Patents

Literature

150results about How to "Little variability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

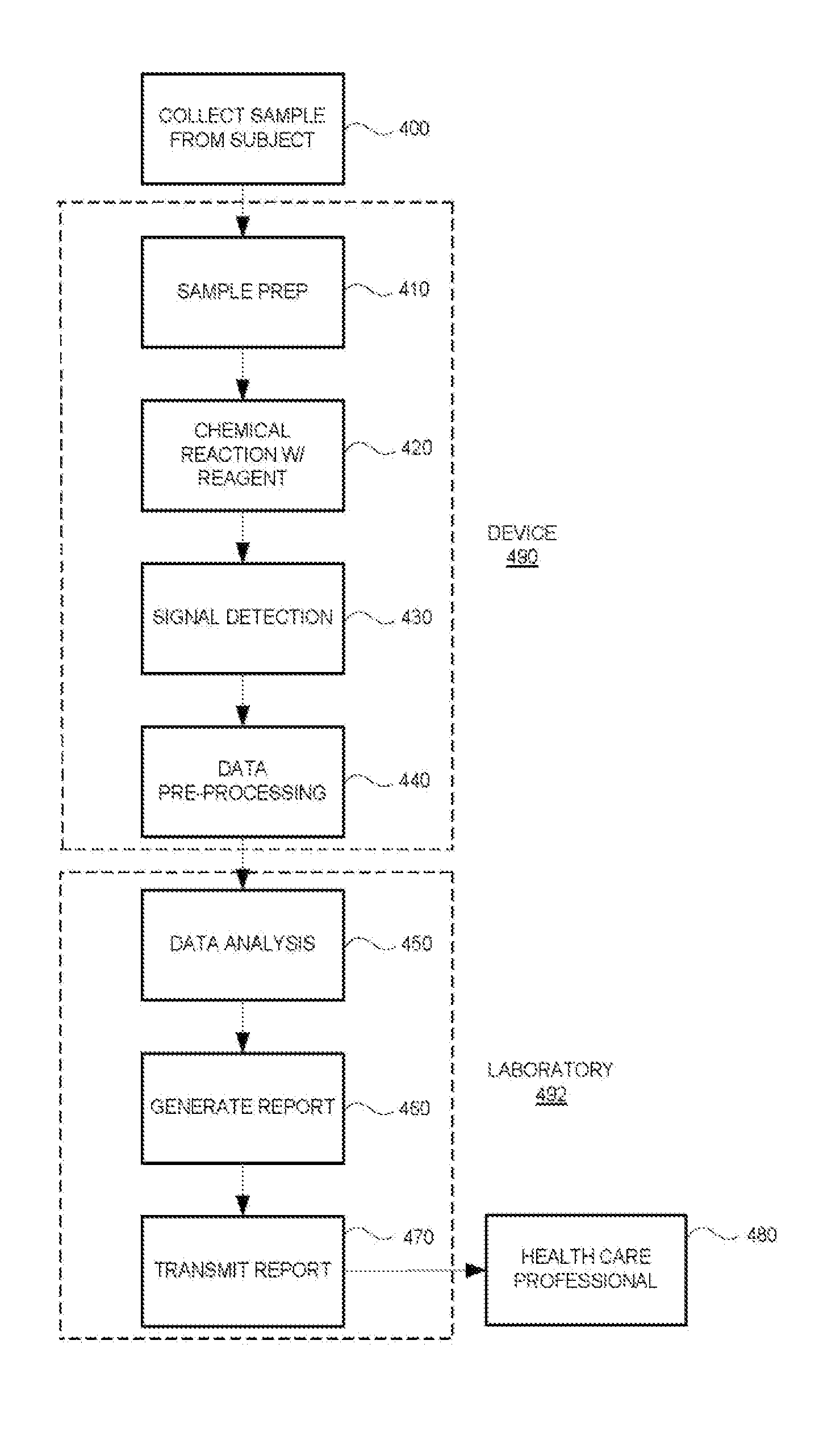

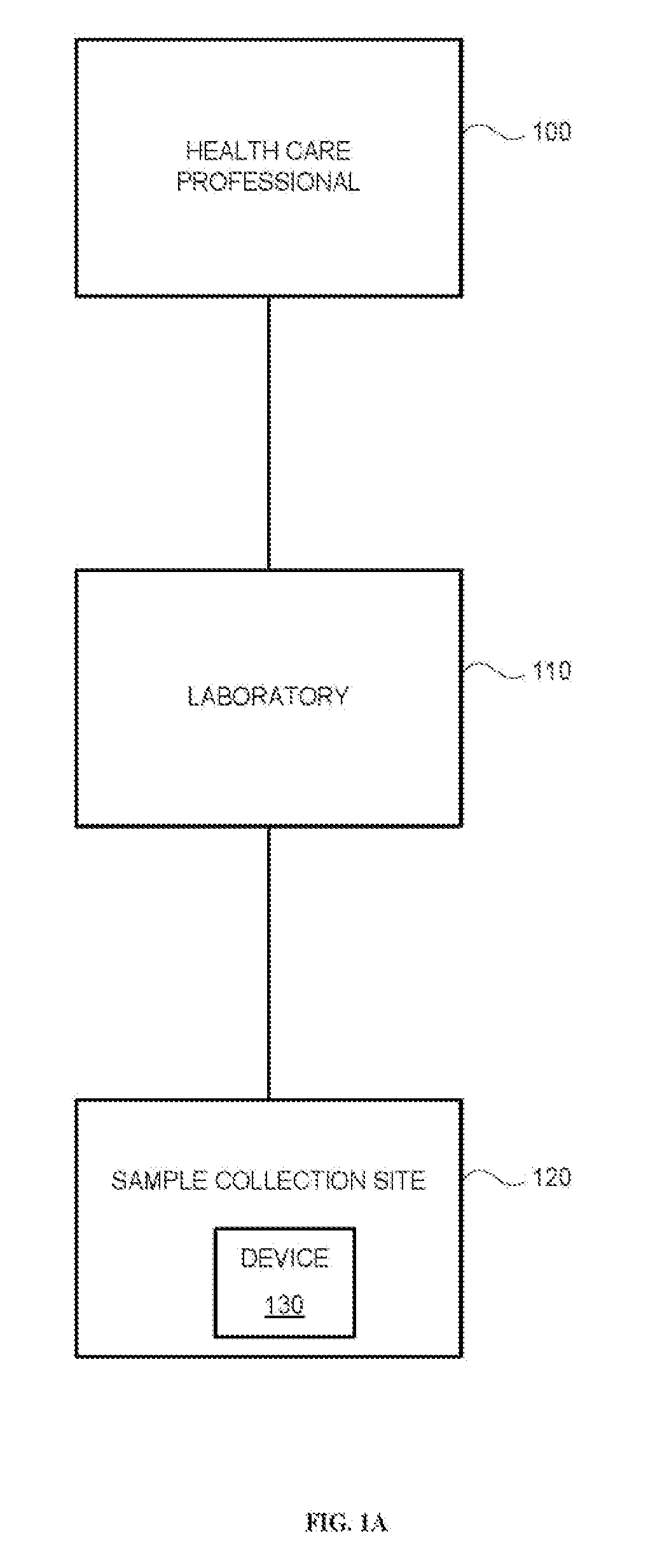

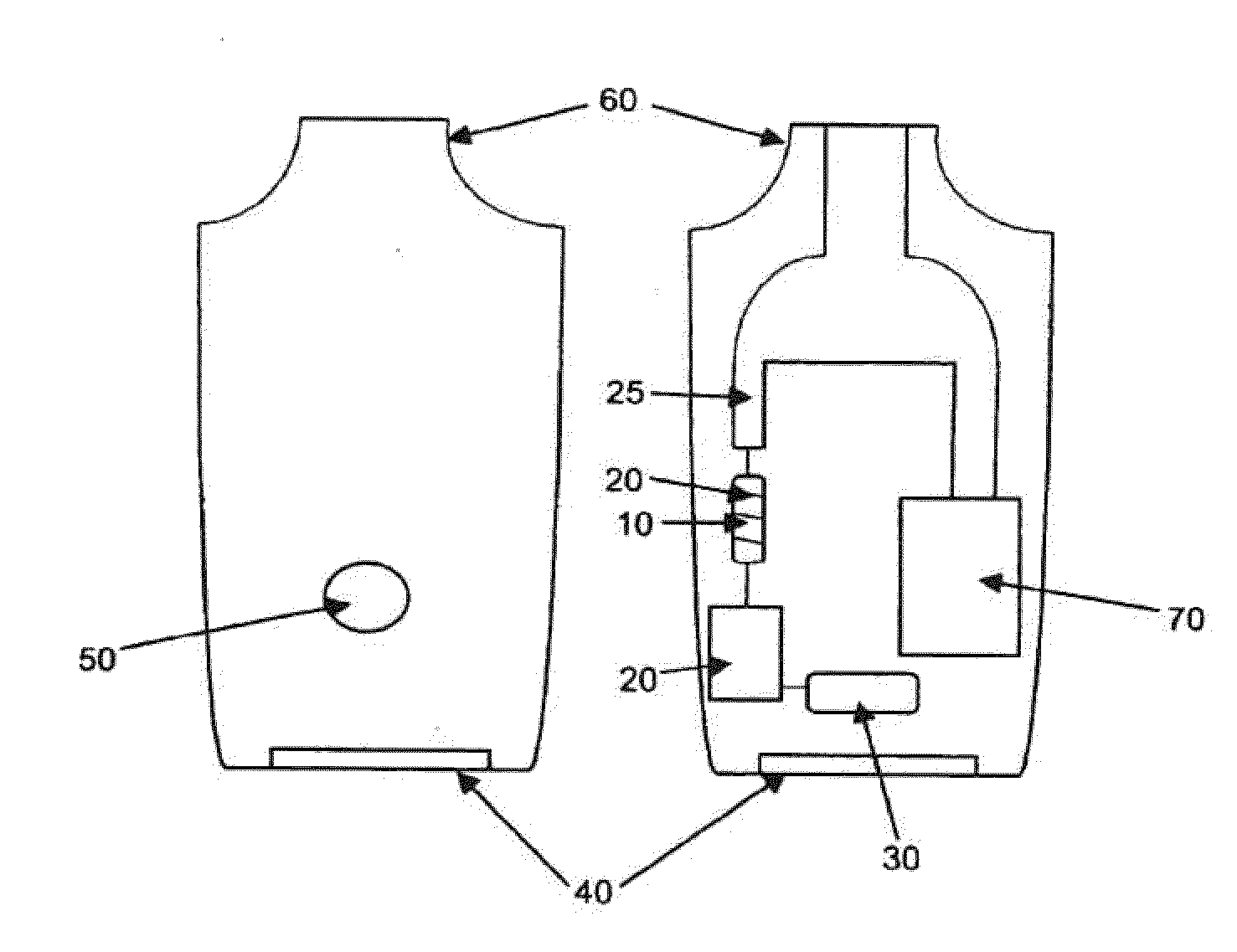

Systems and methods for collecting and transmitting assay results

ActiveUS8380541B1Quality improvementLittle variabilityImage analysisData processing applicationsSample collectionDisease

