Patents

Literature

252 results about "Specimen processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Specimen Processing. A service unit within the Pathology Laboratories, Specimen Processing receives incoming laboratory test specimens from patient floors and clinics (on and off-site) for the University of Michigan Health System.

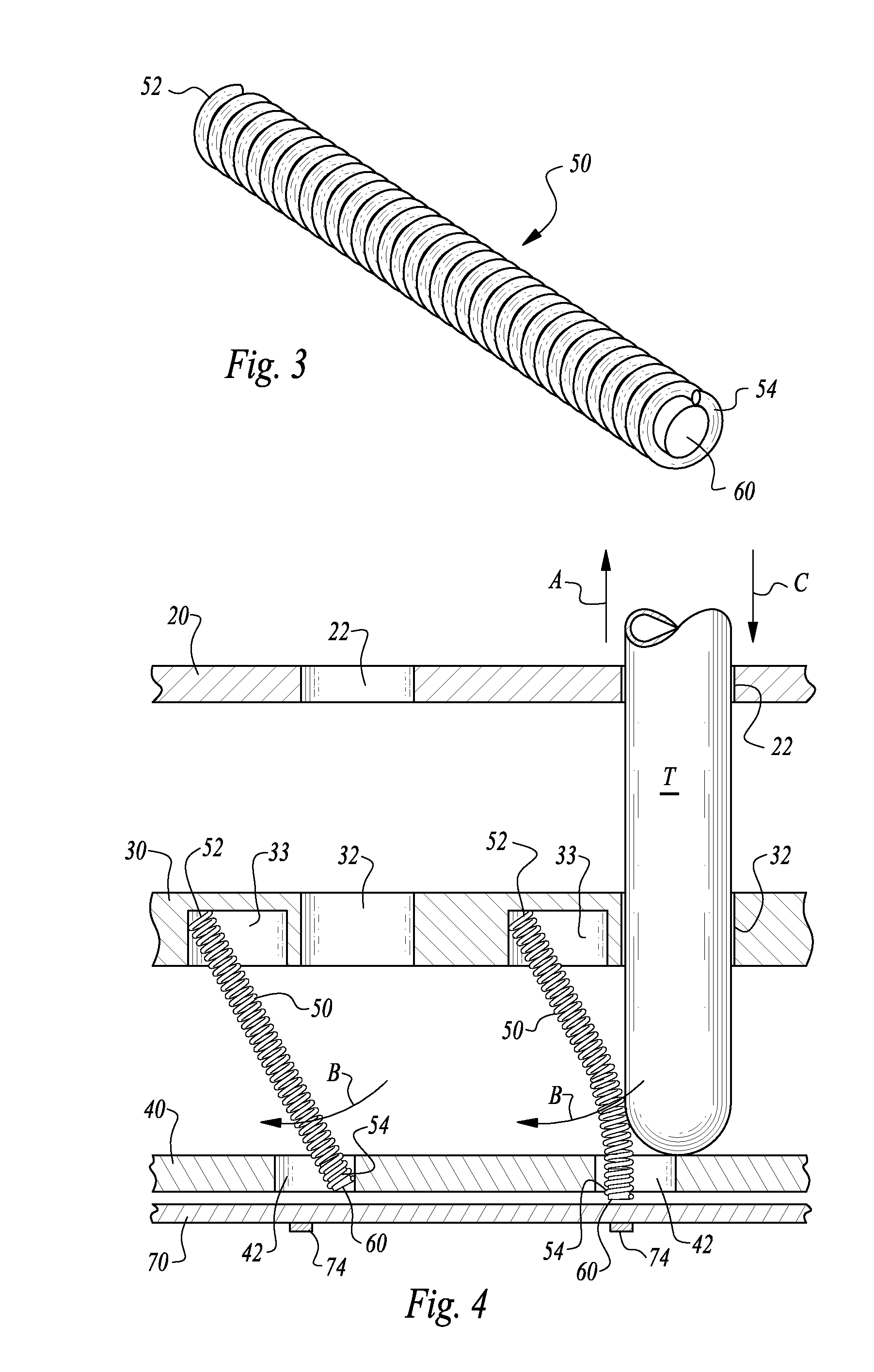

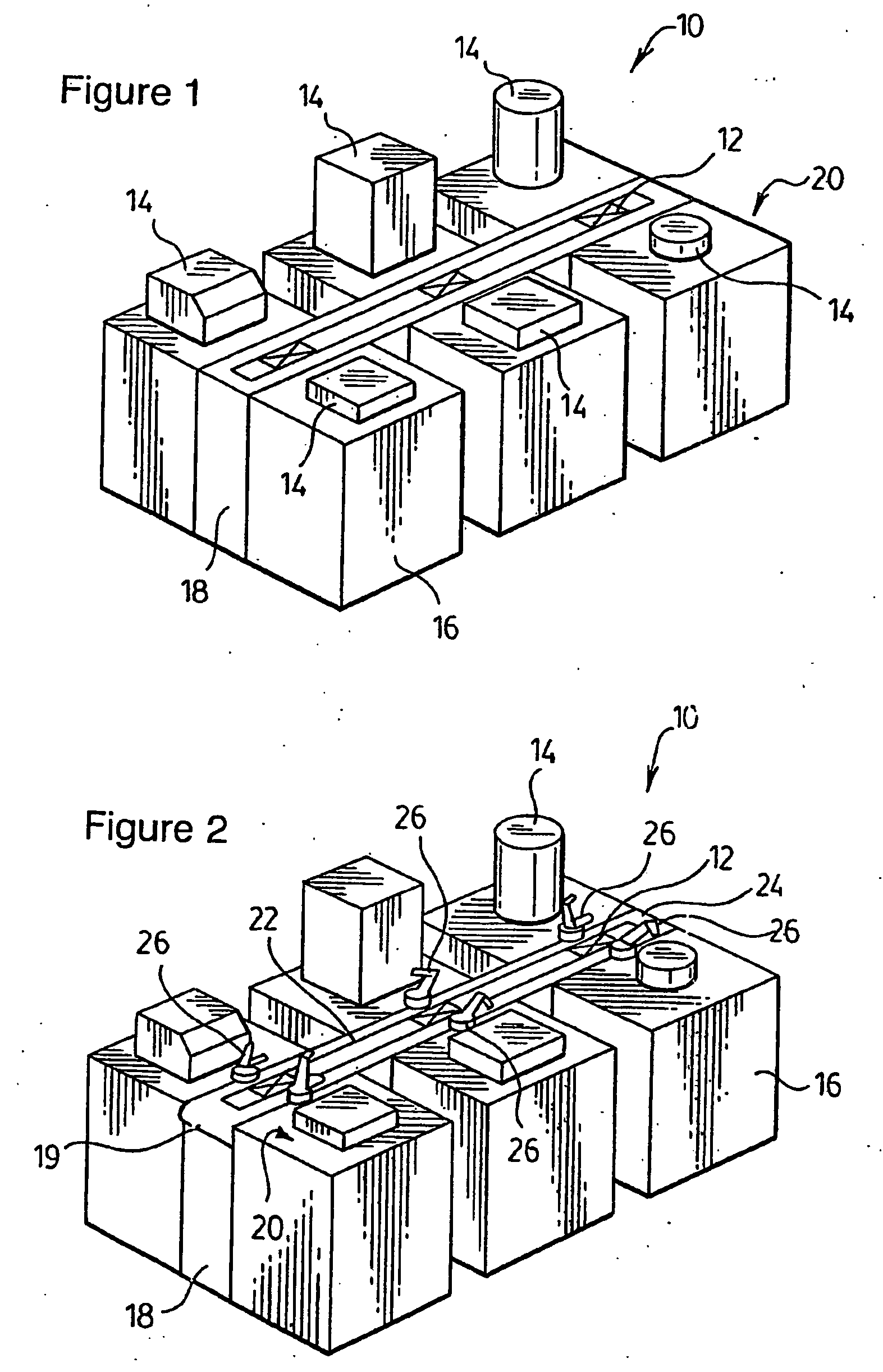

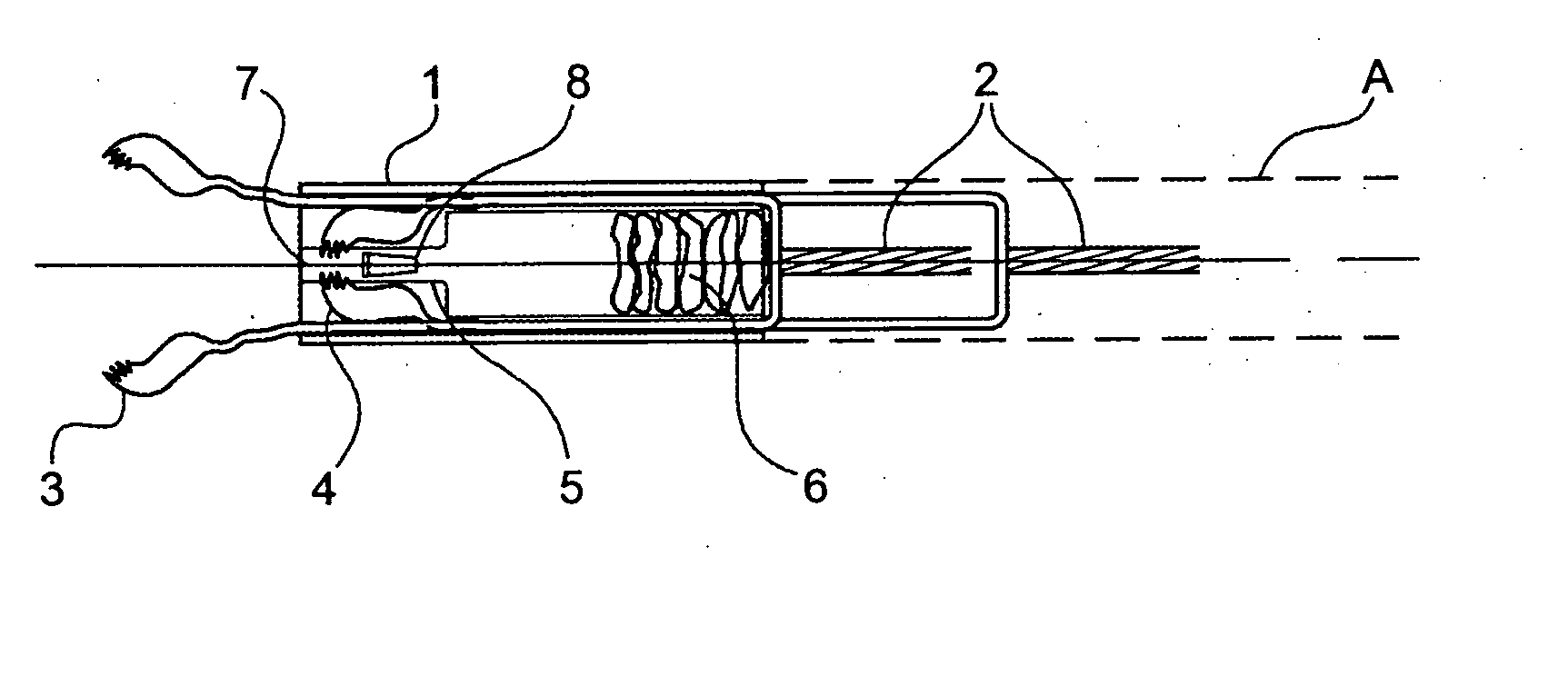

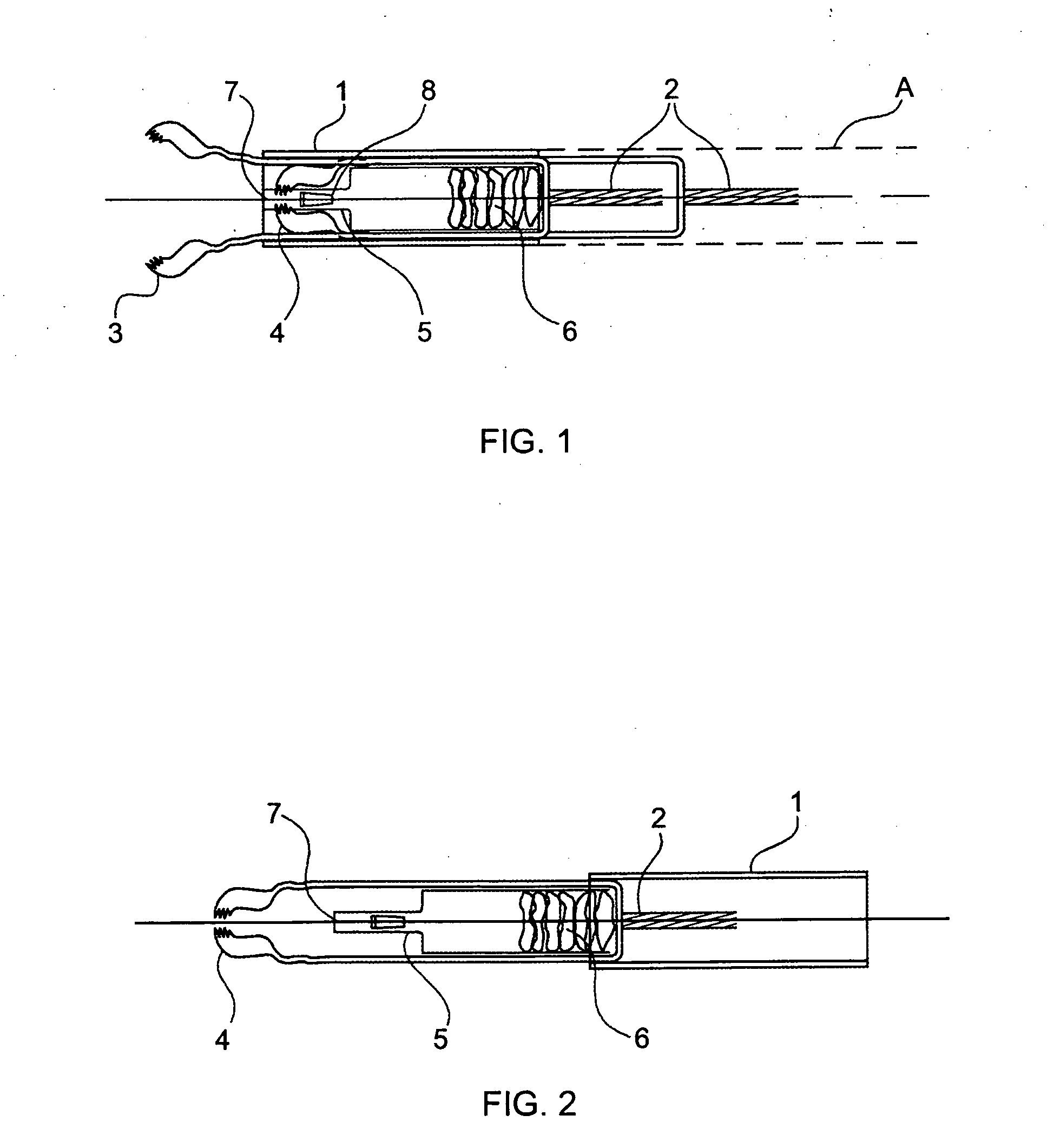

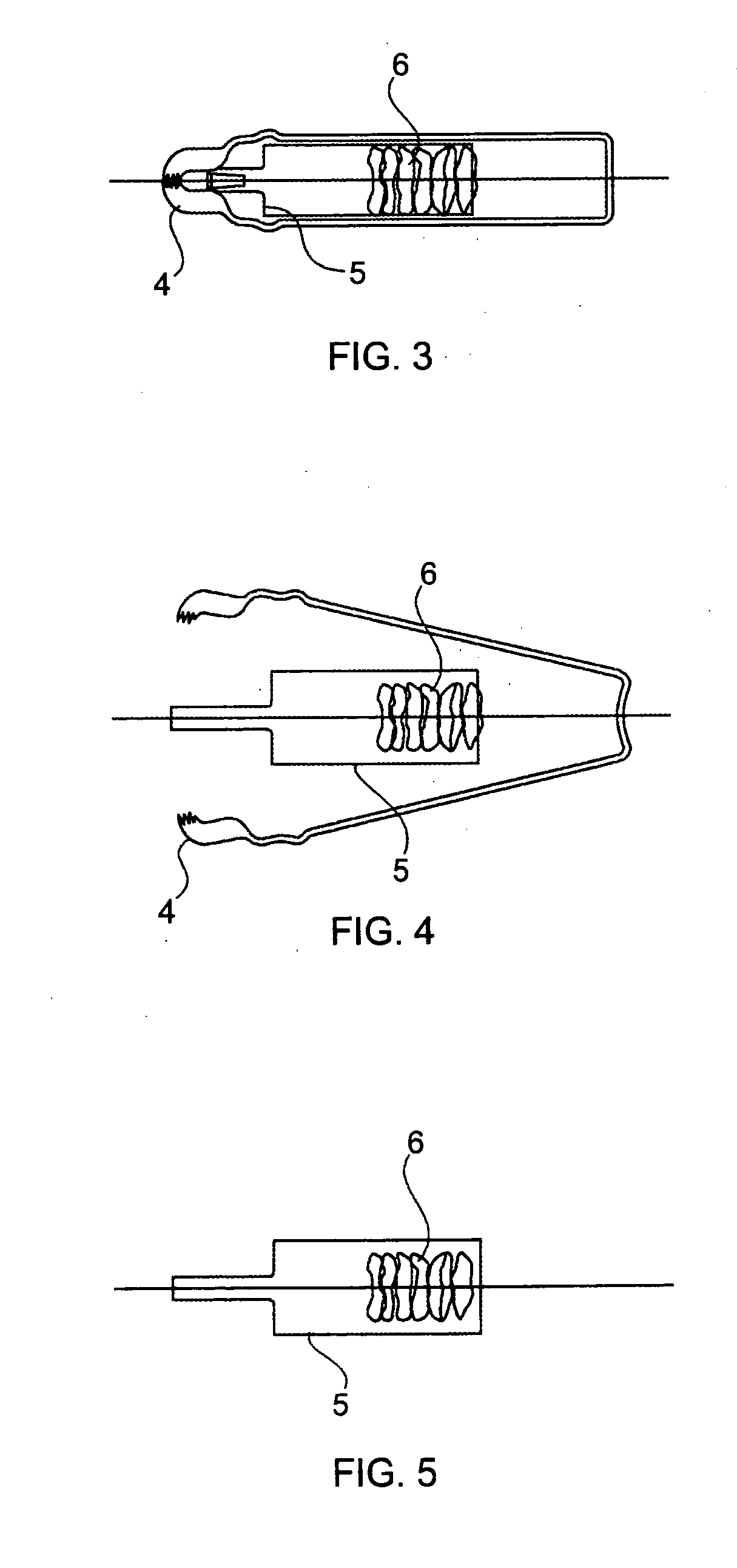

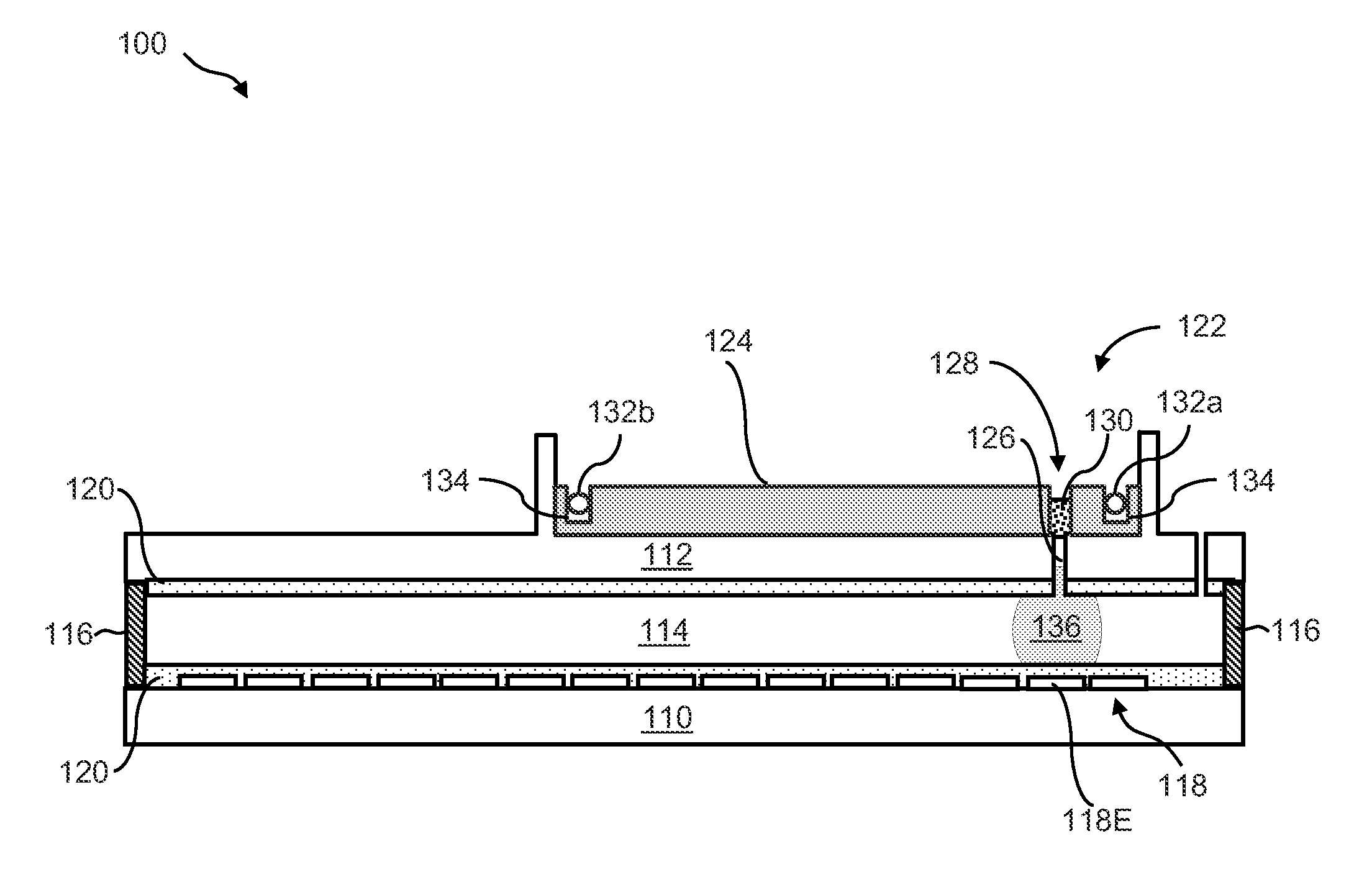

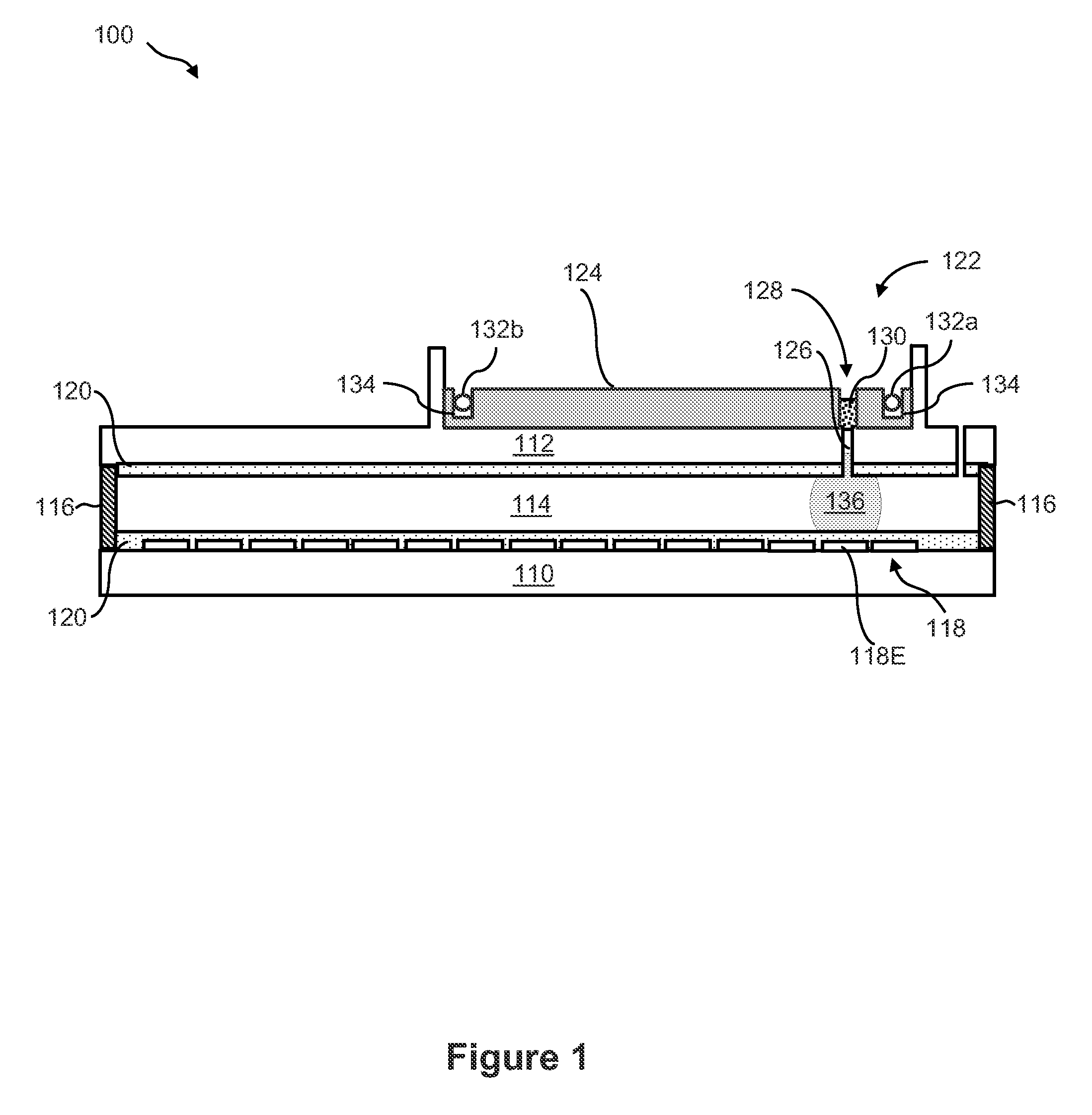

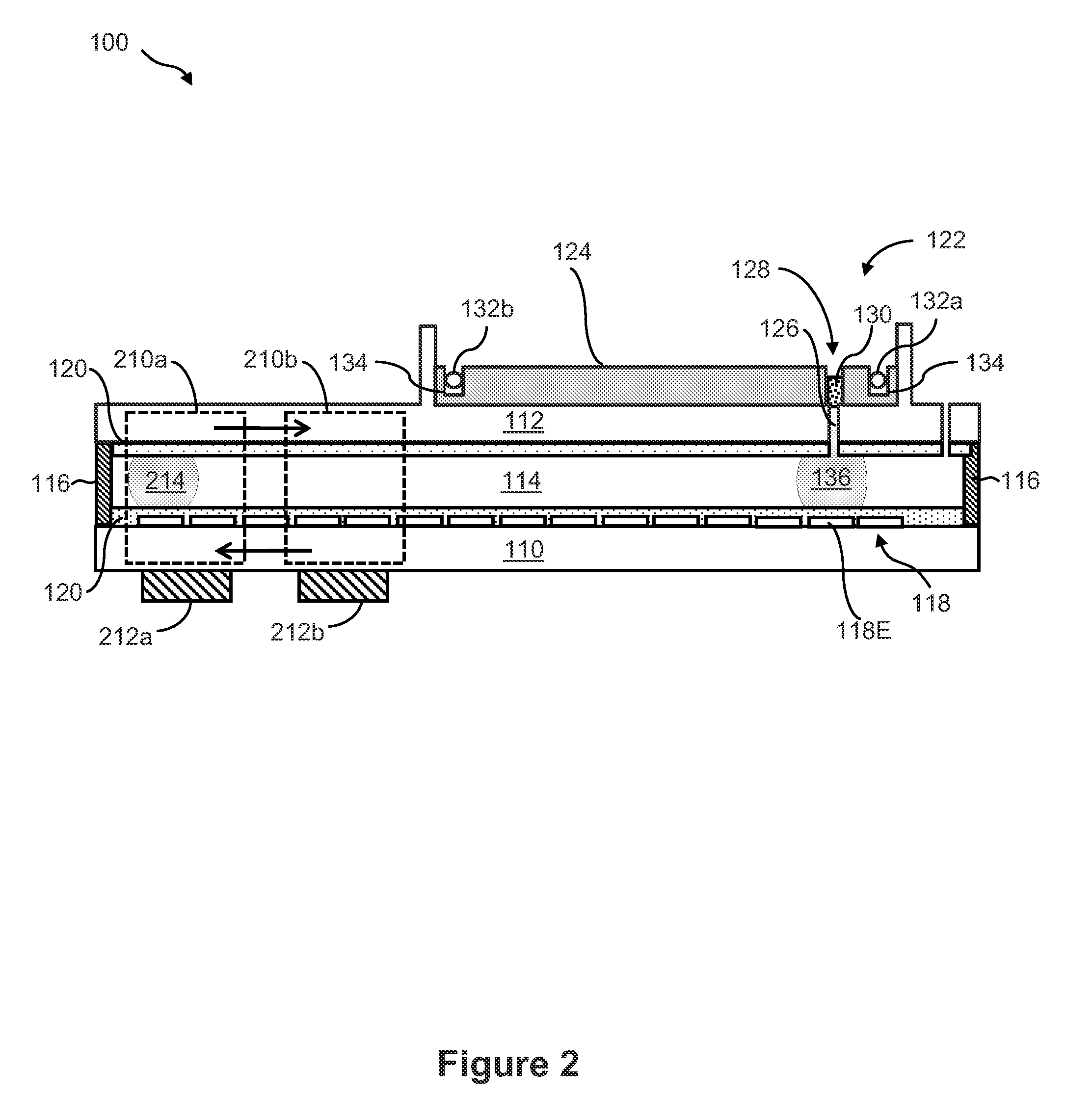

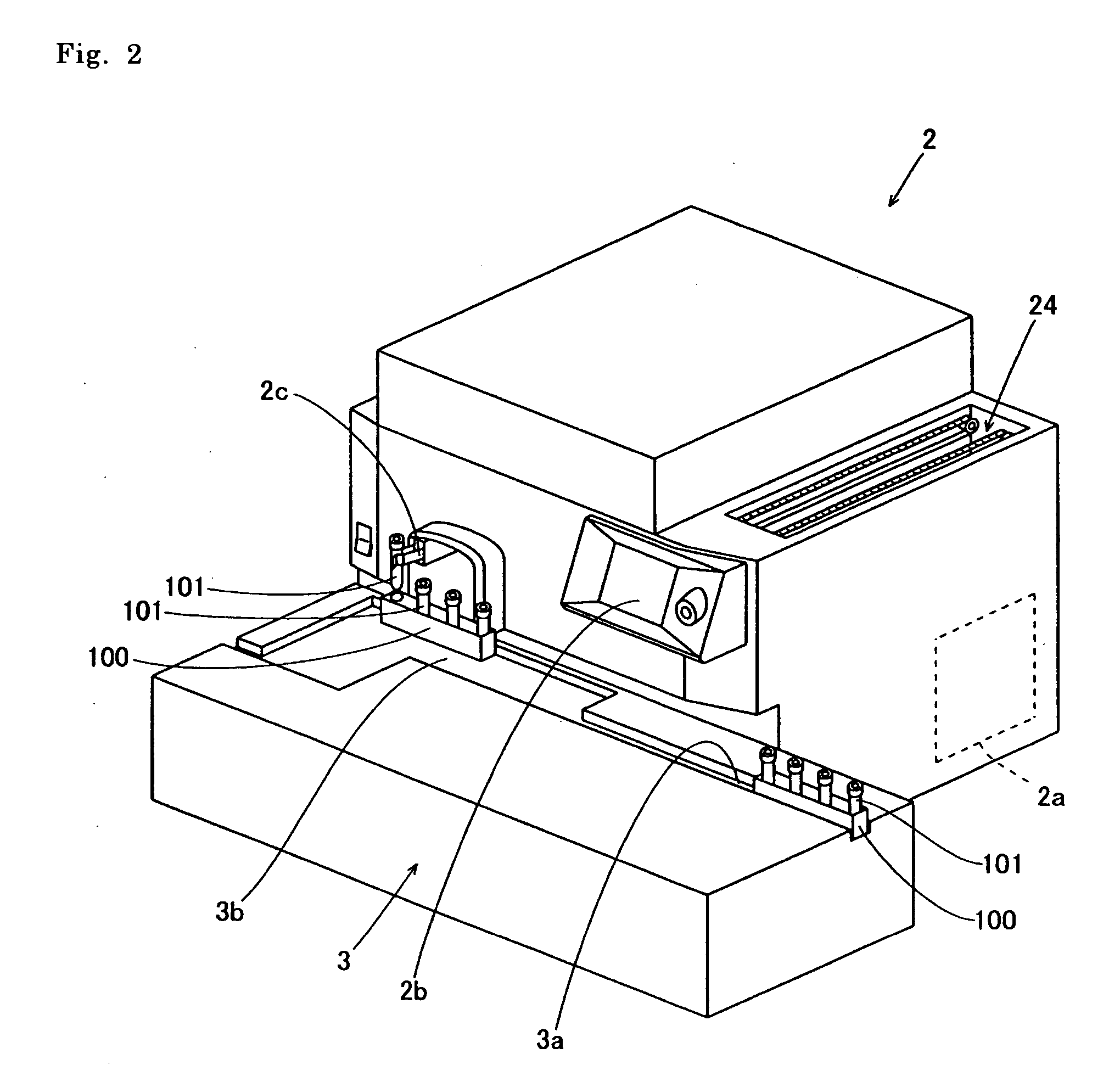

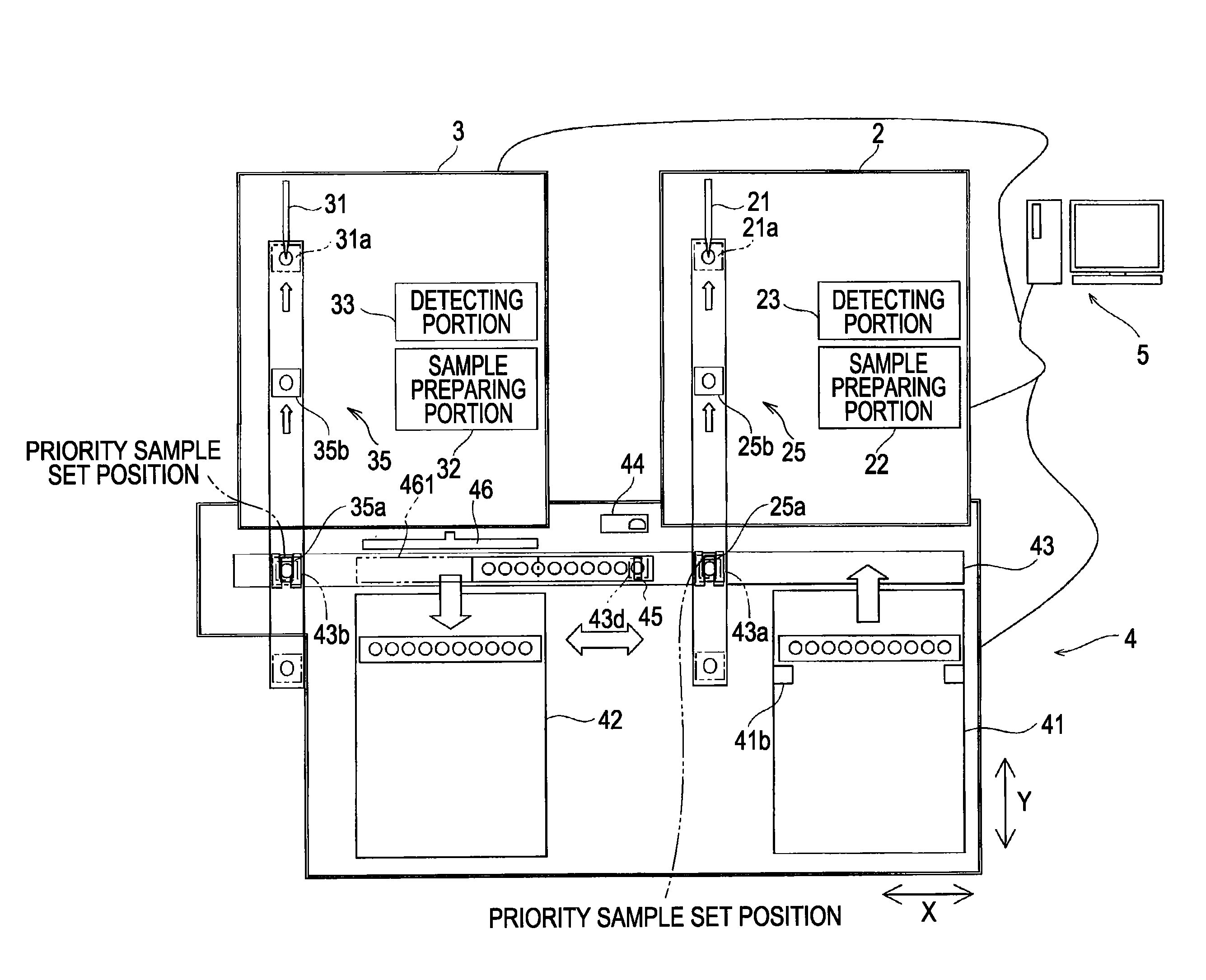

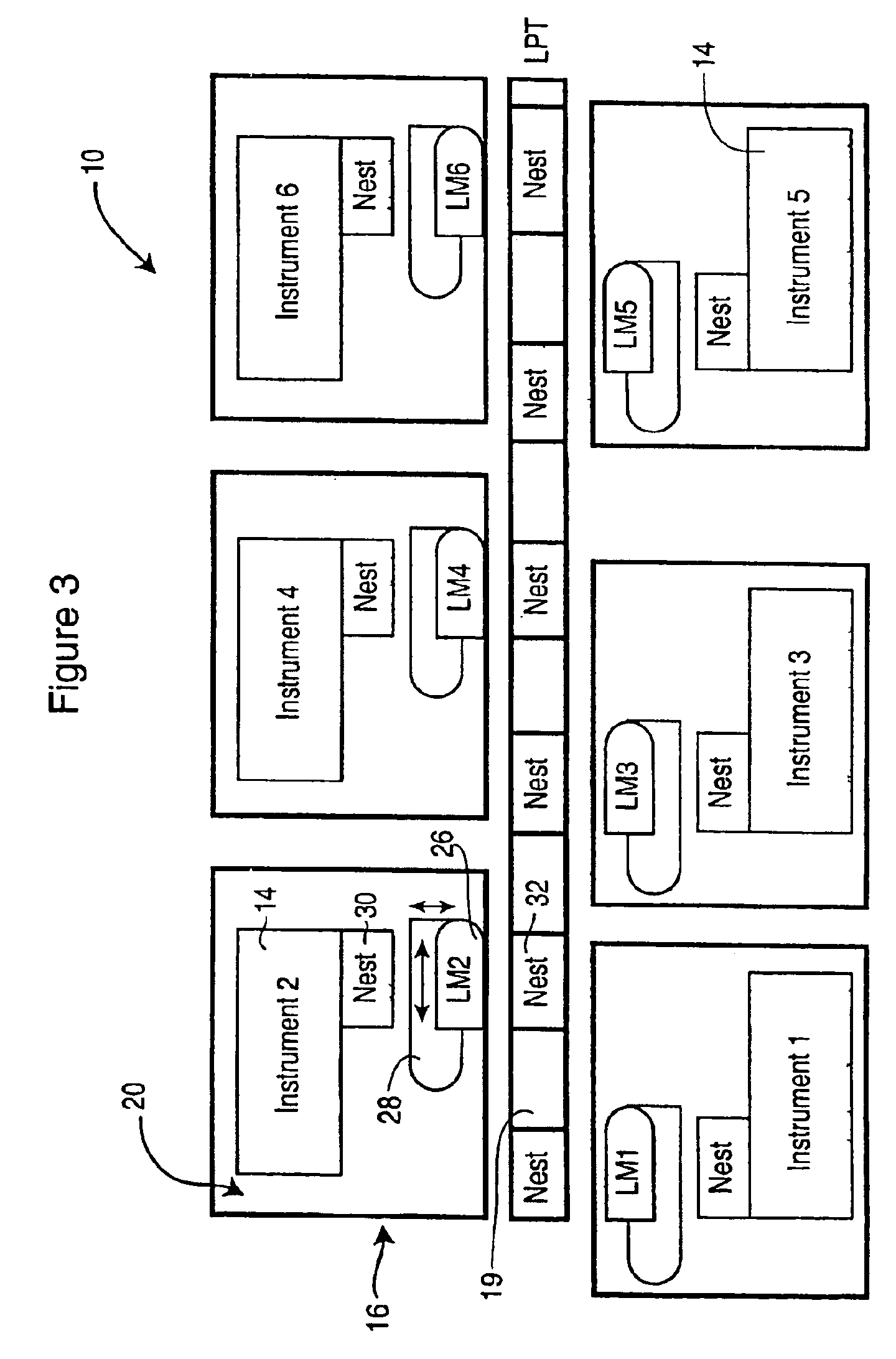

Specimen-transport module for a multi-instrument clinical workcell

ActiveUS20050196320A1Simpler and reliable resultEliminate needMaterial analysis by optical meansCharge manipulationWorkcellTransfer system

A specimen-transport module adapted for use with each of a plurality of specimen-processing instruments of a multi-instrument clinical workcell. Such module is adapted to transport individual racks of specimen-containers relative to a specimen-aspiration probe of an associated instrument in a workcell, as well as to transfer selected racks of specimen-containers to an adjacent and identical specimen-transport module associated with another clinical instrument of the workcell. Since the same transport system is used to both present specimens for aspiration and to transfer specimens between instruments, there is no need for two independent conveyances as is characteristic of the prior art. Preferably, the specimen-transport module includes a magnetic X / Y transport system that operates beneath a rack-supporting surface to advance racks in mutually perpendicular directions across a supporting surface via magnetic forces.

