Patents

Literature

827results about How to "Evenly doped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

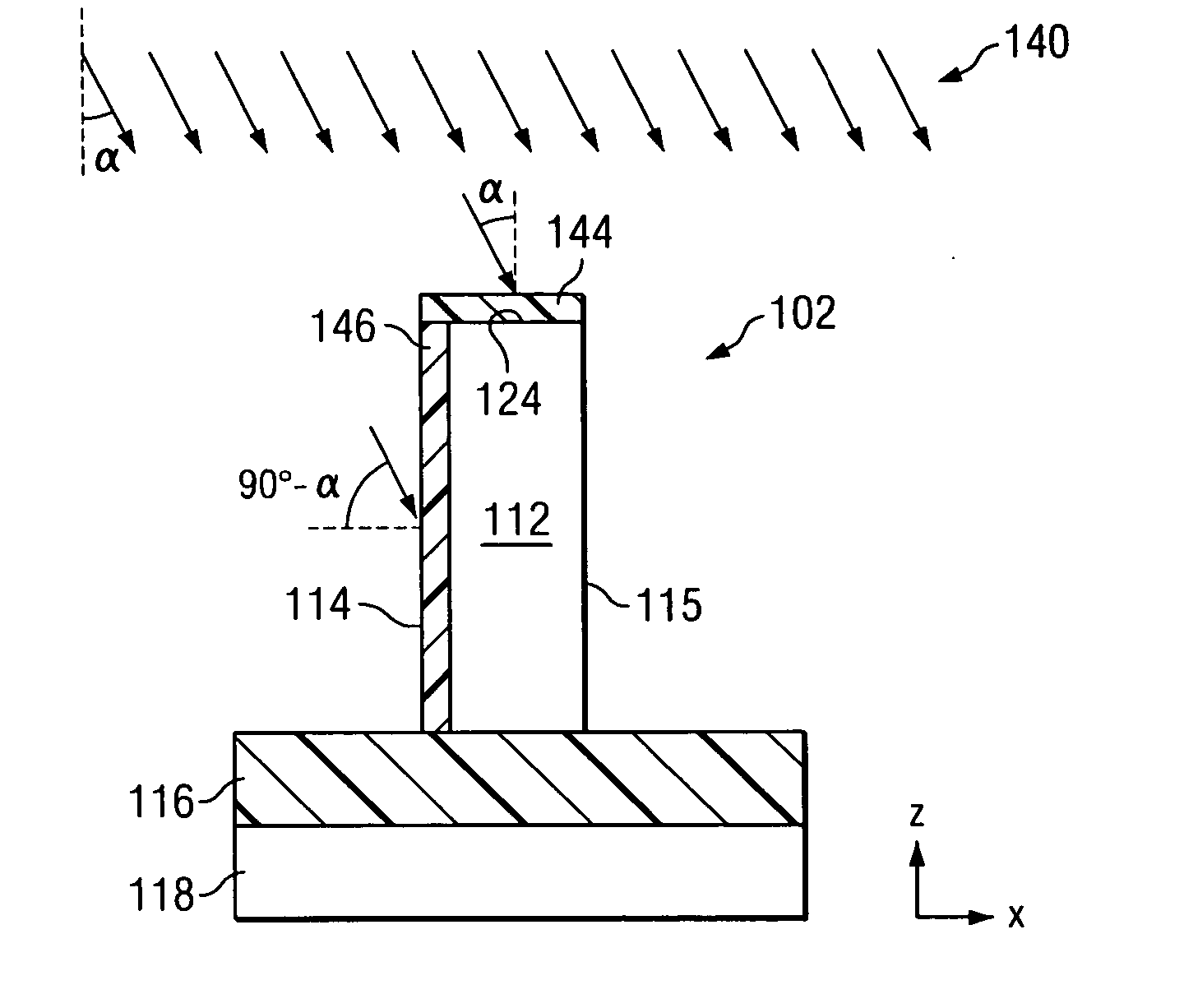

Doping of semiconductor fin devices

ActiveUS7074656B2Improve performanceEvenly dopedTransistorSemiconductor/solid-state device manufacturingIonDoping

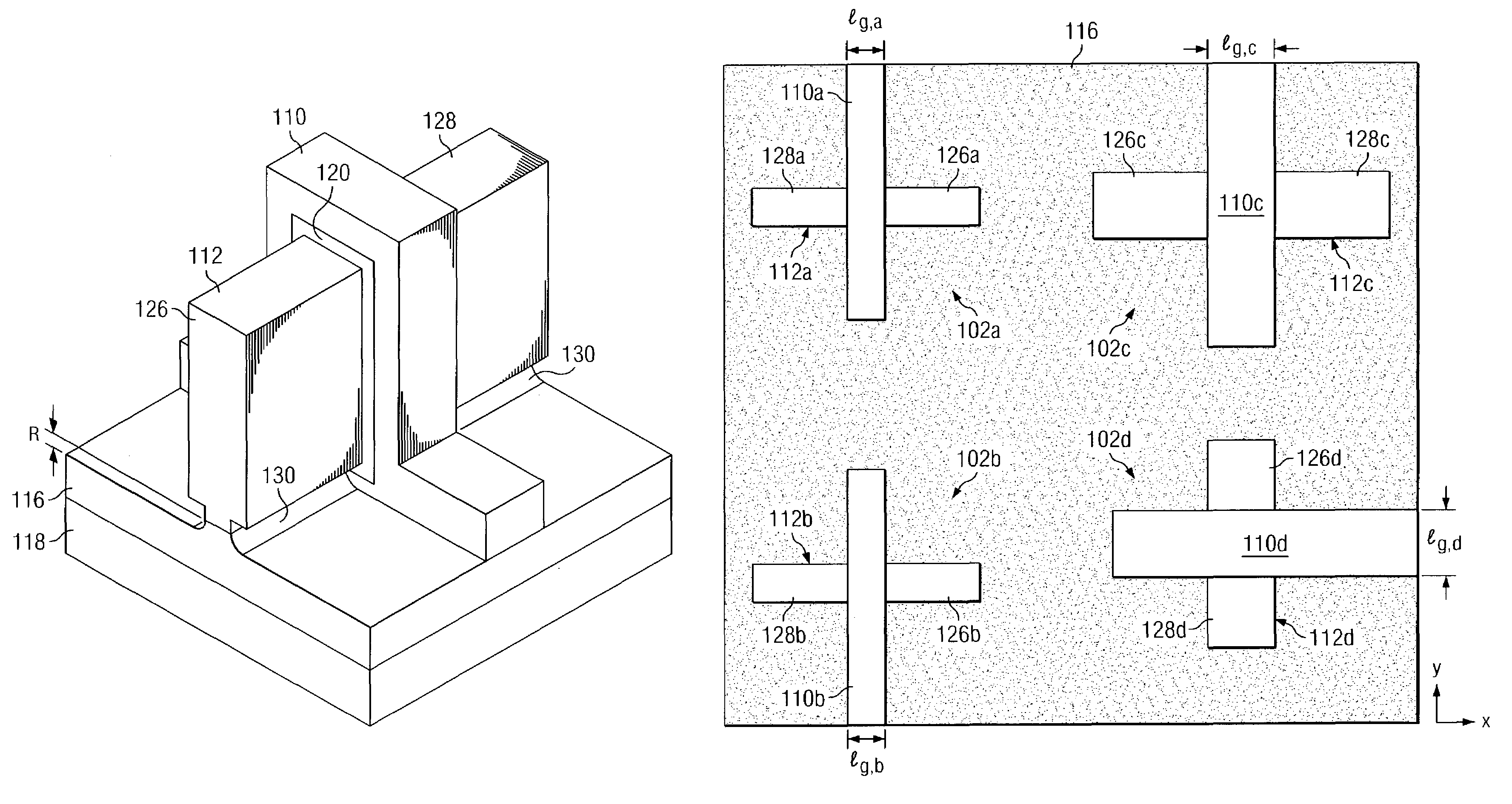

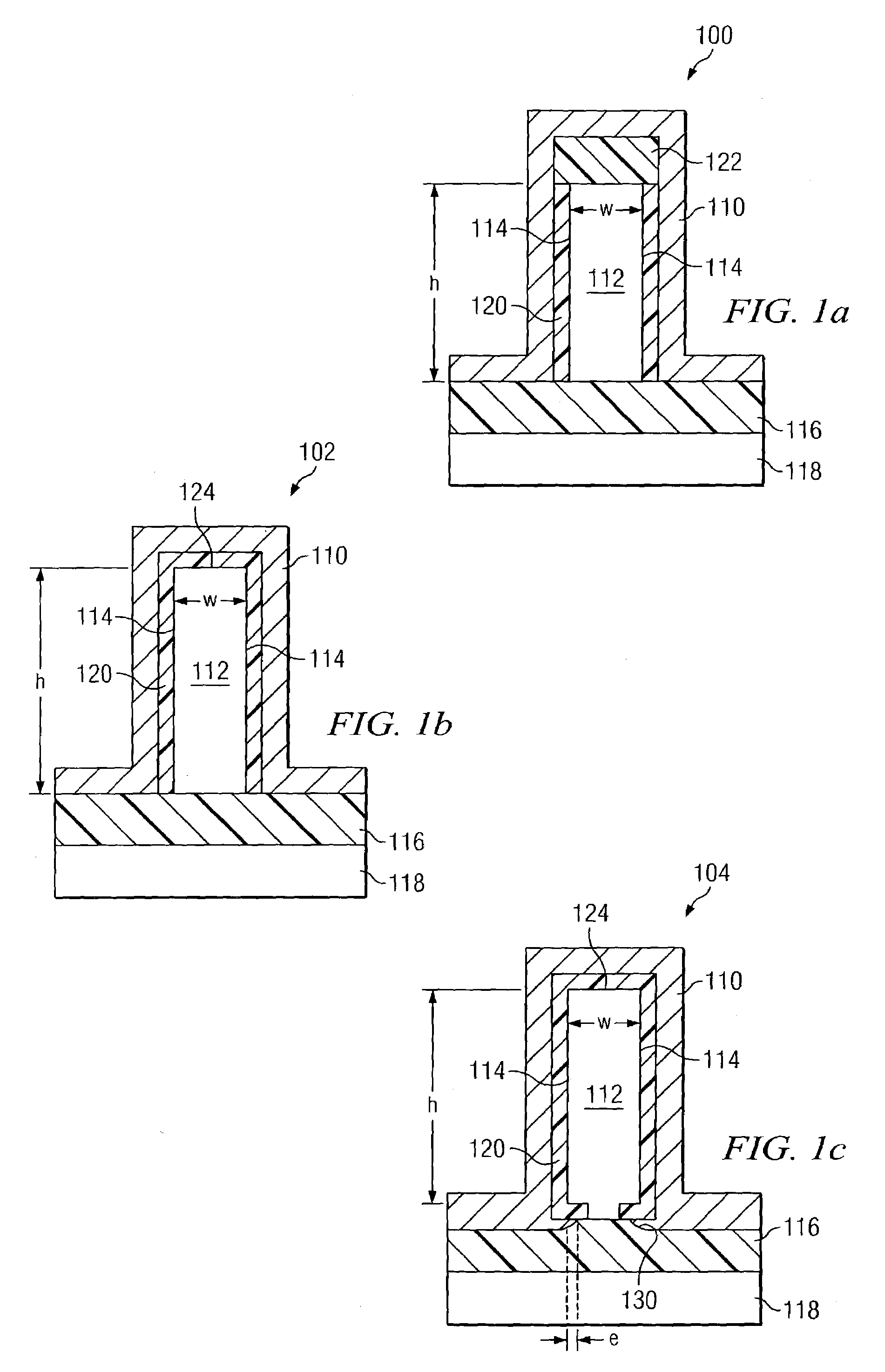

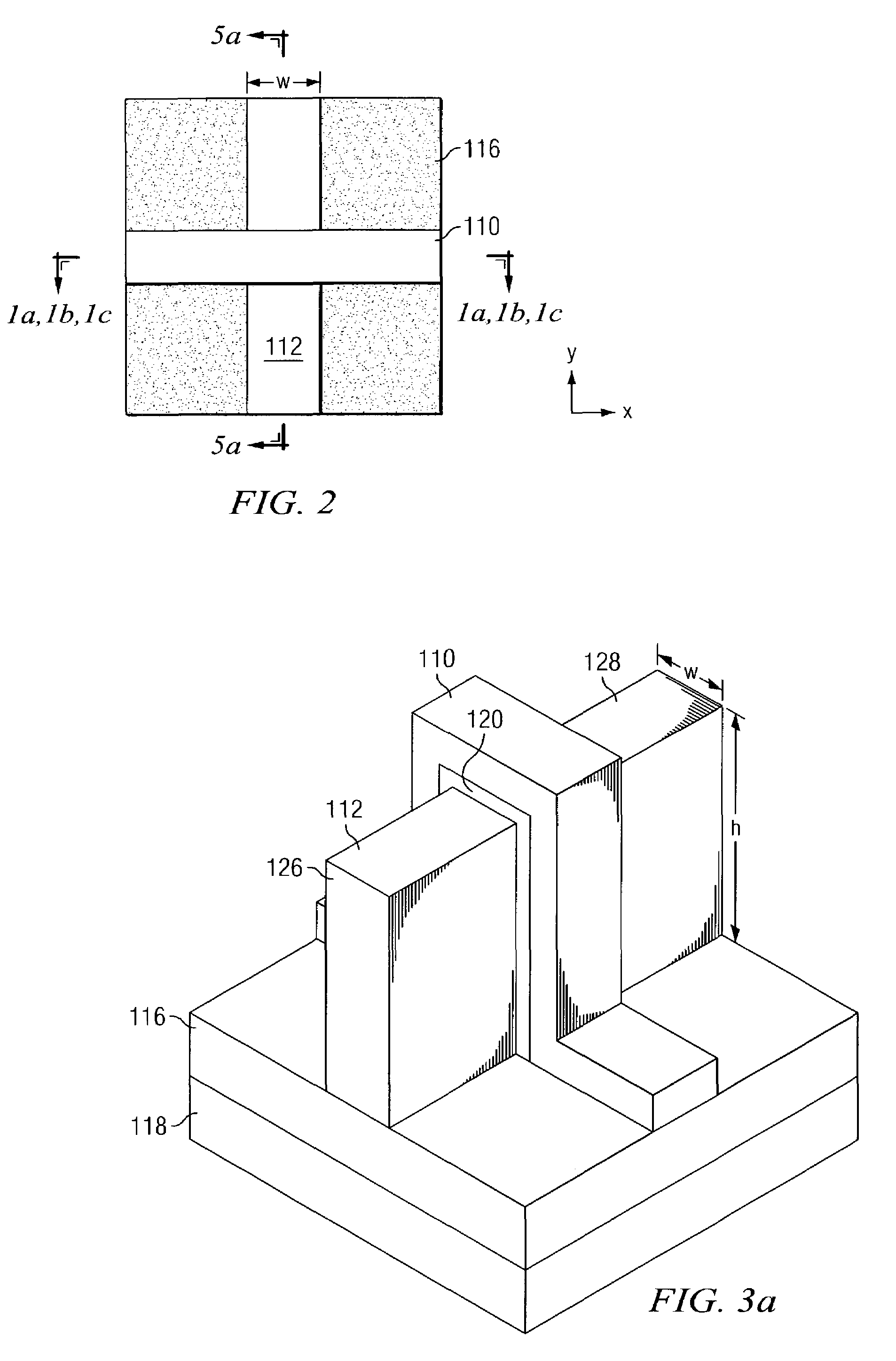

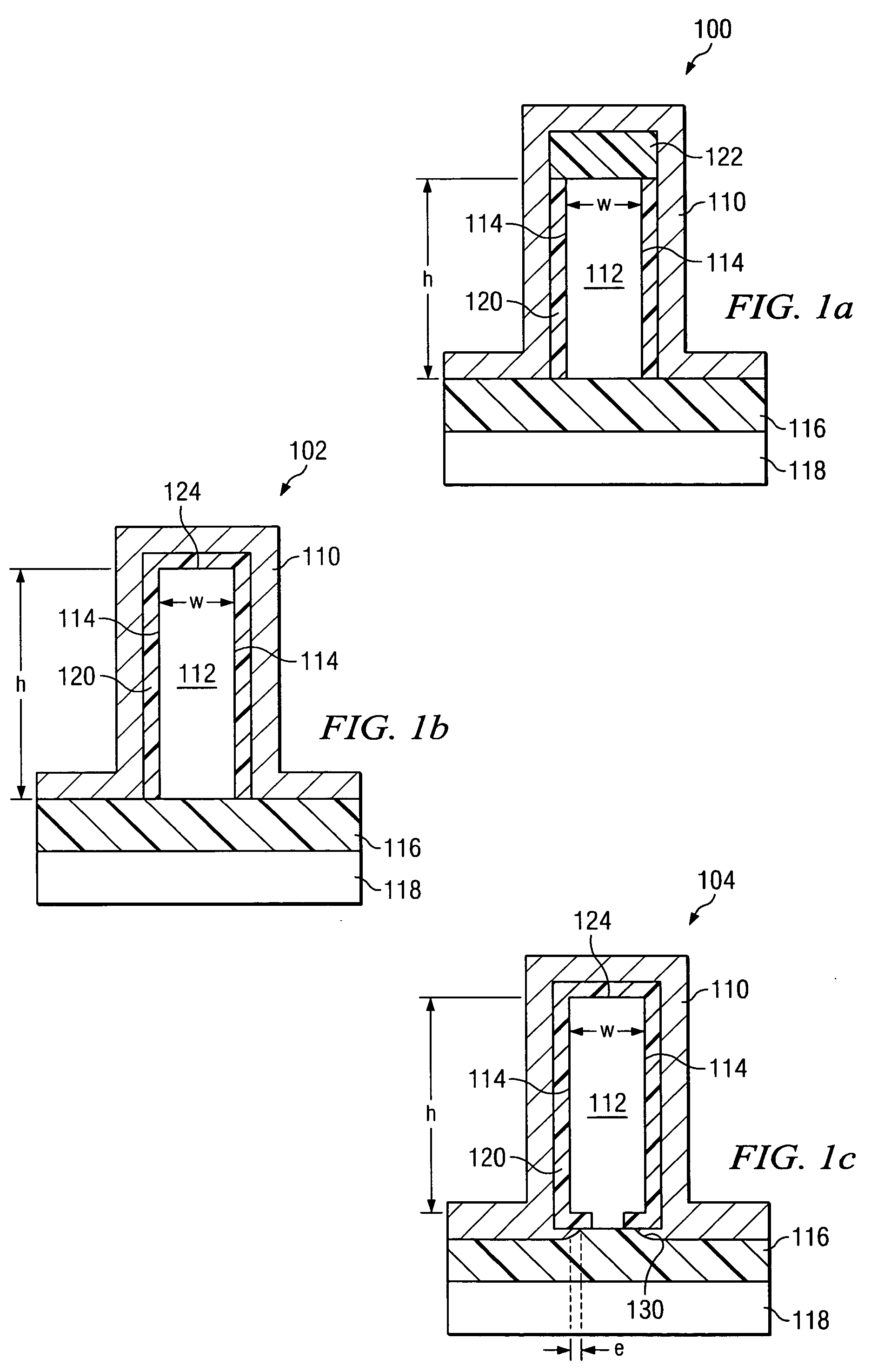

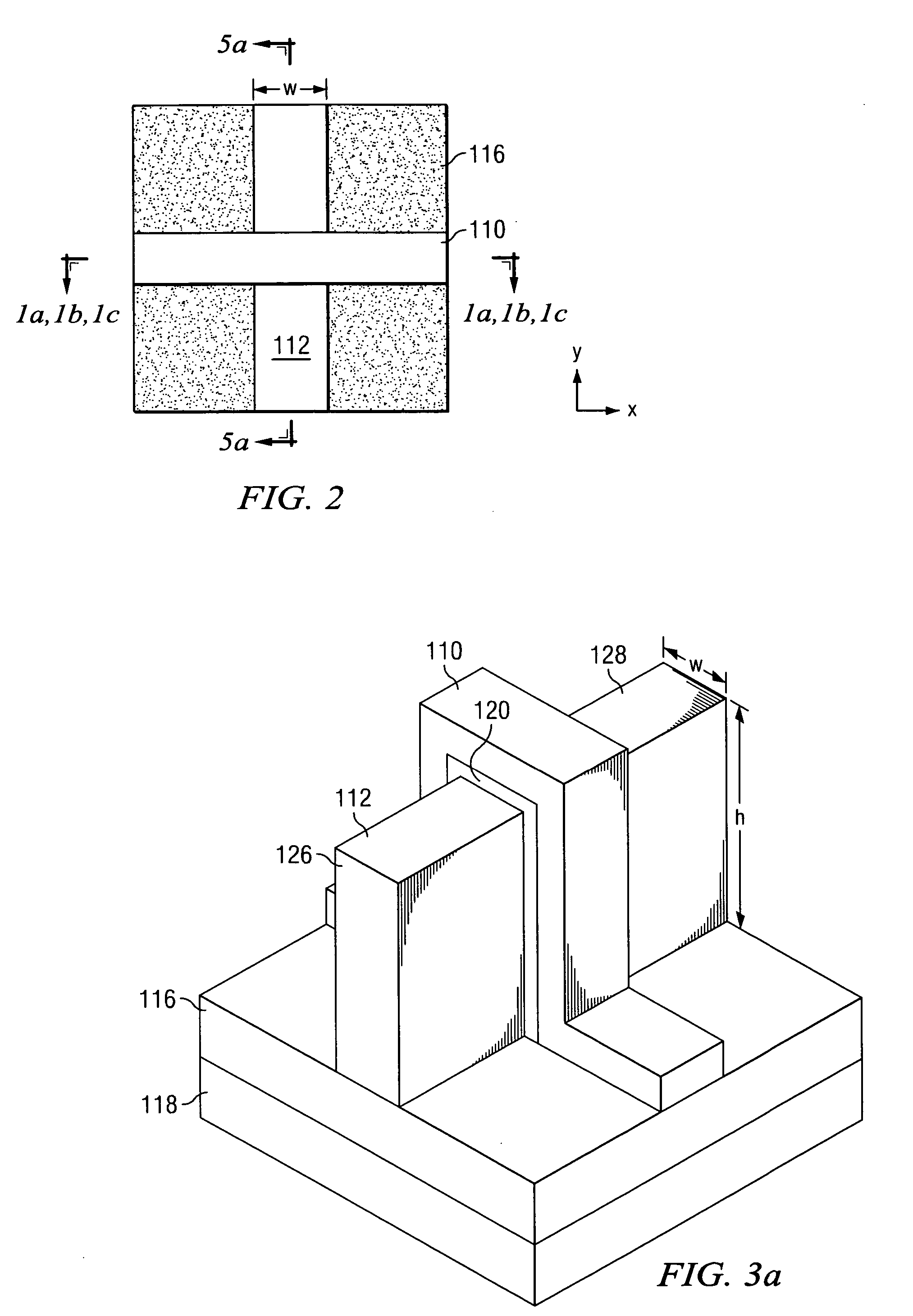

A semiconductor structure includes of a plurality of semiconductor fins overlying an insulator layer, a gate dielectric overlying a portion of said semiconductor fin, and a gate electrode overlying the gate dielectric. Each of the semiconductor fins has a top surface, a first sidewall surface, and a second sidewall surface. Dopant ions are implanted at a first angle (e.g., greater than about 7°) with respect to the normal of the top surface of the semiconductor fin to dope the first sidewall surface and the top surface. Further dopant ions are implanted with respect to the normal of the top surface of the semiconductor fin to dope the second sidewall surface and the top surface.

Owner:TAIWAN SEMICON MFG CO LTD

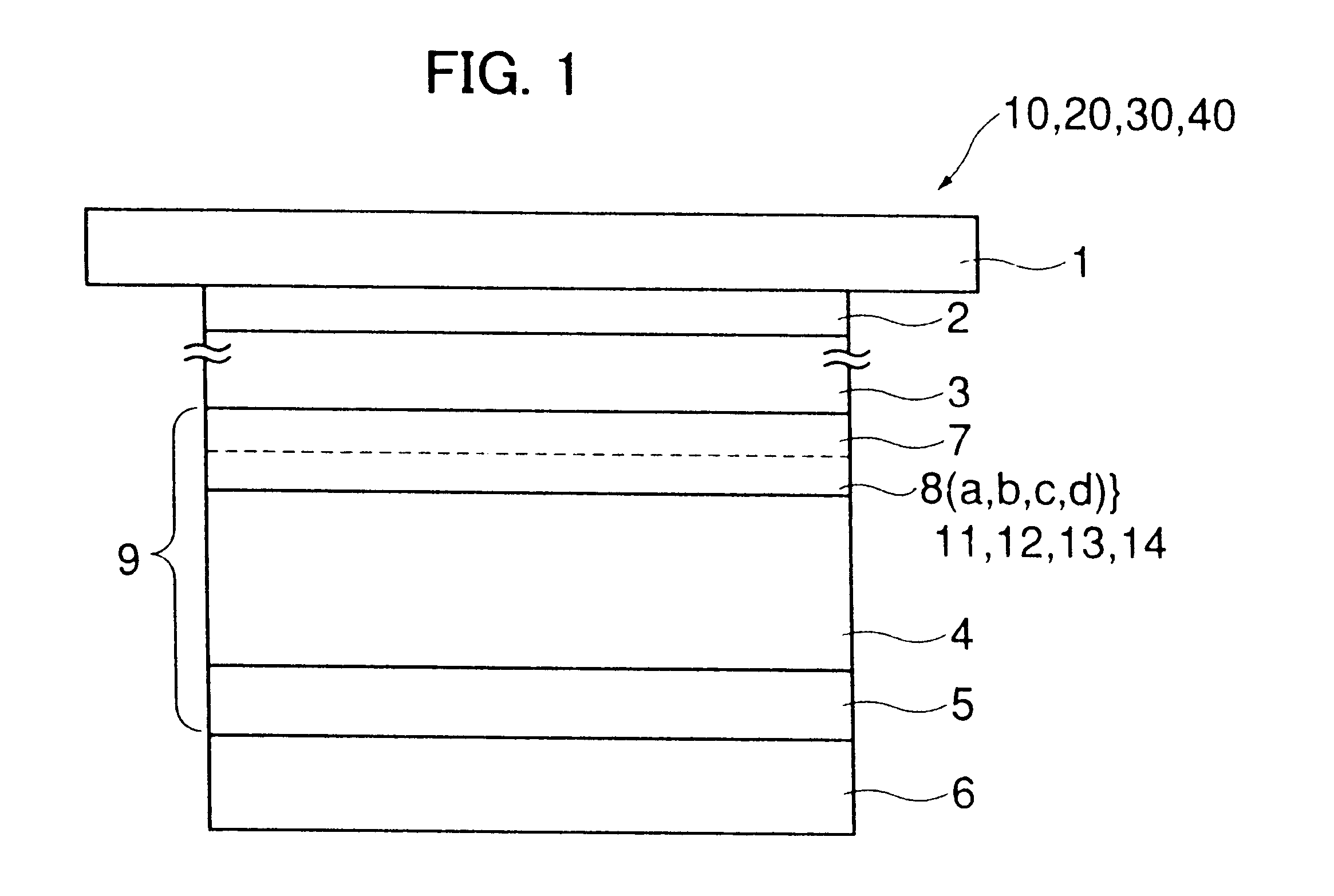

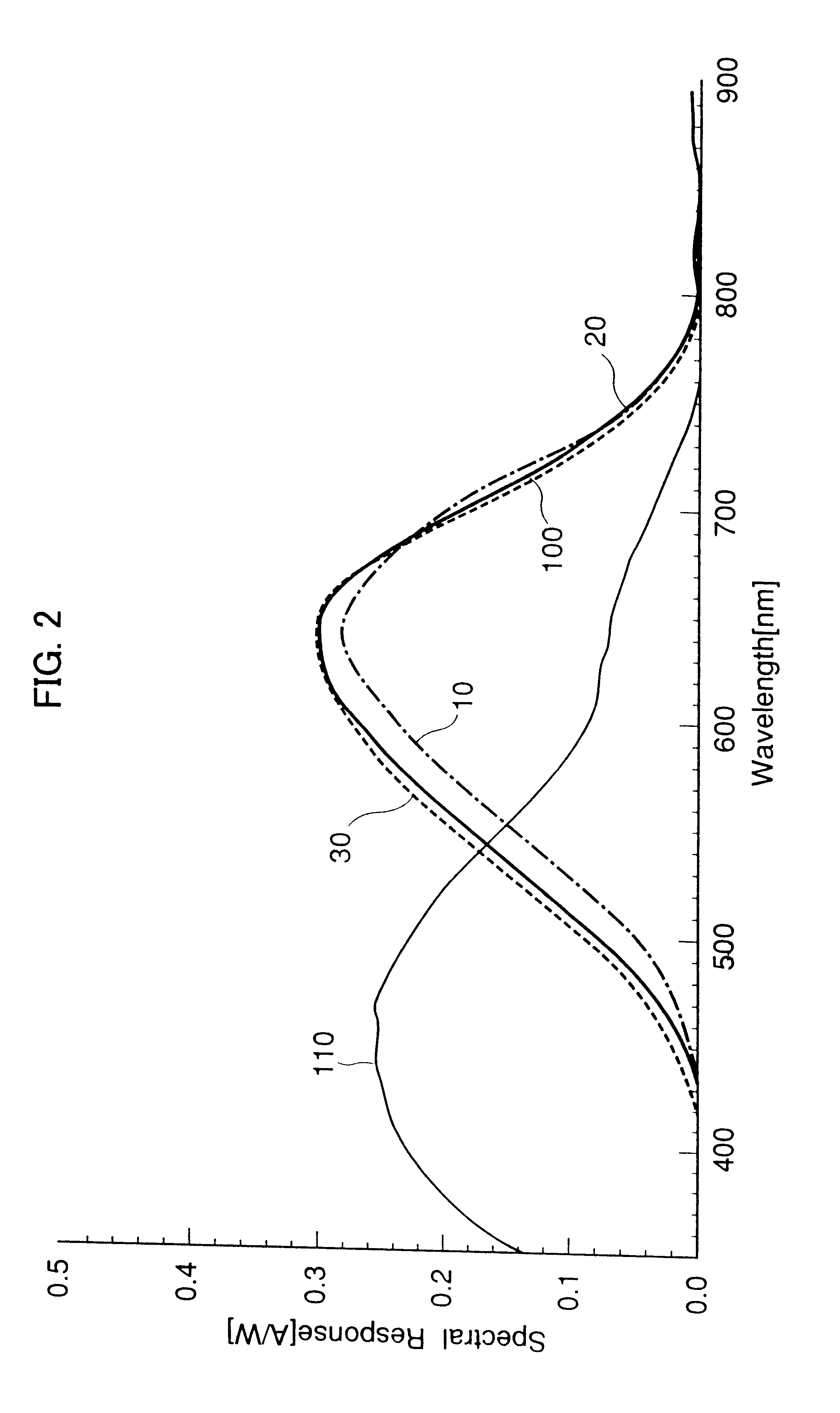

Method for manufacturing photoelectric conversion device

InactiveUS6383898B1Increase light absorption coefficientReduce the amount of lightFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringPhotoelectric conversion

