Patents

Literature

761results about How to "Easy to roll" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process method for preparing ultra-hydrophobic surface by electrochemical method

ActiveCN101665968AEndows the superior performance of "self-cleaning"Apparent nanostructureAnodisationSpecial surfacesPhysical chemistryElectrochemistry

The invention discloses a process method for preparing an ultra-hydrophobic surface by the electrochemical method. The process adopts two processing steps: forming the micro nanometer double-structurerough surface by first electrochemical etching and then oxalic acid anodic oxidation; and preparing the ultra-hydrophobic surface by modifying the surface with fluorosilane. The method is simple andpractical, uses mature electrochemical etching and anodic oxidation technology, allows for easy mass production and avoids environmental pollution.

Owner:甘肃中安瑞科科技有限公司

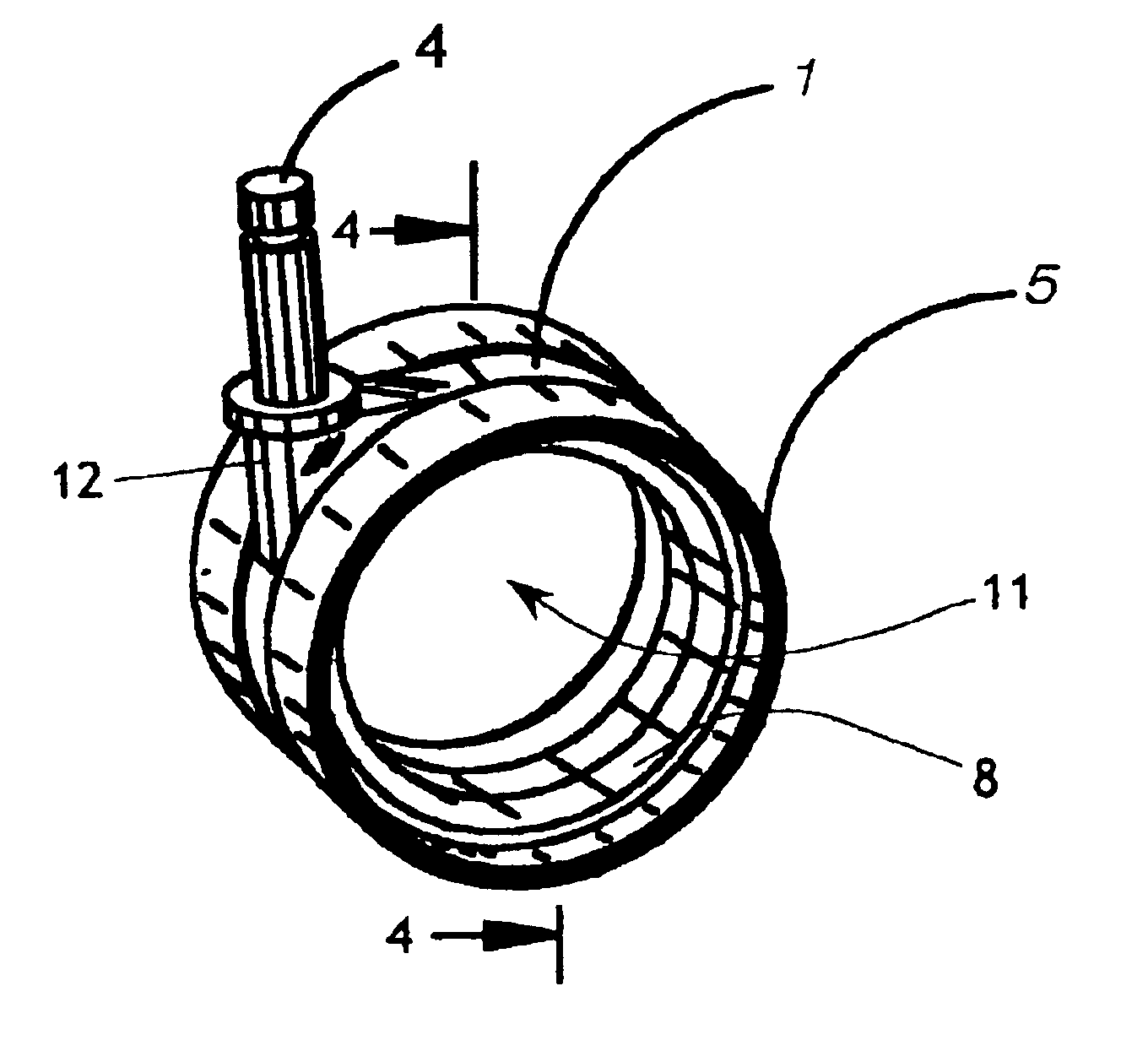

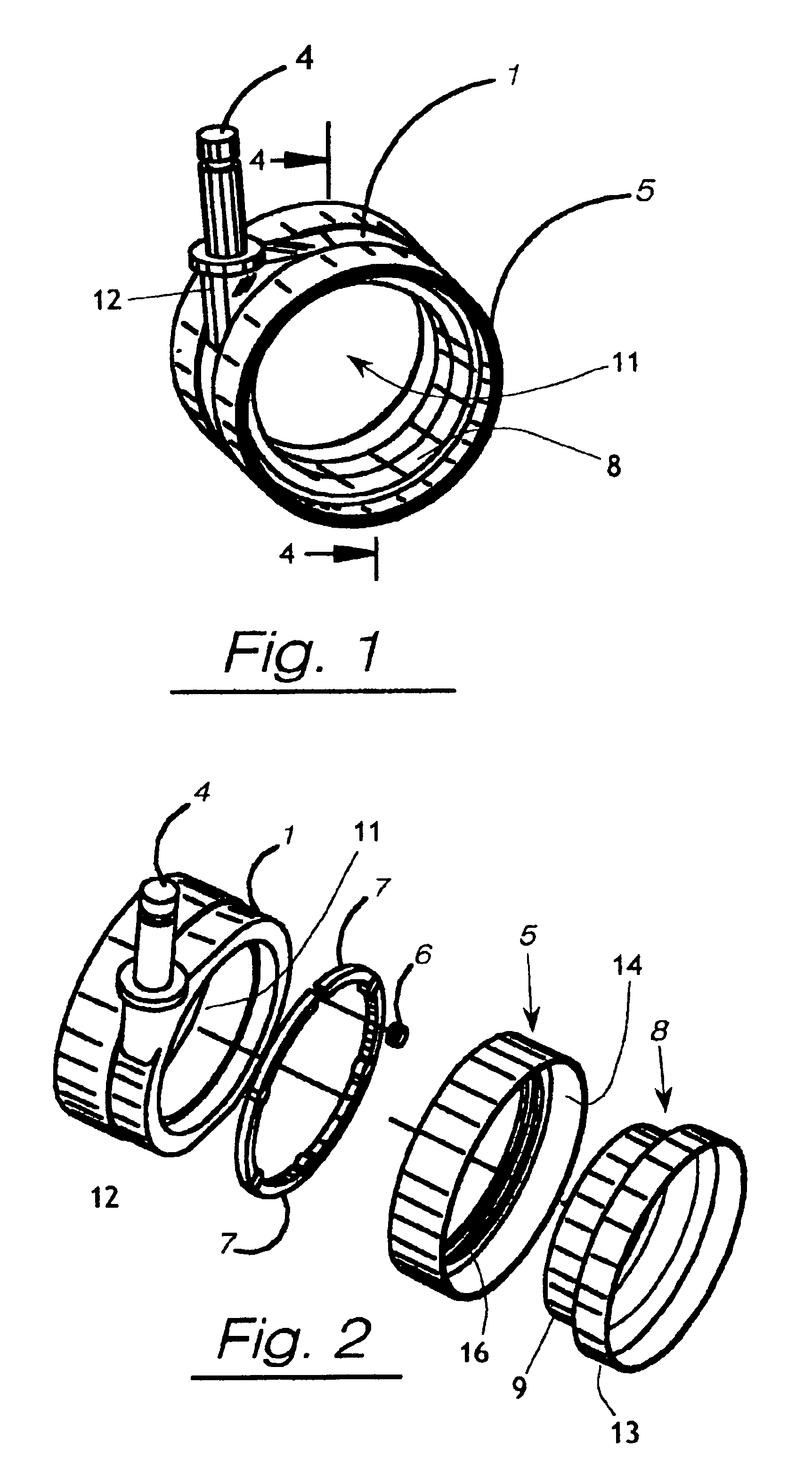

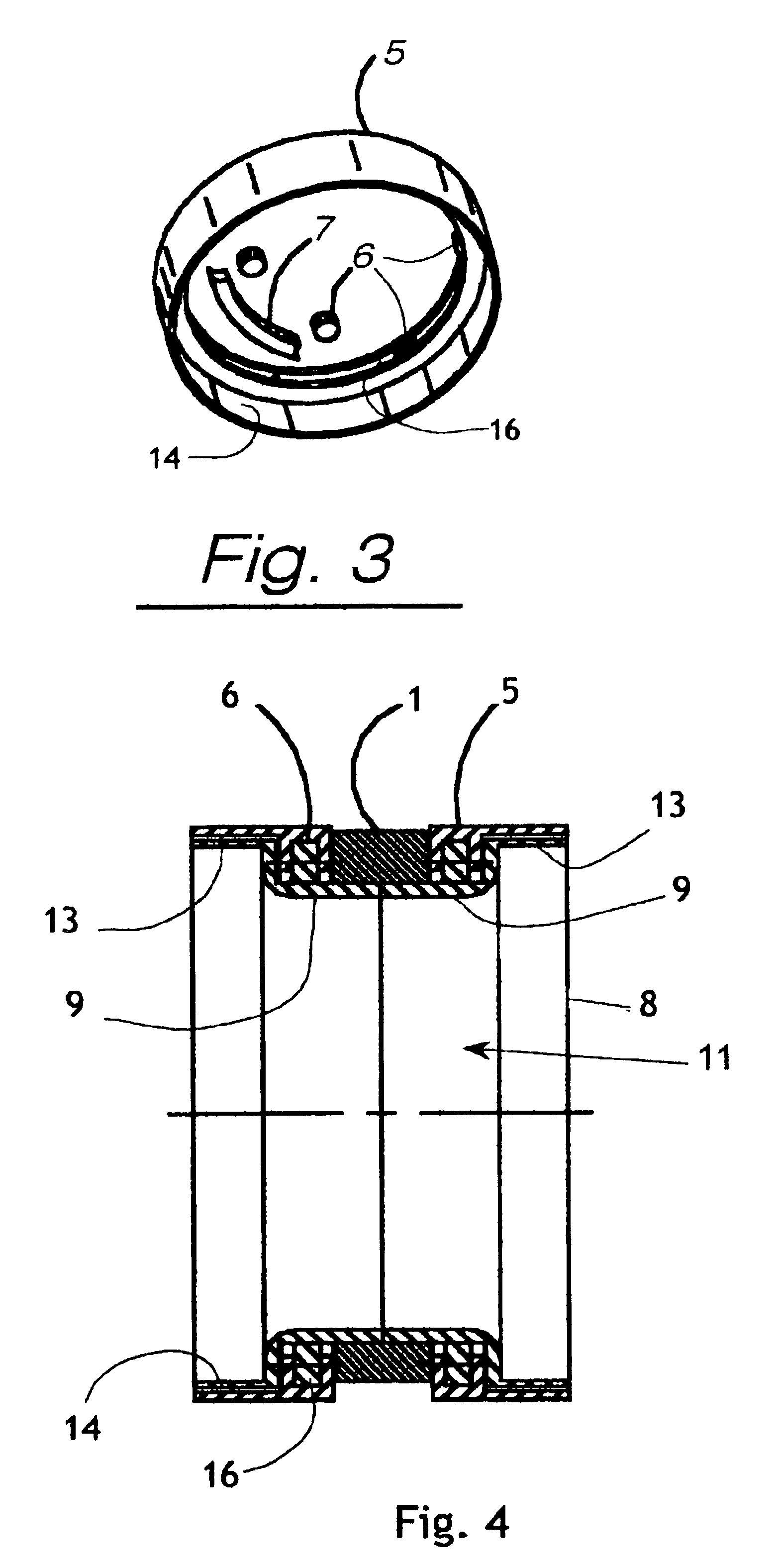

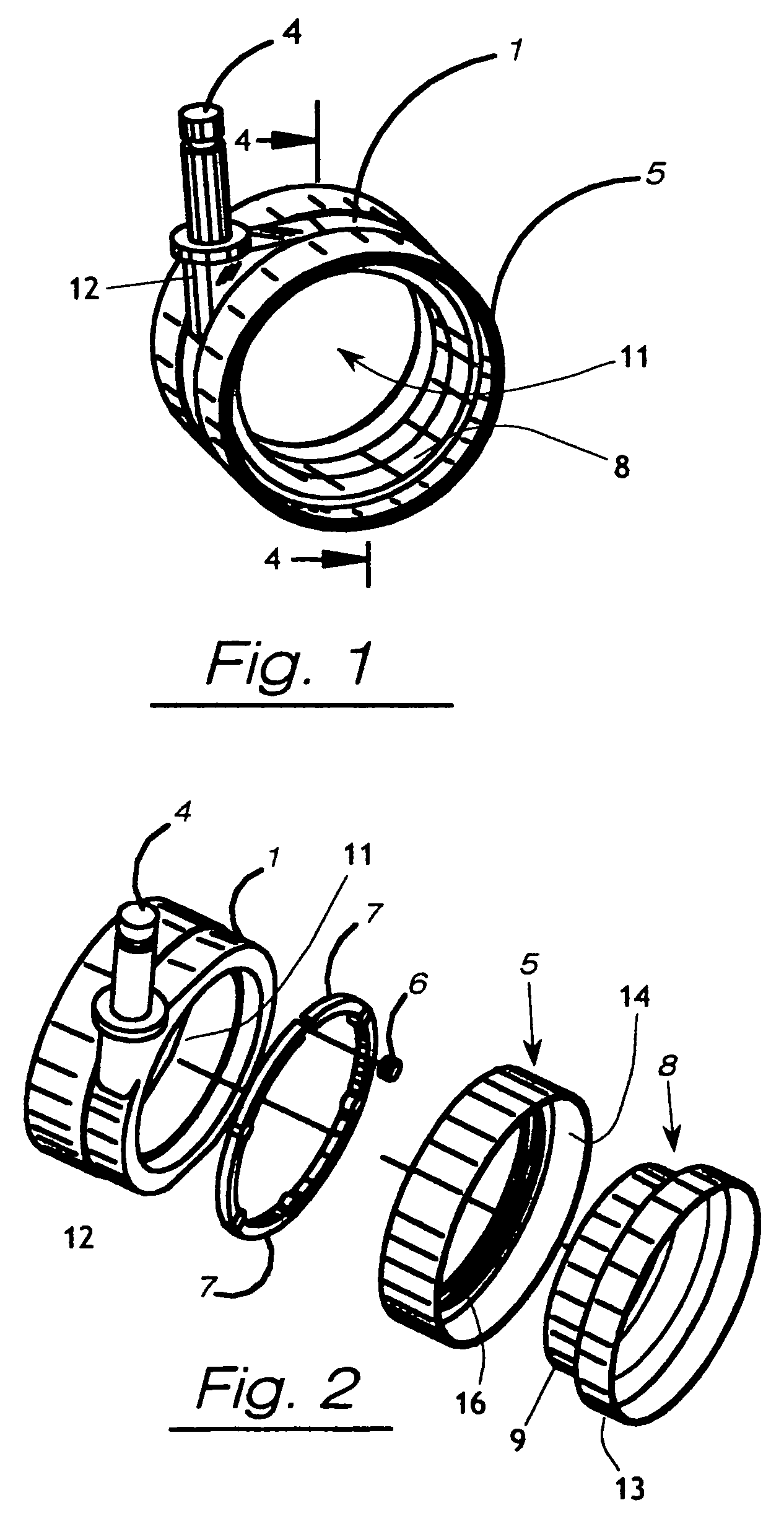

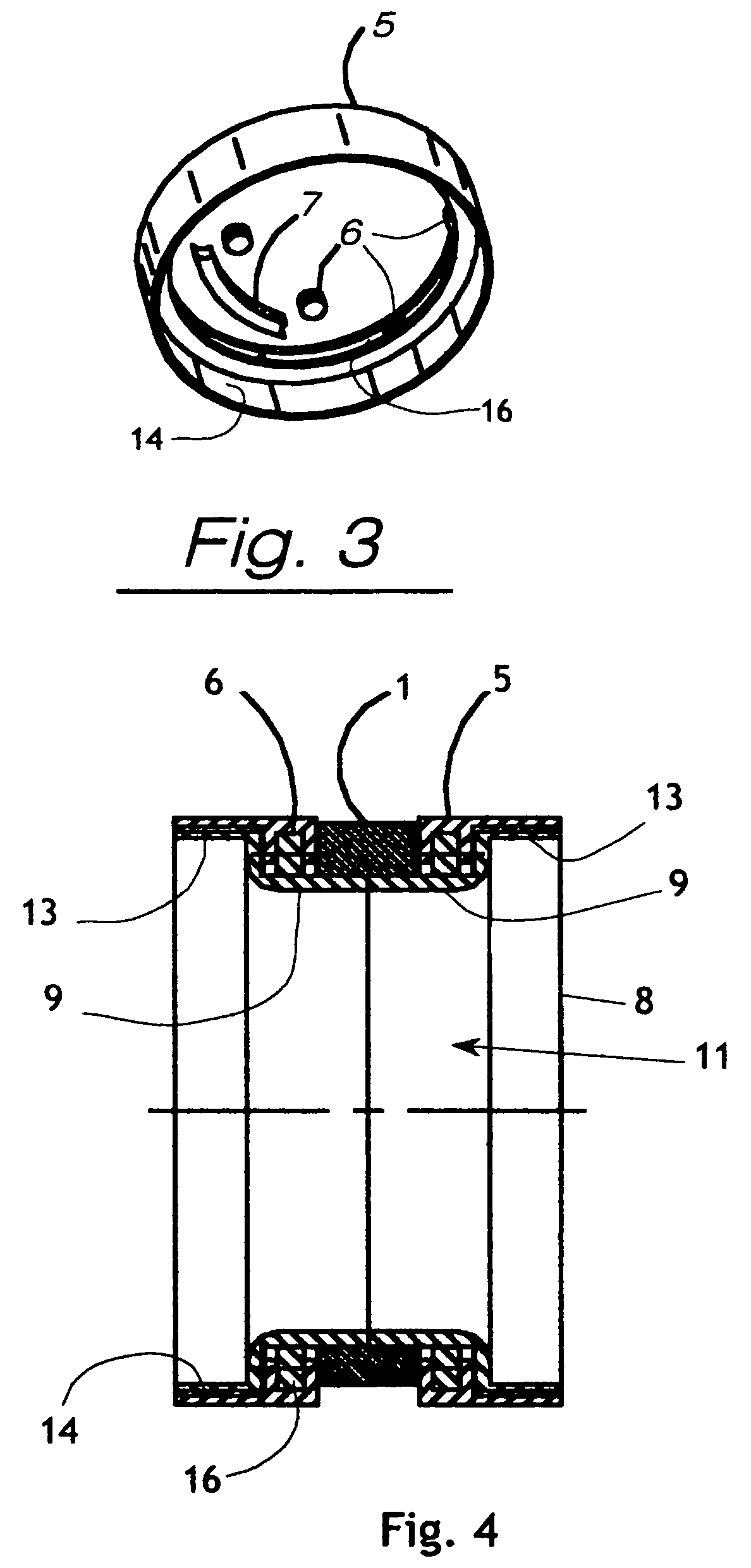

Hubless caster

InactiveUS6839939B2Alter visual appearanceReduce lever armSuction cleanersCastorsEngineeringFree rotation

A hubless caster assembly includes a caster body and at least one wheel, the wheel comprising a toroidal member having a bearing race, and a complementary bearing race supported by the caster body. Bearing elements in the races support the wheel in free rotation. The caster body may comprise a ring body having an axial opening, whereby the caster assembly has a large central aperture extending entirely therethrough. A centering ring may be secured in the axial opening with the complementary bearing race formed therein. A hub cap with visual treatment may be secured over the central aperture.

Owner:OCONOMOWOC MFG

Processing method of aluminum and aluminum alloy super hydrophobic surface

InactiveCN101007304ASuperhydrophobicEasy to rollAntifouling/underwater paintsPretreated surfacesNickel saltCopper

The invention involves an aluminum or aluminum alloy super-hydrophobic surface preparation method. The method is: polishing the surface of aluminum or aluminum alloy using metallographic sandpaper or polishing paste, pure water washing, acetone ultrasonic cleaning, pure water washing and other clean treatment, handing it with chemical etching solution containing nitric acid and metal salts (copper or nickel salt) 30s-20min under 90 ~ 100 degree C, then coating low surface energy material on its surface to get super-hydrophobic property. The aluminum or aluminum alloy surface treated by the invention has excellent hydrophobicity, the contact angle of water and surface can be as high as 150-165 degree, droplets are easy to roll on the surface. The method of the invention need not complex equipment, cost is low, technology is simple and repeatability is good.

Owner:SOUTH CHINA UNIV OF TECH

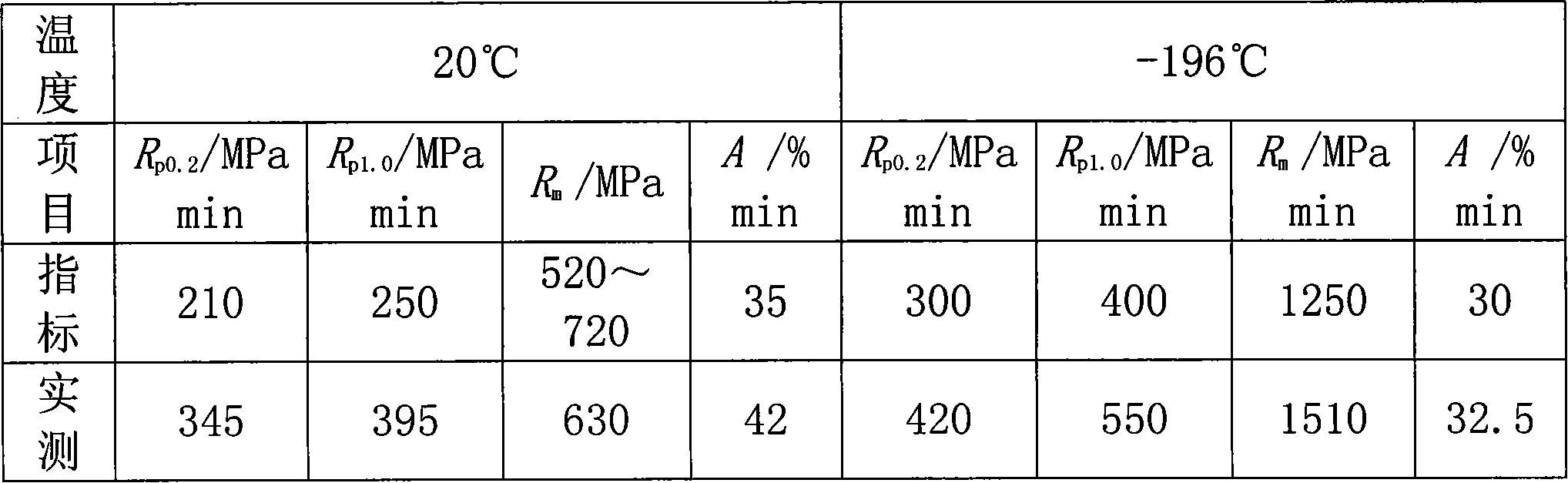

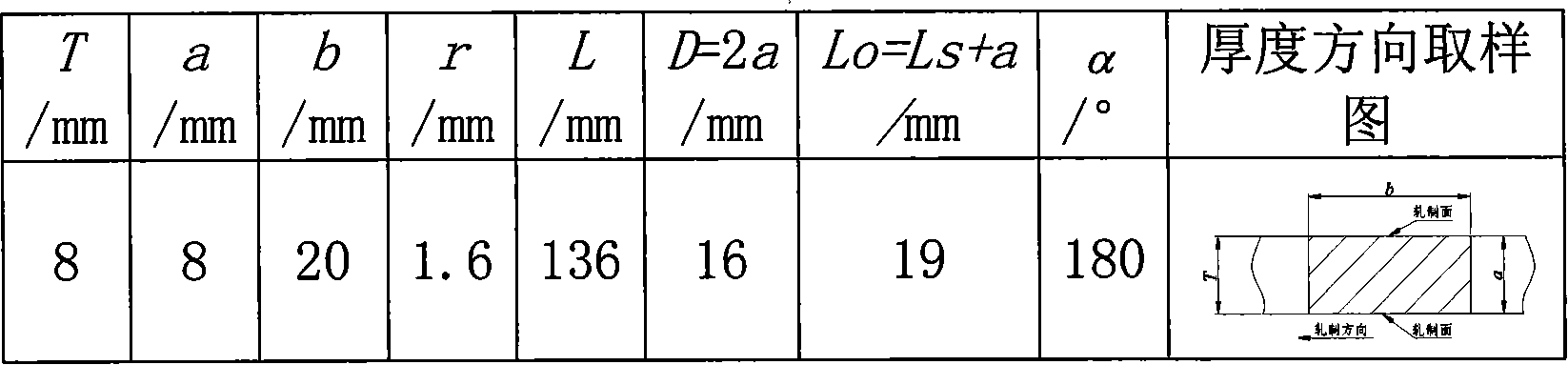

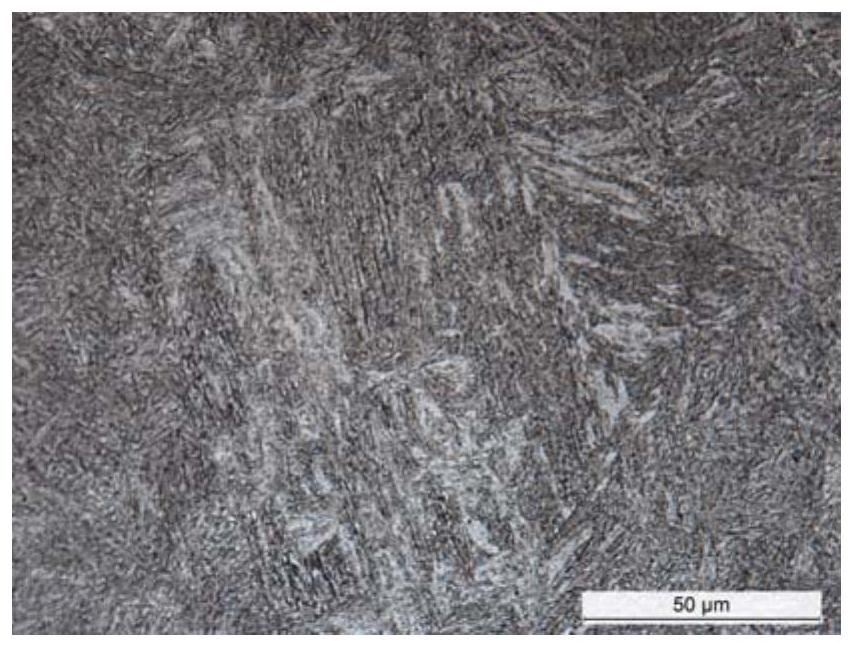

Austenitic stainless steel buried arc welding wire for low-temperature equipment

ActiveCN101244494AEasy to rollImprove low temperature resistanceWelding/cutting media/materialsSoldering mediaSteelmakingChemical composition

The invention relates to a welding wire, in particular to a welding wire applying to austenitic submerged arc welding for low-temperature equipments, in terms of chemical composition and weight percent, comprising Cr: 19.0 to 23.0%, Ni: 9.0 to 12.0%, C: <=0.03%, Mn: 1.60 to 2.50%, Si: 0.30 to 0.60%, Mo: <=0.30%, Cu: <=0.30%, Co: <=0.20%, Ti: <=0.015%, Nb: <=0.05%, V: <=0.10%, B: <=0.005% and Fe as allowance. The welding wire has the advantages that: the welding wire steelmaking craft is stable; the drawing performance is good; the invention meets the welding technical requirements of the high-intensity, high-toughness and anti-corrosion steel with low temperature and low temperature equipments; the invention can apply to the steel of 500 to 750MPa strength level; the invention is suitable for large range of welding current and no blowhole; the moulding is beautiful; the weld joint can be well matched with the base material.

