Patents

Literature

395results about How to "No pores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

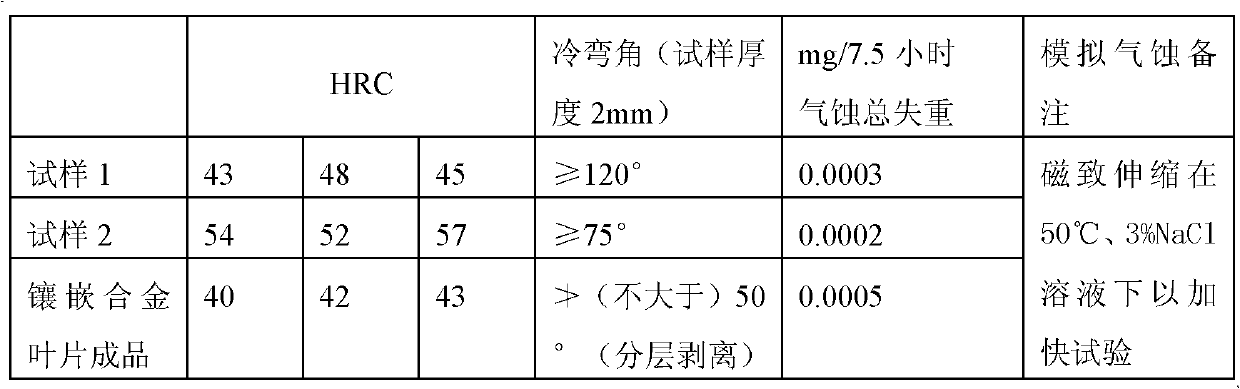

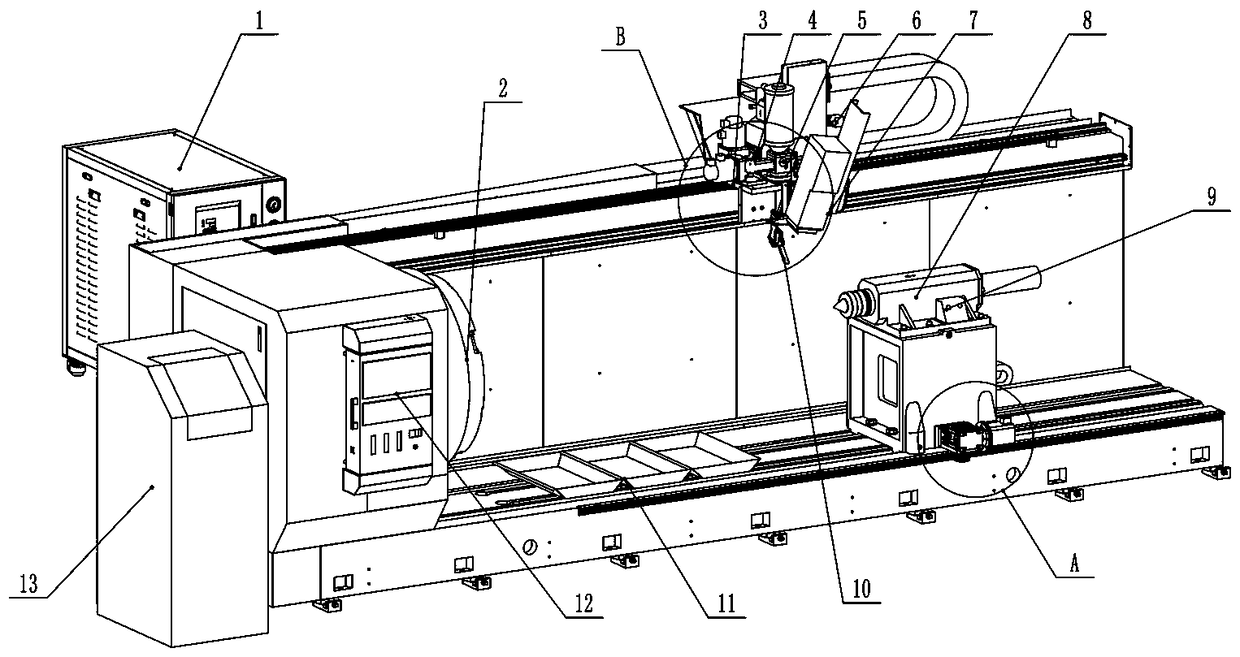

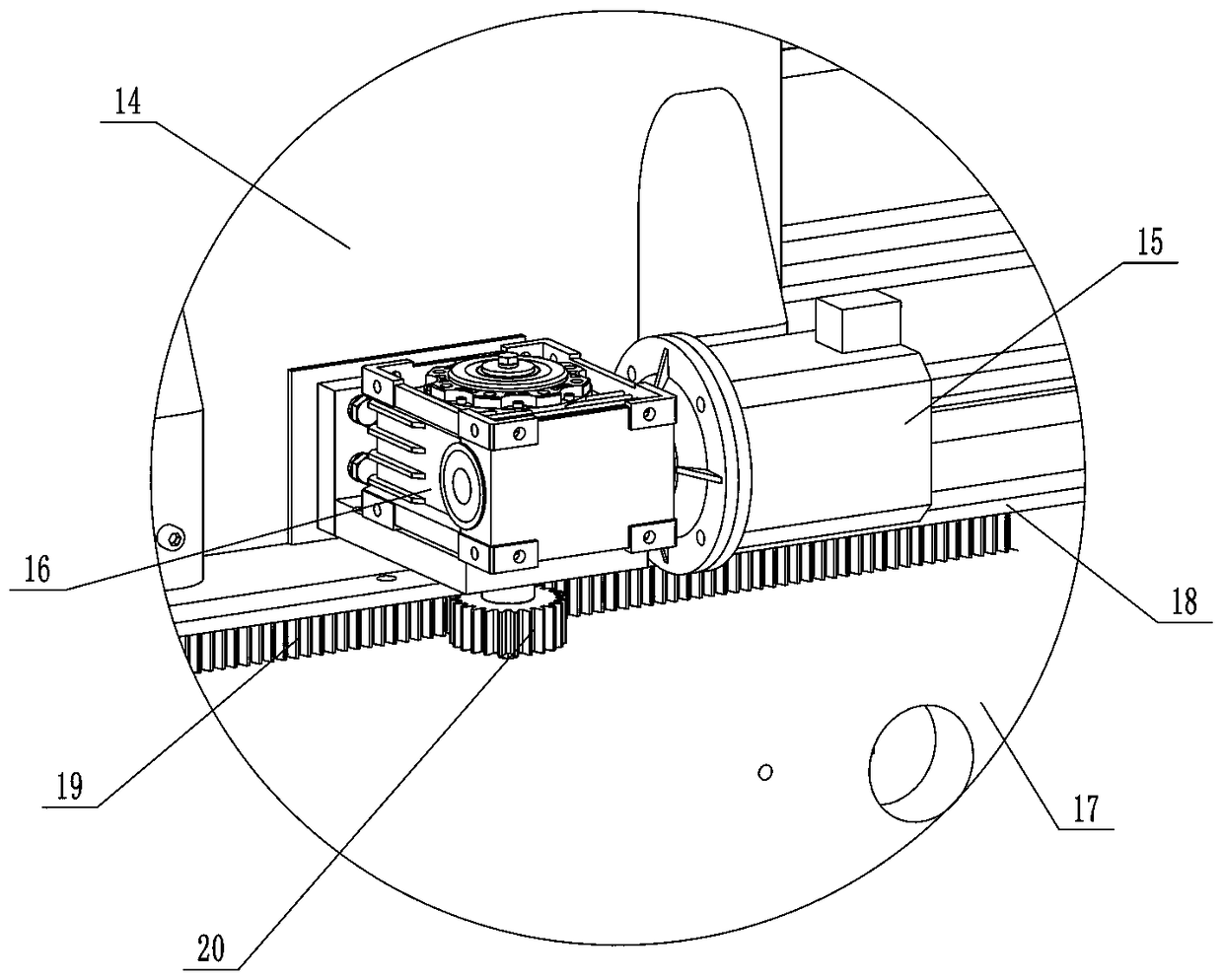

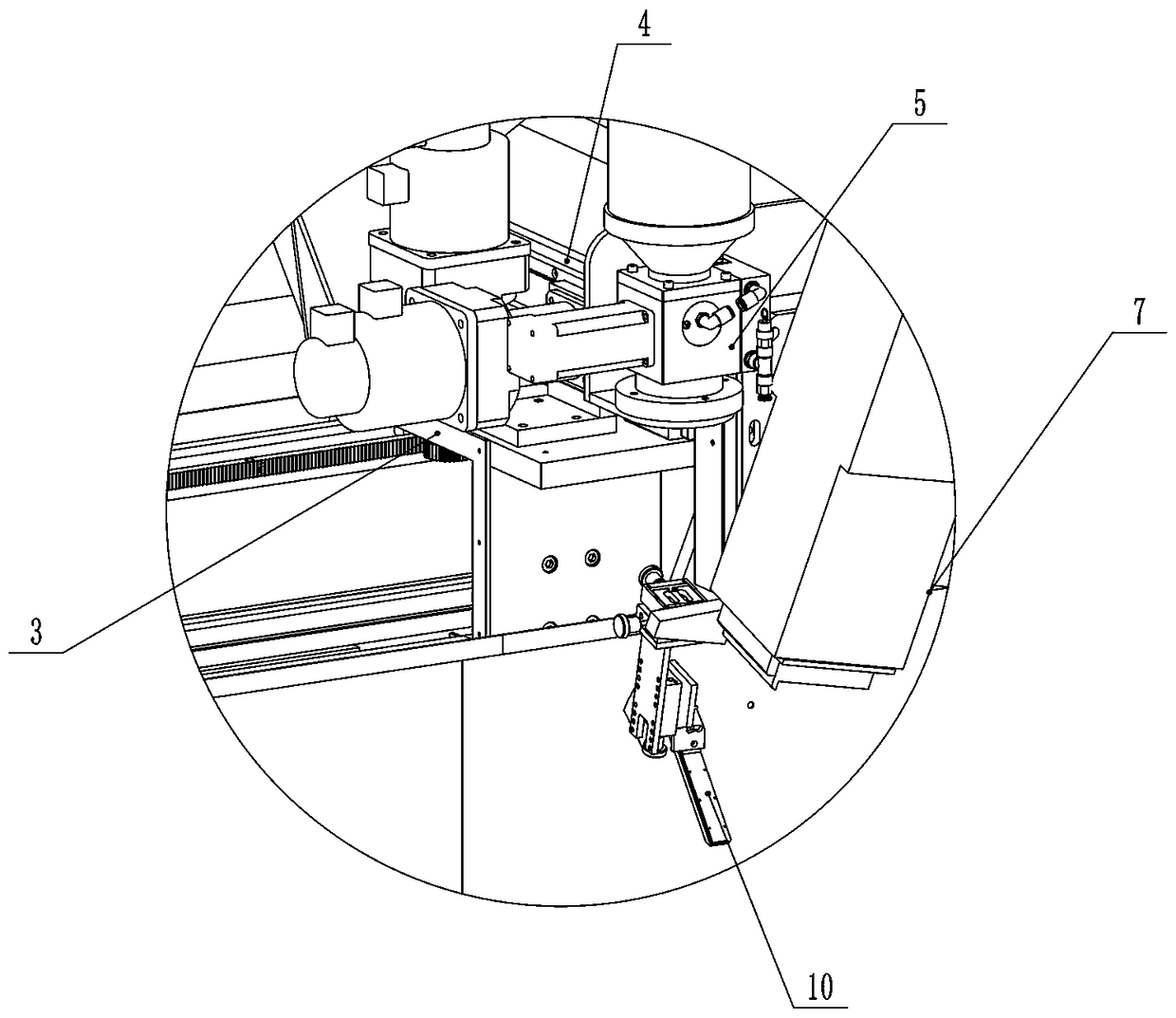

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

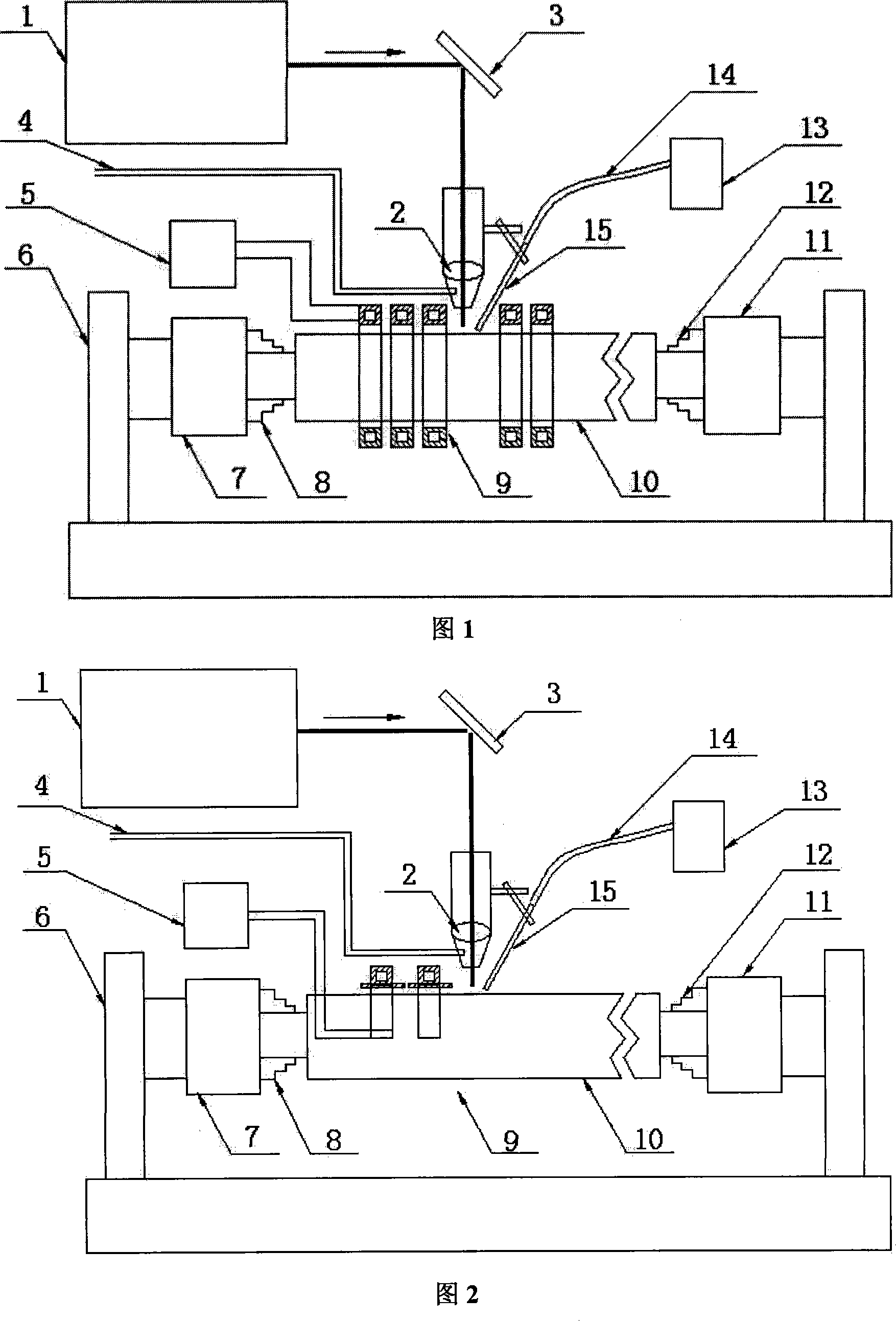

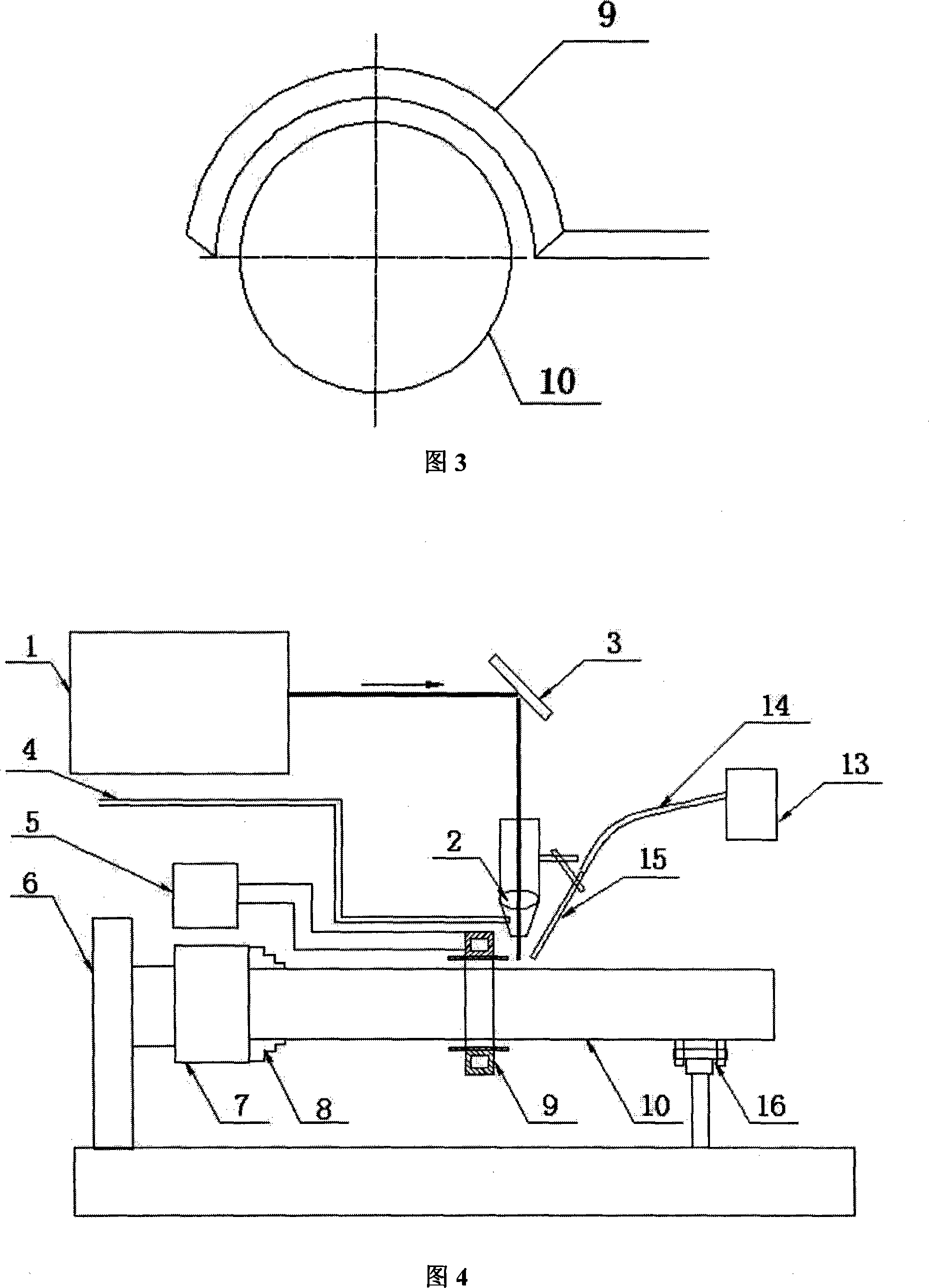

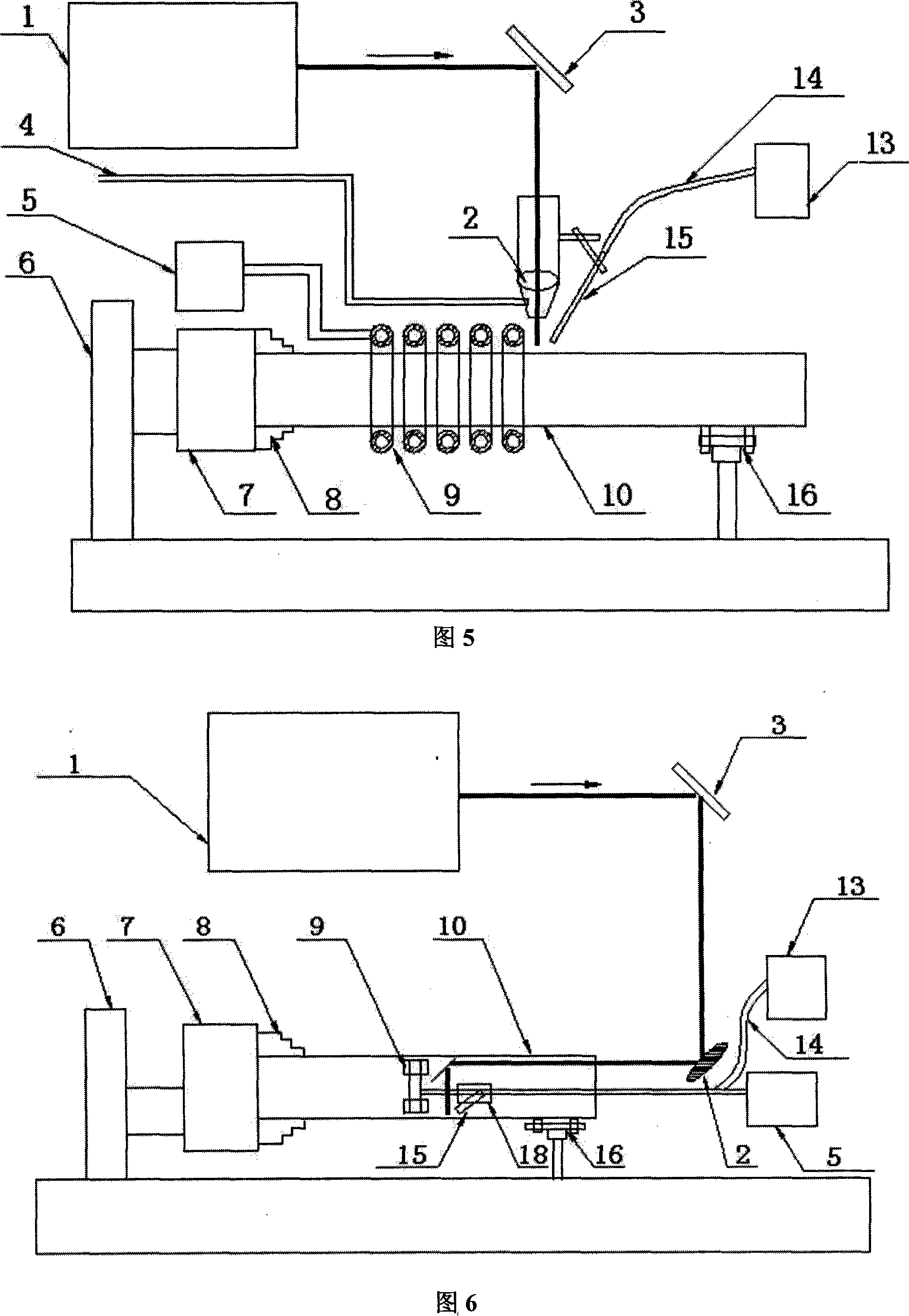

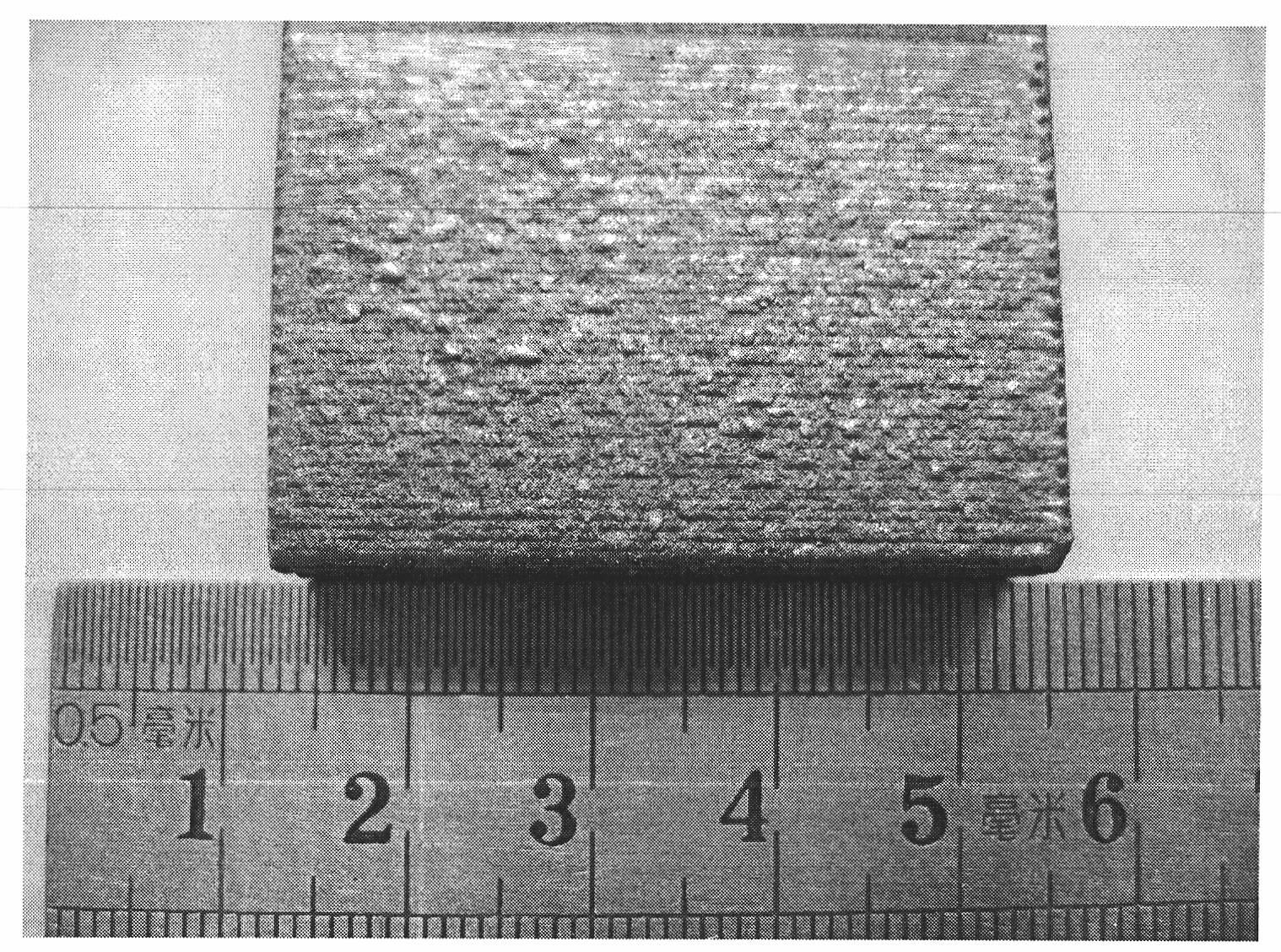

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

Laser-cladded composite wear-resisting layer on surfaces of copper and copper alloys and preparation method

InactiveCN102041503ADense tissueReduce energy consumptionMetallic material coating processesCobalt based alloyCopper alloy

The invention relates to a laser-cladded composite wear-resisting layer on the surfaces of copper and copper alloys and a preparation method. The composite wearing layer is a multi-layered laser cladding layer comprising at least two or more than two layers, wherein the coating connected with a substrate is the first layer, which is also called as a transition layer and is a copper-based alloy prepared from the following components in percentage by weight: 20.0-30.0 percent of Cu, 6.0-8.0 percent of Al, 0.3-0.6 percent of Si, 1.7-2.4 percent of Zr and the balance of Ni; and the rest layer is a cobalt-based alloy prepared from the following components in percentage by weight: 1.0-1.5 percent of C, 25-30 percent of Cr, 2-4 percent of Fe, 10-15 percent of W, 0.8-1.2 percent of Si, 3-4 percent of B, 8-12 percent of Ti, 10-12 percent of Ni and the balance of Co. The composite wear-resisting layer provided by the invention has compact tissues without cracks or pores and forms favorable metallurgy combination with the surfaces of copper and copper alloys. The preparation method provided by the invention can be used for accurately controlling the thickness of the composite wear-resisting layer and automatically controlling the whole process, and has the advantages of low energy consumption, no pollution, high efficiency and low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