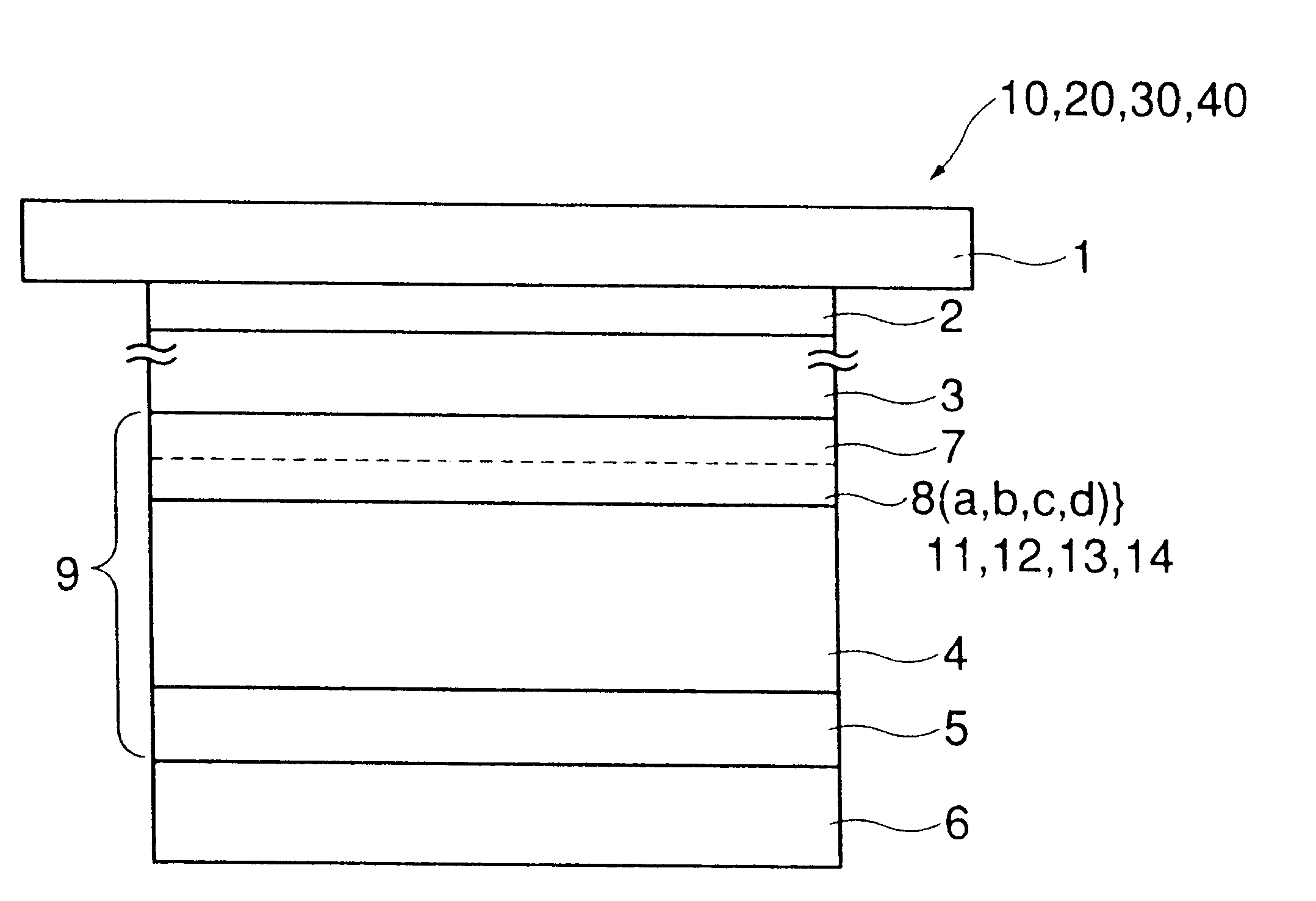

A photoelectric conversion device including a plurality of pin junction layers, wherein at least a p-layer adjacent to an n-layer is formed of a stack of an amorphous silicon layer as a first p-layer and an amorphous silicon layer as a second p-layer, the first p-layer having a thickness of 5 nm or less and containing a p-type impurity and an n-type impurity, and the second p-layer having a p-type impurity concentration gradually decreasing as it is closer to an i-layer.

Owner:SHARP KK

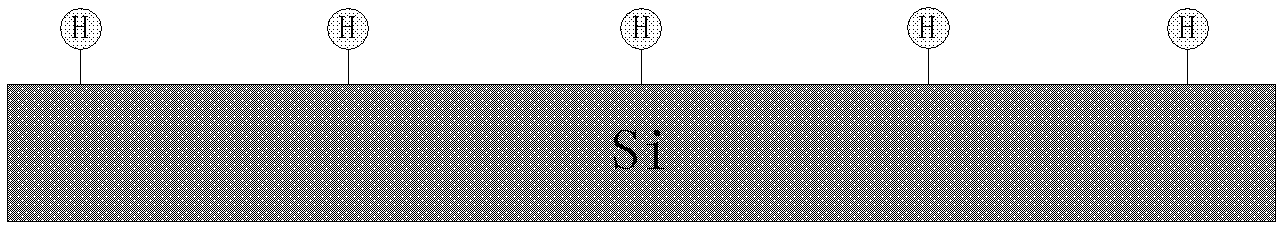

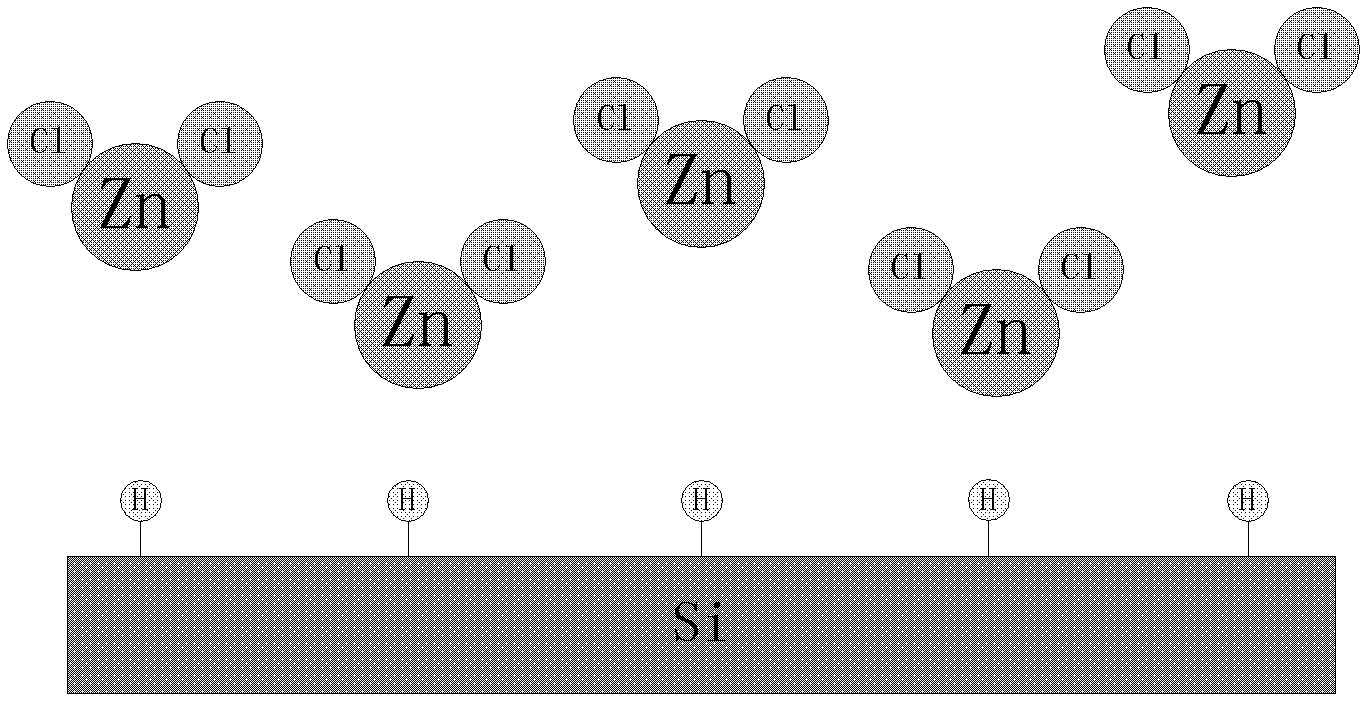

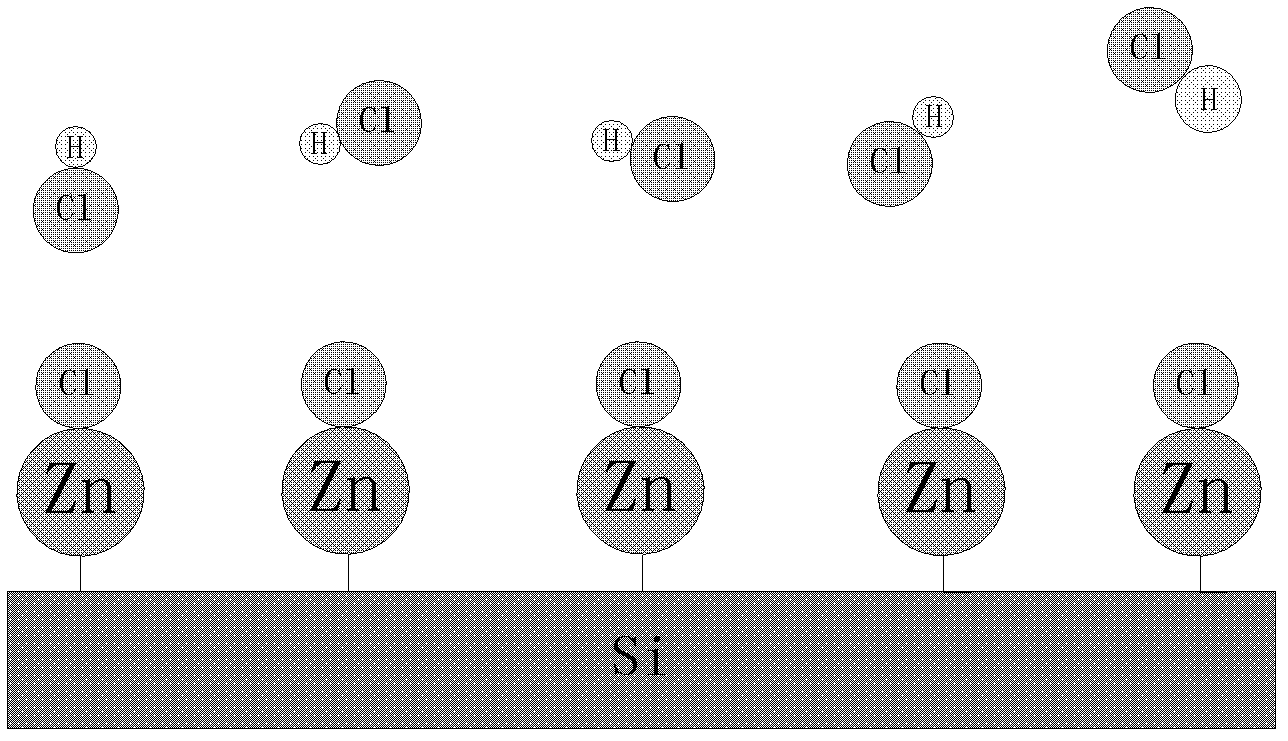

Preparation method of nitrogen-doped zinc oxide film

ActiveCN102304700AImprove performanceSimple methodFinal product manufactureSemiconductor/solid-state device manufacturingOxygenNitrogen gas

The invention relates to the technical field of zinc oxide preparation, and in particular relates to a preparation method of a nitrogen-doped zinc oxide film. The preparation method comprises: placing a silicon substrate in the reaction cavity of atomic layer deposition (ALD) equipment; introducing gas containing a zinc source into the reaction cavity of the ALD equipment, wherein the zinc atoms in the gas containing the zinc source are adsorbed to the silicon substrate; conveying hydrogen to the reaction cavity of the ALD equipment based on nitrogen as a carrier gas, and simultaneously carrying out plasma discharge; introducing an oxygen-containing source to the reaction cavity of the ALD equipment, wherein the zinc atoms which do not react with nitrogen atoms form zinc-oxygen bonds withthe oxygen atoms in the oxygen-containing source; and repeating the steps, so as to grow the zinc oxide film containing the nitrogen atoms layer by layer. In the preparation method provided by the invention, nitrogen doping is carried out on the zinc oxide film by utilizing the ALD equipment; the method is simple and practicable; by utilizing the characteristic of atomic layer deposition and single-layer cycle growth, the uniform nitrogen doping in the whole film structure can be achieved in the process of zinc oxide film growth so that the doped film is complete in structure and excellent inproperty.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

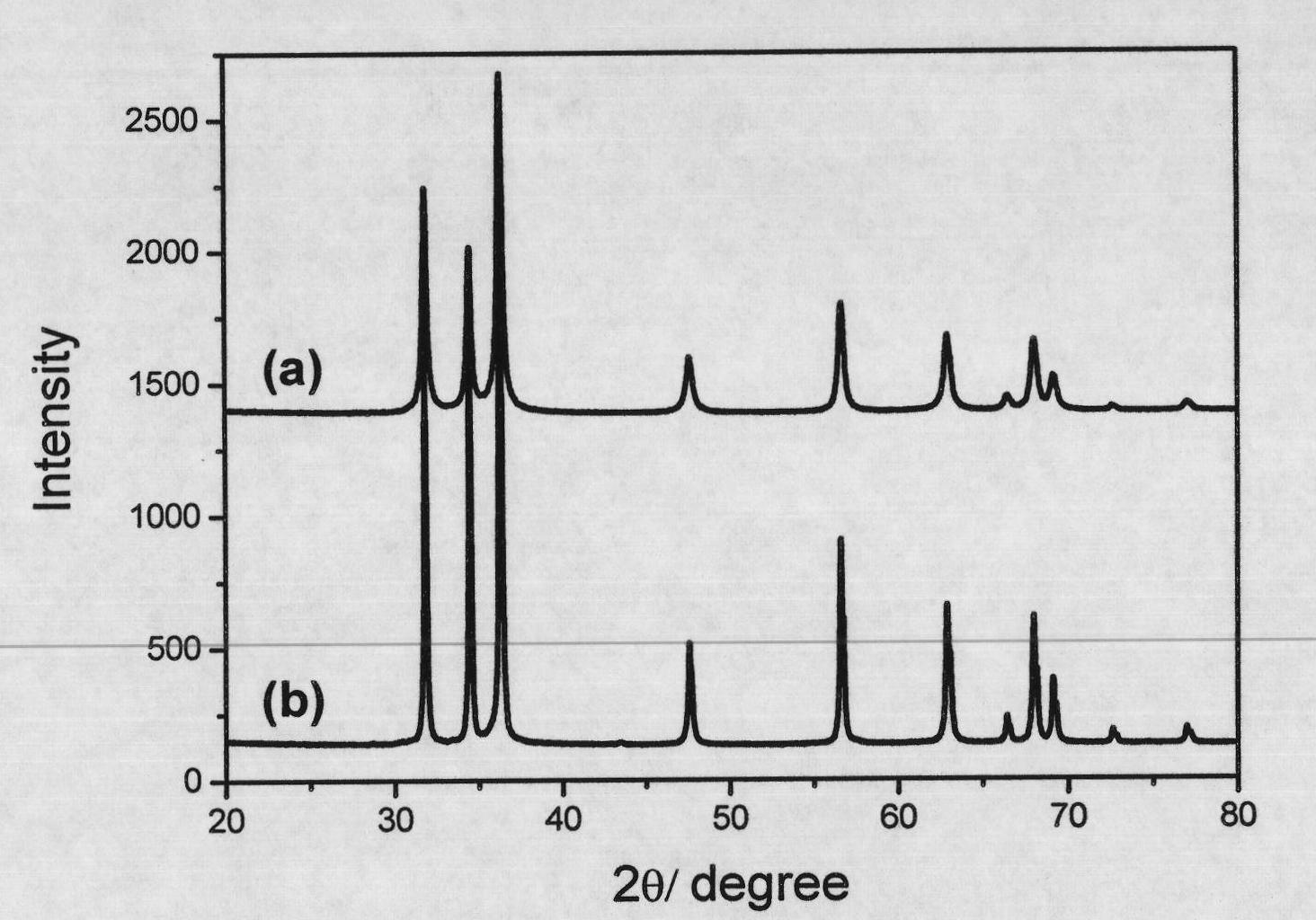

Method for preparing high-density spherical lithium iron phosphate

InactiveCN1632969AHigh bulk densitySimple processElectrode manufacturing processesPhosphatesKeroseneHexamethylenetetramine

This invention discloses a high density ball ferric phosphate lithium process method in energy material process technique, which comprises the following steps: to use ferric nitrate, phosphate chrome and acetic acid lithium as materials and to add deionized water to process solution A; to mix impurity metal compound or carbon source into the solution A; to make solution of hexamethylenetetramine and carbamide to process solution B; to make solution C by adding solution B into solution A; to drop solution C with kerosene and to heat it into gel for deposition; to get the ball dry gel front driver after centrifugal separation; to get the high volume proportion capacity high density ferric phosphate lithium through high temperature process.

