Patents

Literature

102results about How to "Improve intrinsic viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

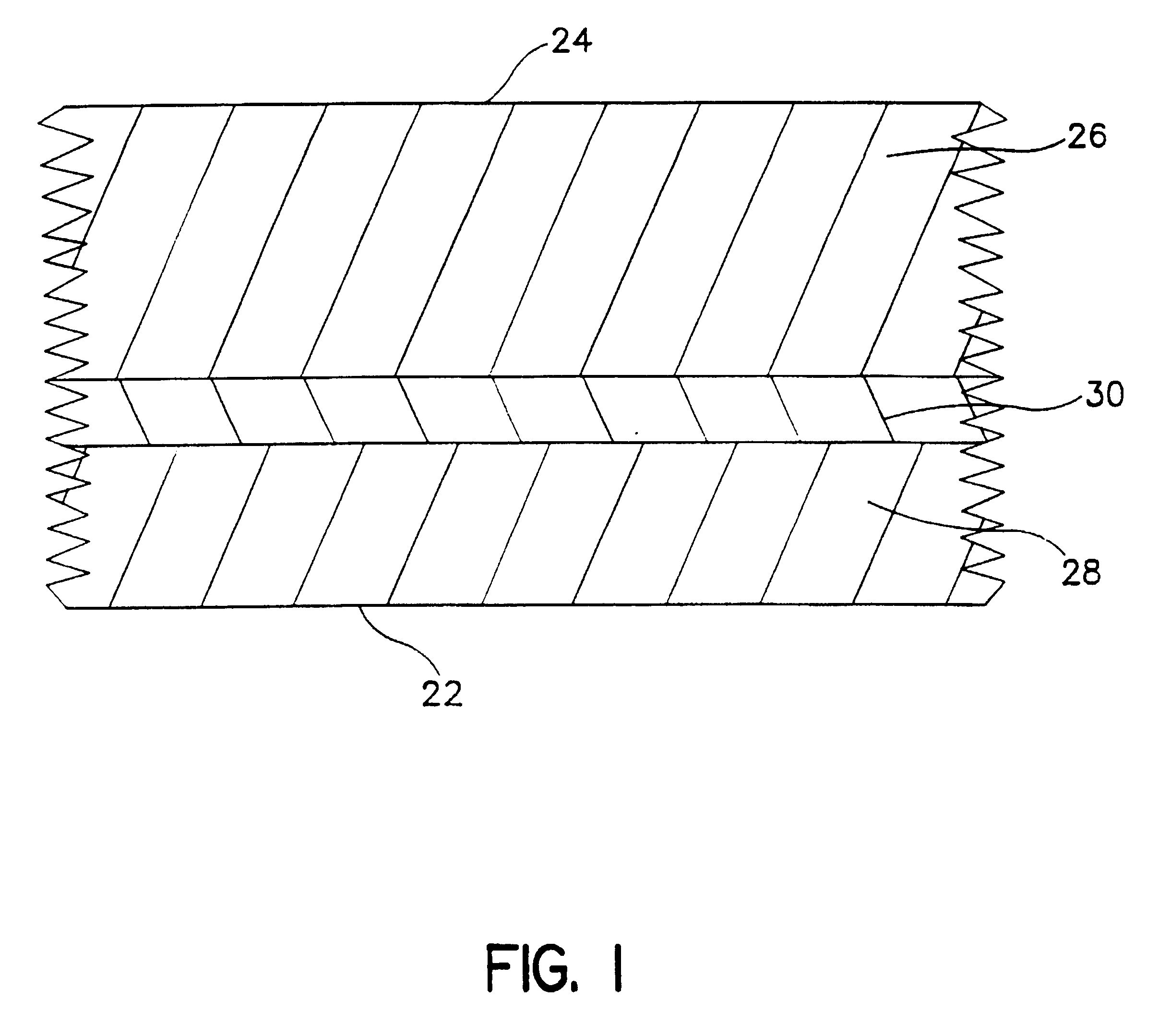

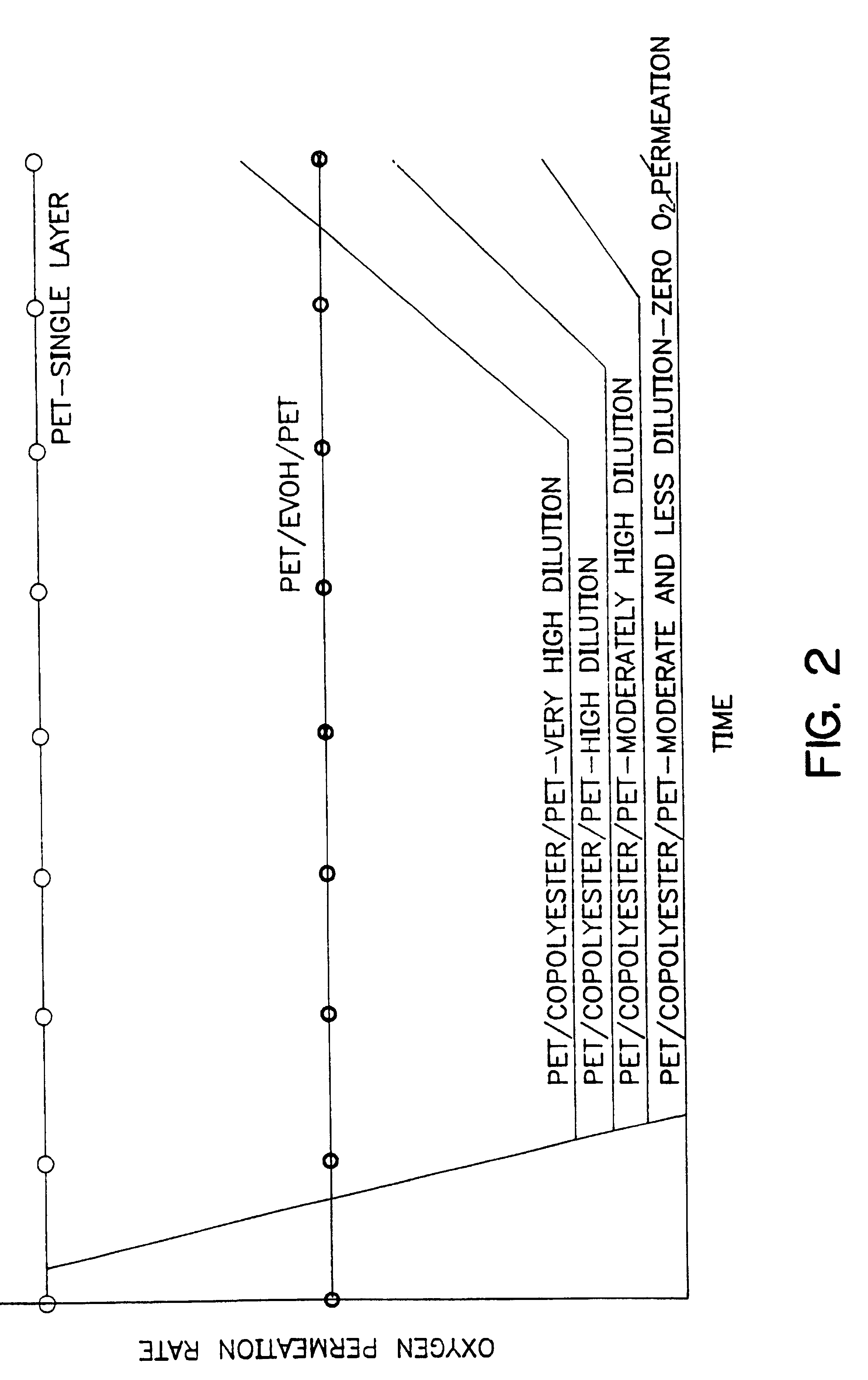

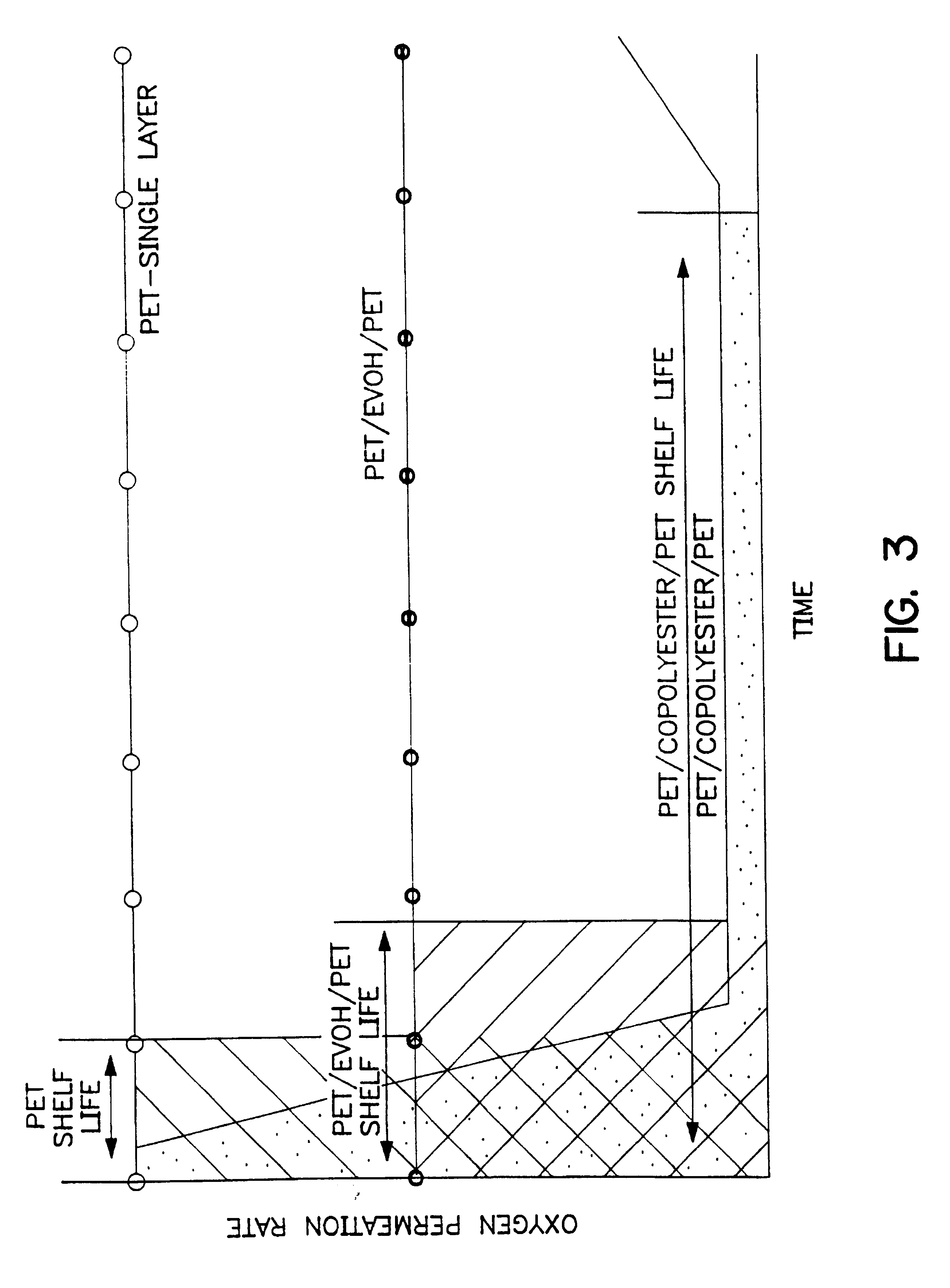

Zero oxygen permeation plastic bottle for beer and other applications

InactiveUS6365247B1Increased molecular weightImprove intrinsic viscosityLayered product treatmentBottlesCopolyesterChemistry

Multilayered plastic bottles are disclosed having oxygen scavenging capacity sufficient to maintain substantially zero or near zero (depending on product requirements) presence of oxygen in the bottle cavity for the planned shelf life of the bottled product under specified storage conditions. The bottles feature a layer comprised of oxygen scavenger copolyester and may be used for bottling beer and other products requiring nearly total absence of oxygen for the duration of the target product shelf life.

Owner:COLORMATRIX HLDG +1

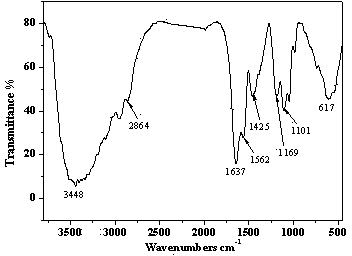

Polyamide and amine hybridized nanosilicon dioxide hyperbranched polymer and preparation method thereof

ActiveCN103865008AImprove temperature resistanceStrong salt resistanceDrilling compositionEthylenediaminePolymer science

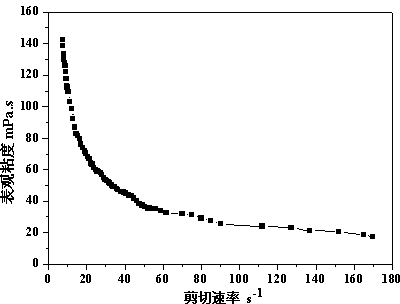

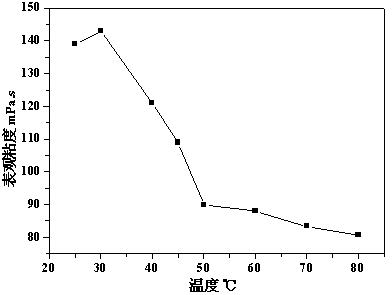

The invention discloses a polyamide and amine hybridized nanosilicon dioxide hyperbranched polymer and a preparation method thereof. The preparation method of the polymer comprises the following steps of firstly, modifying the surface of nanosilicon dioxide by using a coupling agent; then, carrying out Michael addition reaction and amidation reaction on the modified nanosilicon dioxide by using ethylenediamine and methyl acrylate; finally, carrying out functional modification by using allyl glycidyl ether to obtain a functional polyamide and amine hybridized nanosilicon dioxide monomer, and initiating polymerization reaction on the functional polyamide and amine hybridized nanosilicon dioxide monomer, acrylamide, acrylic acid and a heat-resistant and salt-tolerant monomer by using a redox initiator or azobis(isobutylamidine) initiator. The hyperbranched polymer has a network structure with a polyamide and amine hybridized nanosilicon dioxide unit as a center, has excellent shear resistance, strong thickening property, heat resistance and salt tolerance, and is wide in adaptability and capable of being used as an oil displacement agent for increasing the recovery rate of raw oil in an oil field environment with a high mineralization degree and a wide temperature range; the preparation method of the polyamide and amine hybridized nanosilicon dioxide hyperbranched polymer is reliable in principle, simple and convenient to operate and wide in application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing semi-aromatic polyamide

The invention discloses a method for preparing a semi-aromatic polyamide. The method comprises the steps of adding aromatic dicarboxylic acid and aliphatic diamine containing 4 to 14 carbon atoms into a high-pressure autoclave, applying nitrogen pressure in the autoclave under a condition of water existence, rising the temperature so as to pre-polymerize, and then preparing high viscosity semi-aromatic polyamide resin by performing tackifying reaction on the pre-polymerized materials. The method of the invention prepares the semi-aromatic polyamide by applying nitrogen pressure, the diamine loss is avoided and the mole ratio of the dicarboxylic acid and the diamine can be accurately controlled so as to acquire the high viscosity semi-aromatic polyamide. The pre-polymerized material which has a viscosity eta ranged from 0.06 to 0.3 dl / g tested in 96% sulfuric acid at 25 DEG C by performing the pre-polymerization reaction is acquired. After the tackifying reaction is performed, the viscosity eta of the semi-aromatic aromatic polyamide is ranged from 0.8 to 2.5 dl / g, the melting point of the semi-aromatic aromatic polyamide is ranged from 270 to 330 DEG C, the content of the end carboxyl is ranged from 15 to 80 mol / t and the content of the end amino is ranged from 15 to 80 mol / t.

