Patents

Literature

360results about How to "Improve ironing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cloth ironing machine

InactiveCN105463745AAvoid damageQuality improvementHeating/cooling textile fabricsTextile treatment by spraying/projectingEngineeringEnergy consumption

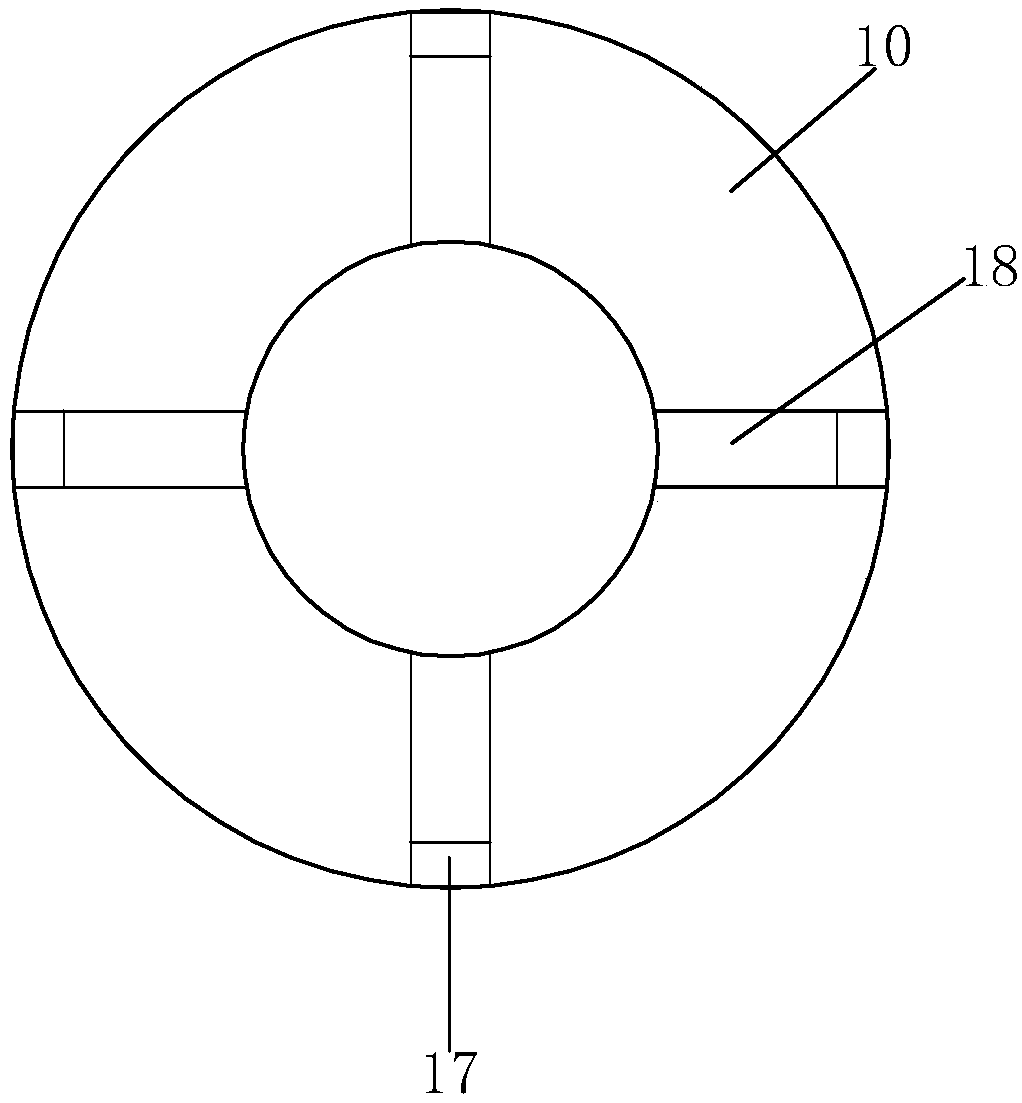

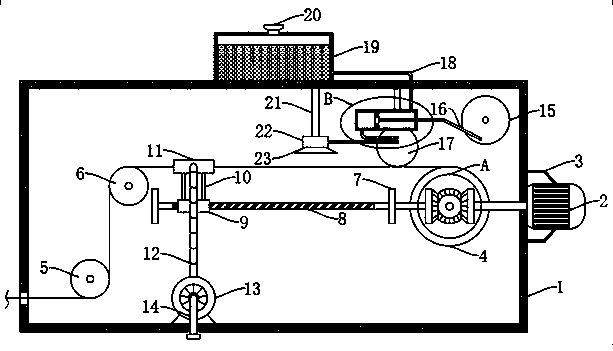

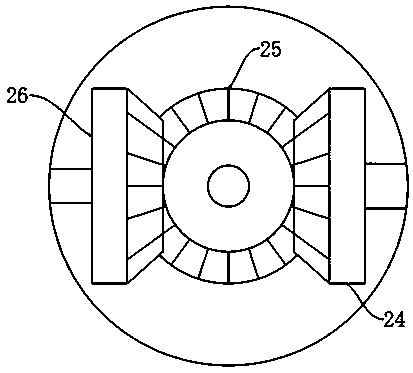

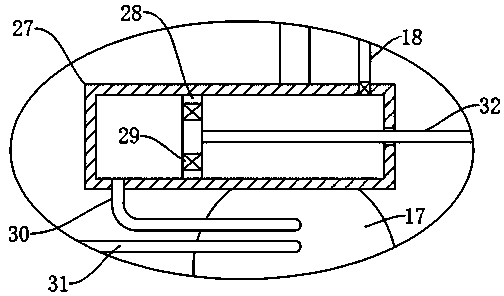

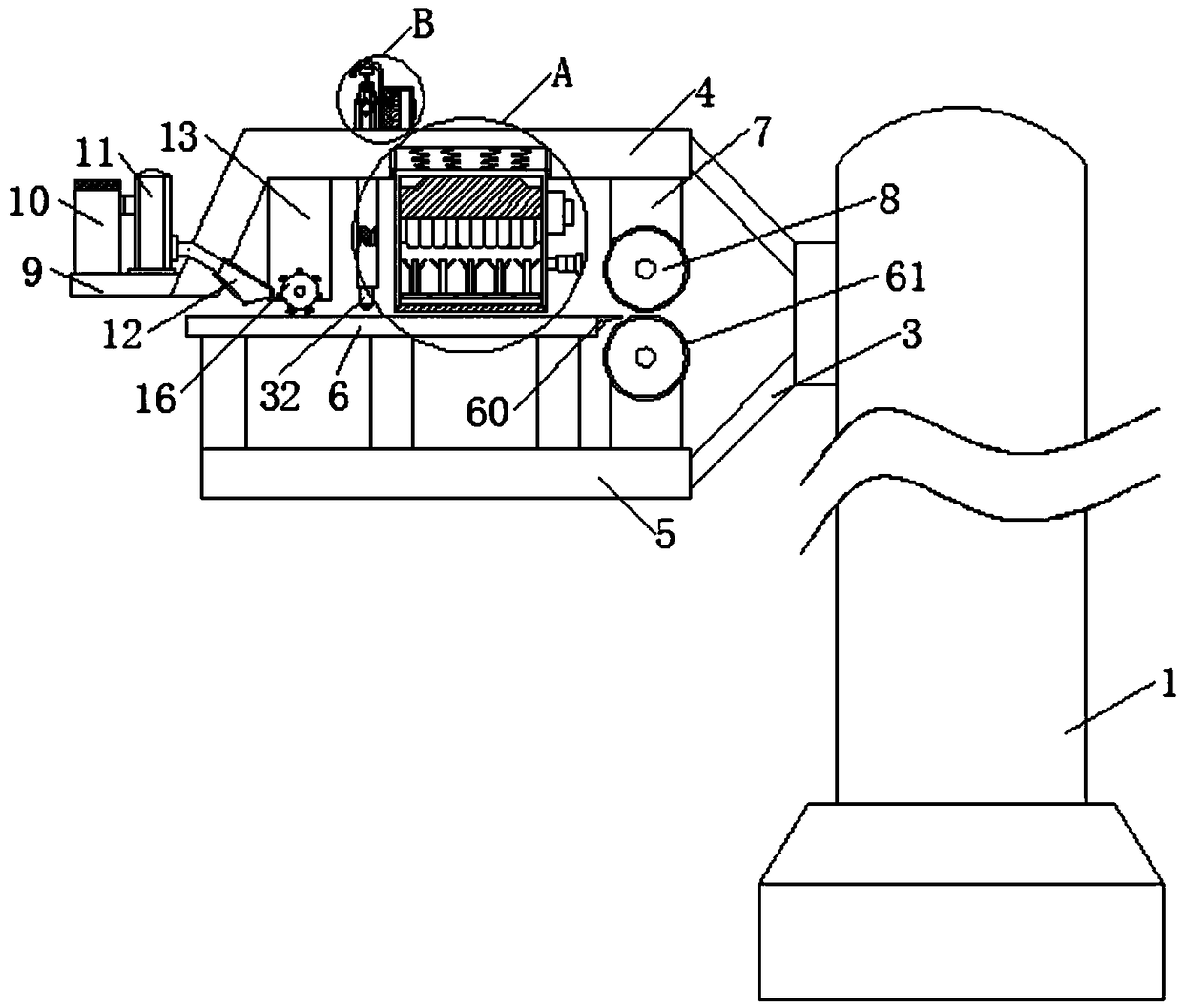

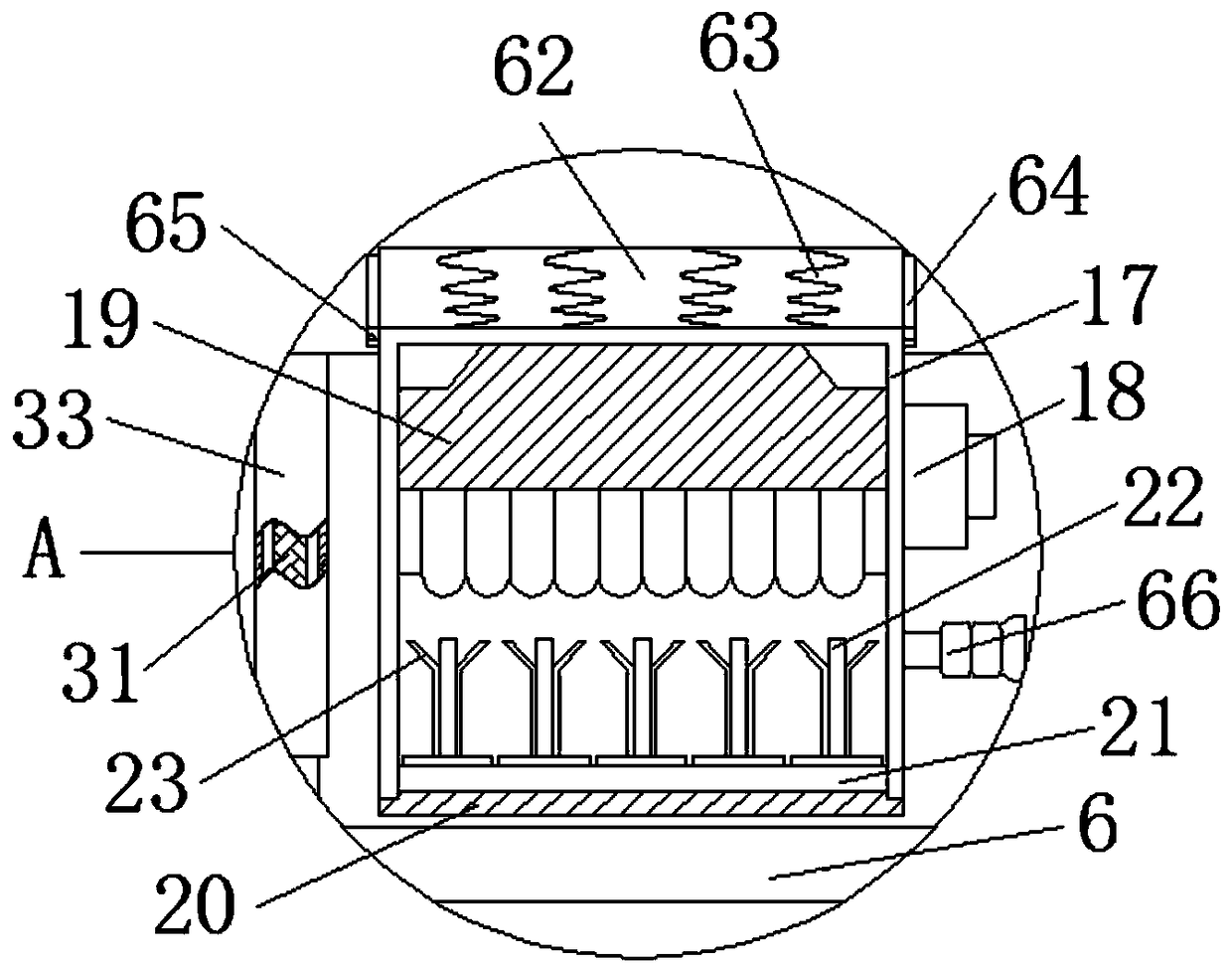

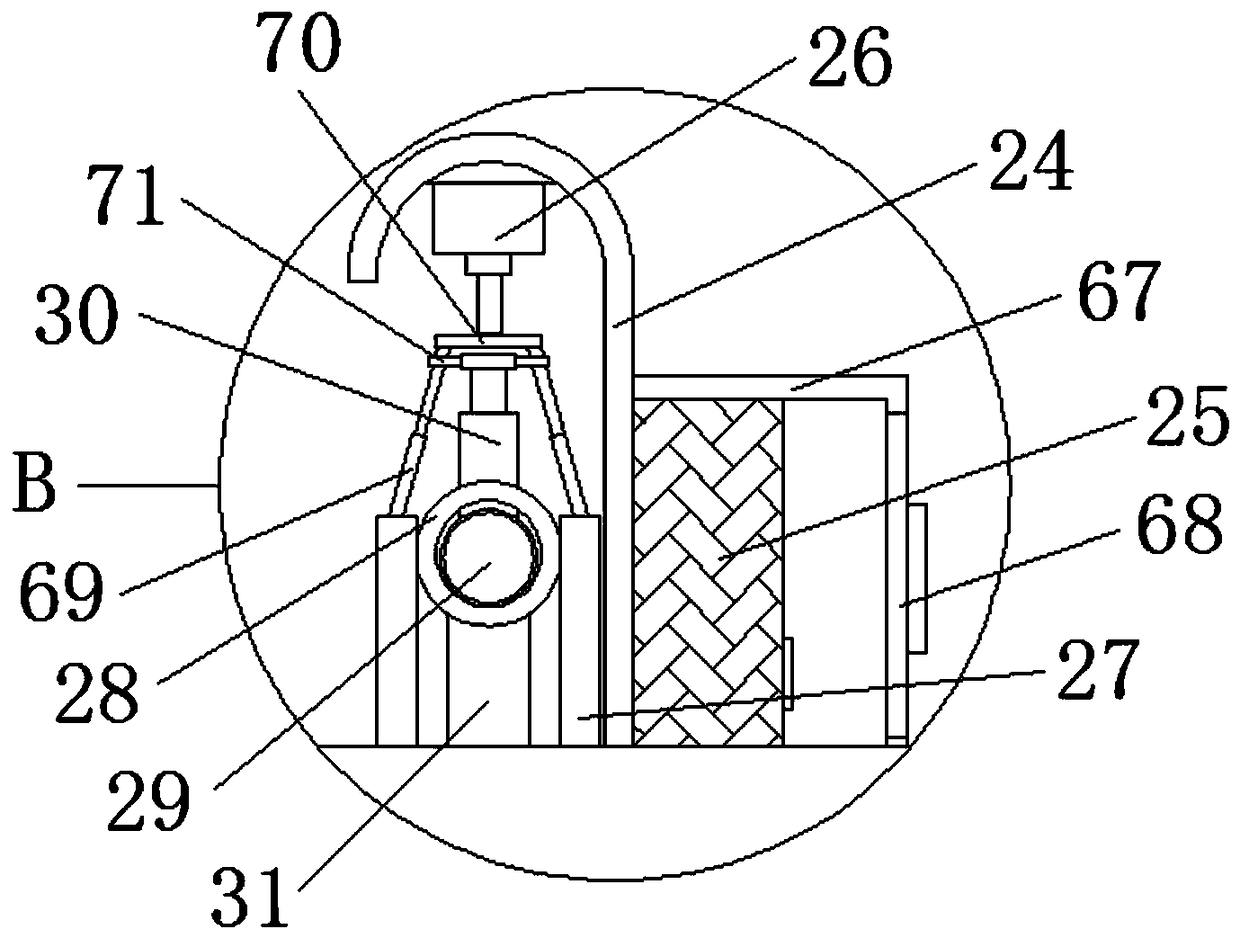

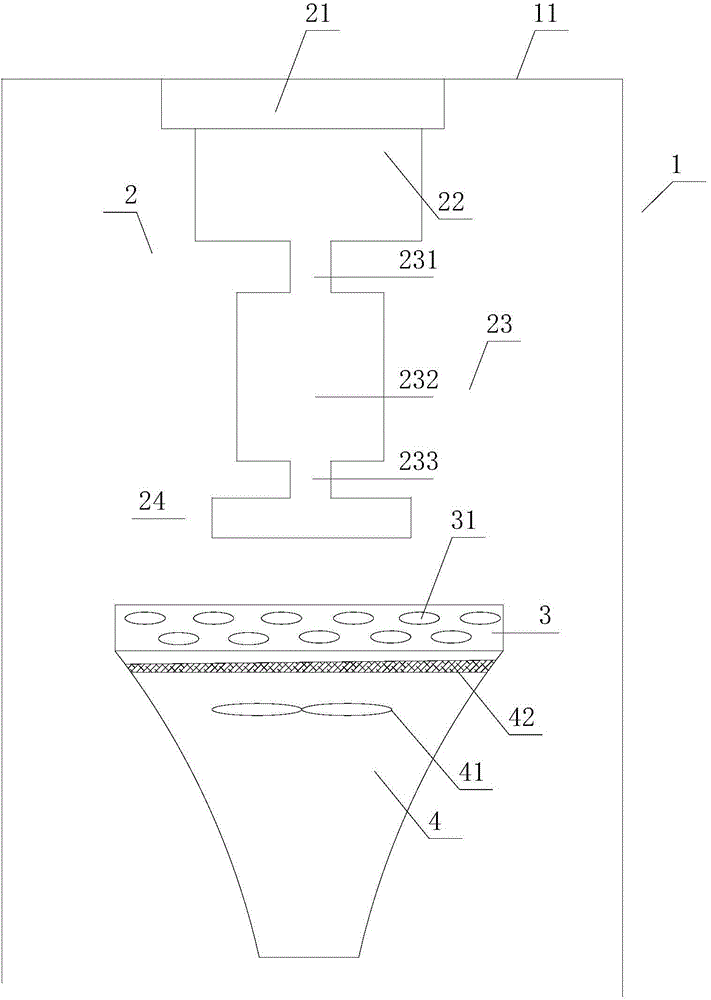

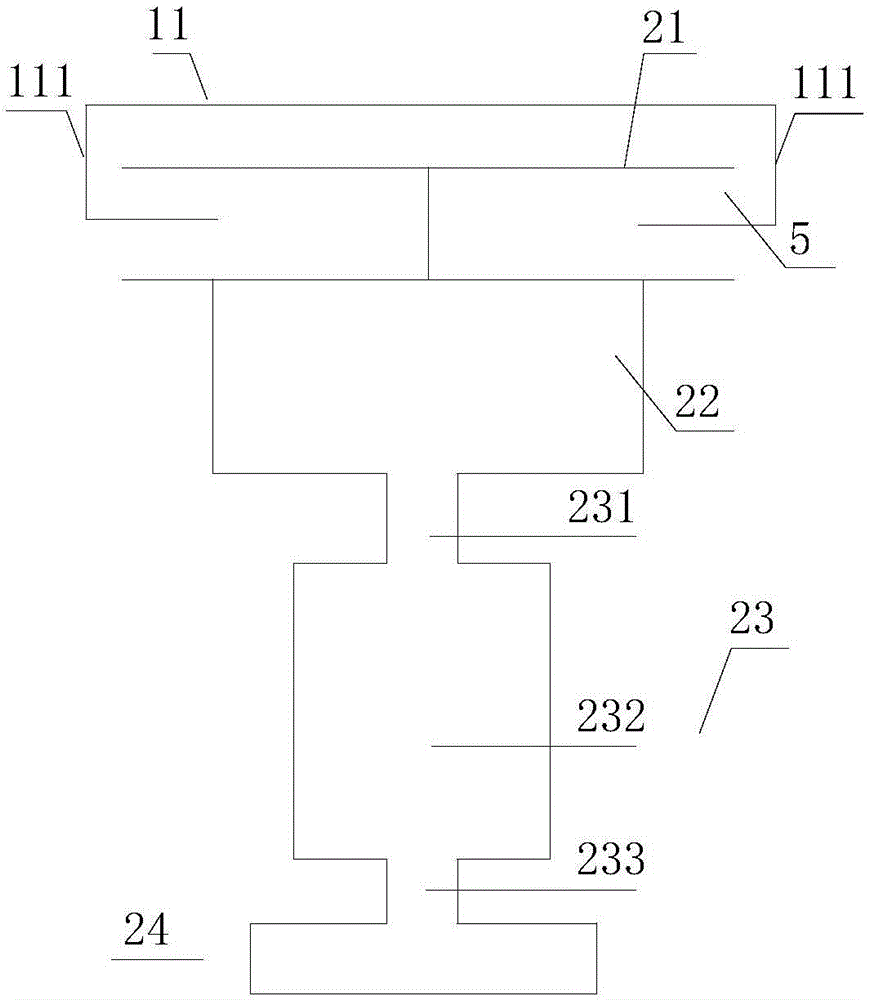

The invention mainly discloses a cloth ironing machine. The technical scheme is that the cloth ironing machine comprises a rack, an ironing mechanism, a conveying mechanism, a preheating mechanism, a sterilization mechanism and a drying mechanism, wherein the conveying mechanism comprises a putting table, cloth putting rollers and a cloth reeling roller, the putting table is provided with hanging rings, two ends of the cloth putting rollers are respectively hung on the hanging rings, one side of the cloth reeling roller is provided with a cooling roller, the ironing mechanism comprises an upper press mould, a lower press mould and an ironing table, the lower sides of the upper press mould and the lower press mould are respectively provided with a first transmission mechanism and a second transmission mechanism for driving the upper press mould and the lower press mould to be in force fit, the preheating mechanism comprises a preheating plate provided with steam holes and a water tank with an electric heater, the sterilization mechanism comprises a lamp base, a lamp holder and an ultraviolet tube with a cleaning device, the drying mechanism comprises a drying plate provided with air outlets and a warm air chamber provided with a warm air machine, and sliding wheels are arranged below the rack. The cloth ironing machine has the advantages of good ironing effect, shaping in one step, high work efficiency and less energy consumption.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

