Patents

Literature

80results about How to "Won't soften" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

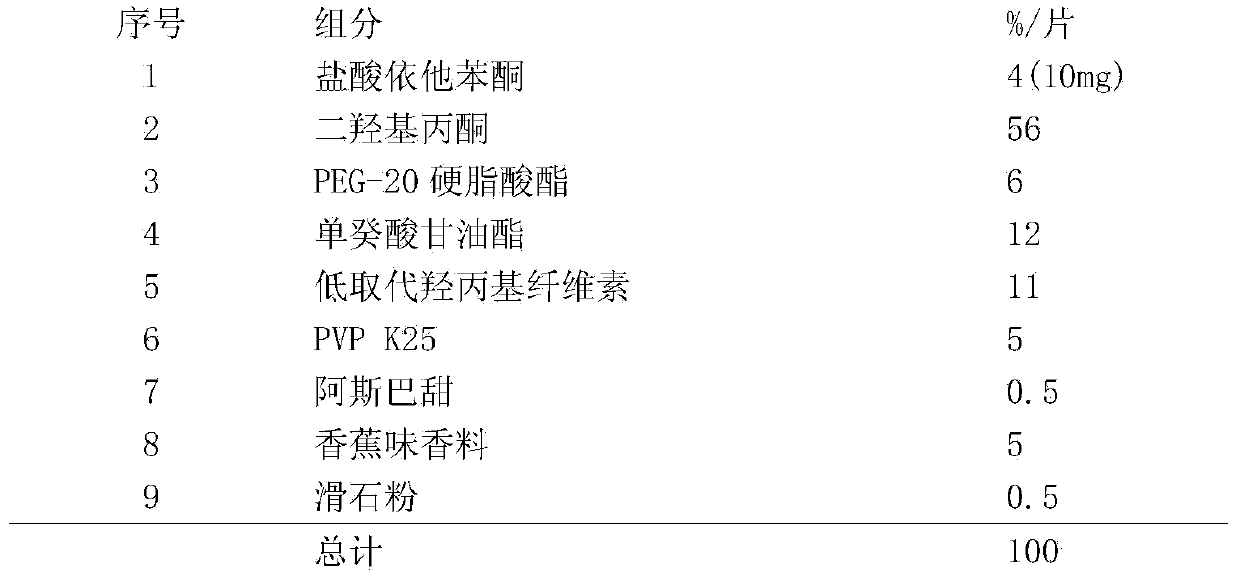

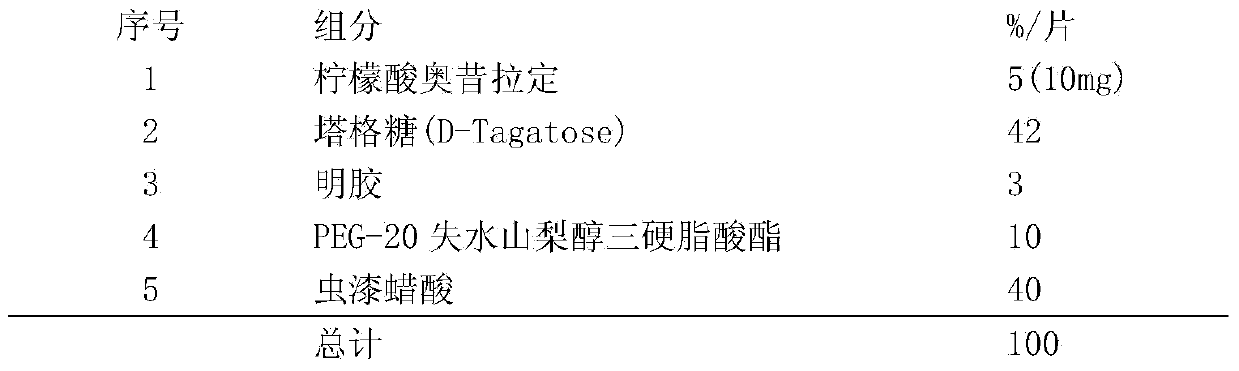

Improved-performance tablet and preparation method thereof

InactiveCN103432091AMaintain integrityPrevent or reduce cracksPill deliveryPorosityWeather resistance

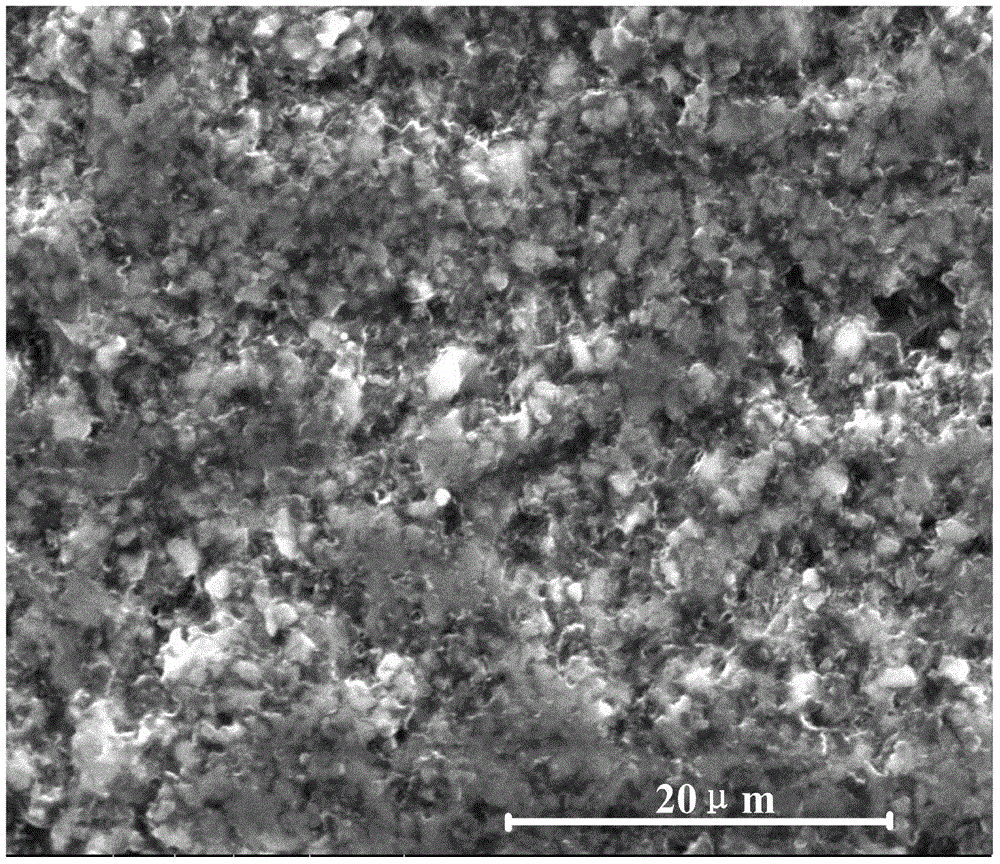

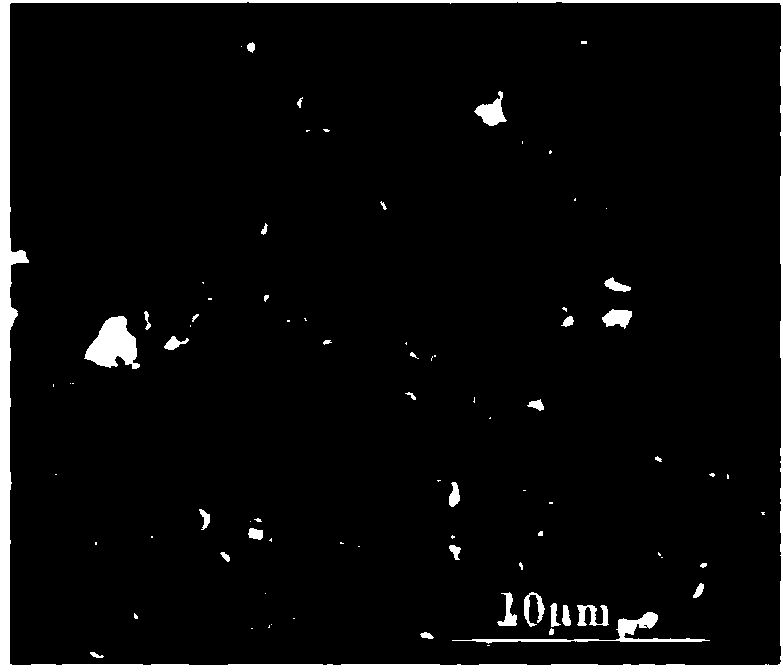

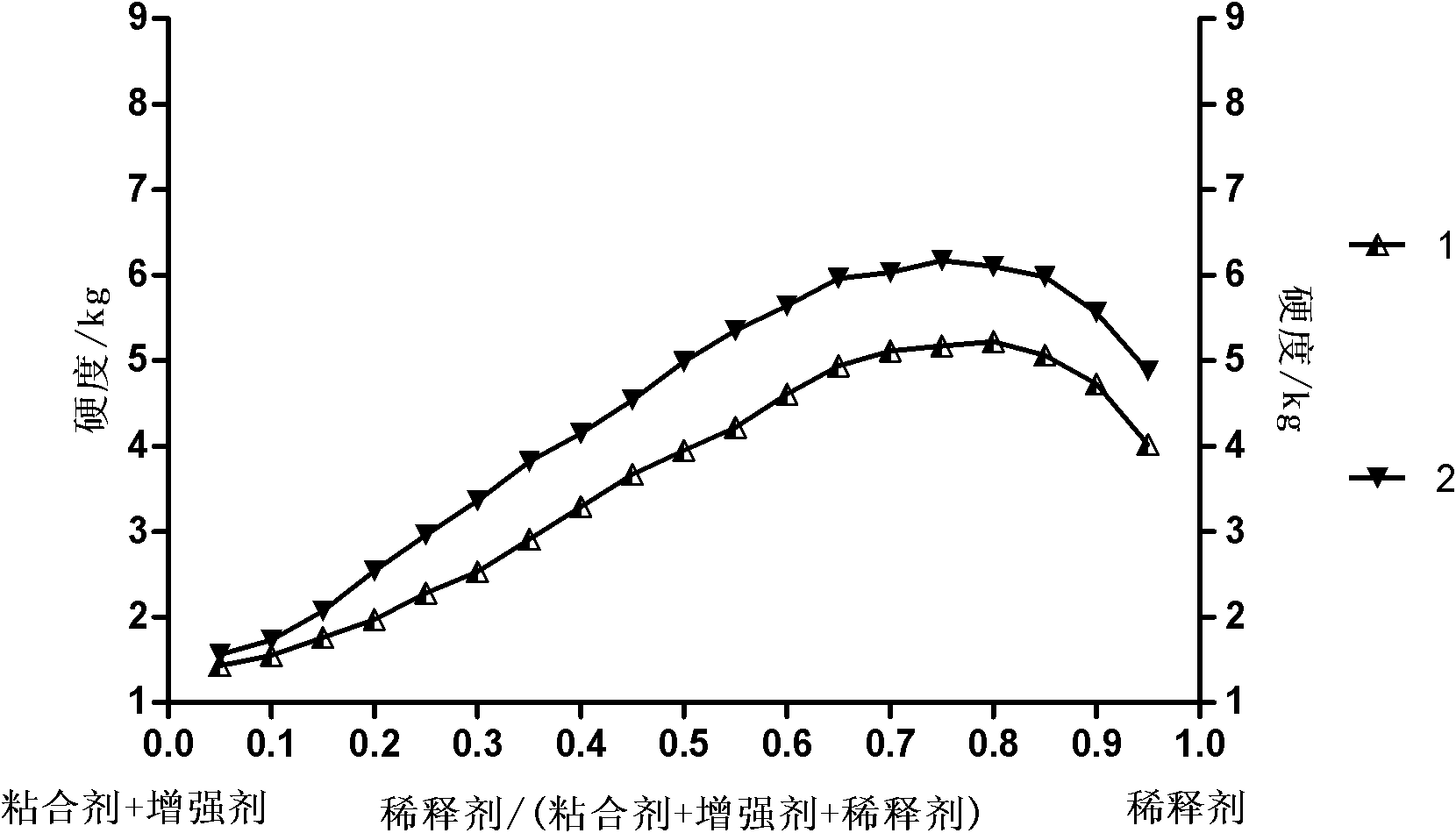

The invention discloses an improved-performance tablet which comprises an active component A1, a hydrophilic diluent B1 and a meltable solid dispersion and / or a solid coating C1, wherein the diluent B1 and / or the active component A1 are / is bonded and bridged by the solidified melt of the meltable solid dispersion and / or solid coating C1; and / or the tablet comprises a hydrophilic diluent B2 and a meltable solid dispersion containing an active component A2 and / or a solid coating C2, wherein the diluent B2 is bonded and bridged by the solidified melt of the meltable solid dispersion and / or solid coating C2. The invention also discloses a preparation method of the tablet. The tablet has stronger mechanical performance and / or better weather resistance and / or better hydrophilcity or better disintegration property or better medicine dissolubility and higher porosity.

Owner:钟术光

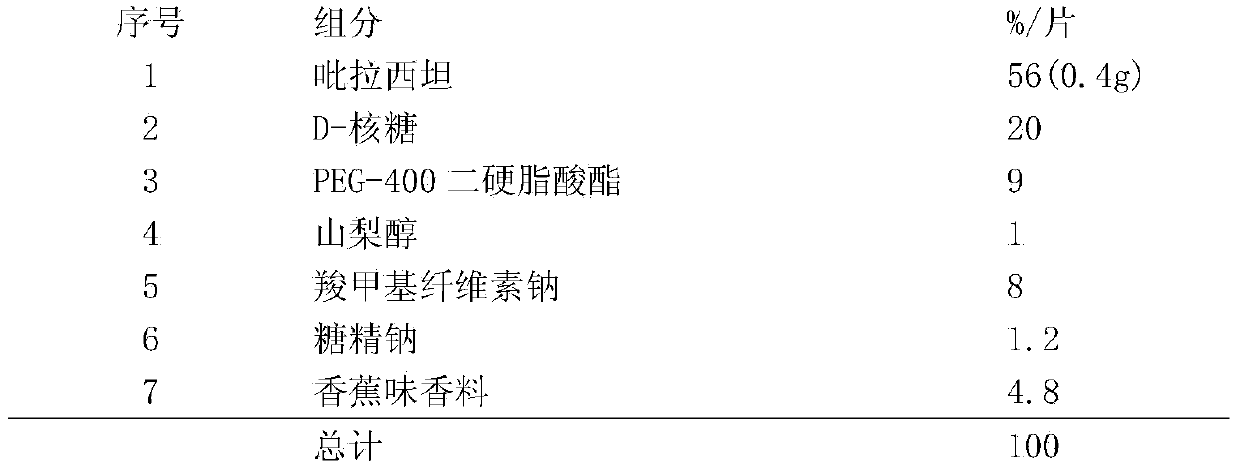

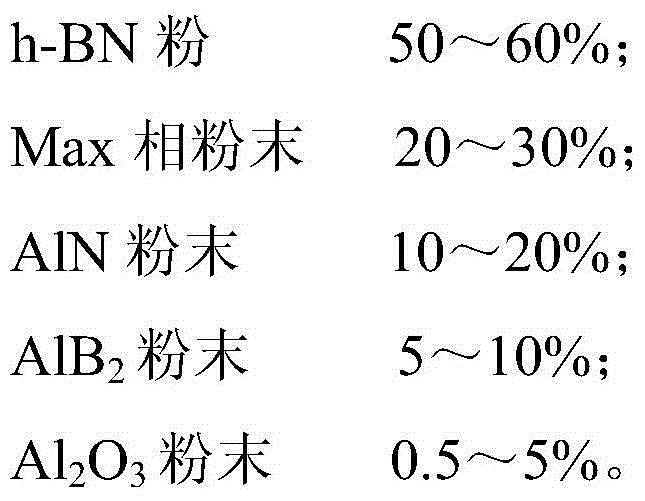

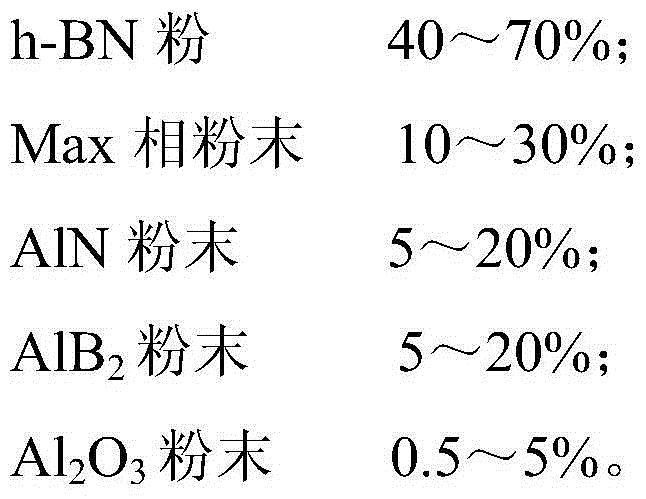

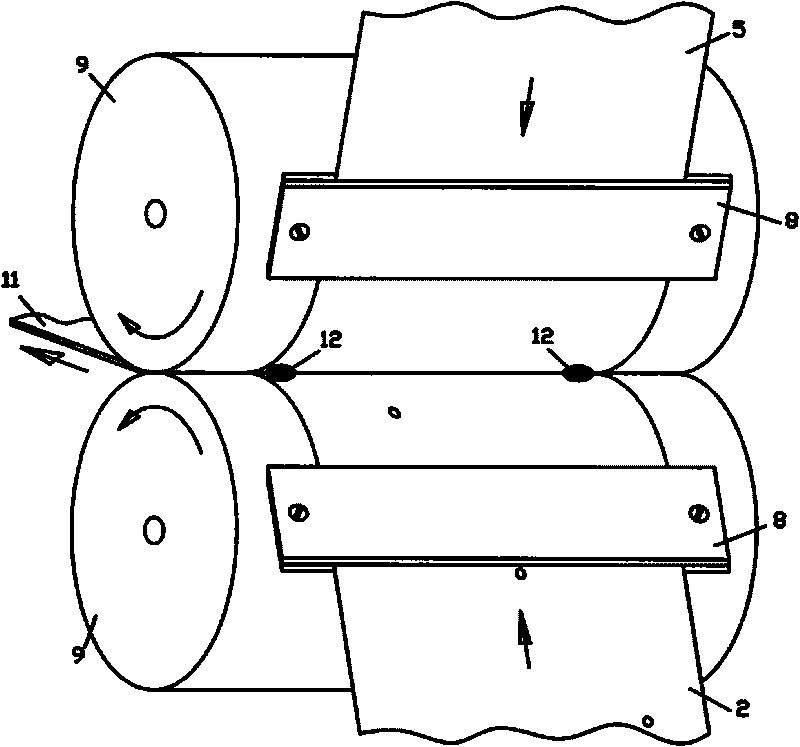

Max phase-boron nitride composite ceramic side seal plate for thin-strip casting and manufacturing method of Max phase-boron nitride composite ceramic side seal plate

The invention discloses a Max phase-boron nitride composite ceramic side seal plate for thin-strip casting and a manufacturing method of the Max phase-boron nitride composite ceramic side seal plate. The side seal plate comprises the following components in percentage by mass: 40-70% of h-BN powder, 10-30% of Max phase powder, 5-20% of AlN powder, 5-20% of AlB2 powder and 0.5-5% of Al2O3 powder. The manufacturing method comprises the following steps: 1) preparing Max phase powder; 2) preparing mixed slurry: namely mixing the h-BN powder, the Max phase powder, the AlN powder, the AlB2 powder and the Al2O3 powder in percentage by mass and then adding a mixed solvent to mix and fully and uniformly mixing the mixture to obtain mixed slurry; 3) preparing mixed powder; and 4) sintering the mixed powder. According to the method disclosed by the invention, the ceramic side seal plate for double roll thin-strip casting is manufactured by using a ceramic formula. The prepared side seal plate has the characteristics of being high in compactness and high in rupture strength. The compactness is 93-98%, the rupture strength at the room temperature reaches 300-500MPa, the strength of the side seal plate in the using process is fully guaranteed, and the side seal plate is not hardened.