Owner:KINGFA SCI & TECH CO LTD +1

Process for preparing semi-aromatic polyamides

The invention discloses a method for preparing semi-aromatic polyamide. The method adopts low temperature of 170 DEG C to 190 DEG C for dehydration firstly, and then adopts a method for temperature-raising and prepolymerization to prepare the semi-aromatic polyamide, thus avoiding the loss of diamine and being capable of accurately controlling the molar ratio of the dicarboxylic acids and the diamine, obtaining the polyamide with high intrinsic viscosity and improving the quality of semi-aromatic polyamide. By the prepolymerization reaction, the prepolymer which is measured in 96 percent of sulphuric acid with the temperature of 25 DEG C and has the intrinsic viscosity Eta of 0.06 to 0.3dl / g can be obtained. After viscosifying reaction, the intrinsic viscosity Eta of the semi-aromatic polyamide is 0.8 to 2.5 dl / g and the melting point of the semi-aromatic polyamide is 270 to 330 DEG C; the content of terminal carboxyl group is 15 to 80 mol / t; and the content of amino-terminated group is 15 to 80 mol / t.

Owner:KINGFA SCI & TECH CO LTD +1

Semi-aromatic polyamide and preparation method thereof

The invention discloses a semi-aromatic polyamide and a preparation method thereof. The method of the invention uses the aromatic dicarboxylic acid and aliphatic diamine containing 4 to 14 carbon atoms as the raw materials in order to prepare the semi-aromatic polyamide and acquire a new structure of the semi-aromatic polyamide. The semi-aromatic polyamide is prepared by combining high purity semi-aromatic polyamide salt so the polyamine loss is avoided and the mole ratio of the dicarboxylic acid and the diamine can be accurately controlled so as to acquire the high viscosity semi-aromatic polyamide. The monomer is purified in the salifying process, so the melting point, the crystallinity and the mechanical property of the semi-aromatic polyamide are promoted. The pre-polymerized material which has a viscosity eta ranged from 0.06 to 0.3 dl / g tested in 96% sulfuric acid at 25 DEG C by performing the pre-polymerization reaction is acquired. After the tackifying reaction is performed, the viscosity eta of the semi-aromatic aromatic polyamide is ranged from 0.8 to 2.5 dl / g, the melting point of the semi-aromatic aromatic polyamide is ranged from 270 to 330 DEG C, the content of the end carboxyl is ranged from 15 to 80 mol / t and the content of the end amino is ranged from 15 to 80 mol / t.

Owner:KINGFA SCI & TECH CO LTD +1

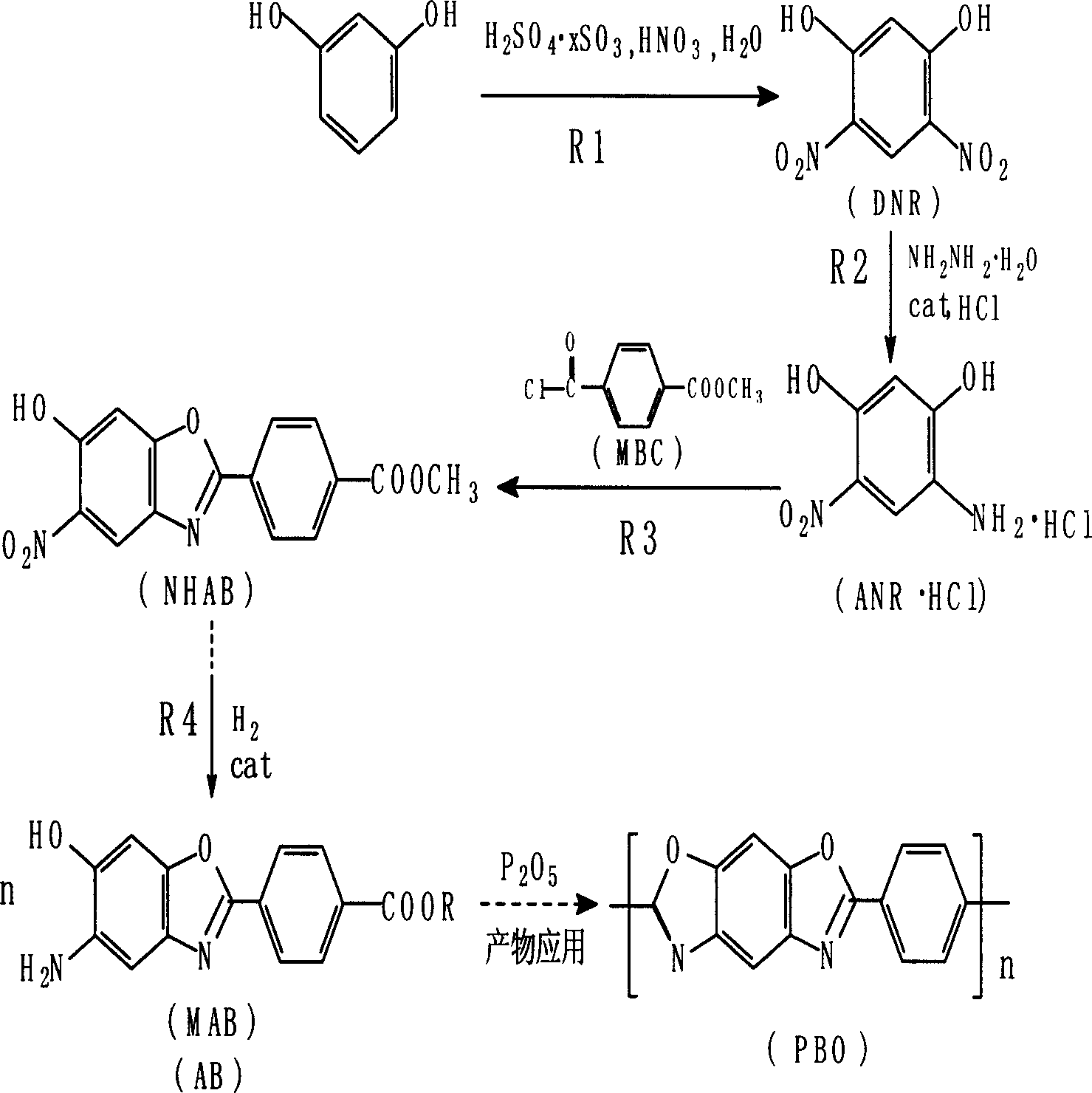

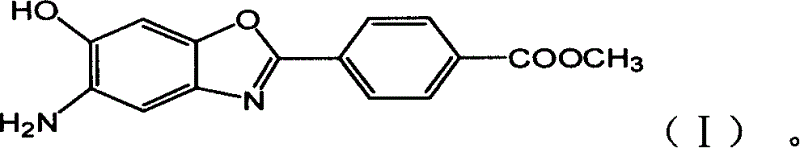

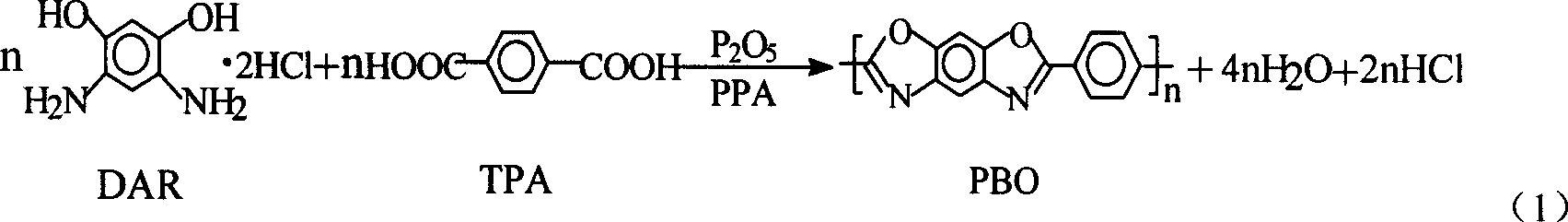

AB type poly(p-phenyl) benzdioxan monomer and its preparation and use

A 5- amino-6-hydroxy-2-MAB and its production are disclosed. The production is carried out by: (1) R1-R2, green synthesizing 4-amino-6-ANR.HCL by resorcinol; (2) R3: preparing AB monomer precursor 5-nitro-6-hydroxy-2-NHAB, and refining purifying; (3) R4: catalyst hydrogenating reducing NHBA nitro group, and obtaining high-purity AB PBO monomer. It achieves simple process, short polymeric time and normal polymeric apparatus.

Owner:ZHEJIANG UNIV OF TECH

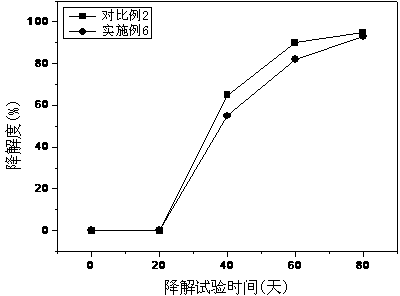

Preparation method of degradable glycolic acid copolyester

The invention discloses a preparation method of degradable glycolic acid copolyester. Glycolic acid copolyester with high molecular weight is obtained by condensation polymerization of glycollic acid, adipic acid and ethylene glycol. The direct condensation polymerization is adopted, so that the whole process is short in procedure, less in side reaction and low in energy consumption during production; glycollic acid, adipic acid and ethylene glycol are taken as raw materials, so that the cost of the raw materials is low. Thus, the finally obtained glycolic acid copolyester is low in production cost. The prepared glycolic acid copolyester is high in intrinsic viscosity, good in mechanical property and excellent in practicability. In addition, the glycolic acid copolyester is completely prepared by the condensation polymerization of biodegradable monomers, so that the glycolic acid copolyester has the complete biodegradability; catalysts containing stannum, plumbum and the like, which have large toxicity, are not adopted in the preparation process, so that the glycolic acid copolyester is nonhazardous to a human body. As a result, the glycolic acid copolyester disclosed by the invention is a safe and environment-friendly high molecular material.

Owner:JIANGSU JINJU ALLOY MATERIAL

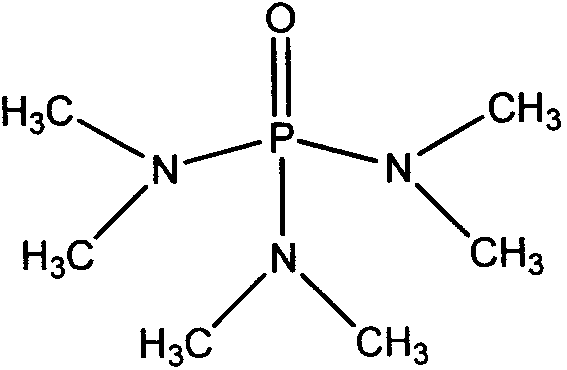

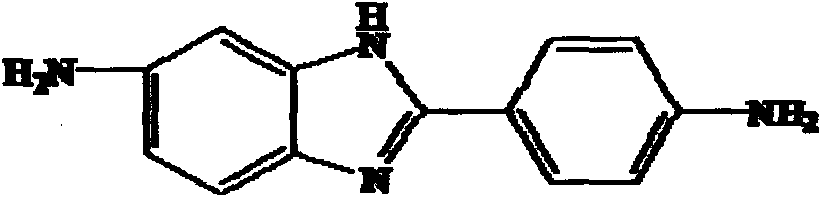

Method for preparing heterocyclic aramid solution

InactiveCN106700065AStrong ability to dissolve heterocyclic aramid fibersHigh solid contentArtificial filament recoveryMonocomponent copolyamides artificial filamentHexamethylphosphoric TriamideChloride

The invention belongs to the technical fields of heterocyclic aramid solution and preparation thereof, and specifically, relates to a method for preparing a heterocyclic aramid solution, wherein the method comprises the steps: a diamine substance and an aromatic dicarbonyl chloride are subjected to a polymerization reaction in an inert gas atmosphere and in a hexamethylphosphoric triamide solution containing no cosolvent, wherein the diamine substance comprises 2-(4-aminophenyl)-5-aminobenzimidazole.

Owner:SICHUAN UNIV

Preparation method of polyfurandioctyl phthalate glycol ester

ActiveCN106243331AReduce dependence on petroleum resourcesGood mechanical propertiesFuranHigh selectivity

The invention discloses a preparation method of polyfuran dioctyl phthalate glycol ester. The preparation method comprises the following steps: (1) esterification or ester exchange reaction: adding furan dioctyl phthalate or furan dioctyl phthalate diester, ethylene and nitrogen-containing catalyst to a reactor, and reacting for 2-5 hours at 160-210 DEG C to obtain an esterification or ester exchange product; (2) polycondensation: reacting the esterification or ester exchange product in the conditions of pressure of less than or equal to 150Pa and temperature of 220-250 DEG C to prepare polyfuran dioctyl phthalate glycol ester. According to the invention, the efficient and high-selectivity nitrogen-containing catalyst is adopted, thus being favorable for improving the esterification or ester exchange rate, promoting polycondensation and improving molecular weight; and the prepared product is colorless or shallow in color, less in byproducts and good in structure regularity. According to the preparation method, only one nitrogen-containing catalyst is needed and is only added before reaction, adding of catalyst is not needed in the medium process, the process is very simple, the process is environmentally friendly, and realization of industrialization is facilitated.

