Patents

Literature

175results about How to "Fluffy structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

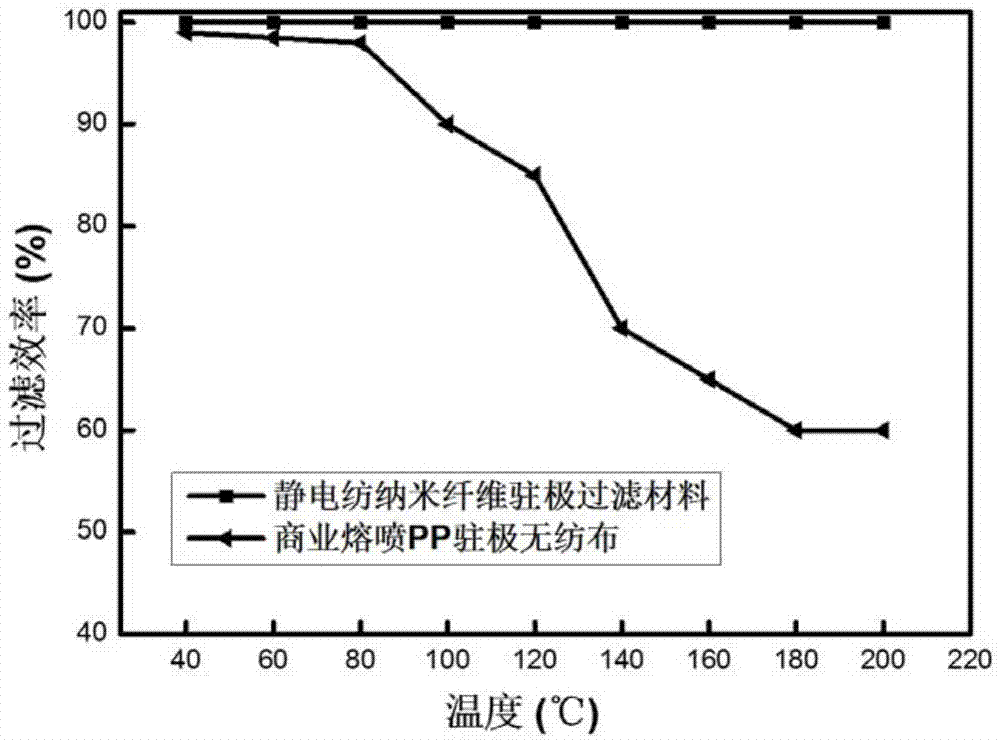

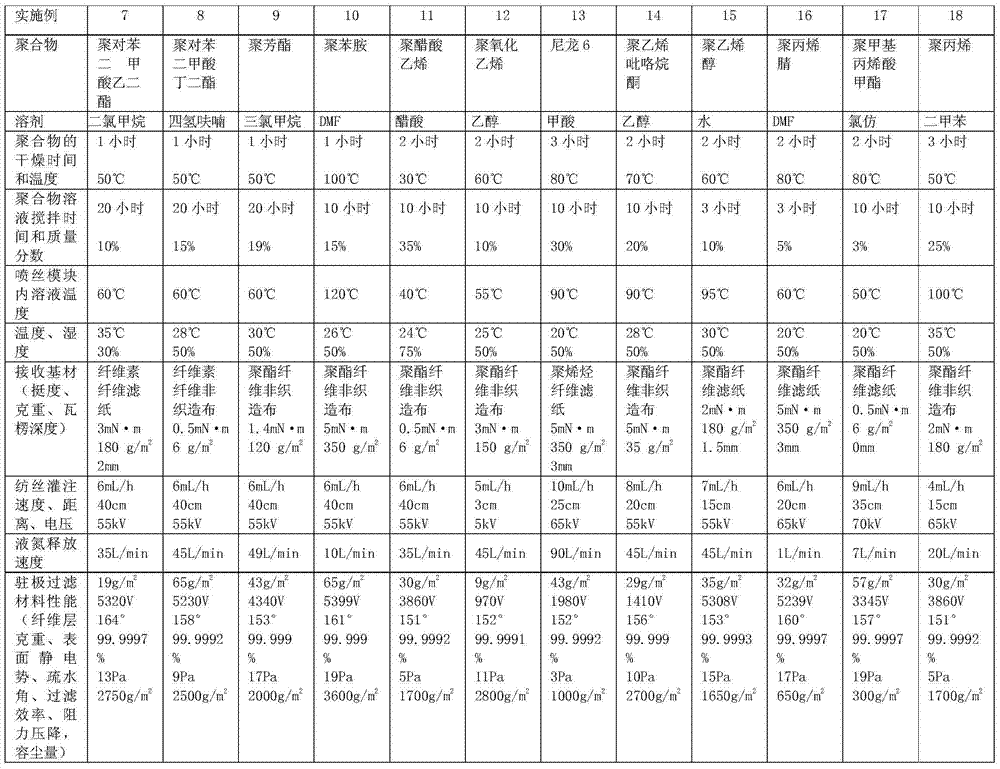

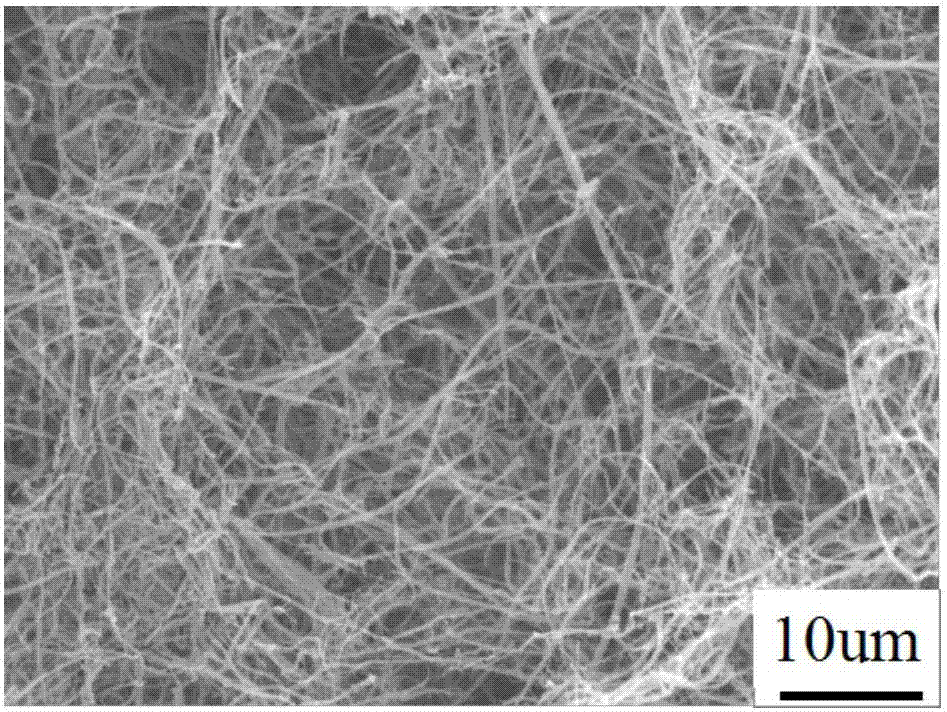

Electrospinning nano-fiber electret filtering material and its preparation method

ActiveCN104289042AHigh surface electrostatic potentialHigh super strong electrostatic adsorption performanceSynthetic resin layered productsFiltration separationPorosityFiber

The invention relates to an electrospinning nano-fiber electret filtering material and its preparation method. The high-efficiency and low-resistsance nano-fiber electret filtering material having no interfibrous adhesion and having a fluffy three-dimensional netted intercommunication structure is prepared through controlling the component and the temperatures of a polymer solution in an electrospinning process and carrying out one-step forming in the nano-fiber forming rapid cooling process, wherein the gram weight of the above nanofiber layer is 0.01-70g / m<2>, and the porosity is not less than 80%. The surface electrostatic potential of the nano-fiber electret filtering material is 800-6000V, and the surface charges have lasting storage stability, the hydrophobic angle is greater than 150DEG, the filtering efficiency of the material to particles of 0.006-1[mu]m can reach above 99.999%, the piezoresistance is less than 20Pa, and the dust containing capacity is 300-3600g / m<2>. The preparation method is simple, and the filtering material has wide application prospects in the fields of individual protection mouth mask filtration, indoor air purification and filtration, and high efficiency / ultrahigh efficiency air filtration.

Owner:DONGHUA UNIV

Saline-sodic land reclamation and control method

InactiveCN101578935AIncrease the granular structureIncrease ventilationSoil lifting machinesClimate change adaptationHigh yieldingEuryhaline

The invention relates to a saline-sodic land reclamation and control method. Wide and deep research is long developed on the reclamation of saline-sodic land at home and abroad, and more focuses on engineering measures than applies biological techniques; although achievement has been made, some insurmountable difficulties still exist. The saline-sodic land reclamation and control method comprises the following steps: bulk deep loosening, applying soil deep loosening agents and saline-sodic soil improvement agents to deep loosening soil, purposefully and proportionally applying biologically organic fertilizer according to the composition of soil detected by adopting a nutrient balance method and a nitrogen phosphorus and potassium proportioning method which both comprise the following steps: subtracting soil nutrient-supplying amount from the fertilizer requirement of target yield, supplementing the balance through fertilizing, hathpace ridge forming, draining water and controlling salt, planting green manure-saline alkali tolerant high-yielding grass crop jerusalem artichoke to thoroughly improve the soil.

