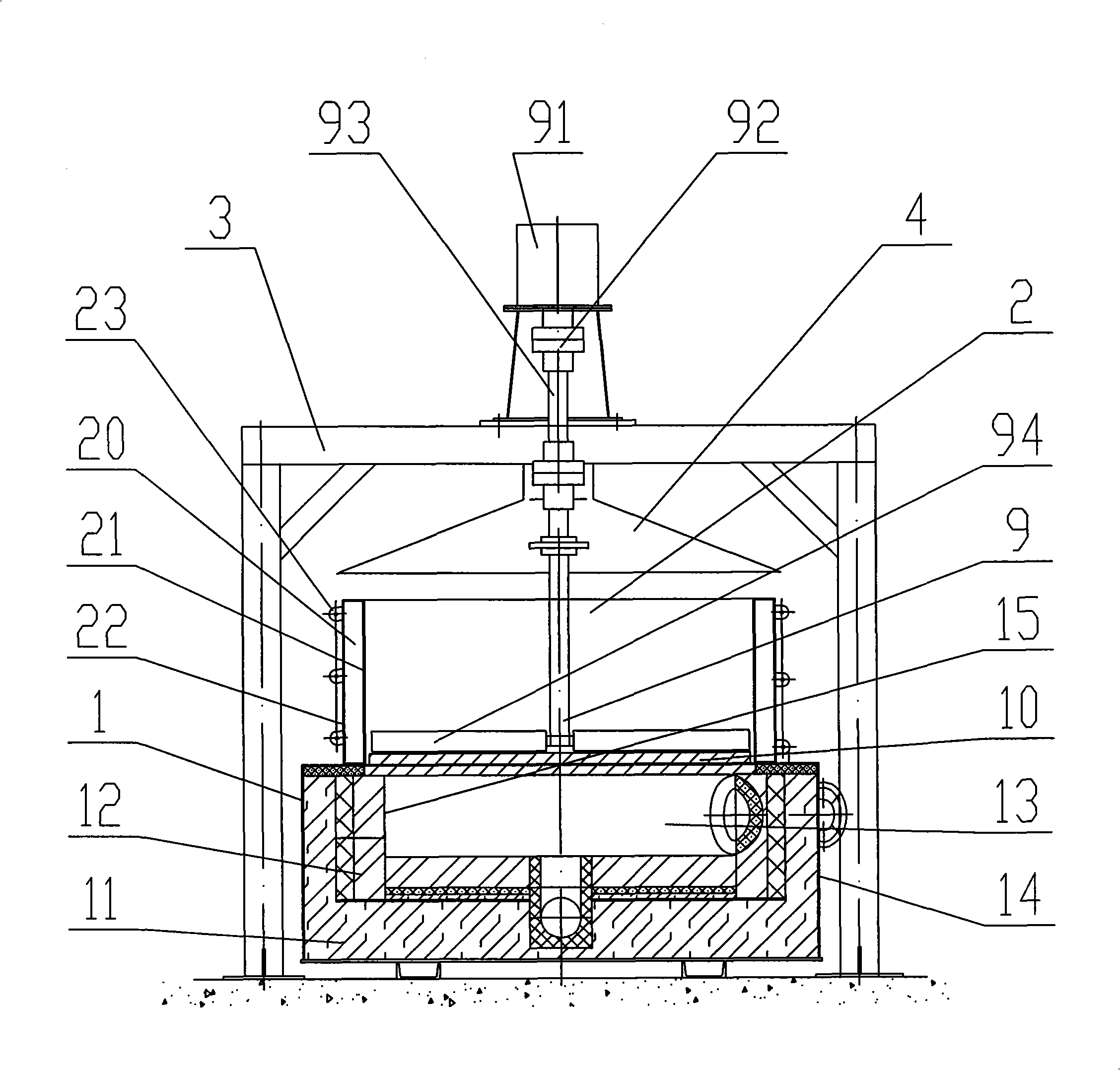

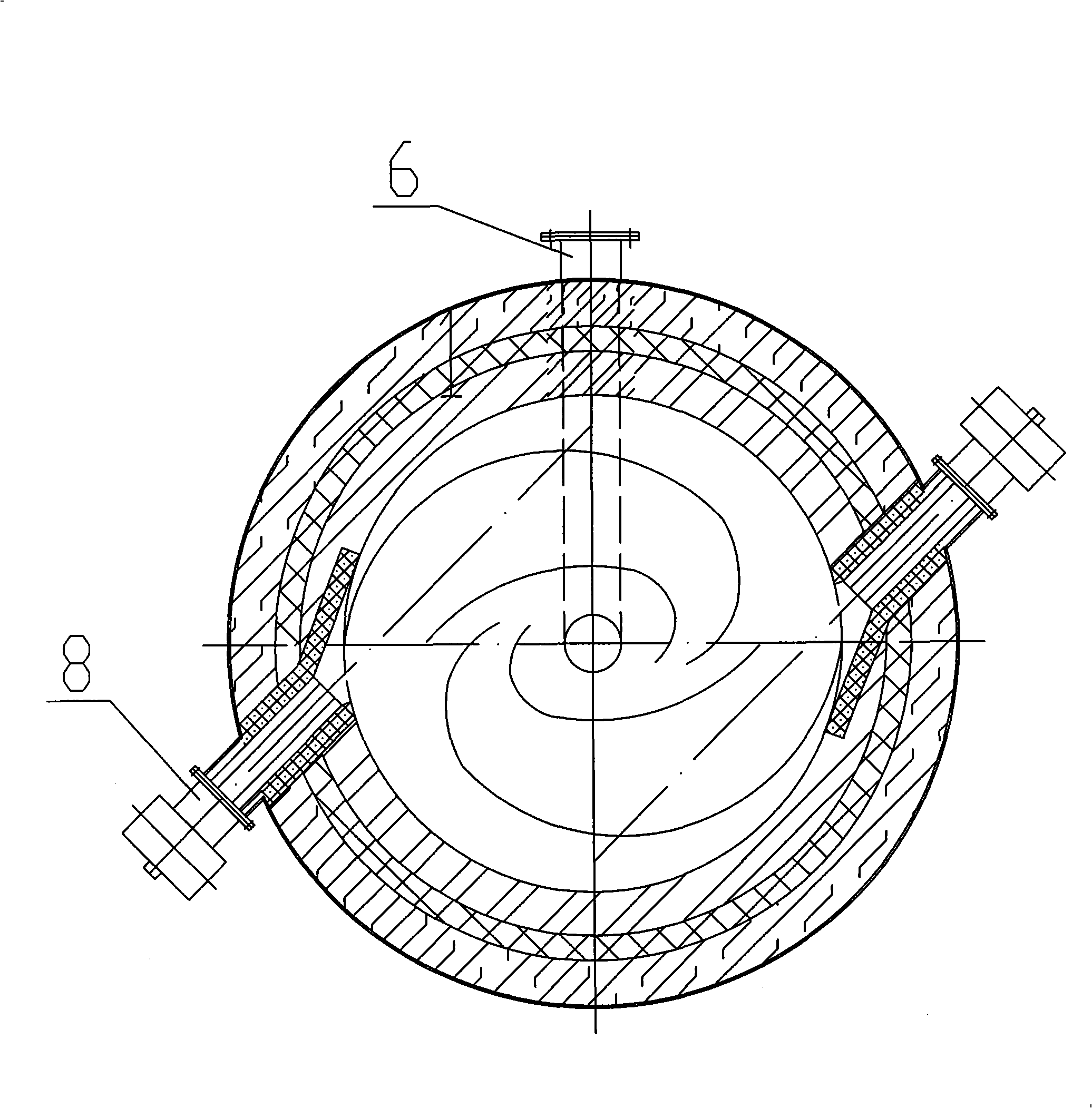

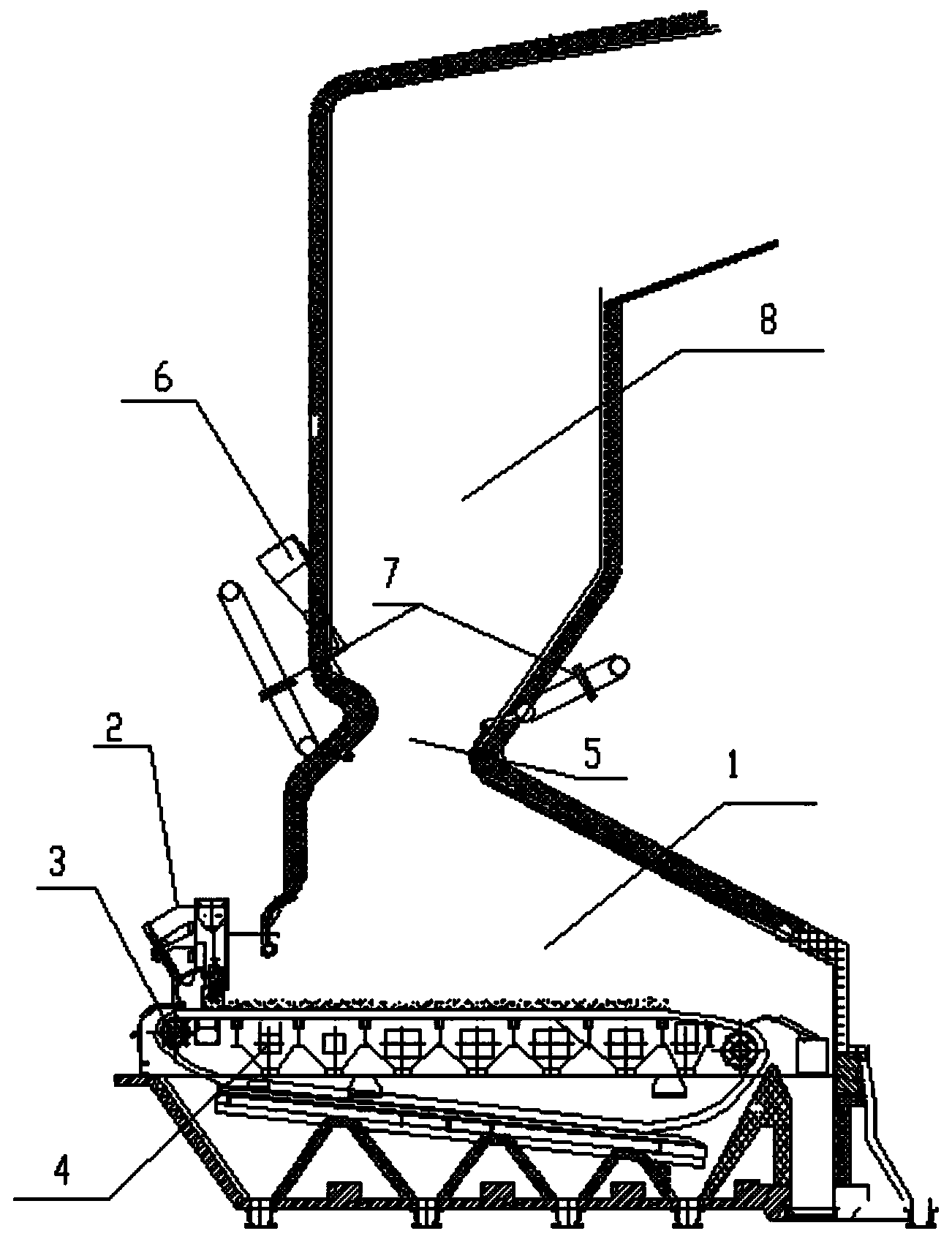

Gasification method and gasification furnace of coal seams based on branch wells

ActiveCN104695933ACalorific value stableImprove recovery rateConstructionsCoal gasificationCoal miningInjection well

