Patents

Literature

63 results about "Workcell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A workcell is an arrangement of resources in a manufacturing environment to improve the quality, speed and cost of the process. Workcells are designed to improve these by improving process flow and eliminating waste. They are based on the principles of Lean Manufacturing as described in The Machine That Changed the World by Womack, Jones and Roos.

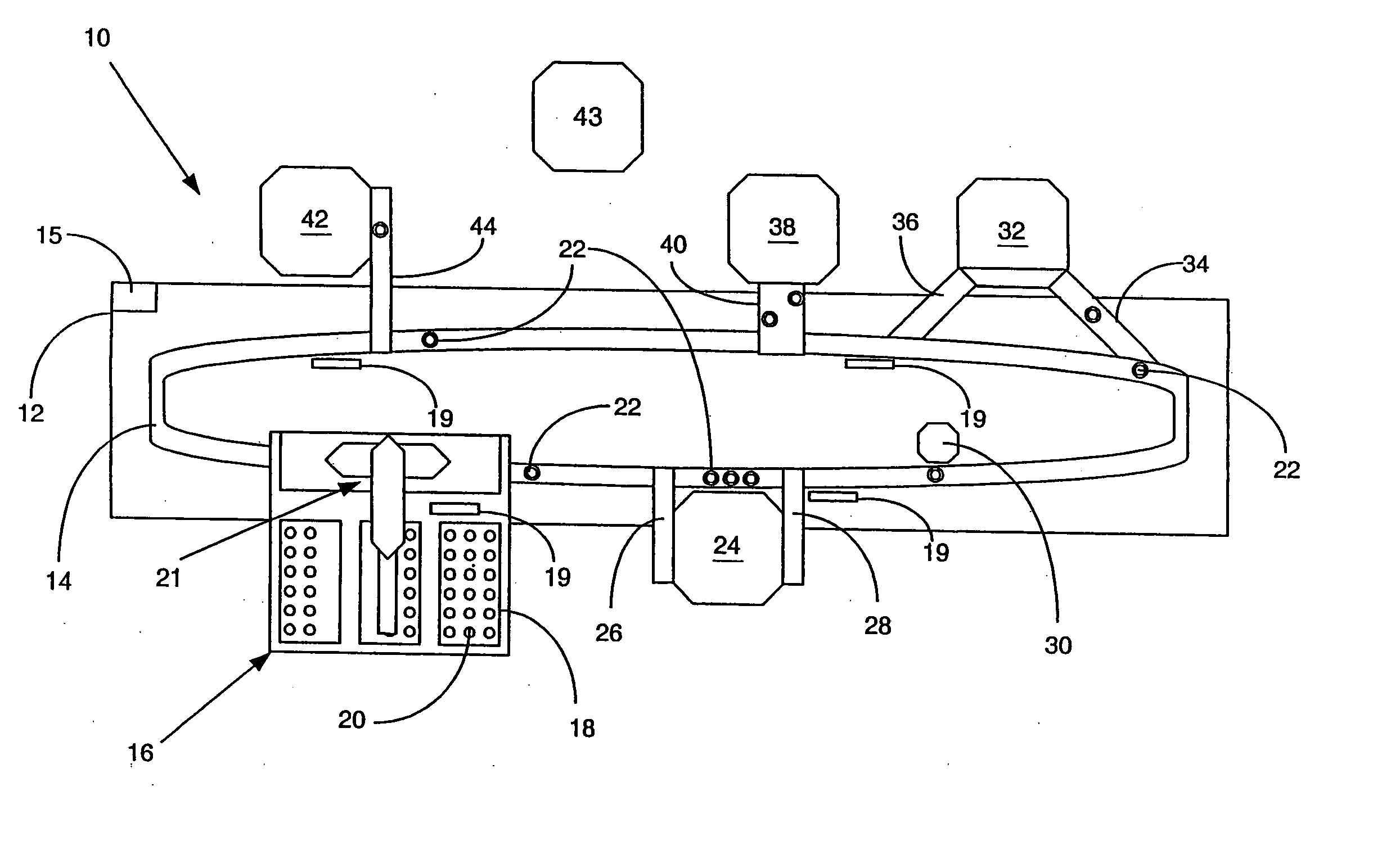

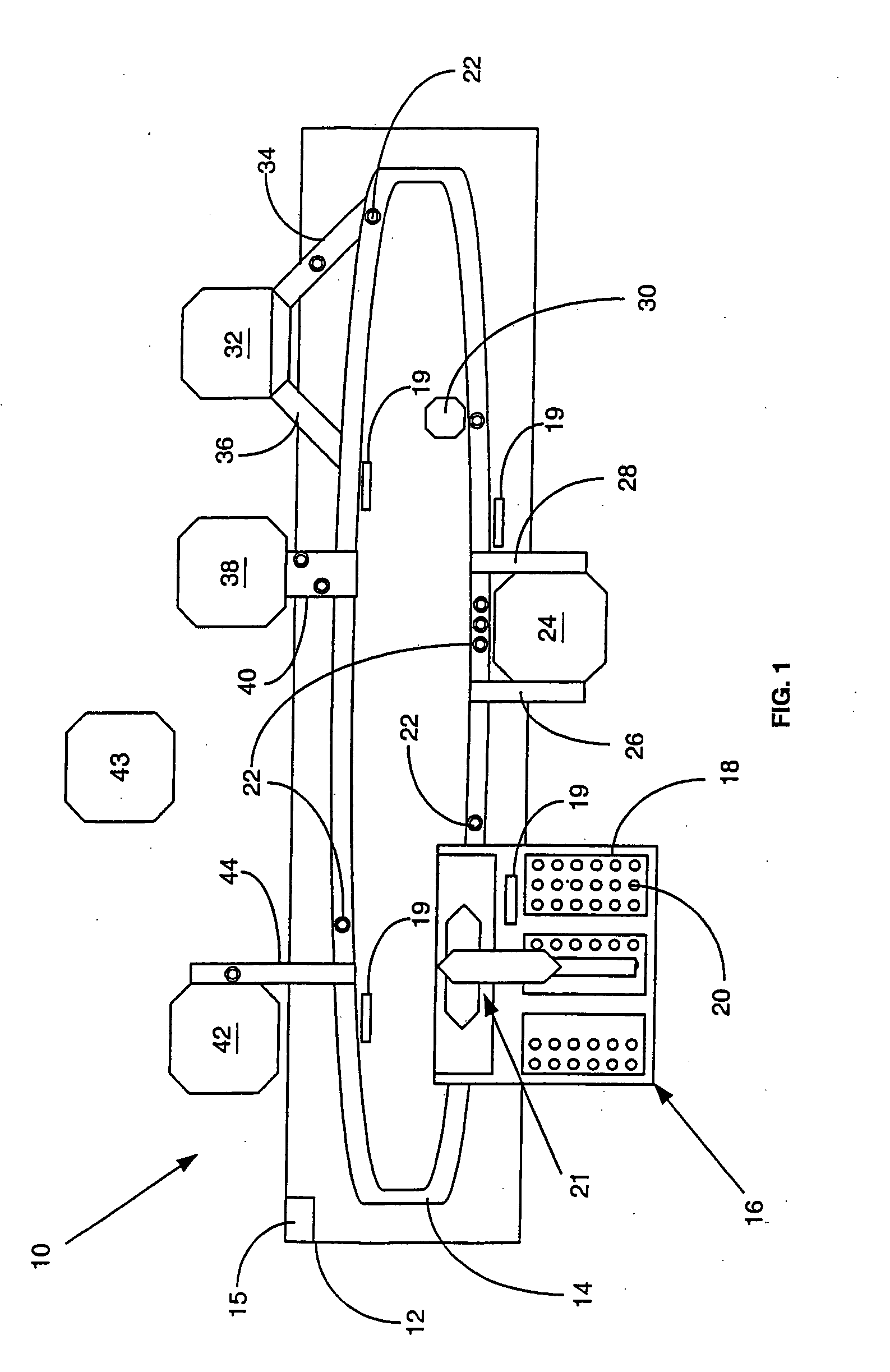

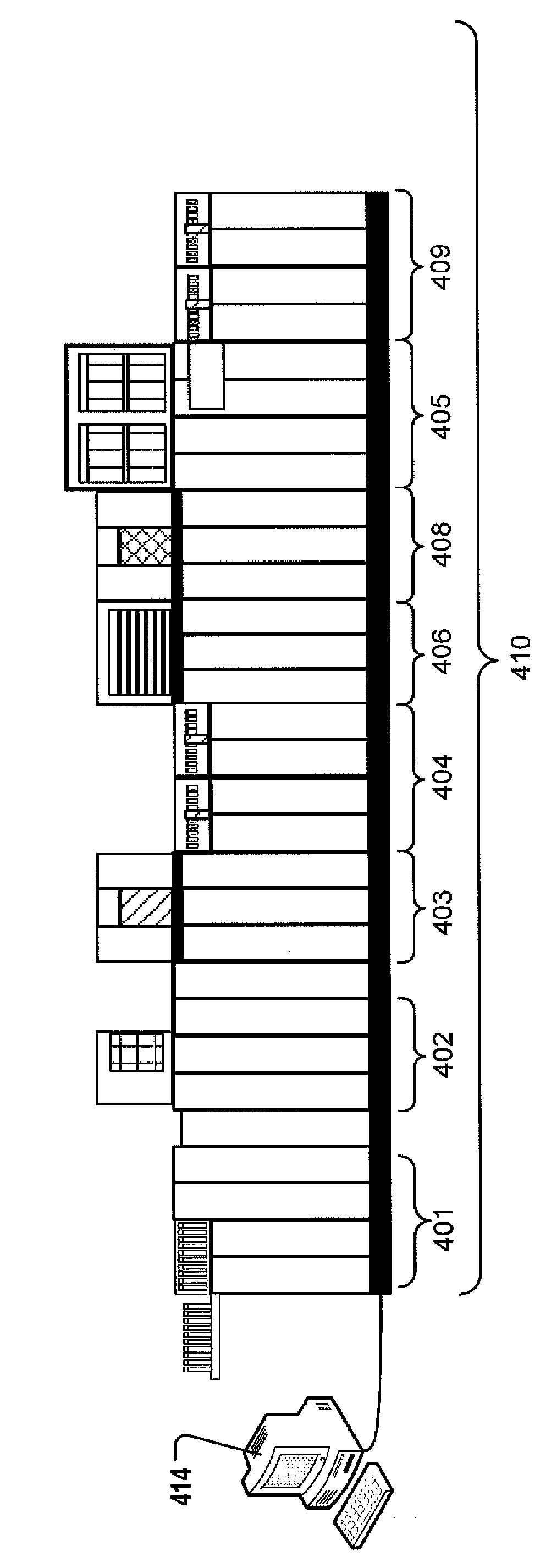

Specimen-transport module for a multi-instrument clinical workcell

ActiveUS20050196320A1Simpler and reliable resultEliminate needMaterial analysis by optical meansCharge manipulationWorkcellTransfer system

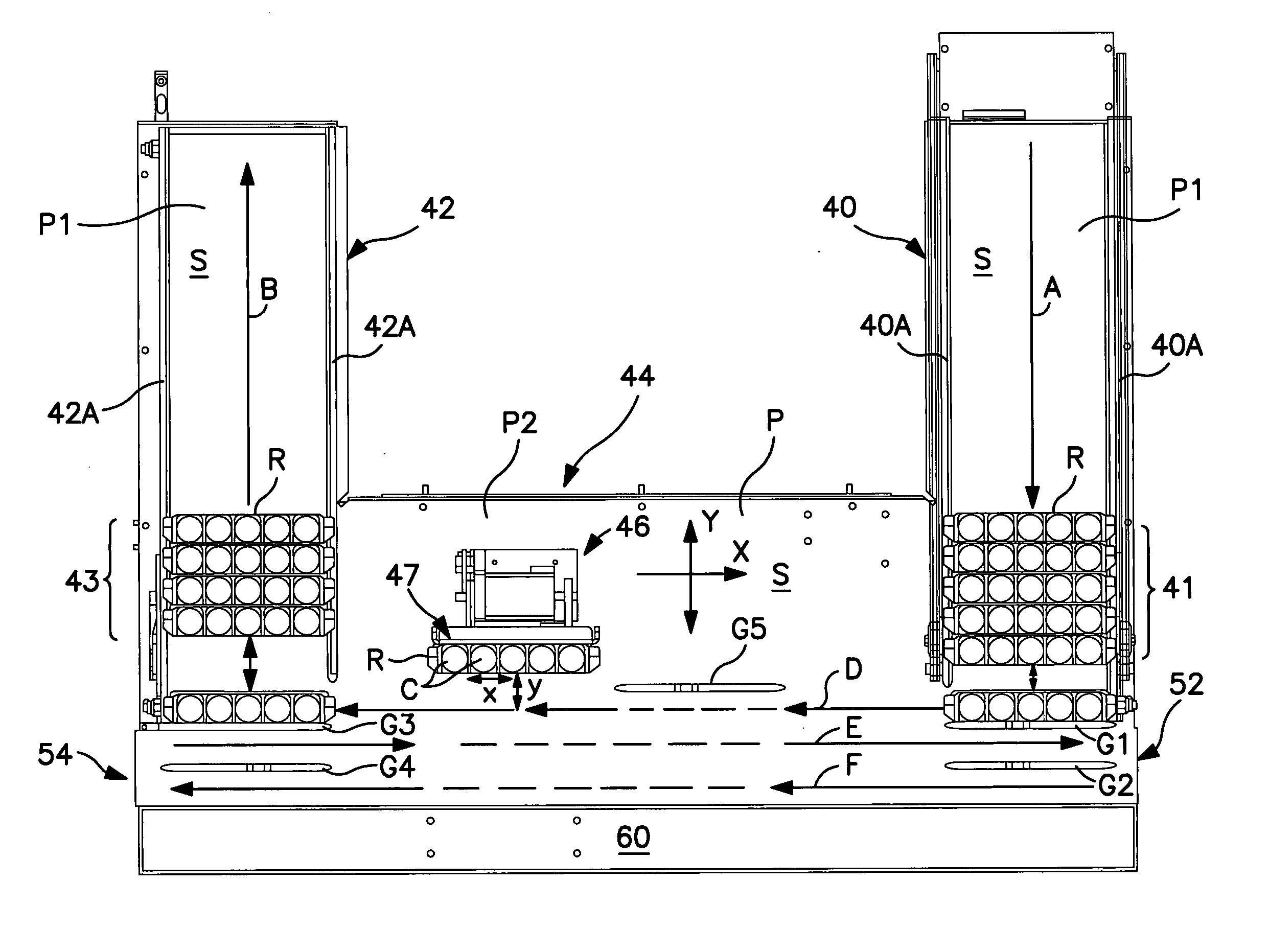

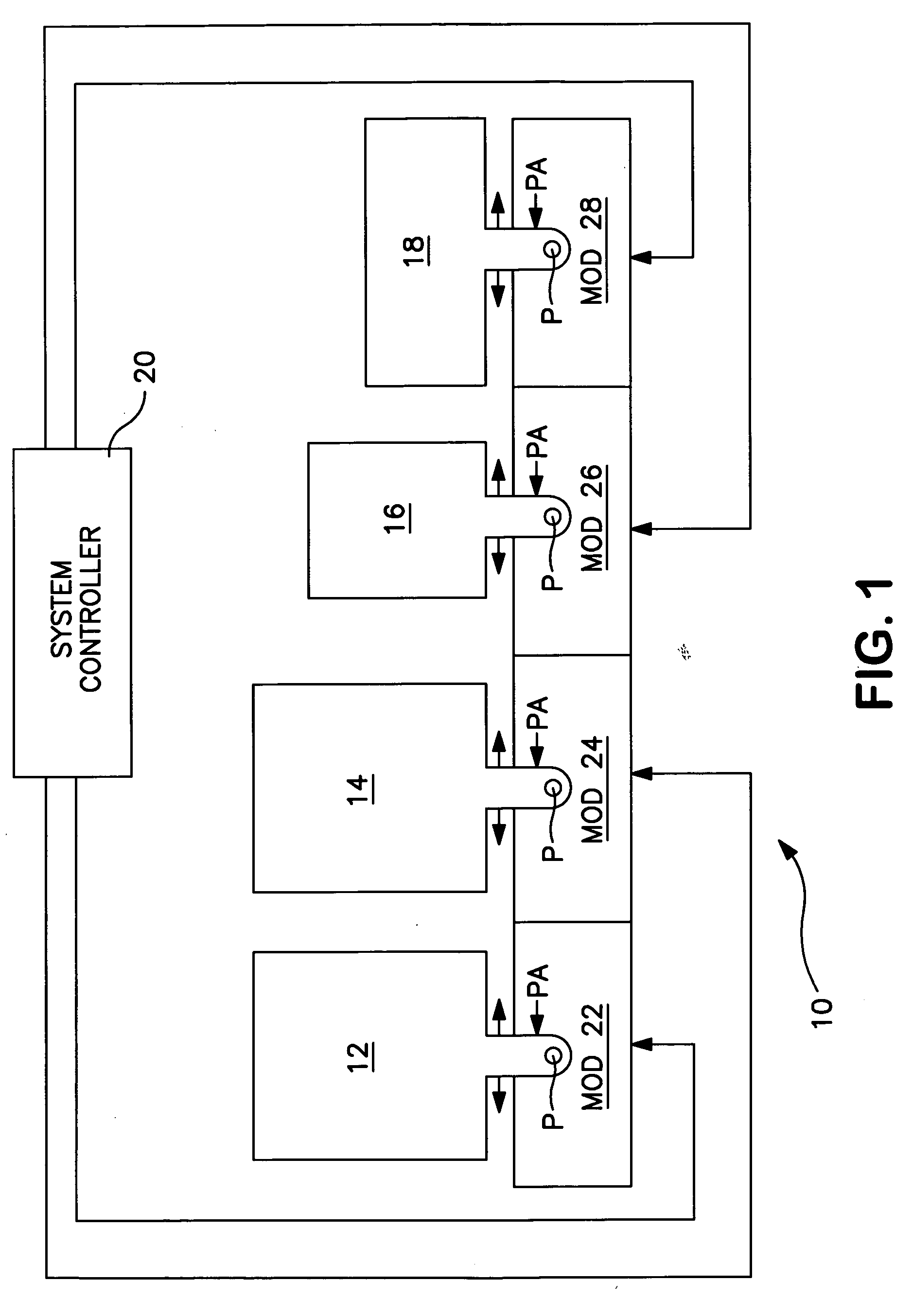

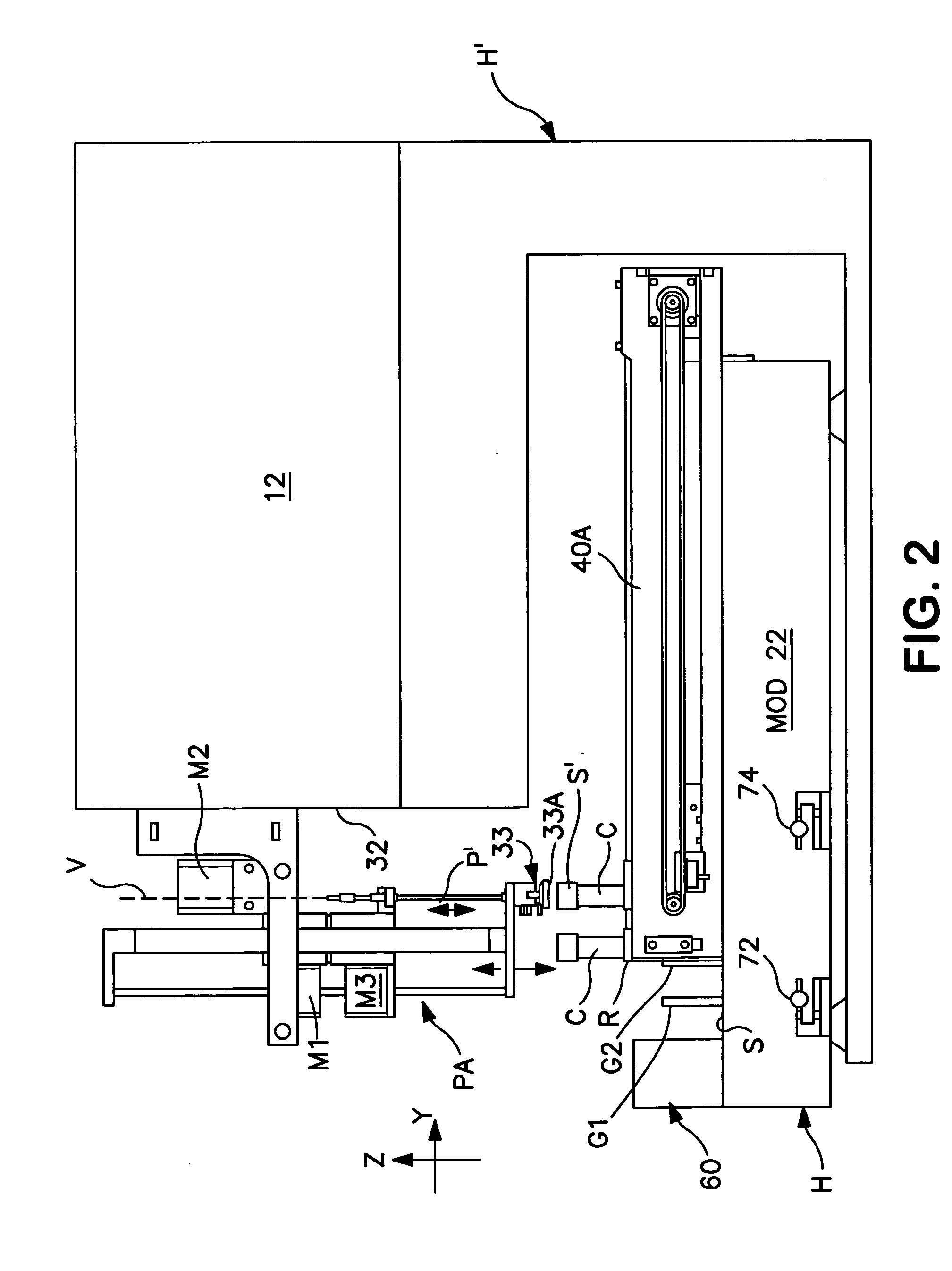

A specimen-transport module adapted for use with each of a plurality of specimen-processing instruments of a multi-instrument clinical workcell. Such module is adapted to transport individual racks of specimen-containers relative to a specimen-aspiration probe of an associated instrument in a workcell, as well as to transfer selected racks of specimen-containers to an adjacent and identical specimen-transport module associated with another clinical instrument of the workcell. Since the same transport system is used to both present specimens for aspiration and to transfer specimens between instruments, there is no need for two independent conveyances as is characteristic of the prior art. Preferably, the specimen-transport module includes a magnetic X / Y transport system that operates beneath a rack-supporting surface to advance racks in mutually perpendicular directions across a supporting surface via magnetic forces.

Owner:BECKMAN COULTER INC

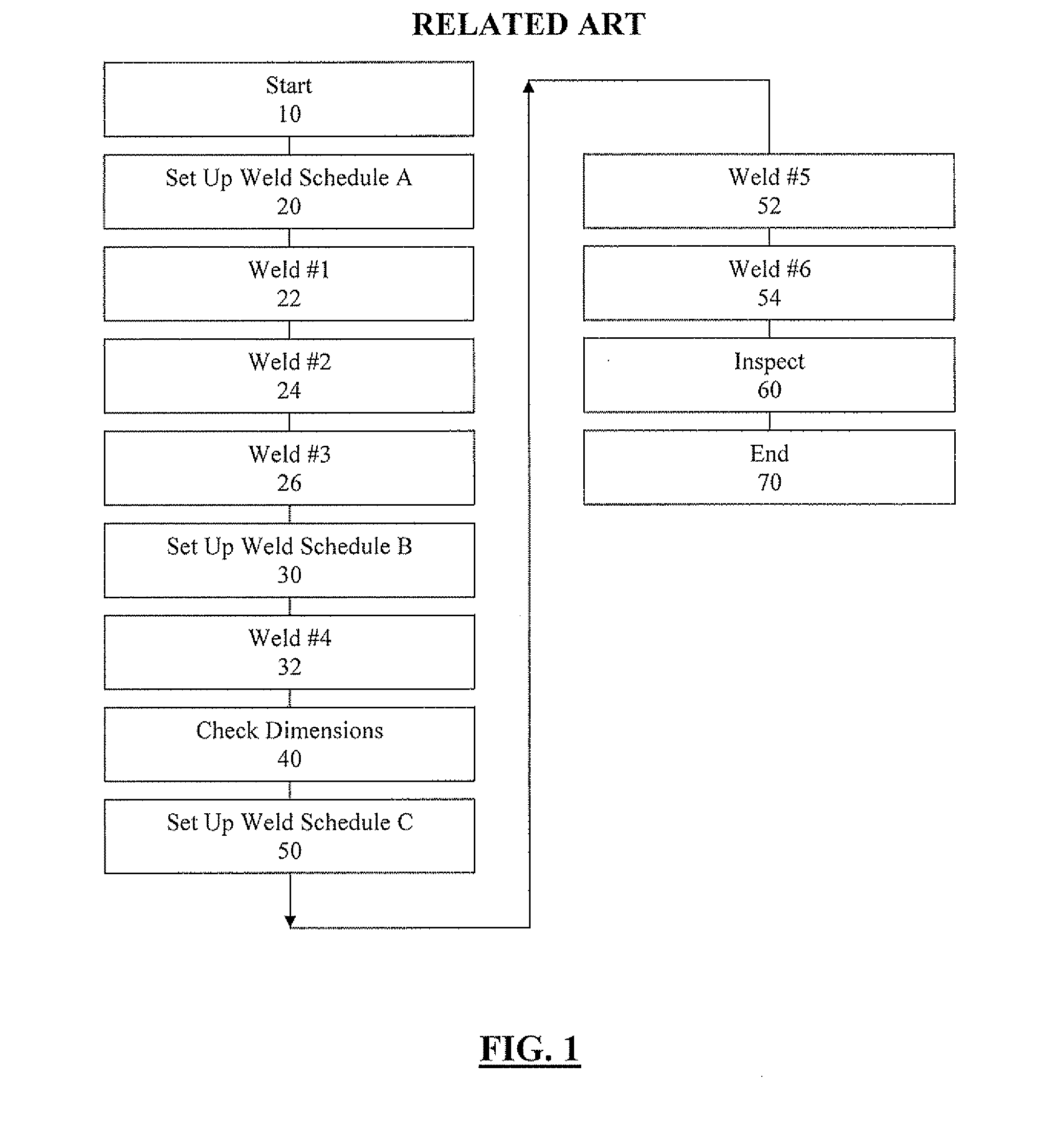

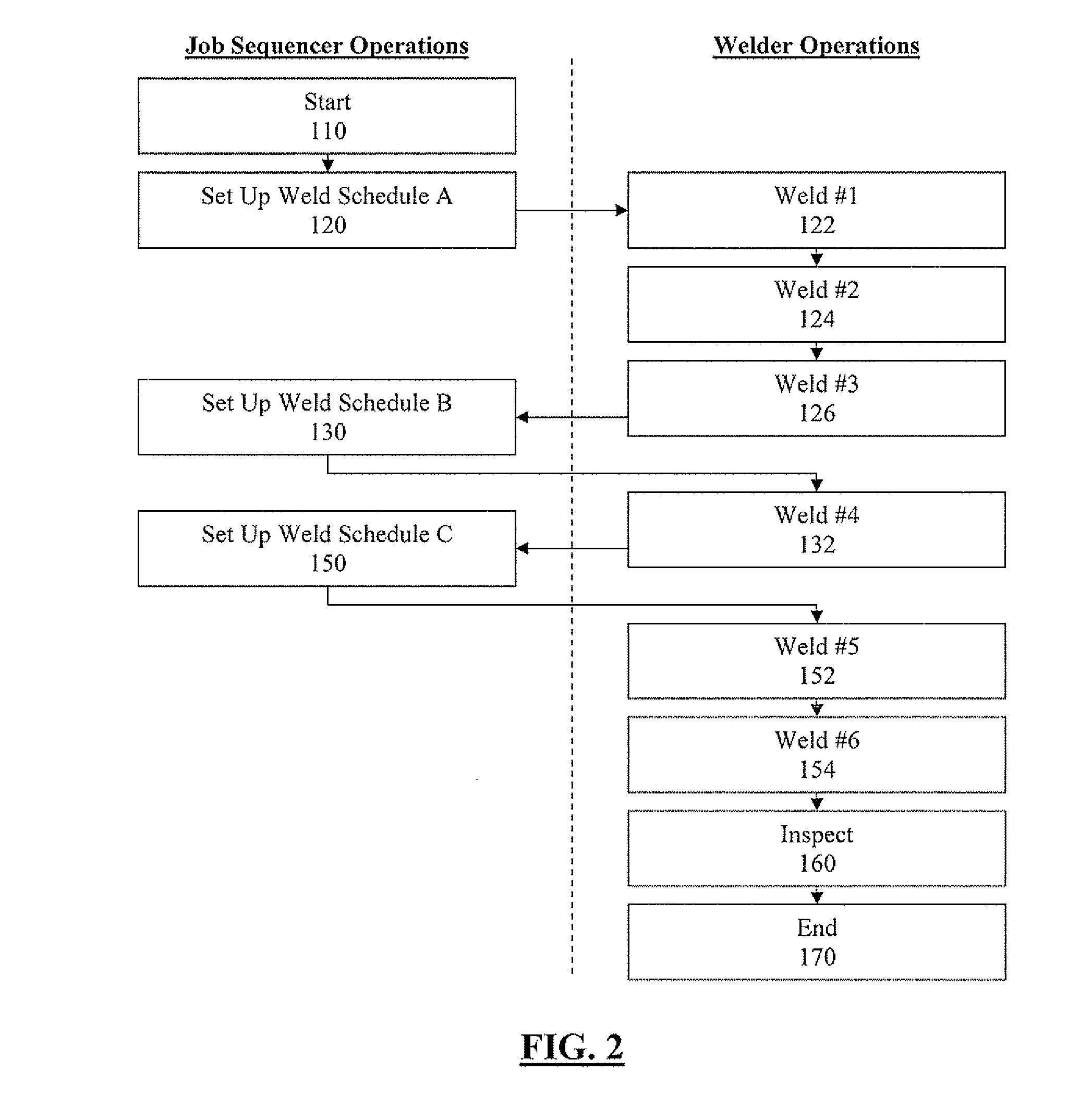

Welding Job Sequencer

A semi-automatic welding work cell, including a welding job sequencer that automatically selects a welding schedule for use by an operator in the semi-automatic welding work cell. The automatic selection may be by way of elapsed time, a detection of welding operations, a detection of the amount of welding wire supplied for the welding operation, or a detection of the amount of energy supplied for the welding operation.