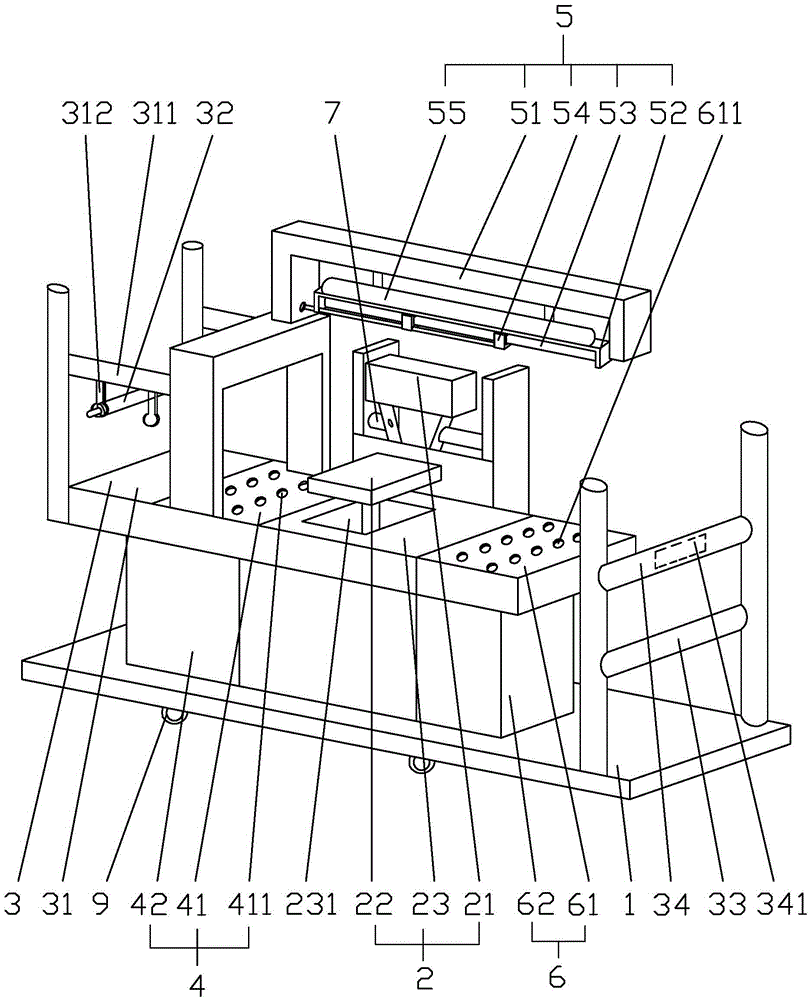

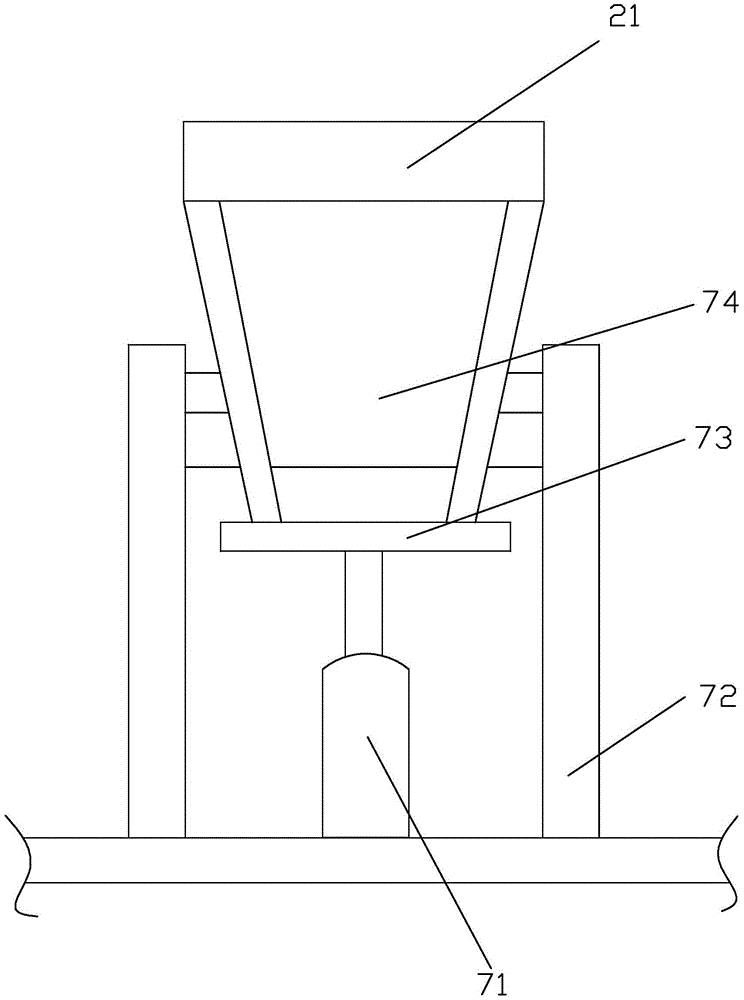

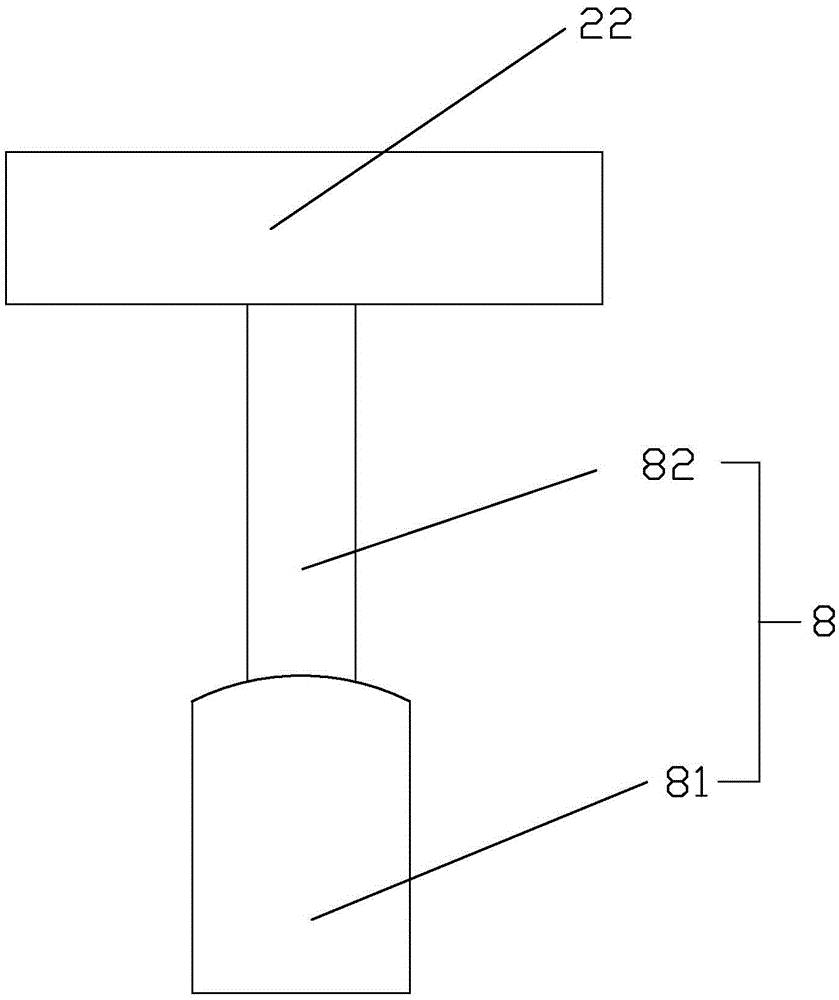

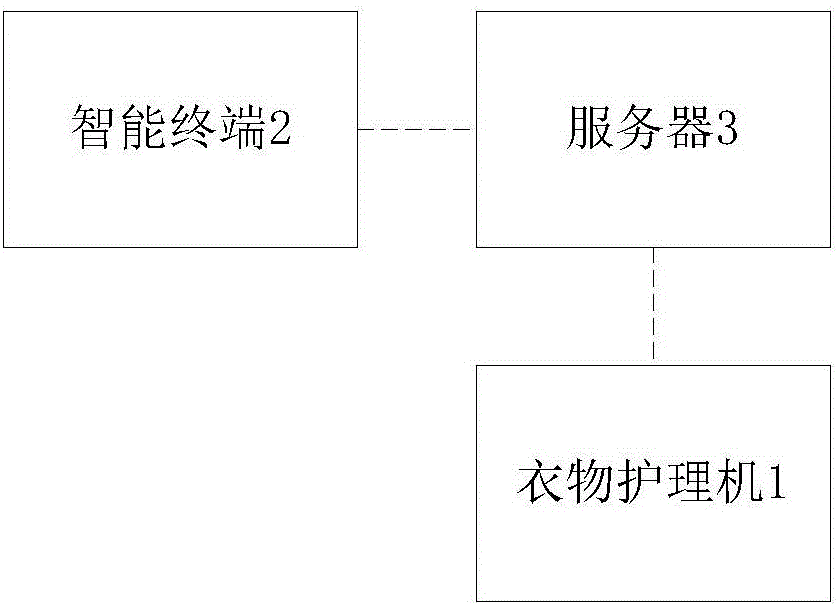

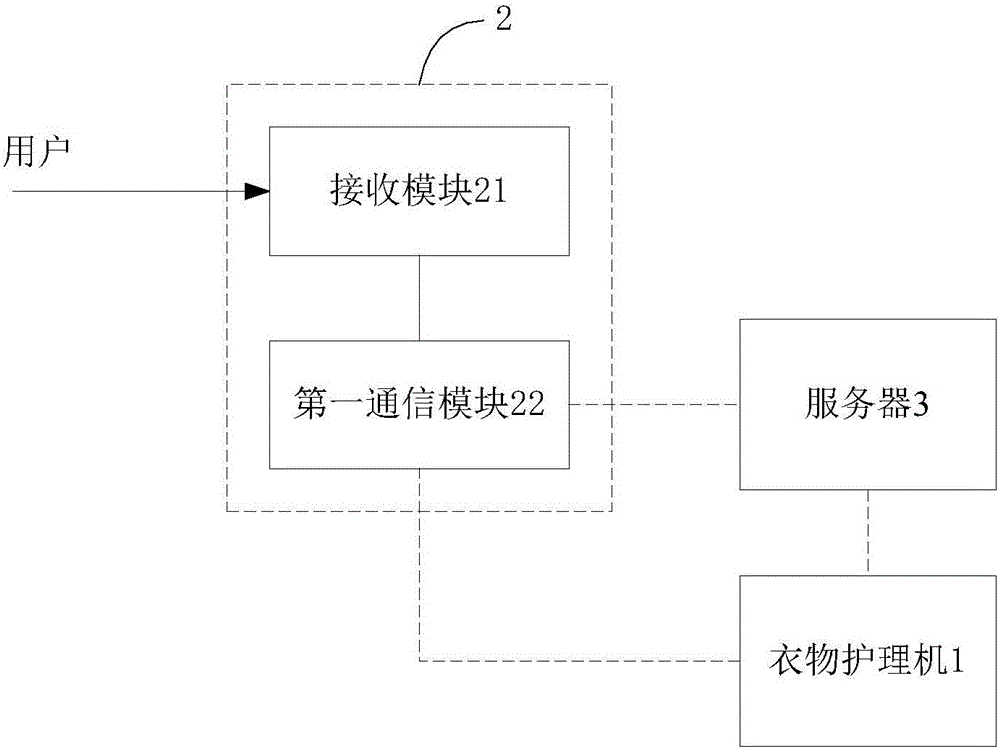

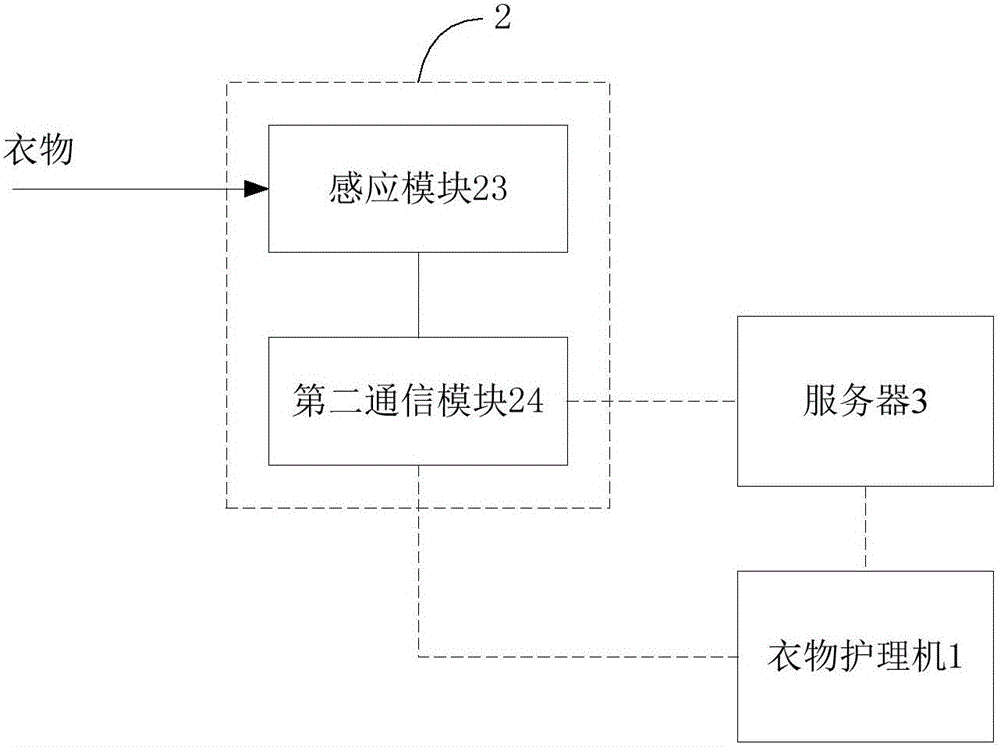

Clothing care system, ironing method thereof and server

InactiveCN106012460AImprove experienceImprove ironing effectHand ironIroning apparatusSystem of careEngineering

The invention discloses a clothing care system, an ironing method thereof and a server. The clothing care system comprises a clothing care machine, an intelligent terminal and the server, wherein the intelligent terminal is used for acquiring the clothing feature information and also communicates with the server to upload the clothing feature information to the server; the server generates ironing parameters according to the received clothing feature information so that the clothing care machine carries out ironing according to the generated ironing parameters, thus the clothing can be ironed by adopting the optimal ironing parameters and then the ironing effect is improved; therefore, the products are more intelligent and the user experience is improved.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

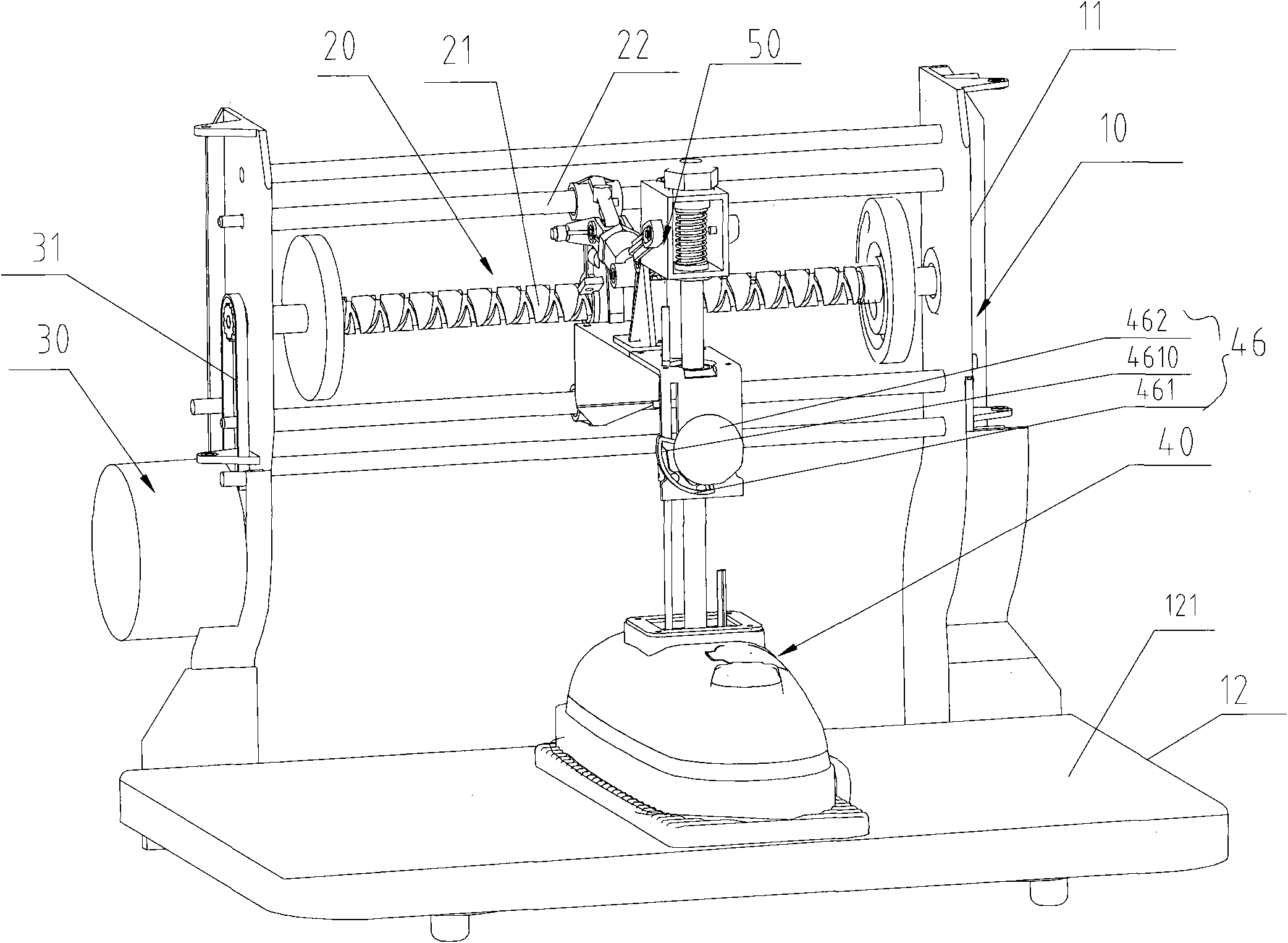

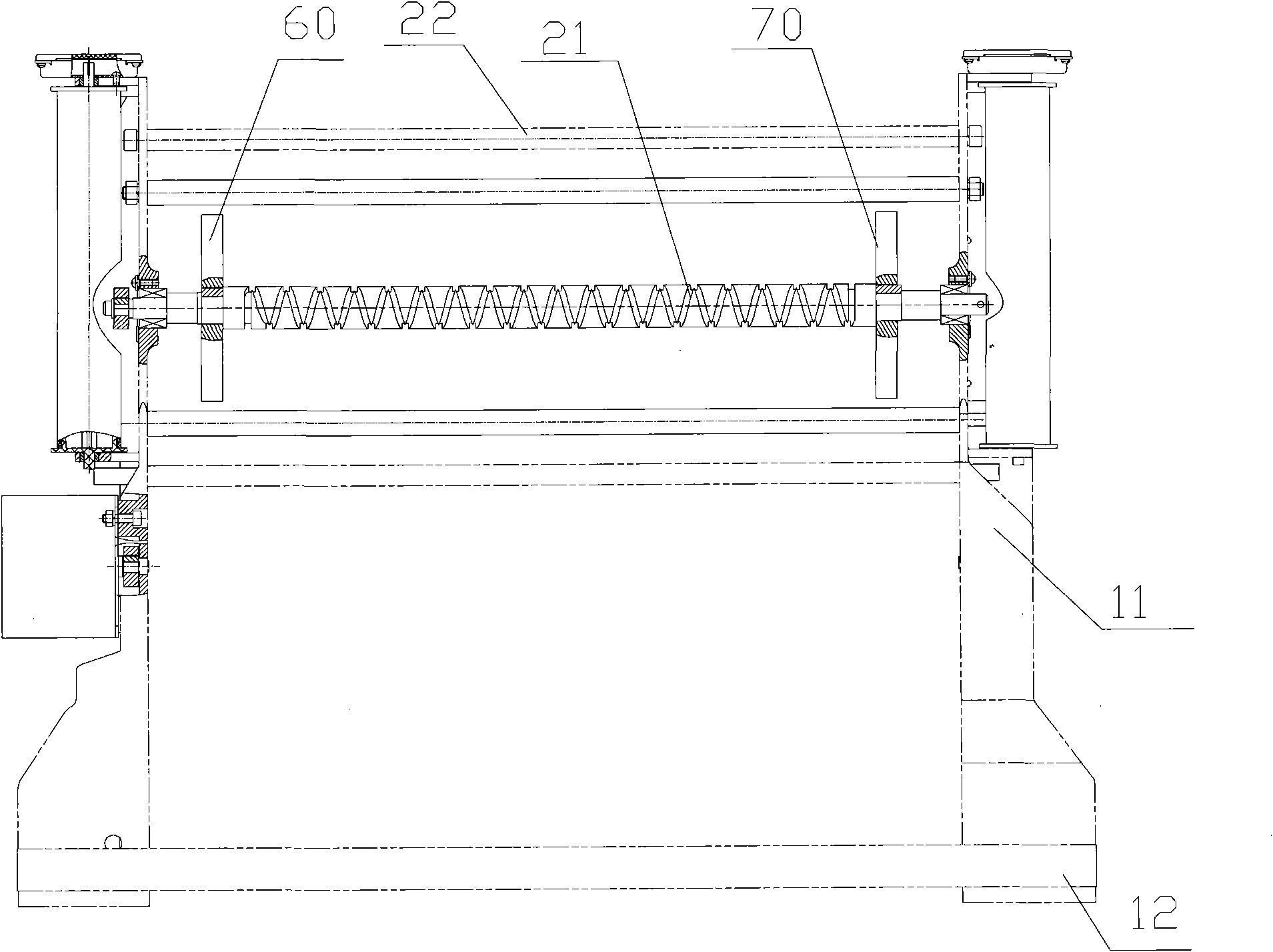

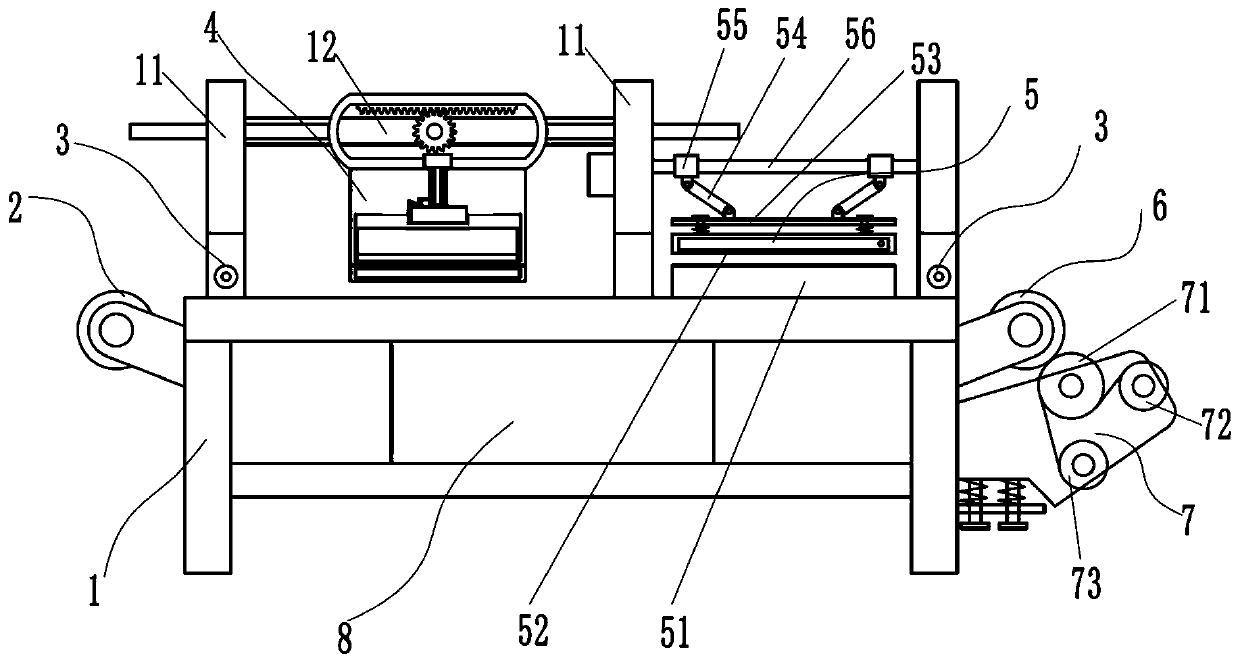

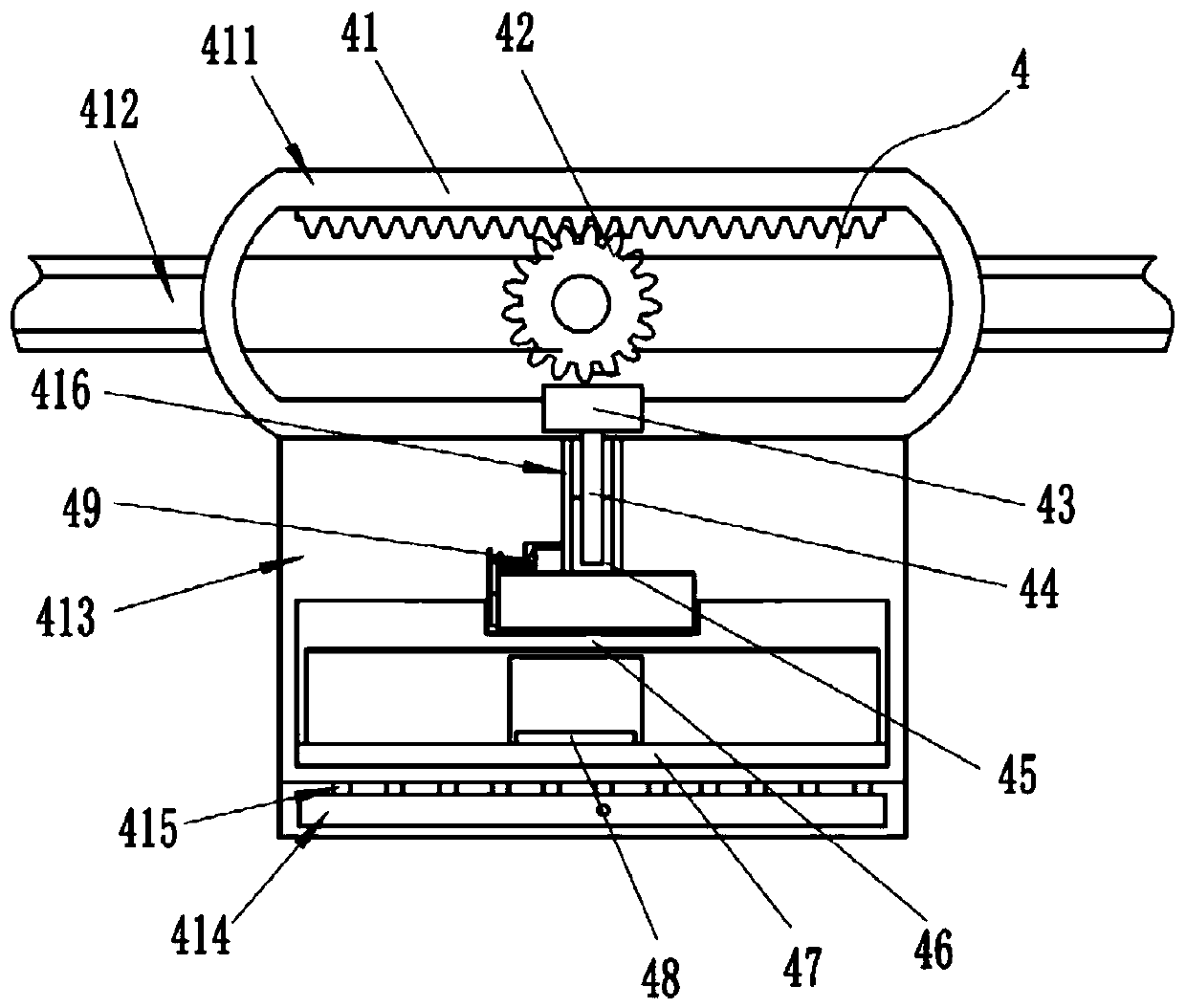

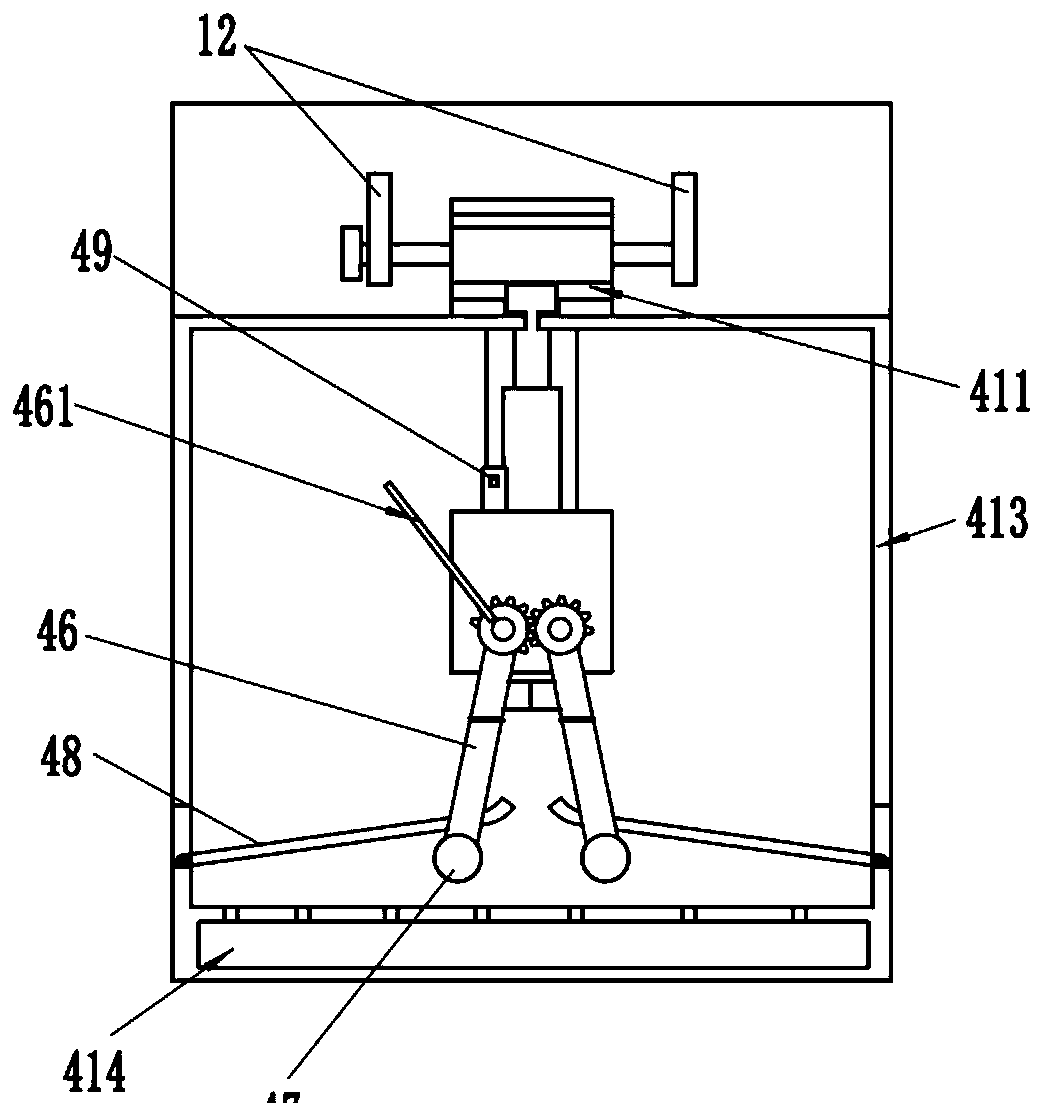

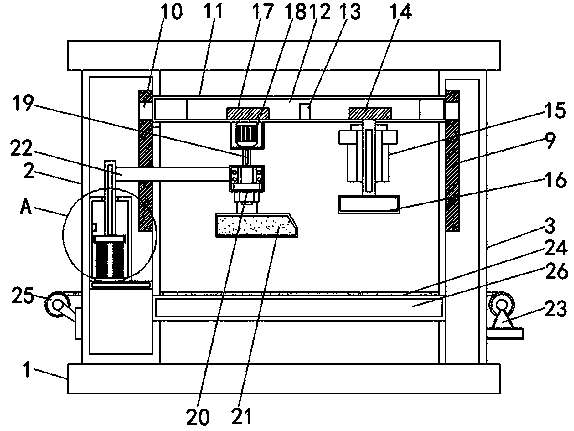

Automatic ironing equipment

InactiveCN101787640ARealize automatic ironingImprove ironing effectIroning machinesTextiles and paperEngineeringMechanical engineering

