Patents

Literature

986 results about "Print-through" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Print-through is a generally undesirable effect that arises in the use of magnetic tape for storing analogue information, in particular music, caused by contact transfer of signal patterns from one layer of tape to another.

Ink refill and recharging system

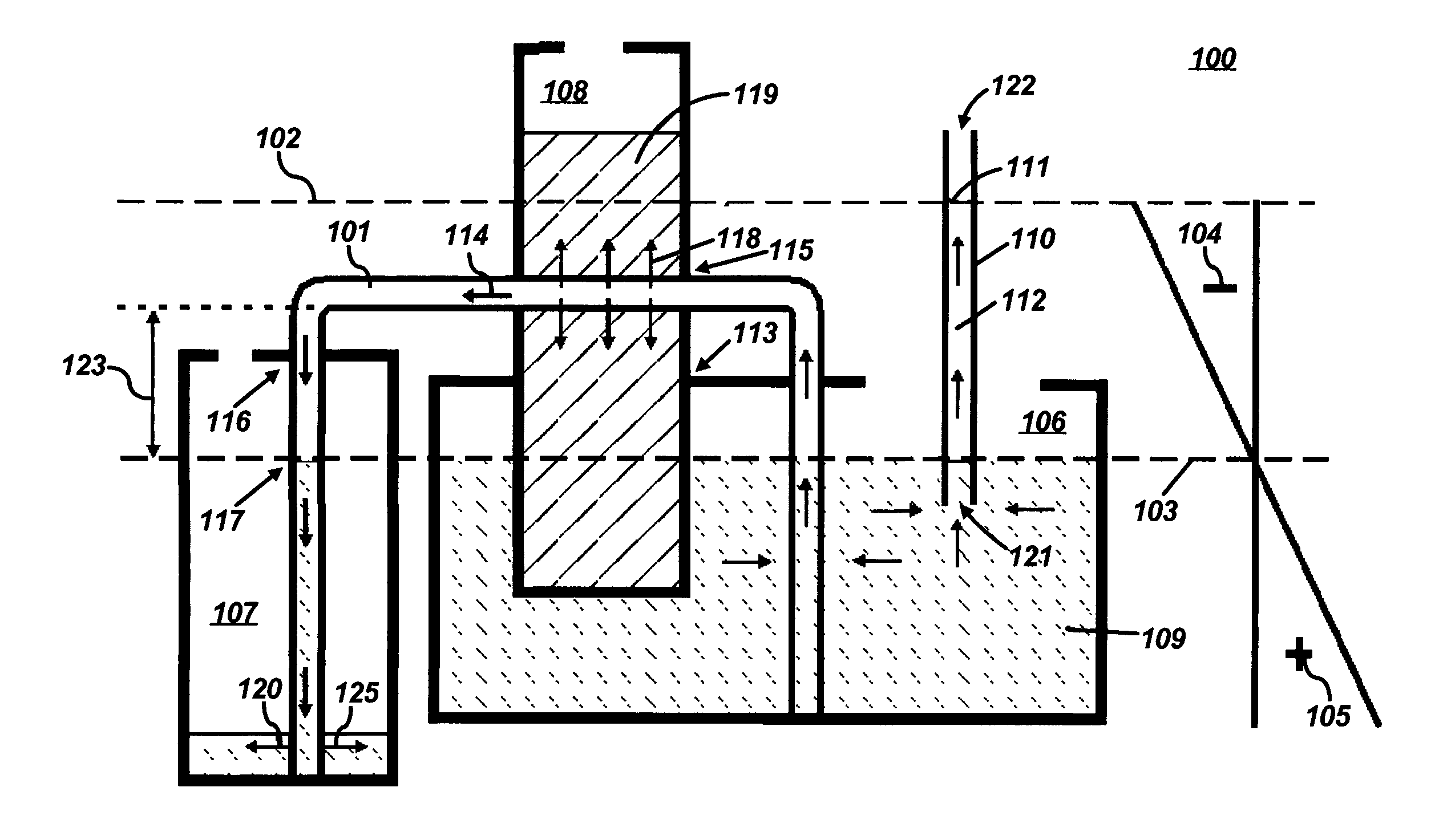

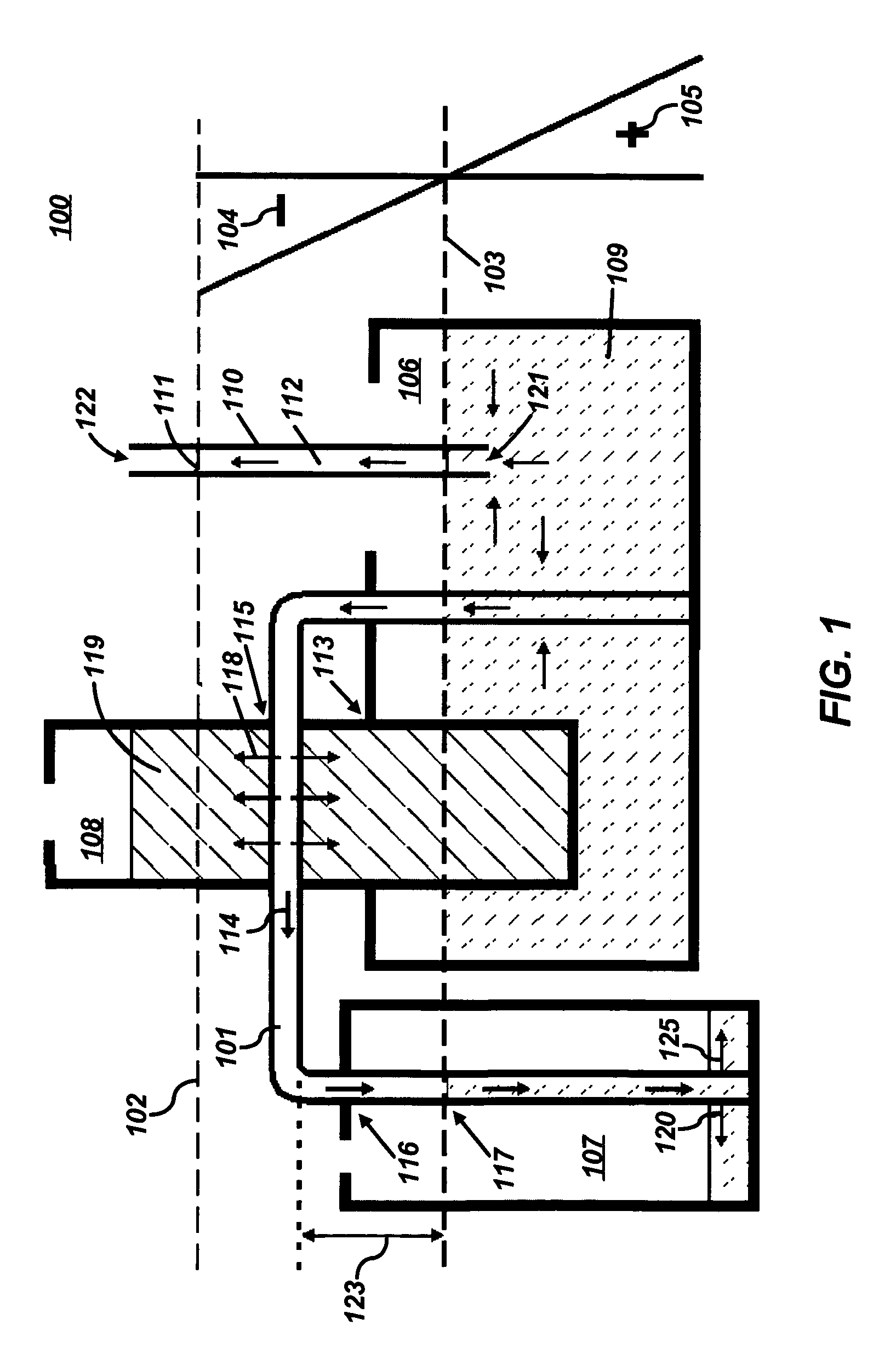

InactiveUS7066586B2Improve reliabilityPrecise deliveryPipeline systemsPrintingEngineeringPrint-through

Ink refill systems are disclosed. In general, an ink source comprising a saturated zone and a tubarc porous microstructure for conducting ink from the saturated zone to an unsaturated zone are provided. The ink can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the ink to be harnessed for ink writing and / or printing through the unsaturated hydrodynamic flow of the ink from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

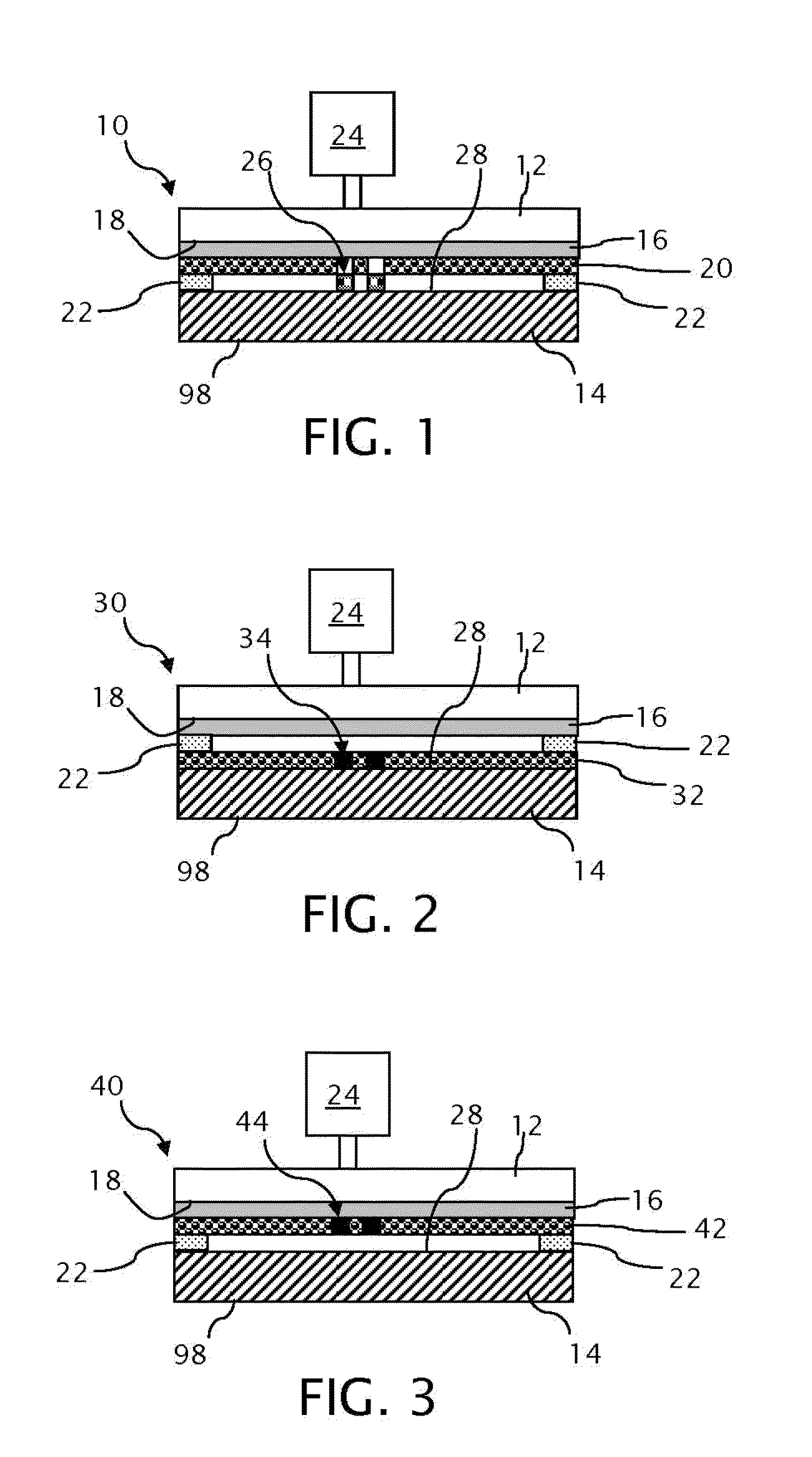

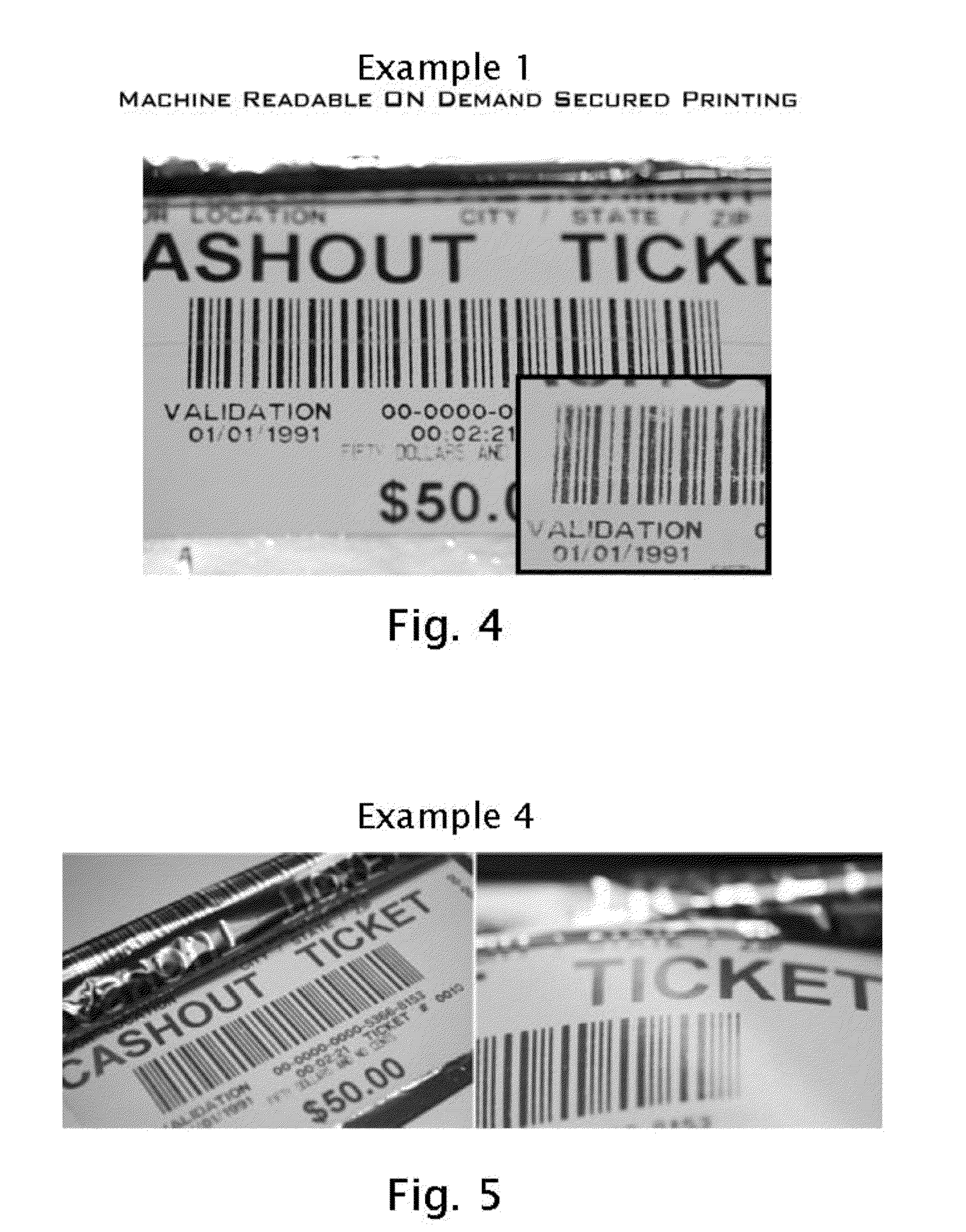

On-demand printable construct

ActiveUS20120149561A1Enhanced interactive responseAvoid contactBoard gamesPattern printingEngineeringThermal printing