Owner:武汉钢铁有限公司

High polymer composite electrothermal film and preparation method thereof

ActiveCN106183239AImprove heat resistanceHigh strengthPolyureas/polyurethane adhesivesChemical industryCarbon nanotubeHeat generation

The invention discloses a high polymer composite electrothermal film. The film comprises a carbon-nano-tube polyurethane resin thermal film and an electrode, and is characterized in that the carbon-nano-tube polyurethane resin thermal film is composed of a thermosetting polyurethane resin conductive heating layer and a polyurethane resin insulating layer by hot-pressing. Compared with the existing thermosetting polyurethane resin electrothermal film, the electrothermal film disclosed by the invention is high in heat resistance and strength, is not softened within the temperature range of 160 DEG C, can maintain the strength, meets the halogen-free flame-retardant and environmental-friendly requirements and reaches the level UL 94V-0; the application safety performance is high, the heat generation efficiency is improved by 10%, the heat transfer efficiency of the electrothermal film is improved by 20-30%, and temperature rise is rapid.

Owner:江苏康尼纺织品有限公司

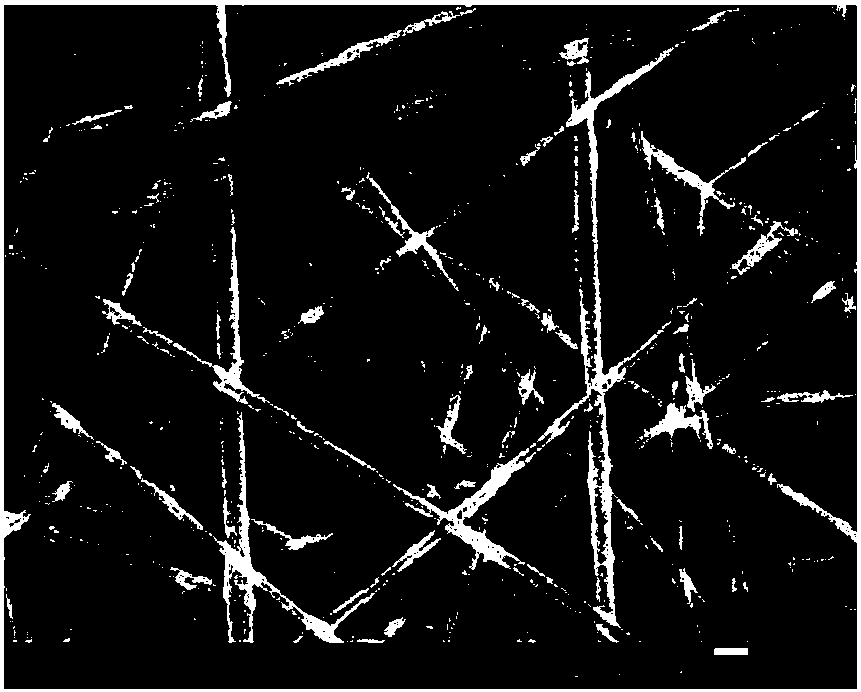

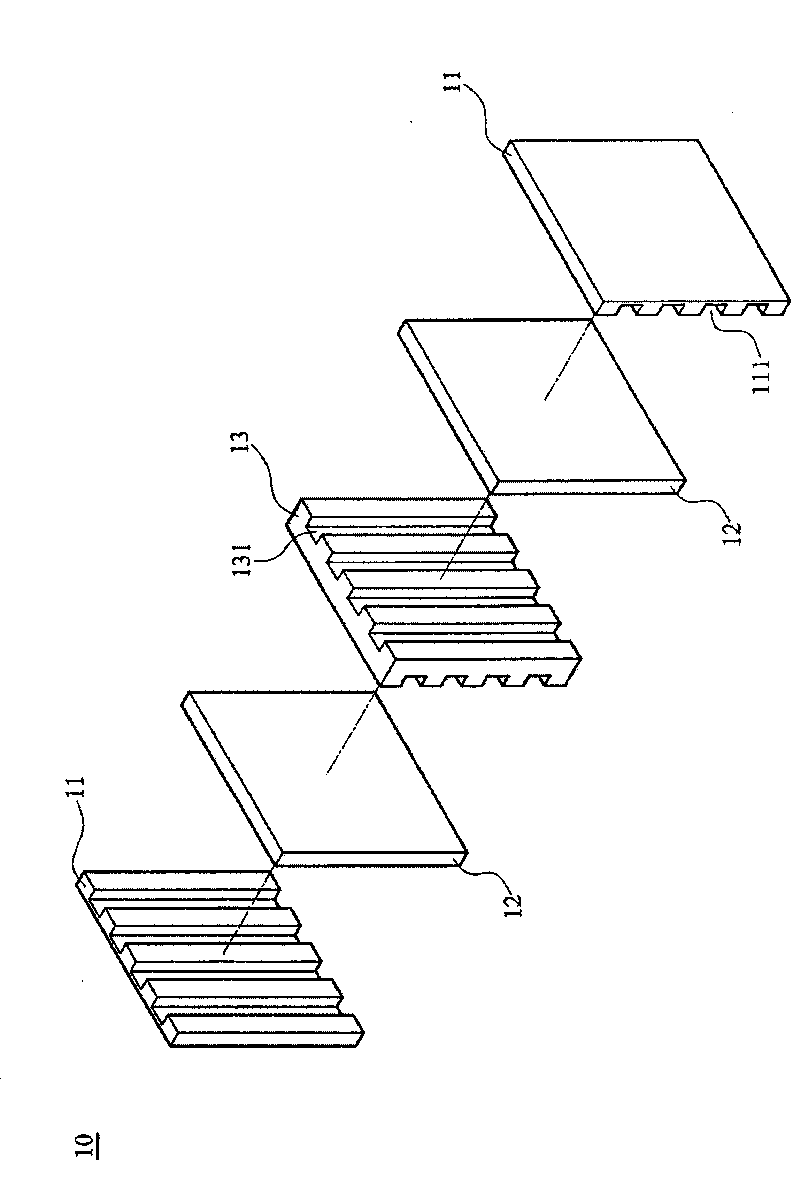

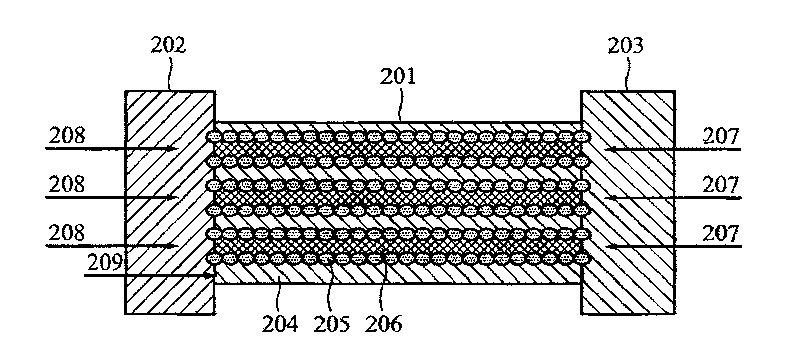

Polymer composite film, preparation method thereof and lithium ion battery comprising same

ActiveCN108242522AMeet porosity requirementsImprove securitySecondary cellsCell component detailsPorosityFiber

The invention discloses a polymer composite film, a preparation method thereof and a lithium ion battery comprising the polymer composite film. The polymer composite film comprises a porous base filmand a heat-resistant layer covering at least one side surface of the porous base film, wherein the heat-resistant layer comprises a heat-resistant macromolecular material and has a fibrous network structure, and the heat-resistant macromolecular material comprises one or more than one of poly (p-phenylene terephthalamide), polyisophthaloyl metaphenylene diamine, poly p-benzamide, poly-p-phenyleneben-zobisthiazole, polyphenylene benzobisthiazole, polybenzoxazole and polybenzimidazole. The polymer composite film disclosed by the invention has the advantages that a specific heat-resistant macromolecular material is adopted for forming the heat-resistant layer, high temperature (180 DEG C) stability of the polymer composite film can be beneficially improved while porosity requirement of the polymer composite film is met, lithium ion migration is facilitated, and safety performance of a battery is improved.

Owner:BYD CO LTD

High yield veiled lady seed preparing and cultivating process

InactiveCN101019491AEffective and strongWon't softenBio-organic fraction processingFungiHyphaHyphomycetes

The high yield veiled lady cultivar preparing and cultivating process includes compounding culture medium, bottling or bagging, sterilizing, inoculating, covering the mouth with cotton, culturing to obtain white hypha, eliminating the cotton cover after the hypha grows to 2-2.5 cm thickness and further culturing to obtain the veiled lady cultivar with high vitality, and further cultivating in fermented culture medium and through spraying herbicide, covering with fermented rice straw, etc. The present invention has greatly raised veiled lady yield.

Owner:张远富

Ceramic side sealing plate for twin-roll thin-strip continuous casting and preparation method thereof

The invention discloses a ceramic side sealing plate for twin-roll thin-strip continuous casting. The ceramic side sealing plate is characterized by comprising the following chemical components in percentage by mass: 40-75% of hexagonal boron nitride powder, 10-45% of Si3N4 powder, 10-30% of zirconia-mullite powder, 3-15% of TiN powder and 0.5-10% of additive, wherein the additive is one or a combination of several of Y2O3, industrial Al2O3, MgO and light magnesium carbonate. The side sealing plate has high temperature resistance, high strength, thermal shock resistance and low heat conductivity by developing the novel formula of the novel side sealing plate and adjusting a preparation method of the novel side sealing plate.

Owner:武汉钢铁有限公司

Boron nitride ceramic side seal plate for continuous thin-strip casting and manufacturing method of side seal plate

The invention discloses a boron nitride ceramic side seal plate for continuous thin-strip casting. The boron nitride ceramic side seal plate is characterized by comprising the following chemical components by mass percent: 20%-75% of hexagonal boron nitride, 10%-55% of aluminum nitride powder, 5%-40% of magnesium aluminate spinel, 5%-20% of mullite and 0.5%-15% of an additive, wherein the additive is selected from one or combination of several of MgAlON, AlON, CaAl4O7, CaZrO3 and CaTiO3. The boron nitride ceramic side seal plate manufactured by adopting novel ceramic formula and preparation method is relatively high in density, fire-resistant degree and rupture strength, so that the side seal plate is fully ensured to be not softened in a use process. Meanwhile, the side seal plate is low in heat conduction rate and good in thermal shock resistance, so that the side seal plate can well resist the thermal shock of molten steel in the use process and the service life of the side seal plate is prolonged.

Owner:武汉钢铁有限公司

Tablet with improved combination properties and preparation method thereof

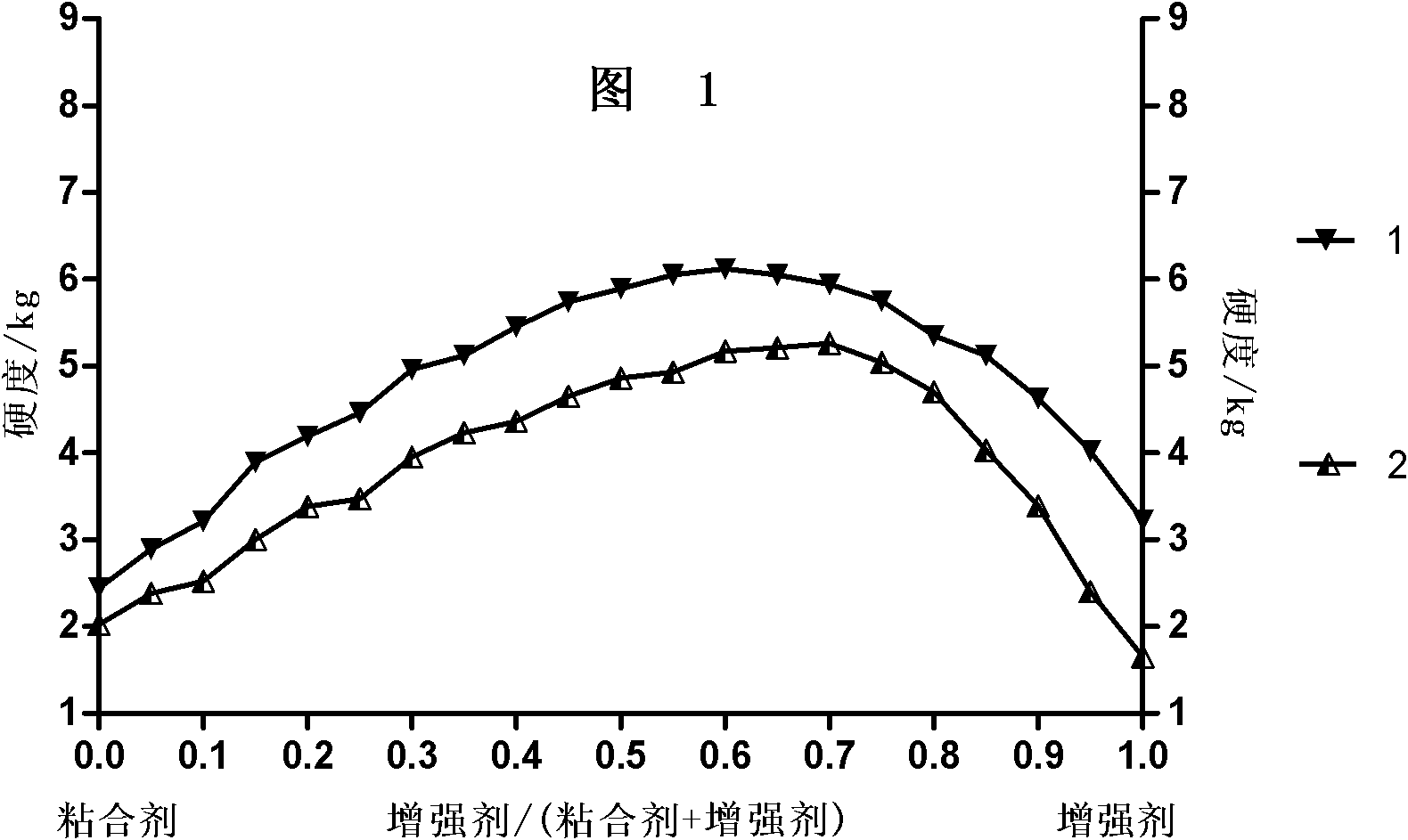

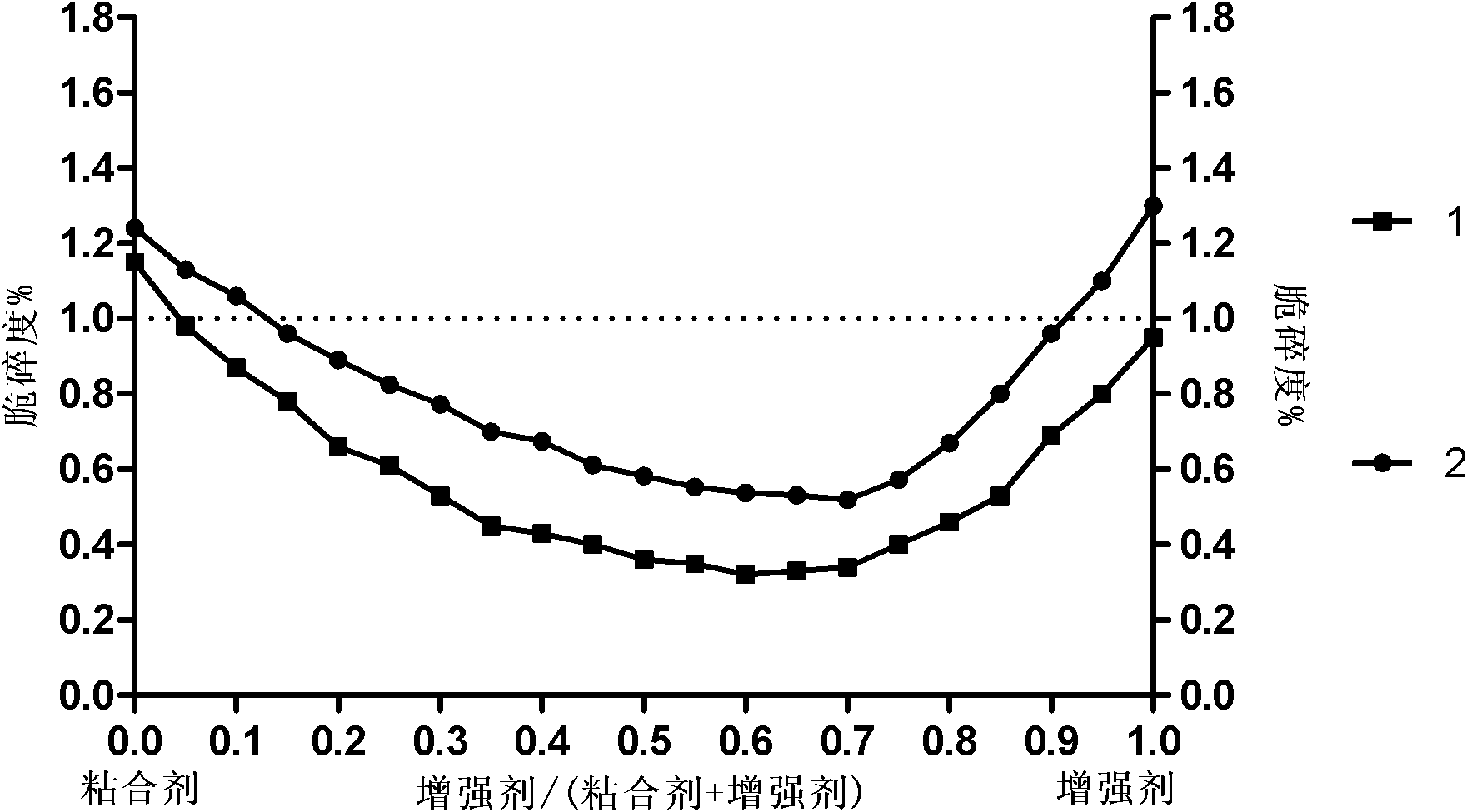

InactiveCN101919822AMaintain integrityAvoid crackingPill deliveryOil/fats/waxes non-active ingredientsPolymer scienceAdhesive

The invention discloses a tablet with improved combination properties. The tablet comprises an active constituent, a water soluble crystalline granular or powdered diluent, a melting adhesive, a melting mechanical property improver and / or does not comprise a pharmaceutically acceptable additive, wherein the diluent and / or the active constituent are / is adhered and bridged by the cured smelt of theadhesive and the mechanical property improver; the ratio of the mechanical property improver to the summation of the adhesive and the mechanical property improver is 0.25-0.70, and the ratio of the diluent to the summation of the adhesive, the mechanical property improver and the diluent is 0.40-0.93; the content of the diluent is not lower than 25 percent; and the contents of the adhesive and the mechanical property improver are not lower than 5 percent. The invention also discloses a preparation method of the tablet. The tablet has the advantages of stronger mechanical property, better weather resistance, better hydrophilcity, higher porosity and better disintegration property.

