Water-soluble quenching medium for hot die steel

A technology of quenching medium and hot die steel, applied in the direction of quenching agent, manufacturing tools, heat treatment equipment, etc., can solve the problems of flammability, poor environmental protection performance, high cost of quenching oil, etc., and achieve the effect of solving high cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A polyalkylene glycol (molecular weight: 22000) 35 parts

[0034] B Polyvinylpyrrolidone (molecular weight: 360,000) 10 parts

[0035] C rust inhibitor 5 parts

[0036] D Fungicide 2×10 -4 share

[0037] E PH adjuster 2 parts

[0038] F Settling agent 0.5 part

[0039] G defoamer 0.2 part

[0040]47 parts of H water

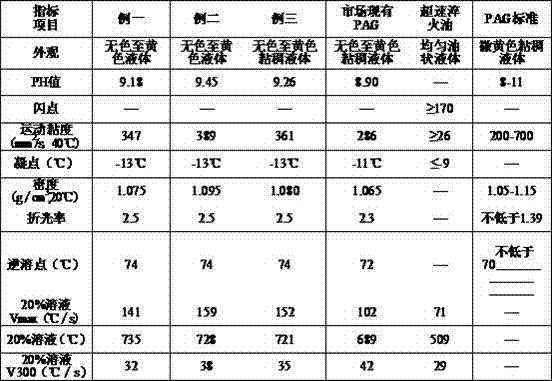

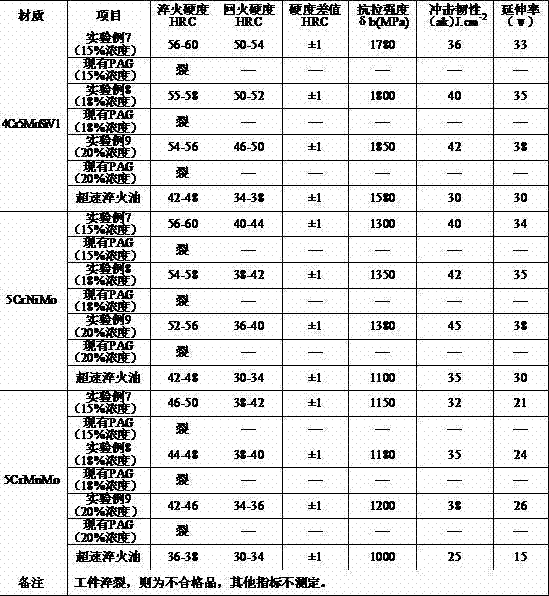

[0041] Because 4Cr5MoSiV1 contains high alloy and silicon, its hardenability is very good, which requires that the polyalkylene glycol component in the medium that affects the cooling rate in the high temperature area is slightly lower, and the cooling rate in the low temperature area is affected. The content of polyvinylpyrrolidone is appropriately increased to ensure that the quenching effect of this medium on 4Cr5MoSiV1 reaches an ideal state.

Embodiment 2

[0043] A polyalkylene glycol (molecular weight: 22000) 45 parts

[0044] B Polyvinylpyrrolidone (molecular weight: 360,000) 5 parts

[0045] C rust inhibitor 2 parts

[0046] D Fungicide 2×10 -4 share

[0047] E PH adjuster 5 parts

[0048] F Settling agent 0.5 part

[0049] G defoamer 0.2 part

[0050] 42 parts of H water

[0051] 5CrNiMo hot work die steel has to withstand repeated heating and cooling due to its nickel content and working conditions, and requires good heat resistance, wear resistance and hardenability, so the content of polyalkylene glycol is higher, and the medium The hardenability should also be better to ensure that 5CrNiMo has high hardenability, and the uniformity of 5CrNiMo is higher.

Embodiment 3

[0053] A polyalkylene glycol (molecular weight: 22000) 40 parts

[0054] B polyvinylpyrrolidone (molecular weight: 360,000) 8 parts

[0055] C rust inhibitor 3 parts

[0056] D Fungicide 2×10 -4 share

[0057] E PH adjuster 3 parts

[0058] F Settling agent 0.5 part

[0059] G defoamer 0.2 part

[0060] 45 parts of H water

[0061] The hardenability of 5CrMnMo hot work die steel is relatively poor, so a higher content of polyalkylene glycol quenching agent is required to ensure that the die has high mechanical properties and high uniformity after quenching.

[0062] The raw material composition of the above-mentioned embodiment is the weight ratio.

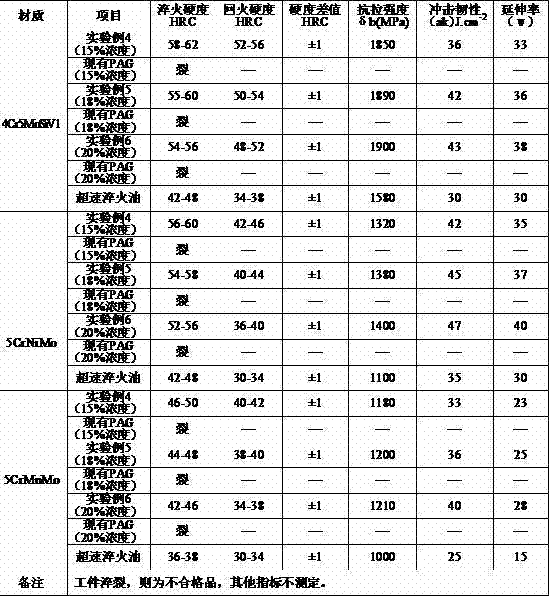

[0063] Table 1 Comparison of typical values of technical indicators

[0064]

[0065] Note:

[0066] Appearance: Visual inspection. PH value: GB / T9724. Kinematic viscosity: GB / T265. Flash point: GB / T3536. Freezing point: GB / T3535. Density: GB / T1884. Refractive index: GB / T614. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com