Owner:王彤

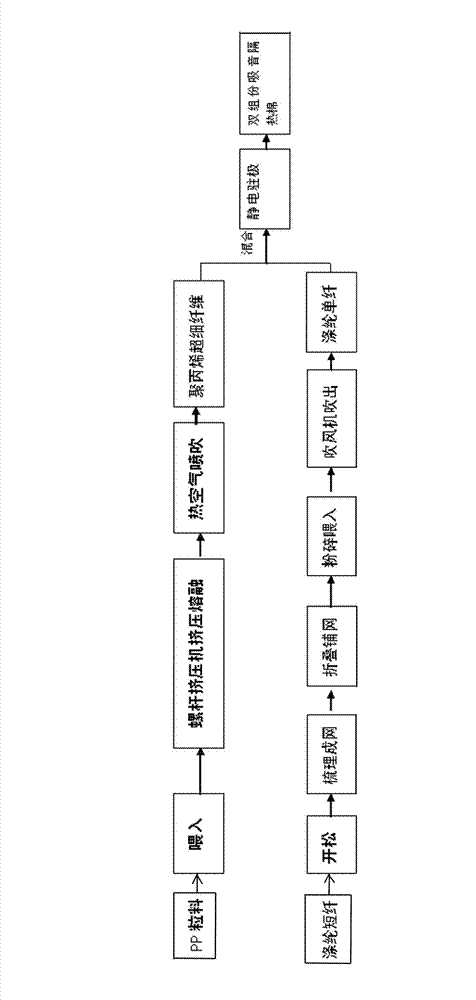

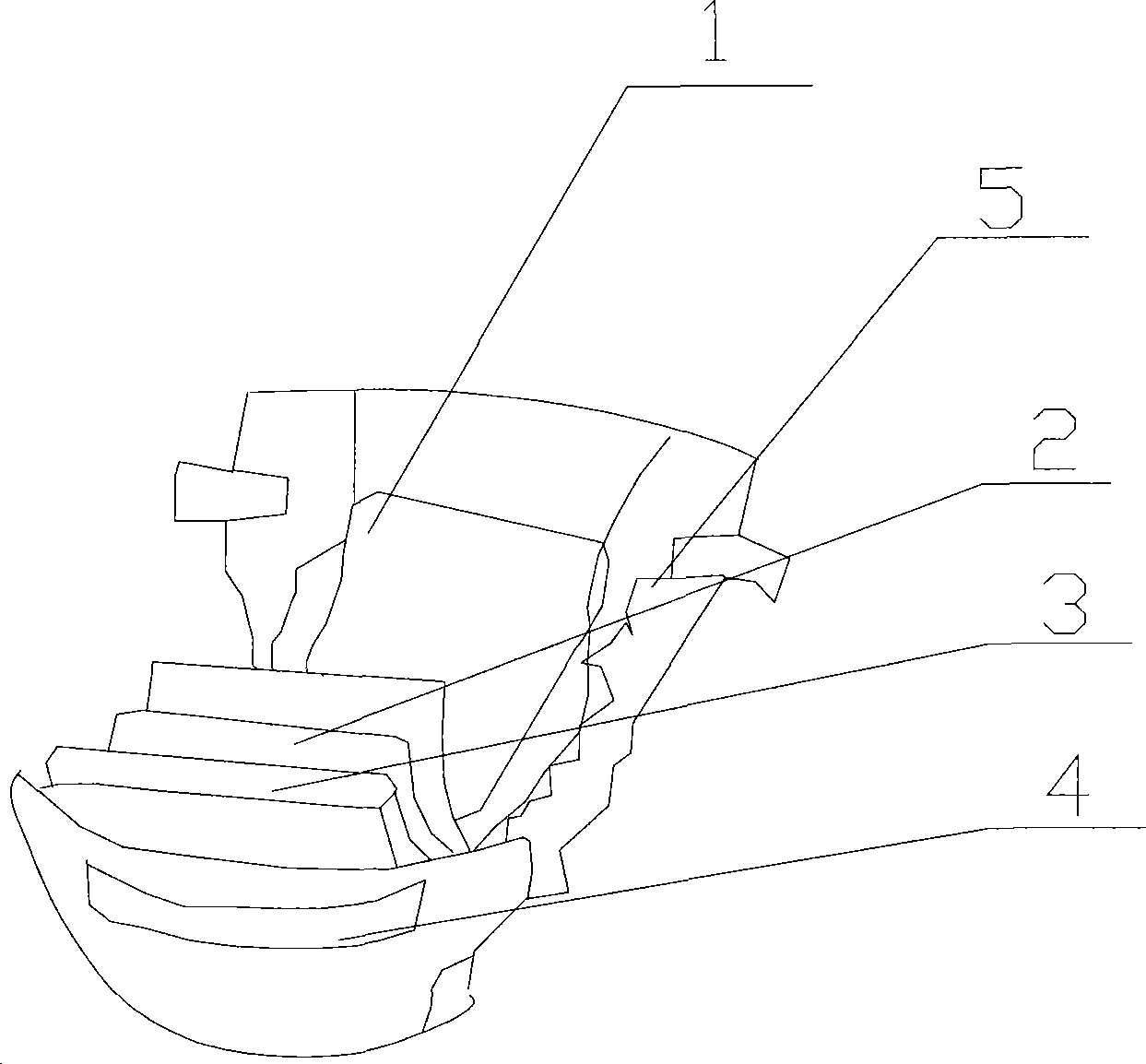

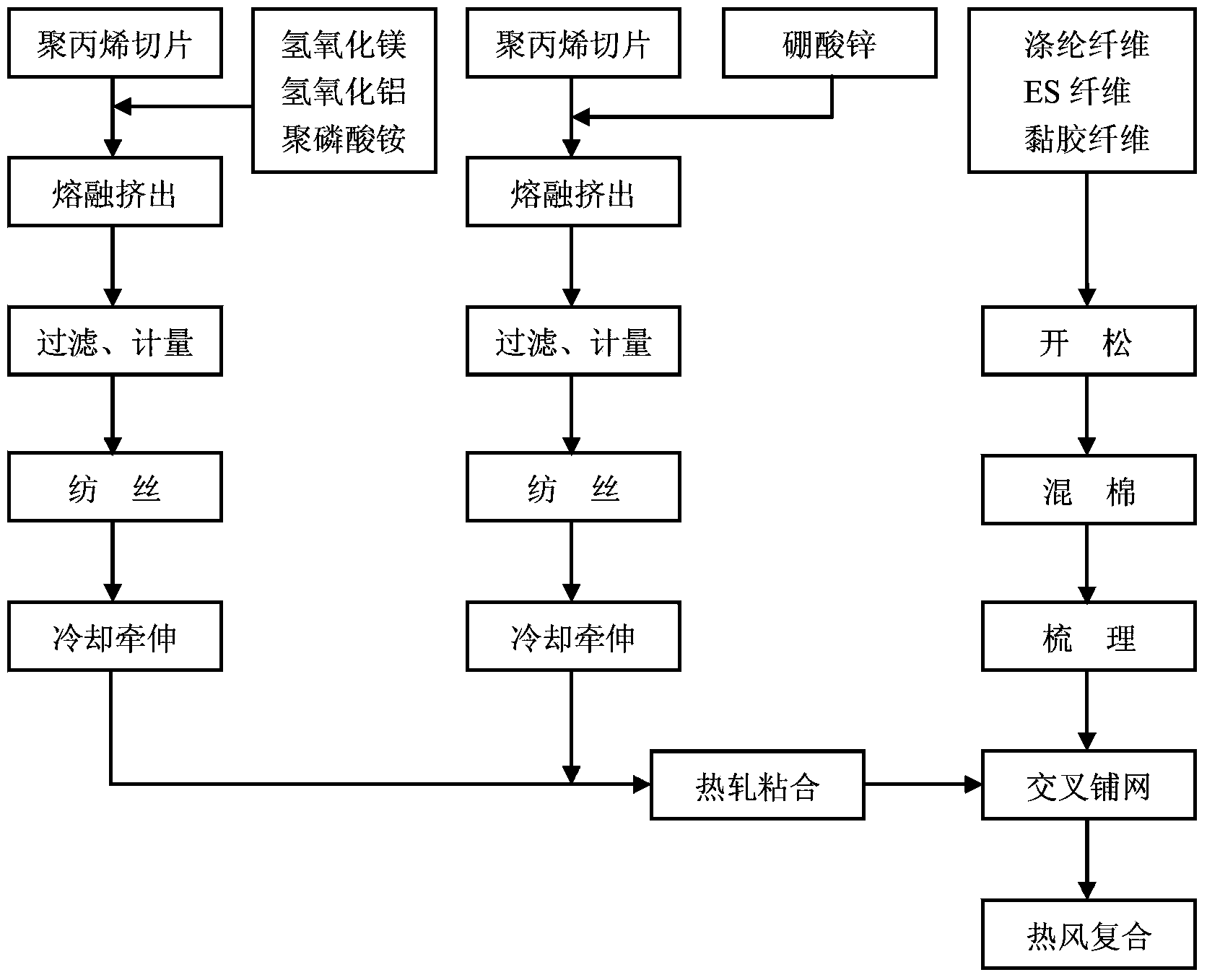

Two-component sound absorption and heat insulation cotton based on polypropylene superfine fibers and polyester staple fibers and preparation method thereof

InactiveCN103088549AFluffy structureHas a three-dimensional network structureNon-woven fabricsPolyesterPolymer science

The invention relates to two-component superfine fiber material used for heat insulation and sound absorption based on polypropylene superfine fibers and polyester staple fibers and a preparation method thereof, in particular to two-component sound absorption and heat insulation cotton based on the polypropylene superfine fibers and the polyester staple fibers and a preparation method thereof. The material is specially designed for reducing noise power in a high-noise environment, and has the effects of sound absorption and heat insulation particularly in the aspects of automobiles, high speed trains and the like. The material is also suitable for the aspects of pocket-type or plate-and-frame type filters of heating and ventilating systems, household air cleaners and vacuum dust catchers, factory purification and the like. The two-component sound absorption and heat insulation cotton based on the polypropylene superfine fibers and the polyester staple fibers comprises the polypropylene superfine fibers and the polyester staple fibers, wherein the average fineness of the polypropylene superfine fibers is 1-2 micrometers, and the fineness of the polyester staple fibers is 25-35 micrometers. The two-component material formed by mixing of the polypropylene superfine fibers and the polyester staple fibers is processed through electrostatic electrets, and then the two-component sound absorption and heat insulation cotton is formed.

Owner:SHANGHAI LIUXIN NEW MATERIAL

Method for preparing Nano silicon dioxide

A process for preparing nano-SiO2 includes such steps as adding water-soluble polymer and / or water-soluble organic C1-C8 alcohol to the solution alkali-metal silicate, stirring adding weak organic acid as catalyst, hydrolyzing reaction to obtain the hydrosol, washing, filter, and natural drying or supercritical extracting. The obtained amorphous nano-SiO2 has high purity and dispersity and large specific surface area.

Owner:BEIJING UNIV OF CHEM TECH +1

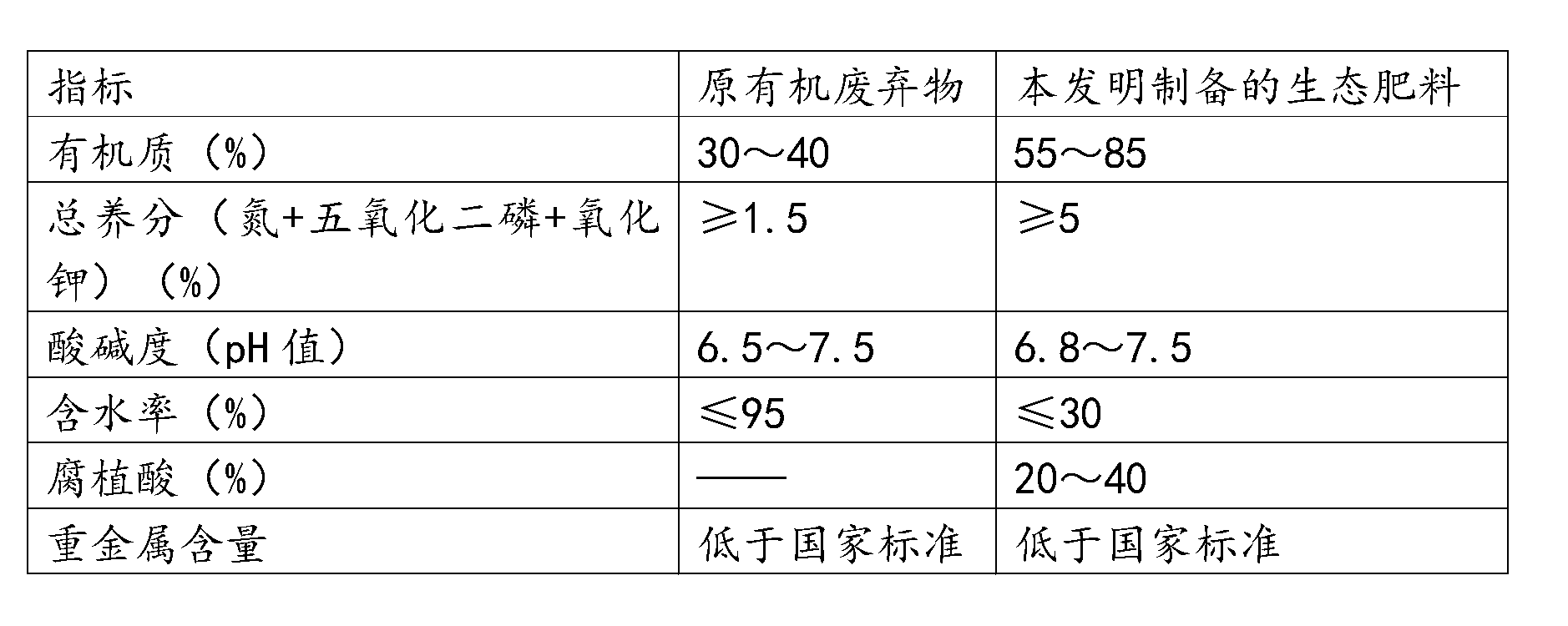

Method for preparing ecological organic fertilizer from organic waste

InactiveCN103183541ANo secondary environmental pollution problemsGood wall breaking effectBio-organic fraction processingOrganic fertiliser preparationResource utilizationMicrobial agent

The invention relates to a method for preparing an ecological organic fertilizer from organic waste. The method comprises the following steps of putting the organic waste of which the moisture content is within 95% into a subcritical water reaction kettle, adding biomass which is 0-10% of the organic waste, feeding NaOH to the reaction kettle to adjust the pH to 7.5-8.5; leading steam into the reaction kettle, adjusting the temperature to 150-300 DEG C and the pressure to 0.5-5.0MPa to react for 15-60 minutes; baking or dewatering the product until the moisture content is 50-65%; feeding a microbial agent which is 0.5-1% of weight of the product to the baked or dewatered product; evenly mixing and then piling, heating the pile to 60-70 DEG C after 2-3 days to be stable, and carrying out heat preservation at 55-65 DEG C to maintain for 5-7 days, and turning when the temperature exceeds 65 DEG C and preparing the product until the temperature is not changed. By adopting the method, the limitation of the traditional aerobic fermentation is broken through; pathogene can be thoroughly killed; no bad smell or heavy metal pollution appears; the treatment cost is reduced; the treatment efficiency is improved; and the highest target of resource utilization of the organic waste is achieved.

Owner:ROAD ENVIRONMENT TECH

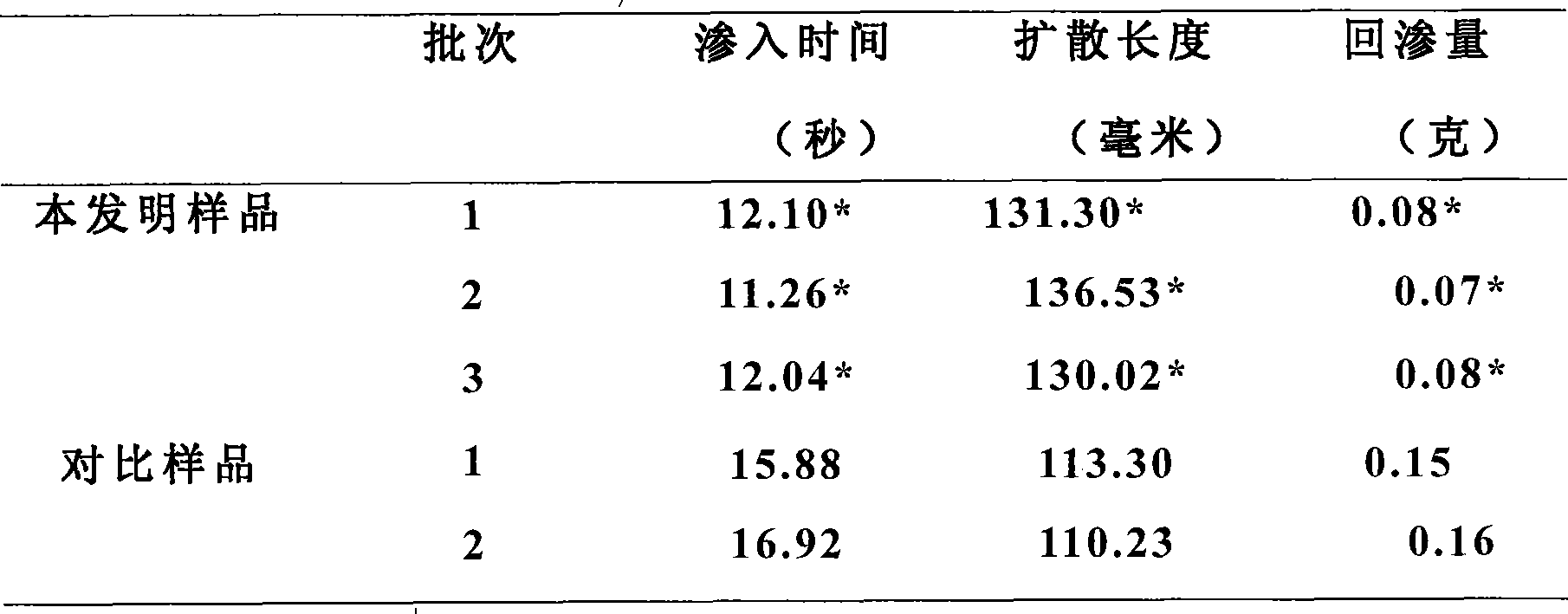

Nonwoven fabric containing polyester complex fiber, preparation thereof and use as hydroscopic substance flow guiding layer

InactiveCN101481852AGood flexibilityLow melting pointFilament/thread formingAbsorbent padsPolyesterPolymer science

The invention discloses a nonwoven fabric. The nonwoven fabric is characterized by comprising a polyethylene / polyester complex fiber material and a polyethylene / polypropylene complex fiber material, wherein, the polyethylene / polyester complex fiber material is 1-100% of the nonwoven fabric of a diversion layer, and the polyethylene / polypropylene complex fiber material is 0-99% of the nonwoven fabric of the diversion layer. The nonwoven fabric has the advantages of good diversion effect, excellent reverse osmosis effect, as well as good bulkiness and softness.