Owner:别道庭

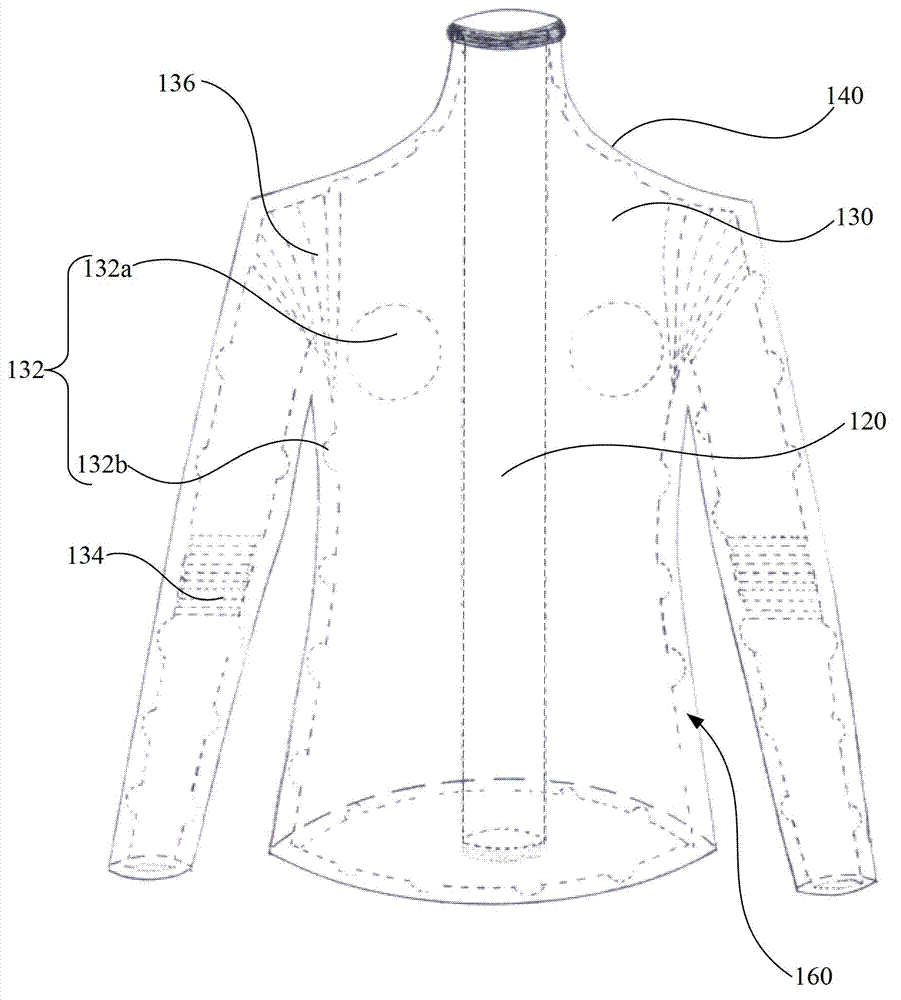

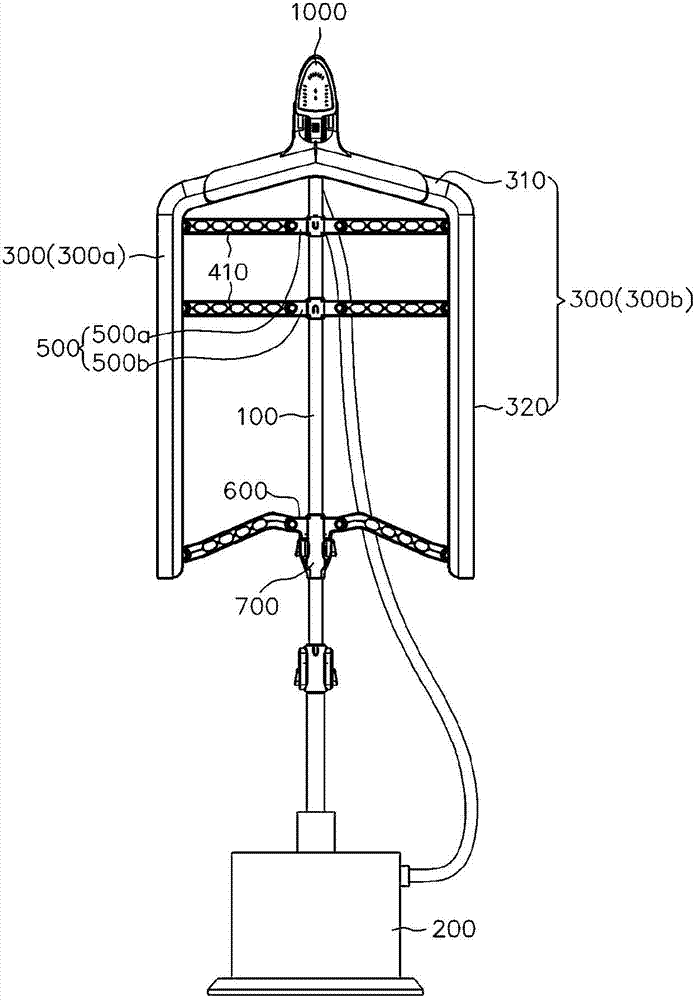

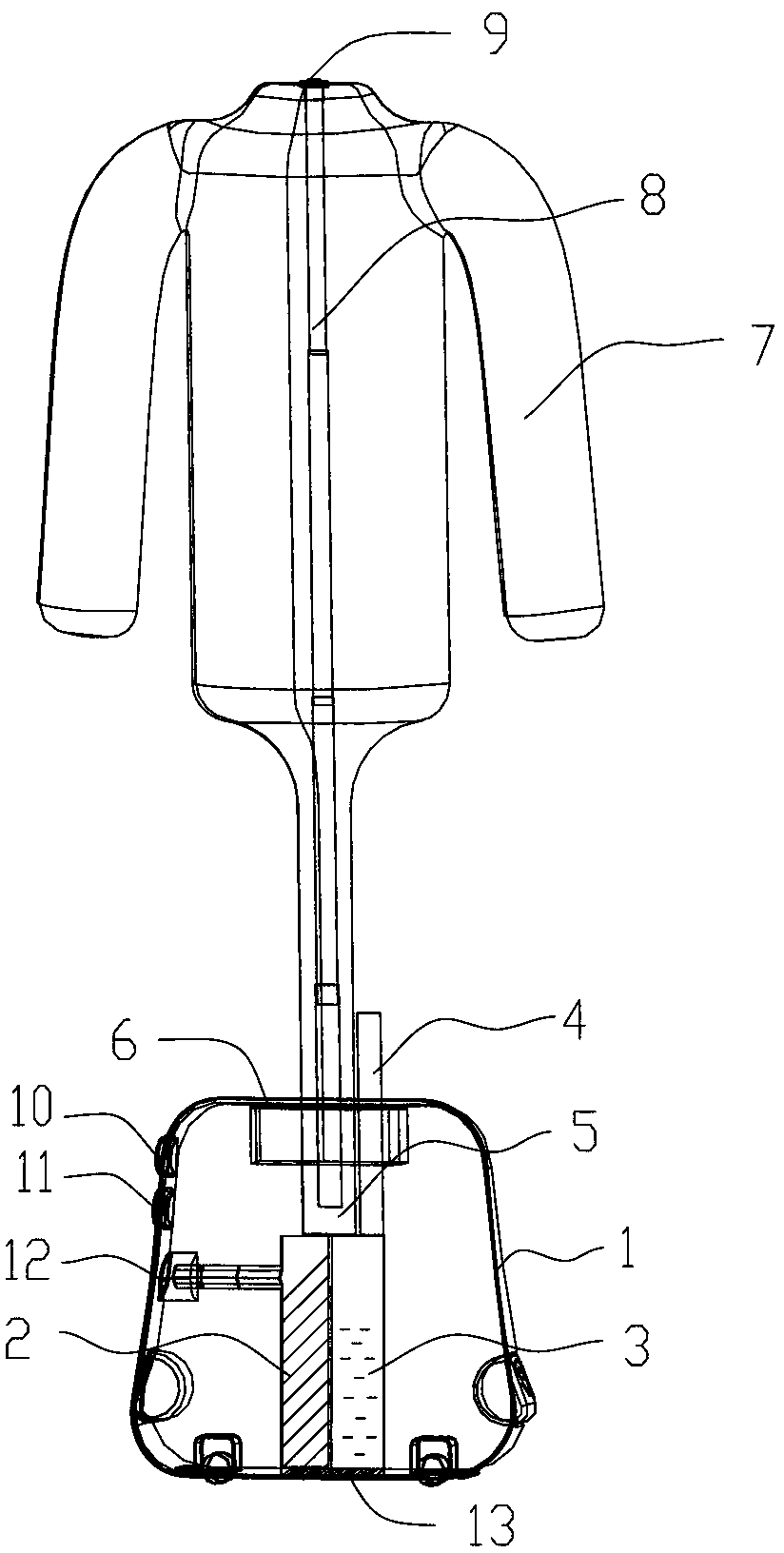

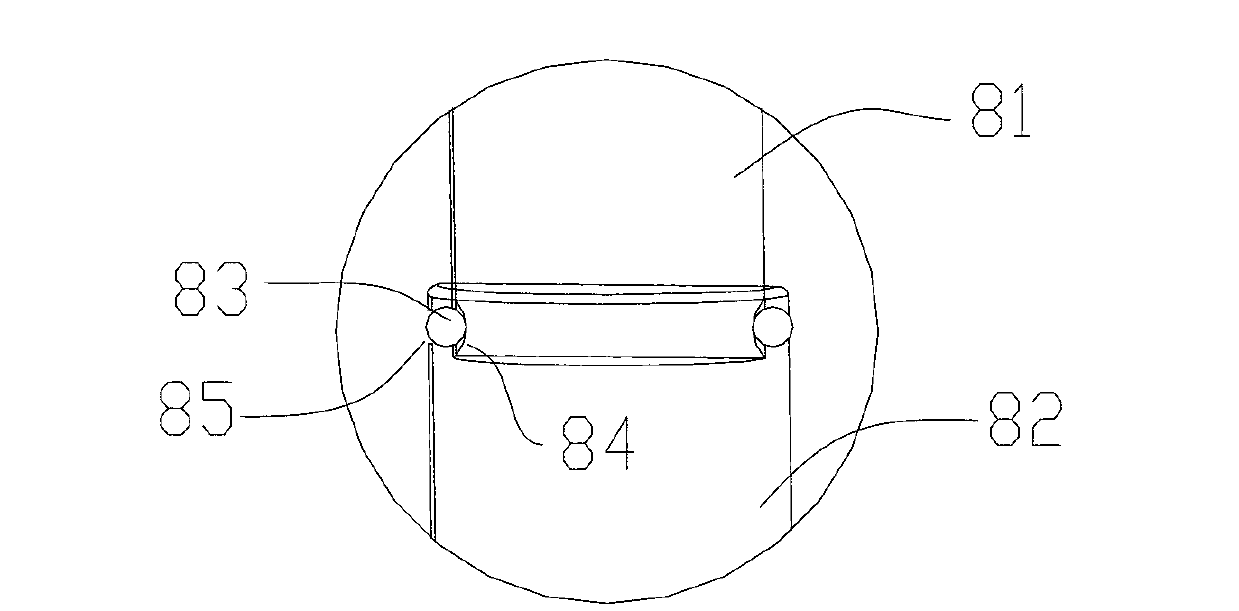

Three-dimensional clothes ironing dryer

ActiveCN103243529AImprove ironing effectImprove fullyIroning apparatusOther drying apparatusEngineeringAirbag

A three-dimensional clothes ironing dryer comprises a base, an airbag fixing support and an inflatable clothes rack. The inflatable clothes rack is arranged on the airbag-fixing support, and is composed of an inner airbag and an outer airbag. The inner airbag is made of heat-resisting non-breathable fabric, and can be attached to the airbag-fixing support. The inner airbag can be inflated to form a sealed human body model structure of an upper body shape or a lower body shape. The outer airbag is made of heat-resisting breathable fabric and sleeved on the outer side of the inner airbag, the outer airbag and the inner airbag form a ventilation space in between when plumped up, and are attached to the airbag-fixing support when contracted. The clothes are sleeved on the outer airbag, and warm air permeates to the surface of the clothes from the side wall of the outer airbag. By the three-dimensional clothes ironing dryer, irregular parts of the clothes can be ironed preferably.

Owner:齐志鲲

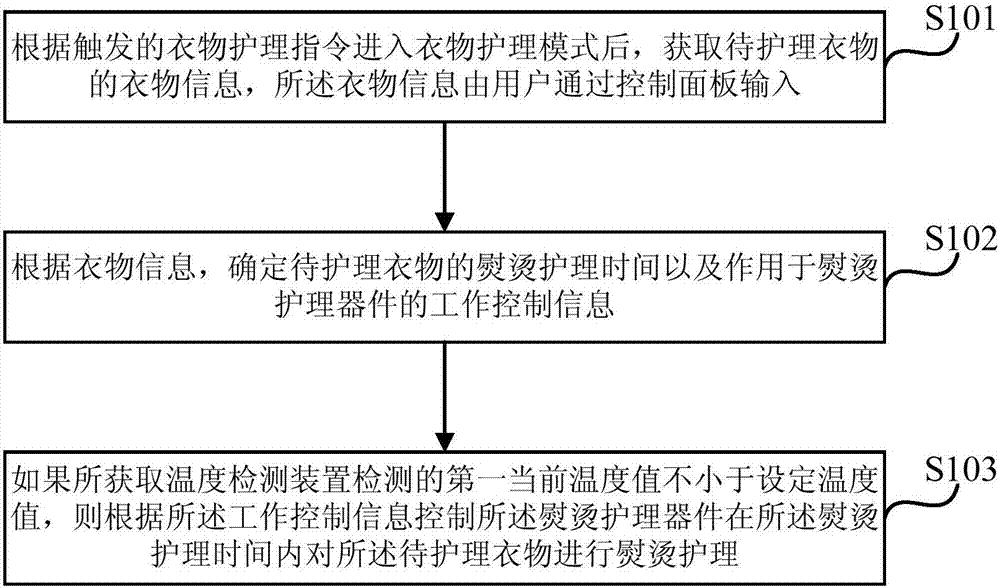

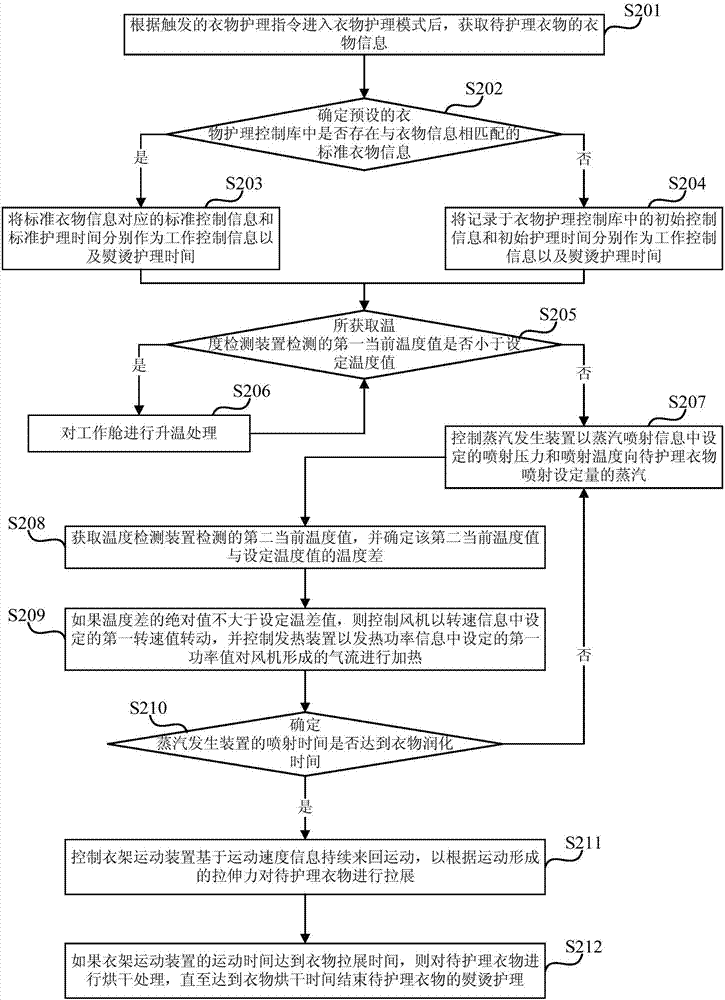

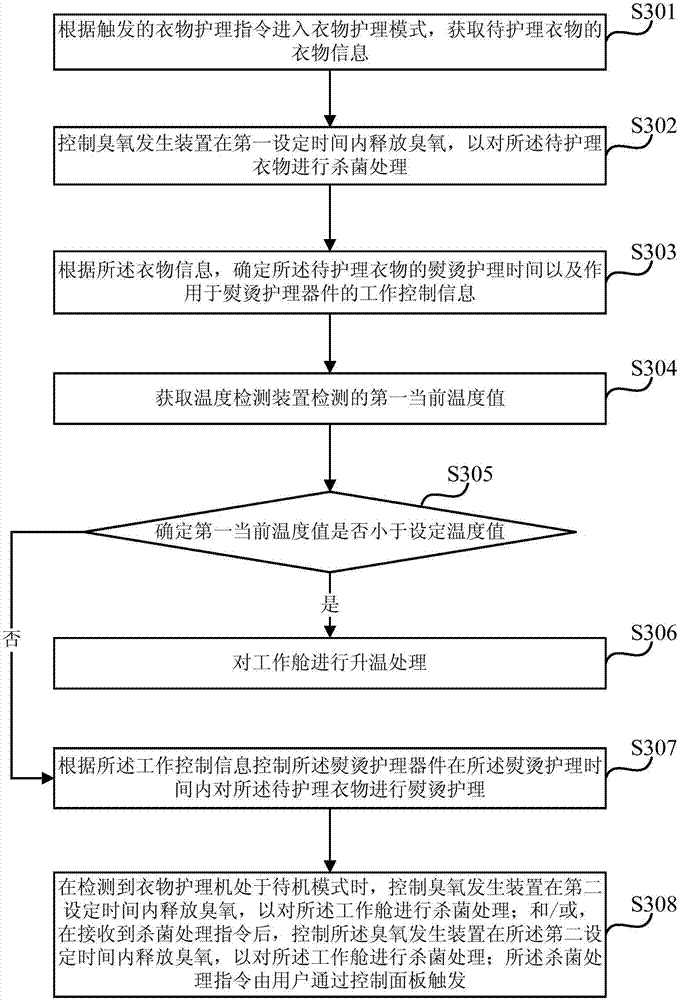

Clothes conditioner, control method and device thereof and storage medium

ActiveCN106894218AImprove ironing effectEnhance the clothing care experienceHand ironIroning apparatusEngineering

The invention discloses a clothes conditioner, a control method and device thereof and a storage medium. The control method includes: after entering a clothes conditioning mode according to a triggered clothes conditioning instruction, acquiring clothes information of to-be-conditioned clothes; determining ironing and conditioning time of the to-be-conditioned clothes and working control information acting on an ironing and conditioning device according to the clothes information; if a first current temperature value acquired by the ironing and conditioning device through detection is not smaller than a set temperature value, controlling the ironing and conditioning device to iron and condition the to-be-conditioned clothes within the ironing and conditioning time according to the working control information. By utilizing the control method, different ironing modes can be selected automatically for ironing according to different clothes, ironing effect of the clothes is improved effectively, and clothes conditioning experience of users is better improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

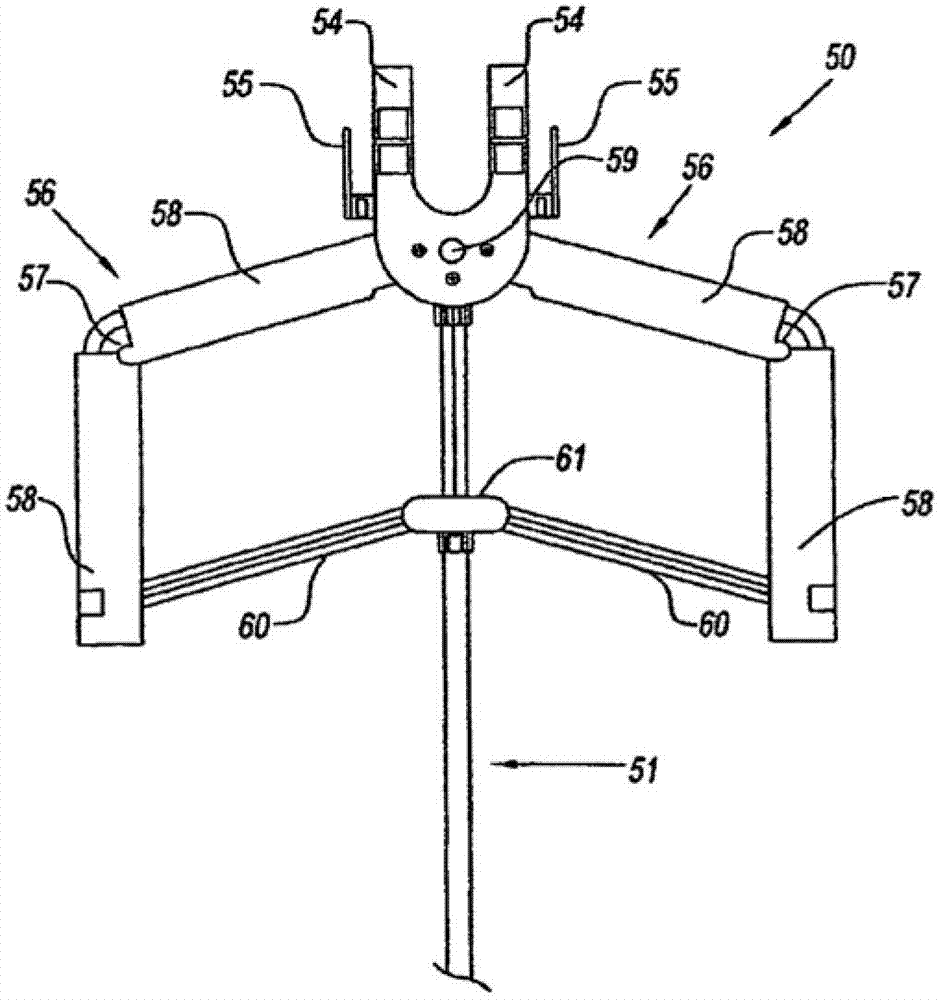

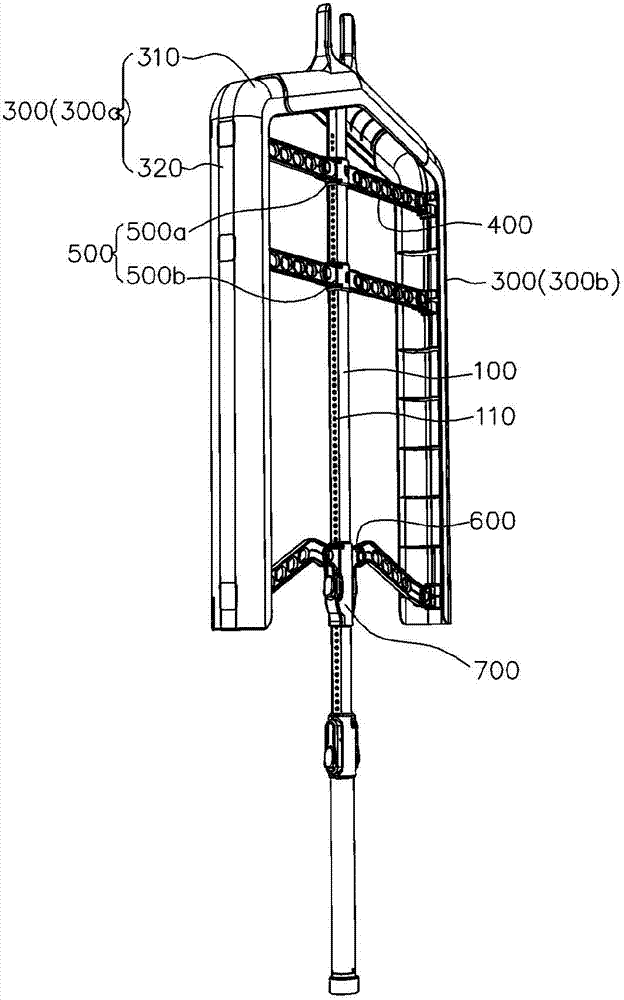

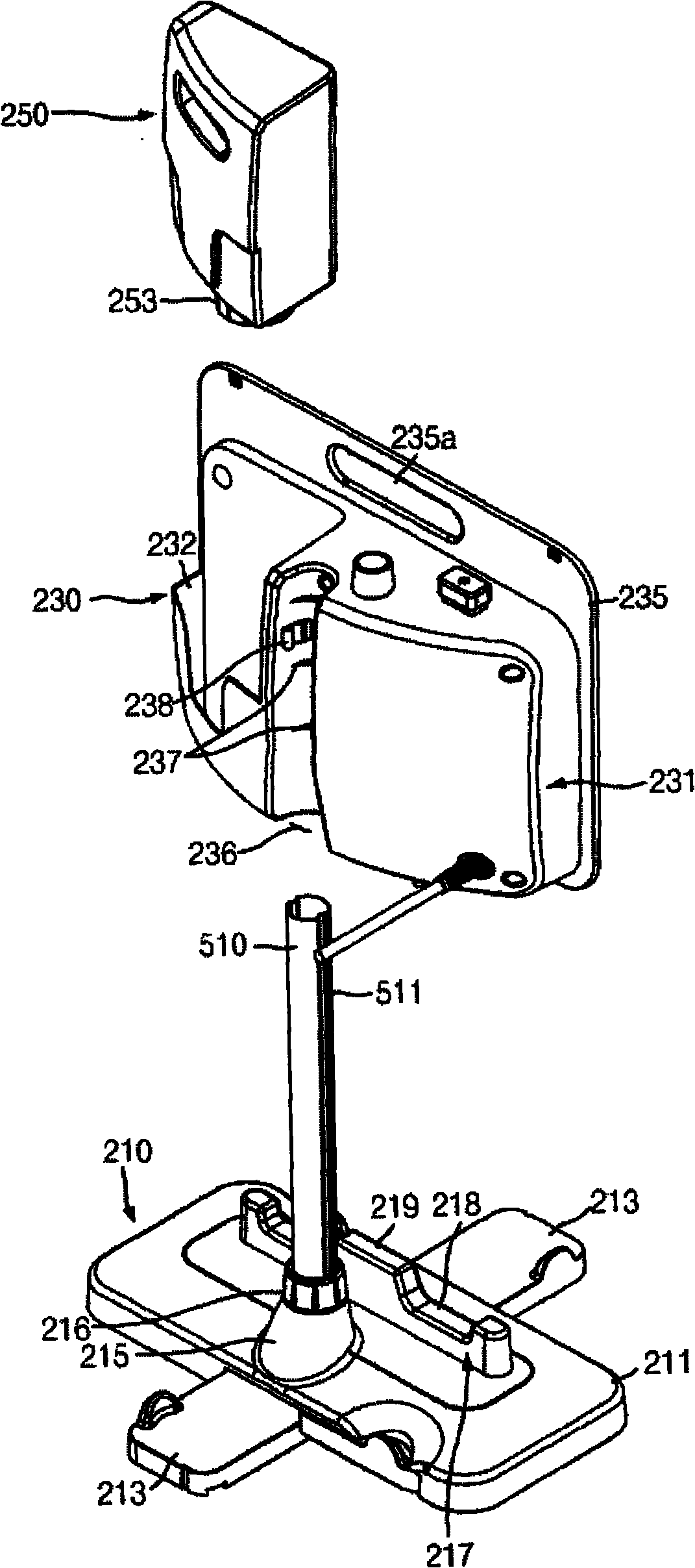

Standing steam iron

InactiveCN102713048AEasy to operateImprove convenienceHand ironIroning apparatusEngineeringSloping shoulders

The present invention relates to a standing steam iron. The standing steam iron according to the present invention comprises a post where rails are formed at left and right lateral sides,a pair of support frames which are arranged at the right and left of the post so as to face each other, are connected to one end of a plurality of link plates, and comprise a sloped shoulder support portion and a straight torso support portion,an upper moving body which is connected to the other end of a first link plate among the plurality of link plates and is fixed to the post or is mounted to the post for up and down movement,a lower moving body which is connected to the other end of a second link plate among the plurality of link plates, is mounted to move up and down the post if the upper moving body is fixed, and is fixed to the post if mounted for up and down movement,and a stopper which is formed below the up and down movable moving body between the upper moving body or the lower moving body, and is engaged with the rails to be coupled or de-coupled. The distance between a pair of the support frames is controlled through the interlocking of the up and down movement of an up and down movably mounted moving body the upper moving body or the lower moving body.

