Patents

Literature

304 results about "Material volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

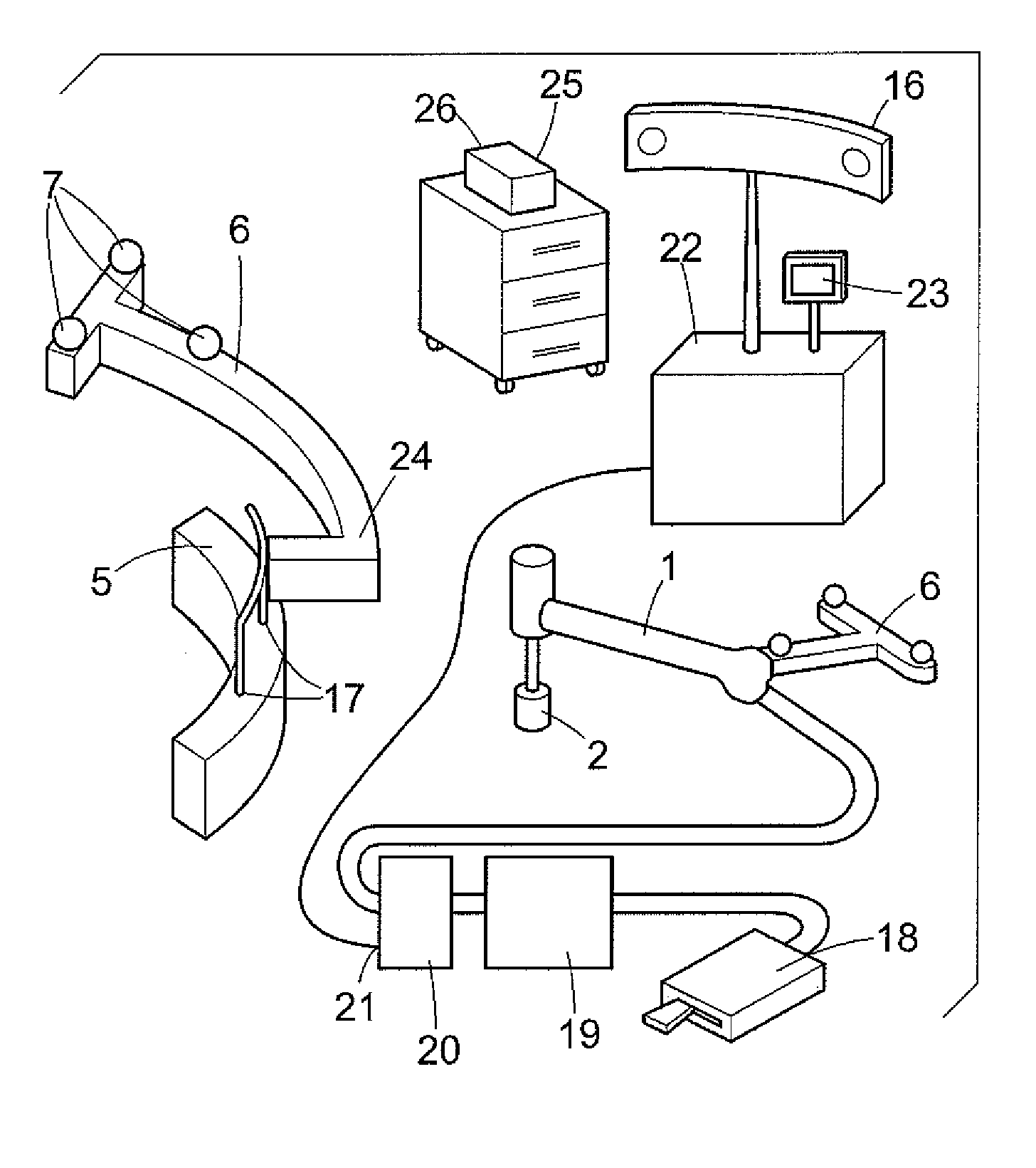

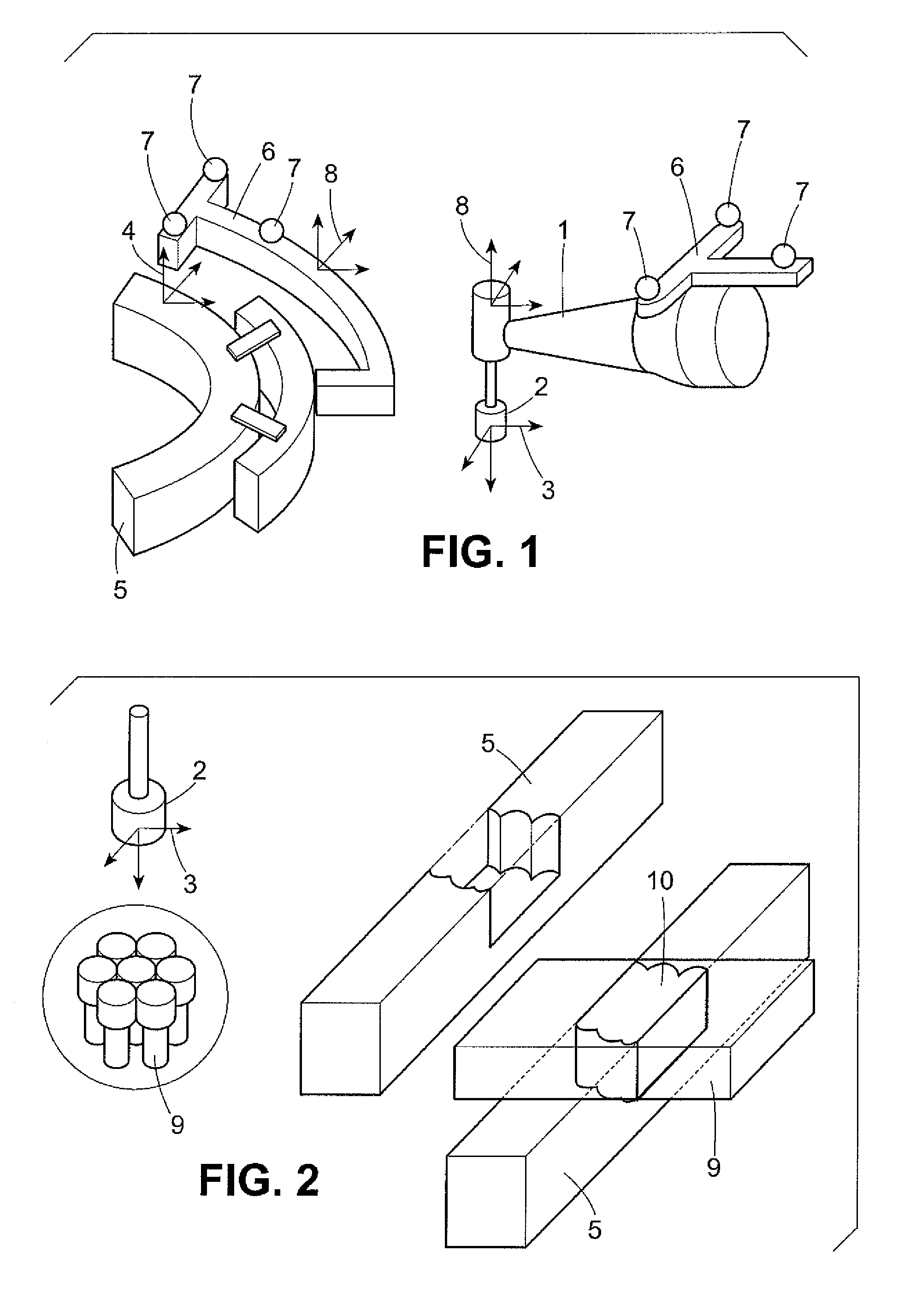

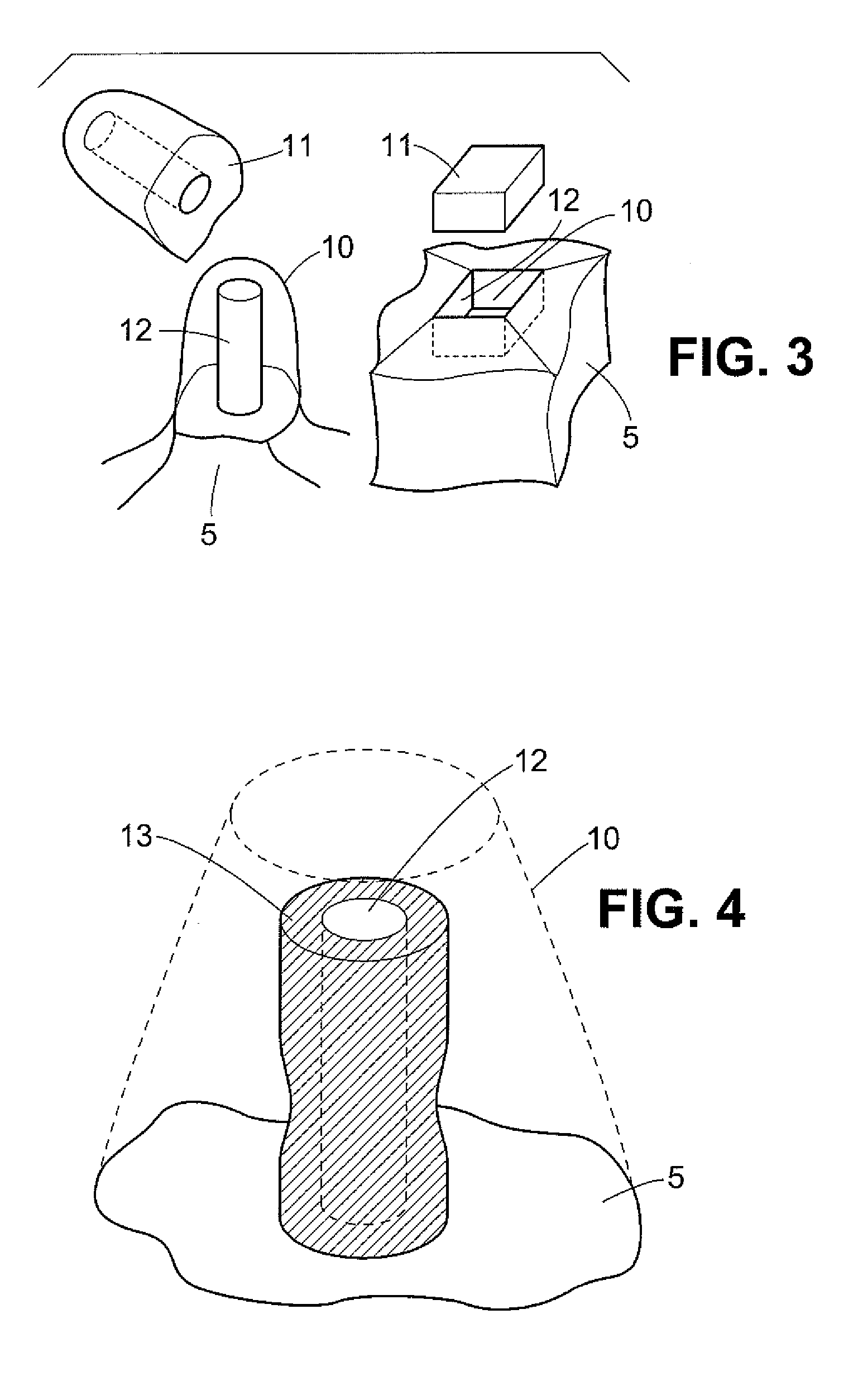

Method and device system for removing material or for working material

Method and system, for which can be used in the fields of medicine and dentistry as well as for the most varied types of material working in different areas of application and model working, provides that an exact removal of material or a highly precise, reproducible material working can be realized by acquiring, storing and processing data pertaining to position and / or orientation of an effector and their changes relative to the position of at least one reference body. The effector is controlled and / or regulated with regard to its power and / or parameterization based on a predetermined working volume, material volume removed and remaining material volume. A first marking support with markings is arranged on a handpiece with the effector, where the handpiece is connected to a control unit, and a second marking support with markings is attached to the material object or tissue object.

