On-line vision detecting system for automatic impact specimen processing device and image processing method thereof

An automatic processing and impact sample technology, applied in the direction of using one impact force to test the strength of materials, preparation of samples for testing, etc. Improve the degree of flexibility and automation, solve low quality efficiency, and improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

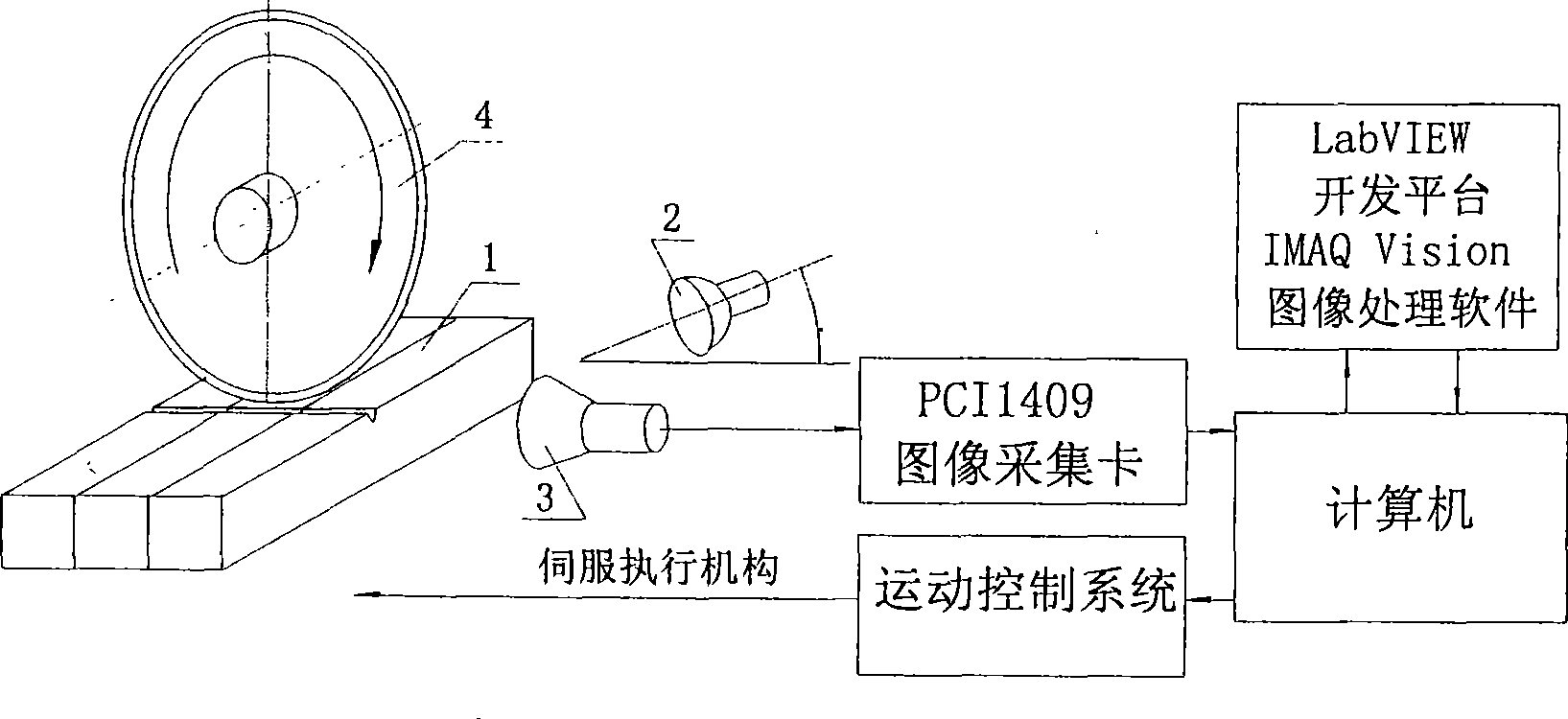

[0036] The visual inspection system is an integral part of the impact sample processing center, as shown in Figure 1. It mainly completes the detection of the shape and size of the V-shaped notch, as well as the thickness of the test piece, and is organically integrated with the PLC and motion control system of the system. Combined to realize intelligent automatic processing. Its working process is that the light source 2 first irradiates the sample 1, and then the sample is imaged on the CCD camera 3 through the lens, and the image acquisition card converts the optical signal on the CCD camera into an electrical signal, that is, converts the original image into Digital image, the computer uses the image processing software IMAQ Vision and the software system developed by LabVIEW to process, measure and judge the digital image, and display the measurement result and judgment information. The motion control system determines the motion program according to the judgment informati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com