Owner:哈焊所华通(常州)焊业股份有限公司

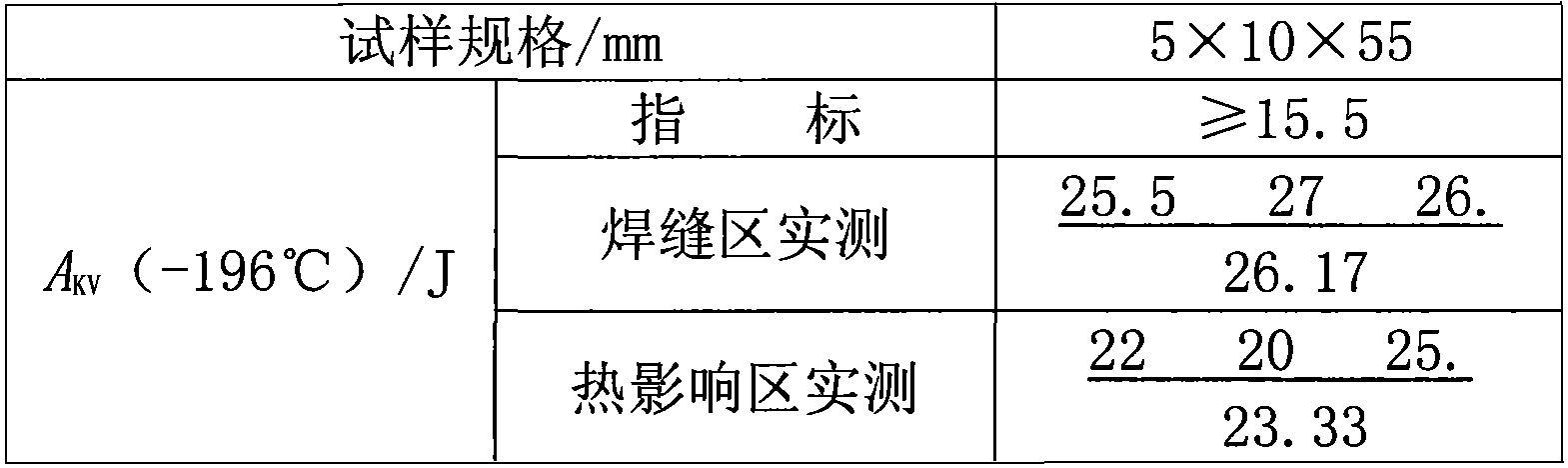

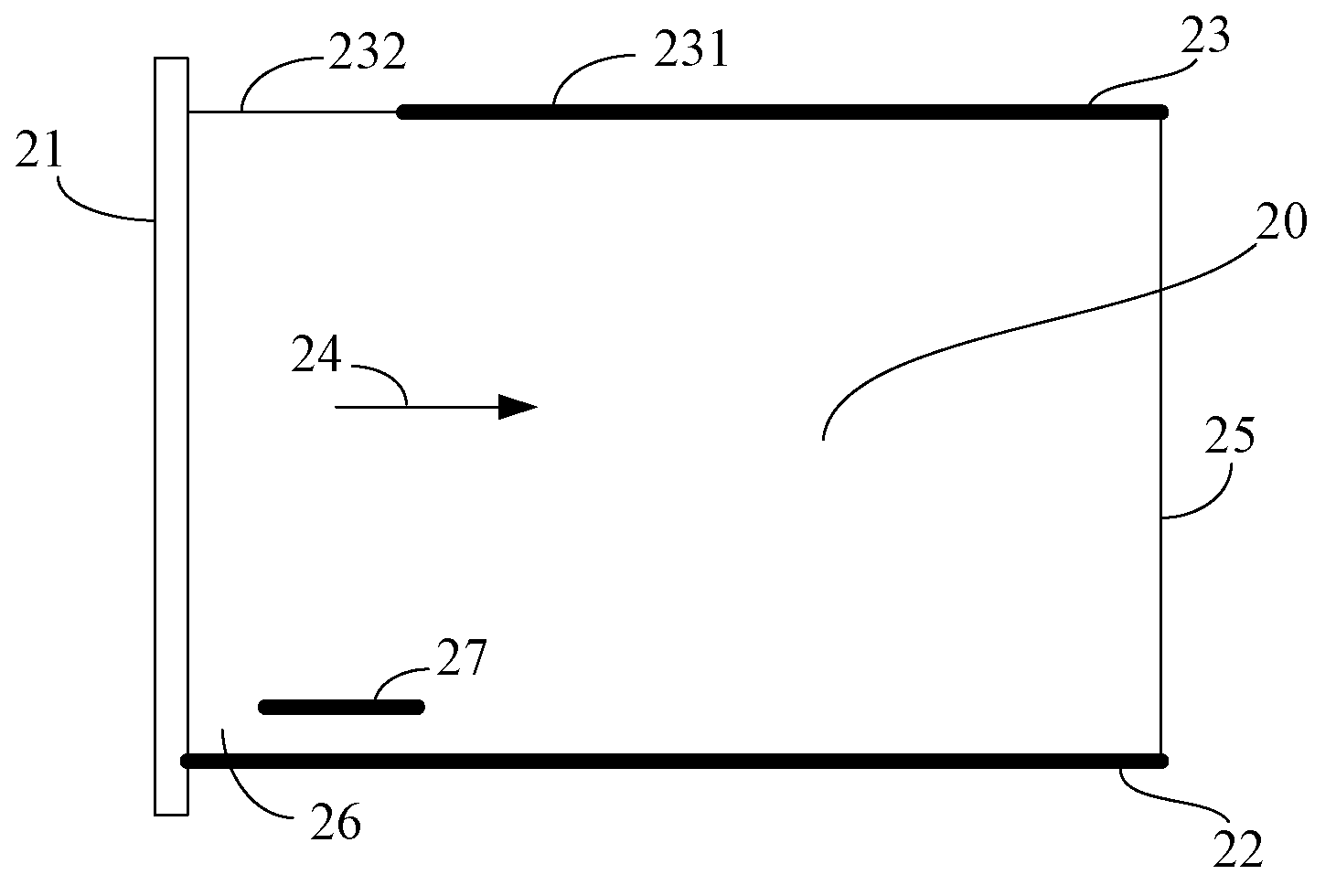

Flexible screen support structure, flexible display screen module and mobile terminal

ActiveCN106125846AEasy to rollEasy to shrinkCircuit bendability/stretchabilityDigital data processing detailsEngineeringFlexible display

The invention discloses a flexible screen support structure, a flexible display screen module and a mobile terminal. The flexible screen support structure comprises a first flexible board, a second flexible board, a side plate and multiple electromagnets; the first flexible board is used for being attached to a flexible display screen, the second flexible board is arranged opposite to the first flexible board, and a gap is formed between the first flexible board and the second flexible board and filled with an electrorheological fluid; the side plate is arranged on the peripheral sides of the first flexible board and the second flexible board in an enclosing mode and seals the gap; the electromagnets are fixed on the first flexible board and located in the gap, each electromagnet is provided with a support face attached to the first flexible board and a side face which has an acute included angle with the support face, the side faces of every two adjacent electromagnets are attached to each other, and therefore the first flexible board is driven to be coiled. The flexible screen support structure supports the flexible display screen when the flexible display screen is unfolded, when the flexible display screen is coiled, the flexible display screen can be tightly coiled and contract conveniently, and therefore the user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

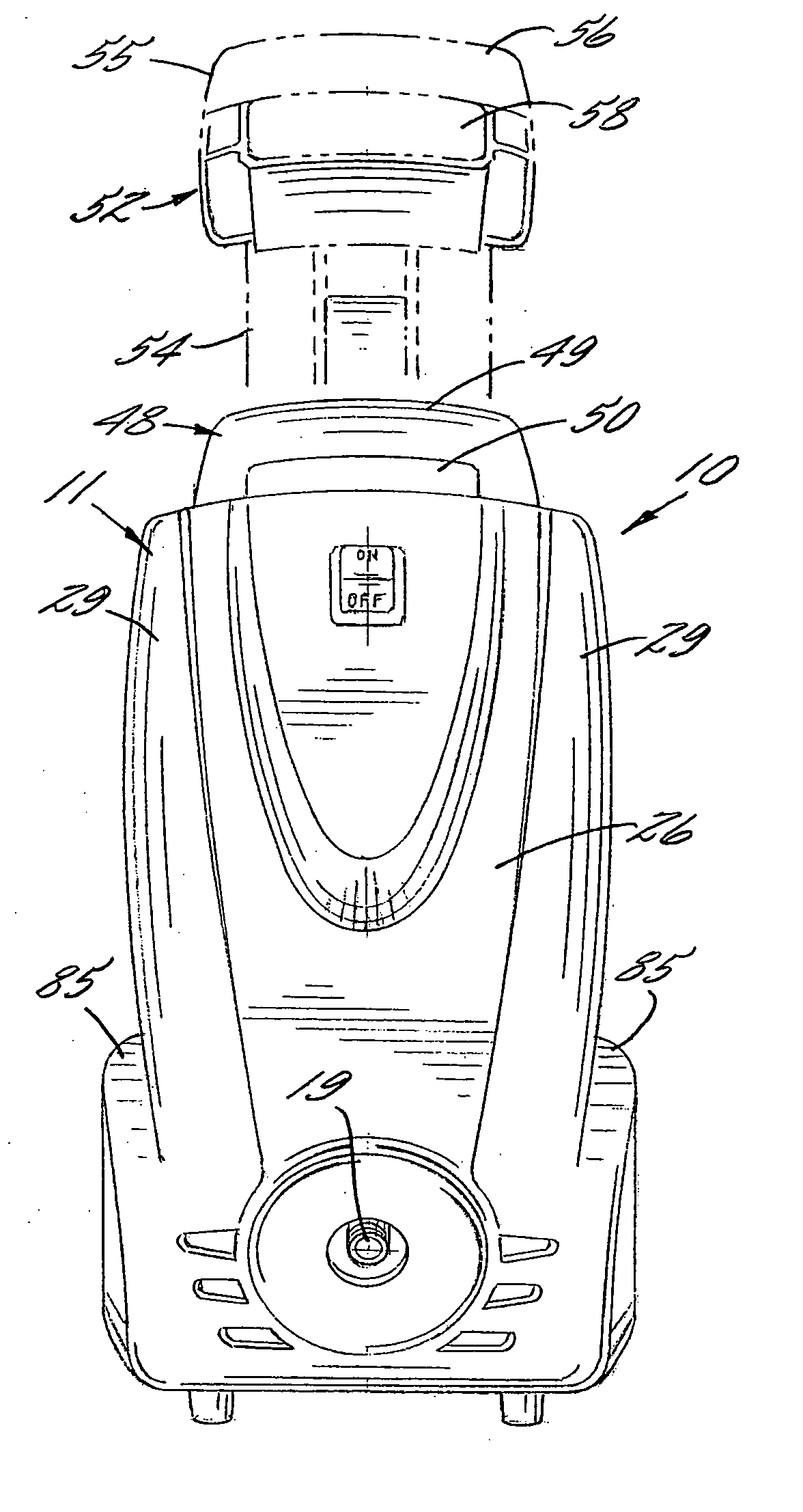

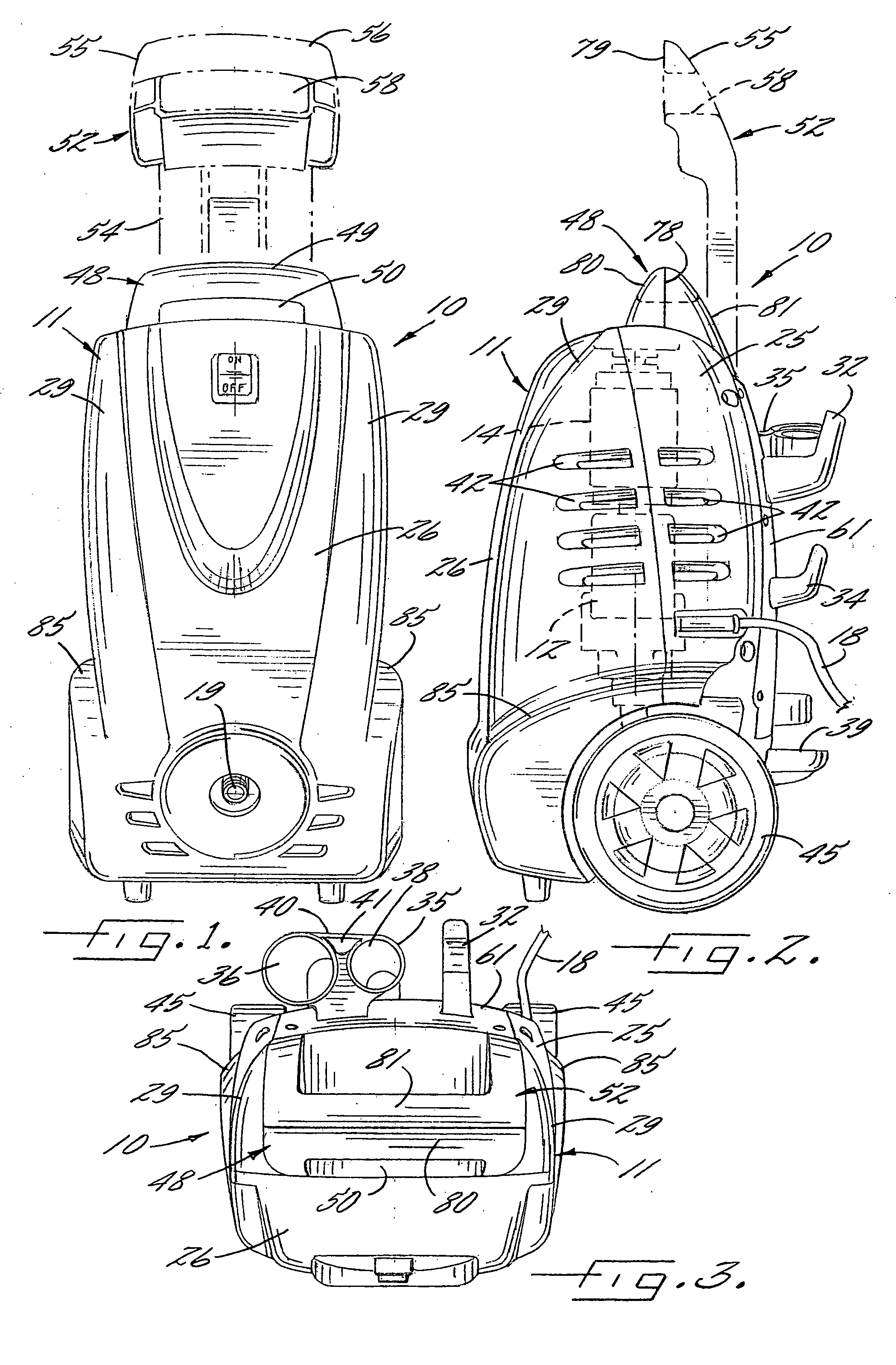

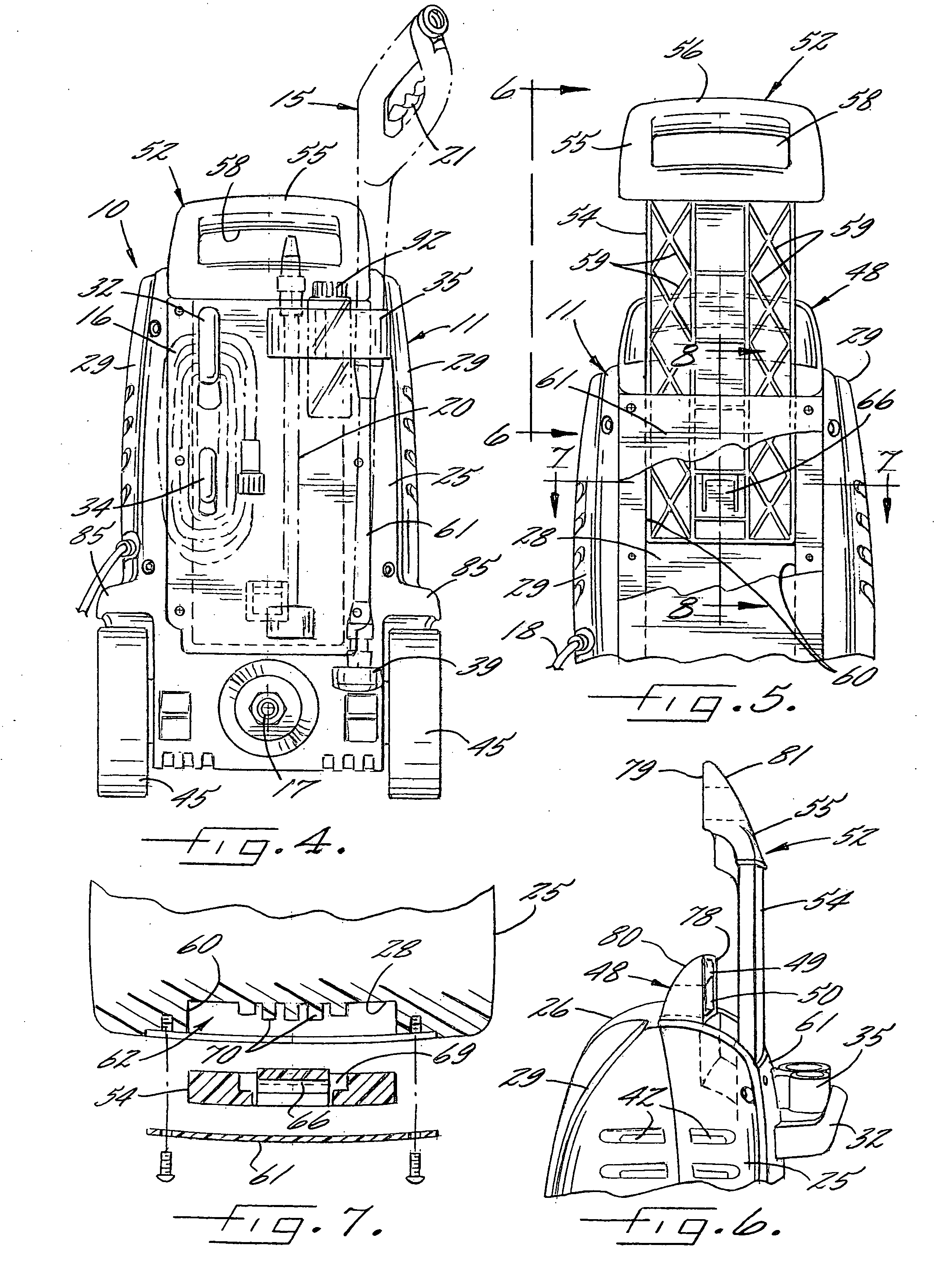

Pressure washer

ActiveUS20080245425A1Facilitates compact shippingEasy to liftWatering devicesCleaning using liquidsEngineeringMechanical engineering

A pressure washer is provided including a housing. A pump is contained within the housing for pressurizing fluid received through a water inlet port and for pumping the pressurized fluid through an outlet port. An application wand is connected to the water outlet for outputting a pressurized stream of fluid. At least one wheel is supported on the housing so as to enable rolling movement of the housing. A first handle is arranged on the housing for movement between a retracted position in which a gripping portion of the handle is arranged relatively closer to the housing and an extended position in which the gripping portion of the handle is arranged relatively further away from the housing.

