Patents

Literature

184 results about "Digital manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

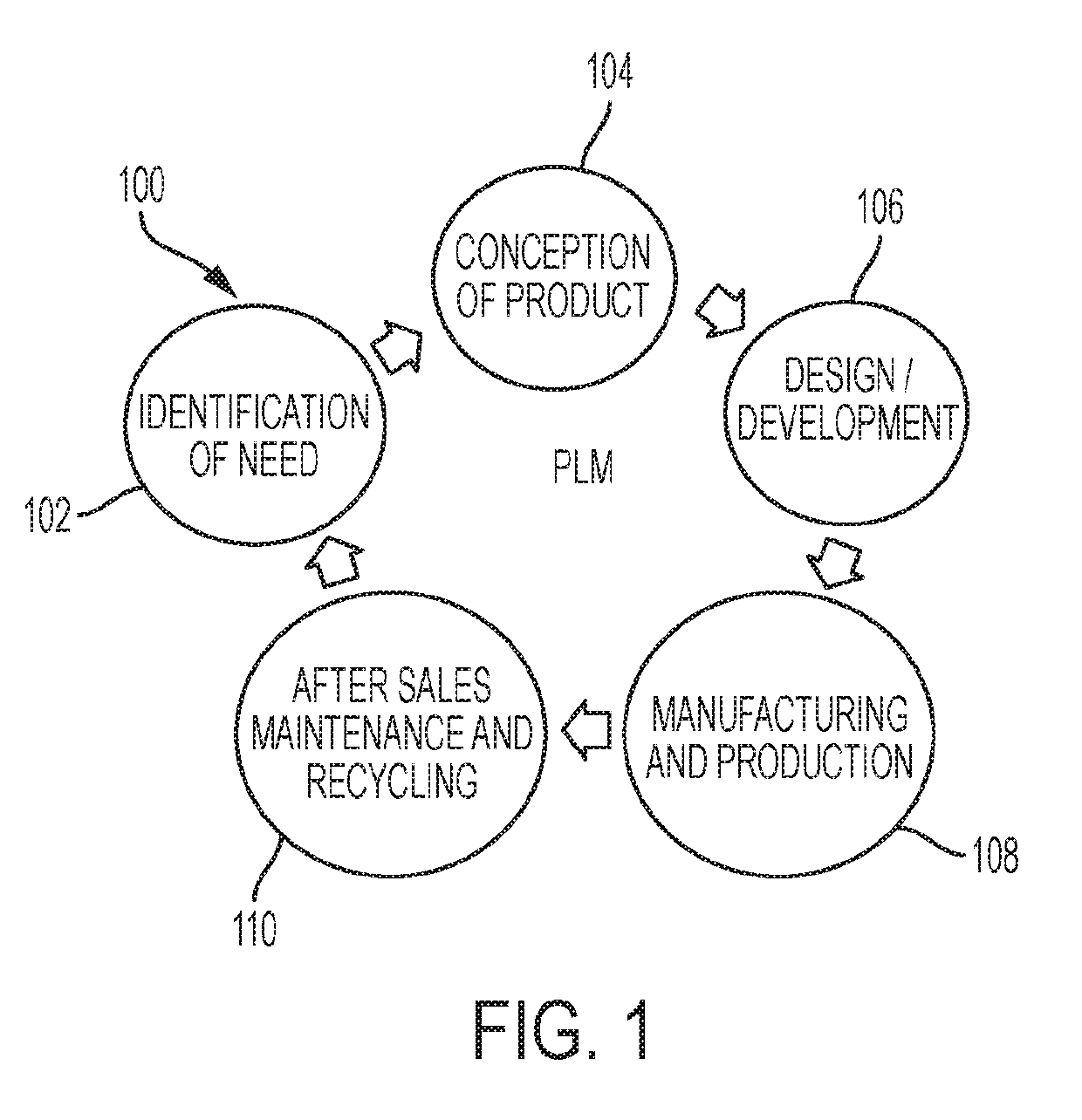

Digital manufacturing is an integrated approach to manufacturing that is centered around a computer system. The transition to digital manufacturing has become more popular with the rise in the quantity and quality of computer systems in manufacturing plants. As more automated tools have become used in manufacturing plants it has become necessary to model, simulate, and analyze all of the machines, tooling, and input materials in order to optimize the manufacturing process. Overall, digital manufacturing can be seen sharing the same goals as computer-integrated manufacturing (CIM), flexible manufacturing, lean manufacturing, and design for manufacturability (DFM). The main difference is that digital manufacturing was evolved for use in the computerized world.