Owner:钟术光

Integrated floor-heating flexible ceramic tile and production method thereof

ActiveCN106433096AHigh hardnessImprove heat resistanceHeating fuelNon-macromolecular adhesive additivesElastomerEpoxy

The invention relates to an integrated floor-heating flexible ceramic tile and a production method thereof. The integrated floor-heating flexible ceramic tile combined by a flexible ceramic layer and a polymer composite electric-heating film is good in flexibility, high in tear resistance, high in elongation at break, high in heat resistance, high in heat efficiency, fast in heating, and the like. The flexible ceramic layer is produced by inorganic powder and polymer materials, and the polymer materials are water-borne epoxy resin emulsion, water-soluble epoxy resin curing agent, rubber elastomer and fluorine-containing polyacrylate elastic emulsion. The polymer composite electric-heating film comprises a polyurethane resin heat-conducting insulating layer, a carbon nanotube polyurethane resin heating layer, a polyurethane resin insulating layer and electrodes. The polymer composite electric-heating film is formed by the heat-conducting insulating layer semi-cured by polyurethane resin, the heating layer semi-cured by carbon nanotube polyurethane resin and the insulating layer semi-cured by polyurethane resin through hot pressing. The soft ceramic layer is integrally connected with the polymer composite electric-heating film through the polyurethane resin heat-conducting insulating layer to form the integrated floor-heating flexible ceramic tile.

Owner:万卓(江苏)新材料有限公司

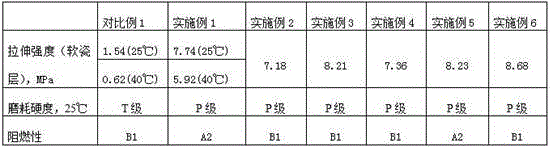

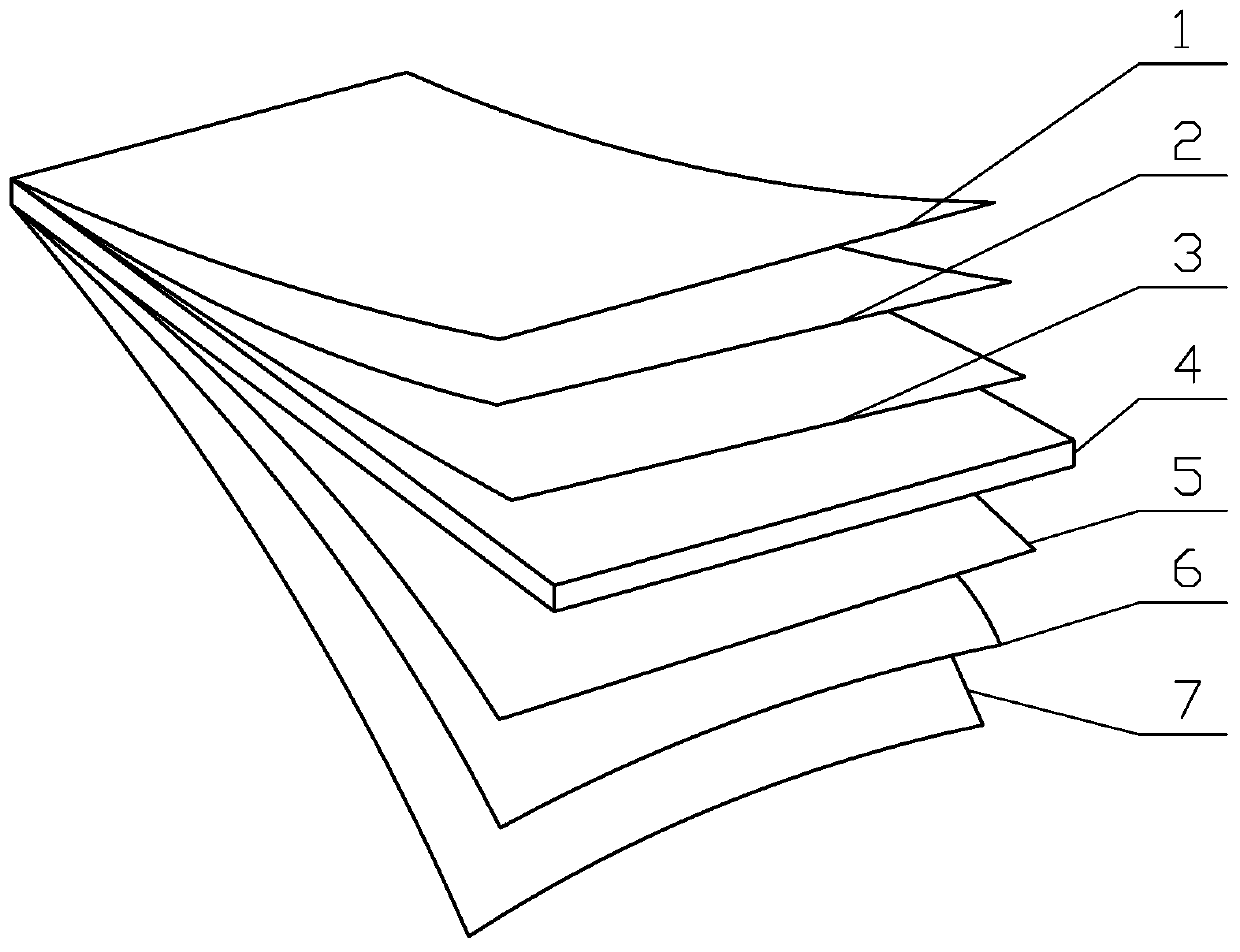

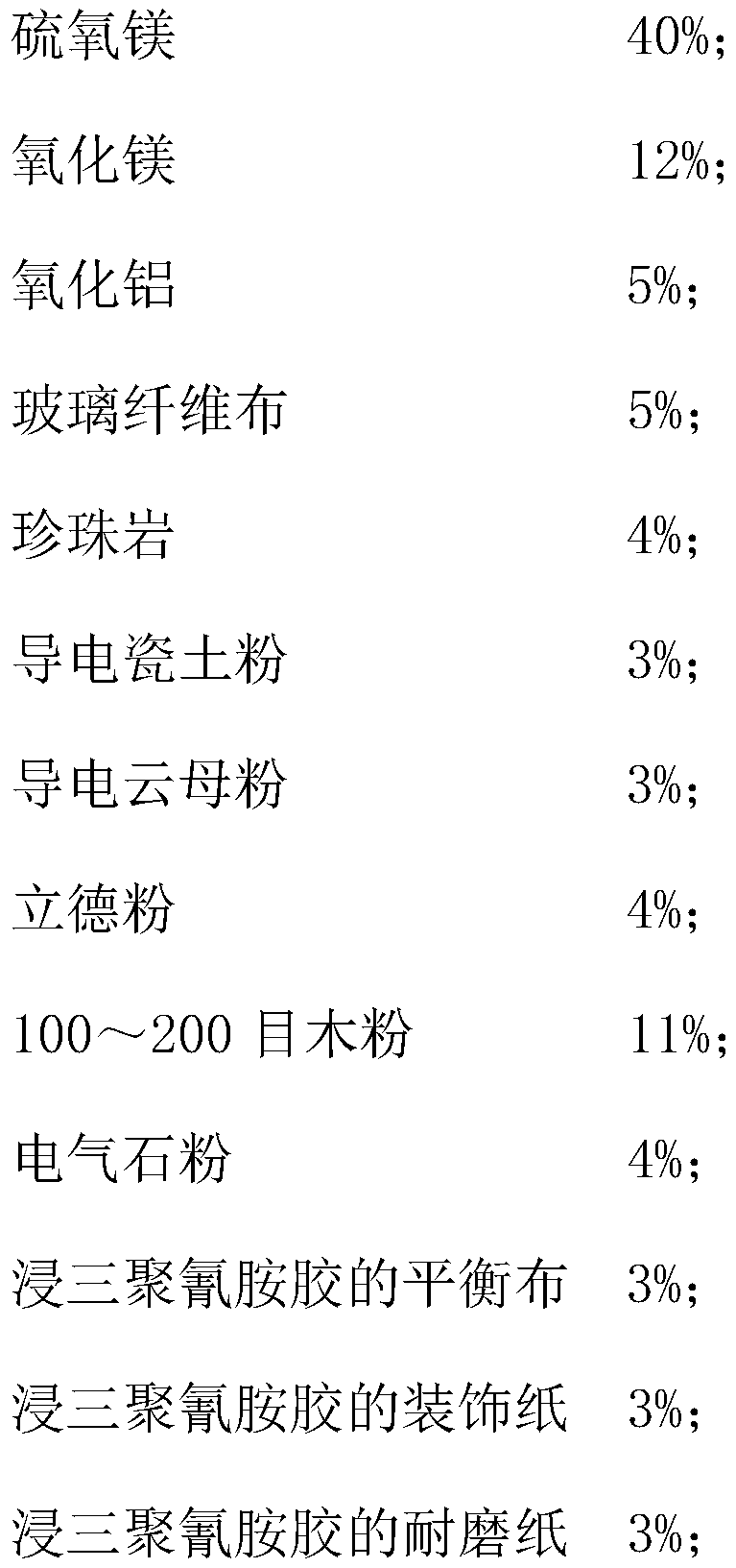

Magnesium oxysulfate melamine paper decoration surface inorganic rock porcelain non-combustible board and production method thereof

PendingCN110091570AImprove insulation performanceStrong weather resistanceCovering/liningsLaminationThermal insulationWear resistant

The invention particularly relates to a magnesium oxysulfate melamine paper decoration surface inorganic rock porcelain non-combustible board and a production method thereof, wherein the raw materialscomprise: 40% of magnesium oxysulfate, 12% of magnesium oxide, 5% of alumina, 5% of a glass fiber cloth, 4% of perlite, 3% of electric-conduction procelain clay powder, 3% of electric-conduction micapowder, 4% of lithopone, 11% of 100-200 mesh wood powder, 4% of tourmaline powder, 3% of a balance cloth immersed with a melamine glue, 3% of decoration paper immersed with a melamine glue, and 3% ofwear-resistant paper immersed with a melamine glue. The production method comprises: 1) preparing a magnesium oxysulfate substrate having a fine pore structure; 2) respectively spreading both surfaces of the magnesium oxysulfate substrate with a balance cloth immersed with a melamine glue, decoration paper immersed with a melamine glue, and wear-resistant paper immersed with a melamine glue; and3) carrying out hot pressing molding. According to the present invention, the magnesium oxysulfate melamine paper decoration surface inorganic rock porcelain non-combustible board has advantages of light weight, smooth surface, high hardness, good fireproof performance, good moisture proof performance, good temperature-difference resistance, strong water resistance, no moisture absorption halogenaccumulation, good thermal insulation effect and wide application range, and does not contain asbestos, formaldehyde and harmful radioactive elements.

Owner:山东凯勒蓝房家居文化发展有限公司

Conductive grease and preparation method thereof

InactiveCN102768873AImprove conductivityAccelerated corrosionNon-conductive material with dispersed conductive materialCable/conductor manufactureLithium soapHeat resistance

The invention relates to the technical field of conductive materials and preparation methods thereof, in particular to conductive grease and a preparation method thereof. The conductive grease comprises the following components in part by weight: 5 to 15 percent of lithium soap, 60 to 70 percent of synthetic basic oil, 23 to 33 percent of pure copper powder, 1 to 2 percent of tin powder and 1 to 2 percent of silver powder. The preparation method comprises the following steps of: weighing the synthetic basic oil, the pure copper powder, the tin powder and the silver powder, adding the synthetic basic oil, the pure copper powder, the tin powder and the silver powder into a reactor, and uniformly mixing to obtain a pasty mixture for backup use; weighing the lithium soap, and smashing the lithium soap into powder; adding the lithium soap powder into the pasty mixture, uniformly mixing, and stirring and grinding to obtain the conductive grease; and putting the conductive grease into a package bottle to obtain a finished product. The conductive grease is relatively high in electrical conductivity, high in electrochemical corrosion resistance and heat resistance and high in conductive connection reliability; the preparation method for the conductive grease is scientific and rational; and the process is simple and convenient.

Owner:上海库革电气设备制造有限公司

Diamond coating cutter and manufacturing method thereof

InactiveCN106583803AConcentricity is not affectedWon't meltMilling cuttersWorkpiecesButt jointMetallic materials

The invention aims at providing a diamond coating cutter and a manufacturing method thereof. The diamond coating cutter comprises a first section of cylindrical bar, a second section of cylindrical bar, a welding part and a diamond film. The first section of cylindrical bar is made of sintered tungsten carbide materials. The second section of cylindrical bar is made of metal materials. The welding part is located between the first section of bar and the second section of bar. The whole surface of the first section of bar is coated with the diamond film through a chemical vapor deposition manufacturing procedure. The manufacturing method of the diamond coating cutter comprises the steps that firstly, sintered tungsten carbide and the metal bar are combined into a bar material with high-temperature solder through a hard soldering manufacturing procedure in a butt joint mode; then after forming machining, the cutter with the first section of bar, the second section of bar and the welding part can be obtained preliminarily; and then the chemical vapor deposition manufacturing procedure is conducted on the cutter, so that the whole surface of the first section of bar is coated with the diamond film, and finally the diamond coating cutter is obtained.

