Patents

Literature

631results about How to "Improve fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internal fixation devices

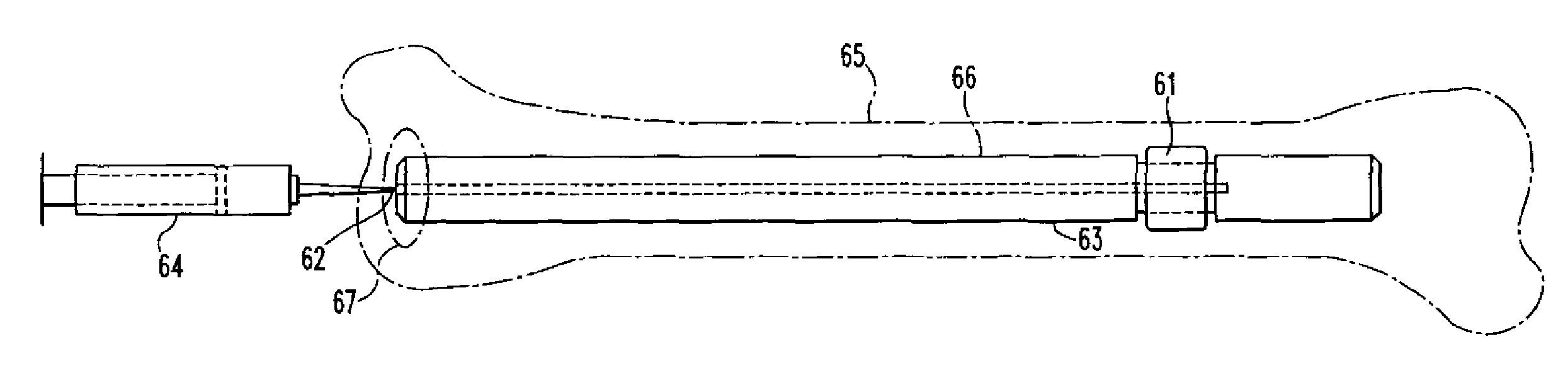

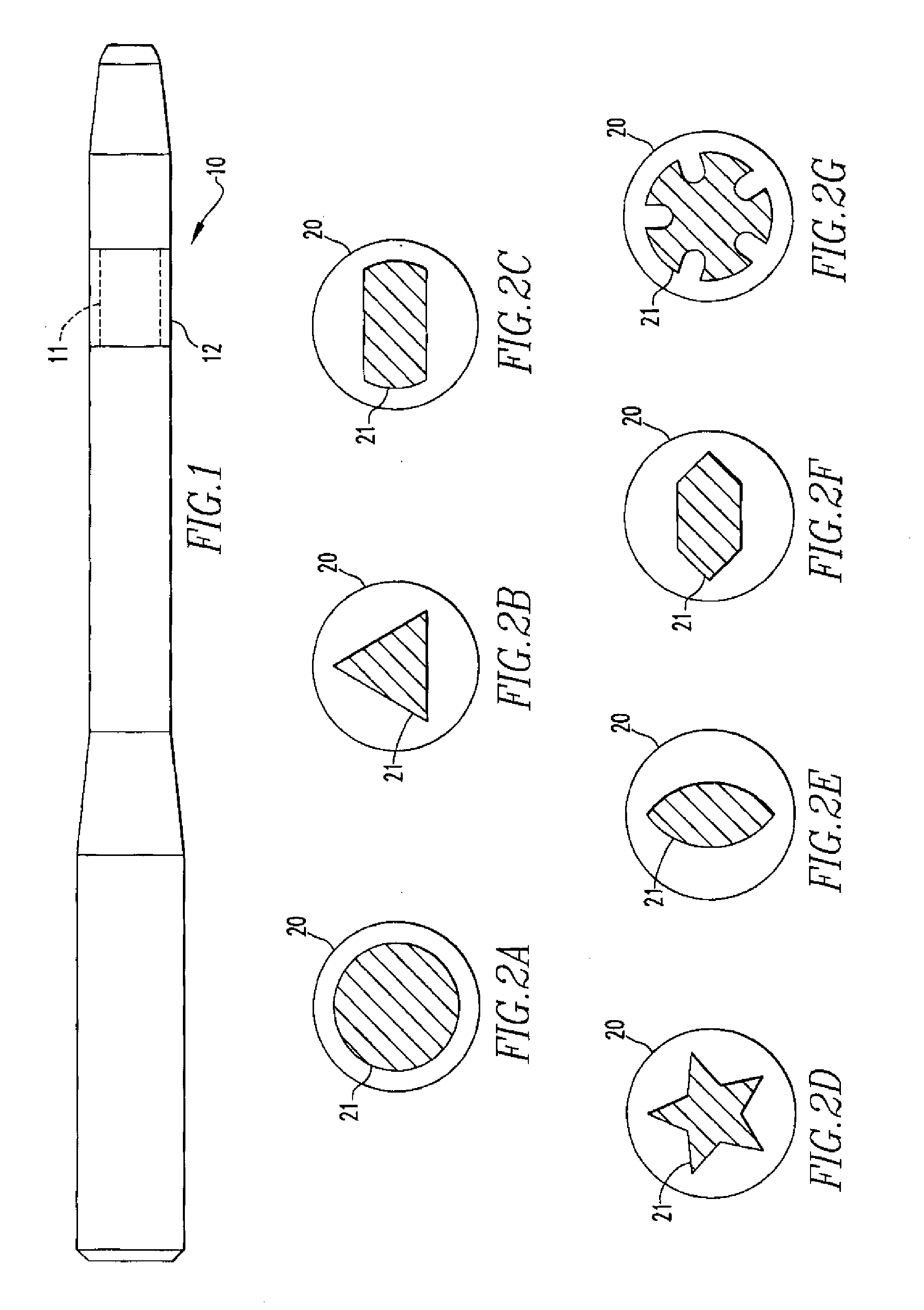

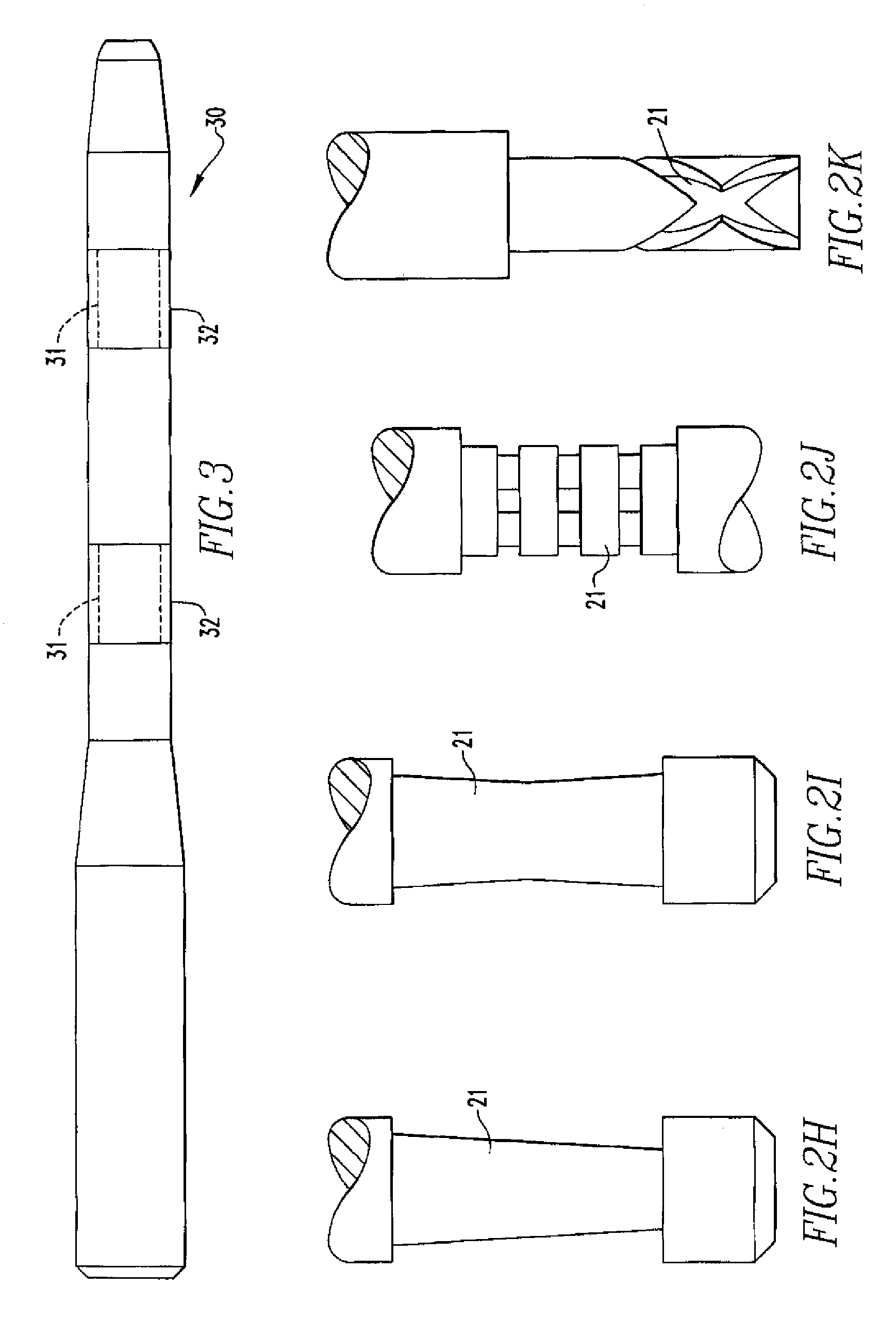

InactiveUS20100318085A1Sufficient expansionImprove fullySuture equipmentsInternal osteosythesisBiomedical engineeringPolymer

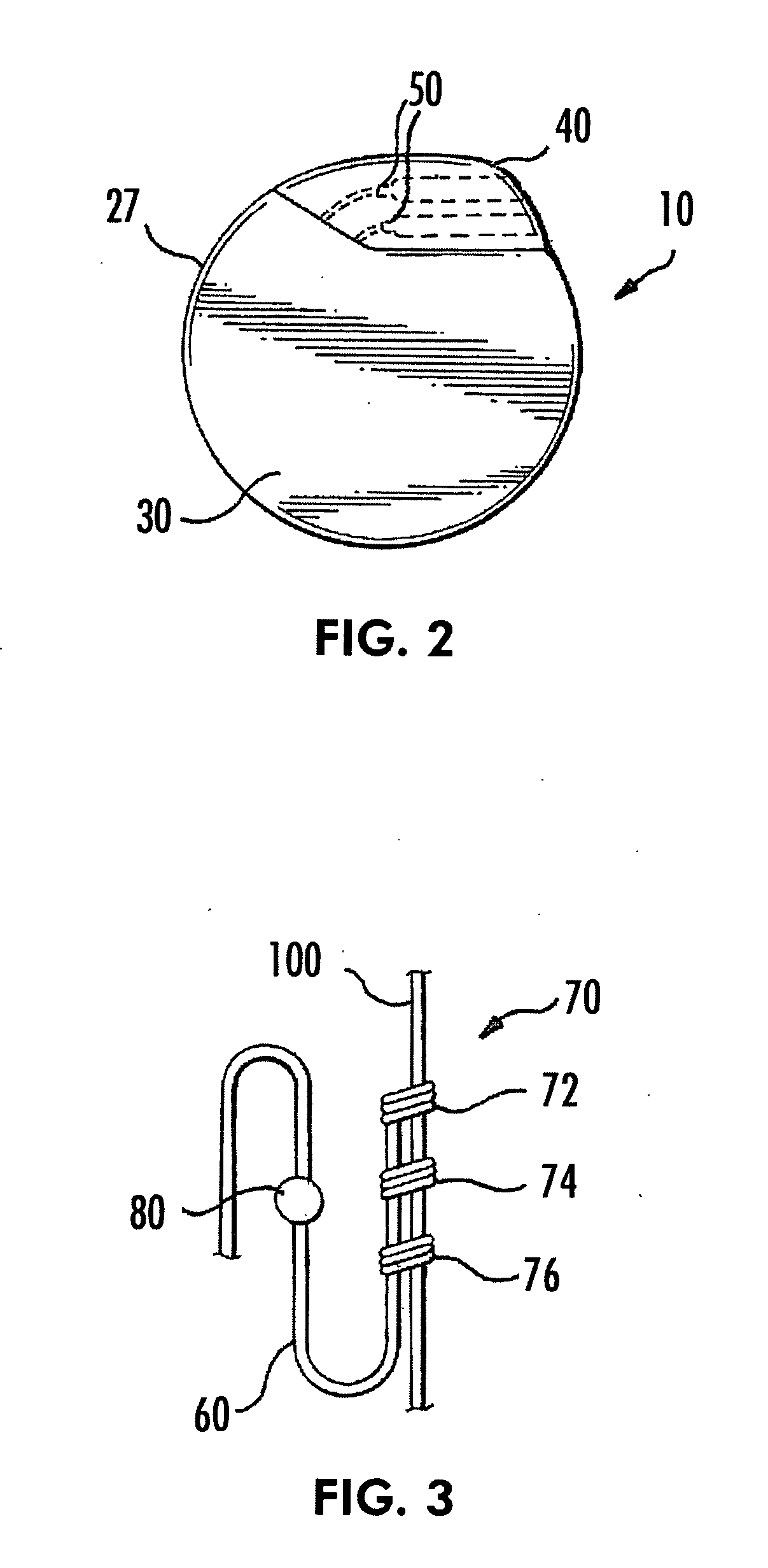

The present disclosure relates to an internal fixation device including an interface portion, a polymer material coupled to the interface portion, wherein the polymer material includes at least one feature on a surface of the polymer material, and means for allowing adequate expansion of the polymer material on each side of the bone fracture site. A method of fixating the internal fixation device to a bone and other internal fixation devices and methods for fixating are also disclosed.

