Patents

Literature

124 results about "Polyester mesh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

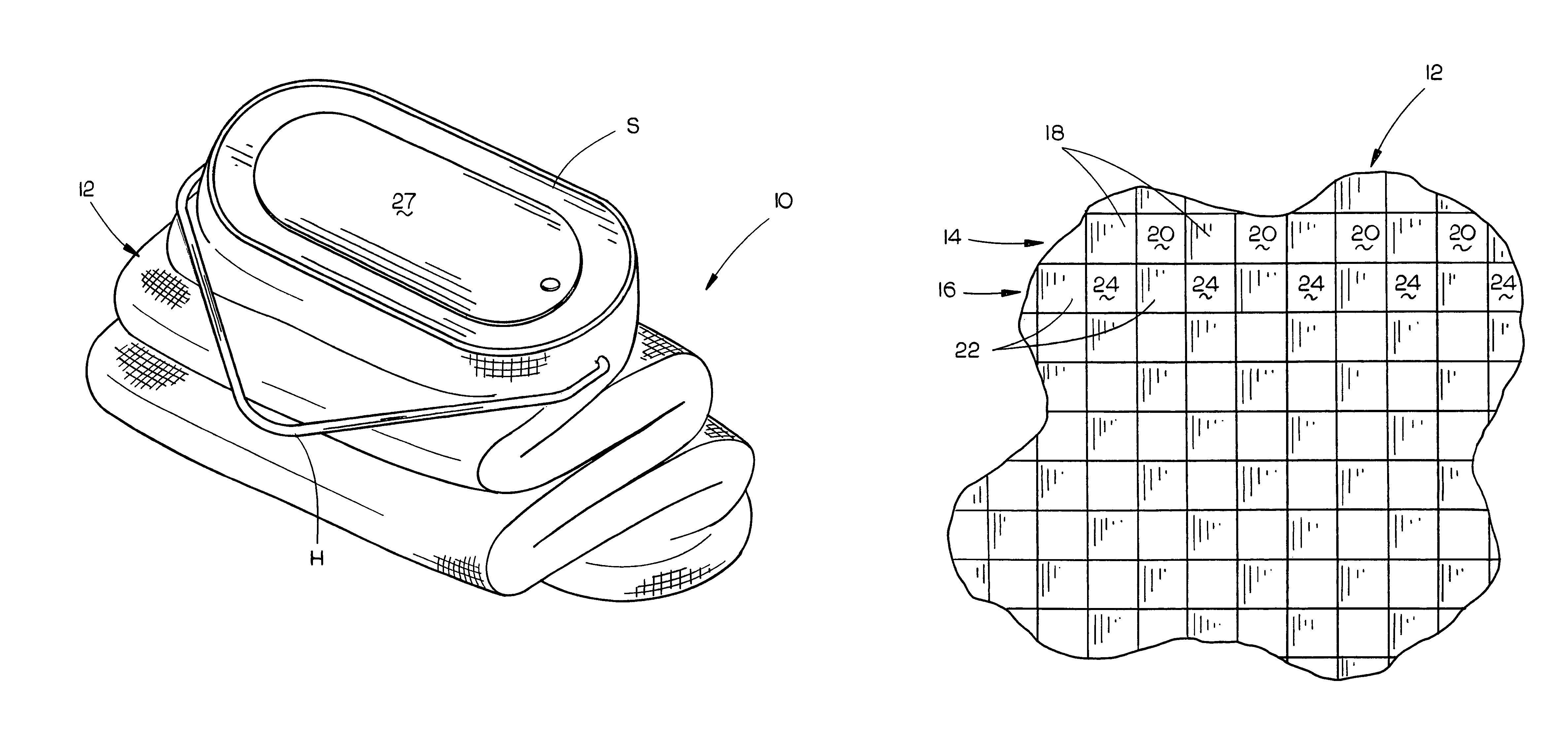

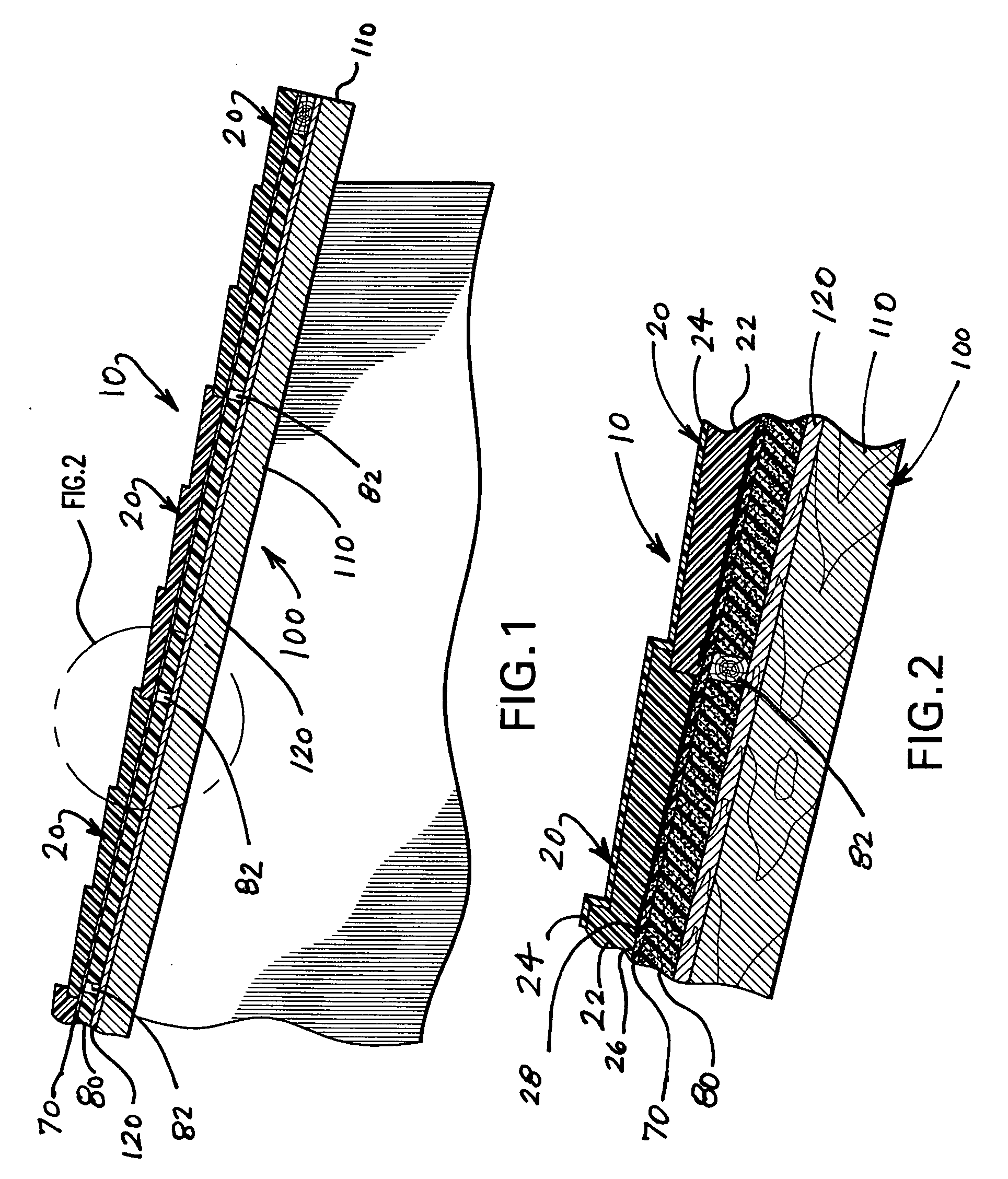

Multi-panelled protective undergarment

ActiveUS20120117700A1Good leg mobilityImprove protectionChemical protectionHeat protectionButtocksThigh

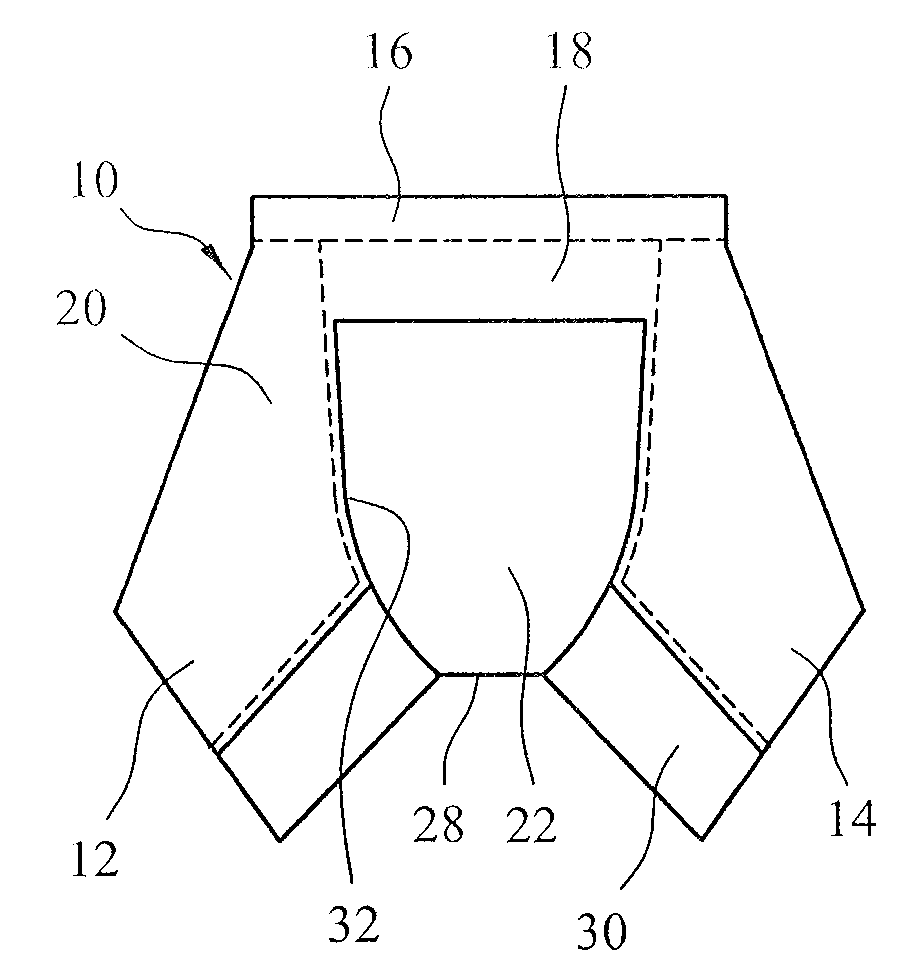

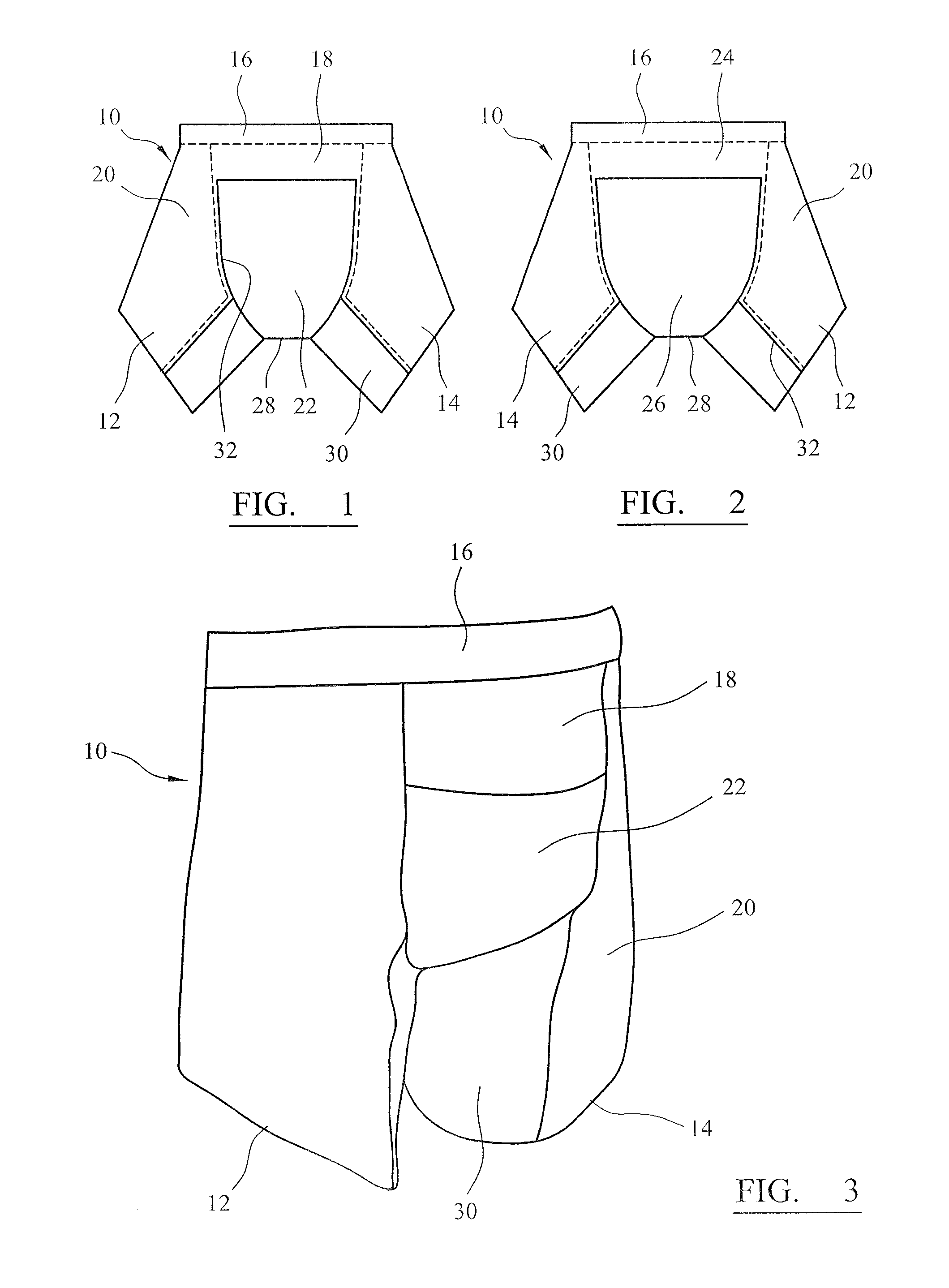

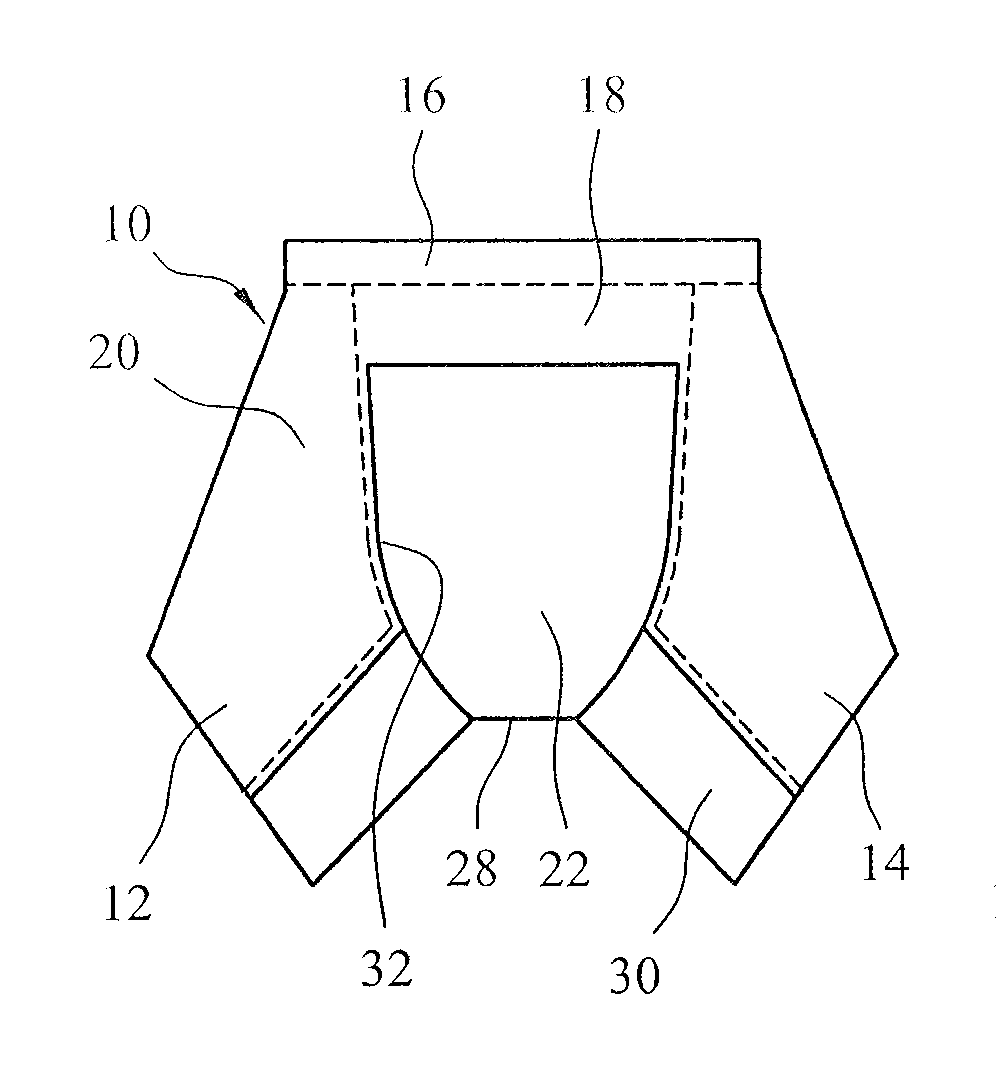

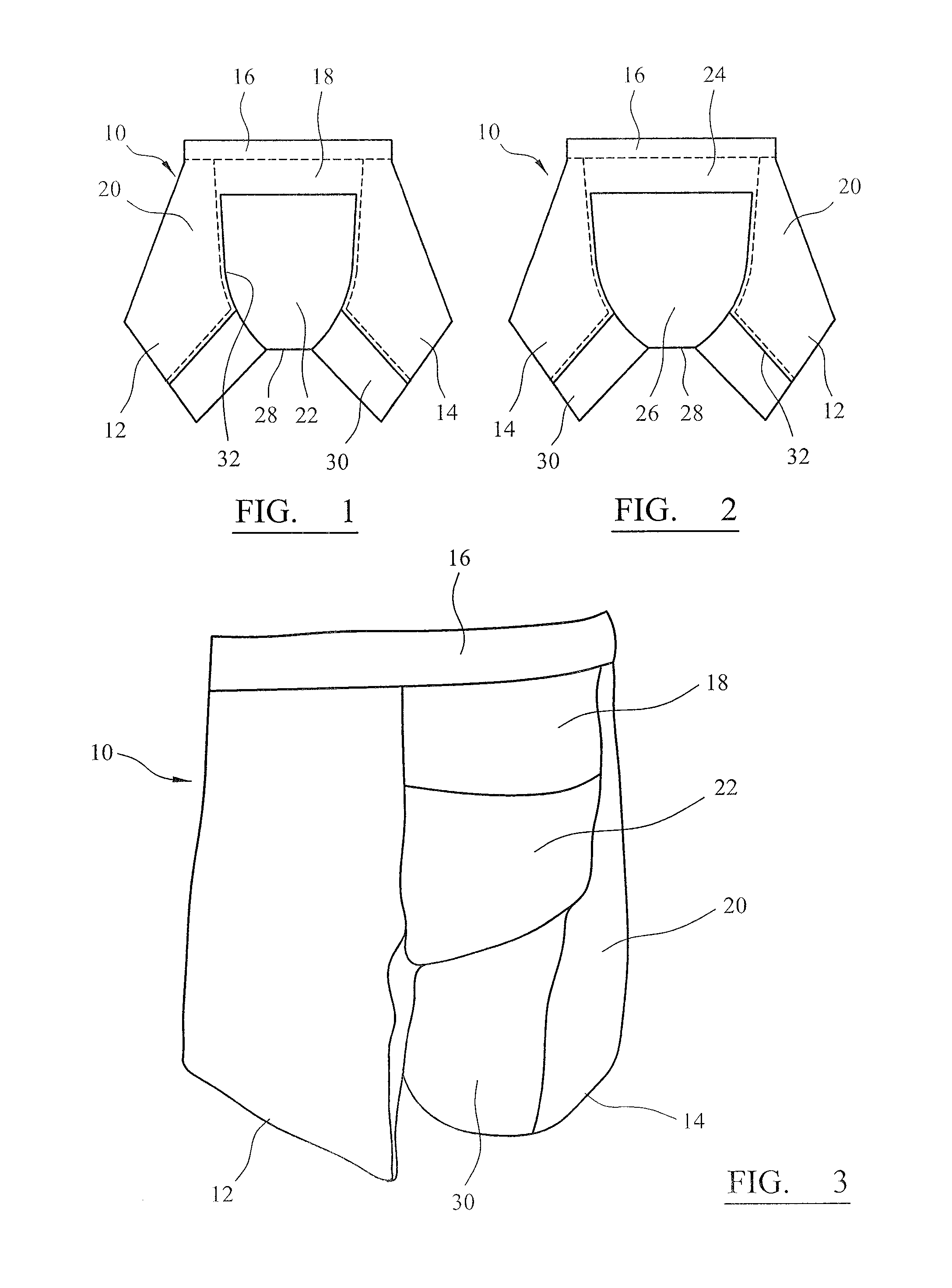

A protective undergarment (10), shown in the form of shorts, includes integrally formed protective panels (22, 26, 30) that exhibit slash-proof properties. The protective areas (22, 26, 30) are made from a flexible Kevlar® knit or the like, and extend to cover the groin, crotch, substantial areas of the buttocks and the inner thigh regions of both legs. The protective panels (22, 26, 30) are externally snitched to a low thermal burden material (18, 20), such as a polyester mesh, that provides elasticity and completes the structure of the shorts (10). The Kevlar® knit is flexible and preferably lies directly against the skin of a user to provide blast wave and ballistic fragment deflection whilst permitting mobility in a lightweight arrangement. Varying thickness of the Kevlar® knit can be used in the protective areas (22, 26, 30) selectively to enhance protection against blast wave and fragment penetration. The shorts (10) find particular application in battlefield theatres where military personnel are exposed to bomb threats.

Owner:BCB INT

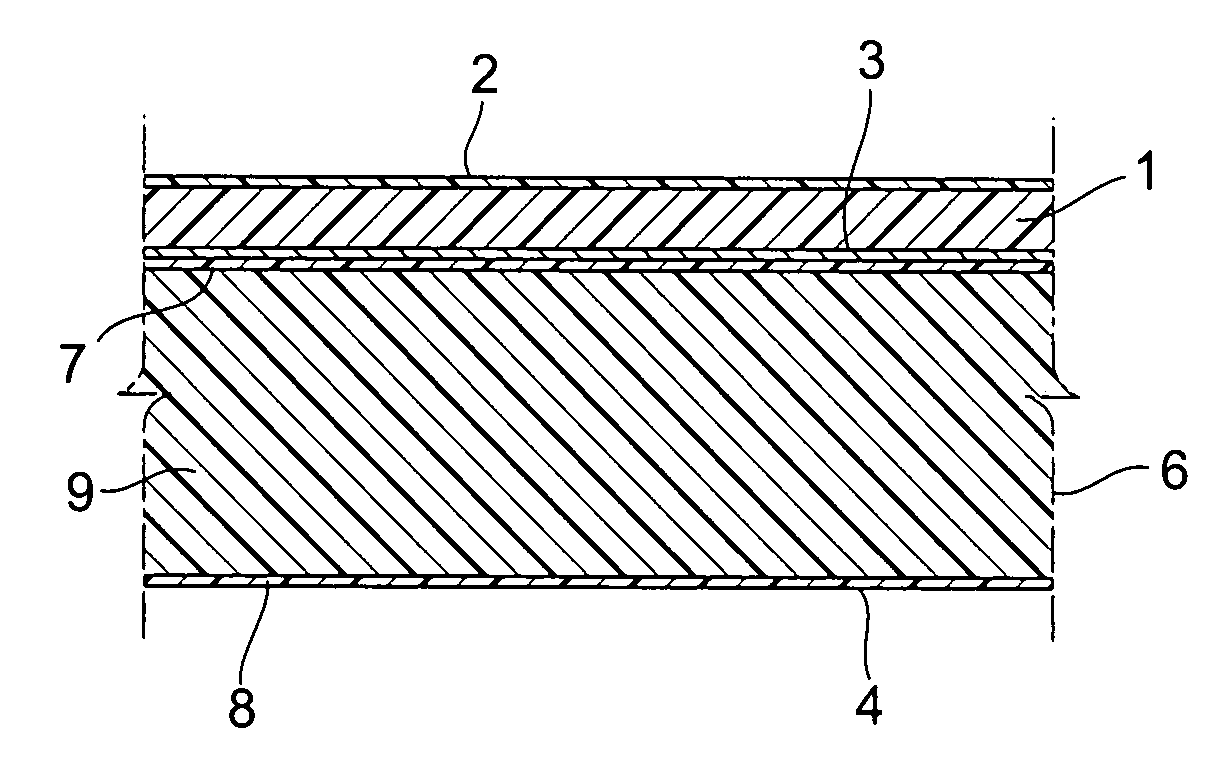

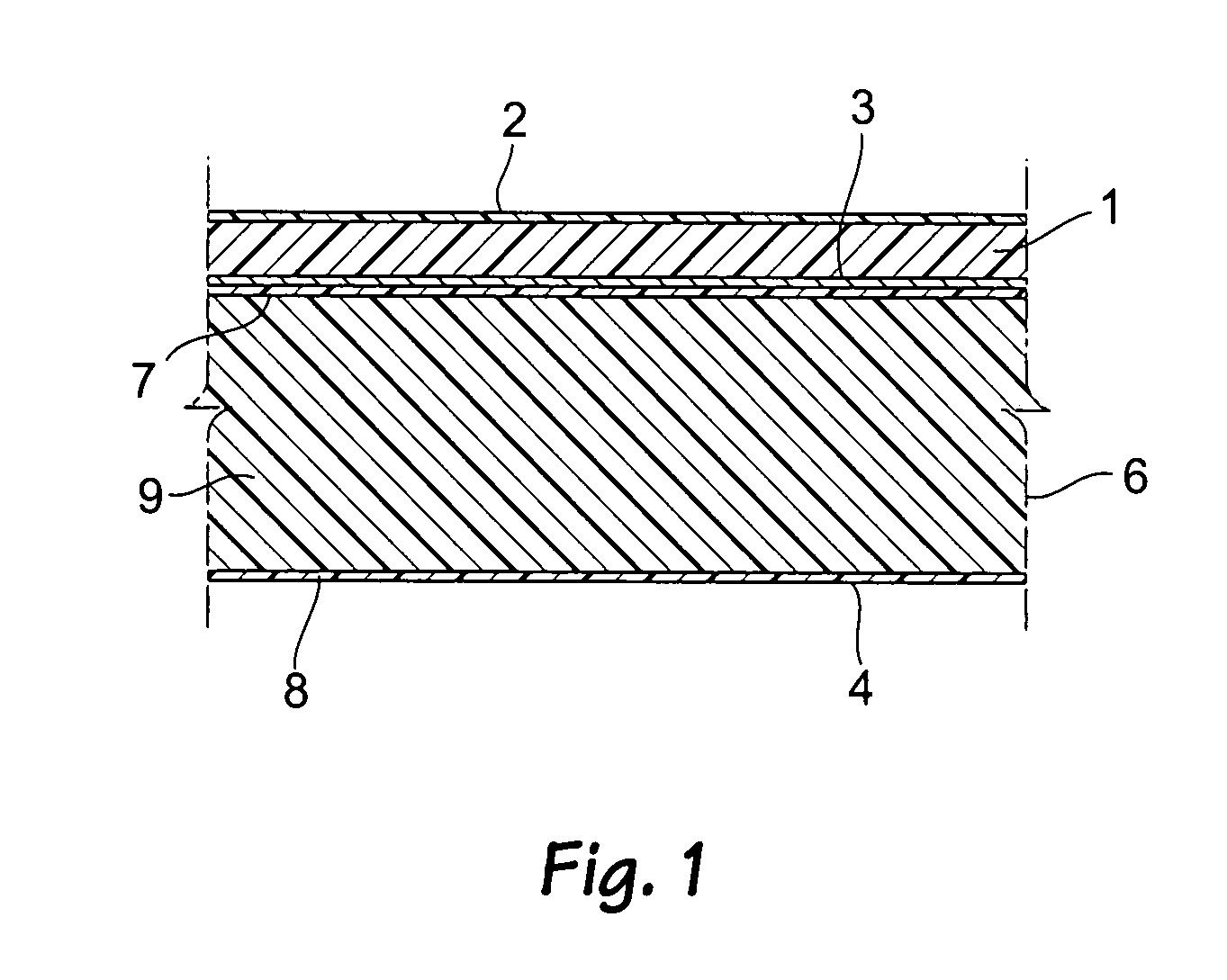

Breathable, waterproofing, tear-resistant fabric

The present invention relates to a composite sheet material that is moisture vapor permeable and substantially liquid impermeable, the composite sheet material including as layers a lightweight, non-wet laid polyester nonwoven, a polyurethane breathable film, a polymer-coated, high tenacity polyester mesh, and a lightweight, non-wet laid, polyester nonwoven material. The material is also abrasion, tear, mildew and fire resistant.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Method

InactiveUS20060238587A1Prevents nozzle depriming problemHigh viscosityInking apparatusMeasurement apparatus componentsInk printerEngineering

A method of printing onto one or more sides of a mesh fabric, such a polyester mesh typically used for flags and banners, using a drop on demand ink printer, wherein the printer is operated at a fluid pressure of between 1 and 3.5 bar and that the image forming composition has a viscosity of less than 100 cp.