Owner:天钻科技股份有限公司

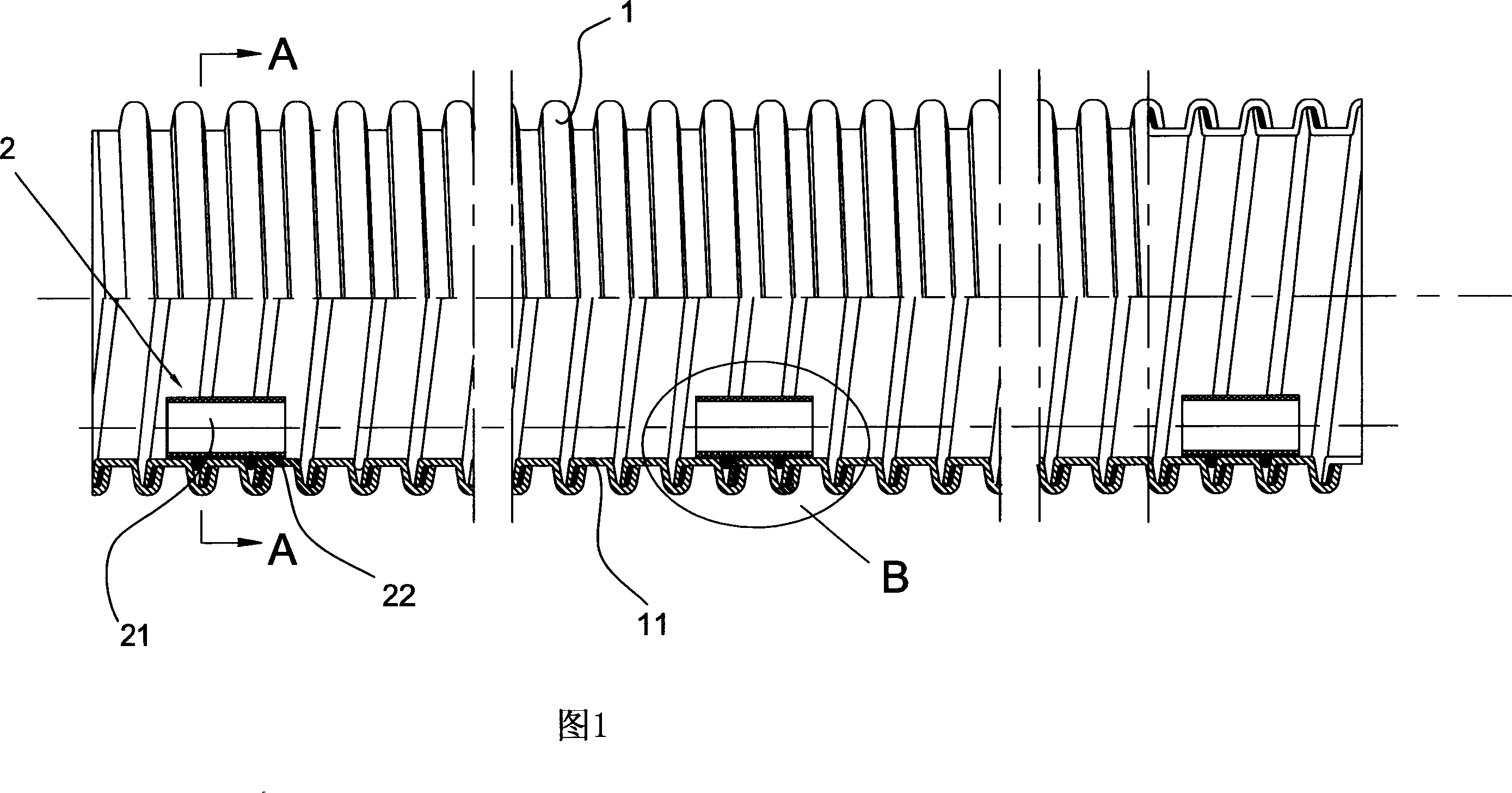

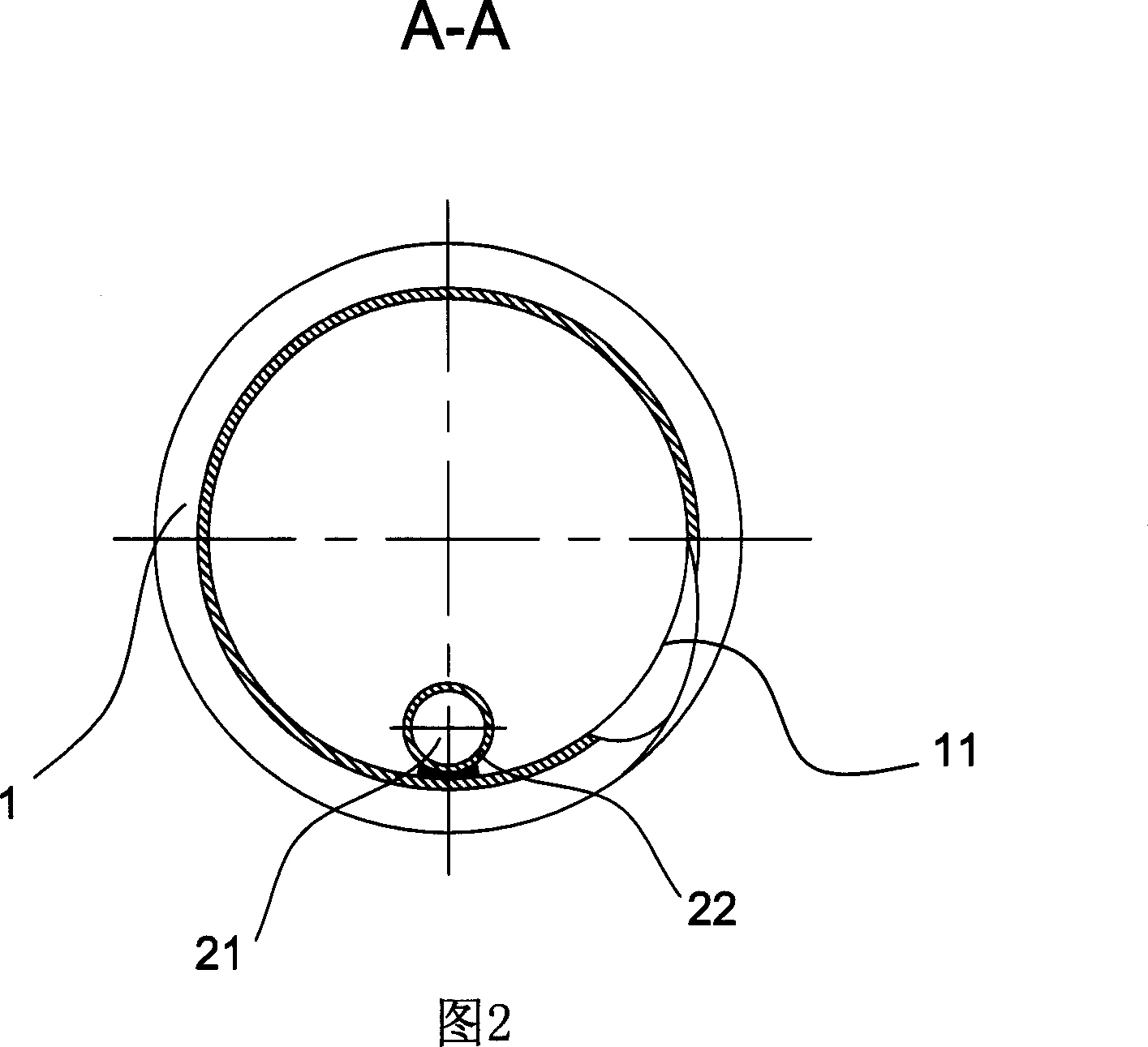

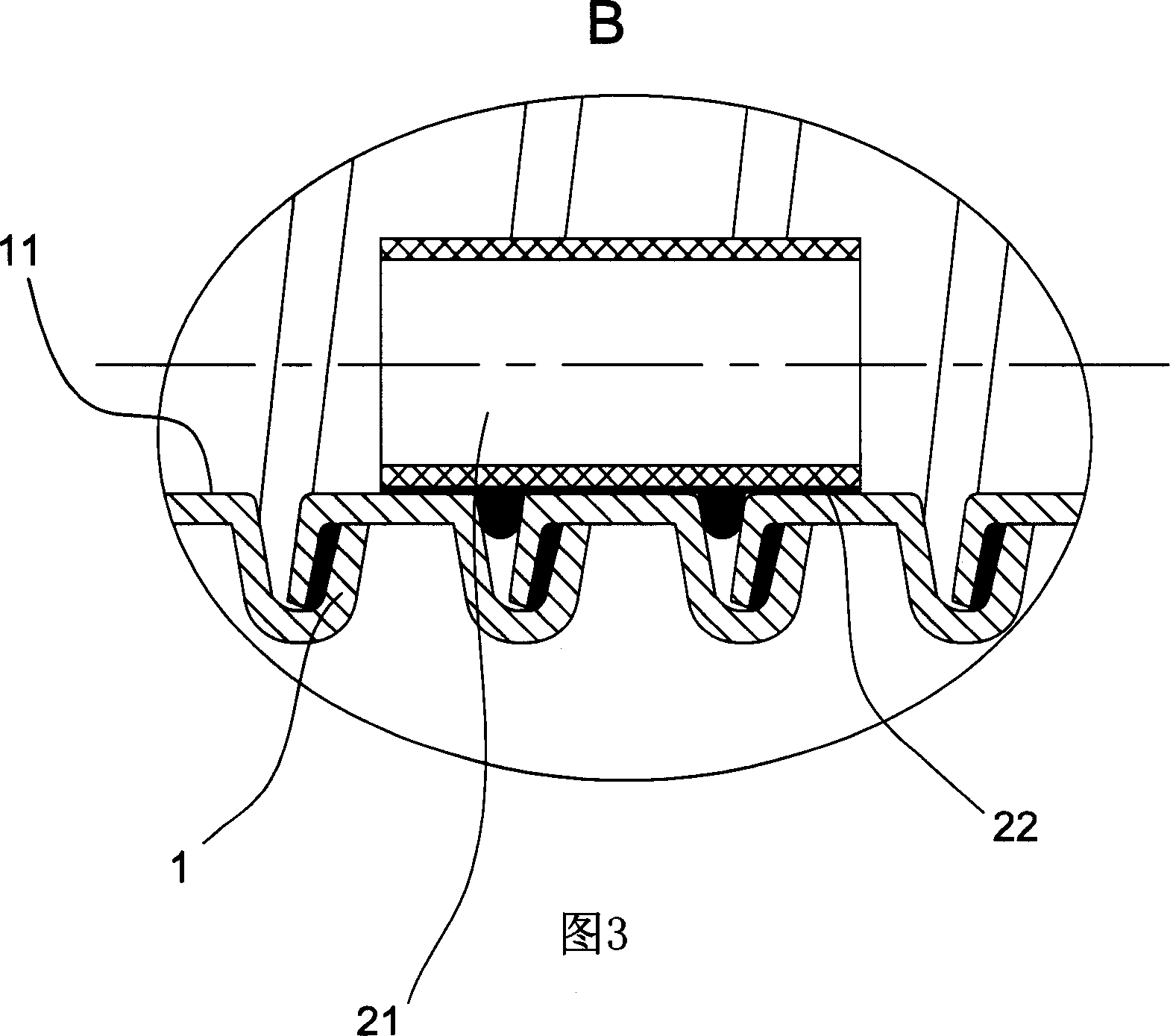

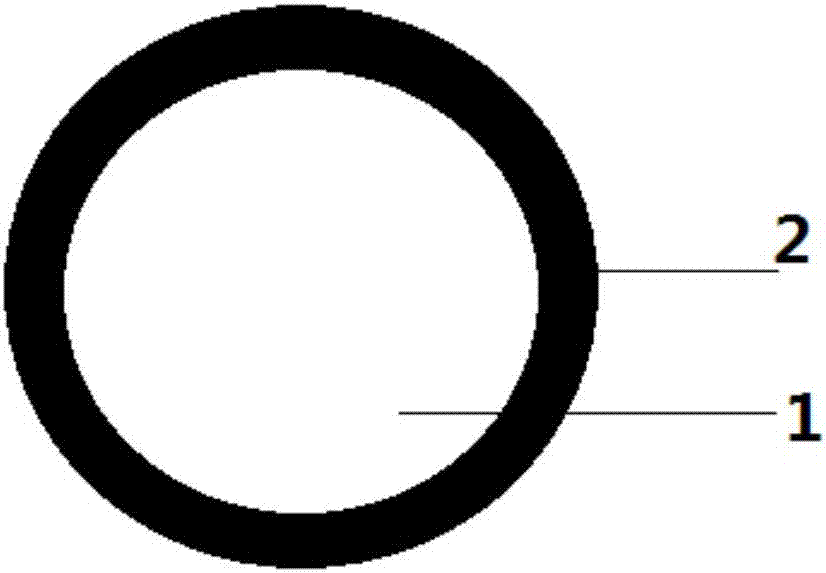

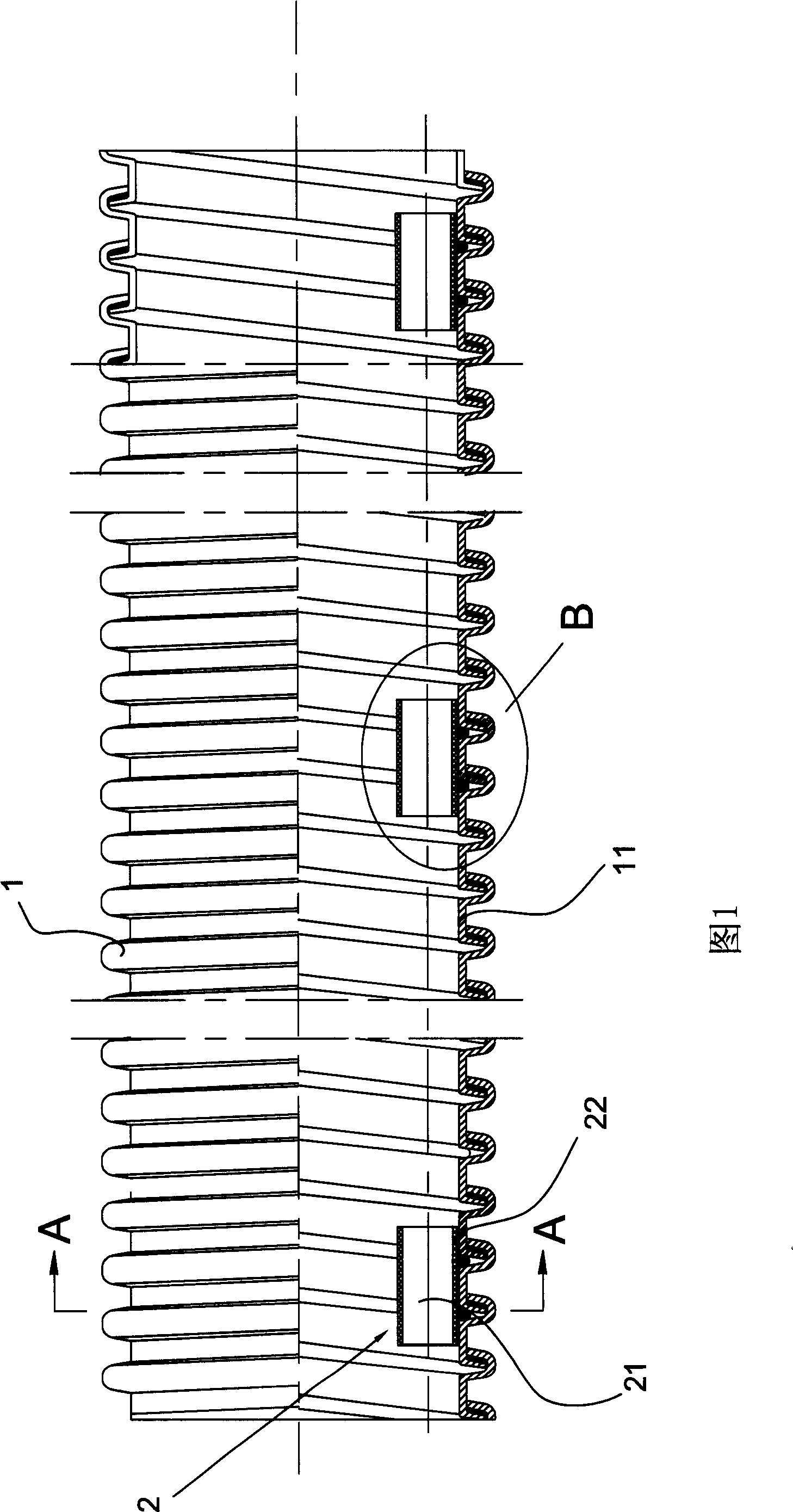

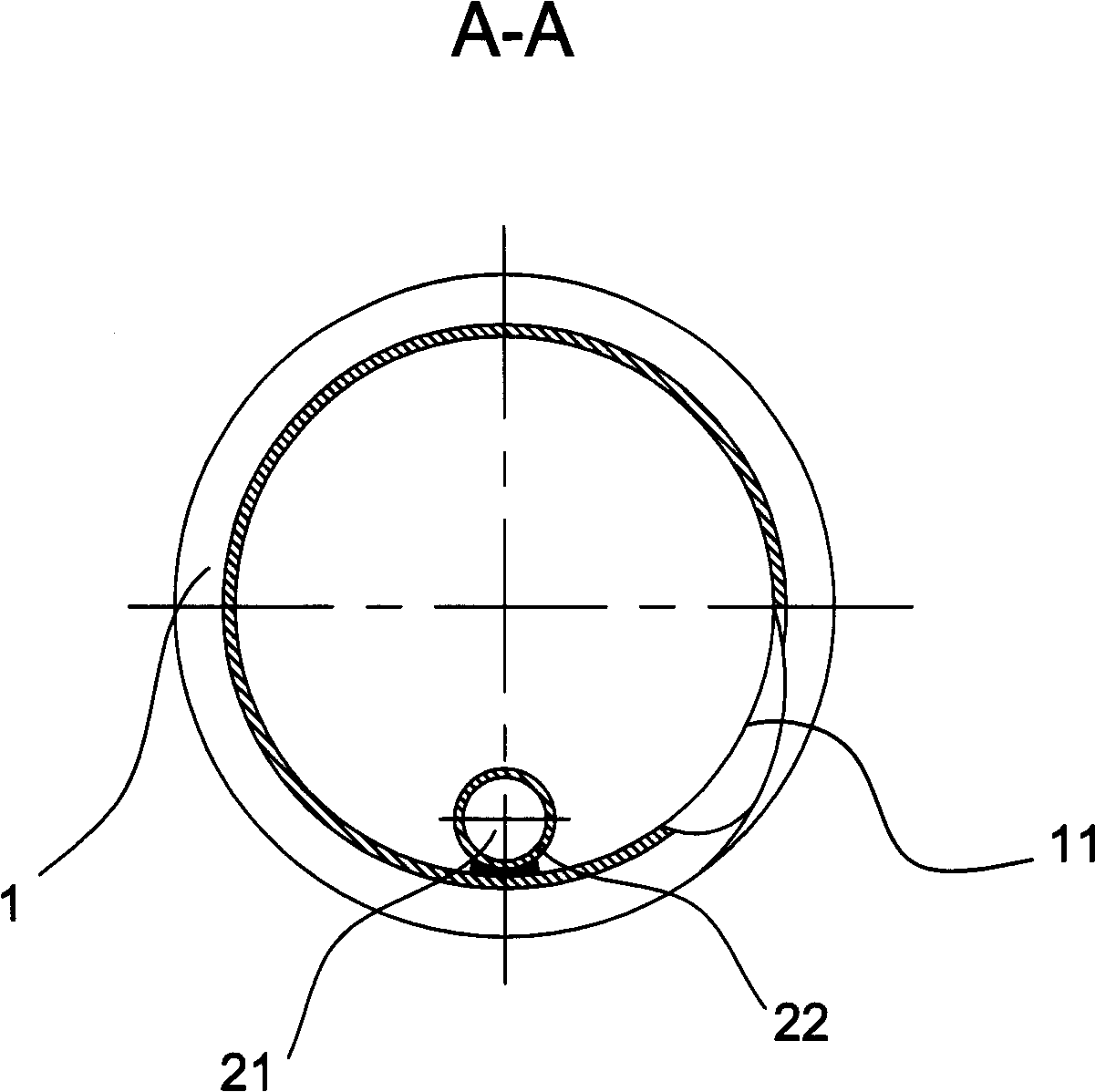

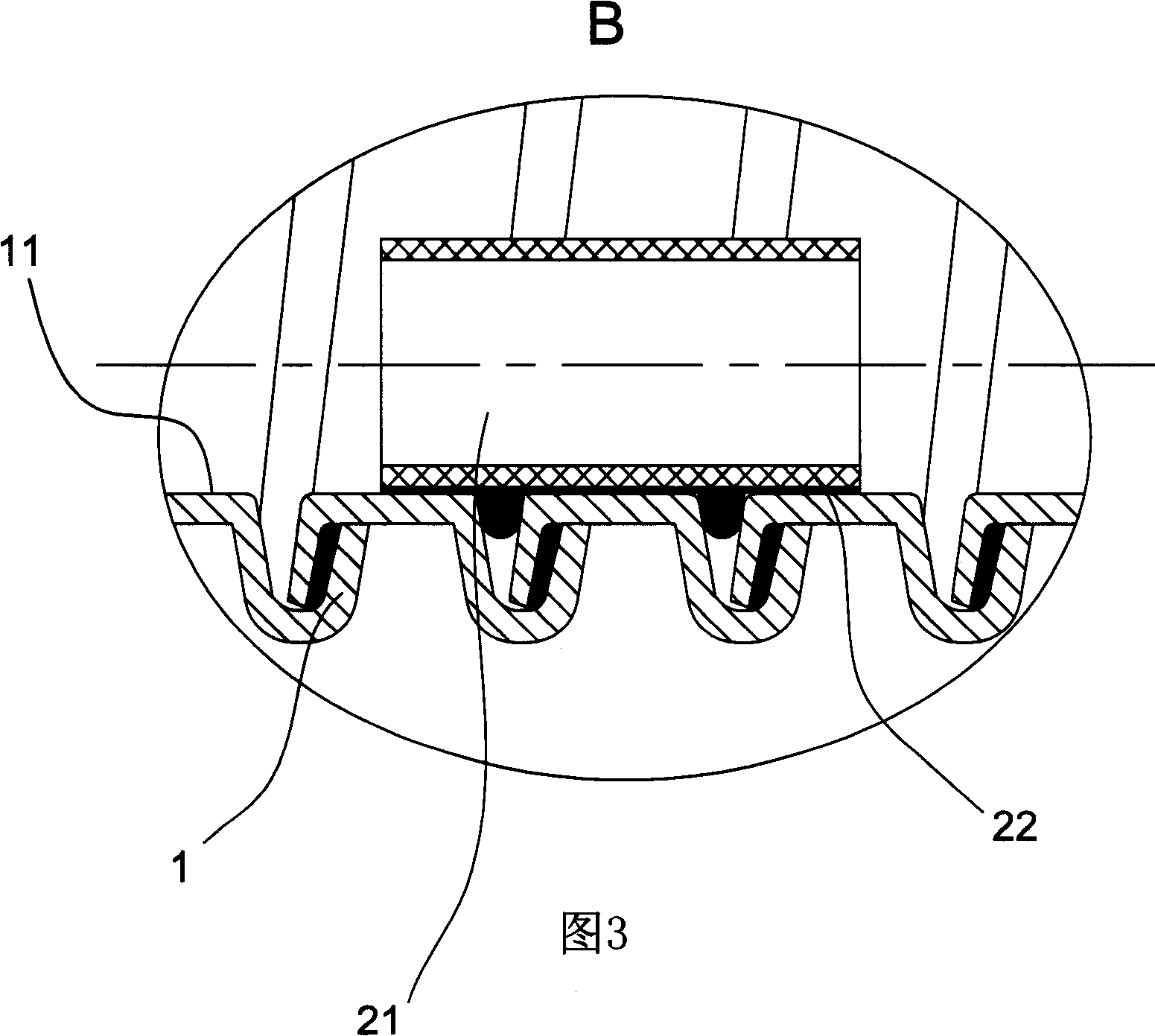

Multipurpose soft tube

ActiveCN101050832AWon't softenWill not deformSuction hosesFlexible pipesElectrical and Electronics engineering