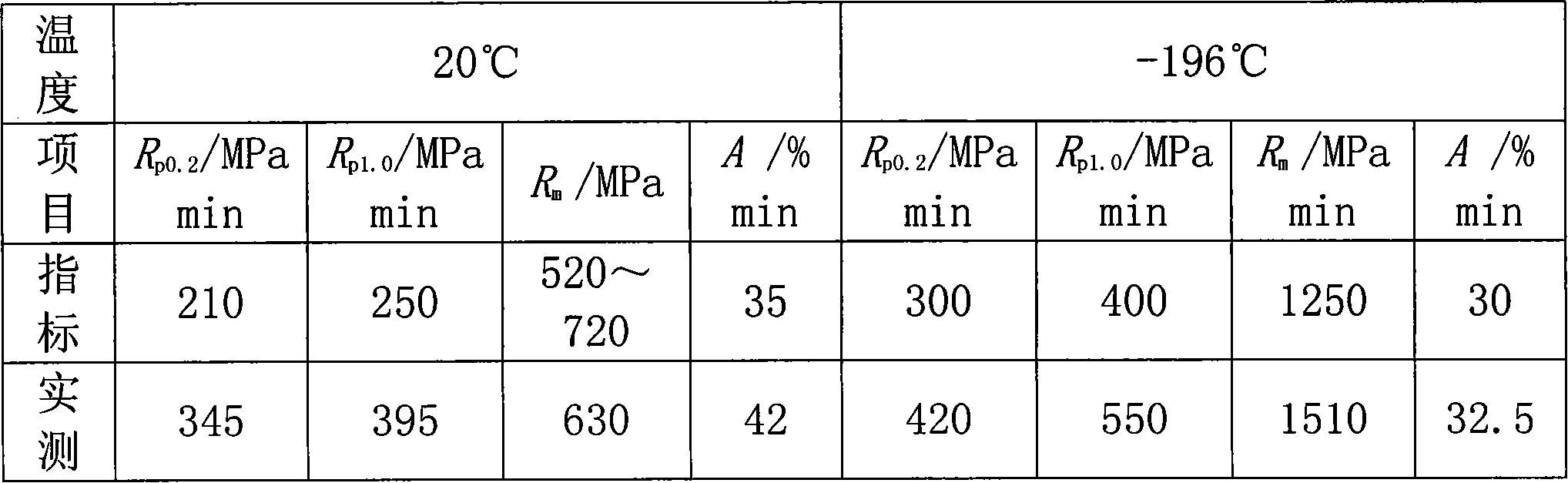

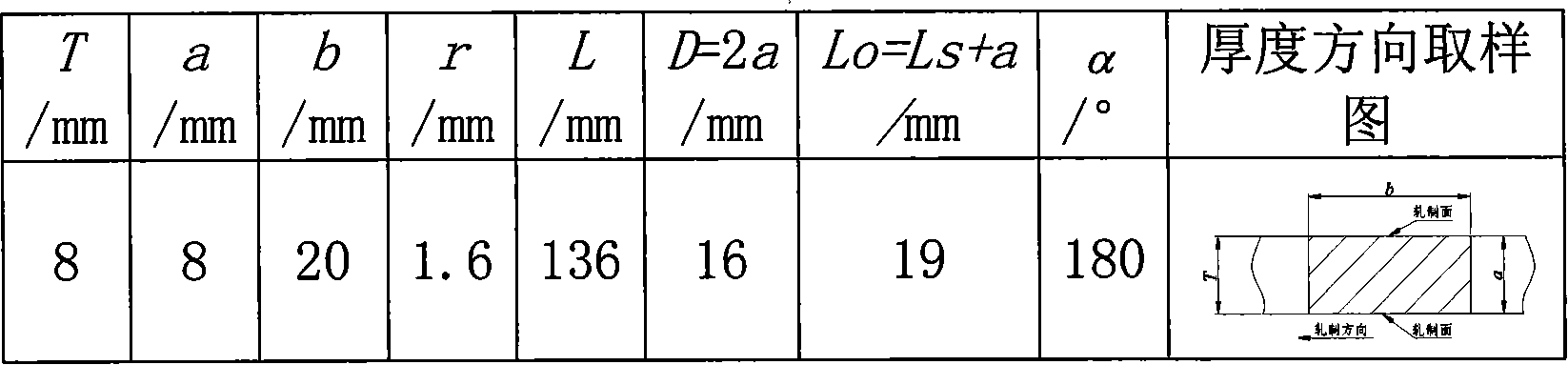

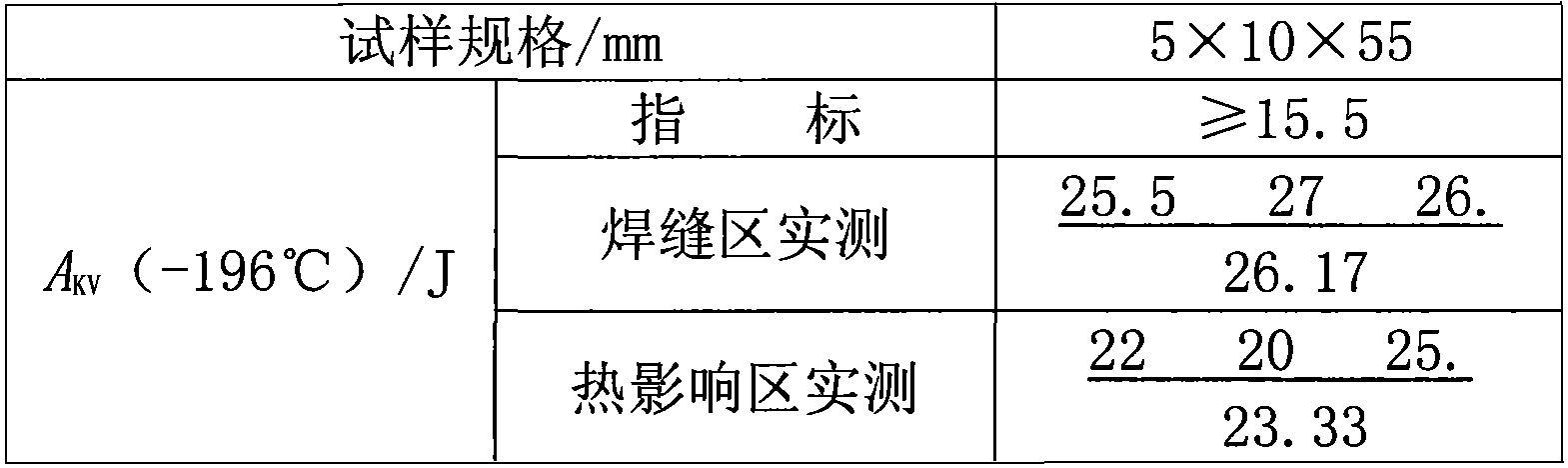

Austenitic stainless steel buried arc welding wire for low-temperature equipment

ActiveCN101244494AEasy to rollImprove low temperature resistanceWelding/cutting media/materialsSoldering mediaSteelmakingChemical composition

The invention relates to a welding wire, in particular to a welding wire applying to austenitic submerged arc welding for low-temperature equipments, in terms of chemical composition and weight percent, comprising Cr: 19.0 to 23.0%, Ni: 9.0 to 12.0%, C: <=0.03%, Mn: 1.60 to 2.50%, Si: 0.30 to 0.60%, Mo: <=0.30%, Cu: <=0.30%, Co: <=0.20%, Ti: <=0.015%, Nb: <=0.05%, V: <=0.10%, B: <=0.005% and Fe as allowance. The welding wire has the advantages that: the welding wire steelmaking craft is stable; the drawing performance is good; the invention meets the welding technical requirements of the high-intensity, high-toughness and anti-corrosion steel with low temperature and low temperature equipments; the invention can apply to the steel of 500 to 750MPa strength level; the invention is suitable for large range of welding current and no blowhole; the moulding is beautiful; the weld joint can be well matched with the base material.

Owner:哈焊所华通(常州)焊业股份有限公司

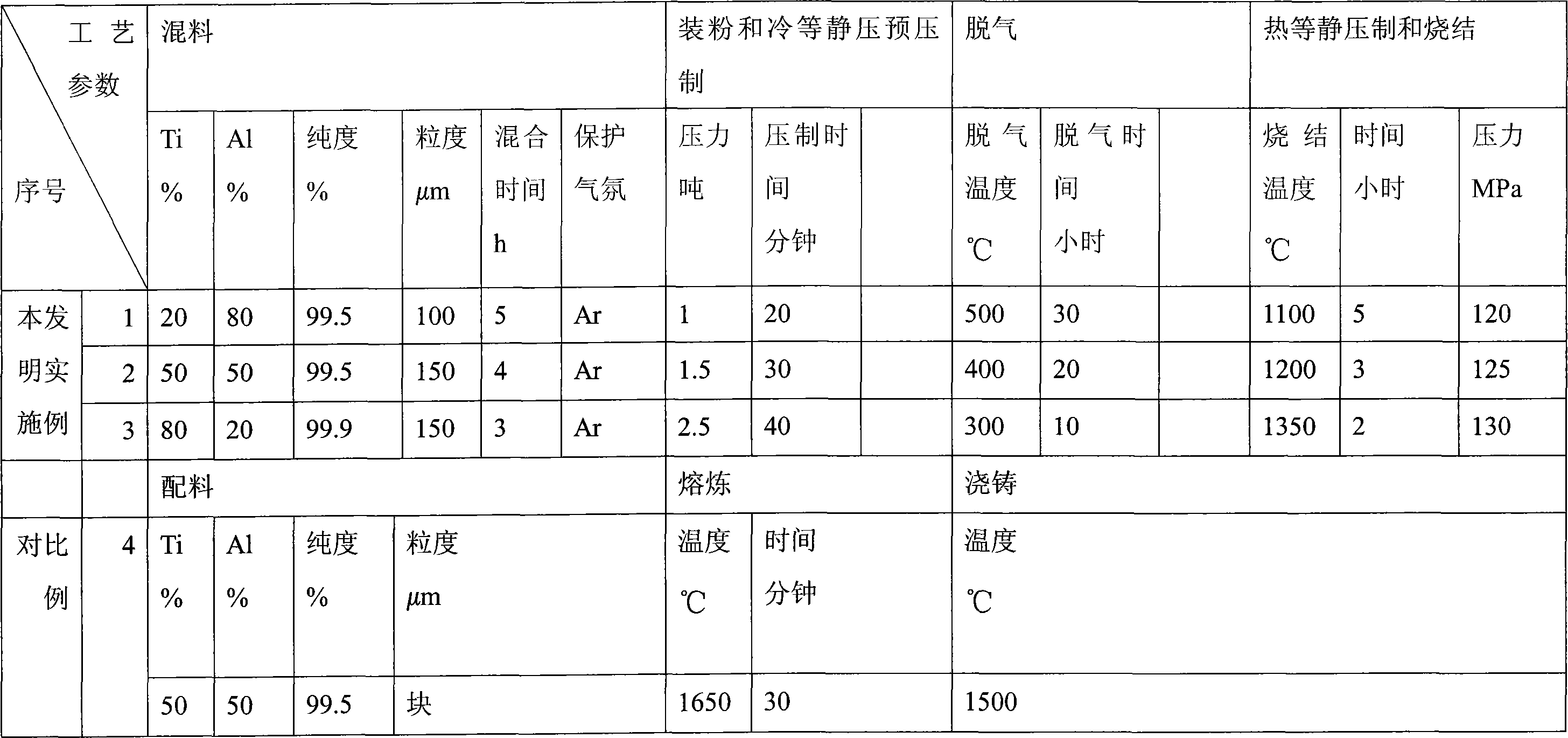

Method for preparing powder metallurgy of titanium-aluminium alloy target material

The invention belongs to the preparing field of powder metallurgy, in particular to the powder metallurgy preparing method for titanium aluminum alloy target material. The components of the titanium aluminum alloy target material relates to: Ti to Al is equal to 80 percent to 20 percent or Ti to Al is equal to 20 to 80 percent. The powder metallurgy preparing method for the titanium aluminum alloy target material is to adopt a pulverization method to acquire the titanium aluminum alloy or mix the titanium powder and the aluminum powder and then pre-pressing through powder mounting and isostatic cool pressing, and then carries out hot isostatic pressing forming after the technique of desaeration and finally carries out sintering process and machining to acquire the titanium aluminum alloy target material. Compared with the exiting casting target material, the titanium aluminum alloy target material of the invention has the advantages of good compactness, no air holes, no loosening and aliquation, uniform component, petty crystal particle, big specification dimension, etc., and is suitable for hard coat needed by various tools and dies.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Thermal protection coating with component gradient change and preparation method

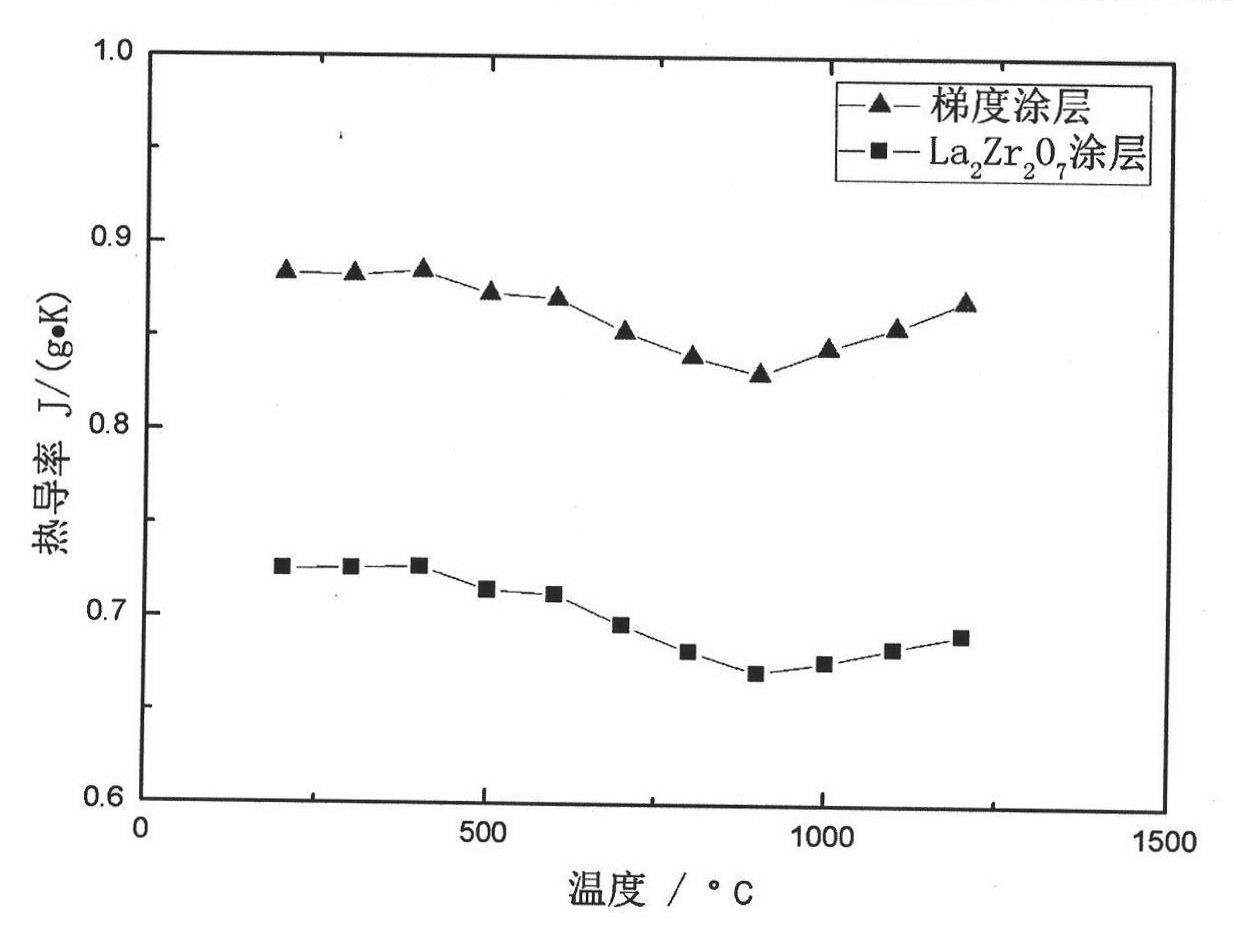

InactiveCN101768380AReduce heat stress concentrationImprove thermal shock resistanceMolten spray coatingRare-earth elementLanthanum aluminate