Owner:LINCOLN GLOBAL INC

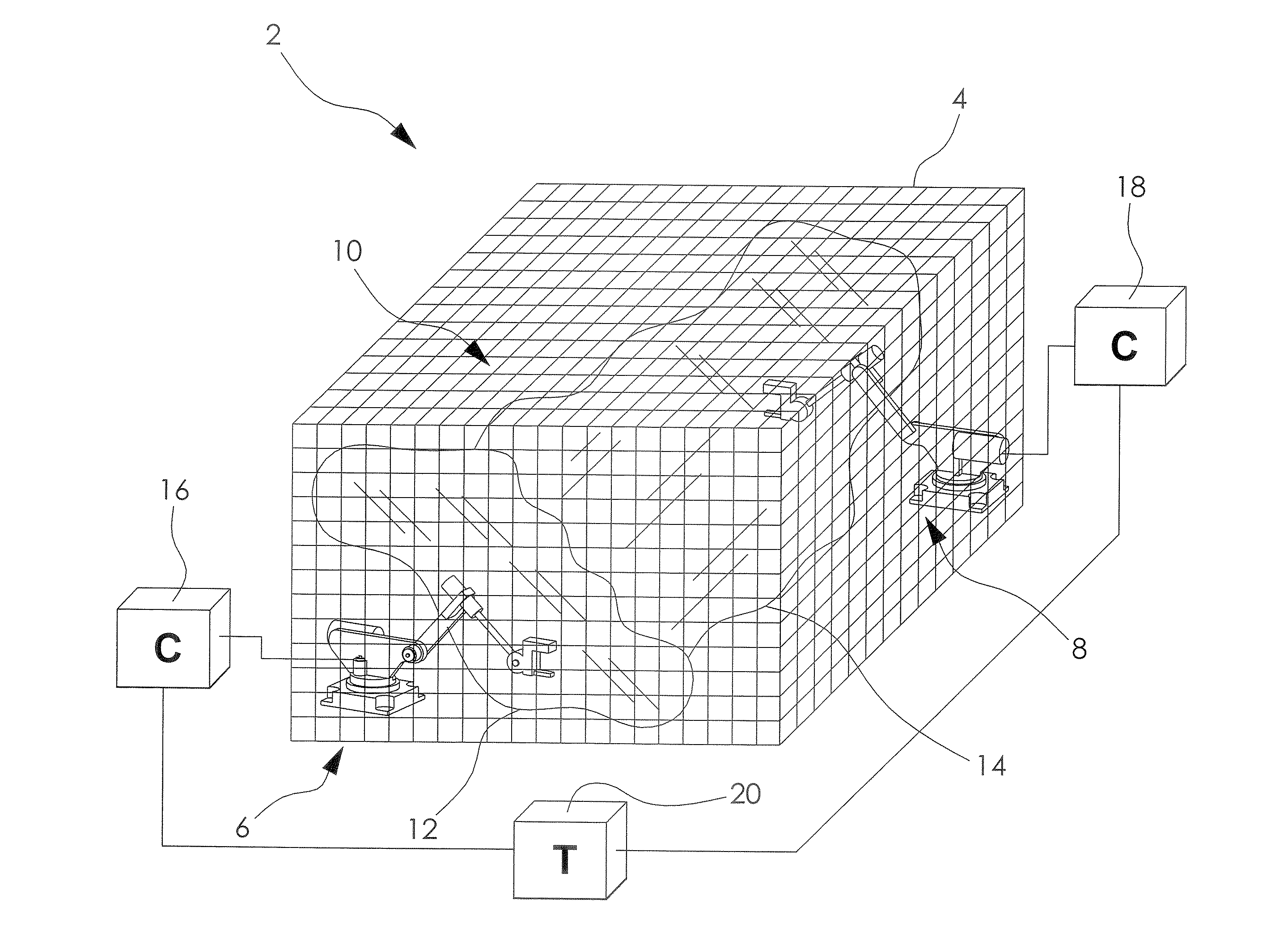

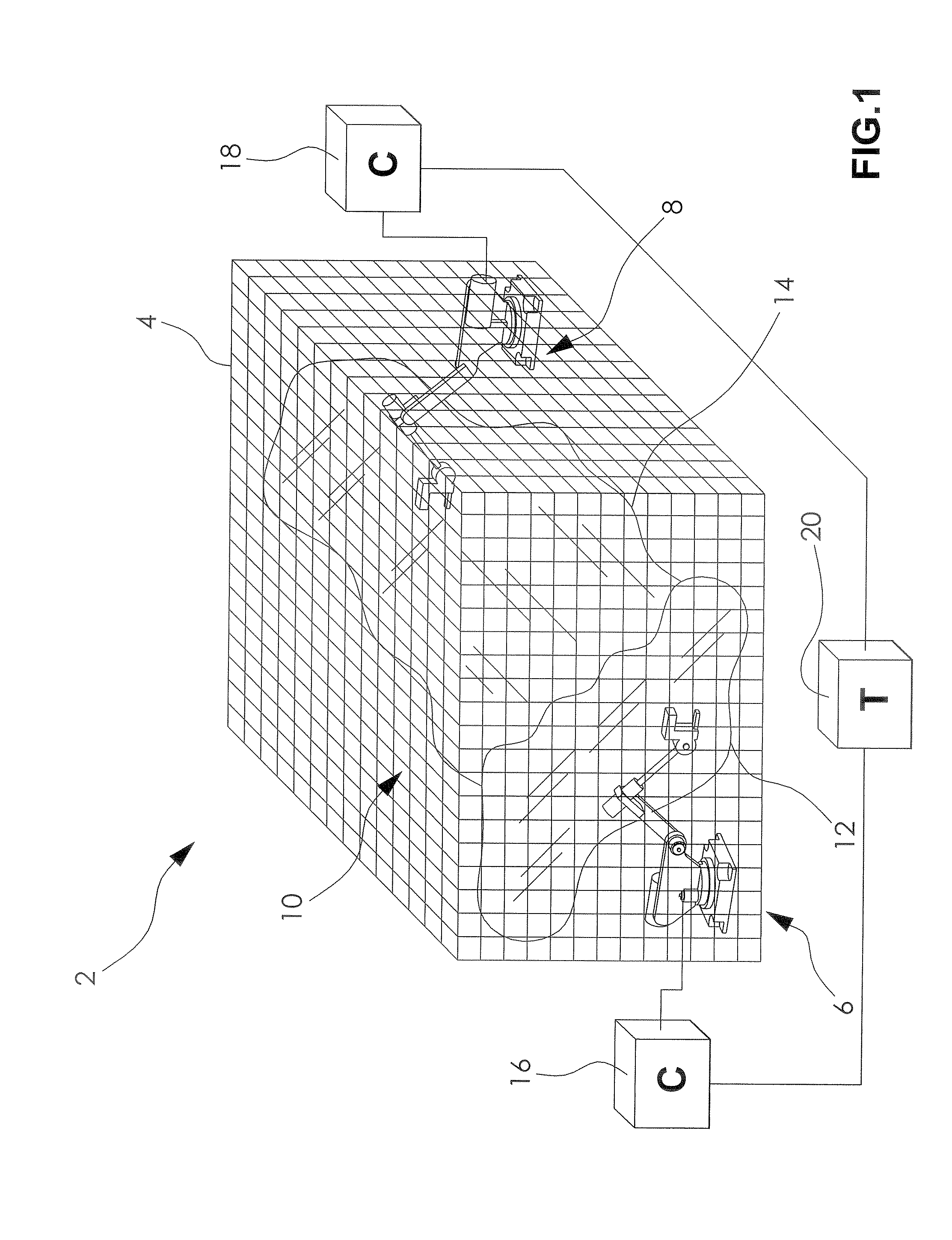

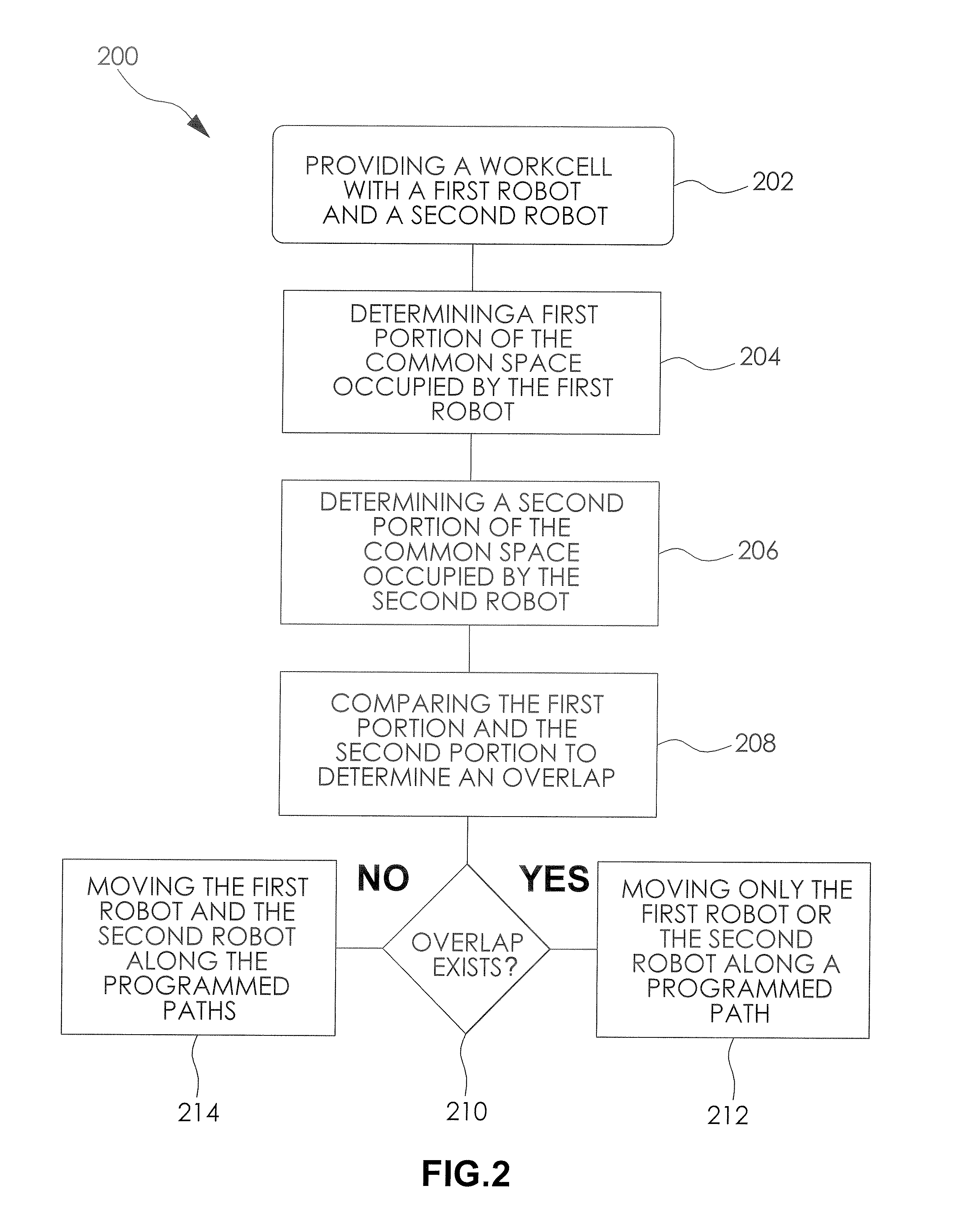

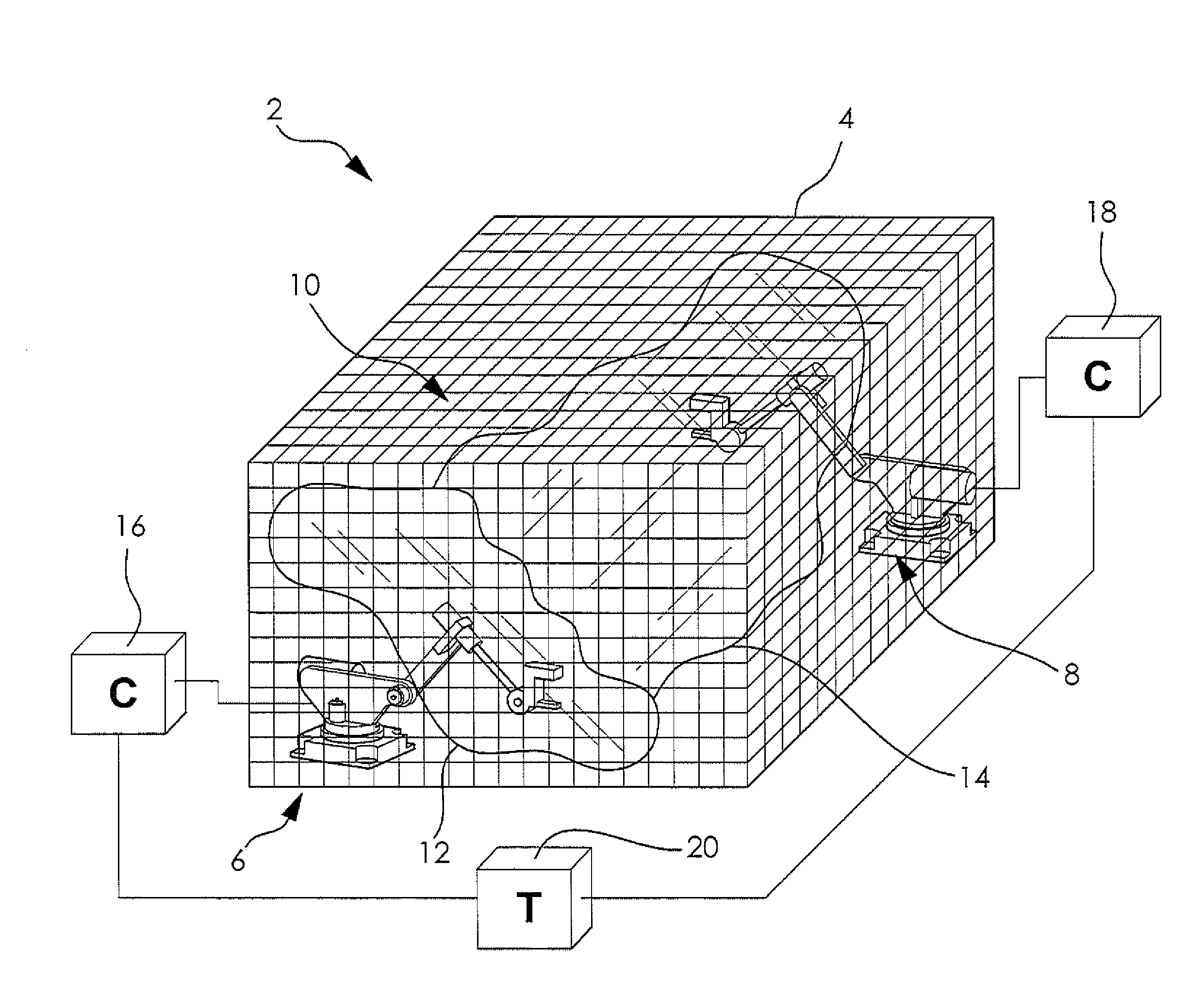

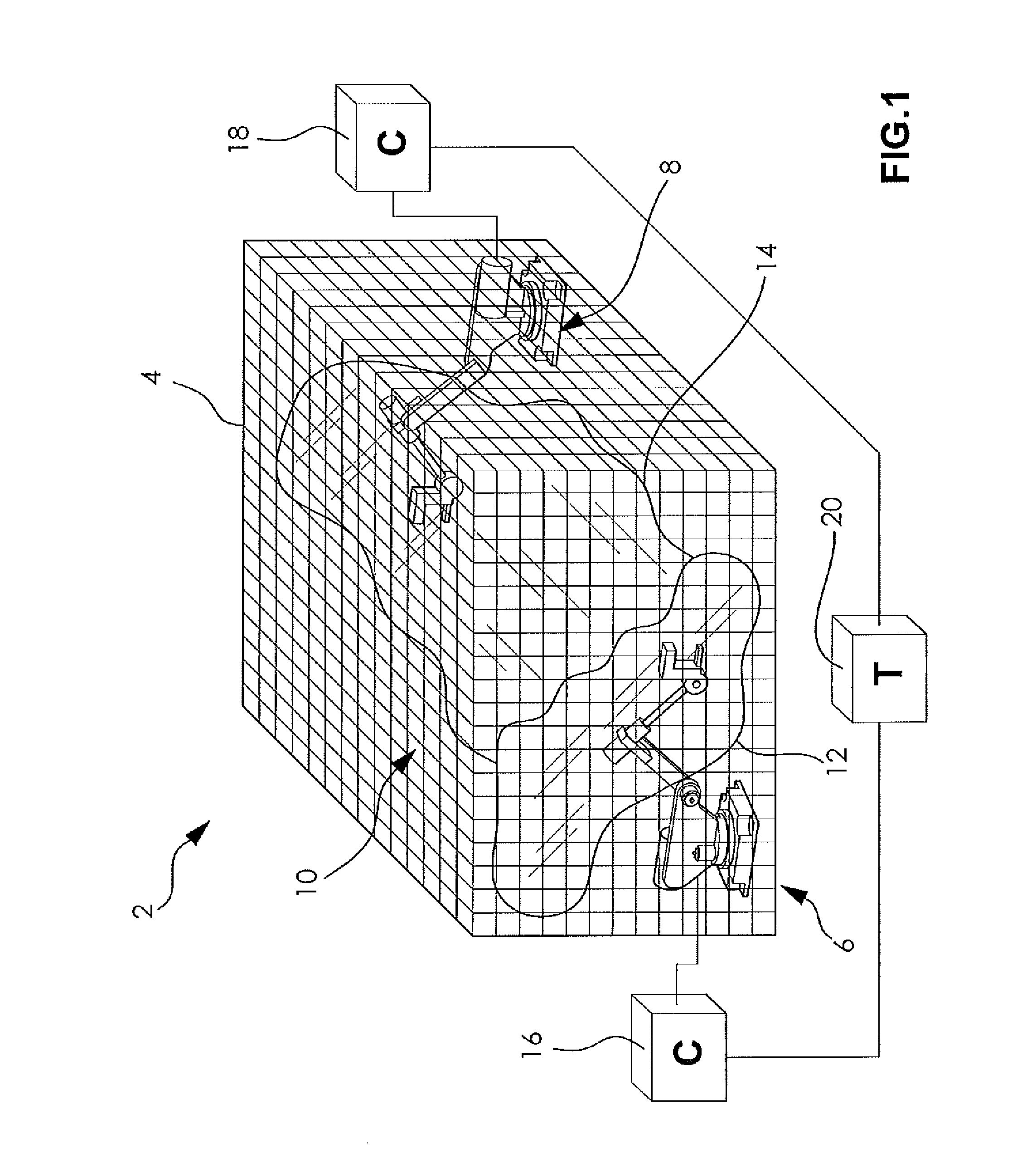

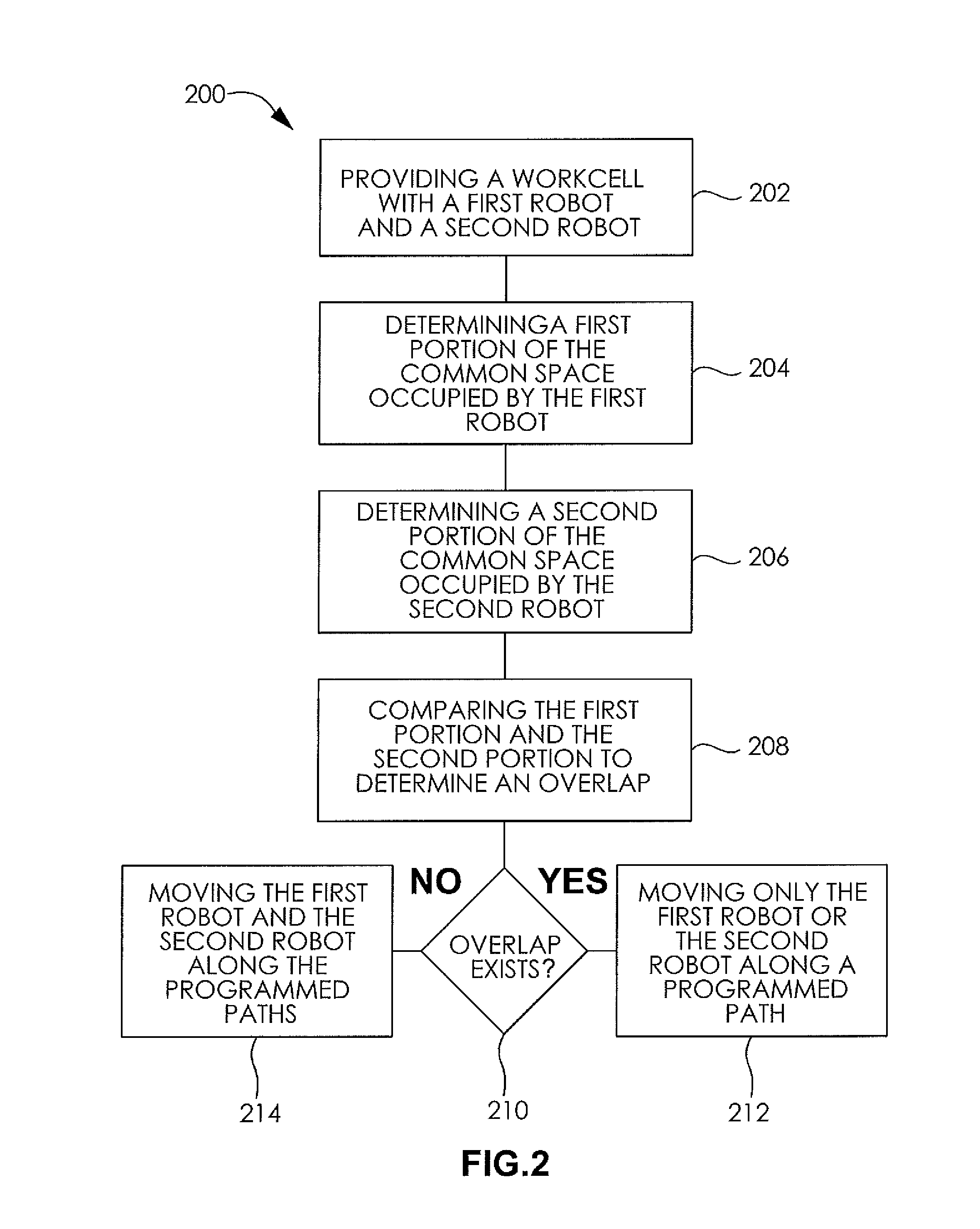

Multi-arm robot system interference check via three dimensional automatic zones

A system and method for controlling avoiding collisions in a workcell containing multiple robots is provided. The system includes a sequence of instructions residing on a controller for execution thereon to perform an interference check automatic zone method. The interference check automatic zone method includes the steps of: determining a first portion of a common space that is occupied during a movement of a first robot along a first programmed path; determining a second portion of the common space that is occupied during a movement of a second robot along a second programmed path; comparing the first portion and the second portion to determine if an overlap exists therebetween; and moving the first robot and the second robot in response to whether or not the overlap exists.

Owner:FANUC ROBOTICS NORTH AMERICA

Method for processing chemistry and coagulation test samples in a laboratory workcell

A method for automatically providing for classification of samples at the input station of a clinical laboratory workcell and allowing only those samples that have centrifuging requirements which are satisfied by currently established centrifuge operating protocols to be processed by a centrifuge and by an analyzer associated with said workcell.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

Systems and methods for automated proteomics research

InactiveUS20070184546A1Bioreactor/fermenter combinationsBiological substance pretreatmentsWorkcellBiological body

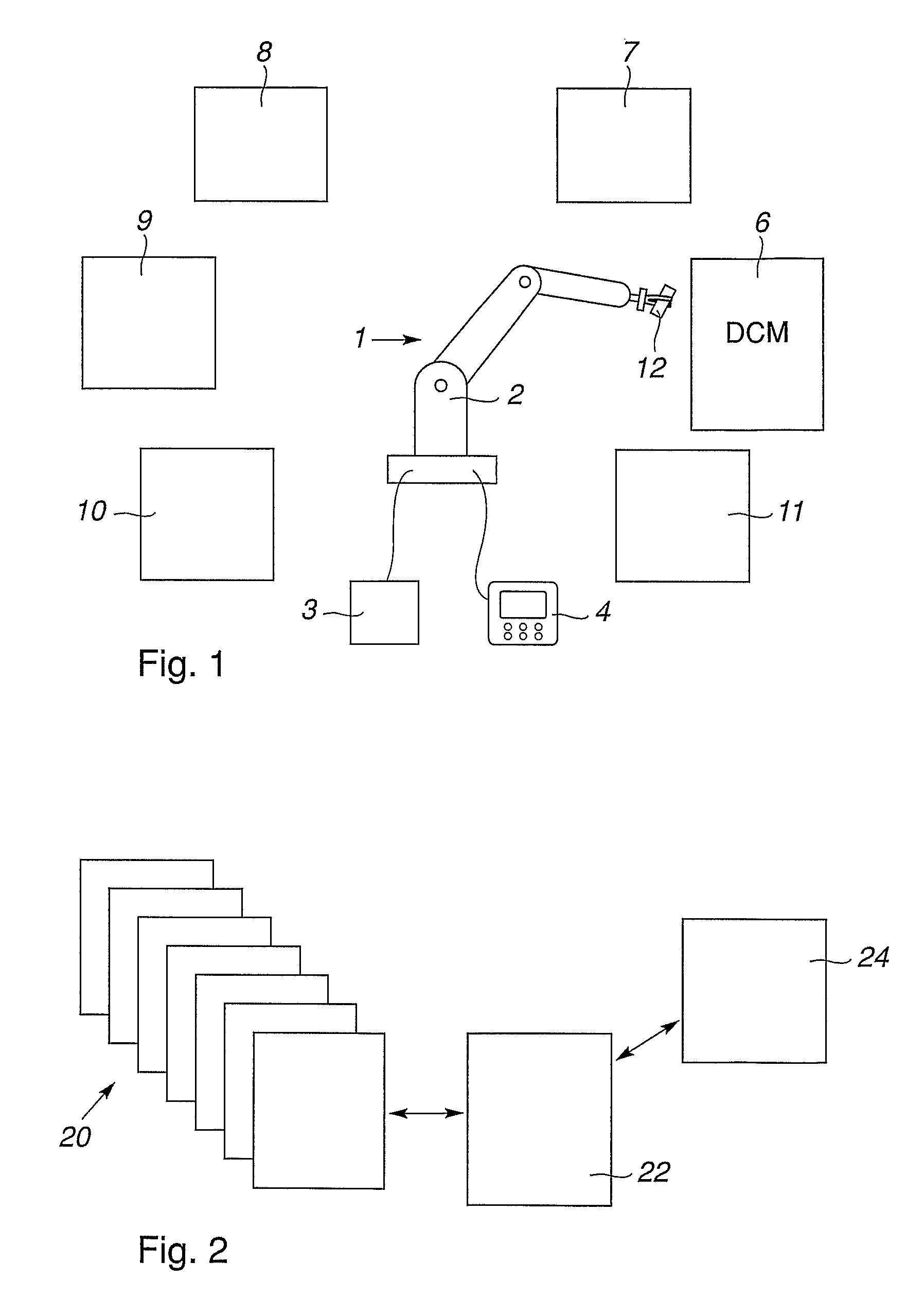

A robotic laboratory automation workcell preferably includes instruments and equipment that are integrated by using conveyor or track elements and a robotic arm. The automation workcell is controlled by a centralized or main controller or processor using specialized control software to automate the proteomics research process. The automated workcell is capable of performing genetic laboratory experiments from start to finish by moving samples or microplates between the instruments for analysis. A goal of the automated workcell is to perform repetitive procedures in an effort to build and maximize the efficiency of a gene(s) of a targeted organism.

Owner:HUDSON CONTROL GROUP

Method and system for automatically preventing deadlock in multi-robot systems

ActiveUS20120215351A1Avoid deadlockAvoid adjustmentProgramme-controlled manipulatorComputer controlWorkcellMultirobot systems

A system and method for controlling avoiding collisions and deadlocks in a workcell containing multiple robots automatically determines the potential deadlock conditions and identifies a way to avoid these conditions. Deadlock conditions are eliminated by determining the deadlock-free motion statements prior to execution of the motions that have potential deadlock conditions. This determination of deadlock-free motion statements can be done offline, outside normal execution, or it can be done during normal production execution. If there is sufficient CPU processing time available, the determination during normal production execution provides the most flexibility to respond to dynamic conditions such as changes in I / O timing or the timing of external events or sequences. For minimal CPU impact the determination is done offline where many permutations of programming sequences can be analyzed and an optimized sequence of execution may be found.

Owner:FANUC ROBOTICS NORTH AMERICA

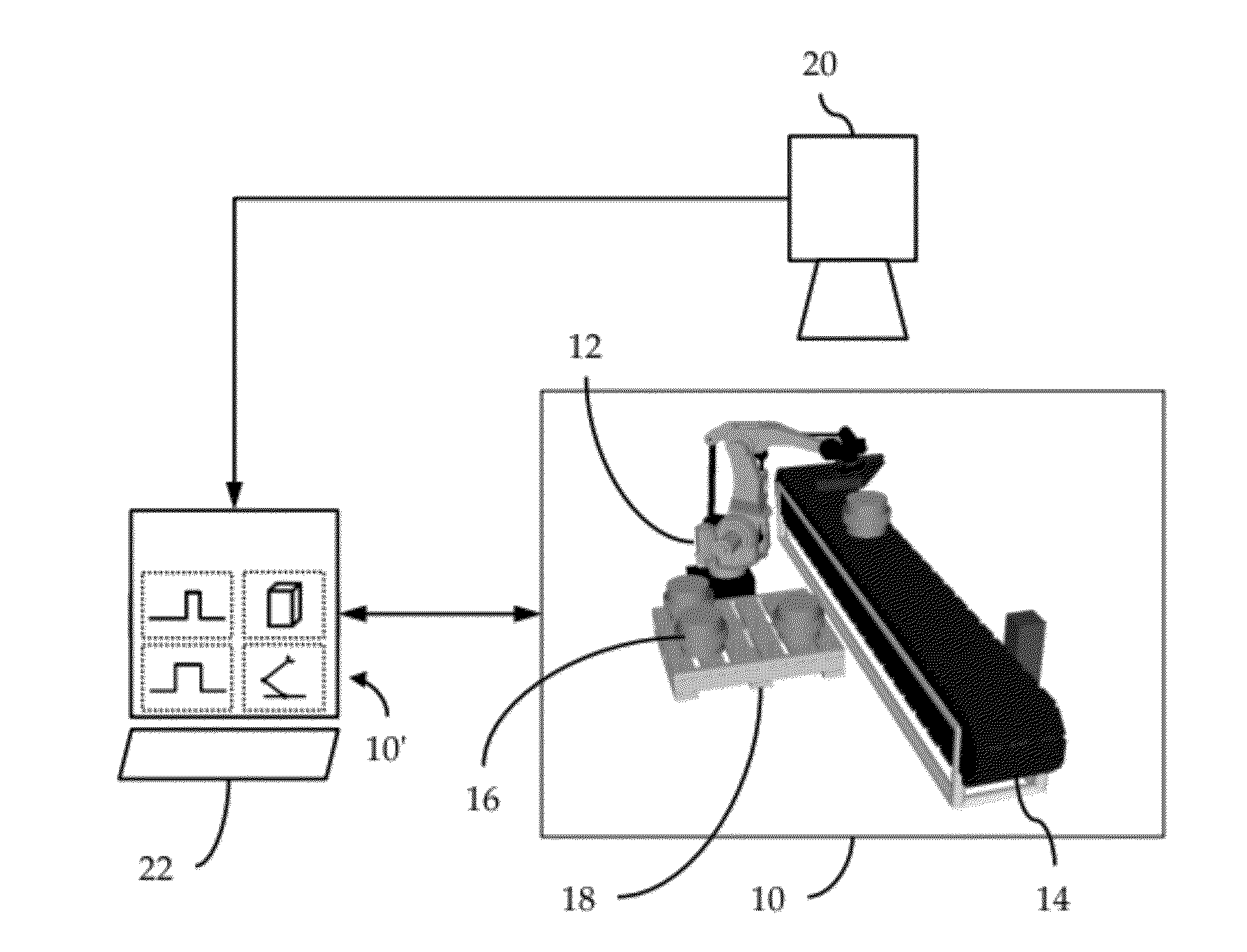

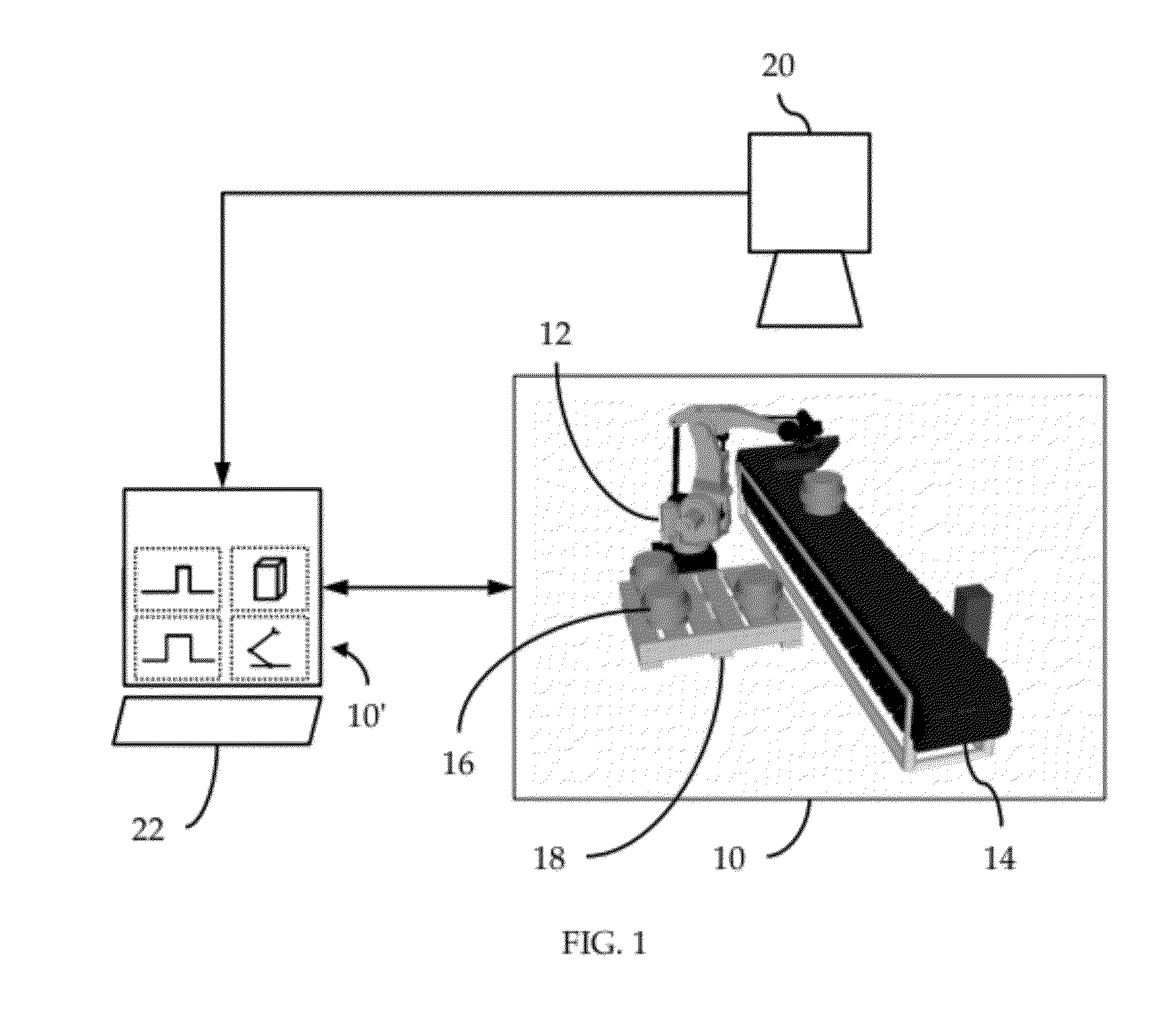

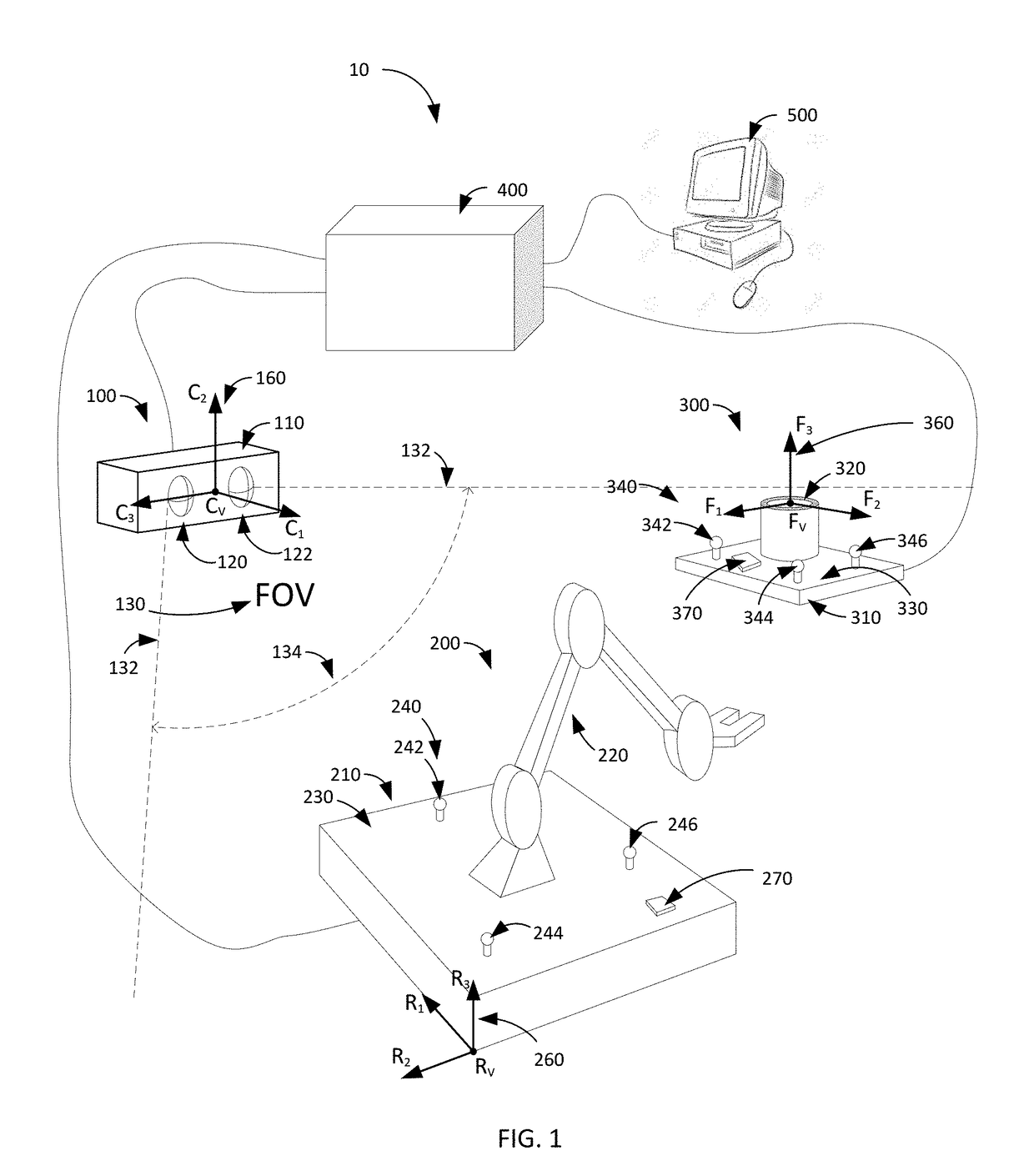

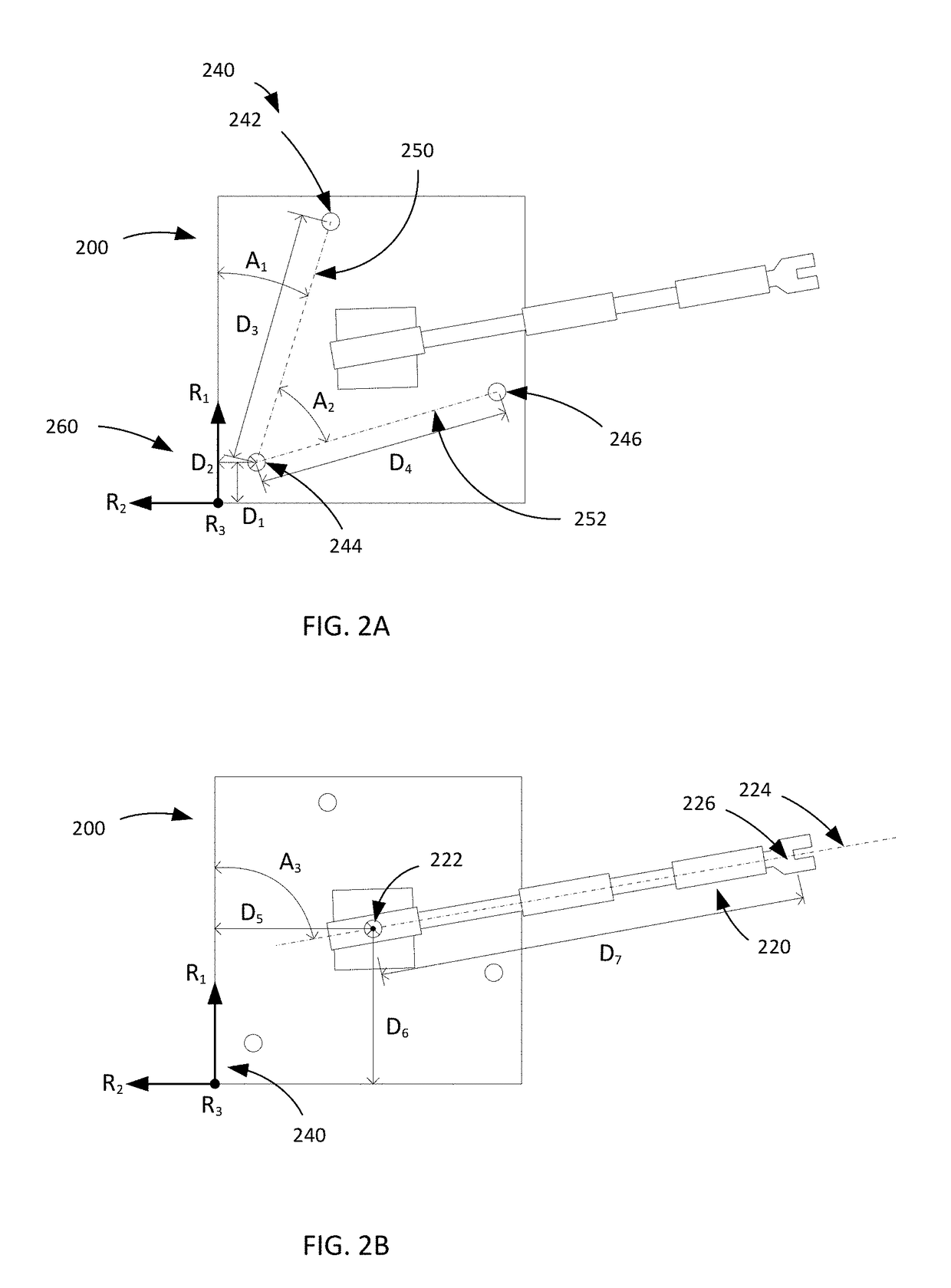

Method to Model and Program a Robotic Workcell

InactiveUS20120290130A1Reduces time to operationLess iterationProgramme-controlled manipulatorComputer controlWorkcellComputer graphics (images)

An improved method to model and program a robotic workcell. Two-dimensional (2D) images of a physical workcell are captured to facilitate, in part, initial integration of any preexisting three-dimensional (3D) component models into a 3D model workcell. 3D models of other essential workcell components are synthesized and integrated into the 3D workcell model. The robot is then configured and programmed. The resultant 3D workcell model more faithfully reflects the “as-built” workcell than a traditional model that represents the “as-designed” workcell.