Owner:FNA GROUP INC

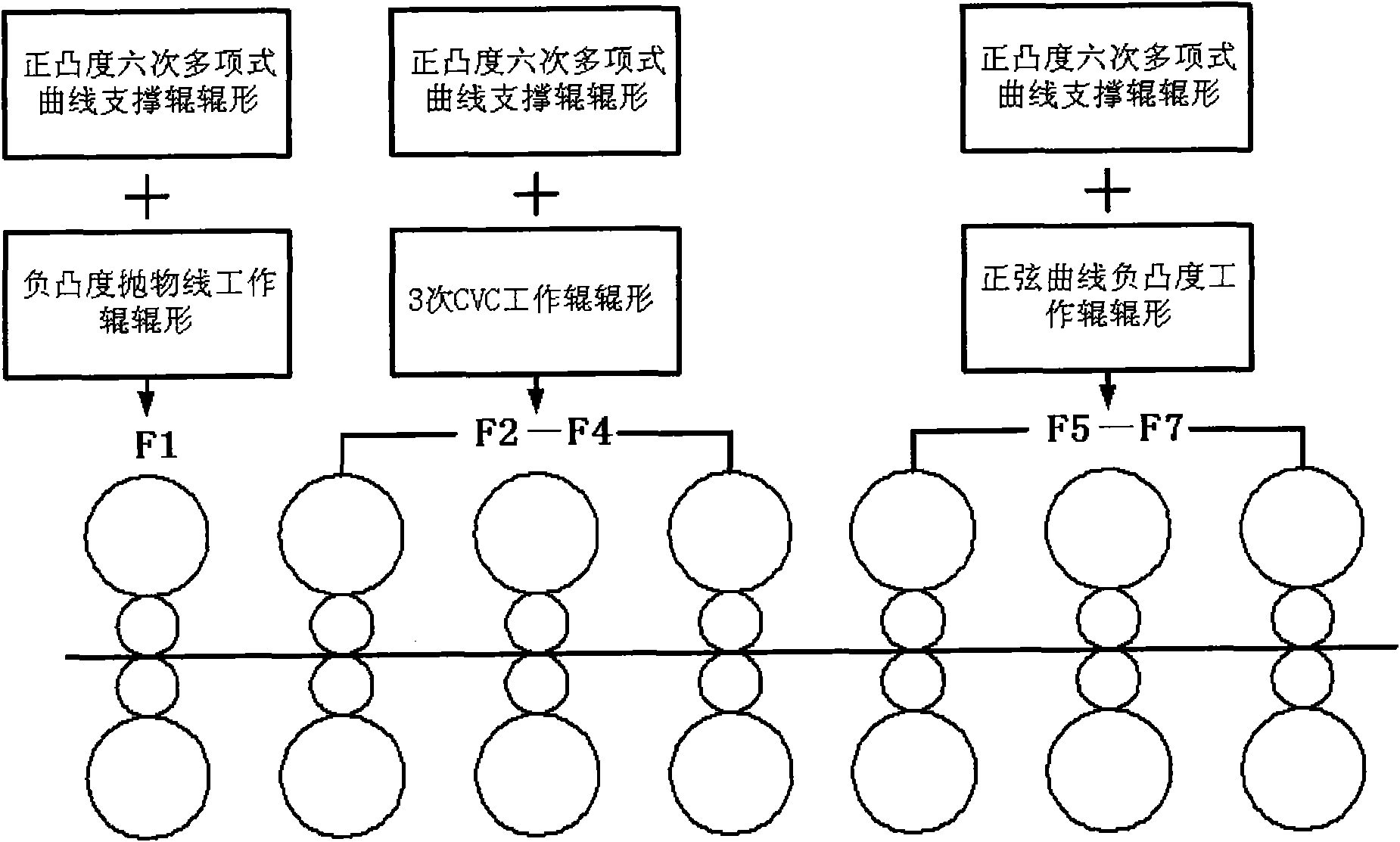

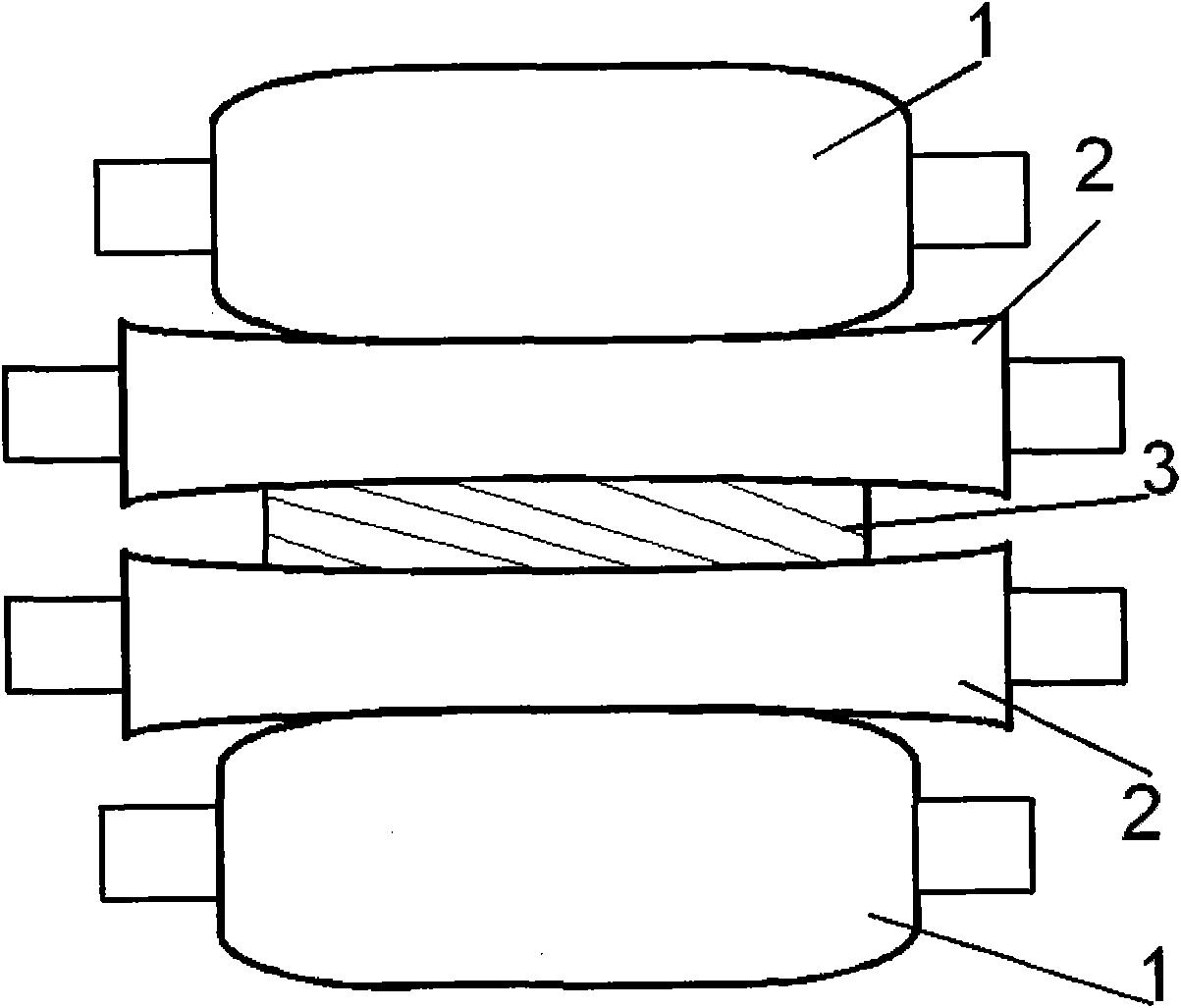

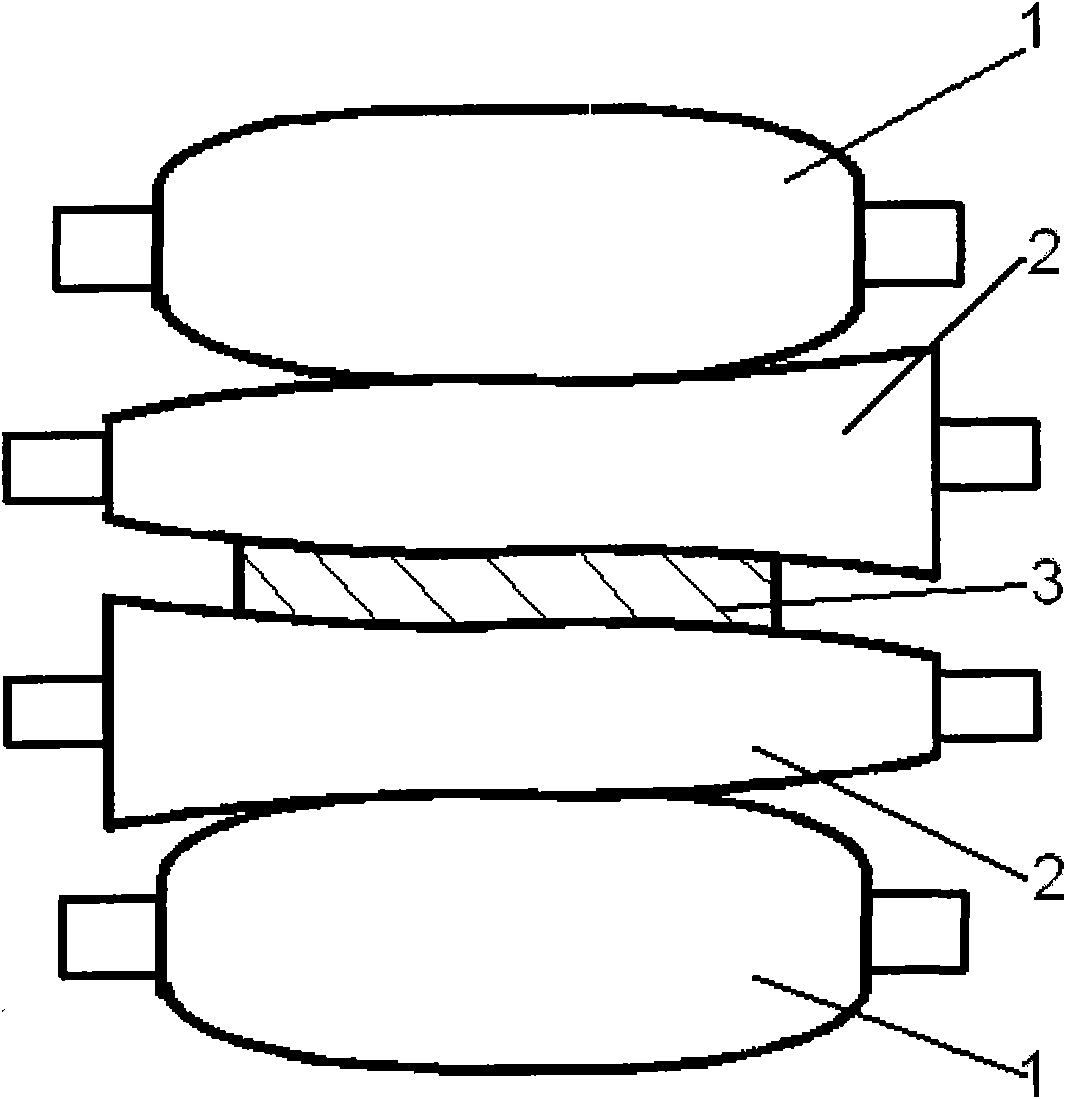

Complete roll forming configuring method for wide flat steel hot rolling finish mill set

ActiveCN101890429AReasonable configurationHigh precisionRollsMetal rolling arrangementsWork rollRoll forming

The invention relates to a complete roll forming configuring method for a wide flat steel hot rolling finish mill set. According to the characteristics that an upstream machine frame controls the convexity and a downstream machine frame controls the flatness in the seven-machine frame and four-roll hot rolling wide flat steel finish mill, a finish rolling inlet machine frame F1 adopts negative convexity working roll forming, a machine frame F2, a machine frame F3 and a machine frame F4 adopt cubic CVC working roll forming, and a machine frame F5, a machine frame F6, and a machine frame F7 adopt negative convexity working roll forming of sine curves and are matched with periodic roll shifting of the working roll with long stroke. The supporting rolls of all the machine frames of the finish mill set adopt positive convexity roll forming of sextic polynomes. The method improves the transverse rigidity of the machine frames of the finish mill, improves regulation and control efficiency of roll bending force of the working roll, and reduces flexibility deformation of the roll. The roll forming configuring method for the finish mill set improves stability of the wide flat steel rolling, reduces the deflection amount of the wide flat steel, prolongs the planned length for rolling and greatly improves profile shape control precision of the wide flat steel.

Owner:SHOUGANG CORPORATION

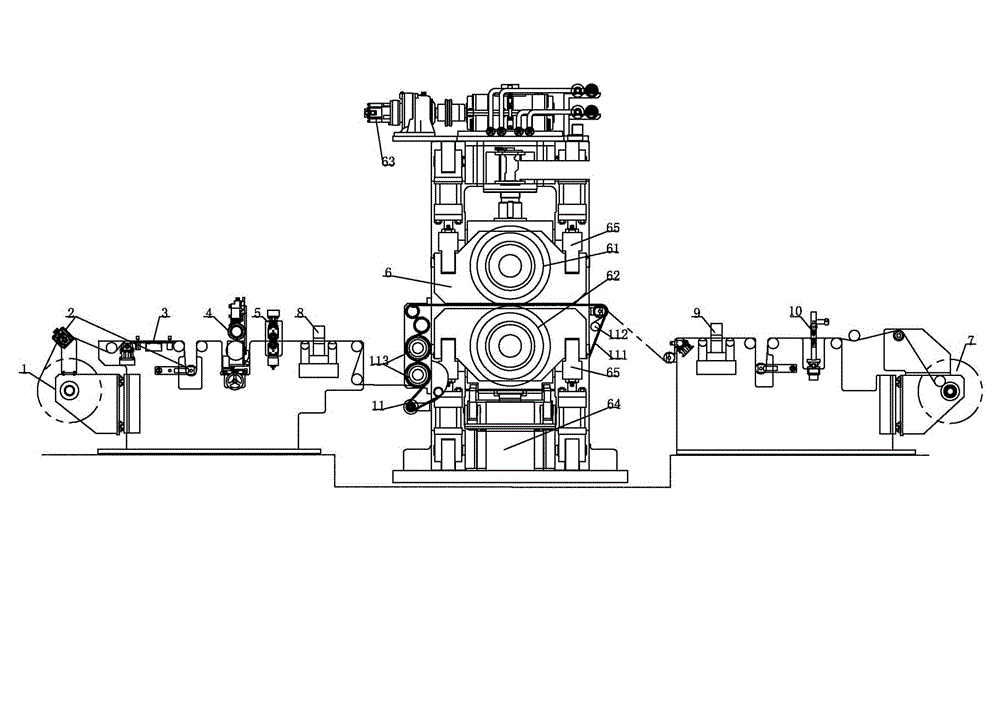

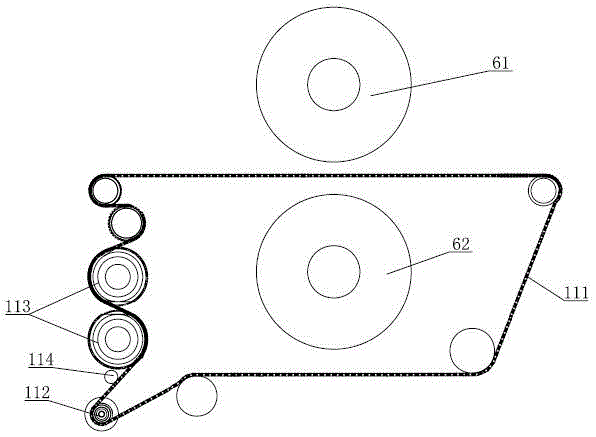

Pole piece roller compression machine

ActiveCN102723461AGuaranteed service lifeGap changes smoothlyElectrode manufacturing processesPulp and paper industry

The invention discloses a pole piece roller compression machine which comprises an unrolling mechanism, a delivery mechanism, a roller compression mechanism and a rolling mechanism. The roller compression mechanism comprises an upper compression roller and a lower compression roller which are oppositely arranged and a compression roller driving mechanism used for driving the upper compression roller and the lower compression roller to move relatively to conduct roller compression. The roller compression mechanism further comprises an inverse driving mechanism coupled to the upper compression roller and / or the lower compression roller. The inverse driving mechanism controllably applies action force with direction opposite to the compression roller drawing close direction on the upper compression roller and / or the lower compression roller to remove or weaken compression roller shock. The pole piece roller compression machine enables the two compression rollers to maintain stable in interval change, and avoids undesirable change in compression of pole pieces by rollers, so that the machine can improve roller compression quality and prolong service life of devices.

Owner:SHENZHEN YINGHE TECH

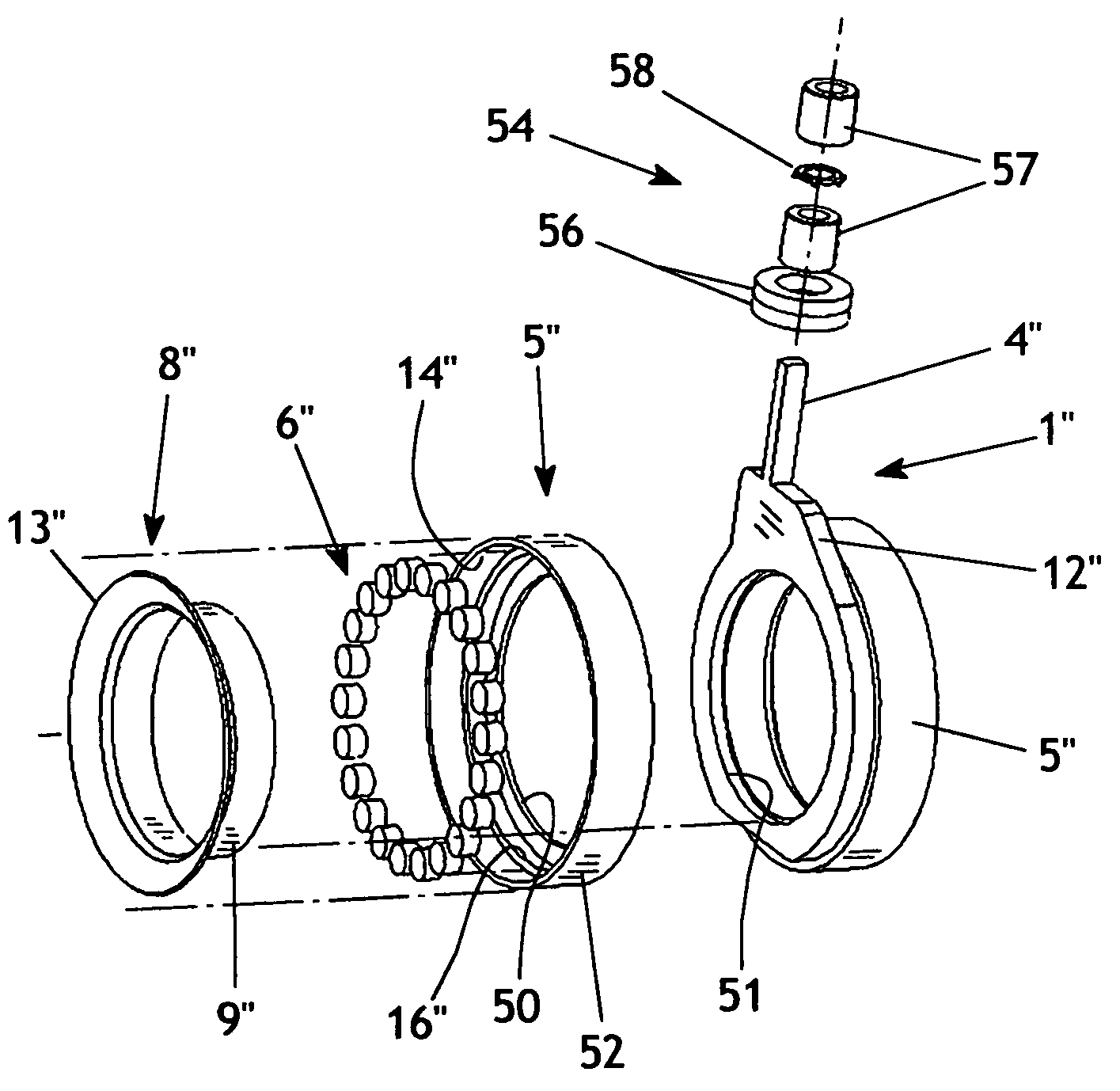

Hubless caster

InactiveUS7150070B2Improve stabilityFunction increaseSuction cleanersCastorsFree rotationEngineering

A hubless caster assembly includes a caster body and at least one wheel, the wheel comprising a toroidal member having a bearing race, and a complementary bearing race supported by the caster body. Bearing elements in the races support the wheel in free rotation. The caster body may comprise a ring body having an axial opening, whereby the caster assembly has a large central aperture extending entirely therethrough. A centering ring may be secured in the axial opening with the complementary bearing race formed therein. A hub cap with visual treatment may be secured over the central aperture.

Owner:OCONOMOWOC MFG

Nb-containing high-carbon and high-duty steel based on sheet bar process and method for manufacturing same

The invention relates to a Nb-containing middle-high carbon high-strength steel based on a sheet billet process and a method for manufacturing the same. In the technical proposal, a steel grade comprises the following chemical compositions by weight percent: 0.25 to 1.25 weight percent of C, 0.01 to 0.15 weight percent of Nb, 0.001 to 0.1 weight percent of Al, 0.0010 to 0.0050 weight percent of Ca and the balance being Fe, inevitable impurity and alloy elements; and the bending strength of the prepared steel plate is between 350 and 1500 MPa. The sheet billet process comprises the following process parameters that: the thickness of the sheet billet is between 50 and 90 mm; the casting speed of the sheet billet is between 2.5 and 6.0 m / min; the temperature when a casting blank enters a heating furnace is between 900 and 1100 DEG C; the temperature when the casting blank enters a soaking furnace is between 1000 and 1250 DEG C; the initial rolling temperature is between 1000 and 1200 DEG C; the finish rolling temperature is between 650 and 950 DEG C; and the coiling temperature is between 450 and 850 DEG C and the thickness of the steel plate is between 1 and 12 mm. The Nb-containing middle-high carbon high-strength steel and the method can improve product quality, improve manufacturing efficiency, reduce manufacturing cost, save resource and energy, etc.

Owner:WUHAN UNIV OF SCI & TECH +1

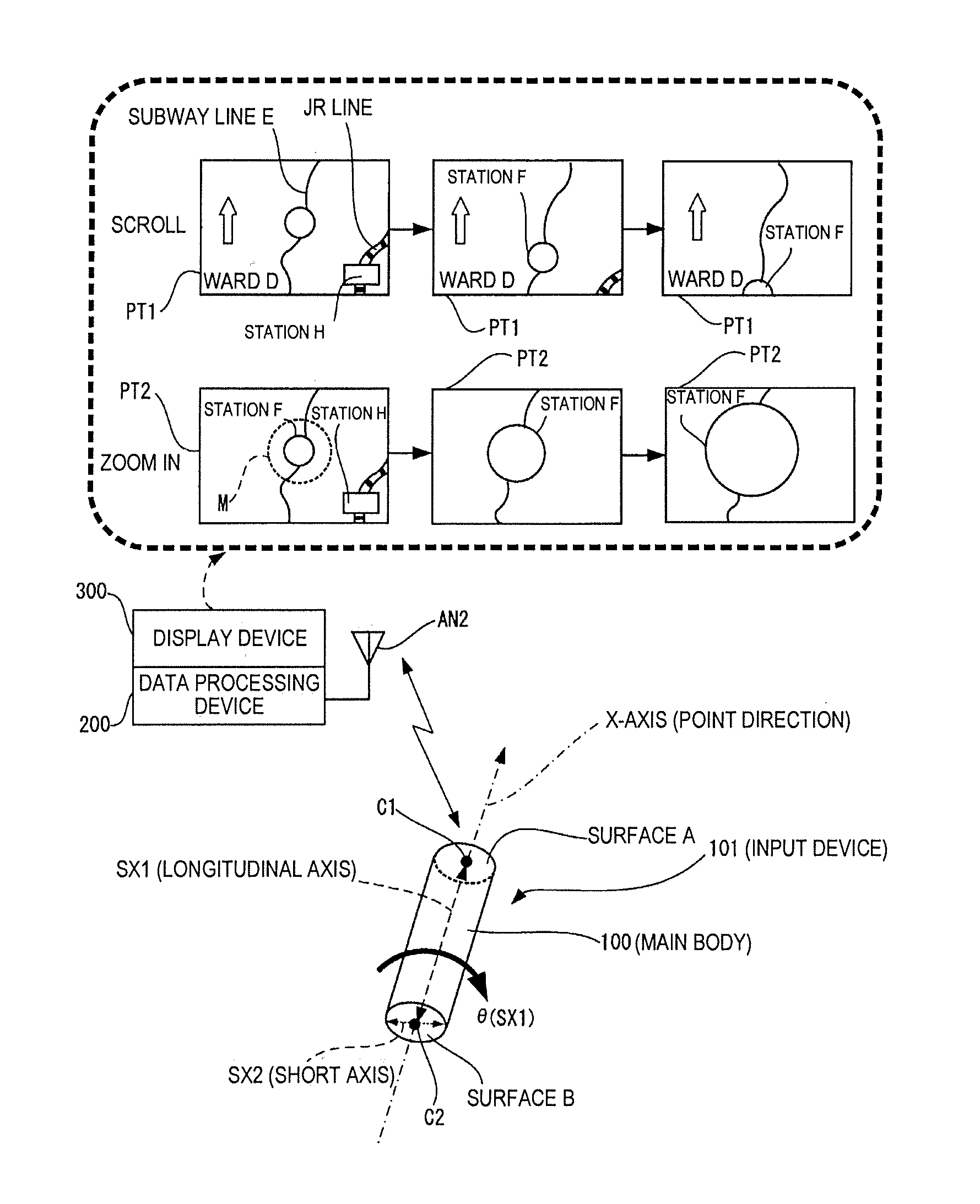

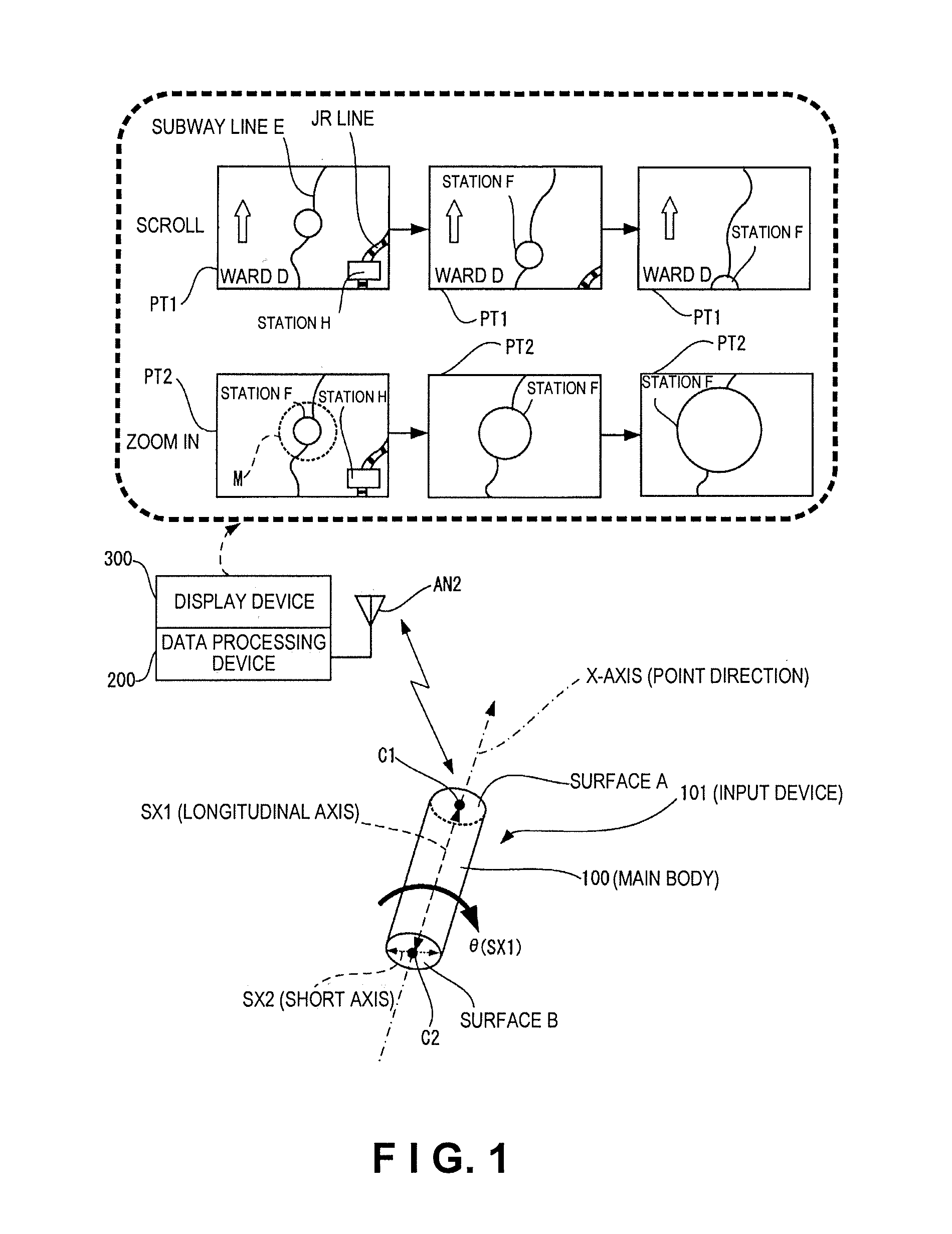

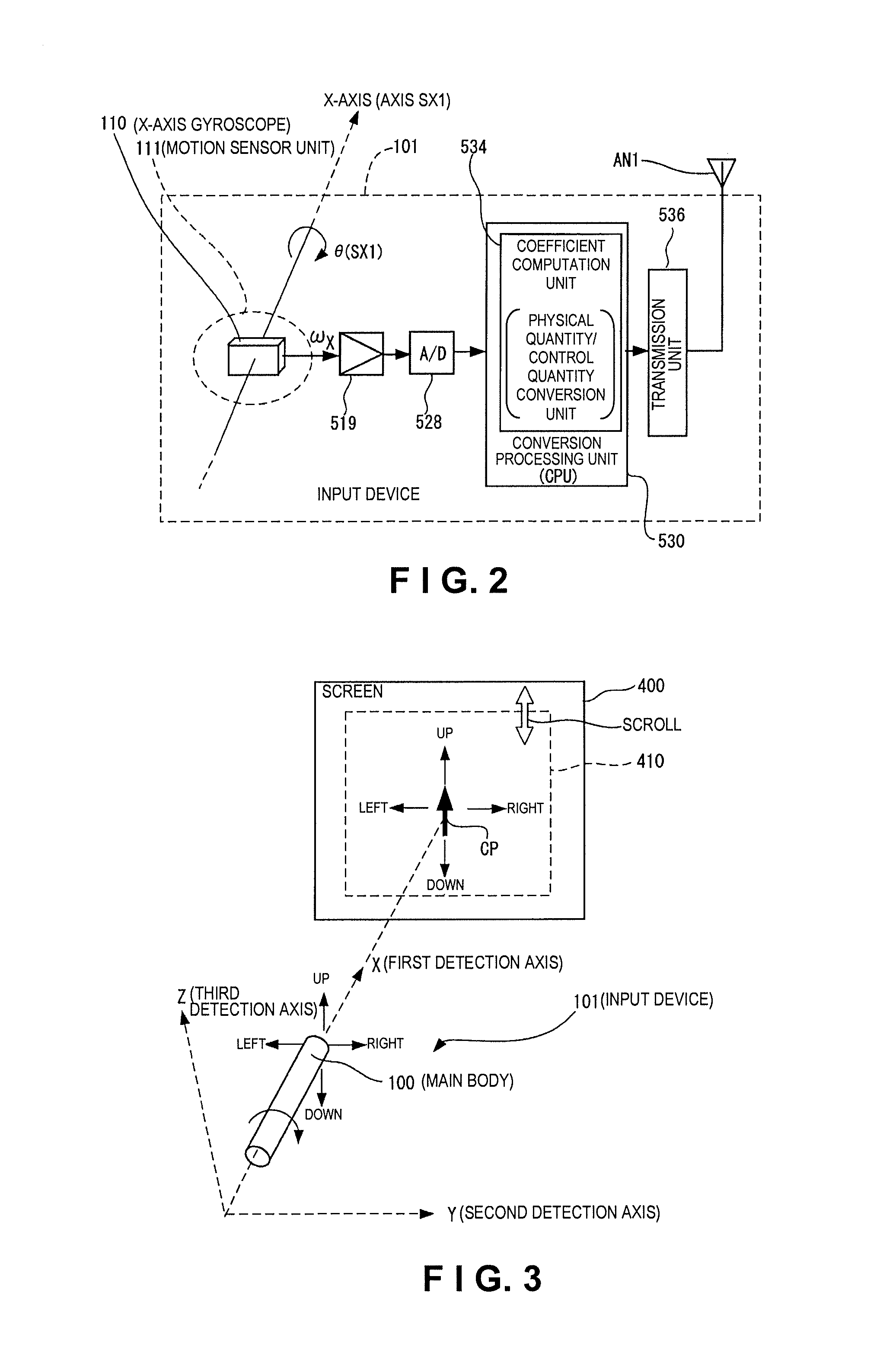

Input device and data processing system

ActiveUS20100156785A1Easy to operateImprove convenienceDigital computer detailsSpeed measurement using gyroscopic effectsAxis–angle representationData processing system

An input device includes a main body and a motion sensor unit. The main body has a longitudinal axis. The motion sensor unit is configured and arranged to detect rotation of the main body about the longitudinal axis. The motion sensor unit has an X-axis angular velocity sensor configured and arranged to detect an angular velocity of the main body about an X-axis in a three-dimensional orthogonal coordinate system defined by the X-axis, a Y-axis and a Z-axis. The X-axis coincides with the longitudinal axis of the main body and the Y-axis and the Z-axis being orthogonal to each other in a first plane perpendicular to the X-axis.