The invention belongs to the field of inorganic materials, particularly relates to a thermal protection coating with component gradient change and a preparation method. The thermal protection coating comprises two components of M1 and M2, wherein the M1 is selected from one of YSZ, lanthanum aluminate, mulite or BSAS, the M2 is selected from one of Ln2Zr2O7, Ln2Ce2O7, Ln2SiO5, Ln2Si2O7 or MoSi2, and Ln is selected from rare earth elements the atom coefficients of which are 57-71, Y or Sc. The thermal protection coating has the characteristics of good coating compactness, high bonding strength with a substrate, low thermal conductivity and the like and has favorable thermal shock resistance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

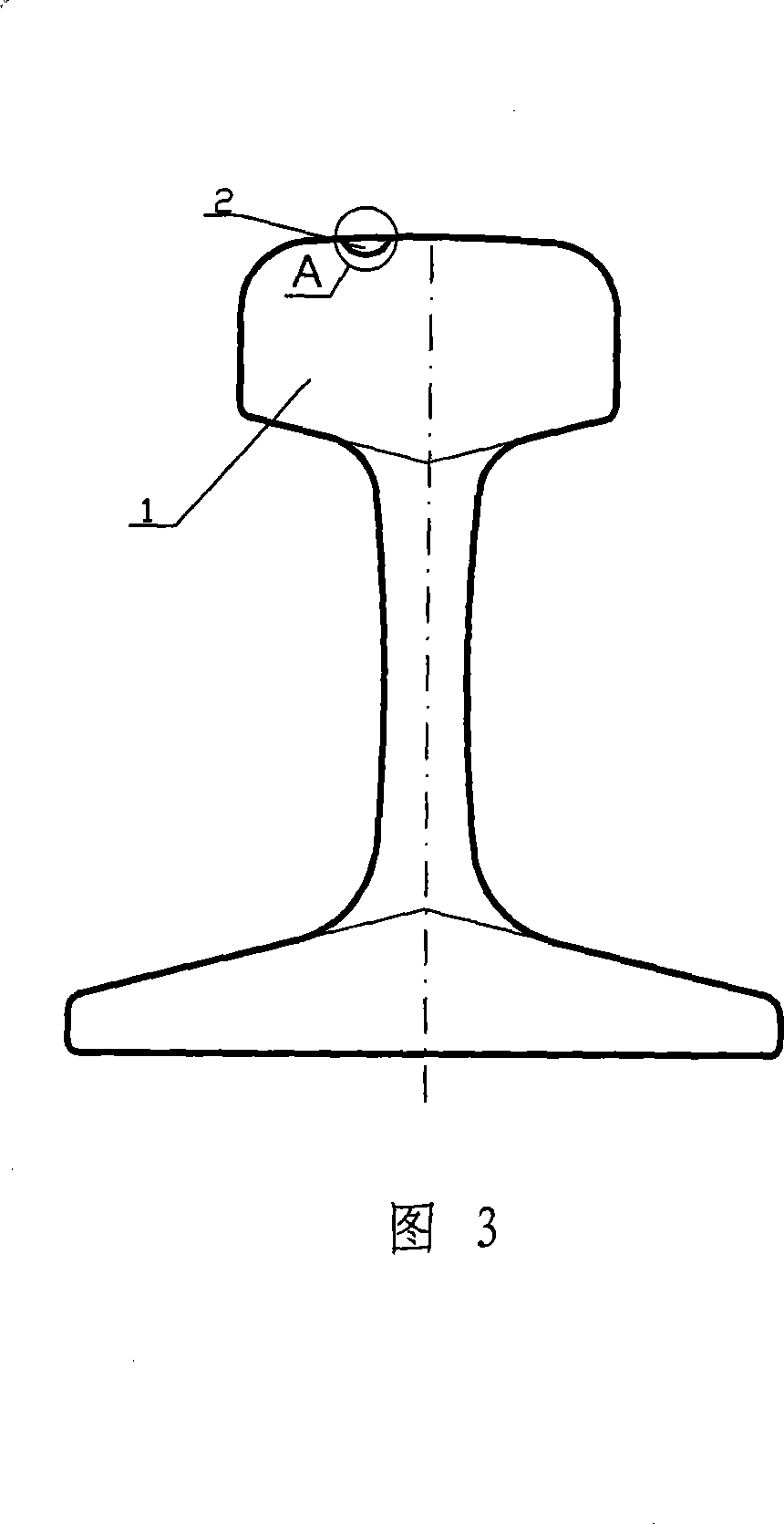

Method for melting and coating anti-rust wear-resistant alloy on steel rail surface

ActiveCN101144160AImprove efficiencyEasy to operateArc welding apparatusMetallic material coating processesBonding strengthWhite light

The present invention discloses a method for smelting rust preventing and wear resistant alloy on the surface of a steel rail. The position needing alloy smelting on the surface of the steel rail head is heated by supersonic frequency or medium frequency induction-heating equipment, the induction heater is arranged above the position needing alloy smelting on the surface of the steel rail head, and the preheating temperature is 290-450 DEG C; the alloy is smelted on the surface of the steel rail head by using plasma smelting or arc welding smelting, when the preheating temperature is 290-450 DEG C, and the welding gun of plasma build up welding or arc welding equipment is moved to the position needing alloy smelting, the alloy powder, the alloy electrode or the alloy welding wire are automatically smelted; the railroad steel rail adopting the present invention can ensure that the train wheels and the rust preventing and wear resistant alloy layer are always in a contacting and compacting state, thereby the rail circuit works normally, and the white light zone phenomenon is completely eliminated; the cracking and breaking phenomena of the steel rail do not occur, the smelted alloy has good rust preventing and wear resistant properties, high bonding strength with the steel rail, and long service life.

Owner:CHENGDU ZHONGGUI TECH CO LTD

High abrasion-proof laser cladding nickel-base alloy powder and preparation method thereof

InactiveCN102943267AHigh hardnessImprove wear resistanceMetallic material coating processesCarbideAlloy

The invention relates to a high abrasion-proof laser cladding nickel-base alloy powder and a preparation method of the alloy powder. The high abrasion-proof laser cladding nickel-base alloy powder is characterized by comprising matrix alloy powder, hard carbide particles and a bonding agent; and the combined powder comprises 50-98% of matrix alloy powder, 1-45% of WC or TiC or mixed powder of WC and TiC, and 1-5% of bonding agent. The preparation method comprises the following steps of: preparing the matrix alloy powder, adding the carbide particles into the prepared matrix alloy powder, adding the bonding agent into the mixture, stirring, ball milling, combining the powder, drying, crushing and screening. The high abrasion-proof laser cladding nickel-base alloy powder not only is high in hardness, but also has excellent wear resistance and corrosion resistance, thus being especially suitable for laser cladding of alloy workpieces with high surface hardness and high wear resistance. Furthermore, the phenomenon of segregation caused by great differences among the specific gravities of all components in the processes of storage, transportation and using can be effectively prevented.

Owner:江苏新亚特钢锻造有限公司

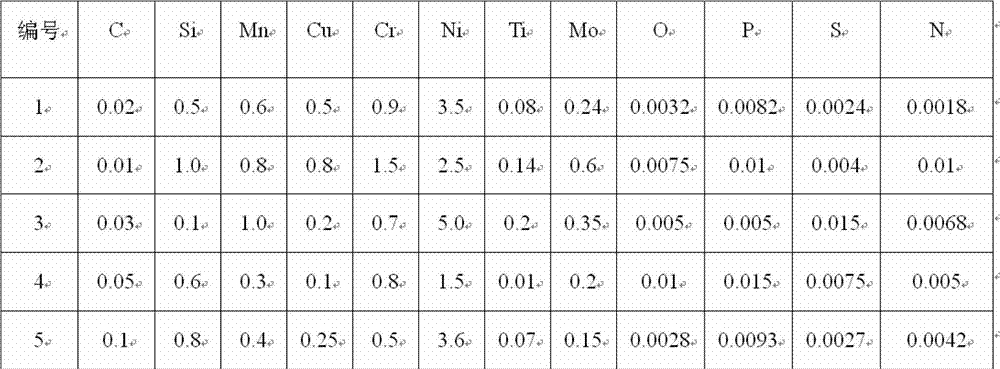

High-strength and high-tenacity gas shielded welding wire

ActiveCN101992365AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaManganeseMixed gas

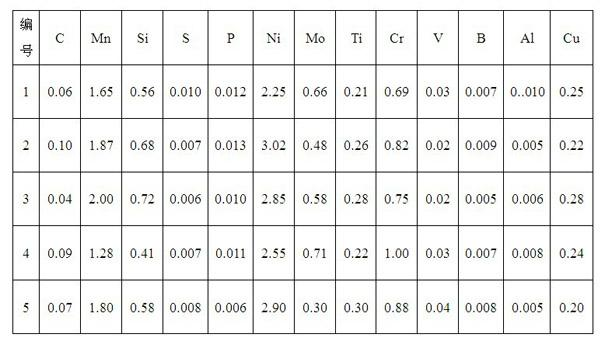

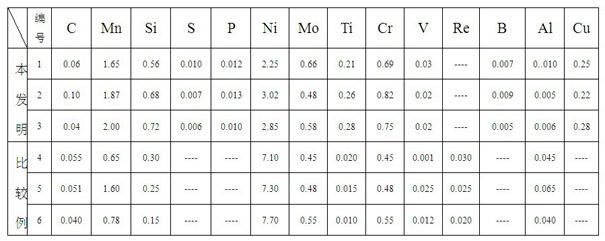

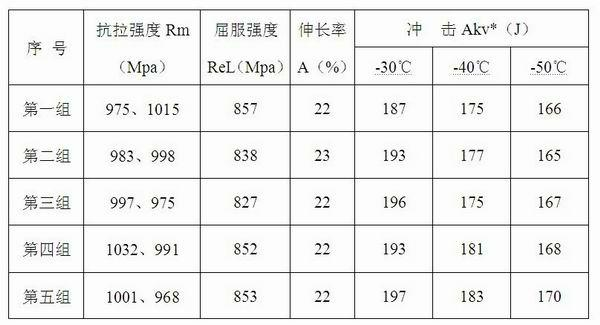

The invention discloses a high-strength and high-tenacity gas shielded welding wire. The welding wire comprises the following chemical composition in percentage by mass: 0.02 to 0.12 percent of carbon (C), 1.20 to 2.10 percent of manganese (Mn), 0.20 to 1.00 percent of silicon (Si), less than or equal to 0.010 percent of sulfur (S), less than or equal to 0.015 percent of phosphorus (P), 2.00 to 3.50 percent of nickel (Ni), 0.20 to 0.80 percent of molybdenum (Mo), 0.20 to 0.30 percent of titanium (Ti), 0.60 to 1.20 percent of chromium (Cr), less than or equal to 0.05 percent of vanadium (V), 0.005 to 0.010 percent of boron (B), less than or equal to 0.015 percent of aluminum (Al), less than or equal to 0.35 percent of copper (Cu) and the balance of iron (Fe). The welding wire is used for welding steels of a strength grade of between 850 and 950MPa; and under the protection of a mixed gas (80 percent of argon (Ar) and 20 percent of carbon dioxide (CO2)), the weld metal tensile strength of the welding wire is more than or equal to 850MPa, the yield strength is more than or equal to 720MPa, the elongation is more than or equal to 22 percent, and the low-temperature impact toughness Akv is more than or equal to 181J at the temperature of -30 DEG C, or more than or equal to 175J at the temperature of -40 DEG C, or more than or equal to 162J at the temperature of -50 DEG C.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

Particle reinforced iron-based metal powder for ultra-high speed laser cladding

ActiveCN108103499AImprove surface wear resistanceExtended service lifeTransportation and packagingMetal-working apparatusUltra high speedChemical composition

The invention provides particle reinforced iron-based alloy powder for ultra-high speed laser cladding. The iron-based alloy powder is composed of iron matrix metal powder and oxide particles or carbide particles and comprises 50-98% of iron matrix metal powder and 2-50% of oxide particles or carbide particles, wherein an iron matrix is composed of, by mass, 0.03-2% of C, 0.50-2.80% of Si, 0.30-1.60% of Mn, 2-12% of Cr, 0.5-3% of V, 0.5-4% of Mo, 0.3-1% of Nb, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 0.05-3.0% of B and the balance Fe and inevitable impurities. Theparticle size of the metal power is 10-100 microns, and the flowability of the metal power is 32-45 s / 100 g. By adopting the particle reinforced iron-based metal powder, the laser cladding technologyis adopted and matched with different processes for reinforcing and repairing matrix surfaces.

Owner:中机新材料研究院(郑州)有限公司

Laser cladding technological method and alloy material for laser cladding

ActiveCN102168210AUniform tissueSmall tissueMetallic material coating processesLaser beam welding apparatusCavitationSlag

The invention discloses an alloy material for laser cladding. The alloy material is alloy powder and contains the following components in percent by weight: C: 0.85-0.98%, Cr: 35-45%, Fe: 3-5%, Si: 0.5-1.0%, W: 3.5-5.5%, Mo: 1 .0-1.5%, Ni: 6-8%, V: 1.5-2.0%, Ti: 1.0-2.0%, B: 0.5-1.5%, Nb: 0.10-0.50%, Re: 0.5-1.5%, and Co: the balance. The invention also discloses a laser cladding technological method adopting the alloy material. In the technical scheme, under the combined action of the added alloy elements, cladding layer tissue is uniform and tiny and has no pore, no inclusion and no included slag; and preheating is not needed when a blade is cladded and crack does not emerge. The alloy material has high rigidity and excellent cavitation resistance; without follow-up heating treatment, a cladded part can be directly fine machined to use; and the laser treatment technology has good adaptivity and is simple and feasible in operation.

Owner:HANGZHOU BOHUA LASER TECH

Laser cladding nickel-based alloy powder and preparation method thereof

InactiveCN102912188AHigh hardnessNo crackMetallic material coating processesChemical compositionCrack free

The invention relates to laser cladding nickel-based alloy powder and a preparation method thereof. The laser cladding nickel-based alloy powder is characterized by comprising the following components by weight percent: 0.2-0.7% of C, 2-3.5% of Si, 1.5-3% of B, 1.0-1.5% of Mn, 3-10% of Cr, 2-5% of W, 3-5% of Mo, 0.5-1% of Nb, 0.5-2% of Co, less than 15% of Fe, 0.2-0.4% of Y, 0.2-0.5% of Ce and Ni and the balance of unavoidable impurity elements. A manufacturing process flow of the laser cladding nickel-based alloy powder is as follows: burdening, smelting, atomizing, drying and sieving. The alloy powder used for laser cladding provided by the invention is corrosion-resistant and also has higher hardness, and a treated laser cladding layer has the advantages of no crack, no pore, no impurity, compact structure and refined grain. A large-area thick crack-free laser cladding alloy layer can be obtained without preheating or follow-up heat treatment, and the cladding layer has the advantages of high strength, hardness and abrasion performance, good plasticity and toughness and low cost.