Digital manufacturing of removable oral appliances

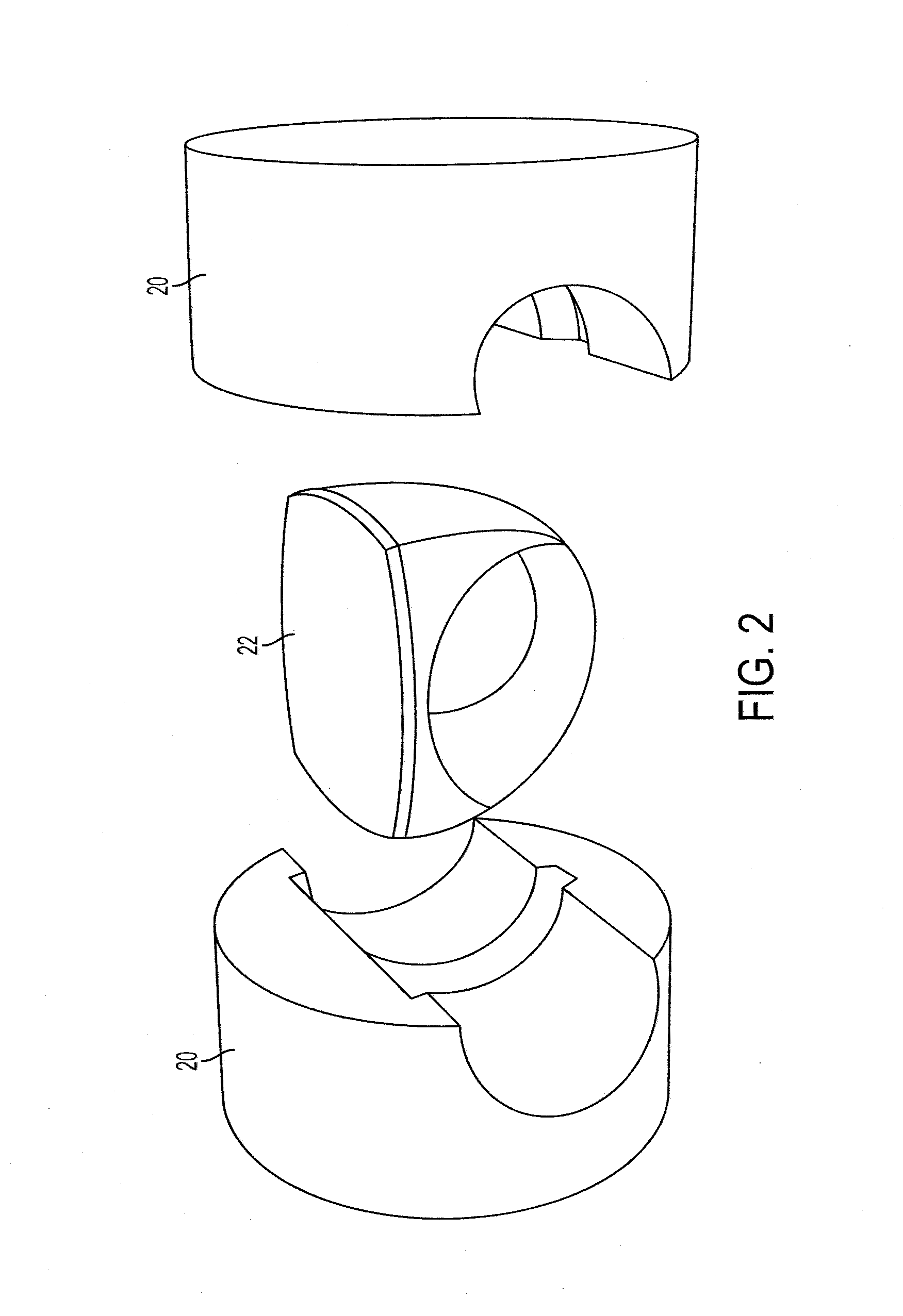

InactiveUS20060003292A1Improved of final shapeReduce trimming timeMechanical/radiation/invasive therapiesOthrodonticsDental ArticulatorsCentric occlusion