Owner:SMITH & NEPHEW INC

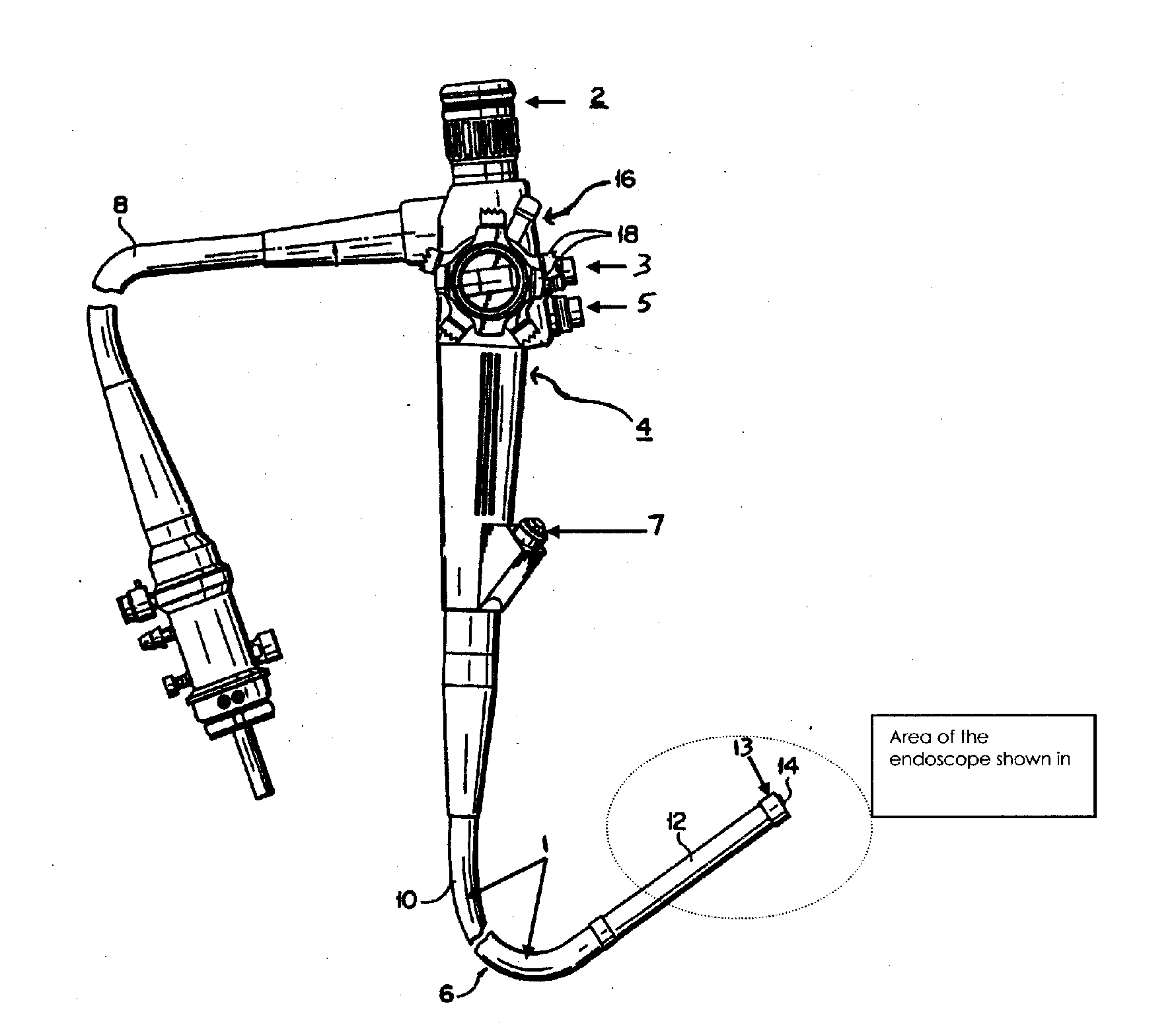

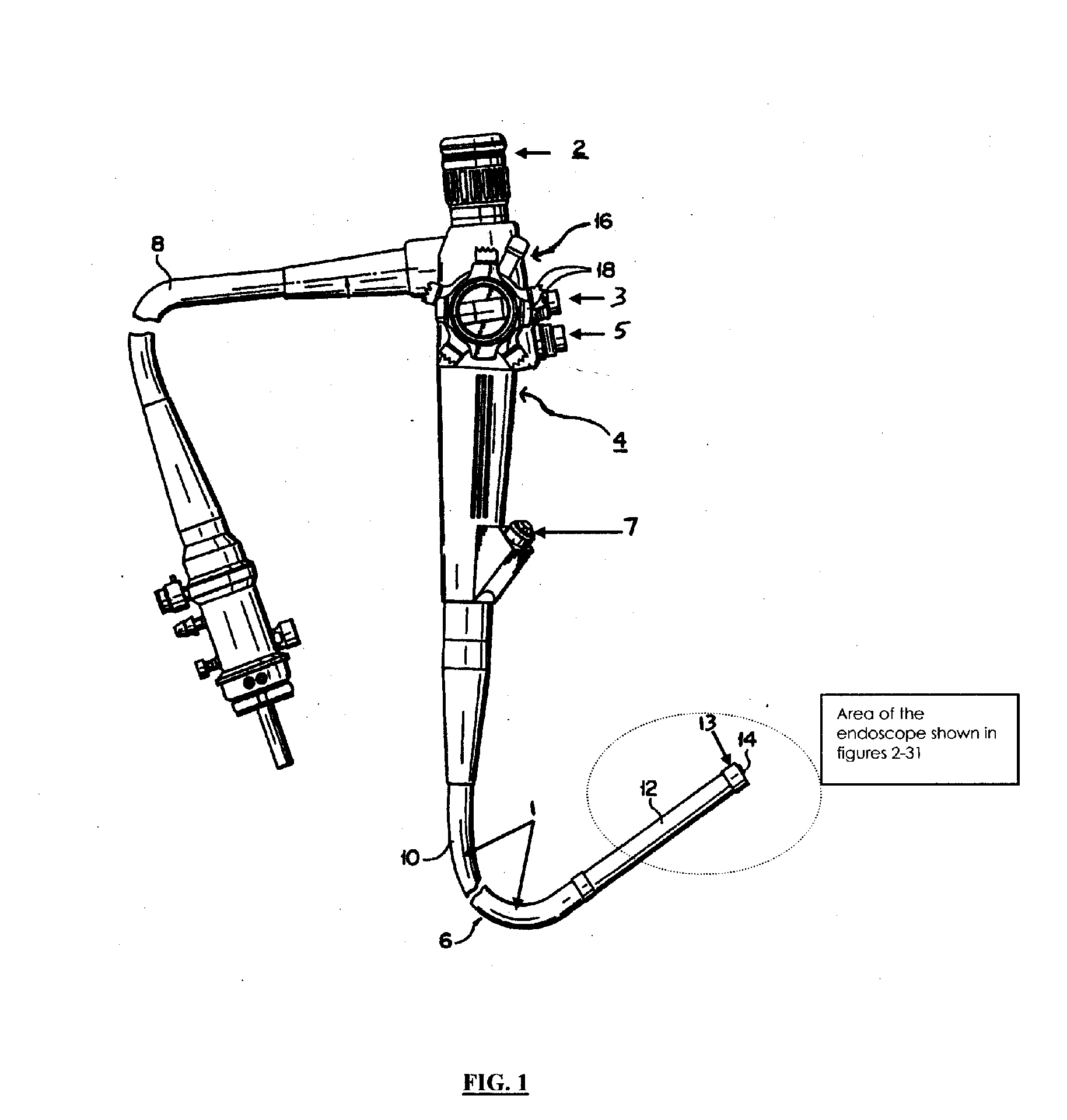

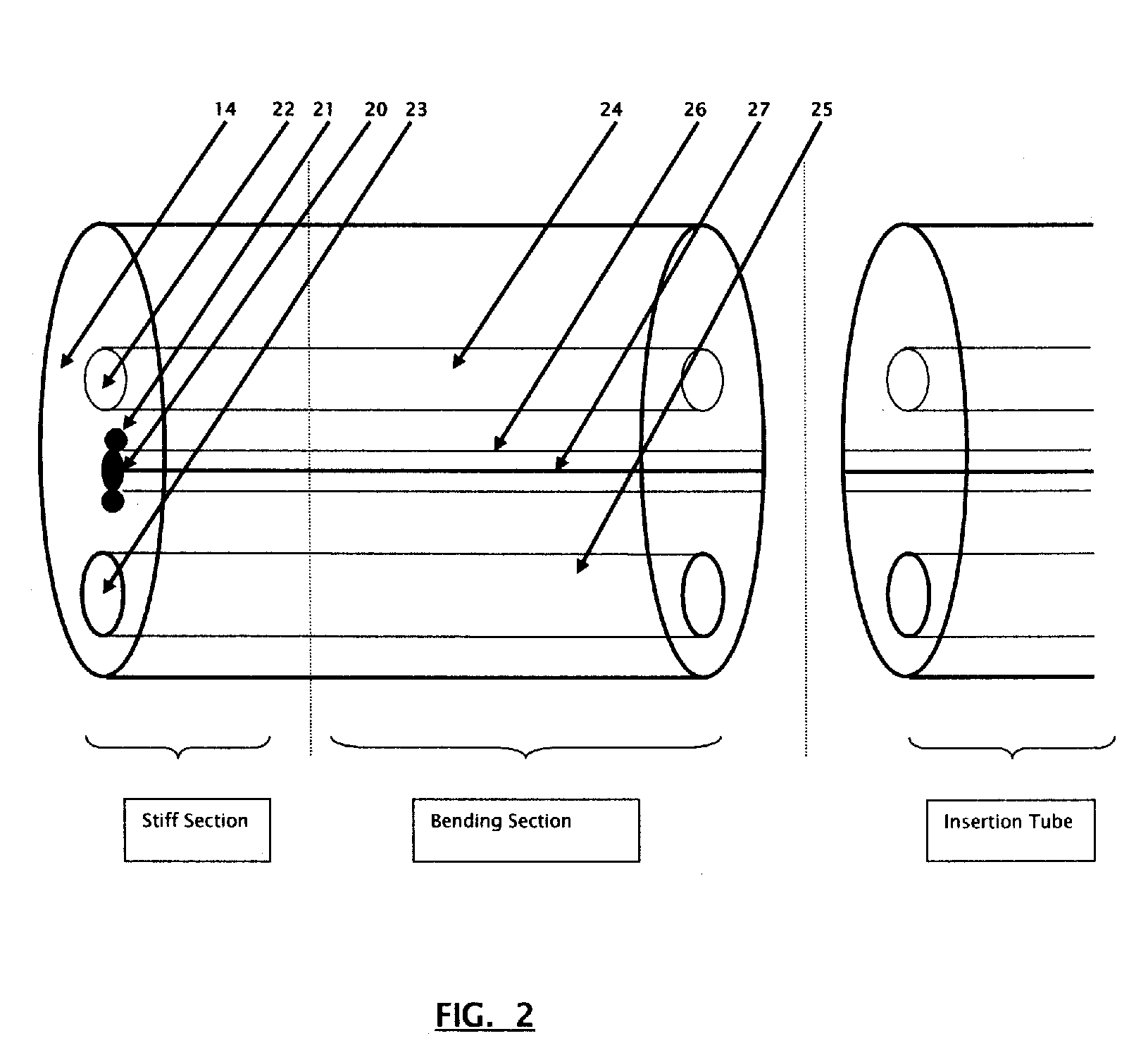

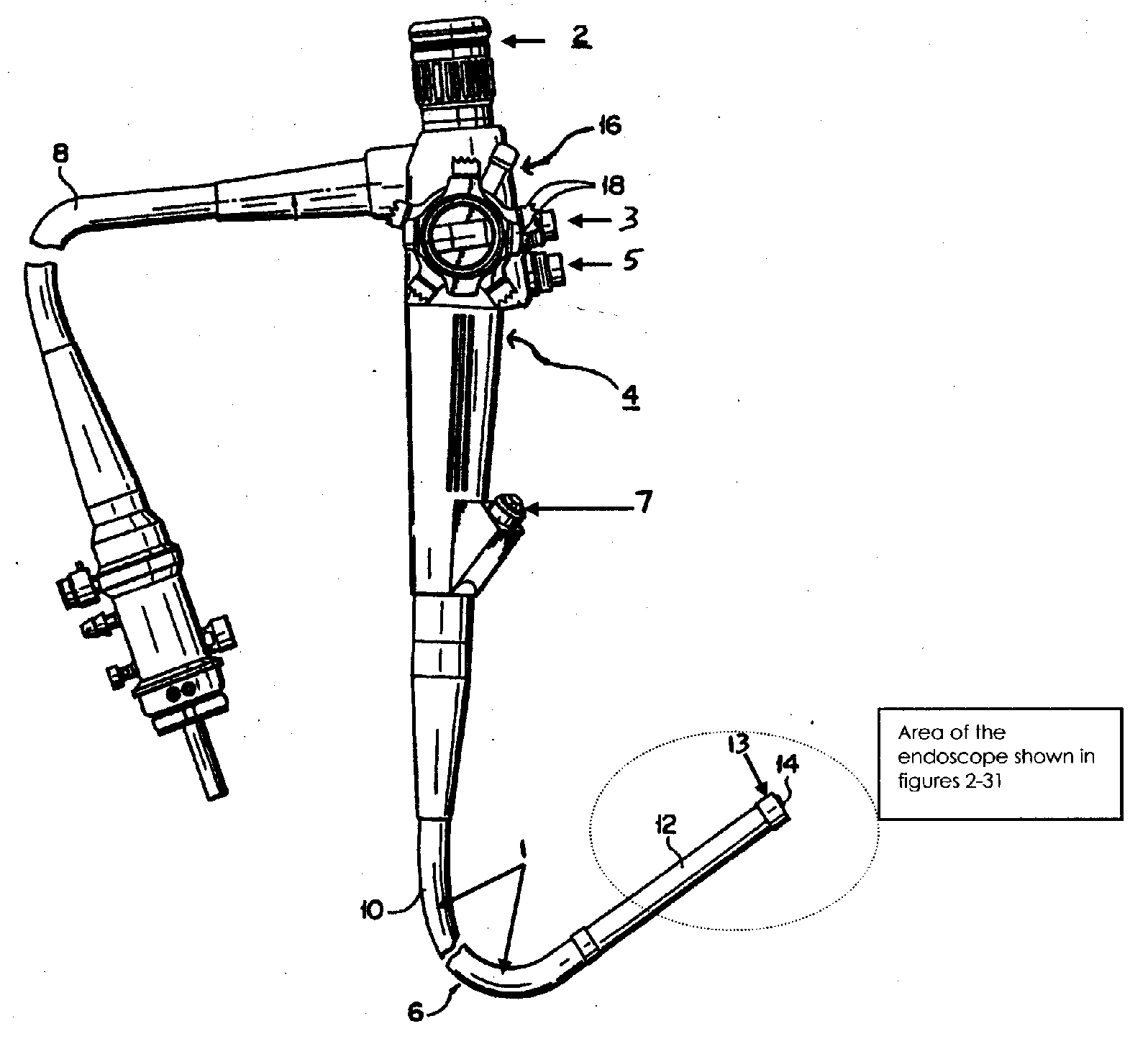

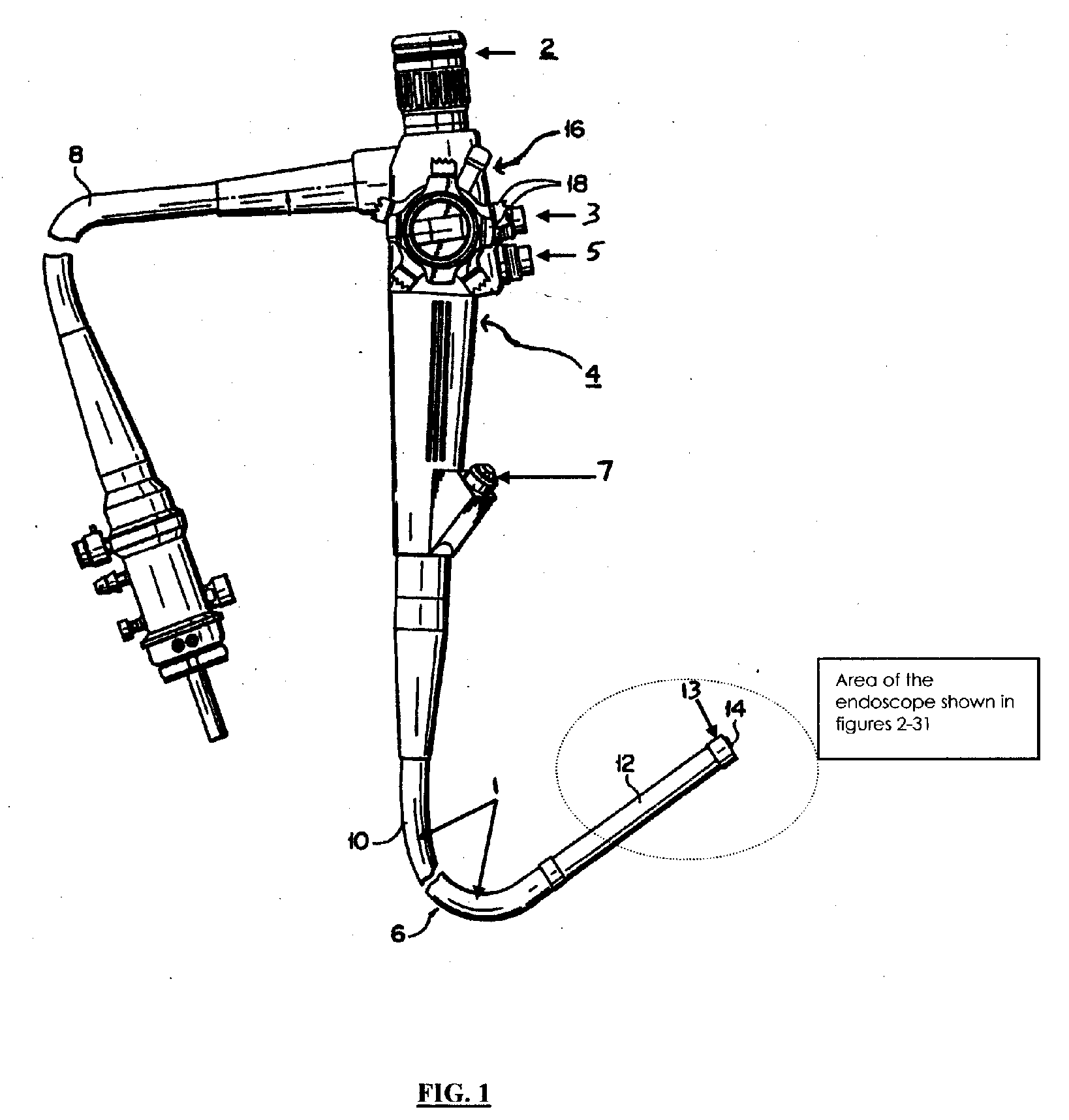

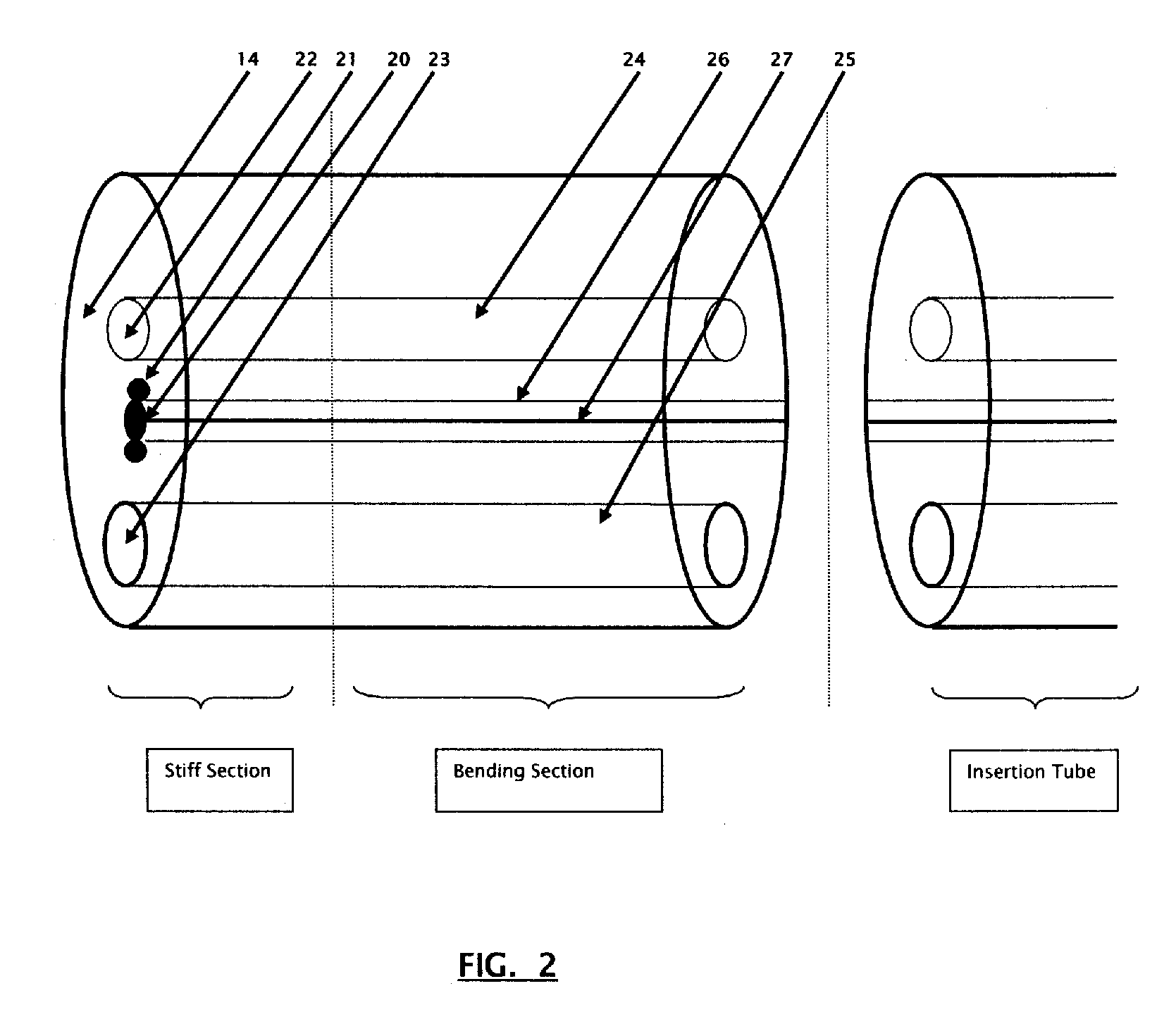

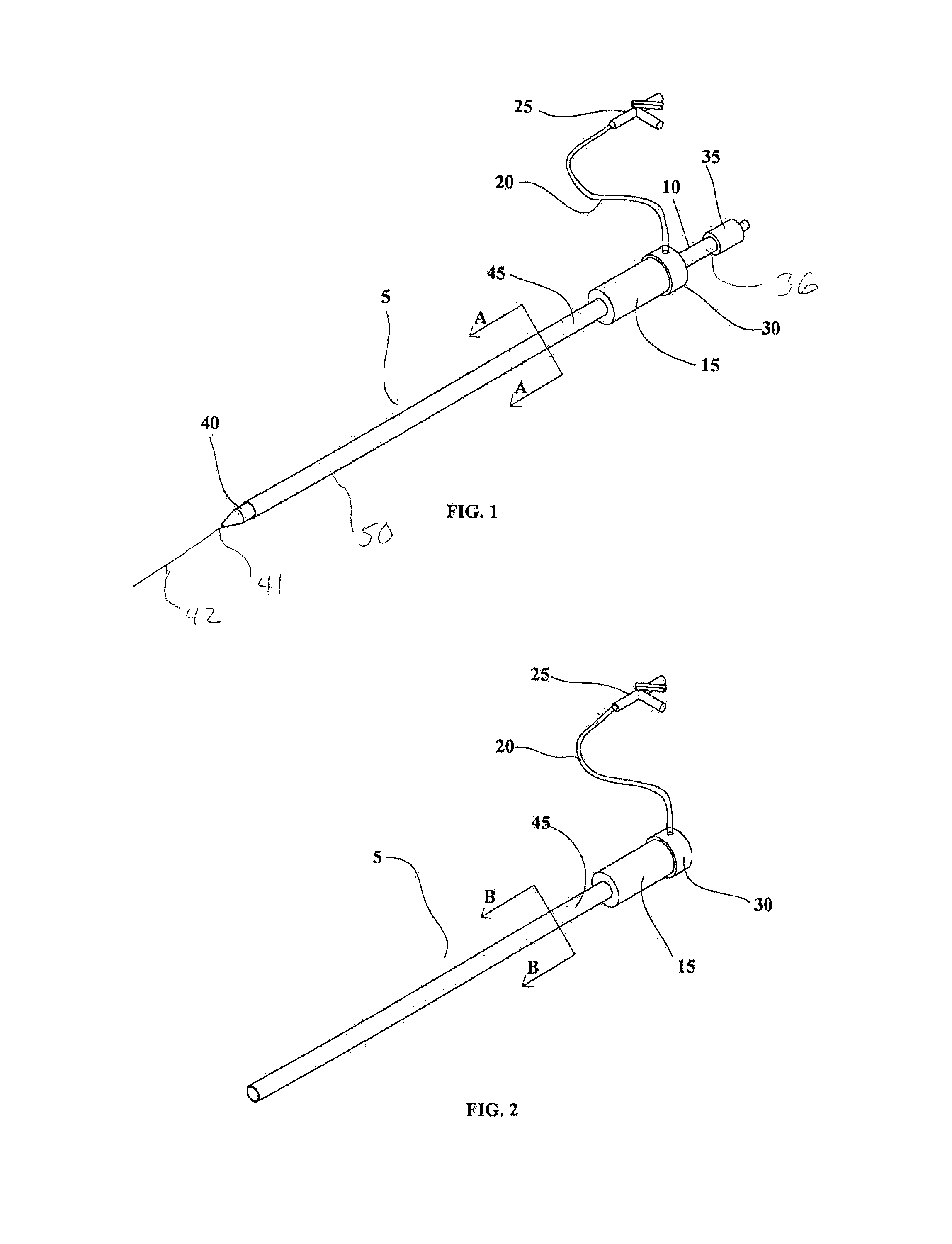

Dual View Endoscope

The present invention relates to an endoscope, more specifically to an endoscope that provides both forward view and rear view of a hollow body organ. It comprises of a rear view module that contains a rear image lens and a rear illumination bulb. The rear view module is designed and is attached to a conventional endoscope in a way that when deployed, the rear image lens and the rear illumination bulb face backward. In this position, the rear image lens provides a rear view and the rear illumination bulb illuminates the area under view of the rear image lens. The present invention enables the operator to obtain forward and rear views of a hollow organ either separately or simultaneously. The ability to obtain forward and rear view at the same time enables the operator to perform a complete examination of a hollow organ that includes both forward and rear view in a single insertion. The present invention enables surgical procedures to be performed in areas that are otherwise inaccessible and out of view of conventional endoscopes. This is made possible by a rear instrument channel located proximal to the rear view module. The present invention also improves distension and visualization of a hollow internal organ by having a rear air / water channel also located proximal to the rear view module. The present invention widens the field of vision of conventional endoscopes by enabling the addition of more than one forward image lens and more than one forward illumination bulb.

Owner:RATNAKAR NITESH

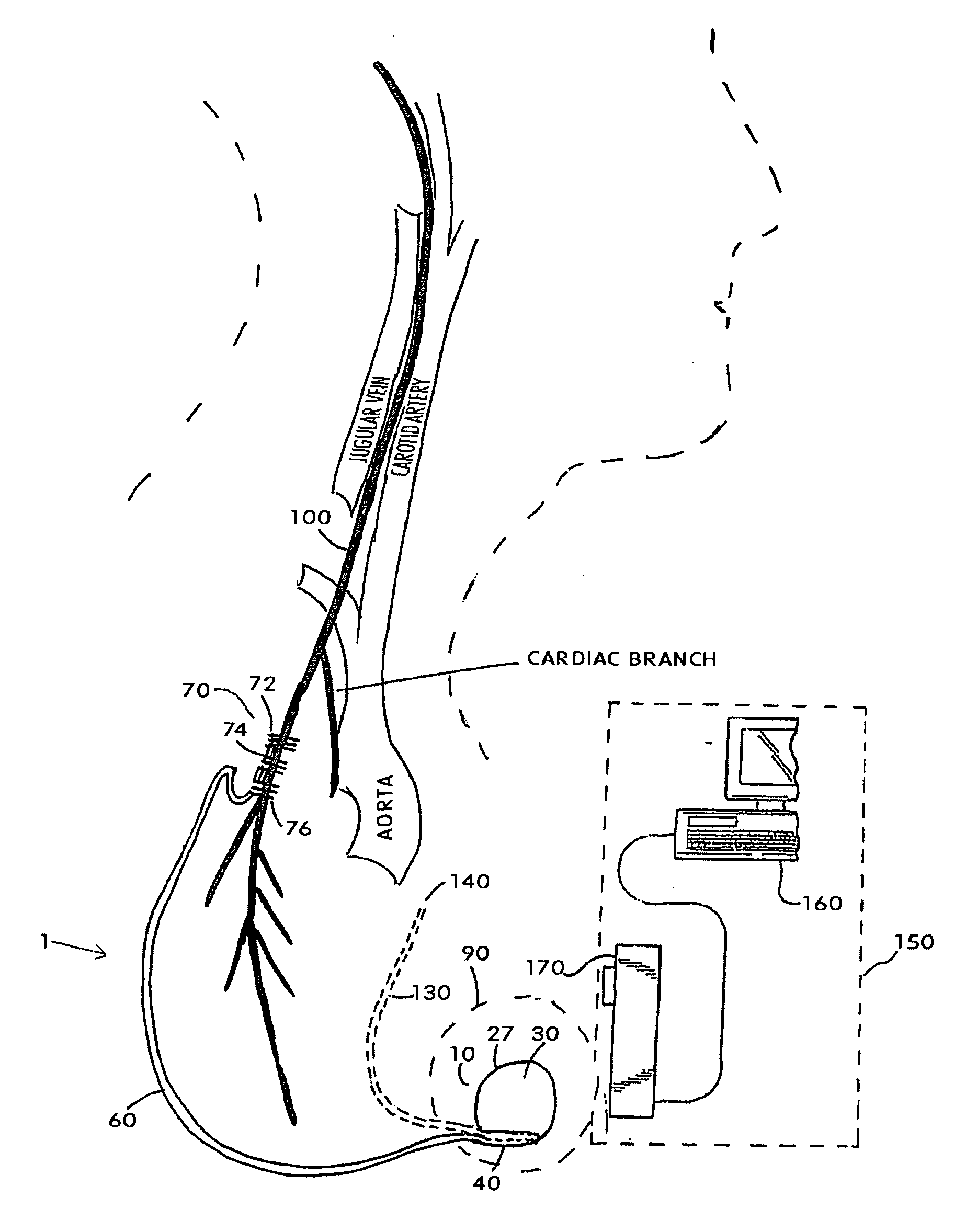

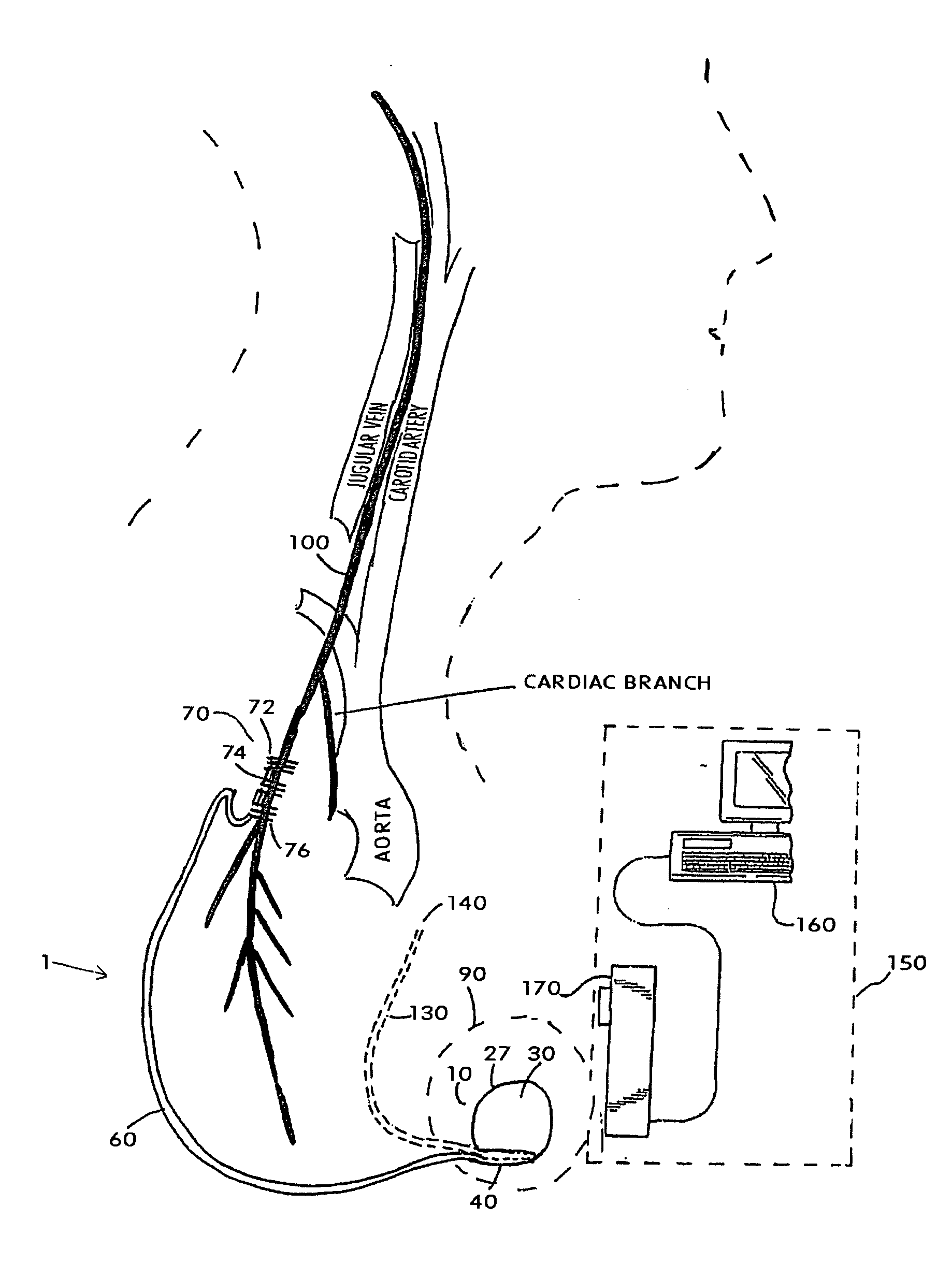

Selective nerve stimulation for the treatment of angina pectoris

InactiveUS20070021786A1Alleviate and deter onsetof painModulate electrical activityElectrotherapyCoronary arteriesMedicine

A method is disclosed for electrically stimulating a cranial nerve, especially a vagus nerve, to treat or alleviate angina pectoris. Pain is lessened or prevented by application of predetermined therapeutic electrical signal to a selected location on the cranial nerve of a patient using an implanted neurostimulating device. Such method employs selective application of electrical signals to a predetermined location on the nerve to alter the activity of the nerve and cause dilation of a coronary artery in the patient, which in turn provides complete or partial relief of chest pain or deters the onset of such pain.