Owner:ALON MAXEY CORP

Textile ironing device

InactiveCN109183341AAchieve clearingGuarantee product qualityMechanical cleaningPressure cleaningEngineeringTextile

The invention provides a textile ironing device and relates to the technical field of textile equipment. The textile ironing device realizes treatment on dust on a fabric and ensures the ironing effect of the fabric. The textile ironing device comprises a base device, a dust removing device and an ironing device. The base device is provided with the dust removing device and the ironing device. Thebase device comprises a work table. The top of the work table is fixedly provided with a feeding roller, a collection roller and an operation box. The interior of the operation box is divided into adust removal chamber and an ironing chamber through a partition plate. A suction fan is arranged in the dust removal chamber. Through cooperation of a rotary motor, a cam, a curved block, a dust removing roller, a return spring and the suction fan, the impurities shaken out of the dust removal chamber are sucked out so that impurities are prevented from being adsorbed onto the fabric again, impurities on the fabric are removed, the subsequent ironing is promoted, the quality of the fabric is guaranteed and the wrinkles are reduced.

Owner:射阳县汇佳纺织有限公司

Waterborne polyurethane leather finishing agent and preparation method thereof

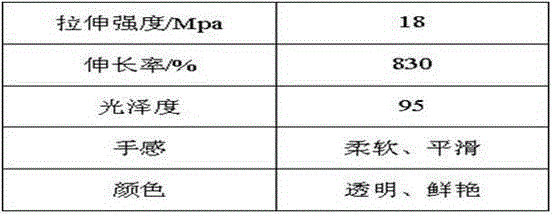

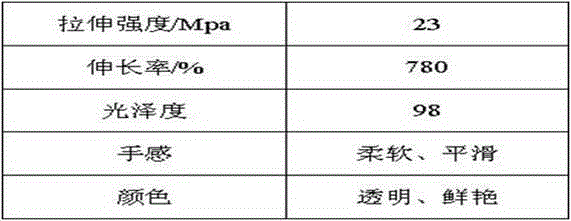

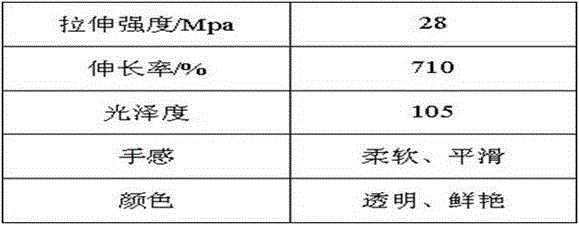

ActiveCN104448193AHigh glossImprove picking ratePolyurea/polyurethane coatingsLeather surface finishingPolyurethane dispersionEthylenediamine

The invention discloses a waterborne polyurethane leather finishing agent and a preparation method thereof. The method comprises steps as follows: using diisocyanate, CAB (cellulose acetate butyrate) and a polyether polyol to generate an isocyanate-group-terminated prepolymer, then performing neutralization with triethylamine after extending a chain with a hydrophilic chain extender, and finally, extending a chain with ethylenediamine to form a CAB-modified waterborne polyurethane dispersion so as to obtain the waterborne polyurethane leather finishing agent. According to the waterborne polyurethane leather finishing agent and the preparation method thereof, waterborne polyurethane is modified with the CAB, and the CAB-modified waterborne polyurethane dispersion is obtained. A resin film is bright, firm and good in deflection resistance, leather is endowed with the excellently high gloss, the smooth and soft hand feeling, the good ironing performance and excellent characteristics of light fastness, heat resistance, non-yellowing performance and the like, the selection rate of the leather is greatly increased after top finishing, and the grade of the leather is increased.

Owner:泰兴市华盛银洋新材料科技有限公司

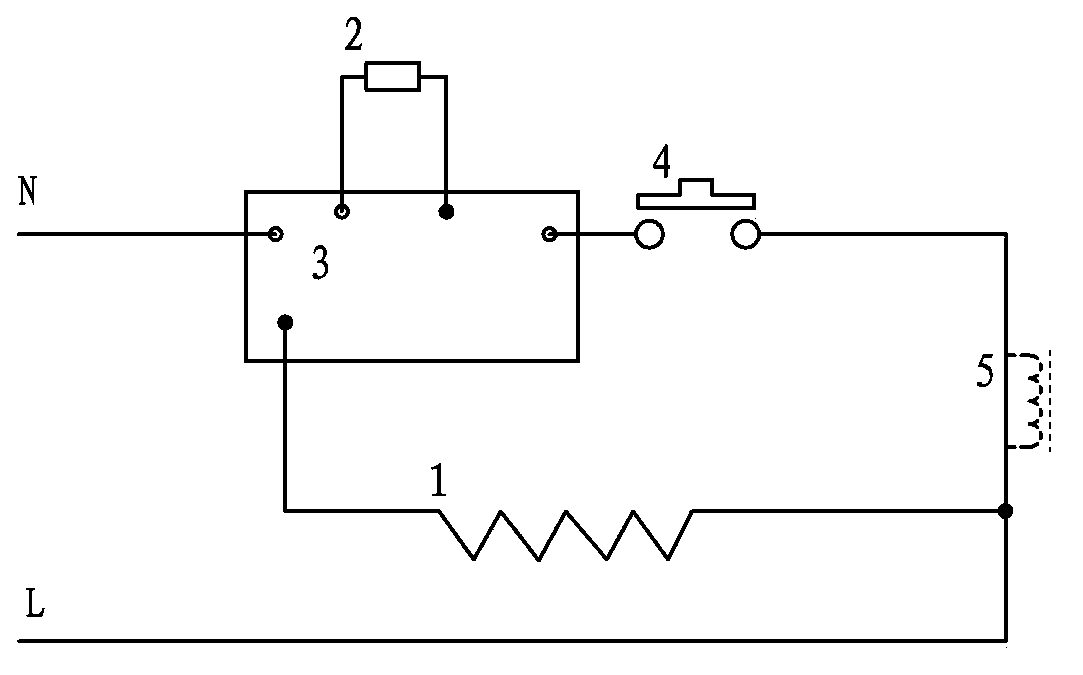

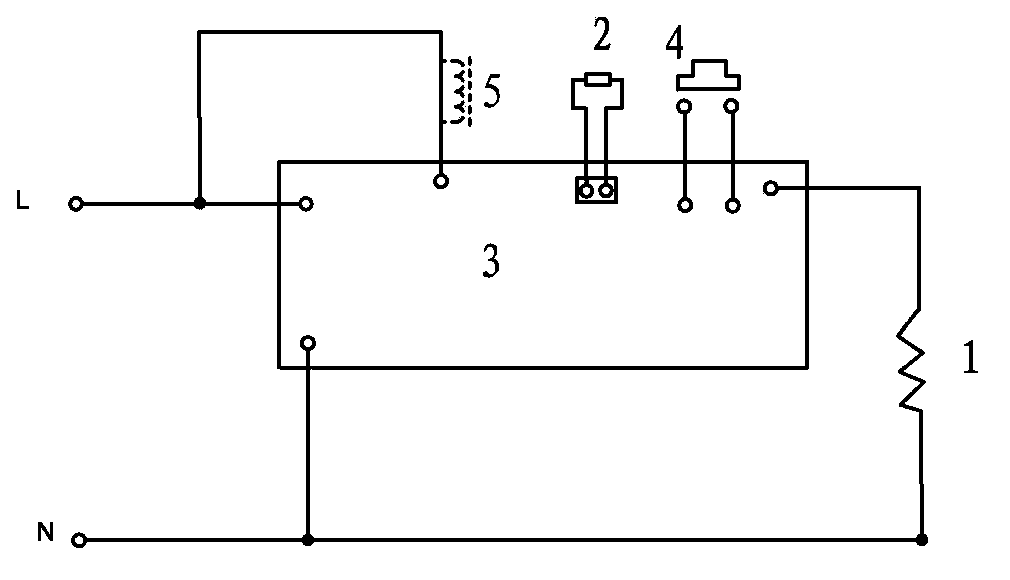

Vapor-type electric iron and control method thereof

InactiveCN103374812AImprove ironing effectSensitive and accurate controlHand ironTextiles and paperElectricityProcess engineering

Disclosed are a vapor-type electric iron and a control method thereof. The vapor-type electric iron comprises a vaporizing cavity arranged on a baseplate and used for converting water into vapor, and a controller used for controlling quantity of the water entering the vaporizing cavity, and a water supply device, a heating device is arranged on the baseplate, a vapor hole is formed in the baseplate, the vaporizing cavity is communicated with the vapor hole, vapor generated in the vaporizing cavity is discharged through the vapor hole, a temperature sensor is arranged on the baseplate, the controller is electrically connected with the heating device and the temperature sensor respectively, temperature signals of the baseplate are fed back to the controller while two-way control on temperature and vapor quantity of the base is realized through the temperature sensor, and the controller is electrically connected with the water supply device and controls water supply quantity of the water supply device according to the temperature signals of the base to adjust the vapor quantity of the vaporizing cavity. The vapor-type electric iron has the advantages of simple and reasonable structure, flexibility in operation, sensitivity and accuracy in control, simplified production process and high production efficiency.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

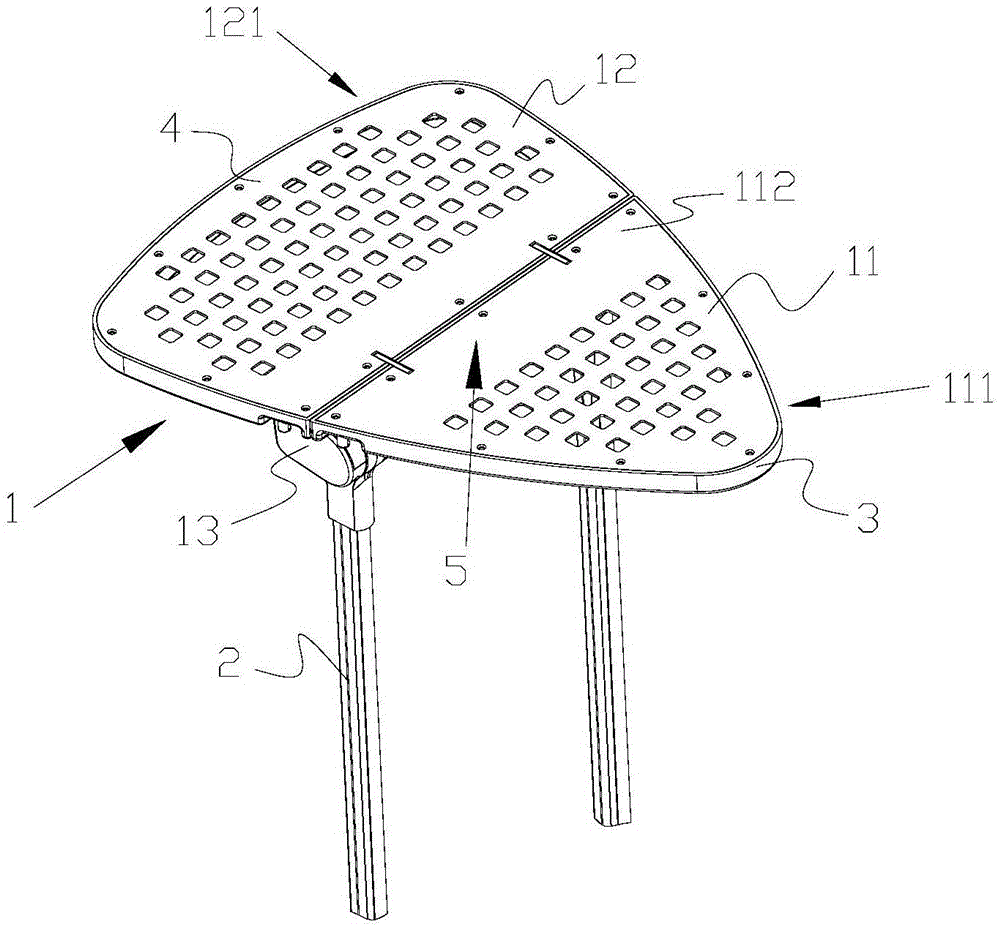

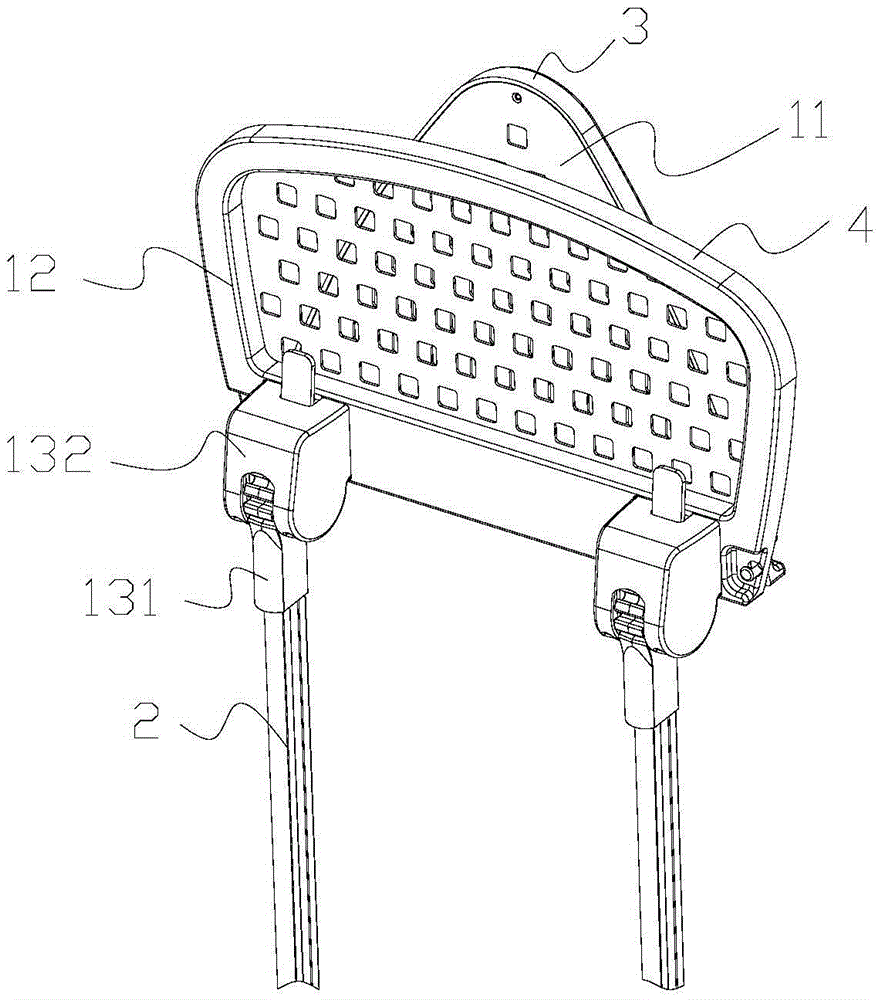

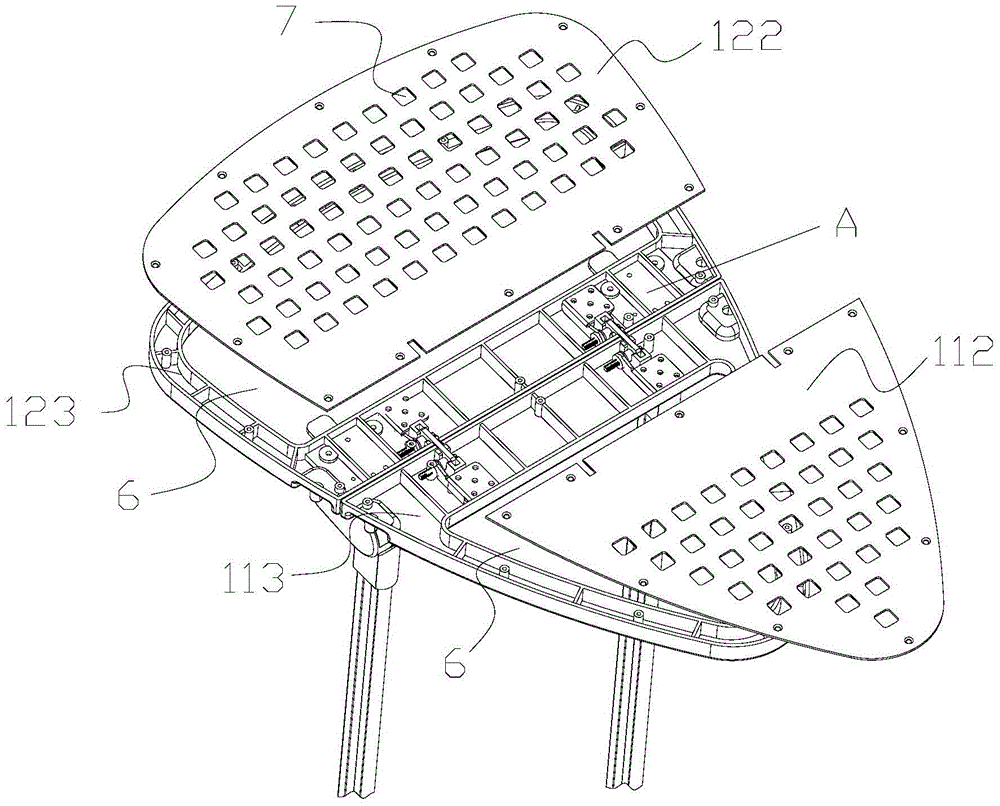

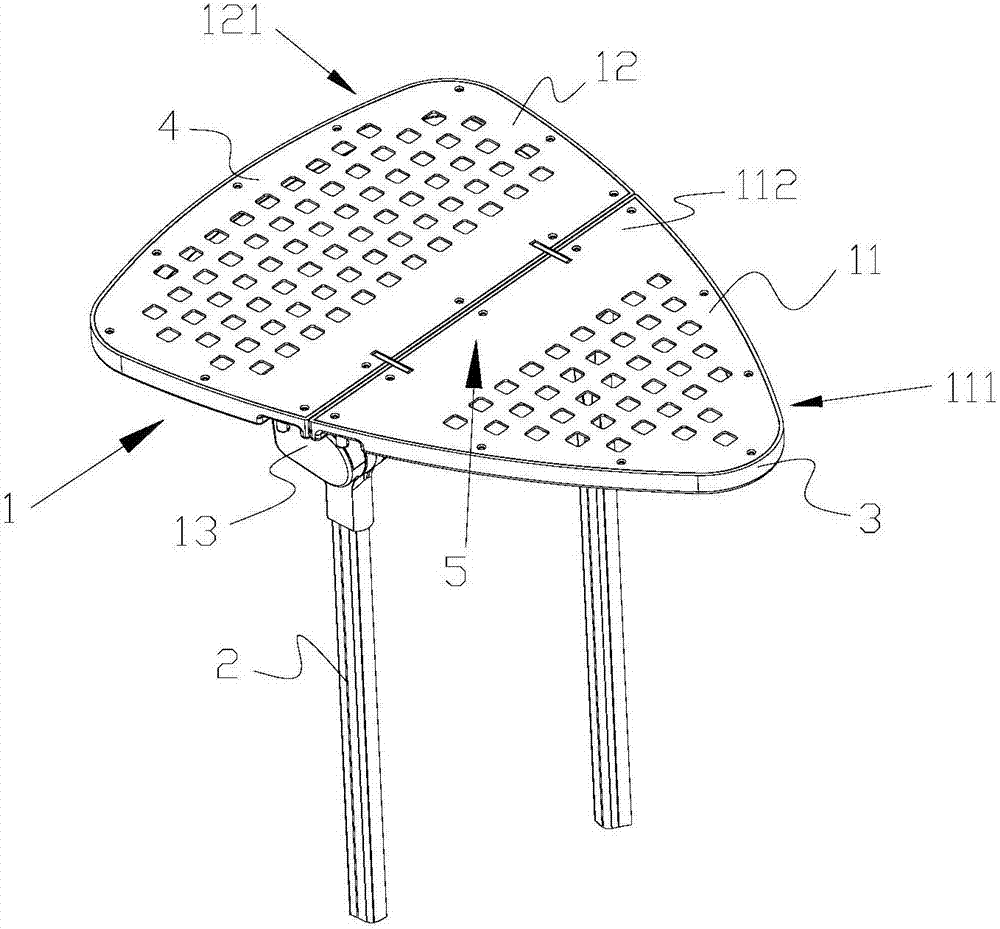

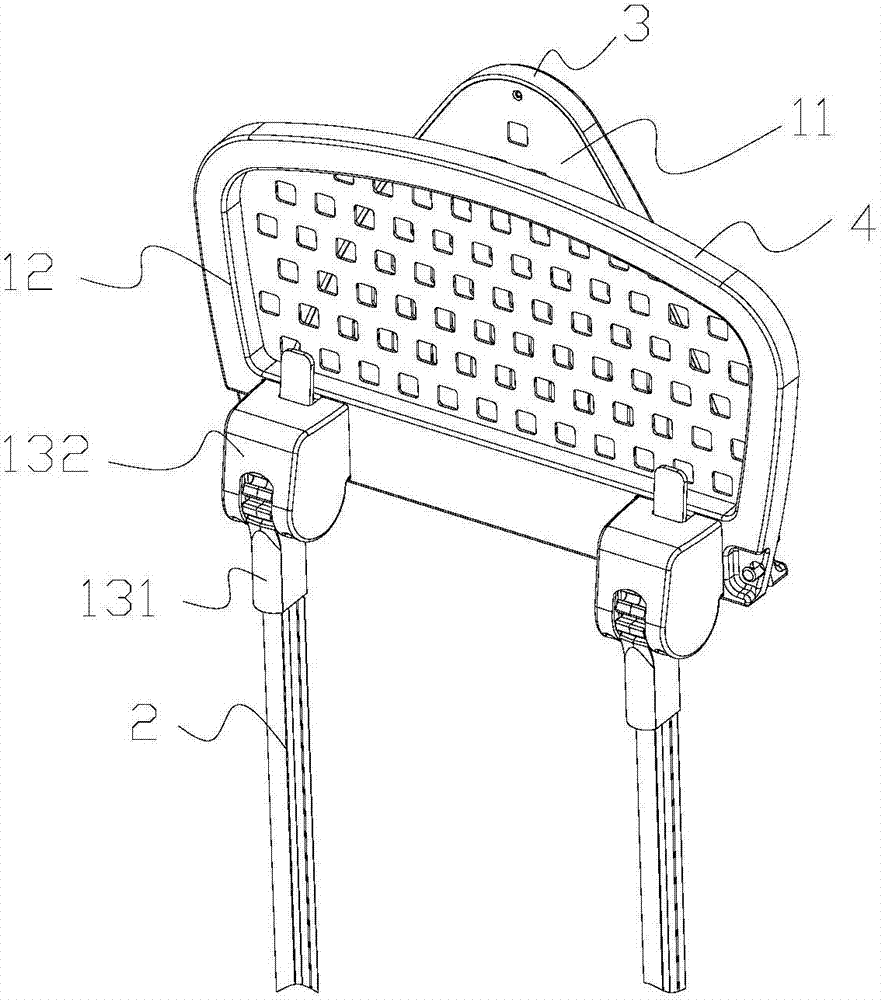

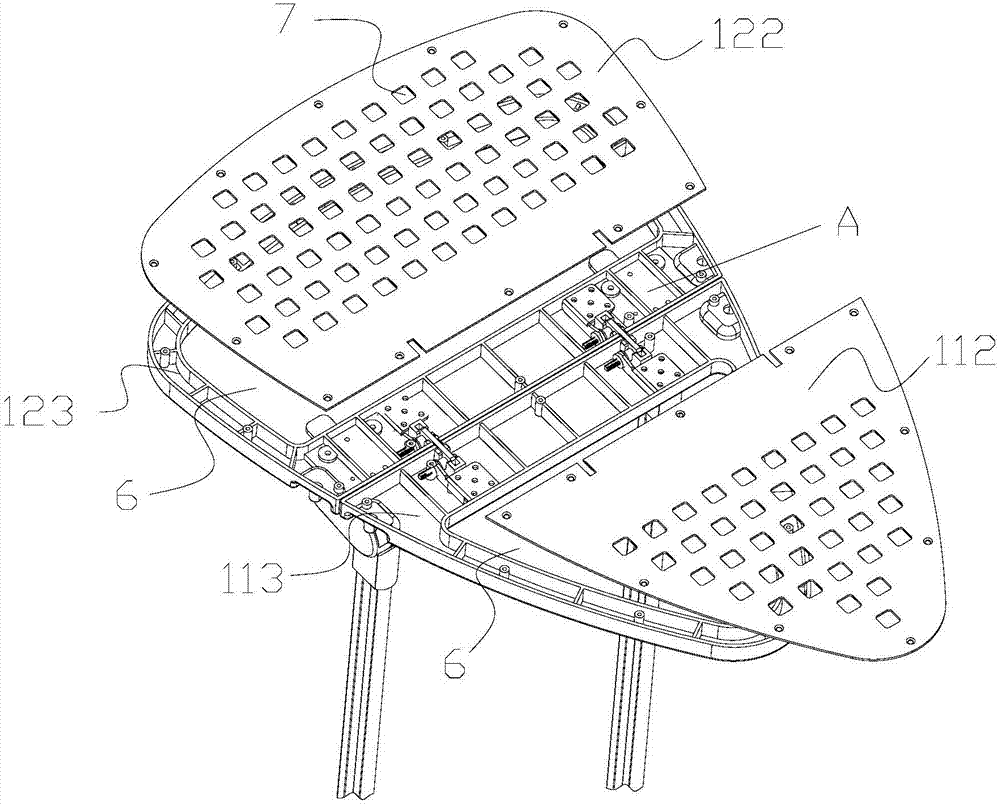

Folding type ironing plate assembly and ironing device

ActiveCN105671927ASimple structureEasy to produceIroning boardsIroning apparatusAgricultural engineeringClothes hanger

The invention provides a folding type ironing plate assembly which comprises an ironing plate and a bracket, wherein the ironing plate comprises a first folding part and a second folding part; the tail end of the first folding part is hinged to the front end of the second folding part, so that the first folding part and the second folding part can be relatively folded; a supporting protrusion is arranged at the front end of the first folding part; a hanging part for hanging clothes is arranged at the outer end of the second folding part; the first folding part or the second folding part is connected to the upper end of the bracket through a connection piece and is connected with the connection piece in a turning manner; a positioning mechanism for positioning the angle of the ironing plate is arranged on the connection piece; the first folding part and the second folding part can be unfolded to form an ironing plane; the positioning mechanism realizes flat ironing in different angles; the first folding part and the second folding part can be vertically folded to form a clothes hanger for hanging ironing; and the supporting protrusion is higher than the hanging part. The ironing plate of the folding type ironing plate assembly positions the collar through the supporting protrusion and can better iron the collar during clothes ironing.