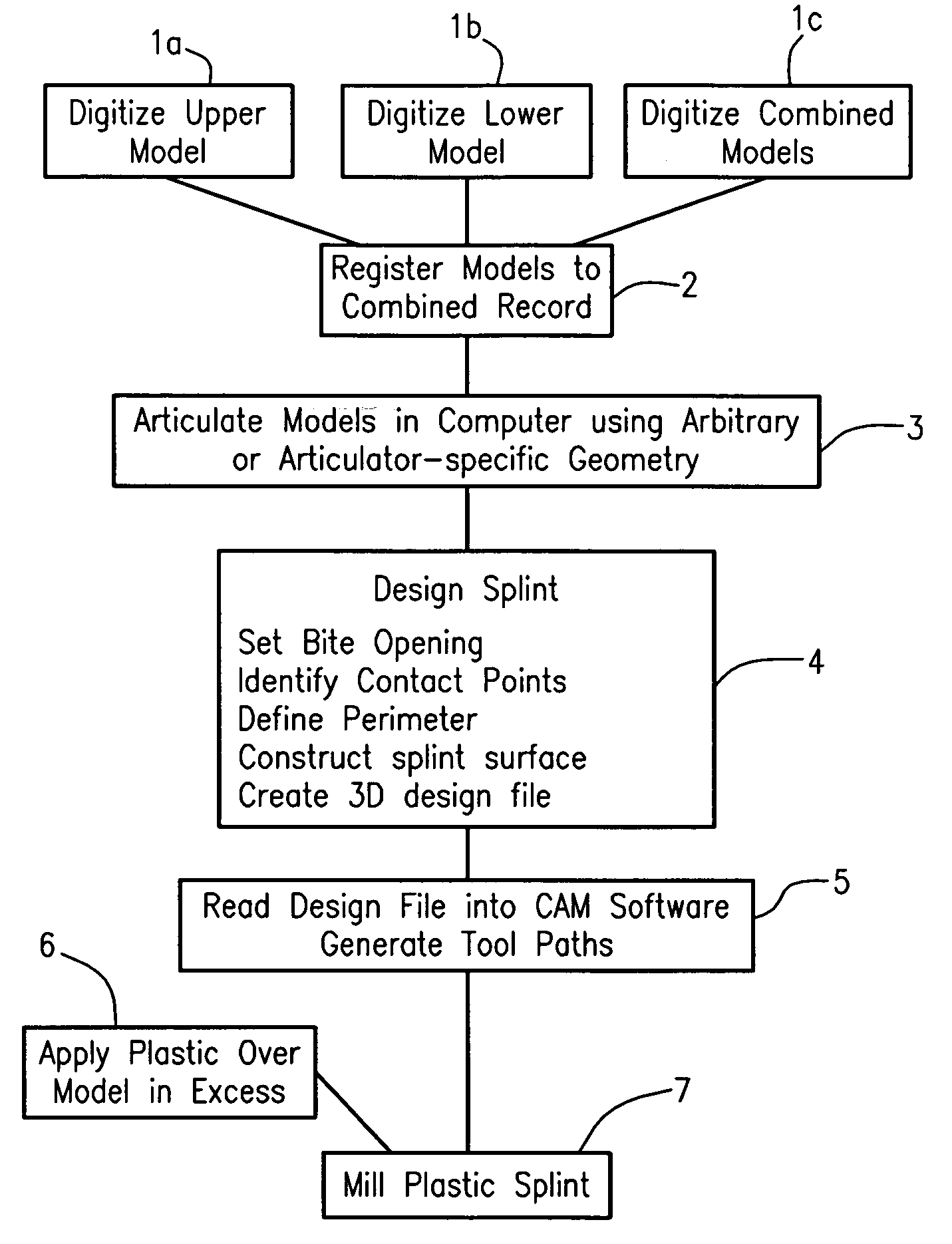

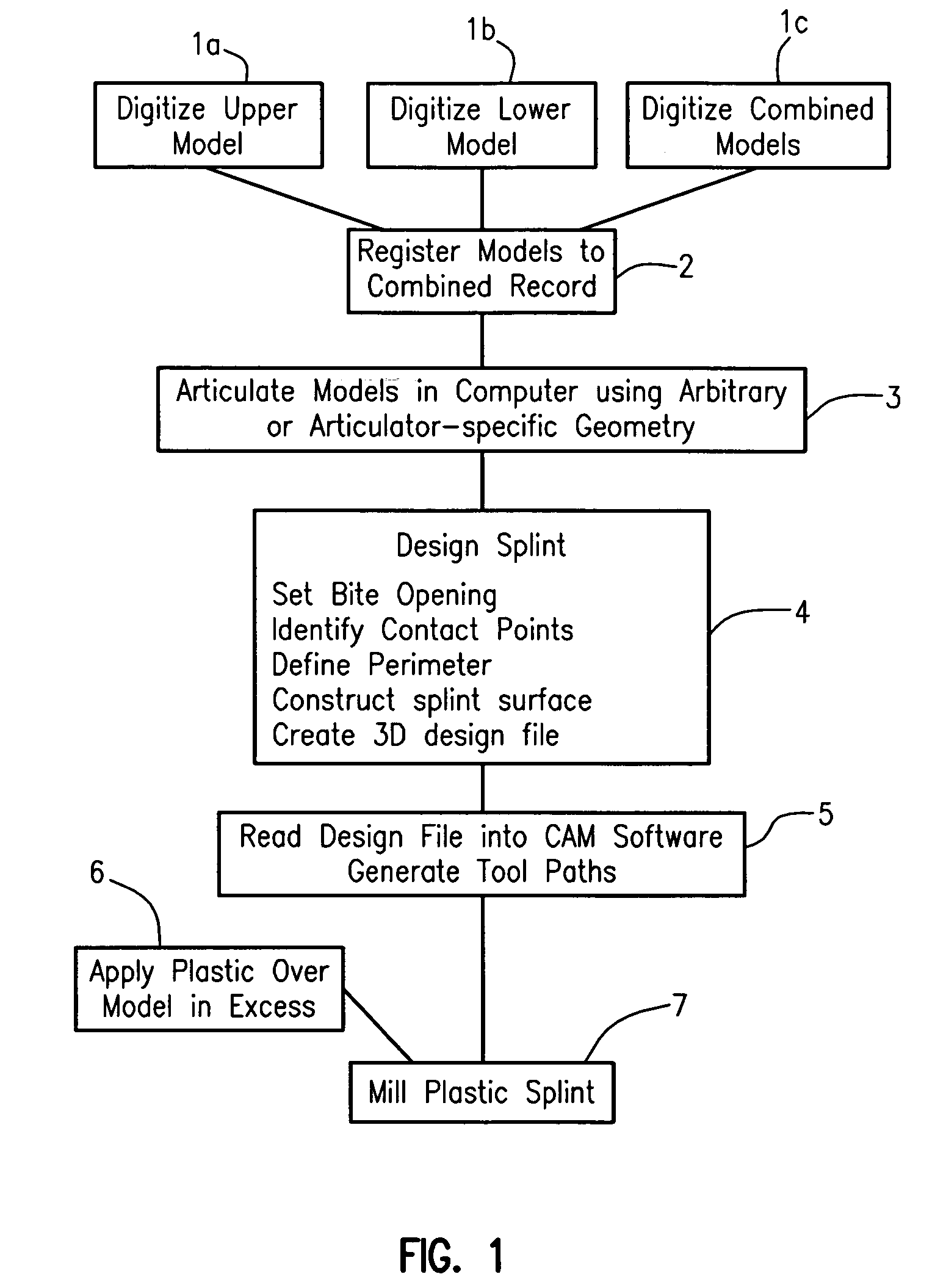

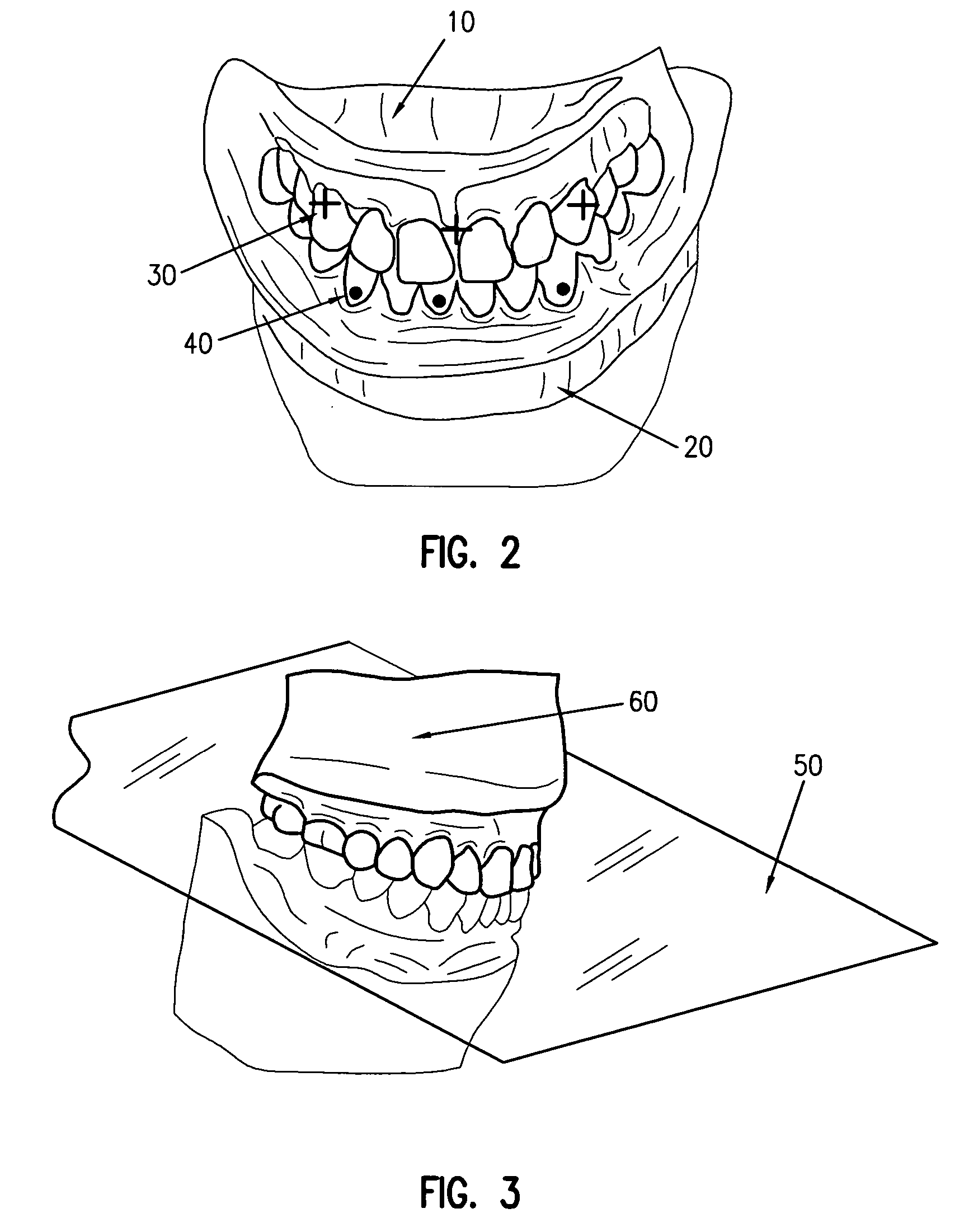

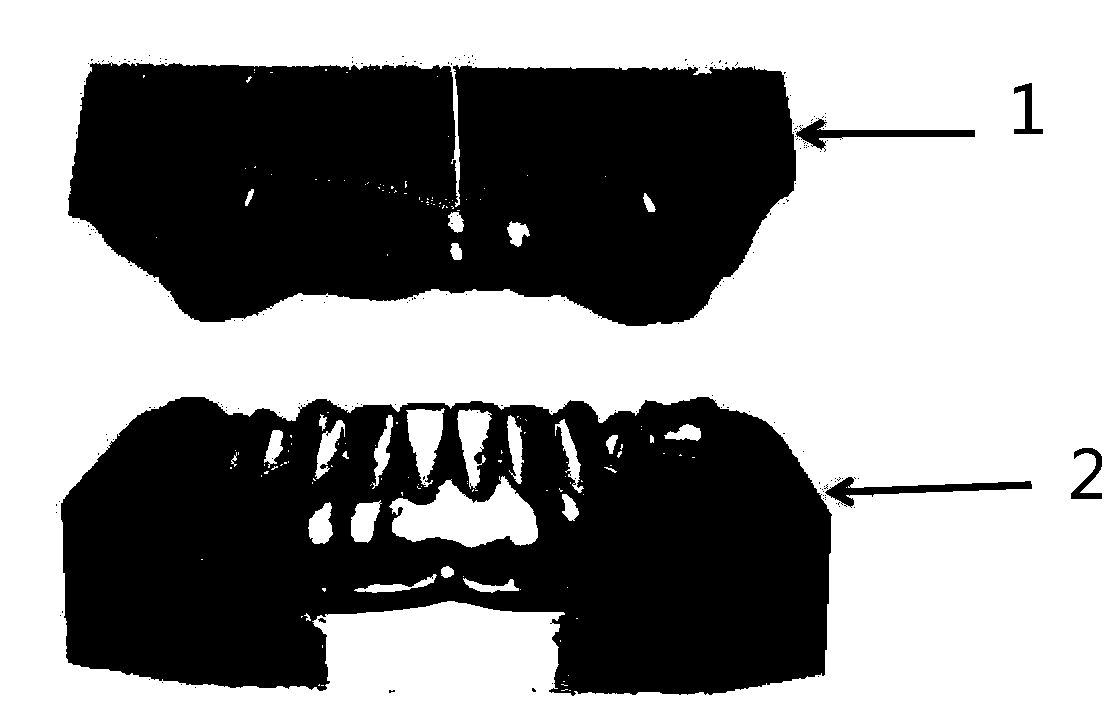

A digitally-based method is described for the design and production of customized removable dental appliances. The plastic component of custom appliances is designed using software, and milled directly over a plaster model of the dentition. A patient's upper, lower, and bite-registered arches are digitized, registered to a bite or centric occlusion position, and articulated in software using either an average geometry or the geometry of a specific articulator. Appliance design is performed by defining the desired plastic surfaces and margins as dictated by the relative movement and positions of the arches as functionally required for a specific appliance. Standard CAM software is used to read the design file and command a multiaxis machine center to mill the plastic while directly on a plaster model.