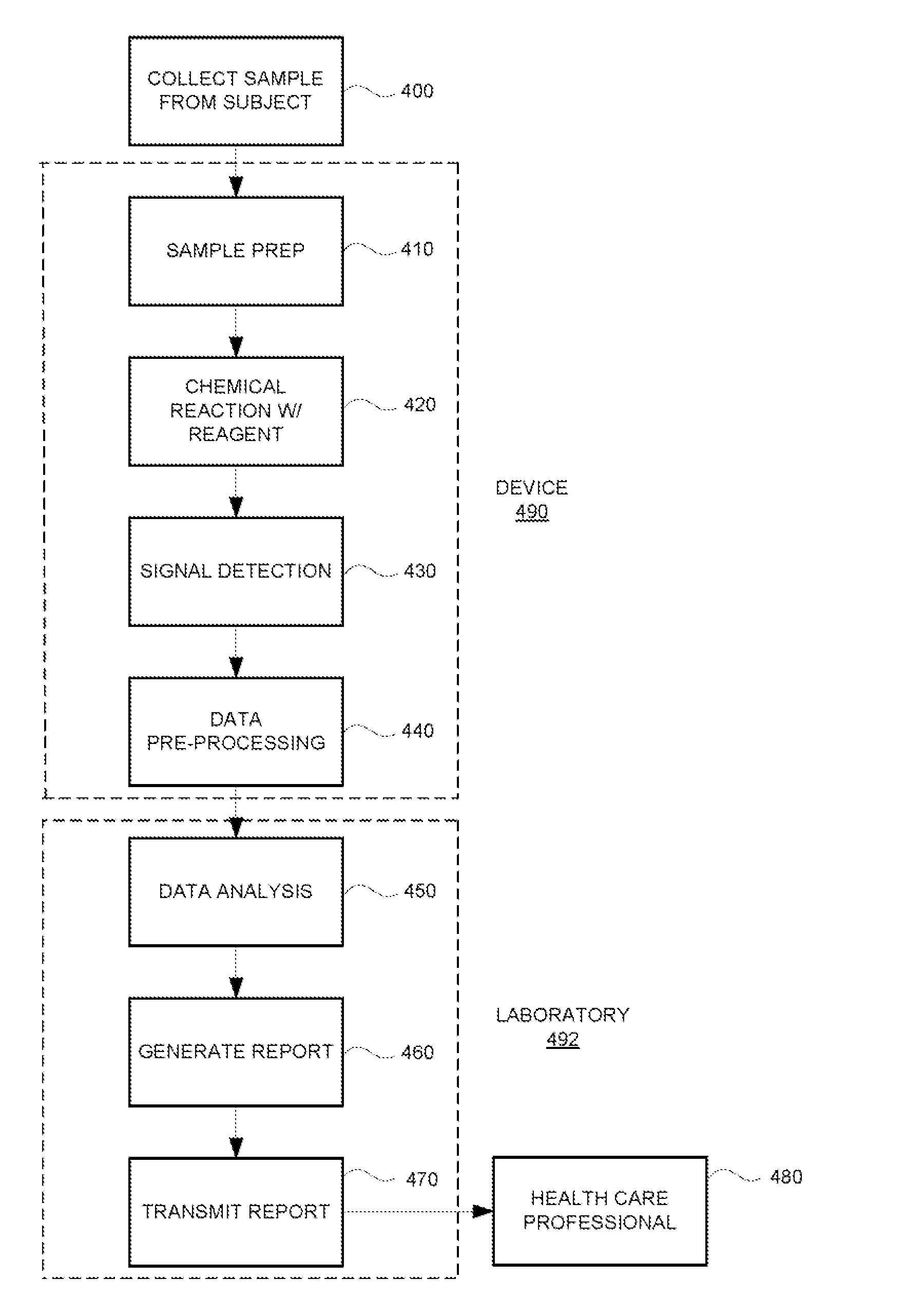

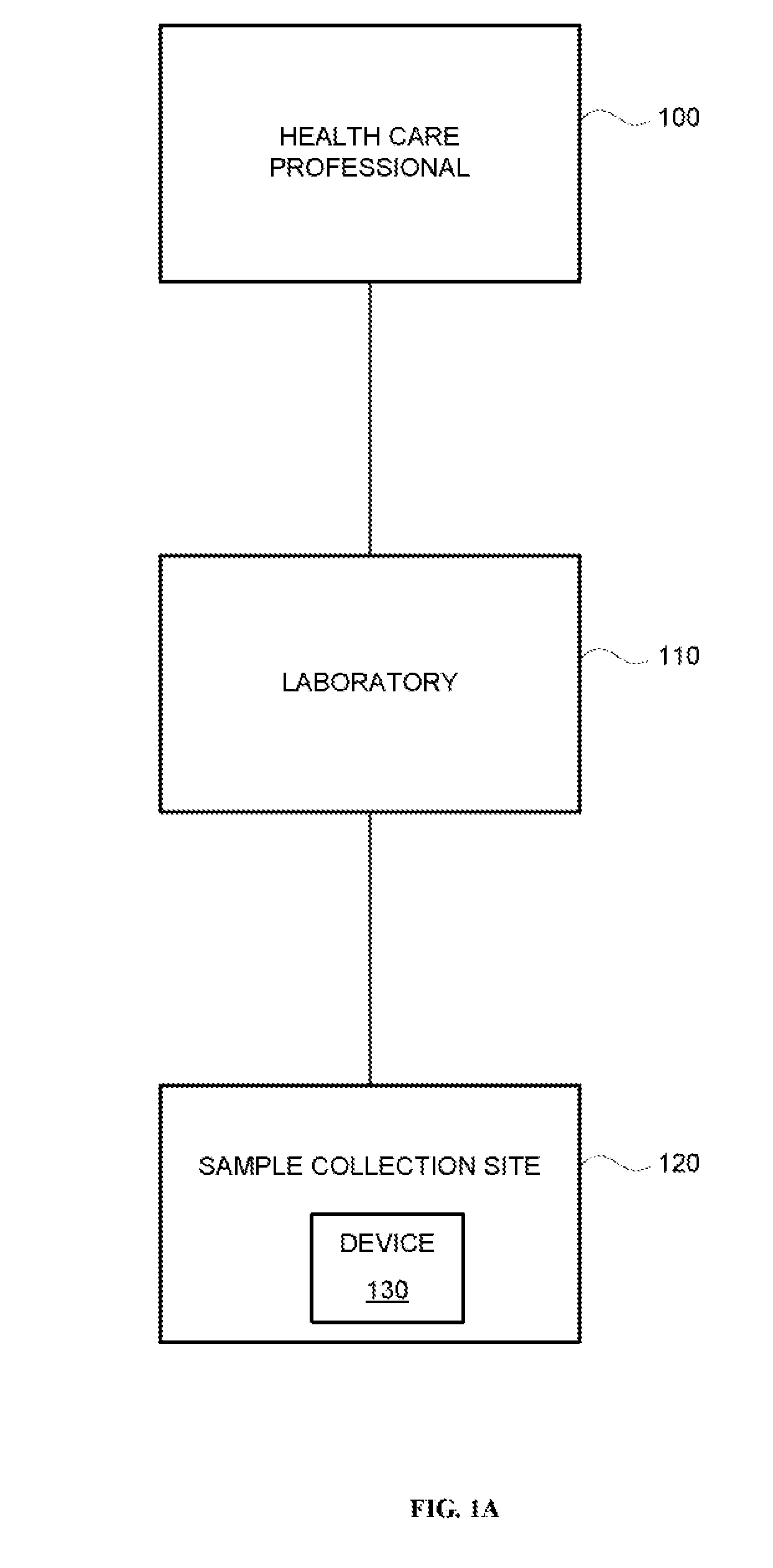

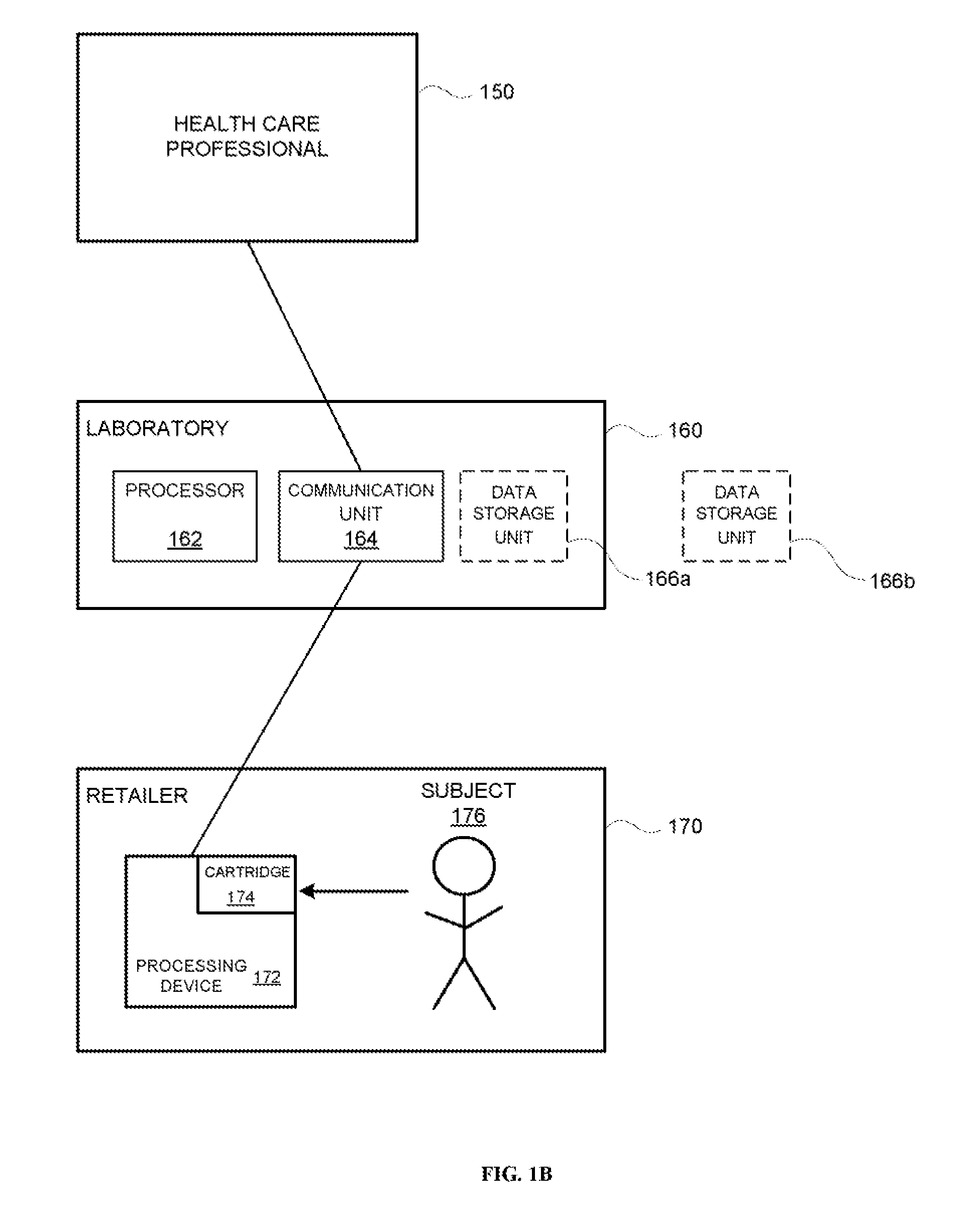

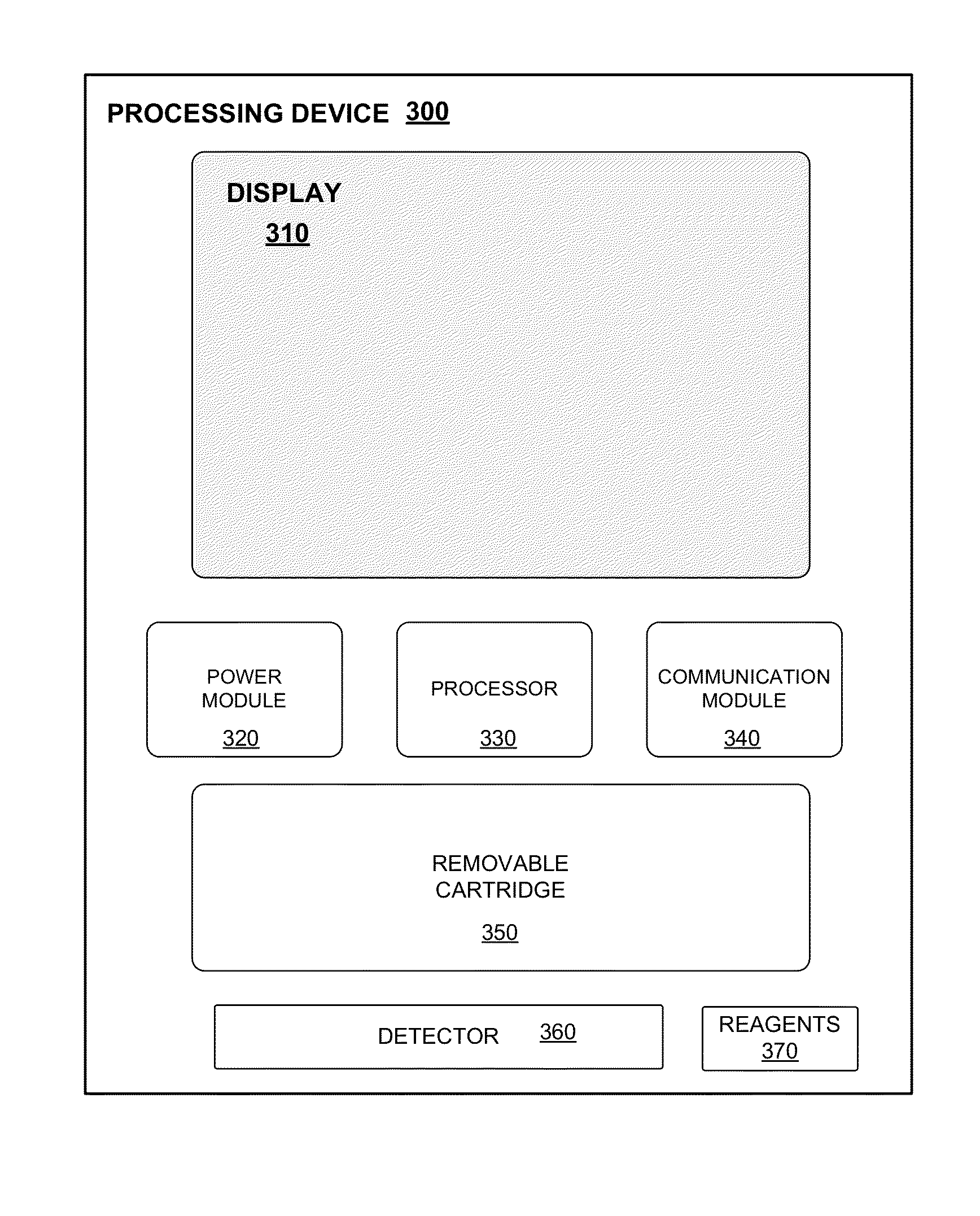

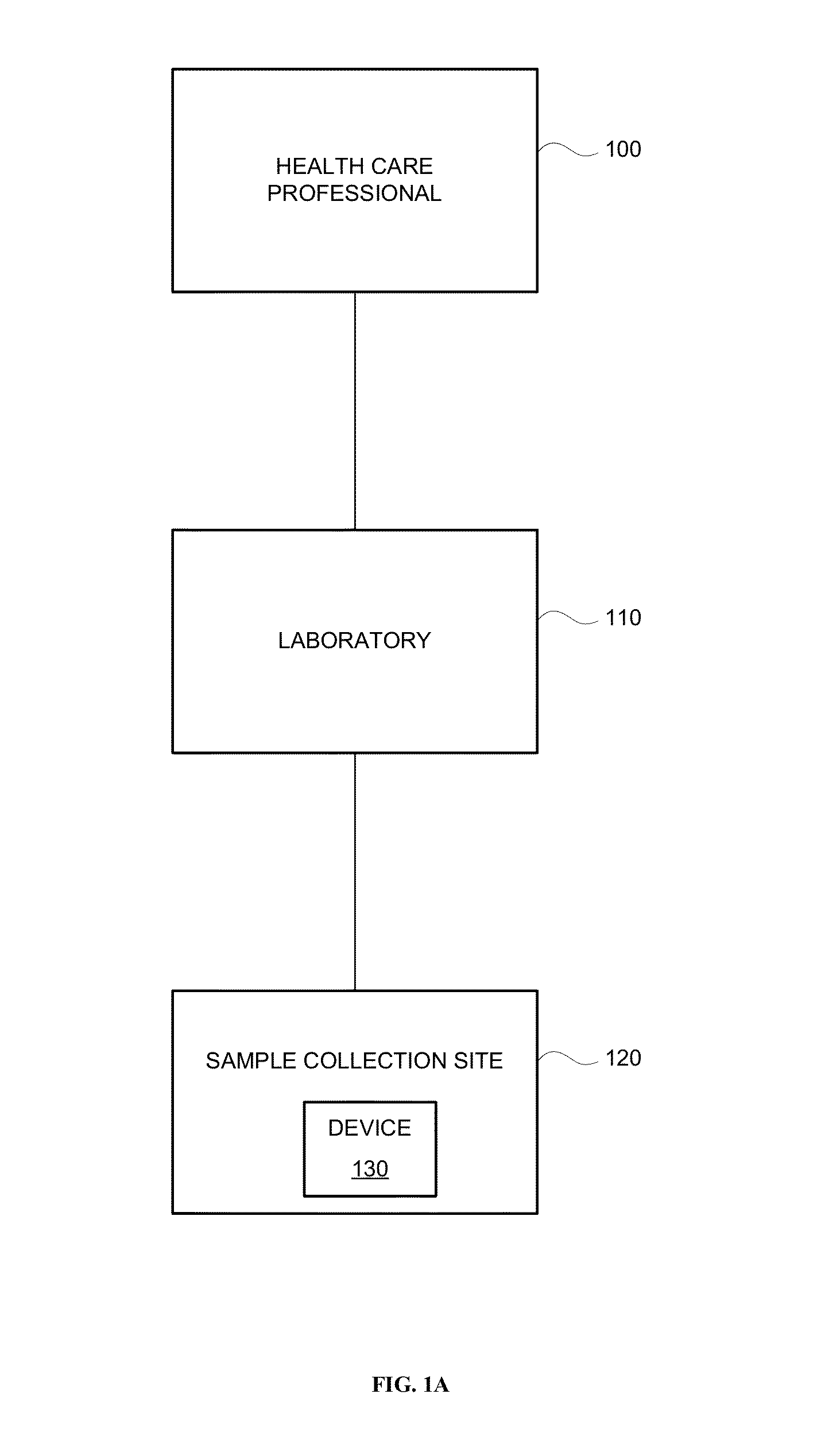

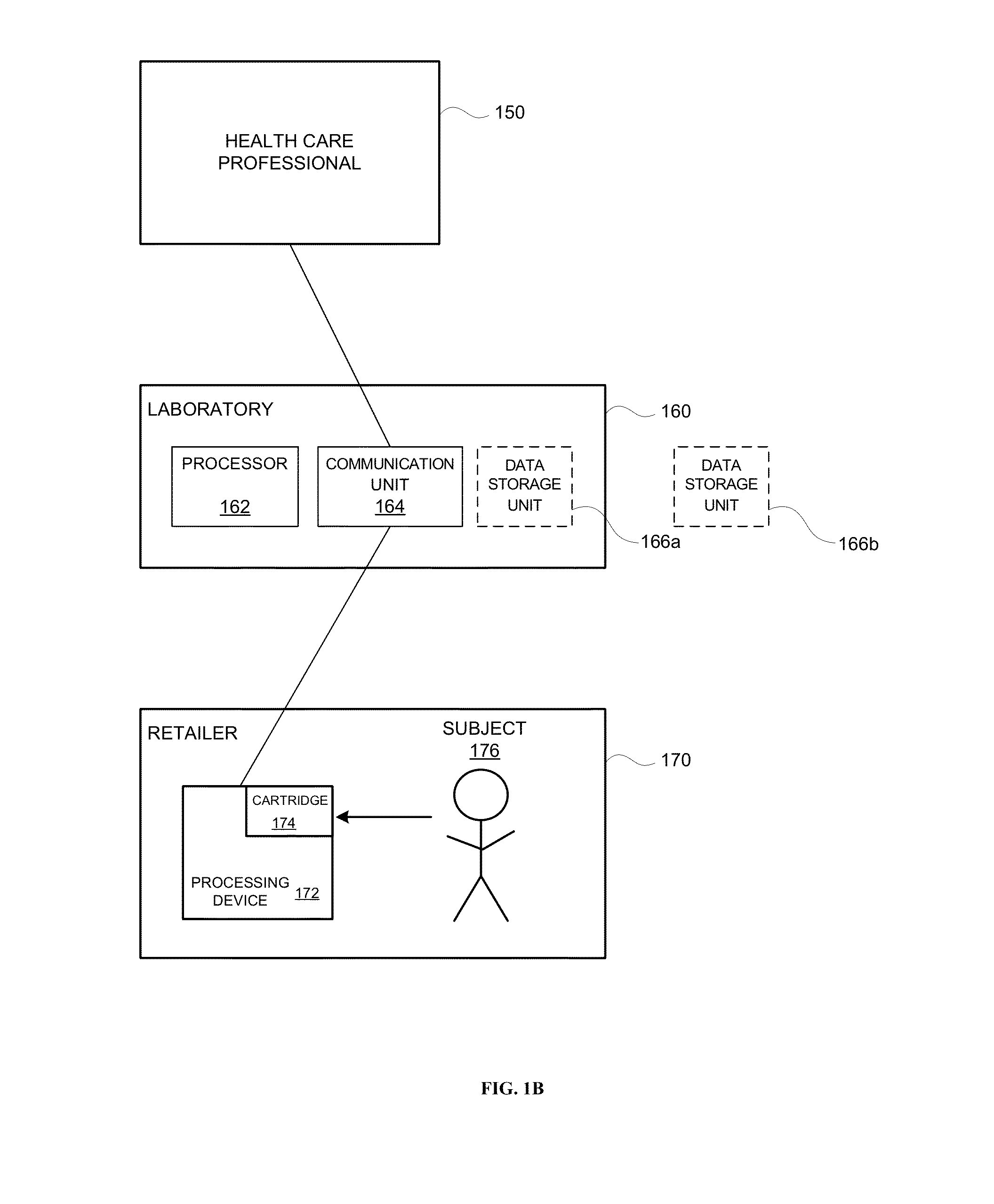

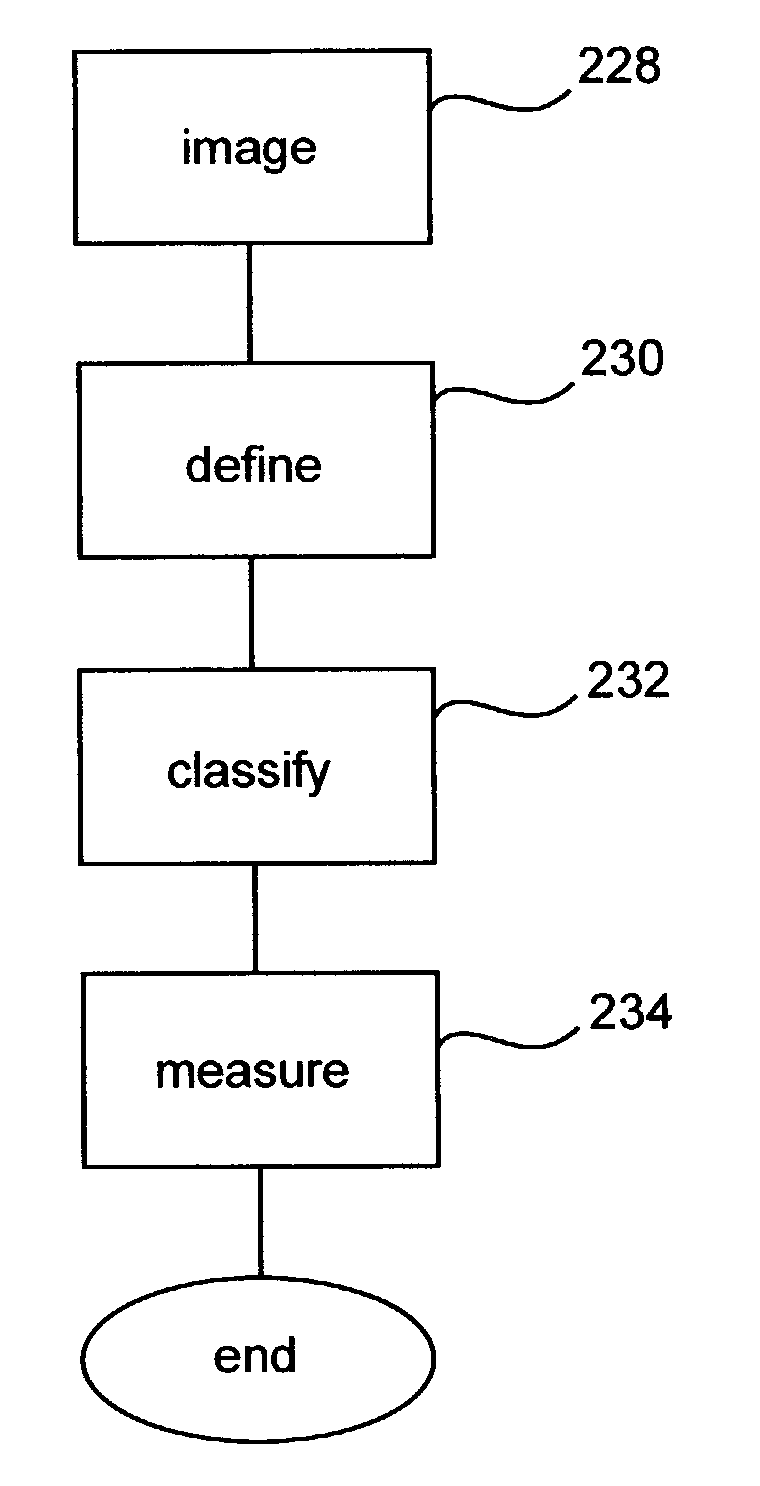

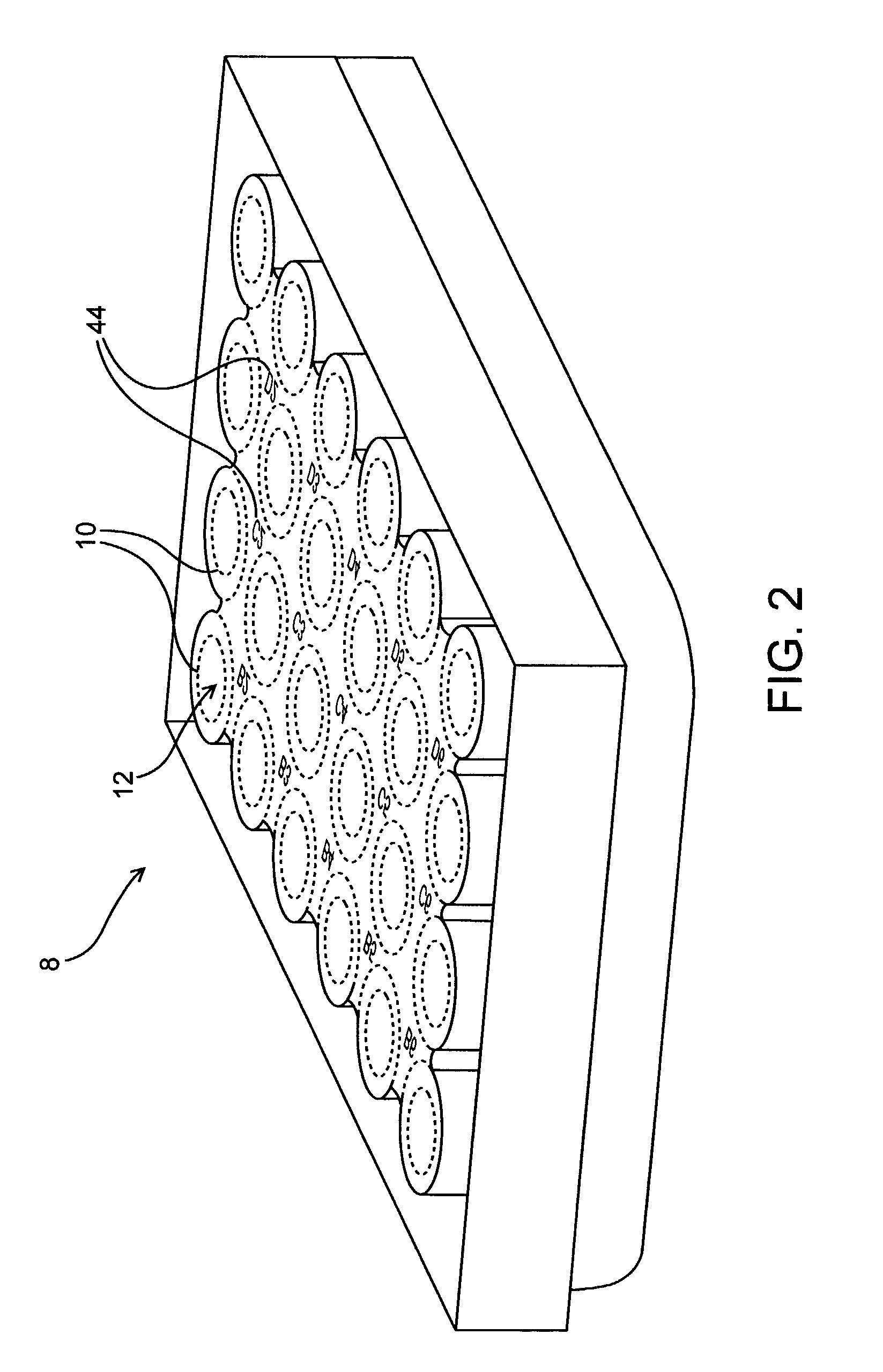

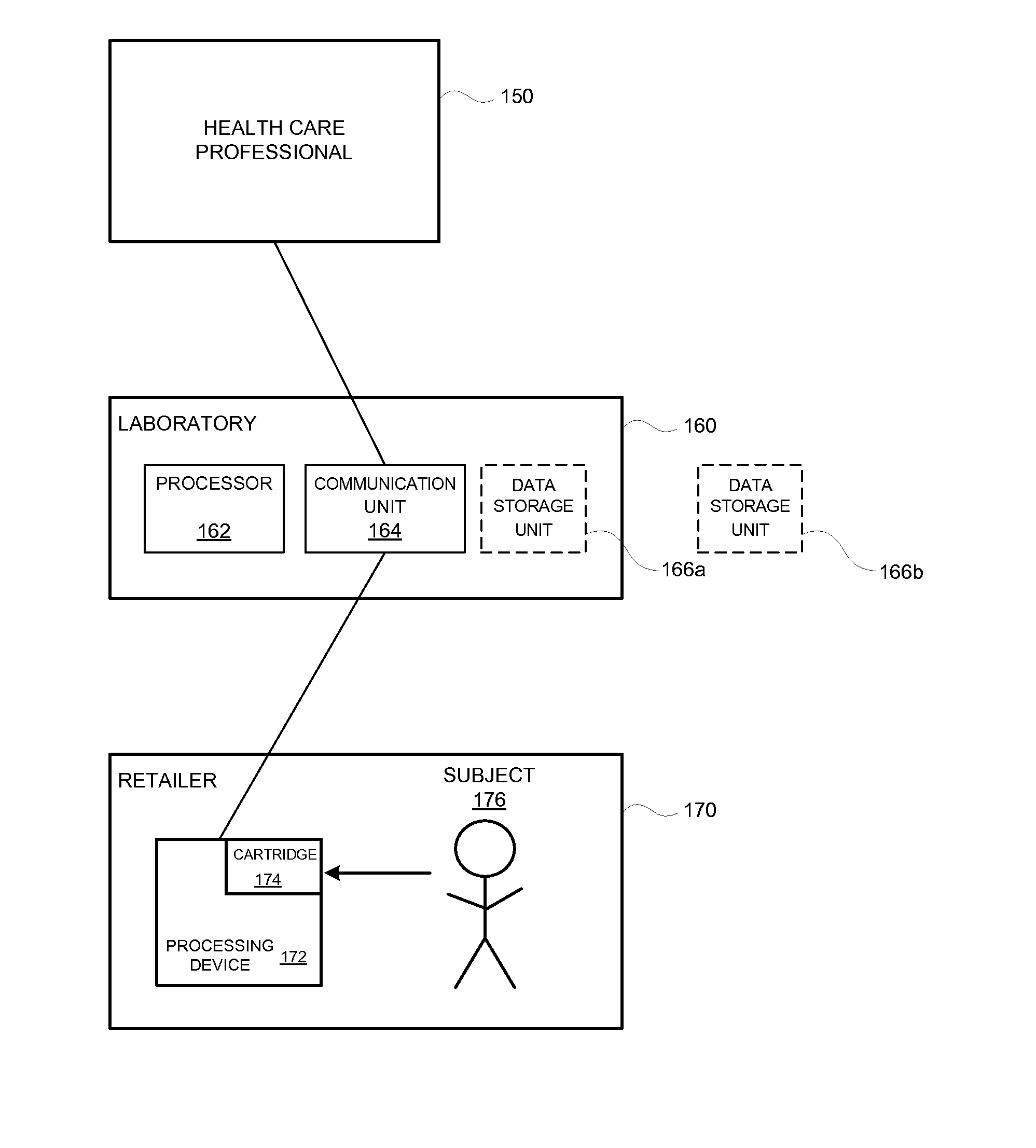

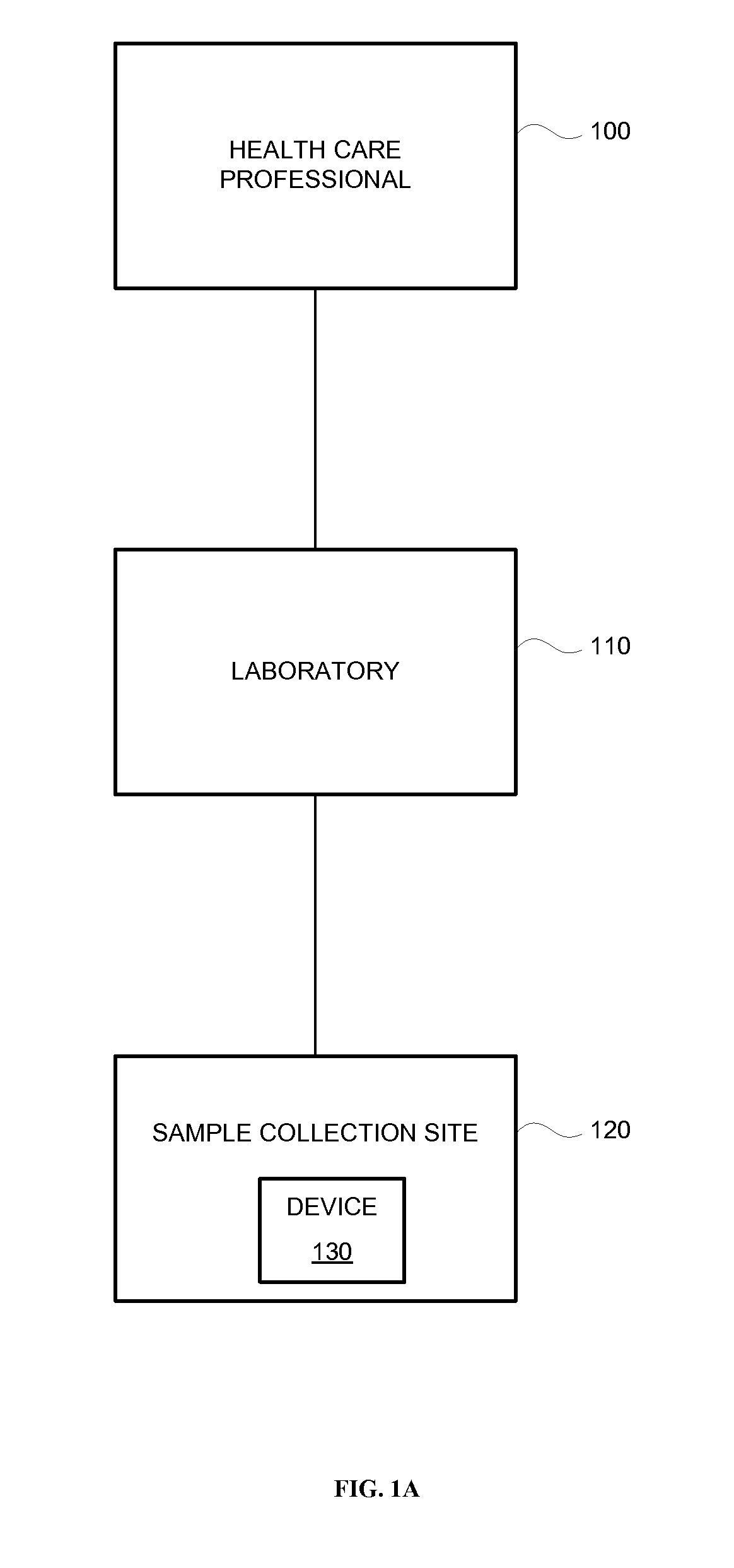

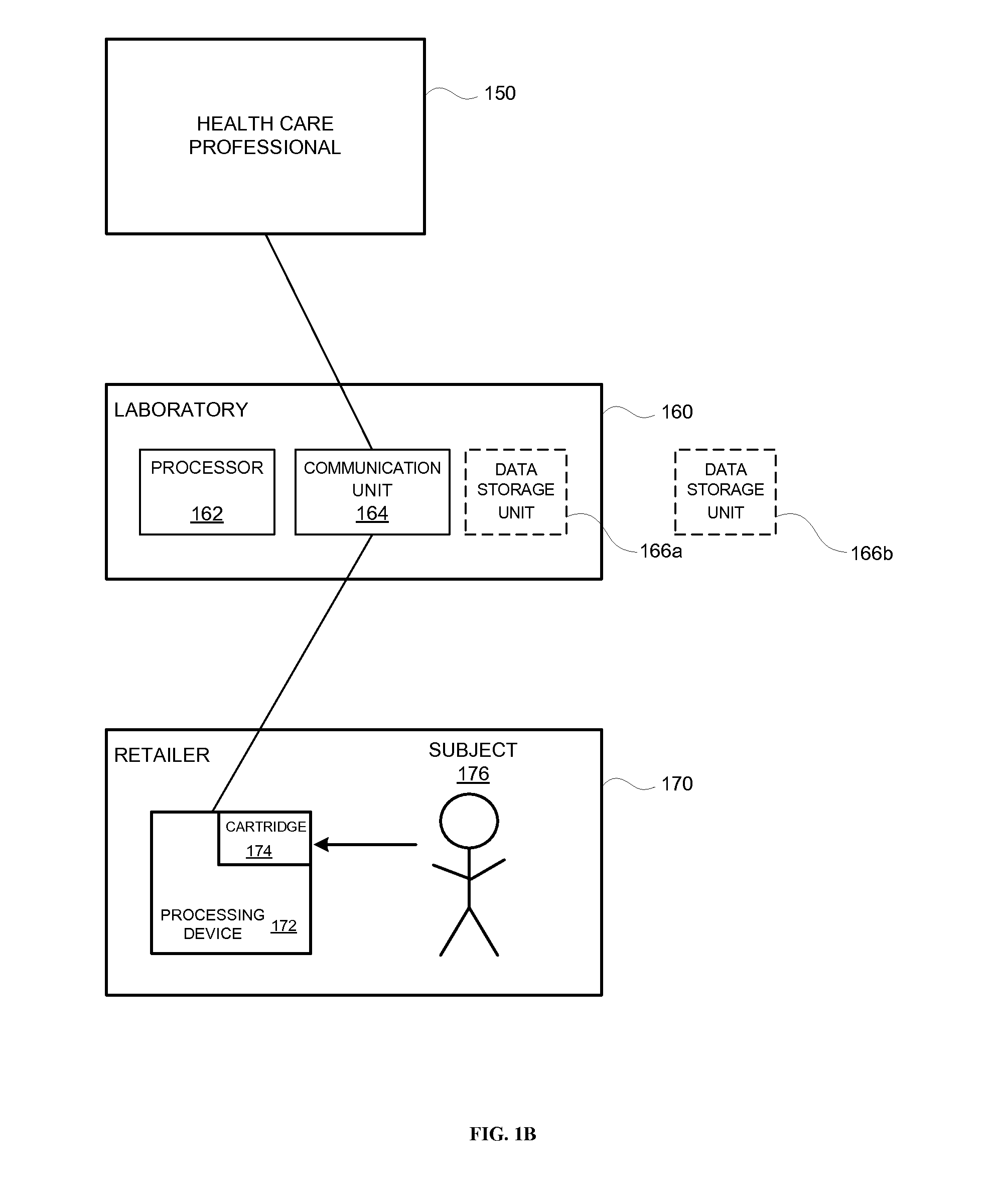

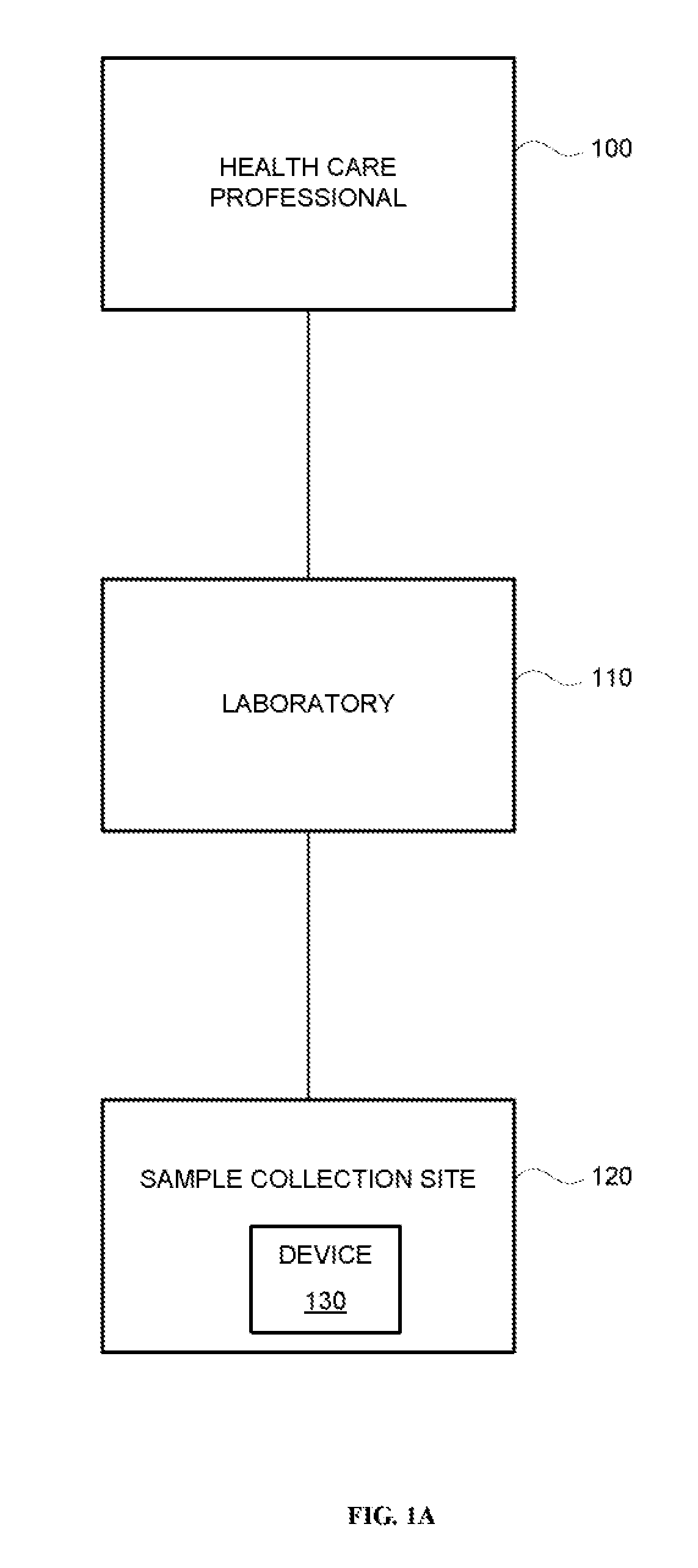

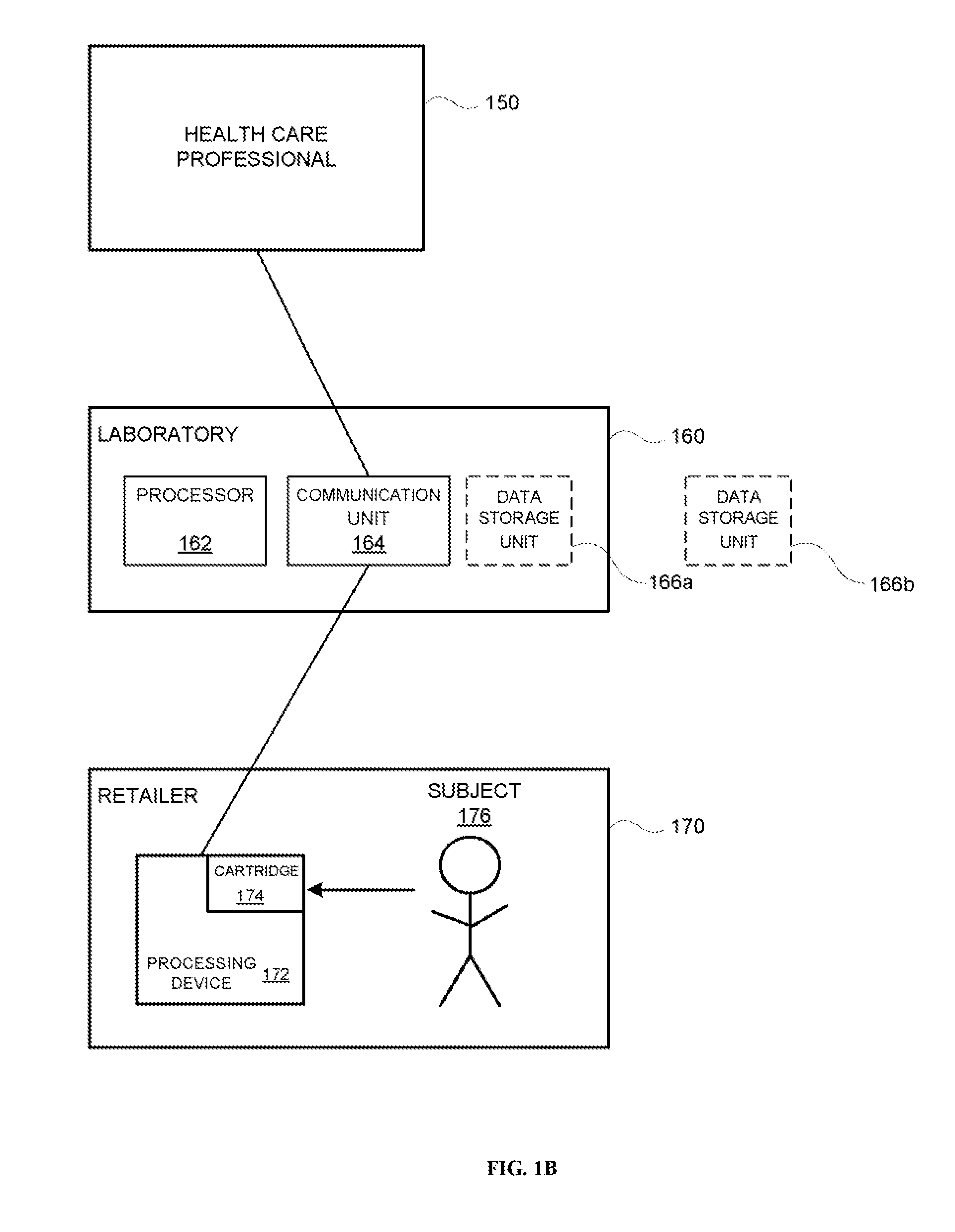

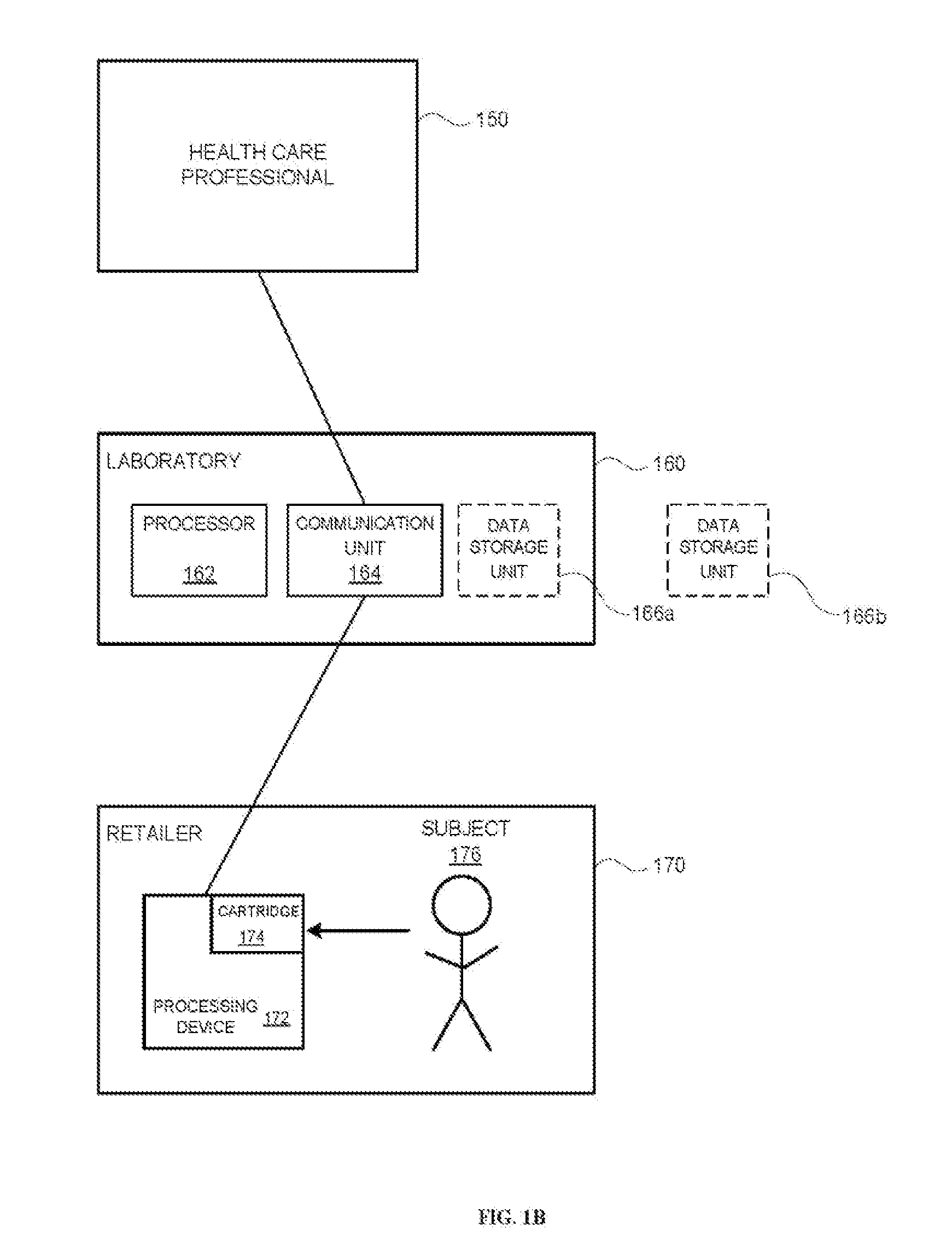

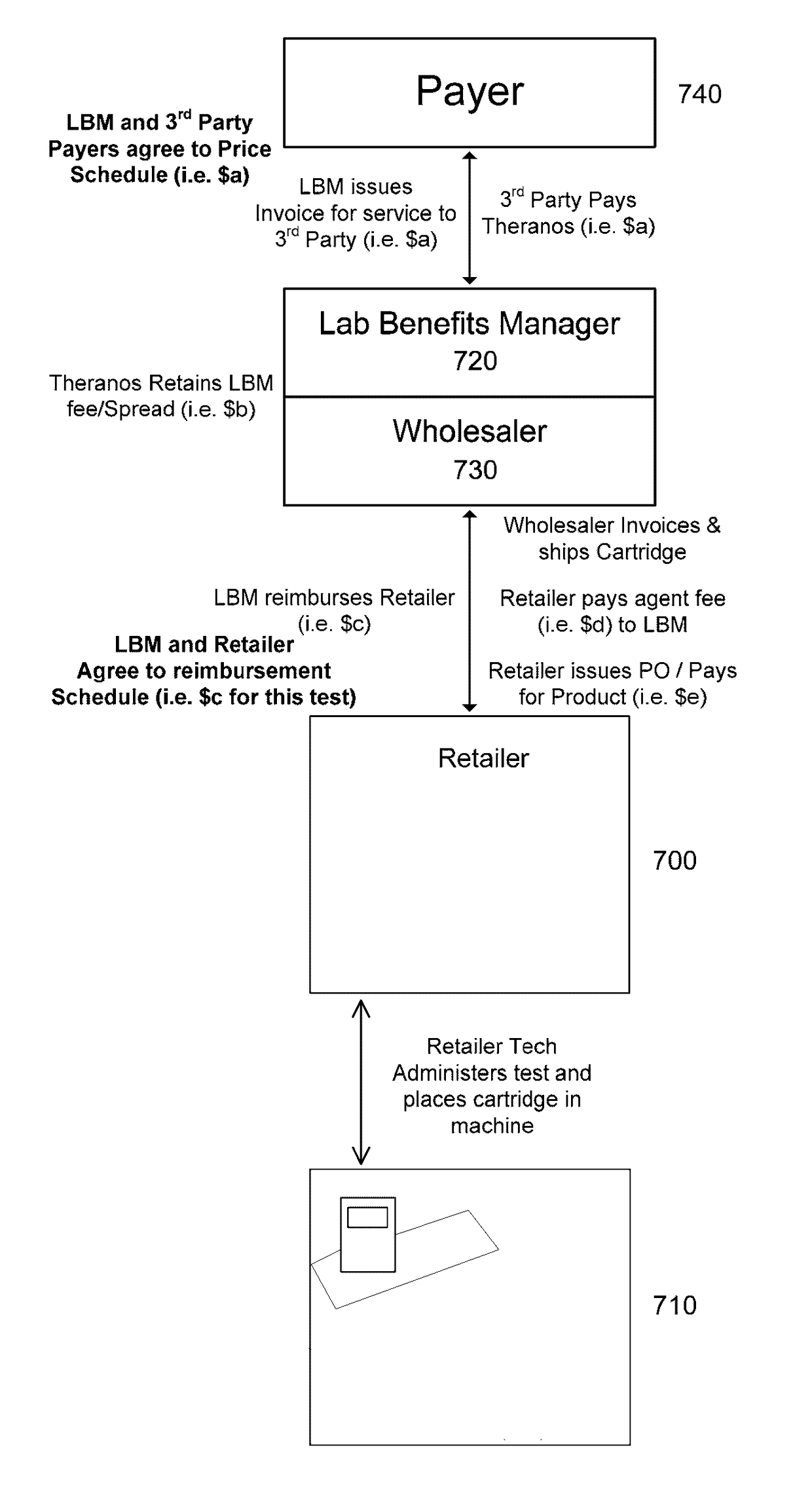

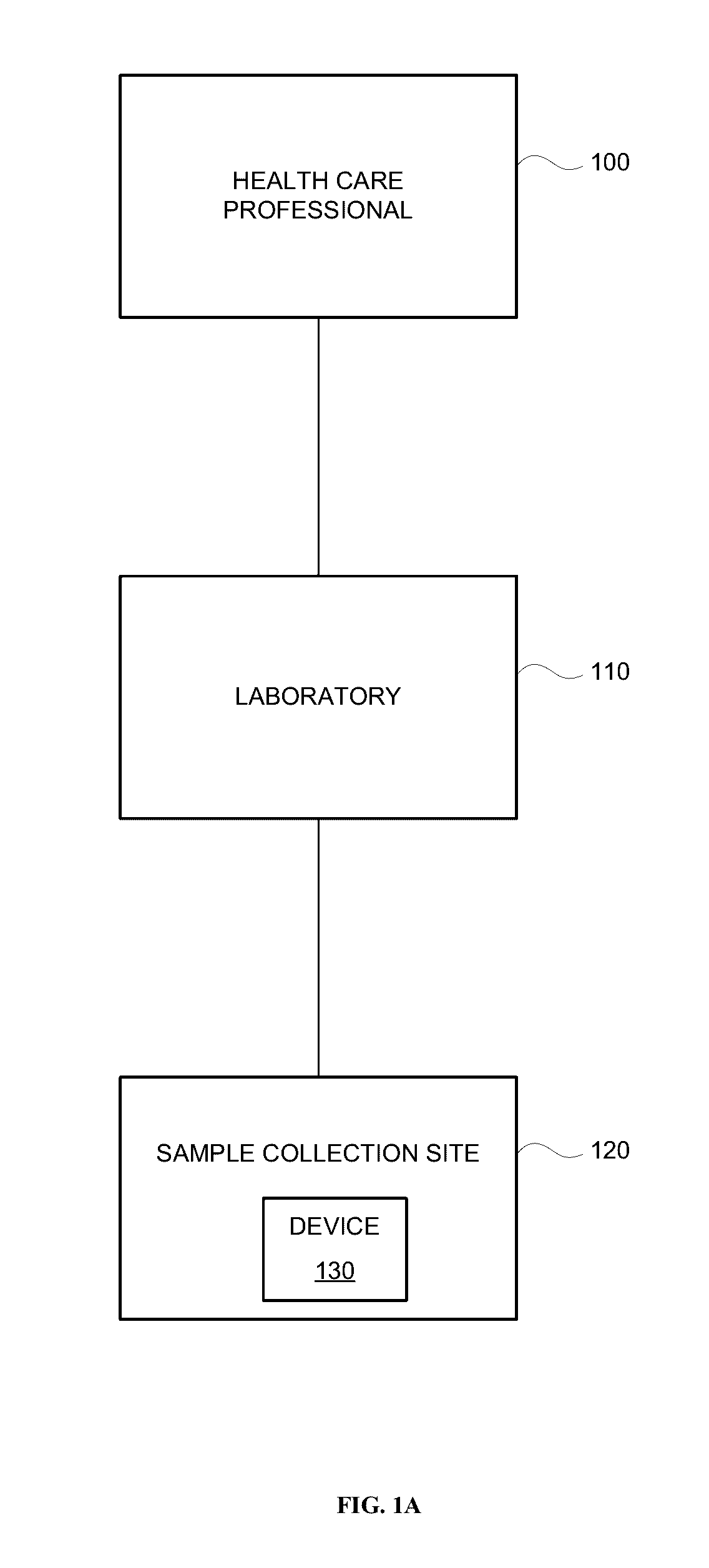

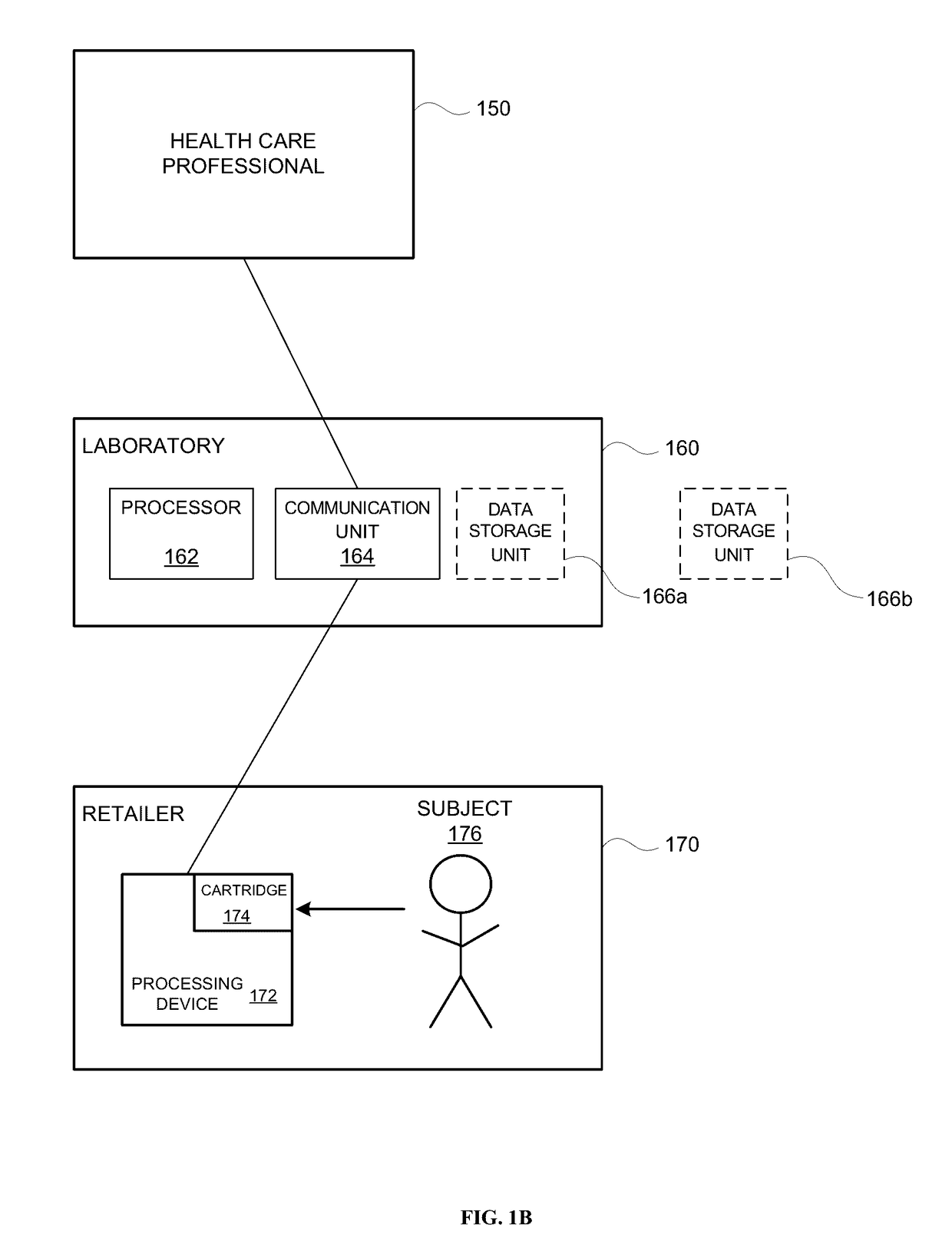

Systems and methods are provided for collecting, preparing, and / or analyzing a biological sample. A sample collection site may be utilized with one or more sample processing device. The sample processing device may be configured to accept a sample from a subject. The sample processing device may perform one or more sample preparation step and / or chemical reaction involving the sample. Data related to the sample may be sent from the device to a laboratory. The laboratory may be a certified laboratory that may generate a report that is transmitted to a health care professional. The health care professional may rely on the report for diagnosing, treating, and / or preventing a disease in the subject.

Owner:LABRADOR DIAGNOSTICS LLC

Systems and Methods for Collecting and Transmitting Assay Results

ActiveUS20140057255A1Quality improvementLittle variabilityMicrobiological testing/measurementMaterial analysis by optical meansDiseaseChemical reaction

Systems and methods are provided for collecting, preparing, and / or analyzing a biological sample. A sample collection site may be utilized with one or more sample processing device. The sample processing device may be configured to accept a sample from a subject. The sample processing device may perform one or more sample preparation step and / or chemical reaction involving the sample. Data related to the sample may be sent from the device to a laboratory. The laboratory may be a certified laboratory that may generate a report that is transmitted to a health care professional. The health care professional may rely on the report for diagnosing, treating, and / or preventing a disease in the subject.