Owner:SEIKO EPSON CORP

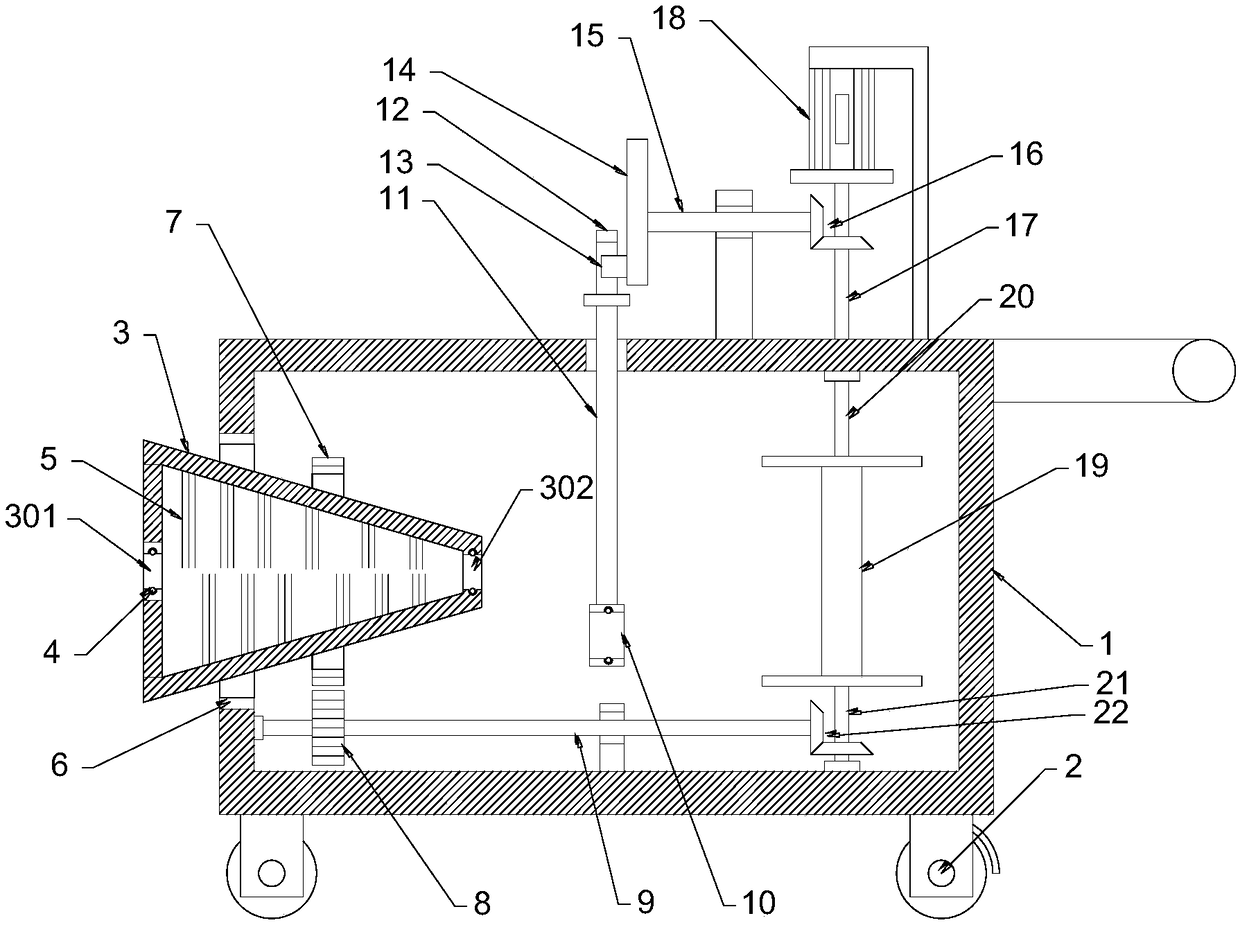

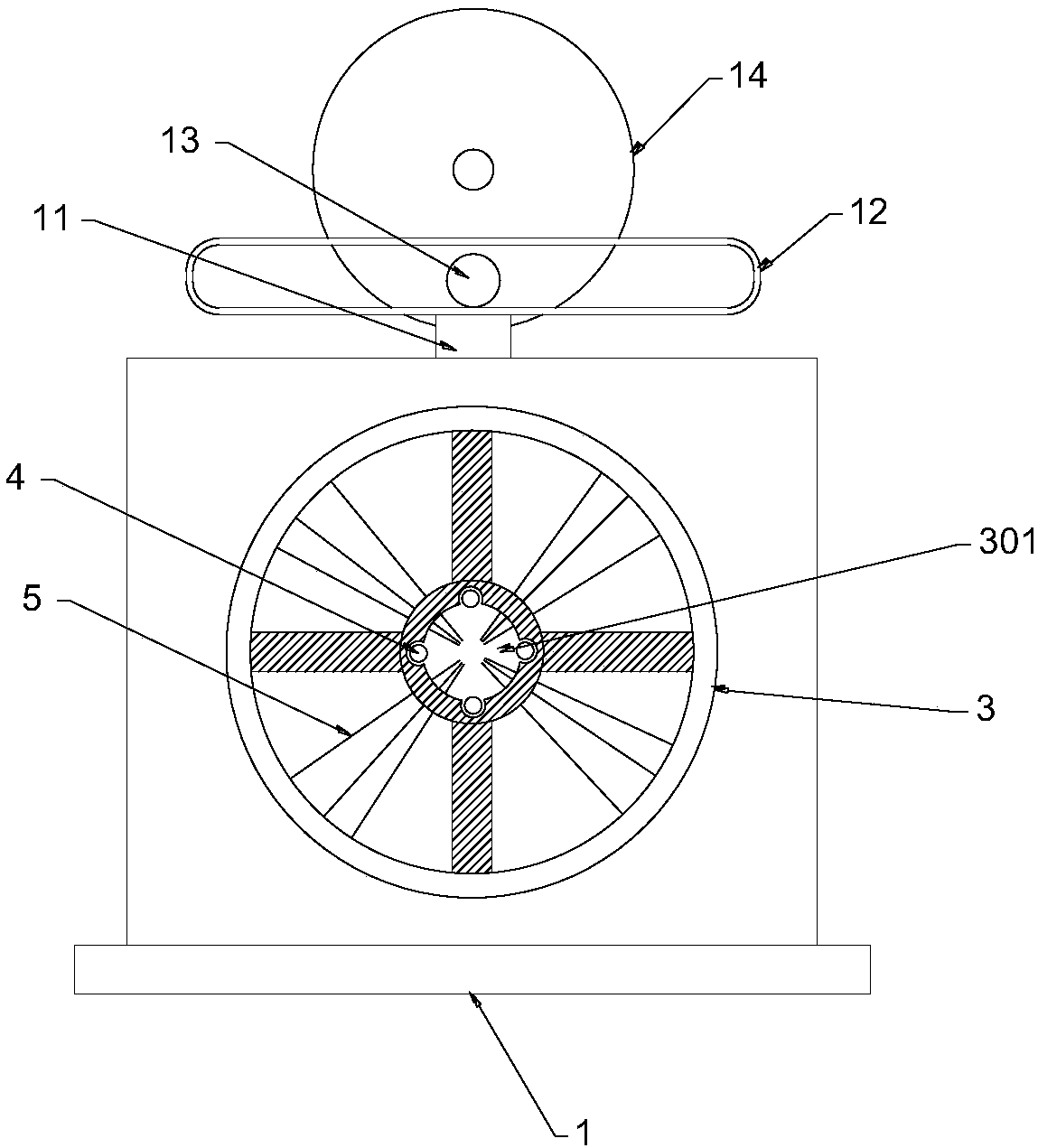

High-efficiency cable winding device for power cable

The invention discloses a high-efficiency cable winding device for a power cable. The high-efficiency cable winding device comprises a trolley body, a cleaning mechanism and a winding mechanism; a cleaning device is arranged at the left side of the trolley body; the cleaning device comprises a cleaning cone; brush bristles are uniformly distributed at the inner surface of the cleaning cone; the winding mechanism is arranged at the right side of the cleaning cone; and the winding mechanism comprises a limiting ring and a winding roller. According to the high-efficiency cable winding device disclosed by the invention, the rotating cleaning cone is arranged for brushing the surface of the cable so as to remove dust and other particles on the surface of the cable, thus convenience is providedfor subsequent winding of the cable; the cable is kept clean; the service life of the cable is prolonged; by arranging the limiting ring, the cable can be wound on the winding roller according to a certain sequence in a winding process of the cable, thus the cable is wound on the winding roller more uniformly and more compactly, the winding quantity is increased and the winding effect is improved.

Owner:安徽盛琛电力工程有限公司

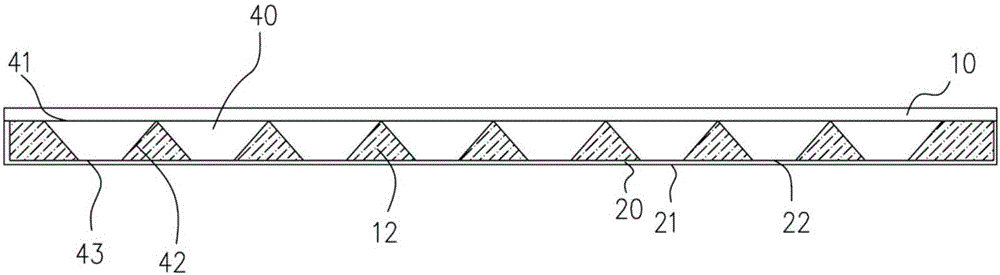

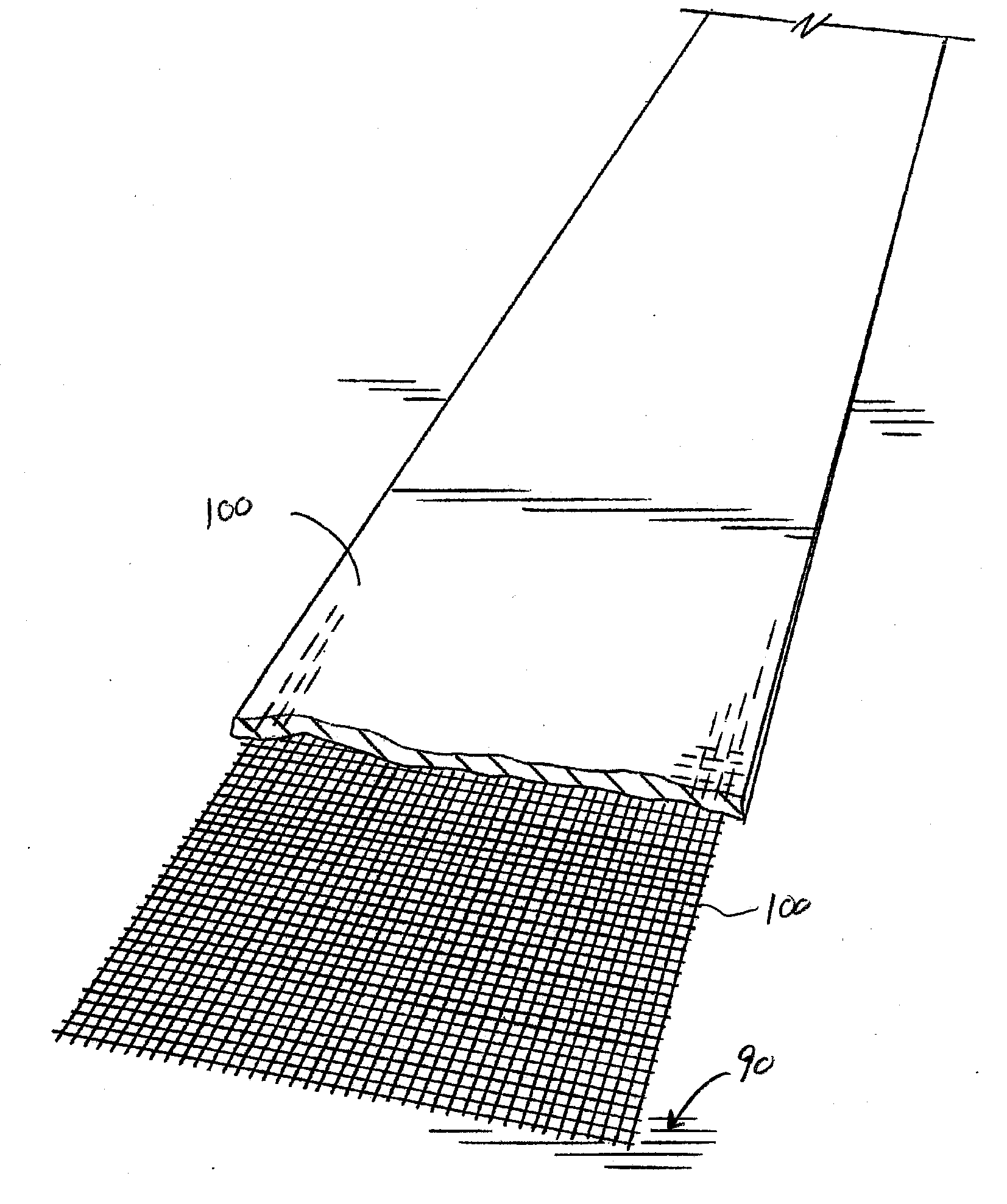

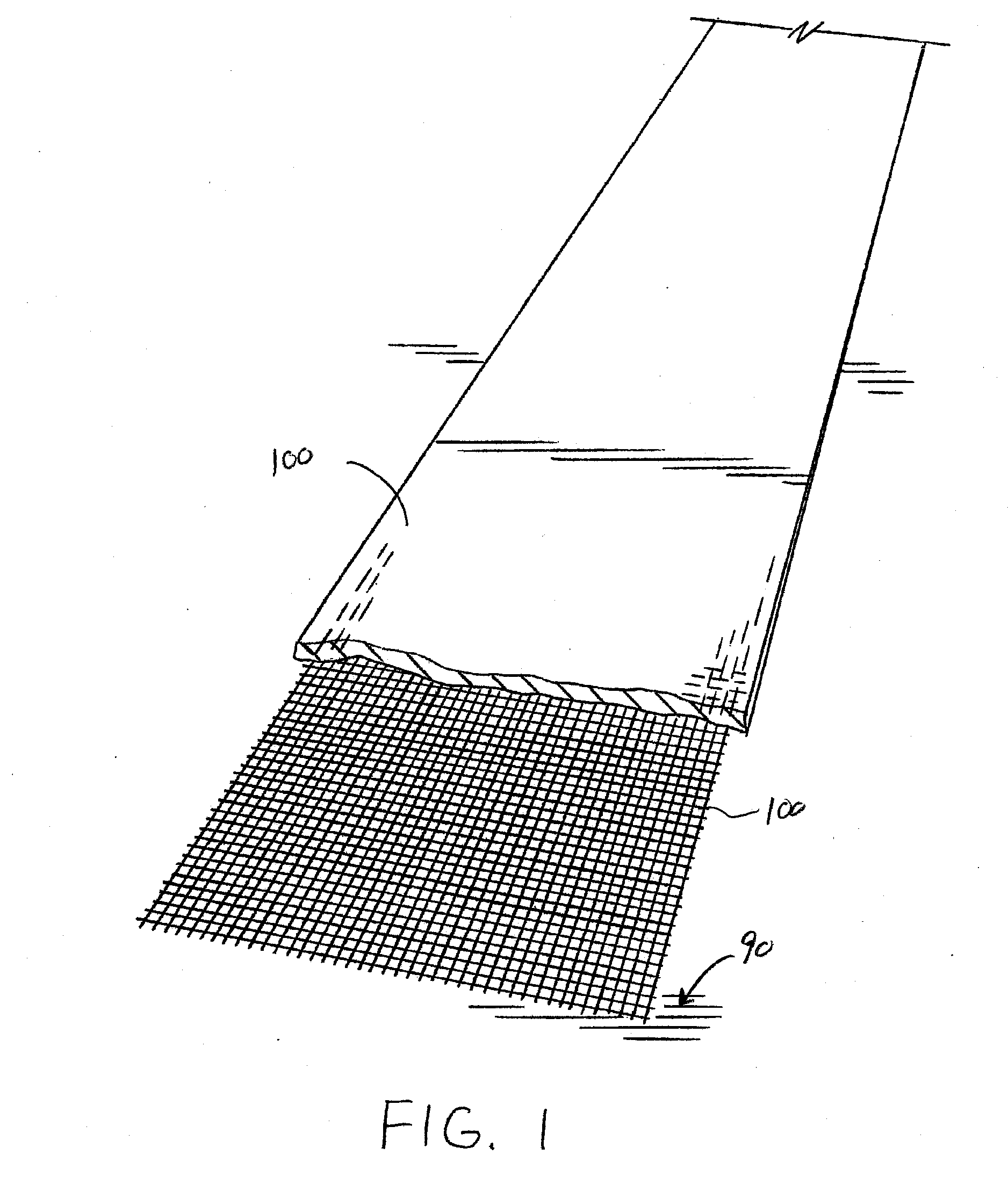

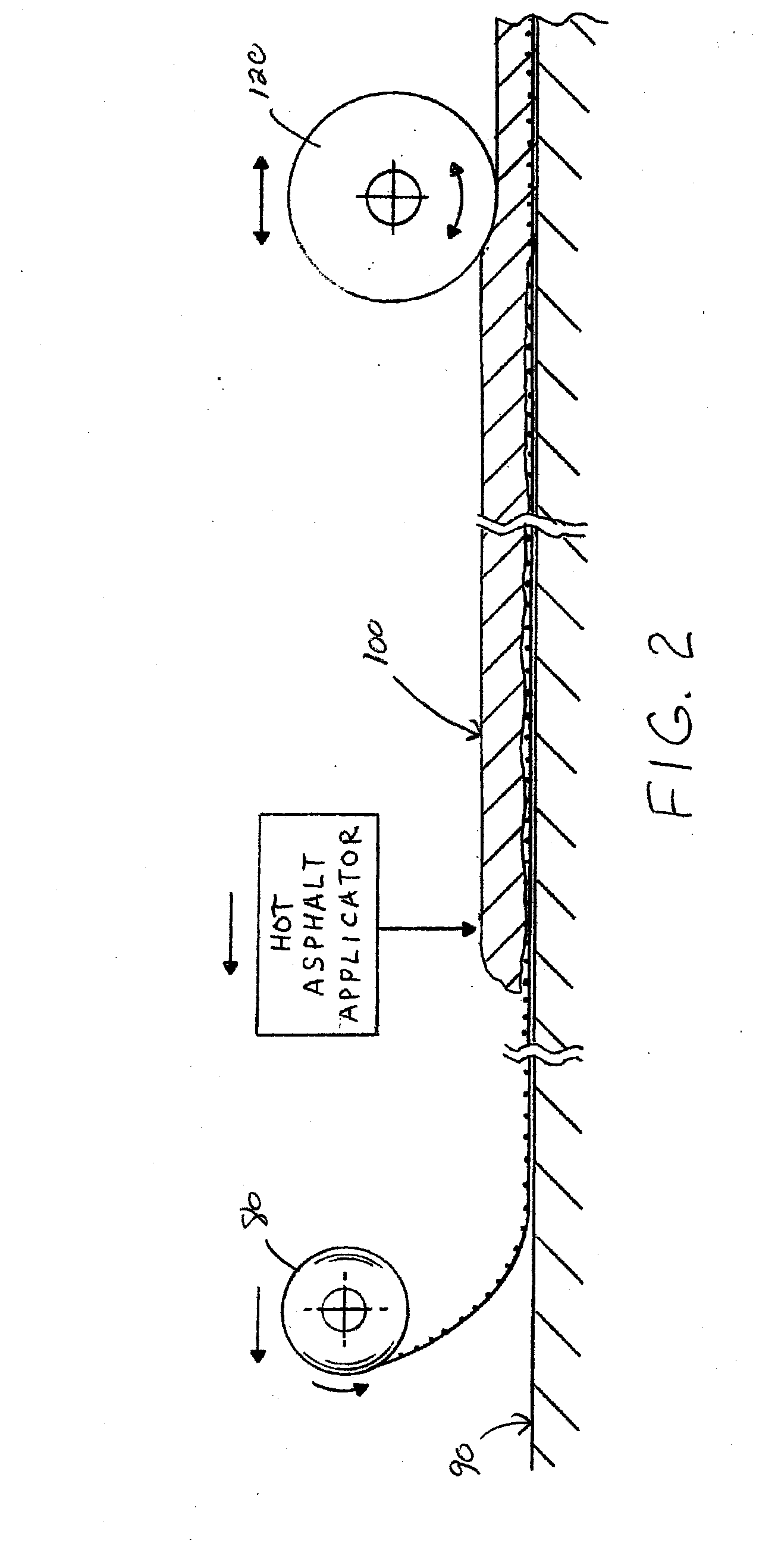

Reinforced fiber mats for use in paved surfaces

InactiveUS20130156501A1Easy to shapeGood for scrollingIn situ pavingsMedical patchesFiberEngineering

A reinforcement mat that can be used to improve the durability and life of an asphalt paved surface. The reinforcement mat is partially or fully coated with a resin. The resin generally has a cure temperature in excess of about 140° F.

Owner:HEMPHILL WILLIAM SCOTT

Austenitic stainless steel gas shield welding wire for vehicle

ActiveCN101100021AExcellent rolling and wire drawing propertiesGood welding performanceWelding/cutting media/materialsSoldering mediaIn vehicleWeld seam

The present invention relates to austenitic stainless steel welding wire for gas protected welding in vehicle. The austenitic stainless steel welding wire has the chemical composition comprising C not more than 0.03 wt%, Si 0.50-0.90 wt%, Mn 1.00-2.50 wt%, P not more than 0.025 wt%, S not more than 0.015 wt%, Ni 9.0-14.0 wt%, Cr 19.5-24.5 wt%, and Fe and inevitable impurity for the rest. The austenitic stainless steel welding wire produced through smelting, rolling, drawing and other steps has excellent performance, including excellent welding performance, is applied for welding steel of 500-700 MPa strength to form weld seam with high strength, high toughness and high corrosion resistance.

