Three-roller linkage adjustable numerical control four-roller veneer reeling machine

The technology of a four-roller plate rolling machine and linkage mechanism is applied in the field of plate rolling machine, which can solve the problems of cumbersome operation, slowness, poor accuracy of side roller lifting movement and precise positioning, etc., and achieves the effect of good quality, high efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

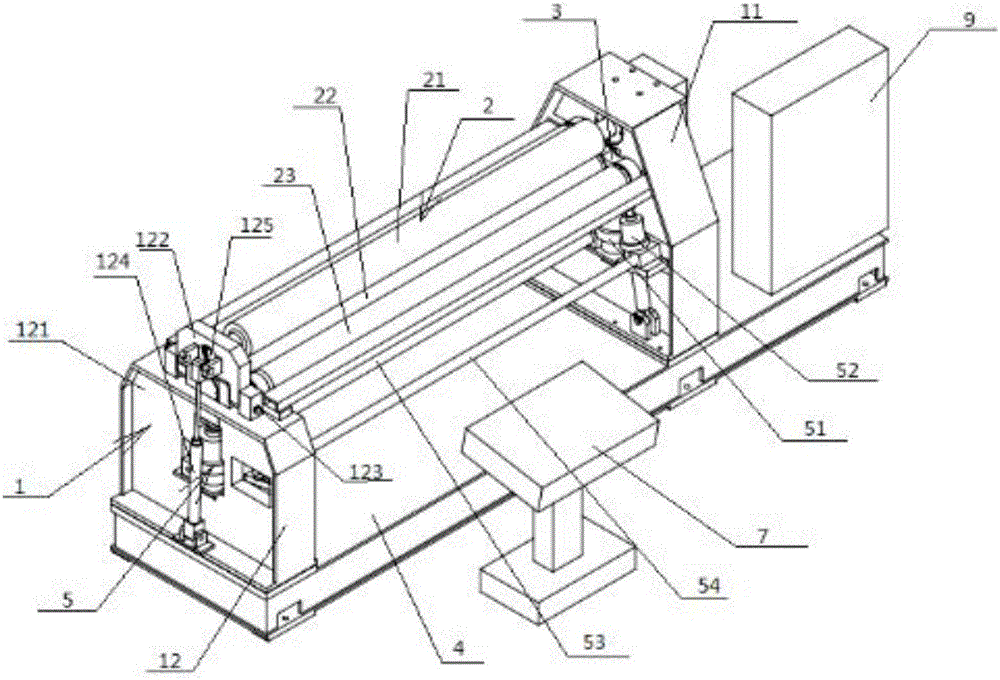

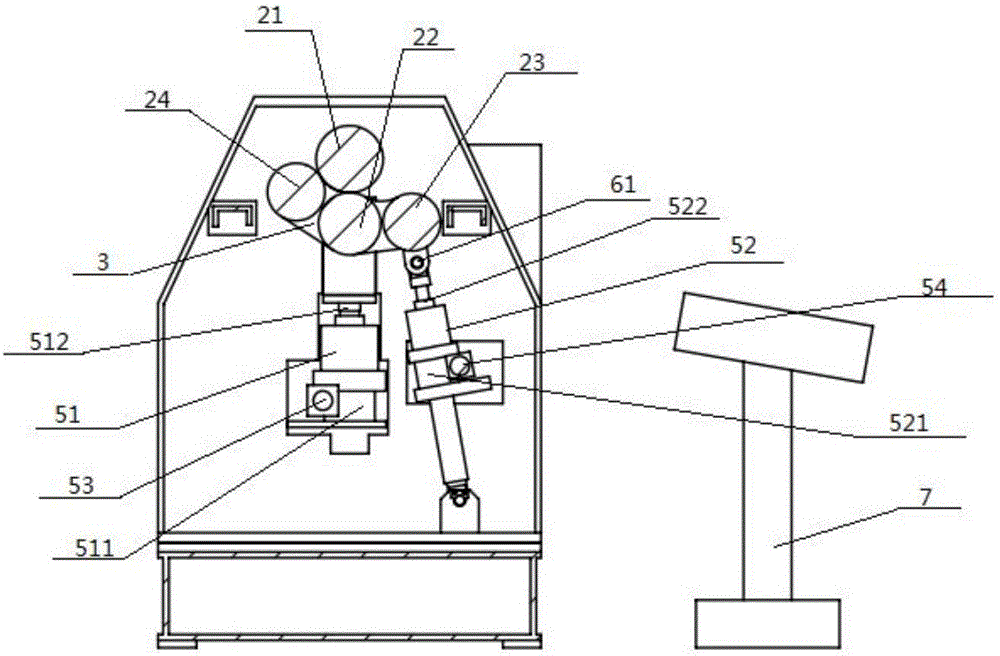

[0036] Figure 1 to Figure 4 It schematically shows a three-roller linkage adjustable numerical control four-roller plate bending machine according to the first embodiment of the present invention.

