Preparation method of nano calcium carbonate for MS glue

A nano calcium carbonate, calcium hydroxide technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, adhesives, etc., can solve the problem of poor compatibility between calcium carbonate and MS glue, poor tensile strength and elongation at break , poor processing performance and other problems, to achieve low oil absorption value, eliminate surface energy, prevent the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

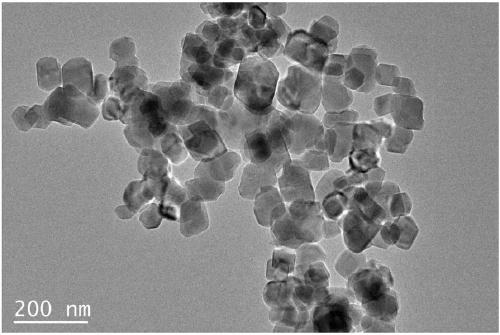

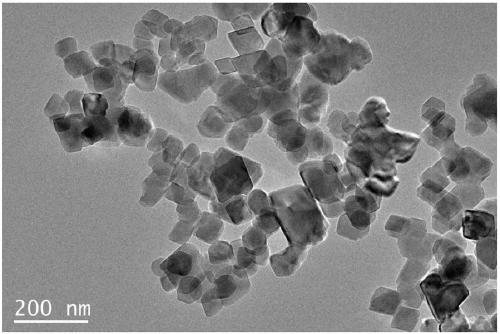

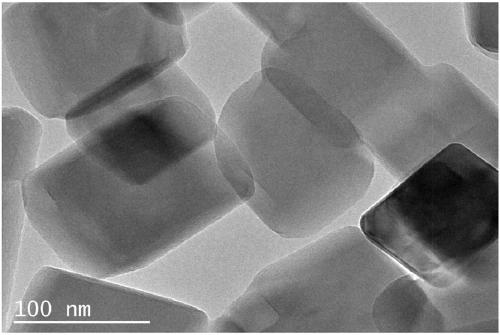

Image

Examples

Embodiment 1

[0038] A preparation method of nano calcium carbonate for MS glue, including the following processes:

[0039] Step 1. Digest the quicklime with the activity of 360ml and water according to the mass ratio of 1:6, and then carry out the digestion reaction. After the reaction is completed, it is sieved twice through a 200-mesh and 320-mesh vibrating screen. The two-stage suspension separator is connected in series to remove impurities to obtain calcium hydroxide refined slurry. The temperature of the digested water is 55°C. Using this highly active lime and a reasonable ratio of gray-water reaction, and adopting two screening and three-stage suspension separator to remove impurities, it can ensure that the calcium hydroxide required by the core carbonization process is more delicate and uniform, and the product is guaranteed The uniformity of the particles ensures that the product does not return to alkali, and ensures the product's low oil absorption value and low pH value. Amon...

Embodiment 2

[0048] A preparation method of nano calcium carbonate for MS glue includes the following steps:

[0049] Step 1. Digest the quicklime with activity of 380ml and digestion water according to the mass ratio of 1:6, and then carry out the digestion reaction. After the reaction is completed, it is sieved twice through a 200-mesh and 320-mesh vibrating screen, and then used after sieving The three-stage suspension separator is connected in series to remove impurities to obtain calcium hydroxide refined slurry. The temperature of the digested water is 55°C. Using this highly active lime and a reasonable ratio of gray-water reaction, and adopting two screening and three-stage suspension separator to remove impurities, it can ensure that the calcium hydroxide required by the core carbonization process is more delicate and uniform, and the product is guaranteed The uniformity of the particles ensures that the product does not return to alkali, and ensures the product's low oil absorption...

Embodiment 3

[0058] A preparation method of nano calcium carbonate for MS glue includes the following steps:

[0059] Step 1. Digest the quicklime with activity of 400ml and water according to the mass ratio of 1:6, and then carry out the digestion reaction. After the reaction is completed, it is sieved twice through a 200-mesh and 320-mesh vibrating screen. The two-stage suspension separator is connected in series to remove impurities to obtain calcium hydroxide refined slurry. The temperature of the digested water is 55°C. Using this highly active lime and a reasonable ratio of gray-water reaction, and adopting two screening and three-stage suspension separator to remove impurities, it can ensure that the calcium hydroxide required by the core carbonization process is more delicate and uniform, and the product is guaranteed The uniformity of the particles ensures that the product does not return to alkali, and ensures the product's low oil absorption value and low pH value.

[0060] Step tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com