Owner:WILLETT INT

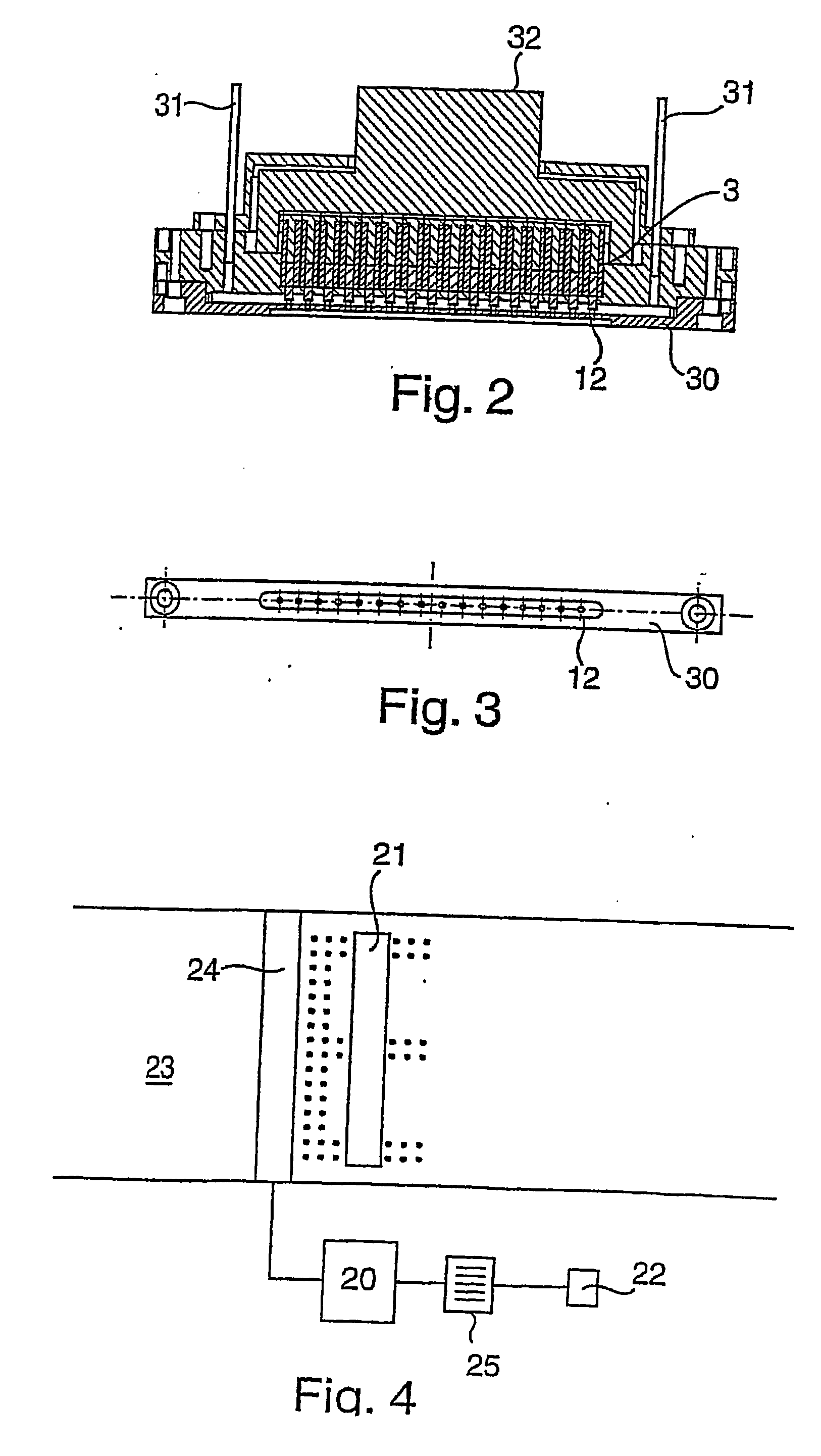

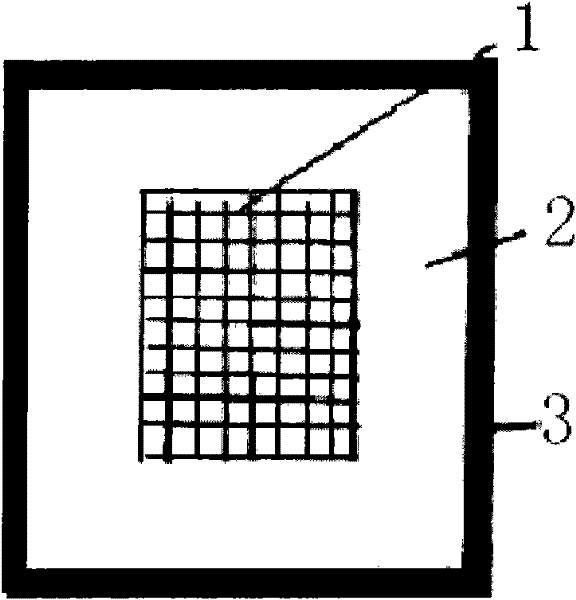

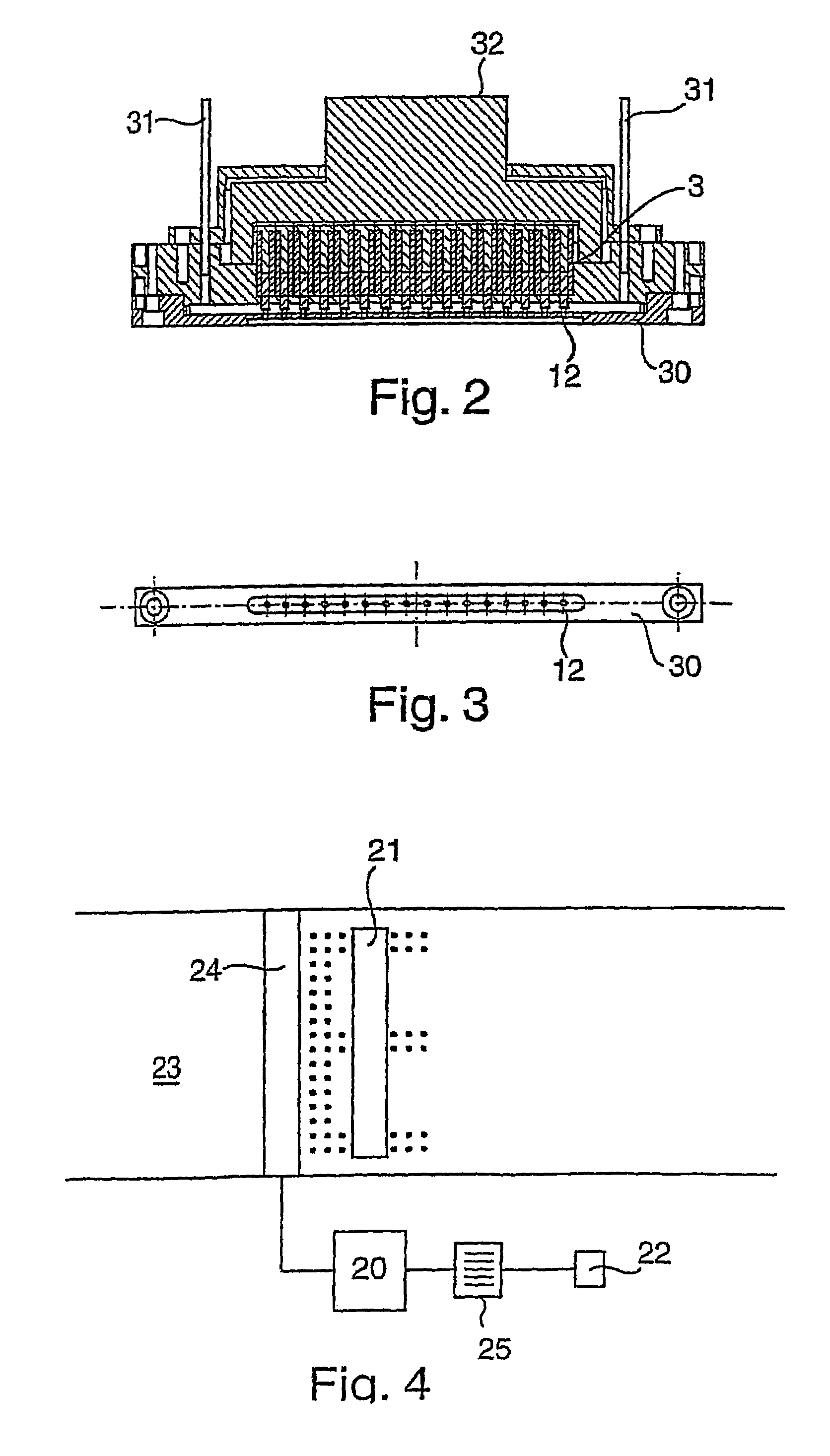

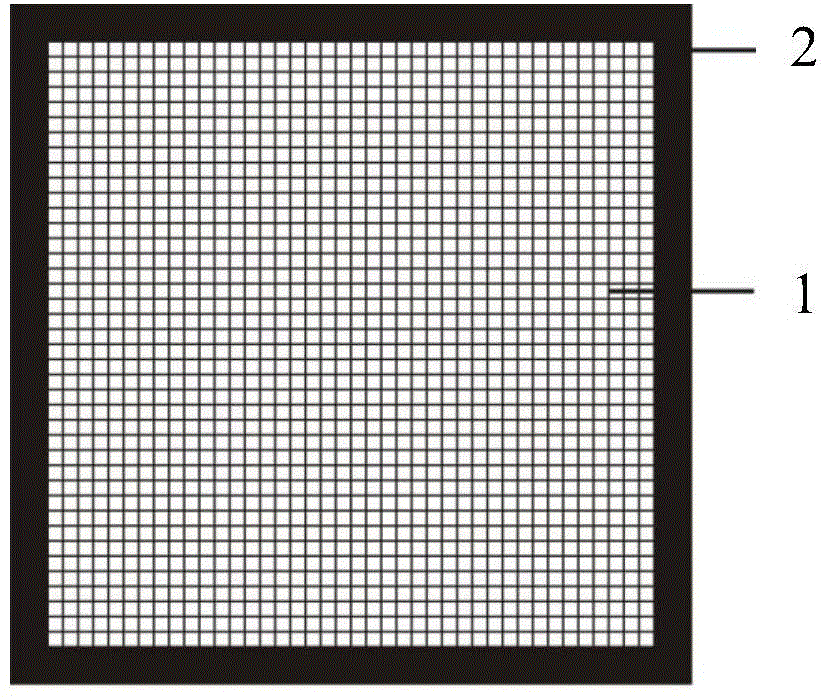

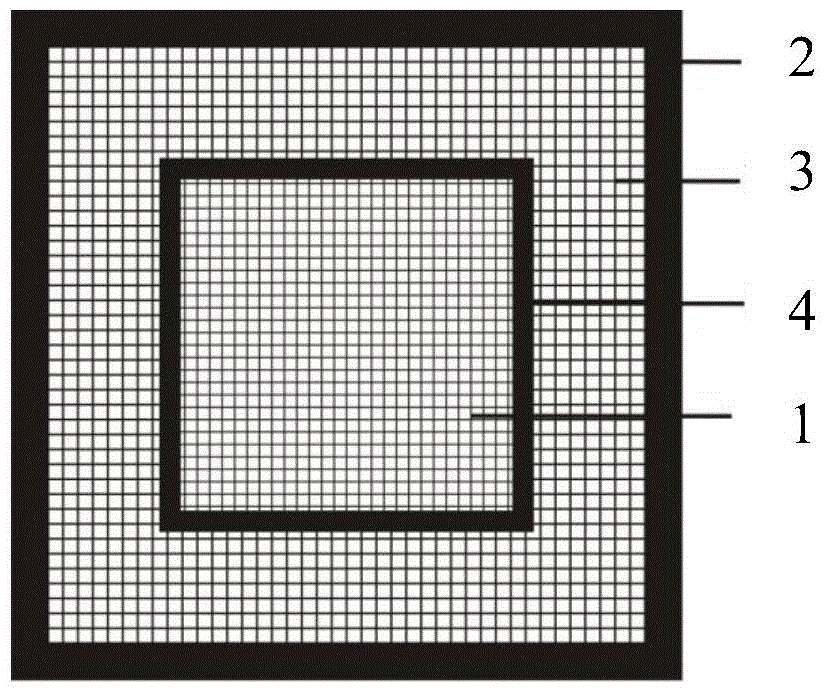

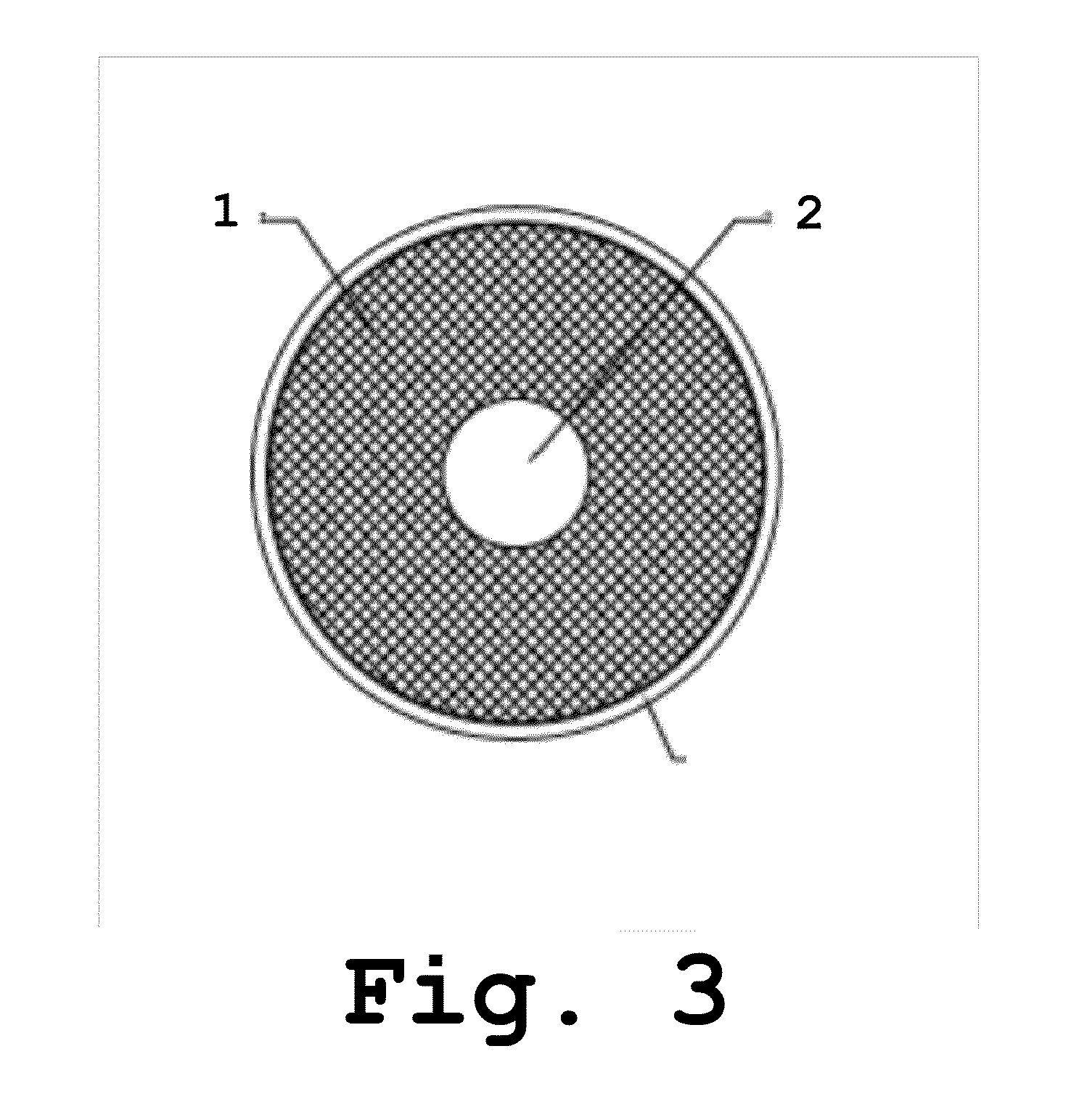

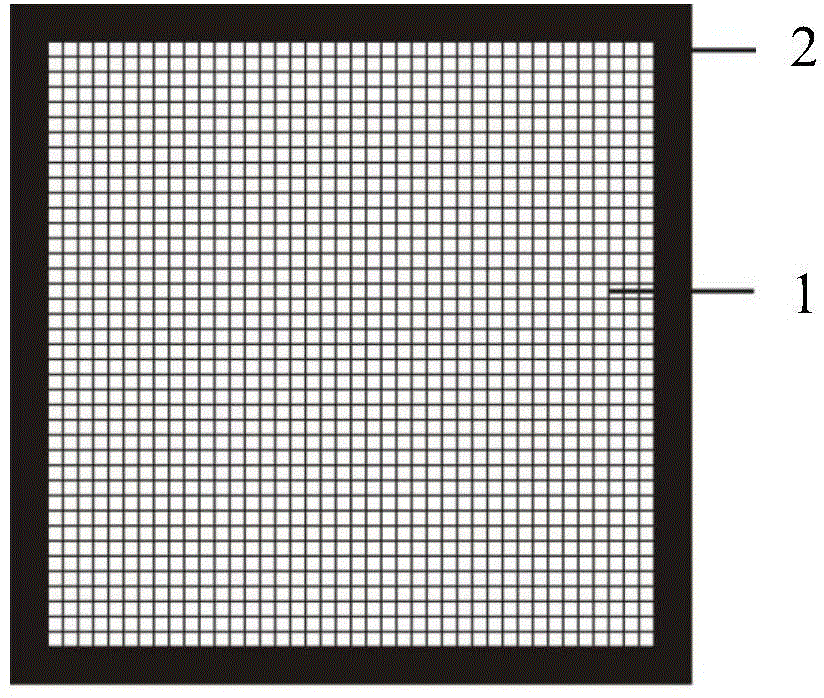

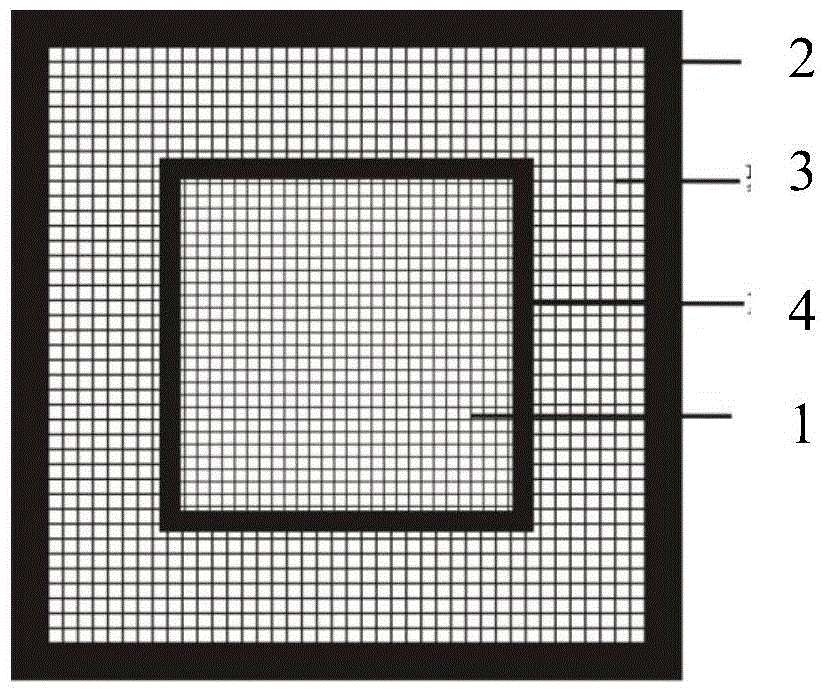

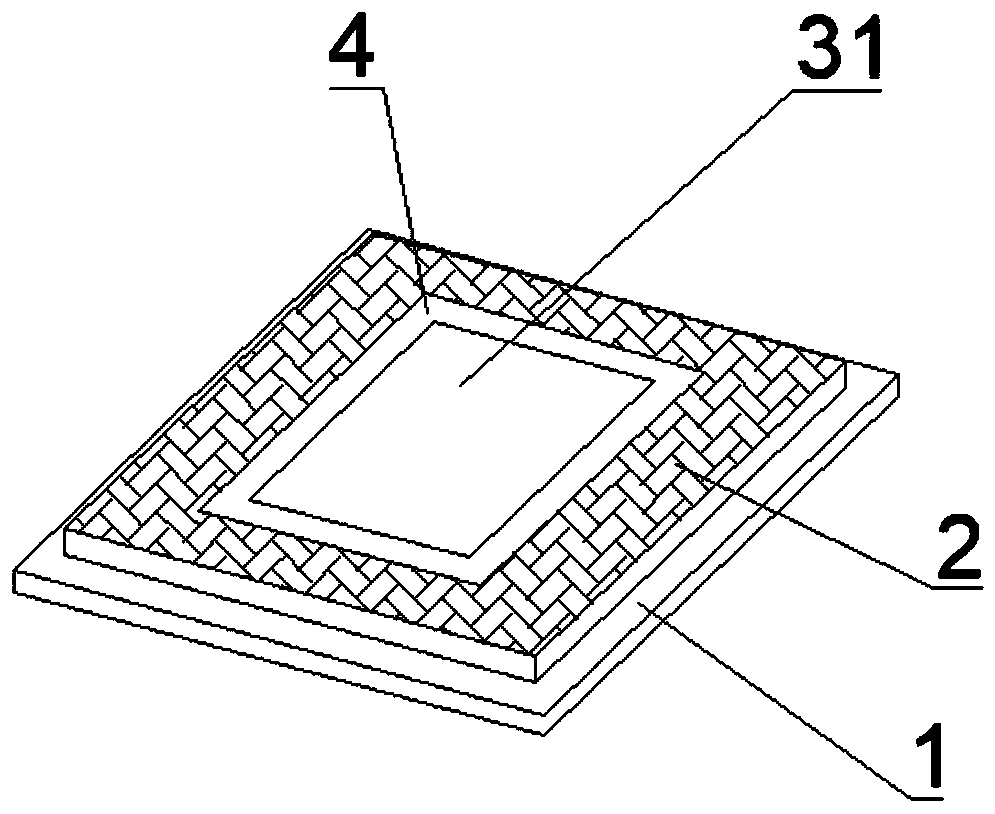

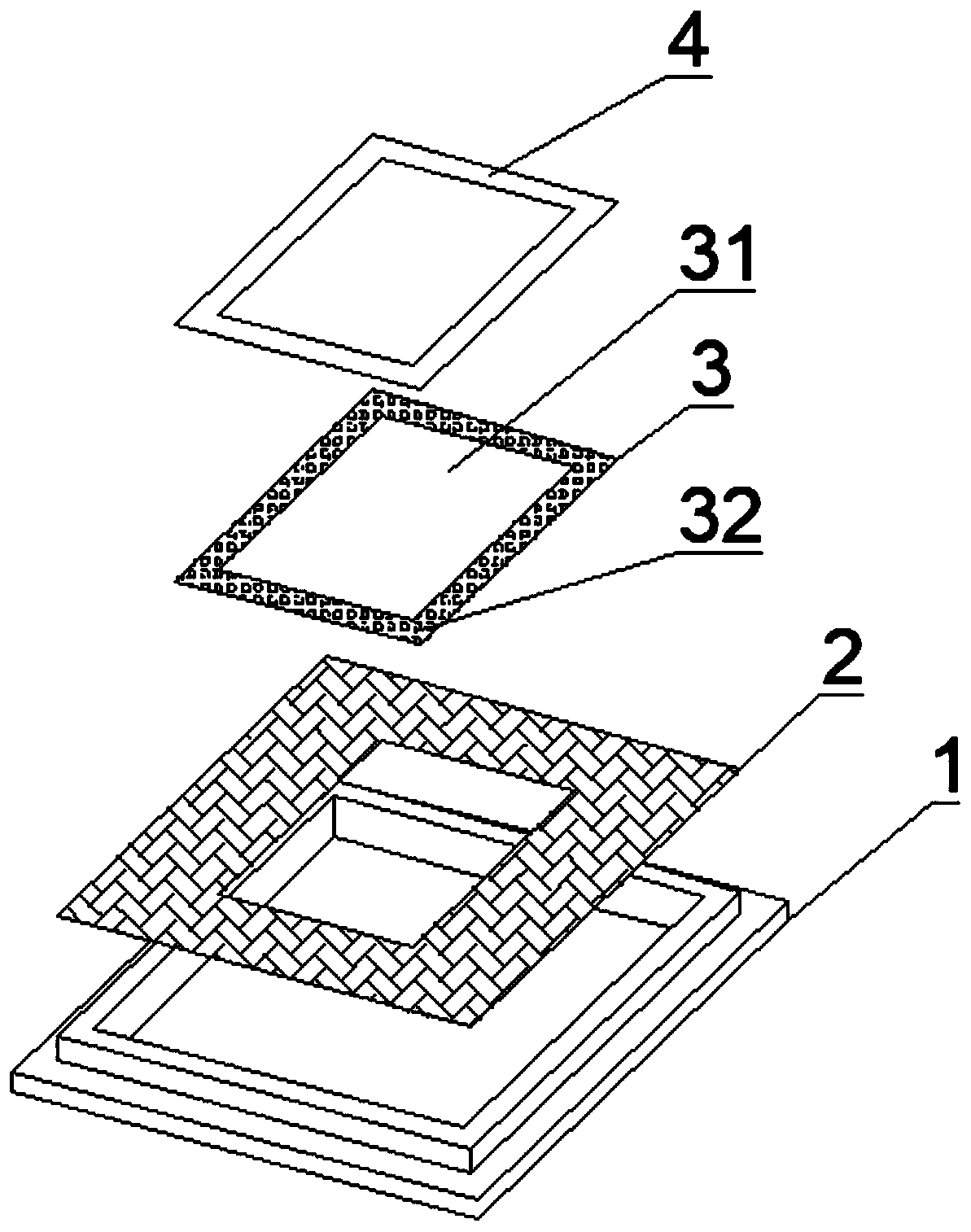

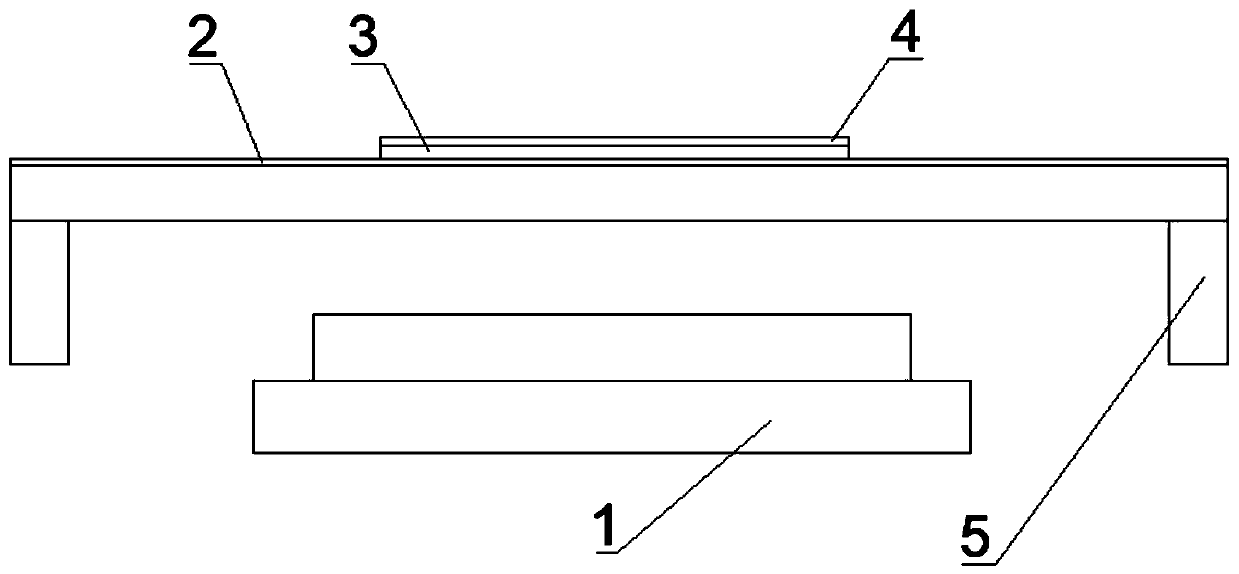

Printing screen for solar cell and method for producing solar cell

InactiveCN102214725ANot easy to distortExtended service lifeFinal product manufactureScreen printersPolyesterScreen printing

The invention discloses a printing screen for a solar cell and a method for producing the solar cell. The printing screen for the solar cell comprises a printing screen frame part, a polyester mesh part and a printing part, wherein the polyester mesh part is connected with the printing screen frame part and the printing part; the printing part is a meshed metal sheet; and mesh openings on the meshed metal sheet are evenly arranged in a matrix shape. The invention also discloses a method for producing the solar cell. The method comprises the step of using the printing screen for the solar cell to produce the solar cell. In the process of the producing the solar cell, the printing screen is utilized to print metal electrodes of the solar cell, thus not only prolonging the service life of the printing screen and reducing the production cost, but also keeping graphs required by the solar cell printed through using a silk-screen printing technology unchanged and controlling the width of electrodes accurately, thus improving the product quality.