Owner:BECKMAN COULTER INC

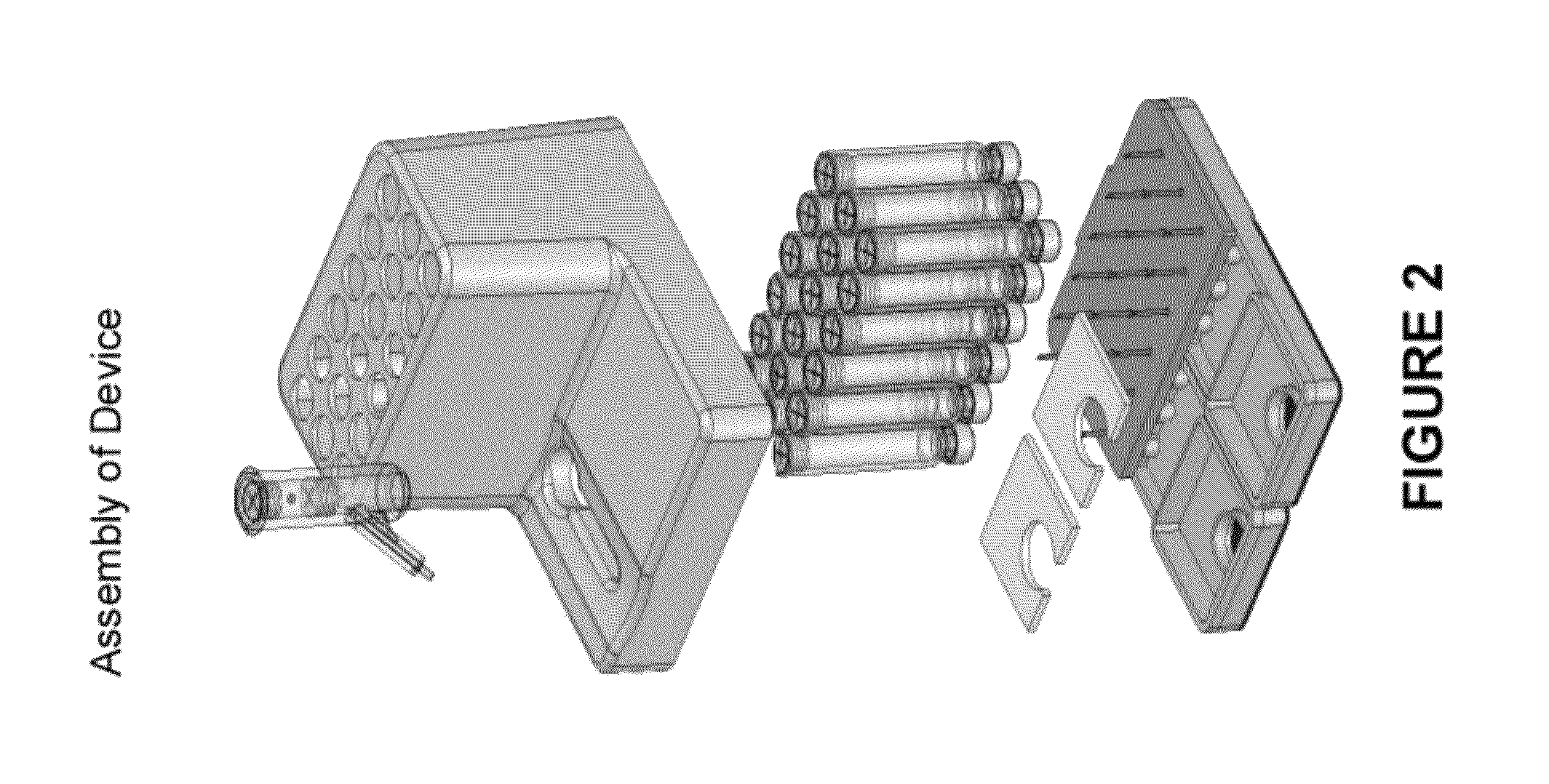

High temperature fluid sample aging cell

ActiveUS9784667B2Engine sealsWeather/light/corrosion resistanceAge methodPressure controlled ventilation

Owner:OFI TESTING EQUIP

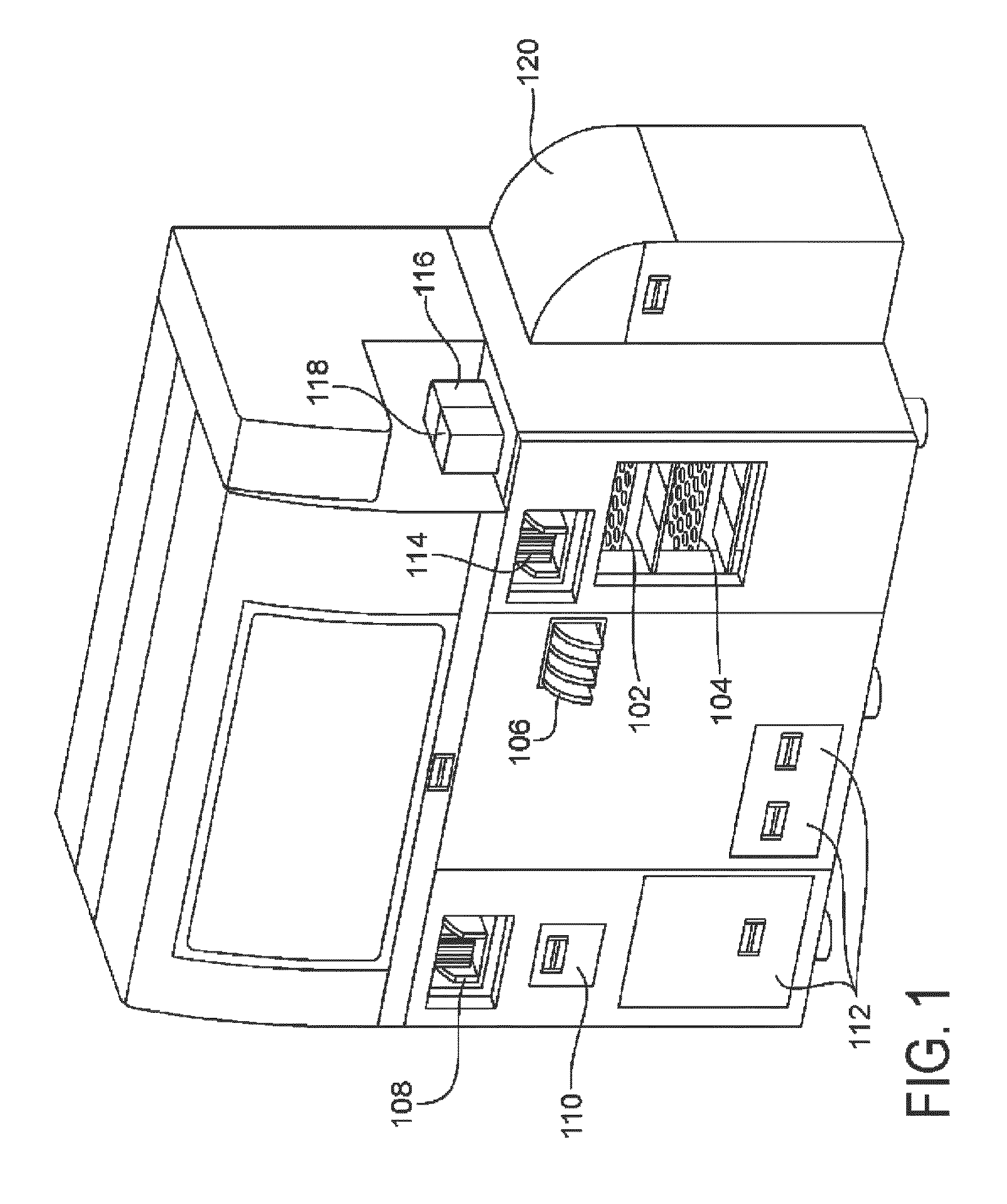

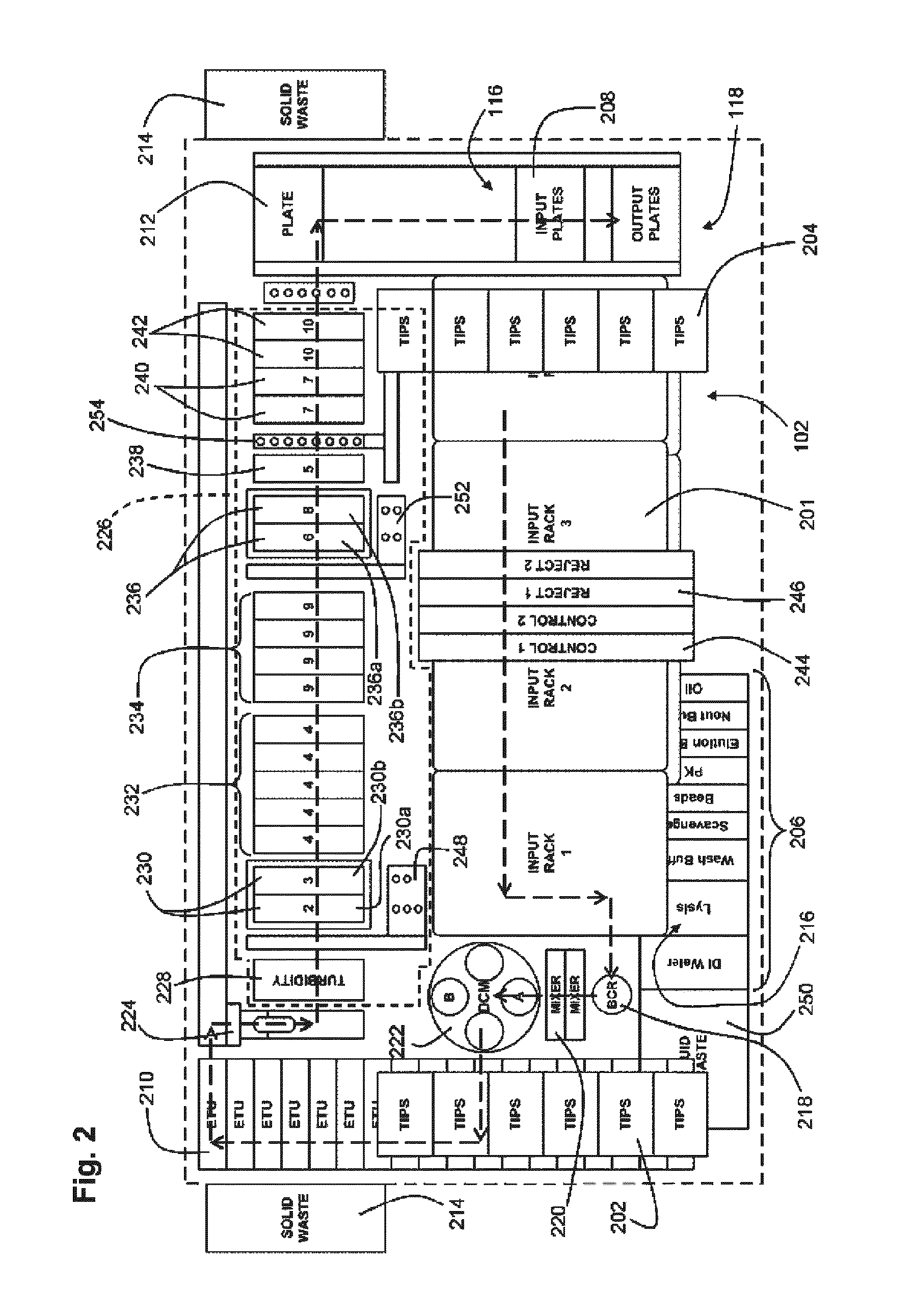

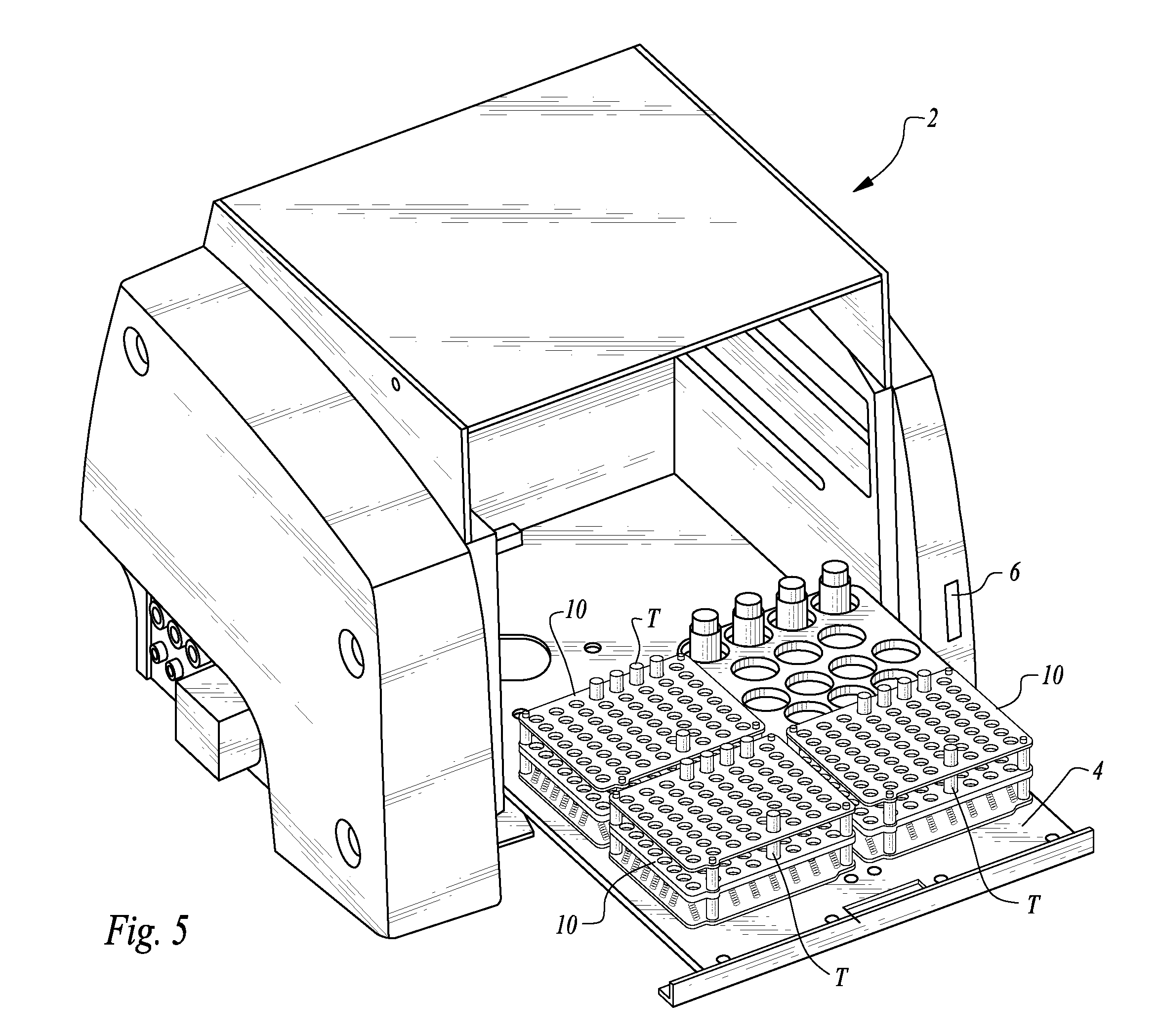

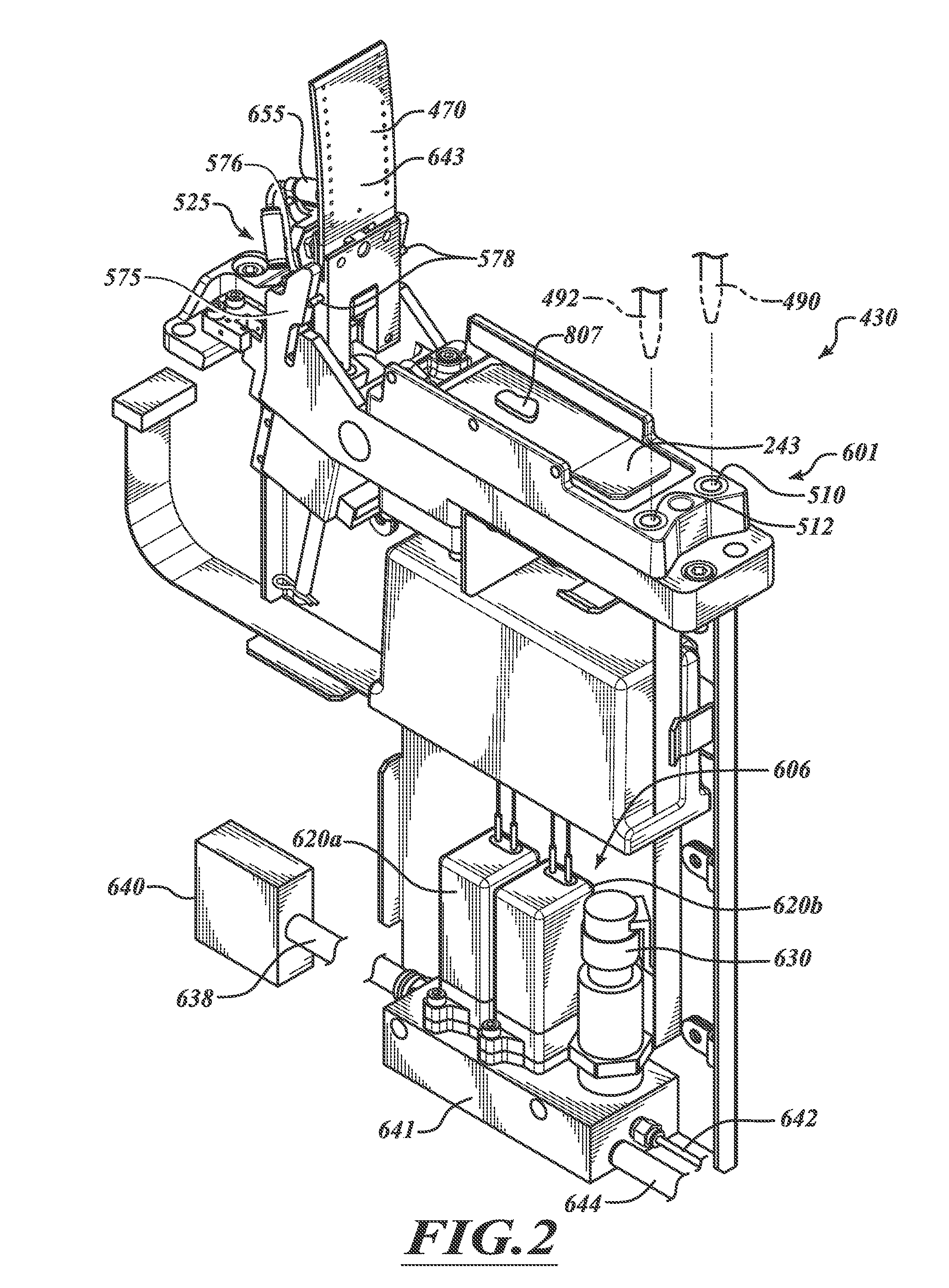

Open platform automated sample processing system

ActiveUS20100126286A1Analysis using chemical indicatorsWithdrawing sample devicesLiquid wasteOpen platform

An automated sample processing system having a sample input adapted to simultaneously receive a number of sample containers, a reagent input adapted to receive one or more new reagent supplies, a consumable input adapted to receive one or more new consumable supplies, a solid waste output adapted to receive used consumable supplies, a liquid waste output adapted to receive one or more used reagent supplies, and a processing center. The processing center includes a decapper adapted to remove a lid from at least one sample container, an aspirator adapted to remove a specimen from the at least one sample container and transfer the specimen to an output vessel, and a capper adapted to replace the lid on the at least one sample container. The system also includes a sample output adapted to receive the output vessel, and a user interface adapted to receive an input from the user to indicate the identity of the at least one sample container, and control at least one operation based on a physical property of the at least one sample container.

Owner:BECTON DICKINSON & CO

Automated laboratory system and analytical module

InactiveUS20050158212A1Rapid phase separationEasy to separateAnalysis using chemical indicatorsLaboratory glasswaresMicrowell PlateBiomedical engineering

Laboratory Automated System and method for specimen processing, comprising several Clinical and Biological Analytical Modules is provided. The Module consists of coupling centrifuge, analyzers and robot. System produces rapid phase separation, cap removing and testing in one sequential, unbroken process. Several multi-item carriers for tubes and microplates loading provided.

Owner:YAVILEVICH MICHAEL

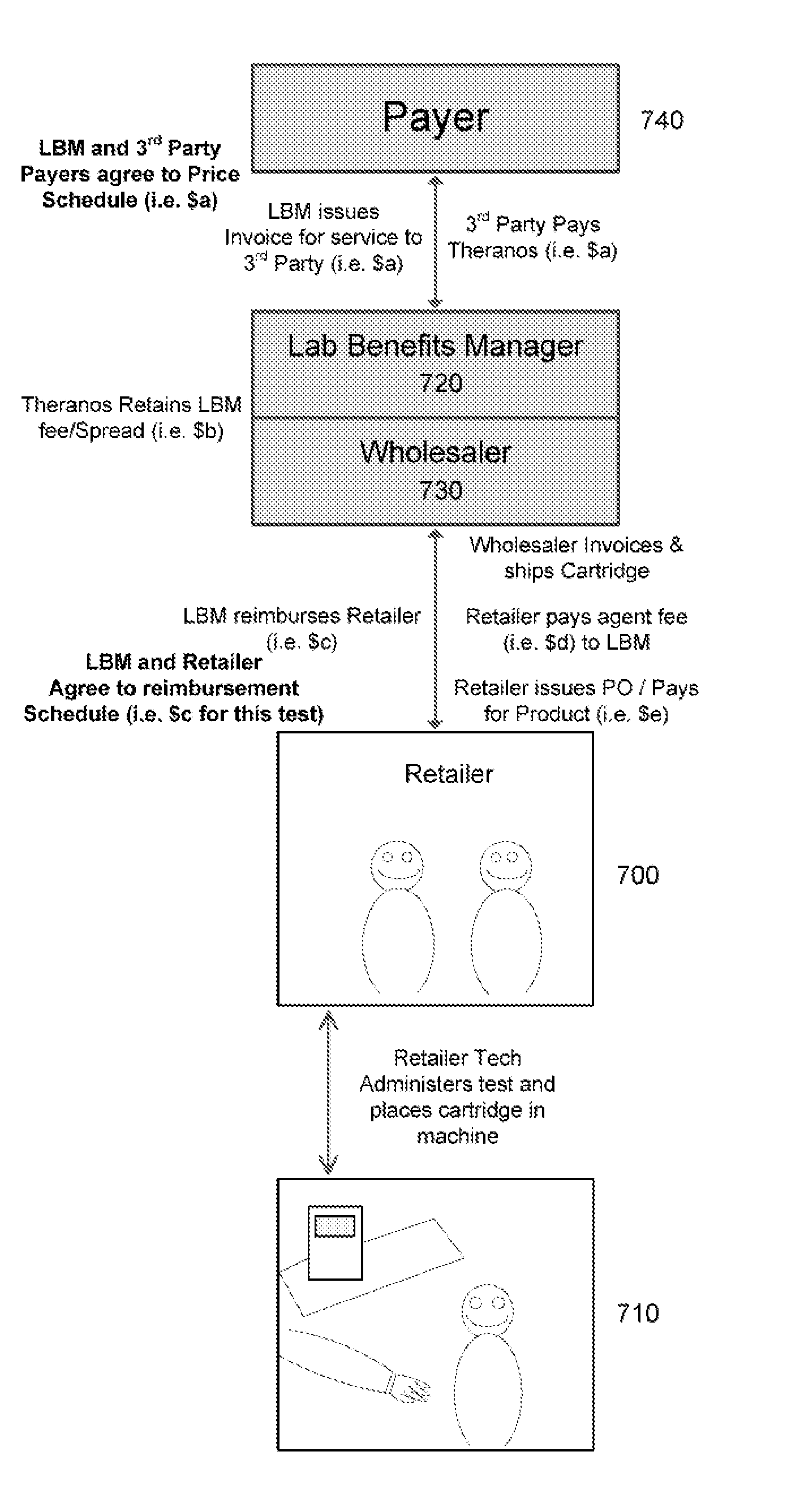

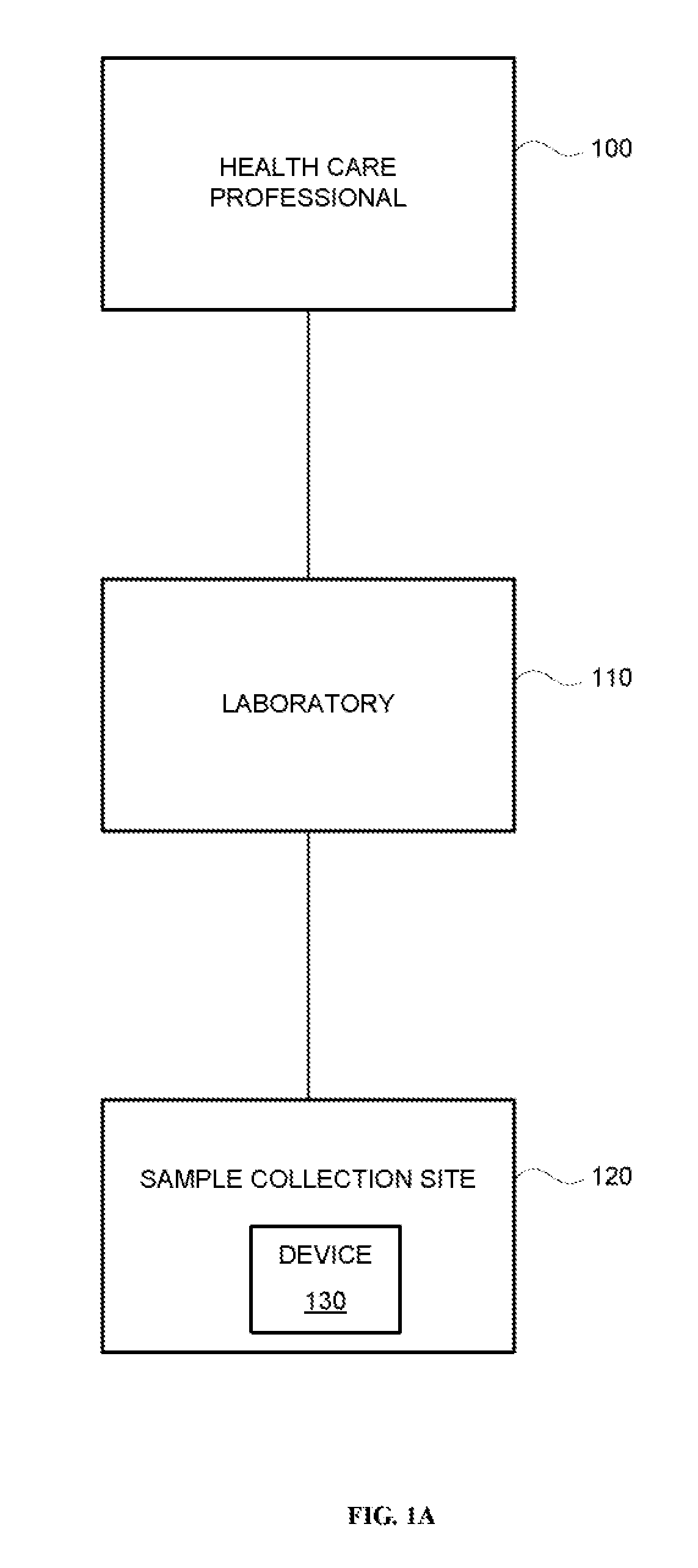

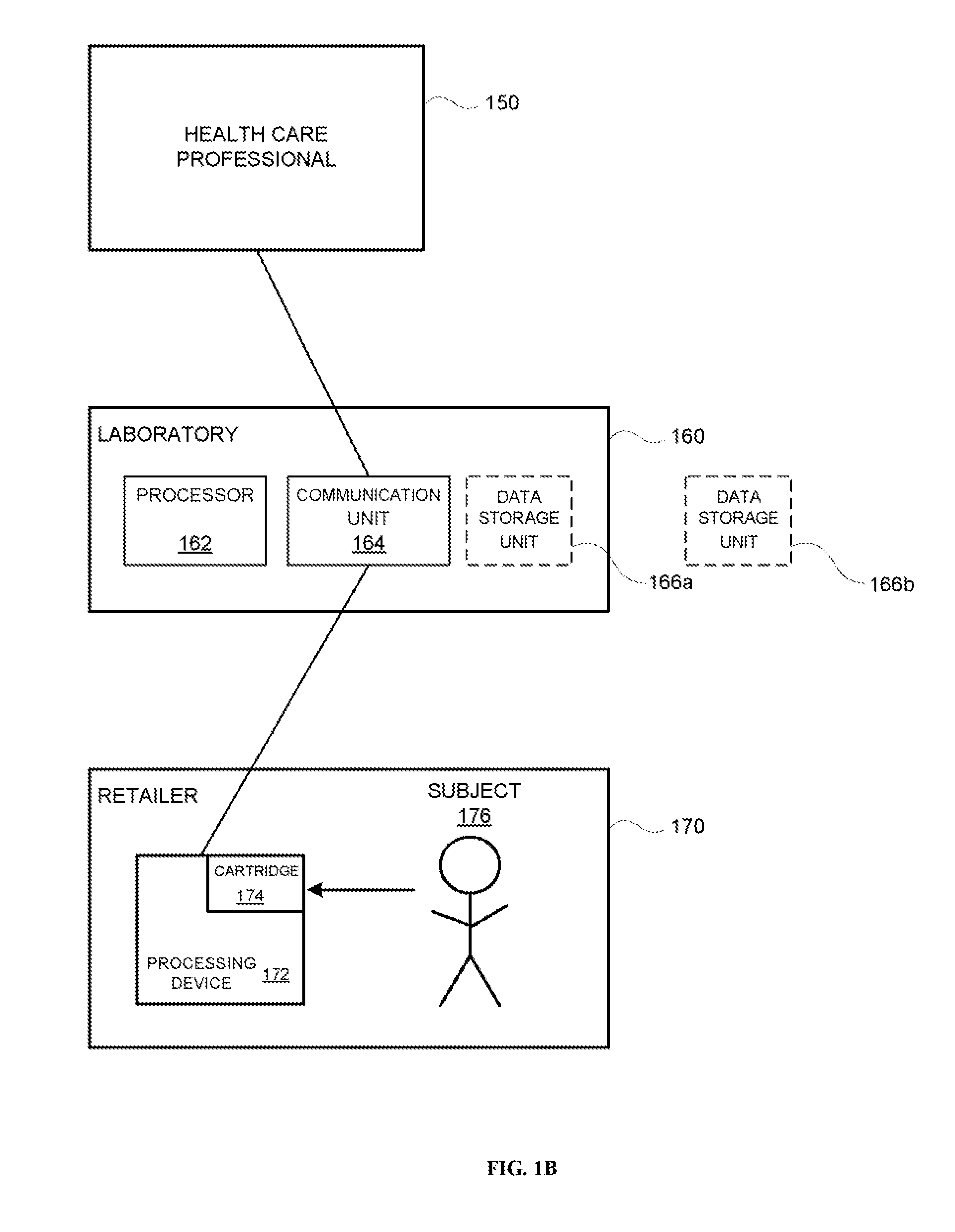

Systems and methods for sample processing and analysis

InactiveUS20130080071A1Quality improvementLittle variabilityComputer-assisted medical data acquisitionBiological testingDiseaseChemical reaction

Systems and methods are provided for collecting, preparing, and / or analyzing a biological sample. A sample collection site may be utilized with one or more sample processing device. The sample processing device may be configured to accept a sample from a subject. The sample processing device may perform one or more sample preparation step and / or chemical reaction involving the sample. Data related to the sample may be sent from the device to a laboratory. The laboratory may be a certified laboratory that may generate a report that is transmitted to a health care professional. The health care professional may rely on the report for diagnosing, treating, and / or preventing a disease in the subject.

