Composite type high-temperature proton exchange membrane (PEM) based on sulfonated aryl ether type polybenzimidazole (PBI) and sulfonated polysilsesquioxane and preparation method of composite type high-temperature proton exchange membrane

A technology of polybenzimidazole and silsesquioxane, which is applied in the manufacture of final products, electrochemical generators, sustainable manufacturing/processing, etc., can solve problems such as difficult separation, impurities, and low efficiency, and achieve low cost , reduce the swelling rate, improve the effect of adsorption level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

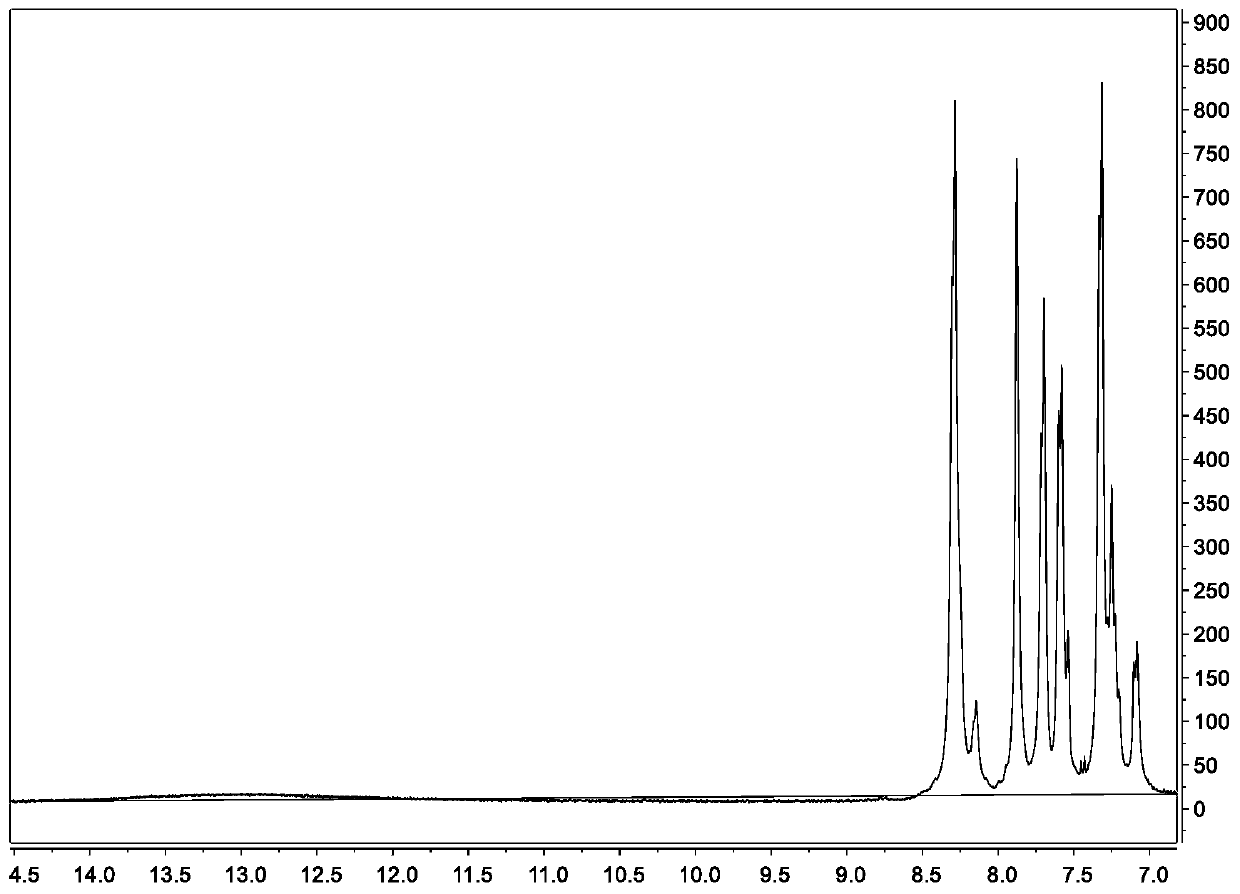

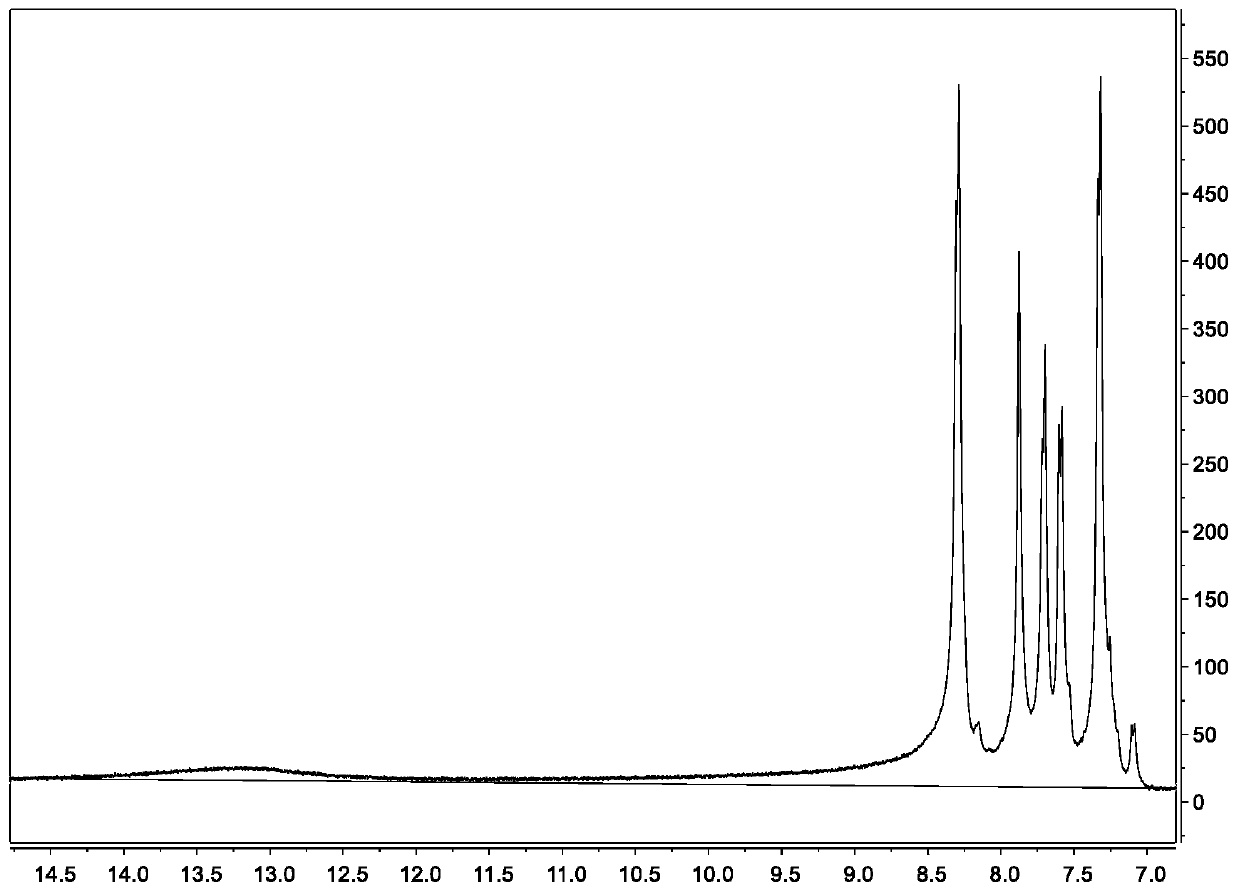

[0038] 1) Synthesis of diacid monomer

[0039] Put 0.1mol of potassium 2,5-dihydroxybenzenesulfonate and 0.21mol of potassium carbonate in a three-neck flask, add 200mL of N,N-dimethylacetamide and 40mL of toluene into the three-necked flask, and use nitrogen as a protection gas. Under mechanical stirring, heat the reaction system to 150°C to make it evenly reflux, remove the water generated by the reaction in the system by azeotroping, and use an oil-water separator to keep the system in this state for 3.5 hours. After fully removing water, release the excess water in the system. toluene. Add 0.21 mol p-fluorobenzonitrile solid to the system, and raise the temperature to 160°C. After reacting for 7 hours, pour the reaction solution into cold water, and obtain a solid product after suction filtration, and wash with ethanol several times to obtain a white solid.

[0040]Add the white solid obtained above and 4 mol of potassium hydroxide solid into a three-necked flask, and ad...