Owner:ZHEJIANG UNIV

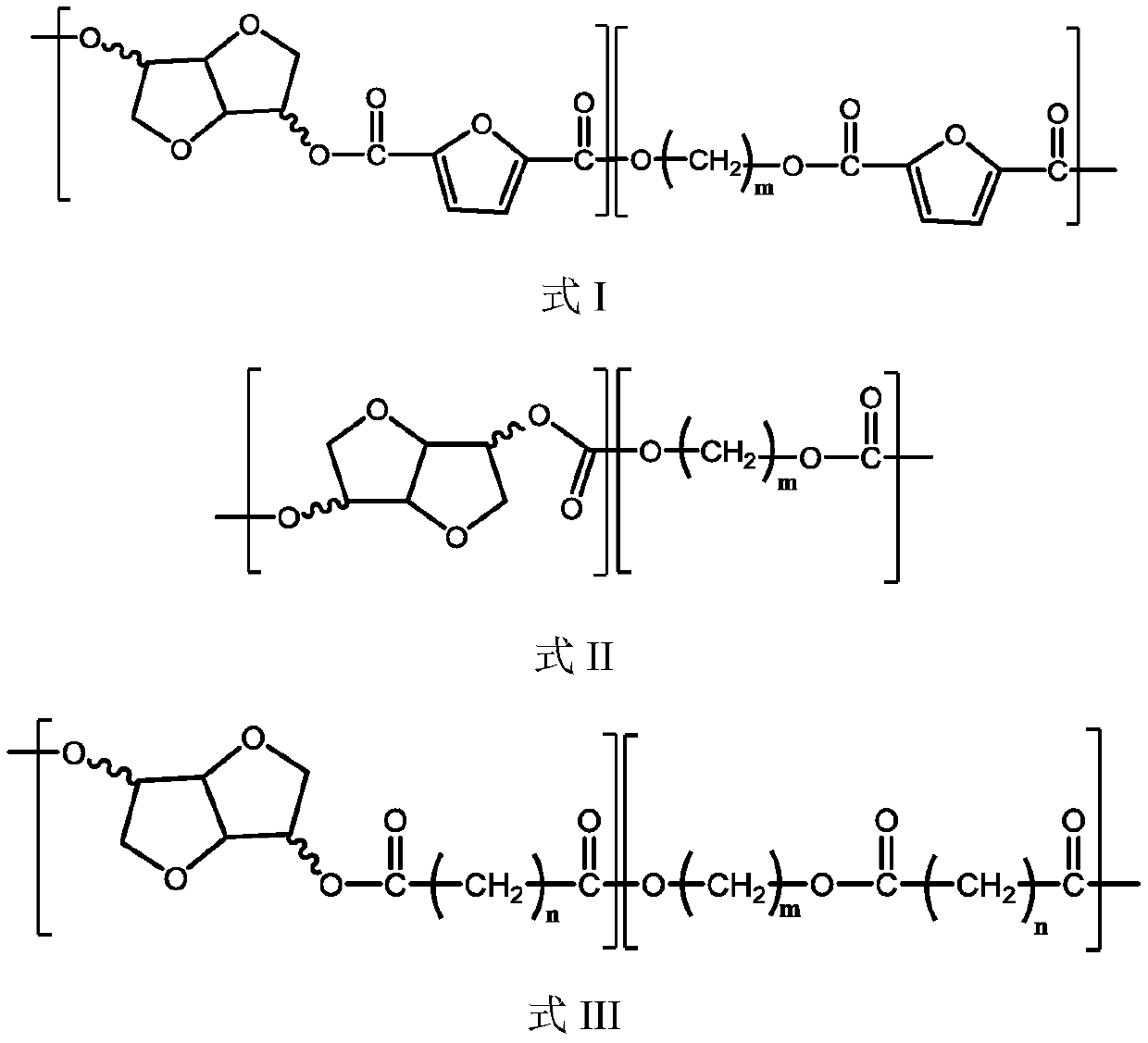

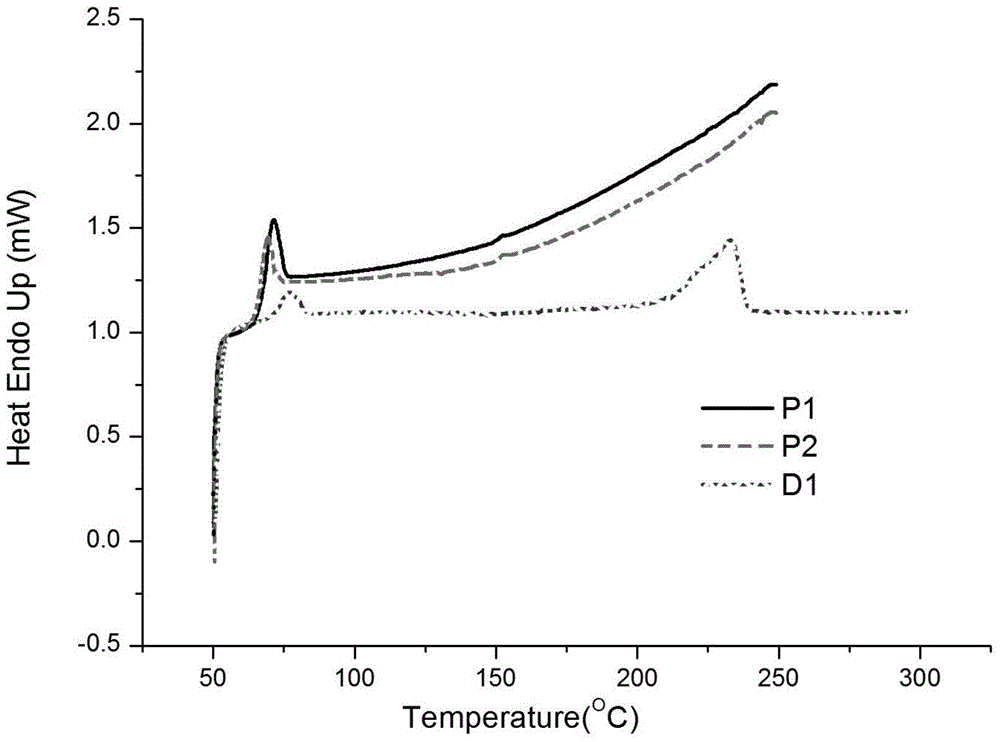

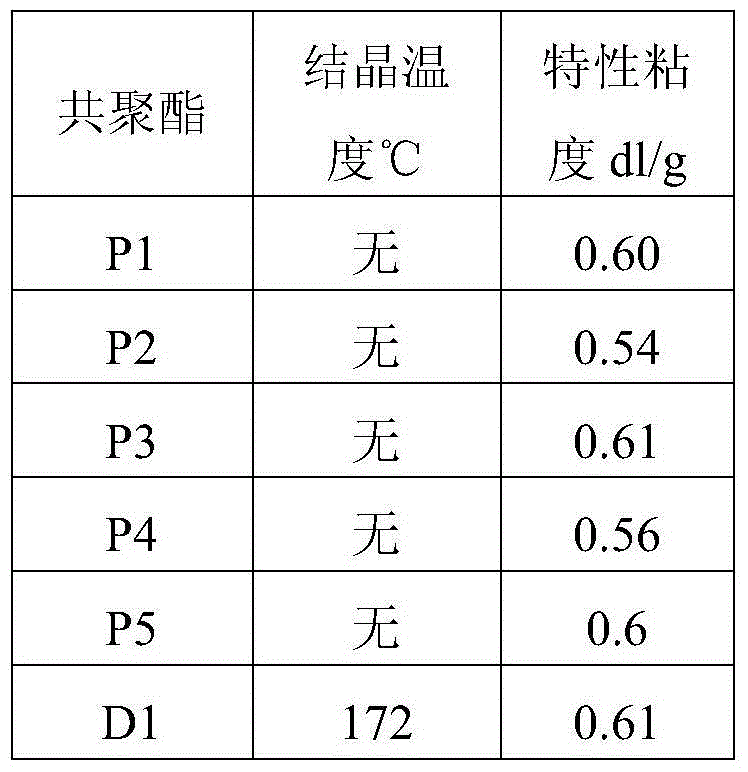

1,4;3,6-dianhydro mannitol modified furan dicarboxylic acid-based random copolymer, preparation method and applications thereof

The invention belongs to the field of polymer materials, and particularly relates to a 1,4;3,6-dianhydro mannitol modified furan dicarboxylic acid-based random copolymer, a preparation method and applications thereof, wherein the furan dicarboxylic acid-based random copolymer has a furan dicarboxylate-based repeating unit represented by a formula I, a carbonate repeating unit represented by a formula II, and a fatty acid ester repeating unit represented by a formula III, m is an integer of 2-4, and n is an integer of 3-18. According to the present invention, the prepared bio-based random copolymer has advantages of high molecular weight, high modulus, high strength, good thermal stability, excellent gas barrier property, biodegradability and the like, further has high glass transition temperature, and can be used for preparing polymer alloys, heat-resistant packaging materials, bottles, films, fibers, sheets, optical products and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Copolyester preparation method and application of copolyester prepared thereby in 3 D printing

The present invention provides a copolyester preparation method comprising successive esterification and polycondensation of a dihydric alcohol, a fatty diacid and two or more aromatic diacid in the presence of a catalyst for preparation of an amorphous copolyester. The present invention also provides a method for using the copolyester material for preparation of a wire material and application of the wire material in 3D printing. The printing temperature of the wire material used in fused deposition method 3D printing is low, an obtained product is small in size deviation, and sample shrinkage rate is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