Owner:TSINGHUA UNIV

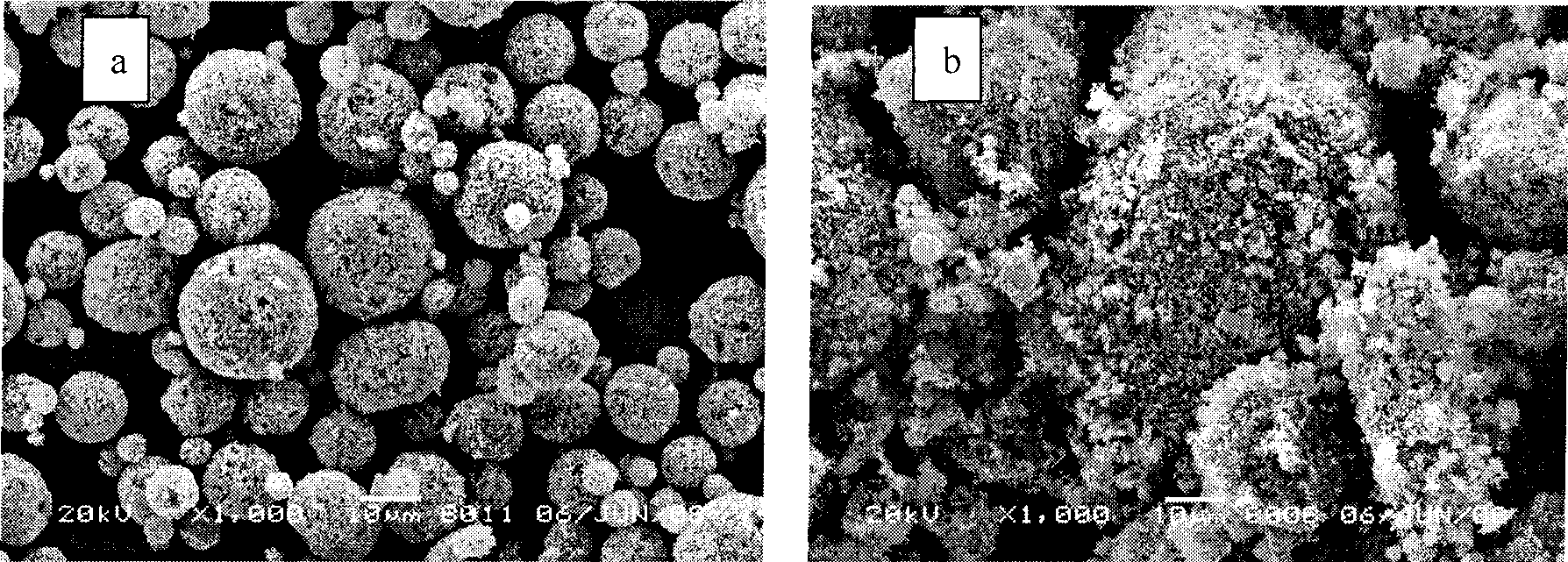

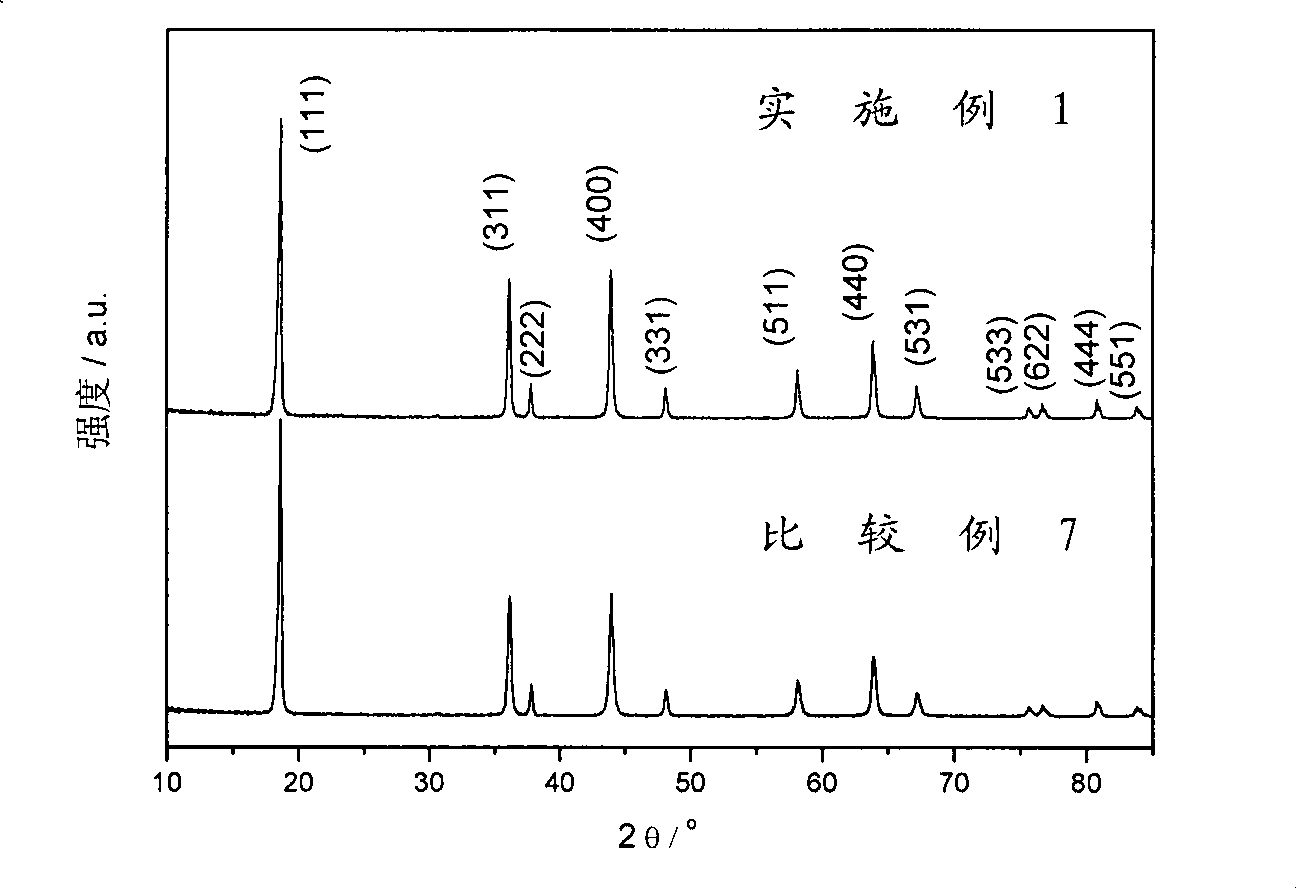

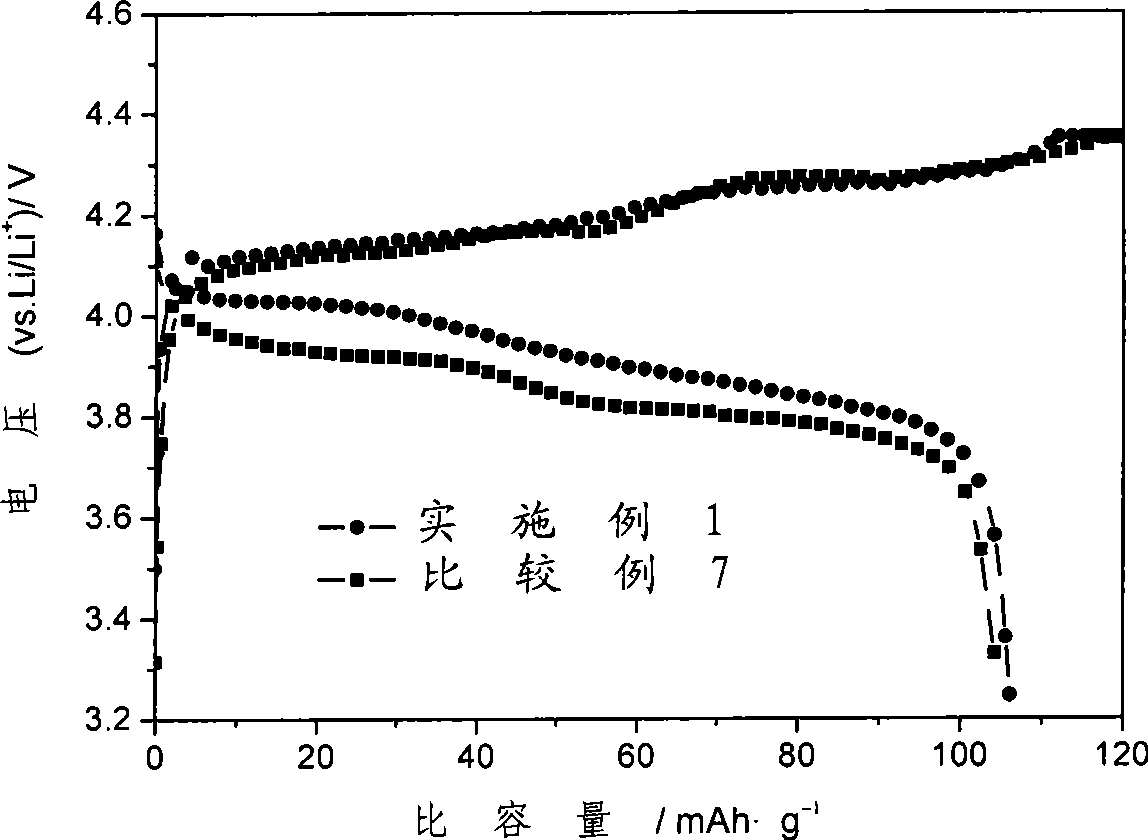

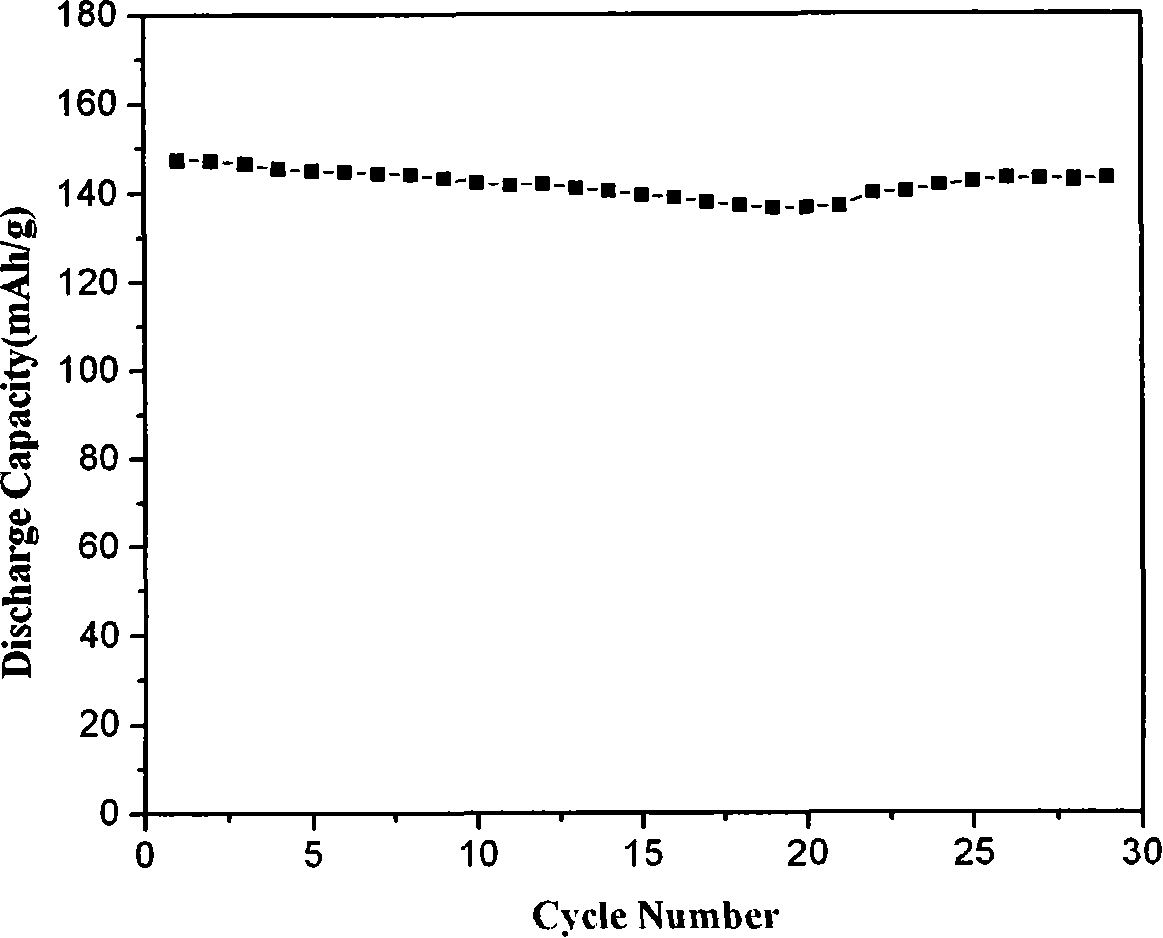

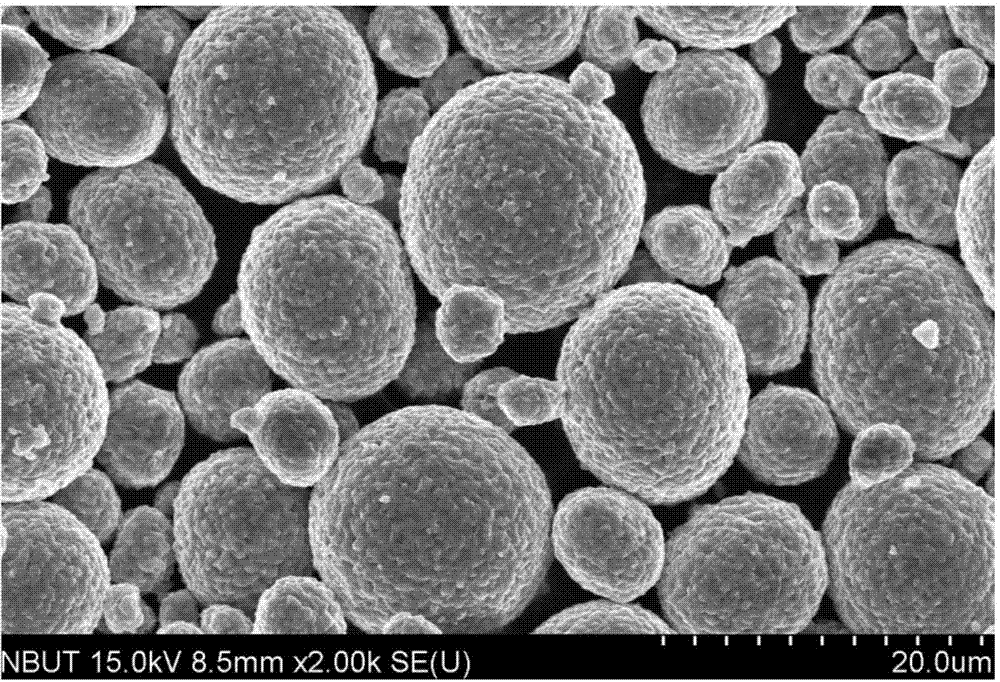

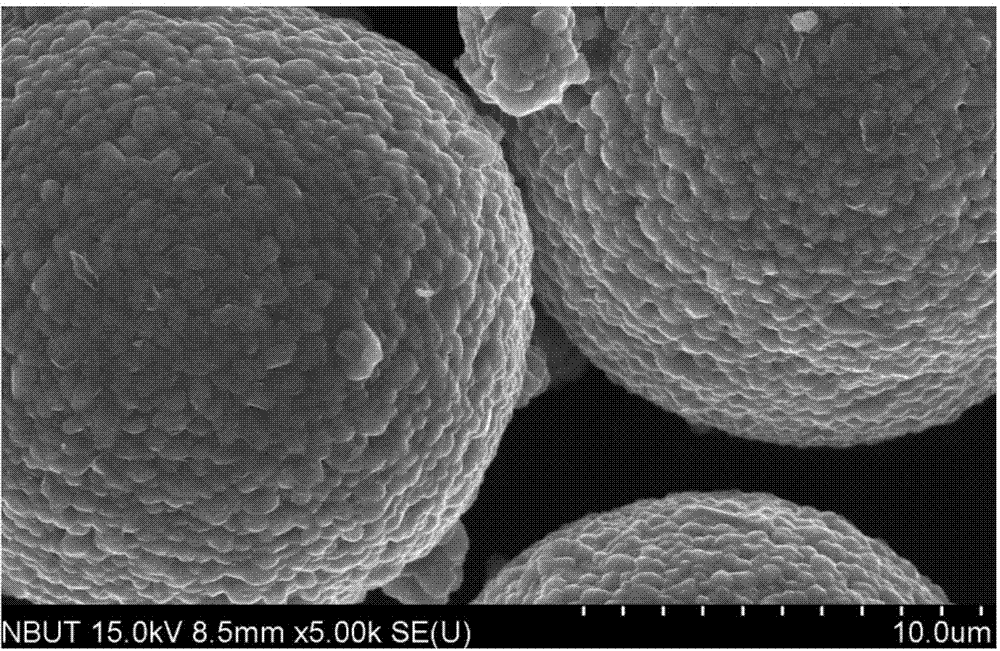

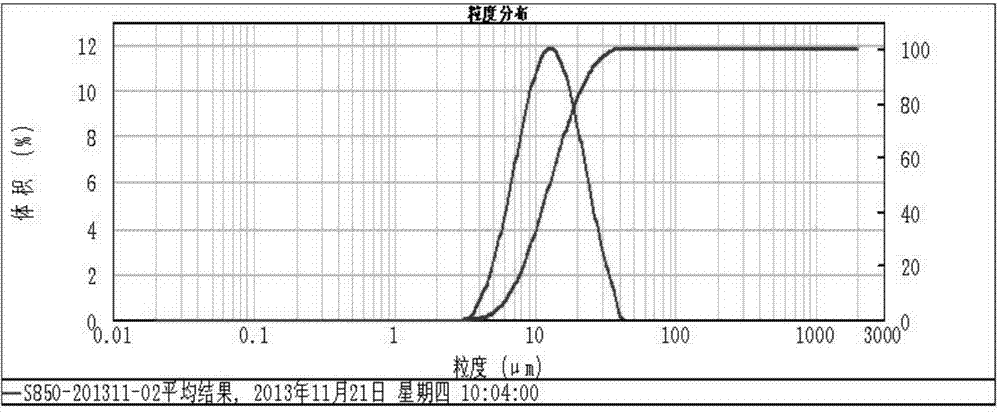

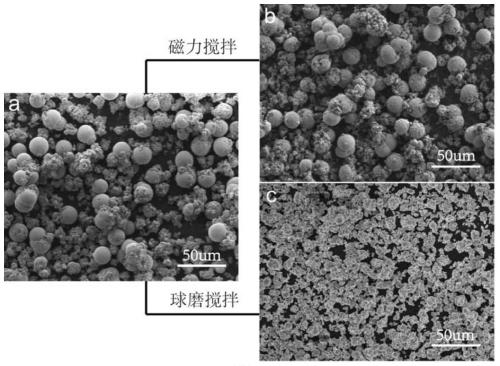

Spray drying preparation of spherical lithium manganate doped slurry

InactiveCN101462773AEvenly dopedUniform particle sizeManganates/permanganatesGranularityLithium carbonate

The invention relates to a method for the spray drying of spherical doped lithium maganate slurry. The method comprises: mixing manganese dioxide, lithium carbonate, doped metal salt and a solution containing a dispersant according to a certain proportion; subjecting the mixture to mechanical mixing to obtain a uniformly mixed slurry; subjecting the uniformly mixed slurry to spray drying to obtain a spherical precursor; and roasting the precursor sectionally to obtain a spherical doped lithium manganate slurry cathode material product. The lithium manganate cathode material for lithium ion batteries has uniform granularity which averagely is 15mu m, uniform spherical shape and good cycle performance. The invention is simple in process, convenient in operation, environmentally friendly and applicable to industrial production.

Owner:CENT SOUTH UNIV

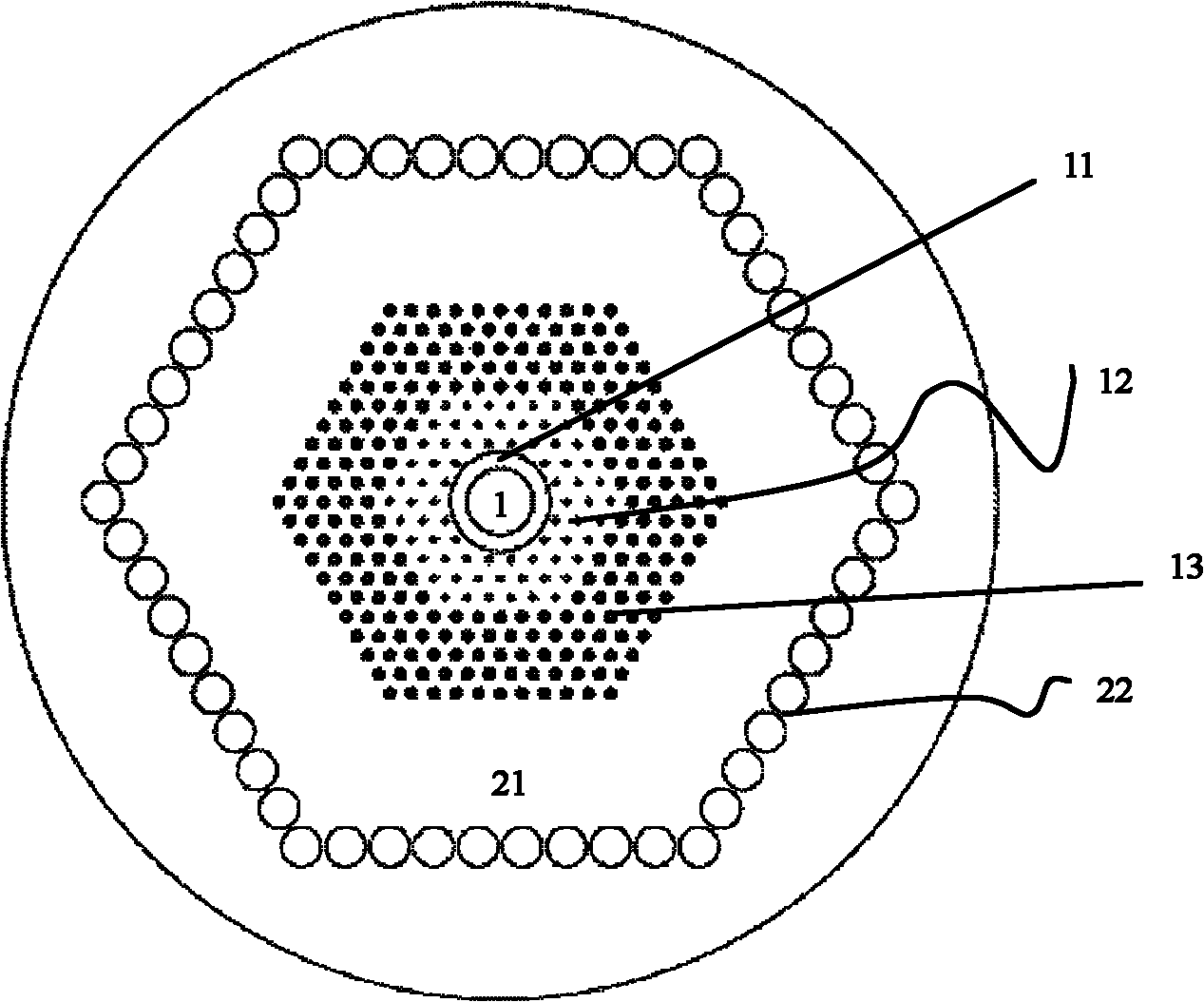

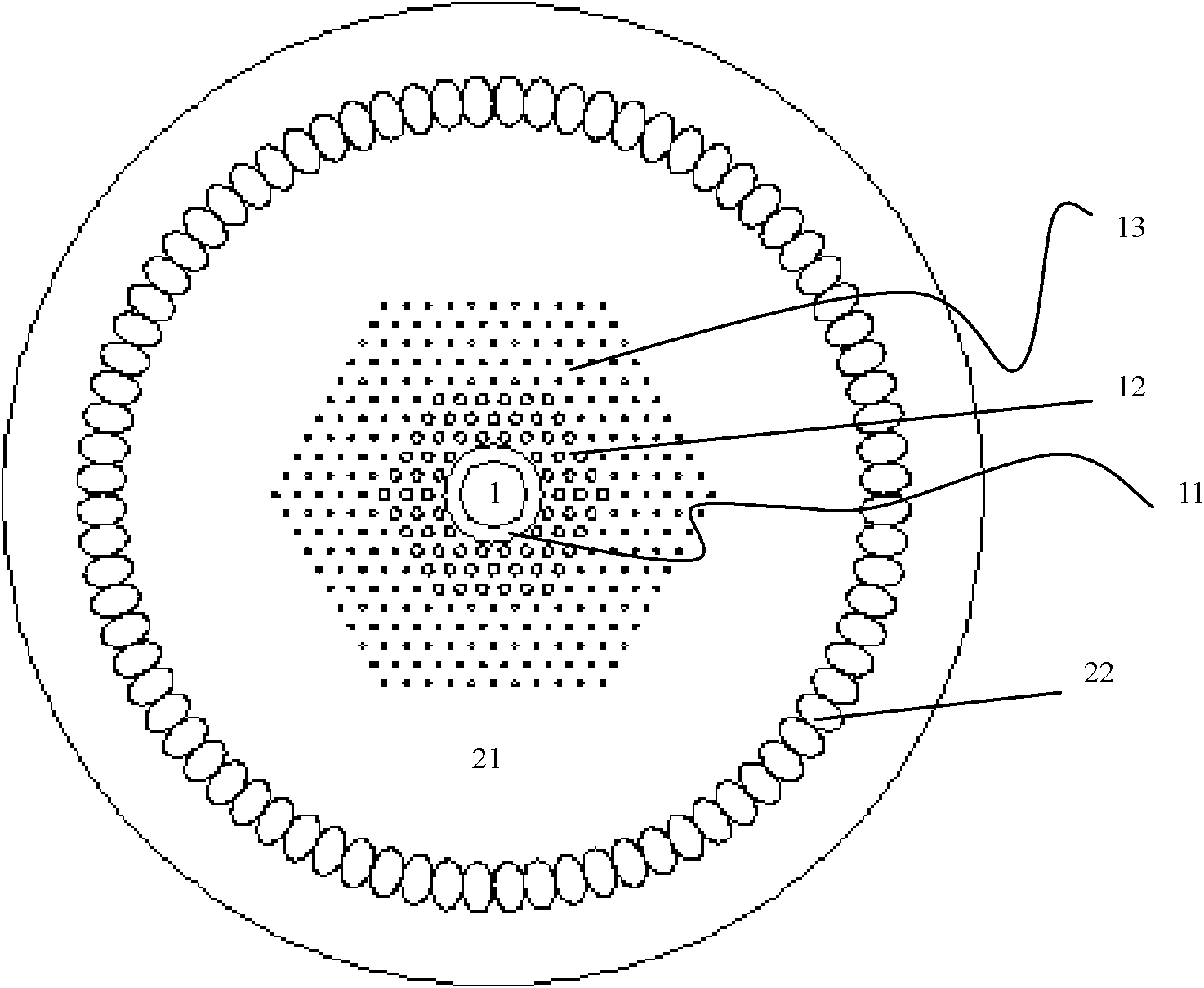

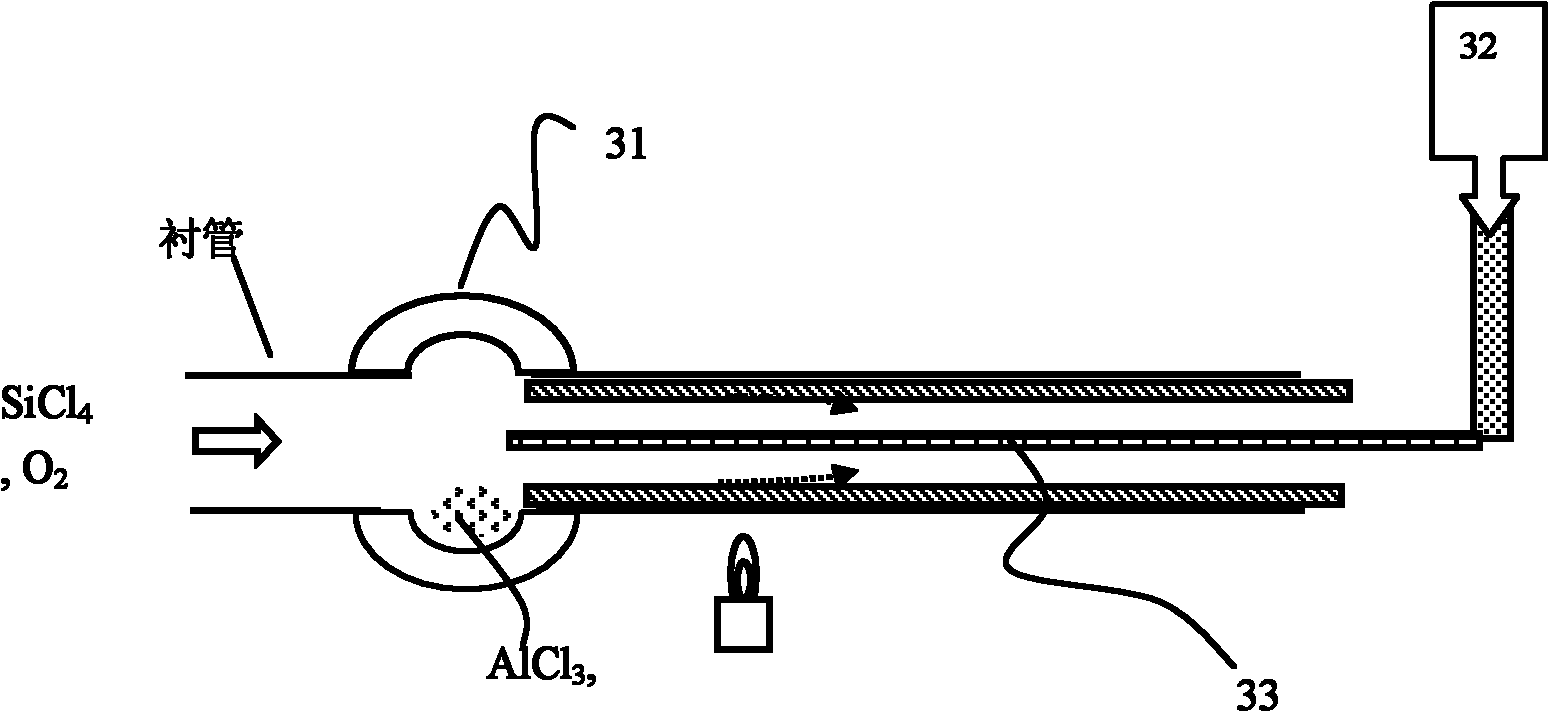

Large-mode-area active optical fiber and preparation method thereof

ActiveCN102213792ALow refractive indexChange the effective refractive indexGlass making apparatusOptical fibre with multilayer core/claddingFiberGas phase

The invention provides a large-mode-area active optical fiber, which comprises a fiber core, a first cladding, a second cladding and a third cladding, wherein the first cladding, the second cladding and the third cladding sequentially encircle the periphery of the fiber core; the effective refractive index of the second cladding is lower than the effective refractive indexes of the first claddingand the fiber core; a pump core area encircles the outer side of the third cladding; an external cladding encircles the outer side of the pump core area and comprises a layer of air vent holes or capillary bars doped with quartz glass; and the effective refractive index of the external cladding is lower than that of the pump core area. On the premise of ensuring a large mode area of the active optical fiber, the optical fiber suppresses amplified spontaneous radiation, improves the stability of the optical fiber, and ensures the quality of light beam. The invention also provides a preparationmethod of the active optical fiber. By adopting a liquid phase multi-point doping mode of gas-phase aluminum doping and rare-earth ions, continuous doping for many times can be flexibly controlled and realized, the size of a rare-earth doped core bar is greatly increased, and uniform doping of the rare-earth ions and aluminum is simultaneously realized.

