Patents

Literature

95 results about "Composite mesh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A composite mesh in particular is a mesh that has differing properties on the visceral and parietal sides. You want the mesh to support the hernia and wall without adhering to organs. There are two kinds of surgical mesh, absorbable and non-absorbable.

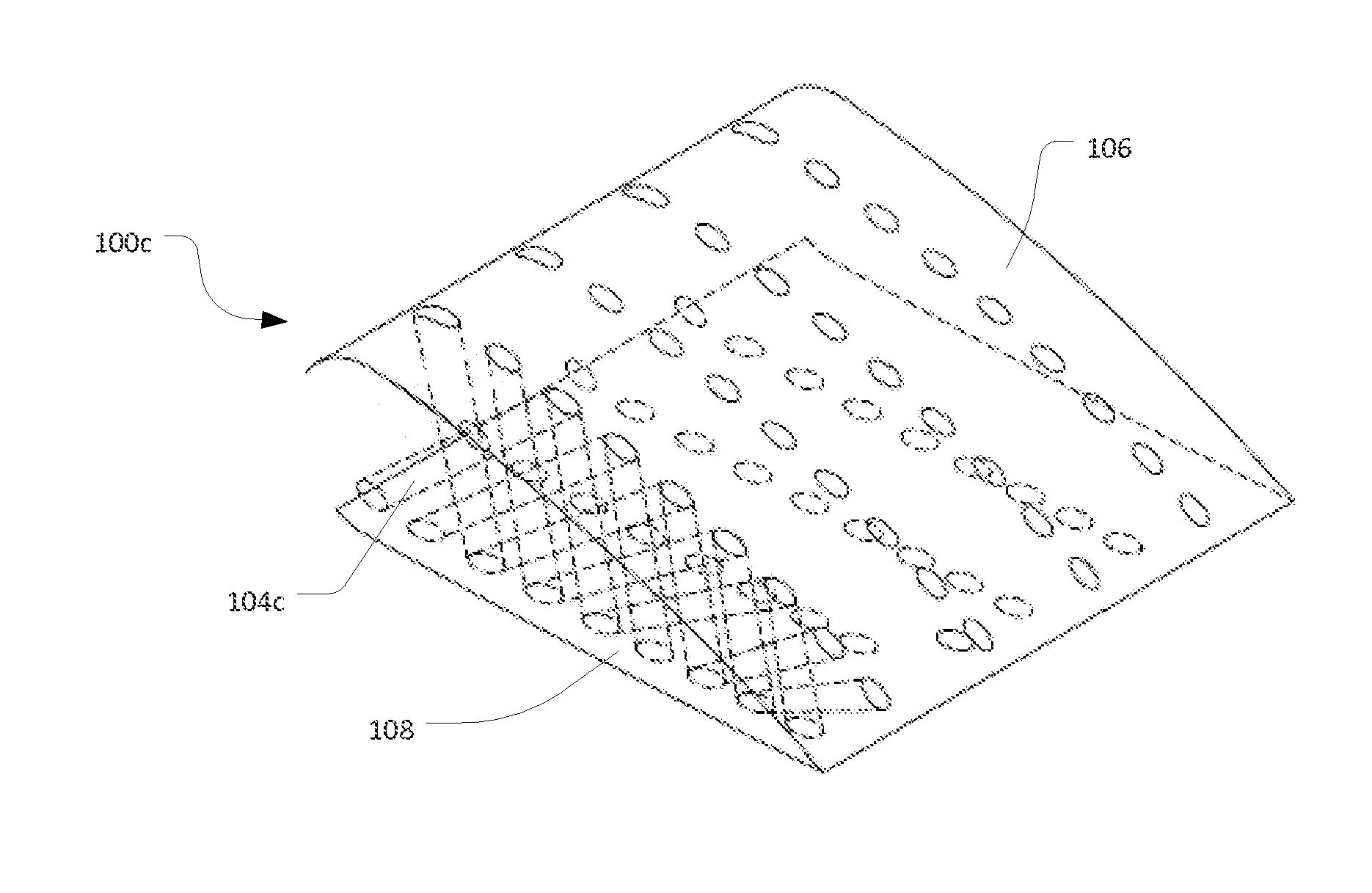

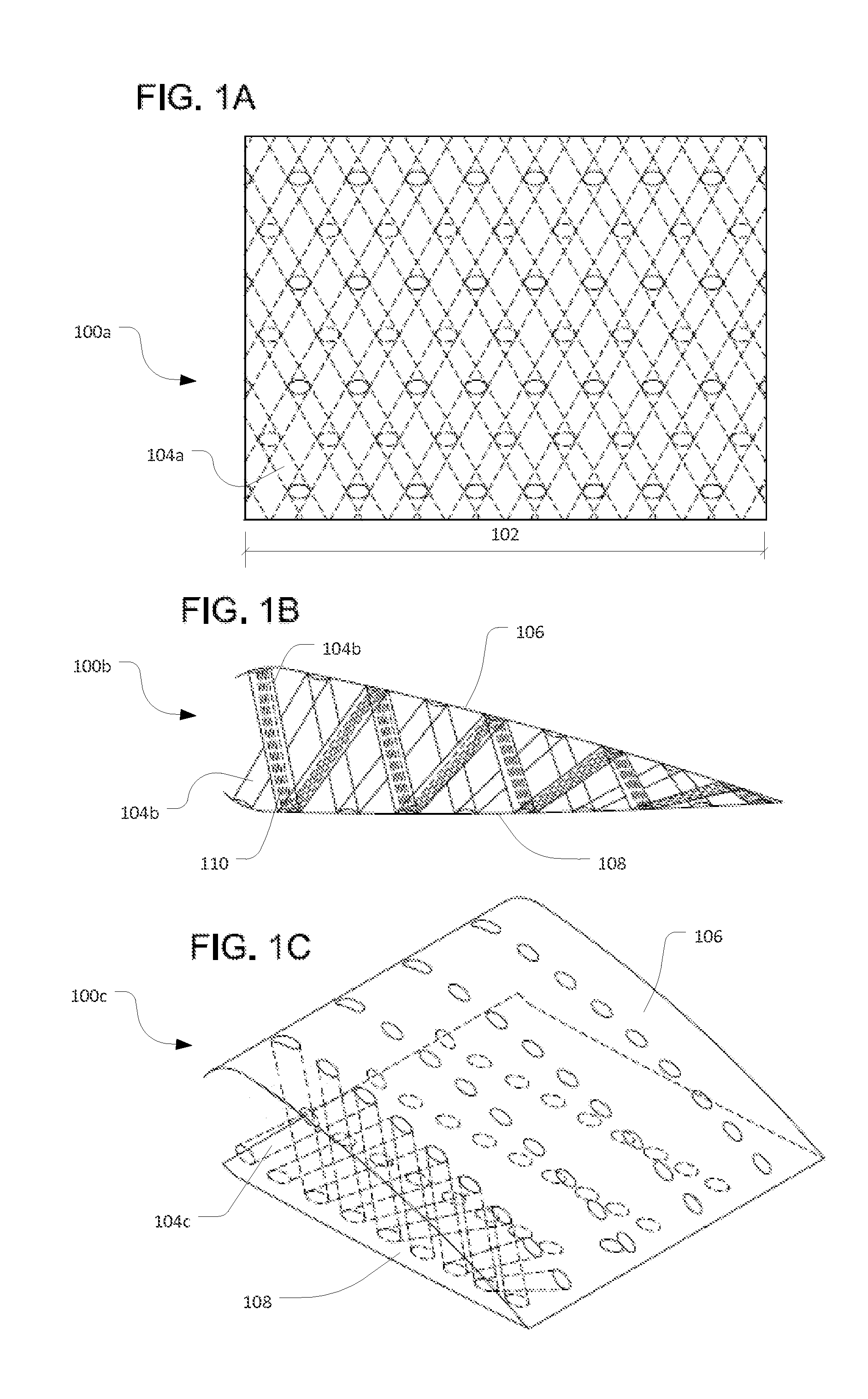

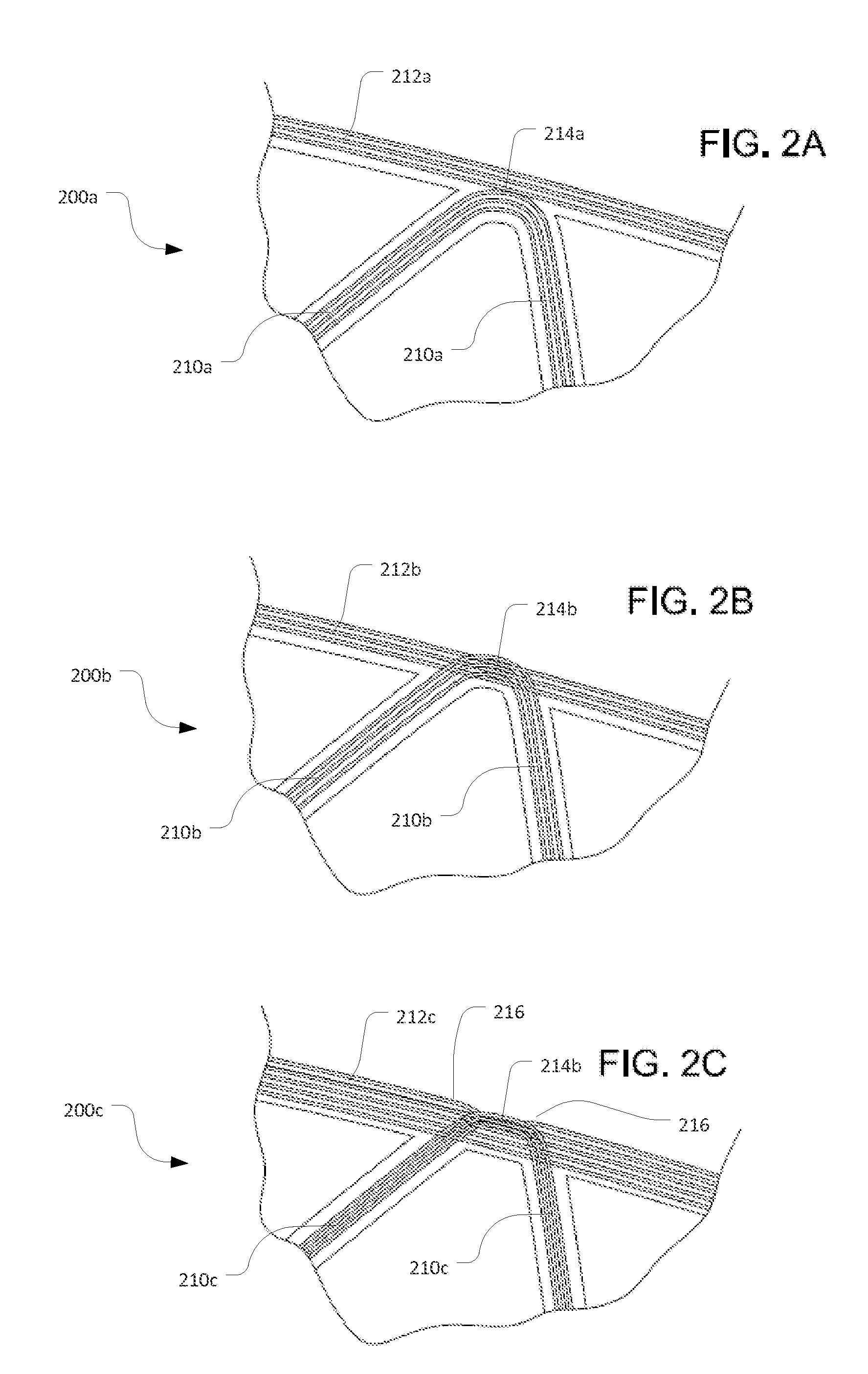

Composite mesh devices and methods for soft tissue repair

InactiveUS20100318108A1Reduce adhesionDifferent and simple configurationCovering/liningsWarp knittingComposite meshSoft tissue repair