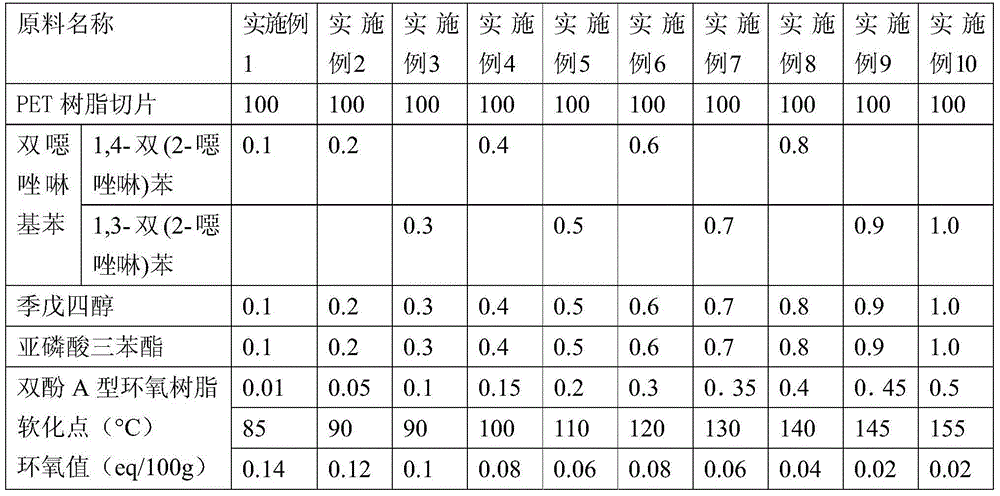

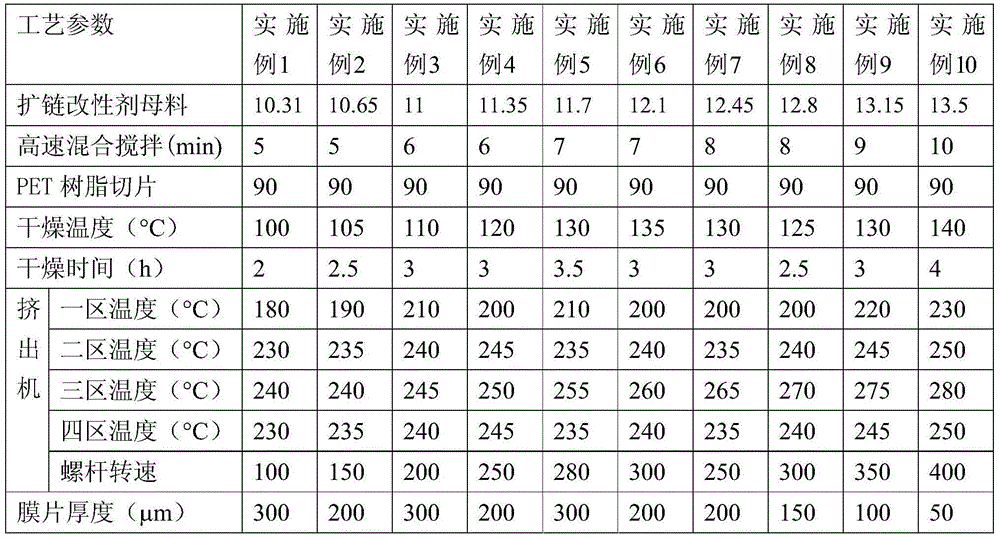

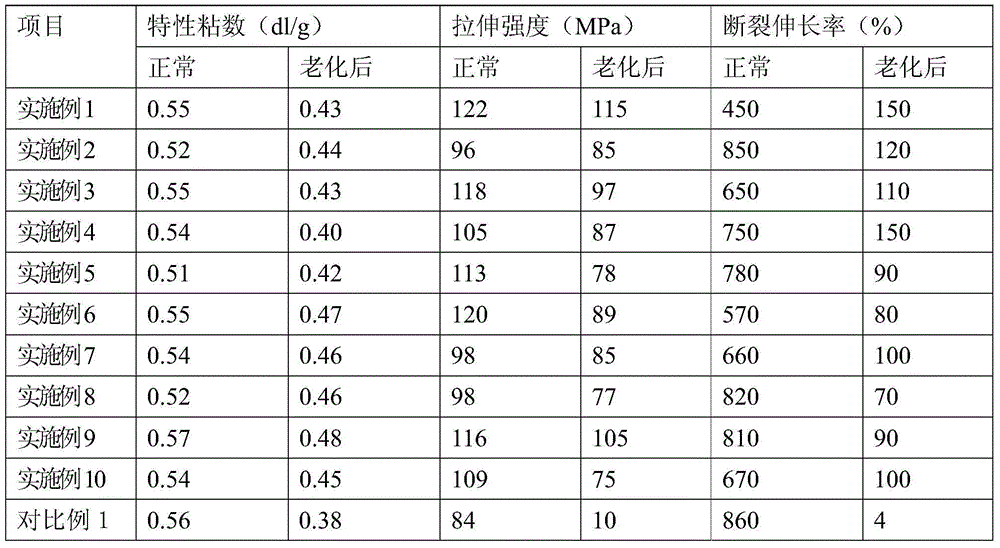

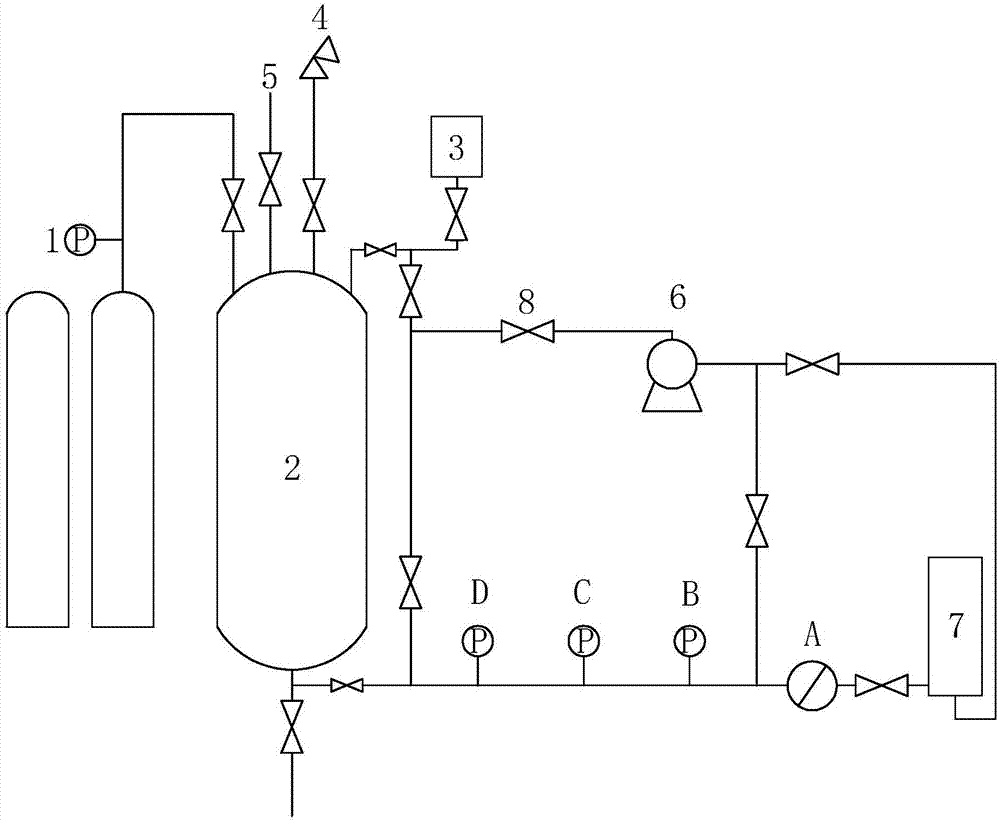

PET (polyethylene terephthalate) composite for producing thermal aging resistant insulating film and preparation method of PET compound

ActiveCN106317793AImprove intrinsic viscosityProperties that reduce chain extension reactionsBenzenePolyethylene terephthalate glycol

The invention relates to a PET (polyethylene terephthalate) composite for producing a thermal aging resistant insulating film. The PET composite comprises the following raw materials in parts by mass: 100 parts of PET chips, 0.1-1.0 part of bisoxazolinyl benzene, 0.1-1.0 part of pentaerythritol, 0.1-1.0 part of triphenyl phosphite and 0.01-0.50 part of bisphenol A type epoxy resin, wherein the softening point of the bisphenol A type epoxy resin is 85-155 DEG C; the epoxy value of the bisphenol A type epoxy resin is 0.02-0.14eq / 100g. The PET composite is simple in process procedures, the high-temperature degradation speed of the PET can be reduced, the thermal aging resistance of the PET composite can be improved, the service life of the insulating film under a high-temperature condition can be prolonged, and the PET composite is free of additives harmful for human bodies and the environment, and can be used for producing the thermal aging resistant insulating film of a grade of 190 DEG C.

Owner:JIANGSU YUXING FILM TECH

Preparation method of high-molecular-weight polyacrylamide

ActiveCN105585650AHigh molecular weightImprove intrinsic viscosityBulk chemical productionHigh molecular massHigh pressure

The invention provides a preparation method of high-molecular-weight polyacrylamide. The method includes the steps of performing segmented polymerization to acrylamide and an initiator in a high-pressure kettle with a supercritical CO2 medium to obtain high-molecular-weight polyacrylamide; and then performing supercritical CO2 fluid extraction to extract small-molecular monomers which are incompletely reacted to obtain high-purity polyacrylamide. The product is pure and is free of follow-up treatment. The reaction medium is toxic-free and environment-friendly. The preparation method is economic and practical, and is green and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

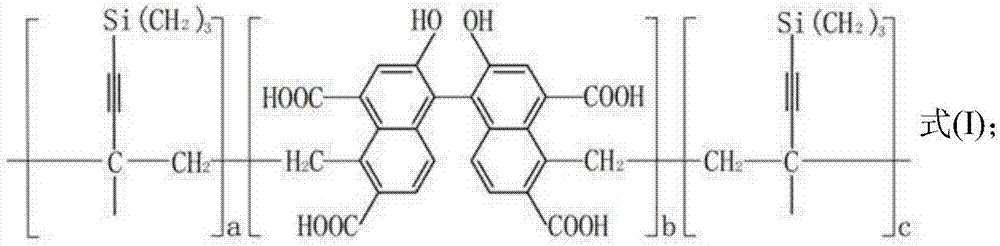

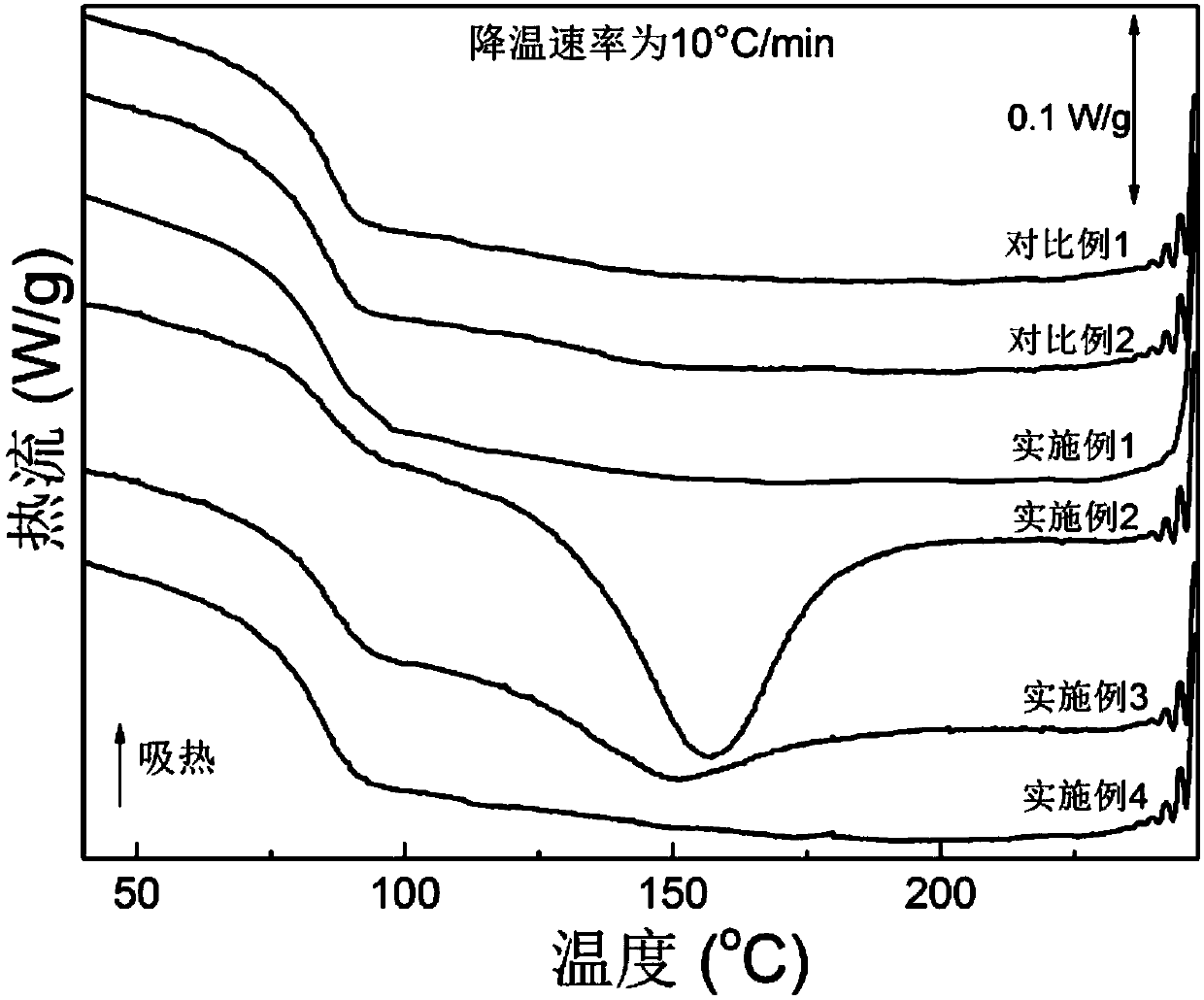

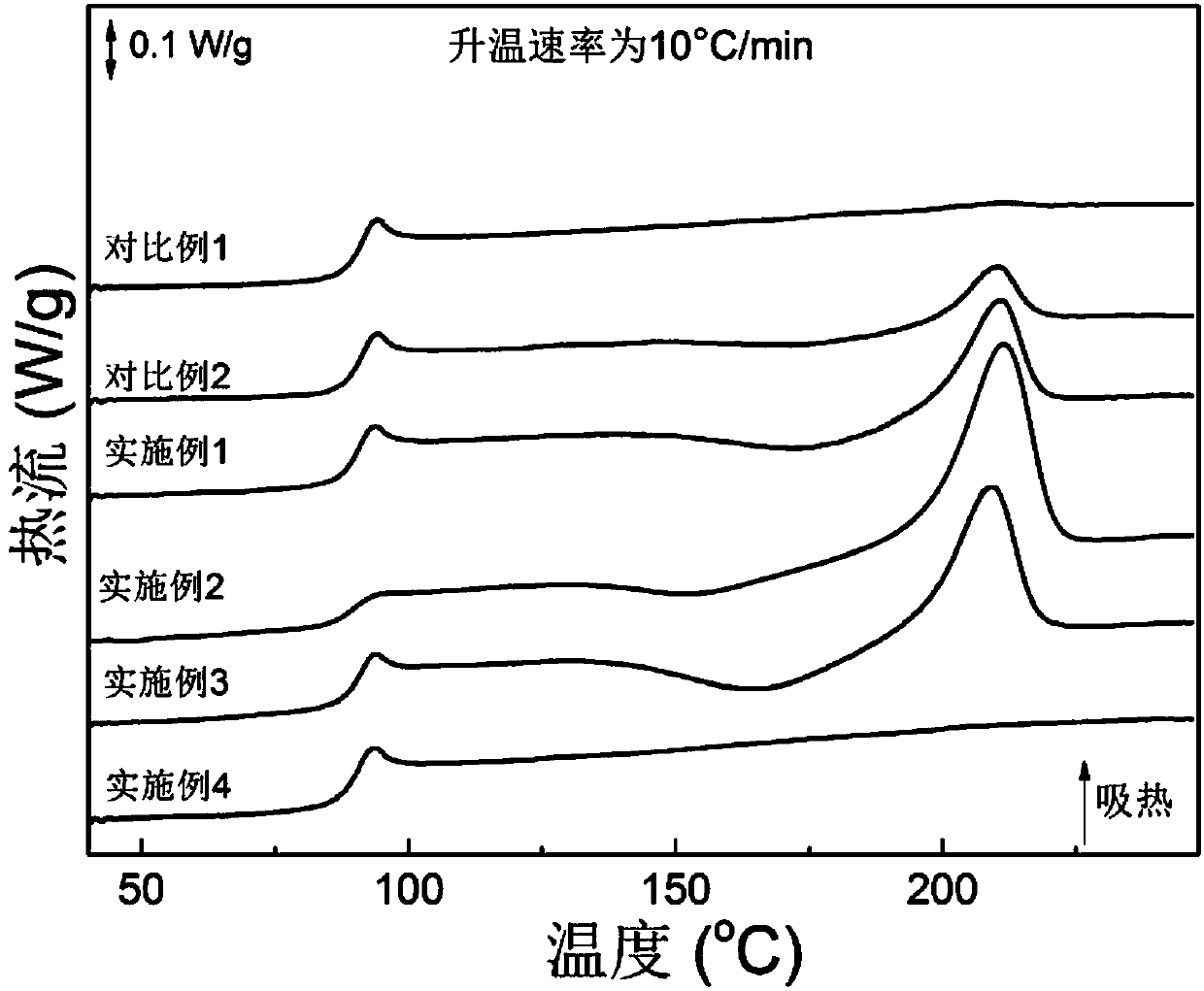

Macromolecular drag reducer, preparation method and application thereof

The invention relates to a macromolecular drag reducer, a preparation method and application thereof. The macromolecular drag reducer is prepared by slurry polymerization reaction of a macromolecular compound shown as formula (I), an alpha-olefin monomer and a catalytic system in an inert solvent, wherein the macromolecular compound shown as formula (I), the alpha-olefin monomer and the inert solvent are in a weight ratio of 0.1-0.3:1:0.5-0.8, the catalytic system is composed of a main catalyst and a cocatalyst, wherein the total weight of the main catalyst and the cocatalyst is 5-10% of the weight of the alpha-olefin monomer, and the weight ratio of the main catalyst to the cocatalyst is 1:0.3-0.5; and specifically, a, b and c are the number of links of repetitive unit, and the macromolecular compound shown as formula (I) has a molecular weight of 5000-10000. The macromolecular drag reducer provided by the invention has superior shear resistance and stability, even if after a fluid flows through a high shear part, the drag reduction effect is slightly reduced, the macromolecular drag reducer still has good drag reduction effect.