Owner:KAPOOR CHETAN

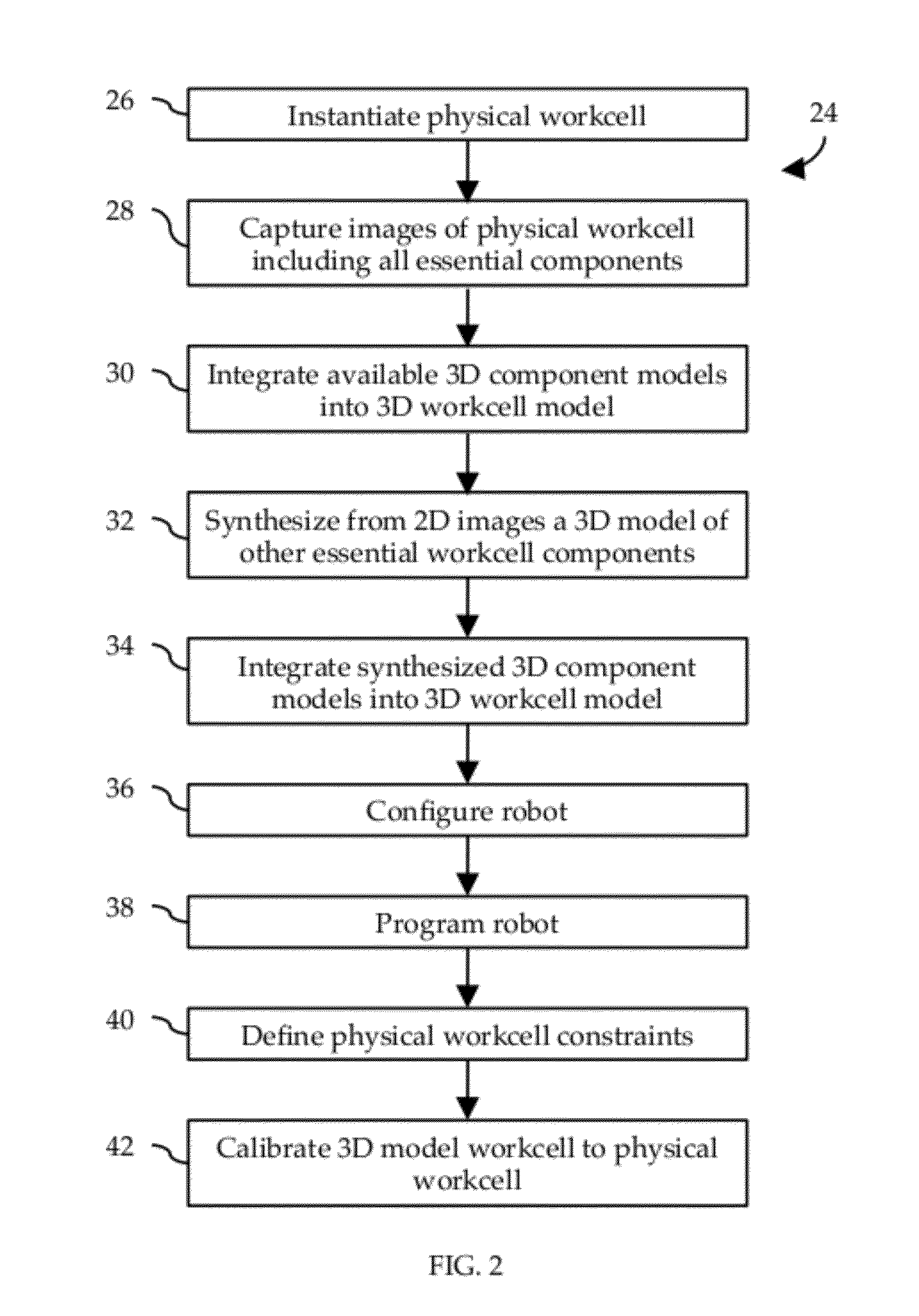

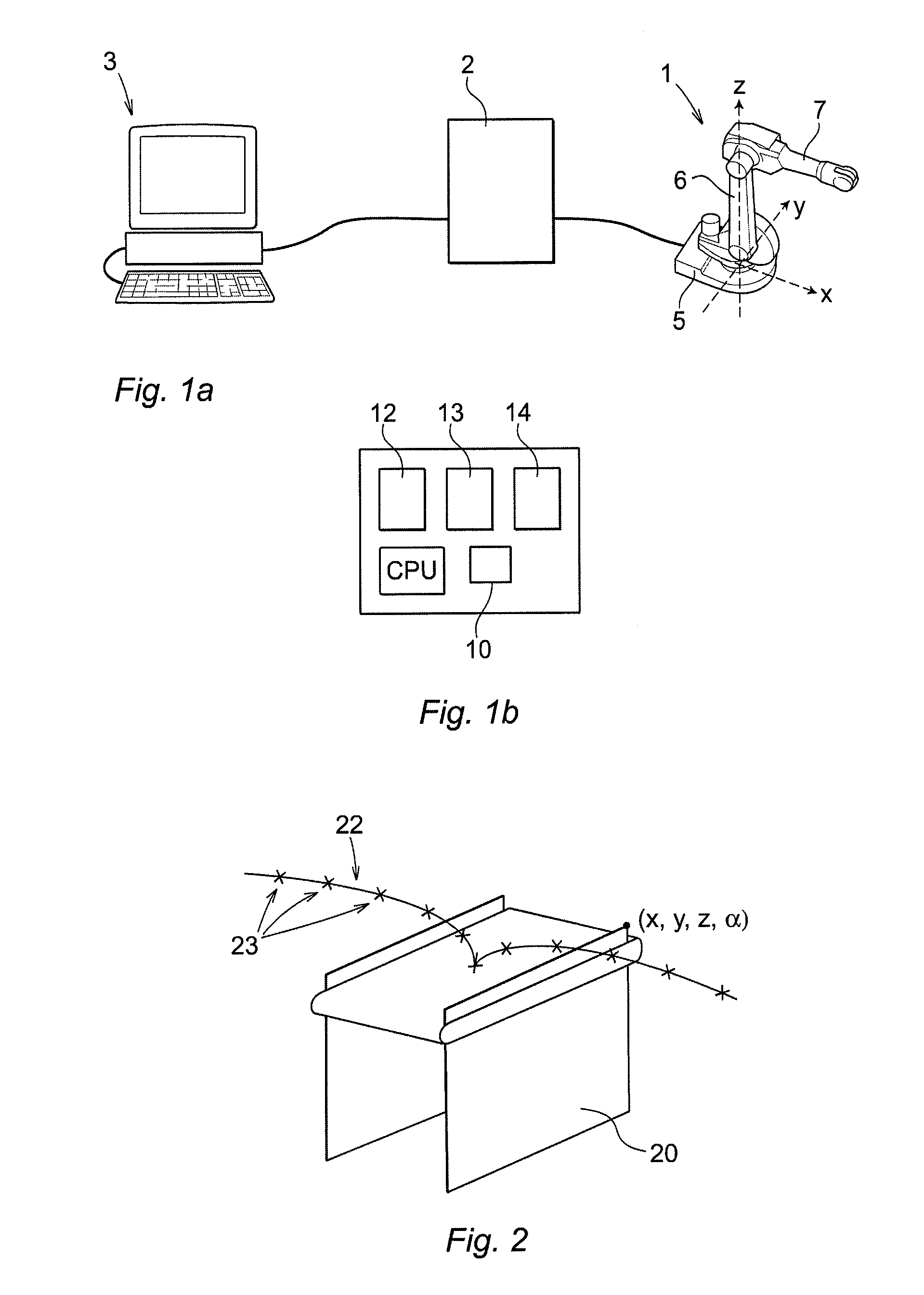

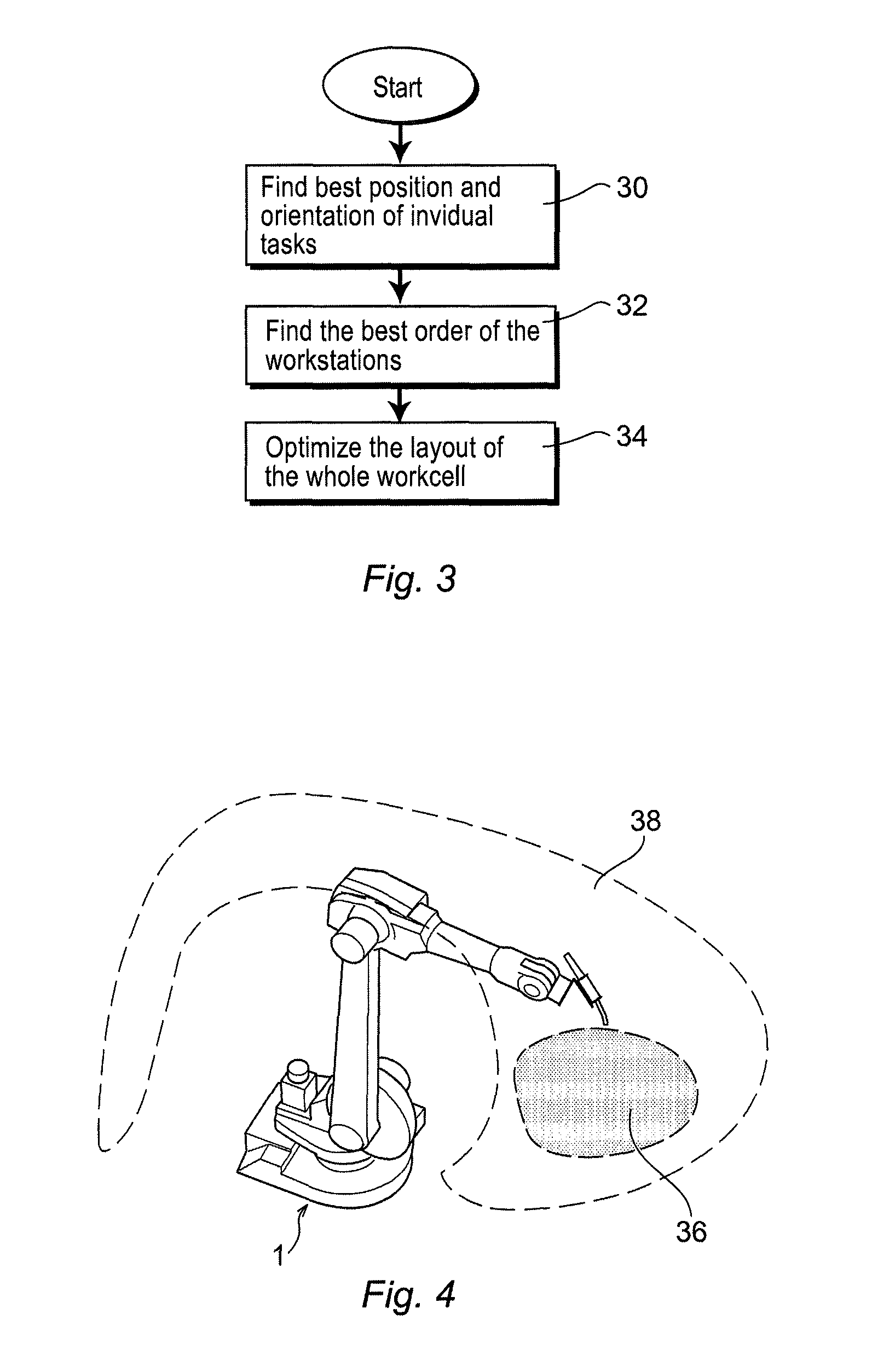

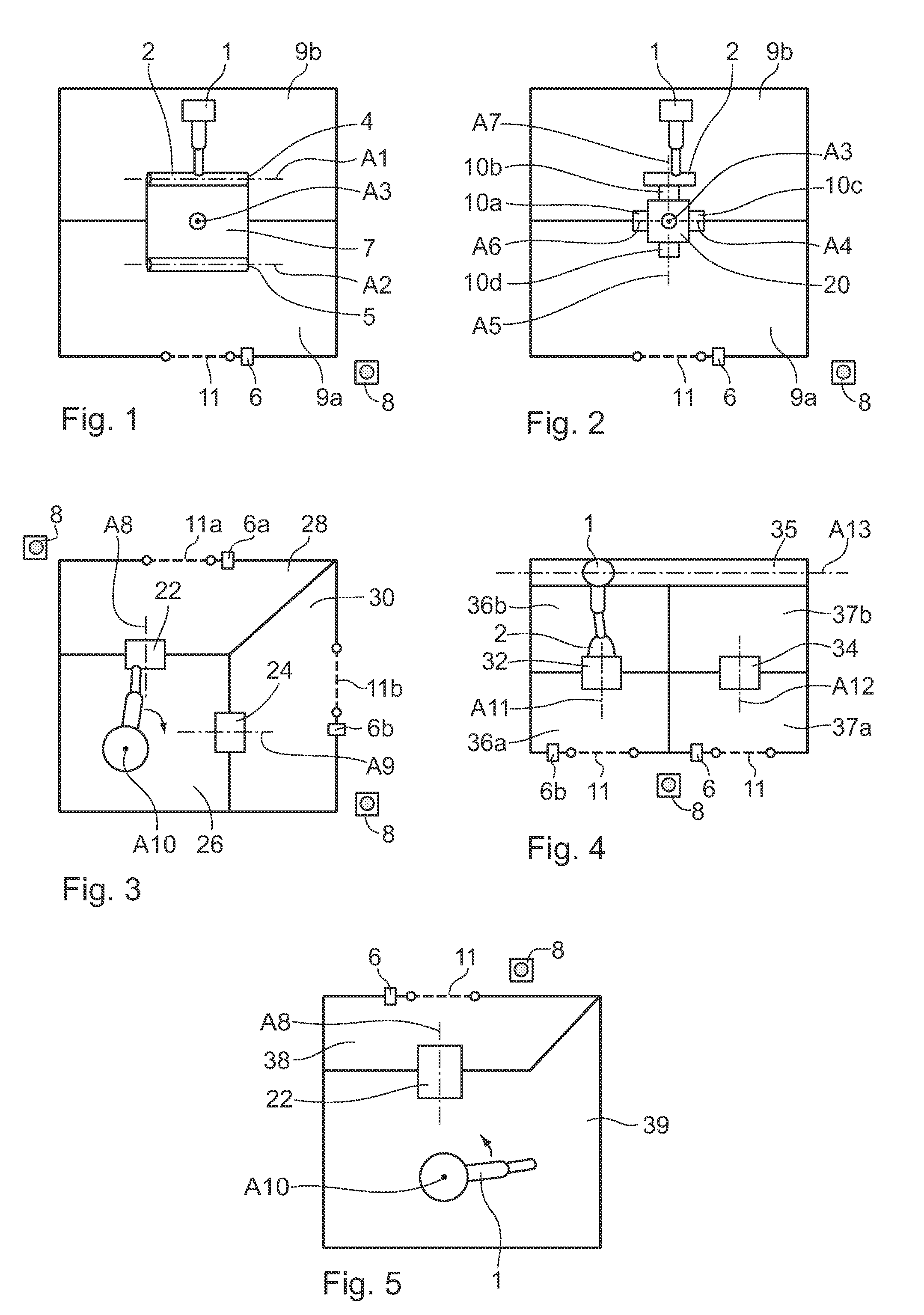

Method and system for optimizing the layout of a robot work cell

InactiveUS8571706B2Improve productivityImprove performanceComputer controlSimulator controlWorkcellSimulation

A method for optimizing placement of a plurality of workstations in a workcell including an industrial robot programmed to execute a sequence of tasks on the workstations. Each task contains robot targets to be visited by the robot when executing the task. A preferred region is defined within the reachable range of the robot. Tasks are placed inside or as close as possible to the preferred region using an evaluation criterion and an optimization algorithm. The tasks are assigned to each workstation a position inside or close to the preferred region. A best order of the workstations and a defined order in which the tasks are to be executed are determined. The positions of the workstations are adjusted utilizing an optimization algorithm configured to run the robot program iteratively in order to optimize the placement of the workstations with regard to the robot performance.

Owner:ABB RES LTD

Machine vision system for lab workcells

A robotic laboratory automation system includes a vision feedback apparatus with one or more teaching plates adapted for placement in a microplate or other specimen holder of a laboratory instrument or stack to represent the location of the microplate. The vision feedback system is adapted to control the robotic manipulator to automatically adjust the location of the manipulator to a position adjacent to a teaching plate upon locating a pattern on the teaching plate and then store the coordinates of the determined position. With the stored position coordinates the robot can return to the determined positions previously represented by the location of teaching plates to locate an actual microplate or specimen holder at the determined position without the vision feedback system.

Owner:HUDSON CONTROL GROUP

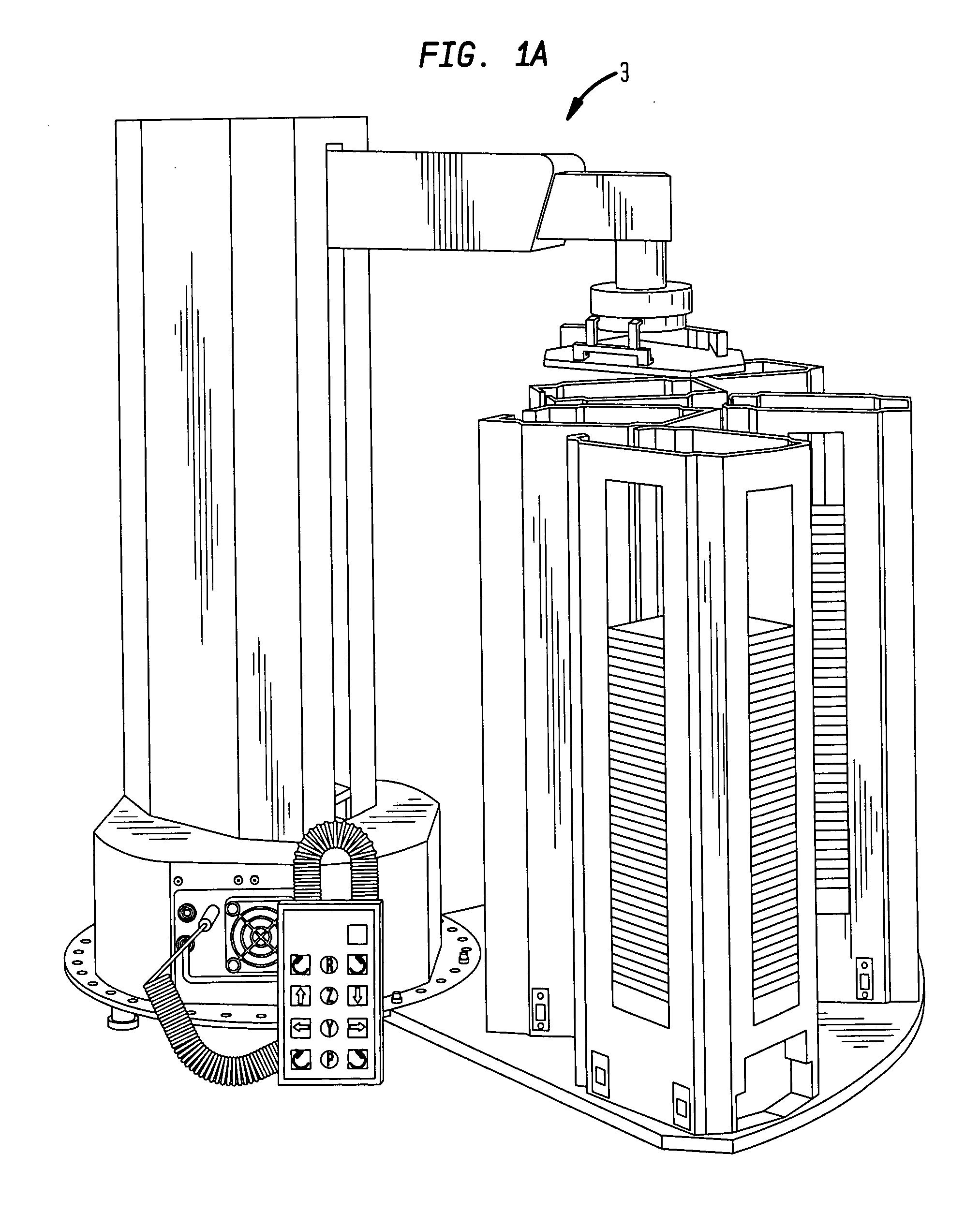

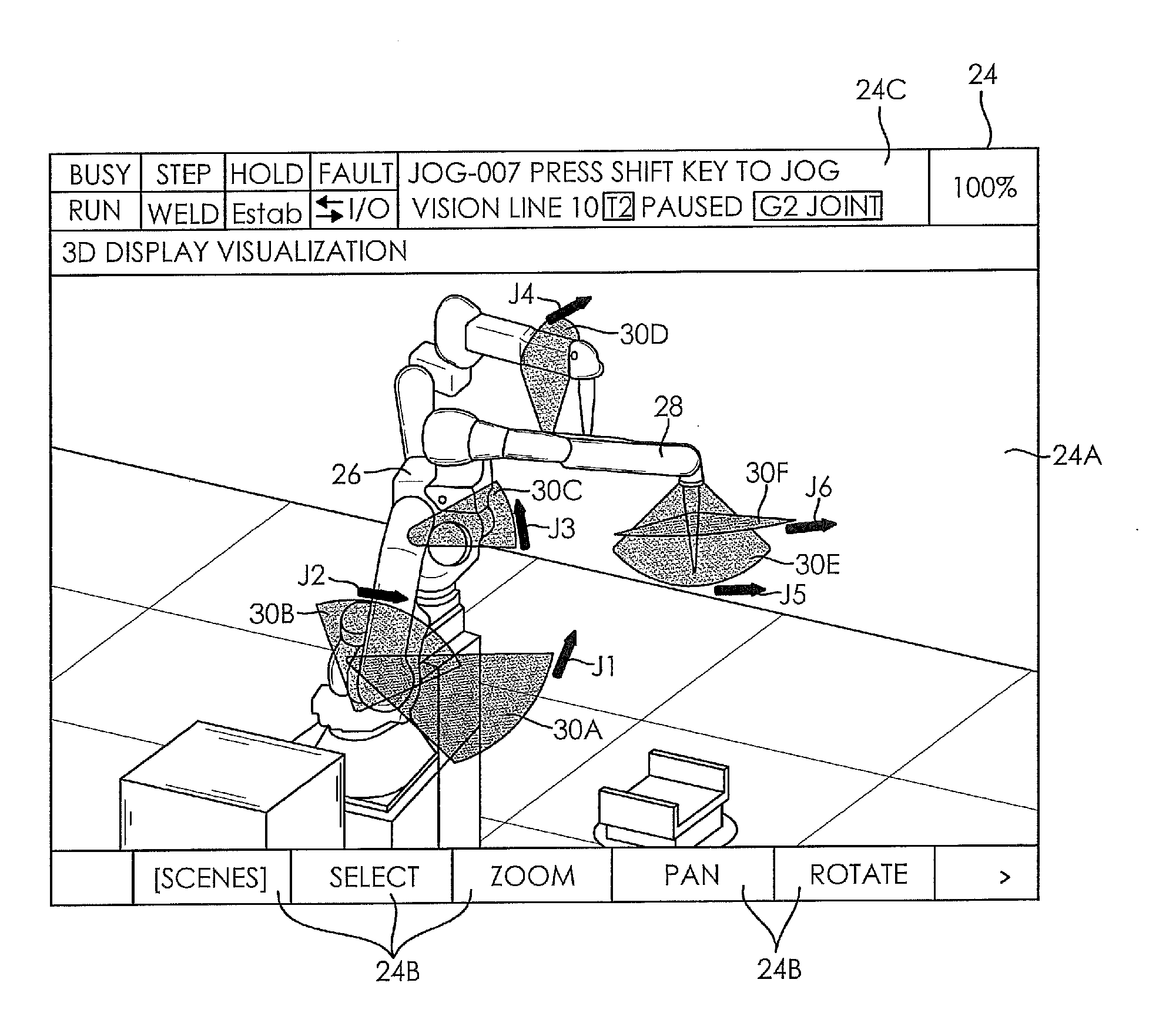

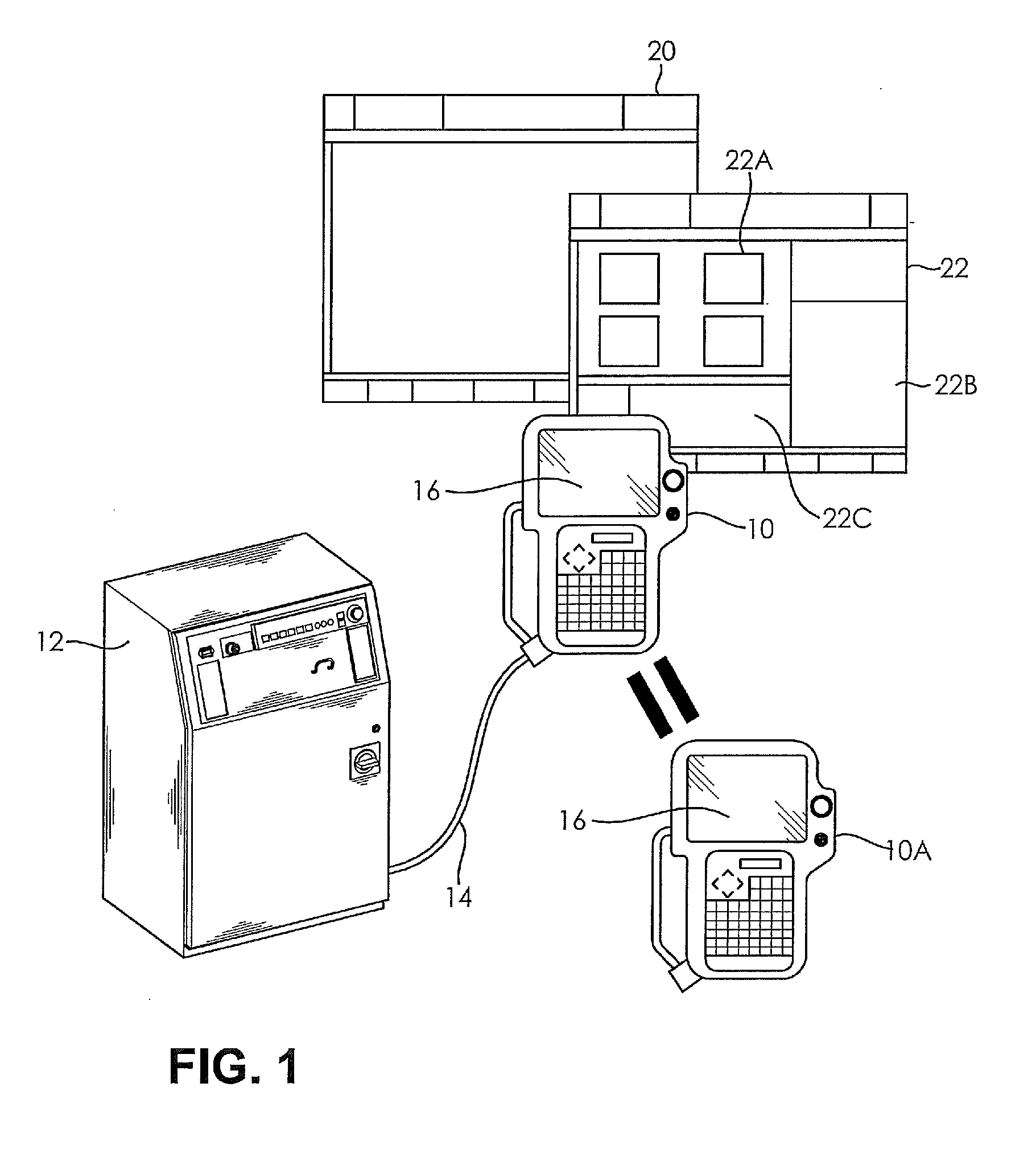

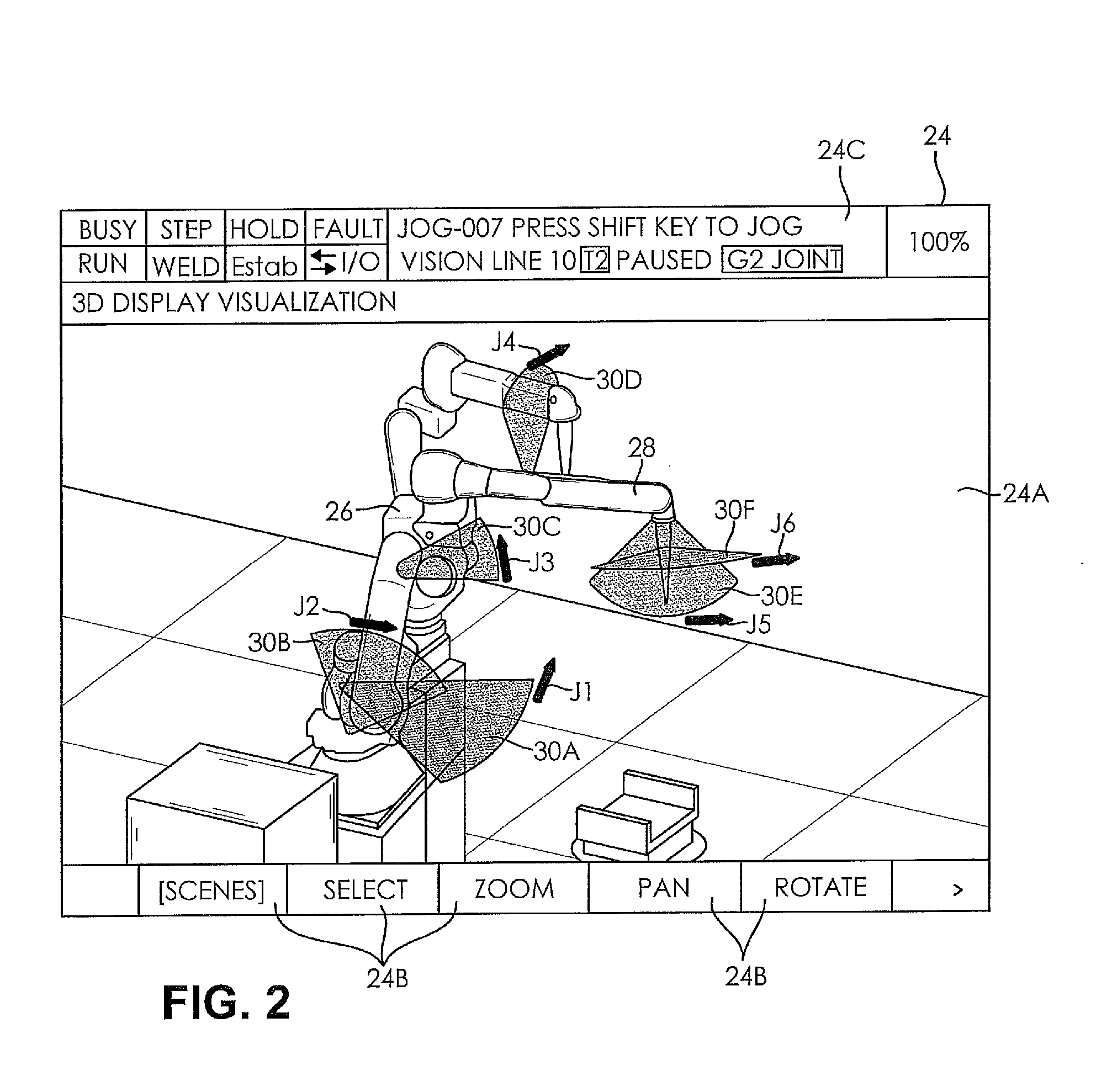

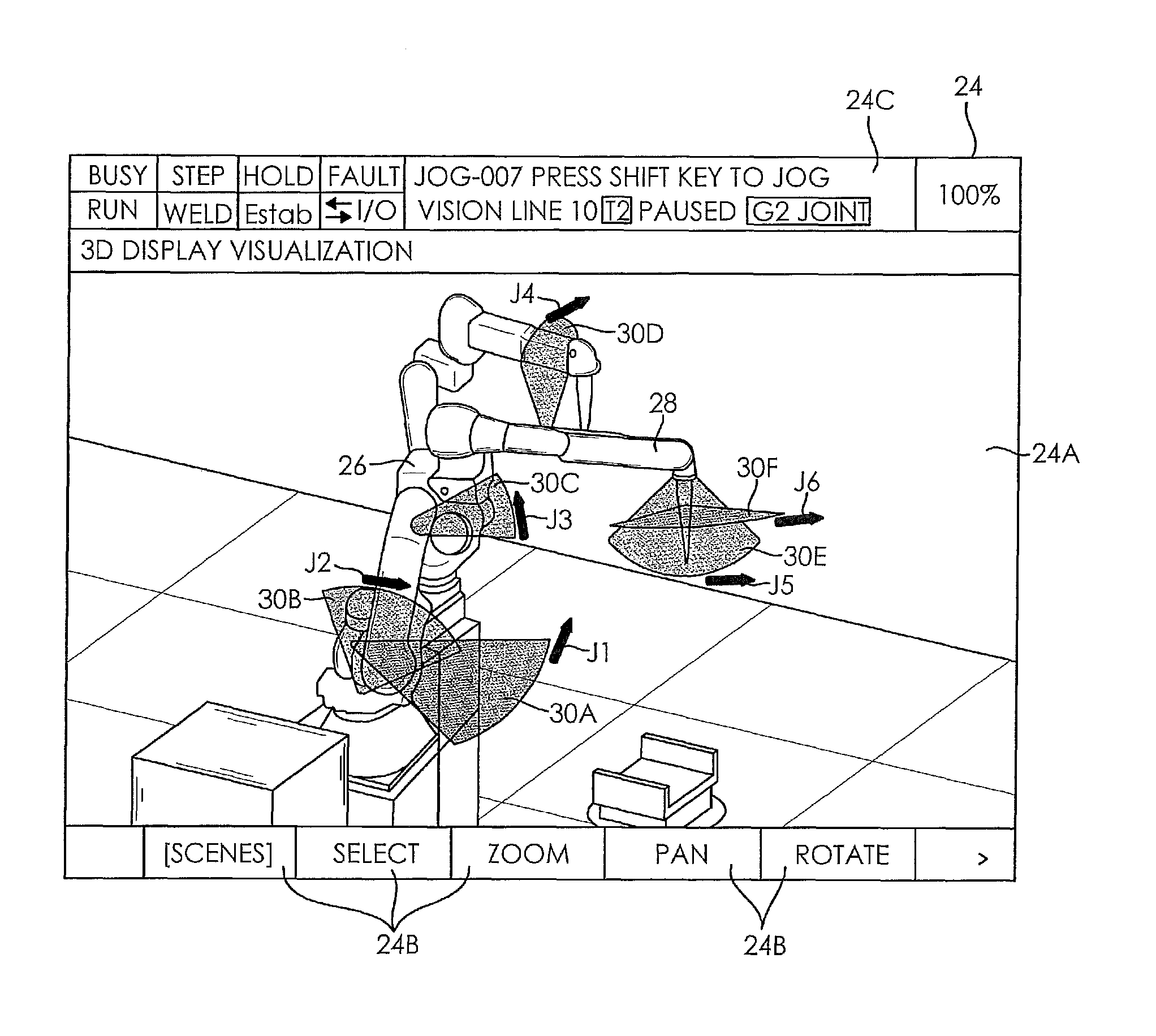

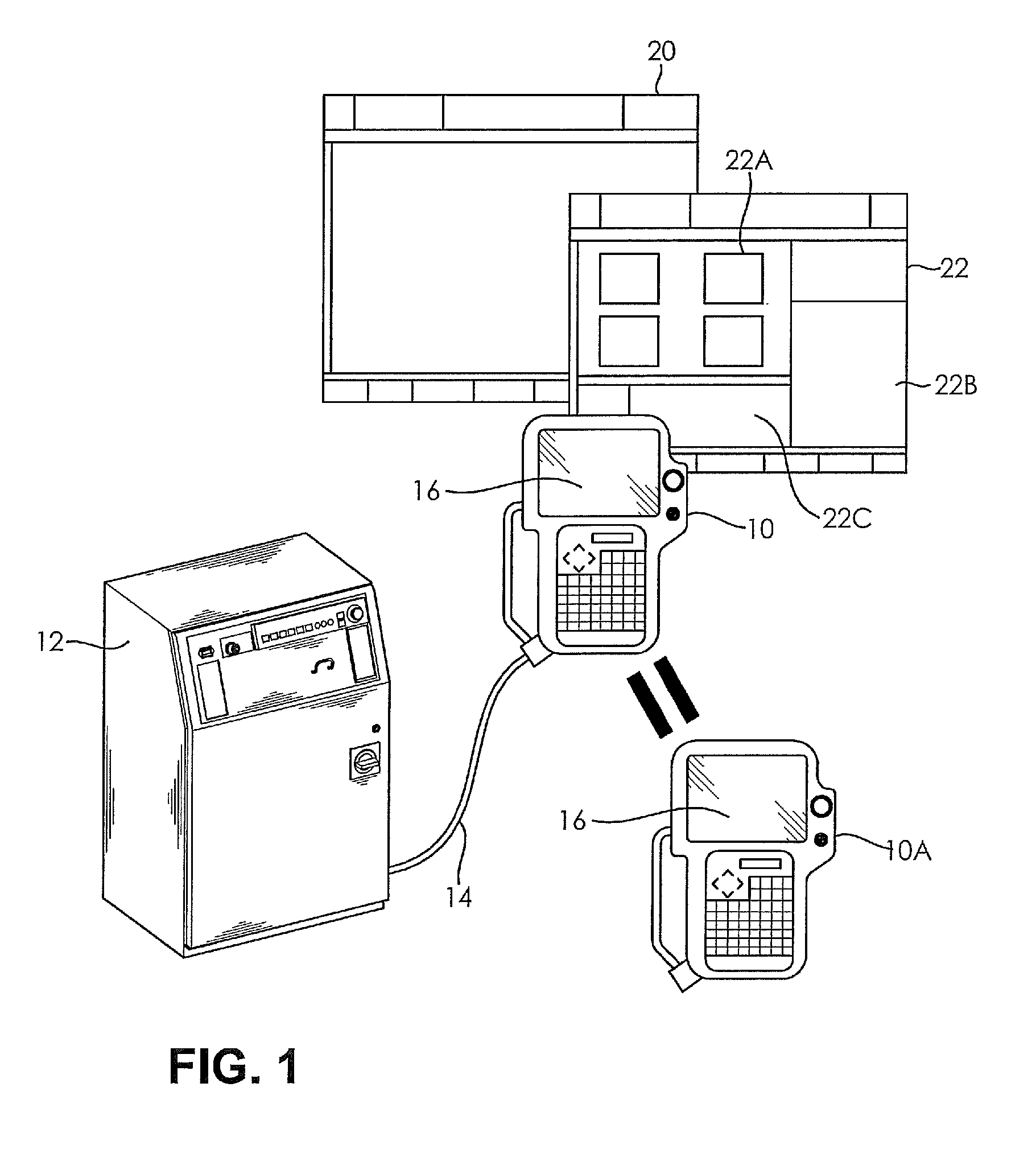

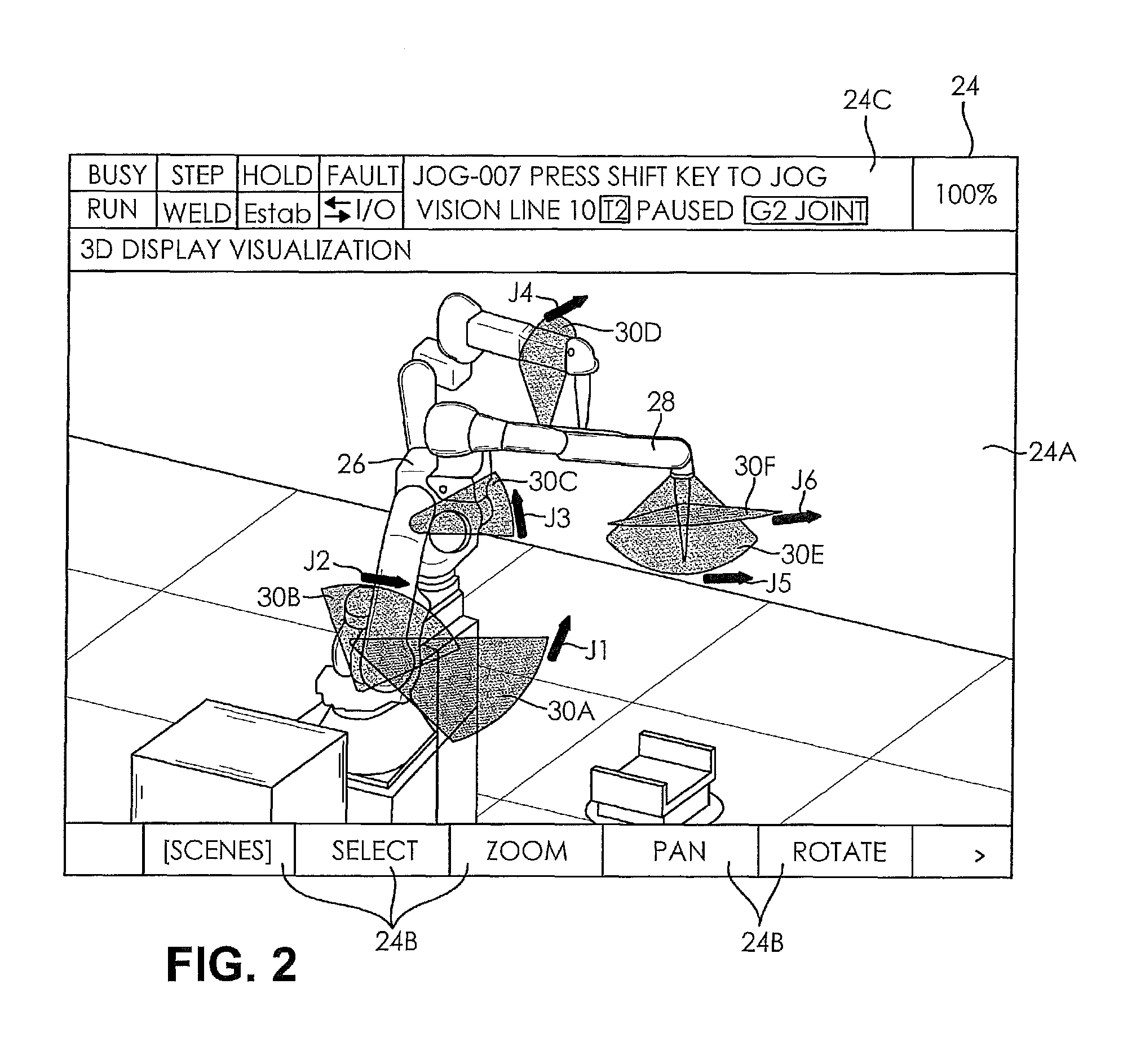

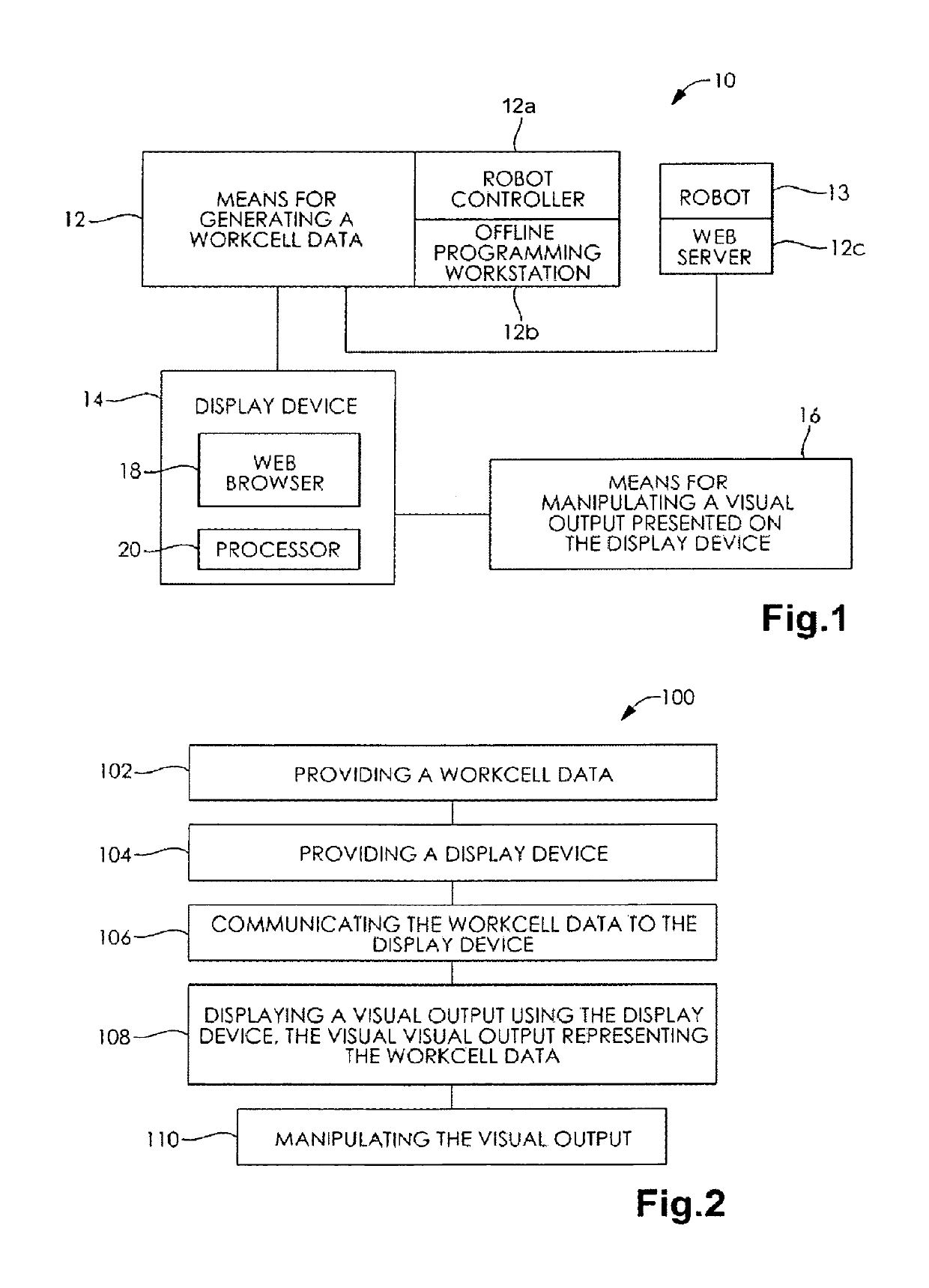

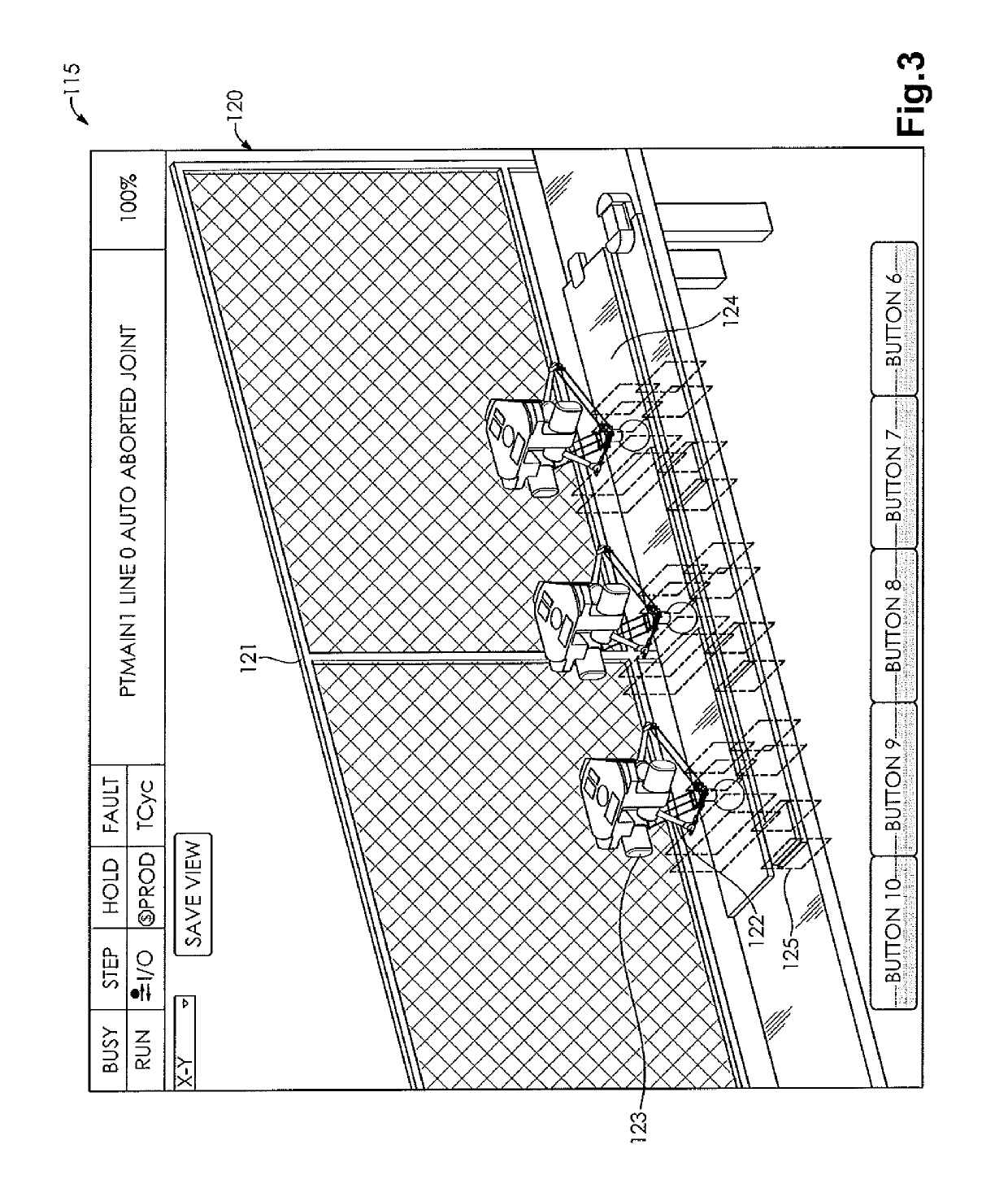

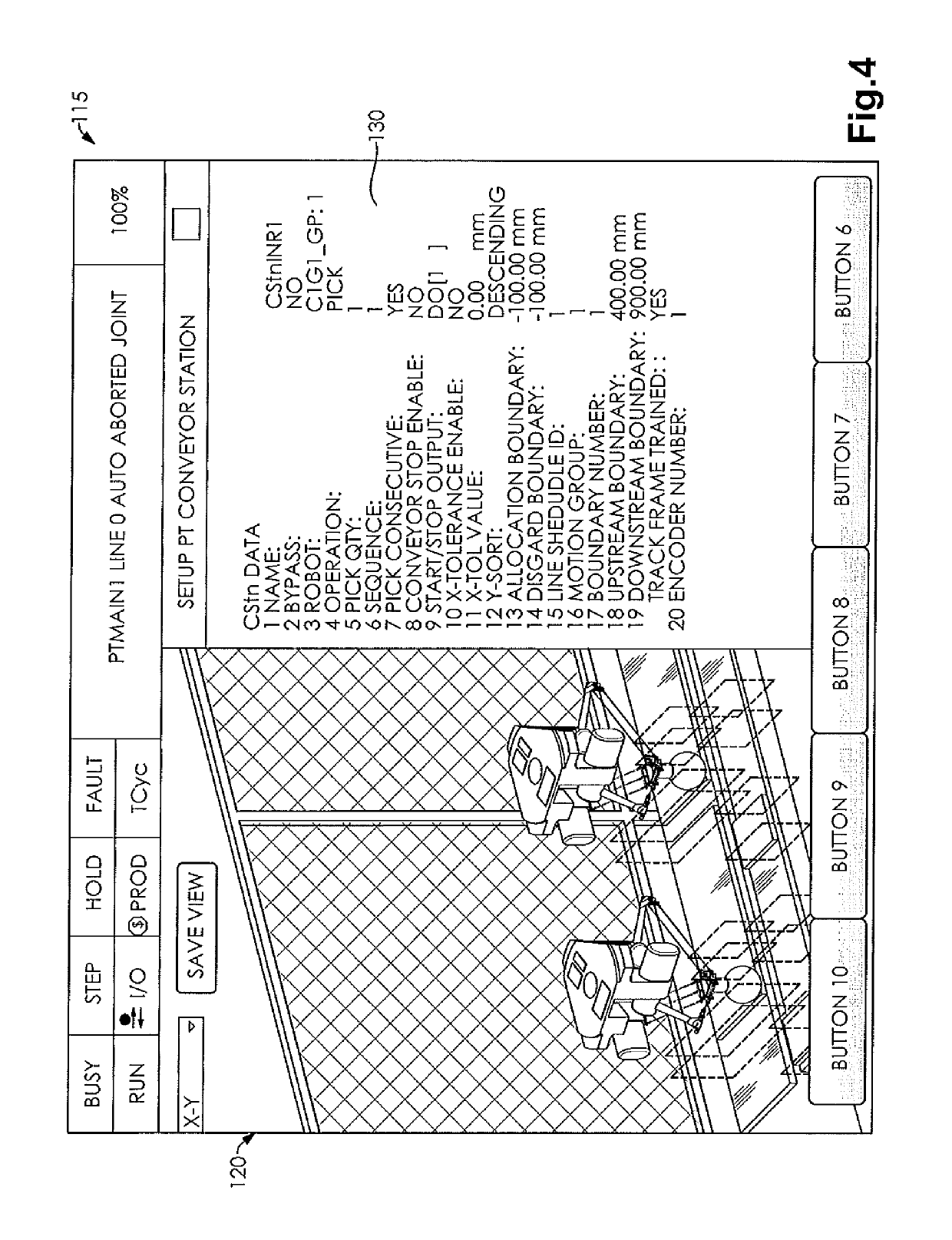

Robot teach device with 3-d display

ActiveUS20130116828A1High resolutionOvercomes shortcomingProgramme controlProgramme-controlled manipulatorWorkcellViewpoints