Owner:WUXI SUNTECH POWER CO LTD

System and method for providing image forming composition on a substrate using a drop on demand ink printer

InactiveUS7604333B2High viscosityAvoid problemsInking apparatusTypewritersInk printerImage formation

A method of printing onto one or more sides of a mesh fabric, such a polyester mesh typically used for flags and banners, using a drop on demand ink printer, wherein the printer is operated at a fluid pressure of between 1 and 3.5 bar and that the image forming composition has a viscosity of less than 100 cp.

Owner:WILLETT INT

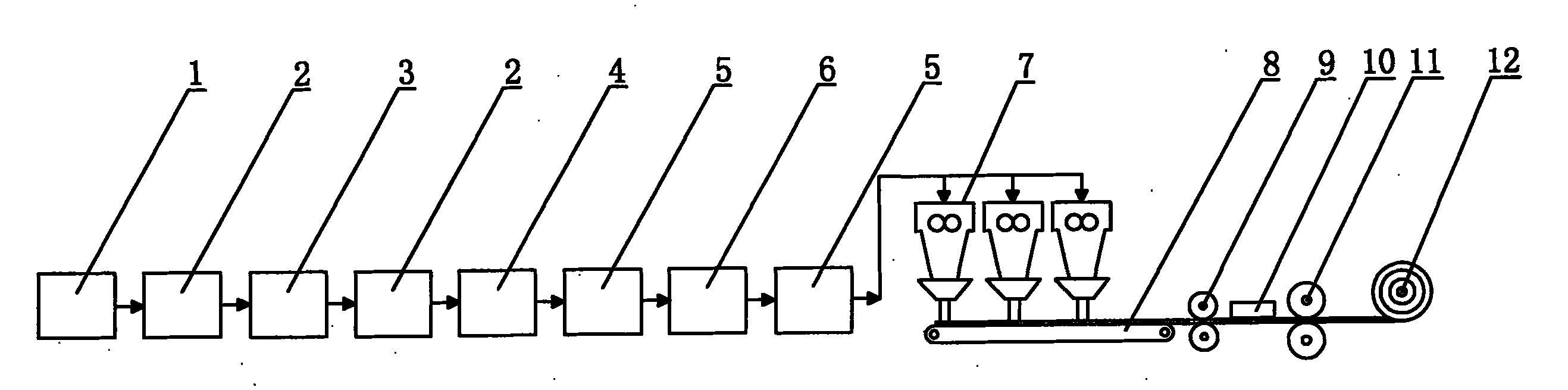

Straw non-woven fabric and production method of straw non-woven fabric

The invention discloses a straw non-woven fabric and a production method of the straw non-woven fabric. Straws, a conveying mesh belt, a straw chopper, a primary fiber separator, a fan, a fine fiber separator, an air chamber, a polyester mesh, a pre-roller, an infrared heater, a hot roller and a non-woven fabric roll are adopted. The non-woven fabric is produced by effectively using the straws, the waste is changed into valuable, and the cost is low. The straw non-woven fabric manufactured by using the method has good use performance, soft handfeel and good water absorption, does not cause fiber drop, is particularly suitable for manufacturing industrial wiping cloth, is used for automobile heat insulation layers or building heat insulation layers and the like, and can also be used as moisture absorption cores in the middle of incontinence products such as paper diapers, sanitary towels and the like. A chemical processing method is not used for manufacturing the straw non-woven fabric, so the straw non-woven fabric has no secondary pollution, is totally biodegradable and is an environmentally-friendly product. The flow can be performed in fields, and the operation is simple, convenient and safe.

Owner:YANCHENG INST OF IND TECH

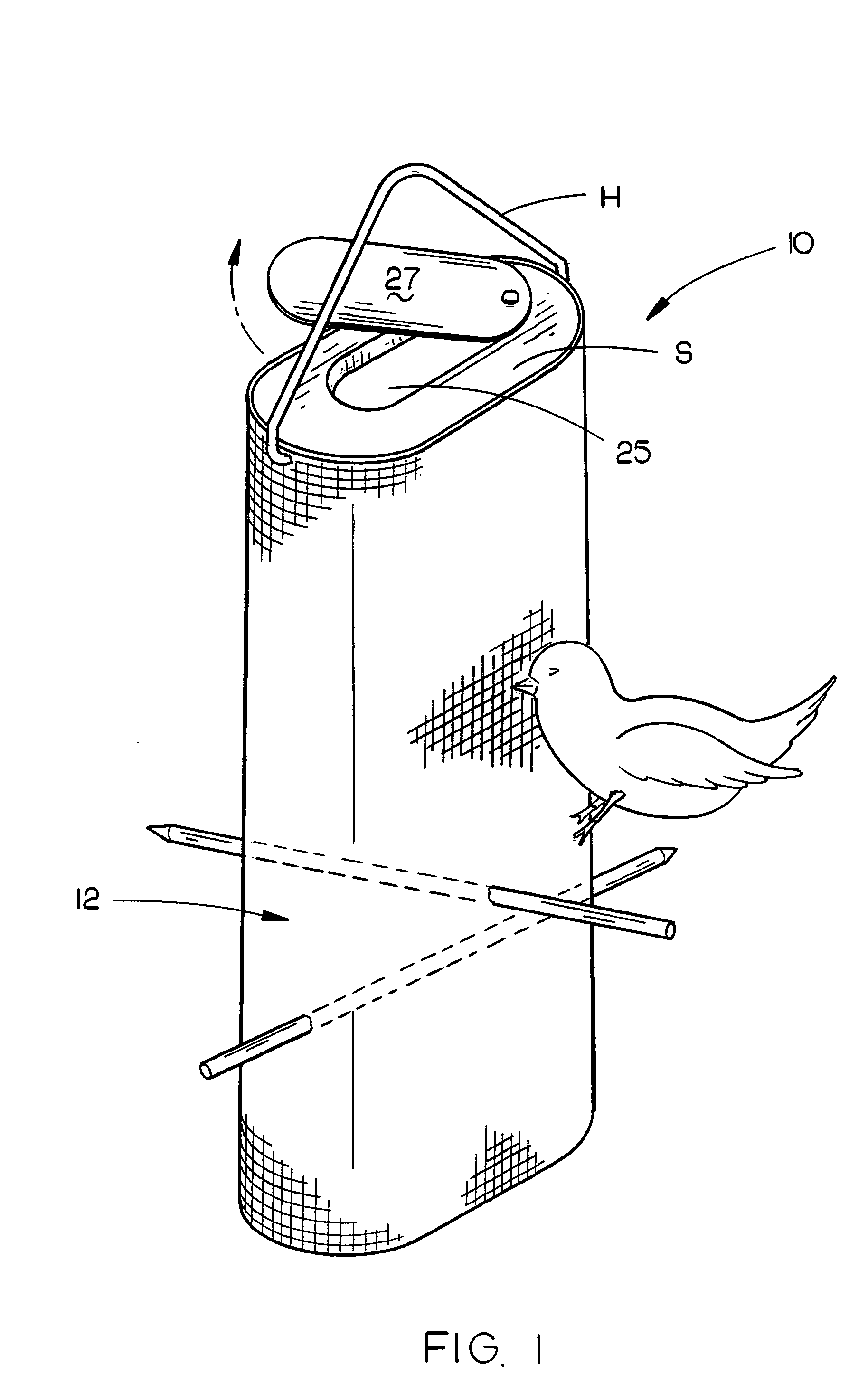

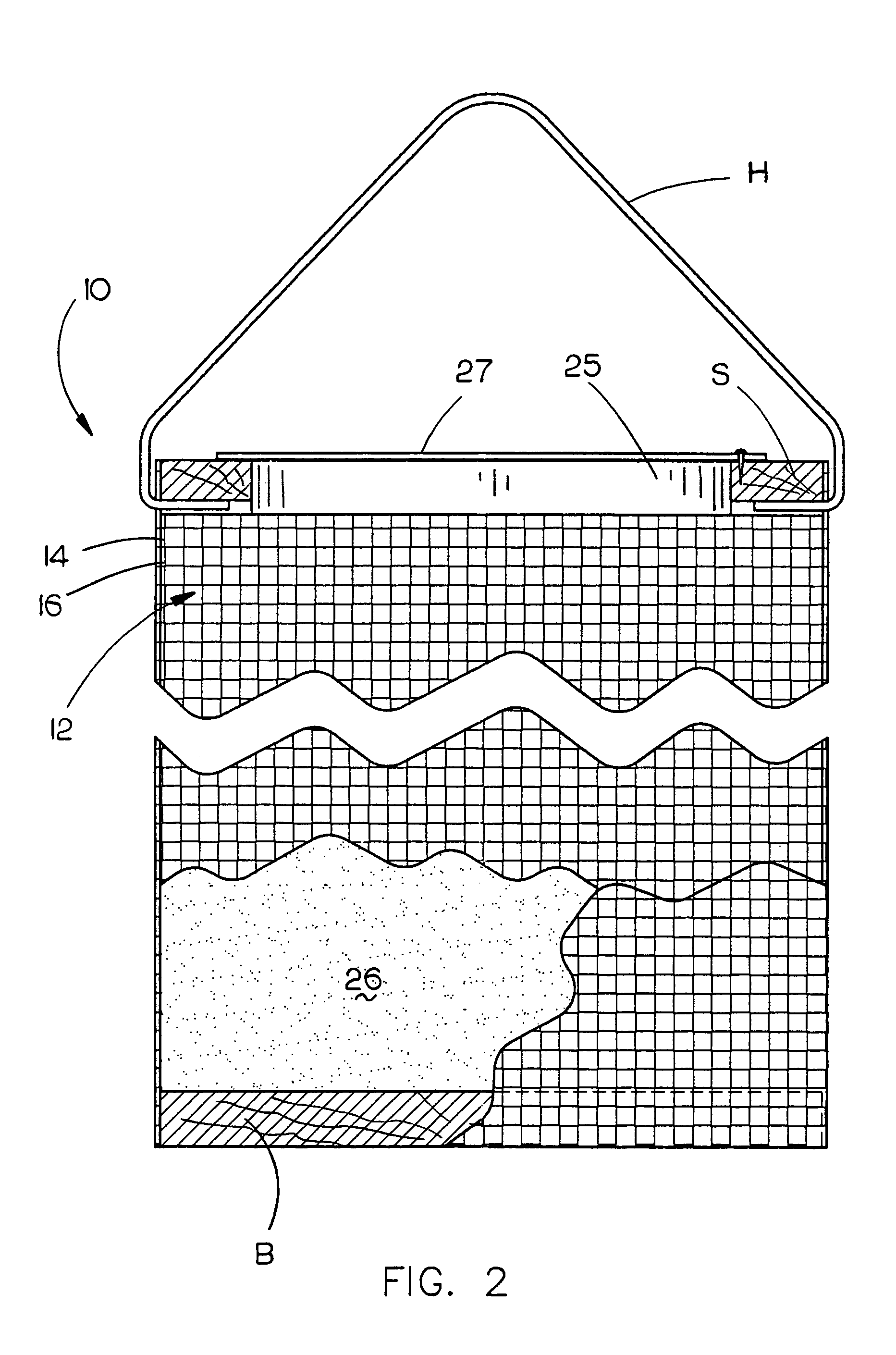

Collapsible mesh feeder

A collapsible feeder for birds comprising a mesh feeder body wall which is constructed of either a polyester mesh coated with PVC or a material containing rubber. The mesh wall defines alternating first and second rows with each of the rows having spaced-apart wall members which are separated by an opening. The first and second rows are staggered with respect to one another so that the openings in one row are positioned below or above the wall members in adjacent rows to define feed openings. Preferably, the feeder body is generally tubular-shaped but may have other shapes such as frusto-conical or inverted frusto-conical shapes.

