Preparation method of composite screen printing plate

A technology of compounding screen plates and screen frames, applied in the direction of plate preparation, printing, etc., can solve the problems of uneven coating film thickness, uneven layout, affecting the quality of the screen, so as to improve the quality of the screen and reduce the uneven layout. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

[0027] Such as Figure 1 to Figure 8 Shown, the preparation method corresponding to the compound screen plate of a kind of preferred embodiment of the present invention, comprises the steps:

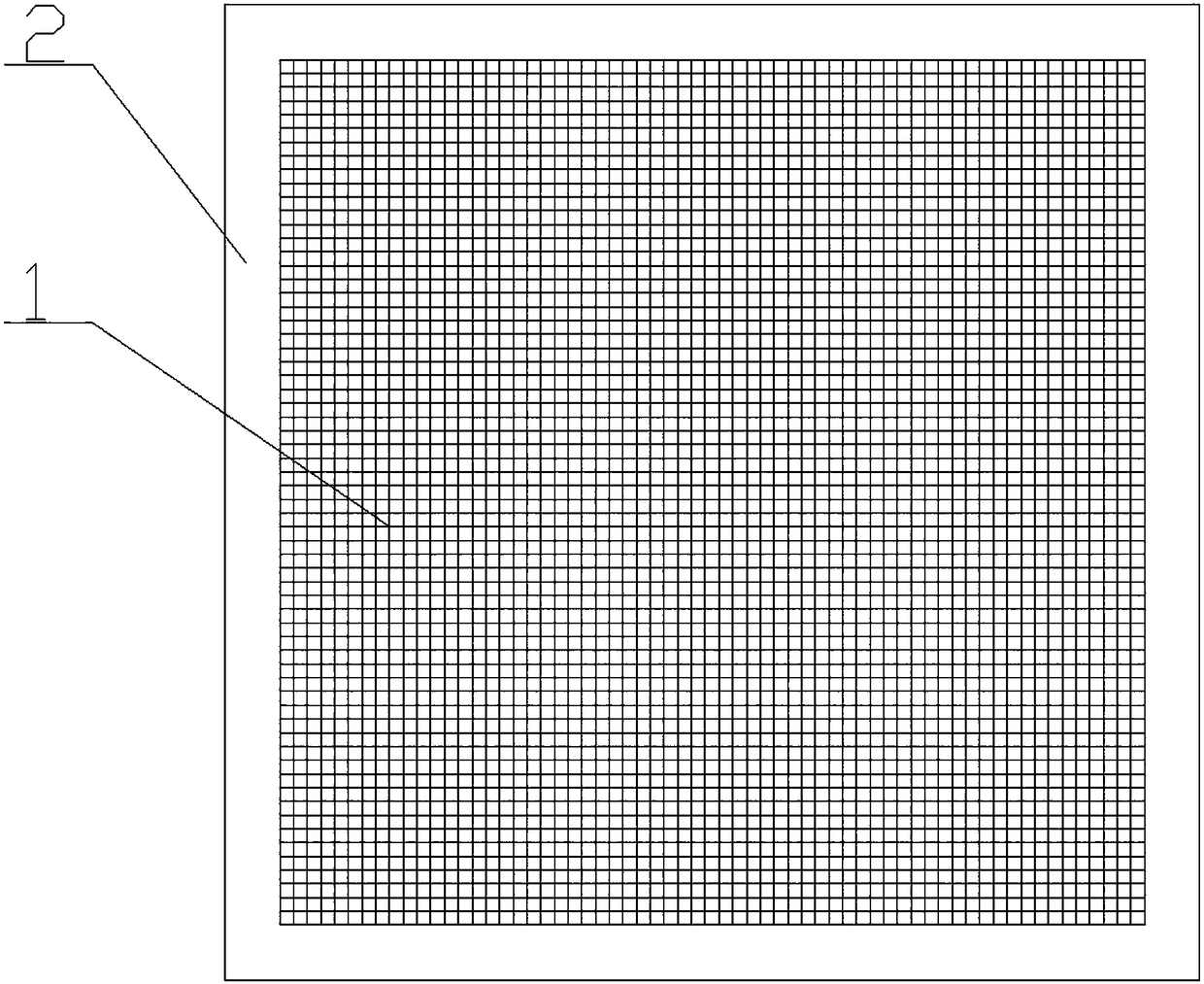

[0028] The first step, refer to figure 1 , using a stretching machine to tighten the polyester mesh 1 to a certain tension and fix it on the first screen frame 2 to form a polyester screen, the size of the first screen frame 2 is larger than the second frame of the composite steel wire screen to be made The size of the screen frame 6, preferably the inner size of the first screen frame 6 is more than 4CM larger than the second screen frame 6 outer size;