Owner:GREAT LAKES ORTHODONTICS

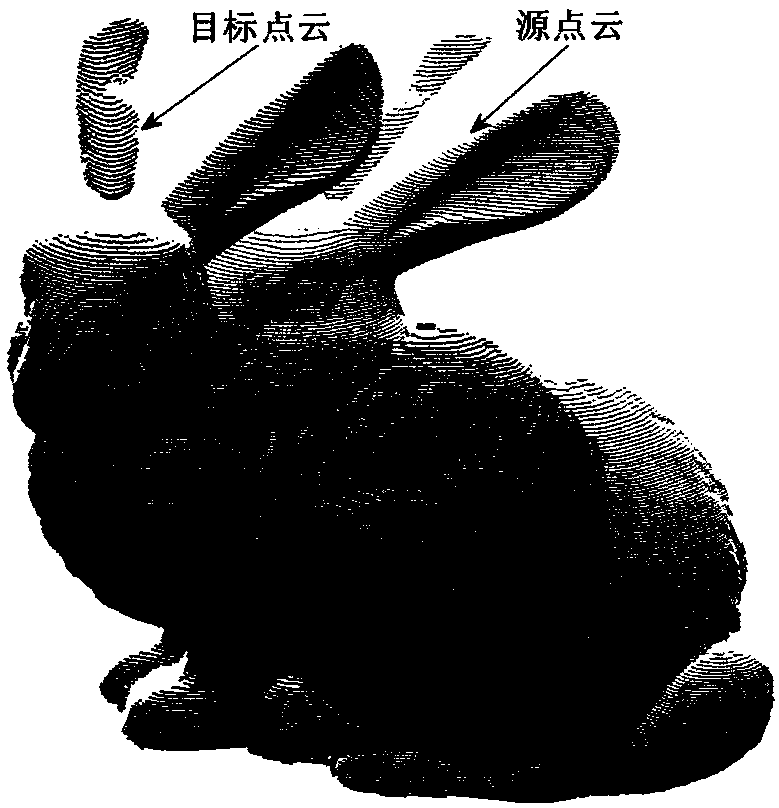

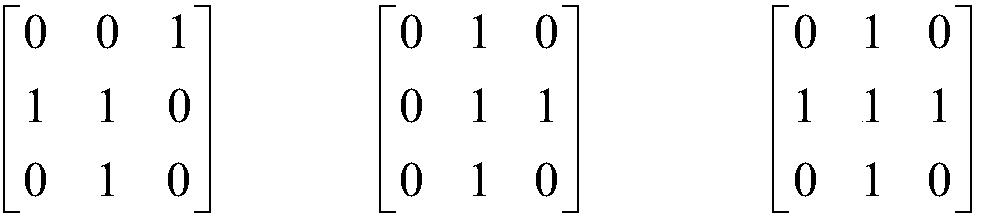

Three-dimensional measurement point cloud optimization registration method

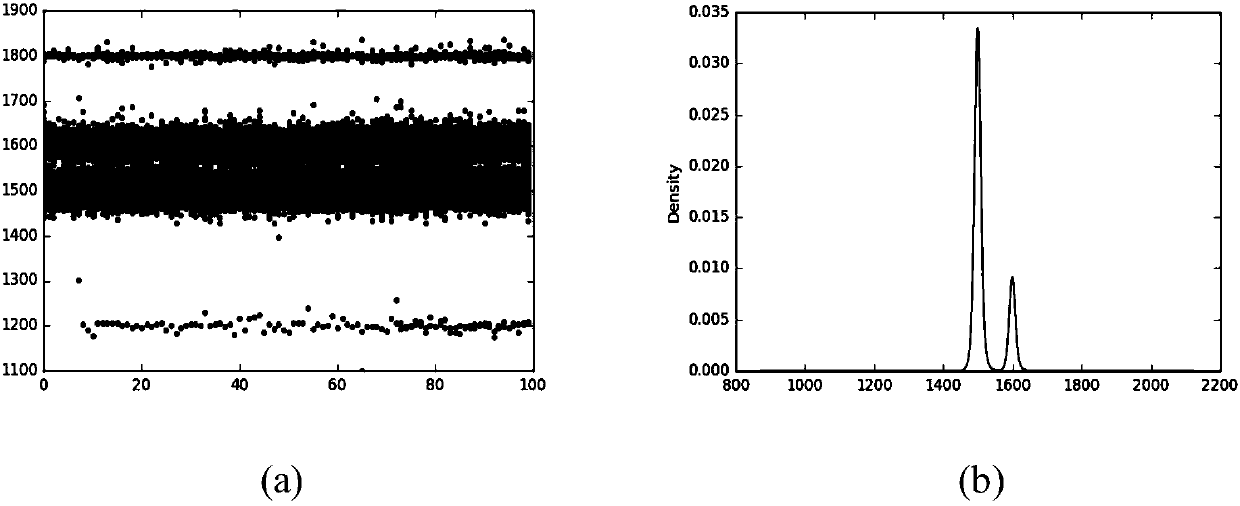

ActiveCN108564605AImprove registration accuracyHigh precisionImage enhancementImage analysisLocal optimumPoint cloud

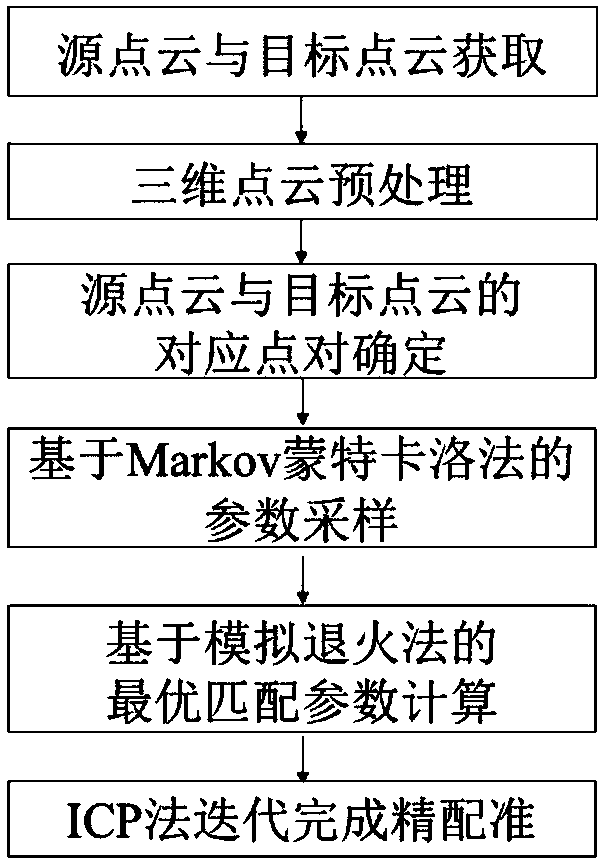

The present invention belongs to the technical field of digital manufacturing, and particularly relates to a three-dimensional measurement point cloud optimization registration method. The method comprises: obtaining the source point cloud and the target point cloud; performing denoising preprocessing on the three-dimensional measurement point cloud; using the Markov Monte Carlo-based simulated annealing registration algorithm to solve the global optimal registration transformation matrix; and finally, using the ICP registration method to iteratively complete precise registration. According tothe method provided by the present invention, the problem of convergence to the local optimal solution in the ICP registration method is solved, the global optimization solution of the transformationmatrix in the process of three-dimensional point cloud registration is realized, falling into the local optimum is avoided, the precision of three-dimensional point cloud registration is improved, and the method is superior to the traditional ICP registration; and parameter sampling is realized based on the Markov Monte Carlo method, the convergence speed of the algorithm is accelerated, the accuracy of point cloud registration is improved, the method has strong adaptability to the point cloud, and the algorithm has good robustness.