Owner:LIVANOVA USA INC

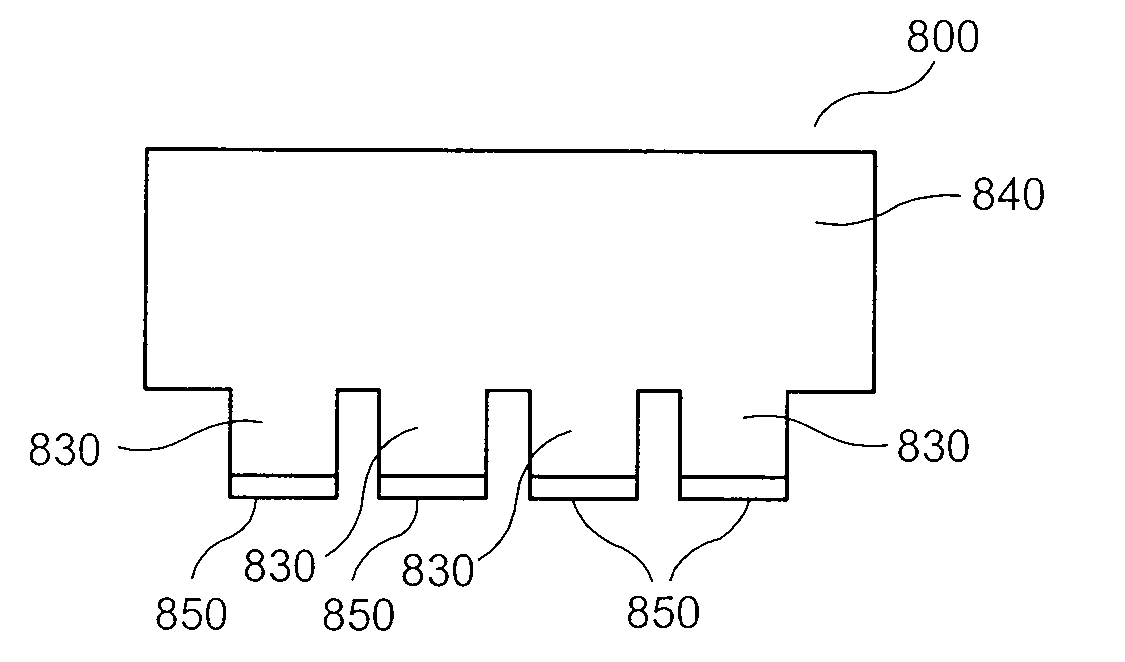

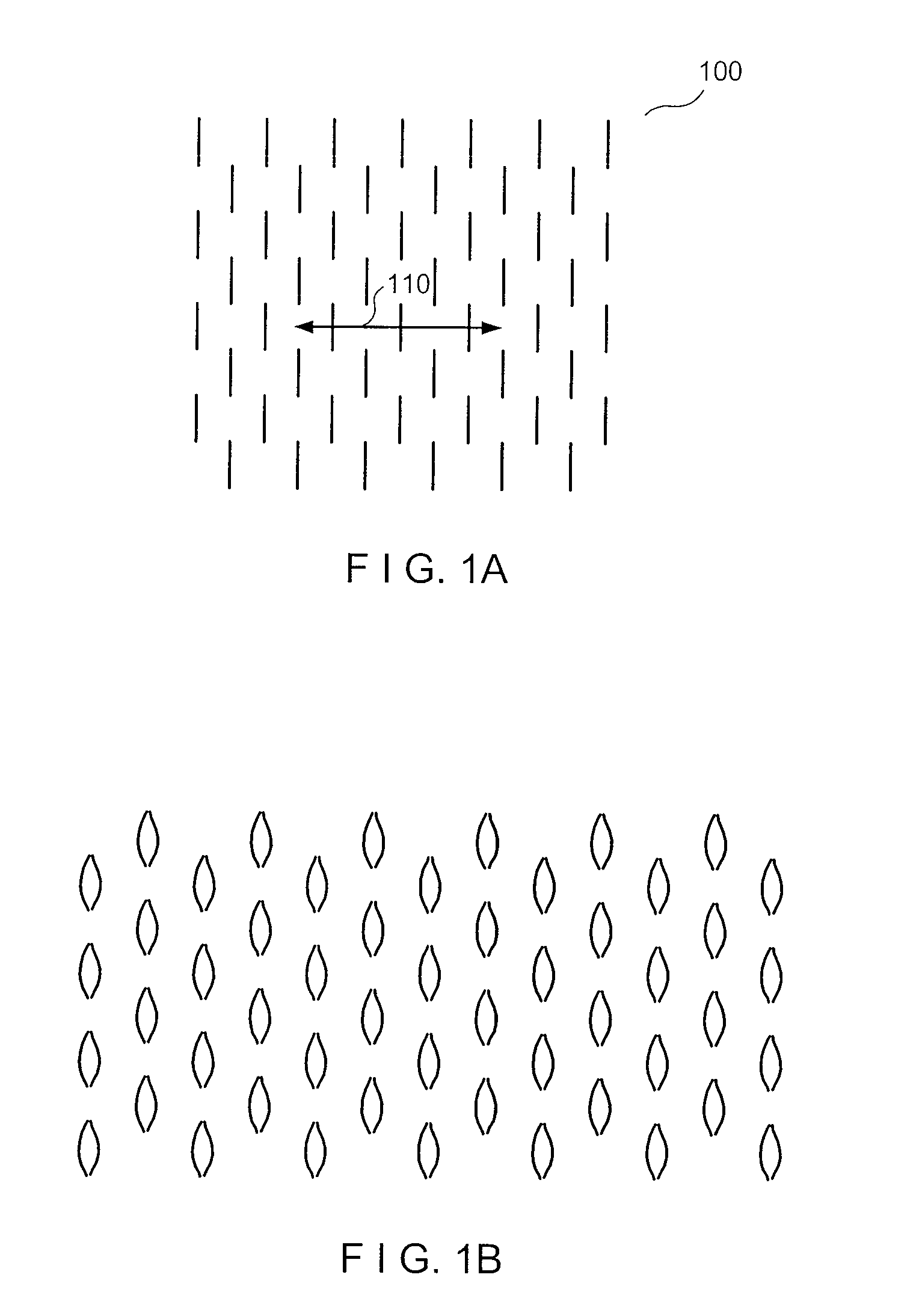

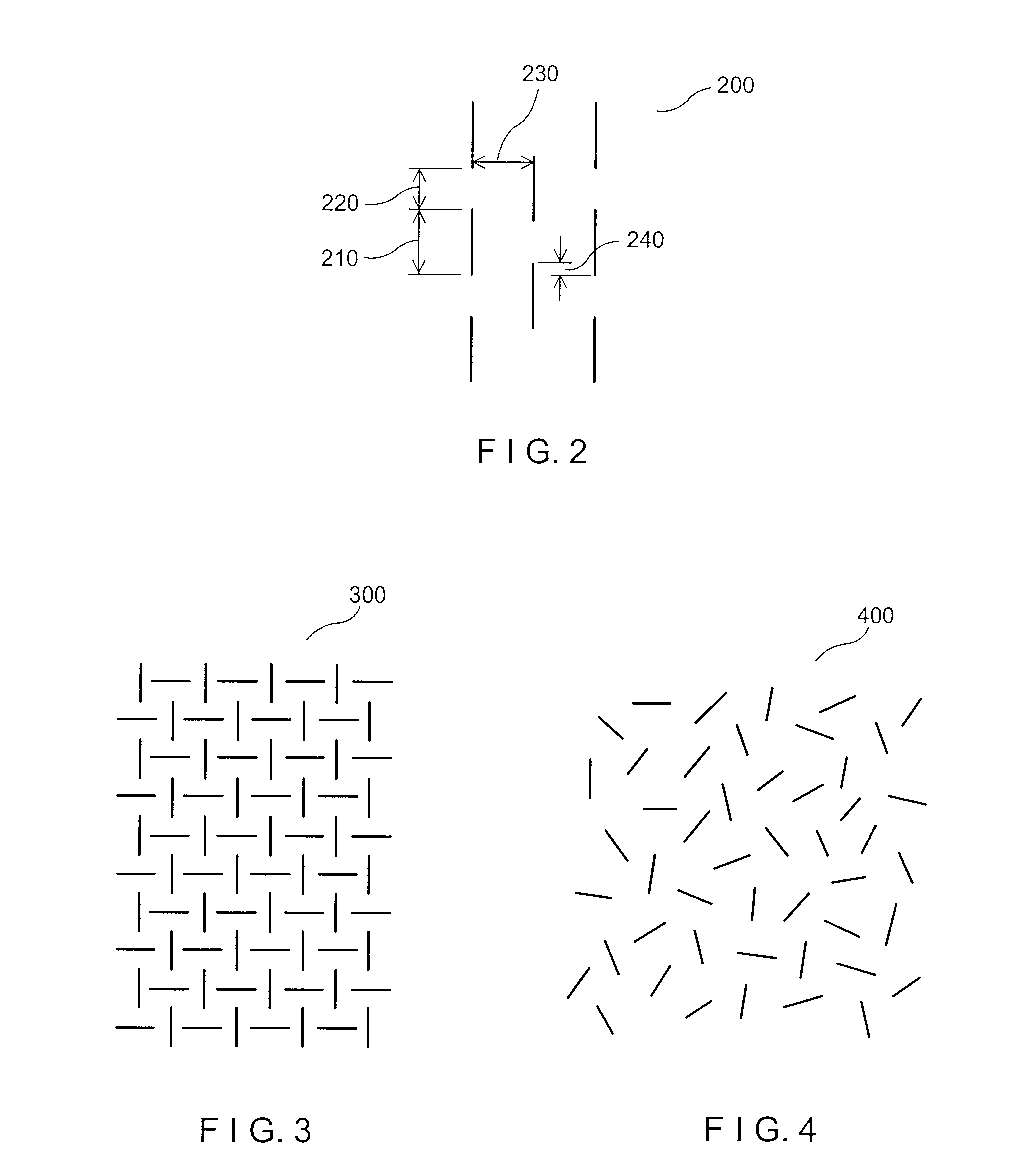

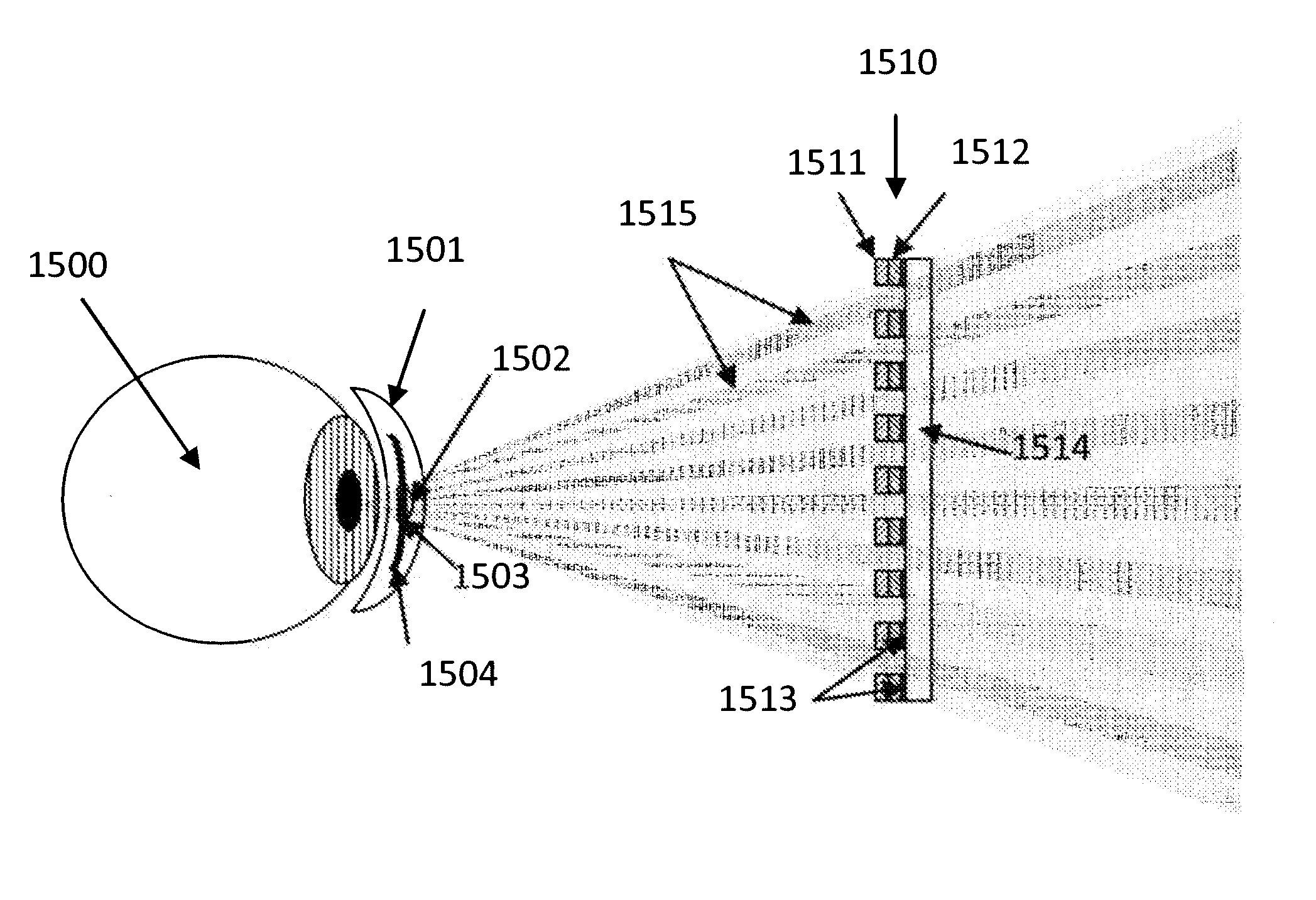

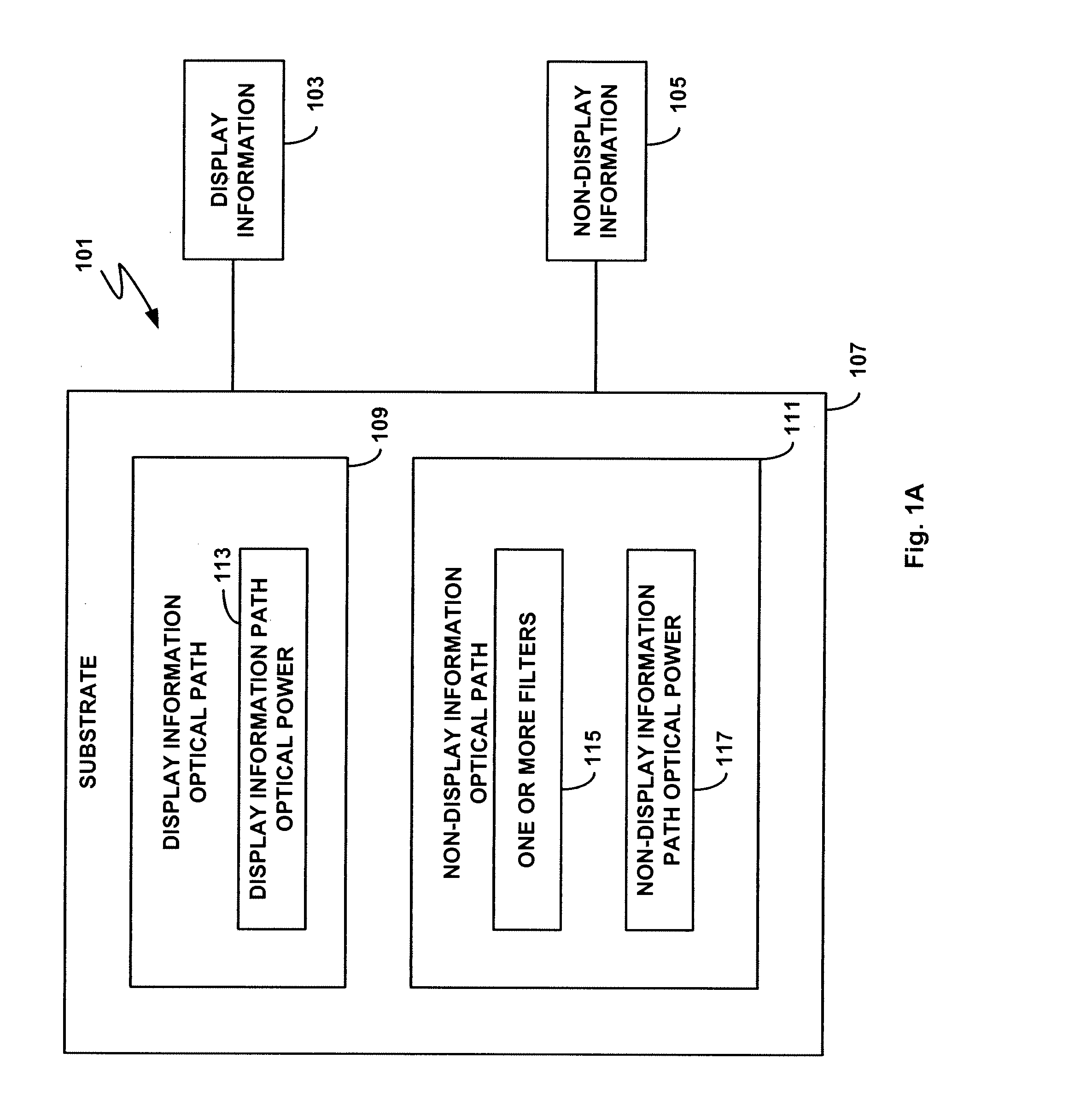

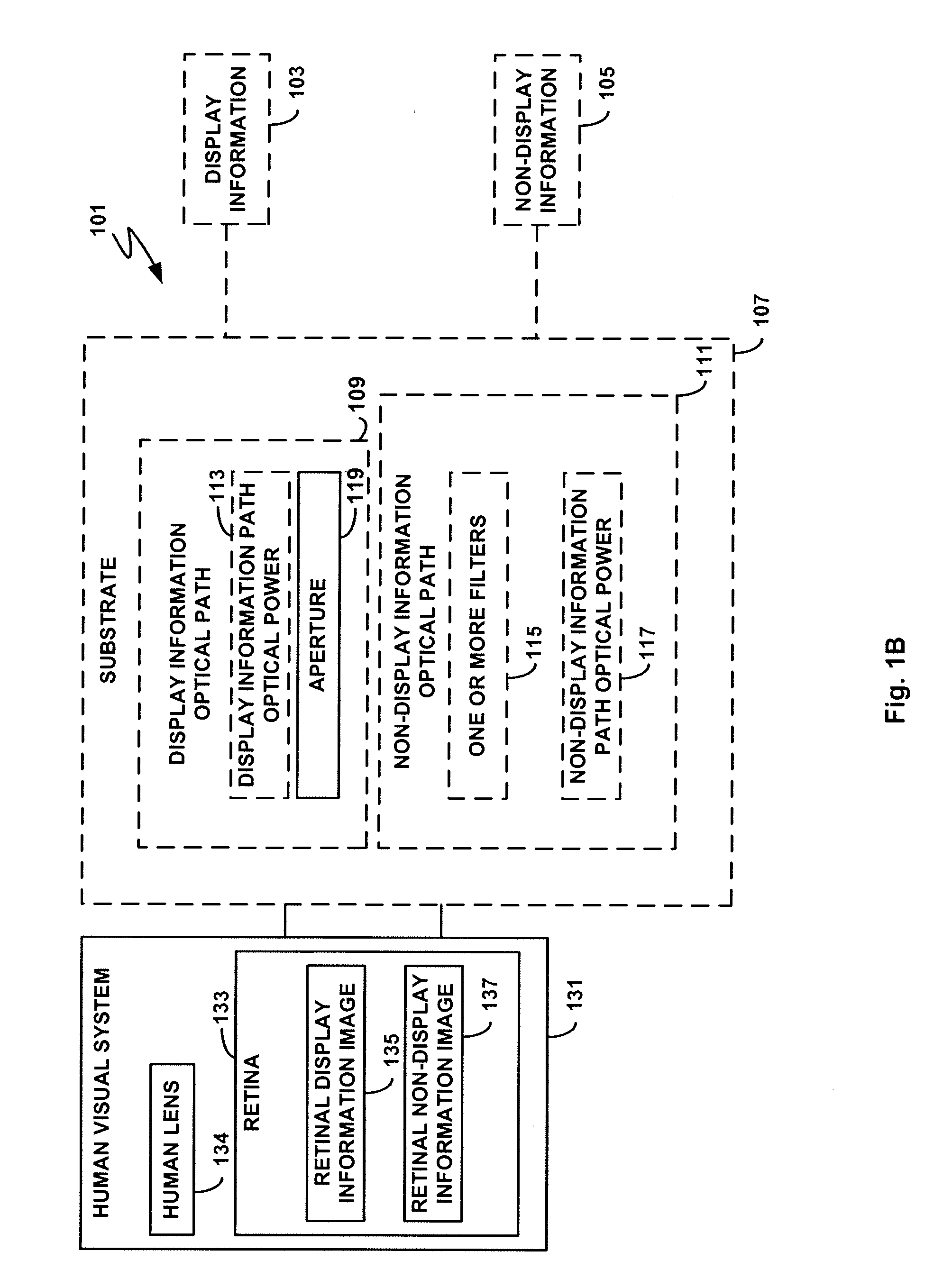

System and apparatus for pixel matrix see-through display panels

ActiveUS8441731B2Improve fullyReduce the overall heightStatic indicating devicesOptical filtersBandpass filteringElectrical polarity

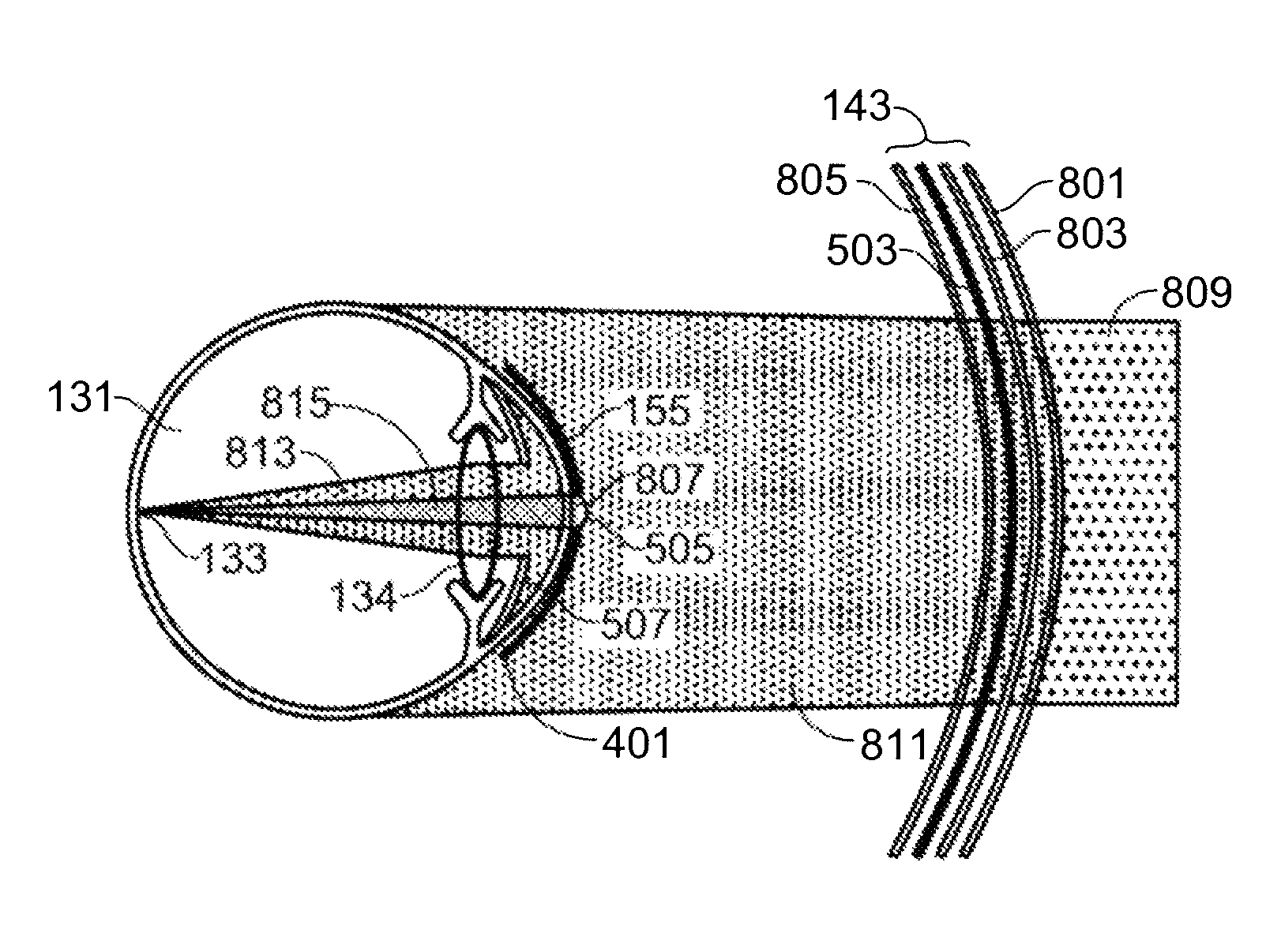

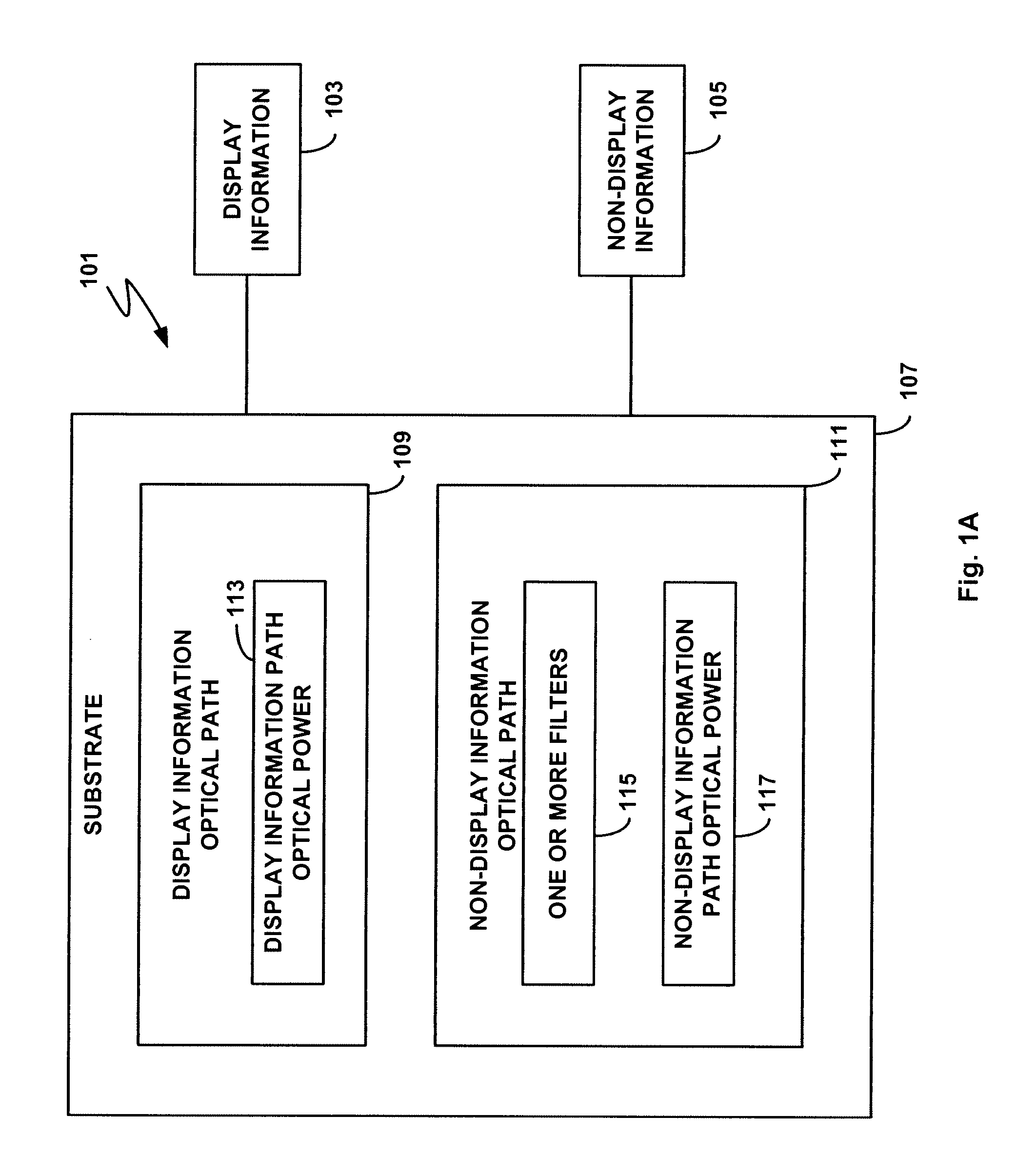

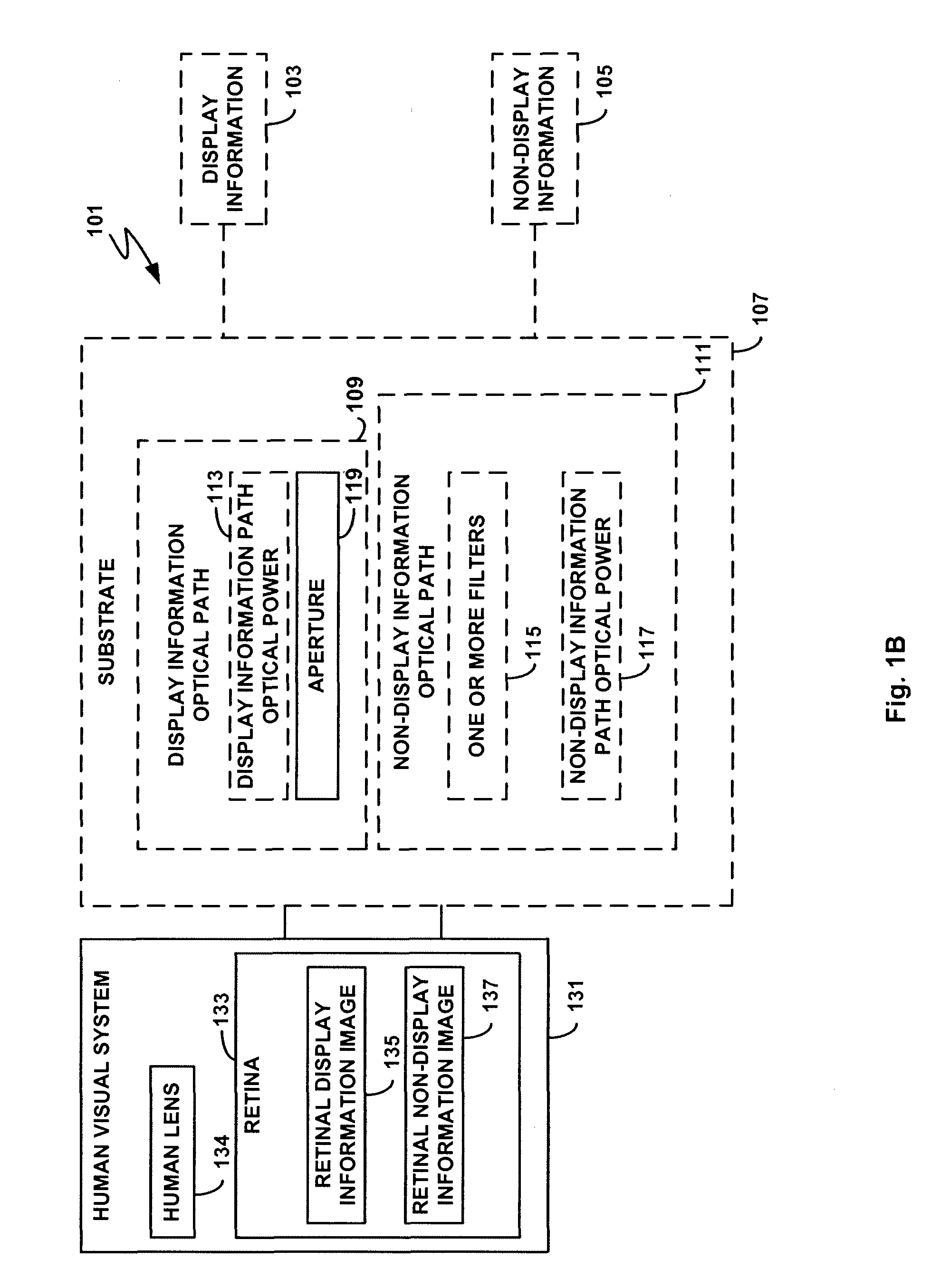

Various embodiments of the present invention provide systems and apparatus directed toward using a contact lens and deflection optics to process display information and non-display information. In one embodiment of the invention, a display panel assembly is provided, comprising: a transparent substrate that permits light to pass through substantially undistorted; a two-dimensional display panel disposed on the transparent substrate, wherein the display panel comprises pixel elements sufficiently spaced with respect to each other to allow light to pass through the display panel assembly; and at least one filter disposed on at least one pixel element. The filter may comprise a bandpass filter that reduces bandwidths of emitted light from the pixel element, or a polarizer filter that limits polarity of emitted light from the pixel element.