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG

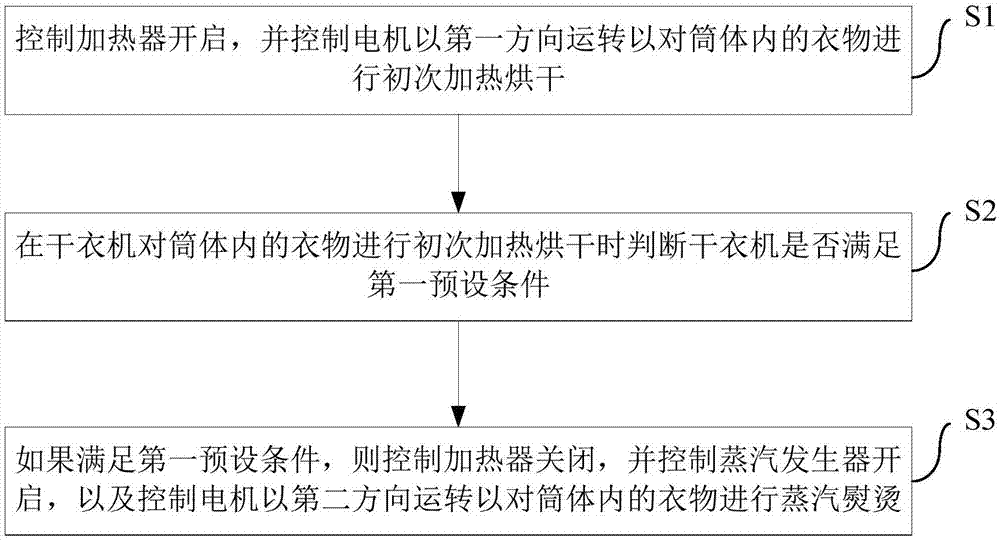

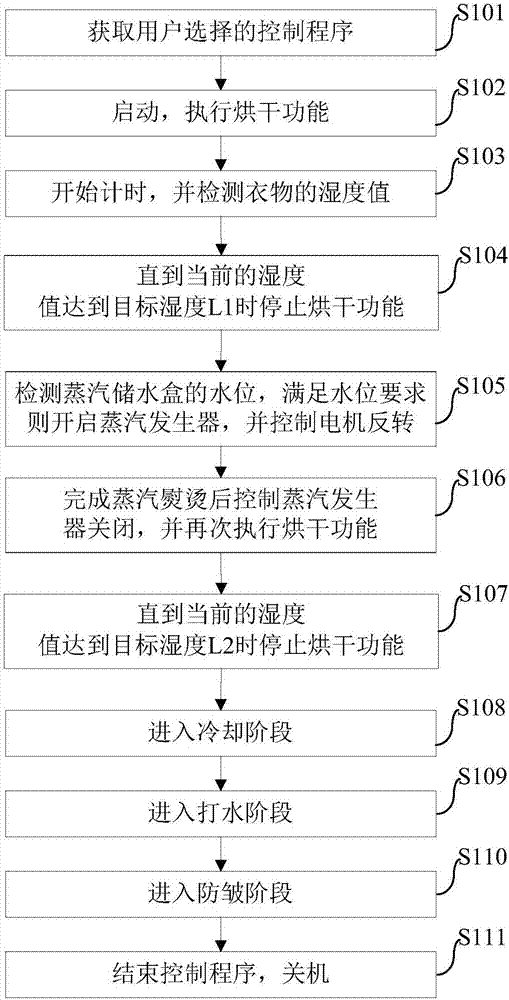

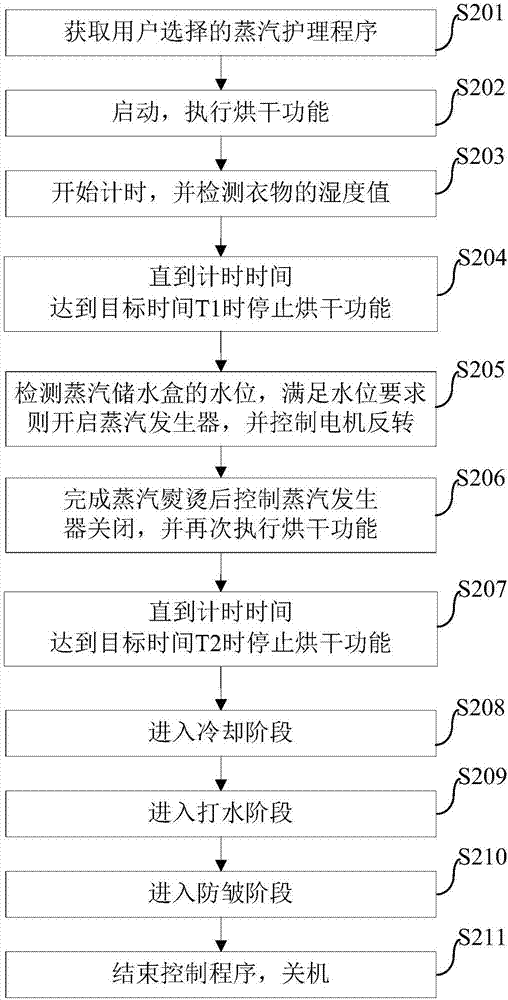

Clothes dryer and steam ironing control method and device thereof

ActiveCN108004738AGuaranteed flatnessEasy to controlTextiles and paperLaundry driersMotor driveEngineering

The invention discloses a clothes dryer and a steam ironing control method and device thereof. The clothes dryer includes a heater, a steam generator, a motor, a wind wheel, and a barrel; and the motor drives the wind wheel and the barrel to rotate at the same time. The steam ironing control method includes the following steps: controlling the heater to start, and controlling the motor to operatein the first direction so as to perform initial heating and drying on clothes in the barrel; determining if the clothes dryer meets a first preset condition or not while the clothes dryer performs initial heating and drying on the clothes in the barrel; and controlling the heater to shut down, controlling the steam generator to start, and controlling the motor to operate in the second direction soas to perform steam ironing on the clothes in the barrel. The steam ironing control method is easy to control, is low in cost, can improve the steam ironing effect of the clothes dryer, and can effectively ensure the flatness of the clothes.

Owner:WUXI FILIN ELECTRONICS CO LTD

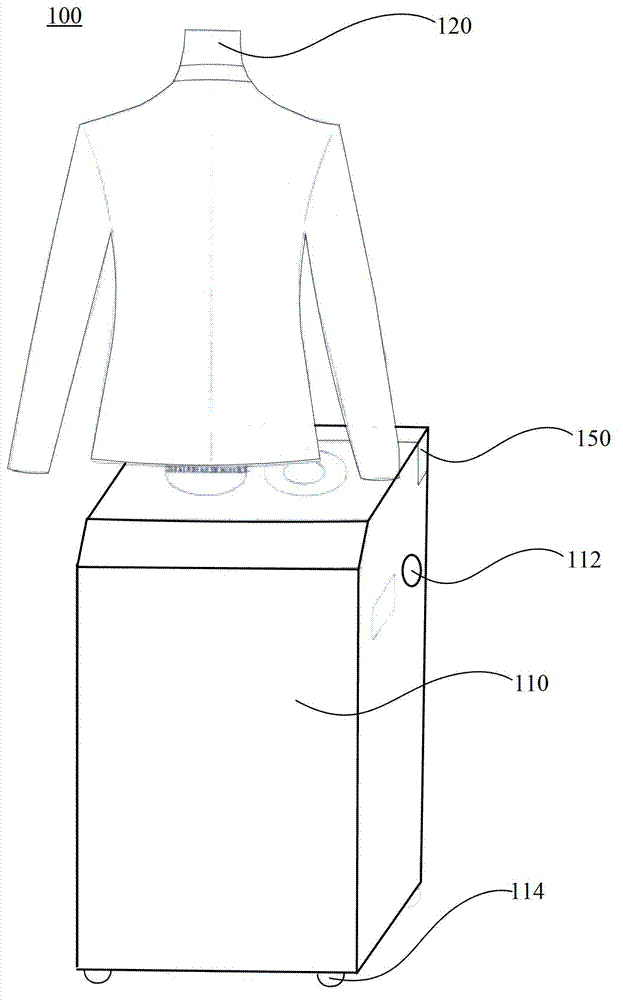

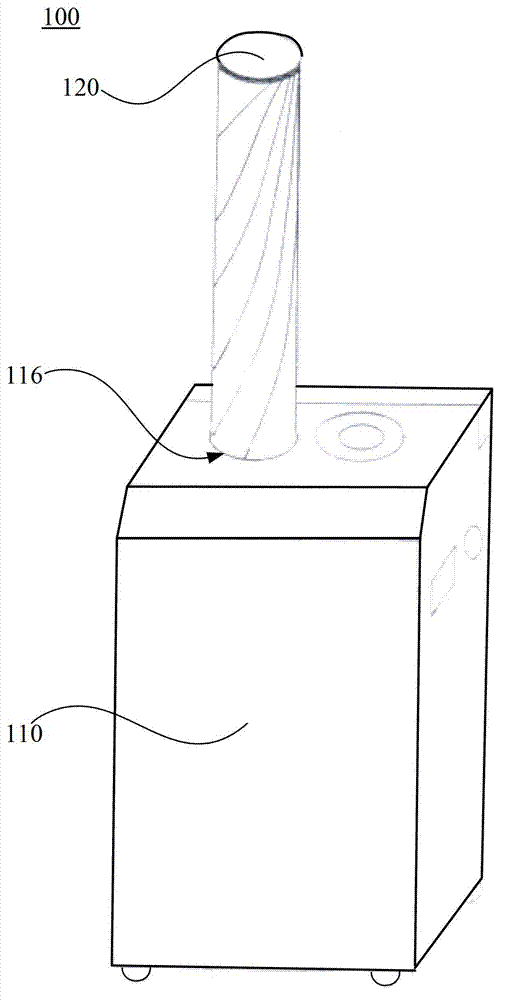

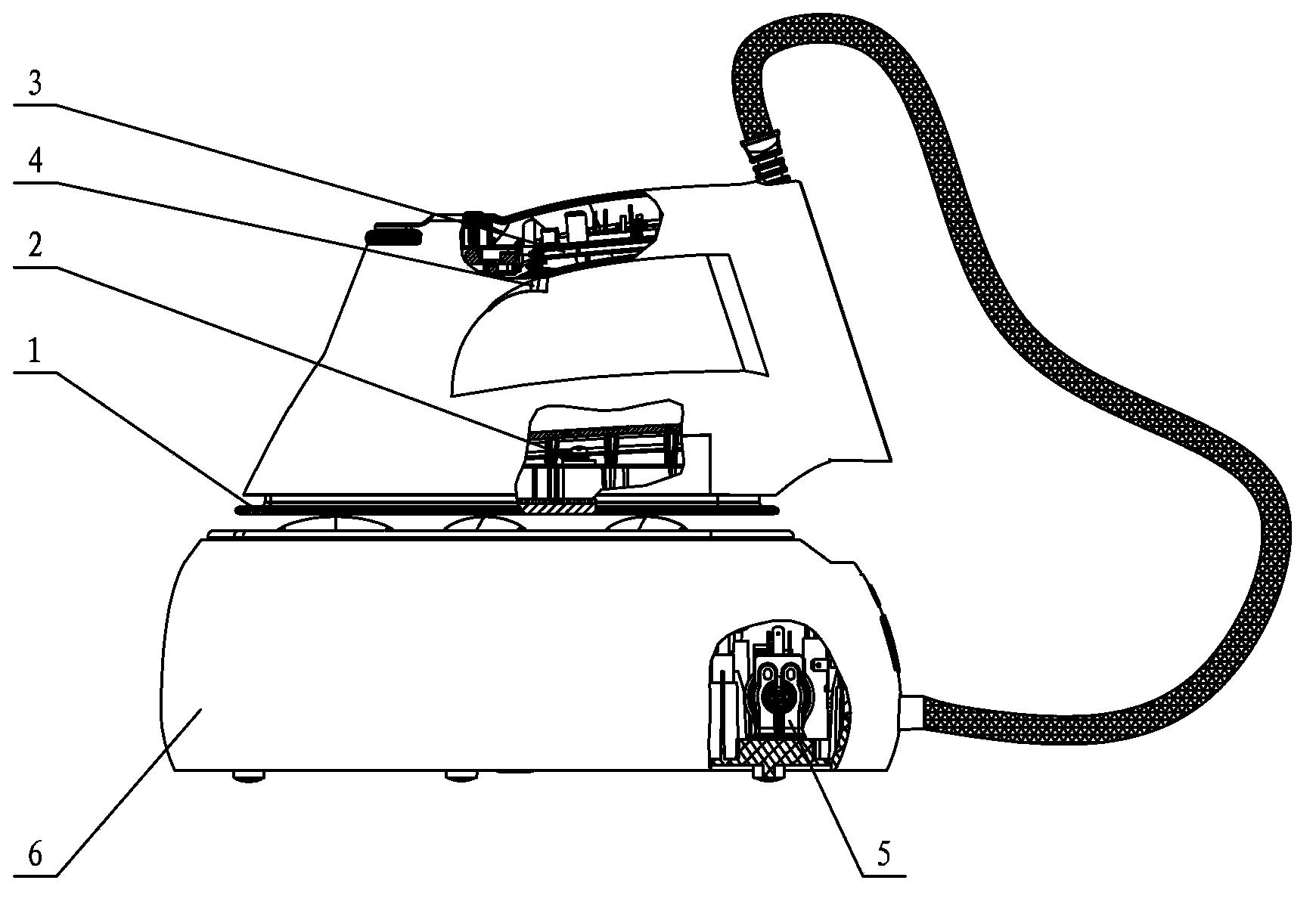

Steam ironing machine

ActiveCN102995371AWith support effectHave a plastic effectIroning apparatusTextiles and paperEngineeringAir blower

The invention provides a steam ironing machine, comprising a shell, a water tank, a heating body and a nozzle, and further comprising an air blower, wherein the air blower is connected with an inflating pipe; an inflatable contraction die is sleeved with the inflating pipe; the contraction die is expanded from a contraction state to an expansion state after being inflated by the air blower; and at the expansion state, the contraction die is located at the top of the shell, and keeps the shape of a cloth mould. With the adoption of the steam ironing machine provided by the invention, clothes can be ironed on the die when being worn by a user, so that the ironing and shaping effects of the clothes are better.

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG CO LTD

Foldable ironing board assembly and ironing device

ActiveCN105671927BEasy ironingIdeal ironing effectIroning boardsIroning apparatusEngineeringClothes hanger

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG CO LTD

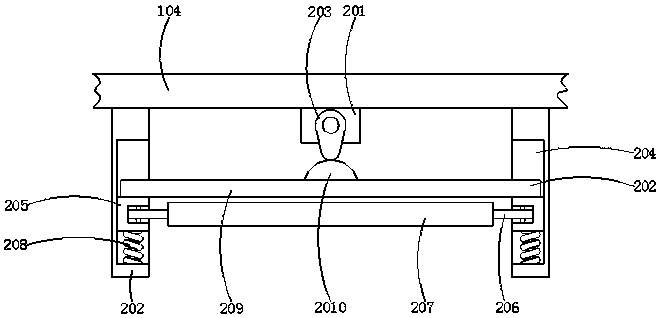

Cloth ironing device for garment production

ActiveCN111254677AKeep clean and hygienicImprove ironing effectMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention provides a cloth ironing device for garment production. The cloth ironing device comprises a transverse ironing assembly, the transverse ironing assembly comprises a moving frame, the moving frame is provided with a rectangular frame and a U-shaped frame fixedly arranged on the rectangular frame, and a pair of door-shaped frames distributed in a splayed shape are pivoted on a liftingblock of a lifting mechanism arranged on the rectangular frame; a pressing roller is fixedly arranged at the opening end of each door-shaped frame, two pressing plates are connected with the U-shapedframe in a pivoted mode, torsional springs enable the pressing plates to abut against the upper portions of the corresponding pressing rollers, the lifting block descends to enable the pair of pressing rollers to be pushed and pressed from the center to the two sides along the inner bottom face of the U-shaped frame, and the advancing speed of the moving frame is the same as that of cloth; and when the door-shaped frames turn over by more than certain angle, a lock rod located on one door-shaped frame crosses over an elastic stop piece on the lifting block, the moving frame retreats after theprocess is finished, the lifting block ascends, and after a driving piece located on the rectangular frame acts on the elastic stop piece, the pair of door-shaped frames rapidly reset under the action of the pair of pressing plates. According to the cloth ironing device for the garment production, the ironing effect is good, and the working efficiency is high.

Owner:WENZHOU POLYTECHNIC

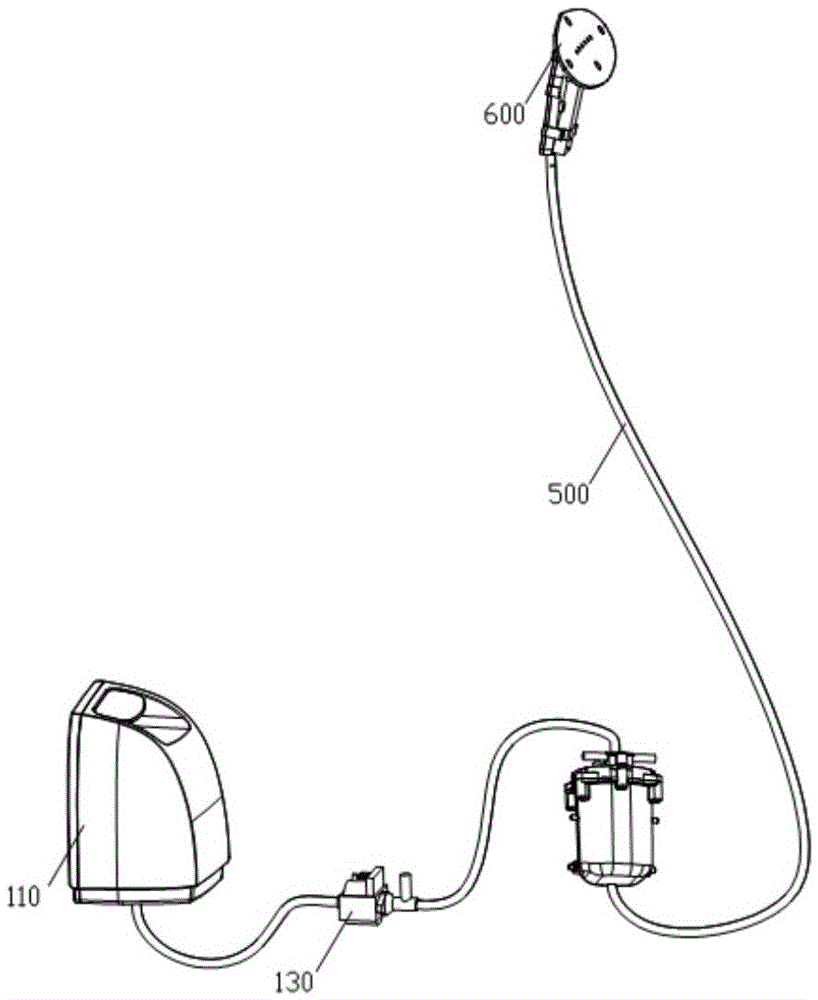

Steam quantity controllable instant-heating garment steamer

ActiveCN105544168AContinuous generationImprove ironing effectIroning apparatusTextiles and paperWater storage tankEngineering

The invention discloses a steam quantity controllable instant-heating garment steamer which comprises a steamer body, a primary heating pot, a water pump and an ironing head. An accommodating cavity is formed in the steamer body, a water storage tank is arranged in the accommodating cavity, the primary heating pot is fixed in the accommodating cavity and is an instant-heating pot, the water pump is connected between the water storage tank and a water inlet of the primary heating pot and is connected with a controller arranged on the steamer body, the ironing head is communicated with a steam outlet of the primary heating pot through a steam hose, and a secondary heating pot is arranged in the ironing head. A steam inlet of the secondary heating pot is communicated with the steam outlet of the primary heating pot, and a steam outlet of the secondary heating pot is communicated with an ironing plate steam outlet of the ironing head. The steamer has a transient heating function, the efficiency of converting water into steam is high, and the technical problems of uncontrollable steam quantity output by the garment steamer and high water content in steam are solved.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