Owner:江苏新亚特钢锻造有限公司

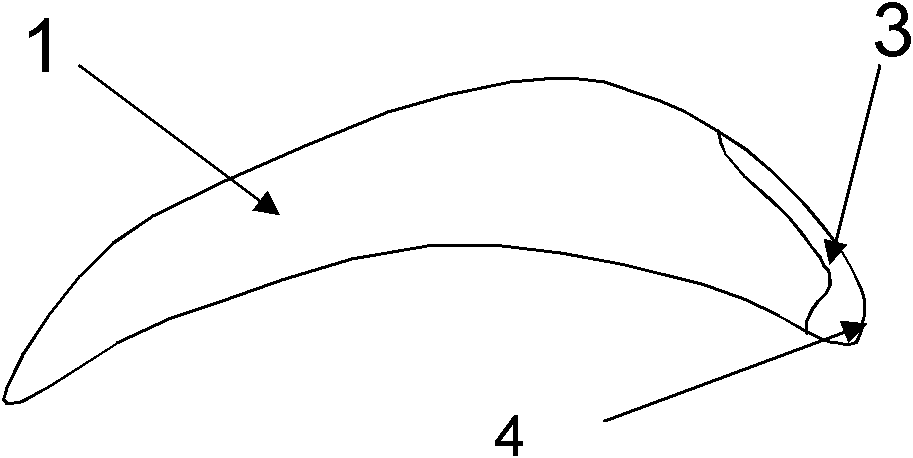

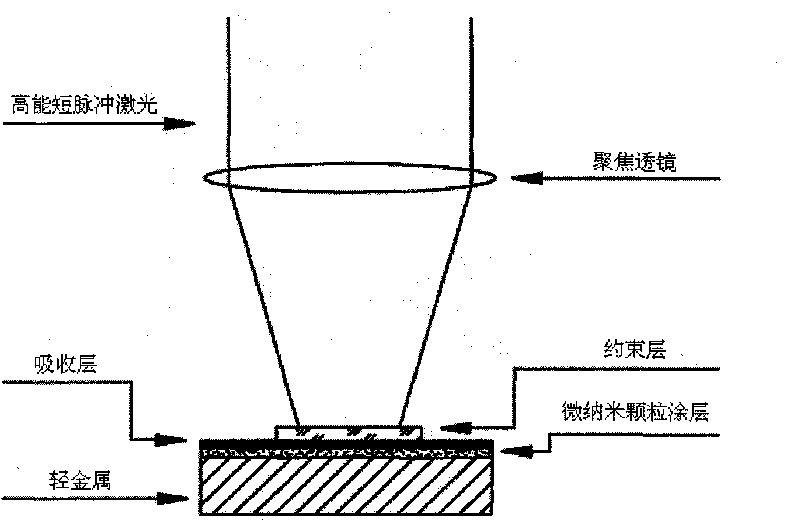

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

Laser-cladding high-toughness high-hardness nickel-base alloy powder and preparation method thereof

InactiveCN102719708AHigh hardnessNo crackMetallic material coating processesChemical compositionRare earth

The invention discloses laser-cladding high-toughness high-hardness nickel-base alloy powder and a preparation method thereof. The nickel-base alloy powder is characterized by comprising the following chemical components in percentage by mass: 0.4-0.8% of C, 2-3% of Si, 1-3% of B, 12-18% of Cr, 6-8% of Cu, 0.5-1% of Sn, 10-15% of Fe, 0.2-0.5% of rare earth and the balance of Ni and inevitable impurity elements. The preparation process flow sequentially comprises: dosing, smelting, atomizing, drying and screening. The laser-cladding alloy powder disclosed by the invention has corrosion resistance and relatively high hardness; and the processed laser-cladding layer has the advantages of no crack, no air hole, no impurity, dense tissue, grain refinement and the like. Through the invention, a large-area great-thickness laser-cladding alloy layer without cracks can be obtained without preheating or follow-up thermal treatment, and the laser-cladding alloy layer has the advantages of high strength, hardness and abrasion resistance, good plasticity and toughness, low cost and the like.

Owner:丹阳市协昌合金有限公司

Hydraulic support plunger outer surface laser cladding repairing method

ActiveCN108559996AGuaranteed performanceImprove performanceMetallic material coating processesHardnessOptoelectronics

The invention discloses a hydraulic support plunger outer surface laser cladding repairing method. The hydraulic support plunger outer surface laser cladding repairing method comprises the following steps that firstly, turning is carried out on the outer surface of a hydraulic support plunger to be repaired to remove a fatigue layer and an electroplated layer on the outer surface of the hydraulicsupport plunger, and the outer surface of the hydraulic support plunger is washed; secondly, iron-base alloy powder for laser cladding is put into laser cladding equipment, the laser cladding equipment is used for carrying out laser cladding on the outer surface of the hydraulic support plunger, and a laser cladding layer is formed; thirdly, rough turning is carried out on the hydraulic support plunger which is subjected to laser cladding; fourthly, abrasive machining and polishing treatment are carried out on the hydraulic support plunger which is subjected to rough turning, and the roughnessRa of the outer surface of the polished hydraulic support plunger is smaller than or equal to 0.4; and fifthly, checking and flaw detection are carried out on the outer surface of the polished hydraulic support plunger, and laser cladding repairing of the outer surface of the hydraulic support plunger is completed after it is ensured that no defect exists. The laser cladding layer formed throughthe repairing method is high in hardness, large in thickness and high in corrosion resistance and longer in service life.