Owner:李馥波

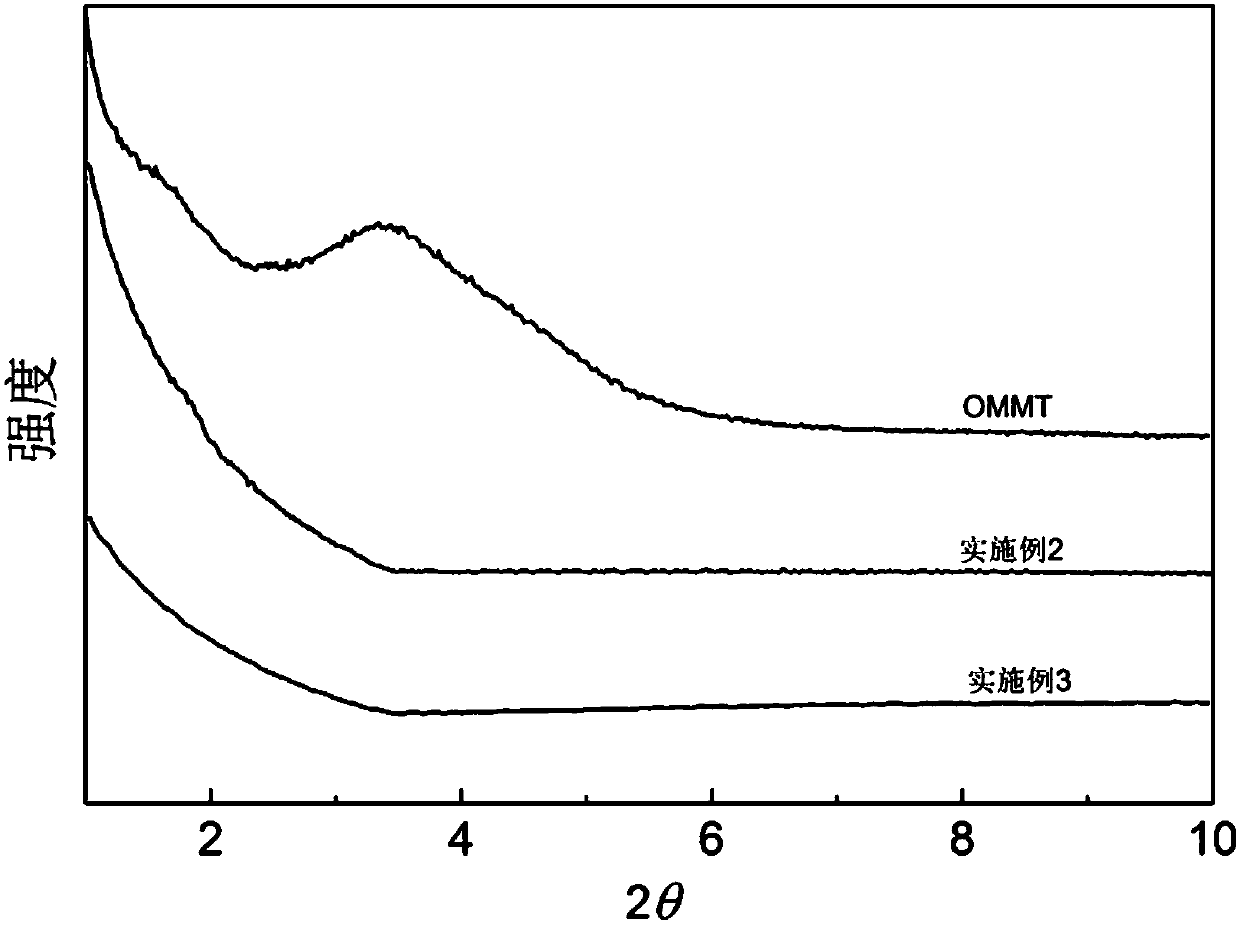

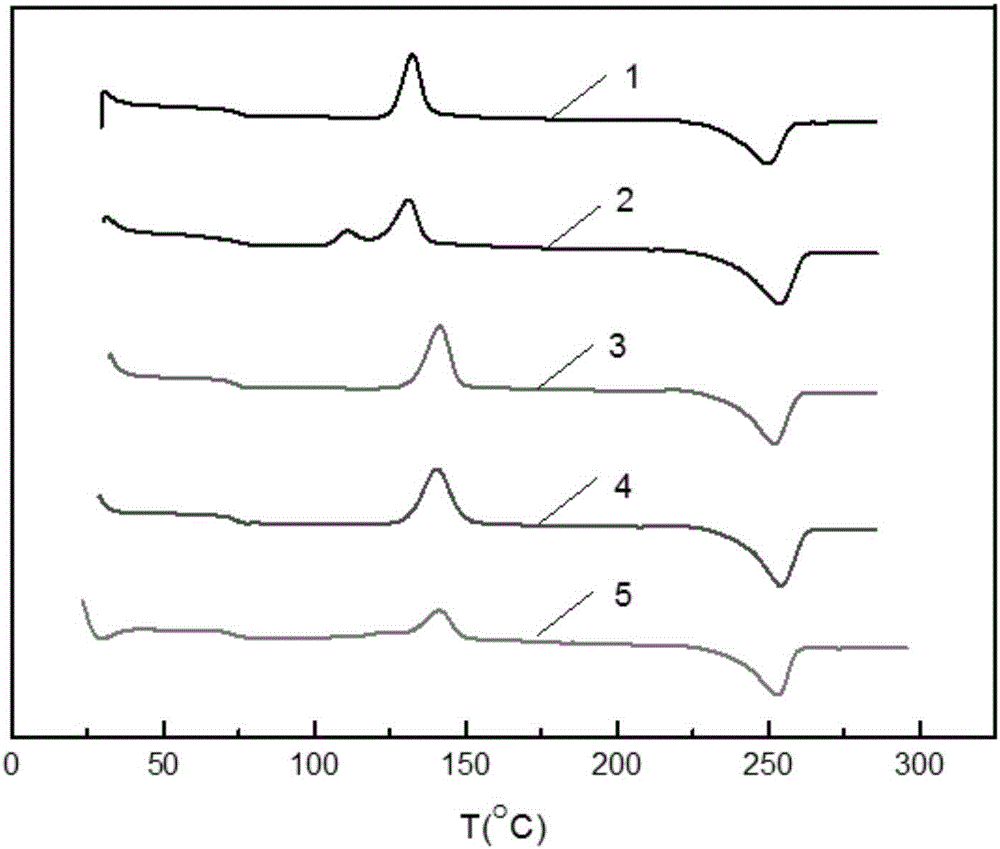

2, 5-furan dicarboxylic polyester/layered silicate nano-composite material, preparation method thereof and application of material

The invention discloses a 2, 5-furan dicarboxylic polyester / layered silicate nano-composite material, a preparation method thereof and an application of the material. The composite material comprises2, 5-furan dicarboxylic polyester and layered silicate and is prepared by an in-situ polymerization method, the stripping degree of the organically-treated layered silicate in an acquired product substrate is high, the molecular weight of the organically-treated layered silicate is high, the tensile strength of the organically-treated layered silicate is high, and the organically-treated layered silicate has a certain crystallization property. The preparation method is simple and feasible and solves the problem of slow crystallization rate of the2, 5-furan dicarboxylic polyester, applicationsof the preparation method can further be widened in the high-resistance air packaging market, and a good foundation is provided for subsequent industrialization.

Owner:ZHEJIANG UNIV

Method for preparing semi-aromatic polyamide

The invention discloses a method for preparing a semi-aromatic polyamide. The method comprises the steps of adding aromatic dicarboxylic acid and aliphatic diamine containing 4 to 14 carbon atoms into a high-pressure autoclave, applying nitrogen pressure in the autoclave under a condition of water existence, rising the temperature so as to pre-polymerize, and then preparing high viscosity semi-aromatic polyamide resin by performing tackifying reaction on the pre-polymerized materials. The method of the invention prepares the semi-aromatic polyamide by applying nitrogen pressure, the diamine loss is avoided and the mole ratio of the dicarboxylic acid and the diamine can be accurately controlled so as to acquire the high viscosity semi-aromatic polyamide. The pre-polymerized material which has a viscosity eta ranged from 0.06 to 0.3 dl / g tested in 96% sulfuric acid at 25 DEG C by performing the pre-polymerization reaction is acquired. After the tackifying reaction is performed, the viscosity eta of the semi-aromatic aromatic polyamide is ranged from 0.8 to 2.5 dl / g, the melting point of the semi-aromatic aromatic polyamide is ranged from 270 to 330 DEG C, the content of the end carboxyl is ranged from 15 to 80 mol / t and the content of the end amino is ranged from 15 to 80 mol / t.

Owner:KINGFA SCI & TECH CO LTD +1

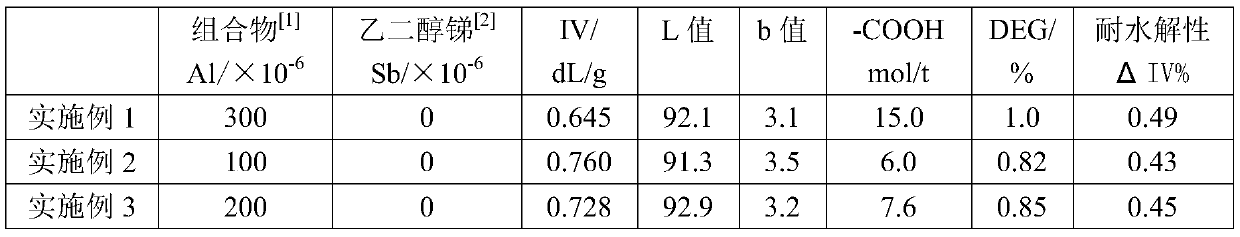

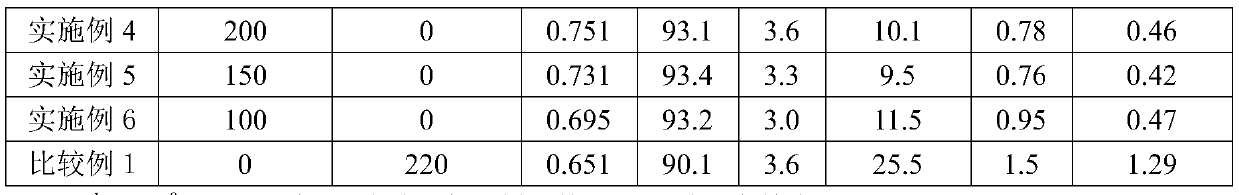

Hydrolysis-resistant polyester composition and preparation method of the composition solution and application thereof

ActiveCN110183629AGood hueImprove hydrolysis resistancePolyethylene terephthalate glycolPolyethylene glycol

The invention discloses a hydrolysis-resistant polyester composition and a preparation method of the composition solution and an application. As that aluminum compound and a basic compound are stirredand reacted in ethylene glycol to form an intermediate solution, a titanium compound, a phosphorus compound and polyethylene glycol are added into the intermediate solution, the temperature is raisedto 80-170 DEG C for stirring reaction to remove small molecules with low boiling point, and the temperature is cooled to room temperature to form a stable composition solution. A composition solutionis applied to the synthesis of polyethylene terephthalate, a polyester is synthesized by esterification and polymerization in a reactant system of purified terephthalic acid, ethylene glycol, and oneof micron titanium dioxide, micron barium sulfate, and micron calcium carbonate without the need to add other polymerization catalysts, and the composition may be added to the reaction system beforeor after esterification. The intrinsic viscosity of the polyester is 0.645-0.760 dL / g, and the content of carboxyl terminated group is low, so the polyester is widely used in photovoltaic solar backplane film and other fields.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing PET (polyethylene glycol terephthalate) by composite catalyst

ActiveCN106832241ASimple compositionHigh catalytic activityPolyethylene terephthalatePolymer science

The invention discloses a method for preparing PET (polyethylene glycol terephthalate) by a composite catalyst. The method is characterized in that when terephthalic acid and ethylene glycol are used as raw materials to prepare the PET, the composite catalyst containing tetrabutyl titanate, tetraethl silicate and phenylphosphonic acid is used for catalyzing, so as to obtain PET with high molecular weight, narrow molecular weight distribution and good mechanical property and heat stability; the catalyzing activity of the composite catalyst is 17 or more times of the activity of an antimony based catalyst.

Owner:BEIJING INST OF CLOTHING TECH

Method for preparing titanium-based matte polyester fiber through direct melt spinning and product

ActiveCN111286805AReduce adverse effectsReduce usageMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention relates to a method for preparing a titanium-based matte polyester fiber through direct melt spinning and a product. The preparation method comprises the steps of firstly synthesizing atitanium-based matte polyester melt by taking PTA, EG, a polyester titanium catalyst composite material system and a nanocomposite material for in-situ polymerization of polyester as main raw materials, and then carrying out direct melt spinning to obtain a titanium-based matte polyester fiber, wherein the polyester titanium catalyst composite material system is mainly composed of a polyester prepolymer I with the polymerization degree of 3-50 and a titanium catalyst dispersed into the polyester prepolymer I, and the nanocomposite material for in-situ polymerization of the polyester is mainlycomposed of a polyester prepolymer II with the polymerization degree of 3-30 and TiO2 particles dispersed into the polyester prepolymer II; and the finally prepared titanium-based matte polyester fiber is mainly composed of a polyester fiber matrix, and a titanium catalyst and TiO2 particles dispersed into the polyester fiber matrix. According to the method, the stability and the dispersity of thecatalyst can be improved, the activity of the catalyst is ensured and the usage of the catalyst is reduced.