Owner:武汉长进光子技术股份有限公司

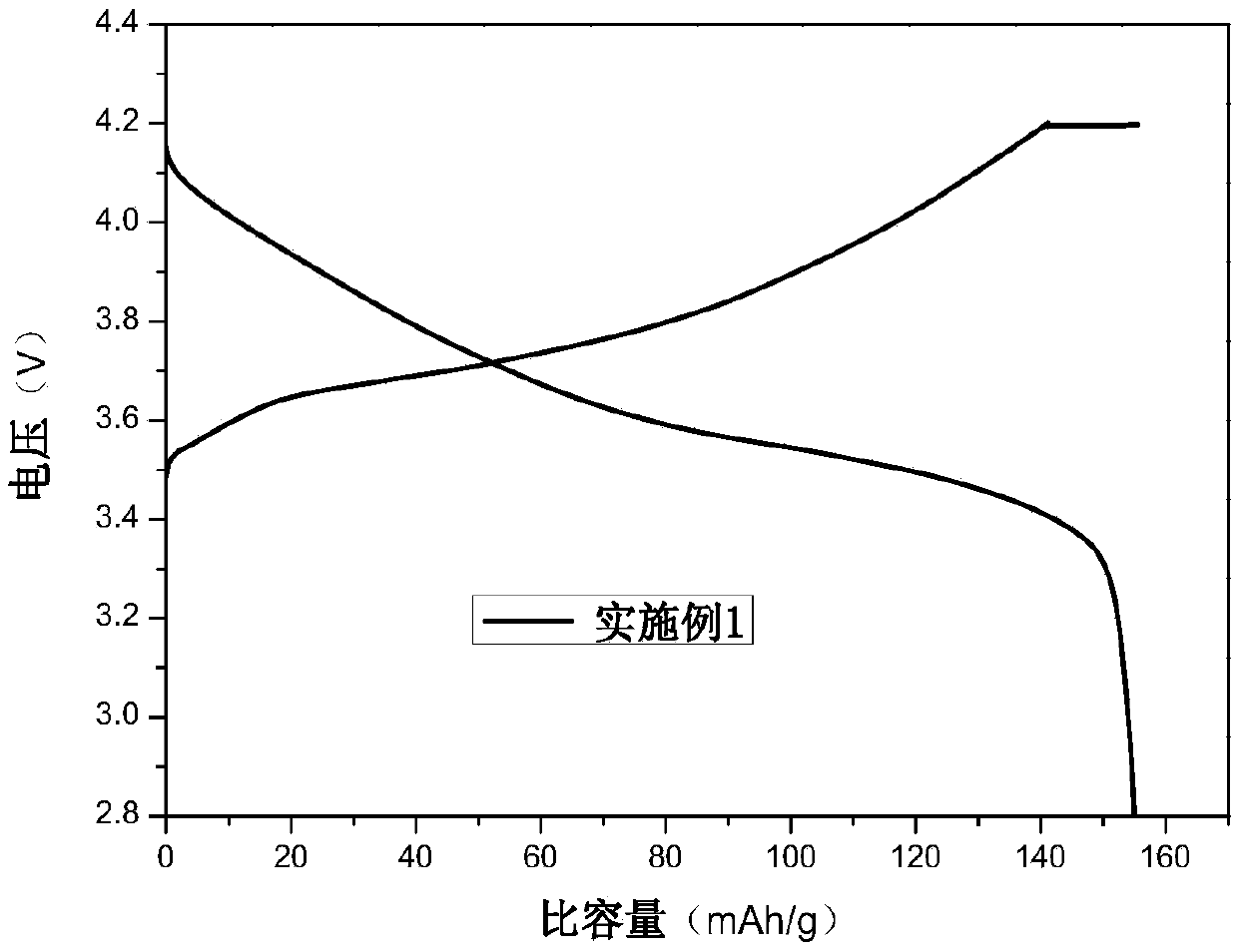

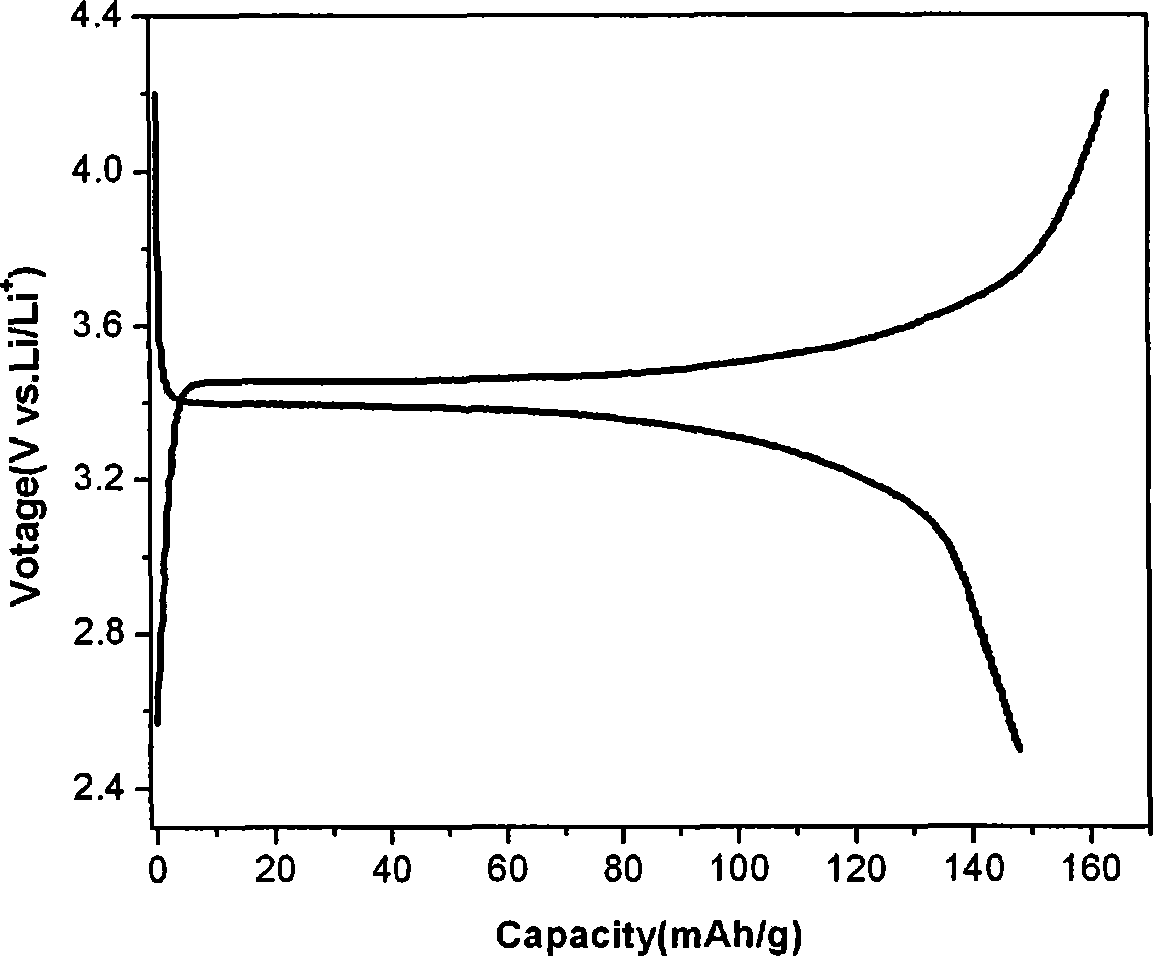

Preparation method of high compaction density lithium ion cathode material

The invention relates to a preparation method of a high compaction density lithium ion cathode material. The preparation method comprises the following steps: (1) uniformly mixing a boron compound with a precursor material to obtain a pretreated precursor material; (2) sufficiently mixing the pretreated precursor material with a lithium salt to obtain a mixture; and (3) carrying out solid phase sintering on the mixture in an oxidizing atmosphere, cooling and crushing to obtain the high compaction density lithium ion cathode material. According to the preparation method, the precursor material is pretreated, the boron compound is firstly uniformly attached to the precursor, and then the pretreated precursor material is mixed with the lithium salt for sintering, so that doped element boron is uniformly distributed in a product phase so as to achieve the purpose of uniform doping. According to the high compaction density lithium ion cathode material prepared by the invention, the tap density is greater than or equal to 2.3 g / cm<3>, the manufacturing compaction density is greater than or equal to 3.70 g / cm<3>, the primary discharge gram capacity can reach more than 153 mAh / g, and the circulating capacity retention rate in 300 circles reaches more than 85%.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

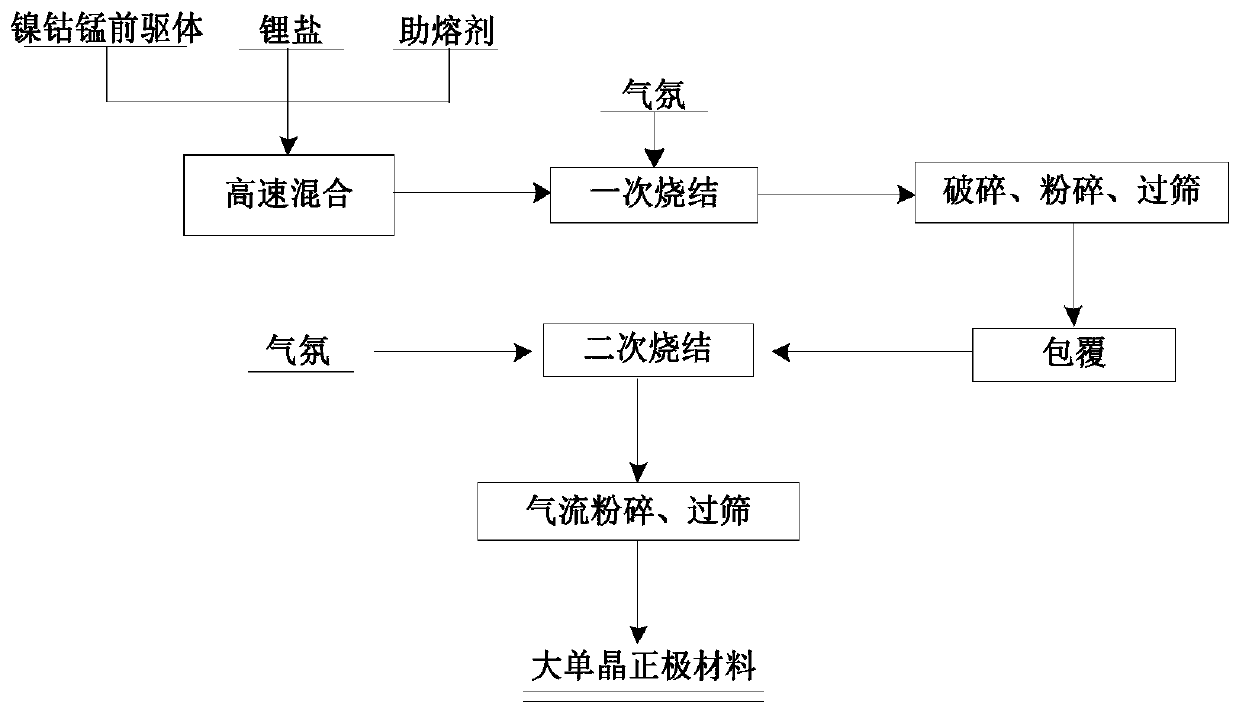

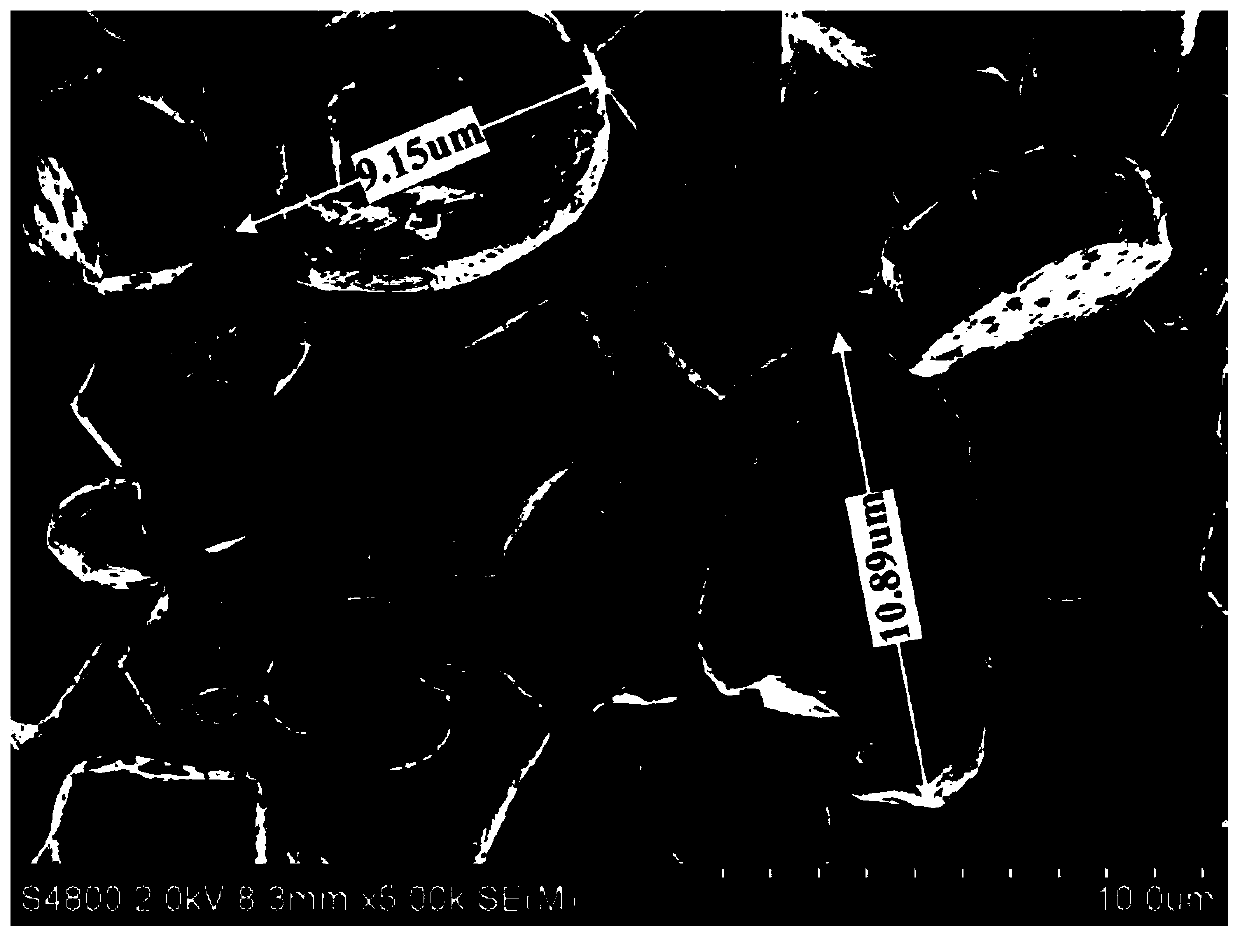

Preparation method of large single crystal lithium ion battery nickel cobalt lithium manganate cathode material

InactiveCN110534733AUniform thicknessHigh crystallinitySecondary cellsPositive electrodesDispersityManganate

The invention relates to a preparation method of a single crystal lithium ion battery nickel cobalt lithium manganate cathode material. The method comprises the following steps of: (1) taking a small-grain crystal spherical NCM ternary precursor, a lithium salt and an A element-containing nano fluxing agent as raw materials, uniformly mixing the raw materials by adopting a dry-method high-speed mixing mode, and performing primary sintering under an oxygen-enriched atmosphere condition; (2) subjecting the sintered material to jaw breaking, roller pairing, crushing and sieving so as to obtain asingle-crystal once-sintered base material; and (3) mixing the primary sintering base material with a B element-containing nano coating agent, sintering again under an oxygen-enriched atmosphere condition, and then performing jaw breaking, roller pairing, crushing and sieving to obtain the large single crystal lithium nickel cobalt manganate cathode material. The cathode material prepared by the invention has the characteristics of the large particle size, the good dispersity, the moderate specific surface area, the high compaction density, the high voltage, the good high-temperature cycle performance and the like.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

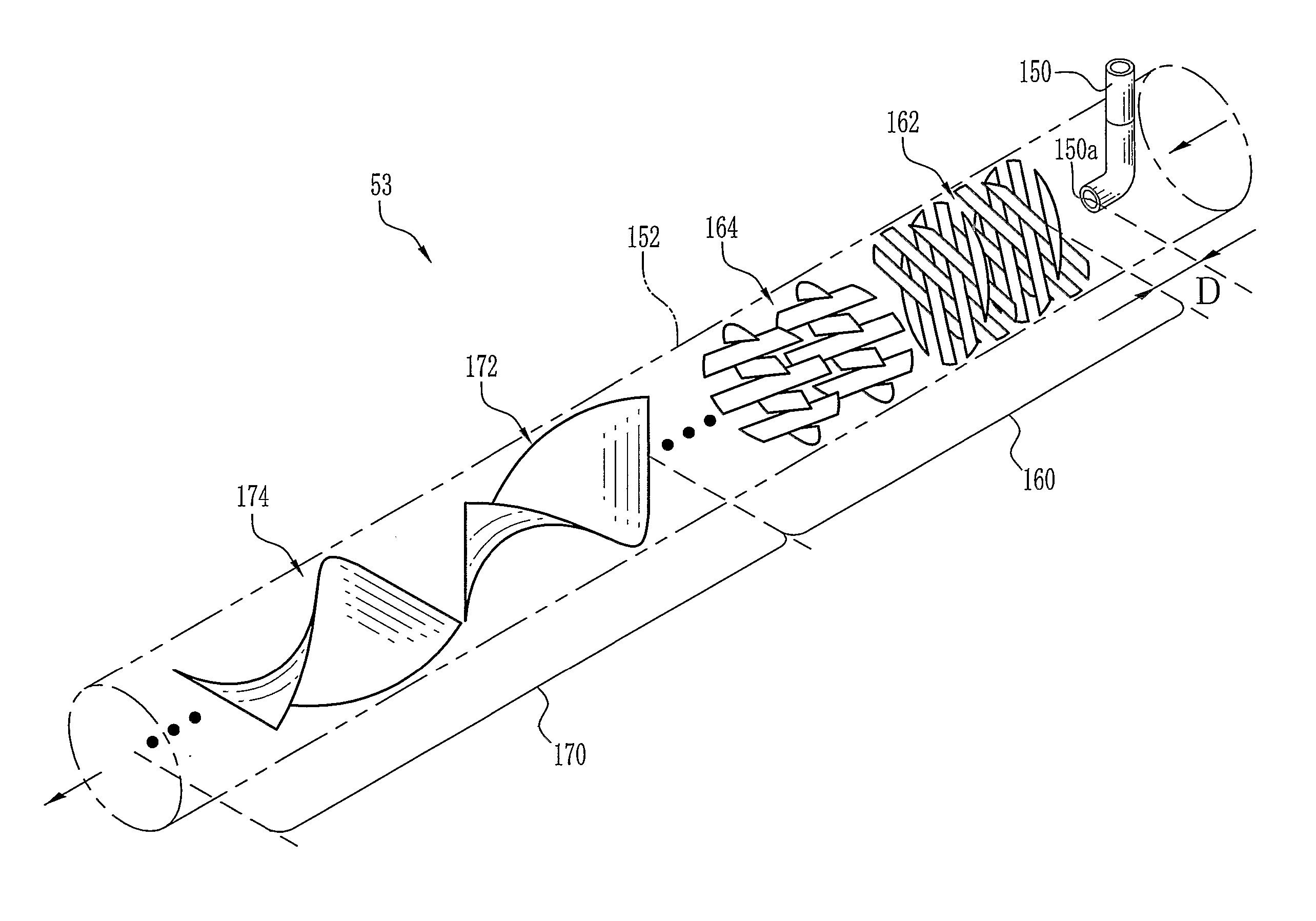

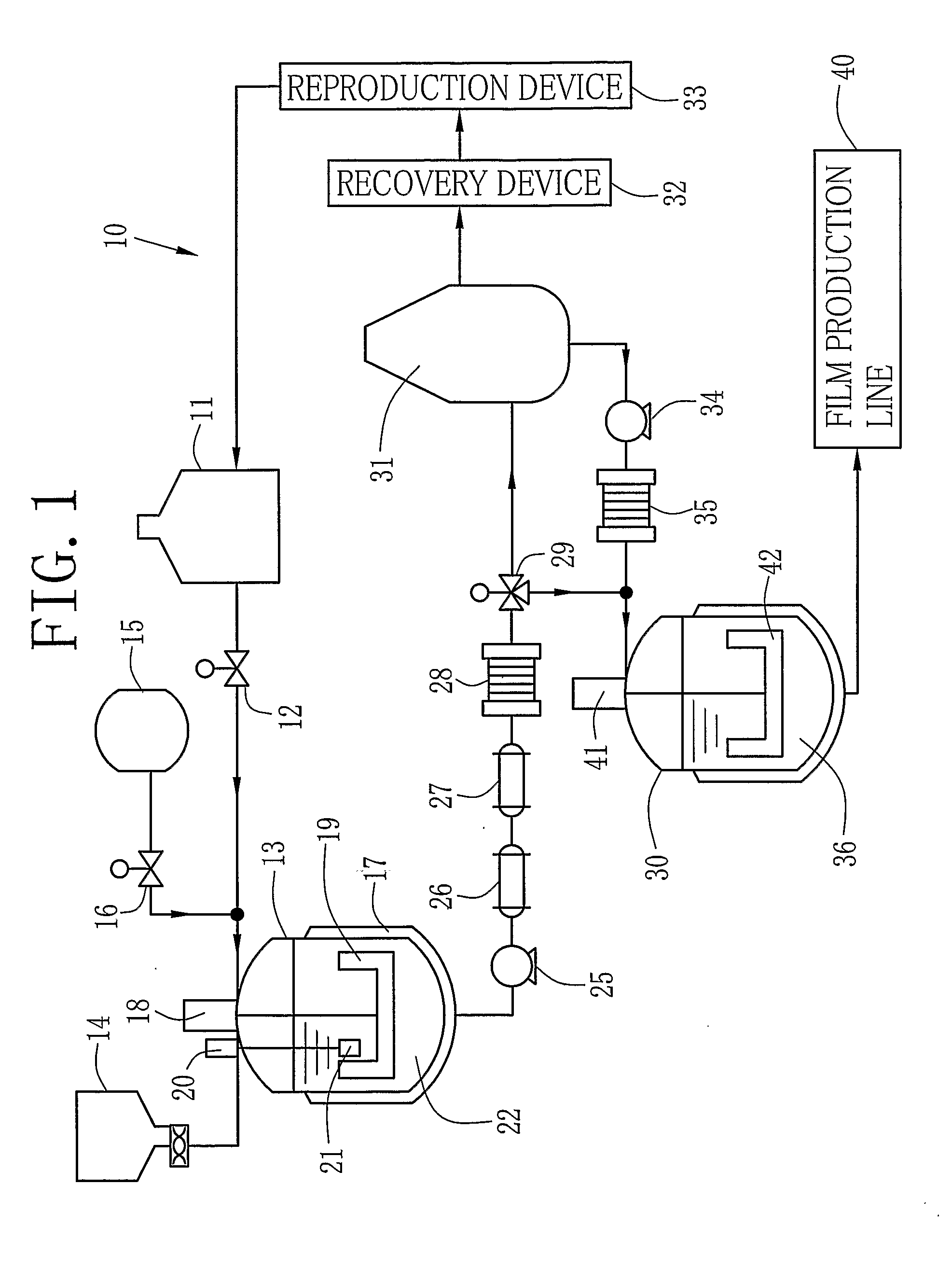

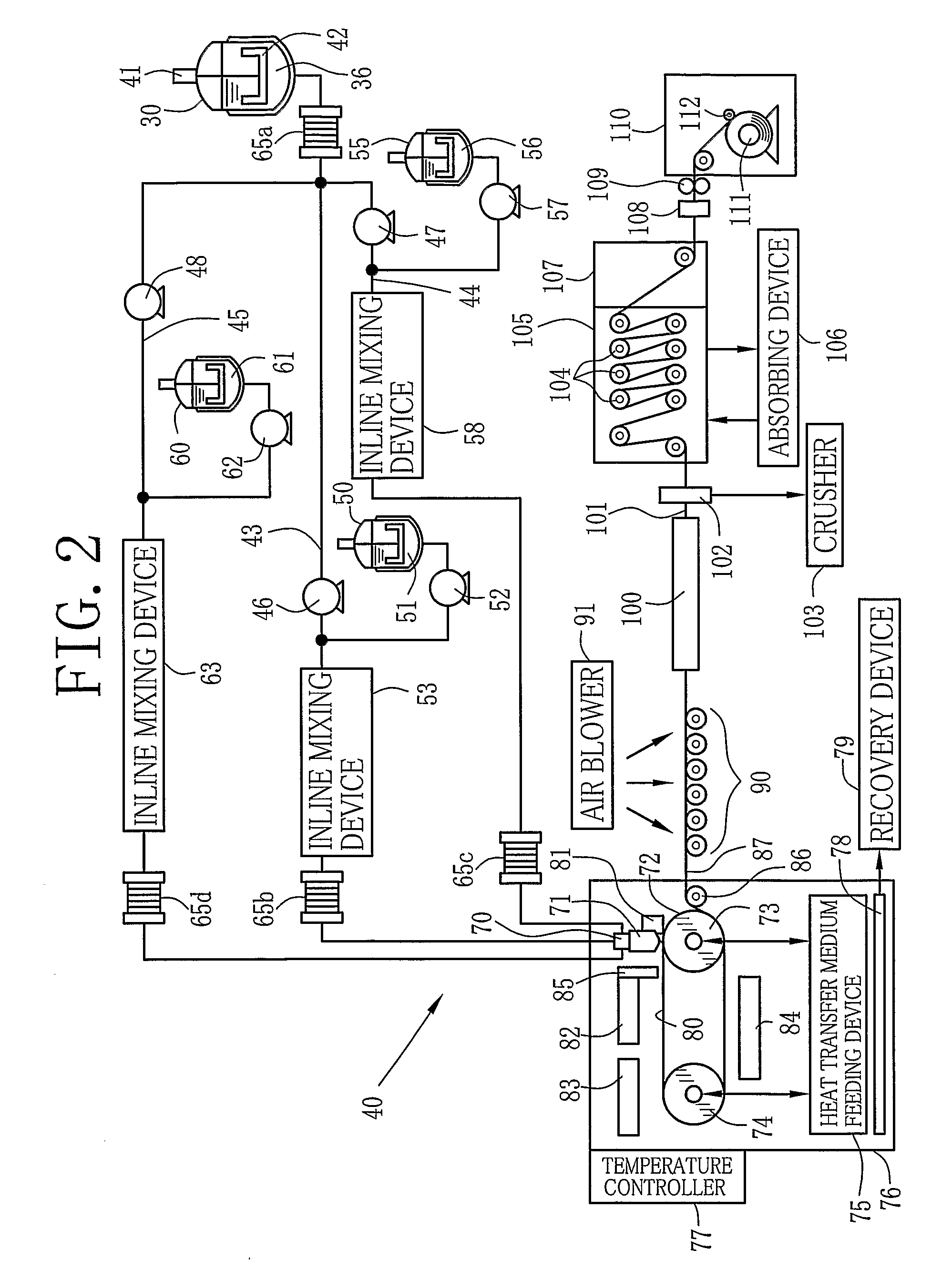

Method and Apparatus for Producing Dope, and Method for Producing Film

InactiveUS20080056064A1Efficient executionReduce in quantityFlow mixersTransportation and packagingEngineeringStatic mixer

An inline mixing device (53) is constituted of a sulzer mixer (160) disposed in an upper stream and a static mixer (170) disposed in a downstream. An additive supplied through an orifice (150a) passes through the sulzer mixer (160) disposed in the upstream. As the sulzer mixer (160) is superior in dividing the flow, the additive is uniformly dispersed in a dope pipe (152). Thereafter, the additive passes through the static mixer (170). As the static mixer (170) is superior in reversing the flow, the additive and the primary dope are further stirred and kneaded. The inline mixing device (53) uses the two different kinds of mixers for effectively mixing the additive and the dope while taking advantages of each mixer.