Owner:河南省煤科院耐磨技术有限公司

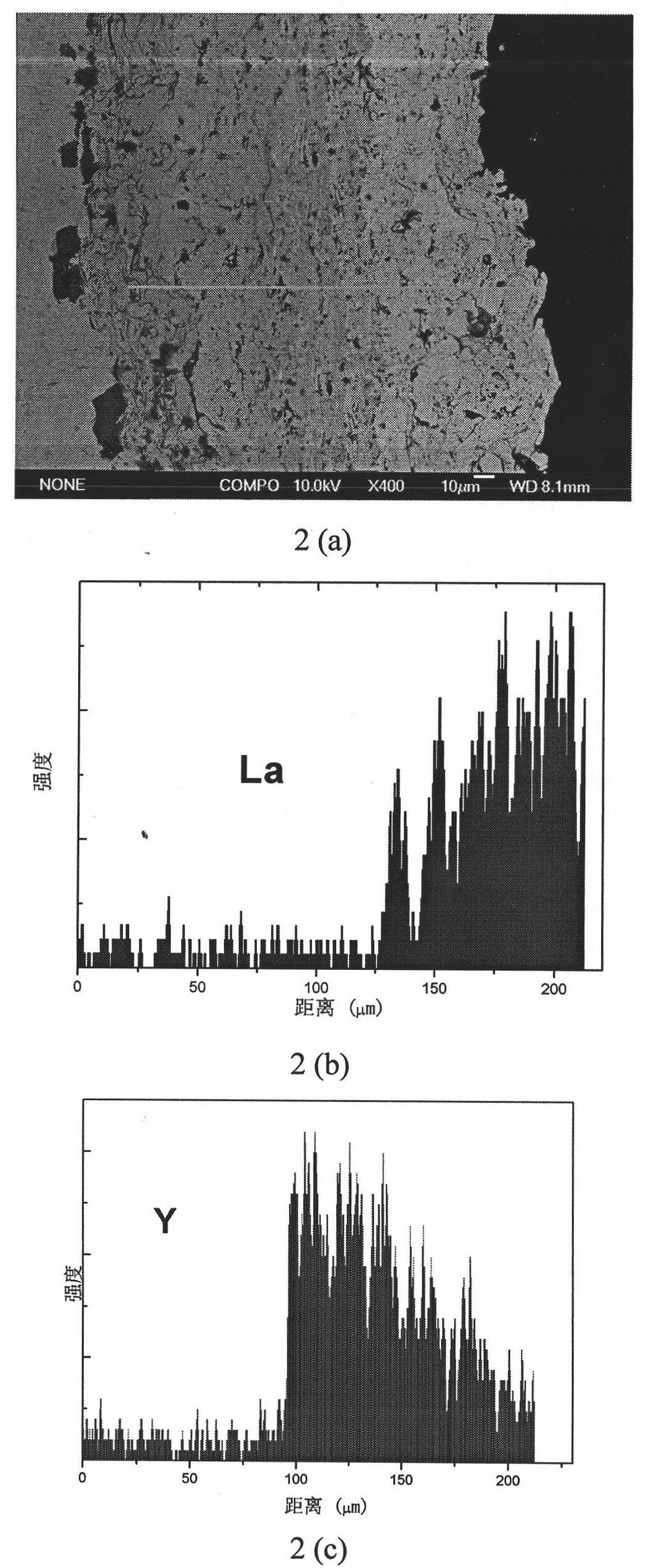

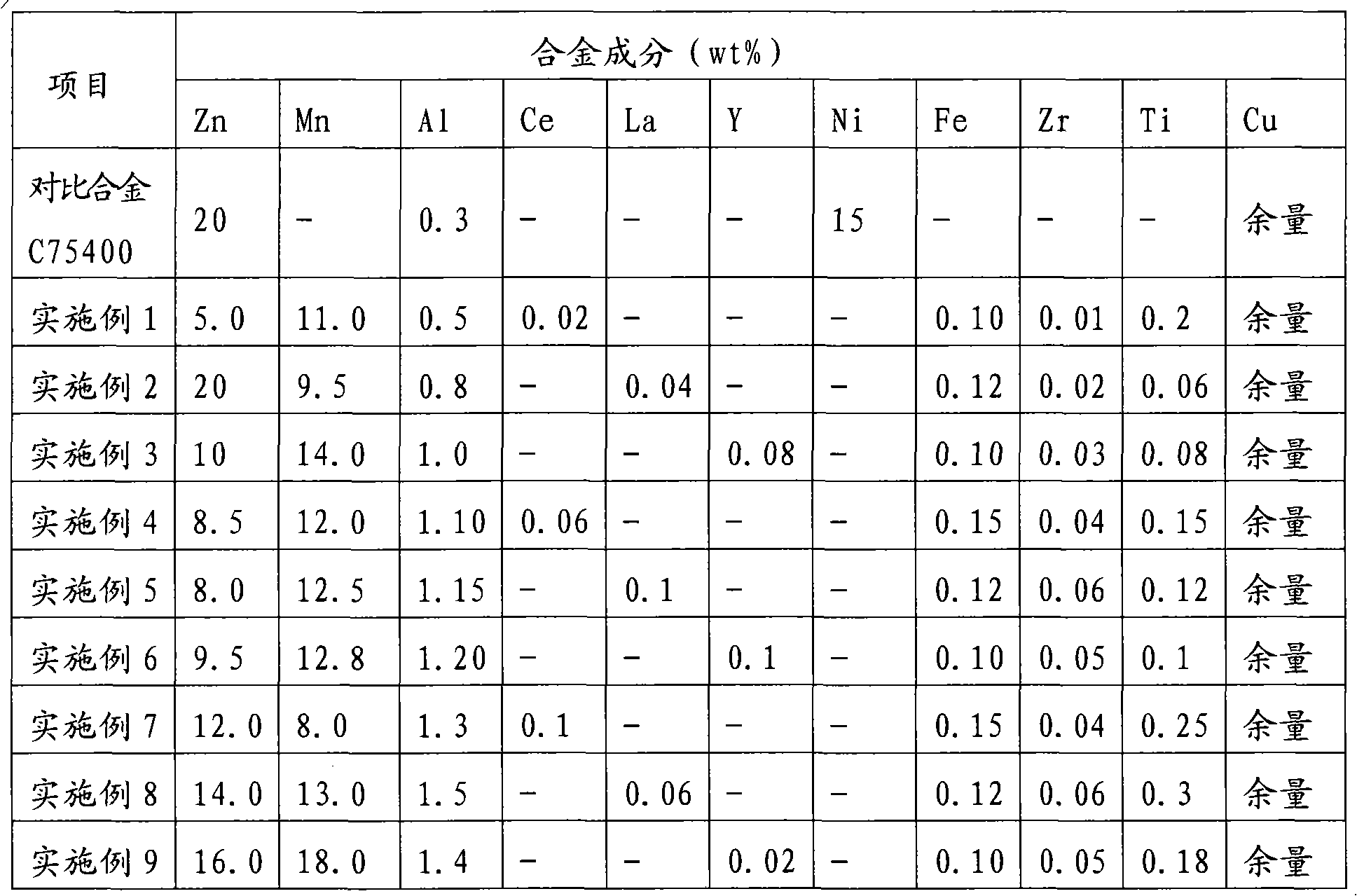

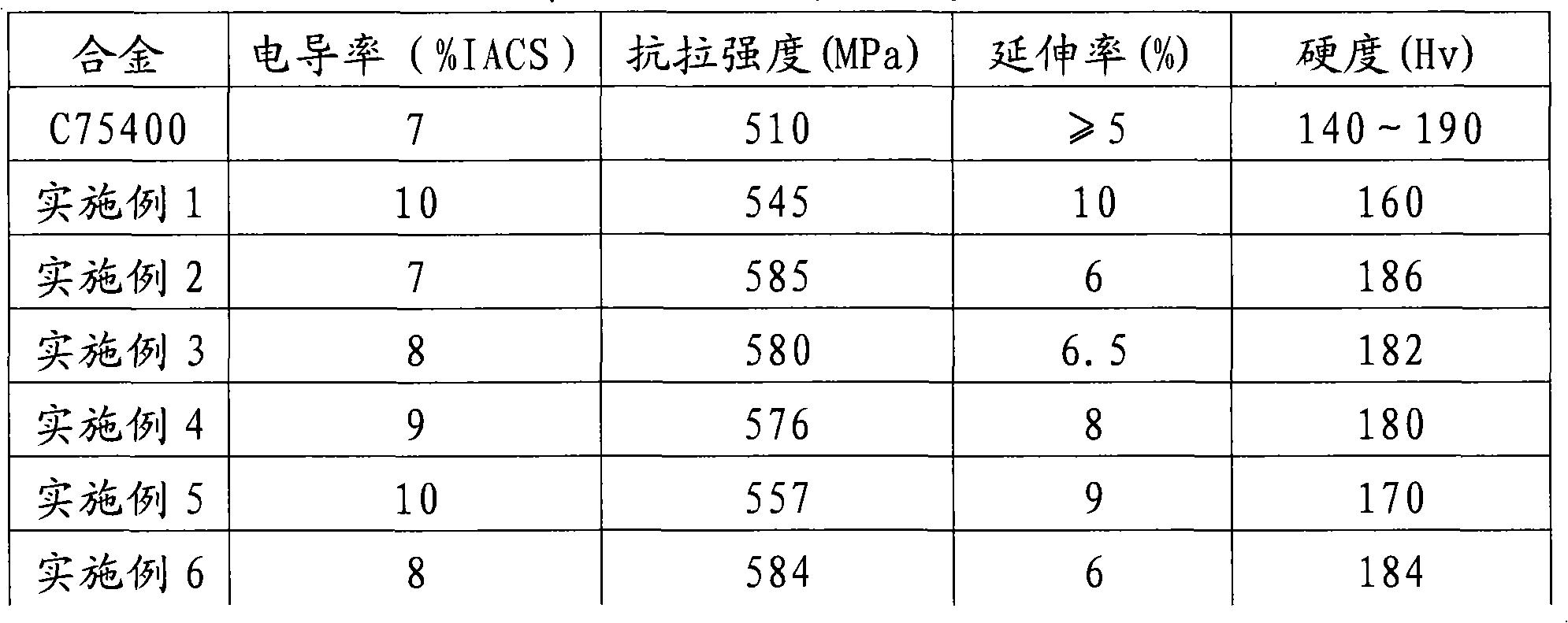

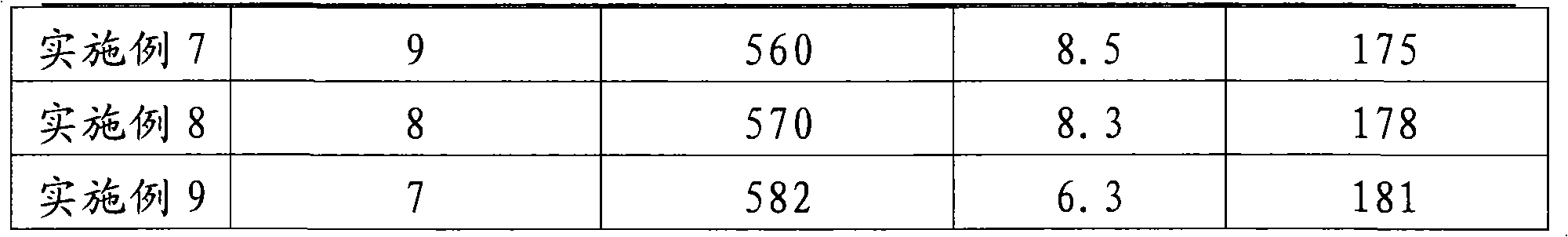

Nickel-free white copper alloy containing rare earth additional elements and method for manufacturing plates made of same

The invention discloses nickel-free white copper alloy containing rare earth additional elements and a method for processing plates made of the same. The nickel-free white copper alloy comprises the following components in percentage by weight: 0.02 to 0.1 percent of rare earth elements, 5 to 20 percent of zinc, 8 to 18 percent of manganese, 0.5 to 2.0 percent aluminum, 0 to 0.5 percent of iron, 0 to 0.5 percent of titanium, 0 to 0.1 percent of zirconium and the balance of copper. An alloy processing method comprises the following major technological processes of: alloy smelting and casting, hot rolling, thermal annealing, cold rolling and the like. The method is characterized in that: copper, zinc, manganese and aluminum are taken as main alloy elements; rare earth elements such as lanthanum, cerium and iridium as well as trace elements such as iron, zirconium and titanium are added in an alloy smelting process; and a human-friendly and environmental-friendly nickel-free white copper alloy plate is manufactured by the technological methods of high-temperature alloying, degassing, impurity removing, casting, cast ingot hot rolling, thermal annealing, cold rolling, finished product annealing and the like.

Owner:JIANGXI UNIV OF SCI & TECH

Oxide particle reinforced laser cladding high-wear resistance nickel-base alloy powder and preparation method thereof

InactiveCN103014475AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHigh surface

The invention provides oxide particle reinforced laser cladding high-wear resistance nickel-base alloy powder and a preparation method thereof. The powder is characterized by comprising basal body alloy powder, oxide hard particles and binding agent, and is proportioned as follows: 50-98 percent of basal body alloy powder, 1-45 percent of one of Al2O3, Cr3C2 and ZrO2 or combined mixture powder of more than two thereof, and 1-5 percent of binding agent are prepared to combined powder. The preparation method comprises the technique steps of preparation of basal body alloy powder, addition of oxide particles, addition of binding agent, stirring and ball milling, powder combination, drying, crushing and screening. The oxide particle reinforced laser cladding alloy powder has higher hardness and toughness, has excellent wear resistance and corrosion resistance, and is particularly suitable for laser cladding of alloy workpieces with higher surface hardness and high wear resistance; and the powder can effectively prevent segregation caused by great difference among specific gravities of all components in the process of storage, transportation and use.

Owner:江苏新亚特钢锻造有限公司

High abrasion-proof laser cladding cobalt-base alloy powder and preparation method thereof

InactiveCN102943266AImprove toughnessHigh hardnessMetallic material coating processesCarbideHardness

The invention relates to a high abrasion-proof laser cladding cobalt-base alloy powder and a preparation method of the alloy powder. The high abrasion-proof laser cladding cobalt-base alloy powder is characterized by comprising matrix alloy powder, hard carbide particles and a bonding agent; and the combined powder comprises 50-98% of matrix alloy powder, 1-45% of WC or TiC or mixed powder of WC and TiC, and 1-5% of bonding agent. The preparation method comprises the following steps of: preparing the matrix alloy powder, adding the carbide particles into the prepared matrix alloy powder, adding bonding agent into the mixture, stirring, ball milling, combining the powder, drying, crushing and screening. The high abrasion-proof laser cladding cobalt-base alloy powder not only is high in hardness and toughness, but also has excellent wear resistance and corrosion resistance, thus being especially suitable for laser cladding of parts with high impact resistance and high abrasion-proof property. Furthermore, the phenomenon of segregation caused by great differences among the specific gravities of all components in the processes of storage, transportation and using can be effectively prevented.

Owner:江苏新亚特钢锻造有限公司

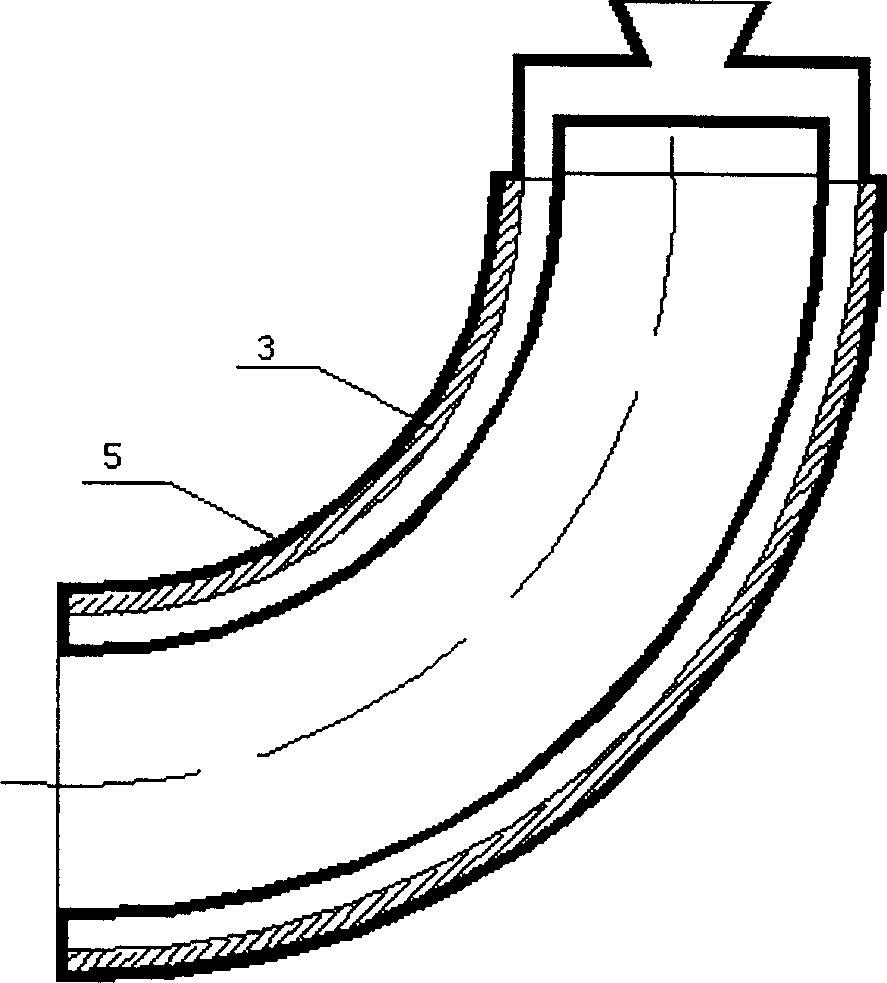

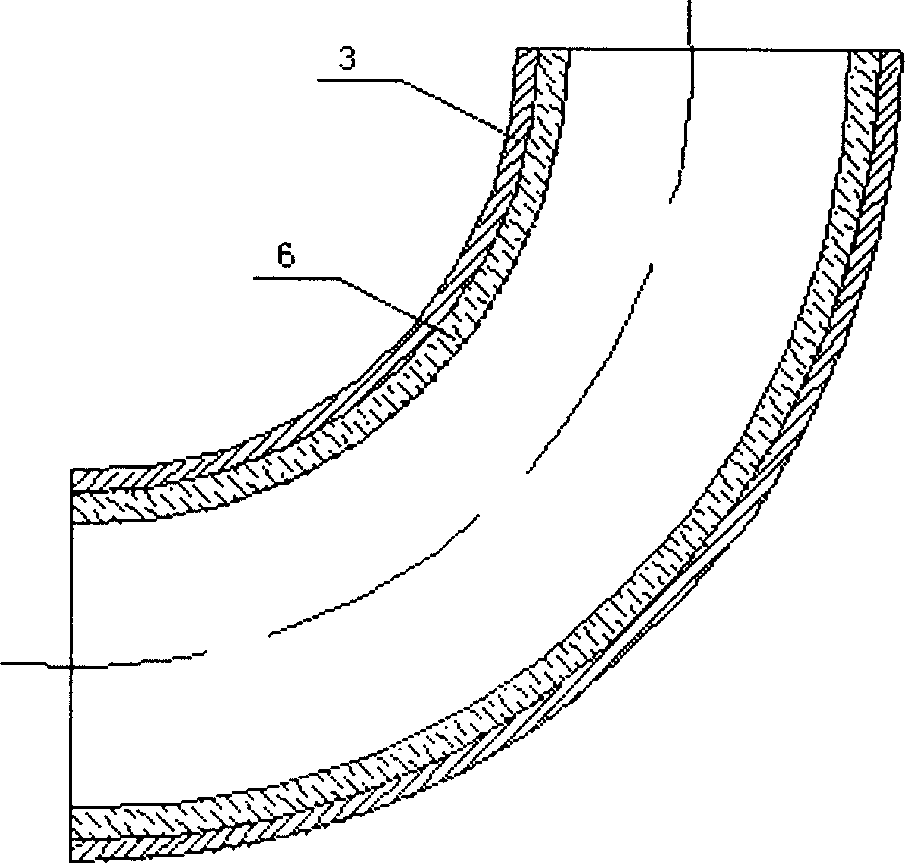

Technique for manufacturing wearable pipe made from composite bimetal

A technology for manufacturing the antiwear bimetal tube includes such steps as providing an ordinary steel tube as external sleeve tube, installing a consumable mold made of foam polystyrene plastics in it, installing pouring system to it, dipping paint and adhering sand several times to form a shell, high-temp calcining for gasifying said plastics and preheating steel tube, pouring molten antiwear alloy, and cooling.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

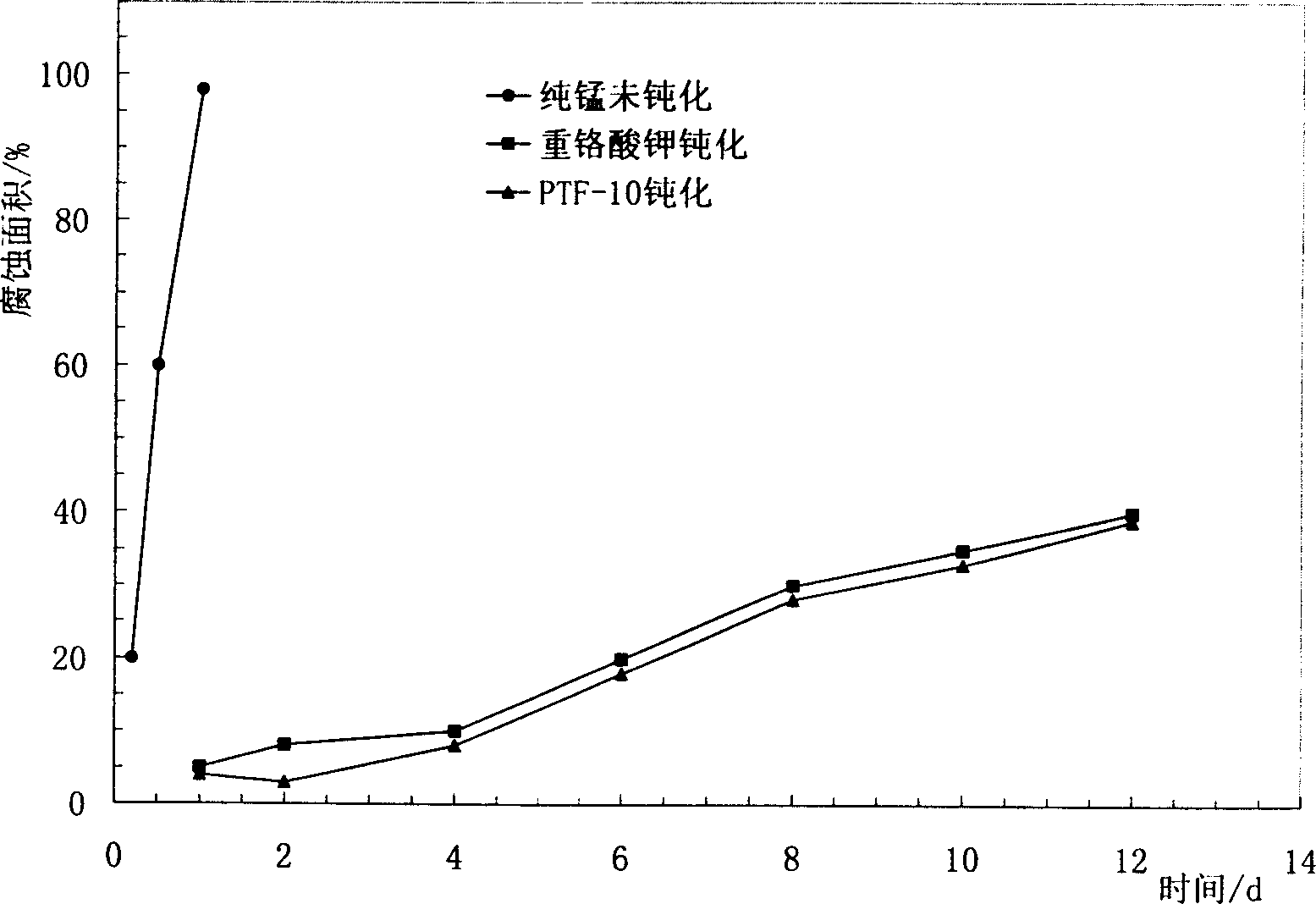

Passivator for treatment of electrolytic manganese metal surface and process for preparing same