Owner:THERANOS

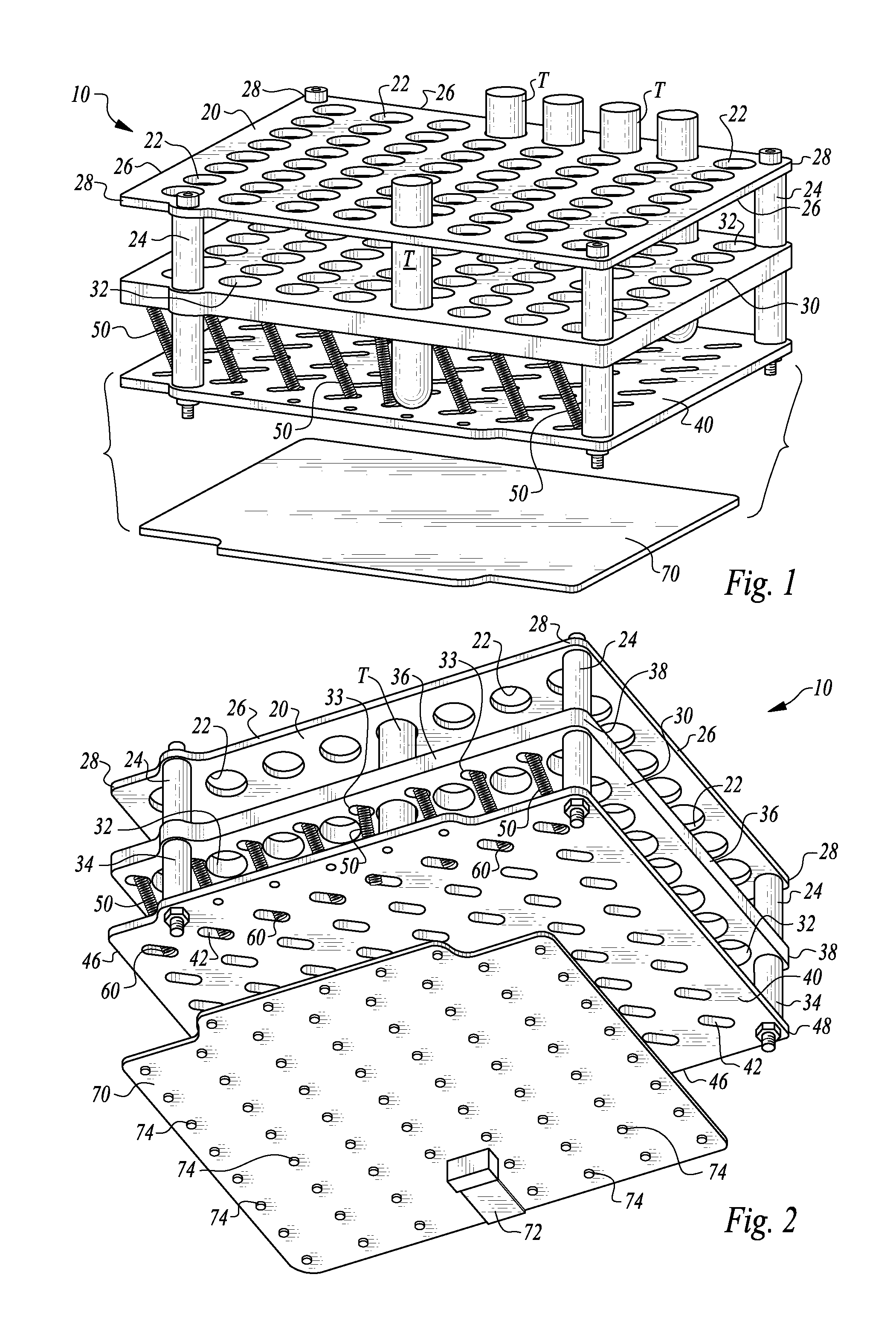

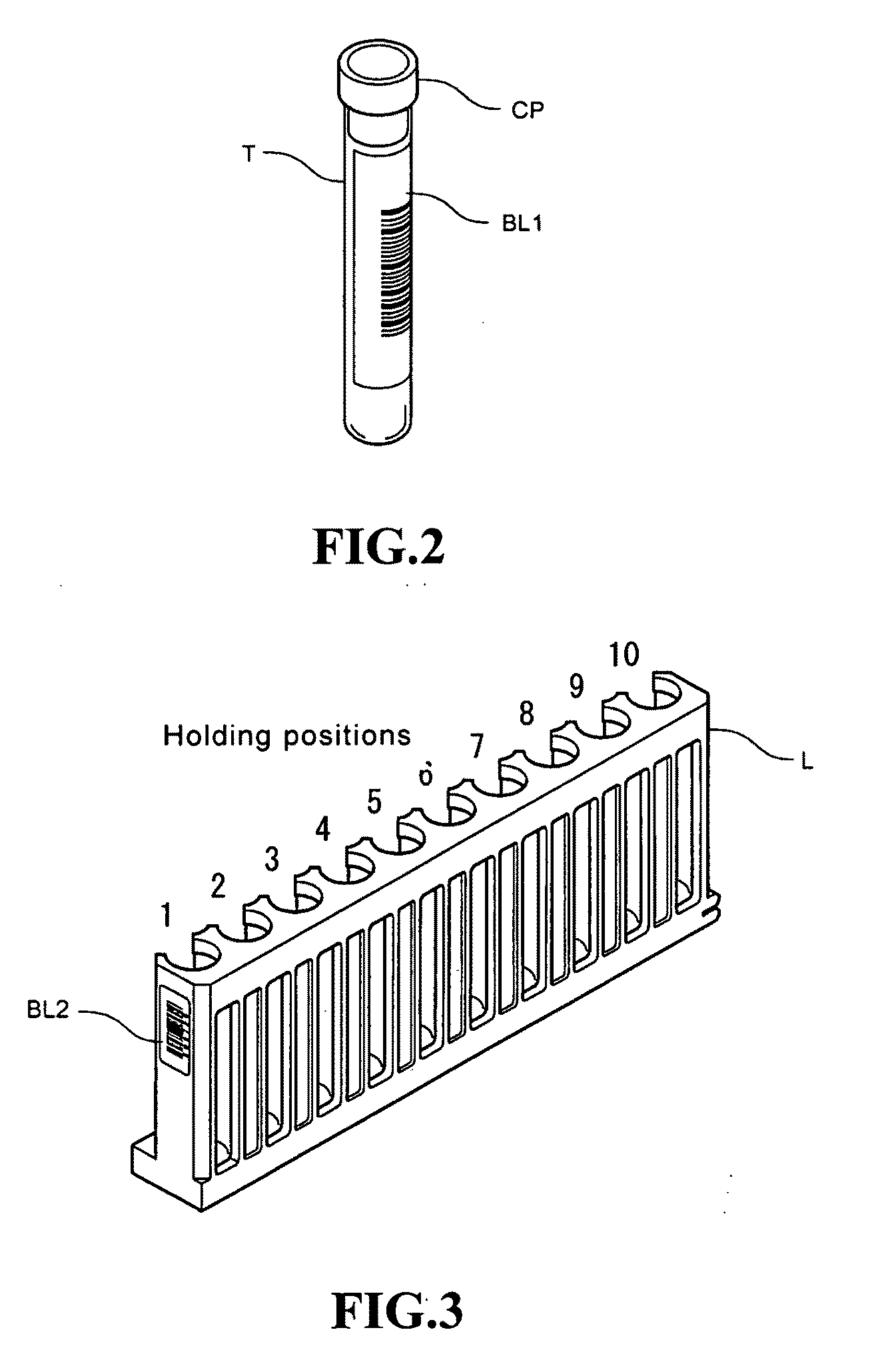

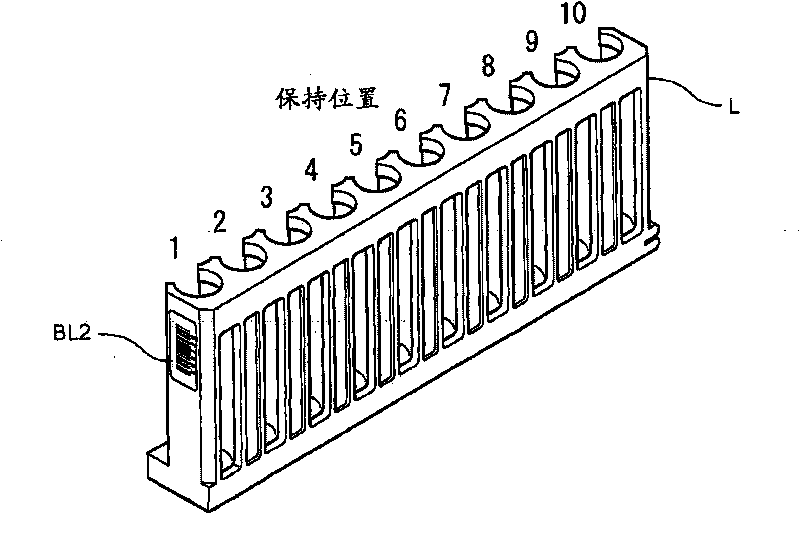

Sample container intelligent rack and loading method

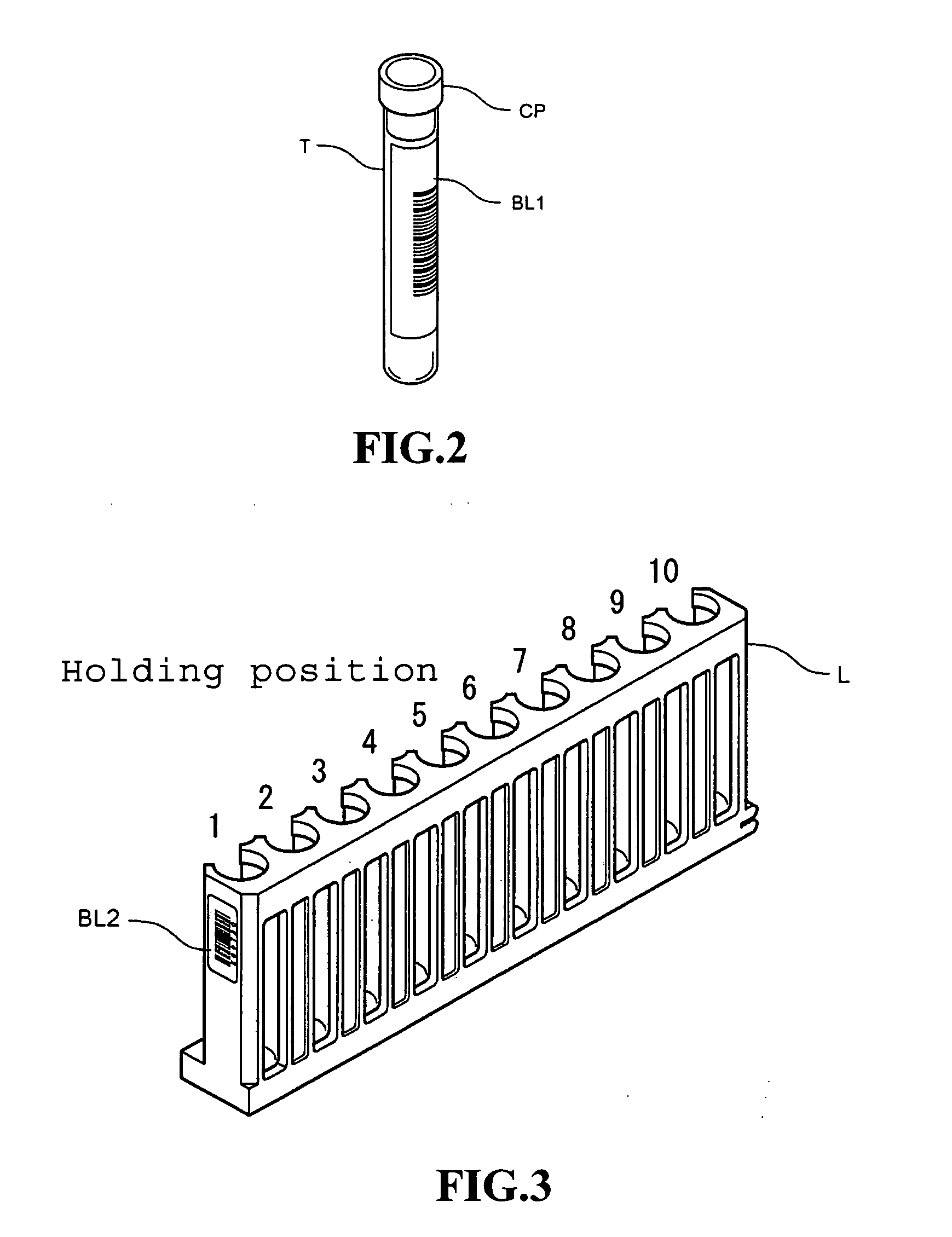

InactiveUS20120178170A1Risk minimizationEfficient processingMaterial analysis by optical meansBiological testingBarcodeBiomedical engineering

An intelligent rack automatically detects the position of a specimen tube within a multiple specimen tube containing rack such as that utilized within automatic specimen processing apparatuses. The rack has a plurality of positions with a moving element located adjacent each position. The moving element, such as a spring, is positioned so that it moves when a specimen tube is placed within an adjacent position. A magnet or other sensor on the moving element interacts with a detector to sense when a particular position has received a specimen tube. A computer controlling the apparatus receives specimen information for each specimen tube and has an identifier for the specimen tube, such as a bar code, scanned into the computer before placement of the specimen tube into a rack position. Removal of the specimen tube from a position on the rack causes correlating removal of specimen tube position information from the computer.

Owner:VAN PRAET PETER

Systems and methods of fluidic sample processing

The present invention provides fluidic devices and systems that allow detection of analytes from a biological fluid. The methods and devices are particularly useful for providing point-of-care testing for a variety of medical applications.

Owner:LABRADOR DIAGNOSTICS LLC

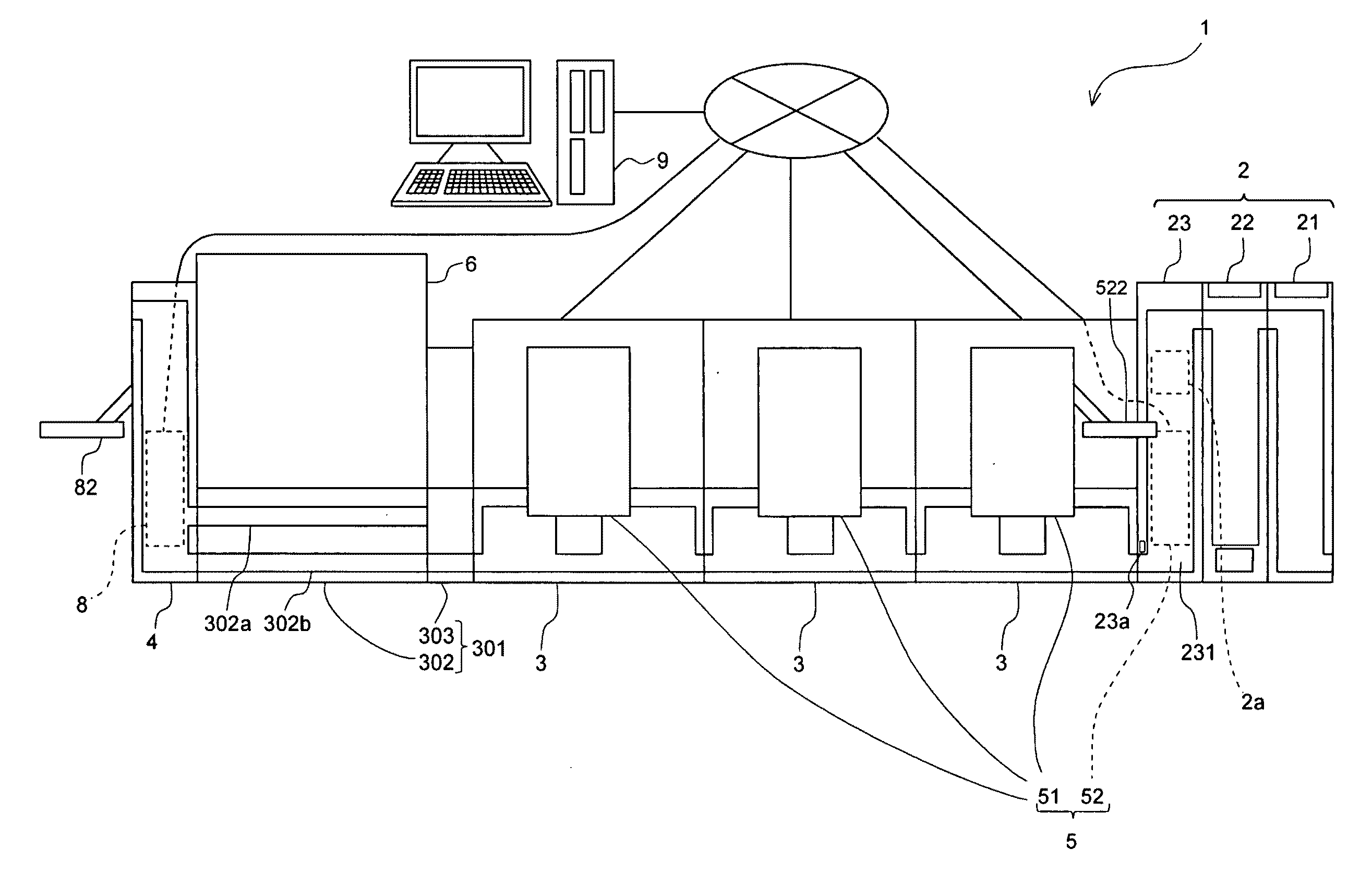

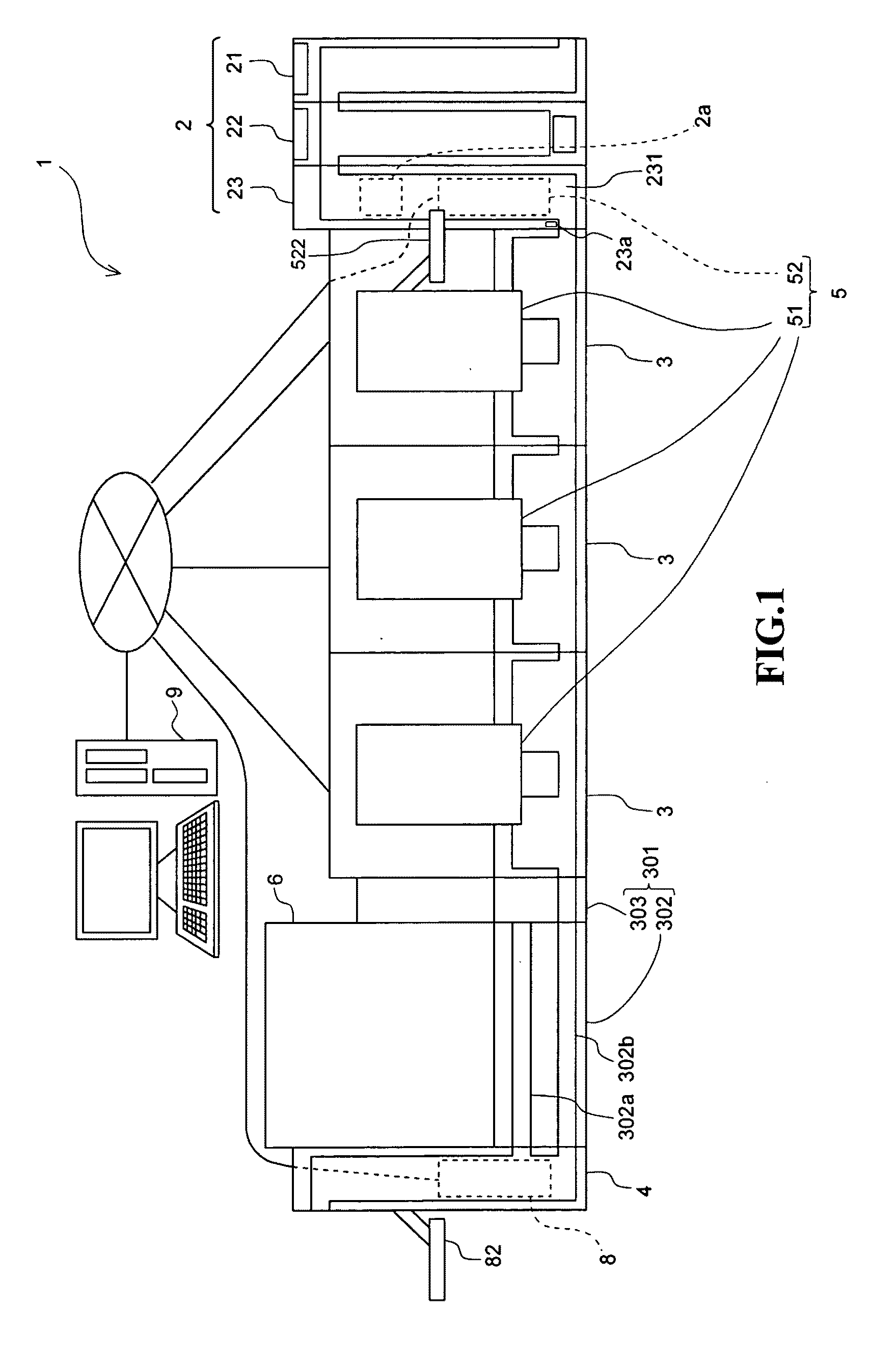

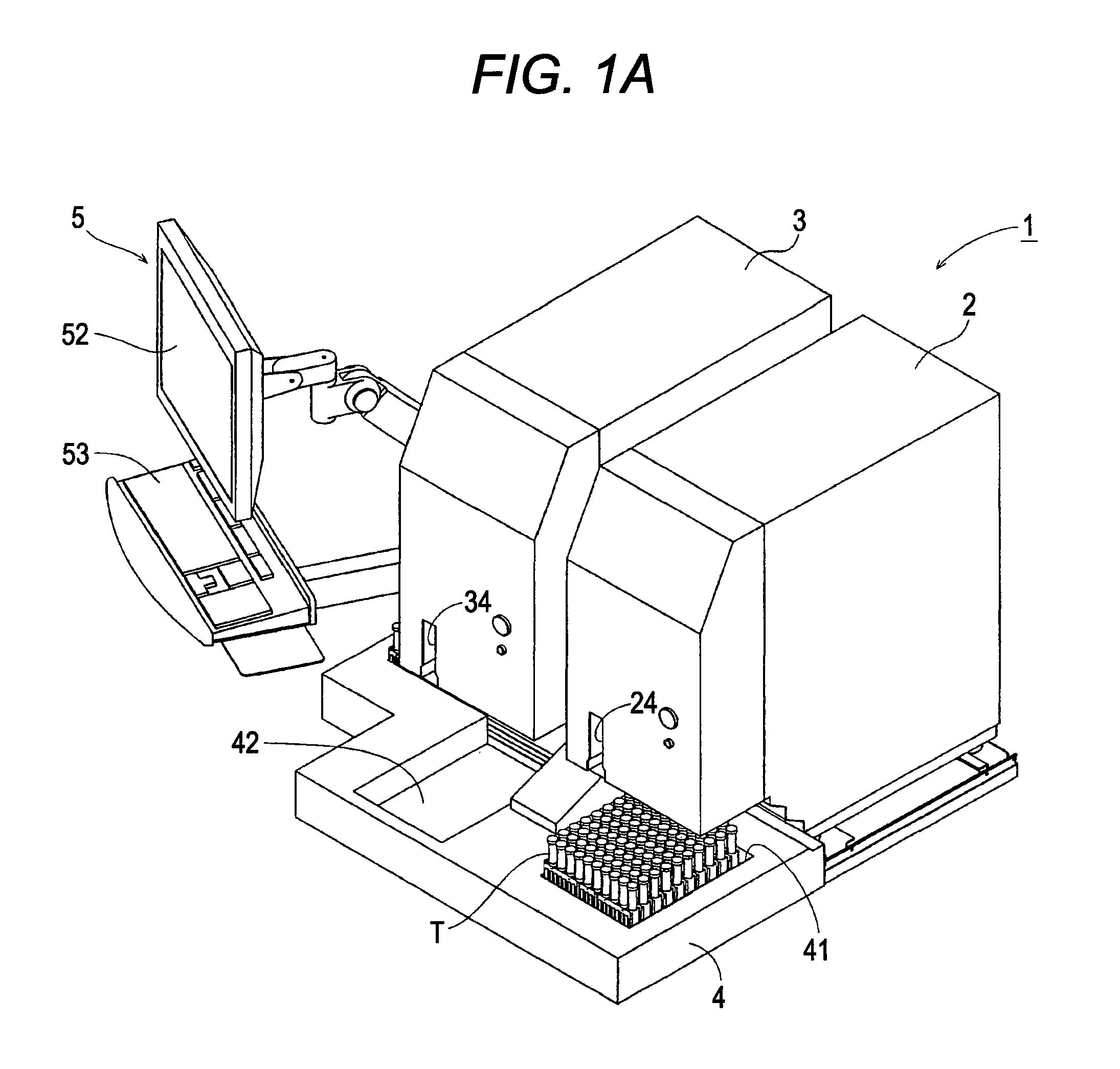

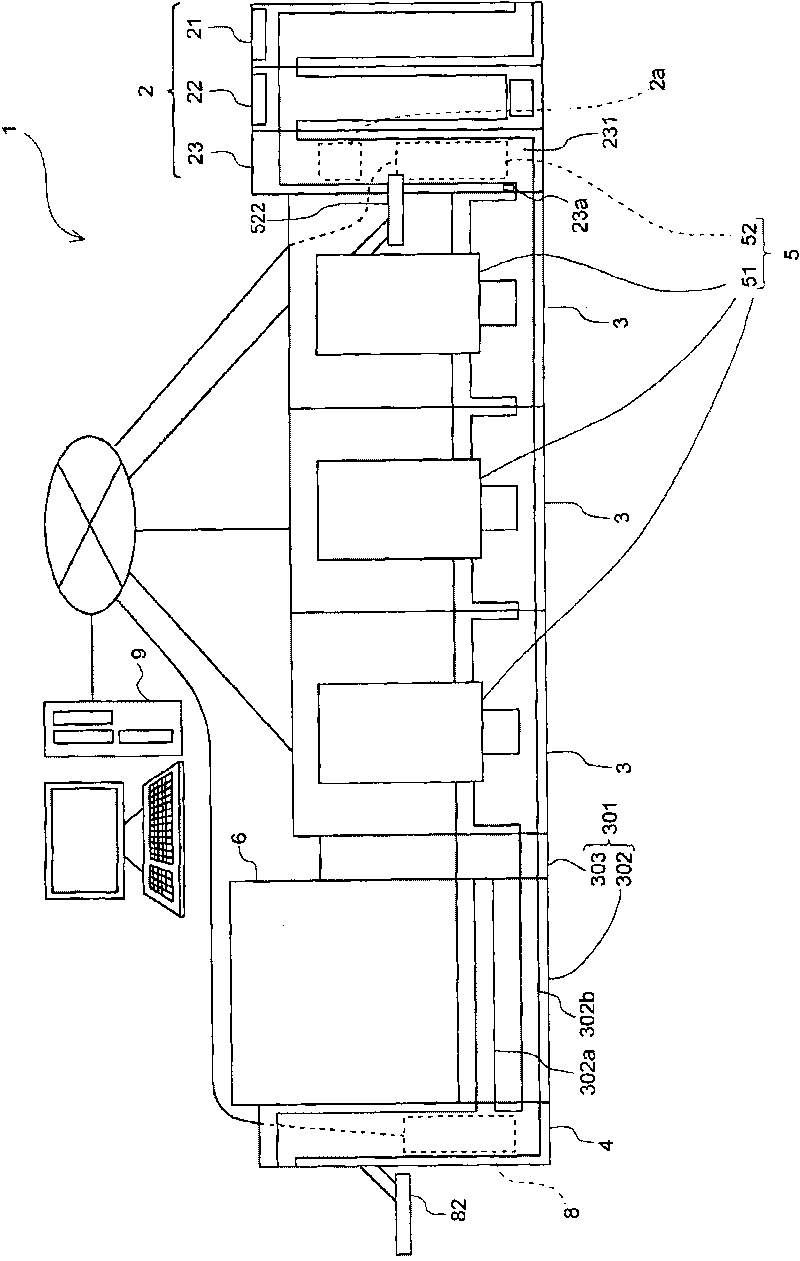

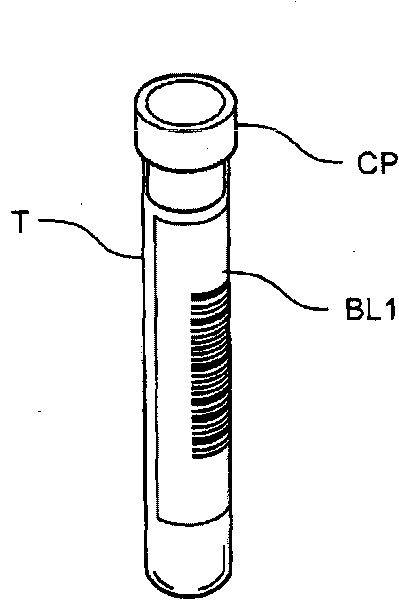

Specimen processing system and specimen container classifying apparatus

ActiveUS20100111767A1Material analysis by optical meansBiological testingSpecimen HandlingEngineering

A specimen processing system comprising: a specimen measuring section for measuring specimens accommodated in specimen containers; a transport section for transporting specimen containers to the specimen measuring section; a specimen container collect section for collecting specimen containers; an obtainer for obtaining shape information on specimen containers or state information on specimens accommodated in specimen containers; a supply judger configured for determining whether specimen containers are to be supplied to the specimen measuring section on the basis of the result obtained by the obtainer; and a delivery section for delivering specimen containers, which are determined to be supplied to the specimen measuring section by the supply judger, toward the transport section, and delivering specimen containers, which are determined not to be supplied to the specimen measuring section by the supply judger, toward the specimen container collect section, is disclosed. A specimen container classifying apparatus is also disclosed.

Owner:SYSMEX CORP

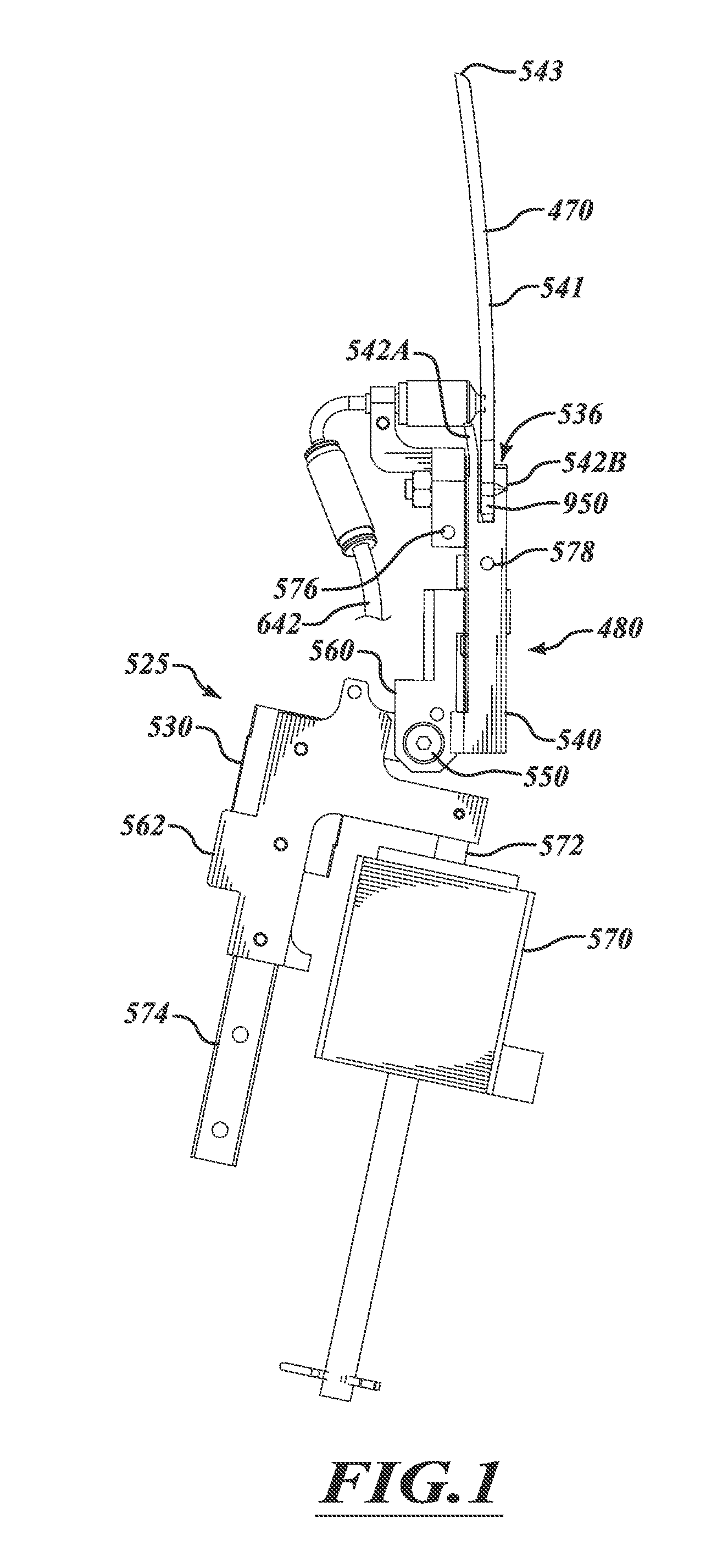

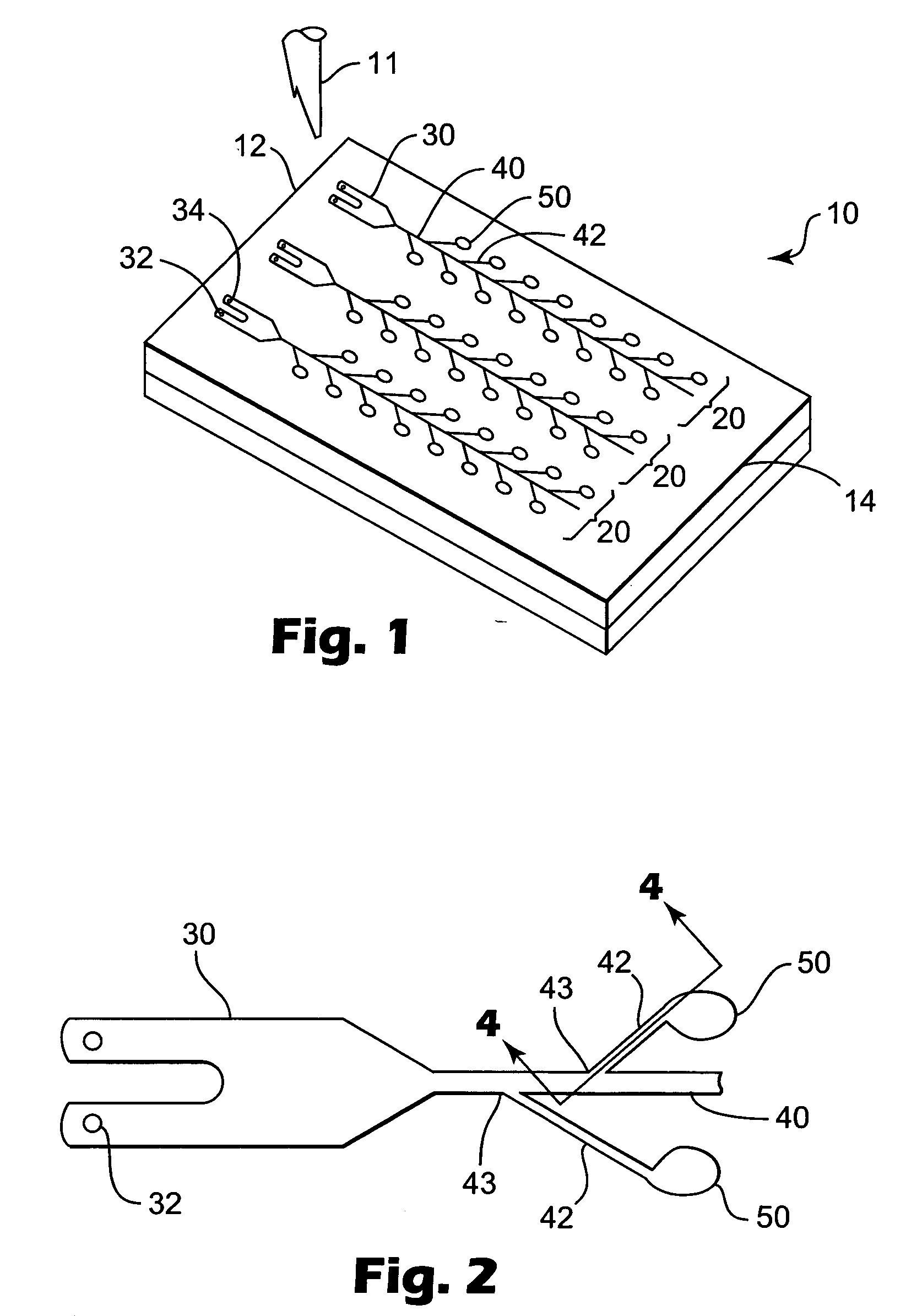

Opposables and automated specimen processing systems with opposables

A specimen processing system is capable of processing specimens carried on slides. The specimen processing system can sequentially deliver slides and opposables to specimen processing stations. The specimen processing stations can use the opposables to apply a series of liquids to the specimens. The applied liquid can be moved along the slide using capillary action while the specimen processing stations control the processing temperatures. The applied liquid can be in a fluid-carrying gap. The opposable can contact the slide to vary a cross section of the fluid-carrying gap.