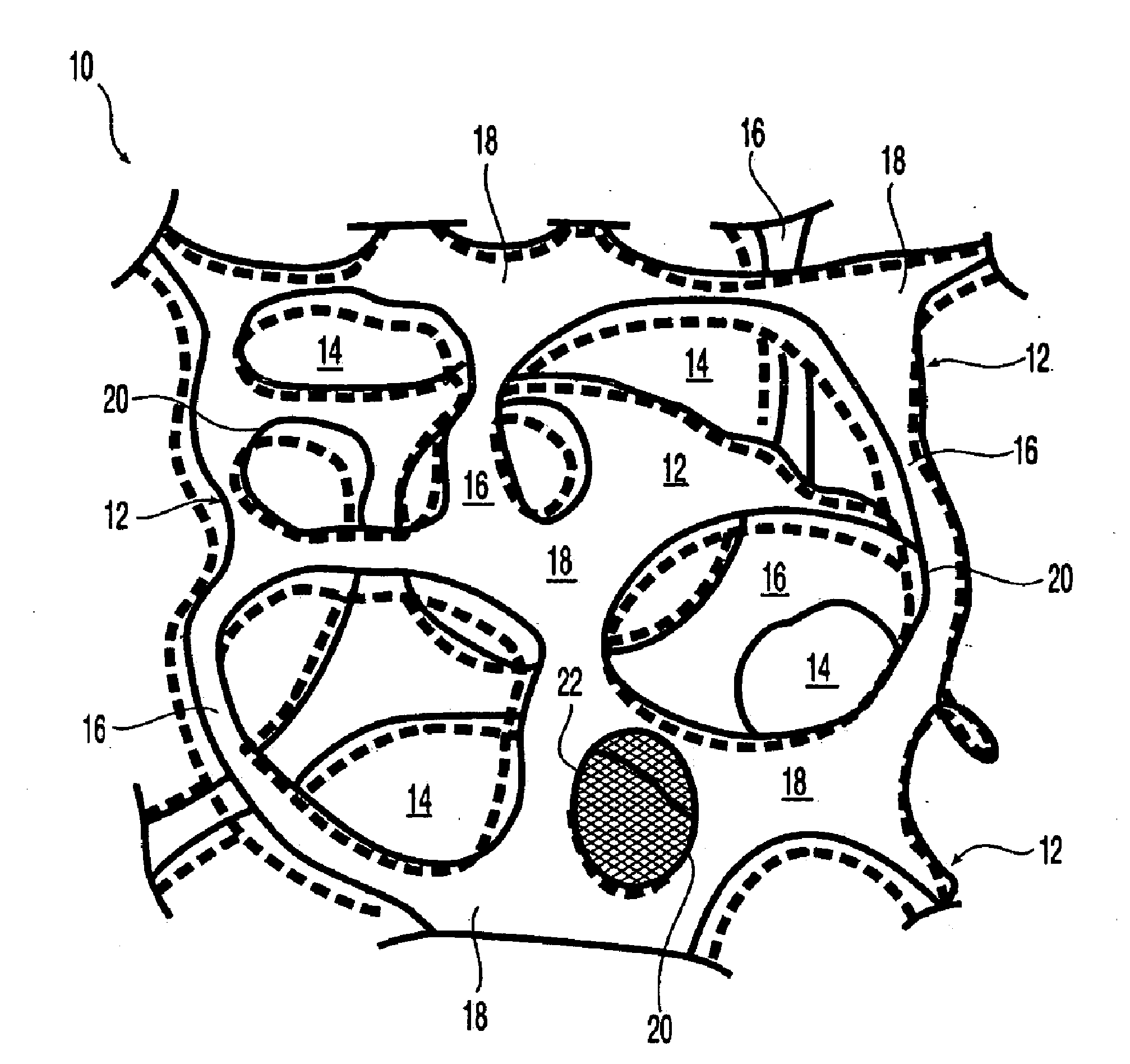

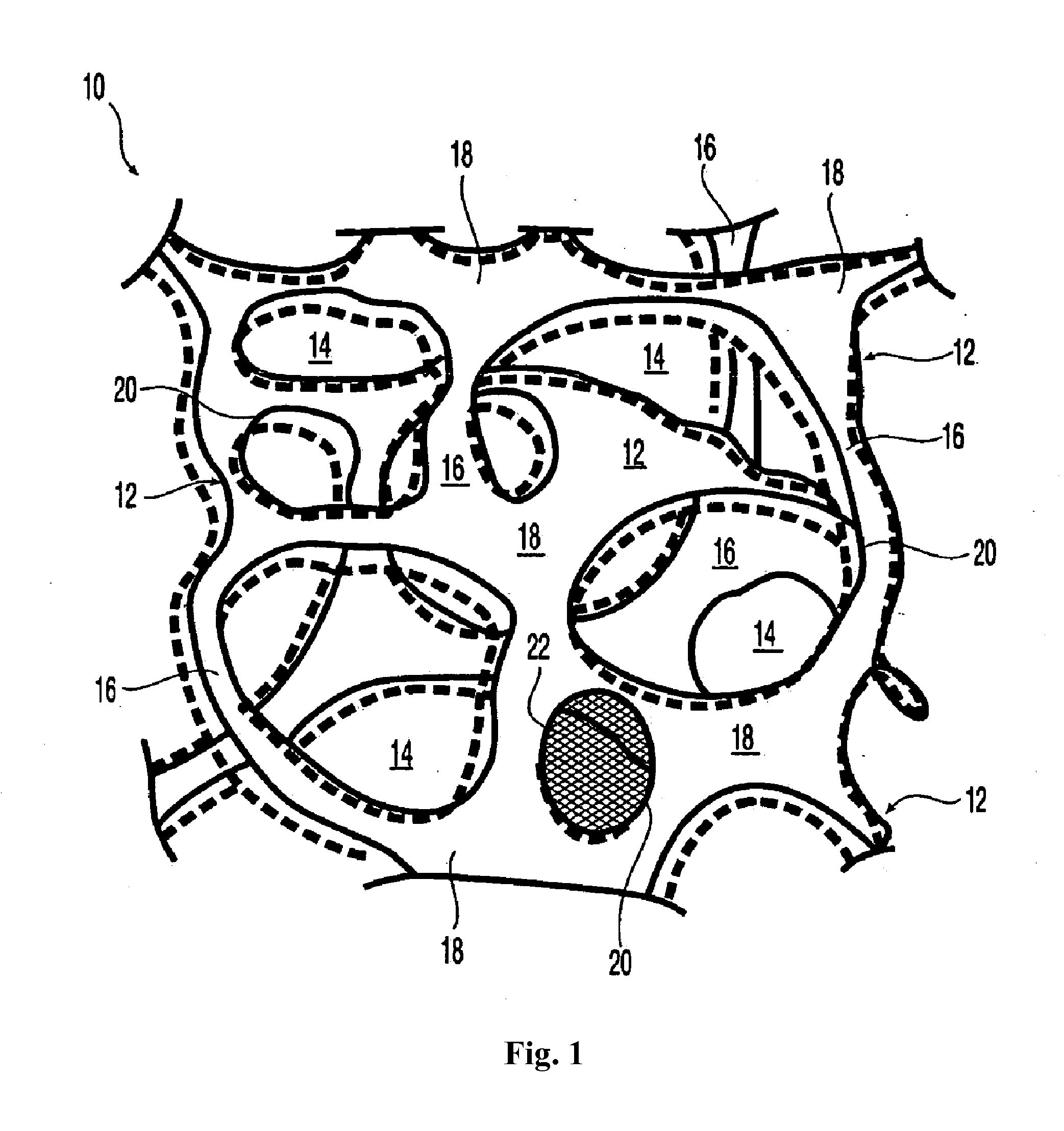

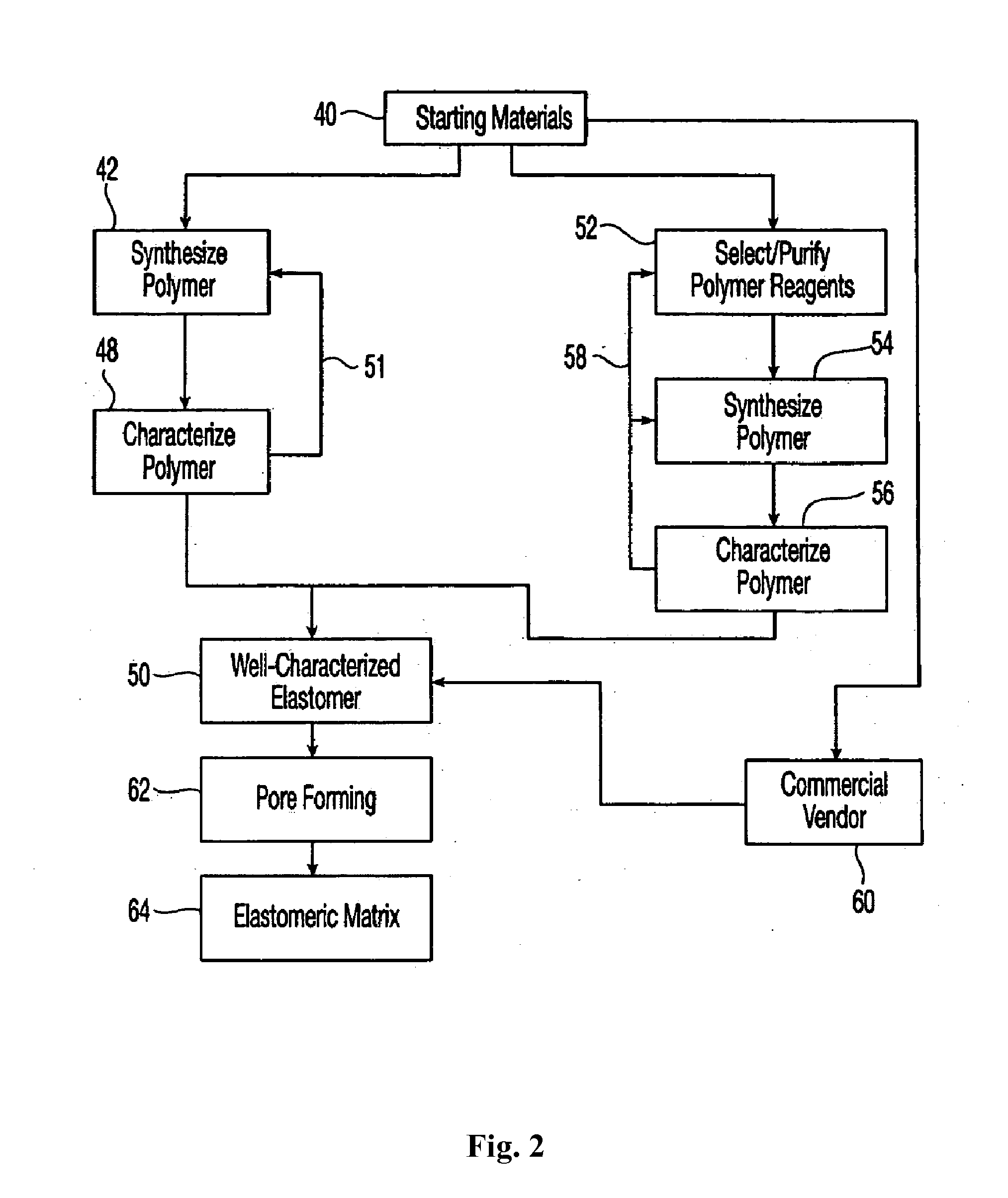

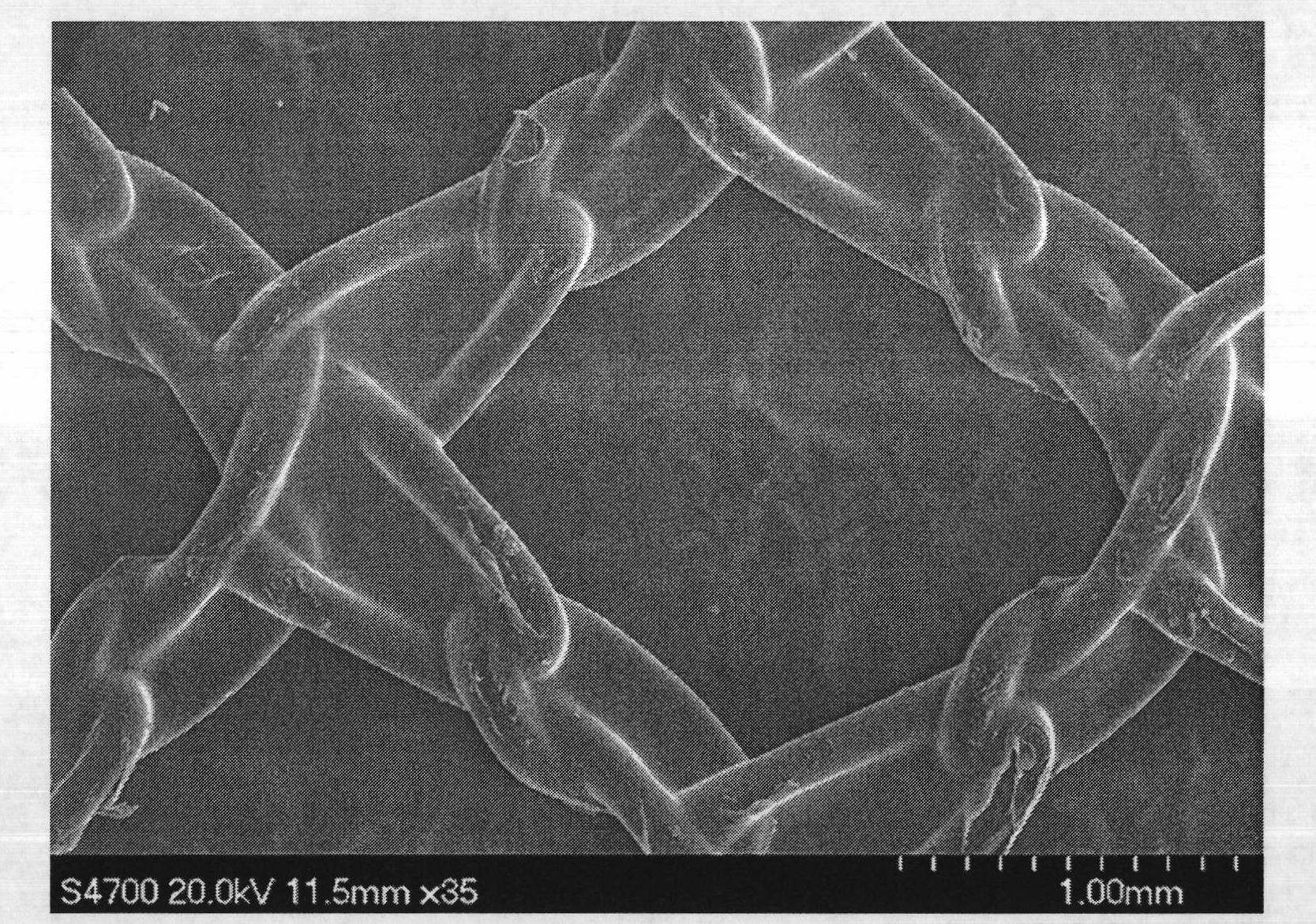

A composite implantable device for promoting tissue ingrowth therein comprising a biodurable reticulated elastomeric matrix having a three-dimensional porous structure having a continueous network of interconnected and intercommunicating open pores and a support structure is disclosed. The support structure may be a polymeric surgical mesh comprising a plurality of intersecting one-dimensional reinforcement elements, wherein said mesh is affixed to a face of said first matrix. Methods of making and using the implantable device are also provided.

Owner:BIOMERIX CORP

Multi-layer hernia repairing patch and preparation method thereof

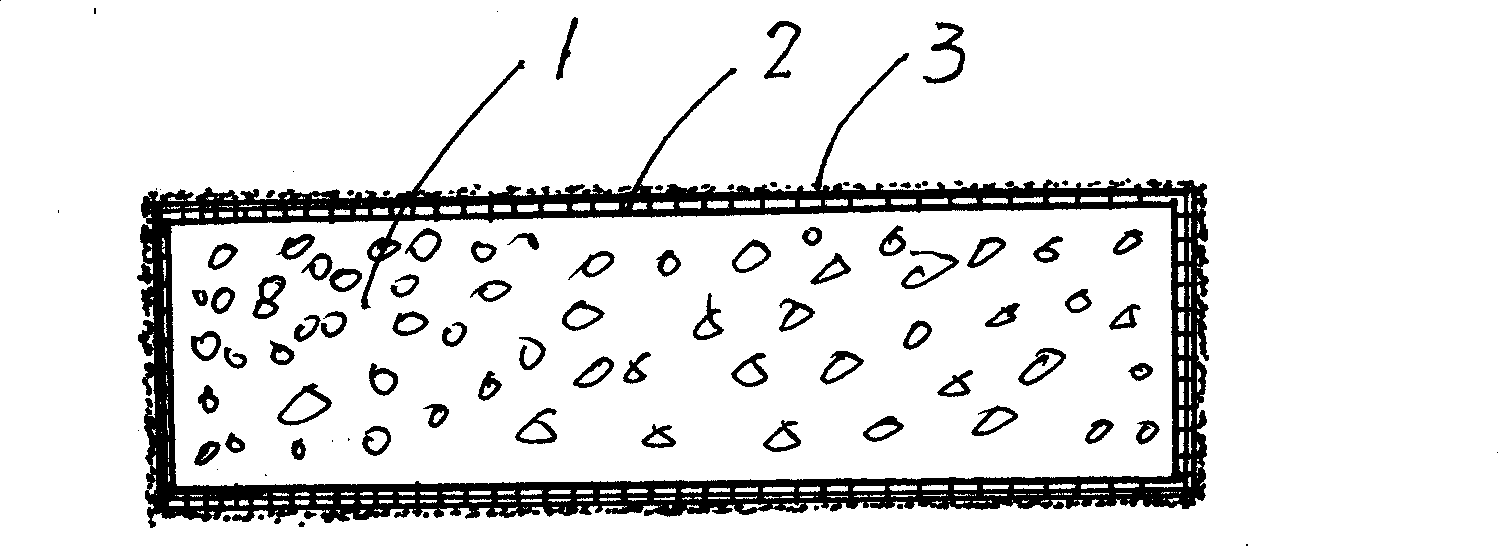

The invention provides a multi-layer hernia repairing patch which comprises a nondegradable polymer mesh panel and a polymeric membrane layer manufactured by biocompatible natural high polymer materials. The nondegradable polymer mesh panel and the polymeric membrane layer are combined together by a degradable polyester interlayer. The invention also provides a multi-layer hernia repairing patch preparation method, which comprises the steps as follows: firstly, a polyester solution is prepared; secondarily, the polyester solution is poured on the nondegradable polymer mesh panel to obtain a composite mesh panel with a polyester layer on a single side after volatilization and then a composite mesh panel comprising uniform gap areas is obtained after the polyester layer is partially dissolved; thirdly, the polymeric membrane layer manufactured by the biocompatible natural high polymer materials is obtained; fourthly, the polymeric membrane layer is paved on the polyester solution to obtain a composite membrane with a polyester layer on a single side after volatilization; and fifthly, the polyester layer of the composite mesh panel and the polyester layer of the composite membrane are opposite to each other and are thermally pressed into a whole body, thereby forming the multi-layer hernia repairing patch. As the multiple layers of the multi-layer hernia repairing patch are combined firmly, the multi-layer hernia repairing patch can be used for implantation in enterocoelia, can realize the function of strengthening weak or defected tissues, and meanwhile, can reduce the sticking risk between a viscera and the nondegradable polymer mesh panel.

Owner:TRANSEASY MEDICAL TECH

Antiblocking hernia patch and preparation method thereof

InactiveCN101579540AReduce the chance of adverse reactionsOutstanding FeaturesSurgeryWater solubleAbsorbent material

The present invention discloses an antiblocking hernia patch and a preparation method thereof. A polypropylene net is combined with an absorptive material chitosan antiblocking piece to prepare a partial absorptive composite mesh. The invention is characterized in that the absorptive material chitosan antiblocking piece is prepared from water-soluble chitosan by a tap casting method. The chitosan phlegm is arranged between the polypropylene net and the absorptive material chitosan antiblocking piece. The preparation method comprises the steps of preparing the chitosan antiblocking piece, uniformly coating one layer of chitosan on the polypropylene woven mesh, then placing the chitosan antiblocking piece on the polypropylene woven mesh, placing the polypropylene woven mesh between the moulds after compressing, and obtaining the antiblocking hernia patch after drying by a film isolation method in the environment at a temperature of between 15 DEG C below zero and 150 DEG C and pressure of 0 to 0.6MPa. The antiblocking hernia patch of the invention has the advantages of effectively preventing the blocking after surgery, increasing the anti-inflection effect, sustaining the excellent repairing strength, reducing the recurrence rate and complication after surgery, reducing the probability of adverse effect caused by the unthorough elimination of acid, simply controlling preparation process and eliminating the adverse effect which may be caused by the chemical process.

Owner:都本立

PET/PP composite sound-absorbing material preparation method

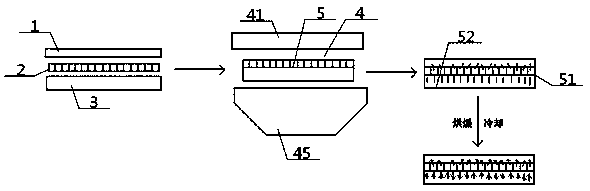

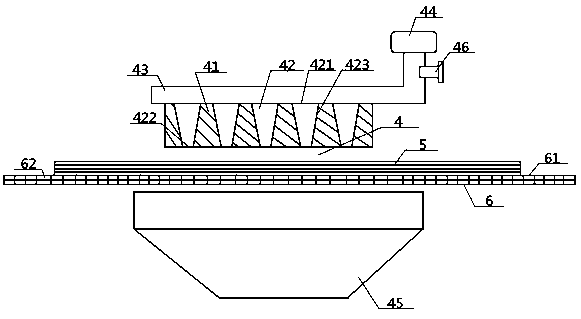

ActiveCN107599564AGood sound absorptionImprove aestheticsLamination ancillary operationsSynthetic resin layered productsMaterials preparationBest fitting

The invention discloses a PET / PP composite sound-absorbing material preparation method, and relates to the technical field of vehicle interior decoration member processing, wherein the sound insulation pad comprises two layers of sound insulation cotton felts, and the preparation method comprises: melt spinning of a PET / PP mixture, steam mold pre-molding, cooling setting, water cutting and packaging warehousing. According to the present invention, the PET / PP composite sound-absorbing material is formed by compounding the multiple layer sound absorbing materials, comprises six layers, has characteristics of good sound absorbing effect, good fitting degree and good aesthetics; and in the preparation method, the high temperature steam is introduced into the interior of the sound absorbing material by using the steam mold and the steam engine so as to completely absorb water, the PET / PP composite mesh surface can fully expand and coil so as to fill the entire molding cavity, and the shaping with the cold mold is performed, such that the sound insulation pad prepared from the sound absorbing material can be attached to the vehicle front enclose member, the volume of the cavity is small,and the sound transmission medium (air) is reduced; and through the tight attachment of the sound insulation pad, the vibration of the attached surface is reduced, and the noise is reduced.

Owner:宁波尚唯汽车饰件有限公司

Lightweight composite lattice structures

A composite lattice structure formed of one or more face sheets connected with lattice members, where the lattice members are formed of single or multiple contiguous fiber tows, and the lattice members and face sheets are interfused in a matrix.

Owner:AEROSPACE HLDG CO LLC +1

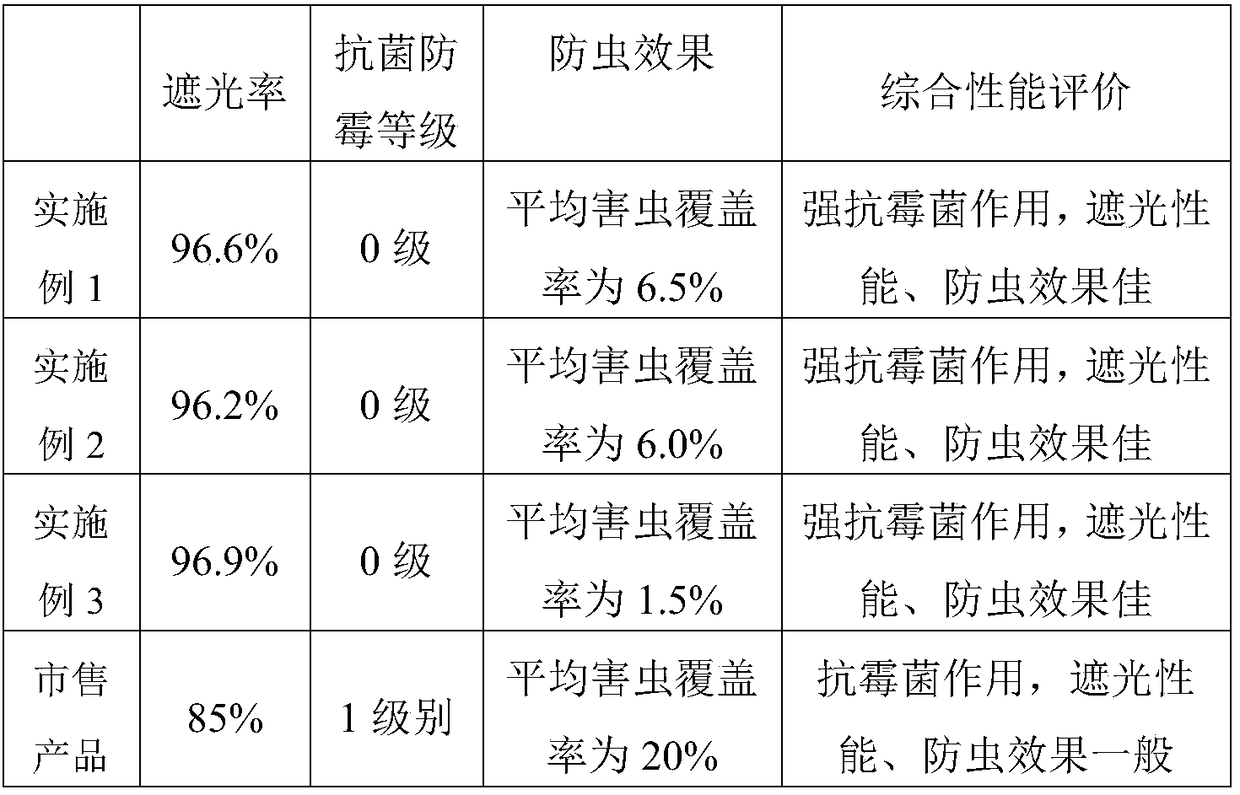

Preparation method of sunshade mesh cloth with insect-proof efficacy

InactiveCN108166262AStrong shadingStrong corrosion resistance and chemical resistanceBiochemical treatment with enzymes/microorganismsWoven fabricsAdhesiveInsect pest

The invention discloses a processing method of a sunshade mesh cloth with an insect-proof efficacy, wherein the method comprises the steps: firstly, two layers of composite mesh cloth structures, namely an outer antibacterial and insect-proof layer and an inner sunshade base layer, are respectively processed, wherein a spinning material of the outer antibacterial and insect-proof layer is formed by soaking with a compound insect-proof mixed solution and then spinning; and finally, the double-layer mesh cloth is preheated and melted through adjustment and change of the temperature of a heatingroller, under assisting of an adhesive, laminating is performed through a rubber roller and an iron roller in order, and then cooling setting is performed to form the product, wherein the process conditions comprise that the preheating temperature of the outer antibacterial insect-proof mesh cloth is 55 DEG C, the preheating temperature of the inner sunshade base layer mesh cloth is 70 DEG C, andthe laminating pressure of the rubber roller and the iron roller is 50-54 kg / cm<2>. Compared with the prior art, the processing method has the following advantages of strong sunshading property, strong anti-bacterial, insect-proof and mildew-proof properties, strong corrosion resistance and chemical resistance, prevention of erosion of insect pests and long service life.

Owner:苏州市欧贝遮阳科技有限公司

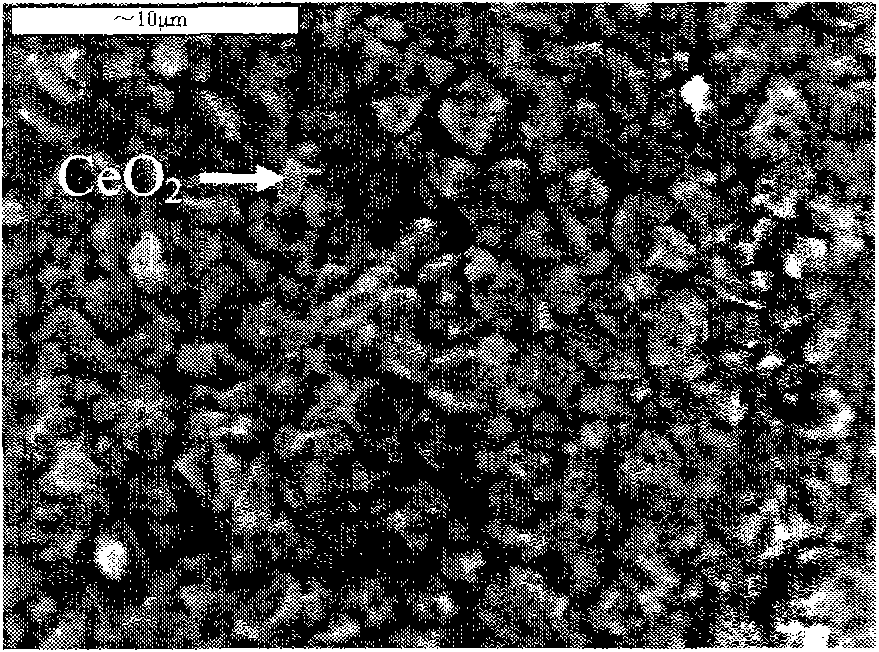

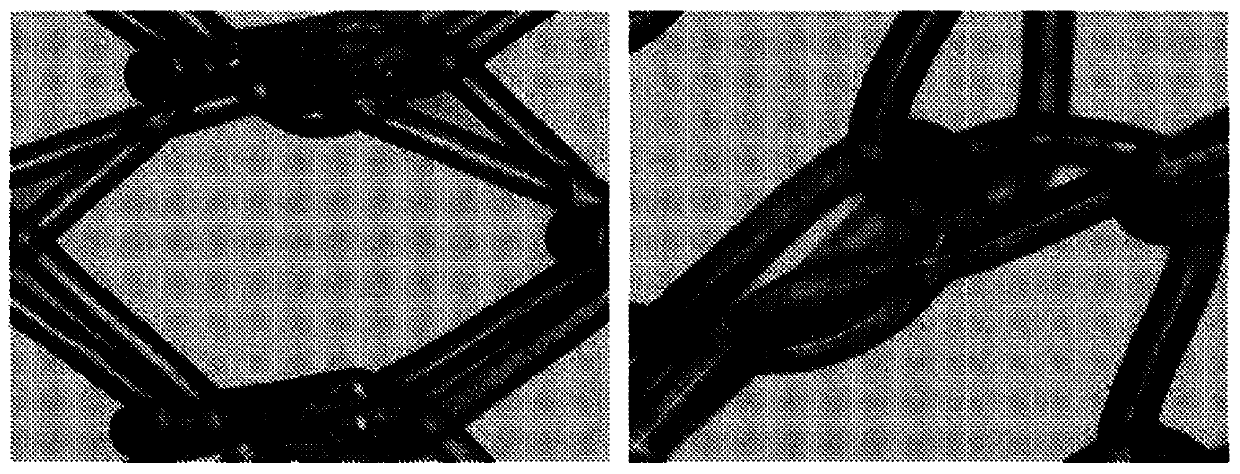

Antiseptic filtering metal material by plating Cu and CeO2 on surface of copper wire mesh, and preparation and application thereof

InactiveCN101637680AHigh temperature resistanceWith fire performanceVacuum evaporation coatingSputtering coatingCopper wireMetallic materials

The invention relates to the technology for preparing a filter screen material, in particular to a (Cu+CeO2) / Cu composite mesh antiseptic filtering metal material with good antiseptic performance, anda preparation method and application thereof to solve the problems of bacteria breeding, insufficient copper intake of a human body and the like; and the antiseptic filtering metal material can be applied to production and filter devices for gases or liquid such as foods, drinks, alcohols and the like and filter screens in air conditioners. The foam sponge taken as a substrate material is loadedwith metal (Cu+CeO2) / Cu to form the high-porosity mesh antiseptic filtering metal material. The preparation method comprises that: the substrate material after conductive treatment is plated with an antiseptic Cu coating; when the copper coating film reaches required thickness, the substrate material is subjected to heat treatment in a vacuum furnace or an argon protection furnace to form a metalcopper mesh; and finally, the surface of the metal copper mesh is plated with (Cu+CeO2) to prepare the metal (Cu+CeO2) / Cu loaded composite mesh antiseptic filtering metal material of which the porosity is between 85 and 96 percent, and the pore diameter can be adjusted in a range between 350 and 500 micrometers according to actual requirement.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