InactiveCN1865502AIncrease irritationImprove solubilityMetallic material coating processesElectrolysisManganese

The invention discloses a passivator and preparing method of electrolytic metal Mn surface, which comprises the following parts: 70-80 percent silicate, 0.1-0.2 percent cosolvent, 0.3-0.5 percent inhibitor, 0.05-0.1 percent accelerant and water. The invention improves the operational environment for workers, which solves the problem of serious pollution of electrolytic Mn factory.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Hard surfacing sintered flux and manufacturing method thereof

InactiveCN101564804AMeet different requirements of hardnessImprove performanceWelding/cutting media/materialsSoldering mediaMaterials preparationThermal fatigue

The invention relates to a hard surfacing sintered flux and a manufacturing method thereof. The sintered flux comprises MgO of 30 percent to 50 precent, CaO of 2 percent to 10 percent, Al2O3 of 10 percent to 20 percent, CaF2 of 18 percent to 28 percent, SiO2 of 10 percent to 20 percent, SiC of 0 percent to 1.5 percent and other components of 0 percent to 5 percent such as ferroalloy mainly playing a role of desoxidation and the like. Material preparation, dry mixing and wet mixing by adding soluble glass into a blender are conducted until granules which have the required sizes are formed, then the granules are dried in a rotary drying way at the low temperature of 200 DEG C to 250 DEG C, and then finished products are obtained by high-temperature sintering in a rotary drying oven at the high temperature of 700 DEG C to 750 DEG C, sieving and packaging. The invention has low flux cost so as to meet the requirements of different hardness, excellent technique and good high-temperature slag detachability; the deposited metal has no gas hole, no crackle but adjustable hardness; and the high-temperature wear-resistance, oxide etch resistance and cold and thermal fatigue resistance of a hot roll are greatly improved.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

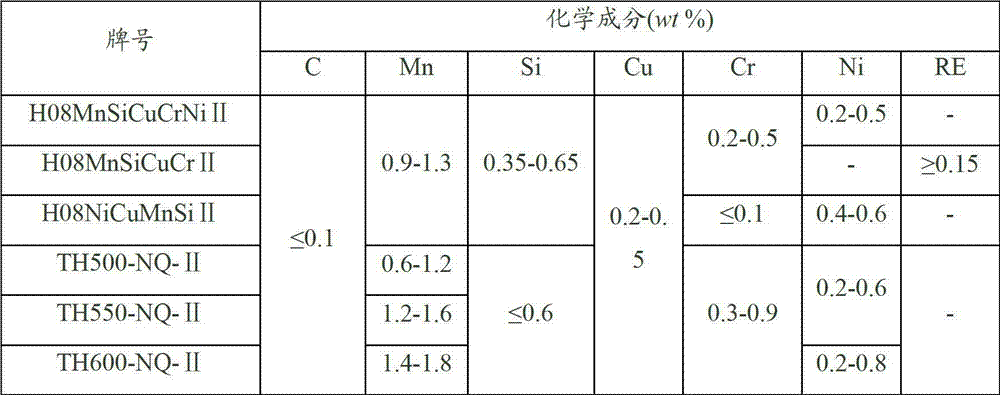

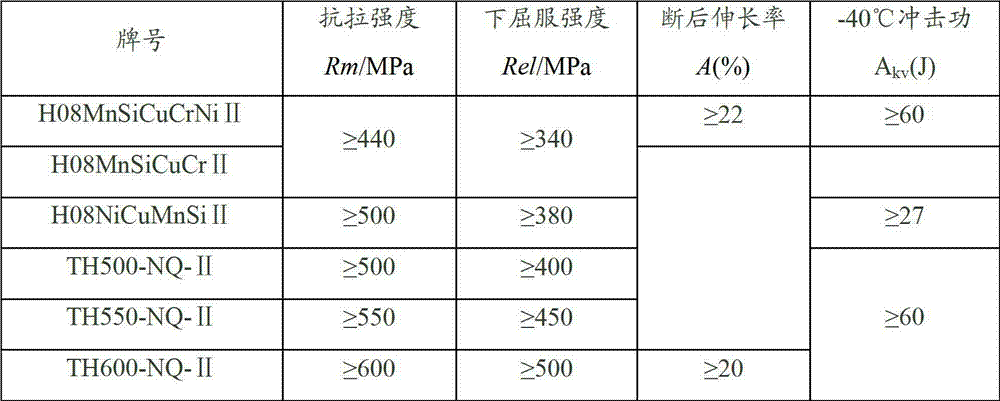

High-corrosion-resistance gas protection welding wire

ActiveCN103028865AGood atmospheric corrosion resistanceGood comprehensive mechanical propertiesWelding/cutting media/materialsSoldering mediaCorrosionGas protection

The invention belongs to the field of welding materials, and relates to a high-corrosion-resistance gas protection welding wire. The welding wire comprises the following chemical compositions in percentage by mass: 0.01-0.1 percent of C, 0.1-1.0 percent of Si, 0.3-1.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.015 percent of S, 1.5-5 percent of Ni, 0.5-1.5 percent of Cr, 0.1-0.8 percent of Cu, 0.01-0.2 percent of Ti, 0.15-0.6 percent of Mo, less than or equal to 0.01 percent of O, less than or equal to 0.01 percent of N and the balance of ferrum. The welding wire has stable welding performance, and obtained deposited metal is matched with the corrosion resistance of parent metal; and meanwhile, the welding wire has high comprehensive mechanical performance, and is particularly suitable for novel high-weather-proof steel.

Owner:CENT IRON & STEEL RES INST

Processing method of anti-fatigue aluminum alloy foaming die cast

The invention discloses a processing method of an anti-fatigue aluminum alloy foaming die cast. The processing method comprises the four steps of compounding, smelting, pouring, and thermal treatment. According to the invention, an appropriate amount of rare earth elements La, Ce and Y are added to the aluminum alloy, so that the hydrogen content in the alloy and the alloy yielding anisotropy can be reduced, the alloy plasticity and the anti-fatigue property of the alloy are obviously increased, and at the same time the wear resistance, thermal resistance and high-temperature strength of the alloy can also be improved. The processed aluminum alloy refrigerator foaming die cast has the advantages of good mechanical properties, high strength, good thermal resistance, good usability, good internal structure compactness, no pore and peeling defects, good wear resistance, good corrosion resistance and oxidation resistance, small expansion coefficient and the like.

Owner:滁州晨润工贸有限公司

Austenitic stainless steel gas shield welding wire for vehicle

ActiveCN101100021AExcellent rolling and wire drawing propertiesGood welding performanceWelding/cutting media/materialsSoldering mediaIn vehicleWeld seam

The present invention relates to austenitic stainless steel welding wire for gas protected welding in vehicle. The austenitic stainless steel welding wire has the chemical composition comprising C not more than 0.03 wt%, Si 0.50-0.90 wt%, Mn 1.00-2.50 wt%, P not more than 0.025 wt%, S not more than 0.015 wt%, Ni 9.0-14.0 wt%, Cr 19.5-24.5 wt%, and Fe and inevitable impurity for the rest. The austenitic stainless steel welding wire produced through smelting, rolling, drawing and other steps has excellent performance, including excellent welding performance, is applied for welding steel of 500-700 MPa strength to form weld seam with high strength, high toughness and high corrosion resistance.

Owner:哈焊所华通(常州)焊业股份有限公司

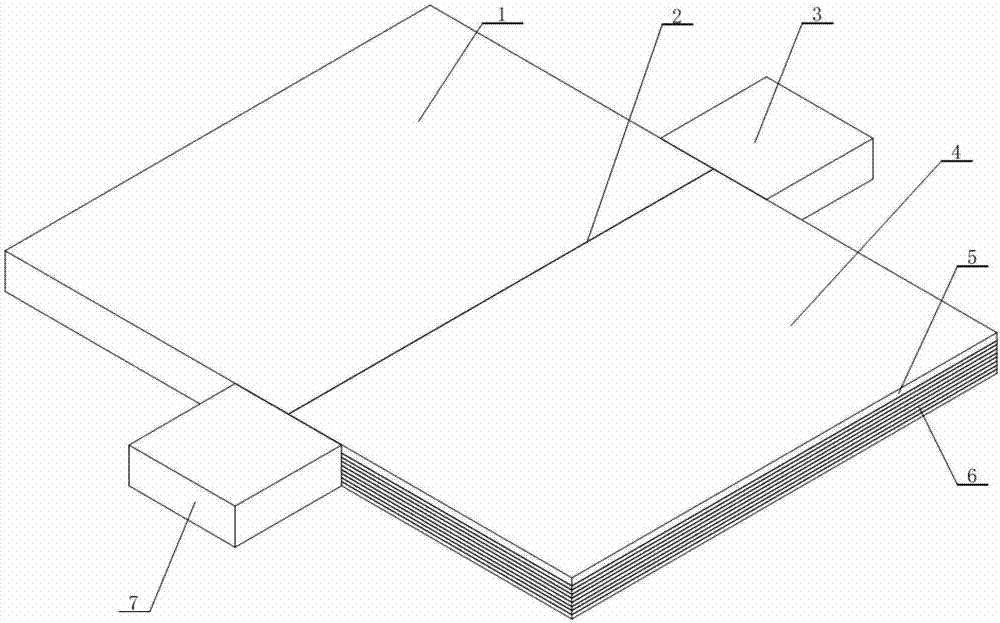

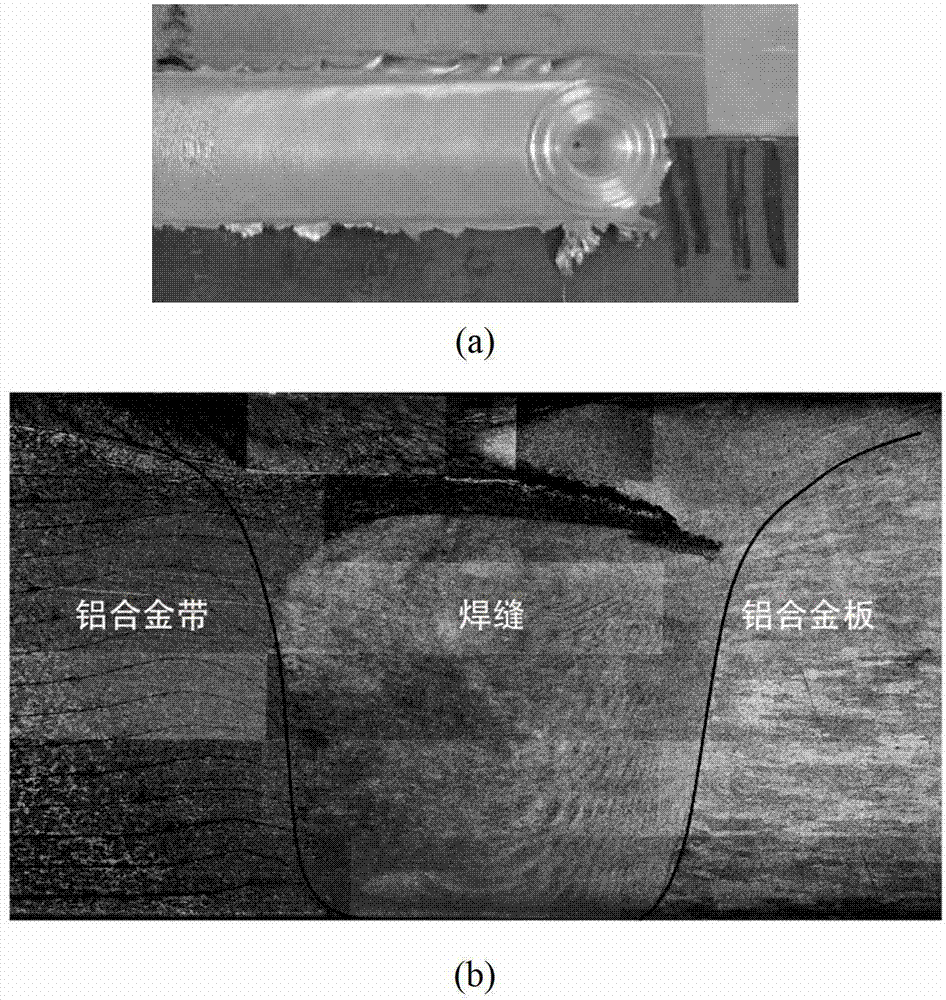

Welding method for multi-layer metal strip

ActiveCN102873454AQuality improvementGuaranteed electrical conductivityNon-electric welding apparatusMetal stripsControllability

The invention relates to a welding method for a multi-layer metal strip. The method is characterized by comprising the following steps of: stacking the multi-layer metal strip to be welded to reach the required thickness, and aligning the multi-layer metal strip with the weld of another stacked multi-layer metal strip or metal plate; fixing a welding guiding plate of which the thickness is the same as that of the multi-layer metal strip to be welded at the starting end of a weld joint along the welding direction; selecting a stirring head, wherein the diameter of a shaft shoulder of the stirring head is 2 to 3 times the plate thickness, the length of a stirring needle on the stirring head is 0.05 to 0.2mm less than the plate thickness, and the press amount of the shaft shoulder is 0.1 to 0.3mm; and selecting rotation speed and welding speed according to a welding material, and welding. The method is energy-saving and environment-friendly, an operation process is greatly simplified, and production efficiency is improved; the quality of a joint is improved, the conductivity of the joint is ensured, and production cost is reduced; controllability is high, and industrial application is easy to implement; and the obtained joint has a compact structure, does not have any pore or crack and is slightly deformed, the operation process is simple, the production period is short, efficiency is high, and the production cost is low.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

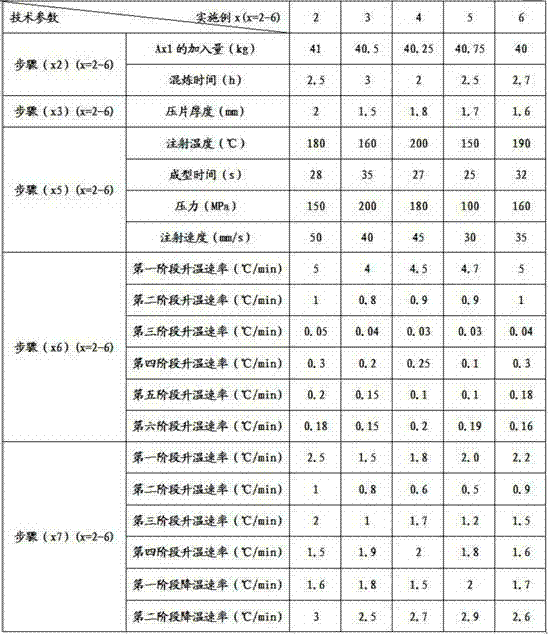

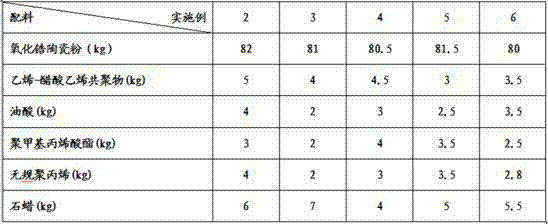

Zirconia ceramic ferrule and production process thereof

InactiveCN104261820AGuaranteed compactnessNo poresCeramic shaping apparatusMethacrylateInjection molding process

The invention discloses a zirconia ceramic ferrule. With zirconia ceramic powder as a main material, an ethylene-vinyl acetate copolymer, an oleic acid, polymethacrylate, atactic polypropylene and paraffin are added in the mixing process, and thus the prepared zirconia ceramic ferrule is good in abrasive resistance, strong in ageing resistance, strong in environmental adaptability, and high in strength. The invention also discloses a production process of the zirconia ceramic ferrule. The process comprises the following steps: sequentially drying, mixing, preforming, crushing, injection molding, thermal debinding, sintering, grinding and the like. High-pressure low-speed injection is adopted in the injection molding process; the compactness and absence of an air hole are ensured; the preparation method is simple, easy to control, low in cost, and high in production efficiency; the pass rate of the produced product is high; and the production process is suitable for production of the zirconia ceramic ferrule.