Owner:ALL OF INNOVATION MBH

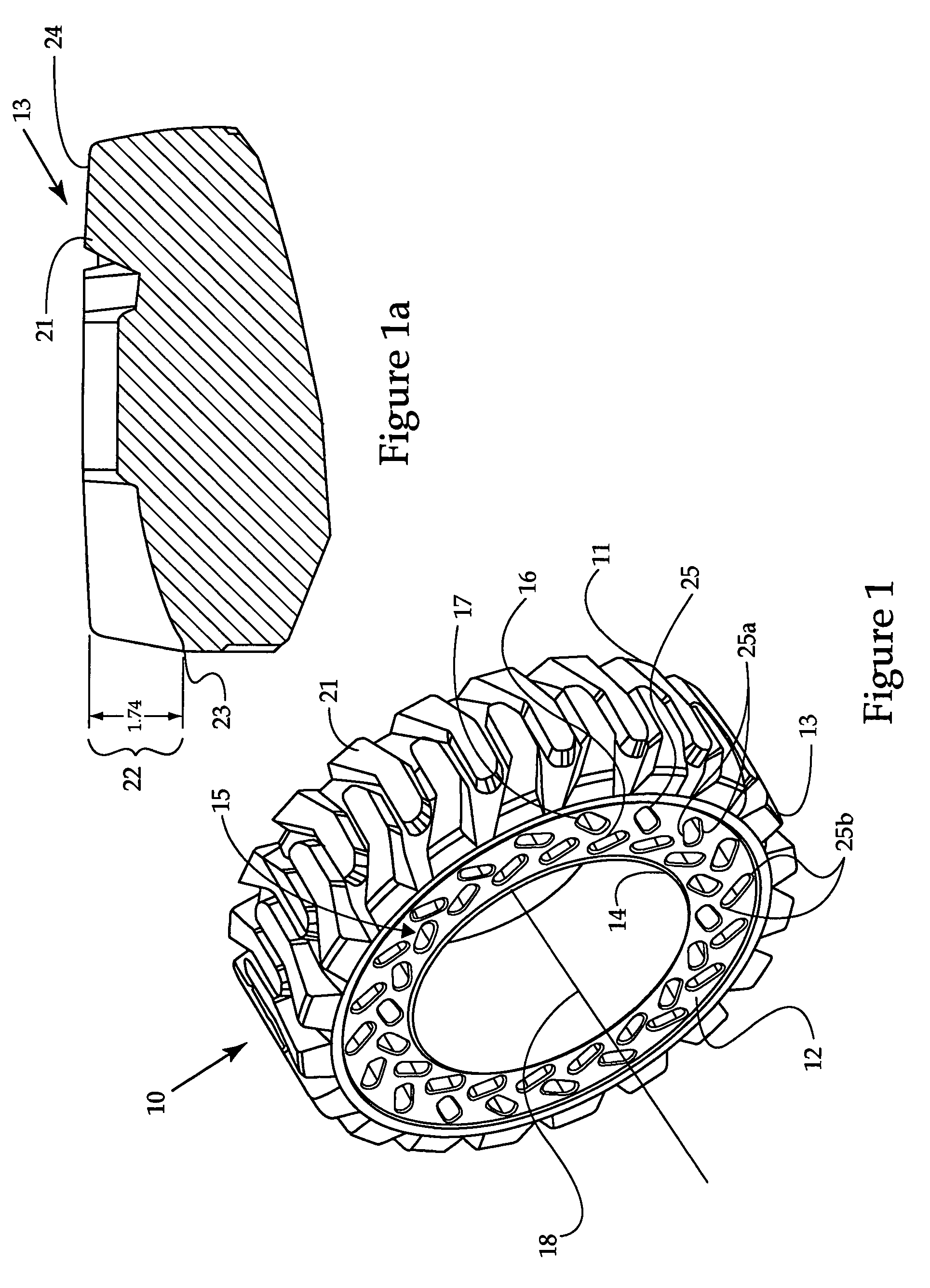

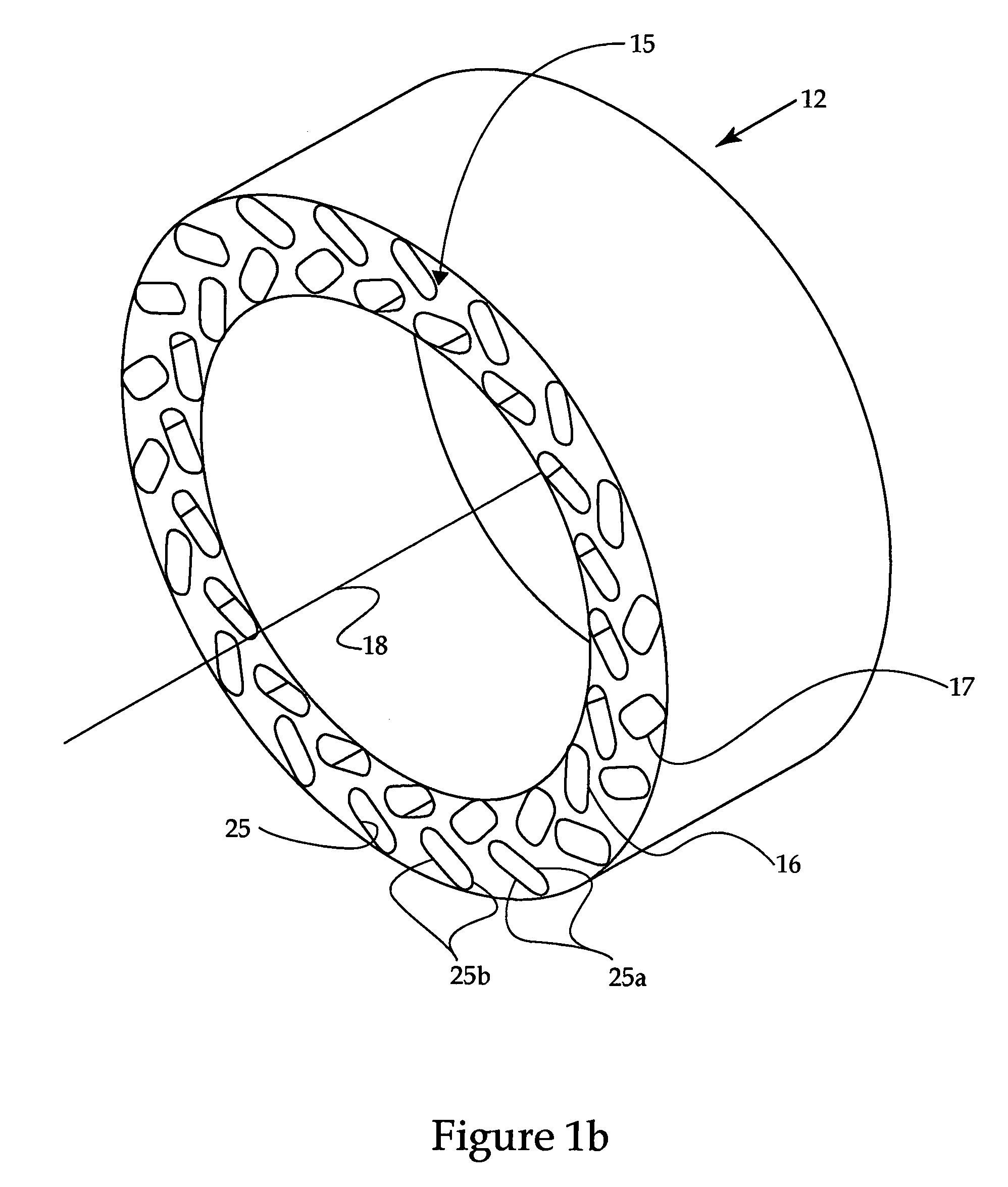

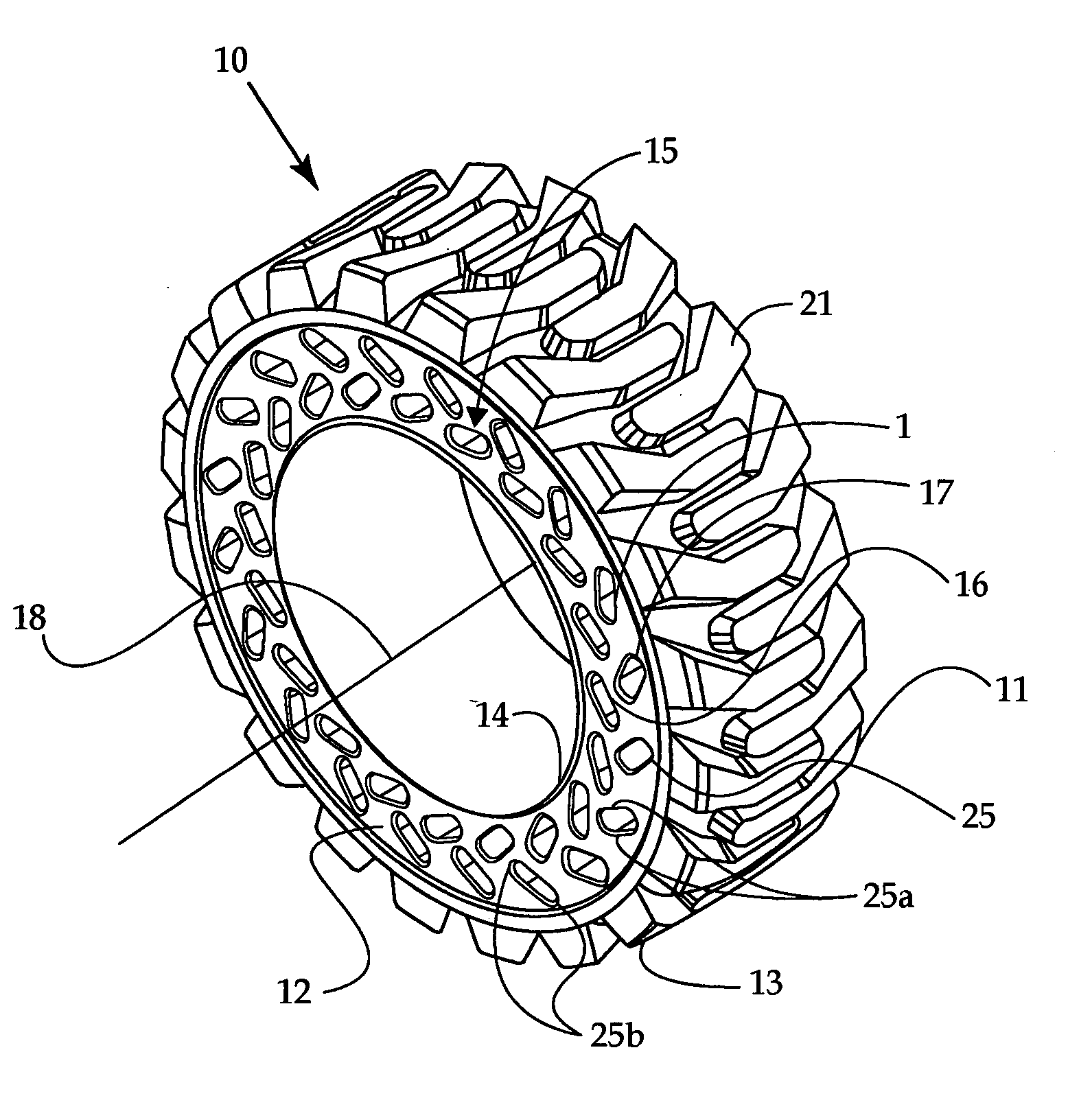

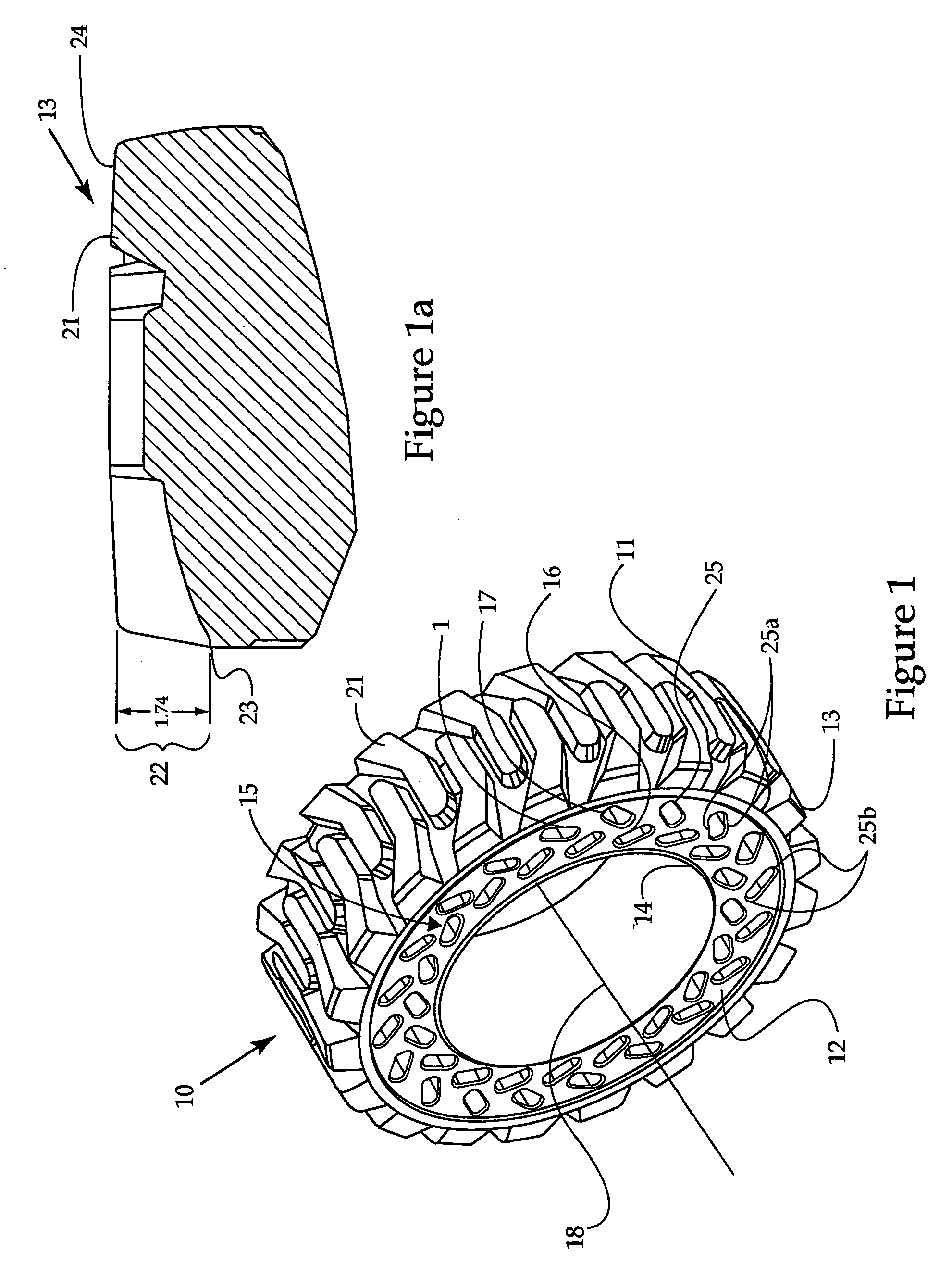

Solid suspended work machine tire

Owner:CATERPILLAR INC

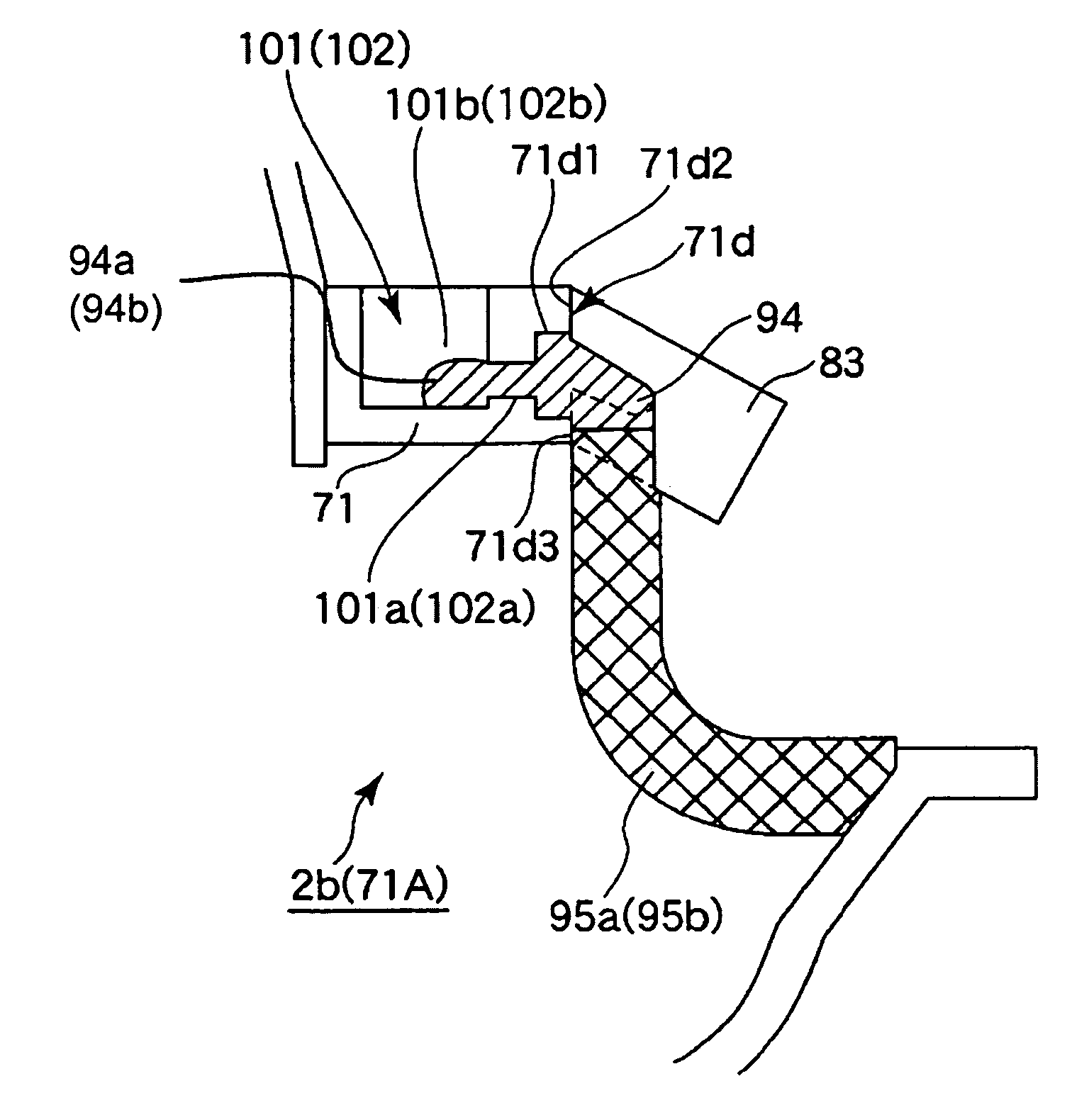

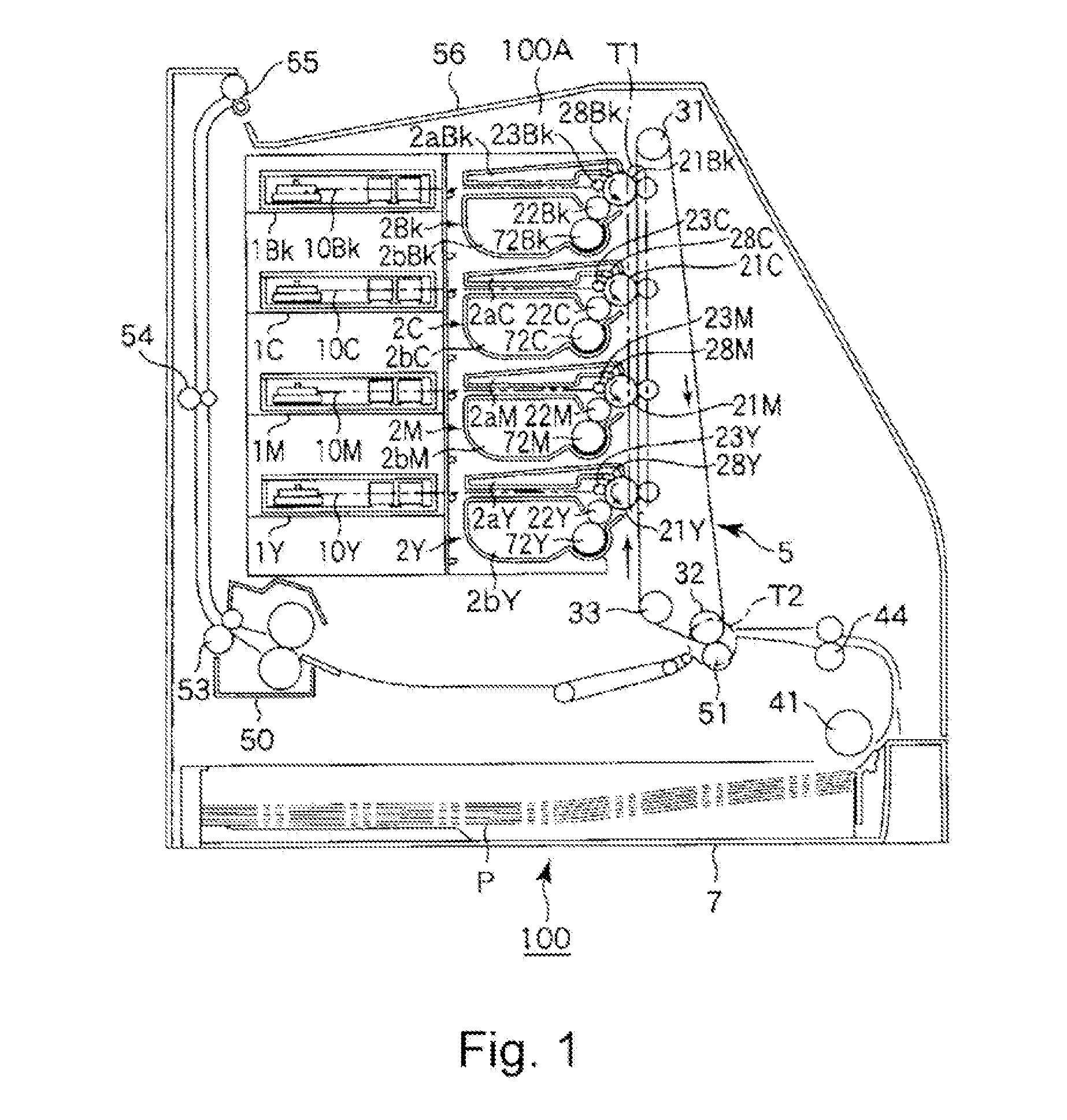

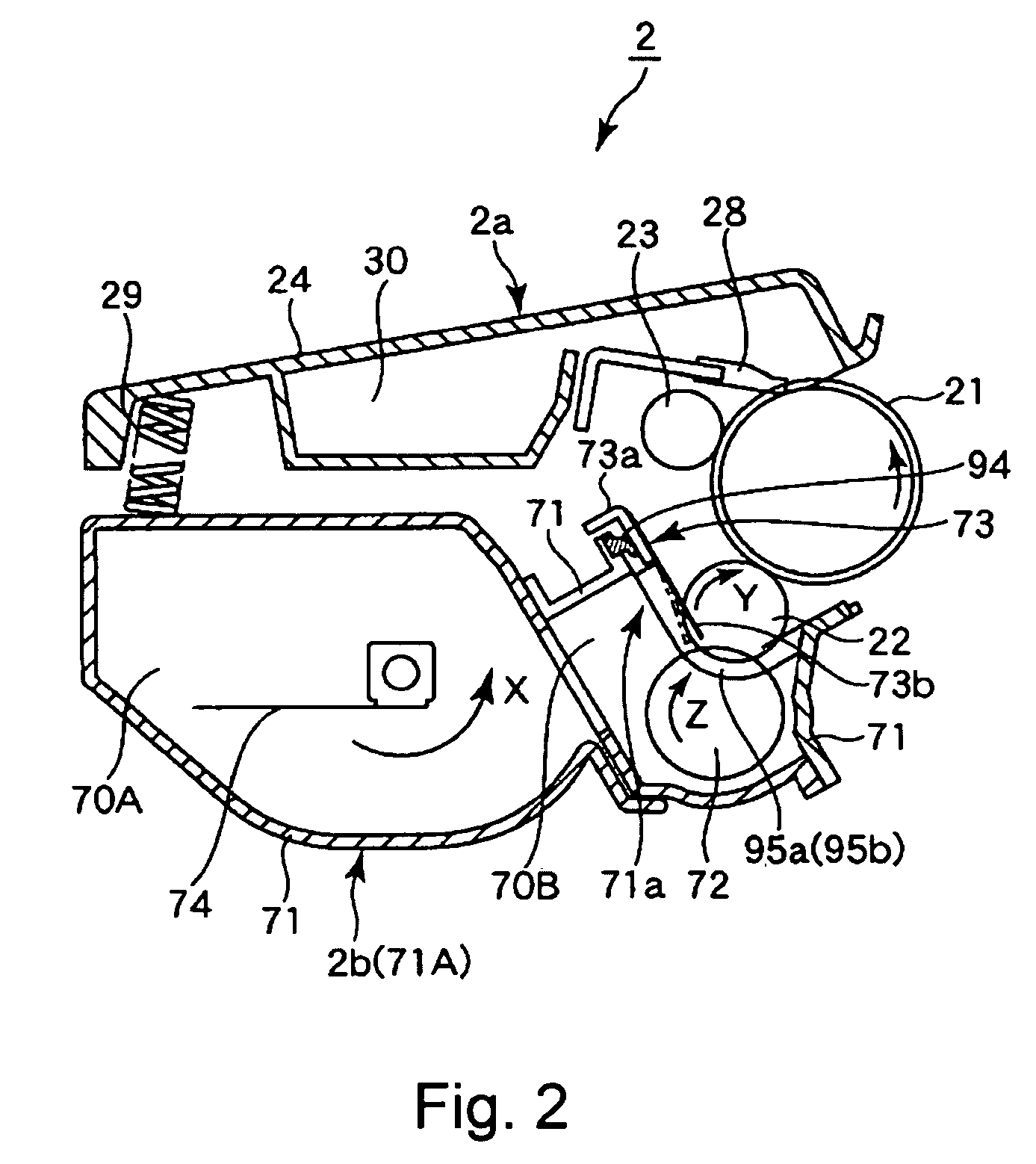

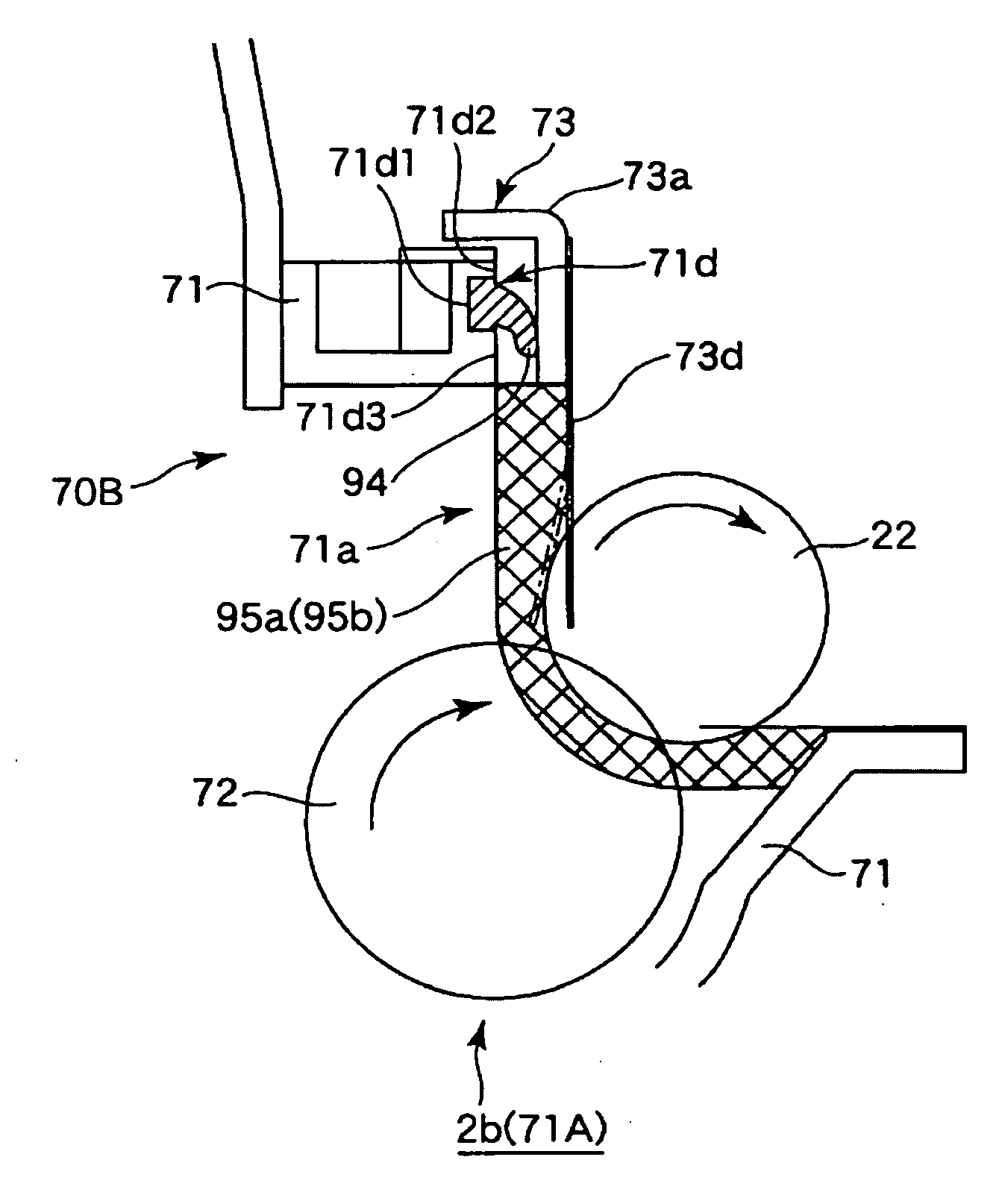

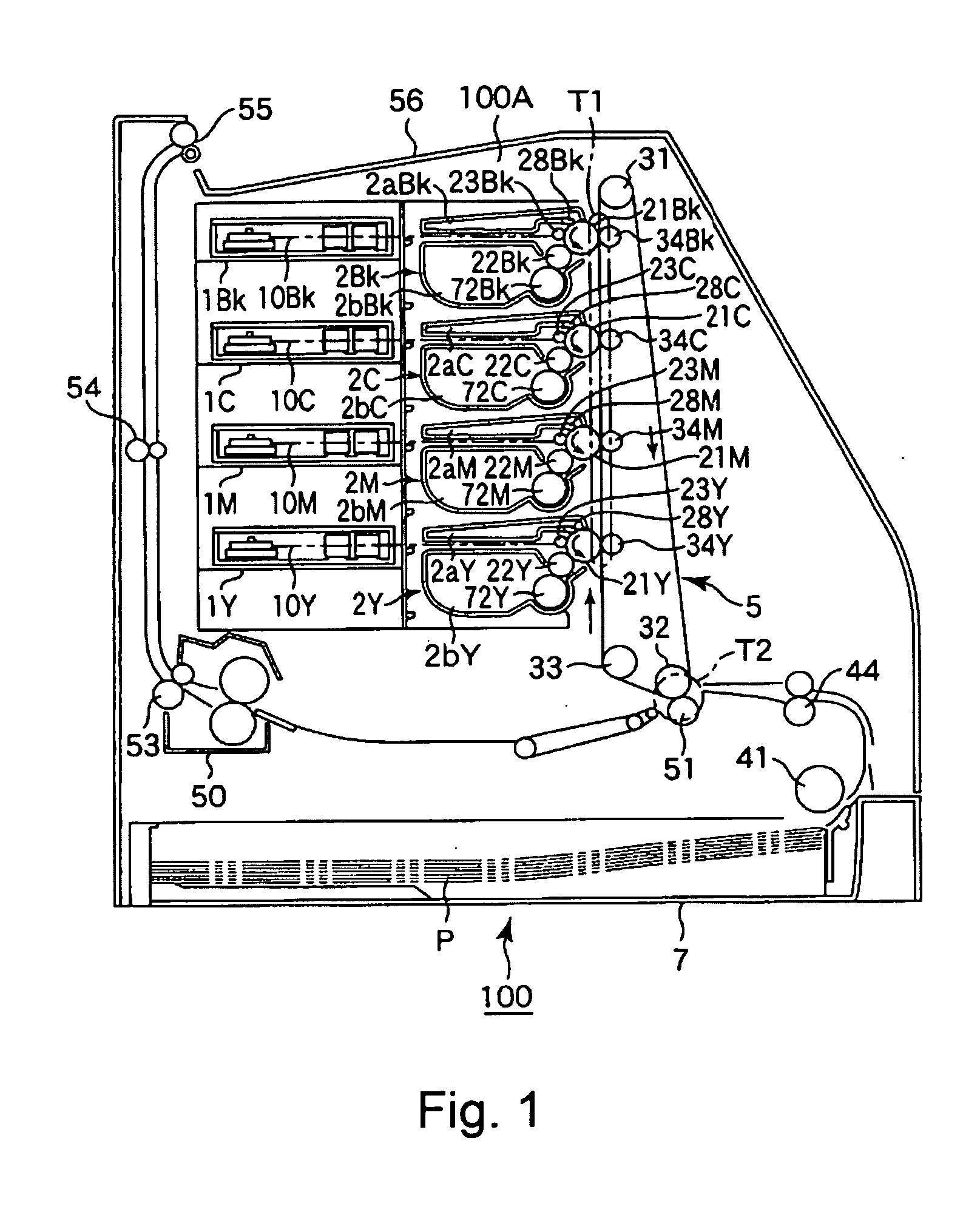

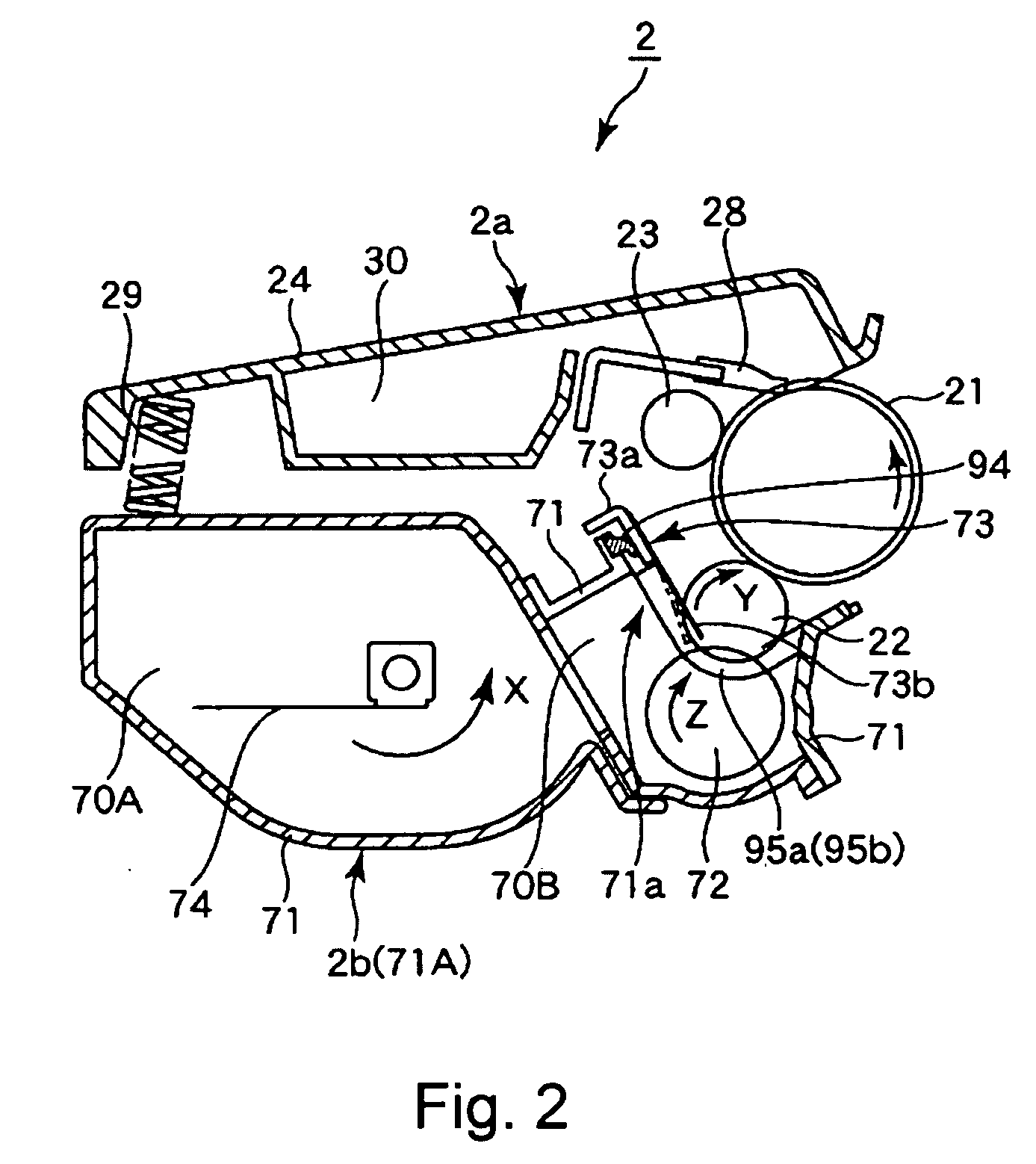

Developing device frame unit, developing device, process cartridge, and manufacturing method of the developing device frame unit

ActiveUS7933534B2Improve sealingReduce component countElectrographic process apparatusElastomerEngineering

A developing device frame unit supporting a regulating member regulating the layer thickness of developer on a developer carrier. The unit includes a frame having a seal forming portion, first and second, first and second end seals contactable to the carrier surface to prevent carrier-axial-direction leaking of the developer, and a blade sealer sealing between the regulating member and the frame to prevent developer leaking when the regulating member is mounted. The blade sealer is an elastomer resin material which is injection-molded with a metal mold and in the seal forming portion where the end seals are provided. The blade sealer connects the end seals with each other, and a protrusion provided by a squeezed-out portion of the resin material is provided by injecting, into a space defined by the metal mold, the seal forming portion, and the end seal seals, a resin material volume larger than a volume of the space.

Owner:CANON KK

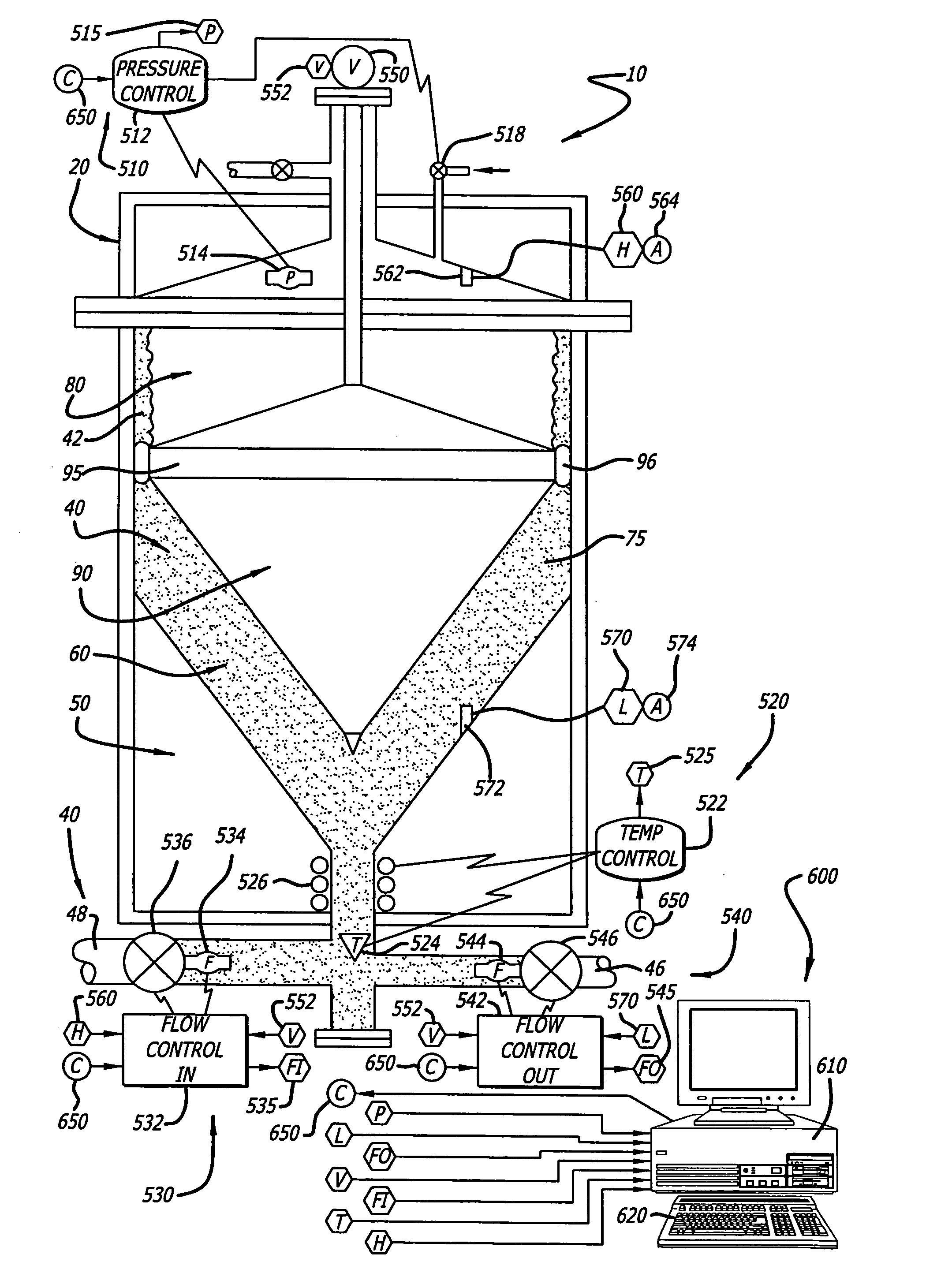

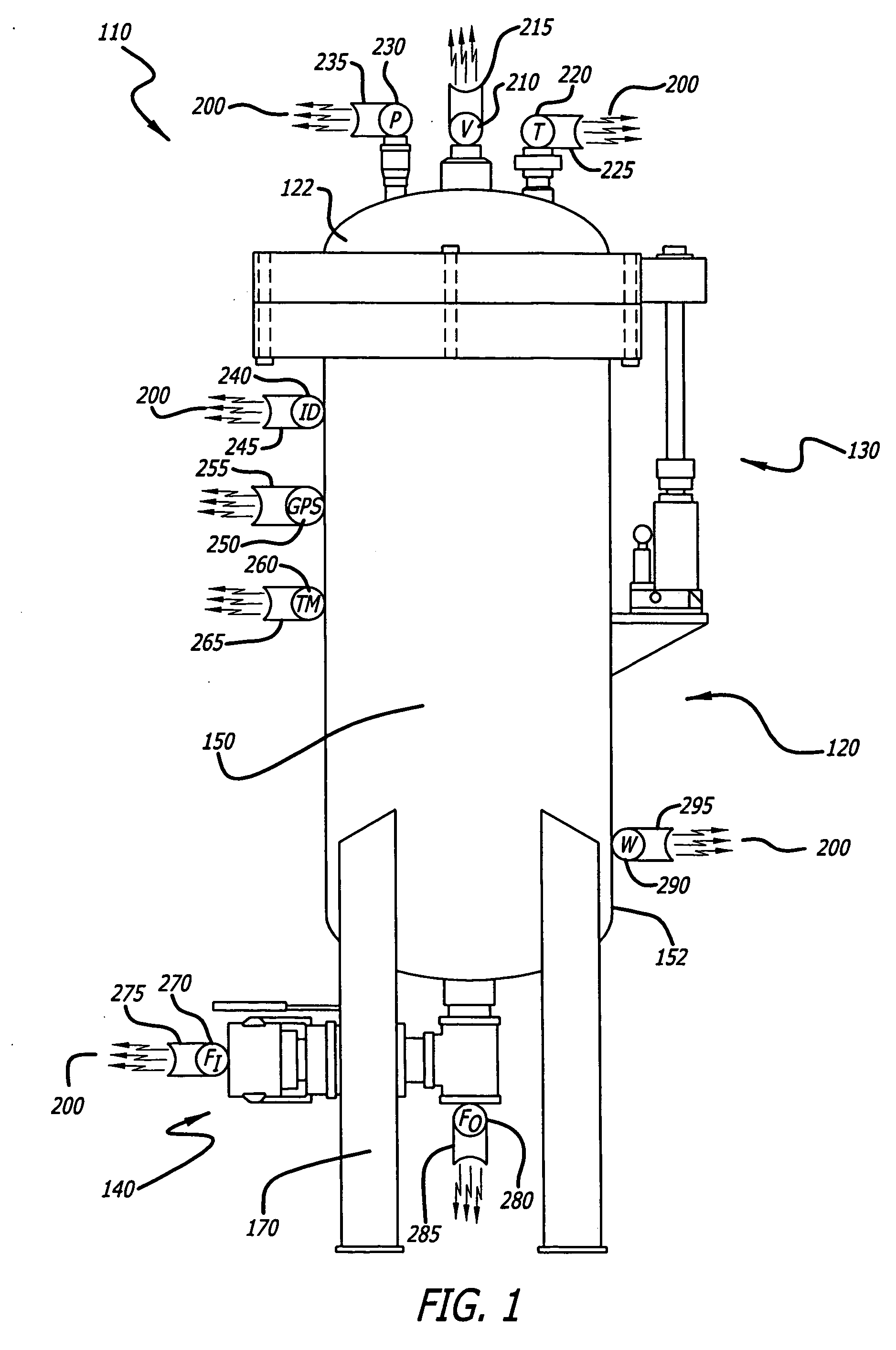

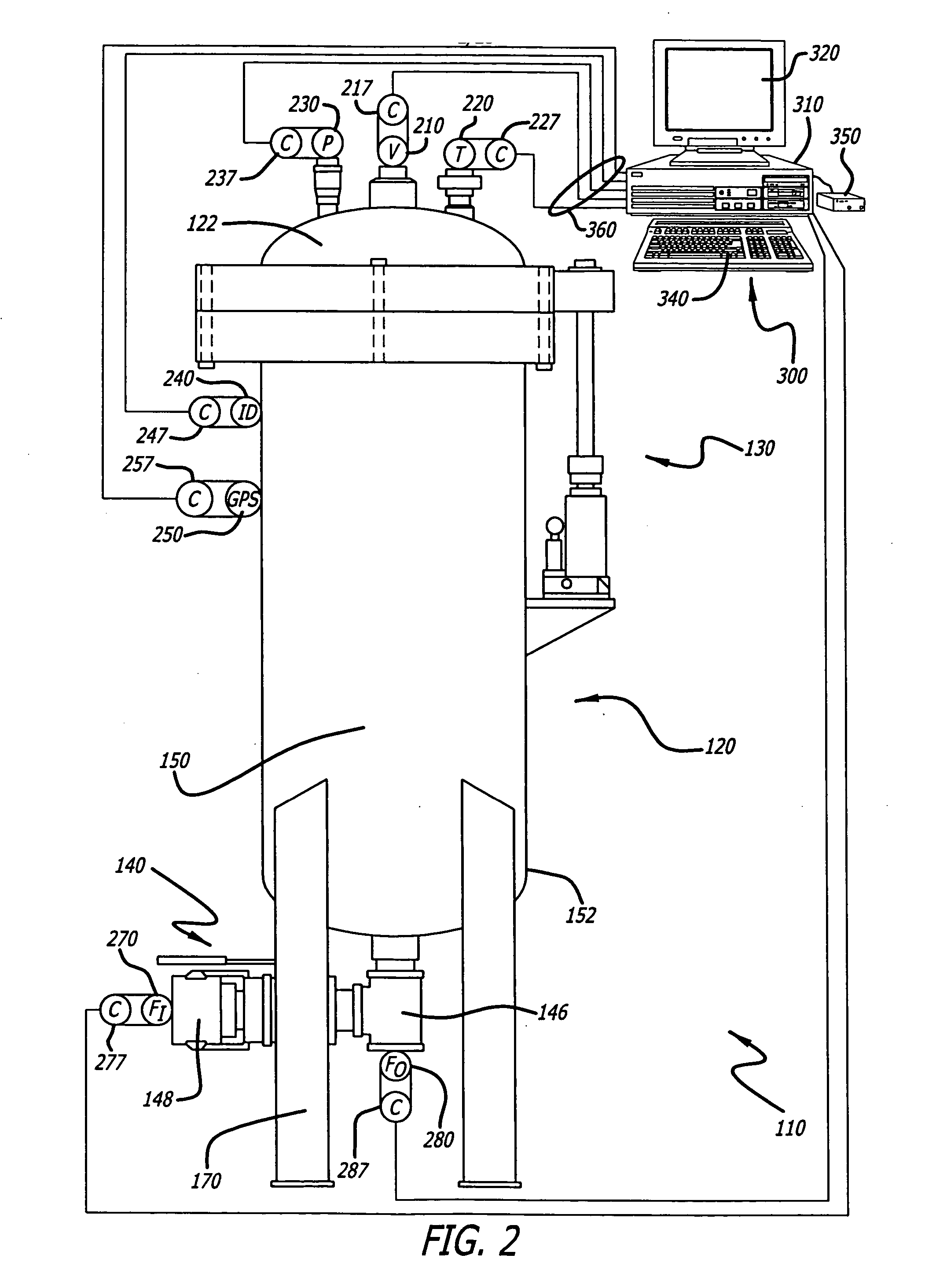

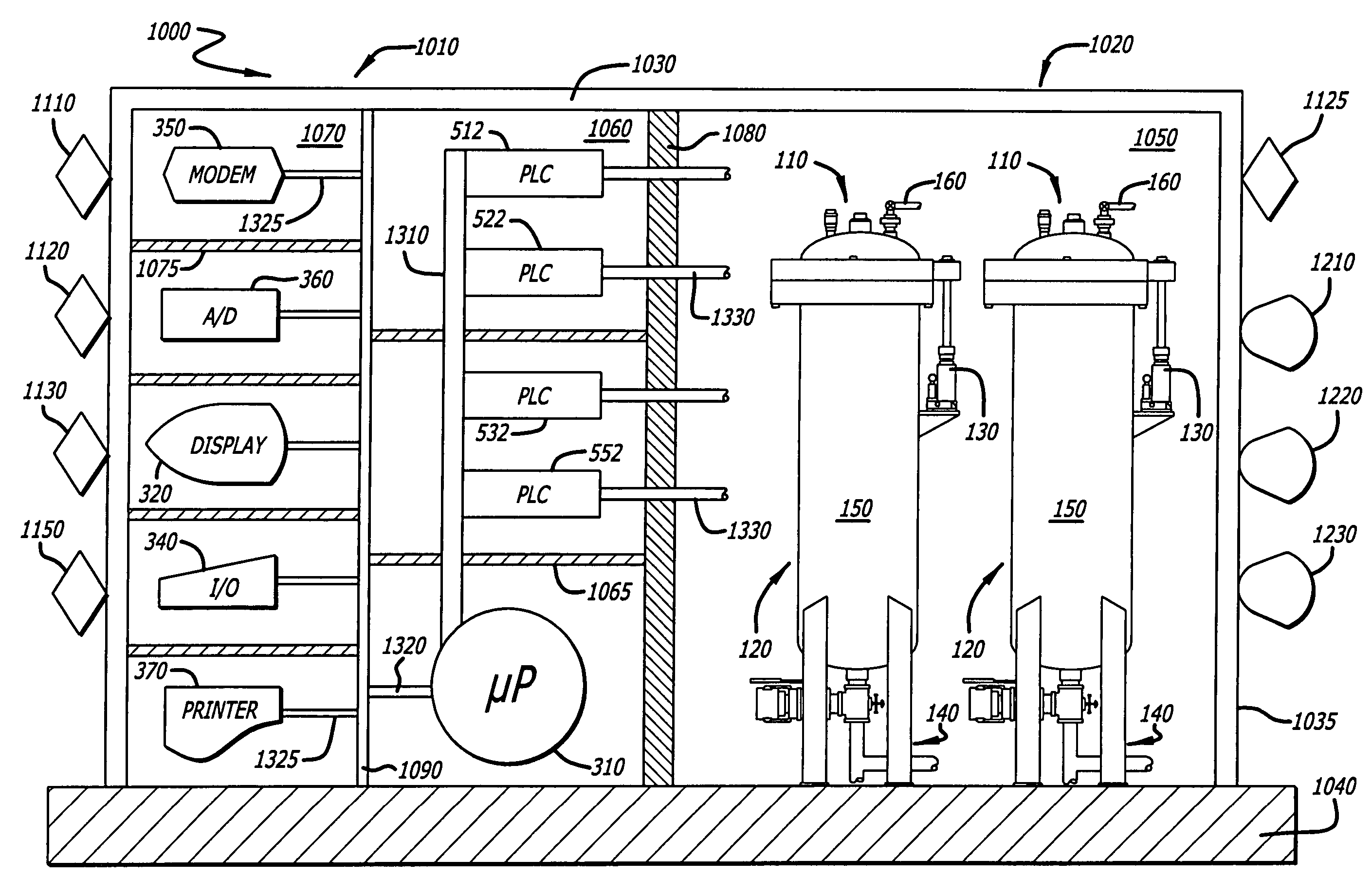

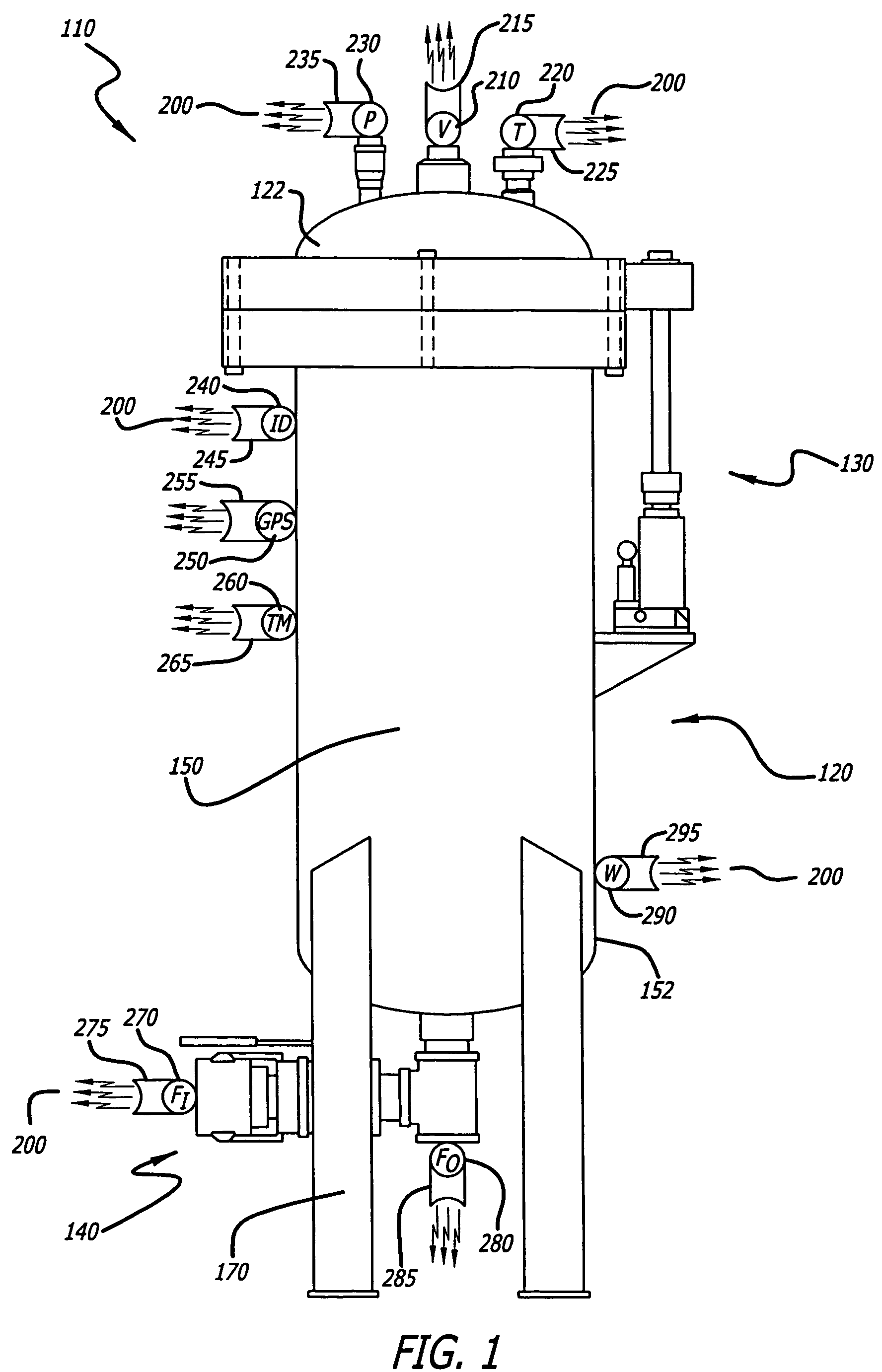

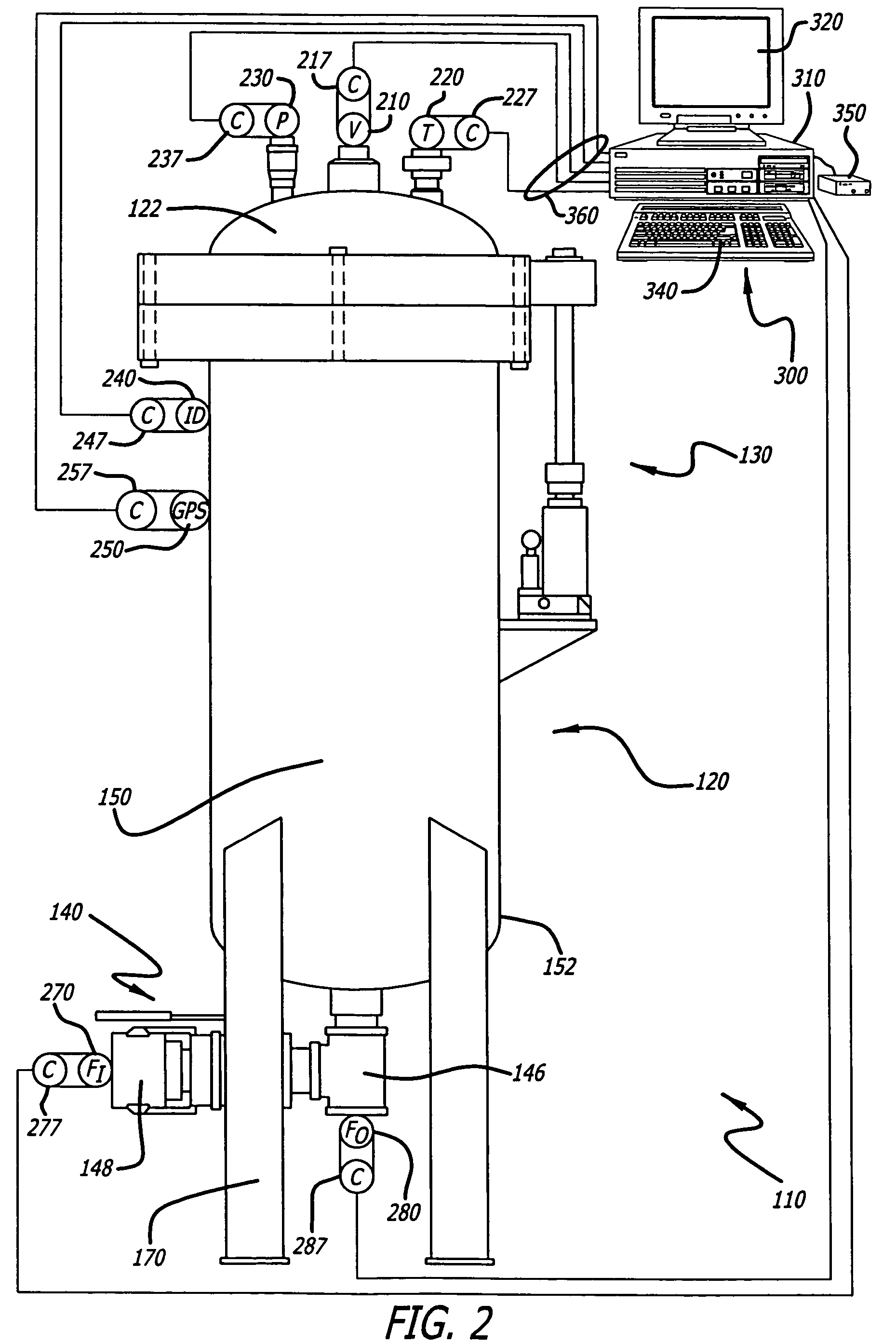

Integrated material transfer and dispensing system

ActiveUS20070090132A1Increase fluid velocityWide operating temperature rangeLiquid flow controllersLiquid transferring devicesStream flowMaterial transfer

An integrated material transfer and dispensing system for storing, transferring and dispensing materials, such as fluids, and liquids, for example, liquid applied sound deadener (LASD). The system includes at least one vessel having a force transfer device. Each vessel may be removably enclosed in cabinet to form an automated station. Each vessel may be configured with a data logger, cleanout port, a sample valve at least one sight window and an access port for introducing a compound such as a biocide. Each vessel may be configured with instruments including sensors for measuring process variables, such as material volume, level, temperature, pressure and flow. The system may further include a metering device system and a robotic material dispenser system without a pump interface. The robotic system may further include a computer control system connected to flow and pressure sensors. The system may directly feed an applicator without an intervening pump.

