Robot system and method for operating the same

A technology of robot system and operation method, which is applied in the field of robot system and its operation, can solve problems such as complex control, achieve simple control, and respond to the increase or decrease of production volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

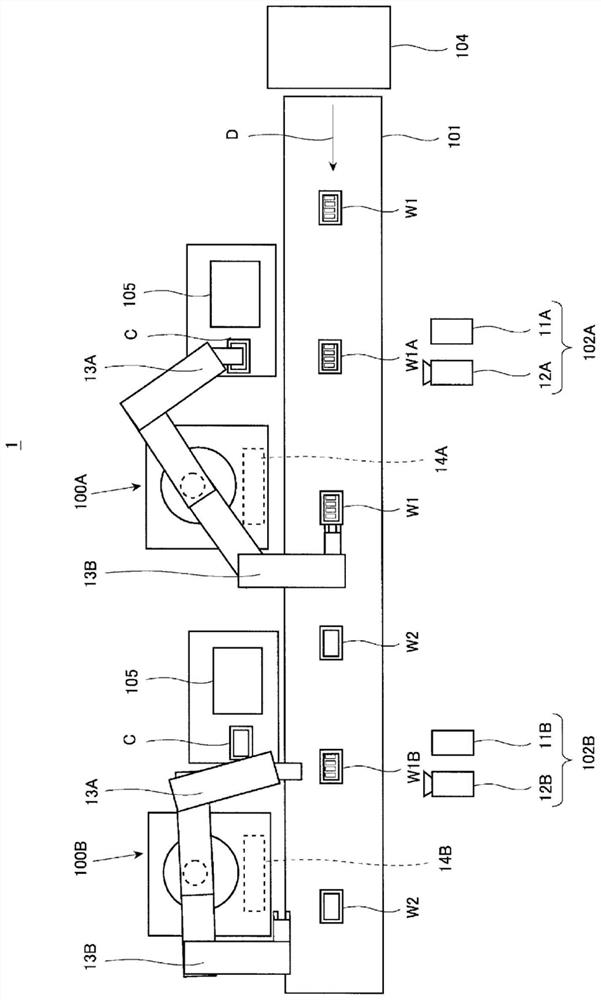

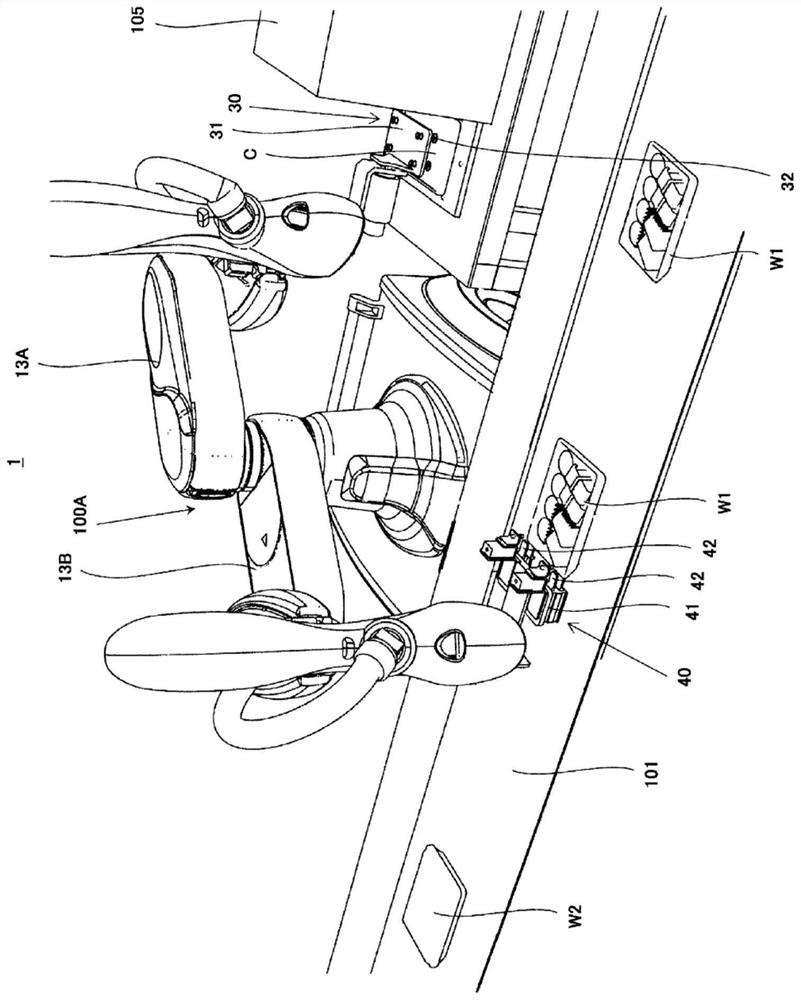

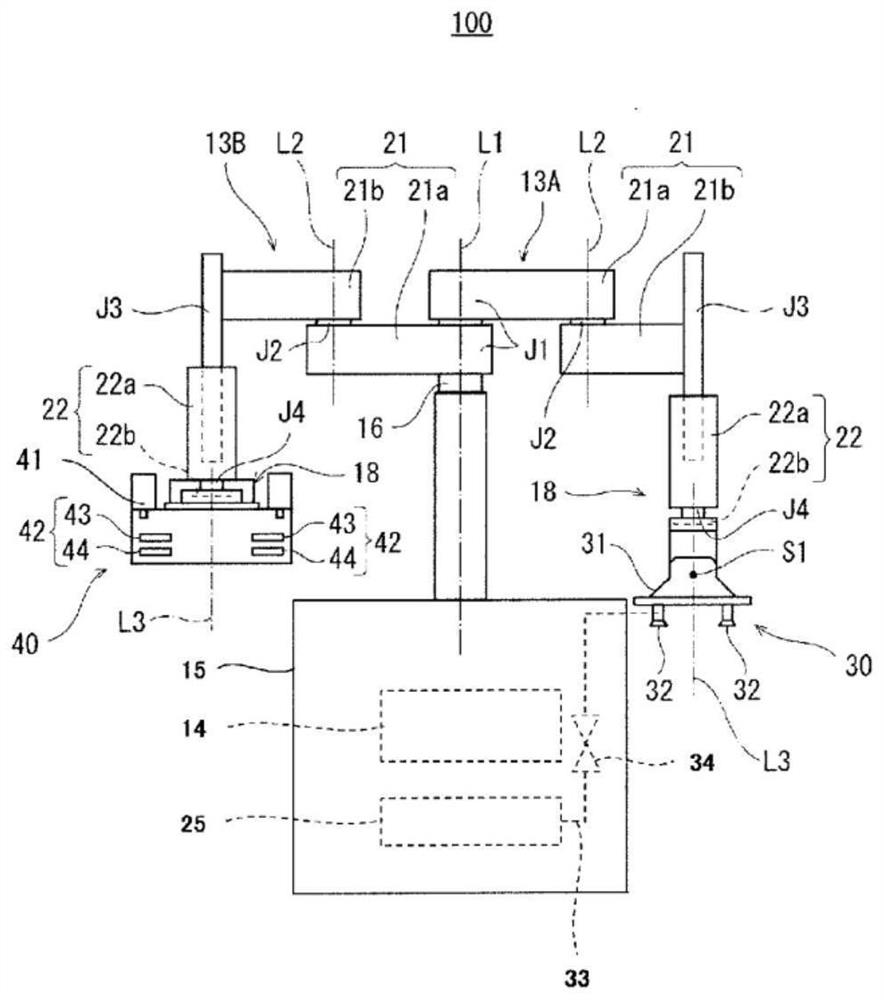

[0022] The robot system according to Embodiment 1 is configured to include: a transfer device; a plurality of robots; a sensor for detecting unworked workpieces; The robot is arranged in series with respect to the conveying direction of the workpiece. When the sensor detects the unworked workpiece and the robot is in the standby state, the robot will perform the operation on the unoperated workpiece, and when the sensor detects If the workpiece is not being operated, and the robot is working, the robot will not perform work on the unoperated workpiece.

[0023] In addition, in the robot system according to the first embodiment, the sensors may be arranged for each of the plurality of robots.

[0024] In addition, in the robot system according to the first embodiment, the sensor may be constituted by a first sensor that detects the position of the workpiece with respect to the conveyance direction, and a second sensor that detects the state of the workpiece.

[0025] In additi...

Deformed example 1

[0084] Next, refer to Figure 5 A modified example of the robot system 1 according to the first embodiment will be described. In addition, since the configuration of the robot system 1 according to Modification 1 of the first embodiment is the same as that of the robot system 1 according to the first embodiment, detailed description thereof will be omitted.

[0085] Figure 5 It is a flowchart showing an example of the operation of the robot system according to Modification 1.

[0086] First, as in the first embodiment, the workpiece supply device 104 supplies the unworked workpiece W1 to the conveyance device 101 , and the conveyance device 101 compares the unworked workpiece W1 supplied by the workpiece supply device 104 with the work performed by the robot 100 . The workpiece W2 is conveyed.

[0087] Then, an operator (operator) inputs instruction information indicating to execute a job of closing the unworked workpiece W1 with the cover member C to the control device 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com