Patents

Literature

249results about How to "Small size deviation" patented technology

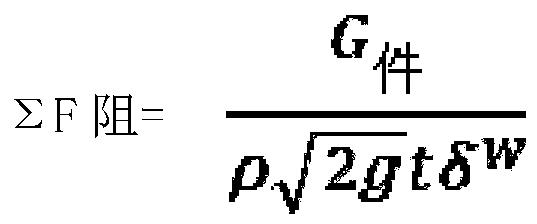

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Building material based on interaction of alkali and CO2

ActiveCN101381217AWiden the range of process parametersReduce carbonization depth requirementsSolid waste managementSlagCarbonization

The invention discloses a building material product based on the synergic action between alkali and CO2 and a method for preparing the same, which belongs to the field of silicate building material and product thereof. In the building material product, the fly ash the fineness of which is controlled in the range of between 400 and 600m<2> / Kg and the slag form a mixed powder material, and an aggregate and water glass are added into the mixed powder material for forming so as to obtain a blank, and the blank is subjected to natural curing and carbonization to obtain the building material product. In the invention, the industrial waste slag is used as raw materials, the high-performance silicate product is prepared under the conditions of low alkali and not doping lime and cement clinker, so that the strength level is high, no scumming phenomenon occurs on the surface of the product, the release quantities of various toxic and harmful ions are far below the threshold value; moreover, the building material product has the advantages of good durability, strong freezeproof and weather resistance capabilities, and is suitable to be the building wall material. The invention has active effect on utilizing waste slag resources, saving energy and reducing emission.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Process for producing thin-walled aluminum alloy tube material

The invention discloses a process for producing a thin-walled aluminum alloy tube material. The process comprises the steps of composition optimization, casting for blank preparation, extrusion molding, quenching, stretching and straightening and aging treatment; after composition optimization, the alloy comprises the following composition: 0.55-0.65 wt% of Si, 0.32-0.38 wt% of Fe, 0.17-0.25 wt% of Cu, 0.09-0.11 wt% of Mn, 0.88-0.98 wt% of Mg, 0.06-0.15 wt% of Cr, 0.09-0.11 wt% of Zn, 0.09-0.11 wt% of Ti, and the balance being Al; the quenching step is carried out by two steps, the first step is to adopt high pressure water mist quenching, and the second step is to adopt a water cooling mode to quench. The aluminum alloy tube material produced by the process has small size deviation, and has excellent comprehensive mechanical properties, wherein the yield strength is not less than 270 MPa, the tensile strength is not less than 340 MPa, and the elongation rate after fracture is not less than 10%.

Owner:CHINA ZHONGWANG

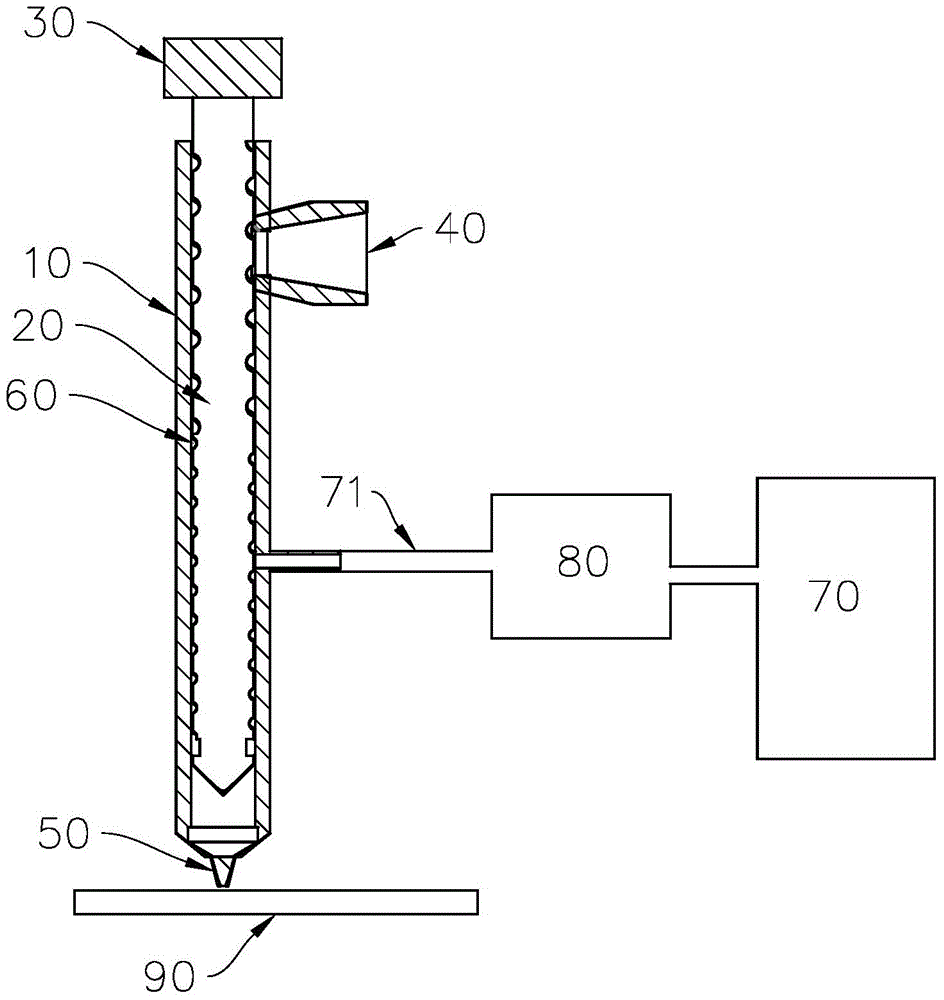

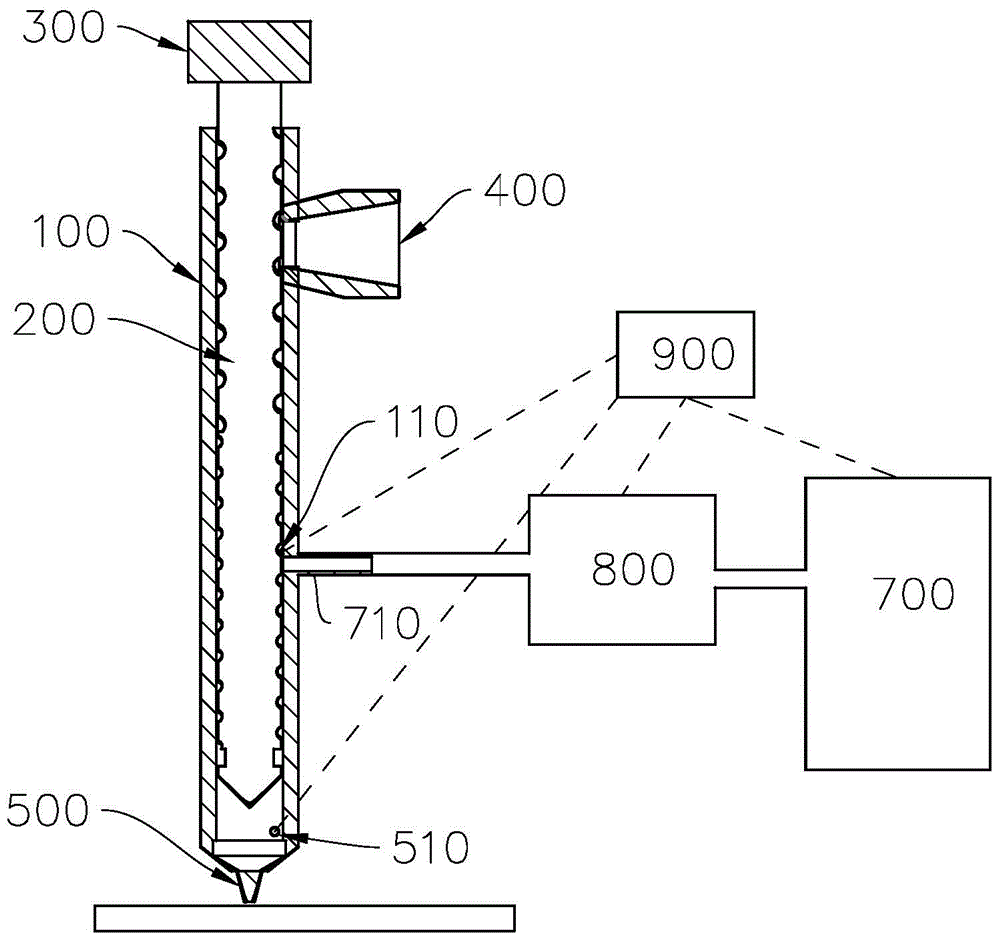

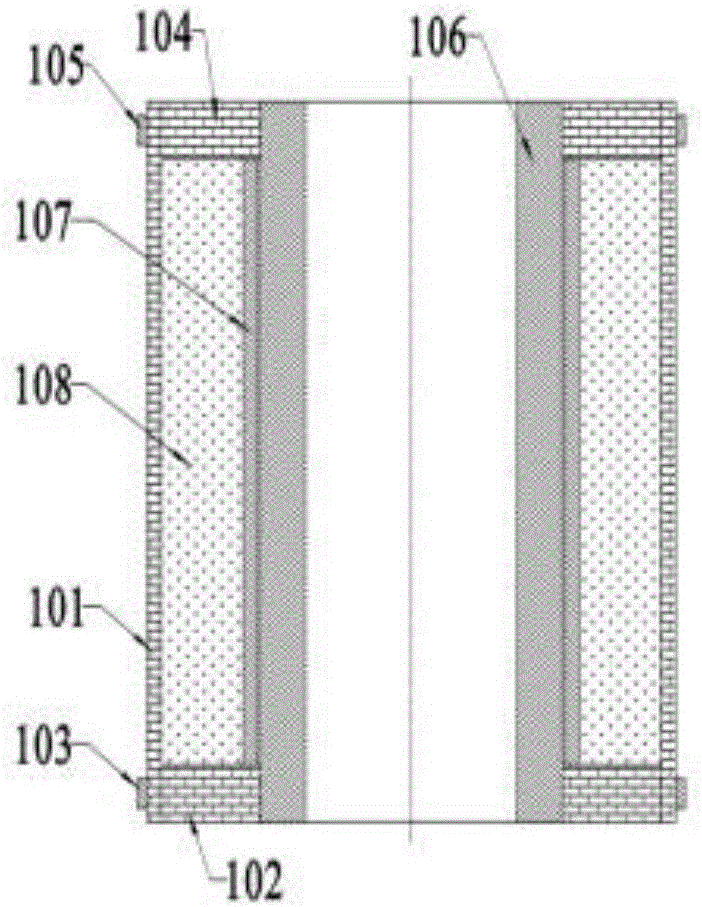

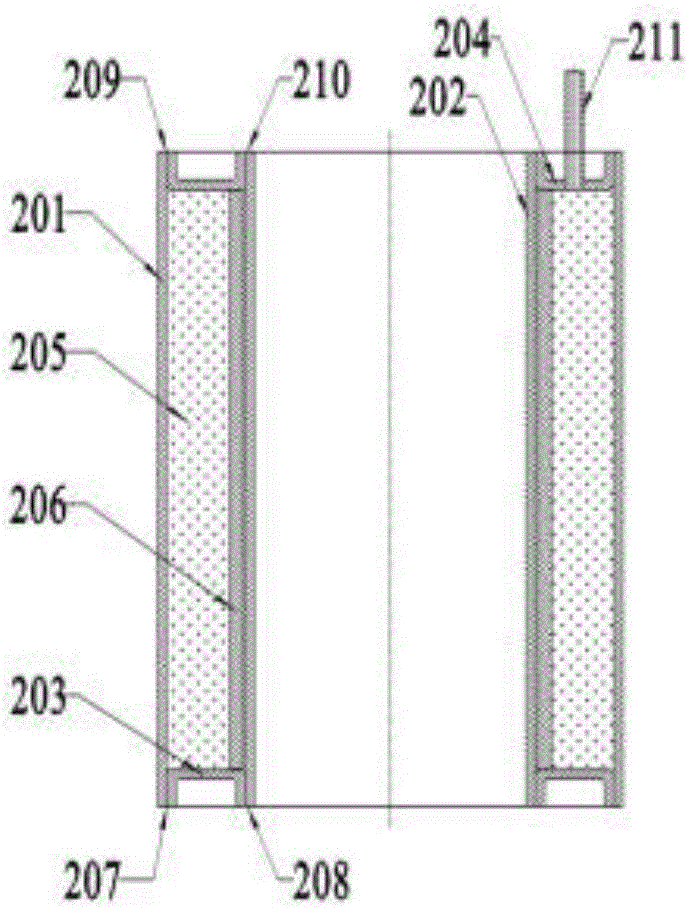

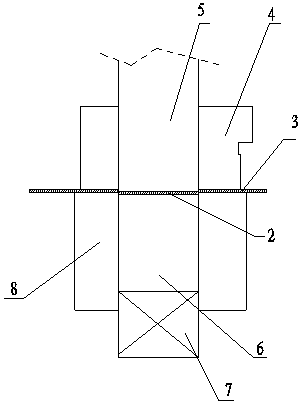

Three-dimensional printer and printing method and three-dimensional printing head

ActiveCN104875389ALow densityReduce the density valueAdditive manufacturing apparatusEngineeringVolumetric Mass Density

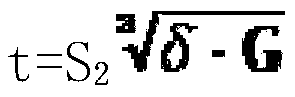

The invention relates to a three-dimensional printer, a three-dimensional printing head and a printing method. The three-dimensional printing head comprises a material volume cavity, wherein a screw rod is arranged in the material volume cavity, a motor is connected with the screw rod, a material supply device is communicated with the material volume cavity, a printing nozzle is arranged on the end part of the material volume cavity, a heater is arranged on the material volume cavity and positioned between the material supply device and the printing nozzle, and a supercritical fluid supply system is communicated with the material volume cavity. A molten printing material is mixed with supercritical fluid to generate a single-phase molten mixture under the mixing and stirring effect of the screw rod, and a uniform microporous bubble formation effect is formed, so that the density value of a printing object can be reduced, the size deviation of the three-dimensional printing object can be alleviated, the flatness and straightness of the three-dimensional printing object can be improved by more than 50 percent, the temperature for printing the molten printing material is effectively lowered, the energy is saved, and the operation personnel is prevented from being scalded.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

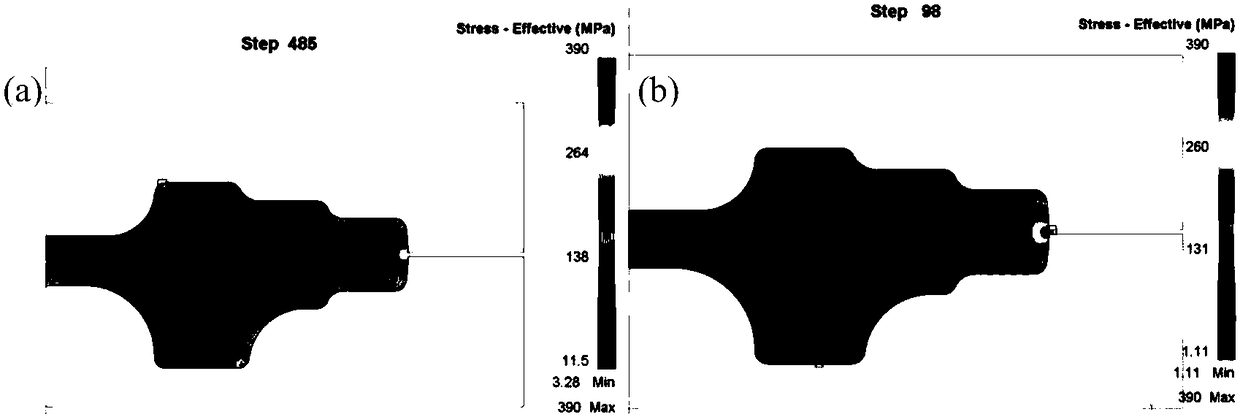

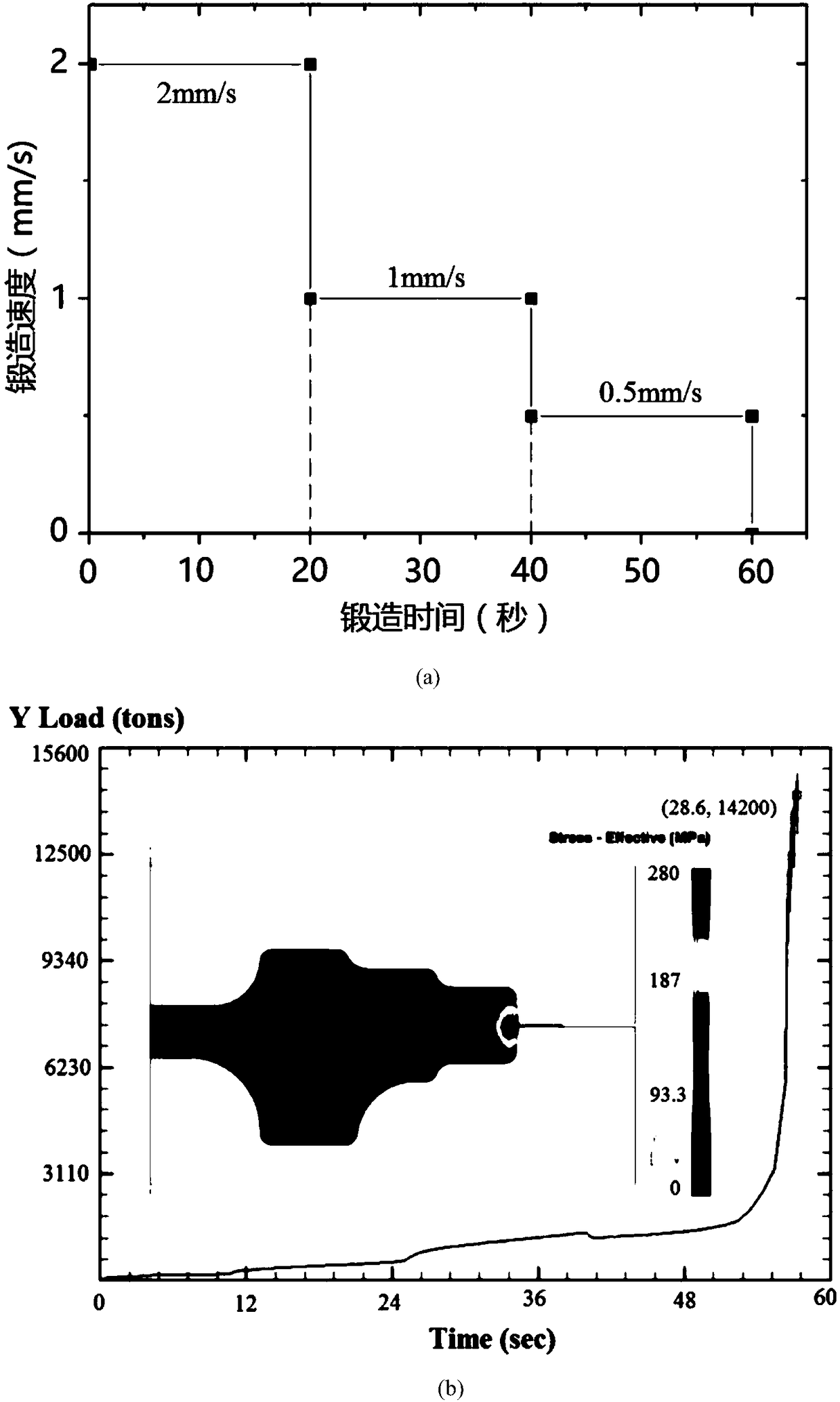

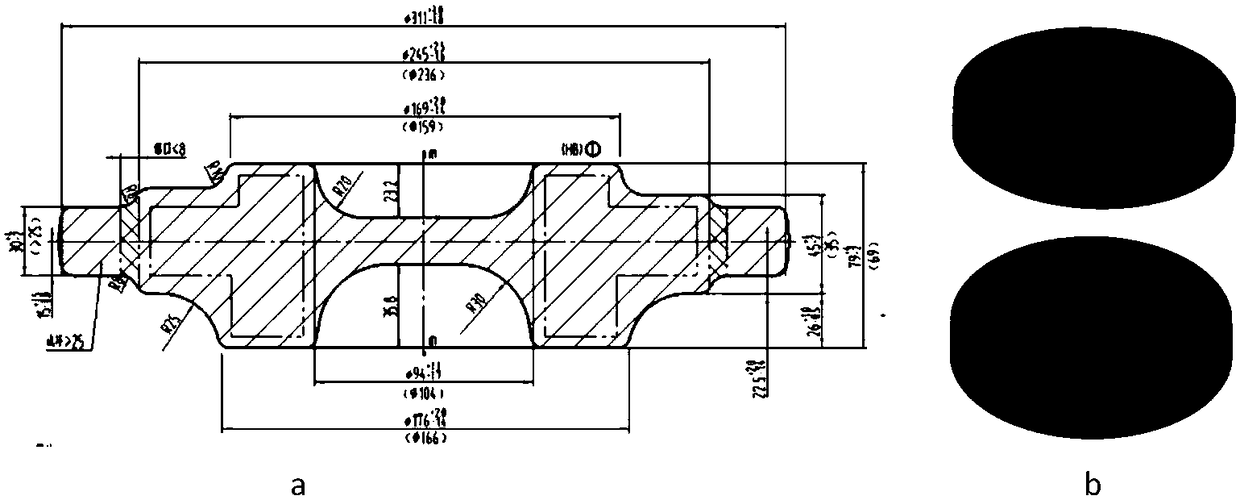

Method for reducing forging residual stress of turbine disks via gradient speed control on basis of numerical calculation

