Three-dimensional reduced graphene oxide aerogel material and preparation method thereof

A graphene aerogel, graphene technology, applied in aerogel preparation, chemical instruments and methods, colloid chemistry and other directions, can solve problems such as difficult to meet comprehensive performance requirements, achieve low density, simple preparation method, structure Stable and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

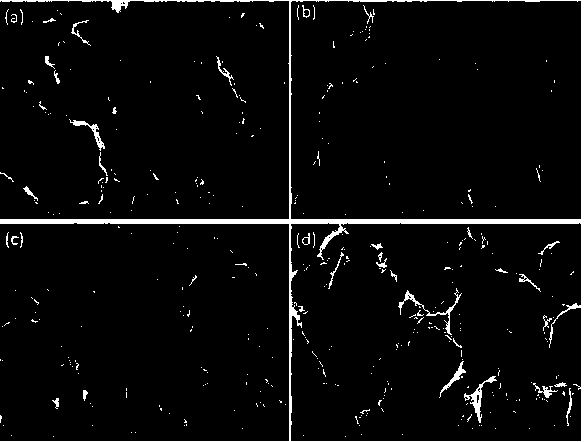

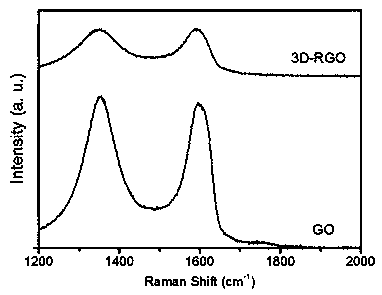

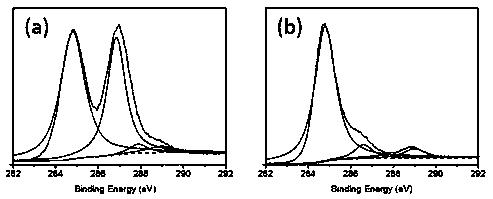

Image

Examples

Embodiment 1

[0027] The preparation method of the present embodiment is as follows: 3g graphite powder is added in the beaker that 105ml concentrated sulfuric acid is housed, and ice bath is stirred for 3h, and then the potassium permanganate of 15g is added in the mixed solution, continues ice bath and stirs for 2h and changes to normal temperature After the water bath, slowly add 210ml of deionized water along the wall of the cup, continue to stir for 30min, then slowly add 15ml of 30% hydrogen peroxide dropwise into the beaker, let the solution stand for 24h, pour off the supernatant, and use deionized water at 4500 rpm min, 15min / time, washed with water several times, centrifuged, and finally dried and collected to obtain graphite oxide. Dissolve graphite oxide in deionized water to make a 1.5 mg / ml solution, and then centrifuge at 10,000 rpm after ultrasonication for 2 hours, take the centrifuged supernatant, and dry it to obtain graphene oxide powder; 60 mg of graphene oxide powder D...

Embodiment 2

[0030] The preparation method of the present embodiment is as follows: 3g graphite powder is added in the beaker that 105ml concentrated sulfuric acid is housed, and ice bath is stirred for 3h, and then the potassium permanganate of 15g is added in the mixed solution, continues ice bath and stirs for 2h and changes to normal temperature After the water bath, slowly add 210ml of deionized water along the wall of the cup, continue to stir for 30min, then slowly add 15ml of 30% hydrogen peroxide dropwise into the beaker, let the solution stand for 24h, pour off the supernatant, and use deionized water at 4500 rpm min, 15min / time, washed with water several times, centrifuged, and finally dried and collected to obtain graphite oxide. Dissolve graphite oxide in deionized water to make a 1.5 mg / ml solution, and then centrifuge at 10,000 rpm after ultrasonication for 2 hours, take the centrifuged supernatant, and dry it to obtain graphene oxide powder; 60 mg of graphene oxide powder D...

Embodiment 3

[0035] The preparation method of the present embodiment is as follows: 3g graphite powder is added in the beaker that 105ml concentrated sulfuric acid is housed, and ice bath is stirred for 3h, and then the potassium permanganate of 15g is added in the mixed solution, continues ice bath and stirs for 2h and changes to normal temperature After the water bath, slowly add 210ml of deionized water along the wall of the cup, continue to stir for 30min, then slowly add 15ml of 30% hydrogen peroxide dropwise into the beaker, let the solution stand for 24h, pour off the supernatant, and use deionized water at 4500 rpm min, 15min / time, washed with water several times, centrifuged, and finally dried and collected to obtain graphite oxide. Dissolve graphite oxide in deionized water to make a 1.5 mg / ml solution, and then centrifuge at 10,000 rpm after ultrasonication for 2 hours, take the centrifuged supernatant, and dry it to obtain graphene oxide powder; 60 mg of graphene oxide powder D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com