Owner:WS PACKAGING GROUP

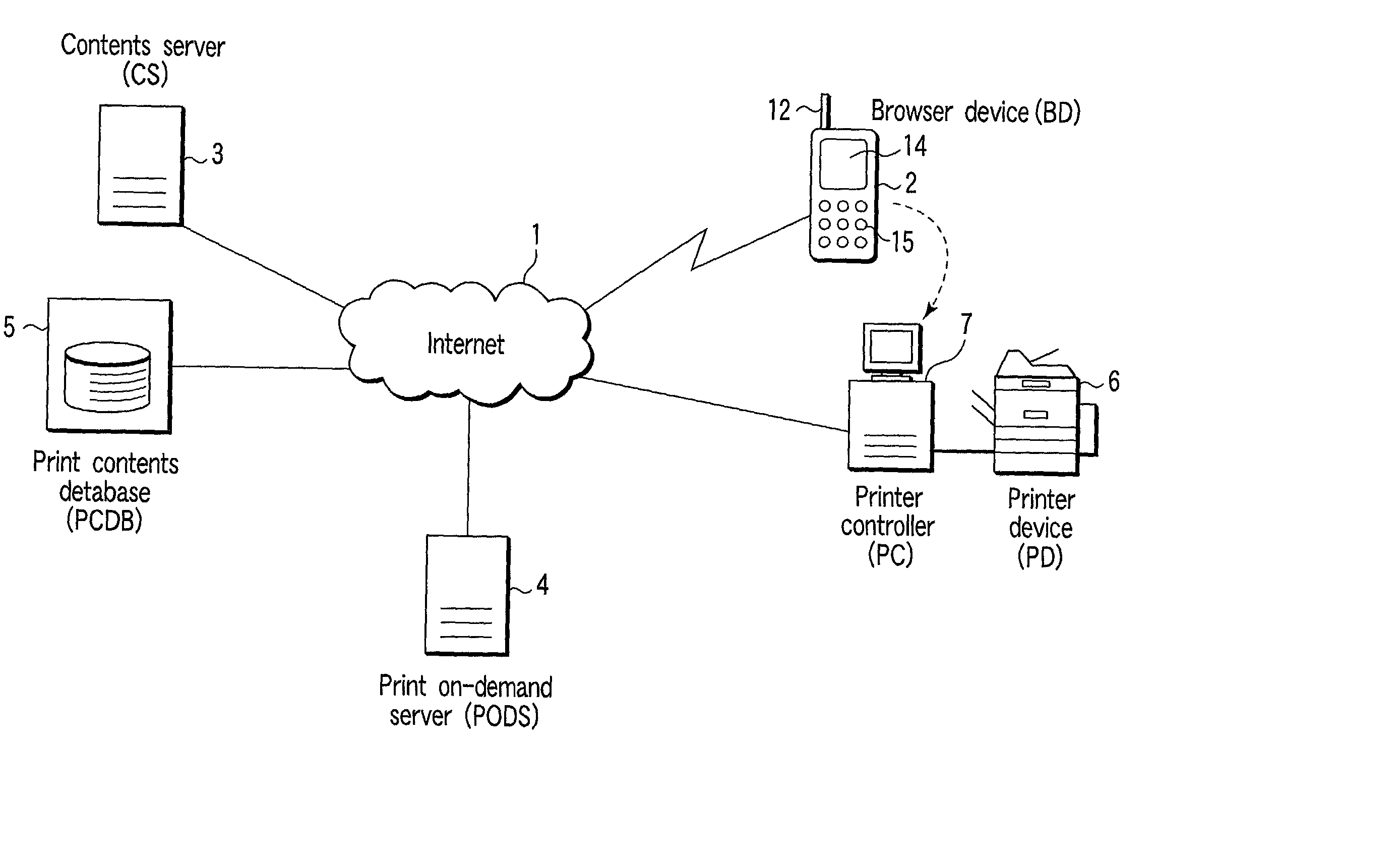

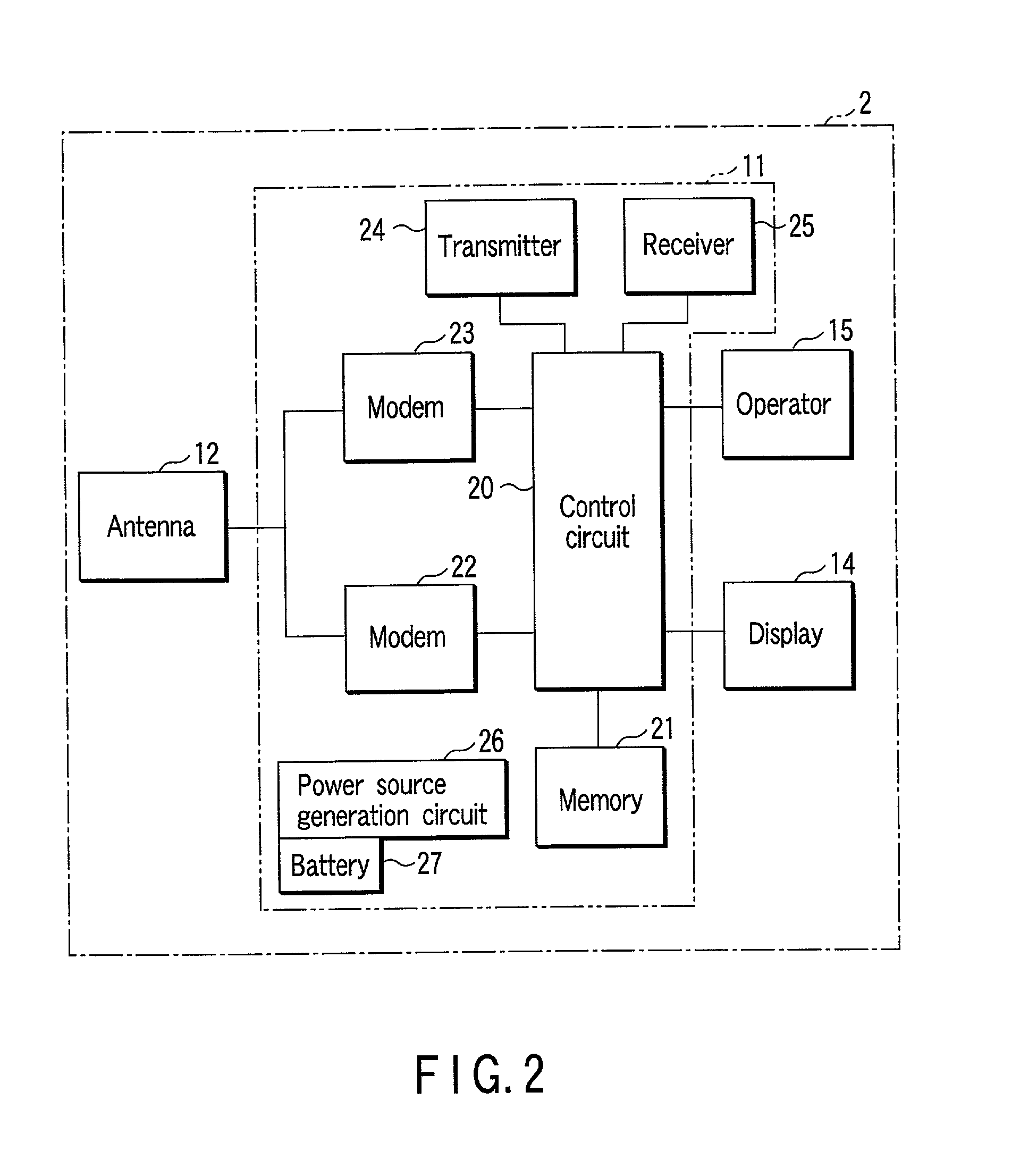

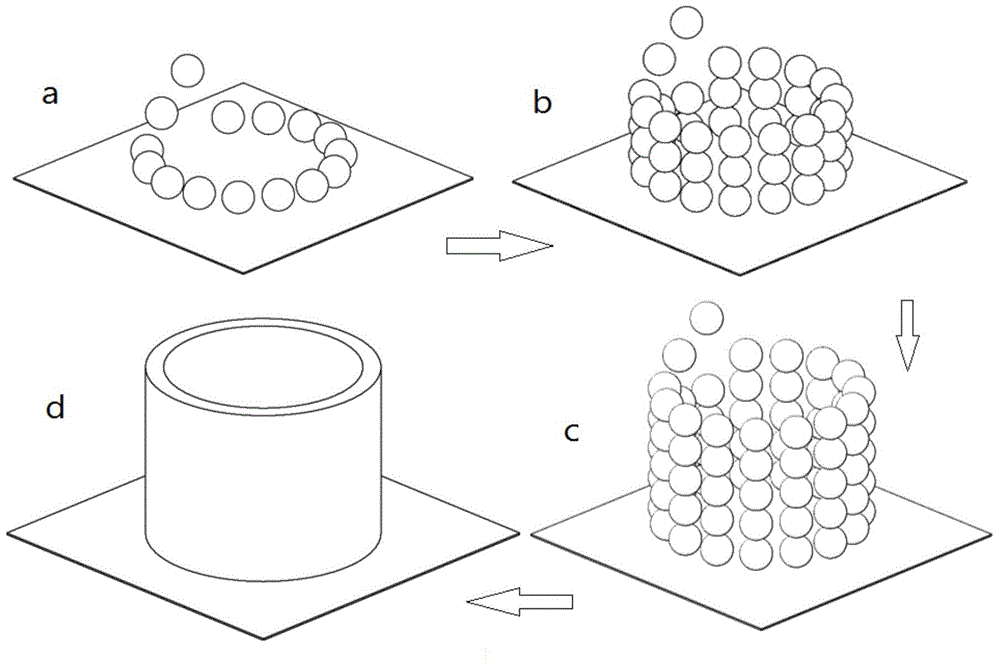

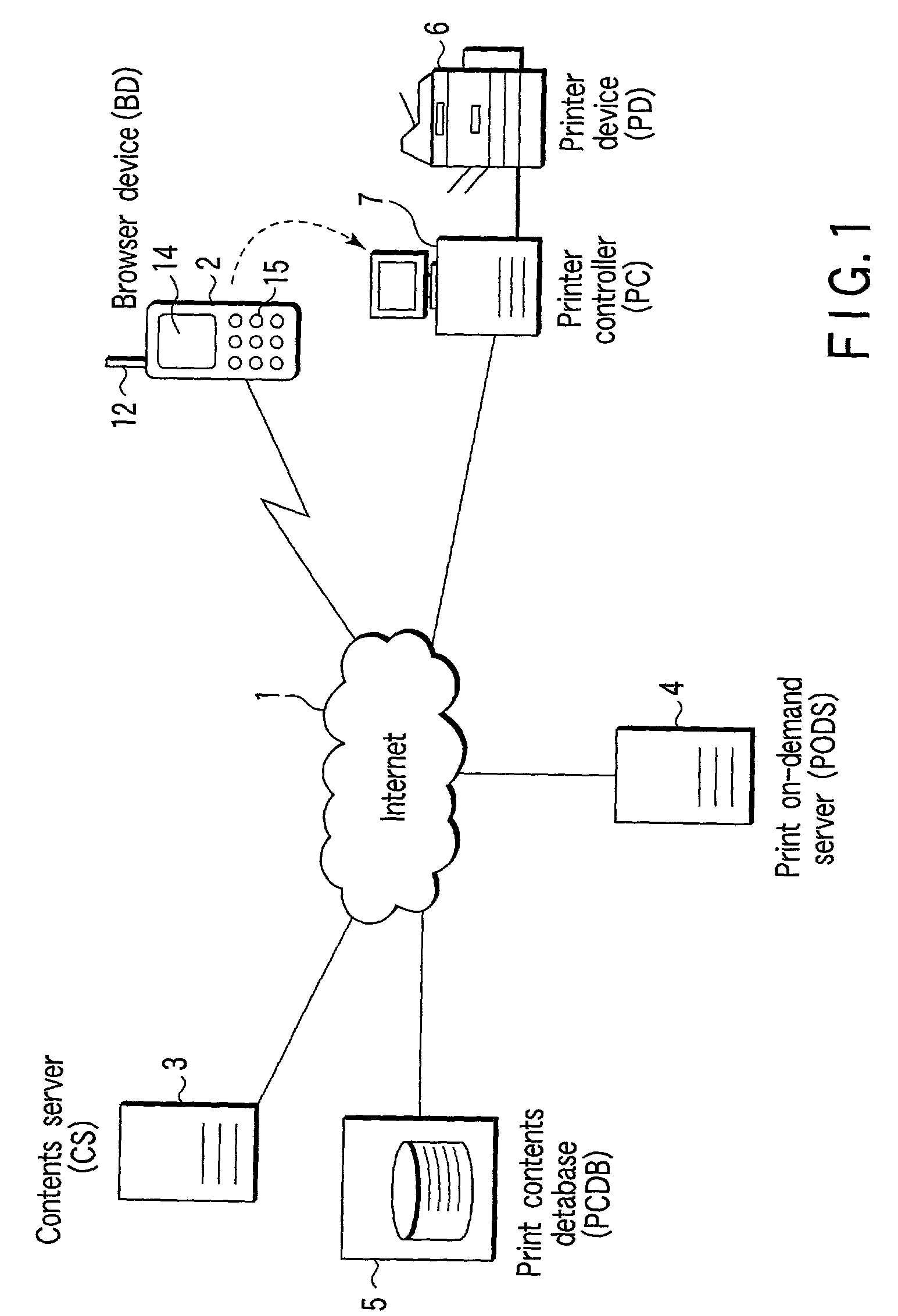

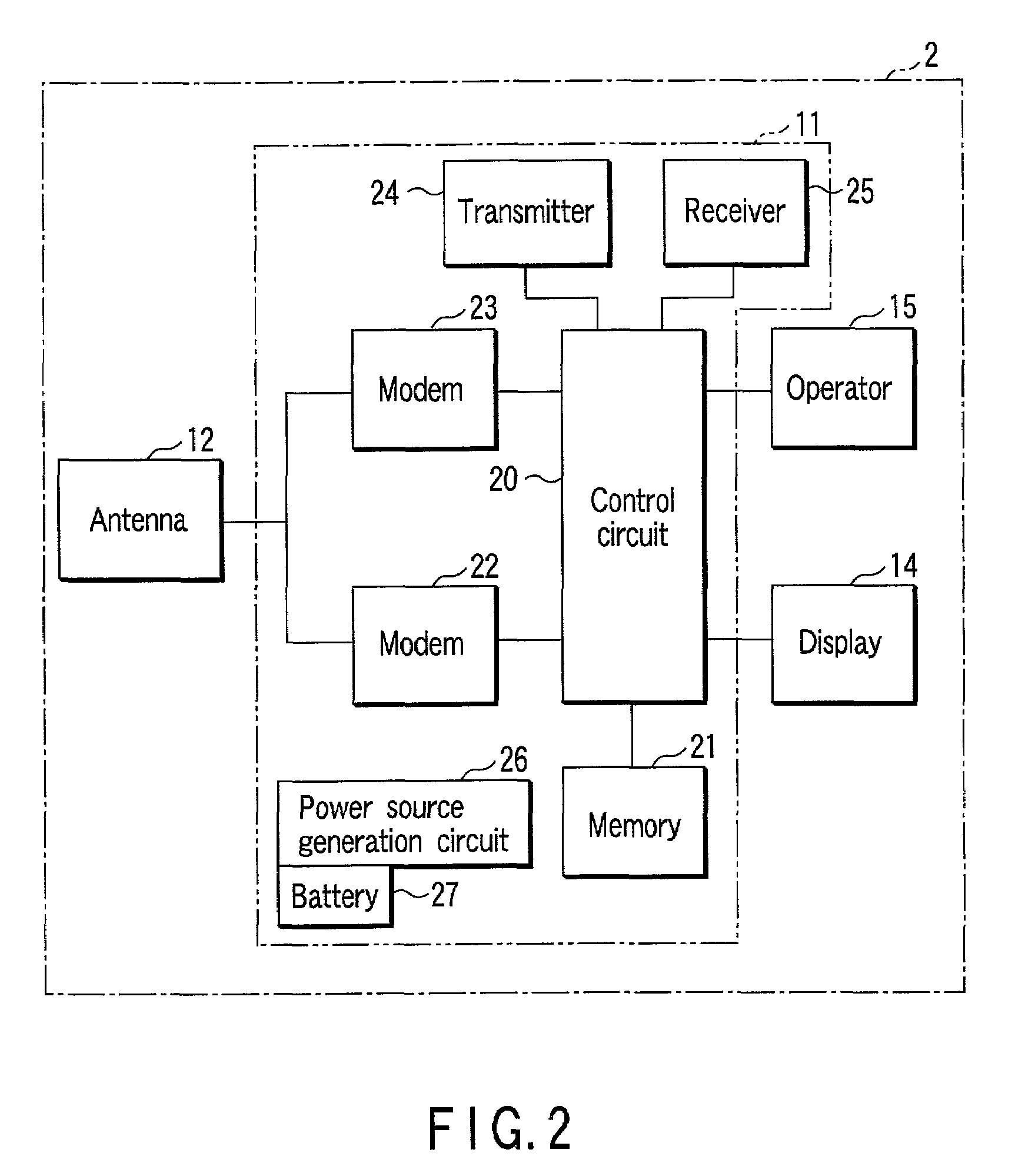

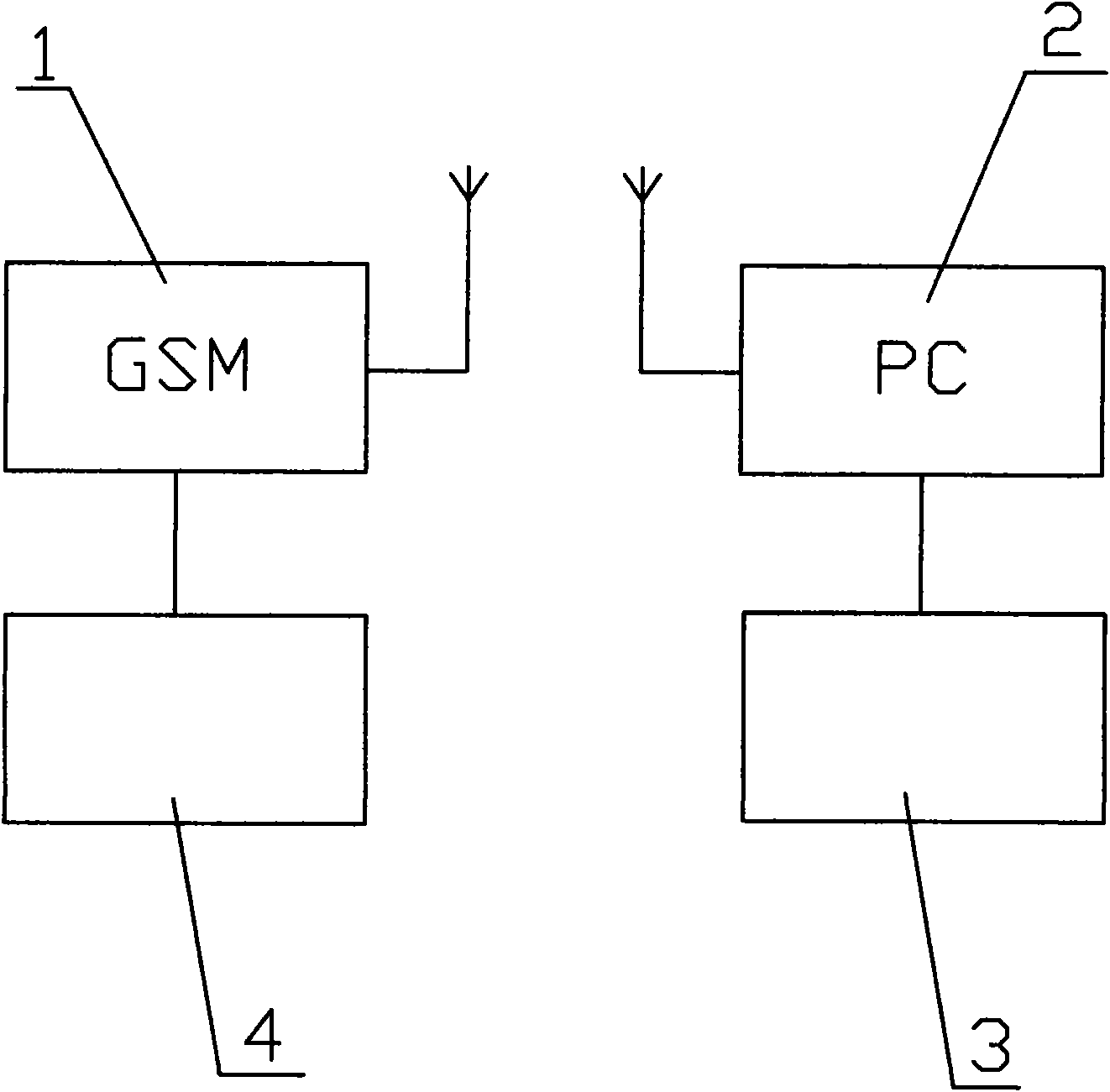

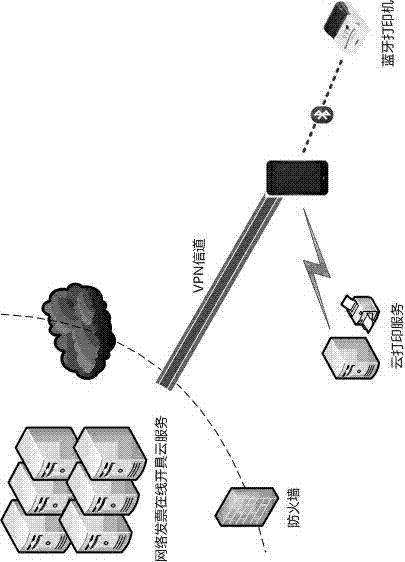

Print system by mobile terminal, and network system using mobile terminal

ActiveUS20020122201A1Multiple digital computer combinationsVisual presentationPrint-throughComputer science

There is disclosed a print system in which BD acquires a printing ID (hereinafter referred to as the PID) issued by PODS through CS, BD transmits PID to PC, PC receives printing data from PCDB via PODS, and the data is printed through PD.

Owner:KK TOSHIBA +1

Metal 3D printing product production method by means of low-power laser sintering

InactiveCN103769586ACeramic shaping apparatusIncreasing energy efficiencySelective laser sinteringAdhesive

The invention discloses a metal 3D printing product production method by means of low-power laser sintering. According to the metal 3D printing product production method, metal powder materials and thermoplastic molding adhesives are adopted to prepare a low-melting-point 3D metal printing raw material mixture; due to the fact that the thin-layer thermoplastic adhesives are formed on the surfaces of metal powder particles, low-power (smaller than 50 W) selective laser sintering or electron beam sintering 3D printer is used, the metal powder materials are stacked to be molded through surface layer thermoplastic adhesive low-temperature melting-cooling adhesive solidification, then metal part product green bodies can be printed through the prepared metal powder raw materials, the molded adhesives in the part green bodies are removed through thermal debinding or chemocatalysis debinding or other technologies, high-temperature sintering is conducted on the green bodies without the molded adhesives through a vacuum sintering method or an atmosphere protection sintering method, and alloying compact high-performance complex metal part products are produced. The metal 3D printing product production method by means of low-power laser sintering has the advantage that the 3D printing device and technology for producing the metal parts are low in cost.

Owner:王利民

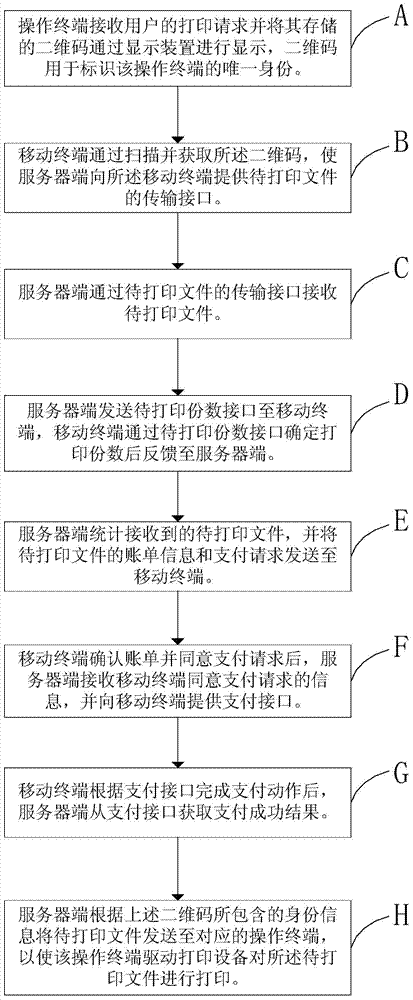

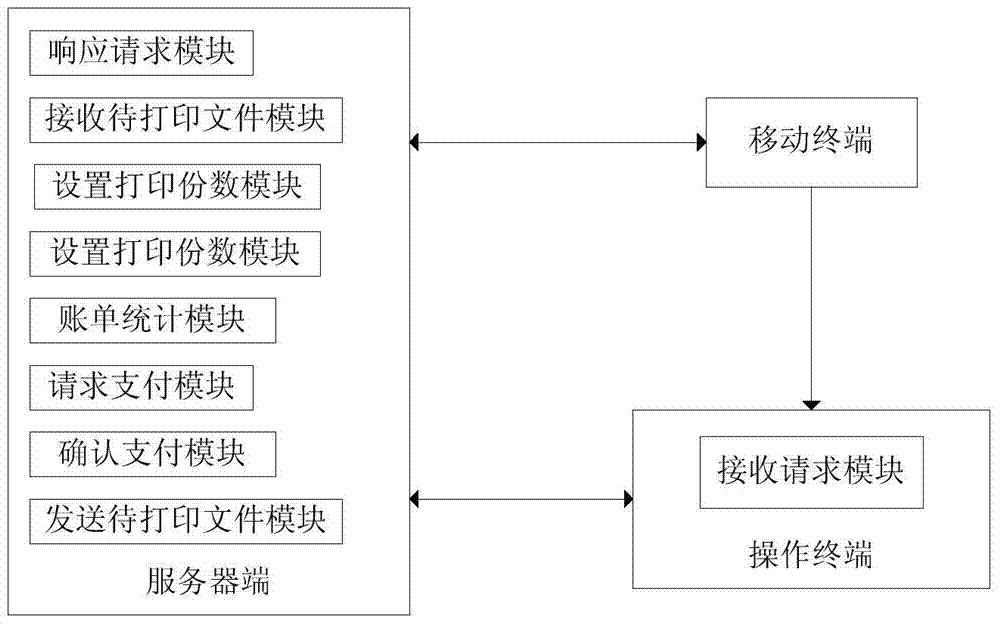

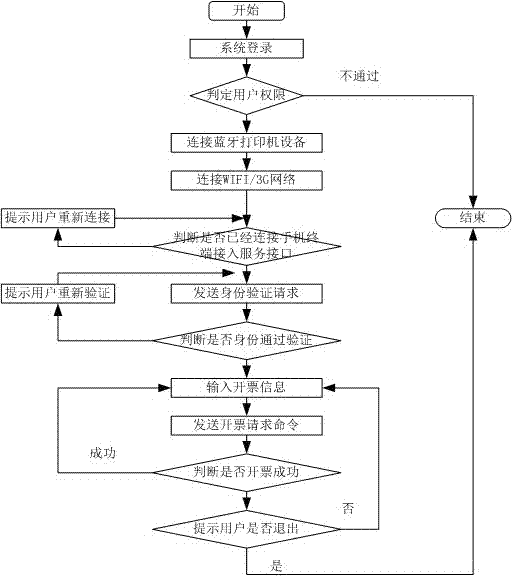

Self-service printing method and system

ActiveCN103942016AQuickly establish connectionsEnhanced interactionPayment protocolsTransmissionDisplay deviceComputer terminal

The invention discloses a self-service printing method. The self-service printing method comprises the following steps that step A, an operating terminal receives a printing request and displays two-dimension codes stored in the printing request through a display device; step B, a mobile terminal scans the two-dimension codes so that a server can provide a transmission interface of a file to be printed for the mobile terminal; step C, the server receives the file to be printed through the transmission interface of the file to be printed; step H, the server sends the file to be printed to the corresponding operating terminal according to information contained in the two-dimension codes, so that the operating terminal drives a printing device to print the file to be printed. According to the self-service printing method and system, operating terminals and printers are distributed off-line, connecting relation between the mobile terminals, the operating terminals and the servers is rapidly built through the two-dimension codes, the mobile terminals are devices to be carried about, and can conveniently interact with the servers, and the purpose that a user carries out printing in a self-service mode is achieved.

Owner:杨文晖

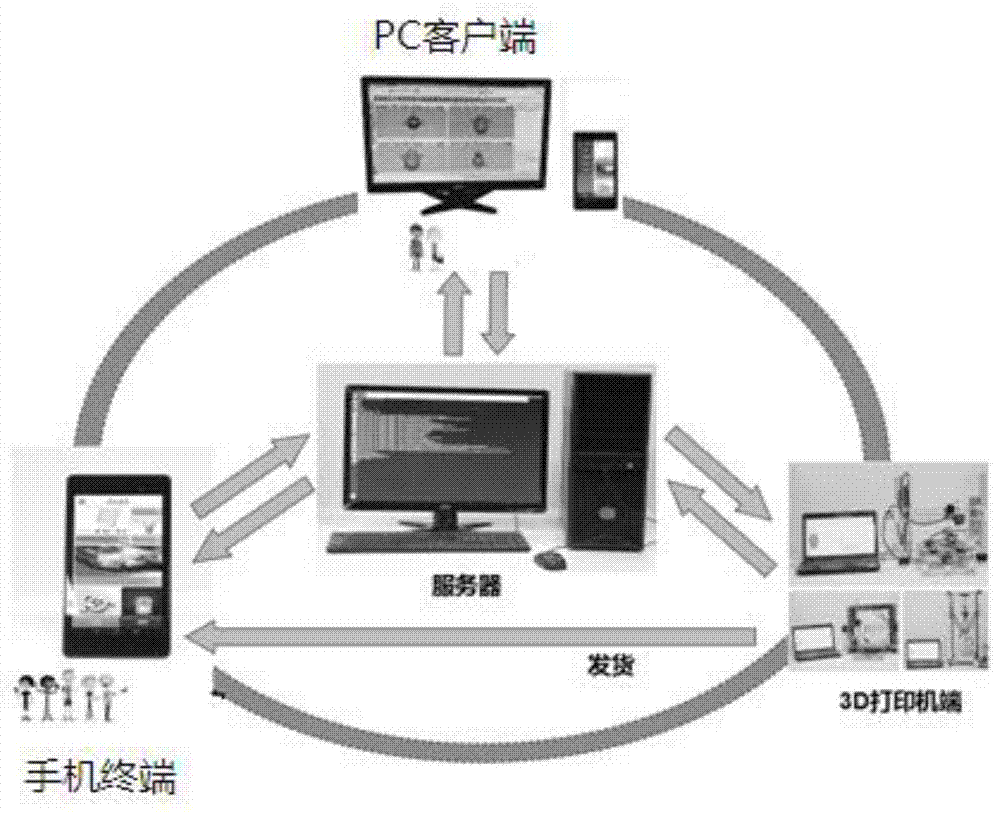

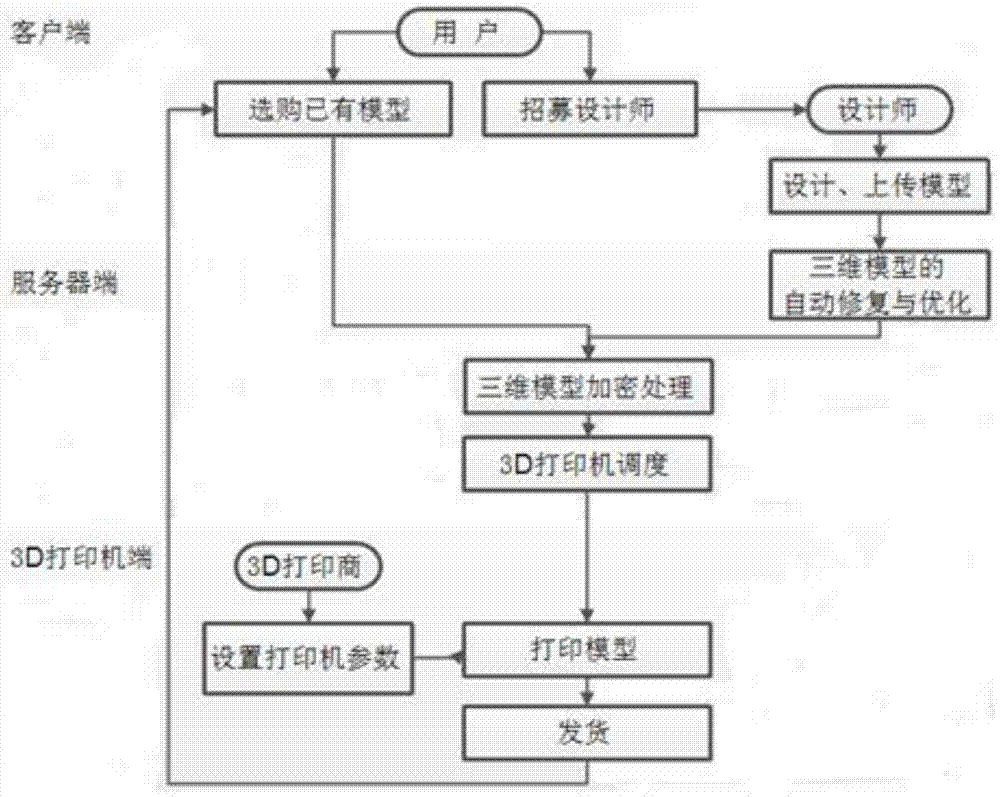

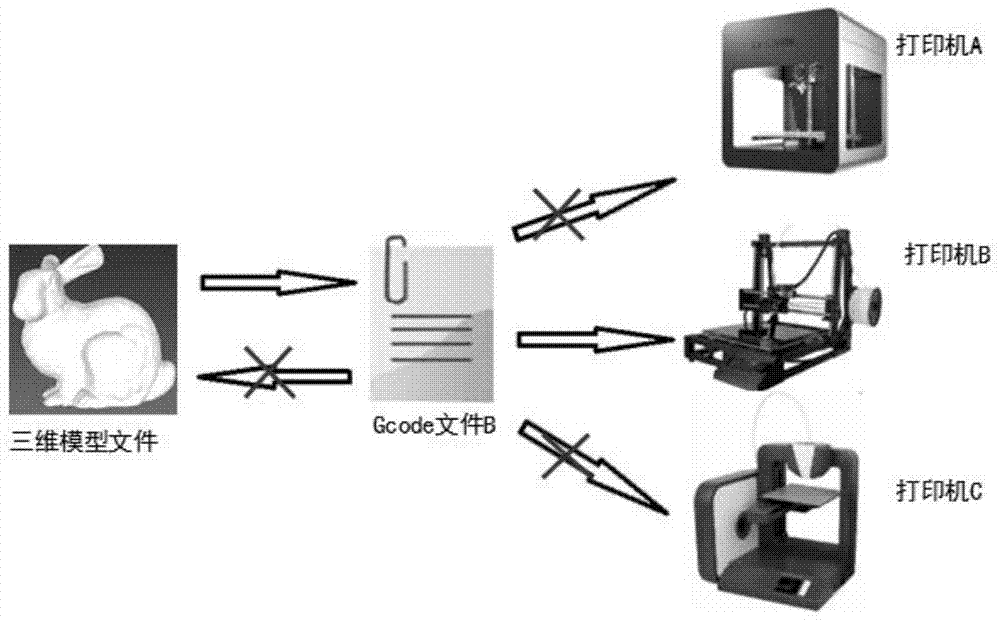

Cloud manufacturing system and method based on cloud computing and three-dimensional printing

ActiveCN104780214ACentralized schedulingScheduling is efficient and preciseTransmissionGenetic algorithmMaximum efficiency

The invention discloses a cloud manufacturing system and a cloud manufacturing method based on cloud computing and three-dimensional printing. The cloud manufacturing system comprises a client, a server side and a 3D printer side, wherein the server side is connected with the 3D printer side; the 3D printer side comprises a plurality of printers; the server side encrypts the 3D model to be printed through section engine processing to obtain a Gcode file of the 3D model, and then provides a single irreversible Gcode file for printing to the 3D printer side; the server side dispatches the printers according to a printer dispatching algorithm based on a genetic algorithm. According to the cloud manufacturing system and a cloud manufacturing method based on cloud computing and three-dimensional printing disclosed by the invention, the server side and the printer side are collaboratively established to achieve the purpose of utilizing hardware resources at the maximum efficiency, the hardware resources are utilized at the maximum efficiency, the fault freedom is good, and the printers are dispatched based on the genetic algorithm in the whole network range to fully consider about the factors influencing the printer dispatching, acquire the computing resources according to the requirement, and achieve the extendibility and the reliability of the distributed system.