Owner:INNOVEGA

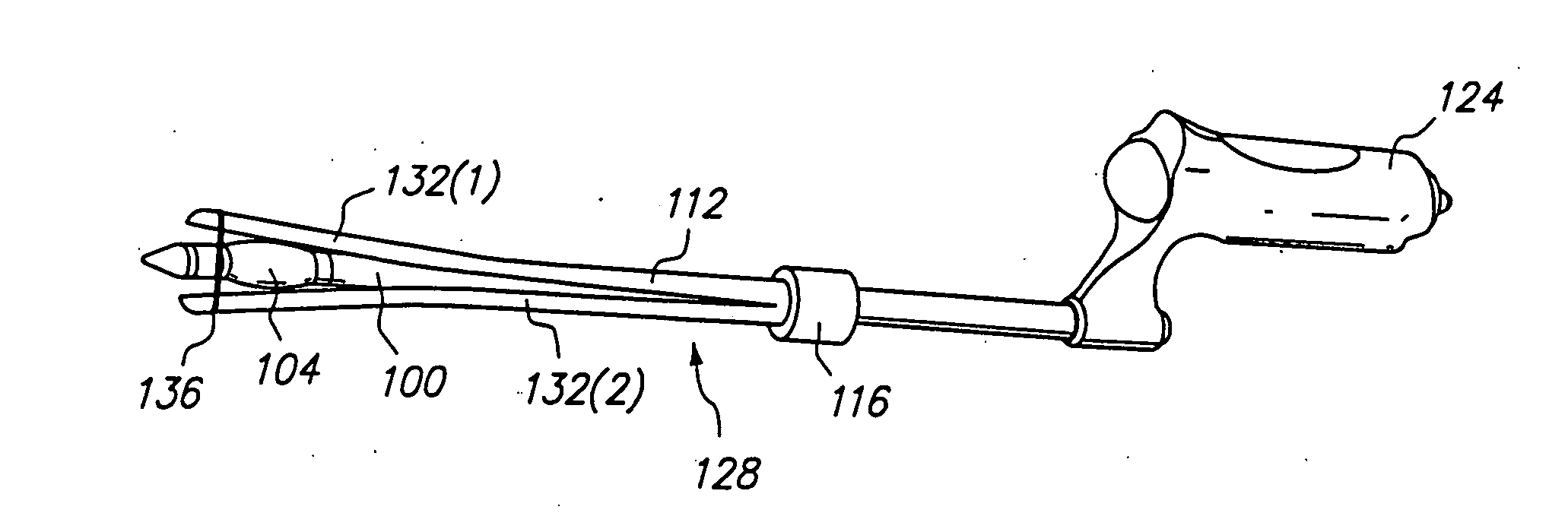

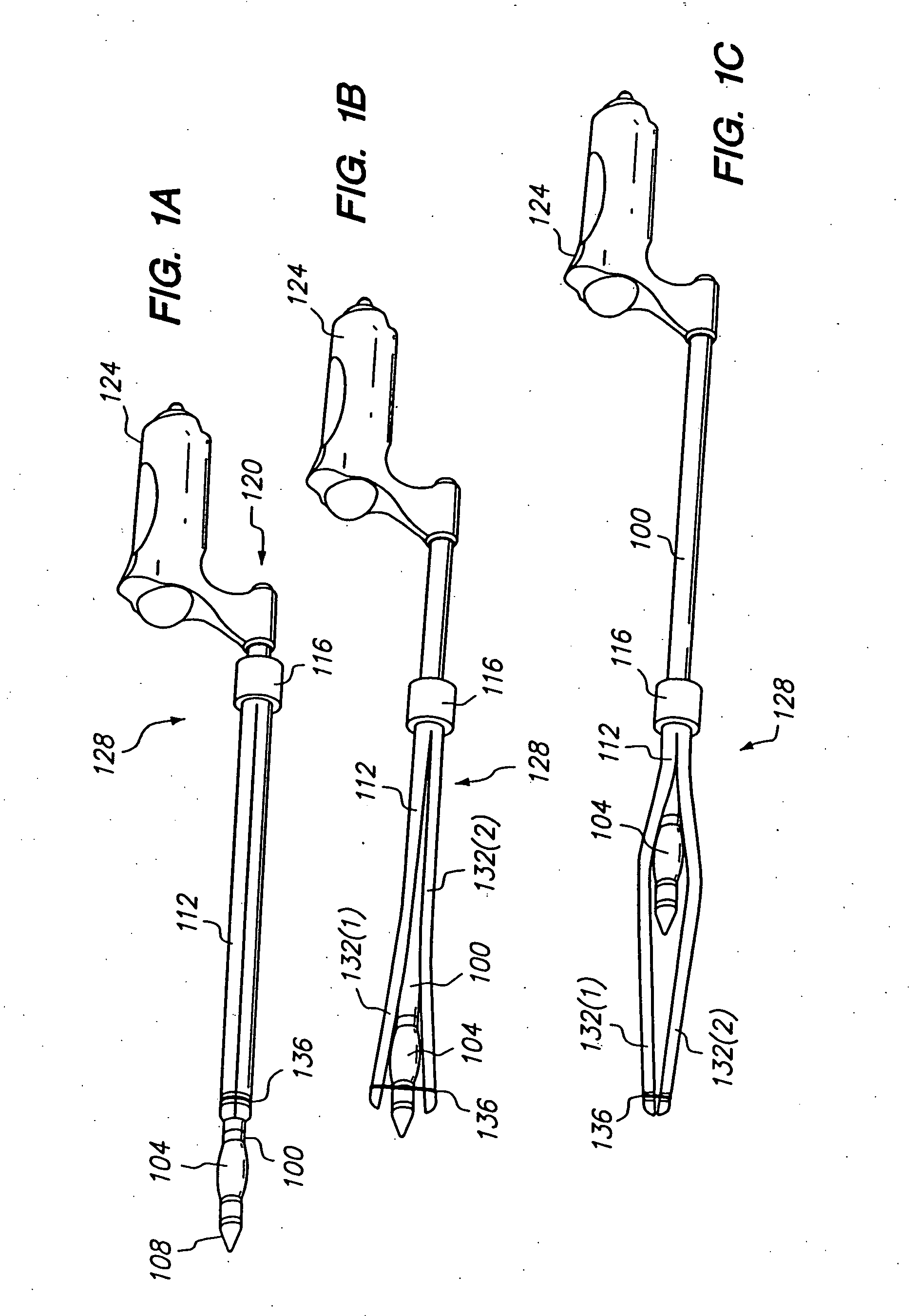

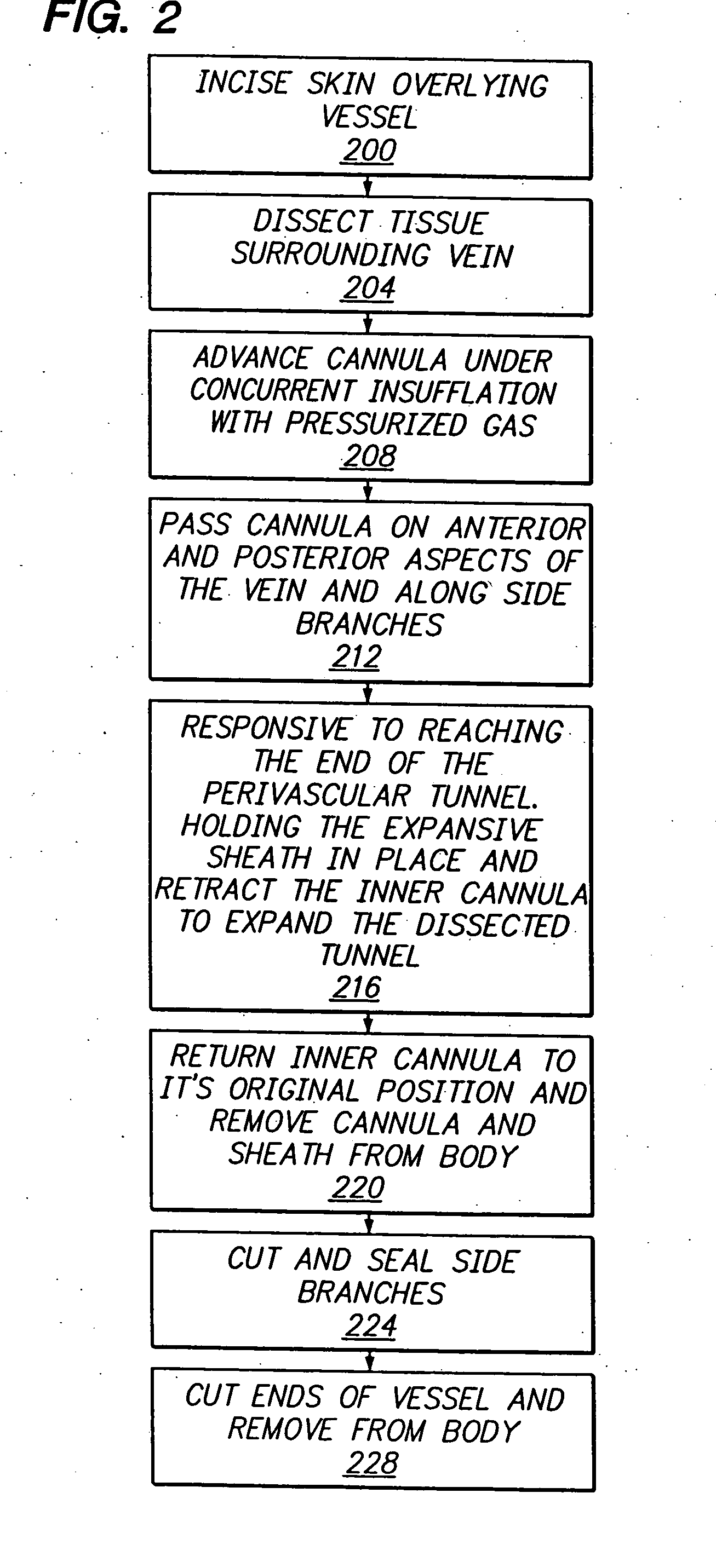

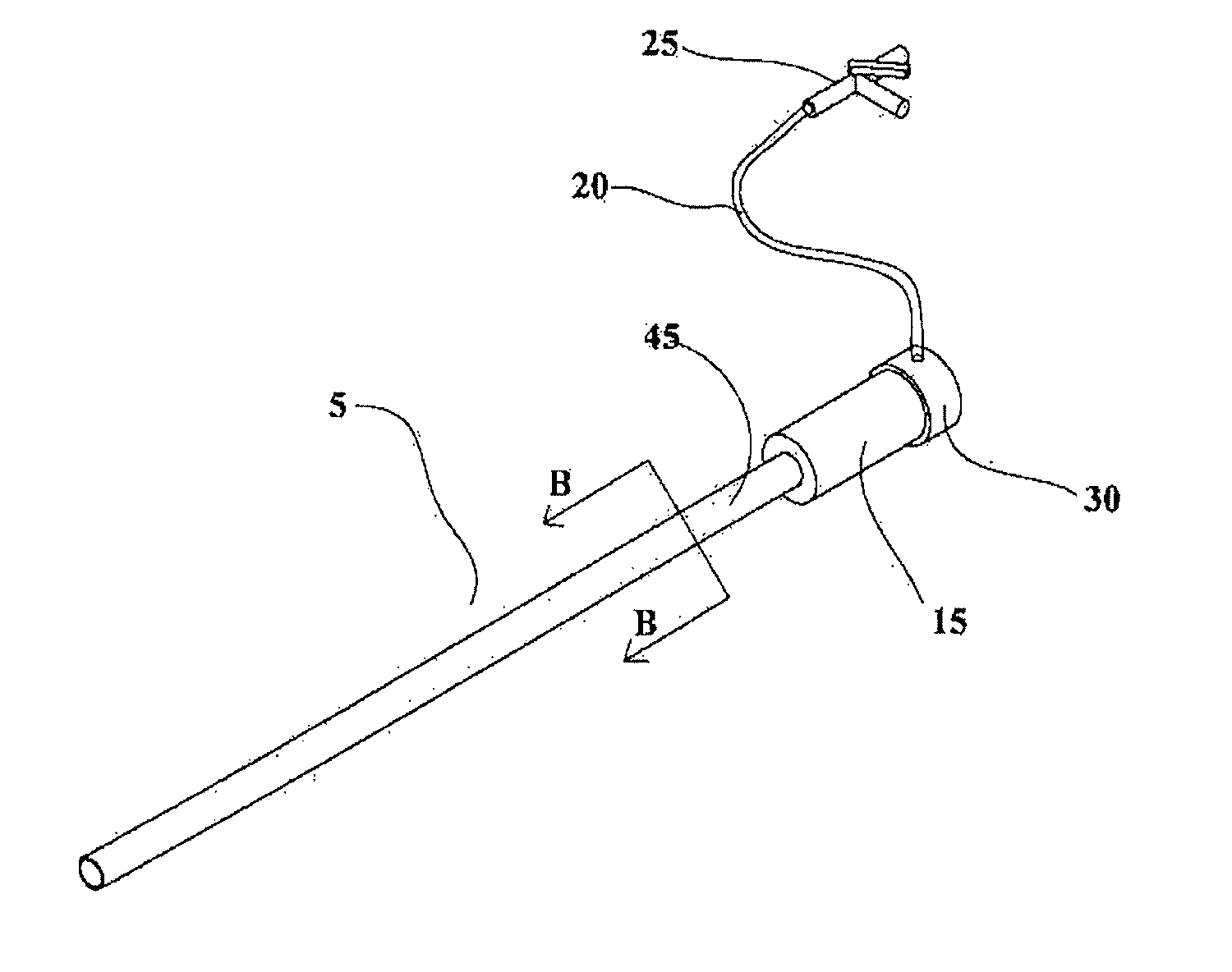

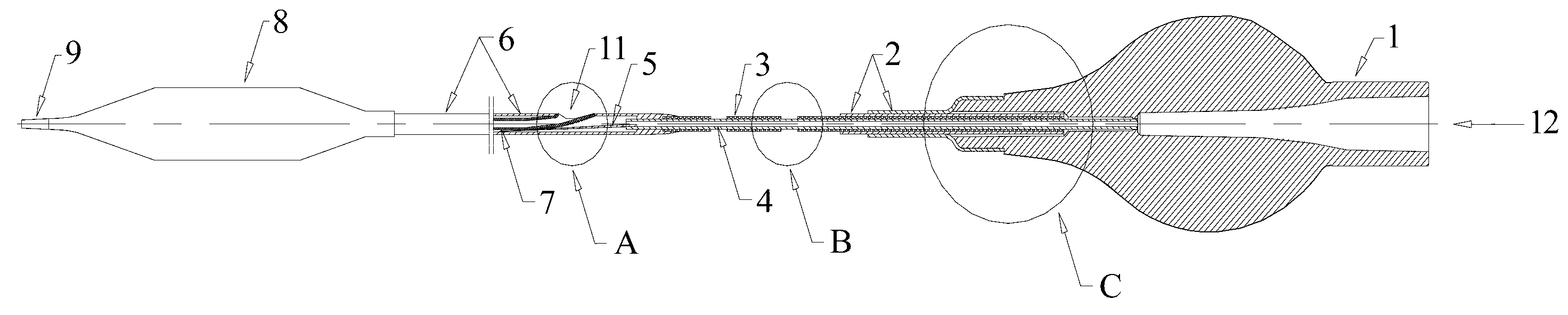

Longitudinal dilator

Apparatus and method for dilation of tissue utilize a tissue expansion device positioned on an inner cannula with an outer overlying expansive sheath that expands upon translation of the tissue expansion device therethrough. The tissue expansion device may be an olive or wedge formed near the tip of the cannula, and the expansible sheath includes two elongated shells that are fixably attached near proximal ends, and that are resiliently connected near distal ends. Translating the tissue expansion device through the expansible sheath expands the dimension of the shells to provide even dilation of surrounding tissue. Additionally, tissue dilation is performed in one continuous motion of retracting the inner cannula through the expansible sheath or pushing the tissue expansion device through the expansible sheath. The outer expansible sheath may be removed from the inner cannula to provide a dissection instrument having minimal outer diameter. The tissue expansion device may provide two stage expansion from a minimal outer dimension in one configuration to a second larger outer dimension in response to an applied axial force to provide enhanced tissue dilation.

Owner:MAQUET CARDIOVASCULAR LLC

Method and apparatus for tissue expansion

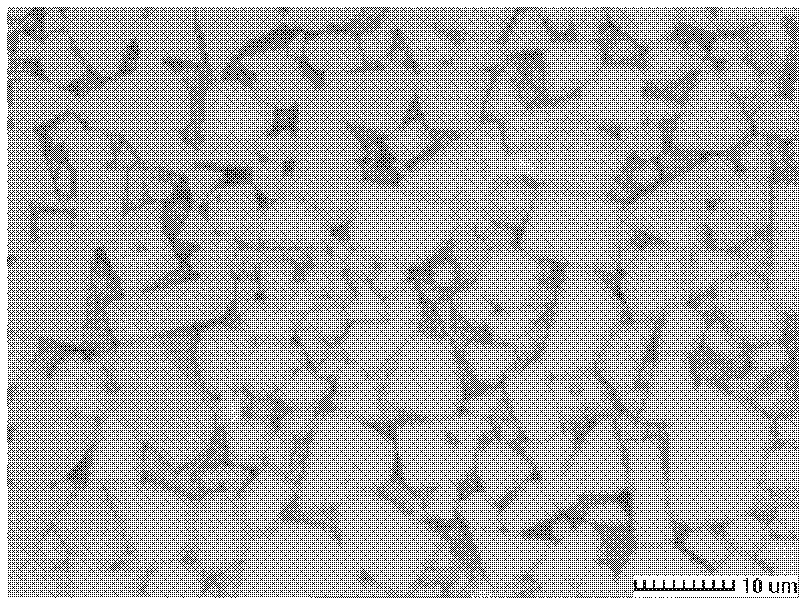

InactiveUS20110251602A1Reduce presenceReduced likelihoodSkin implantsIncision instrumentsMedicineTissue expansion

Exemplary embodiments of the present disclosure provide method and apparatus for facilitating stretching of a bio-logical tissue by forming a plurality of micro-slits in the tissue. Each micro-slit can be less than about 2 mm or less than about 1.5 mm long, or even less than about 1 mm, such that small gaps that can heal quickly can be formed when the tissue is stretched. The micro-slits can be formed using a plurality of cutting arrangements or an ablative laser. The micro-slits can be formed in various patterns, including staggered rows, circular or spiral patterns, or random patterns.

Owner:THE GENERAL HOSPITAL CORP

Biological deodorization and purification agent, and its use

A biologic deodoring and cleaning agent for treating the refuse to prepare fertilizer and cleaning and activating water area contains high-safety yeast, lactobacillus, nitrogen-fixing bacteria, functional bacillus, and photosynthetic bacteria.

Owner:CHINA AGRI UNIV

Dual view endoscope

Owner:RATNAKAR NITESH

System and apparatus for pixel matrix see-through display panels

ActiveUS20100149618A1Improve fullyReduce the overall heightStatic indicating devicesOptical filtersBandpass filteringElectrical polarity

Various embodiments of the present invention provide systems and apparatus directed toward using a contact lens and deflection optics to process display information and non-display information. In one embodiment of the invention, a display panel assembly is provided, comprising: a transparent substrate that permits light to pass through substantially undistorted; a two-dimensional display panel disposed on the transparent substrate, wherein the display panel comprises pixel elements sufficiently spaced with respect to each other to allow light to pass through the display panel assembly; and at least one filter disposed on at least one pixel element. The filter may comprise a bandpass filter that reduces bandwidths of emitted light from the pixel element, or a polarizer filter that limits polarity of emitted light from the pixel element.

Owner:INNOVEGA

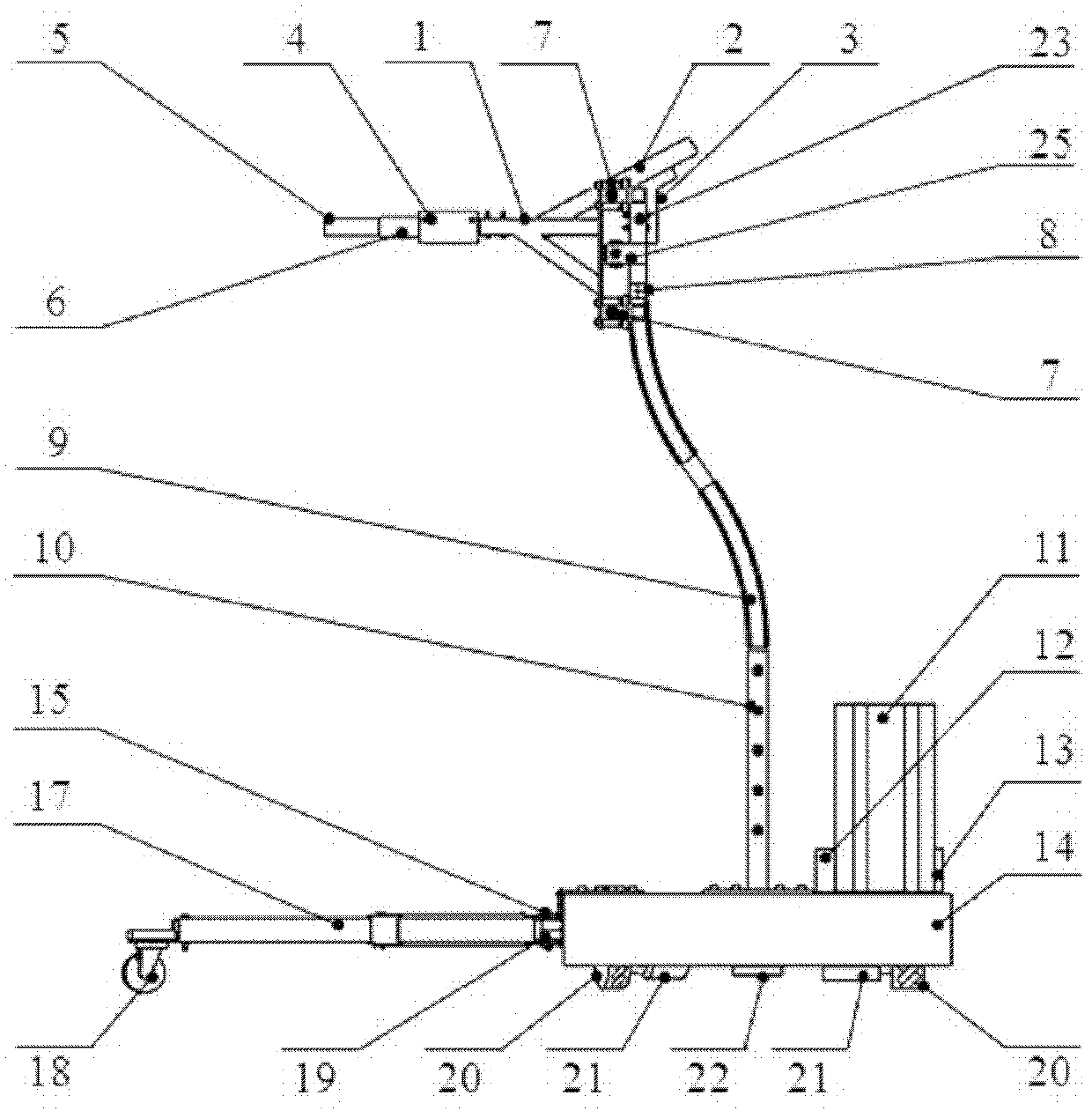

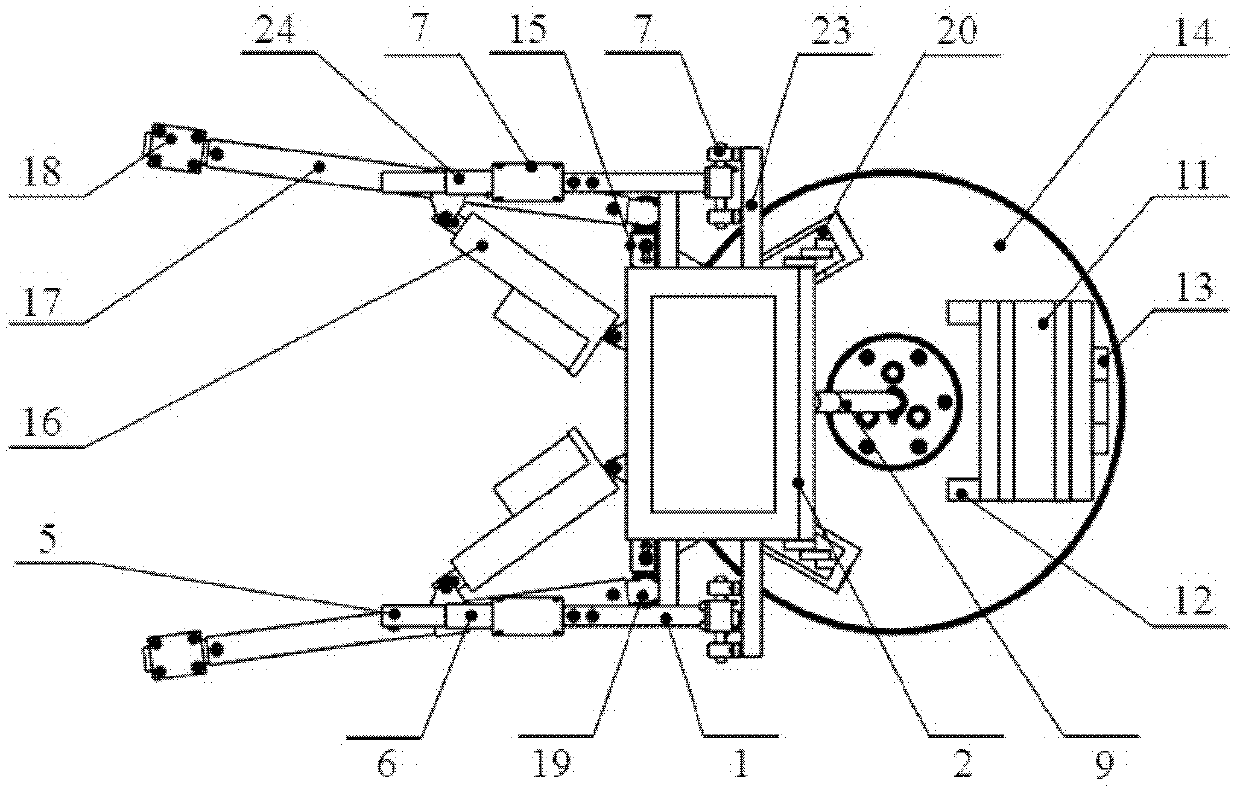

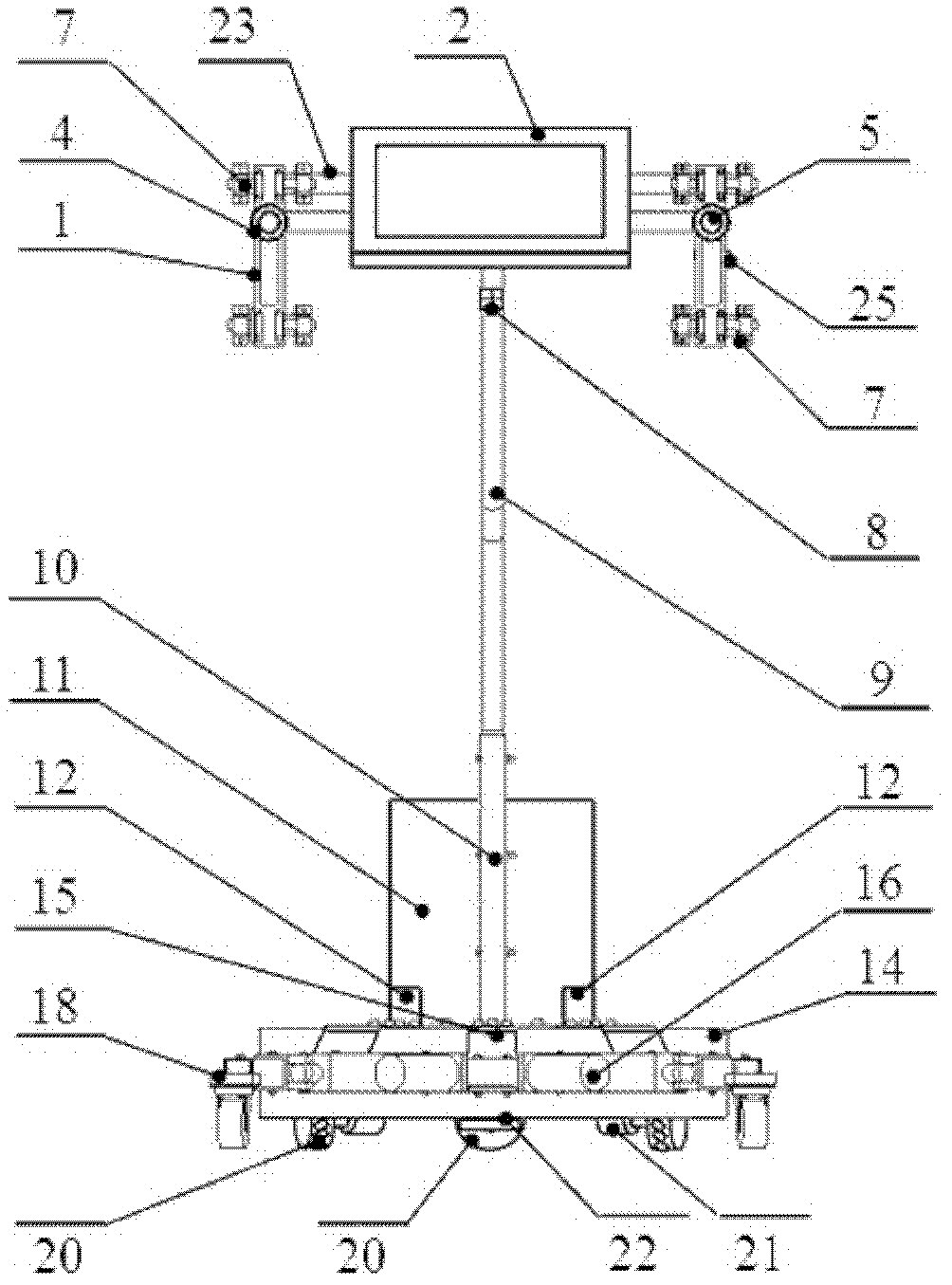

Recovery walking aiding robot

A recovery walking aiding robot belongs to walking aiding robots and recovery machinery, solves the problem that an existing recovery walking aiding robot is inflexible to pass through the narrow environment, simple in motion function and high in requirements for operation flexibility of users, and well meets actual recovery requirements. The recovery walking aiding robot comprises a handrail frame, a connection frame, a flat type microcomputer, an S-shaped support rod and a base plate, wherein the handrail frame is fixed with the connection frame through a linear bearing, the flat type microcomputer is installed on the connection frame through a support seat, the connection frame is arranged on the base plate through the S-shaped support rod, a control box is arranged on the base plate, and an environmental self-adaption module, a motion intention identification module, a speed control module, a falling prevention module and a motor driving module are loaded on the flat type microcomputer. The recovery walking aiding robot can automatically adapt to complex external environments, can achieve the functions of detecting and avoiding obstacles, preventing sliding and the like, provides falling prevention, and solves contradiction between dyskinesia of users and operation requirements of the robot.