Owner:哈焊所华通(常州)焊业股份有限公司

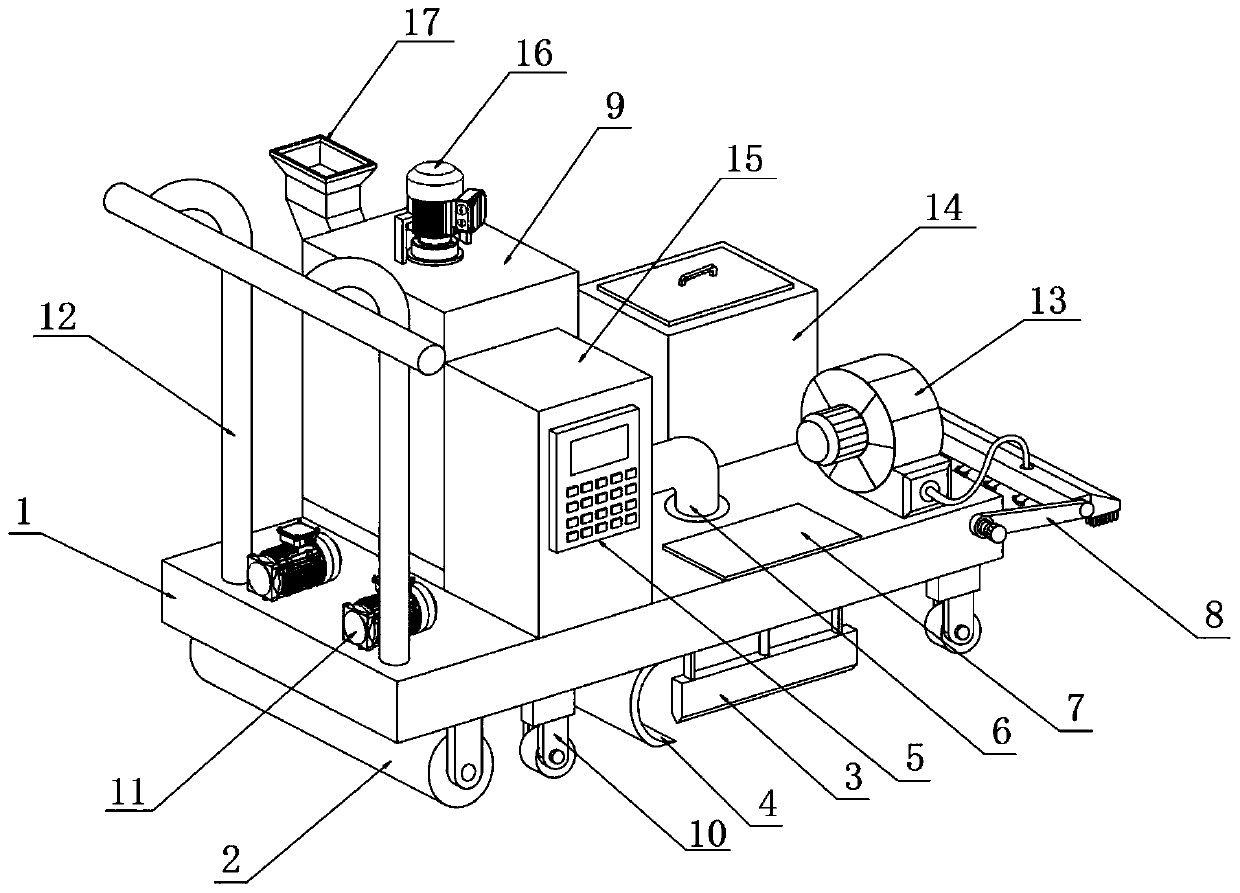

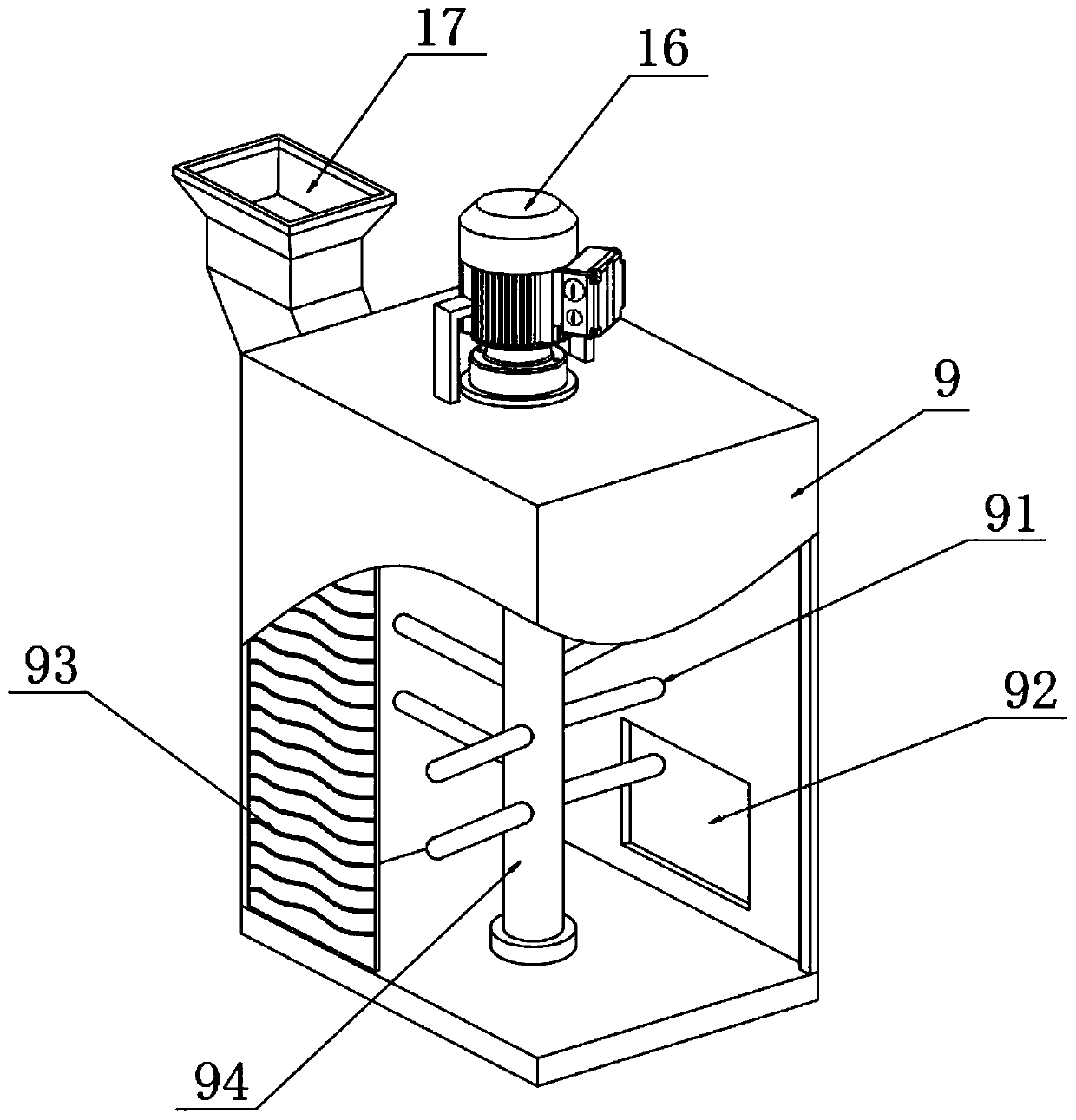

Road engineering pavement asphalt paving equipment

InactiveCN110424220AEnsure smoothness and uniformityEasy to rollRoad cleaningRoads maintainenceRoad engineeringVibration motor

The invention relates to the technical field of road engineering, in particular to road engineering pavement asphalt paving equipment. The road engineering pavement asphalt paving equipment comprisesa base, a pressing roller is installed at the rear end of the lower surface of the base, and a vibration motor is installed at one side position, close to a pushing handle, of the upper surface of thebase; and a stirring bin is installed on the upper surface, on the front side of the vibration motor, of the base, a discharging pipe is connected to the lower end of the front surface of the stirring bin in a penetrating mode, and a sweeping mechanism is arranged at the front end of the base. According to the road engineering pavement asphalt paving equipment, the adjustable sweeping mechanism is additionally arranged, so that the road surface can be further cleaned when the road is laid, and the quality of asphalt paving is ensured; and a paving board is additionally arranged at the bottomof the device and is matched with a threaded rod and a servo motor for using so that the paving board can uniformly spread the discharged asphalt, the flatness and uniformity of asphalt paving are ensured, rolling of the asphalt by a compression roller in subsequent process is facilitated, the operation is simple and convenient, the cost is low, and the paving effect of the asphalt is good.

Owner:淄博询知方技术开发有限公司

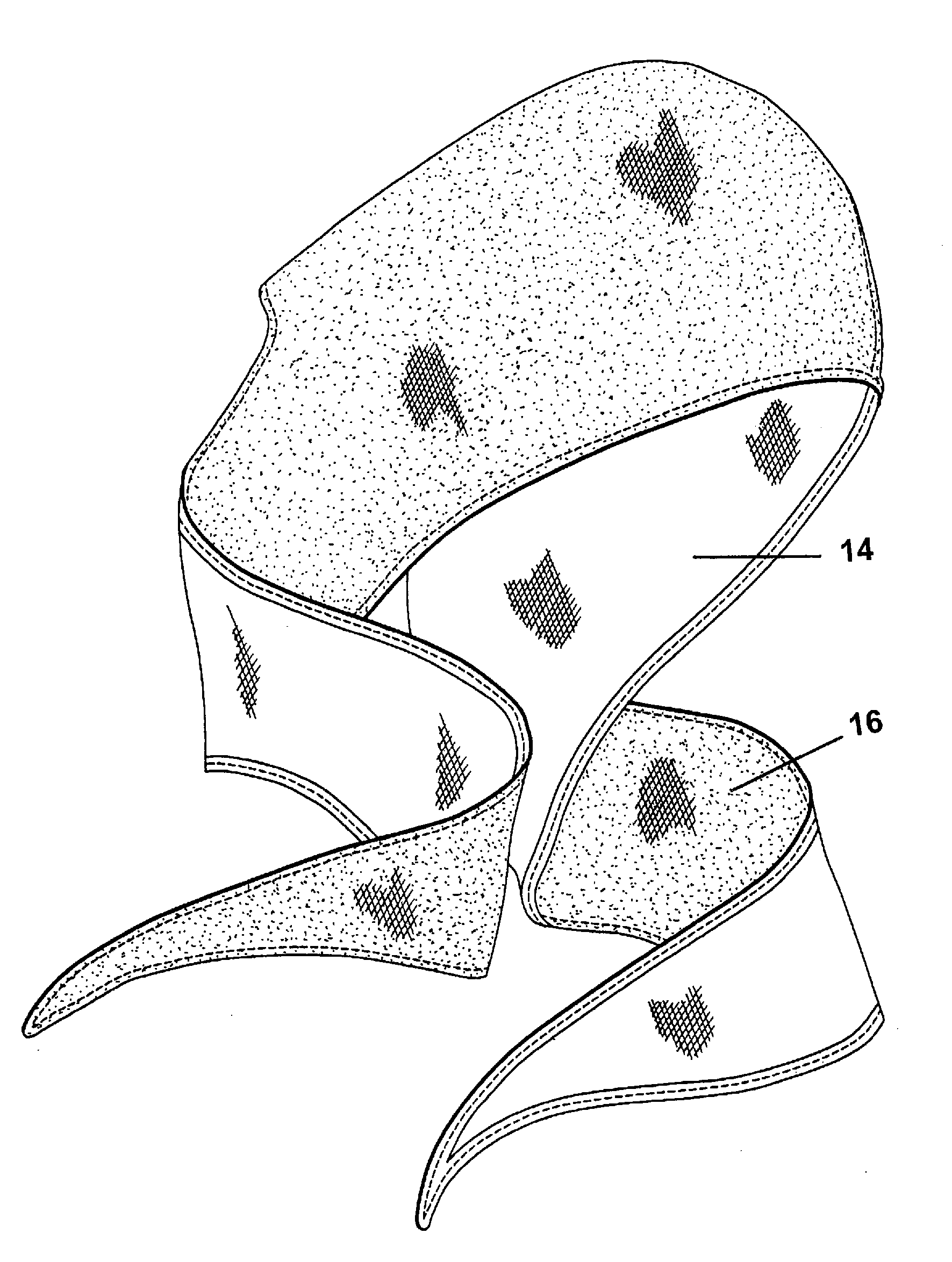

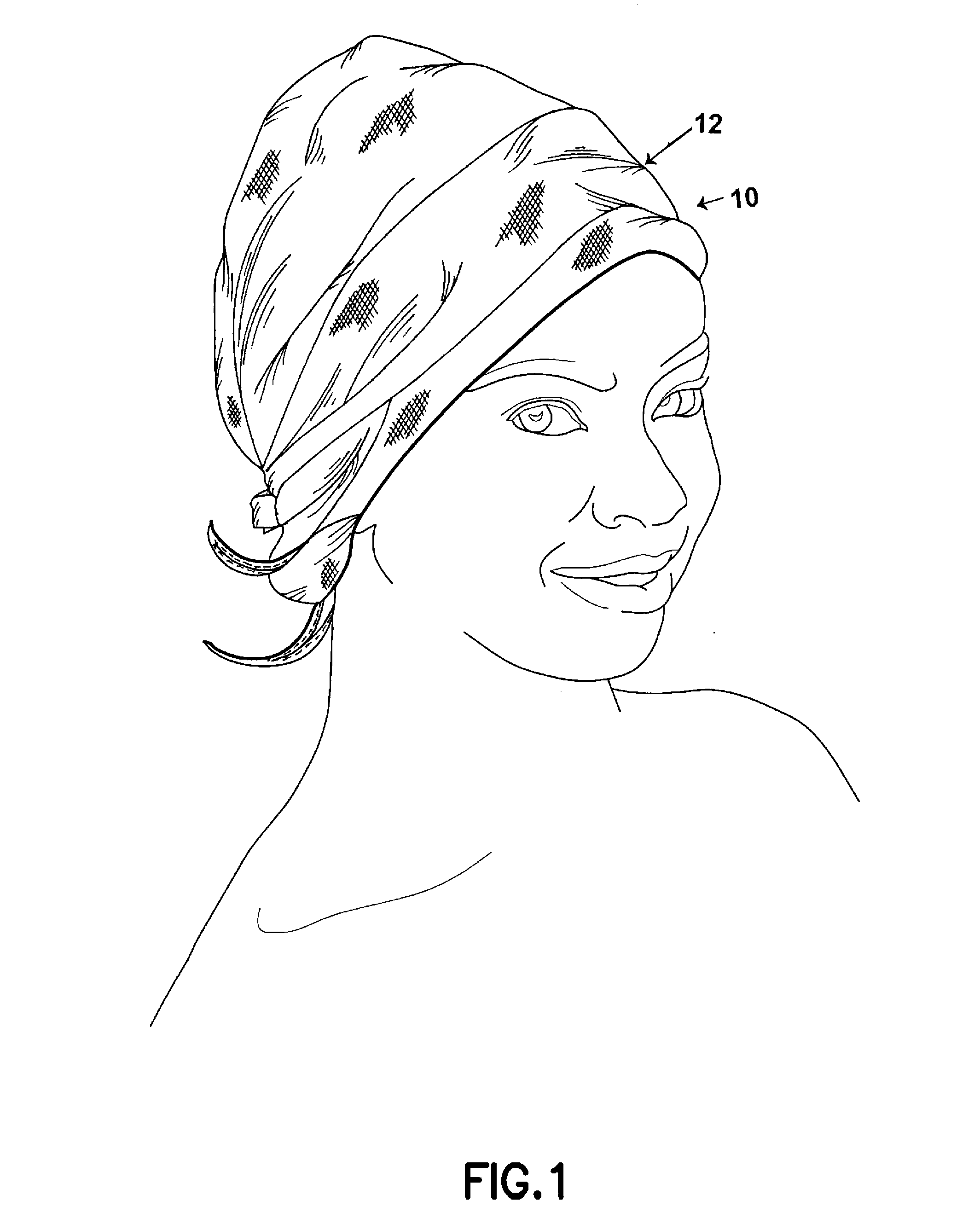

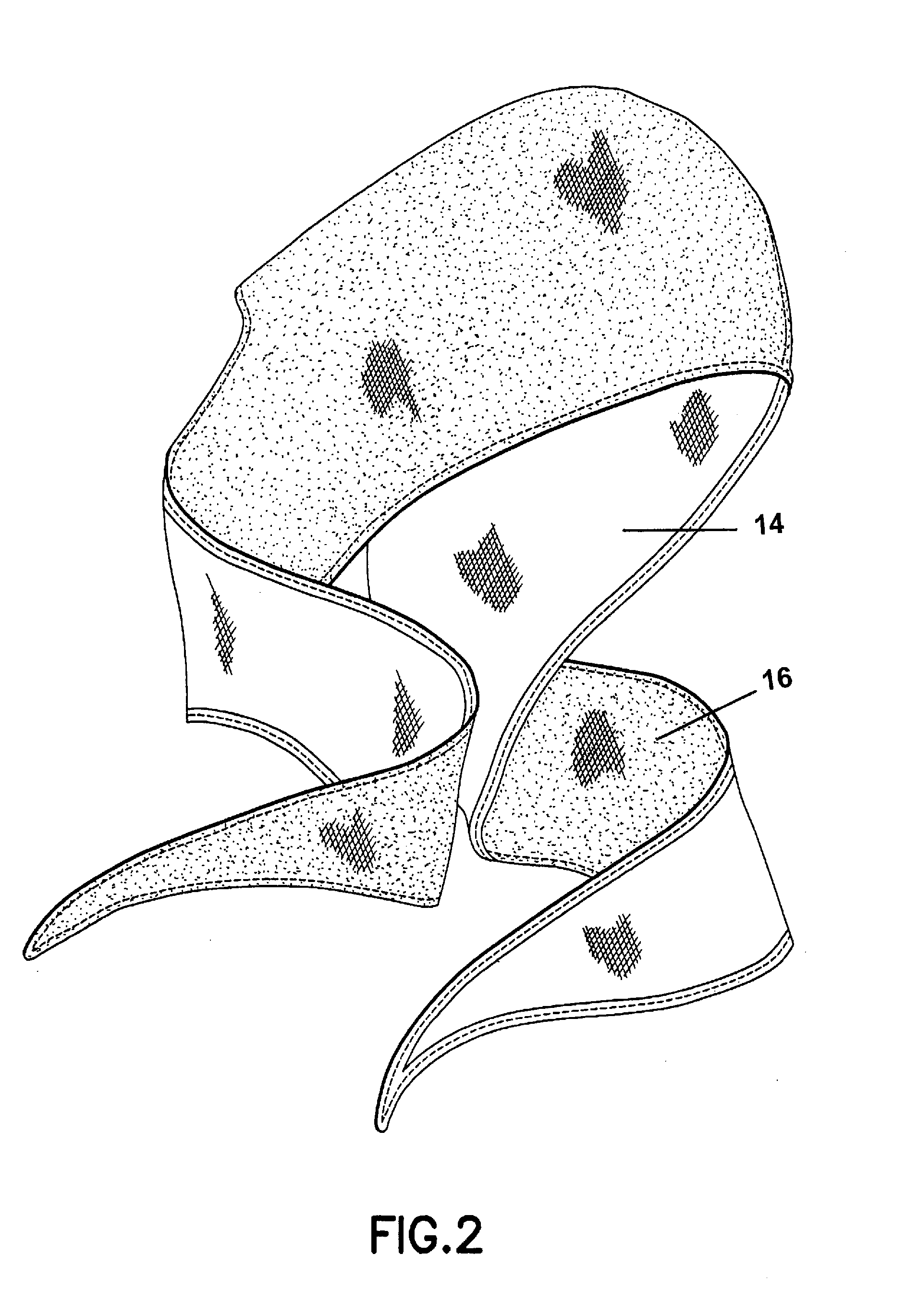

Single layer, two different sided hair wrap

Owner:GREY GARY

Aluminium foil material for tableware and manufacturing method of aluminium foil for tableware

InactiveCN101812616AHigh strengthReduce supersaturationMetal rolling arrangementsAluminum foilGrain growth

The invention relates to an aluminium foil material for tableware and a manufacturing method of aluminium foils for the tableware, belonging to the technical field of manufacture of aluminium alloy materials and the aluminium foils. The aluminium foil material comprises the following components in percentage by weight: 0.2-0.30% of Si, 1.40-1.50% of Fe, 0.05% of Cu, 0.50-0.60% of Mn, 0.05% of Mg, 0.01% of Cr, 0.05% of Zn, 0.05% of Ti, and the balance of Al, wherein the components are smelted into an alloy. The manufacturing method of the aluminium foils for the tableware comprises the following steps of: a, smelting; b, casting; c, uniform annealing; d, cold rolling; e, foil rolling; and f, finished product annealing. The invention can prevent an aluminium coil from generating grain growth during the uniform annealing and also has better machining property and easy rolling.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

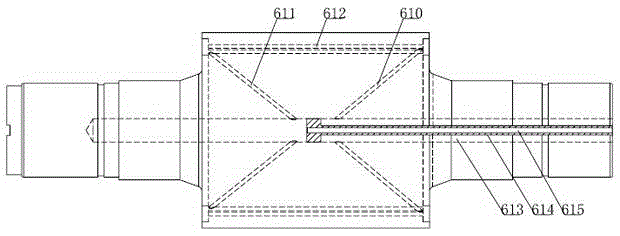

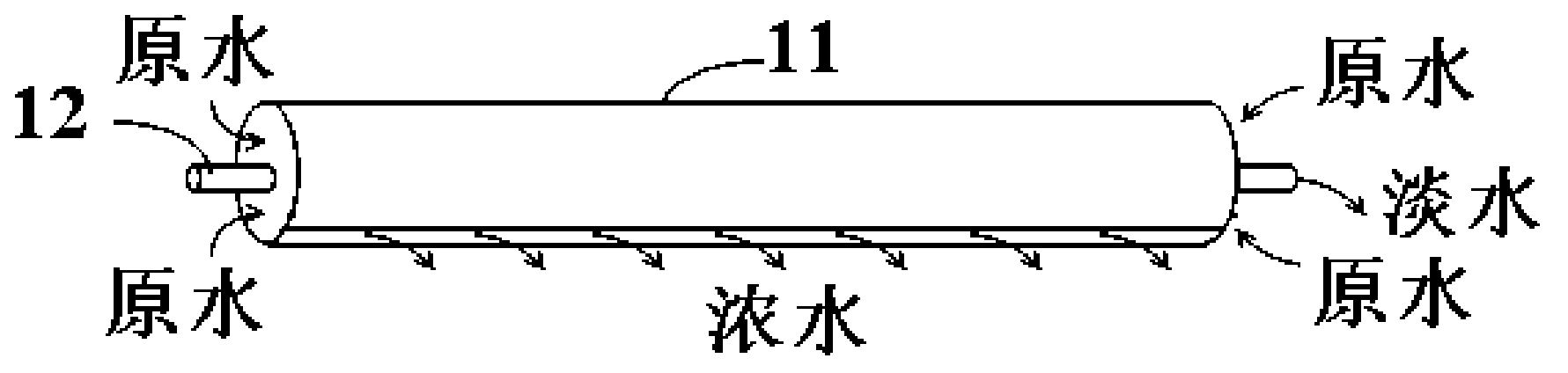

Sidestream reverse osmosis membrane element

ActiveCN102976447AExtend your lifeSimple waterwayWater/sewage treatment bu osmosis/dialysisReverse osmosisMembrane surfaceReverse osmosis

The invention provides a sidestream reverse osmosis membrane element which has a simple water way. A side surface of the sidestream reverse osmosis membrane element is a water outlet and one end of the sidestream reverse osmosis membrane element is a water inlet, or the side surface is the water inlet and the end is the water outlet. According to a technical scheme provided by the invention, the reverse osmosis membrane element only has one water inlet, so the water way is simple, convenient installation is realized, and advantages of the sidestream reverse osmosis membrane element are reserved, e.g., easy rolling and a great flow velocity on a membrane surface.