Owner:VENTANA MEDICAL SYST INC

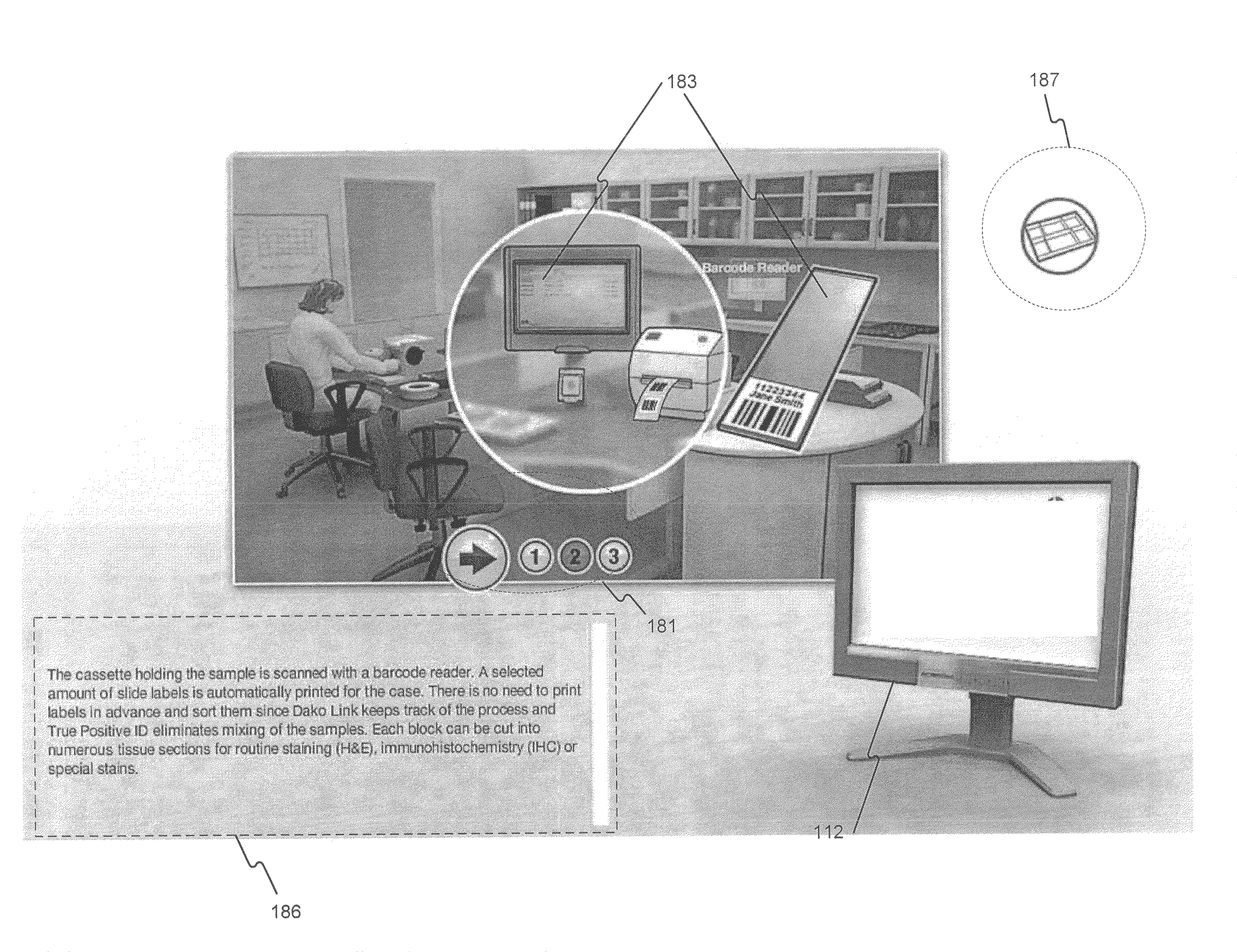

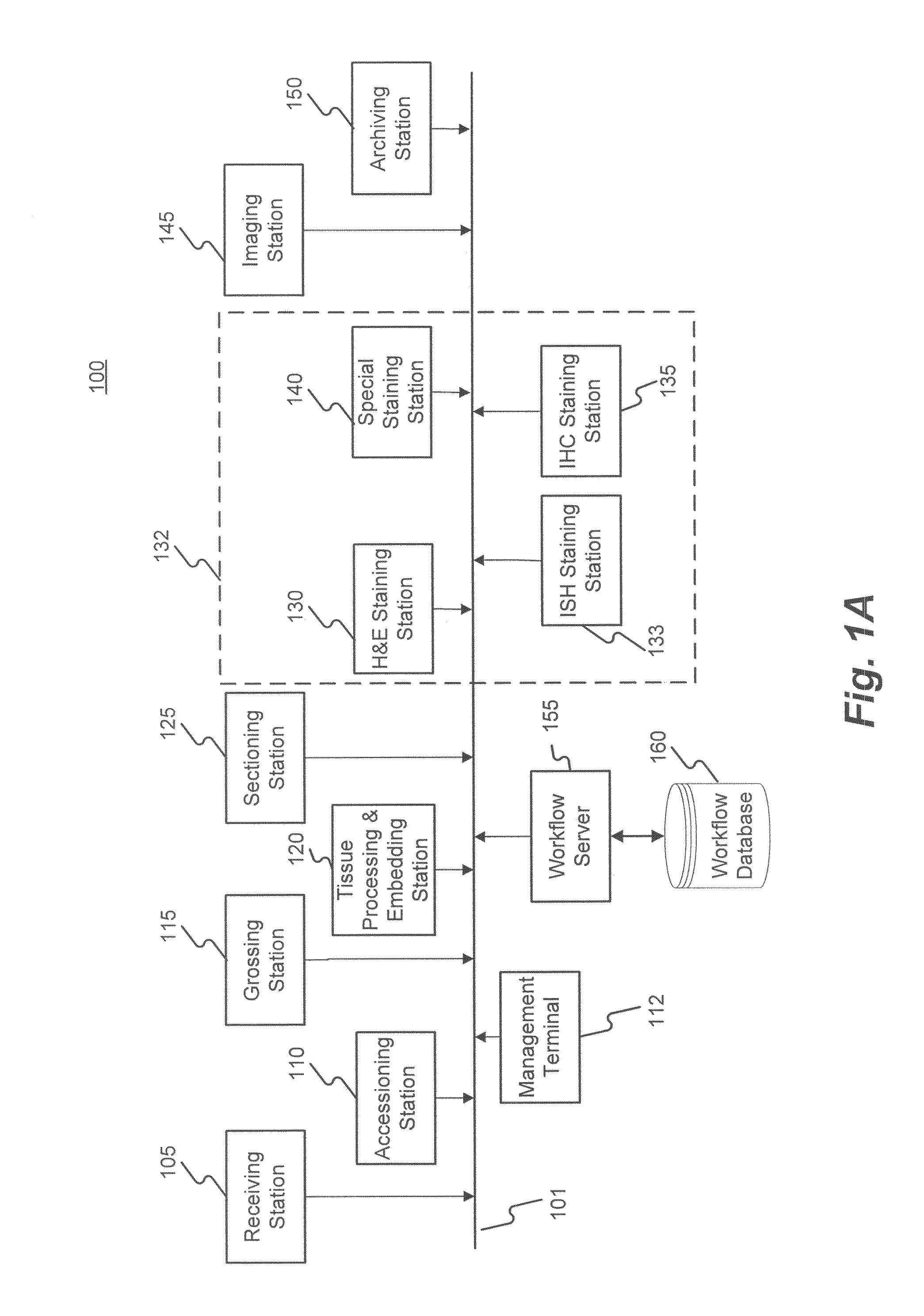

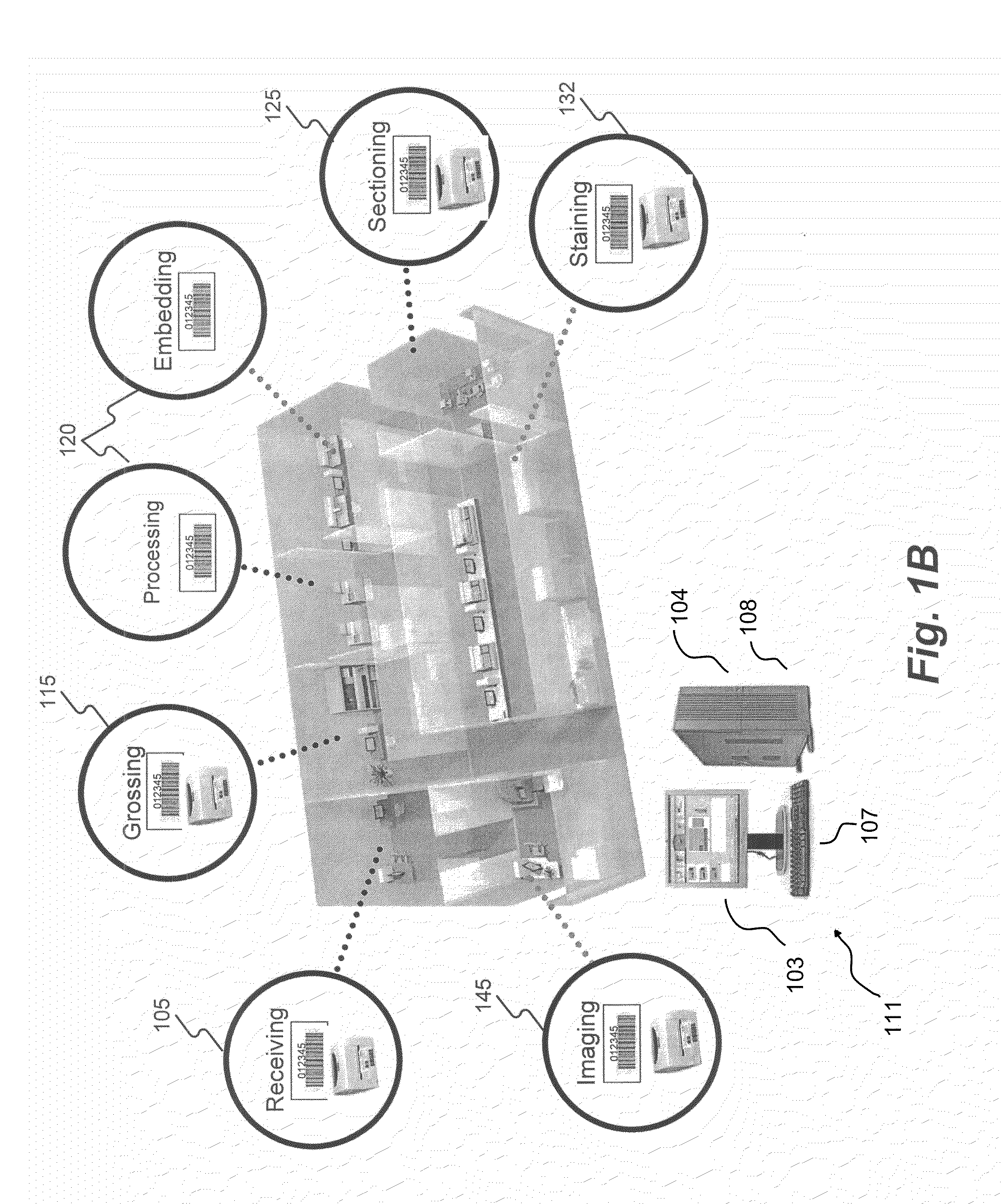

Systems and methods for analyzing workflow associated with a pathology laboratory

ActiveUS20090316977A1FinanceComputer-assisted medical data acquisitionComputerized systemDisplay device

A computer system for analyzing a specimen processing workflow in a pathology laboratory including a display and a processor configured to provide a first interface, a second interface, and a third interface to the display, receive, via the first interface, a first set of parameters associated with an existing specimen processing workflow in a pathology laboratory, the first set of parameters including a workflow process and a workflow scale, and determine, based on the first set of parameters, current performance data of the existing specimen processing workflow having an associated current cost information and current time utilization. The processor may further be configured to receive, via the second interface, a second set of parameters associated with a proposed modification to the existing specimen processing workflow, the second set of parameters including parameters associated with at least one laboratory device, determine, based on the first and second sets of parameters, revised performance data having an associated revised cost information and revised time utilization, and provide an output comprising a comparison between revised performance data and the current performance data.

