Composite material as well as preparation method and application thereof

A technology of composite materials and doped materials, which is applied in the field of composite materials and their preparation, can solve problems such as inability to carry out quality control, decrease in physical properties of materials, and large gaps, etc., to achieve good drug sustained release effects, strong mechanical properties of materials, and high loading capacity. drug distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1. Preparation of Aminocellulose / Carboxyl Surface Polystyrene Micron-scale Microsphere Membrane Material

[0053] The sieved polystyrene balls (Ps, 10 micron particle size, product of Aladdin Company, P107783) were placed in a sand core funnel, swollen with dichloromethane, washed twice with tetrahydrofuran, and washed with tetrahydrofuran for two times. Then, the volume ratios of tetrahydrofuran and distilled water are 3:1, 1:1, 1:3, respectively, for 1 time filtration, and then 10 times with cold distilled water and boiled distilled water to remove the monomers and low molecular weights in Ps. Finally, wash and filter twice with absolute ethanol and methanol, and vacuum dry to constant weight for use. Add phthalic anhydride powder and a certain amount of anhydrous methanol to the three-necked flask, ultrasonically vibrate for 10 min, and then add the treated Ps (the mass ratio of Ps to phthalic anhydride is 3:1), add to the reaction flask After passing the pu...

Embodiment 2

[0058] Example 2. Preparation of pyrazinamide-loaded urethane starch / carboxyl surface-modified polystyrene nanoscale microsphere porous material

[0059] The sieved polystyrene balls (Ps, 200 nanometer particle size, product of Aladdin Company, P107773) were placed in a sand core funnel, swollen with dichloromethane, washed and filtered twice, and then washed with tetrahydrofuran twice. Then, the volume ratios of tetrahydrofuran and distilled water are 3:1, 1:1, 1:3, respectively, for 1 time filtration, and then 10 times with cold distilled water and boiled distilled water to remove the monomers and low molecular weights in Ps. Finally, wash and filter twice with absolute ethanol and methanol, and vacuum dry to constant weight for use. Add phthalic anhydride powder and a certain amount of anhydrous methanol to the three-necked flask, ultrasonically vibrate for 20 min, and then add the treated Ps (the mass ratio of Ps to phthalic anhydride is 3:1), and add it to the reaction fl...