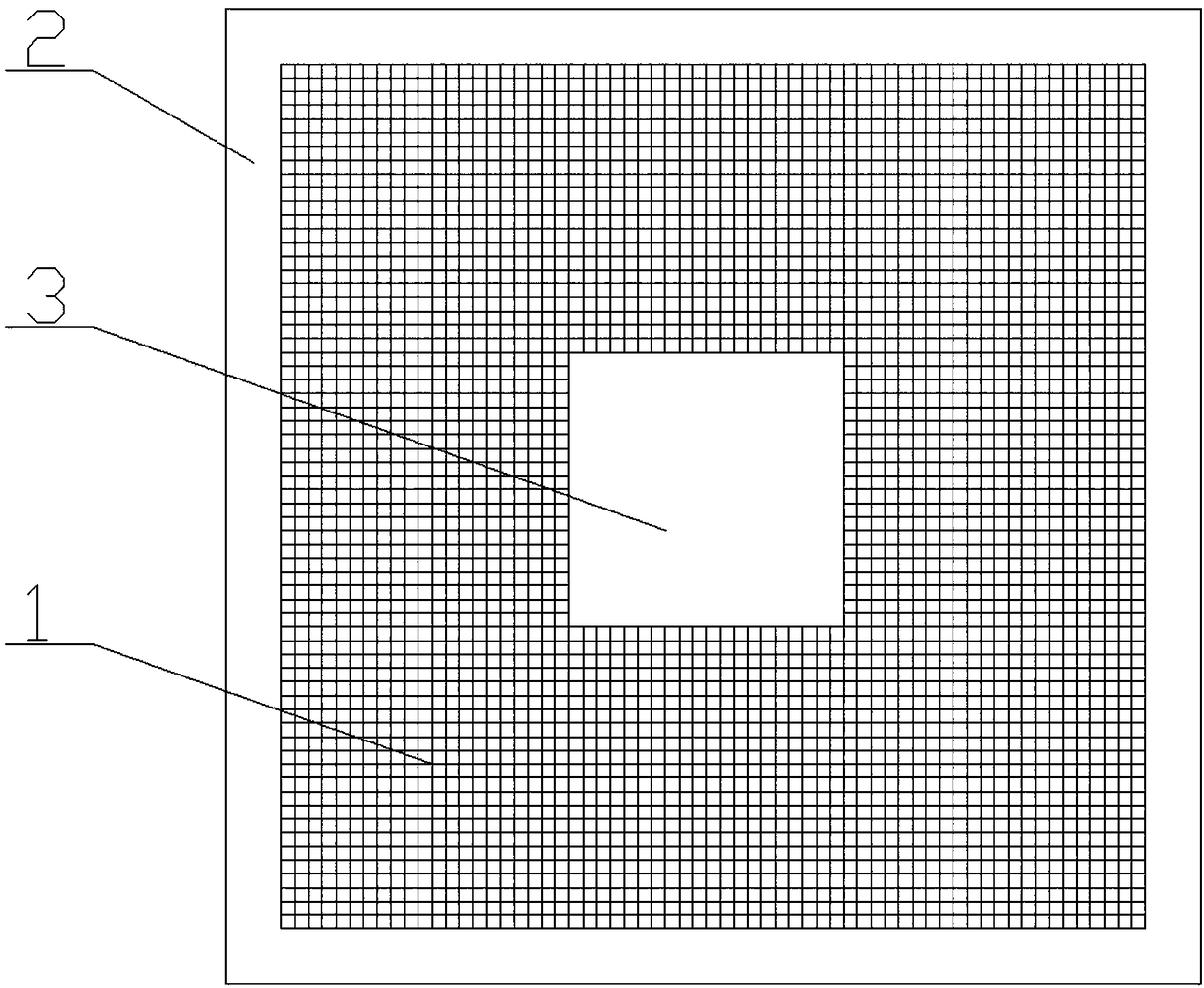

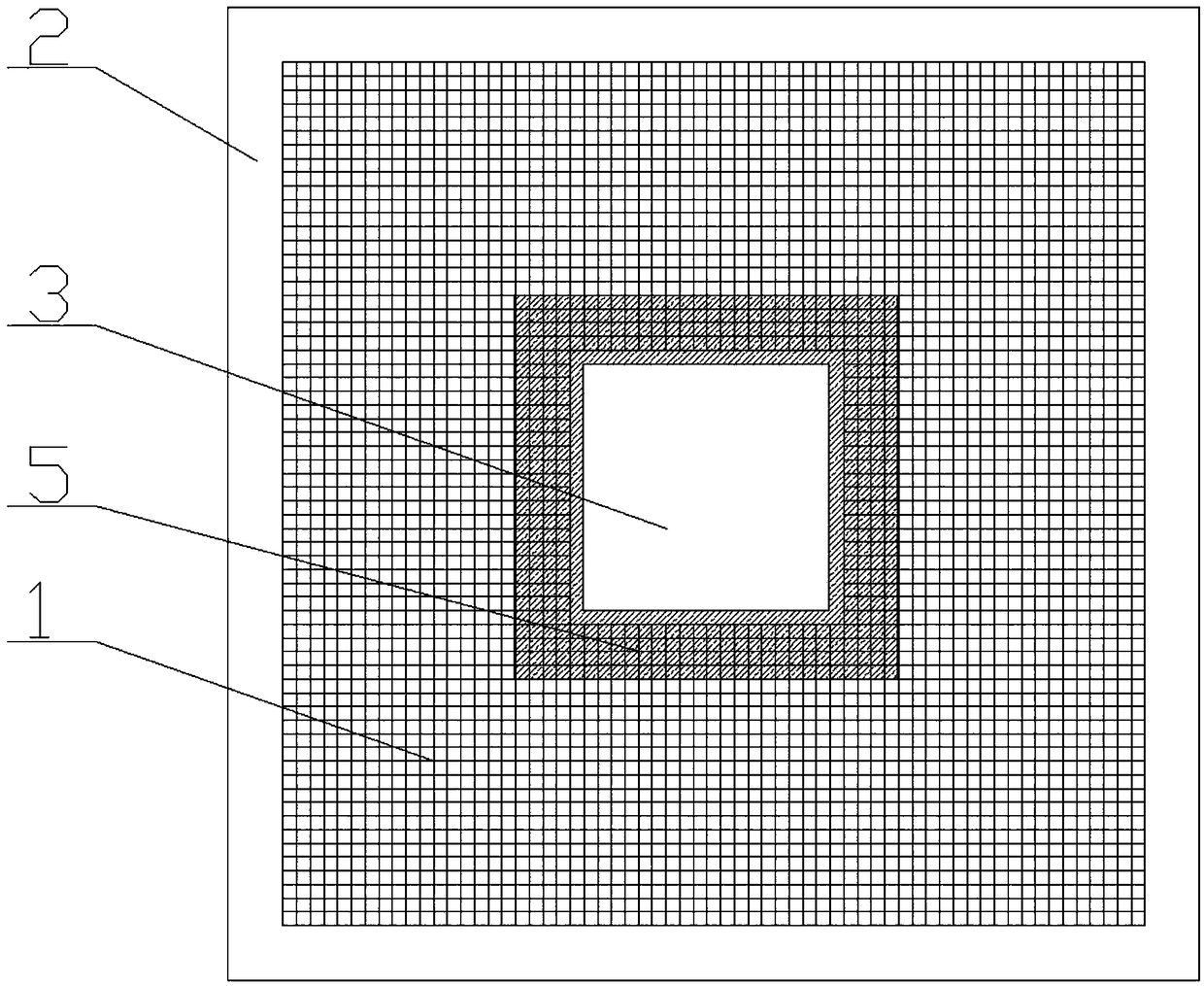

[0029] The second step, refer to figure 2 , removing the polyester mesh cloth 1 in the central area of the polyester mesh to form a cavity 3, the cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com