Owner:AGILENT TECH INC

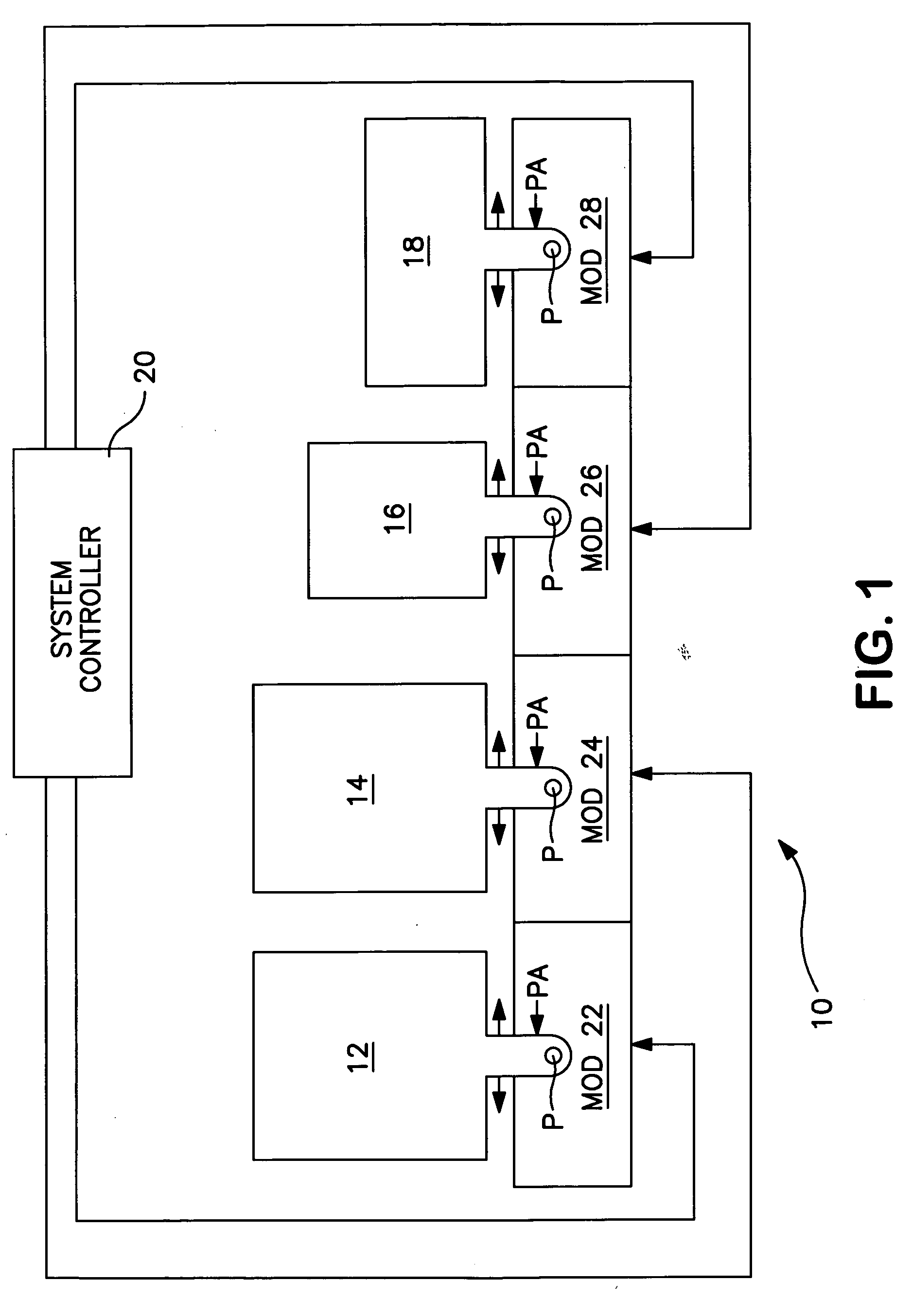

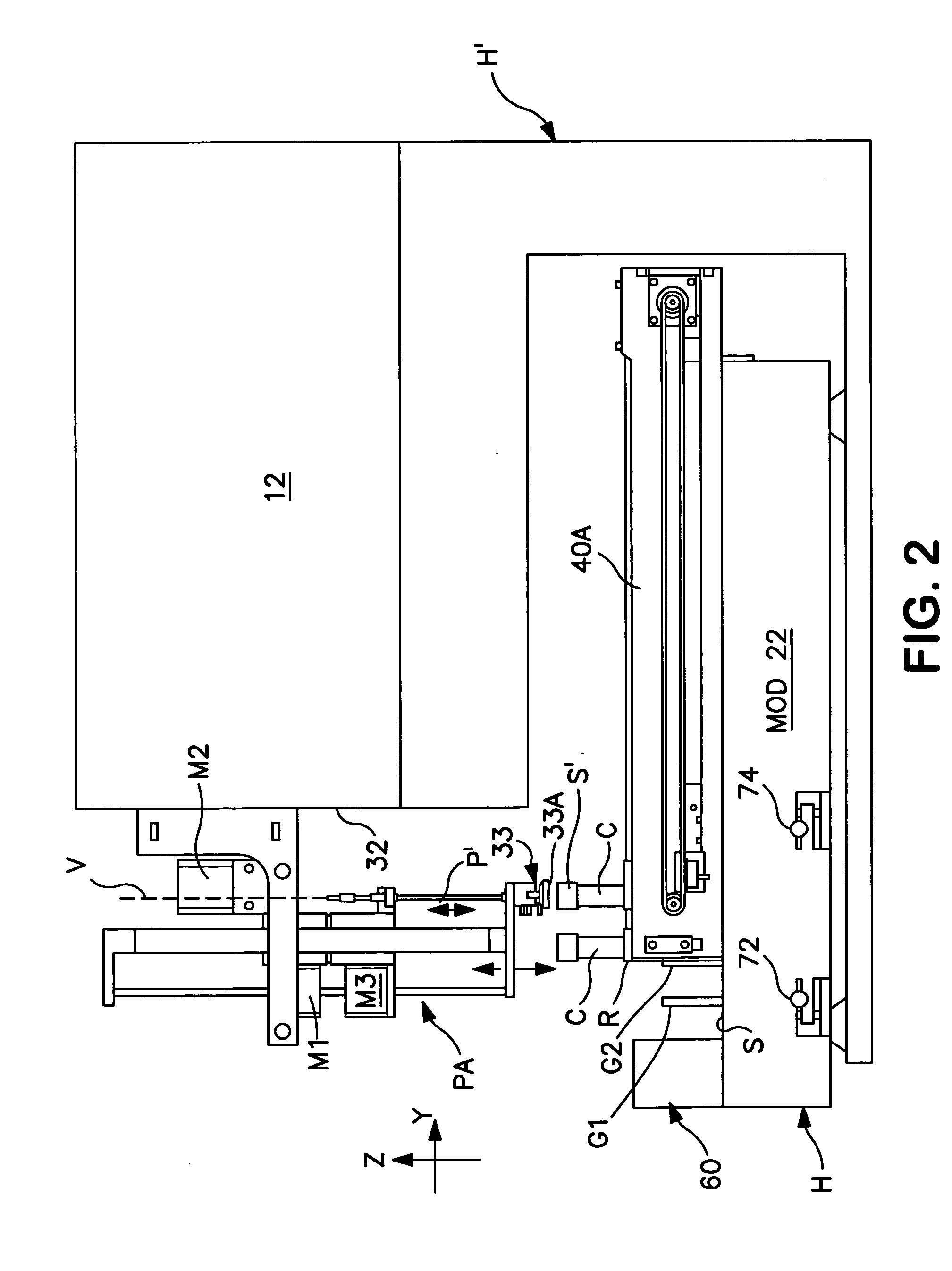

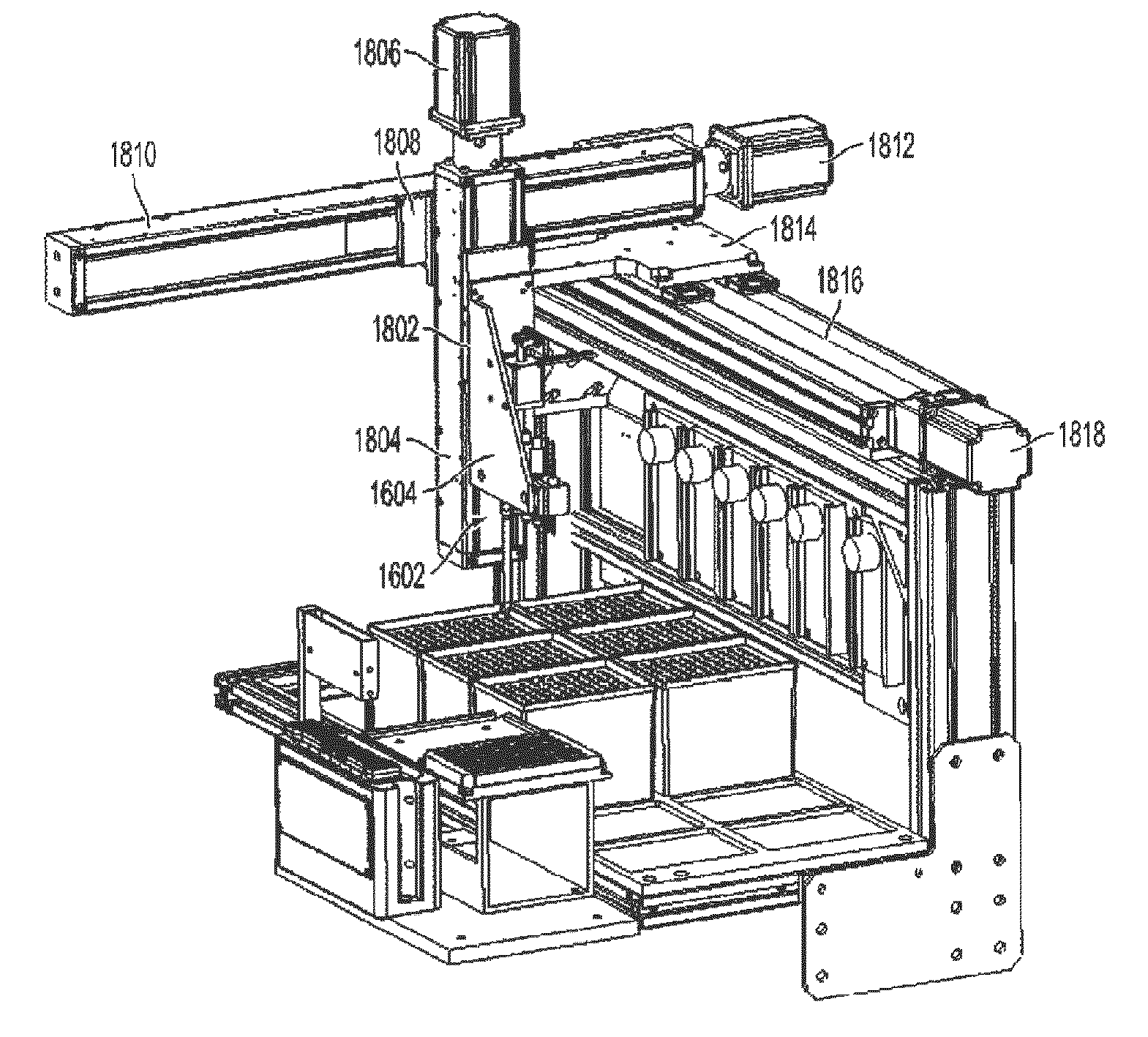

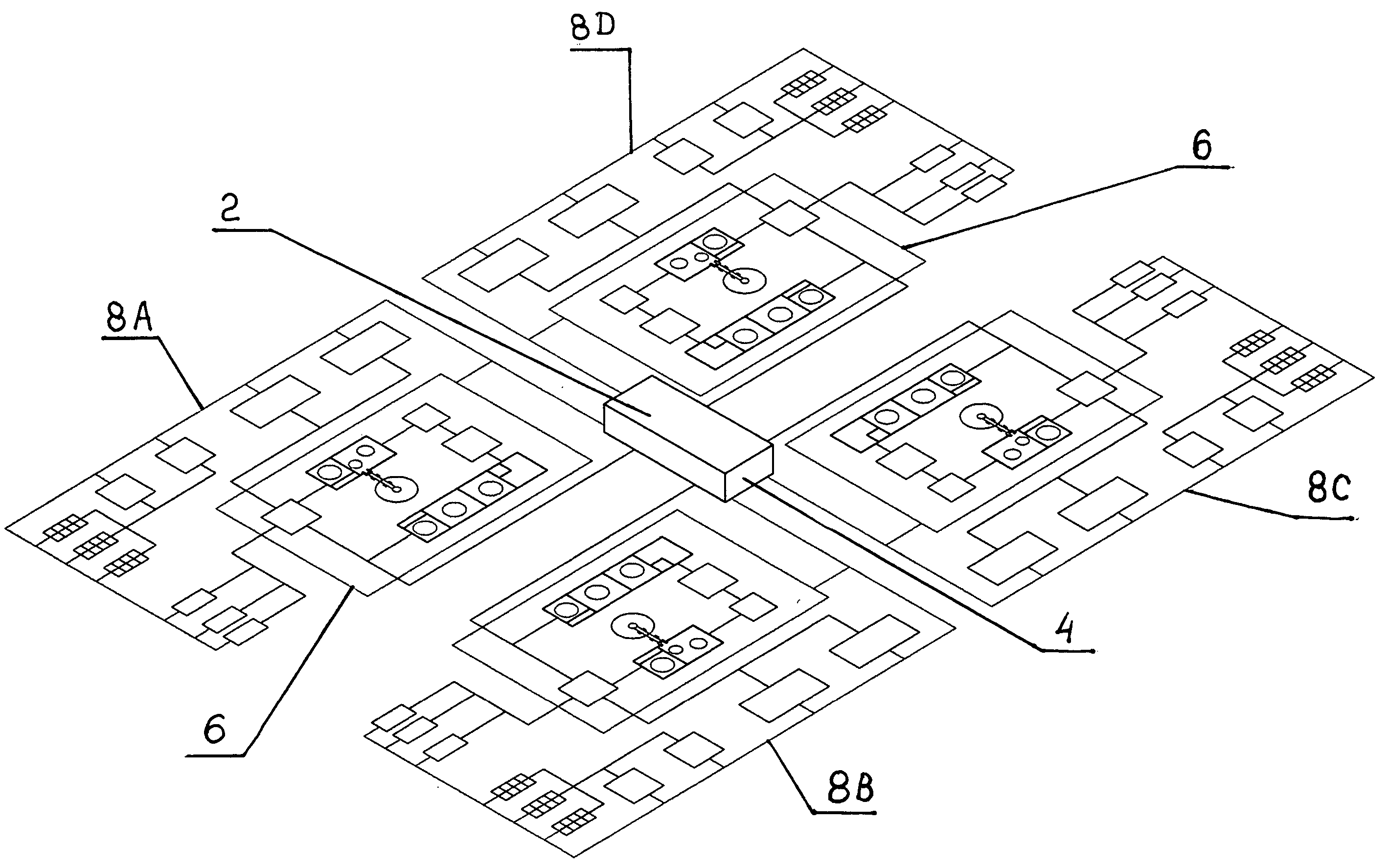

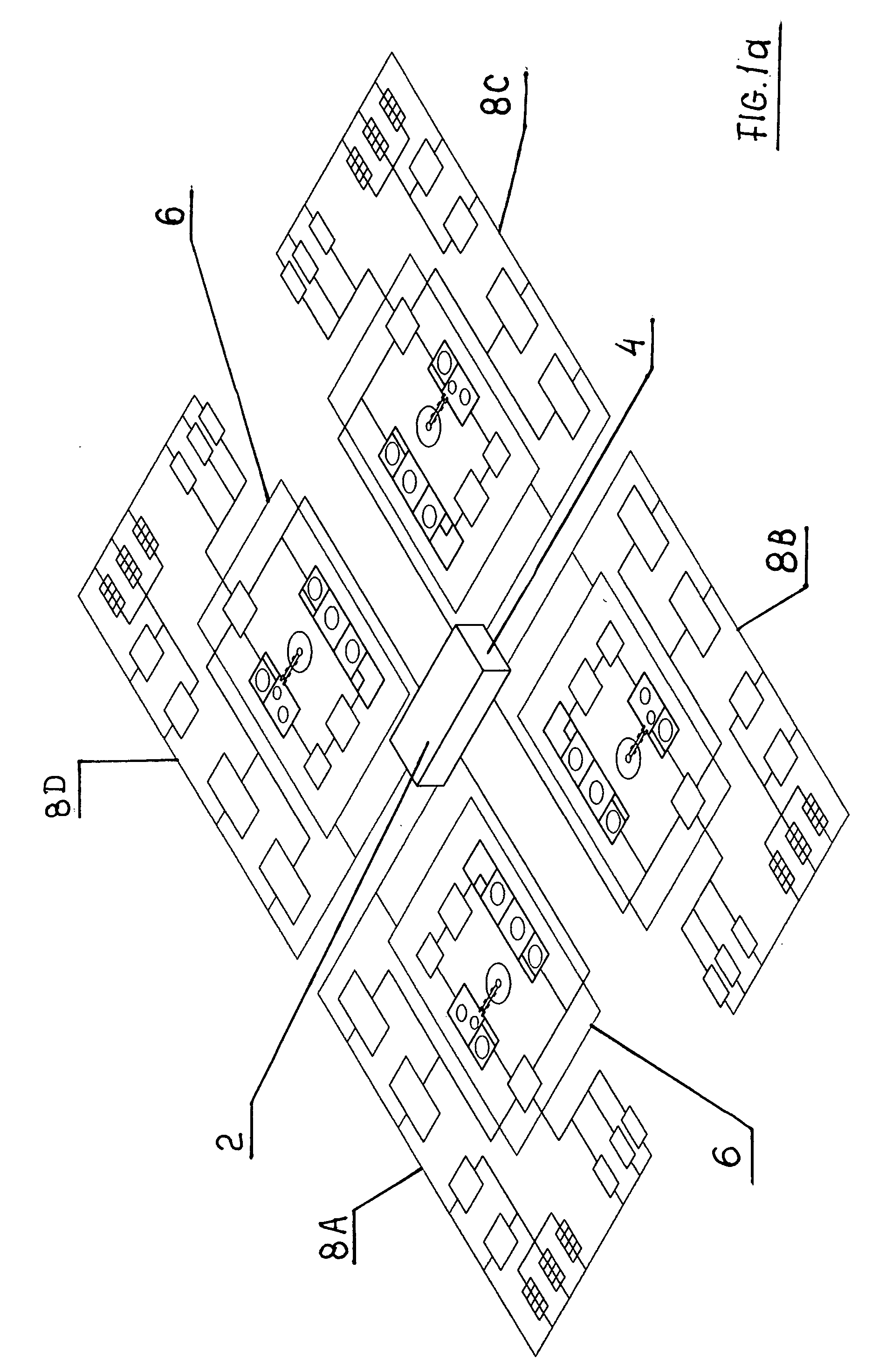

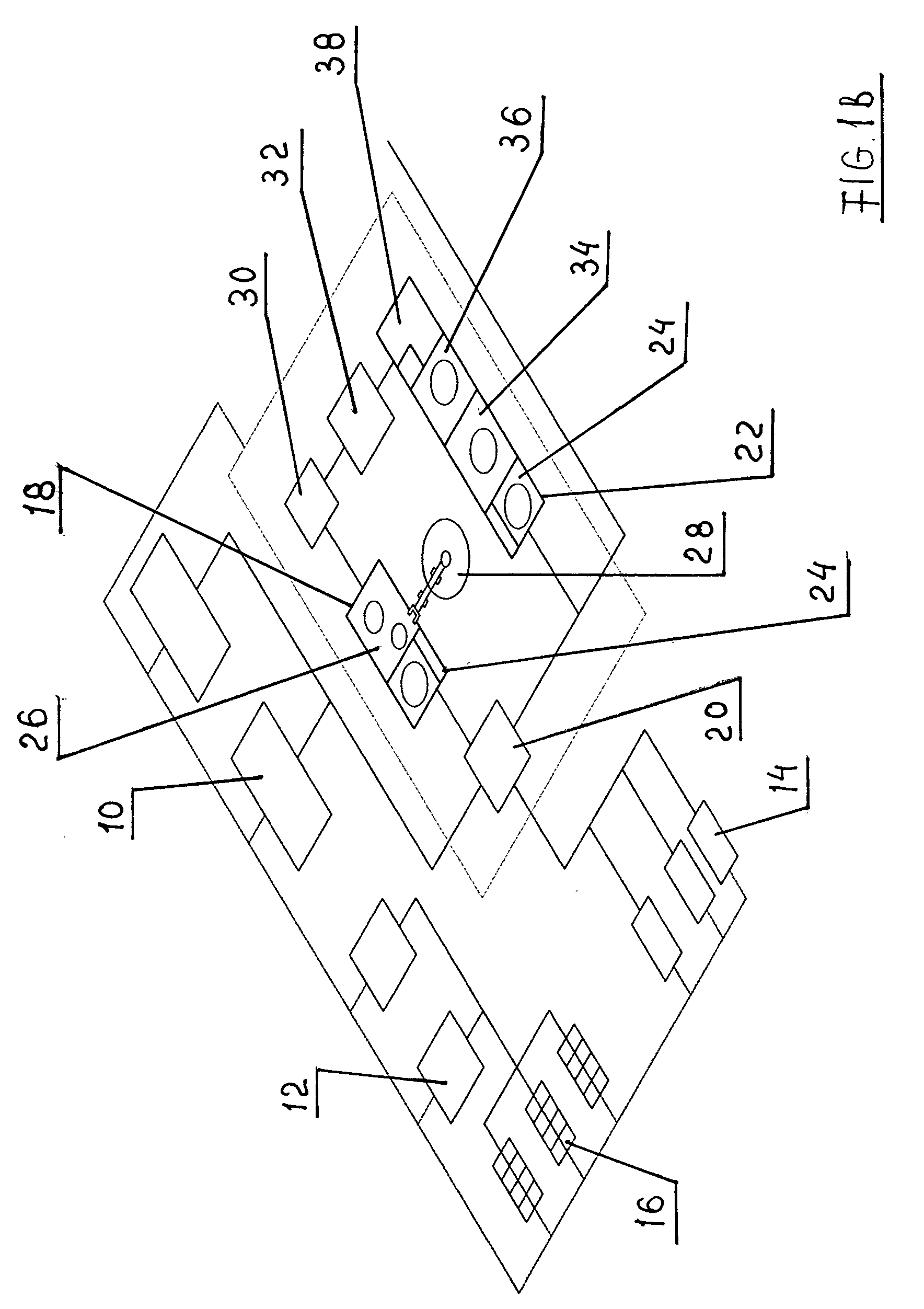

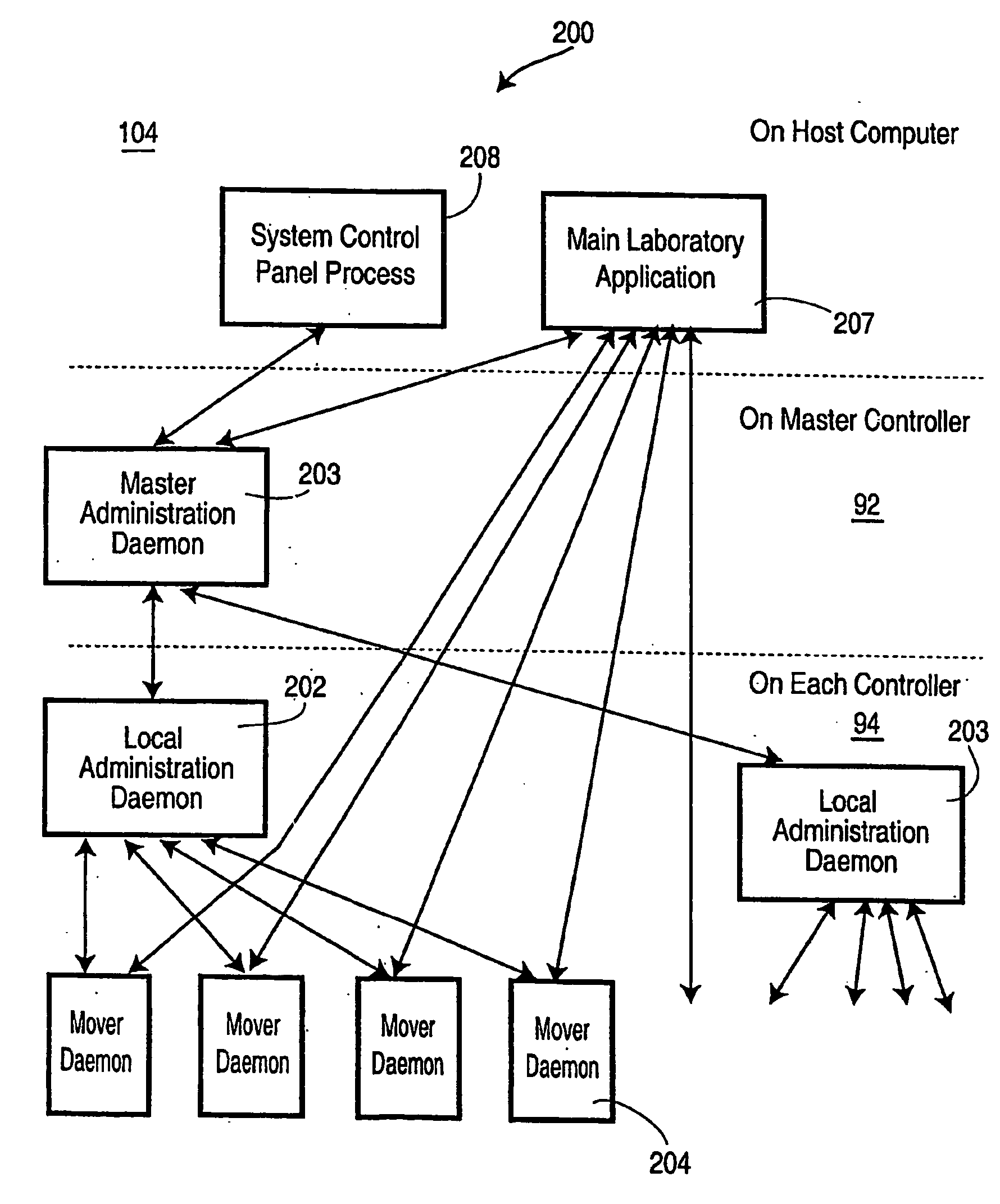

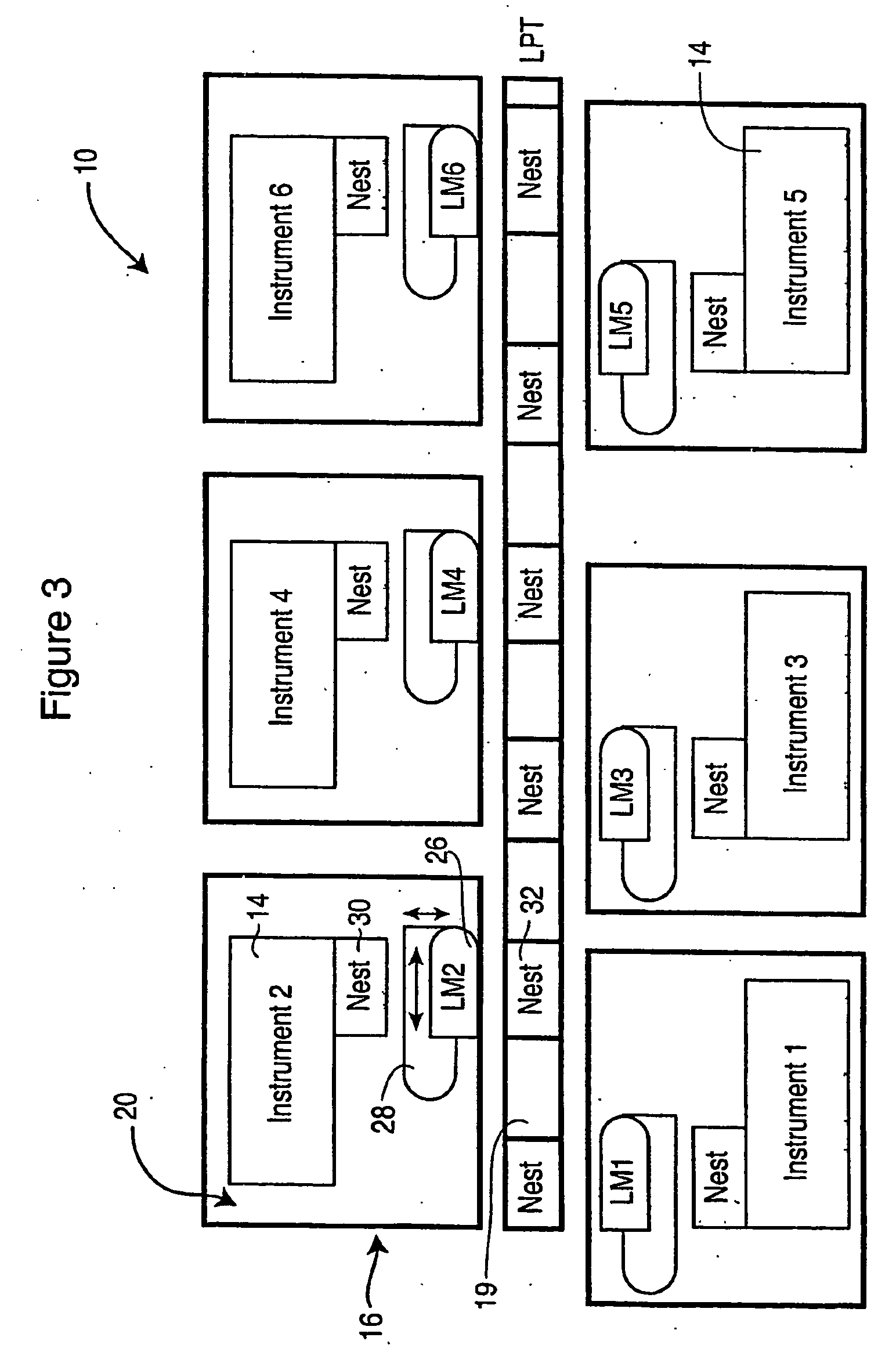

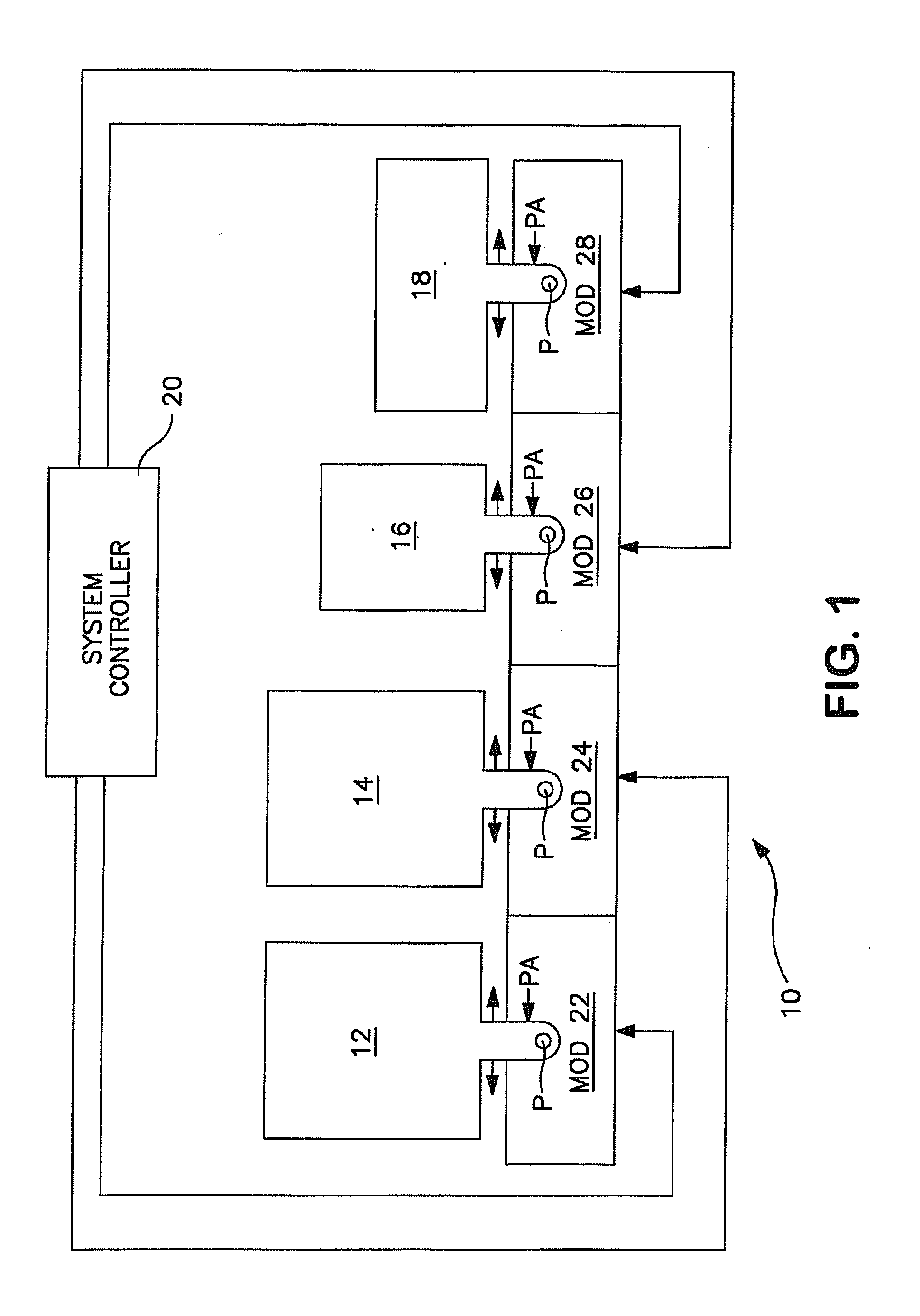

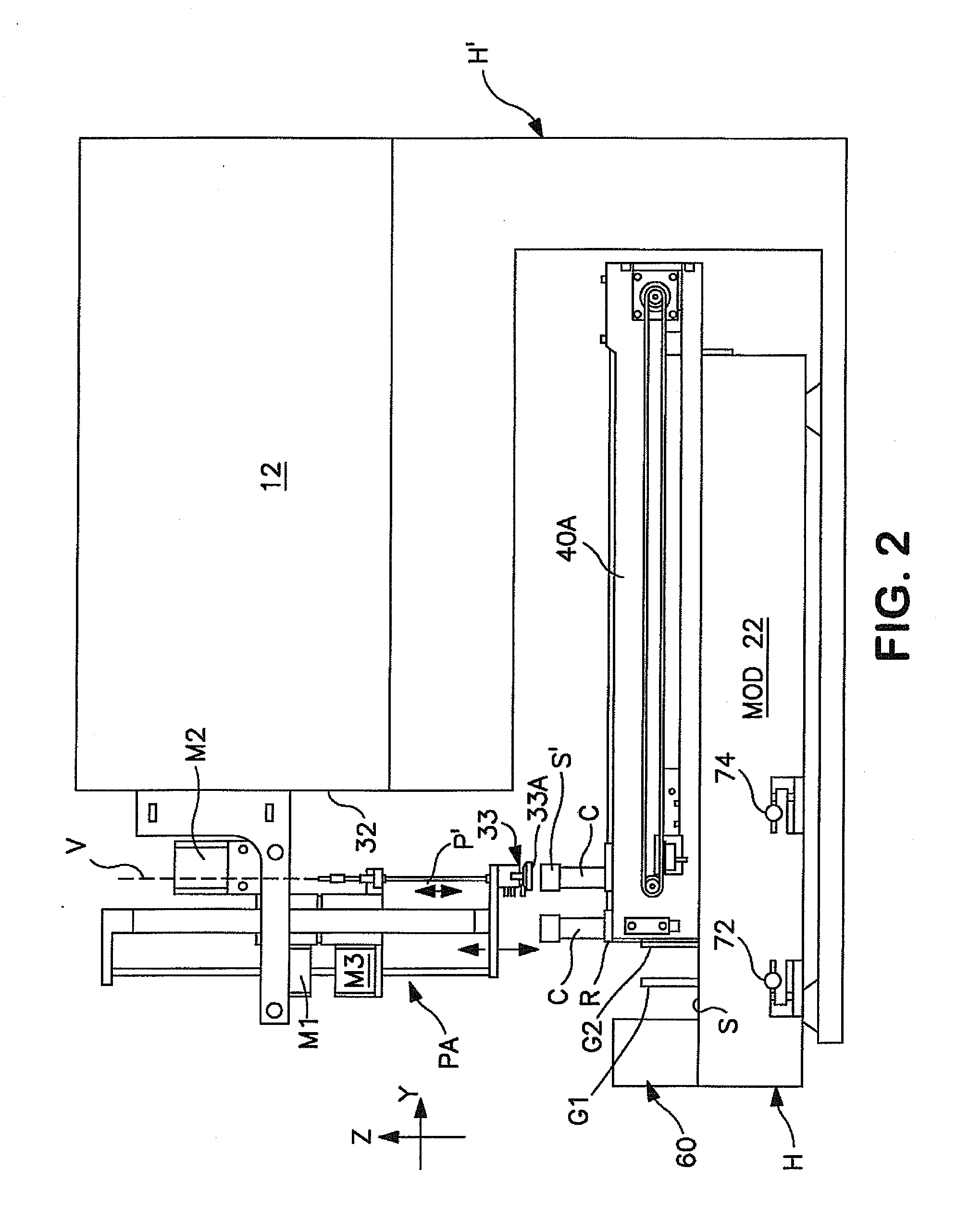

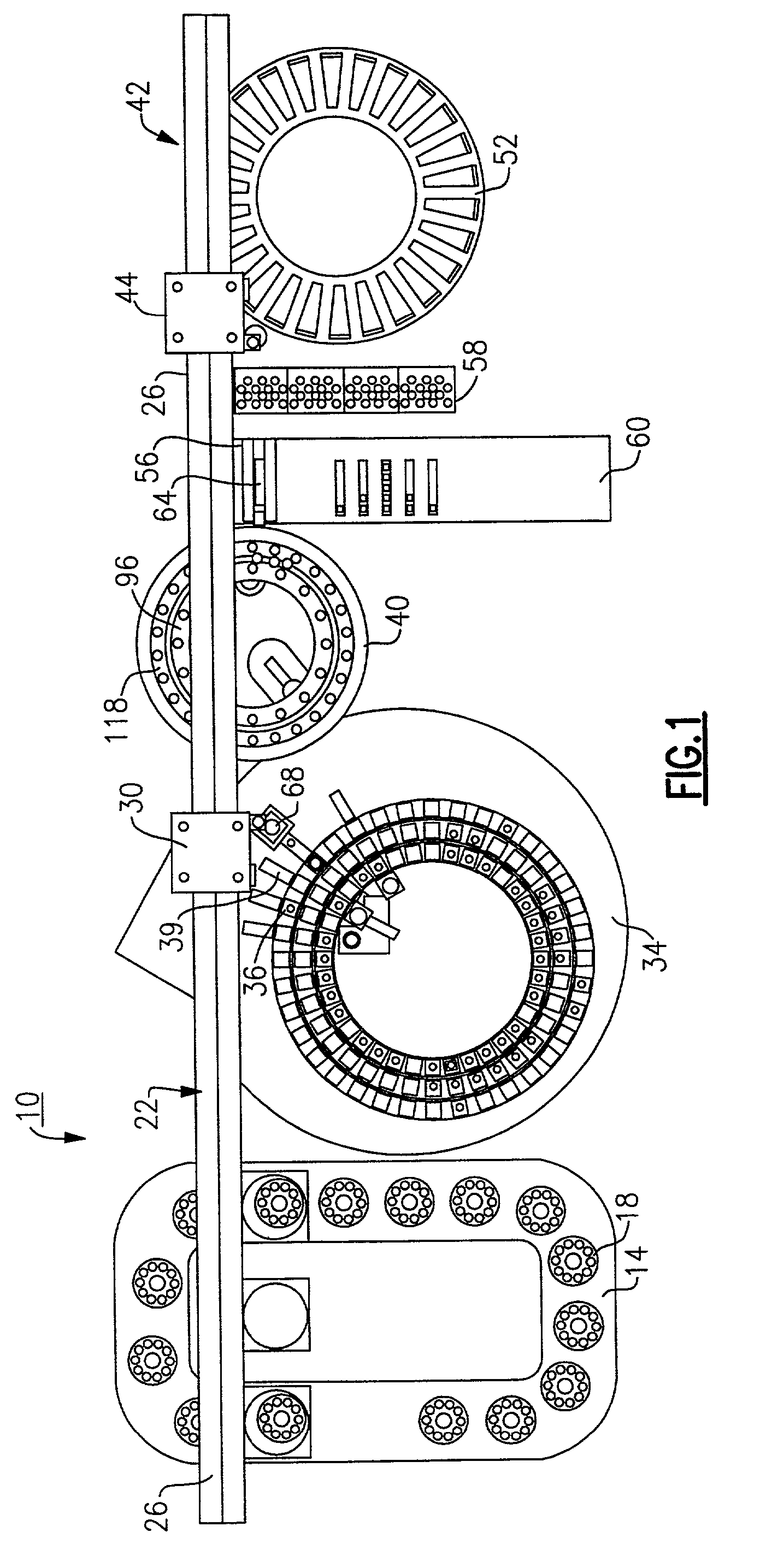

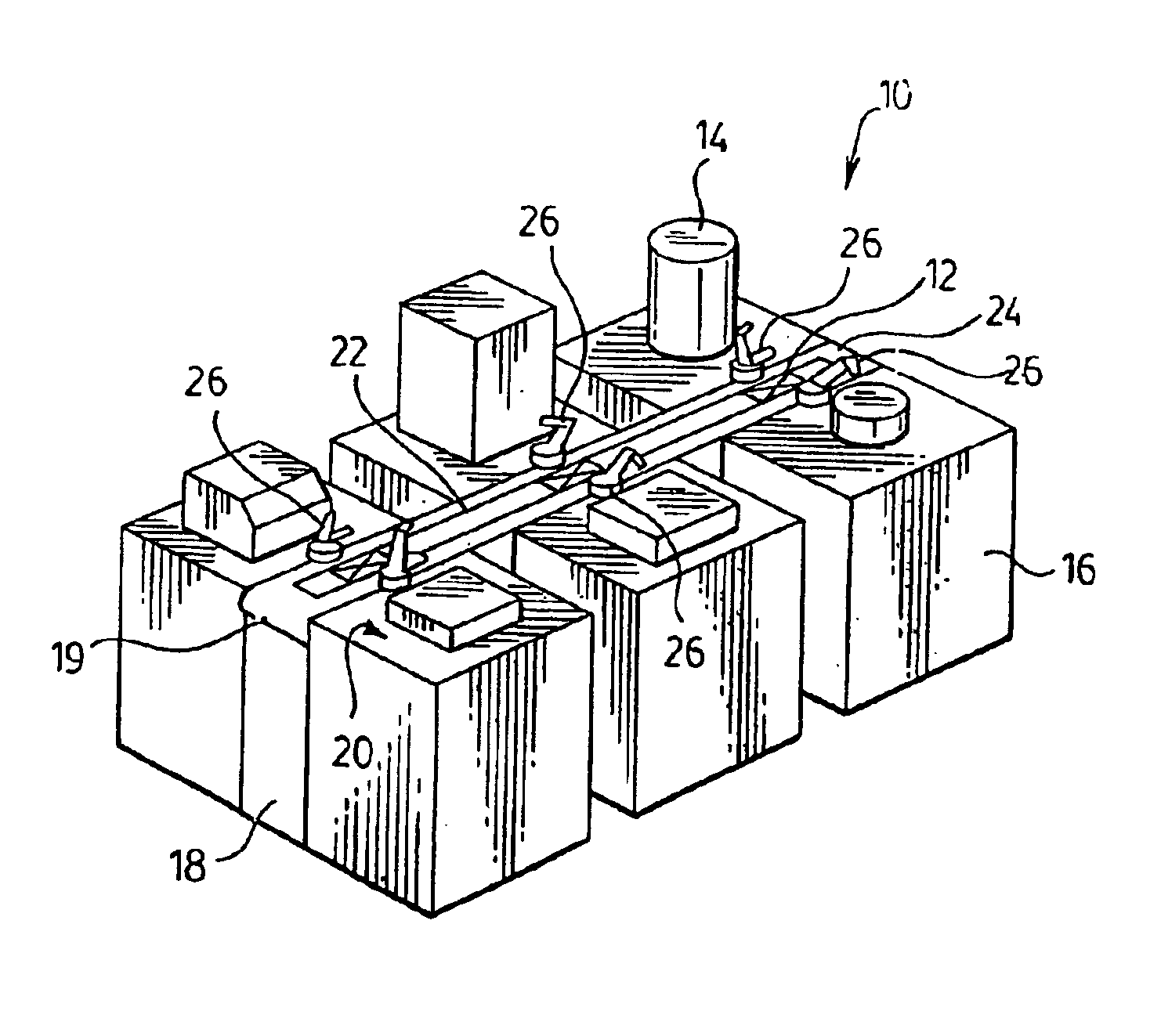

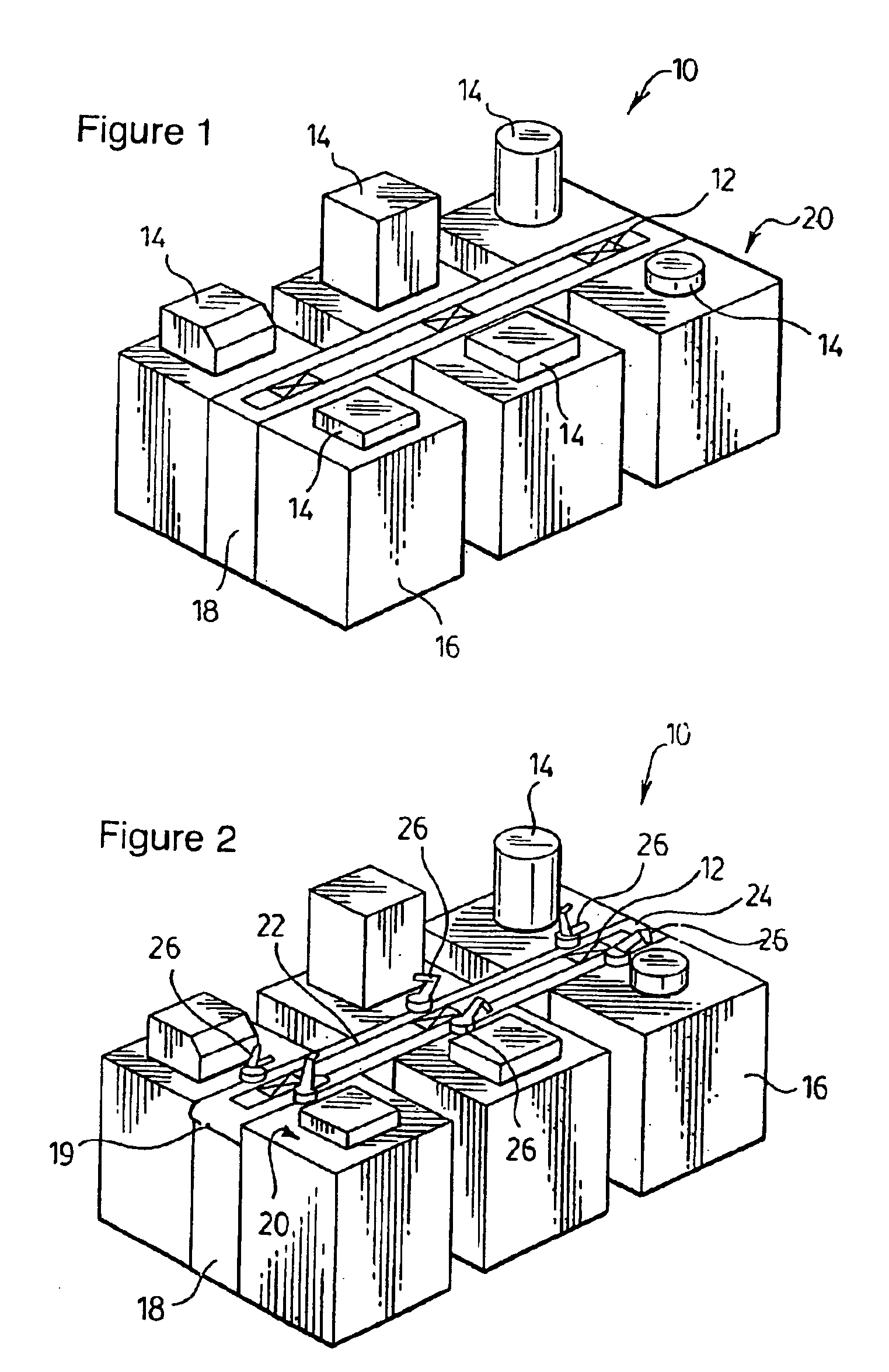

Modular robotic system and method for sample processing

InactiveUS20050075757A1Laboratory apparatusSpecial data processing applicationsRobotic systemsModularity

A method of processing objects using a bilateral architecture. The method comprises the steps of: arranging a plurality of instruments around a bi-directional conveyance device, the instruments spaced at fixed pitch intervals along the conveyor device; assigning dedicated movers to each of the instruments, the dedicated movers for loading and unloading of the objects to and from the instruments and the conveyance device; and controlling the operation of the conveyance device to have an interrupted motion, the interrupted motion for co-ordinating the loading and unloading of the objects; wherein the dedicated movers are positioned such that adjacent movers operate independently of one another. The method can be operated on an automated robotic system having a modular architecture. The system comprises; a backbone having a plurality of backbone connectors; a module having a module connector for releasably coupling with a respective one of the backbone connectors; a bi-directional motion device connected to the backbone, the motion device for presenting an object adjacent to the module when the module is coupled to the backbone; a connection interface formable by coupling the backbone and module connectors, the connection interface for providing an operation coupling between the backbone and the module when adjacent thereto; wherein the connection interface provides a repeatable connection and disconnection capability between the backbone and the module for ready reconfiguration of the modular architecture.

Owner:THERMO CRS LTD

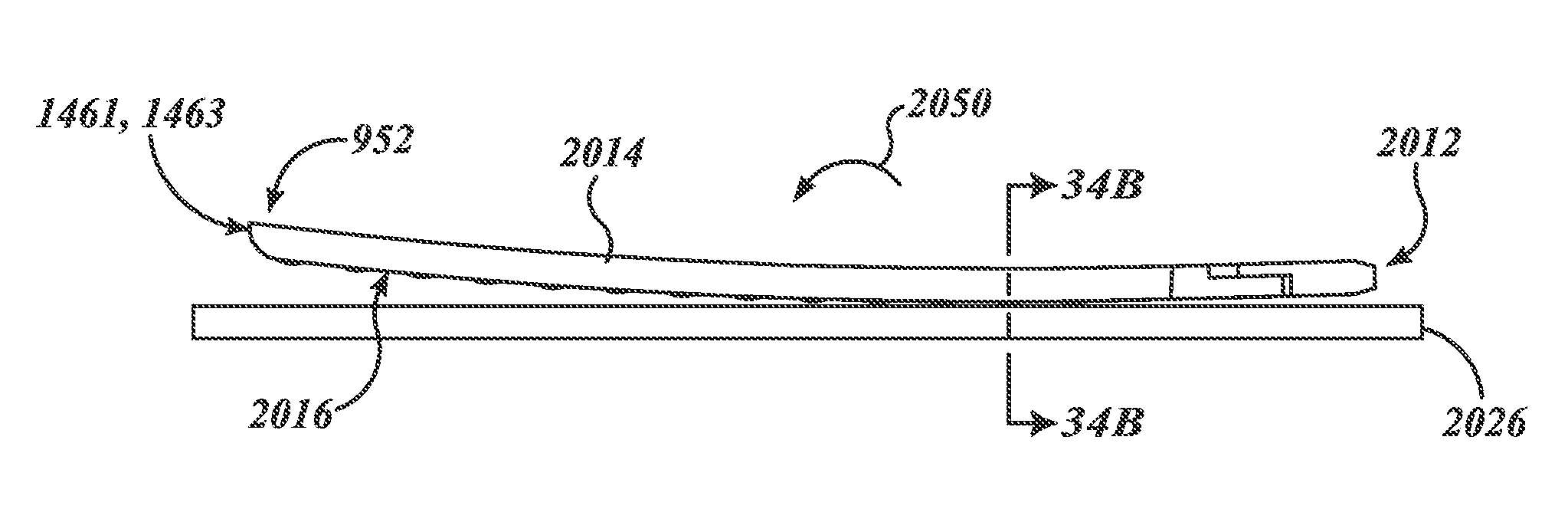

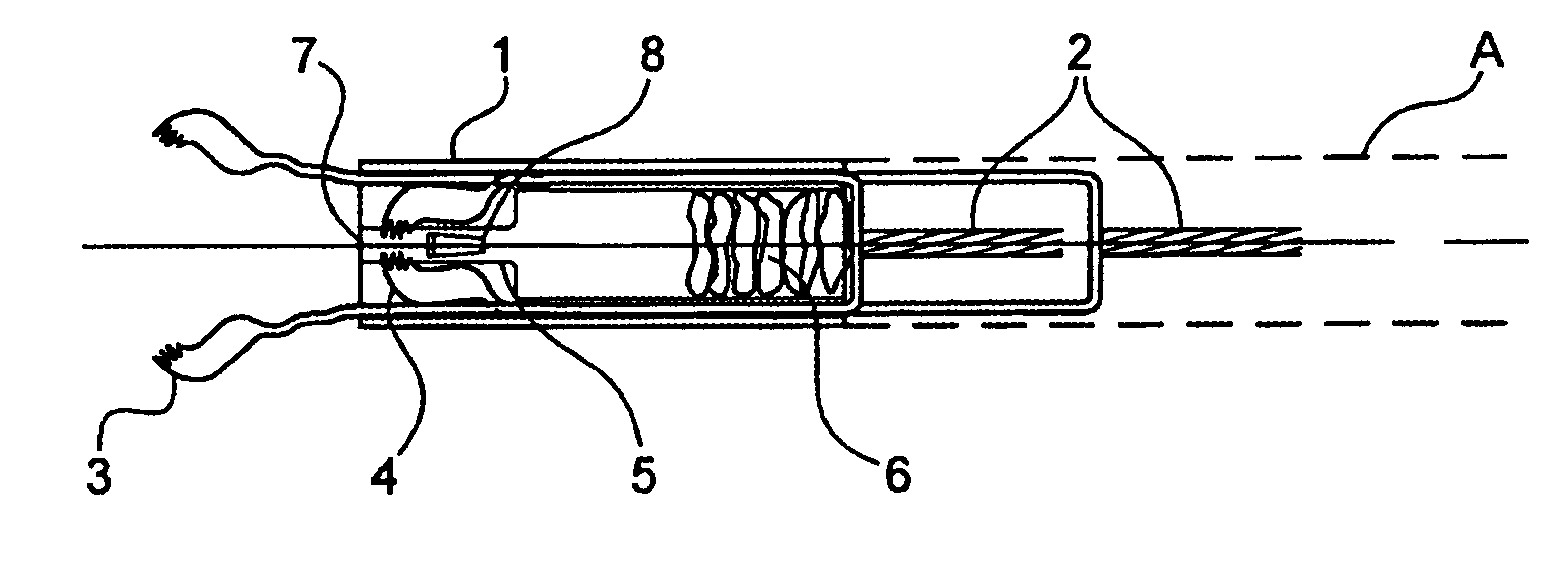

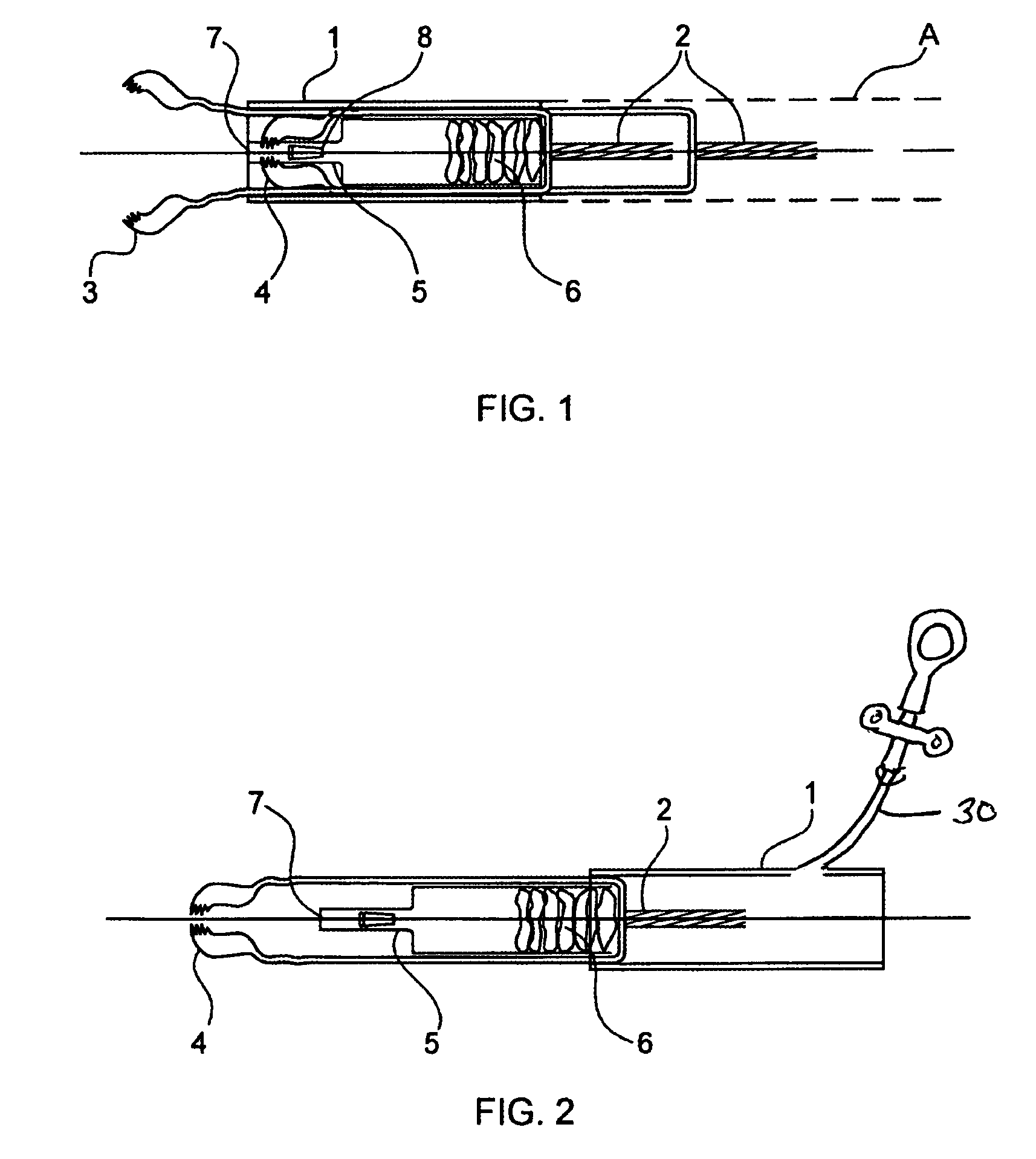

Apparatus for removable distal internal cassette for in situ fixation and specimen processing with serial collection and storage of biopsy specimens

ActiveUS20050256424A1Reduce riskSimple designSurgical needlesVaccination/ovulation diagnosticsIn situ fixationSpecimen Handling

An apparatus for performing a medical procedure comprises an elongated flexible member having an aperture extending longitudinally therethrough and an actuator positioned within the aperture. There is a biopsy means connected to the distal end of the actuator for cutting and collecting biopsy specimens and a removable distal storage and collection chamber connected to the elongated flexible member for receiving biopsy specimens cut and collected by the biopsy means. The removable storage and collection chamber is a means for immediate contact of the collected biopsy specimens with fixatives or reagents. The distal cassette is separable from the flexible member and can be sealed by a cap positionable over the storage and collection cassette for storage, in situ fixation and processing or later processing and analysis of biopsy specimens collected by the biopsy means in the order of collection.