Owner:CH & I TECH INC

Developing device frame unit, developing device, process cartridge, and manufacturing method of the developing device frame unit

ActiveUS20090245851A1Improve sealingReduce component countElectrographic process apparatusElastomerEngineering

A developing device frame unit supporting a regulating member regulating the layer thickness of developer on a developer carrier. The unit includes a frame having a seal forming portion, first and second end seals contactable to the carrier surface to prevent carrier-axial-direction leaking of the developer, and a blade sealer sealing between the regulating member and the frame to prevent developer leaking when the regulating member is mounted. The blade sealer is an elastomer resin material which is injection-molded with a metal mold and in the seal forming portion where the end seals are provided. The blade sealer connects the end seals with each other, and a protrusion provided by a squeezed-out portion of the resin material is provided by injecting, into a space defined by the metal mold, the seal forming portion, and the end seals, a resin material volume larger than a volume of the space.

Owner:CANON KK

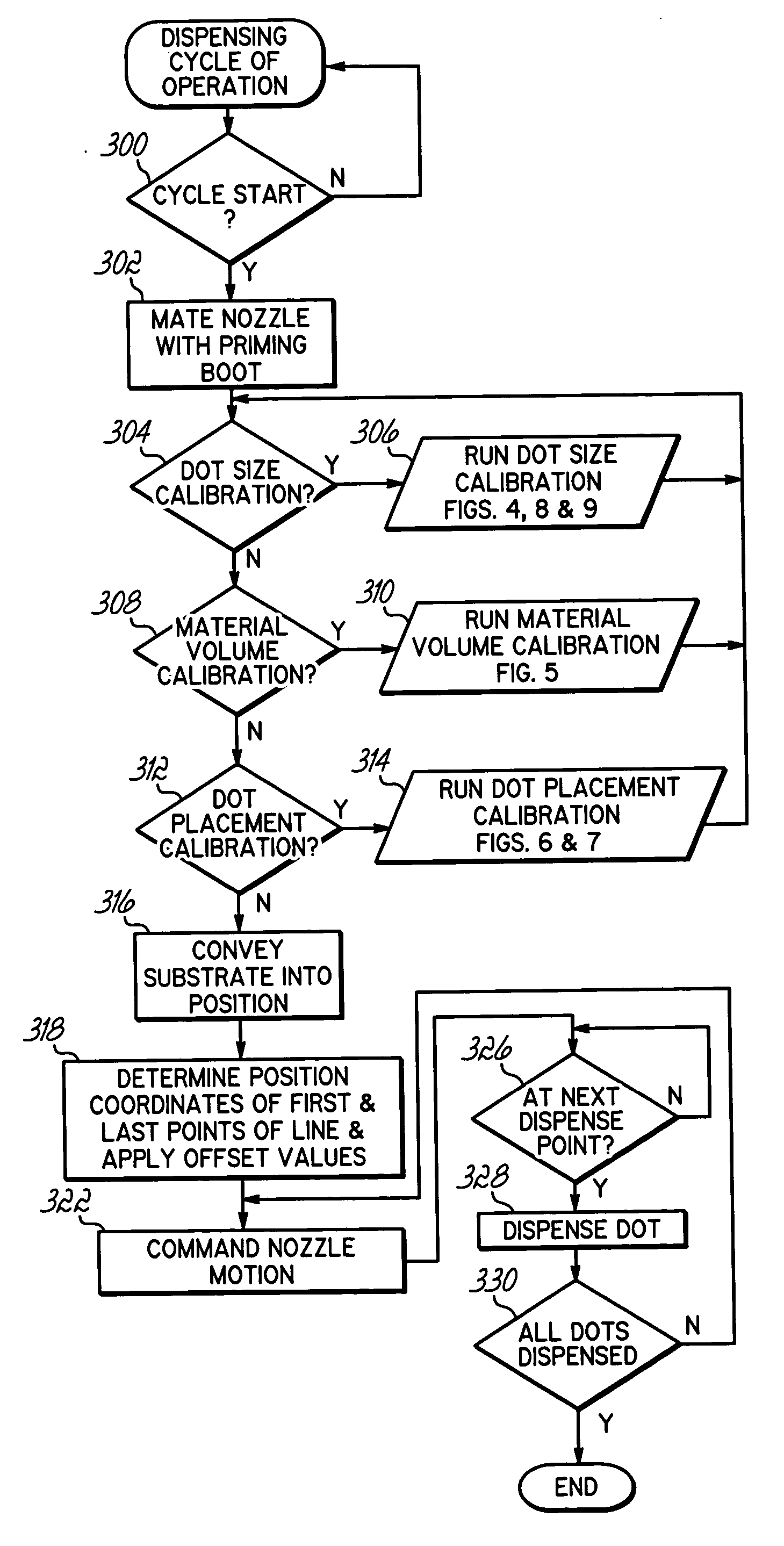

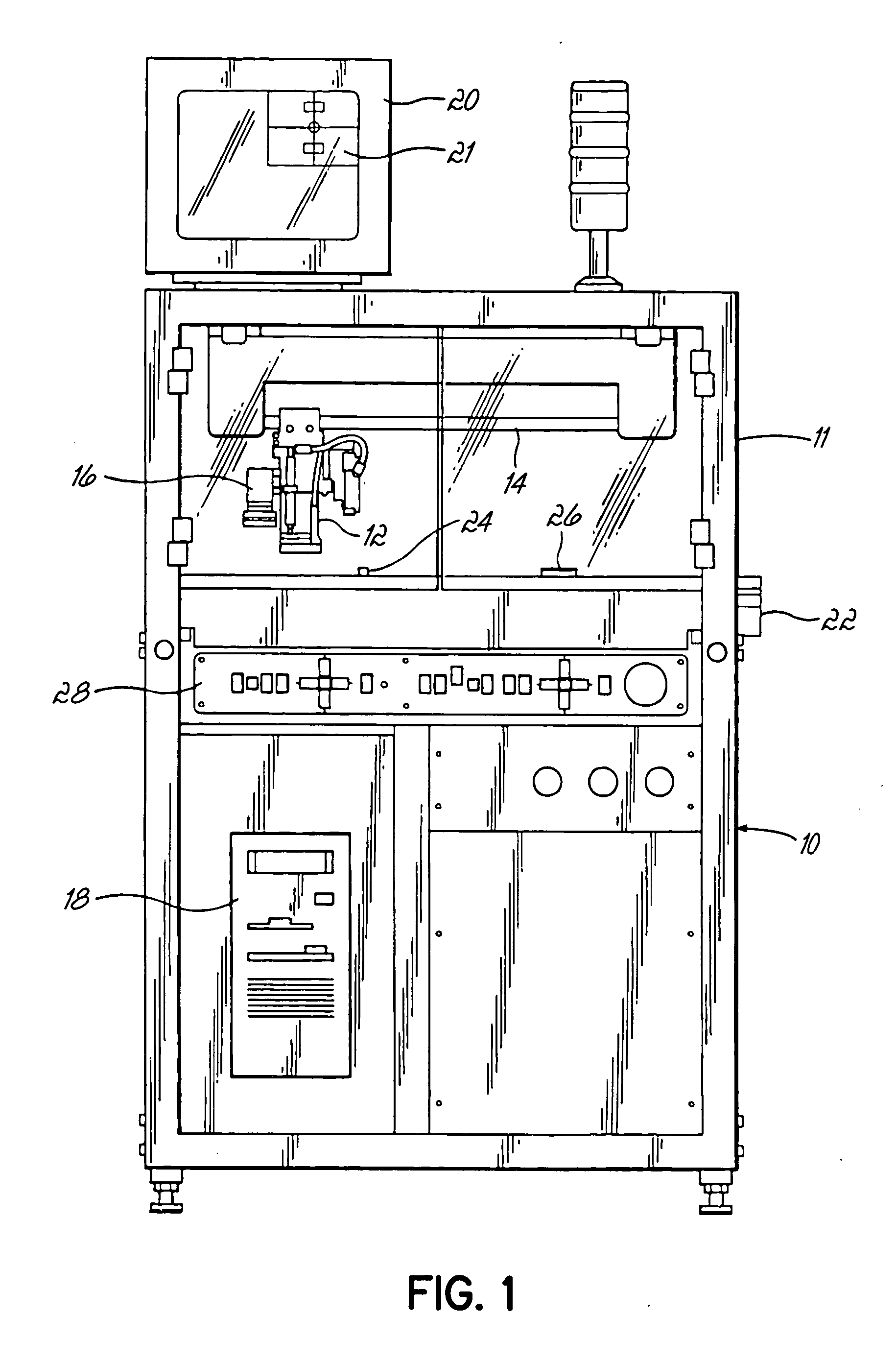

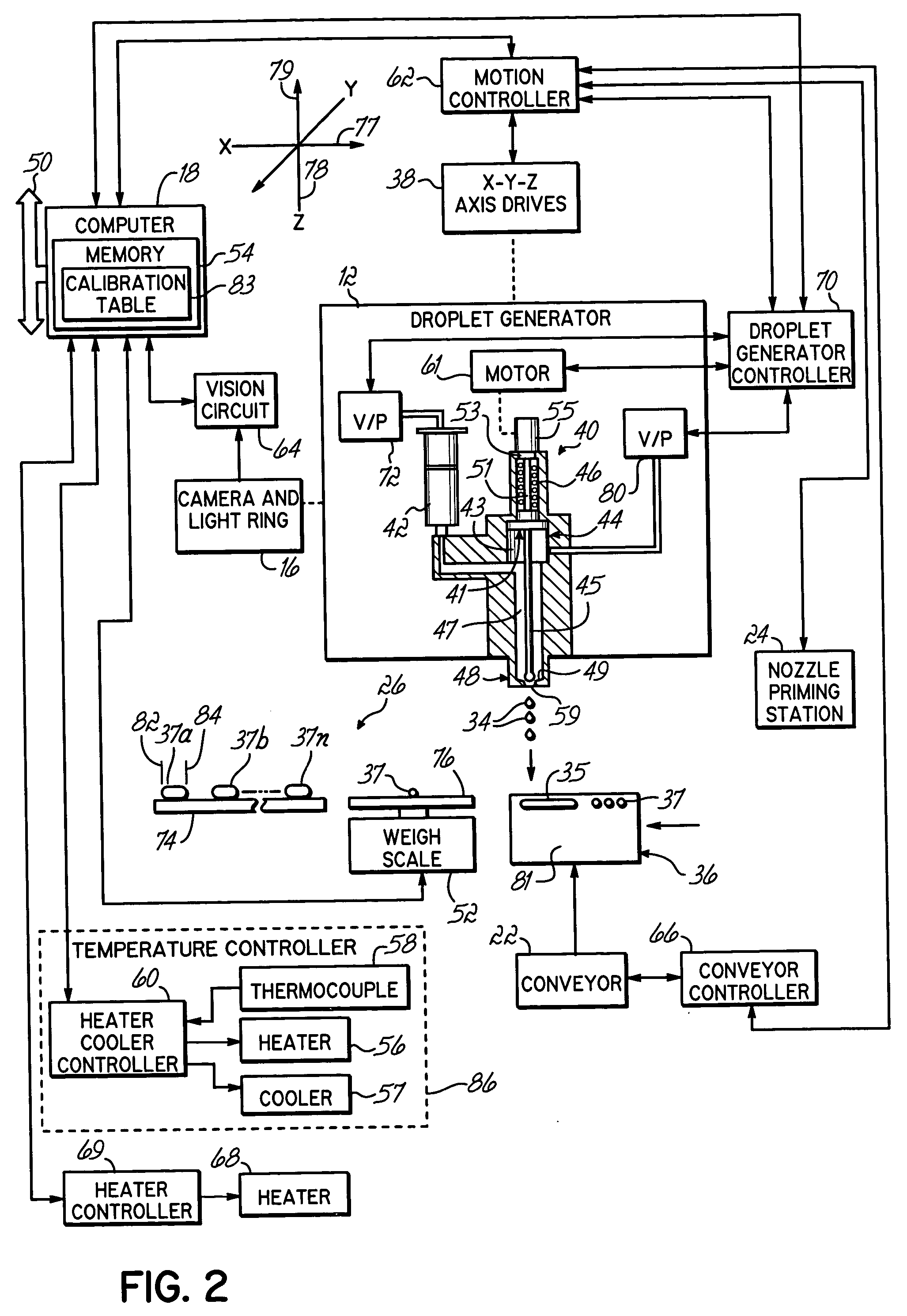

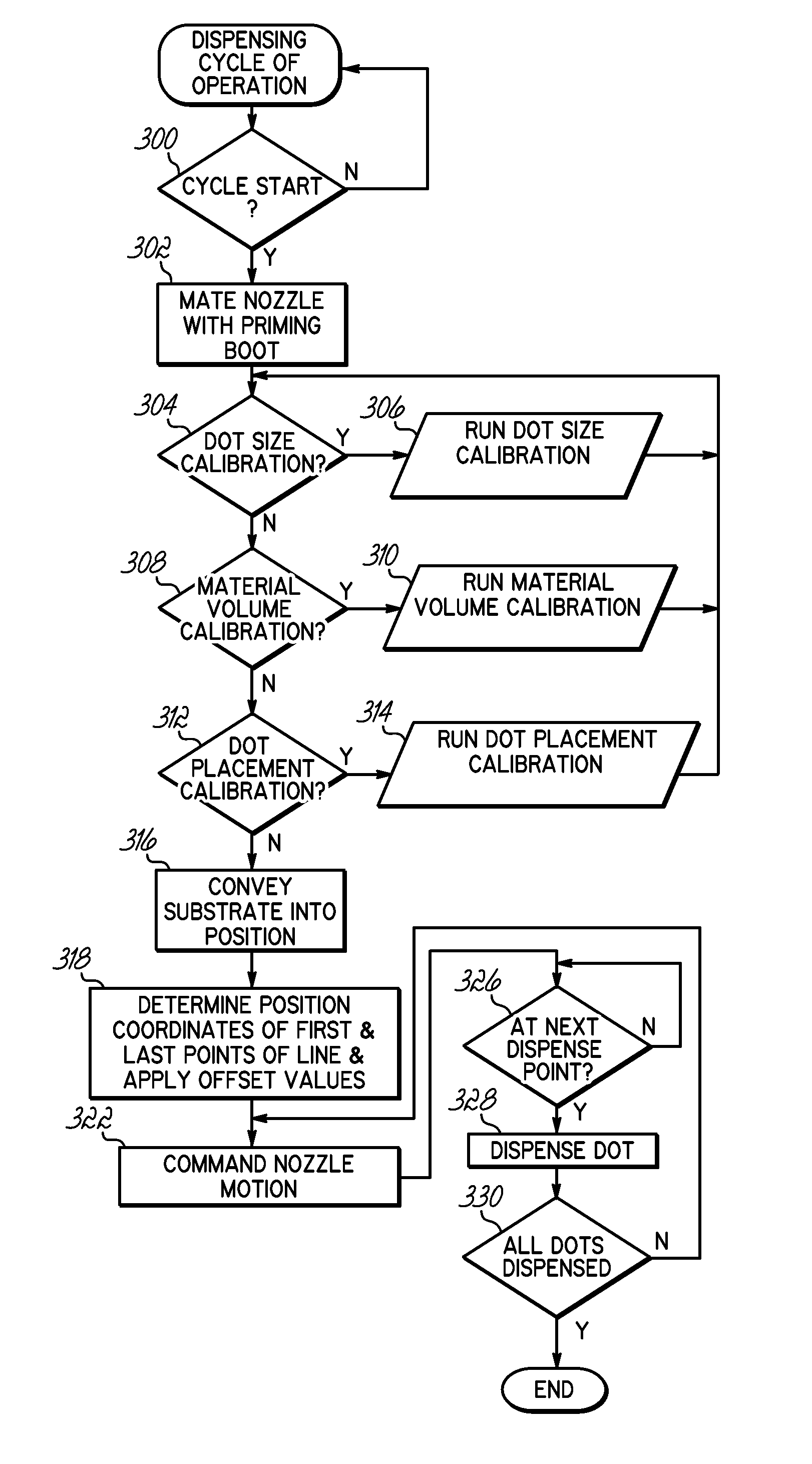

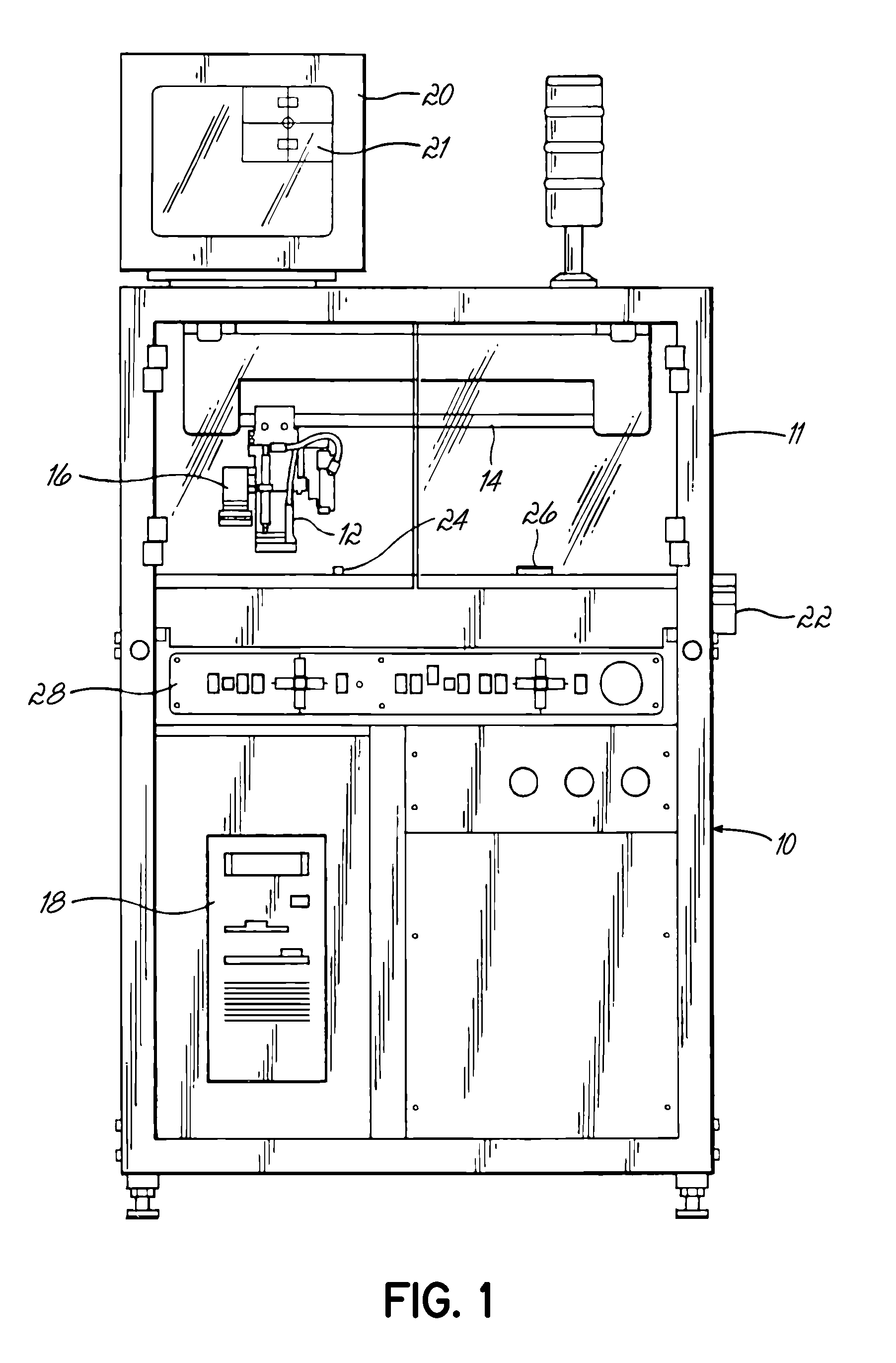

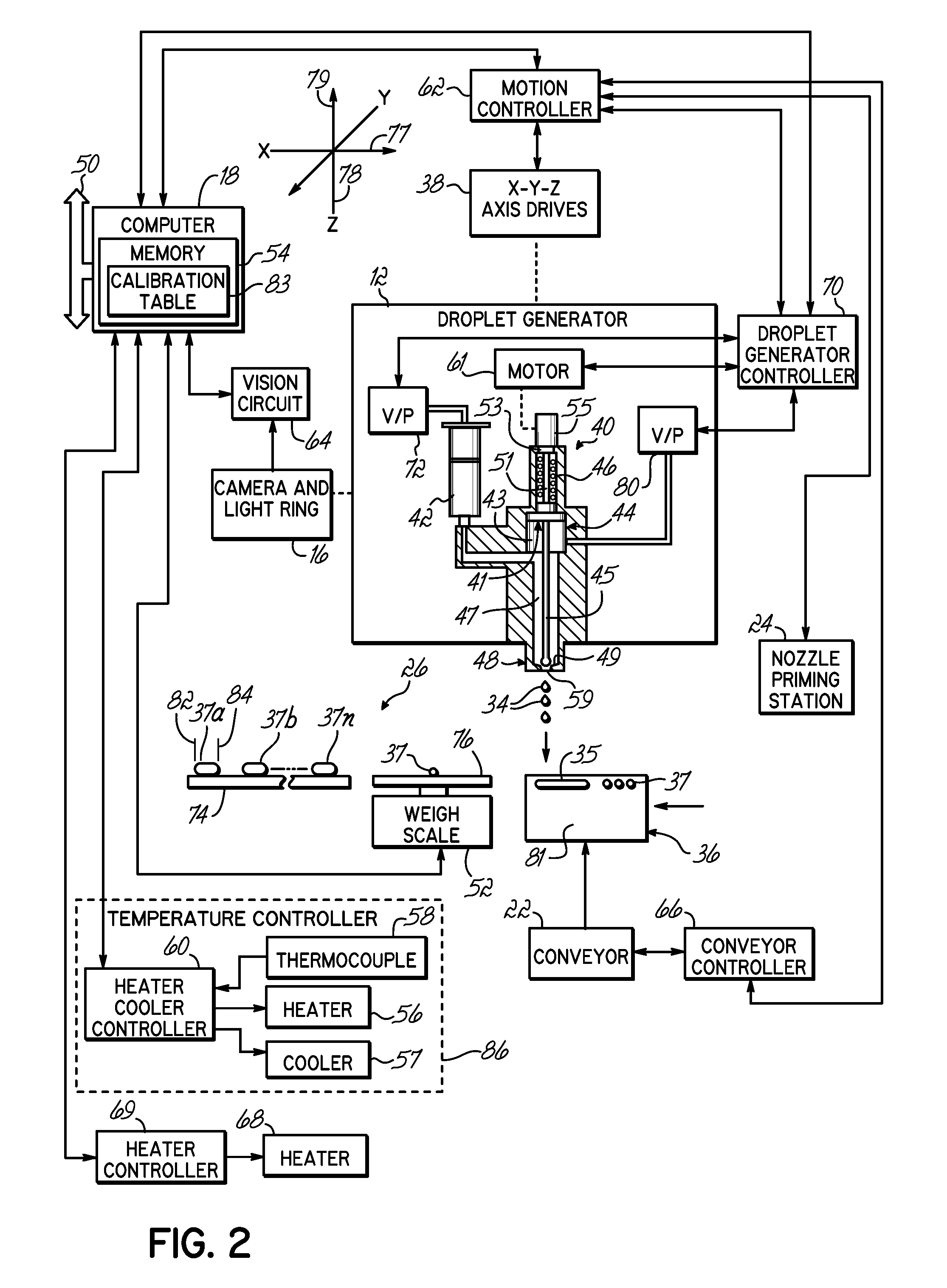

Viscous material noncontact jetting system

InactiveUS20050001869A1Precise applicationSimpler and less-expensivePrinted circuit assemblingSpraying apparatusEngineeringRelative motion

A viscous material noncontact jetting system has a jetting dispenser mounted for relative motion with respect to a surface. A control is operable to cause the jetting dispenser to jet a viscous material droplet that is applied to the surface as a viscous material dot. A device, such as a camera or weigh scale, is connected to the control and provides a feedback signal representing a size-related physical characteristic of the dot applied to the surface. The size-related physical characteristics of subsequently applied dots is controlled by heating and cooling, or adjusting a piston stroke in the jetting dispenser, in response to the size-related physical characteristic feedback. Dispensed material volume control and velocity offset compensation are also provided.

Owner:NORDSON CORP

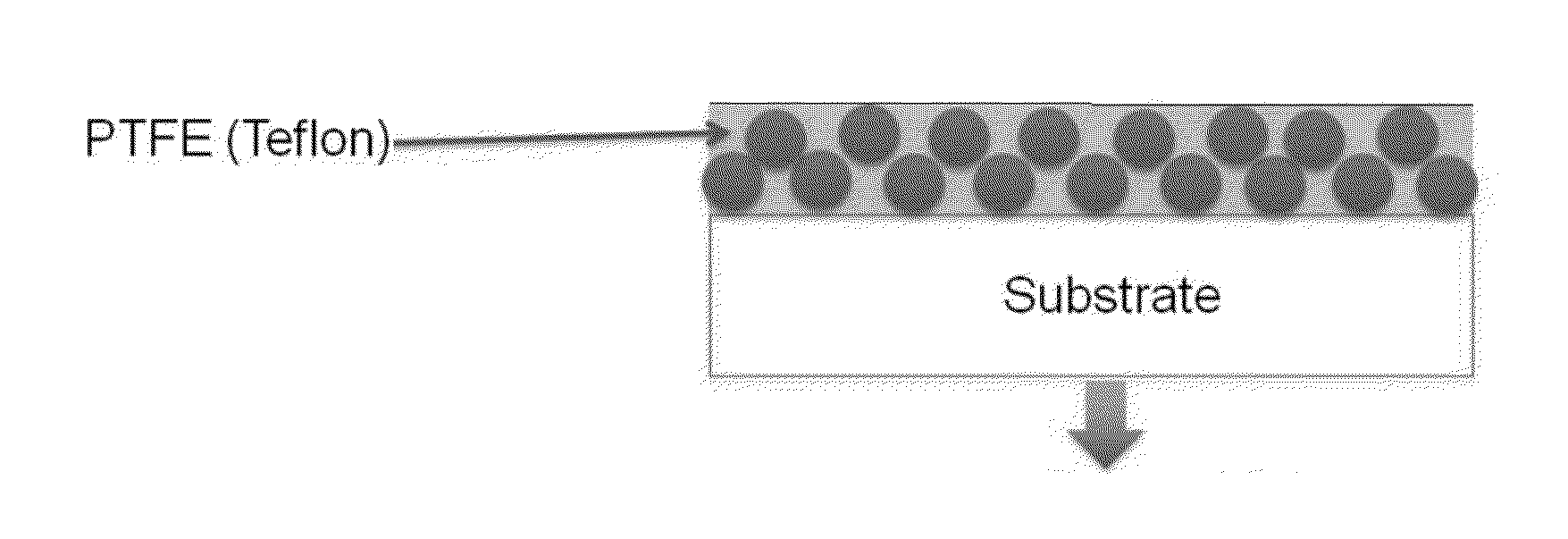

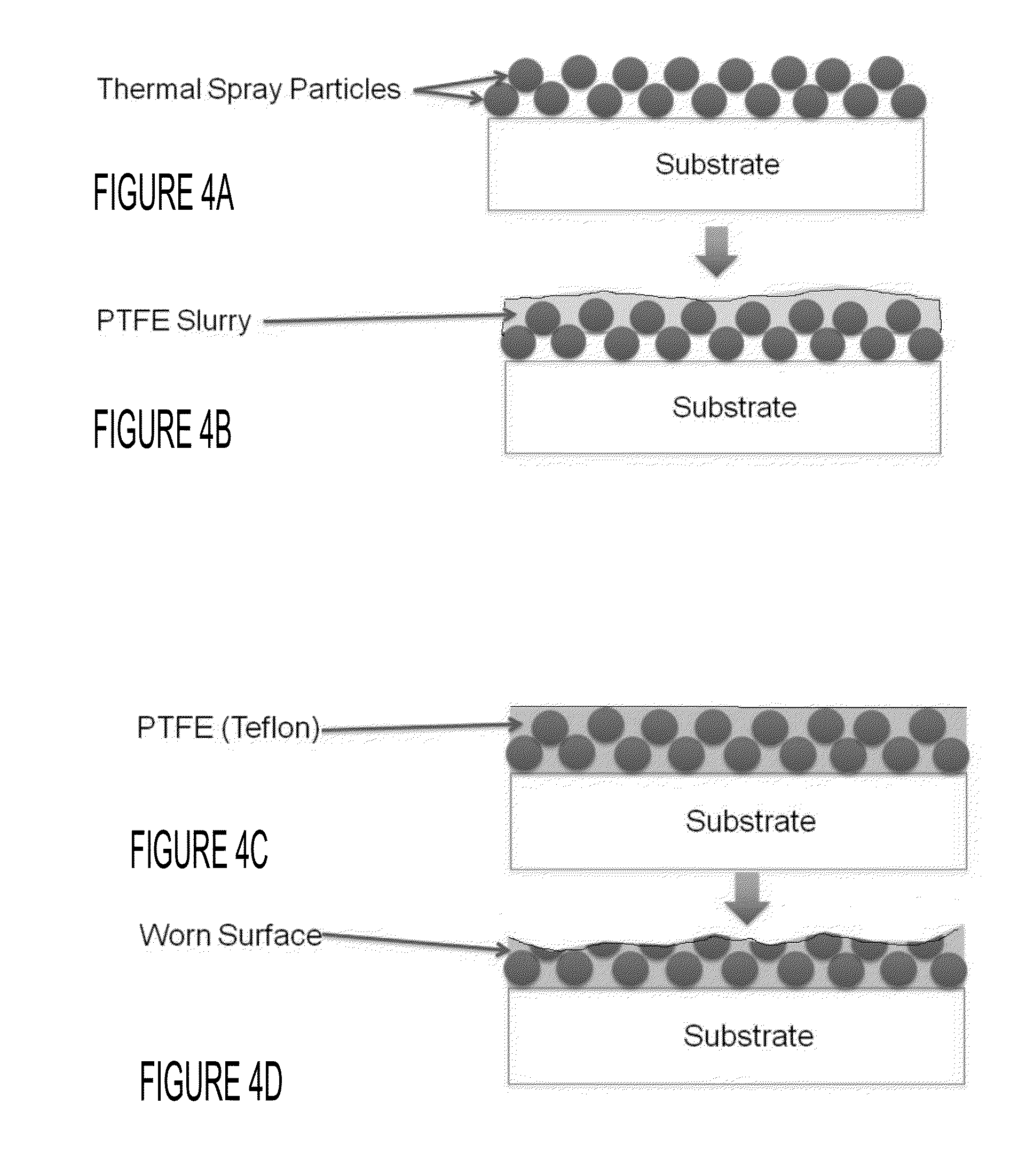

Coating compositions, applications thereof, and methods of forming

InactiveUS20130167965A1Reduced growth rateReduced adhesion strengthMolten spray coatingSynthetic resin layered productsSurface layerLubricant

Disclosed herein is an article having a surface modified to alter its surface tension property and increase resistance to sand abrasion as characterized by a material volume loss of less than 75 mm3 according to ASTM G65-04 Procedure B. In one embodiment of the method, an intermediate layer is first deposited onto a substrate of the article. At least a substrate on the article is protected by a coating layer, which comprises: an intermediate layer adjacent to the substrate with a thickness of at least 2 mils containing a plurality of pores with a total pore volume of 5 to 50% within a depth of at least 2 mils; and a surface layer comprising a lubricant material deposited onto the intermediate layer. The lubricant material infiltrates at least a portion of the pores for the coating to have the desired surface tension depending on the application.