Owner:WOODSTREAM CORP

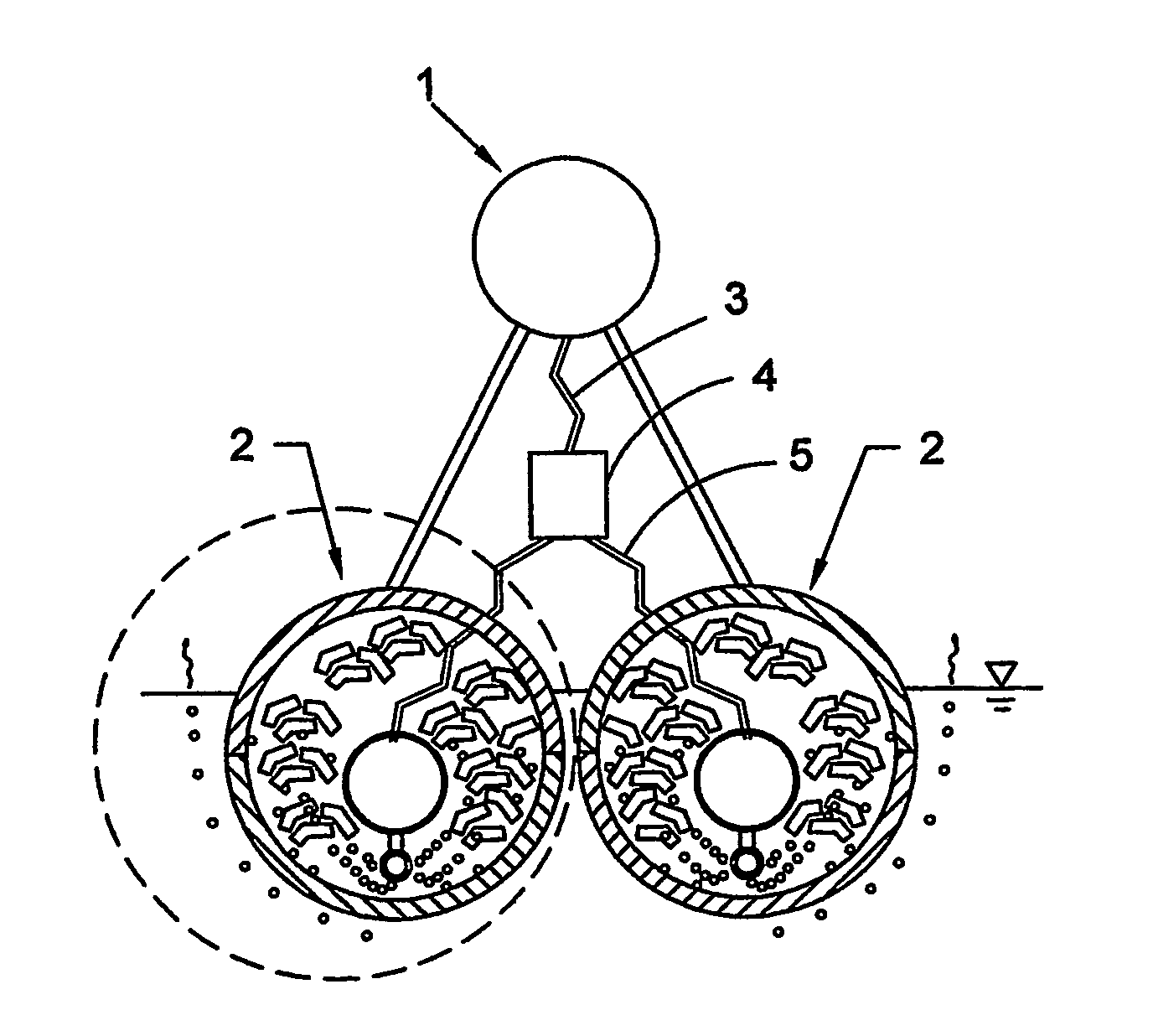

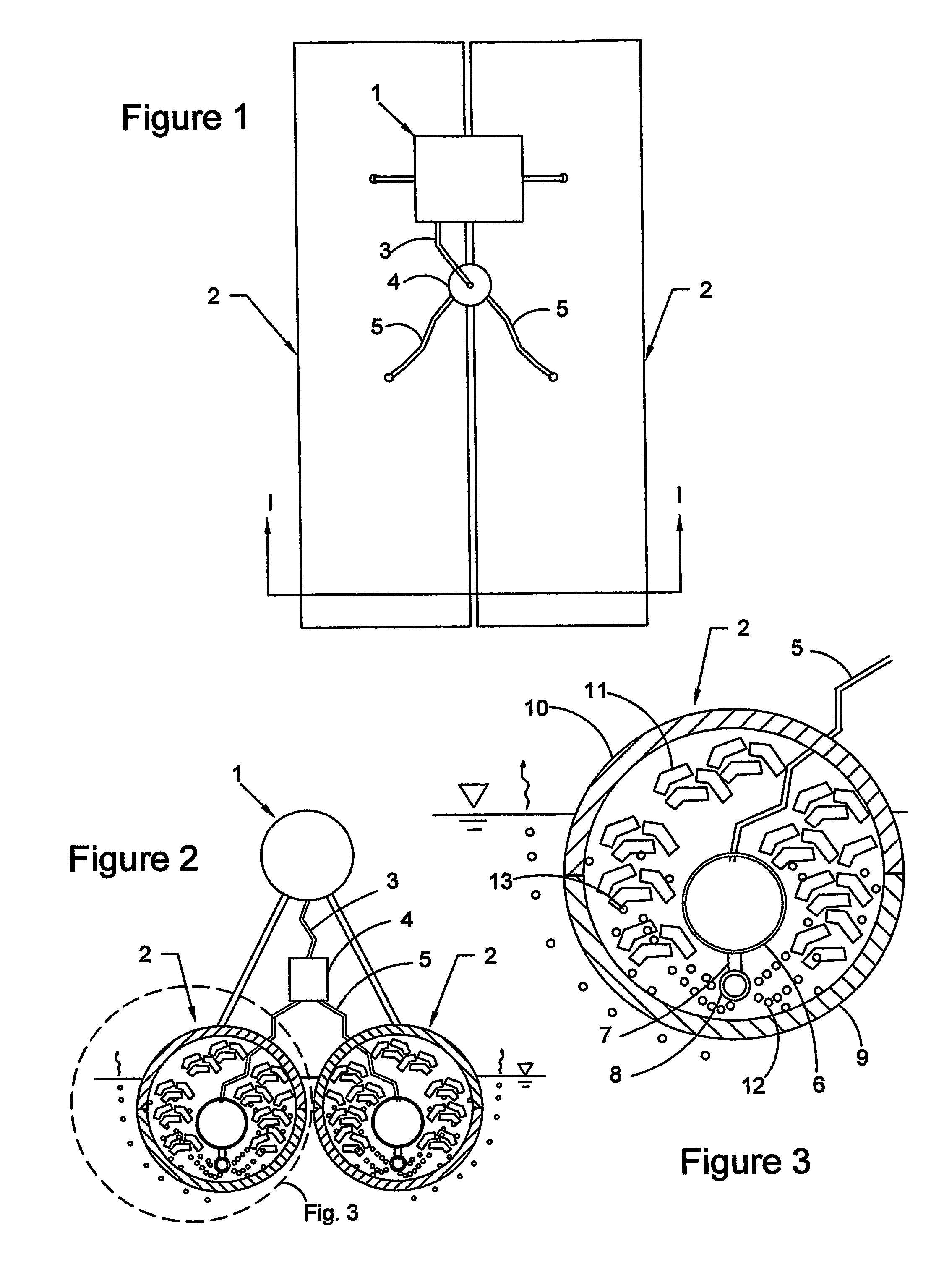

Renewably buoyant, self-protective floating habitat

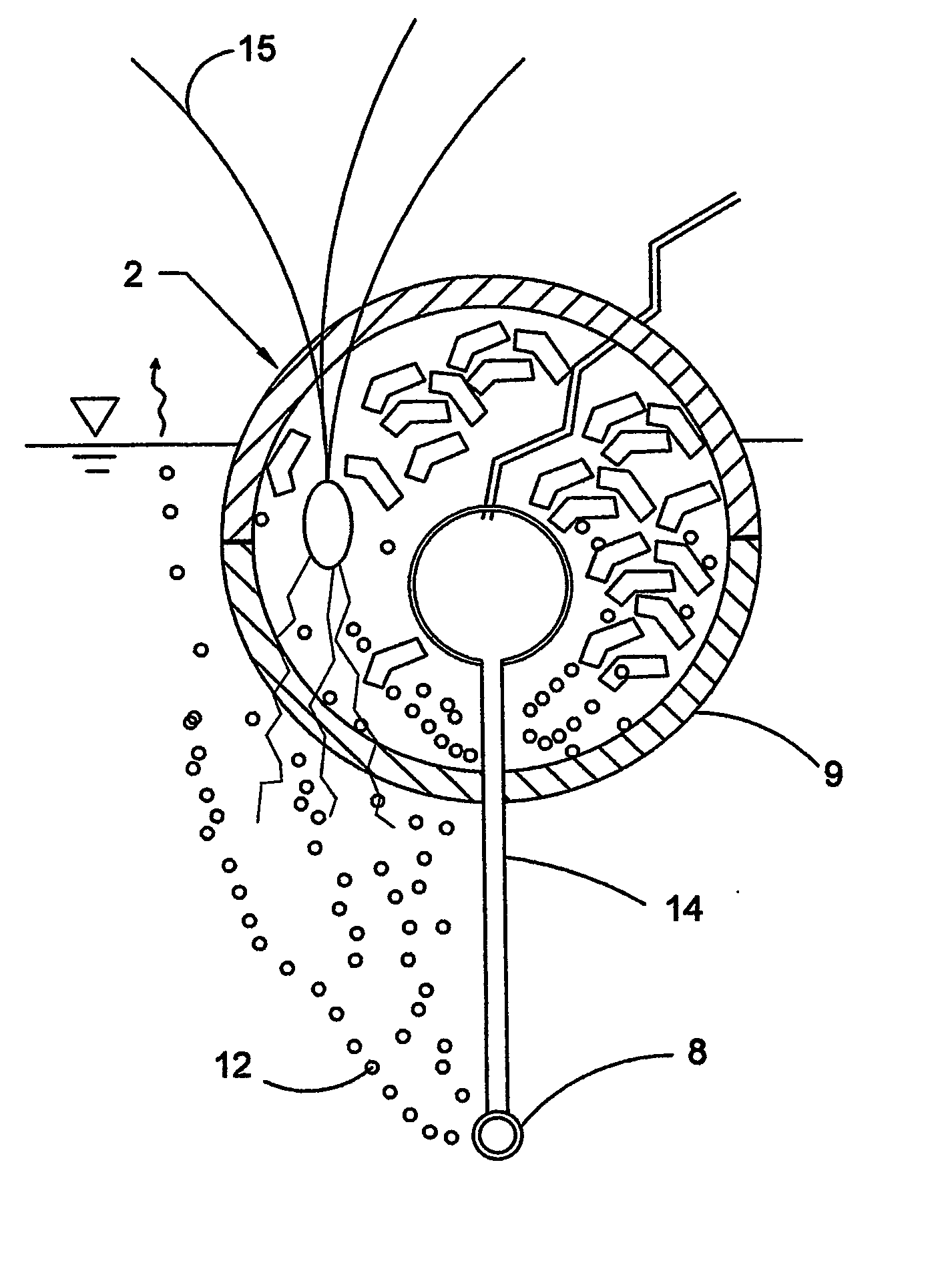

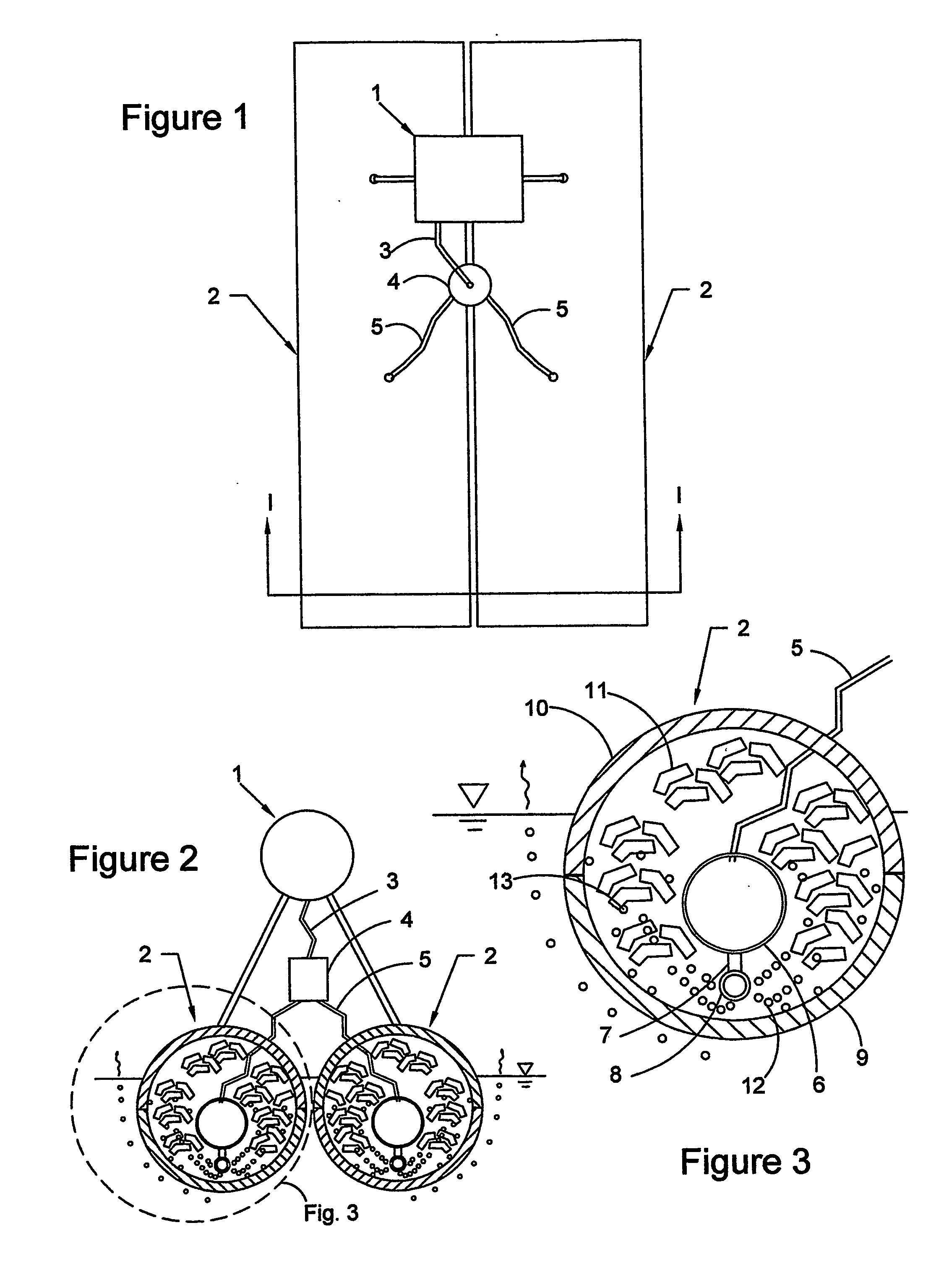

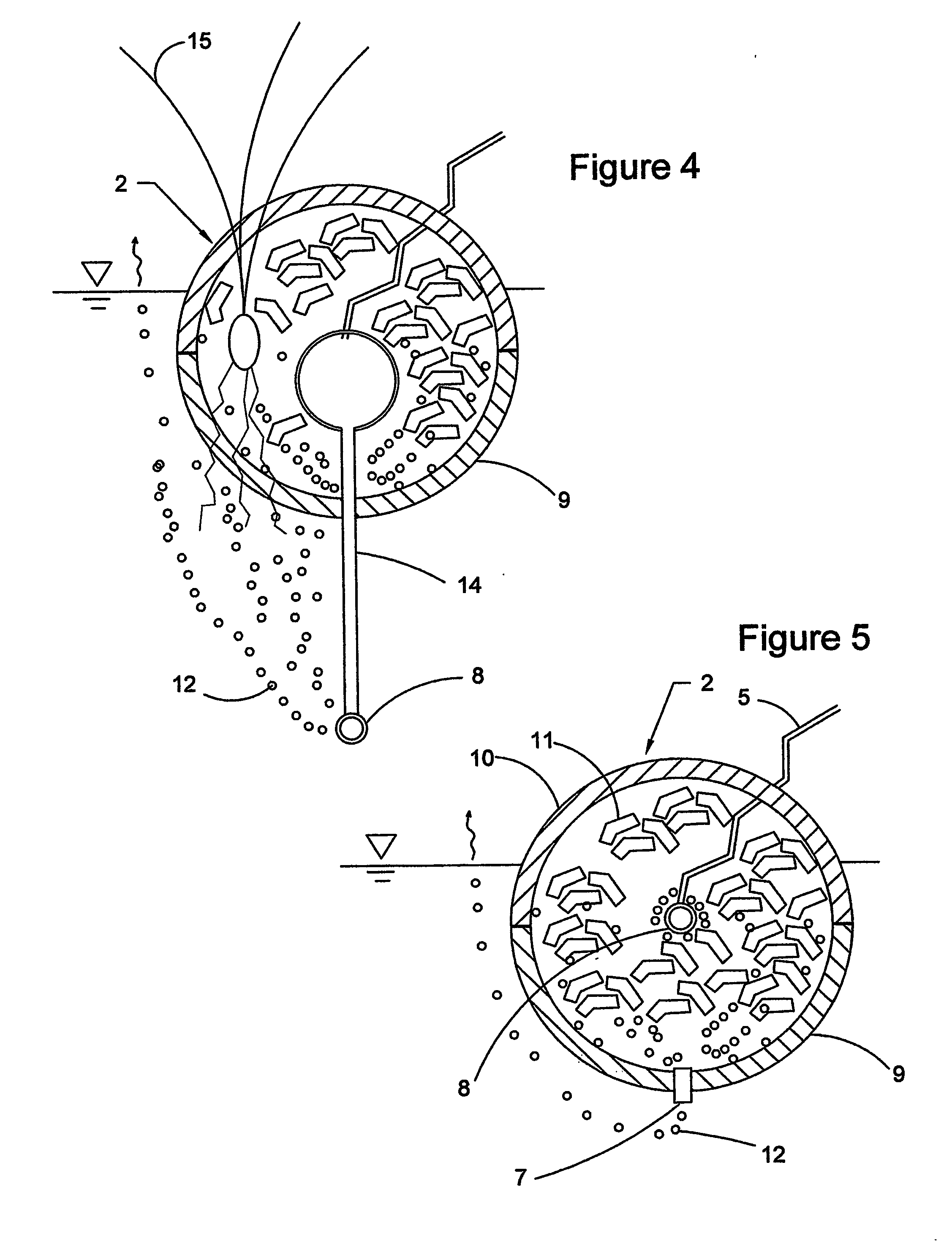

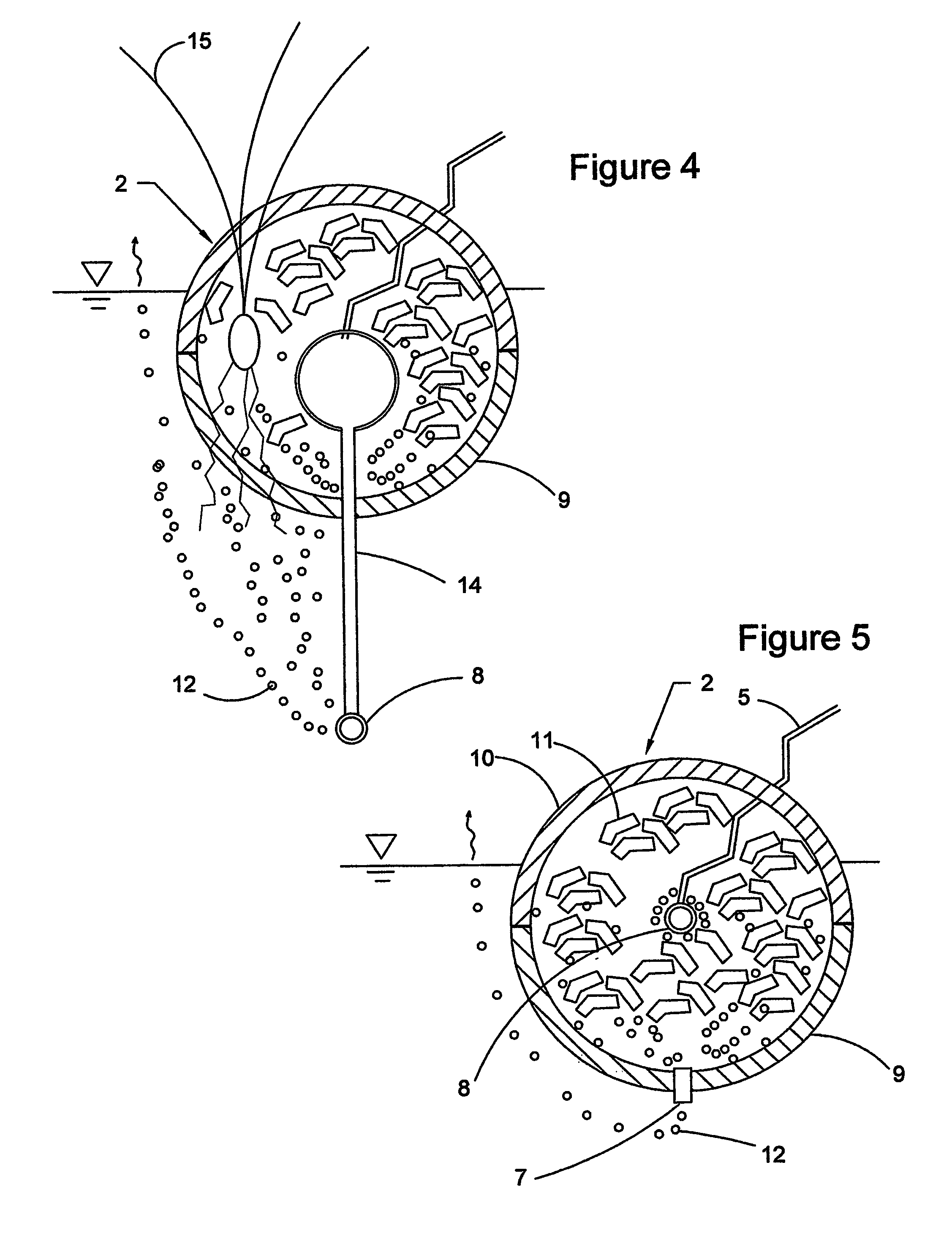

InactiveUS20070124995A1Optimize nesting habitatGood lookingClimate change adaptationAgricultural fishingCell culture mediaEngineering

A floating habitat designed to be renewably buoyant, self-sustaining and optionally specialized for waterfowl nesting. The first embodiment comprises one or more flotation units, a source of compressed air, and a means for connecting the source of compressed air to the flotation units. Each flotation unit comprises an individual supply hose, an inflatable bladder, a relief valve, a diffusing manifold, bottom mesh, top mesh, and buoyant growth medium. An alternative embodiment comprises a self-compensating buoyancy system. In the waterfowl nesting embodiment, the floating habitat includes one or more waterfowl nesting structures and construction material selected to optimize the nesting habitat. The floating habitat can be comprised of scrap pieces or layers of polyester mesh material. The floating habitats can be combined to provide safe habitat for juvenile waterfowl, encourage colony nesting, or allow a variety of waterfowl or shore bird species to enjoy suitable habitat on the same floating habitat.

Owner:FOUNTAINHEAD

Breathable, waterproofing, tear-resistant fabric

The present invention relates to a composite sheet material that is moisture vapor permeable and substantially liquid impermeable, the composite sheet material including as layers a lightweight, non-wet laid polyester nonwoven, a polyurethane breathable film, a polymer-coated, high tenacity polyester mesh, and a lightweight, non-wet laid, polyester nonwoven material. The material is also abrasion, tear, mildew and fire resistant.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Composite steel wire net plate and preparation method thereof

InactiveCN104669776AImprove quality levelReduce manufacturing costScreen printersPolyesterStainless steel wire

The invention discloses a composite steel wire net plate and a preparation method thereof. The composite steel wire net plate is mainly formed by compounding polyester mesh fabrics and stainless steel wire mesh fabrics, a compounded net sheet is stuck to the upper surface of a net frame to form the net plate; the stainless steel wire mesh fabrics are positioned in the areas where the stainless steel wire mesh fabrics are hollowed; overlapped interfaces are formed at the places where the stainless steel wire mesh fabrics and the stainless steel wire mesh fabrics are connected; the front and back surfaces of the overlapped interfaces are smooth and flat and are not gradient. The preparation method comprises the following steps of forming a polyester net plate; hollowing the middle polyester mesh fabrics; fixing the hollowed polyester net plate to a tabletop; placing the to-be-compounded steel wire mesh fabrics on the hollowed polyester net plate; printing glue to the places where the stainless steel wire mesh fabrics and the polyester mesh fabrics are overlapped; curing the glue; placing the compounded net plate of the steel wire mesh fabrics in a top frame device; upwards jacking the to-be-stuck net frame below the compounded net plate of the steel wire mesh fabrics; coating glue to a contact surface between the net frame and the mesh fabrics; curing the coated glue. The problem of obvious gradient caused when polyester mesh fabric cuts are exposed at the composite interfaces after the composite steel wire net plate is opened is solved.

Owner:ZHEJIANG SHUOKE SCI & TECH

Renewably buoyant, self-protective floating habitat

InactiveUS7555866B2Provide additional buoyancyOptimize the nesting habitatClimate change adaptationAgricultural fishingCell culture mediaWater bird

A floating habitat designed to be renewably buoyant, self-sustaining and optionally specialized for waterfowl nesting. The first embodiment comprises one or more flotation units and a source of compressed air that is connected to the flotation units. Each flotation unit comprises an individual supply hose, an inflatable bladder, a relief valve, a diffusing manifold, bottom mesh, top mesh, and buoyant growth medium. An alternative embodiment comprises a self compensating buoyancy system. In the waterfowl nesting embodiment, the floating habitat includes one or more waterfowl nesting structures and construction material selected to optimize the nesting habitat. The floating habitat can be comprised of scrap pieces or layers of polyester mesh material. The Boating habitats can be combined to provide safe habitat for juvenile waterfowl, encourage colony nesting, or allow a variety of waterfowl or shore bird species to enjoy suitable habitat on the same floating habitat.

Owner:FOUNTAINHEAD

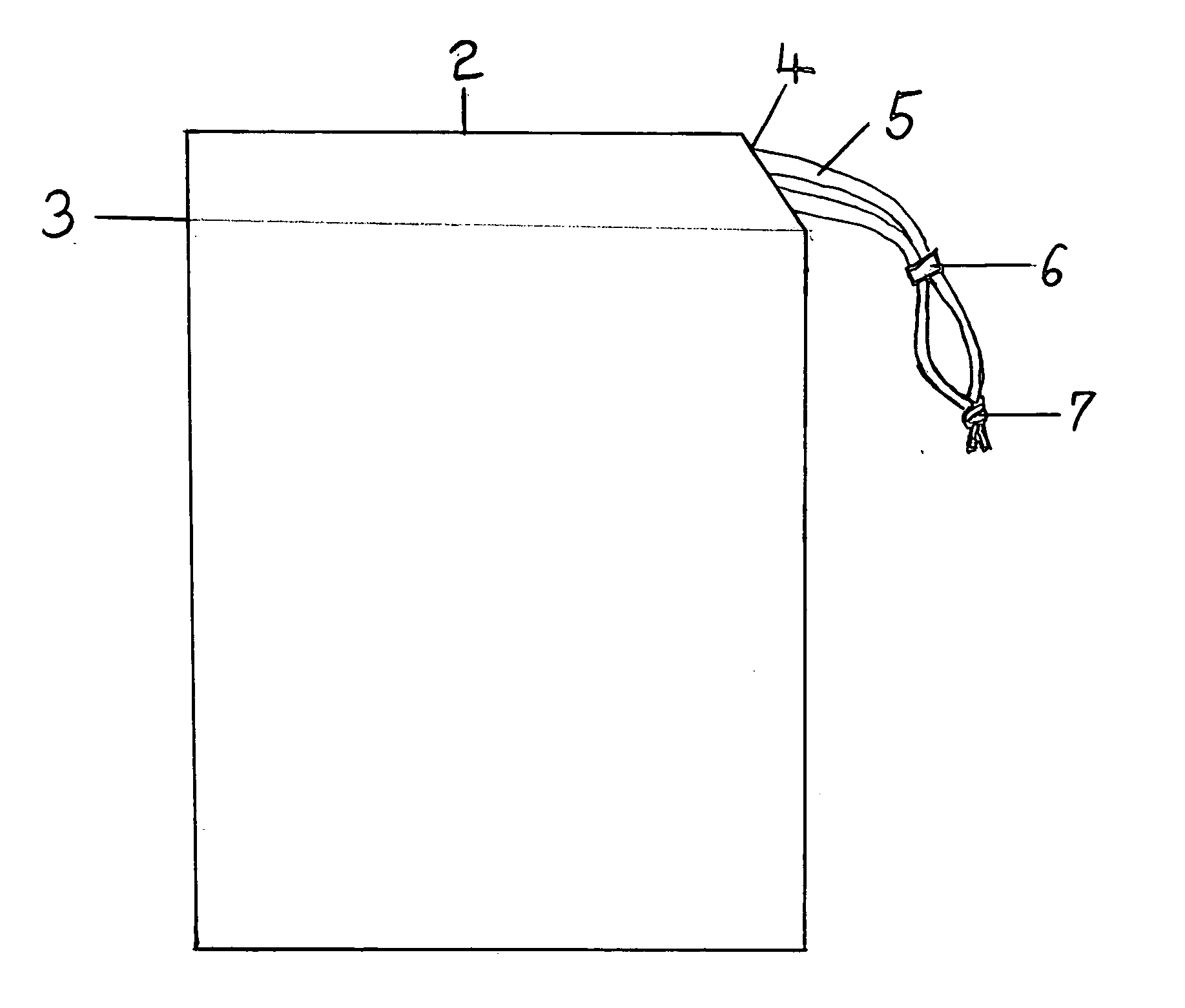

Scrub 'N' bag

InactiveUS20050095056A1Eliminate the problemLoose materialBathroom accessoriesOther pensPolyesterEngineering

The SCRUB'N'BAG is a personal bathing accessory which is composed of polyester mesh material. There is a cord channel around the top opening of the bag through which a nylon cord is threaded. Once the soap bar is placed in the bag, the cord is drawn to close the top of the bag. The excess nylon cord can be placed around the wrist and the vinyl slide is used to comfortably secure the bag to the wrist, eliminating the need to ever have to retrieve a dropped bar of soap again. The material at the top half of the bag can be used instead of a washcloth, or the bather may hold the lower half of the bag, which contains the bar of soap, and wash the body. The mesh polyester material allows the soap suds to pass through while also providing gentle exfoliation of skin.

Owner:KING ELAINE

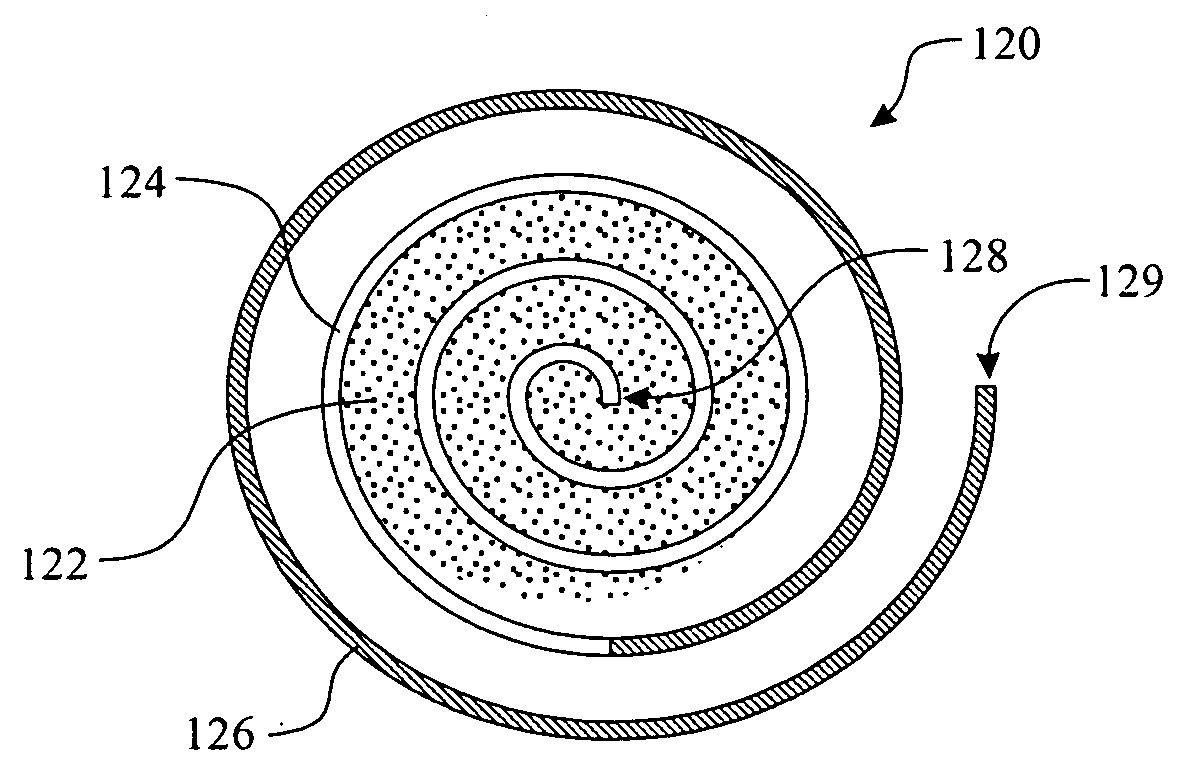

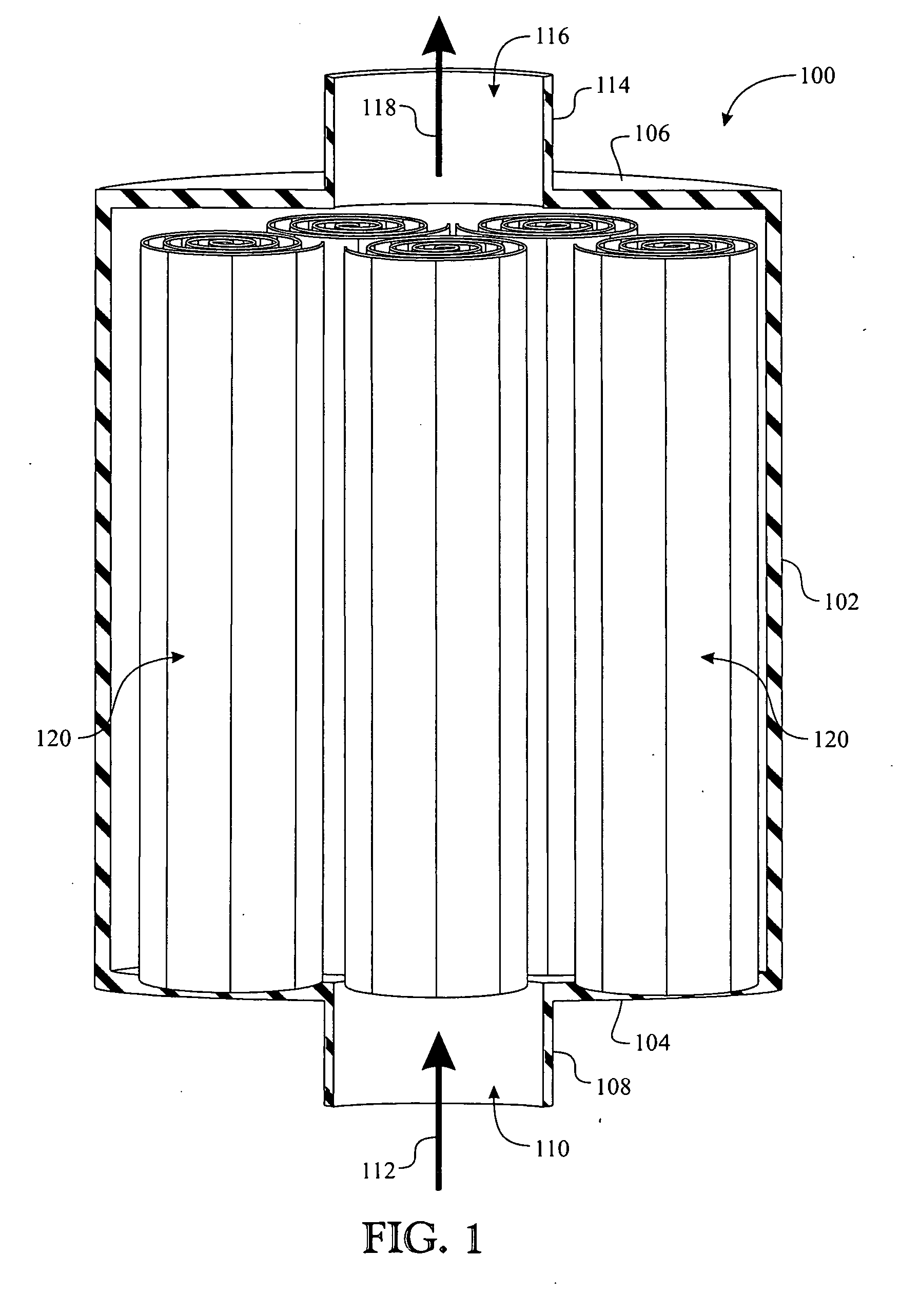

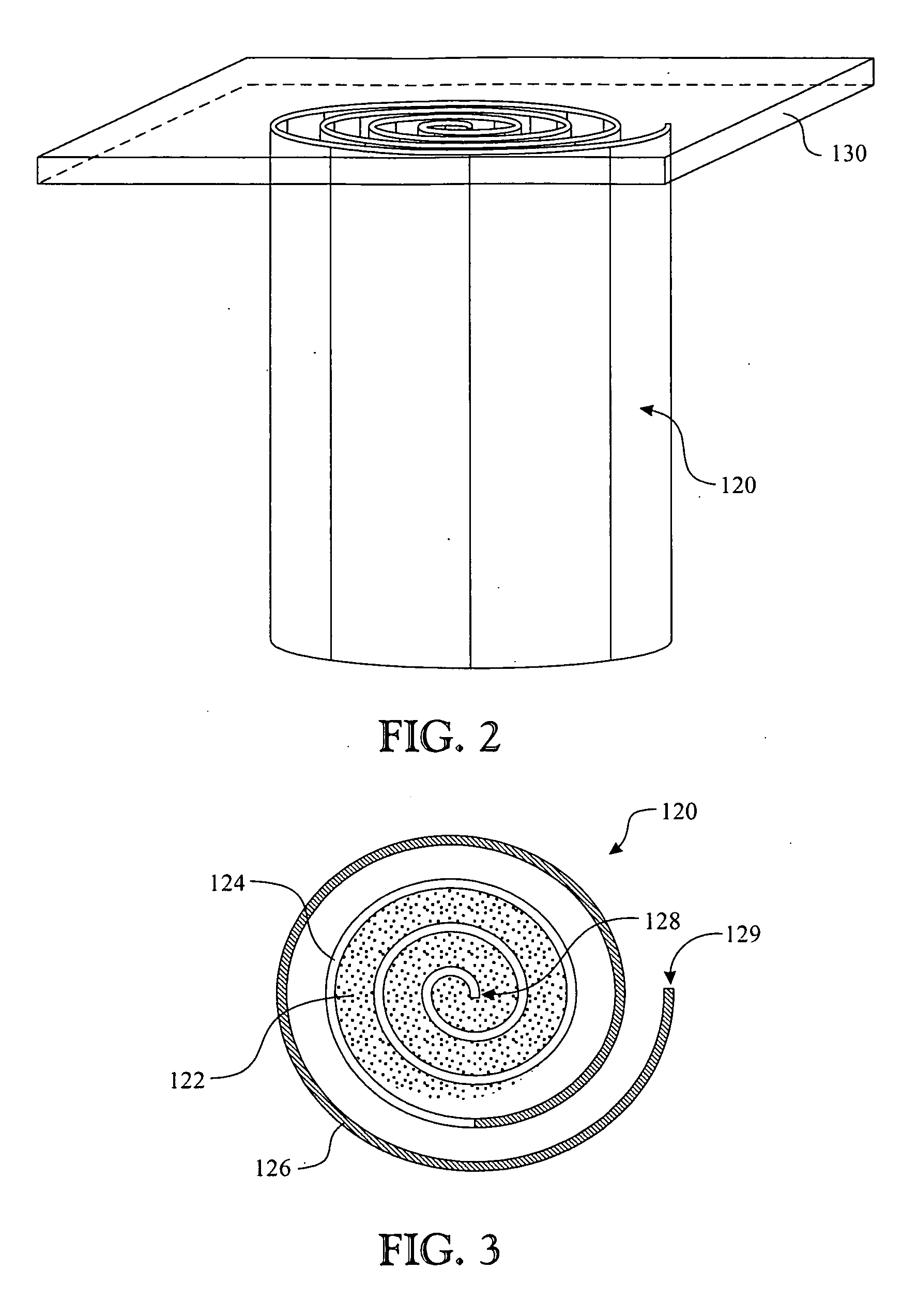

Air and contaminant isolation and removal apparatus and method

ActiveUS20110056879A1Liquid suspension thickening by filtrationUsing liquid separation agentPolyesterSorbent