Owner:LABRADOR DIAGNOSTICS LLC

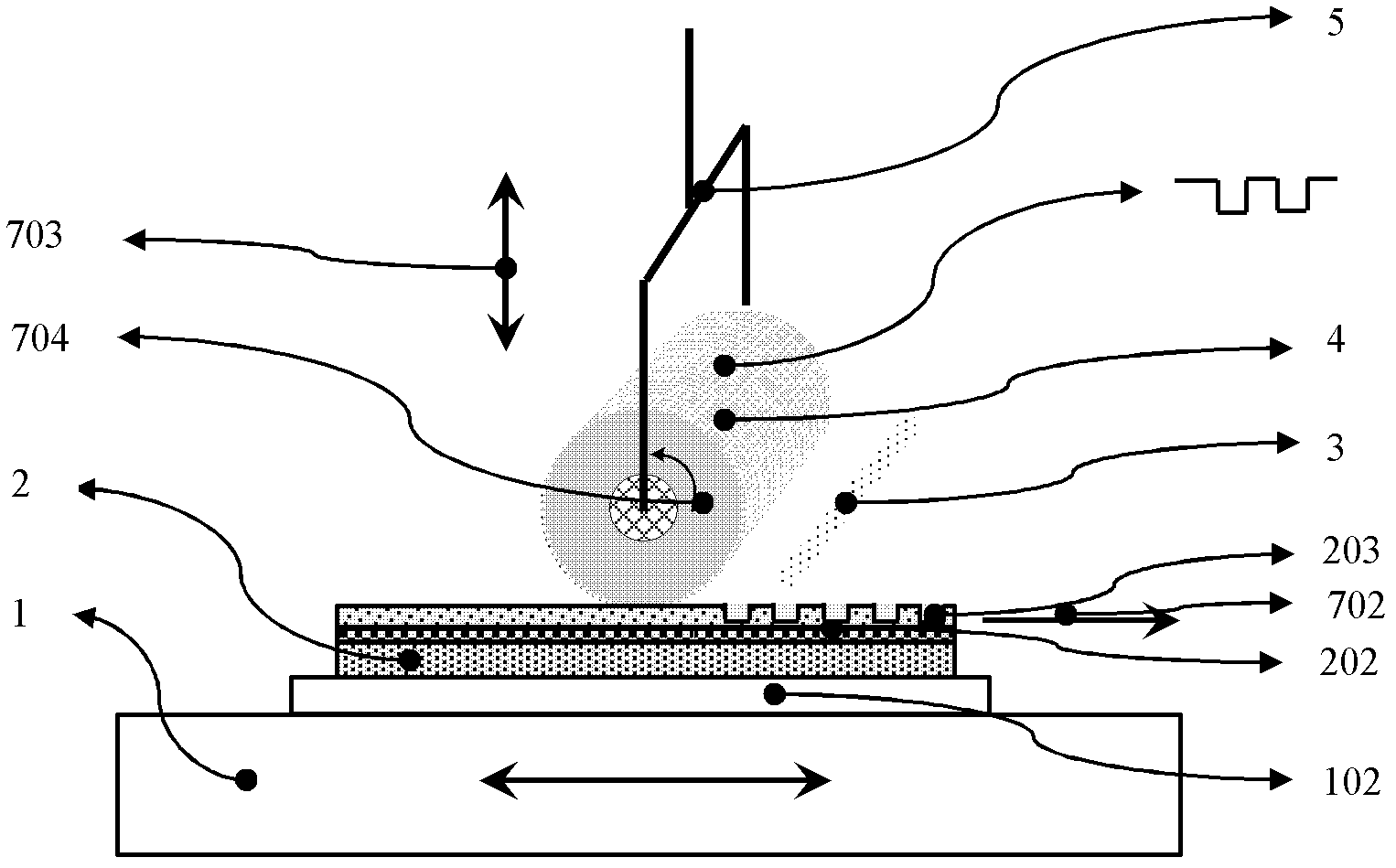

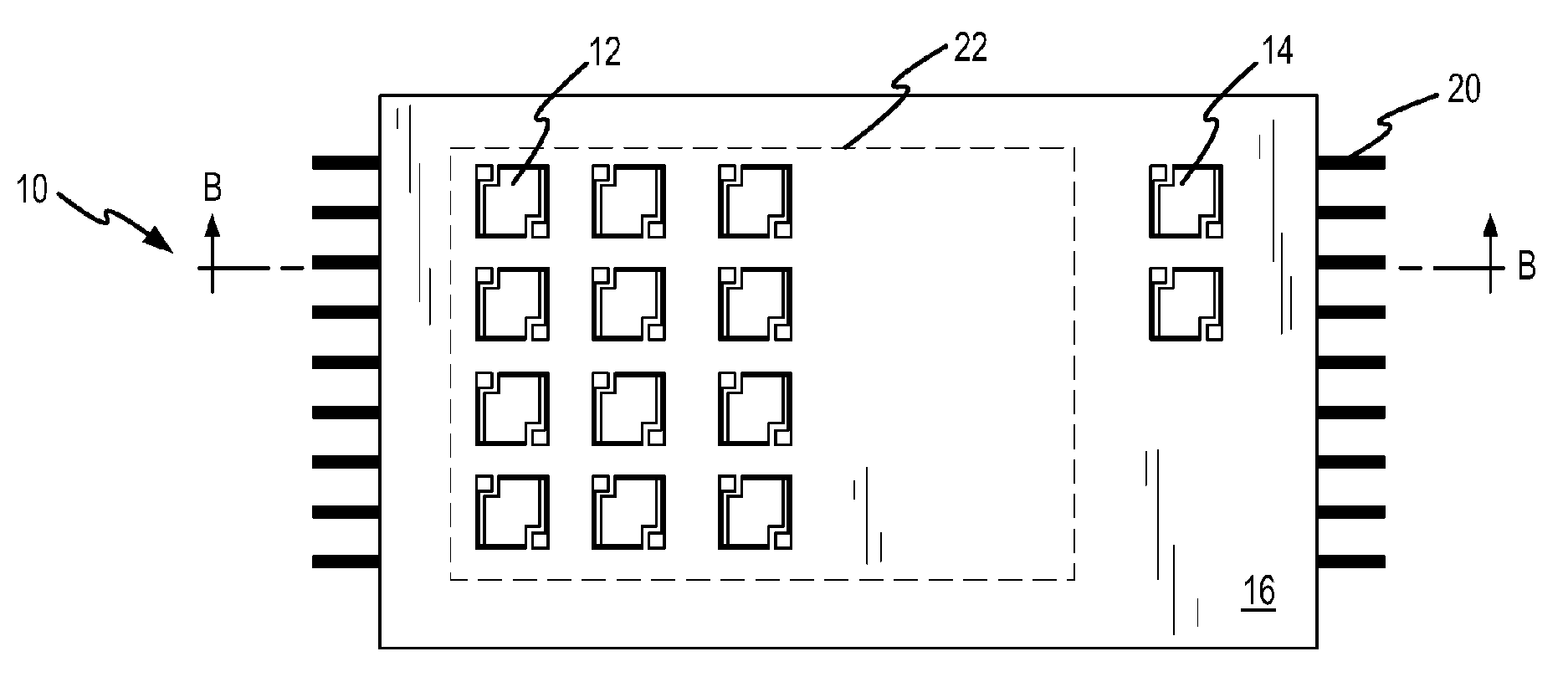

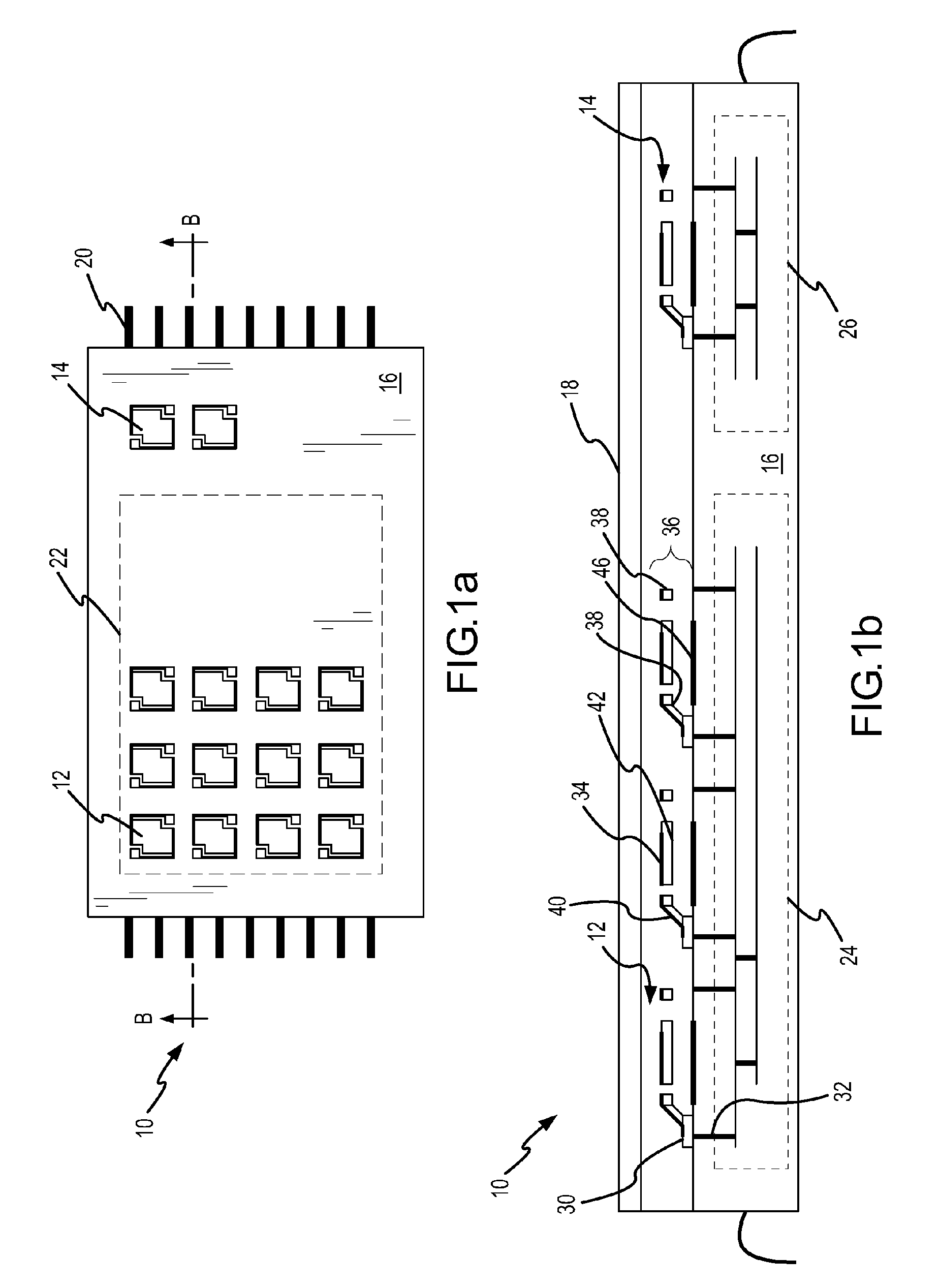

Robotic microscopy systems

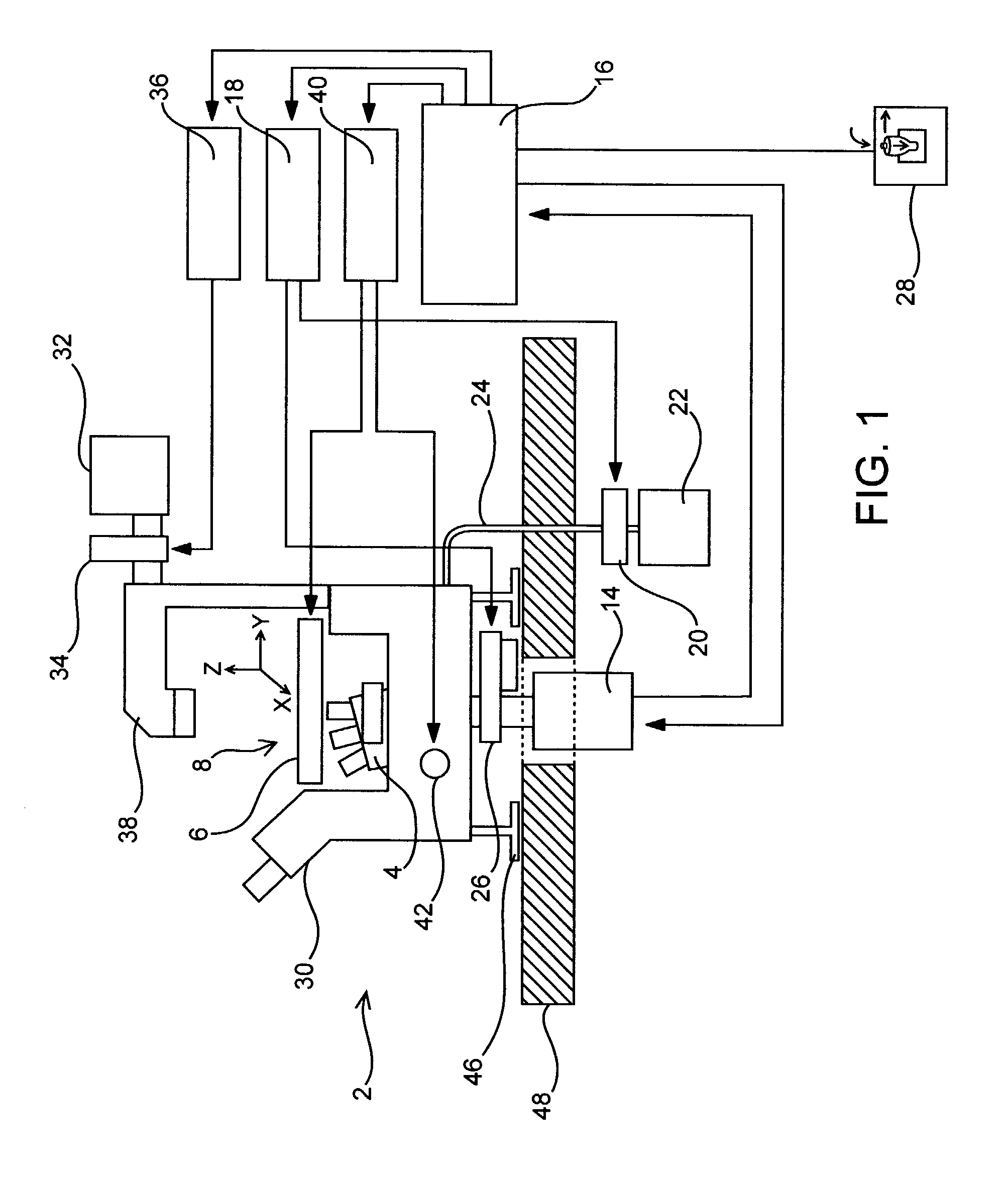

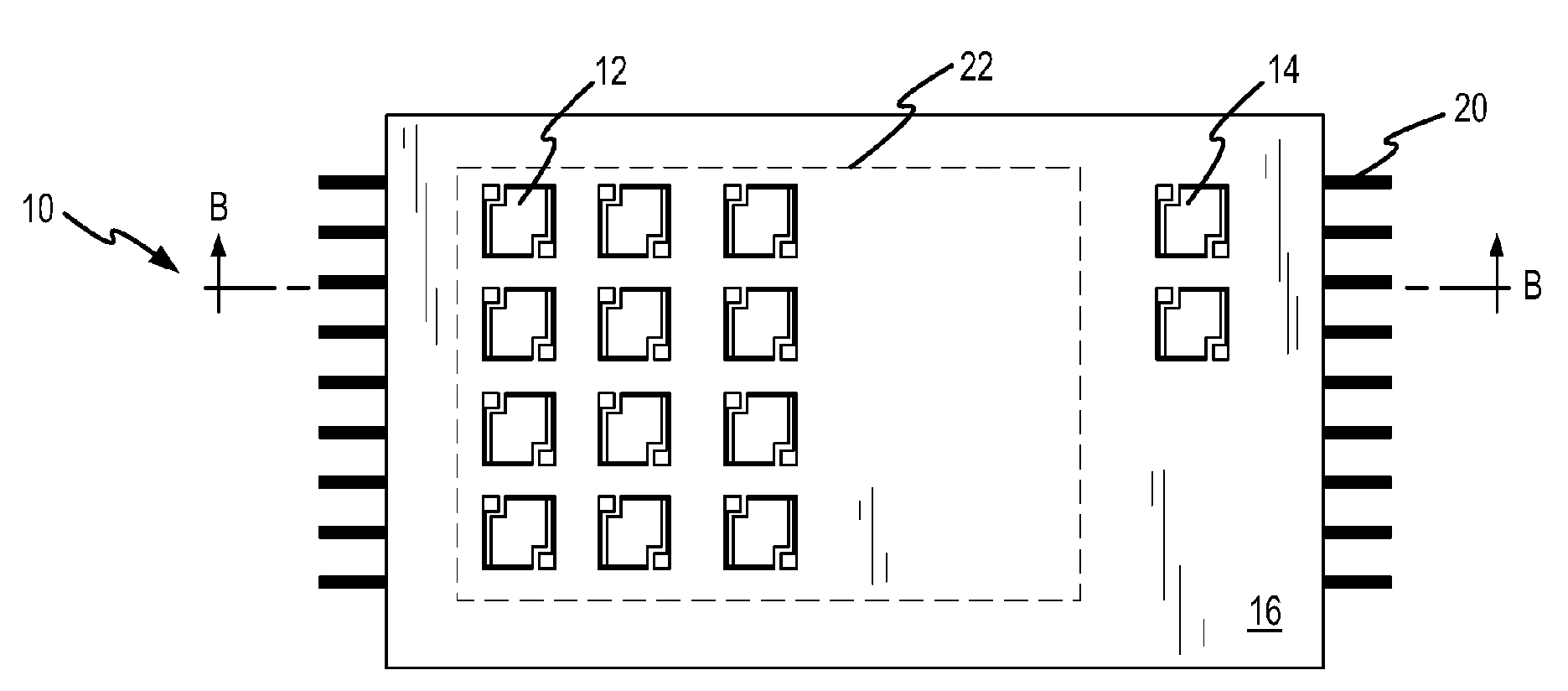

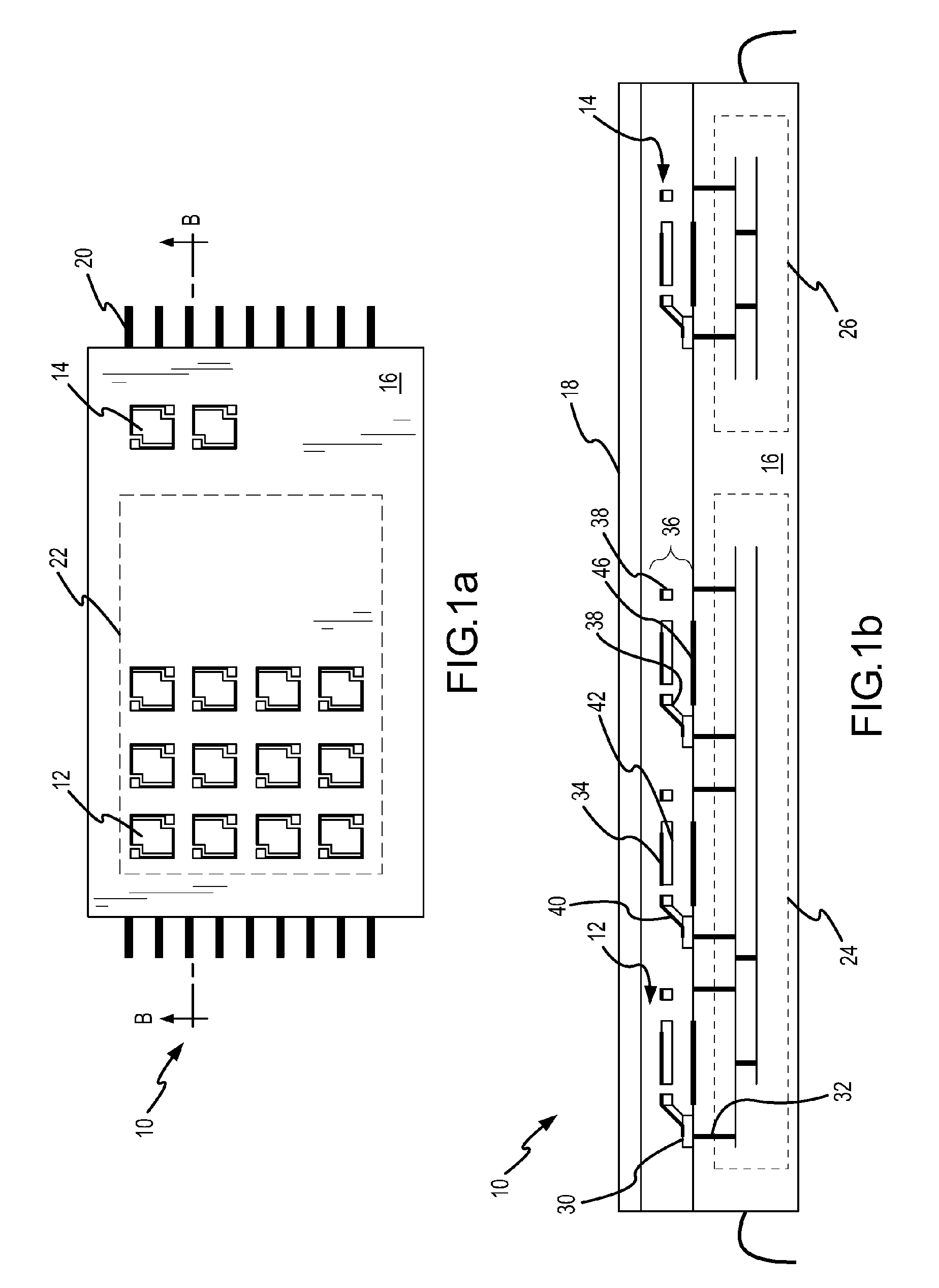

ActiveUS7139415B2High through-put analysisHigh analysisMaterial analysis by observing effect on chemical indicatorCharacter and pattern recognitionCausalityLiving cell

The invention comprises a robotic microscope system and methods that allow high through-put analysis biological materials, particularly living cells, and allows precise return to and re-imaging of the same field (e.g., the same cell) that has been imaged earlier. This capability enables experiments and testing hypotheses that deal with causality over time intervals which are not possible with conventional microscopy methods.

Owner:THE J DAVID GLADSTONE INST A TESTAMENTARY TRUST ESTABLISHED UNDER THE WILL OF J DAVID GLADS

Systems and methods for collecting and transmitting assay results

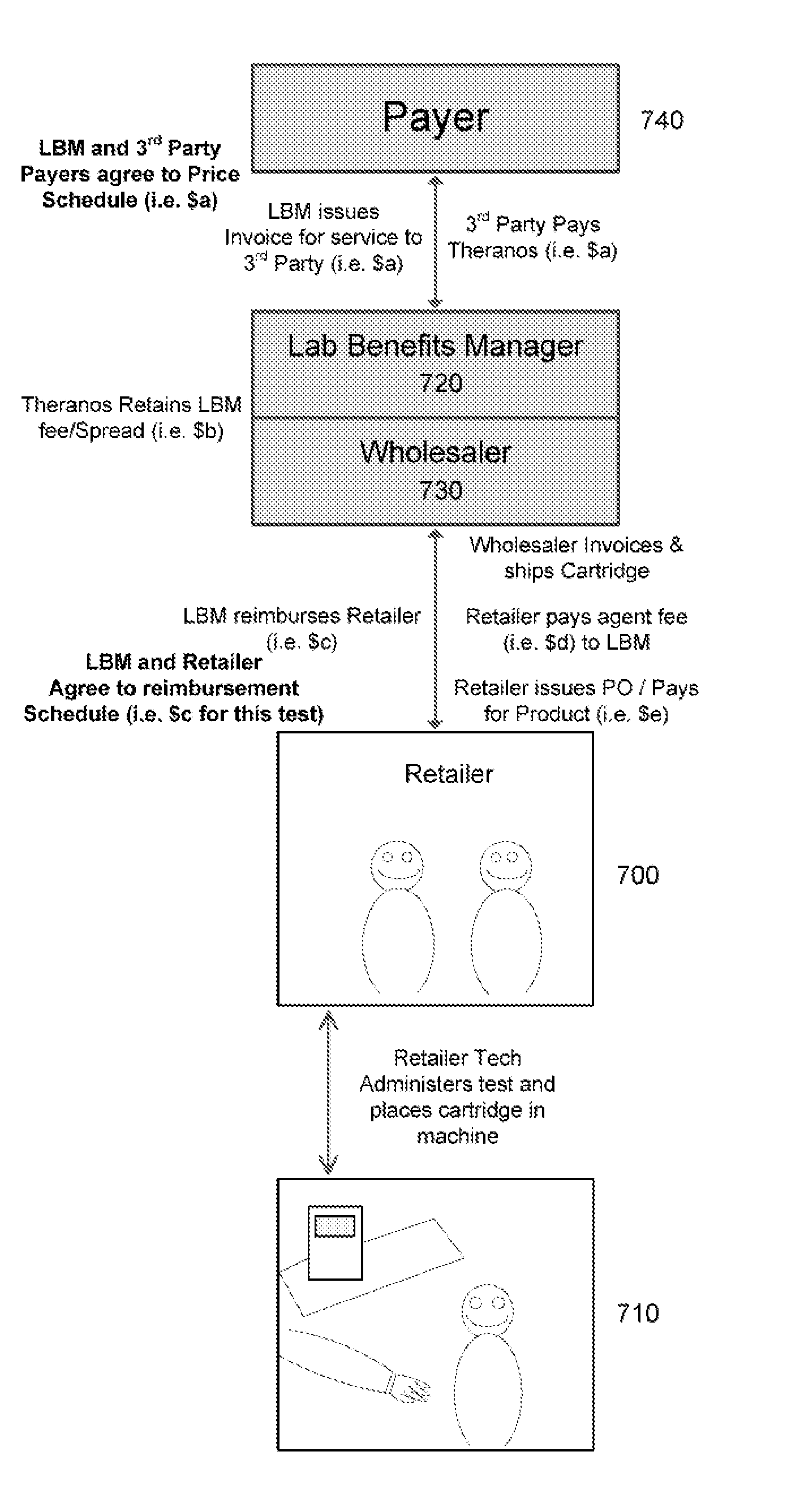

InactiveUS20140335505A1Accessible and faster test resultQuality improvementBioreactor/fermenter combinationsBiological substance pretreatmentsDiseaseChemical reaction

Systems and methods are provided for collecting, preparing, and / or analyzing a biological sample. A sample collection site may be utilized with one or more sample processing device. The sample processing device may be configured to accept a sample from a subject. The sample processing device may perform one or more sample preparation step and / or chemical reaction involving the sample. Data related to the sample may be sent from the device to a laboratory. The laboratory may be a certified laboratory that may generate a report that is transmitted to a health care professional. The health care professional may rely on the report for diagnosing, treating, and / or preventing a disease in the subject.

Owner:THERANOS IP CO LLC

Systems and methods for sample processing and analysis

InactiveUS20130080071A1Quality improvementLittle variabilityComputer-assisted medical data acquisitionBiological testingDiseaseChemical reaction

Systems and methods are provided for collecting, preparing, and / or analyzing a biological sample. A sample collection site may be utilized with one or more sample processing device. The sample processing device may be configured to accept a sample from a subject. The sample processing device may perform one or more sample preparation step and / or chemical reaction involving the sample. Data related to the sample may be sent from the device to a laboratory. The laboratory may be a certified laboratory that may generate a report that is transmitted to a health care professional. The health care professional may rely on the report for diagnosing, treating, and / or preventing a disease in the subject.

Owner:THERANOS

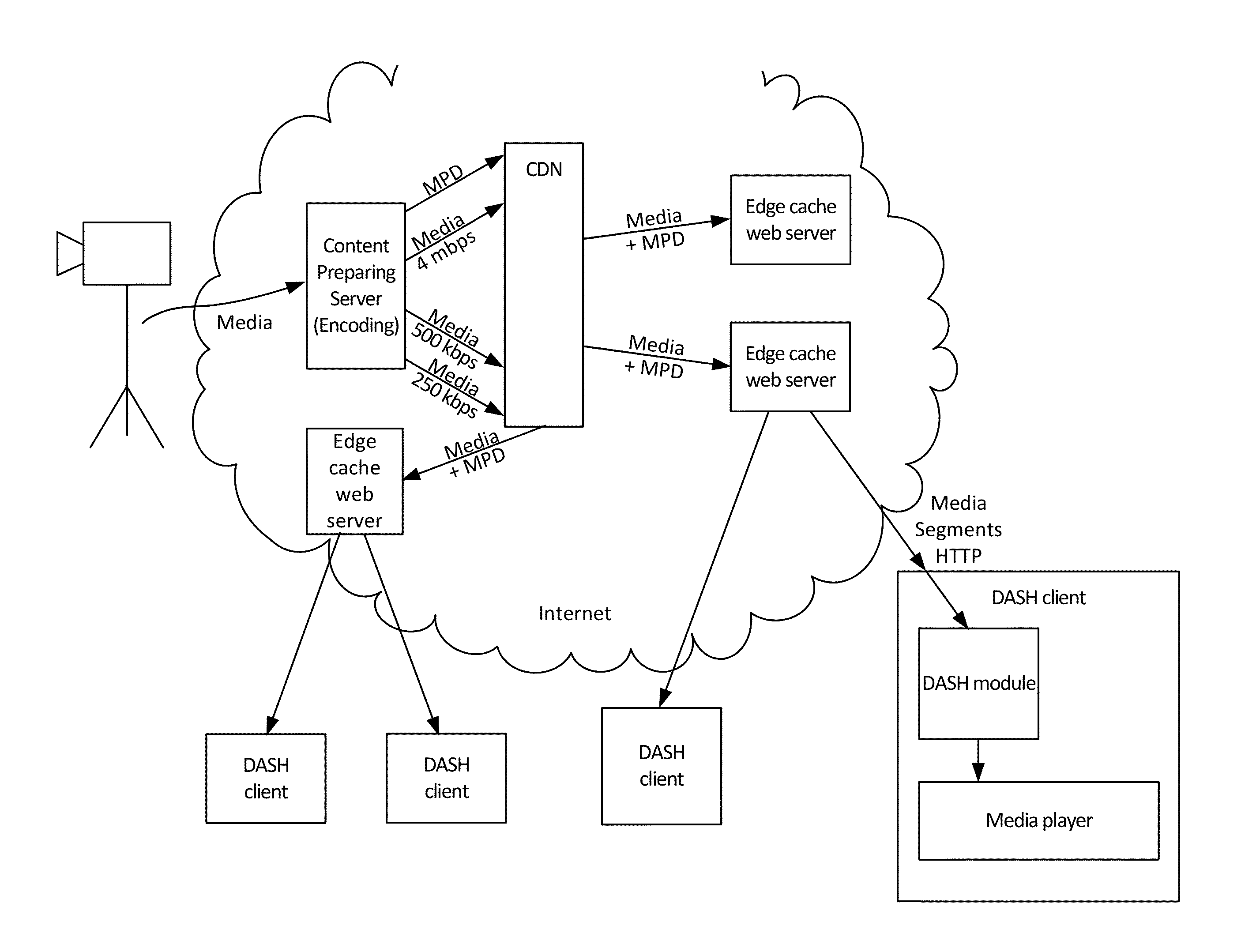

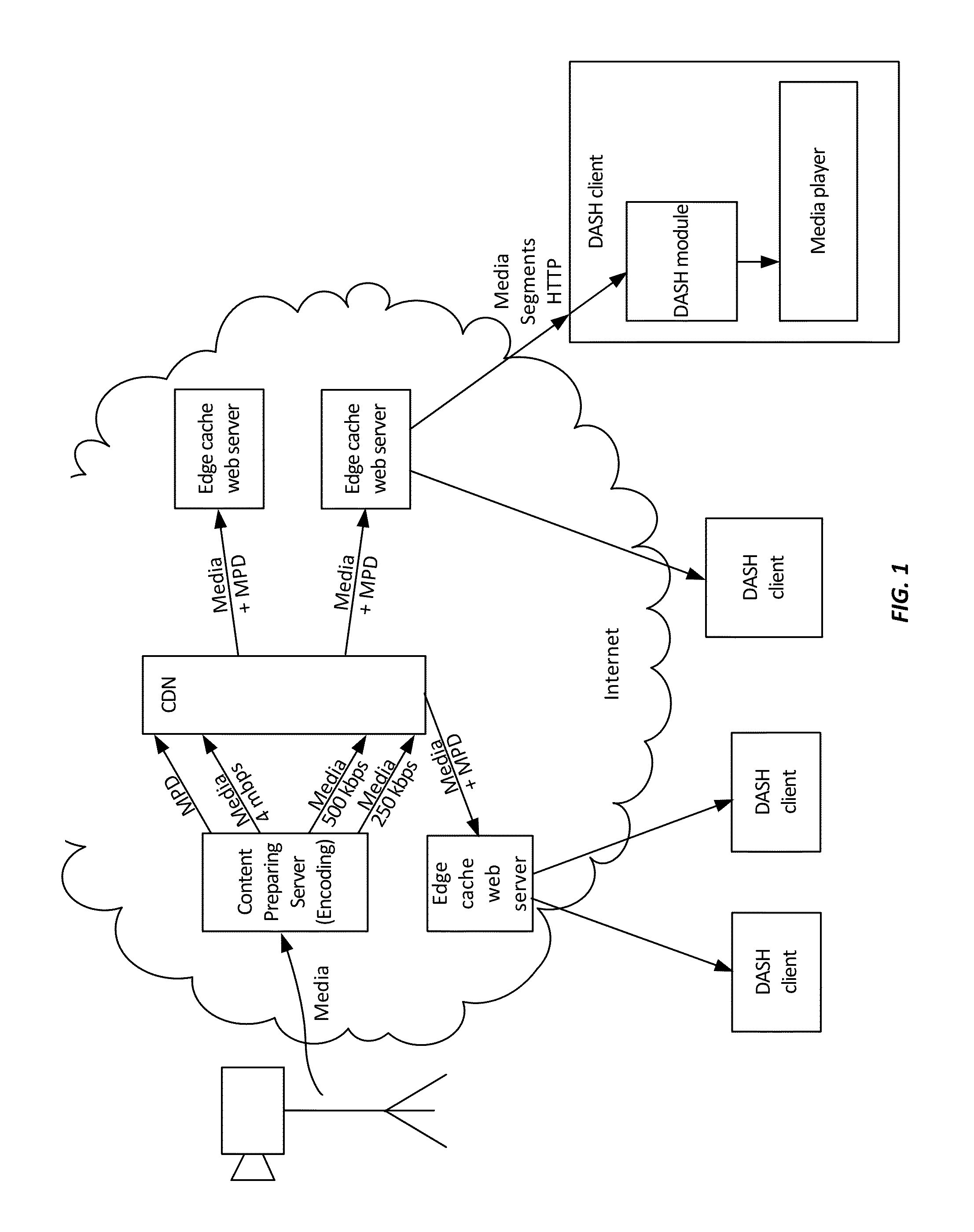

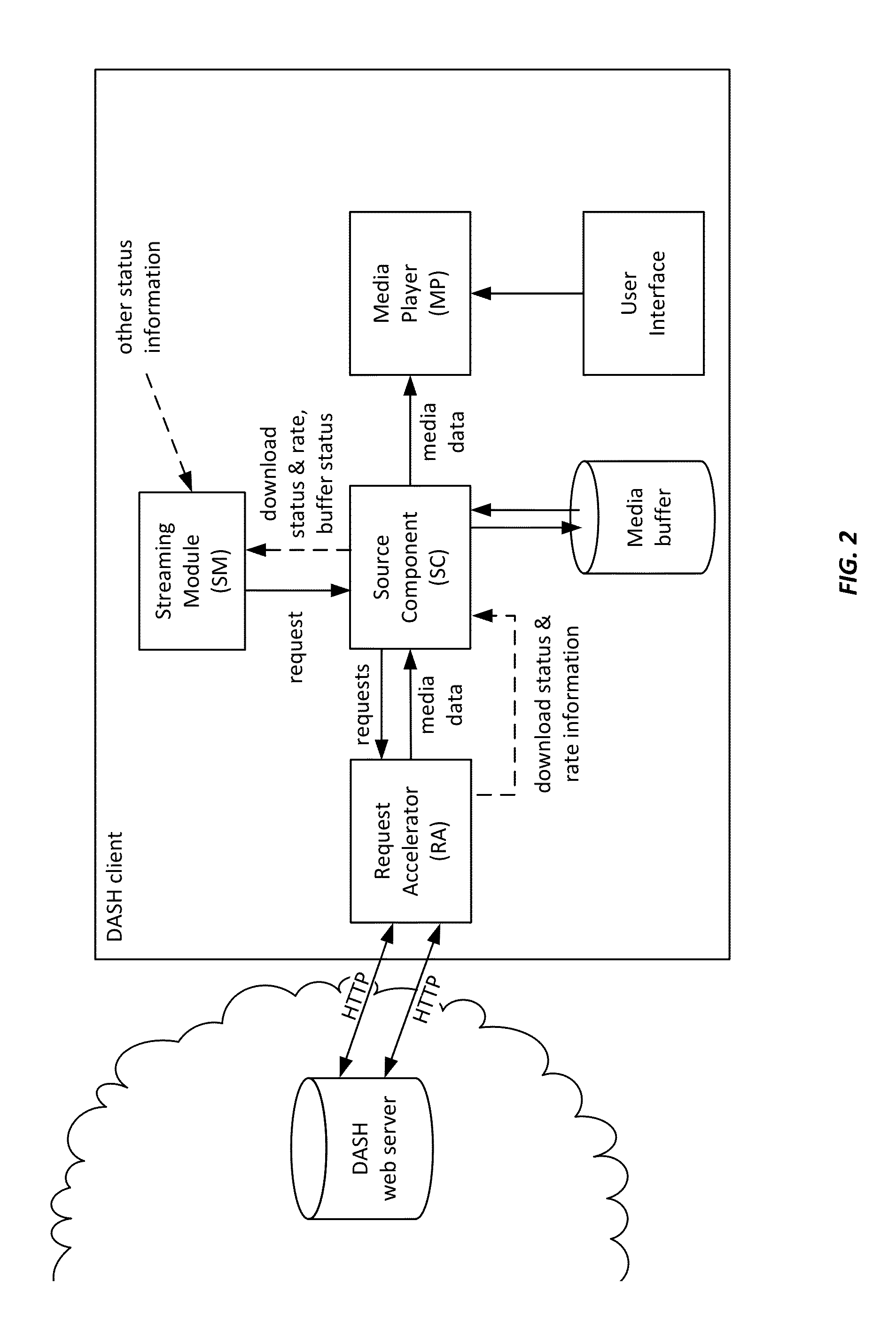

Dash client and receiver with playback rate selection

ActiveUS20130227080A1Efficiently streamedStable rateTelevision system detailsMultiple digital computer combinationsDownload rateShort Term Variability

A client device presents streaming media and includes a stream manager, a request accelerator, and a source component coupled to the stream manager and the request accelerator for determining which requests to make. A rate selection process can make rate decisions so that the buffer is filled when it is low, avoiding erratically changing rates and can choose the correct steady rate quickly. Multimedia download strategies can be used for HTTP that allow for accurate rate estimations, achieving link capacity even if network delays and packet loss rates are high, achieving timely delivery of the stream, and achieving relatively steady download rates with little short term variability. A receiver might use multiple HTTP connections, decompose media requests into smaller chunk requests, synchronize the connections using TCP flow control mechanisms, and request data in bursts. In addition, the receiver might use an HTTP pipelining process to keep the connections busy.