Owner:SCOPERTA INC

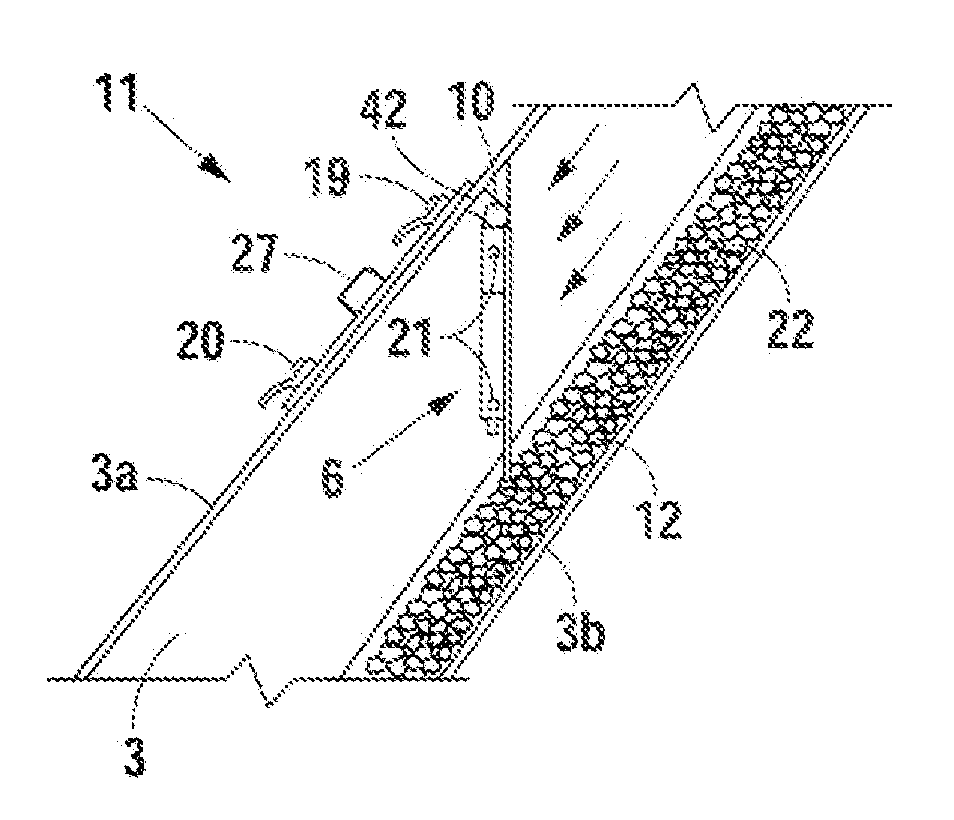

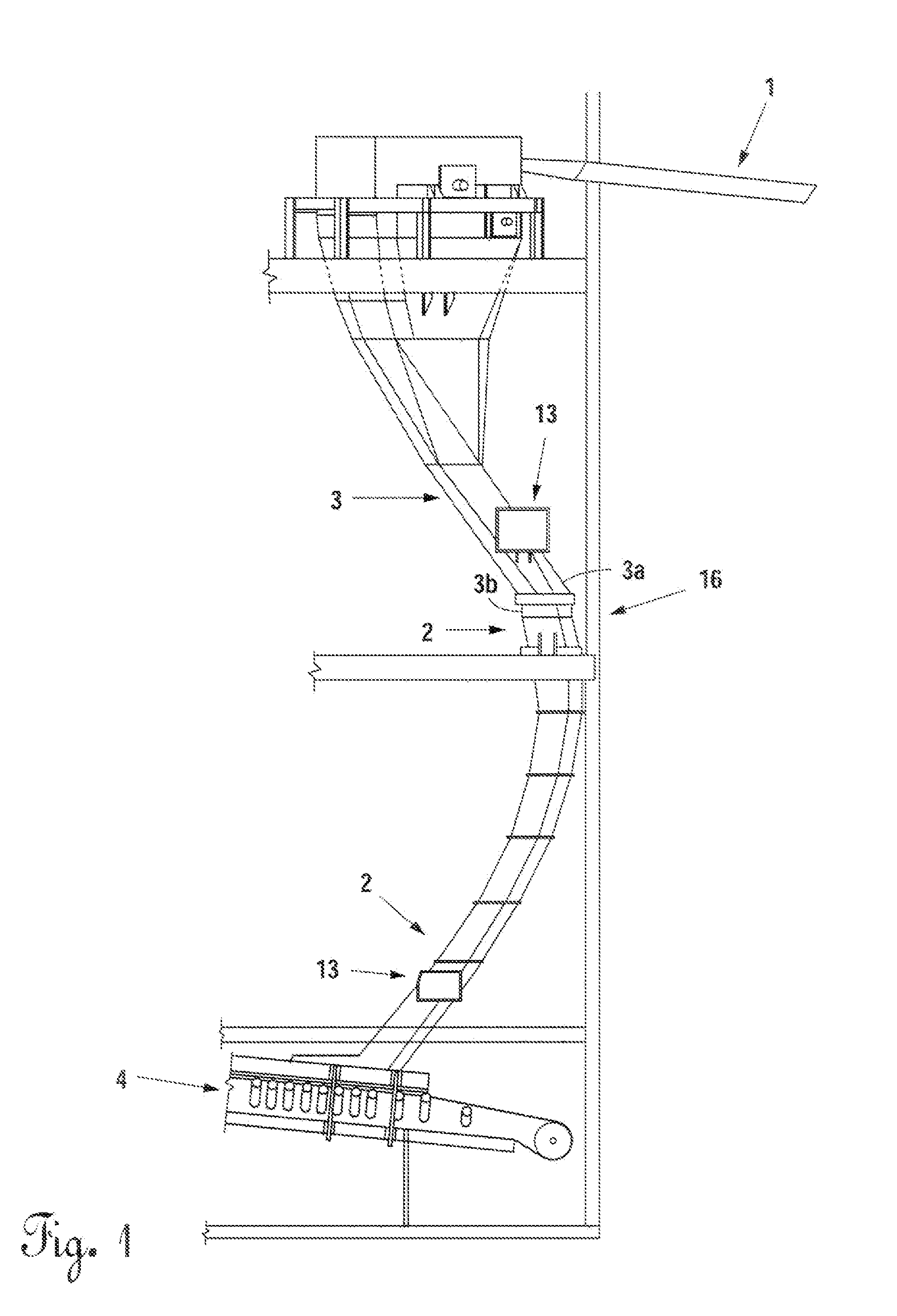

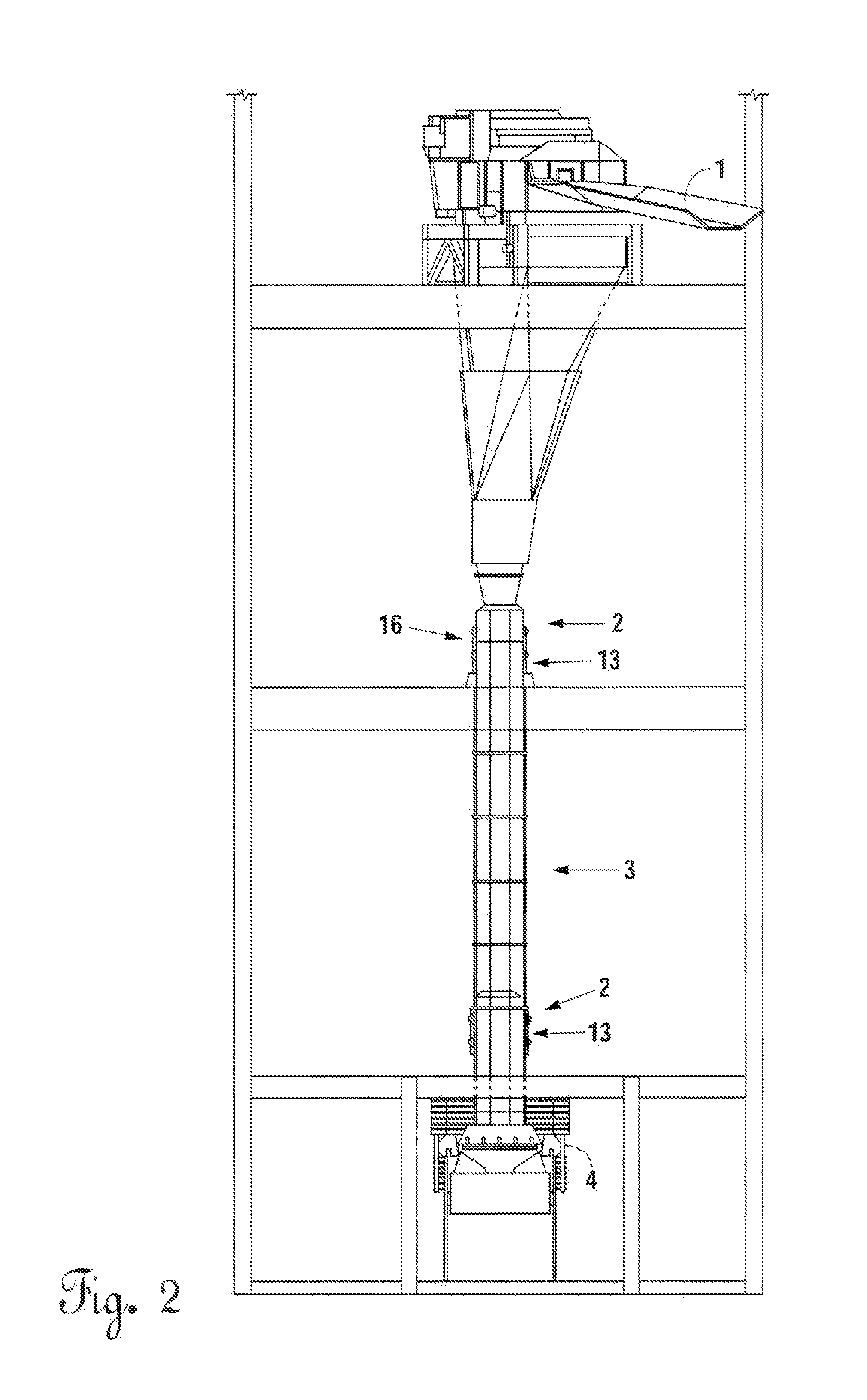

Apparatus and Method for Passive Dust Control in a Transfer Chute

InactiveUS20120090956A1Minimize air flowReduce dust emissionsLoading/unloadingConveyor partsTransfer systemDust control

A dust control apparatus and method for a bulk material handling transfer system having a chute comprising a pathway there through for handling varying volumes of bulk material flowing through the chute using gravity flow. A self-adjusting air restrictor gate is mounted in the chute for engaging the upper surface of flowing bulk material through the chute for restricting the air pathway during material volume flow variations to reduce dust emissions. The gate member contacts the upper surface of flowing bulk material and moves up and down in response to the flow of bulk material through the chute to restrict the flow of air to reduce dust. A counterweight mechanism and a damper helps maintain controlled contact of the air restrictor gate with the upper surface of bulk material flowing through the chute.

Owner:BROBST STEVEN HAYS

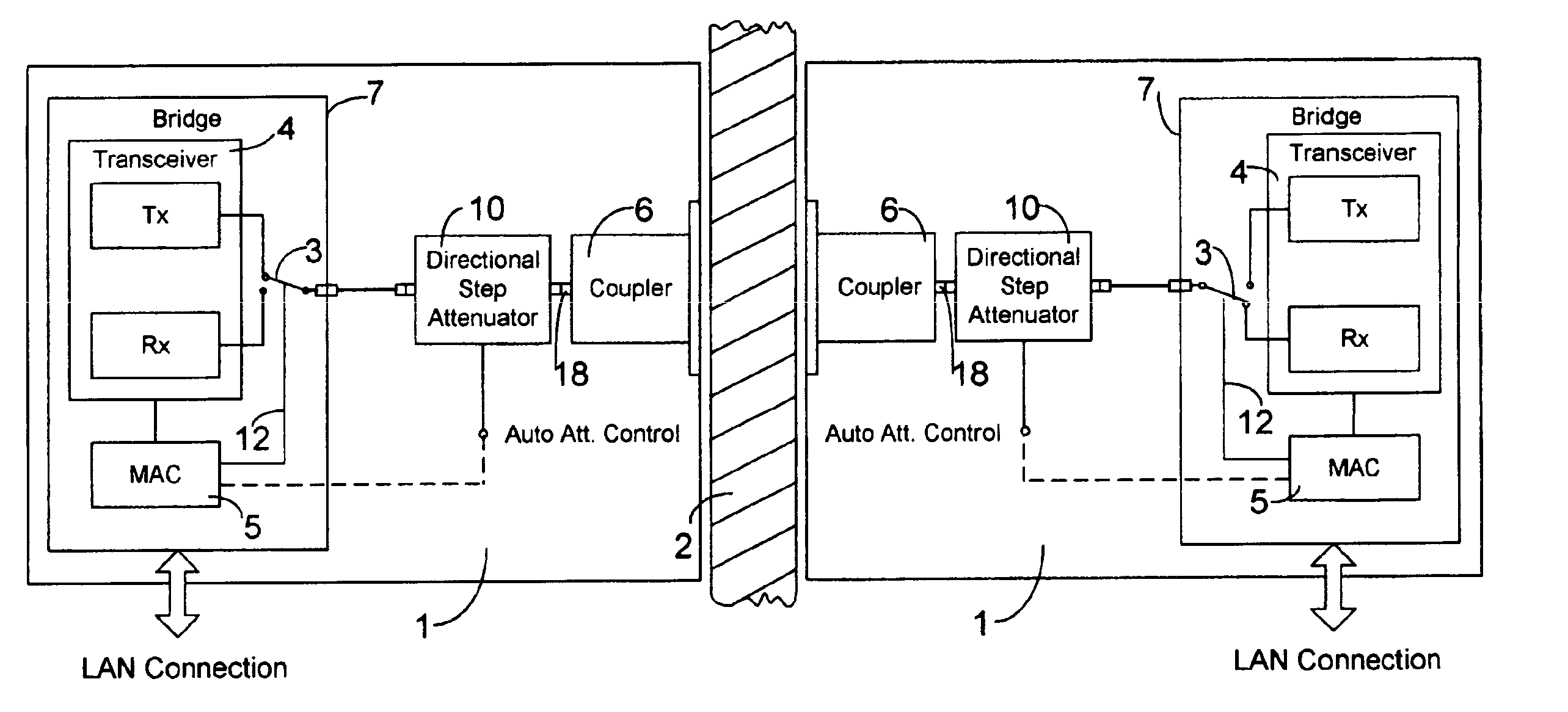

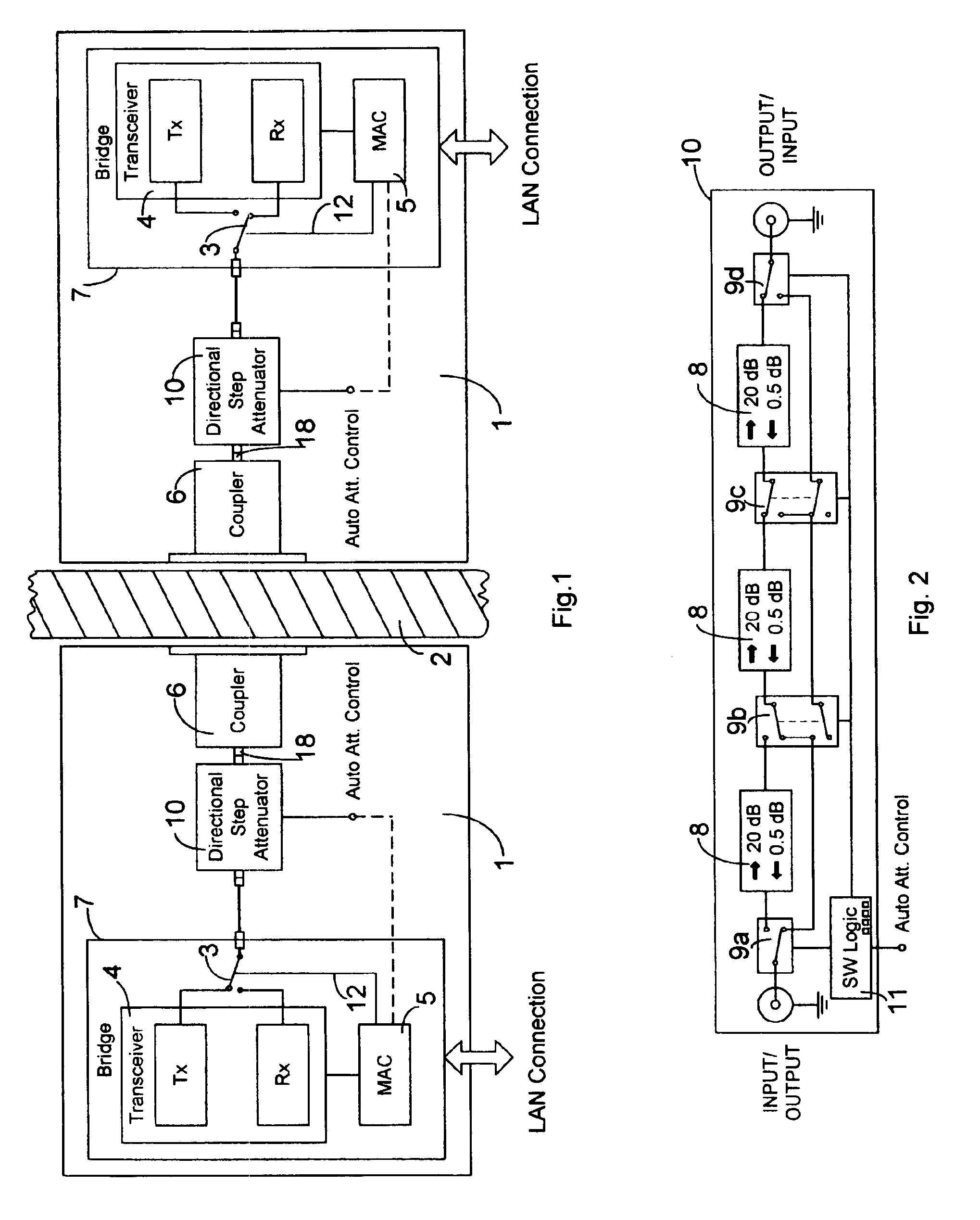

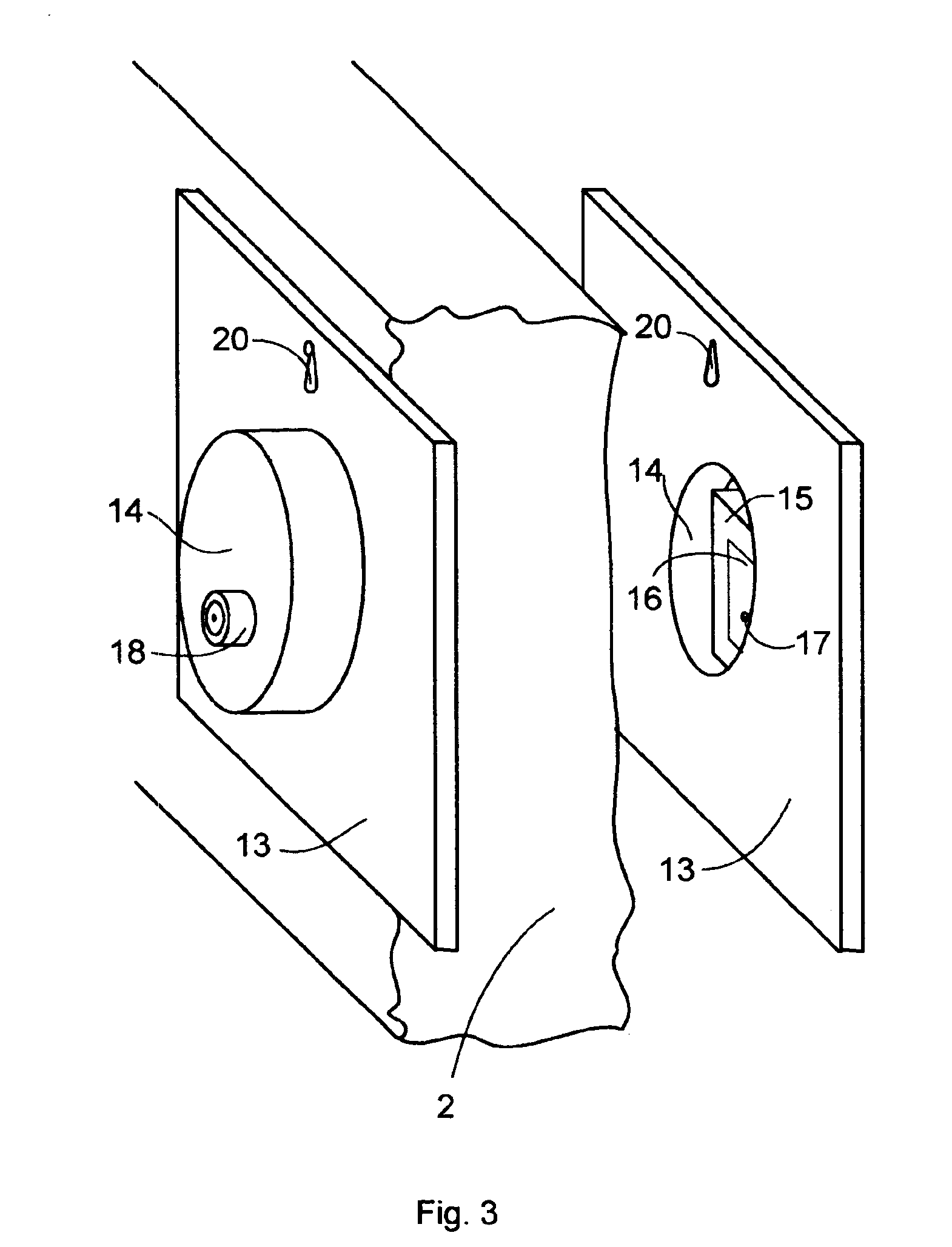

Electromagnetic coupler system

InactiveUS6963305B2Simplify and optimize operationLow powerMultiple-port networksEnergy efficient ICTElectromagnetic couplingEngineering

This invention makes it possible to communicate through solid non-metallic walls or ceilings with low microwave power levels. RF beam forming couplers are driven by common networks.For connection to a LAN segment at the other side of a wall or ceiling, transceiver 4 transmits data modulated microwave RF to coupler 6 through a directional step attenuator 10. The reduced signal is received by the coupler system at the other side with a power level low enough to eliminate wireless detection from the outside. However, the directional step attenuator on the receive side reduces the signal power only by an insignificant amount due to its low directional losses during receive signal flow. Each coupler's geometry is minimizing the radiation exposed material volume by RF field concentration, therefore, enabling transmission through thick concrete walls at microwave frequencies without compromising privacy. When used as wireless access point, coupler transmits through a floor to wireless devices below. The preferred embodiment operates in the 5-GHz ISM band.

Owner:KNAPP GUENTHER

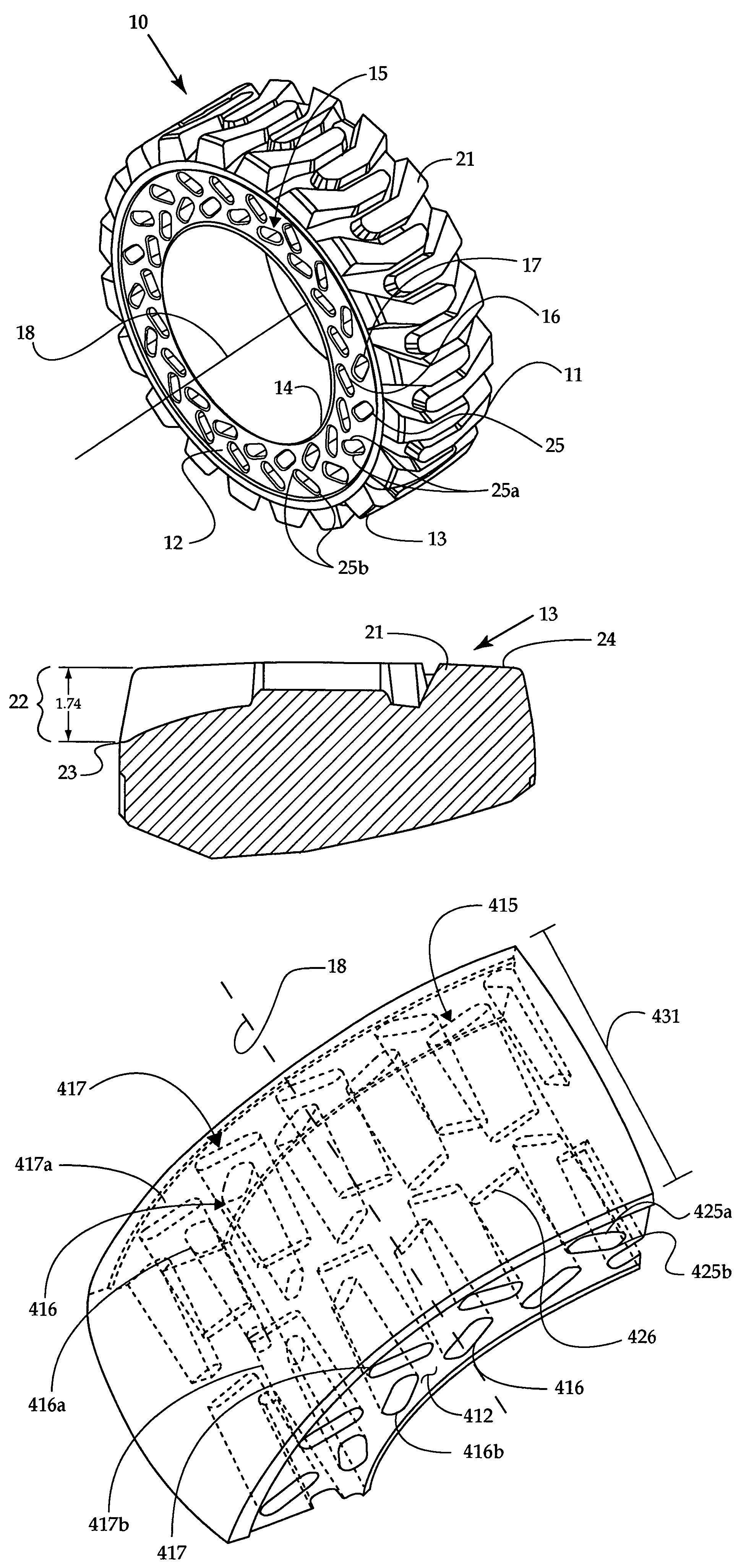

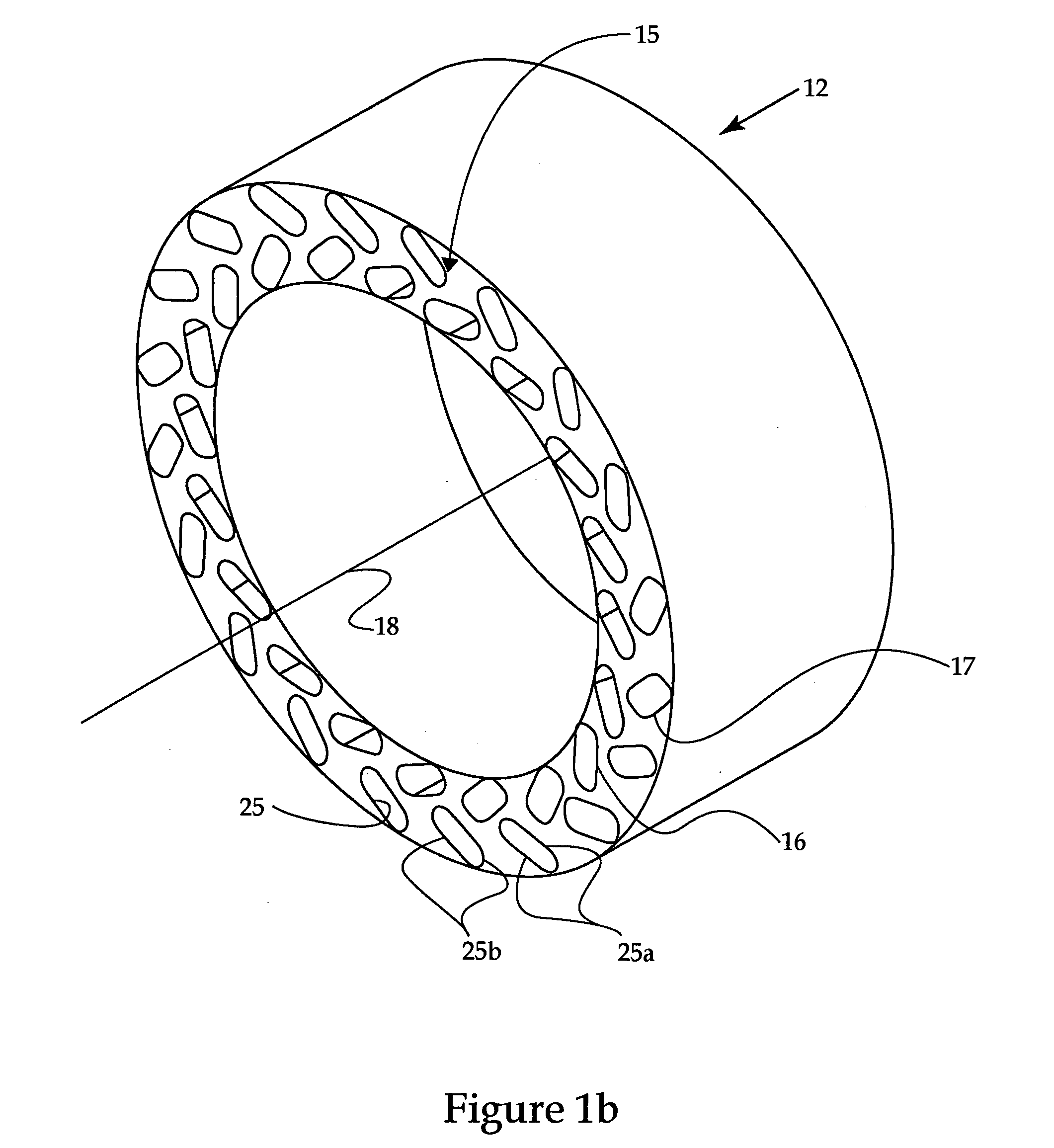

Solid suspended work machine tire

A work machine tire includes an annular body of elastomeric material that includes a middle radial region. A plurality of unpressurized cavities are defined by the middle radial region and are distributed in a pattern that includes a first radial band of cavities and a second radial band of cavities. Each cavity of the first radial band of cavities is oriented at a positive angle with respect to a radius therethrough, and each cavity of the second radial band of cavities is oriented at a negative angle with respect to a radius therethrough. A material volume of the middle radial region is more than one and a half times greater than the combined void volume of the plurality of cavities.