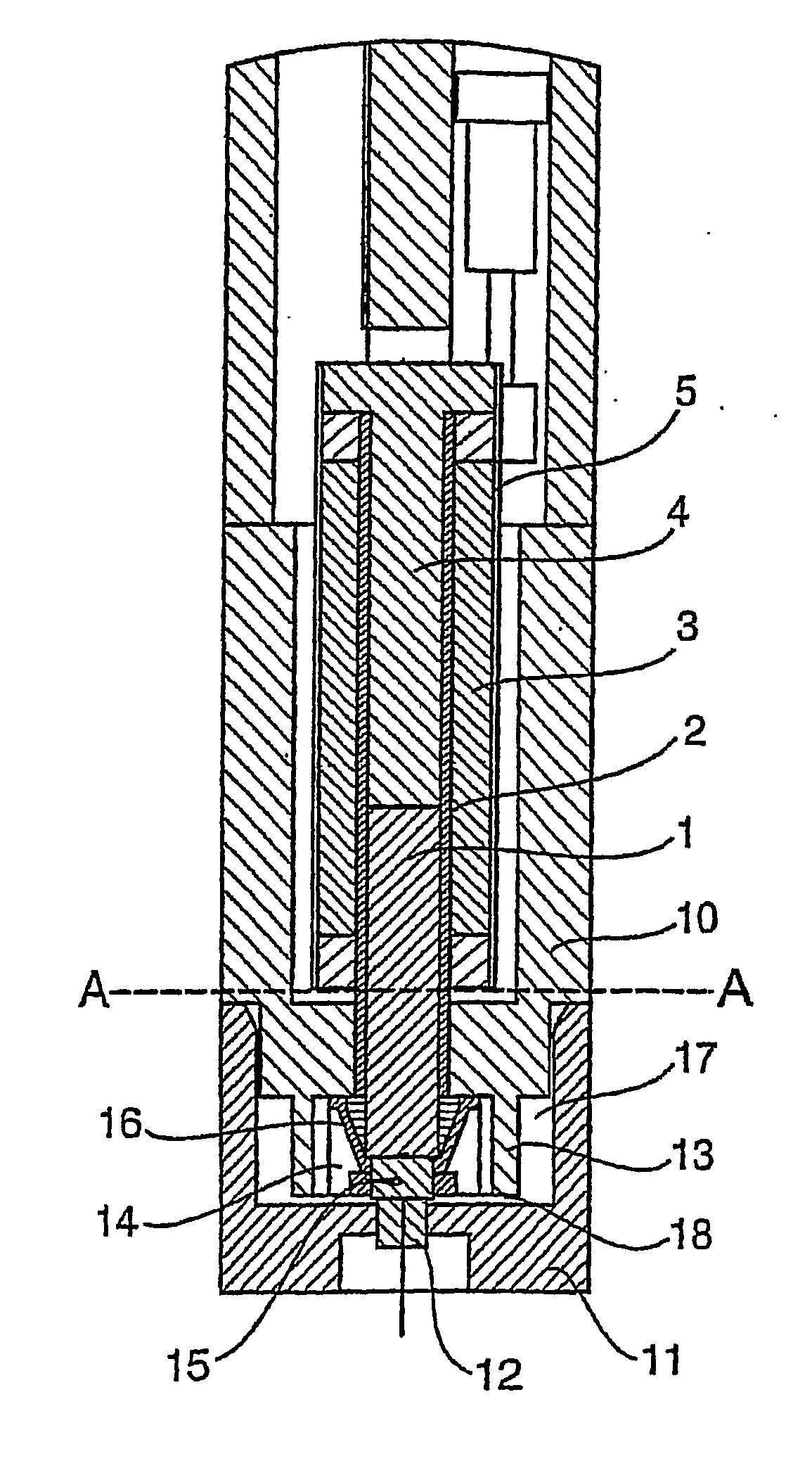

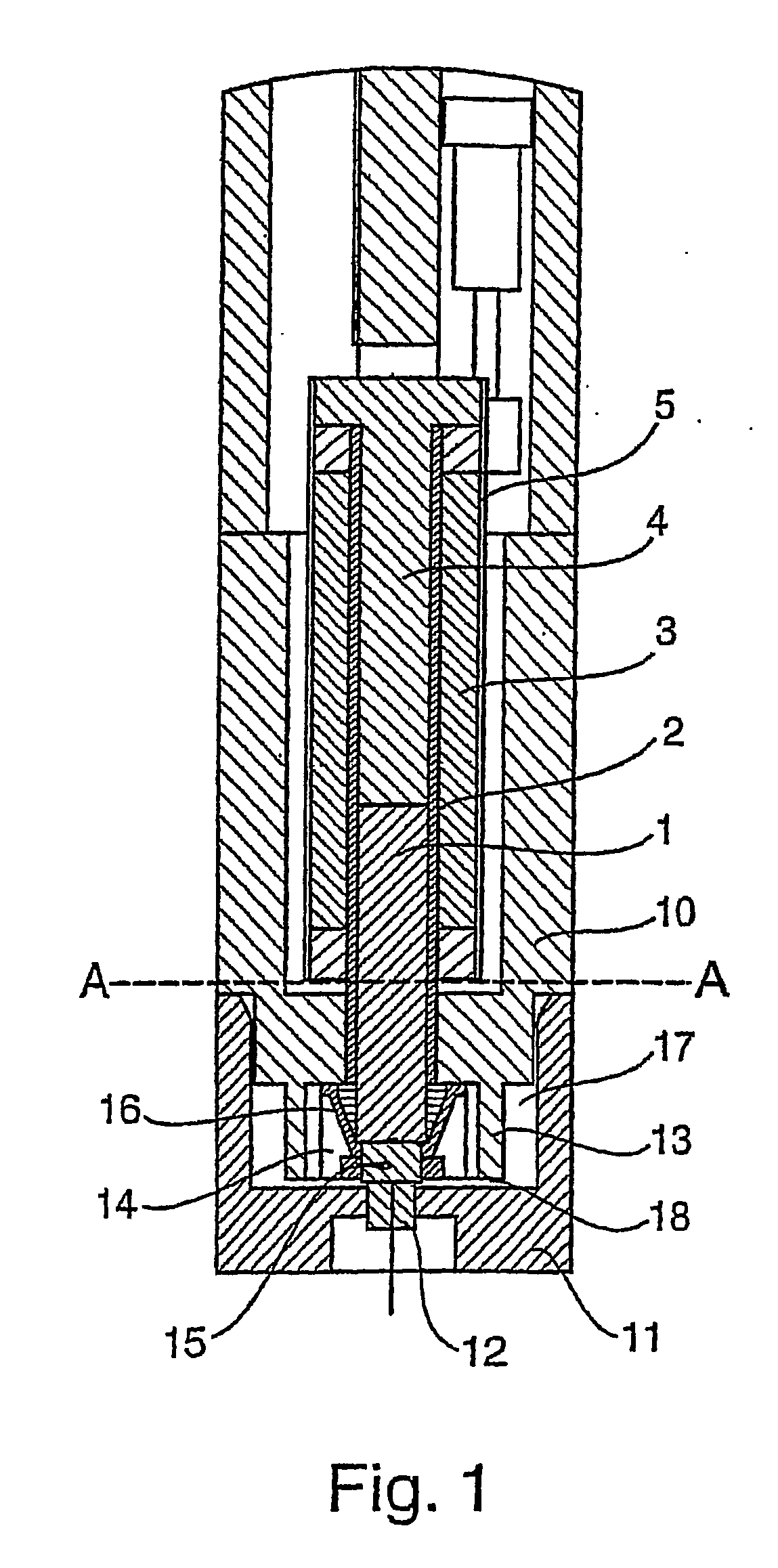

A lubricant reclamation system having a moisture absorbent cartridge (140). The cartridge (140) is fabricated placing a Superabsorbant Polymer (SAP) (142) within a boundary of polyester mesh (143). Moisture is extracted from a lubricant or other fluid and absorbed by the SAP. The moisture latent SAP bonds to the polyester mesh (143), potentially turning into a gel. A layer of polypropylene sorbent (144) is placed about the exterior of the boundary material (143), ensuring any moisture remains exterior to the sorbent layer (144). A resin layer can optionally be placed within a fluid flow following the discharge from polypropylene sorbent extracting aerosol from within the lubricant and as a barrier of detrimental ions with an exchange of beneficial ions. The entire cartridge can be placed within an enclosure or pouch body (162). The body (162) is designed to expand, accommodating a resultant increase in SAP volume. The cartridges can be integrated into filters comprising commonly known filtration elements.

Owner:PURADYN FILTER TECH

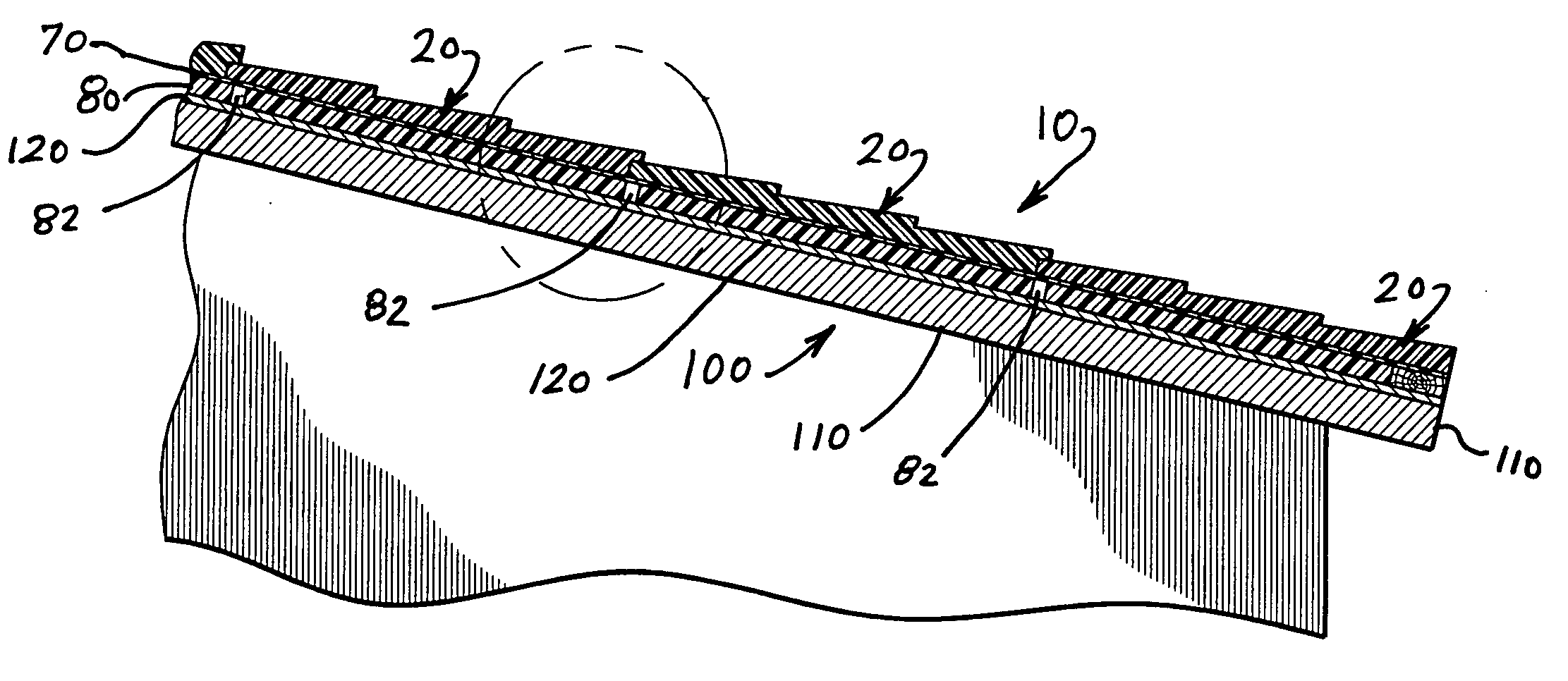

Roof system and method of fabrication and installation

In a roof system having exceptional insulating value, high density polyurethane foam or extruded polystyrene is used to form molded panels of predetermined size, shape and ornamental configuration. A non-skid primer coat is applied to the top surfaces and sides of the panels at the time of manufacture. A fabric layer or polyester mesh may be embedded in the bottom of the molded foam panels to enhance adhesion characteristics. During installation, the panels are set in a layer of low rise foam adhesive that is applied to the underlying roof deck or other surface (e.g., plywood, concrete, roofing felts, or spray foam), thereby avoiding the use of penetrating fasteners while enhancing wind uplift resistance. The panels may include interlocking structure for side-by-side and / or overlapping installation. Edges of the foam panels that need to be cut for fitting at valleys, hips, ridges, etc. are repaired in the field using factory supplied fabric and coating. After complete installation of the panels, a final topcoat composition such as, but not limited to, acrylic epoxy, silicon, or polyurea is applied to seal the roof system and provide a select roof color and desired grade.

Owner:ANAYA RICHARD J

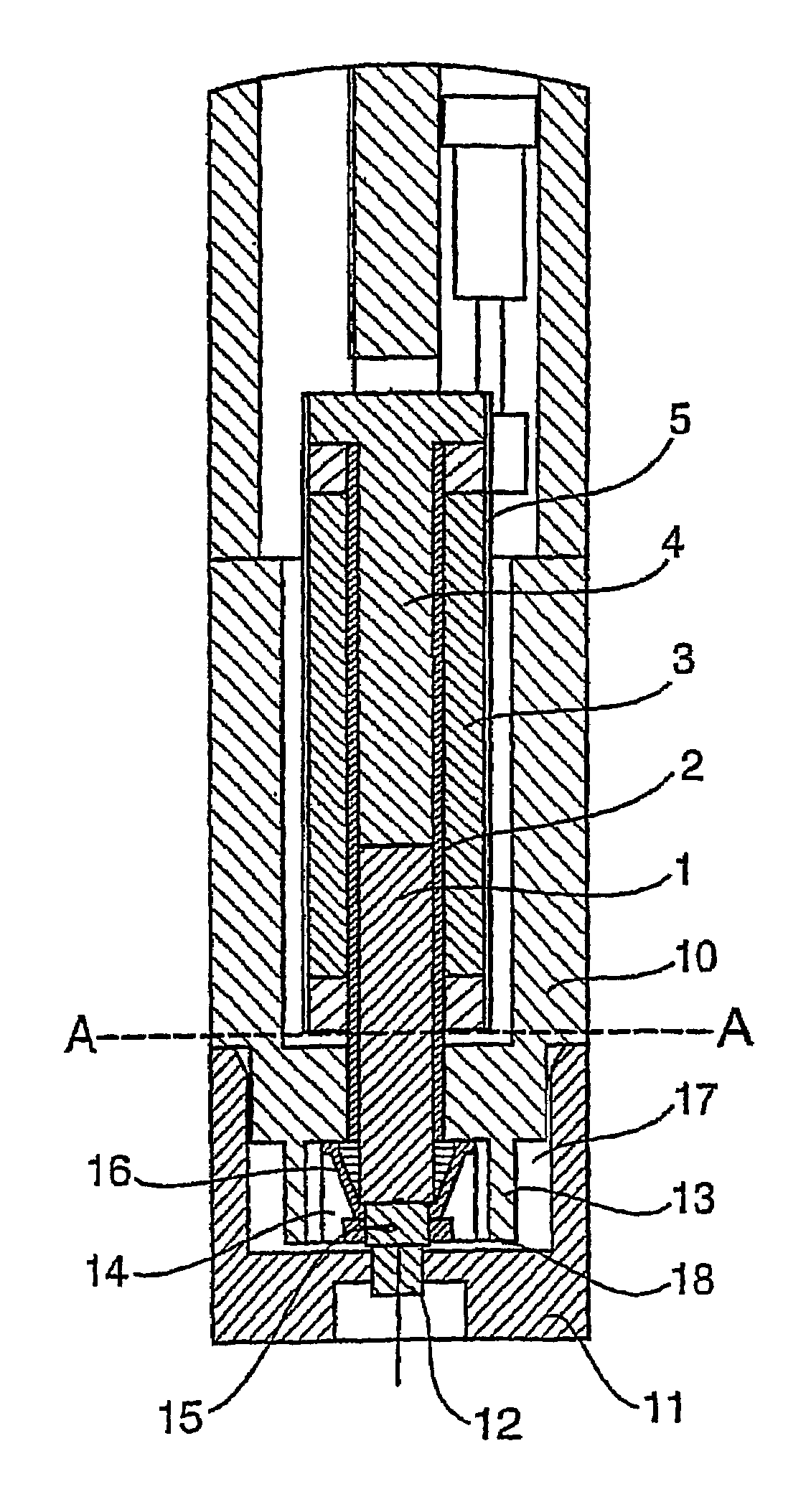

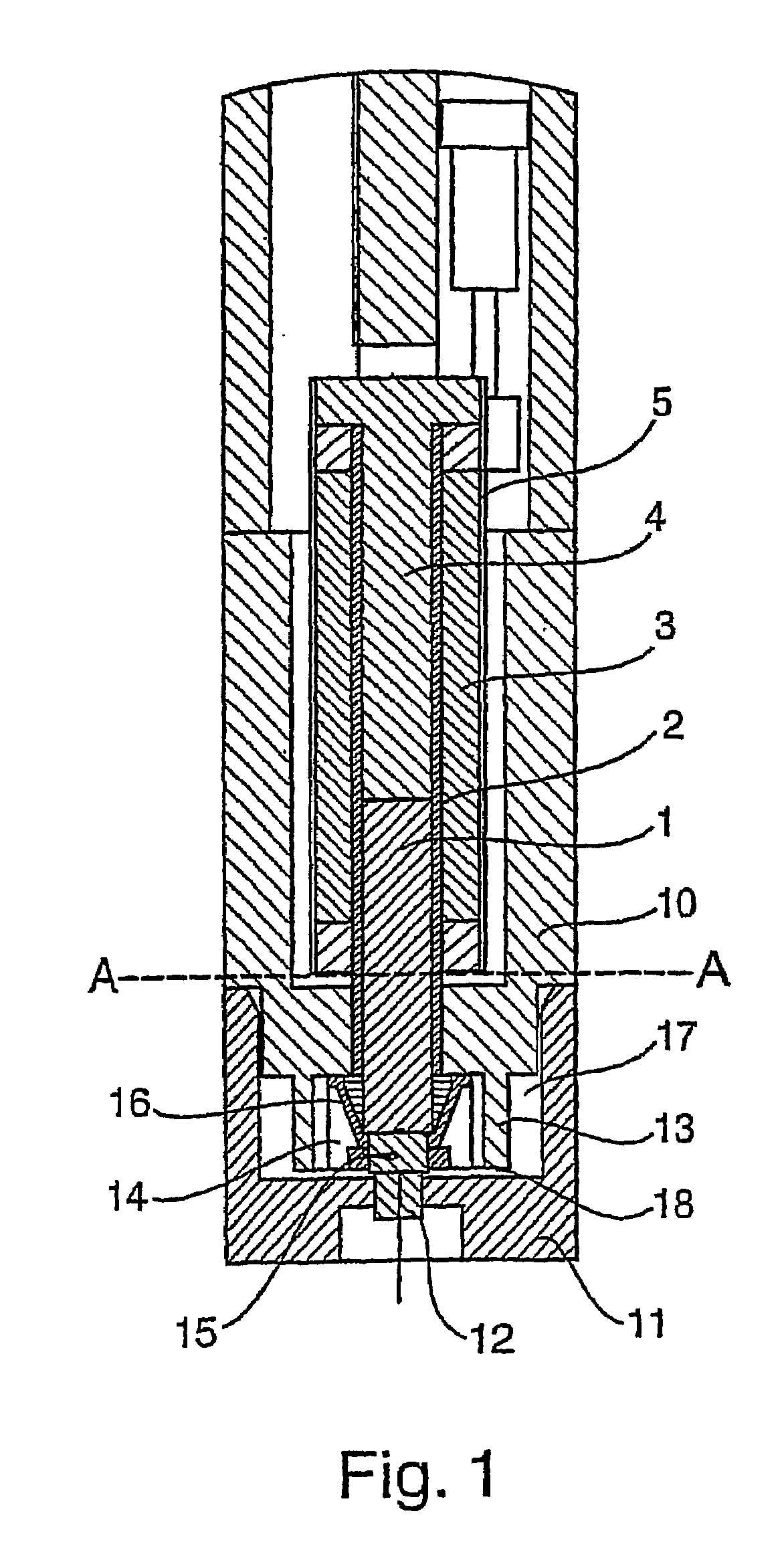

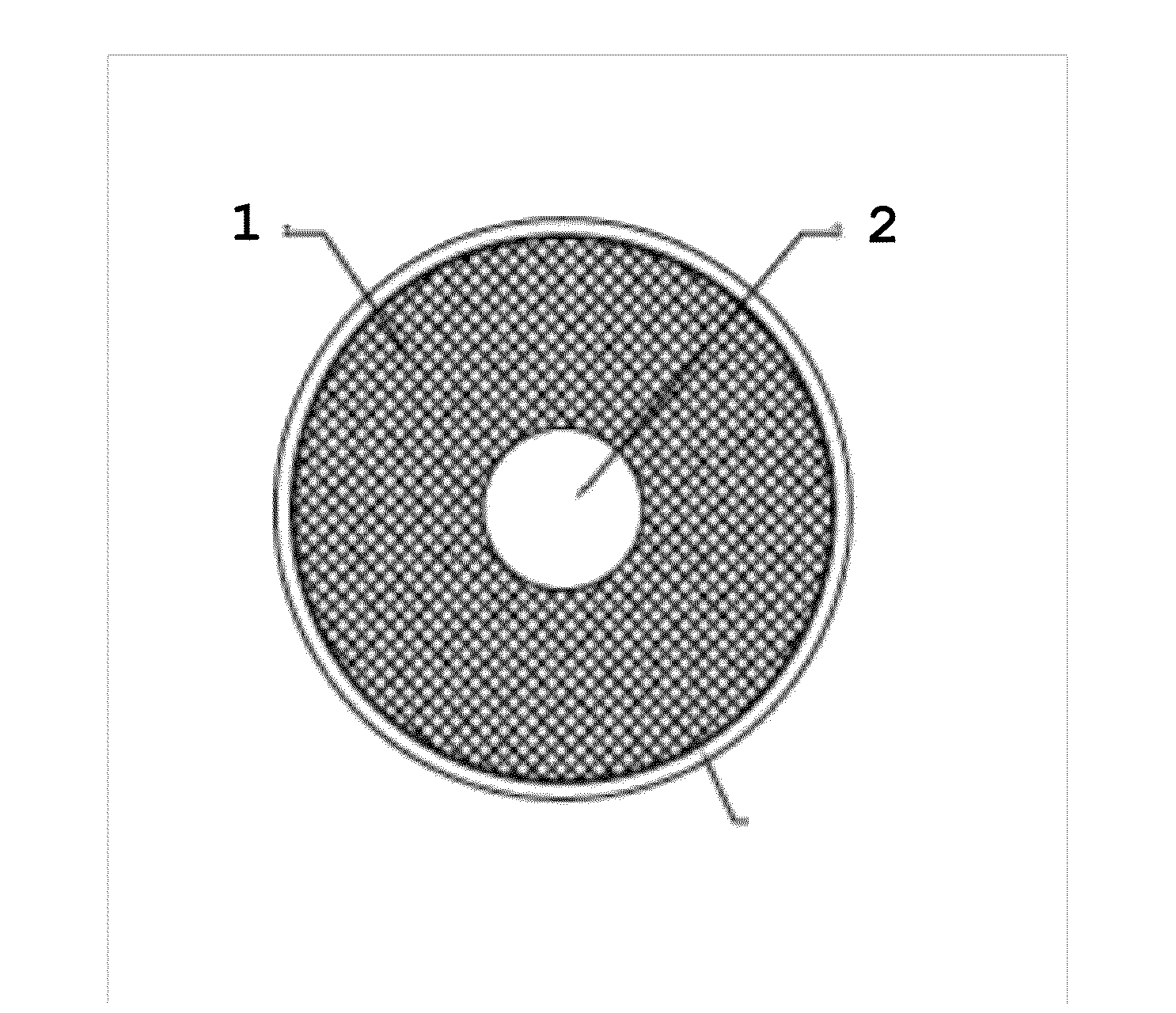

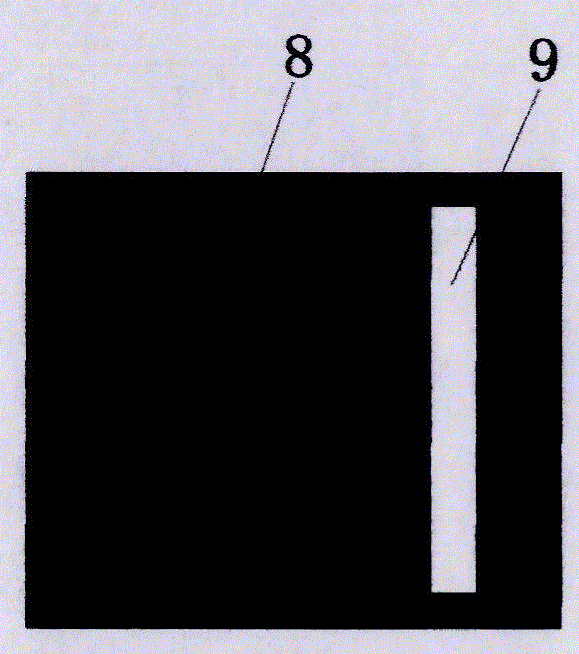

Drum skin for volume-reduced or electronic drums

InactiveUS20130312585A1Extended service lifeIncrease elasticityPercussion musical instrumentsPretreated surfacesPolyesterDrumhead

The invention relates to a drumhead for volume-reduced and electronic drums, comprising an elastic mesh, fixed on a drumframe and elastic colloidal coatings integrally formed on the upper and lower surfaces of the elastic mesh. The colloidal coating covers at least a part of the surfaces of the elastic mesh. The elastic mesh uses one of polyester mesh, nylon mesh, cotton-fiber and mesh. Said elastic colloidal coating is round and located at the center of the drum, and has an area of 5%-100% of the entire drumhead surface. By injecting the colloid on the mesh according to the invention, the strength, elasticity and wear resistance of the elastic mesh body can be improved, and the lifetime of the drumhead can be extended up to five times. The invention reduces the sound of the drumstick by 20 dB.