ActiveCN108062427AReduce residual stressMeet the control requirementsDesign optimisation/simulationSpecial data processing applicationsMetallic materialsMaterials processing

The invention belongs to the technical field of metal material processing, and relates to a method for reducing forging residual stress of turbine disks via gradient speed control on the basis of numerical calculation. According to the method, influences, on residual stress distribution, of forging speeds of turbine disks in the forging process are analyzed by combining a numerical simulation method and experimental tests, and a novel method for reducing residual stress of turbine disks via gradient speed control is given on the basis of a law of influences, on the residual stress, of the forging speeds, so that the shaping quality and service life of the turbine disks can be improved and prolonged. Aiming at the residual stress problems of turbine disks, numerical modeling is carried outon the forging process to analyze the stress strain and temperature field distribution, in each stage in the forging process, of the turbine disks, so that important information such as flowing law inthe turbine disk forging process, thermal parameter distribution in disk forge pieces, load-stroke / energy-stroke curves, mould working stress and the like in forging process and mould design processis disclosed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

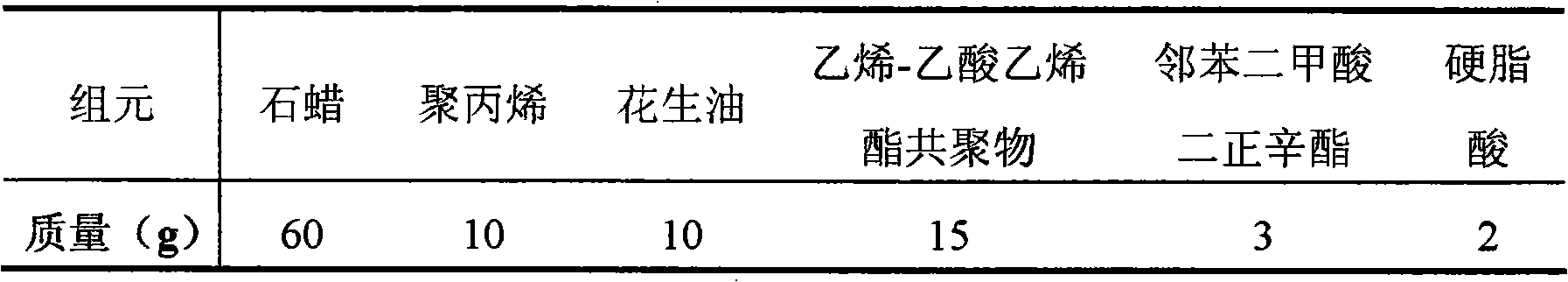

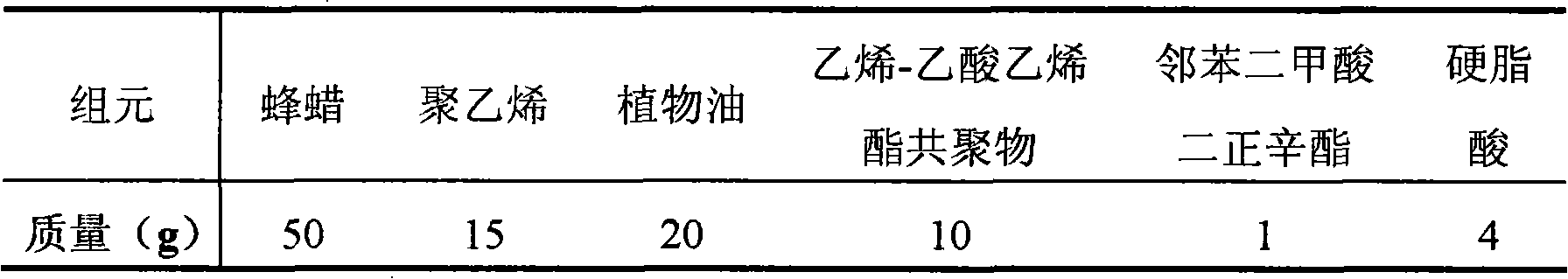

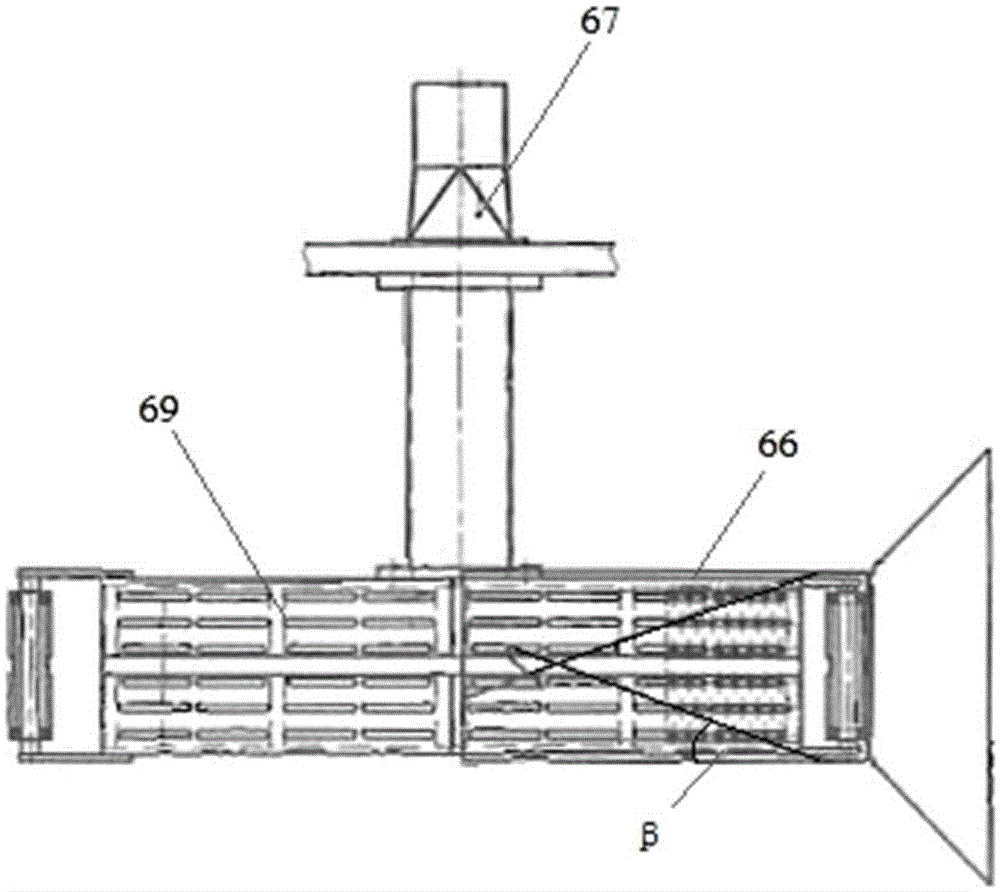

Method for preparing molybdenum and molybdenum alloys effuser by powder injection forming

A molybdenum or molybdenum alloy nozzle with very complicated shape is manufactured by powder injection molding. The molybdenum or molybdenum alloy nozzle is prepared by the following steps: mixing molybdenum or molybdenum alloy powder with a multi-component bonding agent consisting of paraffin wax, oil, low-molecule coupling agent and polymer to obtain uniform feeding material, injecting the feeding material on an injecting machine to obtain the injected blank of molybdenum or molybdenum alloy nozzle, degreasing solvent of the injected blank at a degreasing rate between 50% to 65%, pre-heating the solvent degreasing blank in a hot degreasing furnace, and high-temperature sintering the sample after hot degreasing pre-heating to obtain the molybdenum or molybdenum alloy nozzle with no deformation and stable performance.

Owner:CENT SOUTH UNIV

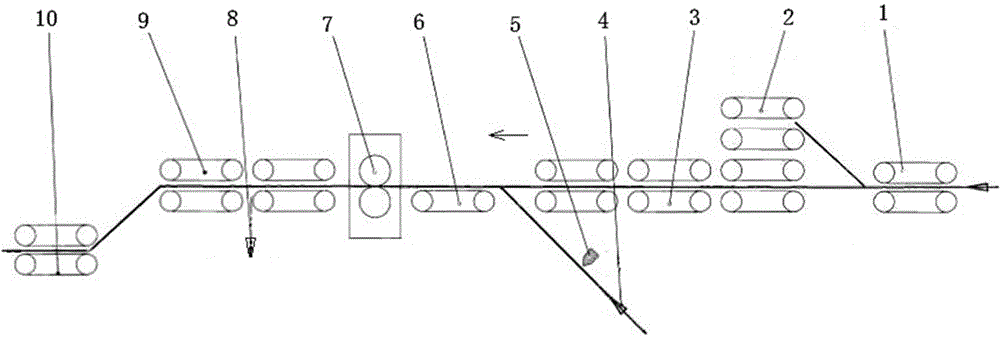

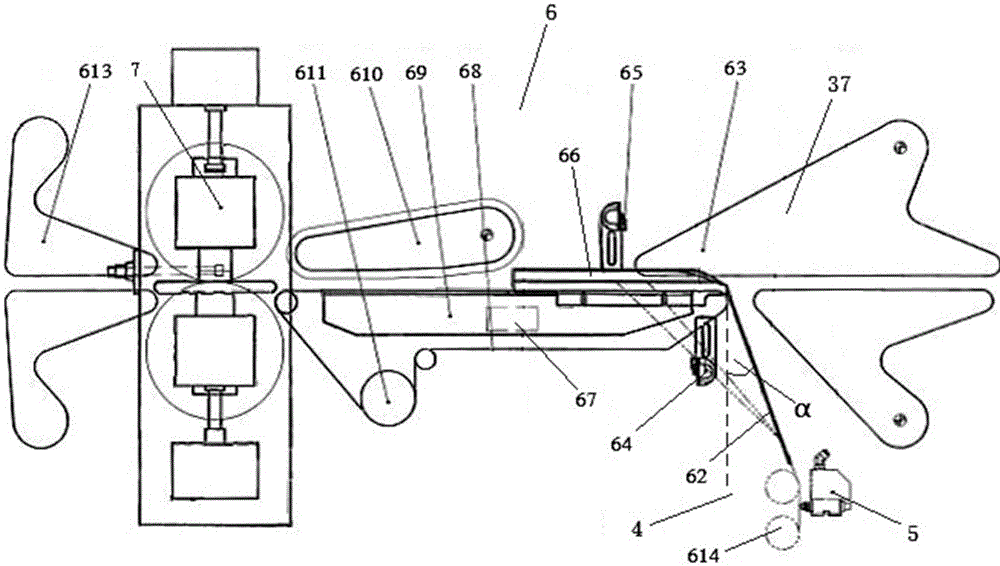

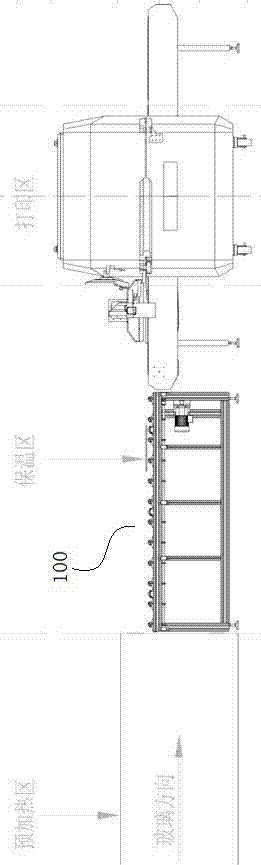

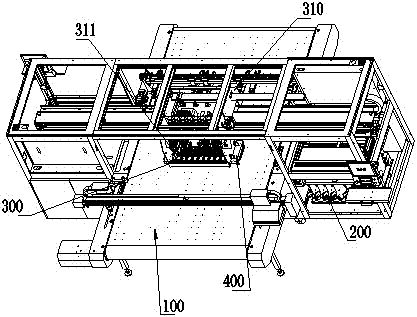

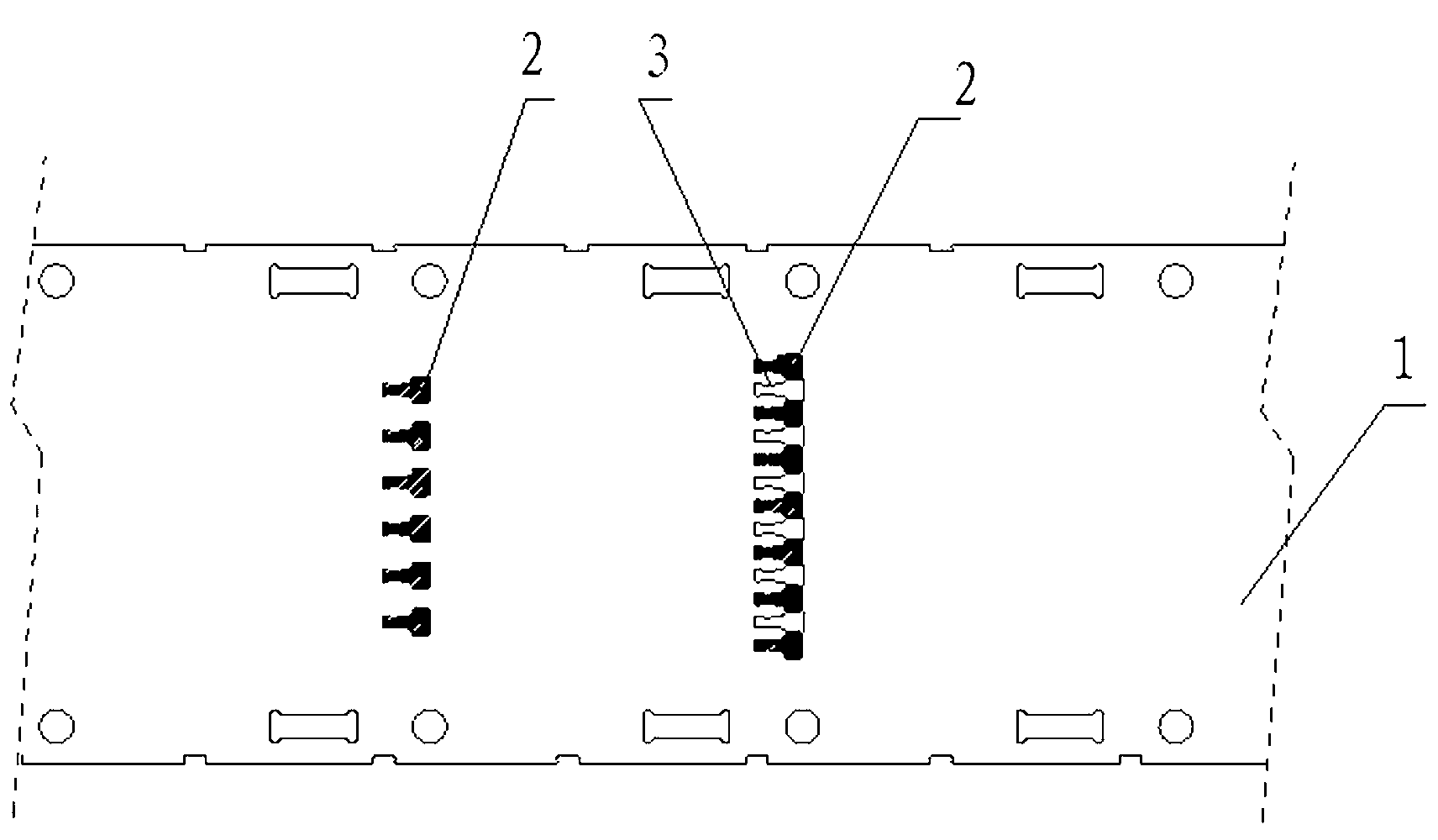

Automatic packaging mechanism for single-piece absorptive hygienic product

ActiveCN105083629AAdjust intervalImprove pass ratePaper article packagingWrappingMechanical engineeringFast speed

The invention belongs to the technical field of production equipment of absorptive hygienic products, and discloses an automatic packaging mechanism for a single-piece absorptive hygienic product. A packing system is sequentially provided with a multi-stage conveying unit, a film packaging and folding device and a heat sealing and cutting combination unit in the conveying direction. The multi-stage conveying unit sequentially comprises a front portion conveying unit, a middle conveying unit in the middle and a rear portion conveying unit which are operated independently. The middle conveying unit is provided with a synchronous conveying belt, baffles which protrude out of the surface of the conveying belt are evenly arranged on the surface of the conveying belt at intervals, and the hygienic product is conveyed on the portion, between the adjacent baffles, of the synchronous conveying belt. The automatic packaging mechanism for the single-piece absorptive hygienic product can be applied to single-piece packaging of the larger and thicker hygienic product such as sweat pants, has the beneficial effects of being high in packaging yield, low in size deviation, high in production speed and the like, and can adapt to high-speed development requirements of the hygienic products.

Owner:ZUIKO (SHANGHAI) CORP

Method for producing super fine silk yarn

InactiveCN1943332ASmall size deviationImprove cleanlinessOrganic active ingredientsSilk reelingYarnFineness

Method for preparing fine silk thread is characterized by inducing tetramolter with superfine agent to tri-molt to produce tetramolter silk, wherein the single yarn fineness is 1 Denier. It has better colored, refraction, and crease-resisting property than tetramolter silk, it has small fibre finess deviation, high lustration, low cost, products made by such silk have improved luster and chromaticity.

Owner:ZHEJIANG UNIV

Tube truss manufacture process

The invention provides a tube truss manufacture process which comprises the steps as follows: blanking of steel tubes, positioning of intersecting points of tube fitting, welding of tube fitting, calibrating of members, pre-assembling, and disassembling of the pre-assembled truss, wherein all the manufacturing and processing links are carried out in sequence. The manufacture process has the advantages as follows: the assembly precisions of intersecting ends and intersecting holes are high; the size deviation is small; a truss body can be assembled quickly; the workload of calibration is small; formation of physical appearance is good; workload and time for polishing are greatly reduced; the quality of construction and formation can be guaranteed; smoothness and progression of all manufacture links are guaranteed; total construction period is guaranteed; material cost of manufacturing of the tube truss can be saved; inputs of manpower and goods and materials are saved; and economical effects of production are improved.