Owner:CATERPILLAR INC

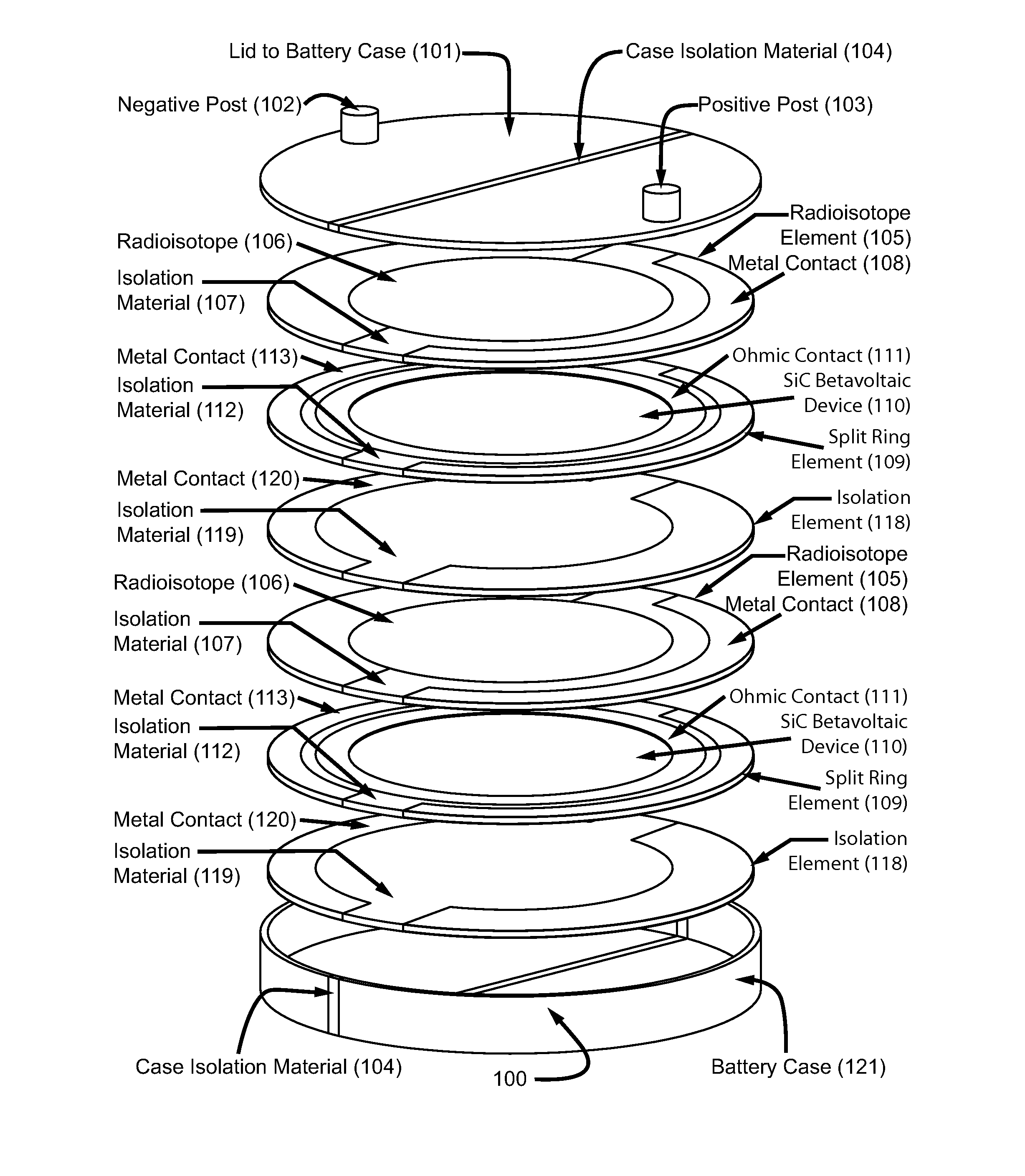

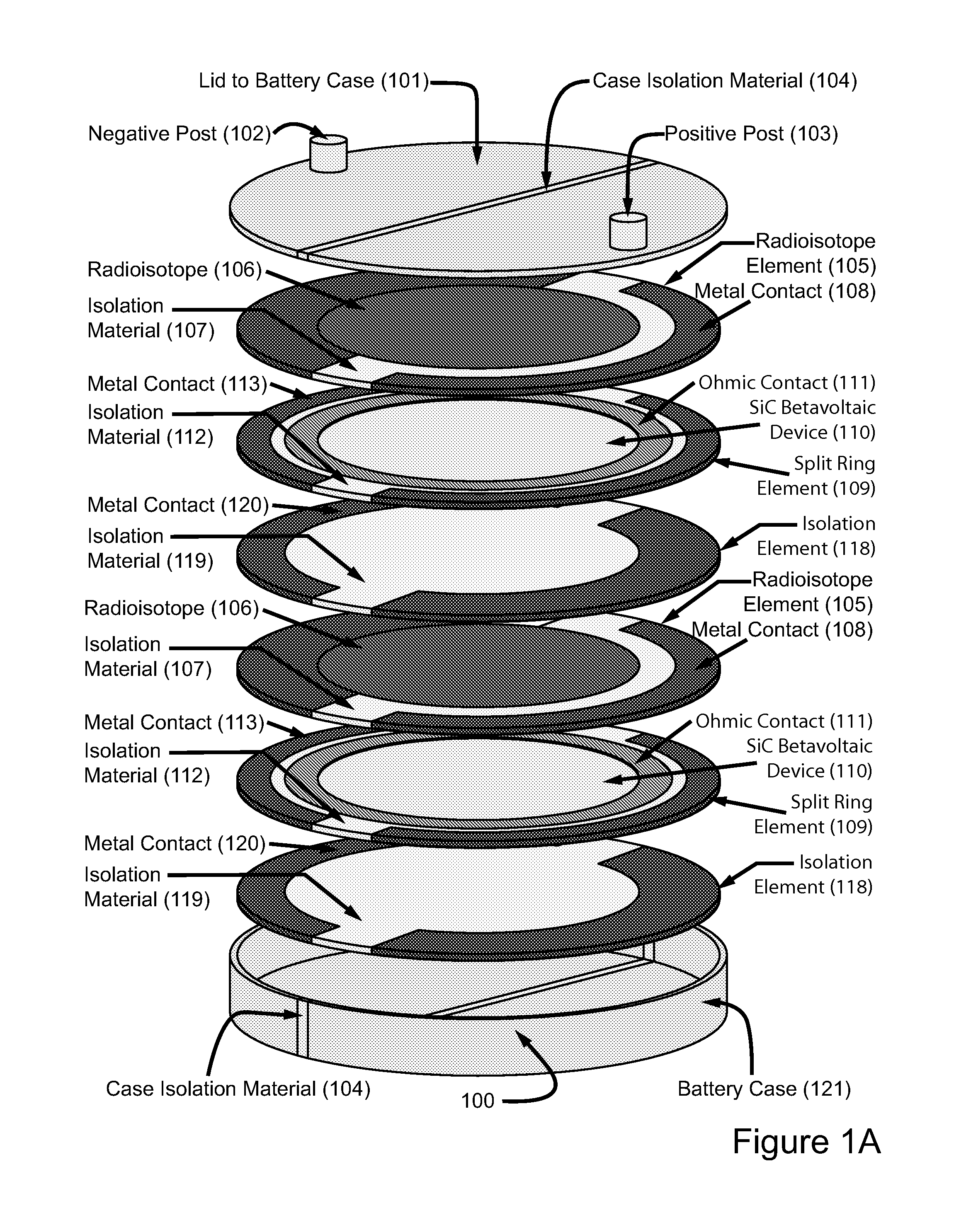

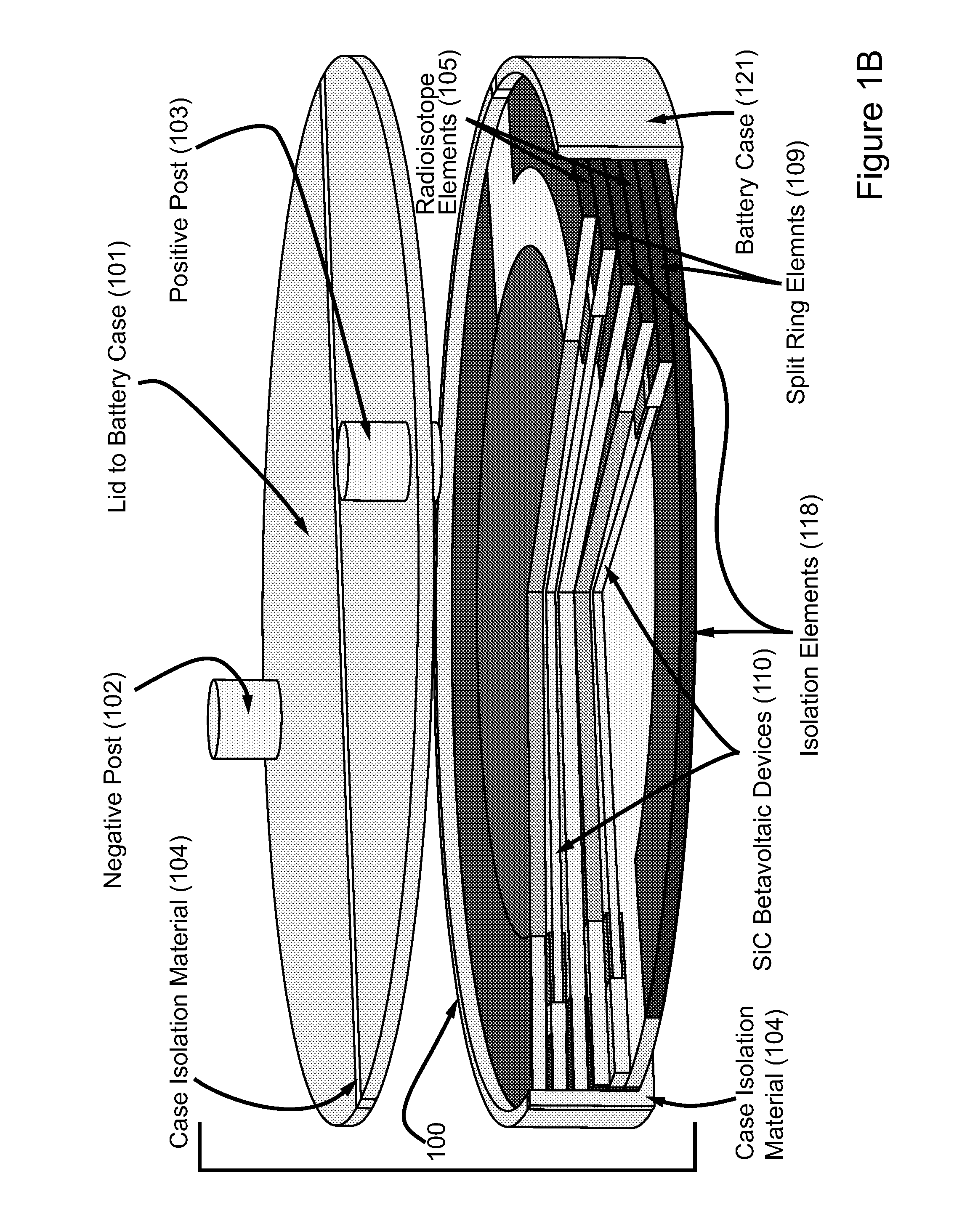

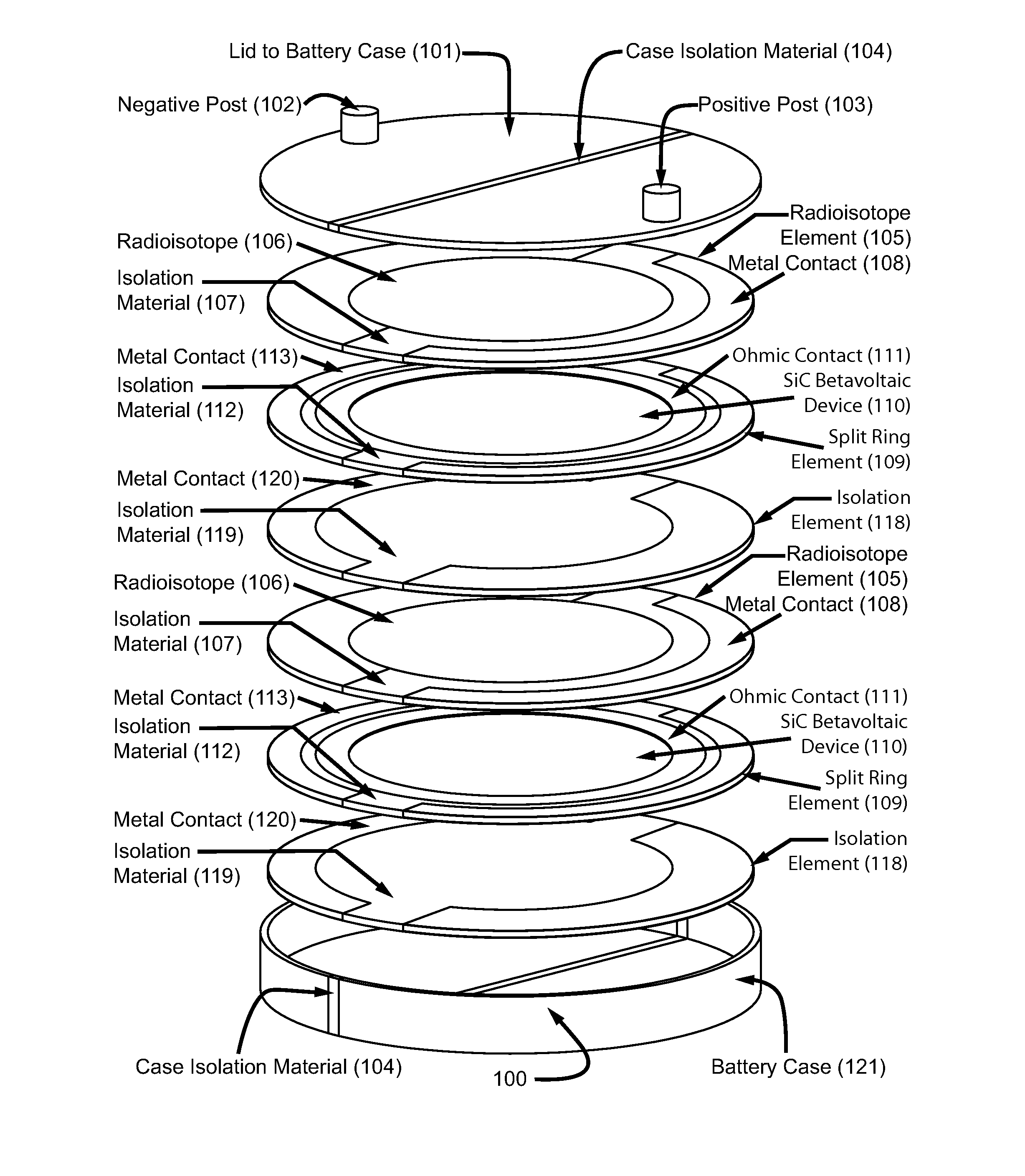

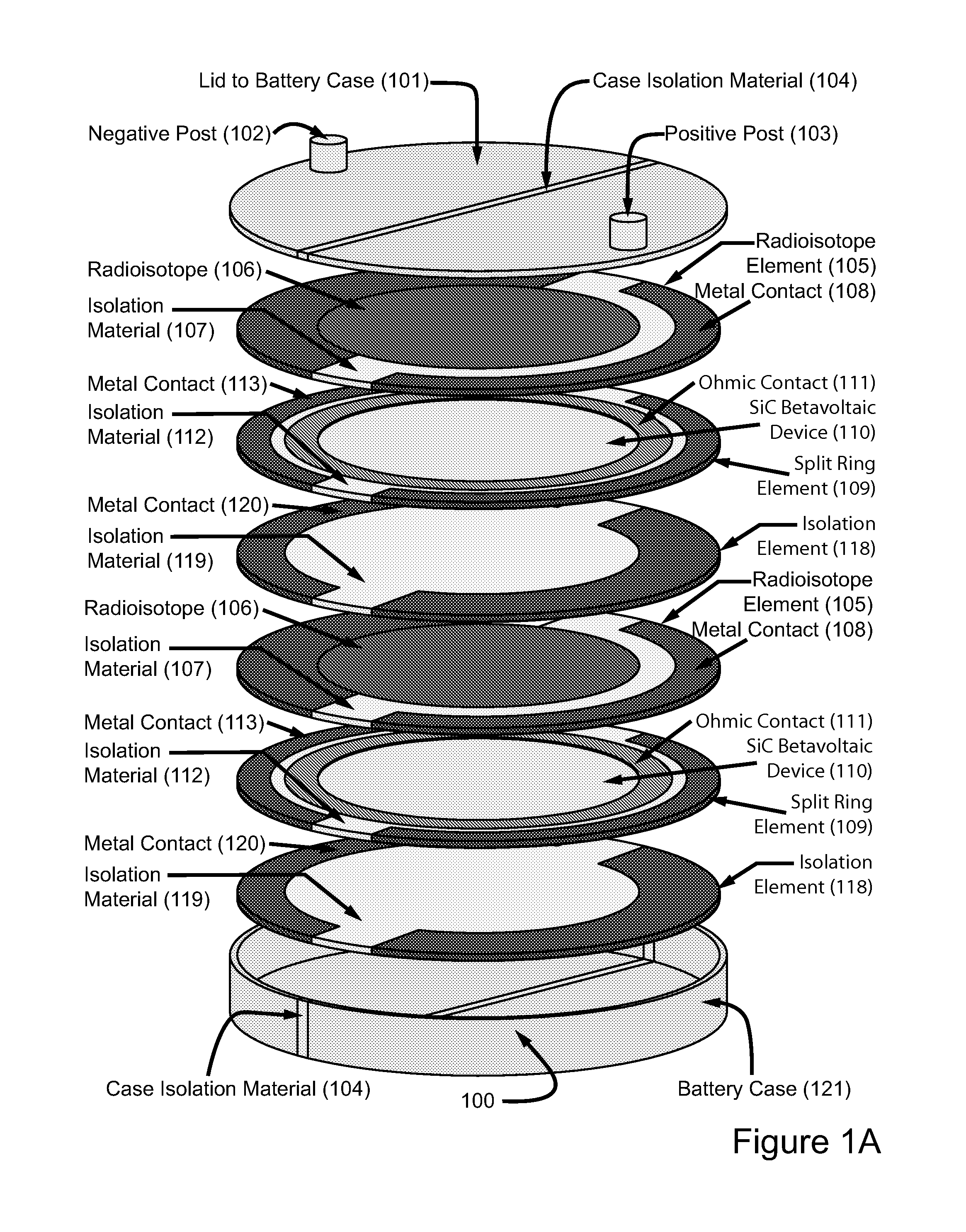

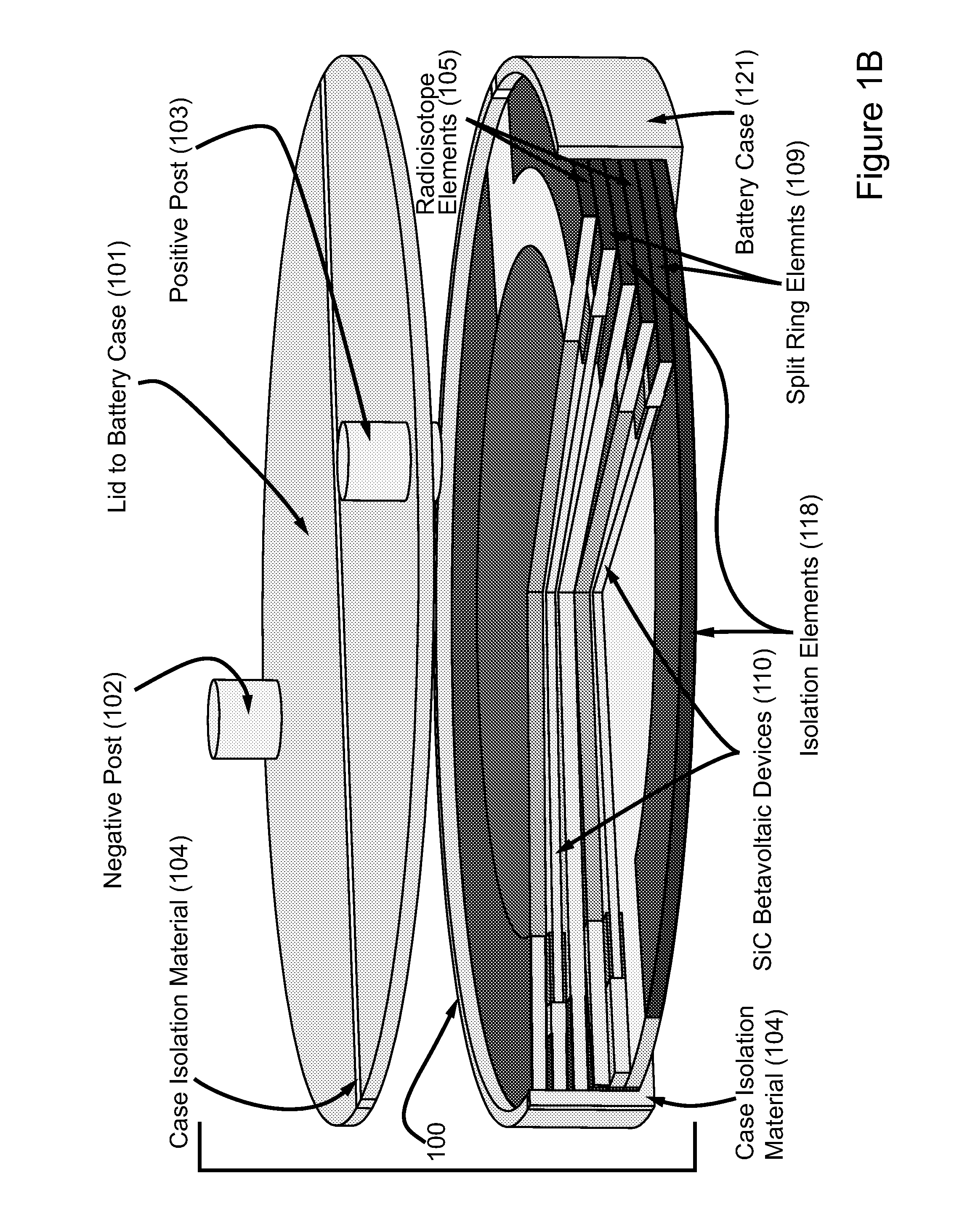

High power density betavoltaic battery

ActiveUS20110031572A1Improve power densitySolid-state devicesSemiconductor/solid-state device manufacturingBetavoltaicsSemiconductor materials

To increase total power in a betavoltaic device, it is desirable to have greater radioisotope material and / or semiconductor surface area, rather than greater radioisotope material volume. An example of this invention is a high power density betavoltaic battery. In one example of this invention, tritium is used as a fuel source. In other examples, radioisotopes, such as Nickel-63, Phosphorus-33 or promethium, may be used. The semiconductor used in this invention may include, but is not limited to, Si, GaAs, GaP, GaN, diamond, and SiC. For example (for purposes of illustration / example, only), tritium will be referenced as an exemplary fuel source, and SiC will be referenced as an exemplary semiconductor material. Other variations and examples are also discussed and given.

Owner:WIDETRONIX

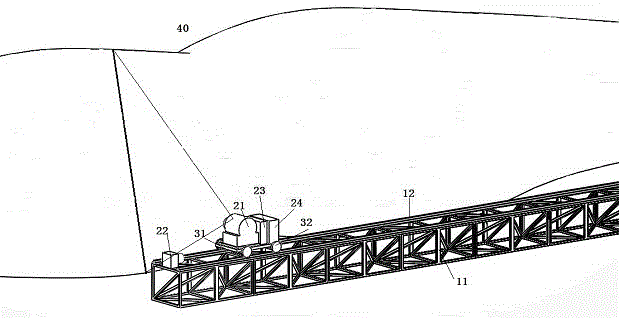

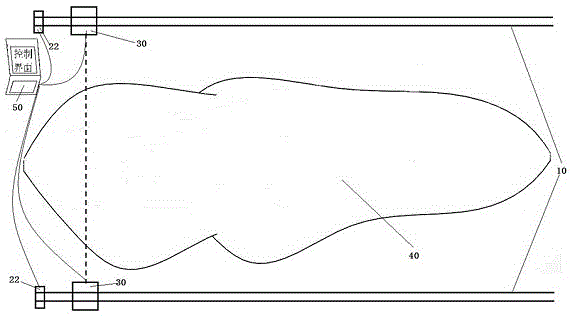

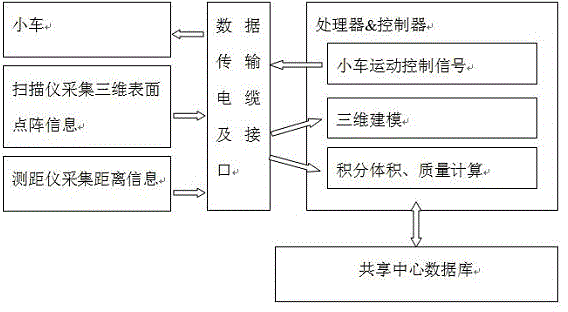

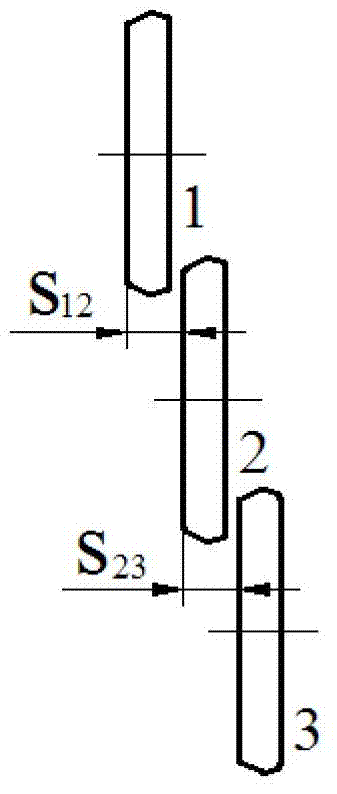

Large-scale piled material volume two-side parallel measuring device and method

The invention relates to a large-scale piled material volume two-side parallel measuring device and method. In the method, a laser scanner and a laser distance measuring sensor are adopted to cooperate with each other to synchronously collect material pile contour information. The laser scanner is installed on a trolley capable of conducting stable and uniform motion. In the moving process, the laser scanner constantly scans the material pile contour information, the laser distance measuring sensor collects motion displacement of the laser scanner, and two groups of synchronous information forms three-dimensional contour information of a material pile. The trolley moves on a specific track, so that stable motion is achieved. The measuring device is specifically arranged in the mode that two sets of measuring equipment are installed on the two sides of the material pile in parallel respectively so that the material pile contour information can be completely scanned. The collected material pile contour information is transmitted to a PC, the appearance and the volume of the material pile are reconstructed in an integral reconstruction mode, and consequently the volume measurement of large-scale piled materials are achieved. In addition, data obtained through measurement are received by an administrator so that the administrator can make corresponding decisions timely; therefore, the large-scale piled material volume two-side parallel measuring device and method provide a technical support for an enterprise to manage the large-scale piled materials.

Owner:SHANGHAI UNIV

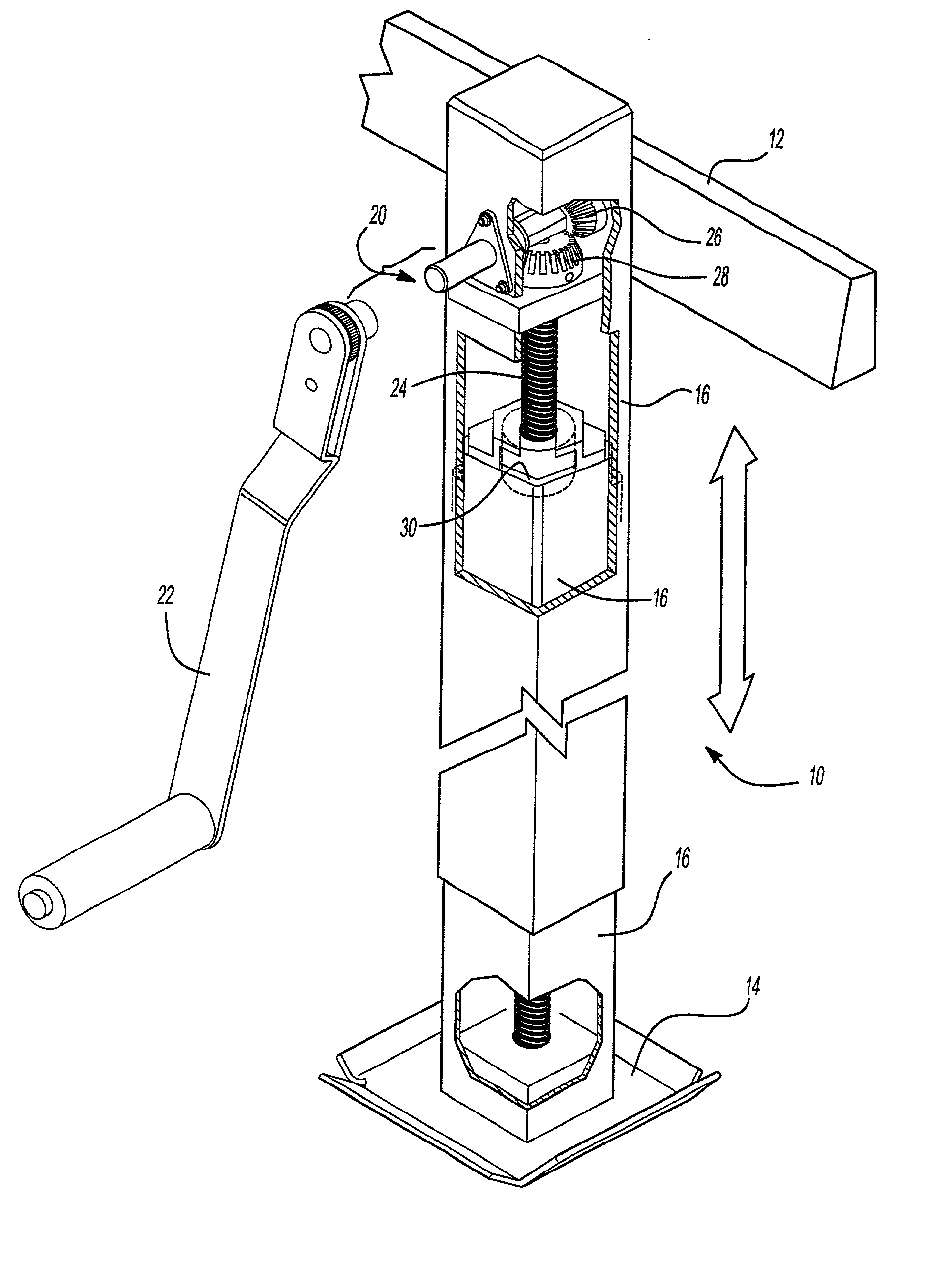

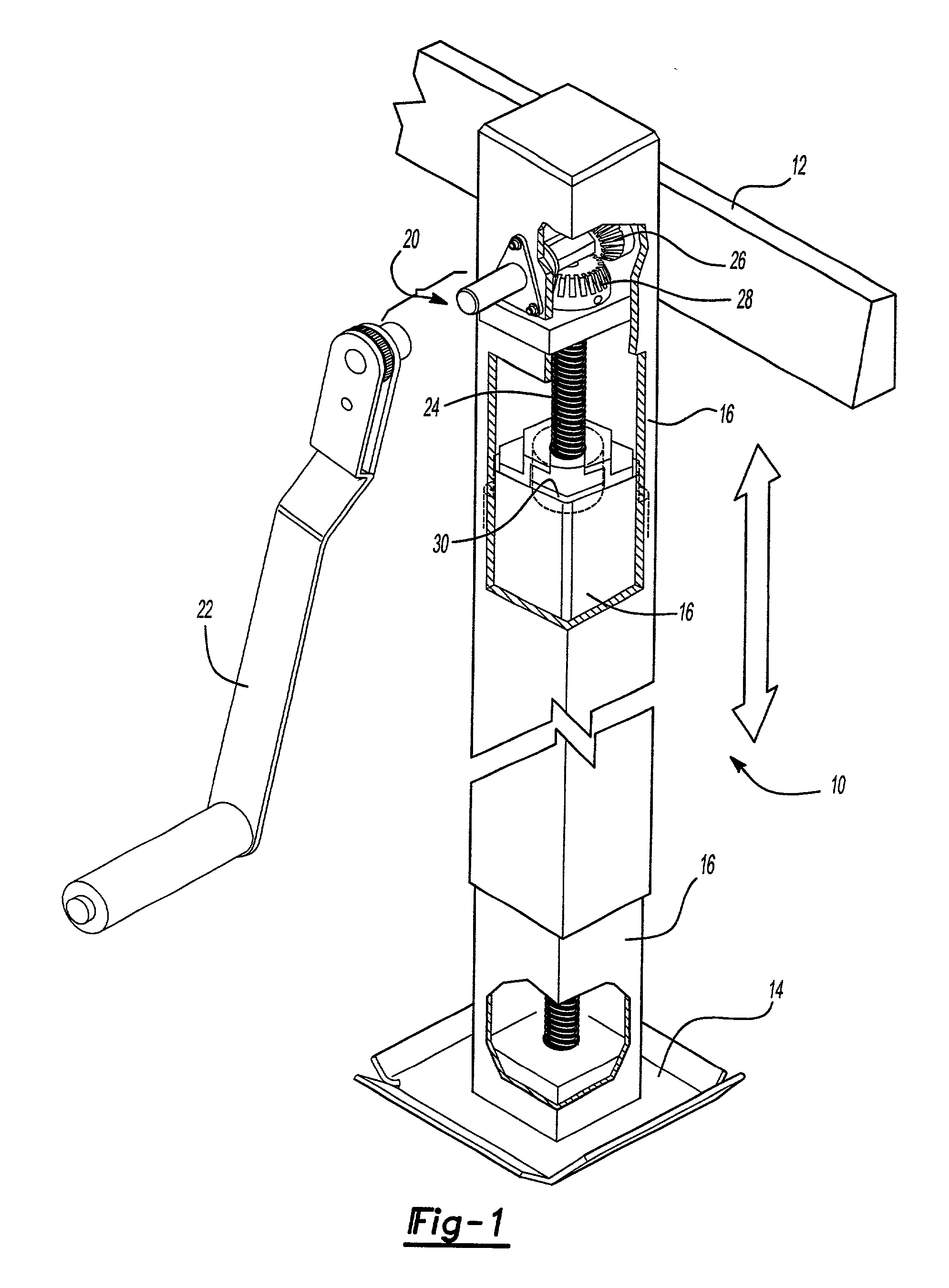

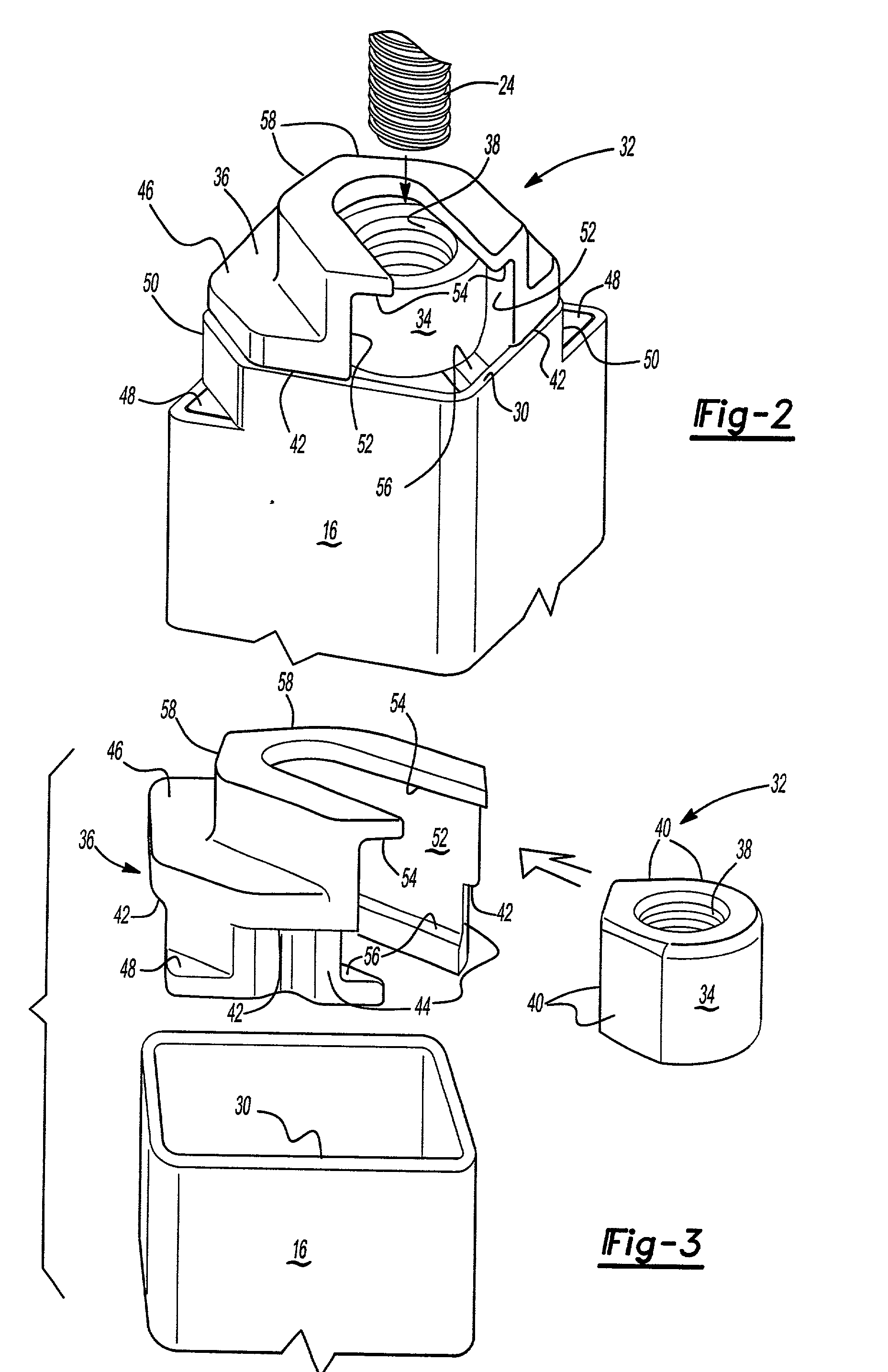

Screw nut holder for heavy-duty jack assembly

InactiveUS20030089898A1Low costOvercome disadvantagesVehicle fittings for liftingVehicle cleaning apparatusJackscrewEngineering

A jack assembly for altering the height of an object such a recreational vehicle. The jack includes an outer tube secured to the vehicle and an inner tube having a ground engaging portion and telescopingly received within the outer tube. An axial screw operably connected to a crank at the top of the jack extends through the tubes for altering the length of the jack. The screw threadably engages a screw nut mounted within the inner tube. In order to reduce the material volume of the screw nut, the nut is positionally captured within a retainer seated within the lower tube The retainer is configured to seat within the upper end of the lower tube and includes a slot for receiving the screw nut. The nut and the retainer include corresponding flats to prevent rotation of the nut within the retainer.

Owner:CEQUENT TRAILER PRODS

High power density betavoltaic battery

ActiveUS20110298071A9Solid-state devicesSemiconductor/solid-state device manufacturingBetavoltaicsSemiconductor materials

To increase total power in a betavoltaic device, it is desirable to have greater radioisotope material and / or semiconductor surface area, rather than greater radioisotope material volume. An example of this invention is a high power density betavoltaic battery. In one example of this invention, tritium is used as a fuel source. In other examples, radioisotopes, such as Nickel-63, Phosphorus-33 or promethium, may be used. The semiconductor used in this invention may include, but is not limited to, Si, GaAs, GaP, GaN, diamond, and SiC. For example (for purposes of illustration / example, only), tritium will be referenced as an exemplary fuel source, and SiC will be referenced as an exemplary semiconductor material. Other variations and examples are also discussed and given.