Owner:FUJIFILM CORP

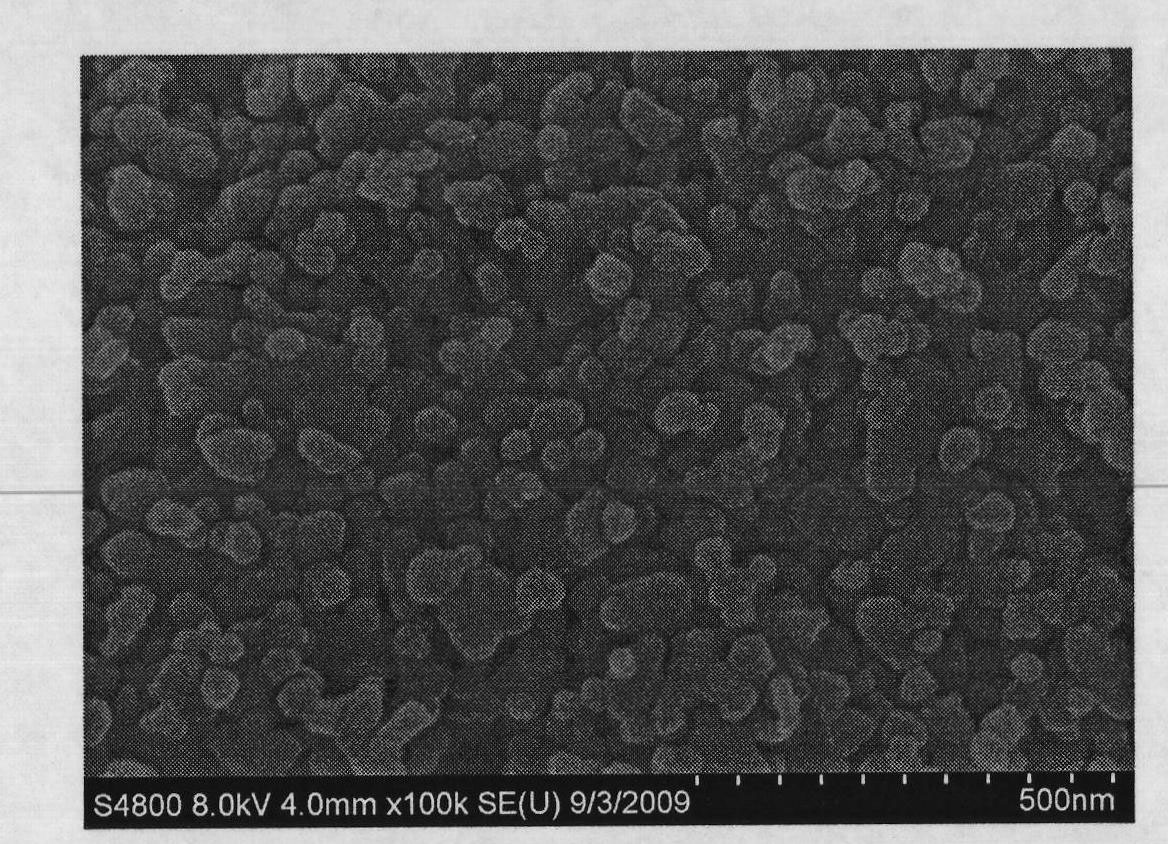

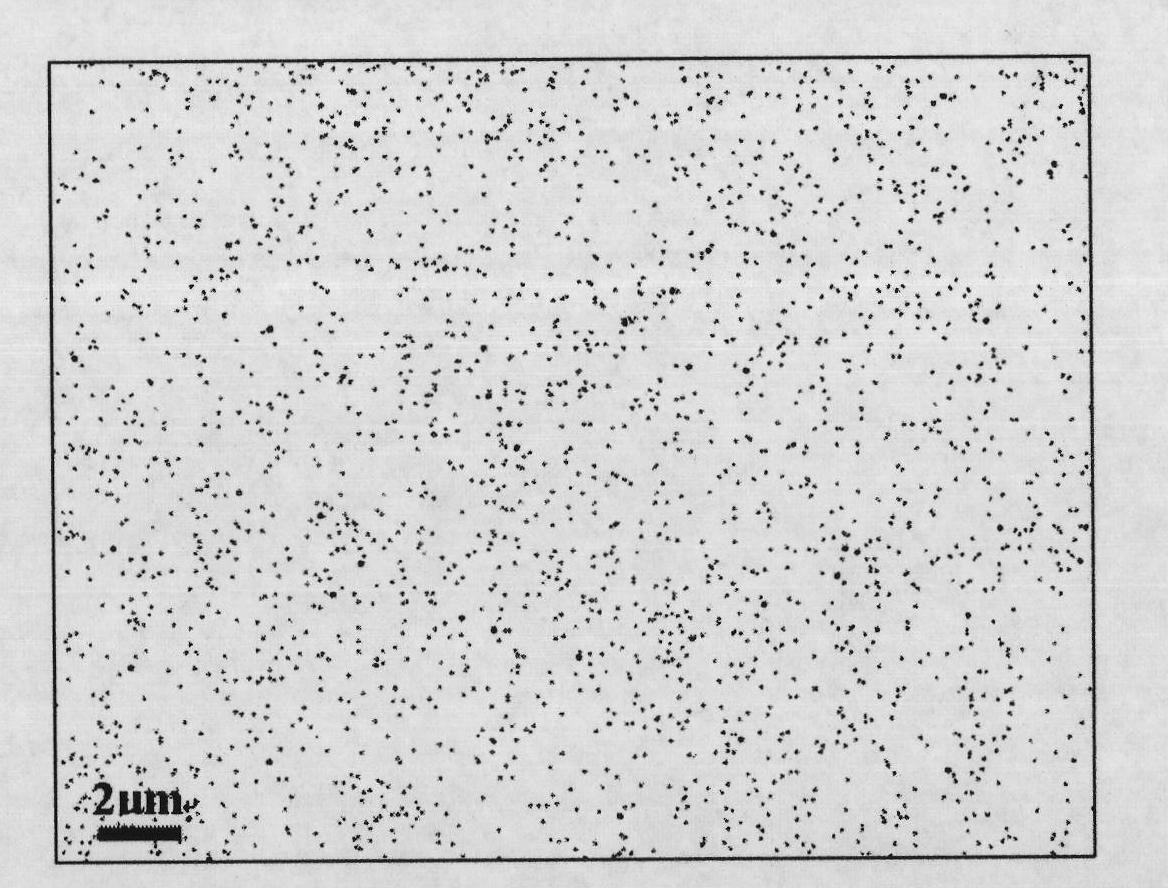

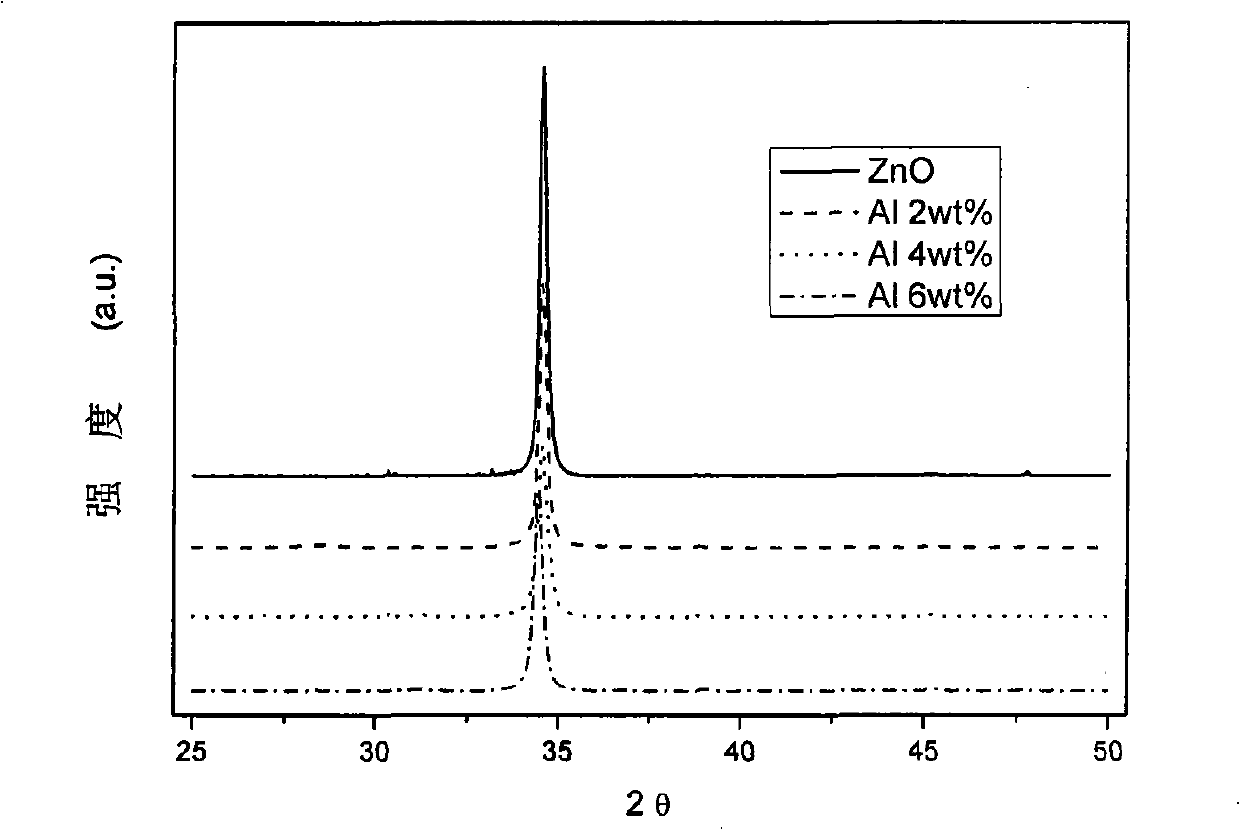

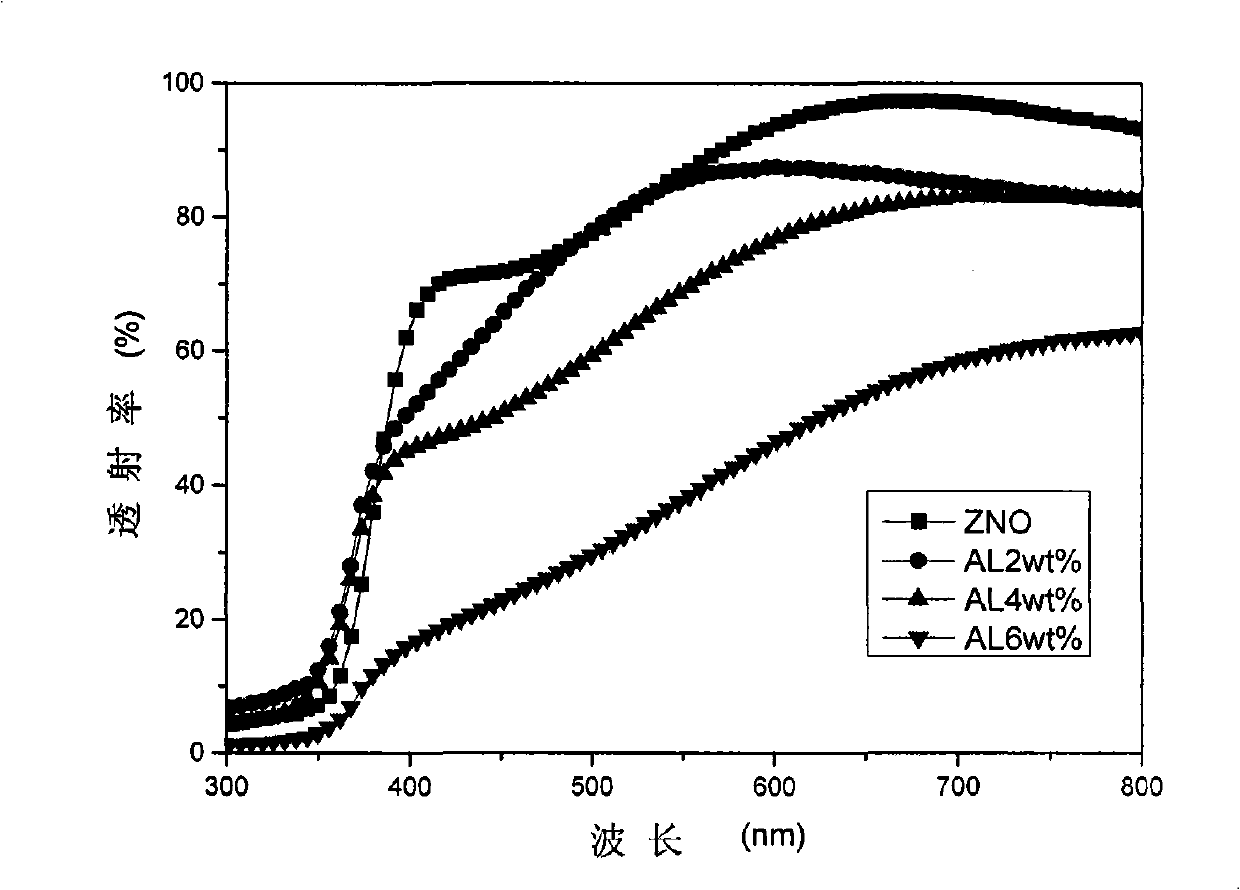

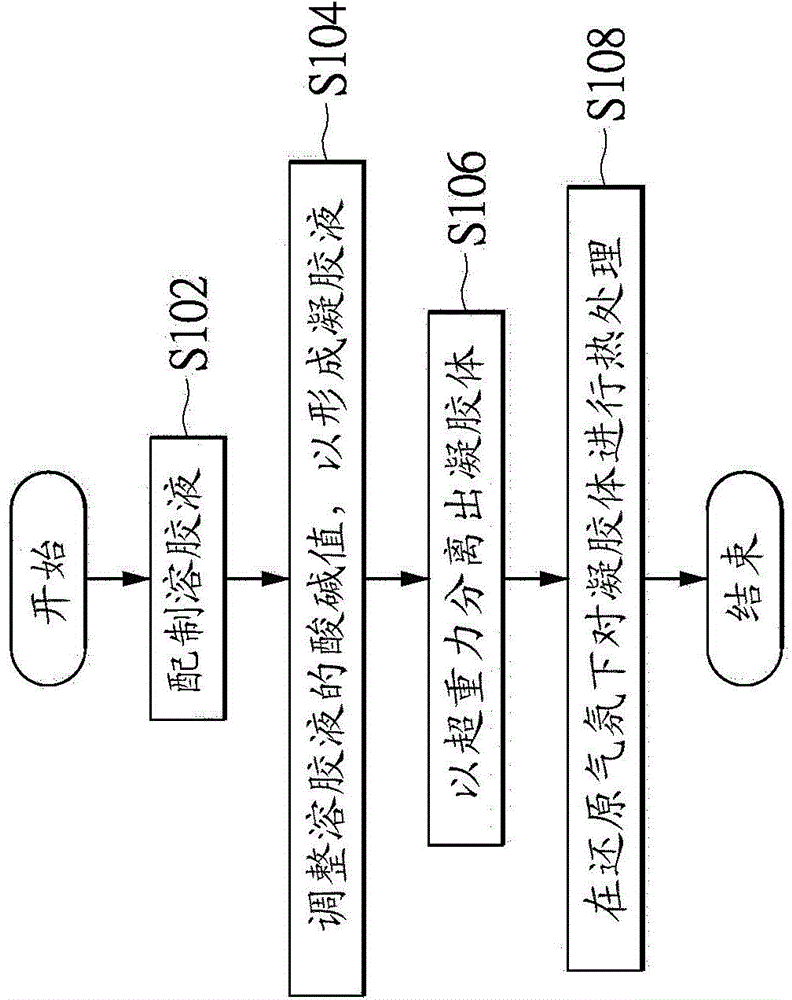

Preparation method of doped zinc oxide nano powder

The invention discloses a preparation method of doped zinc oxide nano powder, which comprises the following steps that: doped metal salt and zinc salt are dissolved in water to form salt solution; under intense stirring, the salt solution is uniformly dripped into precipitant solution, the pH value of a mixed system is kept to be 5 to 10 and the temperature is kept to be 10 to 80DEG C during the dripping process to obtain a coprecipitation product; after the coprecipitation product is aged for 10 to 30h, precipitate is sequentially washed by deionzied water and absolute ethyl alcohol and is dried to obtain a white product; and the white product is calcined for 1 to 5h at 400 to 800DEG C to prepare the doped zinc oxide nano powder. The method has the advantages of low cost, simple used equipment and easy large-scale industrial production, and the prepared doped zinc oxide nano powder has the advantages of uniform distribution, high purity and no non-conductive second phase, and can be used for preparing high-quality zinc oxide-based sputtering targets.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

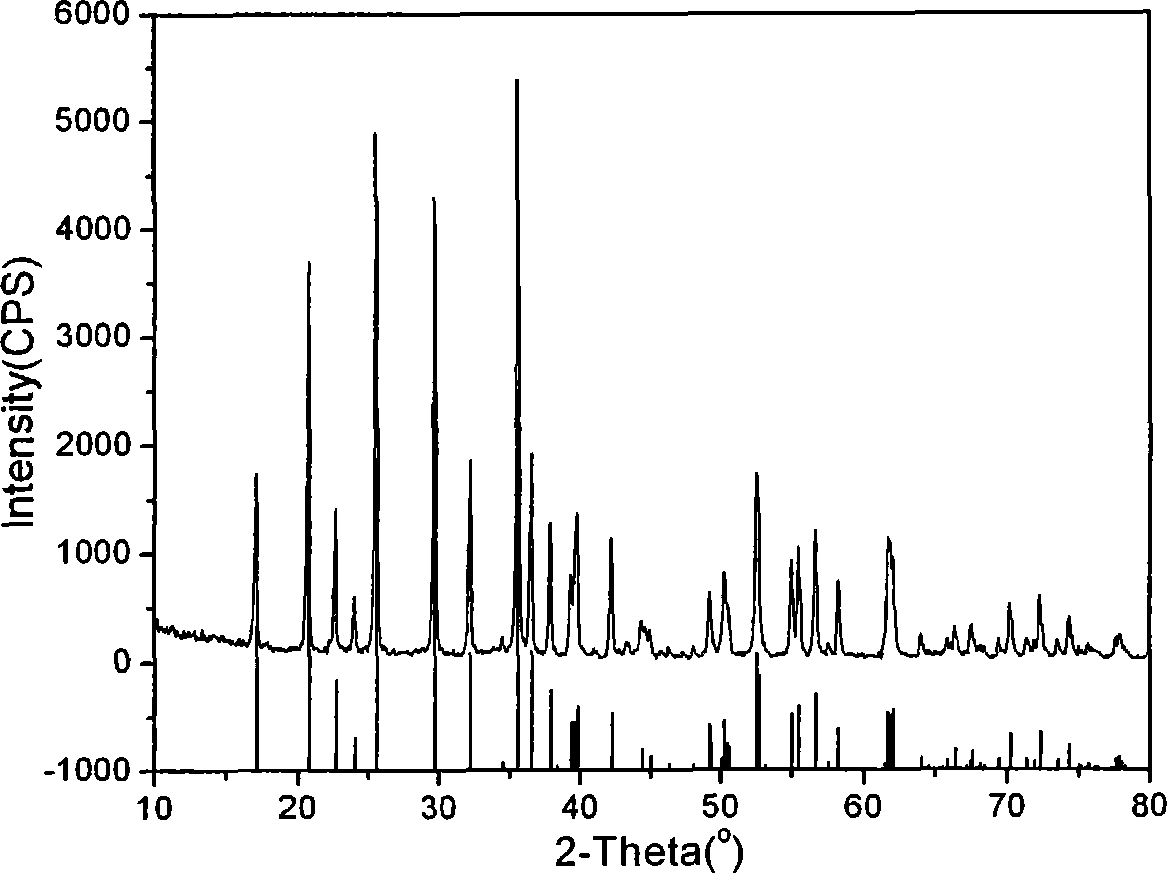

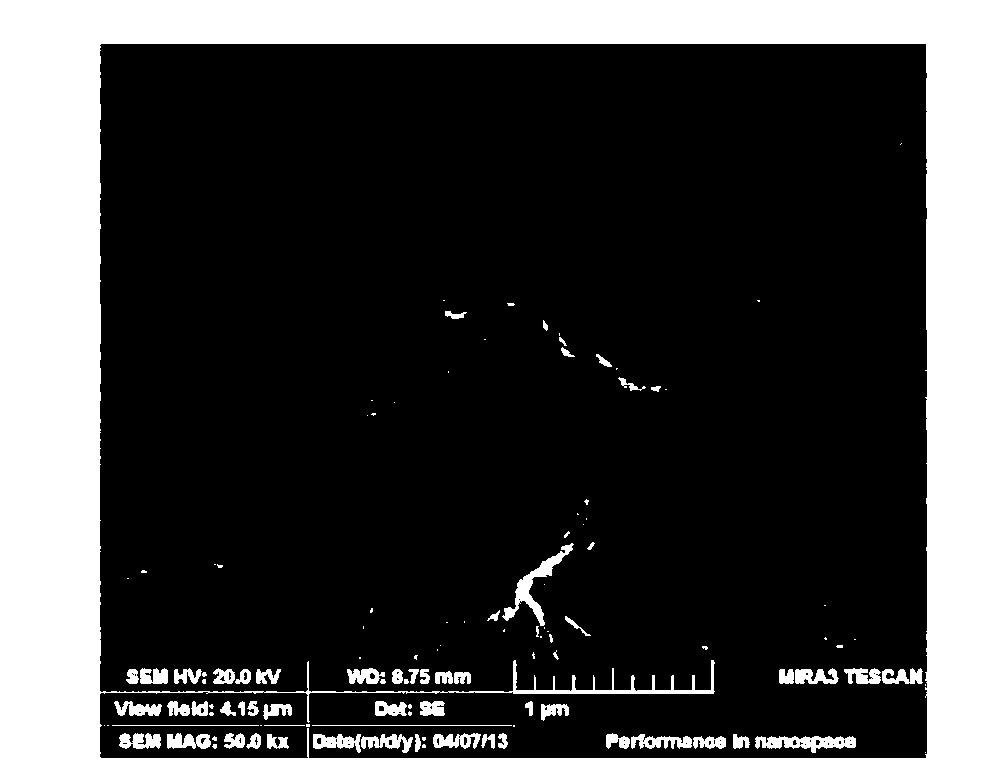

LiFePO4/C nano composite positive pole material and preparation method thereof

InactiveCN101159328AAchieve hybridControl chemical compositionElectrode manufacturing processesChemical industryPhosphateLithium-ion battery

The invention discloses a nano-composite positive material LiFePO4 / C and a fabrication method, relating to a fabrication method of positive material of a lithium-ion battery. The invention uses the method of liquid-phase coprecipitation, the certain amount of lithium resource, iron resource and phosphate resource is weighted as the quality mol ratio of Li:Fe:P = (3.0-3.3):(1.0-1.1):(1.0-1.1), and the appropriate amount of carbon-doped material and organic surfactant is added in the reaction vessel; by controlling the reaction conditions like concentration, temperature etc. of the reaction solution, precursor gels are fabricated, and the precursor gels are separated, cleaned, filtered and dried to obtain precursor powder; the precursor powder is tableted and put into the crucible with microwave absorbent, and then the crucible is placed in the microwave oven, with the microwave power controlled between 100 to 600W and heated for 30 min, to obtain nano-sized composite positive material LiFePO4 / C. The technique method in the invention has the advantages of short periods, saved energy consumption, ease to control the process, suitability for industrialization and so on. The composite positive material LiFePO4 / C fabricated in the invention is characterized by high purity, small particle size lower than 100 nm, and good electrochemical properties.

Owner:上海微纳科技有限公司

Highly stable lithium nickel cobalt aluminate positive electrode material and its preparation method

ActiveCN104218243AFacilitate conductionImprove side effectsCell electrodesSecondary cellsBattery chargeHigh energy

The invention provides a highly stable lithium nickel cobalt aluminate positive electrode material and its preparation method. The characteristic chemical formula of the lithium nickel cobalt aluminate material is LinNi1-x-yCoxAlyO2.mLiMaOb, wherein n is not less than 0.95 and not more than 1.15, x is more than 0.00 and less than 0.30, y is not less than 0.01 and not more than 0.10, m is more than 0.00 and less than 0.05, a is more than 0.0 and less than 3.0, b is a valence matching coefficient, and b is (M valence * a +1) / 2. The morphology of the material is a spheroidic secondary particle structure formed by a primary particle, the average particle size of the primary particle is 0.10-2.5mum, and the average particle size of the secondary particle is 3.0-20.0mum. LiMaOb is a composite oxide lithium ion conductor coating and is uniformly distributed on the surface of the primary and secondary particle, so the removal and embedding of lithium ions in the battery charge and discharge process are promoted, and the side reactions of the lithium nickel cobalt aluminate material and an electrolyte can be inhibited. The above lithium ion battery positive electrode material has the advantages of high energy, high safety and long cycle life.

Owner:HUBEI RONGBAI LITHIUM BATTERY MATERIAL CO LTD

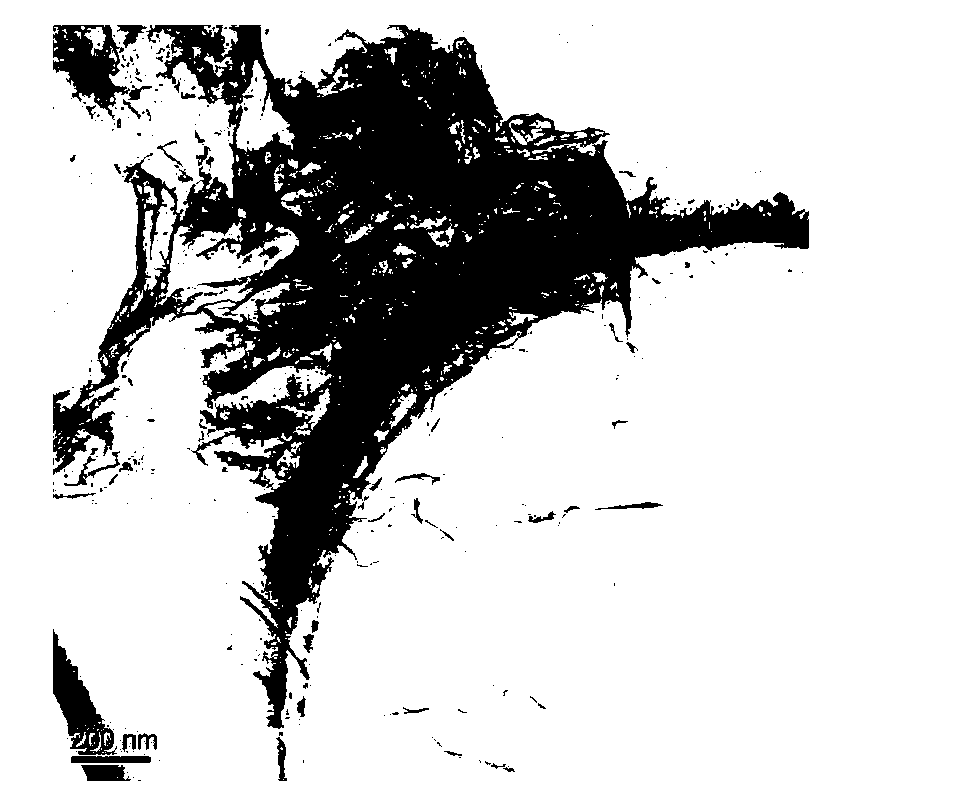

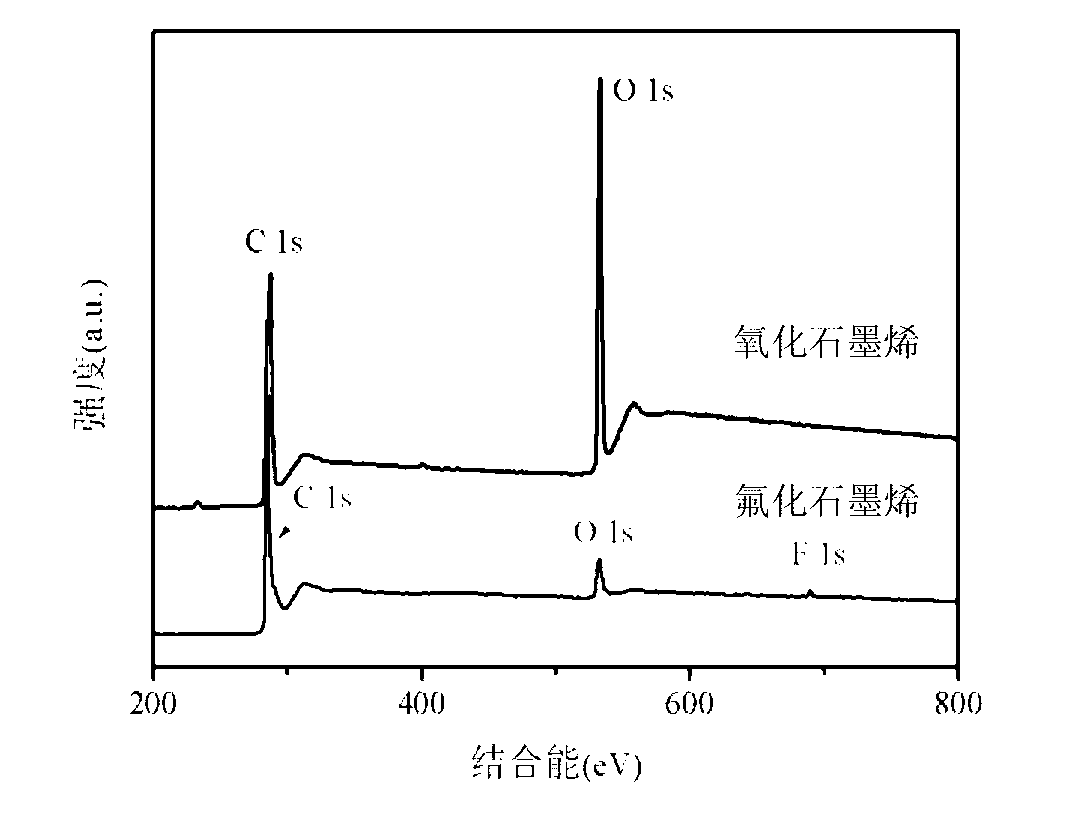

Method for preparing fluorinated graphene through microwave hydrothermal method

The invention provides a method for preparing fluorinated graphene through a microwave hydrothermal method. The fluorinated graphene is prepared by employing the microwave hydrothermal method and is rapidly heated by utilizing the change of the electric field and magnetic field in the space, the low-temperature (150-200 DEG C) temperature is realized, the reaction time (30-60 minutes) is greatly shortened, the energy consumption is reduced, and the preparation efficiency is improved. The adopted preparation method does not have temperature gradient in the reaction process, a hysteresis effect is avoided, and the reaction process is easy to control and fewer in influence factors; and the prepared fluorinated graphene is uniform in fluorine doping and high in experimental repeatability. The process conditions such as raw material ratio, reaction temperature and reaction time are adjusted, and the fluorinated graphene of different fluorine contents can be prepared. The prepared fluorinated graphene is high in yield, and the yield is up to 90-95 percent. The preparation method is easily popularized and applied.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