The invention discloses a gasification method and gasification furnace of coal seams based on branch wells, and aims to solve the problems that a gasification technique of coal seams is high in cost and low in recovery ratio in the prior art. The gasification method comprises the following steps: after finishing drilling construction, enabling gasification channels to be run-through, respectively downwards placing packers or guidance devices in different branch wells, downwards placing gas injecting devices in corresponding branch wells through the guidance devices, injecting a gasifying agent, confirming the gasifying time of coal seam regions to be gasified through calculation, and completing the gasifying process of the coal seam regions to be gasified; replacing the packers or the guidance devices in the branch wells, completing the gasifying process of the coal seam regions to be gasified of all branch wells, and outputting generated fuel gas to the ground through gas exhaust wells. Through the adoption of the gasification method disclosed by the invention, the fixed point quantitative controllable injection of the gasifying agent is realized, the process of gas generation is stable, the demands of the deep processing of fuel gas are satisfied, the gasification coal mining output and the recovery ratio of single well are effectively increased, besides, the service life of each gas injection well is prolonged, the cost of building furnaces and drilling is reduced, and the cost of ground construction and operation is reduced.

Owner:ENN SCI & TECH DEV

Formulation for composite briquette

The recipe of composite briquette includes anthracite, inflammable waste papermaking pulp slurry, and coal sludge from coal washing. The present invention can eliminate the environmental pollution caused by waste papermaking pulp slurry and coal sludge and lower briquette producing cost by 15-20 %, while ensuring the stable combustion and avoiding black smoke produced during combustion. In addition, the burnt cinder contains potassium, phosphate and other components essential for crops and may be used in improving soil.

Owner:孙孝成

Efficient energy-saving environment protective beige frying kitchen range

The invention provides a high-efficiency energy-saving environment-friendly fried rice color cooker. The cooker comprises an upper barrel body, a fried pot, a cooker body and a stirring device, wherein the cooker body comprises a cooker wall and a circular hearth; the fried pot is arranged in the upper barrel body and on the upper end of the circular hearth; the bottom surface of the fried pot and the upper end of the cooker body are in sealing fit; the upper barrel body is positioned on the upper end of the cooker body, the lower end of the upper barrel body and the upper end of the cooker body are in sealing fit; the stirring device is fix above the fried pot by a portal frame; and the inner wall of the circular hearth is provided with two burners respectively. The cooker of the invention has the advantages of improving the utilization ratio of heat energy in the fried color technological process and the production efficiency, lowering the labor intensity and improving the production environment.

Owner:JIANGSU HENGSHUN VINEGAR IND +1

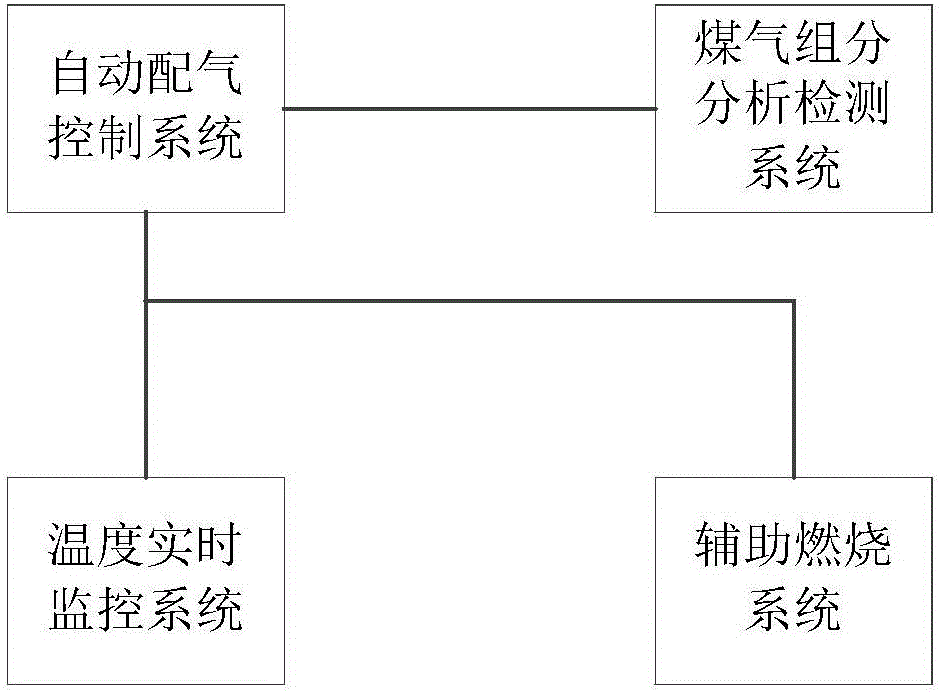

Coal underground gasification temperature control system

ActiveCN104989365AComposition is stableStable outputConstructionsCoal gasificationCombustion systemTemperature control

The invention discloses a coal underground gasification temperature control system. The coal underground gasification temperature control system comprises an automatic distribution control system, a gas component analysis and detection system, an underground real-time temperature monitoring system and an auxiliary combustion system, wherein the automatic distribution control system and the gas component analysis and detection system are arranged on the ground. The technical problem that the coal underground gasification process cannot be controlled can be solved, the production process can be regulated according to the product requirement, and automatic operation and continuous production are achieved. A coal underground gasification temperature control technology and device can also make timely response and remedy for the gasification process obstacle caused by sudden change of the gasification environment, the gasification process can rapidly return to the dynamic balance, and the stable and continuous product gas output is guaranteed; the automation degree is high, the adaptability range is wide, operation is easy, safety is good, and economical efficiency and environment friendliness are achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