Owner:TIANJIN JINBAO MUSICAL INSTR

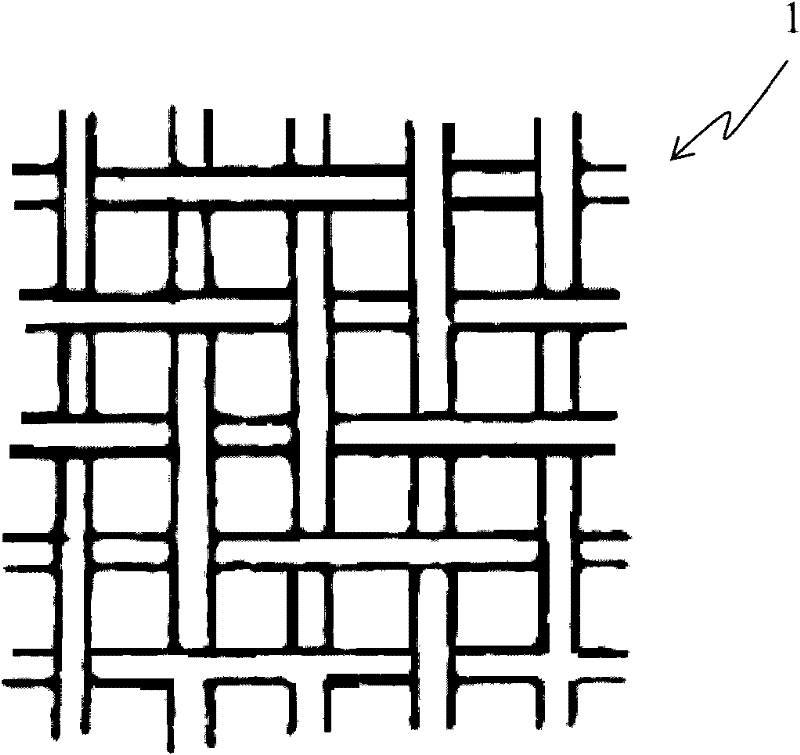

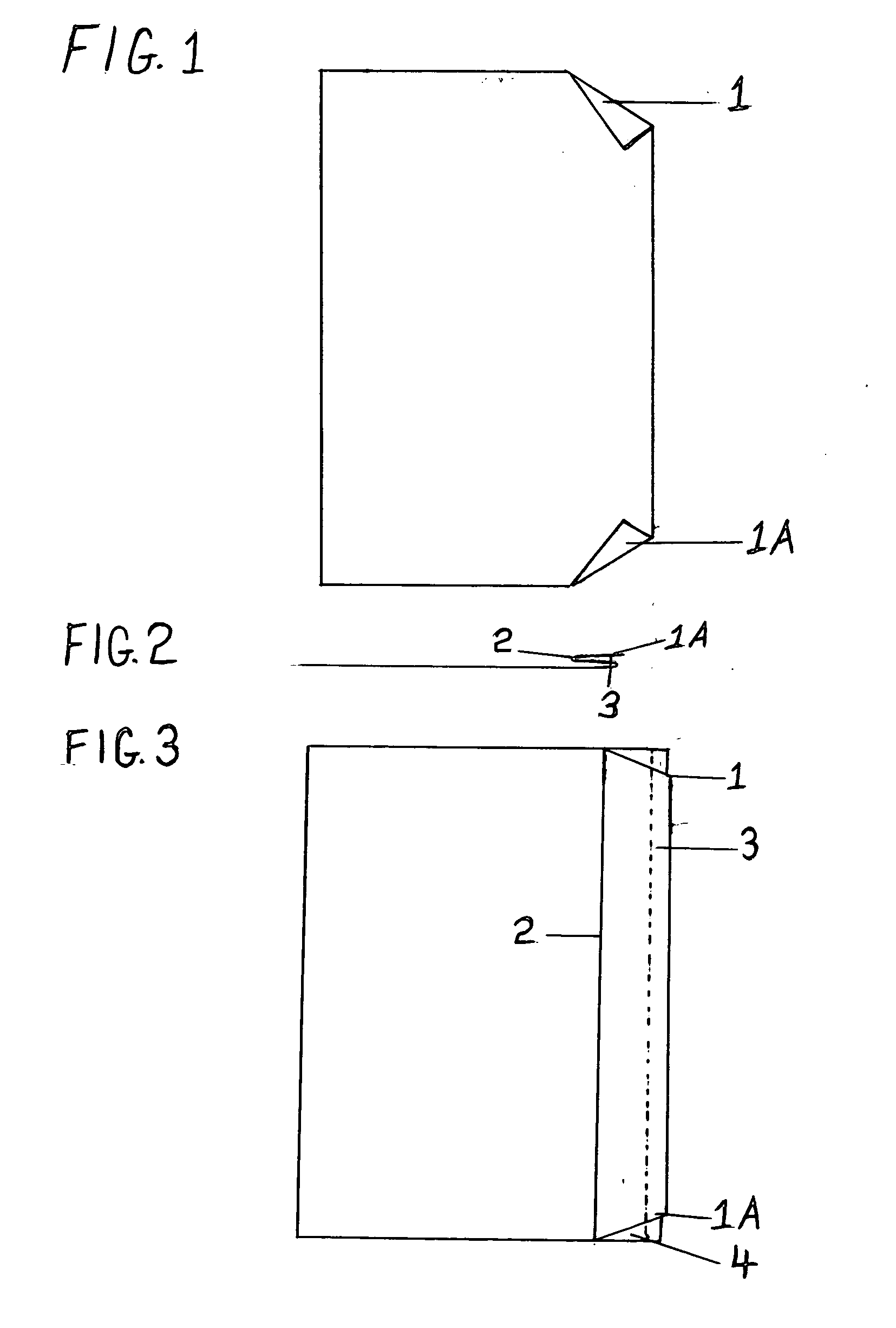

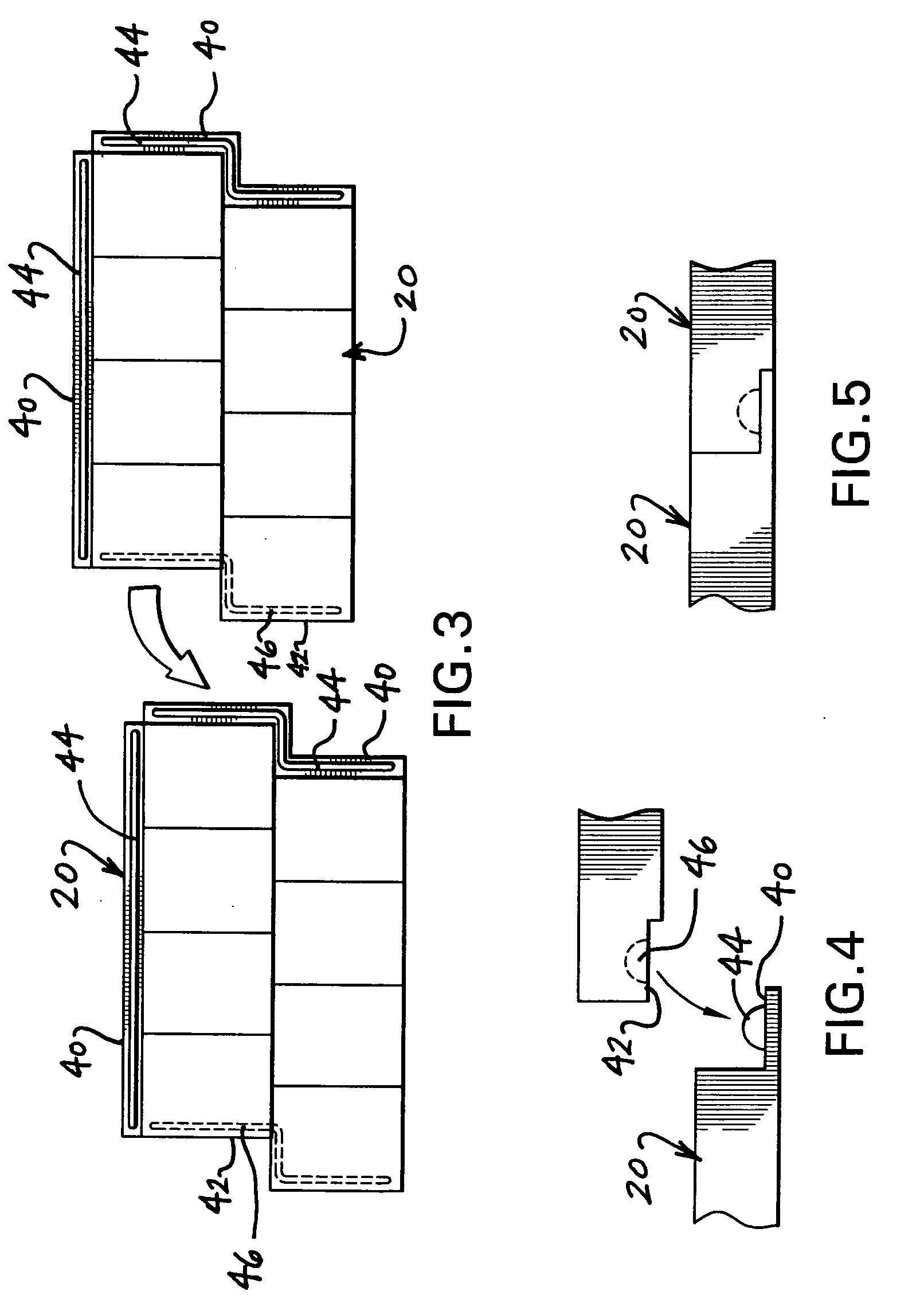

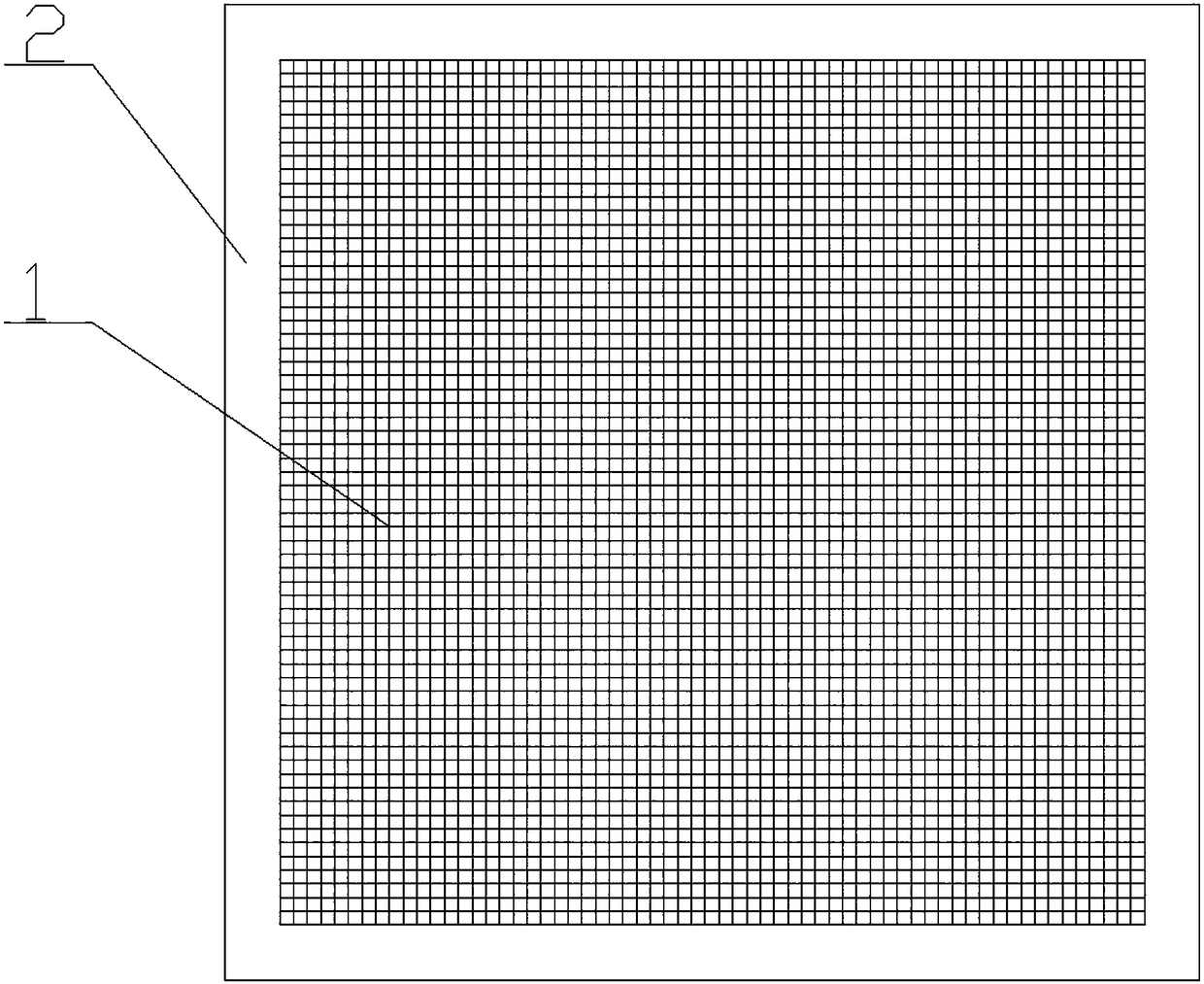

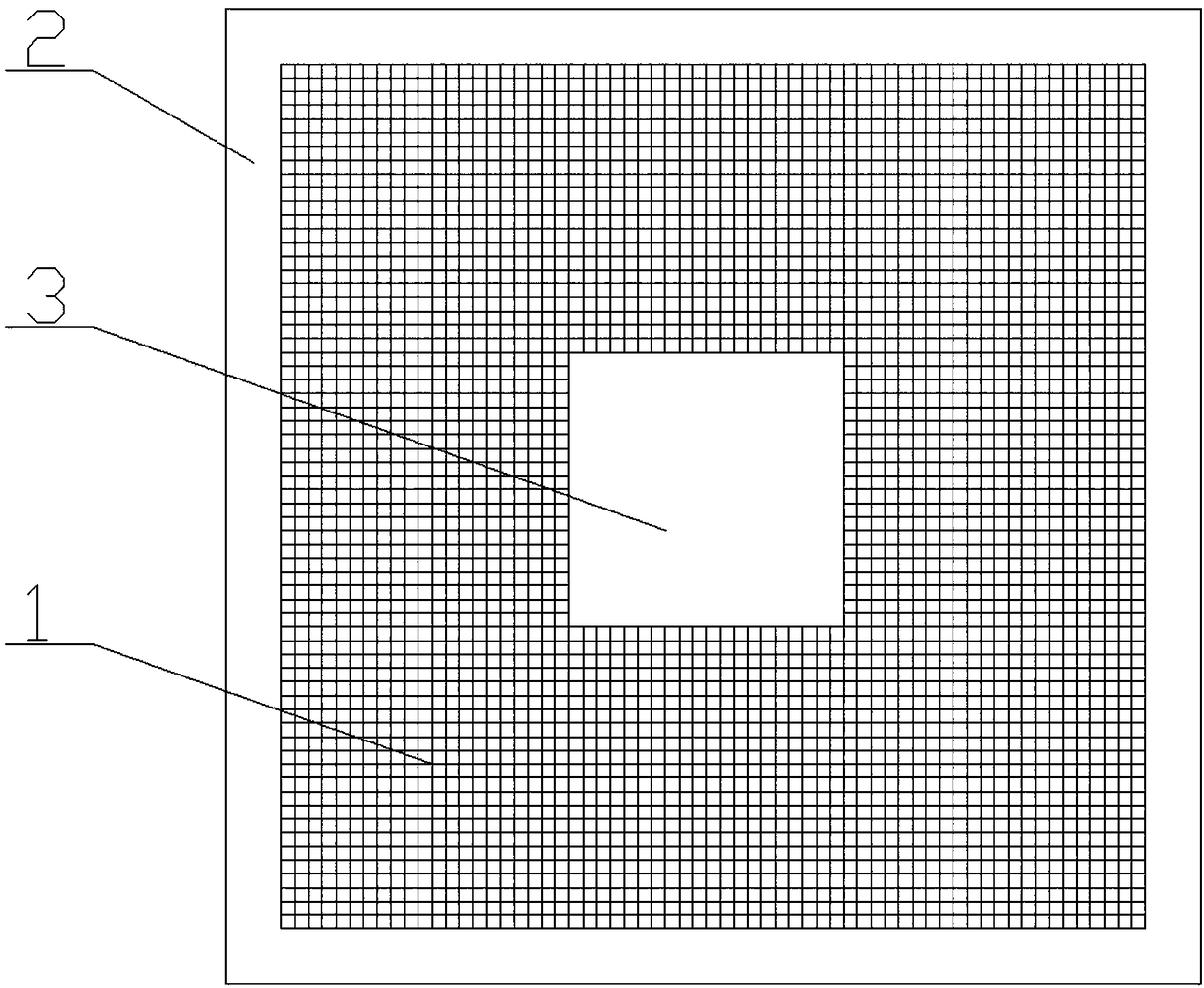

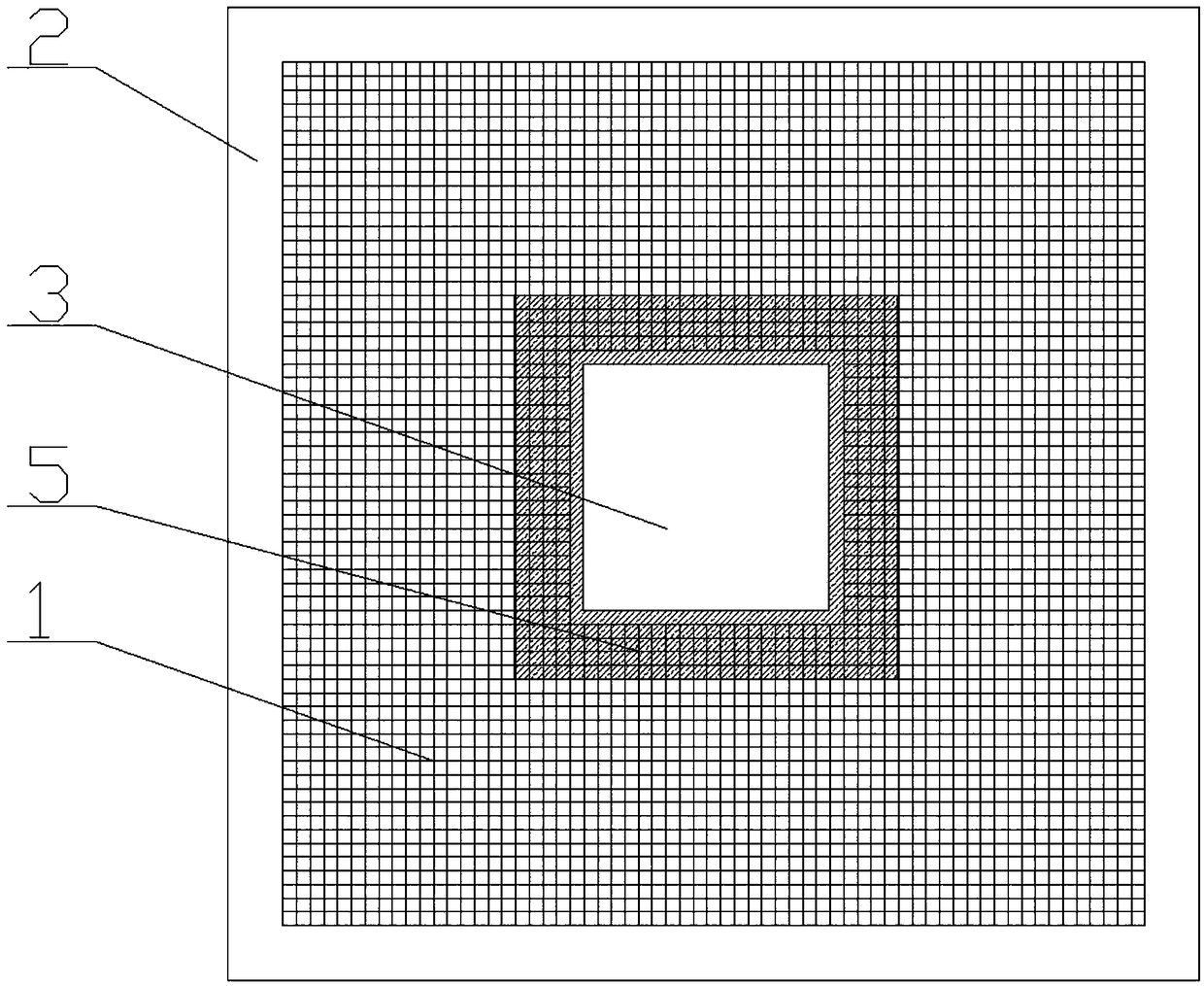

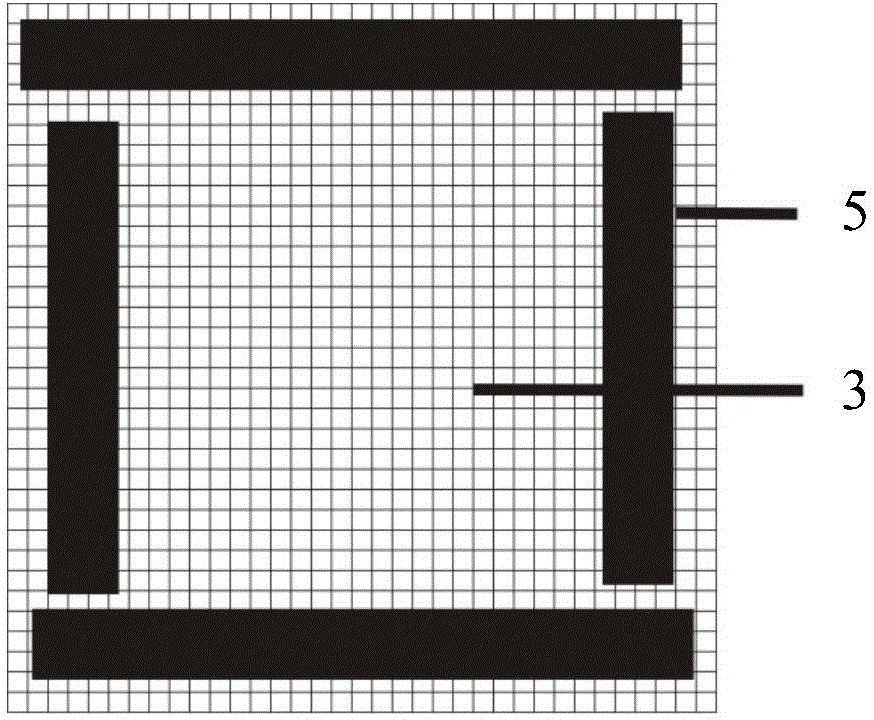

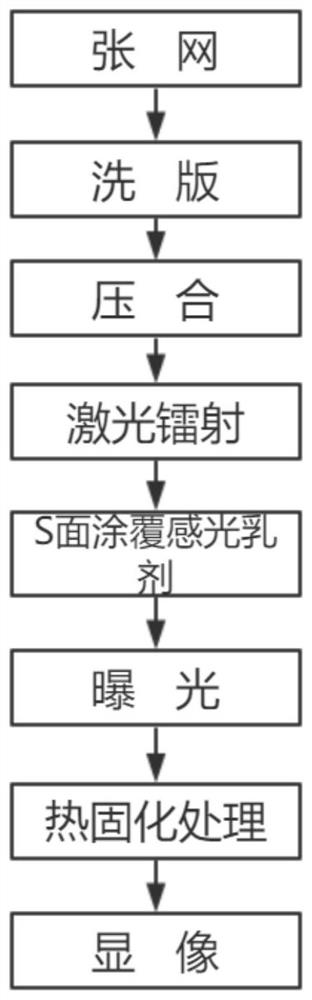

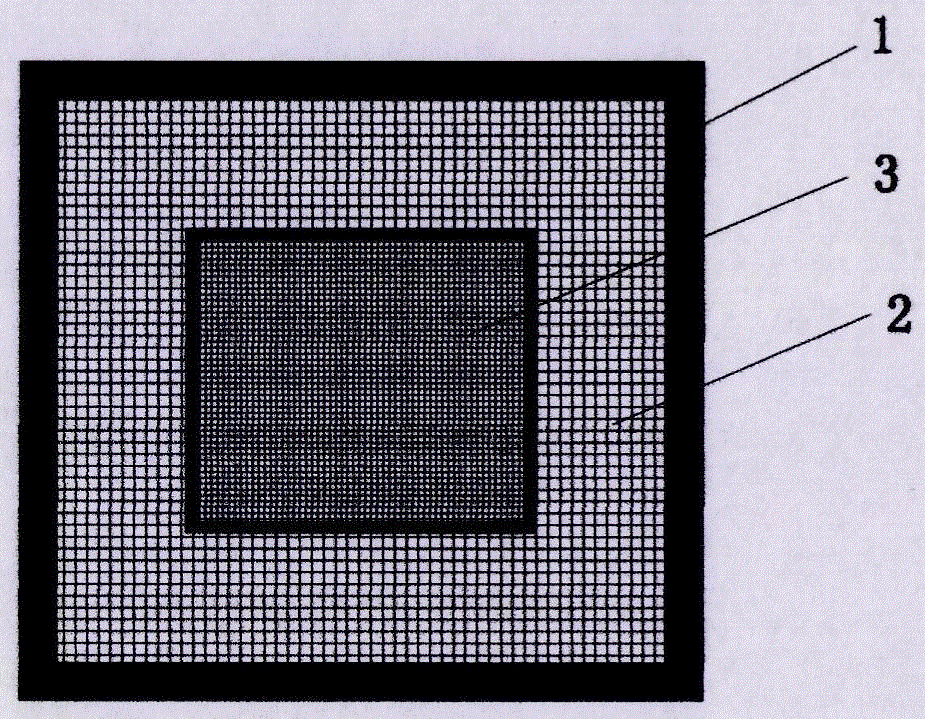

Preparation method of composite screen printing plate

The invention discloses a preparation method of a composite screen printing plate. The preparation method is characterized by comprising the following steps of: providing a polyester screen printing plate, a hot-melt adhesive sheet (5) and steel wire mesh cloth (4), wherein the polyester screen printing plate comprises polyester mesh cloth; emptying the center of the polyester mesh cloth (1) to form a cavity (3); placing the hot-melt adhesive sheet (5) on the polyester mesh cloth (1) to make sure that the hot-melt adhesive sheet (5) covers the boundary of the cavity (3) and a part of the cavity (3) is exposed; placing the steel wire mesh cloth (4) on the hot-melt adhesive sheet (5) and covering the cavity (3); and combining the steel wire mesh cloth (4) with the polyester mesh cloth (1) through the hot-melt adhesive sheet (5) in a melting manner. According to the preparation method disclosed by the invention, the steel wire mesh cloth is combined with the step of the polyester mesh cloth in a hot-melting manner through the hot-melt adhesive sheet so that a gradual bevel interface is formed at the step, the quality of the screen printing plate is improved, and the defects that the plate surface is out of flatness, the coated film thickness is not uniform, explosion is easily generated and the like are alleviated.

Owner:LOBON SCREEN PRINTING EQUIP

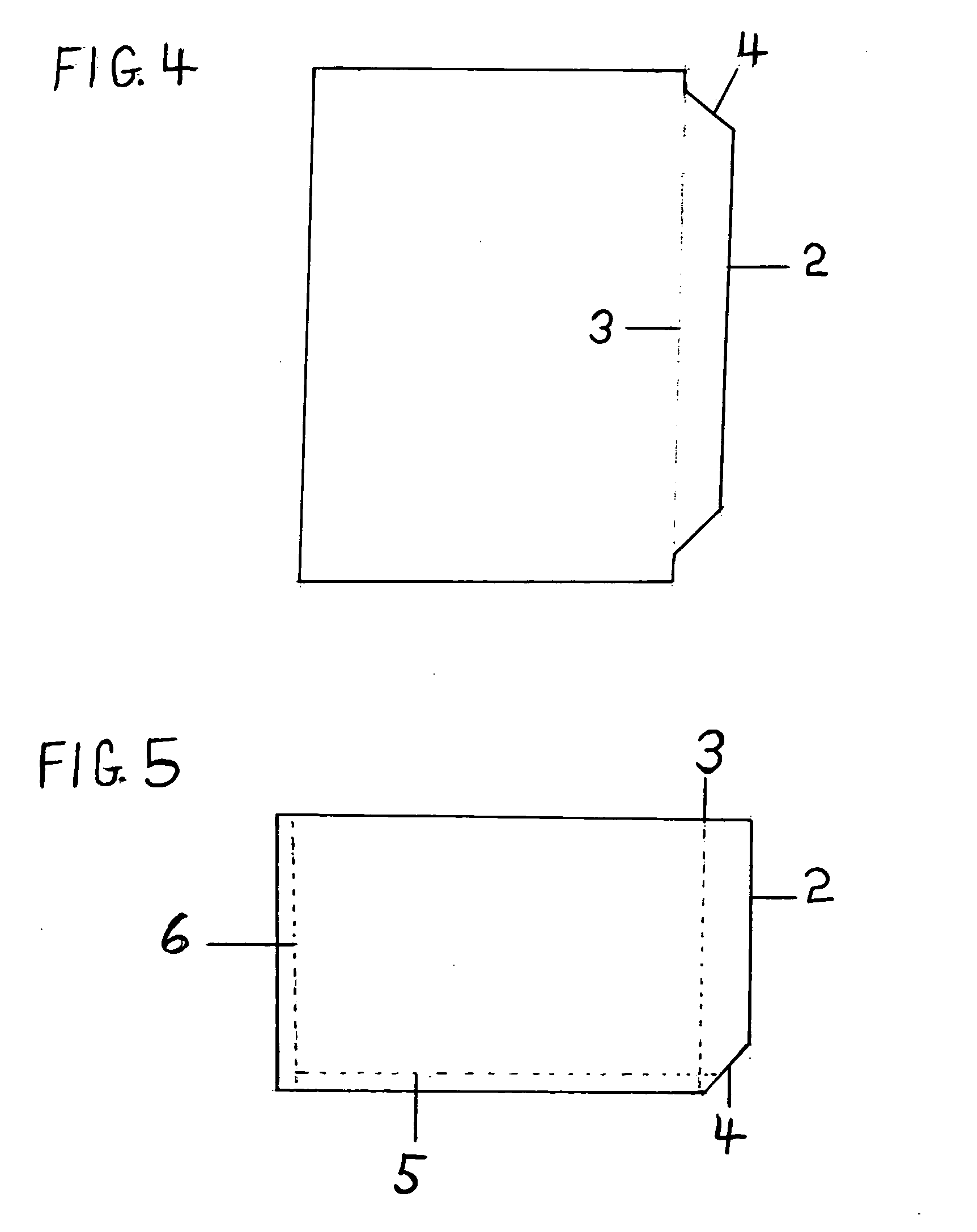

Composite steel wire mesh cloth and preparation method thereof

InactiveCN104669769AUniform thicknessImprove straightnessScreen printersForme preparationPolyesterPet substrate

The invention discloses composite steel wire mesh cloth and a preparation method thereof. The composite steel wire mesh cloth is mainly formed by compounding polyester mesh cloth and stainless steel wire mesh cloth, wherein the stainless steel wire mesh cloth is located in a hollowed region in the middle of the polyester mesh cloth; an overlapping connector is arranged at the connection part of the stainless steel wire mesh cloth and the polyester mesh cloth; and the front and back surfaces of the overlapping connector are smooth and flat and have no gradient. The preparation method comprises the following steps: cutting the polyester mesh cloth; putting a PET substrate in the middle of a pre-set tabletop; fixing the polyester mesh cloth on the PET substrate; putting the stainless steel wire mesh cloth to be compounded on the hollowed polyester mesh cloth; printing the overlapped part of the stainless steel wire mesh cloth and the hollowed polyester mesh cloth with glue; curing the printed glue under UV light; and step 8, finishing compounding. By virtue of the composite steel wire mesh cloth, the problems that the stainless steel wire mesh cloth and the polyester mesh cloth are compounded, and the compounding connector has the obvious gradient when the polyester mesh cloth is cut and naked are solved.