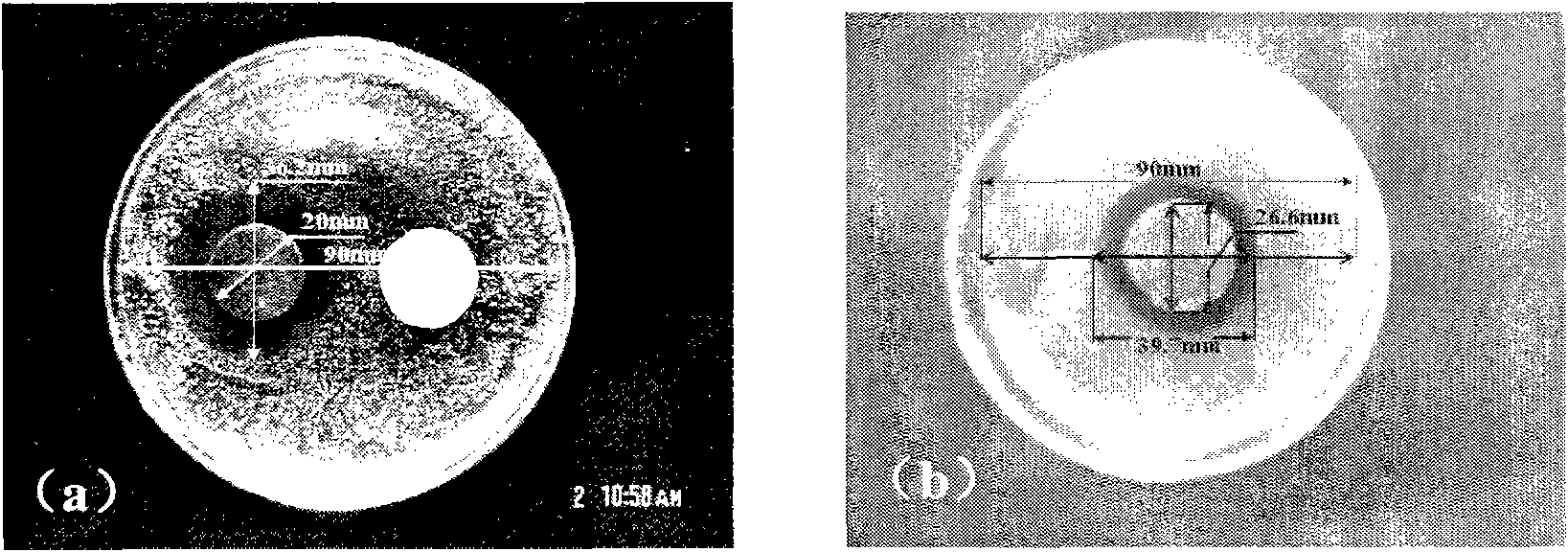

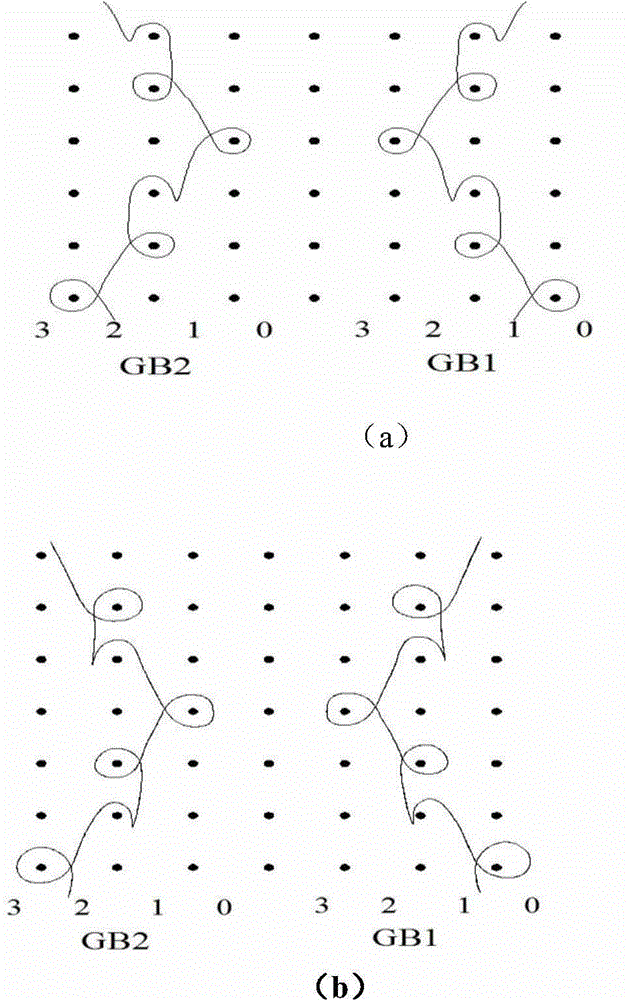

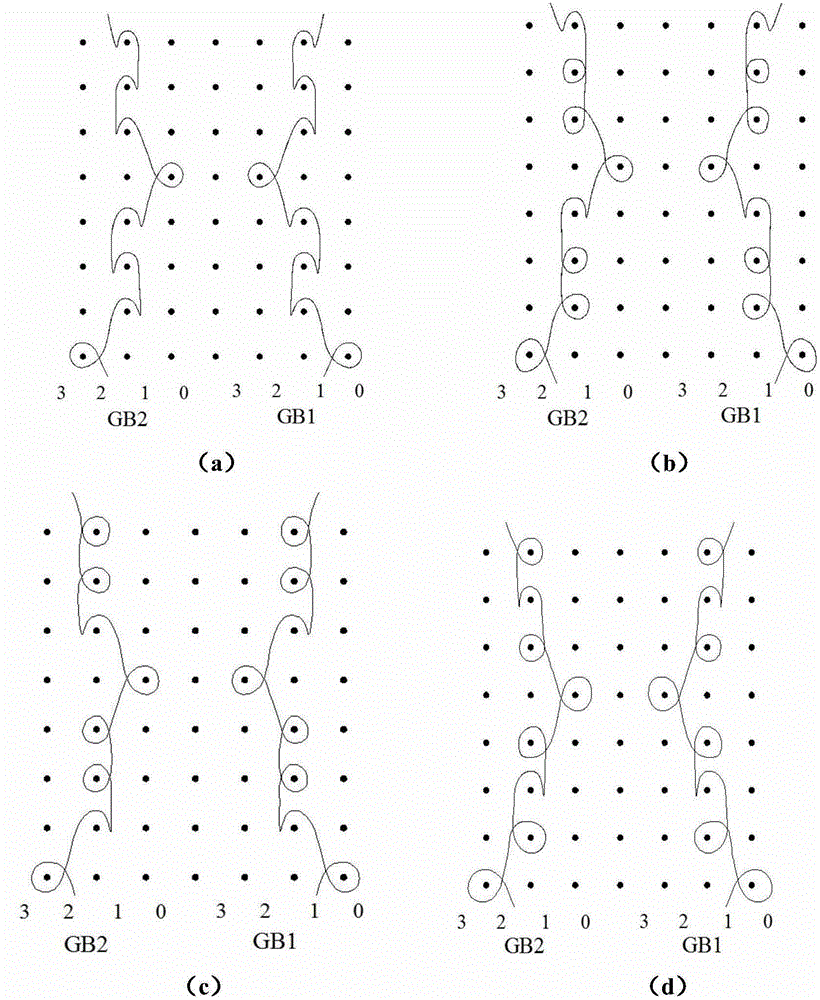

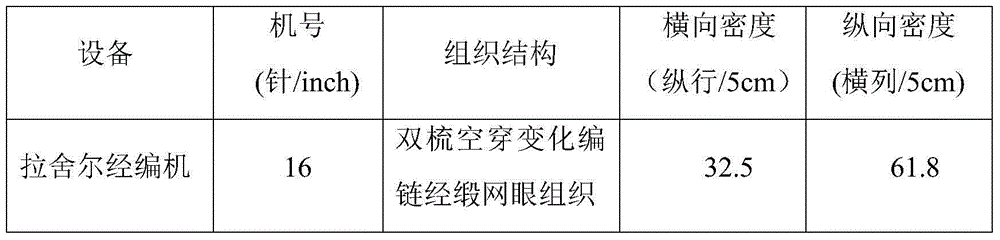

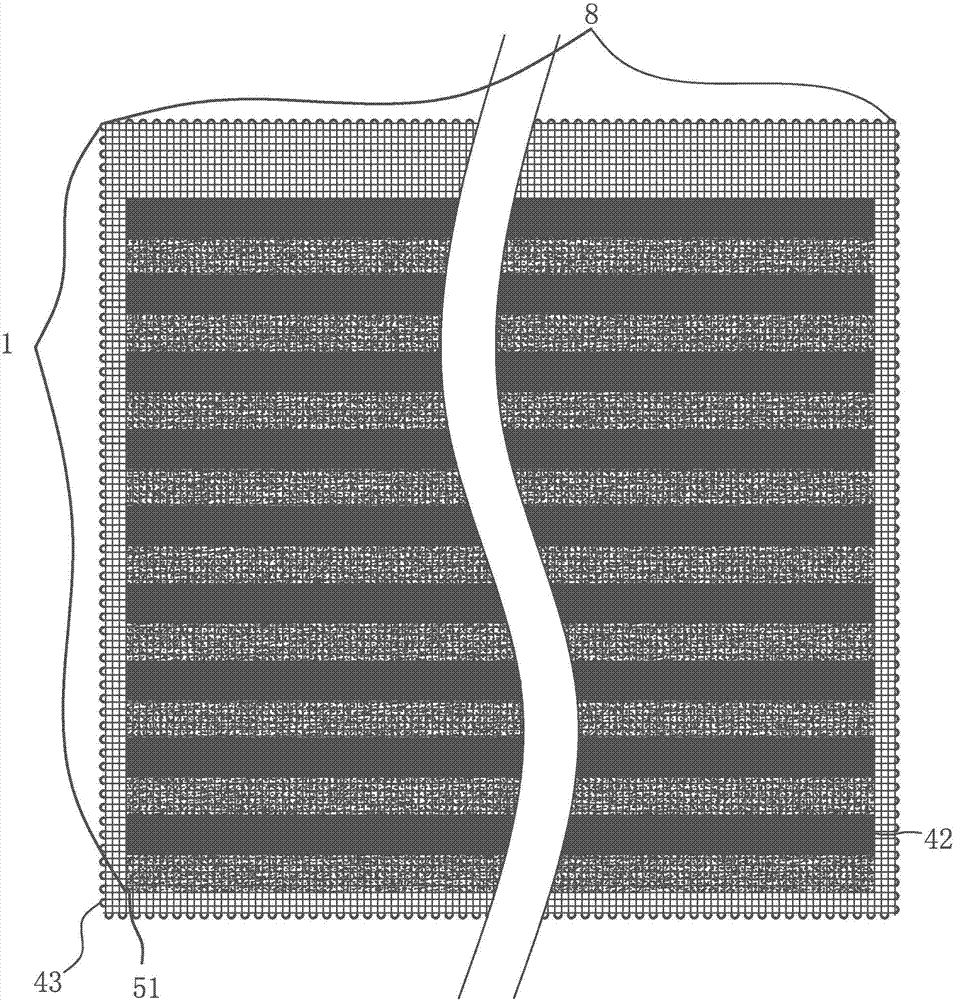

Large-pore light hernia repair mesh and knitting method thereof

The invention discloses a large-pore light hernia repair mesh. The structure of the hernia repair mesh is in a double-carded perforating queenscord atlas net structure knitted by medical synthetic monofilaments. The hernia repair mesh is mesh knitted fabric and has rhombus-shaped meshes in a surface thereof. The hernia repair mesh ranges from 2.6 to 7.5 mm in pore diameter and ranges from 18 to 55g / m2 in gram weight. Additionally, the invention further discloses a knitting method of the large-pore light hernia repair mesh.The large-pore light hernia repair mesh has following beneficial effects: the large-pore light hernia repair mesh is good in structural compliance, low in weight, large in pores and high in ability of anti-infection, which is desirable to ingrowth of fibroblasts and penetration of macrophage and leucocyte; chronic abdominal wall pains and foreign body sensation of a patient are relieved so that comfort level of the patient is greatly increased; the large-pore light hernia repair mesh can be tailored to be a flat sheet, a mesh plug by hot pressing or a specially-designed three-dimensional structure and serves as a part of a composite mesh; and the large-pore light hernia repair mesh has fine an application prospect.

Owner:SHANGHAI XINHUA RUISI MEDICAL SCI & TECH

TPU high-and-low-temperature membrane composite mesh cloth and preparation method thereof

ActiveCN109624422AAvoid breakingGuaranteed wear resistanceSynthetic resin layered productsLaminationComposite meshWear resistance

The invention discloses a piece of TPU high-and-low-temperature membrane composite mesh cloth and a preparation method thereof. A TPU high-and-low-temperature membrane is compounded with the mesh cloth sequentially through manners of initial compounding and vacuum stripe suction, a traditional mesh cloth product is improved by the method, the advantages of excellent water repellent and wind resistance performance, high self-repairing capability, diversified surface effect, strong three-dimensional sense, the unnecessity of dyeing of the mesh cloth, the reduction of environmental pollution, excellent wear resistance and scratching resistance, good shaping performance after a shoe is produced, good durability and good deformation and damage resistance are achieved on the basis that the advantages of softness, light weight and comfort of a piece of traditional mesh cloth are maintained, and the demands on the functionality and diversity of traditional mesh clothe products and traditionalpolyurethane synthesis products by markets can be met.

Owner:ANHUI ANLI MATERIAL TECH

Novel biodegradable vascular stent preparation method

ActiveCN103432631AInhibit dysplasiaRapid endothelializationSurgeryFilament/thread formingDiseaseVascular endothelium

The present invention relates to a novel biodegradable vascular stent preparation method, which specifically comprises: taking a raw material, heating to achieve a melting state, and cooling to a room temperature to obtain a blank material; adopting a self-made mold, a temperature control device, a heating rod, a clamping device, a data acquisition card, a computer monitoring system and other components to form a set of preparation equipment, paving the blank material in the mold cavity, placing the mold in the clamping device after the blank material achieves a set temperature, tightening the clamping device, and carrying out thermal insulation, cooling, mold opening, polishing and cleaning to obtain a primary stent; and placing the stent in an electrostatic spinning device to carry out electrostatic spinning direct-writing to prepare the composite mesh film stent. The prepared stent has characteristics of degradability, smooth surface and substantially increased mechanical strength, wherein a radial strength of the stent can be effectively enhanced and malformation proliferation hyperplasia of vascular endothelium on the stent can be inhibited with the mesh film. In addition, the whole preparation process is easy and easy to performe, and great practical significances are provided for treatment of cadiovascular or lumen stenosis diseases.

Owner:SHANGHAI UNIV

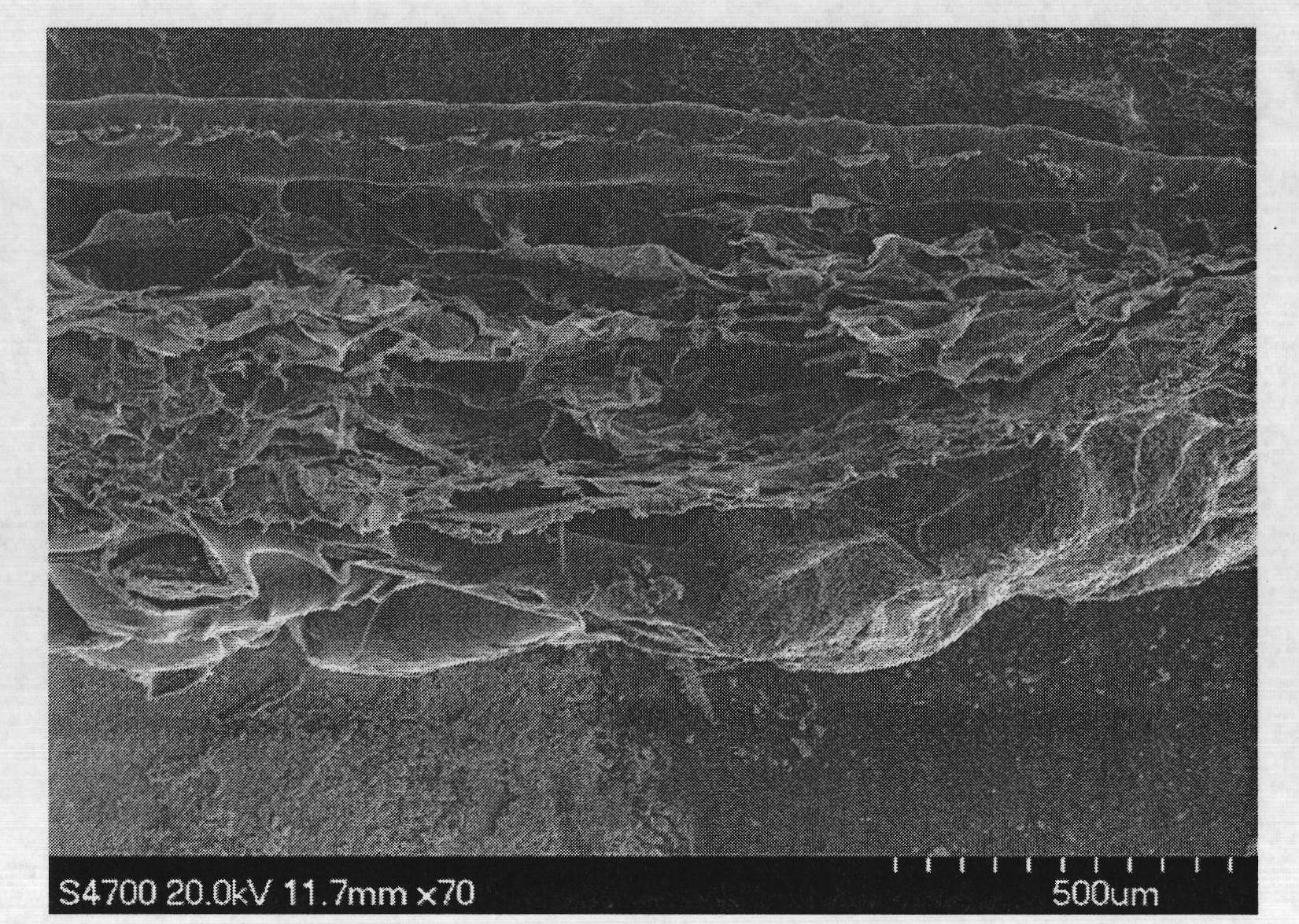

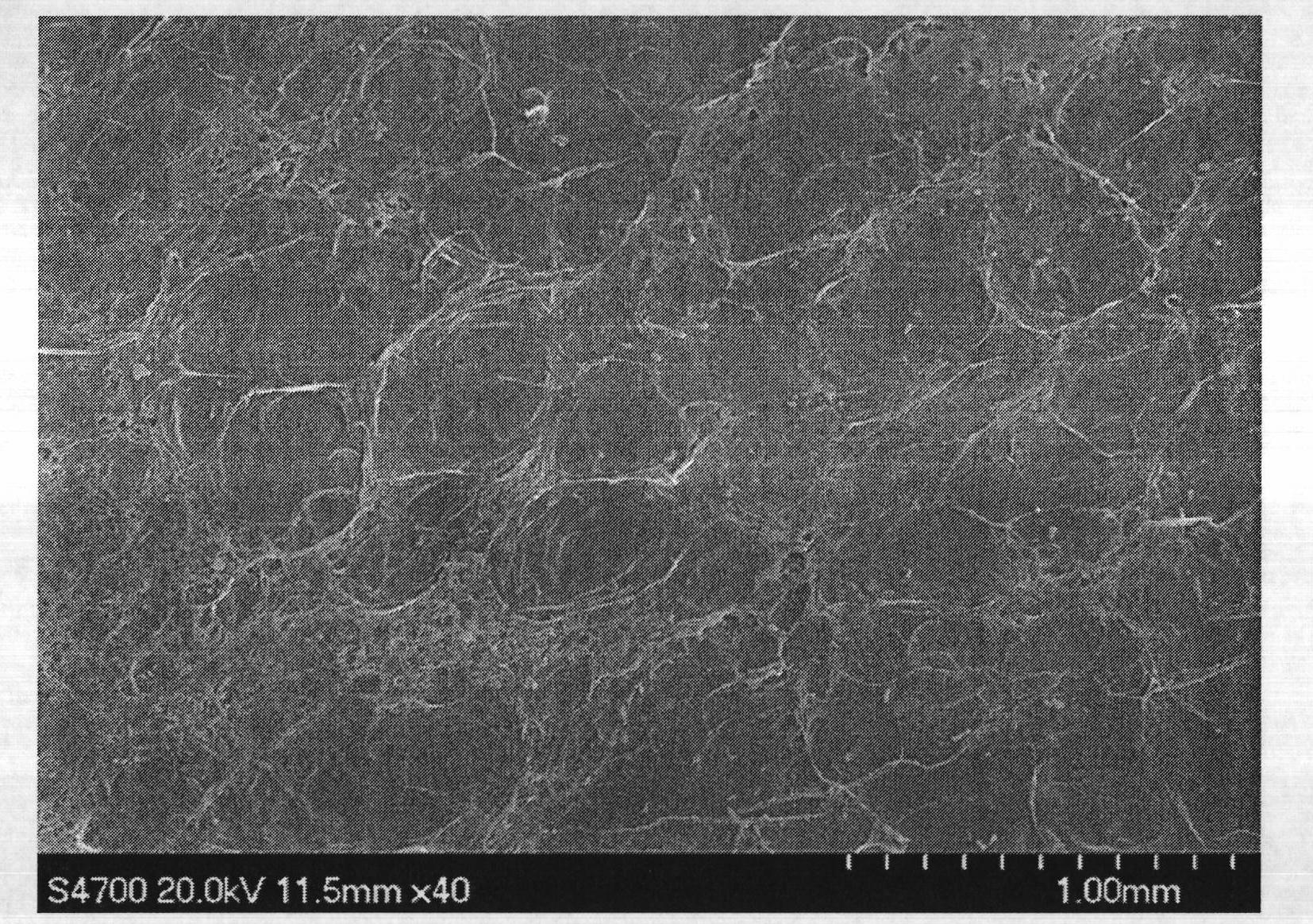

Spunlaced nonwoven fabric of ultra-high molecular weight polyethylene film and preparation thereof

ActiveCN106801292AHigh tear strengthImprove tensile strength at breakNon-woven fabricsBursting strengthPolymer science

The invention discloses a spunlaced nonwoven fabric of ultra-high molecular weight polyethylene film and preparation thereof, which comprises an ultra-high molecular weight polyethylene film. The ultra-high molecular weight polyethylene film layer is opened by spraying the high-pressure fine water onto one or more layers of the ultra-high molecular weight polyethylene film. High-pressure fine water sprays to composite mesh in a form of tangling, and repeatly spunlaces, making the fiber mesh to be compressed, reinforced, dried to form the spunlace non-woven fabrics of ultra-high molecular weight polyethylene film. The preparation process comprises(1) preparating; (2) paving; (3) spunlace reinforcing; (4) stretching; (5) secondary spunlace reinforcing; (6) drying; (7) winding up. One-off molding manufacturing of spunlaced nonwoven fabric of ultra-high molecular weight polyethylene film and preparation thereof has the advantages of enhancing the overall mechanical properties, being not only with higher tear strength, tensile breaking strength, bursting strength, but also good permeable, breathable and widely used.

Owner:QINGDAO UNIV

Composite sieve for vibrating sieve

InactiveCN102284420AThrough the smallThe chance of jamming the sieve hole is smallSievingScreeningEngineeringEntrapment

The invention discloses a composite screen for vibrating sieves, which comprises a base plate with regularly and evenly distributed screen holes, and a flat woven net is pasted on the base plate, and the flat woven net includes a plurality of warp threads and a plurality of weft threads interwoven with each other. In the present invention, a plain woven net including multiple interwoven warp threads and multiple weft threads is pasted on the substrate with regular and evenly distributed screen holes, so that when the particles to be cleaned move on the screen, they are repeatedly blocked by the warp threads and weft threads. The direction and trajectory of the movement are changed by collision to improve the probability and efficiency of falling from the sieve holes into the particle bin; and the warp and weft threads are used to cause the impurities to tilt during the movement, which is more conducive to the rolling of the particles from above the impurities, and is conducive to the complete removal of the particles and impurities. Separation, improve the separation effect; and reduce or prevent impurities from passing through or jamming the sieve hole.