Owner:QUALCOMM INC

Systems and methods for collecting and transmitting assay results

ActiveUS20130156286A1Quality improvementLittle variabilityImage analysisCharacter and pattern recognitionDiseaseChemical reaction

Owner:LABRADOR DIAGNOSTICS LLC

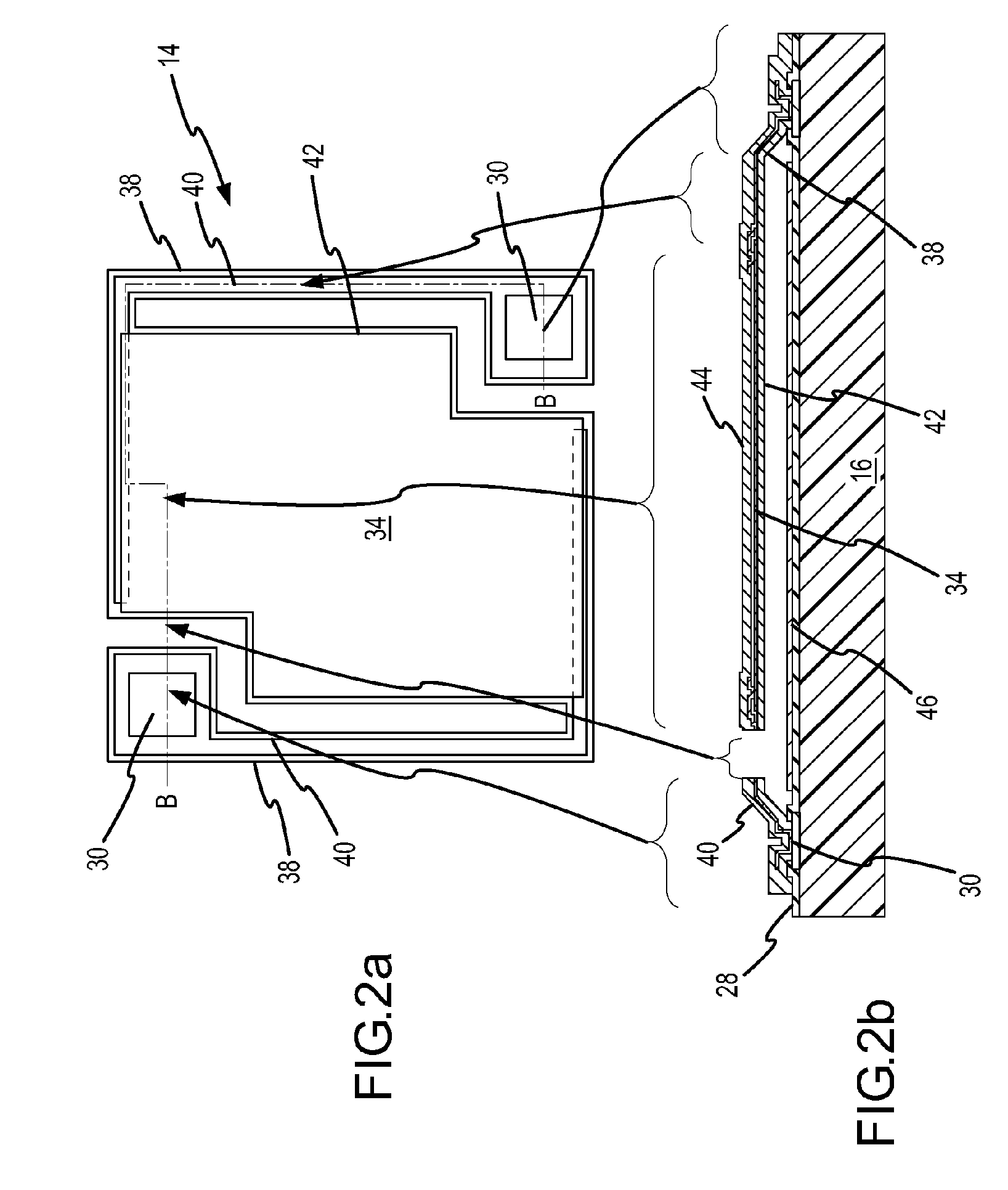

Microbolometer IR Focal Plane Array (FPA) with In-Situ Micro Vacuum Sensor and Method of Fabrication

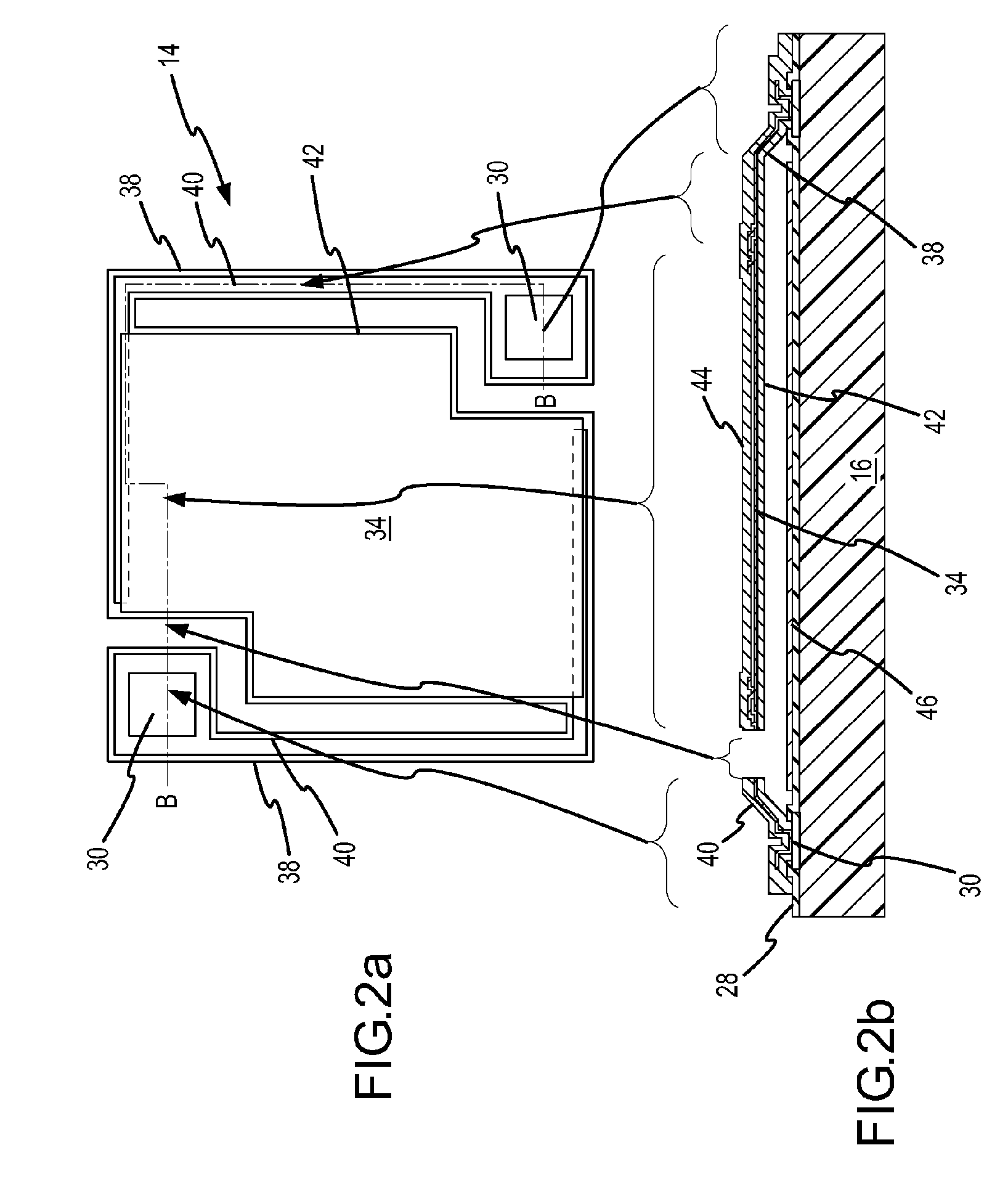

ActiveUS20070069133A1Poor heat transferSubstantial temperature increaseVacuum gauge using heat conductivity variationMaterial analysis by optical meansElectrical resistance and conductanceElectricity

A microbolometer IR FPA is provided with in-situ vacuum sensing capability by realizing that the IR sensor microbolometer pixel element itself may be used as a vacuum sensor. The application of an electrical signal to the resistive element heats the bolometer material thereby producing a variable resistance related to vacuum level. The degree of variability for a given material depends on the efficiency of heat transfer from the material to the surrounding environment. In a good vacuum, heat transfer is poor, and thus heat will be retained in the material to produce a relatively large temperature increase and the resistance variability will be large. In a poor vacuum, heat is readily transferred to the environment and the temperature rise will be relatively small and thus resistance variability will be small. Consequently, the variable resistance magnitude can be readout to determine the vacuum level.

Owner:TELEDYNE SCI & IMAGING

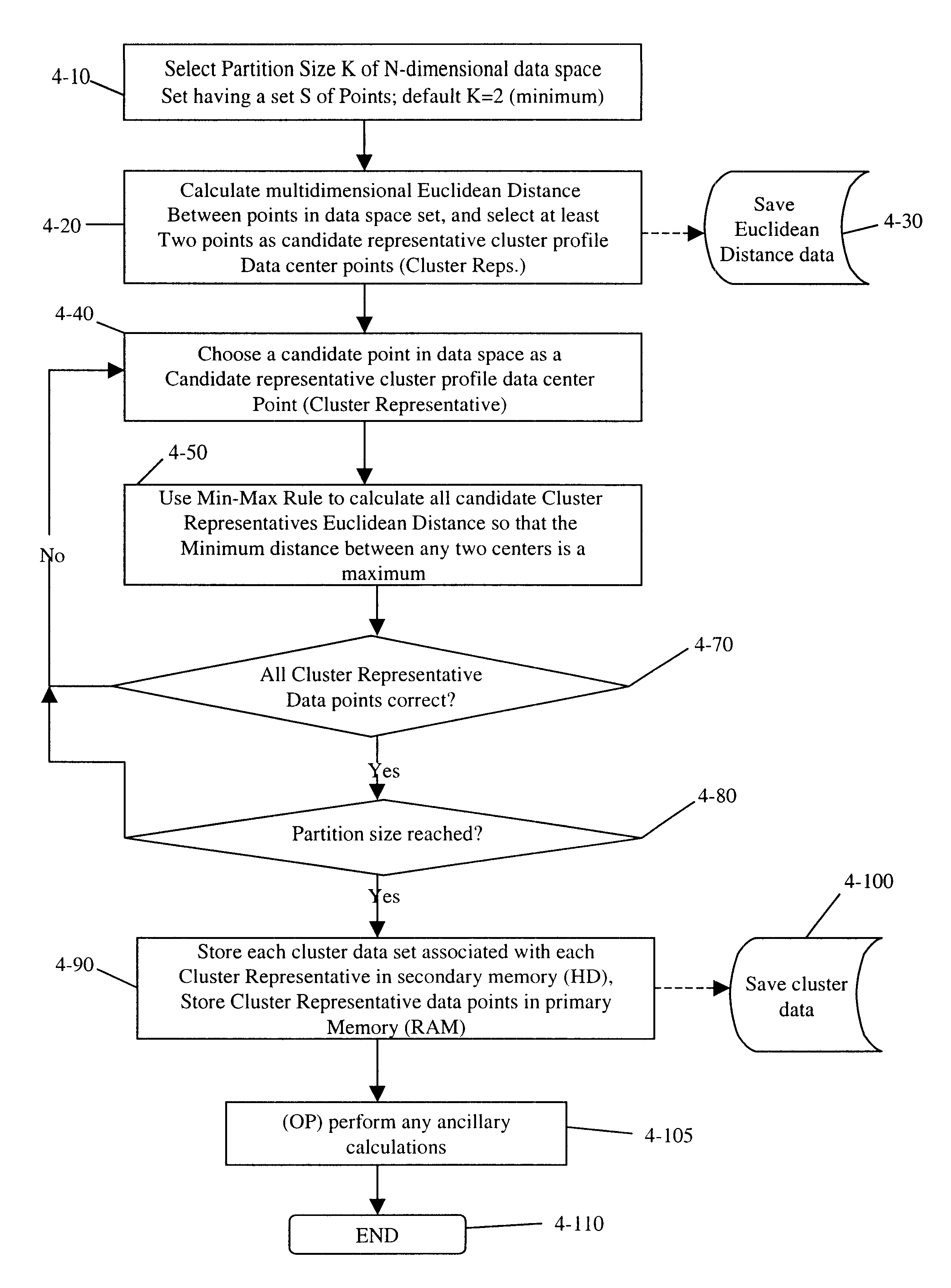

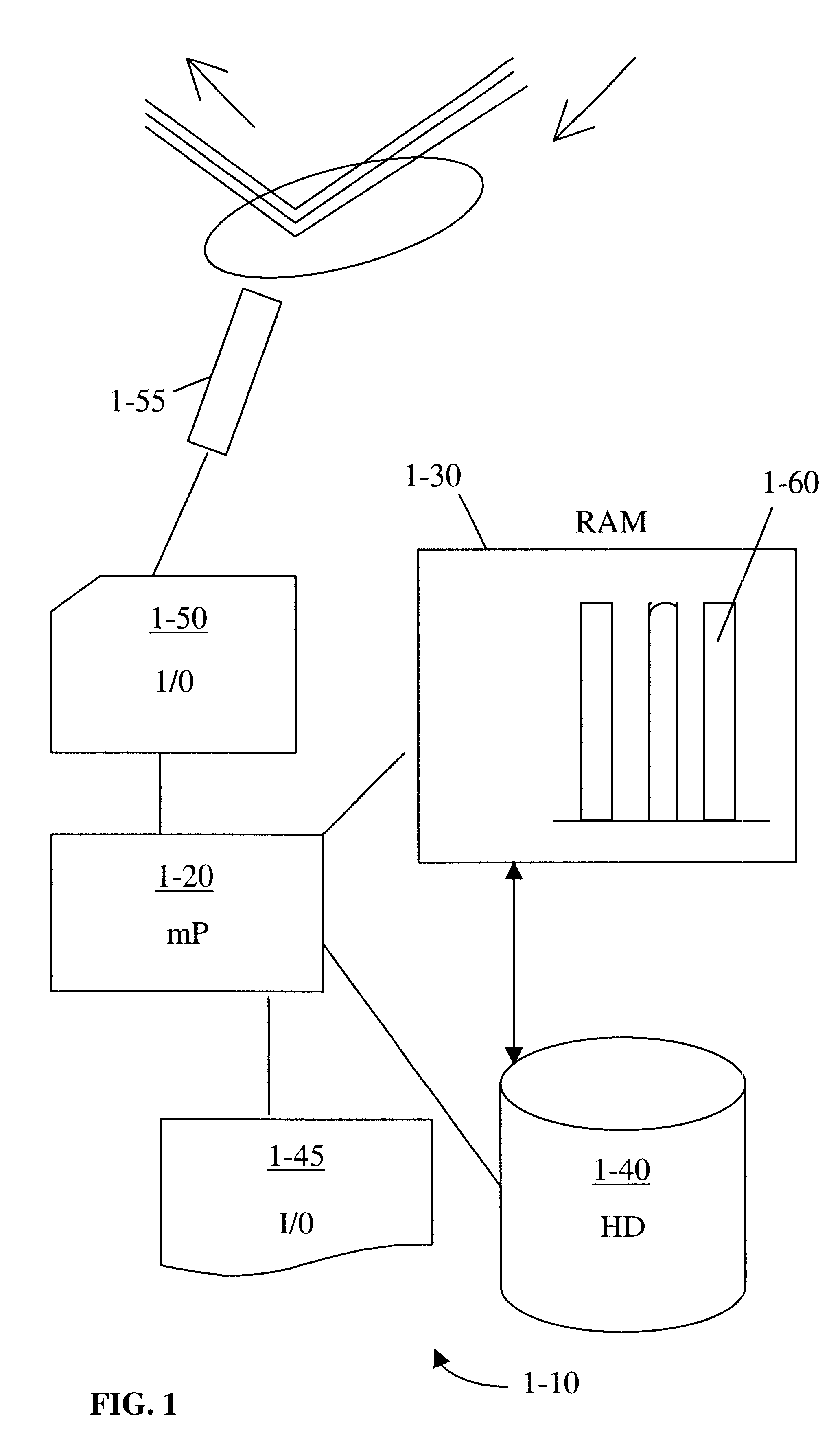

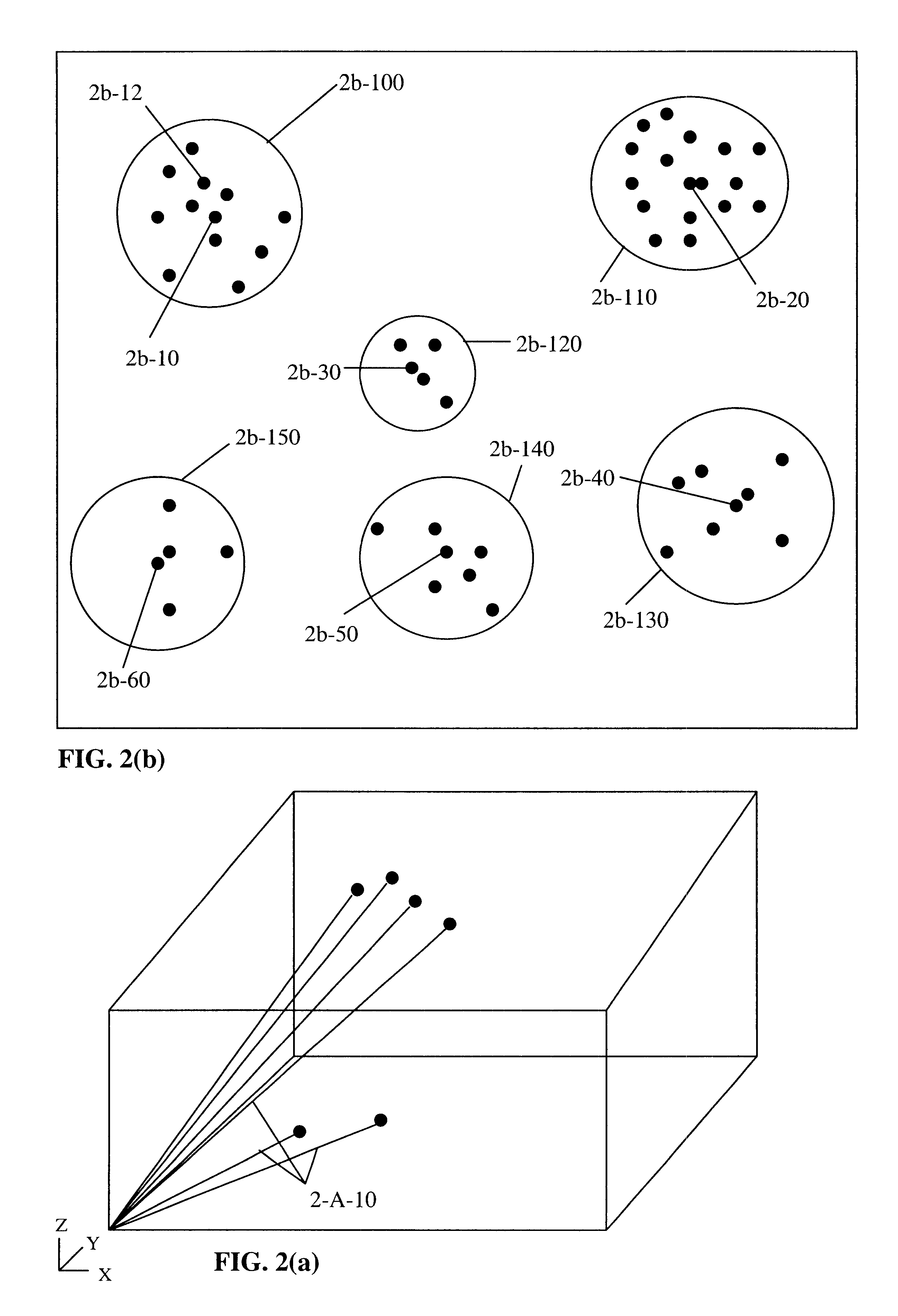

Clustering for data compression

InactiveUS6591405B1Avoids excessive disk thrashingAvoids the excessive disk thrashingProgramme controlData processing applicationsData compressionHard disc drive

An improved profileometry data collection and analysis system employing software that performs clustering analysis on library data stored in memory that represent semiconductor chip wafer profiles, for use in matching real-time data signals from data collected by profileometry instruments. To better perform a match in real-time between the incoming real-time data signals and the profile library data, cluster analysis is performed on the library data to partition the library data into clusters, and to extract representative cluster data points of the clusters. The representatives of the clusters are stored in primary memory (e.g., RAM), while the data forming the clusters are stored in secondary memory (e.g., a hard drive). A real-time data signal is then first compared to the representative cluster data points, and when a match is made with a particular representative cluster data point, the cluster associated with the representative cluster data point is loaded from secondary memory into primary memory. Next a further search is made with the incoming real-time data signal to find the closest match to the data in the cluster. In this way the entire library data does not have to be searched sequentially, and the entire library does not have to reside in primary memory in order to be quickly searched, which both conserves time and primary memory.

Owner:TOKYO ELECTRON US HOLDINGS INC

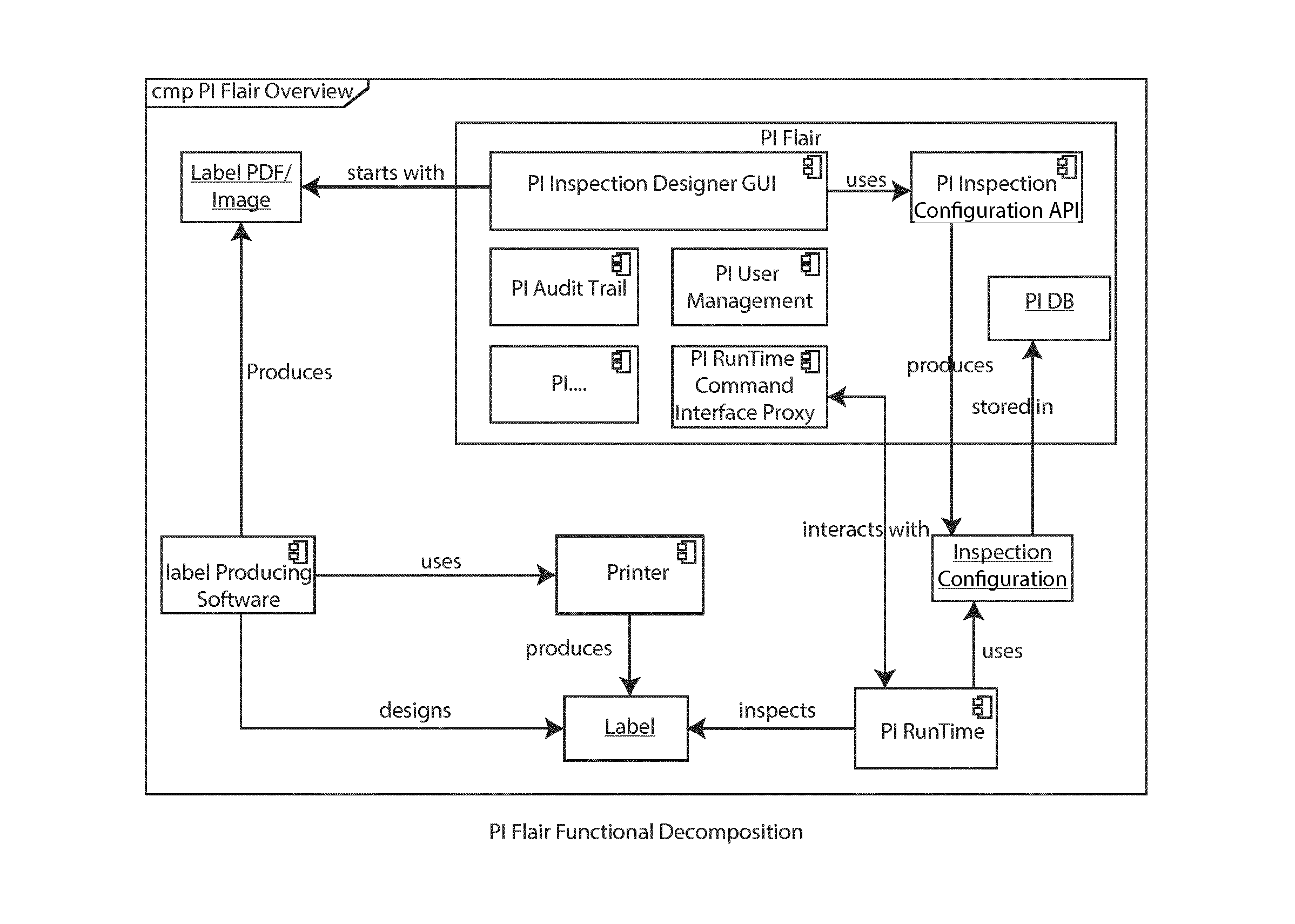

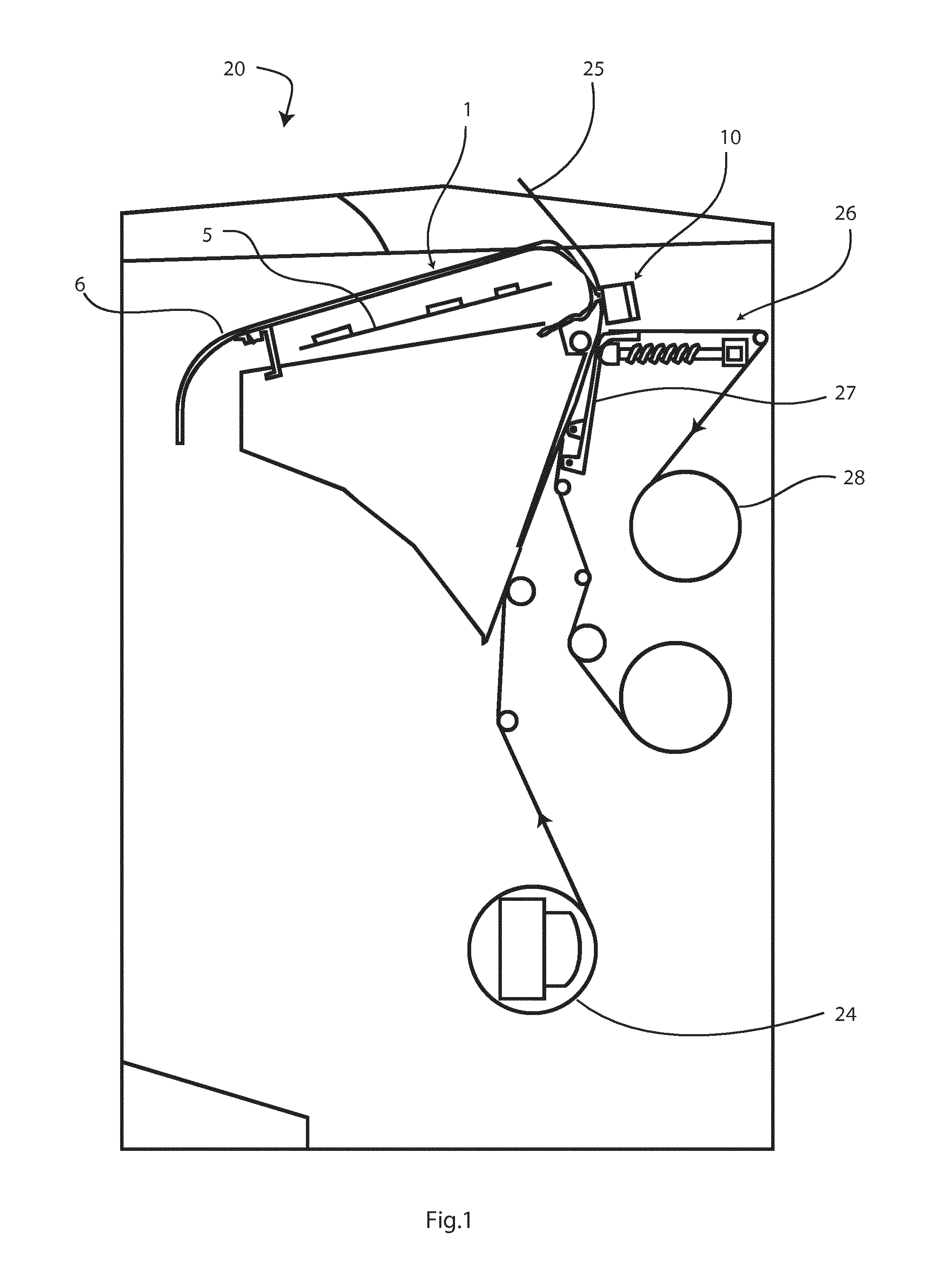

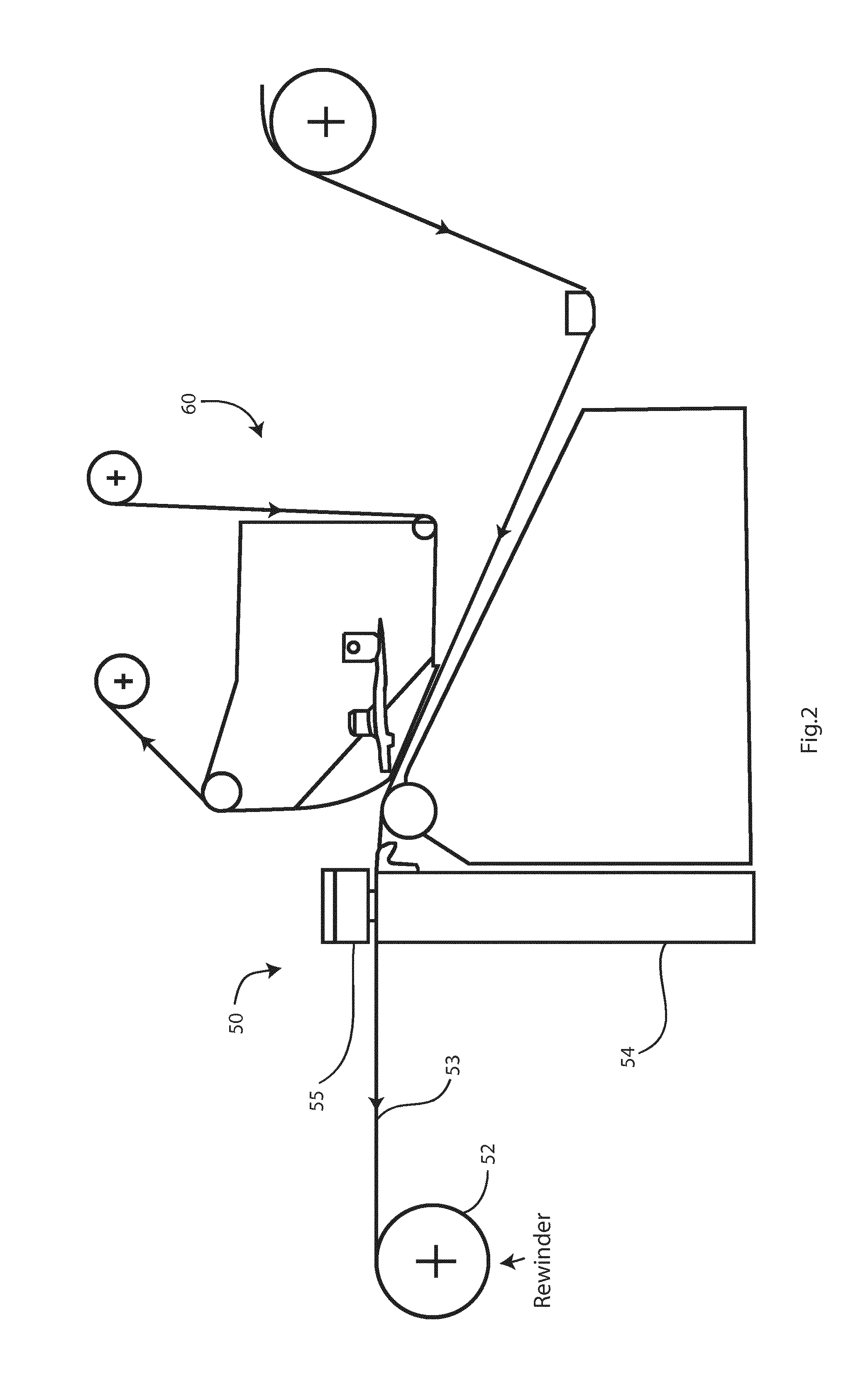

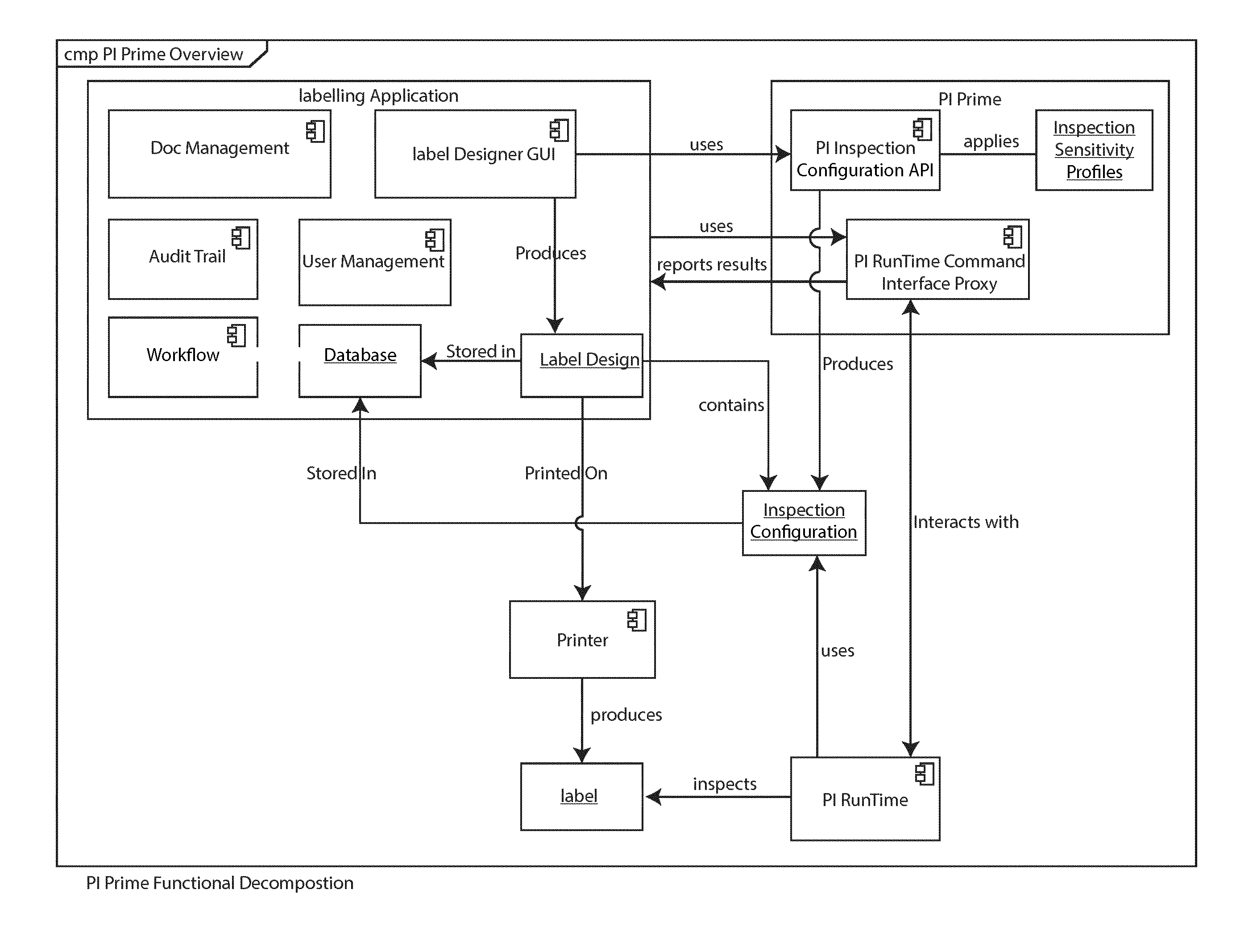

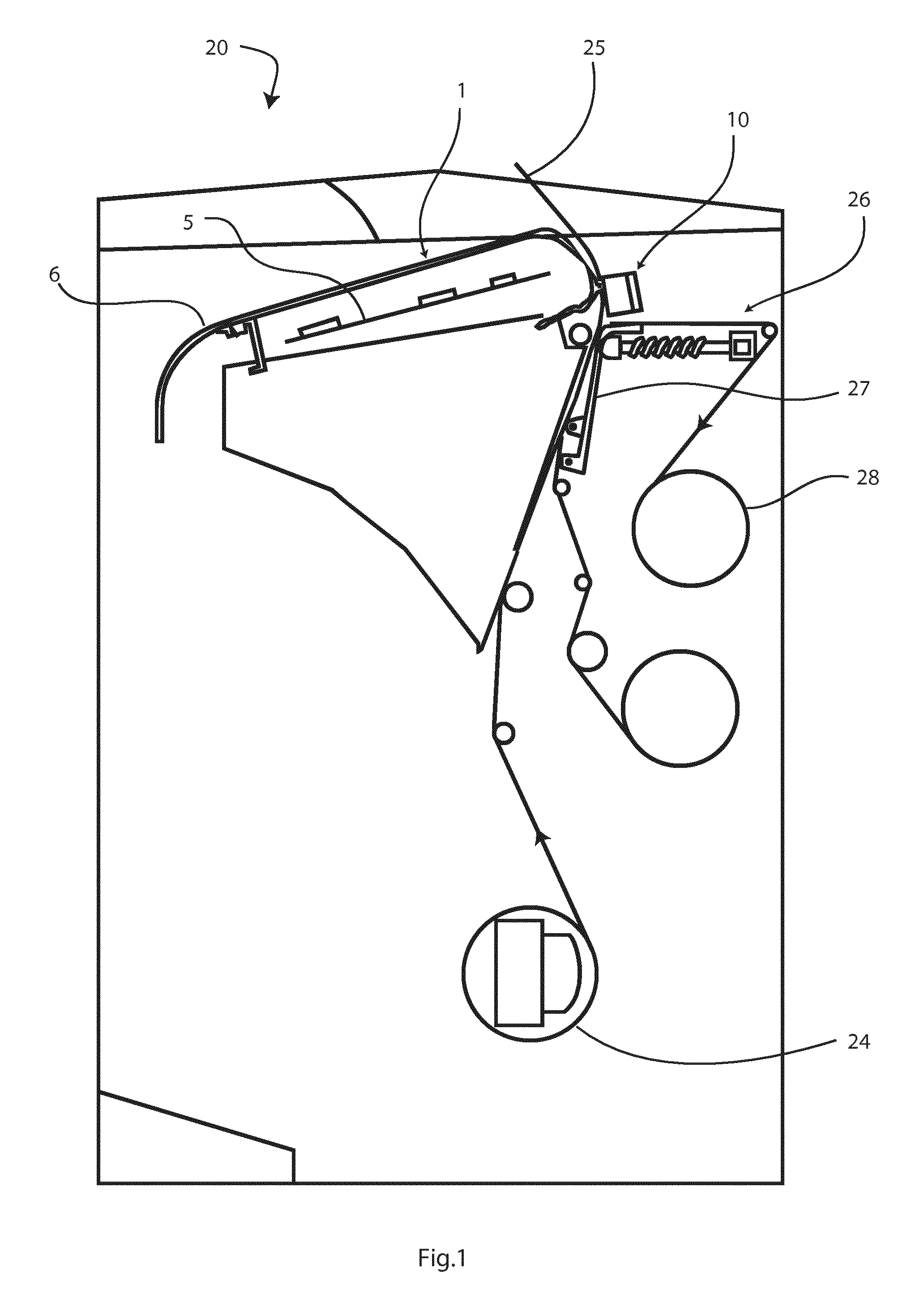

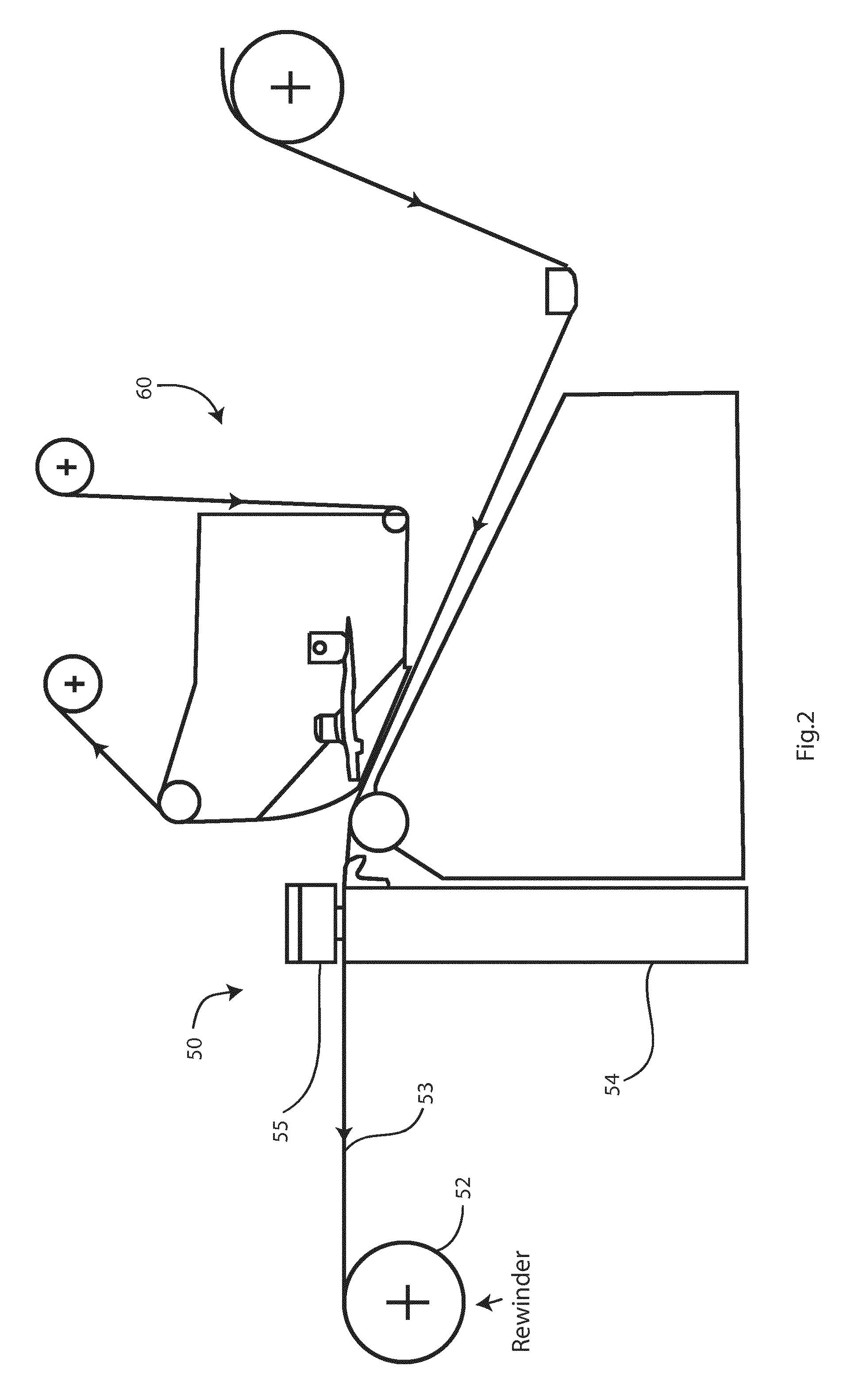

A label inspection system and method

ActiveUS20150356717A1Small differenceLittle variabilityImage enhancementDigitally marking record carriersEngineeringControl circuit

A label inspection system fixture (1) has a scanner and housing (10) for performing full inline or offline inspection within a printer (20). The fixture (1) comprises a control circuit (5) with a processor within a curved guide plate (6). The scanner (10) communicates with the circuit (5), which in turn communicates with a host computer (VPU). The VPU identifies regions in a scanned label and applies to each region an inspection tool associated with that region. At least some of said tools include a stored training image and associated test data defining said regions and inspection criteria for the regions.

