Cloth ironing printing flow line

An ironing printing and assembly line technology, applied in printing, printing machines, transfer printing, etc., can solve problems such as poor connection, increased labor costs, and reduced production efficiency, so as to achieve beautiful printing patterns, save manpower and material resources, Good ironing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

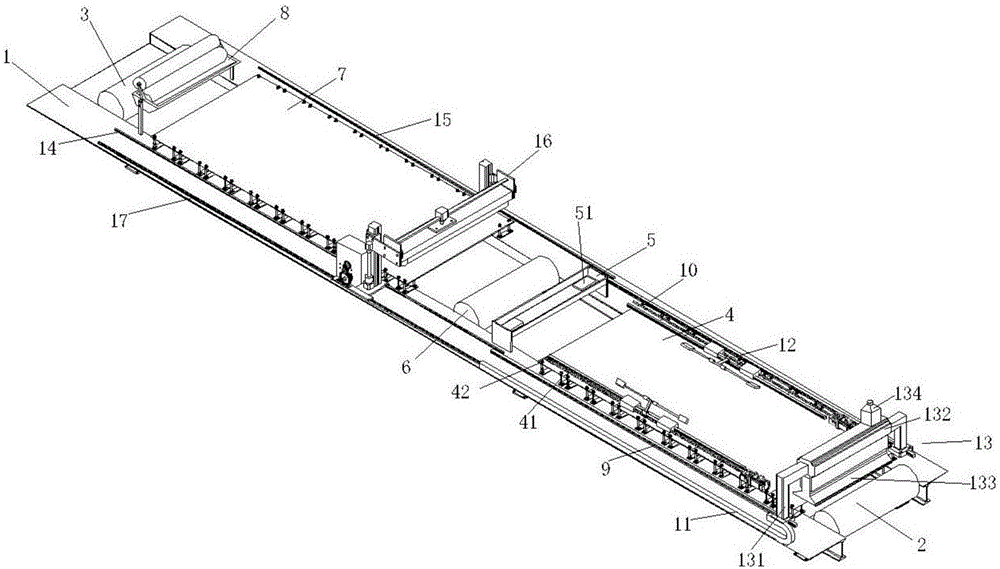

[0022] As shown in the figure, the present invention relates to a fabric ironing and printing line, including a workbench 1, two ends of the workbench 1 are provided with a roller one 2 and a roller two 3, and the roller one 2 and the roller A panel 1 4, an ultrasonic cleaning tank 5, a roller 3 6, a panel 2 7, and a slurry feeding device 8 are arranged in sequence between the shafts 2 and 3; the ultrasonic cleaning tank 5 is provided with an ultrasonic vibration box 51;

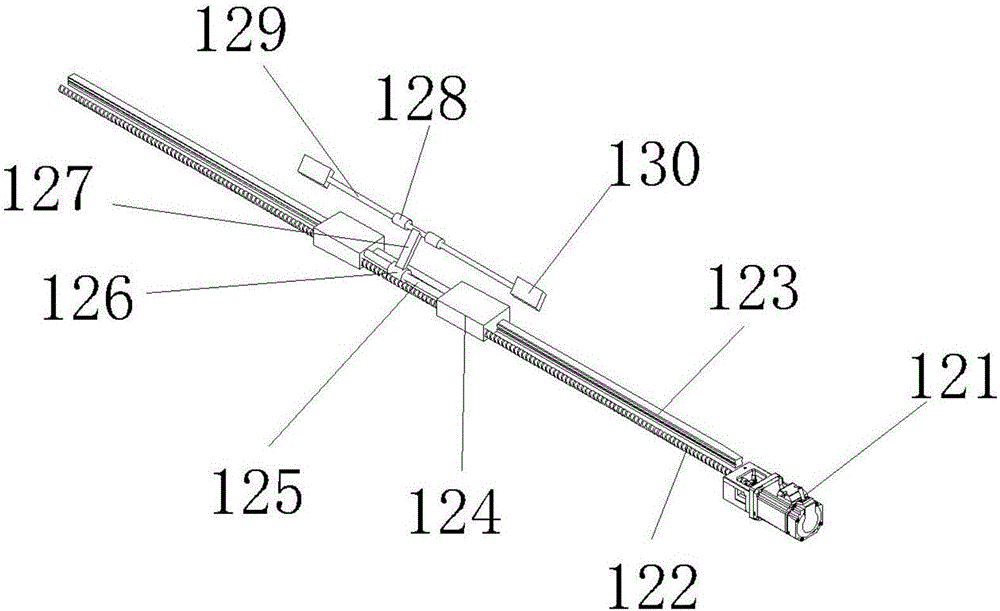

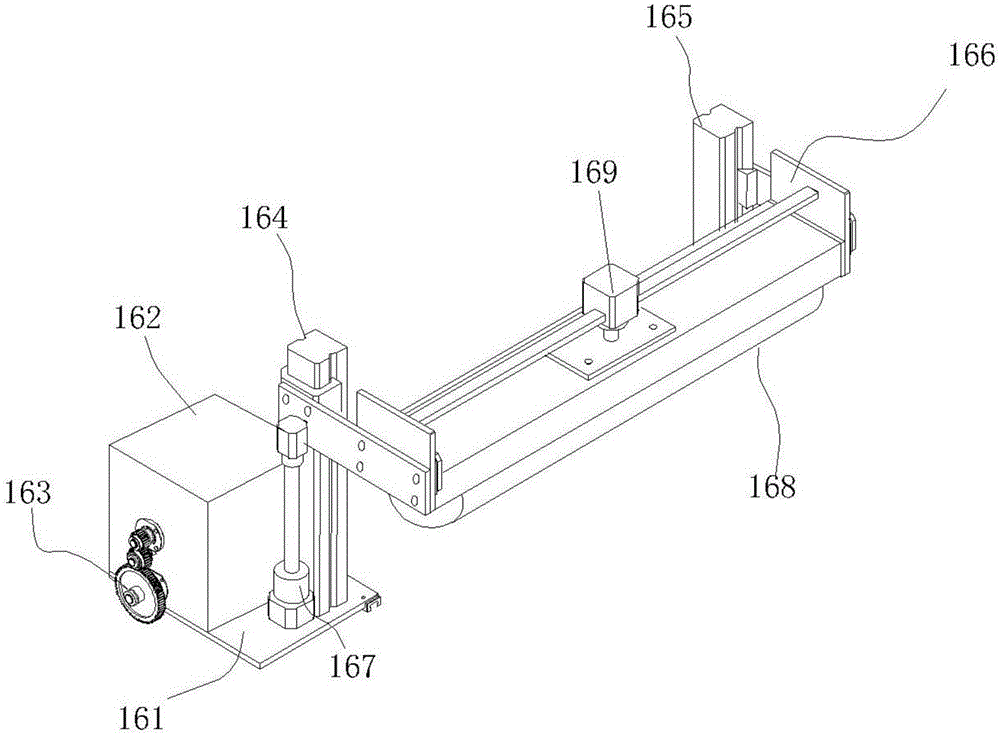

[0023] The workbench 1 on both sides of the panel one 4 is provided with a guide rail one 9 and a guide rail two 10, an ironing device 13 is arranged between the one guide rail 9 and the two guide rails 10, and the ironing device 13 includes an installation Between the guide rail one 9 and the guide rail two 10 and the support one 131 driven by the drag chain 11 on the workbench 1, the cylinder one 132 is installed on the support one 131, and the cylinder one 132 is provided with a liquid storage tank 134 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com