Owner:ZHEJIANG SHUOKE SCI & TECH

Desert camouflage

ActiveUS20090104419A1Reduce indoor temperatureReduce heat transferSynthetic resin layered productsWarp knittingGlass fiberPolyester

A thermal camouflage material for use on a tank or other military vehicle in a desert environment includes an outer layer of knitted fiberglass alone or with polyester having an outer coating of PVC and carbon black, and an inner film of aluminum; and an inner layer defined by a three-dimensional decoupling fabric between the aluminum film on the outer layer. The decoupling fabric is formed of outer and inner polyester mesh films with polyaramid sandwiched therebetween.

Owner:HER MAJESTY THE QUEEN AS REPRESENTED BY THE MINIST OF NAT DEFENCE OF HER MAJESTYS CANADIAN GOVERNMENT

Multi-paneled protective undergarment

InactiveUS20130019365A1Improve mobilityImprove protectionPersonal protection gearProtective garmentThighButtocks

A protective undergarment (10), shown in the form of shorts, includes integrally formed protective panels (22, 26, 30) that exhibit slash-proof properties. The protective areas (22, 26, 30) are made from a flexible Kevlar® knit or the like, and extend to cover the groin, crotch, substantial areas of the buttocks and the inner thigh regions of both legs. The protective panels (22, 26, 30) are externally snitched to a low thermal burden material (18, 20), such as a polyester mesh, that provides elasticity and completes the structure of the shorts (10). The Kevlar® knit is flexible and preferably lies directly against the skin of a user to provide blast wave and ballistic fragment deflection whilst permitting mobility in a lightweight arrangement. Varying thickness of the Kevlar® knit can be used in the protective areas (22, 26, 30) selectively to enhance protection against blast wave and fragment penetration. The shorts (10) find particular application in battlefield theatres where military personnel are exposed to bomb threats.

Owner:BCB INT

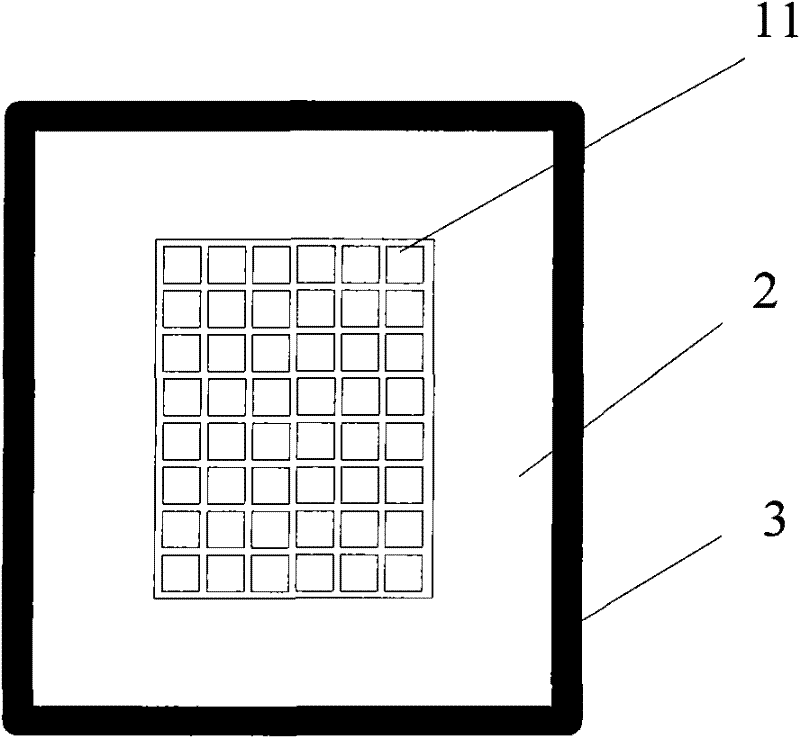

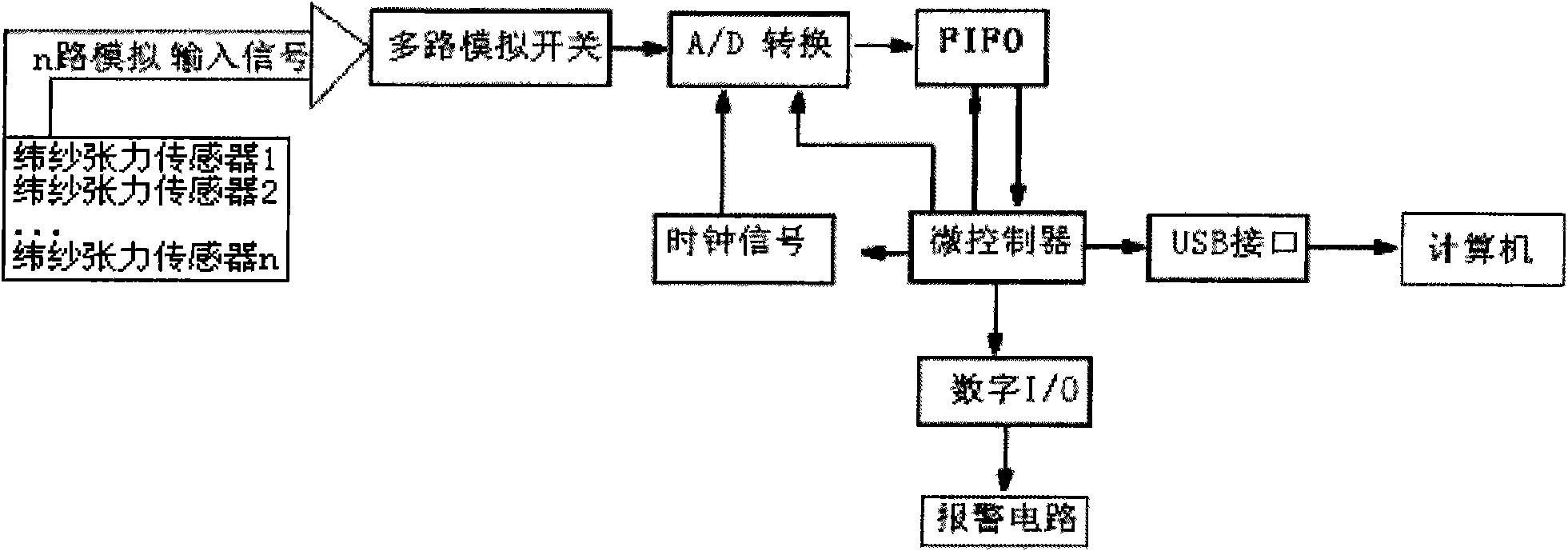

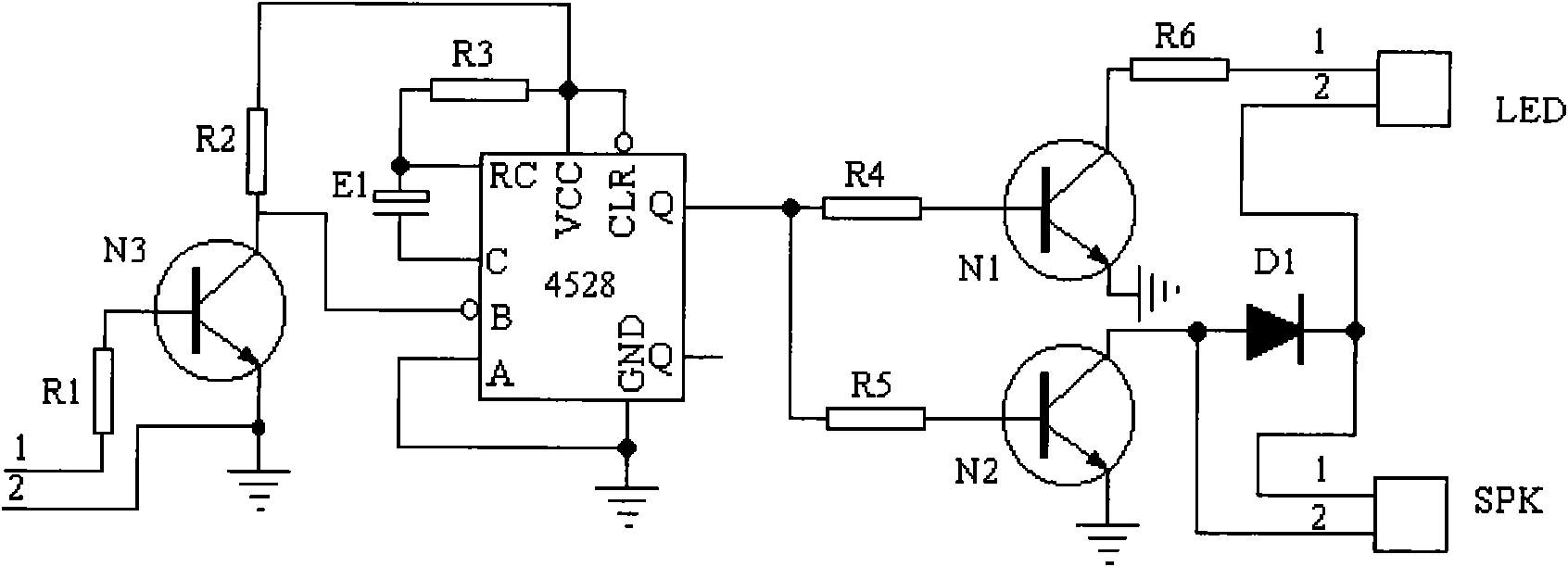

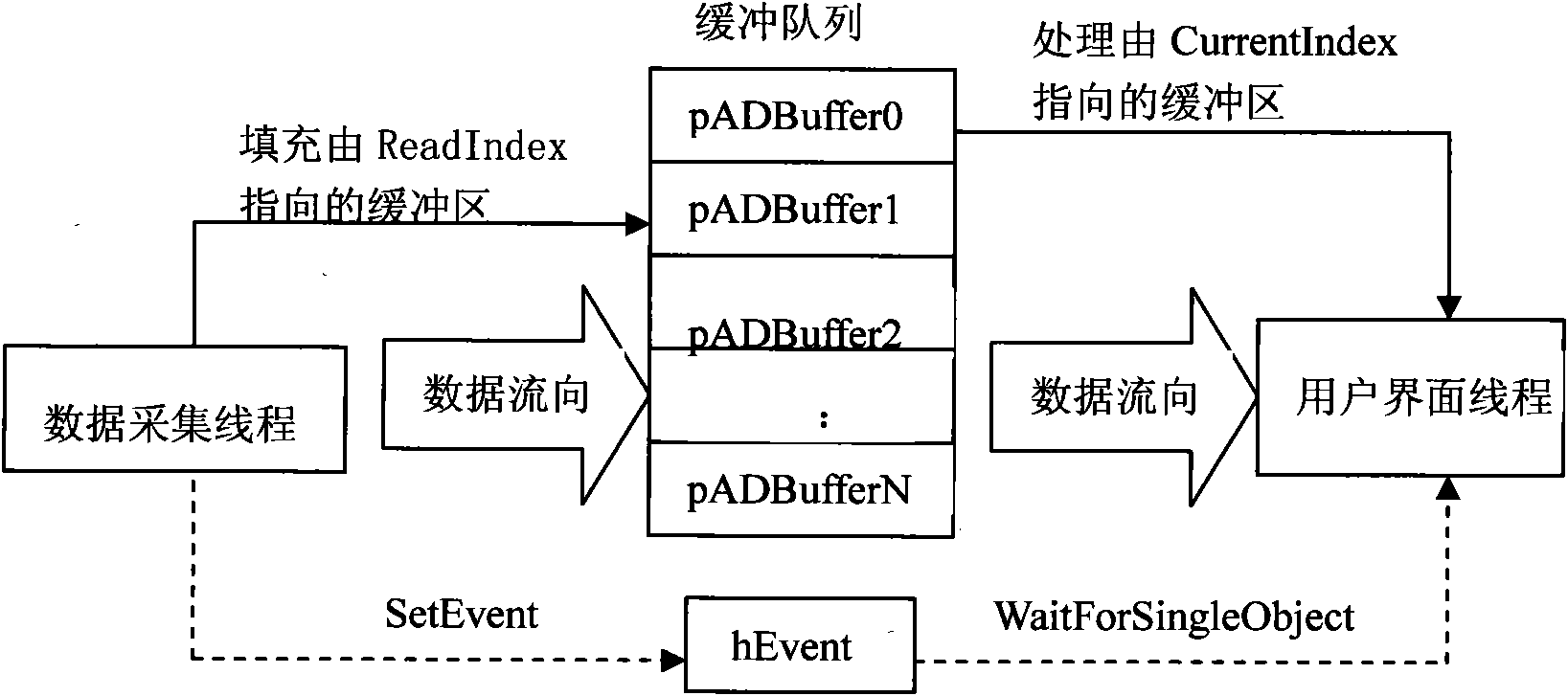

Method for measuring weft yarn tension of polyester weaving machine based on multithreading

InactiveCN101900619AHigh degree of automationHigh degree of informatizationTension measurementShuttlesPolyesterData acquisition

The invention discloses a method for measuring a weft yarn tension of a polyester weaving machine based on multithreading, which is characterized in that the weft yarn tension is on-line measured and real-time displayed by using a multithreading technique and a speedy acquisition system. A data speedy acquisition system is used. A system hardware module comprises a sensor, a signal regulator, an A / D converter, a micro controller chip, a USB interface chip, a FIFO memorizer and a clock signal circuit, and the like. The multithreading technique comprises a data acquisition threading and a user interface threading. In the weaving process of the weaving machine, as shooting-in, the data acquisition threading has a higher priority working threading in order to ensure the data acquisition for high-capacity continuous data. When the weaving machine is not shooting-in, the user interface threading will recover the running state immediately and rapidly treat the data, such as drawing a tension curve in a screen window, saving, and the like. The method takes full advantage of the weaving machine, realizes the on-line measurement for the weft yarn tension and the real-time display for the tension curve, has concise outlook, realizes high degree of automation, and promotes the weaving quality of the texture.

Owner:TIANJIN POLYTECHNIC UNIV

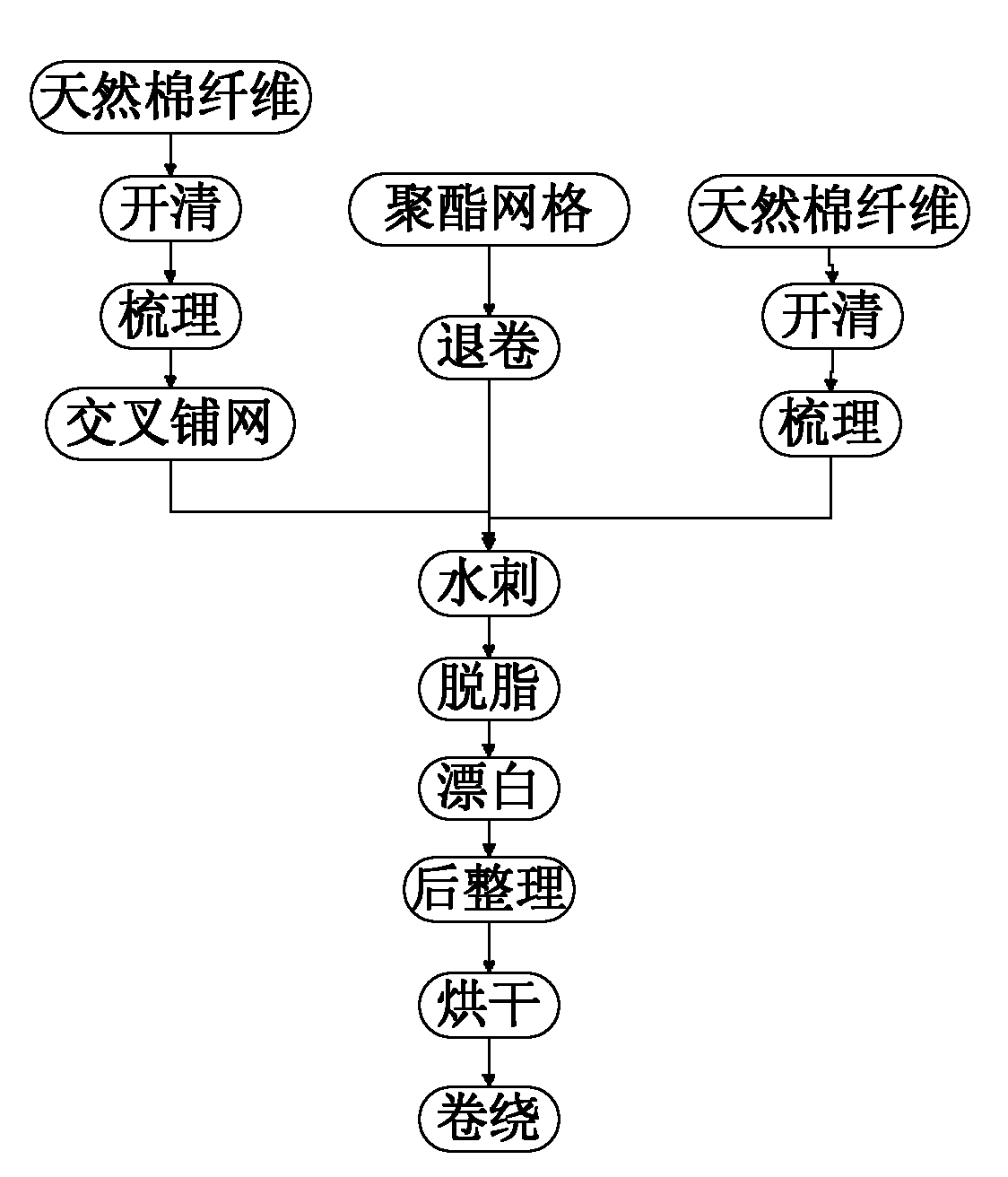

Oxygen release hydrogel dressing and preparation method thereof

The invention provides an oxygen release hydrogel dressing. The oxygen release hydrogel dressing is characterized by comprising a first dressing and a second dressing, wherein the first dressing is prepared from a hydrogel dressing body, glucose, an oxygen release catalyst and a polyester mesh sheet having a pore structure, the second dressing comprises a hydrogel dressing body and glucose oxidase, and the first dressing and the second dressing cooperate for use. The oxygen release hydrogel material provided by the invention has good water vapor permeability and good water absorption performance, and a final product can release oxygen, iodine elementary substances and water after being in contact with air, so that the oxygen release hydrogel material as a novel functional material can be used for various acute and chronic wounds, can autonomously remove exudate of damaged tissue, and can guarantee a wet wound environment; and besides, the local oxygen concentration is also increased, anti-inflammatory iodine elementary substances are released, and the oxygen release hydrogel material has the effects of relieving wound pain and accelerating the healing speed of the damaged tissue.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

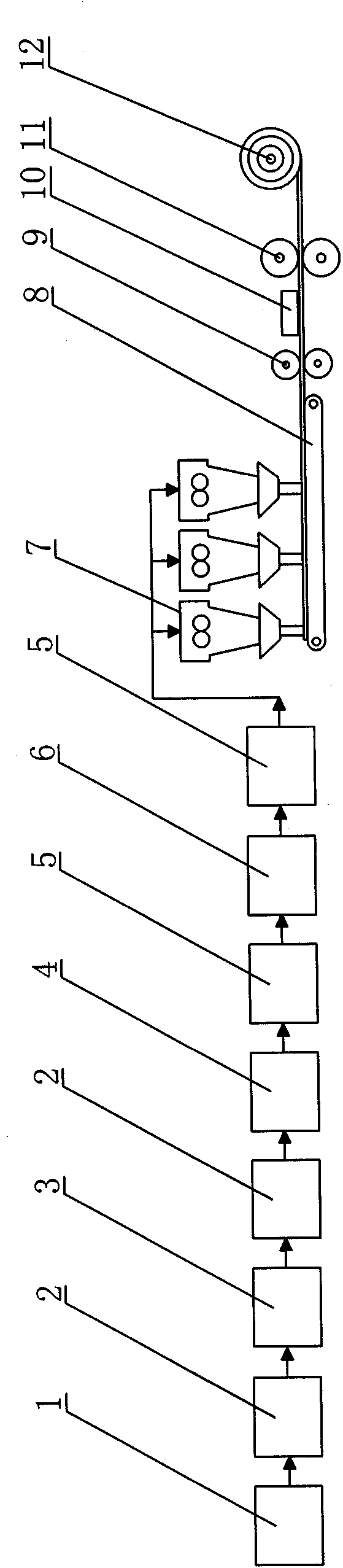

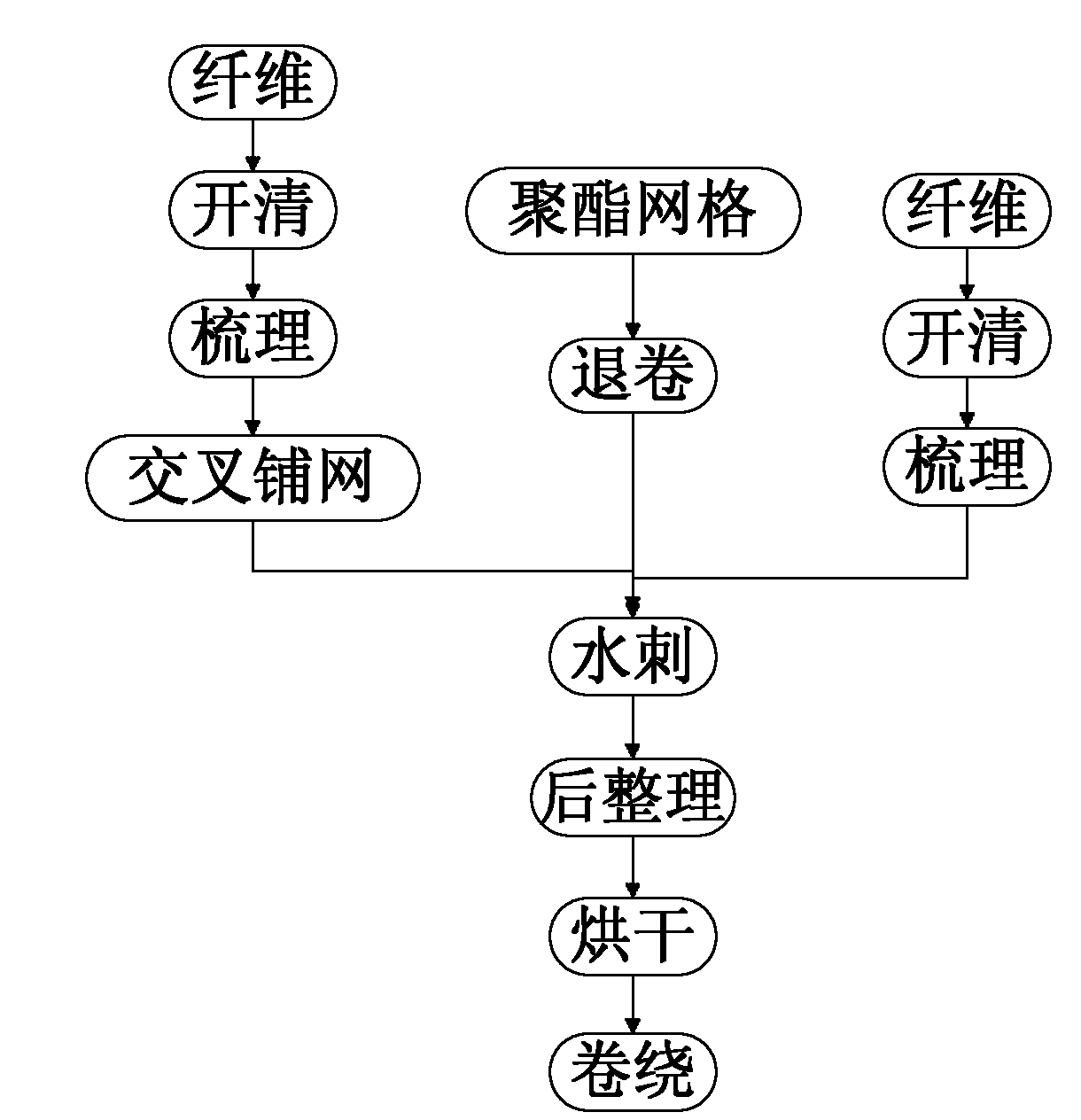

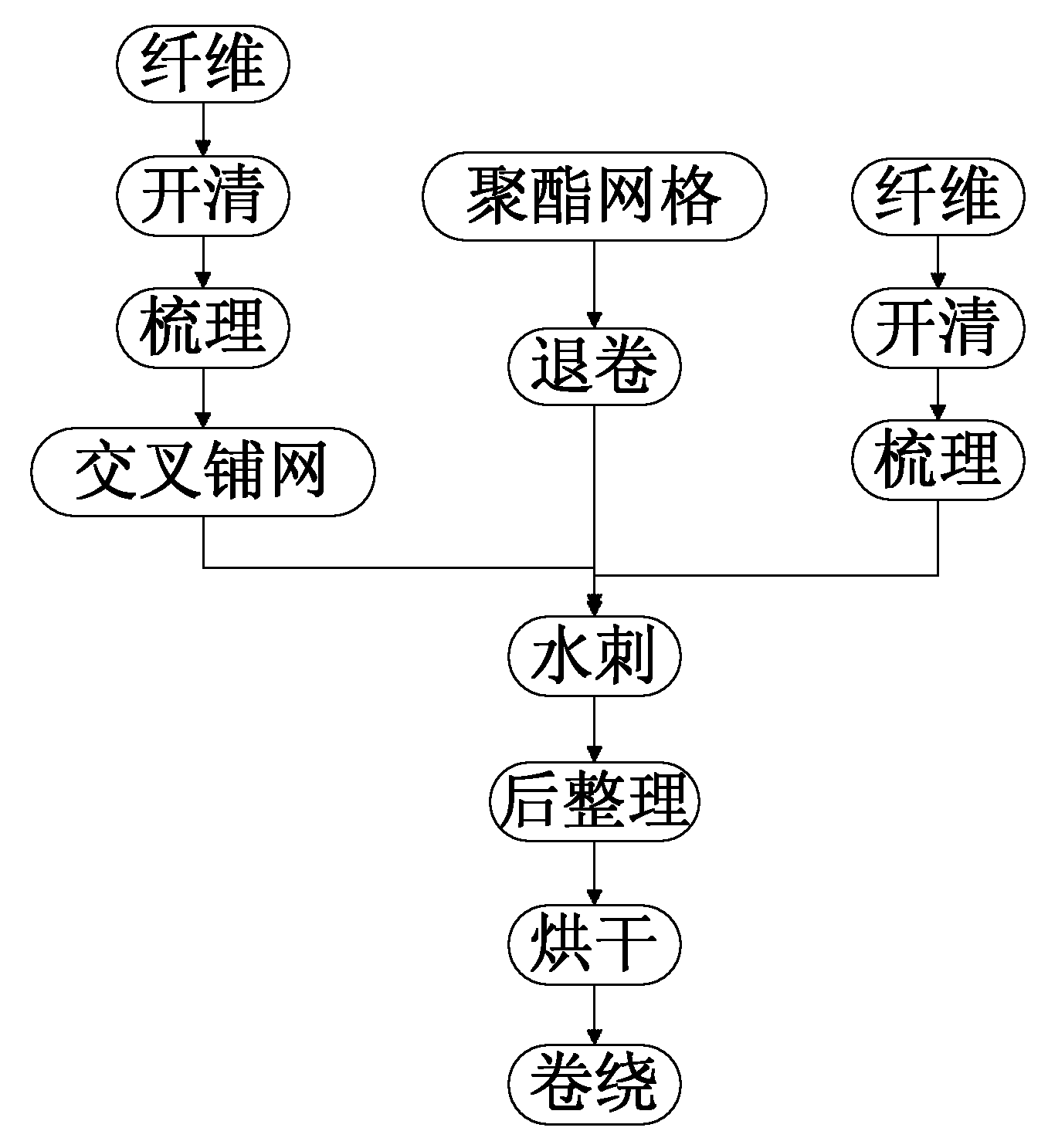

Spunlaced nonwoven fabric for clothing and production method and equipment thereof

ActiveCN102312353ASimple processReduced reinvestment costsFibre treatmentNon-woven fabricsProduction linePolyester

The invention discloses a spunlaced nonwoven fabric for clothing and a production method and equipment thereof, which relate to the field of the nonwoven fabric. A triple-layered composite structure is formed by an upper layer and a lower layer of fiber meshes which are produced by a polyester mesh and a laying net, and then after spunlaced fixation and post treatment, the spunlaced nonwoven fabric for clothing is produced and has good elasticity, washing resistance, wear resistance and air permeability. The production method only needs to simply remold the existing spunlaced production line, only one polyester mesh uncoil stand is needed to be added, so the spunlaced nonwoven fabric for clothing can be produced, and the reinvestment cost of the equipment is greatly reduced; and the manufacture and the technology are simple and easy to process, and the production cost of the product is low.