Owner:河北二十冶建设有限公司

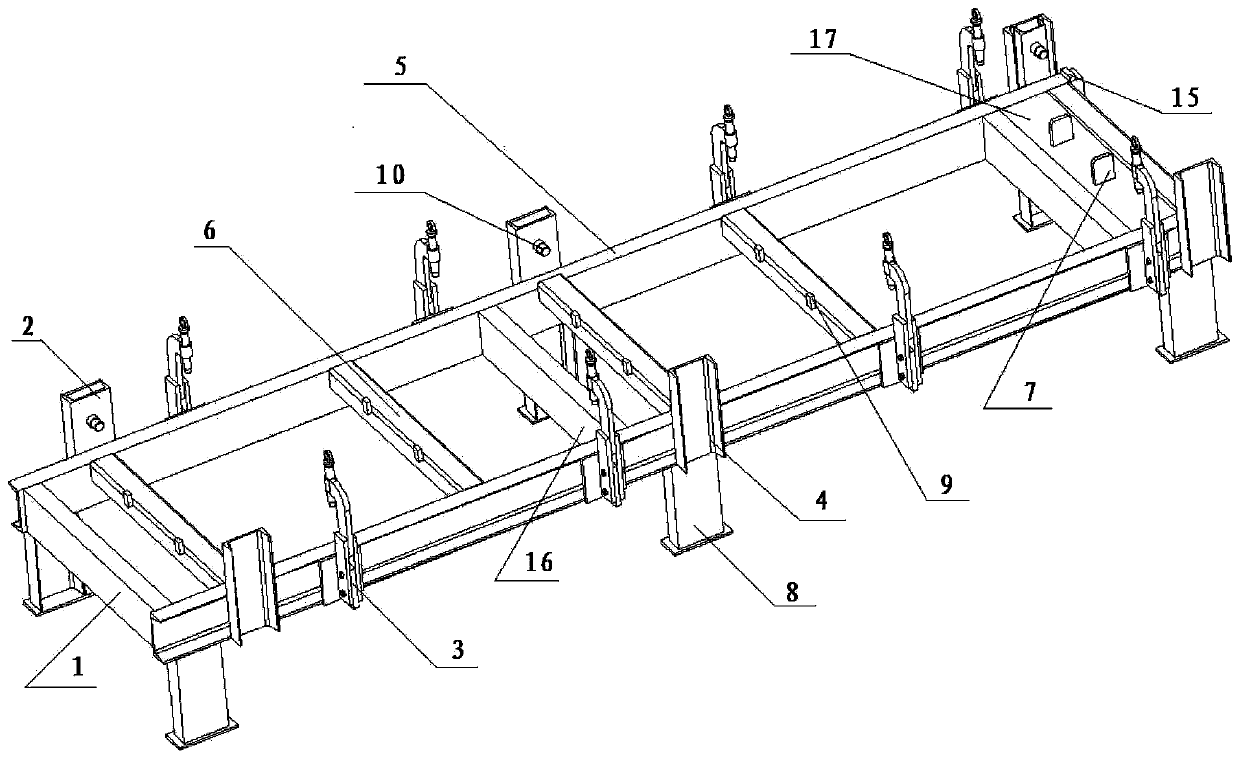

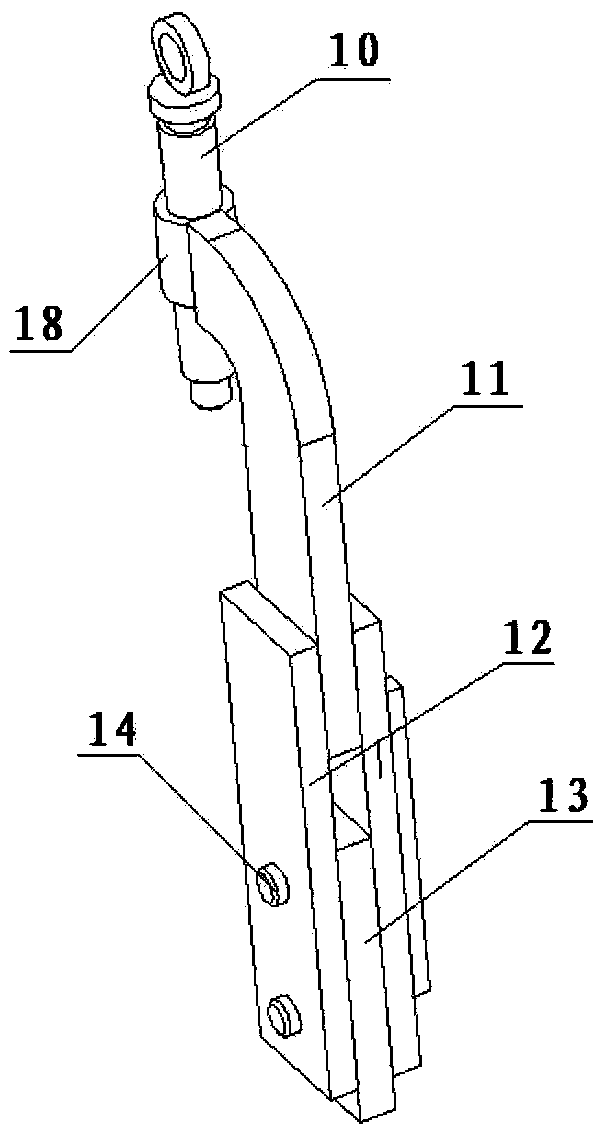

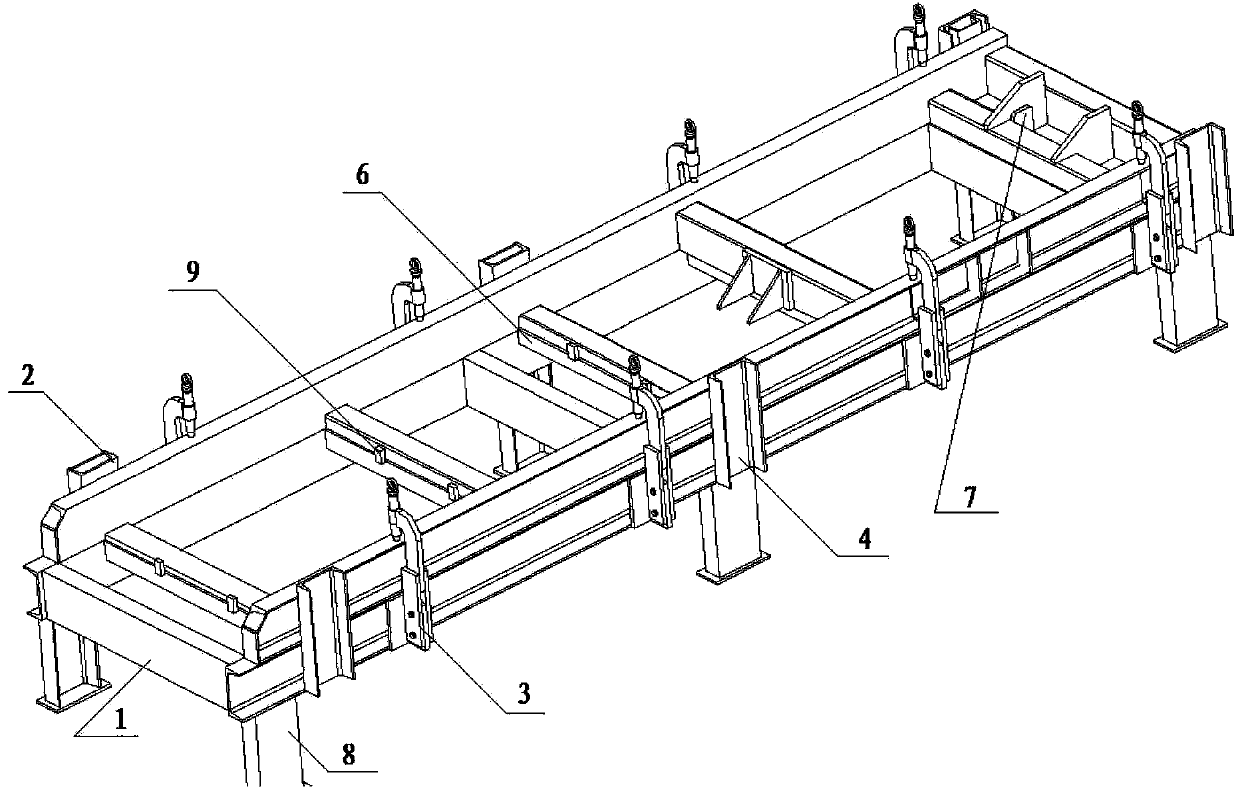

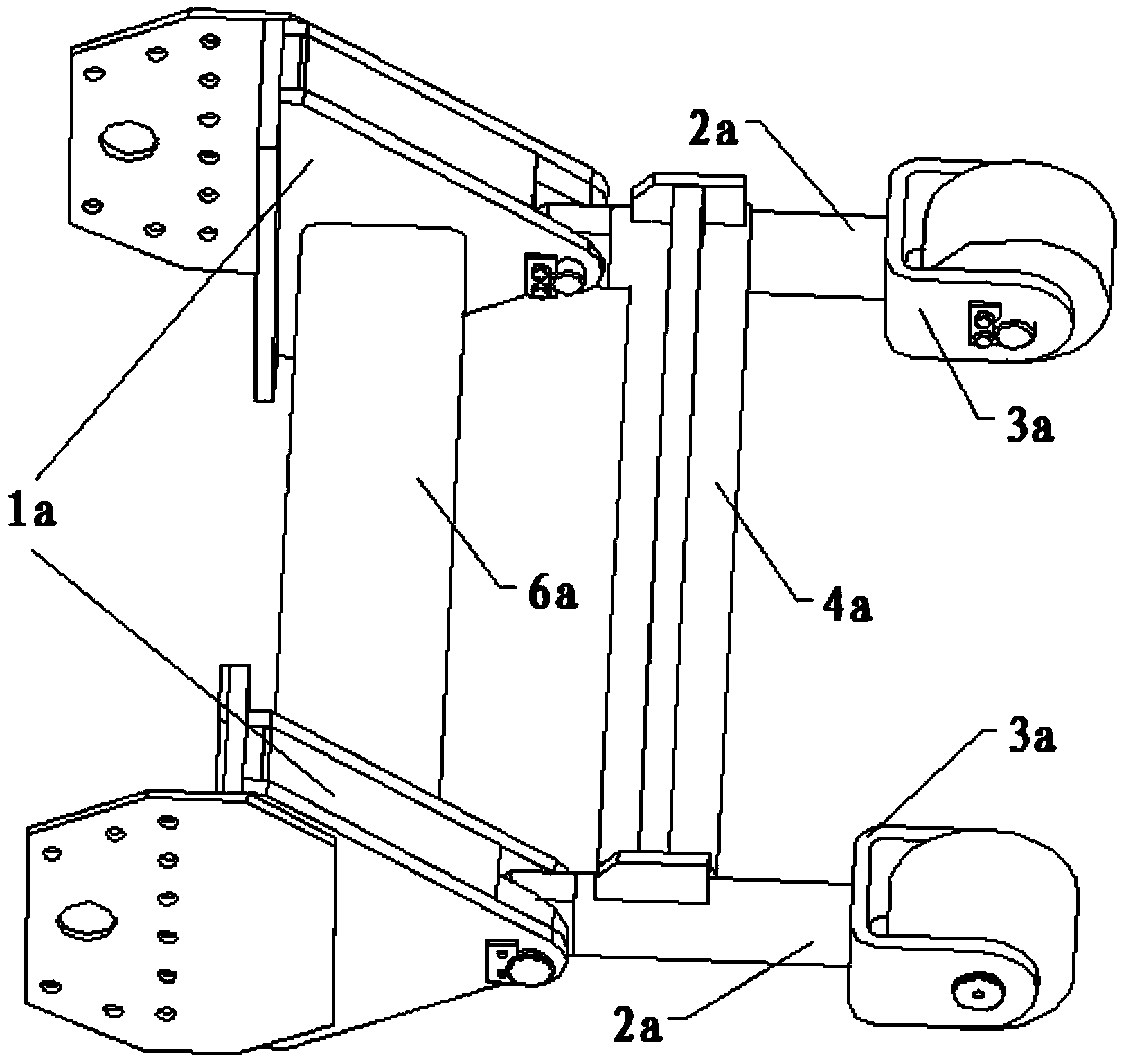

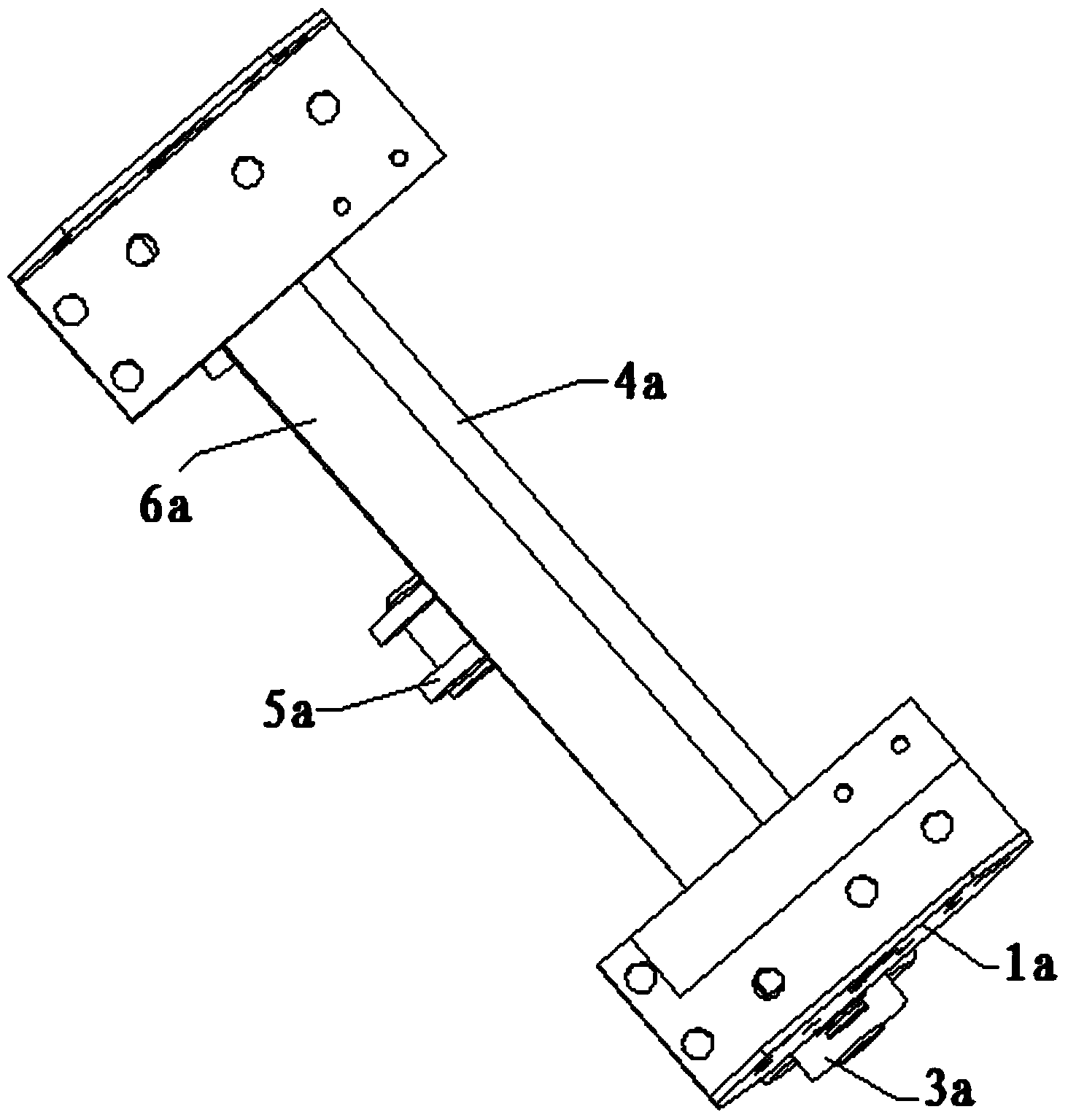

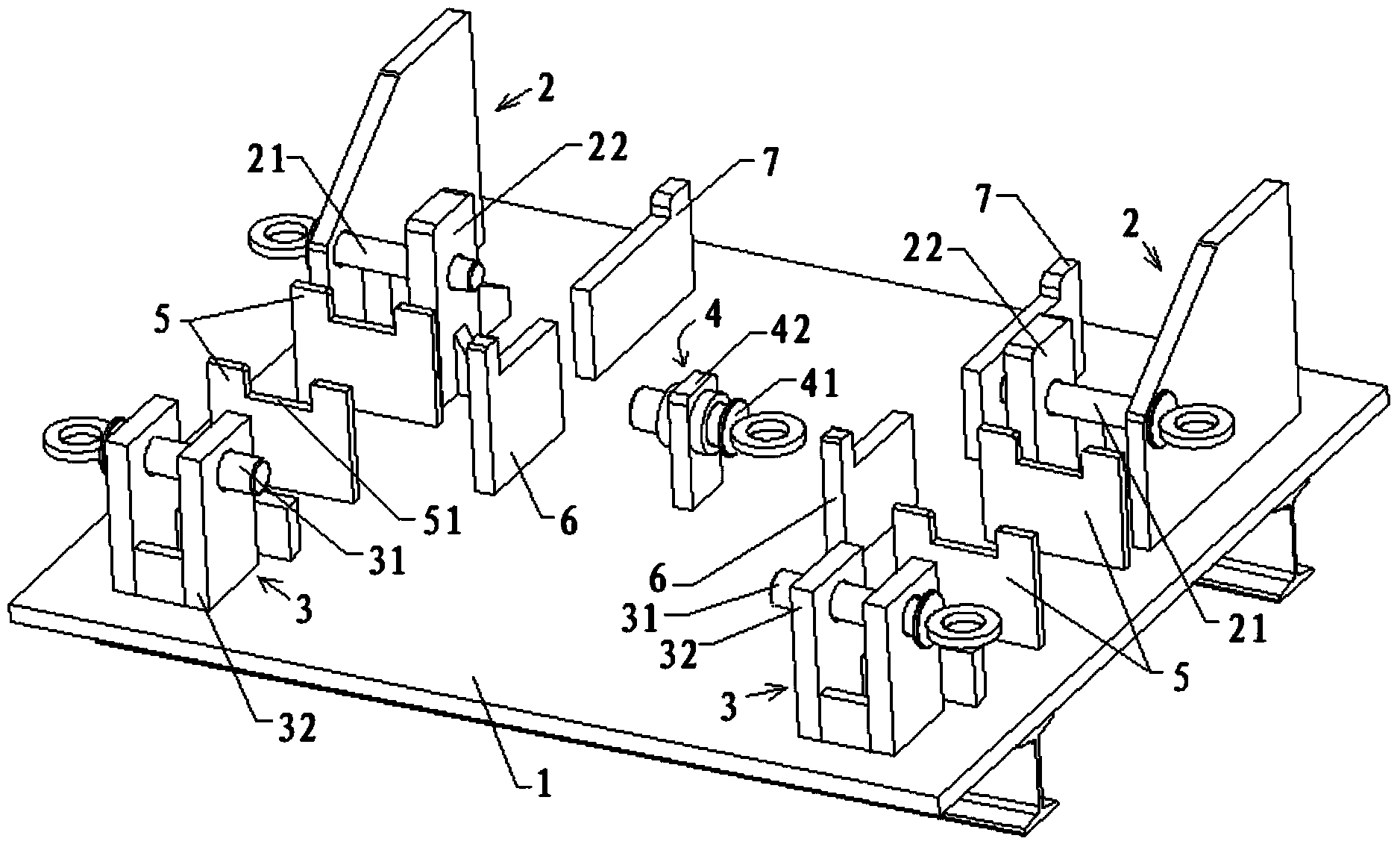

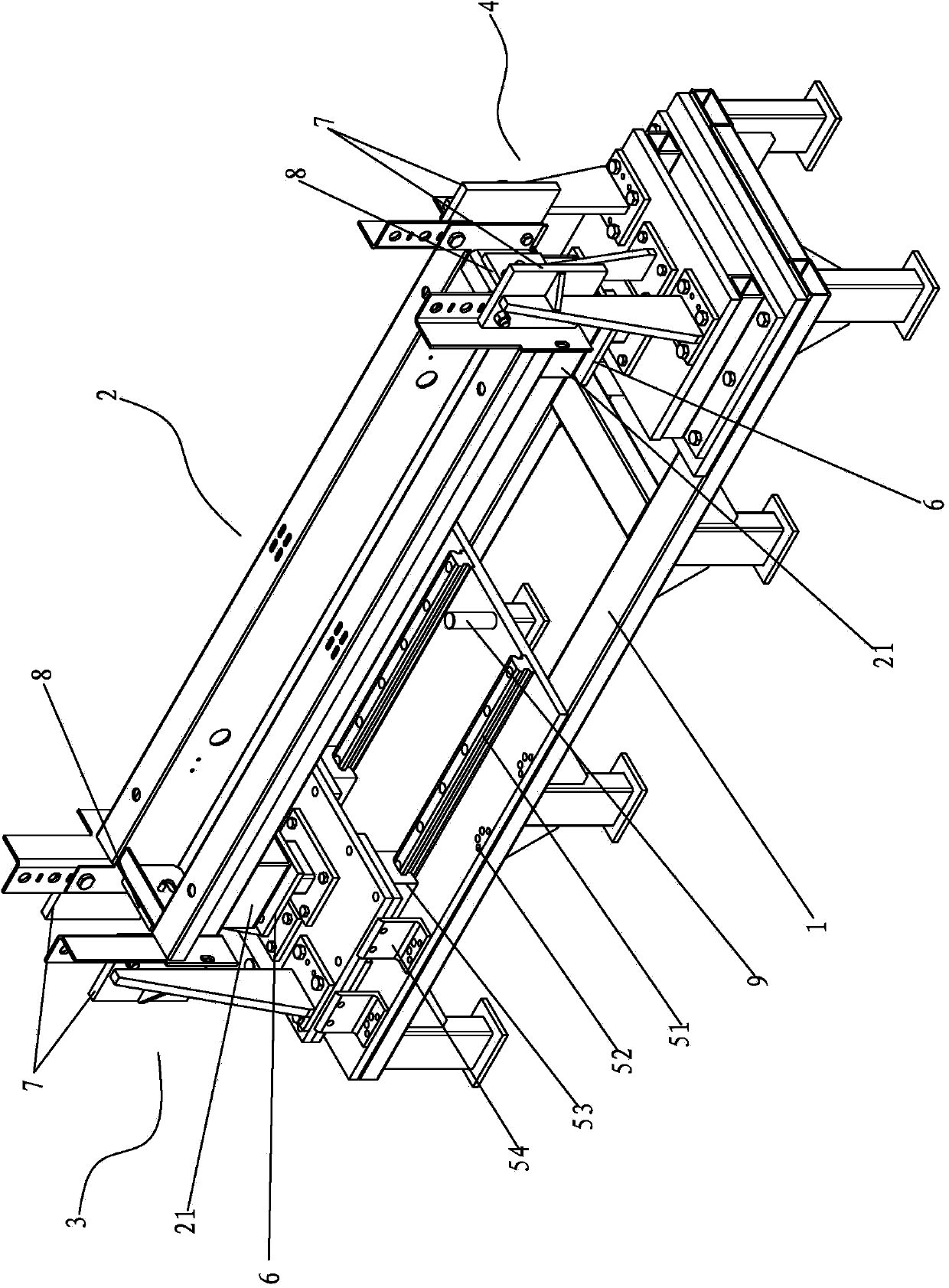

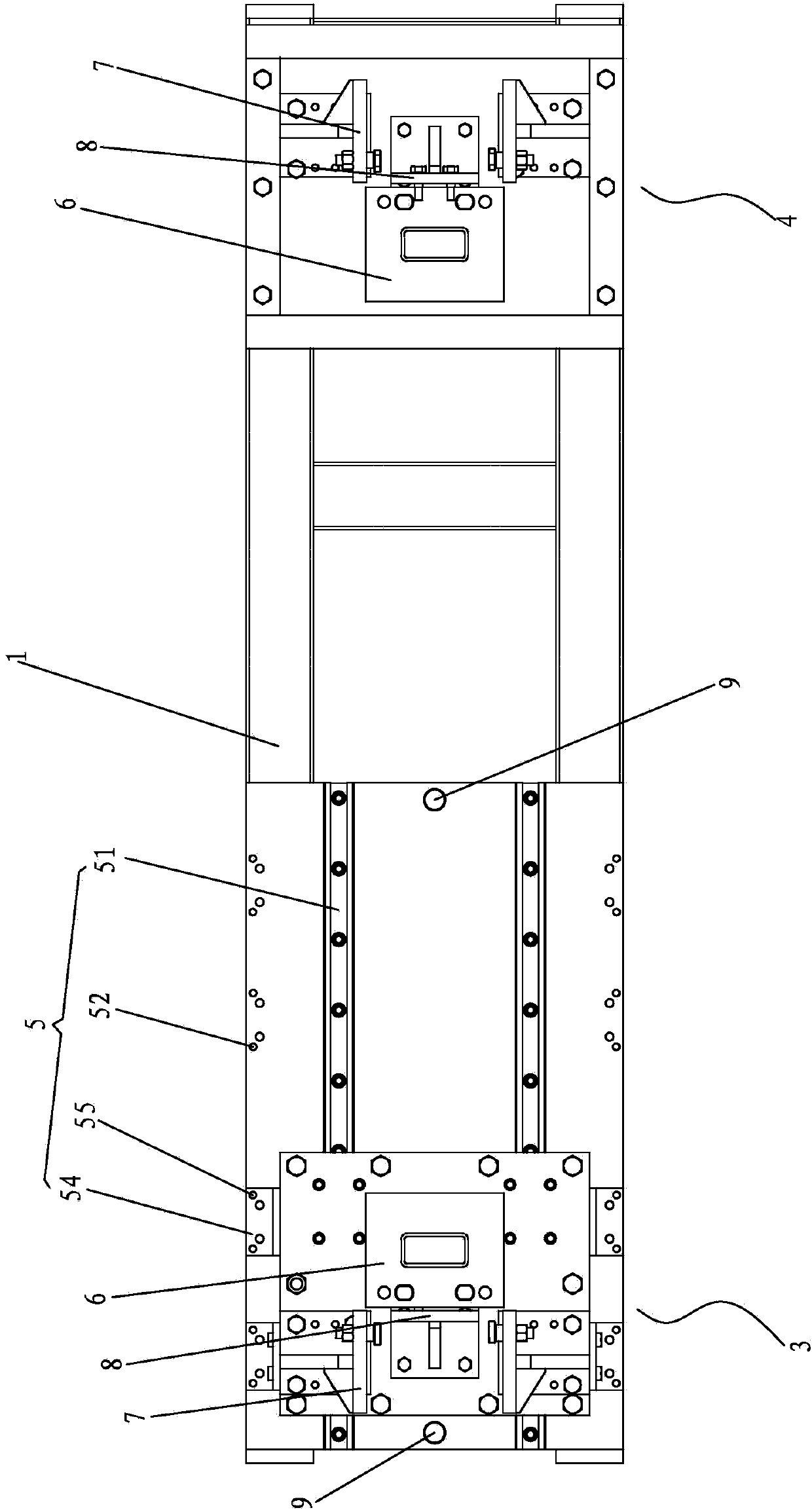

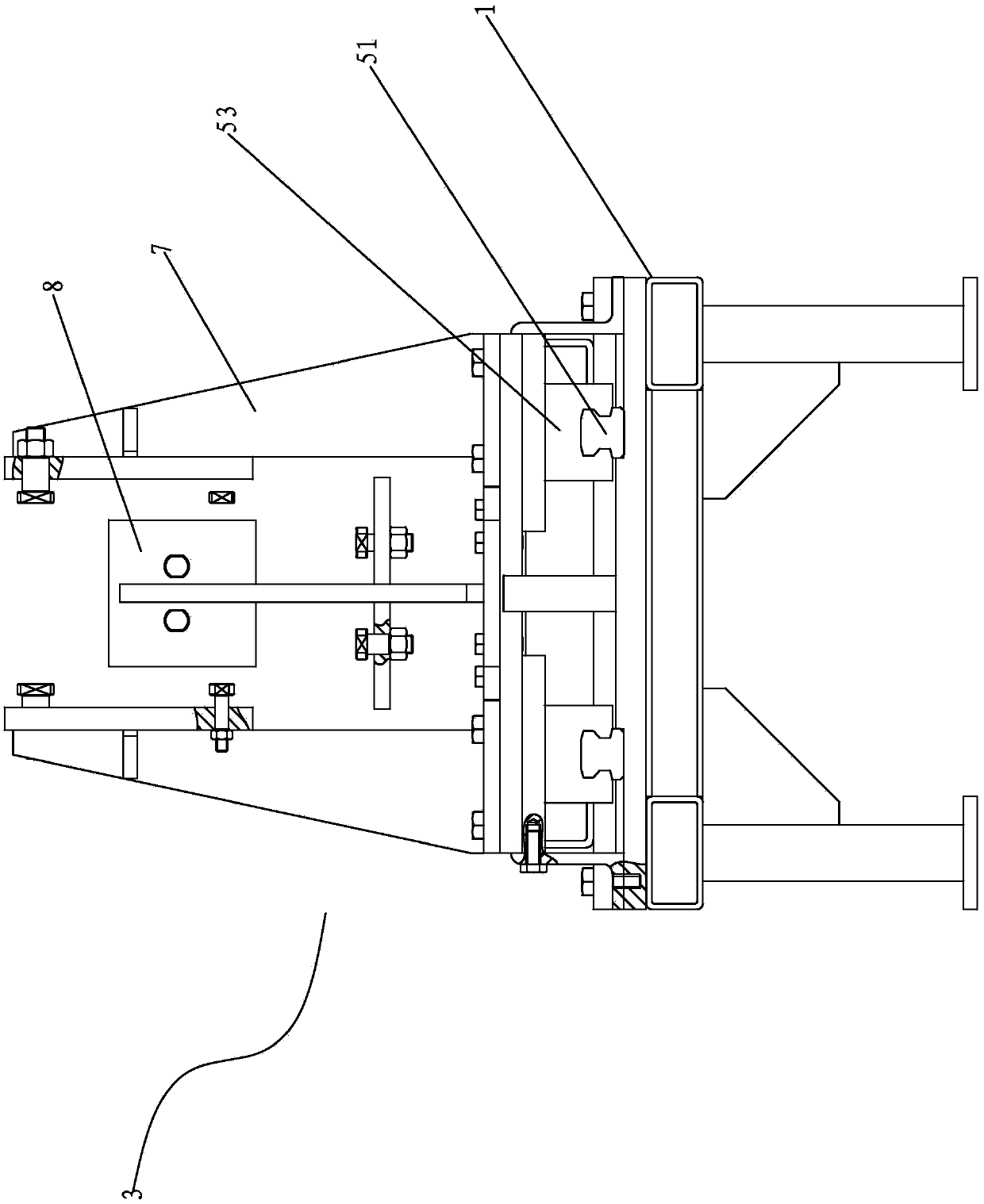

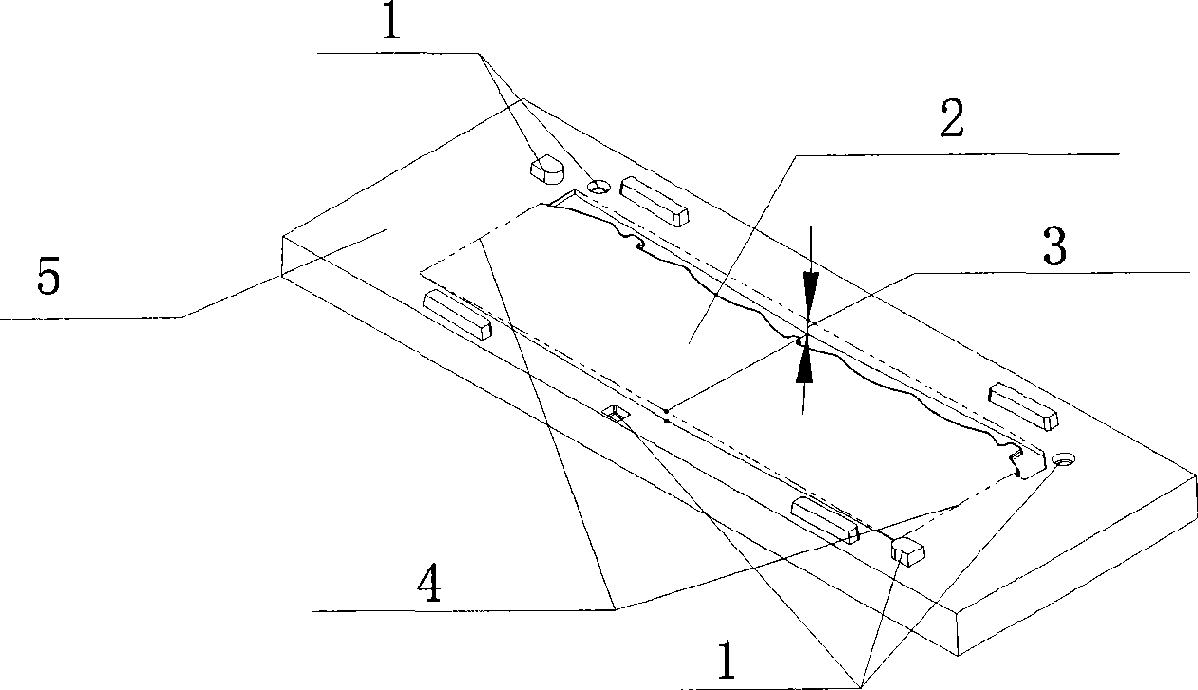

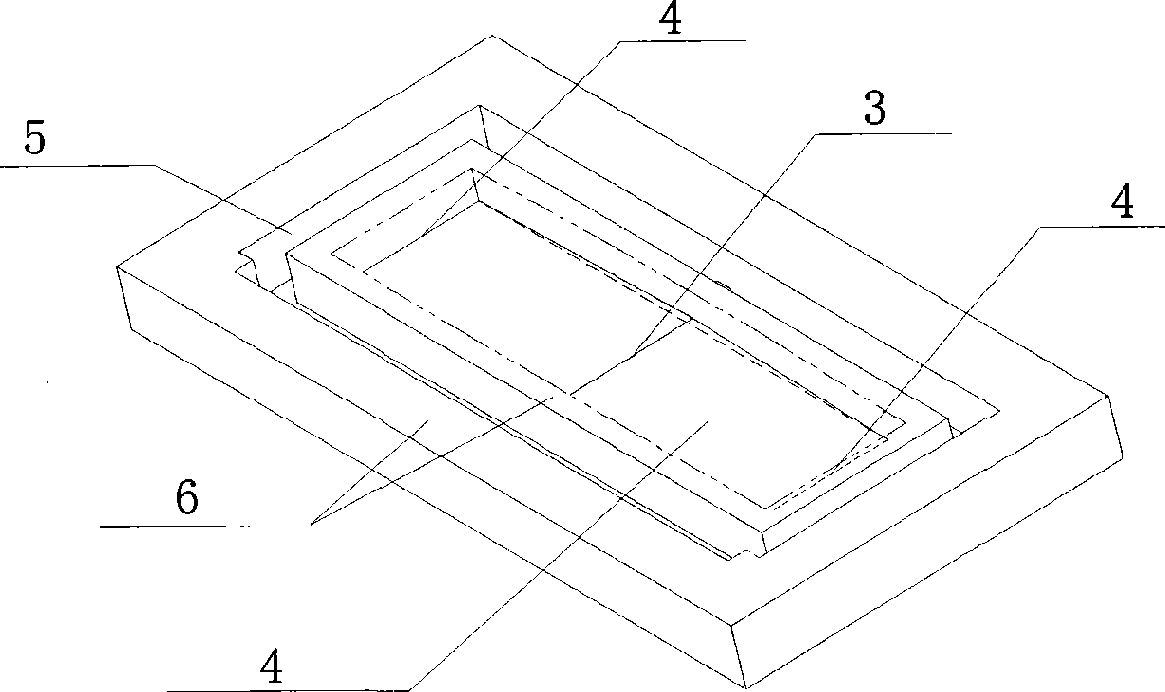

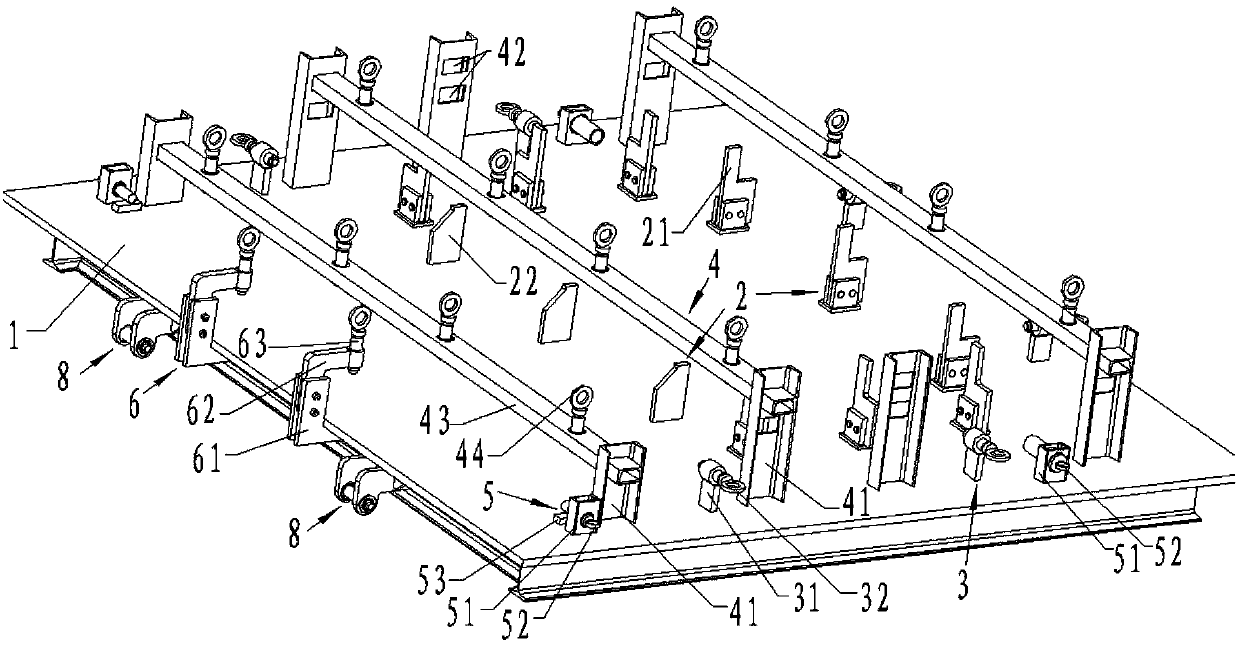

Carriage longitudinal beam tailor welding tool

ActiveCN103418965ASave adjustment timeHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention relates to a carriage longitudinal beam tailor welding tool. The carriage longitudinal beam tailor welding tool comprises a fixing frame and a first stand column which is fixed on the edge of one side of the fixing frame, wherein the edge of the other side of the fixing frame is fixedly connected with the lower portion of a second stand column, a regulating rod is fixed on the edge of the position, between the first stand column and the second stand column, of the fixing frame, and a base plate is fixedly connected with the surface of one end of the fixing frame. The carriage longitudinal beam tailor welding tool has the advantages that a part to be welded is accurately located and reliably clamped, so that the part to be welded is conveniently assembled and welded, and structural accuracy of the part to be welded is improved.