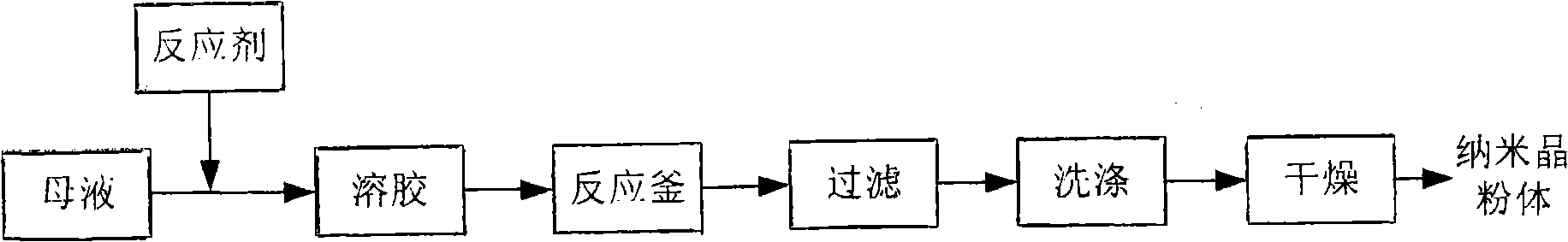

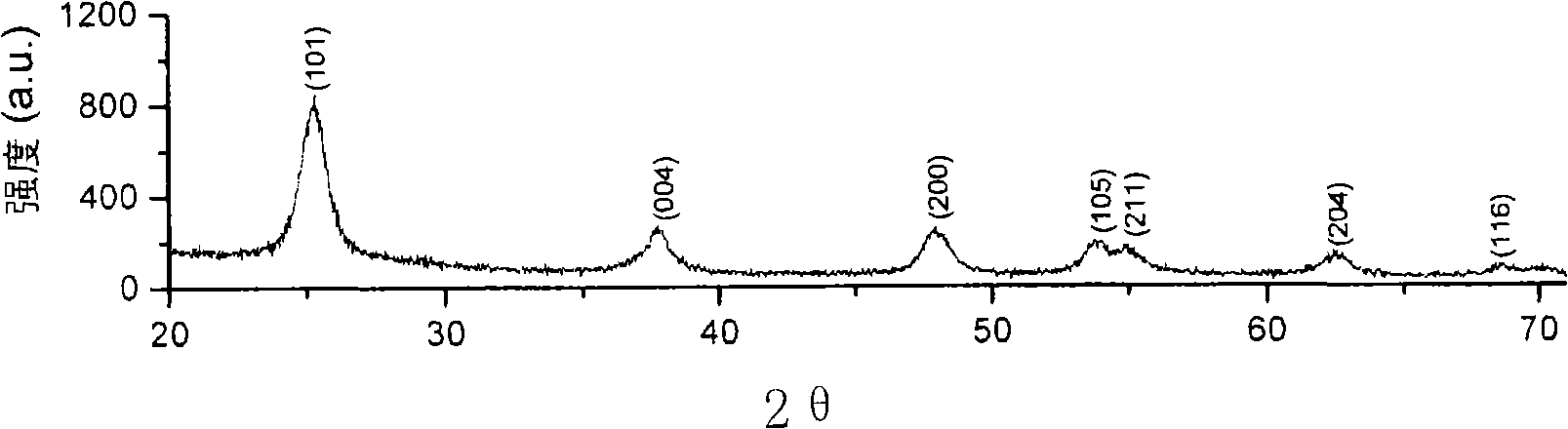

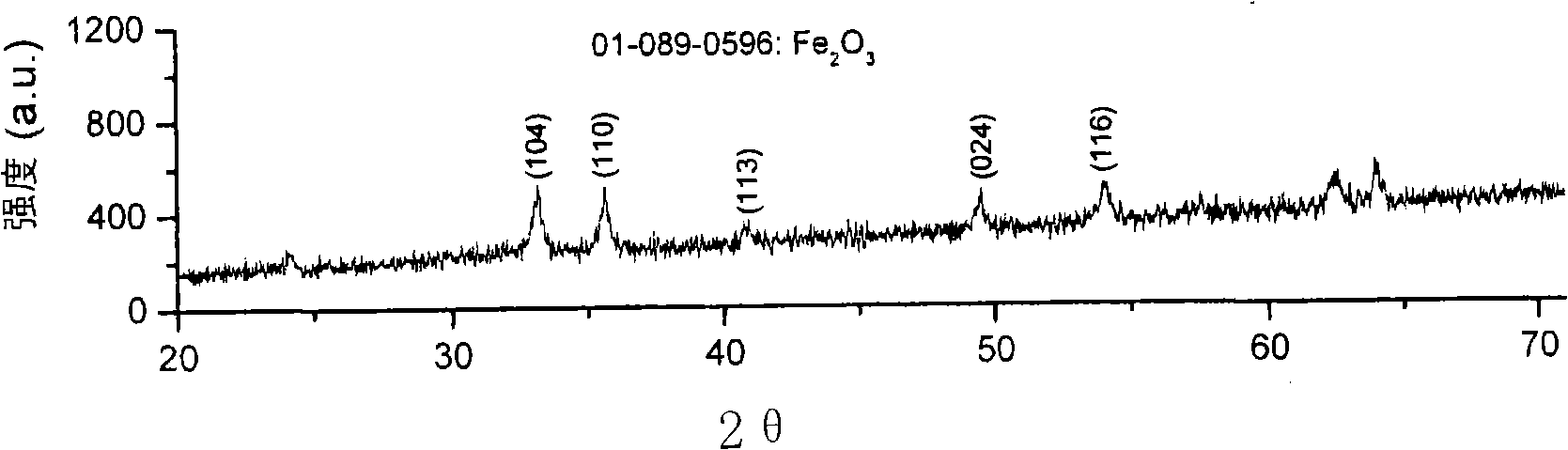

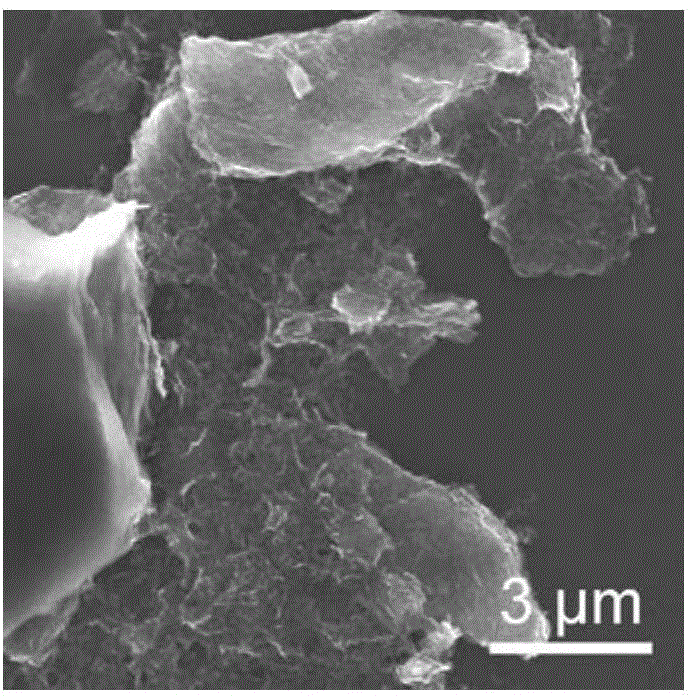

Sol-solvent-thermal method for synthesizing nanocrystalline oxide powder

InactiveCN101348240AUniform particle sizeNarrow distributionOxide/hydroxide preparationIron oxides/hydroxidesInorganic saltsLiquid medium

The invention provides a sol-solvent thermal method for synthesizing a nanocrystalline oxide powder. The method comprises the following: (1) a step of preparation of inorganic salt mother liquids, during which the inorganic salt taken as a material is dissolved in an organic liquid medium or water to prepare a mother liquid of the inorganic salt with definite concentration; (2) a step of preparation of a precipitation reactant liquid, during which alkali is dissolved in an organic liquid medium or water, proper quantity of surfactants are added to prepare the precipitation reactant liquid with definite concentration; (3) a step of preparation of sols, during which, at a certain temperature, while stirring, the prepared reactant liquid is slowly added in the prepared mother liquid of the inorganic salt, the reactant liquid and the mother liquid of the inorganic salt are kept reacting for a period of time after adding the reactant liquids in the mother liquid of the inorganic salt, and the transparent sols are obtained; and (4) a step of solvent thermal reaction of the sols, during which the prepared sols are put in a reaction kettle and reacted for a period of time under a certain temperature and pressure, the products obtained are subjected to filtering, washing and drying, and the nanocrystalline oxide powder is obtained.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method for doped graphene foams

The invention discloses a preparation method for doped graphene foams. The preparation method comprises the following steps: adopting the hydrothermal method to enable nano particles to dope with and generate on oxidized graphene sheets to obtain oxidized graphene aerogel; reducing the oxidized graphene aerogel doped with the nano particles in a controllable manner at the low-temperature gaseous phase condition to obtain the doped graphene foams. According to the preparation method, a reductant is not used in the growing process of the nano particles, and liquid is not introduced into the reaction system, so that excessive overlap of the graphene layers is avoided, porosity of the graphene foams is maintained, polyporous shrinkage caused by surface stress is prevented, and the uniformly doped graphene foam material with the controllable appearance is obtained. The preparation method is convenient to operate, uniform in doping, controllable in product size, economical and fast, is adopted as the novel technology for the large-scale preparation of the doped graphene foam material, and is expected to provide novel materials for graphene adsorbents, graphene capacitors, graphene catalysts and the like.

Owner:四川烯城环保科技有限公司

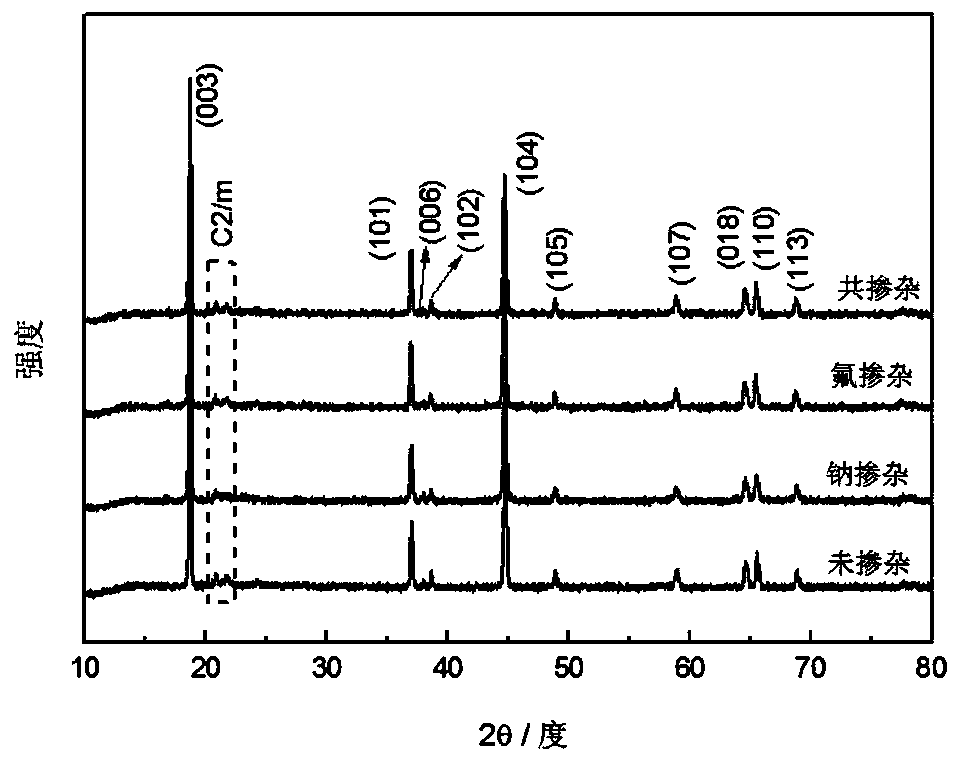

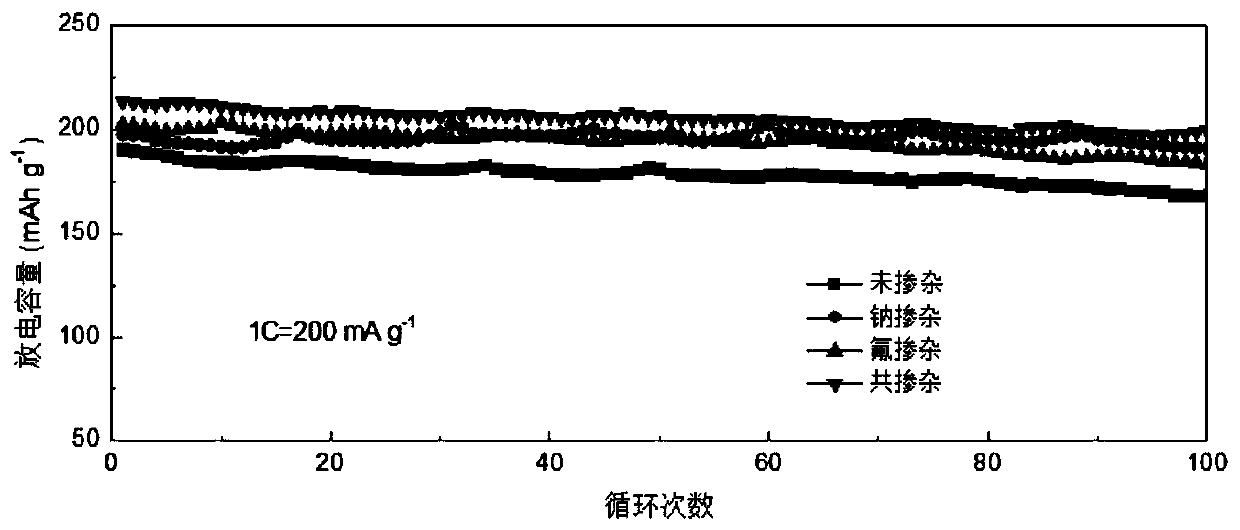

Anion-cation co-doped modified lithium-rich manganese composite positive electrode material and preparation method thereof

InactiveCN111370686AHigh discharge specific capacityImproved magnification performanceSecondary cellsPositive electrodesDopantRubidium

The invention provides an anion-cation co-doped modified lithium-rich manganese composite positive electrode material and a preparation method thereof. The method comprises the steps that a nickel-cobalt-manganese oxide precursor, a doping agent and a lithium source are magnetically stirred and mixed in a solvent, dried and calcined, and the anion-cation co-doped modified lithium-rich manganese composite positive electrode material is obtained; the doping agent is a cationic salt and an anionic salt; the cationic salt is selected from one or more of sodium salt, potassium salt, rubidium salt and cesium salt; and the anionic salt is selected from one or more of villiaumite, chlorine salt, sulfur salt and phosphorus salt. By adopting a magnetic stirring mode, the morphology of the precursorcan be kept to the greatest extent; the modified lithium-rich manganese composite positive electrode material with controllable precursor morphology is obtained, the doping agent can be dissolved in the solvent, uniform doping is realized, and the purposes of structure regulation and control and co-doping double modification are achieved, so that the specific discharge capacity, the rate capability and the cycling stability of the composite positive electrode material are improved.

Owner:KUNMING UNIV OF SCI & TECH +1

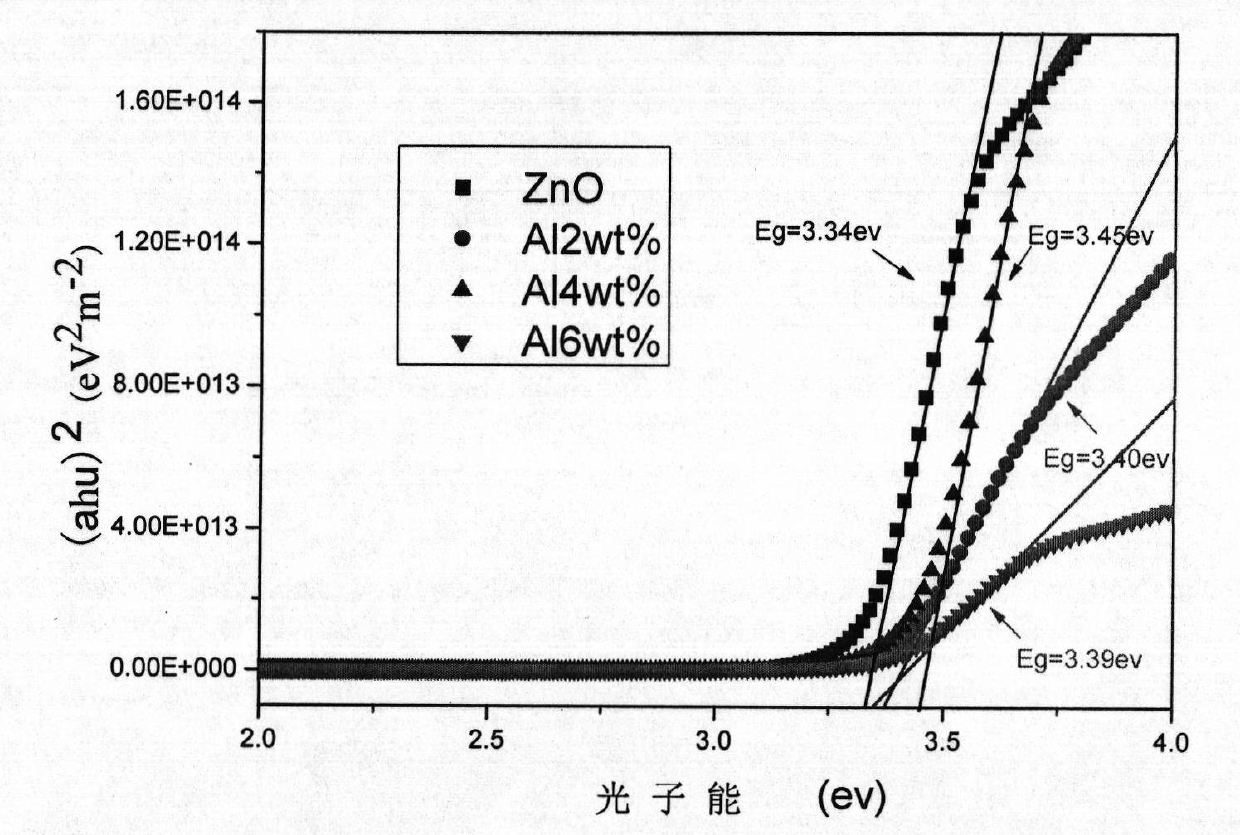

Method for preparing doped ZnO-based film through magnetron sputtering

InactiveCN101768728ALow costSimple and fast operationVacuum evaporation coatingSputtering coatingSputteringRoom temperature

The invention provides a method for doping and growing ZnO-based film through magnetron sputtering. The method comprises the following steps: placing a substrate in the reaction chamber of a magnetron sputtering device, vacuumizing the reaction chamber to lower than 1*10<-4>Pa; separately placing ZnO target and doped source element target on the radio frequency target position and DC or electromagnetic target position of the turntable of the reaction chamber, introducing oxygen and argon, which are used as sputtering atmosphere, in a buffer chamber, fully mixing in the buffer chamber, introducing the mixed gas in a vacuum reaction chamber, performing sputtering growth when the pressure is 1-3Pa and the temperature of the substrate is below the room temperature; selecting a sample position and adjusting the sputtering times of the radio frequency target position and DC or electromagnetic target position through a preset program to alternately grow ZnO films and doped element layers; and after the growth placing the doped ZnO-based film in vacuum, air or nitrogen atmosphere to anneal for 30-60 minutes at 400-800 DEG C.

Owner:SHENZHEN UNIV

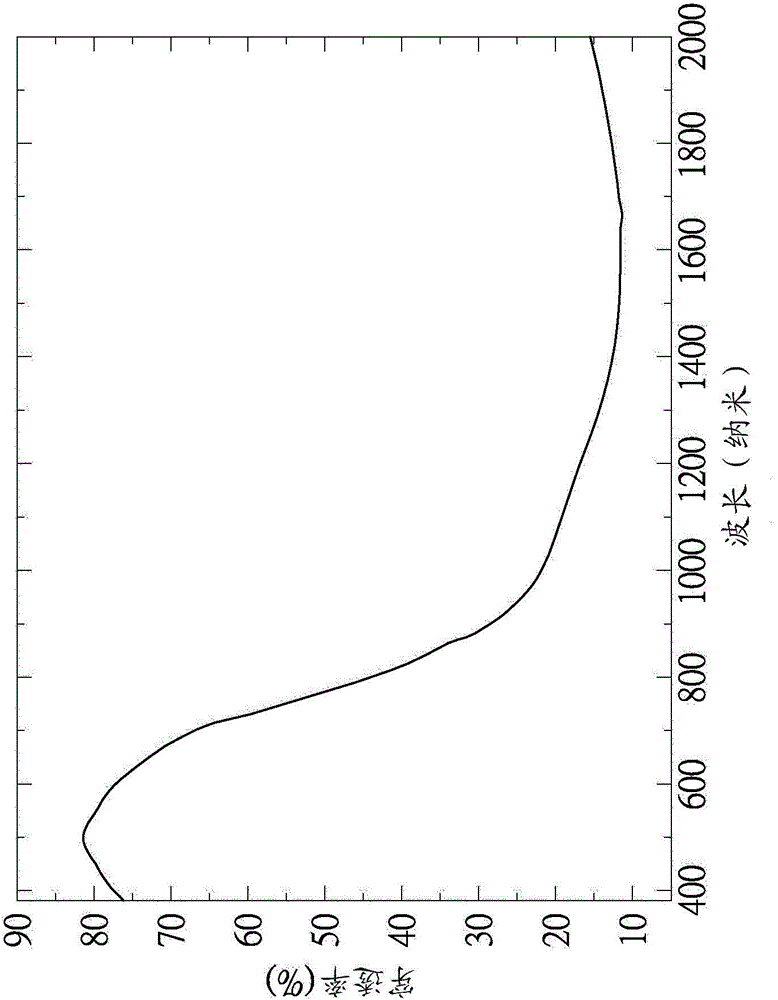

Manufacturing method of composite tungsten oxide nanoparticle, infrared absorbing material and infrared shielding body

InactiveCN104828868AEvenly dopedFast preparationMaterial nanotechnologyTungsten oxides/hydroxidesSol-gelComposite element

A method of manufacturing a composite tungsten oxide nanoparticles, and infrared-shielding infrared absorbing material body, the use of the infrared-absorbing material comprises a composite tungsten oxide nanoparticles are manufactured by sol-gel method, the manufacturing method for the first reaction in the sol-gel process the proportion of the desired composite element directly added to the solution and allowed rapid precipitation, drying and then heat-treated after special atmosphere to obtain a composite tungsten oxide nanoparticle material, or the general formula M1xM2yWO M1xM2yWORz or M1xWORySz, wherein M1 is IA - Group IIIA or a transition metal element, M2 of Group IA - IIIA or a transition metal elements, W is tungsten, O is oxygen, R, S of IVA - VIIA elements, specifically, R, S may be in sol-gel when you import or atmosphere heat treatment during synthesis. This material is used in the field of infrared-absorbing material, and thus the production method can improve the tungsten oxide nanoparticles molecular absorption wavelength greater than 1200nm infrared.

Owner:KAMIKAWA PHOTONICS & MATERIALS

Method for preparing rare earth-doped yag nano-powder by partial liquid phase precipitation method

ActiveCN101302019AEvenly dopedEvenly distributedRare earth metal compoundsAluminium oxides/hydroxidesRare-earth elementMetallurgy

The invention relates to a method for preparing a rare earth doped yttrium aluminum garnet nanometer powder body by a partial liquid phase precipitation method. Y(NO3)3 and Al2O3 are used to synthesize the yttrium aluminum garnet nanometer powder body; and Nd, Yb, Cr and other rare earth elements are used for ion doping. Ammonium oxalate, NH4HCO3 or urea is adopted as a precipitant. Sediment is aged, fully washed, dried and calcined for 15 to 120 minutes at a temperature of between 1000 and 1600 DEG C under the aerobic condition, thereby acquiring the rare earth doped YAG powder body with a grain diameter between 80 to 200 nm. The method can realize the uniform doping of the rare earth elements, also avoid forming a colloidal substance which is unfavorable for washing, and prepare the rare earth doped YAG nanometer powder body material in high efficiency.