Owner:浙江东太新材料有限公司 +1

Method for preparing polytrimethylene terephthalate

The invention relates to the field of polymer materials, and in particular relates to a method for preparing polytrimethylene terephthalate. The method comprises the following steps: (1) preparing a nano-tetrabutyl titanate / nano-silicon dioxide supported catalyst; and (2) synthesizing polytrimethylene terephthalate. The nano-tetrabutyl titanate / nano-silicon dioxide supported catalyst prepared by the method is high in activity, can be used either in a catalytic esterification reaction or a catalytic polycondensation, PPT (polytrimethylene terephthalate) prepared by utilizing the catalyst has high intrinsic viscosity, and is low in content of a terminal carboxyl group, so that titanate can be directly used as a catalyst and has high stability and good color.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

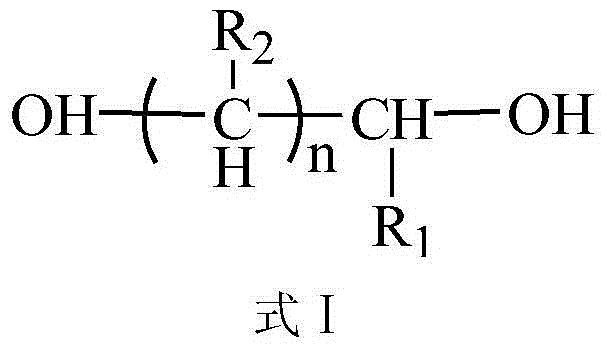

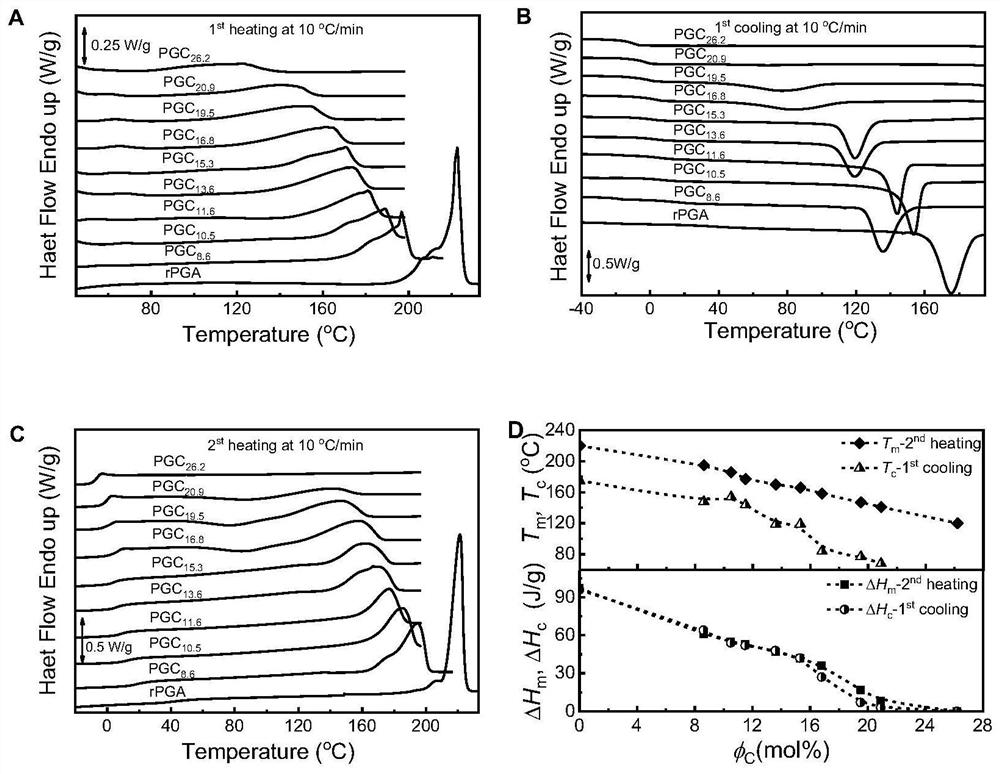

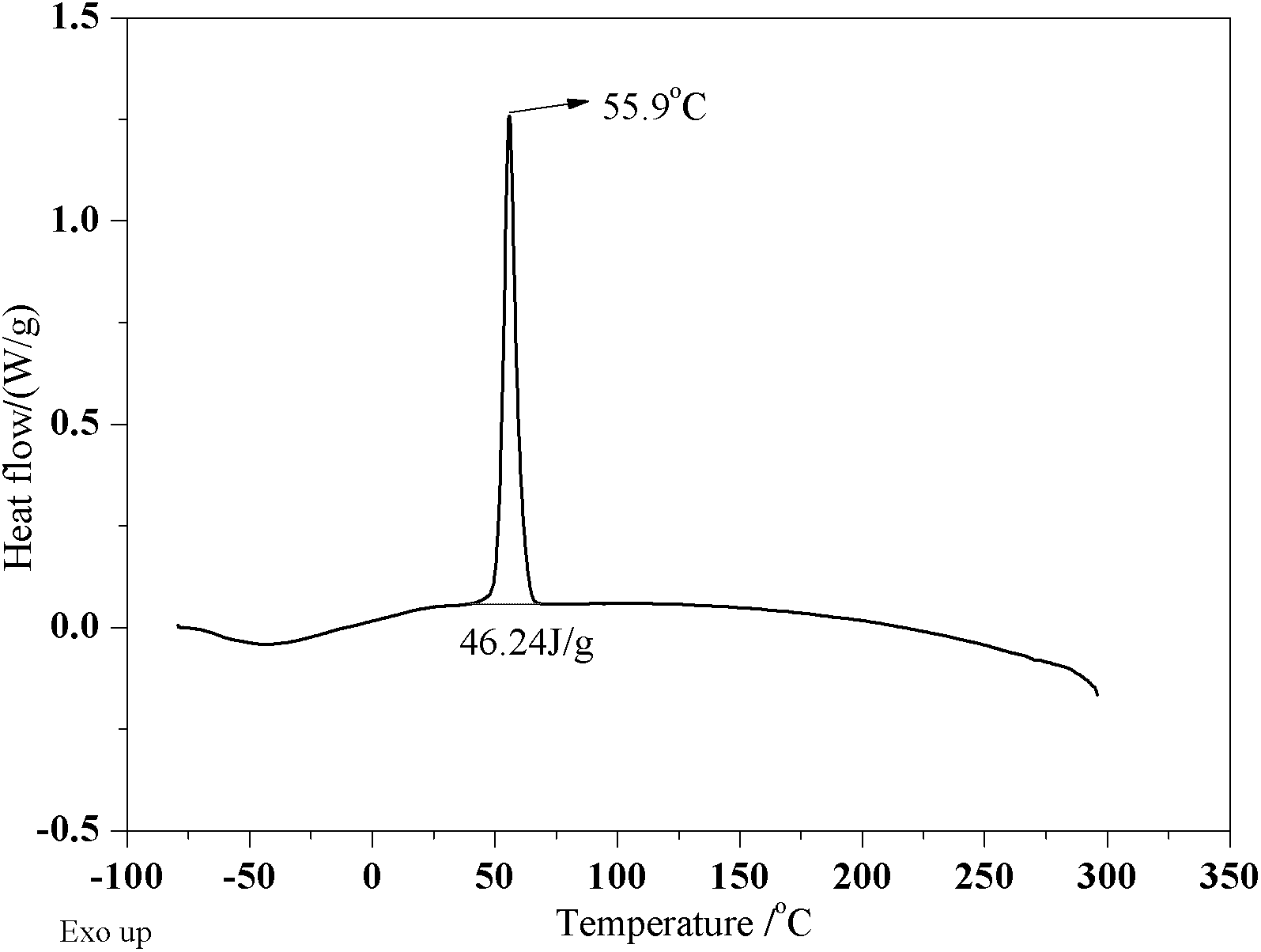

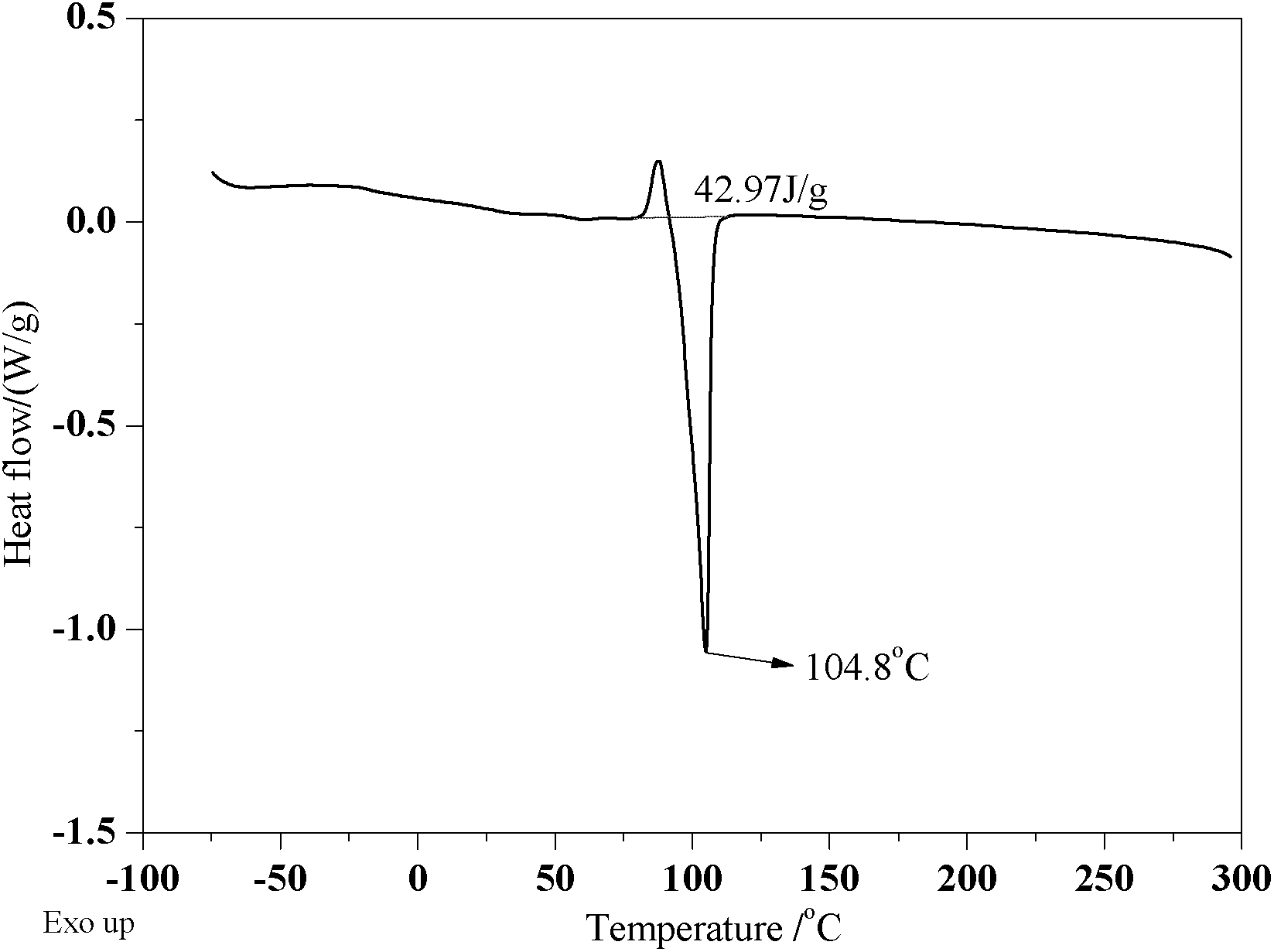

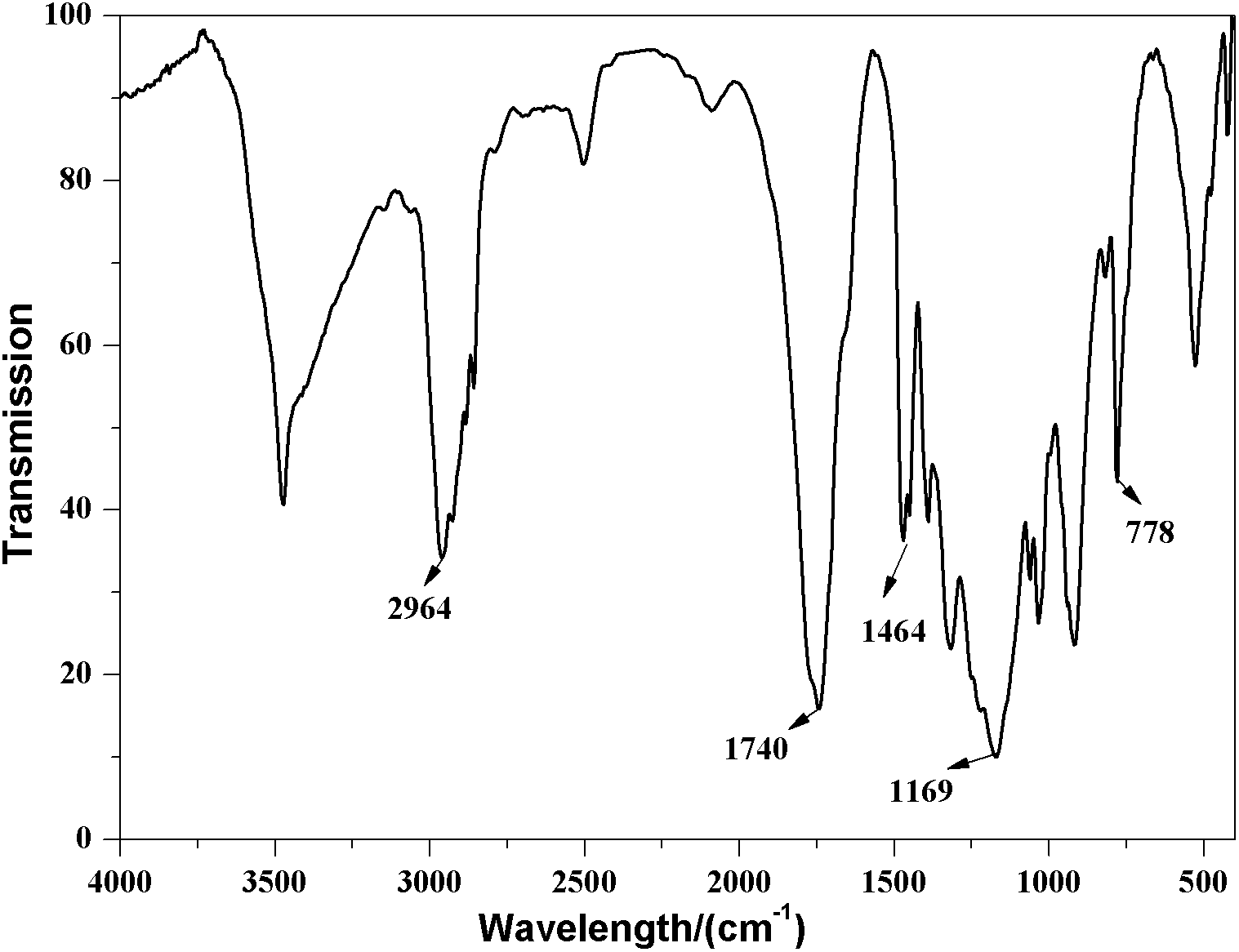

Polyglycolic acid-based biodegradable random copolymer and preparation method thereof