Owner:ZIMMON DAVID S

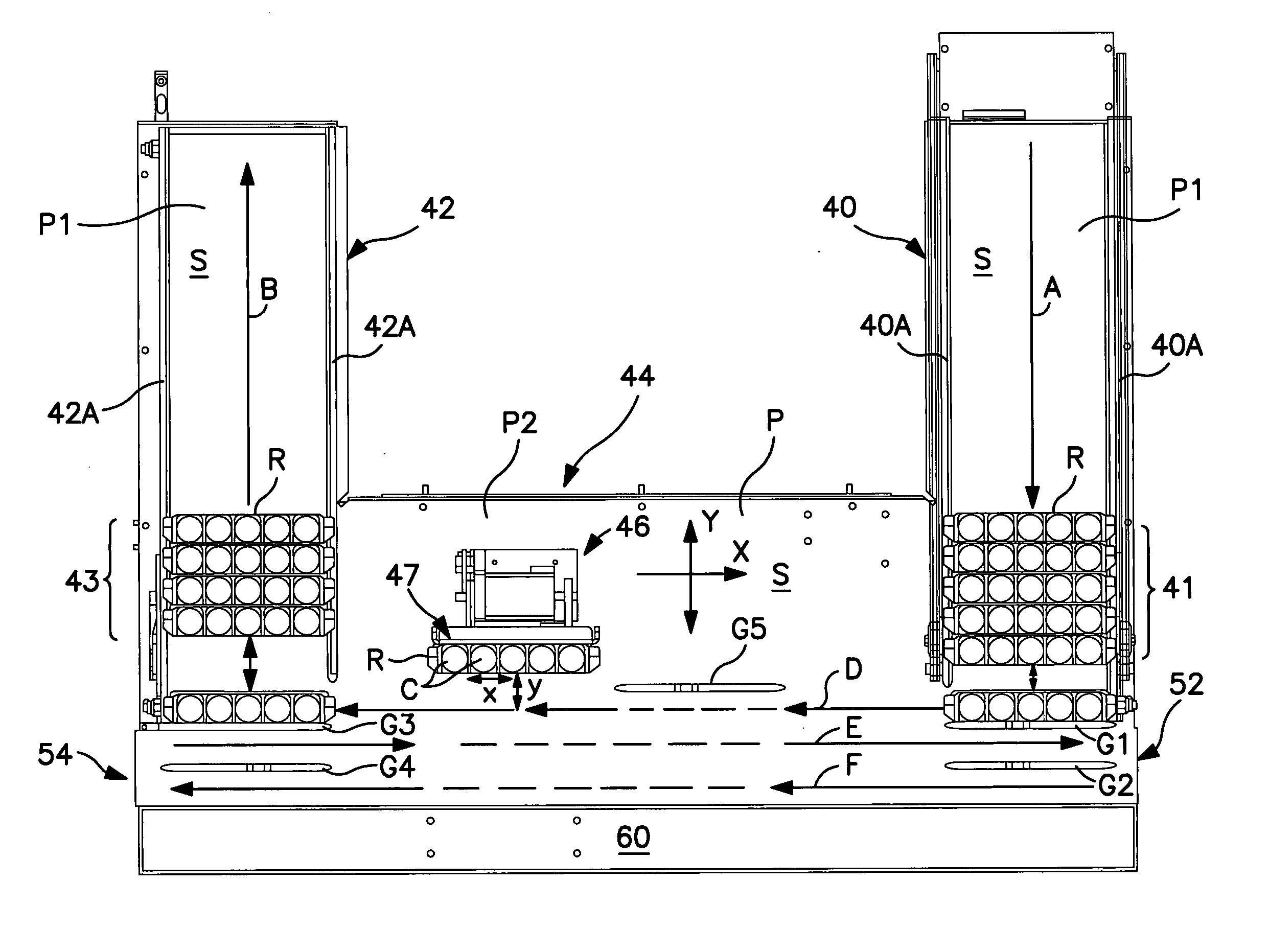

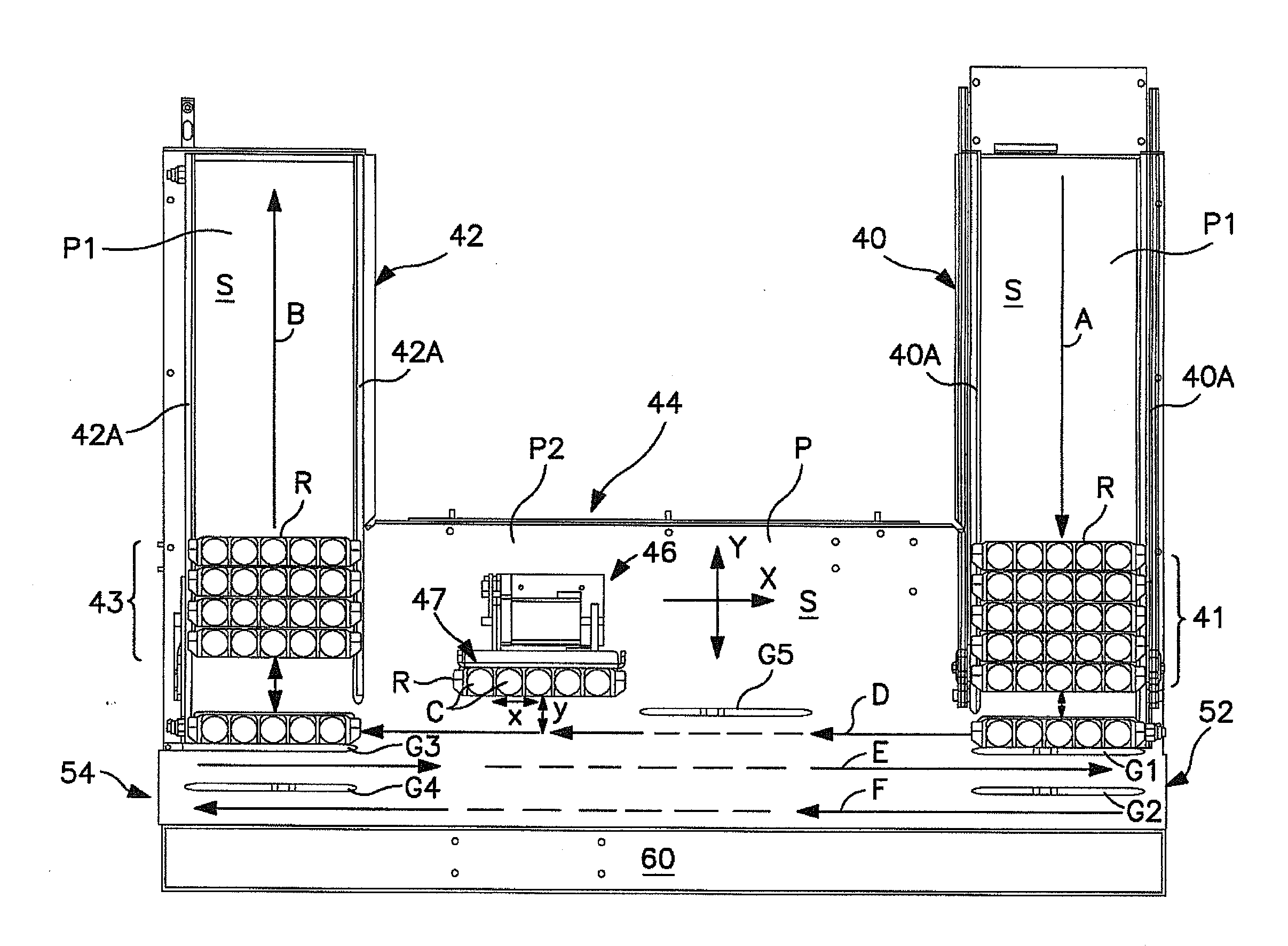

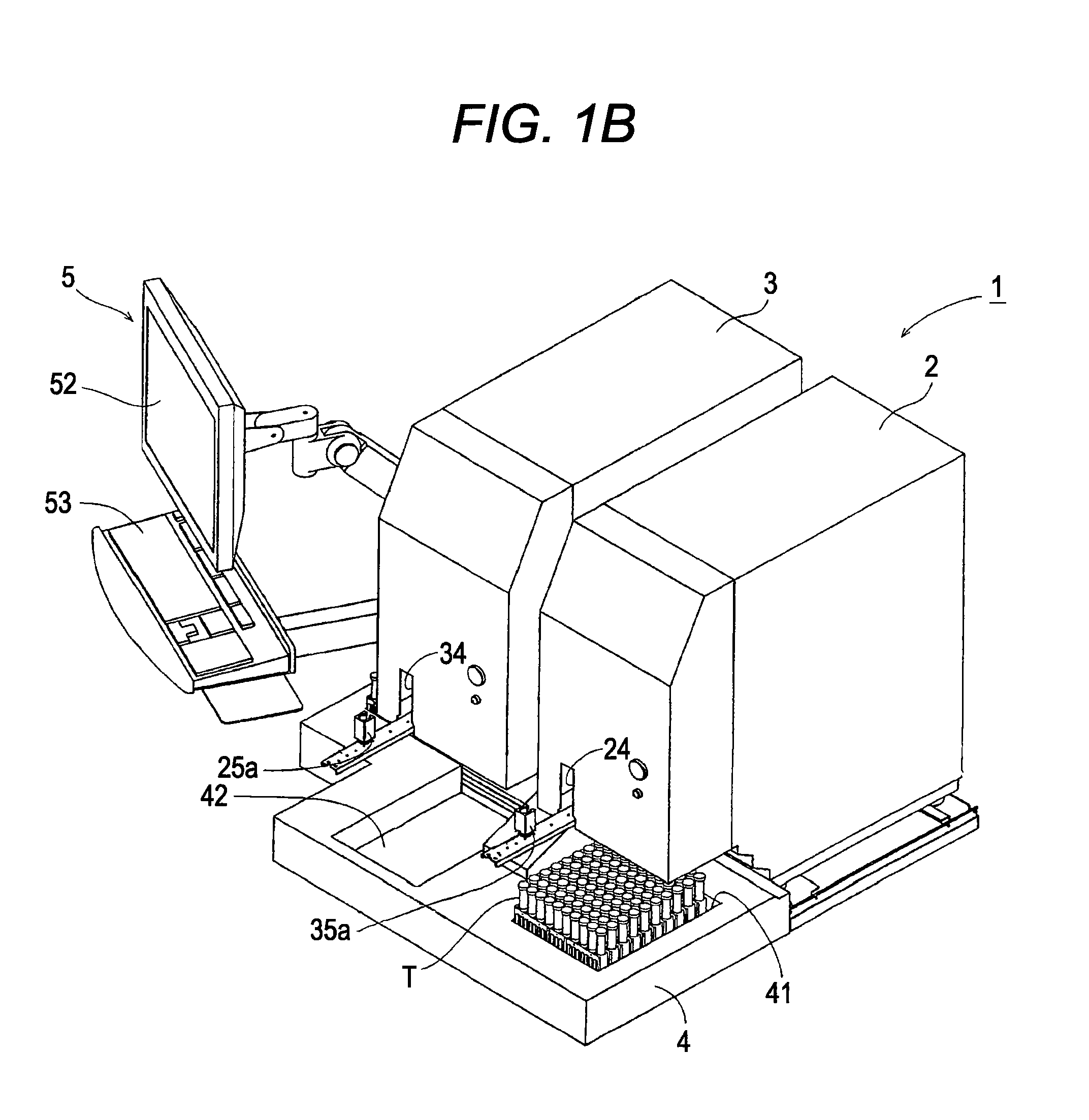

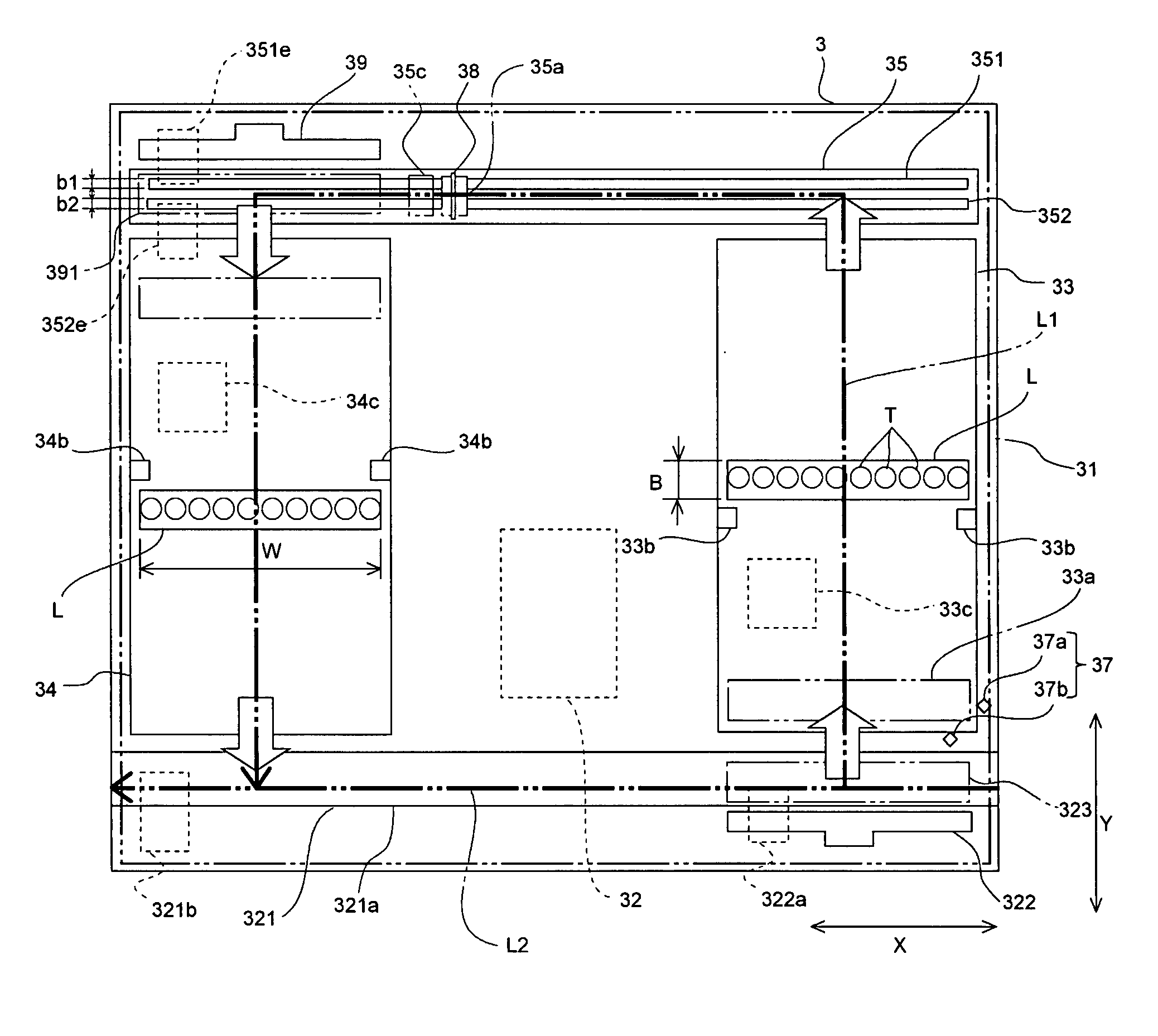

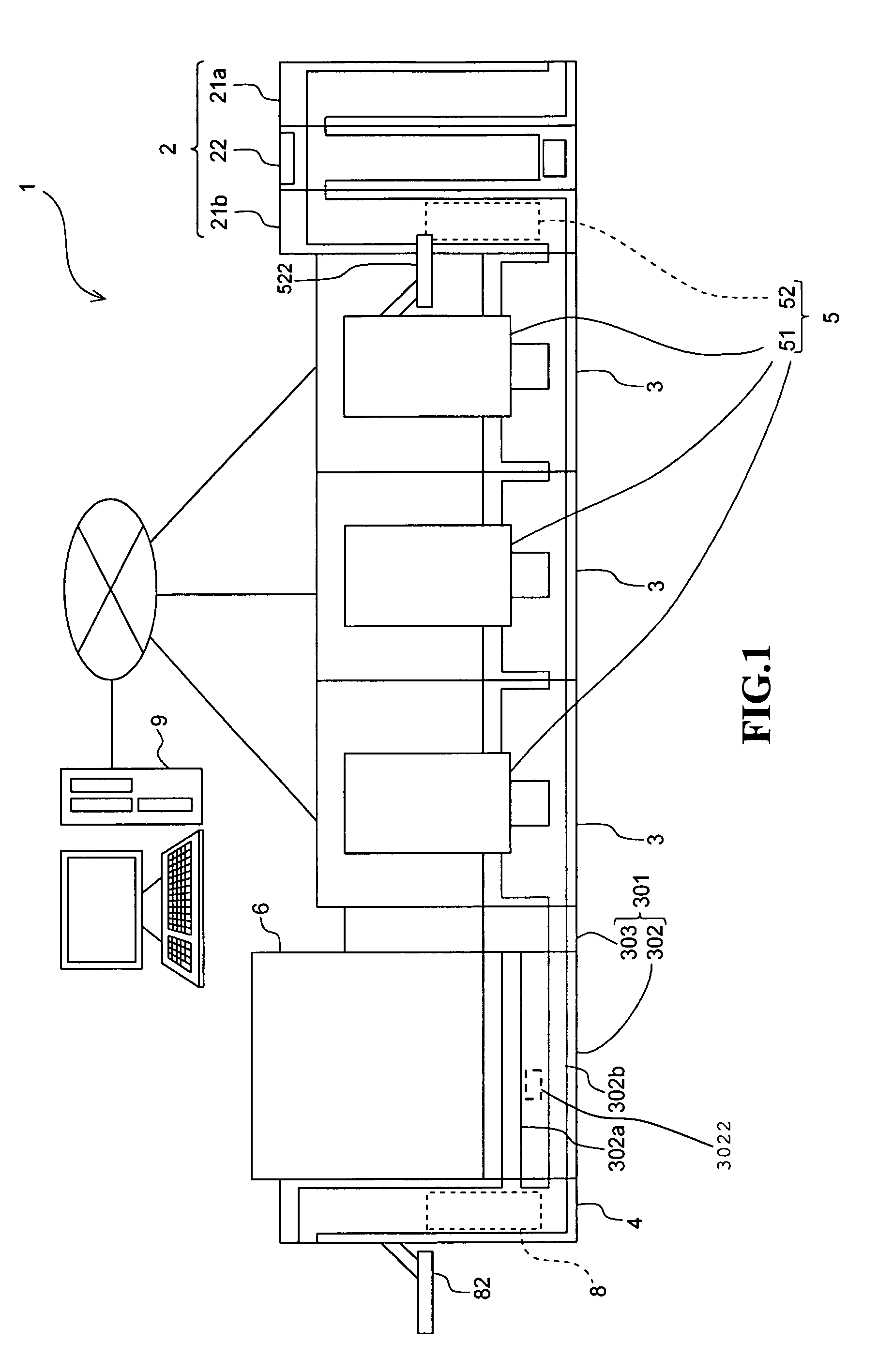

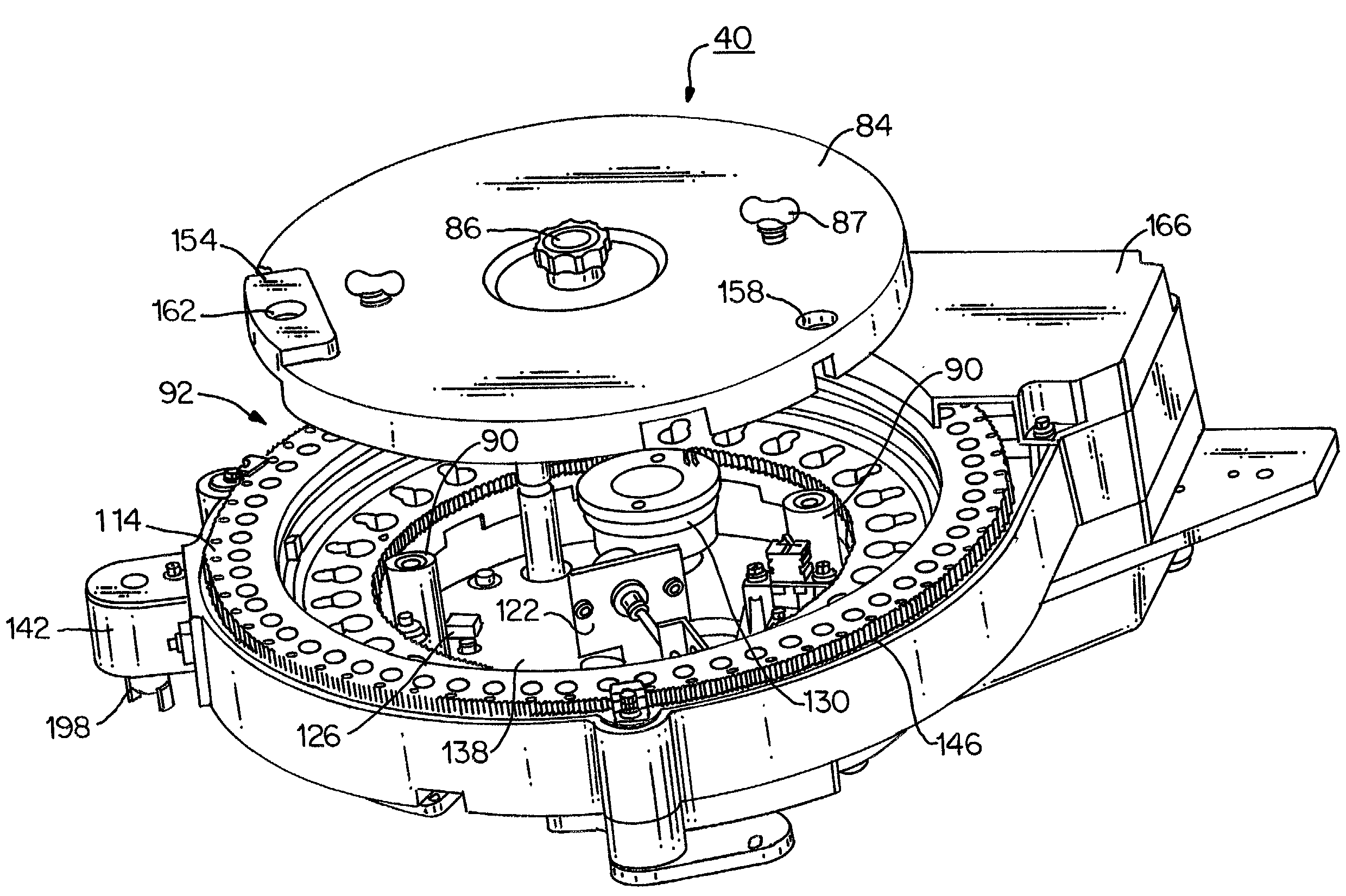

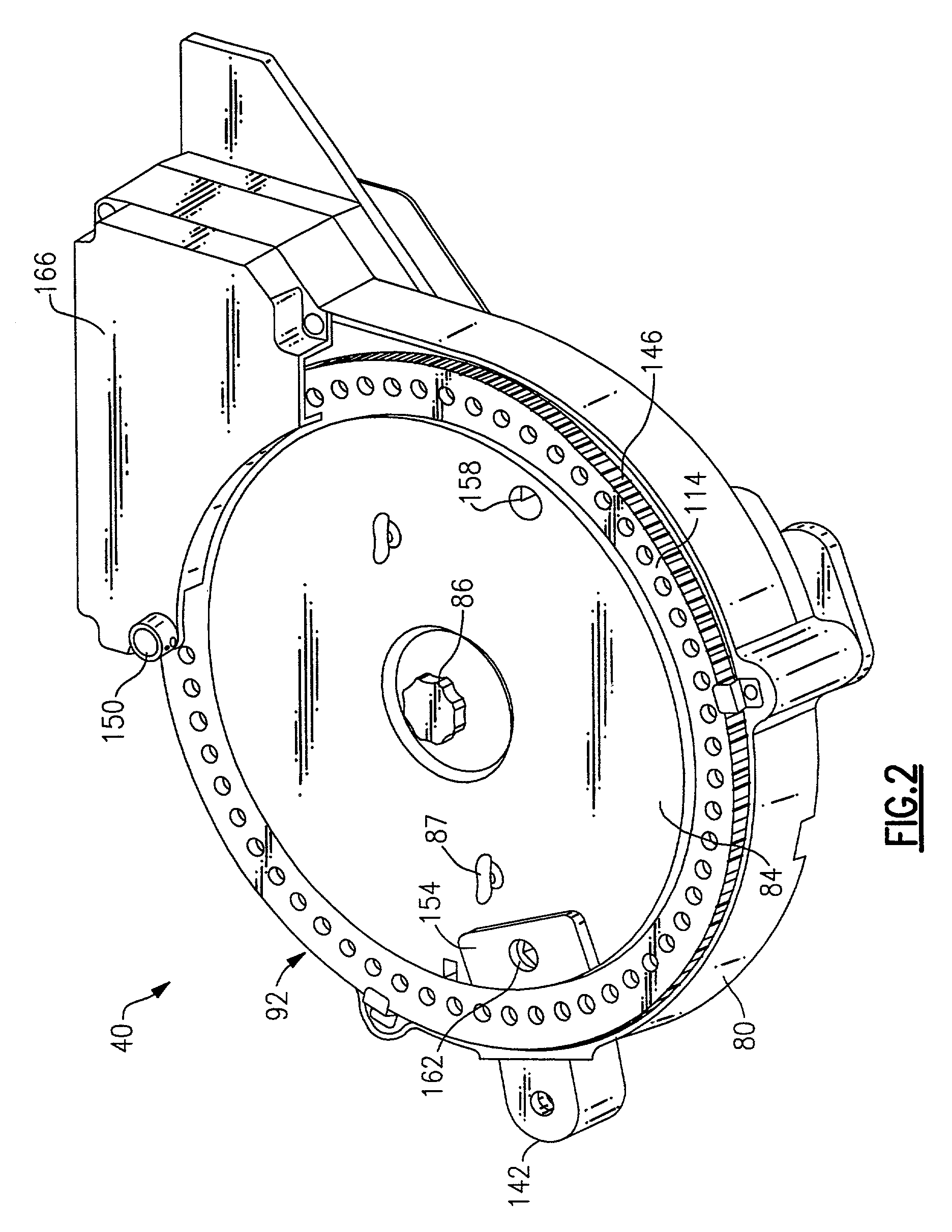

Specimen-transport module

ActiveUS20070207056A1Eliminate needSimpler and reliable workcellMaterial analysis by optical meansCharge manipulationMagnetic tension forceTransport system

A specimen-transport module adapted for use with each of a plurality of specimen-processing instruments of a multi-instrument clinical workcell. Such module is adapted to transport individual racks of specimen-containers relative to a specimen-aspiration probe of an associated instrument in a workcell, as well as to transfer selected racks of specimen-containers to an adjacent and identical specimen-transport module associated with another clinical instrument of the workcell. Since the same transport system is used to both present specimens for aspiration and to transfer specimens between instruments, there is no need for two independent conveyances as is characteristic of the prior art. Preferably, the specimen-transport module includes a magnetic X / Y transport system that operates beneath a rack-supporting surface to advance racks in mutually perpendicular directions across a supporting surface via magnetic forces.

Owner:BECKMAN COULTER INC

Corrosion agent of high-steel-level pipeline steel metallographic structure and display method

ActiveCN101995349ADirect analysisDirect comparisonPreparing sample for investigationAlcoholGrain boundary

The invention provides a corrosion agent of a high-steel-level pipeline steel metallographic structure and a display method. The corrosion agent consists of 1 to 10g of analysis pure picric acid with the purity higher than or equal to 99.8 percent, 100ml of deionized water, 0.1 to 2ml of 10 percent diluted hydrochloric acid and 5 to 25ml of liquid detergent. The display method comprises the following steps of: 1. preparation of the corrosion agent: adding and dissolving 1 to 10g of the analytically pure picric acid into 100ml of the deionized water, uniformly stirring, then dripping 5 to 25mlof the liquid detergent, adding 0.1 to 2ml of the diluted hydrochloric acid, and uniformly stirring; 2. specimen processing: carrying out corrosion for 0.5 to 5 seconds in nitric acid alcohol solution after the specimen polishing, carrying out flowing flushing by clean water, and repeating the operation for 2 to 5 times in such a way; and 3. specimen corrosion: heating the corrosion agent to 50 to 100 DEG C, maintaining the constant temperature at the same time of soaking the specimen into the corrosion agent for 60 to 600 seconds, and continuously wiping the surface of the specimen by cotton. When the invention is adopted, not only various ferritic structures but also the original austenitic grain boundaries can be displayed on the high-steel-level pipeline steel metallographic structure.

Owner:ANGANG STEEL CO LTD

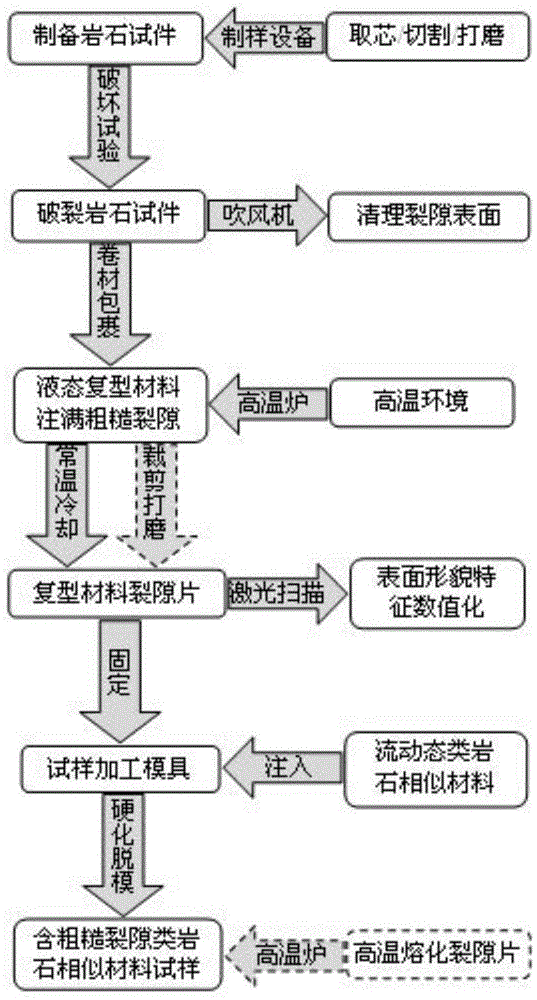

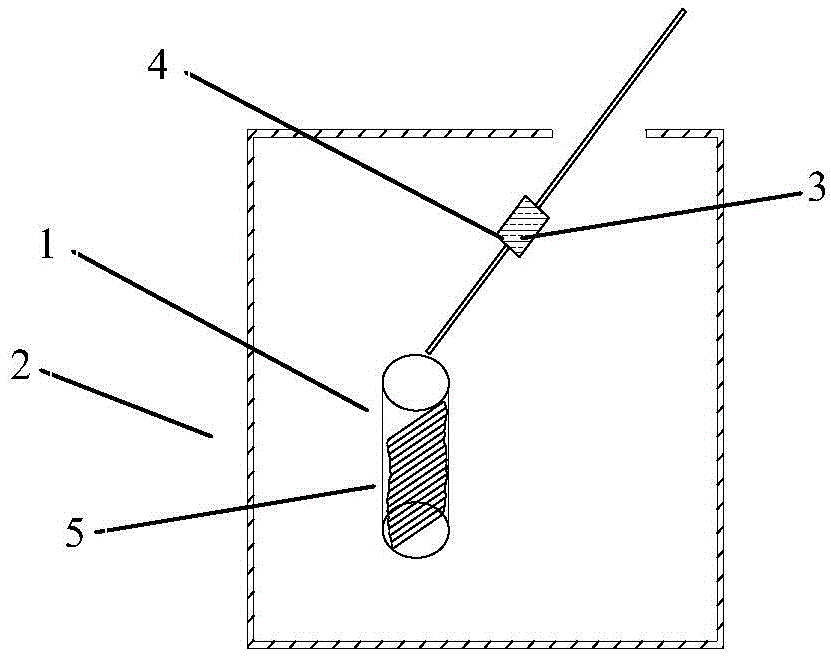

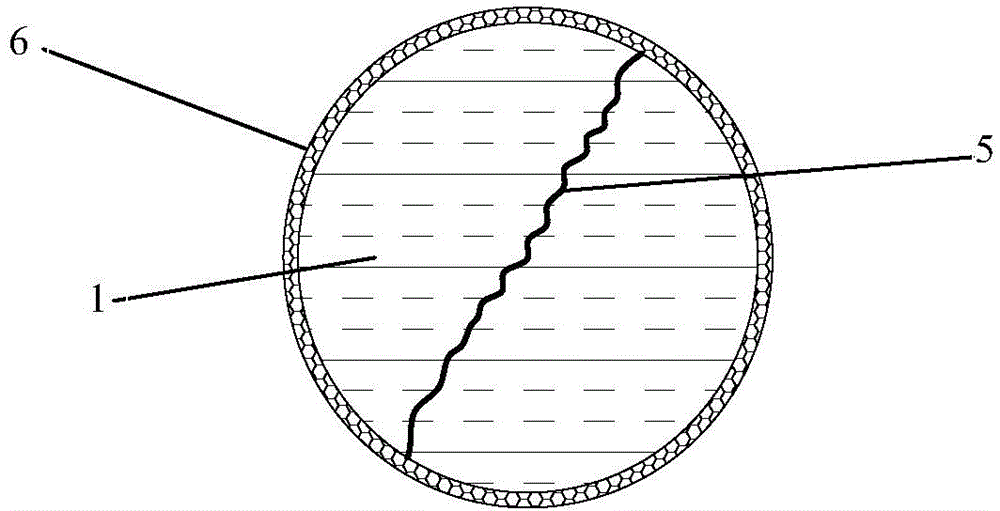

Method for prefabricating rough fractures in rocklike similar material specimen

ActiveCN104865110AAccurately reproduce the stretchAccurate reproduction of propertiesPreparing sample for investigationExperimental methodsStructure of the Earth

The invention relates to a method for prefabricating rough fractures in a rocklike similar material specimen and belongs to experimental methods of rock mechanics. The method comprises the following concrete steps: processing a rock specimen, and carrying out a destruction test with a testing machine, so as to obtain a fractured rock specimen containing a single rough through fracture; then, wrapping the fractured rock specimen with a flexible high-temperature-resistant coil, filling the rough fracture with liquid compound materials at high temperature, and naturally cooling; removing the flexible high-temperature-resisting coil, so as to obtain a compound material fracture piece; digitizing the surface appearance characteristic of the compound material fracture piece with a three-dimensional laser scanner; fixing the compound material fracture piece into a specimen processing mould, and then pouring flowable rocklike similar materials; after a similar material specimen is hardened, demoulding and heating so as to enable the compound material fracture piece to be melted to flow out; cooling, so as to obtain the rocklike material specimen containing rough joints. The method has the characteristics of being simple in process, low in cost, good in repeatability and high in precision and has a wide application prospect in a physical and mechanical property test of rock structure planes.

Owner:CHINA UNIV OF MINING & TECH

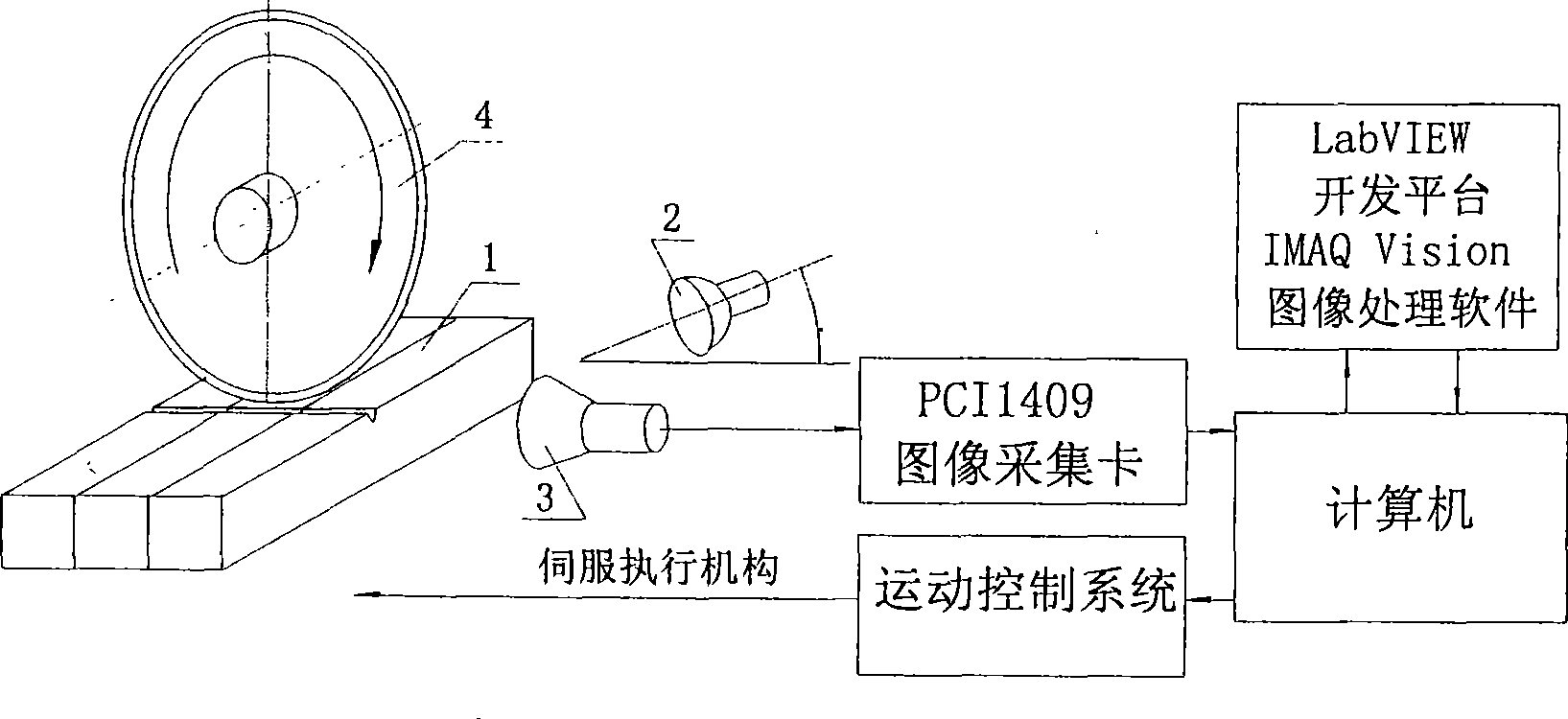

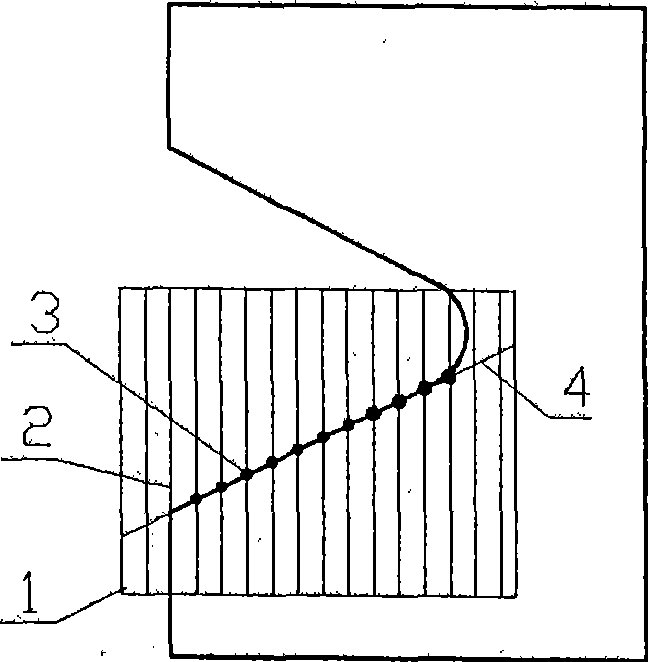

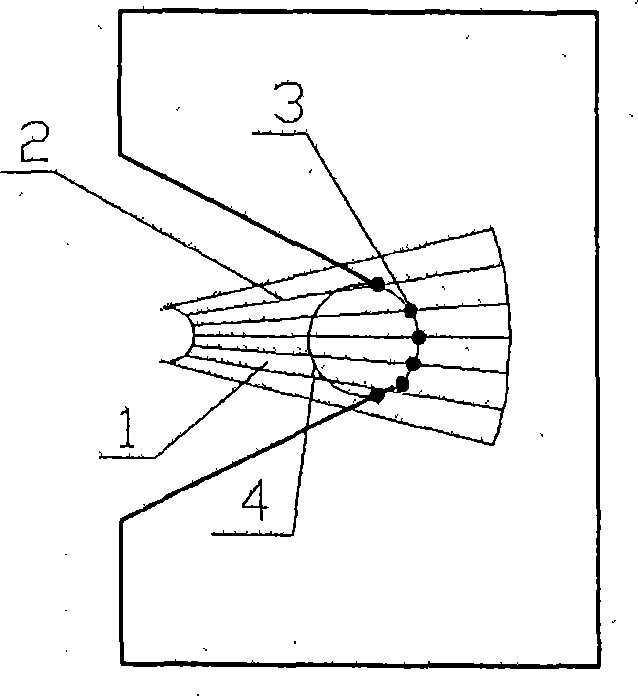

On-line vision detecting system for automatic impact specimen processing device and image processing method thereof

InactiveCN101532926AImprove flexibilityHigh degree of automationPreparing sample for investigationMaterial strength using single impulsive forceVisual technologyMass efficiency

The invention discloses an on-line vision detecting system applied to an automatic impact specimen processing device and an image processing method thereof. Taking vision technology and image processing technology as basis, by adopting image acquisition, display, processing and analysis technology, the on-line vision detecting system finishes impacting the specimen size of an on-line vision detecting system. The system can improve production flexibility and automation degree, is applicable to a large-batch production process, and can overcome the defects of low efficiency, low precision and incapability of real-time on-line measurement during manually detecting product quality. The image processing method comprises the following steps: firstly, acquiring a still image of the end face of a workpiece by using CCD photographing technology and an image acquisition card, transmitting image information to a computer, then processing the information comprehensively by an image processing software, calculating the actual size of the workpiece, transmitting the test result to a control software, acquiring instructions for further processing or stopping processing after determination processing, sending signals, and starting corresponding motion control programs and a servo actuating mechanism to finish subsequent normal automatic processing processes.

Owner:齐齐哈尔华工机床制造有限公司 +1

Transmission electron microscope processing method for insect antenna samples

ActiveCN103115809AEffective immobilizationEffective preservationPreparing sample for investigationElectron microscopeBiology

The invention belongs to the field of experimental sample processing technologies, relates to insect antenna sample processing methods and particularly relates to a transmission electron microscope processing method for insect antenna samples. The method sequentially comprises the following steps of: (A) preparing fixing liquid; (B) preparing various embedding agents; (C) dissecting, fixing and rinsing; (D) dewatering and soaking; and (E) gathering, so as to obtain the samples. The method has the advantages that the problems of difficulty in fixing liquid soaking and insufficiency in embedding agent soaking during the process of insect antenna transmission processing are solved, finally-obtained sample slices can be relatively flat, the phenomena of sample wrinkling, damaging and losing are greatly reduced, internal structures of the sample slices are all effectively fixed, and subcellular structures are clearly visible.

