Improved-performance tablet and preparation method thereof

A tablet, performance technology, applied in the direction of pill delivery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

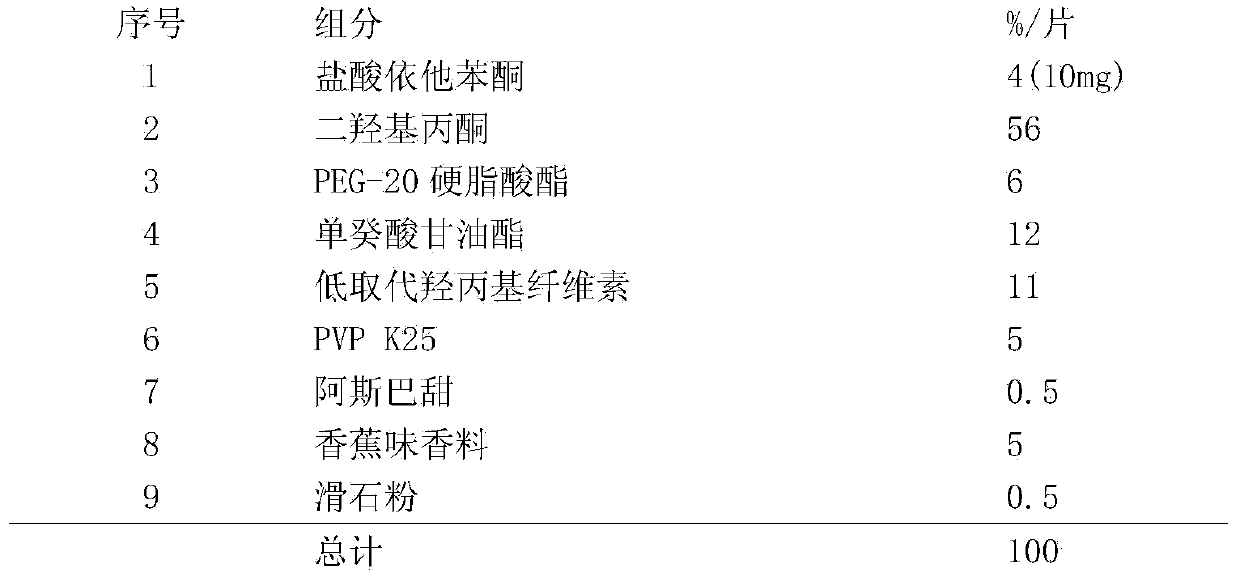

[0417] Embodiment 1 and its comparative example

[0418]

[0419] [Preparation method] Take components 3-4, heat and melt, mix well, cool, and pulverize to 100-120 mesh to obtain solid dispersion ( / body) powder (the average particle size of the dispersoid is not greater than 10nm); the above-mentioned powder Mix with components 1-2, 5-9 that have passed through a 100-mesh sieve (ground if necessary), press the tablet with a pressure of about 0.18t / pestle (tablet hardness 1.5kp, n=5), and reheat the tablet Heat to 80°C and keep warm for 5 minutes, then cool to room temperature.

Embodiment 2

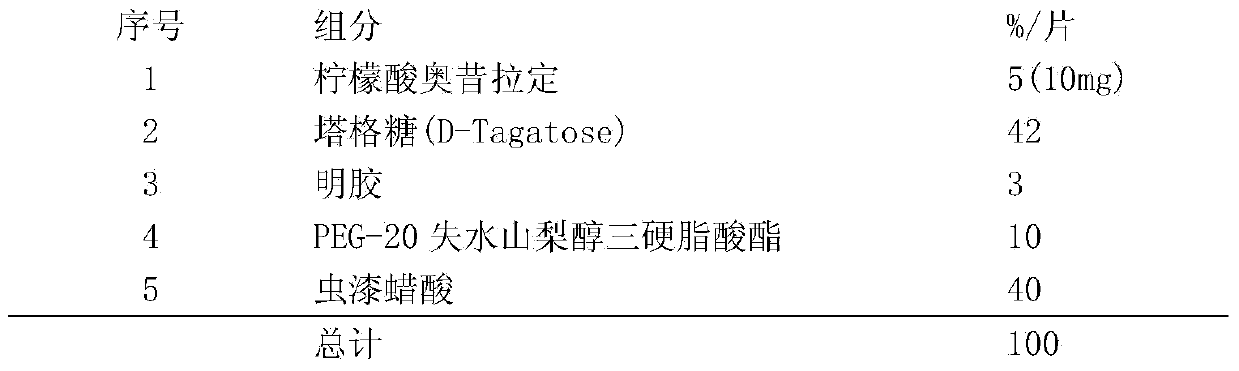

[0421] Embodiment 2 and its comparative example

[0422]

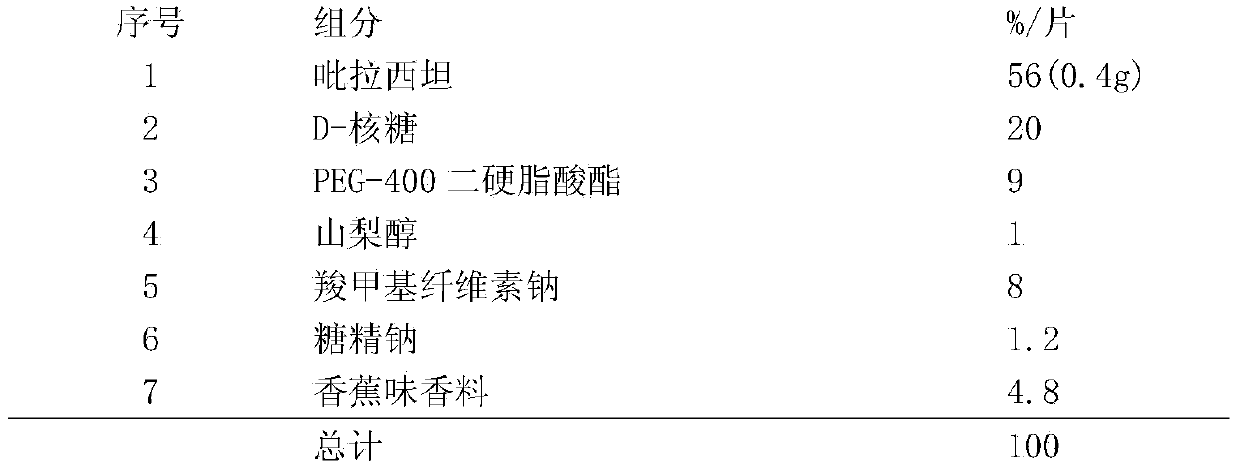

Embodiment 2-1

[0423] [Example 2-1 Preparation method] Take components 1-3 and dissolve or disperse them in an appropriate amount of water, spray or freeze-dry the solution to obtain solid dispersion ( / body) powder 1; take components 4-5, heat and melt, Mix evenly, cool down, and pulverize to 100-120 mesh to obtain solid dispersion ( / body) powder 2 (the average particle size of the dispersoid is about 70-100nm); mix the above-mentioned powder 1 and 2, mix well and put into suitable bubbles Put it in the eye or tablet mold, then heat to 85°C and keep it warm for 15 minutes, then cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com