Owner:SUZHOU KIMBONDLY NONWOVENS FABRIC

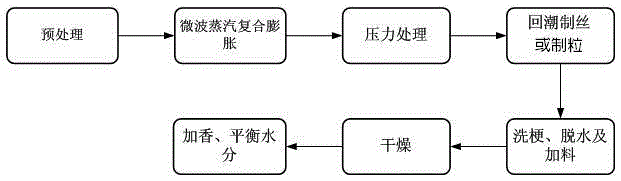

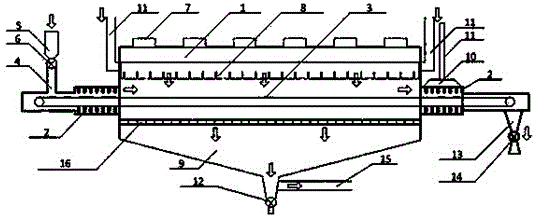

Preparation process of expanded stem products by microwave

InactiveCN105105313AAvoid surface scorchingPrevent microwave ignitionTobacco treatmentTobacco productManufacturing engineering

The invention provides a preparation process of expanded stem products and belongs to the technical field of tobaccos. The preparation process comprises the following steps of: removing impurities such as metal, hemp ropes, stem heads and stem picks in tobacco stems; expanding the tobacco stems by microwave and steam; conveying the expanded tobacco stems into a pressure container to carry out pressure treatment; carrying out moisture regaining on the tobacco stems after pressure treatment and preparing into a certain product form; adopting a soaking mode to wash the stems, then dewatering by a physical mode till the water content is below 70%, and then adding additive feed liquid extracted from the tobaccos; adopting the traditional equipment in the tobacco industry to dry the stem products added with the feed liquid till the water content is 11 to 12%, adopting a flavoring machine to carry out flavoring treatment on the dried stem products, and balancing the water content to 11 to 12%. The preparation process provided by the invention has the advantages that the whole process is simple, the energy consumption is low, the quality of the expanded stem products obtained is close to that of the shredded tobacco product, the filling value is high, and large-scale adding can be achieved, so that the expanded stem product is an excellent tobacco additive.