Owner:JINHUA CHUNGUANG TECHNOLOGY CO LTD

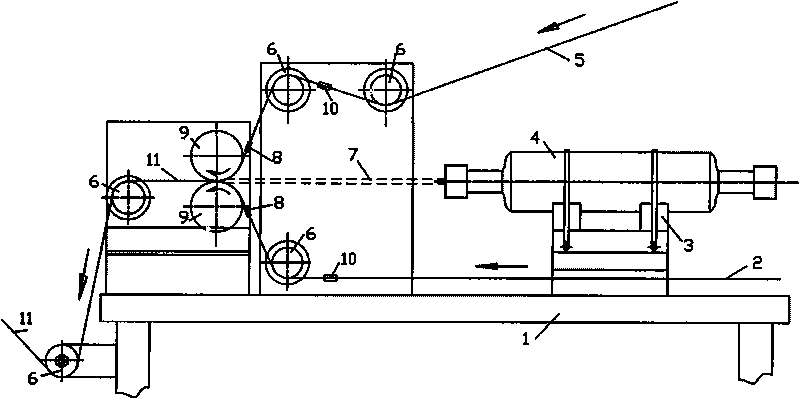

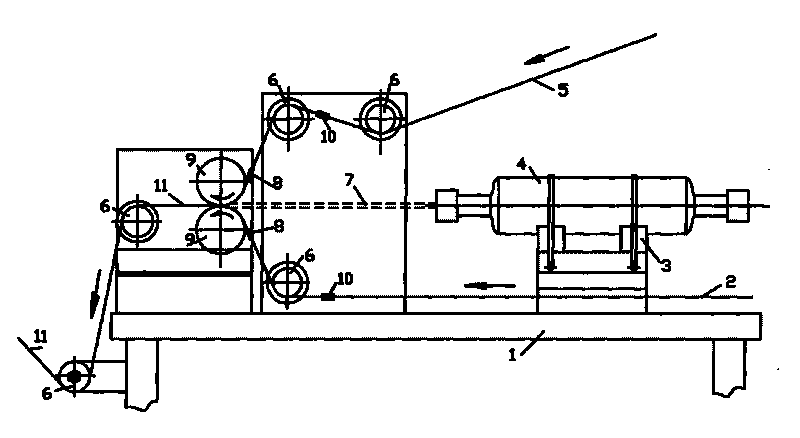

Sprinkler tube plate laser bonder

The invention discloses a sprinkler tube plate laser bonder. A laser gun is fixed on a support which is connected with a worktable as a whole. The laser gun is adjustable in the positions of front and back, and high and low. Two tube plates penetrate through along a laser tube and are jointed at a compression roller after passing through a guide wheel and a guide slot. The laser gun shoots continuous beams to form a circular spot at the joint position of the tube plates in order to melt the inner surfaces of the two tube plates in an extremely short time, and then the tube plates are compressed and bonded firmly by the compression roller and are finally wound up by a wind-up roller. The sprinkler tube has firm bonding and smooth and attractive surface.

Owner:BEIJING UNIV OF TECH

Bonding agent and membrane electrode group thereof

ActiveCN101752566AHigh tensile strengthExcellent water fixation coefficientCell electrodesBiochemical fuel cellsPolymer substratePolymer chemistry

The present invention provides a bonding agent used by a membrane electrode group. The bonding agent comprises a solvent system, a hyperbranched polymer and an organic polymer capable of conducting ions, wherein the branching degree of the hyperbranched polymer is bigger than 0.5, and the hyperbranched polymer and the organic polymer capable of conducting ions are dispersed in the solvent system.

Owner:IND TECH RES INST

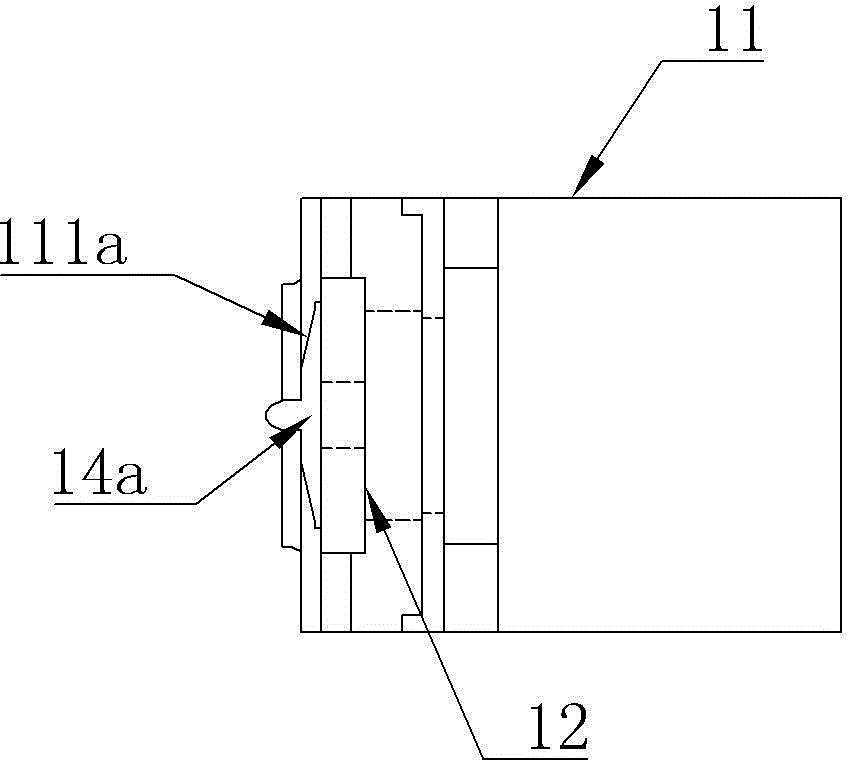

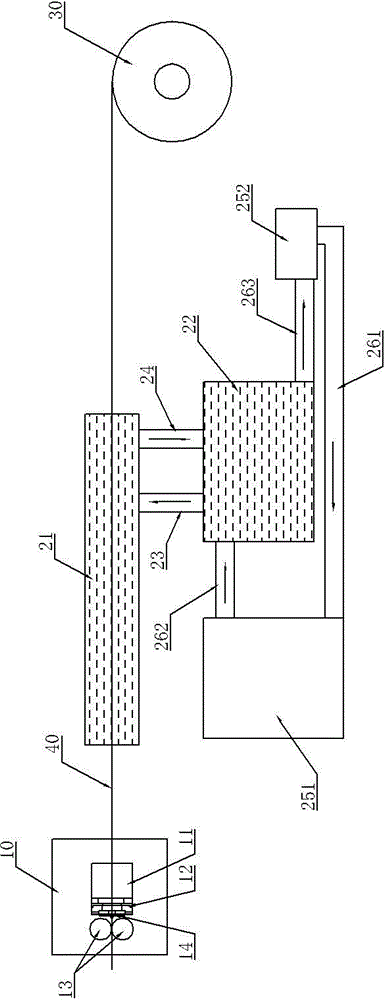

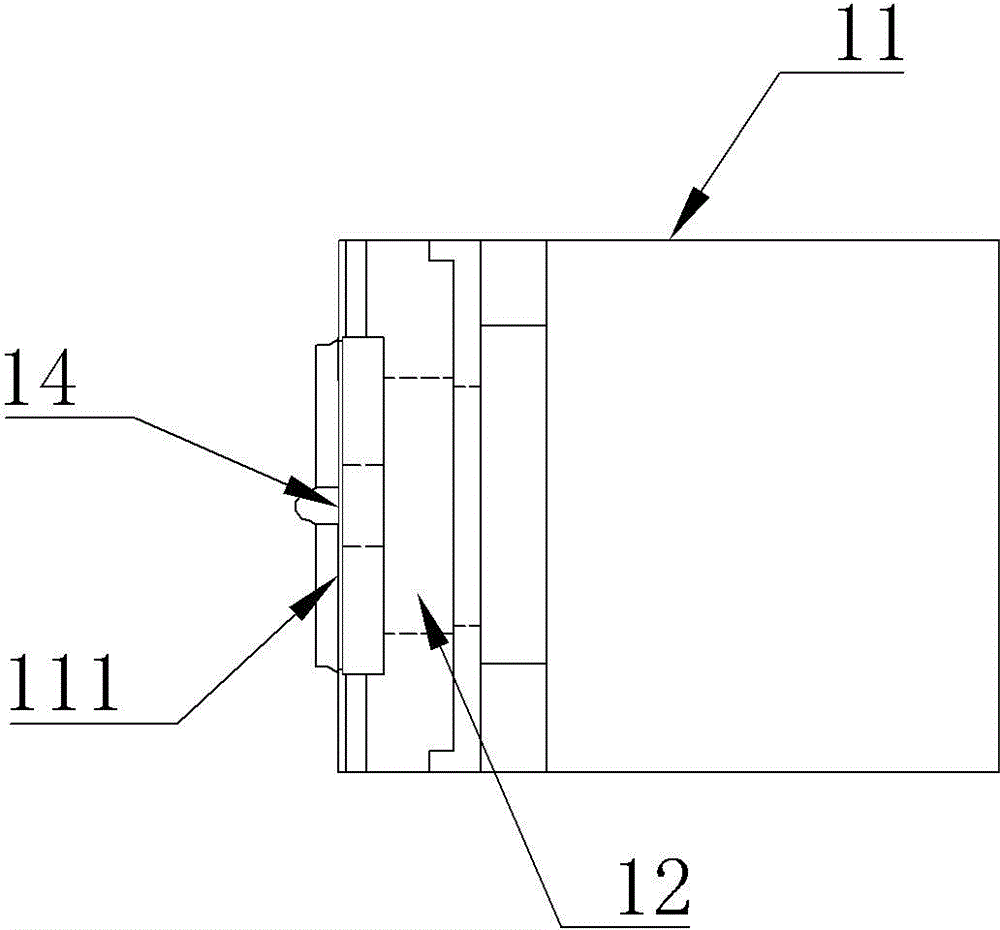

Extrusion processing system for hard flat aluminum wire

ActiveCN104942037AGuaranteed tensile strengthRapid coolingExtrusion diesRefrigeration compressorWater channel

The invention provides an extrusion processing system for a hard flat aluminum wire. The extrusion processing system can solve problems that flat aluminum wires which are processed by using an existing technology are low in tensile strength and cannot meet use requirements. The extrusion processing system comprises a main extrusion machine, a cooling device and a wire-rewinding machine, wherein an extrusion mold sleeve and extrusion wheels are installed in the main extrusion machine; a mold core is installed in the extrusion mold sleeve; the extrusion wheels are arranged on the outer side of an entry end of an aluminum rod of the extrusion mold sleeve; the cooling device comprises a cooling water channel and a water tank; and the cooling water and the water tank are connected through a water inlet pipe and a water outlet pipe, so that a loop-locked cooling water loop is formed. The extrusion processing system for the hard flat aluminum wire is characterized in that the cooling system also comprises an outer circulation cooling mechanism; the outer circulation cooling mechanism comprises a refrigeration compressor and a water pump; and the water tank, the water pump and the refrigeration compressor are sequentially connected through pipelines, so that the loop-locked cooling water loop is formed.

Owner:WUXI XIZHOU MAGNET WIRES

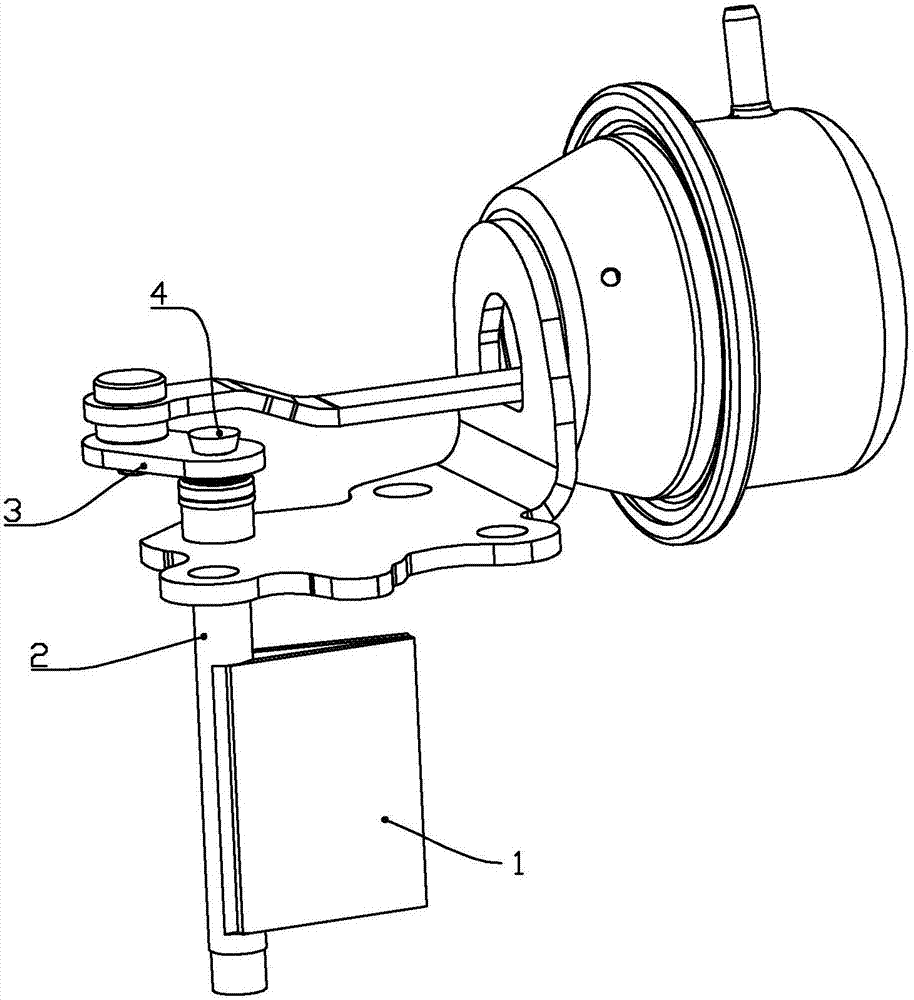

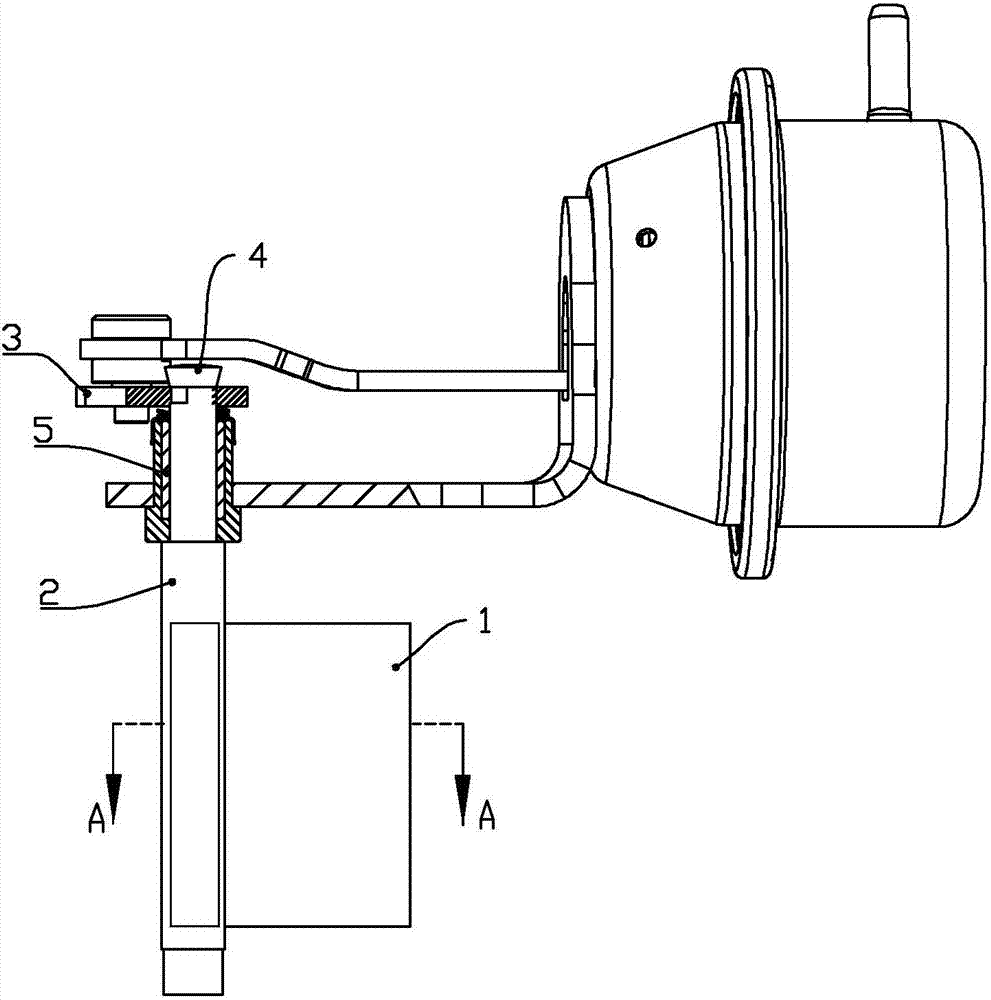

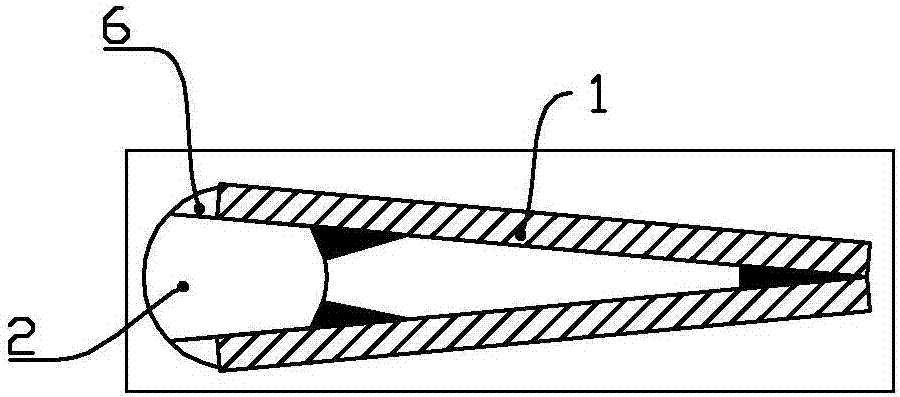

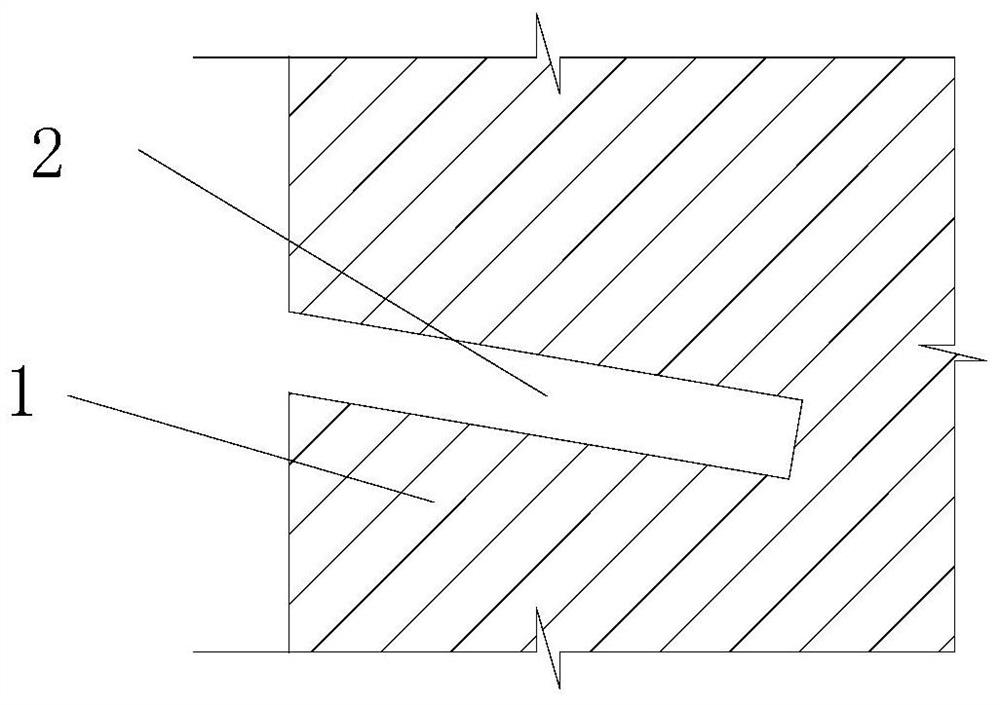

Laser welding technology of bypass valve rod and valve sheet

InactiveCN107035573AOutstanding and Beneficial Technical EffectsRigid enoughExhaust gas recirculationMachines/enginesManufacturing technologySoldering

A manufacturing technology of a bypass valve in engine exhaust gas exhausting and recycling involves a valve rod and a valve sheet which are assembled and then are connected through a laser welding technological mode. With the adoption of the manufacturing technology of the bypass valve in engine exhaust gas exhausting and recycling, the problem of softening and deforming of the valve rod and the valve sheet in a traditional soldering connecting technology of the bypass valve rod and the valve sheet can be solved; the valve rod can be prevented from being bent while screwing and riveting an eccentric wheel and the valve rod in later period; the diameter of the valve rod at the part where the valve rod is in match with a sealing shaft sleeve is prevented from increasing; and the material cost of the bypass valve product can be effectively controlled.