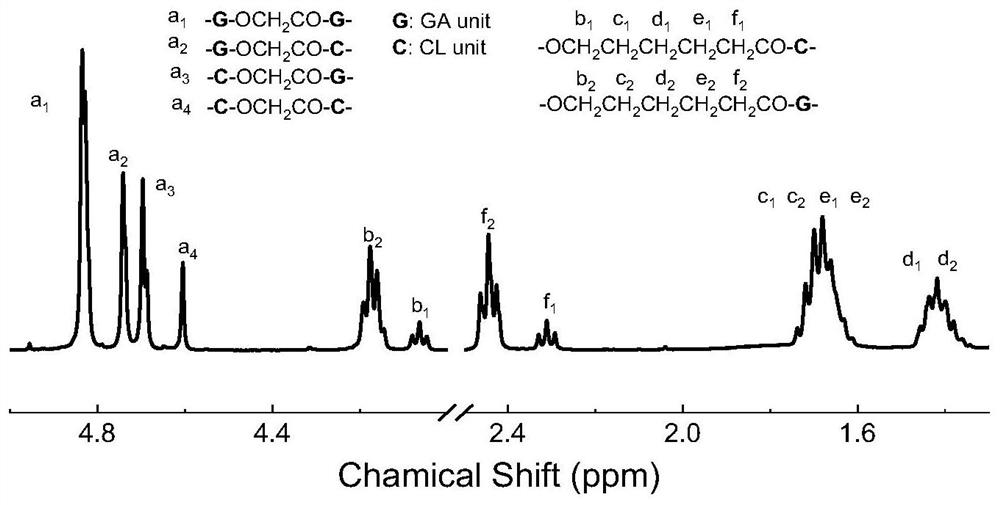

The invention relates to the technical field of biodegradable materials, and discloses a polyglycolic acid-based biodegradable random copolymer and a preparation method thereof, wherein the copolymer comprises 71-95 mol% of a first repetitive unit and 5-29 mol% of a second repetitive unit; the structure of the first repetitive unit is represented by a formula I, and the structure of the second repetitive unit is represented by any one of formulas II-1-II-3; and a first monomer and a second monomer are subjected to esterification, prepolymerization and polycondensation to obtain the polyglycolic acid copolymer, and the copolymer not only has high thermal stability and good toughness, but also has the advantages of biodegradability, high barrier property, high strength and the like, and is excellent in comprehensive performance and wide in application prospect.

Owner:ZHEJIANG UNIV

Method for preparing poly-oxalate-1,4-butylene

The invention relates to a method for preparing poly-oxalate-1,4-butylene, and belongs to the technical field of high polymer materials. The method comprises the following steps of: putting diethyl oxalate, 1,4-butanediol and a catalyst into a reactor, and reacting at the constant temperature of between 80 and 170 DEG C with stirring under the protection of N2 with the flow of between 0.06 and 0.16 m<3> / hour for 0.5 to 5 hours to obtain the poly-oxalate-1,4-butylene, wherein a ratio of the diethyl oxalate to the 1,4-butanediol is 1:1-1:3; and the catalyst is oxalic acid preferably, and the catalyst is 0.1 to 5.0 molar percent based on the diethyl oxalate. In the method, the diethyl oxalate and the 1,4-butanediol also can react at the constant temperature of between 110 and 180 DEG C under the vacuum degree of between 200 and 500 Pa under constant pressure for 3 to 8 hours in the presence of the catalyst to obtain the poly-oxalate-1,4-butylene with higher intrinsic viscosity. By the method, the reaction time is shortened, the vacuum degree of the reaction is reduced, the cost is low, and operation and aftertreatment are simple, so the method is suitable for industrial production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

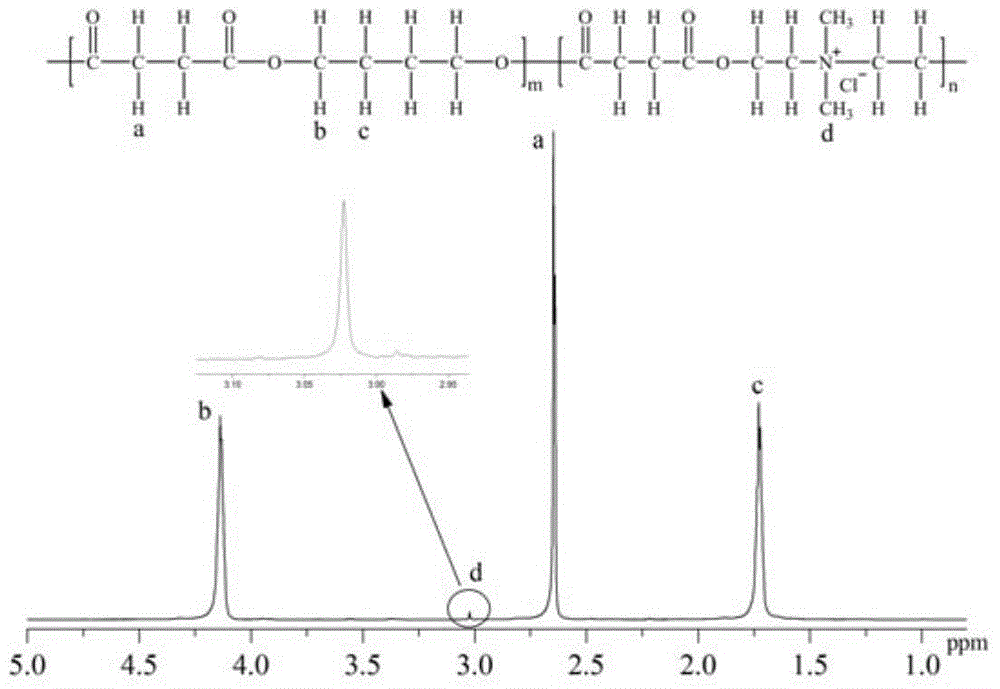

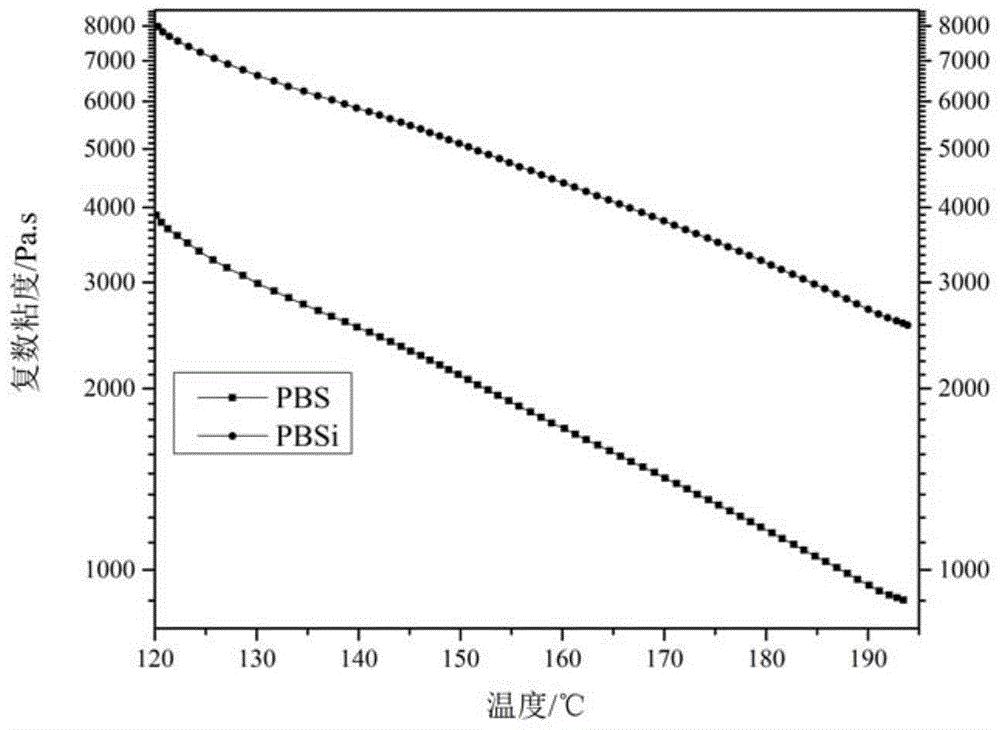

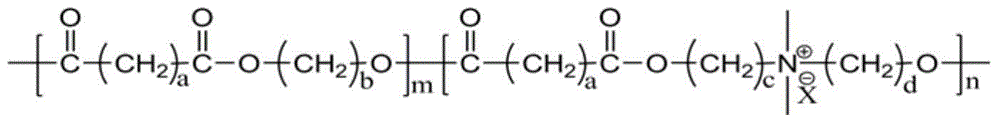

Aliphatic polyester ionic polymer and preparation method thereof

The invention discloses an aliphatic polyester ionic polymer, which is prepared from aliphatic dibasic acid, aliphatic dihydric alcohol and a quaternary ammonium salt ionic monomer according to a mol ratio of 100:99.7:0.3-100:85:15 under the protection of nitrogen through esterification and polycondensation in sequence. The general structural formula of the aliphatic polyester ionic polymer is defined in the description. The aliphatic polyester ionic polymer has the intrinsic viscosity of 1.5-2.0 dL / g and the complex viscosity which is 1.6-3.1 times of that of pure aliphatic polyester at any appointed temperature in a range of 120-200 DEG C. The intrinsic viscosity and complex viscosity of the aliphatic polyester ionic polymer obtained in the invention are greatly improved, so that relatively high melt-strength, a low shear thinning effect, and excellent blow molding ability are ensured during a machine-shaping process, especially a blow molding process, and excellent foundation is laid in the application of extending the aliphatic polyester ionic polymer to the field of a film.