Owner:SHANDONG UNIV

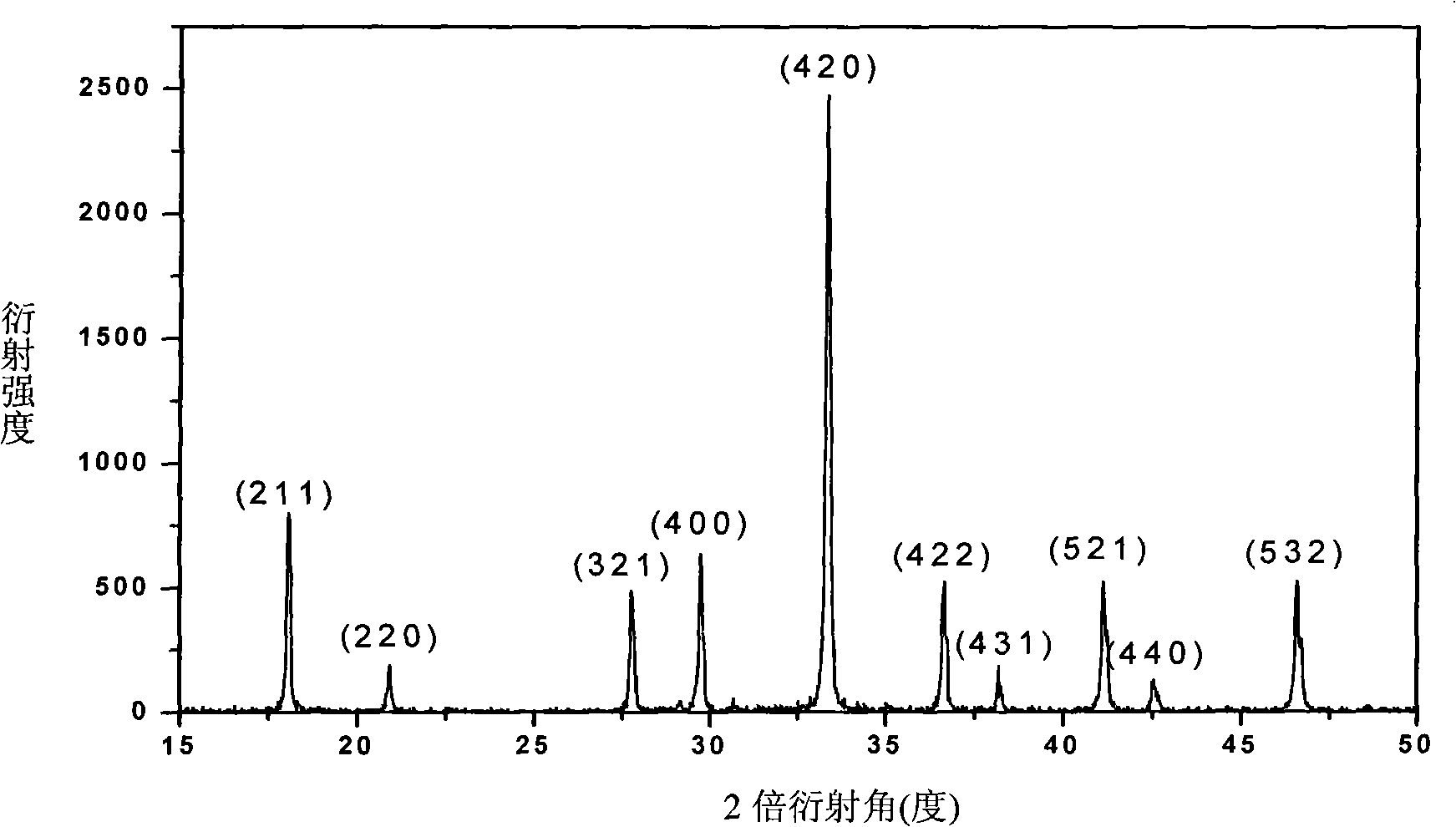

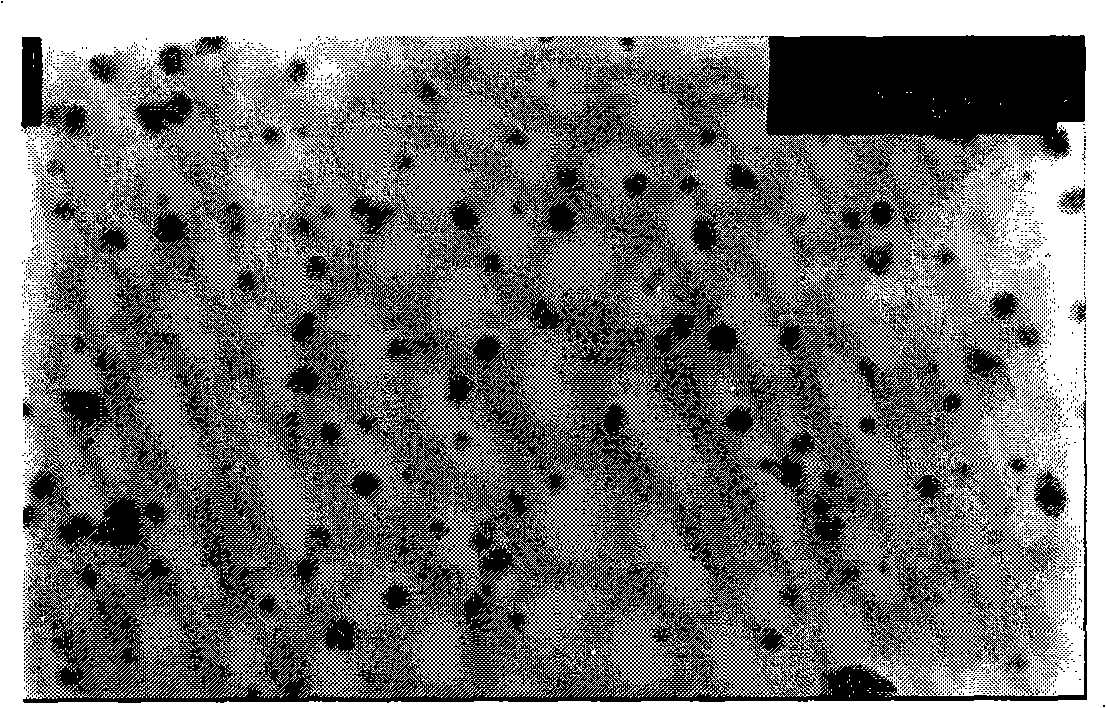

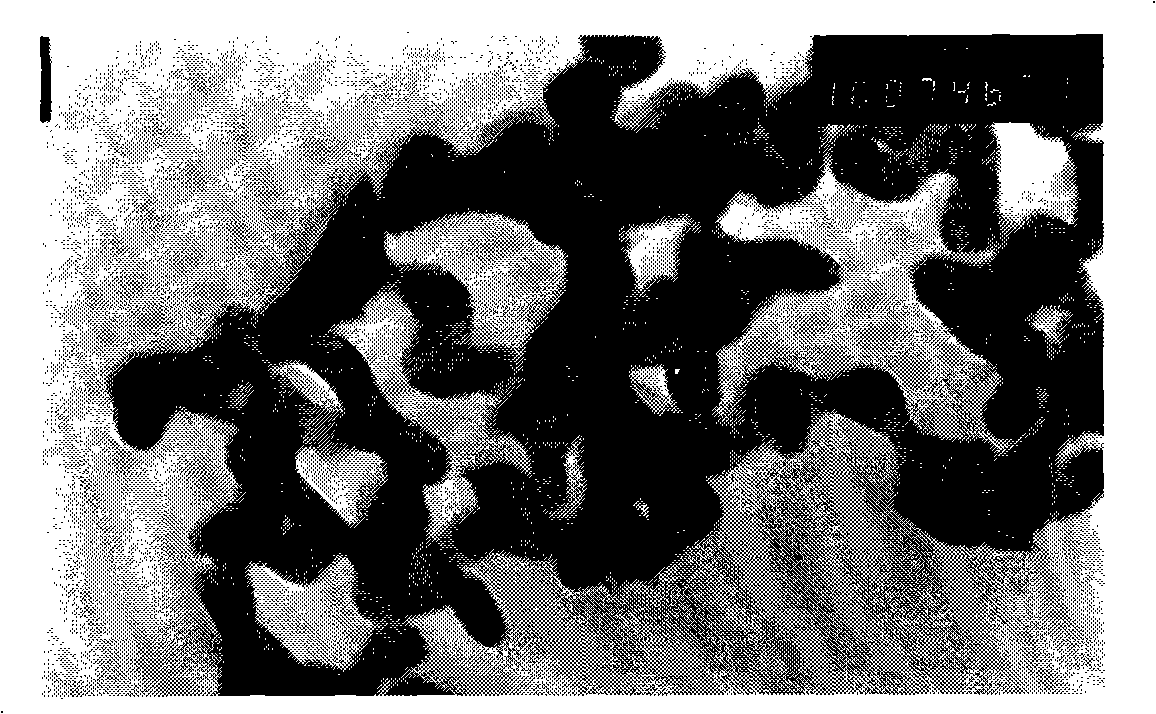

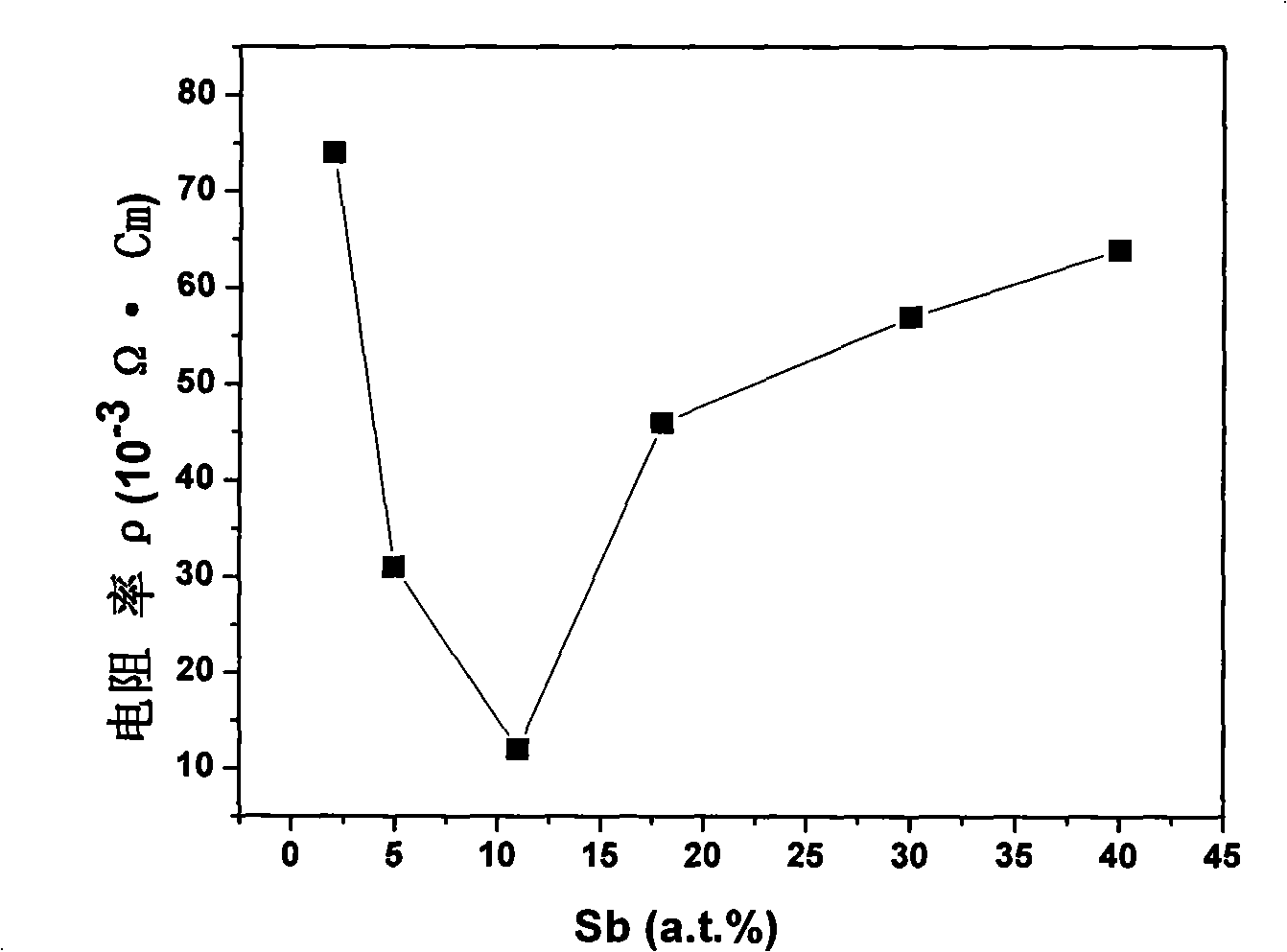

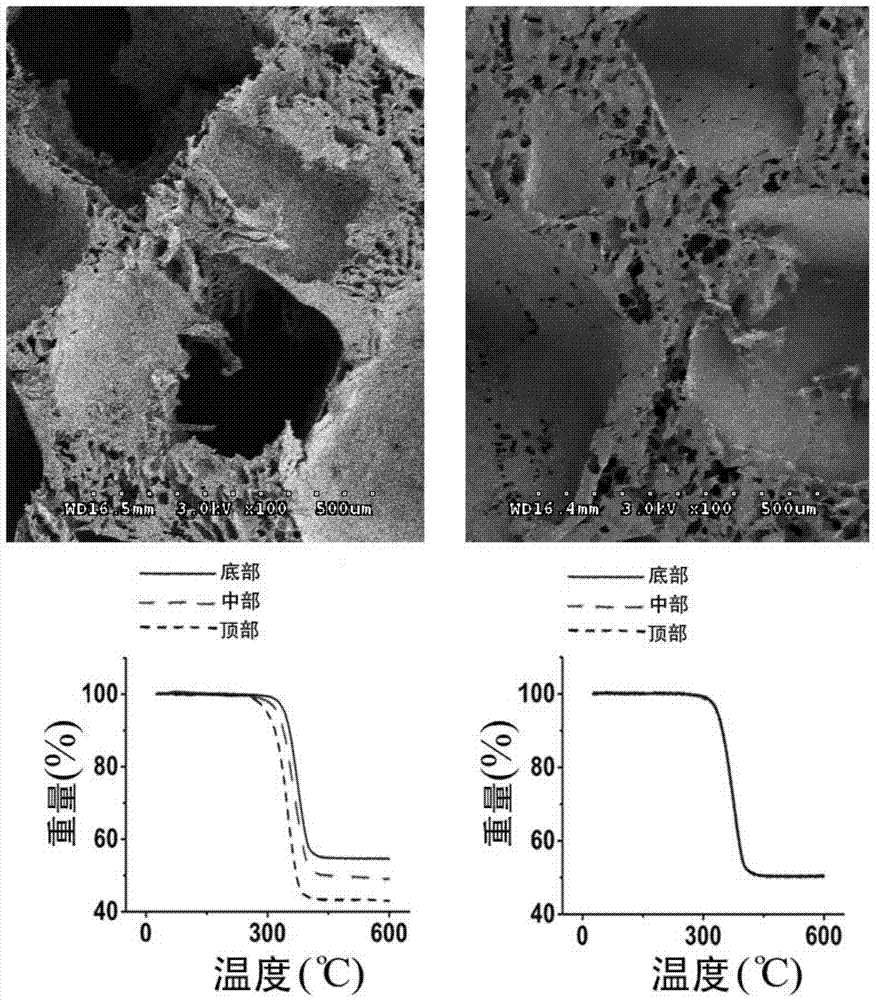

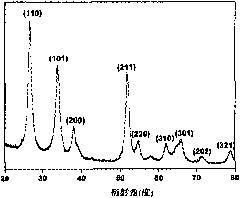

Preparation of stibium doping stannic oxide nanopowder by hydrothermal method

The invention discloses a hydrothermal preparation method of antimony doped tin dioxide nano-powder comprising: respectively preparing a SnCl4 alcohol solution and a SbCl3 alcohol solution, mixing the SnCl4 alcohol solution with the SbCl3 alcohol solution and adding deionized water into the mixture to maintain the concentration of SnCl4 between 0.005 mol / L and 3 mol / L, adjusting the pH value of mixed solution to 8.5-9.5 by ammonia, homogeneously dispersing the mixed solution in a reactor, conducting hydrothermal reaction for 1-2 hours at 100-200 DEG C, centrifugating, washing and drying the products after reaction to obtain powder, heating the powder after the powder is grinded for 0.5-1 hour at 400-700 DEG C, obtaining the antimony doped tin dioxide nano-powder. The powder prepared by the invention has a regular appearance and a narrow granularity distribution. The reaction condition is easy to control for adopting cheap SnCl4.5H2O and SbCl3 as materials, which is suitable for industrial mass production.

Owner:ZHEJIANG UNIV

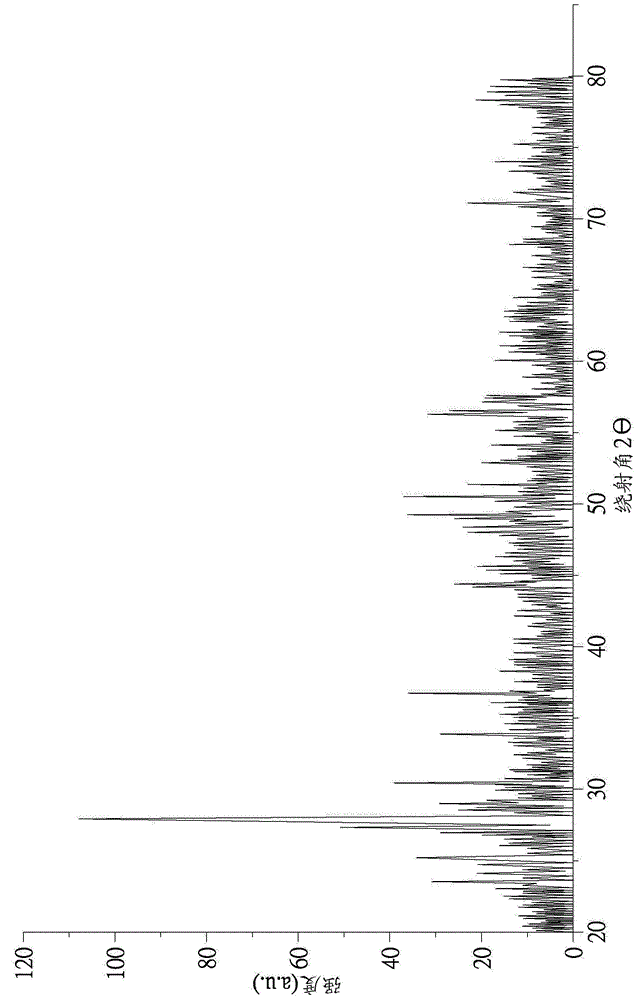

Method for preparing zinc oxide-based sputtering target material

ActiveCN101845614AHigh densityInhibit migrationMolten spray coatingVacuum evaporation coatingRoom temperatureVolumetric Mass Density

The invention discloses a method for preparing a zinc oxide-based sputtering target material. The method comprises the following steps of: performing die pressing on doped zinc oxide nano-powder at the pressure of between 30 and 150 MPa and maintaining the pressure for 30 to 300 seconds; performing isostatic cool pressing on the doped zinc oxide nano-powder at the pressure of between 120 and 300 MPa and maintaining the pressure for 60 to 600 seconds; heating the doped zinc oxide nano-powder to the temperature of between 950 and 1,300 DEG C at a heating rate of between 5 and 10 DEG C per minute, and maintaining the temperature for 1 to 30 minutes; cooling the doped zinc oxide nano-powder to the temperature of between 650 and 1,100 DEG C at a cooling rate of between 10 and 100 DEG C per minute and maintaining the temperature for 2 to 40 hours; and finally, cooling the doped zinc oxide nano-powder to the room temperature at a cooling rate of between 0.5 and 10 DEG C per minute, and performing cutting and polishing on the doped zinc oxide nano-powder to obtain the zinc oxide-based sputtering target material. By adopting specific two-step sintering parameters, the method is used for preparing the target material of which the density is over 98 percent, the grain size is very small and uniform and is between 0.5 and 20 mu m, and the doped components are uniform at a low sintering temperature.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

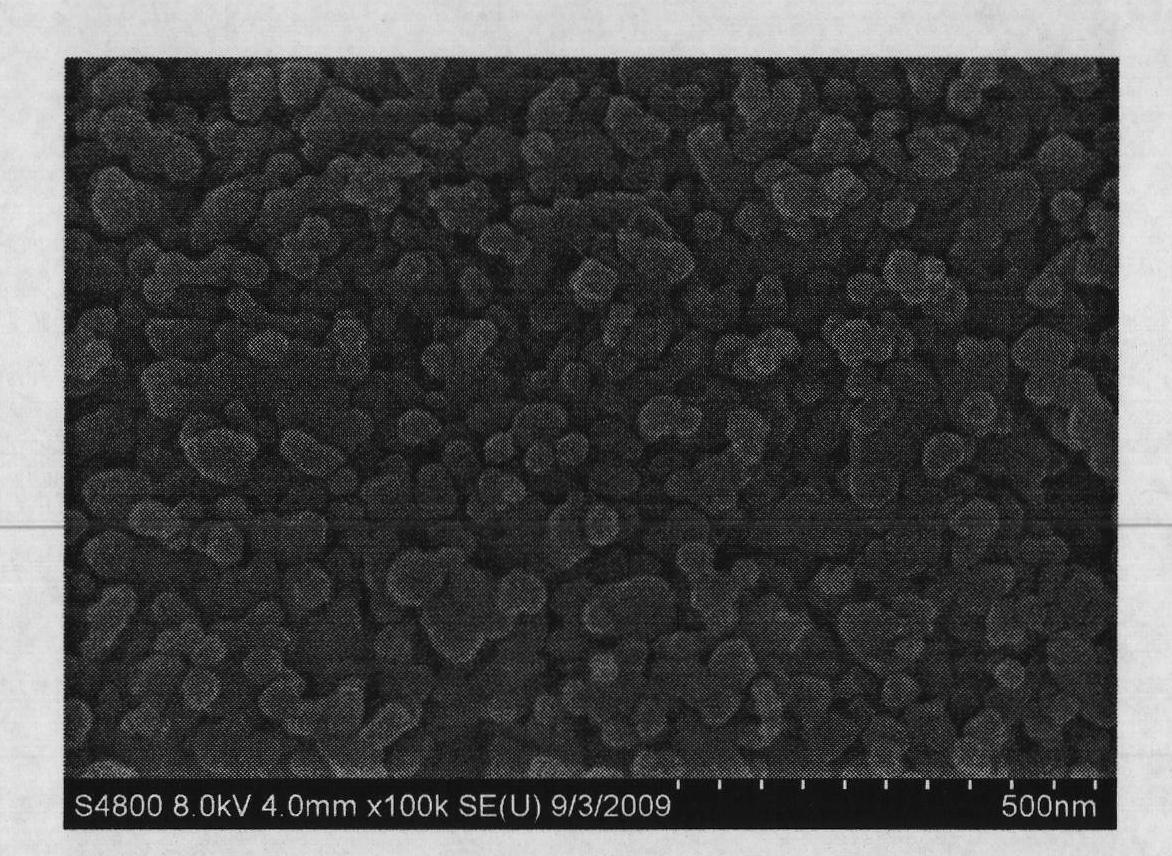

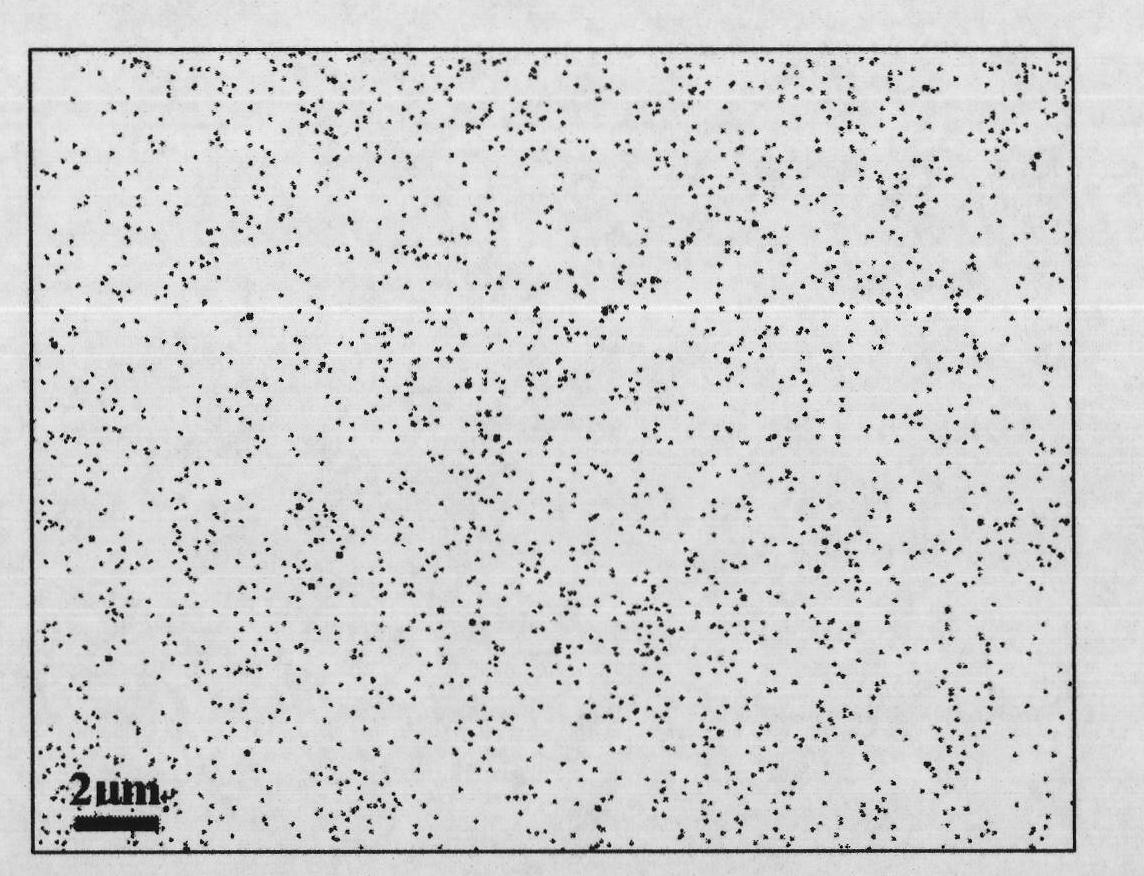

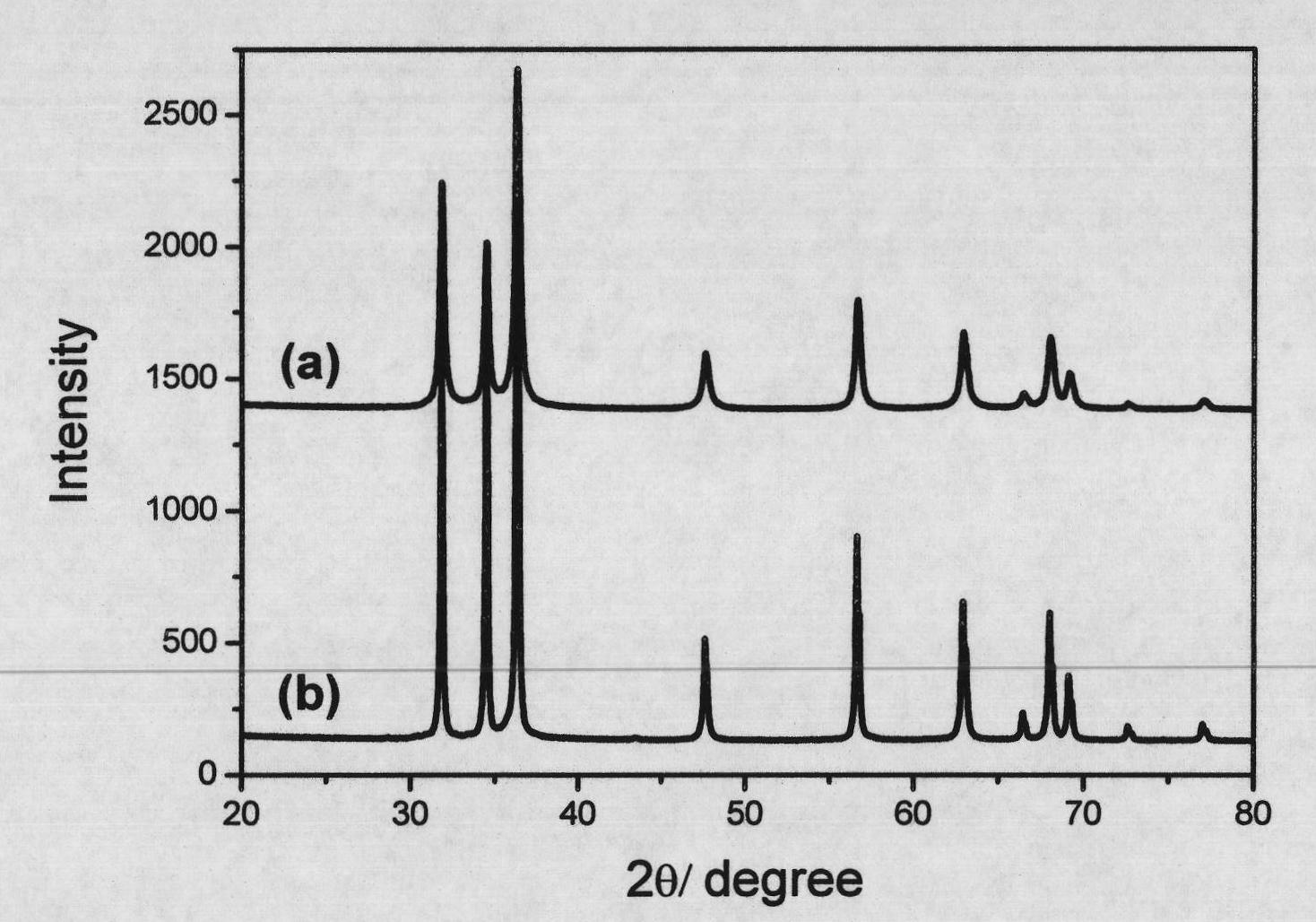

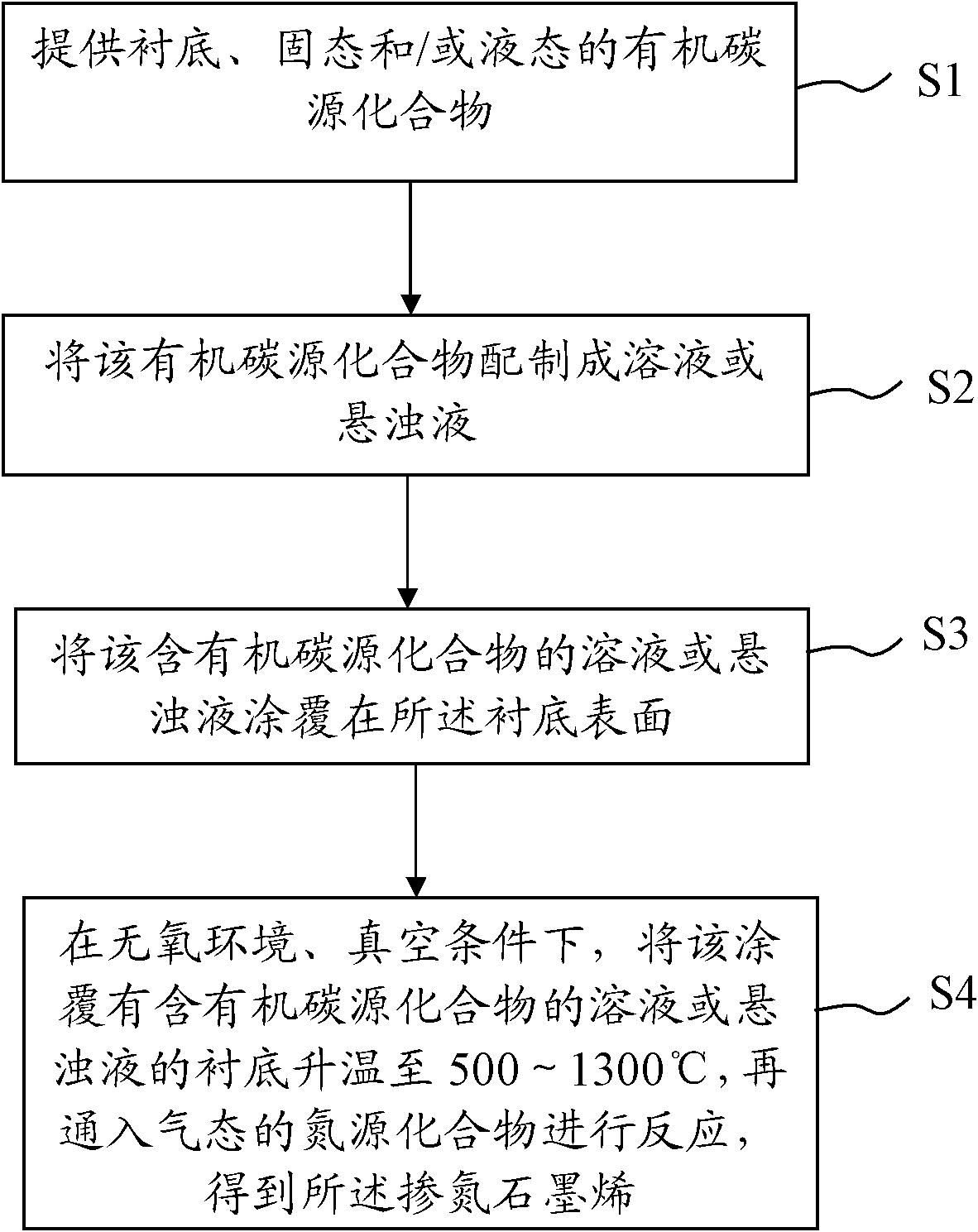

Preparation method of nitrogen-doped graphene

ActiveCN102887498ASimple production processReduce manufacturing costGrapheneDoped grapheneNitrogen doped graphene