Owner:湖南湘源金穗智能装备有限公司

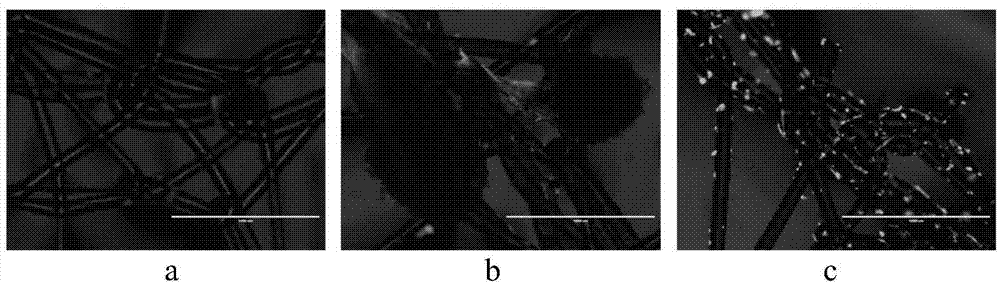

Alginate-bonding composite anti-adhesion mesh and preparation method thereof

InactiveCN109130403AImprove stabilityOptimal Control StructureSynthetic resin layered productsMedical devicesForeign matterFiber

The invention discloses an alginate-bonding composite anti-adhesion mesh and a preparation method thereof. The composite anti-adhesion mesh comprises a supporting layer, a bonding layer and an anti-adhesion layer. The supporting layer is made of a polypropylene mesh, the bonding layer is made of sodium alginate, and the anti-adhesion layer is made of a nano fiber membrane. The preparation method includes: mixing polycaprolactone with polylactide glycolide, dissolving into a solvent to obtain polycaprolactone / polylactide glycolide mixed solution, and subjecting the mixed solution to electrostatic spinning to obtain the nano fiber membrane; coating one surface of the polypropylene mesh with sodium alginate solution, and directly covering the surface with the nano fiber membrane to obtain thecomposite mesh; soaking the composite mesh into calcium chloride solution, and taking out to obtain the alginate-bonding composite anti-adhesion mesh. The composite anti-adhesion mesh is structurallycontrollable, light in weight and soft; by substitution of a traditional anti-adhesion barrier with the nano fiber membrane, material permeability is improved, anti-adhesion time is prolonged, and foreign body reaction is reduced.

Owner:DONGHUA UNIV

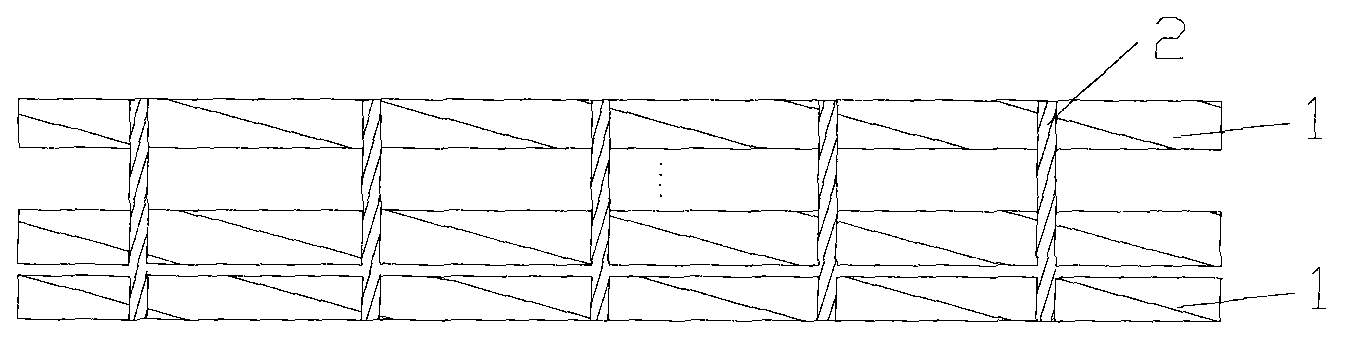

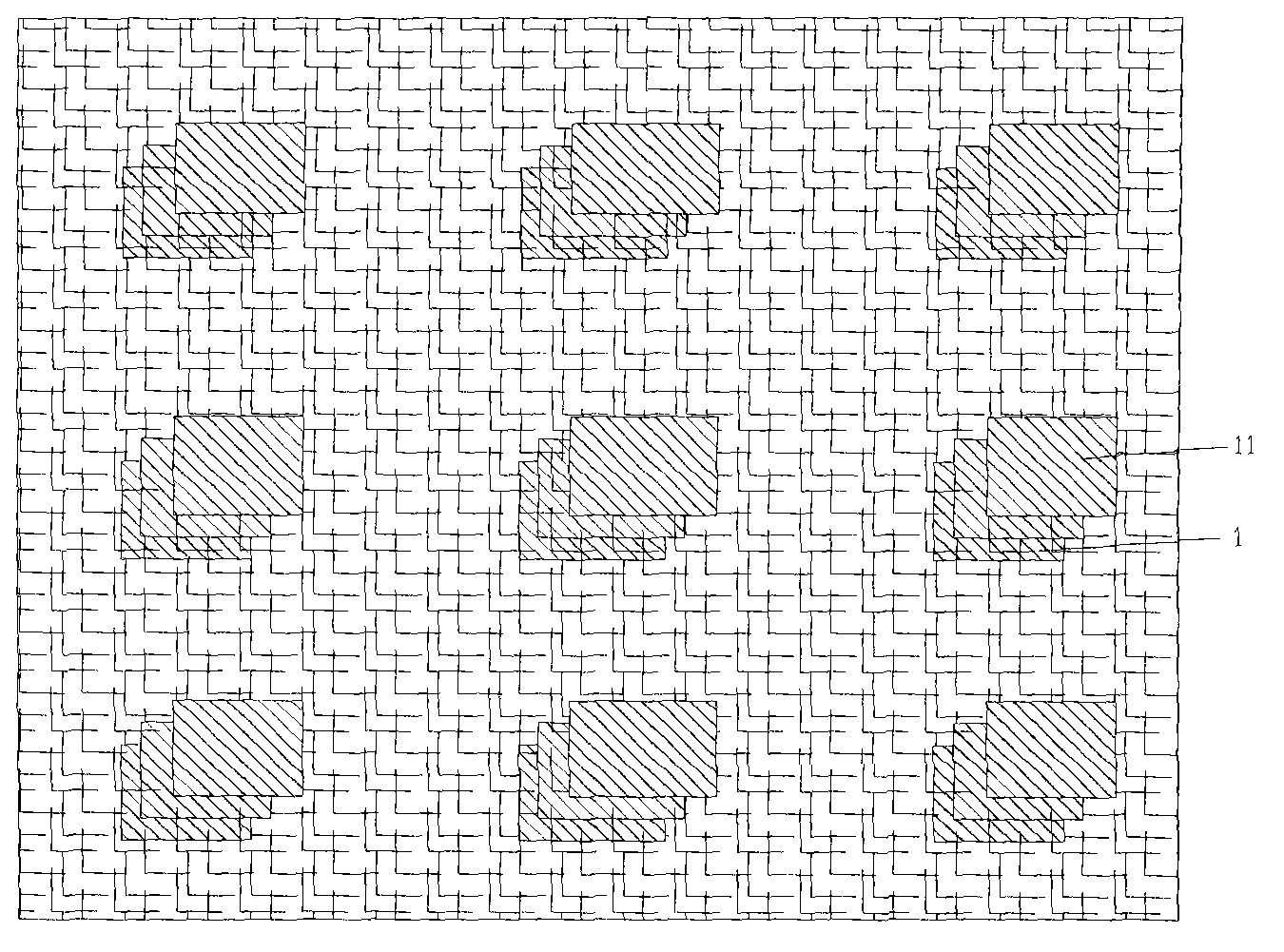

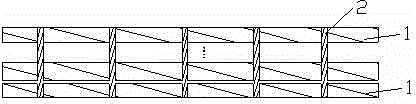

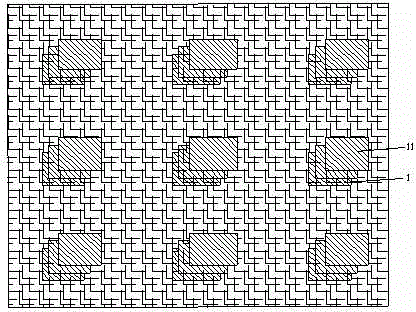

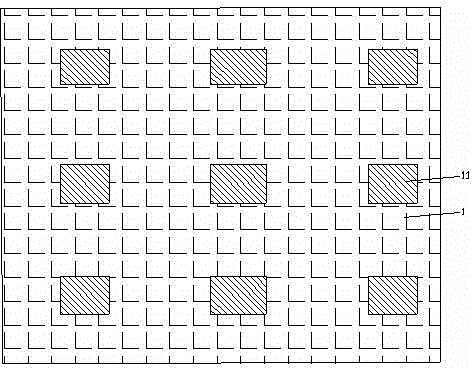

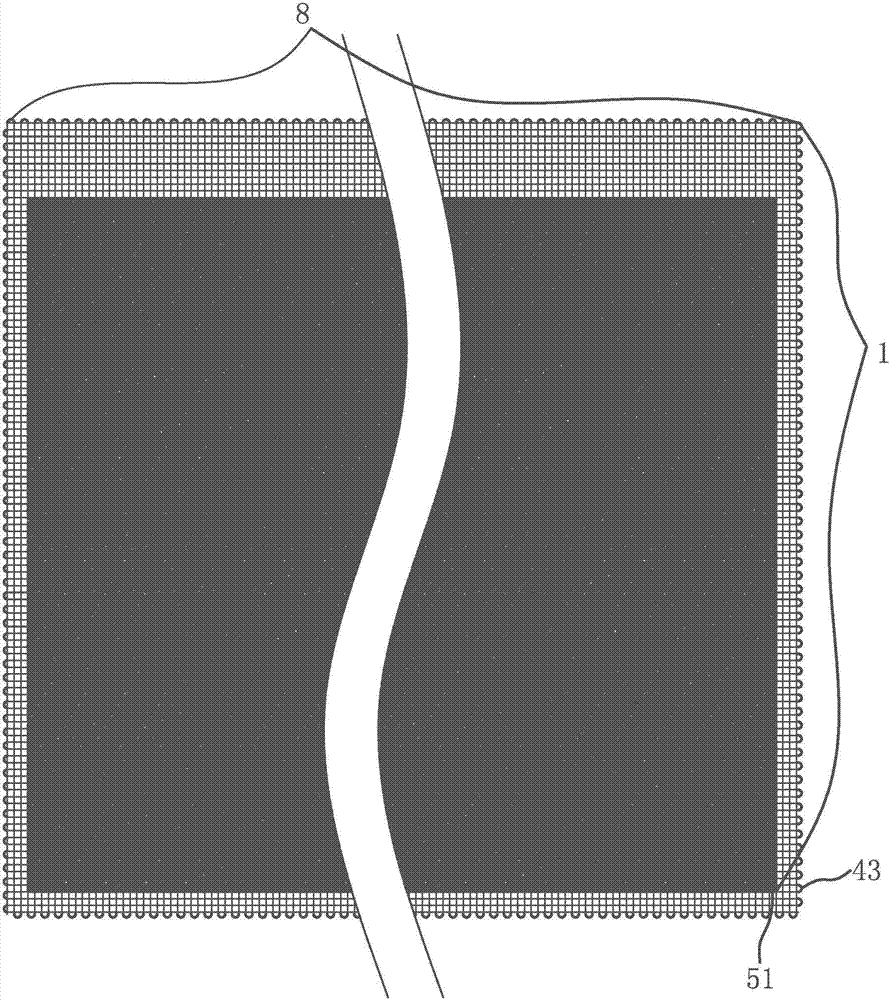

Elastic fabric with composite mesh layers

InactiveCN103817983ARich layersBright colorSynthetic resin layered productsWarp knittingSurface layerEngineering

The invention relates to an elastic fabric with composite mesh layers, which comprises a plurality of mesh surface layers (1), wherein the mesh surface layers (1) adopt mesh surface fabrics; a plurality of non-mesh surface fabrics (11) are arranged on the mesh surface layers (1), and adjacent two mesh surface layers (1) are sequentially arranged in a misplaced mode and are vertically connected with each other through bright silk threads (2); the mesh surface fabrics are made of a fabric, the fabric is a warp-knitted fabric, and the yarn laying rule is 1-0 / 2-3; face yarns adopt 75D / 36 T400 polyester fiber fully-drawn-yarn filaments, and bottom yarns adopt FDY 84D / 36F polyester filaments; the T400 polyester fiber fully-drawn-yarn filaments are hollow, and the section is crossed. Bright colors are added to the elastic fabric.

Owner:包敢锋

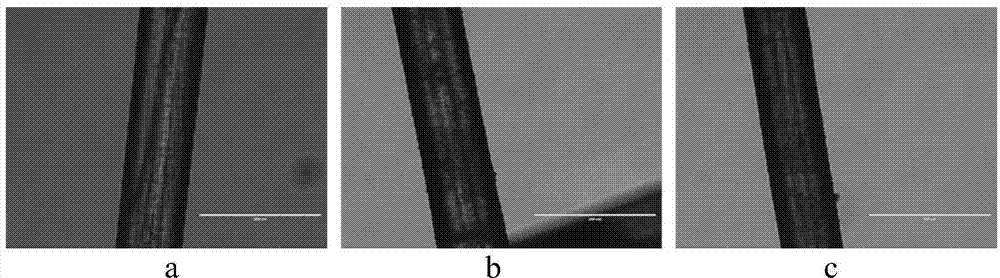

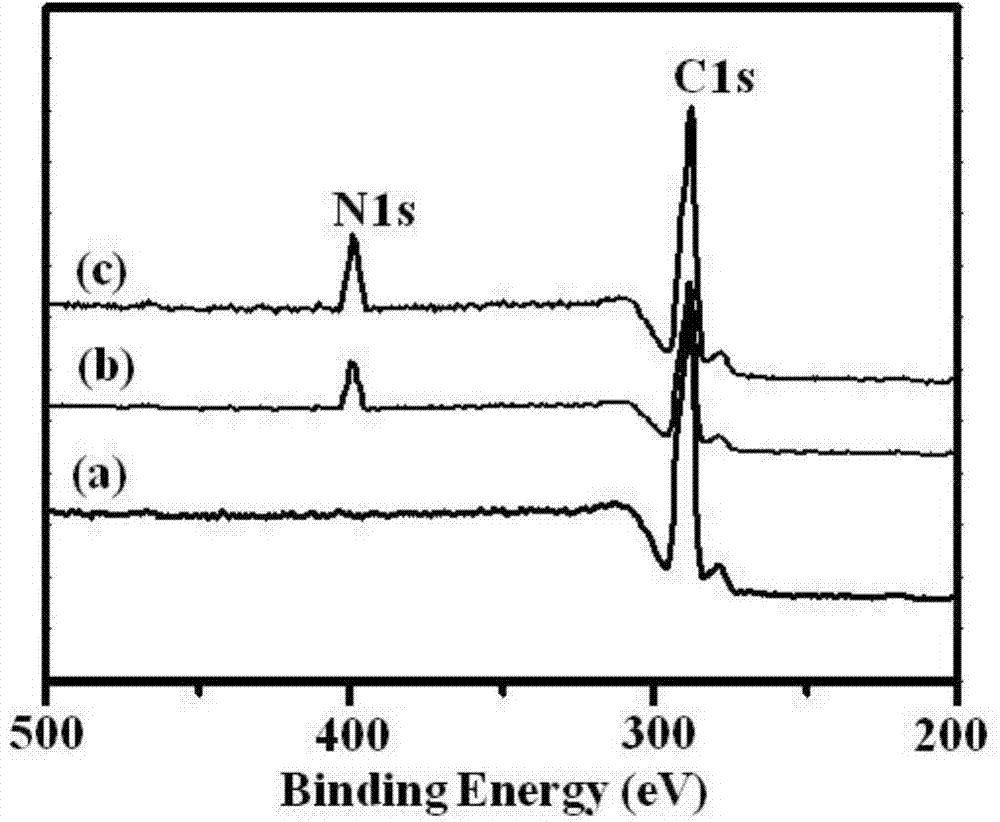

Composite polypropylene mesh and preparation method thereof

The invention discloses a composite polypropylene mesh. The composite polypropylene mesh is bonded by a polypropylene mesh and a fibroblast growth factor through polydopamine. In the premise condition of not changing the mechanical strength and the surface structure of the original polypropylene mesh, the fibroblast growth factor is grafted on the surface of the polydopamine after the polydopamine is grafted on the surface of the polypropylene mesh, and the composite mesh separation phenomenon cannot be generated. Simultaneously the fibroblast growth factor is hard to degrade in the body, the fibroblast growth can be induced and then the fascia reconstruction is induced.

Owner:海南德拉米克投资有限公司

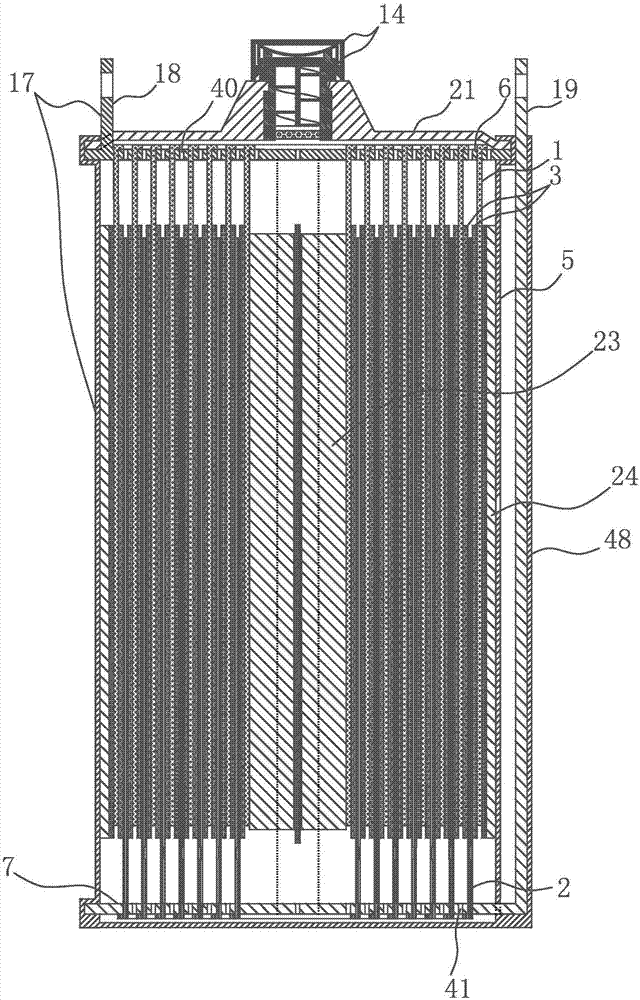

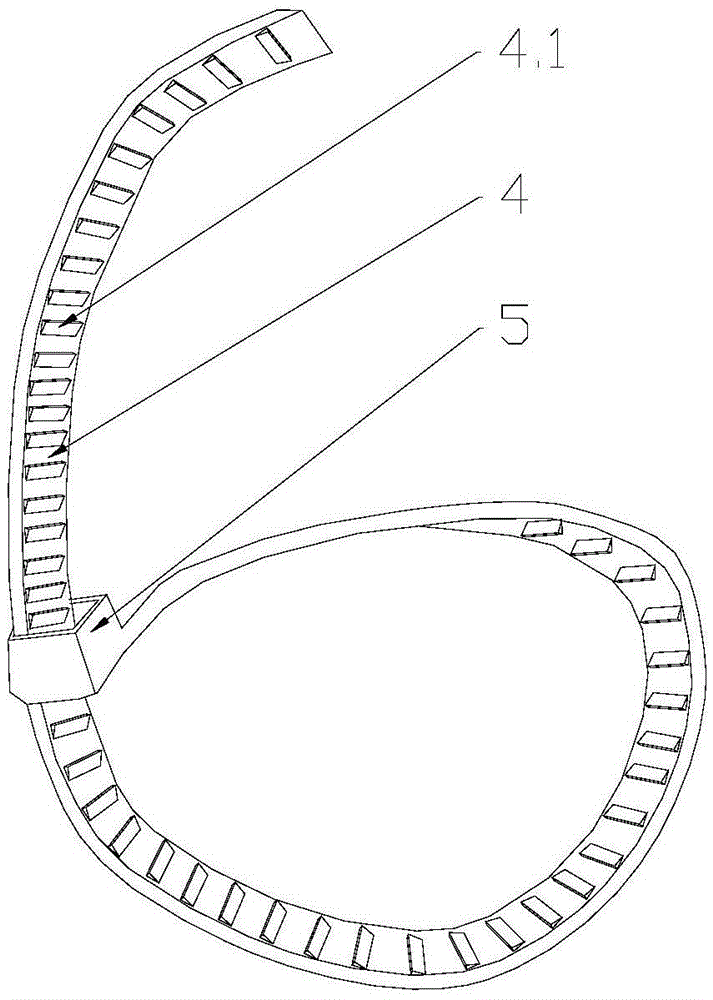

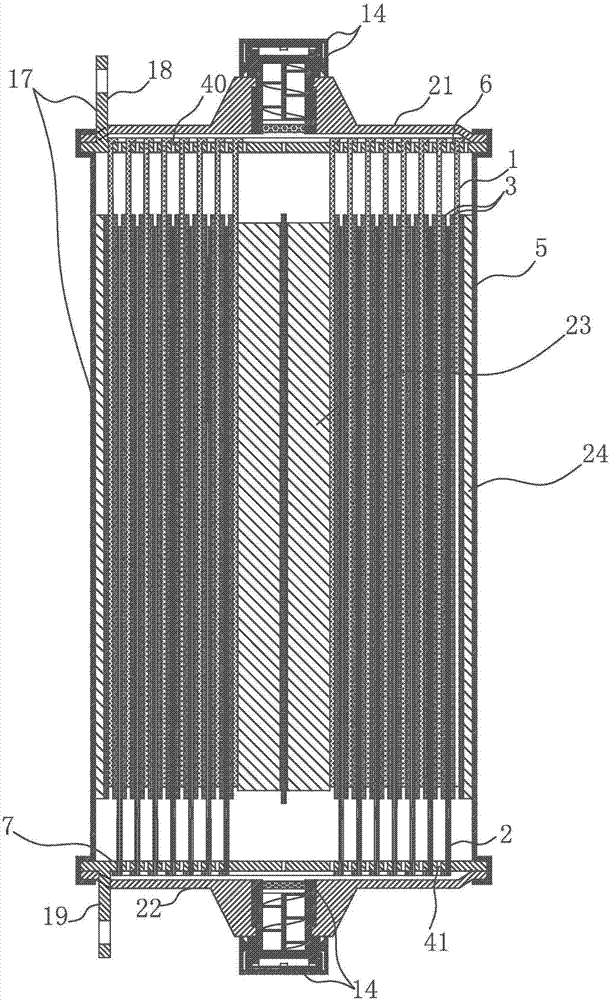

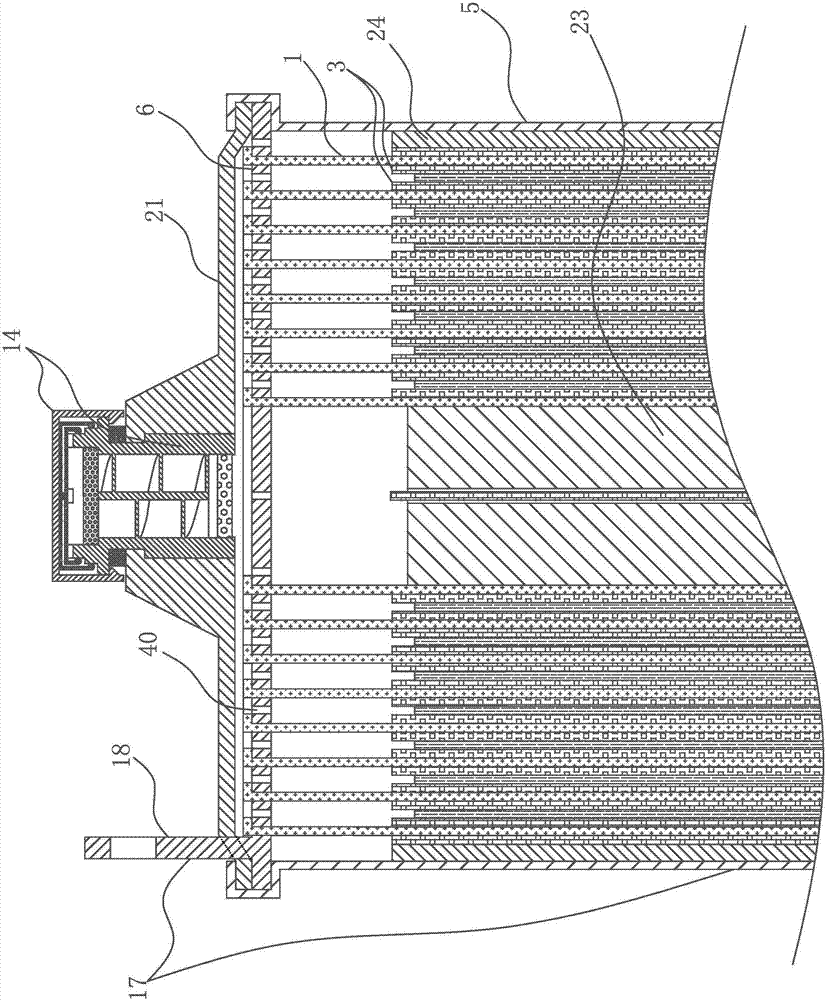

Coiled battery with symmetrical composite mesh pole pieces, cocurrent electrodes and envelope-membrane safety valve

InactiveCN107069114AIncrease the collecting areaHigh strengthFinal product manufactureElectrode carriers/collectorsFiberCapacitance

The invention provides a coiled battery with symmetrical composite mesh electrode pieces, cocurrent electrodes and an envelope-membrane safety valve. The coiled battery comprises a battery casing and a battery core. The coiled battery is characterized in that the battery core is wound into a columnar body by winding a positive electrode piece, a negative electrode piece and a membrane around a core reel; a positive electrode current collecting plate and a negative electrode current collecting plate are arranged on the top of both ends of the battery core separately; the positive electrode piece is provided with a tab, with the same length as that of the positive electrode piece, on a top end of the positive electrode current collecting plate, the current collecting plate is provided with a spiral groove; a negative terminal is guided to a direction of the positive terminal of the battery through an electrode terminal protective jacket arranged on a side face of the battery casing; and the positive electrode piece and the negative electrode piece are composite mesh electrodes, a conductive fiber web with high strength is used as a bottom plate, a metal oxide coating such as ruthenium oxide which are distributed in strips and a negative electrode active material are arranged on the bottom plate. According to the coiled battery with symmetrical composite mesh pole pieces, cocurrent electrodes and an envelope-membrane safety valve, due to a unique end-face current collecting structure, as well as composite mesh electrodes, current conducting ability can be effectively improved, the battery has high-rate charge-discharge characteristics of a supercapacitor, a double-membrane safety valve is more safe and battery performance is better.