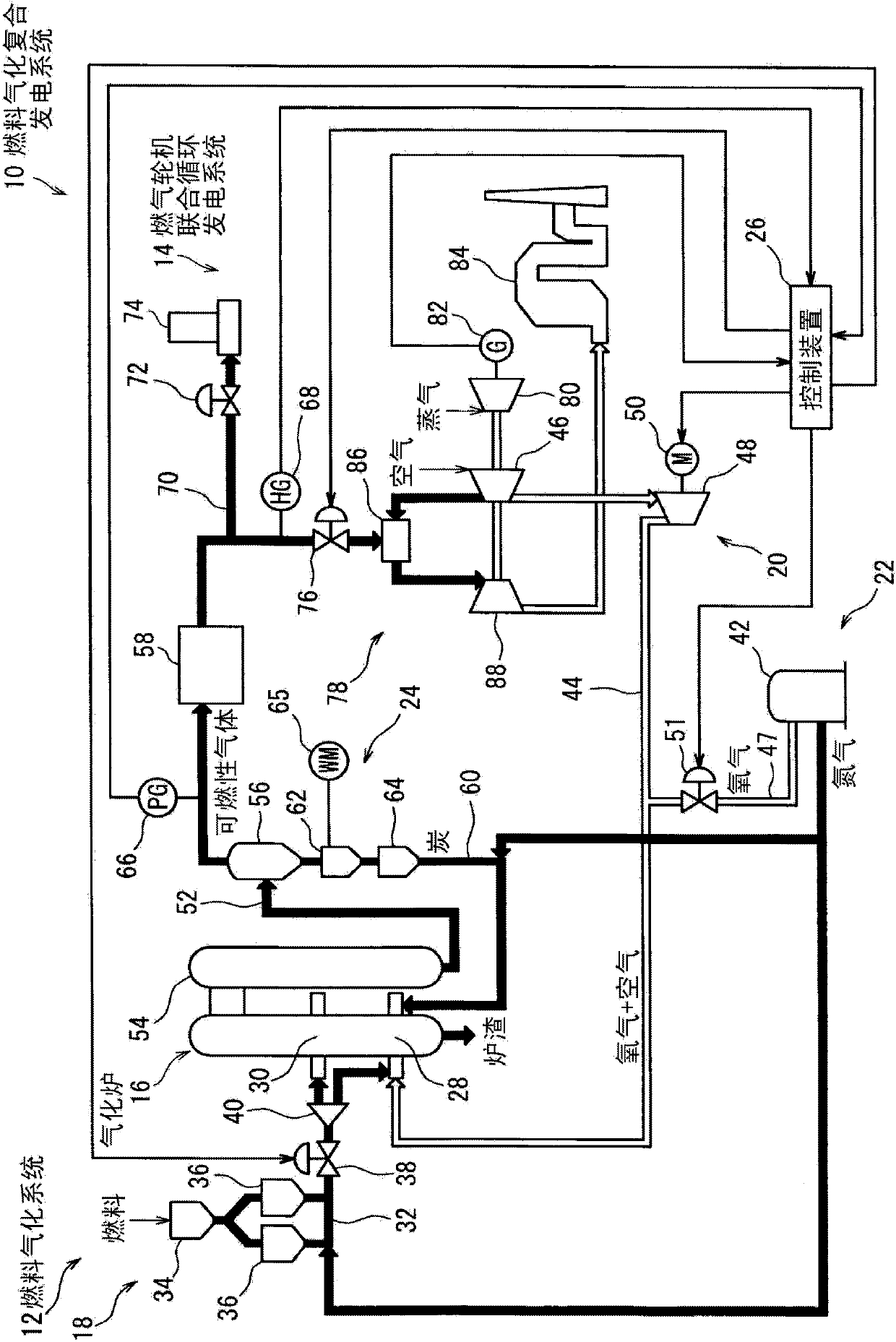

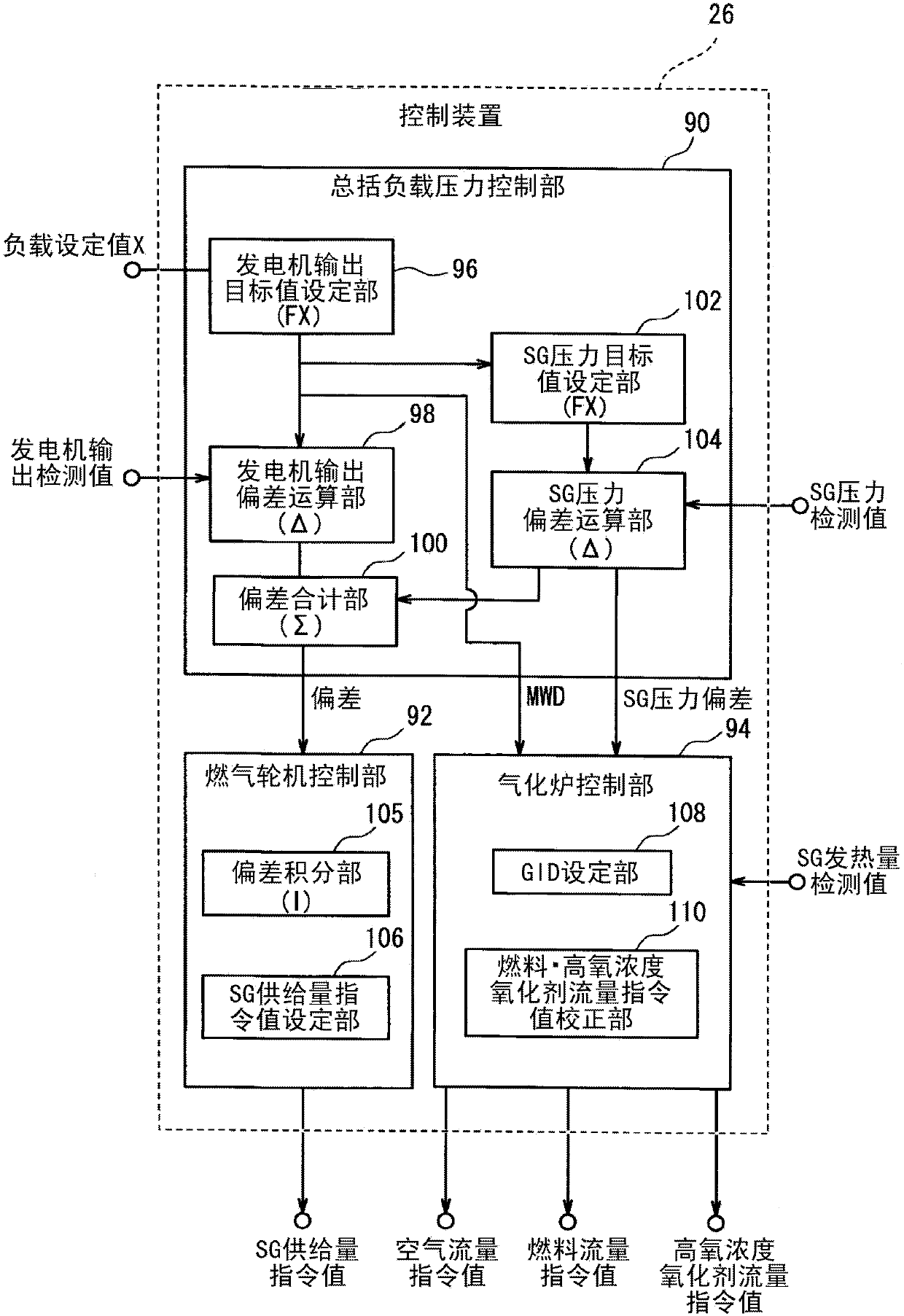

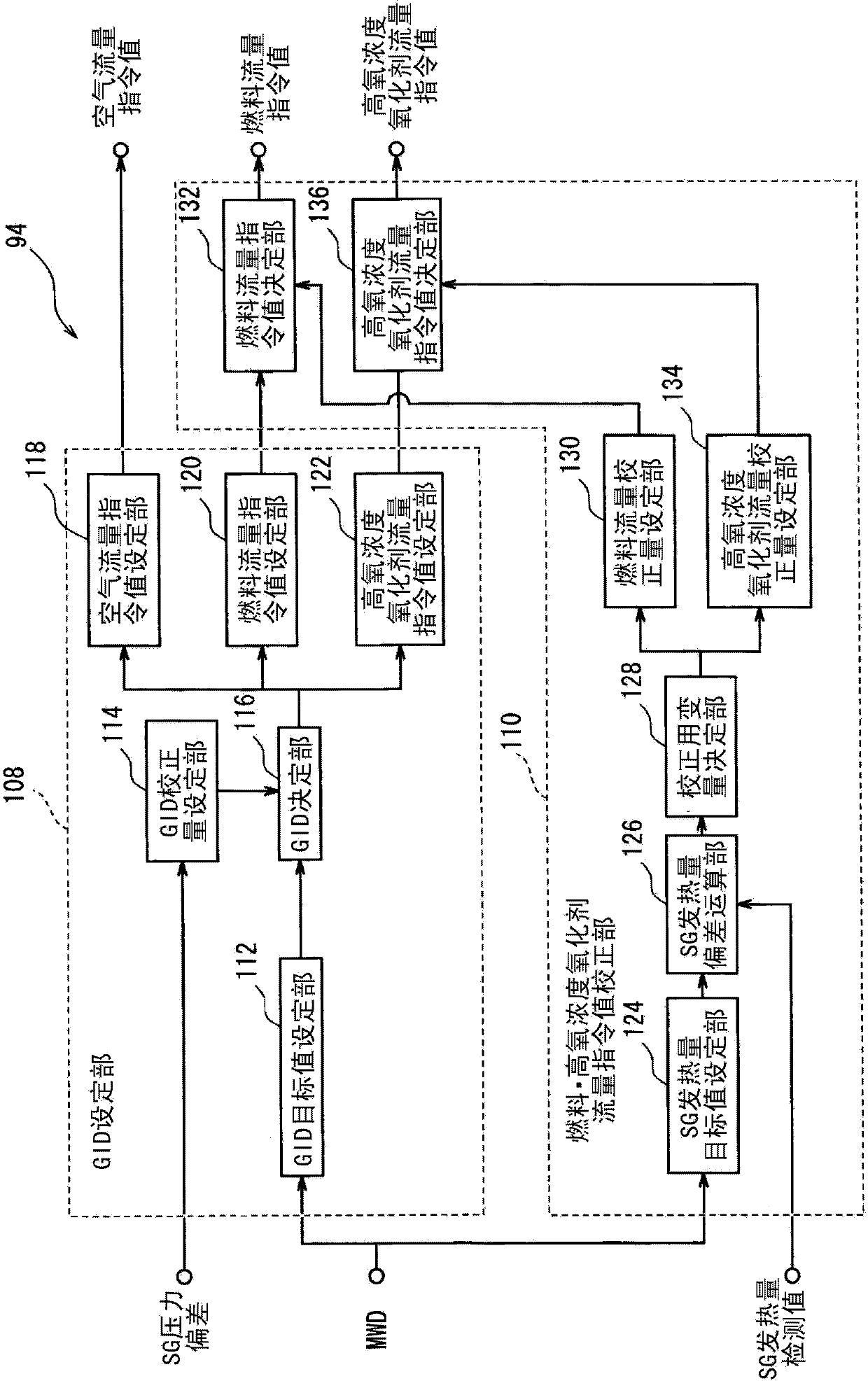

Fuel gasification system, control method and control program therefor, and fuel gasification combined power generation system provided with fuel gasification system

InactiveCN104011183AProduction increase or decreaseCalorific value stableGaseous fuelsGas turbine plantsThermodynamicsFuel gasification

Provided are a fuel gasification system, a control method and control program applied to the fuel gasification system, and a fuel gasification combined power generation system provided with the fuel gasification system, whereby flammable gas obtained by gasifying fuel generates a stable amount of heat while the amount of char generated is also prevented from increasing or decreasing even when the type or behavior of the fuel changes. A control device (26) of a fuel gasification system (12) controls the amount of fuel being supplied to a gasification furnace (16) in accordance with an index corresponding to the amount of heat generated by a flammable gas (an amount of heat generated by SG), and controls the amount of oxygen gas being supplied to the gasification furnace (16) so that the ratio of the amount of oxygen gas being supplied with respect to the amount of air being supplied to the gasification furnace (16) changes.

Owner:MITSUBISHI HEAVY IND LTD

Cracking purification method for combustible gas by gasifying crude material

InactiveCN1190476CHigh temperature pyrolysisCalorific value stableCombustible gas catalytic treatmentPurification methodsDust control

A method of degrading and cleansing combustible gases produced during gasifying biological matters. It comprises) passing a cracking machine with a moving bed, the combustible gases will be cracked by high-temperature and catalysis in the charcoal bed at 800-1200degree C, most of tar is removed; b)reducing the temperature of combustible gases from 800degree C to 300-350degree C; c) dedusting by static electricity at a high-voltage electric field of 80000 volts, reducing the temperature to 250-300degree C; (d) washed by water, debusting and detarring, reducing the temperature to 60-80degree C; (E) washing, filtering and reducing the temperature to below 40degree C, the contents of tar and dust in the combustible gases will be reduced below 50mg / Nm3. The invention could remove completely dust and tar in combustible gases.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Fuel forming method

InactiveCN103305305ASolve the problem that cannot run continuously and stablyReduce demandBiofuelsSolid fuelsFiberEngineering

The invention discloses a fuel forming method which comprises the following steps of: crushing and cleaning herbaceous plant or woody plant raw materials, and removing impurities to obtain fragments with the particle sizes of phi 0.05-10 mm; according to different fragments, mixing sawdust and cotton fibers in different proportions to get a more stable heat value and meet a requirement for stable combustion; and putting the mixture into a fuel forming machine for compression forming. The herbaceous plant or woody plant raw materials can be fully used, have the advantages of high forming property, stable structure, high firing speed, high combustion efficiency, stable heat value, zero alkaline corrosion and the like and can be used for combustion type power generation; the problem that a power generation station cannot continuously and stably run because of insufficient energy is solved; the demand for non-regenerated energy such as coal is reduced; and the problem of environment pollution caused by combustion is solved.

