Complex network modeling method for models of hollowed-out structure products

A hollow structure and complex network technology, applied in the fields of instruments, geometric CAD, calculation, etc., can solve the problems that hollow structure products cannot be modeled, the preparation process of hollow structure is cumbersome and time-consuming, etc., and achieves strong practicability, simplified complexity, design Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] A complex network modeling method for a hollow structure product model includes the following steps:

[0040] 1) Given a surface model of a product, the product surface model can be constructed using existing modeling tools or obtained using reverse engineering methods. In this embodiment, the surface model of the product is a cube.

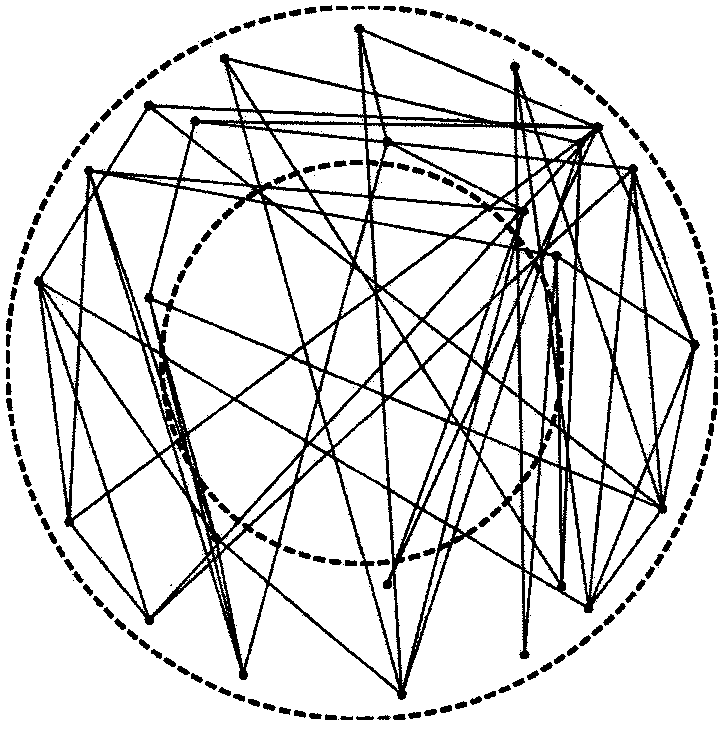

[0041] 2) Multiple points are randomly generated inside the product surface model, and these points are nodes in the BA network.

[0042] 3) Use the BA network evolution model to establish the connection relationship between nodes.

[0043] 4) The entire BA network graph is regarded as a virtual physical system, each node in the system is a particle with a certain energy, there is mutual repulsion between particles, and there is gravitation between connected particles.

[0044] Such as figure 1 As shown, the final position of each node is determined by the force balance graph layout algorithm.

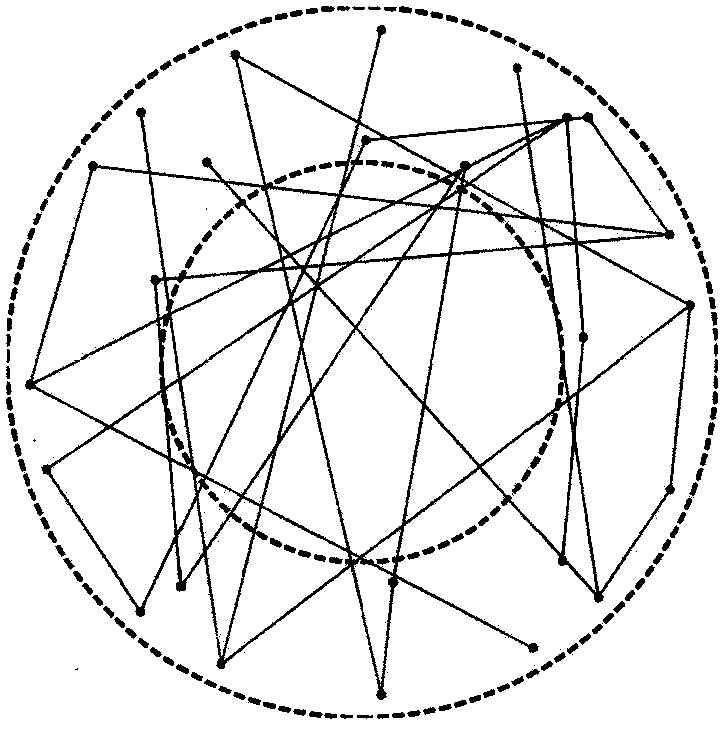

[0045] 5) Generate a Voronoi diagram acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com