Owner:陈学琴

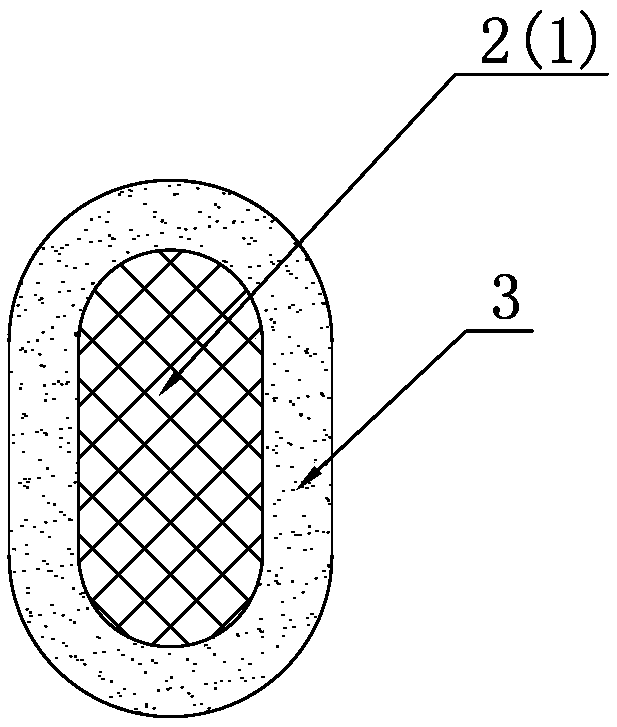

Novel construction method of strengthening pile for deep soft soil foundation

InactiveCN105544502AImprove the consolidation effectReduce or eliminate stress dissipation effectsSoil preservationGeomembraneCrushed stone

The invention discloses a novel construction method of a strengthening pile for a deep soft soil foundation. A pile body manufactured according to the novel construction method is a composite mesh cylinder draining granular pile. The composite mesh cylinder draining granular pile is divided into three layers in the radial direction, including an inner pile body filler, a middle mesh cylinder and an outer permeable geomembrane. The middle mesh cylinder is formed by meshes made of a modified polyethylene material or a modified polypropylene material in an enclosed mode. The novel construction method takes a traditional gravel pile as the prototype, uses the innovative thinkings that an enclosure is additionally arranged around an earth bagged gravel pile and draining is realized through a drain pipe pile for reference, improves the enclosure measures intensity and the drainage capacity of a granular pile body, reduces the implementation difficulty and the measure cost of the pile body, covers the shortages of the traditional gravel pile and the earth bagged gravel pile, and enhances the advantages of the traditional gravel pile and the earth bagged gravel pile.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

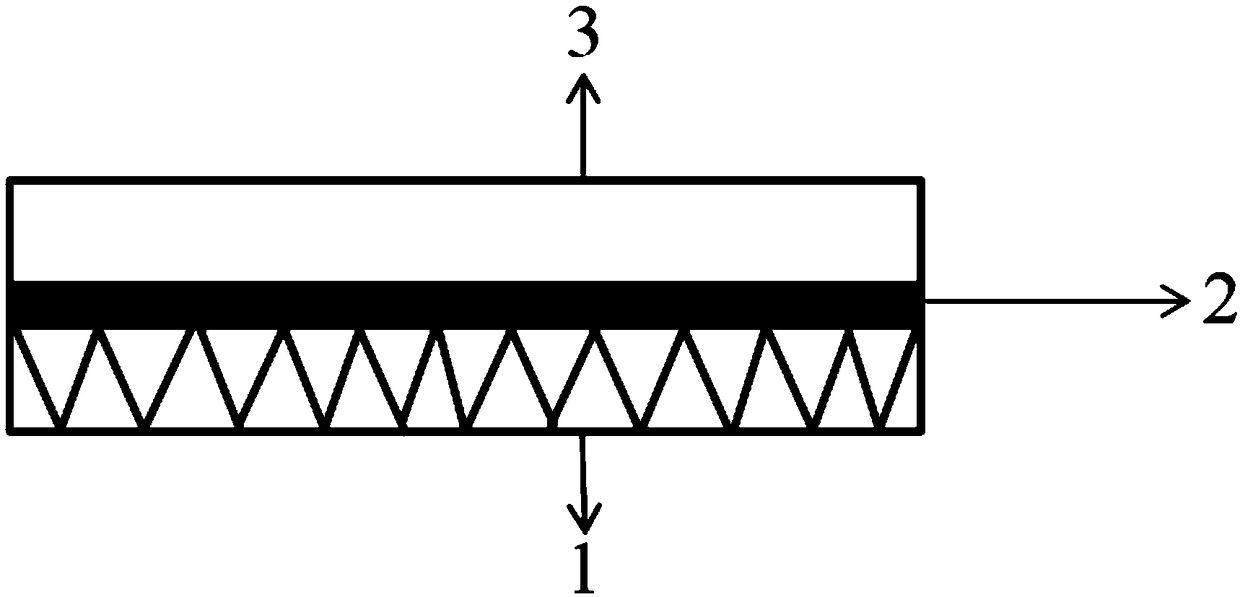

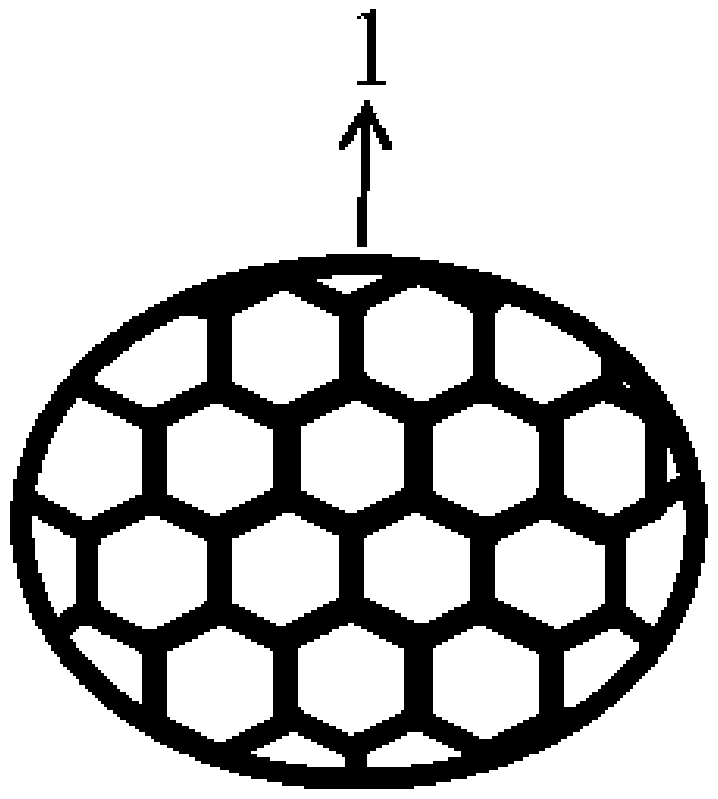

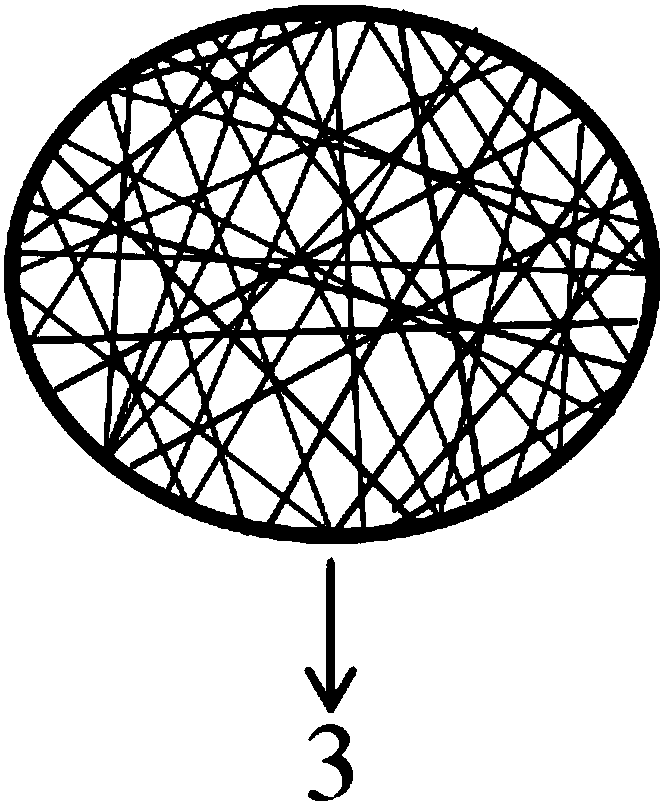

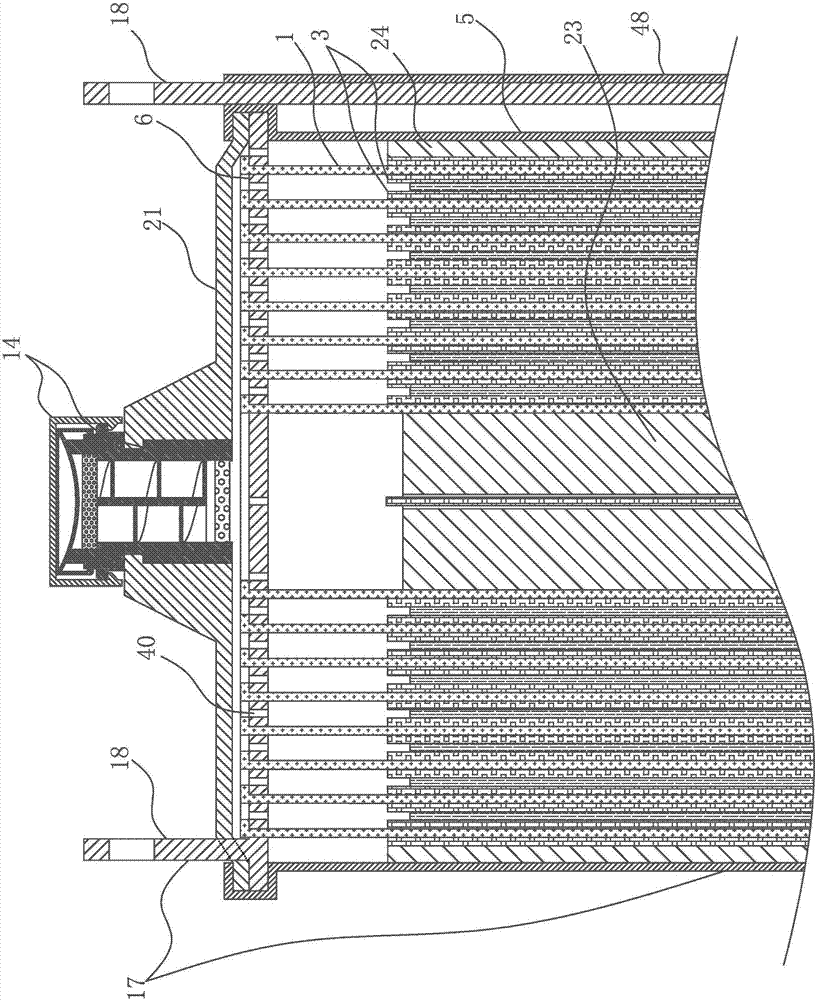

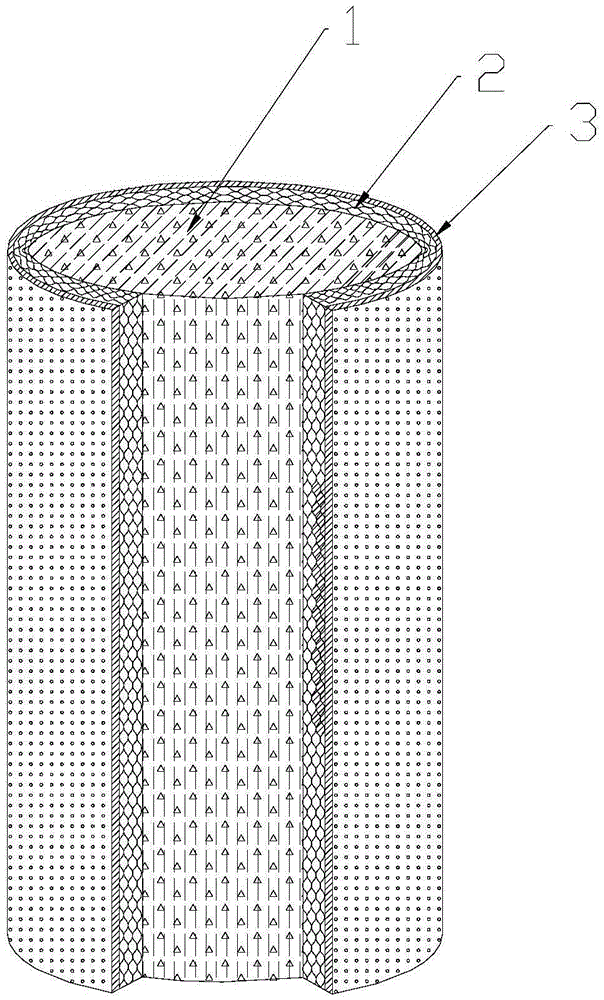

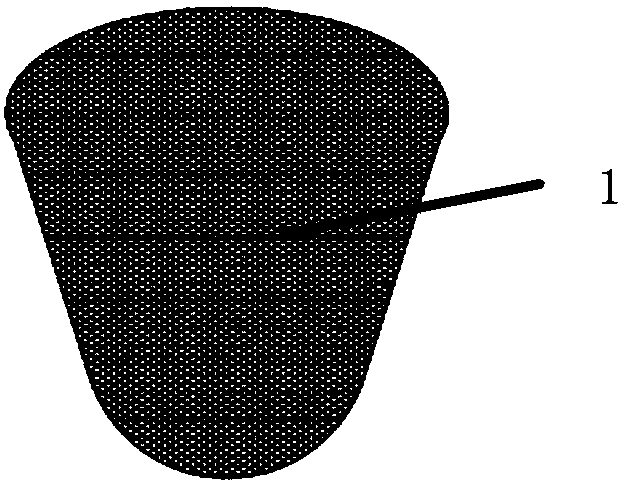

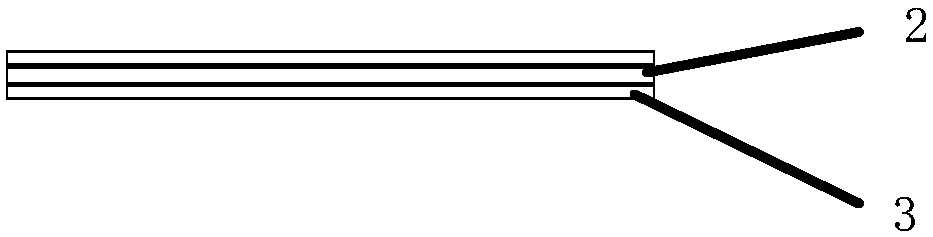

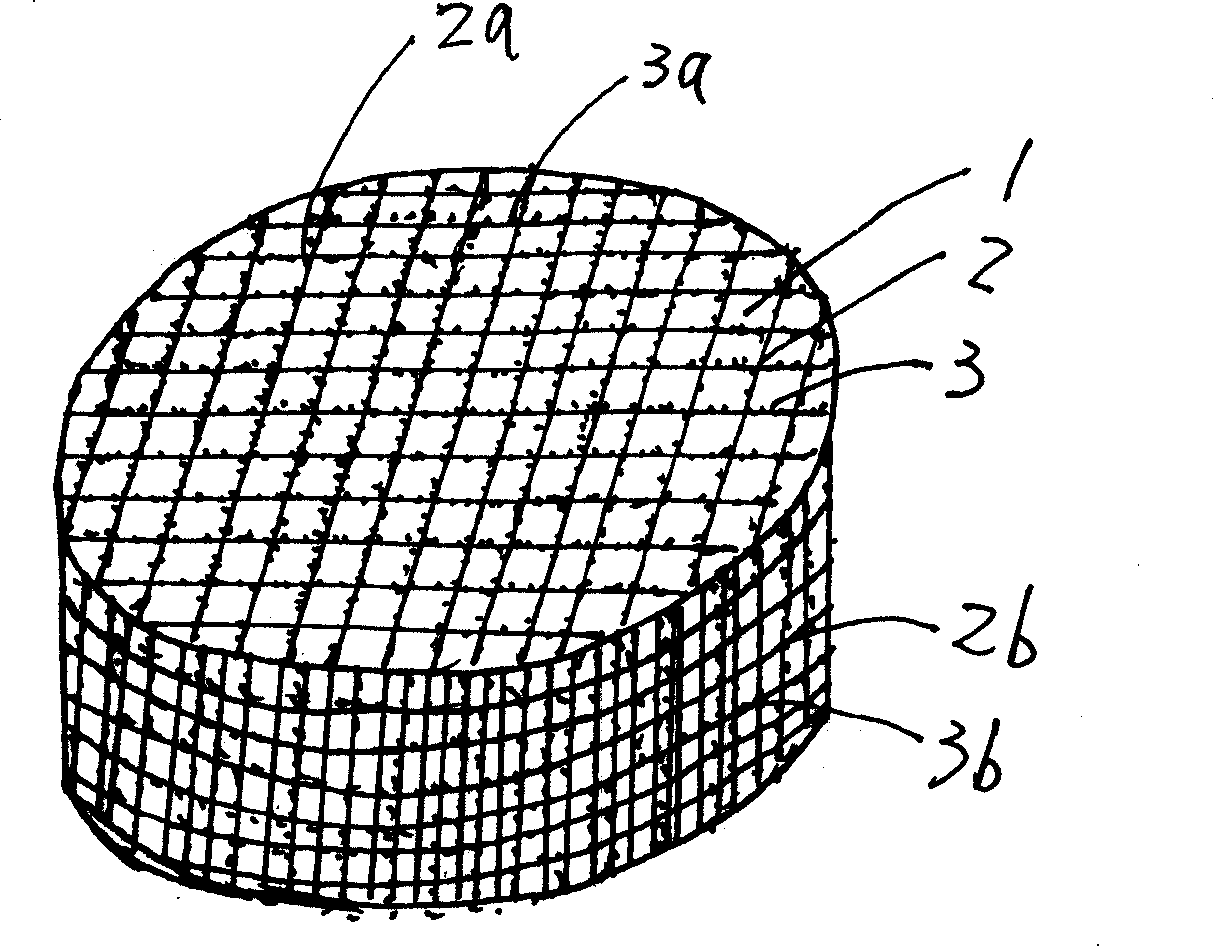

Partially absorbable composite mesh for restoration of rotator cuff and production method thereof

PendingCN107789092APromote healingHigh initial fixation strengthTissue regenerationProsthesisComposite materialComposite mesh

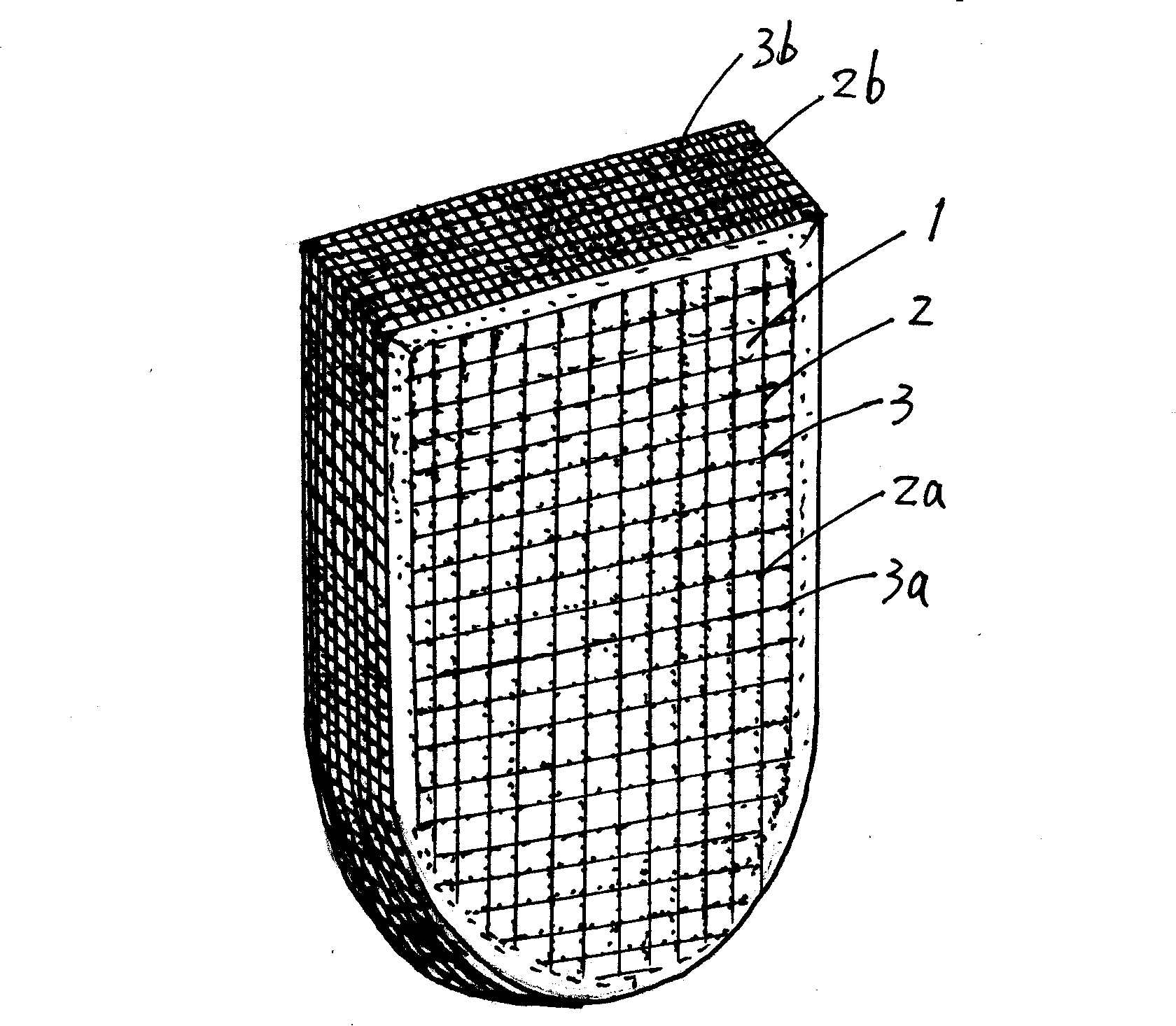

The invention provides a partially absorbable composite mesh for restoration of a rotator cuff. The composite mesh comprises a knitted body, the knitted body comprises one or multiple knitted units, the knitted units are stacked in the thickness extending direction to form a supporting base layer and absorbable layers; the absorbable layers are arranged on one end surface or both end surfaces of the supporting base layer in the thickness extending direction; the supporting base layer is made from a non-degradable material, and the absorbable layers are made from a degradable material. The invention further provides a production method of the partially absorbable composite mesh for restoration of the rotator cuff. The partially absorbable composite mesh for restoration of the rotator cuff has high initial fixing strength, meanwhile the rotator cuff is closely combined with a humerus by means of the composite mesh, and a gap is reduced; moreover, with gradual degradation of collagen, connective tissue of a human body gradually grows into micropores of the mesh to form an integral structure, and healing of the rotator cuff is accelerated.