Owner:周川

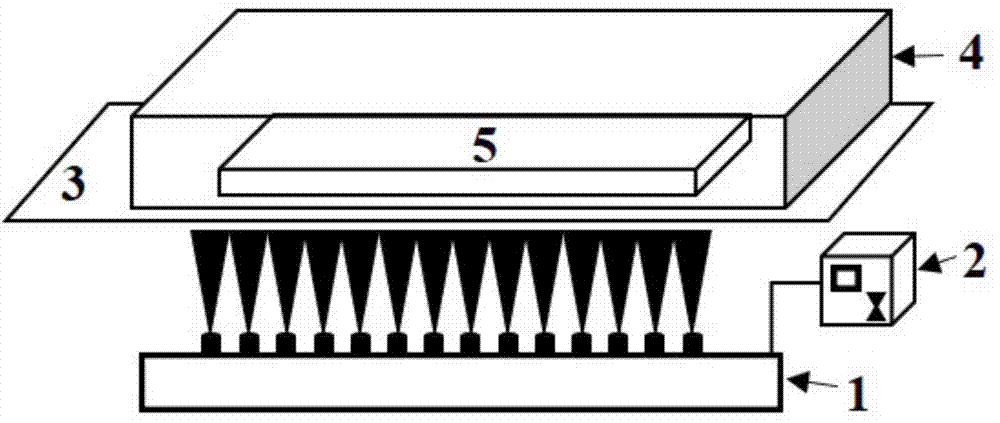

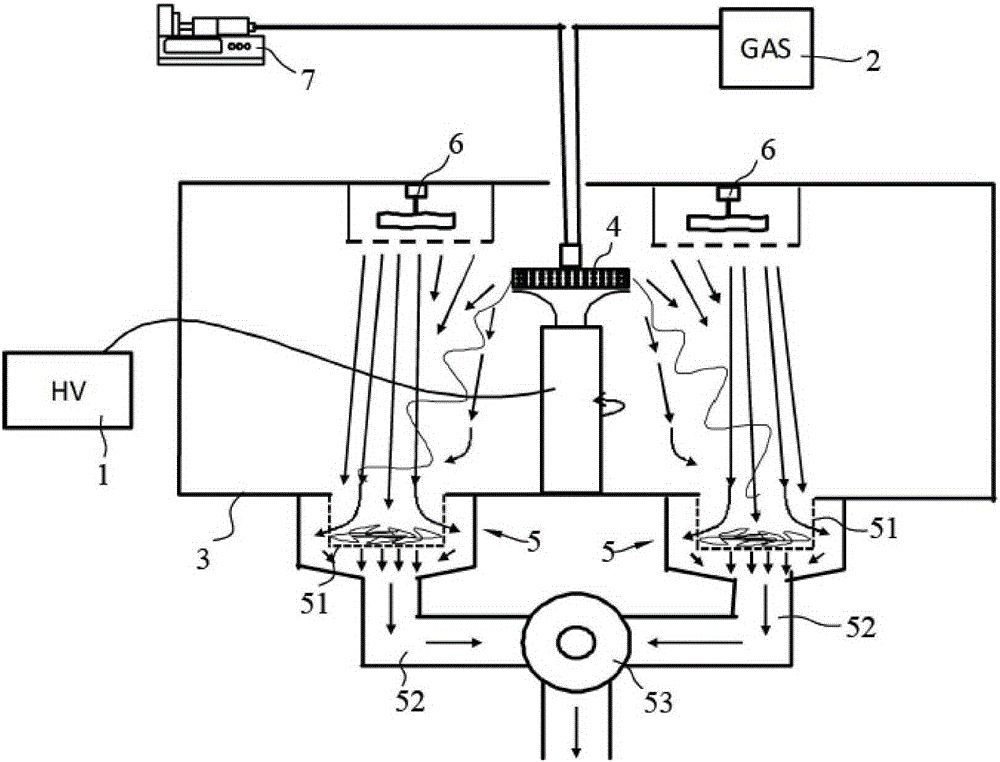

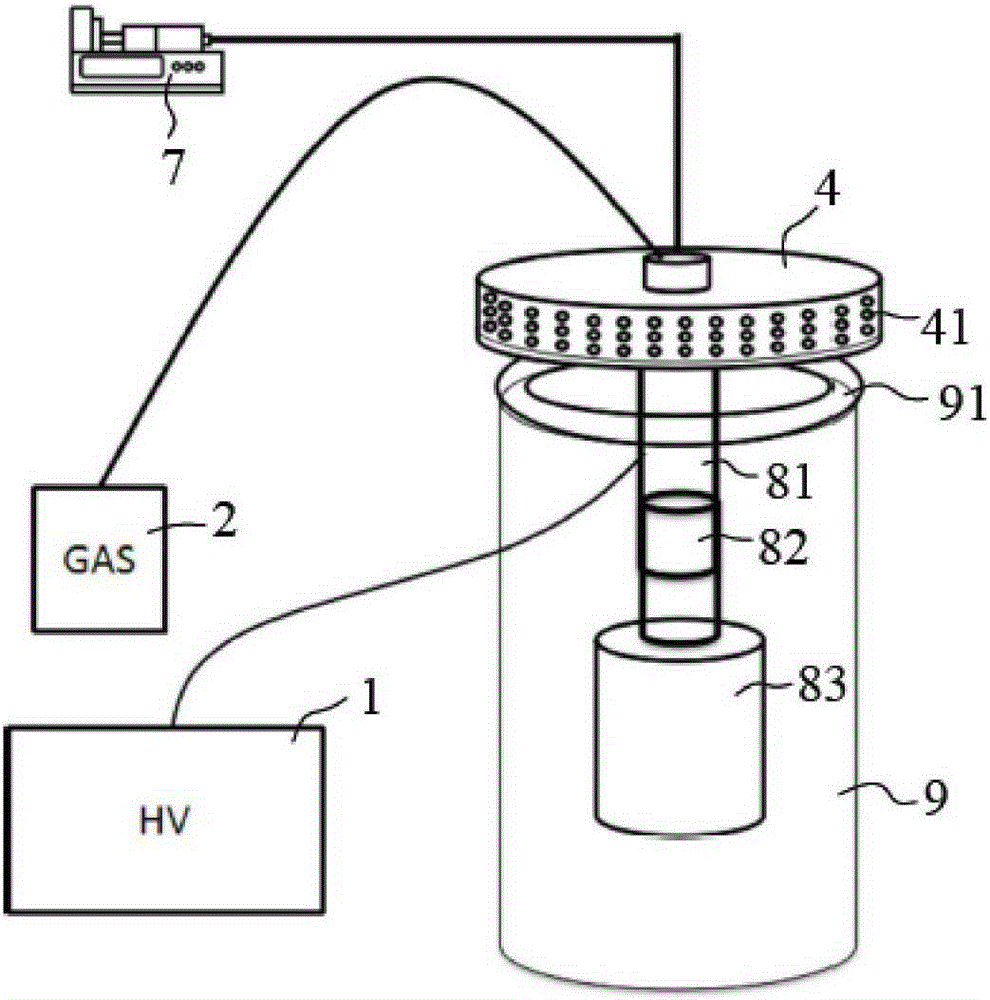

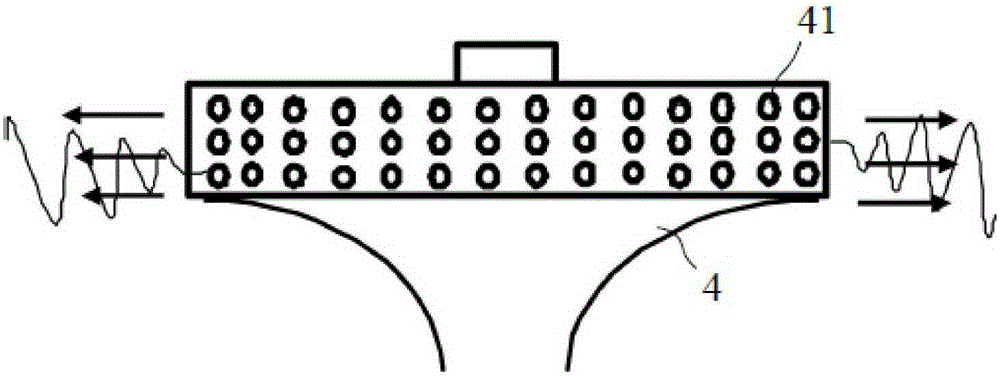

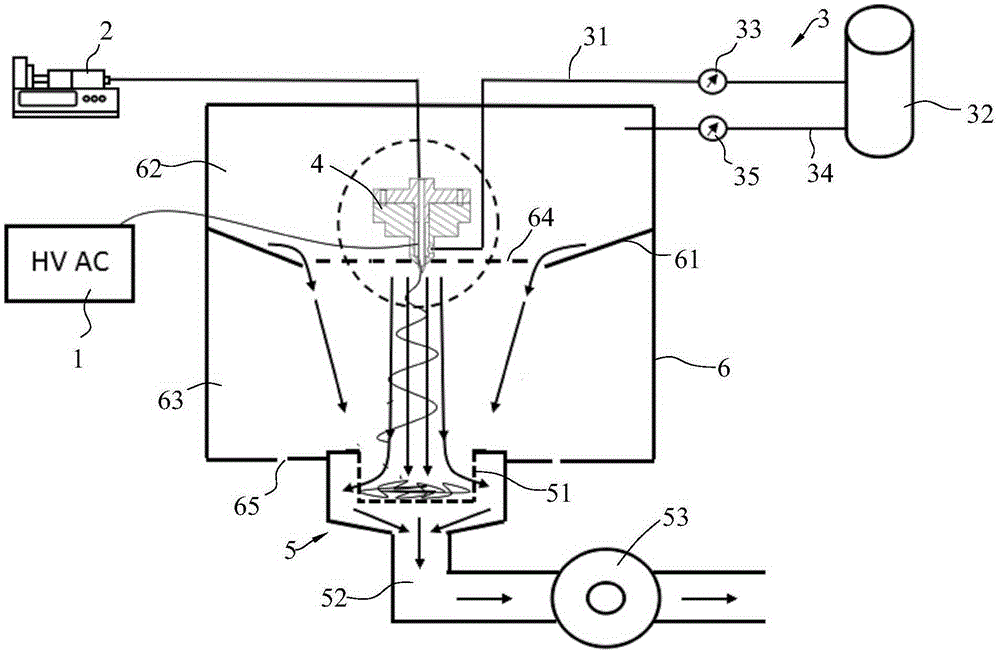

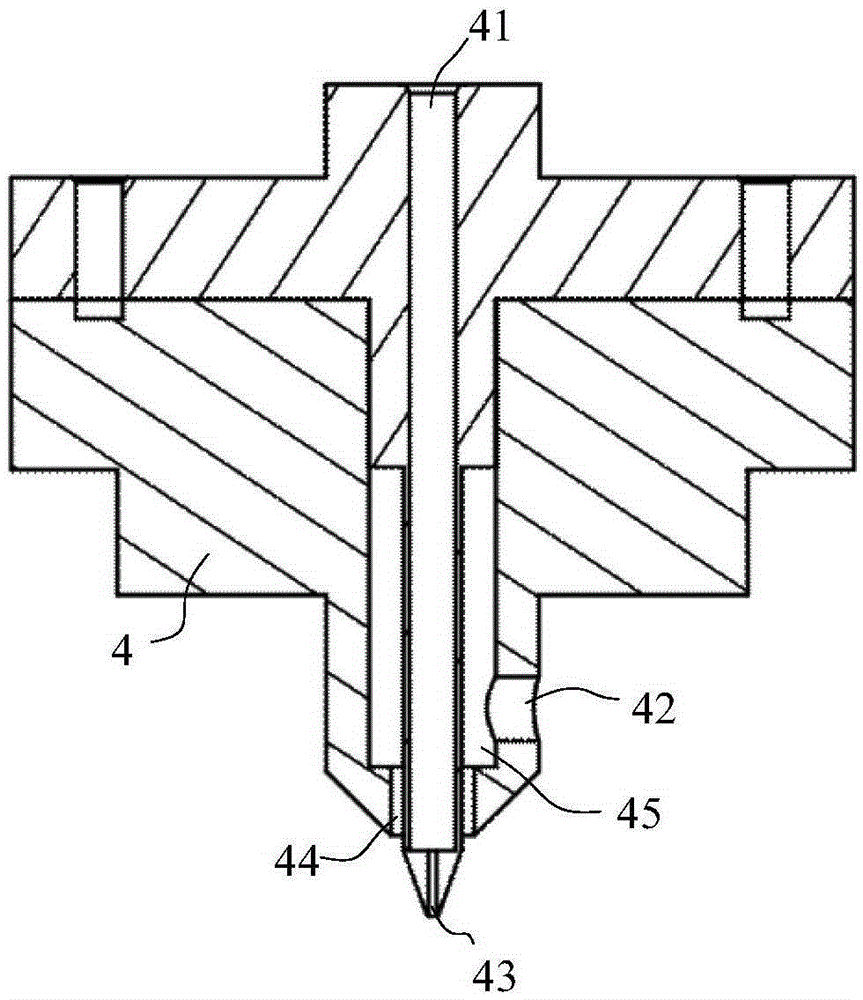

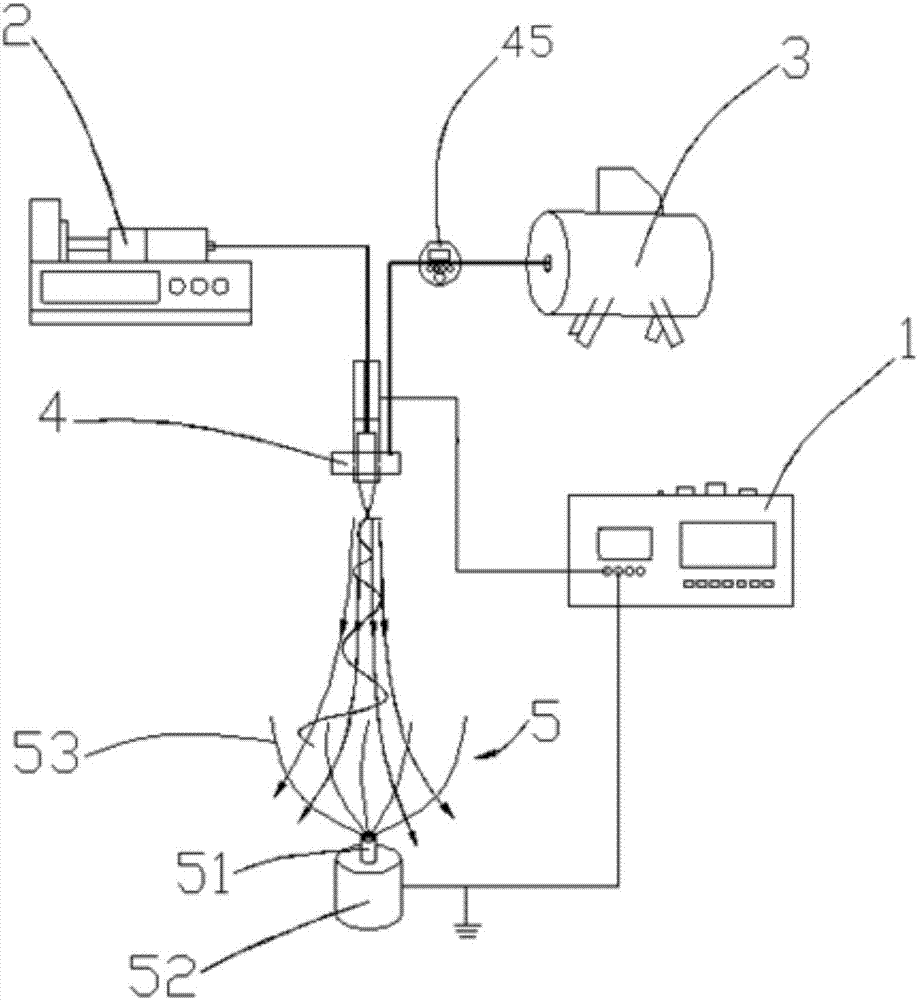

Centrifugal gas-electric spinning device by utilizing negative-pressure array

InactiveCN105350093AAirflow path controllableSimple structureNew-spun product collectionFilament/thread formingFiberEngineering

The invention discloses a centrifugal gas-electric spinning device by utilizing a negative-pressure array. The centrifugal gas-electric spinning device comprises a high-voltage alternating-current generator, an air supply device, a box body, a centrifugal sprayer, a centrifugal driving mechanism and negative-pressure receiving devices. The interior of the centrifugal sprayer is provided with a liquid storage cavity. Filament outlet holes are arranged in the centrifugal sprayer. Each negative-pressure receiving device comprises a collector, a negative-pressure pipe and a negative air-pressure generator. Negative-pressure pipe openings are formed by negative-pressure pipes in the bottom of the box body. Collectors are nested into the negative-pressure pipe openings. The multiple negative-pressure receiving devices are arrayed in an annular array with the centrifugal sprayer as the center. The high-voltage alternating-current generator is formed for generating an electric field. Airflow spraying out of the filament outlet holes is formed by the air supply device. The centrifugal gas-electric spinning device by utilizing the negative-pressure array has following beneficial effects: nanofibers are formed by sprayed polymers under airflow, an electric field, negative pressure and centrifugal force such that a three-dimensional structure is formed by nanofibers on the negative-pressure receiving devices; thickness of fiber disposition is increased; biological materials are better compatible and the application scope of technology materials is broad; and a support structure obtained is beneficial for cell growth of tissue engineering.

Owner:GUANGDONG UNIV OF TECH

Bimetallic catalyst for degrading chlorine substitutional organic pollutant, preparation method and application

InactiveCN1915511ALow priceReduce invalid decompositionMolecular sieve catalystsWater/sewage treatment by reductionTrichloroethyleneReducing agent

A bimetal catalyst for degradating the CCl4, trichlorothene and tetrachloroethene is sewage within one hour is composed of the modified zeolite as carrier and the bimetal Fe-Ni in the mass ratio of (1-10): 100. Said bimetal Fe-Ni is prepared by using sodium dithionite as reducer to reduce the Ni ions on the surfaces of Fe filings.

Owner:XINYI AGRI CHEM PLANT JIANGSU PROV

Preparation method and device for three-dimensional support for spinning by utilizing gas-electro spinning based on negative-pressure collection

ActiveCN105350089ASimple structureSimple processFilament/thread formingEngineeringAlternating current

The invention discloses a preparation method and device for a three-dimensional support for spinning by utilizing gas-electro spinning based on negative-pressure collection. A device comprises an alternating-current high-voltage generator, a liquid supply device, a gas liquid device, a coaxial sprayer and a negative-pressure collecting device. The coaxial sprayer is provided with a liquid outlet and a gas outlet. The gas supply device is used for conveying a spinning solution or melts to the coaxial sprayer and enabling melts to flow out of the liquid outlet. The gas liquid device can generate air flow blowing from the liquid outlet to the negative-pressure collecting device via the liquid outlet. The alternating-current high-voltage generator can form an alternating electric field between the coaxial sprayer and the negative-pressure collecting device. The negative-pressure collecting device comprises a collector, a negative-pressure pipe and a negative-pressure generator. The spinning solution or melts form solution jet flow or melt jet flow in the coaxial sprayer and the collector under effect of airflow and the alternating electric field.The preparation method and device for the three-dimensional support for spinning by utilizing gas-electro spinning based on negative-pressure collection have following beneficial effects: by adoption of spinning technology based on the negative-pressure collector, the nanofiber three-dimensional support featuring a broad range of preparation material, small fiber diameters, uniformly-distributed filament diameters, a loose structure, great thickness and superior mechanical properties is obtained and has great technological universality.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

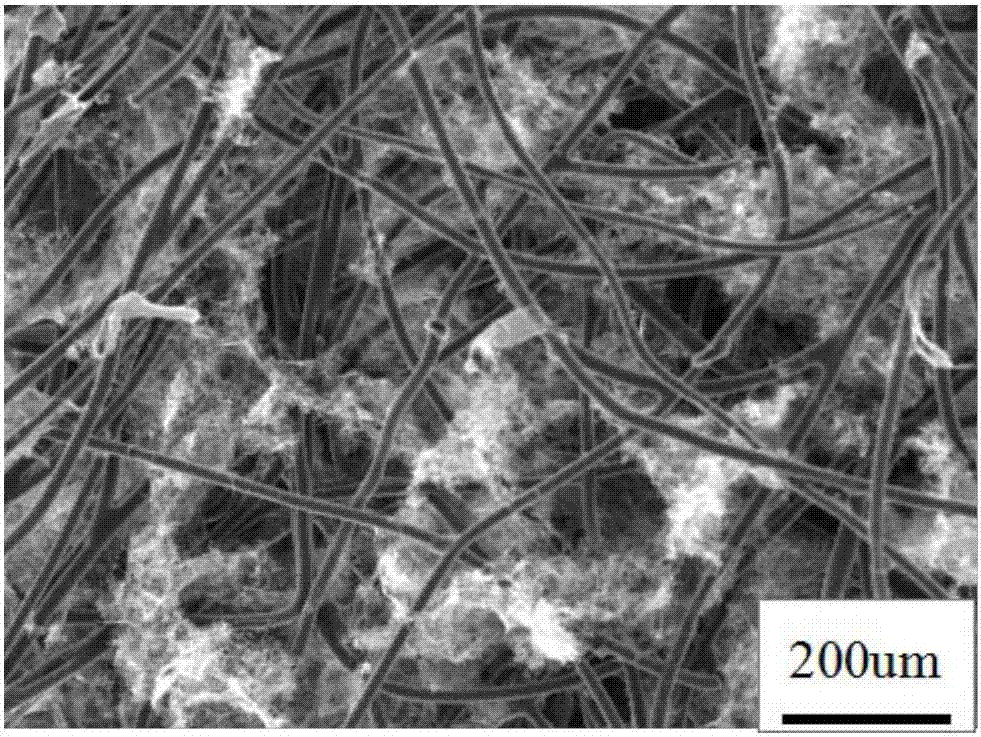

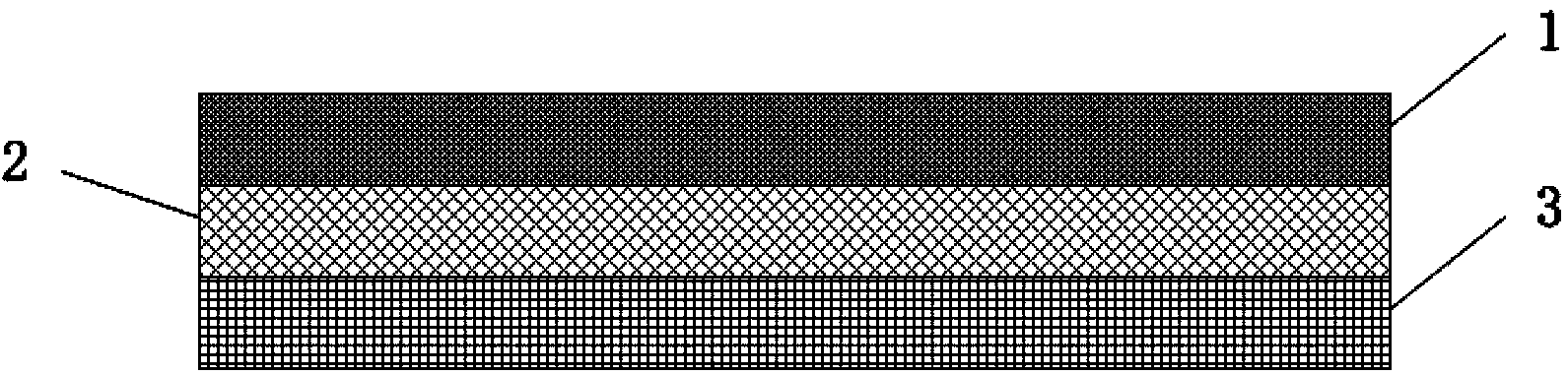

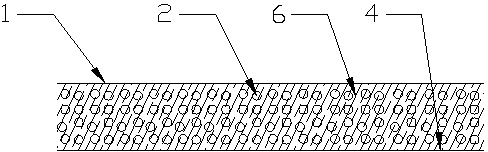

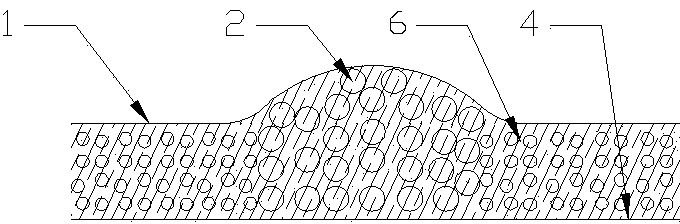

Micron fiber three-dimensional framework/polymer nanofiber composite filter material and preparation method thereof

ActiveCN107137979ALarge specific surface areaImprove mechanical propertiesMembrane filtersFiltration separationAir filtrationPolymer science

The invention belongs to the field of textile materials and discloses a micron fiber three-dimensional framework / polymer nanofiber composite filter material and a preparation method thereof. The preparation method comprises the following steps: preparing polymer nanofibers by adopting a melt blending method; dispersing the polymer nanofibers and a crosslinking agent into a solvent to form a suspension, then soaking micron fiber nonwoven fabric skeletons into the suspension, carrying out freeze drying to form coagulation blocks, and then removing the solvent, so that a nonwoven material with polymer nanofiber aerogel gradiently distributed among the micron fiber nonwoven fabric skeletons is obtained. According to the invention, the adopted preparation technology is simple, raw materials are environment-friendly, conditions are mild, the composite filter material is applicable to industrialized mass production, and the composite filter material product has good flexibility as well as high efficiency and low resistance air filtration performance and can be applied to the field of efficient air purification.

Owner:WUHAN TEXTILE UNIV

Plant filter base material

InactiveCN103285664AImprove filtration efficiencyImprove adsorption efficiencyOther chemical processesFiltration separationPlant fibrePlant stem

The invention discloses a plant filter base material which is prepared by the working procedures of crushing, screening, degreasing, washing, softening, cleaning, puffing and drying a mixture of plant stems and leaves, and the like. According to the filter base material disclosed by the invention, plants are puffed, so that the fiber structure of the plants is fluffy to form a plurality of small gaps, the flow resistance to filter media is reduced, and impurities in filtered substances are effectively intercepted. According to the filter base material, a surface barrier form of a traditional filter material is converted into a volume type echelon filter and deep adsorption form. Additionally, the filter base material disclosed by the invention is in a fluffy structure, so that various additives can be steadily stored in the structures and cell capsules of plant fibers so as to be processed into various gas and liquid filter materials. When the filter media pass through the filter materials, the plant fibers are extruded, so that the additives are slowly released to repair the filter media, and the adverse effect caused by excessive release of the additives can be avoided.