Owner:CREST SOLUTIONS

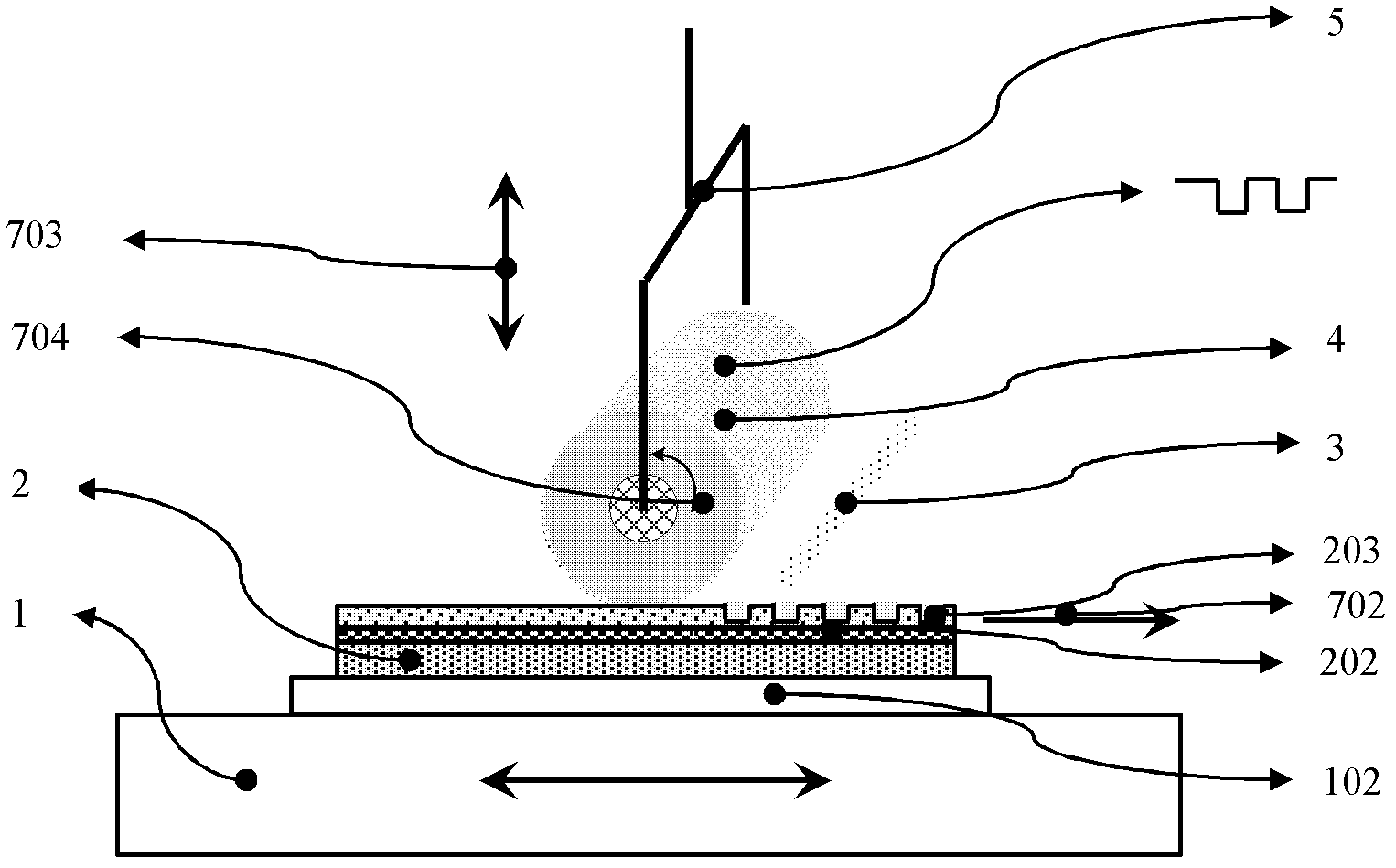

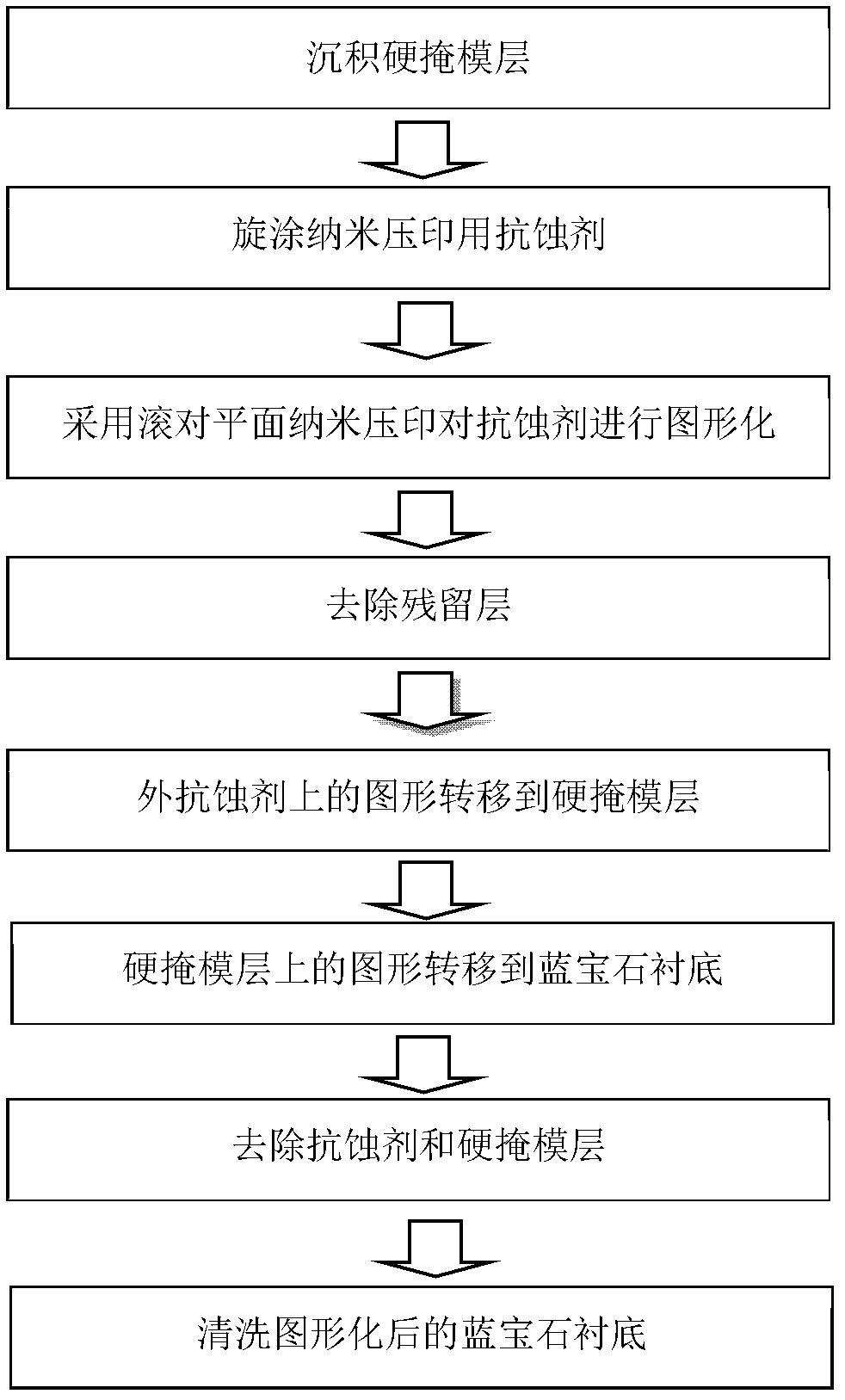

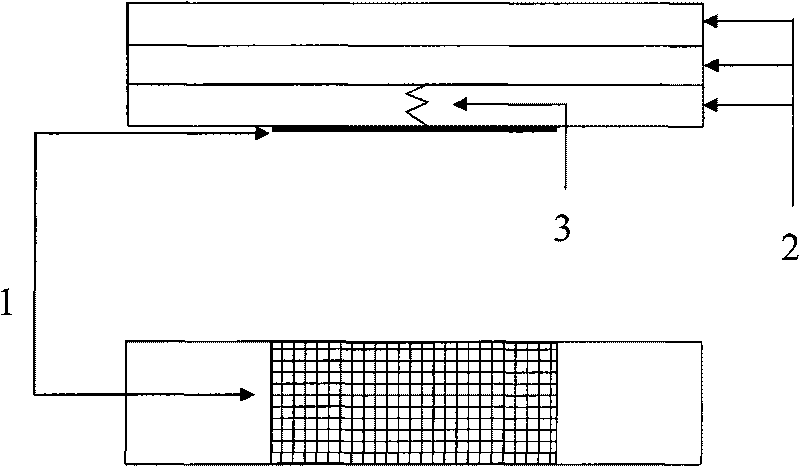

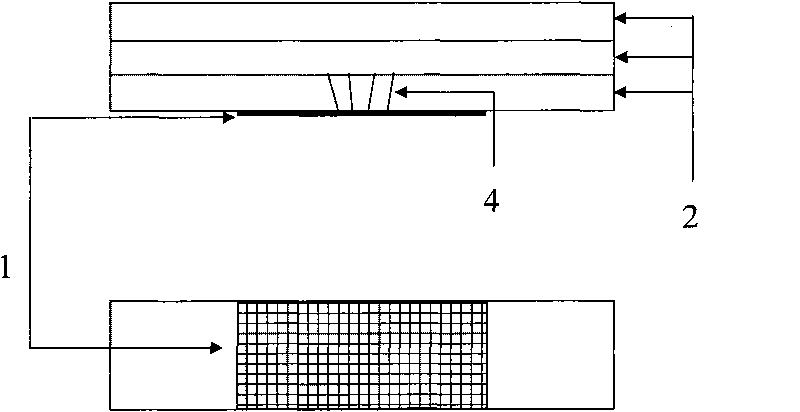

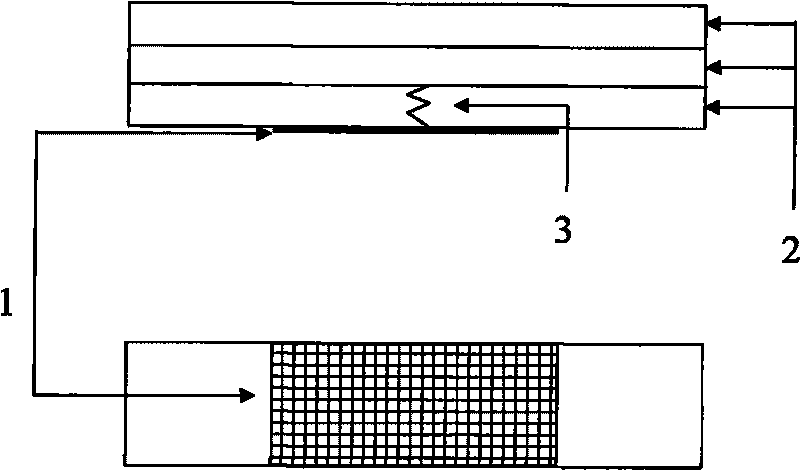

Large-size wafer level nano-patterned sapphire substrate imprinting device and method

InactiveCN102360161AReduce areaUniform embossing forcePhotomechanical exposure apparatusMicrolithography exposure apparatusResistMicro nano

The invention discloses a large-size wafer level nano-patterned sapphire substrate imprinting device and method. The method is characterized by (1) depositing a hard mask layer and spin-coating a resist for nanoimprint on the sapphire substrate; (2) adopting a roll-to-flat nanoimprint process and device to pattern the resist; (3) transferring the patterns on the resist to the hard mask layer and the sapphire substrate; and (4) removing the resist and the hard mask layer and washing the patterned sapphire substrate. The device and the method can be used for patterned manufacturing of the substrates made of silicon carbide, silicon, gallium arsenide, gallium nitride and other materials and manufacturing of such micro-nano structures as solar cells, fuel cell bipolar plates, micro-optical lenses, micro-fluidic devices and the like. The device has the characteristics of simple structure, low cost, high productivity, large imprint area and suitability for scale manufacturing.

Owner:兰红波

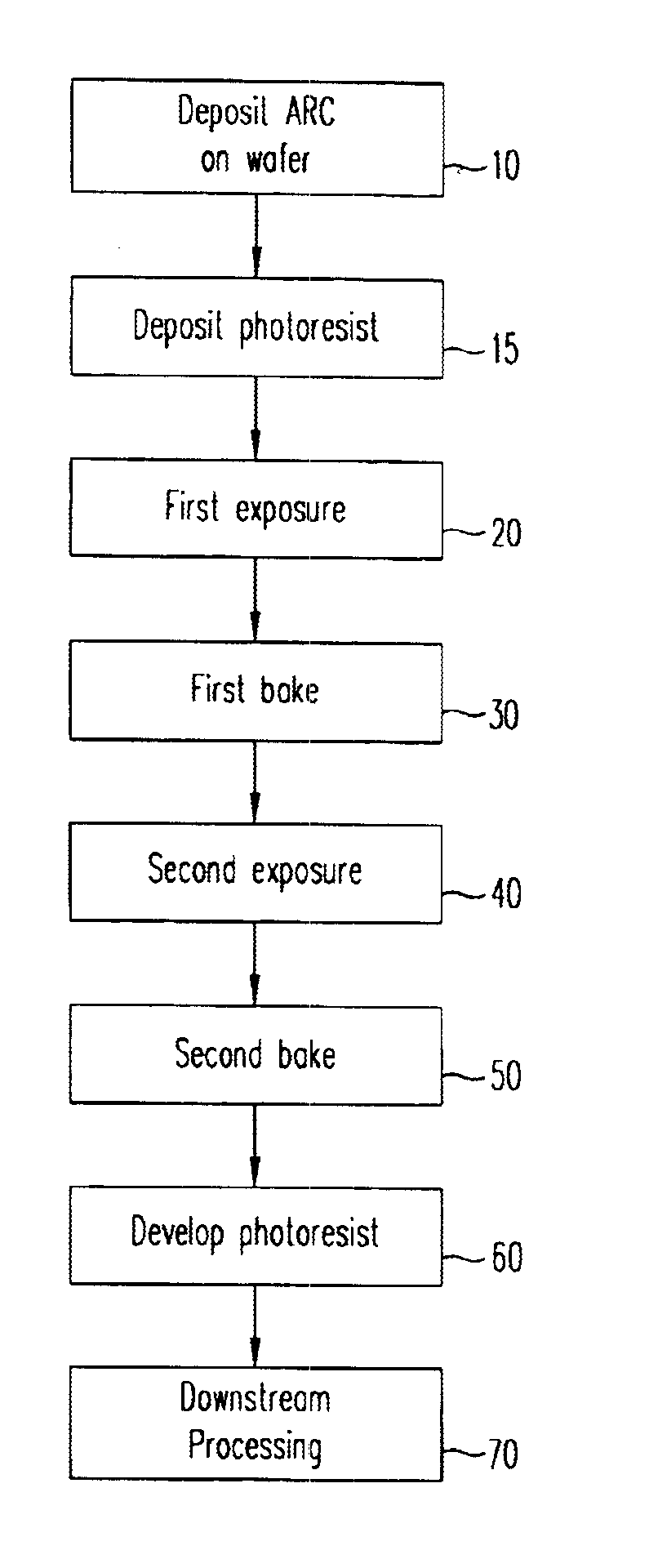

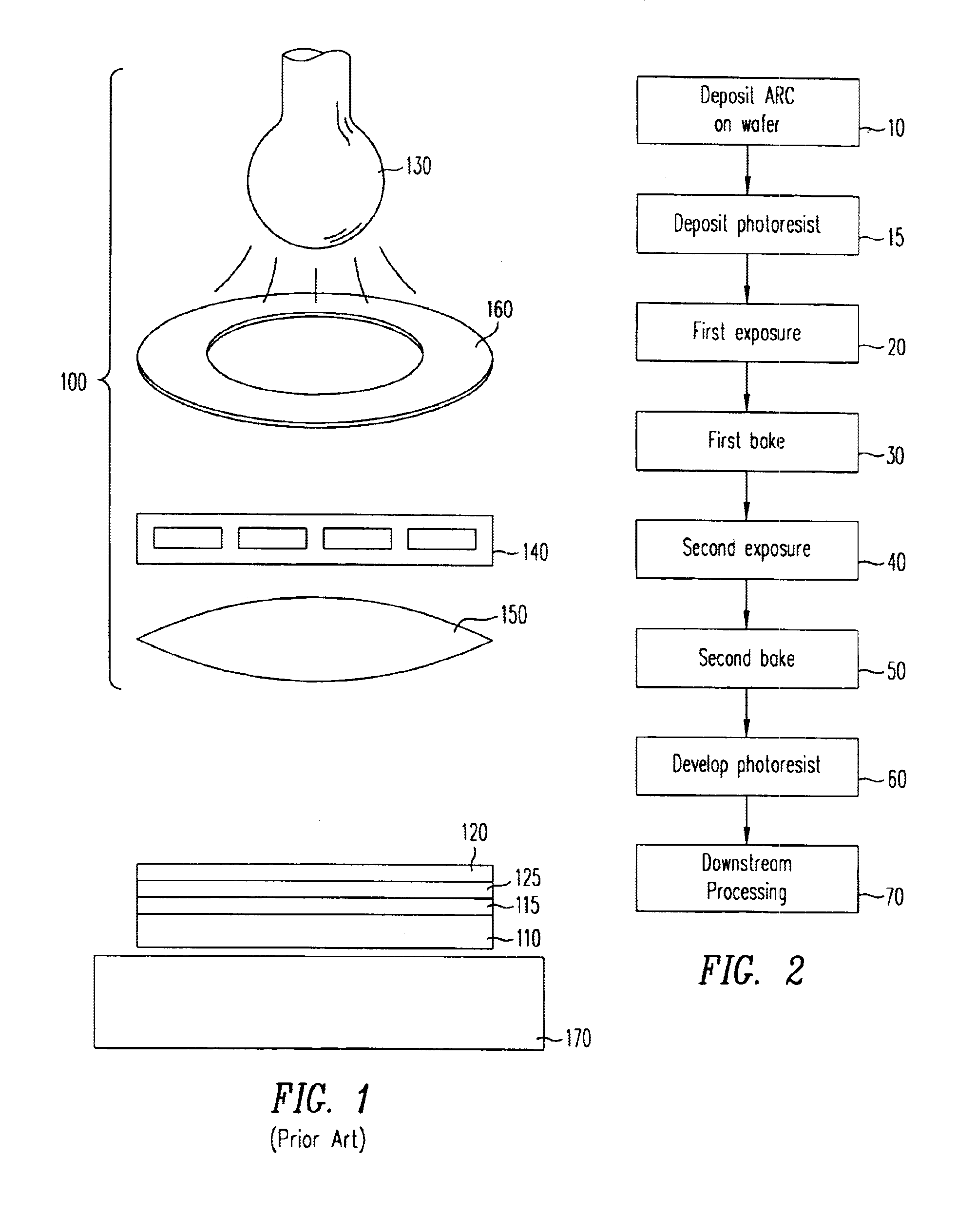

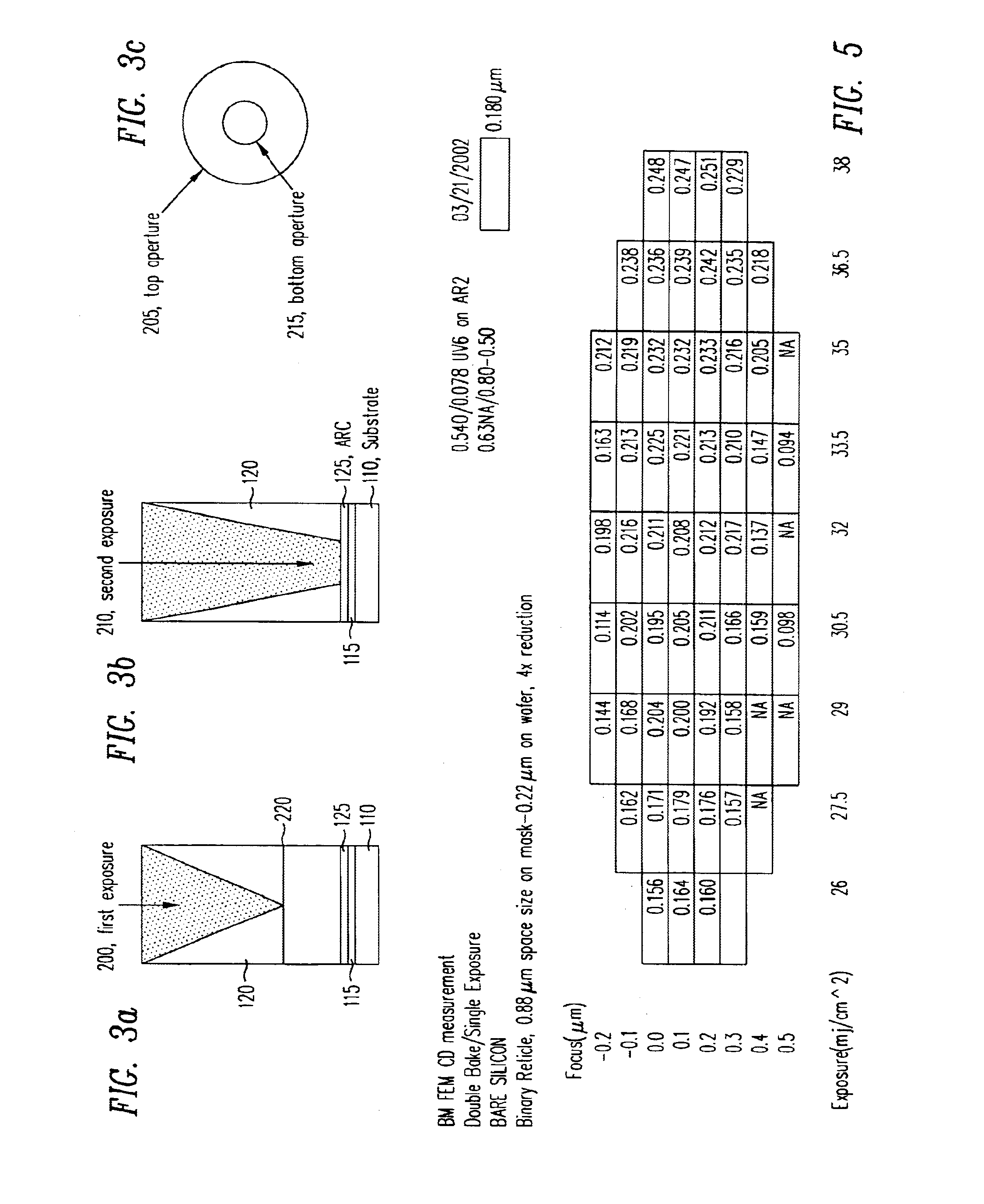

Photolithography method including a double exposure/double bake

InactiveUS6881524B2Little variabilityWider process windowPhotomechanical exposure apparatusMicrolithography exposure apparatusCooking & bakingResist

A photoresist exposure process is disclosed which produces features which are substantially smaller than the aperture dimension of the mask used to make the feature. The smaller feature size results from a double exposure of the photoresist, combined with a double baking process to create the features in the photoresist. The double baking process thins the layer of photoresist, prior to the second exposure, thereby improving the resolution of the mark created by the second exposure on the photoresist. The process also uses a binary bias mask through which the first exposure is made, which overlaps with the area of the second exposure, to allow a process tolerance for the realignment of the mask over the wafer for the second exposure.

Owner:PROMOS TECH INC

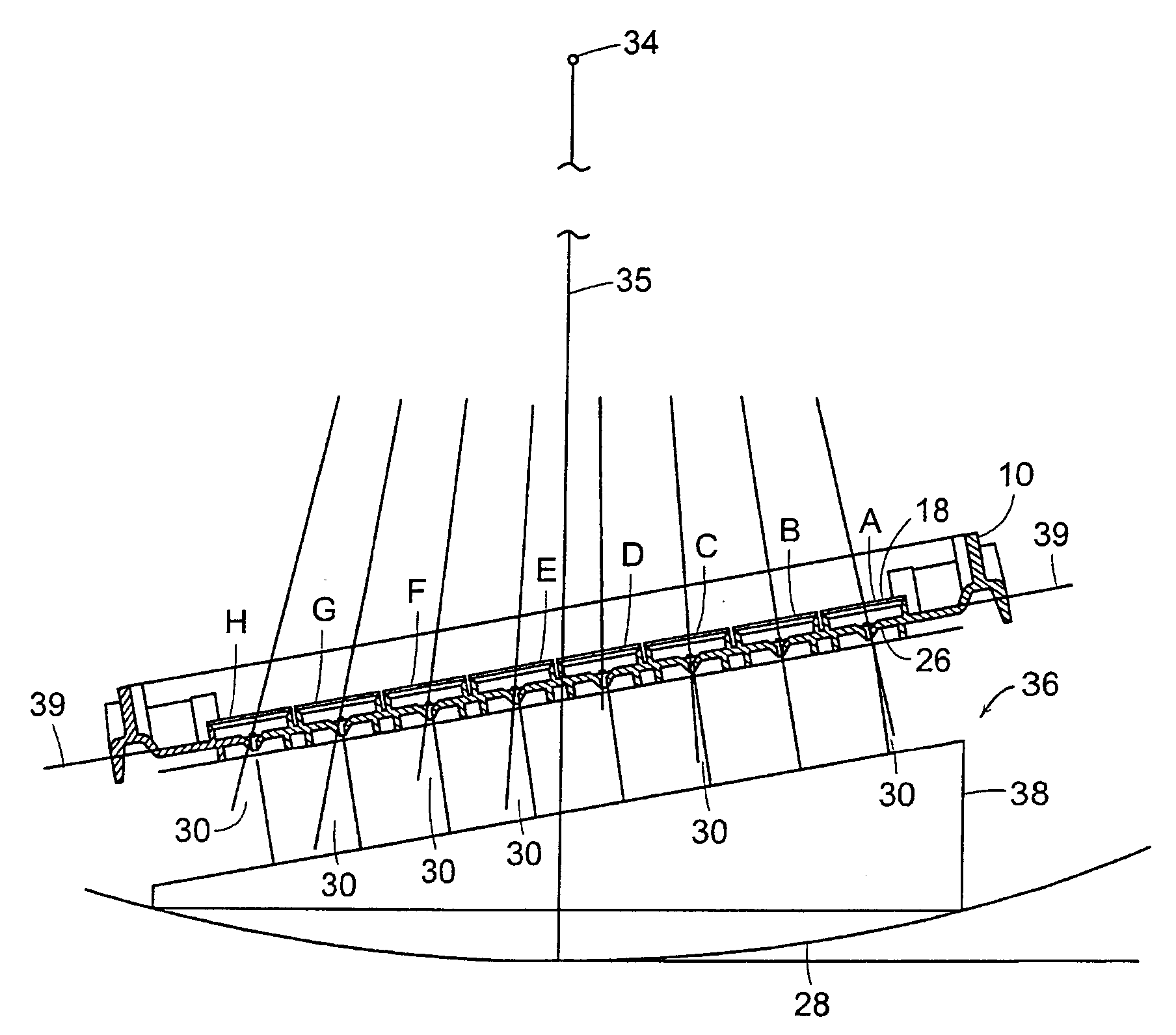

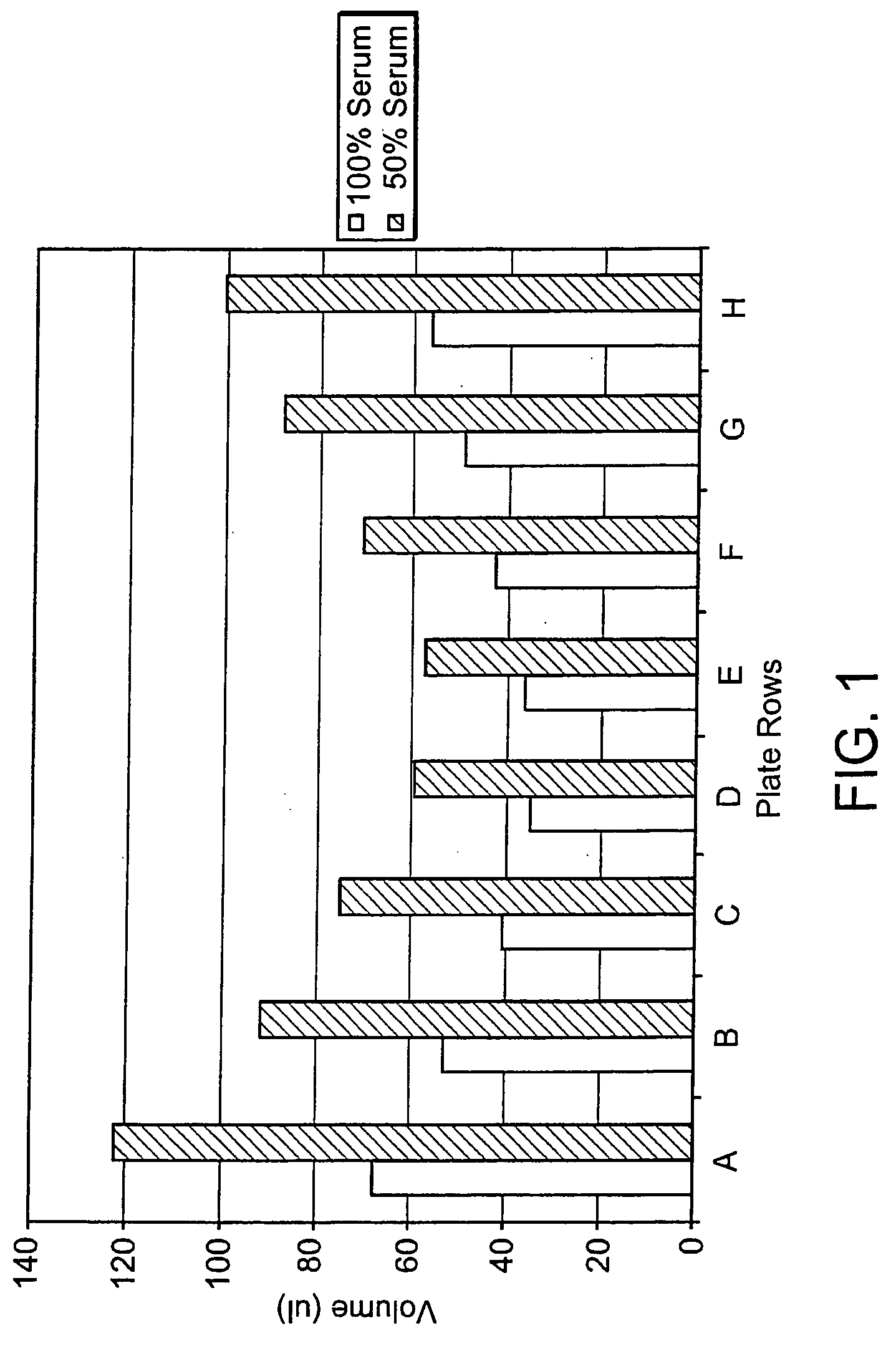

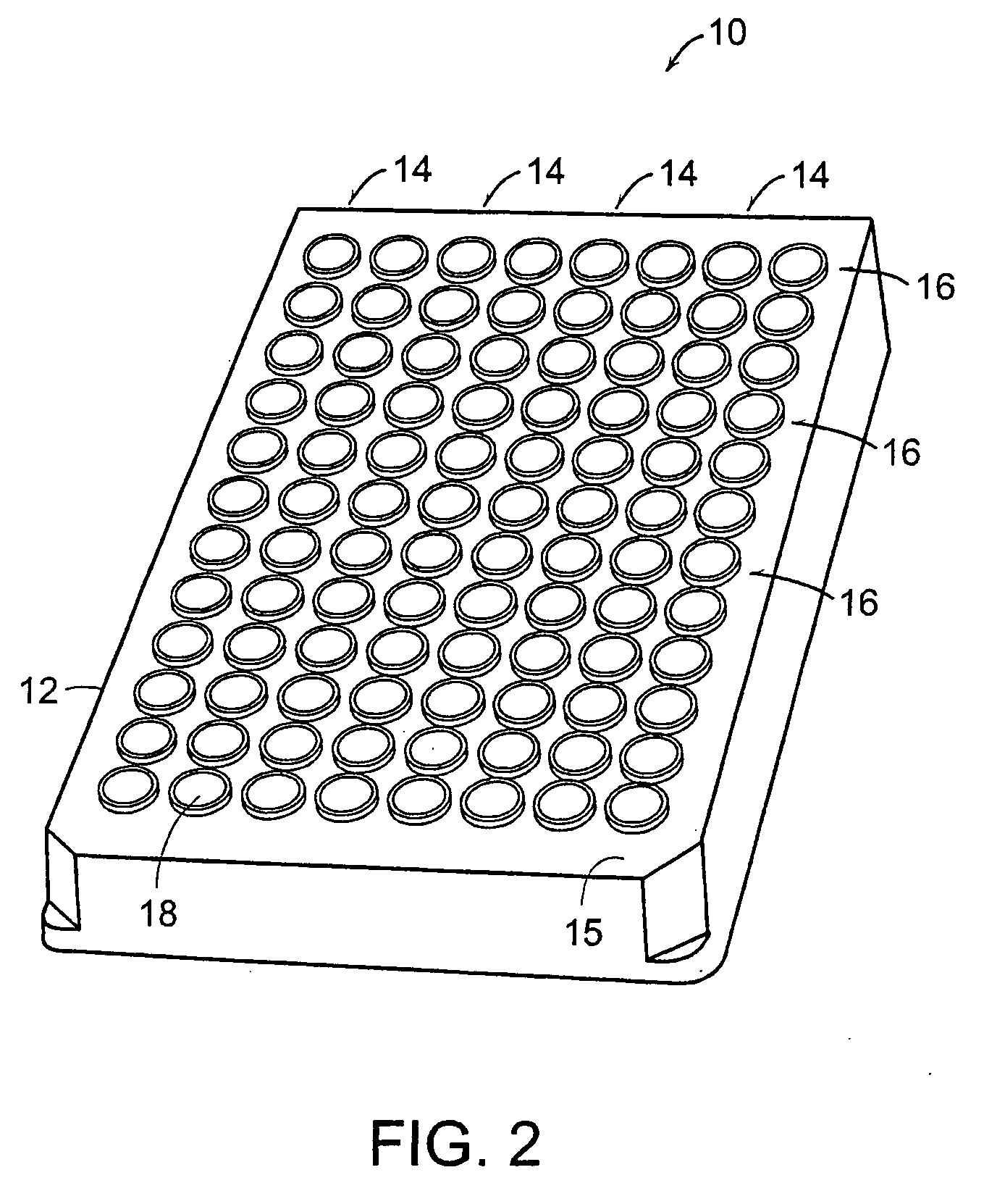

Methods for filtering fluids

InactiveUS20050161400A1Prevent rotationIncrease volumeWater/sewage treatment by centrifugal separationUltrafiltrationEngineeringMembrane configuration

A fluid filtering device includes a plurality of filtering wells and an angling mechanism which adjusts the angle of the membranes within the filtering wells relative to a line of a centrifuge where the line is perpendicular to the axis of rotation of a centrifuge and passes through the center of a major plane of the filtering device. The angling mechanism can include a wedge located between the center of rotation of a centrifuge and a swinging bucket of the centrifuge. The angling mechanism can also be located within each filtering well and can provide individually specified angles for each membrane, relative to the line of the centrifuge.

