Passivator for treatment of electrolytic manganese metal surface and process for preparing same

A technology of electrolytic manganese metal and surface treatment, which is applied in the direction of metal material coating process, etc., to achieve the effect of simple preparation method, uniform film layer and reduced emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

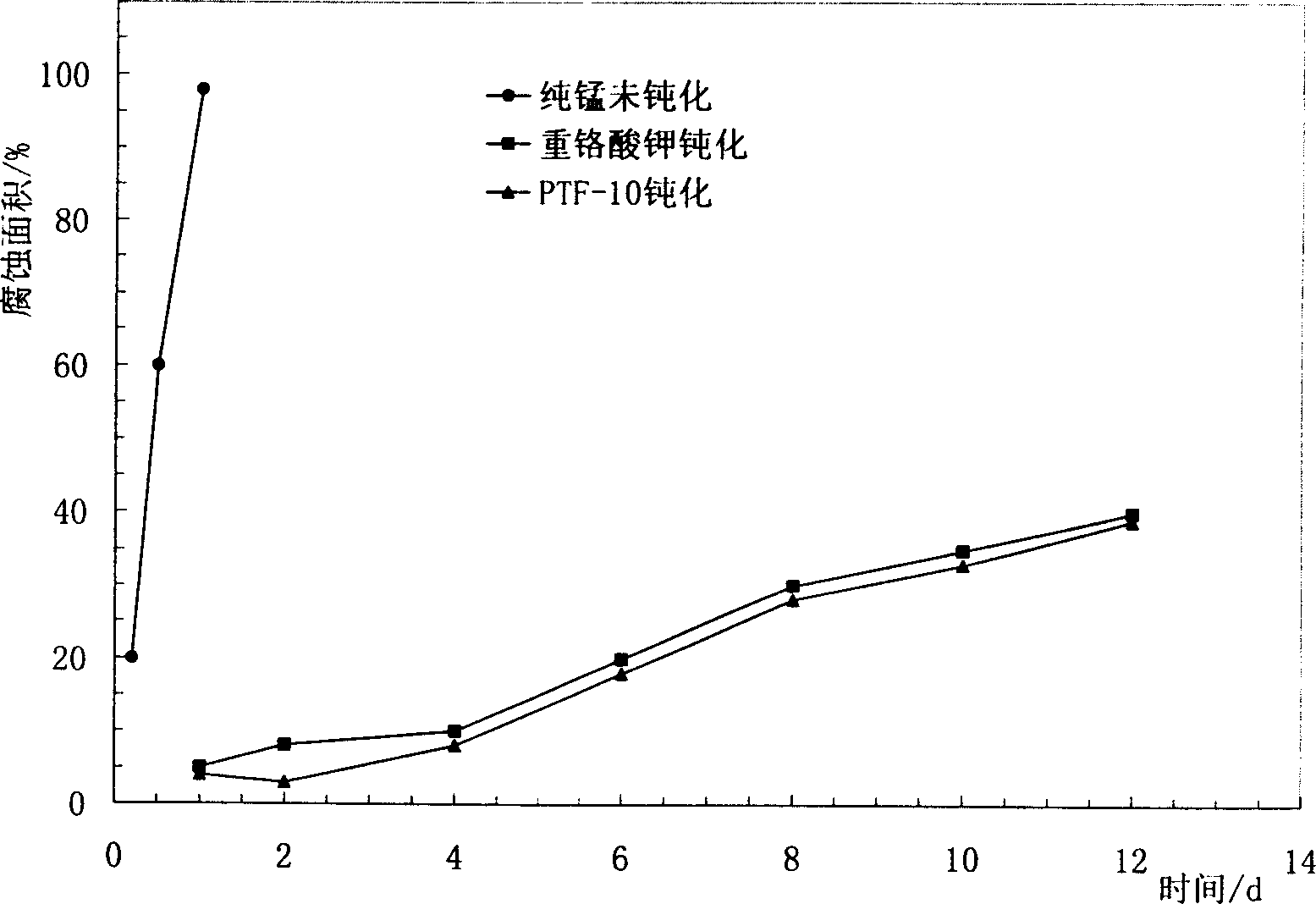

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. The composition of the passivating agent in Example 1 of the present invention is shown in Table 1.

[0022] components

name

molecular formula

Weight (kg)

Weight content%

main component

Silicate series

Na 2 SiO 3 9H 2 o

7.5

75

Co-solvent

(NH 2 ) 2 CS

0.01

0.1

corrosion inhibitor

C14H1009

0.04

0.4

Accelerator

Na 2 MoO 4 2H 2 o

0.008

0.1

C 6 h 5 N 3

0.002

water

2.44

24.4

[0023] 2. Preparation of passivation solution

[0024] Add silicate and water into the reaction tank according to the above ratio, keep warm at 60°C, and stir vigorously for 5 minutes, then add co-solvent and corrosion inhibitor according to the ratio, after stirring for 30 minutes, cool to room temperature, add accelerator, and react In...

Embodiment 2

[0030] 1. The passivating agent composition of embodiment 2 of the present invention is shown in table 3.

[0031] components

name

molecular formula

Weight (kg)

Weight content%

main component

Silicate series

Na 2 SiO 3 9H 2 o

7.8

78

Co-solvent

aminotrimethylene phosphonic acid

N(CH 2 PO 3 h 2 ) 3

0.02

0.2

(ATMP)

corrosion inhibitor

C 6 h 18 o 24 P 6

0.04

0.4

Accelerator

NaClO 3

0.005

0.06

C 6 h 5 N 3

0.001

water

2.134

21.34

[0032] 2. Preparation of passivation solution

[0033] Process is identical with embodiment 1. Prepared with 390L of clear water to obtain a passivation solution with a concentration of 25g / L.

[0034] 3. Use of passivation solution

[0035] The passivation solution ...

Embodiment 3

[0038] 1. The passivating agent composition of embodiment 3 of the present invention is shown in table 5.

[0039] components

name

molecular formula

Weight (kg)

Weight content%

main component

Silicate series

Na 2 SiO 3 9H 2 o

8.0

80

Co-solvent

(NH 2 ) 2 CS

0.02

0.2

C x h y N z Mo m o n

0.05

0.5

Accelerator

(NH 4 ) 6 Mo 7 o 24 4H 2 o

0.008

0.1

C 6 h 5 N 3

0.002

water

1.92

19.2

[0040] 2. Preparation of passivation solution

[0041] Process is identical with embodiment 1. Prepared with 240L of clear water to obtain a passivation solution with a concentration of 40g / L.

[0042] 3. Use of passivation solution

[0043] a. The passivation process using this product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com