Owner:GANSU HENGTONG FILTER IND

Ecological environment-friendly wood-plastic composite panel for advertisement board and preparation method of panel

InactiveCN104191772AImprove thermal stabilityFluffy structureSynthetic resin layered productsChemical recyclingEnvironmental resistanceEcological environment

The invention discloses an ecological environment-friendly wood-plastic composite panel for an advertisement board and a preparation method of the panel, belonging to the technical filed of manufacture of wood-plastic composite materials. The panel is of a three-layer composite structure and is composed of outer surface soft layers and a middle hard layer, wherein the hard layer is clamped between the two soft layers which are completely the same; the thickness of the hard layer is 0.5-5mm, and the thickness of each soft layer is 0.25-2.5mm. By taking recycled wastes such as sunflower straws and wood-plastic waste and PVC as basic materials, the ecological environment-friendly wood-plastic composite panel comprising a soft-surface thermoplastic elastomer as the outer surface layer and a hard support as the middle layer is produced, and is a good substitute for an existing advertisement board. The ecological environment-friendly wood-plastic composite panel is environmentally friendly and low-carbon, harmless to environment and a human body, good in water-resisting property, easy in demolding, long in service life, unlikely to deform, smooth in surface, and good in fire resistance and photostability, and also has antibacterial insect-prevention effect, and the dimension of the composite panel can be specified by customers.

Owner:民勤县华安再生资源开发有限公司

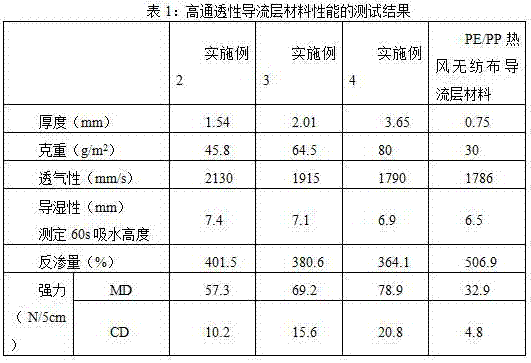

High-permeability diversion layer material and preparation method thereof

ActiveCN106937902AReduce heavinessGood moisture permeabilityAbsorbent padsBaby linensFiberReverse osmosis

The invention discloses a high-permeability diversion layer material and a preparation method thereof, and relates to the field of disposable sanitary products. The preparation method of the high-permeability diversion layer material is characterized in that by compound-superimposing and selecting an upper layer vertical net and a bottom layer direct laying net, matching coarse denier profiled cross-section fibers and fine denier hydrophilic double components in the upper layer vertical net, reasonably matching hydrophilic and water-repellent double-component fiber in the bottom layer direct laying net, selecting a hot air penetration thermal stabilization mode and reasonably selecting lustring and setting technological parameters of a hot pressing roll, the high-permeability diversion layer material with good permeability is prepared. Therefore, the technical problems of poor diversion performance, inability in storing liquid, poor transient sucking effect, complex technology, poor permeability and difficulty in quantity production of a diversion layer material are solved, and the effects of enabling the diversion layer material to have good abilities of transient suction property, diversion property, barrier property and temporary liquid storage and to have good effects of ventilation, moisture permeation and reverse osmosis prevention are achieved.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

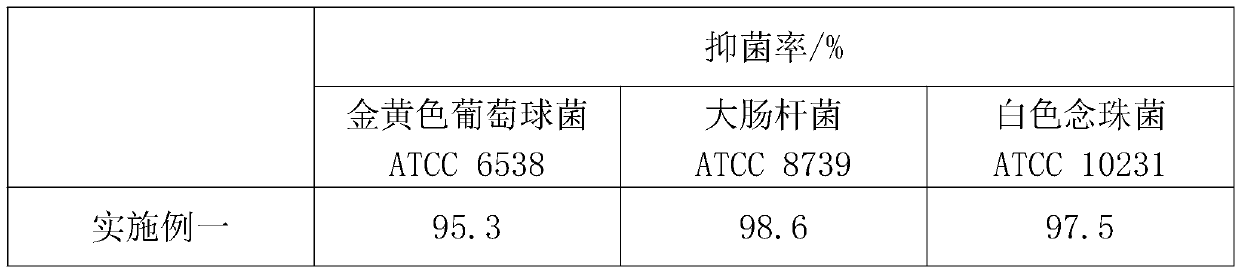

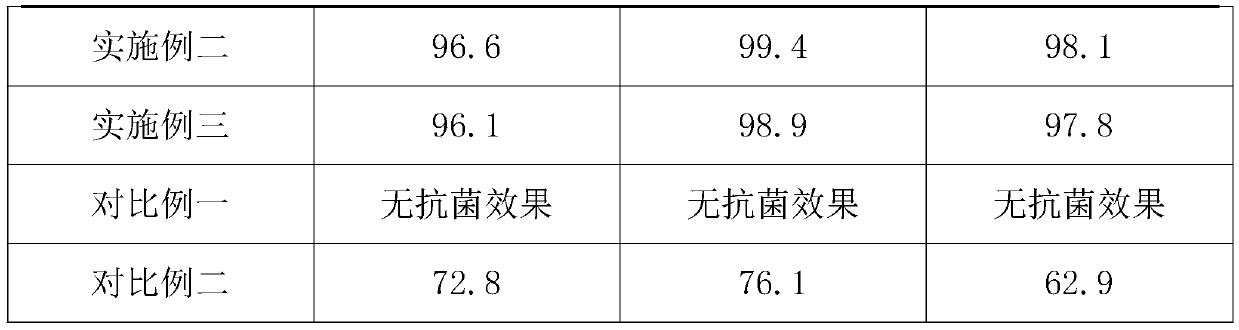

Preparation method for antibacterial melt-blown non-woven fabric

ActiveCN111424428AMany gapsFluffy structurePhysical treatmentBiochemical fibre treatmentPolymer scienceMethacrylate methyl

The invention relates to the technical field of non-woven fabrics, and provides a preparation method for an antibacterial melt-blown non-woven fabric. The preparation method comprises the following steps of (1) carrying out oxygen plasma treatment on a polypropylene non-woven fabric, and carrying out graft modification on the polypropylene non-woven fabric to prepare a modified polypropylene non-woven fabric; (2) polymerizing an amino-terminated hyperbranched polymer with propylene diamine and methyl methacrylate as raw materials, and preparing a modified hyperbranched polymer through polycondensation of carboxymethyl chitosan and the amino-terminated hyperbranched polymer; and (3) adding a copper chloride solution into a modified hyperbranched polymer aqueous solution, dropwise adding a sodium borohydride solution under nitrogen protection and ice bath conditions, carrying out impregnation treatment on the modified polypropylene non-woven fabric in the modified hyperbranched polymer aqueous solution after the reaction is finished, and drying to obtain the antibacterial melt-blown non-woven fabric. The preparation method solves a problem that the melt-blown non-woven fabric in theprior art only has an efficient filtering effect and does not have antibacterial property.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Preparation method of corn dietary fiber micro powder

The invention discloses a preparation method of corn dietary fiber micro powder, belonging to the technical field of agricultural product deep processing. The invention takes the low-price by-product-corn bran residues from deep processed corns as the material to extract important functional health care food-corn dietary fiber micro powder. The preparation method includes the steps of: 1, pretreatment: purifying, grinding, sieving and drying the corn bran residues; 2, alkaline leaching: adding sodium hydroxide solution according to proportion, stirring to be even, centrifugally washing to be neutral, and removing the protein; 3, pickling: transferring the precipitate to dilute sulfuric acid solution, stirring to be even, centrifugally washing to be even so as to remove the macromolecular sugar such as starch and the like; 4, primary drying and grinding: primarily drying and then grinding through a grinder until the grain size is below 100mesh; and 5, drying: drying through a dryer with the water content controlled below 2%. In this way, the corn dietary fiber micro powder product can be obtained. The preparation method is simple in production process, low in cost and easy to realize in industrialized production, truly refines and improves the corn deep processing industry and greatly improves the comprehensive application value of corns, and the corn dietary fiber micro powder product has good performance. Therefore, the preparation method has remarkable economic and social benefits.

Owner:山东福田糖醇有限公司

A preparation method of titanium dioxide fiber with photocatalytic function and nano-polycrystalline structure

InactiveCN102286804AImprove stabilityImprove spinnabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationFiberSteam activation

The invention discloses a preparation method of titanium dioxide fibers with a photocatalysis function and a polycrystalline nanostructure. The preparation method comprises the following steps: respectively diluting titanium tetrachloride and potassium acetate, which are taken as raw materials, in ethanol, mixing at 0-10 DEG C under the condition of stirring to generate titanium acetate and potassium chloride, filtering to remove potassium chloride by taking advantage of the property that potassium chloride is insoluble to ethanol so as to acquire filtrate of ethanol in which titanium acetateis dissolved, concentrating the filtrate to obtain a titanium acetate sol spinning solution, centrifuging and spinning to obtain precursor fibers, and performing steam activation thermal treatment toobtain the titanium dioxide fibers. The preparation method disclosed by the invention has the advantages of lower raw material cost, simpler sol production process and pollution-free preparation process.

Owner:NANJING UNIV OF SCI & TECH

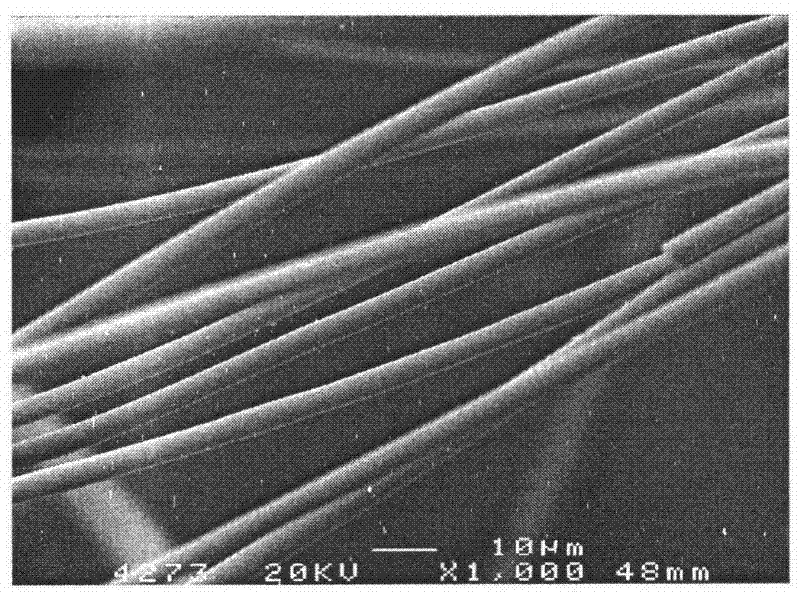

Industrial protection non-woven material and manufacturing method thereof

ActiveCN103526454AImprove breathabilityExcellent flame retardantFlame-proof filament manufactureNon-woven fabricsPolyesterEngineering

The invention discloses an industrial protection non-woven material and a manufacturing method of the industrial protection non-woven material. The industrial protection non-woven material comprises a PP spunbond non-woven fabric layer, an ES-mixed non-woven fabric layer and a PP melt-blown non-woven fabric layer sandwiched between the PP spunbond non-woven fabric layer and the ES-mixed non-woven fabric layer. Fire retardant mixtures of a first component are added to the PP spunbond non-woven fabric layer, and fire retardants of second components of different types are added to the PP melt-blown non-woven fabric layer. Mixed fibers of ES fibers, polyester fibers and viscose fibers are combed into a net to form the ES-mixed non-woven fabric layer. The industrial protection non-woven material has the moisture percentage similar to the moisture percentage of a human body, good gas permeability and soft and fluffy hand feelings, is comfortable to wear, has high tension stress and morphological stability in all directions, protects the structure of the melt-blown non-woven fabric layer and has the good inflaming retarding characteristic and the environment protection effect, and a guarantee is provided for the protection performance of the industrial protection non-woven material.