Owner:ZHEJIANG YINLUN MACHINERY

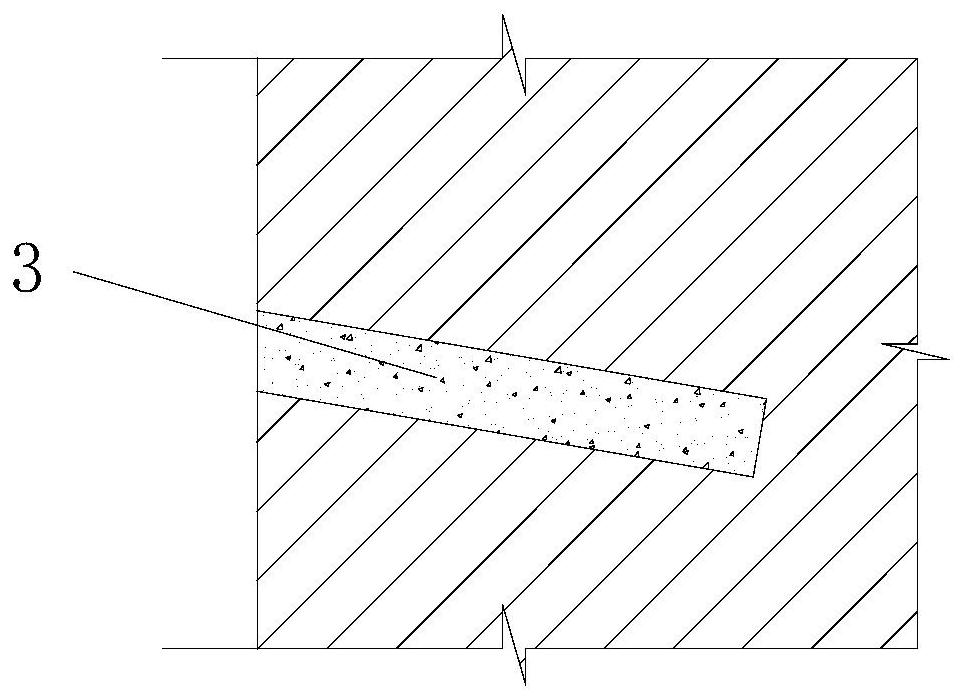

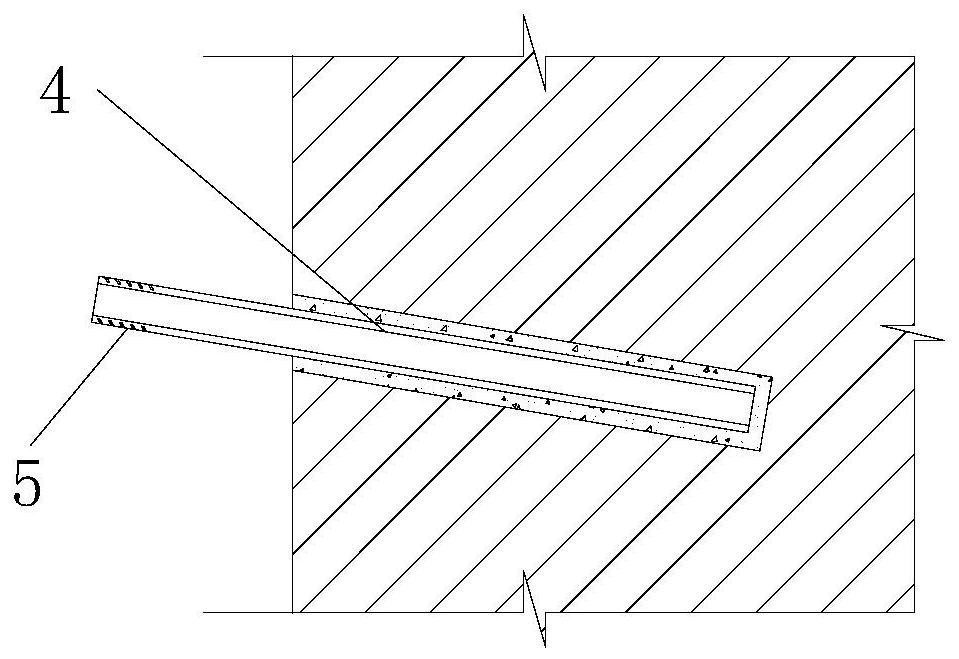

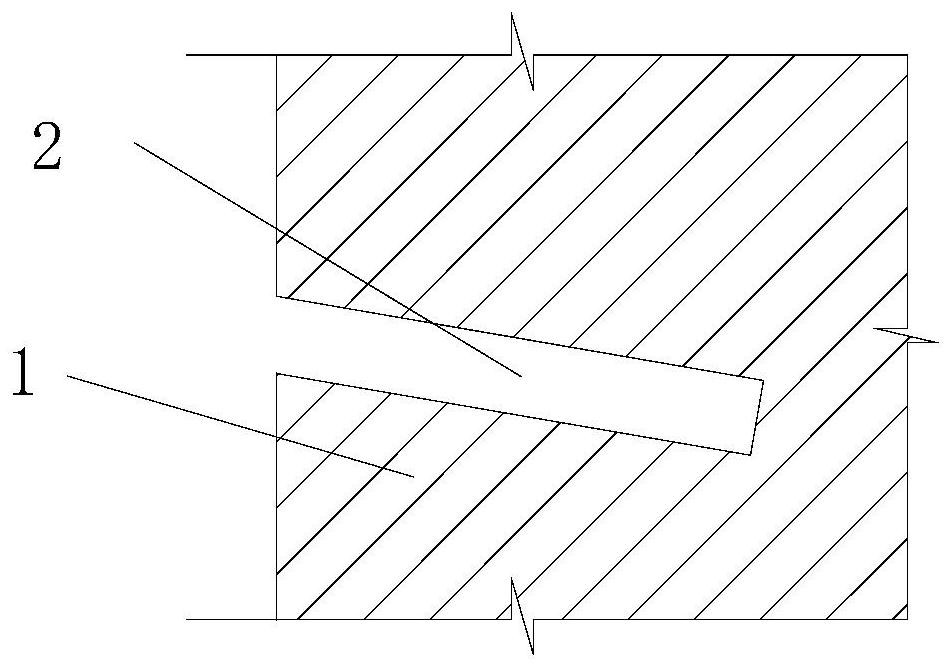

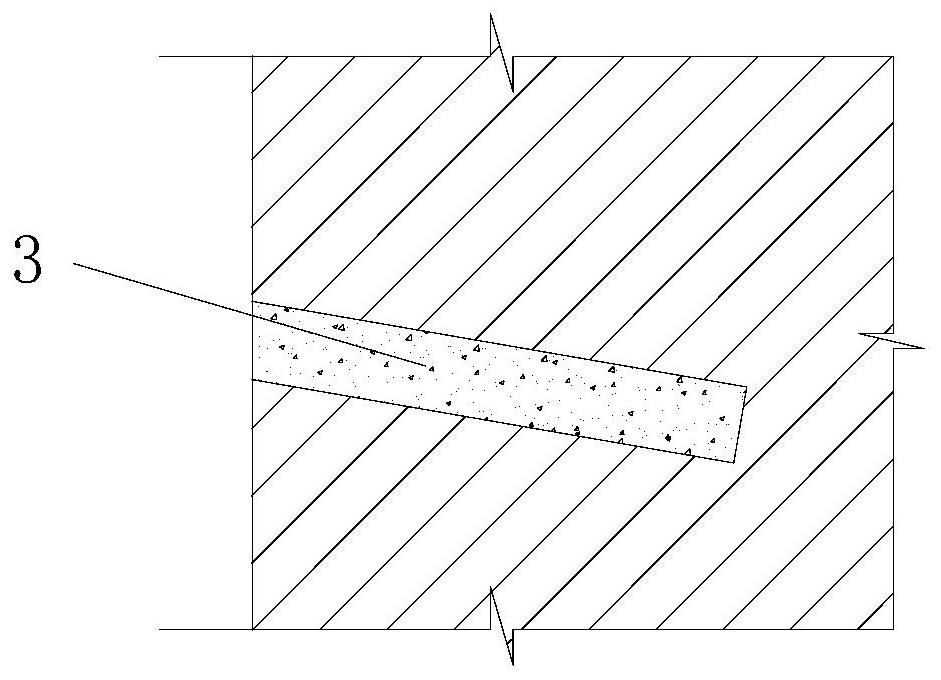

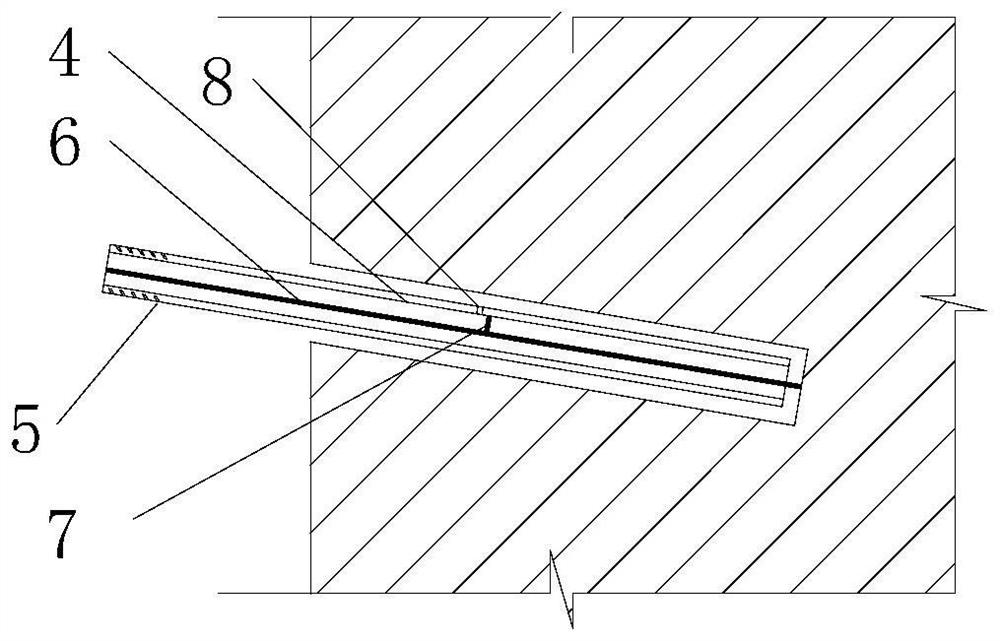

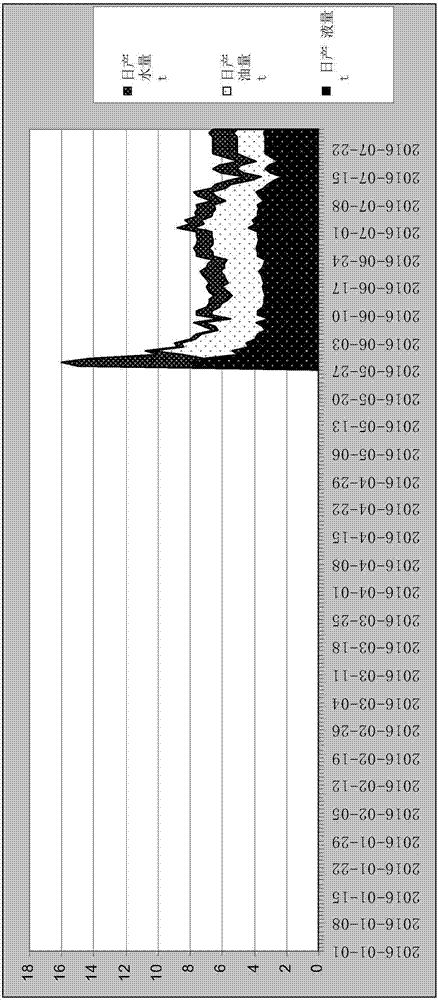

Microbial grouting anchoring method for grouting in cavity and microbial grouting anchoring structure

ActiveCN111877566AIncreased durabilityGuaranteed mechanical propertiesCovering/liningsHeat proofingMicroorganismEngineering

Owner:SHANDONG JIANZHU UNIV +2

Anti-wear and anti-corrosion concrete curb stone with glaze

The invention relates to the technical field of building materials, in particular to an anti-wear and anti-corrosion concrete curb stone with a glaze. The stone material of the curb stone is preparedfrom a concrete material, the anti-corrosion glaze is applied on the upper surface and the side face of the stone material from top to bottom, and the height of the glaze applied face of the side faceof the stone material accounts for two thirds of the whole height; the concrete is prepared from the raw materials of cement, quartz sand, yellow sand, basalt aggregate, mullite fiber, emery, water glass, a water reducing agent and water; the anti-corrosion glaze is prepared from the raw materials of nepheline, potassium feldspar, dolomite, corundum, quartz, grossularite, aluminum triphosphate, strontium carbonate, zinc oxide, zircon sand and a suspending agent. The stone material body of the curb stone is made of the concrete, the surface of the curb stone is coated with the anti-wear and anti-corrosion glaze material, the curb stone is beautiful, and excellent in wear and corrosion resistant performance, has a lower manufacturing cost and is green and environmentally friendly to the environment.

Owner:肥西县碧涛建材有限公司

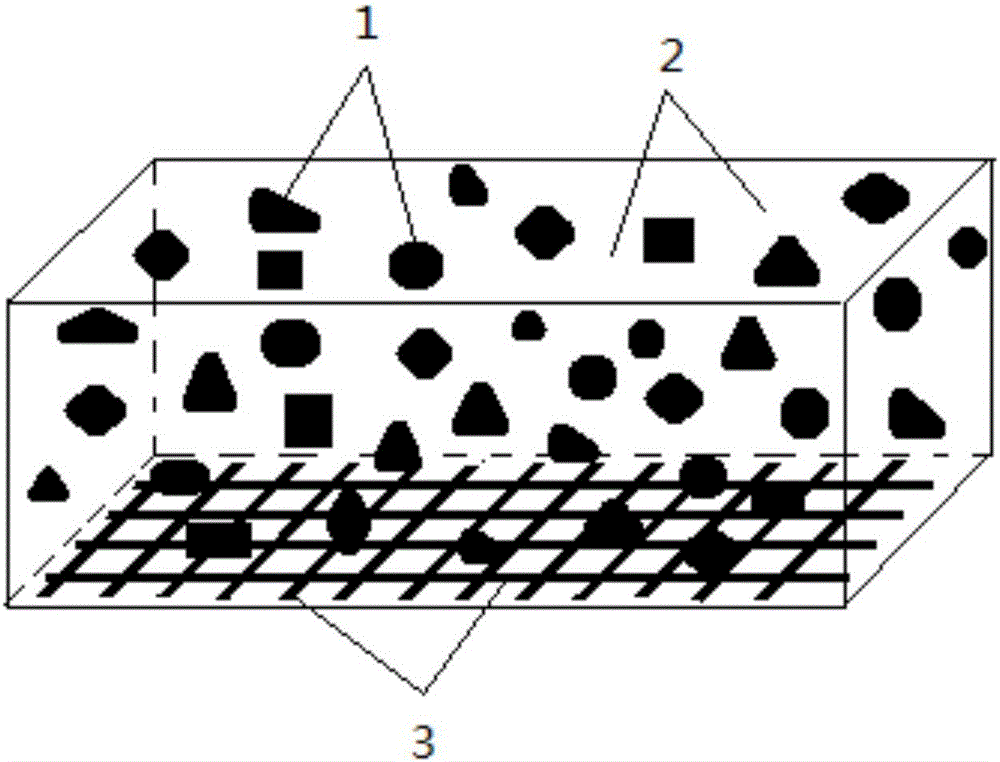

Flexible sound-insulation composite material and preparation method thereof

The invention provides a flexible sound-insulation composite material. The composite material is mainly composed of high-density particles, a viscoelastic thermoplastic material and a flexible framework which is easy to bent and can resist stretching and shearing damages. The composite material prepared by the invention has excellent properties of high strength, high density, fire resistance, no toxin and environment friendliness, corrosion resistance and good sound-insulation effect and can be widely applied to industries including highway traffic, urban rail transit, machinery equipment, house building, ships, home decoration, industrial product packaging and the like. Furthermore, the invention also provides a preparation method of the flexible sound-insulation composite material. A sheet material with low odor, low VOC (Volatile Organic Compound) content, low volatile matter content and good mechanical property indexes of the product is obtained through strictly controlling the extruding temperature and the post-period heating temperature to reduce decomposition and molecular migration of the material, and is an environment-friendly material.