Owner:ZHEJIANG UNIV

Integrated droplet actuator for gel; electrophoresis and molecular analysis

InactiveUS9091649B2Easy to useFacilitates of propertyBioreactor/fermenter combinationsHeating or cooling apparatusElectrophoresisEngineering

Owner:ADVANCED LIQUID LOGIC +1

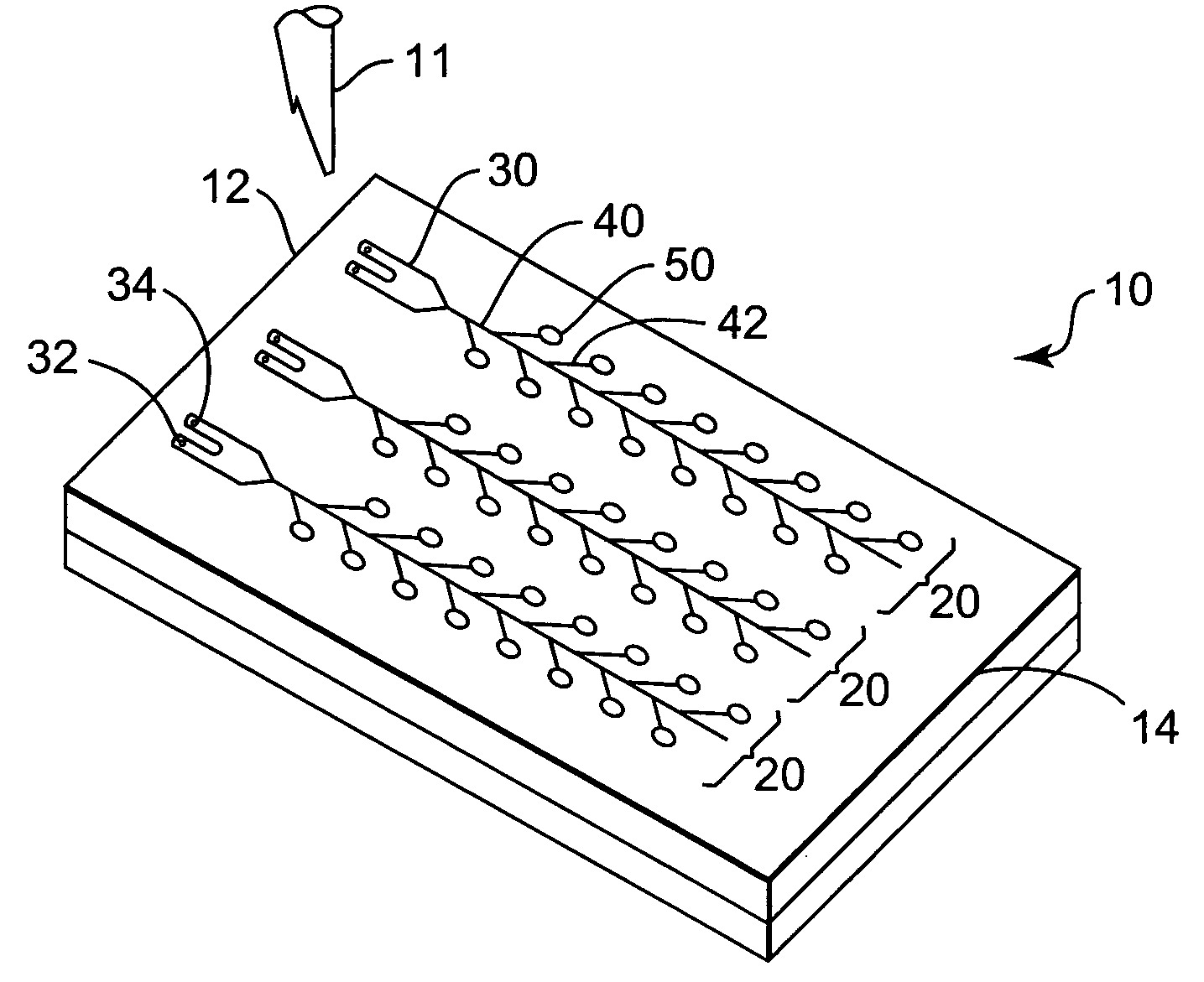

Sample processing devices and carriers

InactiveUS20050031494A1Desired reactionBioreactor/fermenter combinationsFixed microstructural devicesEngineeringHeat treated

Methods and devices for thermal processing of multiple samples at the same time are disclosed. The assemblies include carriers and sample processing devices with process arrays that include conduits useful in distributing sample materials to a group pf process chambers located in fluid communication with the main conduits. The sample processing devices may include one or more of the following features in various combinations: deformable seals, process chambers connected to the main conduit by feeder conduits exiting the main conduit at offset locations, U-shaped loading chambers, and a combination of melt bonded and adhesively bonded areas. The carriers may be used to apply selective compression to the sample processing devices.

Owner:3M INNOVATIVE PROPERTIES CO

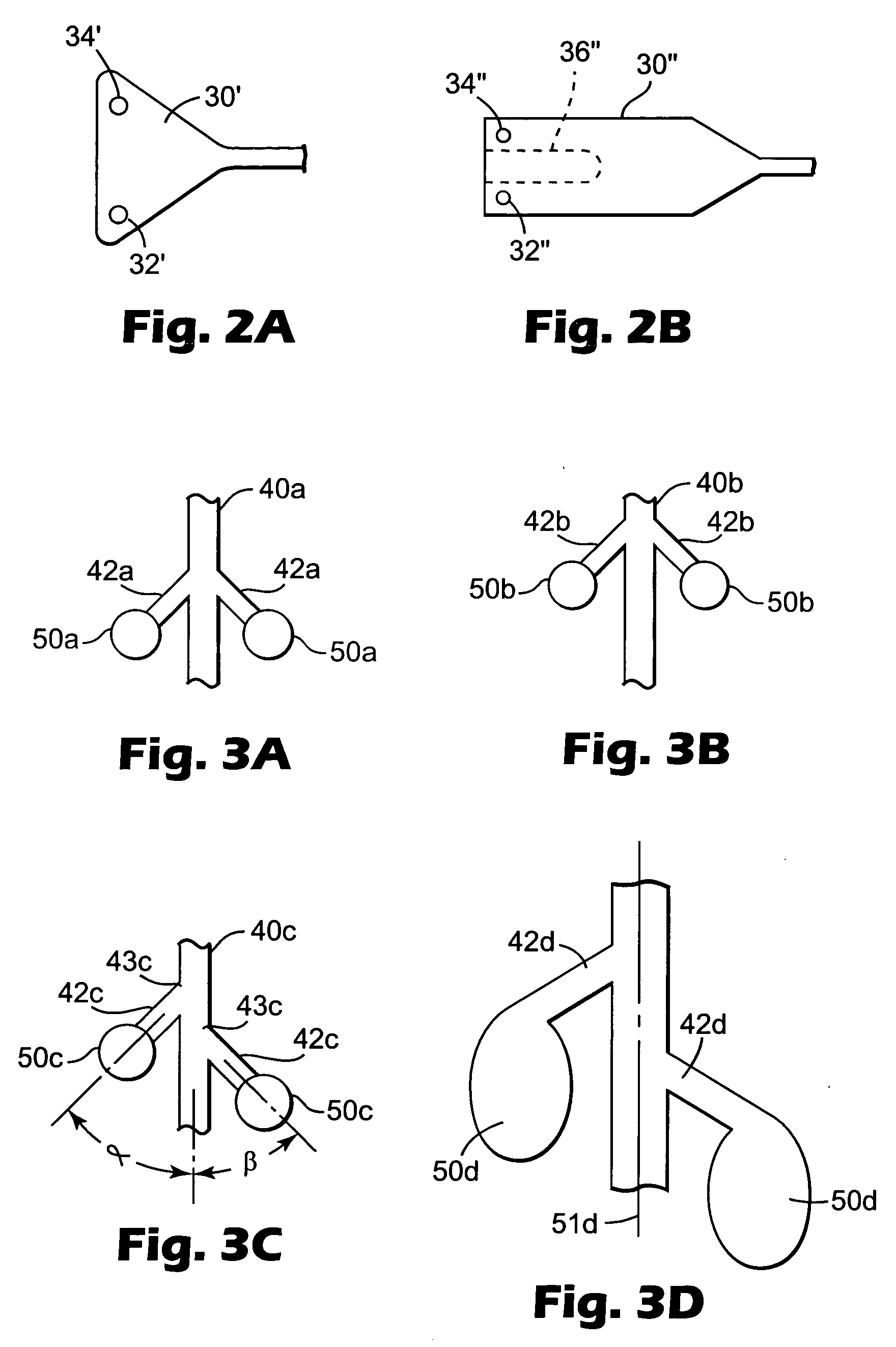

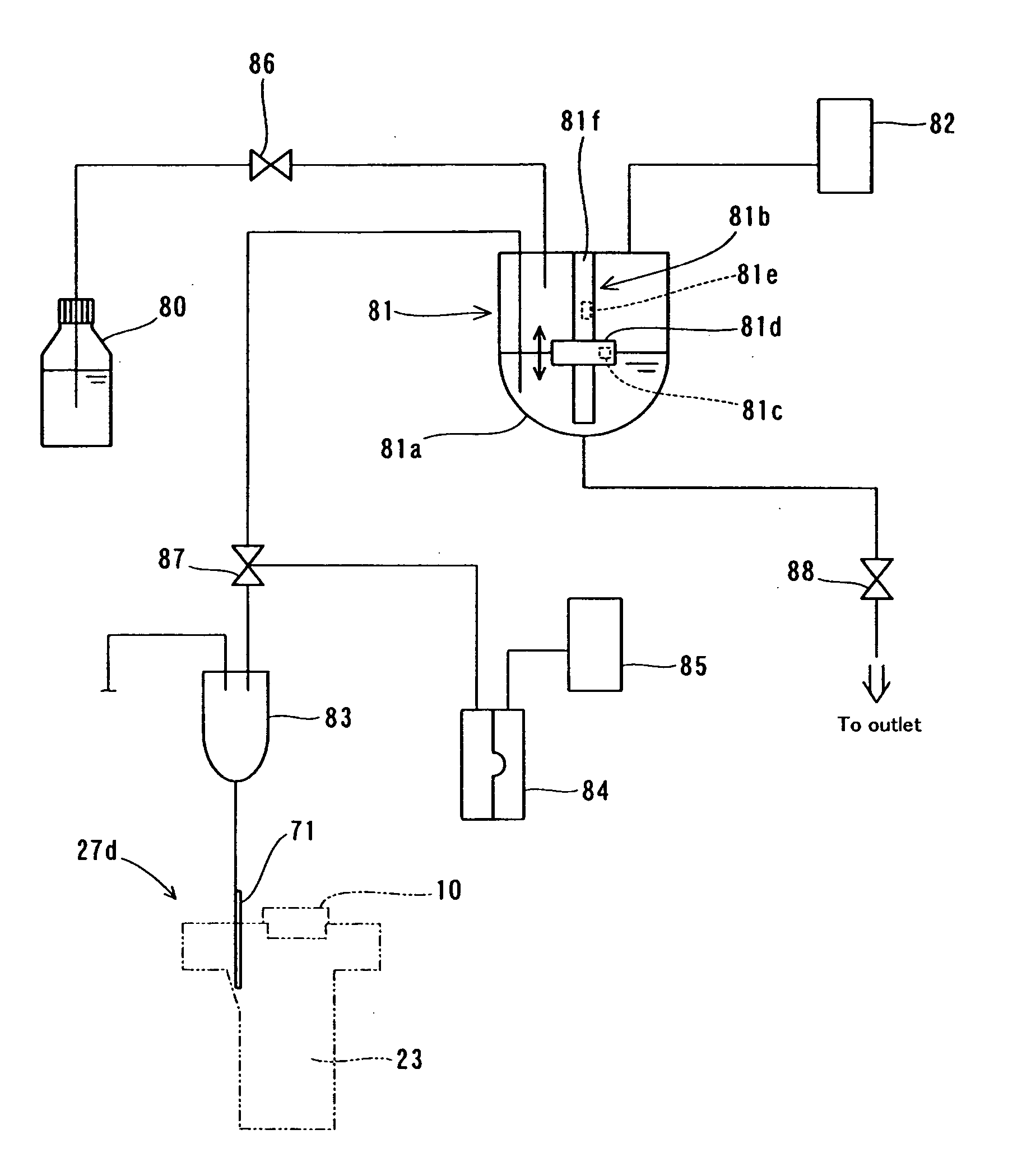

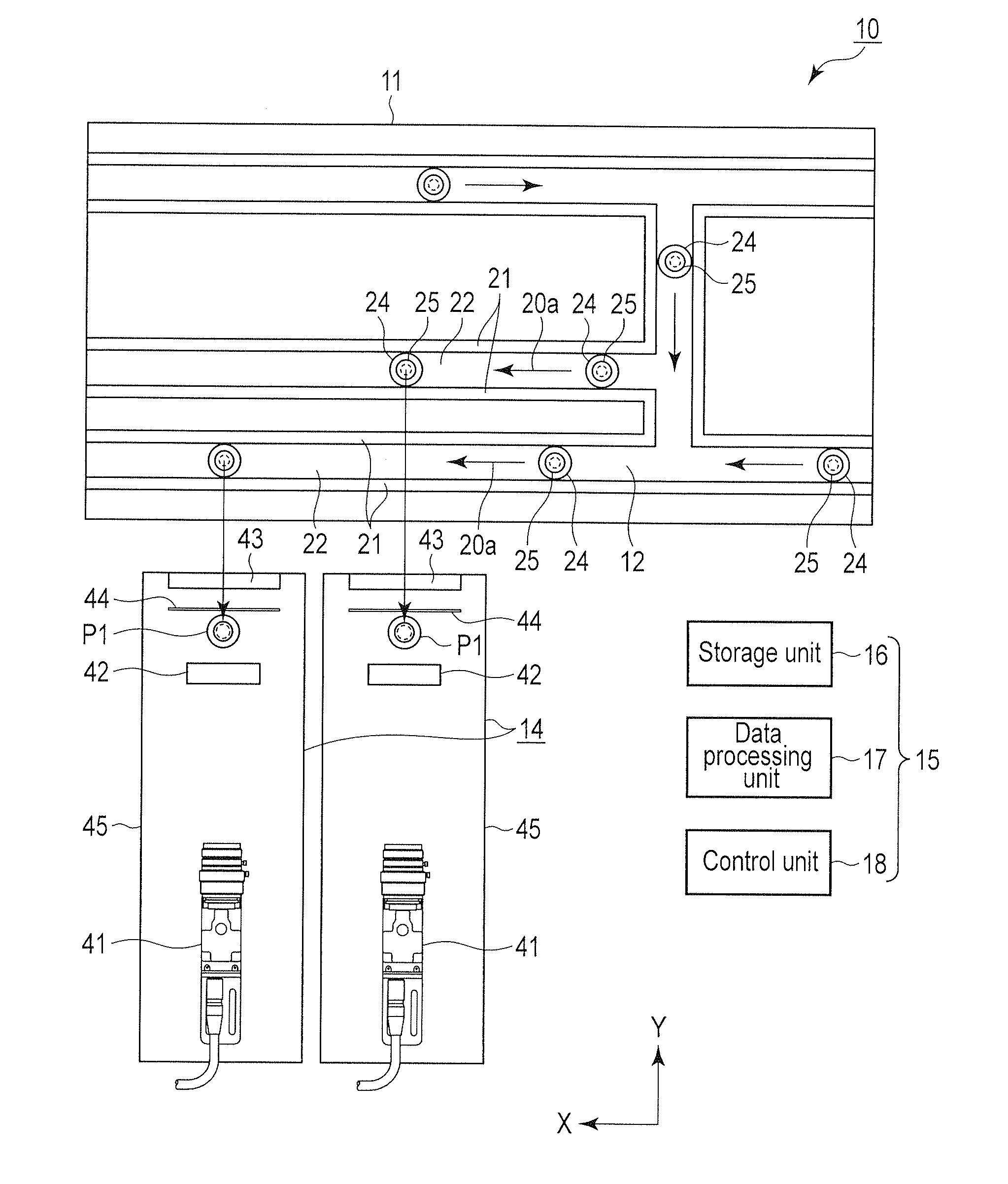

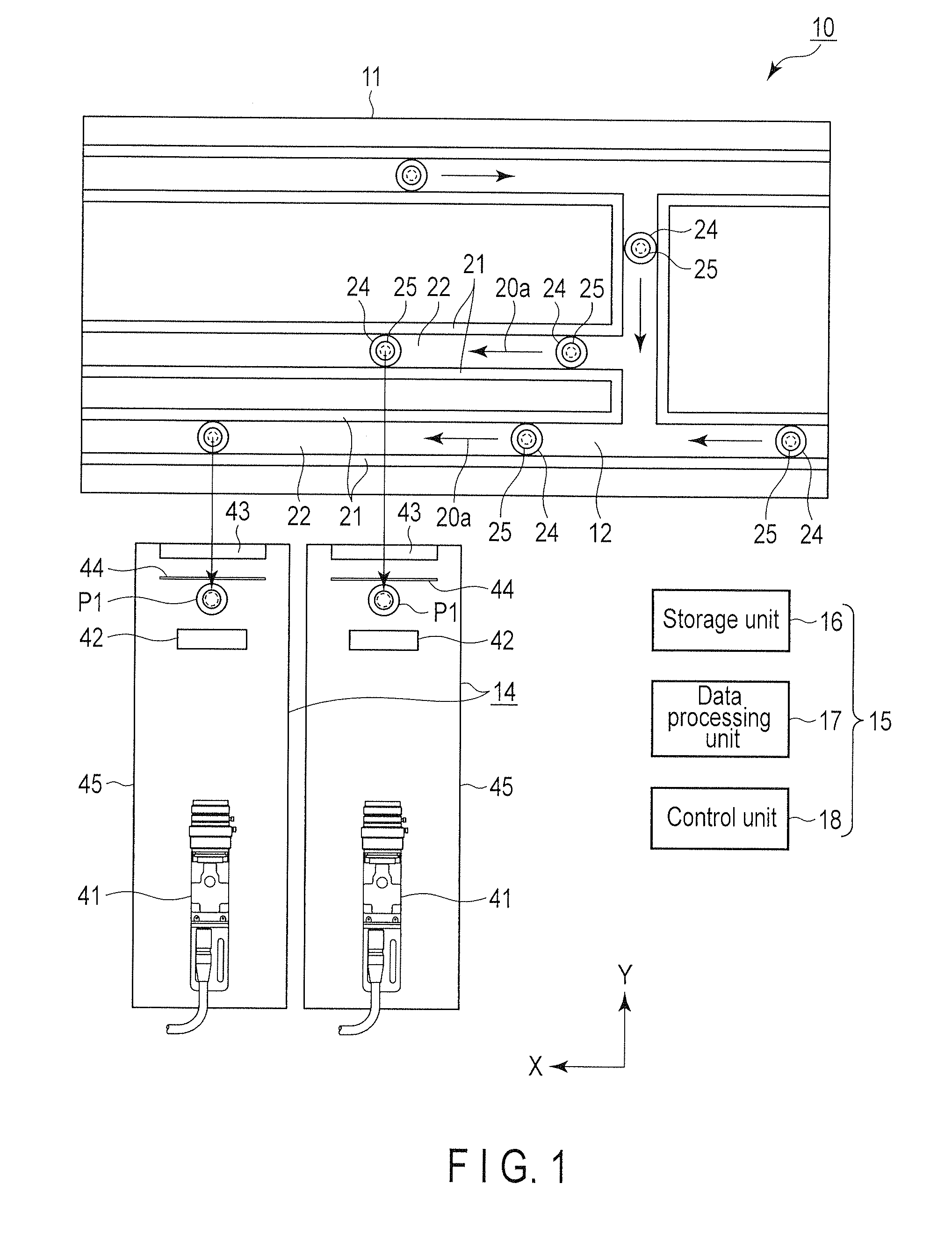

Clinical specimen processing apparatus and clinical specimen processing system

ActiveUS20050281707A1Withdrawing sample devicesMaterial analysis by optical meansSpecimen HandlingEngineering

A clinical specimen processing apparatus are described, a representative one of which includes: an operation means for conducting operations to perform predetermined processing of clinical specimen; a detection means for detecting a operating condition of the operation means which performs the predetermined processing; comparison means for comparing a detection value detected by the detection means to a first threshold value and a second threshold value; and a determination means for determining whether or not the operation means is in any one of three condition stages.

Owner:SYSMEX CORP

Test preprocessing apparatus, test preprocessing method, and specimen processing apparatus

According to an embodiment, a test preprocessing method includes, detecting a brightness of a specimen based on image of the specimen acquired by capturing the specimen before test processing of the specimen, and detecting a chylous state of the specimen based on the brightness, and detecting a hue of the specimen based on the image, and detecting a hemolytic state of the specimen based on the hue.

Owner:AOI SEIKI

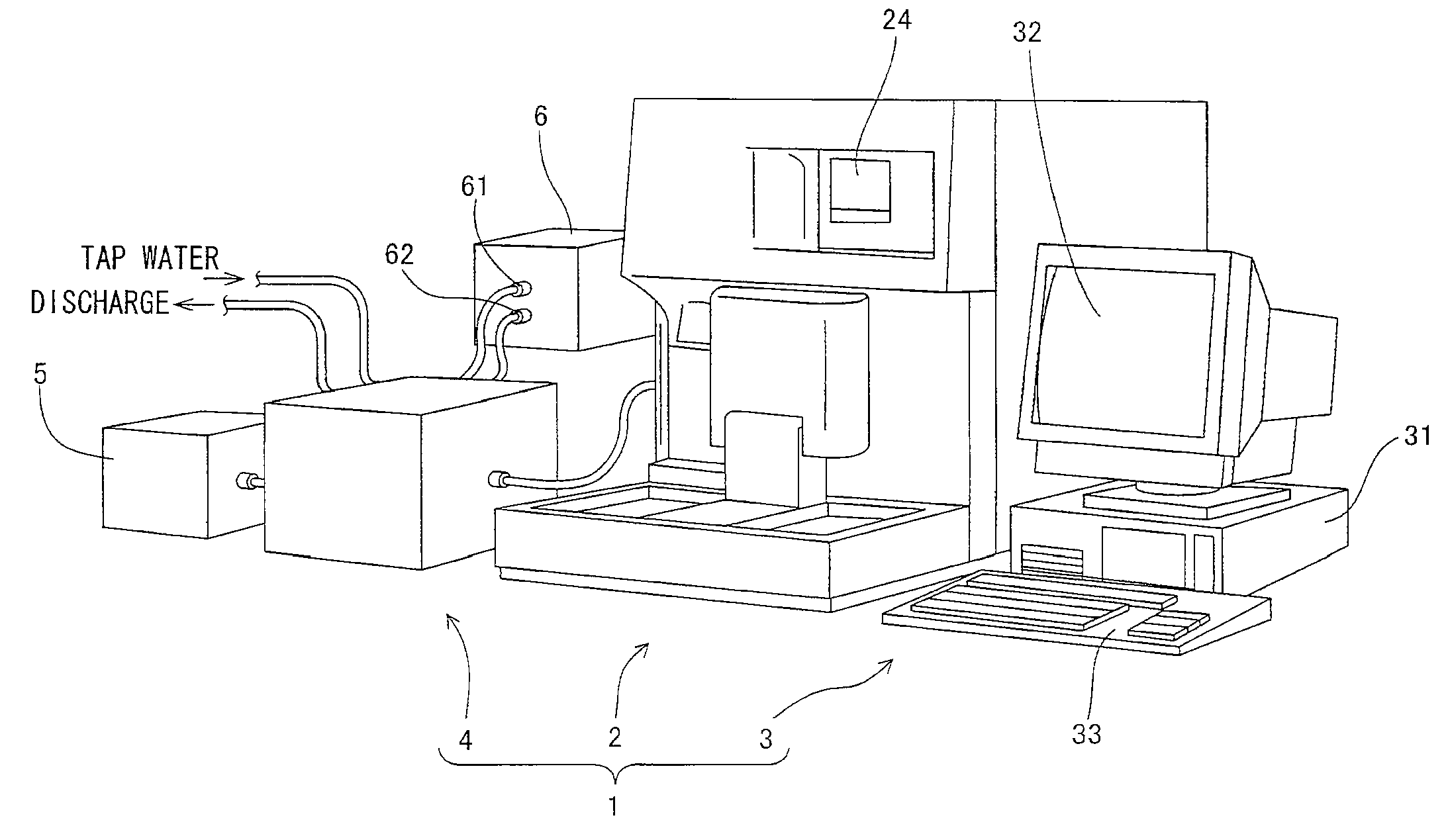

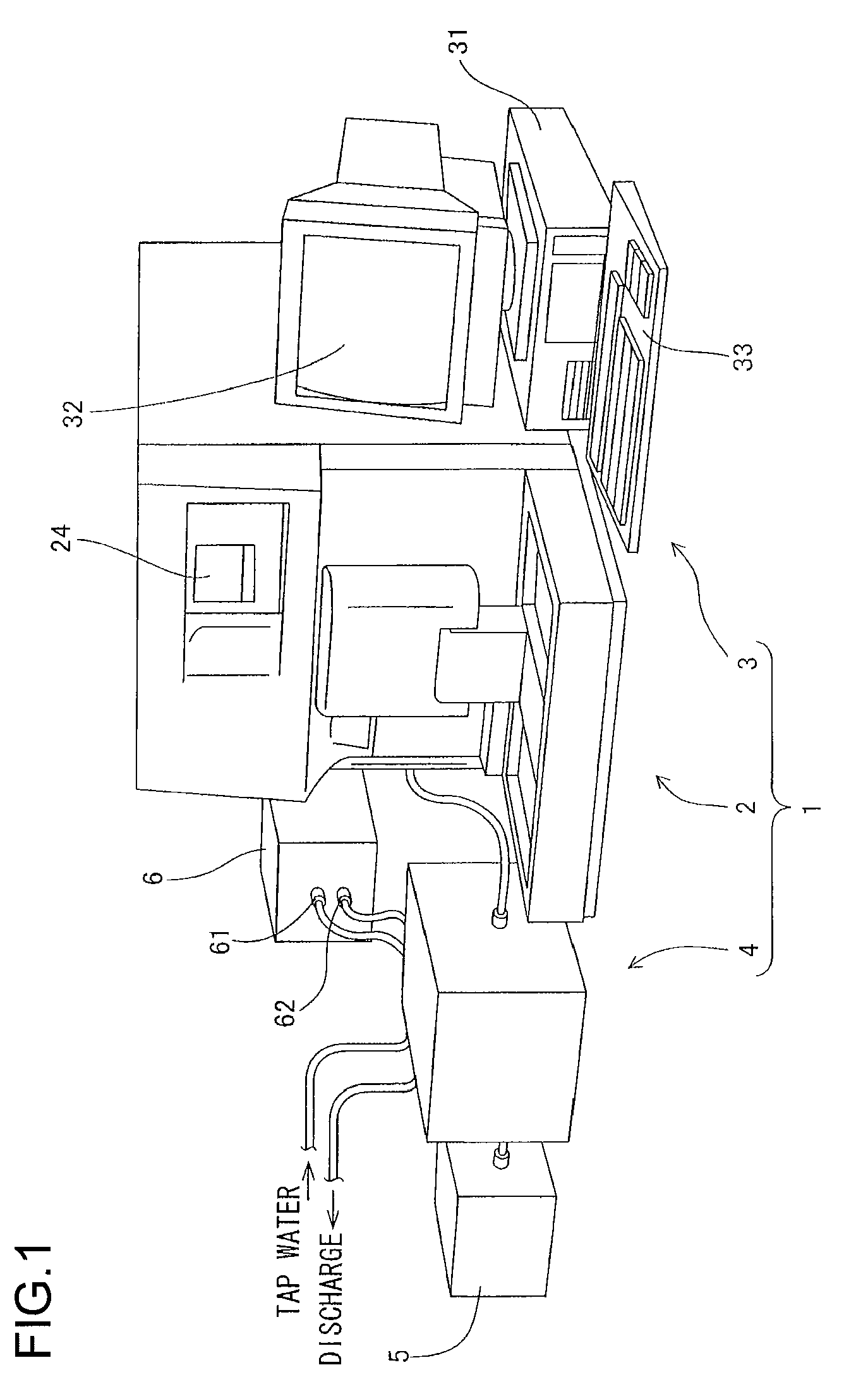

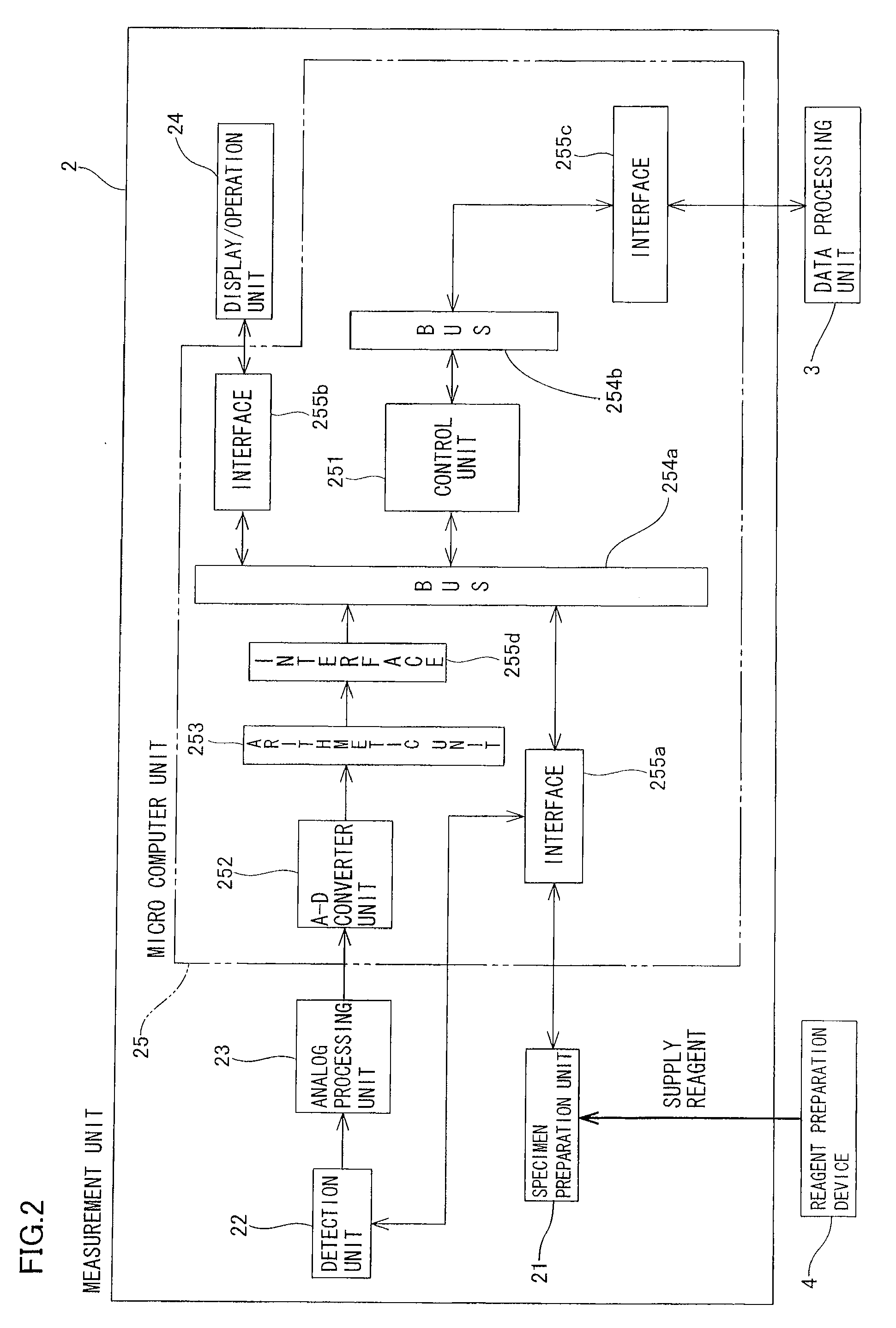

Sample analysis system, reagent preparation device, and sample treating device

ActiveUS20100161243A1Bioreactor/fermenter combinationsBiological substance pretreatmentsDisplay deviceReagent

A sample analysis system includes a reagent preparation unit and a measurement unit. The reagent preparation unit has: a state detector which detects at least one of a state of the reagent preparation unit and a state of the reagent preparation; and a transmission unit which transmits the detected state information to a computer arranged outside the reagent preparation unit. The computer displays the received state information on a display.

Owner:SYSMEX CORP

Apparatus for removable distal internal cassette for in situ fixation and specimen processing with serial collection and storage of biopsy specimens

ActiveUS7445603B2Easy to useLarge central lumenSurgical needlesVaccination/ovulation diagnosticsIn situ fixationSpecimen Handling

An apparatus for performing a medical procedure comprises an elongated flexible member having an aperture extending longitudinally therethrough and an actuator positioned within the aperture. There is a biopsy means connected to the distal end of the actuator for cutting and collecting biopsy specimens and a removable distal storage and collection chamber connected to the elongated flexible member for receiving biopsy specimens cut and collected by the biopsy means. The removable storage and collection chamber is a means for immediate contact of the collected biopsy specimens with fixatives or reagents. The distal cassette is separable from the flexible member and can be sealed by a cap positionable over the storage and collection cassette for storage, in situ fixation and processing or later processing and analysis of biopsy specimens collected by the biopsy means in the order of collection.

Owner:ZIMMON DAVID S

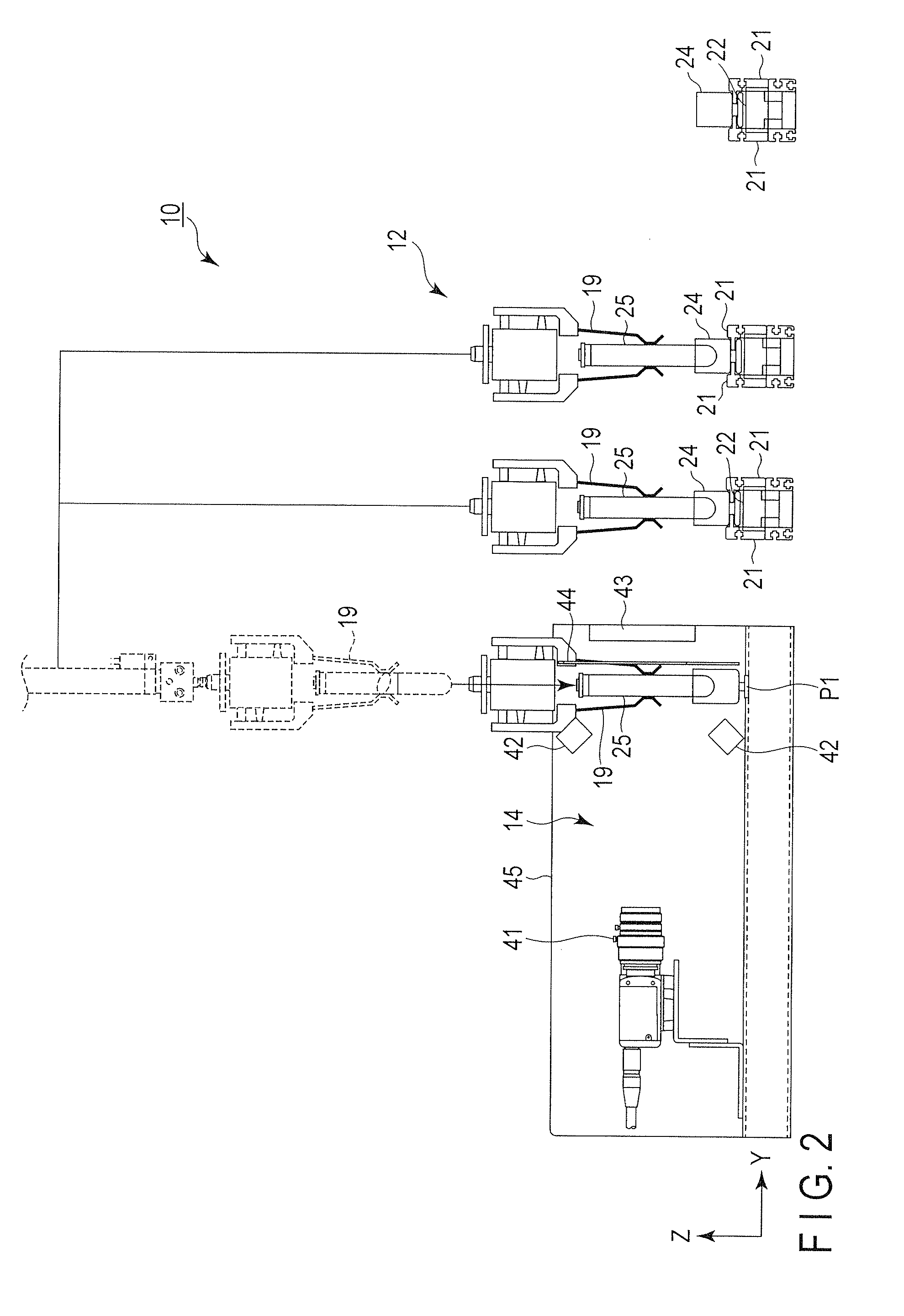

Specimen processing device and specimen processing method

ActiveUS20100282003A1Withdrawing sample devicesMaterial analysis by optical meansEngineeringSpecimen processing

A specimen processing device comprising: first and second units for processing specimens; a conveyance unit for conveying a specimen rack in a first direction from a first position where the specimen is retrieved by the first unit to a second position where the specimen is retrieved by the second unit, and a second direction opposite to the first position; a detector common to the first and second units for executing a detection process with respect to the sample containers; and a conveyance controller controlling the conveyance unit to convey some sample containers of the detected sample containers executed with the detection process to the first position, and to convey the other sample containers of the detected sample containers to the second position, the some sample containers and the other sample containers being held by a common rack, is disclosed. A specimen processing method is also disclosed.