Owner:广西玉柴专用汽车有限公司

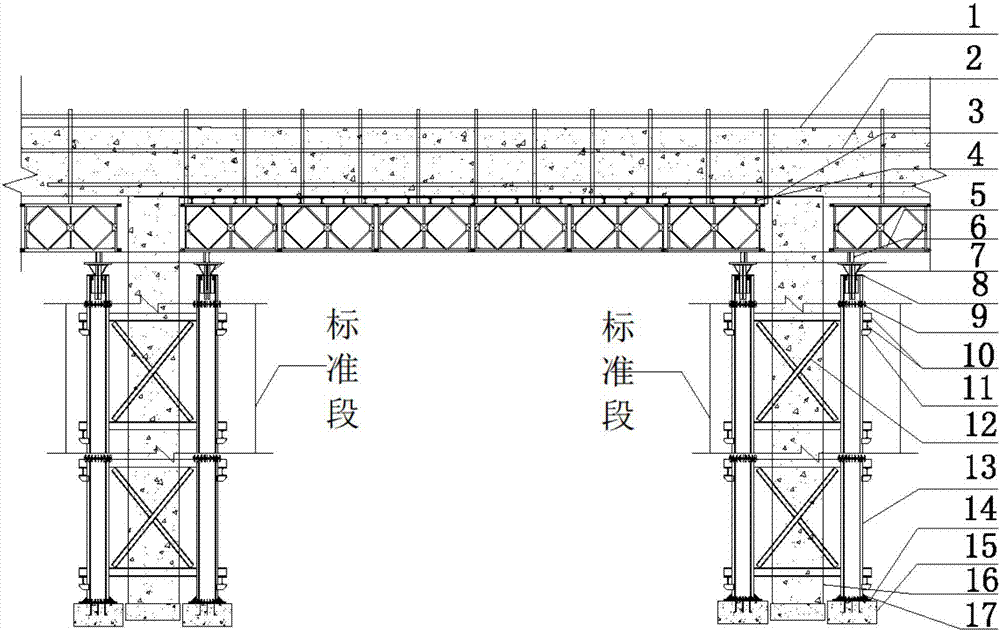

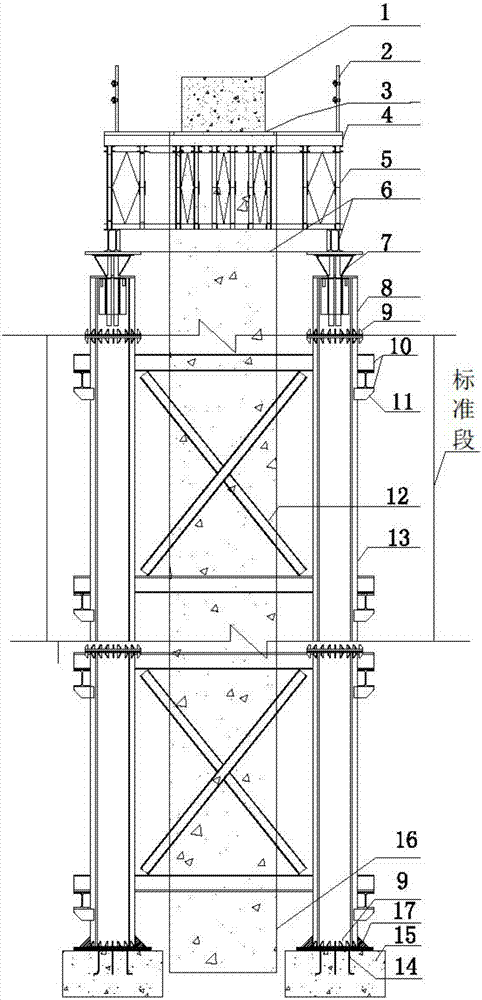

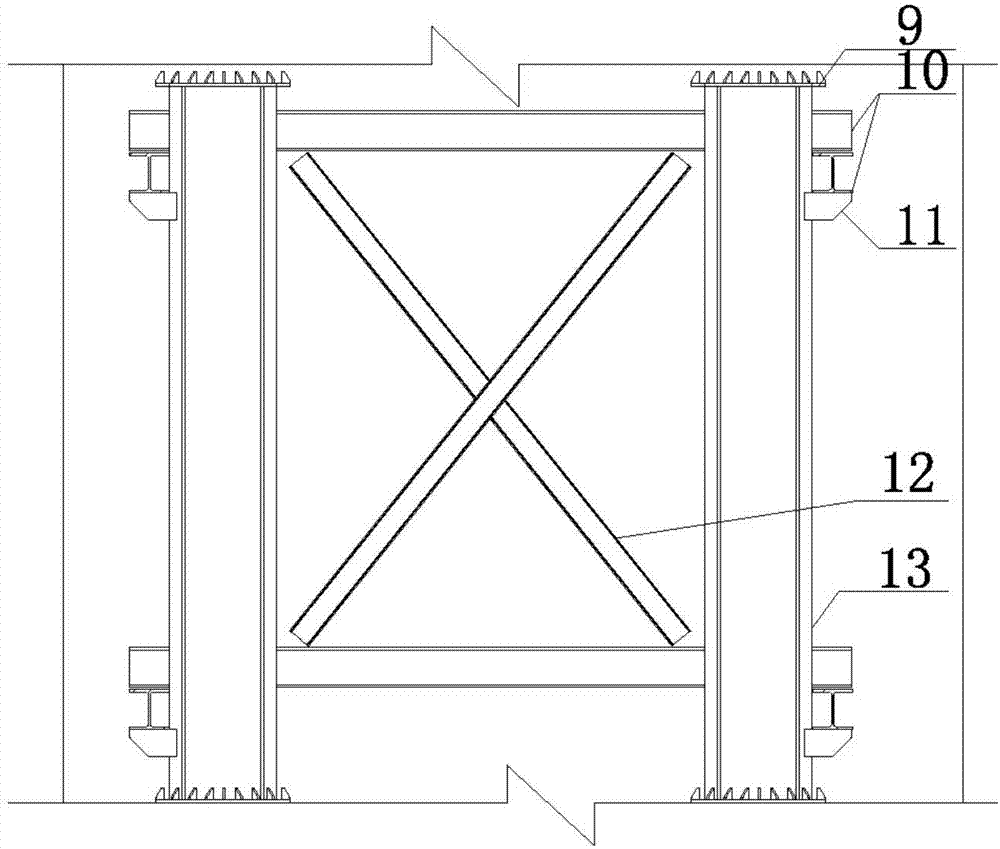

Ultrahigh large-span concrete cast-in-place beam bailey truss framework construction method

ActiveCN107090975AIncrease stiffnessImprove integrityForms/shuttering/falseworksSupporting systemFalsework

Disclosed is an ultrahigh large-span concrete cast-in-place beam bailey truss framework construction method. The measures such as erecting lattice columns and bailey trusses are adopted. The method comprises the steps of arranging a lattice column foundation, erecting the lattice columns, mounting cross bridgings among the columns, installing a top movable head, erecting cover beams, erecting the bailey trusses, installing distributive beams, mounting a side protective barrier, laying a keel, laying templates and the like. A simple framework supporting system which is small in occupied site, solid and reliable and convenient to install and disassemble is formed, a great deal of conventional steel tube floor scaffold material input is avoided, and at the same time, the labor intensity of workers is also reduced. The ultrahigh large-span concrete cast-in-place bailey truss framework construction method can adapt to ultrahigh large-span concrete cast-in-place beam projects in various building constructions.

