Extrusion processing system for hard flat aluminum wire

An extrusion processing and flat wire technology, applied in the direction of metal extrusion dies, etc., can solve the problems of inability to meet the use requirements and low tensile strength of aluminum flat wires, and achieve the purpose of reducing temperature, improving mechanical properties and ensuring tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

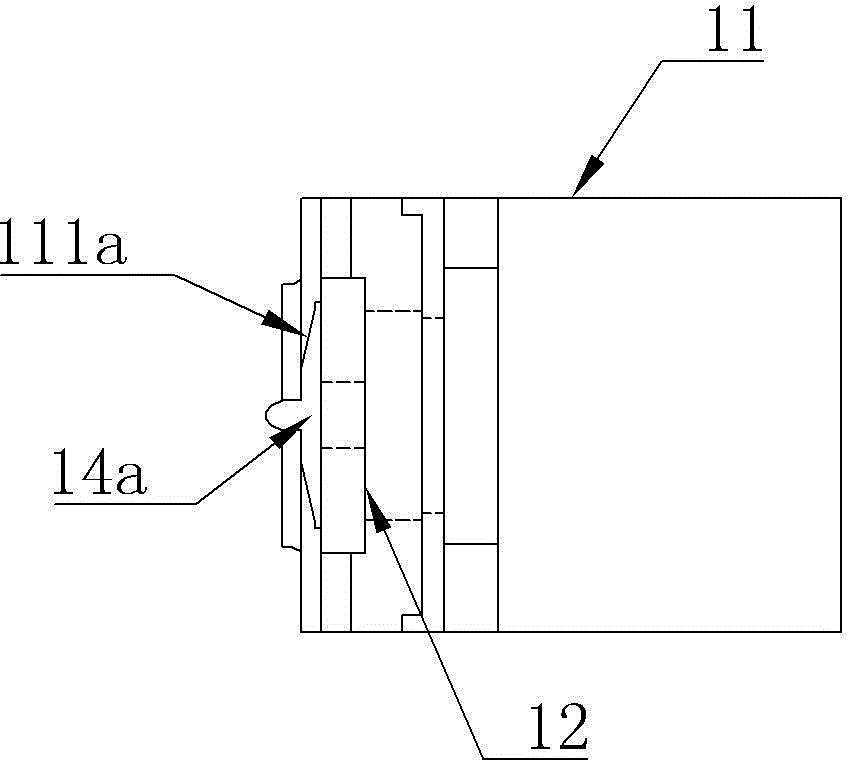

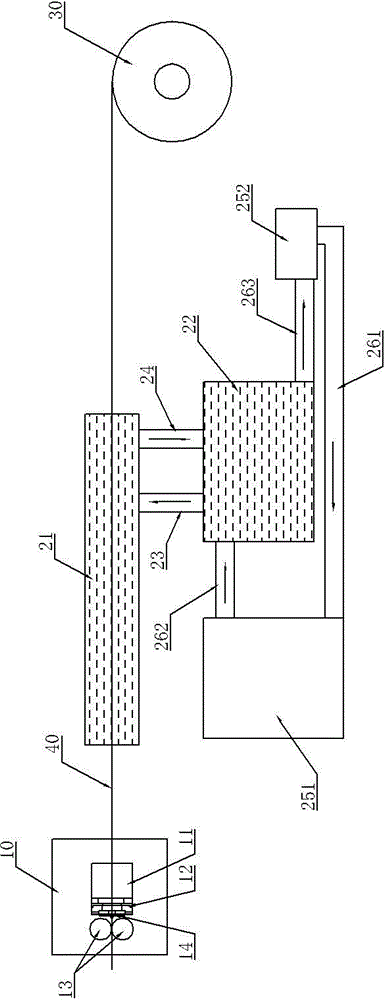

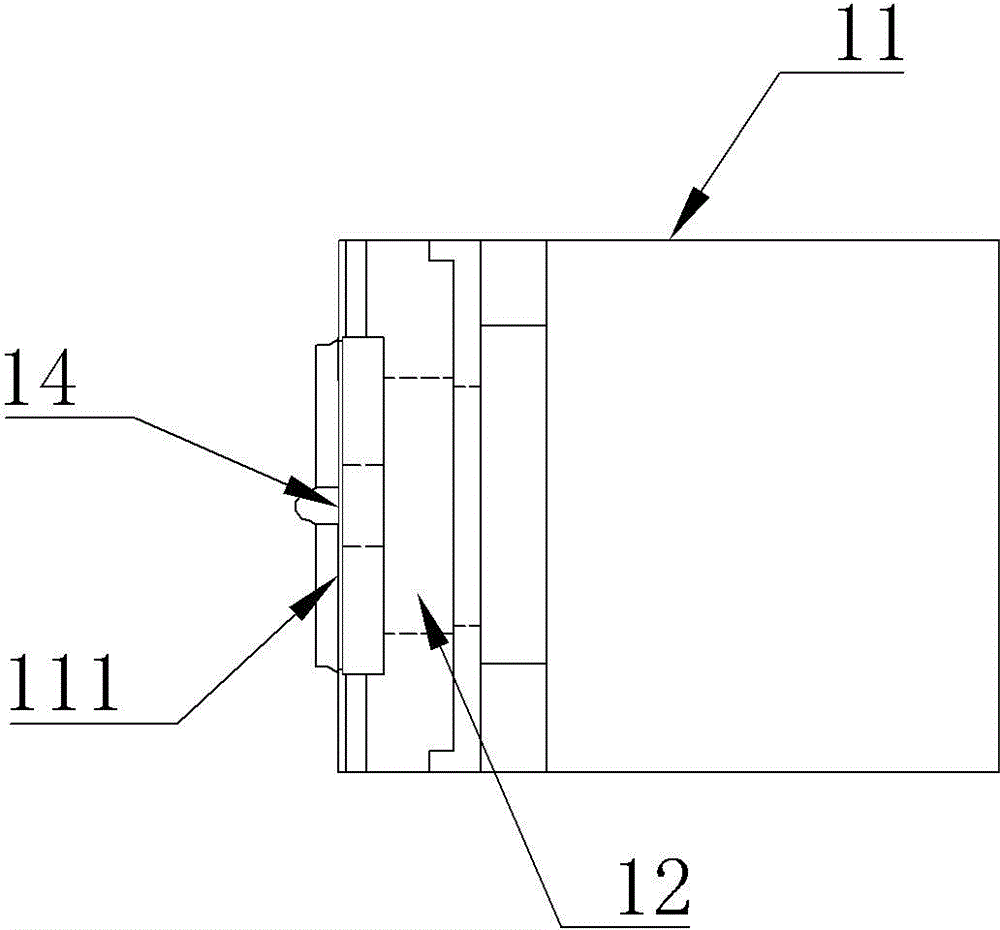

[0011] See figure 2 , the present invention comprises extrusion main frame 10, cooling device and take-up machine 30, and extrusion die cover 11 and extrusion wheel 13 are installed in extrusion main frame 10, and mold core 12 is installed in extrusion die cover 11, extruding Wheel 13 is arranged on the outside of the aluminum rod inlet end of extrusion die cover 11, sees image 3 , the aluminum rod inlet side end face 111 of the extrusion die sleeve 11 is a plane, and a narrow rectangular extrusion cavity 14 is formed between the mold core 12 and the aluminum rod inlet side 111 of the extrusion die sleeve 11; the cooling device includes a cooling water tank 21 , the water tank 22 and the external circulation cooling mechanism, between the cooling water tank 21 and the water tank 22, a closed-loop cooling water circuit is formed through the water inlet pipe 23 and the water outlet pipe 24, and the external circulation cooling mechanism includes a refrigeration compressor 251 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com