Owner:许成荫

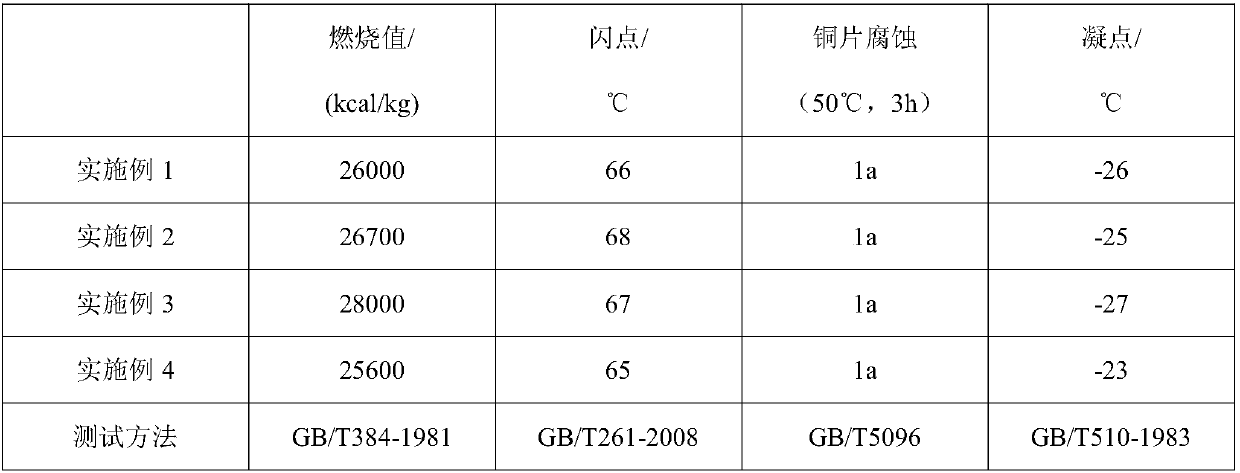

Alcohol-based fuel with high calorific value and preparation method thereof

ActiveCN107892957AHigh calorific valueEliminate odorLiquid carbonaceous fuelsFuel additivesLiquid fuelOctanol

The invention specifically relates to an alcohol-based liquid fuel with high calorific value and a preparation method thereof. The alcohol-based liquid fuel comprises the following raw materials by weight: 85 to 90 parts of methanol, 10 to 15 parts of C12 fuel oil, 5 to 10 parts of octanol, 15 to 20 parts of methylal, 1 to 4 parts of a deodorant and 10 to 15 parts of an additive. The additive comprises the following raw materials by weight: 5 to 10 parts of ethanol, 3 to 5 parts of glyceryl triacetate, 4 to 7 parts of a cationic fluorocarbon surfactant, 3 to 5 parts of ferrocene, 10 to 15 parts of a hydrocarbon compound, 10 to 15 parts of a combustion improver, 3 to 5 parts of a stabilizing agent and 3 to 5 parts of an antidetonant. According to the invention, the components of the alcohol-based liquid fuel with high calorific value cooperate with each other, so the alcohol-based liquid fuel is thorough in combustion, high in combustion heat value and free of carbon deposition, and hasgood intersolubility with gasoline, good corrosion resistance, good vaporability and good positive additivity.

Owner:临沂星火知识产权服务有限公司

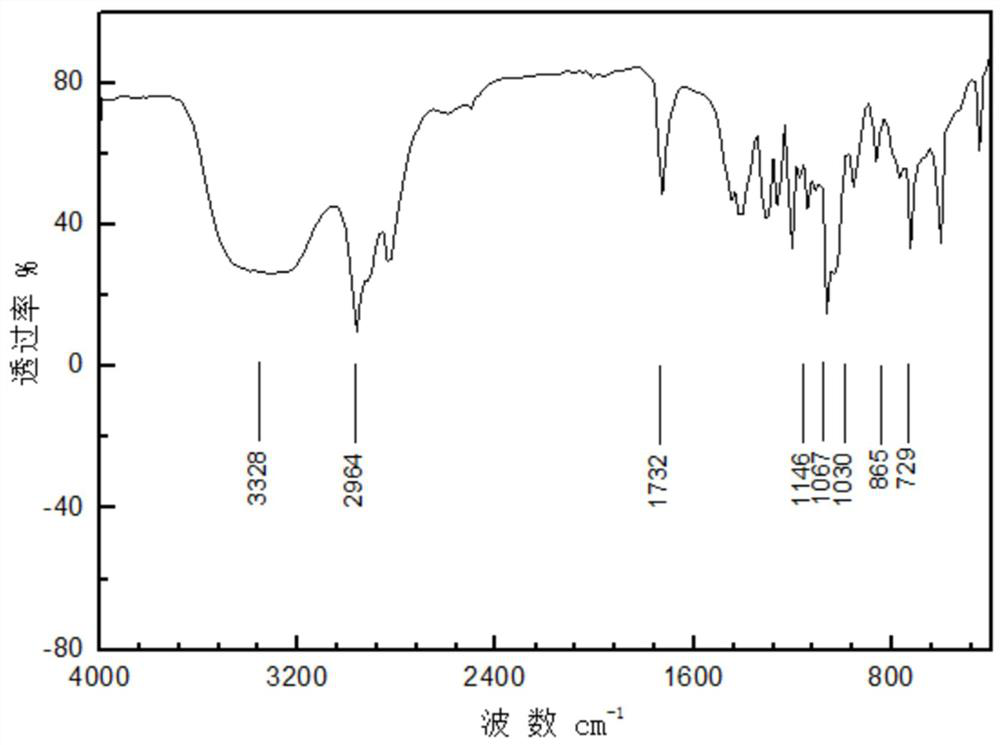

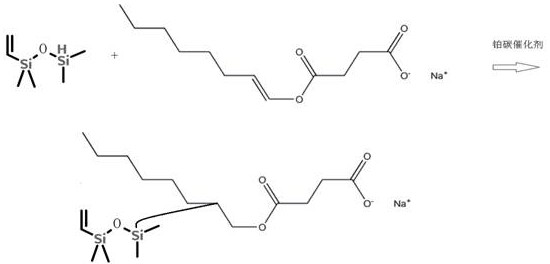

Method for co-processing household garbage by cement kiln

ActiveCN111692592ACalorific value stableUniform qualityRotary drum furnacesIncinerator apparatusProcess engineeringCombustion chamber

The invention relates to the field of environmental protection, and particularly relates to a method for co-processing household garbage by a cement kiln. The method comprises the processing steps ofleaching treatment, sorting, crushing, drying, extrusion granulation and incineration. According to the method, a forming aid obtained by modifying cheap waste plastics is added, so that the householdgarbage is changed into granular cement kiln fuel which is stable in heat value, uniform in quality, stable in component and easy to combust; the characteristics of high temperature, large waste heat, residue utilization and the like of the cement kiln are combined, the waste heat of the cement kiln is fully utilized to dry the garbage, the incinerated ash is used as a cement production raw material, and the household garbage is changed into wealth; and a two-stage incineration technology is adopted, firstly, the garbage granules are subjected to high-temperature thermal decomposition in a low-oxygen environment, and then decomposed solid and gas are guided into a combustion chamber to be fully combusted. According to the method, the problems that the household garbage combustion effect is poor, the tail gas emission quality is poor, the slag combustion is incomplete and the like are solved, and the problem of secondary pollution is avoided.

Owner:浙江红狮环保股份有限公司

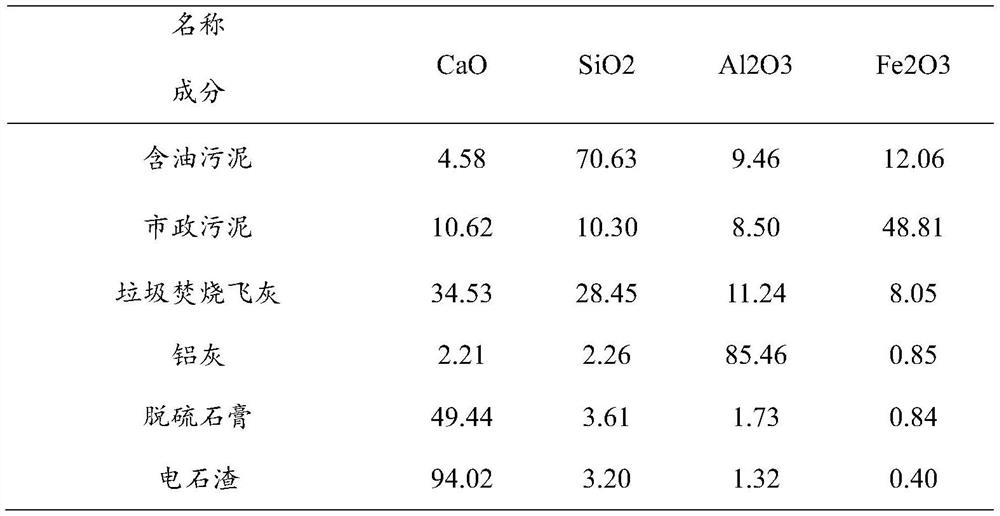

Two-stage cement kiln multi-source solid waste coupling pyrolysis gasification method and device and application thereof

ActiveCN113897225AAvoid the effects of calcinationQuality improvementEnergy inputGasification processes detailsThermodynamicsClinker (waste)

The invention relates to the field of cement production through solid waste treatment, in particular to a two-stage cement kiln multi-source solid waste coupling pyrolysis gasification method and device and application thereof, and aims to solve the problems that according to an existing cement kiln solid waste co-processing technology, the type of solid waste is single, the quality of cement clinker is prone to being affected by component and temperature fluctuation, and waste gas and waste residues are difficult to reasonably utilize. The method comprises the following steps: proportioning organic solid wastes according to heat values and components, and proportioning gasified solid components and preheated inorganic solid wastes. While the solid waste disposal scale and variety are increased, the influence of temperature fluctuation of a smoke chamber of the rotary cement kiln caused by component difference of the solid waste in the co-disposal process is reduced, the calcination temperature of the cement clinker is stabilized, and therefore the yield and quality of the cement clinker are guaranteed.