Owner:MILLIPORE CORP

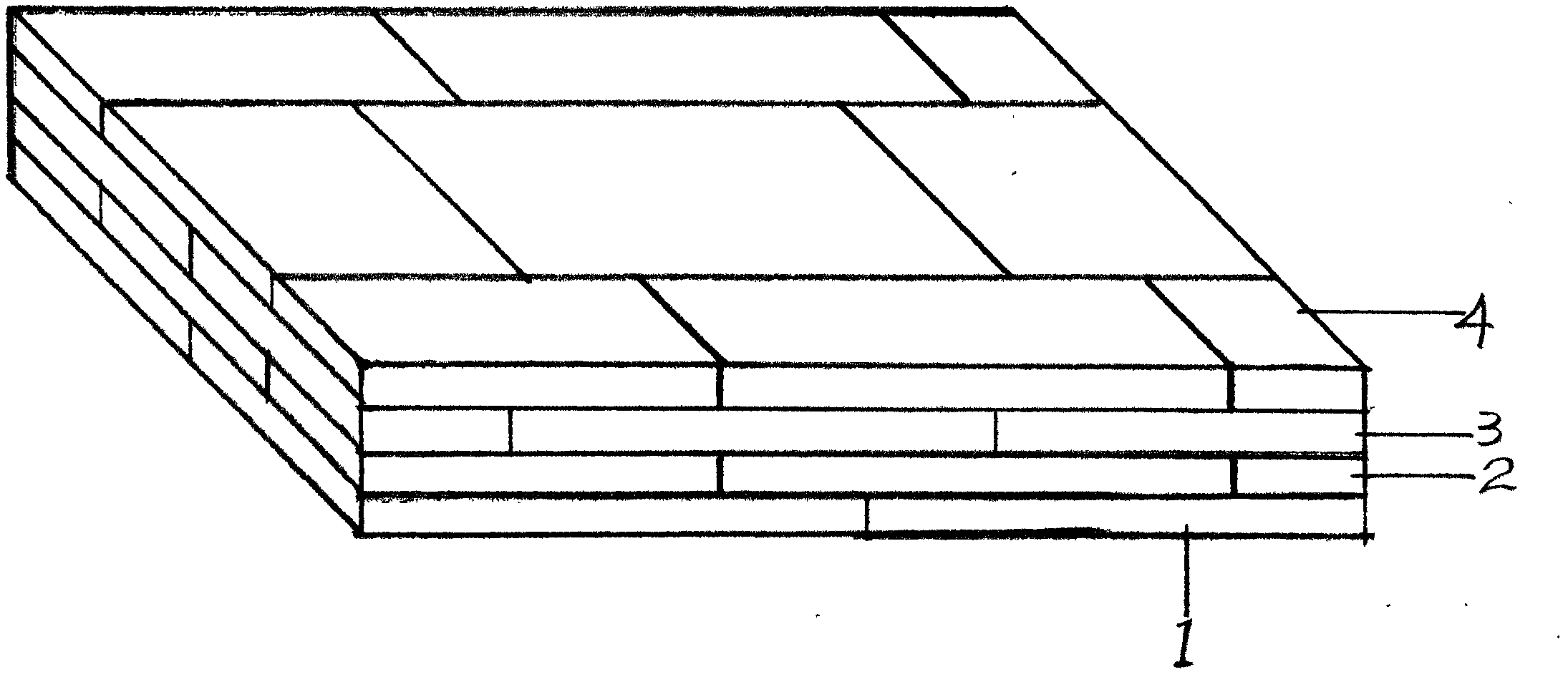

Structural laminwood and preparation method thereof

InactiveCN101564854AImprove structural performanceIncrease profitOther plywood/veneer working apparatusWood veneer joiningLower gradeEngineering

The invention provides a structural laminwood and a preparation method thereof. The laminwood is stacked and glued by 2-7 layers of veneers, wherein the grade of the external layer veneer of the laminwood is equal to the grade of the adjacent internal layer veneer or higher than the adjacent internal layer veneer by one grade; the veneer grade is determined by the average value of flexural elastic modulus of the target grades of all veneers; and compared with the veneers with lower grades, the veneers with higher grades have greater average value of the flexural elastic modulus of the target grades. The method lengthens the stock lumbers of short dimensions by mechanical stress grading and uses the lengthened stock lumbers as the veneers, then configures the veneer structures according to a grade configuration principle and coldly presses and glues the veneers to prepare the structural laminwood. The laminwood has excellent structural performance and can be used for the components such as beams, columns, and the like in wood structure buildings or other buildings.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Microbolometer IR focal plane array (FPA) with in-situ mirco vacuum sensor and method of fabrication

ActiveUS7385199B2Poor heat transferSubstantial temperature increaseVacuum gauge using heat conductivity variationMaterial analysis by optical meansElectricityElectrical resistance and conductance

A microbolometer IR FPA is provided with in-situ vacuum sensing capability by realizing that the IR sensor microbolometer pixel element itself may be used as a vacuum sensor. The application of an electrical signal to the resistive element heats the bolometer material thereby producing a variable resistance related to vacuum level. The degree of variability for a given material depends on the efficiency of heat transfer from the material to the surrounding environment. In a good vacuum, heat transfer is poor, and thus heat will be retained in the material to produce a relatively large temperature increase and the resistance variability will be large. In a poor vacuum, heat is readily transferred to the environment and the temperature rise will be relatively small and thus resistance variability will be small. Consequently, the variable resistance magnitude can be readout to determine the vacuum level.

Owner:TELEDYNE SCI & IMAGING

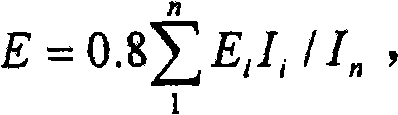

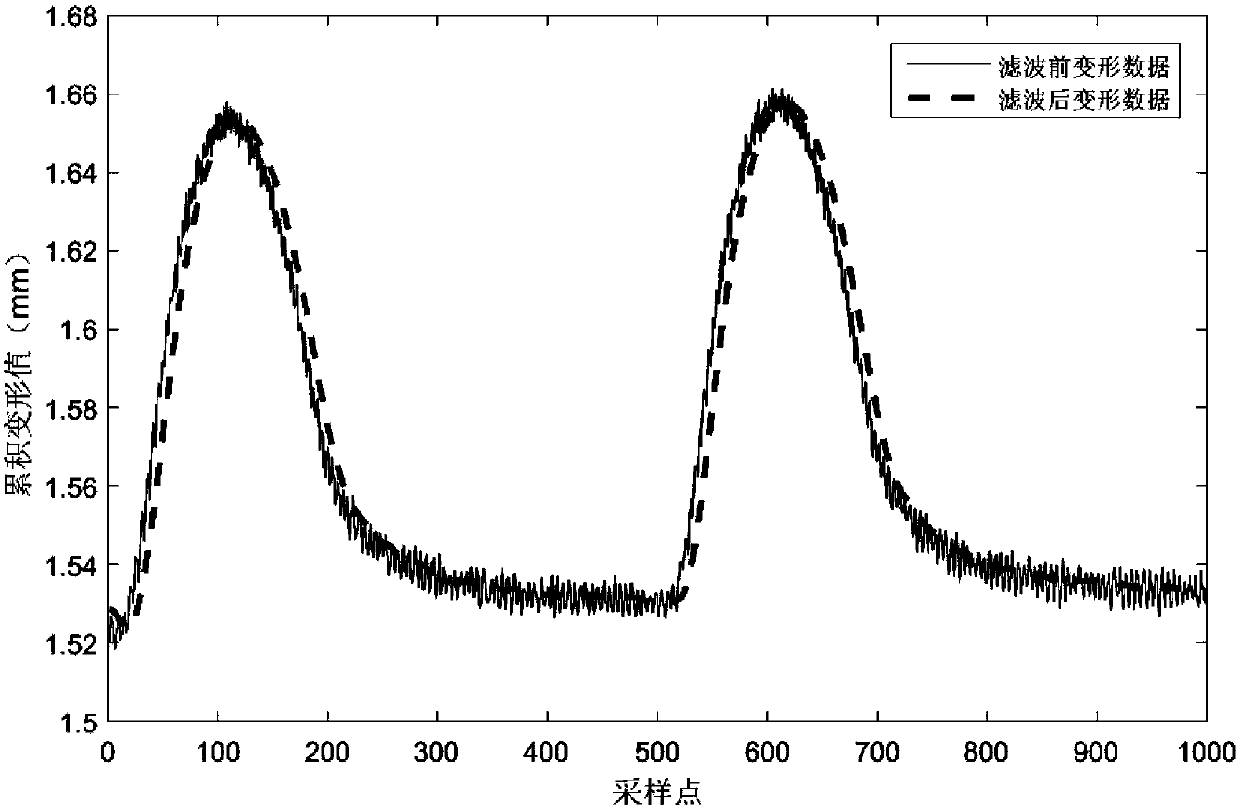

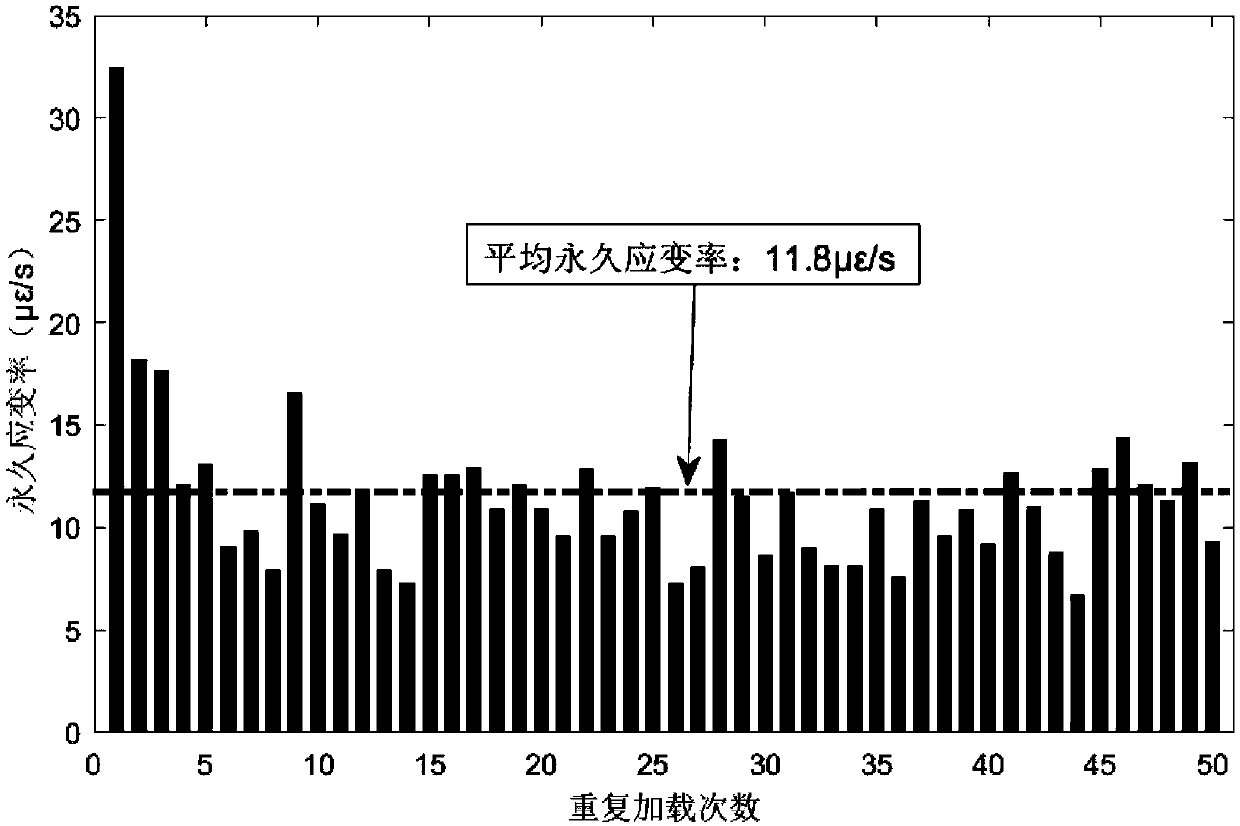

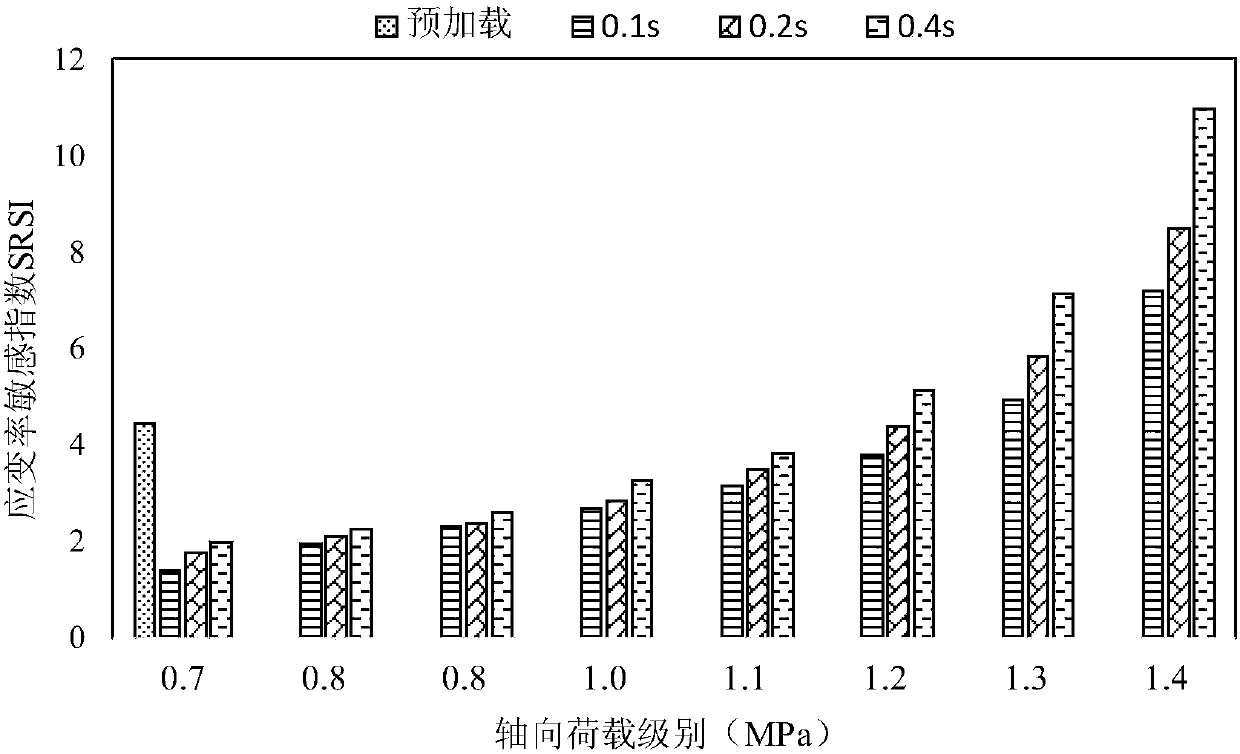

Method for processing and analyzing multi-sequence dynamic creep test data of asphalt mixture

ActiveCN107807055AEasy to calculateHigh precisionMaterial strength using repeated/pulsating forcesStress conditionsEngineering

The invention discloses a method for processing and analyzing multi-sequence dynamic creep test data of an asphalt mixture. Creep data measured by test undergoes low-pass filtering by designing a Butterworth low-pass filter to obtain a smooth creep curve, the average permanent strain rate of every loading sequence is calculated, and the following three indicators for evaluating the creep characteristics of the asphalt mixture are calculated according to a formula: the strain rate sensitivity index SRSI, the composite average permanent strain rate CAPSR and the composite creep stiffness modulusCCSM, wherein the influence of the stress condition on the creep of the above material is positively correlated with the value of the SRSI; the CAPSR represents the equivalent strain rate under various complex stress conditions, the permanent strain generated in one-time loading of the material is positively correlated with the value of the CAPSR, and the high temperature performances of the material are negatively correlated with the value of the CAPSR; and the CCSM represents the resistance of the material to permanent deformation at the end of the creep test, and the high temperature performances of the material are positively correlated with the value of the CCSM.

Owner:SOUTHEAST UNIV

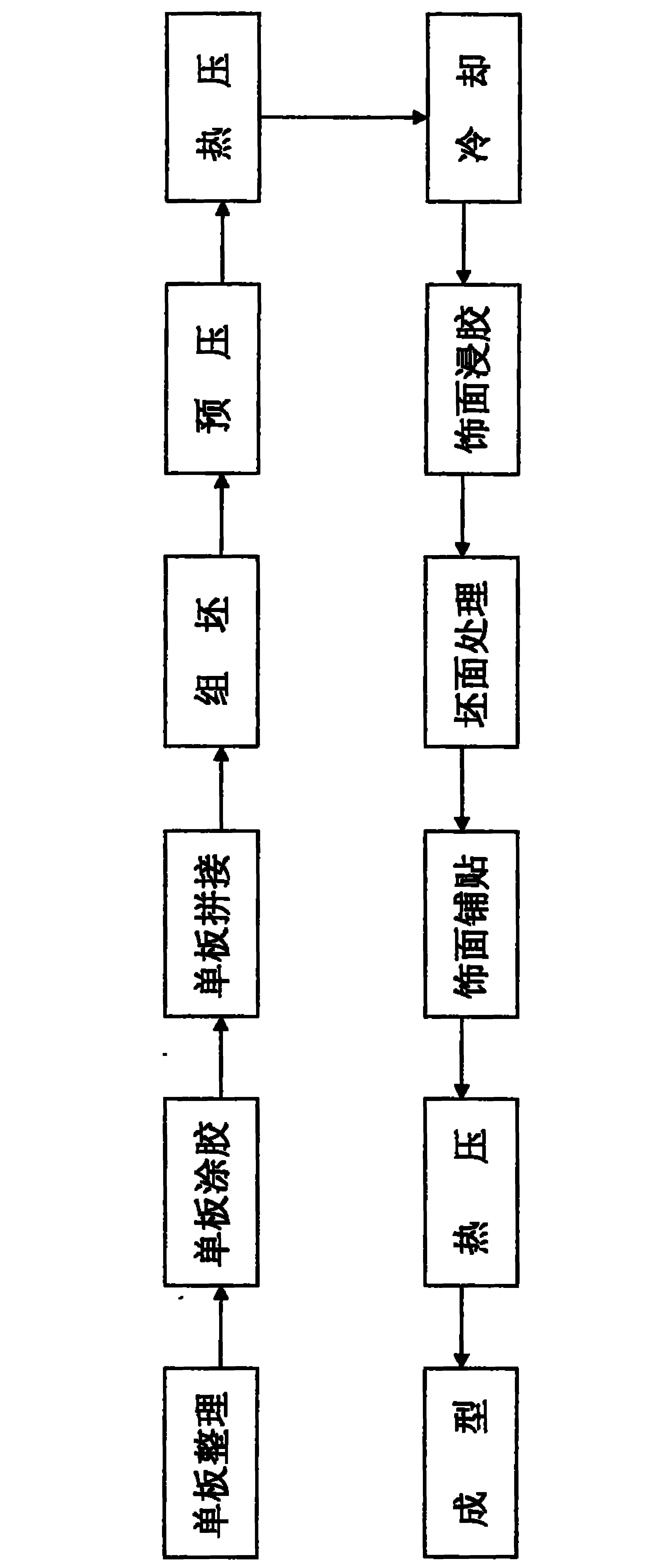

Production method and manufacturing process for environmentally-friendly decorative board

InactiveCN102528861AWaterproofStrong nail gripWood veneer joiningWood layered productsEngineeringMechanical property

The invention relates to a method and a manufacturing process (attached drawing) for producing an environmentally-friendly decorative board by using a fast-growing poplar rotary cut veneer, which mainly solve the problems of low bonding strength, high probability of cracking and warping, uncompacted corner, high formaldehyde release, low nail holding power, high probability of falling, poor water proofing, moisture proofing and fire proofing performance existing in the conventional decorative board. The production method and the manufacturing process are mainly characterized in that: the density of a finished board is determined by using the apparent density (actually measured) of the fast-growing poplar rotary cut veneer in comparison with the density of red pine; a compression ratio is determined according to the two densities; and the thickness of an assembly is determined by using the compression ratio. Modified urea-formaldehyde resin and melamine resin are mixed as an adhesive; and parameters for a hot pressing process of a board blank are determined according to the compression ratio, and curing temperature, time and pressure of an adhesive. Decorative paper which is soaked in the adhesive solution is adhered to the surface and the back surface of the board blank formed after hot pressing, and then secondary hot pressing is performed to finish the final environmentally-friendly decorative board. The production method and the manufacturing process have the advantages of mechanical property of the finished product beyond that of timber, no formaldehyde release, water proofing, moisture proofing, fire proofing and cracking prevention effects, high nail holding power, repeatedly detachable hardware and small variability.

Owner:LIAONING JIUJIU WOOD

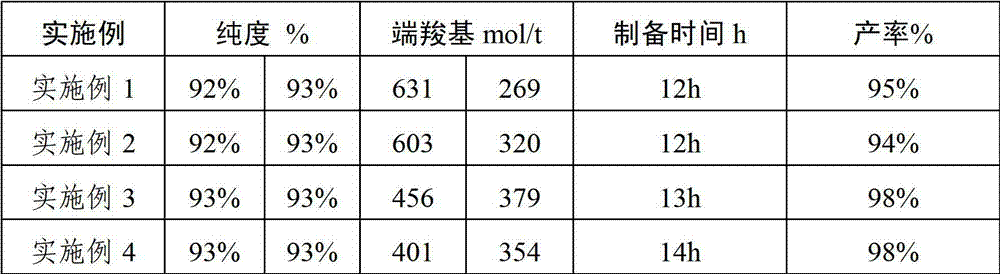

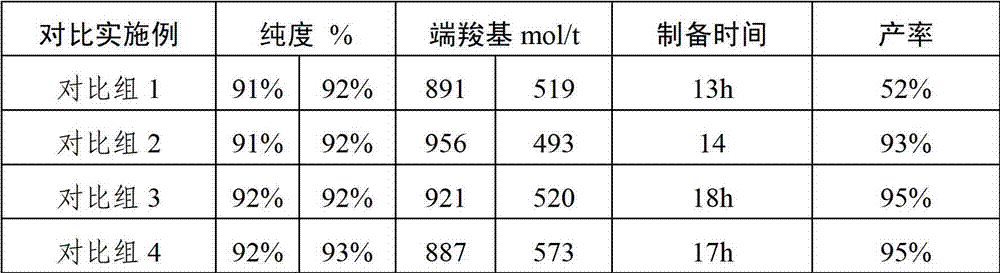

Method for preparing medical lactide

The invention relates to the method for preparing medical lactide. The method includes: adding catalyst and high boiling-point solvent in lactic acid for condensation polymerization to enable the lactic acid to generate lactic-acid oligomer, and adding catalyst in the generated lactic-acid oligomer for depolymerization to obtain the medical lactide. The high boiling-point solvent is added during the condensation polymerization, so that a reaction system during depolymerization cannot become viscous, and is less prone to steam out, carbonize and turn yellow caused by distillation and reduction of lactide, stability of production process, product quality and variability of physical indexes are guaranteed; and the method for preparing medical lactide is high in yield, simple in reaction operation, free of danger, short in production time and beneficial to industrial production, and has quite high economic value.

Owner:上海绿色盛世生态材料有限公司

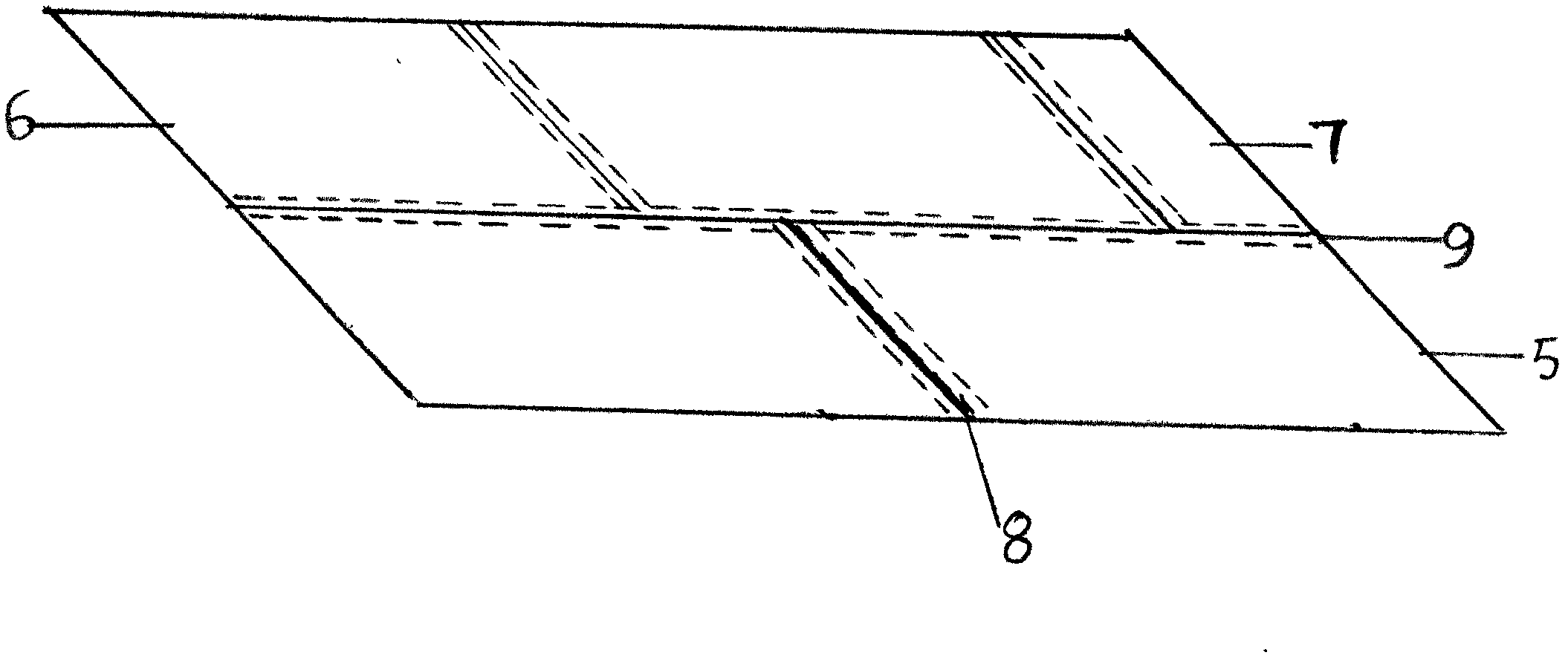

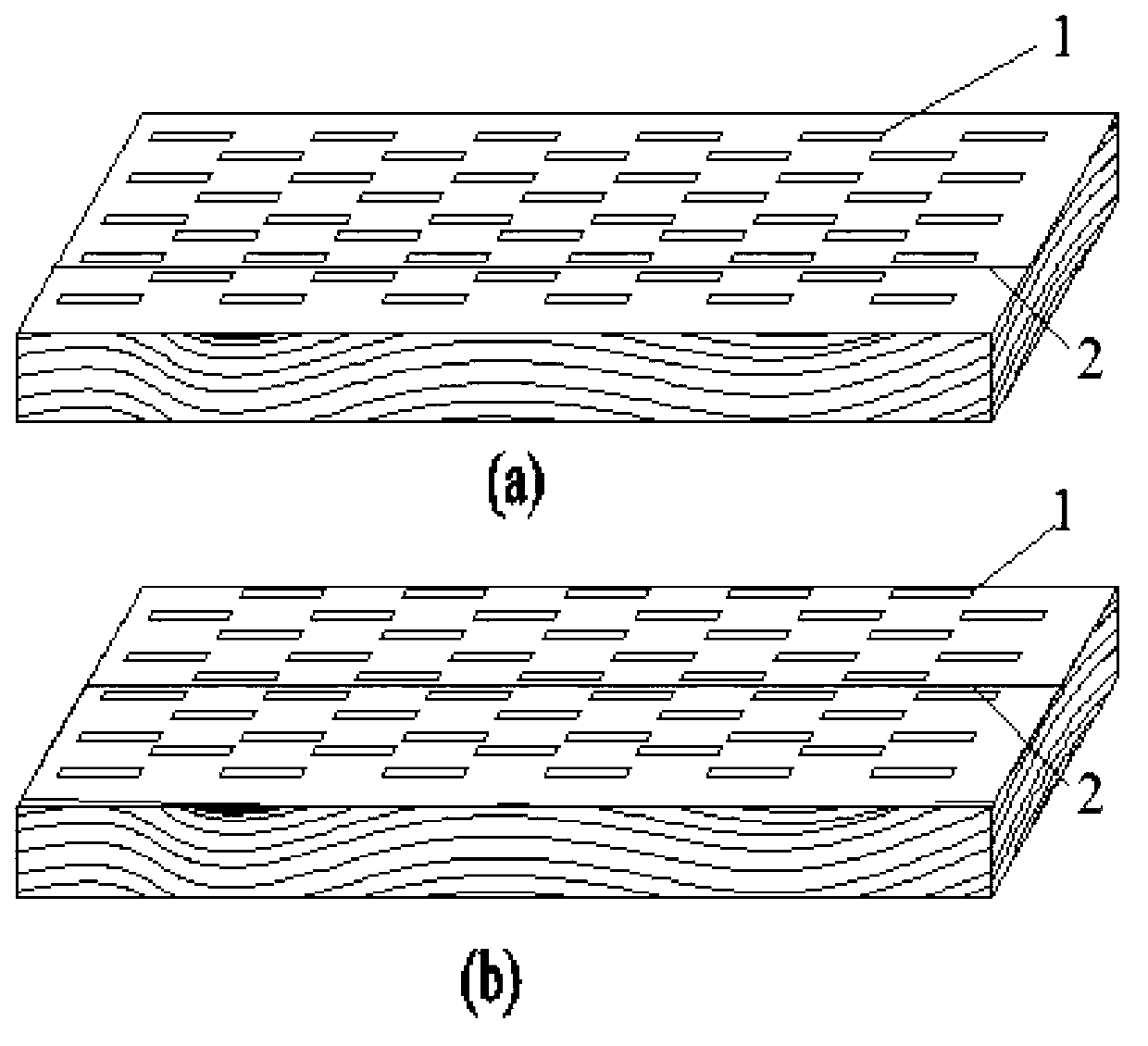

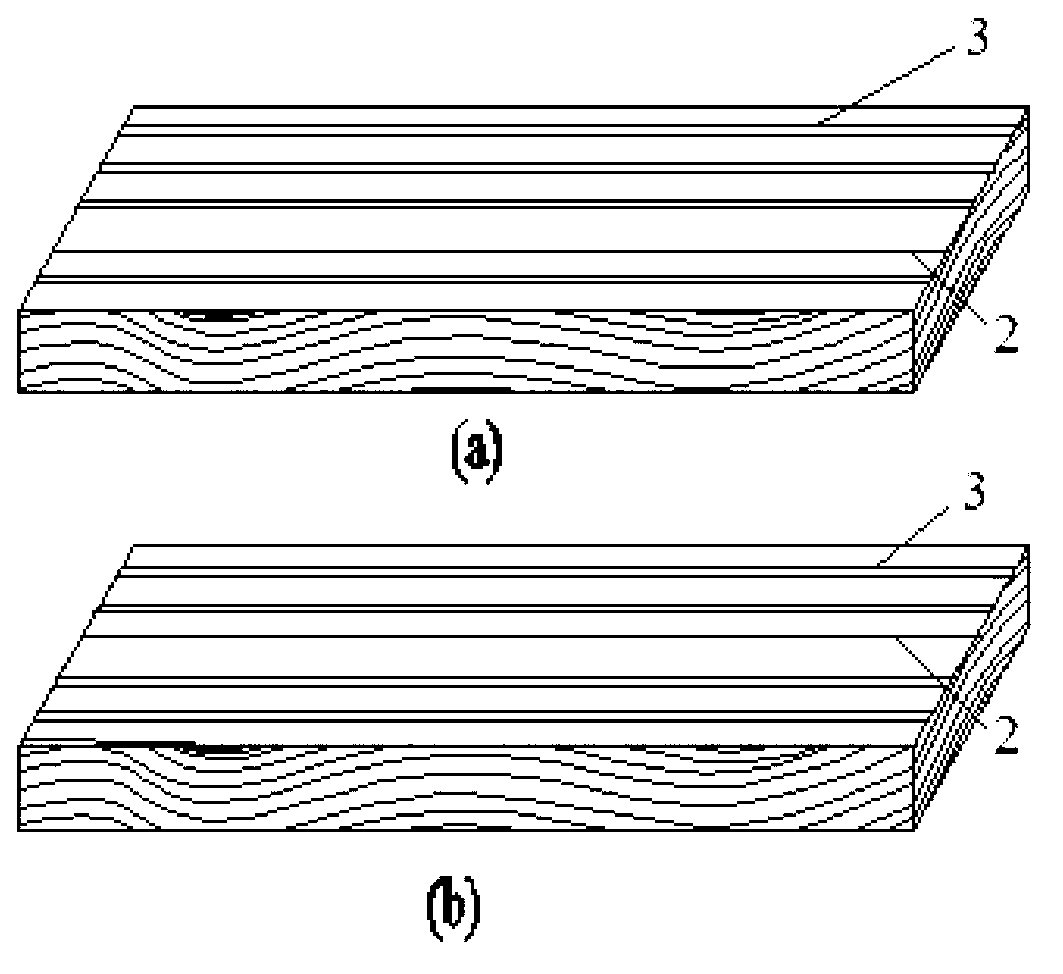

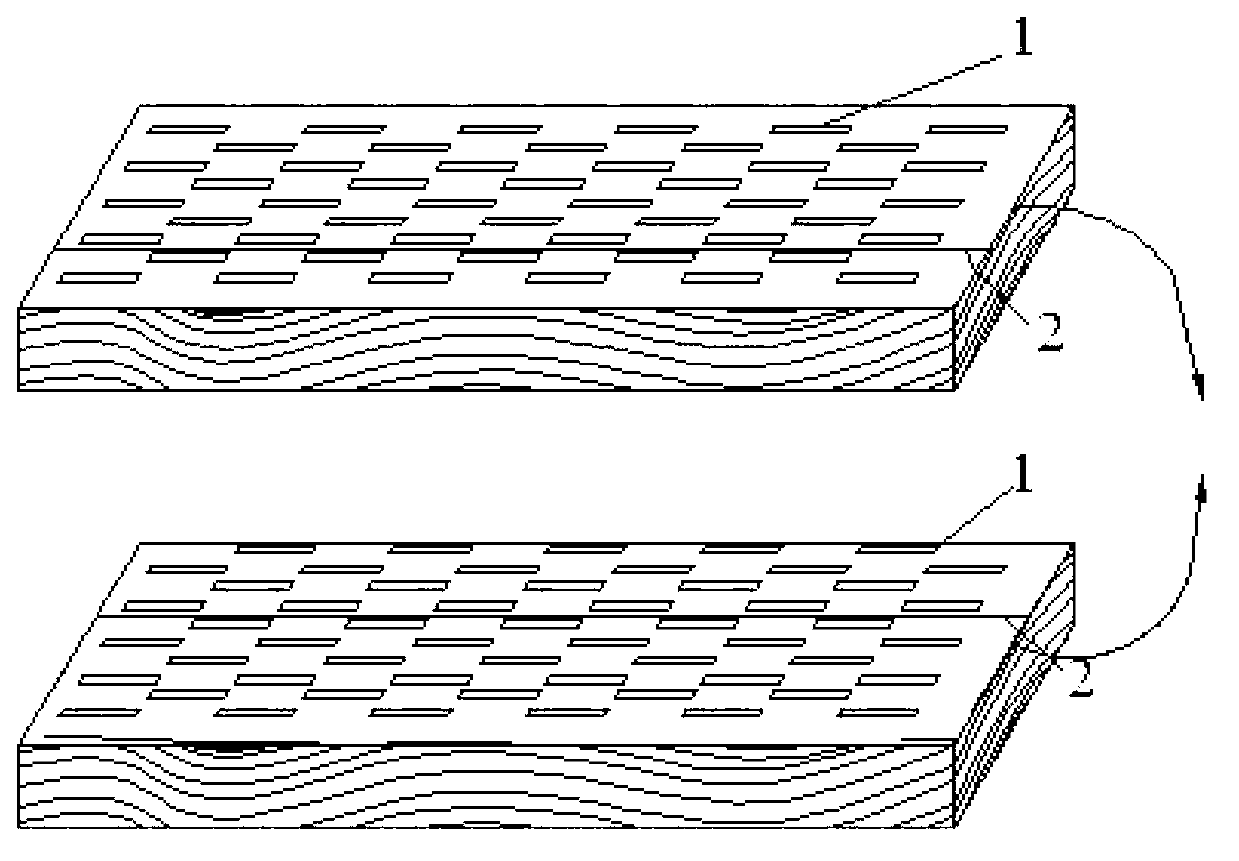

Glue laminated wood member with controllable dimensional stability and preparation method thereof

InactiveCN102990730AReduce crackingReduce laminate delaminationLaminationLamination apparatusSolid woodAdhesive cement

The invention discloses a glue laminated wood member with controllable dimensional stability and a preparation method thereof, belonging to the field of glue laminated wood preparation. The glue laminated wood member with controllable dimensional stability is composed of laminated sheets and adhesive layers through pressed superimposition, wherein each laminated sheet is an indentation laminated sheet which is processed by using solid-wood dimension stocks through transverse widening and longitudinal lengthening, the indentation laminated sheet is provided with continuous or discontinuous indentations along the texture direction, the adhesive layers adhered to the surfaces of the indentation laminated sheets are arranged between adjacent indentation laminated sheets, and adhesives are filled in the indentations. The glue laminated wood member with controllable dimensional stability is prepared through the steps of processing indentations, controlling the moisture content and the like, and the prepared glue laminated wood member with controllable dimensional stability solves the problems that the durability of common glue laminated wood members is poor caused by that middle-layer plates of the common glue laminated wood members are delaminated or subjected to shear failure or the stress between laminated sheets is concentrated due to environment temperature changes, or the quality of members prepared by using fast-growing wood is uncontrollable, the strength of the members is degraded caused by traditional wood removal through slotting, and the like.

