Copolyester preparation method and application of copolyester prepared thereby in 3 D printing

A 3D printing, copolyester technology, applied in the application field of copolyester materials in 3D printing, can solve the problems of high water absorption, difficult 3D printing, easy degradation, etc., to avoid degradation and energy consumption problems, sample size The effect of small deviation and low printing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1B

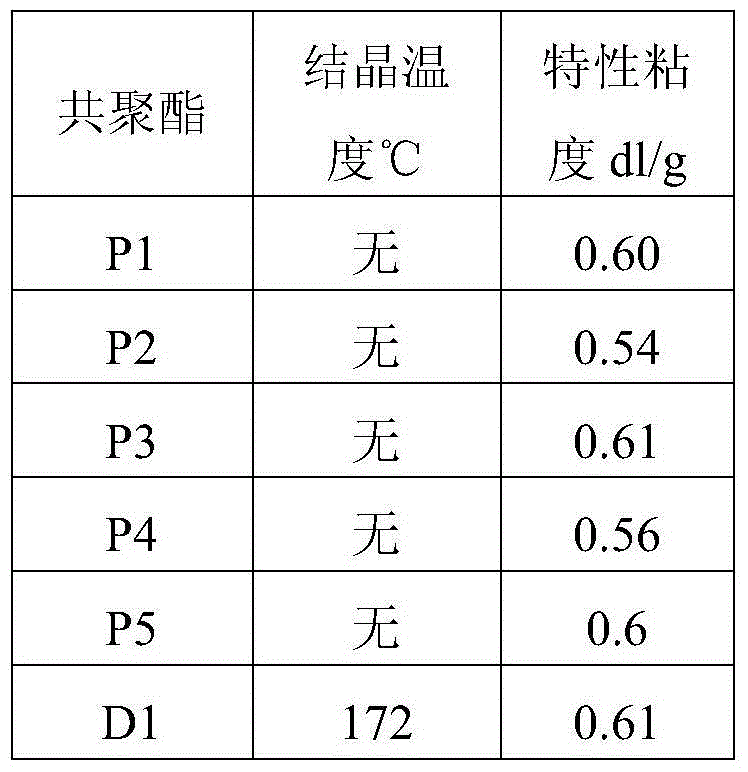

[0049] 1000g of copolyester P1 and 200g of pigment were added to the twin-screw extruder together, and a wire with a diameter of 3 mm was obtained according to the wire preparation method, which was denoted as L1.

Embodiment 2B

[0051] 1000 g of copolyester P2 and 200 g of pigments were added into a twin-screw extruder together, and a wire with a diameter of 3 mm was obtained according to the wire preparation method, which was denoted as L2.

Embodiment 3B

[0053] 1000 g of copolyester P1 and 300 g of pigment were added into a twin-screw extruder together, and a wire rod with a diameter of 3 mm was obtained according to the wire rod preparation method, denoted as L3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com