Owner:秦耀东

Microbial grouting anchoring method for forming pipeline by arranging partition plates in cavity and microbial grouting anchoring structure

ActiveCN111877565AIncreased durabilityAvoid volumeCovering/liningsHeat proofingBiotechnologyMicroorganism

Owner:SHANDONG JIANZHU UNIV +2

Fruit shell high-temperature-resistant resin coated sand and preparation method thereof

The invention relates to fruit shell high-temperature-resistant resin coated sand and a preparation method thereof. The coated sand is prepared from fruit shell particles serving as a kernel propping agent and a resin coating with which the surfaces of the fruit shell particles are coated, wherein fruit shell comprises one or more of walnut shell, apricot pit and peach pit; the resin comprises one or two of a thermosetting phenolic resin and a furan resin. The coated sand is characterized in that the fruit shell (such as the walnut shell, the apricot pit and the peach pit) particles are taken as the kernel propping agent, and the resin coating is taken as a coating layer, so that the coated sand can act effectively at the temperature of 350 DEG C, is low in density, and is easy to prepare; the preparation cost of sand-carrying fluid can be lowered effectively, and the construction success rate is increased effectively.

Owner:PETROCHINA CO LTD

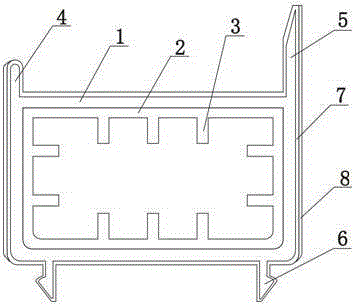

High-strength plastics-steel door and window profile

InactiveCN106555536AHigh strengthImprove the decorative effectWindow/door framesWing framesHeat resistanceEngineering

The invention discloses a high-strength plastics-steel door and window profile which comprises a rectangular hollow profile body, a reinforcing frame, metal nickel layers and decorative layers. The profile body sleeves the reinforcing frame. Reinforcing ribs are arranged on the inner wall of the reinforcing frame. The reinforcing ribs are vertical to the reinforcing frame. A short plate and a long plate are arranged on both end parts of the top of the profile body respectively, wherein the short plate and the long plate are vertical to the profile body. The bottom of the profile body is provided with a buckle rib with a hook. The metal nickel layers are coated on the outer surfaces of the profile body, the short plate, the long plate and the buckle rib. The decorative layers are arranged on both sides of each metal nickel layer. The high-strength plastics-steel door and window profile provided by the invention has the advantages of simple structure, low processing cost, high production efficiency, heat resistance, abrasion resistance, corrosion resistance, long service life and high strength.

Owner:CHONGQING YUANHUA DOORS & WINDOWS

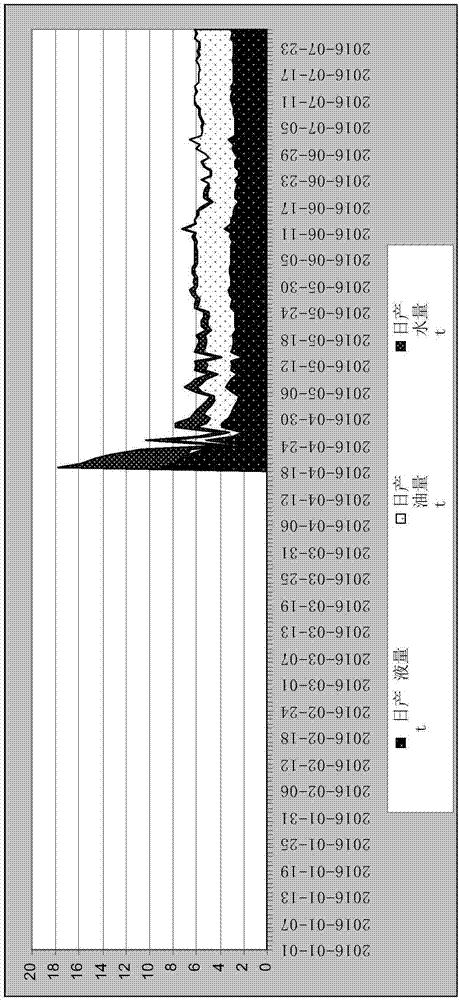

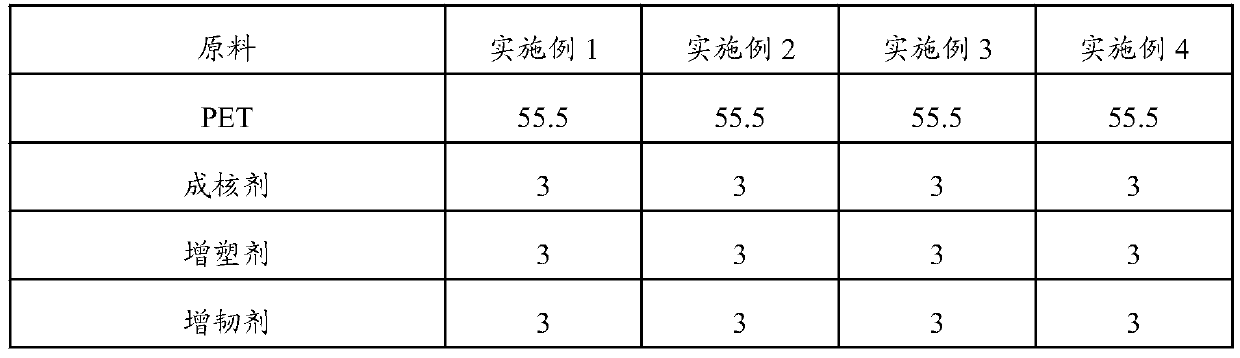

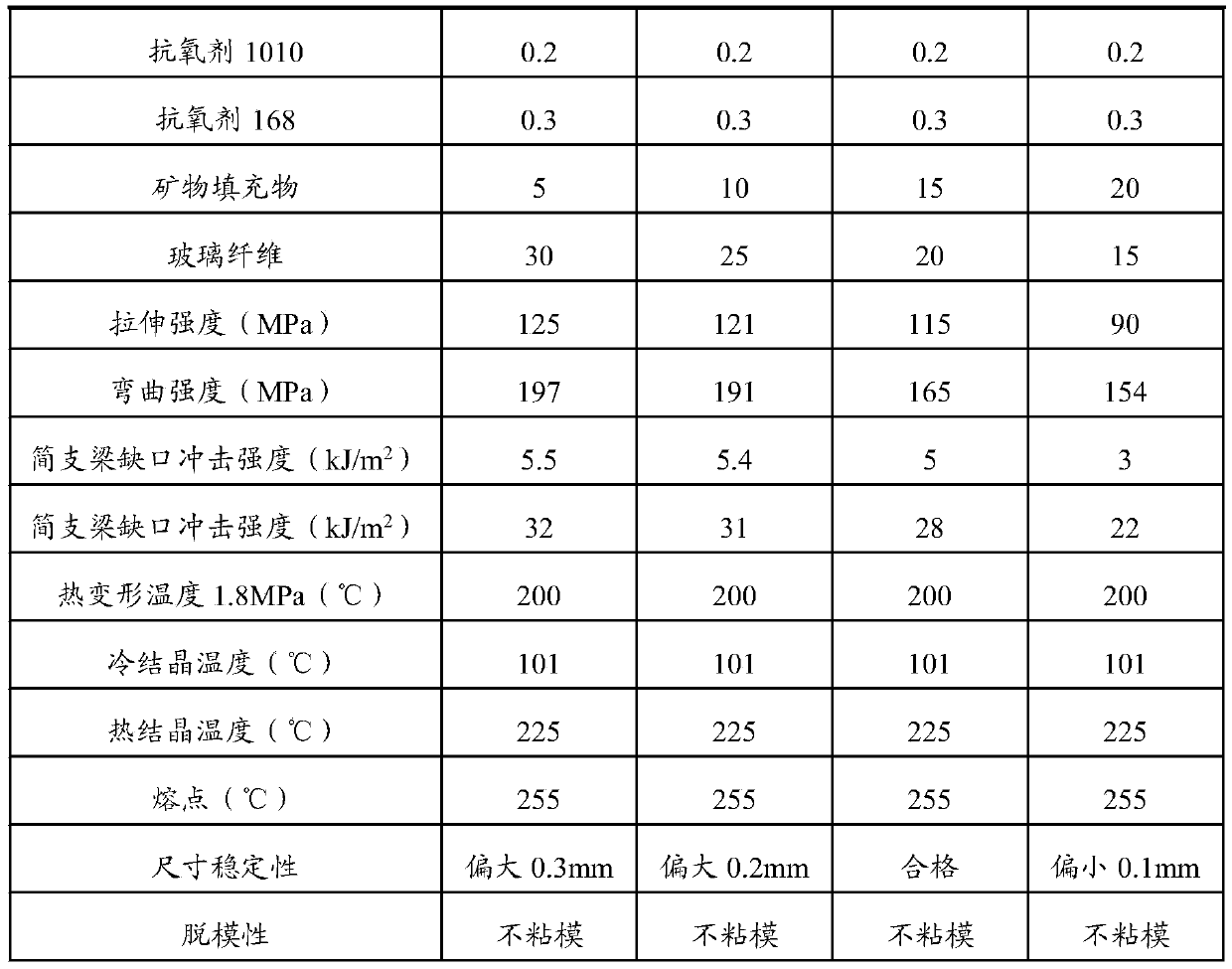

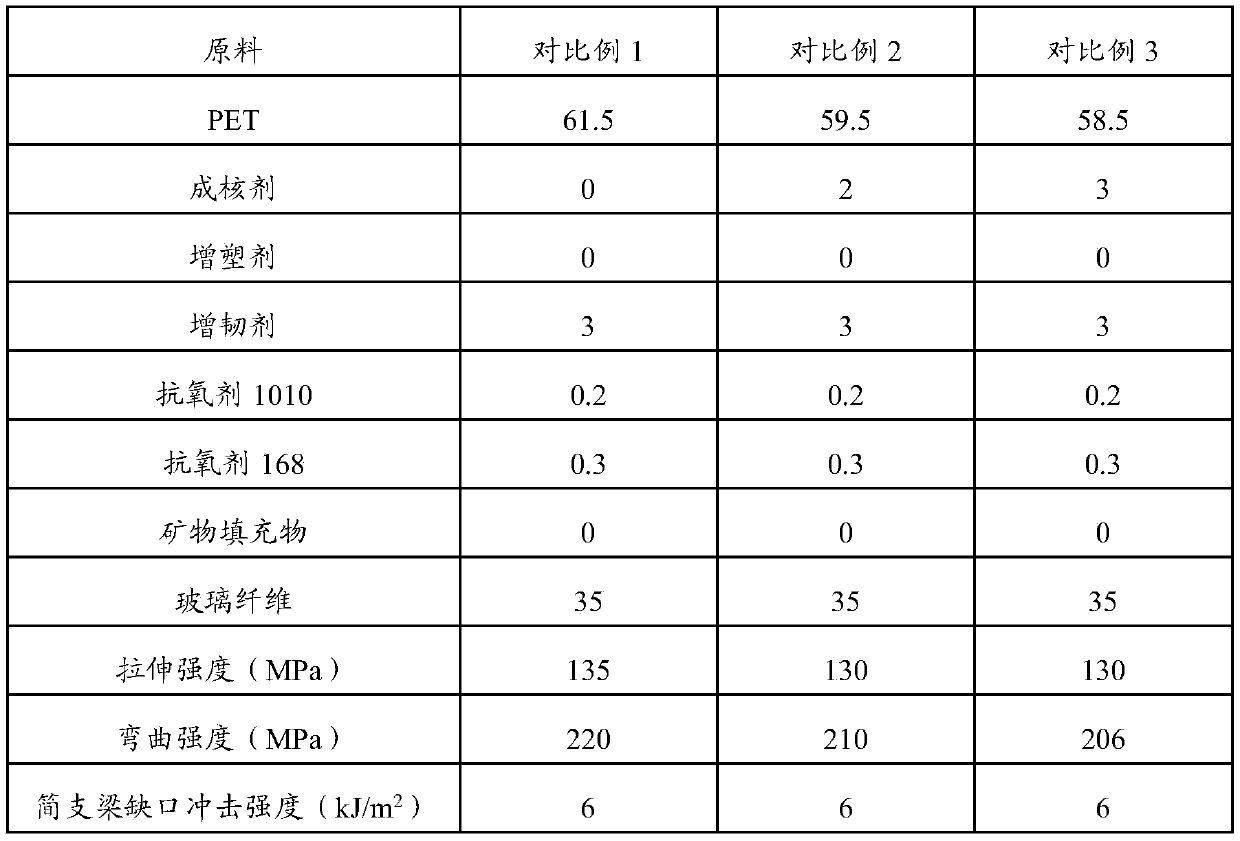

PET composite material and preparation method thereof, and application of PET composite material

The invention provides a PET composite material and a preparation method thereof, and application of a PET composite material, and belongs to the technical field of composite materials. The PET composite material provided by the invention comprises the following preparation raw materials in percentage by mass: 40-60% of PET, 1-3% of an ethylene-(meth)acrylate nucleating agent, 1-3% of a small molecule ester plasticizer, 3-5% of a flexibilizer, 0.5-2% of an antioxidant, 10-30% of a glass fiber and 5-20% of a mineral filler. According to the invention, the PET is used as a base material, the plasticizer is added on the basis of adding the nucleating agent, so that the cold crystallization temperature of PET can obviously move to a low-temperature area, the hot crystallization temperature andthe melting point of PET can obviously move to a high-temperature area, the crystallization speed of PET is increased, molecular chain arrangement is more regular, formed crystals are more perfect, the demolding effect is obviously improved, the formed crystals cannot be rearranged, and the size of a workpiece can be more stable.

Owner:宁波华腾首研新材料有限公司

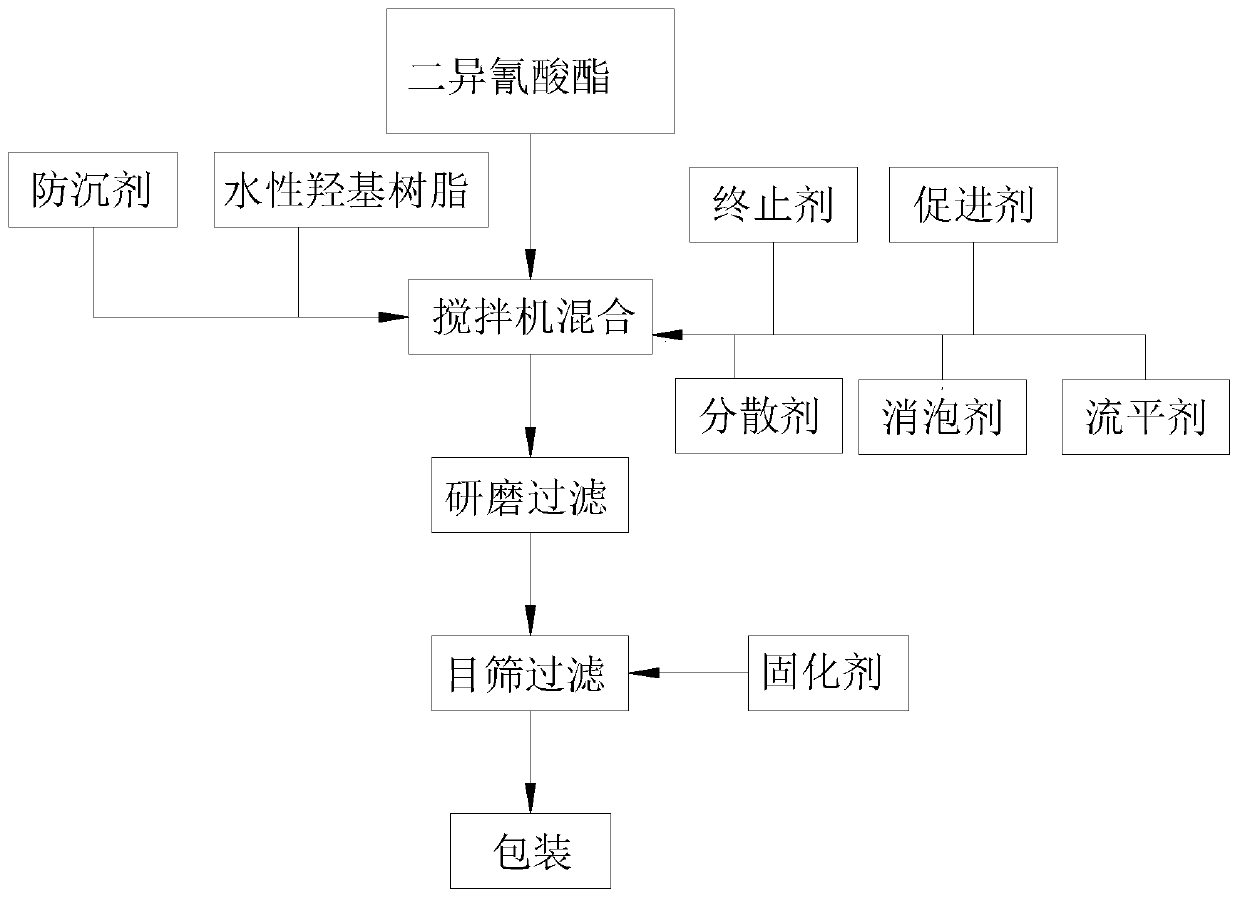

Easily-to-cure waterproof polyurethane wood lacquer and preparation method thereof

The invention discloses an easy-to-cure waterproof polyurethane wood lacquer and a preparation method thereof, and belongs to the technical field of wood lacquer; the easy-to-cure waterproof polyurethane wood lacquer comprises a main lacquer and a curing agent, and the weight ratio of the main lacquer to the curing agent is 100: 7, wherein the main lacquer is prepared from the following componentsin percentage by mass: diisocyanate, water-based hydroxyl resin, an accelerant, a terminating agent, an anti-settling agent, a dispersing agent, an antifoaming agent and a leveling agent; said components are proportioned according to the following mass ratio; the water-based epoxy takes water as a solvent and a diluent; the effect is that the water-based hydroxyl resin achieves the effects of improving the compactness and preventing water; besides, the gel waterproof layer formed by the curing agent improves the mixed waterproof function, and after the diisocyanate forms a film and the effective components act, the cured complex forms a waterproof crystal, so that the waterproof effect is achieved, high wear resistance and impact resistance are achieved, a coating film cannot be softenedafter being heated, the hot spot resistance is extremely high, and the freshness is continuously excellent.