A method and an apparatus for displaying three-dimensional workcell data includes a hand-held pendant that is provided with 3-D workcell data representing a model of a machine and associated components in a workcell. The hand-held pendant has a display that generates a 3-D visual representation of the workcell data. The pendant can be operated by a user to manipulate the visual representation to change a user viewpoint and to show motion of the machine with associated process information.

Owner:FANUC ROBOTICS NORTH AMERICA

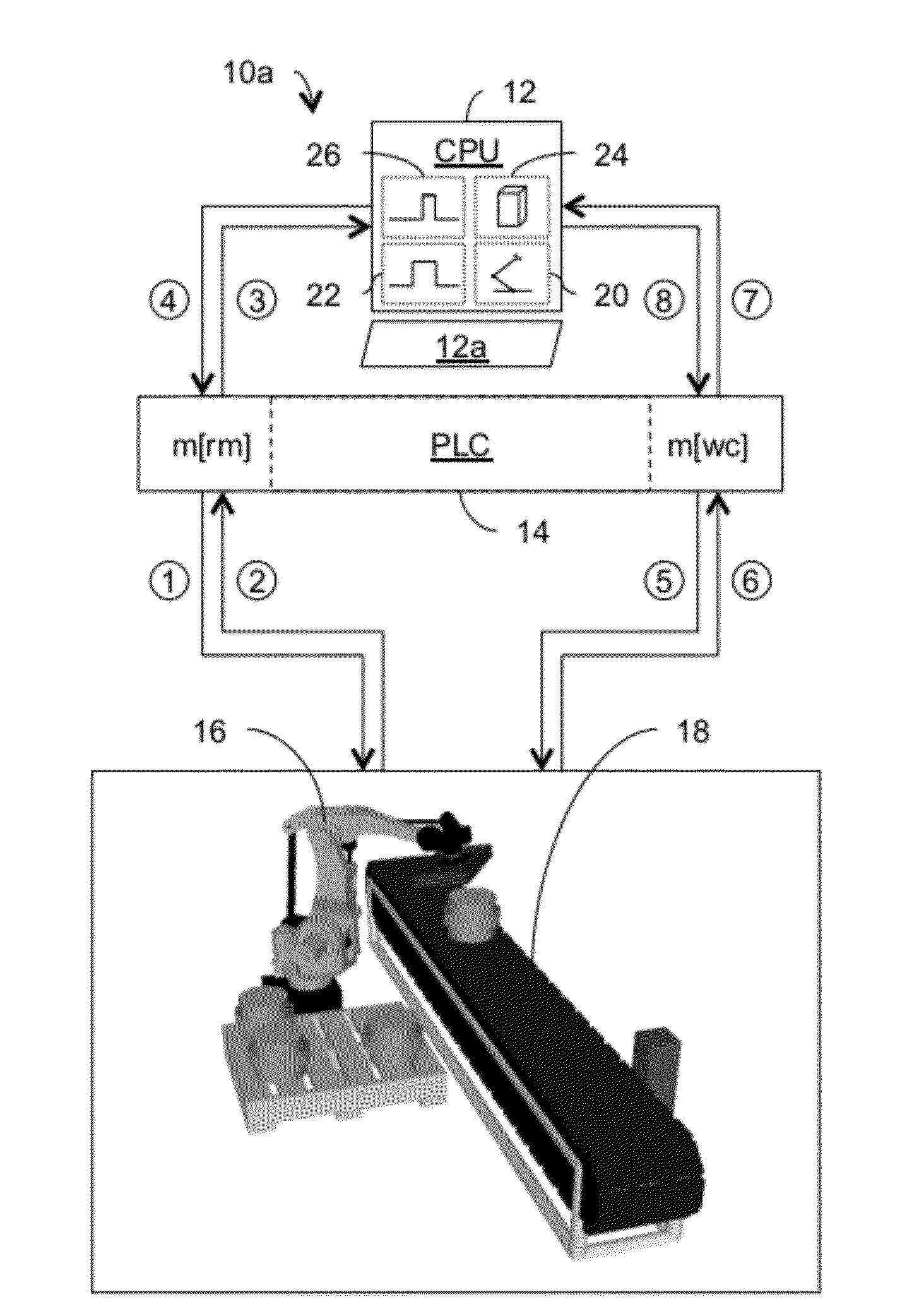

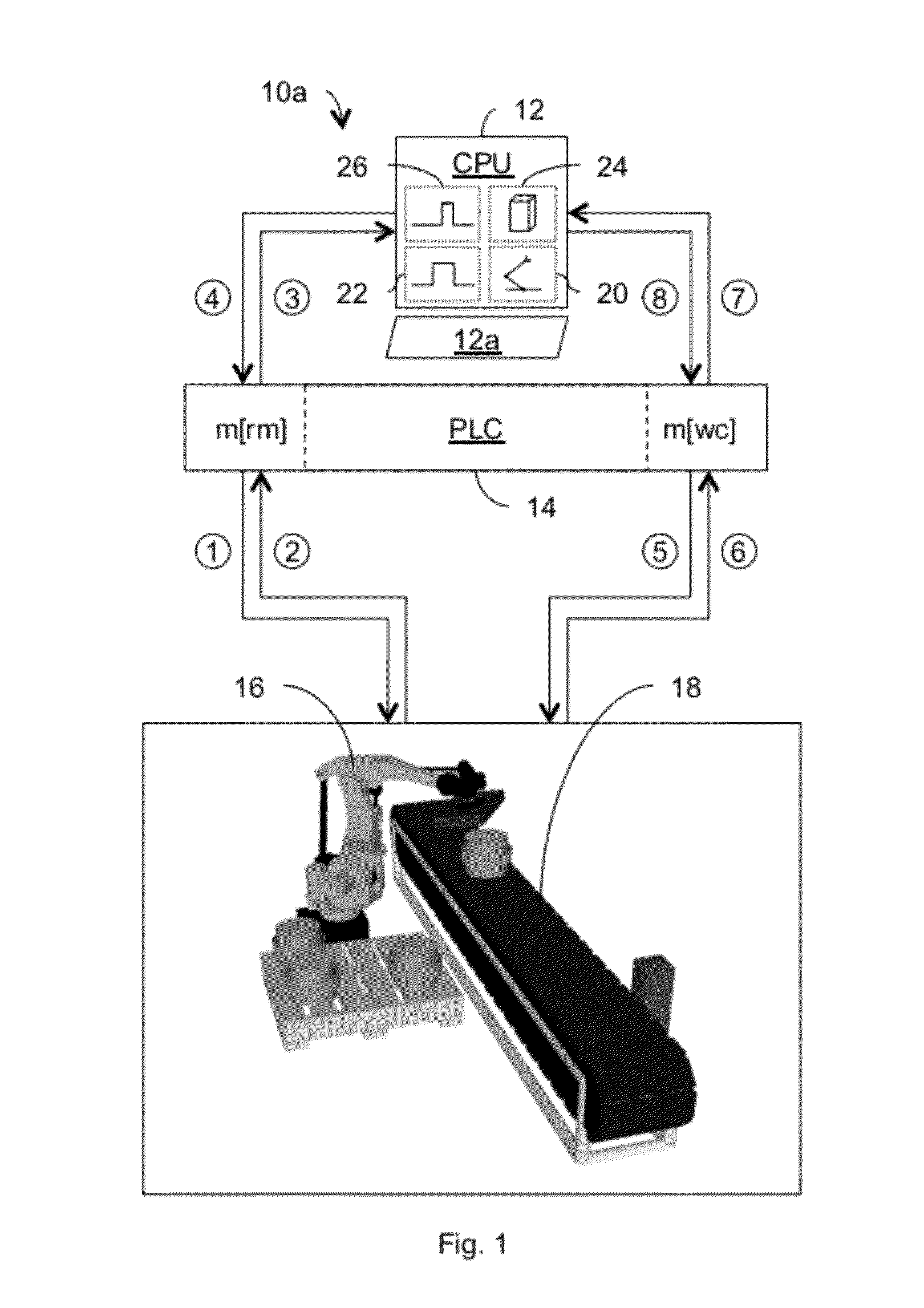

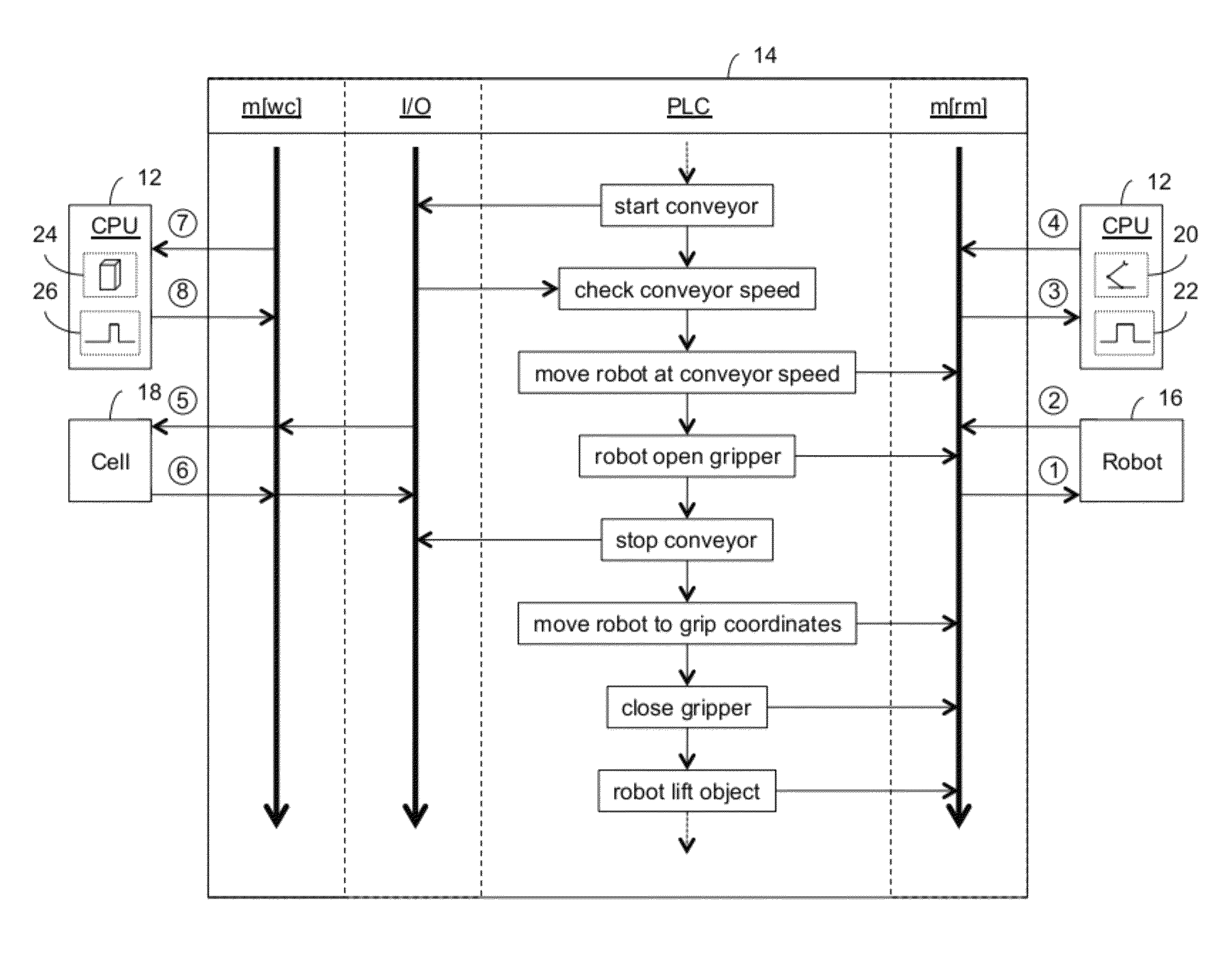

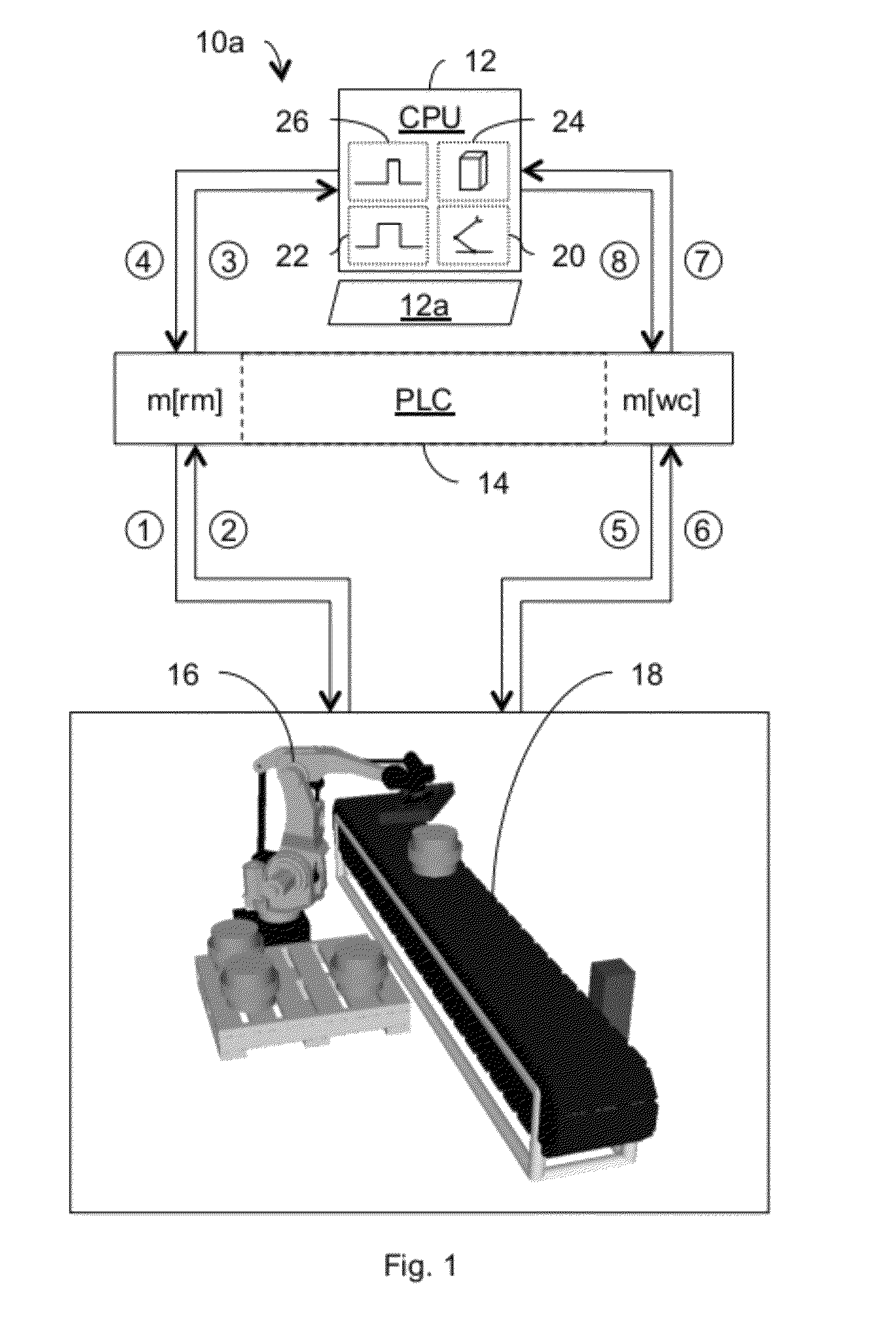

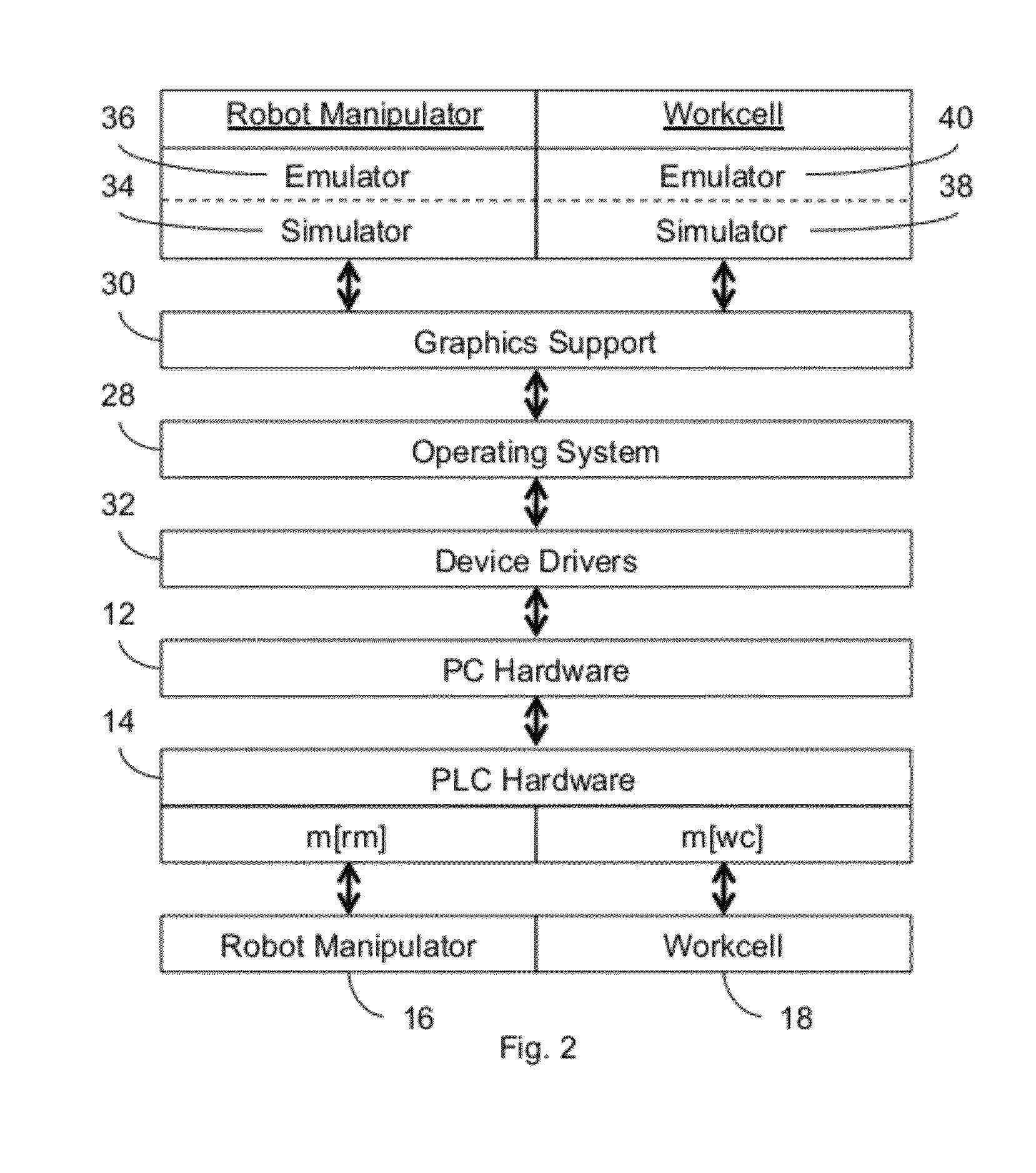

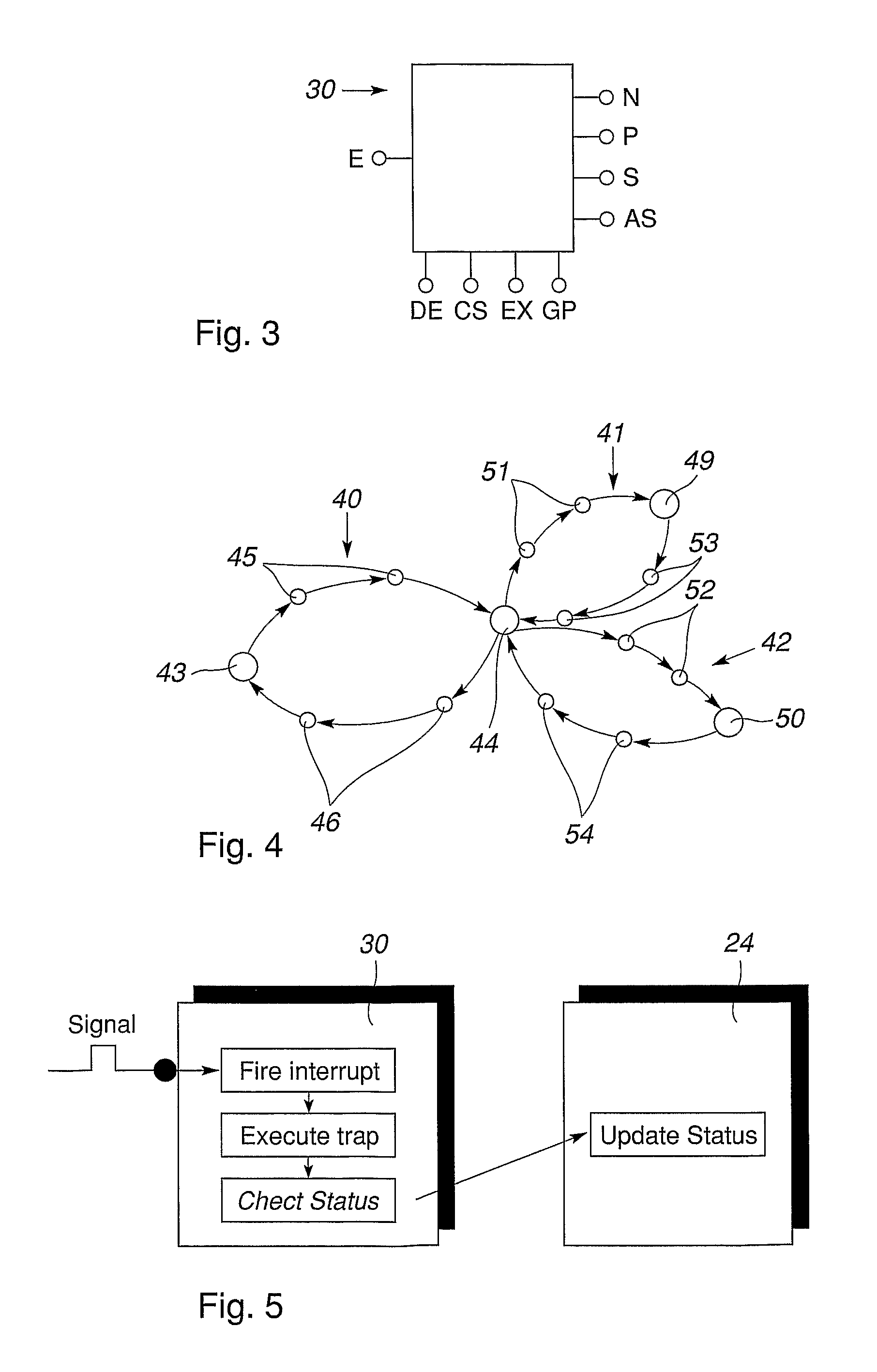

Method and Apparatus for Integrated Simulation

ActiveUS20120101613A1Improve securityFacilitates efficient developmentProgramme controlTechnology managementWorkcellControl system

In an automated system which includes a robot manipulator, a workcell, and a control system implemented on a hardware platform based on a programmable logic controller (“PLC”), a method and apparatus for performing integrated simulation that does not require the presence of both the robot manipulator and the workcell. If one component is real, the other component is simulated so as to be sufficiently responsive to responses from the real component such that the real component is unable to discern that the other component is not also real. A computing device simultaneously displays simulacra of both the components, real and simulated, and visualizations of the responses provided by each.

Owner:YASKAWA INNOVATION INC

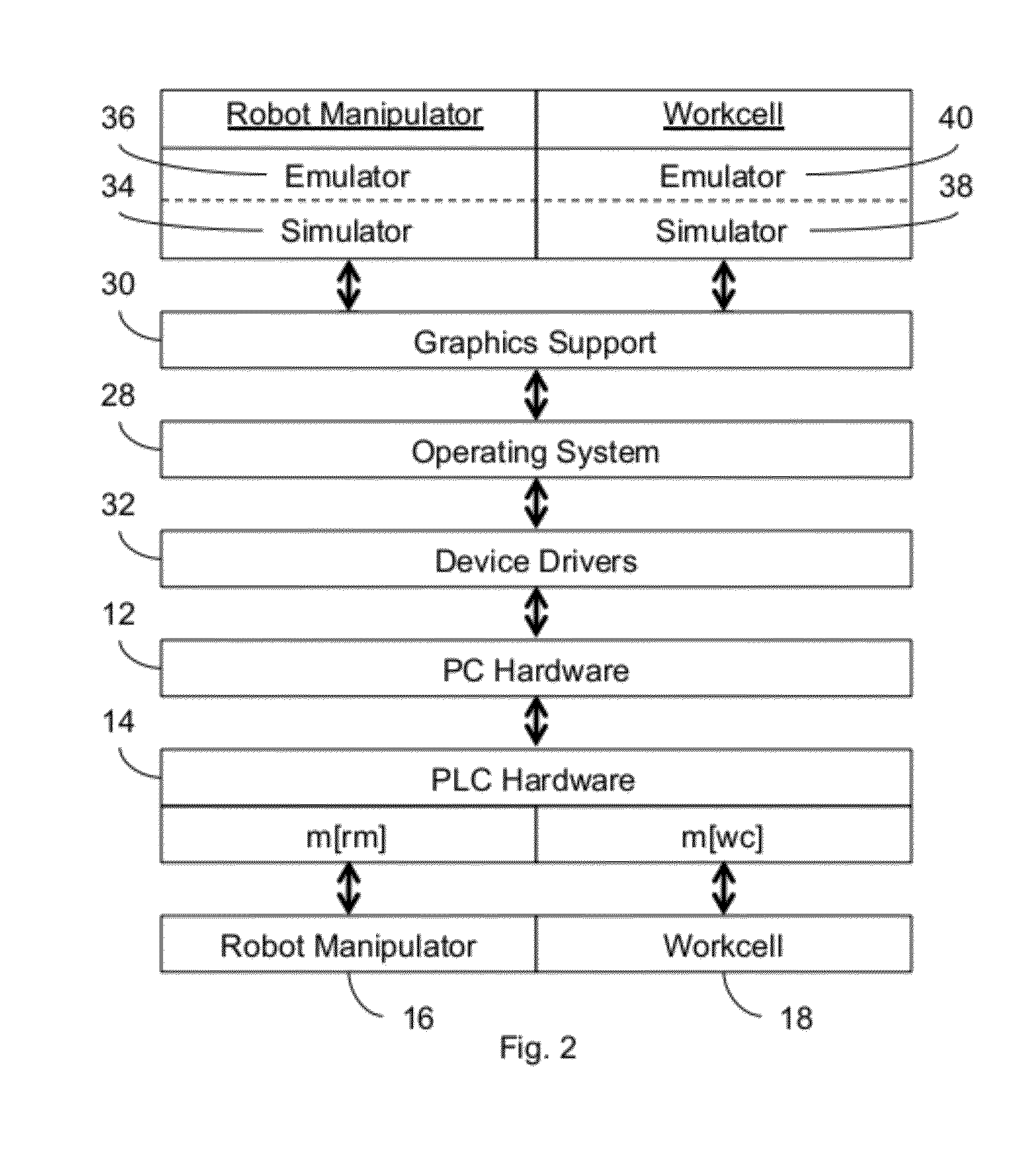

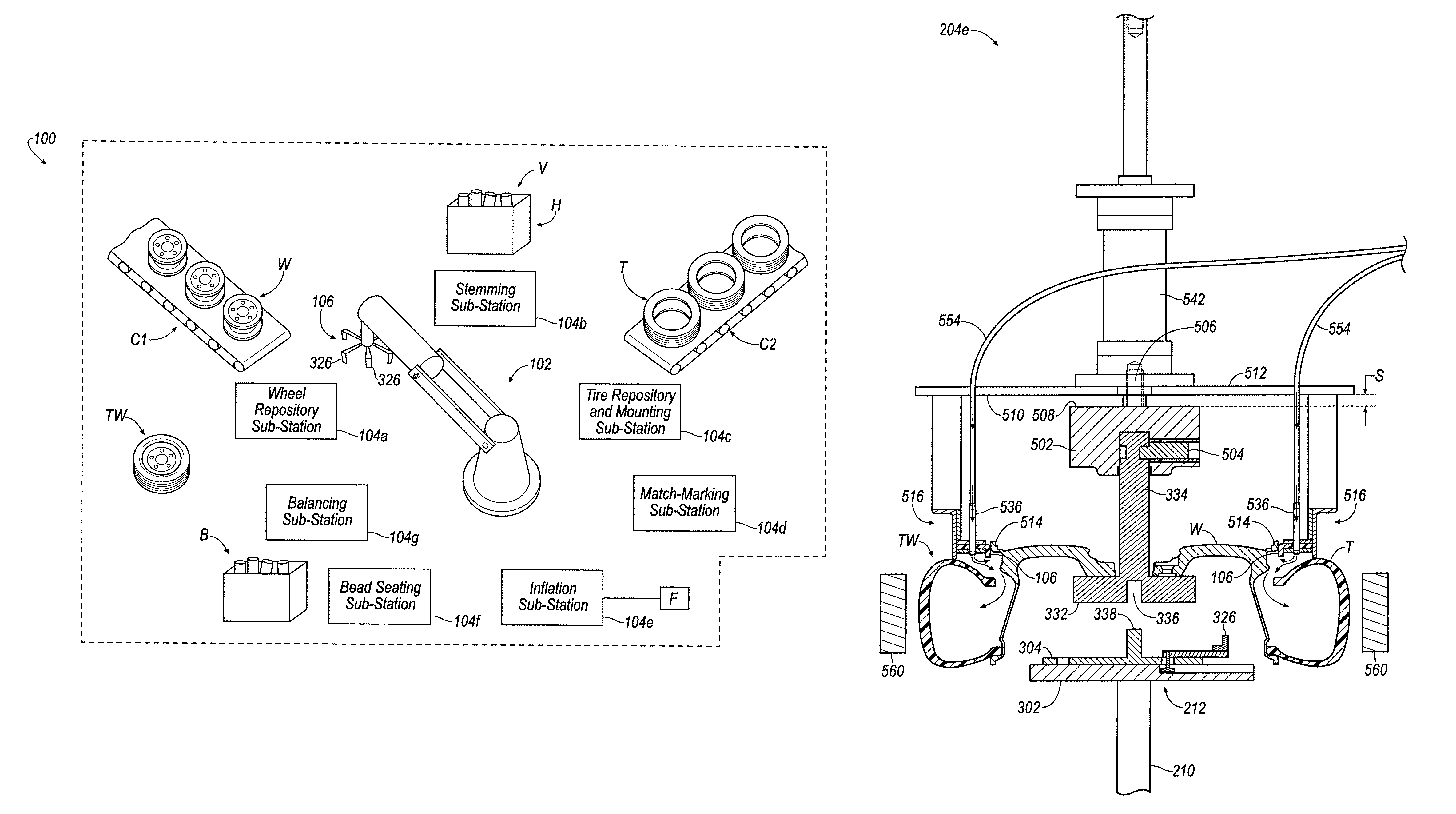

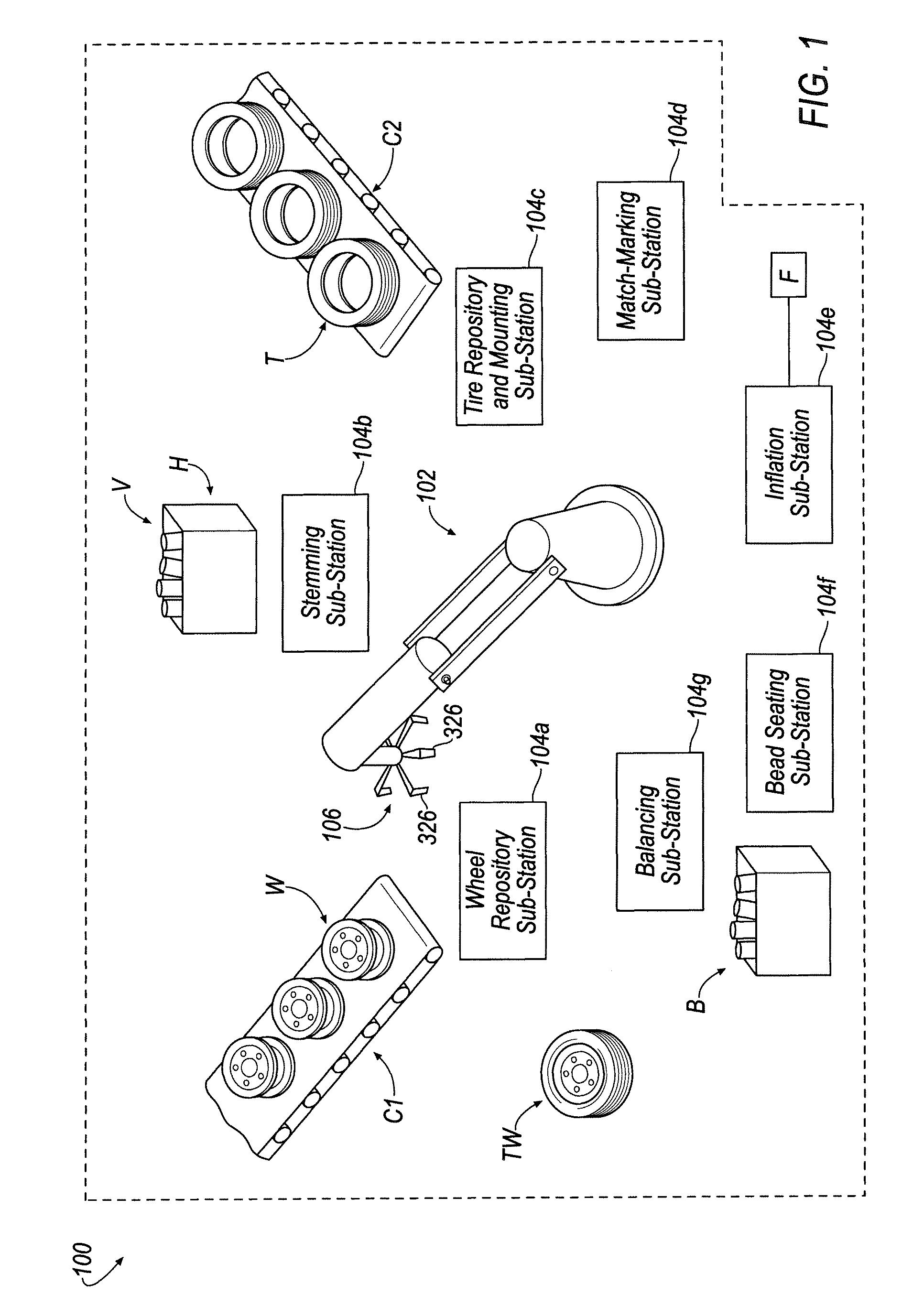

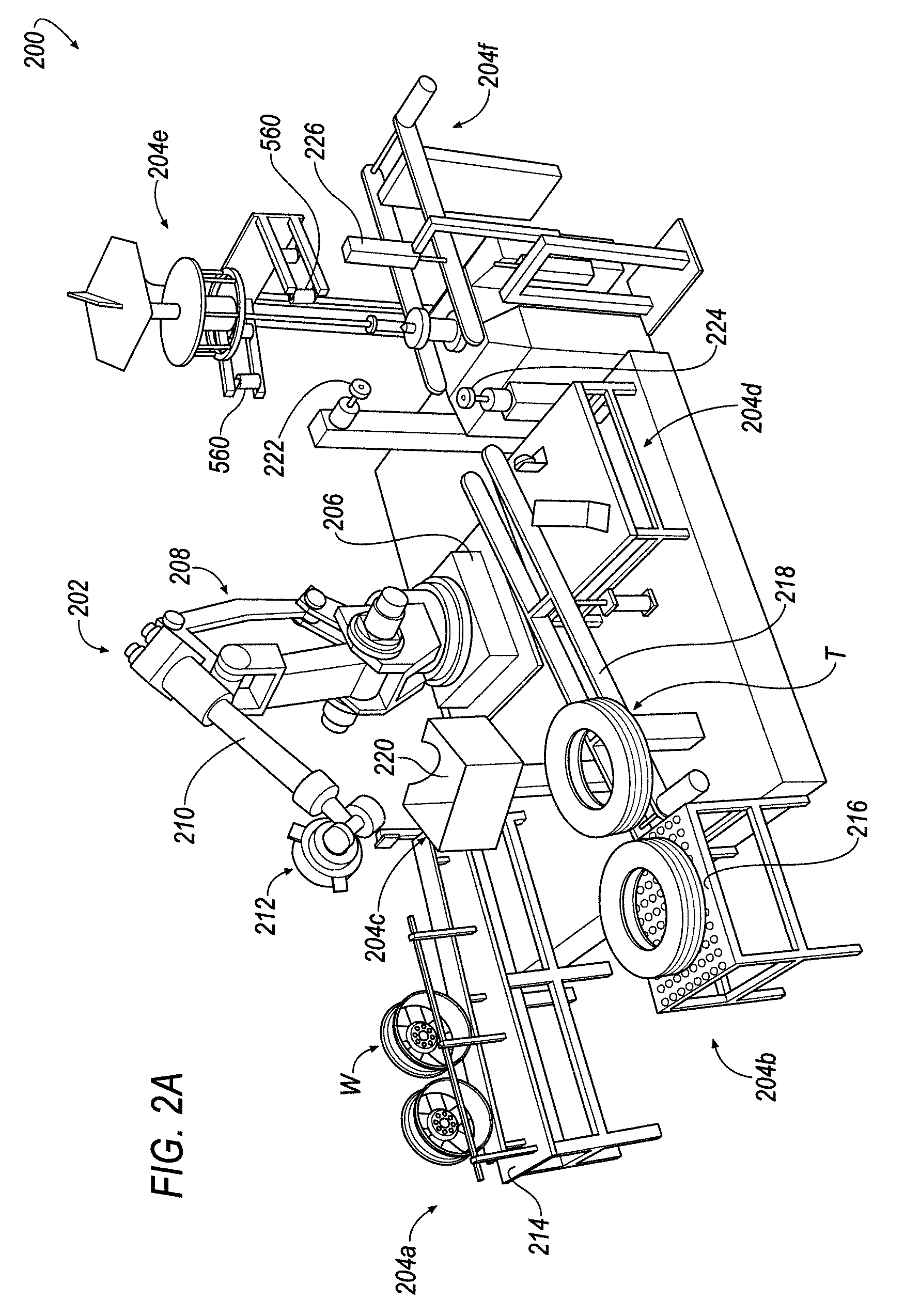

Workcell for tire and wheel assembly including a tire inflating sub-station that utilizes a flexible flip seal

An apparatus for assembling a tire and a wheel is disclosed. The apparatus includes a single-cell workstation including a device that retains a wheel, and a plurality of sub-stations. The device moves the wheel to each of the plurality of sub-stations, without releasing the wheel, to assemble a tire-wheel assembly. A method is also disclosed.