Owner:中建五局第三建设有限公司

Phosphogypsum high-strength wall brick and its production method

The invention discloses a high-intensity ardealite wall brick and the producing method. And the composition weight ratio of semi-hydrated ardealite to anhydrous ardealite to flyash to coagulant is (70-85) : (12-20 ): (15-20 ): (15-25), where the coagulant is 12-20% silicasol water solution. And the invention uniformly blends them in sprinkling mode, mechanically places the mixture into a mould and shapes in high pressure, mechanically demoulds, and naturally hydrates to make it. And the invention firstly uses large amount of ardealite raw material in building materials, where the synthetic utilization of ardealite is up to 80%; and it is low-cost and saves land resources. After processed, it accords with national stipulated nuclear radiation indexes, has high hardness, reduces equipment investment and reduces cost of product.

Owner:重庆金仓龙新型建材有限公司

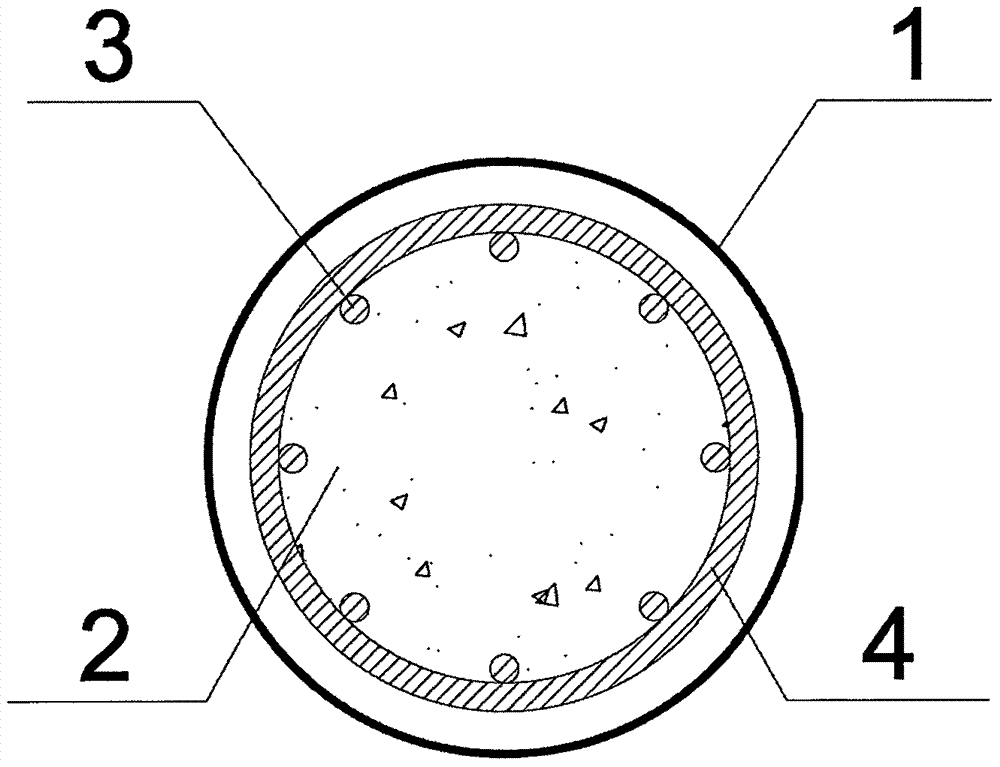

Pre-stress FRP bush-FRP rib sea sand seawater expansion concrete combination column

PendingCN107503470AIncrease profitIncrease the range of axial ultimate bearing capacityStrutsBridge structural detailsEcological environmentPre stress

The present invention relates to the field of building, bridge and harbor engineering, and provides a pre-stress FRP bush-FRP rib sea sand seawater expansion concrete combination column, which comprises an external FRP bush and internal FRP rib sea sand seawater expansion concrete, wherein the FRP bush wraps the sea sand seawater expansion concrete, self-stress is generated in the FRP bush and the concrete through the expansion of the concrete and the restriction of the FRP, uniformly distributed FRP longitudinal ribs are arranged on the periphery close to the sea sand seawater expansion concrete combination column, and penetrate through the sea sand seawater expansion concrete from top to bottom, and FRP spiral stirrups are bound around the FRP longitudinal ribs from the outer side along a top-to-bottom direction of the combination column according to the same interval and the same spiral angle. According to the present invention, the pre-tensile stress is generated in the FRP bush through the micro-expansion of the expanded concrete so as to effectively improve the axial limit bearing force of the combination column; and the river sand is replaced by the sea sand, the fresh water is replaced by the seawater, and the steel bar is replaced by the FRP rib, such that the performance of the combination column is improved, the limitation of the application of the sea sand seawater in the practical engineering is broken through, and the positive effect is provided in the protection of the ecological environment.

Owner:GUANGDONG UNIV OF TECH

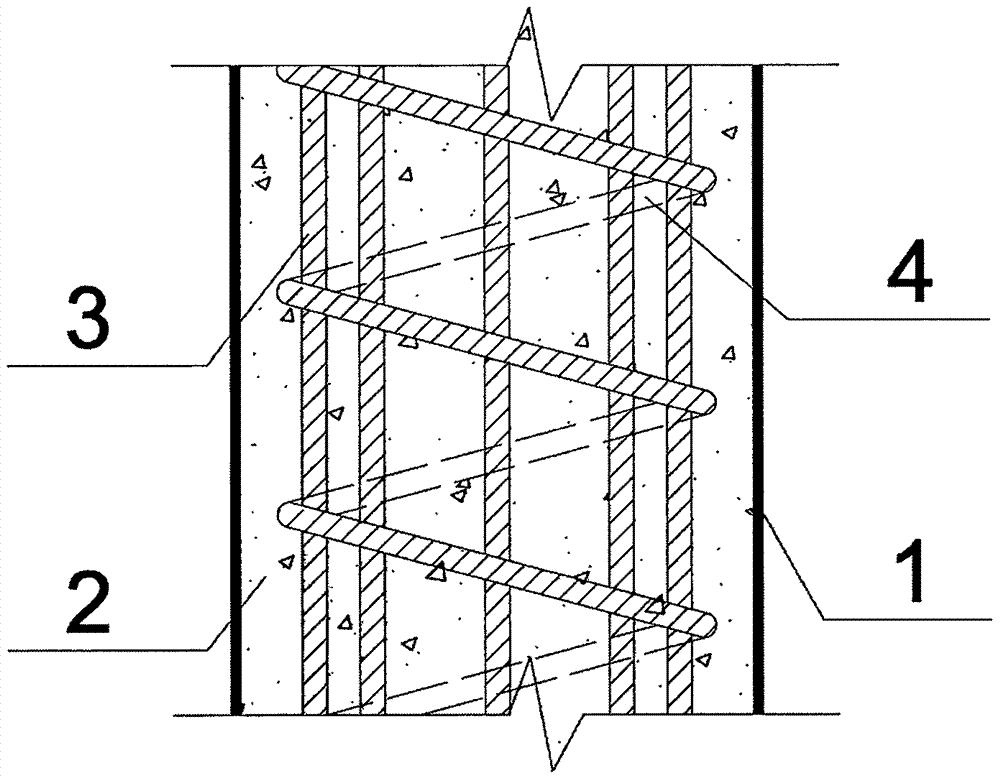

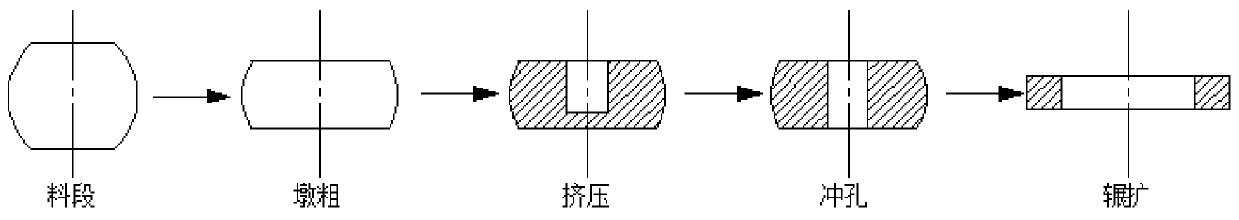

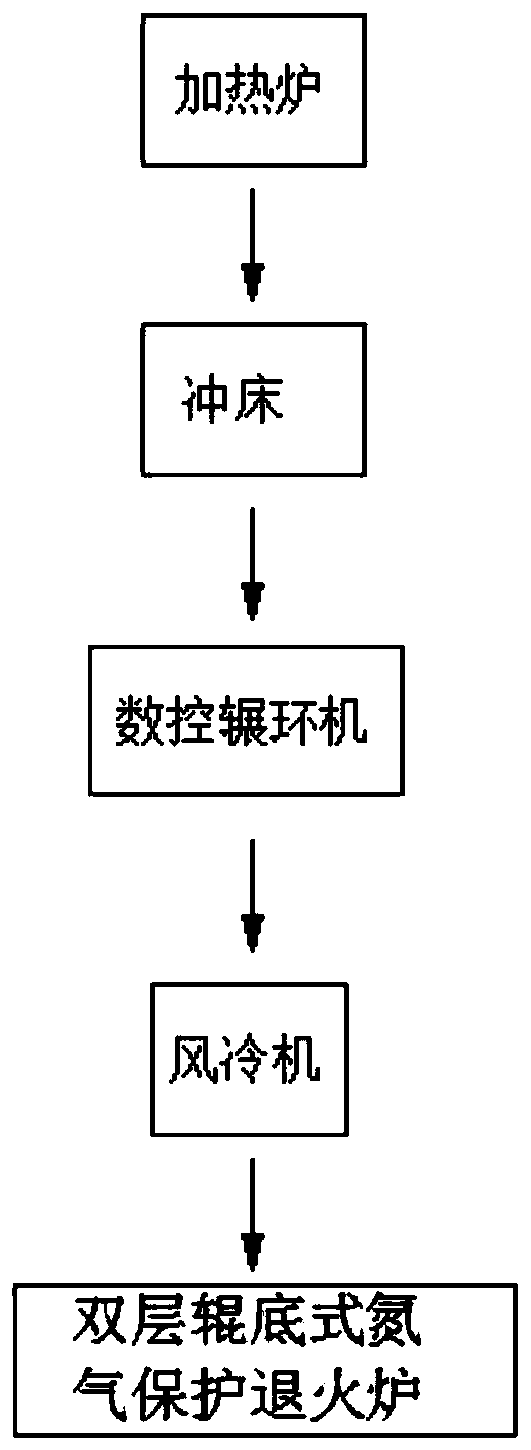

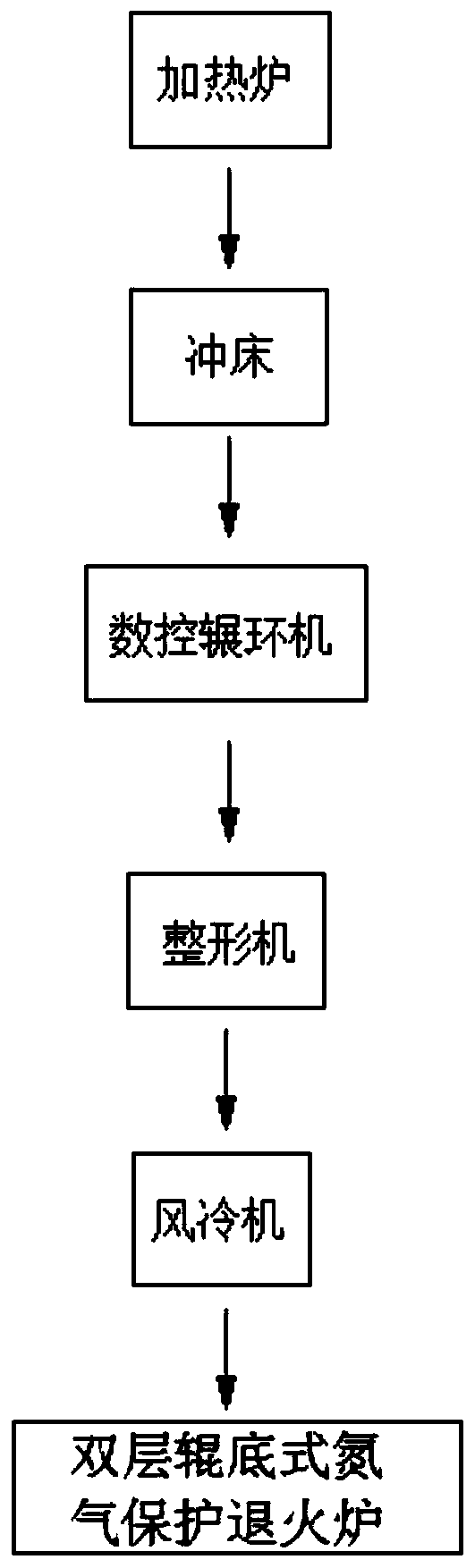

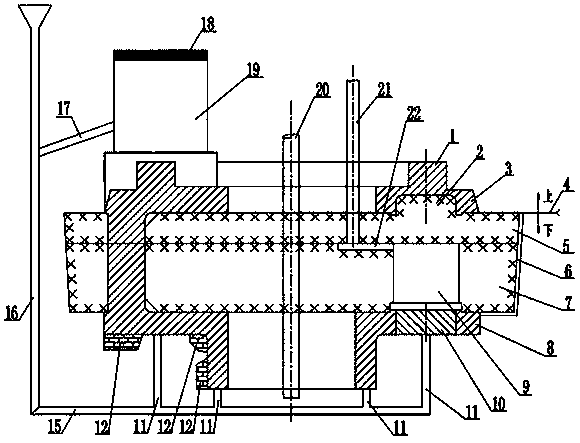

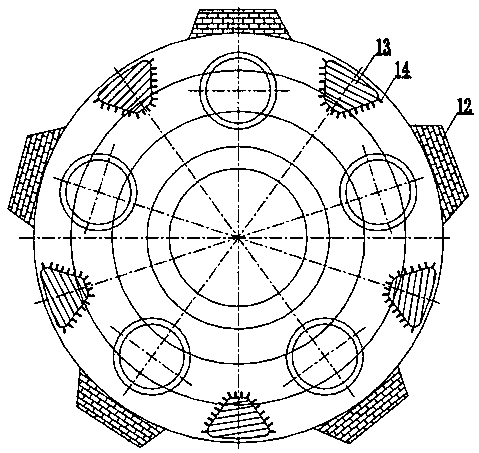

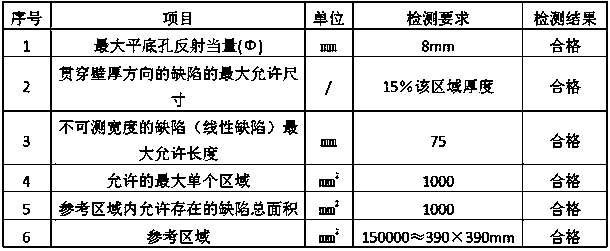

Bearing ring forging machining process and machining system

PendingCN109909437AHigh strengthHigh precisionMetal-working apparatusBearing componentsNumerical controlPunching

The invention discloses a bearing ring forging machining process and machining system, and relates to the technical field of bearing ring forging machining. The process includes the following steps that firstly, a steel material section of a high-carbon chromium bearing is heated to 1130 DEG C to 1180 DEG C; secondly, the heated material section is forged in the axial direction, and a material section subjected to upsetting is obtained; thirdly, the material section subjected to upsetting is extruded so that the middle portion of the material section subjected to upsetting can be indented, theindented portion of the middle portion of the material section is punched through, and a material section subjected to axial punching is obtained; fourthly, ring rolling is conducted on the materialsection, subjected to axial punching, through a numerical control ring rolling machine, and a ring is obtained; fifthly, the ring is air-cooled for 6 min to 8 min to 600 DEG C or below; and sixthly, spheroidizing annealing is conducted on the air-cooled ring through a double-layer roller hearth type nitrogen protection annealing furnace. The machining system comprises a heating furnace, a punchingmachine, the numerical control ring rolling machine, an air cooling machine and the double-layer roller hearth type nitrogen protection annealing furnace. By means of the bearing ring forging machining process and machining system, the surface roughness degree of the bearing ring can be decreased, no decarburized layers are generated after spheroidizing annealing, and therefore the cutting machining allowance is reduced, steel is saved, and the raw material utilization rate is increased.

Owner:临清市同兴轴承锻造有限公司

Etching method and etching polishing liquid

The invention discloses a method for etching a flat surface of a metal product and a curved surface connected with the flat surface. According to the method, a concavo-convex continuous microstructure is formed in the surface of the metal product by controlling the size of mask blocks and mask gap on the flat surface and the curved surface of the metal product and controlling related process parameters such as etching time, etching pressure and the like in an etching process; the depth of each pit is gradually reduced from the center of the flat surface to the edge of the curved surface; the section of the pit is shaped like a trough arc of sine wave; each projection does not have an obvious edge; the adaption part of the projection is in smooth transition; the section of the projection is similar to a quadrangular shape; the whole structure is in gentle transition; the microstructure takes on gradual transition connection of from existence to null and has good visual and tactile effects; and the requirements on higher anti-skid performance and attractive appearance can be met.

Owner:GUANGDONG UNIV OF TECH

Glass printing nanoscale ink and printing method

The invention relates to the printing technical field, particularly to glass printing nanoscale ink and a printing method. The glass printing nanoscale ink comprises an inorganic colorant, a solvent and an inorganic binder; the inorganic binder can be molten or softened under the hearting treatment so as to fix the inorganic colorant on glass; inorganic colorant particles and the inorganic binder are uniformly dispersed in the solvent to form the suspension liquid allowing printing and flowing. The nanoscale ink based glass printing method comprises the steps of printing which comprises printing the glass nanoscale ink onto the surface of the glass through an inkjet printer according to a preset pattern; drying which comprises heating the glass so as to enable the organic solvent to be volatilized; fixation which comprises performing heating treatment on the glass to enable the inorganic binder to be molten or softened so as to fix the inorganic colorant on the glass. According to the glass printing nanoscale ink and the printing method, the size and position accuracy of the printing pattern on the surface of a glass plate can be improved.