Owner:SHANGHAI LIGETAI BIOTECH CO LTD

Composite mesh absorbent water-conductive fabric with composite fabric layer

InactiveCN104921375ARich layersStrong moisture wickingLayered productsTextile decorationYarnPolyester

The invention relates to a composite mesh absorbent water-conductive fabric with a composite fabric layer. The composite mesh absorbent water-conductive fabric comprises a plurality of mesh layers (1) which are made of mesh fabric; each mesh layer (1) provided with a plurality of non-mesh fabric layers (11); the mesh layers (1) are adjacently staggered and are connected through bright yarns (2); the mesh fabric is made of cloth which is polyester / cotton interwoven cloth, made of polyester yarns and polyamide yarns; the polyester yarns are located on the front of the cloth, and the polyamide yarns are located on the back of the cloth. The composite mesh absorbent water-conductive fabric is brighter in color, water absorbent and water conductive.

Owner:JIANGSU HEJIA TEXTILE

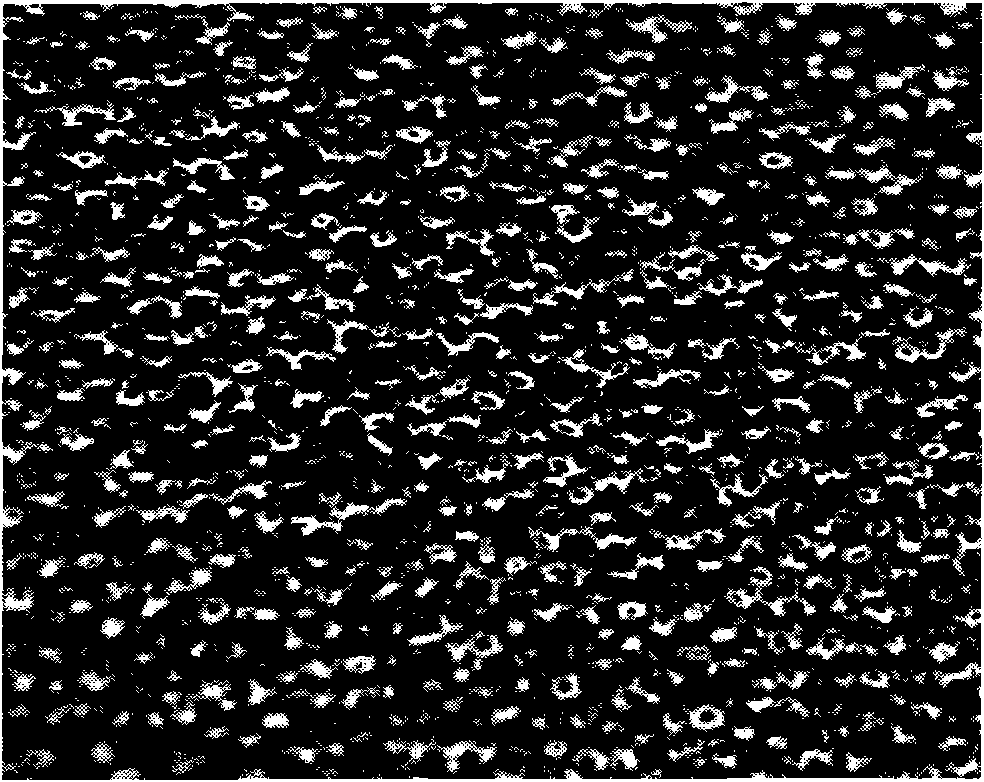

Preparation method of air-jetting solidification-type high-adsorbability non-woven fabric and high-adsorbability non-woven fabric

ActiveCN110016767AIncrease distribution spaceEvenly distributedNon-woven fabricsEngineeringComposite mesh

The invention relates to a preparation method of an air-jetting solidification-type high-adsorbability non-woven fabric. The method comprises the steps that firstly, an upper elastic fiber mesh, a lower elastic fiber mesh and a bamboo charcoal fiber mesh are prepared separately, then the bamboo charcoal fiber mesh covers the top face of the lower elastic fiber mesh for obtaining an overlaying mesh, the overlaying mesh is placed on a conveying curtain, and the conveying curtain is of a grid structure; the conveying curtain drives the overlaying mesh to move forward in the horizontal direction until the overlaying mesh passes through an airflow jetting area so as to obtain a composite mesh, in the process that the overlaying mesh passes through the airflow jetting area, air-jetting holes jetairflow downwards, and the airflow passes through the overlaying mesh and the conveying curtain in sequence and then is jetted into an air suction box; the upper elastic fiber mesh covers the top face of the composite mesh for obtaining a gray fabric, and the gray fabric is dried and cooled in sequence for obtaining the high-adsorbability non-woven fabric. According to the preparation method, theeven dispersion effect is good, exertion of the function of a bamboo charcoal fiber can be improved, leakage is not easily caused, and the comfort feeling is good.

Owner:WUHAN TEXTILE UNIV

Multifunctional hernia patch

ActiveCN109789249AIndustrial applicabilitySolve the problem of postoperative complicationsSurgeryCoatingsFiberPolymer science

This invention is associated with surgical implants with anti-adhesive, antibacterial and hemostatic properties to use in hernia repair. These implants comprise: a) Bilayer intraperitoneal mesh, whichhas certain thickness and porosity was prepared with combination of PP Mesh and blend system of biodegradable polyester-based polymers and polysaccharides coated on PP layer as nanofibers via electrospun technique, and, b) Double and / or triple-layer extraperitonal composite mesh, was prepared with blend systems of biodegradable polyester-based polymers and / or polysaccharides formed on PP / polyester woven material via different coating methods.

Owner:TUBITAK

Sponge composite gridding sanding block and production method thereof

InactiveCN101209544AEasy constructionReduce obturatorAbrasion apparatusGrinding devicesAdhesiveEngineering

The invention relates to a sponge composite mesh grinding block and a production method used for decoration, comprising an internal core which is made of sponge, mesh cloth and a sand layer. The external surface of the internal core is covered by the mesh cloth; the sand layer is fixedly attached on the surface of the mesh cloth; the internal core can be made into different geometrical shapes; the external surface of the internal core is covered by the mesh cloth, which means that the mesh cloth can be fixedly attached on the surface of the internal core by adhesive or can be fixedly fastened on the surface of the internal core by a structural part or can be sheathed on the surface of the internal core; by taking the sponge as the internal core which is made into different geometrical shapes, the grinding operation can be carried out according to different geometrical shapes; the sponge is taken as the internal core and the sands are arranged on the surface of the mesh cloth, the grinding surface is formed, the powder is reduced in the construction process, and the invention can be repeatedly applied at the same time.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

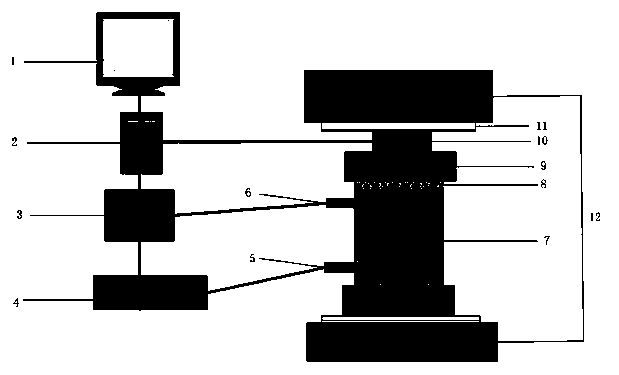

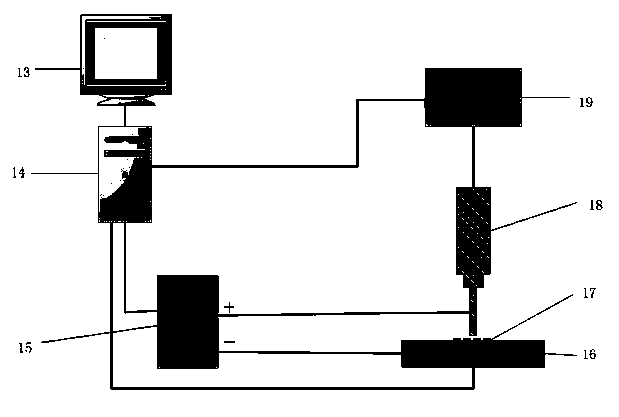

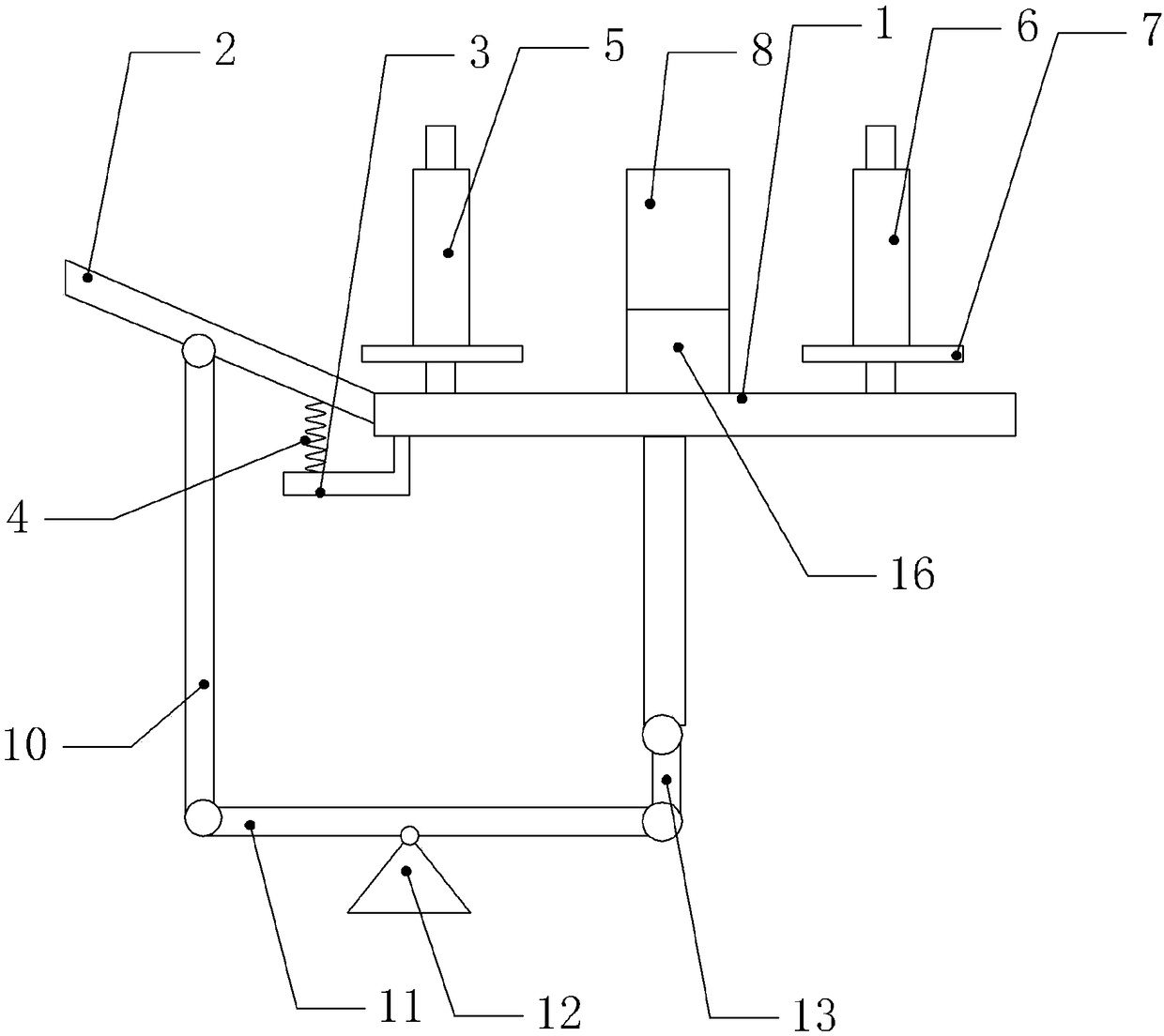

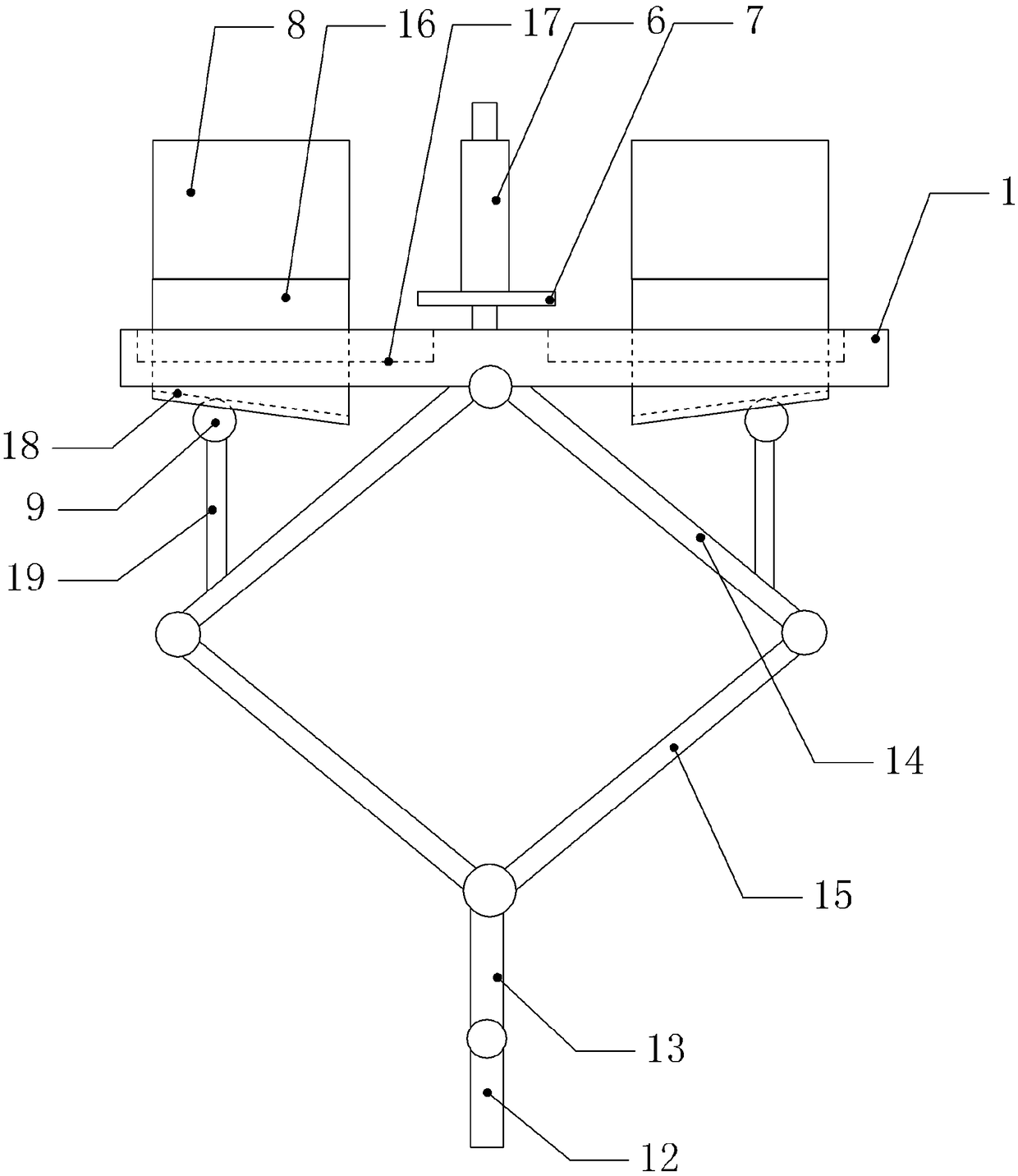

Two-side Heating devices for grid

PendingCN109244476AAvoid loose situationsFully heatedElectrode carriers/collectorsComposite meshMachining

The invention relates to the technical field of grid machining, and discloses a two-side heating device for a grid, which includes a base, a first guide roller and a second guide roller, the first guide roller and the second guide roller are vertically and rotatably connected to both ends of the base, The front end of the base is provided with a feeding table which can move up and down along one side of the base, the base is respectively provided with heating lamps on both sides of the composite mesh grille, and an adjusting mechanism which can adjust the distance according to the weight of the composite mesh grille is arranged between the heating lamps on both sides. The invention improves the utilization rate of heat of the hot melting line and shortens the hot melting time. According tothe weight of the composite mesh grating, the distance between the composite mesh grating and the heating lamp is adjusted, so that the hot melting effect is good.