Owner:SHANDONG UNIV

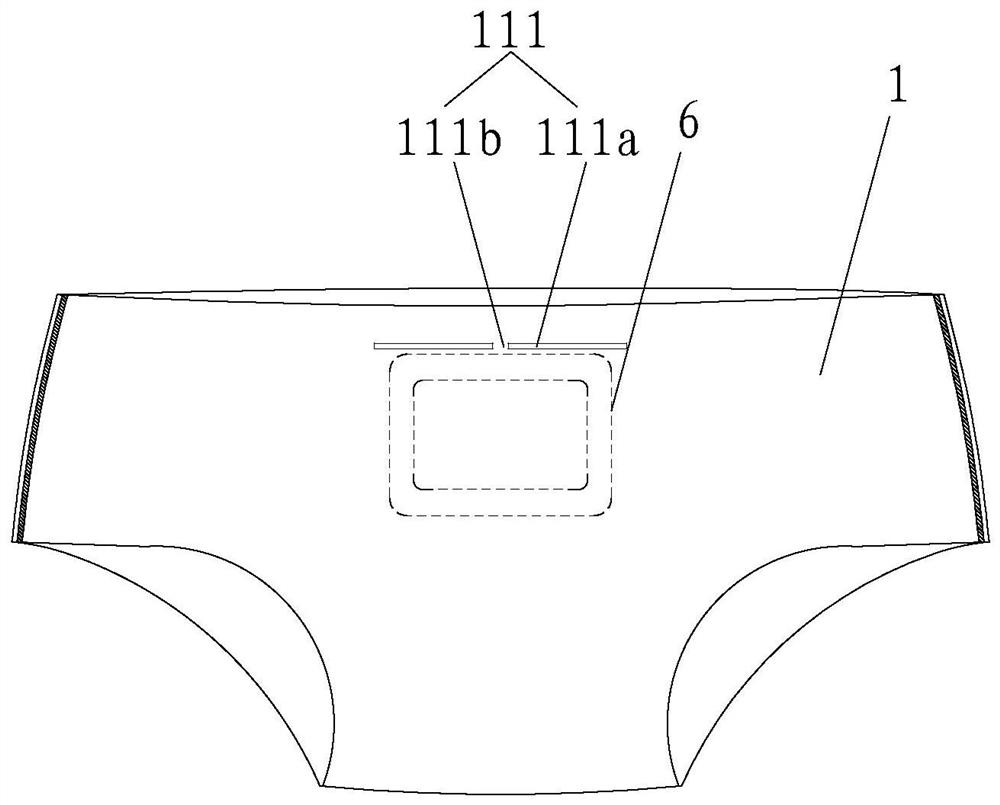

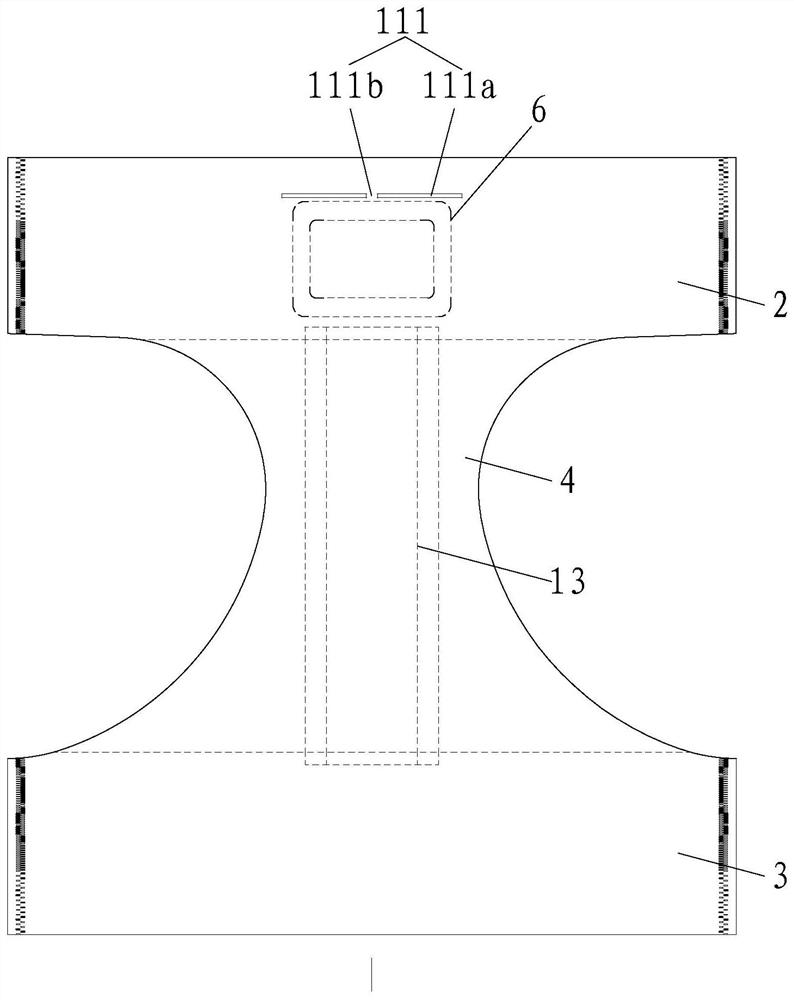

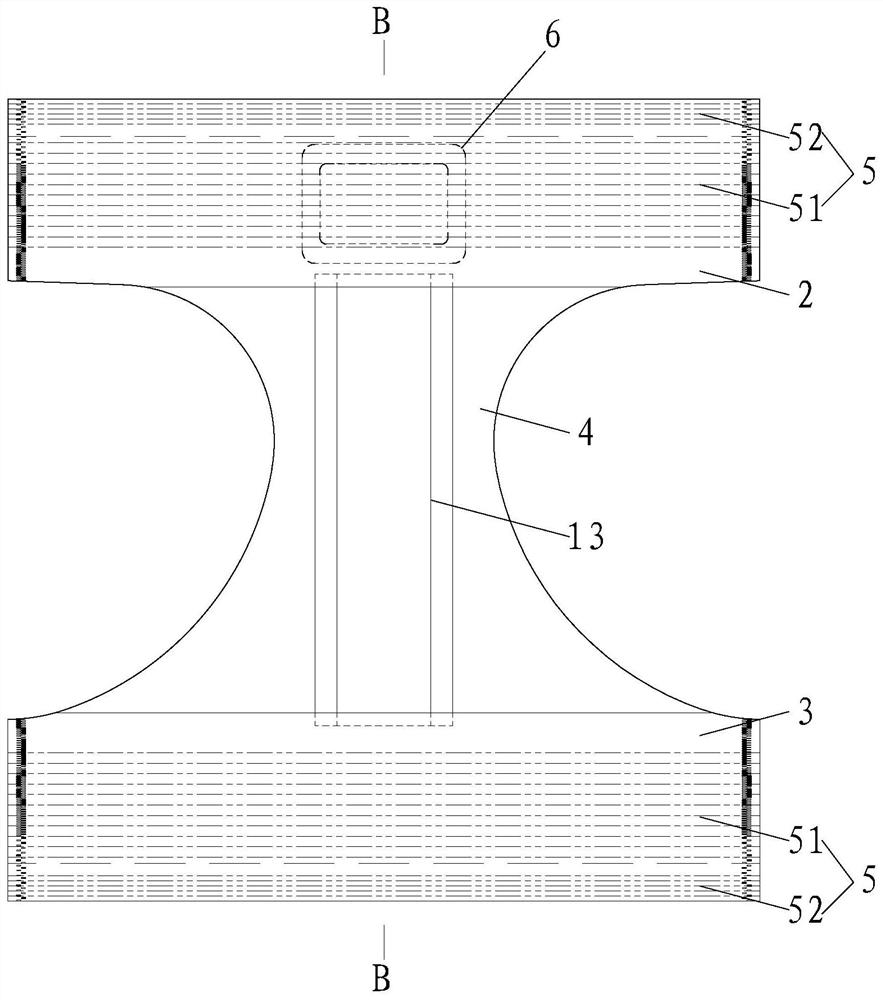

Production process of uterus warming sanitary pants

ActiveCN112603655ARealize the operationFever does not reachAntipyreticAnalgesicsWoven fabricManufacturing engineering

The invention relates to disposable hygienic products, in particular to a production process of uterus-warming hygienic pants. The production process comprises the following steps of: 1, inputting outer-layer non-woven fabric, arranging waist-surrounding waistline rubber bands and abdomen waistline rubber bands at the front waist and the rear waist of the outer-layer non-woven fabric, and forming dummy cutting holes in the outer-layer non-woven fabric; 2, compounding a uterus warming patch at the front waist part of the outer-layer non-woven fabric; 3, compounding an inner-layer non-woven fabric on the outer-layer non-woven fabric; 4, compounding absorption core bodies on the inner-layer non-woven fabric; 5, folding the outer-layer non-woven fabric to enable the outer-layer non-woven fabric to cover the two ends, in the length direction, of each absorption core body; 6, cutting out a leg circumference area between every two adjacent absorption core bodies; 7, folding the middle of the outer-layer non-woven fabric, and then performing thermal compression on the front waist part and the rear waist part; and 8, cutting off the middle part of a thermal compressed part. With the sanitary pants adopted, the technical problems that existing sanitary pants are not reasonable enough in structure, low in production efficiency and high in cost can be solved.