[0037] Such as figure 1 and figure 2 As shown, the three-roll linkage adjustable CNC four-roll plate rolling machine disclosed in the present invention includes a horizontally arranged base 4, two supports 1 are fixed above the base 4, the two supports 1 are perpendicular to the base 4, and the two supports 1 Four roller shafts 2 are fixed between them, and the four roller shafts 2 are arranged in parallel. Such as figure 1As shown, the two supports 1 are respectively the fixed side support 11 and the overturned side support 12, and the four roller shafts are respectively the upper roller 21, the lower roller 22, the first side roller 23 and the second side roller 24, as figure 1 As shown, the upper roller 21, the lower roller 22, the first side roller 23 and the second side ...

Embodiment 2

[0048] figure 1 , figure 2 and Figure 5 It schematically shows a three-roller linkage adjustable numerical control four-roller plate bending machine according to the second embodiment of the present invention.

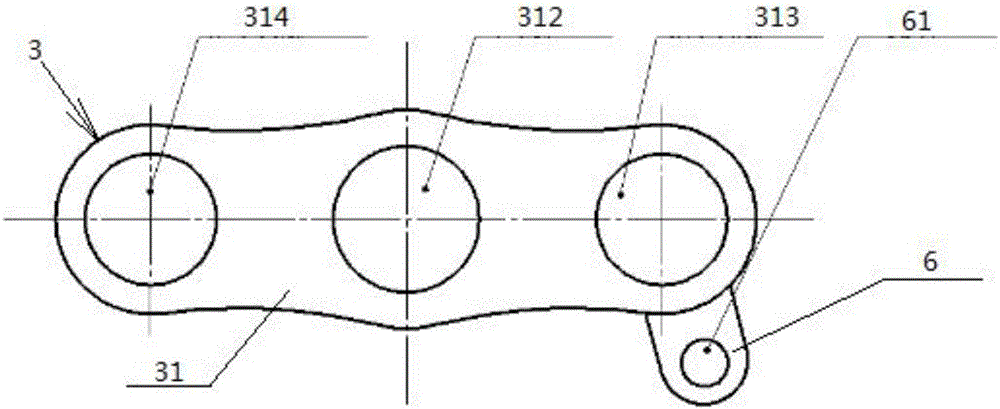

[0049] Such as figure 1 , figure 2 and Figure 5 As shown, the structure of the three-roller linkage adjustable numerical control four-roller plate bending machine provided by the second embodiment of the present invention is basically the same as that in Example 1, the difference lies in the structure of the side-roller linkage mechanism 3 .

[0050] Such as Figure 5 As shown, the side roller linkage mechanism 3 includes a side roller linkage mechanism body 31, and three circular mounting holes are provided on the side roller linkage mechanism body 31, which are respectively the lower roller seat 312, the first side roller seat 313 and the second side roller seat 314, such as Figure 5 As shown, the first side roller seat 313 and the second side roller seat...

Embodiment 3

[0052] figure 1 , figure 2 and Figure 6 to Figure 9 It schematically shows a three-roller linkage adjustable numerical control four-roller plate bending machine according to the third embodiment of the present invention.

[0053] Such as figure 1 , figure 2 and Figure 6 to Figure 9 As shown, the structure of the three-roller linkage adjustable numerical control four-roller plate bending machine provided by the third embodiment of the present invention is basically the same as that in Example 1, and the difference lies in the structure of the side-roller linkage mechanism 3 .

[0054] Such as Figure 6 and Figure 7 As shown, the side roller linkage mechanism 3 includes a side roller linkage mechanism body 31, and the side roller linkage mechanism body 31 includes a convex first linkage arm 3101 and a concave second linkage arm 3102, as Figure 7 As shown, the protruding portion of the first convex linkage arm 3101 is engaged in the groove of the second concave linka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com