Fuel gasification system, control method and control program therefor, and fuel gasification combined power generation system provided with fuel gasification system

A fuel gasification and fuel technology, which is applied in the direction of granular/powder fuel gasification, gasification device feeding tools, fuel, etc., can solve the problem of difficult power generation and keeping constant, and achieve stable calorific value and suppress increase or decrease Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〕

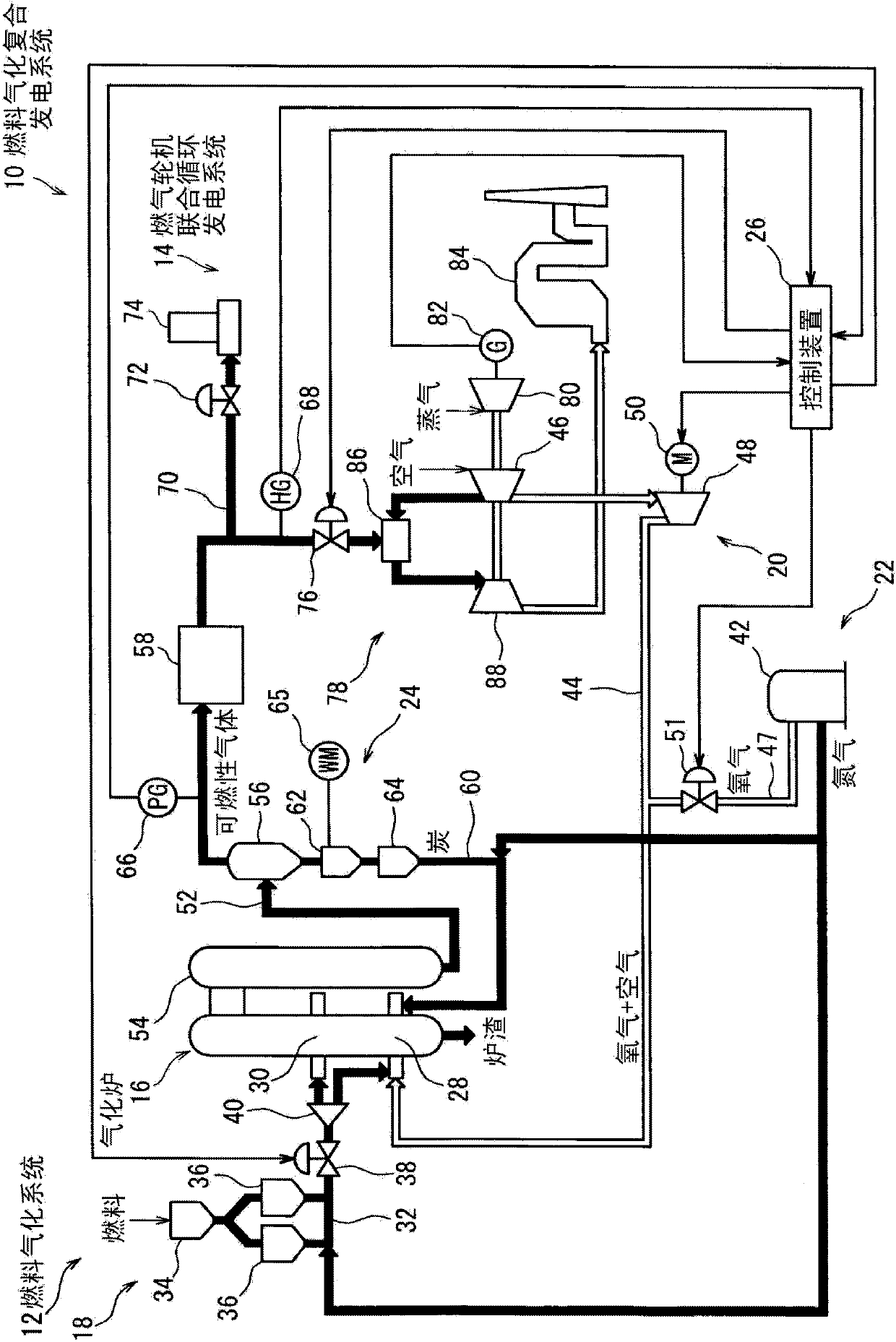

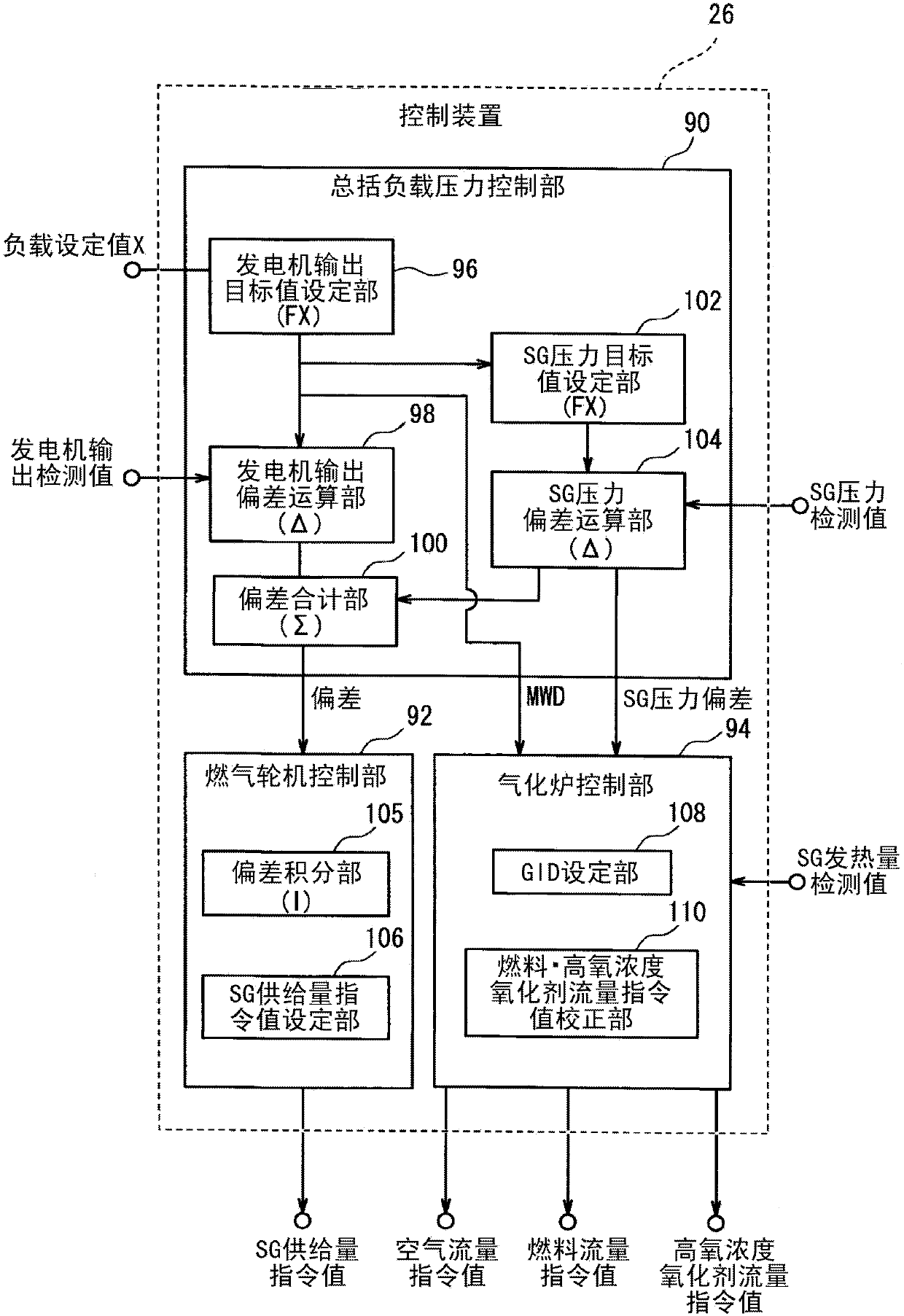

[0060] figure 1 A schematic configuration of a fuel gasification integrated power generation system (hereinafter, also referred to as IGCC) 10 according to the first embodiment is shown. In addition, when the fuel is coal, IGCC10 is a combined coal gasification power generation system.

[0061] The IGCC 10 is composed of a fuel gasification system 12 and a gas turbine combined cycle power generation system (hereinafter also referred to as GTCC) 14 . The fuel gasification system 12 gasifies fuel to generate combustible gas, and the GTCC 14 generates power using the combustible gas. In addition, when the fuel is coal, the fuel gasification system 12 is a coal gasification system.

[0062] 〔Fuel gasification system〕

[0063] The fuel gasification system 12 has a gasifier 16, a fuel supply device 18 for supplying coal as a fuel to the gasifier 16, an air supply device 20 for supplying air as an oxidizing agent to the gasifier 16, A high-oxygen-concentration oxidant supply devi...

no. 2 Embodiment approach 〕

[0171] Hereinafter, the second embodiment will be described.