Owner:ANDROID INDS OF MICHIGAN

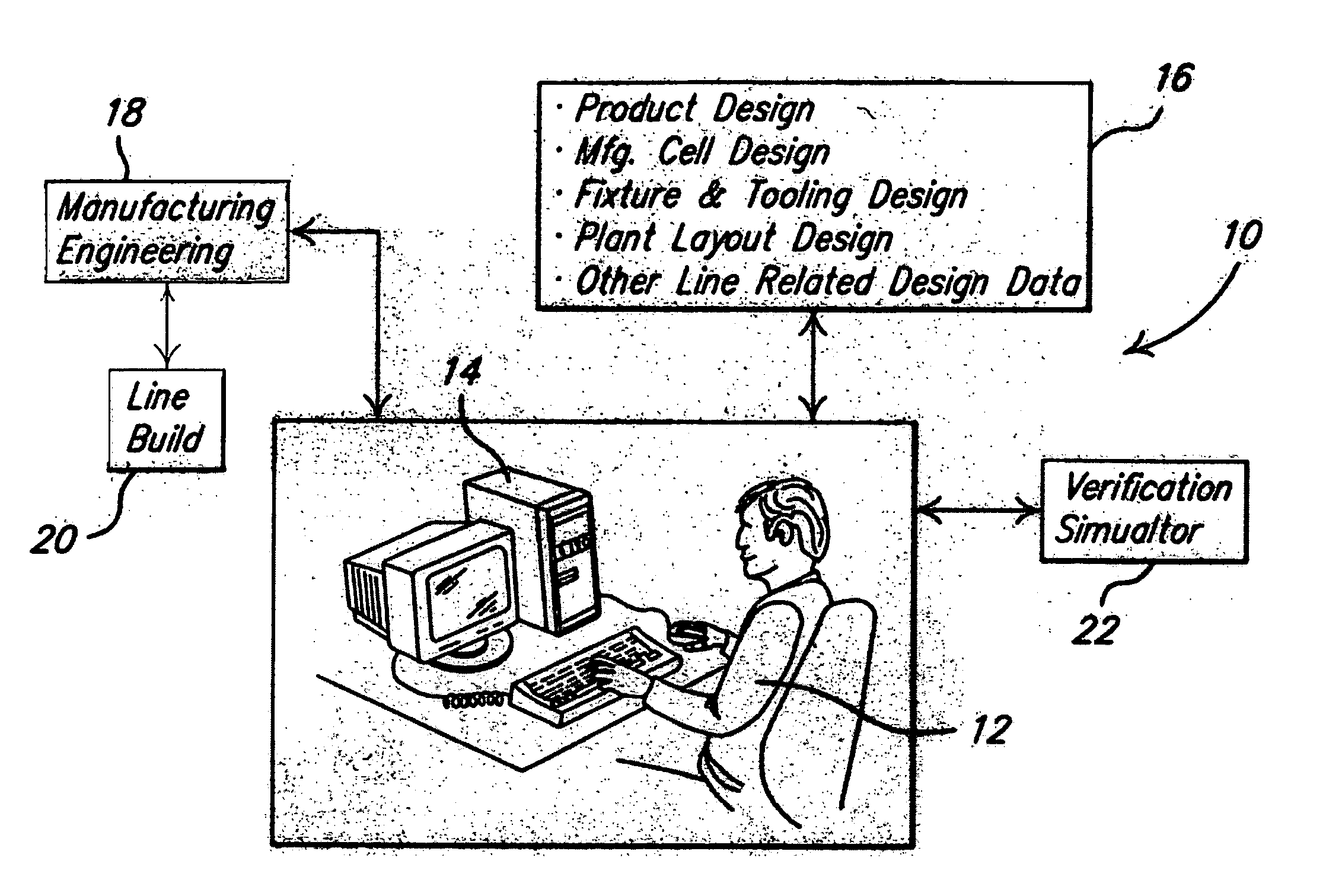

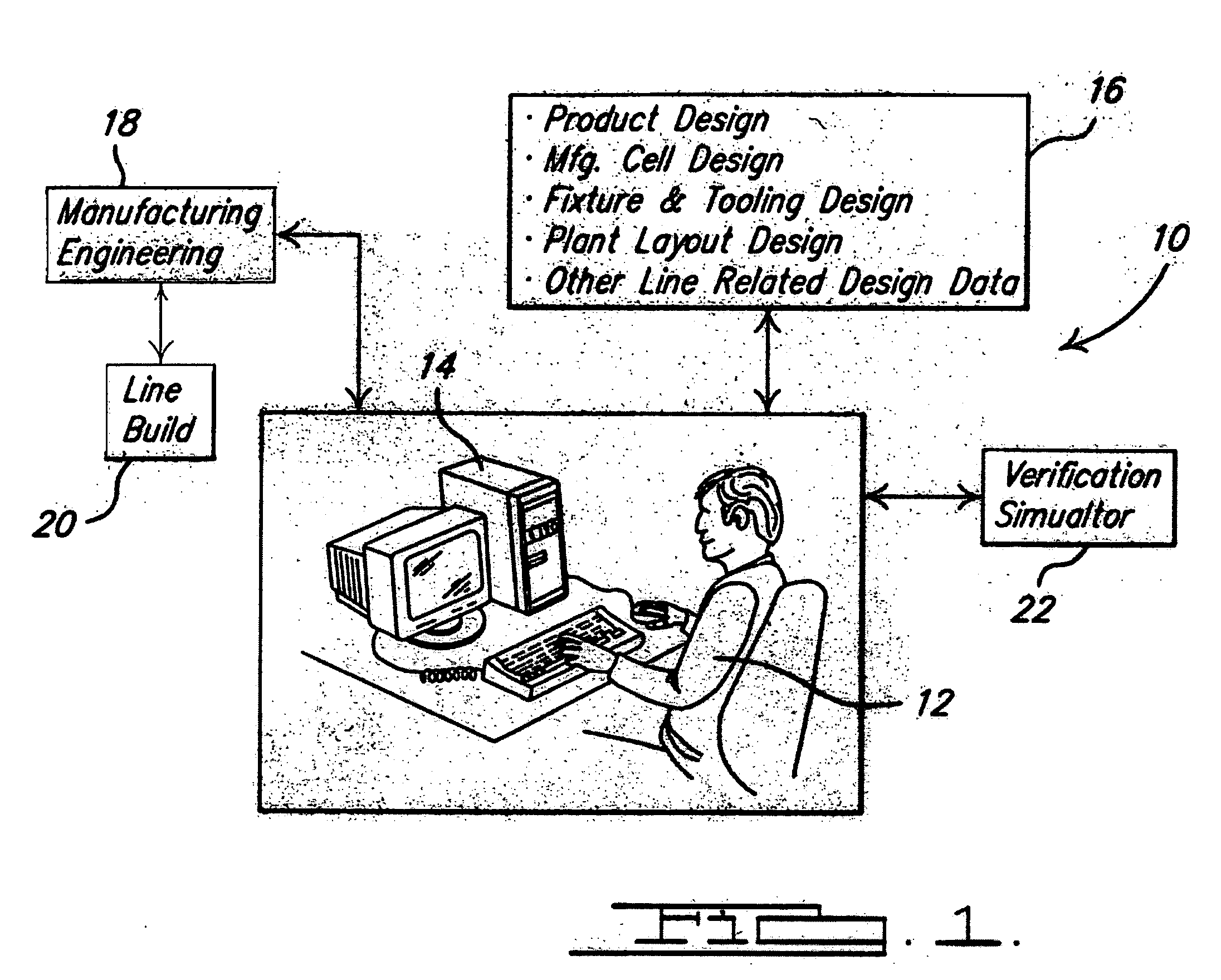

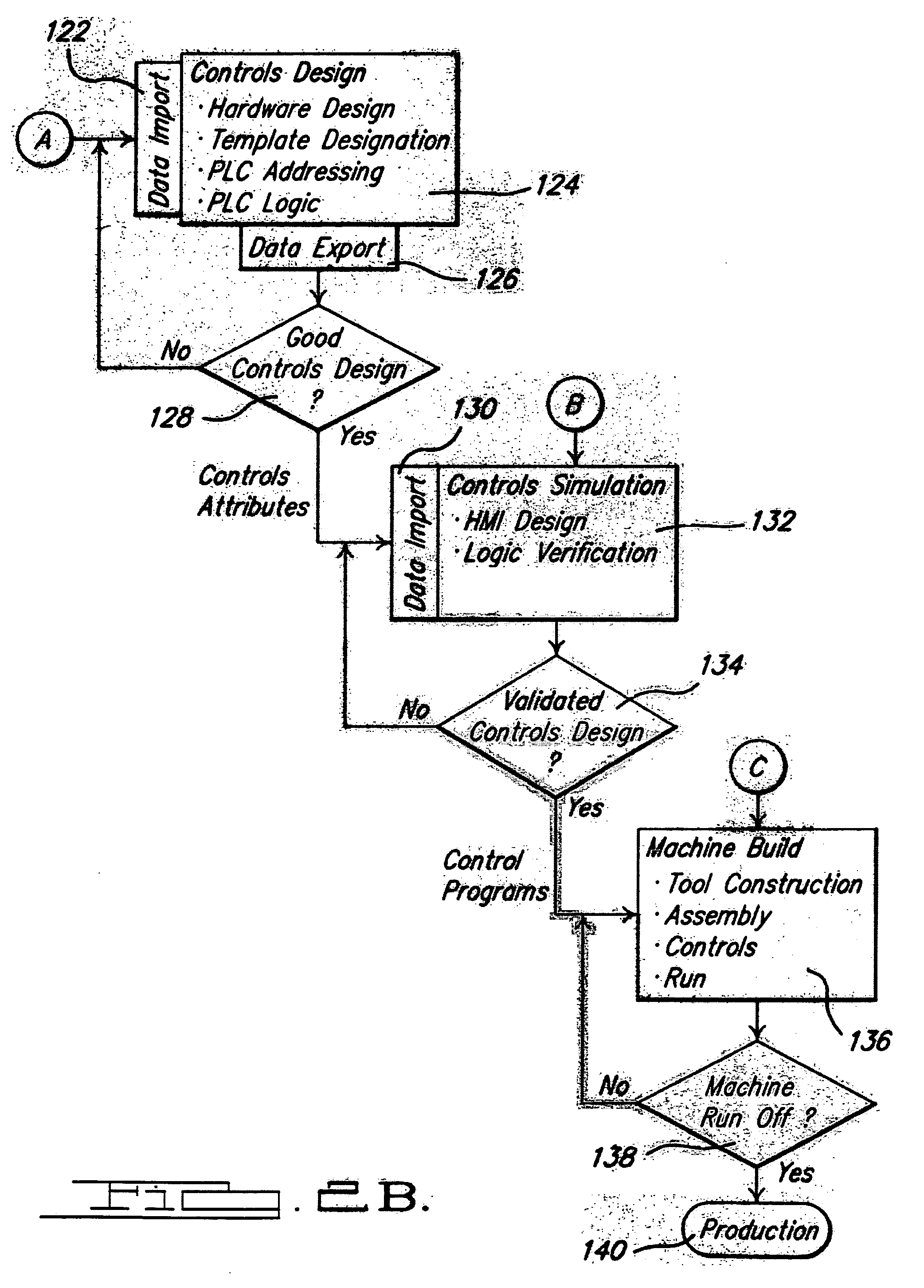

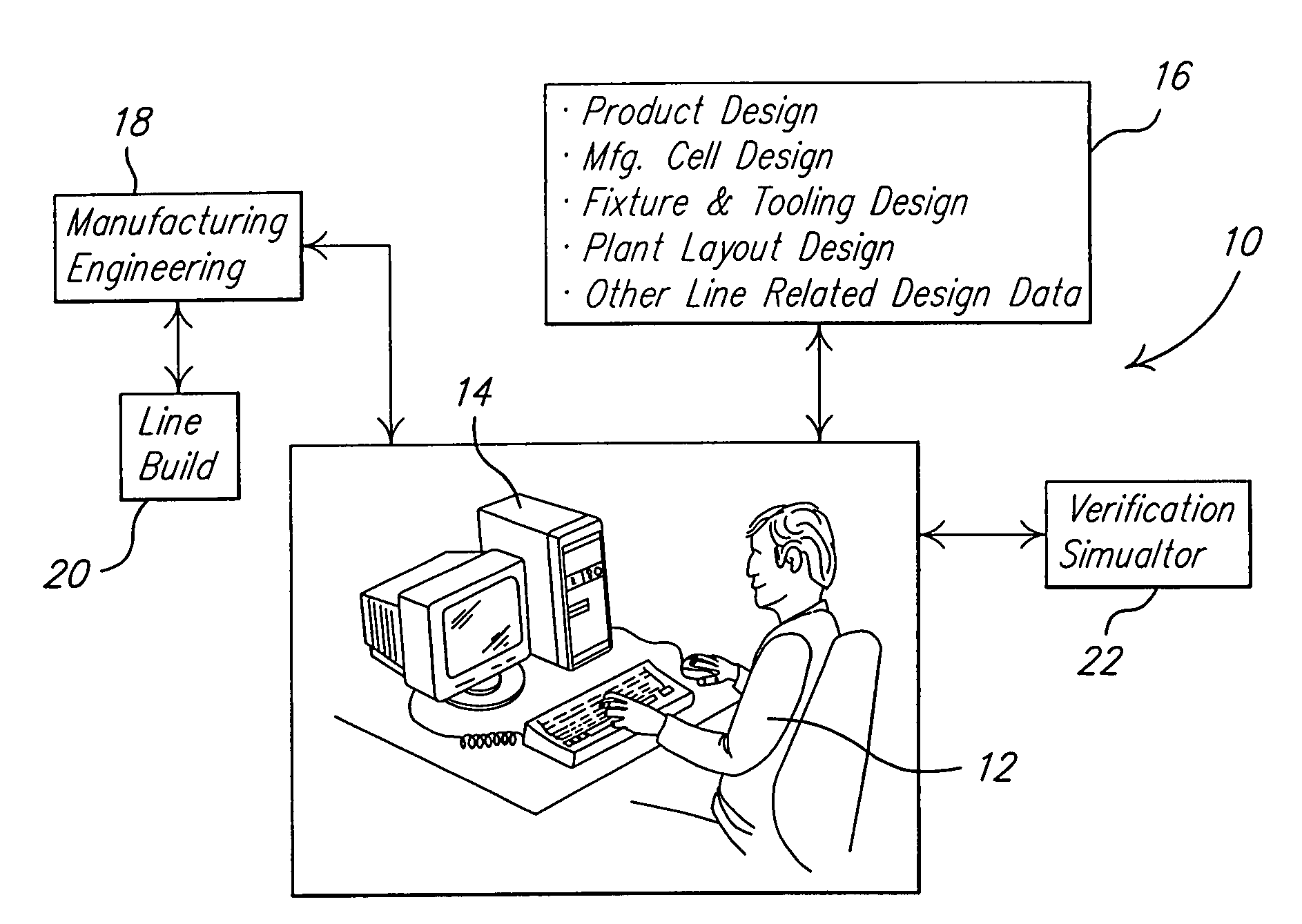

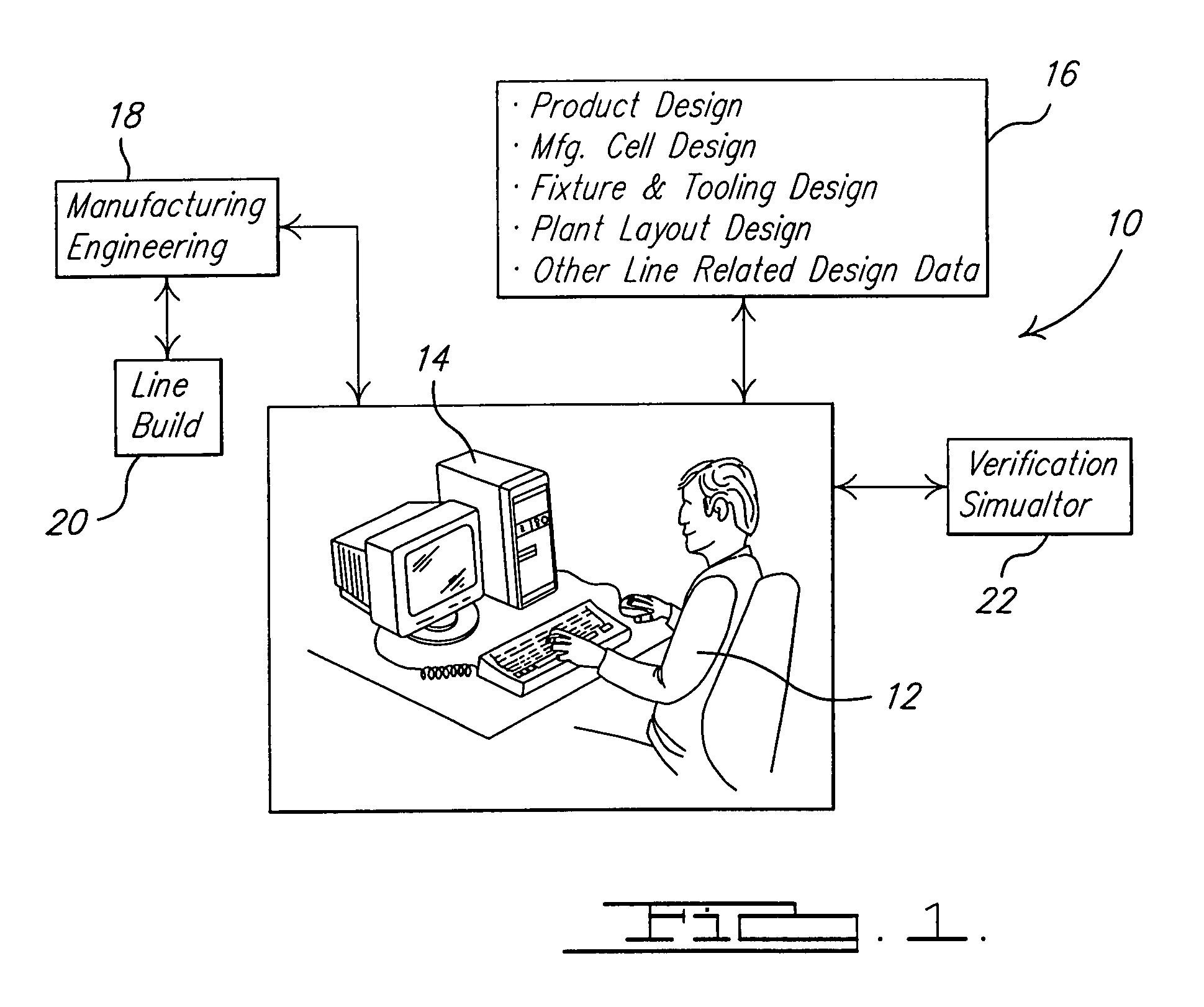

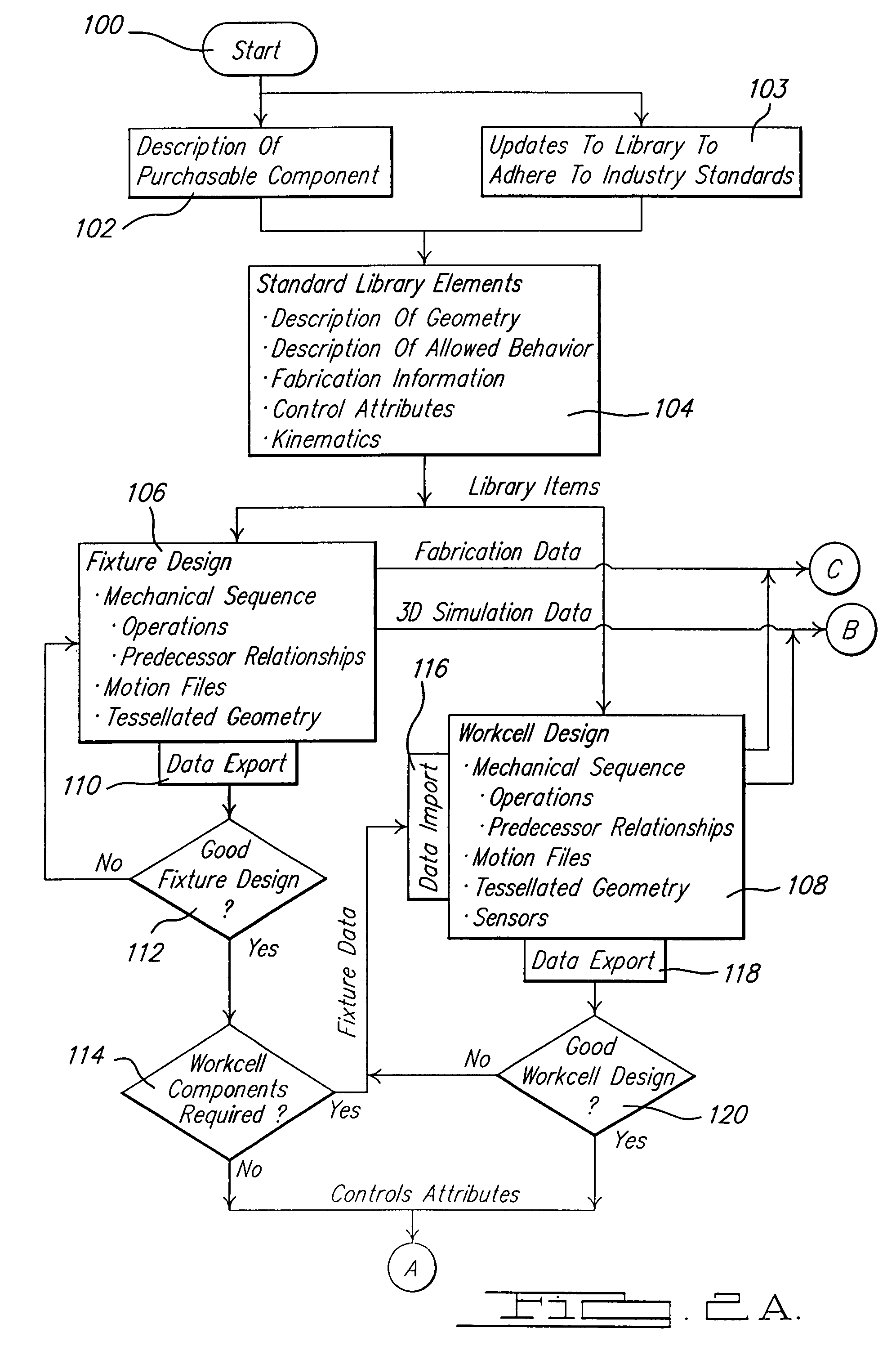

Method of embedding tooling control data within mechanical fixture design to enable programmable logic control verification simulation

InactiveUS20060064289A1Amount of timeImprove accuracyProgramme controlAnalogue computers for electric apparatusWorkcellComputer architecture

A method is provided of embedding tooling control data within a mechanical fixture design to enable programmable logic control verification simulation. The method includes the steps of constructing at least one of a mechanical fixture design, a workcell design, and a controls design. The method also includes the steps of executing a virtual programmable logic control (VPLC) simulation with a VPLC verification simulator to verify the at least one of the mechanical fixture design, the workcell design, and the controls design.

Owner:FORD MOTOR CO

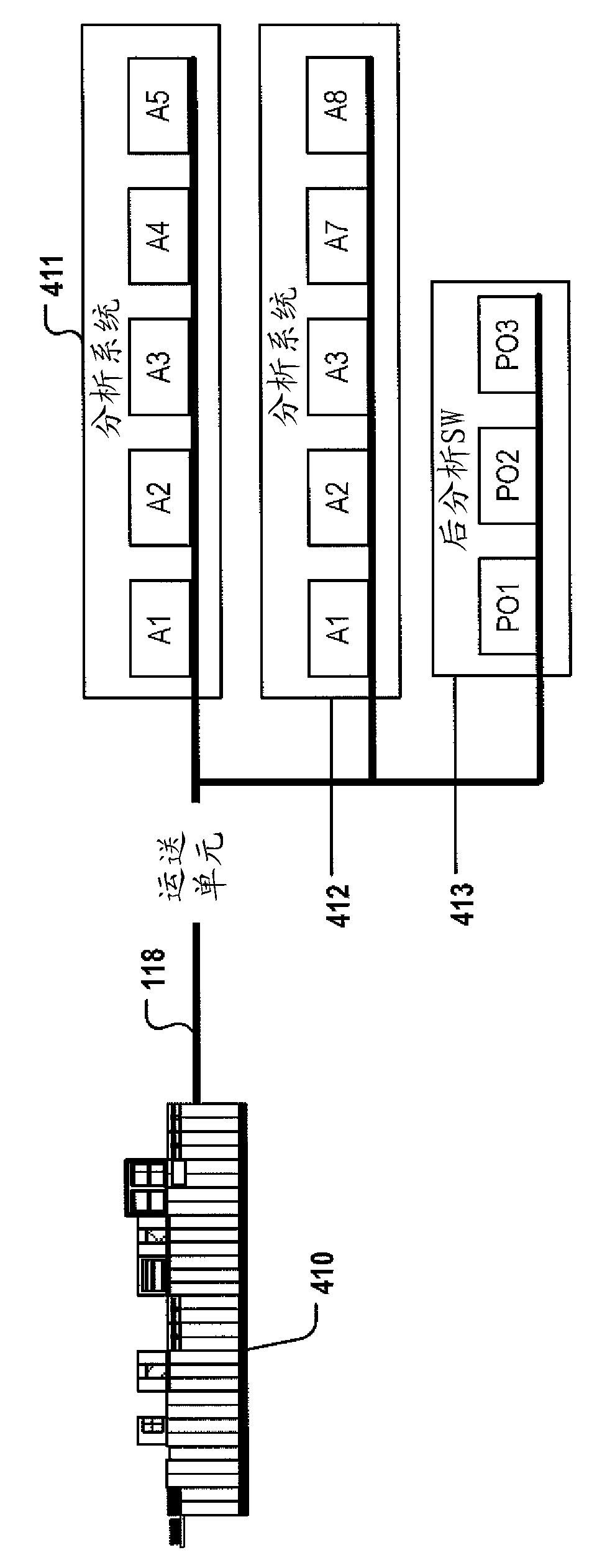

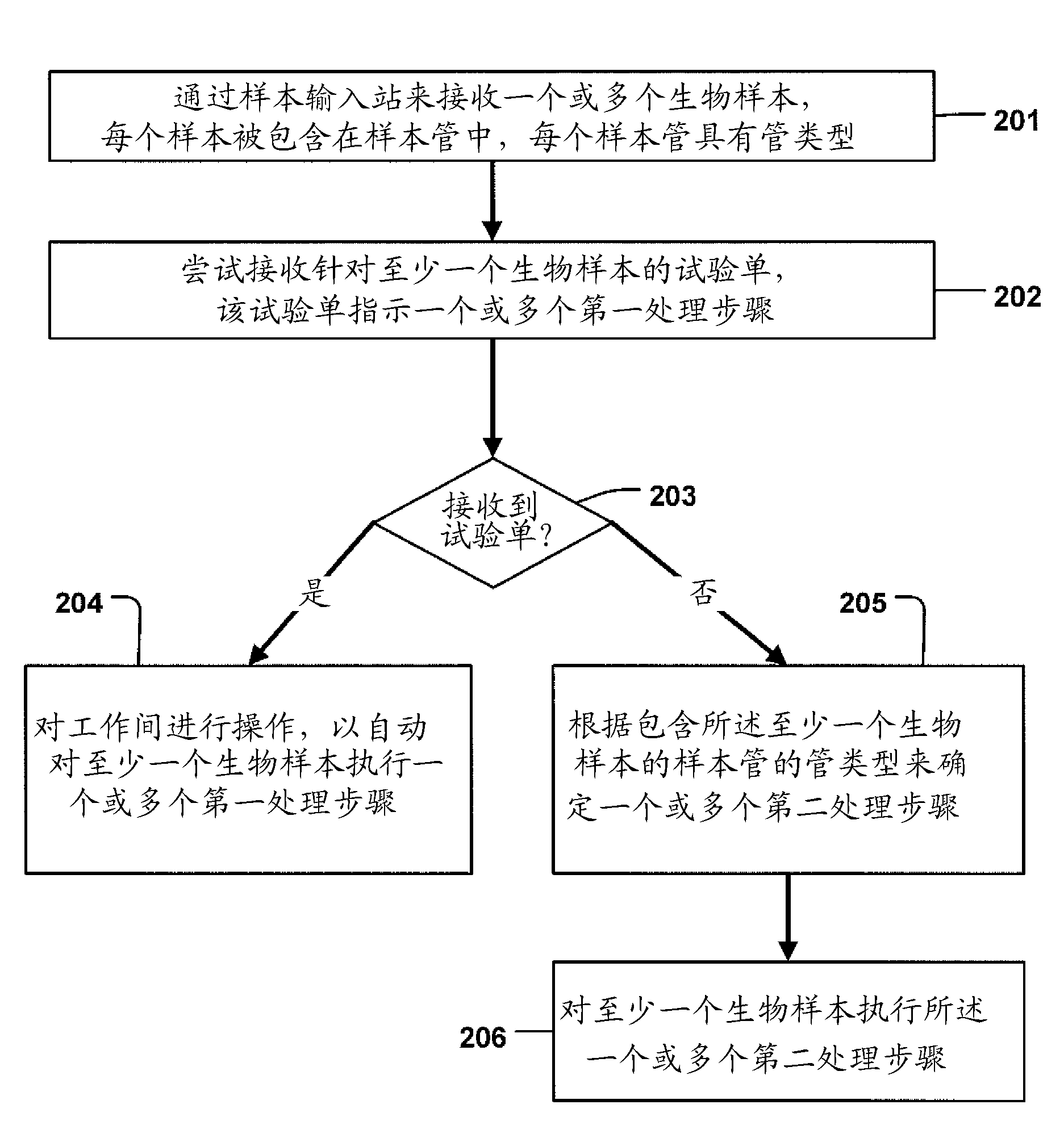

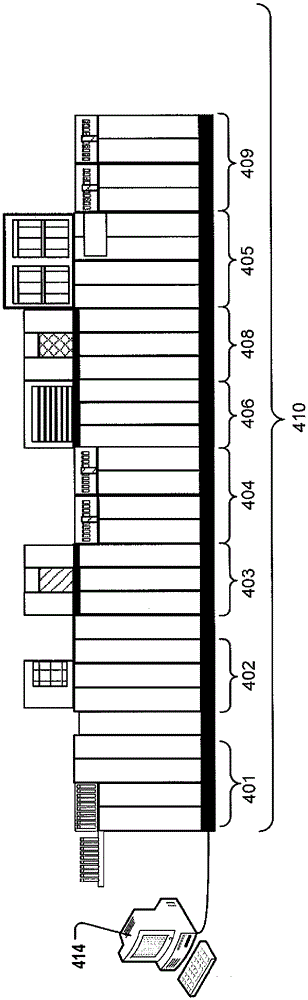

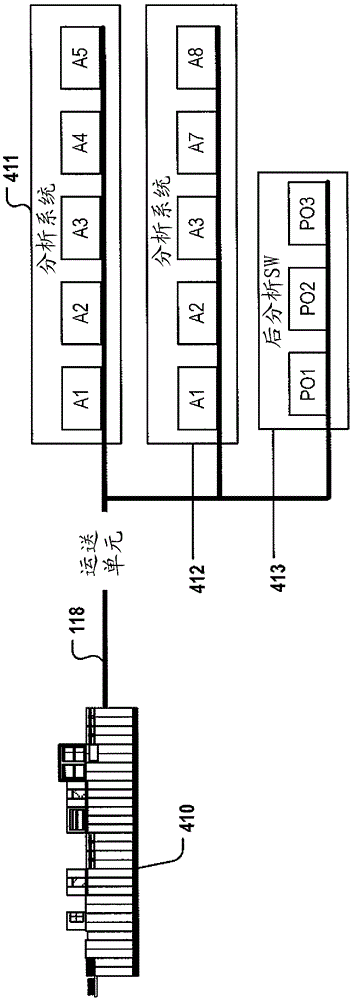

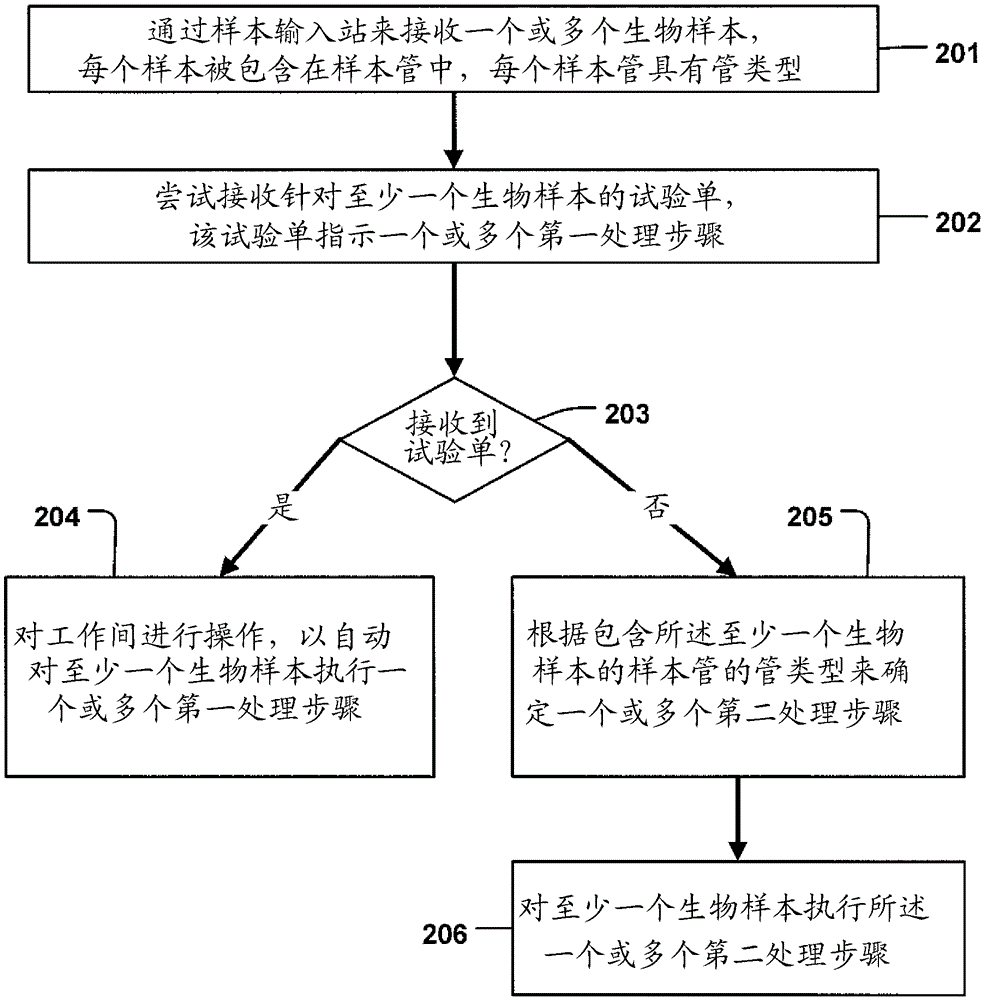

Method for operating automated sample workcell

A method for operating an automated sample workcell (102, 410, 301) for processing one or more biological samples (125-130), the method comprising: - receiving (201) the one or more biological samples, each sample being contained in a sample tube, each sample tube being of a tube type (122-124),- in case a test order (104) was received for at least one of said biological samples, the test order being indicative of one or more first processing steps, operating (204) the workcell for automatically executing the one or more first processing steps, and - in case said test order was not received, determining (205) one or more second processing steps in dependence on the tube type of the sample tube that contains said at least one biological sample, and executing (206) said one or more second processing steps.

Owner:F HOFFMANN LA ROCHE & CO AG

Method of embedding tooling control data within mechanical fixture design to enable programmable logic control verification simulation

InactiveUS7346478B2Amount of timeImprove accuracyProgramme controlAnalogue computers for electric apparatusWorkcellComputer architecture

A method is provided of embedding tooling control data within a mechanical fixture design to enable programmable logic control verification simulation. The method includes the steps of constructing at least one of a mechanical fixture design, a workcell design, and a controls design. The method also includes the steps of executing a virtual programmable logic control (VPLC) simulation with a VPLC verification simulator to verify the at least one of the mechanical fixture design, the workcell design, and the controls design.