Embodiment 2

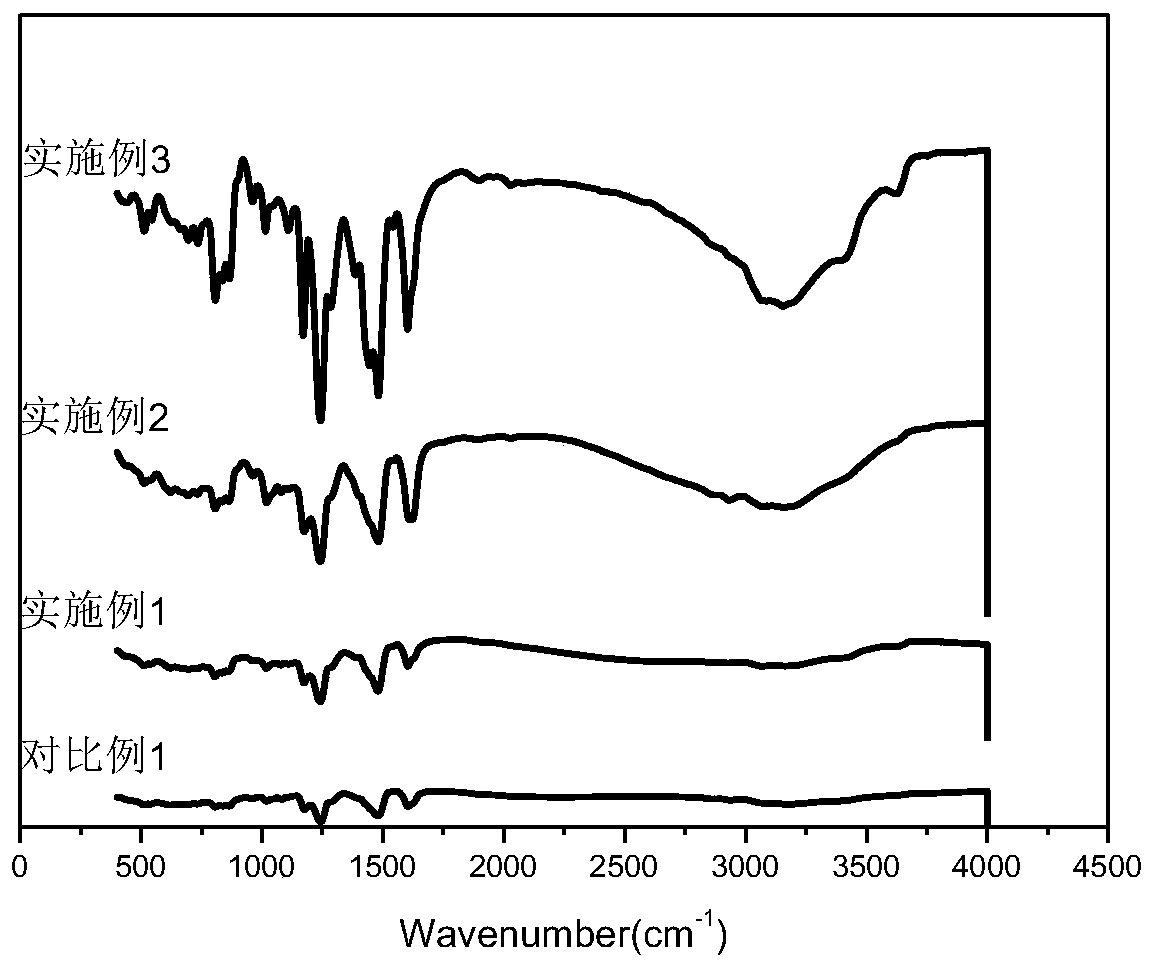

[0050] 1) Dissolve 0.2850 g of sulfonated polybenzimidazole polymer with a sulfonation degree of 30% in 7 mL of DMAc to obtain a polymer solution; Propanesulfonic acid aqueous solution was added to 1mL of DMAc, and then 0.1mL of ammonia water with a mass fraction of 25% was added to obtain a mixed solution. While the polymer solution was constantly stirring, the mixed solution was added to make it evenly mixed, and then poured on a clean glass plate In the oven, dry at 80°C for 24h, at 100°C for 12h, at 120°C for 12h, and finally keep at 120°C for 12h in vacuum, so that the hydrophilic sulfonated aryl ether type polybenzimidazole and sulfonate can be obtained on the glass plate. film of polysilsesquioxane.

[0051] 2) Soak the obtained film based on hydrophilic sulfonated aryl ether polybenzimidazole and sulfonated polysilsesquioxane at 120°C in an aqueous solution of phosphoric acid with a mass fraction of 85% for 48 hours, then take it out and dry it at 120°C After 12 hours...

Embodiment 3

[0054] 1) Dissolve 0.2760 g of sulfonated polybenzimidazole polymer with a sulfonation degree of 30% in 7 mL of DMAc to obtain a polymer solution; then 57 uL of 3-(trihydroxysilyl)- Propanesulfonic acid aqueous solution was added to 1mL of DMAc, and then 0.1mL of ammonia water with a mass fraction of 25% was added to obtain a mixed solution. While the polymer solution was constantly stirring, the mixed solution was added to make it evenly mixed, and then poured on a clean glass plate In the oven, dry at 80°C for 24h, at 100°C for 12h, at 120°C for 12h, and finally keep at 120°C for 12h in vacuum, so that the hydrophilic sulfonated aryl ether type polybenzimidazole and sulfonate can be obtained on the glass plate. film of polysilsesquioxane.

[0055] 2) Soak the obtained film based on hydrophilic sulfonated aryl ether polybenzimidazole and sulfonated polysilsesquioxane at 120°C in an aqueous solution of phosphoric acid with a mass fraction of 85% for 48 hours, then take it out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com