Owner:上海汲臻智能科技有限公司

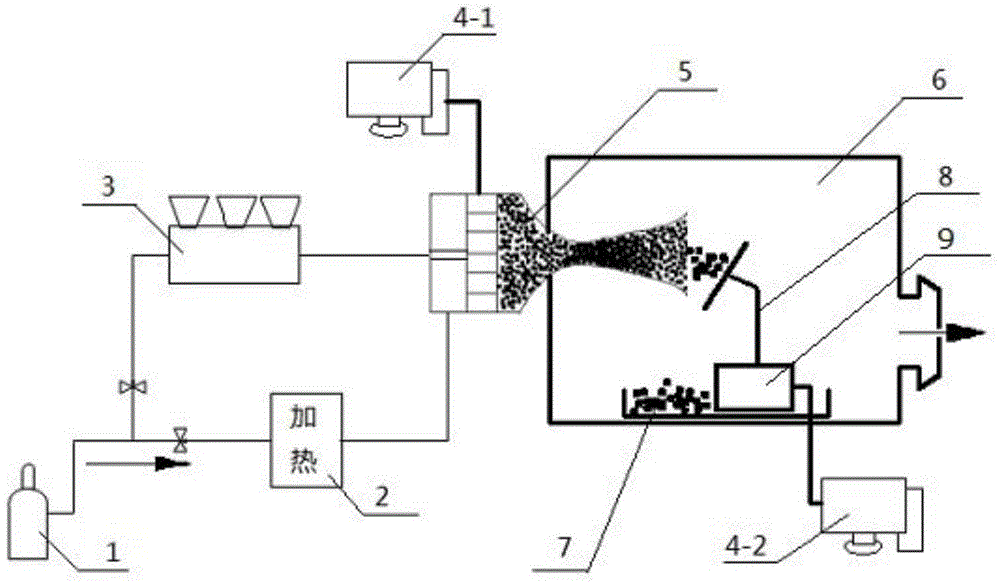

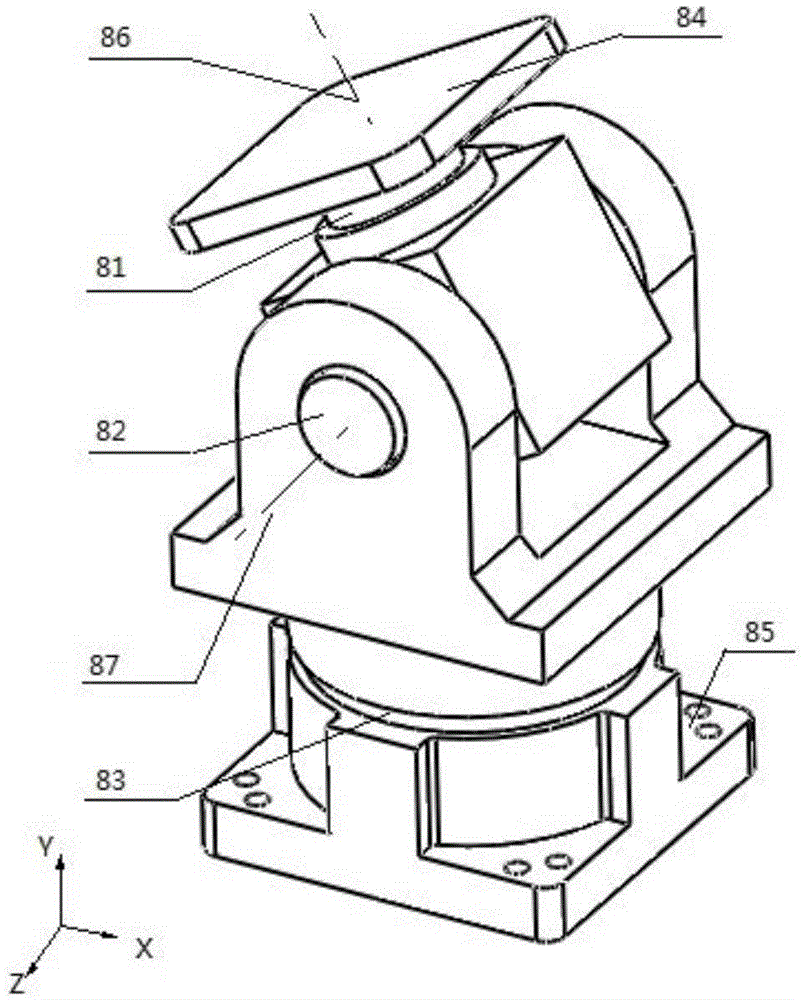

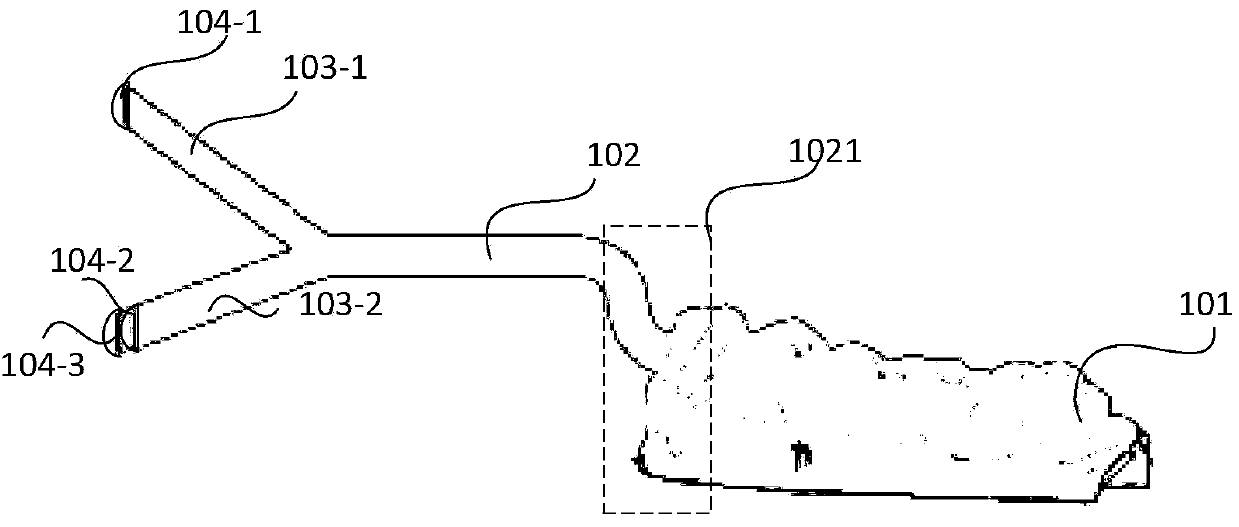

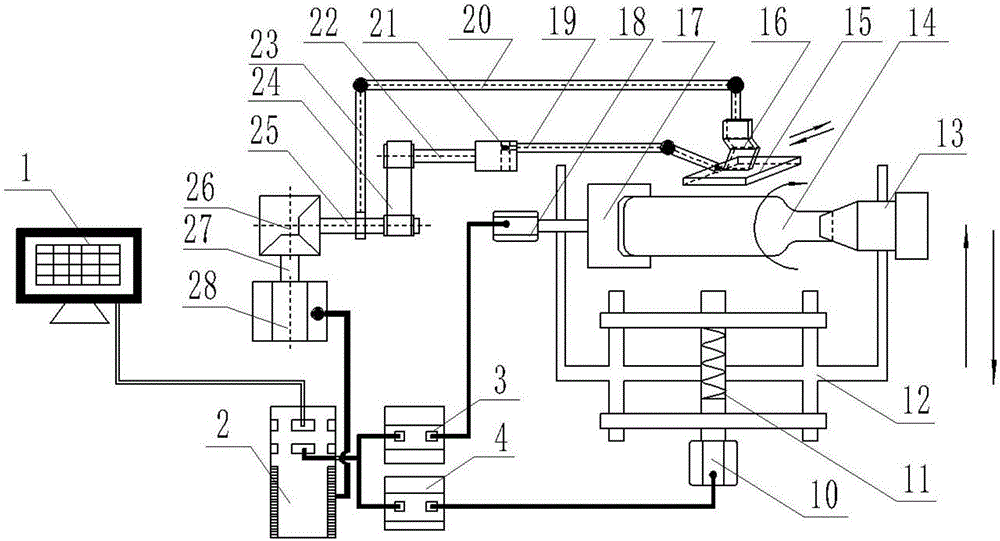

3D printing method and system based on cold spraying

InactiveCN104985813AImprove production efficiencyImprove bindingAdditive manufacturing apparatusIncreasing energy efficiencyThermal printingHigh pressure

The invention discloses a 3D printing method and system based on cold spraying. High-pressure gas carrying powder granular materials needing to be printed through low-temperature preheating generates supersonic speed gas-solid bidirectional flow after passing through a scaling laval nozzle, high-speed particle flow is sprayed from the nozzle in a solid state condition, the high-speed particle flow impacts a substrate, and meanwhile the high-speed particles generate plastic deformation and are cold-welded and bonded onto the substrate; a fact matched with the process exists is that in a vacuum sealing room, a printing platform can be controlled by a computer, and stretching and contracting in the height direction and rotation around three rotating shafts are conducted according to needs; according to actual characteristics of a three-dimensional model needing to be printed, the printing section with better effects is calculated and analyzed automatically through the computer, at the time, the printing platform capable of rotating and lifting freely adjusts self-height and the needed angle to form a relative work position beneficial to an optimal printing section with the printing nozzle, meanwhile, the position of the printing platform is adjusted in real time, and the rapid and efficient printing process is achieved.

Owner:TONGJI UNIV

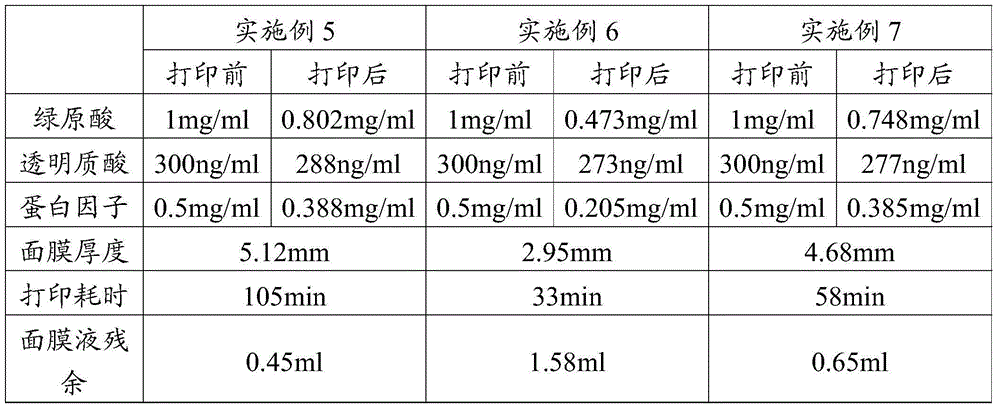

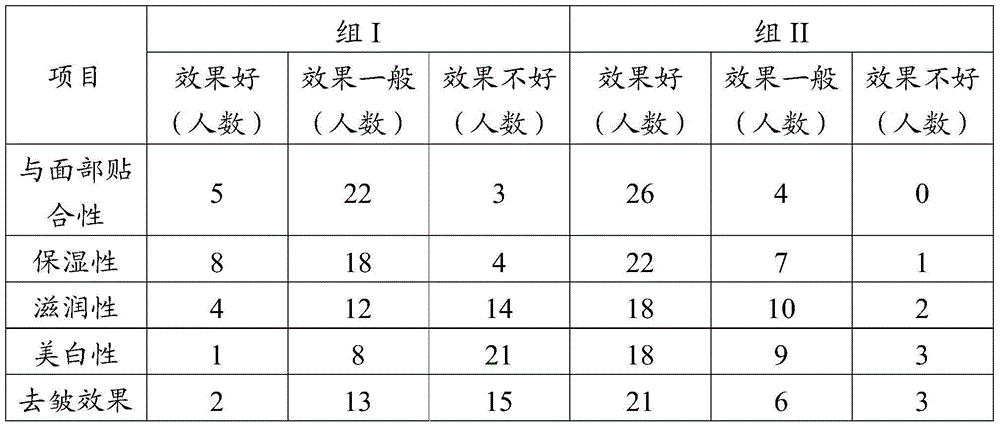

Preparation method of mask for accurate repair and care

InactiveCN105596222AAvoid Bubble ProblemsAvoid the situationCosmetic preparationsAdditive manufacturing apparatusAdditive ingredientData acquisition

The invention relates to a preparation method of a mask for accurate repair and care, and belongs to the technical field of beauty cosmetics. The method comprises the following steps that 1, a facial skin image is obtained through a facial imaging device, a three-dimensional (3D) facial shape image is constructed, and meanwhile analysis and data collection are conducted on the facial skin type and state, target positions, unusual conditions and the like, and a 3D facial skin state data packet is constructed; 2, computer modeling is conducted according to the facial morphology and state data, a mold is printed through a 3D printing technology, and a mask substrate is prepared through the mold; 3, ingredients with corresponding repair and care effectiveness are precisely sprayed on corresponding positions of the mask substrate according to the skin state data packet, rapid vacuum drying is conducted, and a dry mask which has the effectiveness and is precisely distributed is obtained; 4, a wetting penetrating fluid is prepared and packed separately and matched with the dry mask to be applied to a user. The mask prepared through the method has the shape capable of being well attached to the face, and meanwhile the mask has the advantages of achieving personalized accurate care and fixed-point facial drug administration.

Owner:GUANGDONG UNIV OF TECH

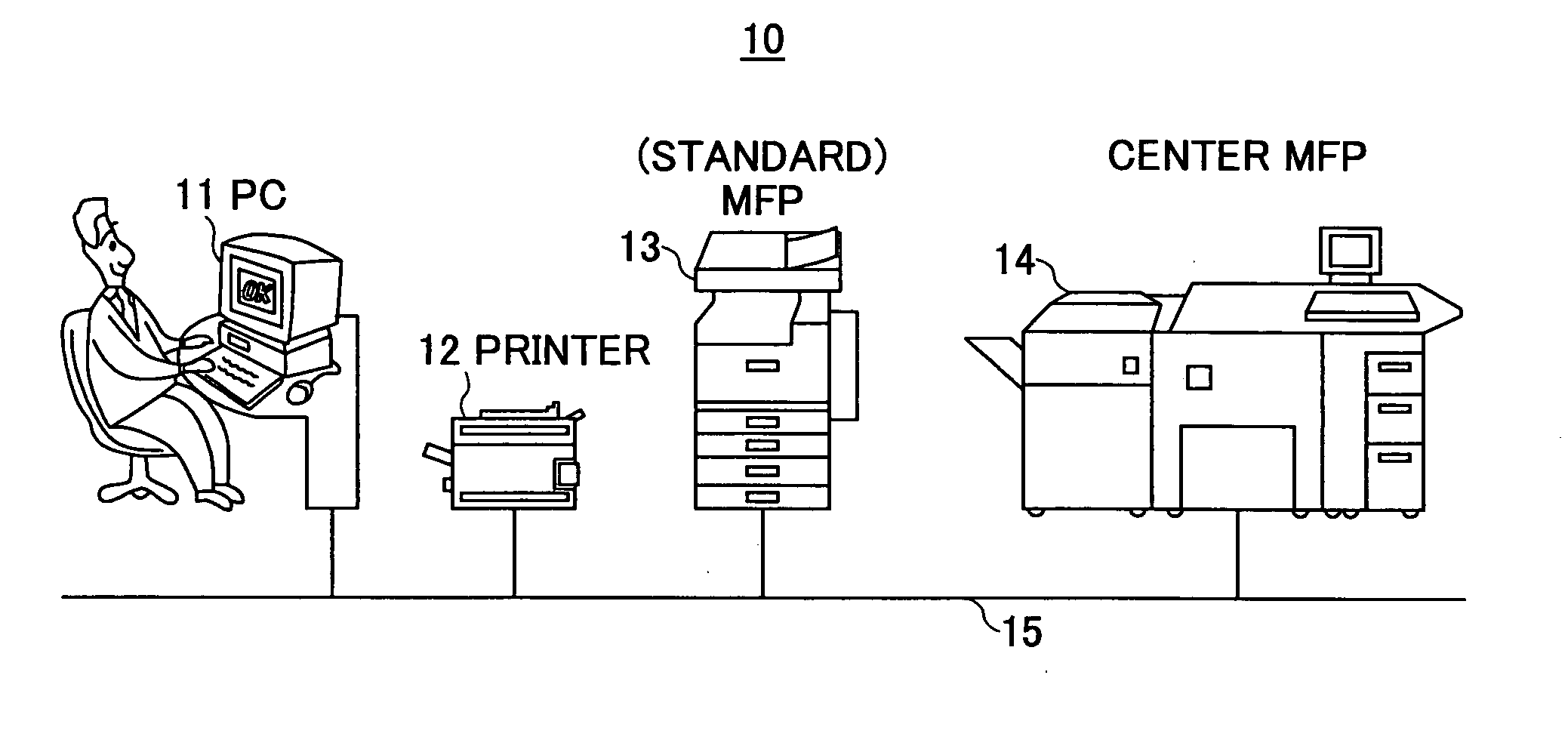

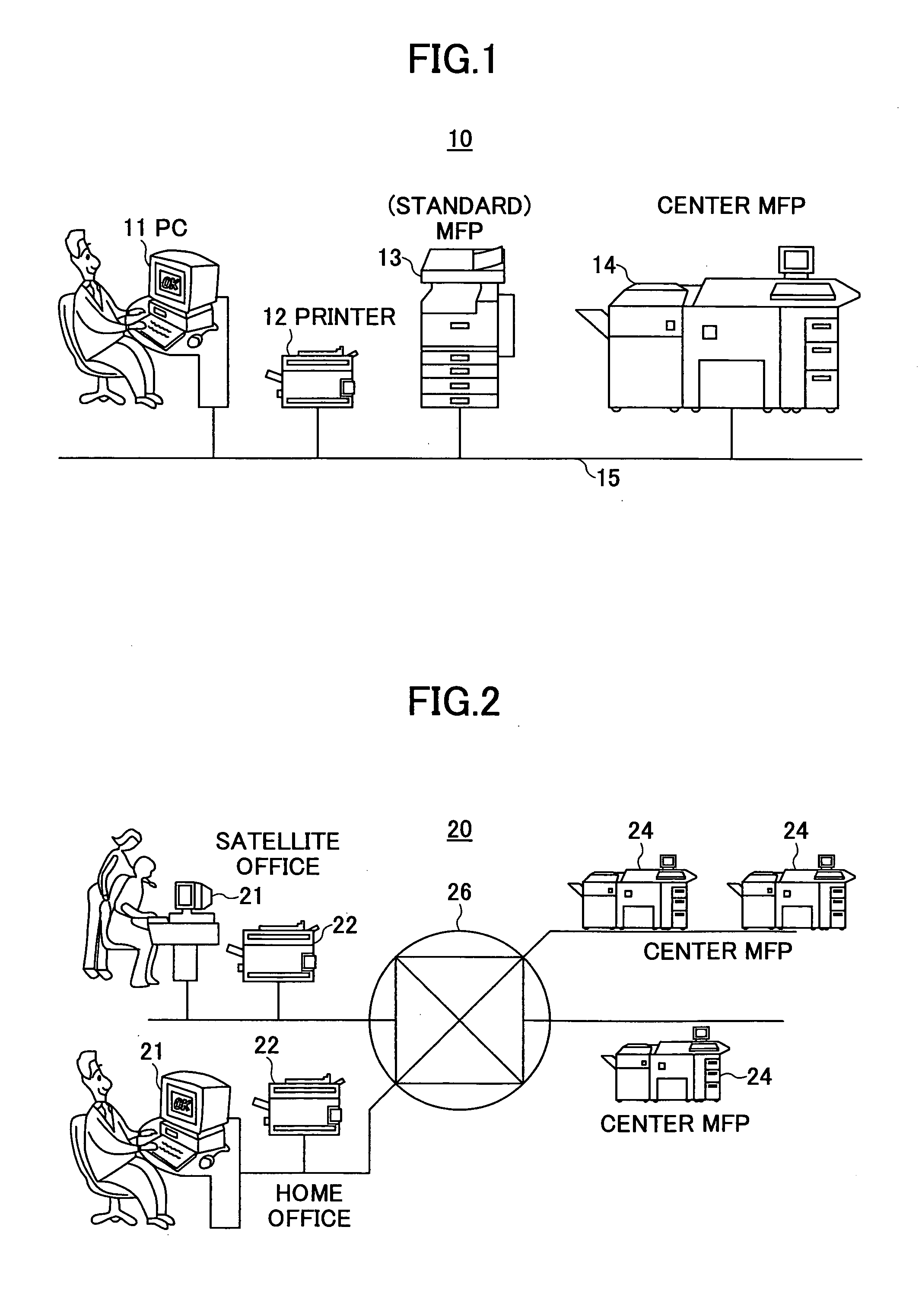

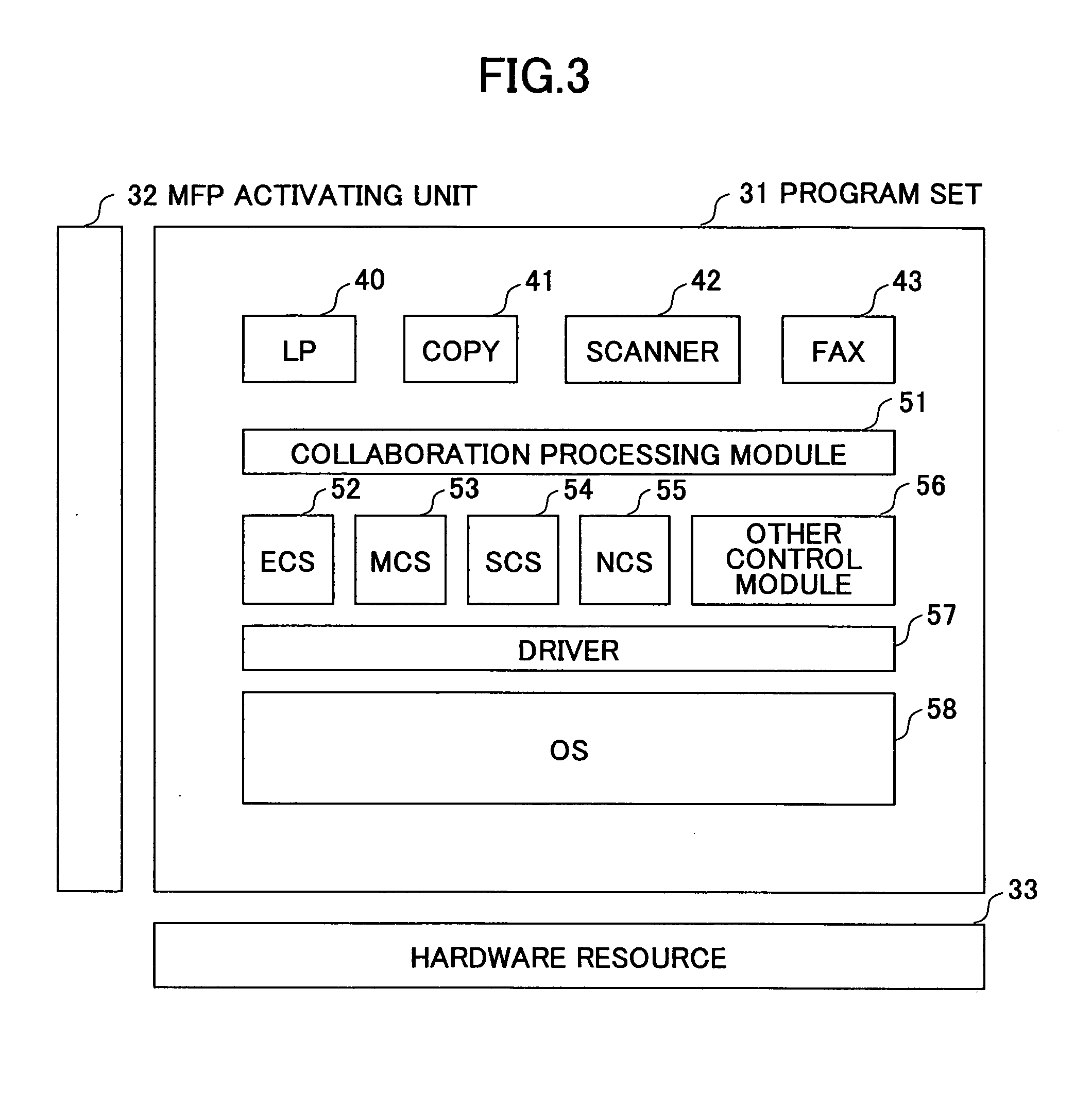

Printing through collaboration of image forming apparatuses

InactiveUS20050030580A1Decreased constSignificant const reductionDigitally marking record carriersVisual presentation using printersPrint-throughData processing

An image forming apparatus, which has hardware for image printing and at least one data processing function for use in the image printing, and is connected to a network, includes an analysis unit configured to analyze data received from the network, a processing unit configured to perform the data processing function according to a result of the analysis by the analysis unit thereby to generate print data from the received data, and a transmission unit configured to transfer the print data to another image forming apparatus connected through the network.