Owner:FORD MOTOR CO

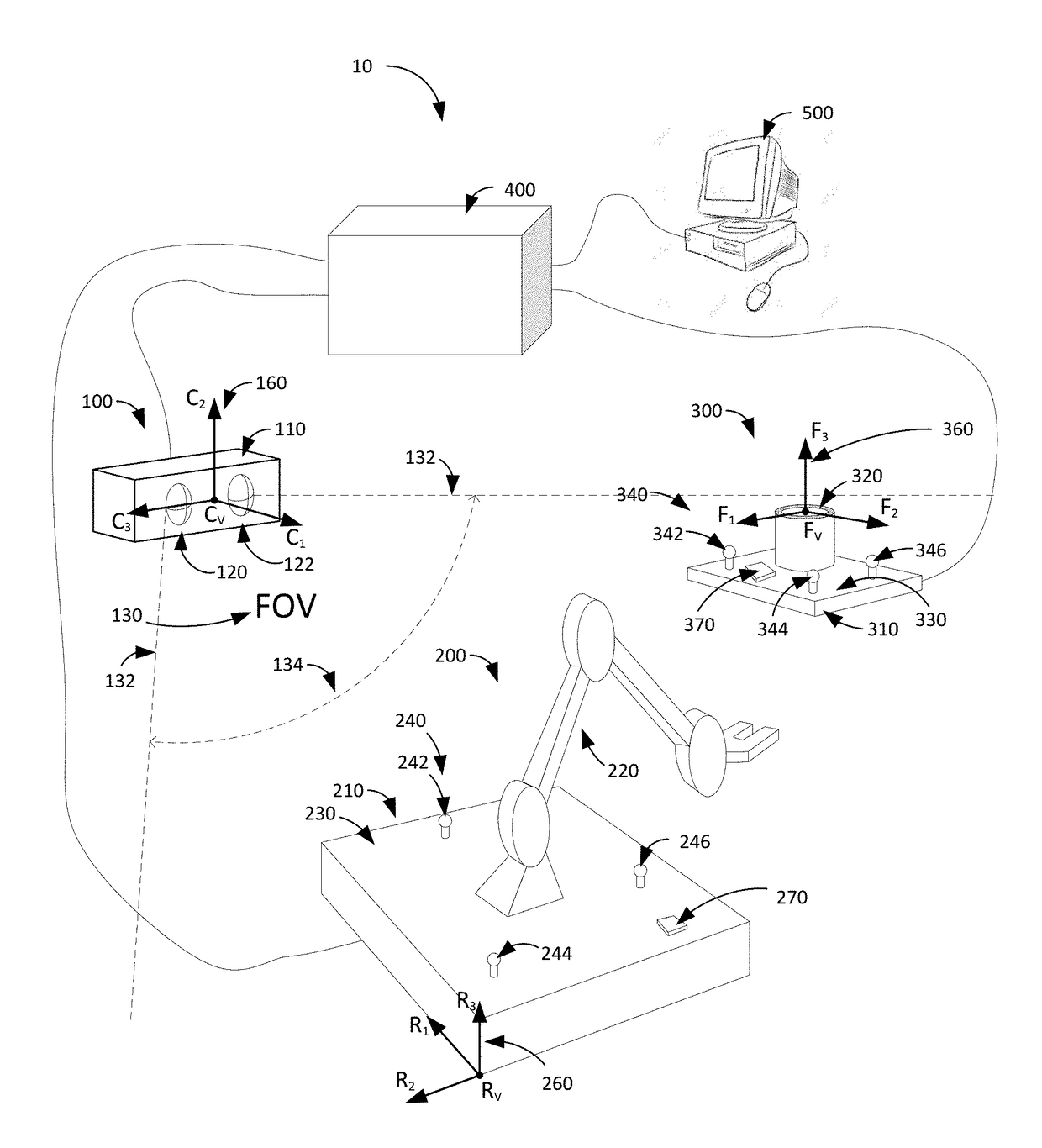

Determination of relative positions

ActiveUS10078908B2Improve simplicityLow costTelevision system detailsImage enhancementWorkcellComputer module

A workcell has a camera module with two optical systems and a memory containing information about the arrangement of the optical systems, a robot module with a first coordinate system, a first set of fiducials, and a memory containing information about the 3D positions of the first set of fiducials defined within the first coordinate system, and a fixture with a second coordinate system, a second set of fiducials, and a memory containing information about the 3D positions of the second set of fiducials defined within the second coordinate system. A processor is communicatively coupled to the camera module, the robot module, and the fixture. The processor is configured to receive information about positions of each of the fiducials as observed by the two optical systems, retrieve from the various memories information about the arrangement of the first and second optical systems, the 3D positions of the first set of fiducials, and the 3D positions of the second set of fiducials, and determine the position and orientation of the fixture in the coordinate system of the robot module.

Owner:K2R2

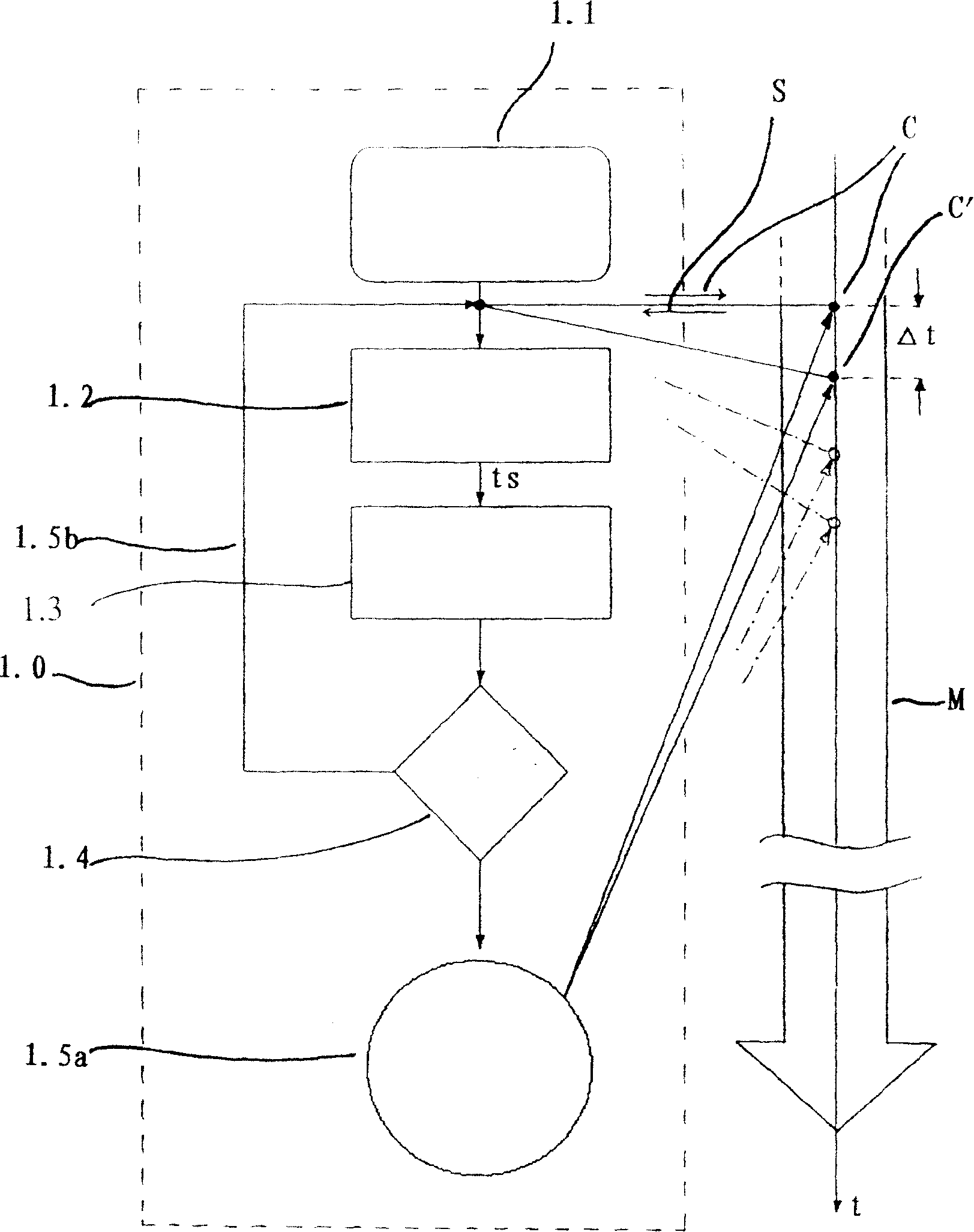

Method for preventing and device for controlling colliding between cooperated manipulators

InactiveCN100380259CSafety stopShort stop timeProgramme controlProgramme-controlled manipulatorWorkcellSimulation

A method of avoiding collisions between a robot and at least one other object, e.g. another robot is disclosed in which the user does not need to make any provisions in a robot program for avoiding collisions, e.g. defining common work-areas. Furthermore, the inventive method allows for automatic configuration of the workcell from a collision avoidance standpoint. It determines automatically which components have potential collisions with which other components. Since the inventive method is based on predicting the configurations of the moving components over a period of time sufficient enough to allow the machines to stop safely and checks for interference, a priori knowledge of trajectories is not required. If a collision is predicted the machines are commanded to a stop on or off their paths. In this way the inventive collision avoidance method can also be used as a safeguard with other explicit methods.

Owner:KUKA ROBOTER

Method and system for optimizing the layout of a robot work cell

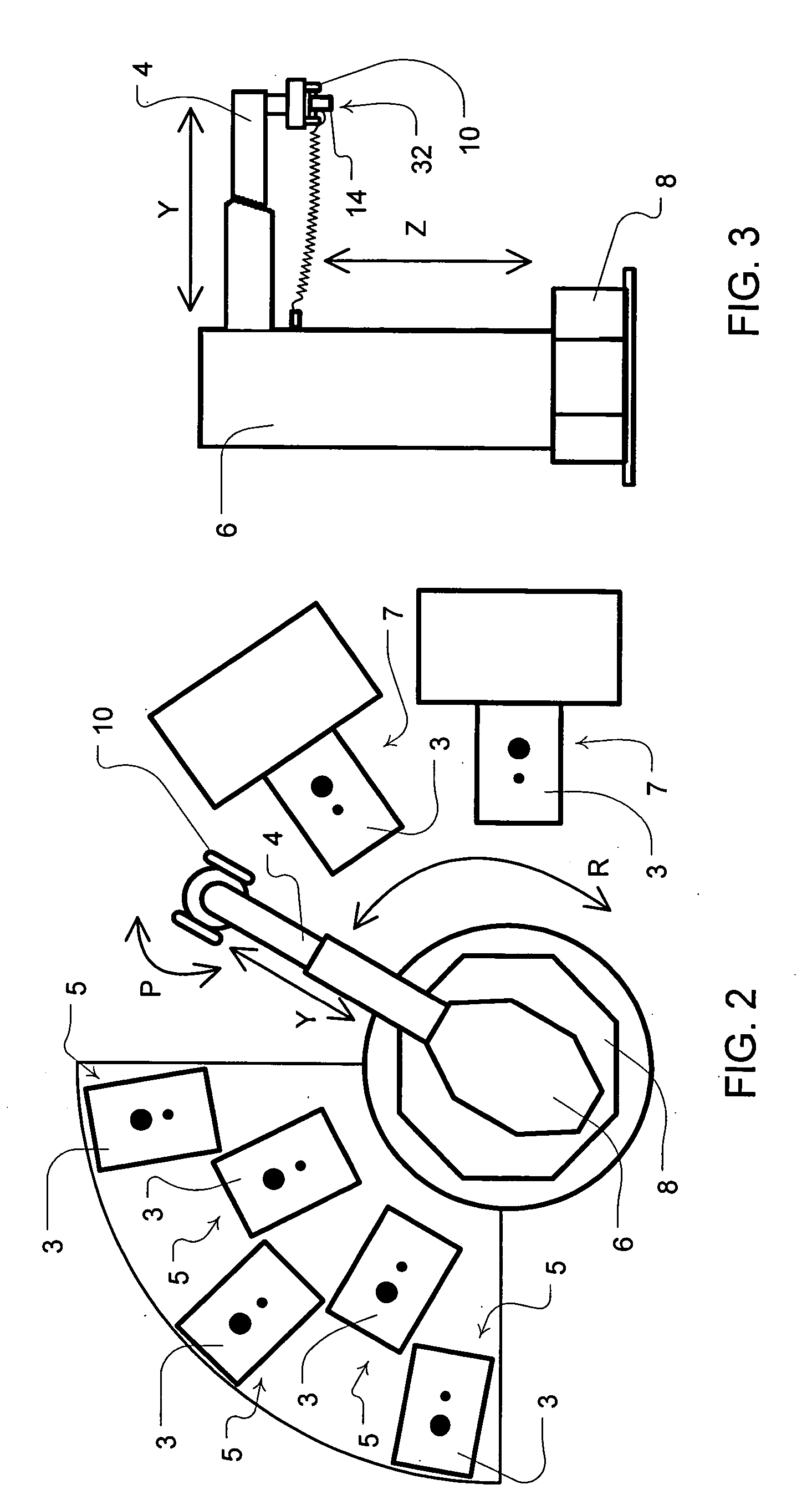

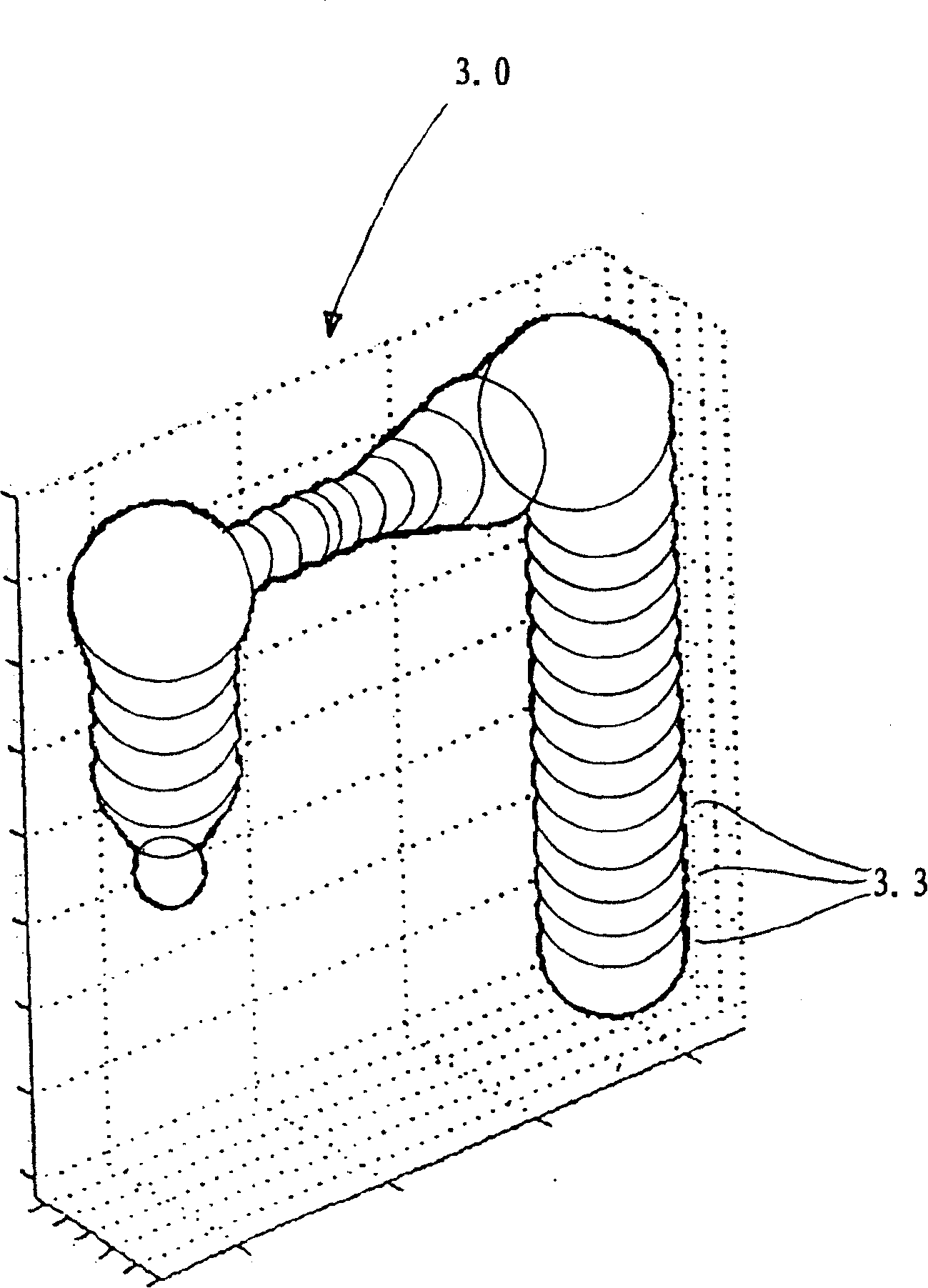

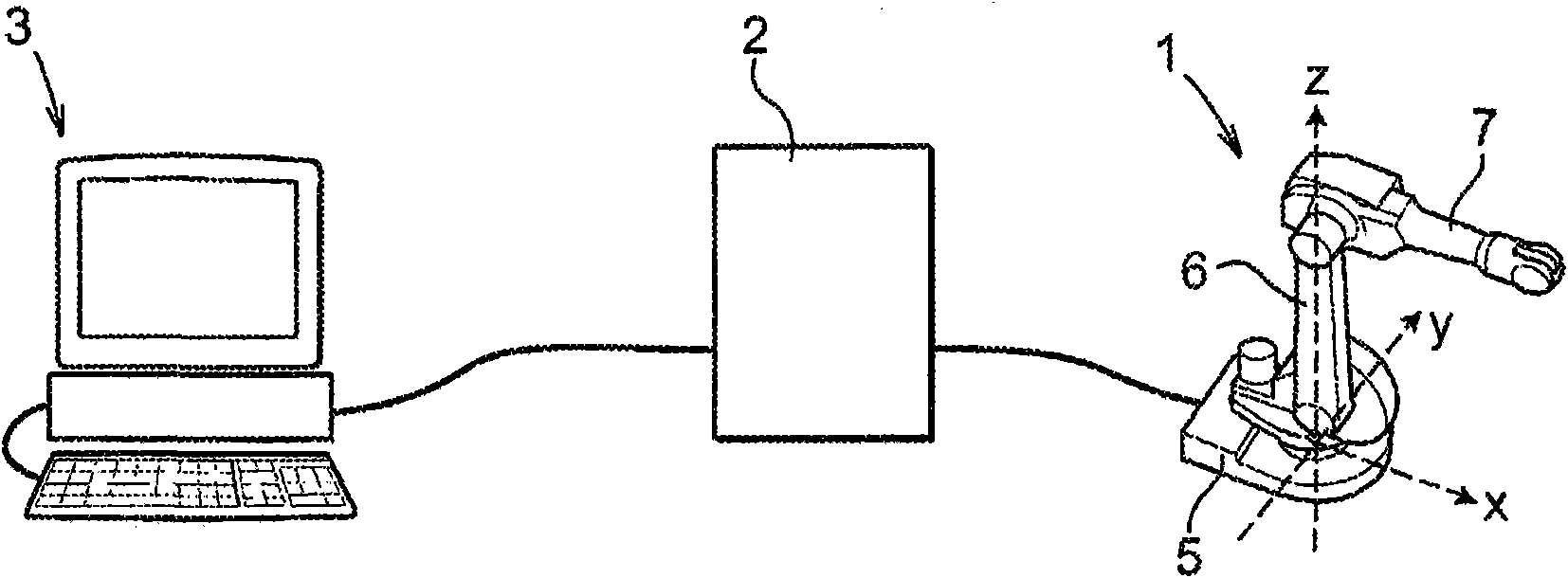

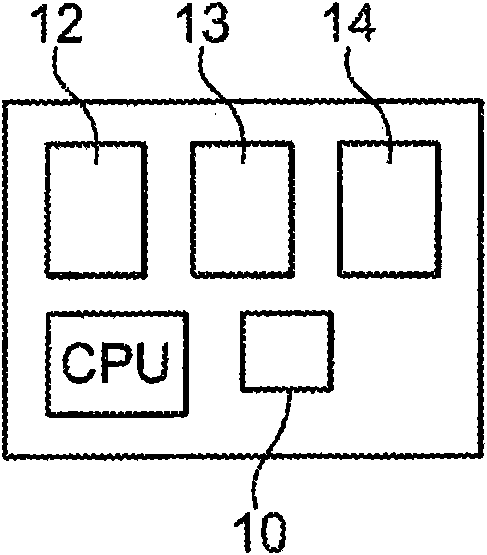

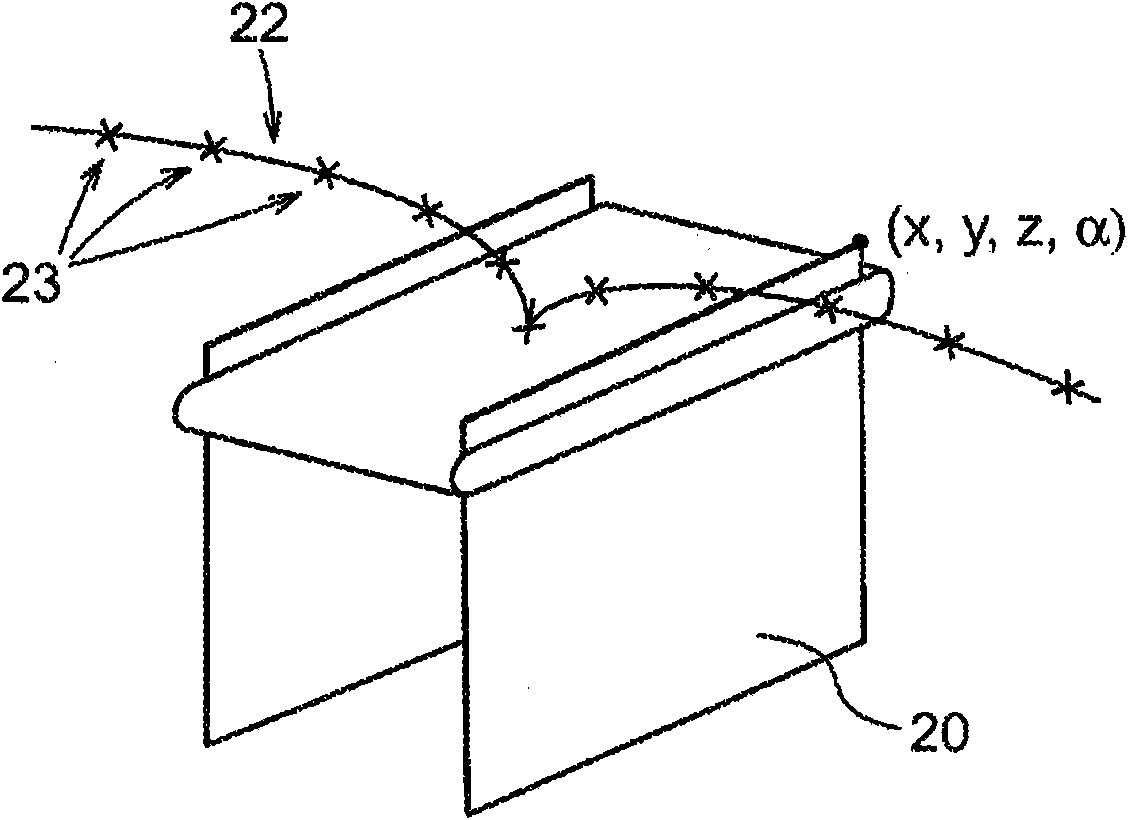

The present invention relates to a method for optimizing the placement of a plurality of workstations (20a-d) in a workcell including an industrial robot (1 ) programmed to execute a sequence of tasks on the workstations, wherein each task contains a series of robot targets linked as one or several paths to be visited by the robot when executing the task at the workstation. The method comprises the following steps: a) defining a preferred region (36) within the reachable range of the robot, placing the tasks inside or as close as possible to the preferred region using an evaluation criterion and an optimization algorithm, and based thereon assigning to each workstation a position inside or close to the preferred region, b) determining by means of an optimization algorithm a best order of the workstations to be placed relative to the robot with regard to the robot performance and a defined order in which the tasks has to be executed, and based thereon adjusting the positions of the workstations, and c) adjusting the positions (x,y,z,[alpha]) of the workstations by means of an optimization algorithm configured to run the robot program iteratively in order to optimize the placement of the workstations with regard to the robot performance.

Owner:ABB RES LTD

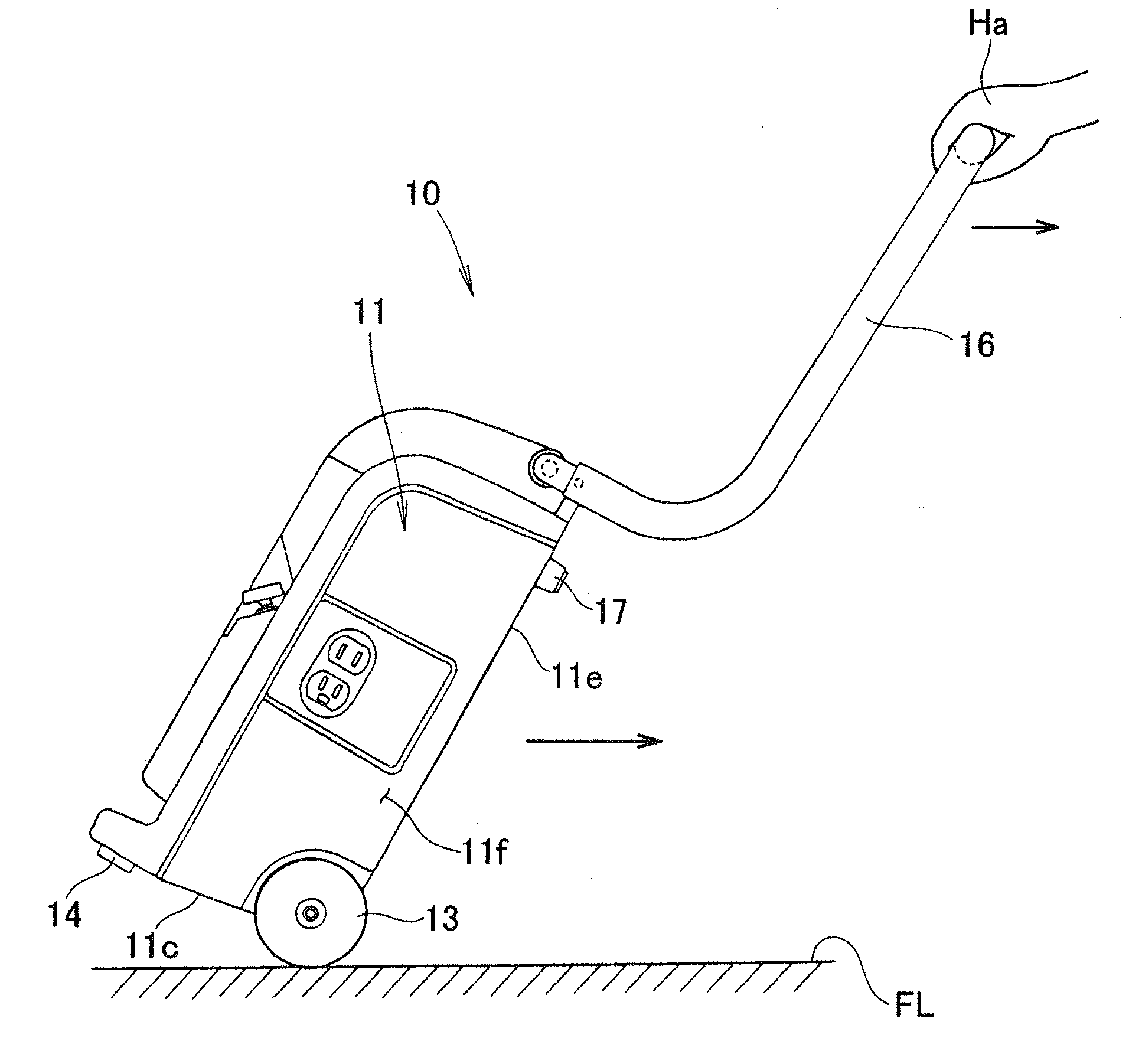

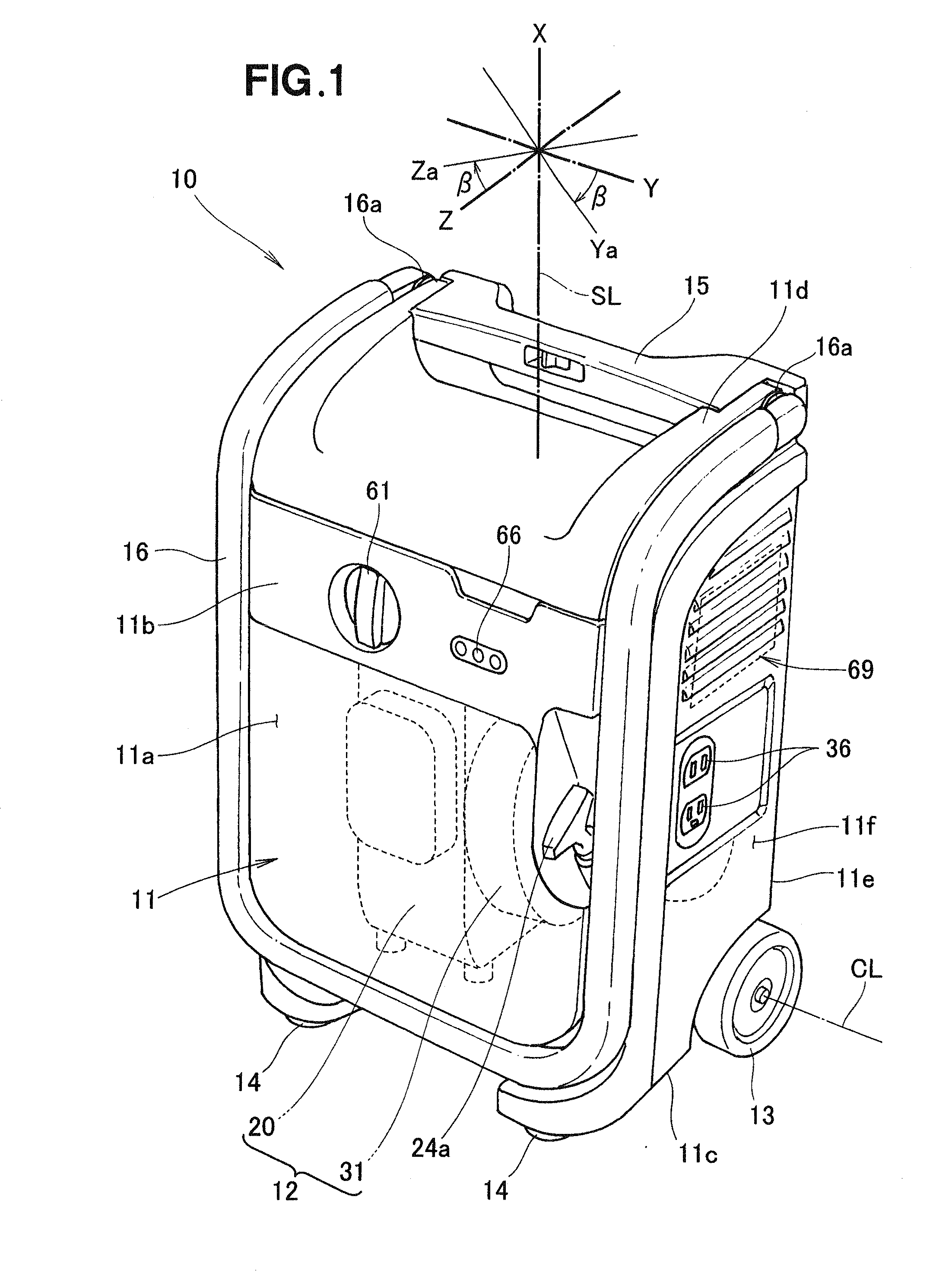

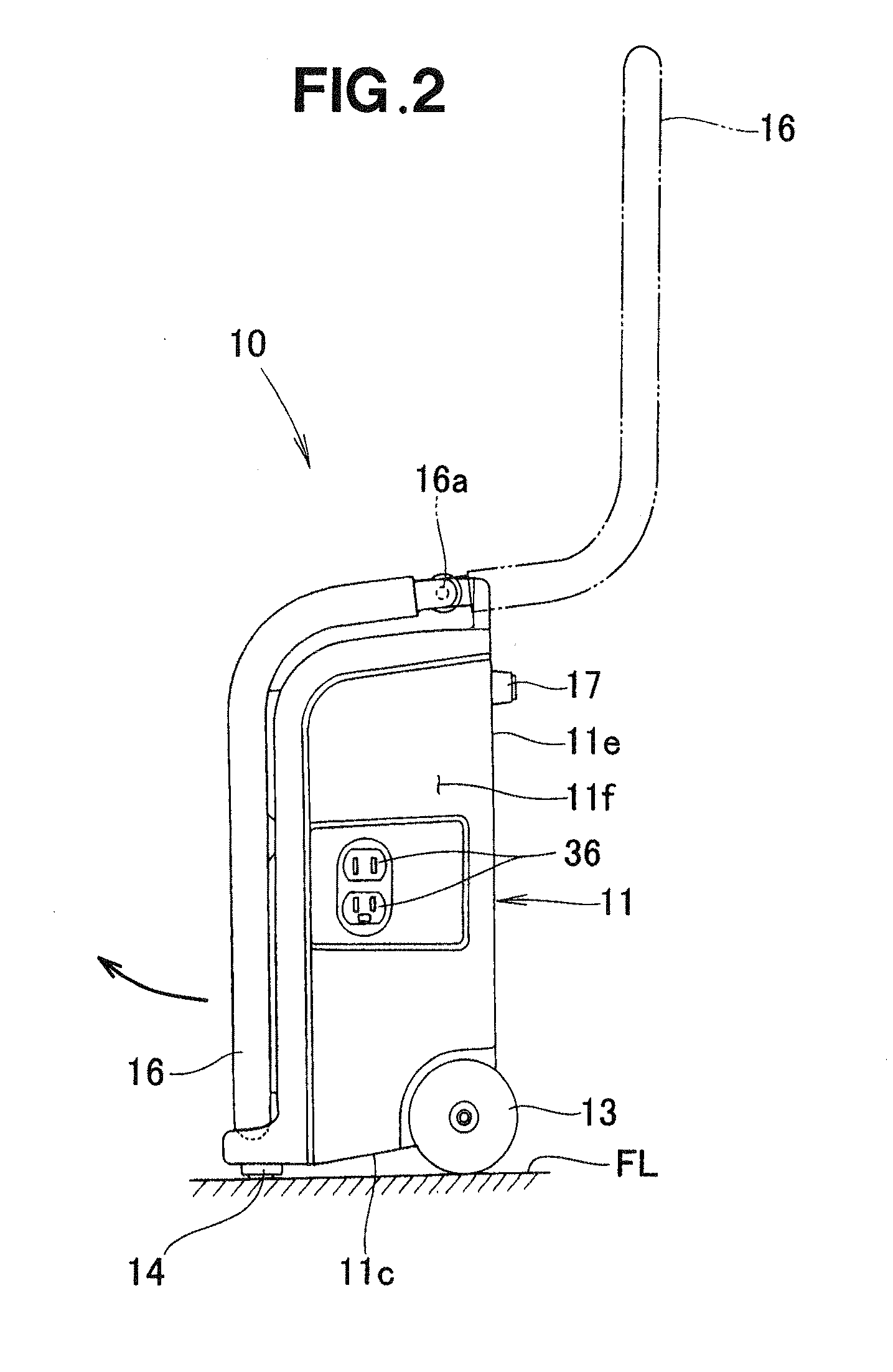

Portable working machine

ActiveUS20110088651A1Damage is causedProtection from damageFuel supply apparatusCombustion enginesWork unitMechanical engineering

A portable working machine includes a gaseous-fueled engine, a working unit driven by the engine, a control unit for controlling the engine and the working unit, and an acceleration sensor capable of detecting accelerations in two mutually perpendicular horizontal directions relative to a vertical line, which is induced in the portable working machine. The control unit is configured to determine a tip angle of the portable working machine based on the horizontal accelerations detected by the acceleration sensor and issue a stop instruction to the engine when it determines that the tip angle exceeds a preset reference angle.

Owner:HONDA MOTOR CO LTD

Robot teach device with 3-D display

ActiveUS9415509B2Overcomes shortcomingProgramme controlProgramme-controlled manipulatorWorkcellViewpoints

A method and an apparatus for displaying three-dimensional workcell data includes a hand-held pendant that is provided with 3-D workcell data representing a model of a machine and associated components in a workcell. The hand-held pendant has a display that generates a 3-D visual representation of the workcell data. The pendant can be operated by a user to manipulate the visual representation to change a user viewpoint and to show motion of the machine with associated process information.

