Technology for manufacturing wheeled engineering machinery vehicle spokerib board and special-purpose vertical coiling machine

A technology of construction machinery and manufacturing process, which is applied in the field of wheel-type construction machinery wheel spoke plate manufacturing technology and its special vertical rolling machine, wheel spoke plate manufacturing technology and its rolling equipment field, which can solve the problem of large blank machining allowance and processing efficiency. It can improve the utilization rate of materials, avoid welding cracks, and reduce the material head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

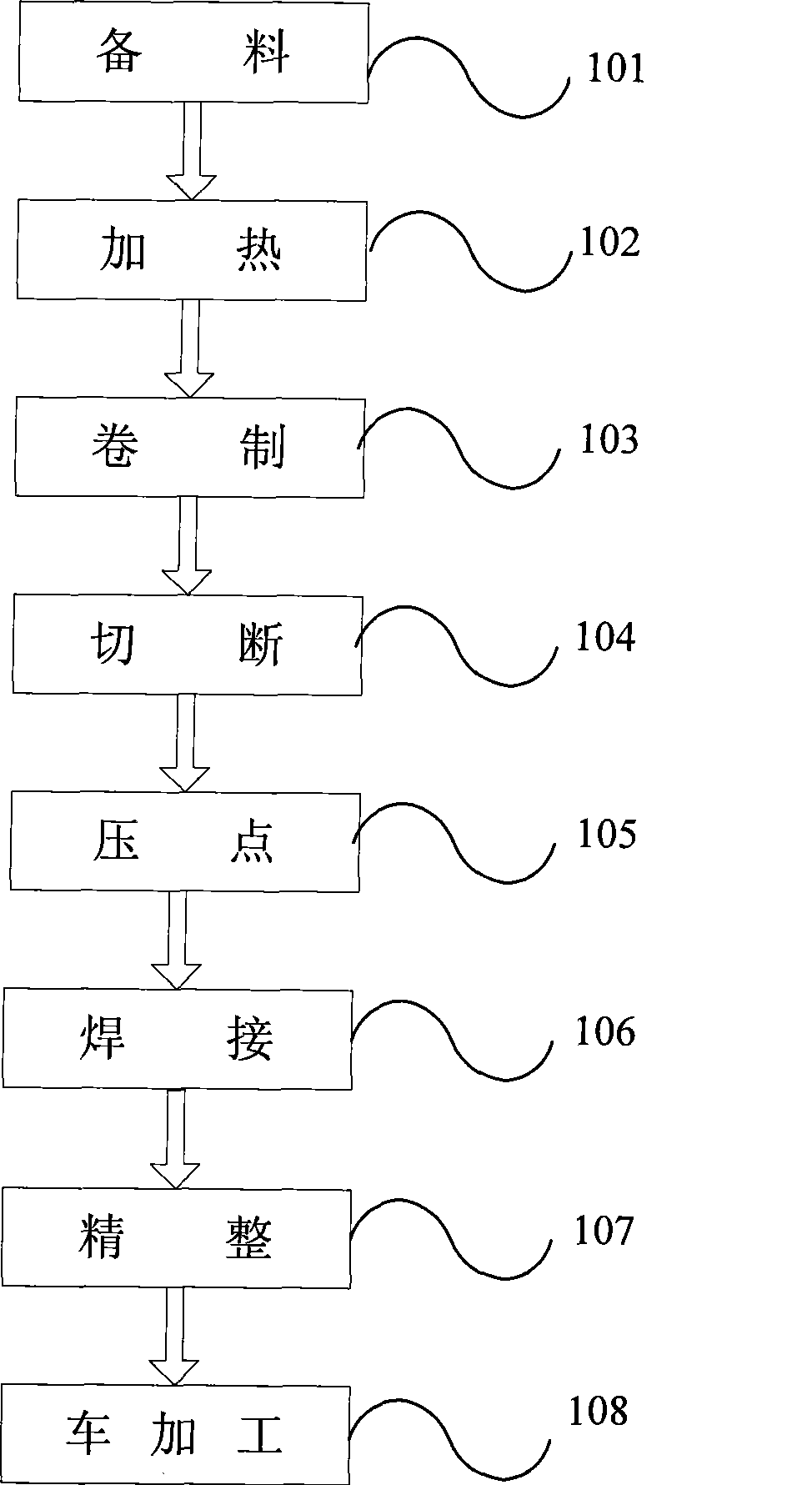

[0038] Such as figure 1 As shown, the manufacturing process of the wheel spoke plate of wheeled engineering machinery provided by the invention comprises the following steps:

[0039] S101 Material preparation Rolling the steel billet into the special steel bar required for the prefabricated web;

[0040] The steel billet is rolled into a special-purpose steel strip of prefabricated web specifications by a rolling mill. The length of the strip is 18000mm-27000mm, which is 12 to 18 times the perimeter of a single prefabricated web; at the same time, considering the external factors during rolling It is thinned by tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com