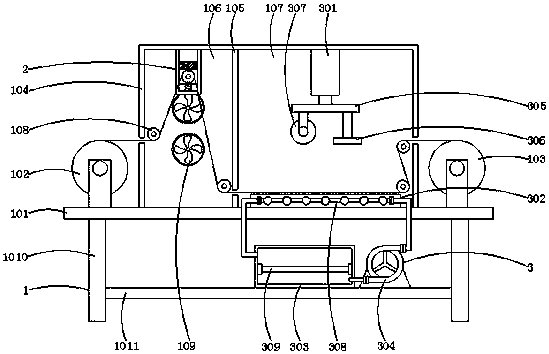

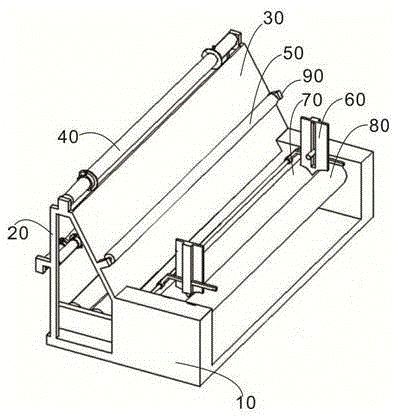

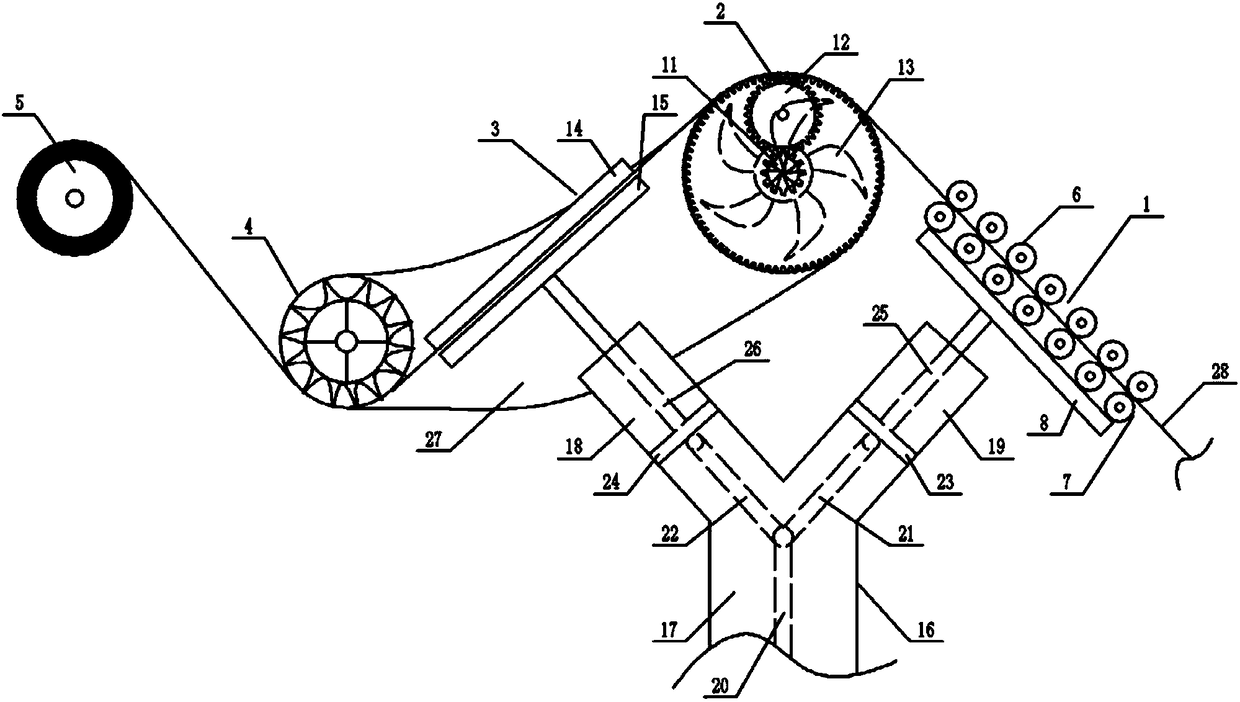

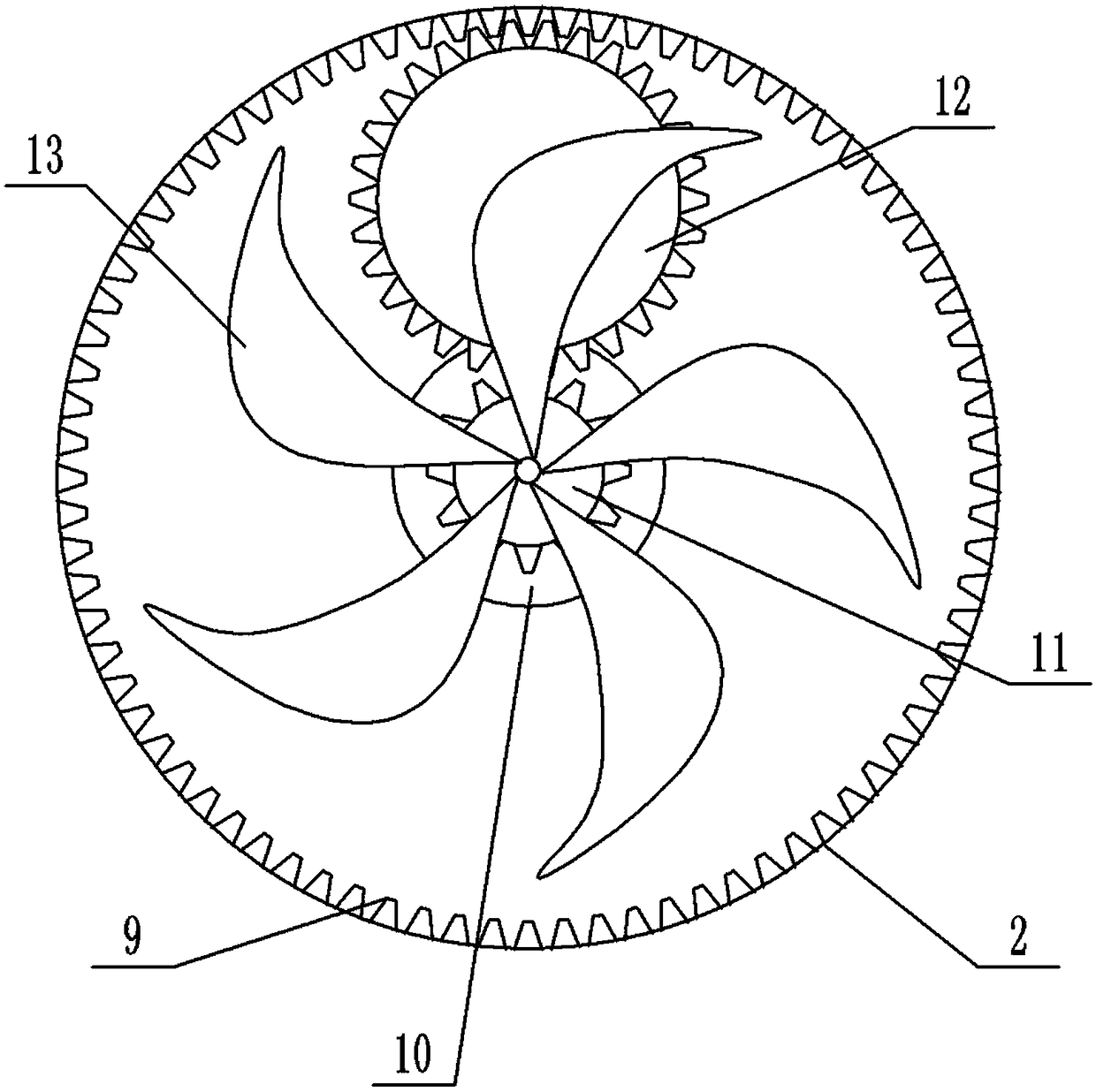

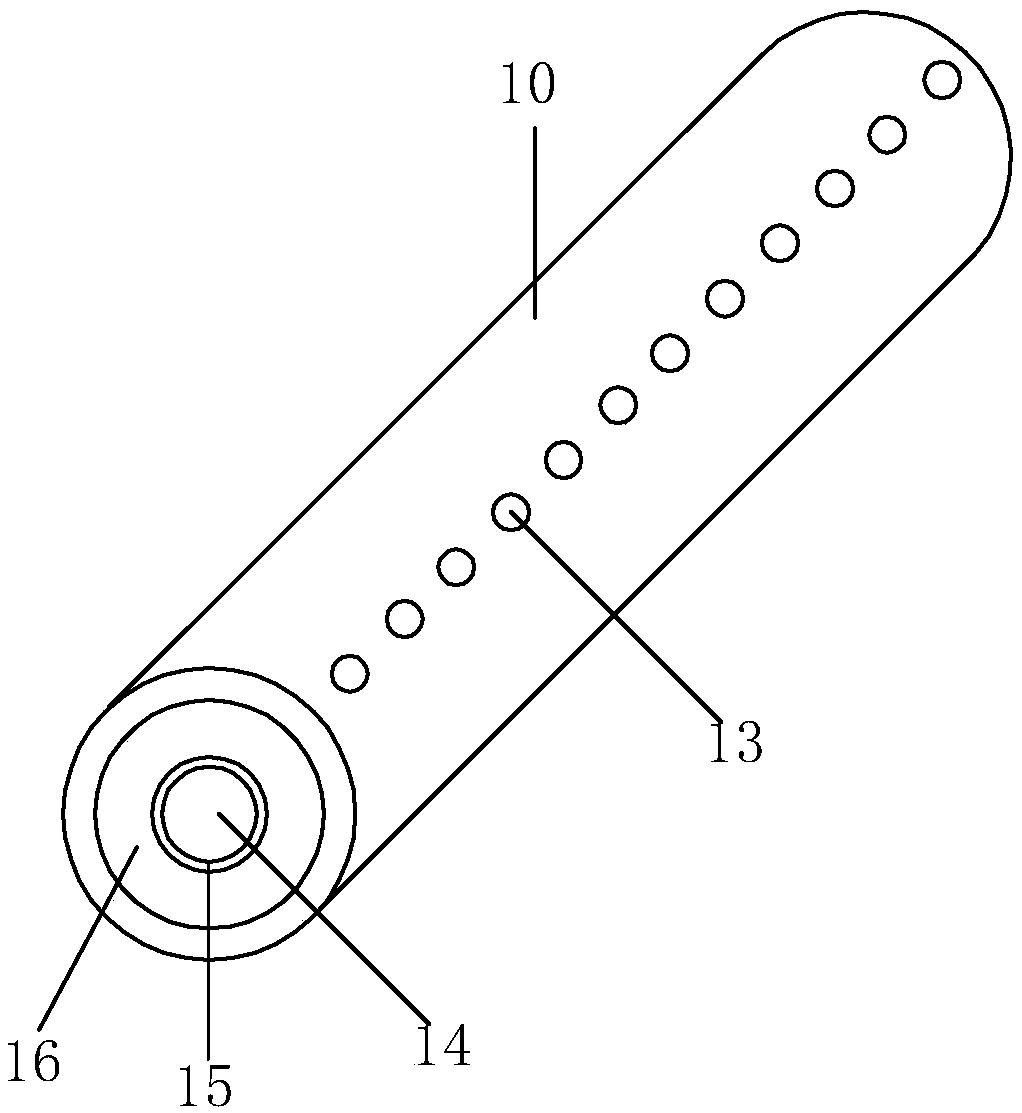

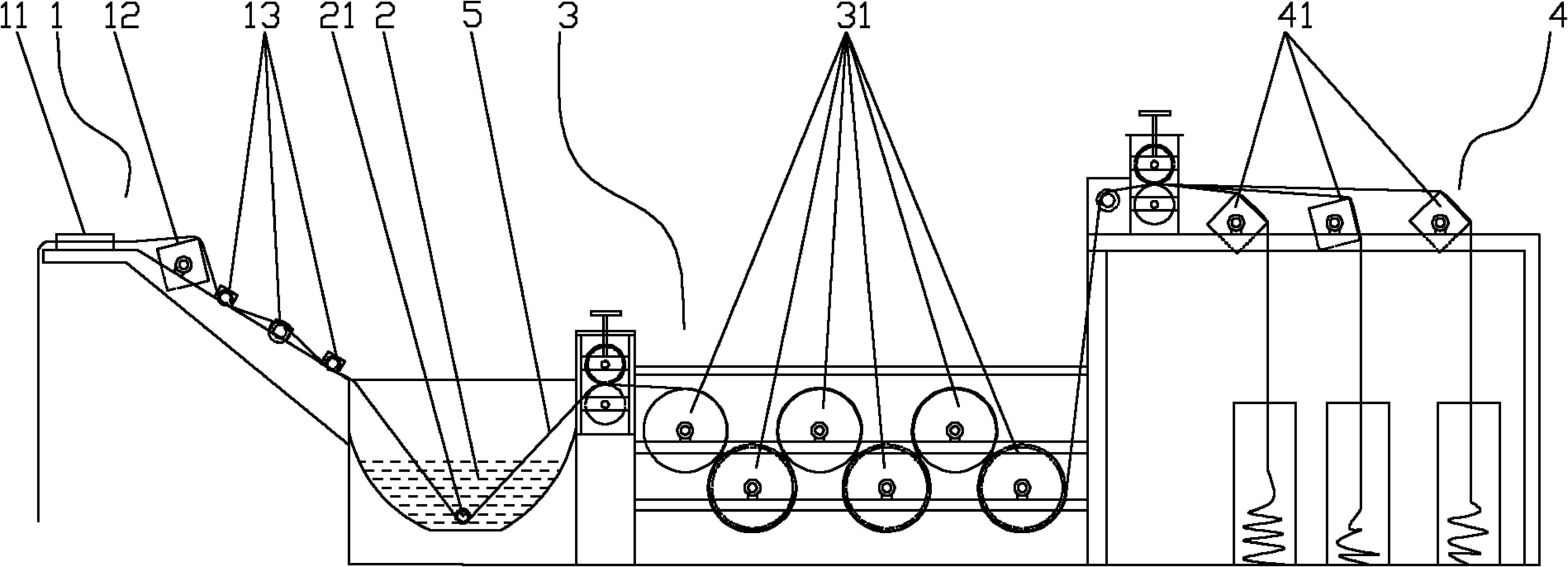

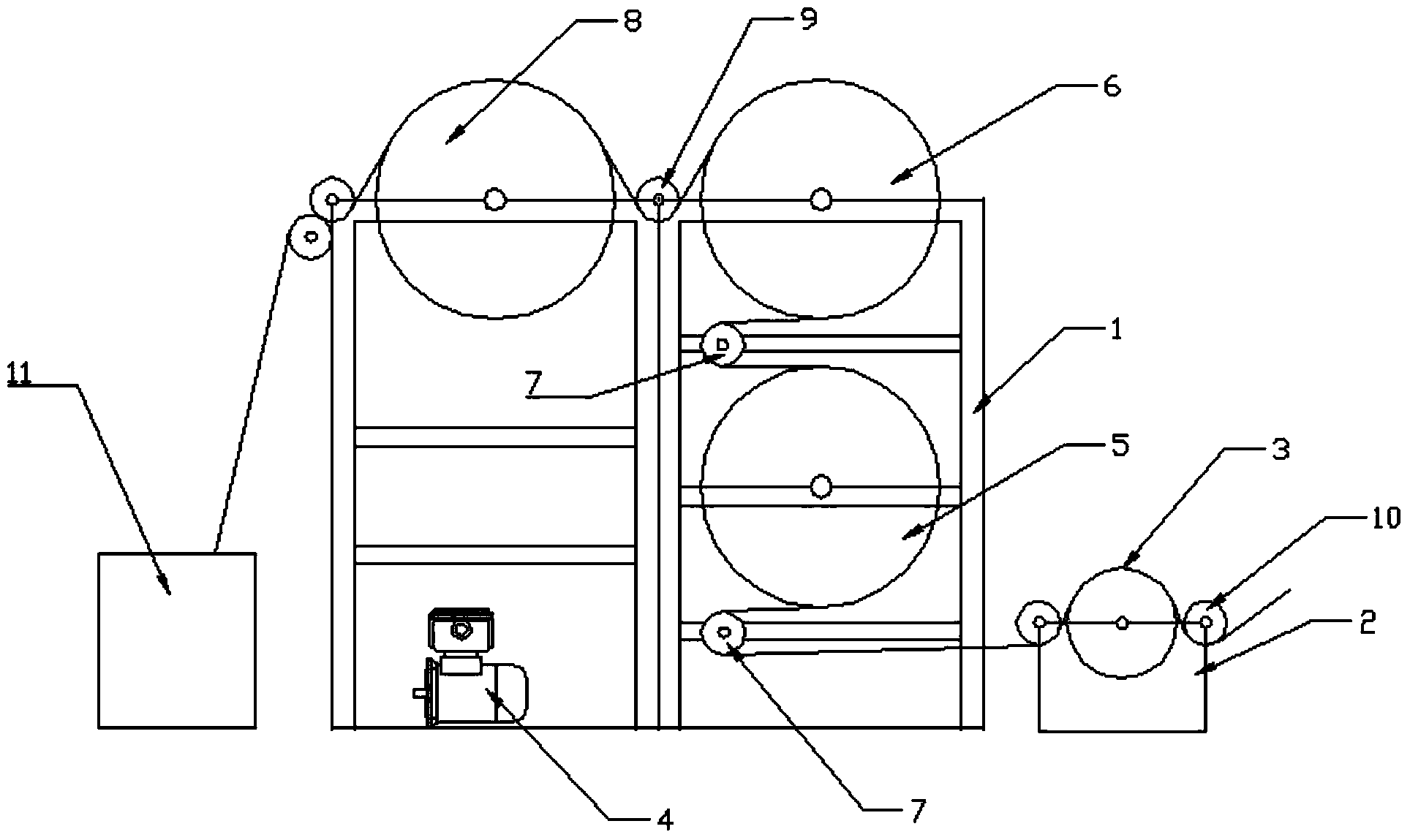

Double-surface ironing winding machine

InactiveCN105417259AImprove ironing effectAvoid wrinklesIroning apparatusTextiles and paperWinding machineEngineering

The invention provides a double-surface ironing winding machine. The machine comprises a base which is fixedly arranged, wherein a rack is arranged at one side of the base; a supporting plate which is obliquely arranged in a preset angle is arranged between the rack and the base; a fabric winding roller is mounted at the upper end of the rack; a guide roller is arranged on the supporting plate; a driving device, a limiting mechanism, a first heating roller and a second heating roller are arranged on the base; the driving device is used for driving the first heating roller and the second heating roller to rotate in opposite directions; the limiting mechanism is used for limiting the moving route of a nonwoven fabric. According to the machine, the first heating roller and the second heating roller which are rotated in the opposite directions are arranged on the winding machine and can be used for performing double-surface ironing for the nonwoven fabric to be wound, so that the nonwoven fabric can be flat, and the ironing effect is improved; meanwhile, the nonwoven fabric can be prevented from wrinkling due to the surface flatness during winding. With the adoption of the machine, the nonwoven fabric can be wound regularly and accurately, so that the winding quality can be improved, and the operation is simplified.

Owner:YANGZHOU XIANGBEI MACHINERY

Textile processing equipment

ActiveCN108517639AReduce speedHigh degree of automationLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsMotor driveElectric machinery

The invention relates to the field of textile processing, and particularly discloses textile processing equipment. The textile processing equipment comprises a rack, and further comprises a water wiping mechanism, a water absorbing roller, an ironing mechanism, a drying roller, a material collecting roller, a first motor and a second motor, wherein the water wiping mechanism, the water absorbing roller, the ironing mechanism, the drying roller, the material collecting roller, the first motor and the second motor are arranged on the rack in the horizontal direction in sequence, the first motordrives the water absorbing roller, and the second motor drives the material collecting roller; the water wiping mechanism is arranged at the discharging end of a textile, the material collecting roller is arranged at the material collecting end of the textile, the water wiping mechanism comprises several water wiping rollers facing the water absorbing roller, the water wiping rollers are divided into a first water wiping set and a second water wiping set, the first water wiping set and the second water wiping set are opposite, the first water wiping set is rotatably connected with the rack, and a water wiping plate is fixedly connected to the second water wiping set. The textile is processed through the four motions of water wiping, water absorbing, ironing and drying in sequence, and thenthe textile is also reeled after being processed; the automated degree is high, and the processing efficiency is high; moreover, when processed by multiple processing steps, the textile does not needto be carried and can be processed at a time, and the time and labor are saved.

Owner:NINGBO WENZE TEXTILE CO LTD

Automatic ironing device for western-style clothes processing

InactiveCN108866867AImprove the three-dimensional effectSimple structure and principleLiquid/gas/vapor textile treatmentTextile shapingAutomatic controlWater vapor

The invention discloses an automatic ironing device for western-style clothes processing. The device comprises an automatic ironing device body. A machine table, a water tank, a water pump, a cloth twisting mechanism, a lower cloth twisting roller, a cloth twisting mechanism mounting support, a lower cloth twisting roller, a steam conveying pipeline, a steam ironing roller, a heating ironing roller, an ironing tabletop, a steam spraying hole, a steam inlet, a sealing ring, a steam spraying pipe cavity, an automatic control valve, an air injection connecting pipe, a heating resistor, a water injection hole and a storage battery are arranged on the automatic ironing device body. The electric heating dry ironing and steam humidifying ironing are combined on the automatic ironing device body,the ironing effect is better, meanwhile, a liner inside the western-style clothes and an external cloth of the western-style clothes are stuck together, the third dimension of the made western-style clothes is better, and according to the ironed western-style clothes, steam is directly dried away under heating ironing of the heating ironing roller.

Owner:浙江百先得服饰有限公司

High-precision textile machine

InactiveCN111155294AGuaranteed cleanlinessQuality assuranceMechanical cleaningPressure cleaningMechanical engineeringIndustrial engineering

The present invention discloses a high-precision textile machine. The high-precision textile machine comprises a main shell, wherein a first driven roller and a second driven roller are inserted and connected in the left side bottom end and the center position of an inner cavity of a main shell respectively, and the two ends of the first driven roller and the second driven roller are in coupling with the inner walls of the main shell through bearings; and a driving roller is rotationally connected with a new position in the right side of the inner cavity of the main shell. By virtue of arrangement of a first driving mechanism, a second driving mechanism, a third driving mechanism, a dust collection mechanism, a negative pressure mechanism and the like, accumulated dust on the textile fabric can be removed firstly during processing of the textile fabric, and the clean degree of the textile fabric is ensured, thereby ensuring the quality of textile fabric; and then ironing of the textilefabric is performed, shaping of the textile fabric is carried out, then the processing quality of the textile fabric is further improved, convenience is brought to the normal work of working staff, and the working efficiency is improved.

Owner:SUZHOU HUAZONG TEXTILE NEW MATERIAL TECH CO LTD

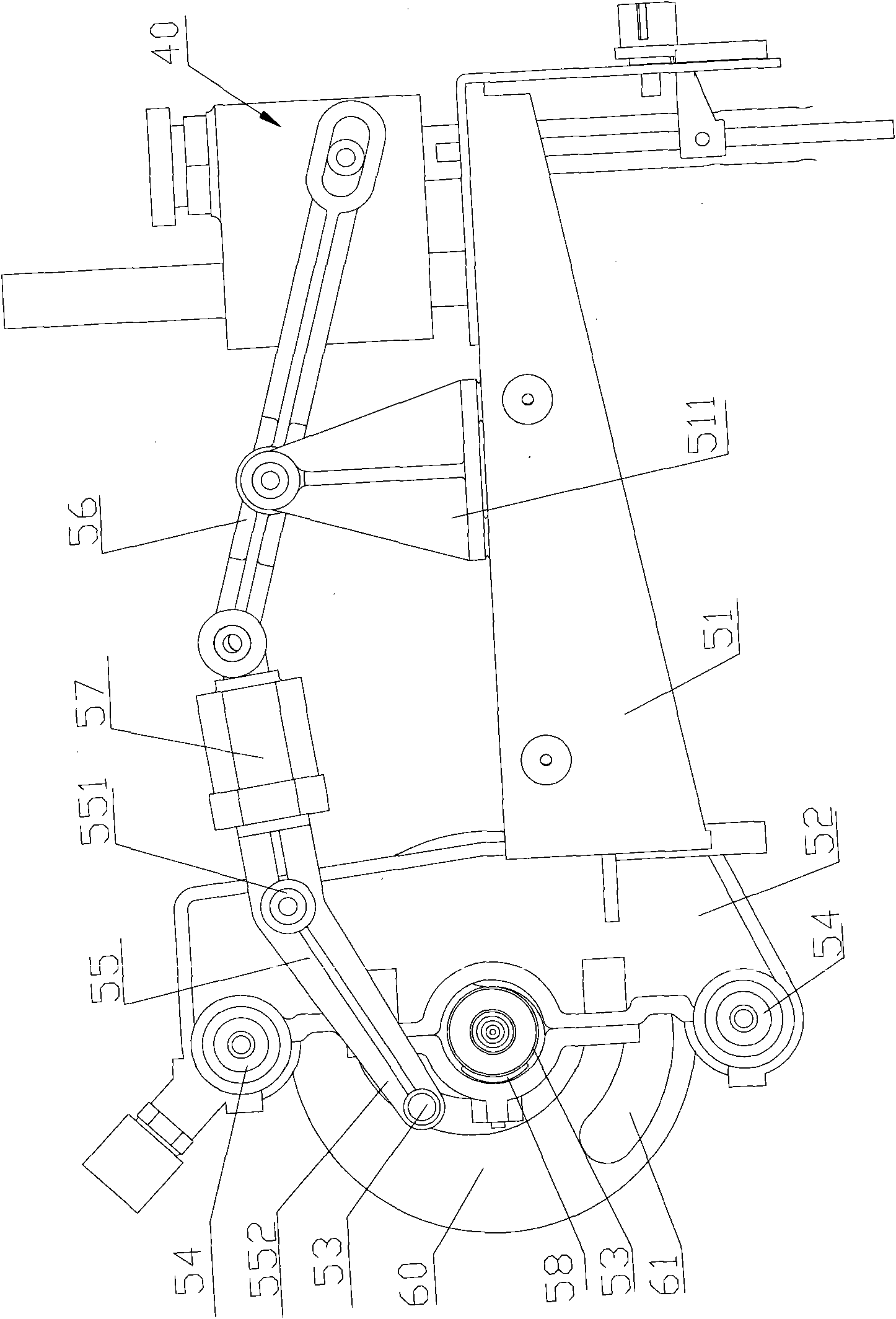

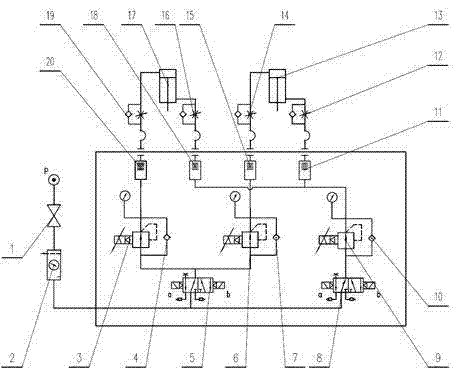

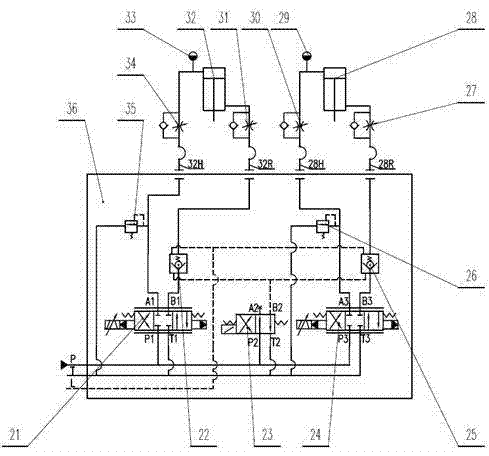

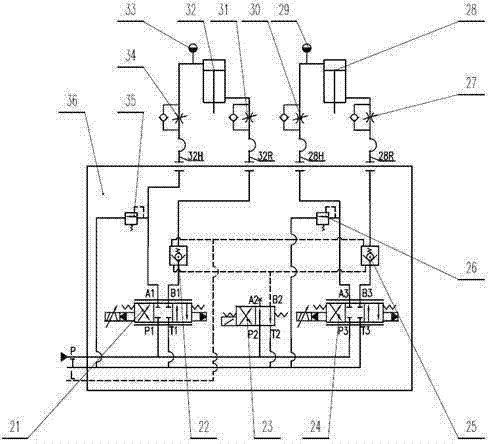

Hydraulic control loop for ironing roller device

ActiveCN102407238AReasonable designReliable designServomotorsMetal rolling arrangementsHydraulic cylinderControl theory

The invention discloses a hydraulic control loop for an ironing roller device, which comprises first and second hydraulic cylinders for driving an ironing roller, first and second pressure sensors arranged on the first and second hydraulic cylinders respectively, and a first servo valve, a second servo valve and an electromagnetic reversal valve which are connected among the first and second hydraulic cylinders and a hydraulic oil source by pipelines. The hydraulic control loop for the ironing roller device can accurately control the ironing pressure of the ironing roller, has high control accuracy, fast response speed, remarkable strip ironing effect and better quality, greatly increases the speed of a unit and increases the finished product ratio of the strip.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

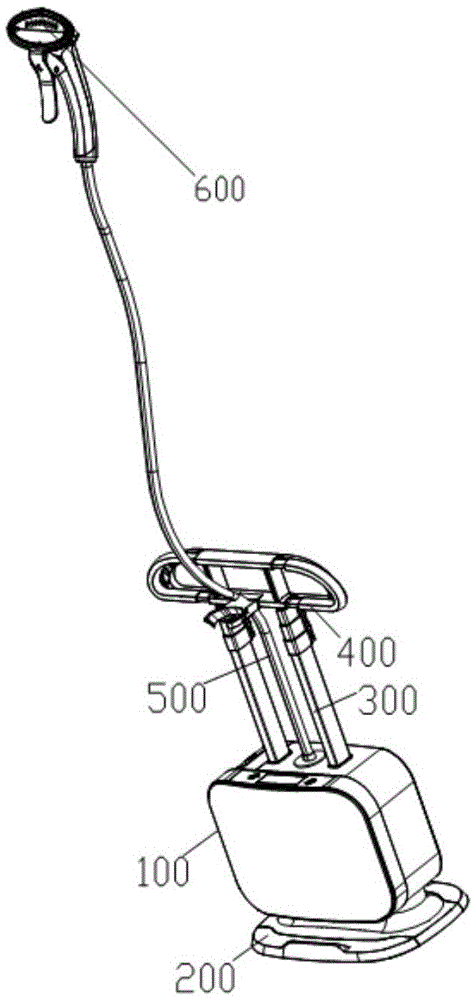

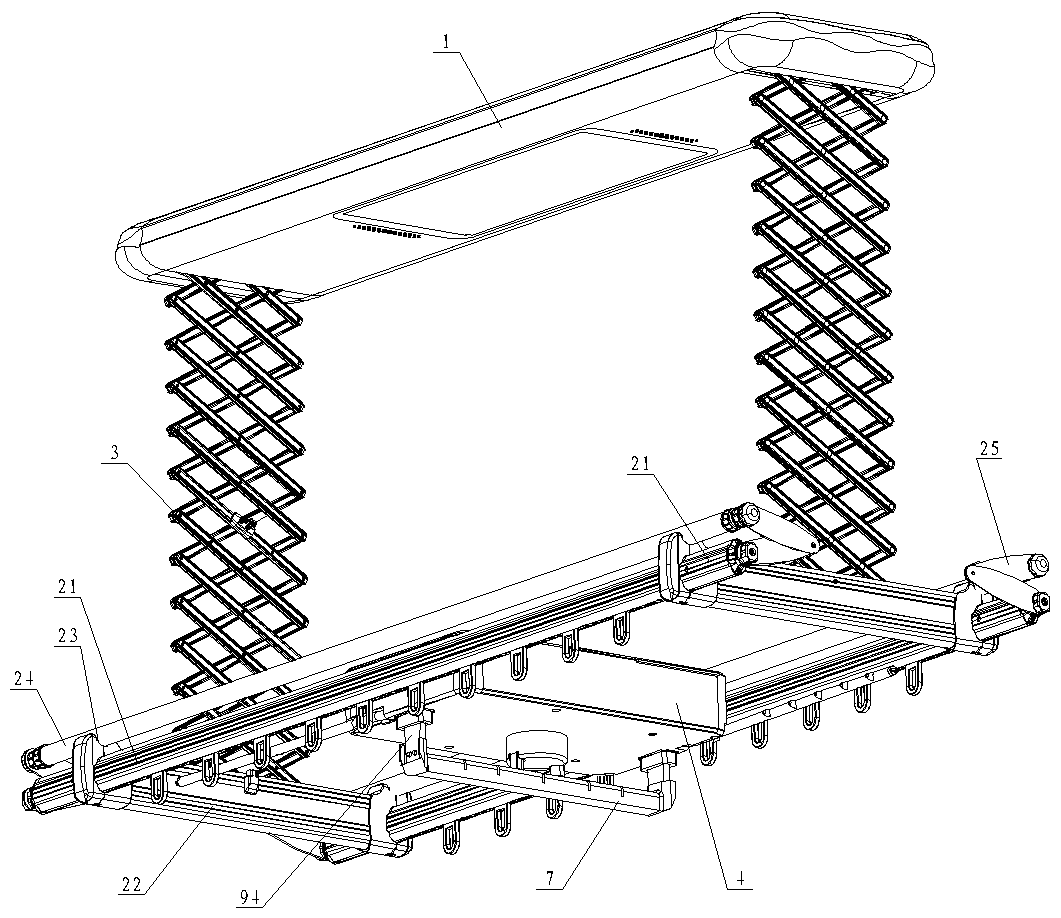

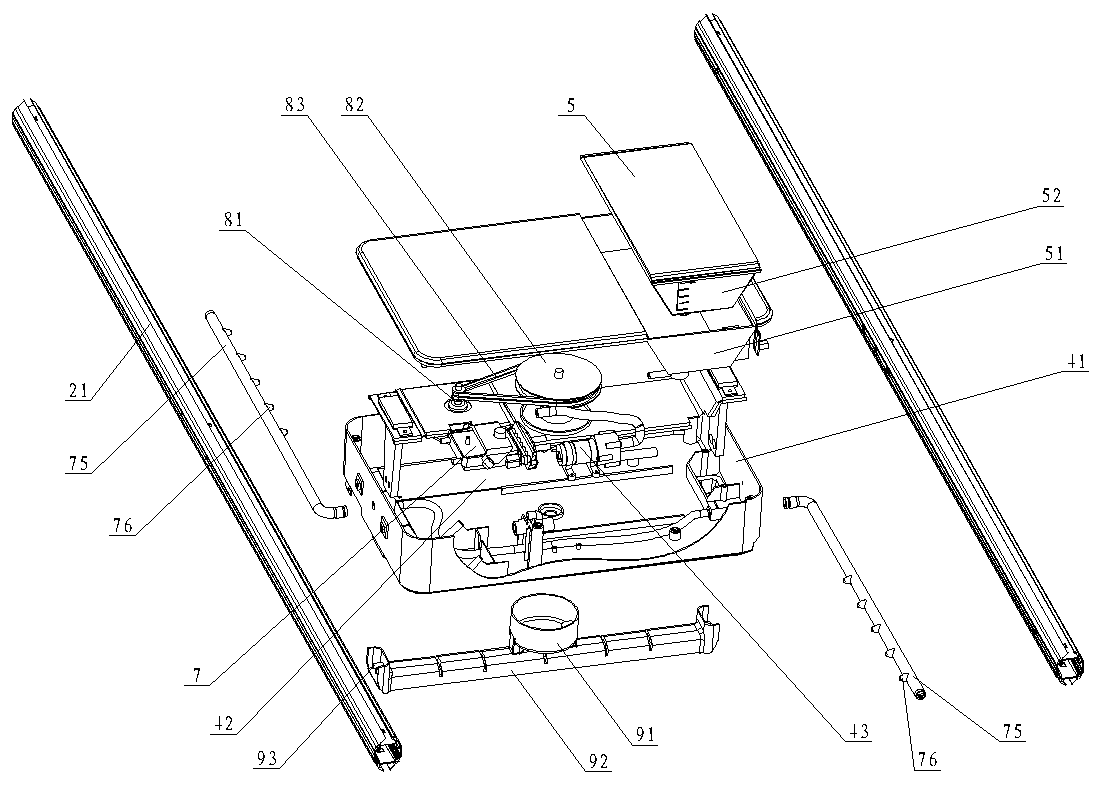

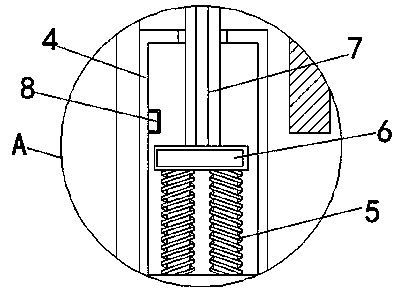

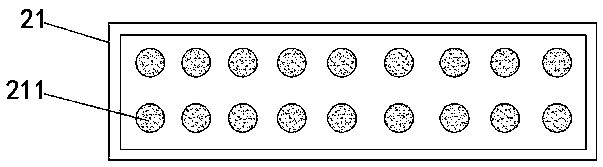

Clothes airing machine having ironing and caring function

ActiveCN108708144AMeet ironing requirementsFree from damageIroning apparatusOther drying apparatusWater volumeWater channel

The invention relates to a clothes airing machine having an ironing and caring function. The clothes drying machine comprises a clothes airing machine body, a lifting mechanism and an airing rod mechanism and is characterized in that an ironing mechanism is arranged on the airing rod mechanism and comprises a machine body shell, a main control board, a water pump mechanism, a water tank mechanism,a heating steam mechanism and a rocking mechanism, and the water tank mechanism comprises a water channel, a water tank body and a water volume monitoring mechanism; a first water outgoing hole is formed in the lower undersurface of the water channel, and an upwards-protruding ejector pin is arranged right below the first water outgoing hole; a second water outgoing hole is formed in the lower undersurface of the water tank body, and a sealing column is arranged at the second water outgoing hole; the rocking mechanism comprises a motor, a small roller, a crankshaft, a big roller and a transmission belt, the lower portion of the crankshaft is connected with a rocking seat, and the lower end of the rocking seat is connected with a transverse rocking rod. The ironing mechanism is modularizedand integrated, so that the modularized ironing mechanism can be mounted with the clothes airing machine in various structural forms in a matched manner; the clothes airing machine has a shaking function, so that wrinkled clothes can be smoothed.