Owner:A O SMITH (CHINA) ENVIRONMENTAL PRODUCTS CO LTD

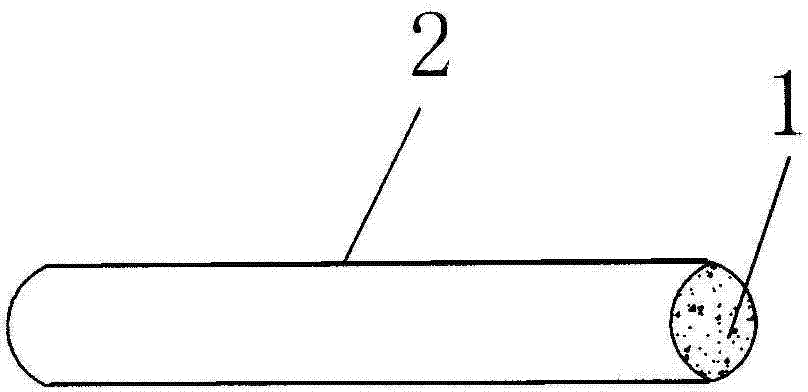

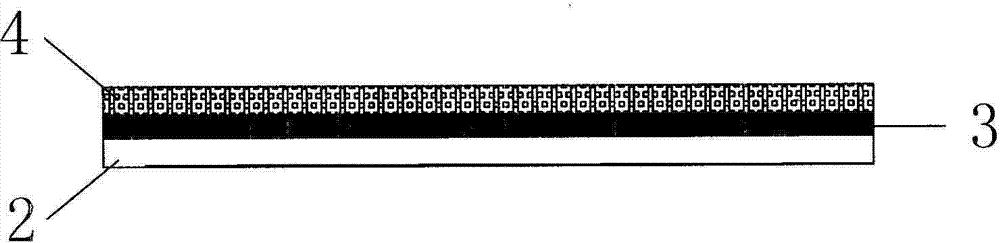

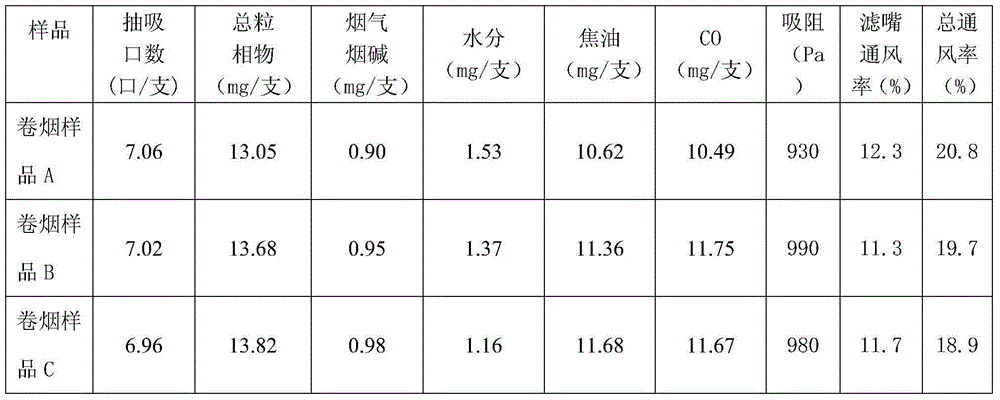

Filtering rod capable of reducing smoke temperature and preparation method of filtering rod

The invention discloses a filtering rod capable of reducing smoke temperature and a preparation method of the filtering rod. Smokers feel obvious hot burning feeling and spicy stimulating feeling when smoking the cigarettes. In order to solve the problem, the invention adopts the following technical scheme: the filtering rod comprises a bundle core rod (1) and externally wrapped molding paper (2). The right side of the molding paper (2) is coated with a microporous aluminum layer (4) through a glue layer (3). The microporous aluminum molding paper is formed by adhering the microporous aluminum onto the the molding paper in a vacuum aluminizing way. Then the molding paper coated with the microporous aluminum is used for coiling to form the filtering rod. The filtering rod containing the microporous aluminum is used, and when high-temperature smoke of smoked cigarettes enters the filtering rod from the tail end of the cigarette, the temperature of smoke entering the mouth can be reduced to 28-32 DEG C because of condensation of the microporous aluminum, thereby enabling harmful substances of the smoke to be easily adhered to the filtering rod and obviously reducing harmful substances of the smoke, so that the hot burning feeling and spicy stimulating feeling of the mouth can be obviously lightened after people smoke.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

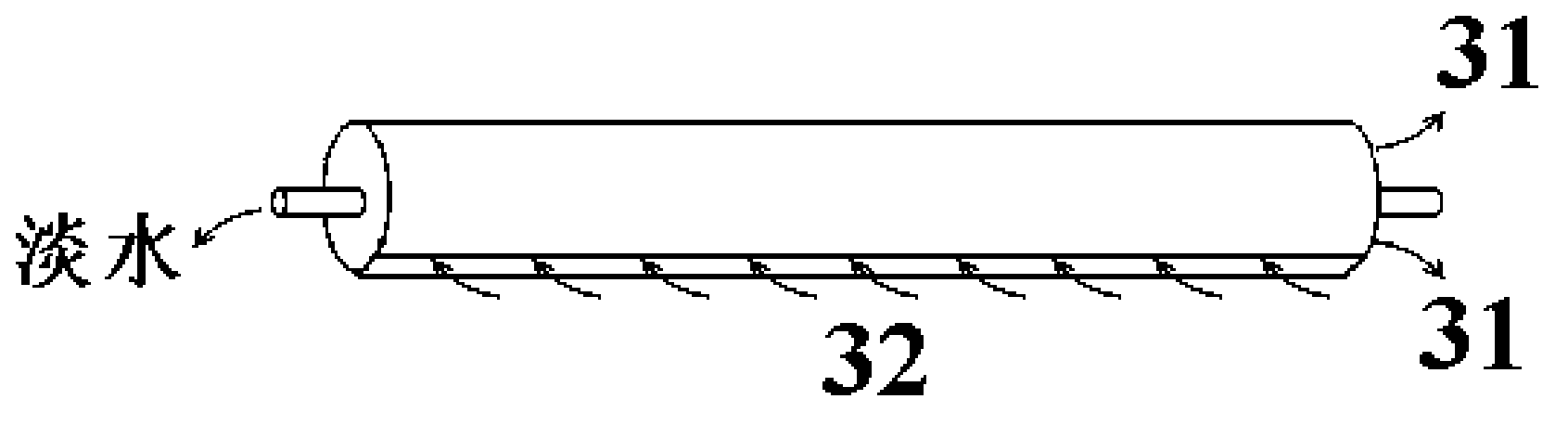

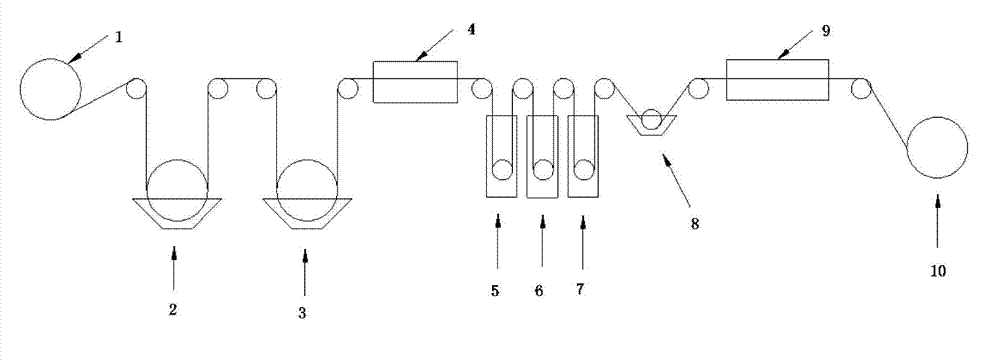

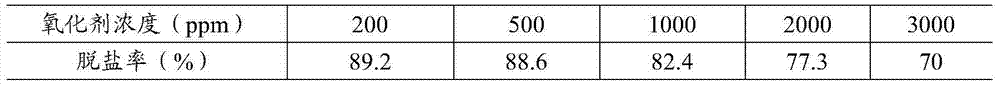

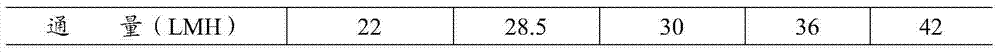

Method for online preparing high-throughput composite reverse osmosis membrane

ActiveCN103657430AReduce crosslink densityIncrease water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUltrafiltrationReverse osmosis

The invention discloses a method for online preparing a high-throughput composite reverse osmosis membrane. The method comprises the following steps of using a membrane coating machine to enable an ultrafiltration base membrane to pass through m-phenylenediamine aqueous solution, normal hexane solution of trimesoyl chloride, an oven, a purge tank, an oxidation tank, a reduction cell, a glycerite tank and a protective liquid tank; drying in the oven to obtain the high-throughput composite reverse osmosis membrane. The method has the characteristics that the process is simple, the water flux of the membrane is high, dry films of the high-throughput composite reverse osmosis membrane can be directly produced, membrane components can be wound conveniently, large-scale production can be realized, the process is stable, and the like. The high-throughput composite reverse osmosis membrane can be applied in the field of household water purification, municipal administration tap water is utilized to supply pressure without an additional booster pump, the cost is greatly reduced, and the energy is saved.

Owner:BEIJING ORIGIN WATER FILM TECH

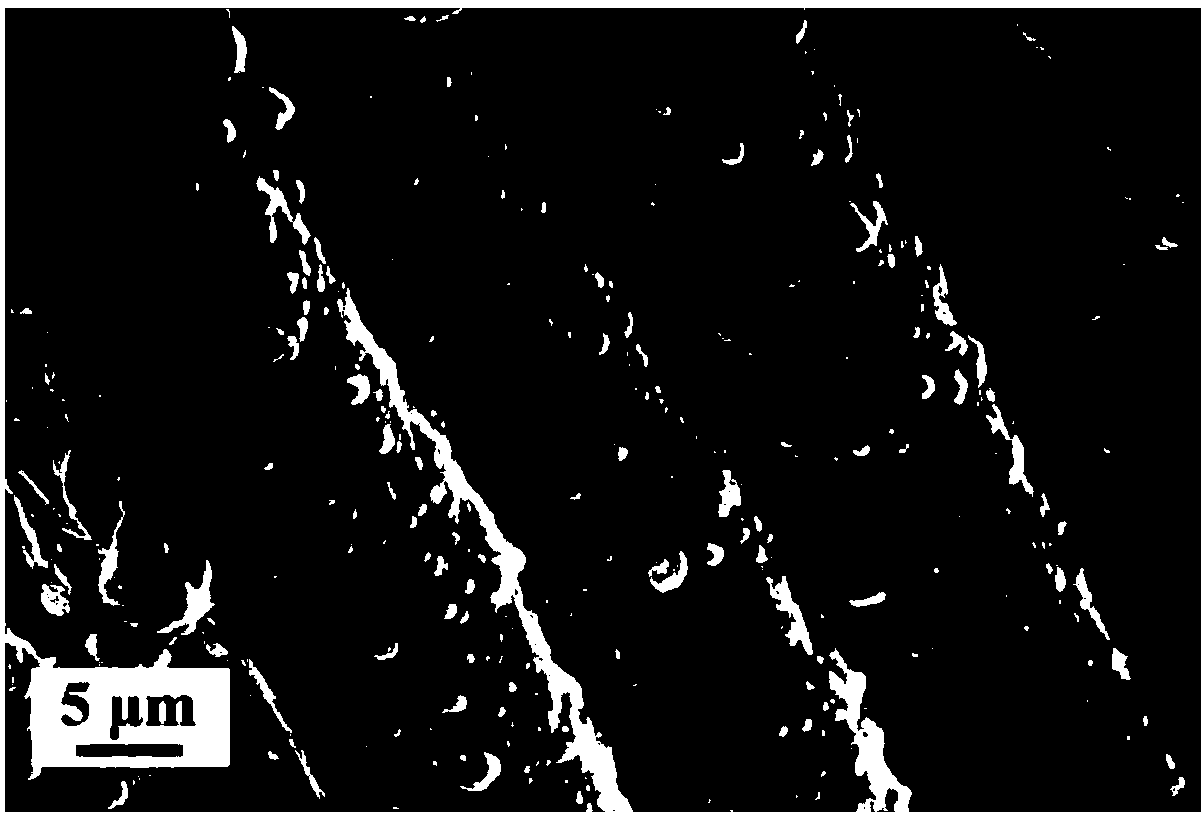

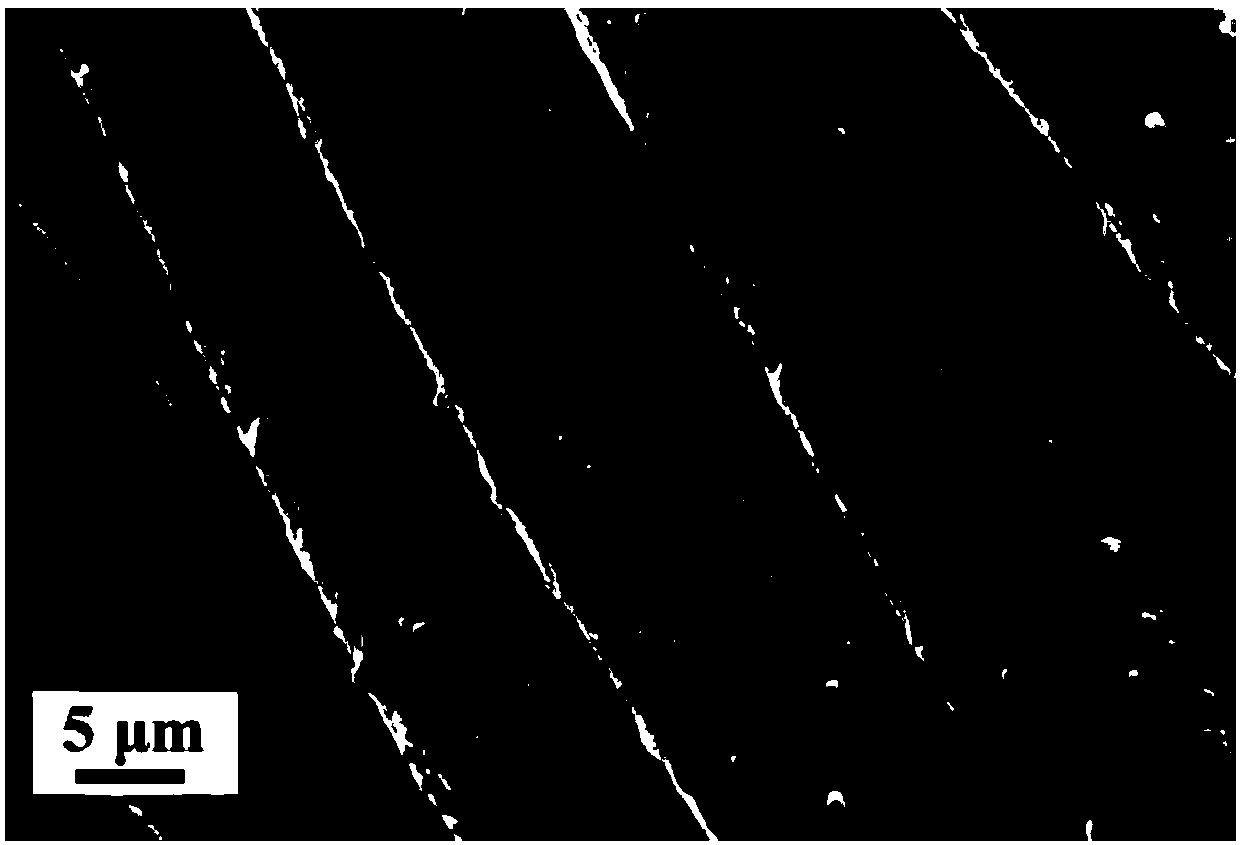

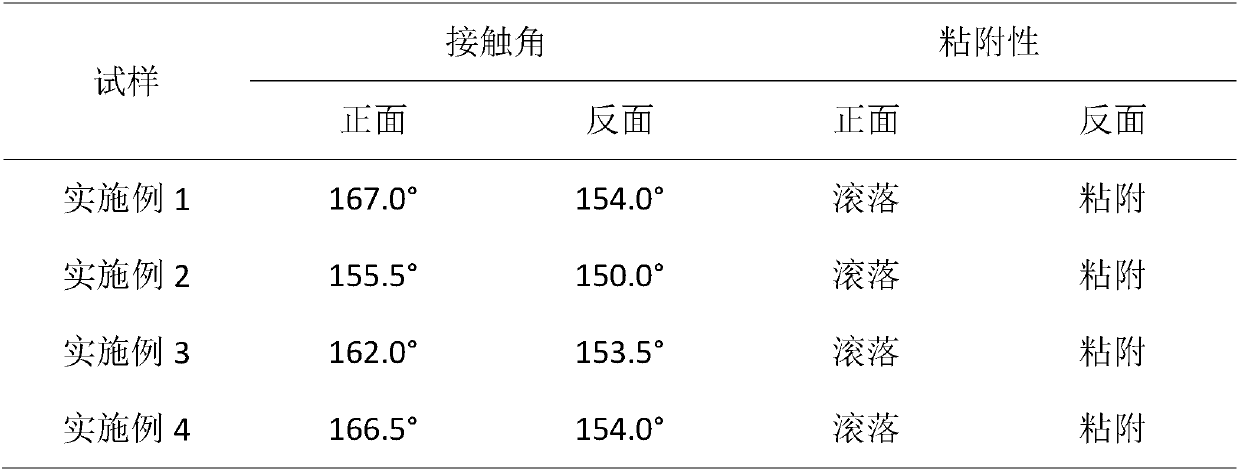

Magnetic super-hydrophobic fabric and preparation method thereof

The invention discloses a magnetic super-hydrophobic fabric and a preparation method thereof. The preparation method comprises the following steps: immersing an ordinary fabric into a mixed solution of polydimethylsiloxane-containing ferric oxide particles modified by a silane coupling agent and an organic solvent to be stirred; taking out the fabric, placing the fabric at a position which is 1-5mm away from the lower side of a magnet, maintaining at a room temperature for 10-60 minutes, and granularly migrating the ferric oxide particles to the polydimethylsiloxane surface layer on the fabricdue to the magnetic field action during solvent evaporation; and finally, placing the fabric at a temperature of 80-130 DEG C, and performing heat curing on the polydimethylsiloxane to form a cross-linked structure, thereby obtaining the magnetic super-hydrophobic fabric with a micro-nano rough structure on the surface. According to the invention, the process is simple, and for the prepared magnetic super-hydrophobic fabric, a front water contact angle is 167 degrees, and water drops easily roll; and an opposite water contact angle is 154 degrees, and the water drops are easily adhered. In addition, the fabric has excellent magnetism and saturation magnetization reaching 1.285emu / g.

Owner:SOUTH CHINA UNIV OF TECH

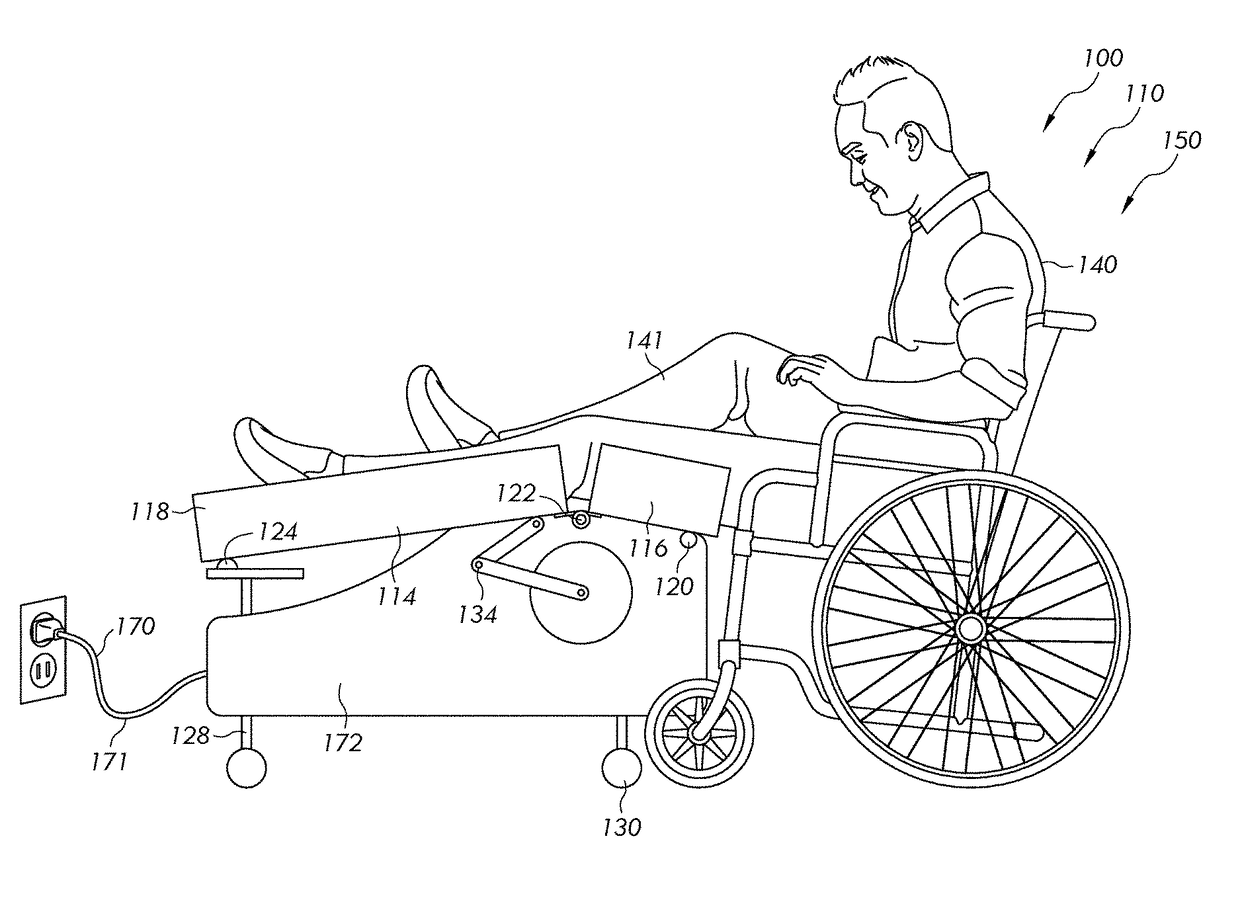

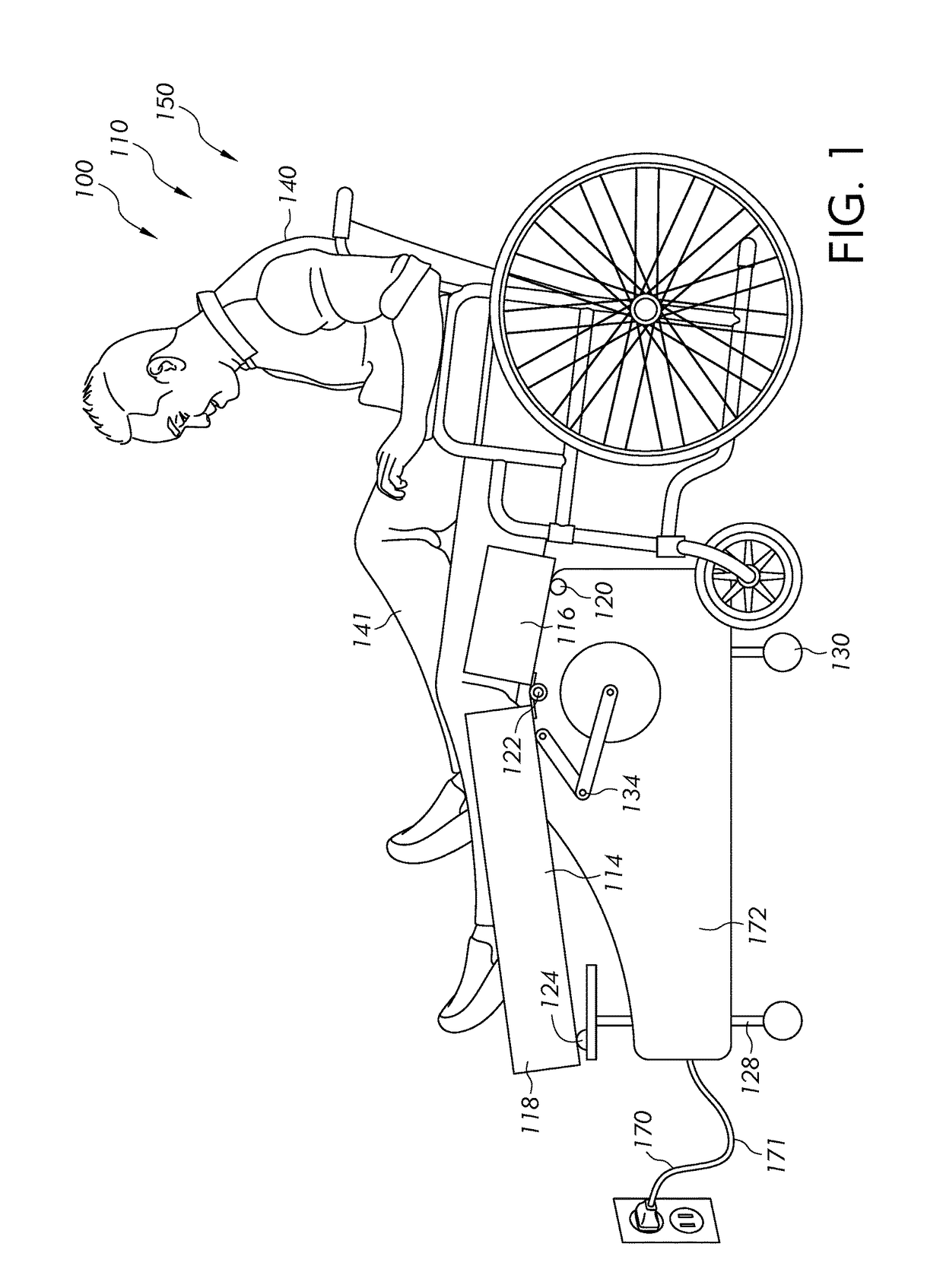

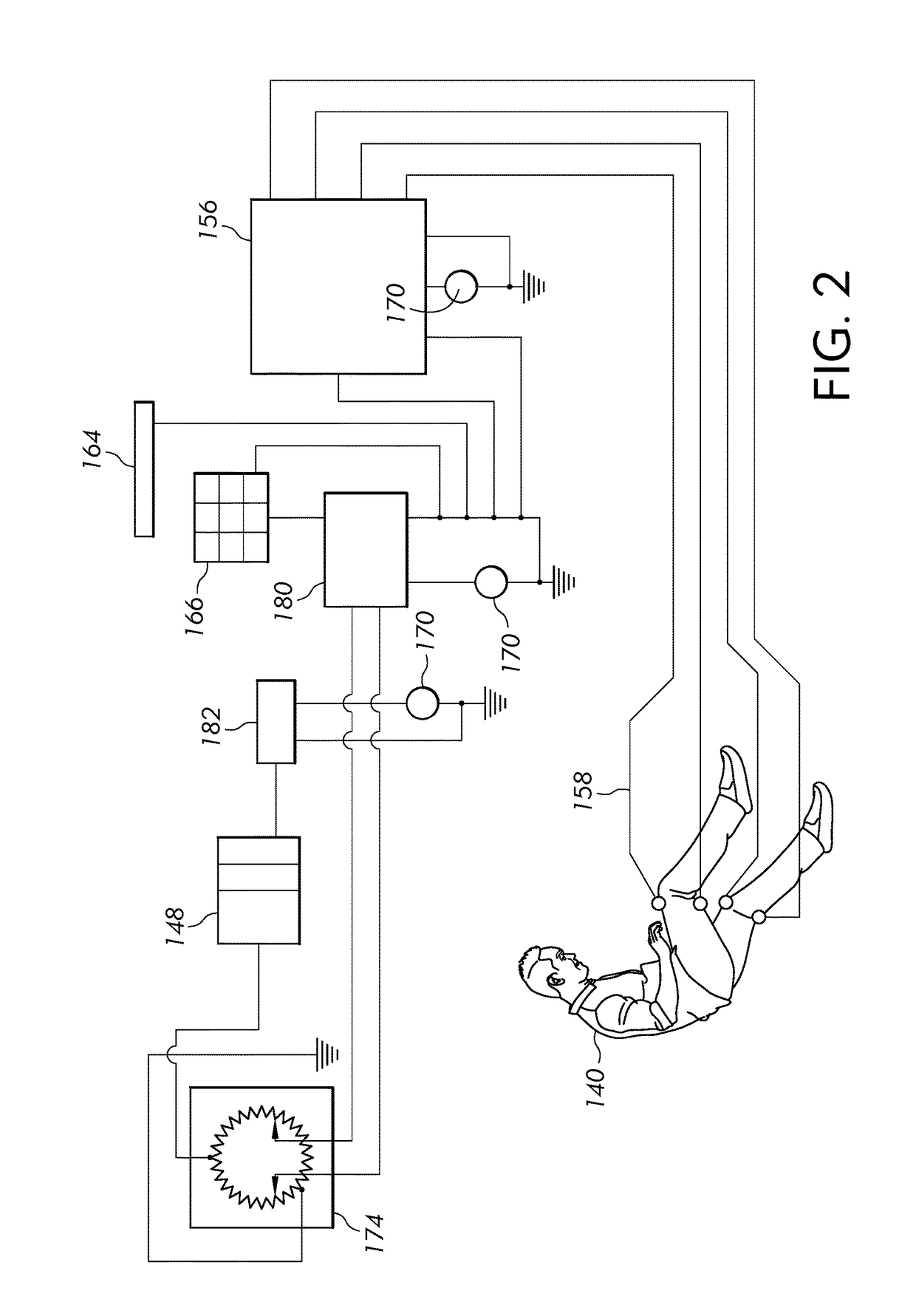

Lower body electrical muscle stimulation exercise systems

InactiveUS9782321B1Easy to moveEasy to rollChiropractic devicesExternal electrodesPhysical exerciseElectricity

A lower body electrical muscle stimulation exercise system for exercising the legs of a paralyzed user which incorporates electrical stimulation of leg muscles. The device is portable, light-weight and functional. The device is placed in front of a user who is sitting in a chair. The user's legs may be placed on moveable leg supports. An electric motor rotates a bicycle crank assembly which moves the legs of a user in a back and forth bending motion. Electrical stimulation is then activated which contracts or relaxes the leg muscles. The stimulation is sequentially activated by a Master Processor and a Transcutaneous Electrical Nerve Stimulator (TENS) unit. The present invention is designed to stop the deterioration of the leg muscles and restore the functionality of the legs.