Owner:东营俊富净化科技有限公司

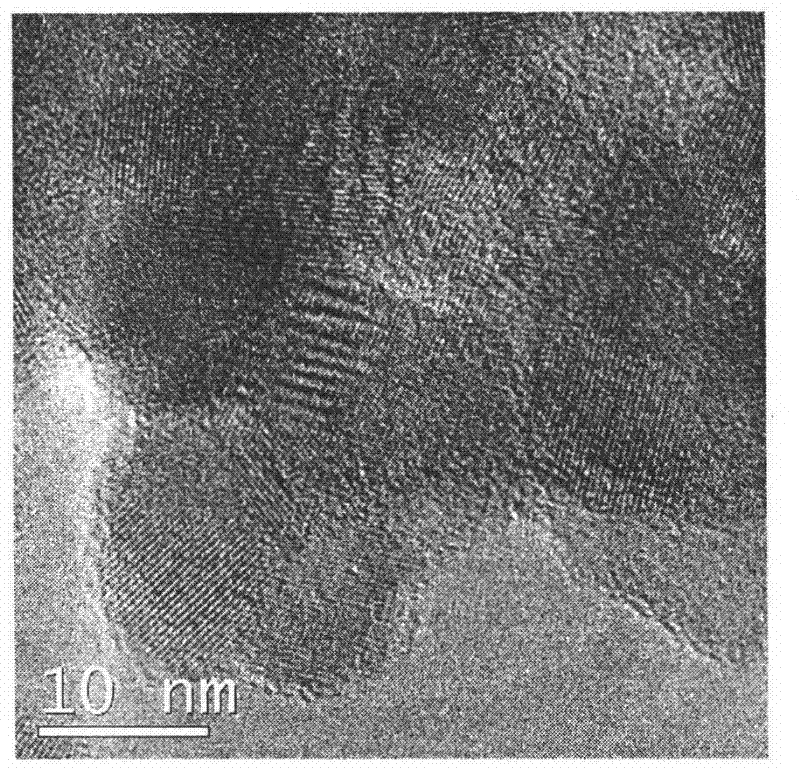

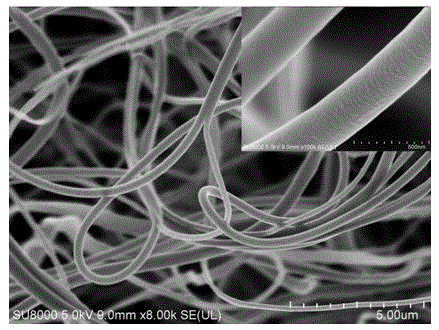

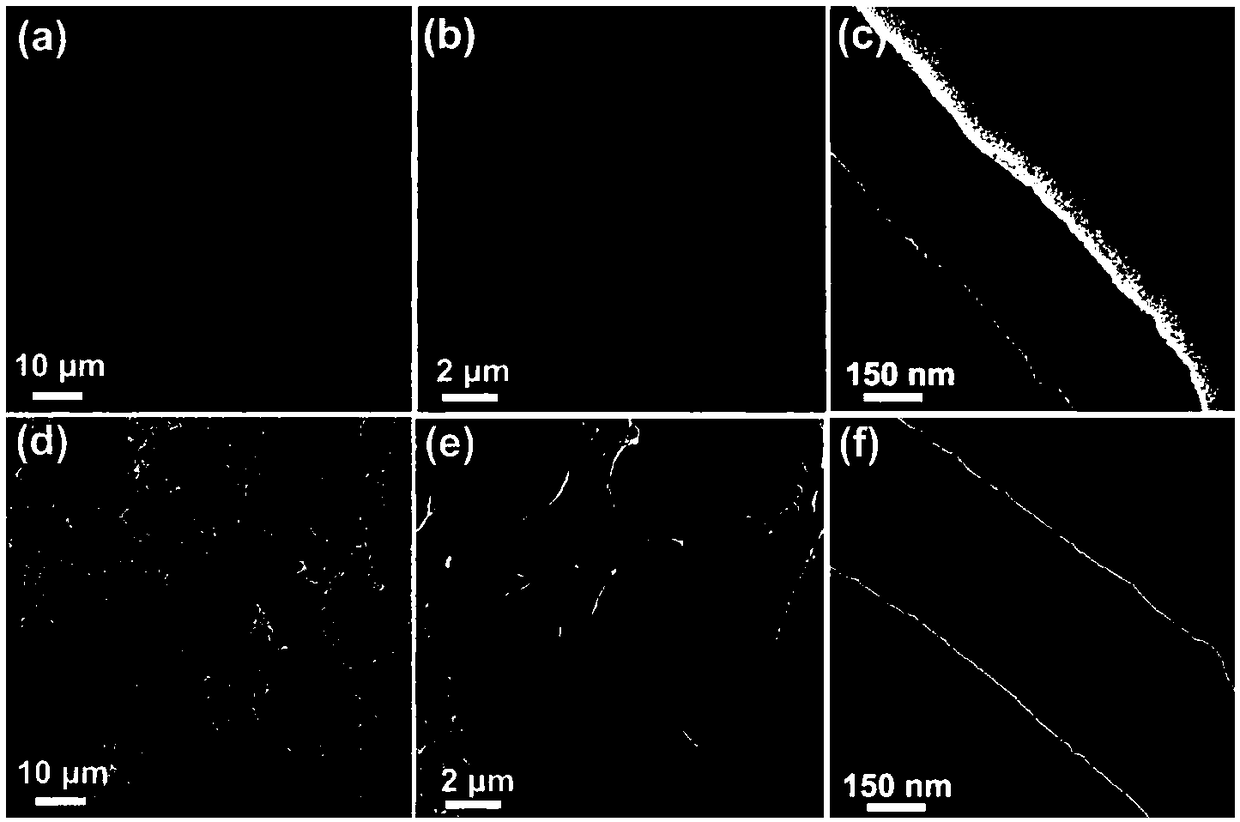

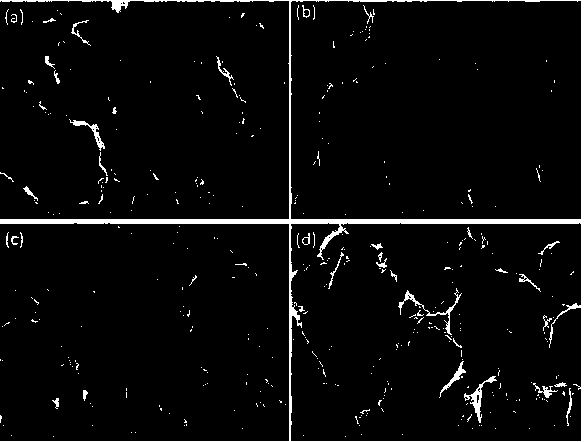

Low-density SiC nanofibers and preparation method thereof

InactiveCN104451957AEasy to operateReduce the temperatureFibre chemical featuresElectrospinningFiber

The invention discloses low-density SiC nanofibers and a preparation method thereof. The density of the SiC nanofibers is about 0.3-0.6g / cubic centimeter (the density of commercialized SiC is about 1.1-1.3g / cubic centimeter), the diameters of the fibers are 100-500 nanometers and the length-diameter is greater than 100. The SiC nanofibers are prepared by adopting an electrospinning technique combined with a high-temperature carbon thermal reduction method, and the obtained SiC nano fibers are uniformly distributed. The SiC nanofibers provided by the invention are simple and feasible in preparation method and low in raw material price, and the structure and the morphology of the fibers are easy to control, so that the preparation method is a synthetic technology which is relatively strong in comprehensiveness and suitable for industrial popularization.

Owner:FUZHOU UNIVERSITY

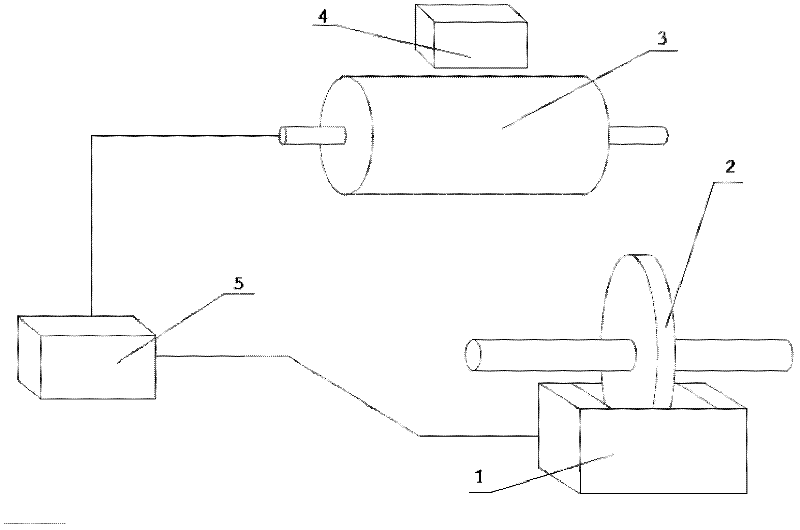

Method for preparing three-dimensional electrostatic-spinning nonwoven support material and device thereof

InactiveCN102586901ASimple and fast operationLow costFilament/thread formingProsthesisFiberBiocompatibility Testing

The invention relates to a method for preparing a three-dimensional electrostatic-spinning nonwoven support material and a device thereof. The method comprises the following steps: (1) dissolving a spinning polymer in a mixed solvent of acetone / dimethyl formamide, and obtaining a spinning solution after mixing; (2) pouring the spinning solution into a solution tank, and grounding a receiving roller to apply high-voltage static electricity to the spinning solution for electrostatic spinning; after electrostatic spinning lasting for 5-20 minutes, taking down a fluffy fiber net from the receiving roller, thus obtaining a three-dimensional nonwoven fiber support material; (3) and carrying out vacuum drying on the three-dimensional nonwoven fiber support material for hours, and removing the residual solvent. The device comprises a motor, the solution tank, a spinning turntable, the receiving roller, an electrostatic generator and an infrared heater. The method of the invention is simple and convenient in operation, low in cost and high in yield. The obtained support material with a three-dimensional structure has advantages of fluffy structure, large hole diameter and good biocompatibility, and is beneficial to cells to inwardly grow.

Owner:DONGHUA UNIV

Preparation method of honeyed bulbus fritillariae cirrhosae

ActiveCN103859405AFacilitated releasePromote absorptionAnthropod material medical ingredientsRespiratory disorderDrug effectPear juice

The invention relates to a preparation method of honeyed bulbus fritillariae cirrhosae. The preparation method comprises the following steps: preprocessing bulbus fritillariae cirrhosae, honeying the bulbus fritillariae cirrhosae, steaming the bulbus fritillariae cirrhosae and drying the bulbus fritillariae cirrhosae. The bulbus fritillariae cirrhosae are steamed after being soaked with honey and snow pear juice to bulk the bulbus fritillariae cirrhosae, so that the honey and the snow pear juice for honeying can be effectively sucked completely, the honeying effect can be improved, and the effects of clearing heat, moistening the lung, eliminating phlegm and stopping cough can be enhanced; the honeyed bulbus fritillariae cirrhosae is convenient to take and relatively good in mouth feel and drug effect. The preparation method is simple, the folk traditional drug administration habit of the bulbus fritillariae cirrhosae and the natural nutritional substances of the raw materials are retained, and the advantages of the bulbus fritillariae cirrhosae, the honey and snow pears are fully utilized and complement one another. The honeyed bulbus fritillariae cirrhosae are comprehensive and rich in nutrition, suitable for various people and favorable for popularization and application of the bulbus fritillariae cirrhosae.

Owner:四川藏域川贝生物研究中心有限公司

Method for improving tobacco stalk quality by combining steam explosion and anaerobic treatment technology

InactiveCN101933655AFluffy structureImprove the smoke effectTobacco preparationTobacco treatmentProcess engineeringAnaerobic microorganisms

The invention discloses a method for improving tobacco stalk quality by combining steam explosion and anaerobic treatment technology. The method comprises the following steps of: performing steam explosion on tobacco stalks by using a steam exploder; placing the exploded tobacco stalks in a sealed container, adding anaerobic microorganisms into the container and forming an anaerobic environment in the container to perform anaerobic treatment by vacuuming or filling the container with an inert gas; taking the tobacco stalks out of an anaerobic treatment container and quickly dehydrating at the low temperature to control water content to be about 20 to 30 percent; and finally slicing the dehydrated tobacco stalks for the production of cigarette. The method can improve the amount of the tobacco stalk added during the production of the cigarette on the premise of not influencing the aesthetic quality of the cigarette, so that the cigarette cost is effectively reduced.

Owner:CHINA TOBACCO CHUANYU IND

Absorbing core for treating excrement and manufacturing method for absorbing core

The invention provides an absorbing core for treating excrement. The absorbing core comprises a surface layer, a bottom layer and SAP (super absorbent polymer) layers, wherein SAP wraps the surface layer and the bottom layer to form the SAP layers; the absorbing core is divided into small absorbing core bodies by adhesion portions; each small absorbing core body is projected relative to the corresponding adhesion portion in the thickness direction; and recesses are formed by the adhesion portions among the small adjacent absorbing core bodies. The invention also provides a manufacturing method for the absorbing core. The manufacturing method comprises the following steps of uniformly spreading the SAP on the bottom layer by using a spreader; covering the material of the surface layer; acting on the paved material by using a roll; and performing final adhesion modeling. By using the absorbing core for treating the excrement and the manufacturing method for the absorbing core, the problems that SAP particles in an adhesion process in the prior art are locally accumulated into clusters, after an absorbing core absorbs liquid, the liquid stays at local portions of the absorbing core, and cannot be quickly spread uniformly are solved. The absorbing core for treating the excrement has the advantages of high SAP utilization rate, high liquid absorbing effect and good tactility.