Owner:安徽名士达新材料有限公司

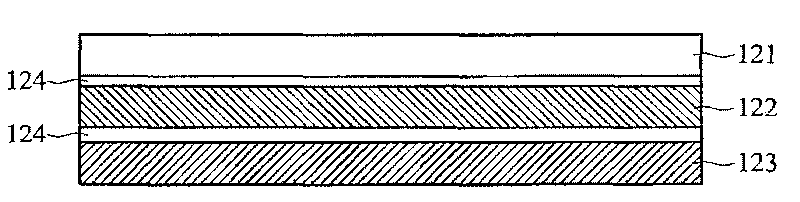

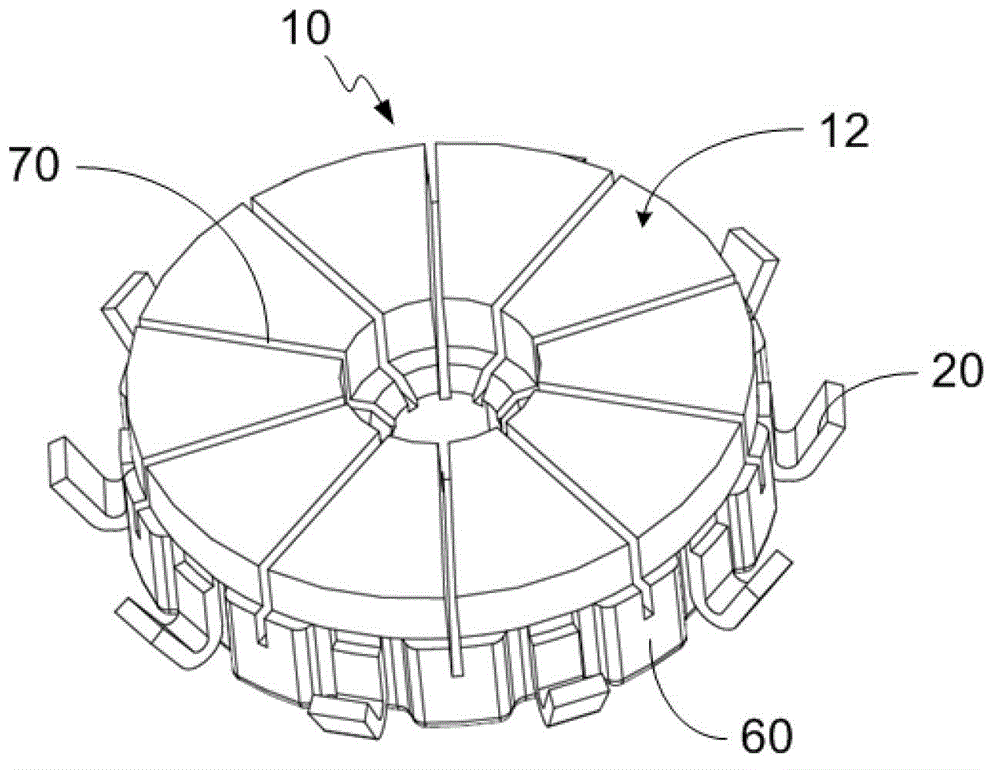

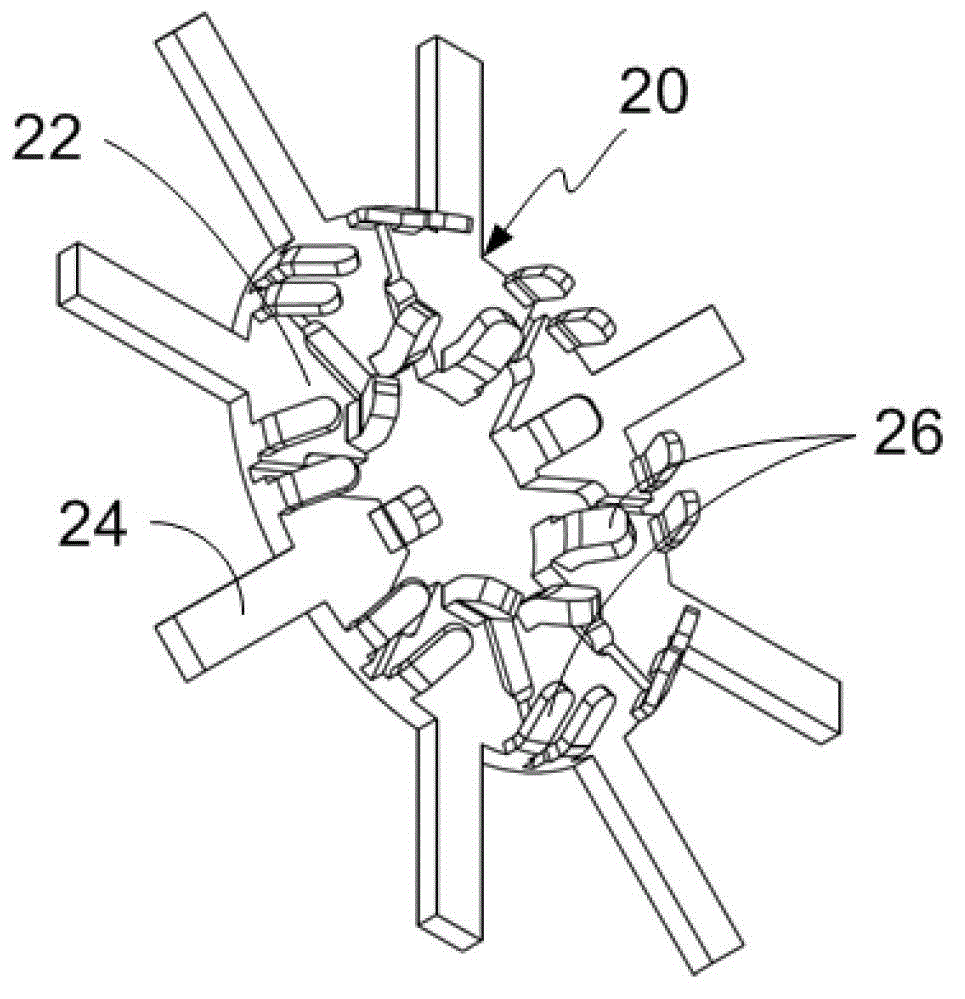

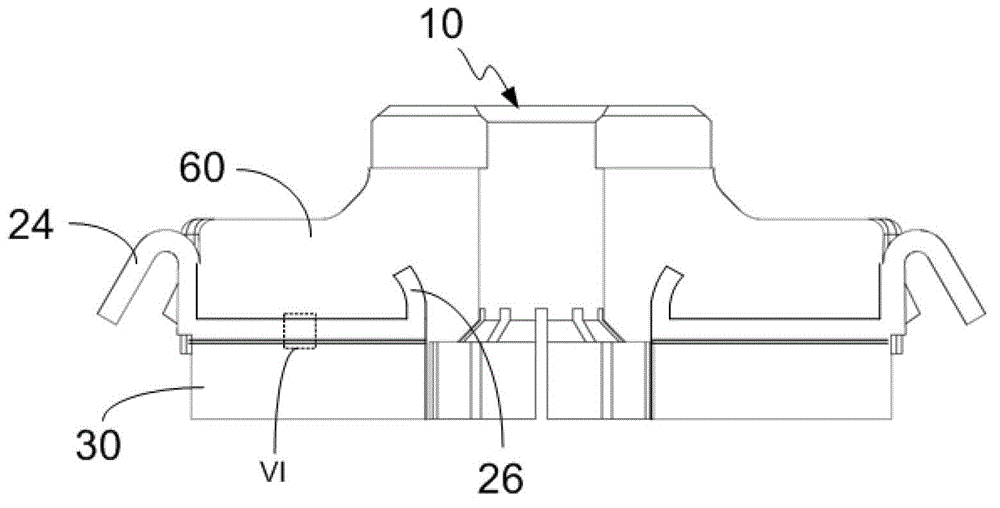

Commutator and manufacture method thereof

InactiveCN104064936AHigh bonding strengthWon't softenRotary current collectorDynamo-electric machinesMetal sheetGraphite

A commutator (10) comprising a plurality of commutator bars (12) formed from a graphite structure (30) and a metal sheet (20) having soldered to the graphite structure (30) includes a brazing process followed by a soldering process. The brazing process includes applying a brazing material the graphite structure (30) and brazing at an elevated temperature to form a brazing layer (40). The soldering process includes applying a solder material to the brazing layer (40), placing the metal sheet (20) on the solder material, and soldering to form a solder layer (50) affixing the metal sheet (20) to the graphite structure (30). A plurality of grooves (70) are cut in the graphite structure (30) and the metal sheet (20) to form the commutator bars (12) arranged in an intermittent ring or circle.

Owner:JOHNSON ELECTRIC SHENZHEN +1

MMA bicomponent protruding road coating and preparation method and application thereof

InactiveCN109517471AMeet the requirements of green environmental protectionWear-resistantCoatingsWeather resistanceQuartz

The invention belongs to the technical field of road coatings, and in particular relates to an MMA bicomponent protruding road coating and a preparation method and an application thereof. The coatingis prepared from a component A, a component B and an initiator in a mass ratio of 50: 50: 2. The component A is prepared from the following raw materials in parts by weight: 20-30 parts of MMA resin 1#, 3-8 parts of a pigment, 20-40 parts of natural quartz sand, 20-40 parts of glass beads and 5-12 parts of an auxiliary agent. The component B is prepared from the following raw materials in parts byweight: 20-30 parts of MMA resin 2#, 3-8 parts of a pigment, 20-30 parts of natural quartz sand, 20-40 parts of glass beads and 5-12 parts of an auxiliary agent. When the road coating is used, the components A and B are uniformly stirred, separately, and the initiator is added into the component B in parts by weight. Then the mixture is mixed with the component A uniformly, the mixture is added into a hopper of a lineating machine, and the coating is protruded, formed and cured to obtain the road coating. The road coating is free of volatile solvent and green and environment-friendly. In thecuring process, heating is needed, so that the road coating is green and environment-friendly. The road coating has the advantages of being unlikely to crack, firm and good in impact resistance, pressure resistance and durability and weather resistance.

Owner:宁夏通特工贸有限公司

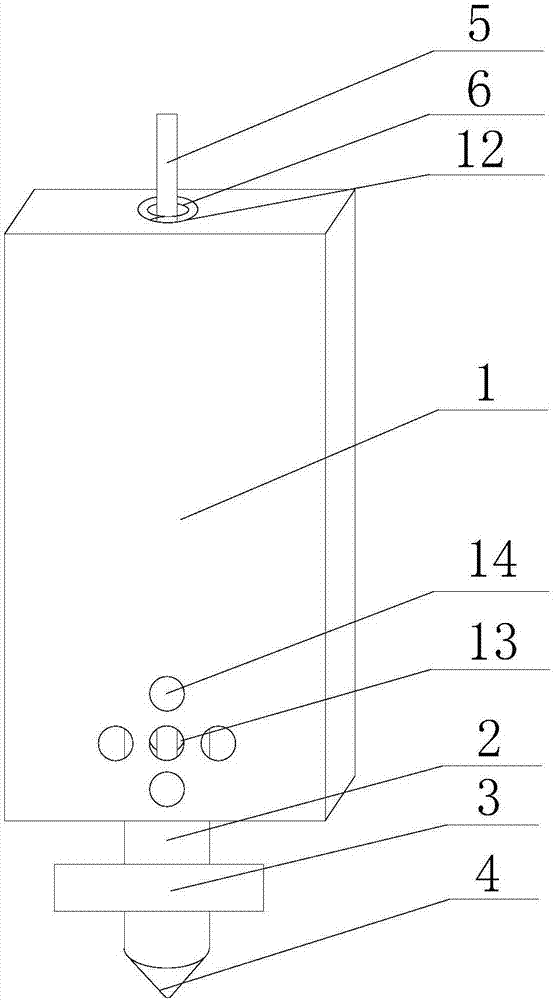

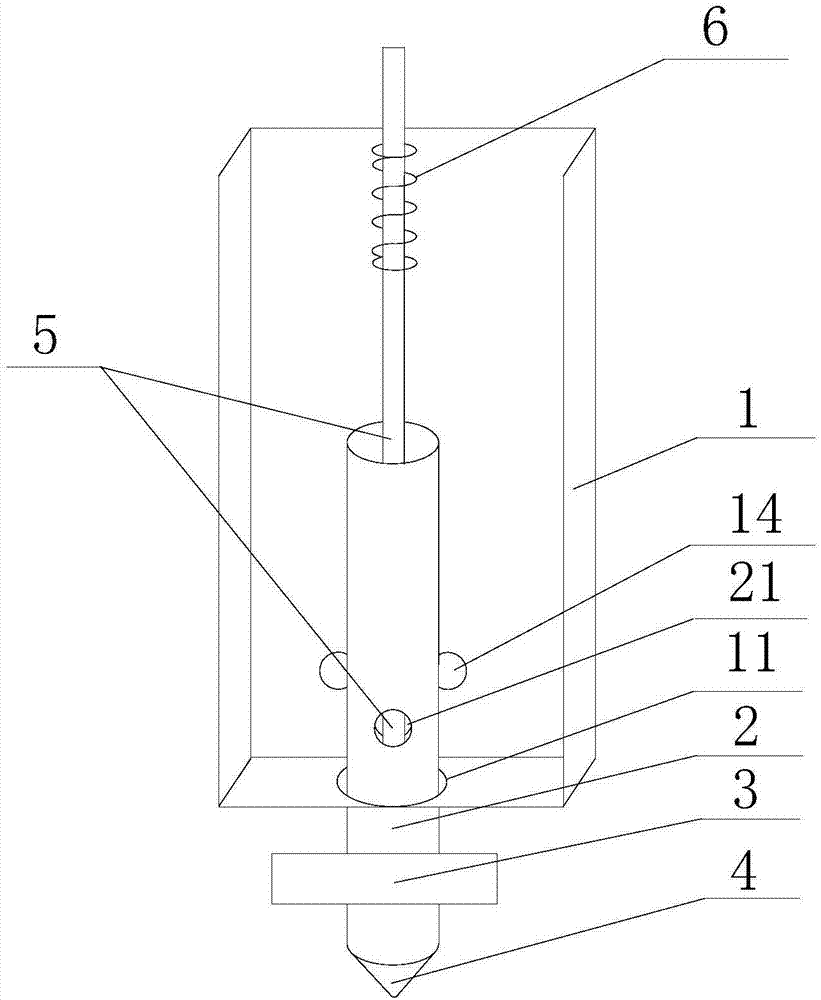

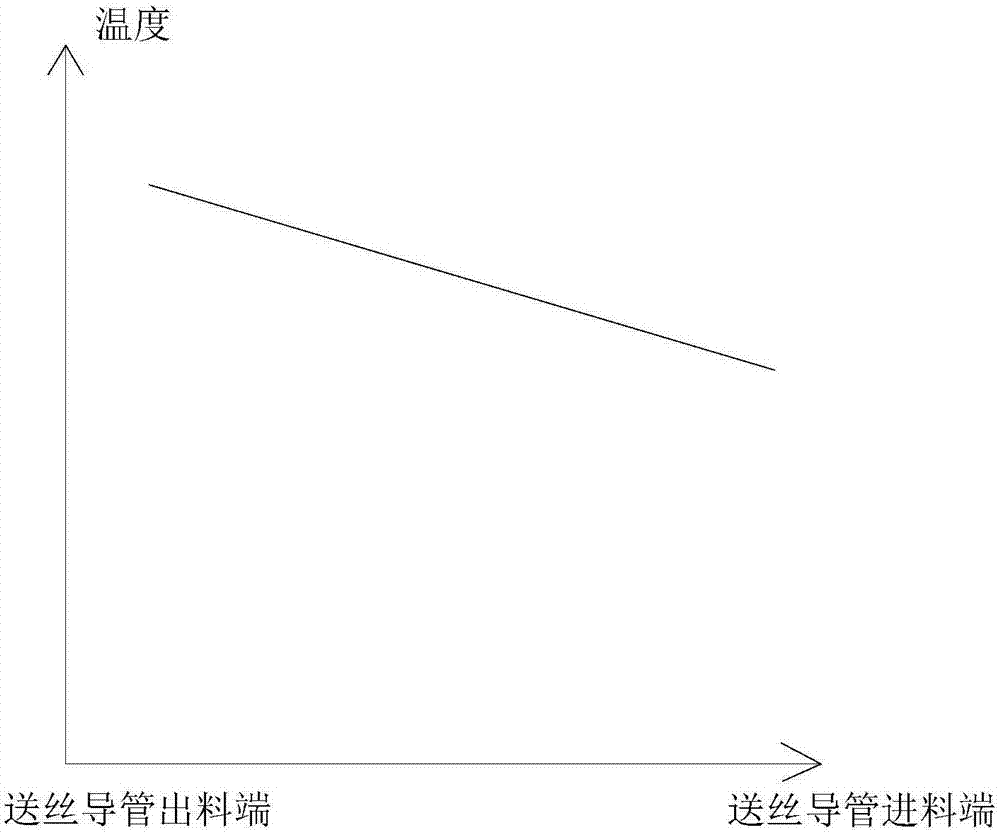

3D printer head with temperature truncation function

InactiveCN107187032AReduce transfer efficiencyReduce resistanceAdditive manufacturing apparatus3D object support structures3D printingNozzle

The invention discloses a 3D printer head with a temperature truncation function. A first hole is formed in a bottom face of a heat dissipation shell, and a second hole is formed in a top face of the heat dissipation shell. A wire feeding guide pipe is arranged in the first hole of the heat dissipation shell, and the two ends of the wire feeding guide pipe are a feeding end and a discharging end. The second hole of the heat dissipation shell communicates with the feeding end and the discharging end of the wire feeding guide pipe to form a wire feeding channel, the part, located outside the heat dissipation shell, of the wire feeding guide pipe is a heating area, the part, located inside the heat dissipation shell, of the wire feeding guide pipe is a heat dissipation area, and temperature truncation through holes which are formed in the radial direction are formed in the heat dissipation area of the wire feeding guide pipe. A heating block is fixedly arranged on the heating area of the wire feeding guide pipe. The feeding end of a printing nozzle is connected with the discharging end of the wire feeding guide pipe. The 3D printer head has the temperature truncation function, conduction of heat to the upper end of the wire feeding guide pipe is reduced, and accordingly the downward extruding resistance of consumable materials is reduced, and the 3D printing precision and the printing efficiency are improved.

Owner:合肥开目管理咨询合伙企业(有限合伙)

Multipurpose soft tube

ActiveCN101050832BWon't softenWill not deformSuction hosesFlexible pipesElectrical and Electronics engineering

Owner:JINHUA CHUNGUANG TECHNOLOGY CO LTD

Salted arctium lappa production method

InactiveCN105145791APrevent discolorationDiscoloration will notFruits/vegetable preservation by heatingFood preparationArctium lappaChange color

The present invention relates to a salted arctium lappa production method. Arctium lappa is steamed at a steam of a temperature of 100 DEG C for 2-5 minutes, peeled, cut into small segments at a length of 2-3 cm, and rapidly soaked in a color protecting liquid which is prepared by a mixture of white vinegar 2%, edible salt 5%, and ascorbic acid 0.4%; white pepper, amomum kravanh, poria cocos, and water are mixed and the mixture is boiled for 15-20 minutes to obtain a decoction liquid; tea polyphenols and calcium stearate with the weight of the decoction liquid are added into the decoction liquid to be prepared into a filling liquid; a PH adjusting agent is added into the filling liquid to maintain the PH of the filing liquid at 3-4; the filling liquid and the arctium lappa are packaged into bags with a weight ratio of the filling liquid to the arctium lappa being 1 to 1.5 and are sealed; and the sealed arctium lappa finished products are sterilized at microwave of a frequency of 2580MHZ for 140s. The obtained salted arctium lappa product has a shelf life up to 12 months, does not easily change color, and does not has phenomena of going moldy, bulging bags, and being soft, rot and stink.

Owner:HEFEI YUANZHENG AFE SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com