Owner:SYSMEX CORP

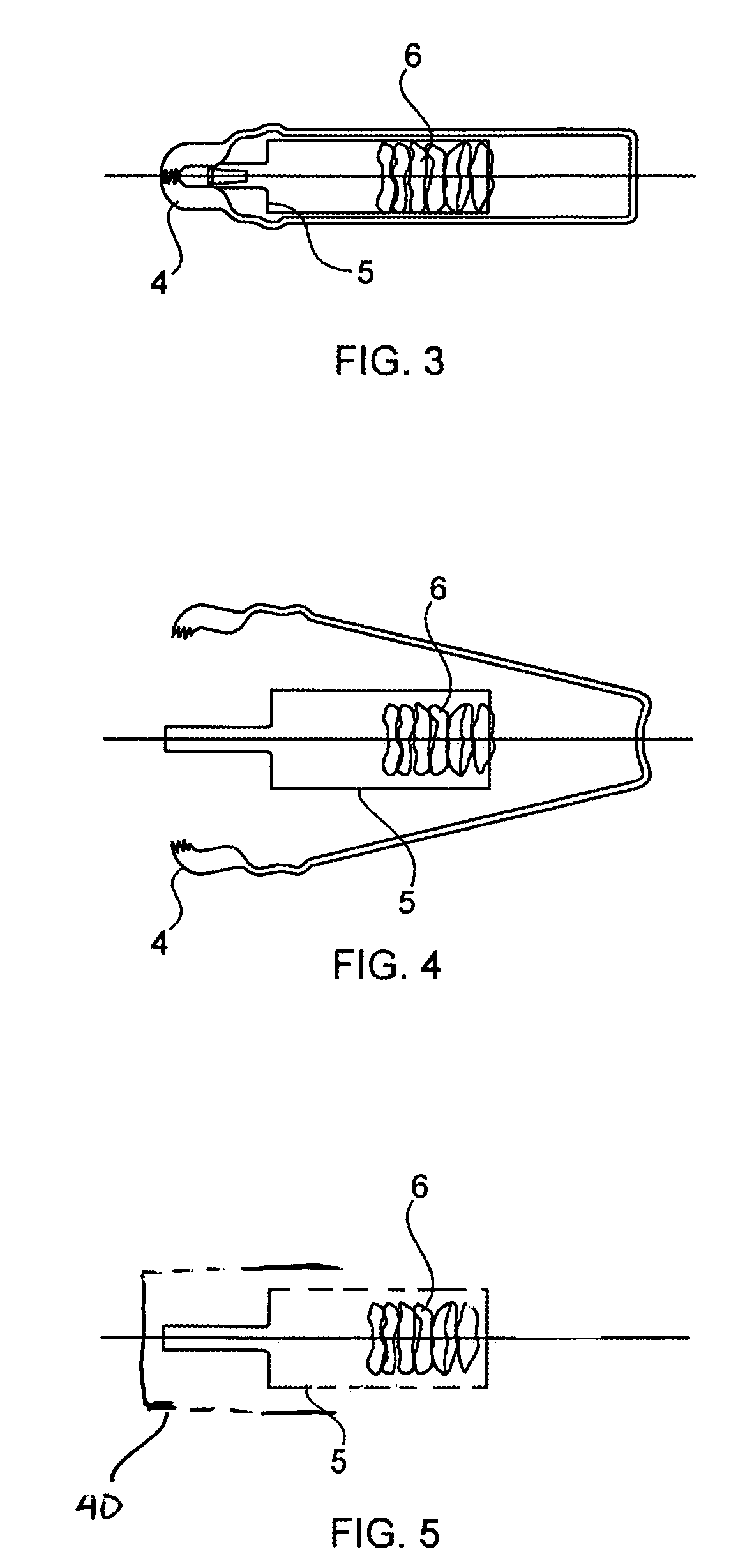

Specimen processing system and specimen conveyance method

A specimen processing system comprising: a plurality of measurement units for acquiring a reagent from each of corresponding reagent containers, and performing measurement of a specimen for a common measurement item by using the reagent; a conveyance mechanism for conveying specimens to the measurement units; a reagent information acquirer for acquiring reagent information related to the reagent stored in each of the reagent containers; a conveying destination determiner for determining a conveying destination of specimens based on the reagent information acquired by the reagent information acquirer; and a conveyance controller for controlling the conveyance mechanism to convey specimens based on the conveying destination determined by the conveying destination determiner, is disclosed. Specimen conveyance method is also disclosed.

Owner:SYSMEX CORP

Auxiliary sample supply for a clinical analyzer

InactiveUS7402282B2Sufficient volumeMaterial analysis by optical meansLaboratory glasswaresBiomedical engineeringSpecimen processing

A sample handler includes a plurality of sealable metering tips, each of the tips, when sealed, containing a fluid volume of a test fluid and in which each of the sealed metering tips acts as an auxiliary sample supply container for use with at least one chemistry system of a clinical analyzer.

Owner:ORTHO-CLINICAL DIAGNOSTICS

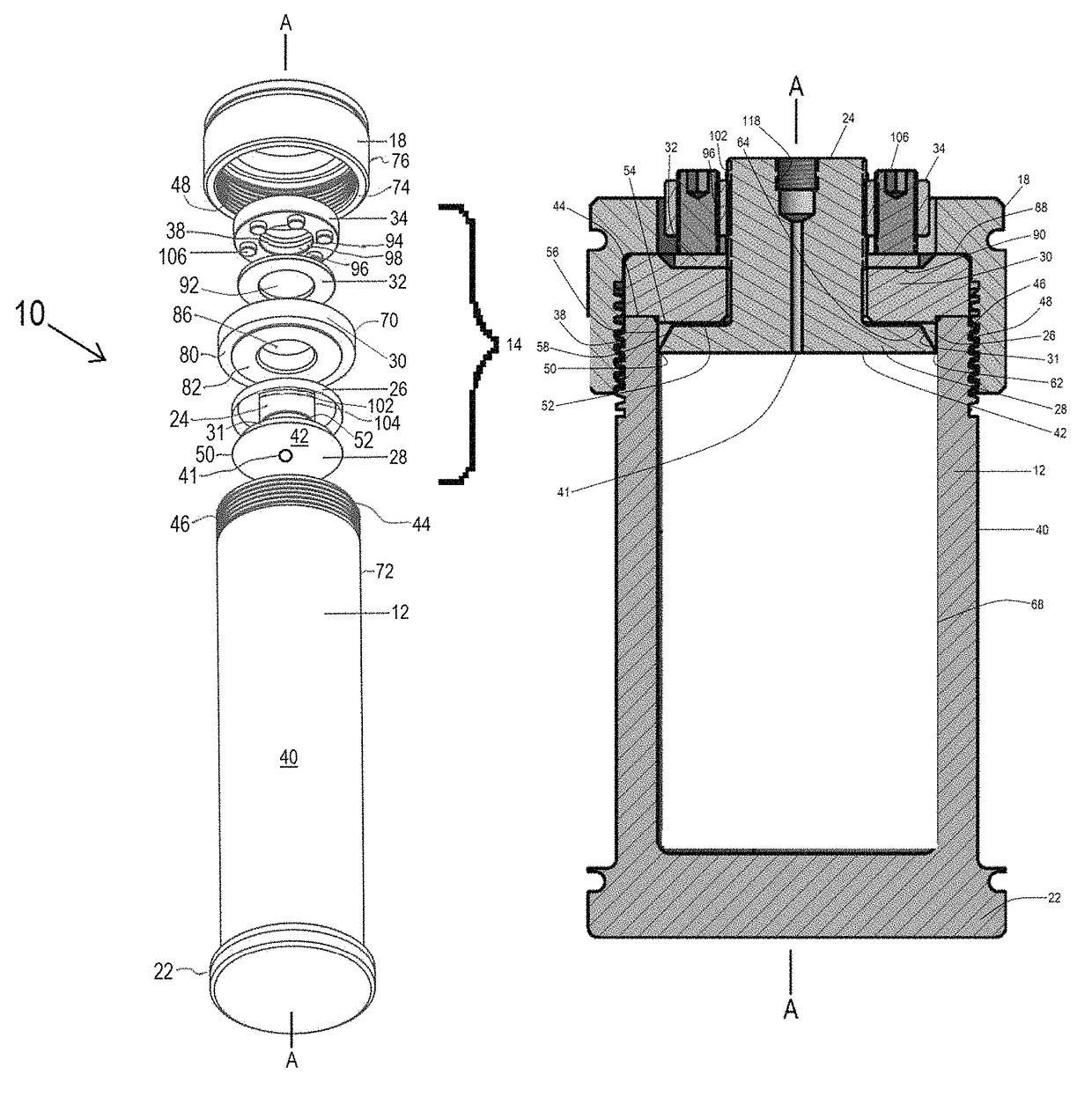

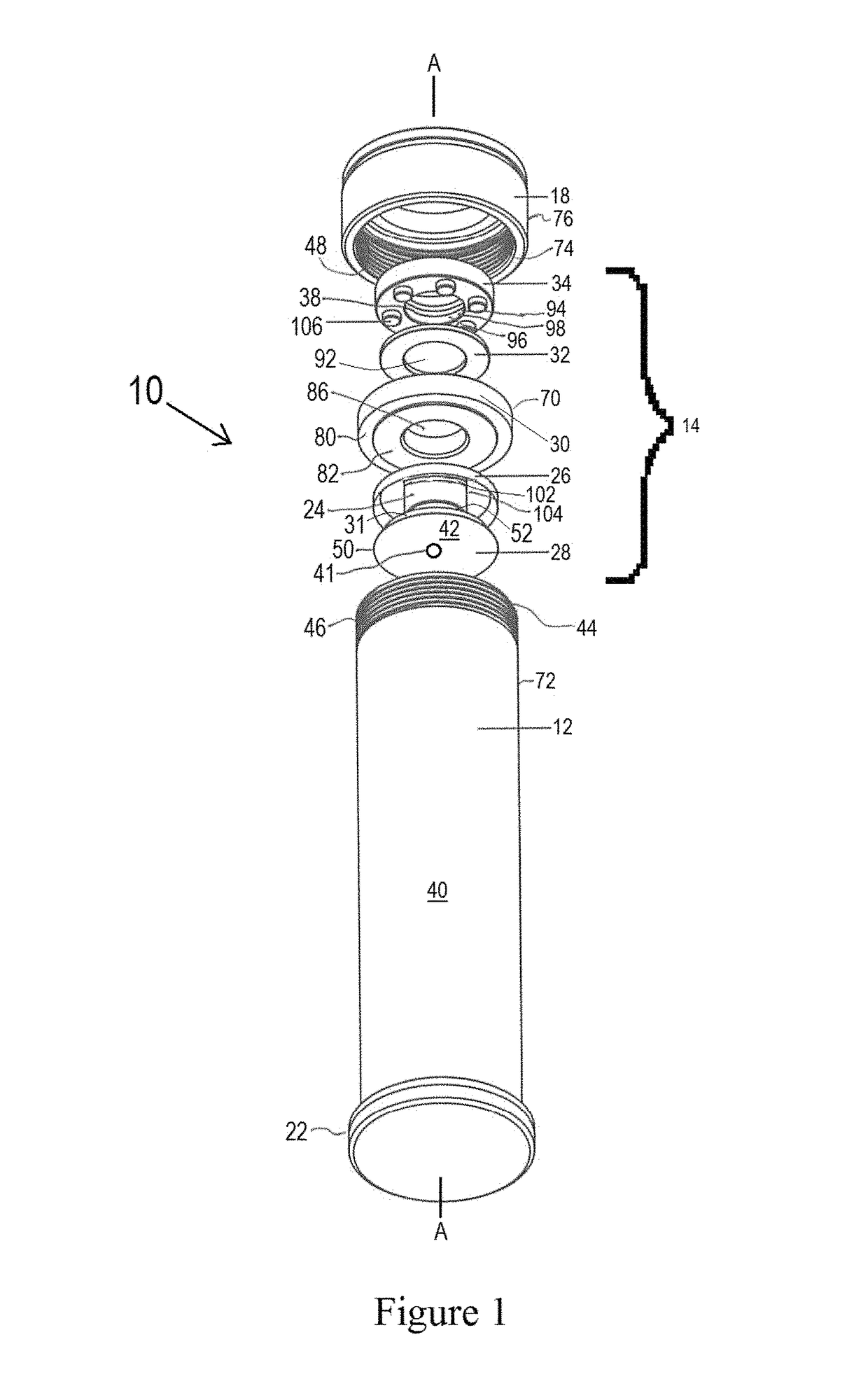

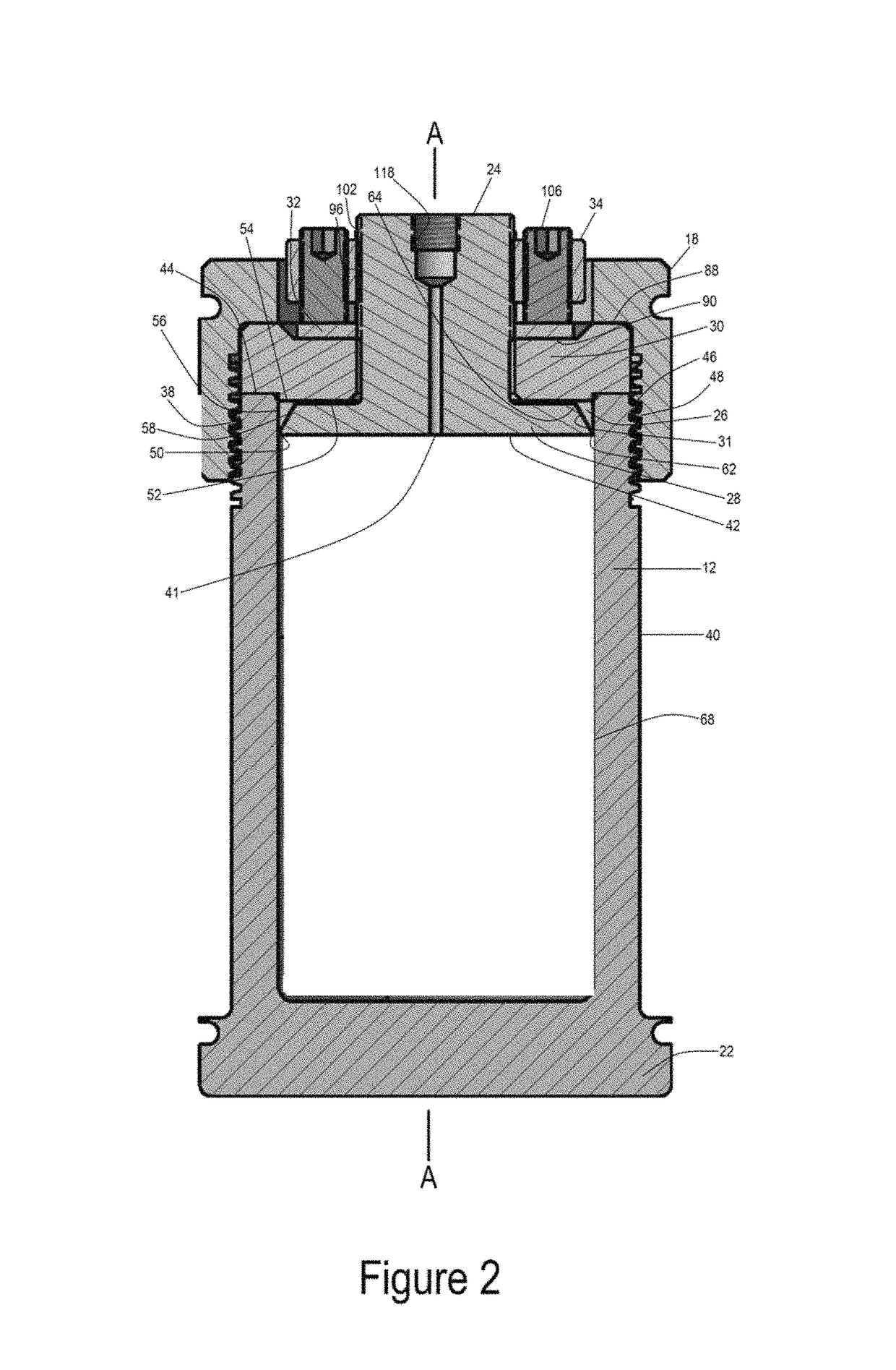

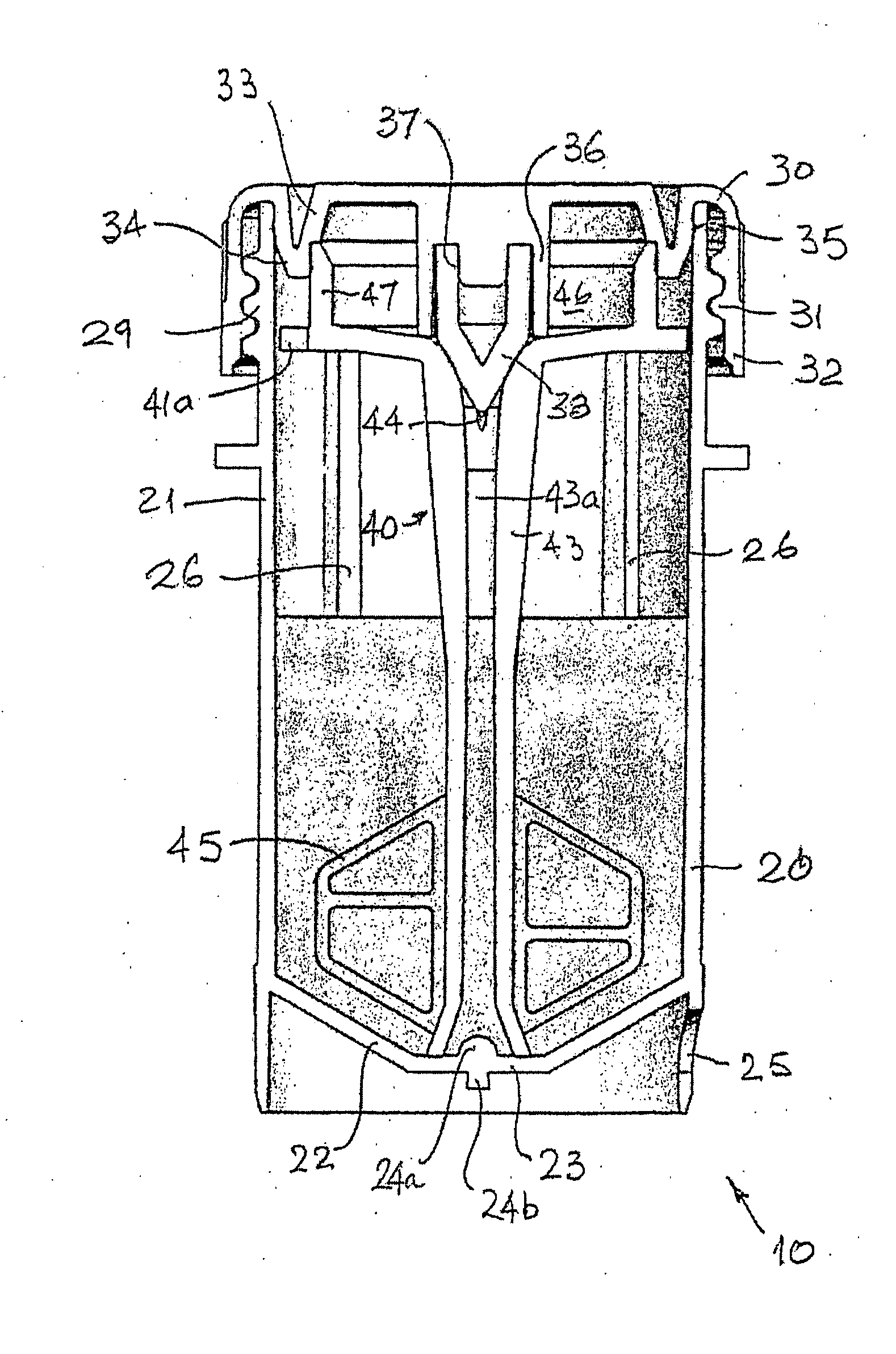

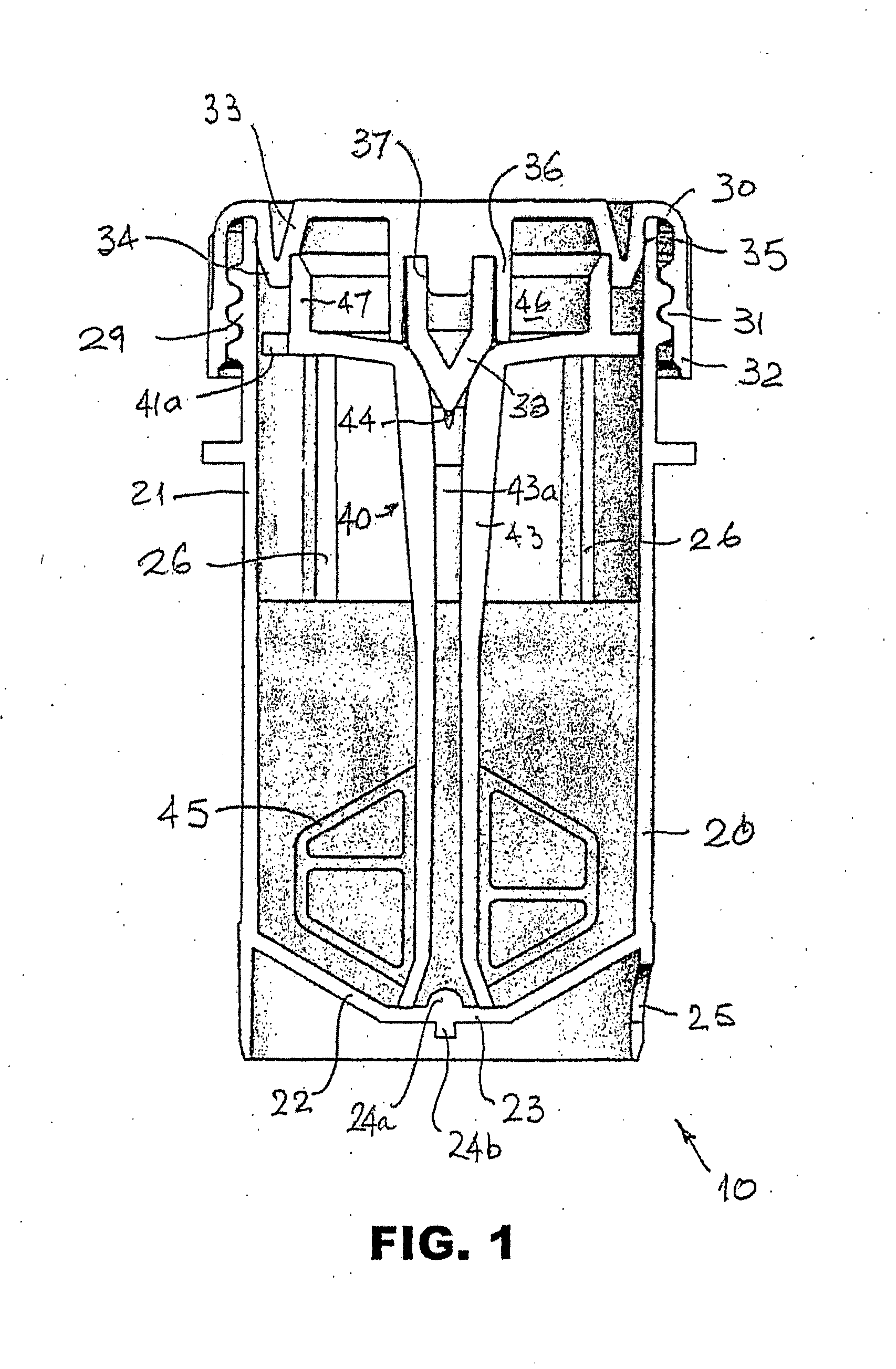

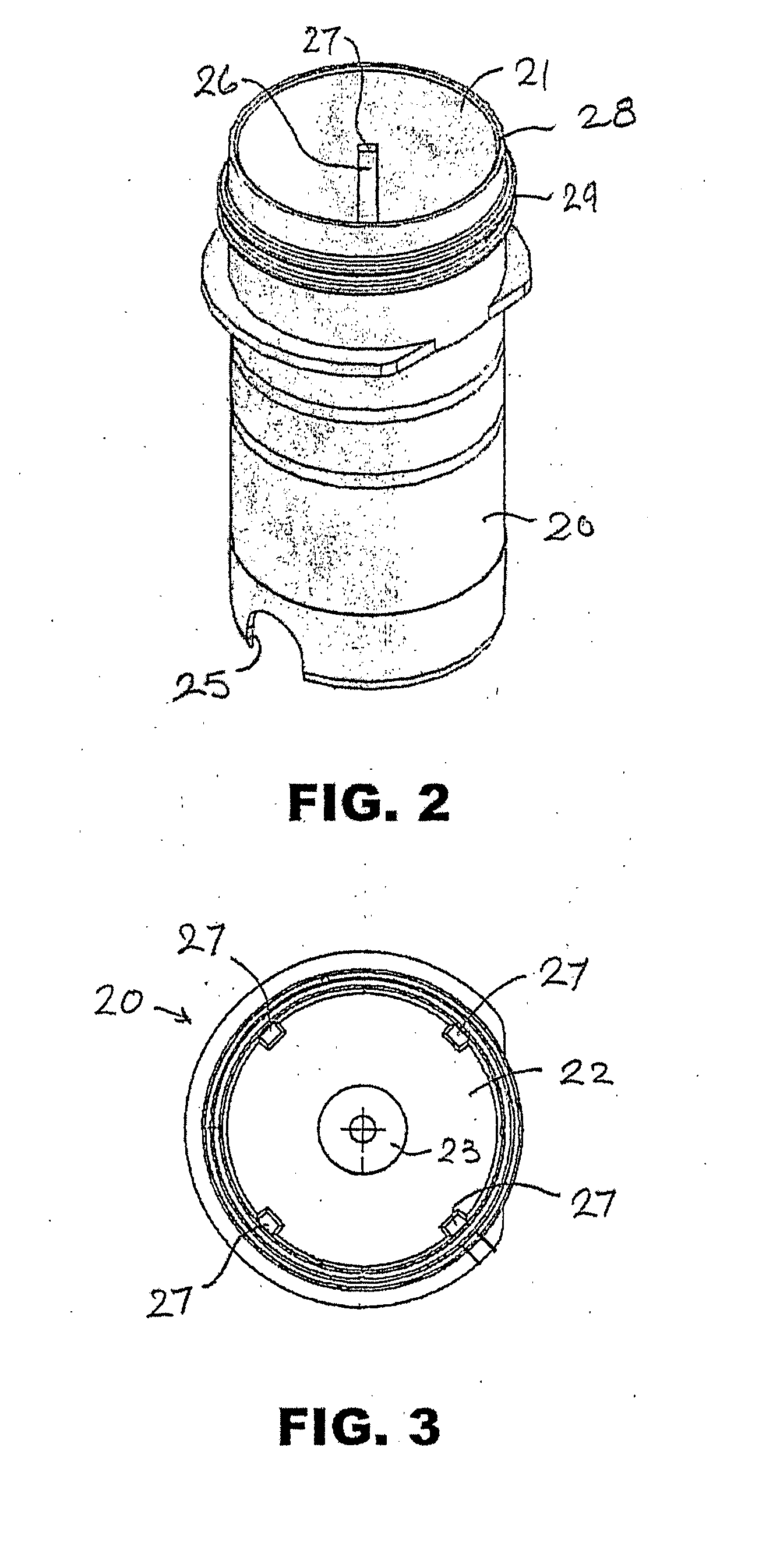

Vial Assembly, Sampling Apparatus And Method For Processing Liquid-Based Specimens

InactiveUS20070287193A1Quality improvementAvoid cross contaminationAnalysis using chemical indicatorsShaking/oscillating/vibrating mixersParticulatesBiomedical engineering

A vial-based system and method for handling and processing specimens of particulate matter-containing liquid directly in the vial. A processing assembly (40), which includes a stirrer (45) and a particulate matter separation chamber (46), is releasably coupled to the inside of a vial cover (30). The processing assembly (40) remains with the cover (30) when the vial is opened to insert a specimen therein. Application of an external force to the cover (30) detaches the processing assembly from the cover so that it remains in the vial, for access by automated or manual laboratory equipment, when the cover (30) is discarded. Sealing and drainage features help prevent cross-contamination during specimen processing.

Owner:HOLOGIC INC

Modular robotic system and method for sample processing

A method of processing objects using a bilateral architecture. The method comprises the steps of: arranging a plurality of instruments around a bi-directional conveyance device, the instruments spaced at fixed pitch intervals along the conveyor device; assigning dedicated movers to each of the instruments, the dedicated movers for loading and unloading of the objects to and from the instruments and the conveyance device; and controlling the operation of the conveyance device to have an interrupted motion, the interrupted motion for co-ordinating the loading and unloading of the objects; wherein the dedicated movers are positioned such that adjacent movers operate independently of one another. The method can be operated on an automated robotic system having a modular architecture. The system comprises; a backbone having a plurality of backbone connectors; a module having a module connector for releasably coupling with a respective one of the backbone connectors; a bi-directional motion device connected to the backbone, the motion device for presenting an object adjacent to the module when the module is coupled to the backbone; a connection interface formable by coupling the backbone and module connectors, the connection interface for providing an operation coupling between the backbone and the module when adjacent thereto; wherein the connection interface provides a repeatable connection and disconnection capability between the backbone and the module for ready reconfiguration of the modular architecture.

Owner:THERMO CRS LTD

Specimen processing apparatus

ActiveCN101726612APreparing sample for investigationBiological testingEngineeringSpecimen containers

The present invention is to present a specimen processing apparatus, comprising: an imaging device for imaging a cap of a covered specimen container containing a specimen; an aspirating device including a specimen aspirating tube, moving the specimen aspirating tube so as to pass the specimen aspirating tube through the cap of the covered specimen container and aspirating the specimen contained in the covered specimen container via the specimen aspirating tube; an aspiration controller for controlling a movement of the specimen aspirating tube into the covered specimen container based on an image obtained by the imaging device; and a specimen processing device for processing the specimen aspirated by the aspirating device.

Owner:SYSMEX CORP

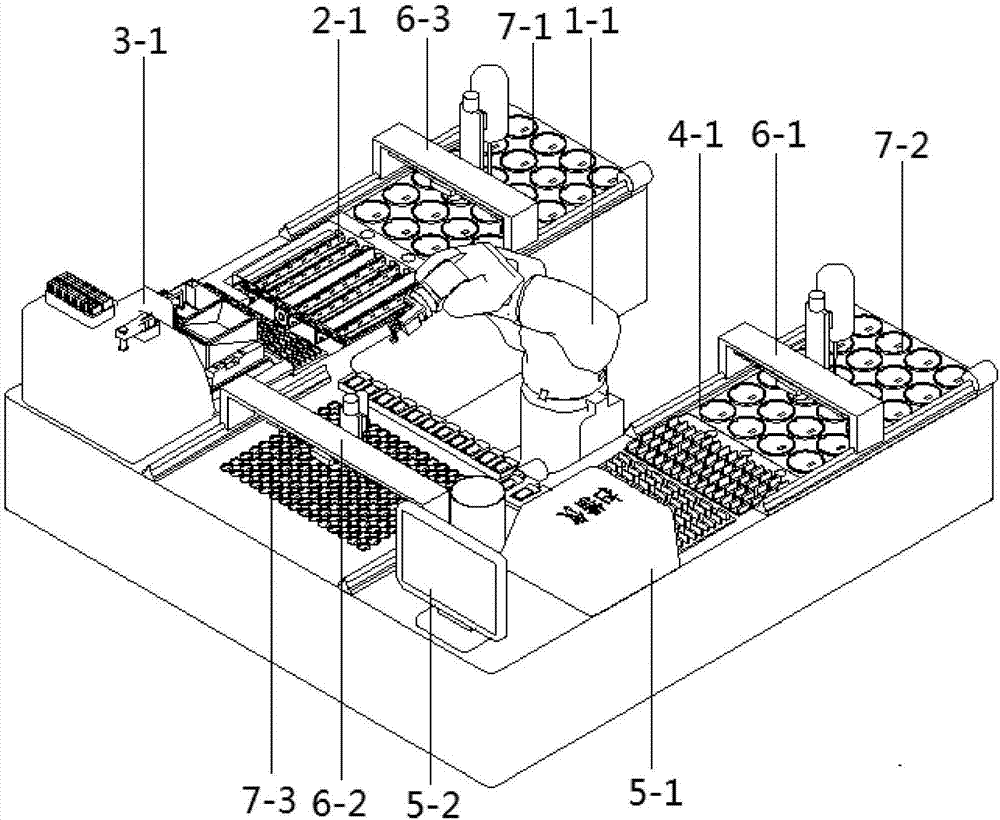

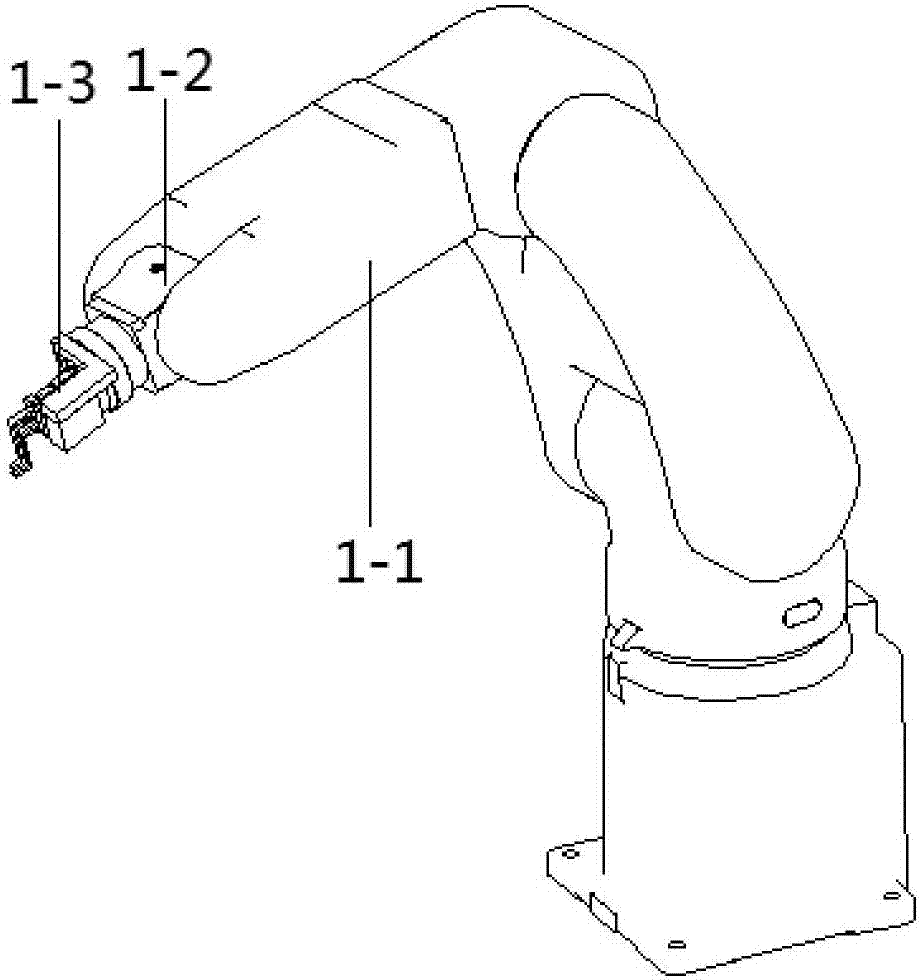

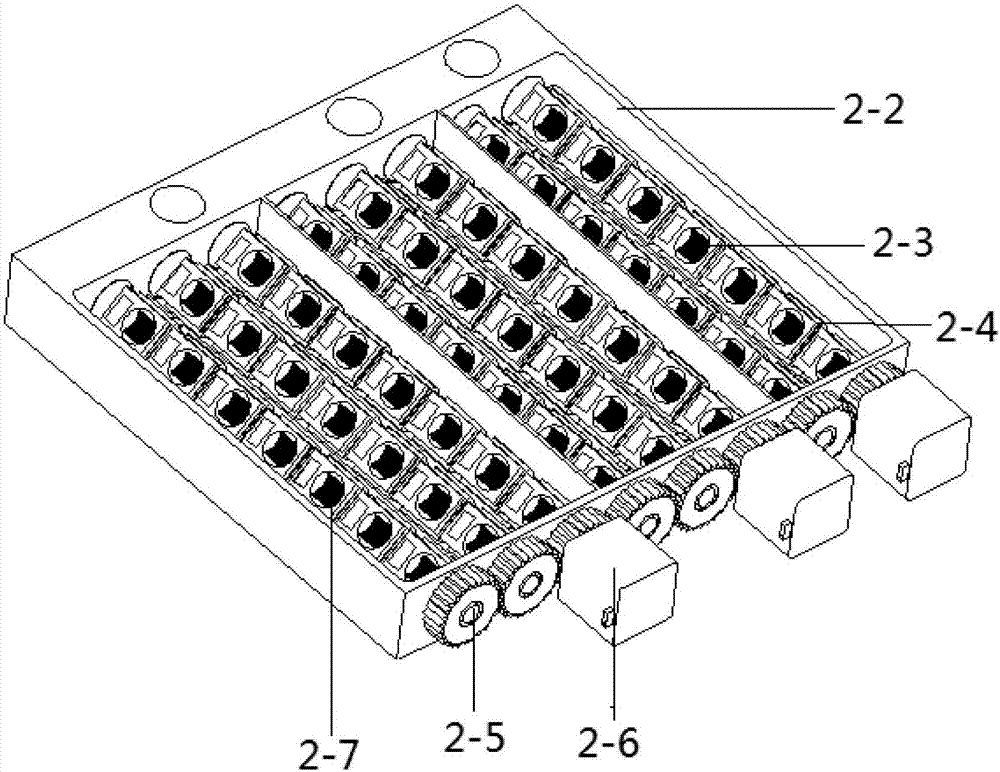

Histopathological specimen processing system

PendingCN106979878AShorten the timeAvoid contactPreparing sample for investigationWaxBiochemical engineering

The invention provides a histopathological specimen processing system and belongs to the technical field of medical instruments. The histopathological specimen processing system comprises a movable clamping unit, a dehydration and wax immersion unit, a slicing unit, a slide glass dyeing unit, an image scanning and display unit and a master control unit. Through various units of the system, a series of processing steps such as fixing, dehydration, embedding, slicing, bleaching, dyeing and photographing of a histopathological specimen after drawing materials can be automatically completed, so that the labor amount of a technician is reduced, the technician is prevented from being in contact with toxic and harmful substances, and the histopathological specimen processing time is shortened.

Owner:贵阳德漫多医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com