Owner:NANJING UNIV OF TECH

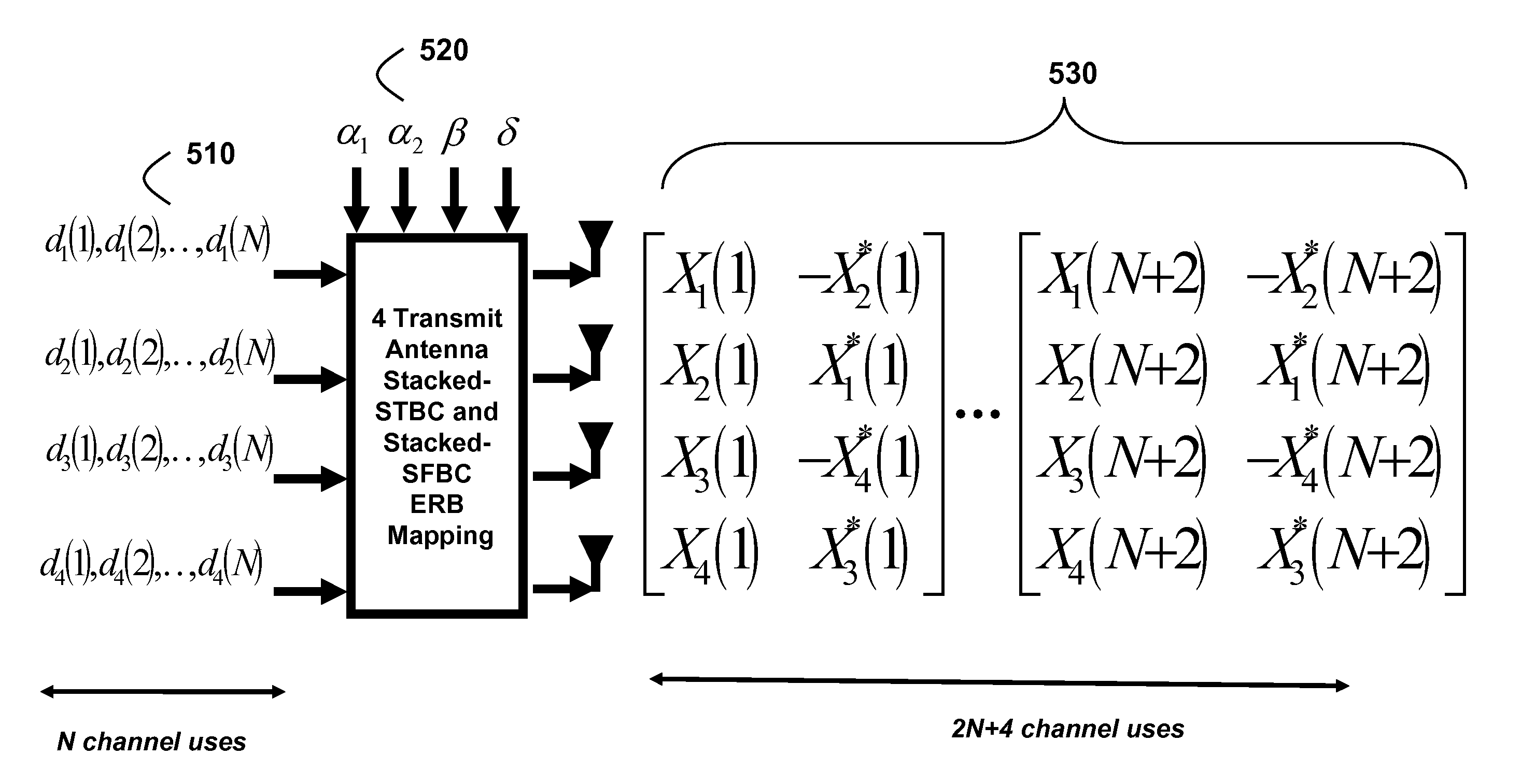

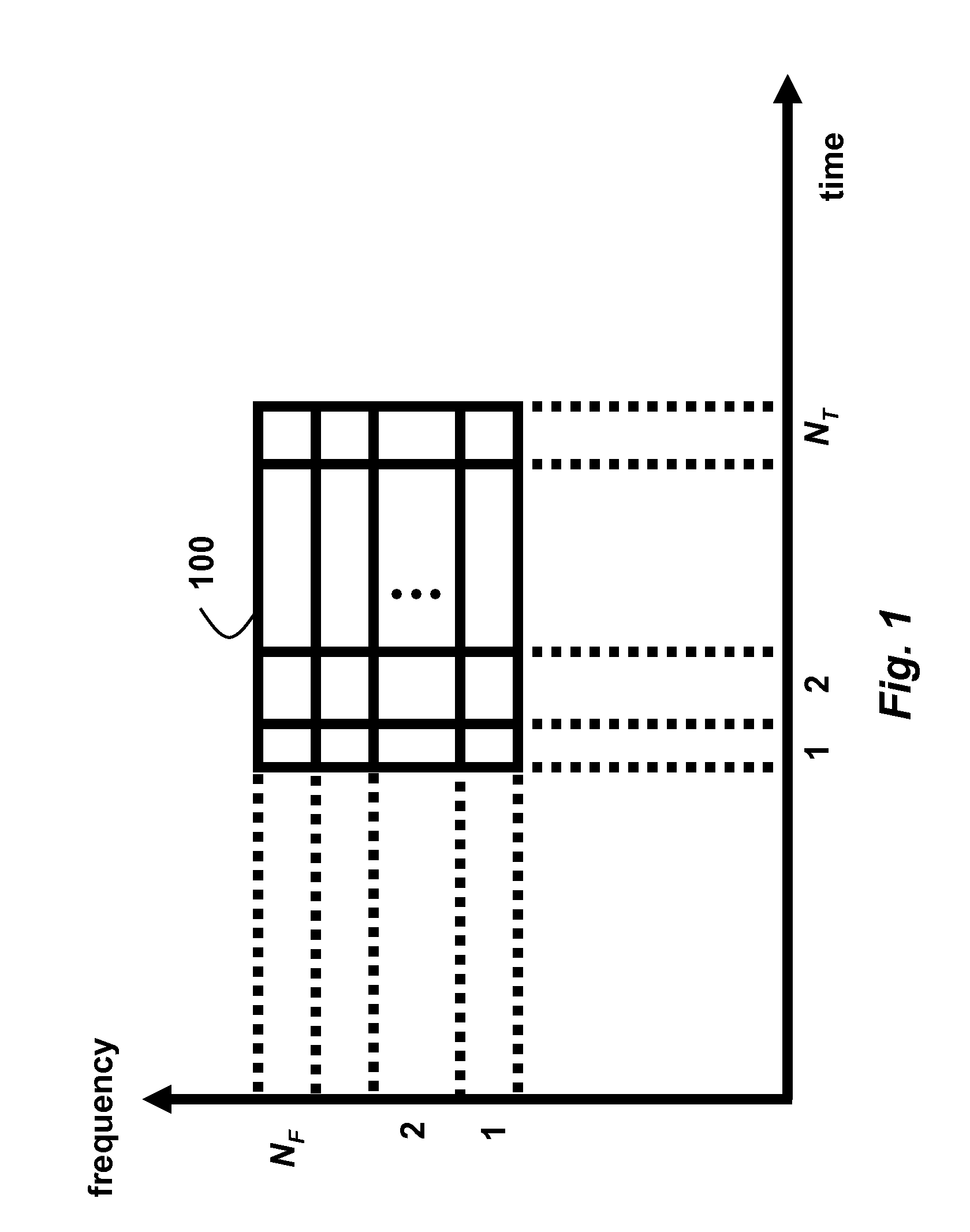

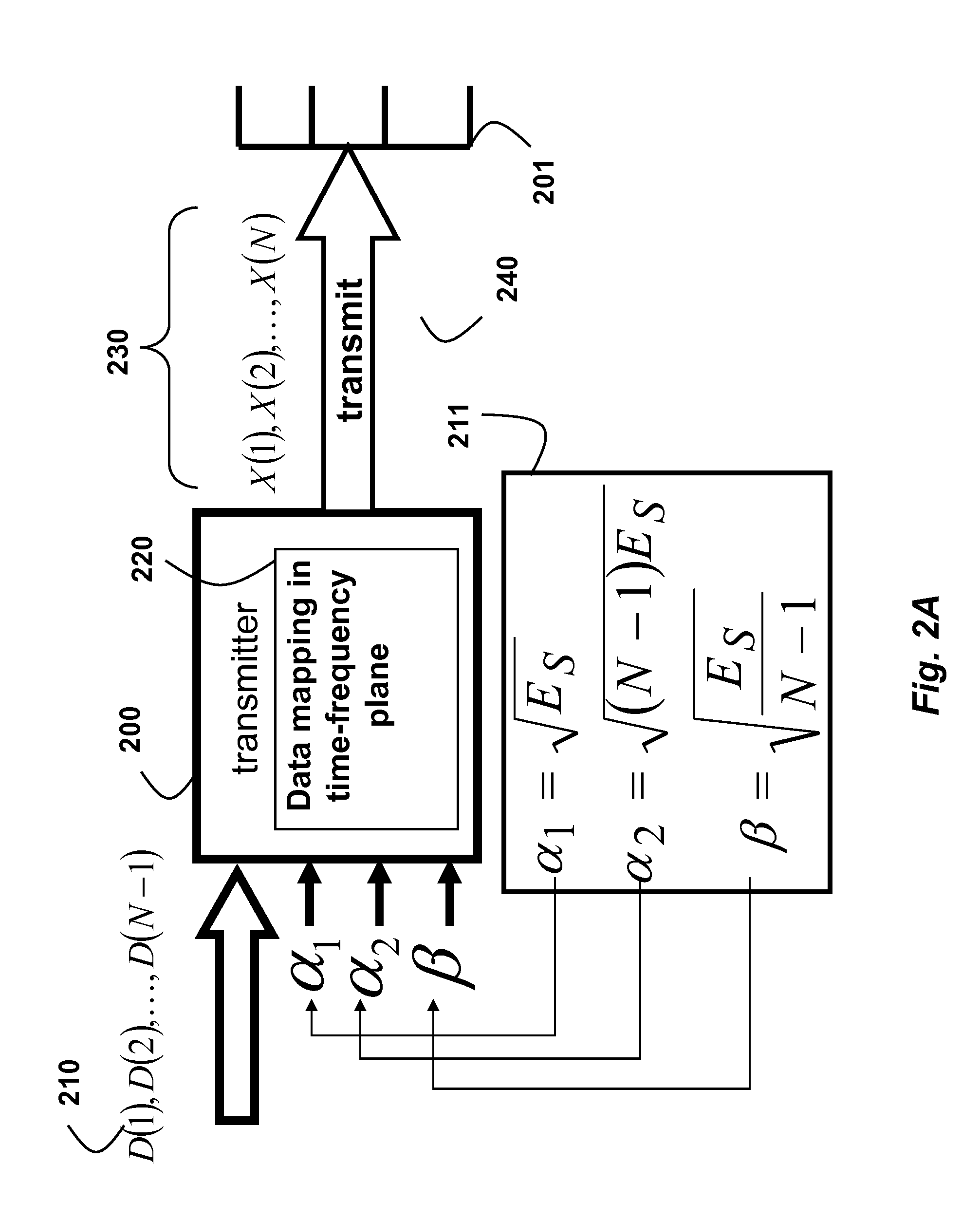

Method for Encoding Data Symbols with Implicitly Embedded Pilot Symbols in Resource Blocks for Wireless Networks

ActiveUS20120002753A1Save bandwidthShorten the timeDiversity/multi-antenna systemsSecret communicationWireless mesh networkResource block

A set of data symbols is selected from a set of modulation constellation, and a sample-mean of the set of data symbols is determined. Each data symbol is first shifted by the sample-mean to obtain a shifted data symbol, and then the shifted symbol is multiplied by a first constant to obtain a scaled data symbol. A second constant is added to the scaled data symbol to obtain a mapped data symbol. The sample-mean is multiplied by a third constant to obtain a sample-mean mapped symbol. The set of mapped data symbols and the sample-mean mapped symbol are then transmitted as a resource block.

Owner:MITSUBISHI ELECTRIC RES LAB INC

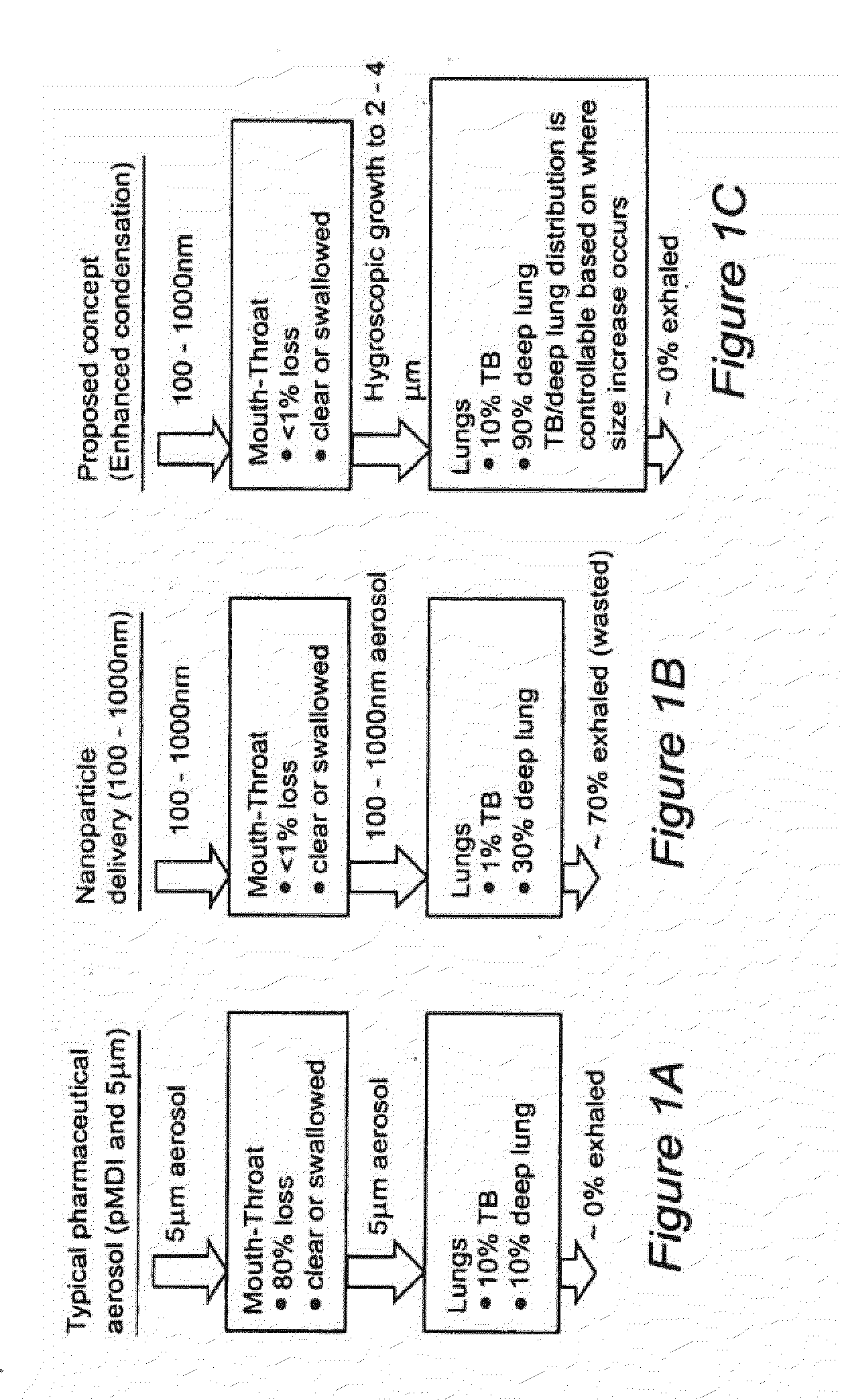

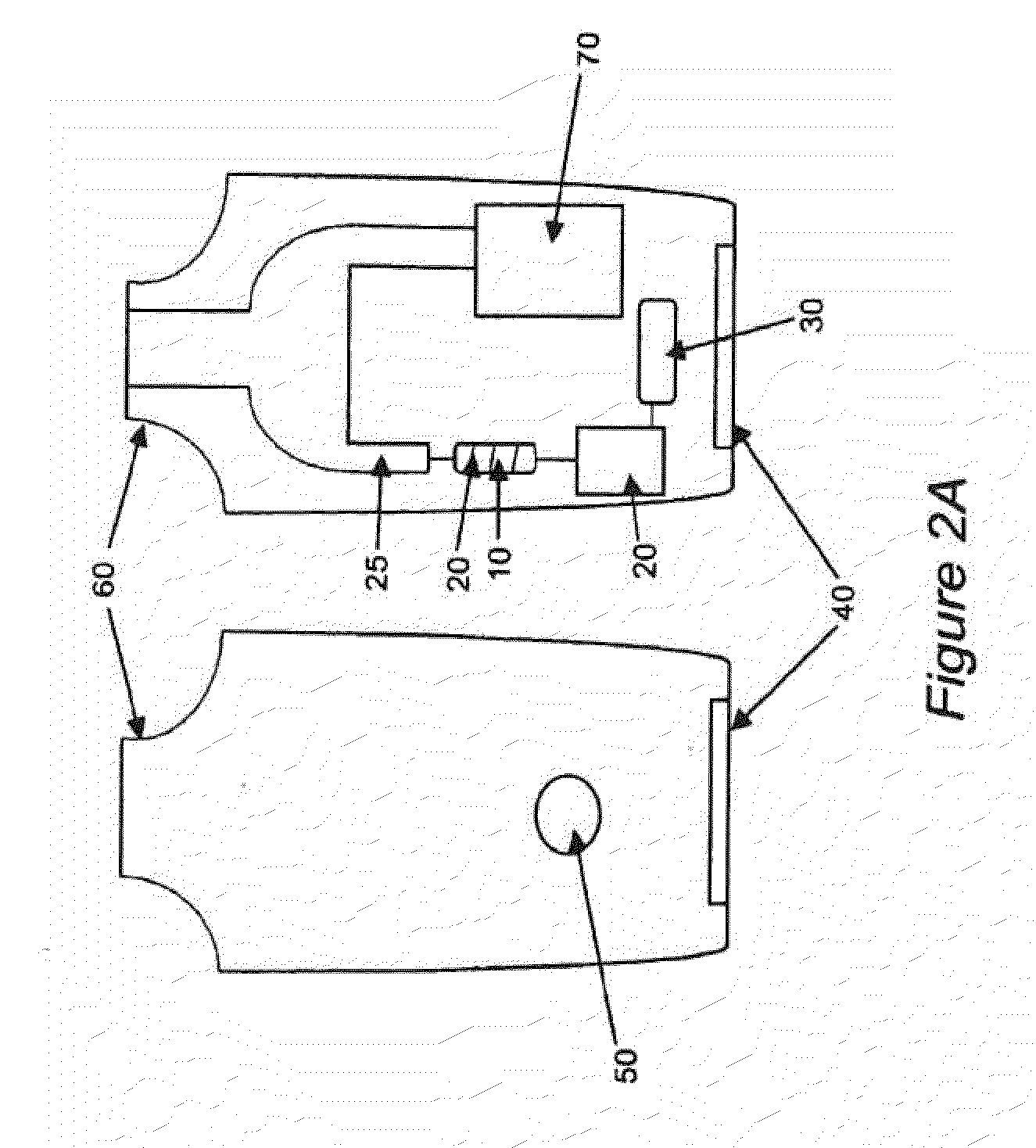

Effective delivery of nanoparticles and micrometer-sized pharmaceutical aerosols to the lung through enhanced condensational growth

ActiveUS20110056492A1Efficient deliveryEffectively penetrate the lungsPowder deliveryBiocideHigh humidityMedicine

Methods and devices for inhalation therapy to deliver and embed (deposit) particles less than about 1 μm in diameter in the lung. High humidity treatment of the lungs causes condensational growth in particle size upon entering the lungs. Increased particle size is conducive to particle embedment (deposition) in deep lung tissue or at a specific targeted lung region.

Owner:VIRGINIA COMMONWEALTH UNIV

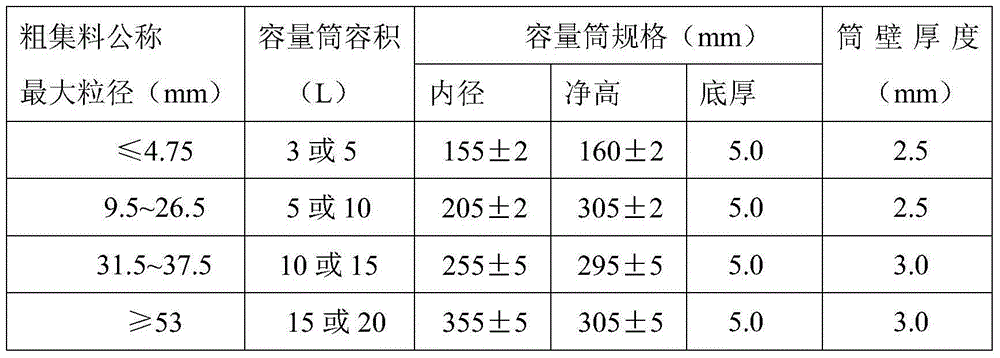

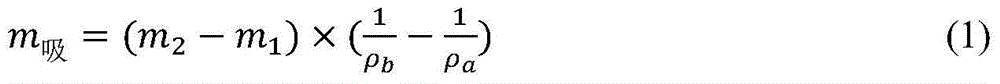

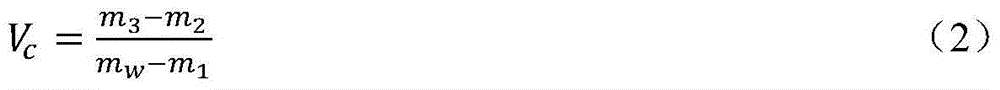

Determination method for bulk density and clearance rate of coarse aggregates

ActiveCN104535458AEasy to identifyLittle variabilityMaterial weighingSpecific gravity measurementStructure of the EarthClearance rate

The invention discloses a determination method for the bulk density and clearance rate of coarse aggregates. Firstly, sampling is carried out, a capacity barrel is selected, the mass of the capacity barrel is measured, the coarse aggregates are contained in the capacity barrel, operation is carried out according to different states of the coarse aggregates needing determining, the total mass of the capacity barrel and the coarse aggregates is obtained by weighing, then water is injected into the capacity barrel, the total mass of the capacity barrel, the coarse aggregates and the water is obtained by weighing, and finally the bulk density and clearance rate of the coarse aggregates are calculated according to measured data and a derived formula. The method can improve the accuracy and stability of measurement of the bulk density and clearance rate of the coarse aggregates, is of great importance in obtaining the accurate clearance rate of the coarse aggregates under the cement concrete compaction state and the clearance rate of a coarse aggregate skeleton under the bituminous mixture compaction state and then provides important help for judging whether an asphalt mastic macadam mixture skeleton stone-to-stone structure is formed or not.

