Method for processing and analyzing multi-sequence dynamic creep test data of asphalt mixture

An asphalt mixture and dynamic creep technology, which is applied in the direction of applying repetitive force/pulse force to test the strength of materials, can solve the problems of increasing workload and data processing difficulty, and achieve convenient and fast rut development, high accuracy, and convenience. Calculated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Taking the test results of AC-20 type 70# asphalt mixture as an example, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods.

[0063] The inventive method comprises the following steps:

[0064] 1) Design the parameters of the Butterworth low-pass filter to remove the noise interference in the creep data of the specimen and obtain a gentle creep curve. Value range, and then make different combinations of the two parameters within the value range, compare the filtering effect under each combination, and finally determine the optimal combination.

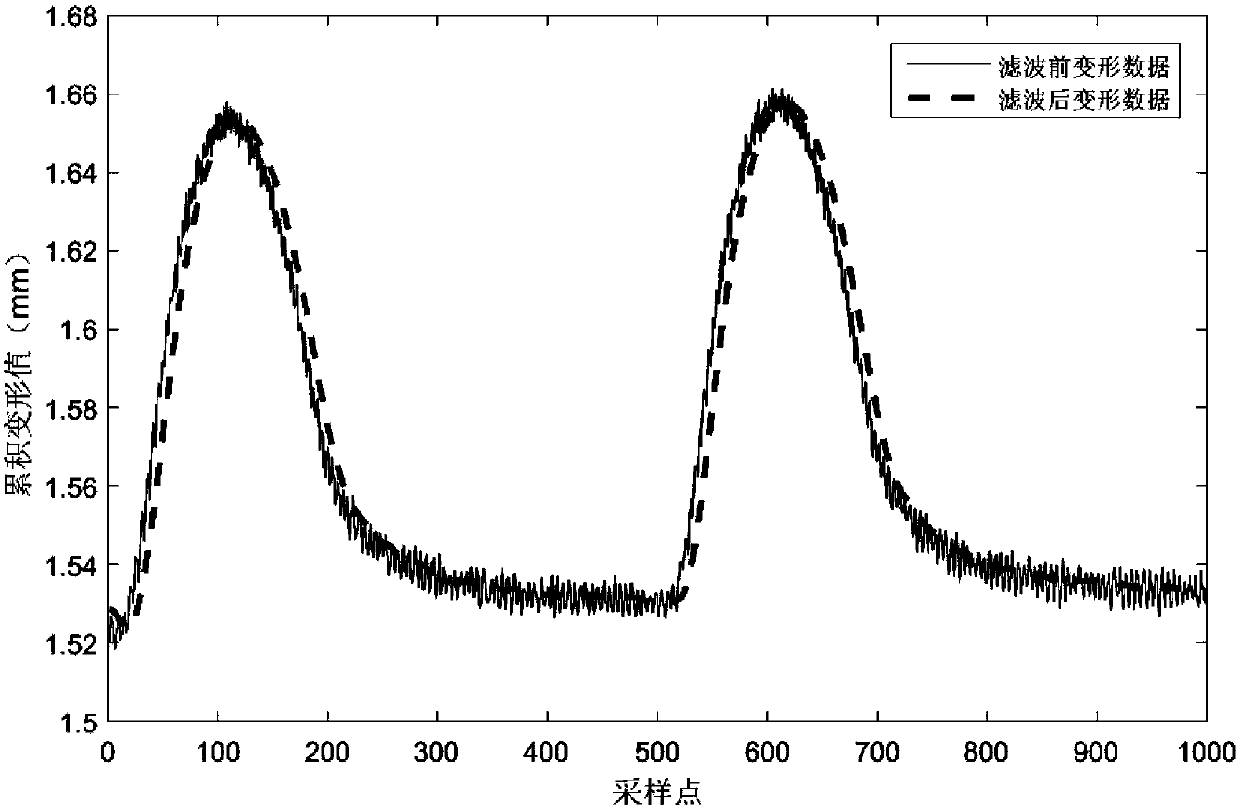

[0065] Such as figure 1 As shown, the figure shows the first two loading cycles (total 2s, 1000 data) in the fourth loading sequence (stress size 0.7MPa, pulse width 0.4s, intermittent time 0.6s) in the multi-sequence local dynamic creep test point) comparison of accumulated deformation data before and after filtering. In this example, the samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com