Composite sieve for vibrating sieve

A technology of vibrating sieve and screen, which is applied in the direction of sieve, solid separation, grid, etc. It can solve the problems that the vibrating sieve cannot work normally, the impurity rate of particles increases, and the cleaning effect is affected, so as to achieve complete separation and improve Probability and efficiency, the effect of improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the embodiments of the present invention will be further described in conjunction with the accompanying drawings.

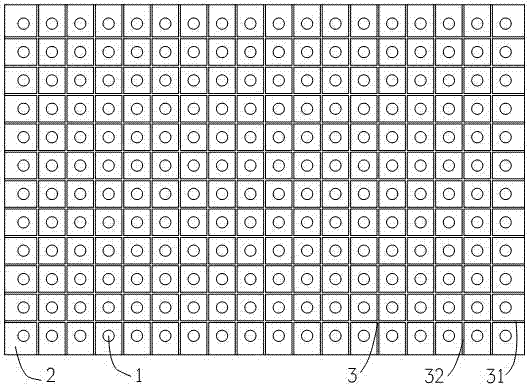

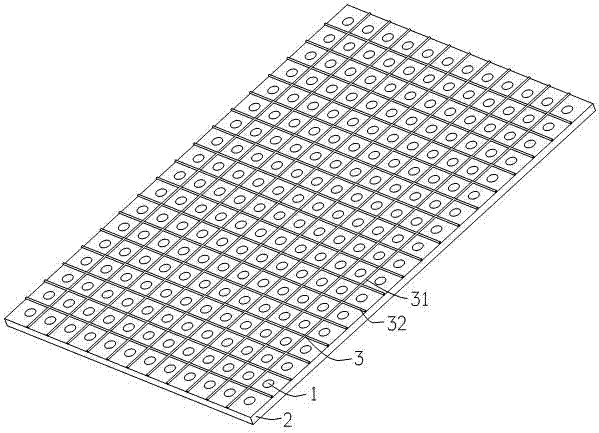

[0021] figure 1 , figure 2 The first embodiment of the composite screen cloth of a vibrating screen is shown, which includes a base plate 2 with a matrix of uniformly distributed screen holes 1, and a flat weaving net 3 is placed on the base plate 2, and the plain weaving net 3 includes a plurality of warp threads 31 interwoven And a plurality of latitude threads 32, the diameter of warp thread 31, weft thread 32 is 0.4mm, and sieve hole 1 is positioned at the fence center that adjacent warp thread 31, weft thread 32 form.

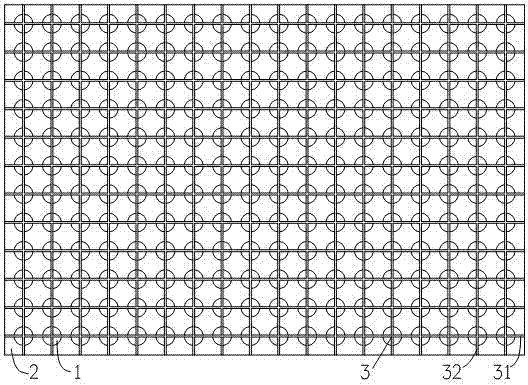

[0022] image 3 , Figure 4 , Figure 5 It shows a second embodiment of the composite screen of a vibrating sieve, which includes a base plate 2 with mesh holes 1 uniformly distributed in a matrix, and a flat weaving net 3 is placed on the base plate 2, and the plain weaving net 3 includes a plurality of interwoven warps 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com