Owner:HUNAN COSOM CARE PROD

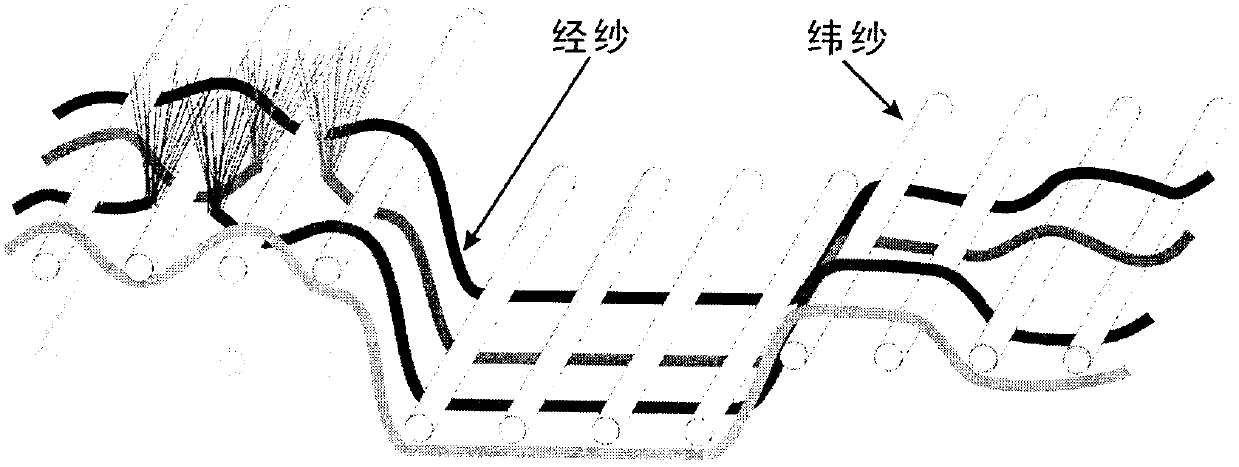

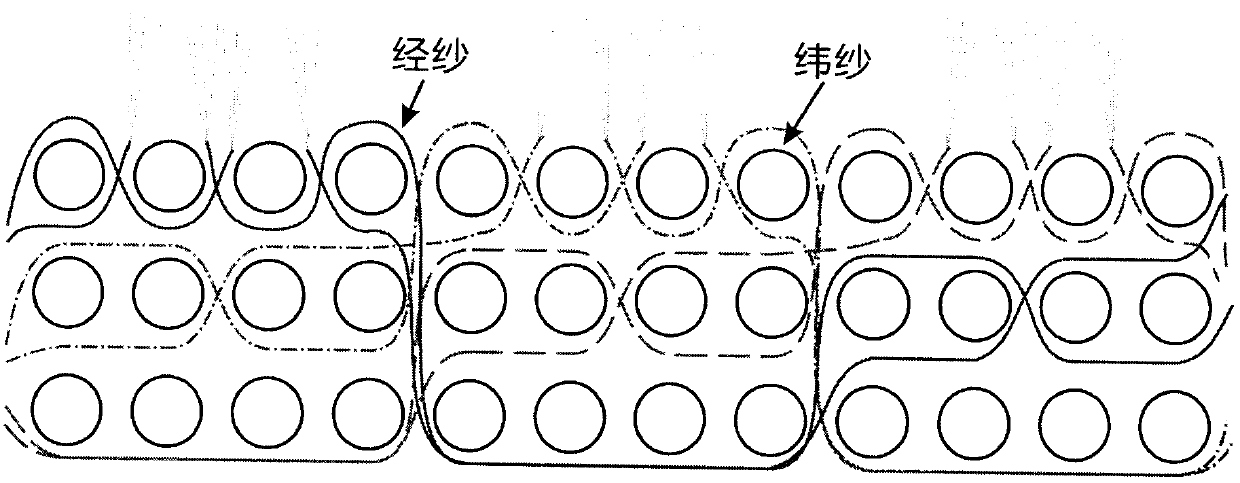

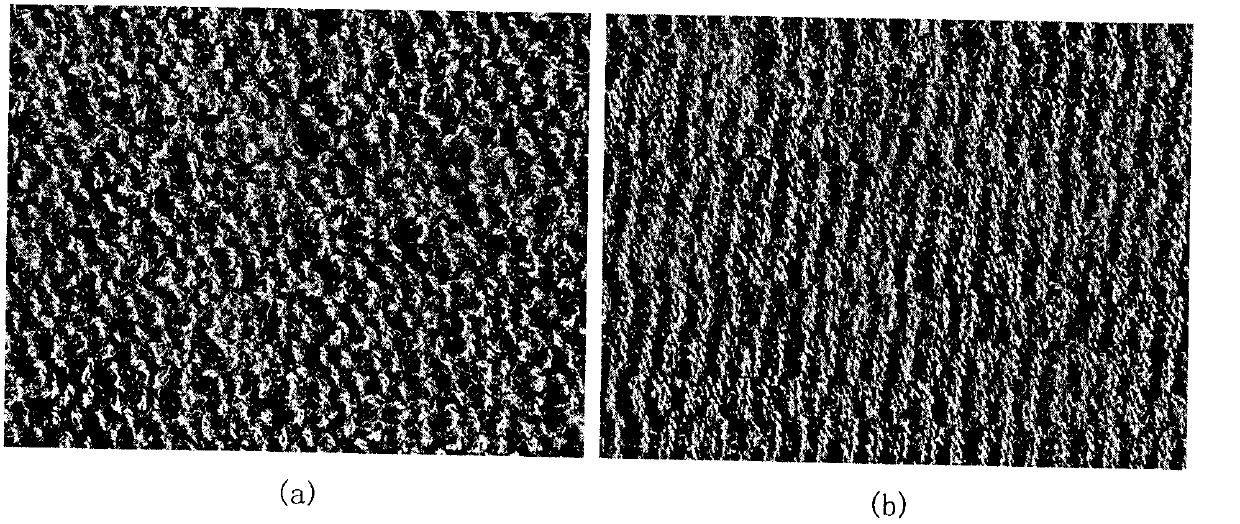

Warm-keeping type moisture absorbing and sweat releasing felt fabric with bionic structure

The invention provides a warm-keeping type moisture absorbing and sweat releasing felt fabric with a bionic structure. The fabric is a multi-layer fabric woven by a double warp beam; a warp system in the fabric is separated layer by layer from a bottom layer of the fabric to a top layer of the fabric in the thickness direction of the fabric to form a multi-level bionic structure similar to wool primary fiber; wool warps in the fabric twists on the surface layer of the fabric and forms felt on the surface of the fabric after felt cutting and loosening; the felt is highly controlled; and in one fabric weave circulation, 12 warps are formed and composed of 6 felt warps, 6 body warps and 36 weft yarns. Due to the structure of the fabric disclosed by the invention, the transmission channel of the water from the fabric bottom layer to the fabric top layer is effectively shortened and the moisture guiding efficiency of the fabric is effectively improved; the bionic felt fabric can be produced on a common weaving machine, so that the production cost is saved; the fabric has good elasticity and fluffiness; the felt on the surface of the fabric is full and good in warm-keeping performance; and a moisture guiding channel of the fabric warp system is continuous, so that the moisture comfort of the fabric is good and the fabric is good warm-keeping fabric in winter.

Owner:TIANJIN POLYTECHNIC UNIV

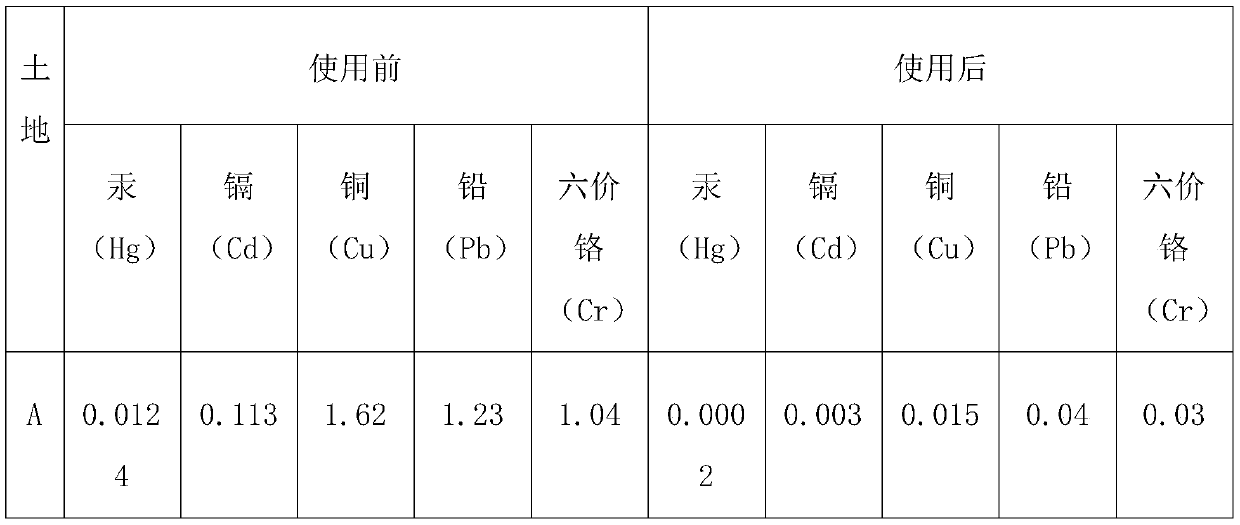

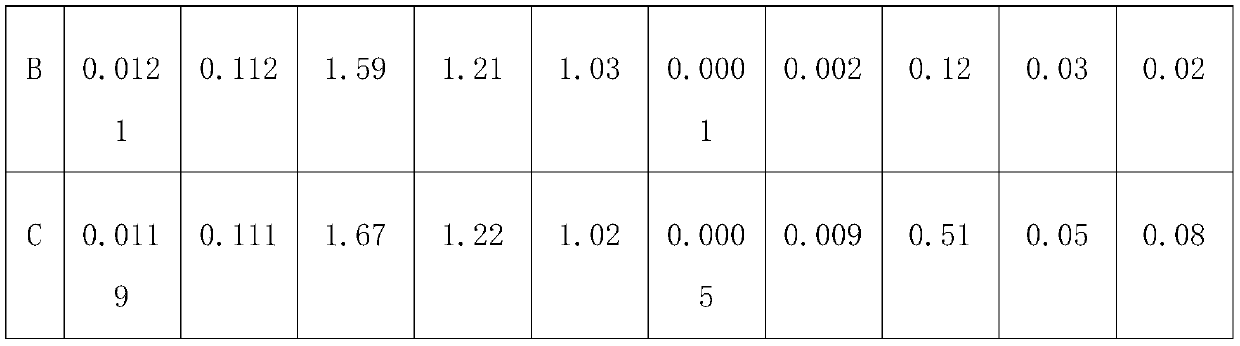

Remediation agent and remediation method for heavy metal contaminated soil

InactiveCN111362746ALow toxicityPromote growthAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSodium phosphatesOsmolyte

The invention relates to the technical field of soil remediation, in particular to a remediation agent and remediation method for heavy metal contaminated soil. The remediation agent for the heavy metal contaminated soil comprises 2-16 parts of humic acid, 5-10 parts of succinic acid, 5-20 parts of sawdust, 2-10 parts of bentonite, 10-20 parts of sodium polyacrylate, 5-10 parts of honeycomb briquette ash, 5-20 parts of seaweed residues, 2-10 parts of zeolite, 5-10 parts of nano hydrogel, 10-30 parts of charcoal, 10-20 parts of Fe-Mn binary oxide, 5-10 parts of sodium pyrophosphate and 2-10 parts of microorganism mixed bacteria. The remediation agent is good in repairing effect and low in cost. The remediation method for remediating the heavy metal contaminated soil through the remediationagent is simple, heavy metal in the soil can be efficiently solidified, and the water quality grade of the soil penetrating fluid is improved.

Owner:WEIFANG UNIV OF SCI & TECH

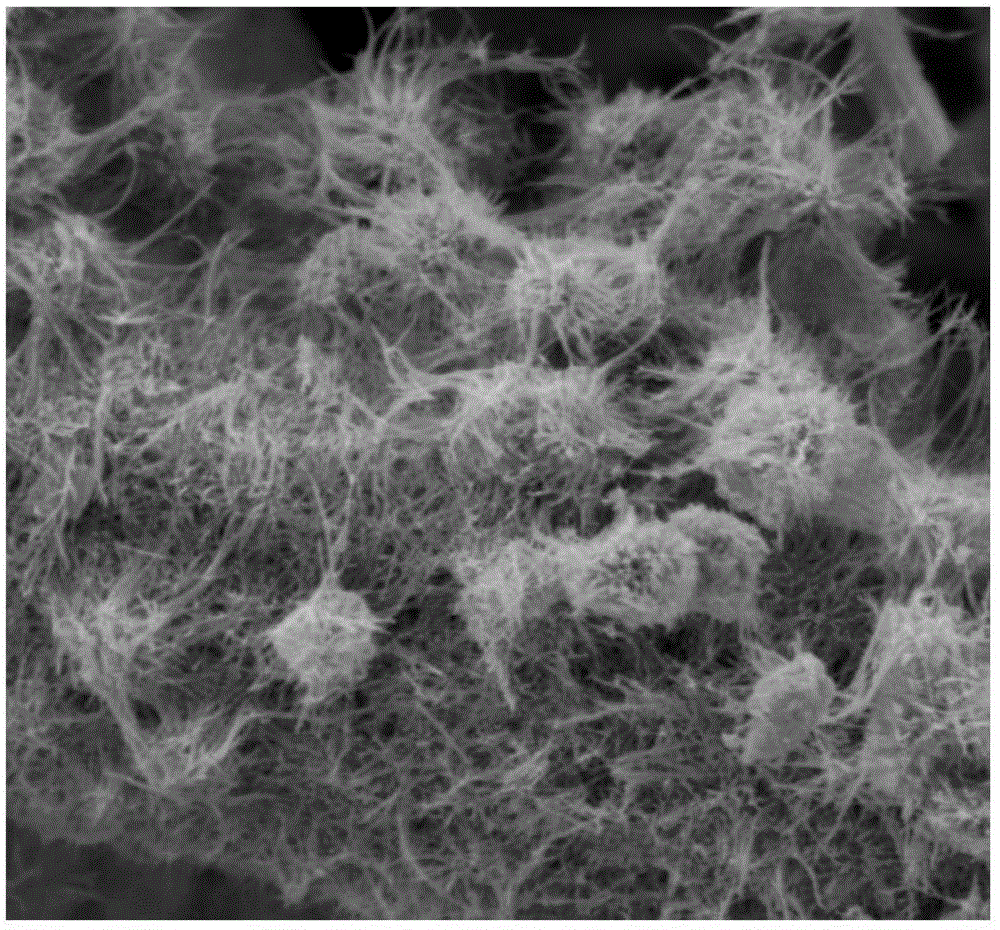

Active carbon/nickel cobaltate nano wire composite electrode material and preparation method thereof

InactiveCN106531448AFluffy structureLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureNickel saltMaterials science

The invention discloses an active carbon / nickel cobaltate nano wire composite electrode material and a preparation method thereof. The nickel cobaltate nano wire has a puffy structure and covers the surface of the active carbon, thereby forming an active / carbon cobaltate nano wire composite electrode material with a core shell structure. The preparation method comprises the steps of cleaning the active carbon by means of dilute hydrochloric acid, washing the cleaned active carbon by means of deionized water, and performing drying for standby; dissolving soluble nickel salt and soluble cobalt salt in the deionized water for preparing mixed metal salt solution; placing the active carbon into the mixed metal salt solution, adding oxalic acid, mixing to uniform and adding ammoniacal liquor for adjusting pH value, thereby obtaining precursor solution; and transferring the precursor solution into a hydrothermal reaction vessel for realizing reaction, then performing filtering, washing, drying and sintering, thereby obtaining a finished product. The active carbon / nickel cobaltate nano wire composite electrode material has advantages of puffy structure, large specific surface area, sufficient contact with electrolyte and short electrolyte ion migration path.