Owner:SICHUAN UNIV

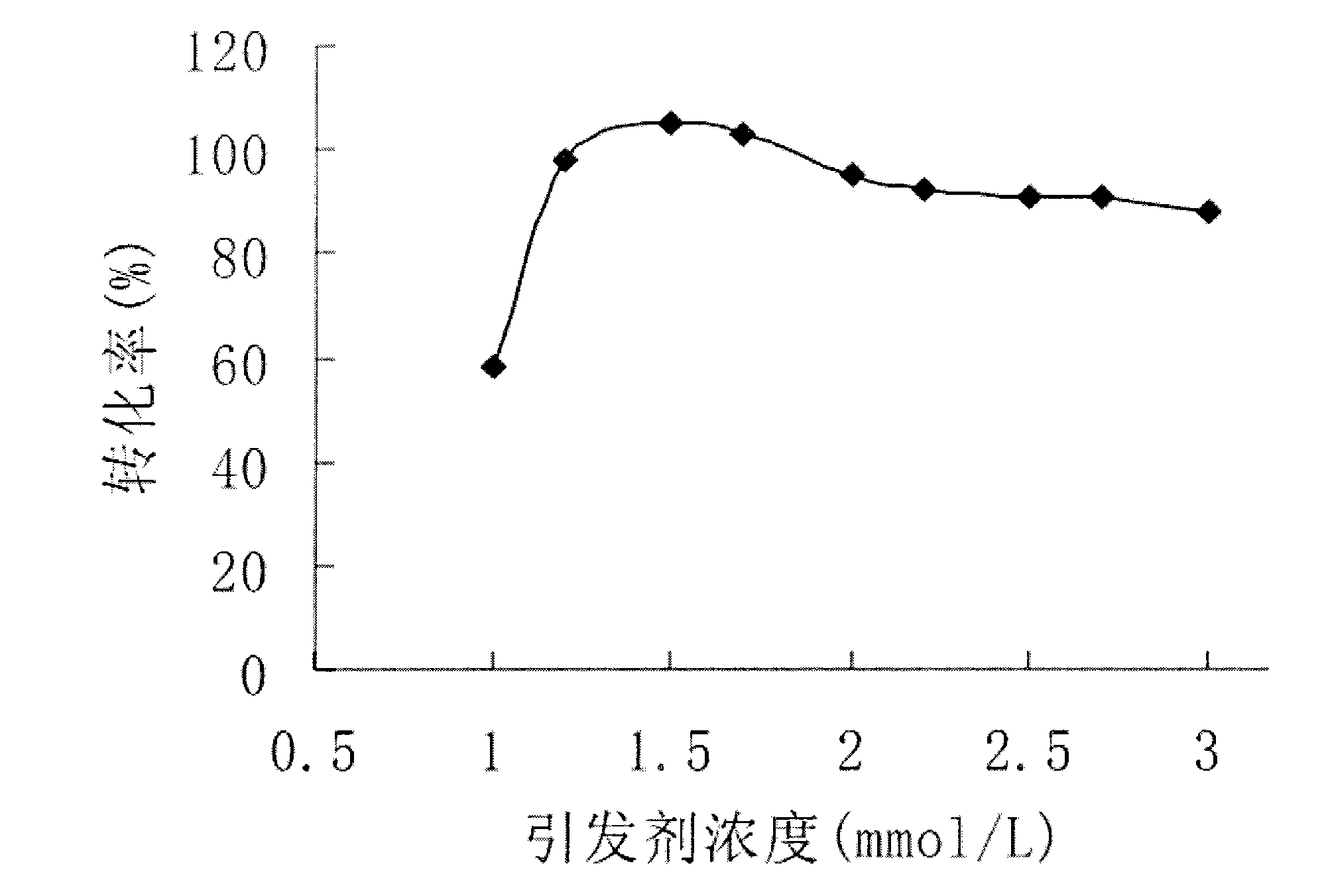

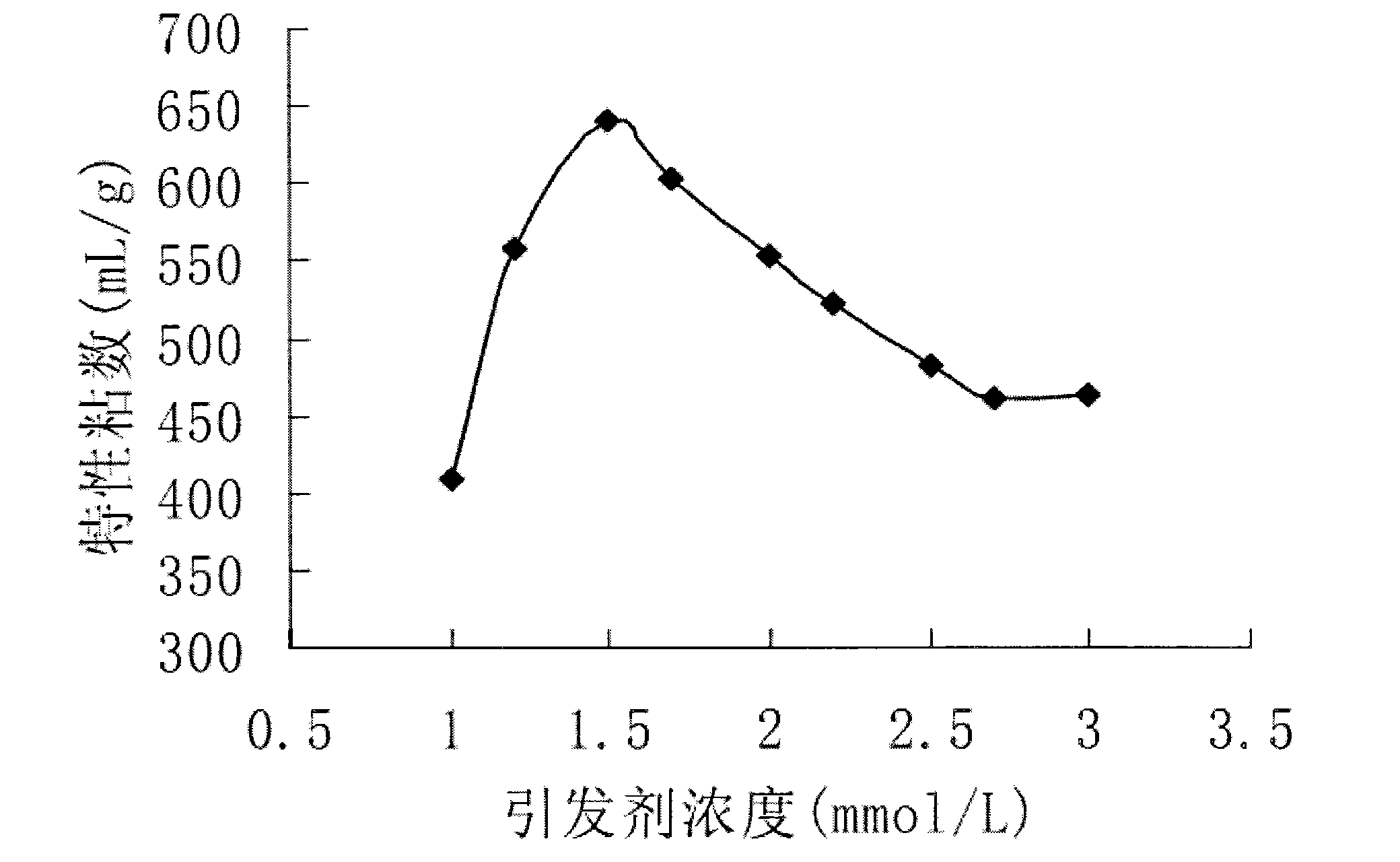

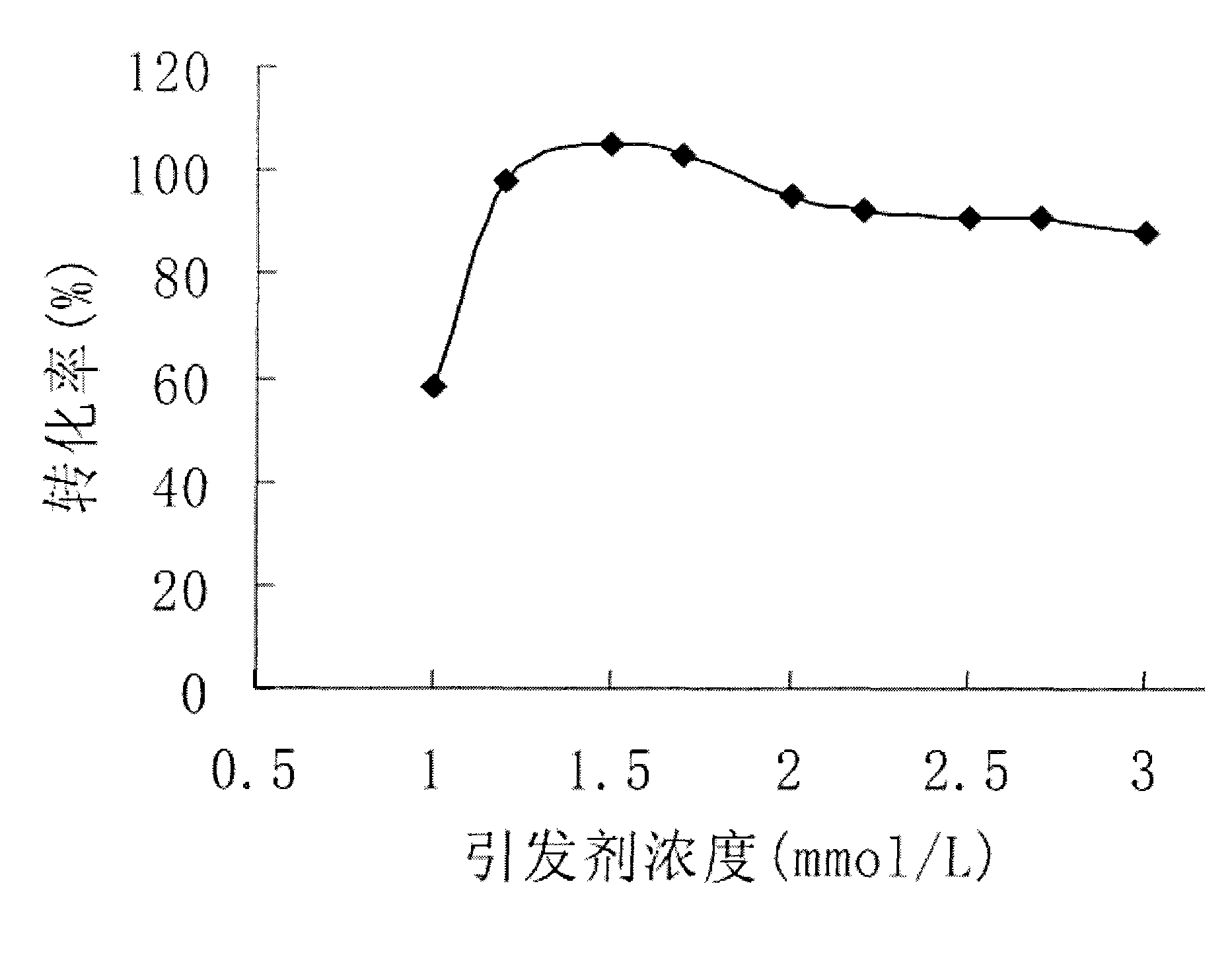

Novel preparation method of starch-acrylamide grafted copolymer

InactiveCN102464772AImprove intrinsic viscosityHigh synthesis efficiencyStarch gelatinizationDistilled water

The invention discloses a novel preparation method of a starch-acrylamide grafted copolymer. The novel preparation method of the starch-acrylamide grafted copolymer comprises the following steps of: weighing starch and distilled water, and putting into a reaction vessel; stirring to gelatinize the starch; and adding an acrylamide monomer for reacting to obtain a product, and the like. In the invention, the starch and the acrylamide are reacted, so that the starch-acrylamide grafted copolymer can be synthesized successfully; moreover, synthesis efficiency is high, synthesis steps are simple, and synthesis cost is reduced; and initiator concentration in a preparation process is controlled, so that the transformation rate of a polymerization reaction and the limiting viscosity number of a polymer are increased.

Owner:李波

Method for synthesizing PBT polyester

The invention belongs to the technical field of polyester production, and particularly discloses a method. The method comprises the following steps: Step 1: preparation of a catalyst: firstly continuously stirring a hydroxycarboxylic acid, dropwise adding titanium alkoxide into the hydroxycarboxylic acid at the same time to carry out stirring reaction, adding an alkali solution, and controlling the pH to be less than or equal to 7, then allowing standing still to layer the solution to obtain lower supernate which is a hydrolysis-resistant titanium-based liquid catalyst, and taking out the lower supernate; Step 2: polyester synthesis: placing terephthalic acid and 1,4-butanediol in a reactor, catalyzing the terephthalic acid and the 1,4-butanediol by using the hydrolysis-resistant titanium-based liquid catalyst prepared in Step 1 for esterification for 60 to 240 min to synthesize a PBT oligomer, lowering the pressure of the PBT oligomer within 30 to 120 min to 1 to 100 Pa, adjusting thetemperature to 240 to 260 DEG C, and performing condensation for 60 to 300 min to synthesize the PBT polyester. The catalyst preparation process used in the method is simple, and no hydrolytic precipitations are produced in the synthesis process; furthermore, the titanium-based liquid catalyst is uniform and high in flowability.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

Organic montmorillonite/halogen-free diphosphonate fire retardation PA6T/6 composite material and preparation method thereof

The present invention relates to a semi-aromatic PA6T / 6 composite material, particularly to an organic montmorillonite (OMMT) / halogen-free diphosphonate fire retardation PA6T / 6 composite material and a preparation method thereof. The organic montmorillonite (OMMT) / halogen-free diphosphonate fire retardation PA6T / 6 composite material comprises, by mass, 20-200 parts of a PA6T / 6 resin, 5-50 parts of a halogen-free diphosphonate fire retardation agent, and 1-10 parts of organic montmorillonite. The fire retardation composite material of the present invention has characteristics of high fire retardation efficiency, halogen-free fire retardation, green environmental protection, low harm on human health, low environment pollution, high fire retardation grade, and significant effect.

Owner:JUNMA TIRE CORD

Montmorillonite modified sodium polyacrylate printing and dyeing sewage treatment agent and preparation method thereof

InactiveCN108658148AImprove intrinsic viscosityEfficient processing effectWater contaminantsWater/sewage treatment by flocculation/precipitationMontmorilloniteSewage

The invention belongs to the technical field of sewage treatment, and particularly relates to a montmorillonite modified sodium polyacrylate printing and dyeing sewage treatment agent and a preparation method thereof. Montmorillonite modified sodium polyacrylate is adopted to replace a traditional coagulating agent (sodium polyacrylate), and because the characteristic viscosity of the sodium polyacrylate is increased by virtue of montmorillonite modification, the printing and dyeing sewage treatment agent compounded by the montmorillonite modified sodium polyacrylate has a more efficient printing and dyeing sewage treatment effect, can obviously improve the chroma removing rate, the turbidity removing rate and the COCcr removing rate of the printing and dyeing sewage, and has excellent properties.

Owner:肇庆市创业帮信息技术有限公司

High-transparency and high-heat-resistance copolyester resin and preparation method thereof

The invention relates to a polyester high polymer material, and discloses a high-transparency and high-heat-resistance copolyester resin and a preparation method thereof. The copolyester resin comprises the following components: (1) a binary acid component comprising: (a) 80-100 mol% of terephthalic acid residue, (b) 0-20 mol% of aromatic diacid residues; and (2) a dihydric alcohol component comprising: (a) 20-85 mol% of 2, 2, 4, 4-tetramethyl-1, 3-cyclobutanediol residues, (b) 15-80 mol% of a first diol residue, and (c) 0-30 mol% of a second diol residue. According to the copolyester resin disclosed by the invention, pentanediol residues or propylene glycol residues are introduced, so that blockage is avoided in the preparation process, the intrinsic viscosity is increased, the loss of CBDO monomers is inhibited, and the obtained copolyester has high glass transition temperature and excellent strength, toughness and thermal stability; and the foaming, foaming and expansion phenomena caused by thermal decomposition can be effectively inhibited in the melt processing process.

Owner:ZHEJIANG UNIV

Synthetic method of polyglycollide

InactiveCN105885021AImprove thermal stabilityUniform performanceSuture equipmentsAcetic acidPolymer science

The invention discloses a synthetic method of polyglycollide in the technical field of polymers. The synthetic method comprises the following steps: respectively preparing chemically pure diglycolide, stannous octoate of which the mole fraction is 0.01% and lauryl alcohol of which the mole fraction is 0.01%; adding the diglycolide, the stannous octoate and the lauryl alcohol into a reaction kettle for reaction, sealing and vacuumizing the reaction kettle, and introducing nitrogen into the reaction kettle; rapidly heating the reaction kettle to 160 DEG C after reacting for 30 minutes, starting stirring the reactants in the reaction kettle at the same time, heating the inside of the reaction kettle to 230 DEG C at a rate of 1.67 DEG C / min after 45 minutes, and taking out a polymer after reacting for 105 minutes; and performing vacuum drying on the polymer for 24 hours at 30-35 DEG C, performing extraction on a dried sample for 48 hours on soxhlet extractor by using ethyl acetate, and performing vacuum drying on the polymer for 24 hours at 30-35 DEG C. the polyglycollide prepared by the synthetic method disclosed by the invention is uniform in performance, can realize batch production, and is relatively high in conversion rate.

Owner:许智静

Method for cleaning and decontaminating polyesters

InactiveCN1321174AImprove intrinsic viscosityExtended durationProductsReagentsPolyesterIntrinsic viscosity

A method for treating polyesters comprises combining discrete particles of a polyester with an alkaline composition such that the alkaline composition coats the polyester particles. The particles are then heated in an environment that is at least substantially free of water. The method can be effectively used in cleaning, decontaminating and even increasing the intrinsic viscosity of polyester materials. Moreover, when used in the recovery of polyester materials containing contaminants and / or impurities, the method can provide a superior polyester product both in terms of intrinsic viscosity and color.

Owner:UNITED RESOURCE RECOVERY CORPORATON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com