Owner:SEMMENS THOMAS

Insulated water-proof attapulgite coating for sun-light green-house

InactiveCN101007927AExtend your lifeImprove waterproof performanceAntifouling/underwater paintsPaints with biocidesFiberEmulsion

The invention discloses a concave-convex bar thermal insulating and water-proof material for sunlight green house. It comprises concave-convex bar clay, plant fiber, rock fiber, modified emulsified asphalt, polyvinyl alcohol and sodium carboxymethylcellulose. The preparation process includes batching, stirring, heating and emulsion, and the final product is concave- convex bar thermal insulating and water-proof coating material, which is characterized by light weight, water-proof, aging resistant and thermal insulation. It is suited to coat the outer surface of covering mateiral such as straw curtain, straw mat, straw mattress, paper quilt or cotton quilt. The life length of covering material can be increased by more than 2- 5 years, and the covering temperature can be increased by 8- 12 degrees.

Owner:袁长兵

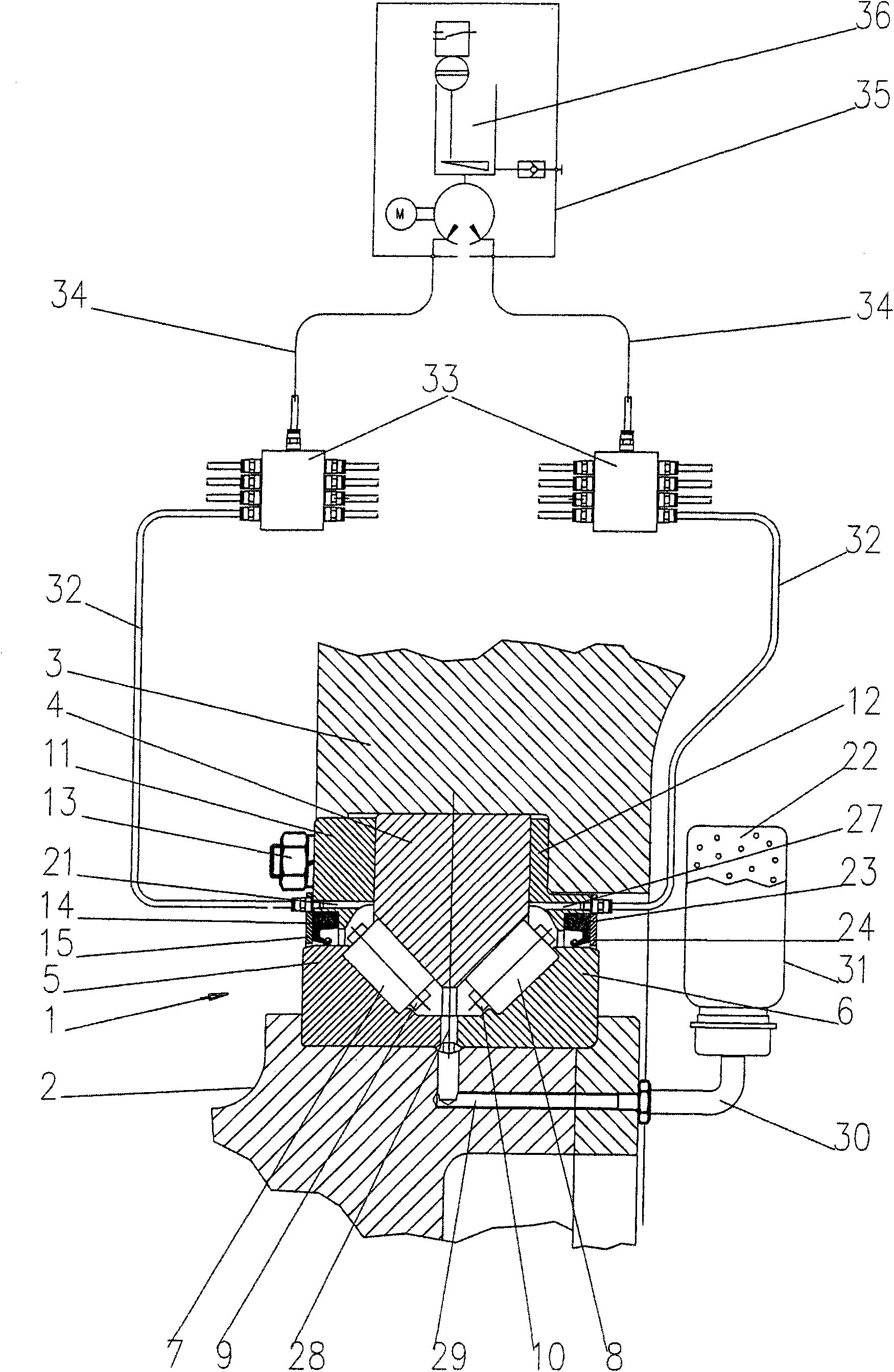

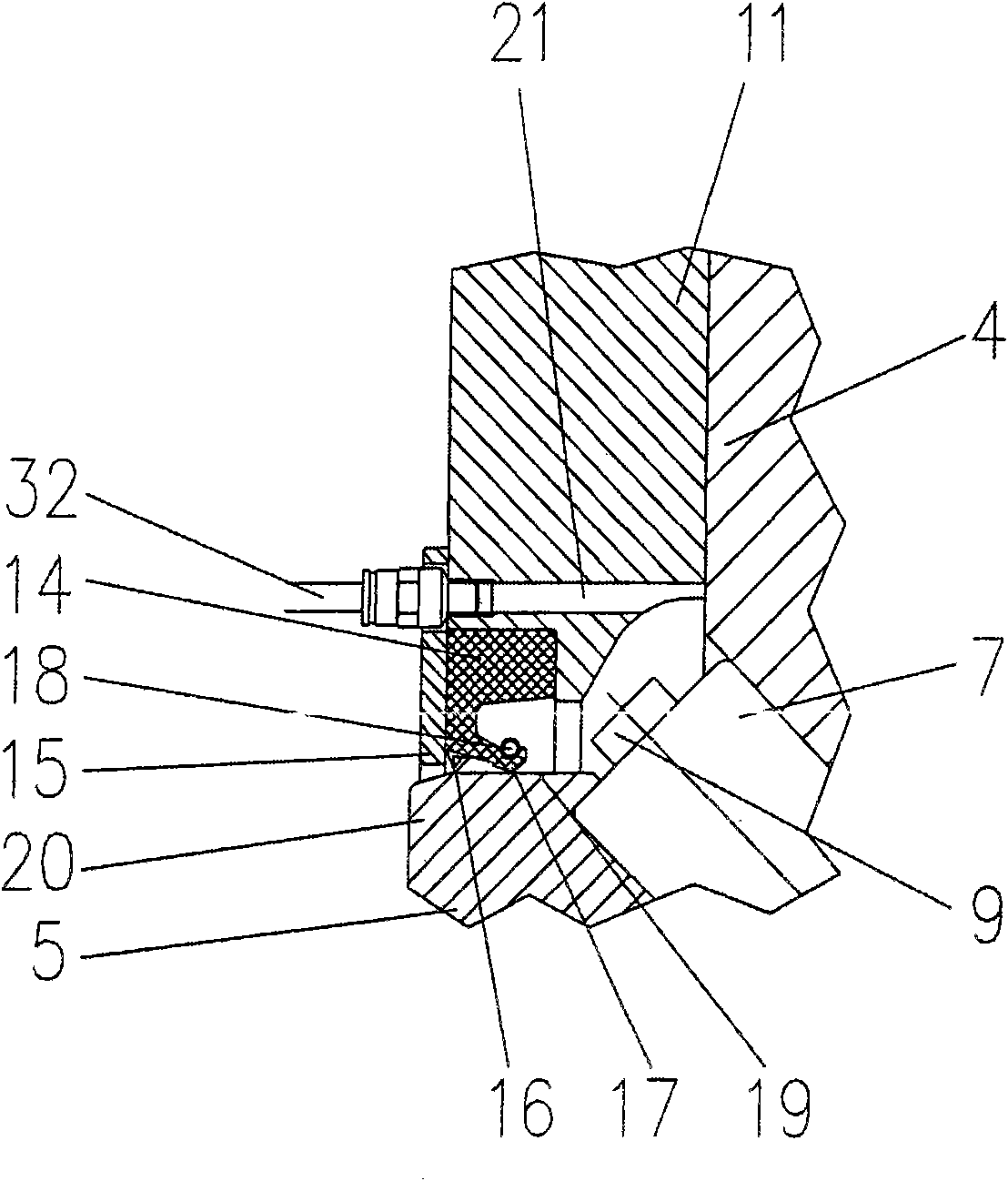

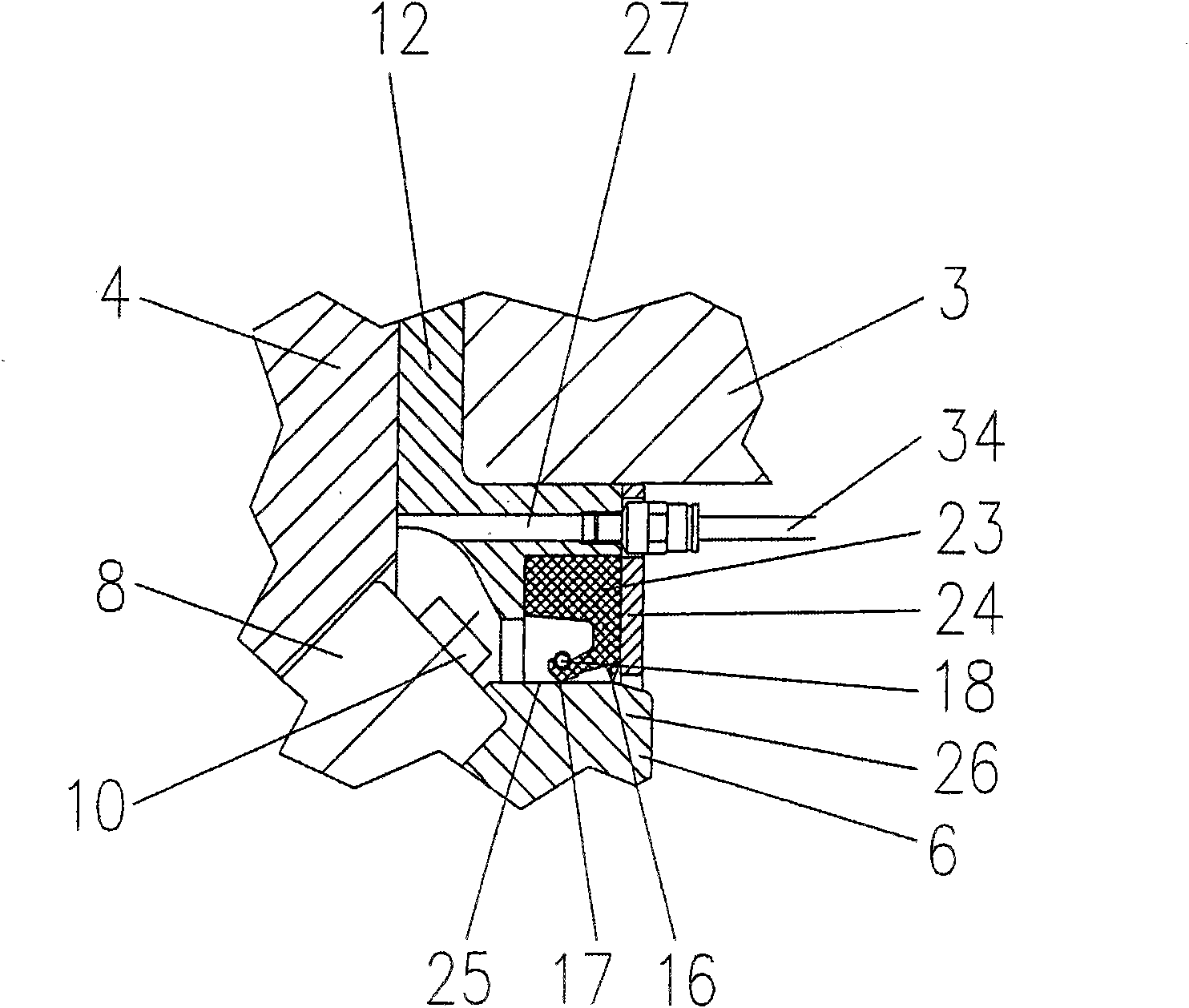

Two-row roller bearing and bearing system with such a roller bearing and a lubricating device

ActiveCN101846129AImprove the lubrication effectFirmly connectedRolling contact bearingsShaftsRolling-element bearingMechanical engineering

The invention relates to a two-row roller bearing (1) for supporting a mechanical part (2) rotatably relatively to a rotation axis. According to the invention, the roller bearing (1) has an outer ring (4) with the outer diameter of at least 1 m, a first inner ring (5), a second inner ring (6) arranged at the side of the first inner ring (5) axially relatively to the rotation axis, a group of first rolling bodies (7) rolling between the outer ring (4) and the first inner ring (5), a group of second rolling bodies (8) arranged at the side of the first rolling bodies (7) along the axial direction relatively to the rotation axis and rolling between the outer ring (4) and the second inner ring (6). The roller bearing (1) is characterized in that a first lubricating grease conveyor (21) is arranged at the first axial side of the outer ring (4) with respect to the rotation axis for supplying the first roller body with lubricating grease (22) and a second lubricating grease conveyor (27) is arranged at the second axial side of the outer ring (4) with respect to the rotation axis for supplying the second roller body with lubricating grease (22).

Owner:AB SKF

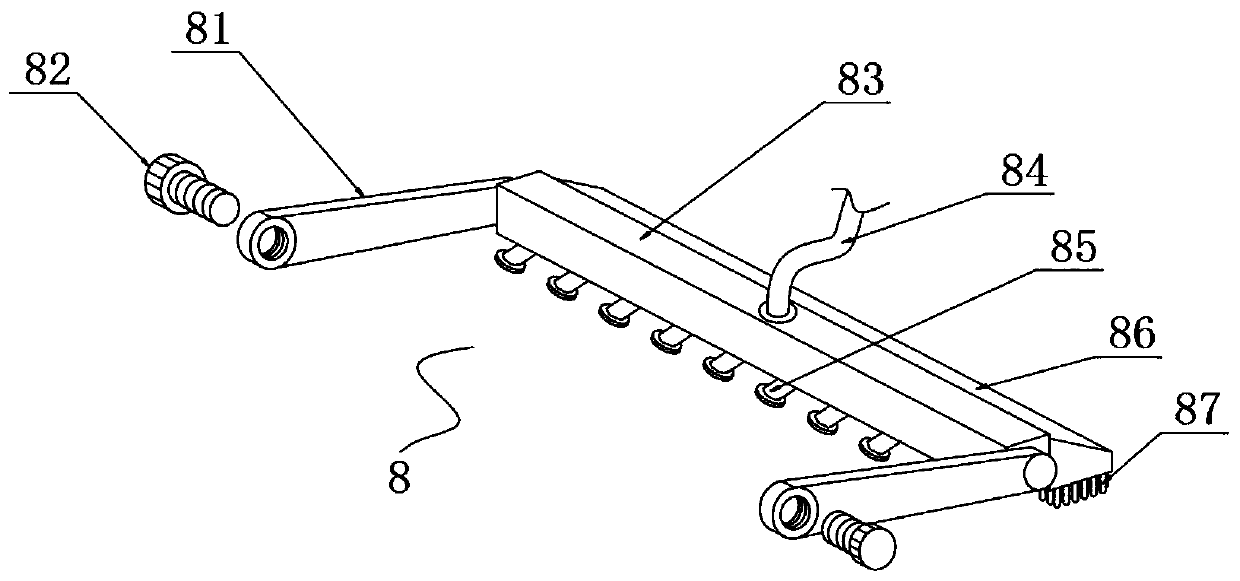

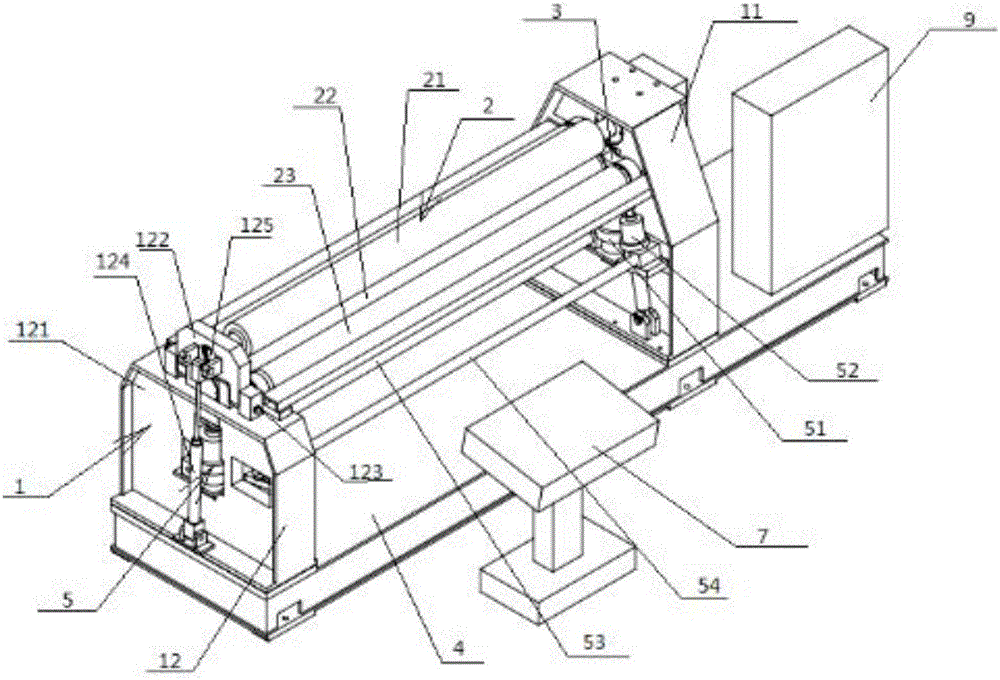

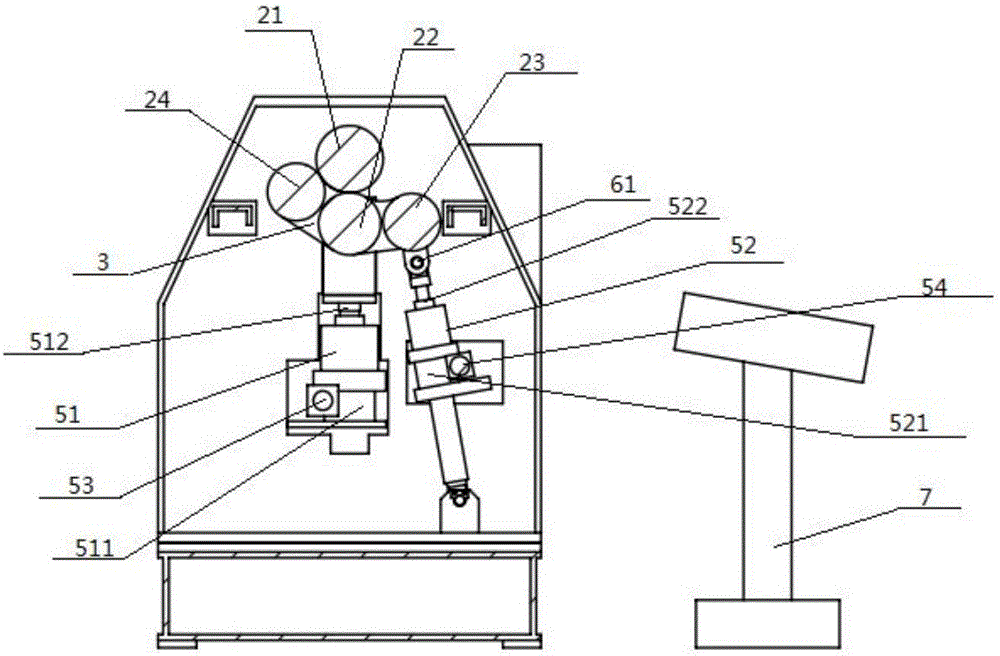

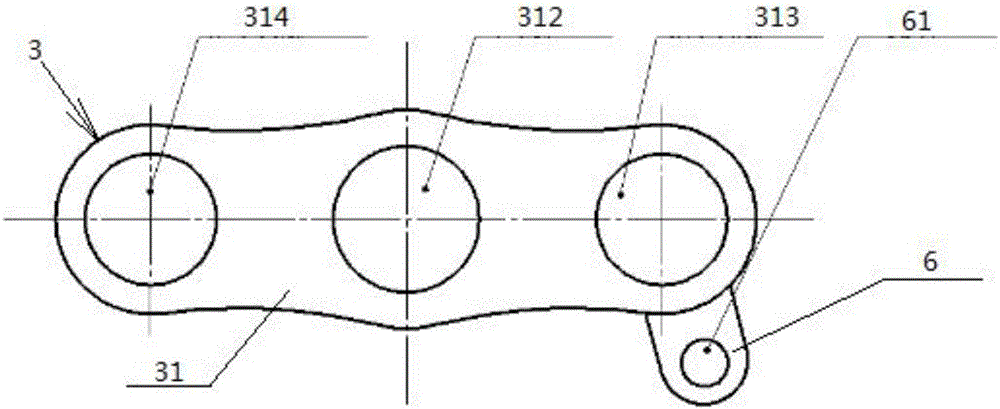

Three-roller linkage adjustable numerical control four-roller veneer reeling machine

The invention discloses a three-roller linkage adjustable numerical control four-roller veneer reeling machine. The veneer reeling machine comprises a base, two brackets located on the base and an upper roller, a lower roller, a first side roller and a second side roll which are located between the two brackets and arranged to be parallel; the lower roller is under the upper roller, the first side roller and the second side roller are located on the two sides of the lower roller respectively, the upper roller is mounted on the brackets and is in rotation connection with the brackets, the upper roller is driven by an upper roller servo drive device to rotate, the two ends of the lower roller, the two ends of the first side roller and the two ends of the second side roller are mounted to side roller linkage mechanisms on the two sides respectively, the relative positions of the rollers maintain unchanged, and the side roller linkage mechanisms on the two sides are connected to the brackets and the base through lifting mechanisms respectively. The three-roller linkage adjustable numerical control four-roller veneer reeling machine is stable in operation, good in precise positioning controllability, high in efficiency, high in numerical control automation degree and good in quality, precision of a formed product is high, and reeling of oval, square and other specially-shaped thin-walled barrel workpieces is achieved easily.