Owner:RICOH KK

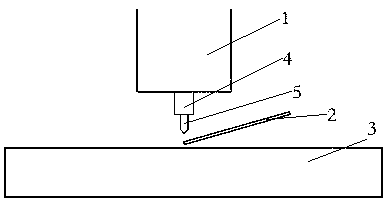

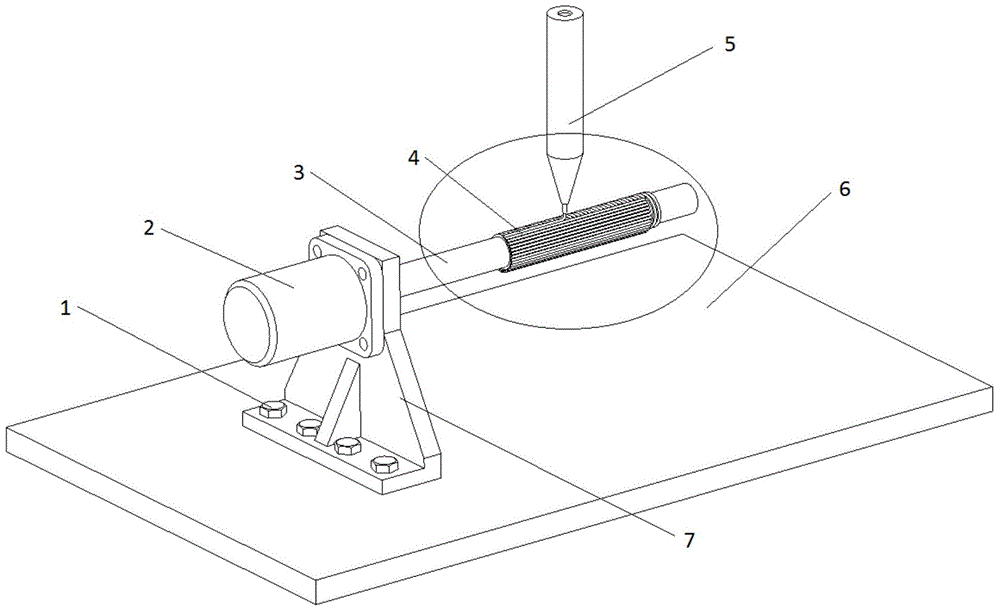

Electric arc additive manufacturing method

InactiveCN108723549AReduce mistakesNo crackElectrode holder supportersWelding accessoriesLoop controlSource type

The invention discloses an electric arc additive manufacturing method which comprises the following steps of (1) selecting a corresponding heat source type, a forming wire material, and a material type of a base plate according to the material requirement of a forming target part; (2) building a computer-aided design (CAD) geometric model of the forming target part, extracting a standard templatelibrary (STL) model, slicing the STL model, generating a G code file required for printing, and transmitting the G code to a printer; (3) setting printing parameters, starting the printer, and printing metal thin layers according to a planned route layer by layer; and (4) after finishing printing all layer sheets through the printer, carrying out arc failure through a welding gun, and obtaining the forming target part. An additive piece printed through the method provided by the invention is less in error and flawless, has the advantage of good surface quality, and is stable in process, high in dimensional accuracy and surface quality, short in processing period, and low in cost at the same time; the printing process is in closed-loop control, so that the automation degree is high, and thelabor intensity of operating personnel can be reduced; and continuous manufacturing can be realized, and the manufacturing efficiency is high.

Owner:HOHAI UNIV CHANGZHOU

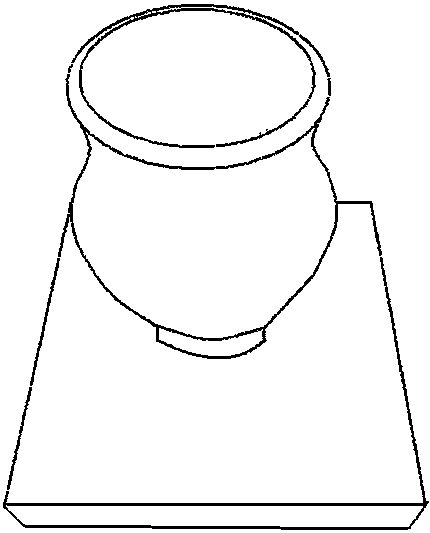

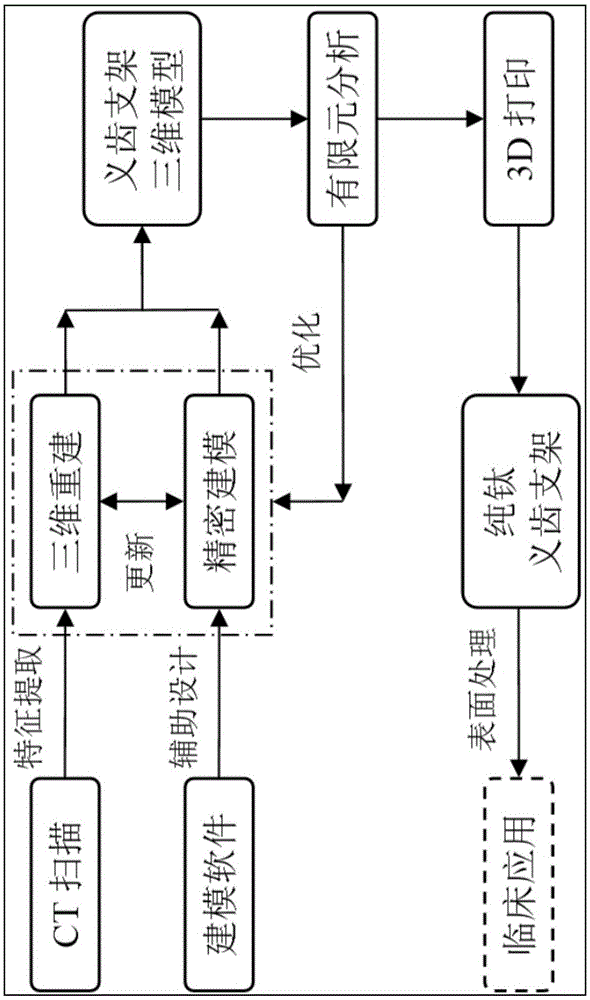

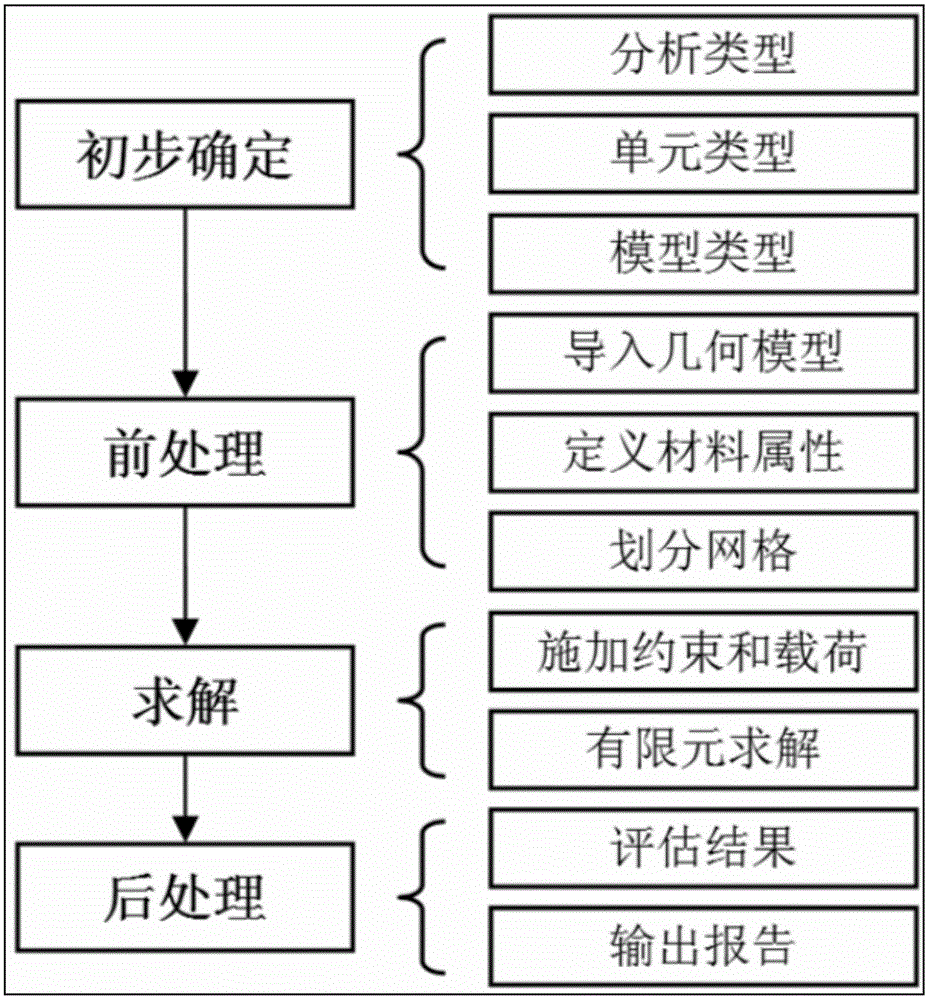

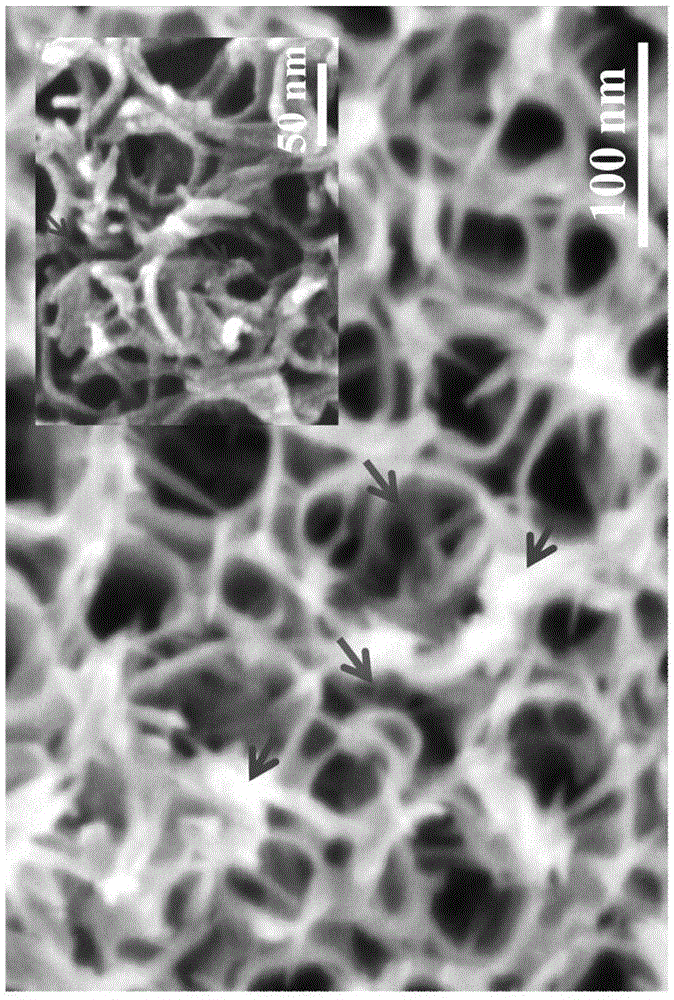

Method for preparing false tooth support through 3D printing laser stereo-lithography technology

InactiveCN104999078AGuaranteed comfortGuaranteed service lifeAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing cost reductionFinite element technique

The invention discloses a method for preparing a false tooth support through a 3D printing laser stereo-lithography technology. According to the method for preparing the false tooth support through the 3D printing laser stereo-lithography technology, the individual false tooth support most suitable for a patient is printed through the 3D printing laser stereo-lithography technology; the comfort level and the service life of the false tooth support are ensured by means of a finite element technology; the operation difficulty of a physician is lowered; the manufacturing cost is reduced; the manufacturing period is shortened. The surface of the false tooth support is processed through an anodizing and / or electrochemical deposition method so that the surface of the false tooth support can have more excellent synosteosis features and biology activity, osteoblast growth and surface calcification are facilitated, and the satisfaction of the patient is improved. The method is suitable for the field of medical devices.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

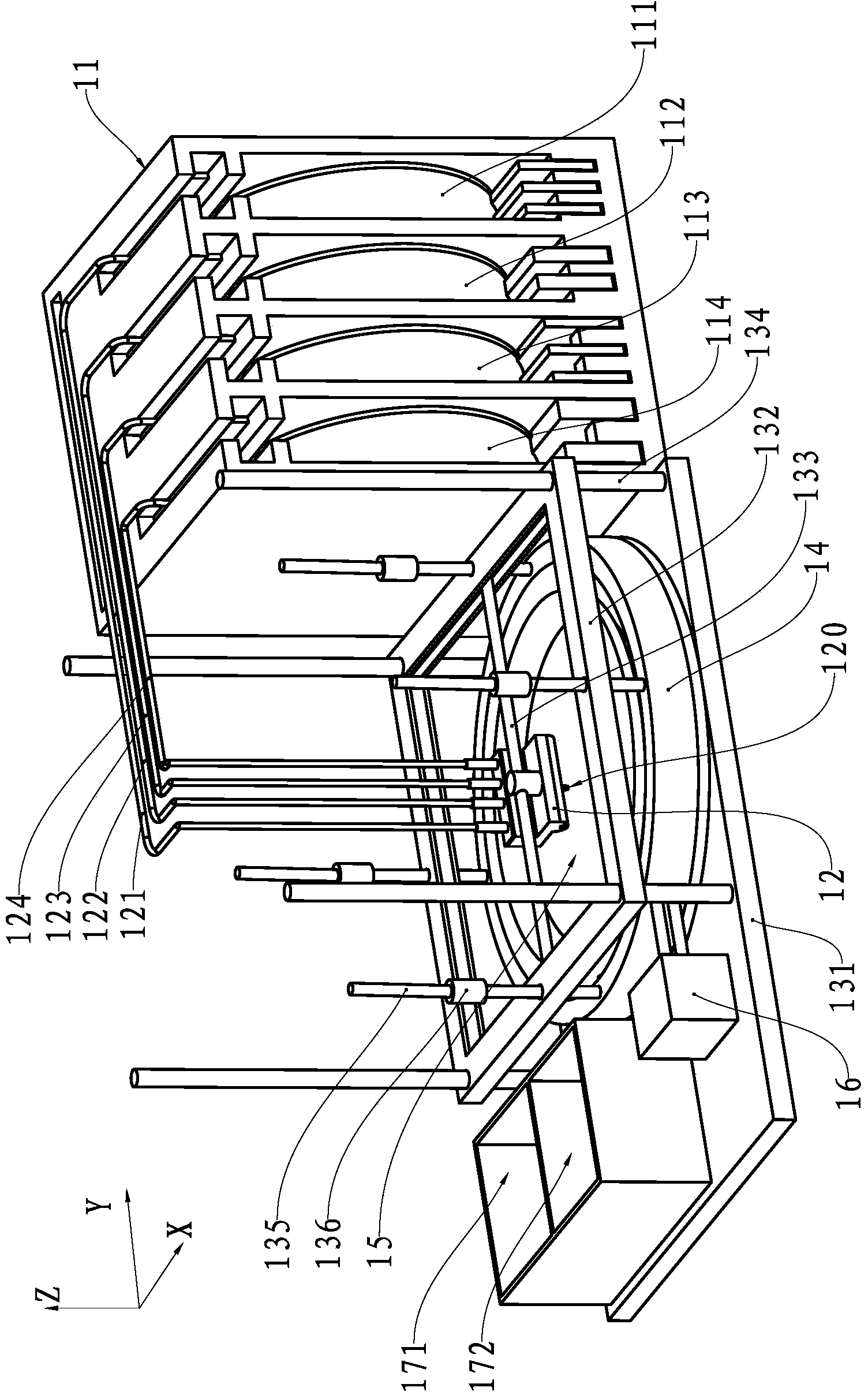

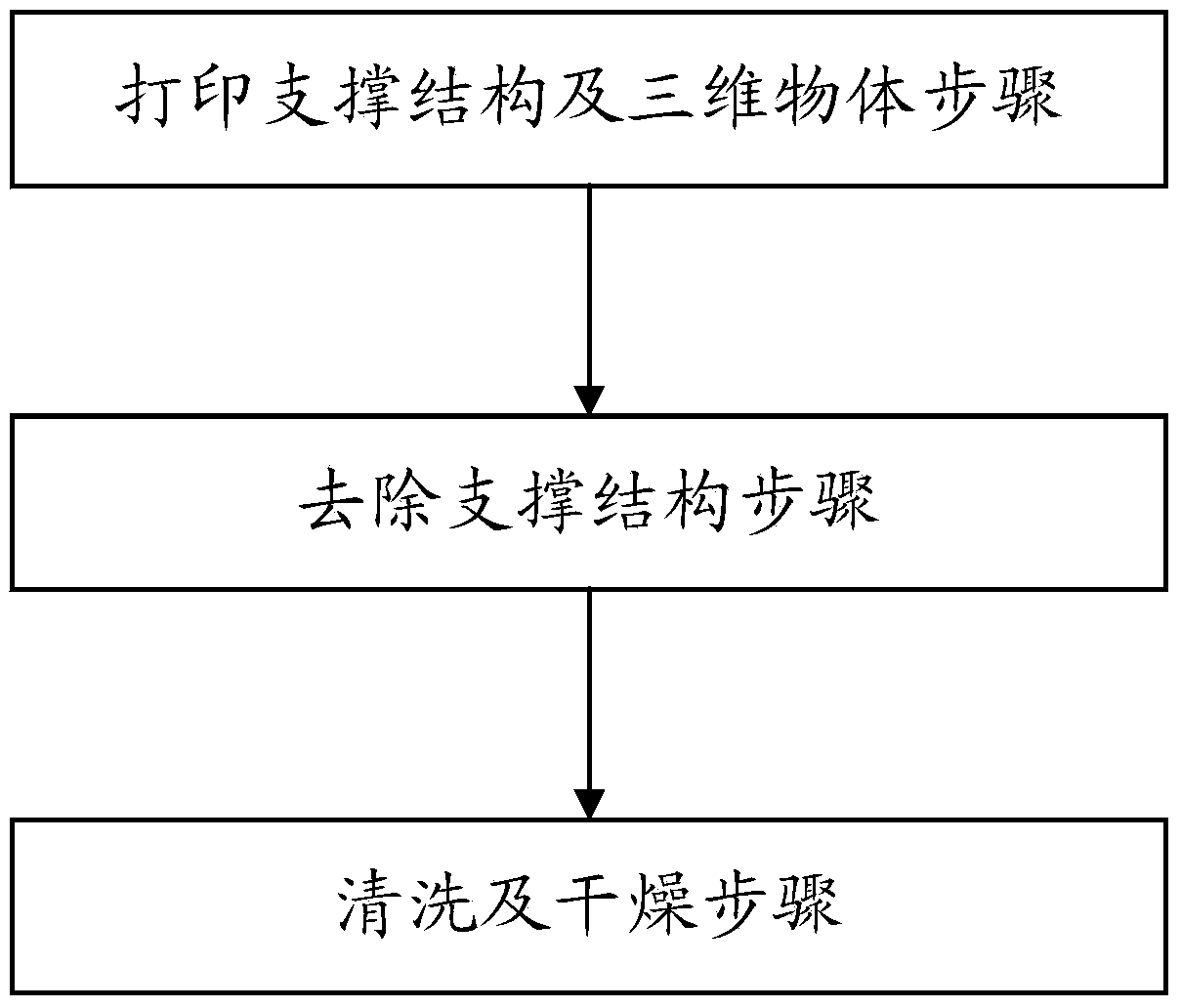

Three-dimensional printing method and machine

The invention relates to a three-dimensional printing method which comprises the steps that a supporting structure and a three-dimensional object are printed, wherein according to a set printing scheme, the supporting structure and the three-dimensional object are printed through a printing head; and the supporting structure is removed, wherein during printing of the supporting structure and the three-dimensional object, when the distance between the printing head and an object carrying table reaches a set value, a solution which can dissolve supporting materials and cannot dissolve forming materials is used for carrying out ultrasonic cleaning on the three-dimensional object and the supporting structure with the distance from a printing face larger than the set value. During a printing process, the supporting structure is removed, and the printing cycle is effectively shortened. In addition, the invention provides a three-dimensional printing machine suitable for the three-dimensional printing method.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Smart additive manufacturing device

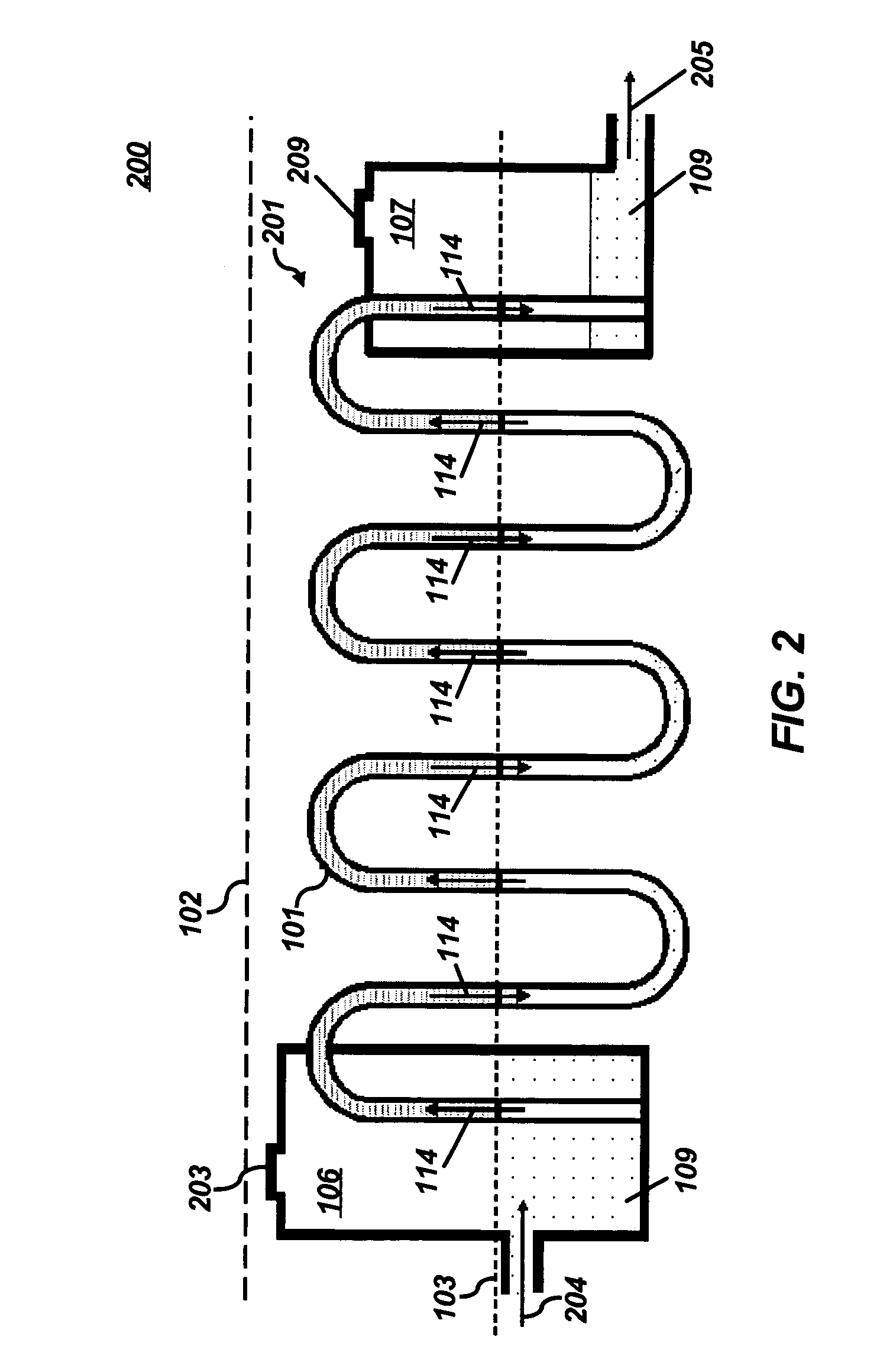

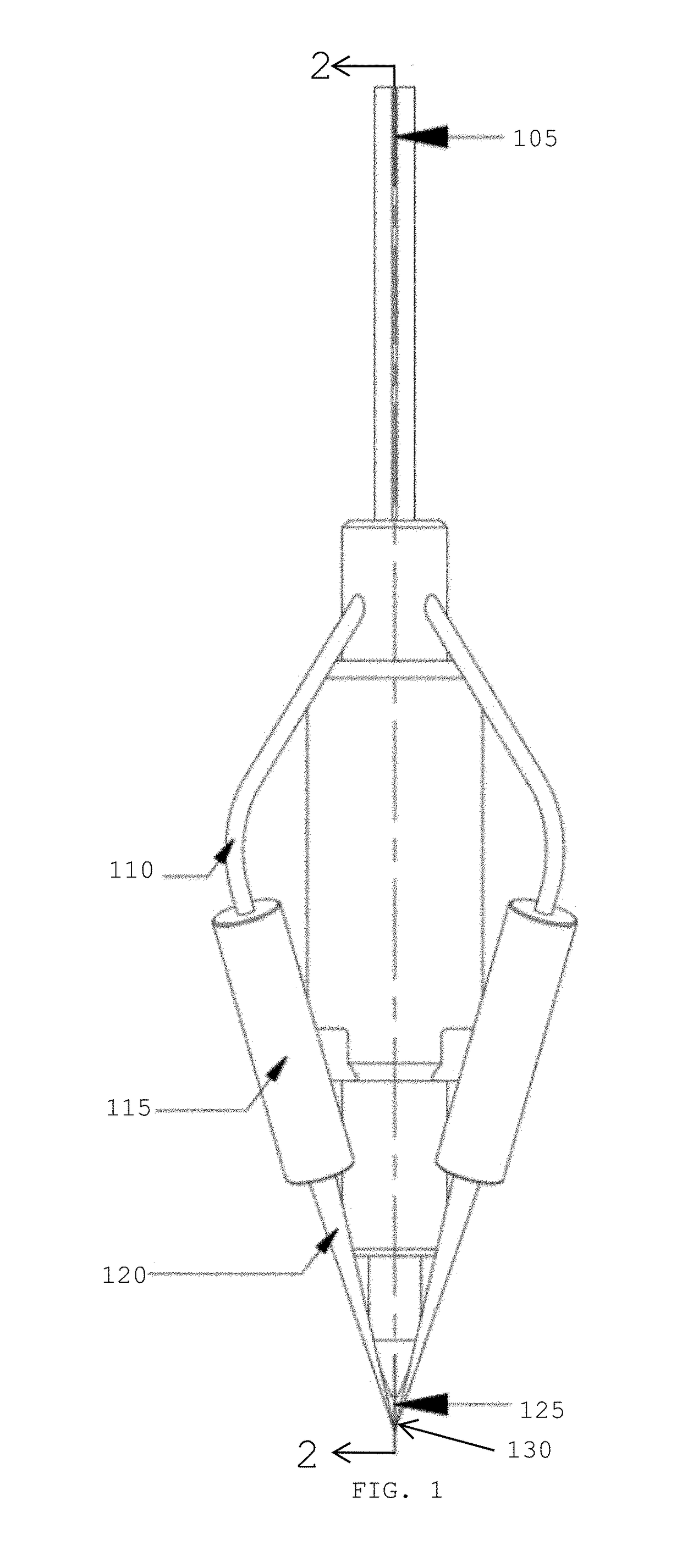

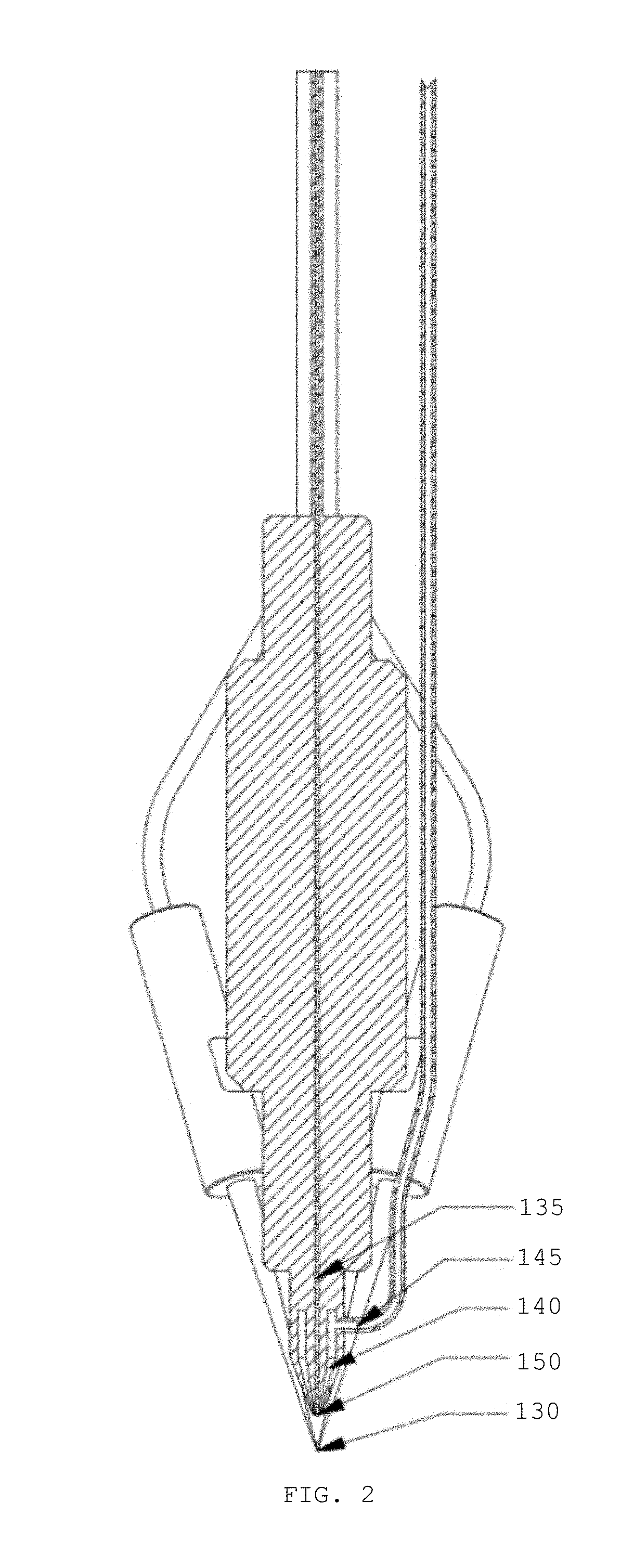

ActiveUS20180318929A1High effective laser powerFacilitate depositionAdditive manufacturing apparatusMolten spray coatingPrint-throughSolid-state