Owner:GUANGZHOU ZHUOYUE POWER NEW ENERGY CO LTD

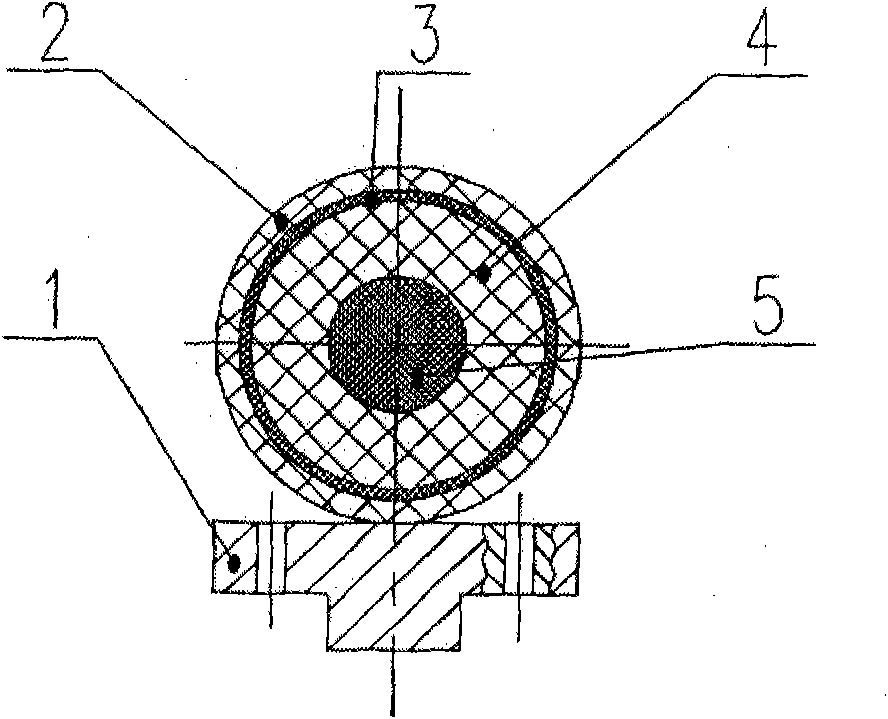

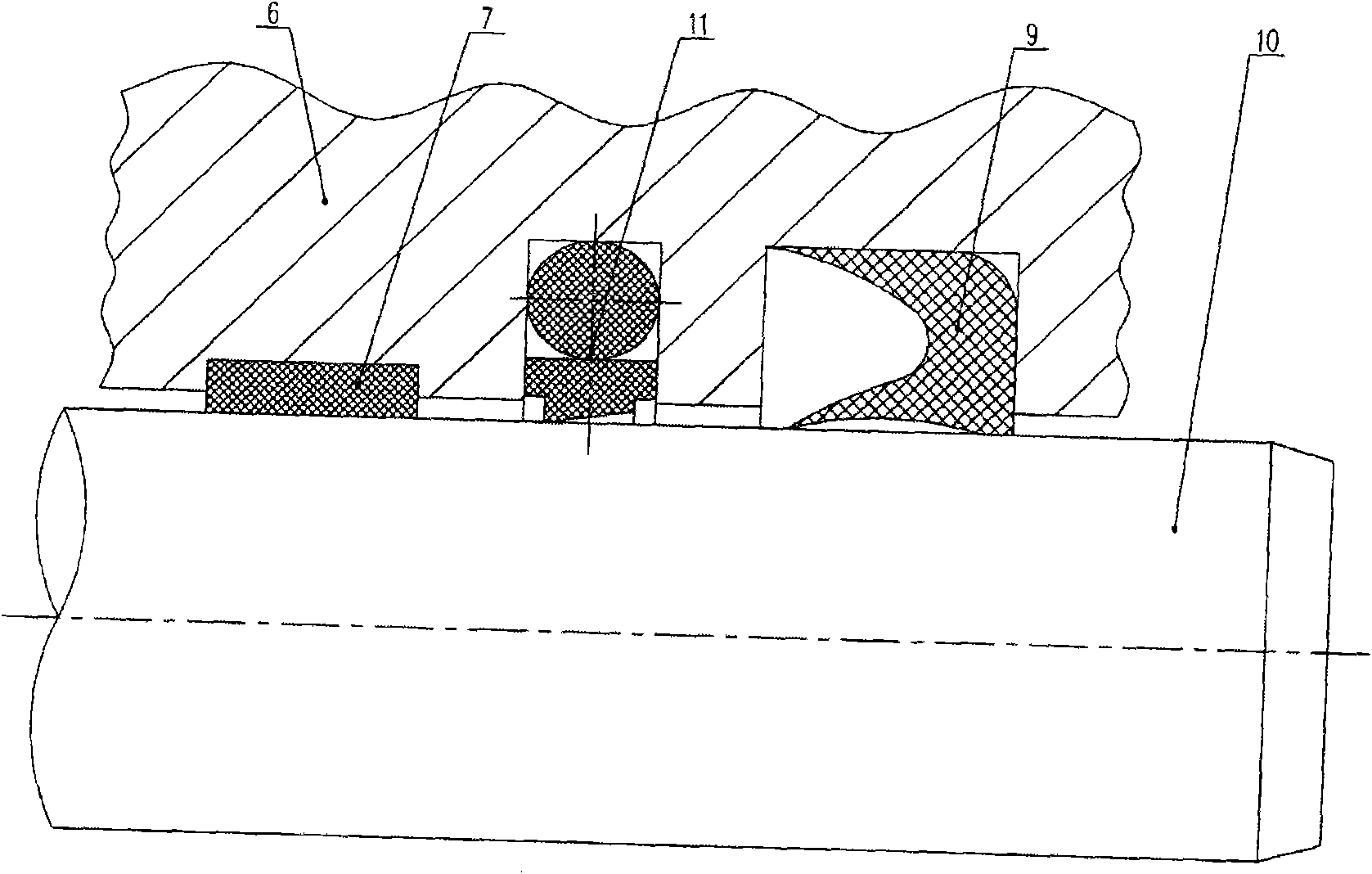

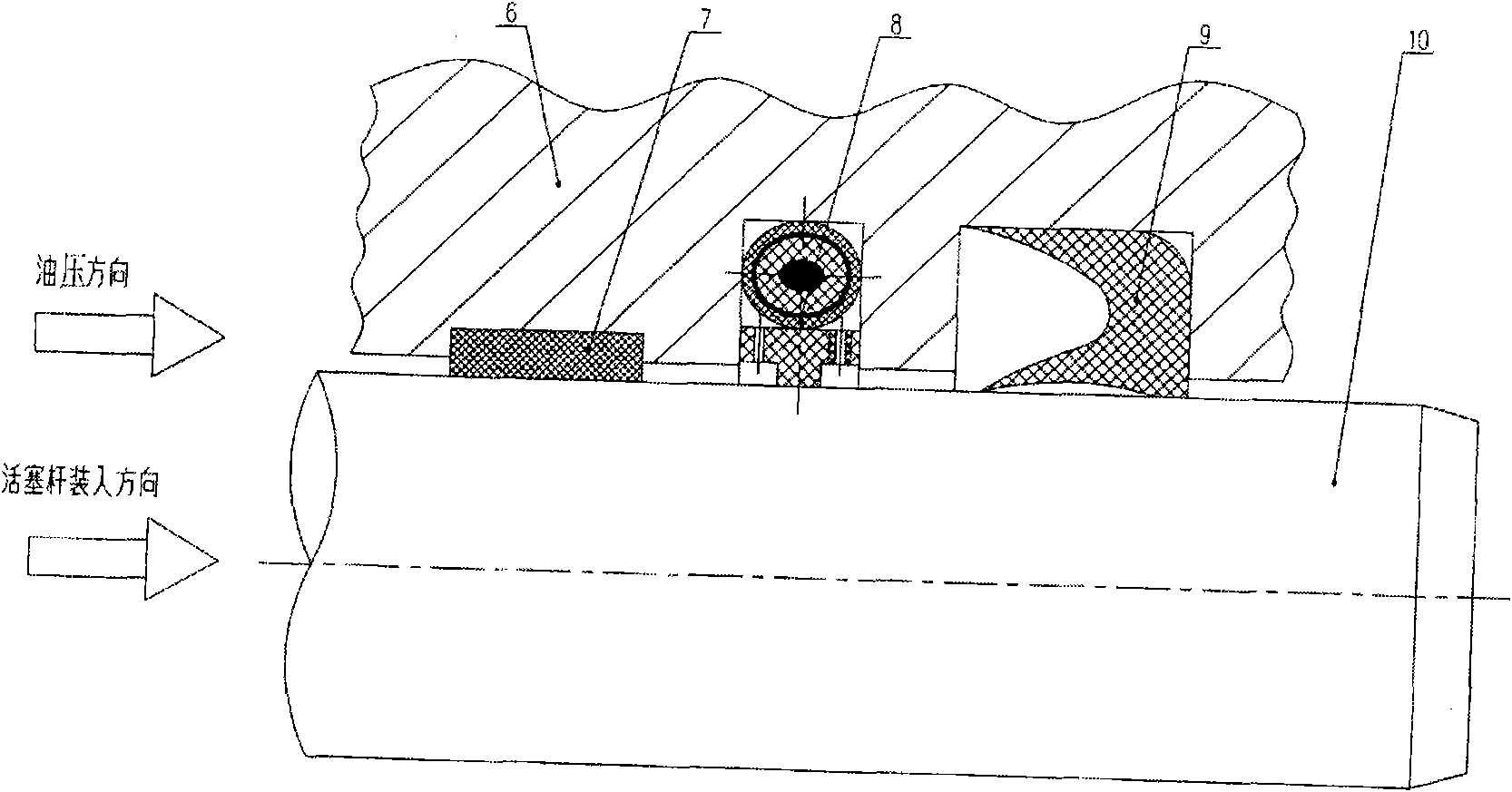

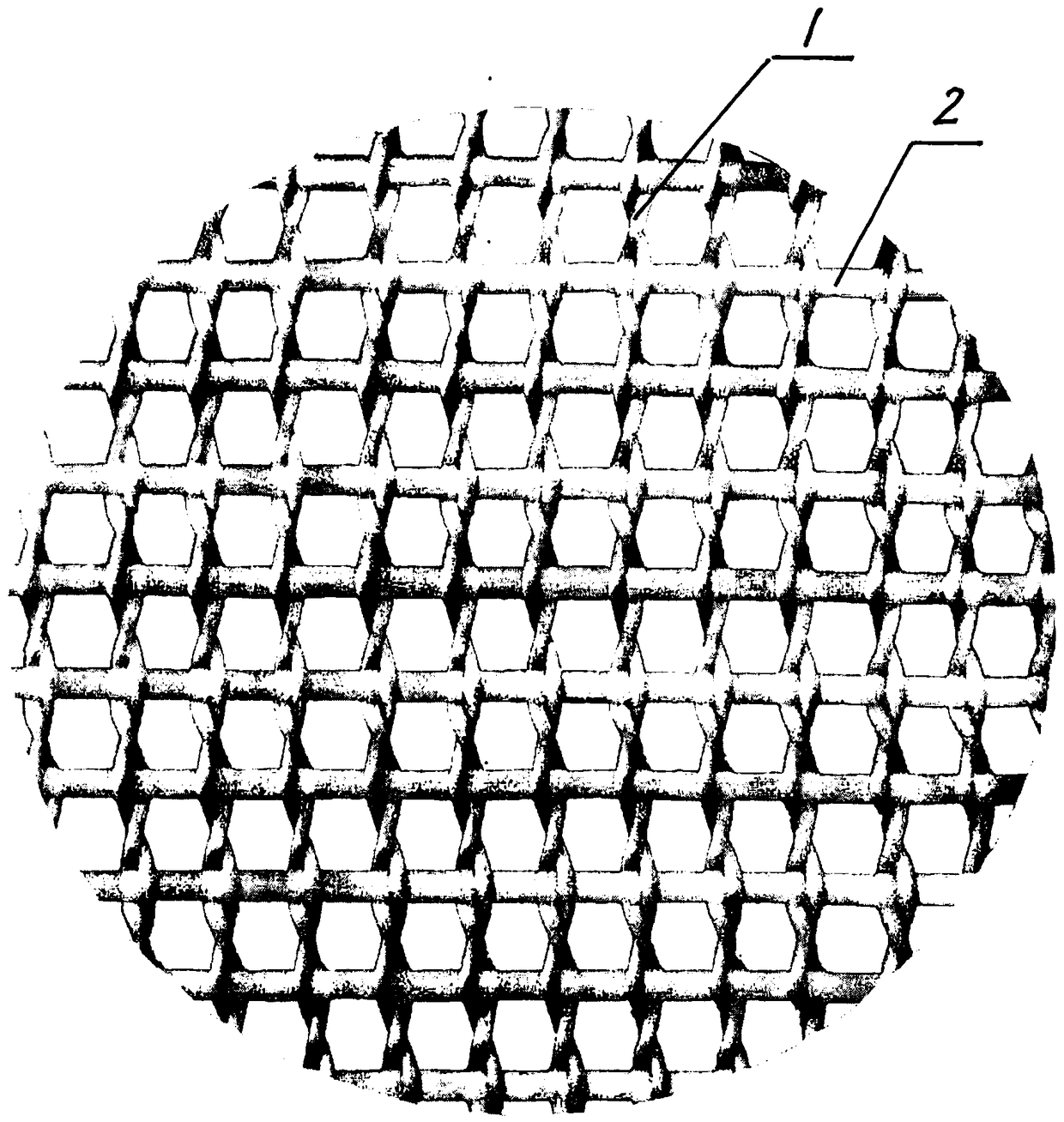

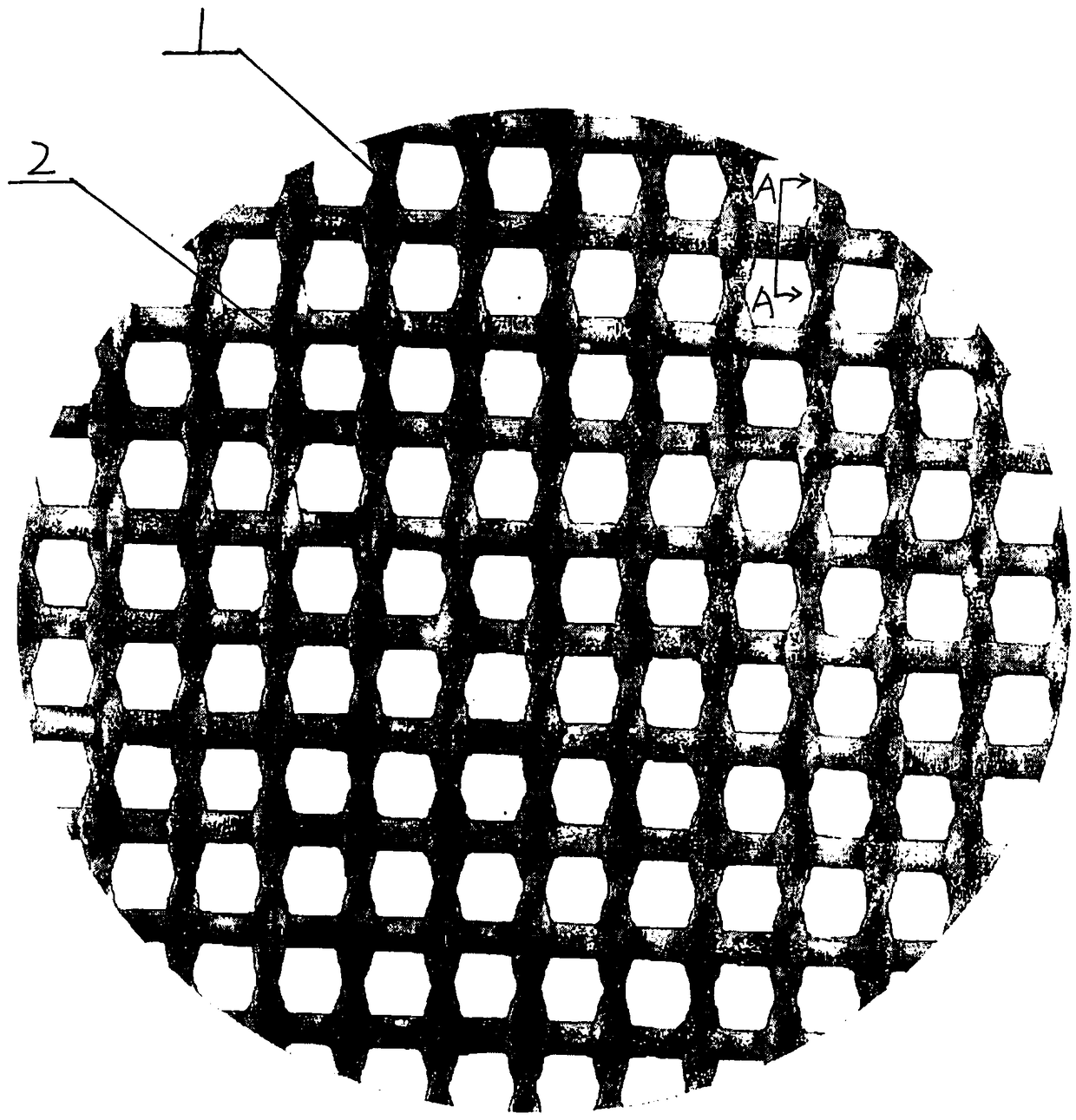

Hydraulic sealing pressure buffer filter

A hydraulic sealing pressure buffer filter belongs to sealing devices of piston rods in engineering hydraulic cylinders. The filter comprises a filter body ring and a support body ring, the filter body ring is formed by sheathing a multi-layer composite mesh ring outside a matrix, the matrix is a rubber O-ring; a nylon wire mesh ring, a metal wire mesh ring and a protective nylon wire mesh ring are sequentially sheathed to form the peripheral multi-layer composite mesh ring. The support body ring is a circular body of a composite material, the filter body ring is circularly arranged on the support body ring; the hydraulic sealing pressure buffer filter is mounted in a groove arranged on a guide sleeve, and the guide sleeve is sheathed outside a piston rod. The filter can meet design requirements of seal rings (of Y shape, U shape, K shape and the like), prolong service life of the seal rings, not be damaged by transient high pressure and foreign materials, cause foreign materials to not remain in the seal rings, improve sealing effect, and effectively relieve transient high pressure.

Owner:段黎明

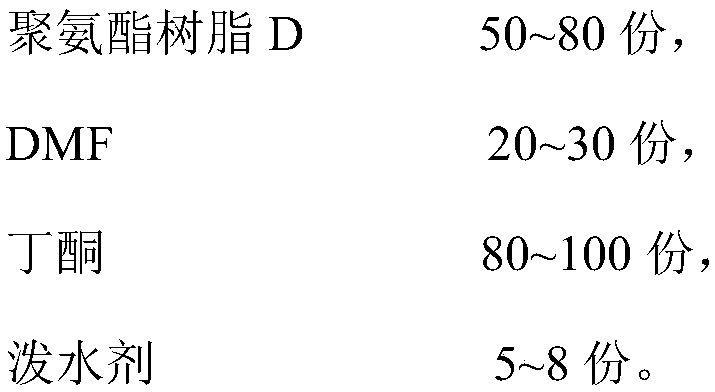

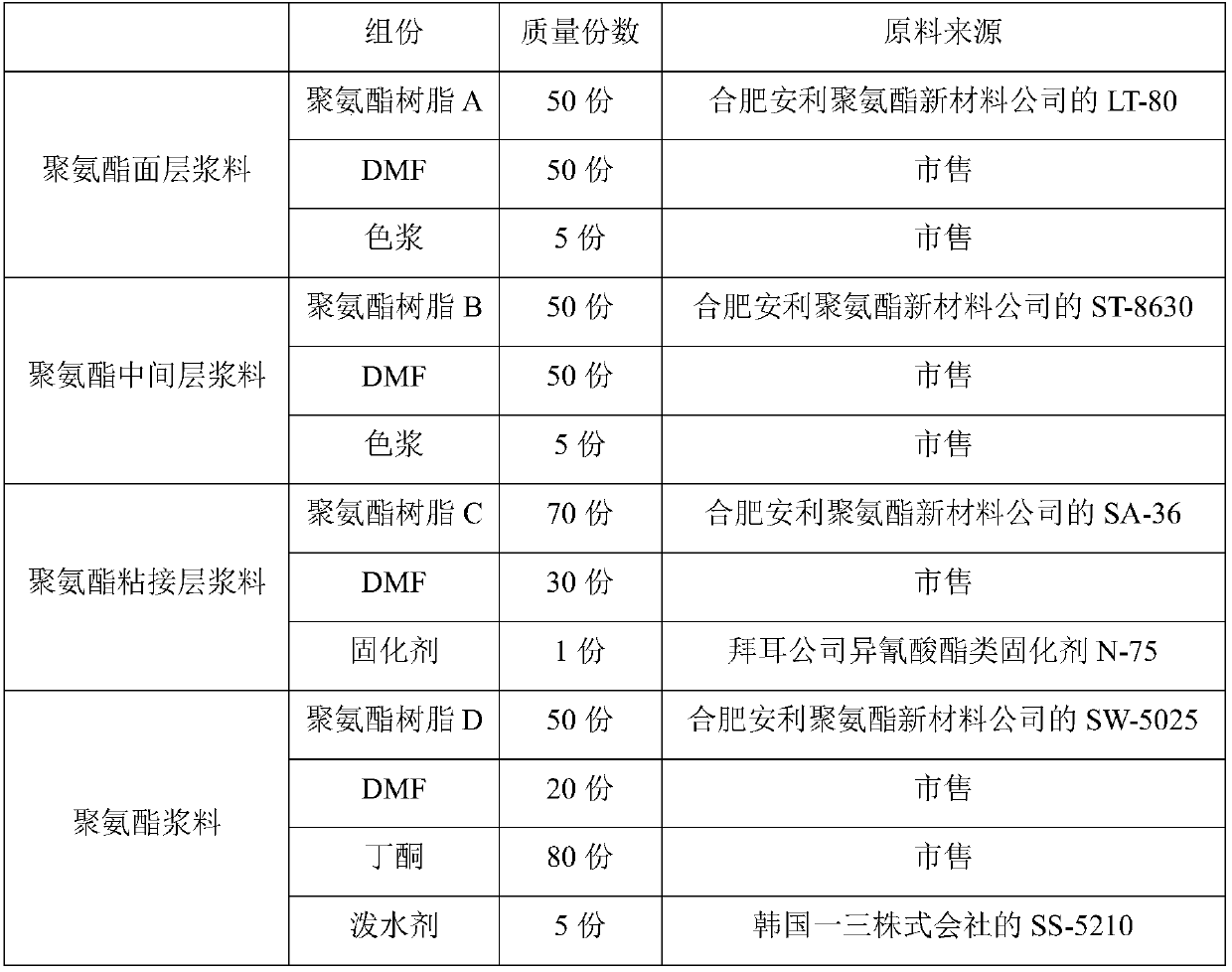

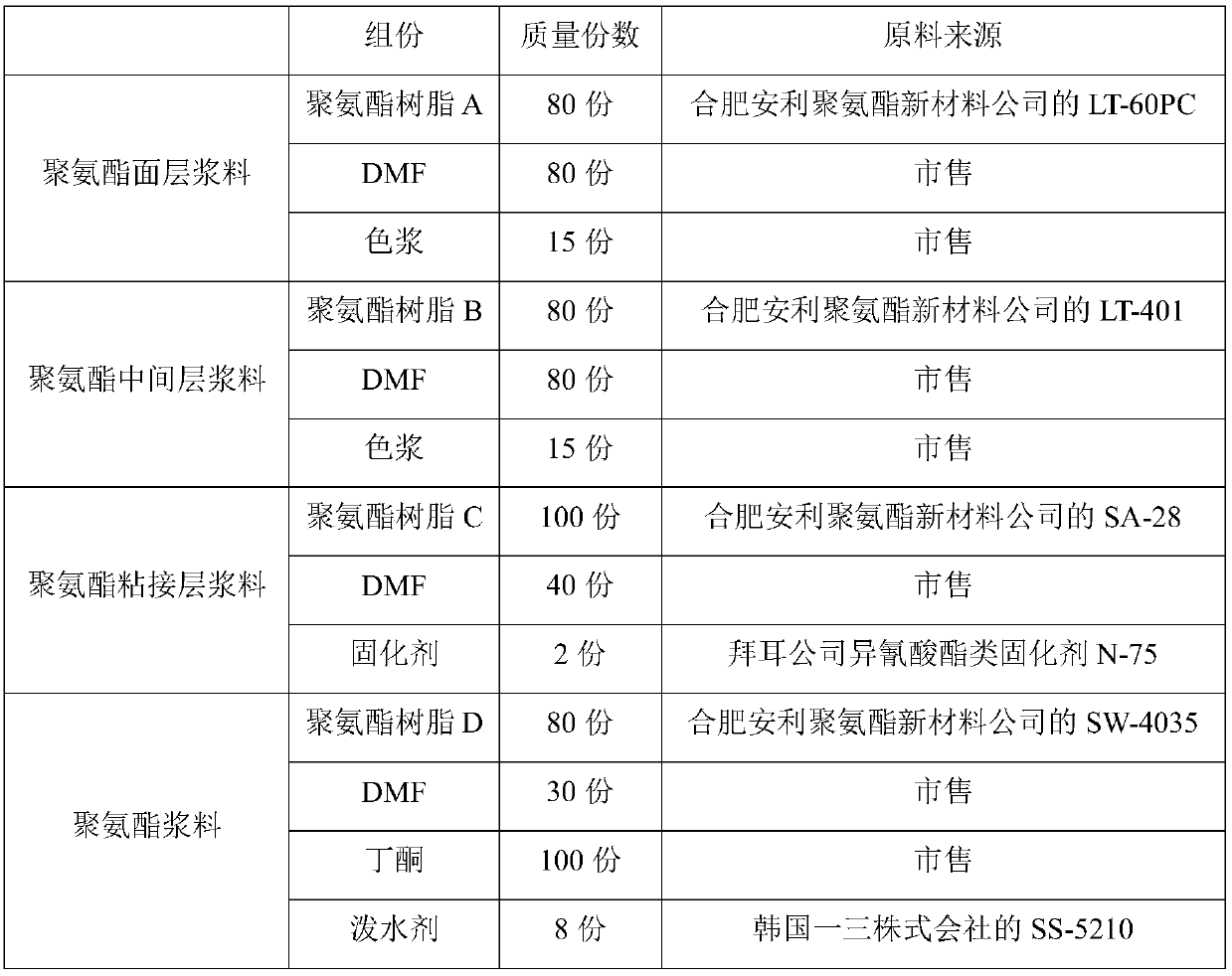

Composite coating slurry special for high-strength flame-retardant type fiberglass composite mesh material as well as preparation method and application thereof

The invention discloses composite coating slurry special for high-strength flame-retardant type fiberglass composite mesh material as well as a preparation method and application thereof. The composite coating slurry for the high-strength flame-retardant type fiberglass composite mesh material is prepared from the following components: water-soluble PP (Polypropylene) emulsion of which the solid content is greater than or equal to 30 percent, a phosphorus-nitrogen halogen-free flame retardant, coating color paste and water. The invention discloses weight proportions of all components, the preparation method and the application. The high-strength flame-retardant type fiberglass composite mesh material obtained by compounding a fiberglass meshy material by using the composite coating slurrynot only has the advantages of light weight, high strength, impact resistance, good flame retardance and melting temperature being up to 1400 DEG C, but also is acid / base-resistant, anti-corrosion andanti-aging, is good in flexibility and is bending-resistant and anti-abrasion.