Owner:QUANZHOU HANWEI MACHINERY MFG

Environment-friendly garbage incineration process and matched device

ActiveCN103712218ARich sourcesCalorific value stableIncinerator apparatusDecompositionCombustion chamber

The invention discloses an environment-friendly garbage incineration process and a matched device. The process includes that when block-shaped biomass fuel burns on the lower portion of a combustion chamber, garbage to be incinerated and powder biomass fuel to be incinerated are fed from the upper portion of the combustion chamber, during the falling process, combustible gas produced by primary combustion and decomposition of the powder biomass fuel and the block-shaped biomass fuel is mixed with secondary air of a boiler, so that high-temperature flue gas is produced through secondary combustion, and garbage entering the combustion chamber from a garbage feed inlet is pre-heated and combusted through the high-temperature flue gas so as to decompose dioxin precursor in the garbage and dioxin produced in the incineration process. Further, light oxide ash content with large quantities of pores is produced due to suspension combustion and semi-suspension combustion of the biomass fuel in the combustion chamber, suspends in the combustion chamber and then makes contact with acid gas produced by garbage incineration to form salt. The combustion characteristics of the biomass fuel are reasonably used, the problem of secondary pollution caused by garbage combustion is effectively solved, and favorable conditions are created for development of garbage power in middle-sized and small cities and solving of environment problems brought by garbage processing and open burning of straws in rural areas.

Owner:WUHAN HANGYU ELECTROMECHANICAL ENG

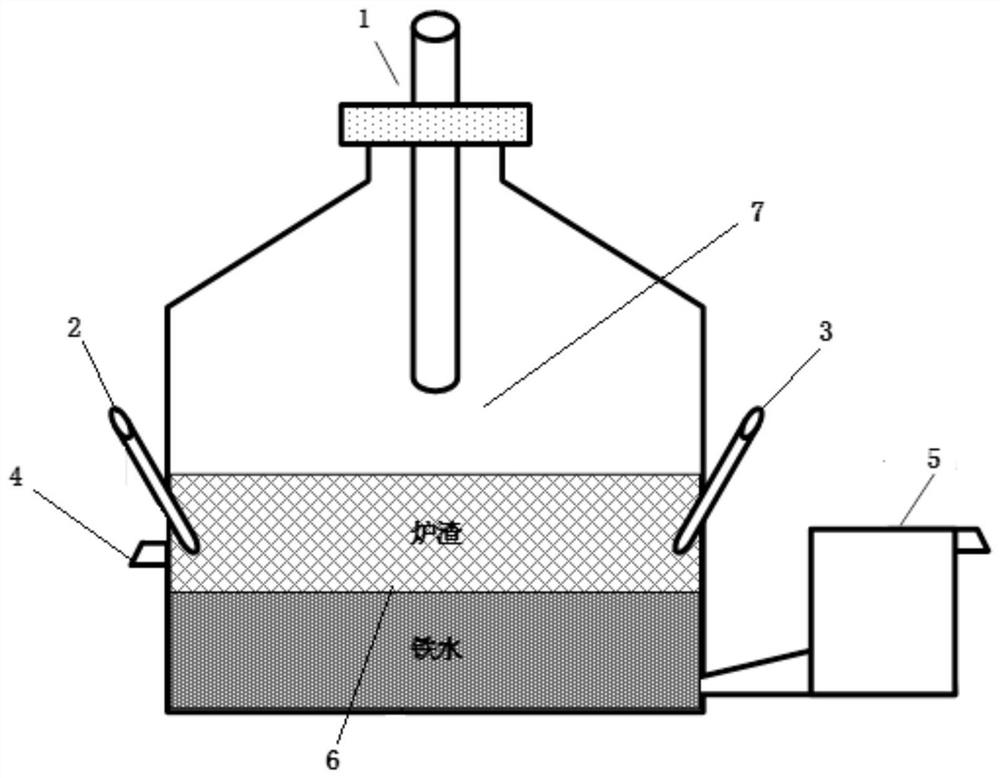

Oxygen spraying smelting reduction iron-making process

InactiveCN111635972AQuality assuranceMelting reduction is smoothGas emission reductionSlagMolten bath

The invention relates to an oxygen spraying smelting reduction iron-making process which comprises the following steps of adding reasonable dolomite and quicklime powder into iron ores in a fit manner, spraying the mixture by an ore powder spray gun (2) into a reduction area (6) of a smelting reduction reaction furnace through a heating system, spraying pulverized coal into the reduction area (6)of a smelting reduction reaction furnace through a pulverized coal spray gun (3) by means of inert gas or reductive gas, and spraying the mixture into a molten iron molten bath through a slag layer tosupplement carbon for molten iron; and blowing normal temperature high purity oxygen from the upper side of the smelting reduction reaction furnace through an oxygen spraying device (1), ensuring a gas component proportion in the slag: (H2+CO) / (CO2+H2O) is smaller than 10 by spraying oxygen, controlling the slag amount to be greater than 0.5 t / tFe, controlling the slagging temperature to be higher than 1400 DEG C, controlling the alkalinity and the tapping temperature to be higher than 1350 DEG C, and desulfurizing the tapped molten iron, wherein the residual magnesium amount after desulfurization shall be controlled at 0.010-0.020%. The process improves the center oxygen spraying depth, reduces disturbance of environmental factors and improves the smelting efficiency.

Owner:内蒙古赛思普科技有限公司

Biomass synthetic fuel

InactiveCN108003944AImprove combustion effectHigh calorific valueLiquid carbonaceous fuelsFuel additivesAlkaneAlcohol

The invention relates to the technical field of biomass fuel, and particularly relates to biomass synthetic fuel. The biomass synthetic fuel comprises the following components in parts by weight: 80-95 parts of an alcohol, 30-50 parts of an alkane, 10-20 parts of diethyl ether, 4-8 parts of a combustion-supporting heat-increasing agent and 0.5-4 parts of a safety stabilizer. The beneficial effectsof the biomass synthetic fuel provided by the invention are that the alkane is added on the basis of an alcohol group, so that the overall combustibility is improved; and the combustion-supporting heat-increasing agent and the safety stabilizer are added, so that the safety of the fuel is improved, the heat value of combustion is improved, and the flame temperature is increased.

Owner:莫祖勇

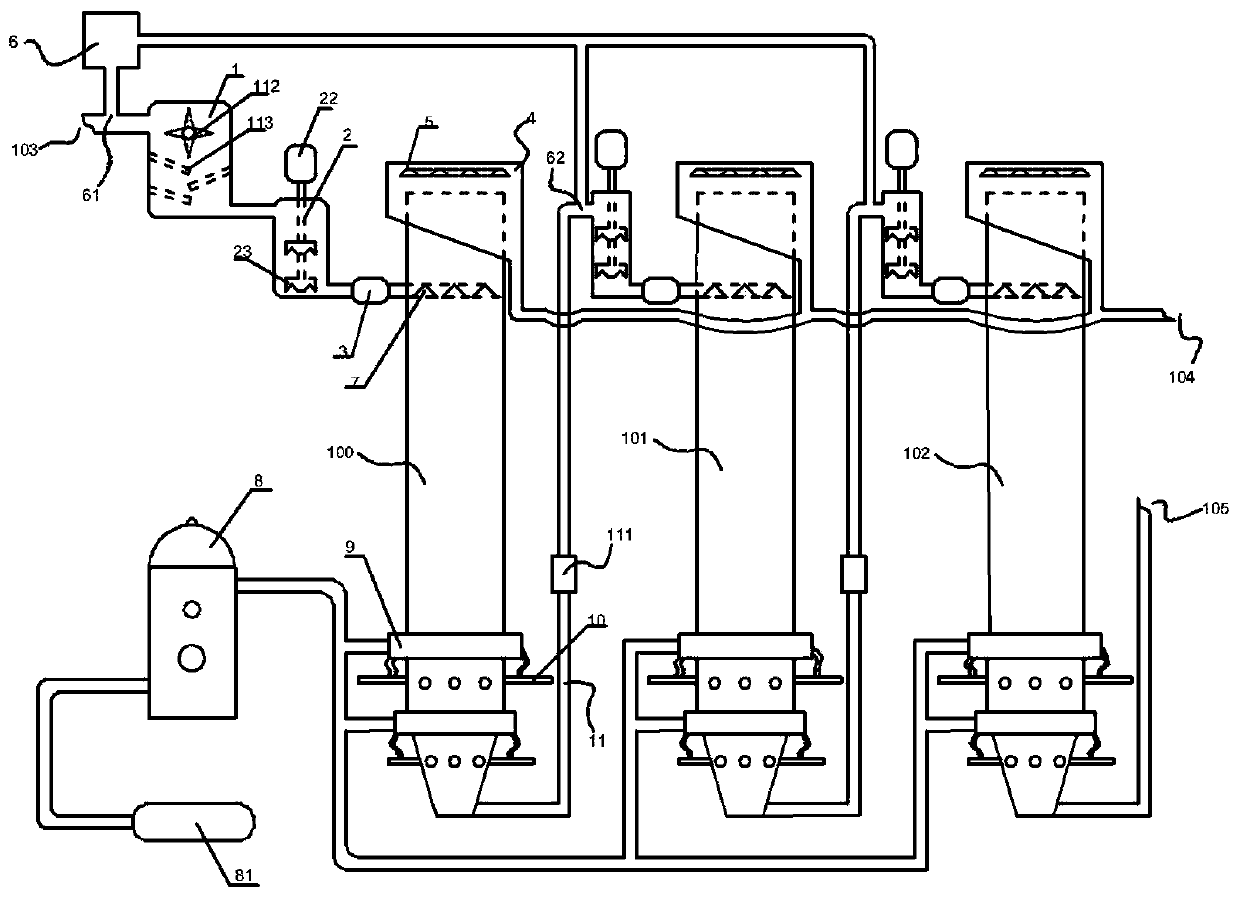

Co-combustion device and method capable of automatically adjusting blending combustion amount of sludge

PendingCN108087895AAppropriate blending ratioGuaranteed uptimeIncinerator apparatusCombustionWater vapor

The invention discloses a co-combustion device capable of automatically adjusting blending combustion amount of sludge. The co-combustion device comprises a mechanical grate furnace, a sludge feedingdevice, a stirring device, a control system and a water vapor sensor. The sludge feeding device, the stirring device and the water vapor sensor are separately connected with the control system, and the mechanical grate furnace is further provided with a temperature sensor. The control system provides power for the sludge feeding device and the stirring device, the water vapor sensor and the temperature sensor acquire water vapor volume fraction at the position of an outlet of a flue and a furnace box temperature to match the sludge feeding speed with the furnace box temperature, the furnace box temperature is controlled between 800 DEG C and 950 DEG C, meanwhile, by control over the stirring device, garbage and a sludge mixture are mixed fully, and combustion is stable. The invention further discloses a co-combustion method of the co-combustion device based on automatic adjustment of the blending combustion amount of the sludge. The blending proportion is proper, fuels are fully and stably combusted, and the equipment runs stably and is long in service life.