Disclosed is a multiple-feature compact direct-metal deposition additive manufacturing (AM) print head. The head configures off-axis, solid-state diode or diode-pumped lasers into an array to perform precision controlled, direct metal deposition printing through a single print nozzle. Dual-mode printing capability using metal wire and powder feedstock sources in the same print nozzle is provided with in-line control, precision wire feed driver / controller, adjustable shield gas diffuser, and nozzles tailored to wire feedstock diameter.

Owner:ADDITEC ADDITIVE TECH LLC

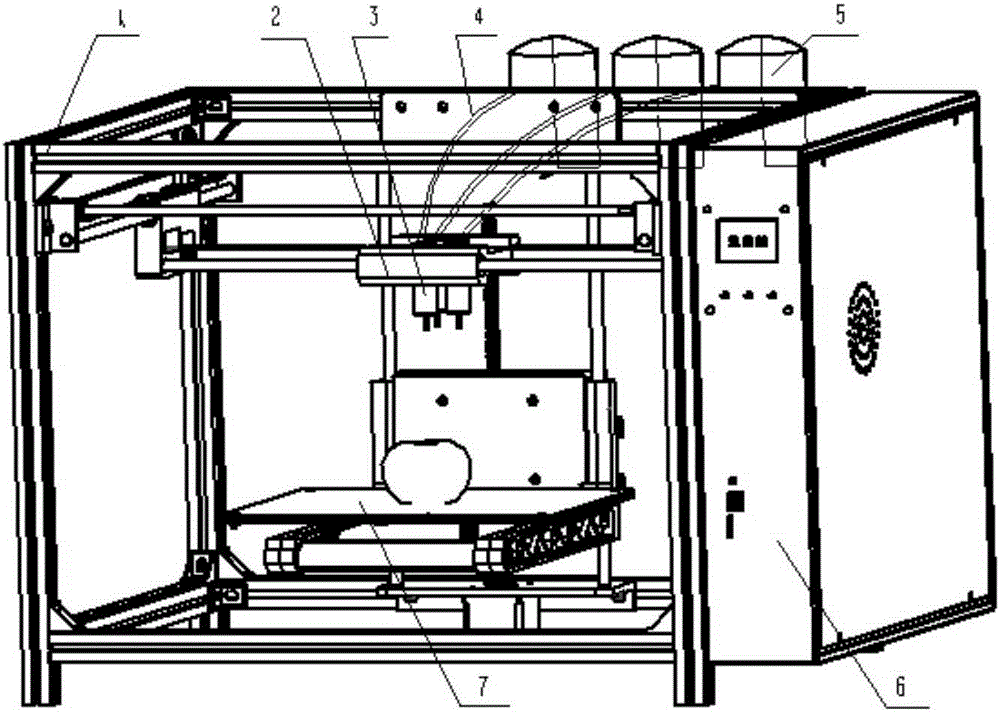

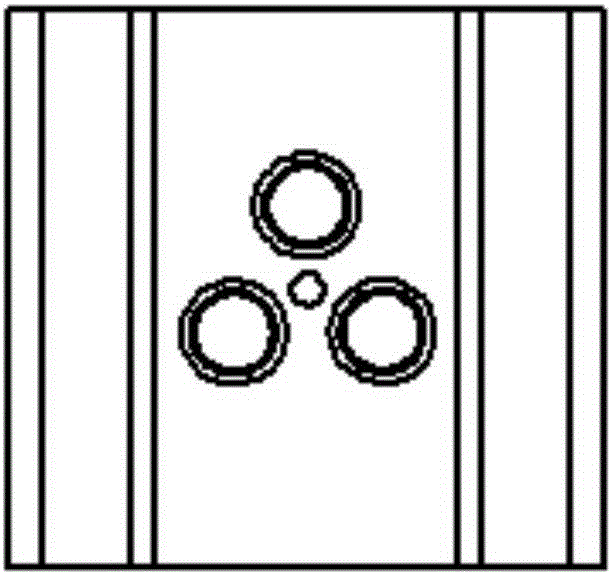

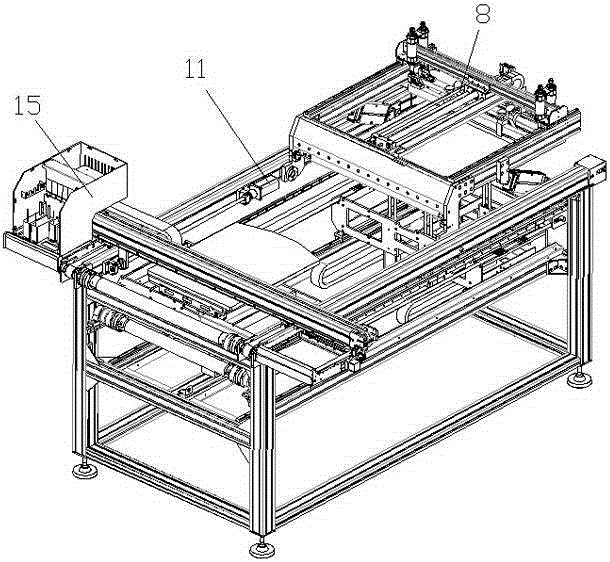

3D (3-dimensional) multifunctional color food printing equipment

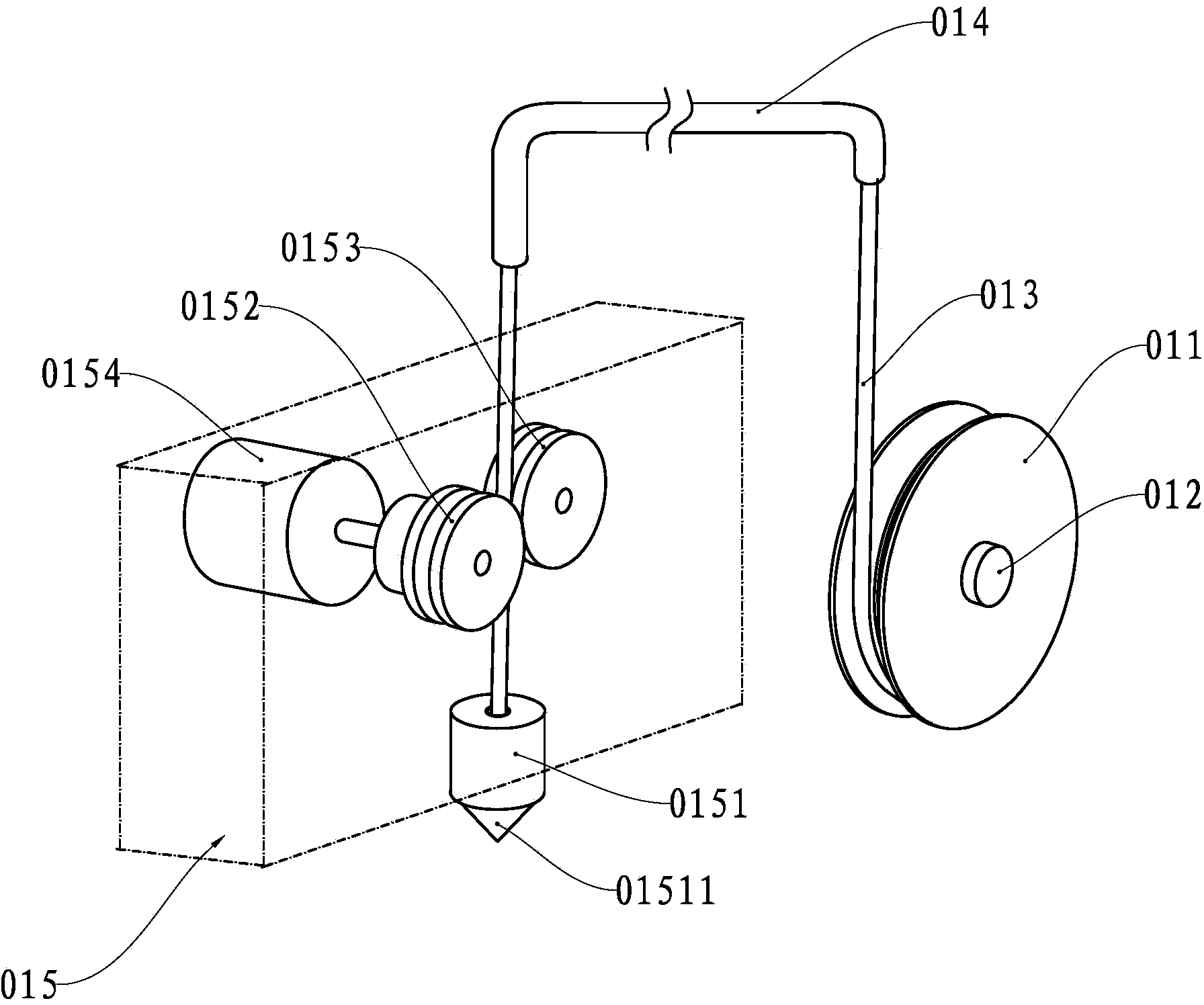

InactiveCN105196553AHigh forming precisionHigh speedAdditive manufacturing apparatusFood coatingControl systemSpray nozzle

The invention relates to 3D (3-dimensional) multifunctional color food printing equipment. The equipment is shown as figure 1, and the working principle of the equipment is basically the same as that of a conventional 3D printer. Besides dynamic three-dimensional accurate positioning in X, Y and Z directions, a printing system comprises three spray nozzles, three dosing pumps provided with servo motors, three containers and a conveying pipe, wherein the spray nozzles adopt a circumferential uniform distribution structure and realize printing of three colors or objects through a control system. The equipment further has the advantages that a touch control screen and templates are arranged in a printer, a larger model base is established in the printer, so that various food prototypes can be printed rapidly and conveniently, or food with irregular animal forms is printed through combined templates, human dimensional imagination and creativity can be particularly stimulated, and green delicious food is made with own hands. The forming precision is higher, the speed is high, the technology is simple, the cost is low, and the equipment can be widely applied to the field of catering industry, the family field and the teaching field.

Owner:WEINAN DINGXIN INNOVATION ZHIZAO TECH CO LTD

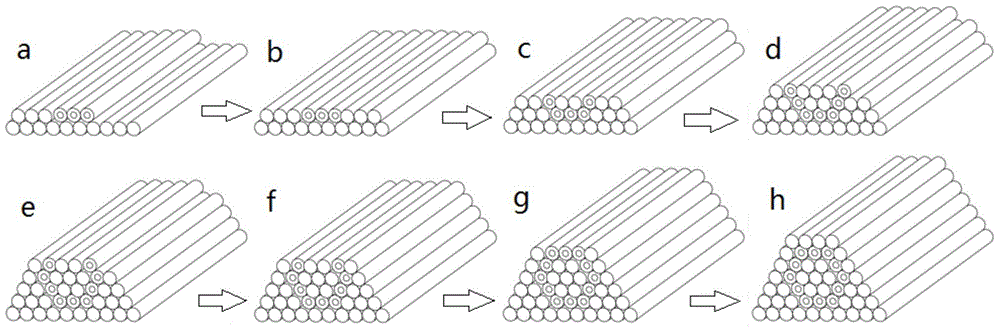

Blood vessel forming device and method for 3D bioprinting

InactiveCN104146794ALess affected by gravityThe overall impact is smallBlood vesselsBiological material testing proceduresBlood Vessel TissueBiomedical engineering

This invention discloses a blood vessel forming device and method for 3D bioprinting. The device and method are used for the bioengineering technology and aim to solve the problems that currently, when blood vessels are printed through the 3D bioprinting technologies, the blood vessels are poor in forming quality and small in forming length. According to the method, biological ink is printed on rotary rods with the surfaces coated with thermo-sensitive hydrogel through the 3D bioprinting technologies, and the needed biological blood vessels can be formed through further biological culture. According to the method, the rotary rods with different diameters and lengths can be prepared for printing the biological blood vessels with different sizes, blood vessel tissue which is uniform in thickness and accurate in printing size can be fast printed, the available 3D printing technologies are diverse, and the device and method are wide in practicability. We call the method a 3D rotational forming printing method (3Denvelop Bioprinting Method).

Owner:周惠兴

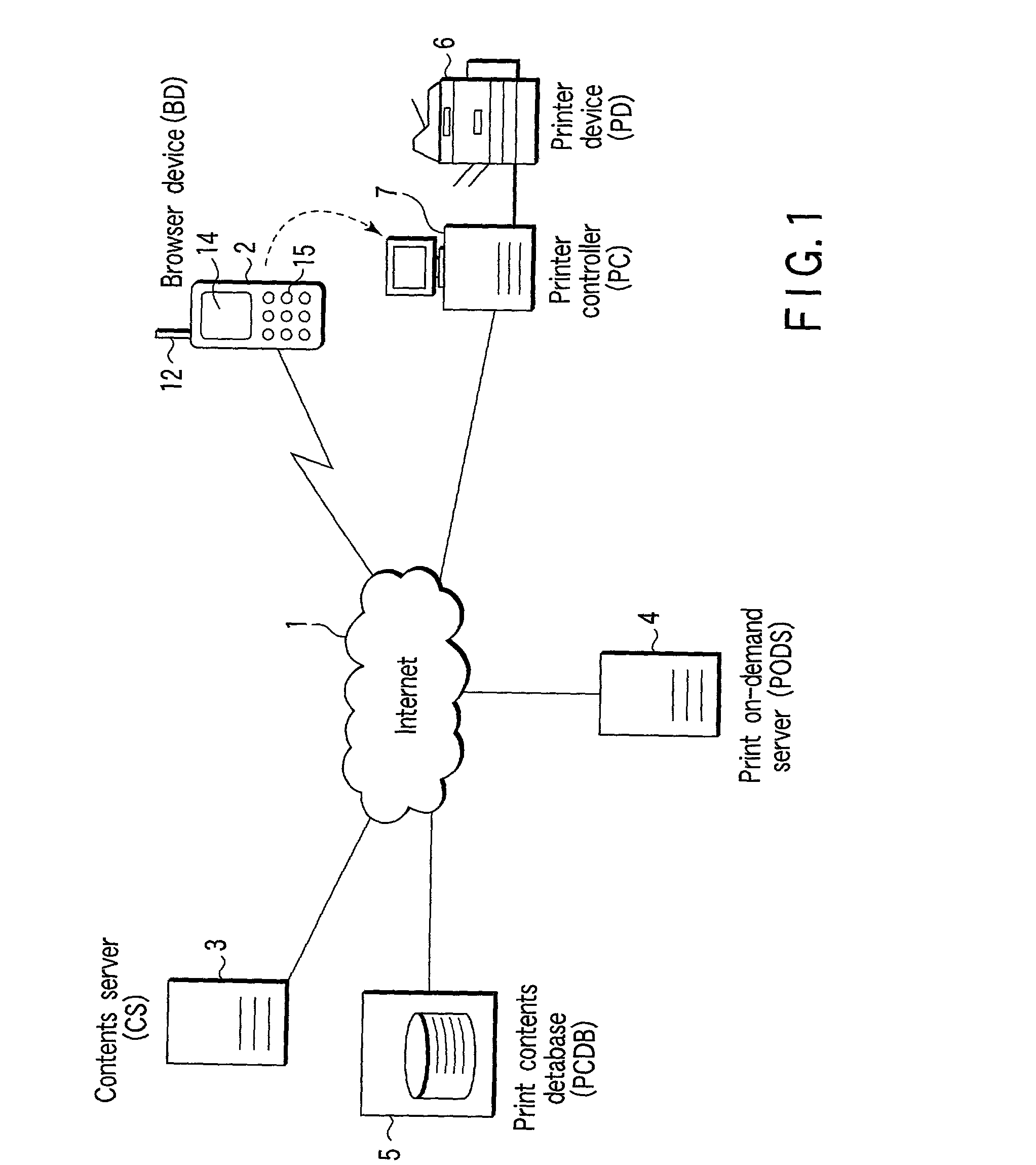

Print system by mobile terminal, and network system using mobile terminal

ActiveUS7272647B2Multiple digital computer combinationsVisual presentationComputer terminalComputer science

There is disclosed a print system in which BD acquires a printing ID (hereinafter referred to as the PID) issued by PODS through CS, BD transmits PID to PC, PC receives printing data from PCDB via PODS, and the data is printed through PD.

Owner:KK TOSHIBA +1

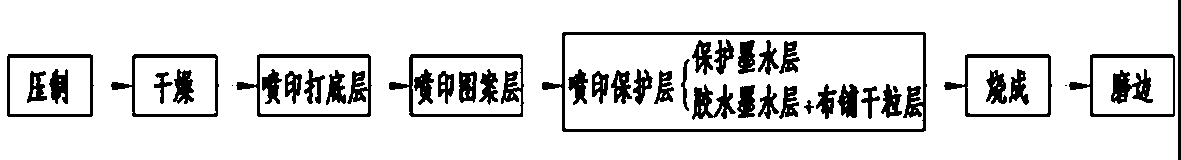

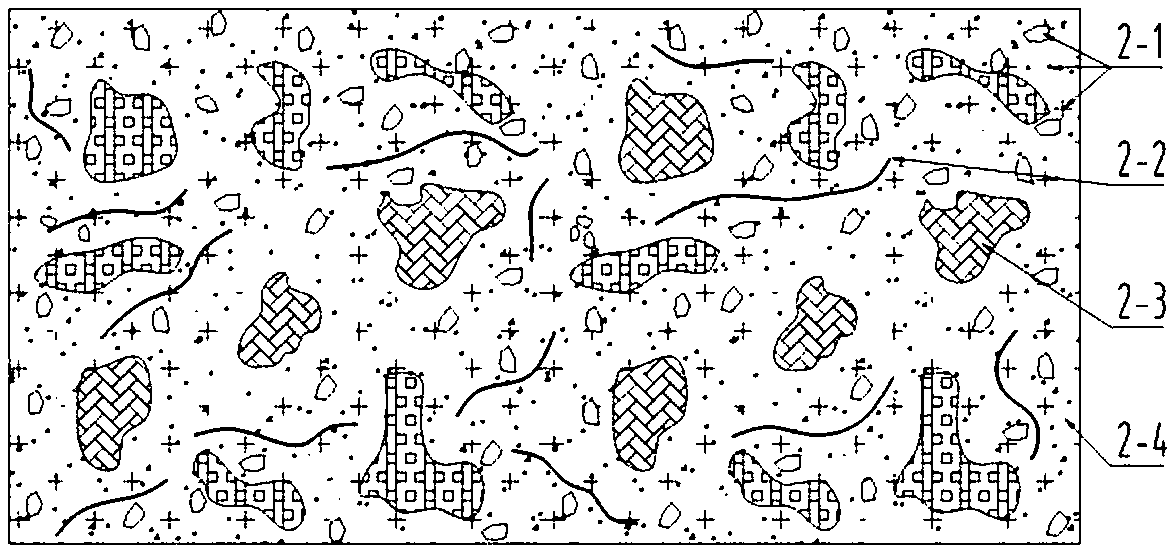

Ceramic large plate of anhydrous glaze line all-digital jet printing process and manufacturing method thereof

InactiveCN108394008AHigh transparencyLabor savingSpecial ornamental structuresCeramic shaping apparatusSurface patternEngineering

The invention discloses a ceramic large plate of an anhydrous glaze line all-digital jet printing process. The large plate comprises a bottom blank layer and a surface pattern layer; the surface pattern layer consists of a jet printing bottoming layer, a jet printing pattern layer, a jet printing protection layer / or a jet printing glue layer bonded with a dry particle layer in sequence from bottomto top; and the bottoming layer, the pattern layer, the protection layer / or the glue layer are formed by digital jet printing through a ceramic ink jet printer. The ceramic large plate and a manufacturing method thereof on a glaze line hardly need manual operation in the whole process for all-digital jet printing of the ceramic large plate and a sheet thereof; the texture is rich; the yield is increased; and anhydrous scene production environment is more accordant with modern green and intelligent manufacturing.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +1