Owner:HEBEI SMART COMM TECH

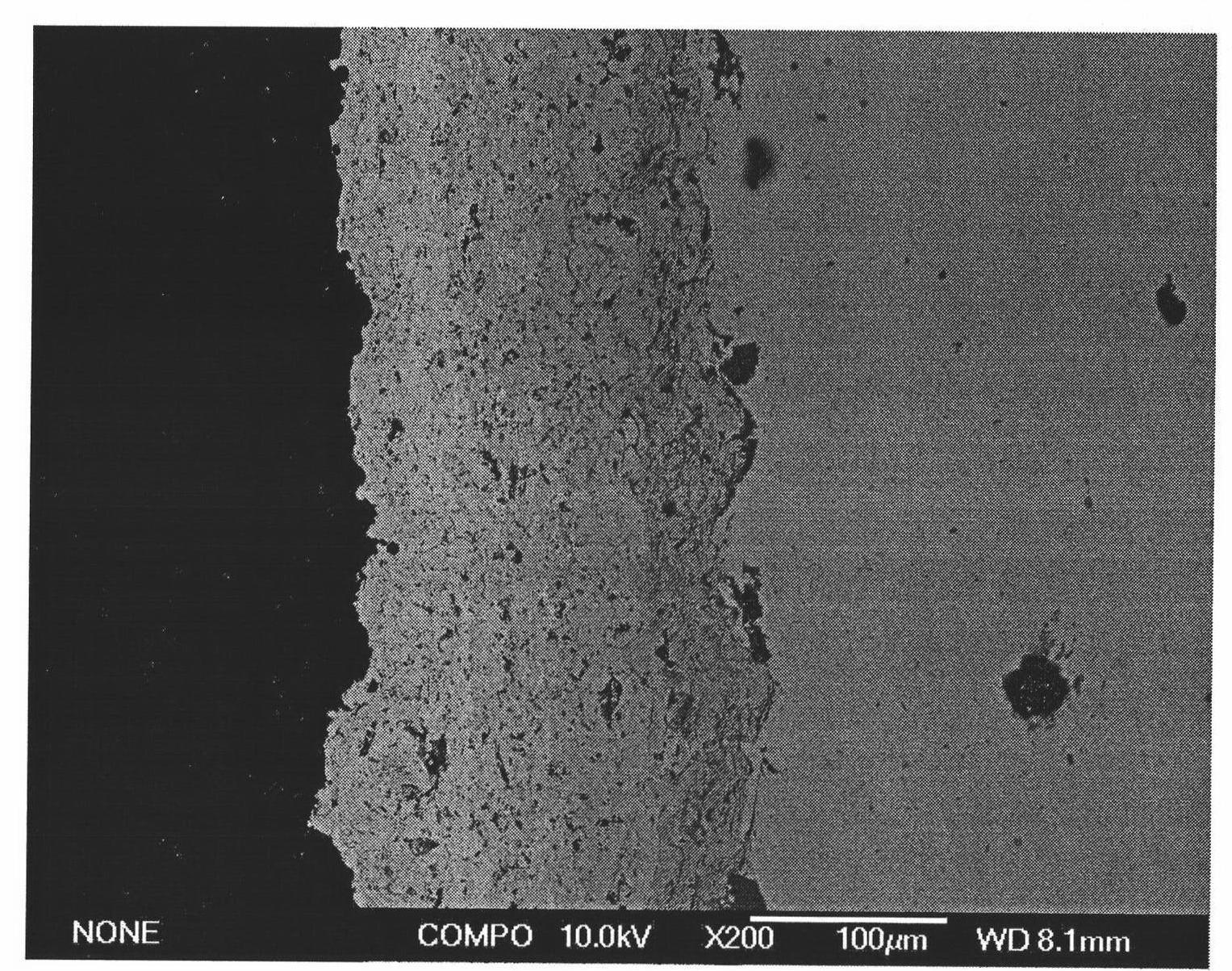

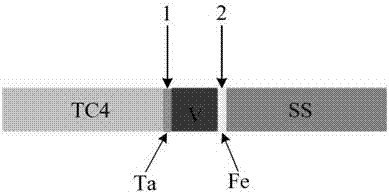

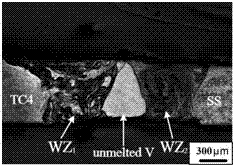

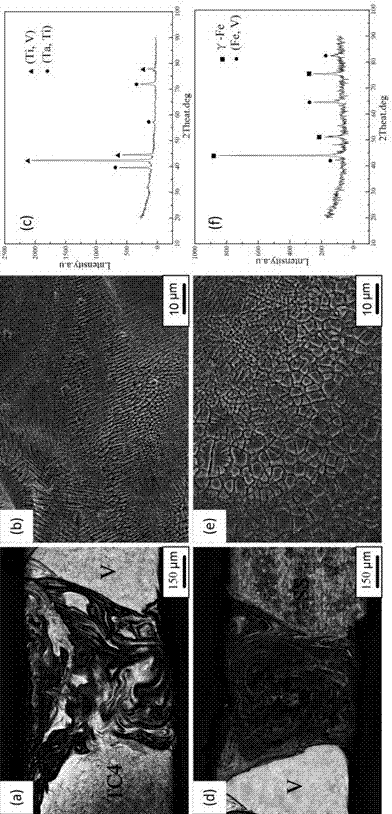

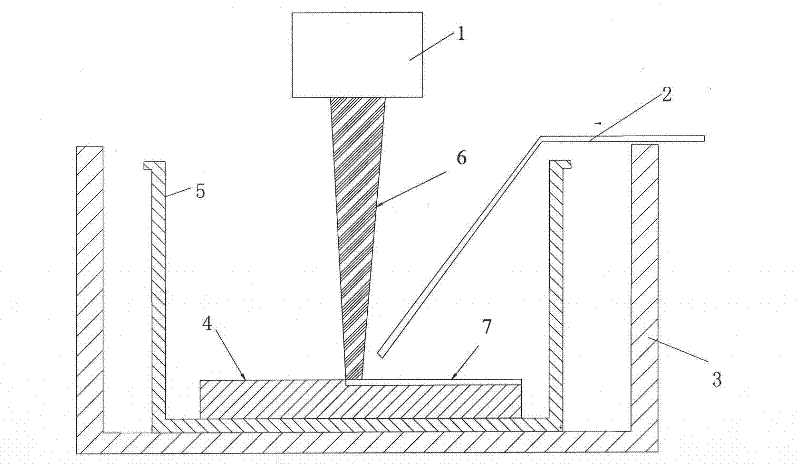

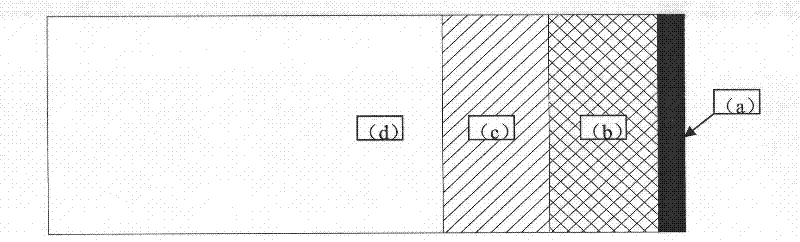

Laser welding method of titanium alloy-stainless steel dissimilar metal by adopting composite intermediate layer

ActiveCN107127454AEasy to shapeAvoid unfusedWelding/soldering/cutting articlesLaser beam welding apparatusOmegaTitanium alloy

The invention relates to a laser welding method of a titanium alloy-stainless steel dissimilar metal by adopting a composite intermediate layer, and belongs to the technical field of material welding (connection). According to the method, laser is adopted as a welding heat source, and a Ta / V / Fe composite layer is used as an intermediate layer material, so that formation of an omega brittle phase in a titanium alloy-vanadium welding line and an alpha brittle phase in a vanadium-stainless steel welding line can be controlled, the joint brittleness can be reduced, and the joint performance can be improved; by adopting the two welding, a high-quality high-efficiency welding joint which is made of a dissimilar metal material and contains a titanium alloy-vanadium welding line, an unmolten vanadium layer and a vanadium-stainless steel welding line can be obtained. The process comprises the steps of plate assembling and clamping, preload adjustment of a titanium alloy-intermediate layer-stainless steel contact face, and laser welding along the center line of a Ta intermediate layer and the center line of a Fe intermediate layer, so that connection of the titanium alloy-stainless steel dissimilar metal can be realized. The method has the advantages of stable welding process, attracted welding line formation, no welding defects including crack, pore, undercutting, uncomplete welding, incomplete fusion and the like, and good welding process performance.

Owner:JILIN UNIV

Microtitanium-boron high-toughness gas protective welding stick

InactiveCN1328897AGood workmanshipStable welding arcWelding/cutting media/materialsSoldering mediaAlloyTitanium

The present invention relates to a micro titanium-boron high-toughness gas shielded welding wire, its chemical components (wt.%) are: C 0.03-0.10, Mn 1.00-1.80, Si 0.20-1.00, Ni 0.50-1.40, Ti 0.10-0.20, B 0.002-0.010, S less than or equal to 0.10, P less than or equal to 0.20 and the rest being Fe and other unavoidable impurity. When the welding wire is used to make protective welding by adopting mixed gas (80% Ar+20% CO2), the wield metal tensile strength is greater than or equal to 580 Mpa, -30 deg.C impact work Akv is greater than or equal to 80J, and it adapts to all-position welding. This invented welding wire possesses excellent processing property, and is suitable for gas protective arc welding of large-type structures of 600 MPa level low-alloy high strength steel, engineering machine, railway bridge, marine installation, high-pressure container and oil-gas transmission pipeline, etc.

Owner:武钢集团有限公司

Method for laser preparation of titanium nitride gradient coating on surface of titanium and titanium alloy

InactiveCN102676981AAvoid crackingSolve large surface roughnessSolid state diffusion coatingSurface cleaningTitanium nitride

The invention provides a method for a laser preparation of a titanium nitride gradient coating on a surface of titanium and titanium alloy. The method comprises the steps of performing surface cleaning treatment, surface blackening treatment and preheating treatment for a workpiece subatrate; and then carrying out laser nitriding treatment. The method is characterized in that the laser nitriding treatment is performed in a condition of filling reaction gas, and simultaneously laser scanning treatment and ultrasonic oscillating treatment for the surface of the workpiece subatrate are carried out. The titanium nitride gradient coating with a thickness of 50-200 [mu]m is obtained on the surface of the titanium and titanium alloy. The titanium nitride gradient coating is mainly composed of a nitride layer and a nitrogen diffusion layer, and has uniform transition of the coating microstructure. The surface hardness, wear resistance and corrosion resistance of the titanium nitride gradient coating are improved significantly than those of the matrix. Also, problems that crack are easy to produce, surface roughness is large, and the crystal grains of dendrite crystals of a nitride layer are coarse, in ordinary laser gas nitriding processes, are solved.

Owner:山东万丰煤化工设备制造有限公司 +1

Laser cladding alloy powder enhanced with oxide particles and preparation method thereof

The invention provides laser cladding alloy powder enhanced with oxide particles and a preparation method thereof. The laser cladding alloy powder enhanced with the oxide particles is characterized in that the laser cladding alloy powder enhanced with the oxide particles consists of a matrix alloy powder, the oxide particles and a binder, wherein the proportion is 50-98% of the matrix alloy powder, 1-45% of WC or TiC or a mixture powder of WC and TiC and 1-45% of a combined mixture powder of more than two or one of Al2O3, Cr3C2 and ZrO2. The preparation technological steps of the laser cladding alloy powder enhanced with the oxide particles are preparing the matrix alloy powder, adding the oxide particles, adding the binder, stirring and ball-milling, combining the powder, drying, crushing and sieving. The laser cladding alloy powder enhanced with the oxide particles provided by the invention not only has higher hardness and flexibility, but also has excellent abrasion resistance and corrosion resistance, thereby being quite applicable for the laser cladding of parts under the working conditions of high impact and high abrasion resistance; and moreover, the segregation generated due to great disparity between the proportions of all components can be effectively prevented during the storage, transportation and use processes.

Owner:江苏新亚特钢锻造有限公司

Electron beam welding method for dissimilar materials of nickel-aluminum bronze alloy and TC4 titanium alloy

InactiveCN101920391AHigh tensile strengthGood metallurgical bondElectron beam welding apparatusWelding defectTitanium alloy

The invention discloses an electron beam welding method for dissimilar materials of a nickel-aluminum bronze alloy and a TC4 titanium alloy, belongs to the field of dissimilar material fusion welding, and aims to solve the problem that an intermetallic compound layered structure is easily produced in the electron beam welding of the dissimilar materials of the nickel-aluminum bronze alloy and the TC4 titanium alloy. Different from the conventional welding method, the electron beam welding method is performed on the abutting surfaces of the TC4 titanium alloy and the nickel-aluminum bronze alloy respectively by deviating a certain distance to a nickel-aluminum bronze alloy side by using a superposition welding method. On the one hand, excellent metallurgical bonding can be formed on the welding line of the TC4 titanium alloy and the nickel-aluminum bronze alloy, and a joint does not have any welding defects, such as pores, cracks and the like; and on the other hand, the intermetallic compound layered structure formed by the welding line and the nickel-aluminum bronze alloy side can be weakened or eliminated, and continuously distributed weld microstructures can be obtained, so that the tensile strength of the joint can be improved to over 70 percent of that of the mother metal of the nickel-aluminum bronze alloy. The welding method in the invention is suitable for welding the conventional plate-like and tubular mother metals.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com