Owner:WIDETRONIX

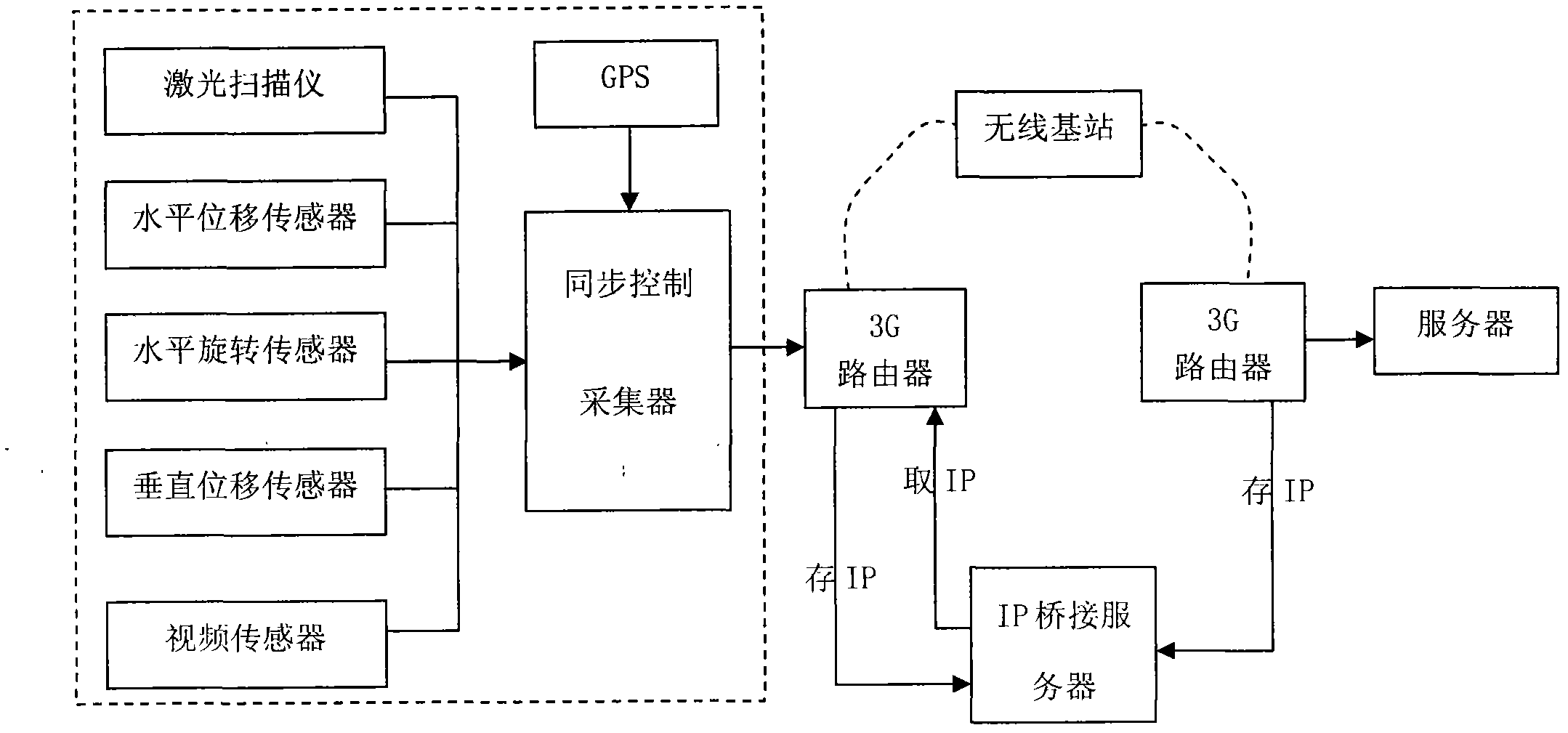

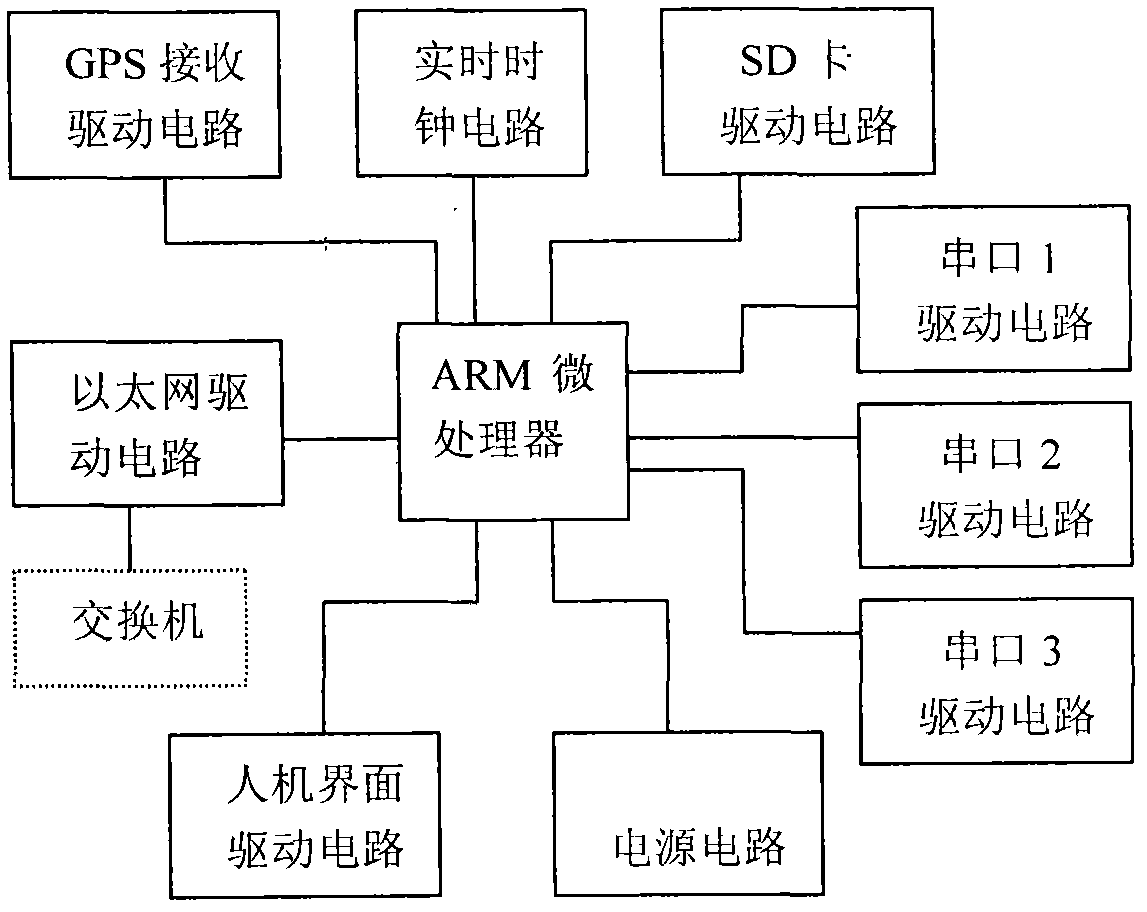

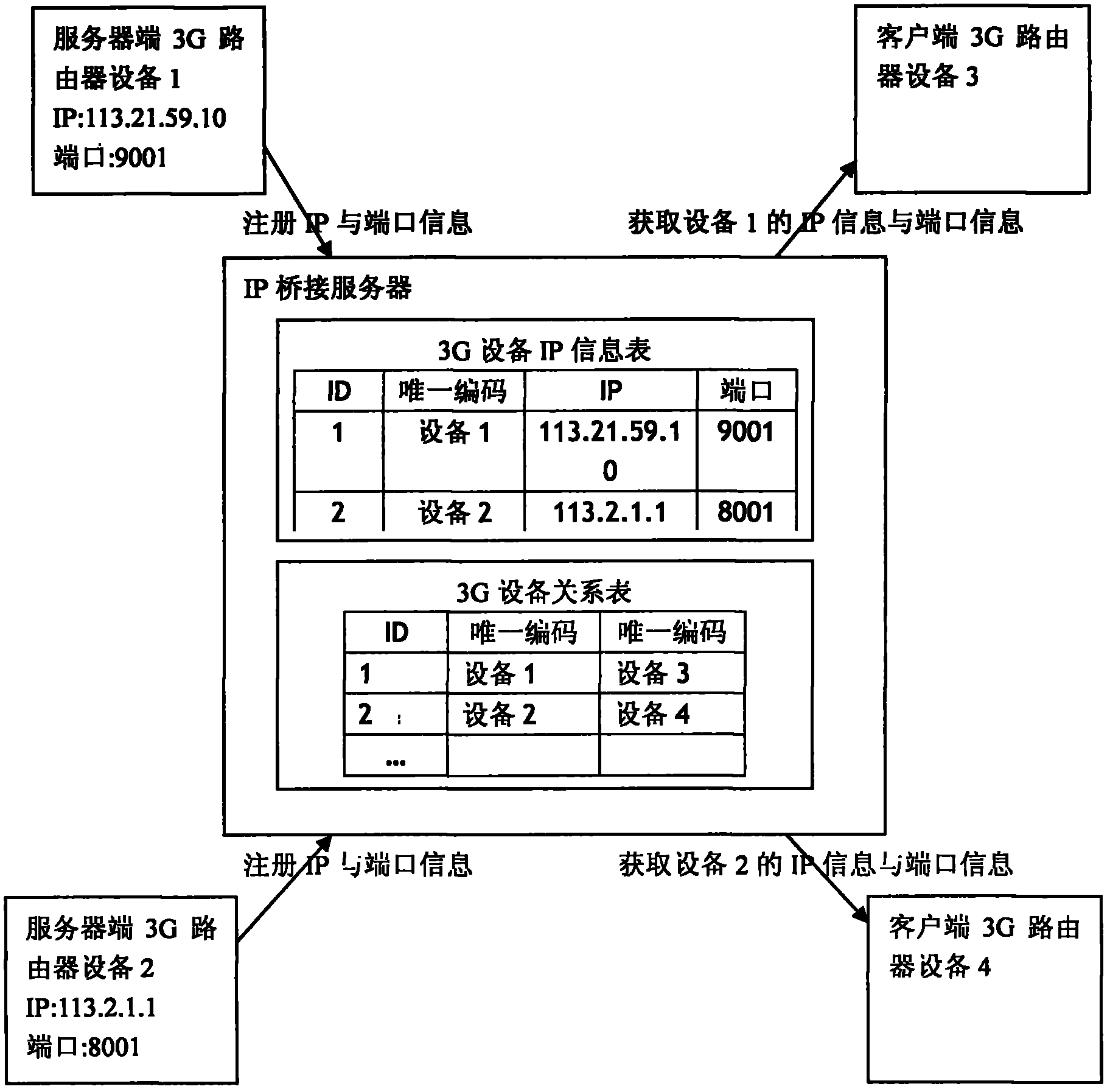

Automation storage yard laser measurement device and application method thereof

ActiveCN102425991ASolving Dynamic Interconnection ProblemsSolve the problem of three-dimensional coordinate settlementUsing optical meansData switching networksWireless controlMeasurement device

The invention relates to an automation storage yard laser measurement device and an application method thereof. In the invention, data acquisition can be realized by using a synchronous control collector which controls a plurality of sensors, a high speed laser scanner, a horizontal displacement sensor, a horizontal rotation sensor, a vertical displacement sensor and a video sensor. The collected data is preliminarily processed by a controller. The completely ineffective data is filtered. And after GPS module time service marking is used, the data is transmitted to a background server through an integrated 3G wireless communication module. Through upper computer software, a three dimensional coordinate calculation algorithm is used to calculate a three dimensional coordinate. A three dimensional modeling algorithm is used to carry out modeling. And then a material volume to be measured can be calculated. For a problem that working time sequences of the sensors are inconsistent, an annular buffer area technology is used to realize asynchronous data acquisition and storage. A dynamic interconnection problem of the 3G router equipment can be solved. A feasible scheme is provided for remote wireless control and implementation costs can be saved.

Owner:WUHAN WUDA ZOYON SCI & TECH

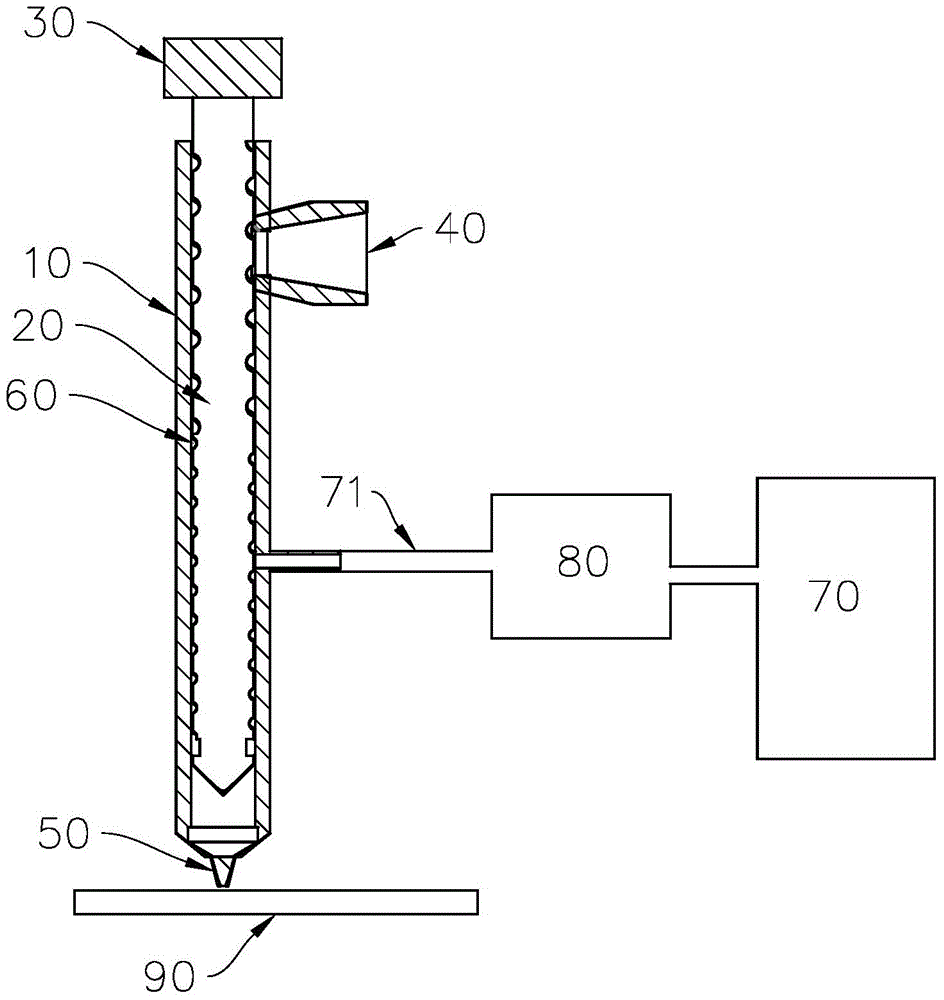

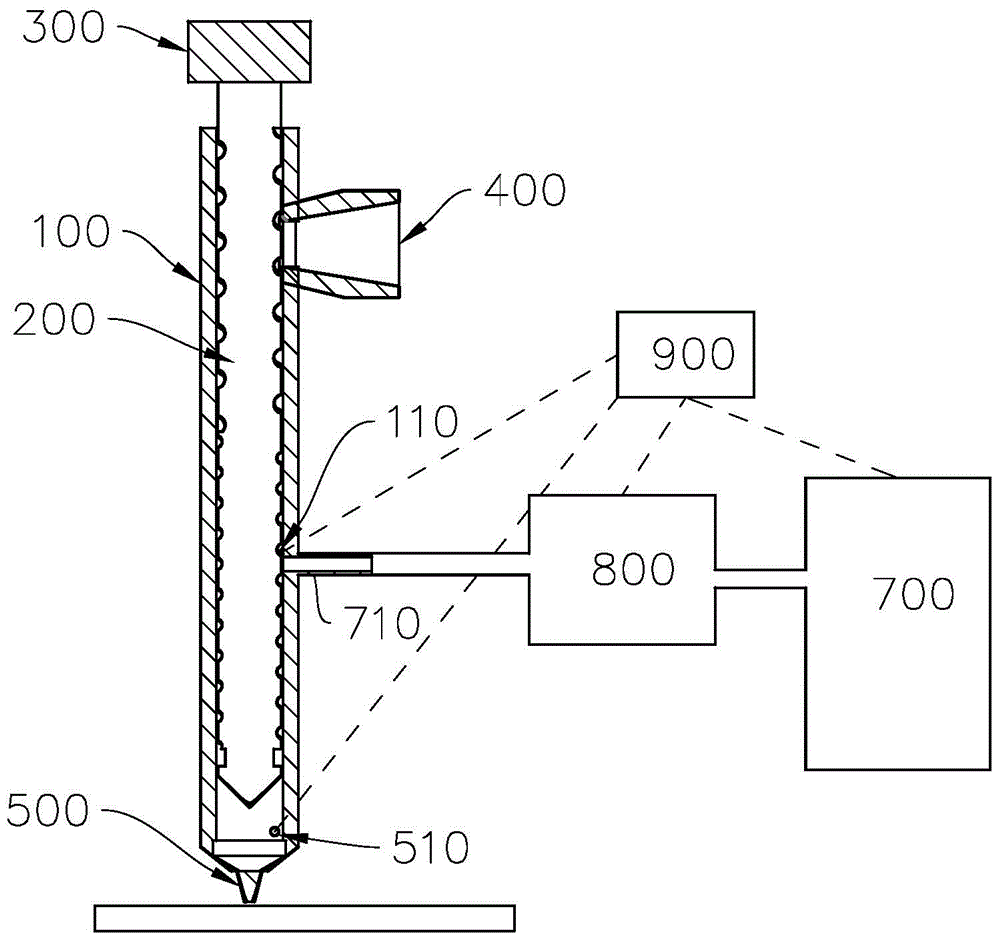

Three-dimensional printer and printing method and three-dimensional printing head

ActiveCN104875389ALow densityReduce the density valueAdditive manufacturing apparatusEngineeringVolumetric Mass Density

The invention relates to a three-dimensional printer, a three-dimensional printing head and a printing method. The three-dimensional printing head comprises a material volume cavity, wherein a screw rod is arranged in the material volume cavity, a motor is connected with the screw rod, a material supply device is communicated with the material volume cavity, a printing nozzle is arranged on the end part of the material volume cavity, a heater is arranged on the material volume cavity and positioned between the material supply device and the printing nozzle, and a supercritical fluid supply system is communicated with the material volume cavity. A molten printing material is mixed with supercritical fluid to generate a single-phase molten mixture under the mixing and stirring effect of the screw rod, and a uniform microporous bubble formation effect is formed, so that the density value of a printing object can be reduced, the size deviation of the three-dimensional printing object can be alleviated, the flatness and straightness of the three-dimensional printing object can be improved by more than 50 percent, the temperature for printing the molten printing material is effectively lowered, the energy is saved, and the operation personnel is prevented from being scalded.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Refrigerant releasing composite

ActiveUS20060147710A1Increase pressureAvoid ignitionLiquid surface applicatorsReactive armourFiberAlkaline earth metal

A composite configured to release refrigerant therefrom comprises a substrate material comprising polarized fibers of glass, polyamide, phenylene sulfide, carbon or graphite having bonded thereon a metal compound comprising a complex compound of a polar gaseous refrigerant and a metal salt and / or a hydrated metal hydroxide and / or a metal hydroxide of a metal selected from the group consisting of alkali metal, alkaline earth metal, transition metal, zinc, cadmium, tin, aluminum, or two or more thereof, at a concentration of at least about 0.3 grams / cc of open substrate material volume, and a coating composition thereon configured to prevent release of internal gaseous refrigerant therethrough at ambient temperatures and pressure and capable of penetration of gaseous refrigerant therethrough from the composite interior at temperatures causing internal gas pressures of 15% or more above exterior pressure for such refrigerant release.

Owner:ROCKY RES

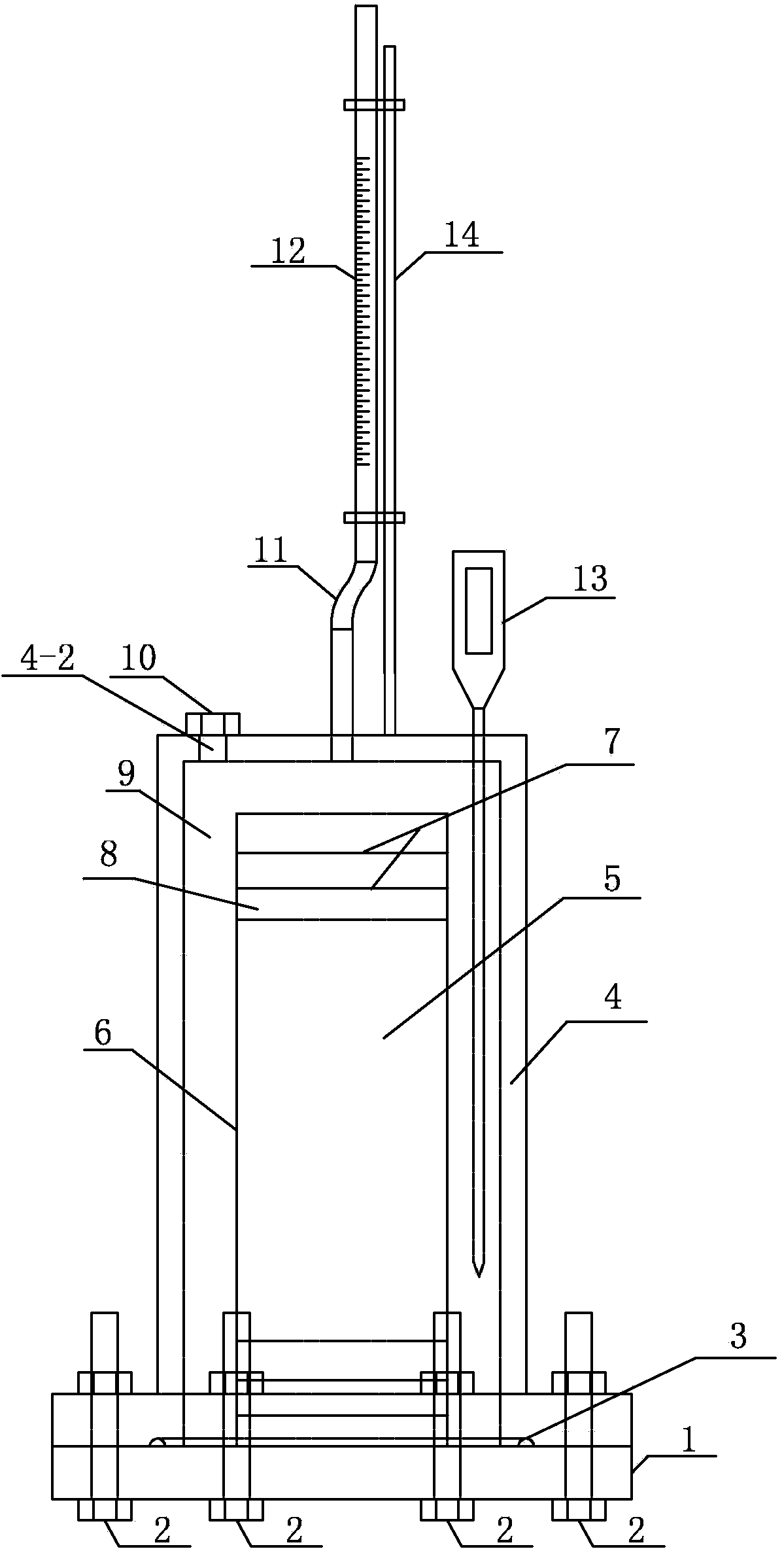

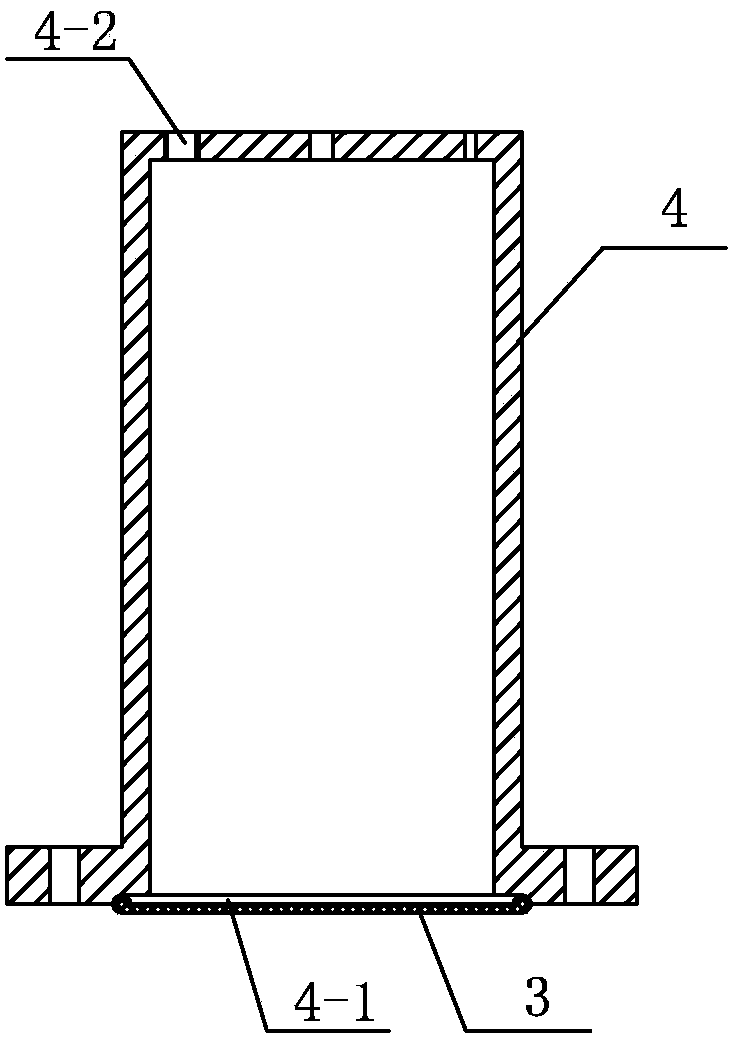

Civil engineering material volume change test instrument and test method

ActiveCN104007135AHigh measurement accuracyHigh precisionMaterial thermal coefficient of expansionRubber ringVolume variation

The invention relates to a civil engineering material volume change test instrument and a test method, in particular to a material volume change test device and test method in civil engineering. According to the test instrument, a sealing rubber ring is arranged in an annular groove, a base is covered with an upper cover, an air intake and exhaust hole is formed in the top end of the upper cover, one end of a probe thermometer is arranged in the upper cover, the other end of the probe thermometer is arranged outside the upper cover, a plastic pipe is arranged on the upper end face of the upper cover and communicated with a cavity, and a graduated glass pipe is communicated with the plastic pipe. The test method comprises the steps that first, a civil engineering material test piece is prepared; second, the volume of the civil engineering test piece before a test is calculated; third, the civil engineering test piece is installed; fourth, liquid is injected into the cavity; fifth, the temperature of the civil engineering test piece is measured in an initial temperature environment; sixth, the temperature of the civil engineering test piece is measured in a measuring temperature environment; seventh, the initial temperature and the measuring temperature of the test piece are measured, and the number of division of the test piece is calibrated; eighth, the volume variation theta Vt of the civil engineering test piece is calculated; ninth, the volume expansion coefficient lambda of the civil engineering test piece is calculated. The civil engineering material volume change test instrument and the test method are used for measuring the volume change situation of the civil engineering material.

Owner:HARBIN INST OF TECH

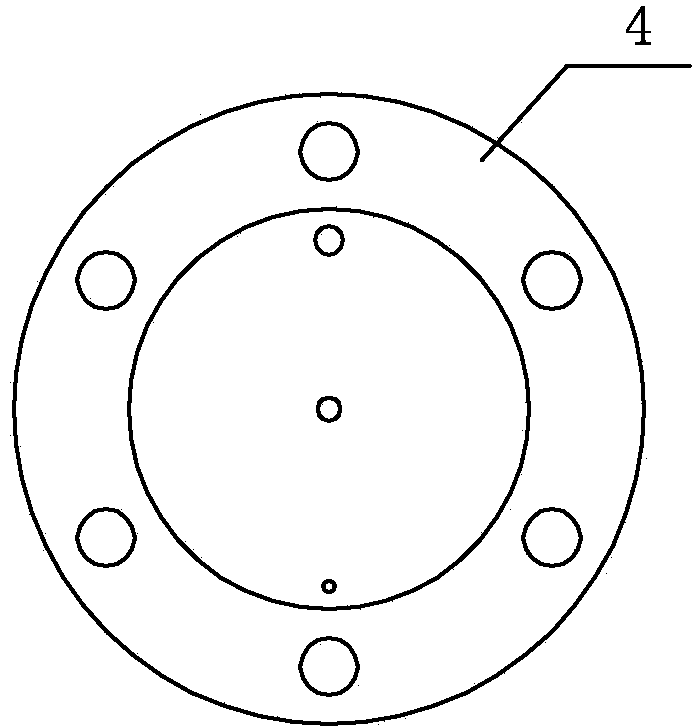

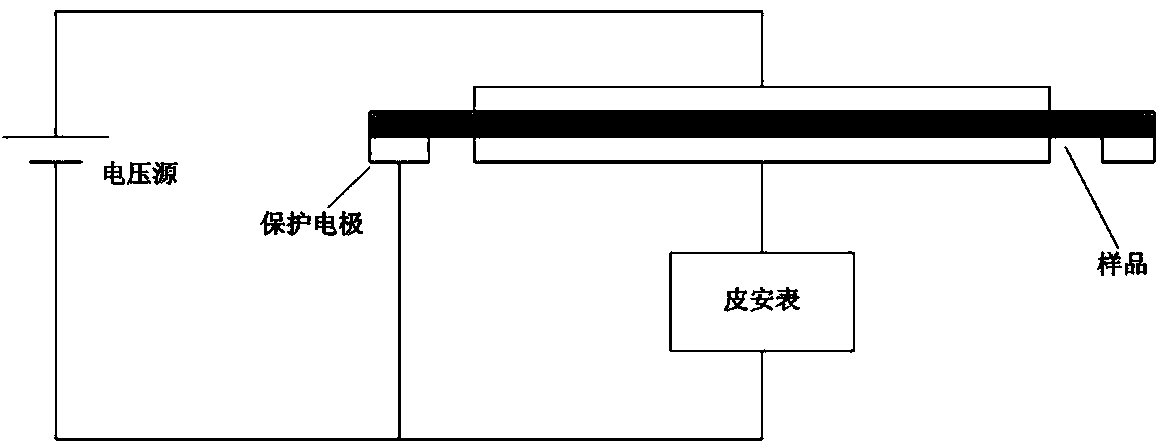

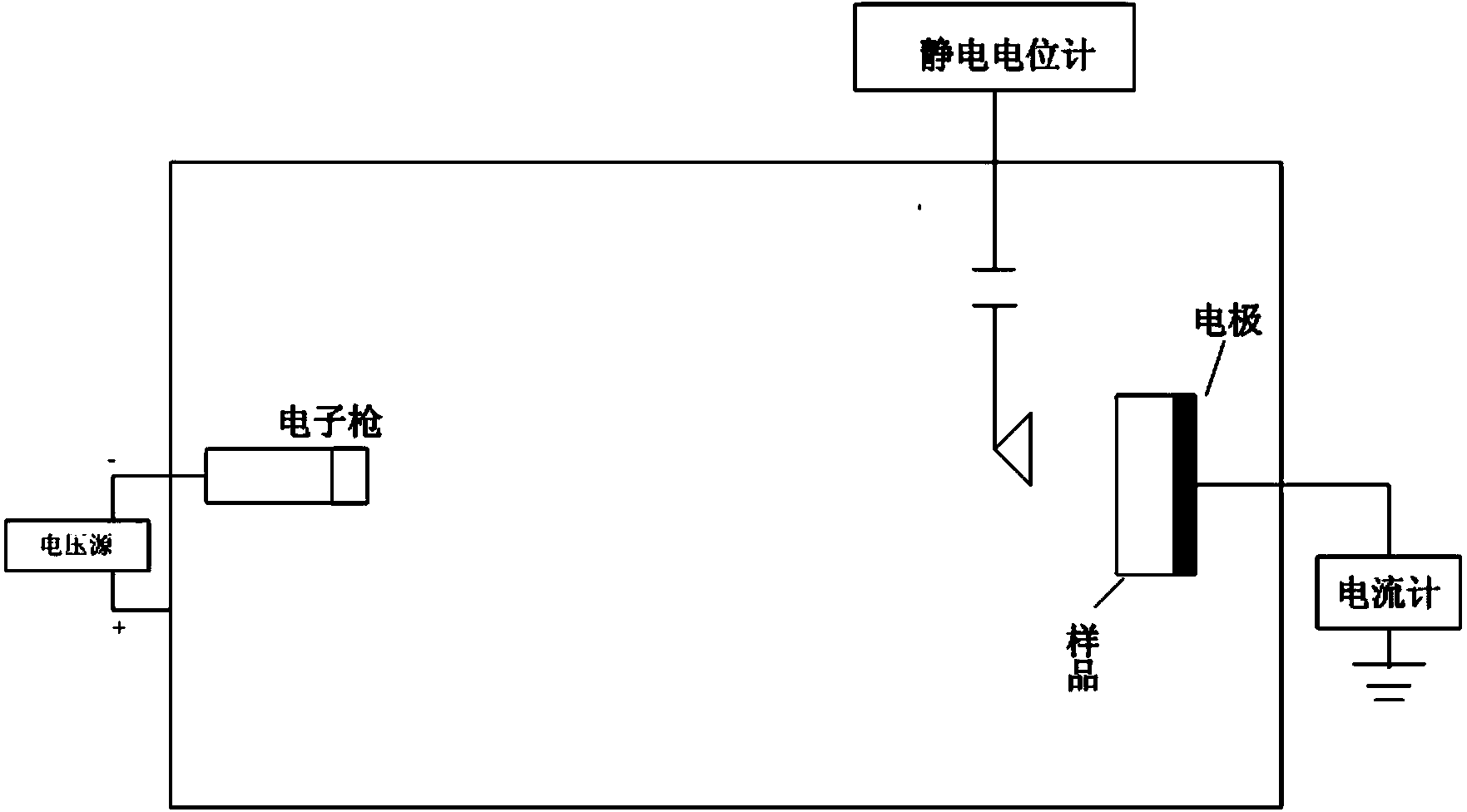

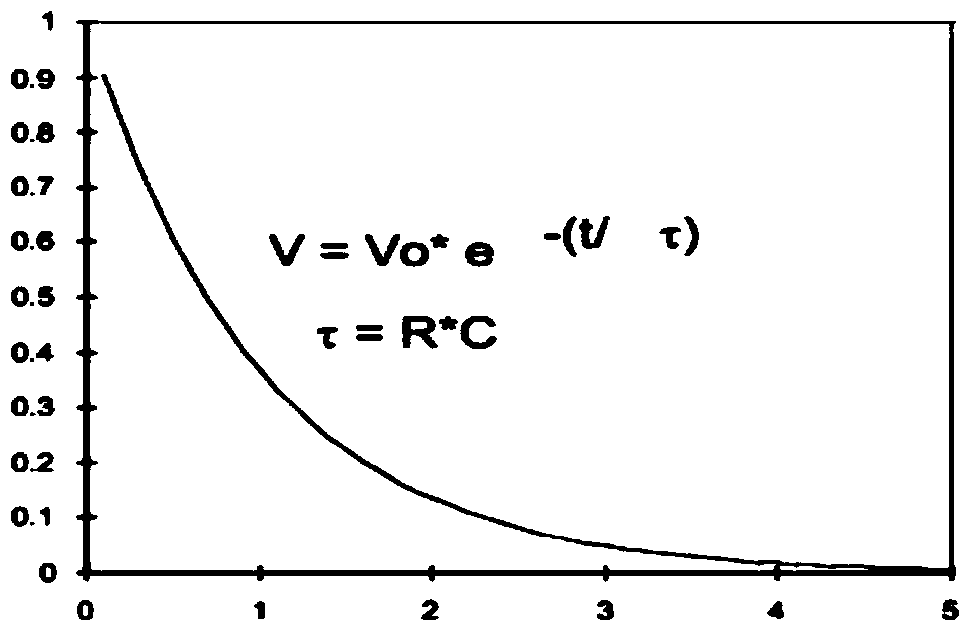

Device and method for measuring deep dielectric charging characteristic parameter of spacecraft dielectric material

InactiveCN103454315AApplicable assessmentEasy to measureResistance/reactance/impedenceMaterial impedanceDielectricDose rate

The invention provides a device and a method for measuring deep dielectric charging characteristic parameter of a spacecraft dielectric material. The device comprises a radiation source, a vacuum unit, a sample target table, a control unit, an electrostatic potentiometer, an electrometer, a total conductivity acquisition unit, a potential attenuation measurement unit, a first processing unit and a second processing unit, wherein the electrostatic potentiometer is used for measuring the surface potential of a sample medium under certain flux; the electrometer is used for measuring the leakage current of the sample under certain flux; the total conductivity acquisition unit is used for acquiring the total conductivity based on the measured surface potential and the leakage current; the first processing unit is used for obtaining dark conductivity values under all fluxes based on the obtained potential attenuation curve along with the passage of time and a charge storage attenuation method, and taking an average to obtain the dark conductivity Sigma O; the second processing unit is used for obtaining radiation induction conductivity corresponding to the dosage rate generated in material volume under two different kinds of beam intensity based on the obtained dark conductivity and the total conductivity, so as to obtain the related parameters Kp and the dimensionless exponent delta value of the sample material.