Owner:SHANGHAI SHANSHAN TECH CO LTD

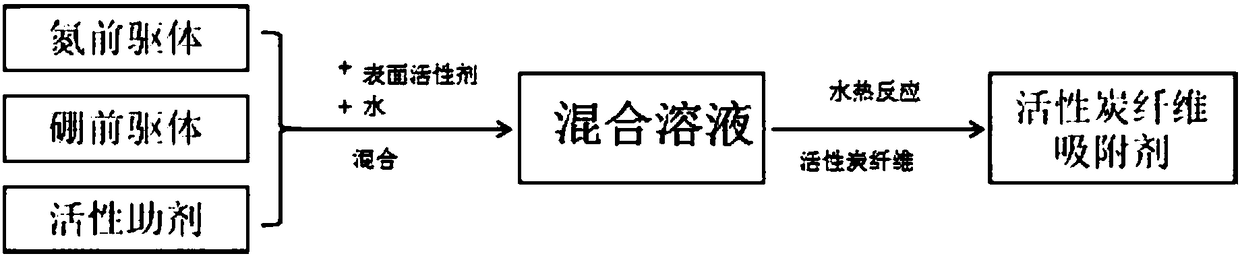

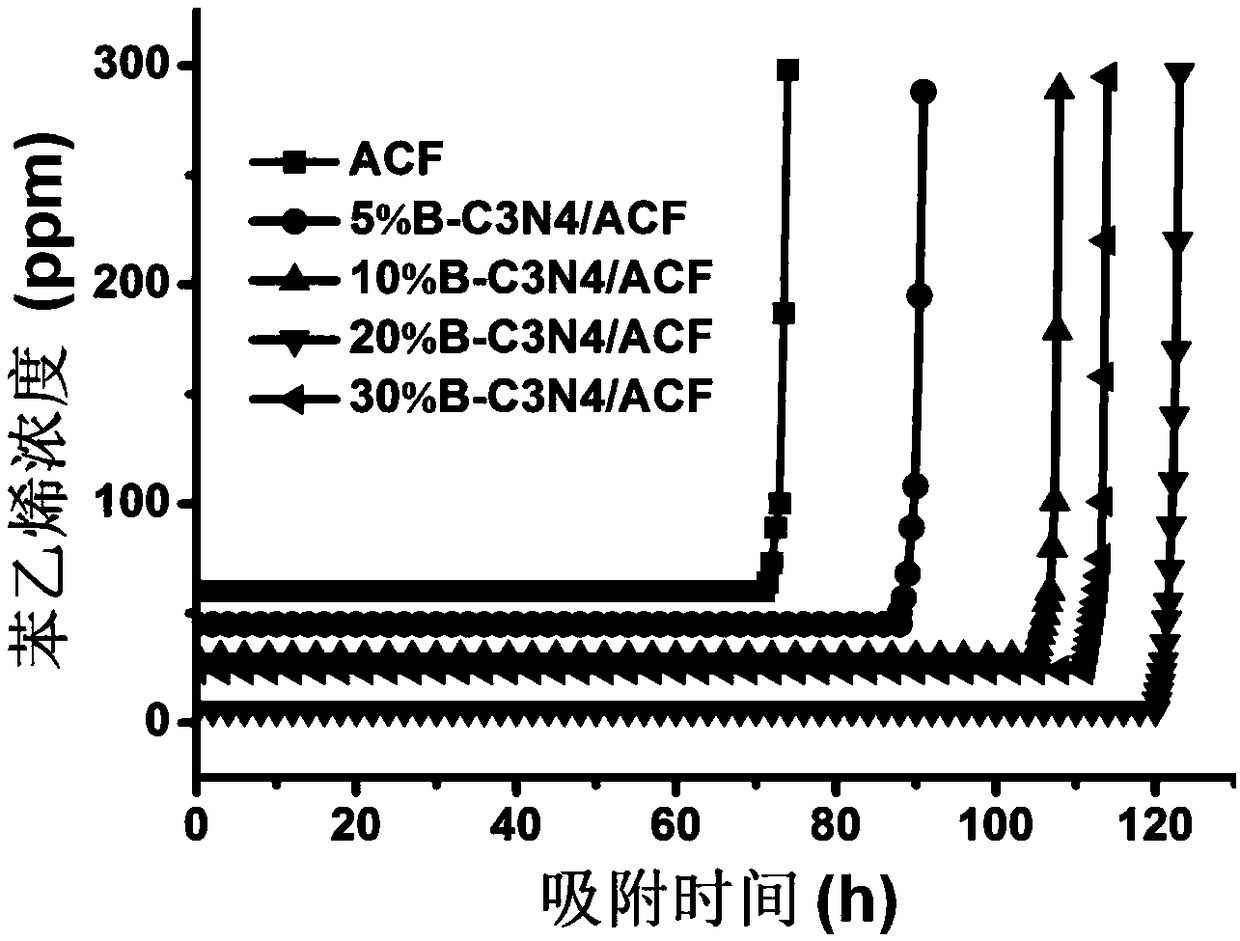

Active carbon fiber adsorbent and preparation method and application of active carbon fiber adsorbent in benzene series adsorption

ActiveCN108262015AIncreased boron contentImprove adsorption efficiencyGas treatmentOther chemical processesFiberCarbide coating

The invention provides an active carbon fiber adsorbent preparation method, which belongs to the field of processing of a volatile organic compound. The method comprises the following steps: mixing aboron precursor, a water-soluble nitrogenous organic substance, an active auxiliary agent, a surfactant and water to obtain a mixed solution, wherein the active auxiliary agent is glucose, citric acidor ascorbic acid, and the boron precursor is m-aminophenylboronic acid, p-aminophenylboronic acid, m-cyanophenylboronic acid or p-cyanophenylboronic acid; and mixing the mixed solution and the activecarbon fiber and performing a hydro-thermal reaction to obtain the active carbon fiber adsorbent. The active carbon fiber adsorbent can generate a fluffy boron doped nitrogen carbide coating layer with a nano size, uniform distribution, high boron element content and taking an active B-N bond as a main form on the active carbon surface, content of boron and nitrogen elements of the surface of a carbon material can be greatly increased, the benzene series adsorption and desorption performance by the active carbon fiber adsorbent is increased, and the cycle adsorption performance of the activecarbon fiber adsorbent can be greatly improved.

Owner:上海申丰地质新技术应用研究所有限公司

Electroplating process of neodymium-iron-boron magnet

The invention discloses an electroplating process of a neodymium-iron-boron magnet. The electroplating process is composed of the following steps that (1) baking is conducted, specifically, the neodymium-iron-boron magnet is placed in a baking oven to be baked; (2) polishing is conducted, specifically, a covering on the surface of the neodymium-iron-boron magnet is removed through rough abrasive paper, and then the surface of the neodymium-iron-boron magnet is polished to be smooth through metallographic abrasive paper; (3) cleaning is conducted, specifically, the surface of the neodymium-iron-boron magnet is scrubbed through alcohol; (4) hole sealing is conducted, specifically, the neodymium-iron-boron magnet is placed in a zinc stearate solution to be dipped; (5) oil removing is conducted, specifically, chemical oil removing is conducted through ultrasonic waves; (6) bright dipping is conducted, specifically, the oil-removed neodymium-iron-boron magnet material is subjected to brightdipping treatment; (7) dip plating is conducted, the magnet material subjected to bright dipping is placed in a dip plating solution to be subjected to dip plating treatment; (8) bright nickel plating is conducted, specifically, the surface of a dip plating layer is plated with bright nickel, and the thickness of a zinc-nickel layer is 5-6 [mu]m; and (9) drying is conducted, specifically, the magnet material is dried in a blown mode through compressed air. The corrosion resistance of the magnet material is improved greatly.

Owner:滁州恒通磁电科技有限公司

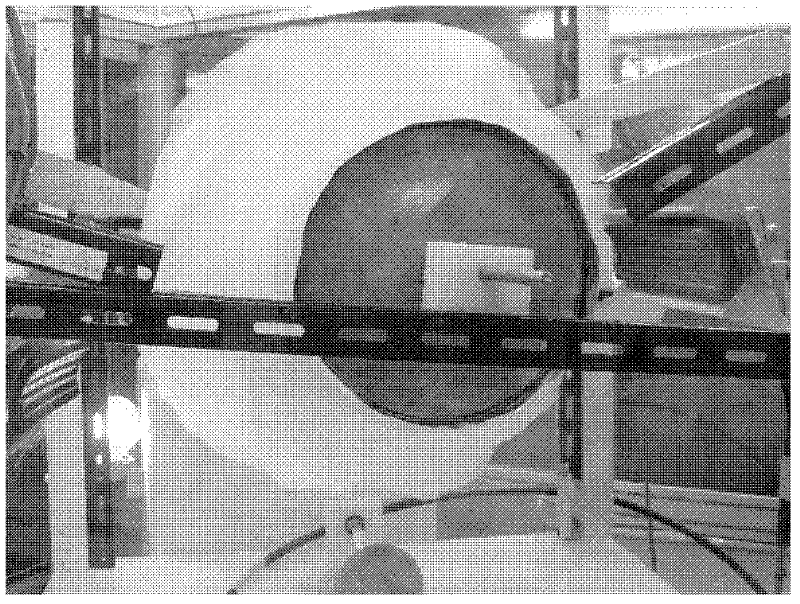

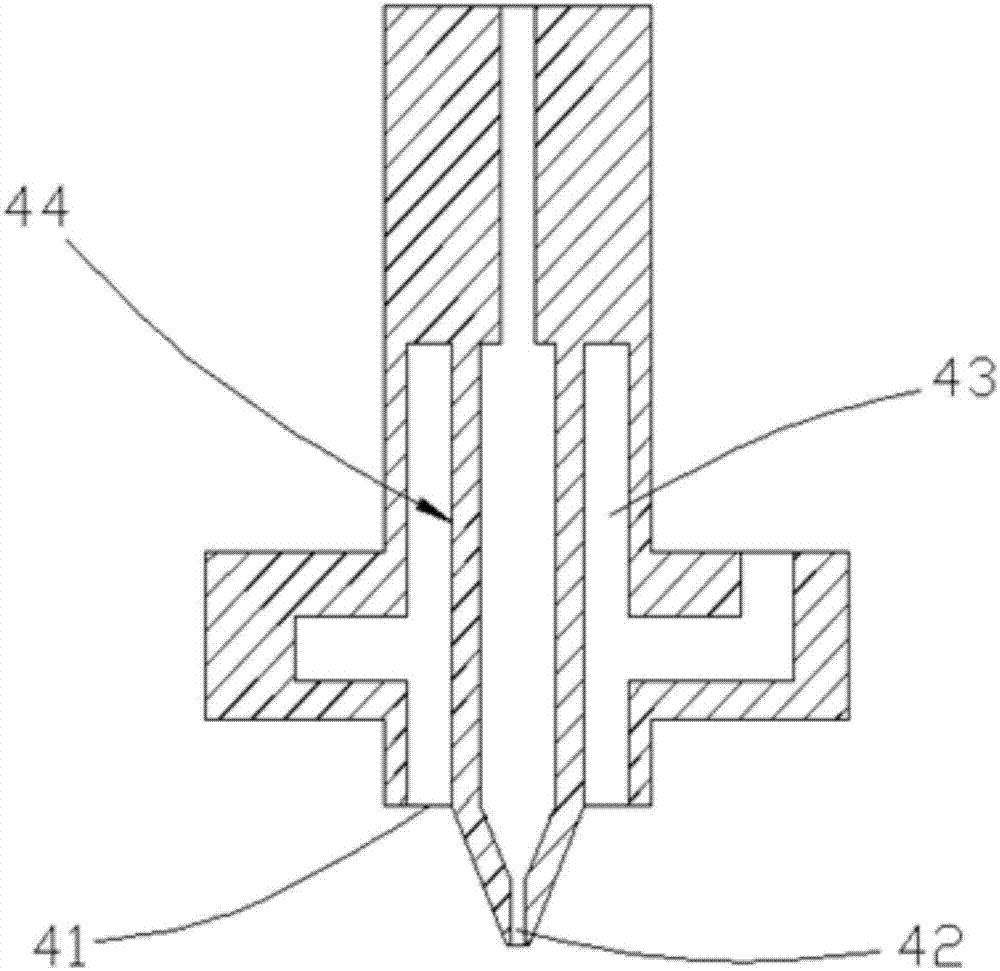

Electrospinning apparatus

PendingCN106917147AUniform fiber diameter distributionFluffy structureFilament/thread formingElectrospinningEngineering

The invention discloses an electrospinning apparatus comprising an AC high-voltage generator, a liquid supplying device including a micro-injection pump, an air supplying device, a spraying head including a liquid supplying channel connected with the liquid supplying device and an annular air supplying channel connected with the air supplying device, and a receiver including at least two rod-like supporting arms, a rotating shaft and a transmission device driving the rotating shaft to rotate. The air supplying channel sleeves the liquid supplying channel; an end part of an outlet section of the liquid supplying channel is provided with a tapered tipped end; the spraying head is connected with the AC high-voltage generator; one end of the supporting arm is fixedly connected with the rotating shaft and the other end is suspended in the air; the adjacent supporting arms are arranged at intervals; all the supporting arms form a bowl type revolving surface during the rotation of the rotating shaft; and the bowl typerevolving surface is opposite to a liquid outlet and an air outlet of the spraying head. Fibers with tiny diameters can be formed by the use of the electrospinning apparatus; the fiber filament diameters are evenly distributed and the fibers have fluffy structure and excellent mechanical properties; backswinging air flows can be avoided; and the electrospinning apparatus can be widely applied to organization engineering field.

Owner:GUANGDONG UNIV OF TECH

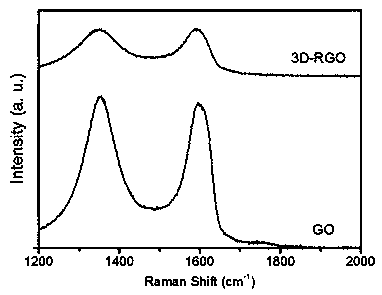

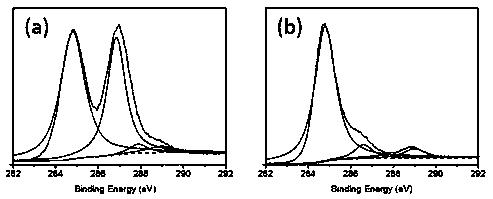

Three-dimensional reduced graphene oxide aerogel material and preparation method thereof

InactiveCN109289718AUniform and stable structureFluffy structureAerogel preparationColloidal chemistry detailsReflection lossPrepared Material

The invention discloses a three-dimensional reduced graphene oxide aerogel material and a preparation method thereof. The aerogel material is composed of graphene oxide and reduced graphene oxide, andis black and fluffy sponge-shaped overall. The three-dimensional reduced graphene oxide aerogel generates a large number of micron-sized pores in the forming process of the three-dimensional structure. After the aerogel material provided by the invention is mixed evenly with the paraffin, under the circumstance that the dosage of the aerogel material accounts for 10% of the total mass and the matching thickness is 2.5mm, in a frequency range of 2-18GHz, the reflection loss can reach -8.2dB. At the same time, in the preparation process of the three-dimensional reduced graphene oxide aerogel, ZnO and other metal nanoparticles can be carried in the pores inside the porous reduced graphene oxide, thus realizing compounding and regulation of the electromagnetic properties of the prepared material.

Owner:ARMY ENG UNIV OF PLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com