Owner:HUAZHONG UNIV OF SCI & TECH

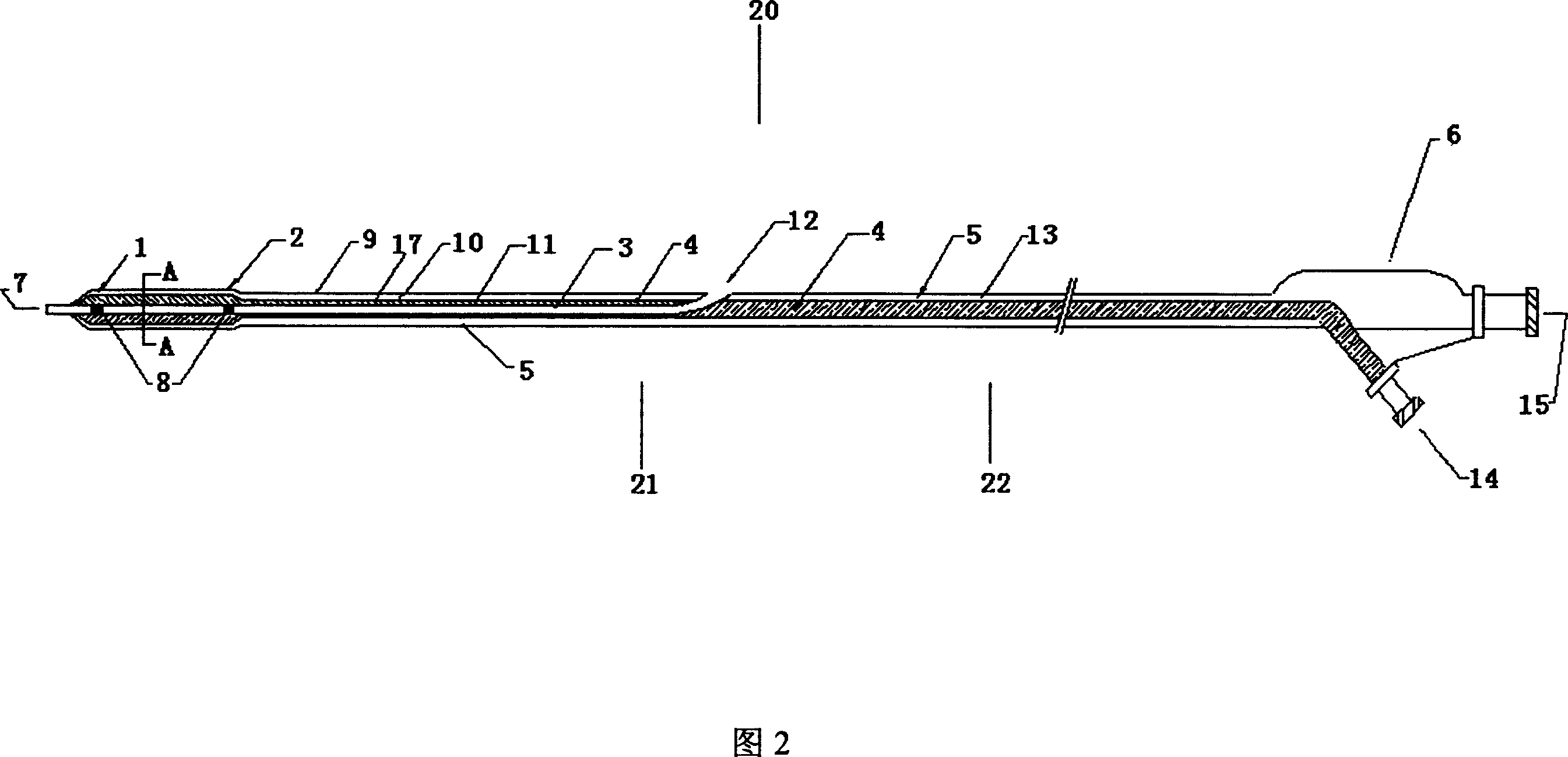

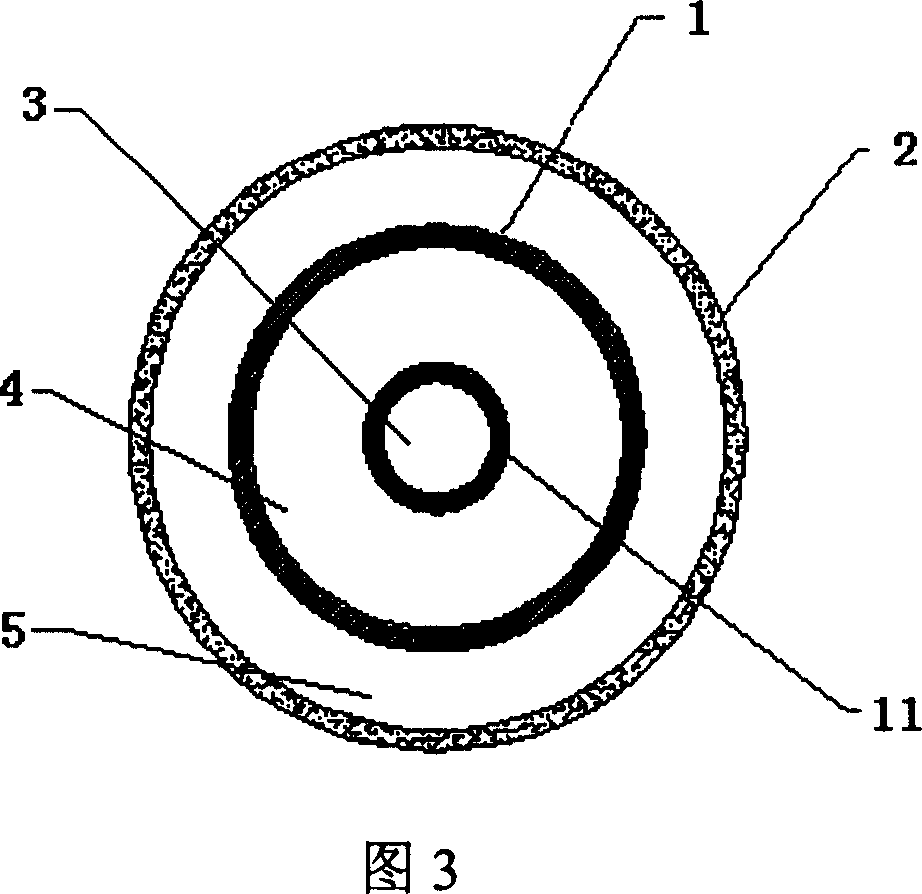

Double-layered balloon catheter

A dual-layer bag catheter is composed of two ball layers and three cavities. Its internal bag layer is used for expanding blood vessel. Its external bag layer made of unique millipore film is used for delivering the therapeutic genes or medicine to the wall of blood vessel or target organ.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

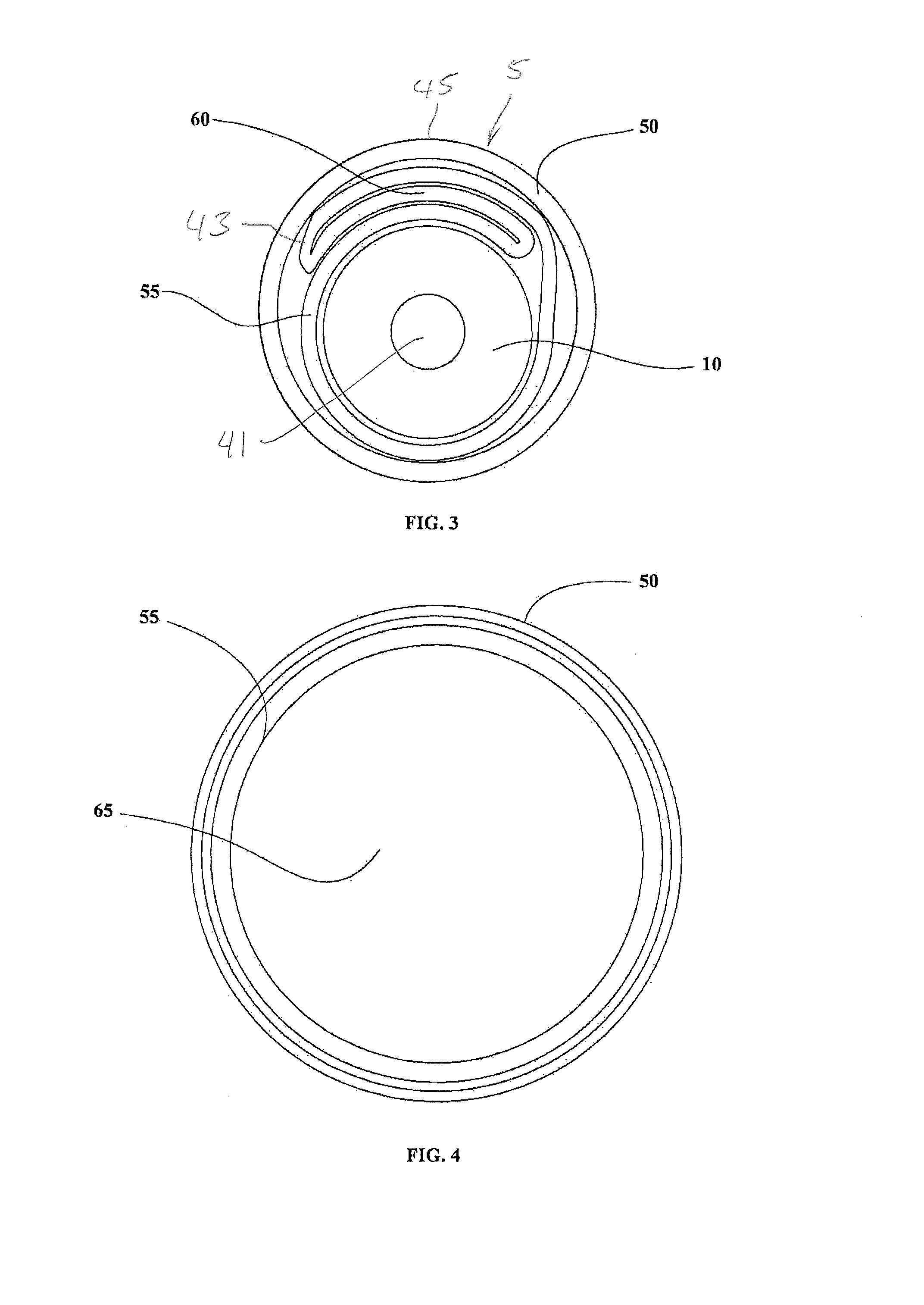

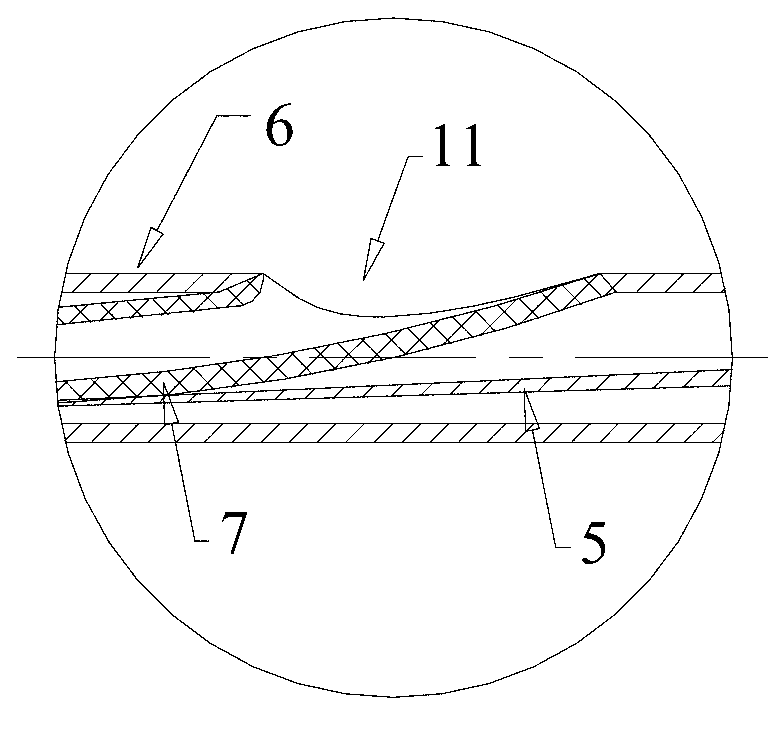

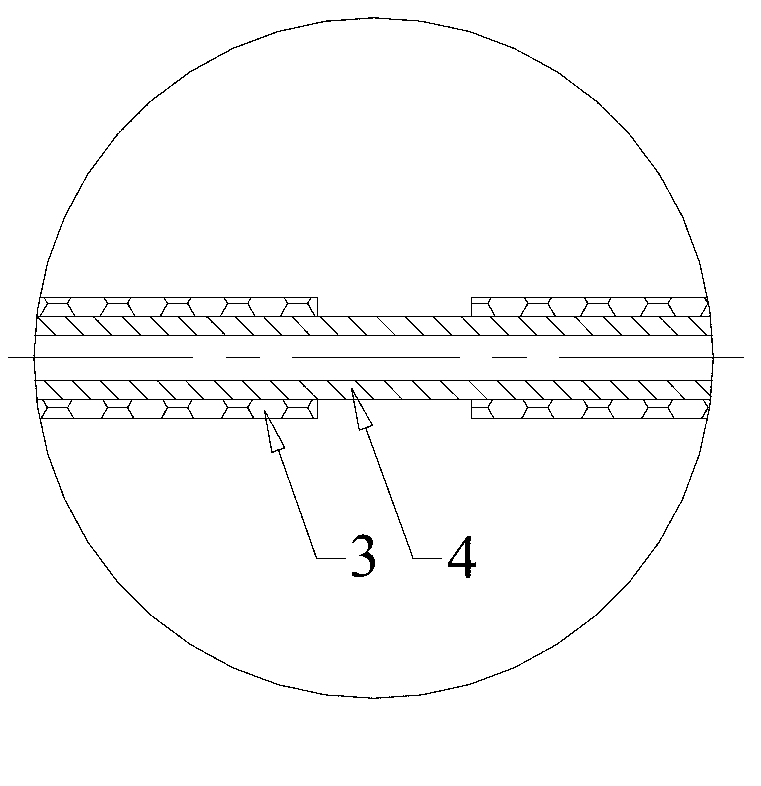

Expandable introducer sheath

ActiveUS20170014157A1Risk minimizationSufficient expansionCannulasSurgical needlesSurgeryBlood vessel

An expandable introducer sheath for use in interventional procedures. The expandable introducer sheath can be inserted into a treatment vessel in a first unexpanded configuration. The expandable introducer sheath can expand in diameter during insertion of a device through its main lumen and can then re-collapse down to its unexpanded diameter. The device comprises an inner heat-set folded layer and an outer elastomeric layer. The outer elastomeric layer provides a barrier between the inner folded layer and a vessel wall during unfolding of the inner folded layer to minimize the risk of vessel trauma.

Owner:CREGANNA UNLTD

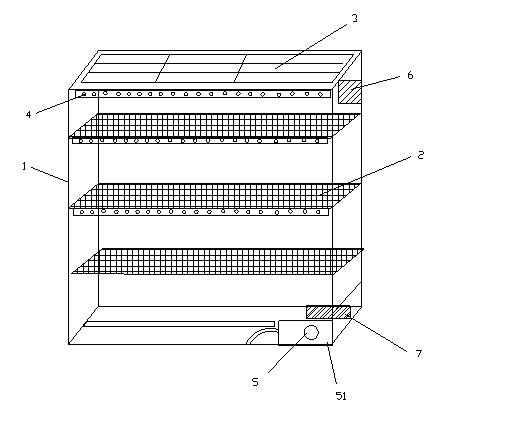

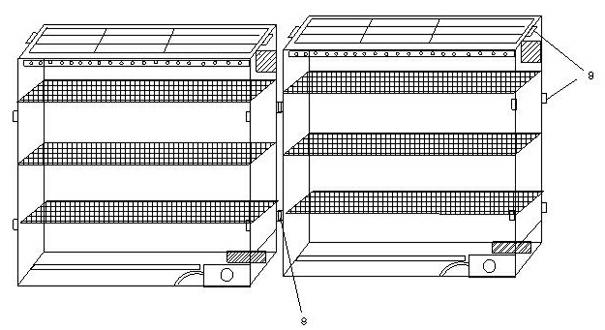

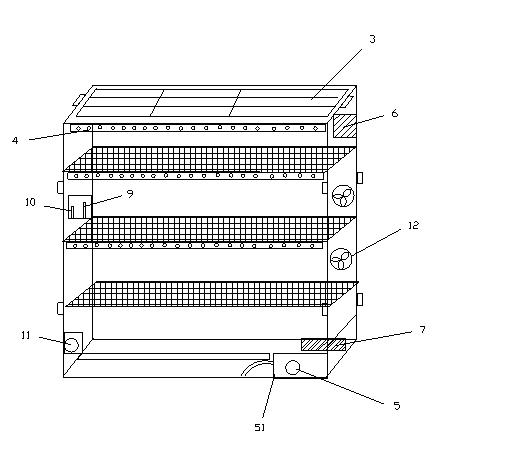

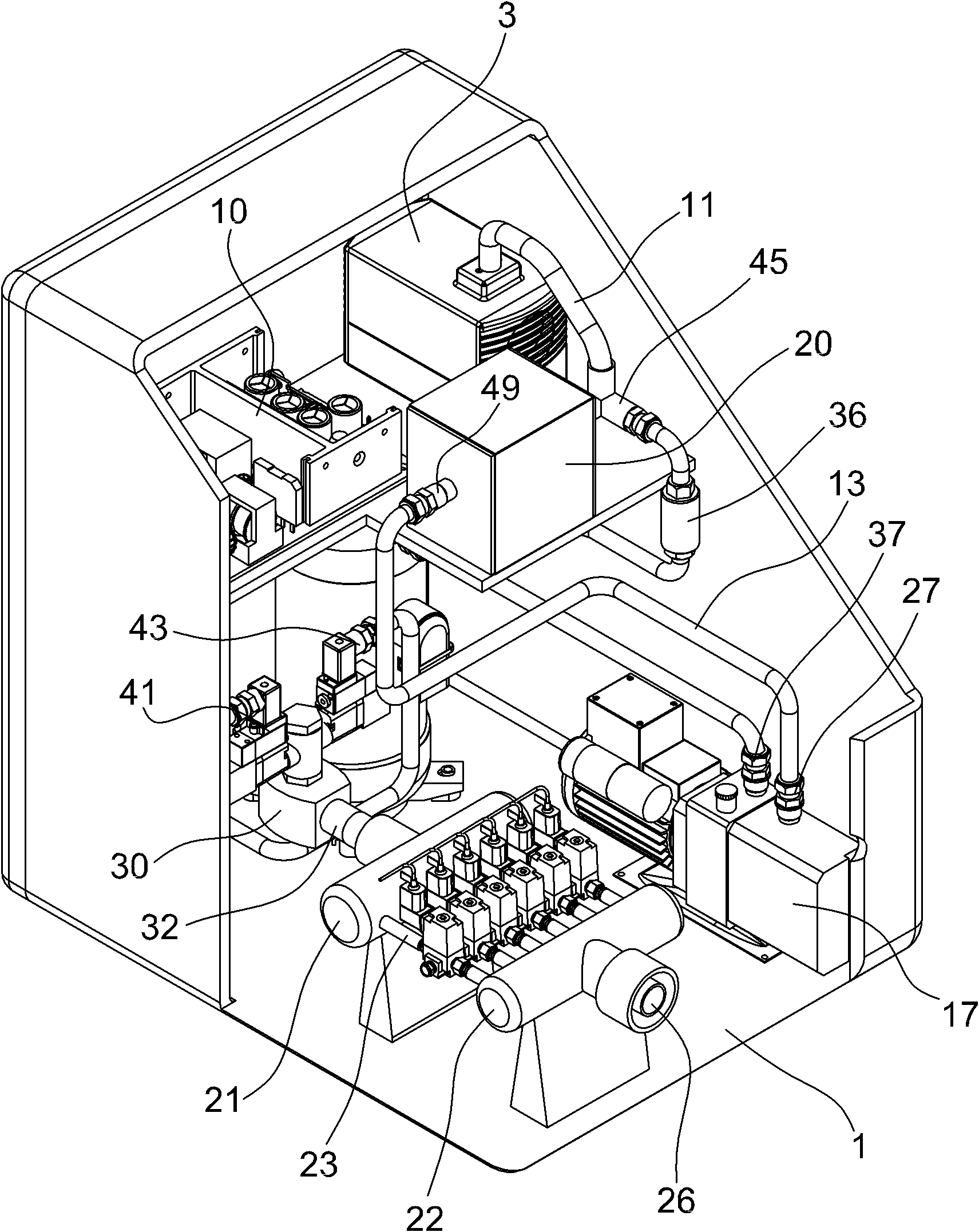

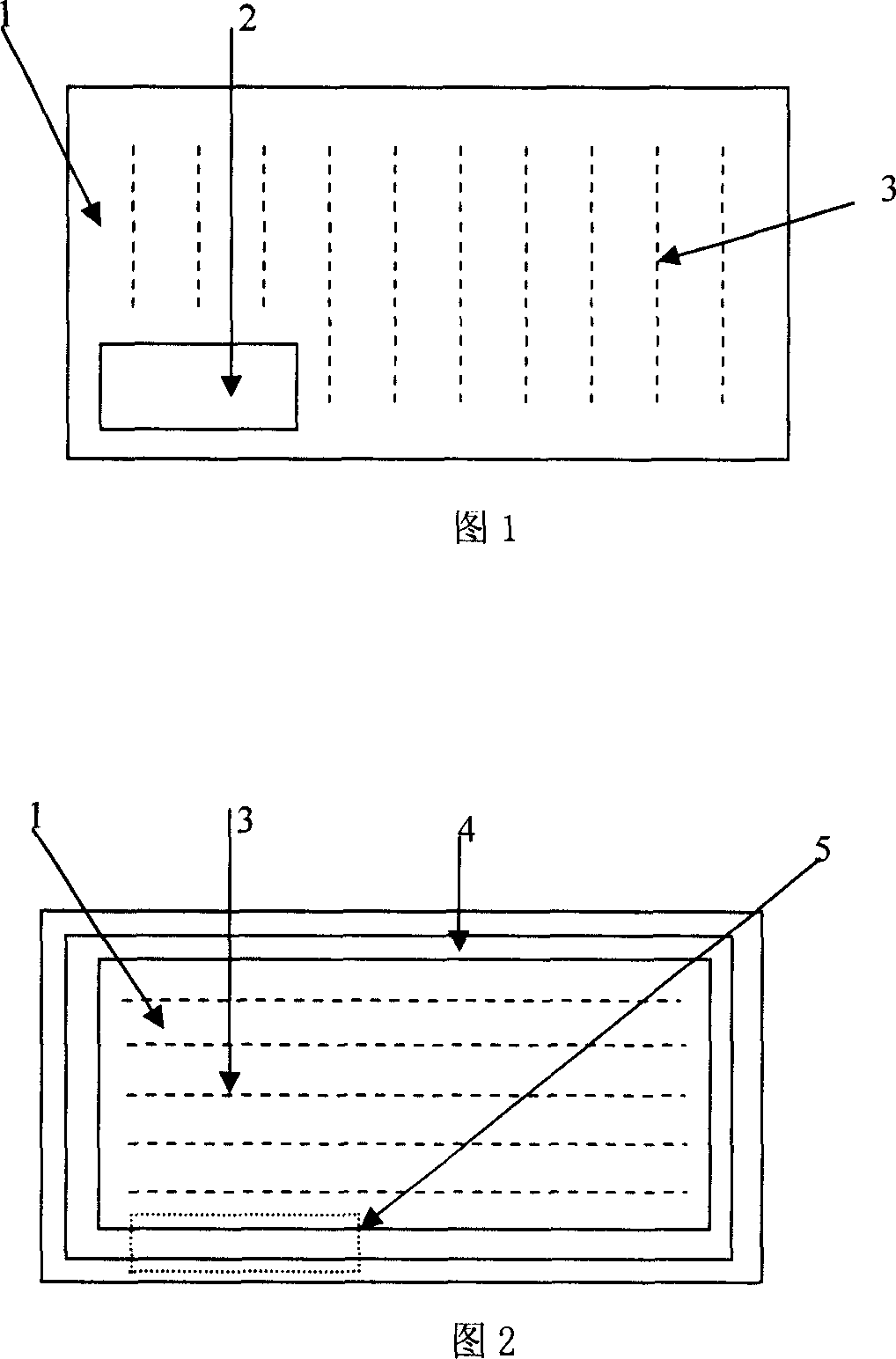

Intelligent integrated control planting device

InactiveCN102084789APromote growthIncrease productionClimate change adaptationGreenhouse cultivationControl dataEngineering

The invention discloses an intelligent integrated control planting device which comprises a planting frame and a planting disk arranged on the planting frame, also comprises a power supply, an LED lighting lamp connected with the power supply, a low-pressure water pump and central control equipment; the LED lighting lamp is arranged the upper end of the planting frame or above the planting disk, the low-pressure water pump is arranged in a water supply system at the bottom of the planting frame and used for conveying water to the planting disk through a water pipe; and the central control equipment reads a correspondingly stored control data command according to different economic planting plants and centrally controls lighting frequency and time, temperature variation and watering quantity. By combining with accurate test planting parameters and through three-dimensionally planting plants in an intelligent integrated control and scientific efficient manner, the device disclosed by the invention greatly increases the output and meets the requirement for environmental protection.