The invention provides a preparation method of nitrogen-doped graphene by a chemical vapor deposition method, which comprises the following steps of: providing a substrate with high temperature resistance, and a solid and / or liquid organic carbon source compound; preparing the organic carbon source compound into solution or suspension; coating the solution or suspension of the organic carbon source compound on the surface of the substrate; heating the substrate coated by solution or suspension containing the organic carbon source compound to 500-1300 DEG C under an oxygen-free and vacuum environment, then leading into gaseous nitrogen compound to react to obtain nitrogen-doped graphene. The preparation method of nitrogen-doped graphene provided by the invention prepares the solid and / or liquid organic carbon source compound into solution or suspension and coats directly on the surface of the substrate to make the organic carbon source compound react with the introduced nitrogen compound. The method provided by the invention has the advantages of having no need of adding a catalyst, simplifying the production process of nitrogen-doped graphene effectively and reducing the production cost. At the same time, the nitrogen-doped graphene prepared by the chemical vapor deposition method enables the doped graphene to be controlled easily in the amount, to be doped uniformly and to be high in electrochemical stability.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

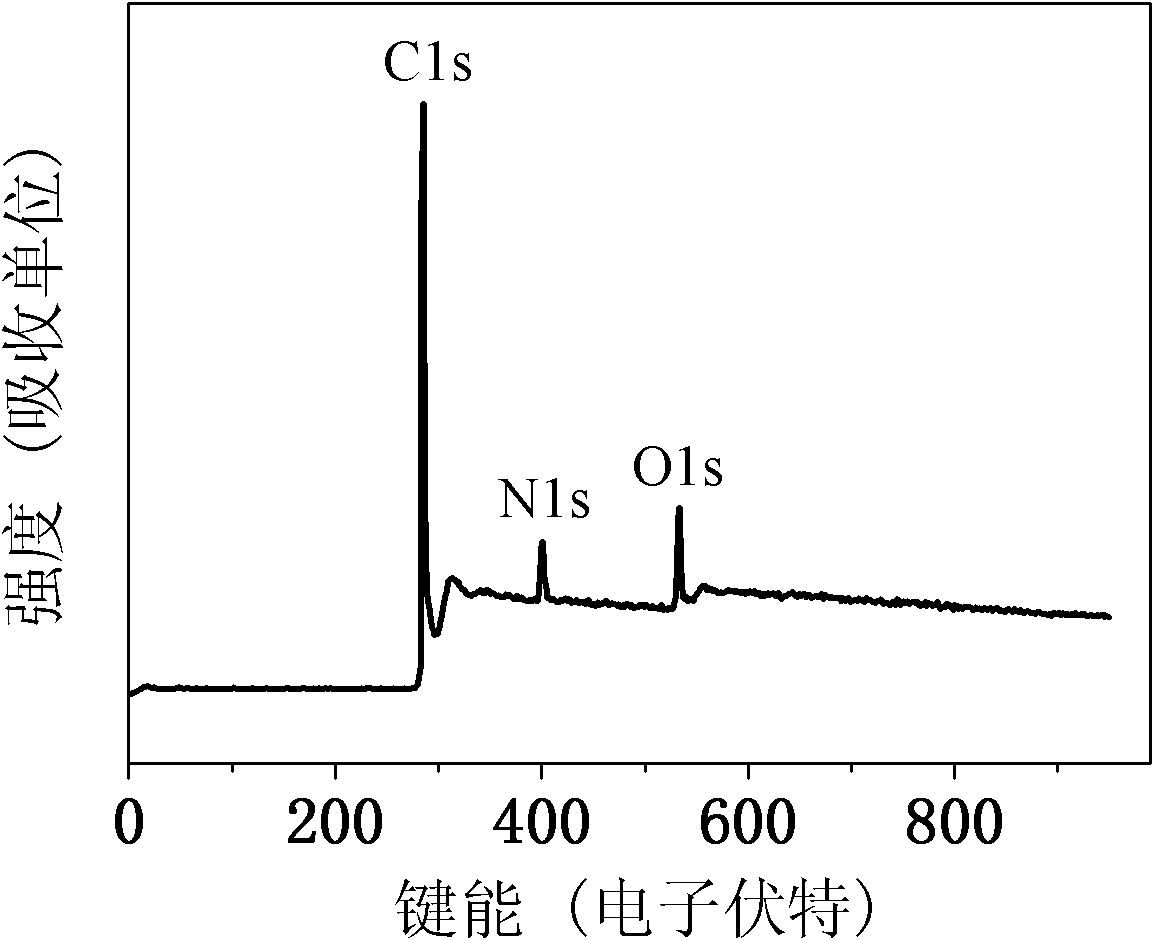

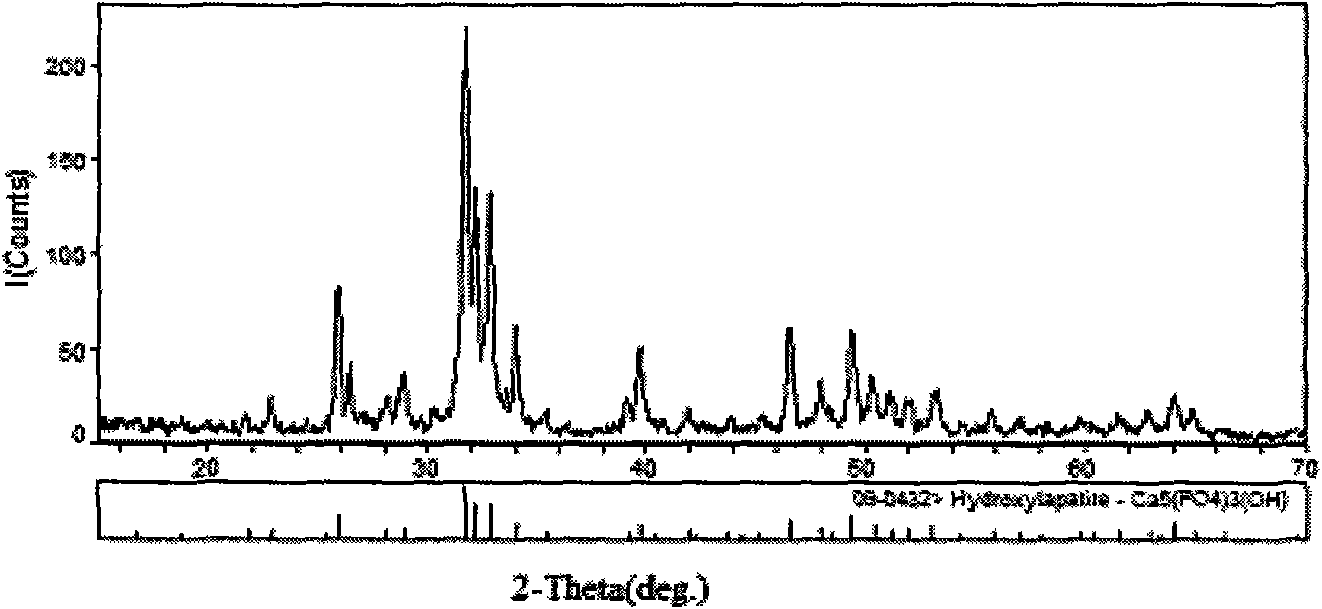

Preparation method for nano hydroxylapatite doped with metal ions

The invention relates to a preparation method of nano hydroxylapatite doped with metal ions, which comprises the following steps of: firstly, respectively preparing Ca(NO3)2 and (NH4)2HPO4 solution, mixing the Ca(NO3)2 and (NH4)2HPO4 solution, and obtaining clear and transparent solution A; adding metal nitrate into solution A and obtaining clear and transparent solution B; adding CO(NH2)2 into solution B, and obtaining solution C; finally heating and backflowing the solution C for 3 to 5 hours with the temperature of 100 DEG C under the magnetic force stirring; after the reaction is end, naturally cooling to room temperature; then vacuum-filtering, cleaning with water, drying for 24 hours under the temperature of 100 DEG C; and finally, obtaining nano hydroxylapatite crystal doped with metal ions. The preparation method adopts a metal salt solution heating even precipitation method, and takes inorganic salts containing calcium and phosphate group as raw materials; urea is acidity of a control reaction system of an additive; metal salts are added according to the doped proportion of 1 percent to 5 percent; reaction is carried out under the magnetic force stirring and heating conditions; and the backflowing of reaction liquid is adopted to synthesize nanoscale metal-doped nano hydroxylapatite crystal by one step. The method is obviously characterized by even doping and easy control for added amount.

Owner:SHAANXI UNIV OF SCI & TECH

Doping of semiconductor fin devices

ActiveUS20060234431A1Improve performanceEvenly dopedTransistorSemiconductor/solid-state device manufacturingDopantGate dielectric

A semiconductor structure includes of a plurality of semiconductor fins overlying an insulator layer, a gate dielectric overlying a portion of said semiconductor fin, and a gate electrode overlying the gate dielectric. Each of the semiconductor fins has a top surface, a first sidewall surface, and a second sidewall surface. Dopant ions are implanted at a first angle (e.g., greater than about 7°) with respect to the normal of the top surface of the semiconductor fin to dope the first sidewall surface and the top surface. Further dopant ions are implanted with respect to the normal of the top surface of the semiconductor fin to dope the second sidewall surface and the top surface.

Owner:TAIWAN SEMICON MFG CO LTD

Composite material as well as preparation method and application thereof

InactiveCN104497363AStrong mechanical propertiesEvenly dopedInorganic non-active ingredientsScale structureThree-dimensional space

The invention provides a composite material as well as a preparation method and an application thereof. The preparation method of the composite material comprises the following steps: carrying out self-assembly reaction on a polymer with charges and micron or nano-scale doped material particles with surface charges in a solvent to generate a colloid, and removing the solvent from the colloid to obtain the composite material. The invention further provides a medicine carrying system which takes the composite material as a carrier. The composite material prepared from micron or nano-scale doped material particles which can be dispersed uniformly by coating the solvent with the colloid has a micron or nano-scale uniform and repetitive structure. Because the micron or nano-scale doped material particles for preparing the composite material are doped uniformly, and the polymer highly coats the micron or nano-scale doped material particles, the composite material has strong mechanical performance. The medicine carrying system with a micron or nano-scale structure can ensure that the medicines carried by the composite material are distributed uniformly. Because the polymer highly coats the micron or nano-scale doped material particles, the medicine carrying system has a better medicine slow-release effect than the traditional medicine carrying systems and can release the medicines more uniformly in a three-dimensional space than the traditional medicine carrying systems.

Owner:INST OF CHEM CHINESE ACAD OF SCI

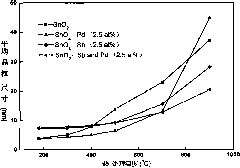

Method for preparing palladium and/or antimony-doping tin oxide nano-powder

InactiveCN101823691ASmall particle sizeImprove thermal stabilityNanostructure manufactureIonTin oxide

The invention discloses a method for preparing palladium and / or antimony-doping tin oxide nano-powder. The method mainly comprises the following steps of: mixing raw materials according to the molar doping ratio of Pd<2+> and / or Sb<3+> to Sn<2+> of 0.5 to 3.5 and dropwise adding at least one of the solution of PdCl2 and the suspension of SbCl3 into the solution of tin salt with stirring to form mixed solution, wherein the raw materials comprise 0.2 to 1 mol / L solution of tin salt, 0.1 to 0.5 mol / L solution of palladium chloride (PbCl2), 0.1 to 0.5 mol / L suspension of antimony chloride (SbCl3)and 0.4 to 1 mol / L solution of alkali source; adding the solution of alkali source dropwise into the mixed solution with stirring until the pH value is between 9 and 13; stirring the solution to formprecursor suspension with a large amount of precipitate; transferring the precursor suspension to a high-pressure reactor to perform reaction for 12 to 36 hours at the temperature of between 100 and 200 DEG C and naturally cooling to room temperature to obtain a hydrothermal product; washing the hydrothermal product for multiple times by using deionized water and ethanol and detecting the productby using silver nitrate until the Cl<-> is removed completely; and drying at the temperature of between 70 and 100 DEG C to obtain the palladium and / or antimony-doping tin oxide nano-powder. The method has the advantages of simple process, environmental friendliness and suitability for industrialized production.

Owner:NINGBO UNIV

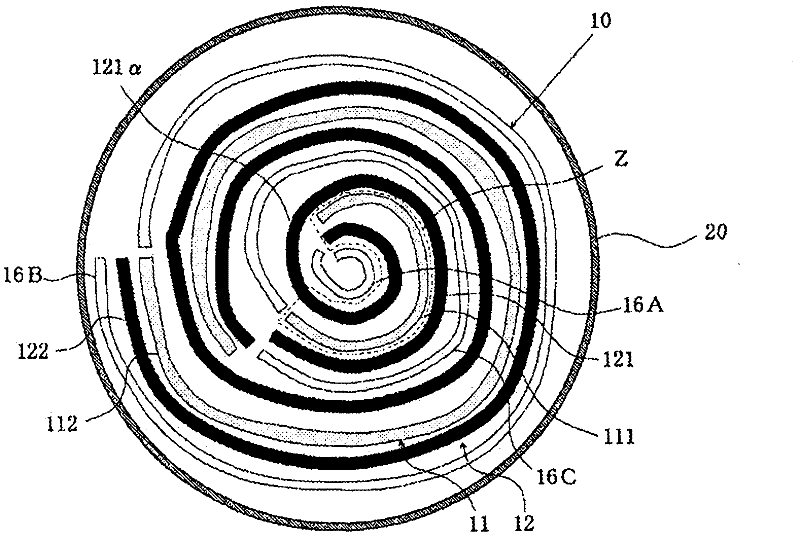

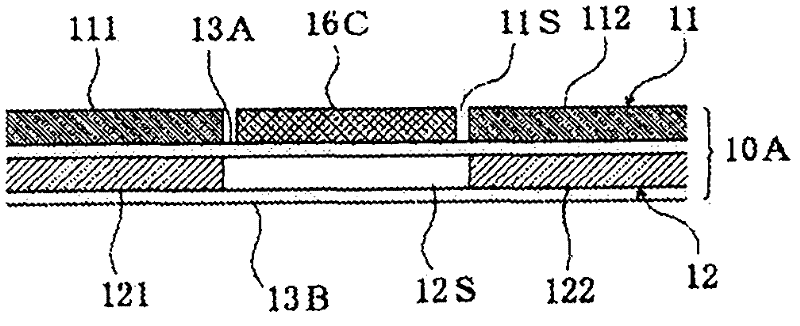

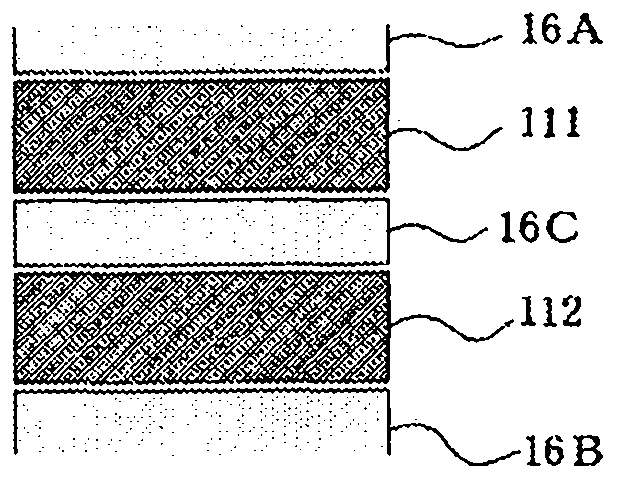

Winding battery

ActiveCN102301439AEasy to assembleShorten pre-doping timeHybrid capacitor electrodesFinal product manufactureLithiumOrganic solvent

A wound-type accumulator which is simplified in the layout of lithium ion sources and shortened in time spent on injecting a nonprotonic organic solvent electrolytic solution and on predoping, so as to allow quick completion of assembly and obtain high productivity. The wound-type accumulator is provided with: a cylindrical wound electrode unit which has cathode and anode strips and is configured by winding from one end an electrode stack comprised of a stack of the cathode and anode with a separator disposed therebetween; and an electrolytic solution. In this wound-type accumulator, the cathode and / or anode is doped with lithium ions and / or anions by means of electrochemical contact of the cathode and / or anode with a lithium ion source. At the cathode, a cathode gap section is formed, and at least one lithium ion source is arranged at the cathode gap section or at a position opposing the cathode gap section at the anode, in a state not contacting the cathode.

Owner:MUSASHI ENERGY SOLUTIONS CO LTD

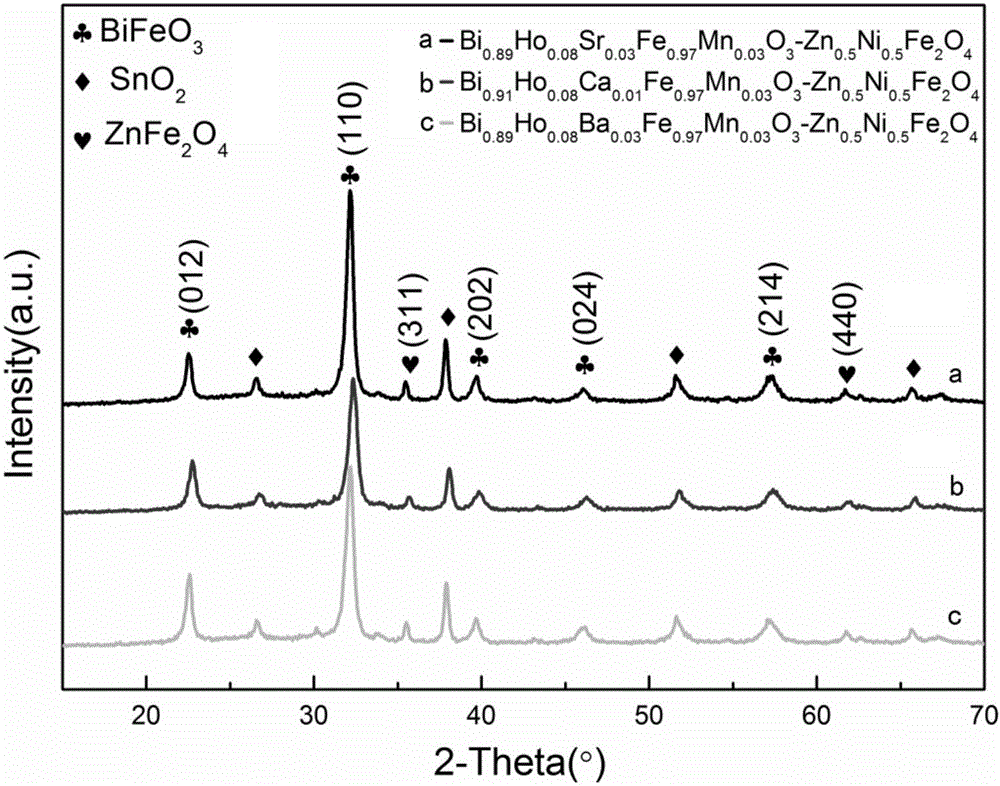

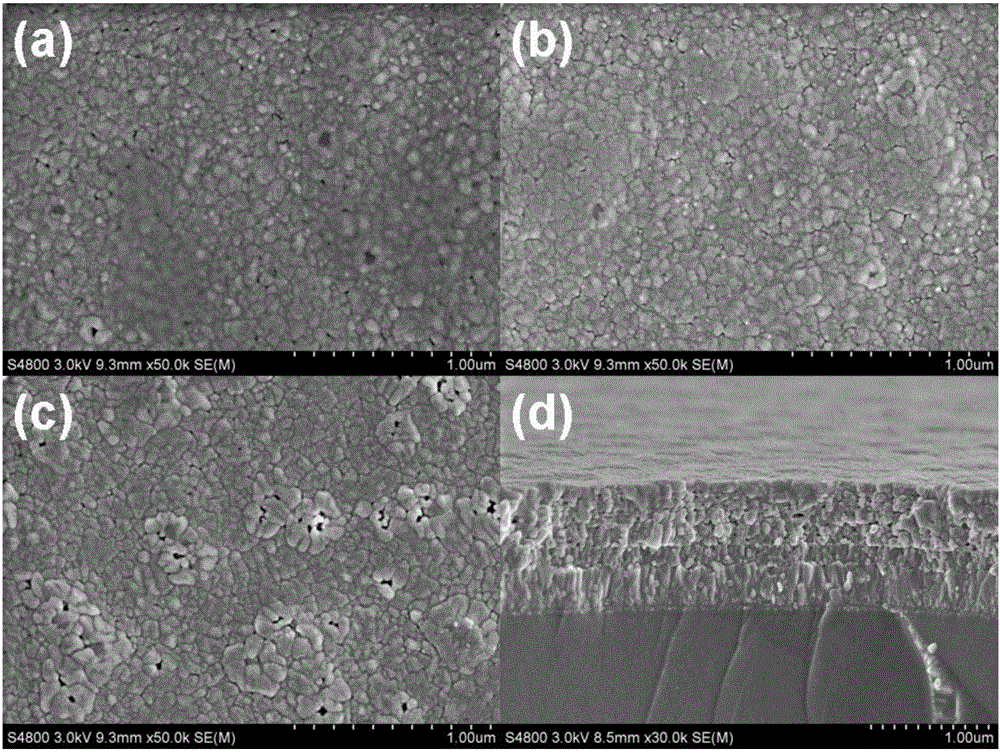

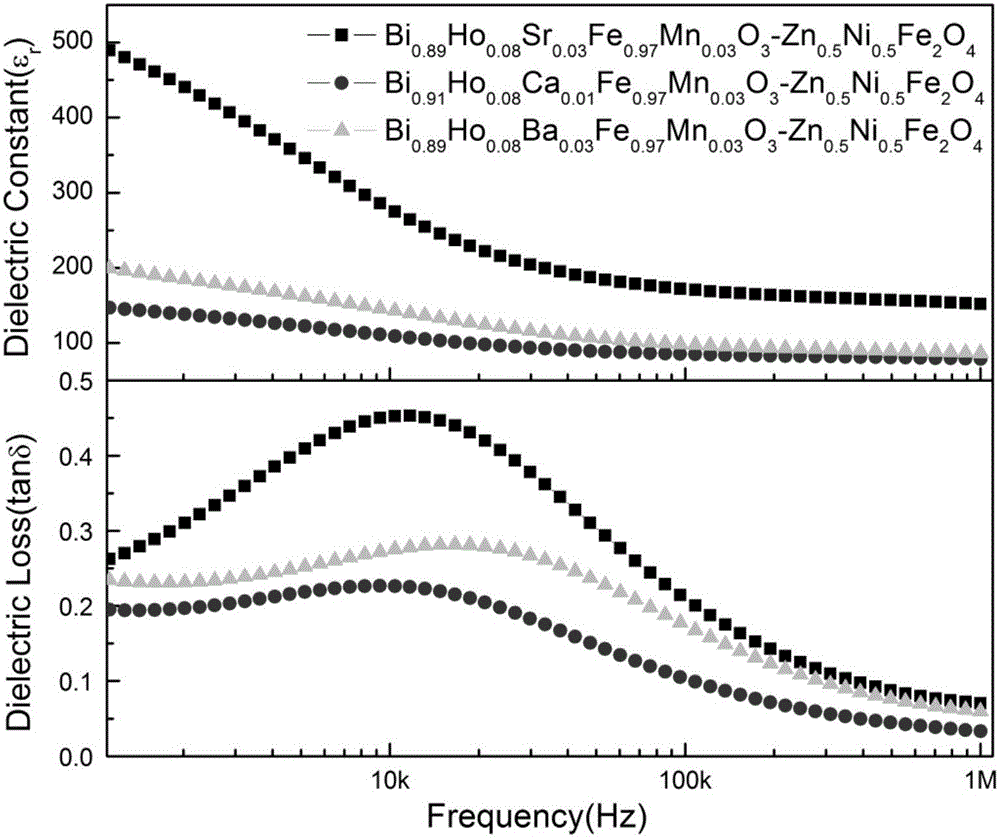

Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and preparation method thereof

InactiveCN105837196AReduce contentHigh polarizationCeramic layered productsMagnetic layerMagnetic composite

The invention provides a Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and a preparation method thereof. The ferromagnetic composite film comprises a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 crystalline film and a Zn1-yNiyFe2O4 crystalline film, which are compounded together. The preparation method is as below: first respectively preparing a Zn1-yNiyFe2O4 precursor solution and a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 precursor solution, wherein AE is Sr, Ca, Ba or Pb, x equals to 0.01-0.04, and y equals to 0.1-0.9; preparing a plurality of Zn1-yNiyFe2O4 films on a substrate by spin coating; and then preparing plurality of Bi0.92-xHo0.08AExFe0.97Mn0.03O3 films on the Zn1-yNiyFe2O4 films by spin coating, so as to obtain the ferromagnetic composite film. The method regulates the crystal structure of BiFeO3 by doping, and uses ferromagnetic Zn1-yNiyFe2O4 as the magnetic layer, so as to substantially increase the ferroelectric and ferromagnetic properties of the film, and effectively reduce the leakage current density of the film.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing antimony doped stannic oxide nano powder

InactiveCN101597022AEvenly distributedReduce reunionNanostructure manufactureHydrogen NitrateAntimony trioxide

The invention relates to a method for preparing antimony doped stannic oxide nano powder and belongs to the field of nanometer materials. The nanometer material is prepared by the following steps that: stannum granules, antimonous oxide powder and an antimony compounding agent in a certain mixing ratio are dissolved in hydrogen nitrate at certain concentration to form light cyan transparent solution; the transparent solution and ammonia water at certain concentration are dripped into a base solution doped with a dispersing agent in a cocurrent flow mode to undergo a coprecipitation reaction; and the ATO nano powder is prepared by washing, azeotropic distillation, drying and calcining of the product of the coprecipitation reaction. The method is characterized in that: the stannum granules and the antimonous oxide powder are used as basic raw materials, the antimony compounding agent is added in a preparation process to process a precursor together with an azeotropic distillation method to prepare the ATO nano powder. The method is easy in accurate measurement, effectively suppresses the early hydrolysis of the antimony, realizes even doping of the ATO nano powder, effectively removes moisture in the precursor and free hydroxyls on the surface, reduces the conglobation of the powder, simplifies a preparation process, reduces preparation period and expends the application range of the ATO nano powder.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of chitosan/titanium dioxide sol antibacterialpackaging film

InactiveCN104479155ALow reaction temperatureGood compatibilityFlexible coversWrappersAlcoholReaction temperature

The invention relates to a method for preparing anenvironment-friendlyhigh polymer material antibacterialpackaging film by mixing chitosan and titanium dioxide sol, and belongs to the technical field of preparation of a novel high polymer material taking renewablebiomass as a raw material. Tetrabutyltitanate, glacial acetic acid and a silane coupling agent (KH570) are slowly dropped in absolute ethyl alcohol respectively and stirred to prepare a precursor, deionized water and hydrochloric acid are sufficiently stirred and dropped in the absolute ethyl alcohol, a dropping liquid is prepared and then dropped in the precursor at a certain speed, modified titanium dioxide sol is obtained, added to a chitosan-acetic acid solution containing glycerin and uniformly stirred, and the chitosan / titanium dioxide sol antibacterialpackaging film is obtained after defoaming and film scraping. According to the preparation method, the titanium dioxide sol reaction temperature is low, the equipment investment is small, and uniform doping of the titanium dioxide sol and a chitosan solution in the molecular level can be realized in shorter time; and the compatibility of the titanium dioxide sol treated by the silanecoupling agentand chitosan is good.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com