Owner:SOUTHEAST UNIV

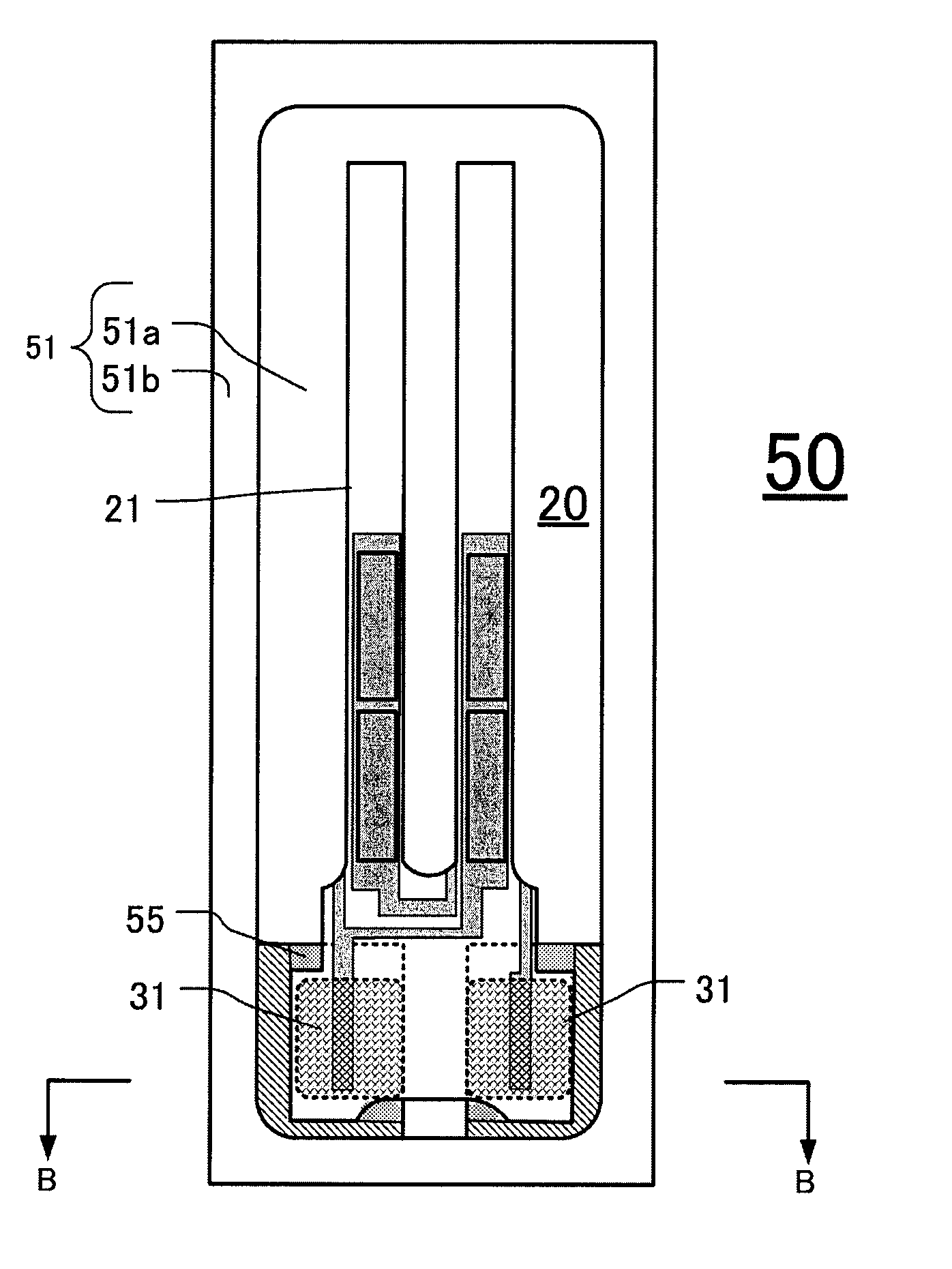

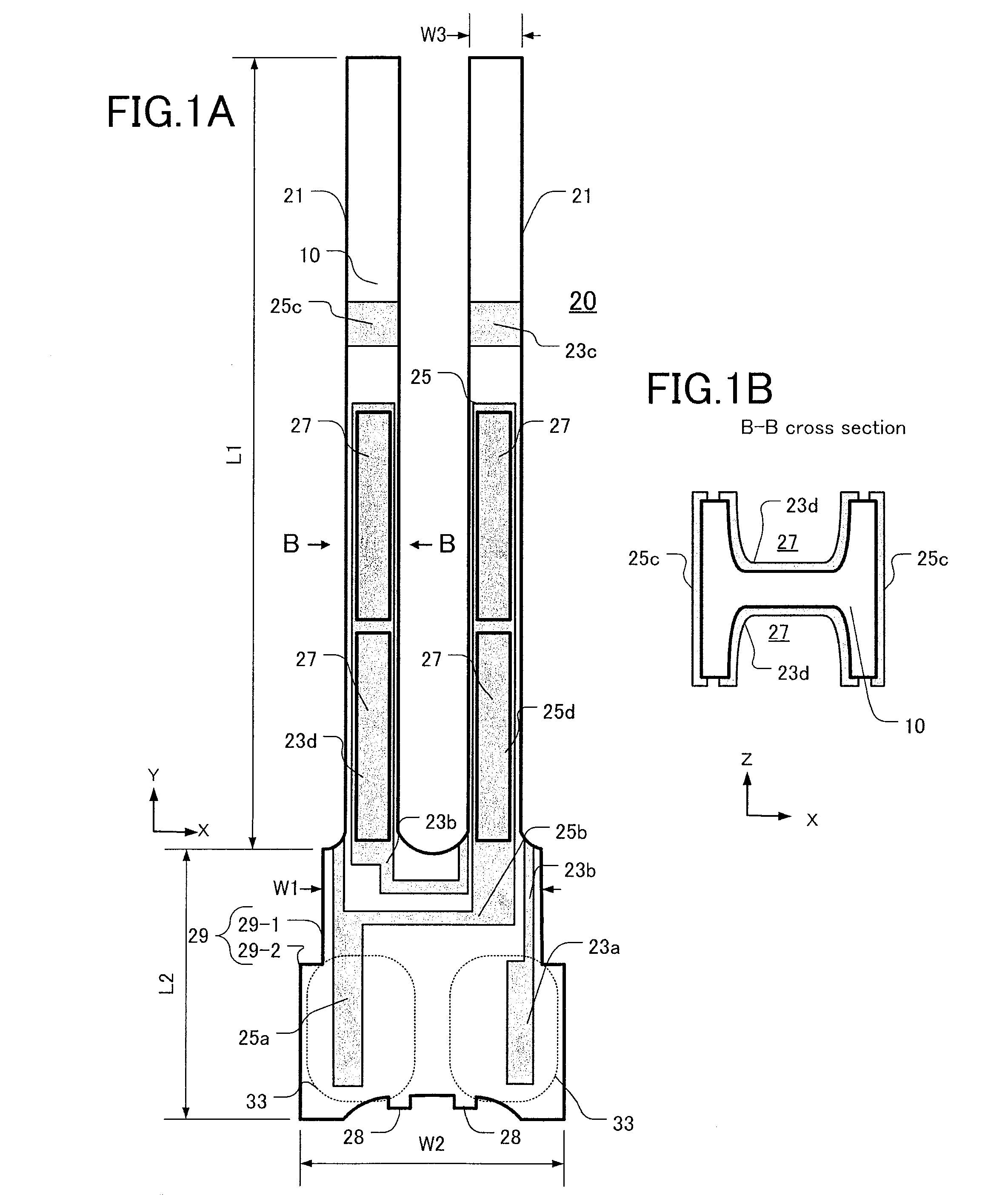

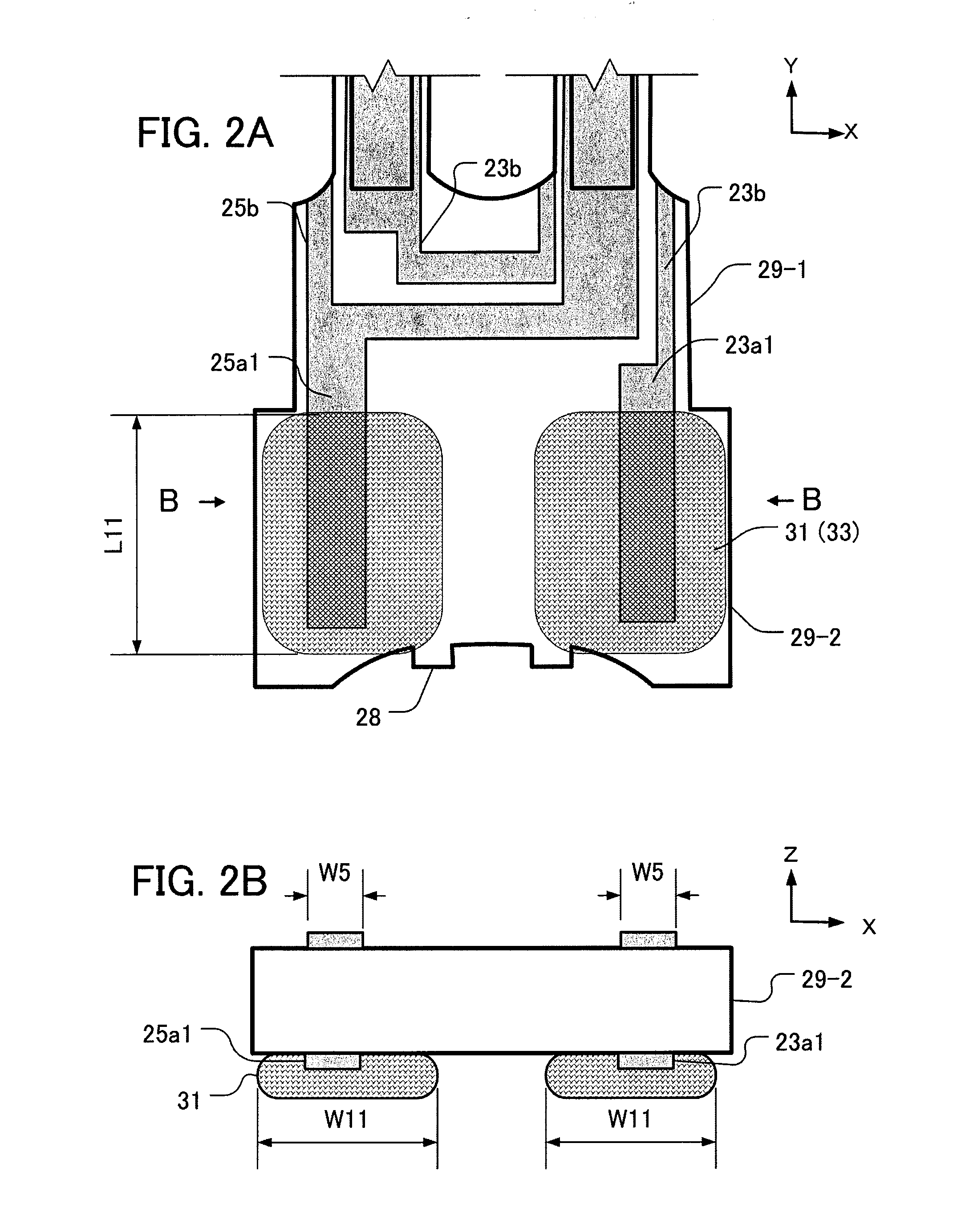

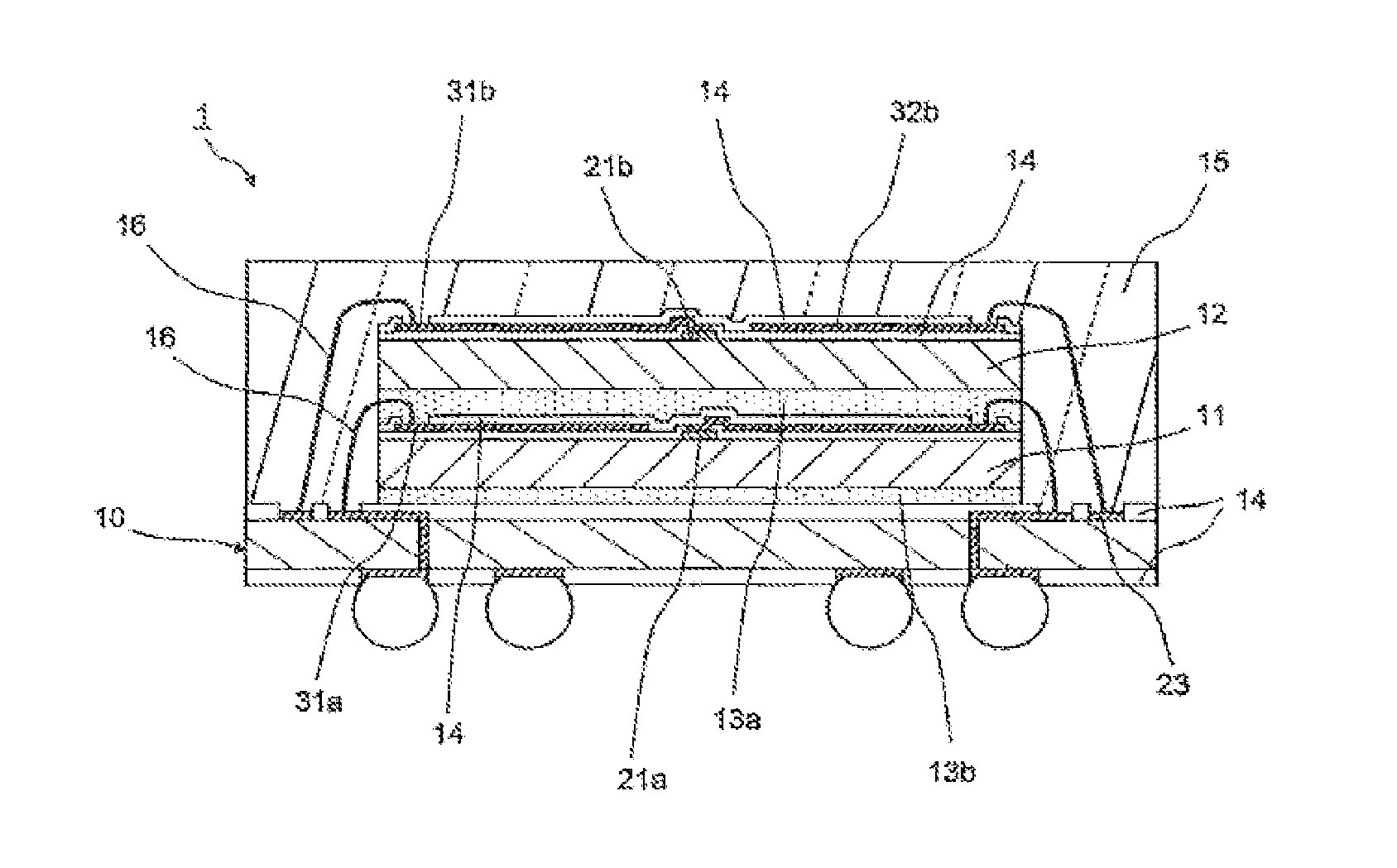

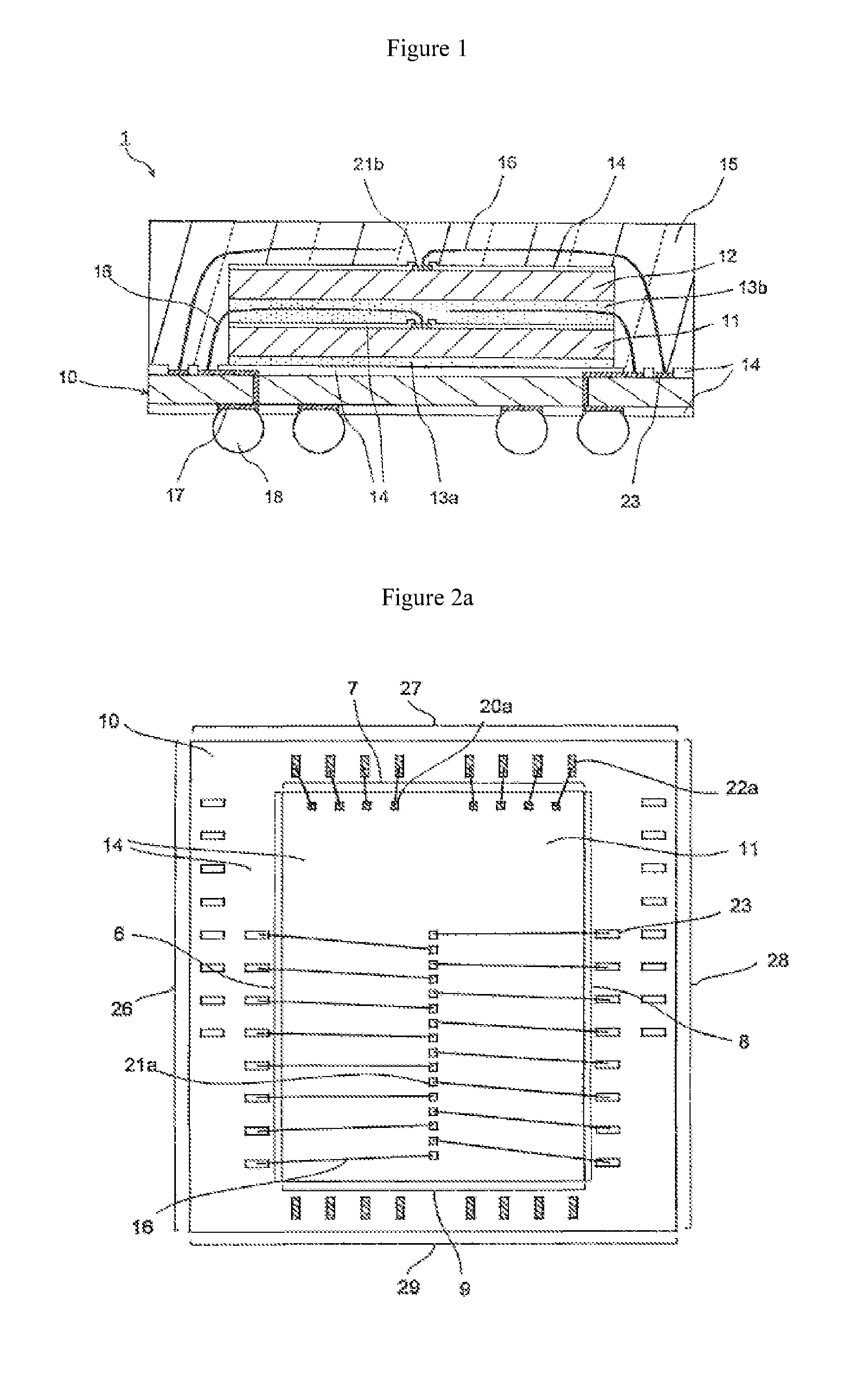

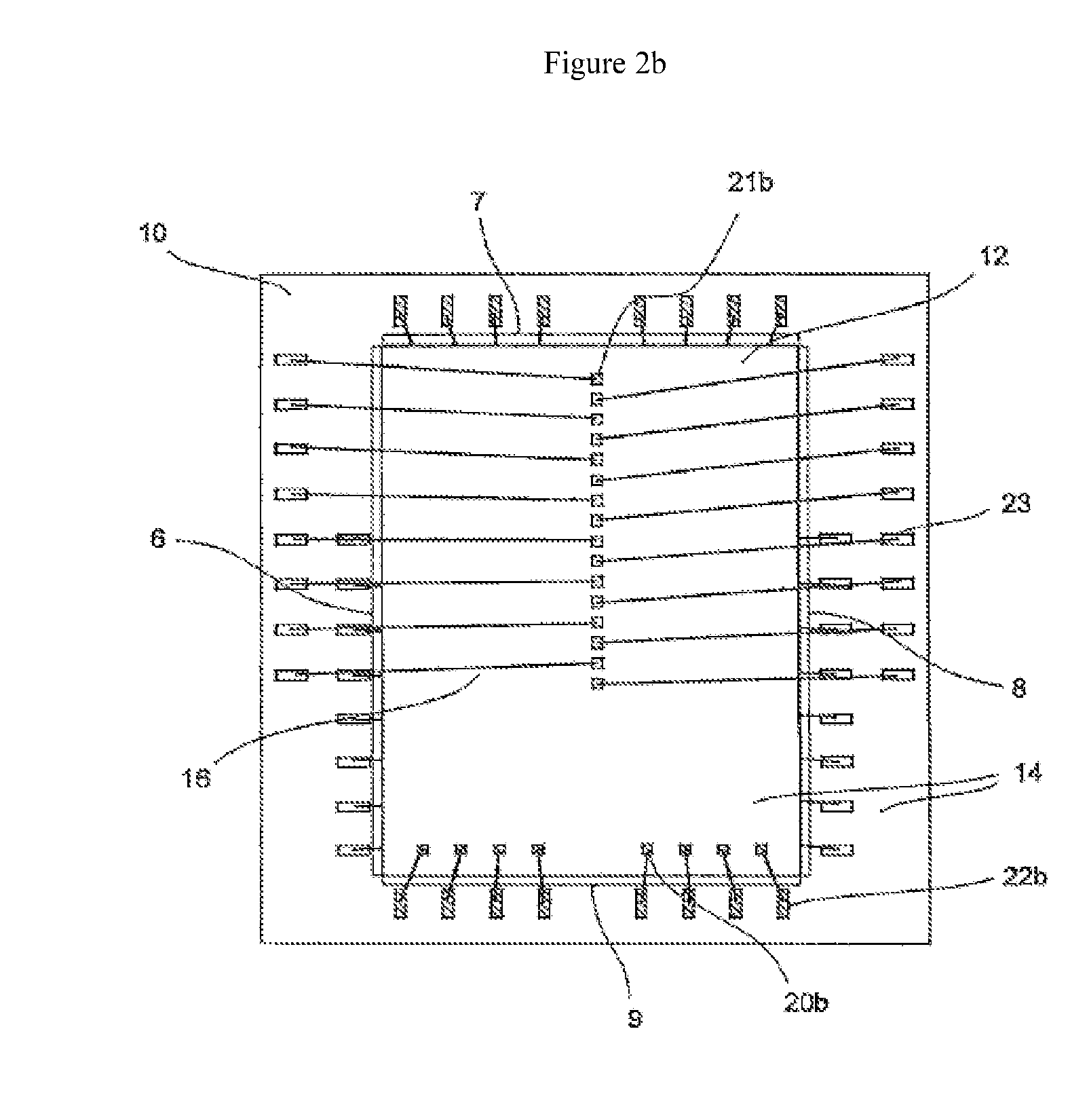

Piezoelectric vibrating pieces and piezoelectric devices

InactiveUS20090009037A1Reduce areaLittle variabilityImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAcousticsElectrically conductive adhesive

The piezoelectric vibrating piece (20) comprises a base portion (29) having an adhesive area on a first surface of electrically conductive adhesive 31 for mounting, a pair of vibrating arms (21) extending in a first direction from one edge of the base portion, base electrodes (23a, 25a) arranged in the base portion, an exciting electrode (23c, 25c) extending in a first direction and connecting the base electrode to excite a pair of vibrating arms. The area where the base electrodes (23a, 25a) conduct the electrically conductive adhesive (31) is smaller than the adhesive area (33).

Owner:NIHON DEMPA KOGYO CO LTD

Label inspection system and method

ActiveUS9569837B2Small differenceLittle variabilityImage enhancementImage analysisEngineeringControl circuit

A label inspection system fixture (1) has a scanner and housing (10) for performing full inline or offline inspection within a printer (20). The fixture (1) comprises a control circuit (5) with a processor within a curved guide plate (6). The scanner (10) communicates with the circuit (5), which in turn communicates with a host computer (VPU). The VPU identifies regions in a scanned label and applies to each region an inspection tool associated with that region. At least some of said tools include a stored training image and associated test data defining said regions and inspection criteria for the regions.

Owner:CREST SOLUTIONS

Systems and methods for collecting and transmitting assay results

ActiveUS9619627B2Quality improvementLittle variabilityData processing applicationsMicrobiological testing/measurementDiseaseChemical reaction

Owner:LABRADOR DIAGNOSTICS LLC

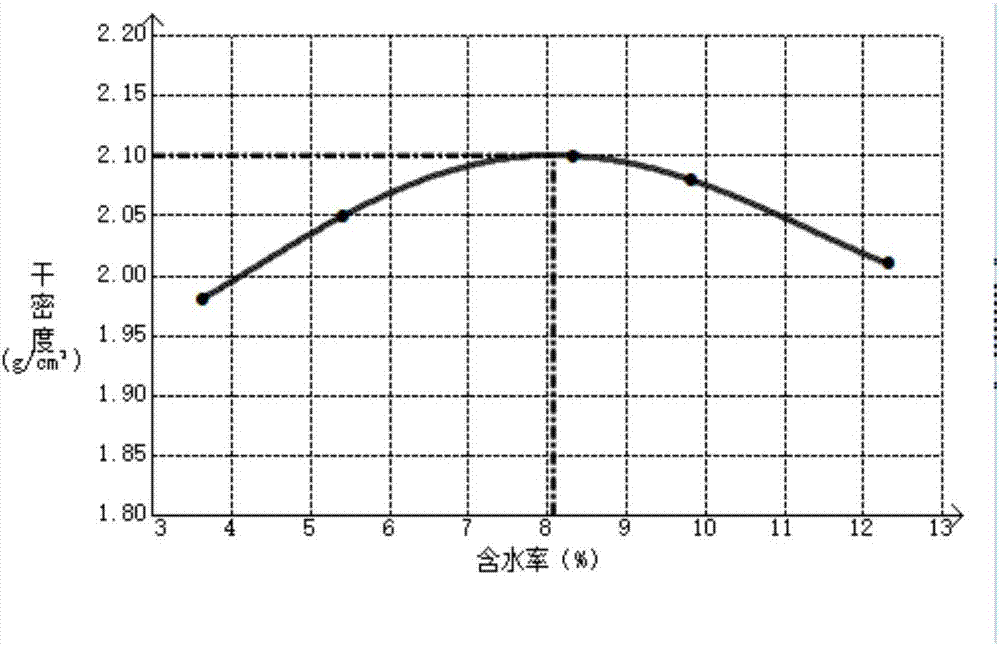

Test method for measuring maximum dry density of soil and stone mixture of road subgrade

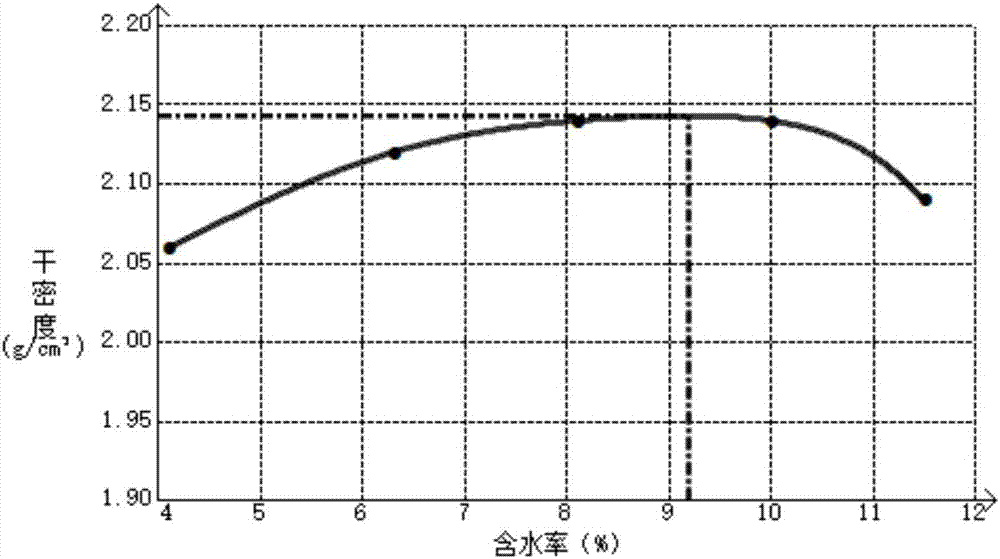

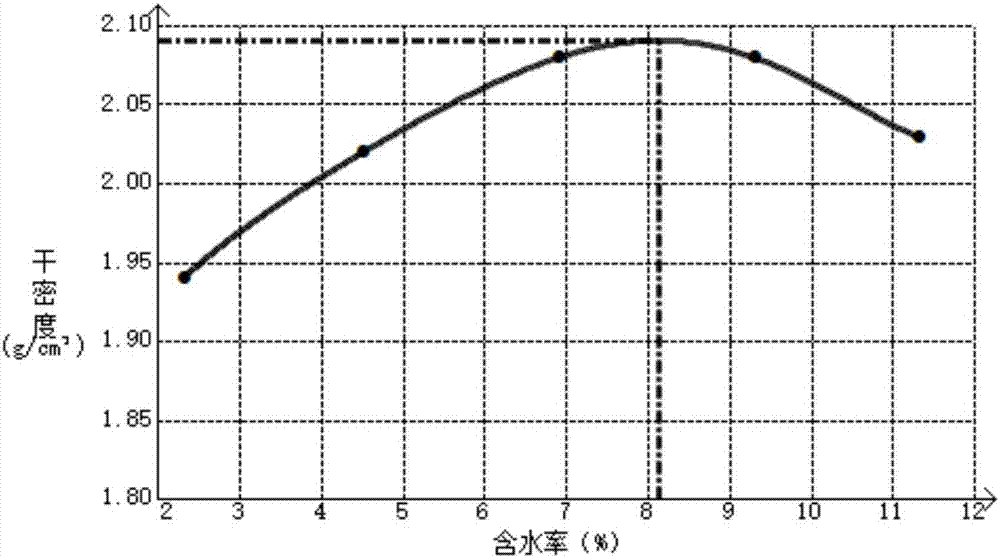

InactiveCN107219151ASmall difference in compactionEnsure complete removalPreparing sample for investigationSpecific gravity measurementVibration amplitudePeak value

The invention discloses a test method for measuring maximum dry density of soil and stone mixture of a road subgrade. The test method comprises the following steps of loading samples into a test die by two times, fixing onto a vibration compaction test instrument, and performing vibration compaction for two times, wherein the vibration compaction time is 50s each time, the parameter setting of the compaction test instrument is as follows: the vibration frequency is 25Hz, the excitation vibration force is 5.5kN, the nominal vibration amplitude is 1.4mm, the loading mass is 110+ / -2kg, the unloading mass is 170+ / -2kg, the eccentric block included angle is 0 degree, and the pressure of the static surface is 109kPa; testing the water content of each sample, and calculating the dry density of each sample; repeating the compaction test for five times, and drawing the dry density-water content relationship curve, wherein the transverse coordinate is the water content, and the longitudinal coordinate is the dry density; the dry density corresponding to the curve peak is the maximum dry density roudmax, and the corresponding water content is optimum water content omega0. The test method has the advantages that the operation is simple and convenient, the results are reliable, the variance is small, and the destroy to the raw materials is small.

Owner:CHANGAN UNIV +1

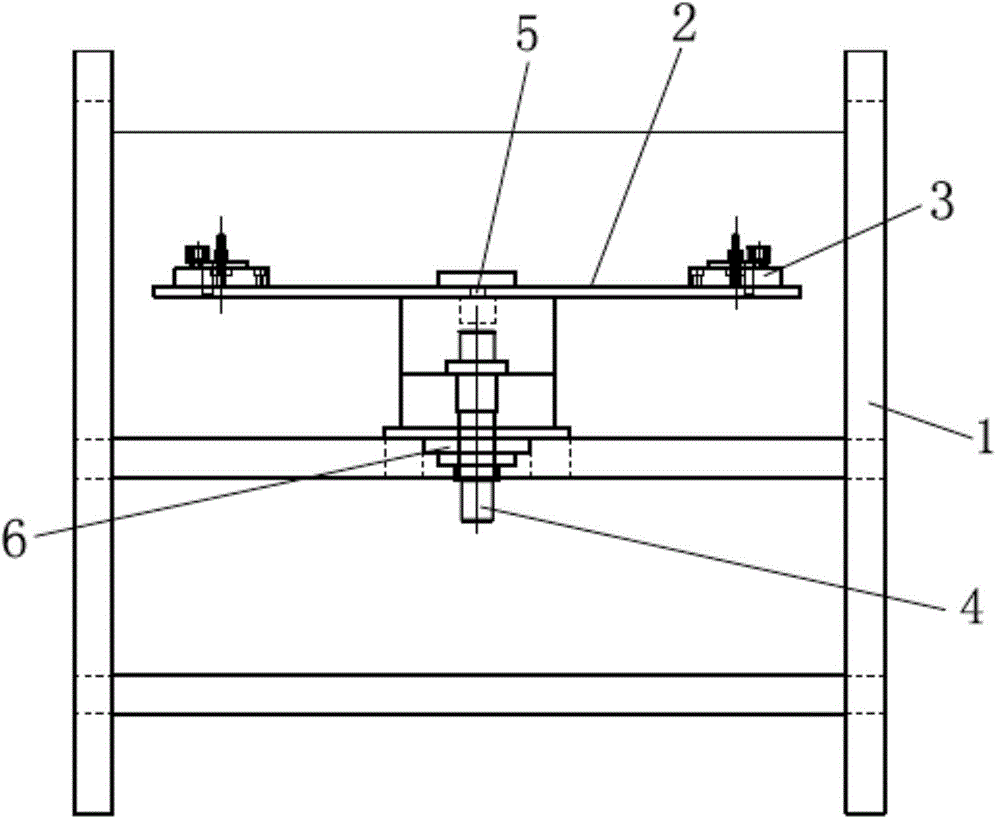

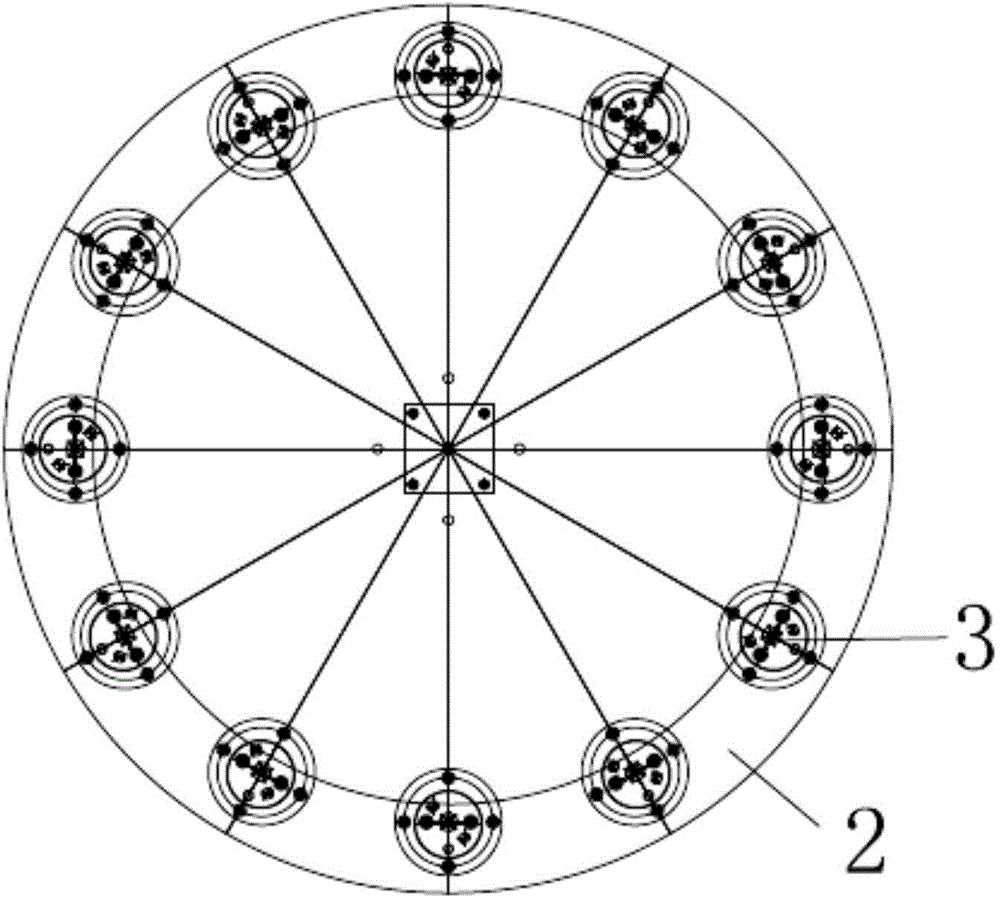

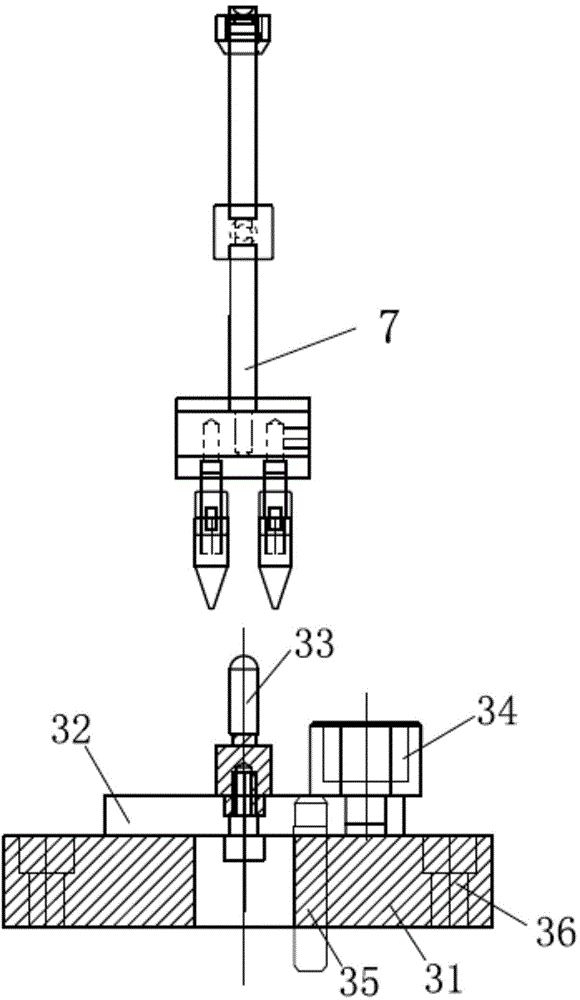

Exhaust pipe welding set of compressor upper shell

InactiveCN104690390ALittle variabilityReduce dependenceHeating appliancesWelding/cutting media/materialsEngineeringExhaust pipe

The invention discloses an exhaust pipe welding set of a compressor upper shell. The exhaust pipe welding set comprises a supporting bracket (1) and a rotating disc which is rotatably connected with the bracket (1), wherein a plurality of welding clamps (3) which are used for fixing the compressor upper shell (8) and an exhaust pipe (9) are uniformly distributed in the circumferential direction of the rotating disc (2); the lower end of the exhaust pipe (9) is sleeved by a welding ring (10); a welding gun (7) which is used for welding is arranged on the side edge of the bracket (1); and the welding device further comprises a controller which is used for controlling the rotating disc (2) and the welding gun (7) to be matched to start and stop intermittently. When the welding device is used for welding, the operation is convenient and orderly, the welding performance is stable the changeability is small, the undesirable phenomenon of weldment leakage is reduced, the welding quality of the weldment is greatly enhanced and relatively strong practicability is achieved.

Owner:WUHU DECHUANG ELECTRIC

Semiconductor device

InactiveUS20150318265A1Little variabilityRun at high speedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

One semiconductor device has a wiring substrate, a first semiconductor chip, and a second semiconductor chip. Each semiconductor chip includes a first side and a third side which are opposed, a second side which is perpendicular to the first side, and a fourth side opposing the second side. A first electrode (CA electrode pad) parallel to the first side, and a second electrode (I / O electrode pad) arranged parallel to the second side near the second side, are provided on the first semiconductor chip. A third electrode (CA electrode pad) parallel to the first side, and a fourth electrode (I / O electrode pad) arranged parallel to the fourth side near the fourth side, are provided on the second semiconductor chip.

Owner:PS4 LUXCO SARL

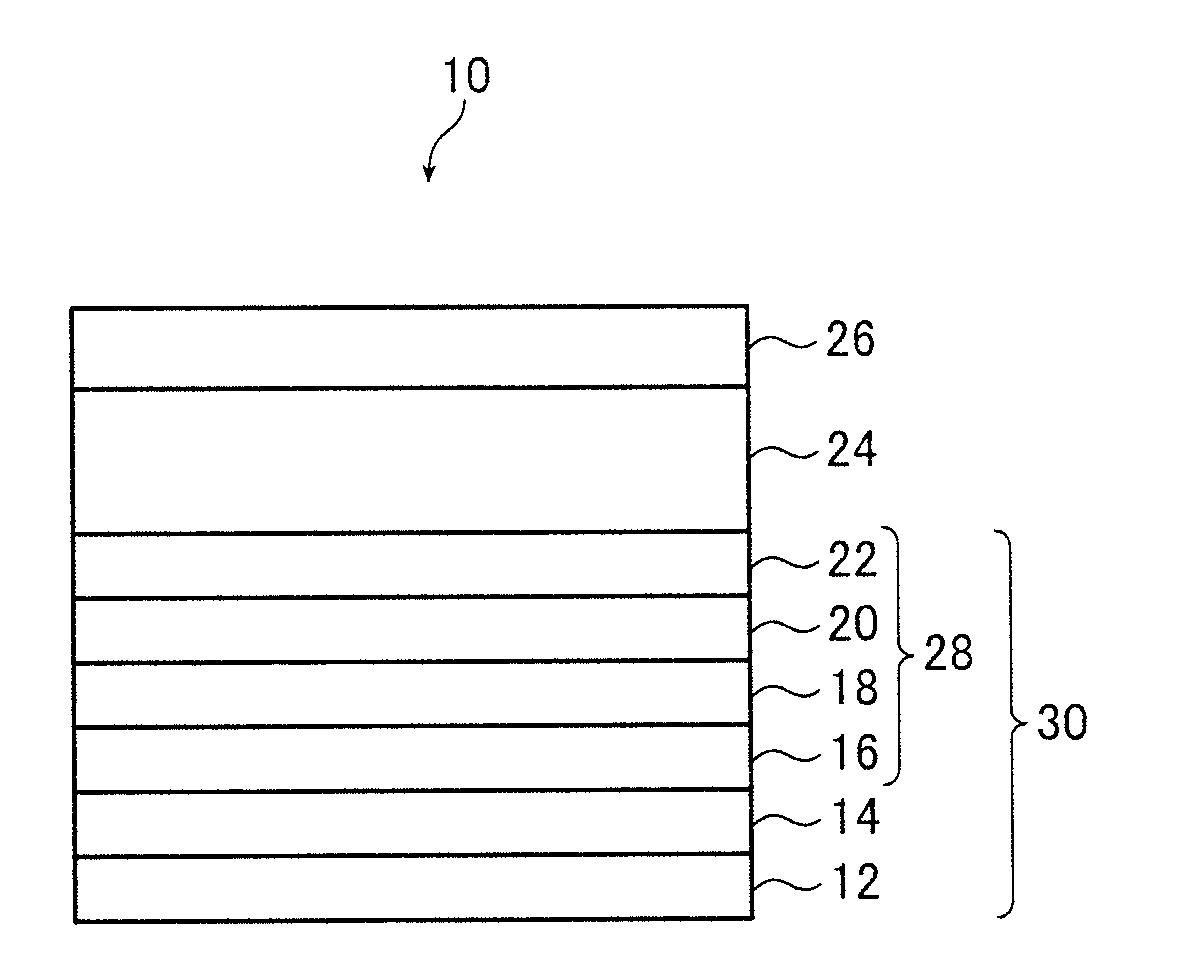

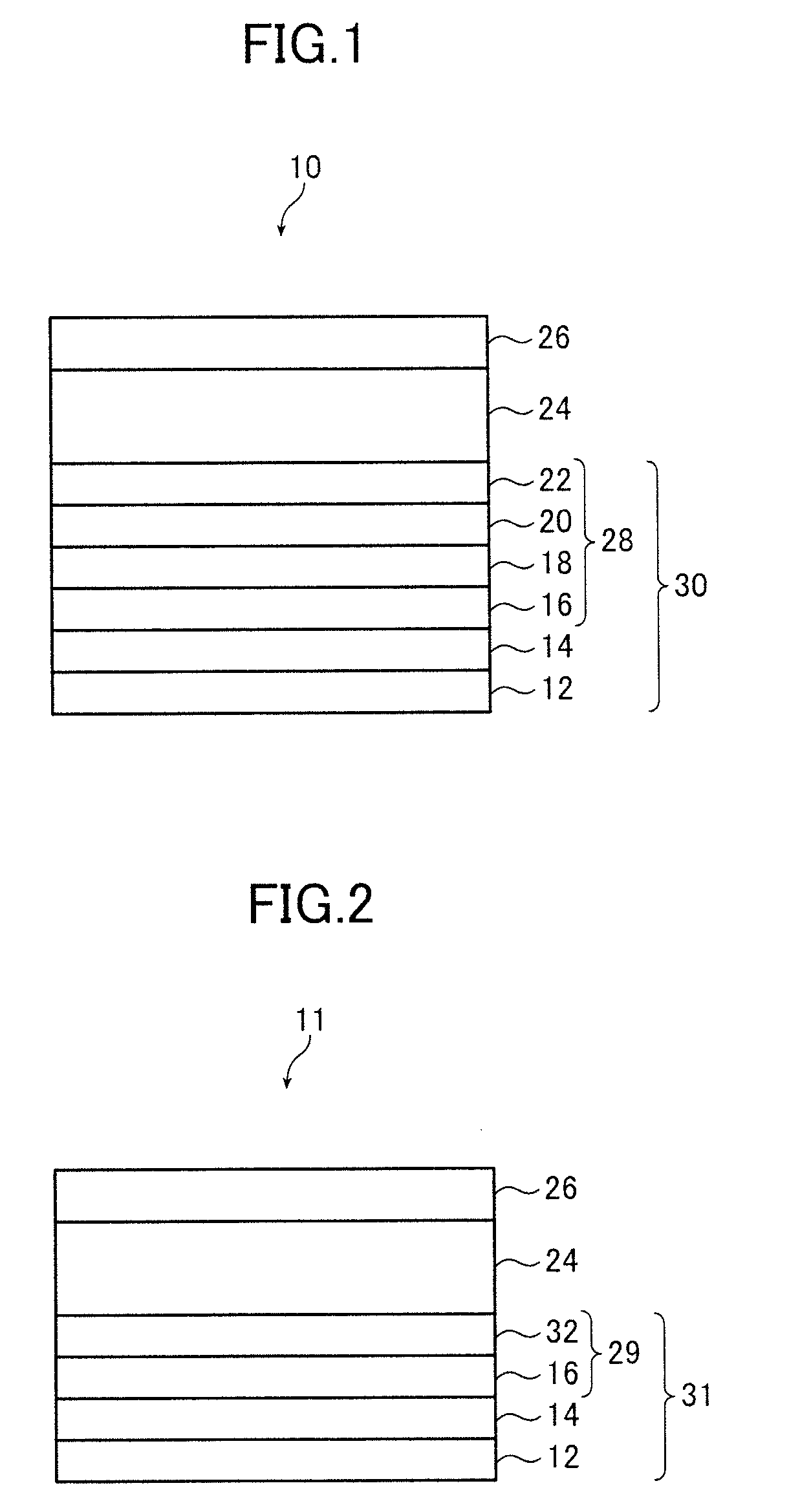

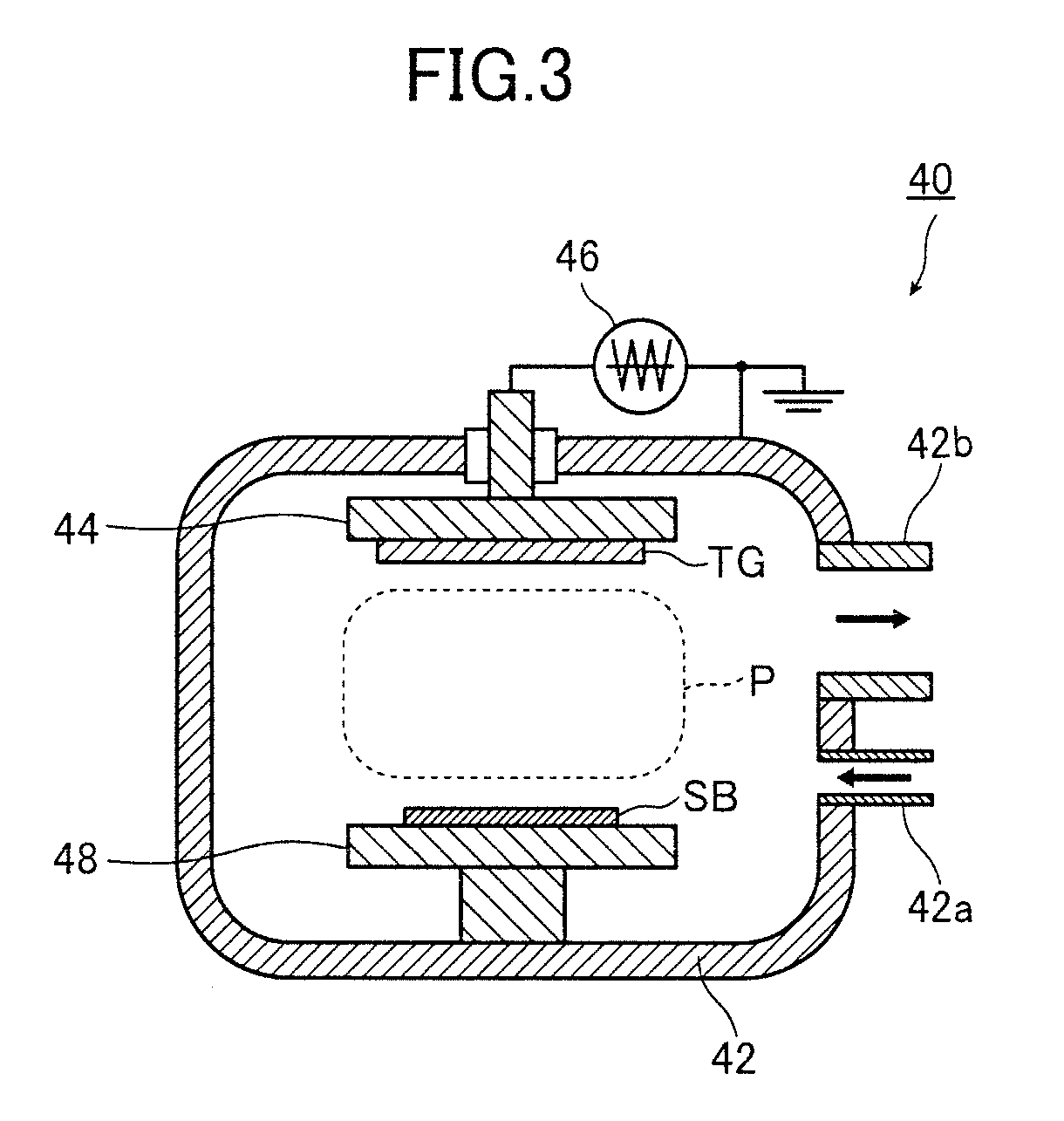

Multilayer body, piezoelectric element, and liquid ejecting device

ActiveUS20100039482A1Affect their durabilityLower performance requirementsPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical resistance and conductanceHeat resistance

Owner:FUJIFILM CORP

Unsaturated polyester-bonded and glass fiber-reinforced beam and implementation method thereof

InactiveCN101725216AHigh mechanical strengthImprove creep resistanceWood working apparatusGirdersGlass fiberPolyester

The invention discloses an unsaturated polyester-bonded and glass fiber-reinforced beam and an implementation method thereof, belonging to the manufacturing field of building structure materials. The glass fiber-reinforced beam mainly consists of glulam beam and glass fiber cloth, and glass fiber cloth is bonded at the partial bottom of the beam by unsaturated polyester so that the beam is reinforced. The preparation method of the glass fiber-reinforced beam realizes the preparation of the glulam beam and the partial reinforcement of the glass fiber cloth through a series of processes of preparing materials, processing, finger jointing, cold pressing, pretreating, post treating and the like. The glass fiber-reinforced beam solves the problems that the structure is difficult to reinforce due to the blockage of connection positions and wood composites have poor performance caused by the quality defects of wood in the mode of partial reinforcement, simultaneously utilizes the unsaturated polyester to bond the glass fibers for reinforcement to save the cost of an adhesive, and can bond multi-layer glass fiber cloth to reach high reinforcement strength.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com