Environment-friendly water-soluble quenching liquid

A quenching liquid and water-soluble technology, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve uncontrollable problems, achieve the effects of reducing quenching deformation and cracking tendency, safe use, and reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

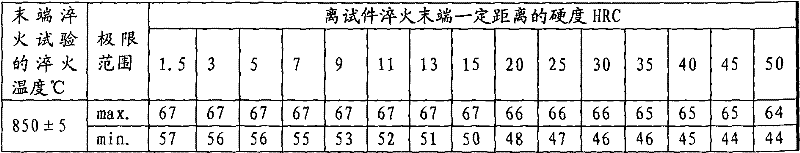

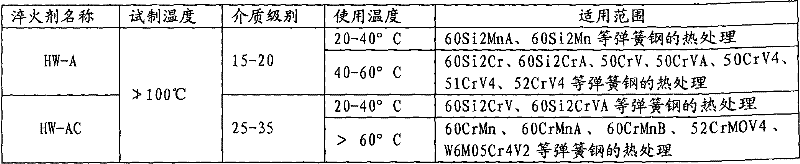

[0009] Further illustrate the present invention in conjunction with embodiment, the present invention is made up of adding certain proportioning sodium chloride, potassium chloride and sodium nitrate in water and water; Its mass percent sodium chloride is 9~13%, and potassium chloride is 8~15%. %, sodium nitrate is 7-10%, and the rest is water and its impurities; the quenching temperature of the workpiece using this quenching liquid is 800-870°C; the temperature of this quenching liquid is 20-70°C during quenching. When the present invention is used, the concentration and temperature of the solution are adjusted according to the steel type, and the aqueous solution with satisfactory cooling performance is prepared, and its cooling speed is close to that of water in the high temperature stage, and close to that of oil in the low temperature stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com