Preparation method for synthesizing graphite particle negative electrode material

A technology for synthesizing graphite and negative electrode materials, applied in the directions of graphite, battery electrodes, electrical components, etc., can solve the problems of limiting the rapid charge and discharge performance of lithium ion batteries, shortening the service life of lithium ion batteries, and the difficulty of pulling the battery pole pieces into pulp sheets. , to achieve the effect of good high current charge and discharge performance, increased end face ratio and high isotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

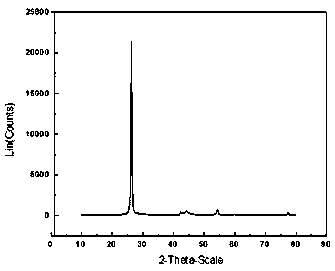

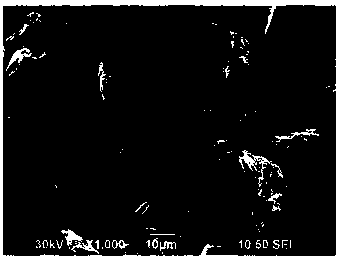

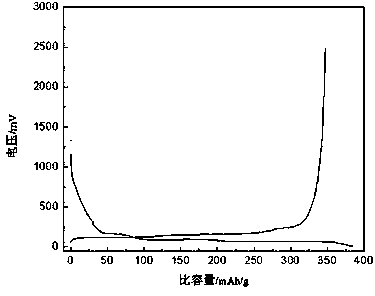

[0023] According to the mass ratio of asphalt and graphite 15:85, take 500.0kg of natural graphite powder with D50=5.0μm obtained through crushing, grading and sieving, and put it into the reaction kettle and heat it while stirring, and the heating temperature is up to 120°C. Take 88.2kg of medium-temperature asphalt with a softening point of 60°C and transport it to an asphalt melting tank through a pipeline. Hour. After the kneading is completed, the material is spread flat on a clean stage, and when the temperature of the material drops to room temperature, it is packaged and then graphitized. The graphitization treatment temperature is 2900° C., and the time period is 15 days. After the graphitization is completed, the material is crushed, classified, surface modified, and sieved to obtain the product.

Embodiment 2

[0025] According to the mass ratio of asphalt and graphite 25:75, take 500.0kg of D50=6.0μm high-purity artificial graphite powder obtained through crushing, grading and sieving, and put it into the reaction kettle while stirring and heating, and the heating temperature is 180°C. Take 166.7kg of medium-temperature asphalt with a softening point of 90°C and transport it to an asphalt melting kettle through a pipeline. Hour. After the kneading is completed, the material is spread flat on a clean stage, and when the temperature of the material drops to room temperature, it is packaged and then graphitized. The graphitization treatment temperature is 3200° C., and the time period is 20 days. After the graphitization is completed, the material is crushed, classified, surface modified, and sieved to obtain the product.

Embodiment 3

[0027] According to pitch and graphite feed mass ratio 30:70, take D50=8.0μm natural graphite powder and high-purity artificial graphite powder that obtain through pulverization, classification, sieving treatment and each 250.0kg puts into reactor while stirring and heating, heating temperature to 160°C. Take 214.3 kg of medium-temperature asphalt with a softening point of 80°C, and transport it to the asphalt melting kettle through a pipeline, the melting temperature is 130°C, and then flow the melted asphalt from the upper end of the reactor for kneading, the kneading temperature is 160°C, and the kneading time is 2.5 Hour. After the kneading is completed, the material is spread flat on a clean stage, and when the temperature of the material drops to room temperature, it is packaged and then graphitized. The graphitization treatment temperature is 3000° C., and the time period is 18 days. After the graphitization is completed, the material is crushed, classified, surface m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com