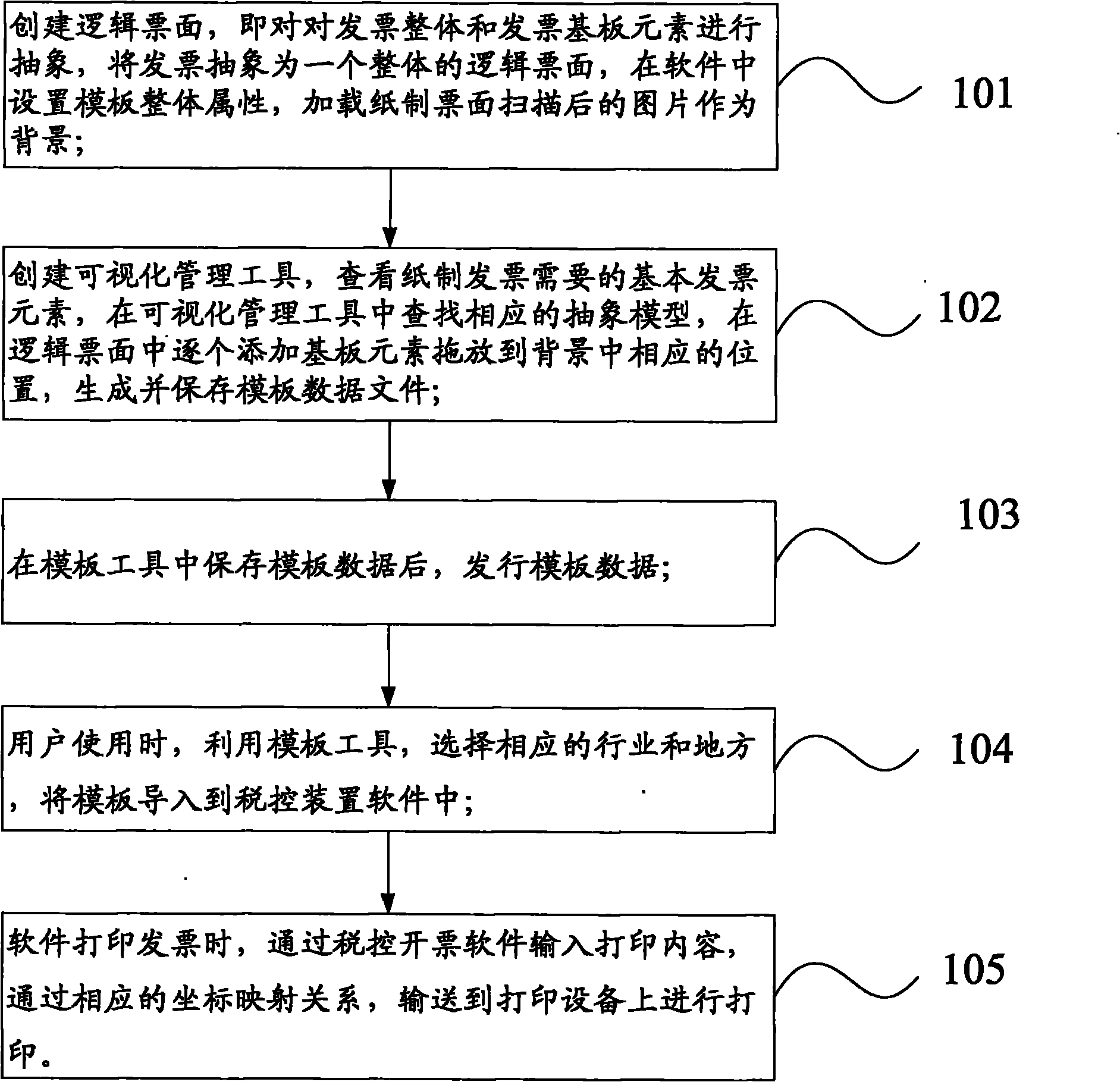

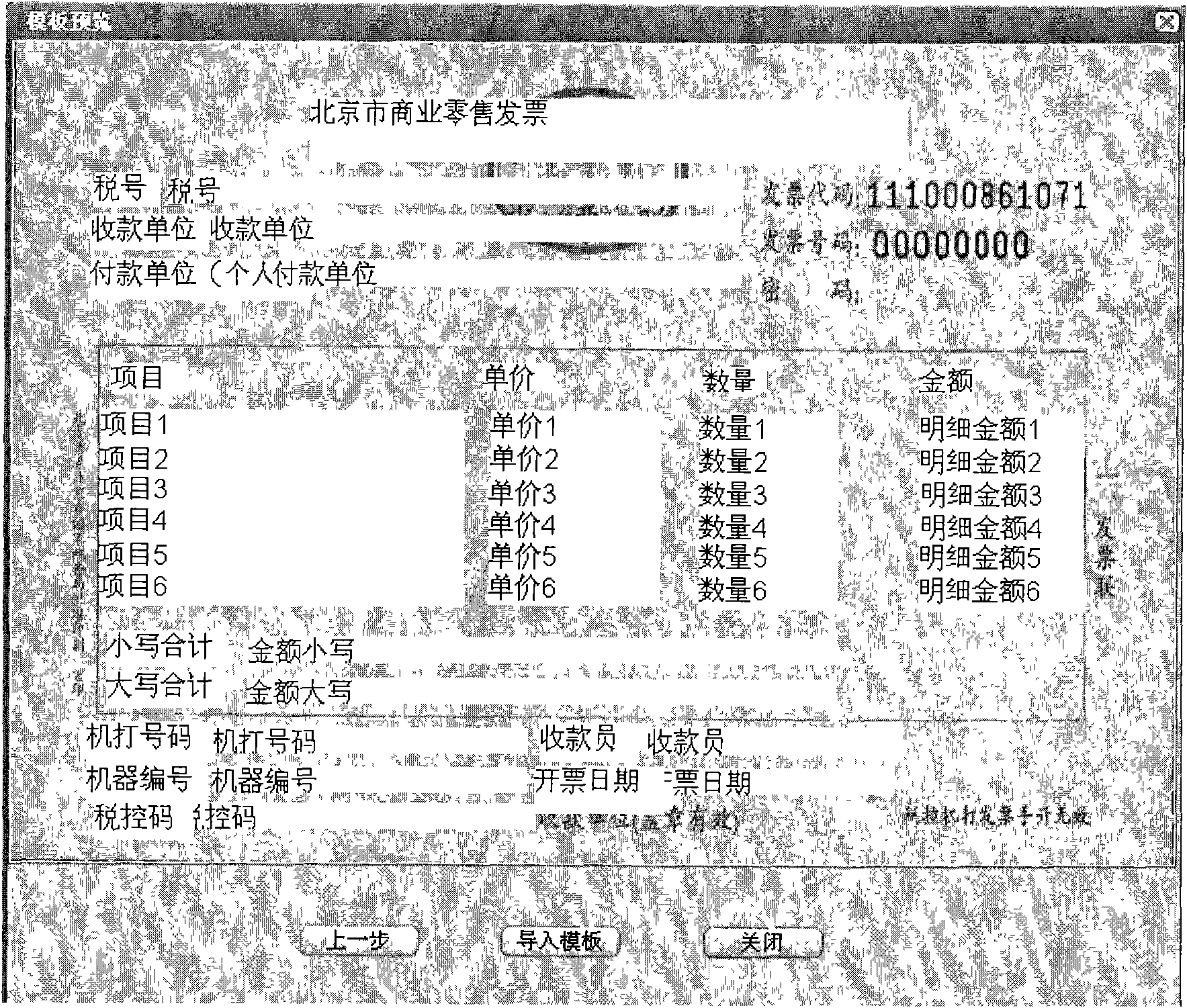

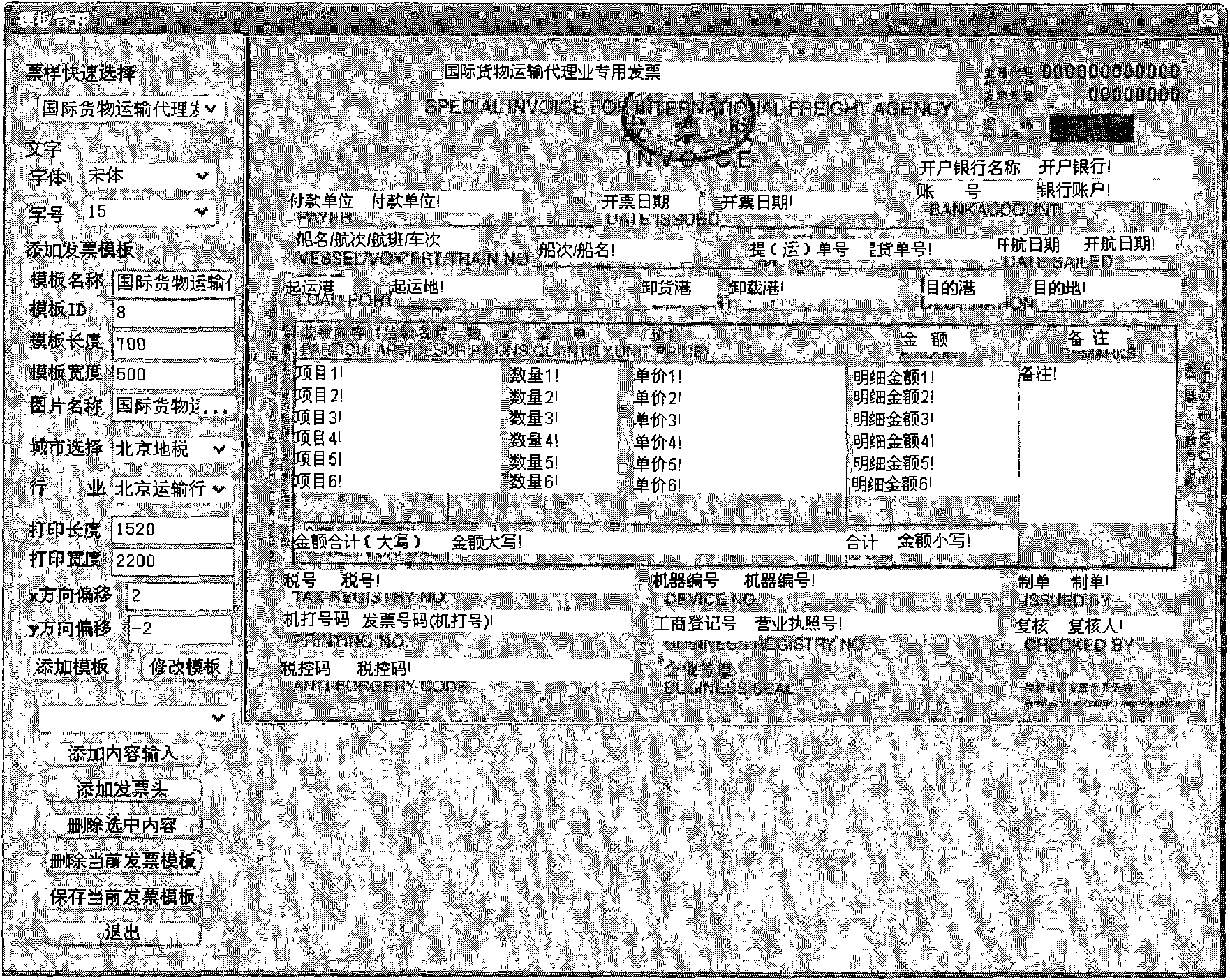

Customization and management method of visual management invoice template

ActiveCN102074080AConvenient template configurationMeet individual (localization) needsCash registersMachines for issuing preprinted ticketsPaper invoiceManagement tool

The invention provides a customization and management method of a visual management invoice template. The customization and management method comprises the following steps of: (a) abstracting a whole invoice and an invoice substrate element, abstracting the invoice into a whole logic invoice face, setting the whole properties of a template in software, loading and using a scanned picture of a paper invoice face as the background; (b) creating a visual management tool, viewing basic invoice elements needed by the paper invoice, searching a corresponding abstracting model in the visual management tool, gradually adding substrate elements to the logic invoice face, dragging into corresponding positions in the background, generating and storing a template data file; (c) storing the template data in a template tool and issuing the template data; (d) selecting corresponding trade and place by a user utilizing the template tool during use to guide the template into tax control device software; and (e) inputting printing content through tax control device software when the invoice is printed through the software and outputting to printing equipment to print through a corresponding coordinate mapping relation.

Owner:AEROSPACE INFORMATION

Identification and monitoring system and method of unsafe driving behaviors

InactiveCN101866502AEfficient extractionReduce traffic accidentsAcceleration measurement using interia forcesRegistering/indicating working of vehiclesThree-dimensional spaceTraffic accident

The invention relates to identification and monitoring system and method of unsafe driving behaviors. The system comprises an acceleration sensor, a transmission device, a data treatment and comparison device and a display or output device, wherein the acceleration sensor is arranged on a vehicle to be monitored and used for acquiring acceleration data in three directions in the driving process of the vehicle, and the acceleration data is transmitted to the data treatment and comparison device through the transmission device and then displayed through the display or output device. The identification and monitoring method of the unsafe driving behaviors comprises the steps of: (1) acquiring acceleration data ax, ay and az in three directions of X, Y and Z in a three-dimensional space; (2) establishing a comparison sample; (3) comparing acceleration actual values of the monitored vehicle in three directions with the sample so as to obtain threshold values of beta x, beta y and beta z for excessive number of times; and (4) displaying or printing through the display or output device. The invention can greatly reduce the probability of the traffic accidents caused by the unsafe driving behaviors.

Owner:陈勃生 +2

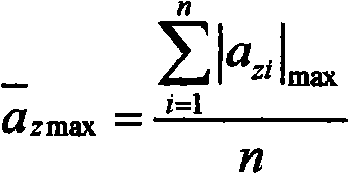

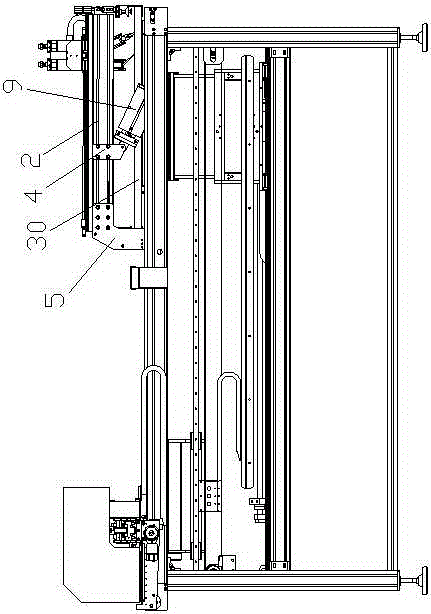

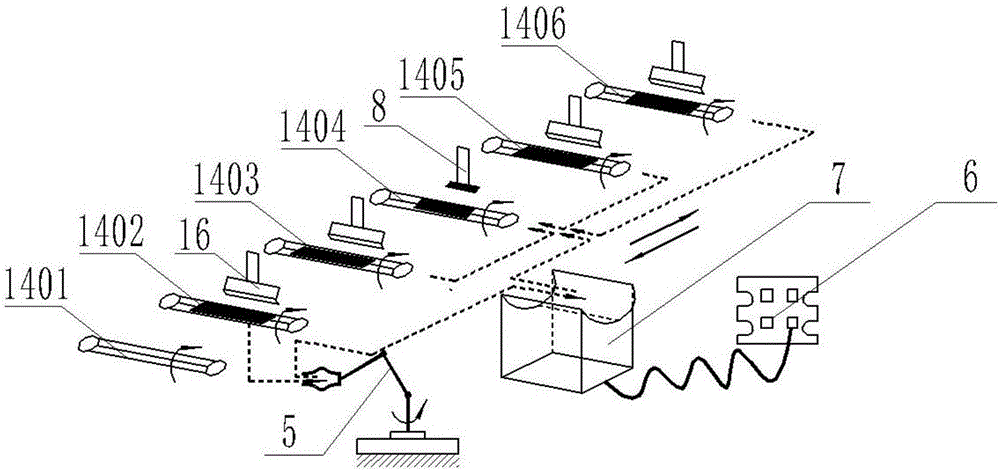

Digital printing machine for ready-made clothes and method for printing ready-made clothes

ActiveCN105235362AImprove printing efficiencyRealize the printing functionDuplicating/marking methodsScreen printersScreen printingDigital printing

The invention provides a digital printing machine for ready-made clothes and a method for printing the ready-made clothes. According to the digital printing machine for the ready-made clothes and the method for printing the ready-made clothes, a screen printing function and an inkjet printing function are combined. A screen printing machine, an inkjet printing machine and a worktable mechanism are installed on a main rack. The ready-made clothes are printed through the inkjet printing machine in an inkjet printing area. The ready-made clothes are printed through the screen printing machine in a screen printing area. The screen printing machine and the inkjet printing machine are arranged on the main rack in a front-and-back manner in the conveying direction of the ready-made clothes. A movable mechanism is connected with worktables and can drive the worktables to move so that the tabletops of the worktables can move to the inkjet printing area and the screen printing area, and in addition, the tabletops of the worktables can move back and forth between the inkjet printing area and the screen printing area. The number of the worktables is two. When the tabletop of one worktable moves to the inkjet printing area, the tabletop of the other worktable moves to the screen printing area; and when the tabletop of one worktable moves to the screen printing area, the tabletop of the other worktable moves to the inkjet printing area.

Owner:HANGZHOU HONGHUA DIGITAL TECH

3D printed mask and manufacturing technology thereof

InactiveCN104940113AKeep the active ingredients intactSimple methodCosmetic preparationsAdditive manufacturing apparatusManufacturing technology3d printer

The invention provides a manufacturing technology of a 3D printed mask. The technology includes the following steps that under sterile vacuum conditions, according to human facial profiles, collagen gel and mask essence are sequentially stacked and printed through a 3D printer to obtain the 3D printed mask. The mask is manufactured through the 3D printing technology, the mask can be obtained by sequentially stacking and printing the collagen gel and the mask essence, the method is simple, and consumed time is short. Besides, the high-temperature process is not needed during printing, and effective components of the mask essence can be completely stored. Besides, a porous mask support is formed through the collagen gel in the vacuum condition, and the mask essence can be adsorbed to the largest extent. The obtained 3D printed mask is specialized according to individuation of the human facial profiles, and can completely fit with pores on human face skin.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

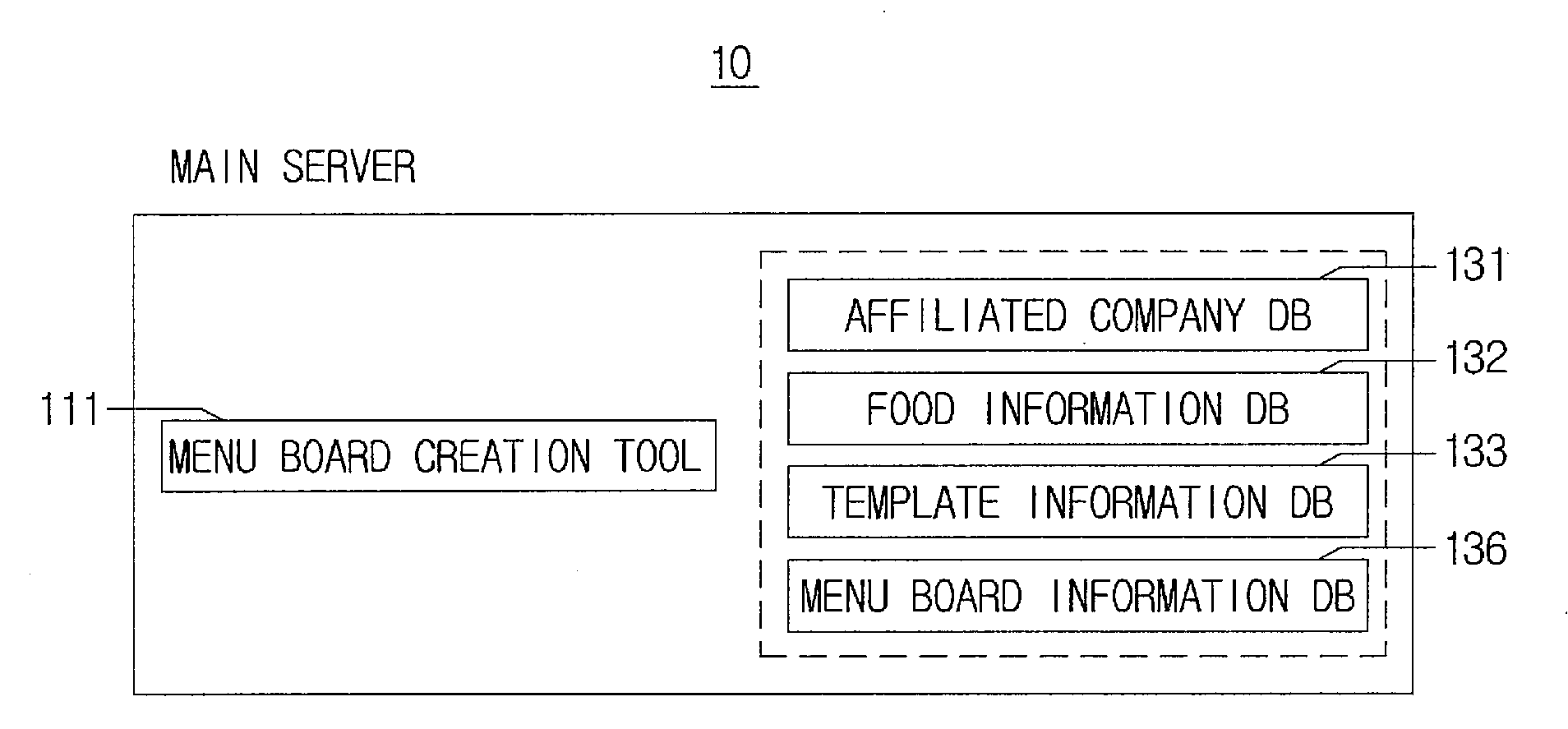

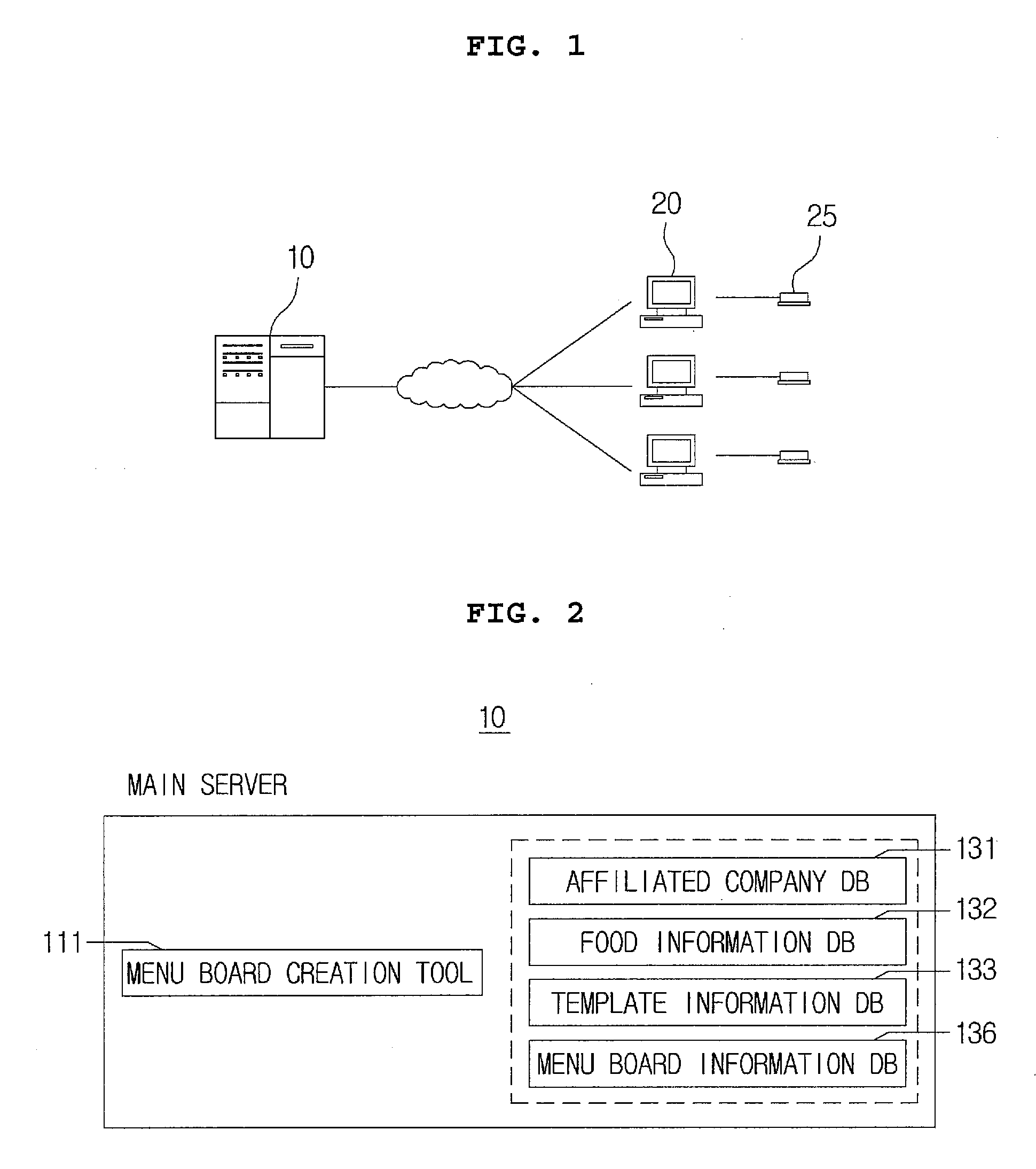

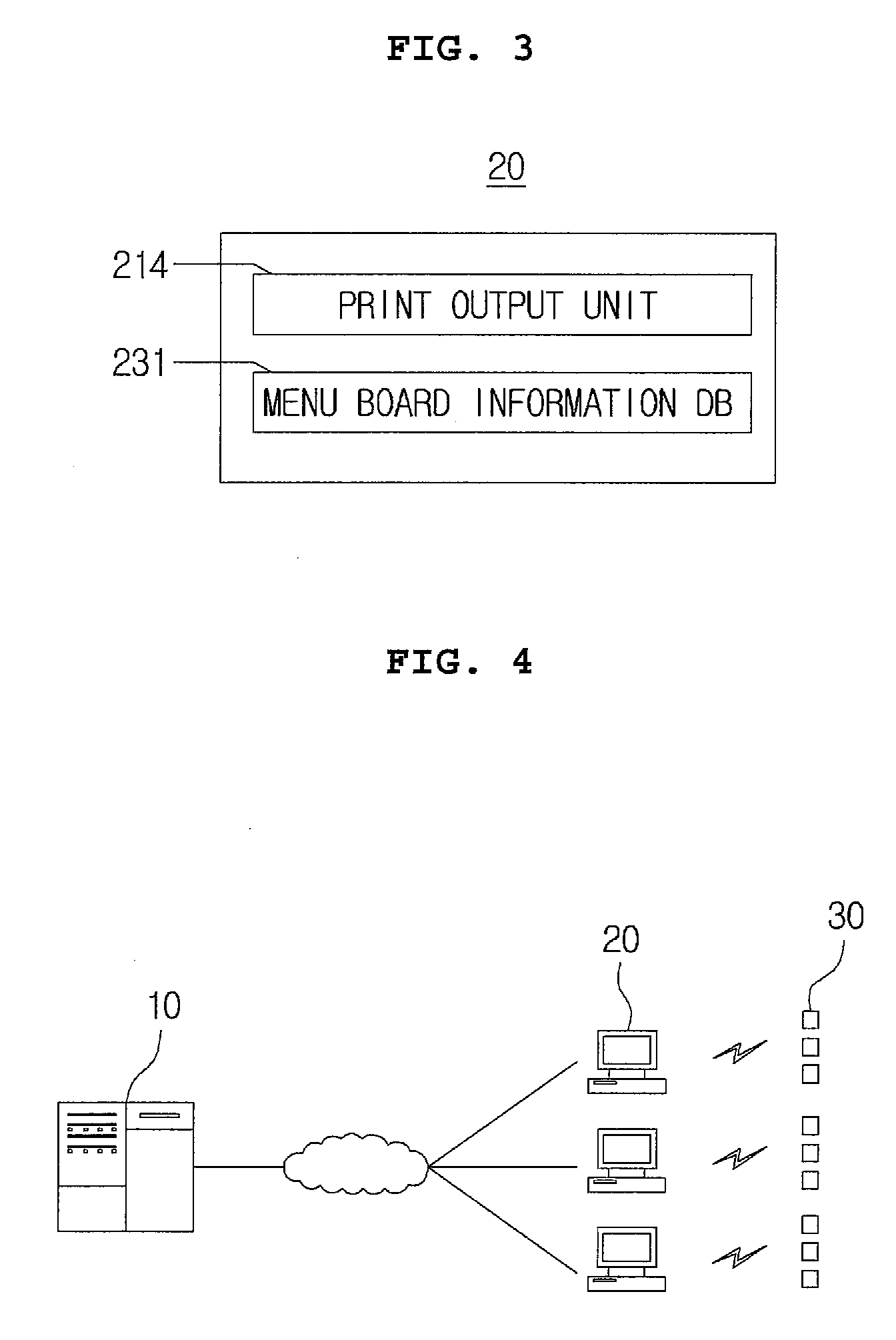

System for creating menu board and food ordering system using electronic menu board module

The present invention relates to a system for creating a menu board and a food ordering system using an electronic menu board module. The system for creating a menu board includes a main server including a template information DB for storing menu board template information related to configuration and arrangement of various menu boards, and a menu board creation tool for creating a menu board using the menu board template information. A restaurant client PC is connected to the main server over a network, and is configured to include a menu board information DB for storing configuration sources of each menu board, created using the menu board creation tool of the main server, and a print output unit for outputting the menu board through a printer. The menu board is printed through the printer and is usable as a typical menu board.