Owner:汤振华

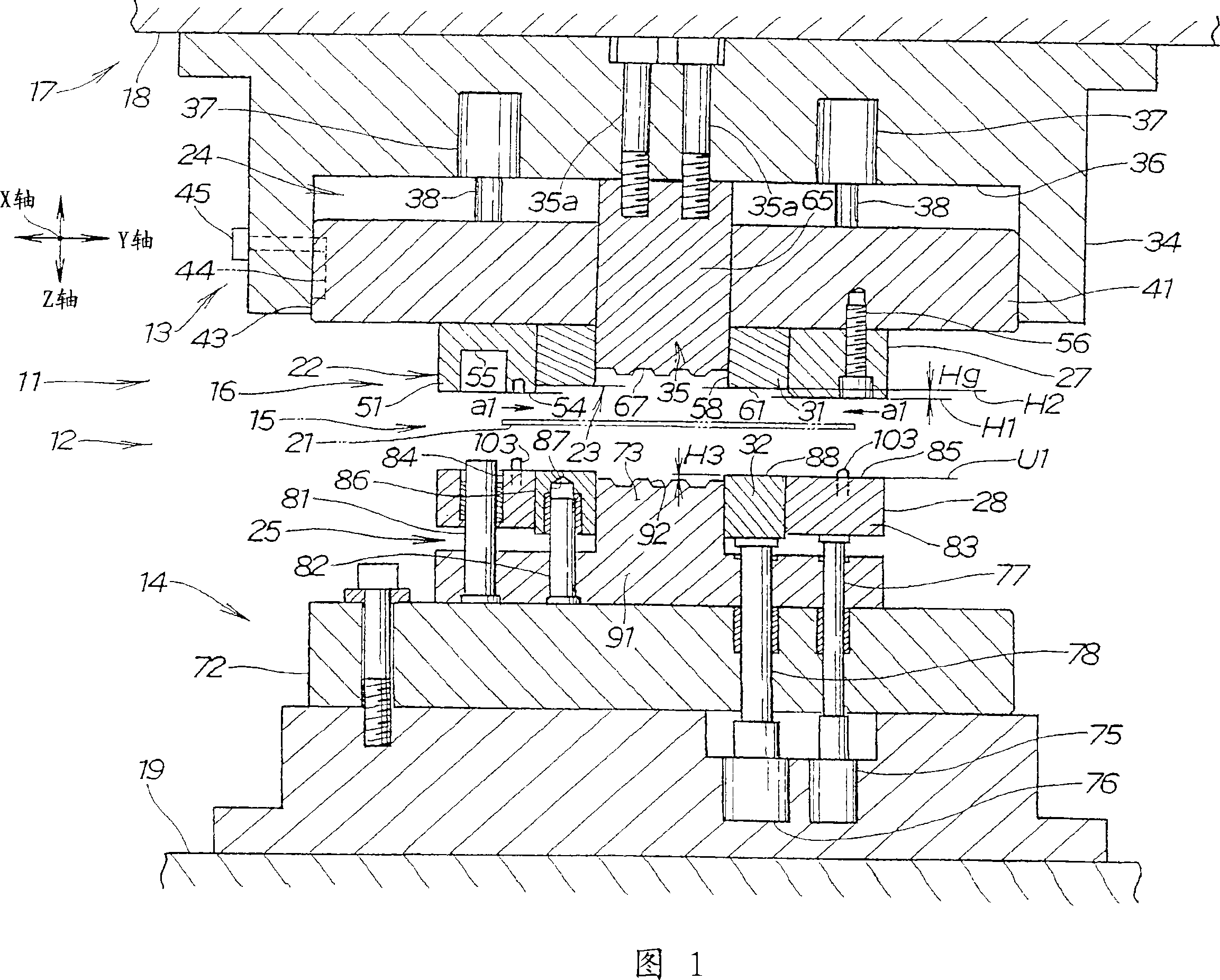

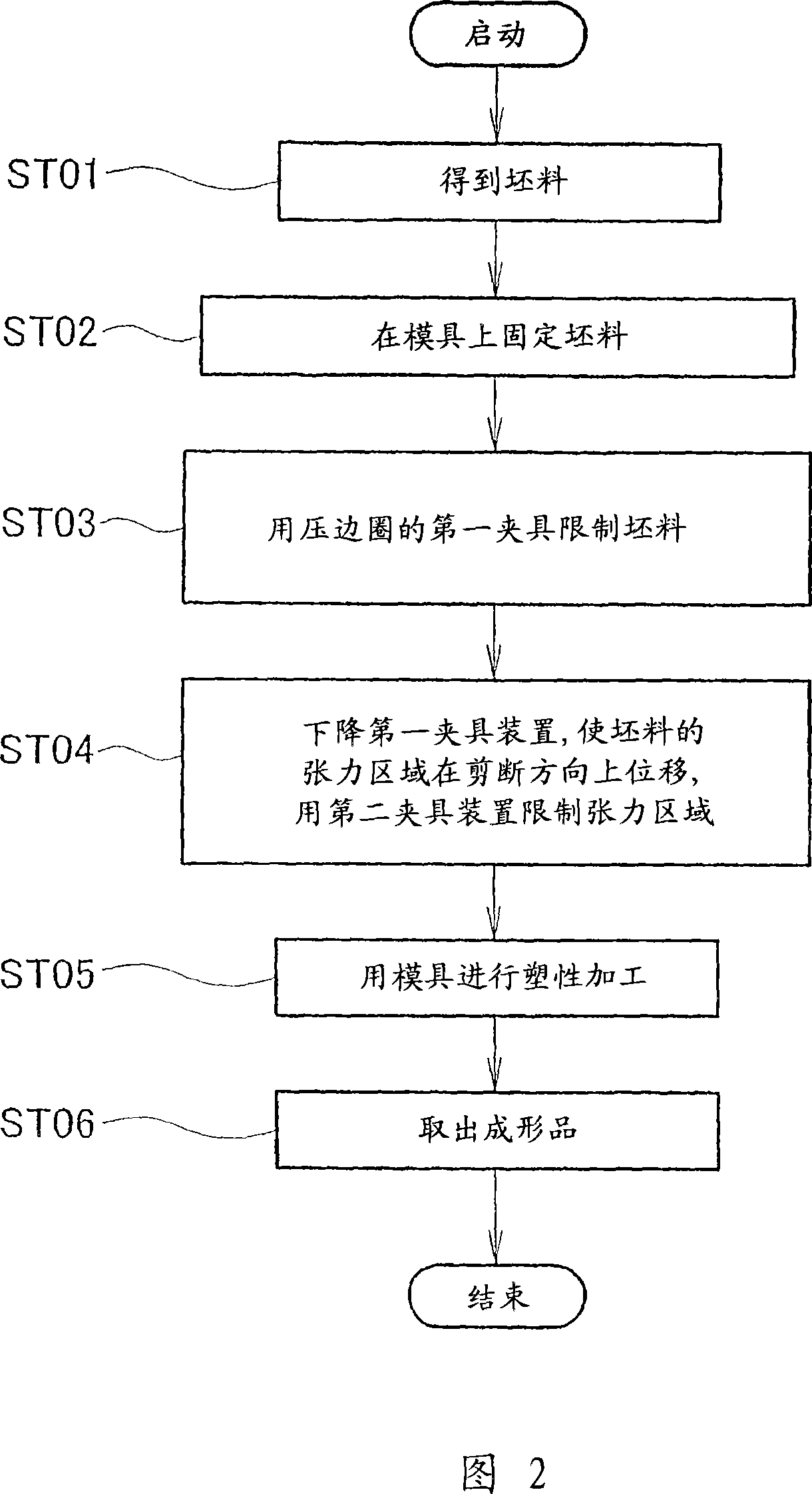

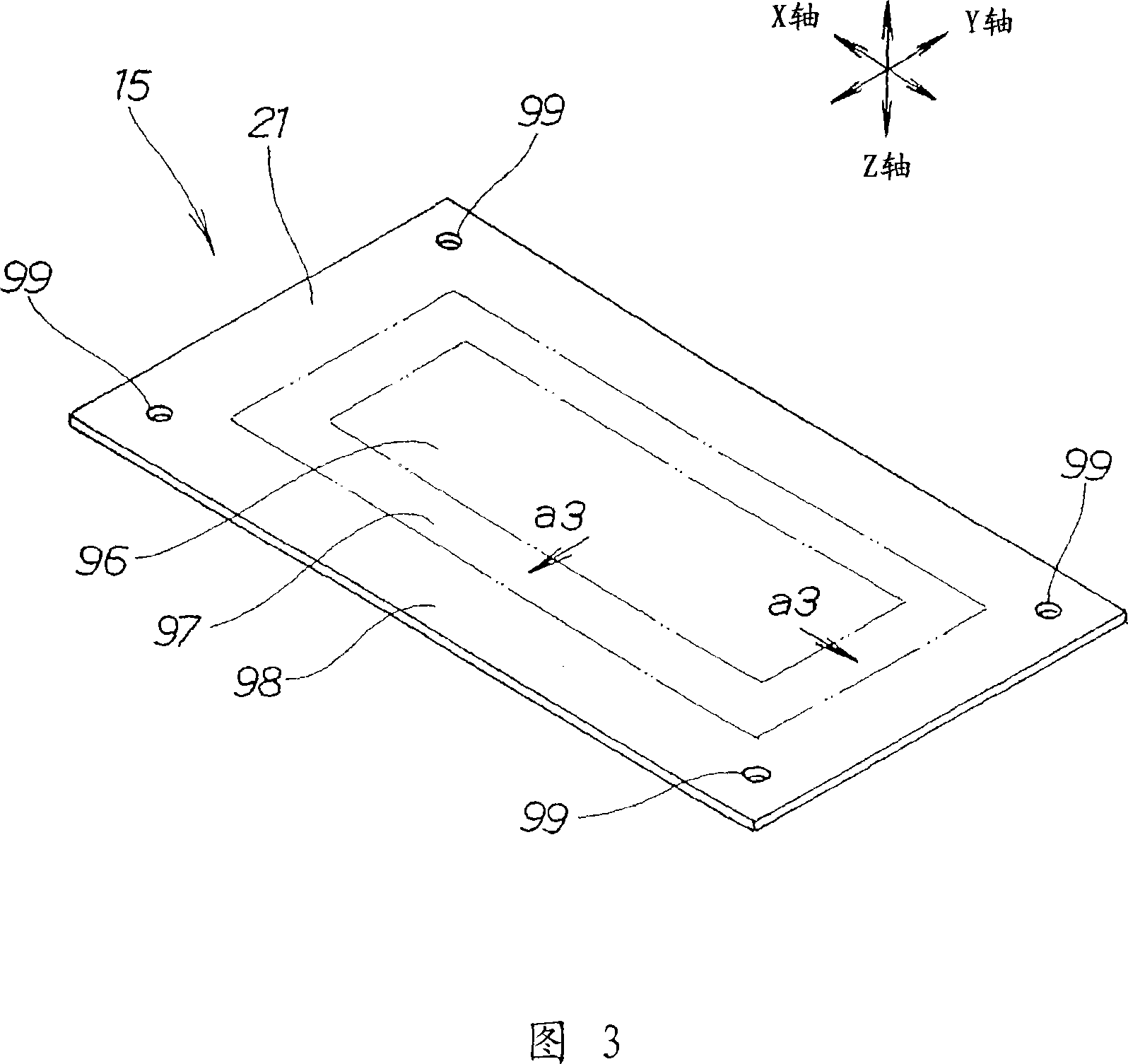

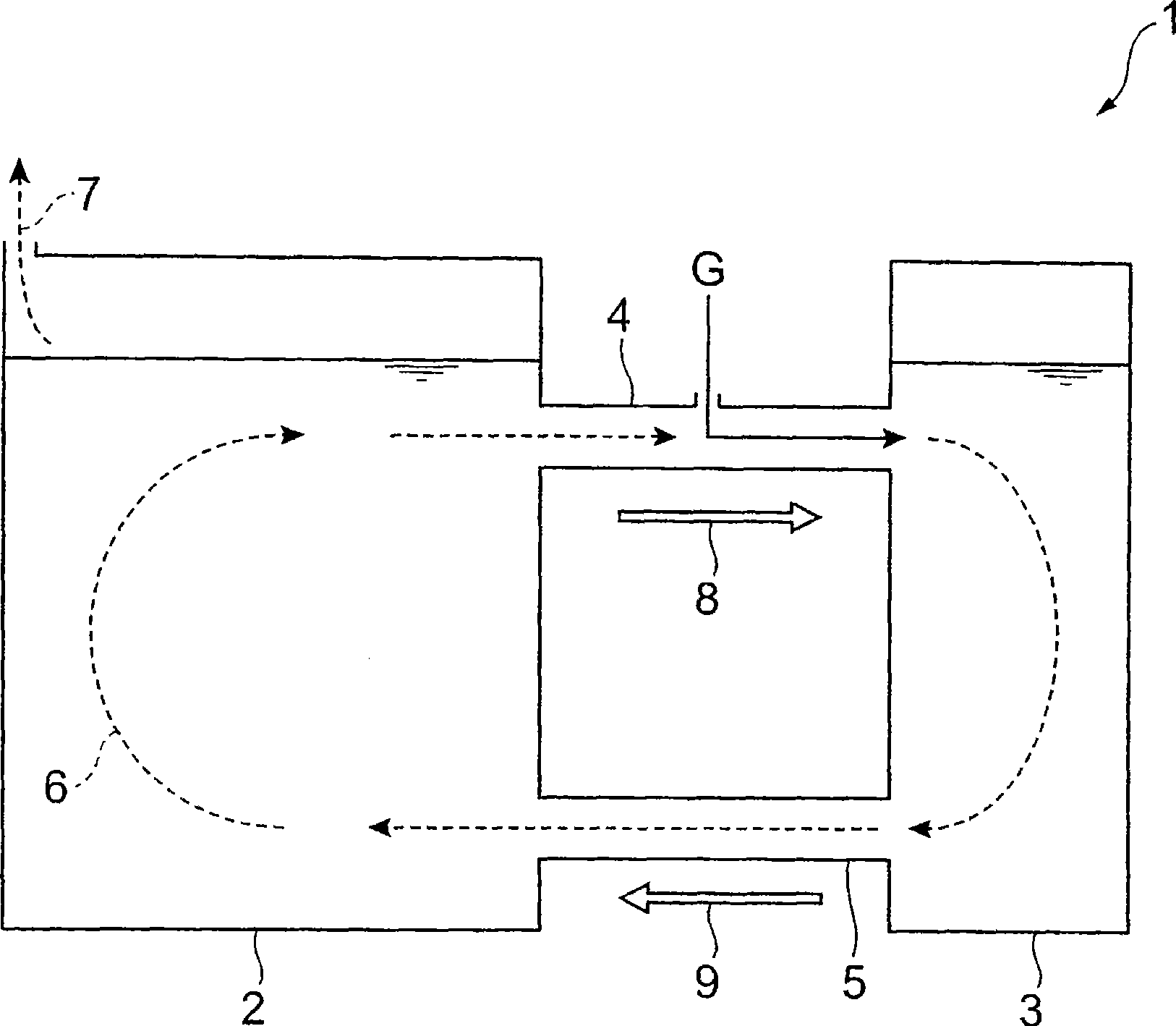

Draw forming method and device

A draw forming method for drawing a blank material (15). In this method, a restraint region (98) that is an outer peripheral section (21) of the blank material is held by a first holder means (22), and then a tension region (97) inside the outer peripheral section is displaced upward by a second holder means (23) relative to the restraint region. The displacement applies tensile force to a drawing region (96) that is the central section of the blank material.

Owner:HONDA MOTOR CO LTD

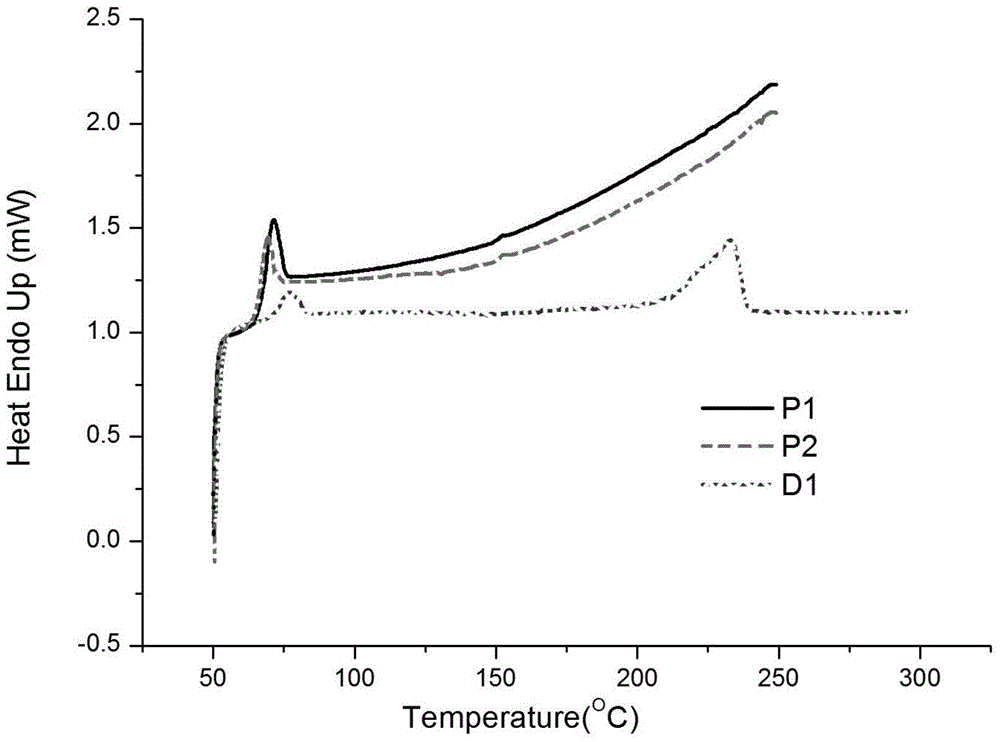

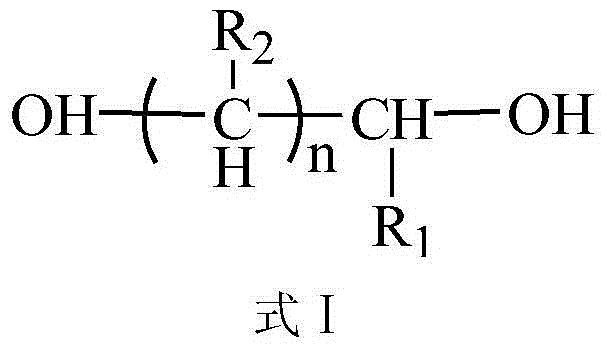

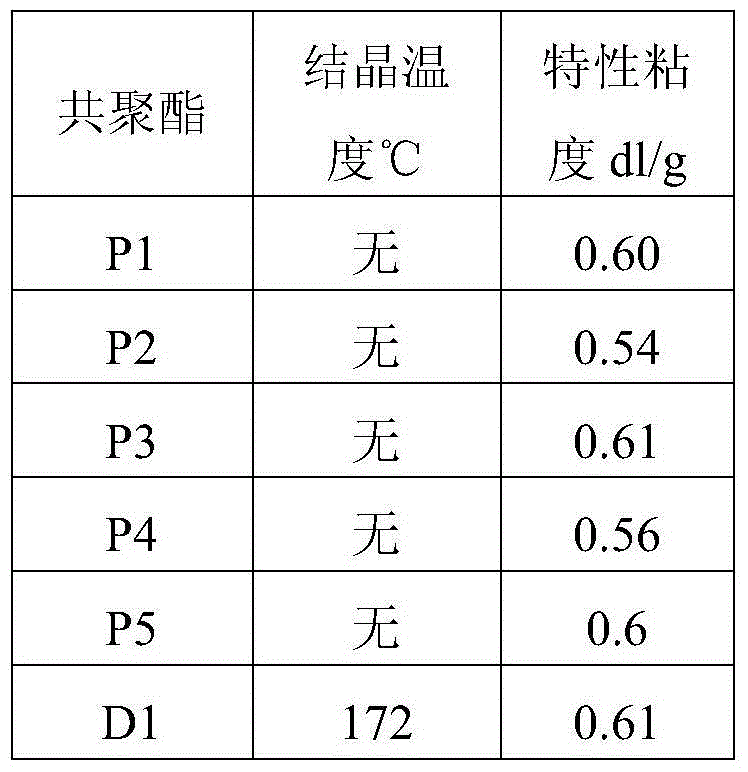

Copolyester preparation method and application of copolyester prepared thereby in 3 D printing

The present invention provides a copolyester preparation method comprising successive esterification and polycondensation of a dihydric alcohol, a fatty diacid and two or more aromatic diacid in the presence of a catalyst for preparation of an amorphous copolyester. The present invention also provides a method for using the copolyester material for preparation of a wire material and application of the wire material in 3D printing. The printing temperature of the wire material used in fused deposition method 3D printing is low, an obtained product is small in size deviation, and sample shrinkage rate is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tailored welding tool for landing leg supports of hooklifts

ActiveCN104259720AReduce failureHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesWelding

The invention discloses a tailored welding tool for landing leg supports of hooklifts. The tailored welding tool comprises a supporting base board and a first positioning base, a second positioning base, a plurality of landing leg base plates, a plurality of drawing arm base plates and a third positioning base which are fixed on the supporting base board. The tailored welding tool can overcome the defects of the landing leg supports of having deviation easily and being difficult to adjust and poor in stability during tailored welding.

Owner:广西玉柴专用汽车有限公司

Casting forming process for large wind power planetary carrier

ActiveCN107790641ASmall size deviationEasy to operateFoundry mouldsFoundry coresElectricityEconomic benefits

The invention discloses a casting forming process for a large wind power planetary carrier casting. The planetary carrier casting comprises an upper annular plate and a lower annular plate which are vertically connected with triangular vertical columns, and a parting face of the planetary carrier casting is arranged on the interfaces of the upper annular plate and the triangular vertical columns;a first sand core and a second sand core are arranged between the upper annular plate and the lower annular plate, a triangular air outlet channel is formed in the outer sides of the sand cores, and vertical air outlet channels are formed in the centers of the sand cores; open risers are arranged right above the intersections of the upper annular plate and the triangular vertical columns, blinderrisers are arranged on the lower annular plate, and external chills are arranged under the lower annular plate. Pouring is carried out by adopting combined pouring mode of bottom-back pouring gates and stepped pouring gates. The planetary carrier produced by the method is good in forming and qualified in size, the matric structure of the casting is compact, joint parts of the triangular verticalcolumns and the upper annular plate and the lower annular plate has no crack defect, the other parts only need to undergo modification repair welding, the production cost of the casting is reduced, and higher economic benefits are achieved.

Owner:兰州兰石铸锻有限责任公司

Welding fixture for elevator underbeams

InactiveCN103769789AEnsure consistencyReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding fixture for elevator underbeams. An adjustable supporting positioning seat and a fixed supporting positioning seat are disposed at left and right ends of a welding working table respectively, the adjustable supporting positioning seat and the welding working table are fixed by an adjustable positioning mechanism through the adjustment of the distance between the adjustable supporting positioning seat and the fixed supporting positioning seat, so that the elevator underbeams in different specifications can be welded, uniformity of welding qualities of the elevator underbeams is guaranteed, and production costs of enterprises are reduced. Compared with manual welding fixtures, the welding fixture has the advantages that the fixture is simple in structure, practical and adaptable to welding the elevator underbeams in various lengths and non-standard design, size deviation of products can be reduced, and uniformity of the product qualities can be improved.

Owner:广东康力电梯有限公司

Casting design method of 38W machine body

InactiveCN109822047AImprove feeding capacityEvenly distributedFoundry mouldsFoundry coresAir cavityDesign methods

The invention discloses a casting design method of a 38W machine body. A main cavity of a casting of the 38W machine body is of a V-shaped structure, the lower part is an air cavity, a plurality of axial baffles are arranged in the middle, the casting design method is sequentially composed of casting design, pouring design and riser design, and optimization is carried out. According to the castingdesign method of the 38W machine body, cracks are reduced, shrinkage porosity is reduced, the size deviation is reduced, sand adherence is reduced, air holes are reduced, the molding quality of the casting is improved, and the production efficiency is improved.