Owner:江苏亿博新材料科技有限公司丹阳分公司

Isolation material and preparation method thereof

InactiveCN108579209AAvoid blockingAvoid drillingLamination ancillary operationsLaminationFilter materialComposite mesh

The invention provides an isolation material and a preparation method thereof. The isolation material comprises at least one layer of metal woven mesh and at least one layer of stainless steel fiber mesh; the metal woven mesh and the stainless steel fiber mesh are superposed and fixed layer by layer to form a metal composite mesh, and the metal composite mesh is uniformly coated with an aluminum oxide coating. According to the isolation material and preparation method provided by the invention, the metal woven mesh and the stainless steel fiber mesh are compounded, mesh pores of the metal woven mesh are blocked by the stainless steel fiber mesh, so that the isolation material has good gas permeability and good isolation performance; and the method prevents fibers from drilling out from themetal woven mesh, avoids the situation that the fibers are not easy to separate because the fibers drilled out from the products have solder joints with one another, improves production efficiency ofa stainless steel fiber sintered filter material, and reduces production costs.

Owner:山东泰鹏新材料有限公司

Wound battery with asymmetric composite mesh electrodes, perforated collector plates and double-membrane safety valves

InactiveCN106972129AIncrease the collecting areaHigh strengthFinal product manufactureLead-acid accumulator electrodesFiberCapacitance

The invention provides a wound battery with asymmetric composite mesh electrodes, perforated collector plates and double-membrane safety valves. The wound battery comprises a battery case and a battery core; the storage battery is characterized in that the battery core is a cylindrical body formed by winding a positive plate, a negative plate and a membrane located between the positive plate and the negative plate through a battery core reel; a positive collector plate and a negative collector plate are arranged at the tops of two ends of the battery core separately; a tab, namely a positive continuous tab, which is equal to the positive plate in length is arranged at the top end of one side, close to the positive collector plate, of the positive plate; and a spiral groove body, namely a positive plate clamping groove is arranged in the corresponding collector plate. The wound battery has the beneficial effects that the current conducting capability is effectively improved through unique end-surface collector structures and high-strength fiber mesh composite electrode plates, and meanwhile, the battery has high-rate charging and discharging characteristics of a super-capacitor; and the double-membrane safety valves are safer, so that the performance of the storage battery is further improved.

Owner:陈学琴

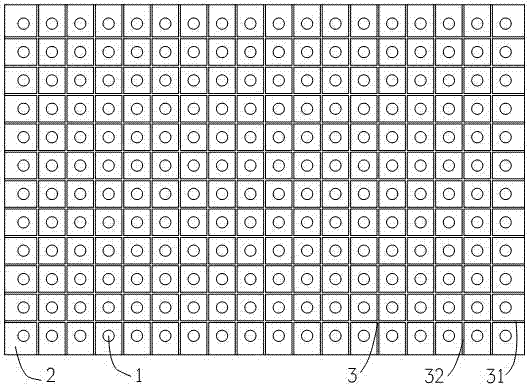

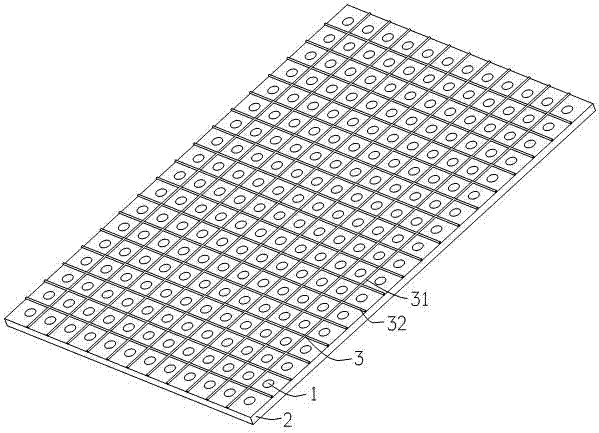

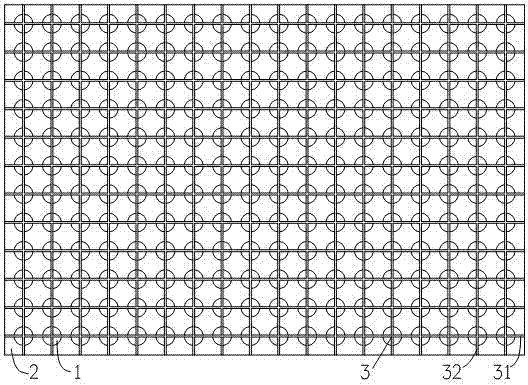

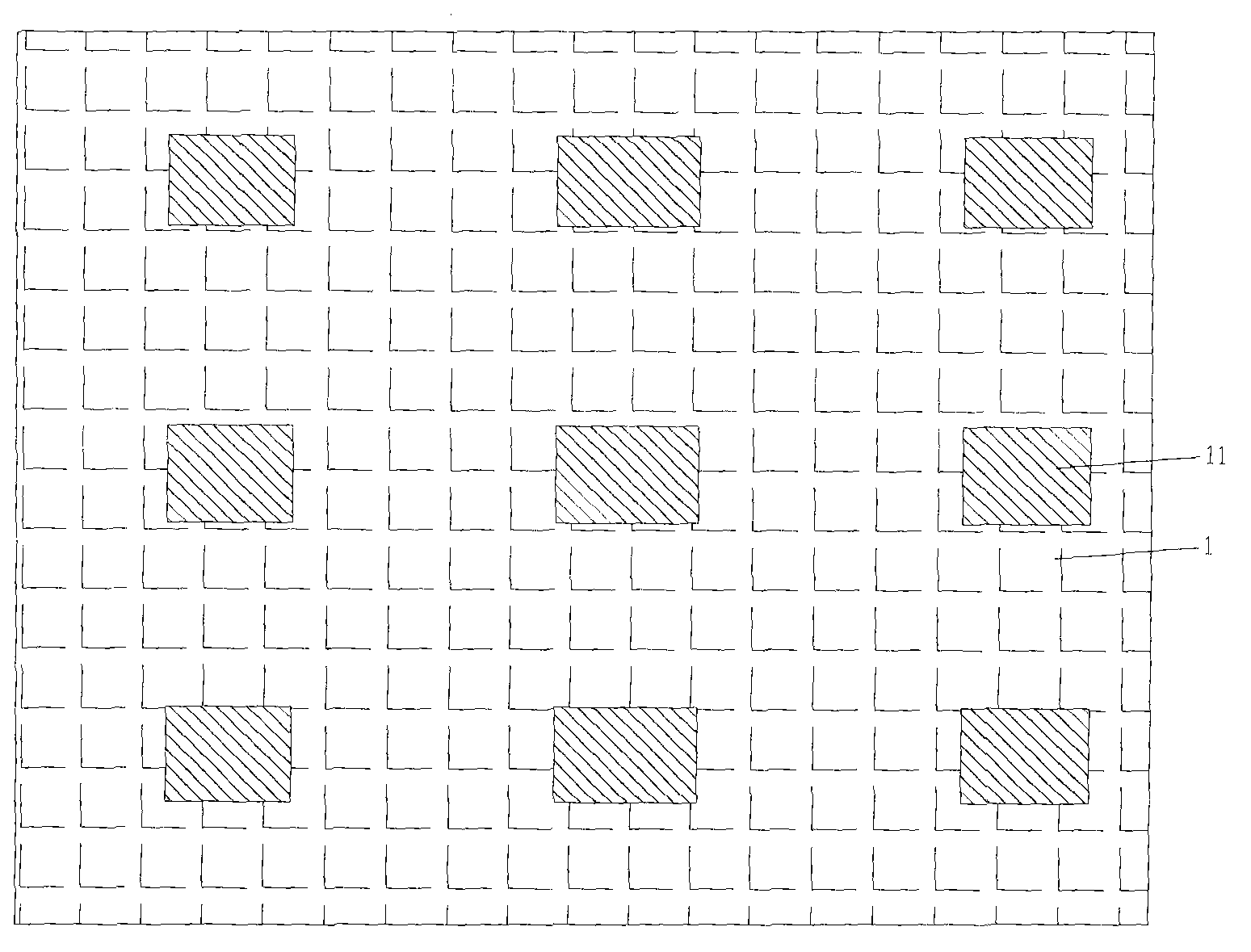

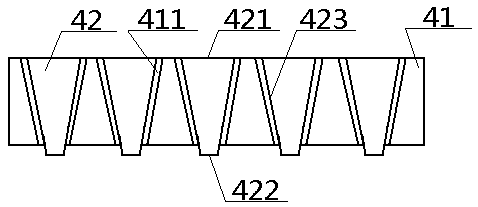

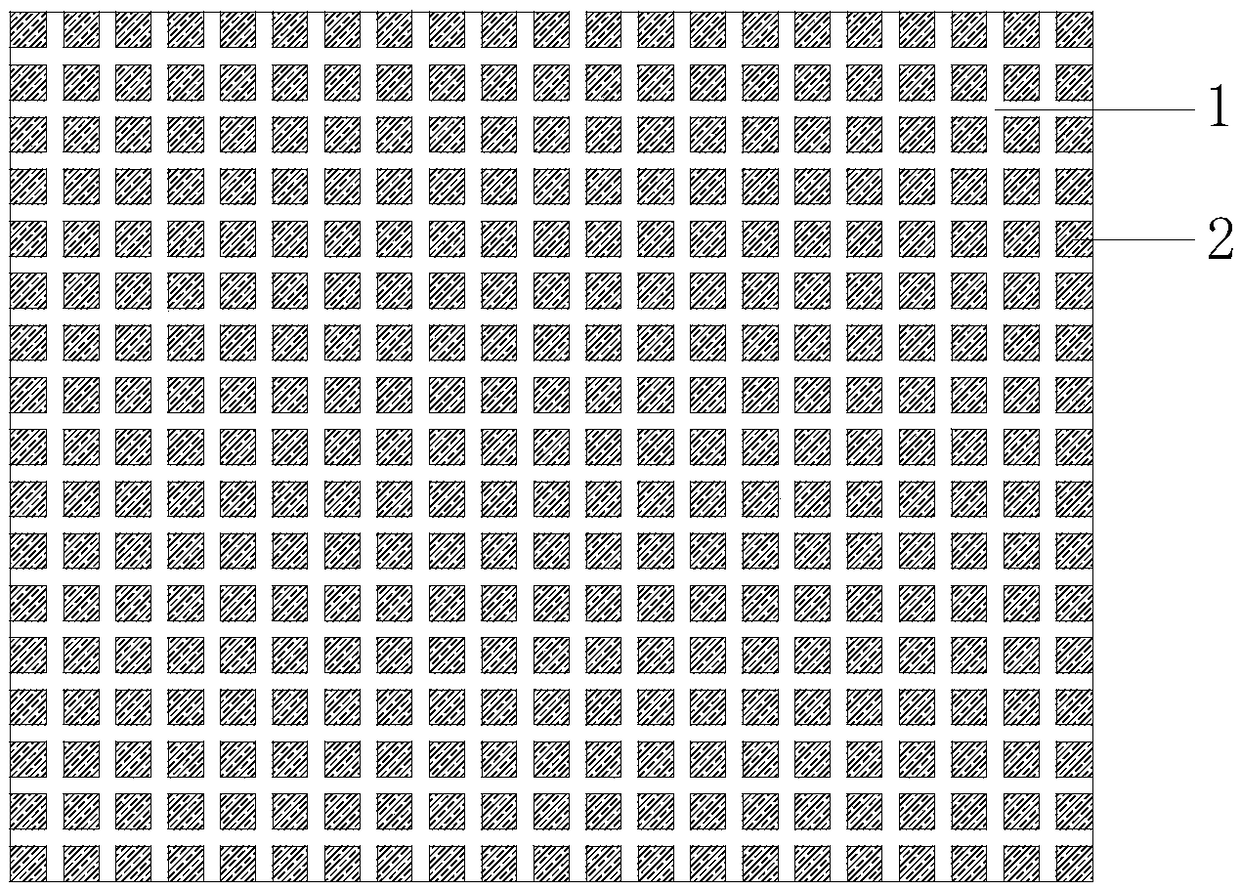

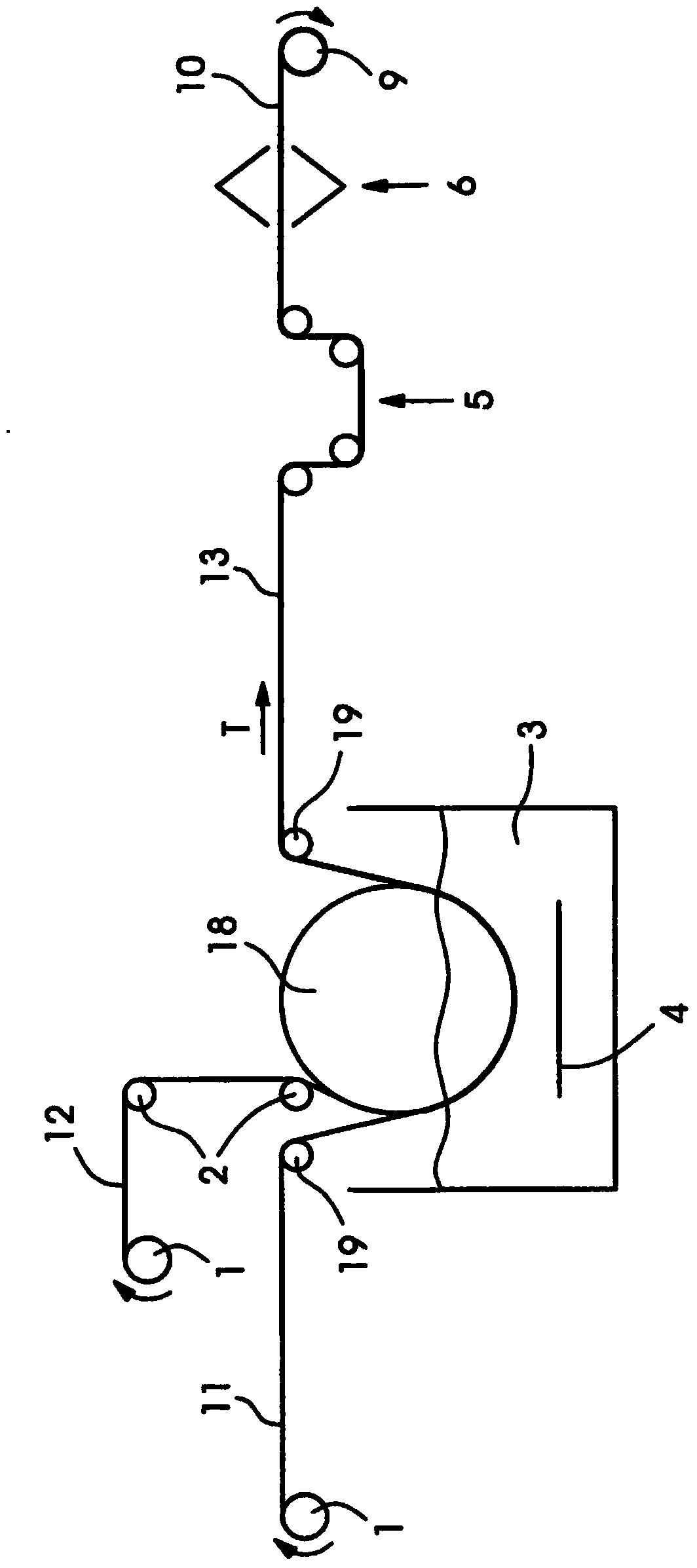

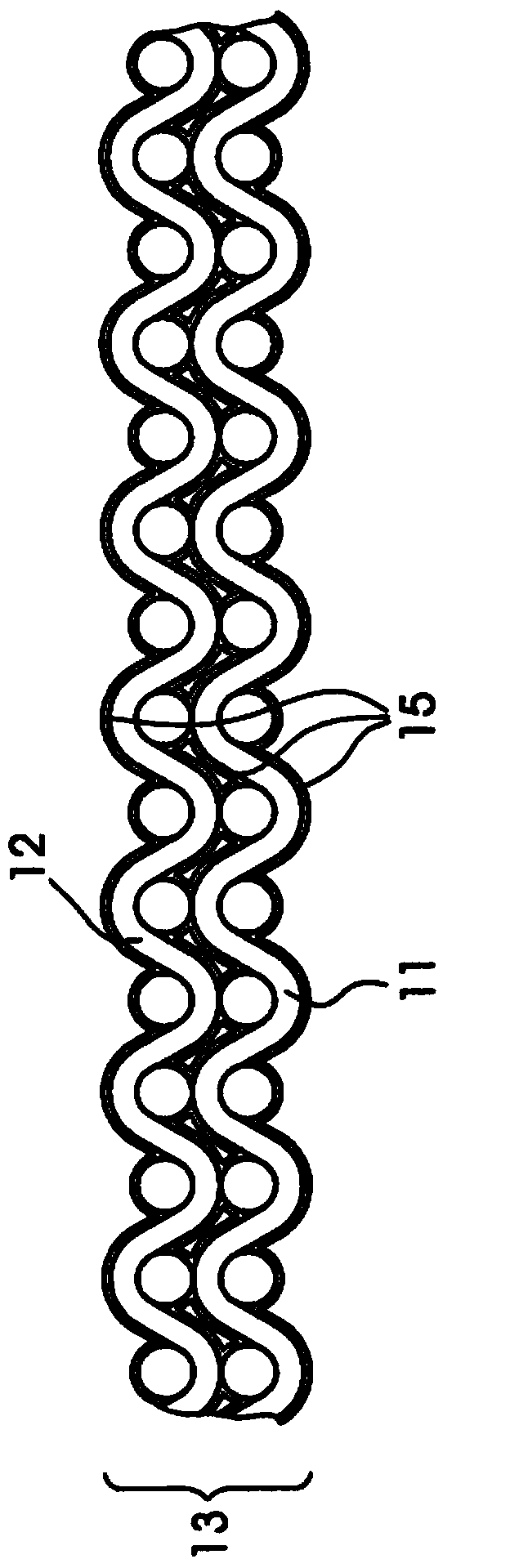

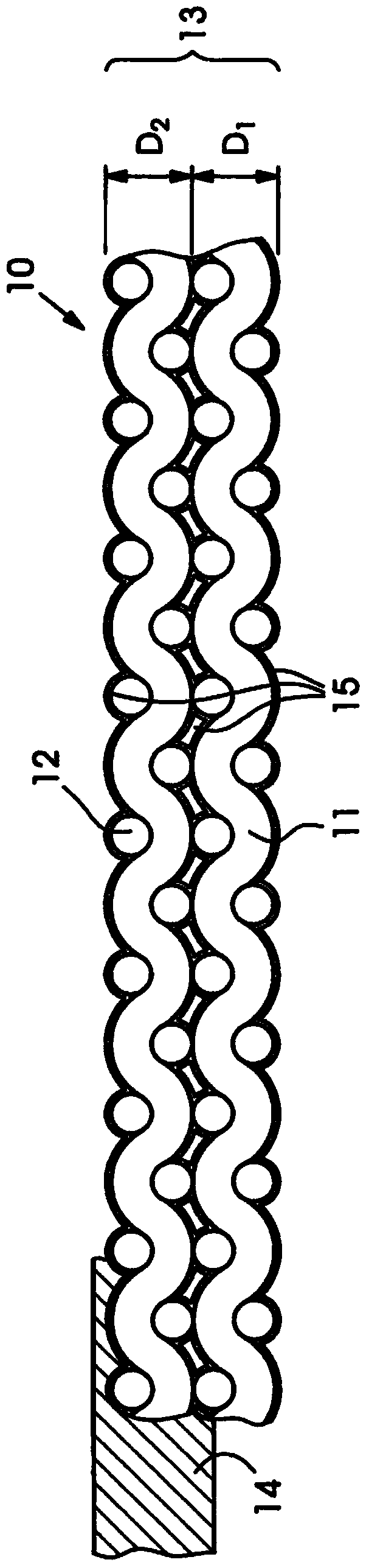

Method for manufacturing a screen structure and screen structure for screen printing

ActiveCN104228313AImprove stabilityLarge amount of ink appliedLayered productsScreen printersScreen printingEngineering

A method for manufacturing a screen structure and a screen structure manufactured in accordance with the method which is used to manufacture the screen structure (10) including at least two mesh layers (11, 12). A first mesh layer (11) and a second mesh layer (12) are provided and brought together to contact each other. Advantageously, the first and second mesh layers (11, 12) are jointly metal-plated. The applied metal (15) firmly bonds the two mesh layers (11, 12)to each other to create a composite mesh (13). An advantage of the screen structure is that it has a particularly great ink application volume and a very high degree of stability.

Owner:GALLUS FERD RUESCH

Carbon fiber reinforced composite honeycomb-structured putty and preparation and construction methods thereof

InactiveCN105694575ALow costExtended service lifeCovering/liningsFilling pastesHigh densityCarbon fiber reinforced composite

The invention discloses carbon fiber reinforced composite honeycomb-structured putty. A polymer high-density composite mesh-structured waterproof film is formed according to the honeycomb principle through the most advanced carbon fiber reinforced composite lightening technology in connection with the mechanical technology, the waterproof film forms on the surface of a wall after being dried, construction is simple, no born weight is brought to a building, and the putty is suitable for renovating an old wall and is an optimal supporting material for painting a new wall; smooth wall renovating and new wall painting for cracking prevention are mainly satisfied, testing via multiple experts shows that the service life is as long as 30 years, and thus the problems of wall cracking, blistering, shedding and seepage are thus solved. A traditional process can be replaced, and construction limitedness of a traditional material is overcome; the putty is useful in single construction on a smooth surface, a glass surface and an old wall for replacing two to four times of construction, labor is saved by 40%, material cost is greatly reduced, no great bearing is brought to the building after rework, and bearing is 50% lower than that of the traditional process.

Owner:腰正钊

Heat preservation system inside external wall of natural-white washed polyphenylene plasteboard, and construction method

InactiveCN1760484AHigh impact strengthSimple and fast constructionHeat proofingBuilding reinforcementsComposite meshGypsum

The present invention relates to a natural plastered gypsum polyphenylene plate external wall internal heat-insulating system and its construction method. The invented material is basically formed from the following materials: adhesive gypsum + polyphenylene plate, gypsum mortar composite mesh fabric and face-layer plastering gypsum composite mesh fabric, and its construction method includes the following steps: cleaning base-layer wall surface; snapping line; sticking polyphenylene plate; plastering gypsum face-protecting mortar, inwards pressing mesh fabric; and plastering face-layer plastering gypsum and inwards pressing mesh fabric.

Owner:上海了望建筑节能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com