Owner:NYTEL CORP

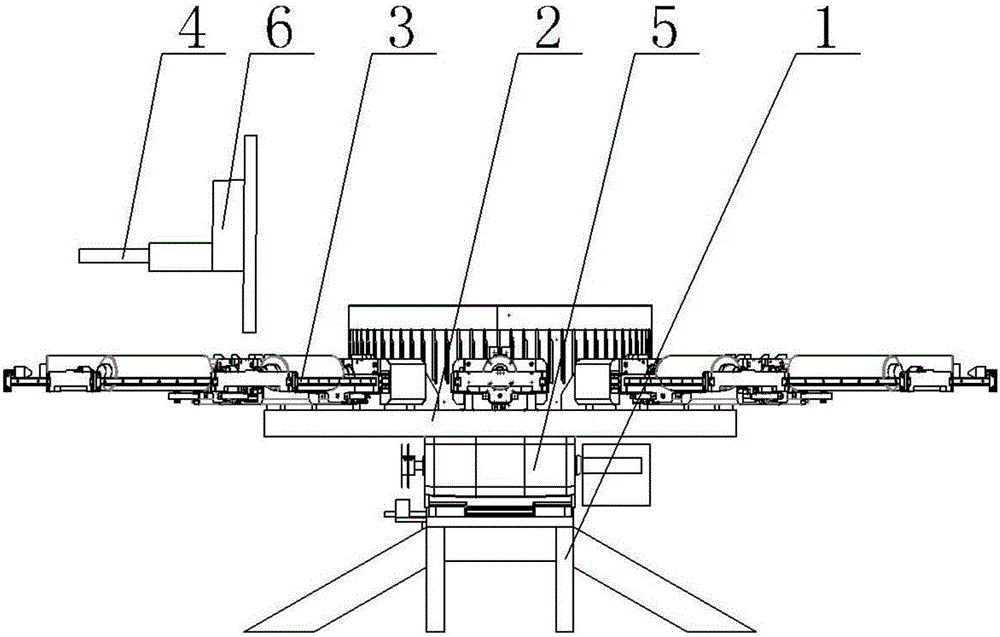

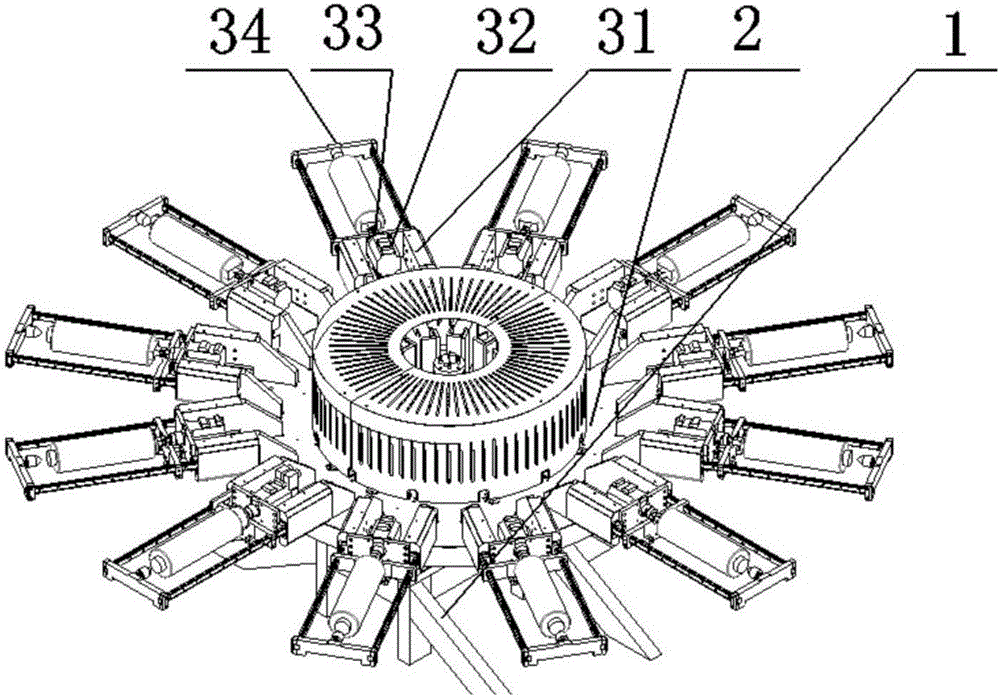

Automatic four-color twelve-station complex curved surface digital rotation printing machine

InactiveCN106427209AAccurate position controlNo need to adjust the mechanical structureTypewritersColor printingElectric machinery

The invention discloses an automatic four-color twelve-station complex curved surface digital rotation printing machine. The printing machine comprises digital printing equipment, a control panel, a digital printing work table, a digital printing head, a manipulator system and a product tool position clamping system. Product rotation and face change, driving the digital printing work table, surface flame processing clamping and rotation, pre-positioning clamping and rotation and material loading and unloading manipulator motions are controlled through employing a servo motor and a high-precision screw nut pair, and precise moving control is realized. According to the machine, digital multi-color printing processing on circular bottles, elliptical double surfaces, square-bottle multiple surfaces, special-bottle multiple surfaces, spherical surfaces and revolving body products with outer bosses can be realized, vertical direction motion of the digital printing head and rotation motion of the product rotation mechanism are utilized to make the digital printing head be close to or away from product surfaces for printing, a problem that a revolving body curved surface with an outer boss can not be printed through a printer in the prior art can be solved through the digital printing machine, and the printing machine further has advantages of convenient bottle change, short period and high efficiency.

Owner:广州市申发机电有限公司

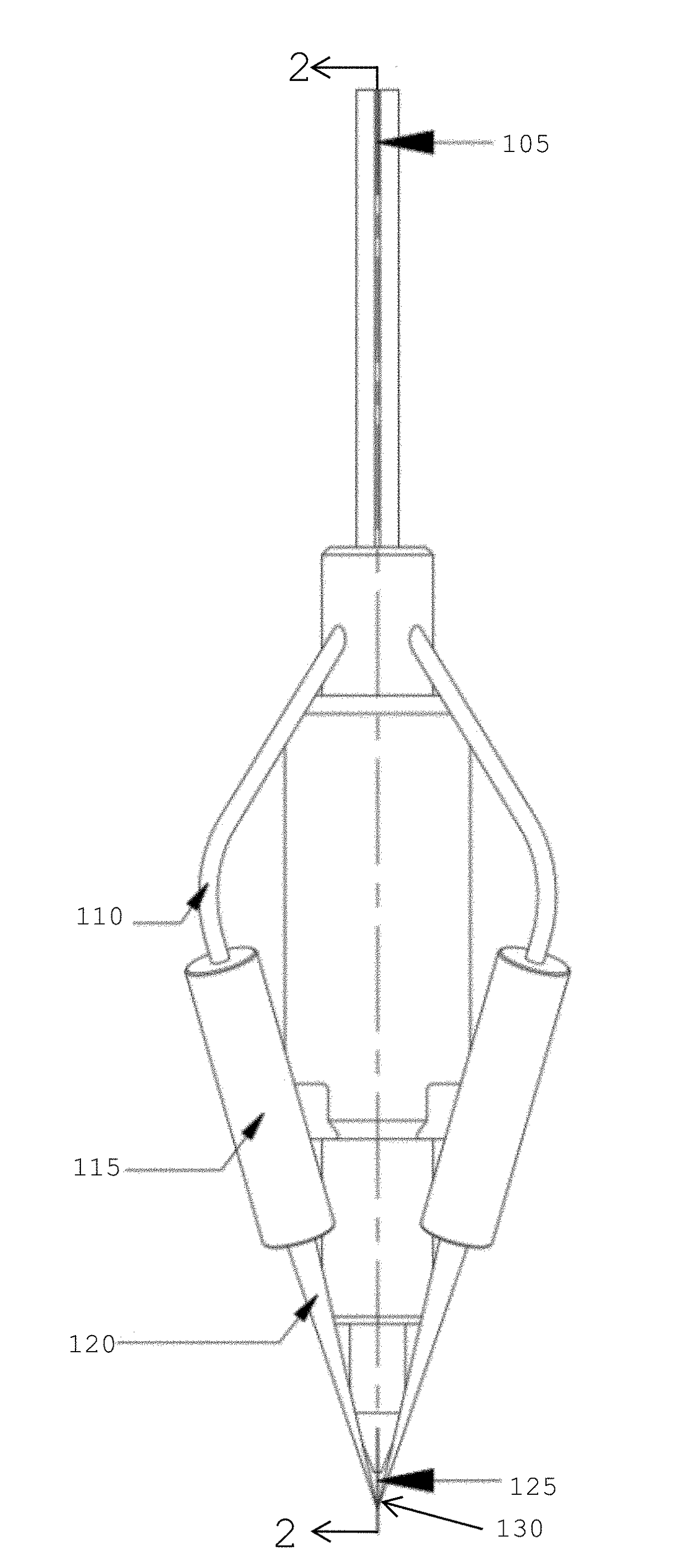

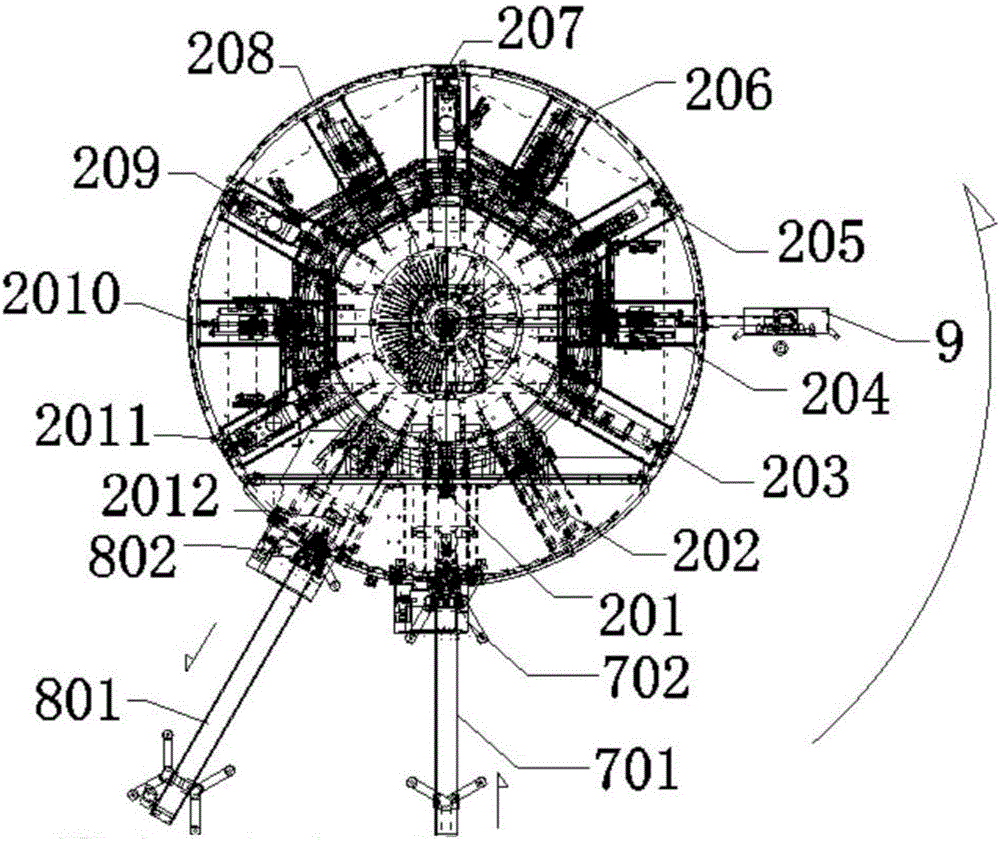

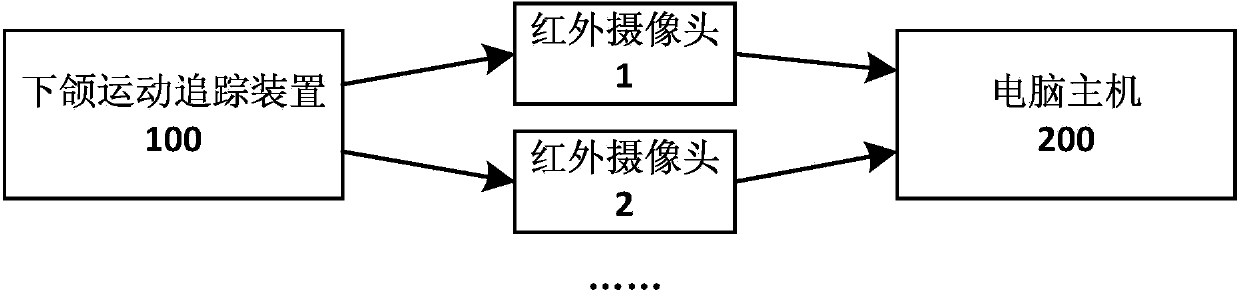

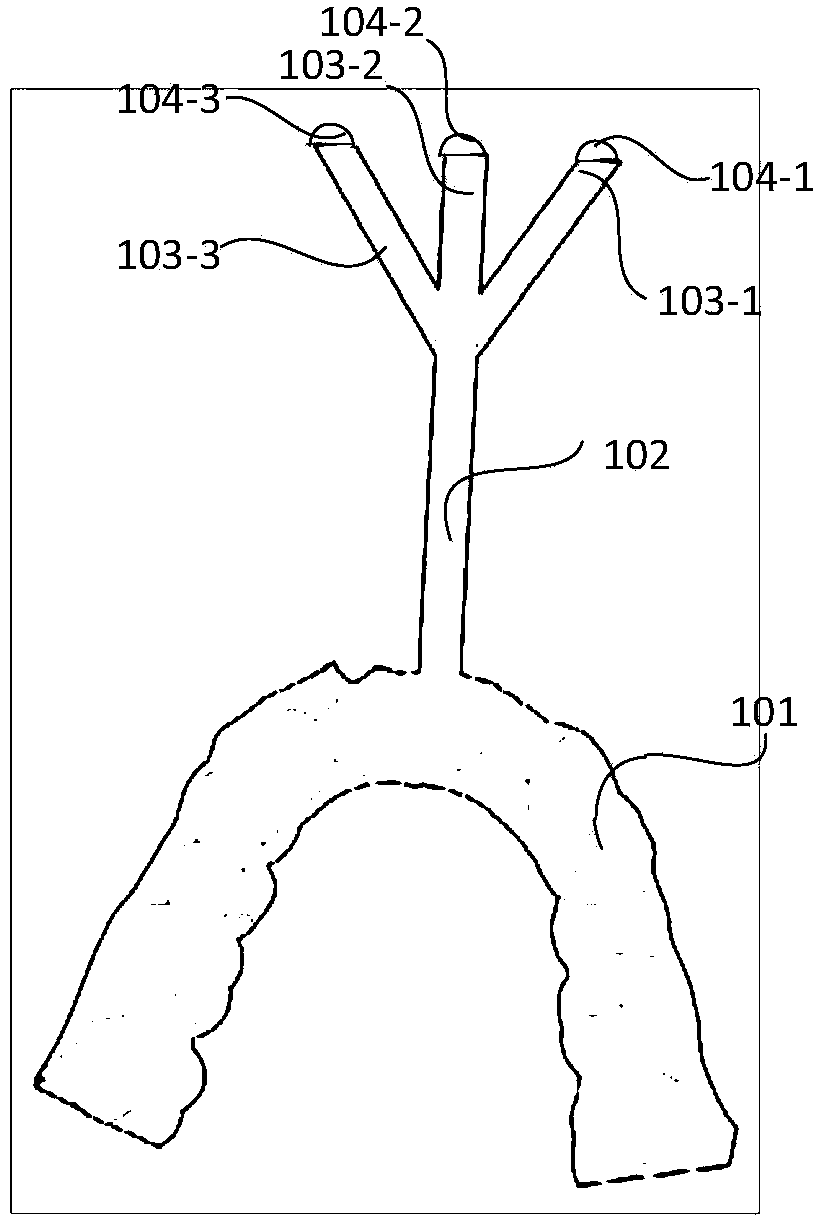

System and method for capturing and visualizing mandibular three-dimensional motion

ActiveCN103690173AExact structure restorationRealize visual displayDentistryDiagnostic recording/measuringThree dimensional ctMotion capture

The invention discloses a system for capturing and visualizing mandibular three-dimensional motion. The system comprises a mandibular motion tracking device for designing and printing through a three-dimensional CT (Computed Tomography) model, at least two infrared cameras, and a host computer for analyzing shooting record data, wherein the mandibular motion tracking device comprises a rear end fixing device, a medium connecting rod, and three marking rods, wherein the three marking rods are arranged at the front end and are not co-planar; one end of each of the marking rods is connected to the medium connecting rod and while the other end of each of the marking rods is provided with a marker; the rear end fixing device is used for designing and printing through the three-dimensional CT model according to the external physical characteristics of lower teeth; the markers expose from the mouth and move together with the mandible; the host computer is used for recovering the overall motion of the mandible of a tested subject so as to determine whether the mandible motion and occlusal contacts are normal. The invention also provides a method for capturing and visualizing the mandibular three-dimensional motion. According to the technical scheme, the system and method have the advantages of low cost, high testing accuracy and the like, and is convenient to operate.

Owner:SUN YAT SEN UNIV

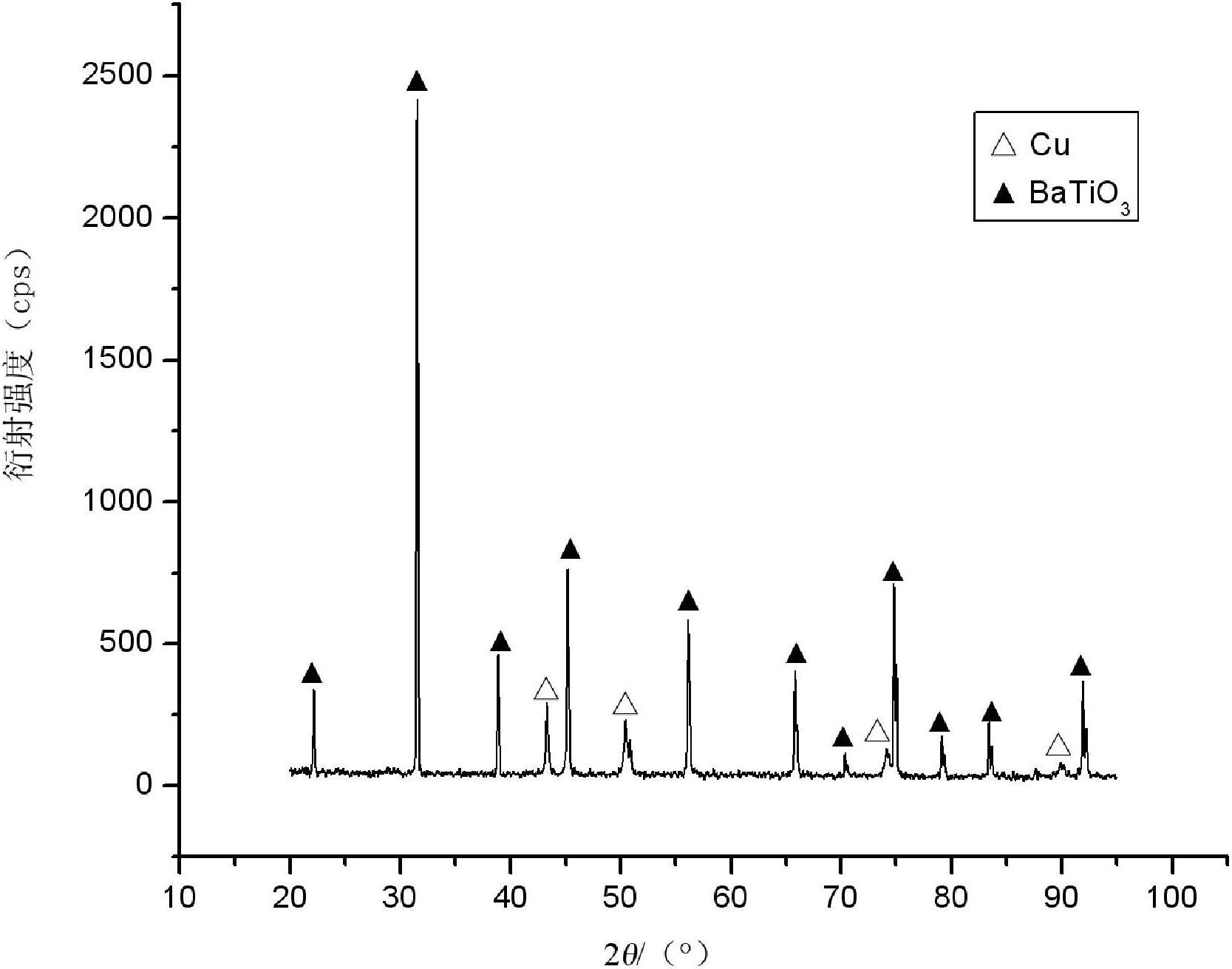

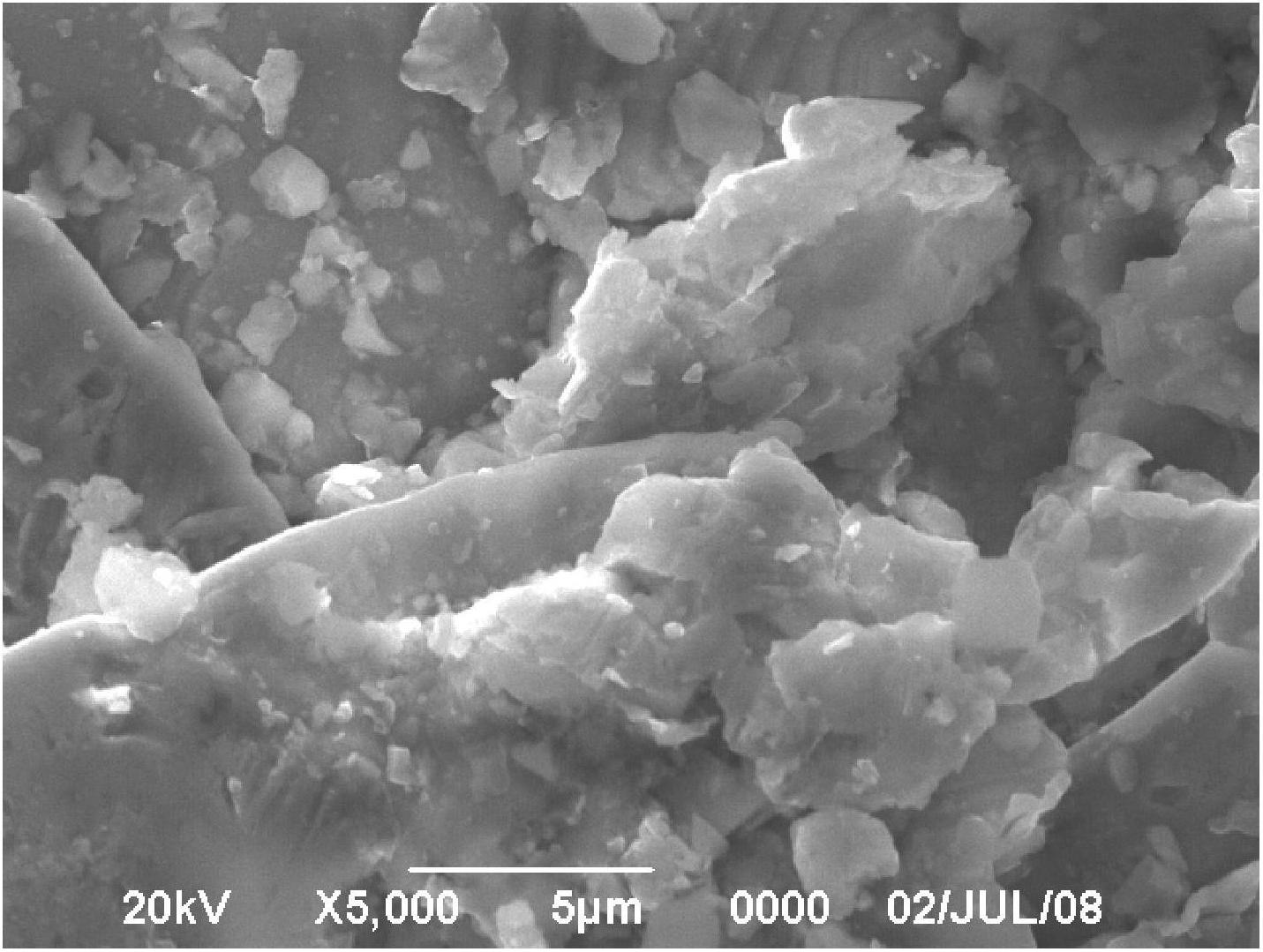

Conductive copper paste for surface electrodes of chip ceramic capacitor and preparation method thereof

InactiveCN102664057AMeet technical requirementsImprove liquidityFixed capacitor electrodesNon-conductive material with dispersed conductive materialScreen printingSilver paste

The invention discloses conductive copper paste for surface electrodes of a chip ceramic capacitor. The conductive copper paste comprises the following raw materials in percentage by mass: 65 to 72 percent of metal powder, 4 to 7 percent of glass powder and 24 to 30 percent of organic binder, wherein the metal powder consists of Cu and W or Cu and Mo; the glass powder consists of CaO, ZnO, Bi2O3, BaO, SiO2, B2O3 and Al2O3; and the organic binder consists of solvent, ethyl cellulose, silane coupling agent and surfactant. The conductive copper paste is printed through silk screens and sintered under the protection of N2 gas, the performance of the obtained finished product of the chip ceramic capacitor can completely meet the technical requirements of the ceramic capacitor, and the conductive copper paste can be used for replacing conductive silver paste on the surface of the corresponding chip ceramic capacitor.