Owner:FANUC ROBOTICS NORTH AMERICA

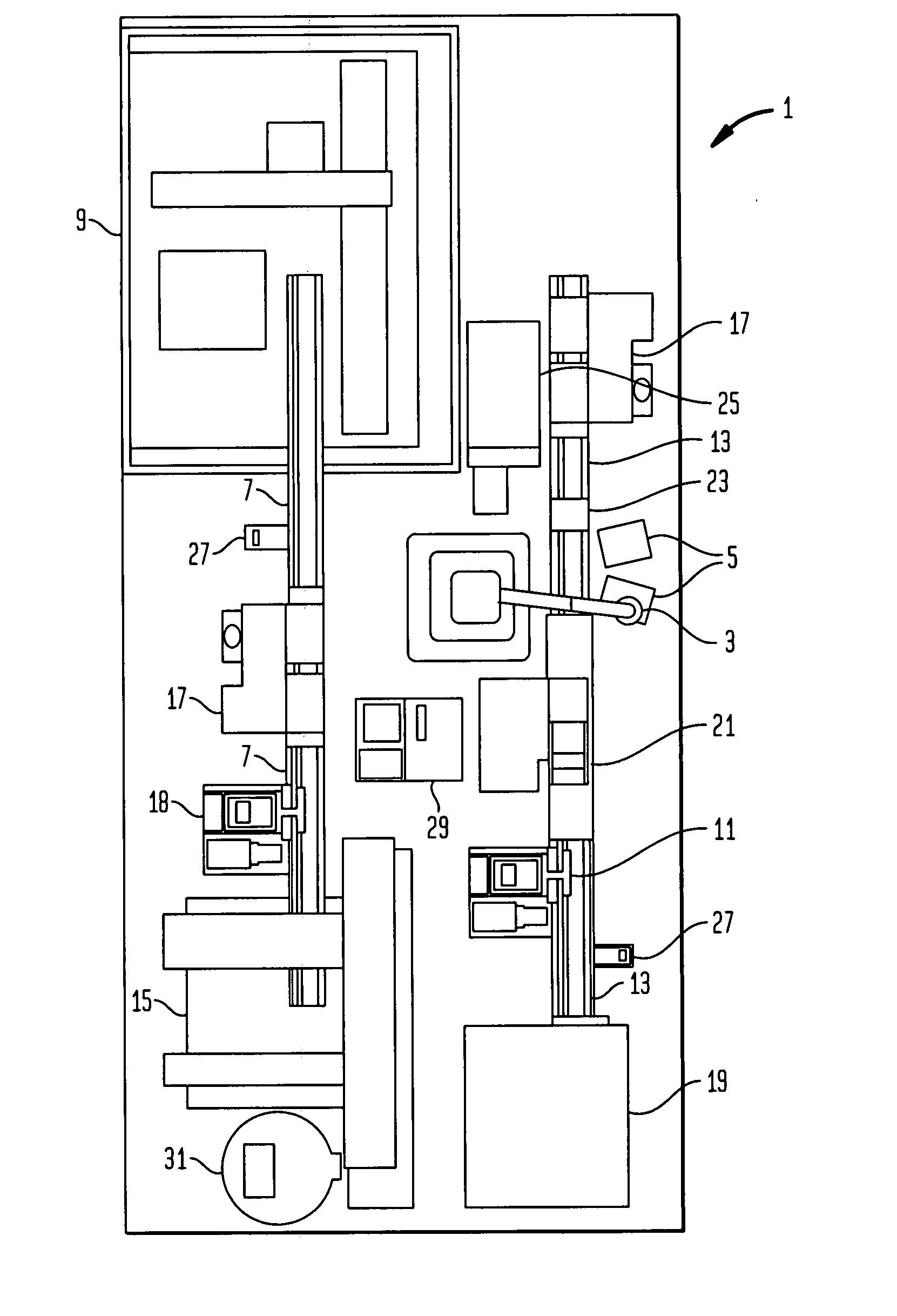

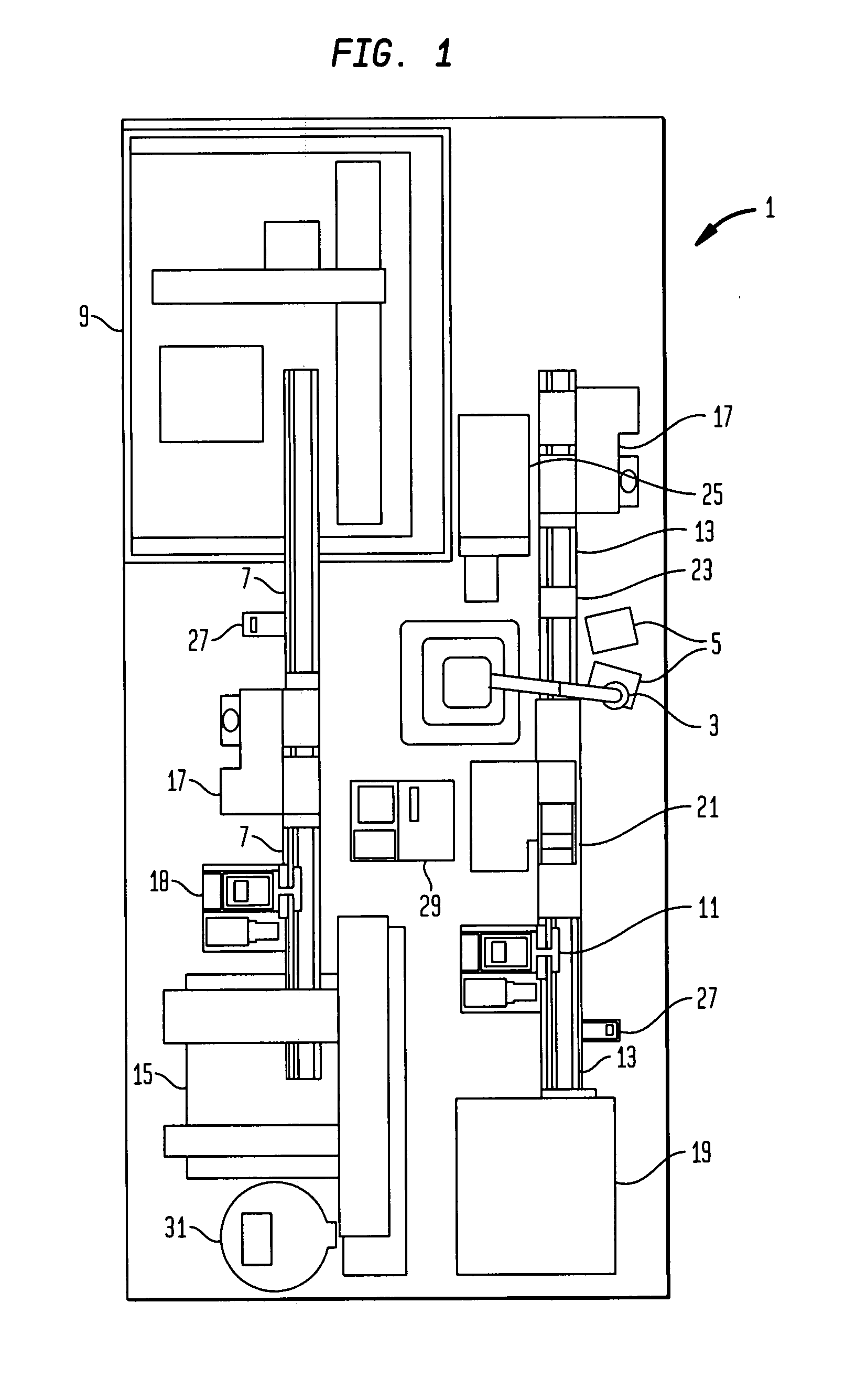

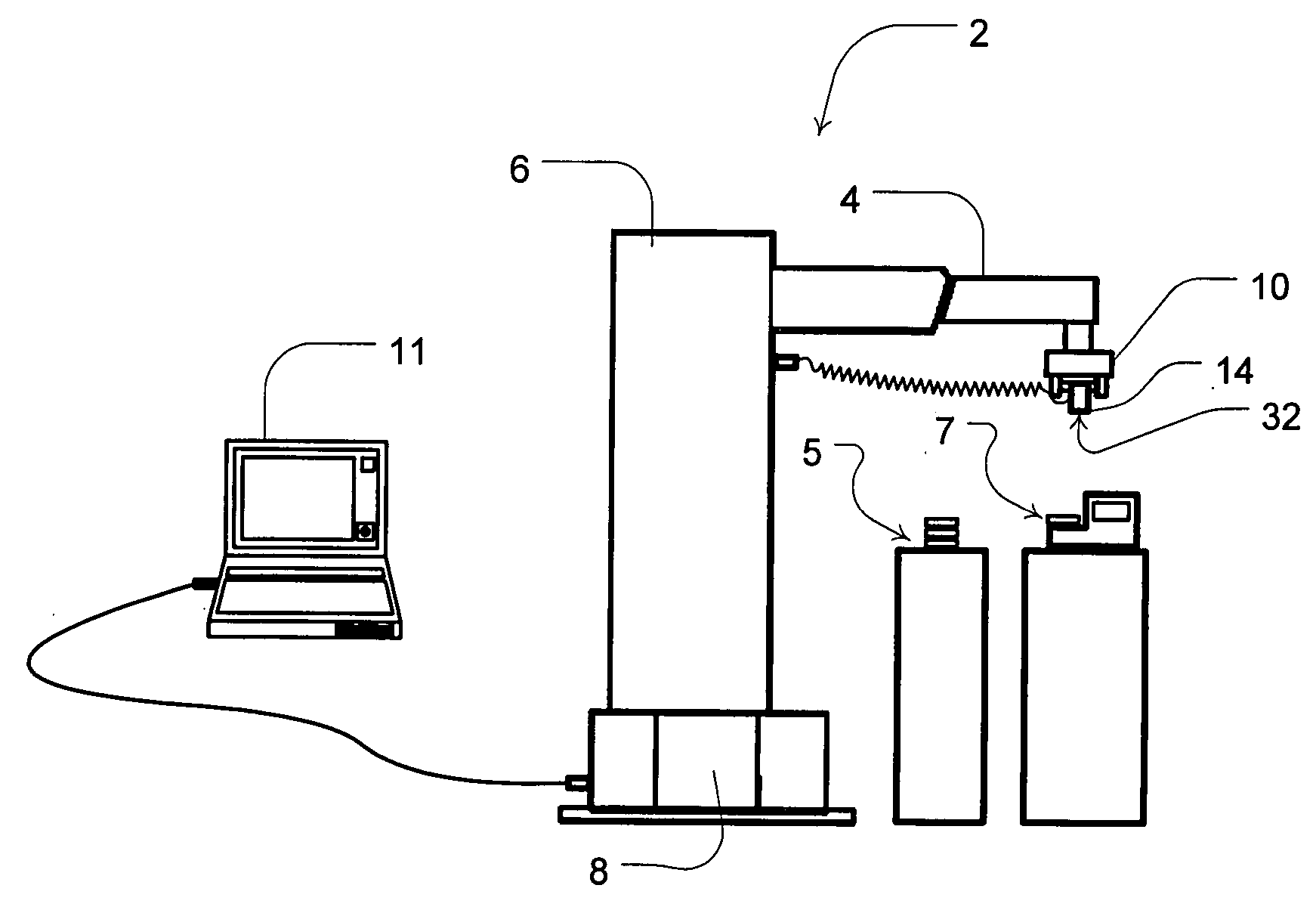

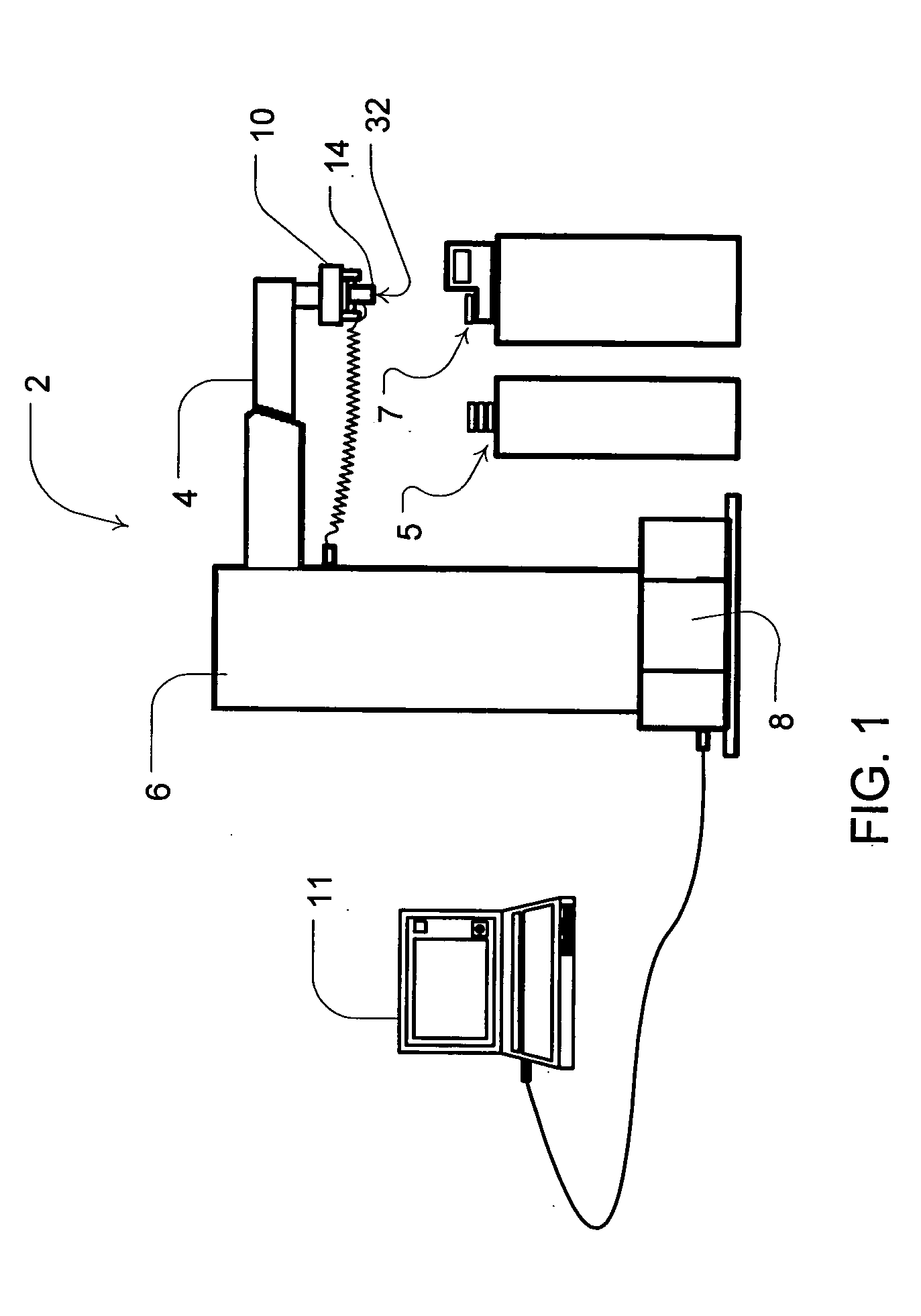

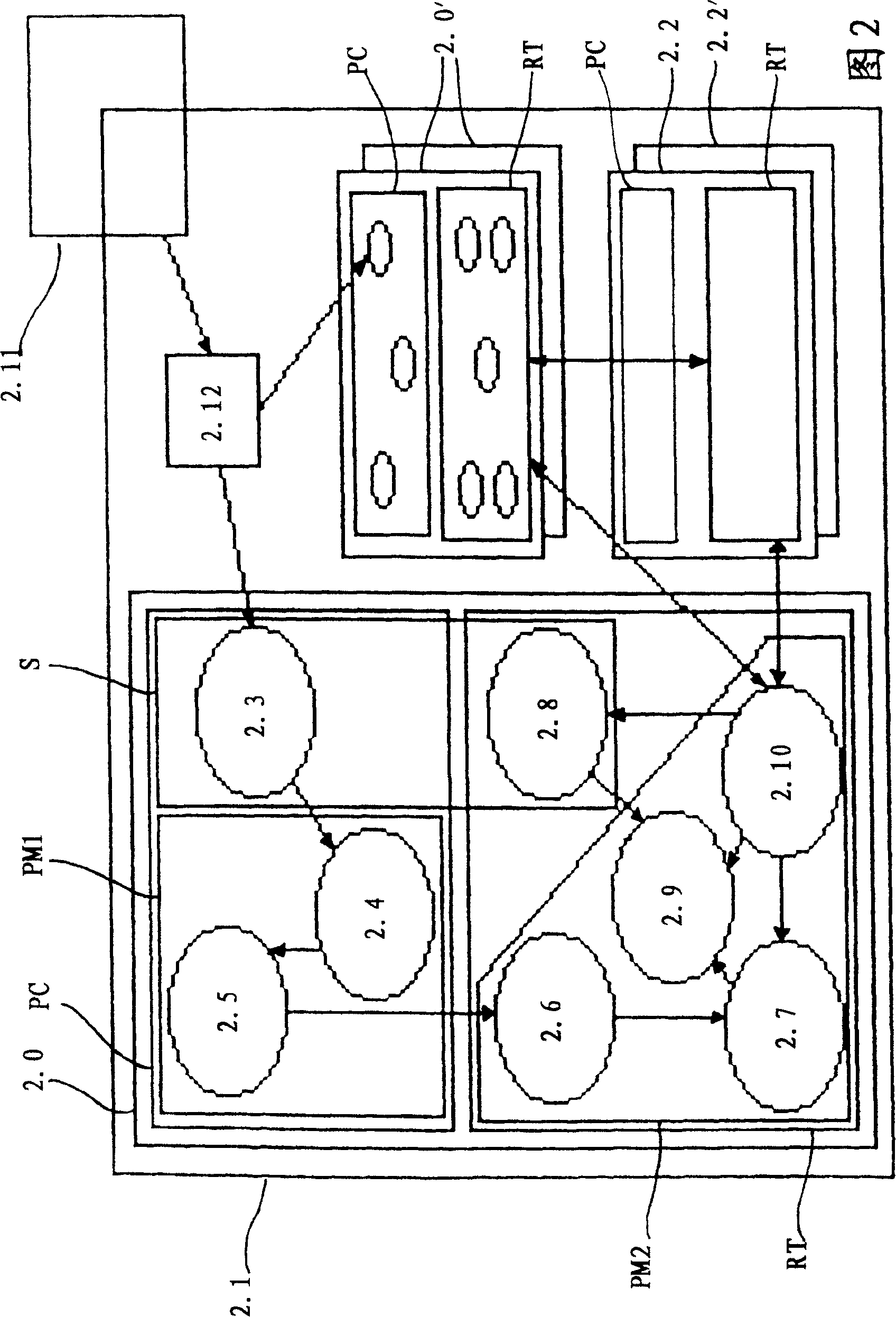

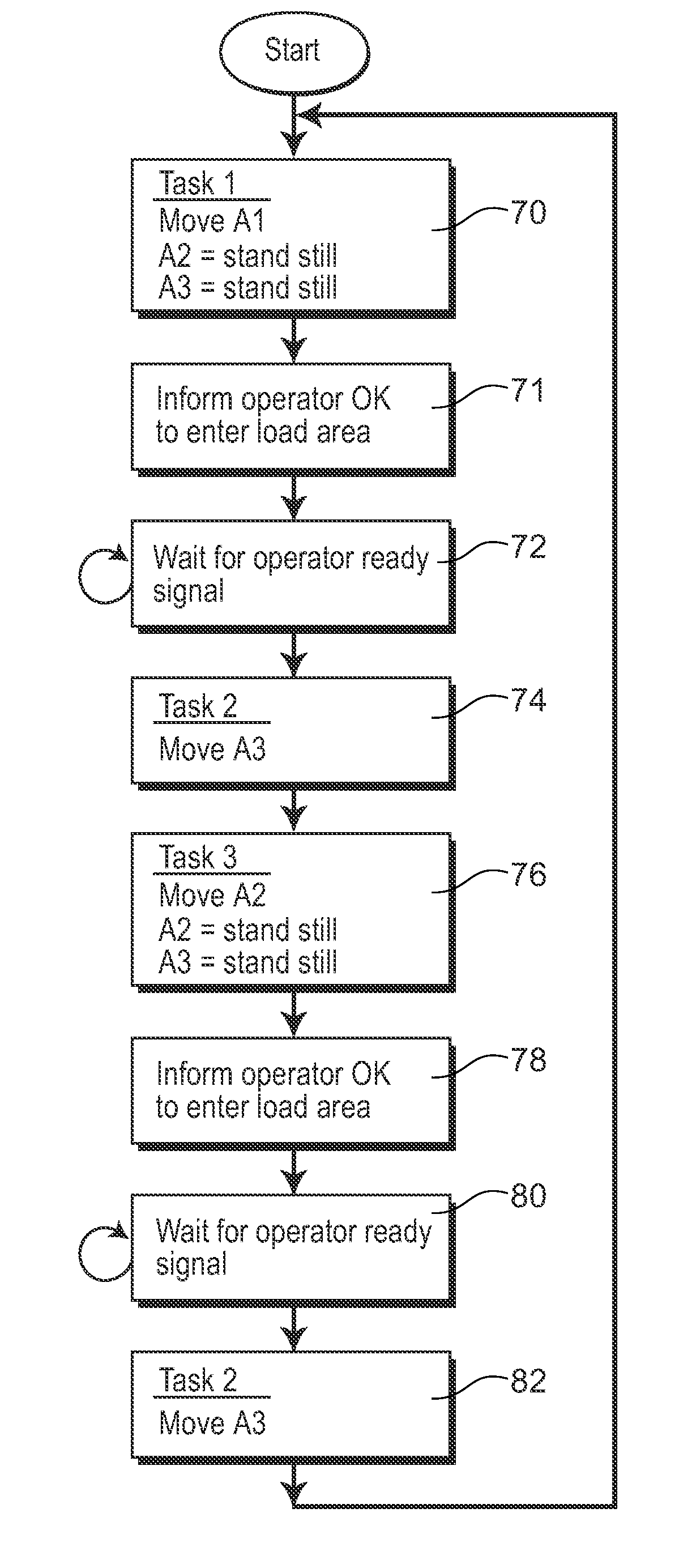

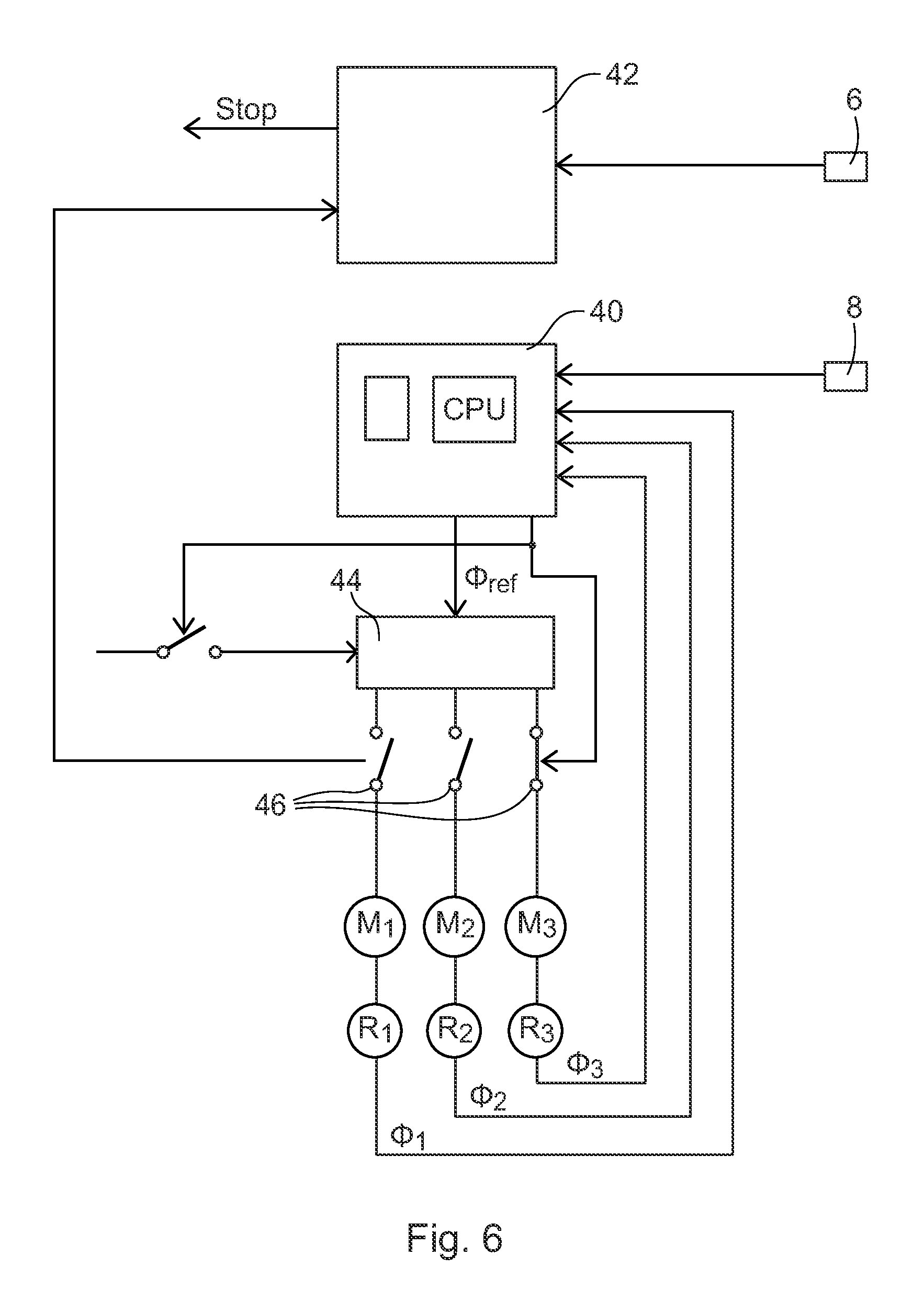

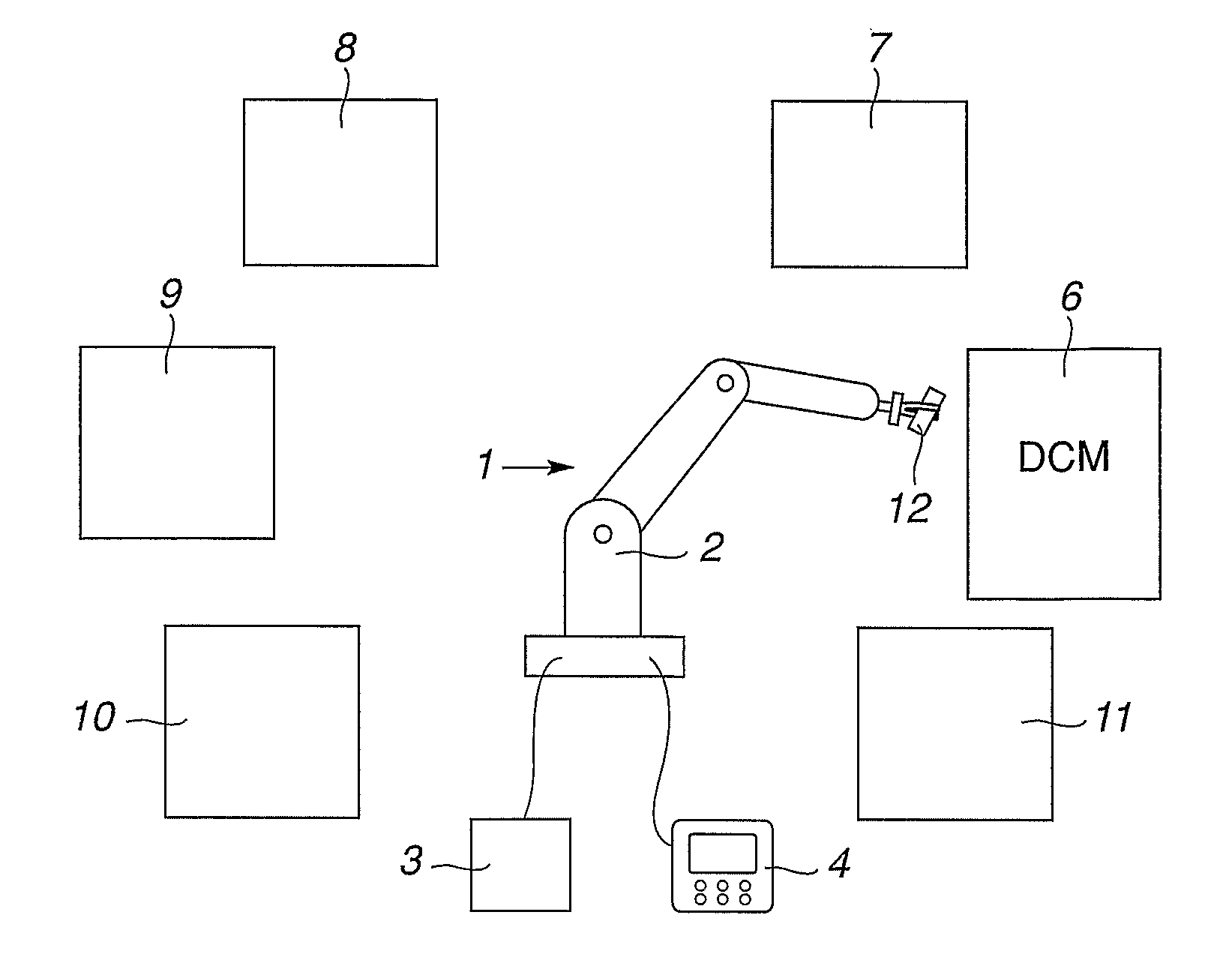

Method for controlling a plurality of axes in an industrial robot system and an industrial robot system

ActiveUS8452443B2Low costShorten the timeProgramme-controlled manipulatorSurgeryWorkcellProcess region

An industrial robot system including a workcell including a load area and a process area. A detector detects when a human enters the load area. A manipulator is located in the workcell. At least one positioner is adapted to hold a workpiece and to change the orientation of the workpiece about at least one axis while the manipulator processes the workpiece. A station exchanger is movable about an axis and adapted to move, upon command, the manipulator or the positioner between the load and process area. Each of the axes is provided with a motor and a drive unit. An axis controller is adapted to switch between executing a first task in which the axes of the positioner and the station exchanger are commanded to a standstill, and a second task in which the axes of the positioner and the station exchanger are allowed to move. A safety controller is adapted to supervise, upon detecting that a human is entering the load area, whether any of the station exchanger or the positioner is moving, and to generate a signal which disables the drive unit of the moving axis if it is detected that any of the supervised axes is moving.

Owner:ABB (SCHWEIZ) AG

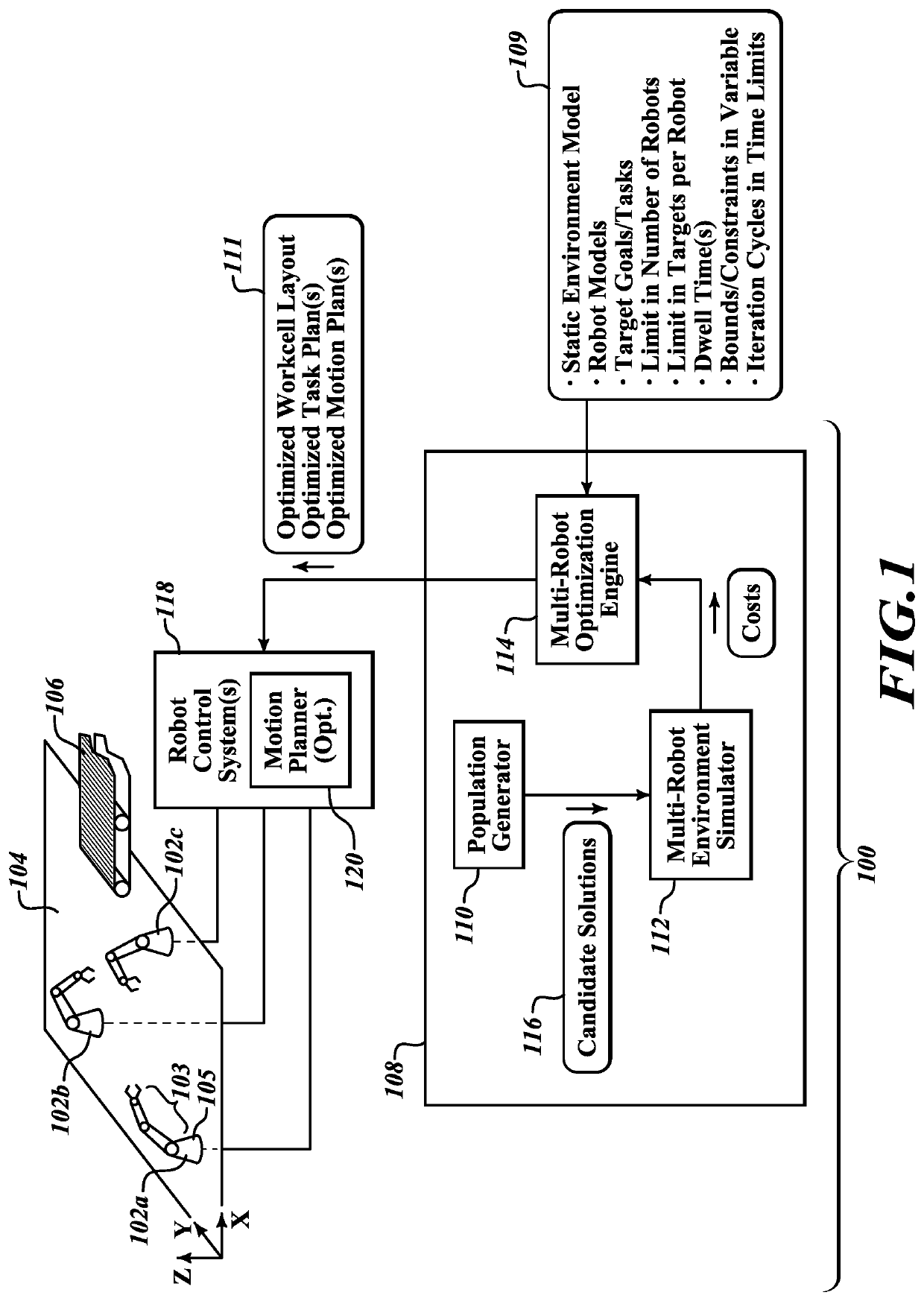

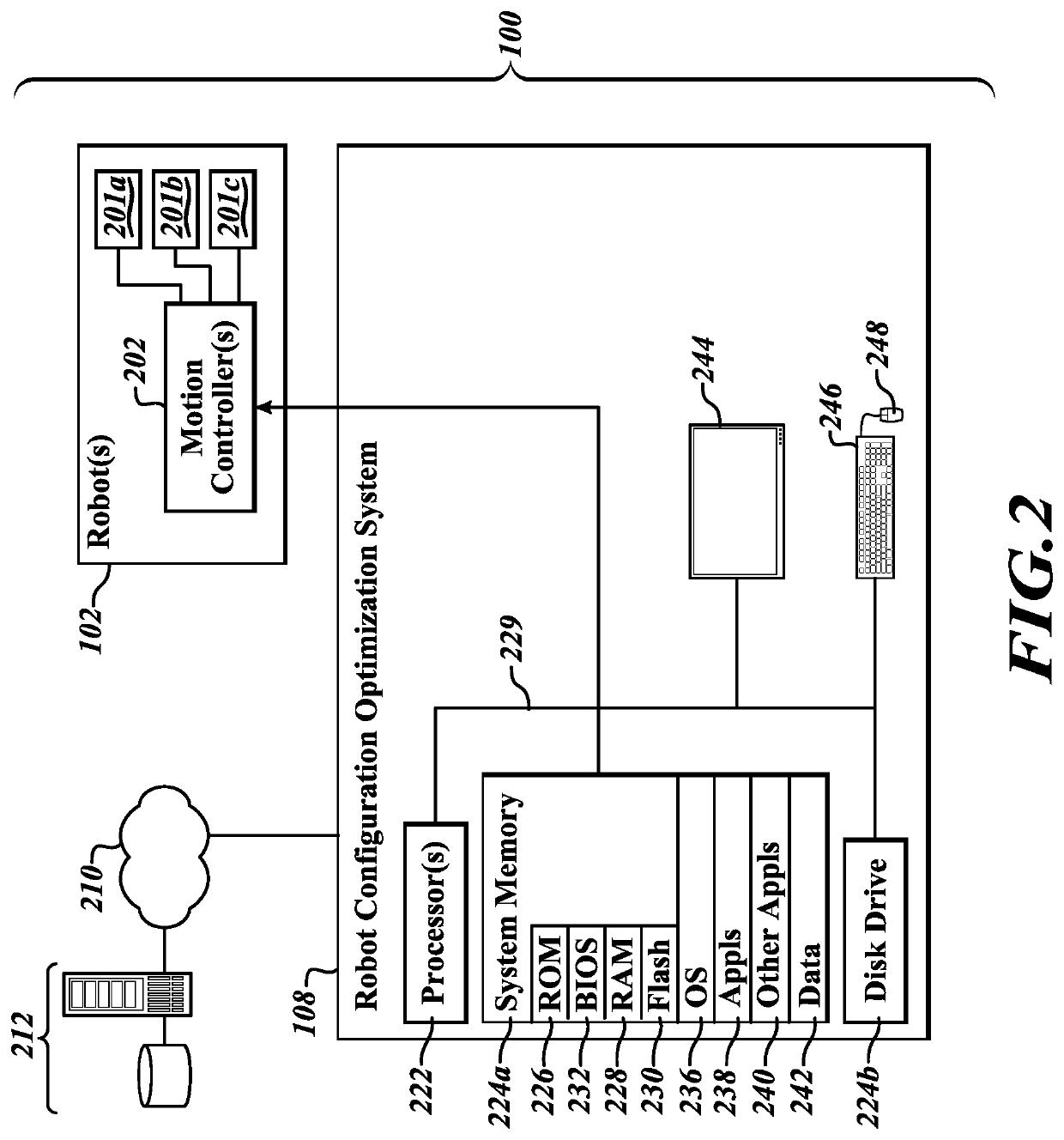

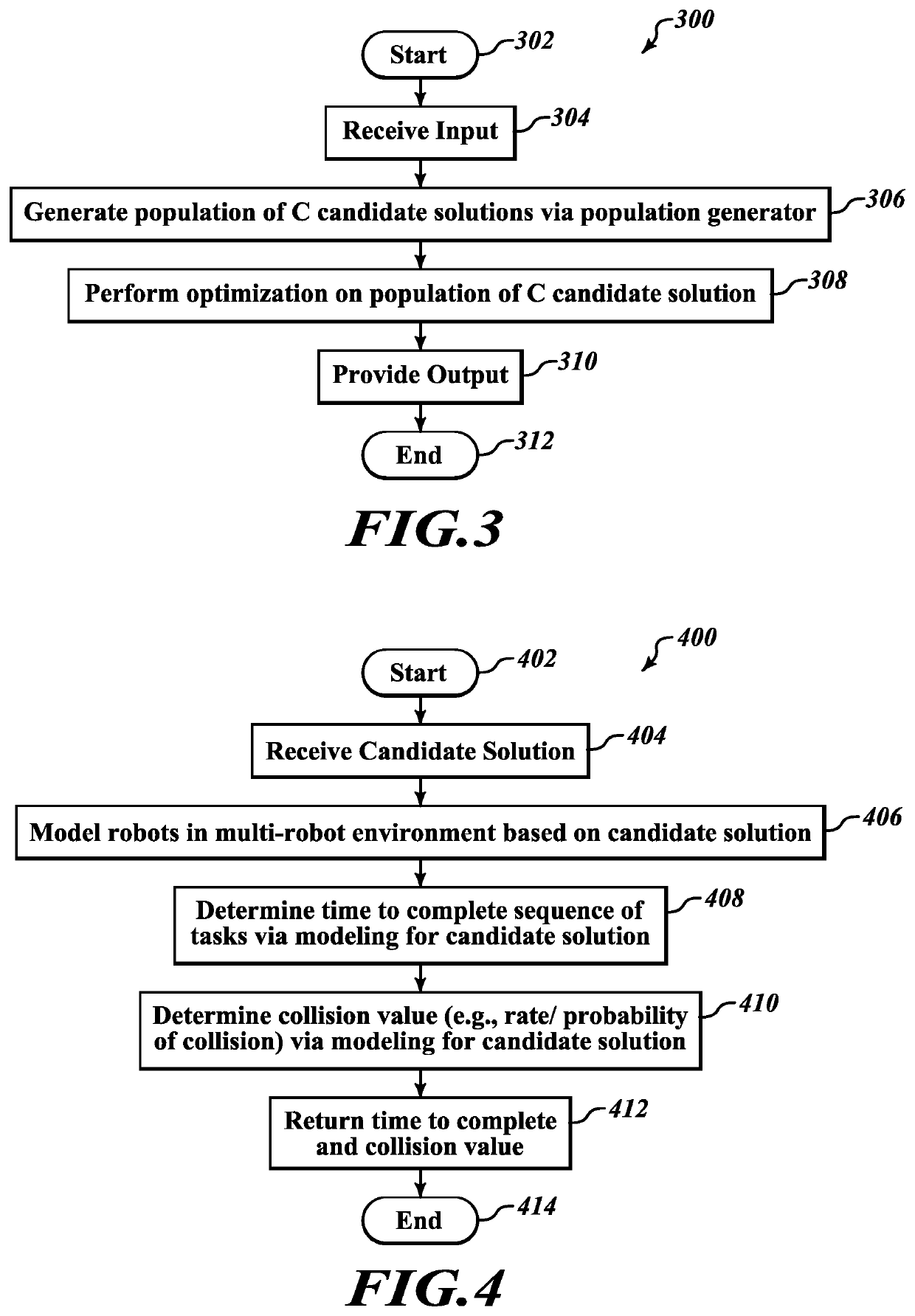

Configuration of robots in multi-robot operational environment

ActiveUS20210220994A1Efficient of energy consumptionEfficient of expenditureProgramme controlProgramme-controlled manipulatorWorkcellSimulation

Solutions for multi-robot configurations are co-optimized, to at least some degree, across a set of non-homogenous parameters based on a given set of tasks to be performed by robots in a multi-robot operational environment. Non-homogenous parameters may include two or more of: the respective base position and orientation of the robots, an allocation of tasks to respective robots, respective target sequences and / or trajectories for the robots. Such may be executed pre-runtime. Output may include for each robot: workcell layout, an ordered list or vector of targets, optionally dwell time durations at respective targets, and paths or trajectories between each pair of consecutive targets. Output may provide a complete, executable, solution to the problem, which in the absence of variability in timing, can be used to control the robots without any modification. A genetic algorithm, e.g., Differential Evolution, may optionally be used in generating a population of candidate solutions.

Owner:REALTIME ROBOTICS INC

Method and apparatus for integrated simulation

ActiveUS8694296B2Facilitates safe and efficient developmentLess development timeAnalogue computers for electric apparatusTechnology managementWorkcellControl system

In an automated system which includes a robot manipulator, a workcell, and a control system implemented on a hardware platform based on a programmable logic controller (“PLC”), a method and apparatus for performing integrated simulation that does not require the presence of both the robot manipulator and the workcell. If one component is real, the other component is simulated so as to be sufficiently responsive to responses from the real component such that the real component is unable to discern that the other component is not also real. A computing device simultaneously displays simulacra of both the components, real and simulated, and visualizations of the responses provided by each.

Owner:YASKAWA INNOVATION INC

System and a method for controlling movements of an industrial robot

ActiveUS9069351B2The process is convenient and fastEasy to adjustProgramme-controlled manipulatorComputer controlWorkcellWork cycle

A system and a method for controlling movements of an industrial robot during a work cycle including visiting and performing work on a plurality of workstations in a work cell. The system includes a set of predefined workstations. Each workstation includes preprogrammed robot code adapted to the workstation, an entry point defining the entrance position to the workstation, and one or more predefined paths to be followed by the robot at the workstation. A user interface is adapted to provide information about the predefined workstations and allows an operator to select one or more of the predefined workstations and to specify a desired part flow between the workstations. A scheduling unit is adapted during execution of the work cycle to schedule the execution order for the workstations based on the workstations selected from the predefined workstations and the desired part flow, and to control the movements of the robot based on the scheduled execution order and the predefined paths.