Owner:ZHEJIANG HOOEASY SMART TECH

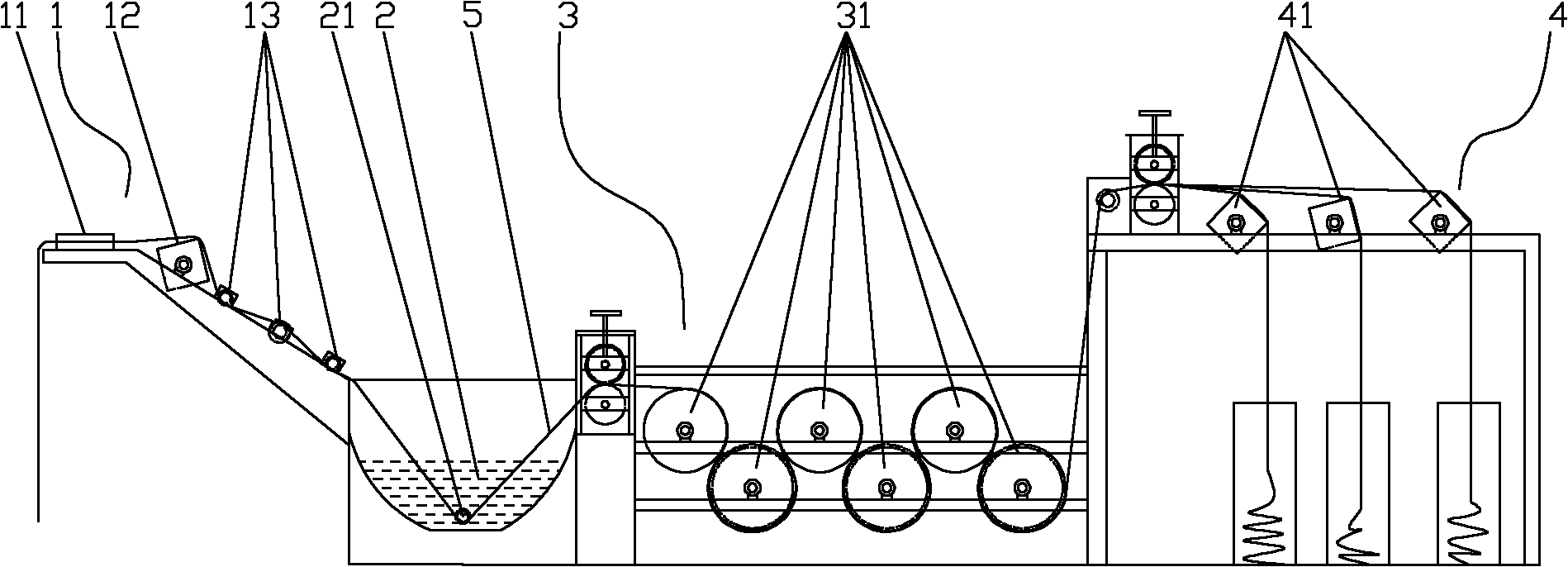

High-efficiency ironing machine for zipper cloth belt

ActiveCN101864660AIncrease feed rateNot intertwinedSlide fastenersIroning machinesTemperature controlEnergy conservation

The invention discloses a high-efficiency ironing machine for zipper cloth belts, which comprises a water trough, an ironing mechanism and a packaging mechanism. The zipper cloth belts are arranged in parallel and sequentially pass through the water trough, the ironing mechanism and the packaging mechanism. The ironing mechanism consists of parallel electric heating rollers which are continuously arranged in a staggering way from top to bottom. The zipper cloth belts are wounded on the electric heating rollers in S-shape. The packaging mechanism consists of parallel friction rollers. The electric heating rollers and the friction rollers rotate at the same speed to drive the zipper cloth belts to move towards the direction of the packaging mechanism. The invention has the advantages that since the ironing machine irons the zipper cloth belts through the electric heating rollers which are arranged in parallel, the temperature control is accurate and the energy is saved; and since a plurality of zipper cloth belts can be transversely arranged and are not twisted with each other, the ironing efficiency is effectively improved.

Owner:XIANGXING FUJIAN BAG ANDLUGGAGE GRP CO LTD

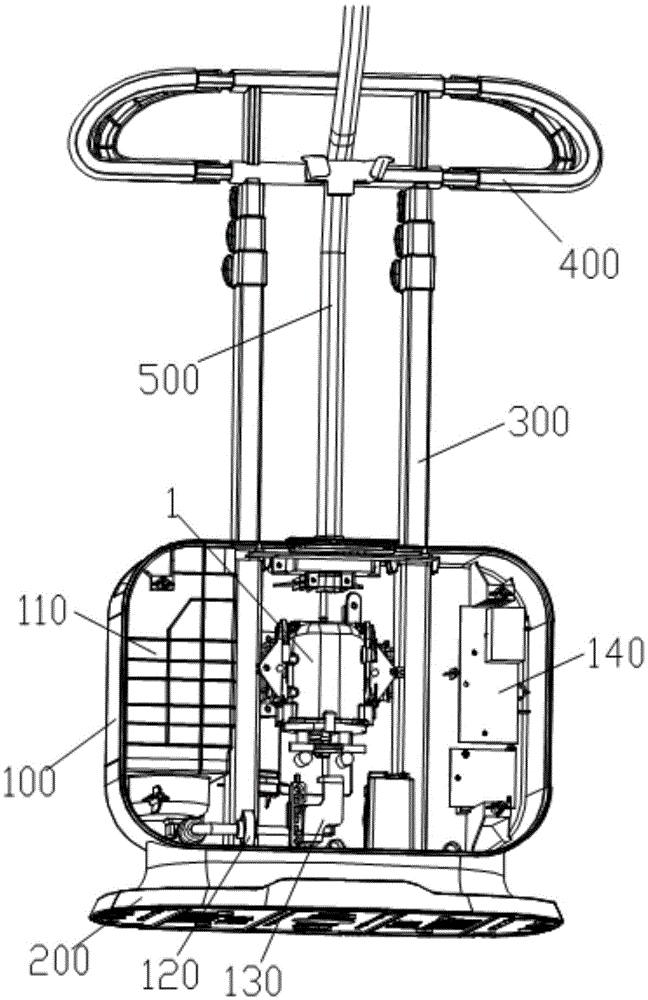

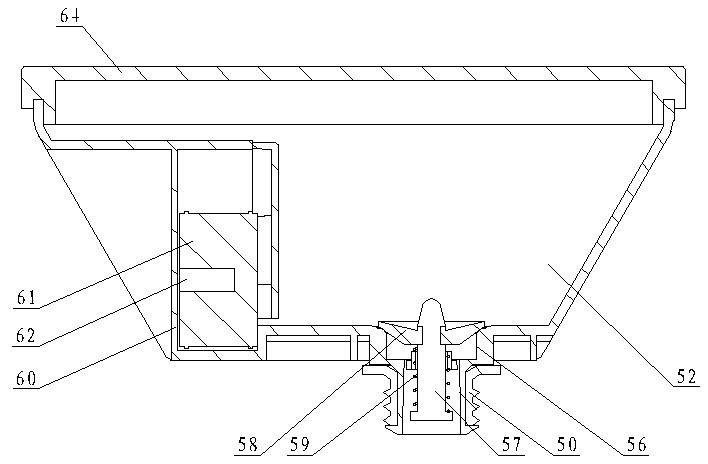

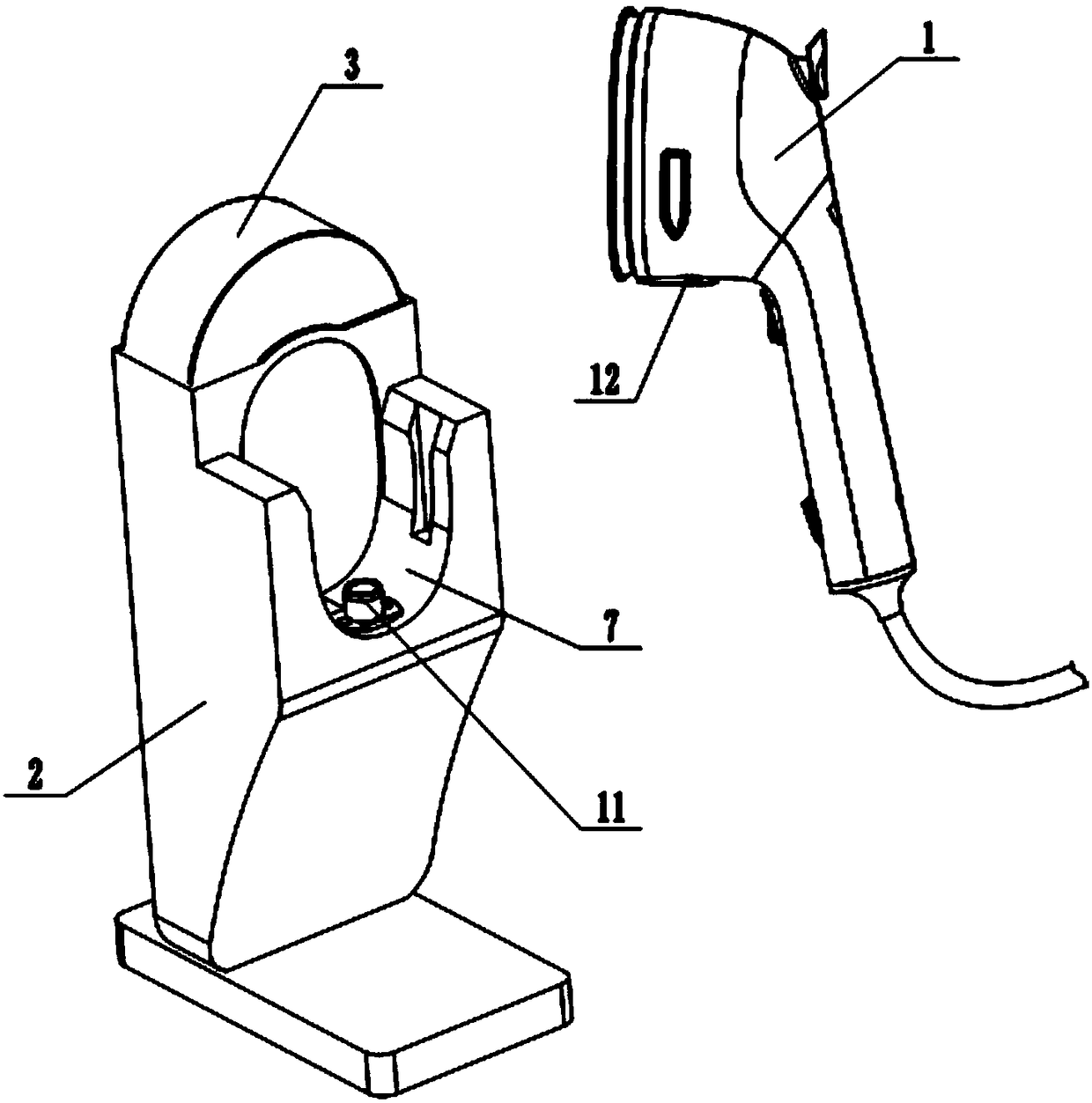

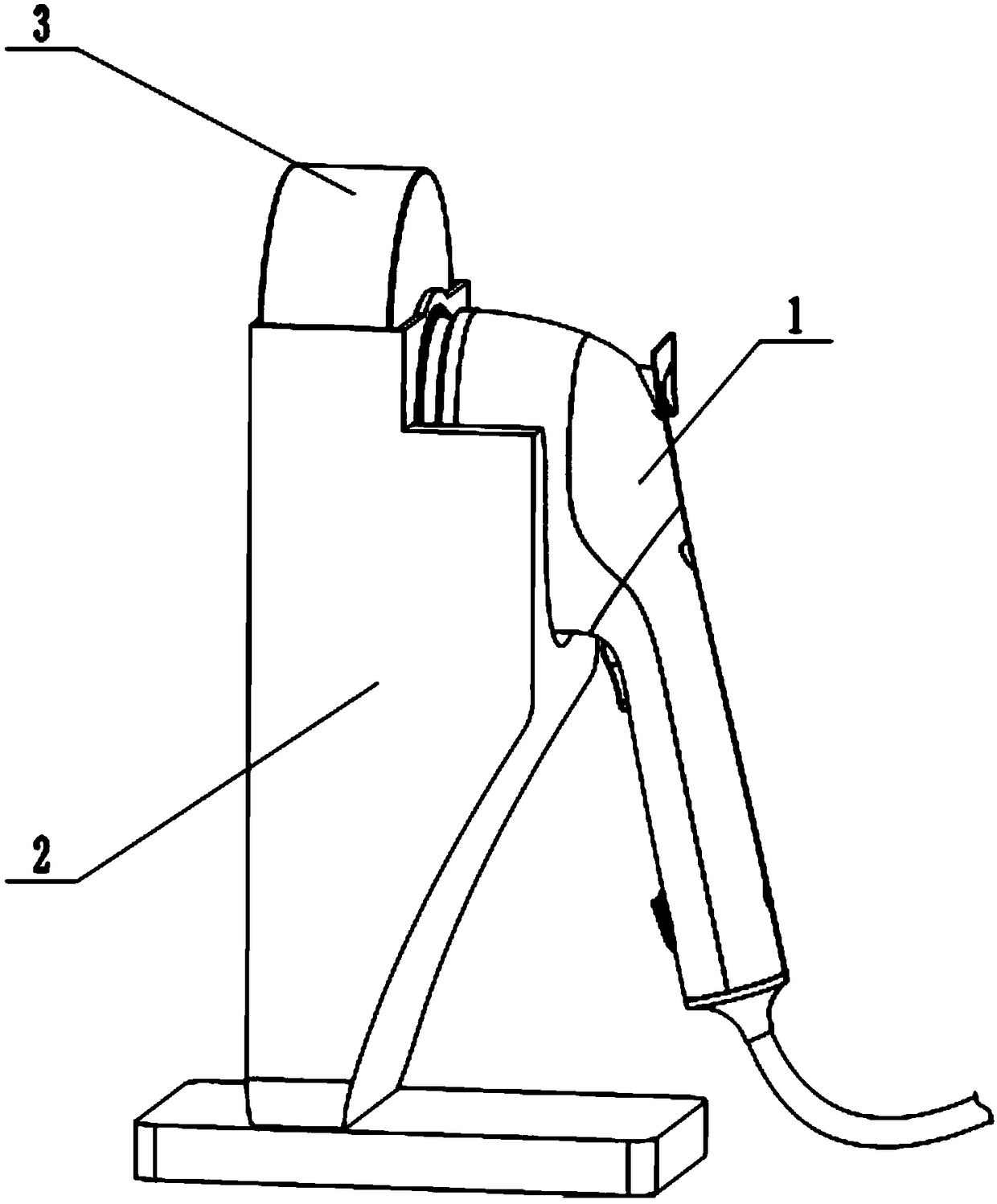

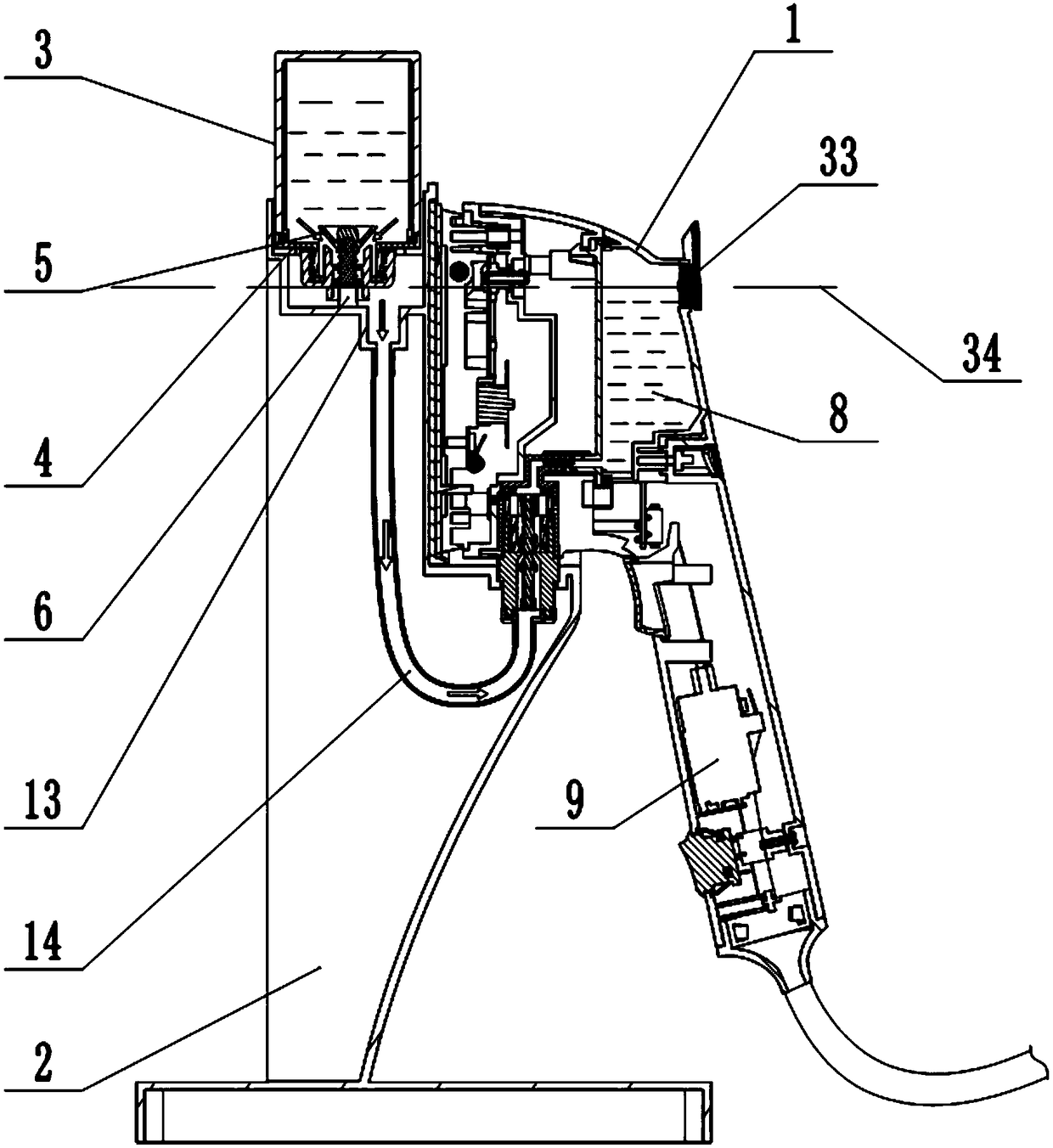

Ironing machine supplementing water rapidly and conveniently

InactiveCN108914521AQuick and easy hydrationSmooth hydrationHand ironTextiles and paperEngineeringWater pipe

The invention relates to the technical field of clothes nursing, and discloses an ironing machine supplementing water rapidly and conveniently. The ironing machine comprises an ironing machine body, abase, and a large water tank. The base is provided with a groove. The ironing machine body is internally provided with a small water tank, a steam generation assembly, and a pump body. A water absorption pipe is communicated between the pump body and the small water tank. The pump body is communicated with a water outlet pipe. The large water tank is provided with a water supplementing cover. Thewater supplementing cover is provided with a water outlet. The water outlet is provided with a valve body. The base is internally provided with a first water supplementing joint. The base is providedwith a trench. A water guiding pipe is communicated between the trench and the first water supplementing joint. The ironing machine body is provided with a second water supplementing joint. One end of the water supplementing joint is communicated with the small water tank. When the ironing machine body is placed in the groove, the first water supplementing joint and the second water supplementingjoint are abutted and communicated, and water in the large water tank flows into the small water tank through the water guiding pipe. When the ironing machine body is separated from the groove, the first water supplementing joint and the second water supplementing joint are separated and communication is stopped. The ironing machine is advantaged by convenient and rapid water supplement.