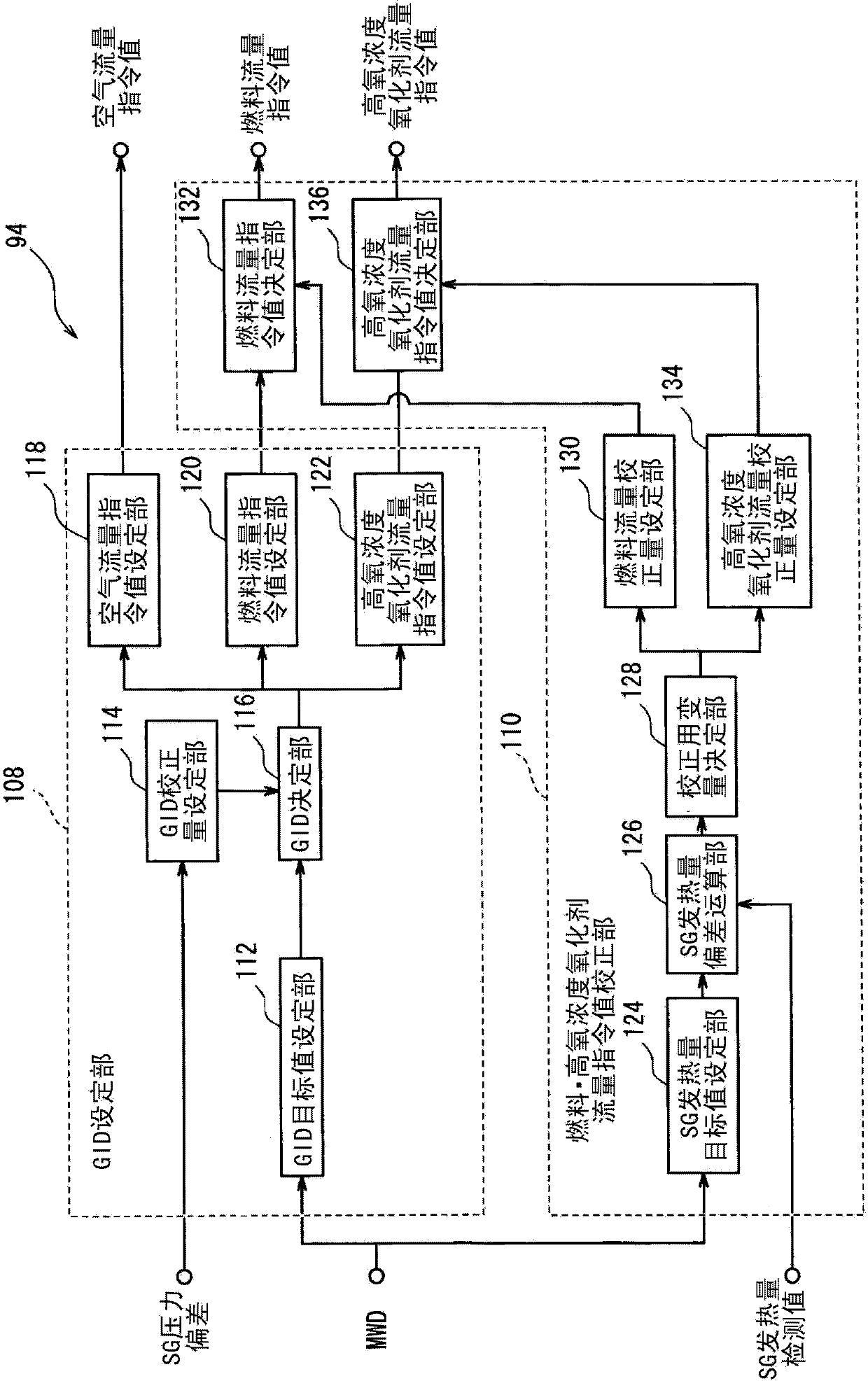

[0172] The second embodiment is as Figure 8 as well as Figure 9 As shown, the configuration of the gasifier control unit 94 in the control device 26 is different from that of the first embodiment.

[0173] Specifically, first, instead of the detected value of the SG calorific value, the detected value of the amount of char generation is input from the meter 65 to the gasifier control unit 94 . Then, the fuel / high oxygen concentration oxidant flow rate command value correcting unit 110 includes a char generation amount target value setting unit 138 and a char generation amount deviation computing unit instead of the SG calorific value target value setting unit 124 and the SG calorific value deviation computing unit 126. 140.

[0174] The char generation amount target value setting unit 138 sets the char generation amount target value using an appropriate function (FX) or map data based on the corrected GID corr...

no. 3 Embodiment approach 〕

[0179] Hereinafter, a third embodiment will be described.

[0180] The third embodiment is as Figure 10 as well as Figure 11 As shown, the configuration of the gasifier control unit 94 in the control device 26 is different from that of the first embodiment.

[0181] Specifically, the gasifier control unit 94 of the third embodiment further includes a fuel flow rate additional correction amount setting unit 144, a fuel flow rate correction amount determination unit 146, a high oxygen concentration oxidant flow rate additional correction amount setting unit 148, and a high Oxygen concentration oxidant flow rate correction amount determination unit 150 .

[0182] The fuel flow rate additional correction amount setting unit 144 performs advance control. Specifically, the fuel flow rate additional correction amount setting unit 144 sets the fuel flow rate additional correction amount using an appropriate function (FX) based on the GID target value set by the GID target value s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com