Owner:ABB (SCHWEIZ) AG

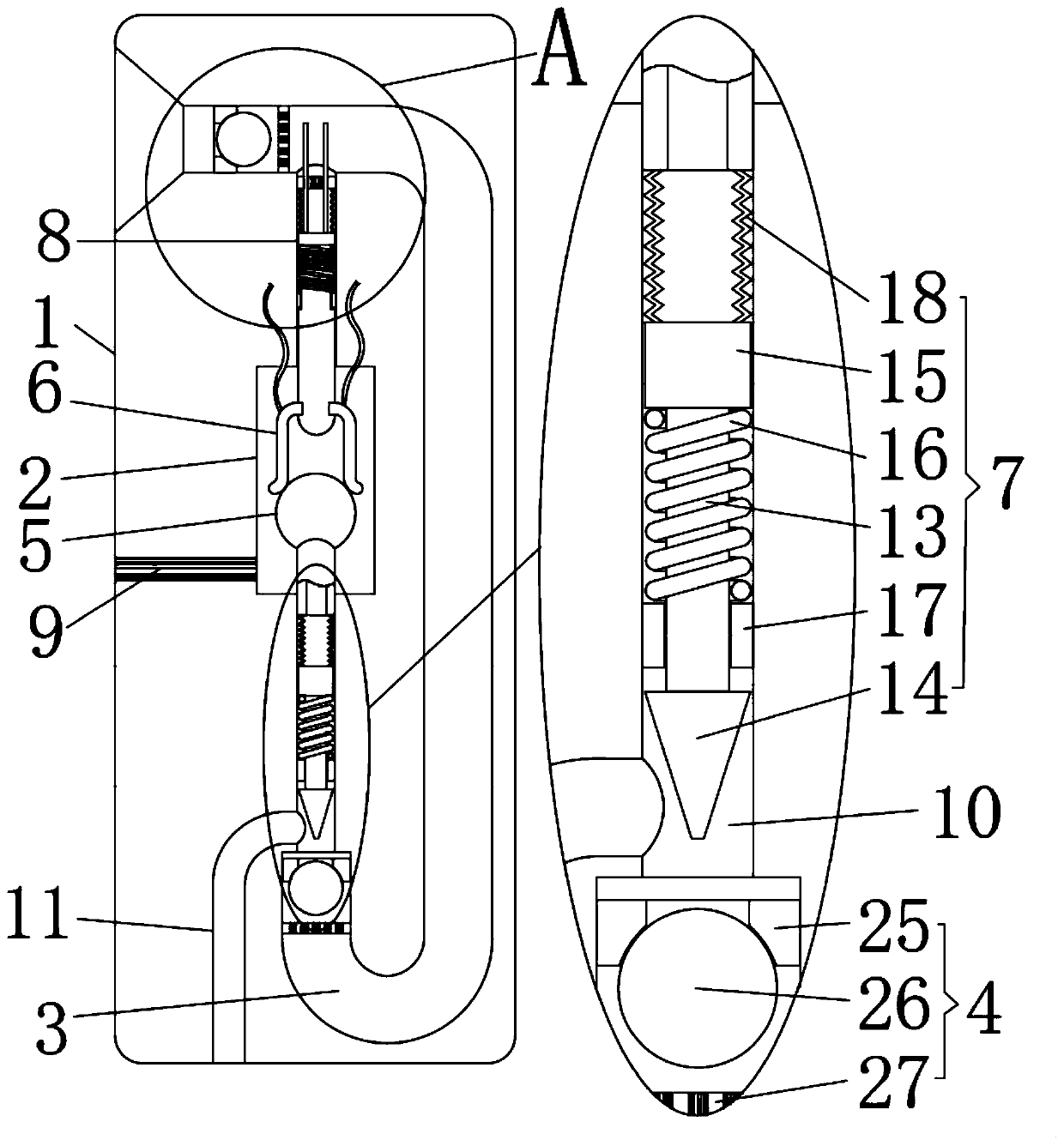

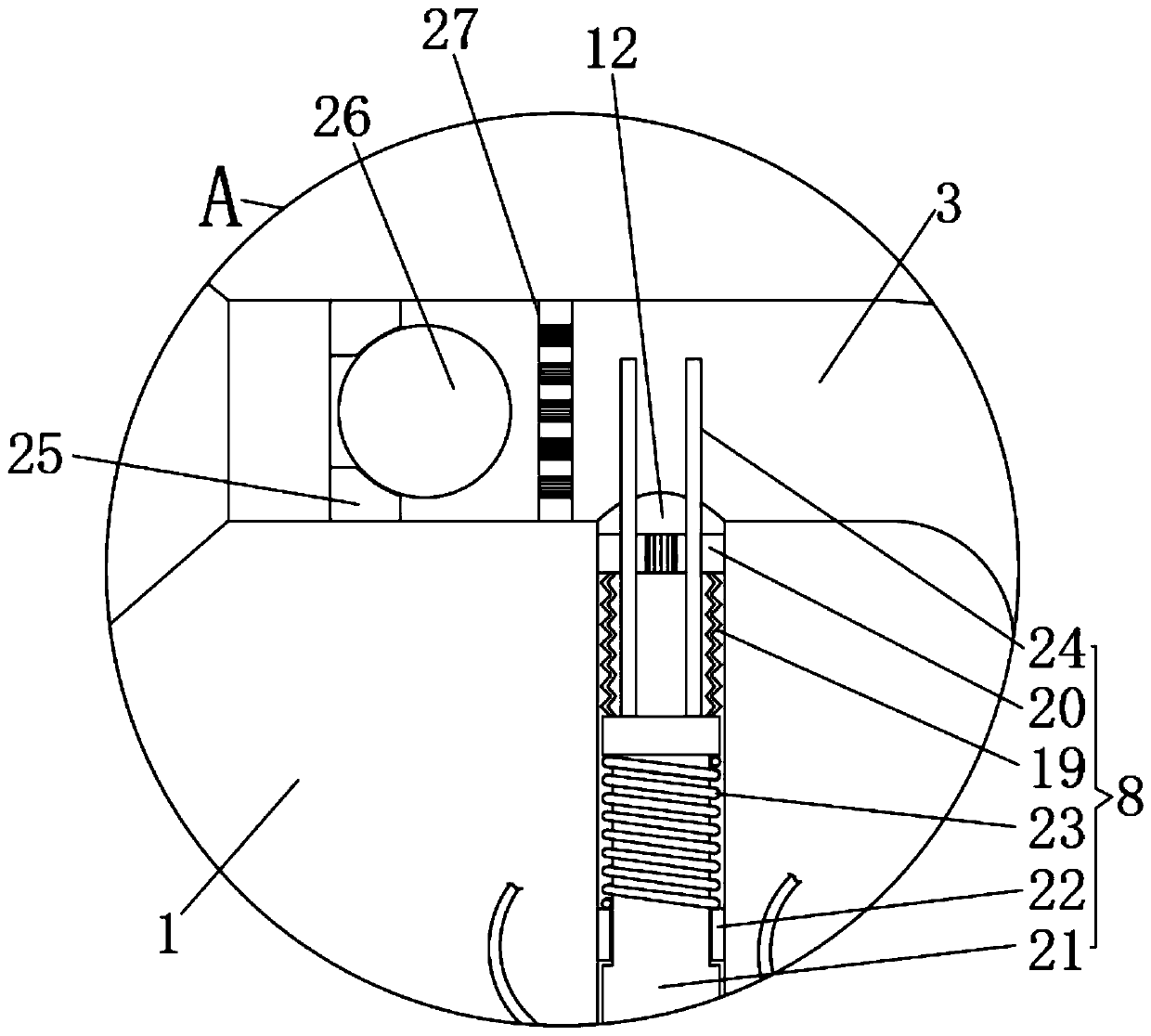

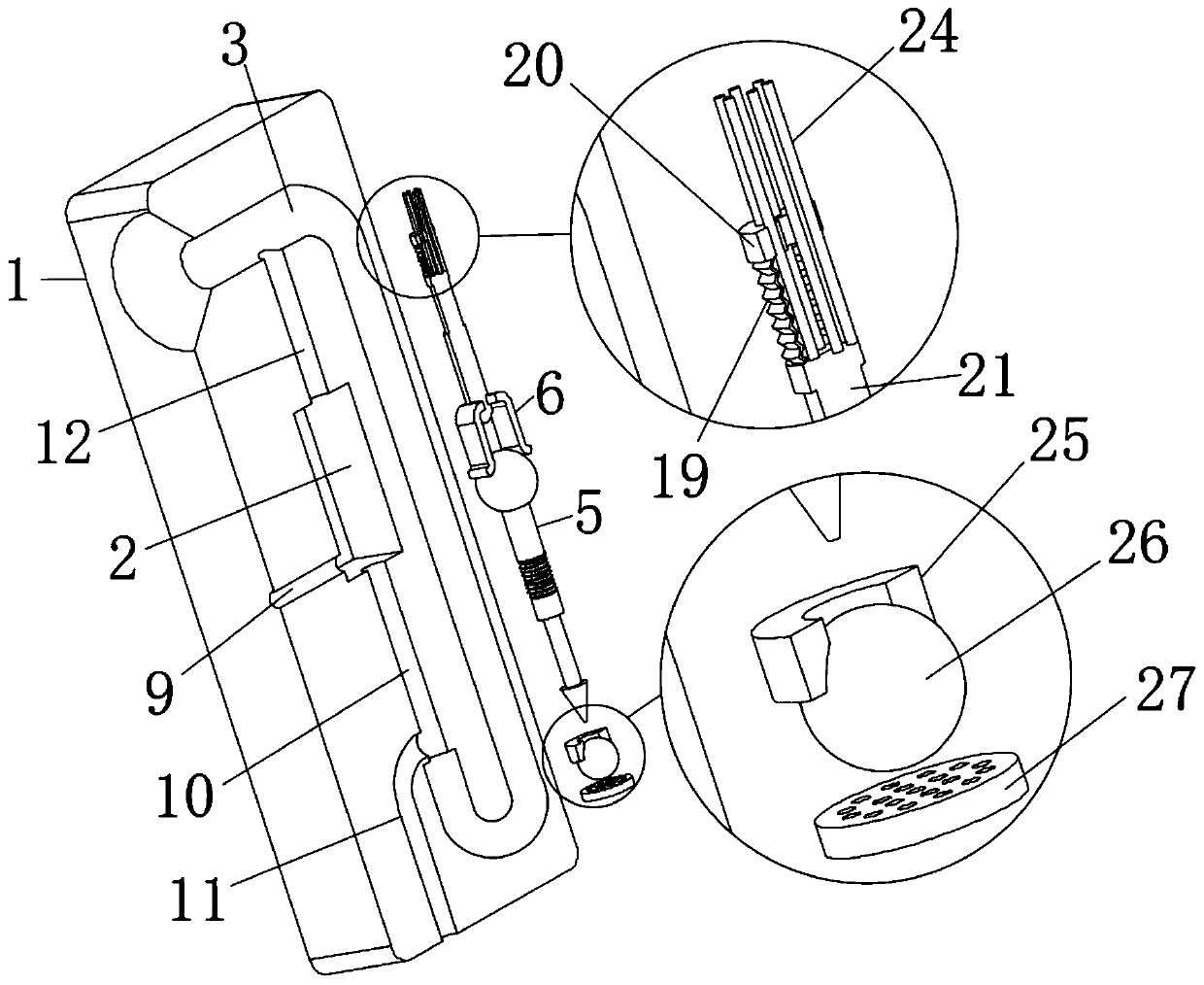

Refined power distribution device for intelligent manufacturing equipment

InactiveCN110942964AStable power supplyEasy to installArrangements responsive to excess currentProtective switch operating/release mechanismsWorkcellHemt circuits

The invention relates to the technical field of power distribution devices. The invention relates to a power distribution device, in particular to a refined power distribution device for intelligent manufacturing equipment. The device comprises a square plate-shaped outer plate, a plate-shaped cavity and an air pipe cavity are formed in the outer plate; the plate-shaped cavity is located in the middle of the outer plate. An air pipe cavity is formed in one side of the plate-shaped cavity; a one-way valve is arranged at each of the two end parts of the air pipe cavity; an electric conductor anda spring part are arranged in the plate-shaped cavity; two symmetrically distributed spring parts are arranged on one side of the electric conductor; a control device is arranged between the conductor and the one-way valve at one end of the air pipe cavity; by means of the structural design, sensitive induction control work of a circuit is achieved, stable power supply between manufacturing equipment is ensured, the independent working unit is adopted, convenience can be brought to installation at the designated position according to actual use requirements, and the function is stable and powerful.

Owner:ZHONGWEI POWER SUPPLY COMPANY OF STATE GRID NINGXIA ELECTRIC POWER

System, method, and apparatus to display three-dimensional robotic workcell data

Owner:FANUC ROBOTICS NORTH AMERICA

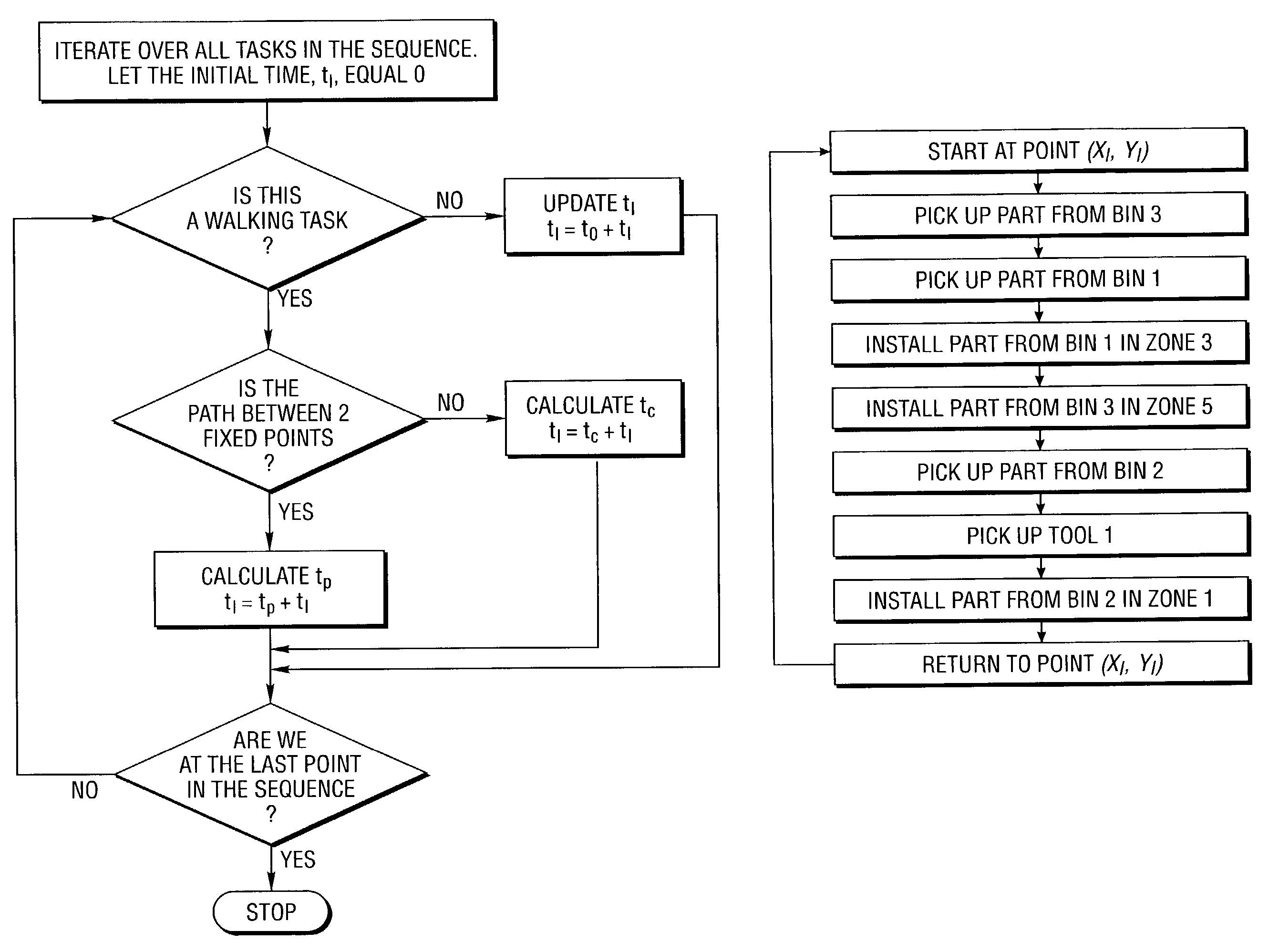

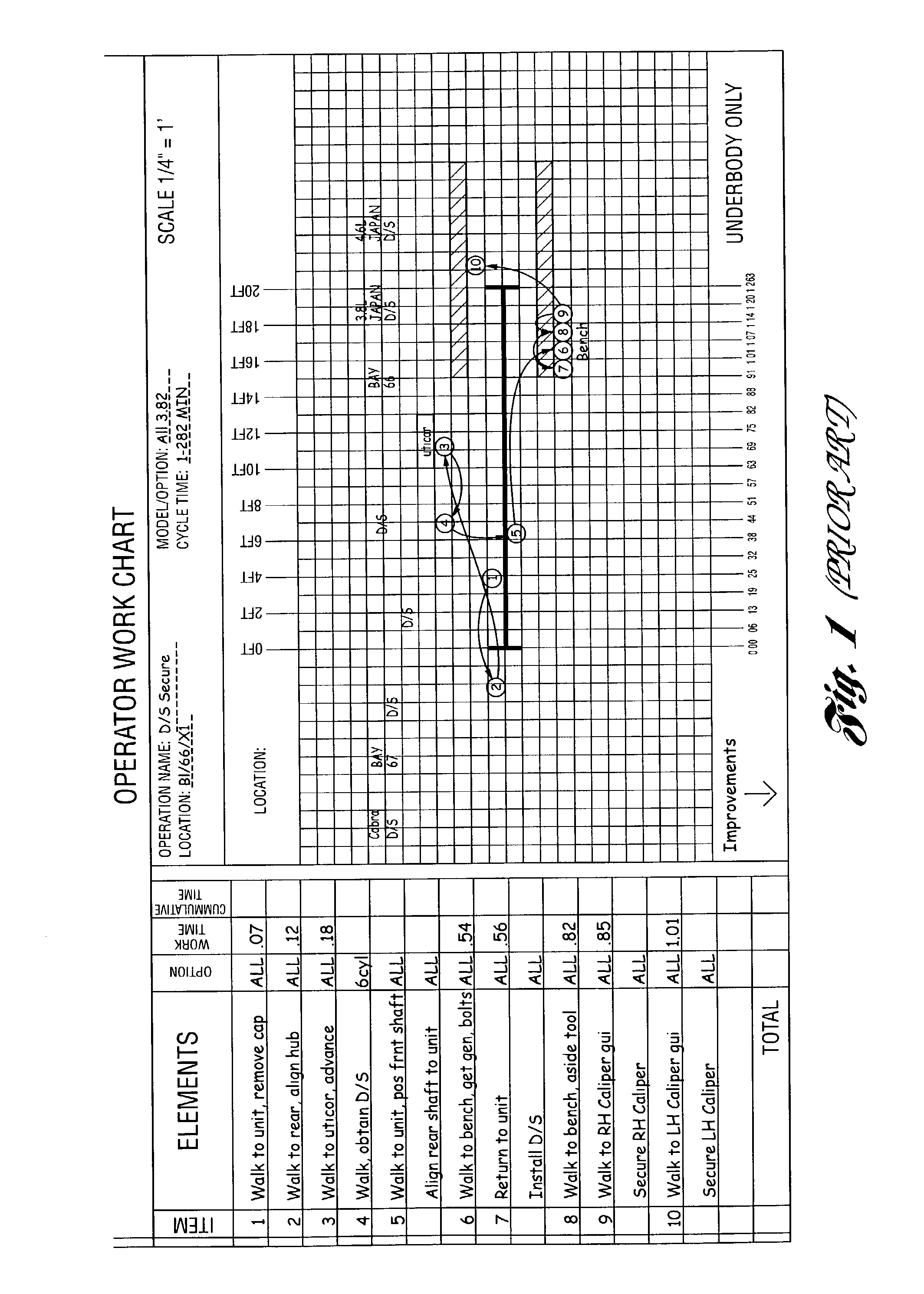

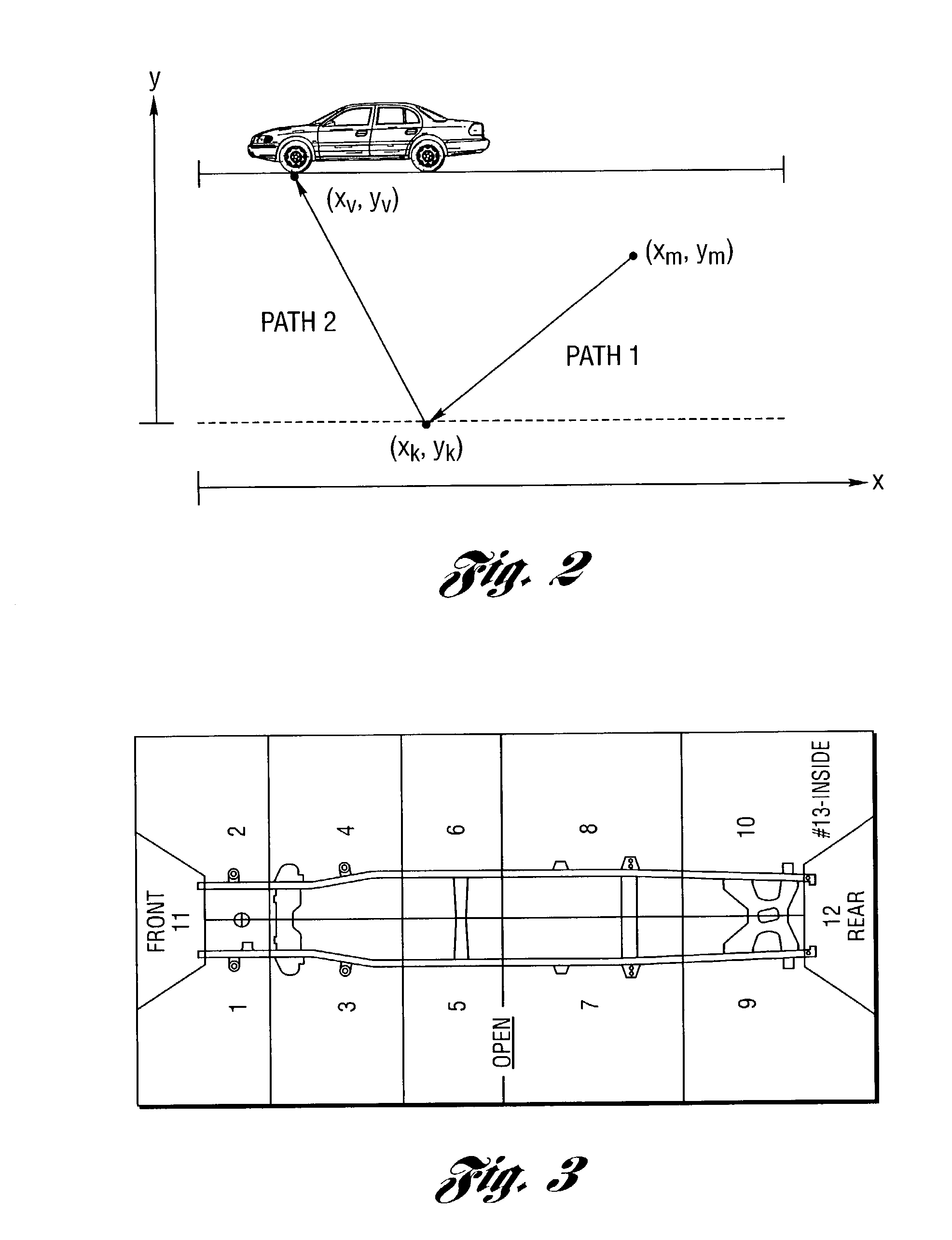

Computer-implemented method and system for designing a workcell layout

InactiveUS7092854B2Flexibility and ease of useRapid assessmentResourcesComputer aided designWorkcellGraphics

Preferred embodiments include receiving input defining dimensions for a workcell and a size and location for one or more objects within the workcell, receiving input defining a walking velocity for an operator within the workcell and one or more tasks to be completed during a workcell cycle, receiving input defining one or more times and locations to complete the one or more tasks within the workcell, calculating a total walking time to complete the one or more tasks during the workcell cycle based upon the size and location of the object(s), the time(s) and location(s) to complete the task(s) and the operator walking velocity, and outputting the total walking time for the workcell cycle and a graphical representation of the workcell including the object(s) and an operator walking path between points within the workcell at which the one or more tasks are completed.

Owner:FORD MOTOR CO

Method for operating an automated sample workshop

The invention relates to a method for operating an automated sample workcell. A method for operating an automated sample workcell (102, 410, 301) for processing one or more biological samples (125-130), said method comprising:- receiving (201) said one or more biological samples, each sample contained in a sample tube, each sample tube having a tube type (122-124); - upon receipt of a test order (104) for at least one of said biological samples, said test order indicating in the case of one or more first processing steps, operating ( 204 ) the workshop to automatically perform said one or more first processing steps; and - in case said test order is not received, according to the The tube type of the sample tube of the at least one biological sample is determined (205) to determine (205) one or more second processing steps, and to perform (206) the one or more second processing steps.

Owner:F HOFFMANN LA ROCHE & CO AG

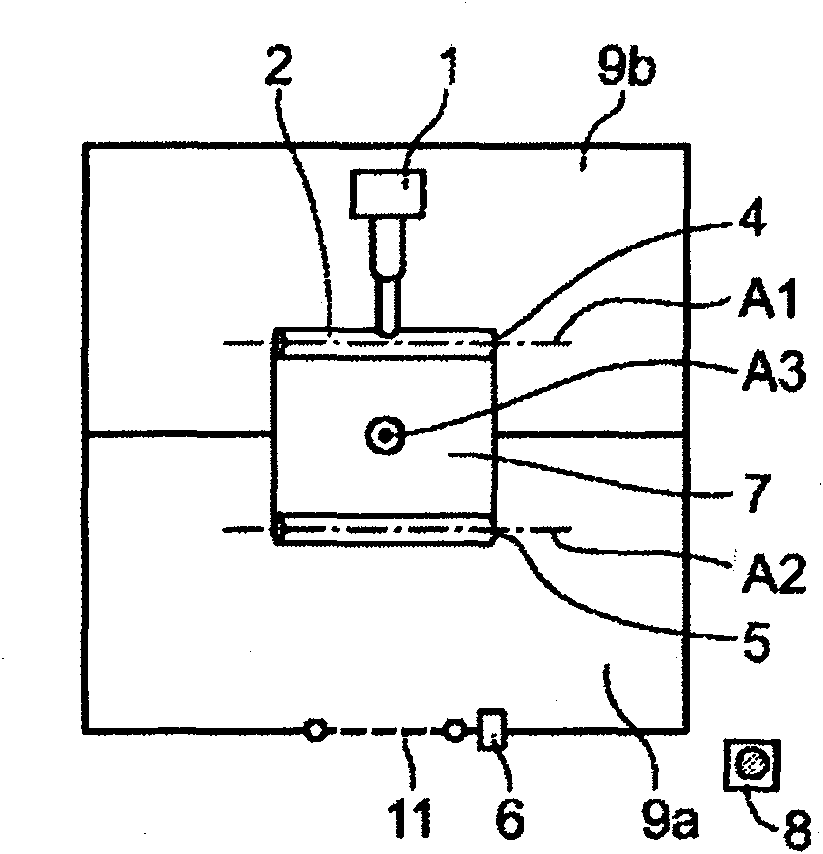

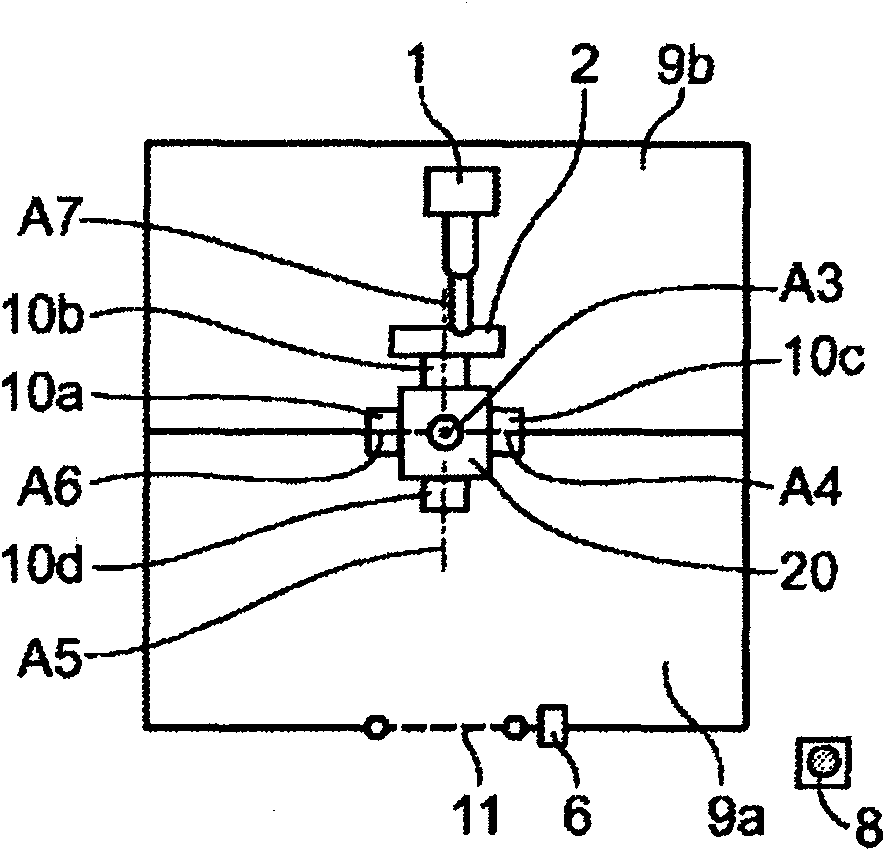

A method for controlling a plurality of axes in an industrial robot system and an industrial robot system

The present invention relates to an industrial robot system comprising a workcell including a load area and a process area, a detector (6) detecting when a human enters the load area, a manipulator located in the workcell, at least one positioner adapted to hold a workpiece and to change the orientation of the workpiece about at least one axis while the manipulator processes the workpiece, and a station exchanger movable about an axis and adapted to move, upon command, the manipulator or the positioner between the load and process area. Each of the axes is provided with a motor (M1-M3) and a drive unit (53-55). An axis controller (50) is adapted to switch between executing a first task in which the axes of the positioner and the station exchanger are commanded to a standstill, and a second task in which the axes of the positioner and the station exchanger are allowed to move. A safety controller (58) is adapted to supervise, upon detecting that a human is entering the load area, whether any of the station exchanger or the positioner is moving, and to generate a signal which disables the drive unit of the moving axis if it is detected that any of the supervised axes is moving.

Owner:ABB (SCHWEIZ) AG

Robotic system for demiliterizing munitions

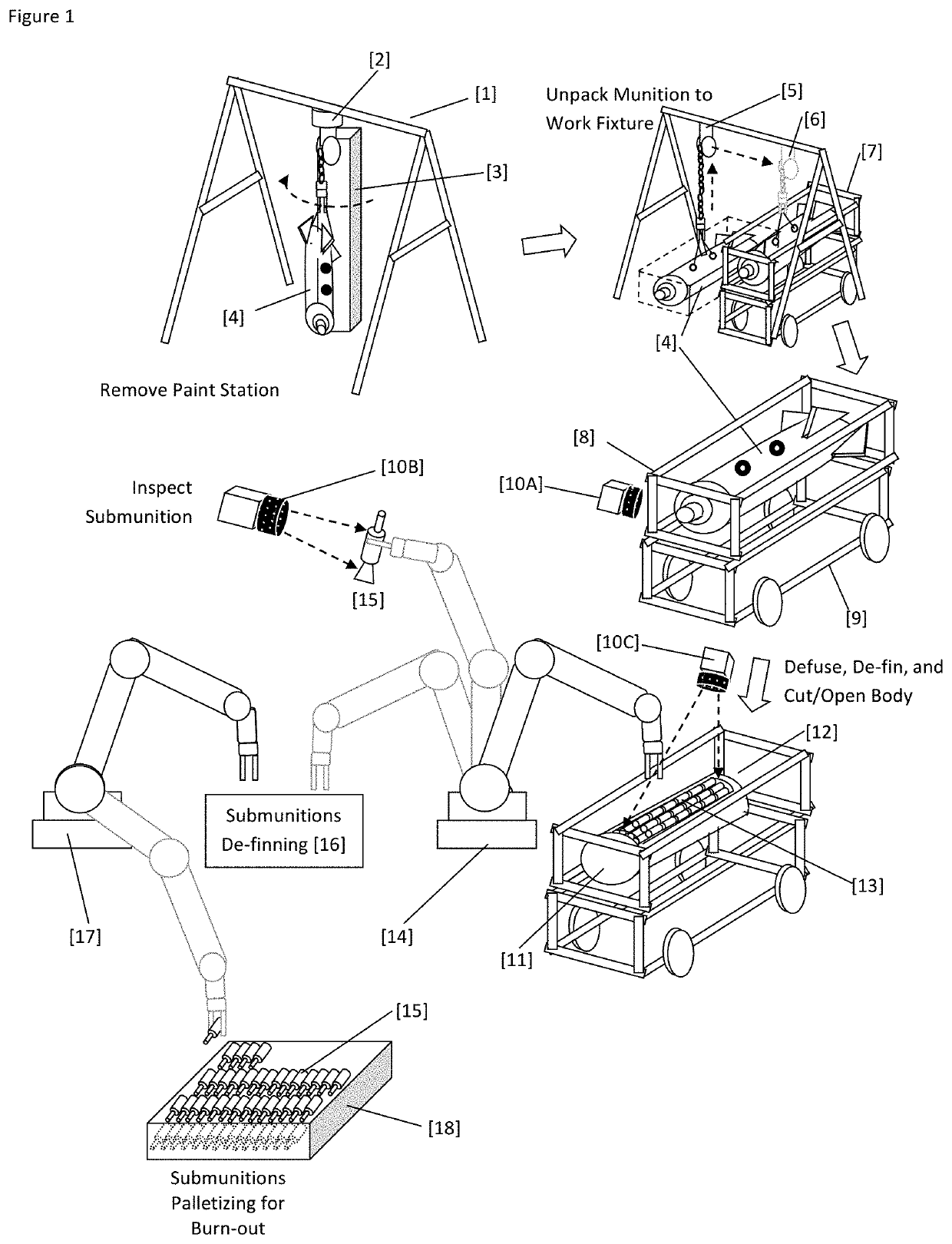

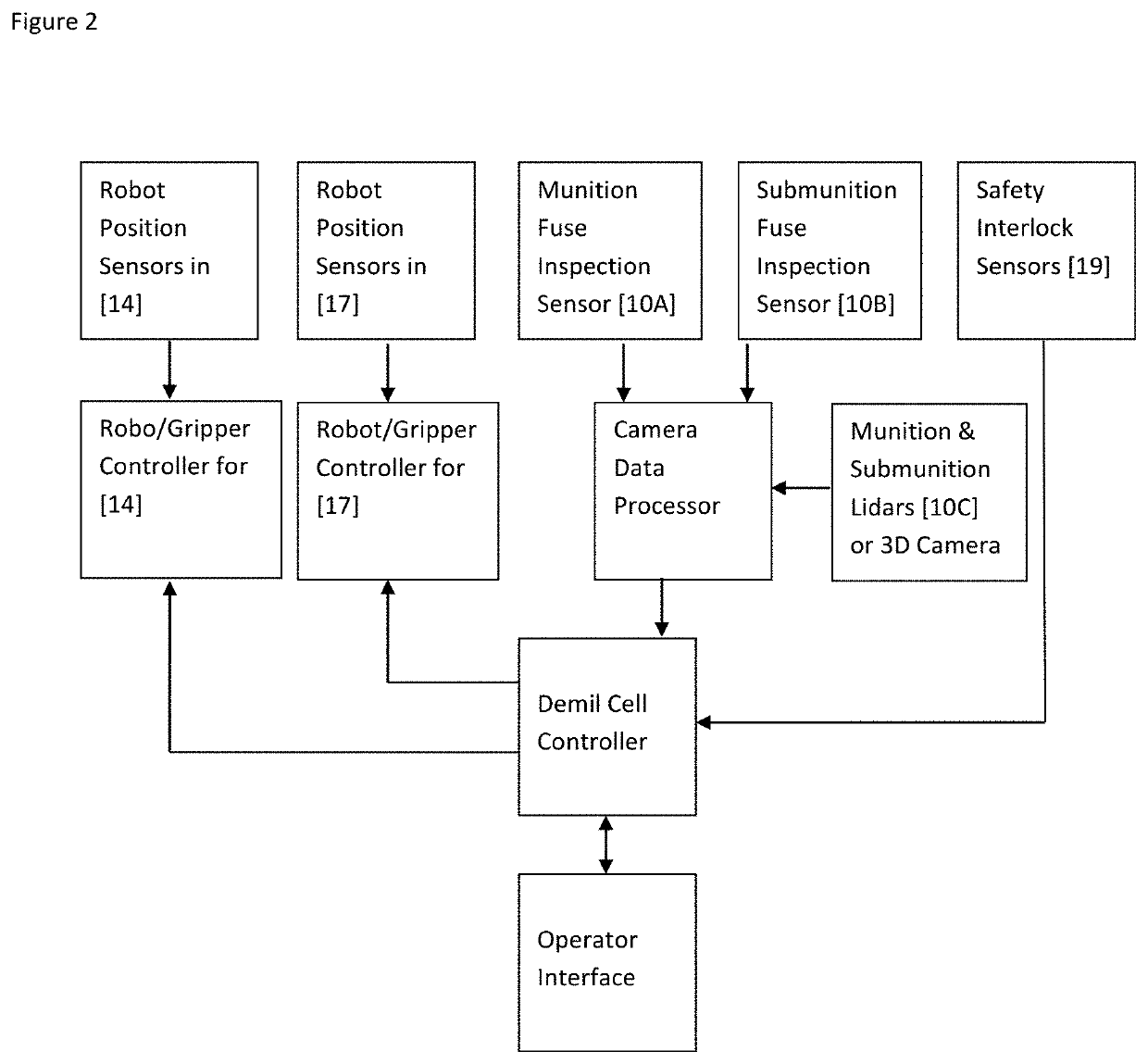

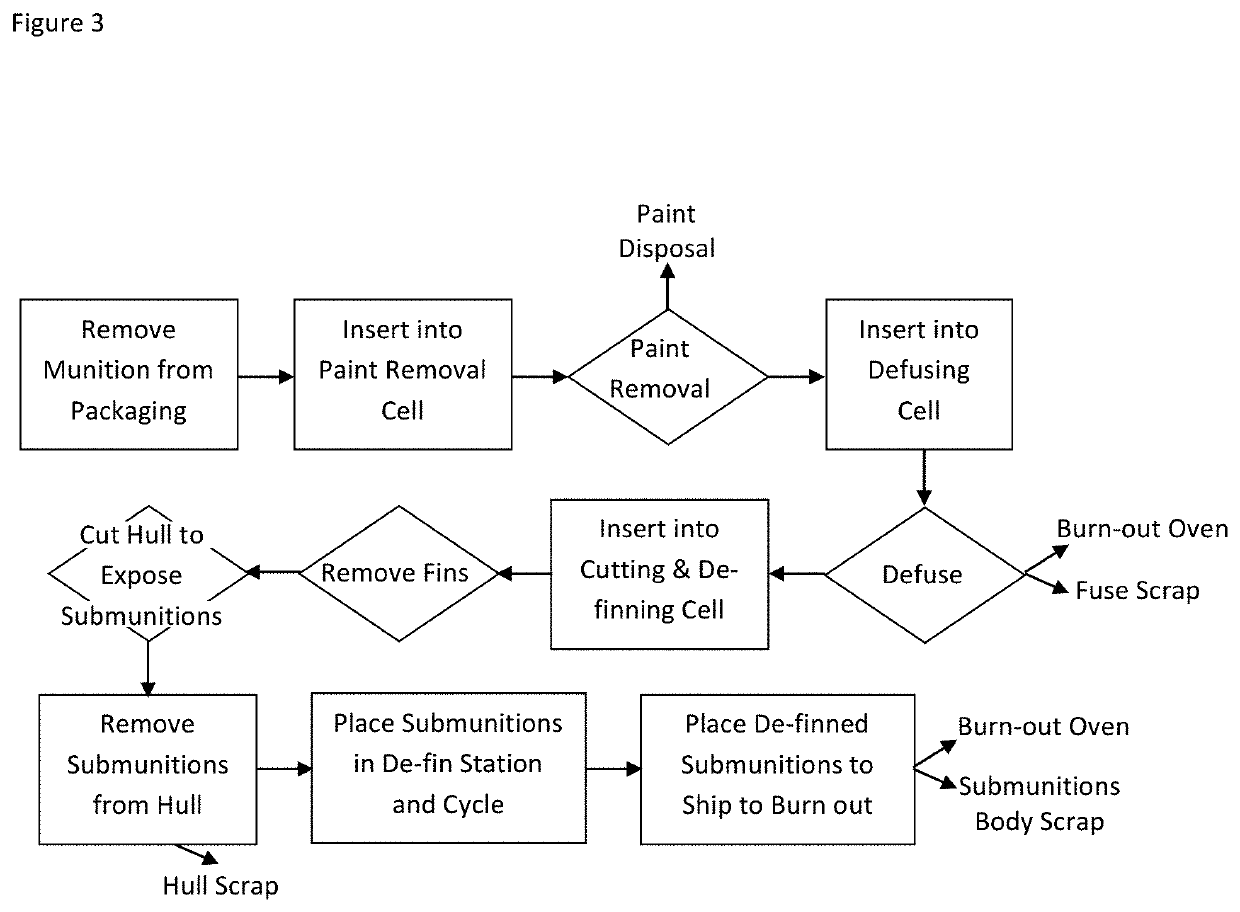

In an automated system and method uses a multi-axis robot arm and computer vision system to perform critical demil processes using a plurality of networked workcells monitored and managed by a central processor. An inspection and paint removal cell strips paint or other coatings from the outer surface of the ordnance for disposal of the paint or other coatings. A defusing cell is operative to remove a fuse from the ordinance for disposal of the fuse, and a cutting and definning cell operative to remove fins from the body of the ordnance, and cut into the body of the ordnance to determine if submunitions are present in the ordnance. A multi-axis robot arm and computer vision system removes submunitions from the ordnance, if present, inspecting the submunitions, and transferring the submunitions to the cutting and definning cell for subsequent processing.

Owner:CYBERNET SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com