Owner:梁雄

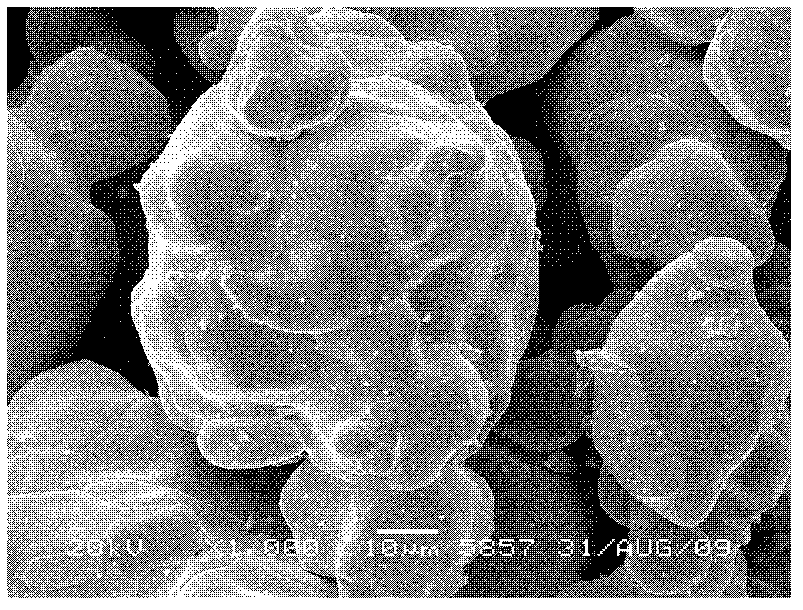

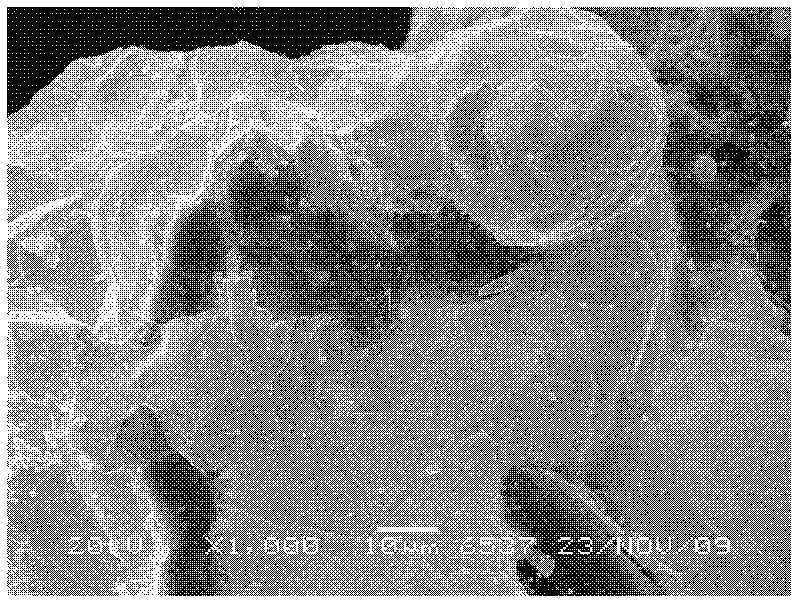

Extra coarse grain WC-Co hard alloy and preparation process thereof

ActiveCN102534344APromote grain growthIncrease the carbon content of tungsten carbideCemented carbideGrain distribution

The invention relates to an extra coarse grain WC-Co hard alloy. The hard alloy comprises 5 to 15 weight percent of Co and the balance of WC, wherein the average grain size of the WC is 6 to 10mu m. A preparation process for the hard alloy comprises the following steps of: pre-ball-milling coarse and fine tungsten carbide to prepare mixed tungsten carbide powder, preparing mixed tungsten carbide powder-cobalt-former mixed powder, pressing, and sintering, wherein the sintering step is divided into a former removing part and a high-temperature sintering part. The average grain size of a metallographic structure of the WC-Co hard alloy prepared by the process is 6mu m or more than 6mu m, the process method is simple and convenient to operate, the prepared hard alloy has a large average grainsize, a narrow grain distribution range, a low thermal expansion coefficient and high heat conductivity, high-temperature wear resistance, transverse rupture strength and rupture toughness, and is suitable for a mining tool and an excavating tool, and the thermal fatigue crack resistance of the alloy is effectively improved.

Owner:HUNAN BOYUN DONGFANG POWDER METALLURGY

Balloon catheter and manufacturing method thereof

The invention discloses a balloon catheter and a manufacturing method thereof and aims to improve pushing capability and permeability of the balloon catheter, lower damage to blood vessels, and increase utilization rate of the balloon catheter. A balloon passes through a far-end outer catheter body and a near-end catheter body to a needle seat to form a pressure cavity. A far end of the balloon is connected with a catheter tip. The far-end outer catheter body is made of nylon or nylon elastomer. The near-end catheter body is made of stainless steel or nickel-titanium memory alloy. An inner catheter is arranged in the pressure cavity. A far end of the inner catheter is connected with the catheter tip. A near end of the inner catheter is a fast switching port for a guide wire. The manufacturing method includes obtaining parts and assembling. Compared with the prior art, by the catheter tip, the far end of the balloon catheter is good in tenacity and in good fit with the guide wire. During treating complex lesion such as curve blood vessels with lesion and chronic fully closed blood vessels with lesion, permeating capability of the balloon catheter through the blood vessels with lesion is high, the blood vessels with lesion can be expanded fully, blood vessel damage which can be caused easily can be reduced, and operation cost is lowered.

Owner:ORBUSNEICH MEDICAL SHENZHEN CO LTD

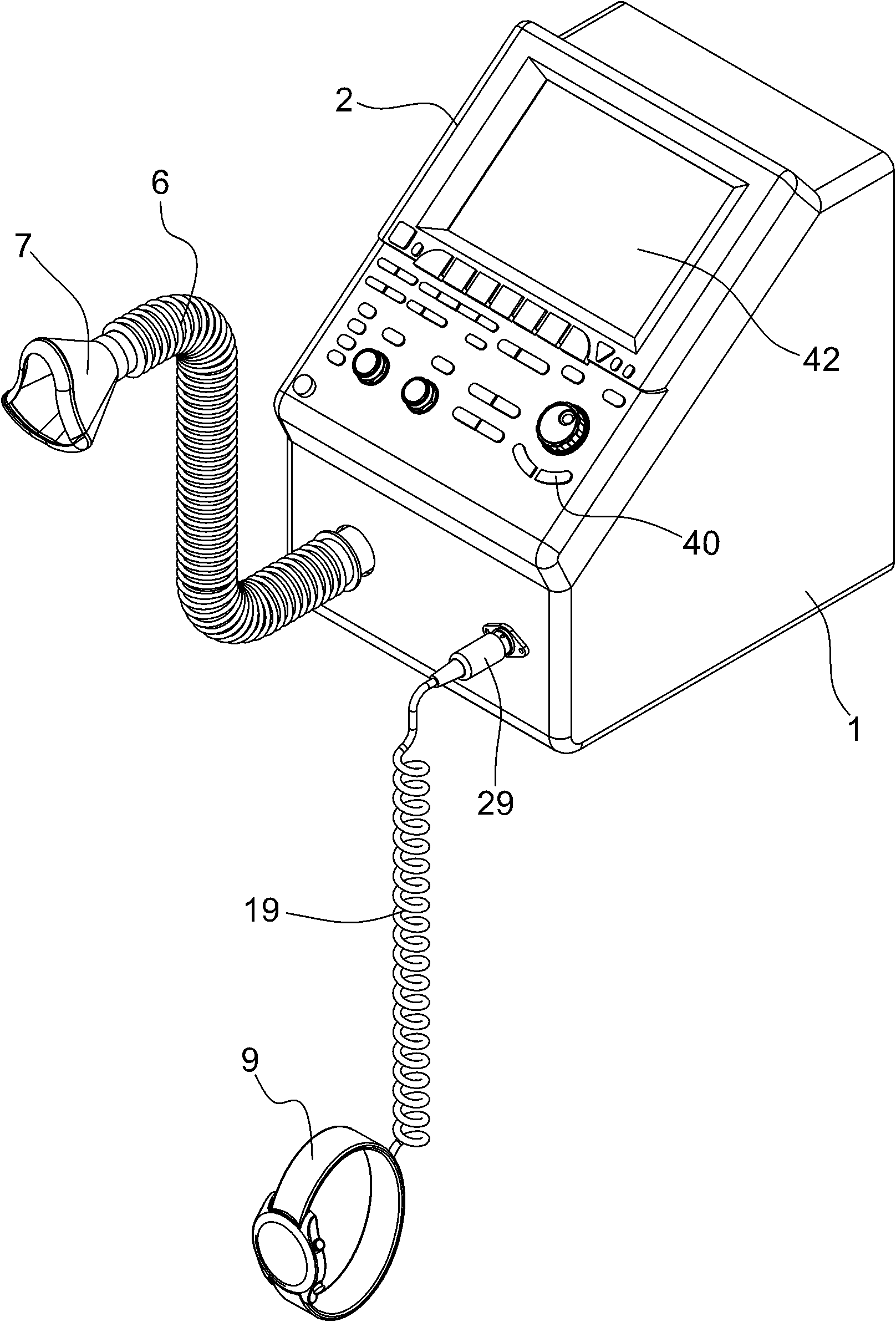

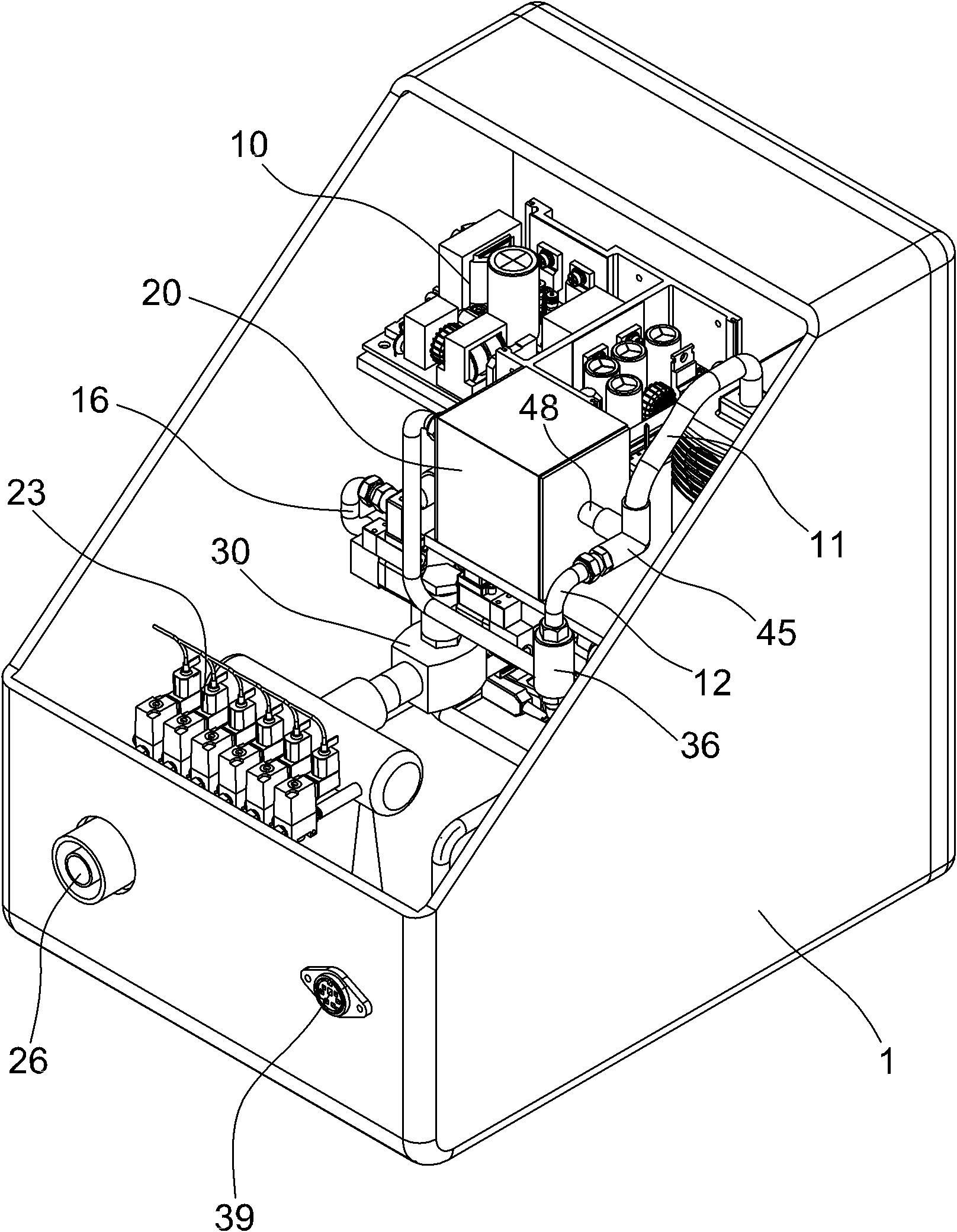

Breath trainer

The invention provides a breath trainer. The breath trainer consists of a chassis, a control panel, a filter box, a buffer pot, a check valve, an air hose, a nose cover, an air discharge pipe, a pulse blood pressure and blood oxygen detector, an oxygen enrichment generation device, a flow control device, a pipeline switching valve, a pressure sensor, a flow sensor and a circuit module; the oxygen enrichment generation device consists of an oxygen enrichment membrane component box and a vacuum pump; the flow control device consists of a first air distribution barrel, a second air distribution barrel and a resistance pipe network; the air discharging pipe is connected with the pressure sensor and the flow sensor through branch pipes; a liquid crystal display screen and a control key are arranged on the control panel; and the circuit module consists of a singlechip, a voice chip, a power amplifier, a loudspeaker, a program memory, a data memory, a display circuit, a keyboard circuit and a signal conditioning circuit. The breath trainer has high intelligent level, can perform human-machine interaction and increase the training interest, and is capable of selecting a training load and a training time according to a parameter input by a user, so a step-by-step exercising effect can be achieved.

Owner:徐赤坤

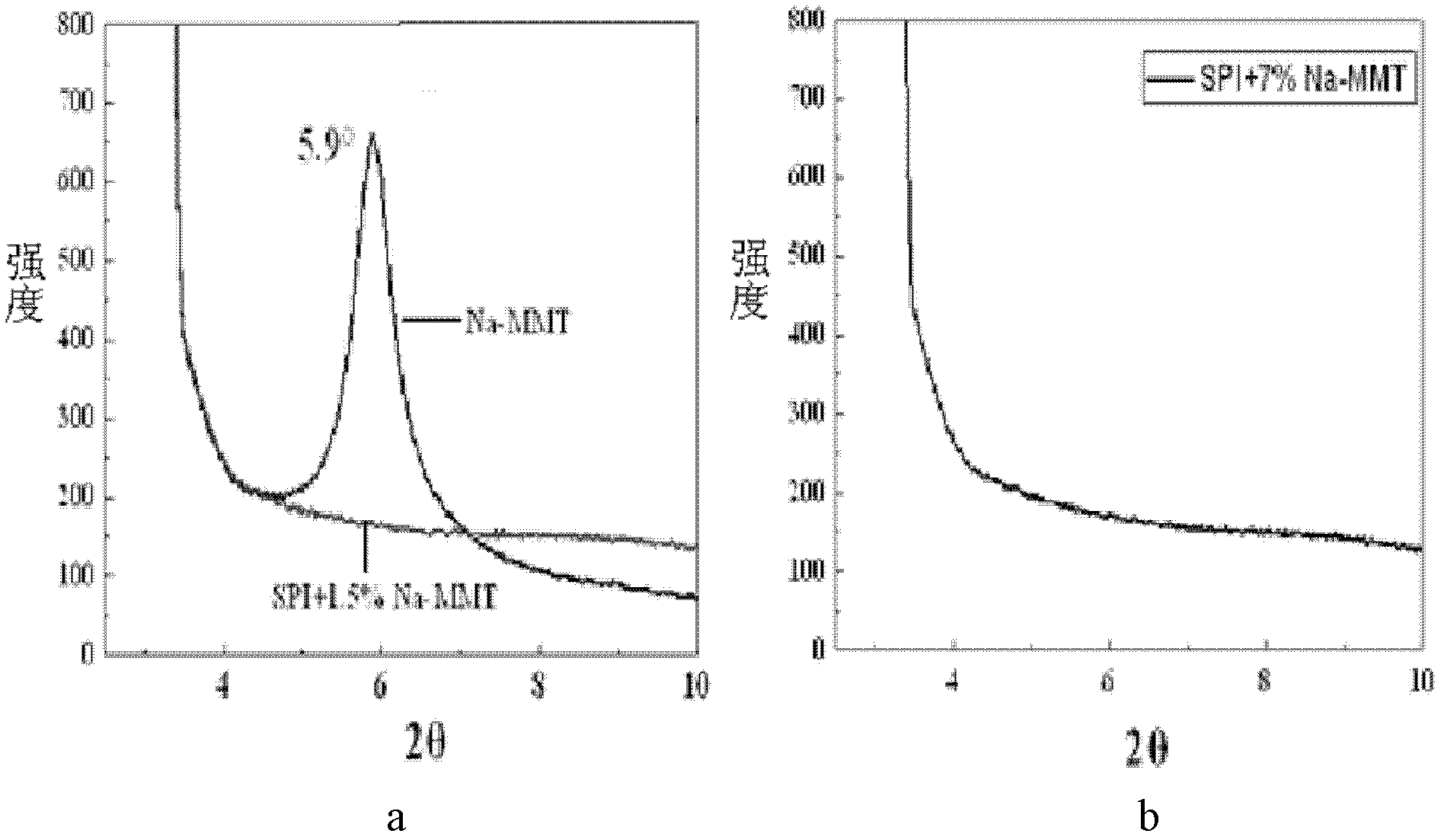

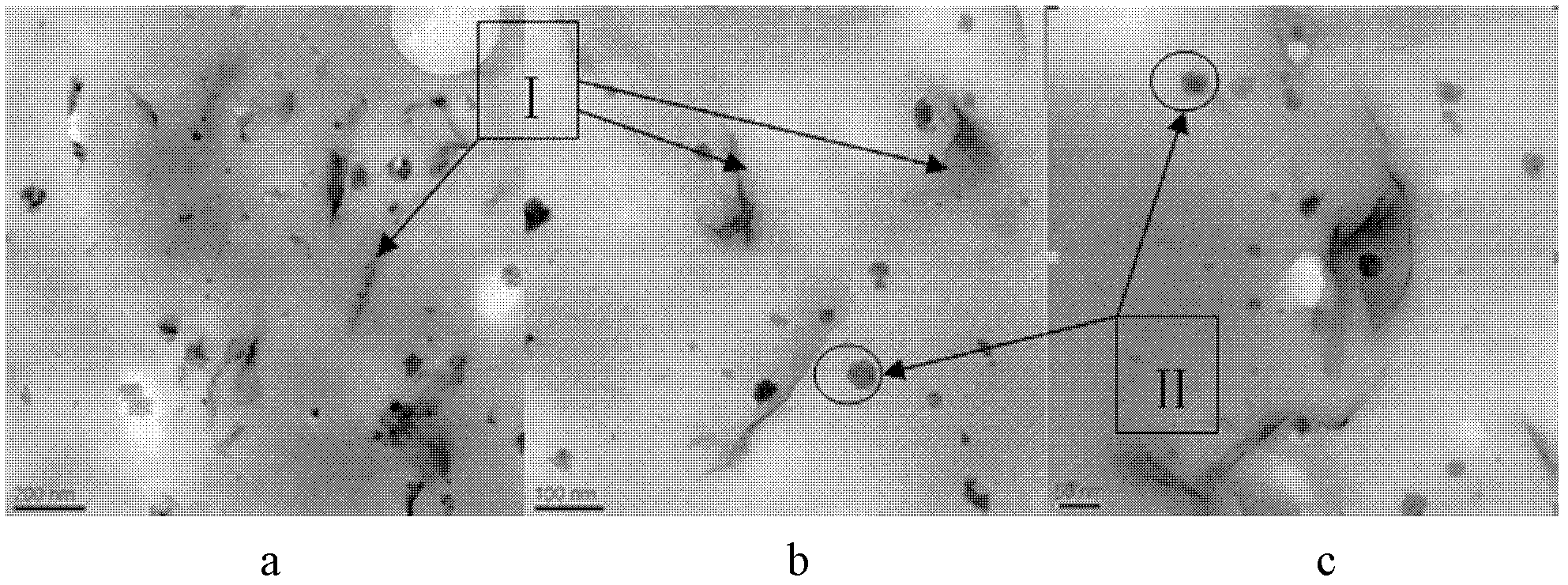

Layered silicate reinforced soybean adhesive, its preparation method and application

ActiveCN102516933AHigh bonding strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesAdhesiveEconomic benefits

The invention discloses a layered silicate reinforced soybean adhesive, comprising 100 weight parts of water, 10-50 weight parts of soybean derivative, 0.1-10 weight parts of modifier, and 0.1-10 weight parts of layered silicate. The soybean adhesive disclosed herein comprises no formaldehyde as a raw material, thus the soybean adhesive belongs to an environmentally friendly adhesive. By using the modifier and layered silicate to modify soybean protein in the soybean derivative, the initial adhesion is raised, and simultaneously the bonding intensity and water resistance of the soybean adhesive are raised. The soybean adhesive is especially suitable for being used as a timber adhesive. The invention further provides a preparation method of the layered silicate reinforced soybean adhesive.The method has the advantages of simple preparation, good controllability, and low production cost, is easy to operate and is easy to industrialize, has good economic benefits, is beneficial for popularization and application, and has a wide application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Production method of double-face coral fleece fabric

InactiveCN101736506AImprove fullyAdd ironing stepWarp knittingHeating/cooling textile fabricsDyeingEngineering

The invention relates to a production method of a double-face coral fleece fabric, which comprises the following steps sequentially: preparing raw materials, warping, weaving, slitting, brushing a white blank, pre-molding, finishing the front face of the white blank, reducing the alkali quantity, dyeing, processing after dyeing, finishing lustre, napping, brushing, finishing, cropping, frizzling, shaping compositely, checking and packaging; double faces of the double-face coral fleece fabric both have the style of coral fleece and both can be used in a skintight way, the double-face coral fleece fabric has better heat retention property, lightness and good flexibility, and the market requirement is fully met. The fabric double faces of which both have the style of the coral fleece can be processed by the production method of the fabric, the market requirement is met, and the method has reasonable process steps.

Owner:王敏其

Technology for producing needle coke by kettle-type coking

ActiveCN101942314AImprove fullyStrong scourThermal non-catalytic crackingCoking carbonaceous materialsSystem pressureEngineering

The invention discloses a technology for producing needle coke by kettle-type coking, comprising the following steps: filling raw oils into a coke still; heating slowly a system to 480-500 DEG C under system pressure of 1.0-2.0MPa; controlling appropriate gas emissions rate, keeping constant temperature for 2-6h when system temperature reaches 480-500 DEG C, and blowing in inert gas from the bottom of the coke still; and heating the system to 520-550 DEG C and continuously baking for 1-4h to generate the needle coke through reaction, wherein the obtained needle coke is deposited at the bottomof a coke tower. The technology of the invention has simple flow and small investment and can obtain the high-quality needle coke.