Owner:NAT SPACE SCI CENT CAS

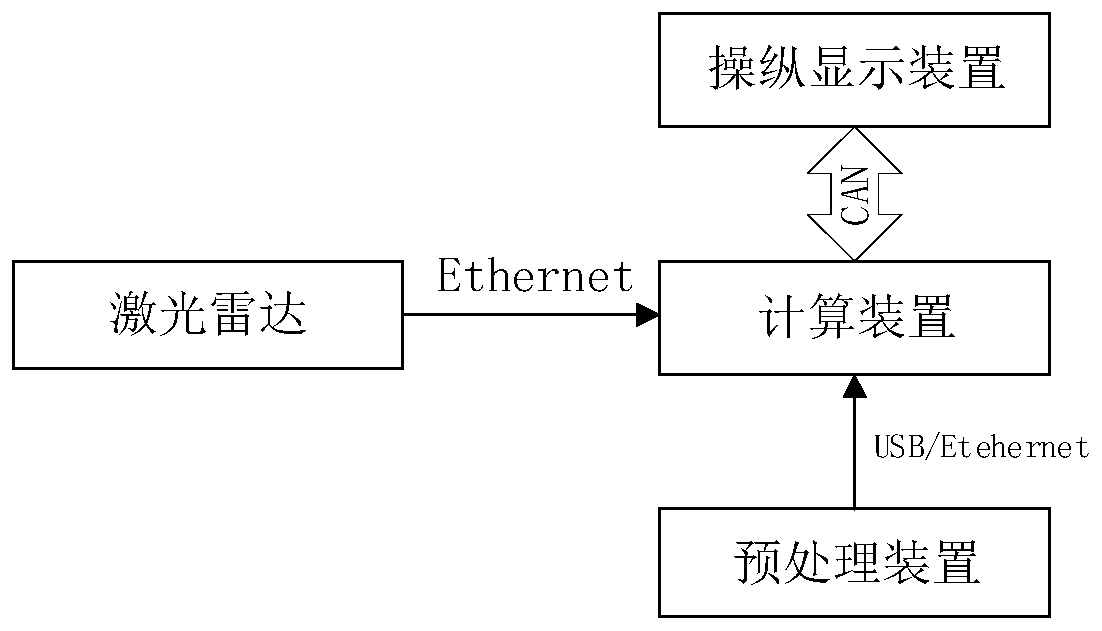

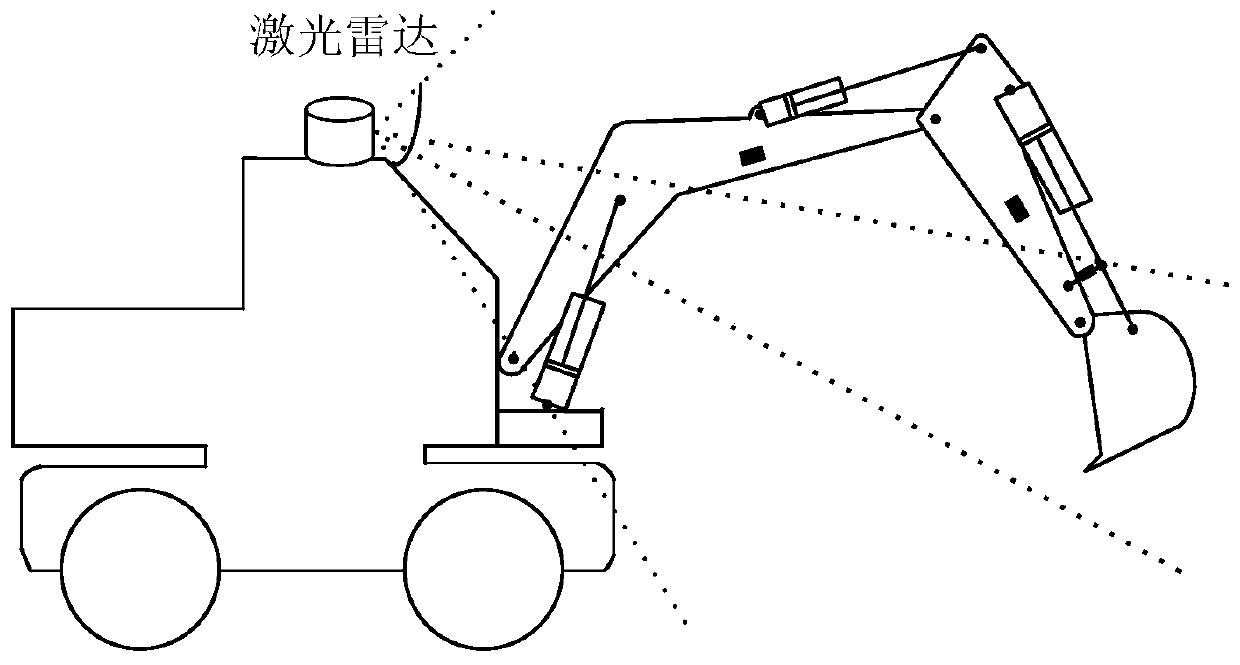

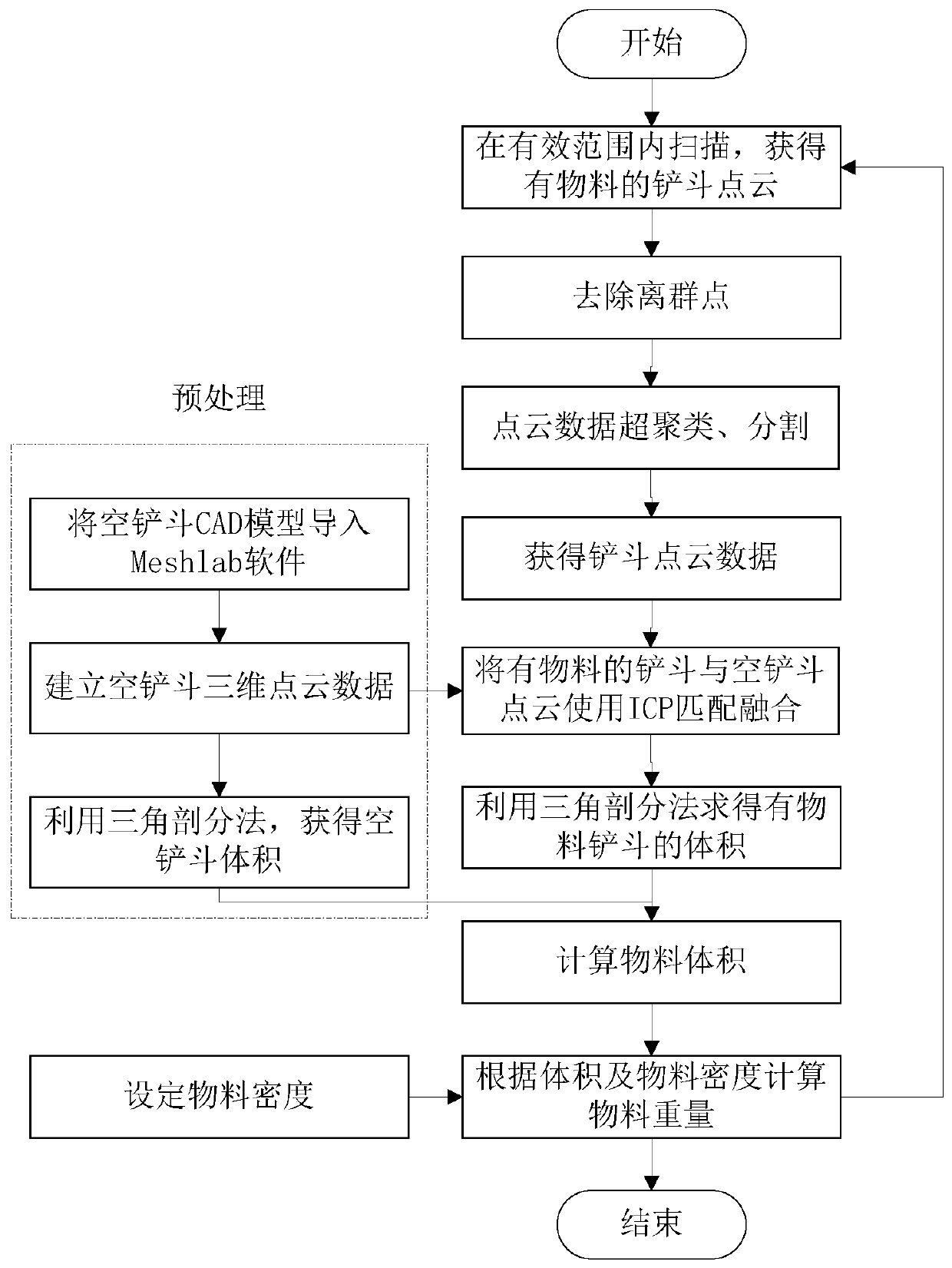

An excavator bucket material volume and weight measuring system

ActiveCN109948189AAchieve volumeAchieved weightSpecial data processing applicationsManufacturing computing systemsPoint cloudMeasurement device

The invention relates to an excavator bucket material volume and weight measuring system, which belongs to the technical field of hydraulic excavator bucket weighing, and comprises a laser radar, a calculating device, a preprocessing device and an operation display device. According to the invention, a laser radar device is used for realizing dynamic volume and weight measurement of materials in the bucket in the operation process of the excavator; effective three-dimensional modeling can be carried out on the empty bucket, point cloud registration fusion is carried out on the bucket filled with materials in the later excavation operation process, the limitation that point cloud data acquisition is blocked by objects and thus point cloud acquisition is incomplete is solved, the measurementprecision is improved, and the complexity of the measurement device is reduced.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

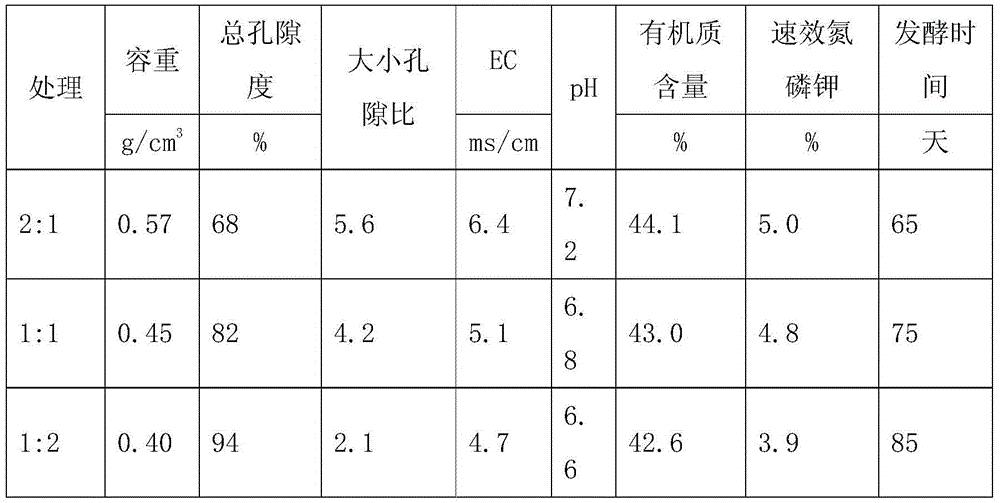

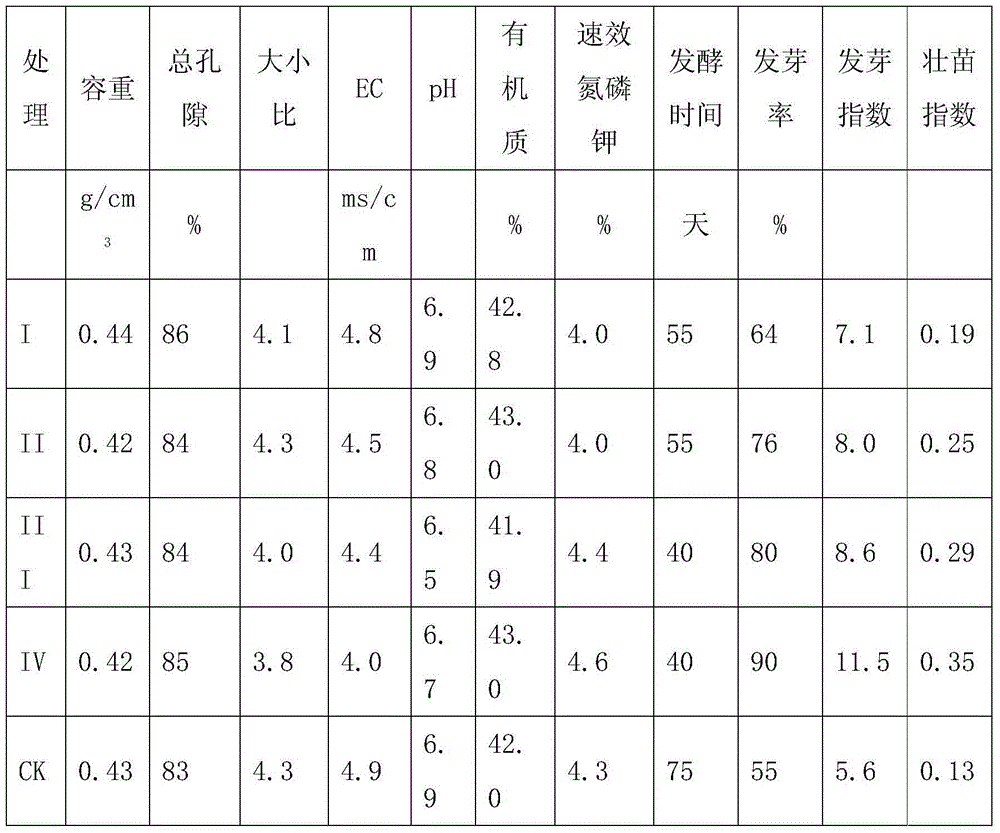

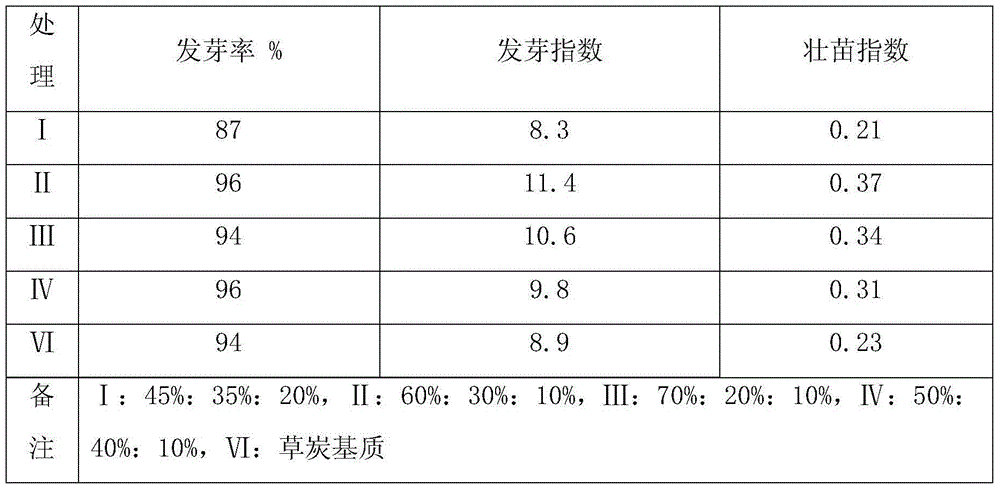

Cucumber seedling-raising substrate and preparation method thereof

PendingCN104909931AImprove colonization survival rateStrong ability to retain water and fertilizerBio-organic fraction processingWaste based fuelPorosityAdditive ingredient

The invention discloses a cucumber seedling-raising substrate and a preparation method thereof. The cucumber seedling-raising substrate comprises a substrate main ingredient and substrate auxiliaries; the volume ratio of the substrate main ingredient to the substrate auxiliaries is (60-70): (30-40). The substrate main ingredient is a thoroughly decomposed material prepared through mixed fermentation of saw dust such as cottonseed mud and word flour such as fruit tree branches, and the auxiliaries include vermiculite and pearlite. The preparation method comprises the following steps: firstly, mixing the cottonseed mud with the saw dust; next, adding zymocyte for fermentation; and after fermentation, adding the auxiliaries and mixing, screening and packaging. The cucumber seedling-raising substrate has the fermented material volume-weight of 0.40-4.5 / cm3, the total porosity of 80-90%, the EC of 3.5-4.0ms / cm, the pH of 6.5-7.0, the total available nitrogen phosphorus and potassium content of 4.5-5.0% and the organic matter content of 40-45%. The cucumber seedling-raising substrate does not need to be added with grass carbon, and is loose and air-permeable, capable of retaining water and fertilizer, harmonious in water, fertilizer and air, and capable of promoting seedlings to grow robustly.

Owner:INST OF GARDENING ANHUI ACADEMY OF AGRI SCI

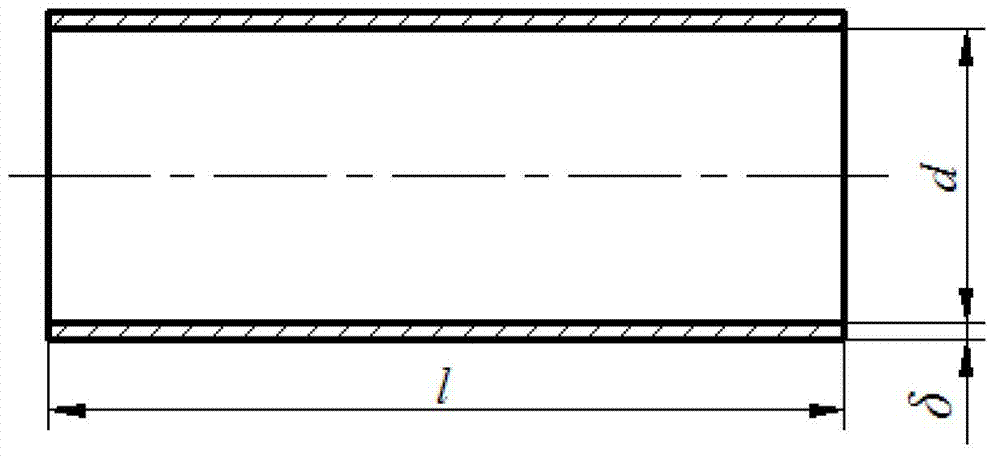

Strong force rotary pressing molding method of nanocrystalline/superfine crystal carbon steel cylindrical piece

The invention discloses a strong force rotary pressing molding method of a nanocrystalline / superfine crystal carbon steel cylindrical piece. The method comprises the following steps of: prefabricating a weld joint free cylindrical or cup-shaped blank in accordance with the invariant material volume principle and the requirements that a workpiece has 85-90% of total thickness reduction during the transformation process according to the size of a metal cylindrical part; subsequently sleeving the blank on a core mold; making the wall thickness reduction achieve 60-70% through multiple separation spinning; further putting the workpiece into an inert gas shielding furnace for recrystallization treatment; and finally sleeving the workpiece on the core mold again, wherein the total wall thickness reduction achieves 85-90% due to the multiple separation spinning. The method aims at the fact that a low carbon steel thin wall cylindrical part not only has a high precision appearance size, but also an overall but not surface superfine crystal / nanocrystallization microcosmic crystal grain structure, so that the cylindrical part has a good overall mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

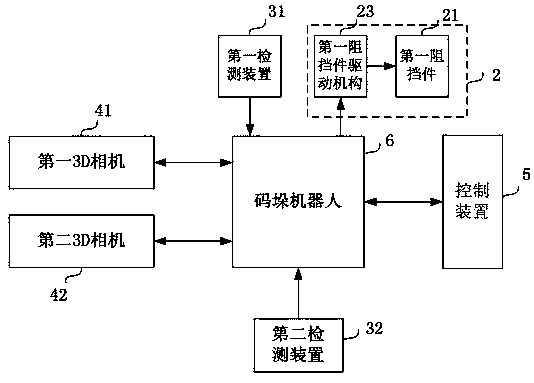

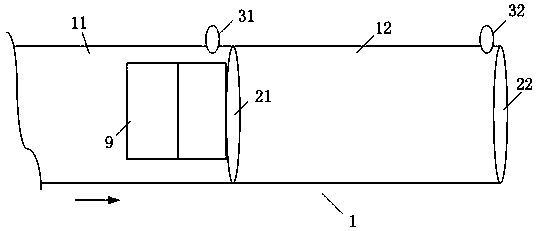

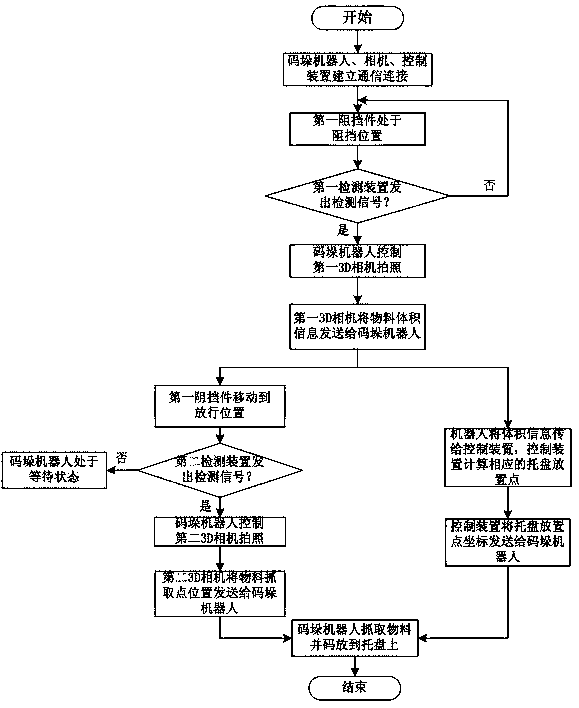

Robot stacking system and stacking method thereof

ActiveCN109625986ARealize automatic identificationImprove palletizing efficiencyStacking articlesEngineering3d camera

The invention provides a robot stacking system which comprises a conveying mechanism, a first blocking mechanism, a first detecting device, a first 3D camera, a second detecting device, a second 3D camera, a control device and a stacking robot. The conveying mechanism is provided with a main conveying area and a temporary storing conveying area. The first blocking mechanism comprises a first blocking part and a first blocking part drive mechanism. The first blocking part is arranged between the main conveying area and the temporary storing conveying area. The first detecting device is used fordetecting whether materials reach the edge position of the main conveying area. The first 3D camera is used for shooting material images of the main conveying area and obtaining material size information. The second detecting device is used for detecting whether the materials reach the preset position of the temporary storing conveying area. The second 3D camera is used for shooting material images of the temporary storing conveying area to determine the material grabbing point position. The control device is used for determining the tray placing point position of the materials according to the size information of the materials. The stacking robot is used for stacking the materials on trays according to the grabbing point of the materials and the tray placing point position. The inventionfurther discloses a stacking method of the robot stacking system. The robot stacking system can stack the materials of different sizes.

Owner:上海新时达机器人有限公司

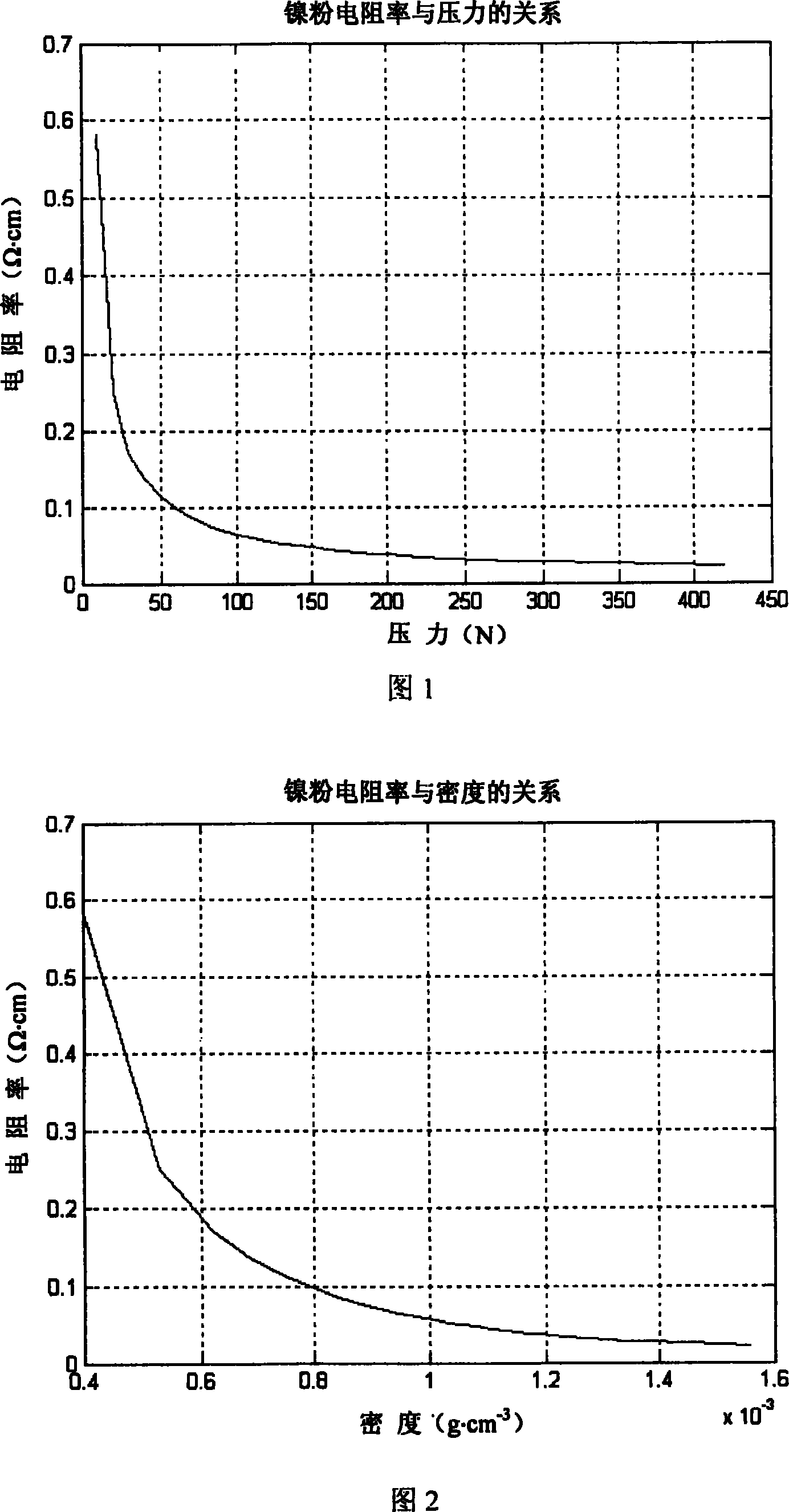

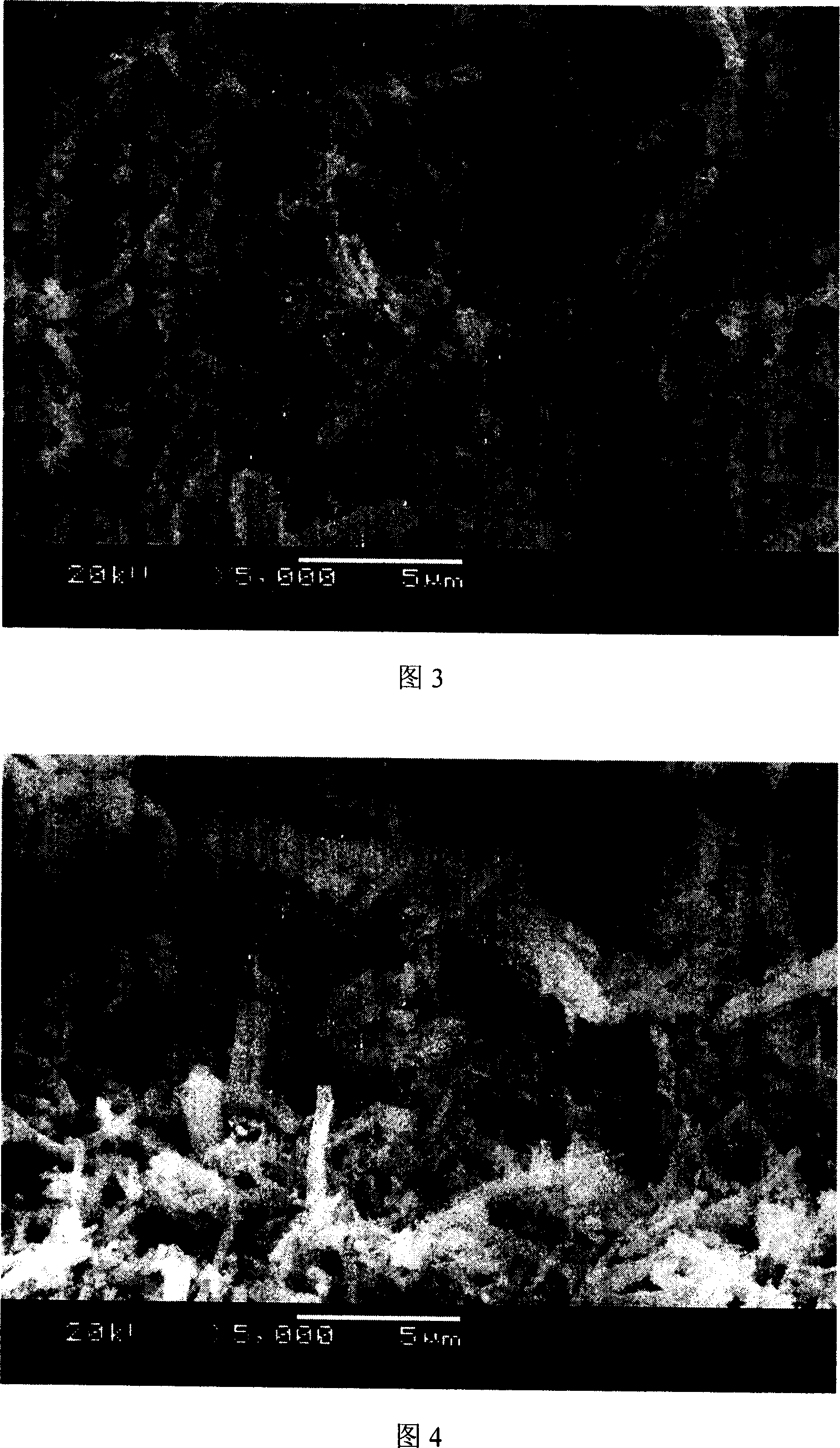

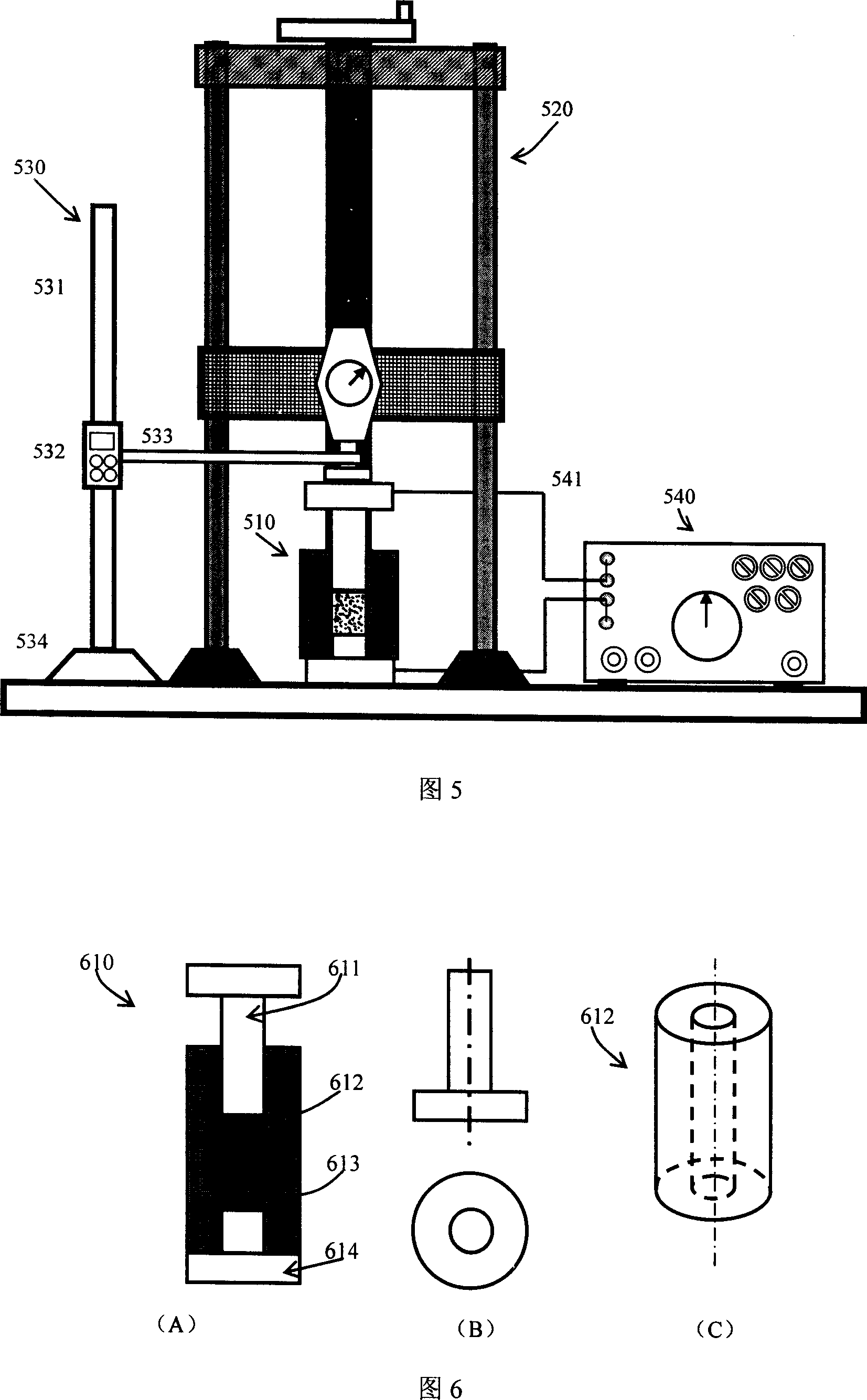

Method and device for investingating resistivity of powder metal

InactiveCN101000319AMeet different testing needsAccurate displacementMaterial impedanceMaterial resistanceElectricityElectrical resistance and conductance

The invention relates to new type powder metallic material resistivity testing method and device. It feature is that it measures the resistivity for the measured powder material with different density, calculates out the corresponding resistivity and conductivity to gain the curve described powder material electricity performance. The testing device is made up of pressure mechanism, micro displacement testing device, rigid bridge, and sample box. The pressure mechanism is used to change the powder material volume in the sample box. The micro displacement measuring device is used to record the change in real time. The rigid bridge is used to record corresponding powder resistance value. This measuring method and device can be used in nickel powder resistivity measuring, other metallic or non metallic powder material, nanometer material resistivity and conductivity measuring. Thus it will play an important role in materials, electronic technology etc.

