Austenitic stainless steel buried arc welding wire for low-temperature equipment

A technology for austenitic stainless steel and equipment, which is applied in the field of austenitic stainless steel submerged arc welding wire for low-temperature equipment, can solve problems such as being difficult to find, and achieve the effects of beautiful shape, good welding process performance, and excellent low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

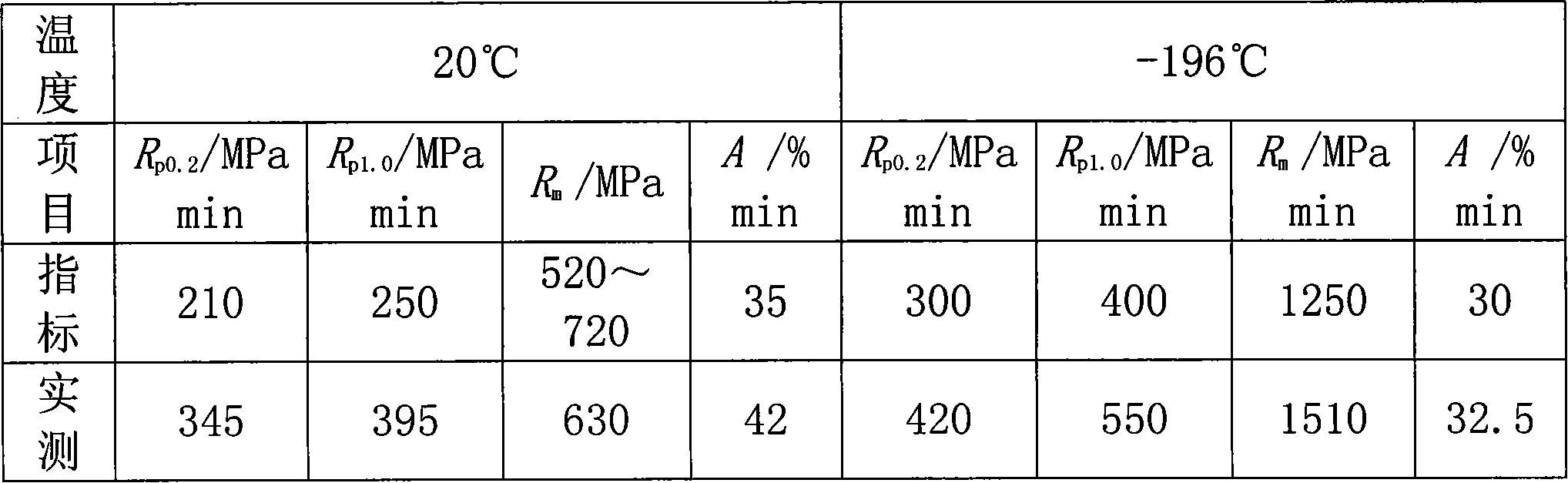

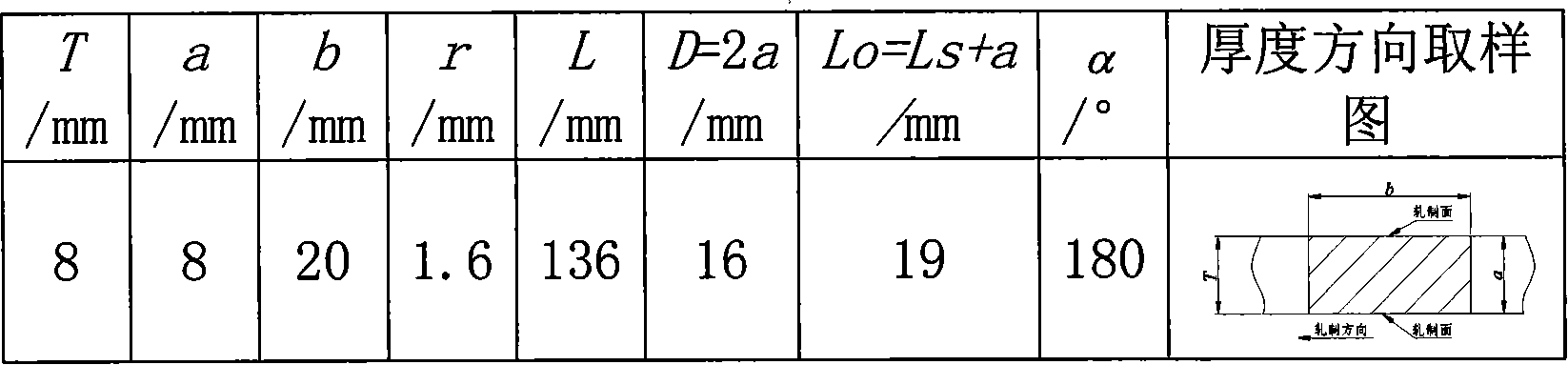

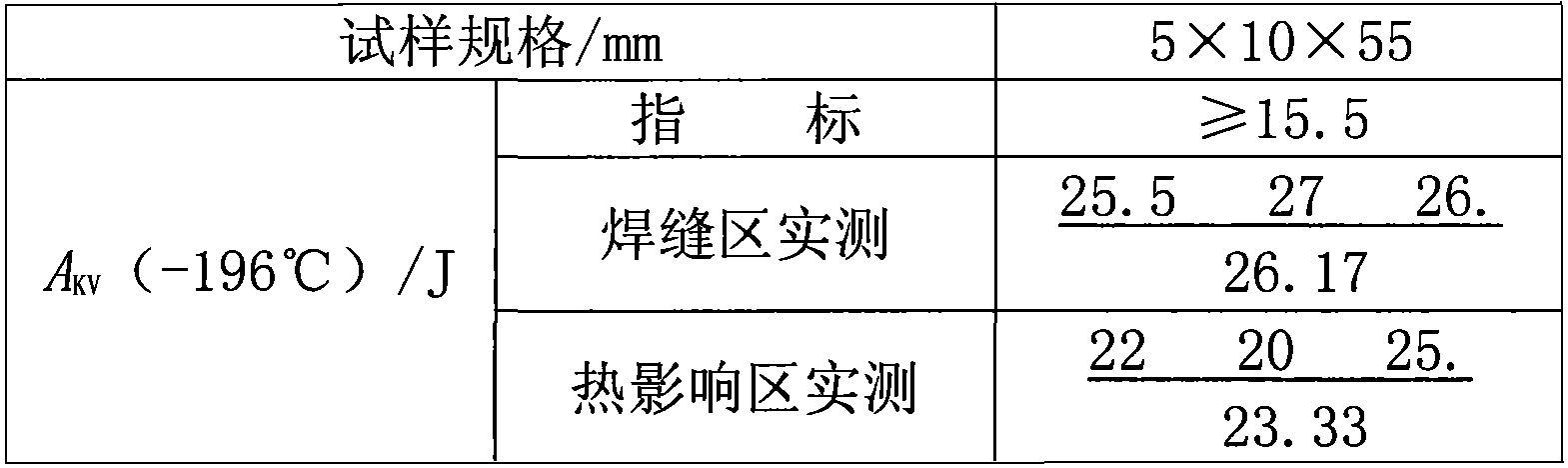

[0024] Embodiment: The preparation process of the welding wire is the same as the prior art. The welding wire is smelted by the supplier's steel plant resources, rolled and drawn into welding wire, and the surface is purified. The diameter of the welding wire is 3.2mm. The mass percentage of the chemical elements that make up the welding wire is: 0.017% carbon, 0.55% Silicon, 2.25% manganese, 0.023% phosphorus, 0.005% sulfur, 9.17% nickel, 20.23% chromium, 0.048% molybdenum, 0.10% copper, 0.045% cobalt, 0.011% titanium, 0.044 niobium , 0.097% vanadium, 0.022% tungsten, 0.002% boron, and the rest is iron. The flux used with the welding wire: SJ601; the material of the test plate: 304; the size of the test plate is length, width and height: 600×150×8mm, 30°V-shaped groove on one side; welding form: flat butt welding; welding current: 380A; Welding voltage: 32~34V; welding speed: 510mm / min; interlayer temperature: 60±15℃; preset anti-deformation 5mm.

[0025] The samples are ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com