Owner:CHINA PETROLEUM & CHEM CORP +1

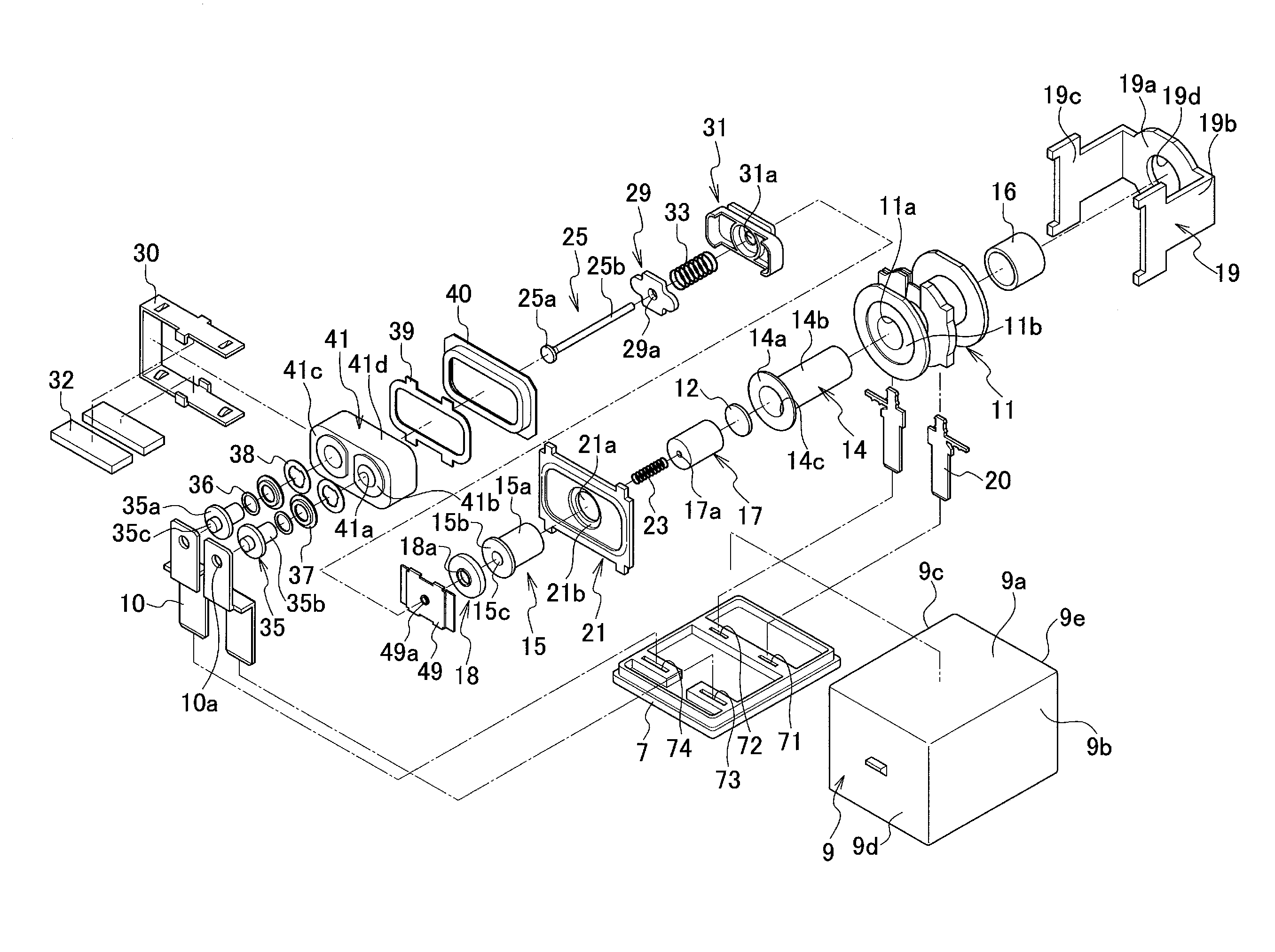

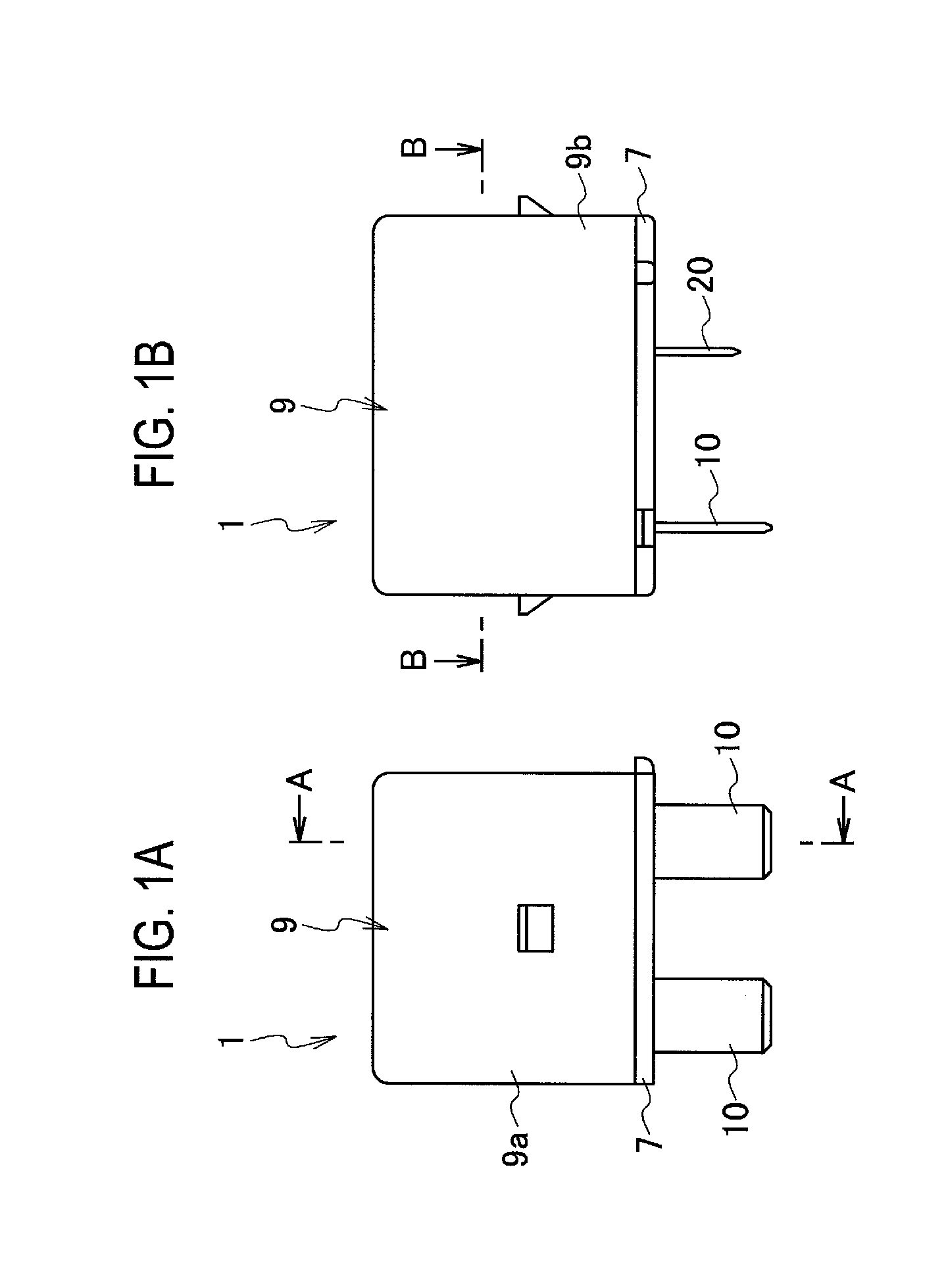

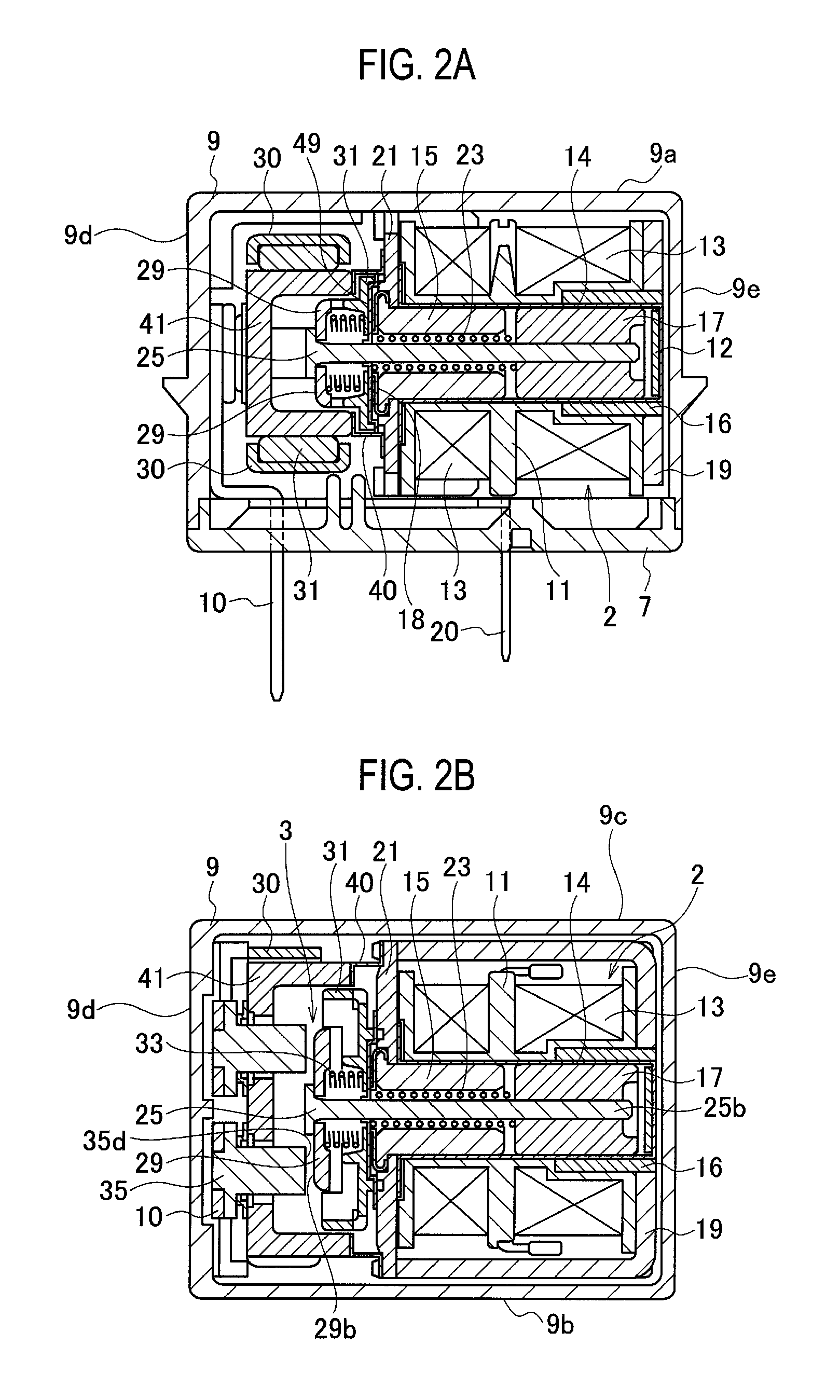

Contact device

InactiveUS20130234811A1Interrupt capacity increaseIncrease capacityContact mechanismsContacts enclosures/screensEngineeringMechanical engineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

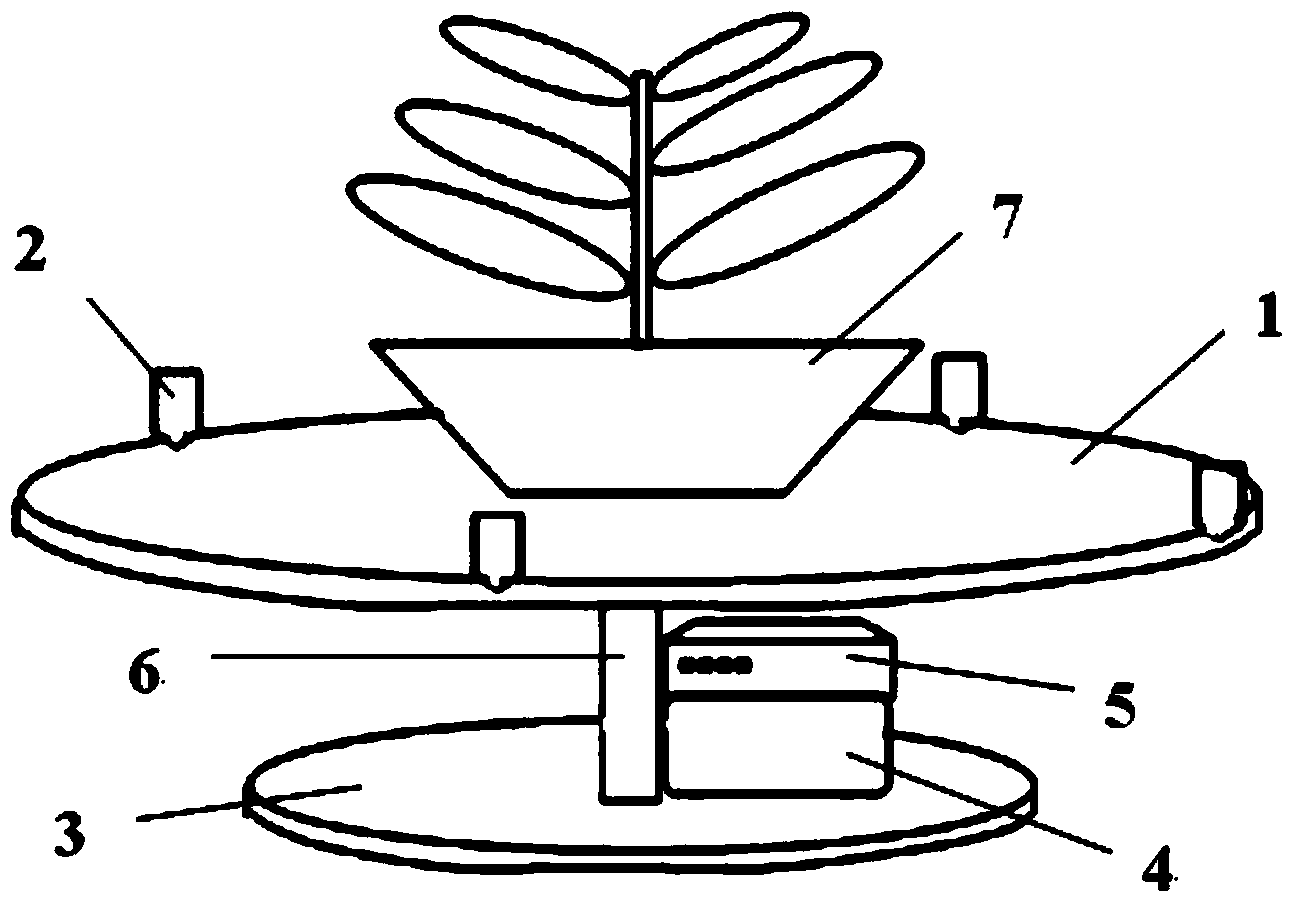

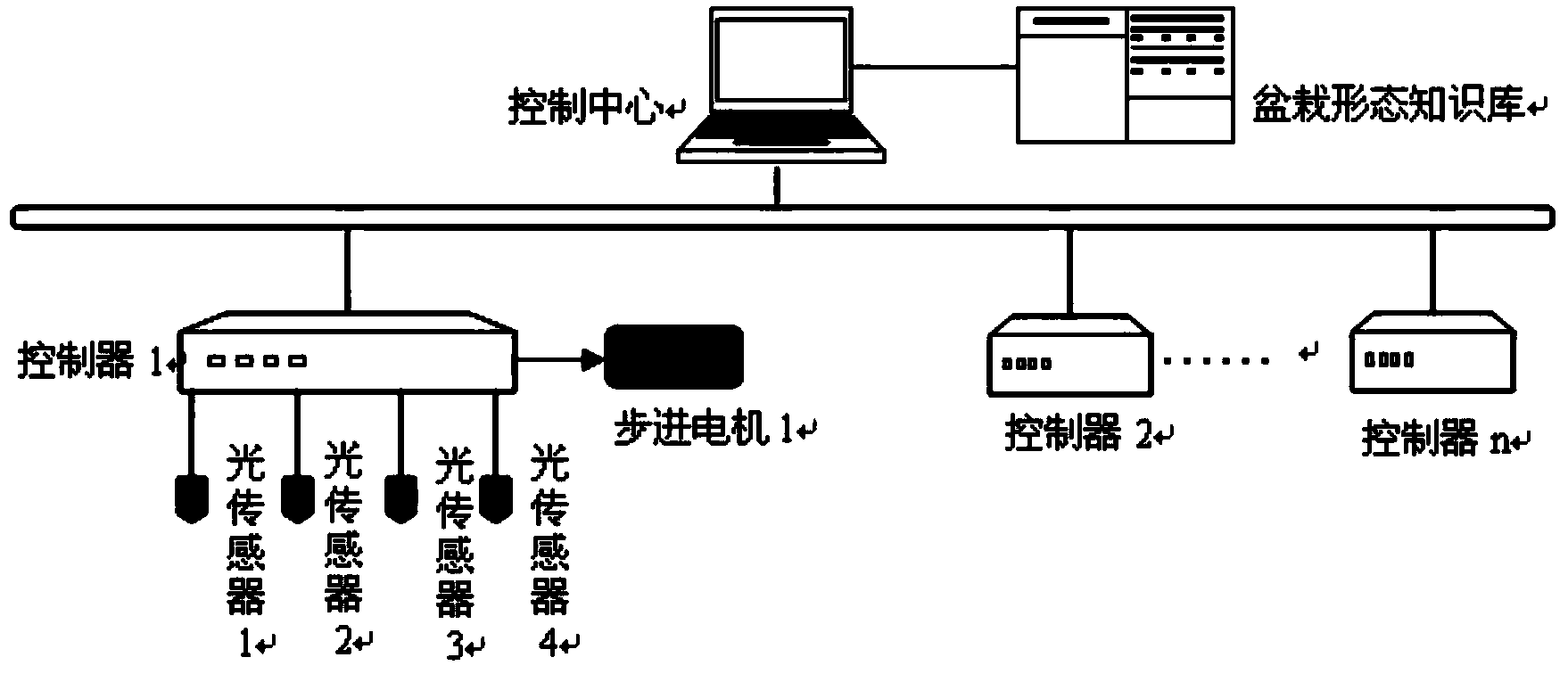

Potting light tracing system

InactiveCN103650950AMeet the needsImprove fullyCultivating equipmentsReceptacle cultivationRotary stageMotor controller

The invention discloses a potting light tracing system. The potting light tracing system comprises a rotary table, a support and a stepping motor, wherein a plurality of sunlight sensors are evenly distributed on the outer side of the upper surface of the rotary table, the rotary table can be horizontally and rotationally arranged on the support through the rotary shaft, the stepping motor is arranged on the support and can be used for driving the rotary shaft to rotate, the stepping motor is controlled by a stepping motor controller to work, when intensity of sunlight sensed by a certain sunlight sensor of the rotary table is stronger than intensity of sunlight sensed by other sunlight sensors, the sunlight sensor which senses the intensity of sunlight controls the stepping motor controller to work, the stepping motor is controlled to work, and the portion, with sunlight shining needing to be strengthened, of potting on the rotary table is made to right face the direction strong in sunlight intensity. According to the potting light tracing system, the portion, with sunlight shining needing to be strengthened, of the potting on the rotary table is made to right face the direction strong in sunlight intensity, and therefore the potting can be cultivated and can grow more adequately, and the requirement of a cultivator can be met.

Owner:SUZHOU VOCATIONAL UNIV

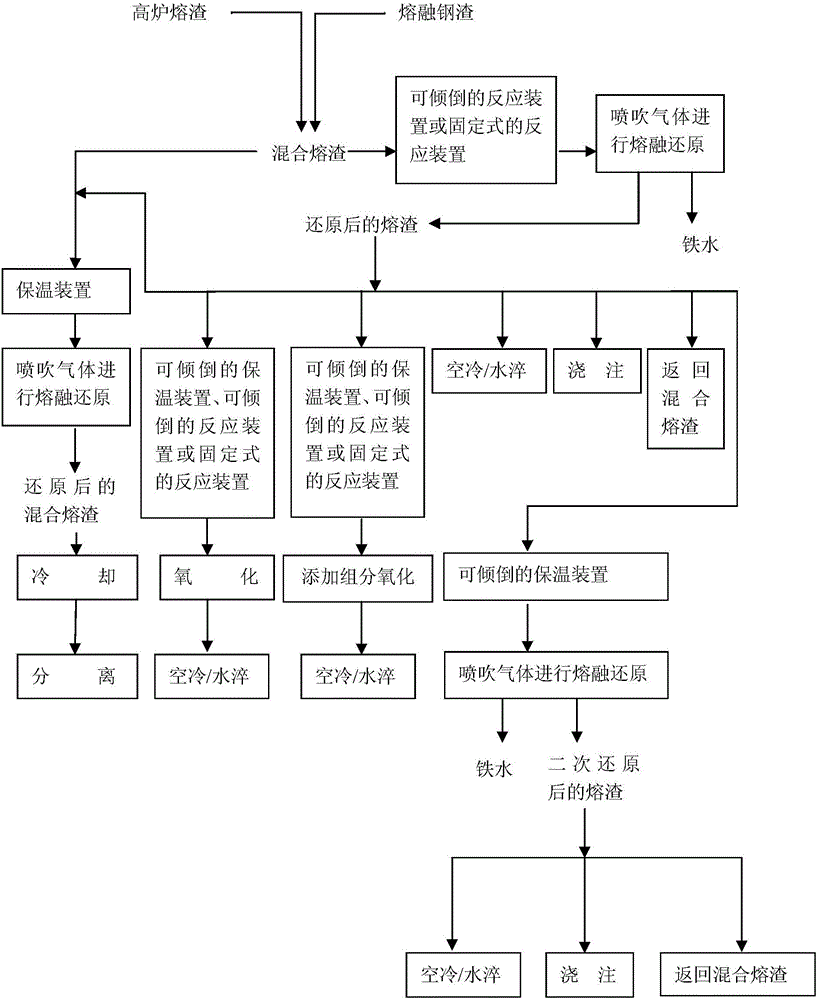

Method for mixed slag smelting reduction recycling and thermal refining

ActiveCN106048109ARealize smelting reduction ironmakingEasy to removeCement productionRecycling and recovery technologiesThermal energyEconomic benefits

The invention discloses a method for mixed slag smelting reduction recycling and thermal refining, and belongs to the field of non-blast furnace iron making and comprehensive utilization of resources. With the method, pig iron or steel and a phosphorus-rich phase are recycled from mixed slag, and slag thermal refining is carried out. The method comprises the following steps that (1) blast furnace slag and molten steel slag are mixed; (2) gas blowing is carried out to carry out smelting reduction; and (3) separation and recycling are carried out. According to the method, blast furnace slag and the molten steel slag are mixed, then, oxidizing gas is blown to carry out molten reduction iron making, the iron in the mixed slag is recycled, phosphorus-rich phase recycling and slag thermal refining are achieved, and the reduced slag can serve as slag cement or a cement regulator or an additive in cement production or cement clinker, or be used for producing high-value-added cement clinker. The method for mixed slag smelting reduction recycling and thermal refining is short in reaction time, high in metal recycling rate, low in production cost, high in material adaptability, high in handling capacity, friendly to the environment, high in economic benefit, and capable of effectively achieving the purpose of high-efficiency recycling of metallurgical resources and thermal energy, and is a new smelting reduction technology.

Owner:NORTHEASTERN UNIV

Fermentation method for producing pullulan polysaccharide

ActiveCN101215592AEasy to purifyHigh yieldMicroorganism based processesFermentationBiotechnologyPullulan

The invention relates to a fermenting method for producing pullulanuse polysaccharide, which is characterized in that the method comprises following steps: firstly, preparing seed culture medium, secondly, preparing fermenting initial culture medium, thirdly, inoculating liquid seeds into the fermenting initial culture medium, wherein the inoculation amount is 3-8%, the fermentation stirring speed is 200-500rpm, the fermentation temperature is 29 DEG C +- 1 DEG C, the ventilation volume is 0.5-10V / V, and the bed pressure is 0.01-0.02MPa, fourthly, complementarily adding the other carbon source after fermenting for 24 hours, wherein the adding amount is 40-80g / L and the adding liuqid is sucrose solution or glucose solution or starch hydrolysate whose pH value is 40-60, and continuingly fermenting for 60-72 hours after adding the carbon source, fifthly, flocculating, hyper-filtrating, barrier-separating, concentrating and drying the fermenting liquid and obtaining the pullulanuse polysaccharide whose molecular weight is between 20-60 million daltons. The invention has simple technique and significant effects and prominently shortens the fermenting time, the fermenting time is 80-100 hours, the production efficiency is increased greatly, energy is saved, the yield rate of product is greatly improved, and the yield can reach by 50%.

Owner:天津量信检验认证技术有限公司

Rice field breeding method for crayfish procambrarus clarkii

InactiveCN101011039AImprove survival rateSolve fishing problemsAnimal reproductionClimate change adaptationProcambarus clarkiiPrawn

The invention relates to a method for cultivating the Krause's crayfish, comprising that cleaning the field, cultivating the parental crayfish, cultivating the seed and taking off, cultivating the rice. The invention is characterized in that the cultivation of parental crayfish is processed in the surrounded groove, which has an anti-jump device and near the ground arranges seed holes at 0.8-1.2cm diameter; the crayfish seed can pass through the holes into the field. The invention can pre-cultivate the parental crayfish to avoid damaging the rice. And the invention can obtain many benthic fauna as the bait of parental crayfish, seed, or the like.

Owner:JIANGSU BAOLONG GROUP +1

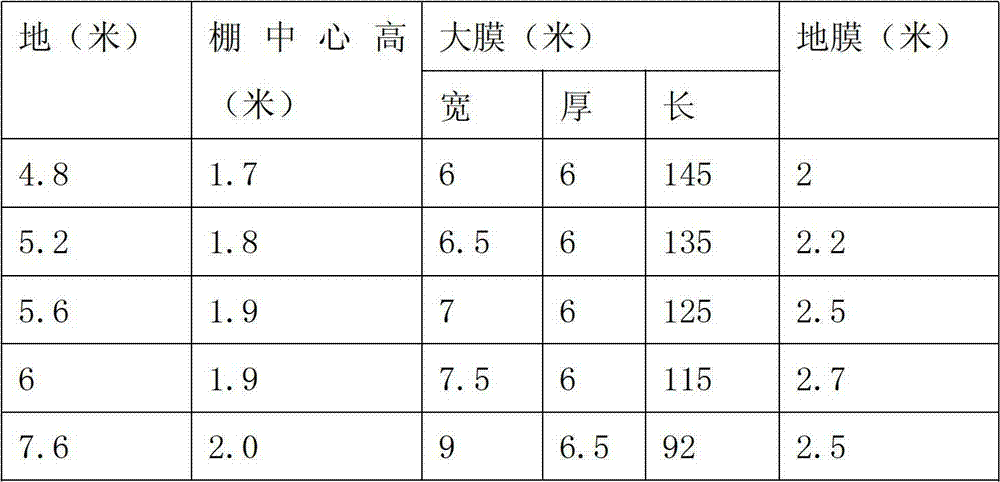

Pollution-free greenhouse watermelon growing method

ActiveCN102860211ASitting melonImprove qualityFertilising methodsHorticultureAdditive ingredientGreenhouse

The invention relates to the field of pollution-free greenhouse watermelon culture and particularly discloses a growing method for a first batch of greenhouse watermelons and a second to fifth batch of greenhouse watermelons. According to the climate and growing characteristics of the greenhouse watermelons in the Yangtze River basin, fertilizer and pesticides are applied according to different growing periods of the watermelons, so that the watermelons at the different periods fully obtain required nutritional ingredients, stable, full and normal growth is maintained, the yield and the quality of the greenhouse watermelons are improved, and the pollution-free and high-quality greenhouse watermelons are obtained.

Owner:GLADSOME MODERN AGRI DEV

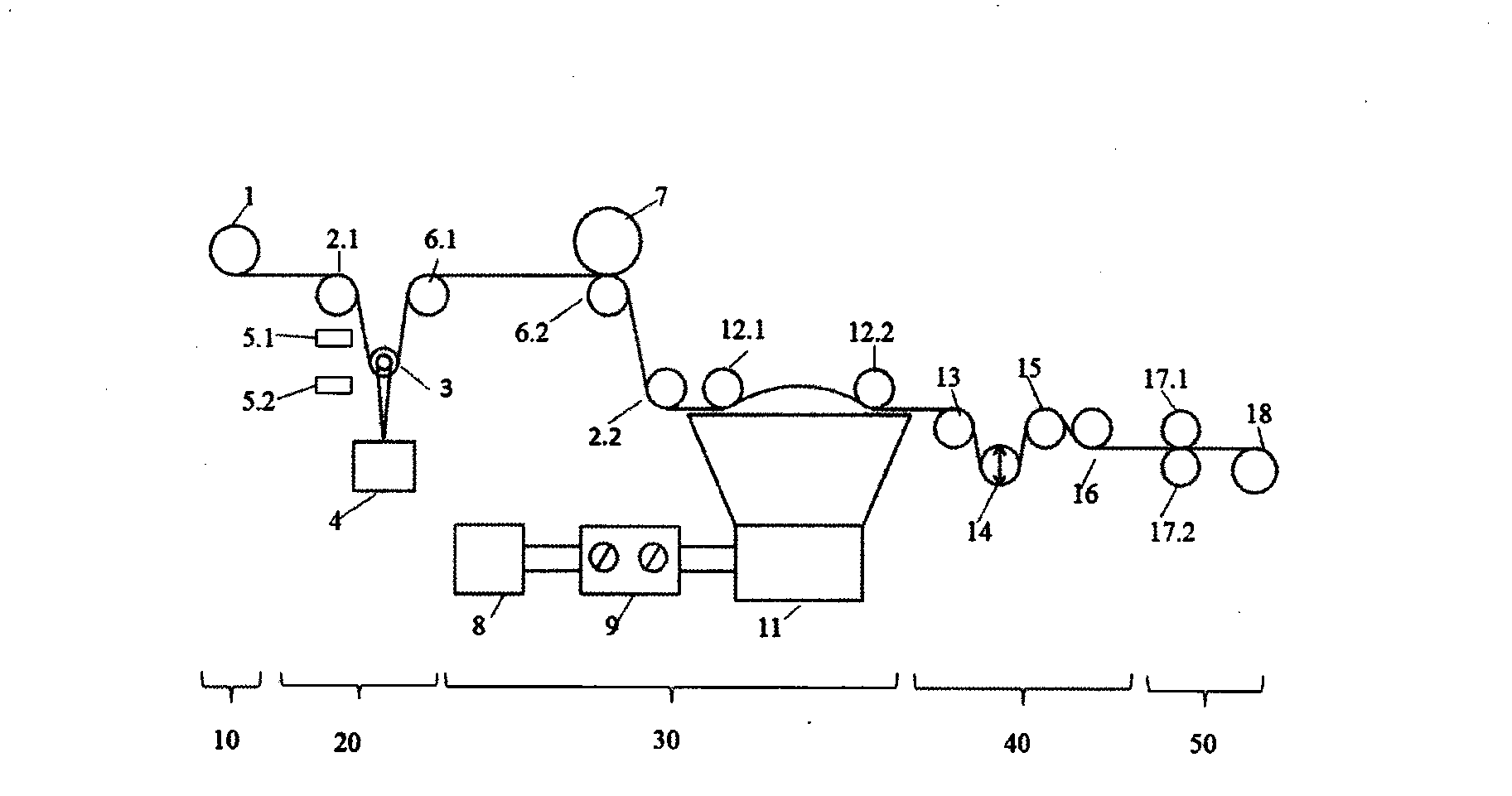

Device for spreading large-tow carbon fibers through combination of sound wave method and mechanical multi-roller method

The invention provides a device for spreading large-tow carbon fibers through combination of a sound wave method and a mechanical multi-roller method. The device for spreading the large-tow carbon fibers comprises a yarn containing device used for containing a fiber tow. The device for spreading the large-tow carbon fibers is characterized in that after being guided out of the yarn containing device, the fiber tow enters a tension control device, the surface tension of the fiber tow is controlled by the tension control device, the tension is kept constant, the fiber tow with the adjusted tension passes through the space between a pressure feeding roller and a second supporting roller and then is guided into a yarn pre-spreading device, the fiber tow is pre-spread by the yarn pre-spreading device according to the sound wave method, the pre-spread fiber tow is guided into the main yarn spreading device, the fiber tow is spread through the mechanical multi-roller fiber expanding method by the main yarn spreading device, and the spread fiber tow is rolled through a traction take-up device. The device for spreading the large-tow carbon fibers can effectively and fully spread the large-tow carbon fibers.