Owner:HEFEI UNIV OF TECH

Cloud computing-based network invoicing method by using mobile phone

The invention discloses a cloud computing-based network invoicing method by using a mobile phone, and belongs to the field of cloud application. The method is characterized by comprising the following steps of: establishing an access service interface for a terminal of the mobile phone at a cloud end; receiving a network invoice business data package sent from the terminal of the mobile phone through a link layer protocol, a data transmission protocol and a security design negotiated with the terminal of the mobile phone; analyzing a communication protocol command and business data of the package, and responding and returning a processing result; and carrying out physical invoice printing through a bonded printer after the terminal of the mobile phone receives a response of the business data so as to finish the operation of the network invoicing. Compared with the prior art, the method disclosed by the invention fully utilizes the characteristics (the application is wide, the cost is low, the carry is easy, and the like) of a terminal device of the mobile phone, so that a safe and reliable mobile network invoicing method is provided for tax payers.

Owner:INSPUR QILU SOFTWARE IND

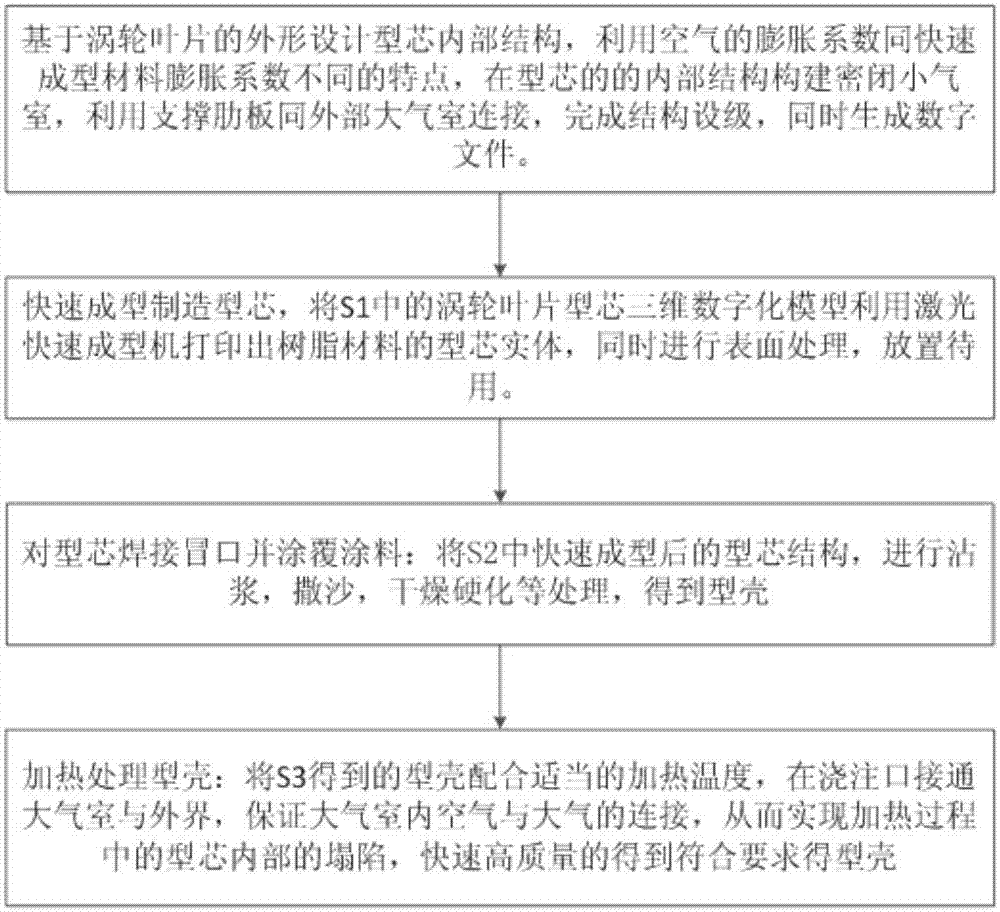

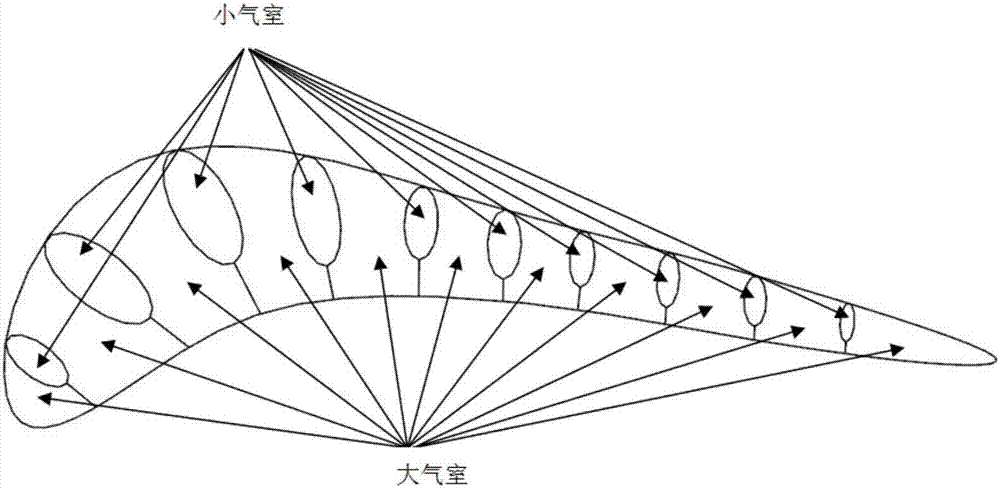

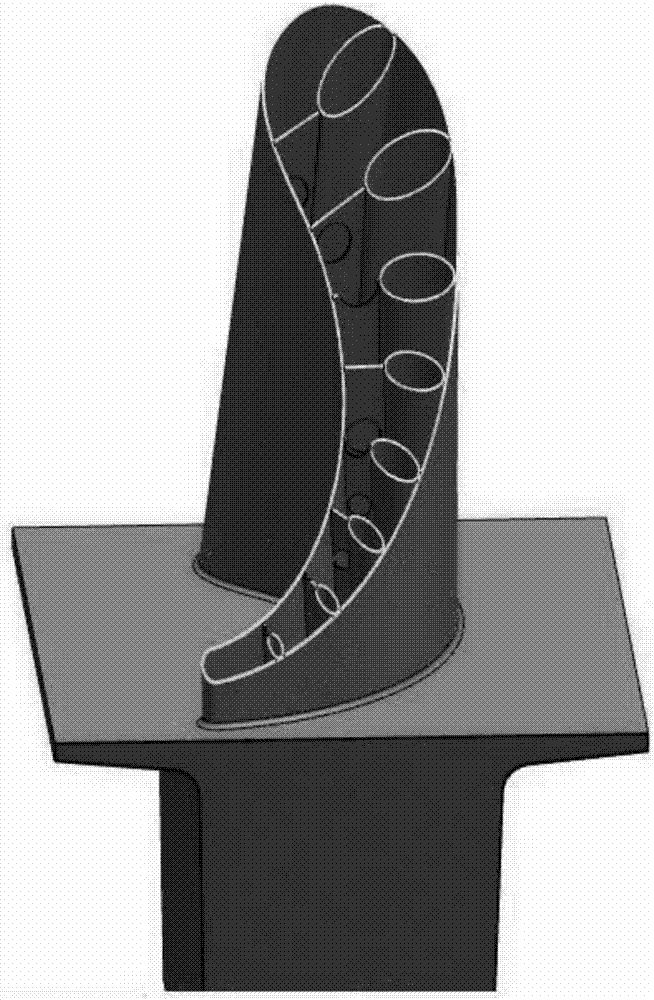

Rapid prototyping and investment casting combined dewaxing method facing turbine blade

InactiveCN107199311ASolve the problem of high burst rateRaise the possibilityAdditive manufacturing apparatusFoundry mouldsEngineeringSlurry

The invention relates to a rapid prototyping and investment casting combined dewaxing method facing a turbine blade. The method includes the steps that an internal structure of a mould core is designed according to the appearance of the turbine blade, closed small gas chambers are established in the internal structure of the mould core through the characteristic that the expansion coefficient of air is different from the expansion coefficient of a rapid prototyping material, the small gas chambers are connected with external large gas chambers through supporting rib plates, the structure design is completed, and a digital file is generated at the same time; operation is conducted on a three-dimensional model of the mould core of the turbine blade, a mould core entity of a resin material is printed through a laser rapid prototyping machine, and surface treatment is conducted at the same time for standby application; slurry dipping, sand spreading and drying hardening treatment are conducted on the mould core structure subjected to rapid prototyping, and a mould shell is obtained; and the obtained mould shell is heated, the large gas chambers communicate with the outside world at a sprue gate, and the mould shell meeting the requirement is rapidly obtained with high quality. By means of the scheme mentioned above, the problem that the ceramic mould shell expansion breakage rate in dewaxing is too high when an additive manufacturing material is used as a wax mould is effectively solved.

Owner:XIAN TECHNOLOGICAL UNIV

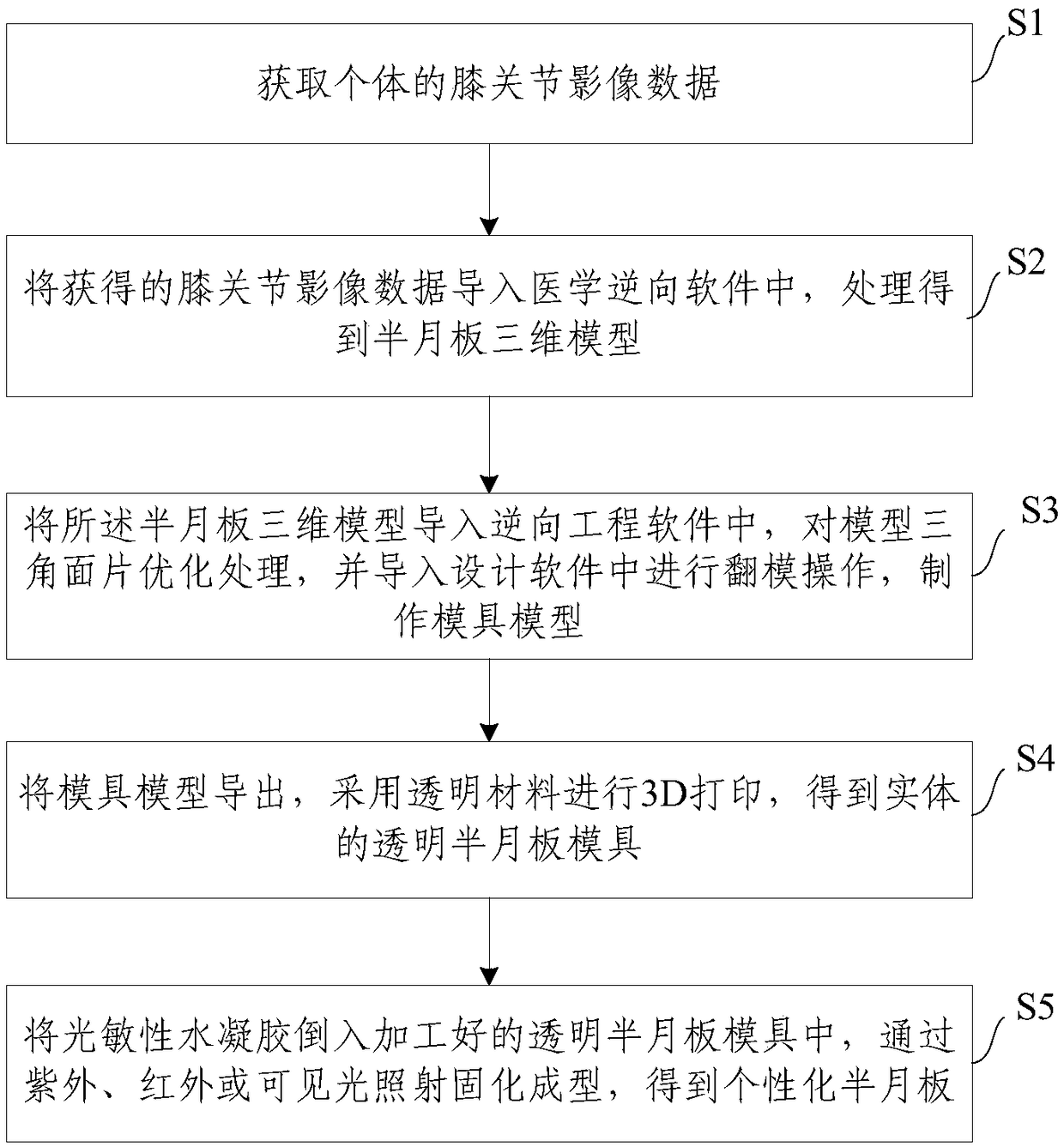

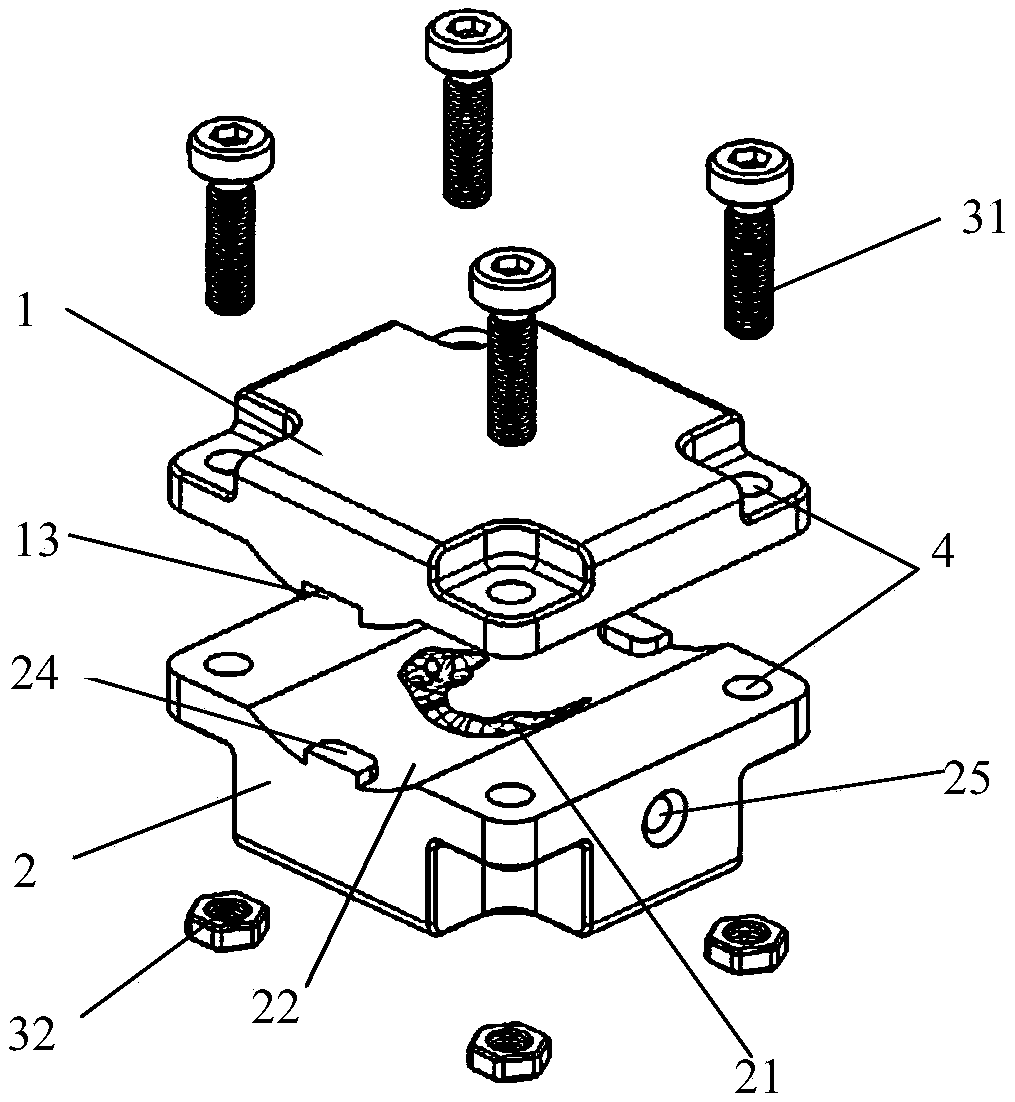

Individualized meniscus forming method based on 3D printing, meniscus and die

PendingCN109501091AGuaranteed accuracyGuaranteed repeatabilityAdditive manufacturing apparatusJoint implantsInfraredDesign software

The invention relates to an individualized meniscus forming method based on 3D printing, a meniscus, a meniscus die and a manufacturing method. The forming method includes the steps that knee joint image data of an individual are acquired; the acquired knee joint image data are guided in medical reverse software, and a meniscus three-dimensional model is obtained after processing is completed; themeniscus three-dimensional model is guided in reverse engineering software, a model triangular patch is optimized and guided in design software for turnover operation, and a die model is manufactured; a transparent material is adopted for 3D printing, and a physical transparent meniscus die is obtained; and light-sensitive hydrogel is poured into the machined meniscus die, curing and forming arecarried out through ultraviolet or infrared or visible light irradiation, and the individualized meniscus is obtained. The meniscus three-dimensional model is established based on the knee joint imagedata of the individual, the transparent die is designed and printed through 3D printing, the light-sensitive hydrogel is injected, curing and forming are completed after light irradiation, the stentprecision is improved, and the mechanical strength is guaranteed.

Owner:PEKING UNIV THIRD HOSPITAL +2

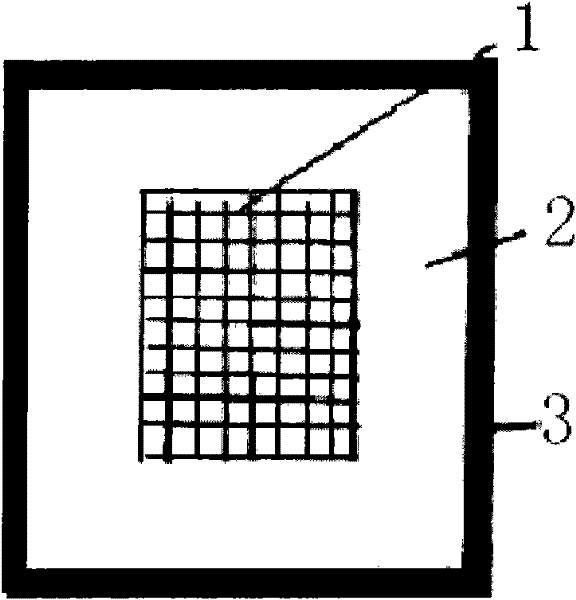

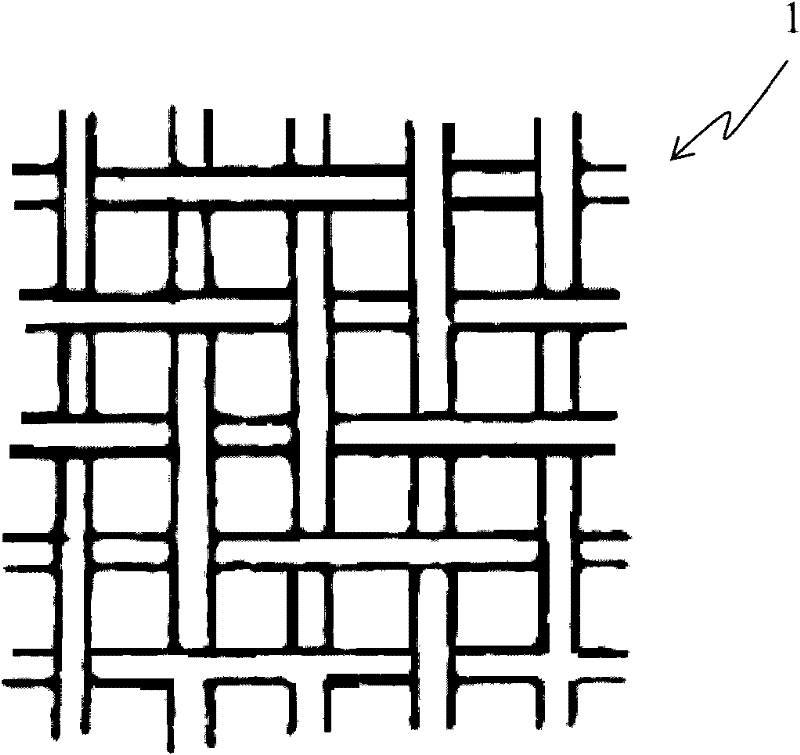

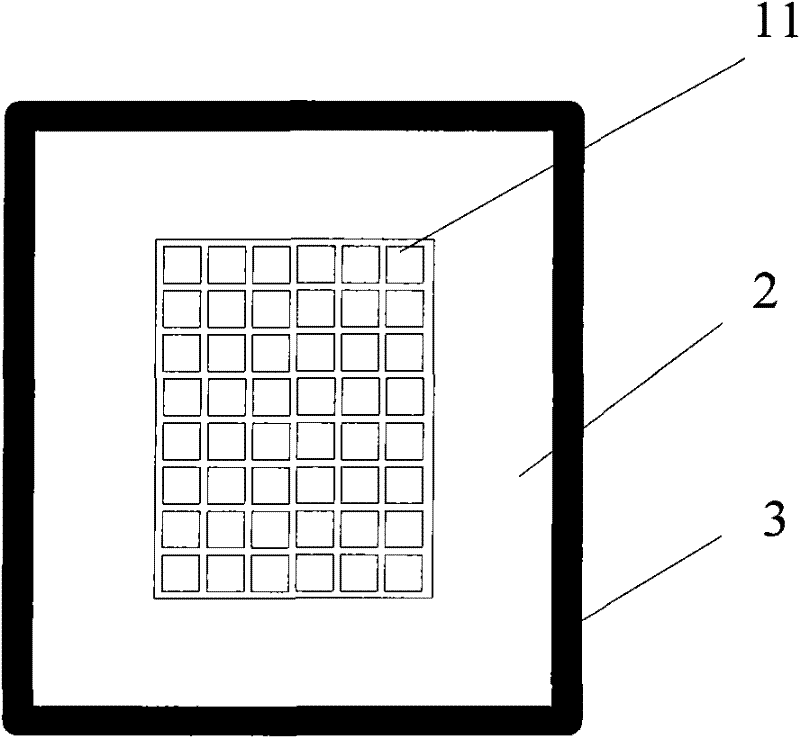

Printing screen for solar cell and method for producing solar cell

InactiveCN102214725ANot easy to distortExtended service lifeFinal product manufactureScreen printersPolyesterScreen printing

The invention discloses a printing screen for a solar cell and a method for producing the solar cell. The printing screen for the solar cell comprises a printing screen frame part, a polyester mesh part and a printing part, wherein the polyester mesh part is connected with the printing screen frame part and the printing part; the printing part is a meshed metal sheet; and mesh openings on the meshed metal sheet are evenly arranged in a matrix shape. The invention also discloses a method for producing the solar cell. The method comprises the step of using the printing screen for the solar cell to produce the solar cell. In the process of the producing the solar cell, the printing screen is utilized to print metal electrodes of the solar cell, thus not only prolonging the service life of the printing screen and reducing the production cost, but also keeping graphs required by the solar cell printed through using a silk-screen printing technology unchanged and controlling the width of electrodes accurately, thus improving the product quality.

Owner:WUXI SUNTECH POWER CO LTD

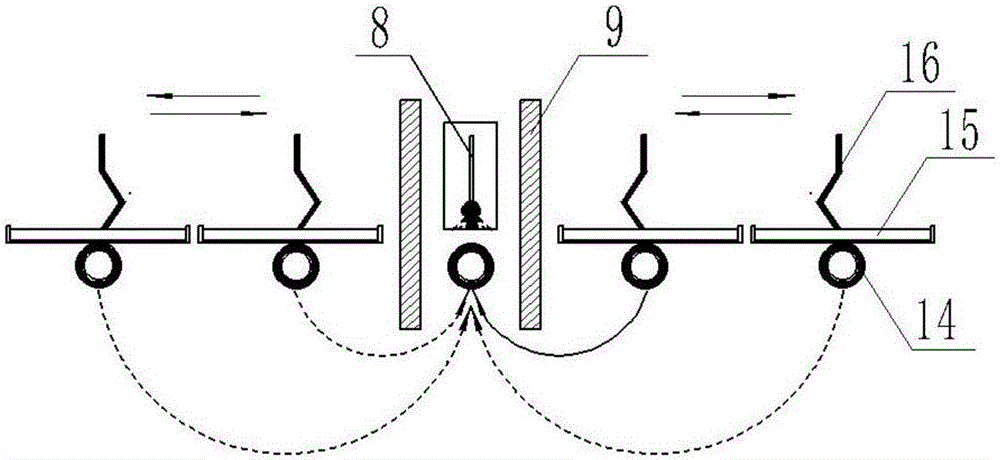

Full-automatic, rapid and efficient multi-color rotation hook face silk screen printing machine

The invention discloses a full-automatic, rapid and efficient multi-color rotation hook face silk screen printing machine. The printing machine comprises a control panel, a printing product lifting workbench, a mechanical arm system, a product tool position clamping system and a silk screen control system. Multiple silk screen printing plate control systems and multiple printing scraper control systems are included, wherein product rotating and face changing, printing product lifting workbench driving, surface photoelectric dust removal treatment, a feeding and discharging industrial robot and the arm action of a product transferring mechanical arm system are controlled by a servo motor and a high-precision screw-nut pair, and walking position control is accurate. The full-automatic, rapid and efficient multi-color rotation hook face silk screen printing machine can conduct multi-color silk screen printing on round bottles, double faces of oval bottles and multiple faces of square bottles, a printing product can be closely attached to a silk screen printing plate to be printed through the movement of the lifting workbench in the vertical direction, the horizontal movement of the silk screening printing plate and scrapers and the product rotation movement. The silk screen printing machine is good in printing effect, bottle replacing is convenient, the period is short, and efficiency is high.

Owner:广州市申发机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com