Owner:上柴动力海安有限公司

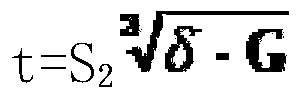

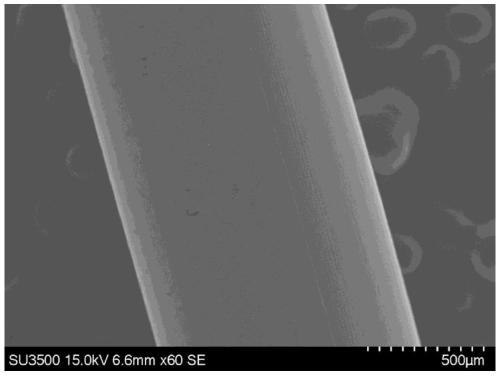

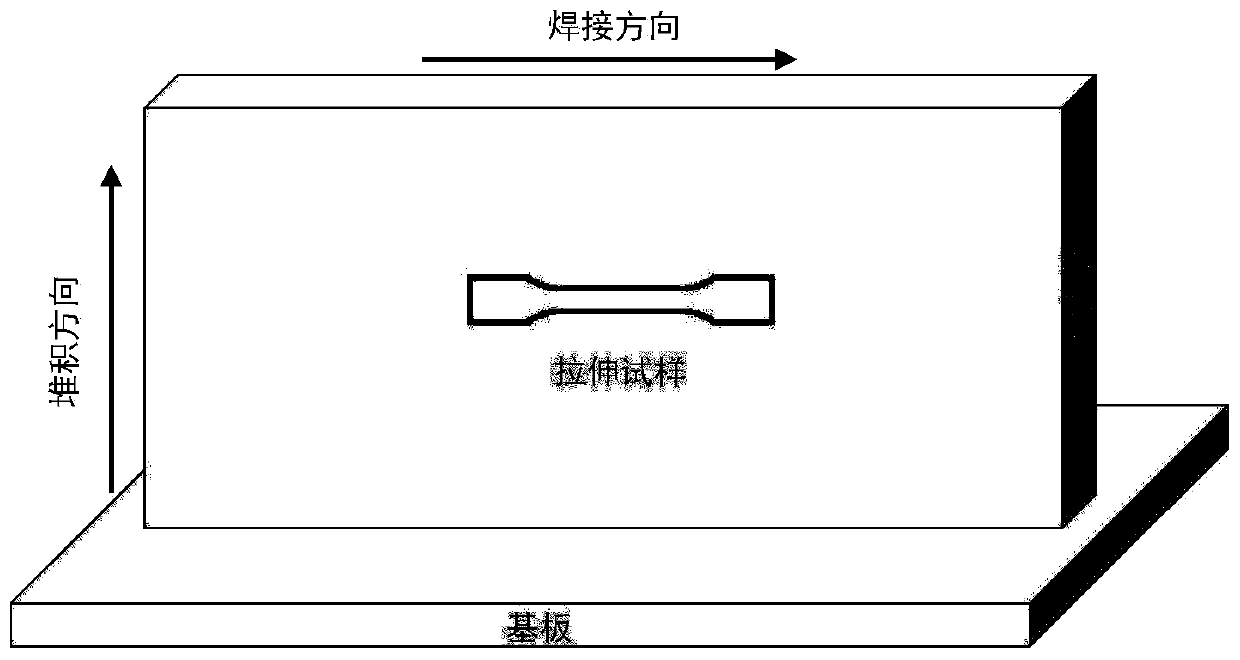

Al-Zn-Mg aluminum alloy welding wire for arc additive manufacturing and preparation method of Al-Zn-Mg aluminum alloy welding wire

ActiveCN111411272AHigh strengthImprove plasticityAdditive manufacturing apparatusUltimate tensile strengthAluminium alloy

The invention discloses an Al-Zn-Mg aluminum alloy welding wire for arc additive manufacturing and a preparation method of the Al-Zn-Mg aluminum alloy welding wire. The welding wire is prepared from Zn, Mg, Al and impurity elements. The welding wire contains the components in percentage by mass as follows: 6.25%-6.75% of Zn, 2.25%-2.75% of Mg and less than 0.2% of the impurity elements, wherein the mass percentage of single impurity element is less than 0.1%. The welding wire can be used for arc additive manufacturing and has high deposit strength.

Owner:XI AN JIAOTONG UNIV

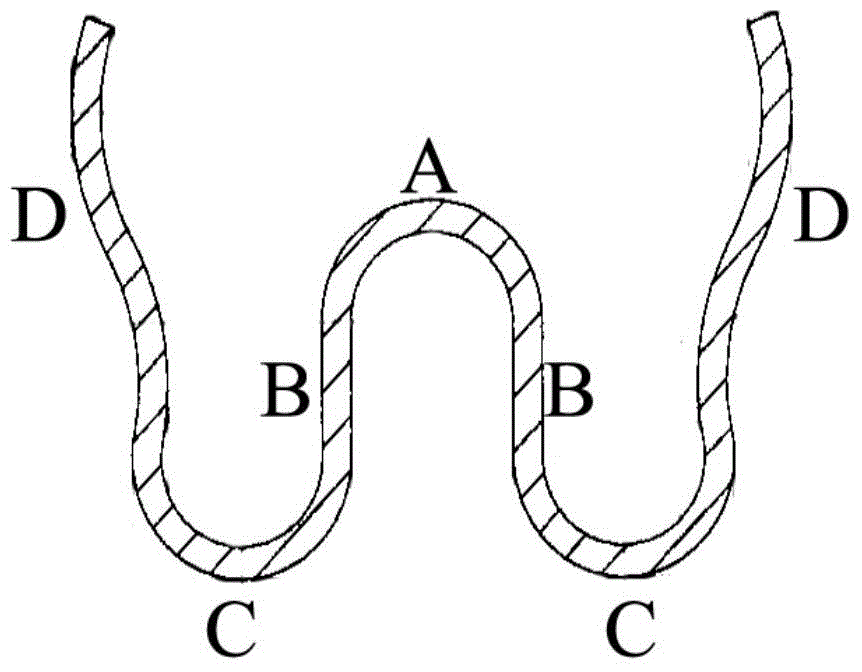

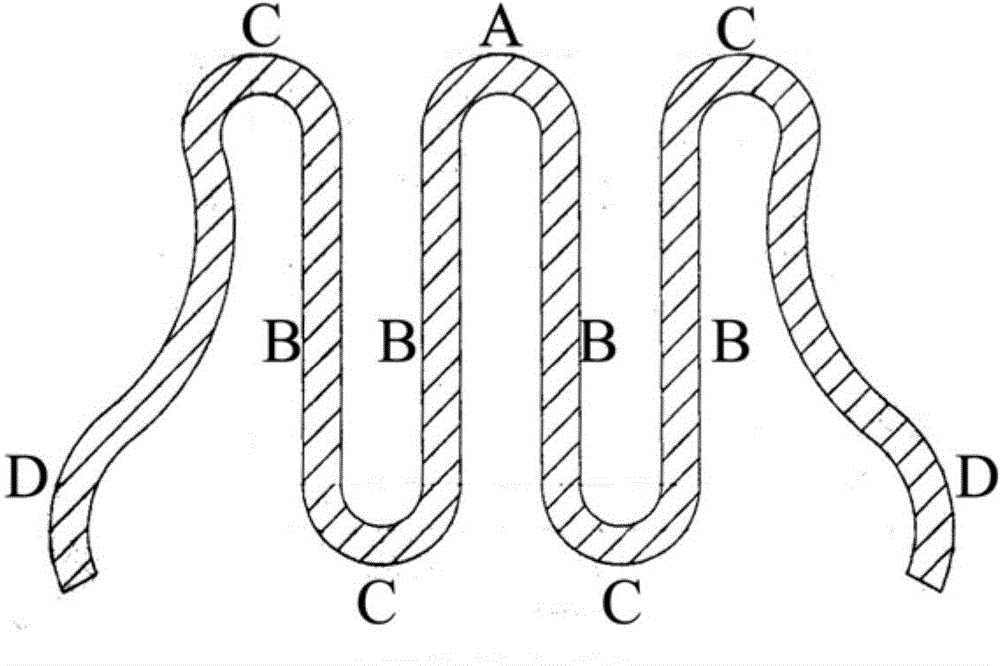

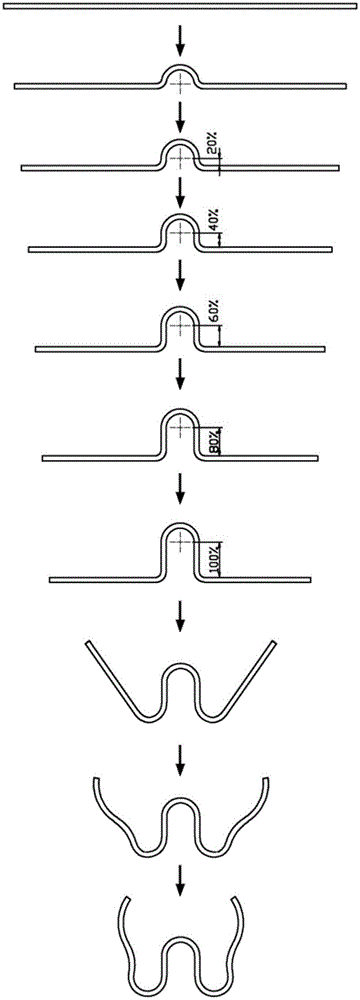

Forming technology for metal elastic sealing ring

The invention discloses a forming technology for a metal elastic sealing ring and belongs to the technical field of cold roll forming. The forming technology includes the following specific technology steps that a strip is cut to be in a corresponding width and a corresponding length according to the finished product size demand and welded to be in a ring shape; a strip ring is fixed, and spinning is conducted on the strip ring through a set of cold rolling rollers; the two sides of a circular arc are downwards extruded and deformed, a central bent circular arc (A) and a flat and straight connecting part (B) connected with the central bent circuit arc (A) are obtained, materials on the two sides of a section are bent upwards through a forming roller, and two elastic bent circular arcs (C) are formed; the obtained ring piece is arranged in a die roller, the two wings of the section are bent to form a left outwards-convex circular arc contact face (D) and a right outwards-convex circular arc contact face (D), and the ring piece is deformed after rotating by a circle; the left outwards-convex circular arc contact face (D) and the right outwards-convex circular arc contact face (D) are extruded from the two sides and are gathered in face-to-face mode and are deformed after rotating by a circle. The forming technology has the advantages that the surface quality of a product is good, the size deviation is small, and the variation of thicknesses of all parts of the section is small.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

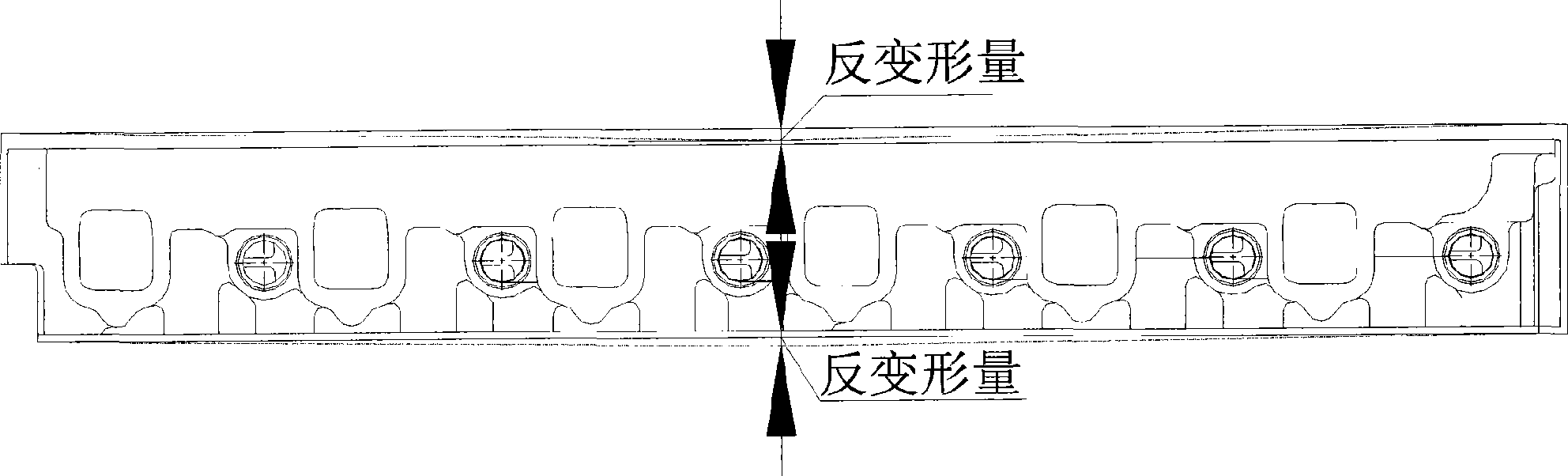

Method for casting cylinder cover of multicylinder one-cover engine

ActiveCN101468383AImprove accuracyUniform machining allowanceFoundry mouldsFoundry coresCylinder headMaterials science

The invention discloses a method for casting a cylinder head of a multi-cylinder single-cover engine, which adopts a reverse deformation amount casting method and comprises the design of shape reverse deformation amount of a casting mould and a mounting structure between sand cores, wherein the reverse deformation amount of the casting mould adopts the design that the part forming the shapes of the bottom and the top of a product is designed into V-shaped, and the initial point of the design of the V-shaped reverse deformation amount takes the central point of longitudinal length of the mould as the highest point, and the design of the V-shaped reverse deformation amount takes a slope surface formed on edges at two initial ends of the longitudinal length of the mould as the lowest final point. The method for casting the cylinder head of the engine adopts a modification method of the reverse deformation amount at the proper position according to the structure of the shape of the cylinder head when designing the mould. The casting process method adopts the structure of reverse deformation shape of the mould to effectively reduce the reverse deformation of a casting, and ensures the accuracy of the shape of the casting, in particular the accuracy of the shape of an air intake and discharge passage at key parts, thereby ensuring the stability of performance parameters of the air passage. The manufacturing cost of the mould and the production cost of the casting do not change.

Owner:GUANGXI YUCHAI MASCH CO LTD

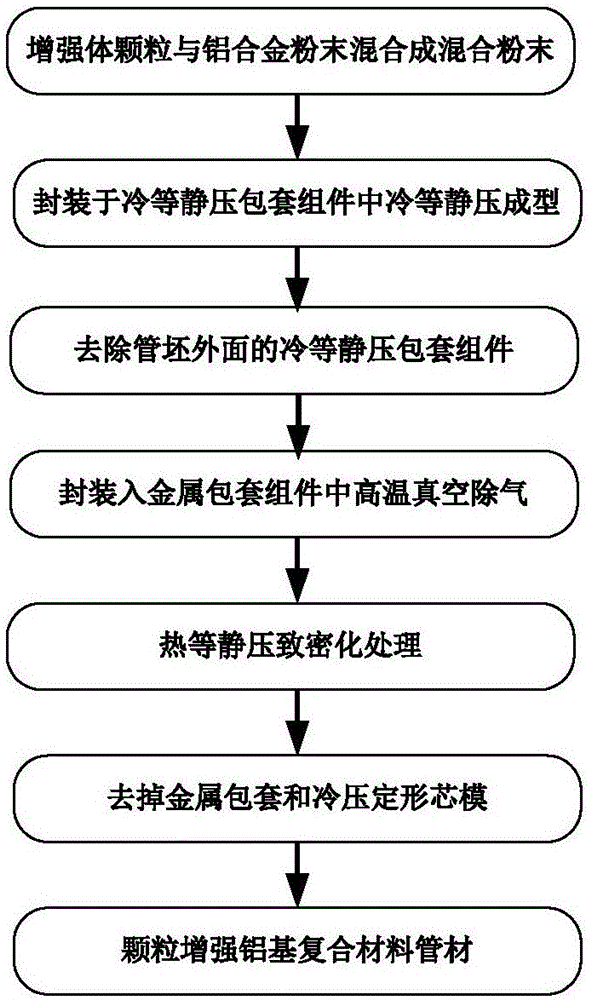

Preparing method for particle reinforcement aluminum matrix composite large-size thick-wall pipe material

The invention discloses a preparing method for a particle reinforcement aluminum matrix composite large-size thick-wall pipe material and belongs to the technical field of preparing of metal matrix composite pipe materials. According to the preparing method, reinforcement particles and aluminum alloy powder are evenly mixed according to a certain proportion; obtained mixed powder is packaged in a cold isostatic pressing sheathing assembly to be subjected to cold isostatic pressing forming, and a pipe blank is formed; the cold pressing pipe blank is subjected to vacuum gas removing, then hot isostatic pressing densifying is conducted, and a completely-dense pipe material is prepared; and finally the composite pipe material is obtained through machining. The prepared large-size thick-wall pipe material has the beneficial effects of being light, high in strength, high in modulus and the like, in addition, the quality is stable, the cost is low, and the large-size thick-wall pipe material can be widely applied to high-strength and light large-size pipes in the fields of aerospace, automobiles, advanced weapons and the like.

