Waterproof reinforcing agent, waterproof foamed concrete and roof waterproof system

A foamed concrete and waterproof technology, which is applied in the field of waterproof foamed concrete, roof waterproofing system and waterproofing enhancer, can solve the problems of easy cracking, thermal insulation and waterproofing effect, poor thermal insulation effect, aging and cracking of materials, etc., and achieves low cost. , The effect of simple construction, light weight and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing the above waterproof foamed concrete, comprising: A) mixing 100 parts by weight of cement, 5-25 parts by weight of inorganic filler, 0.1-0.5 parts by weight of fiber reinforced material, 5-10 parts by weight 40-60 parts by weight of water-repellent enhancer and 40-60 parts by weight of water are mixed to obtain cement slurry; B) the cement slurry and foaming agent are mixed according to the mass ratio of 1: (0.1-1), and poured to obtain water-repellent foam concrete.

[0044] Wherein, the cement, the inorganic filler, the fiber reinforced material, the waterproof enhancer and the water are all the same as above, and will not be repeated here; the rotating speed of the beating is preferably 100-500 rpm, more preferably 200-400 rpm. revolutions / min; the beating time is preferably 5-20 min, more preferably 10-15 min.

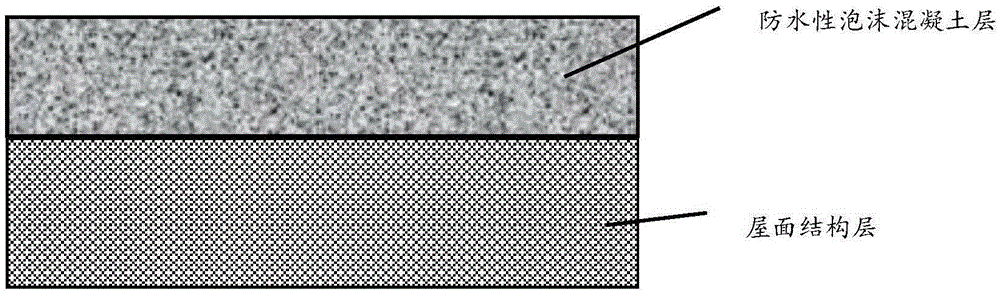

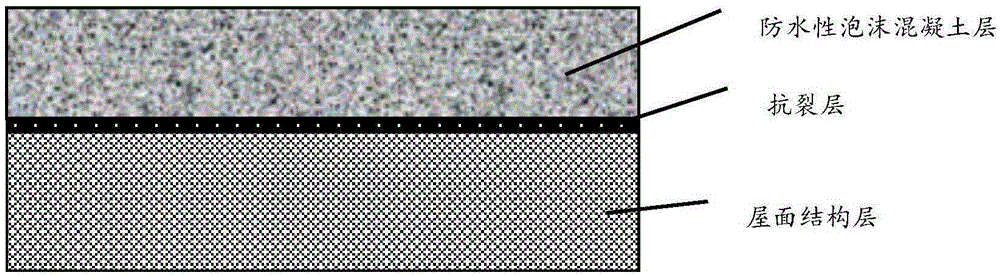

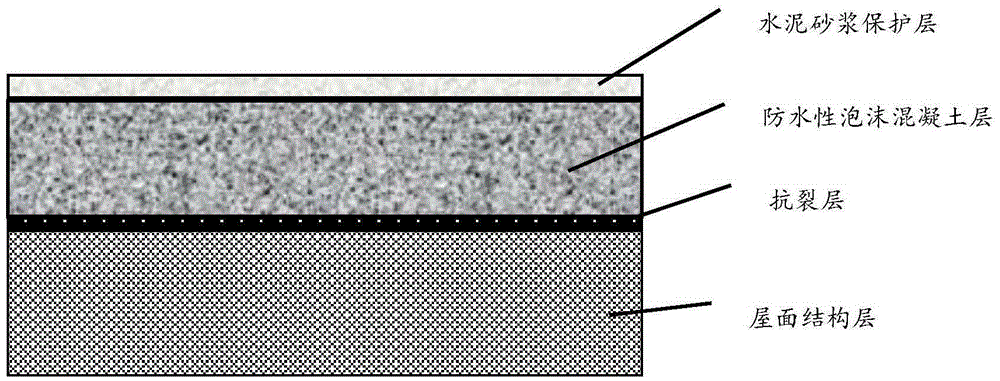

[0045] The present invention also provides a roof waterproof system, comprising a roof structure...

Embodiment 1

[0058] 1.1 Lay 2mm thick glass fiber woven cloth on the roof structure layer to form an organic material anti-crack layer.

[0059] 1.2 35 parts by weight of 0.2wt% polyvinyl alcohol aqueous solution, 35 parts by weight of 0.2wt% methylcellulose aqueous solution, 3 parts by weight of triethanolamine and 3 parts by weight of coconut oil fatty acid diethanolamide are mixed to obtain a waterproof enhancer;

[0060] Mix 100 parts by weight of cement, 10 parts by weight of fly ash, 0.2 parts by weight of polypropylene fiber, 6 parts by weight of waterproof reinforcing agent with 50 parts by weight of water, and beat at 100 rpm for 15 minutes to obtain cement slurry; mix the cement slurry with The animal-type foaming liquid is mixed according to the weight ratio of 1:0.02, stirred evenly, poured on the anti-crack layer of organic materials, the thickness is controlled to 10cm, and naturally cured for 2 days to form a waterproof foam concrete layer.

[0061] 1.3 Mix cement and sand a...

Embodiment 2

[0066] 2.1 Lay 1mm thick glass fiber woven cloth on the roof structure layer to form an organic material anti-crack layer.

[0067] 2.2 45 parts by weight of 0.2wt% polyvinyl alcohol aqueous solution, 35 parts by weight of 0.2wt% methylcellulose aqueous solution, 6 parts by weight of triethanolamine and 6 parts by weight of coconut oil fatty acid diethanolamide are mixed to obtain a waterproof enhancer;

[0068] Mix 100 parts by weight of cement, 15 parts by weight of fly ash, 0.2 parts by weight of polypropylene fiber, 8 parts by weight of waterproof reinforcing agent with 50 parts by weight of water, and beat at 500 rpm for 5 minutes to obtain cement slurry; mix the cement slurry with The animal-type foaming liquid is mixed according to the weight ratio of 1:0.03, stirred evenly, poured on the anti-crack layer of organic materials, the thickness is controlled to 10cm, and naturally cured for 2 days to form a waterproof foam concrete layer.

[0069] 2.3 Mix cement and sand ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com