Owner:SHENZHEN UNIV +1

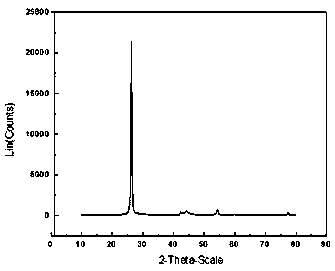

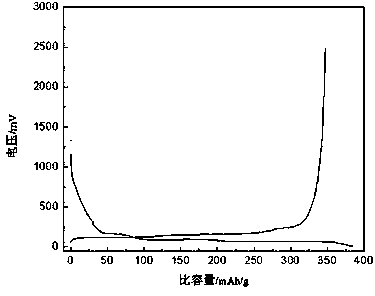

Preparation method for synthesizing graphite particle negative electrode material

InactiveCN103811758AImprove isotropySmall volume changeGraphiteCell electrodesMaterial synthesisLithium-ion battery

The invention belongs to the fields of material synthesis and energy utilization and in particular relates to a preparation method for synthesizing a graphite particle negative electrode material of a lithium ion battery. The method comprises the following steps: crushing, grading and screening an anisotropic graphite raw material to obtain superfine graphite powder with the average particle size of 2-10 microns, and performing secondary granulation technology treatment, namely kneading, molding, carbonizing, graphitizing, crushing, grading, spheroidizing and screening, so that the isotropy of the graphite particles and the end face / base surface ratio of the graphite particles are improved, and the volume expansion and shrinkage effect of the material in the lithium embedding and removal process and the high-current charge and charge performance of the material are improved. The preparation process is safe and controllable, the prepared material is high in isotropy degree, the material volume change in the lithium embedding and removal process is small, the cycle performance can be obviously improved, the end-face ratio of the graphite particles is improved due to secondary granulation treatment, and the material has good high-current charge and charge performance.

Owner:XINXIANG SAIRI NEW ENERGY SCI & TECH

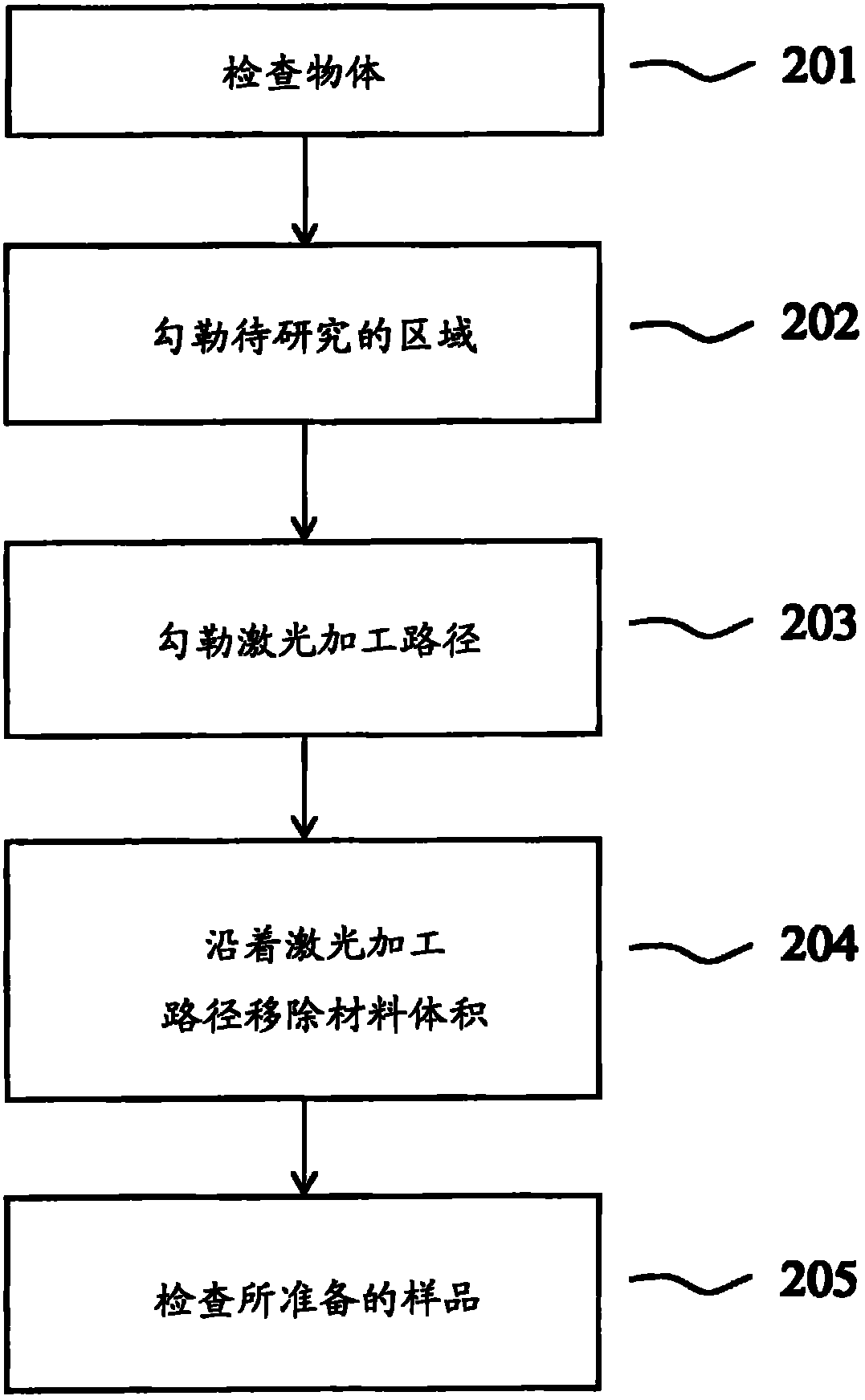

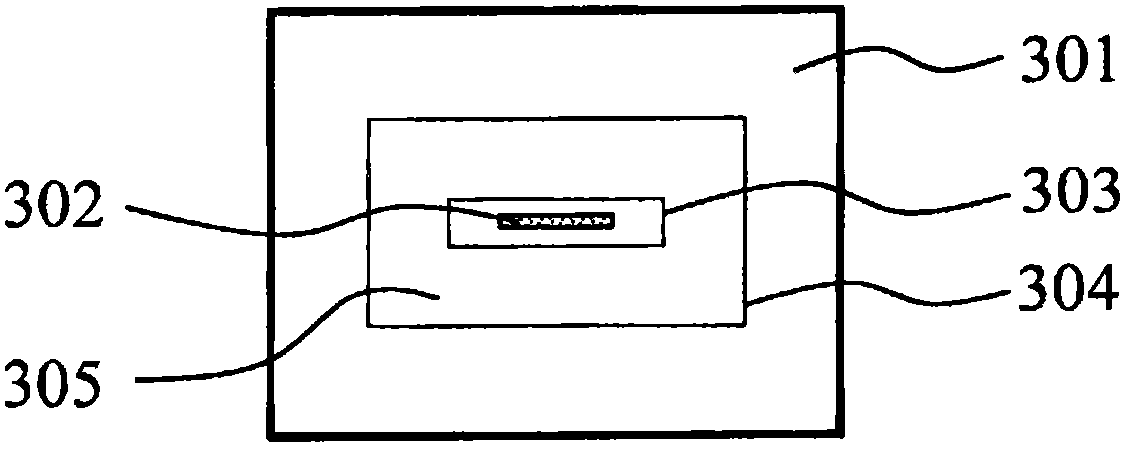

Method and devices for preparing microscopic samples with the aid of pulsed light

ActiveCN103257064AAvoid mechanical propertiesReduce riskElectric discharge tubesPreparing sample for investigationScanning electron microscopeElectron microscope

Methods and apparatus are disclosed for the preparation of microscopic samples using light pulses. Material volumes greater than 100 mum3 are removed. The methods include inspecting an object with a scanning electron microscope (SEM) or a focused ion beam (FIB). The inspection includes recording an image of the object. The methods also includes delineating within the object a region to be investigated, and delineating a laser-machining path based on the image of the object so that a sample can be prepared out of the object. The methods further include using laser-machining along the delineated laser-machining path to remove a volume that is to be ablated, and inspecting the object with the scanning electron microscope (SEM) or a focused ion beam (FIB).

Owner:CARL ZEISS MICROSCOPY GMBH

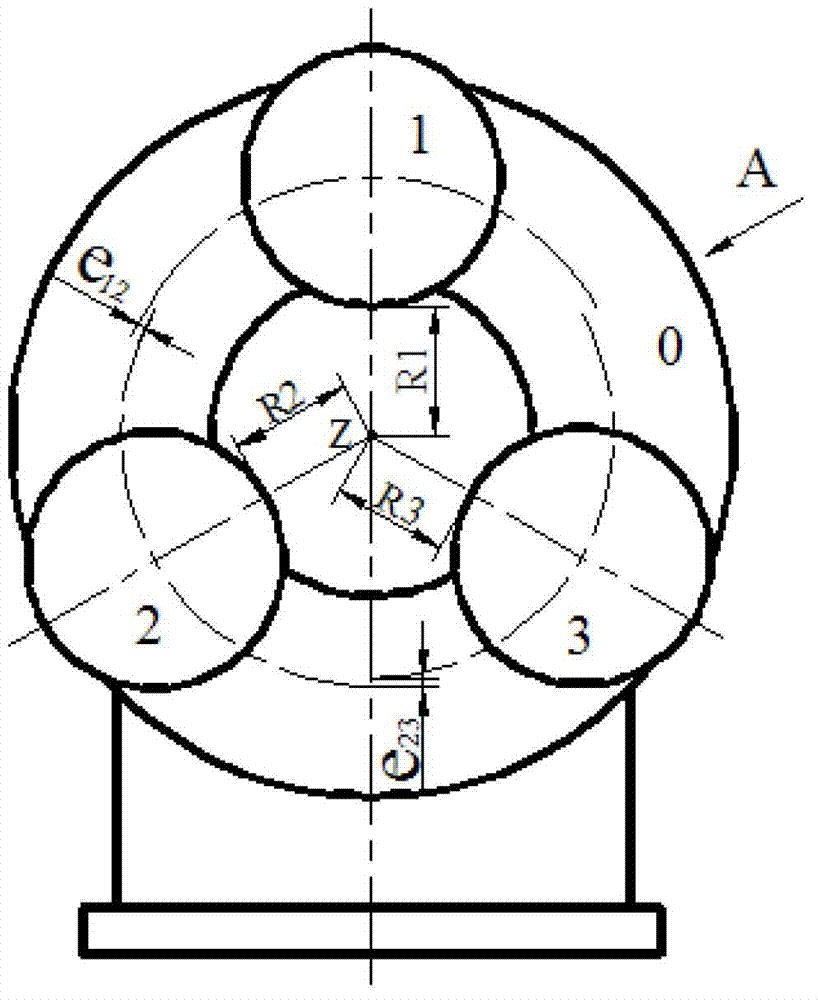

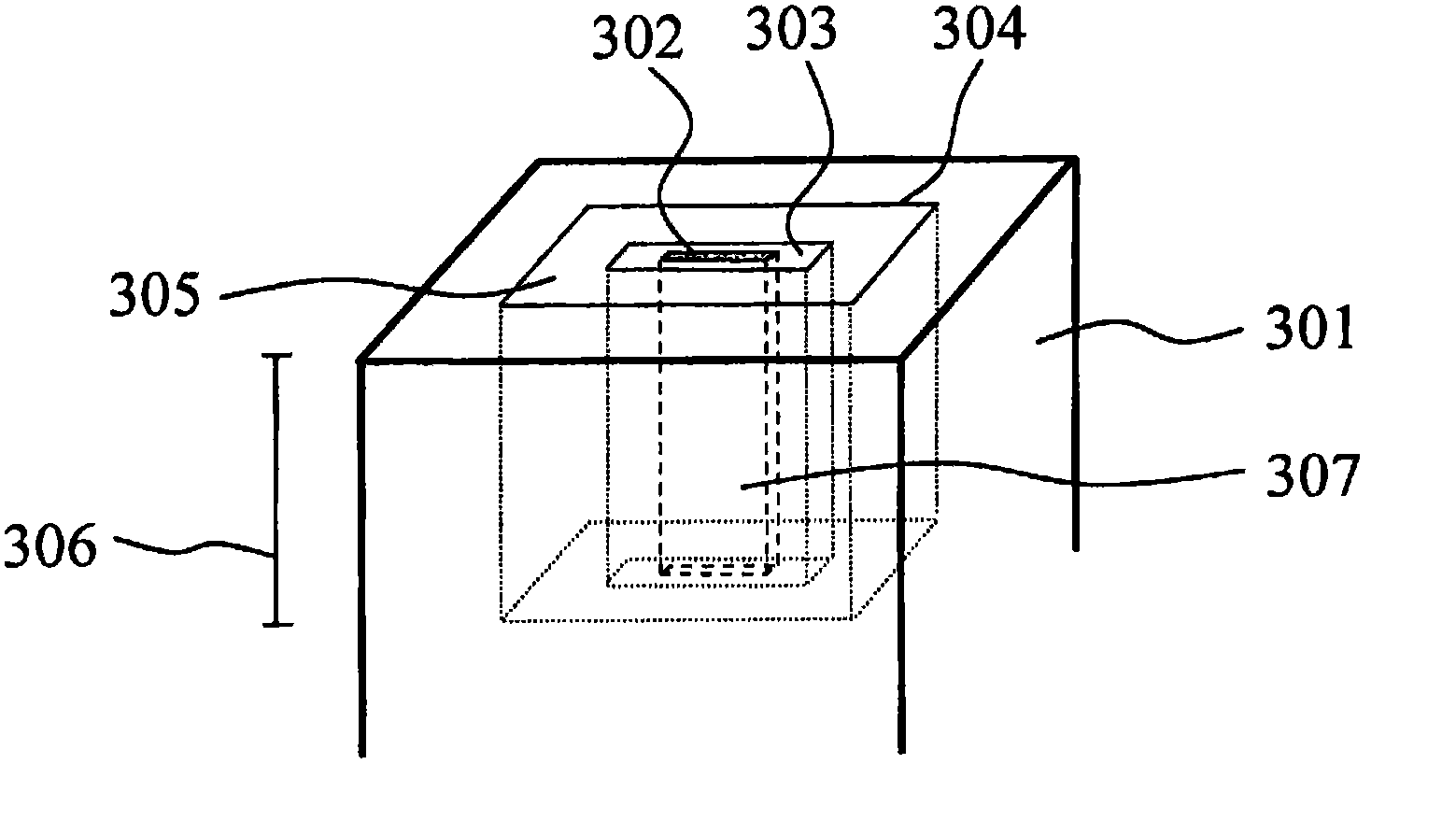

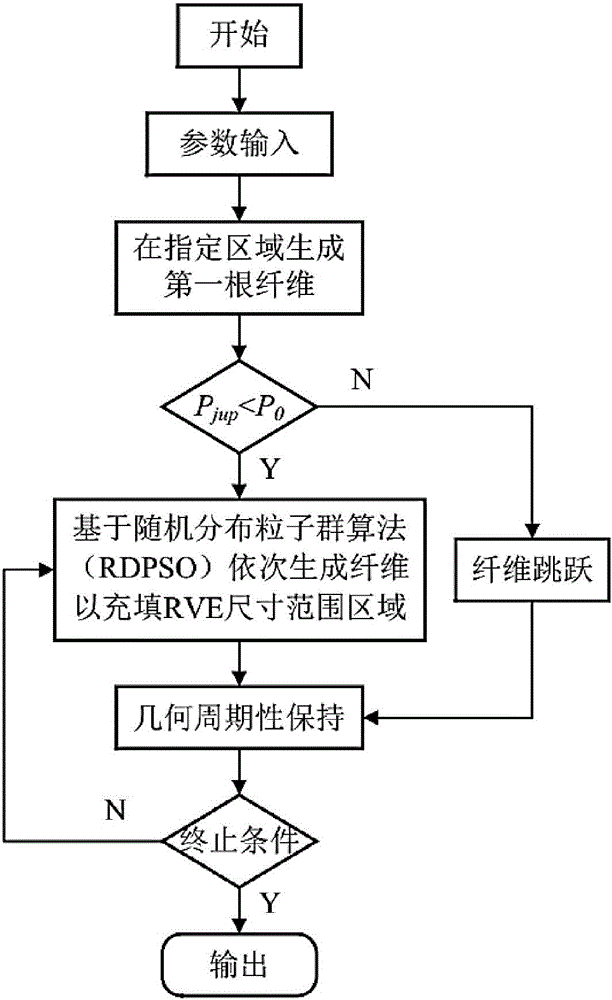

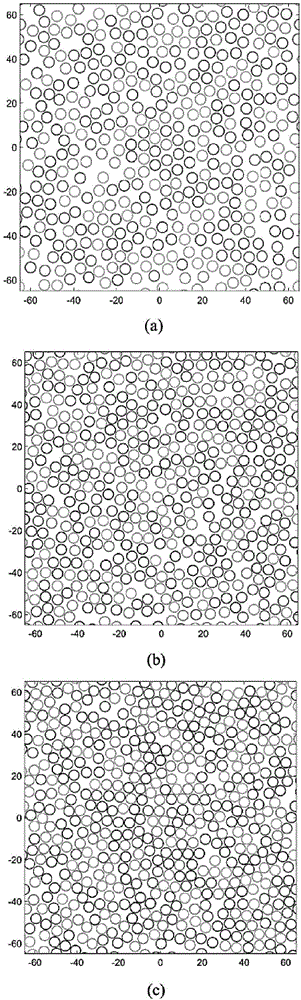

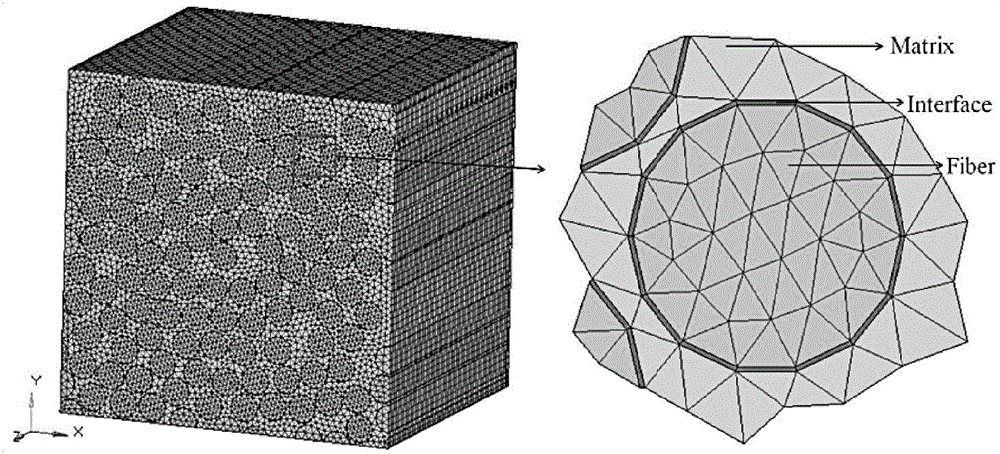

Method for generating random structure of continuous fiber composite material and predicting elastic performance of continuous fiber composite material

ActiveCN106815408AIncrease randomnessImprove production efficiencyDesign optimisation/simulationSpecial data processing applicationsElement modelThree-phase

The invention provides a method for generating a random structure of a continuous fiber composite material and predicting the elastic performance of the continuous fiber composite material. The method comprises the following steps: generating a fiber model by a particle swarm algorithm, and optimizing the fiber model according to fiber jumping treatment to obtain particle space random distribution information for generating a three-phase RVE finite element model; and performing finite element simulation operation on the three-phase RVE finite element model to obtain a prediction result. Based on a representative volume element generation strategy of the particle swarm algorithm, the distance among fibers is controlled by the particle swarm algorithm in the process of generating the representative volume element, the requirement for the material volume percentage is fulfilled while fiber random distribution is ensured; and based on efficient generation of the representative volume unit and a homogenization theory, an elasticity prediction finite element model is established, a periodic boundary condition is applied, and the elasticity performance prediction result of the material can be obtained by microscomic finite element simulation, so that the efficiency of elasticity performance prediction is improved.

Owner:SHANGHAI JIAO TONG UNIV

Viscous material noncontact jetting system

InactiveUS7939125B2Precise applicationFast response timePrinted circuit assemblingMovable spraying apparatusRelative motionPiston

A viscous material noncontact jetting system has a jetting dispenser mounted for relative motion with respect to a surface. A control is operable to cause the jetting dispenser to jet a viscous material droplet that is applied to the surface as a viscous material dot. A device, such as a camera or weigh scale, is connected to the control and provides a feedback signal representing a size-related physical characteristic of the dot applied to the surface. The size-related physical characteristics of subsequently applied dots is controlled by heating and cooling, or adjusting a piston stroke in the jetting dispenser, in response to the size-related physical characteristic feedback. Dispensed material volume control and velocity offset compensation are also provided.

Owner:NORDSON CORP

Integrated material transfer and dispensing system

ActiveUS8534499B2Liquid flow controllersLiquid transferring devicesRobotic systemsComputer control system

An integrated material transfer and dispensing system for storing, transferring and dispensing materials, such as fluids, and liquids, for example, liquid applied sound deadener (LASD). The system includes at least one vessel having a force transfer device. Each vessel may be removably enclosed in cabinet to form an automated station. Each vessel may be configured with a data logger, cleanout port, a sample valve at least one sight window and an access port for introducing a compound such as a biocide. Each vessel may be configured with instruments including sensors for measuring process variables, such as material volume, level, temperature, pressure and flow. The system may further include a metering device system and a robotic material dispenser system without a pump interface. The robotic system may further include a computer control system connected to flow and pressure sensors. The system may directly feed an applicator without an intervening pump.

Owner:CH & I TECH INC

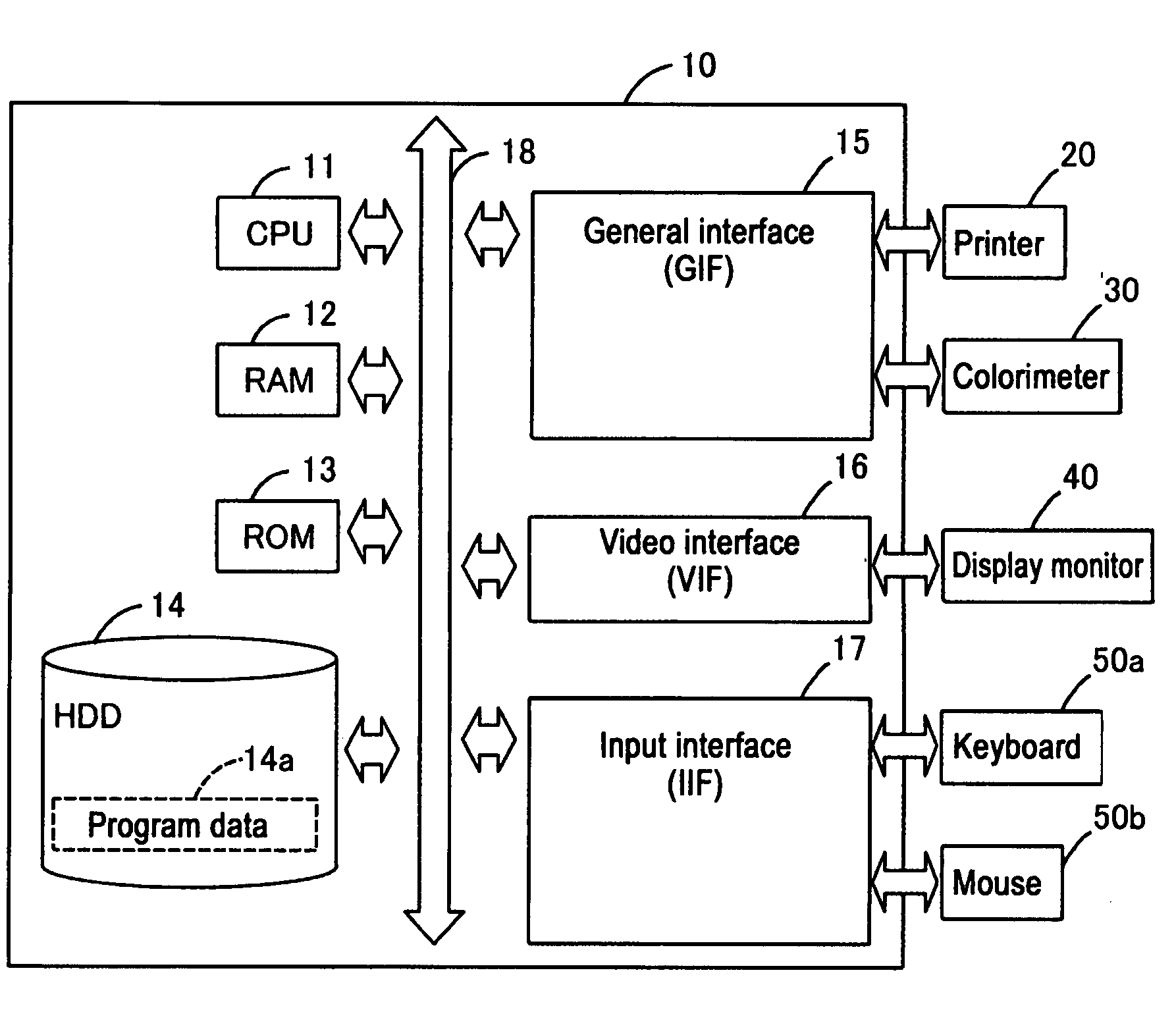

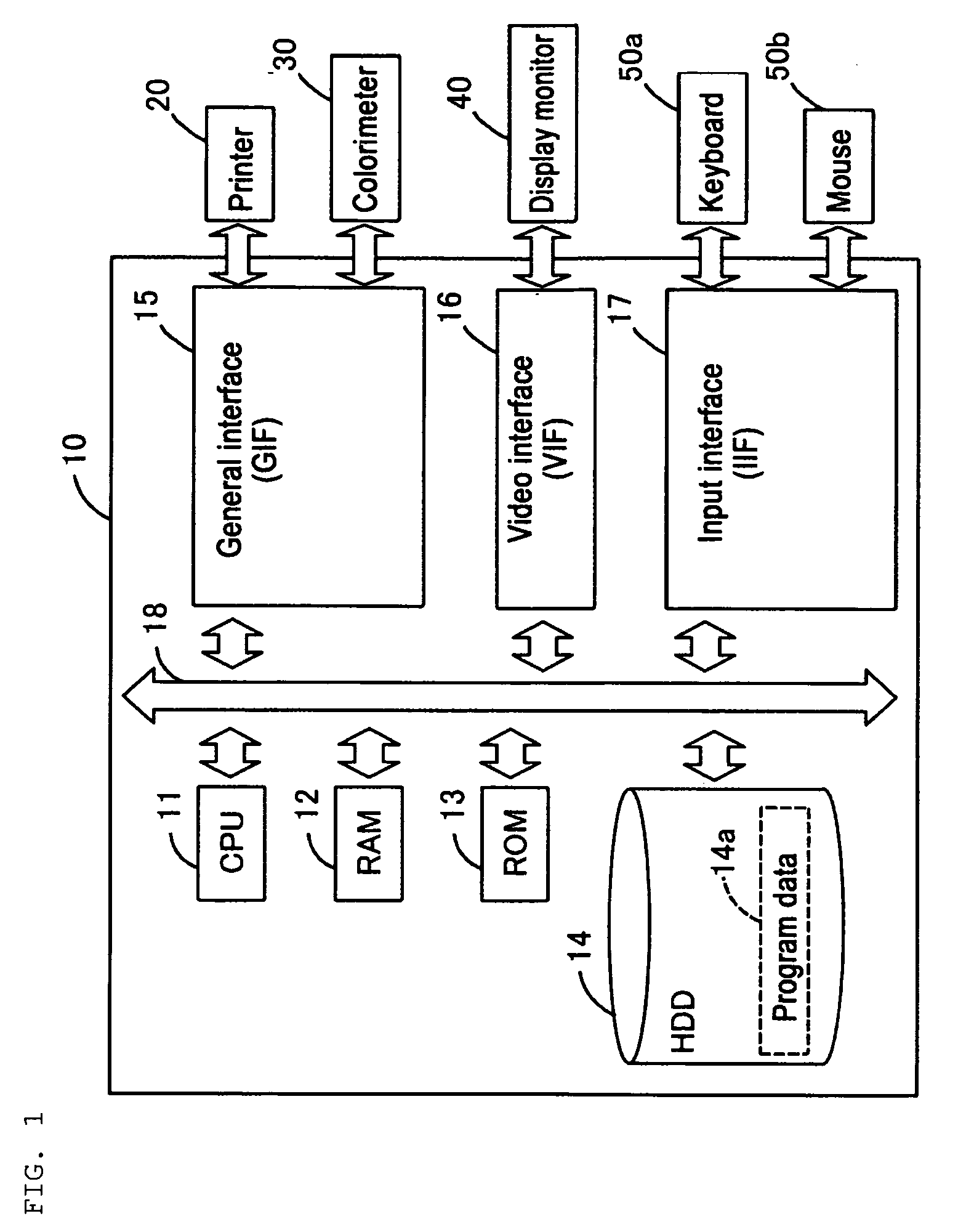

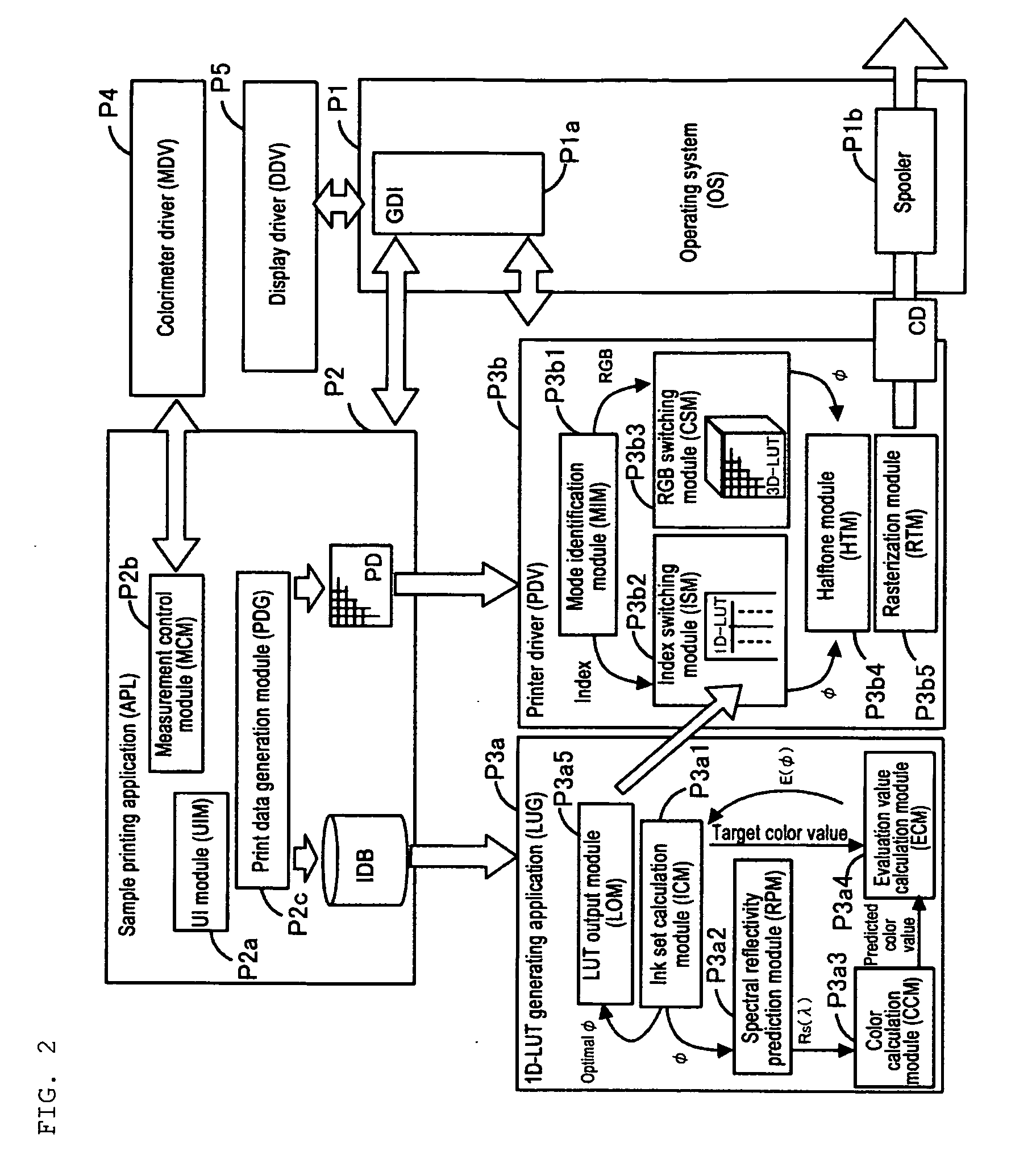

Printing control device, print data generation device, printing system and printing control program

ActiveUS20090195845A1High spectral reproducibilityGood reproducibilityDigitally marking record carriersDigital computer detailsComputer scienceRecording media

A printing control device that specifies to a printing apparatus a coloring material volume set which is a combination of usage amounts of coloring materials when the printing apparatus executes printing by depositing a plurality of coloring materials onto a recording medium, including: a print data acquisition unit that acquires print data of pixels having an information area for storing an index associated with the coloring material volume set; a color conversion unit that acquires the coloring material volume set corresponding to the index stored in the pixel; and a printing control unit that executes printing by specifying to the printing apparatus the coloring material volume set acquired by the color conversion unit.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com