Embodiment 3

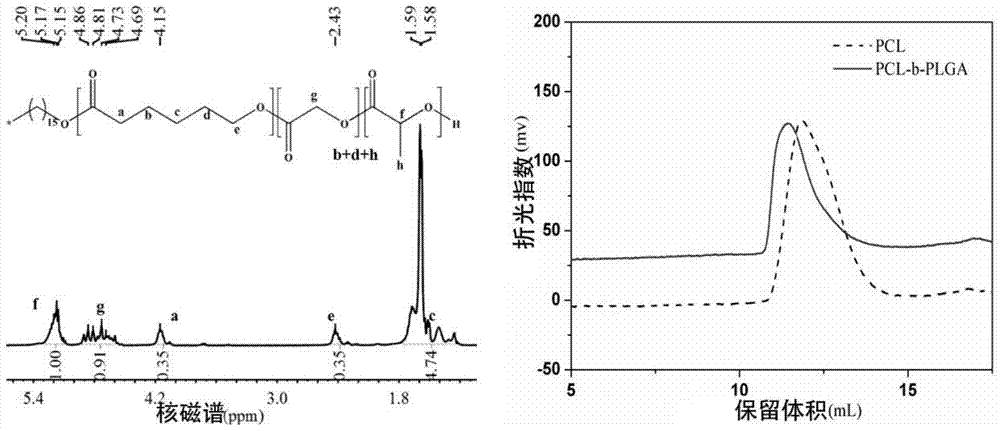

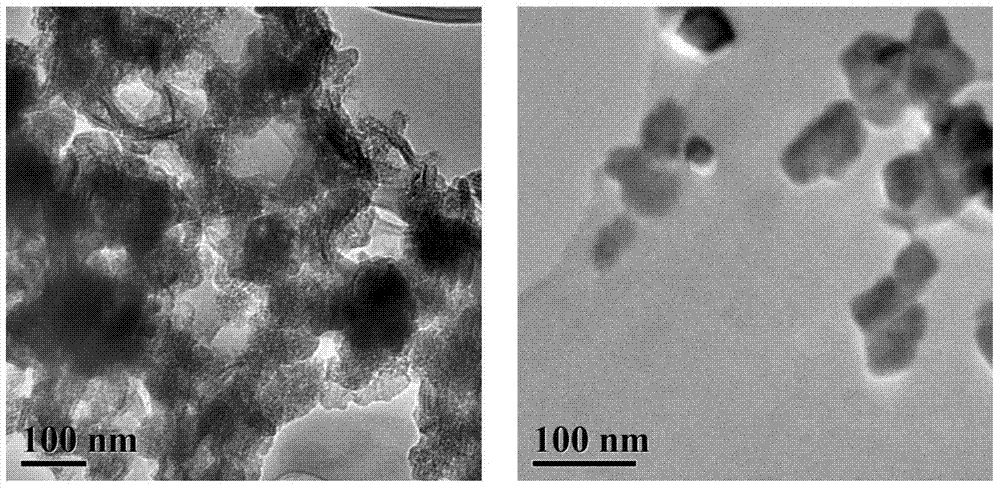

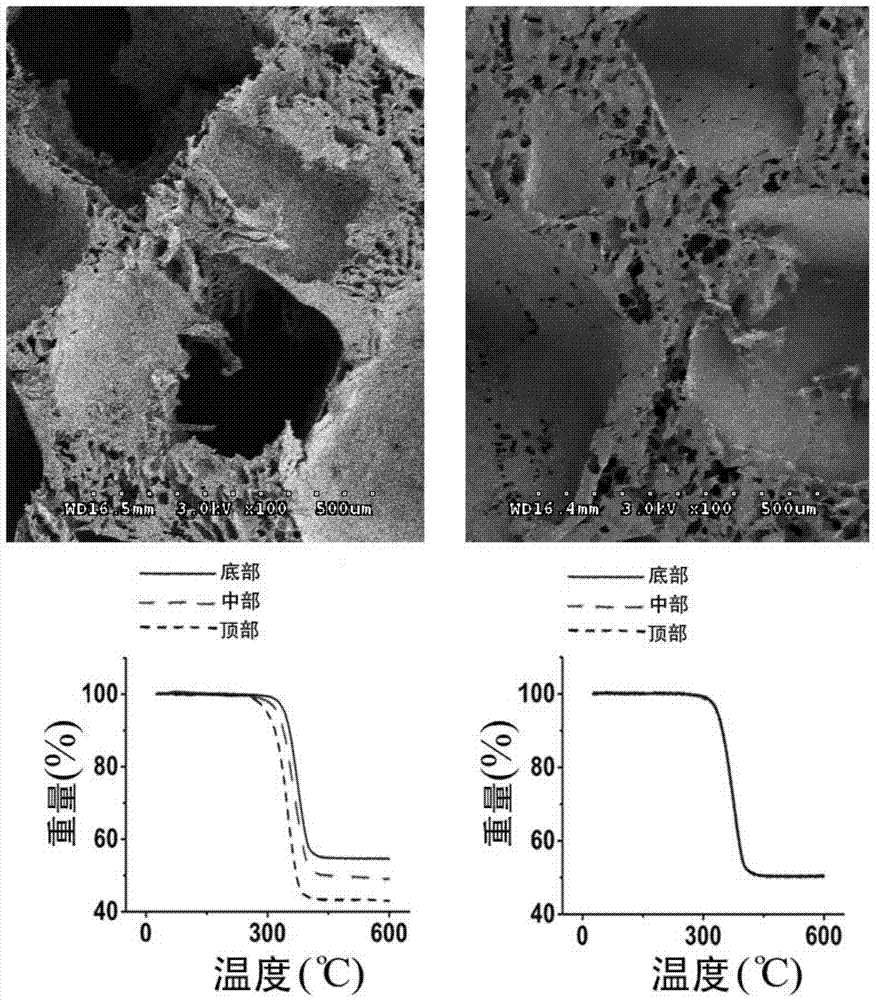

[0064] Example 3. Preparation of amino-terminated polycaprolactone / carboxyl surface-modified ferric oxide particle dense material

[0065] Ferric chloride hexahydrate and ferrous chloride hexahydrate were respectively dissolved in 40ml of deionized water and mixed in a 250ml there-necked flask (the mol ratio of ferric chloride and ferrous chloride was 2:1), placed in the flask. Stir well in a 40°C water bath, add 18ml of concentrated ammonia water dropwise, add 4.26g of oleic acid dropwise after 1min, continue to stir rapidly for 1h in a 70°C water bath, wash twice with alcohol after the reaction to remove excess oleic acid, Then wash with deionized water until neutral. Take 20ml of the magnetic microsphere suspension 40mg / ml prepared above, add 150ml of 20mg / ml KMnO 4 solution, under ice bath conditions, crushed in an ultrasonic cell pulverizer for 20min, placed the oxidized and crushed magnetic microspheres in a three-necked flask, stirred at high speed for 5h and washed 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com