Owner:有研金属复材技术有限公司

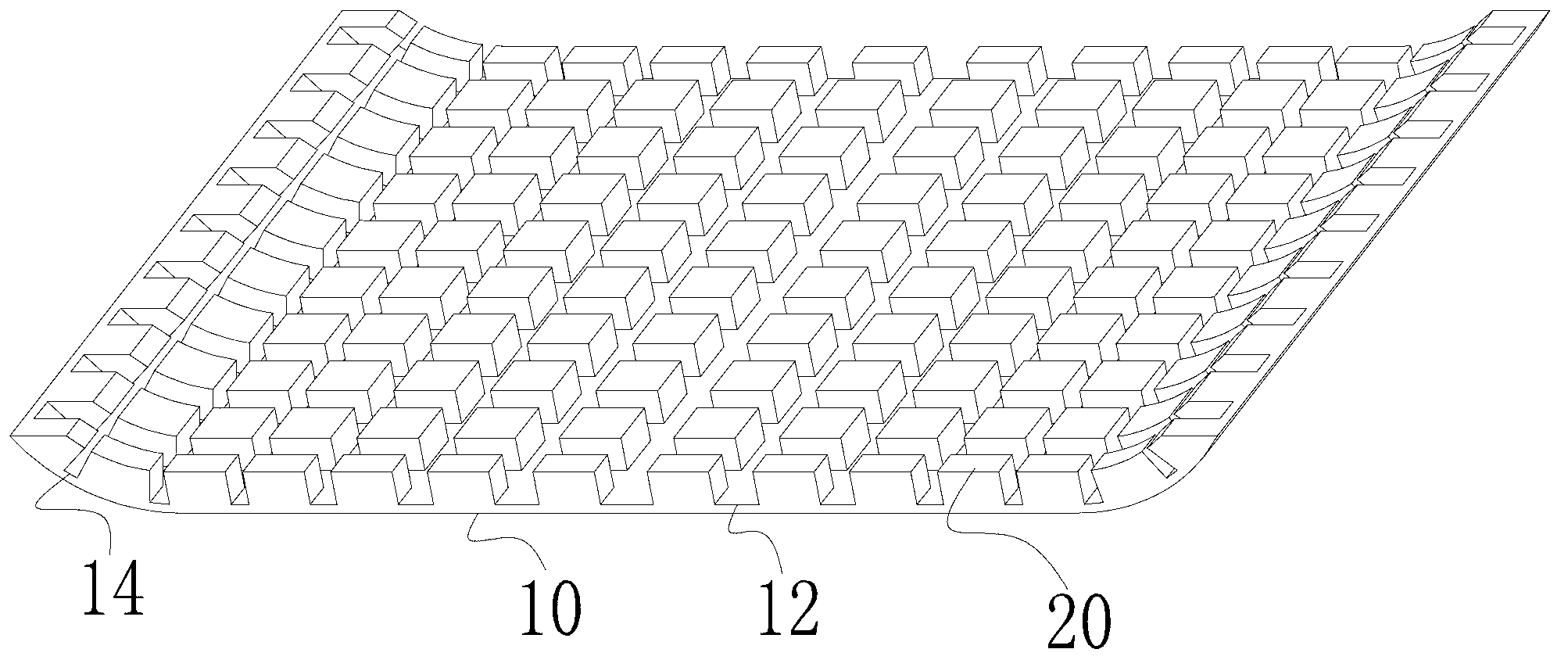

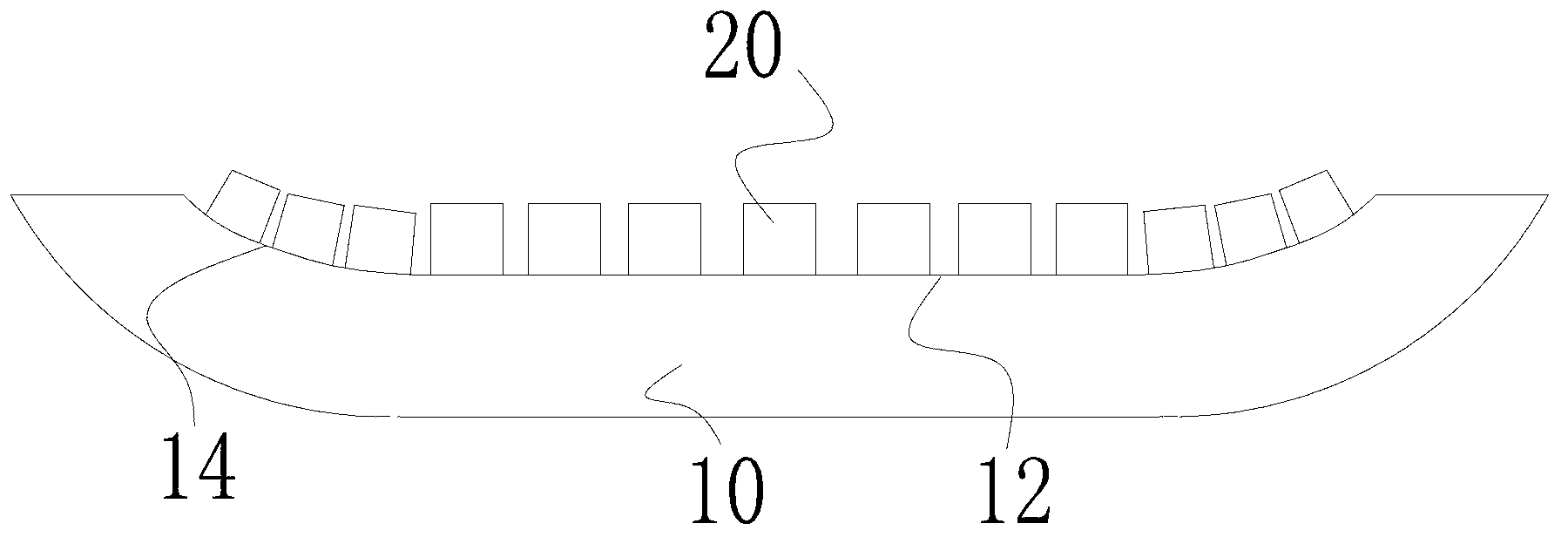

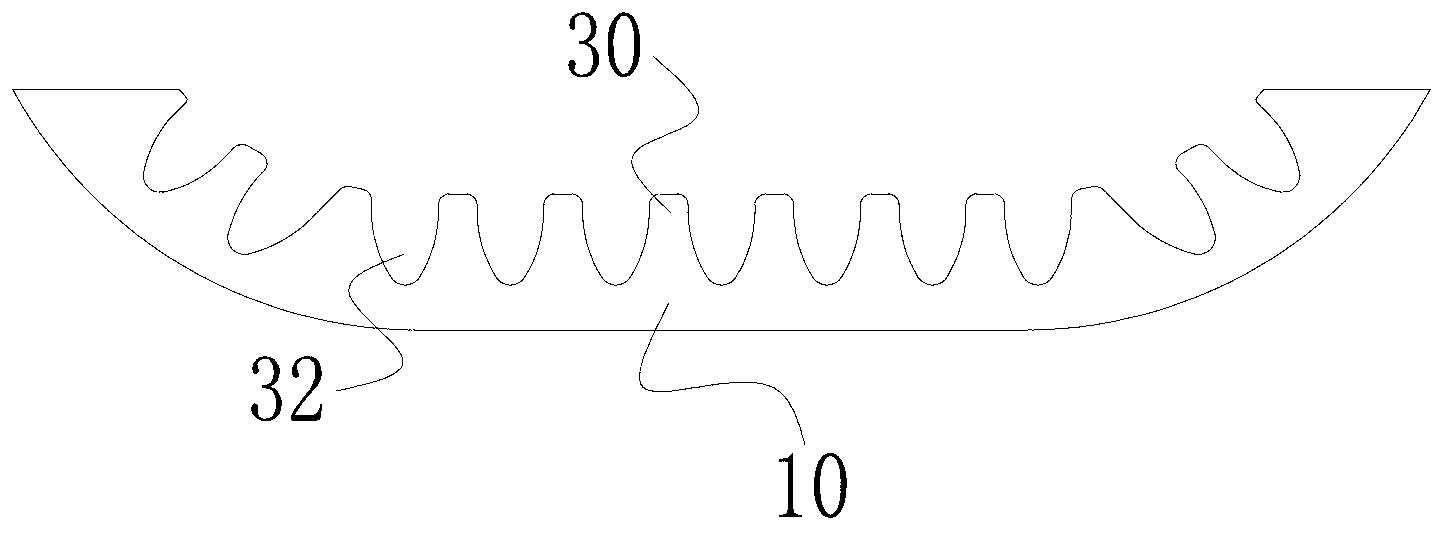

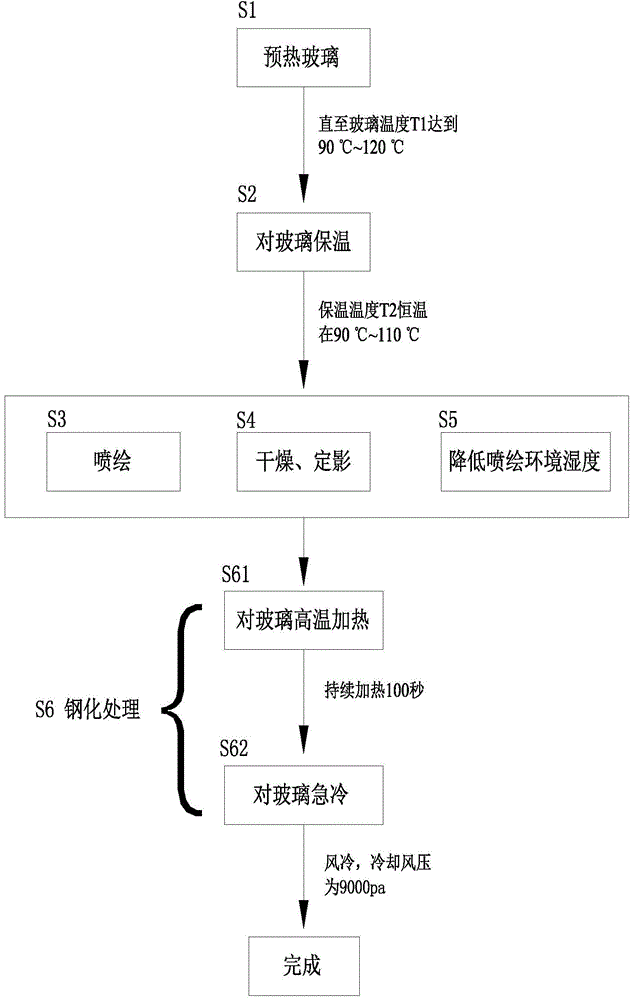

Glass spray painting process and system

InactiveCN107264102ASmall size deviationPrevent slippingDuplicating/marking methodsInksPrinting inkSuspended particles

The invention relates to the technical field of spray painting and in particular relates to a glass spray painting process and system. The process comprises the following steps of: dissolving an inorganic matter material in printing ink in an organic solvent and dissolving silicate or nanosilicon dioxide suspended particles or silicic acid in the organic solvent; spray painting printing ink to the surface of the glass by taking the organic solvent as a carrier, wherein under heating treatment, silicate or nanosilicon dioxide suspended particles or silicic acid is desorbed to the surface of the glass to position the printing ink; and evaporating the organic solvent to cure the inorganic matter material in the positioned printing ink and silicate or nanosilicon dioxide suspended particles or silicic acid. According to the process and system provided by the invention, the dimensional and positional precisions of a spray painting pattern on the surface of a glass sheet can be favorably improved.

Owner:万弋林

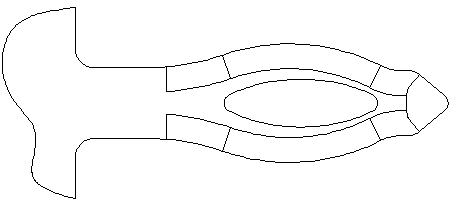

Terminal fisheye contour forming process

InactiveCN103317348AGood workmanshipAccurate shapeOther manufacturing equipments/toolsContour formElectrical and Electronics engineering

The invention relates to a terminal fisheye contour forming process. The process includes the steps of 1, taking a substrate and pre-cutting terminal fisheye contours on the substrate; 2, sending the substrate with the precut fisheye contours to a piercing station for piercing, and allowing the terminal fisheye contours and waste to be incompletely pierced after piercing; 3, sending the pierced substrate to a fisheye waste ejection station to punch off the waste, thus obtaining the terminal fisheye contours; 4, sending the substrate with the waste punched off into a chamfering station for chamfering, and chamfering to obtain four rounded angles of each terminal fisheye contour. The terminal fisheye contours formed by the process are smooth and flat with no bur edge, the formed terminal fisheye contours are precise in size with low fluctuation, chamfers are smooth with small errors, and stripping is easy.

Owner:四川瑞宝电子股份有限公司

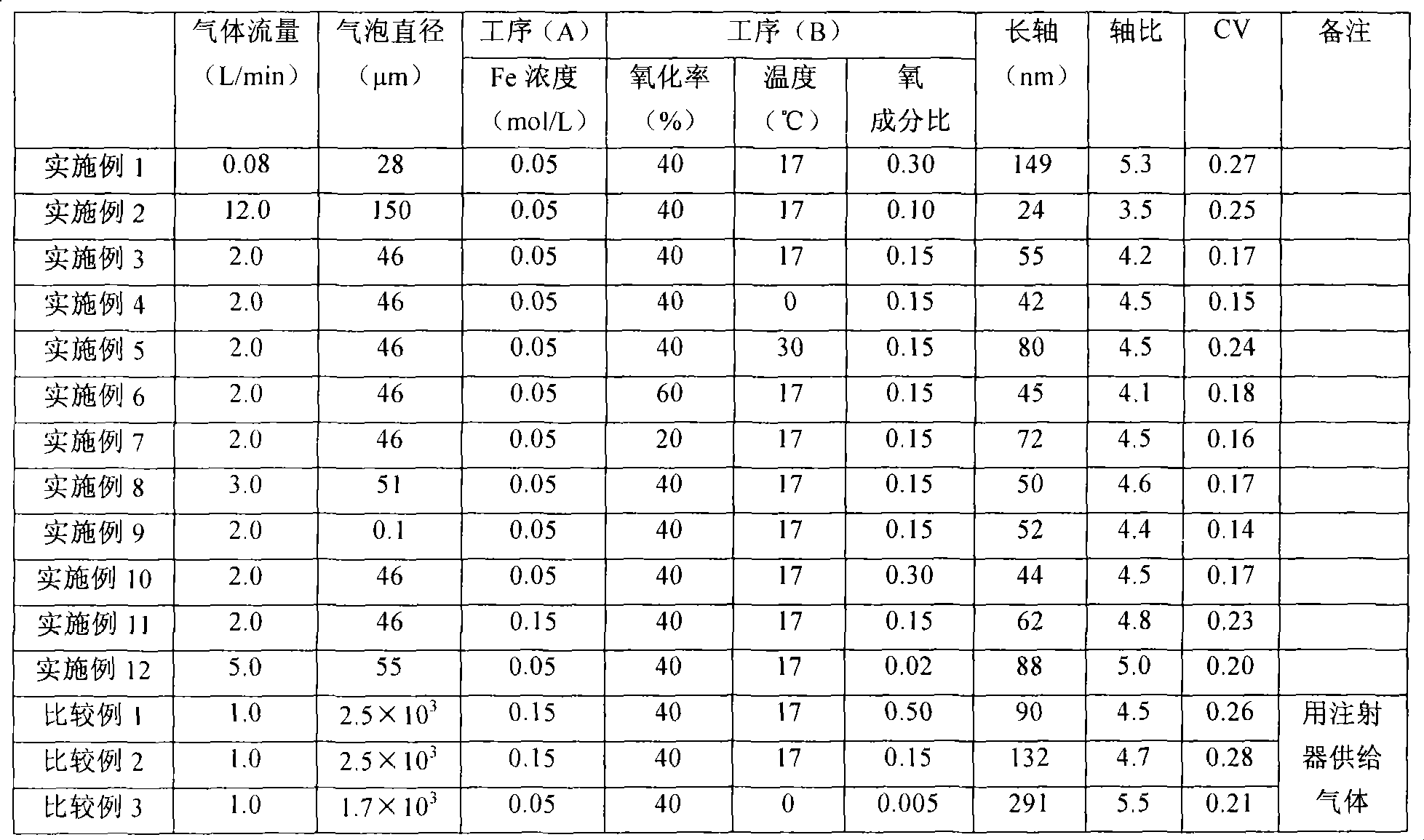

Process for production of iron oxyhydroxide particles

The process for production of iron oxyhydroxide particles according to the invention is characterized by comprising a step (A) in which a suspension containing iron is prepared, and a step (B) in which fine bubbles with diameters of 0.05-500 mum are generated in the suspension to form a reaction mixture, and the iron in the reaction mixture is oxidized by the bubbles to produce iron oxyhydroxide particles.

Owner:TDK CORPARATION

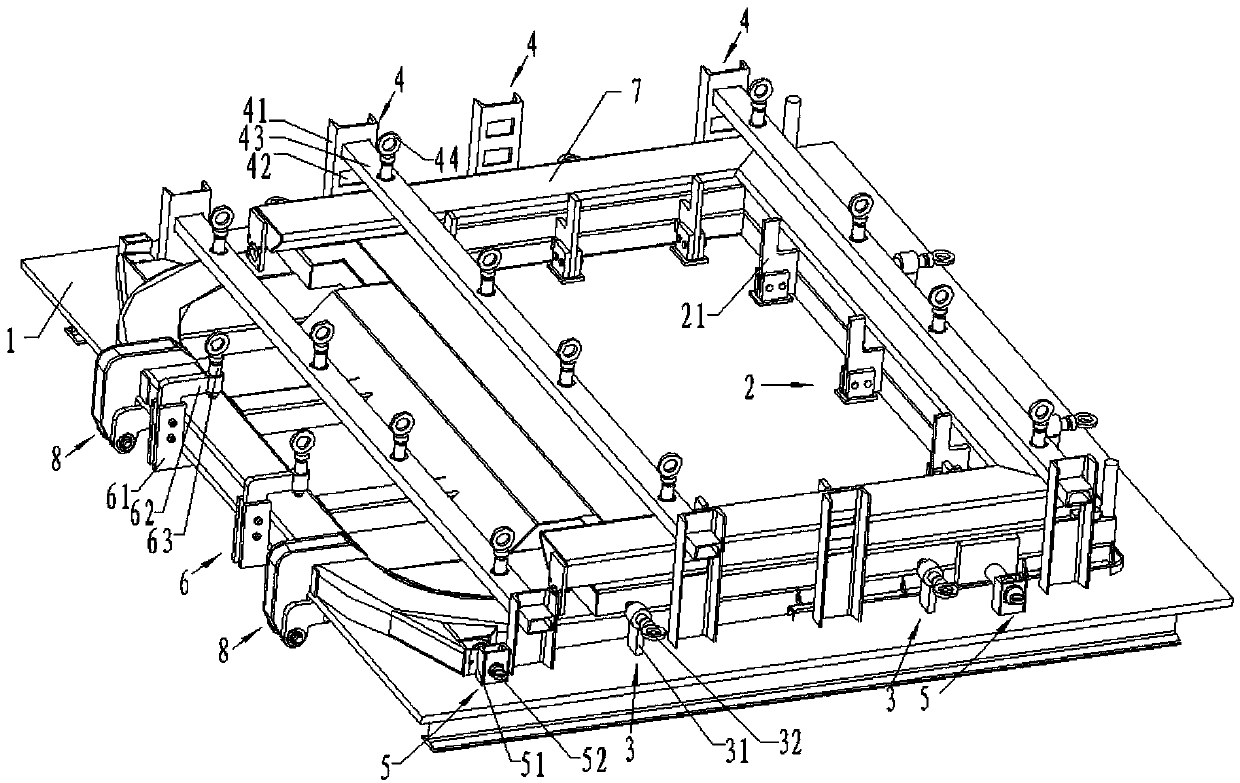

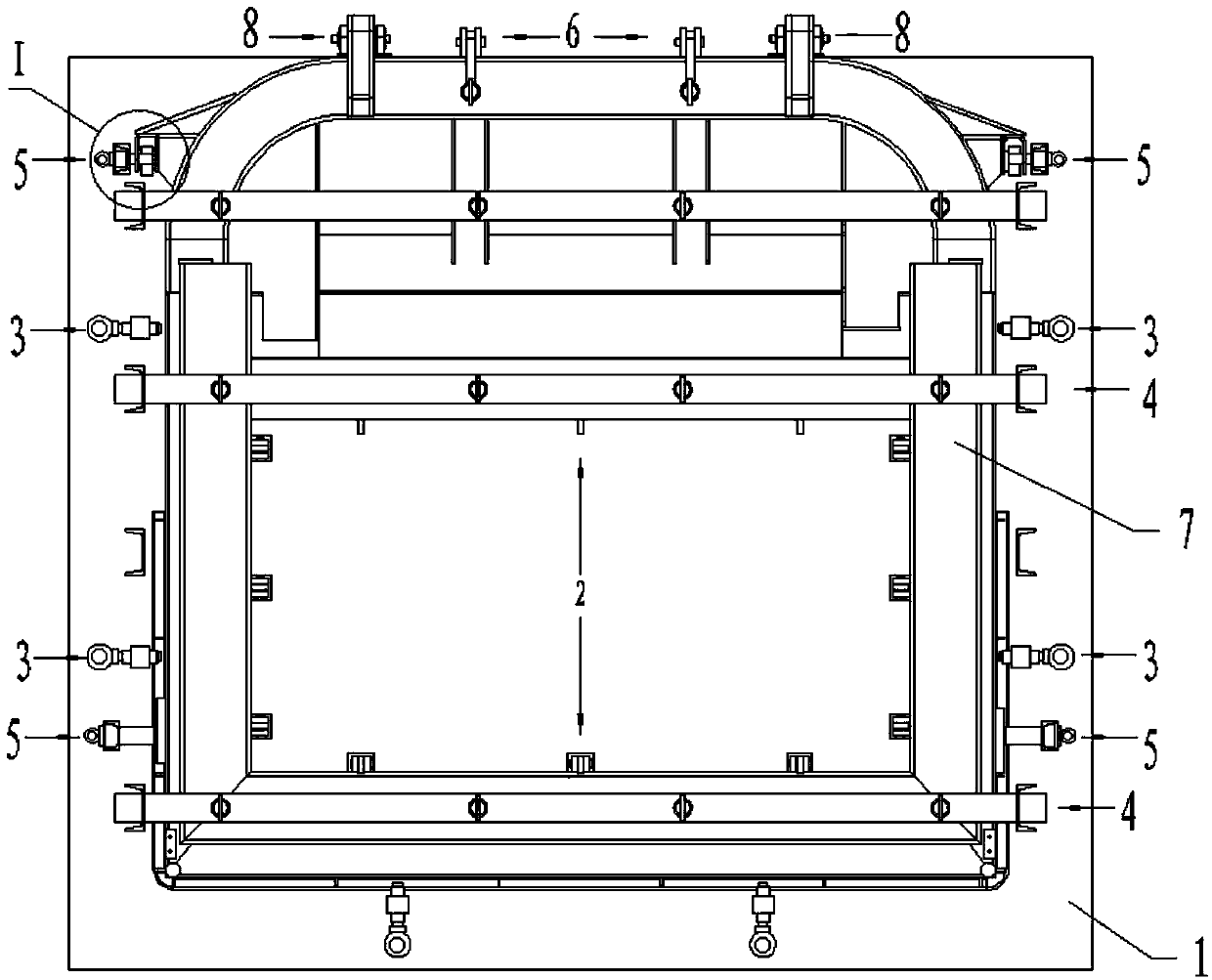

Rear compartment door tailor welding tool

ActiveCN104191132AHigh precisionBest welding positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBack door

The invention discloses a rear compartment door tailor welding tool which comprises a compartment tailor welding base plate, a fixing compression mechanism, clamping mechanisms and a hanging lug mold. The fixing compression mechanism comprises a compartment positioning assembly, a plurality of compartment compression assemblies and a plurality of compartment adjusting assemblies, wherein the compartment positioning assembly is fixed to the upper surface of the compartment tailor welding base plate so as to position a rear compartment door, the compartment compression assemblies are fixed to the two sides of the compartment tailor welding base plate so as to compress the rear compartment door, and the compartment adjusting assemblies are fixed to the surface of the periphery of the compartment tailor welding base plate. The clamping mechanisms are fixed to the front end and the rear end of the upper surface of the compartment tailor welding base plate and matched with clamping portions of the rear compartment door. The hanging lug mold is fixed to the front end of the compartment tailor welding base plate and matched with a hanging lug at the front end of the rear compartment door. According to the rear compartment door tailor welding tool, the problems that deviation is prone to occurrence, adjustment is difficult and stability is poor when manual tailor welding is adopted can be solved, and therefore welding quality can be improved.

Owner:广西玉柴专用汽车有限公司

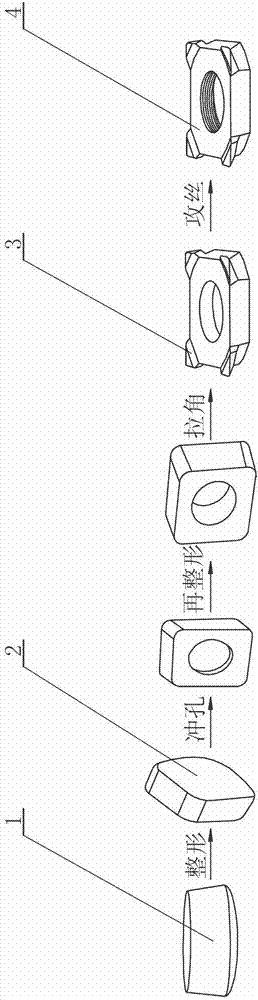

Processing technology of welded nut

Processing technology of a welded nut mainly solves problems that deviation of perpendicularity of a threaded hole is high, sizes of various weld points deviate and heights of the weld points are inconsistent when an existing welded nut is processed. The processing technology is characterized by comprising steps of a, reshaping a nut body (2): forming a blank (1) by a cold header by means of cold heading; b, punching: punching a through hole in the center of the nut body (2) by the cold header; c, reshaping the nut body (2) again: using the center hole of the nut body (2) as a positioning reference to reshape the nut body (2) again; d, drawing a corner: using the center hole of the nut body (2) as the positioning reference to head out weld points (3) on the edge of an end surface of the nut body (2) by the cold header; and e, thread tapping: forming the welded nut (4). The center hole is used for positioning in the corner drawing process, perpendicularities of threaded holes of the welded nut are effectively guaranteed, dimensional deviation of the weld points is low, and heights of the weld points keep consistent.

Owner:浙江明泰控股发展股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com