Owner:GRANTOP GRP CO LTD

Sintered brick and preparation method thereof

ActiveCN111087225AHigh compressive and flexural strengthImprove plasticity indexFlotationCeramic materials productionBrickFly ash

The invention belongs to the field of wall material production, and particularly relates to a sintered brick and a preparation method thereof, wherein the sintered brick raw material is composed of tailings and a preset substance, the preset substance is any one selected from clay, shale powder and fly ash, the mass percent of the tailings is 70-90%, the mass percent of the preset substance is 10-30%, the tailings are directly obtained after coal slime is sorted again through sorting equipment, and the tailings comprise, by mass, 45-65% of SiO2, 18-25% of Al2O3, 3-5% of Fe2O3, 3-5% of CaO, 1-3% of MgO and the balance of other elements, and have the plasticity index of 11-15 and the calorific value of 1.8-2.5 MJ / kg. According to the total internal heat sintered standard brick, energy is saved, the performance of the total internal heat sintered standard brick meets or even exceeds the national standard, and reutilization of coal slime tailings and shale is achieved. The preparation method of the sintered brick is simple in process, and the time cost is greatly saved.

Owner:西安煤科动力科技有限公司

Terracotta brick and preparation method thereof

The invention relates to a terracotta brick and a preparation method thereof. The terracotta brick is composed of 70 to 90 wt.% of tailing and 10 to 30 wt.% of clay. The tailing is directly obtained by resorting coal slurry by a sorting facility. The tailing comprises following components in percentage by weight: 62 to 76% of SiO2, 15 to 17% of Al2O3, 2 to 5% of Fe2O3, 0.5 to 2% of CaO, 0.5 to 2%of MgO, and the balance being other elements; the plasticity index of tailing is 12 to 18; the calorific value is 1.8 to 2.5 MJ / kg, and the loss on ignition is 3 to 10%. The provided terracotta brickmeets or even exceeds the national standards. The coal slurry tailing is reutilized, and the clay resource is saved. The preparation method is simple and the time is greatly saved.