Owner:稳健医疗(武汉)有限公司 +1

Method for preparing battery diaphragm paper by using glass fiber and glass wool

InactiveCN104120619AImprove performanceQuality improvementSynthetic cellulose/non-cellulose material pulp/paperPolyesterPolymer science

The invention discloses a method for preparing a battery diaphragm paper by using glass fiber and glass wool. The method has the advantages that the battery diaphragm paper is prepared by adopting wet papermaking technique; the characteristics of raw materials are fully exerted; the preparation process is simple and the finished product performance is excellent. The method particularly comprises the following steps: (1) dispersing the glass wool in an acid solution, continuously stirring, adding the glass fiber, stirring, defibering by using a standard defibering machine and adding dispersed binder fiber to obtain uniformly-suspended mixed fiber pulp; (2) transferring the formed paper web to a flat and compact polyester mesh, slightly pressing by using a press roll, putting in a microwave oven and carrying out high fire microwaving for 10-30s; (3) transferring the microwaved wet paper web between two copper wire meshes and drying, wherein the drying method comprises far infrared drying and through air-drying. By adopting the method disclosed by the invention, the excellent performances of the glass fiber and the glass wool can be fully exerted and high-quality battery diaphragm body paper is obtained through the wet papermaking technique and the through air-drying process in special paper preparation.

Owner:SHAANXI UNIV OF SCI & TECH

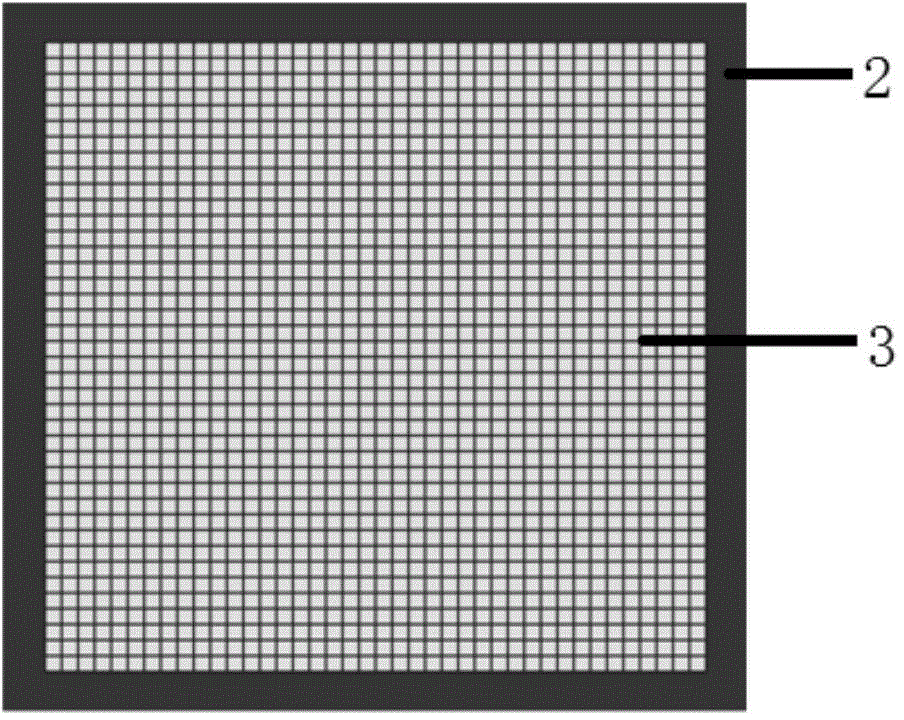

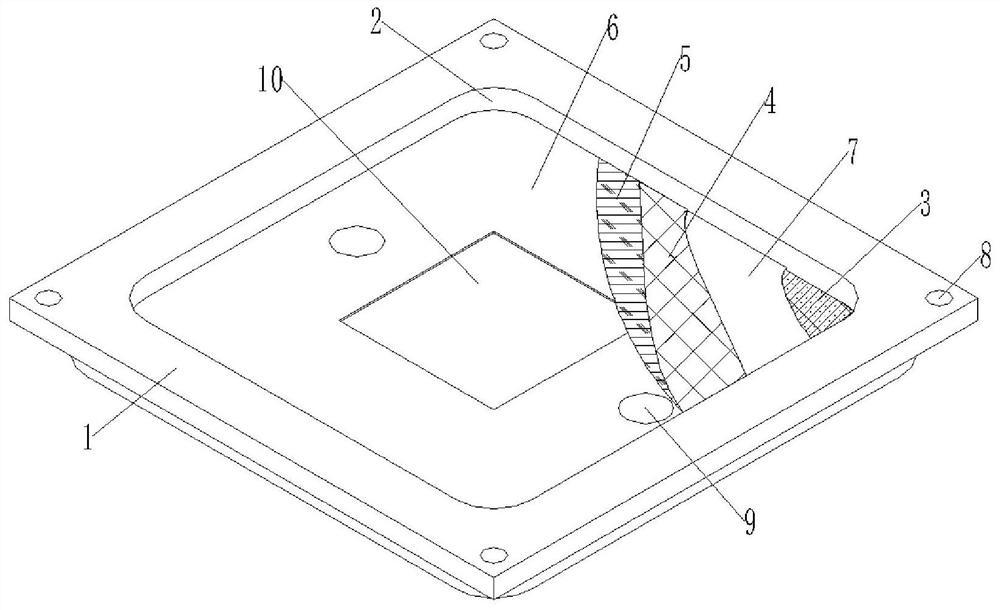

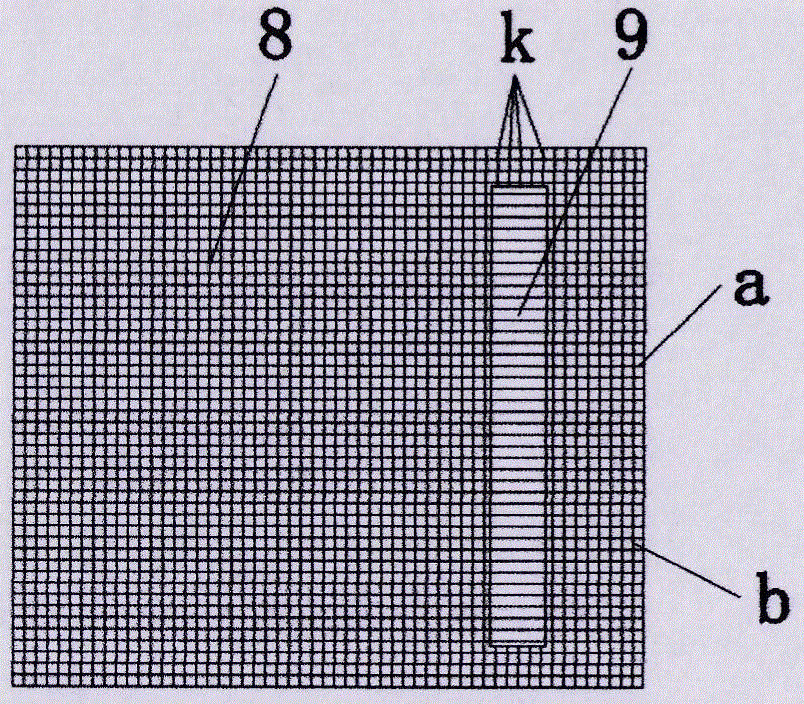

Polymeric membrane screen printing plate with optimized S-face coated structure

PendingCN111923629AImprove printing efficiencyExtended service lifePlate printingFoil printingScreen printingPolyester

The invention discloses a polymeric membrane screen printing plate with an optimized S-face coated structure. The polymeric membrane screen printing plate comprises a screen frame, wherein the interior of the screen frame is of a concave surface structure; a polyester mesh layer is arranged on the concave surface structure, a steel wire mesh layer is arranged at the position, located in the concave surface structure, of the upper portion of the polyester mesh layer, a polymeric membrane layer is arranged on the steel wire mesh layer, and an emulsion layer is arranged on the polymeric membranelayer; and the boundary contour shape of the polyester mesh layer is consistent with the boundary contour shape of the steel wire mesh layer, a hot melt adhesive layer is arranged between the polyester mesh layer and the steel wire mesh layer, and the polyester mesh layer and the steel wire mesh layer are compounded together through hot melt adhesive. The polymeric membrane screen printing plate with the optimized S-face coated structure has the beneficial effects that through the emulsion layer, the problem that the printing height is insufficient is effectively solved, and the printing efficiency of the screen printing plate is improved; the S face is coated with emulsion, so that the abrasion resistance of the S face of the screen printing plate is improved, and the service life of thescreen printing plate is prolonged; in addition, the emulsion layer is additionally arranged, so that the abrasion degree of a printing scraping knife is reduced, the service cycle of the scraping knife is prolonged, and the production cost of customers is reduced.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

Preparation method for cellulose acetate forward osmosis membrane

InactiveCN105561808ASimple processHigh water fluxSemi-permeable membranesMembranesWater bathsPolyester

The invention relates to a preparation method for a cellulose acetate forward osmosis membrane, and belongs to the technical field of membrane separation. The preparation method comprises the steps that dried cellulose acetate powder is dissolved in mixed organic solvent, and the mixture is put into a water bath to be mechanically stirred to form a uniform solution; the solution is put into a vacuum environment for standing and defoaming to form a membrane casting solution; the membrane casting solution is poured on a clean glass board and uniformly applied on the glass board with a scraper; the surface of the membrane casting solution is covered with a polyester screen immediately, and the membrane casting solution is quickly transferred into a baking oven for volatilization; the glass board with the membrane casting solution is put into a flowing deionized water gel bath; a regenerative membrane piece is stripped from the glass board and then put into a water bath at the temperature of 50 DEG C-90 DEG C, and the cellulose acetate forward osmosis membrane is obtained. The preparation method is simple in technology and easy to operate, and the prepared membrane is excellent in mechanical performance and high in water flux and has the higher salt intercepting rate and the lower inner concentration polarization phenomenon.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

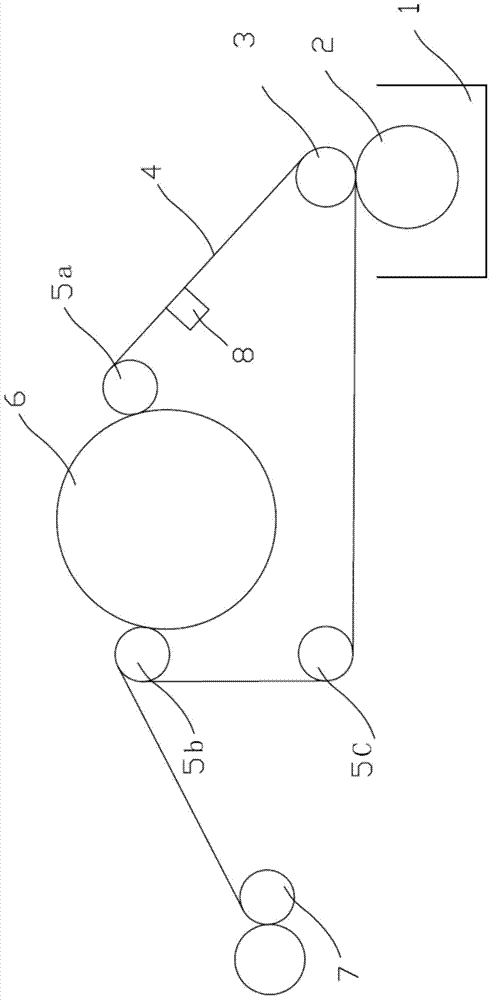

Wet-process non-woven fabric manufacturing method and manufacturing equipment

InactiveCN104711891AShorten the lengthFew equipment partsPaper-making machinesPolyesterTransfer procedure

The invention discloses a wet-process non-woven fabric manufacturing method. The wet-process non-woven fabric manufacturing method sequentially comprises a web-forming procedure, a vacuum-transferring procedure and a drying procedure of a sizing agent. The web-forming procedure comprises that the sizing agent is adhered on a mesh cage roller to form a fibre web. The vacuum-transferring procedure comprises that a vacuum-transferring roller matched with the mesh cage roller transfers the fibre web to a polyester mesh belt through vacuum suction, wherein the polyester mesh belt is wound around multiple working rollers and the vacuum-transferring roller. The wet-process manufacturing method and the manufacturing equipment which are applicable to 15 - 150 g / m2 non-woven fabric are provided. According to the wet-process non-woven fabric manufacturing method and the manufacturing equipment, a felt is no longer used, and meanwhile the whole production line is shortened.

Owner:XINXIANG AT SCI & TECH

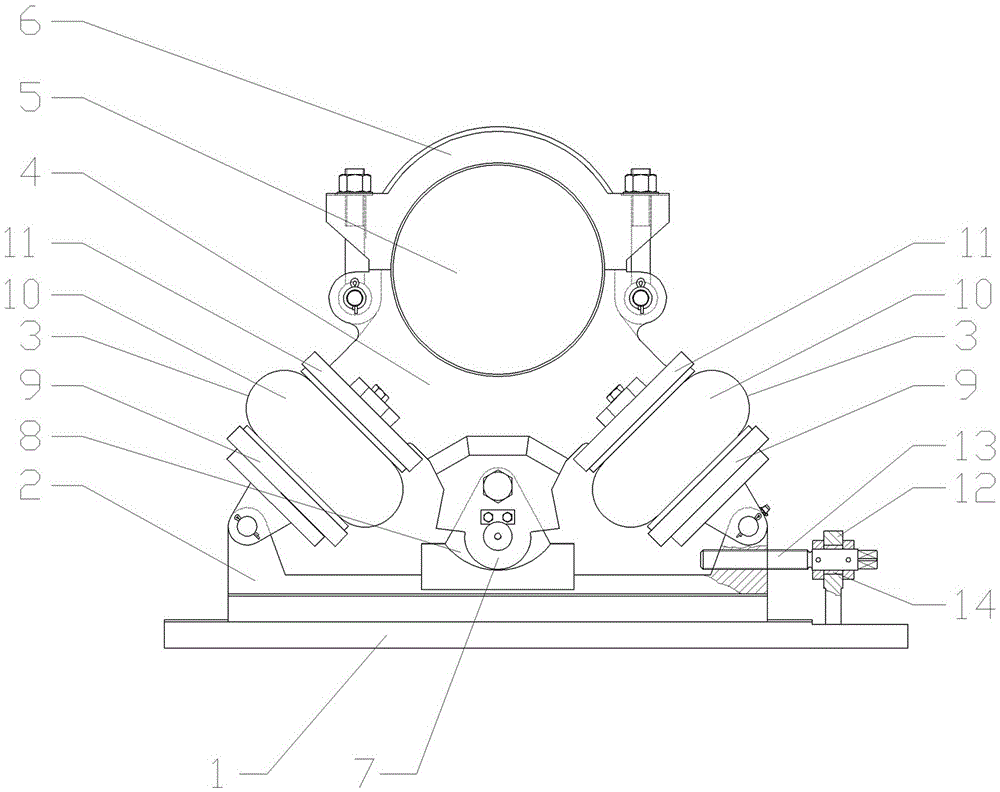

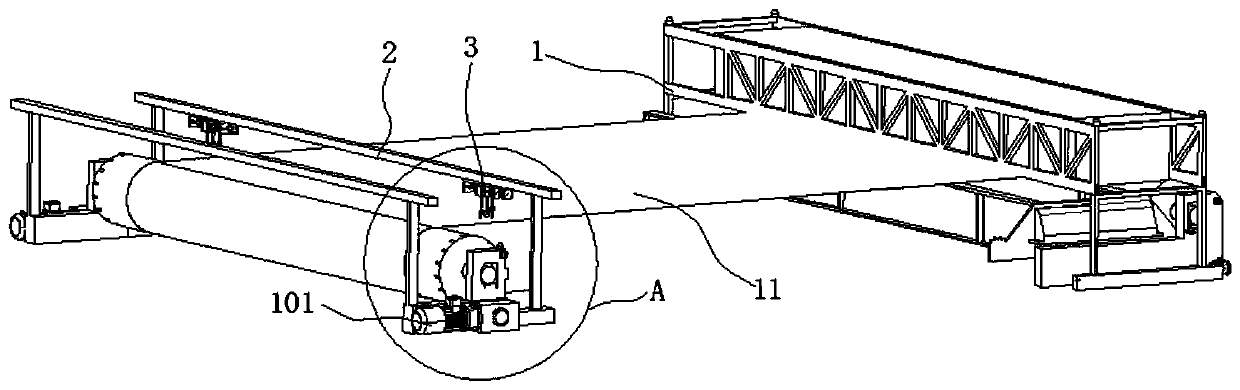

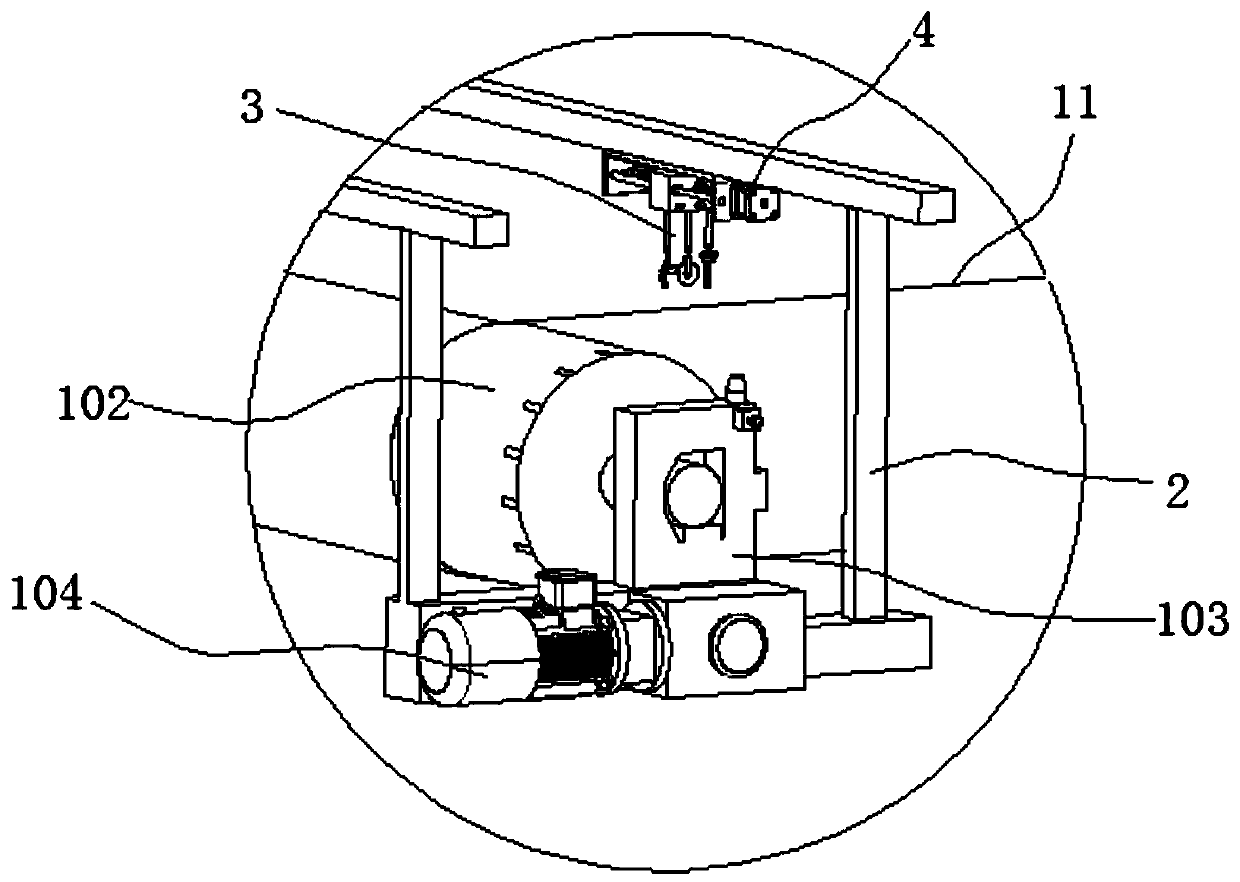

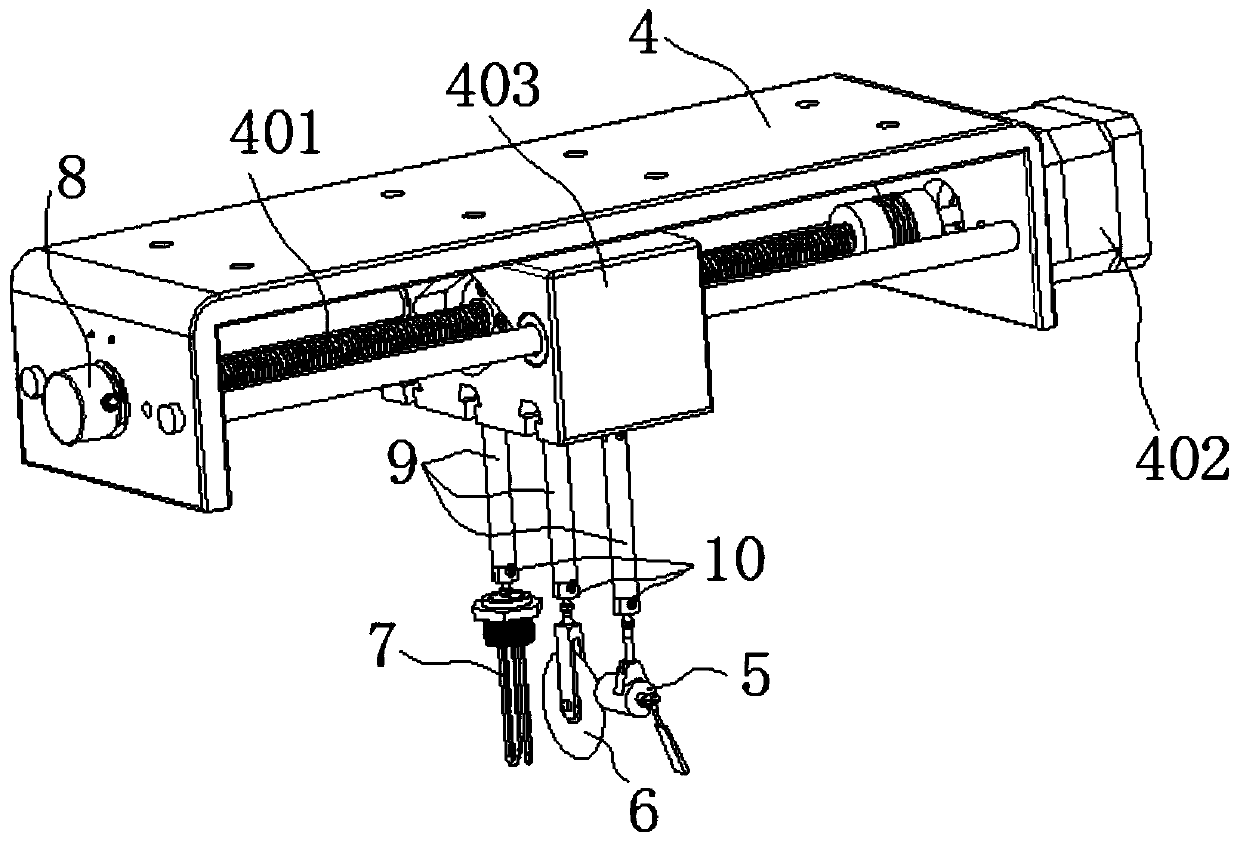

Pneumatic tyre corrector

The invention relates to a part of a paper machine, and specifically relates to a pneumatic tyre corrector. The pneumatic tyre corrector comprises a pedestal, and is characterized in that the upper portion of the pedestal is provided with a supporting seat, the supporting seat is provided with a pneumatic tyre device, the upper portion of the pneumatic tyre device is provided with a support, the support is provided with a roller, the upper portion of the roller is provided with a gland matched with the support, the lower portion of the support is provided with a stop block, and the central portion of the supporting seat is provided with an arc-shaped groove matched with the stop block. The pneumatic tyre corrector being of the above structure is advantaged in that the tensile force of the polyester mesh can be controlled, and the pneumatic tyre corrector is stable in performance, long in stroke and convenient to operate.

Owner:HENAN ZHONGYA PAPERMAKING EQUIP

Metal mesh printing plate and preparation method thereof

PendingCN106585158ANo decrease in strength will occurReduce shadingPhotomechanical apparatusPlate printingEngineeringUltimate tensile strength

The invention discloses a metal mesh printing plate and a preparation method thereof. The metal mesh printing plate comprises a metal mesh and a polyester mesh, wherein a metal layer is arranged on a non-pattern area in the metal mesh; a pattern area is positioned in the non-pattern area; in the weft direction, warps are removed by intercepting treatment at a position corresponding to the pattern area, and / or, in the warp direction, wefts are removed by the cutting treatment at a position corresponding to the pattern area; the quantity of the wefts / warps subjected to the cutting treatment is more than or equal to 1. According to the metal mesh printing plate, the warps / wefts are removed by cutting at the position corresponding to the pattern area; the cut wraps / wefts at the position corresponding to the non-pattern area remain high strength due to that the wraps / wefts are electroplated with metal layers; in addition, printing areas covered by the wefts / wraps can be reduced, and the ink can be leaked uniformly and richly, so that printed patterns are clear and accurate, and as a result, the printing quality can be improved.

Owner:卫巍

Fully-automatic setting machine edge cutting and ironing device and control method thereof

InactiveCN110699943AImprove work efficiencyHigh precisionTextile selvedgesSevering textilesPolyesterEngineering

The invention relates to the technical field of setting machines, in particular to a fully-automatic setting machine edge cutting and ironing device and a control method thereof. The device comprisesa support mounted on a setting machine, edge cutting and ironing components and driving components are arranged on two sides of the support, the driving components drive the edge cutting and ironing components to linearly move along the support, the edge cutting and ironing components comprise sensors, cutting knives and heating devices, the sensors are used for measuring distances among the edgecutting and ironing components and the edges of objects to be processed, the cutting knives are used for cutting the edges, the heating devices are used for ironing the edges. According to the controlmethod, the edge cutting and ironing components are accurately controlled. According to the edge cutting and ironing device, the edge of a polyester wire mesh can be fully automatically cut and ironed, edge cutting and ironing efficiency and edge cutting and ironing accuracy of the polyester wire mesh are improved, and the labor intensity of a worker is reduced.

Owner:GUANGDONG UNIV OF TECH

Composite screen plate based on steel sheet and processing technology thereof

The invention discloses a composite screen plate based on a steel sheet and a processing technology thereof, and belongs to the technical field of screen plate manufacturing. The composite screen plate comprises the steel sheet, a polyester net wound around the steel sheet and fixedly connected with the steel sheet and a frame wound around the polyester net and fixedly connected with the polyesternet; the steel sheet comprises a middle pattern area and an edge connecting area, wherein the connecting area is provided with a through hole. The processing technology comprises the following stepsthat the polyester net, the steel sheet and a PE film are sequentially laid and then combined in a hot-melting mode, so that an adhesive formed by hot melting of the PE film is poured into the throughhole to be connected with the steel sheet as well as the polyester net and meanwhile covers the upper end face of the connecting area to form an adhesive film. According to the composite screen platebased on the steel sheet and the processing technology thereof, the manner that the PE film passes through the hole of the edge of the steel sheet so as to be combined with the polyester net in a hot-melting mode is adopted without bonding the steel sheet and the polyester net, and meanwhile the steel sheet is fixed and cannot easily fall off, so that flatness of the pattern area is ensured.

Owner:SHIJIAZHUANG MINGYUAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com