Printing screen for solar cell and method for producing solar cell

A technology of solar cells and printing screens, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as difficult to accurately control electrode width, prone to quality problems, and affecting product quality, so as to achieve less drop in screen tension and less difficulty Distortion, graphics highly subtle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

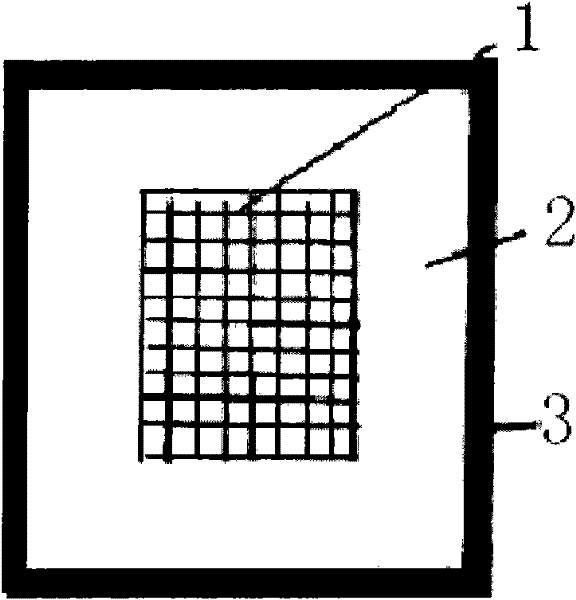

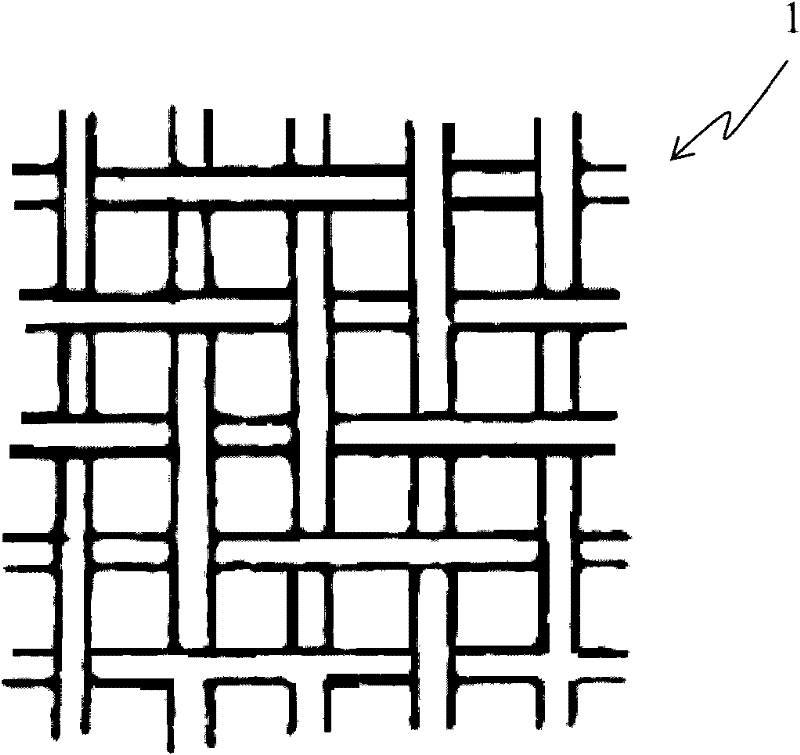

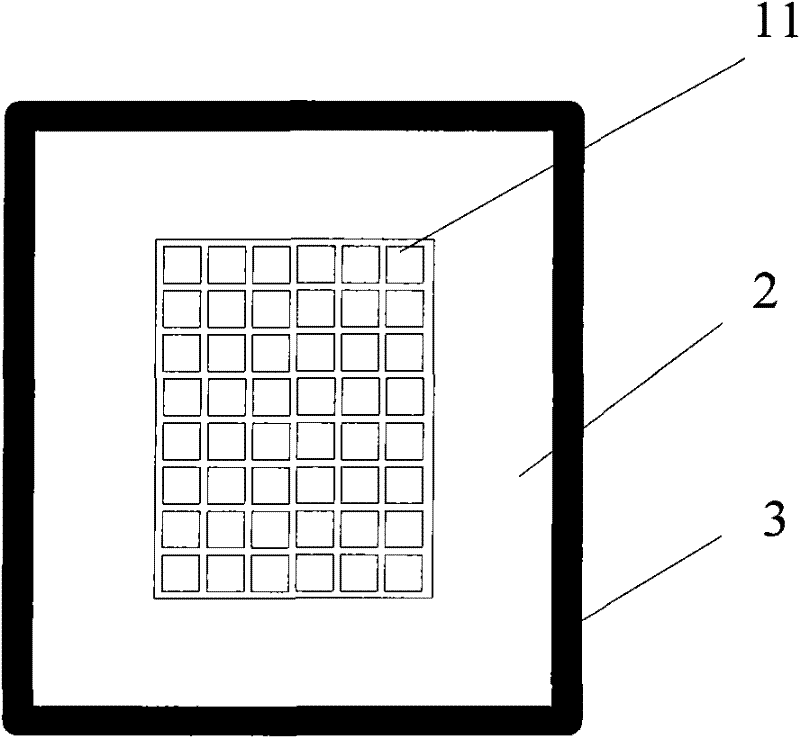

[0035] Such as image 3 and Figure 4 As shown, the solar cell printing screen plate of the present embodiment has a mesh metal sheet 11 (as a printing part) with a plurality of mesh holes, a screen frame part 3, and a mesh frame part 3 located on the mesh metal sheet 11 and the screen frame part. 3. Between 2 sections of elastic polyester mesh. The mesh metal sheet 11 has mesh holes evenly arranged in a matrix or honeycomb shape, that is, the mesh holes are evenly distributed in the row and column direction of the mesh metal sheet 11, and the shape of the mesh holes can be quadrilateral, circular, or other polygonal shapes. (such as pentagon, hexagon, etc.) and one of its combinations. Mesh metal sheet 11 can be directly made by electroforming process, and can also be made by punching a plurality of holes on the metal sheet. Both electroforming tec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com