Owner:西安煤科动力科技有限公司

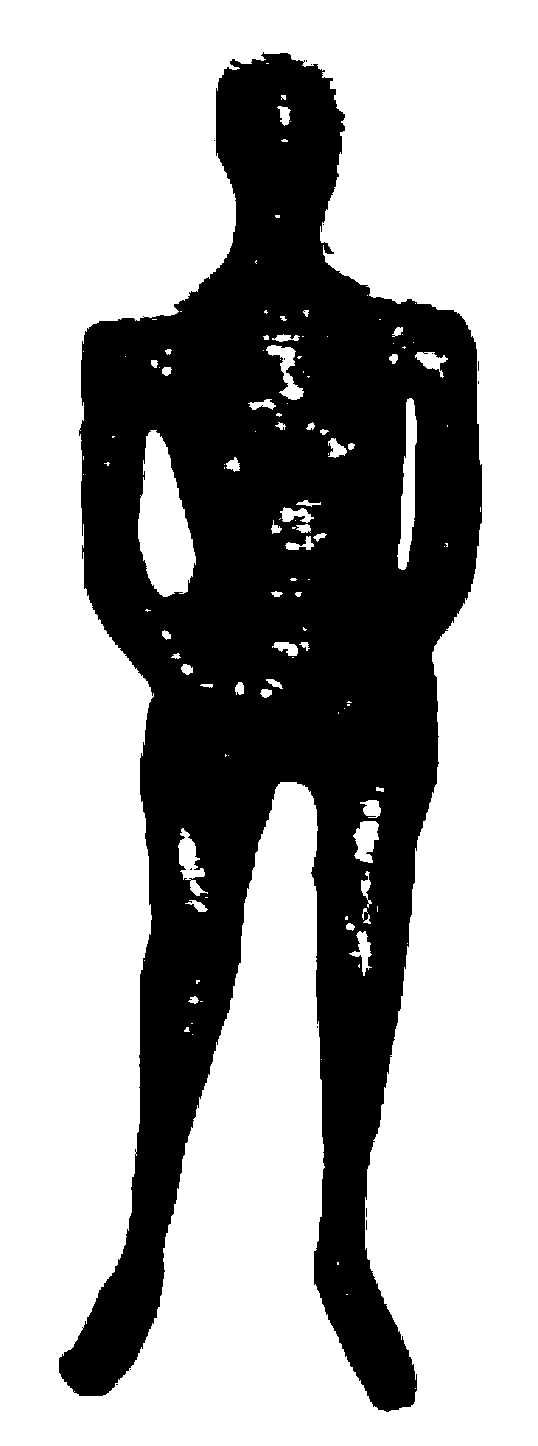

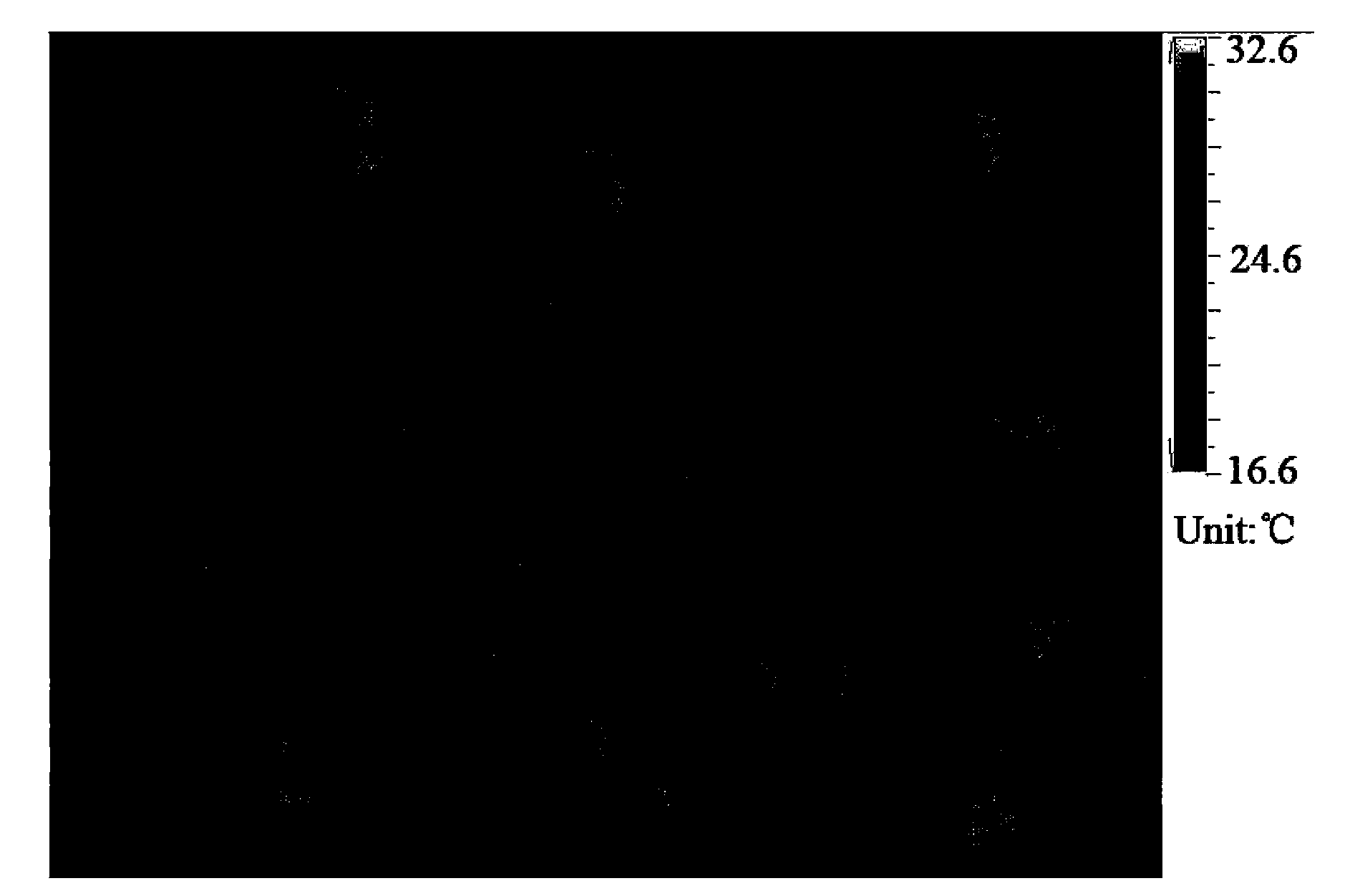

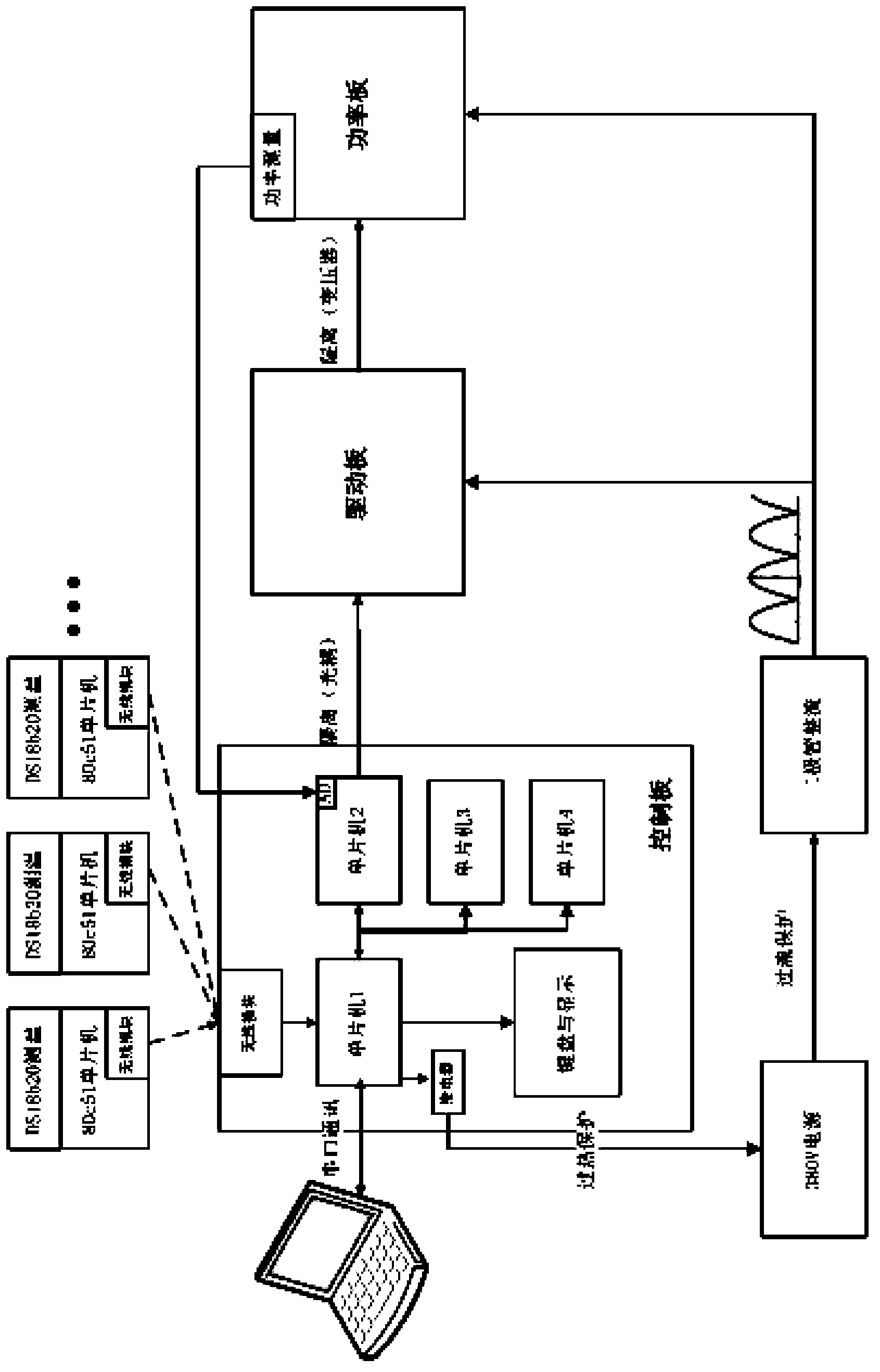

Cluster system of heating dummy model

ActiveCN103365319ACalorific value stableReasonable designAuxillary controllers with auxillary heating devicesMaterial thermal analysisHuman bodyElectrical resistance and conductance

The invention discloses a cluster system of a heating dummy model. The cluster system comprises the heating dummy model and a power control system. The heating dummy model is composed of a head, a trunk, two arms and two legs. The surfaces of the heating dummy model are all wound with heating resistance wires, each arm is wound with four heating resistance wires which are connected in parallel, and other portions are provided with two heating resistance wires which are connected in parallel. The heating resistance wires cover the surface area of the heating dummy model by 97 percent to 97.5 percent, the total resistance of the heating resistance wires after the heating resistance wires are connected in series is 1600 omega to 1699 omega, and the heating amount is 75W. The power control system comprises a 380V power supply, a control panel, a drive board, a power amplifier board, a temperature-measuring sensor and a voltage regulator. The cluster system of the heating dummy model achieves automatic control, is convenient and fast to operate, stable in heating amount and capable of achieving simulation of different human bodies with different dummies working with different power, and has the advantage of being wide in range of application. Meanwhile, the heating dummy model can adjust the heating amount under the control of the voltage regulator.

Owner:TIANJIN UNIV

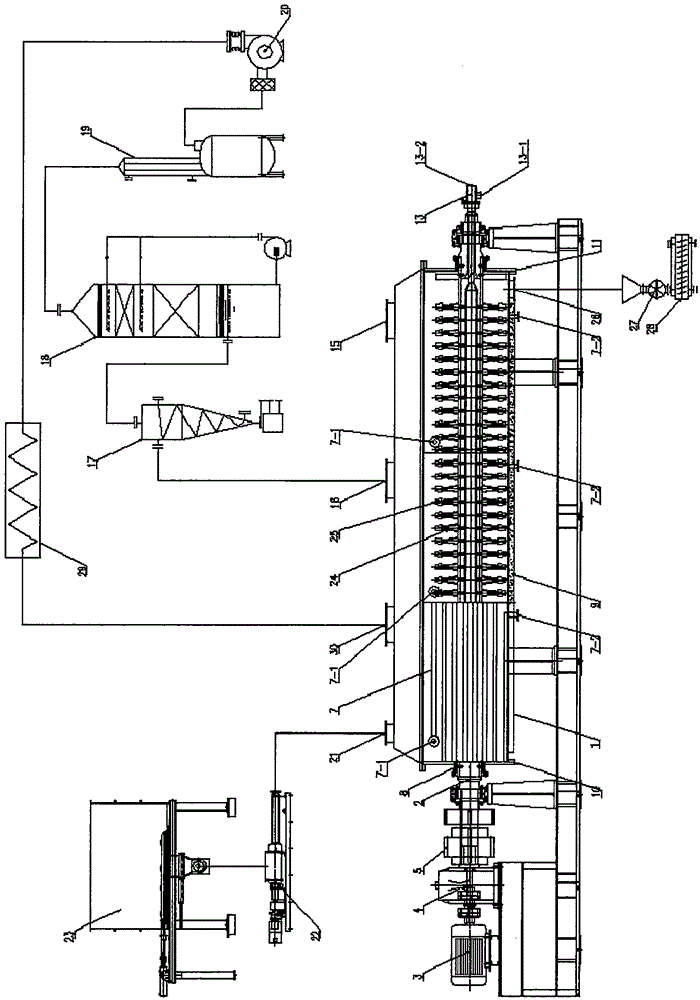

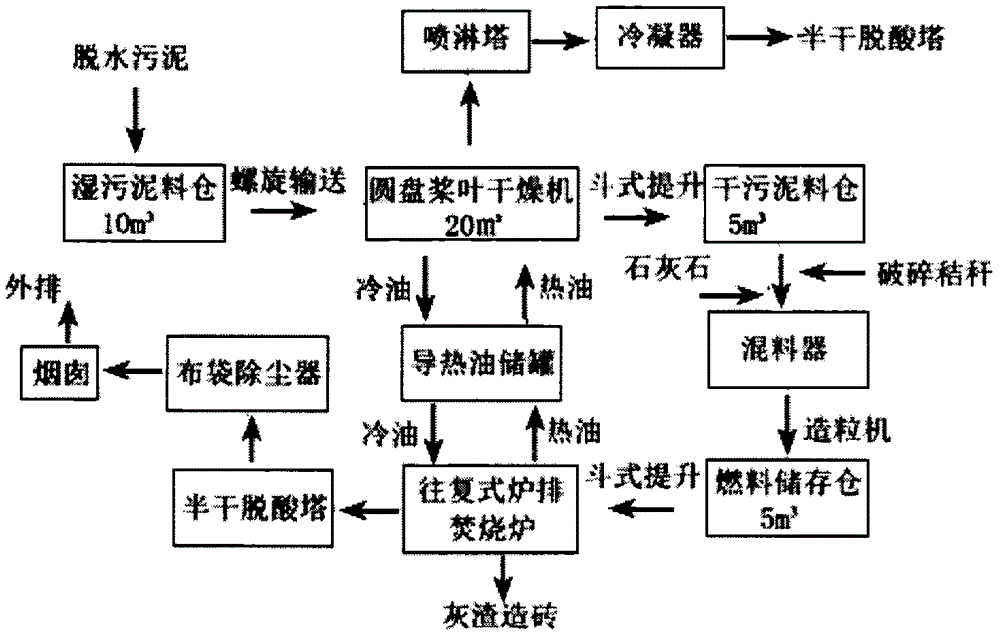

System for cooperative harmless treatment of sludge and straw

InactiveCN106635225ACalorific value stableHigh calorific valueBiofuelsSolid fuelsEnvironmental resistanceProcess systems

The invention specifically relates to a system for cooperative harmless treatment of sludge and straw, belonging to the technical field of environmental protection. The system comprises a sludge pretreatment device, a straw pretreatment device, a mixing device, a pelletizer and a heat-conduction oil heating device. The whole process system realizes high-efficiency cyclic utilization, automatic totally-enclosed continuous operation, and zero-discharge of heat and waste materials; and the system can thoroughly realize reclamation of industrial waste and is low in cost and high in practicality.

Owner:孟祥雷

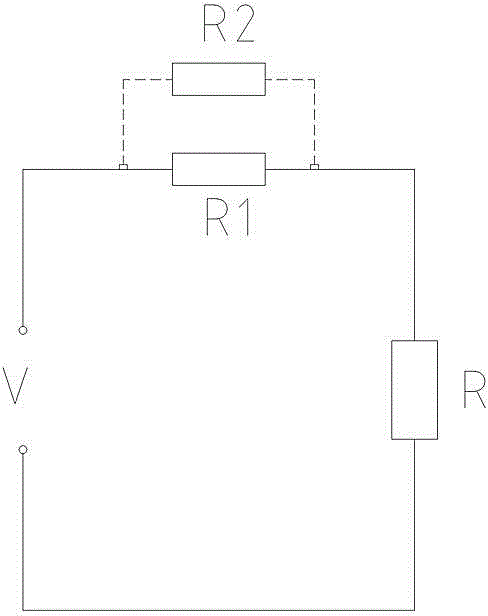

Rapid small water heater

The invention provides a rapid small water heater of the structural style. The rapid small water heater is simple in structure, ingenious in design and reasonable in layout. The structural device which can automatically regulate the heating amount is designed for the defects that a traditional rapid heating type water heater is low in water temperature when water flow is large, and water is prone to boiling when the water flow is small, and therefore the water temperature of the water heater can be more stable. The repulsive force between magnets is creatively utilized, whether an additional resistor is connected into a working circuit in parallel or not is determined according to the size of the water flow, the value of the overall resistance in the working circuit is controlled according to the additional resistor, and therefore the heating amount of a working resistor is changed, the relatively-low-temperature heating can be achieved when the water flow is small, the relatively-high-temperature heating can be achieved when the water flow is large, and warm water or hot water can be provided for users under all water flow conditions. Thus, it can be said that the rapid small water heater has various advantages, is particularly suitable for application and popularization in the field, and is quite wide in market prospect.

Owner:DALIAN OCEAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com