Owner:DONGHUA UNIV +2

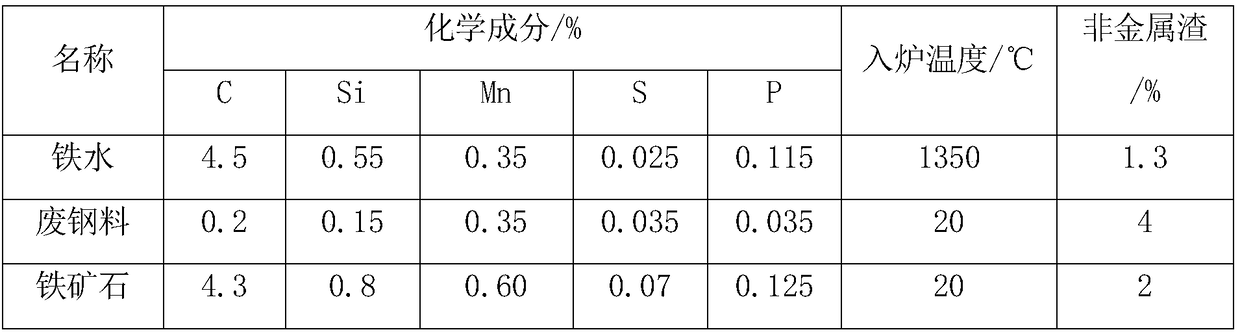

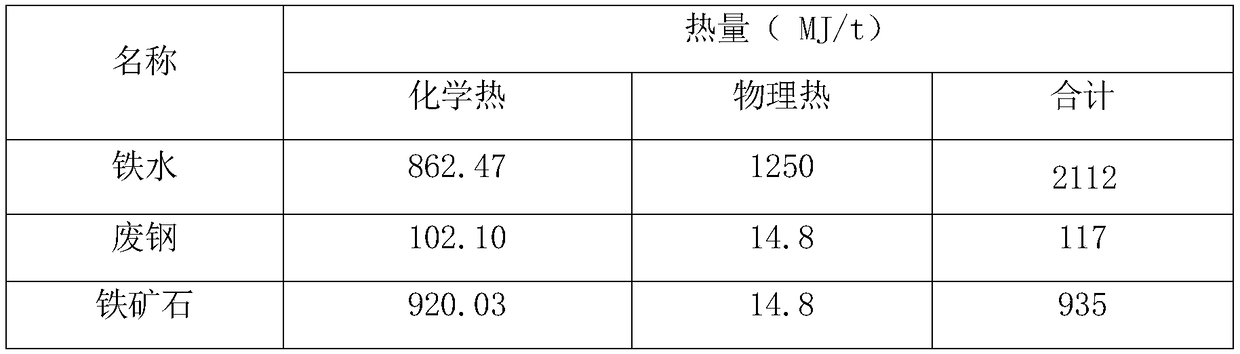

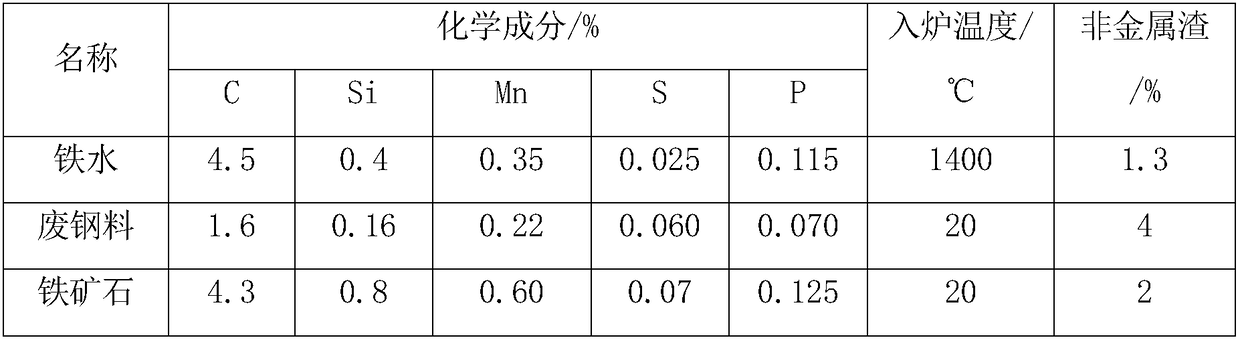

Rotating furnace smelting method with high steel scrap consumption

InactiveCN108165698AImprove fullyIncrease TFe contentManufacturing convertersProcess efficiency improvementScrapOxygen supply

The invention provides a rotating furnace smelting method with high steel scrap consumption. The rotating furnace smelting method with the high steel scrap consumption is conducted according to the following steps of (a) preparation of a heat-carrying material; (b) material preparation of the steel scrap; (c) rotating furnace smelting; (d) furnace rear operation; and (e) refining furnace operation; wherein the step (c) comprises the following material feeding process of a rotating furnace of firstly adding all waste steel material in the steel scrap and 80 percent of all iron ore, and then adding 50 percent of all the heat-carrying material from an overhead bunker, and adding the allowance of the heat-carrying material after adding molten iron, and adding a slag material and finally addingthe rest 20 percent of the iron ore at the time slot of one second to two thirds of oxygen supplying time of the middle and later periods of smelting. According to the method, the coke usage amount that the heat loss which is low in molten iron consumption and high in steel scrap ratio needs is obtained by determining the steel scrap ratio according to the components of the molten iron and then calculating the heat balance, so that the adding amount of the coke can be accurately determined and it can be realized that the coke is used in consideration of both heat loss supplement and cost consumption; the rotating furnace uses the high proportion of steel scrap, so that more industry steel scrap can be consumed and the production cost of steelmaking can be reduced.

Owner:德龙钢铁有限公司

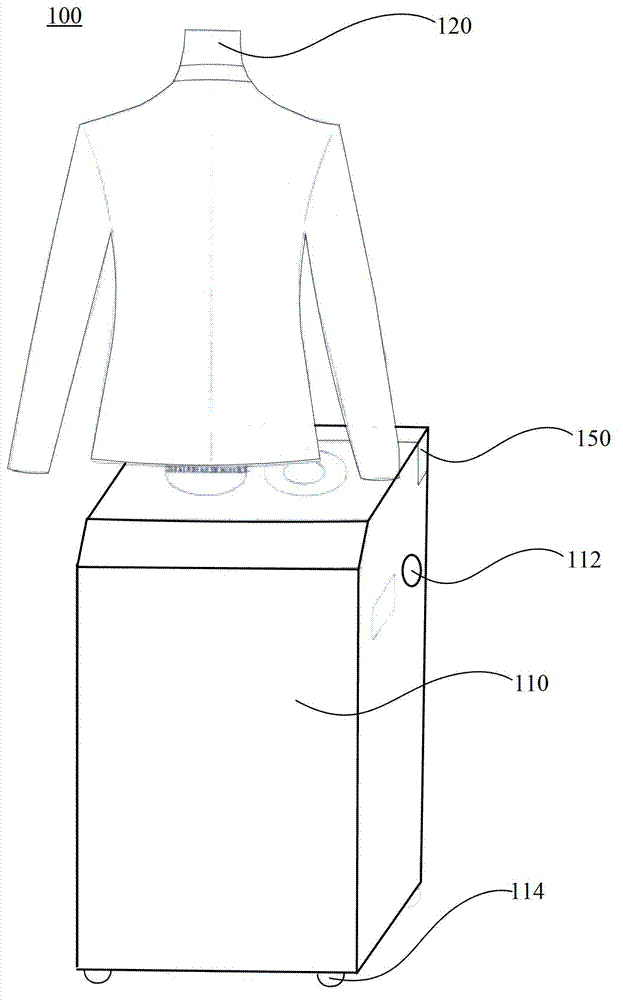

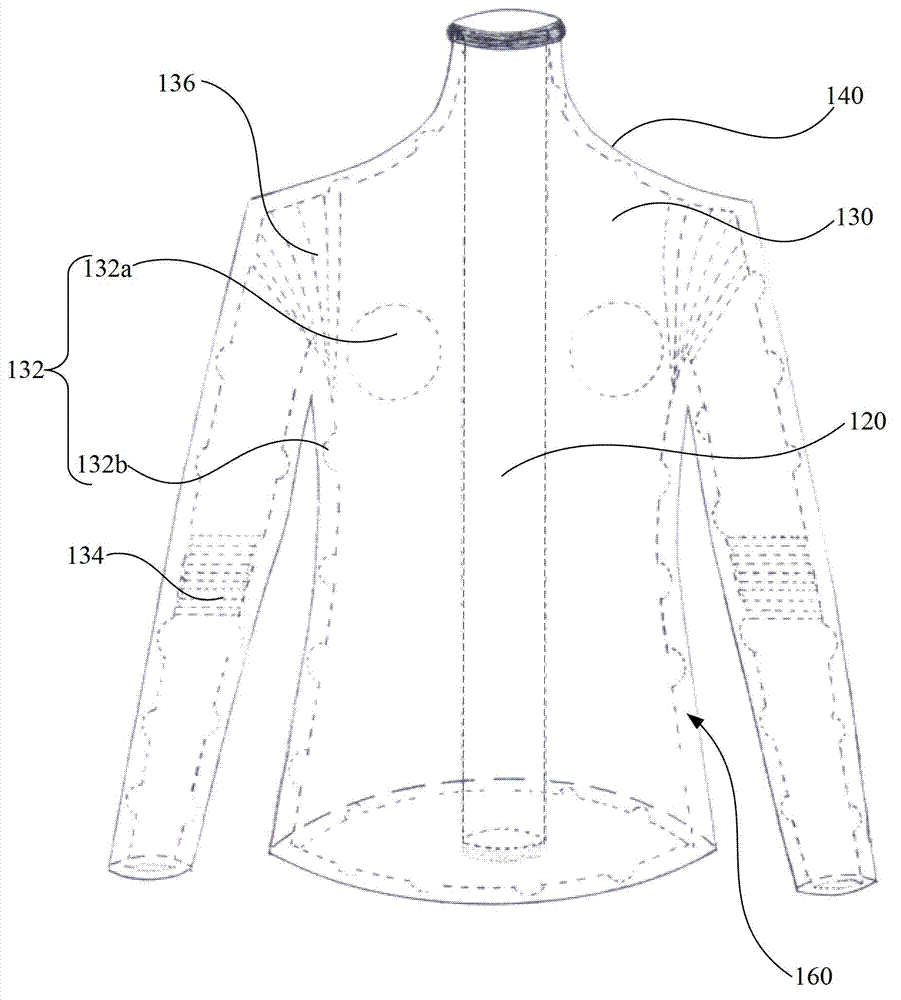

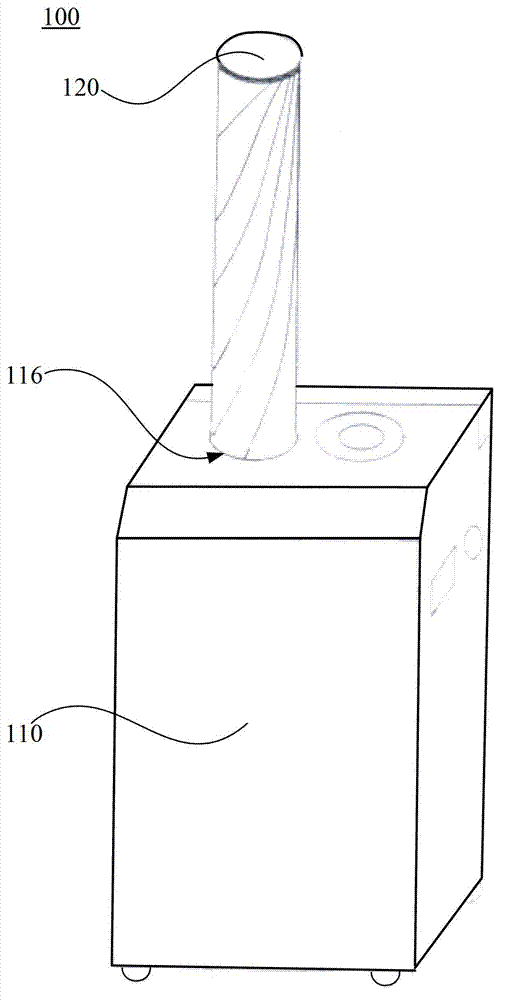

Three-dimensional clothes ironing dryer

ActiveCN103243529AImprove ironing effectImprove fullyIroning apparatusOther drying apparatusEngineeringAirbag

A three-dimensional clothes ironing dryer comprises a base, an airbag fixing support and an inflatable clothes rack. The inflatable clothes rack is arranged on the airbag-fixing support, and is composed of an inner airbag and an outer airbag. The inner airbag is made of heat-resisting non-breathable fabric, and can be attached to the airbag-fixing support. The inner airbag can be inflated to form a sealed human body model structure of an upper body shape or a lower body shape. The outer airbag is made of heat-resisting breathable fabric and sleeved on the outer side of the inner airbag, the outer airbag and the inner airbag form a ventilation space in between when plumped up, and are attached to the airbag-fixing support when contracted. The clothes are sleeved on the outer airbag, and warm air permeates to the surface of the clothes from the side wall of the outer airbag. By the three-dimensional clothes ironing dryer, irregular parts of the clothes can be ironed preferably.

Owner:齐志鲲

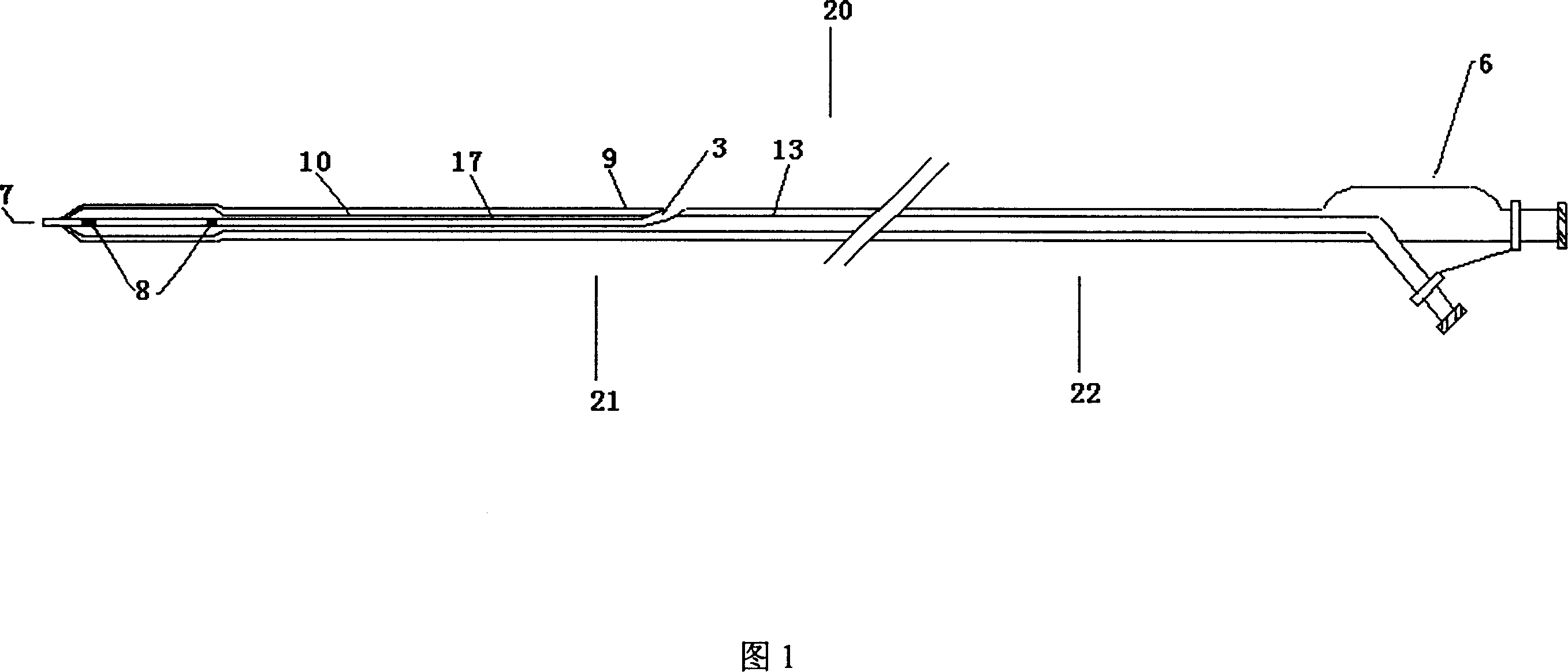

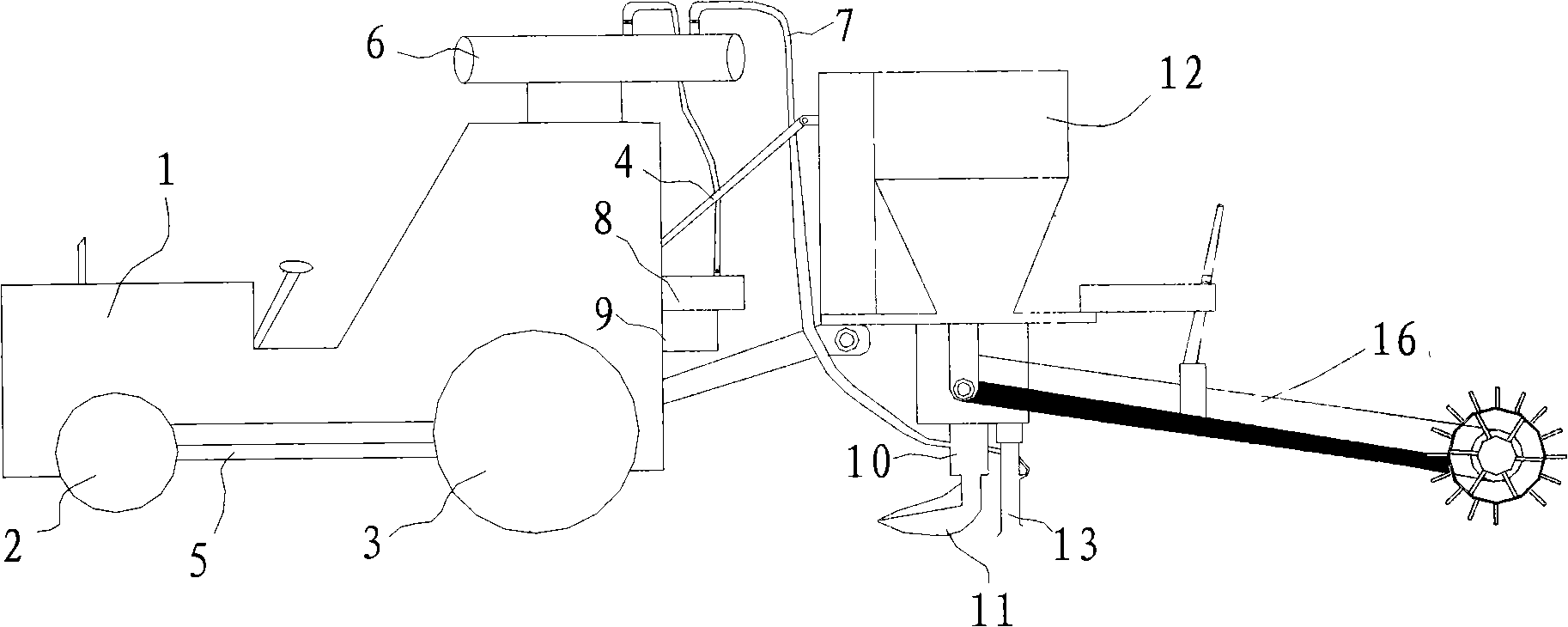

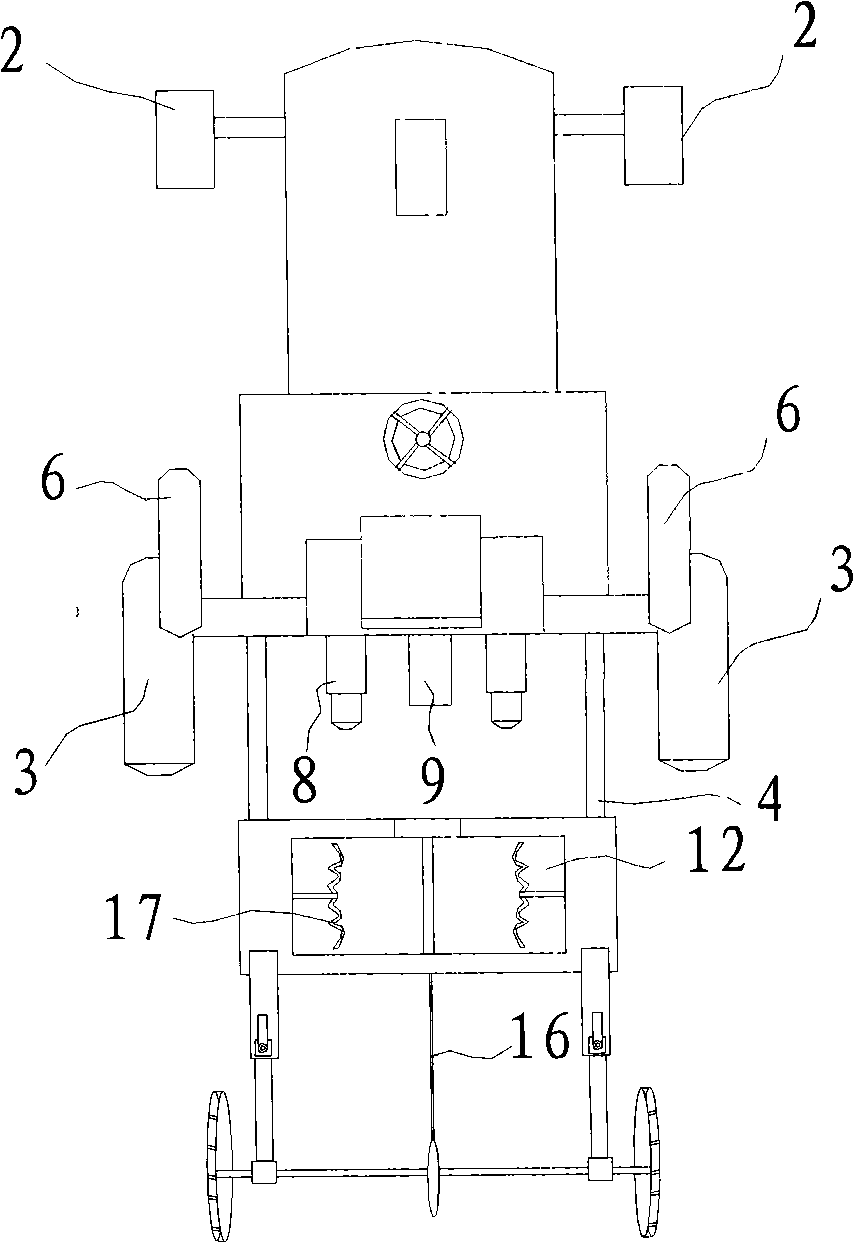

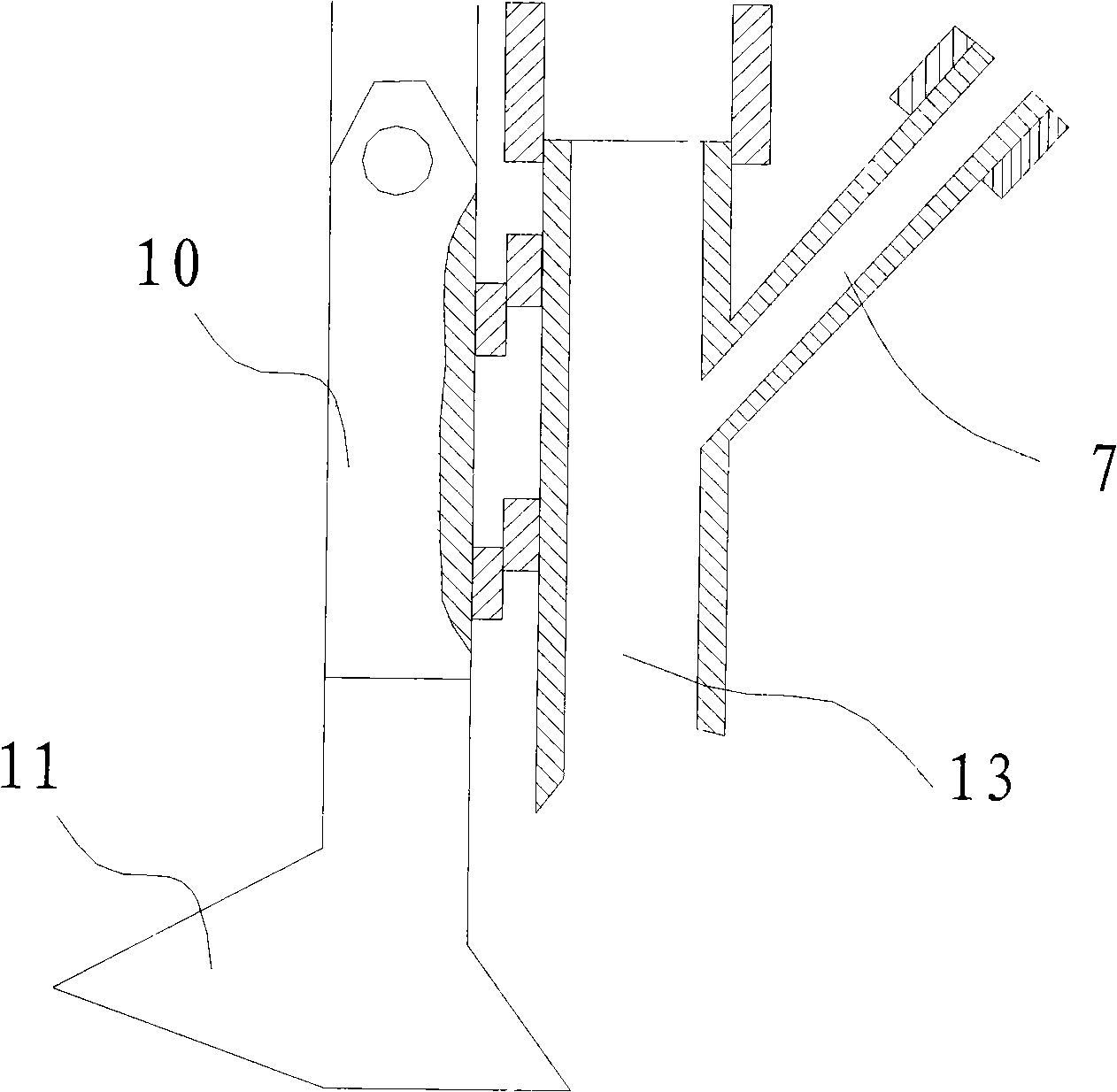

Deep scarification high pressure blowing-in controllable fertilizer distributor

InactiveCN101554103APrevent acidificationImprove fullySpadesPressurised distribution of liquid fertiliserAir compressionGas compressor

The invention relates to a deep scarification high pressure blowing-in controllable fertilizer distributor, which comprises a traction apparatus, an air compression device, a deep scarification device and a material dispatching device; wherein the traction apparatus moves by power; the air compression device comprises a compressed air collecting vat fixed on the traction apparatus, a compressed air conduit fixedly connected with the compressed air collecting vat, an air compressor fixed on a ration axis and an air compressor cooling roller; the air compressor is connected with the compressed air collecting vat by the conduit; the deep scarification device is fixedly connected with the material dispatching device, comprises a deep scarification pillar and a pellet component fixedly connected with one end thereof; the material dispatching device comprises a material box fixedly connected on a raiser and a material pipe fixedly connected with the material box; the material pipe is arranged on the side of the deep scarification pillar and is fixedly connected with the compressed air conduit on the pipe wall thereof. The deep scarification high pressure blowing-in controllable fertilizer can realize the mechanization operation of the soil subsoil application, has high working performance, good quality, can control fertilizing amount, increases the effective rate of utilization of the fertilizer, does not pollute environment and has good environmental protection effect.

Owner:YANTAI UNIV

High-efficiency flower fertilizer

InactiveCN102060581AGood fertilizer effectAdaptableBio-organic fraction processingOrganic fertiliser preparationBiotechnologyPotassium

The invention discloses a high-efficiency flower fertilizer, which is manufactured by uniformly mixing and stirring 8 to 10 weight parts of dregs of traditional Chinese medicines with 12 to 15 weight parts of modified glucose, 3 to 5 weight parts of modified beer liquid, 40 to 50 weight parts of fallen leaves and humus and 80 to 100 weight parts of water under a condition of an air humidity of 60 to 80 percent and a condition of a temperature of between 20 and 30 DEG C, stacking in a form, covering with a plastic film for fermenting for 48 to 72 hours, spreading 2 to 3 weight parts of solution of potassium hypermanganate for deodorization, drying naturally in shade and packaging separately. The fertilizer has the advantages that: the raw materials are readily available; the cost is low; and the fertilizer efficiency is high.

Owner:周皓

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com