Owner:ZHEJIANG YUELI ELECTRICAL

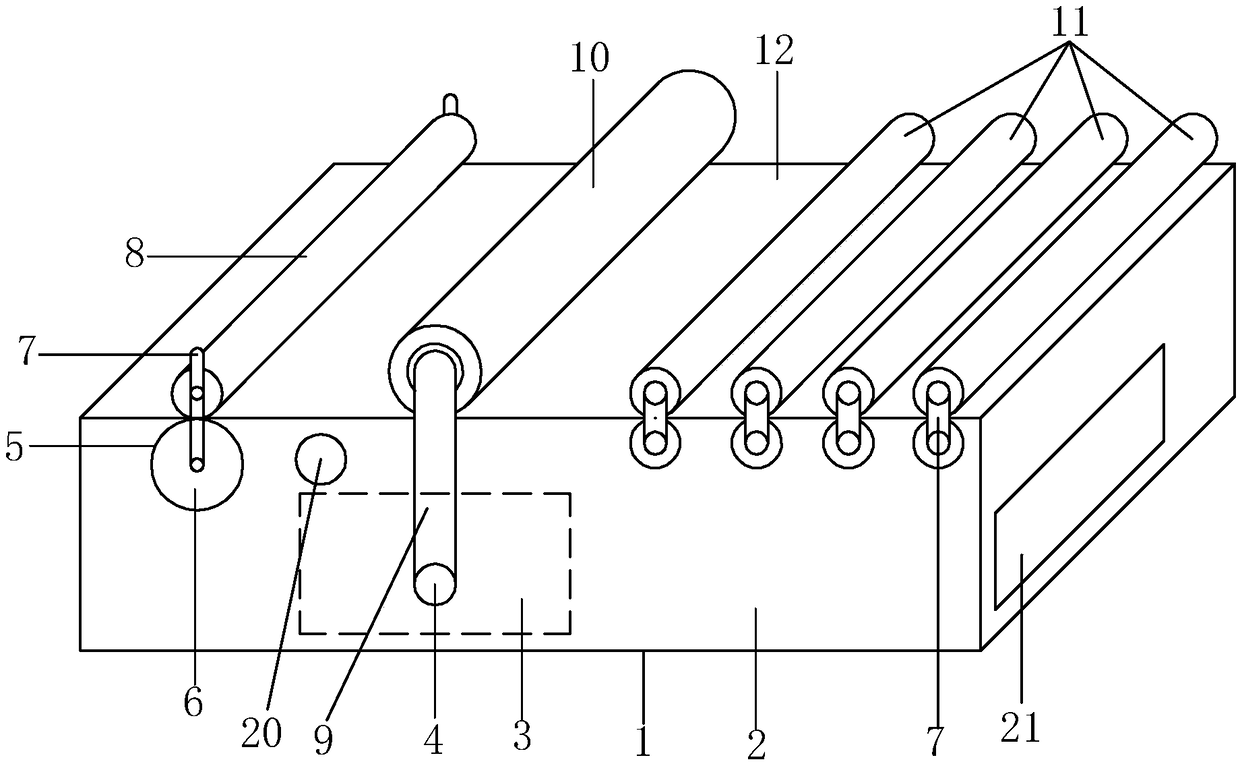

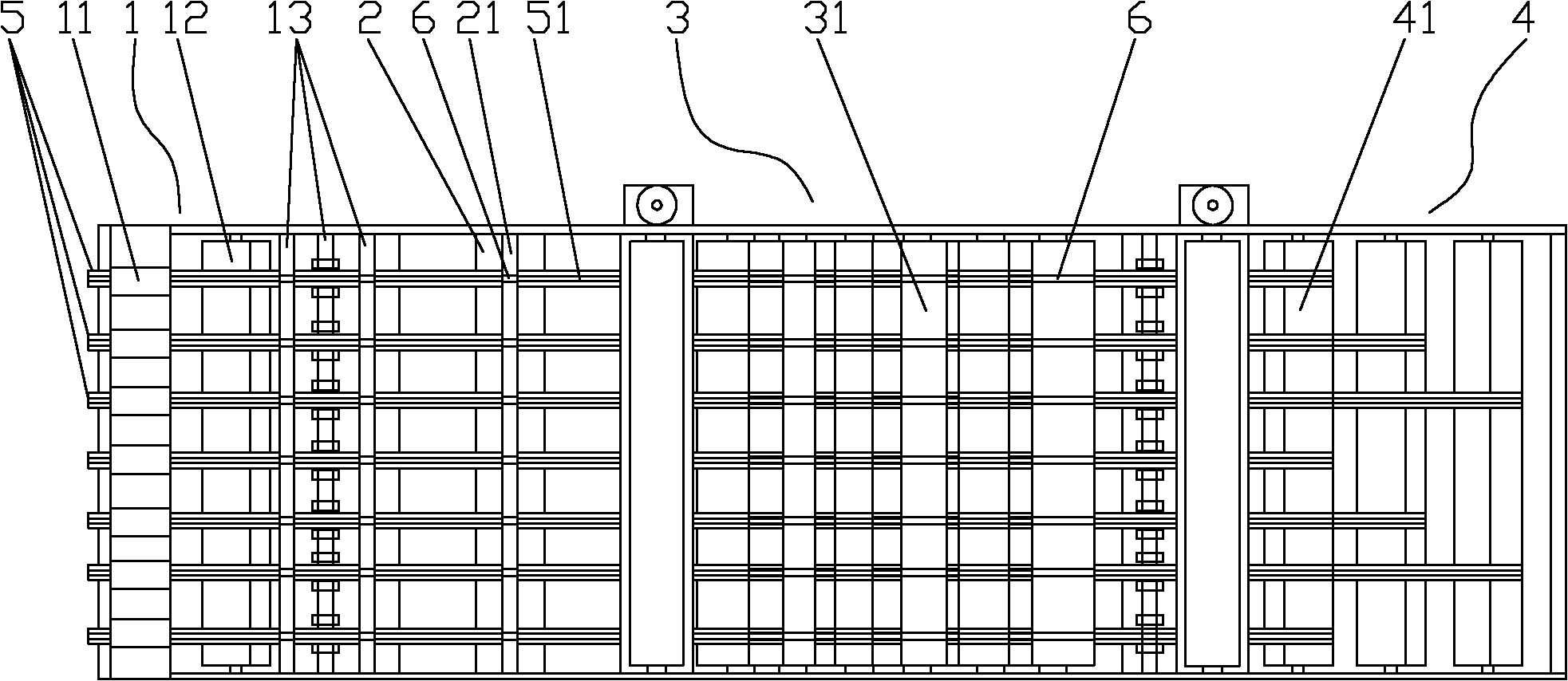

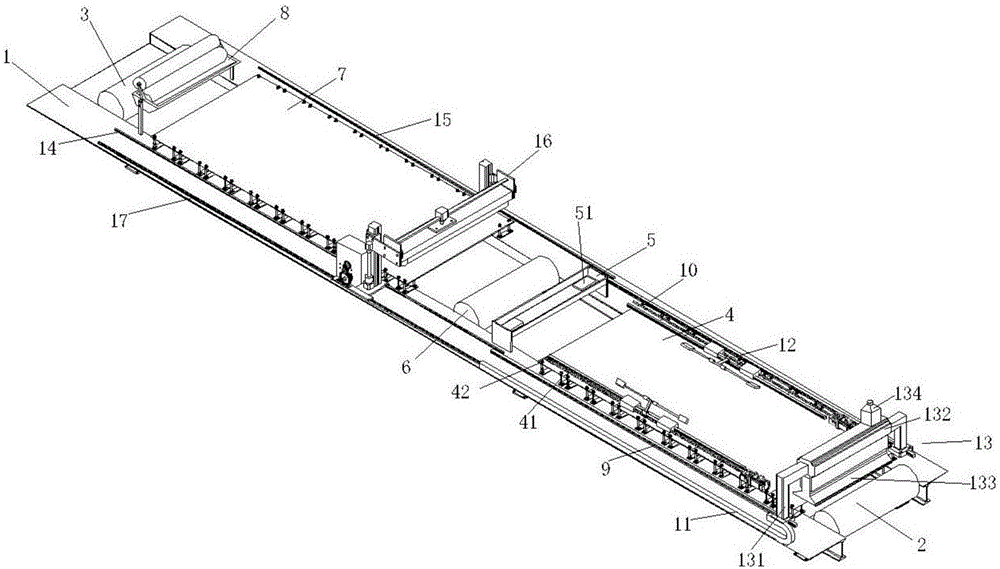

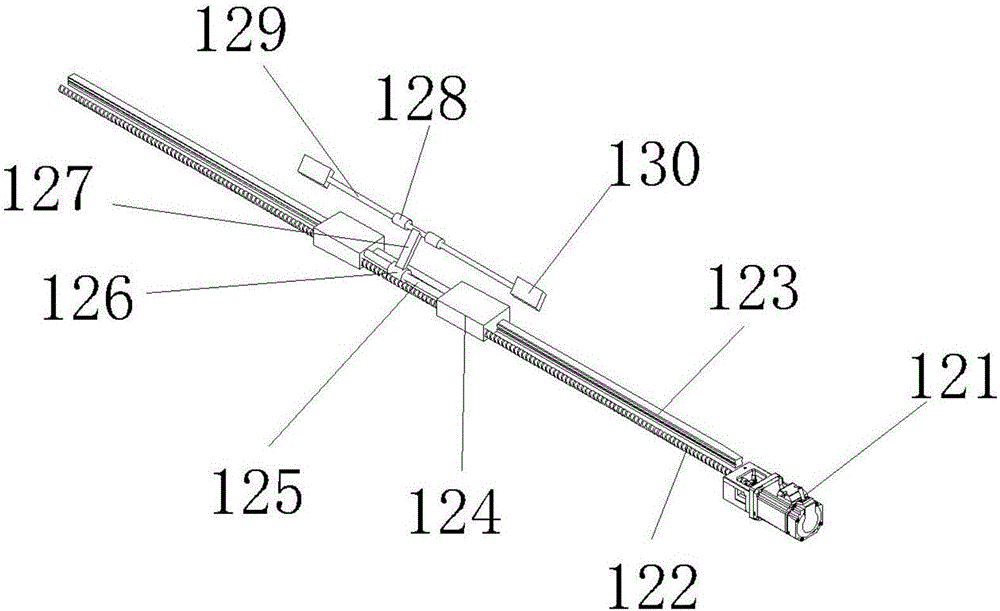

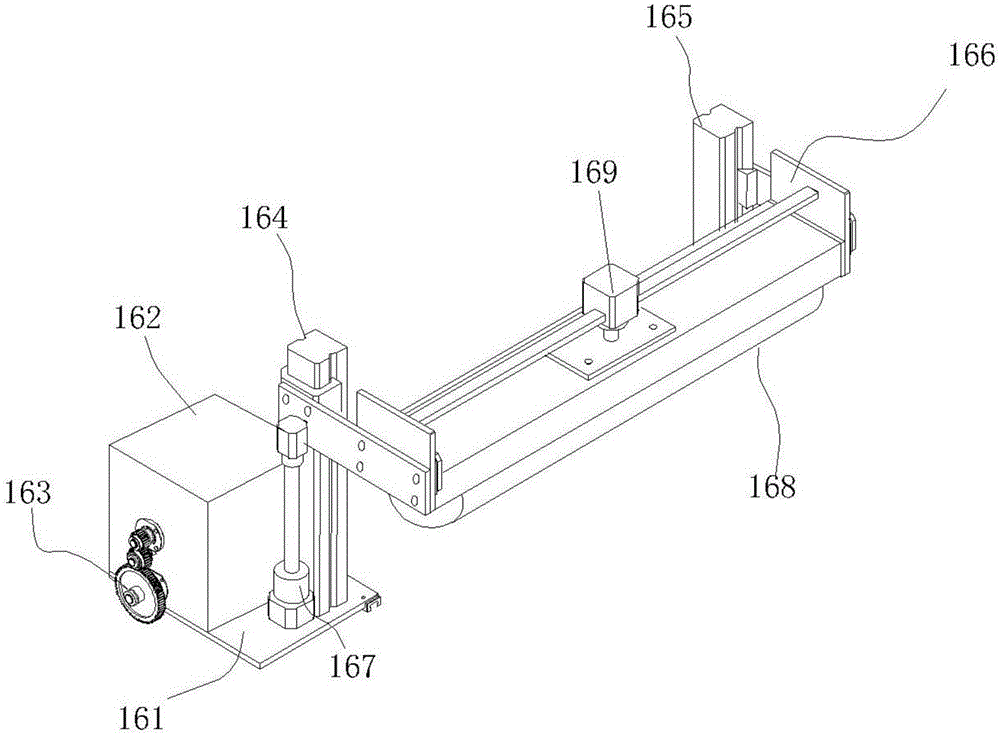

Cloth ironing printing flow line

ActiveCN106319809AImprove efficiencyImplement automatic connectionTransfer printingTextile treatment by spraying/projectingMegasonic cleaningEngineering

Owner:JIANGSU SHUANGYING TEXTILE TECH

Ironing device for garment production

The invention discloses an ironing device for garment production, and relates to the technical field of ironing devices. The ironing device for the garment production comprises a fixing base, whereinthe upper surface of the fixing base is successively provided with a left stand column and a right stand column from left to right, one side of an inner cavity of the left stand column is fixedly connected with a fixing box, the inner wall of the fixing box is fixedly connected with a first limiting block, the interior of the fixing box is fixedly connected with a buffering spring, the top end ofthe buffering spring is fixedly connected with a push plate, the top end of the push plate is fixedly connected with a telescopic sleeve rod one side of each of the inner cavities of the left stand column and the right stand column is provided with a sliding rail, and the interior of each sliding rail is slidably connected with a first slider. Through arranging the buffering spring and the telescopic sleeve rode ironing device for the garment production is capable of achieving a purpose of protecting the telescopic sleeve rod and an ironing head under the action of the buffering spring in a working process of an ironing machine, thereby improving the ironing effect of the ironing device for the garment production, preventing cloth from generating wrinkles, and improving the quality of thecloth in a processing process.

Owner:湖南浚林服饰有限公司

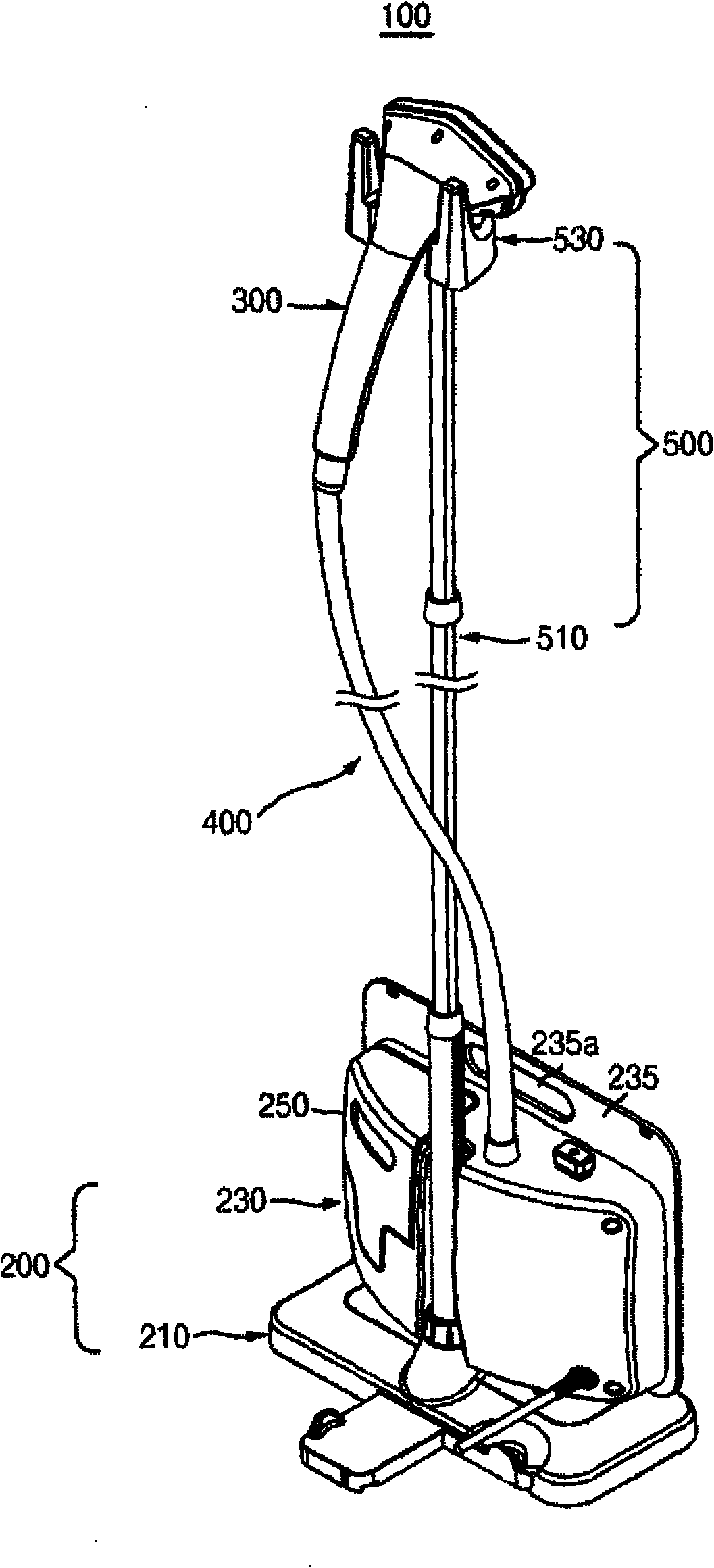

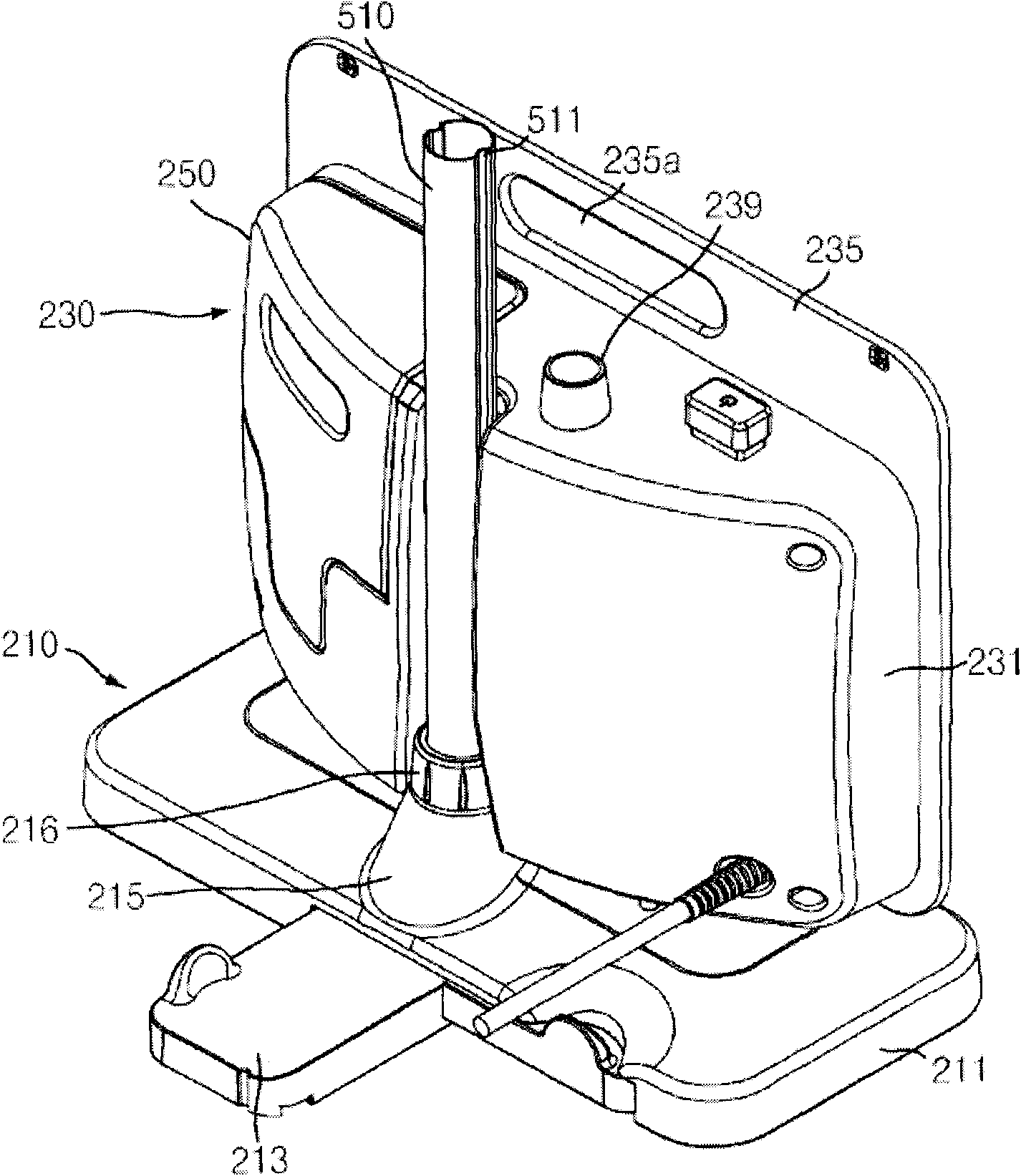

Vertical type steam iron

InactiveCN102134804AImprove ironing effectImprove filtering effectIroning padsWater/sewage treatment by ion-exchangeEngineering

The invention relates to a vertical type steam iron. A bucket part on the base assembly of the steam iron is provided with a changeable filter part for preventing scale deposit, etc.

Owner:SUZHOU HAAN TECH +1

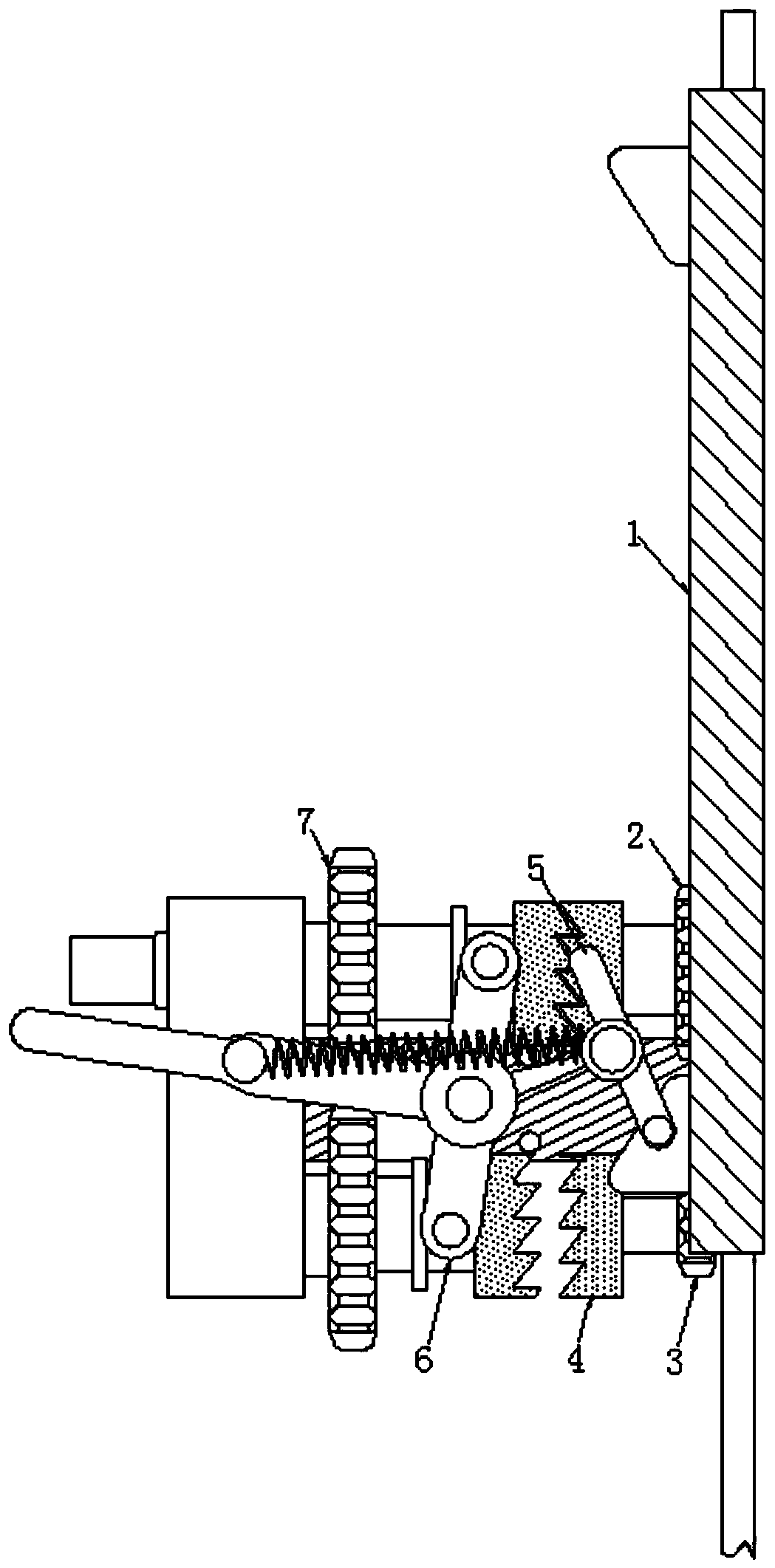

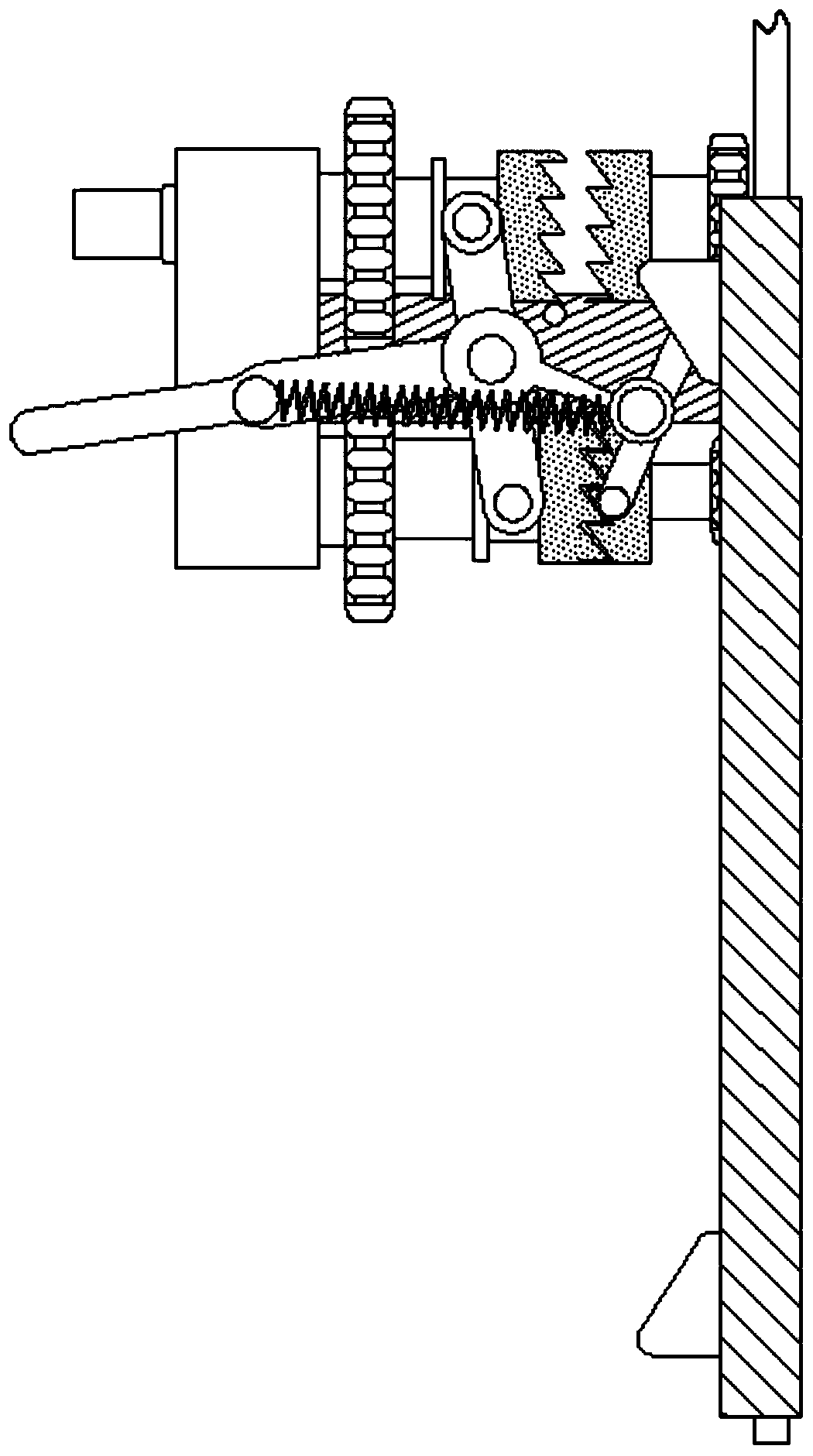

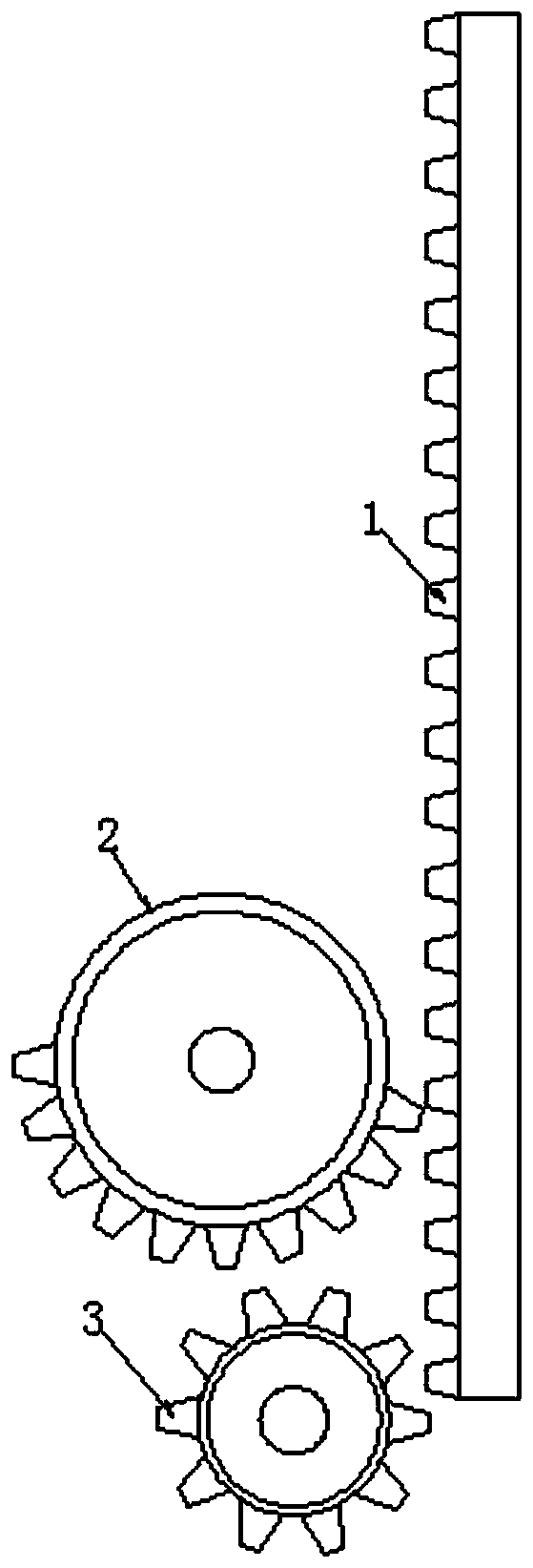

Garment ironing equipment capable of automatically turning garment to achieve double-side ironing

ActiveCN110820288AIncrease linkageImprove ironing effectIroning machinesTextiles and paperEngineeringMechanical engineering

The invention relates to the technical field of garments and discloses garment ironing equipment capable of automatically turning a garment to achieve double-side ironing. The garment ironing equipment comprises a moving plate, wherein a first gear is movably connected to the outer side of the moving plate. The garment ironing equipment has the advantages that a fourth gear rotates to drive a third gear to rotate so as to allow the first gear and a second gear to rotate sequentially, and accordingly the moving plate can stay still, move downwards and move upwards, an ironing mechanism moves synchronously to iron the garment in a reciprocating manner, a good ironing effect is achieved, the ironing mechanism stays still for a moment after each round of ironing to provided sufficient time forgarment turning, and structure co-movement is enhanced; the fourth gear rotates to drive a fifth gear to rotate intermittently so as to drive a slider to move leftwards and rightwards, the slider moves rightwards to drive an object placing plate to turn 180 degrees and then moves leftwards to approach the ironing mechanism so as to iron the side, which is not ironed, of the garment, two hands ofa user are freed, automatic garment turning is achieved, and operation convenience is achieved.

Owner:安徽优定服装科技有限公司

Working method for textile electric cloth canister with ironing and dedusting functions

The invention relates to the technical field of textile cloth, in particular to a textile electric cloth canister with ironing and dedusting functions. The textile electric cloth canister includes a left column and a right column, wherein both the left sides of the left column and the right column are symmetrically connected with slanting rods through mounting plates; the slanting rods are together and correspondingly connected with a top plate and a bottom plate; the upper end of the bottom plate is connected with a placement plate through a support column; the ends, corresponding to each other, of the top plate and the bottom plate are symmetrically connected with first vertical plates; the sides, corresponding to each other, of the first vertical plates are movably connected with leading-in rollers; the left side of the top plate is connected with a first support plate; the upper end of the first support plate is provided with a collecting tank; and the upper end of the first support plate is equidistantly provided with dust suction fans. The textile electric cloth canister has the advantages that the structure design is reasonable; the textile cloth is convenient to stably wind; the textile cloth is dedusted and ironed while being wound; the number of functions of the wind mechanism is increased; the cloth canister is convenient to arrange and disassemble; and the work efficiency can be improved.

Owner:福建省福州市华伟针织有限公司

Zipper cloth belt ironing machine

InactiveCN104389141AImprove ironing effectSimple structureHeating/cooling textile fabricsPulp and paper industryEngineering

The invention provides a zipper cloth belt ironing machine which comprises a rack, a water tank, a humidifying wheel, a roller set and a motor. The zipper cloth belt ironing machine is characterized in that one side of the rack is connected with the water tank, and the humidifying wheel is fixedly arranged above the water tank; the roller set is mounted at the rack and driven by the motor; the roller set comprises an upper roller, a lower roller, heating and reversing shafts, a cooling roller and a cooling and reversing shaft, and the upper roller and the lower roller are arranged on the rack; heating wires are distributed on the inner surfaces of the upper roller and the lower roller, and the heating and reversing shafts are respectively arranged on the lower sides of the upper roller and the lower roller; the cooling roller is positioned on one side of the upper roller and connected with a cooling water inlet pipe and a cooling water outlet pipe, and the cooling and reversing shaft is arranged between the cooling roller and the upper roller; grooves for containing a cloth belt are formed in the surfaces of the upper roller, the lower roller, the heating and reversing shafts, the cooling roller and the cooling and reversing shaft. The zipper cloth belt ironing machine adopts a unique roller guiding and roller cooling design, so that the contact area of the zipper cloth belt and the rollers is increased, the cloth belt ironing effect is improved, and the production efficiency is improved.

Owner:CMZ ZIPPER ANHUI

Ironing device

The invention belongs to the technical field of textile machinery, and particularly relates to an ironing device. Several dense through holes are formed in the upper surface of a placing plate of the ironing device, and the periphery of the lower surface of the placing plate is connected with a suction pipe in a seal manner; an air pump is arranged in the suction pipe. When the air pump is opened, steam from a steam nozzle is pumped by the air pump through the dense through holes in the placing plate, and penetrates through the textile or clothing on the placing plate, so that the obverse side and the reverse side of the textile or clothing can be ironed to achieve a very good ironing effect.

Owner:无锡雅西机电配件厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com