Owner:NANTONG CHAOLI ROLLING MACHINE PRODUCING

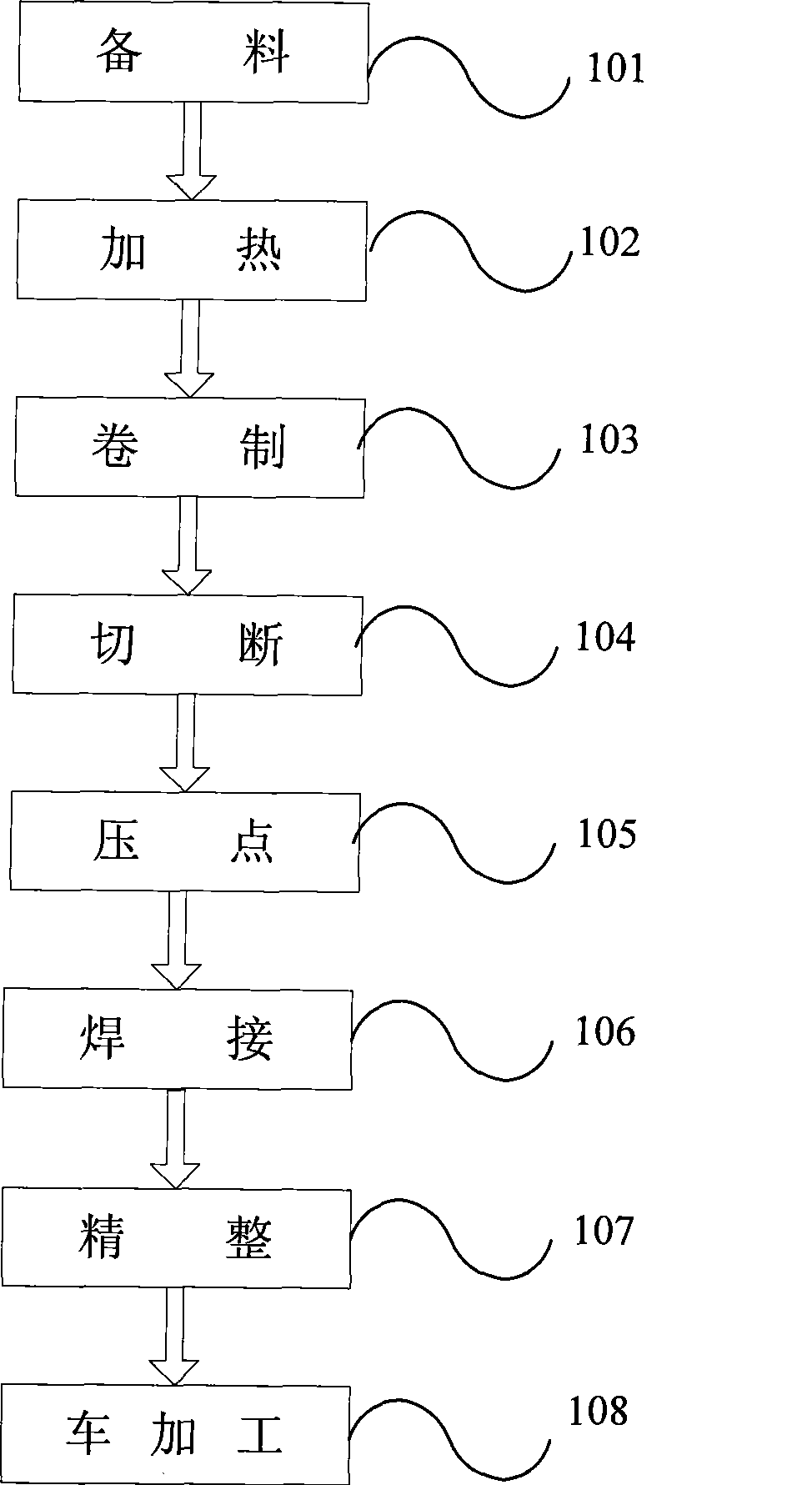

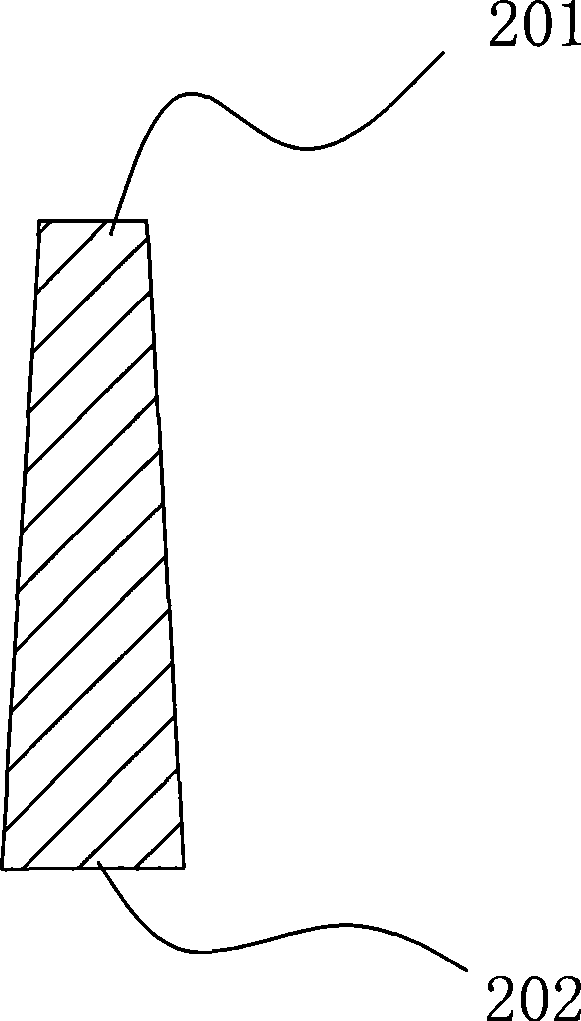

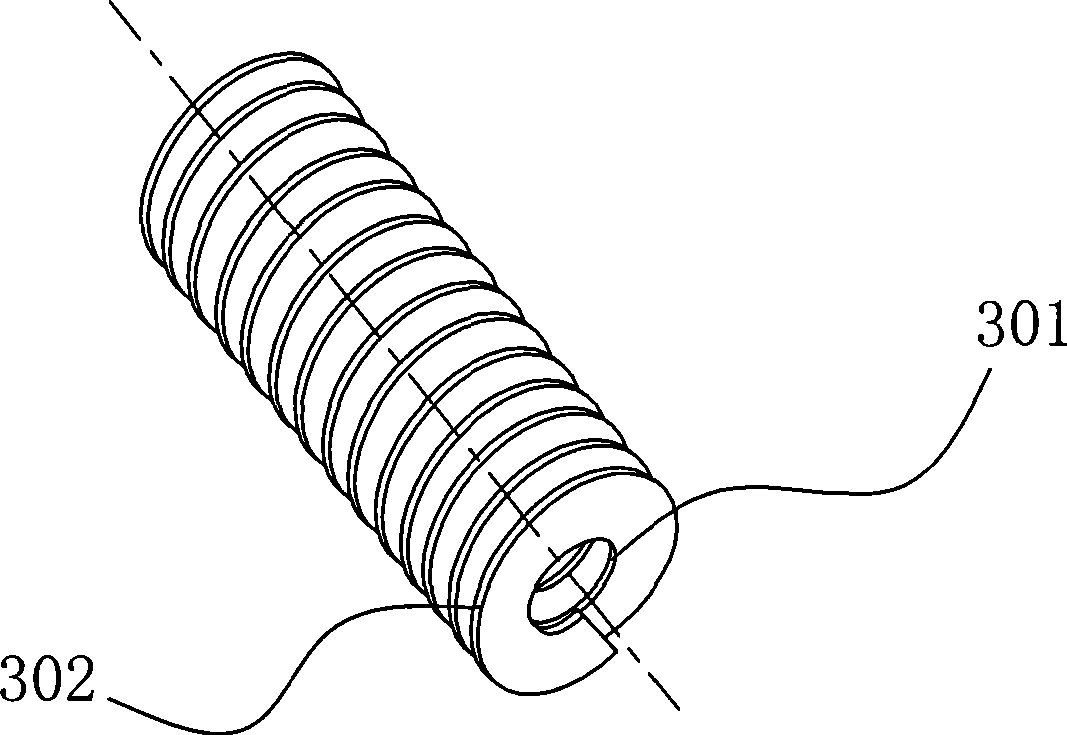

Technology for manufacturing wheeled engineering machinery vehicle spokerib board and special-purpose vertical coiling machine

InactiveCN101486140AReduce intensityIncrease profitMetal-working feeding devicesPositioning devicesWinding machineAgricultural engineering

The invention discloses a process for manufacturing a spoke plate of a wheel type construction machinery vehicle and a special vertical winding machine therefor, and belongs to the technical field of construction machinery. The process comprises the following working procedures: heating, wherein strips are heated to be between 650 and 750 DEG C to form heating strips; winding, wherein the heating strips are fed into the vertical winding machine and the strips are wound into vertical spiral blanks; cutting, wherein the spiral blanks are cut into separate blanks according to the specification of a prefabricated spoke plate; pressing spots, wherein cuts of the separate blanks are aligned for spot welding; welding, wherein the separate blanks after the spot welding are welded to form a spoke plate blank; finishing, wherein the dimensional precision of the welded blank is finished to form the spoke plate blank; and machining, wherein the spoke plate blank is machined to manufacture a spoke plate finished product. The invention is suitable for manufacturing the spoke plate of the wheel type construction machinery vehicle.

Owner:ANYANG HONGYUAN SECTION STEEL

Functional low-gram-weight cigarette paper and preparation method thereof

ActiveCN104790264AGood technical effectImprove sensory qualityFlexible coversCoatings with pigmentsFiberAdditive ingredient

The invention relates to functional low-gram-weight cigarette paper, wherein the body phase thereof contains cut tobacco fibres or a first tobacco powder, a second tobacco powder is attached to the outer surface of at least one side of the body phase, and the first tobacco powder is the same as or different from the second tobacco powder. The invention further relates to a preparation method of the functional low-gram-weight cigarette paper. The preparation method comprises the following steps: (1) preparing paper pulp; (2) preparing special suspension stabilizing fluid for cigarette paper coating; and (3) making paper by a paper machine. The functional low-gram-weight cigarette paper disclosed by the invention is uniform in colouring and capable of improving the non-transparency of the cigarette paper; moreover, the functional low-gram-weight cigarette paper is good in stiffness and beneficial to roll; meanwhile, the functional low-gram-weight cigarette paper is good in ash wrapping force and capable of improving the smoking feeling of cigarettes. The functional low-gram-weight cigarette paper disclosed by the invention is also capable of effectively improving the sensory quality of the rolled cigarette produced during a smoking process and reducing harmful ingredients in the smoke of the cigarettes. Therefore, the functional low-gram-weight cigarette paper disclosed by the invention has a wide application prospect.

Owner:CHINA TOBACCO YUNNAN IND

Container foil material and method for manufacturing container foil

InactiveCN102409200AHigh strengthSatisfy productionMetal rolling arrangementsPunchingUltimate tensile strength

The invention relates to a manufacture method of an aluminum alloy material, concretely relates to a container foil material and a method for manufacturing a container foil. The alloy of the container foil material comprises the following compositions by weight percentage: 0.20-0.26% of Si, 0.42-0.50% of Fe, 0.05% of Cu, 0.15-0.20% of Mn, 0.01% of Mg, 0.1% of Zn, 0.04% of Ti and the balance of Al. According to the invention, the content of Fe and Si are re-allocated by the material on the basis of a 8011 alloy, and certain Mn element is added, so that the material intensity can be raised, and the material has good processing performance and is easy to roll. The detection of the material shows that the when aluminum foil thickness is 0.05-0.06mm, the tensile strength is 120-160MPa, the elongation percentage is greater than or equal to 12% and the cupping value is greater than or equal to 5.0. The material of the invention has good punching performance, and can be used for producing various aviation tableware.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

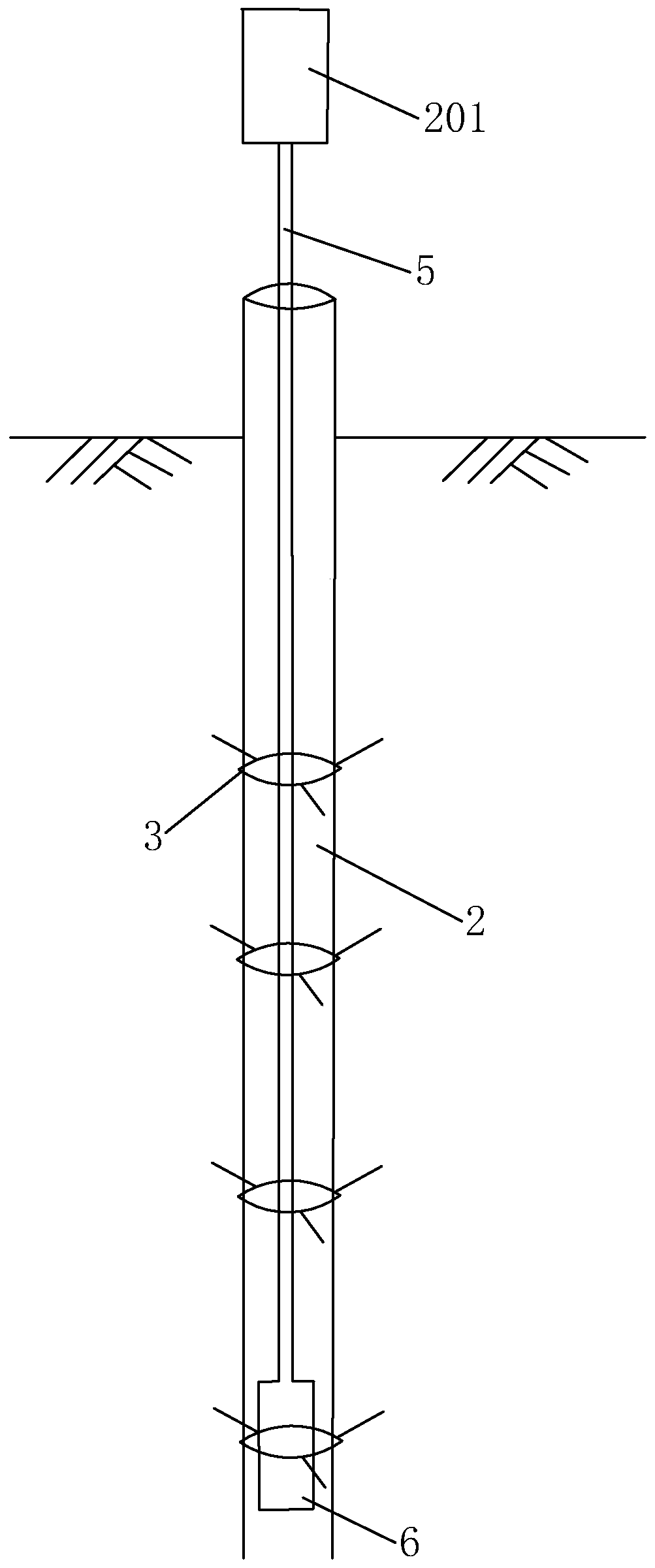

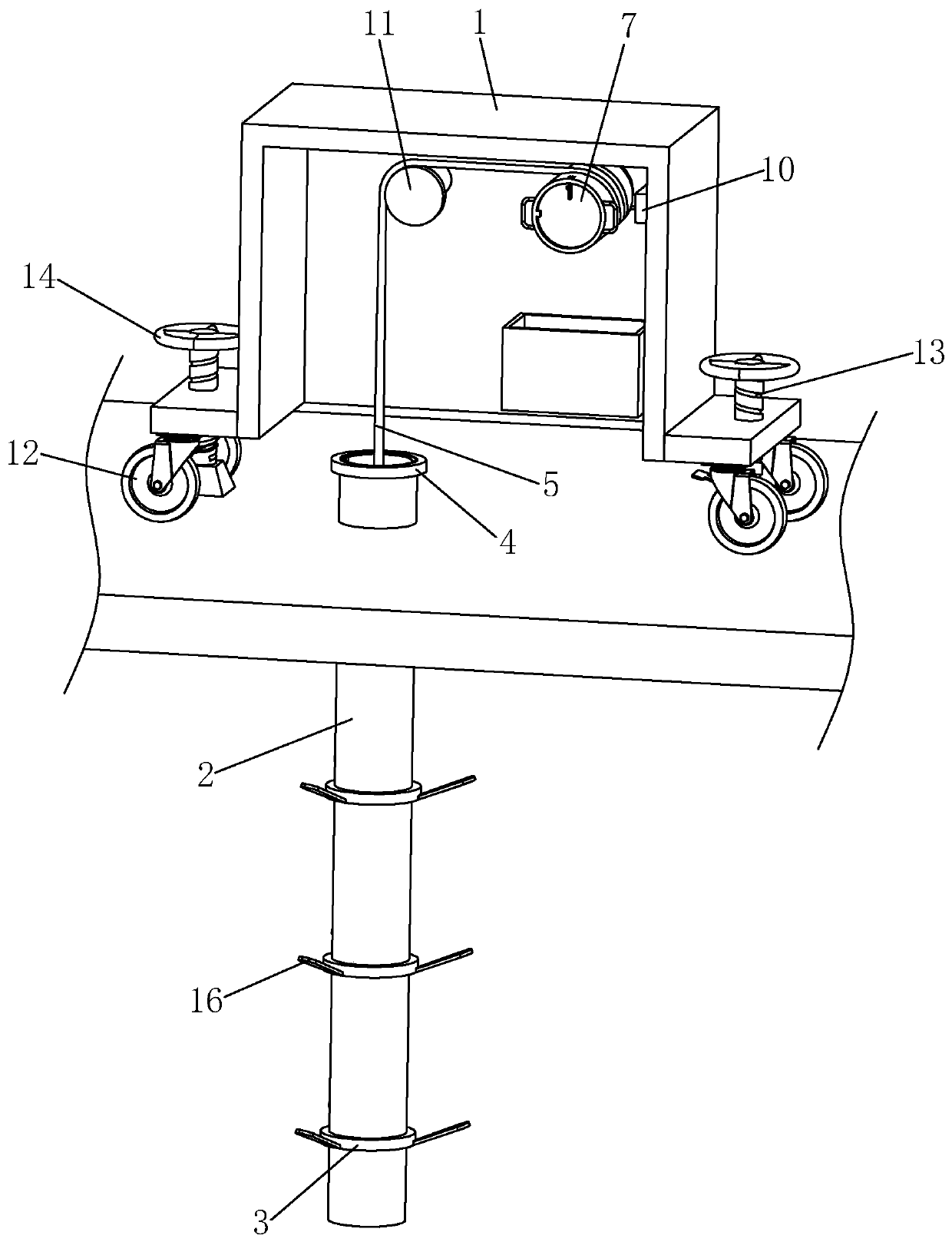

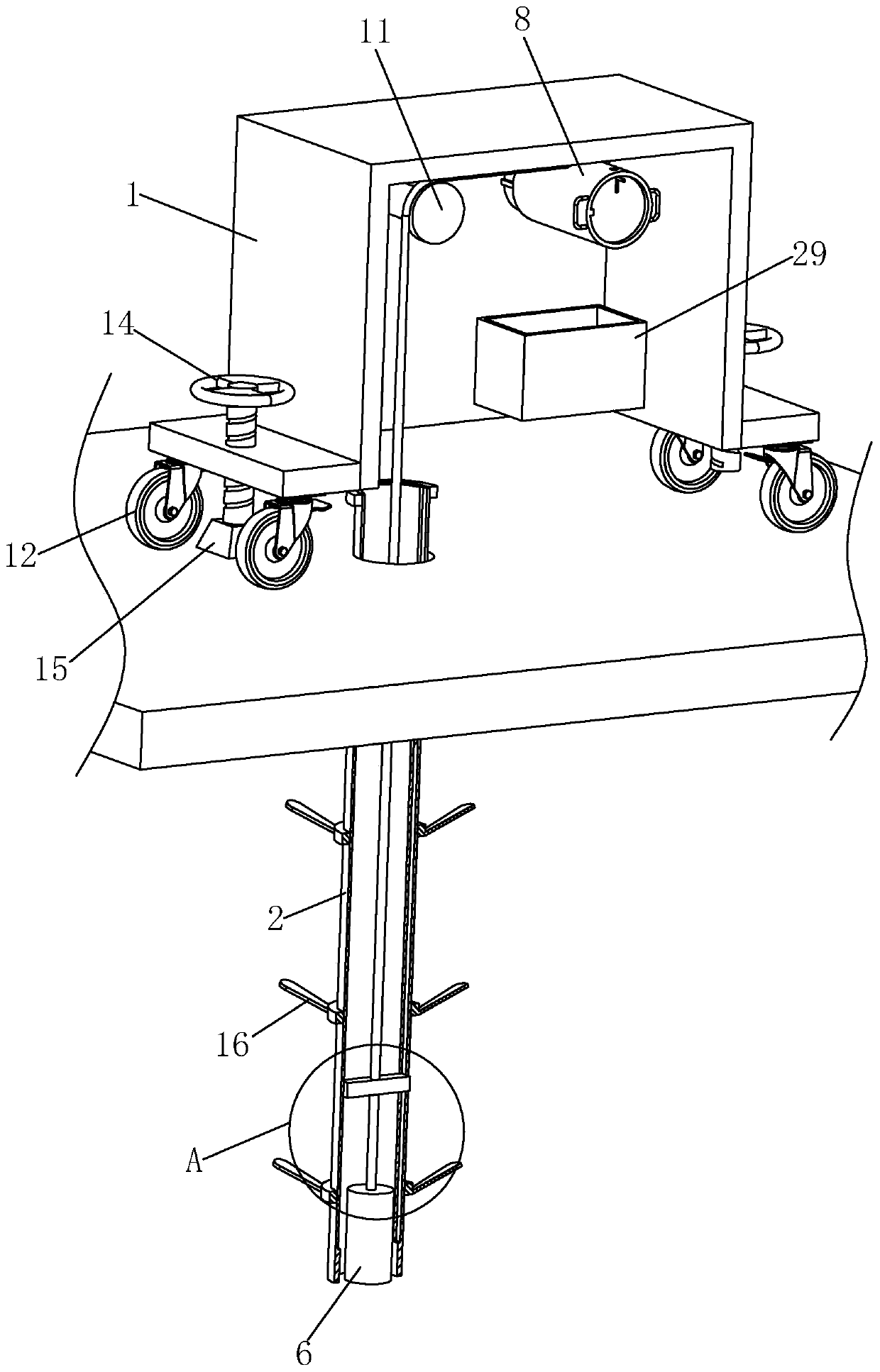

Building foundation settlement monitoring system

The invention relates to the technical field of foundation monitoring, and more particularly relates to a building foundation settlement monitoring system. The key point of the technical scheme is that: the building foundation settlement monitoring system comprises a mounting rack, a settlement monitoring PVC (Polyvinyl Chloride) pipe, settlement magnet rings, a fixing magnet ring, a single-core cable, a measurement probe, an automatic data acquisition system and a rotating shaft, a sleeve for winding the single-core cable is connected on the rotating shaft in a sleeving way, a locking mechanism is arranged between the rotating shaft and the sleeve, a drive motor is arranged at one end of the rotating shaft; the settlement monitoring PVC pipe is vertically arranged in a foundation, a plurality of settlement magnet rings are sleeved at the outer part of the settlement monitoring PVC pipe at equal intervals, the fixing magnet ring is sleeved on a pipe orifice of the settlement monitoringPVC pipe, an idler wheel is arranged at the bottom part of the mounting rack, and a locating mechanism is arranged on the mounting rack. According to the system, the single-core cable arranged on thesleeve is combined with a fixed pulley, and the fixing magnet ring and the automatic data acquisition system are additionally arranged, the measurement accuracy is improved, the maneuverability of the device is improved due to the arrangement of the idler wheel, and the settlement of the building foundation is conveniently monitored.

Owner:广东广强基础工程有限公司

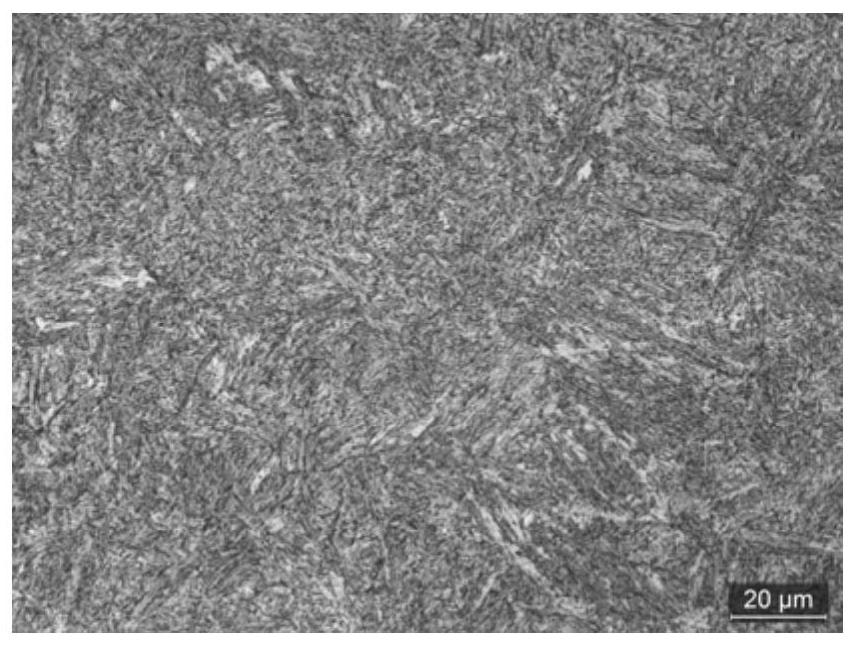

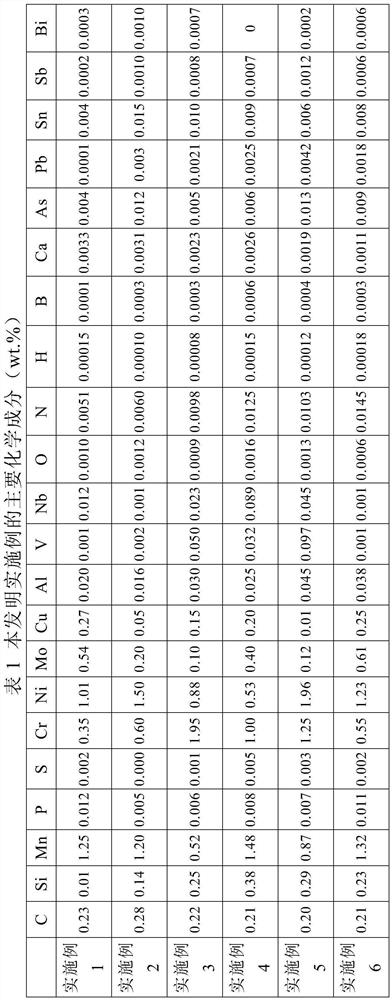

High-toughness mining chain steel and manufacturing method thereof

ActiveCN113322409AEasy to rollReasonable ingredientsFurnace typesForging press detailsTemperingWeather resistance

The invention discloses high-toughness mining chain steel and a manufacturing method thereof. The high-toughness mining chain steel comprises the following components in percentage by weight: 0.20-0.28% of C, 0.01-0.40% of Si, 0.50-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.30-2.00% of Cr, 0.50-2.00% of Ni, 0.10-0.80% of Mo, 0.01-0.30% of Cu, 0.01-0.05% of Al, 0.001-0.10% of Nb, 0.001-0.10% of V, less than or equal to 0.00018% of H, less than or equal to 0.0150% of N, less than or equal to 0.0020% of O and the balance of Fe and inevitable impurities. The manufacturing process comprises the working procedures of smelting, refining, vacuum treatment, casting, heating, forging or rolling, quenching and tempering heat treatment and the like. The chain steel has high strength and good impact toughness, ductility and percentage reduction of area, can resist stress corrosion cracking, has good weather resistance, wear resistance and fatigue resistance, and can be used for engineering machinery, ocean engineering and other occasions needing high-strength and high-toughness steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com