Owner:DALIAN UNIV OF TECH

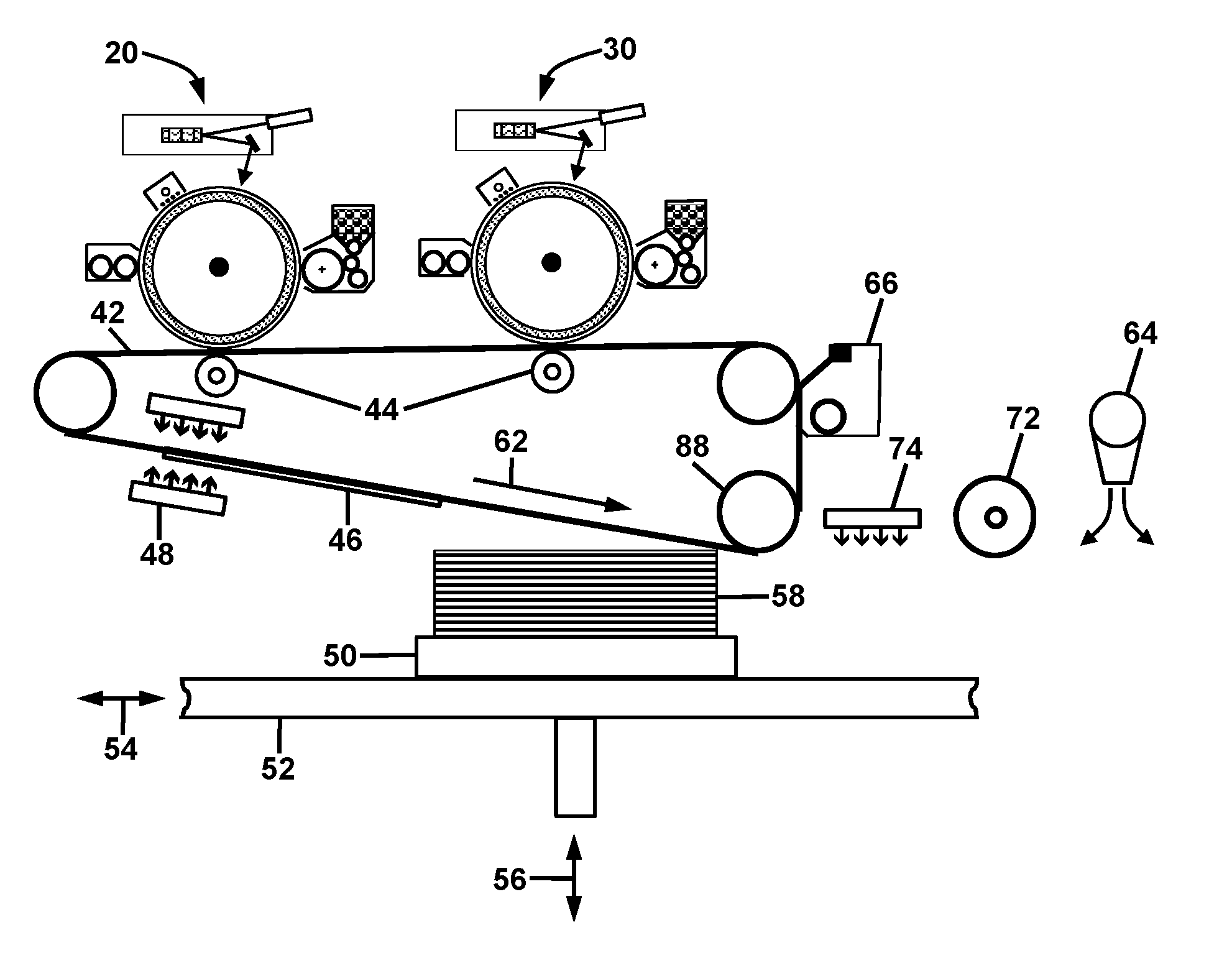

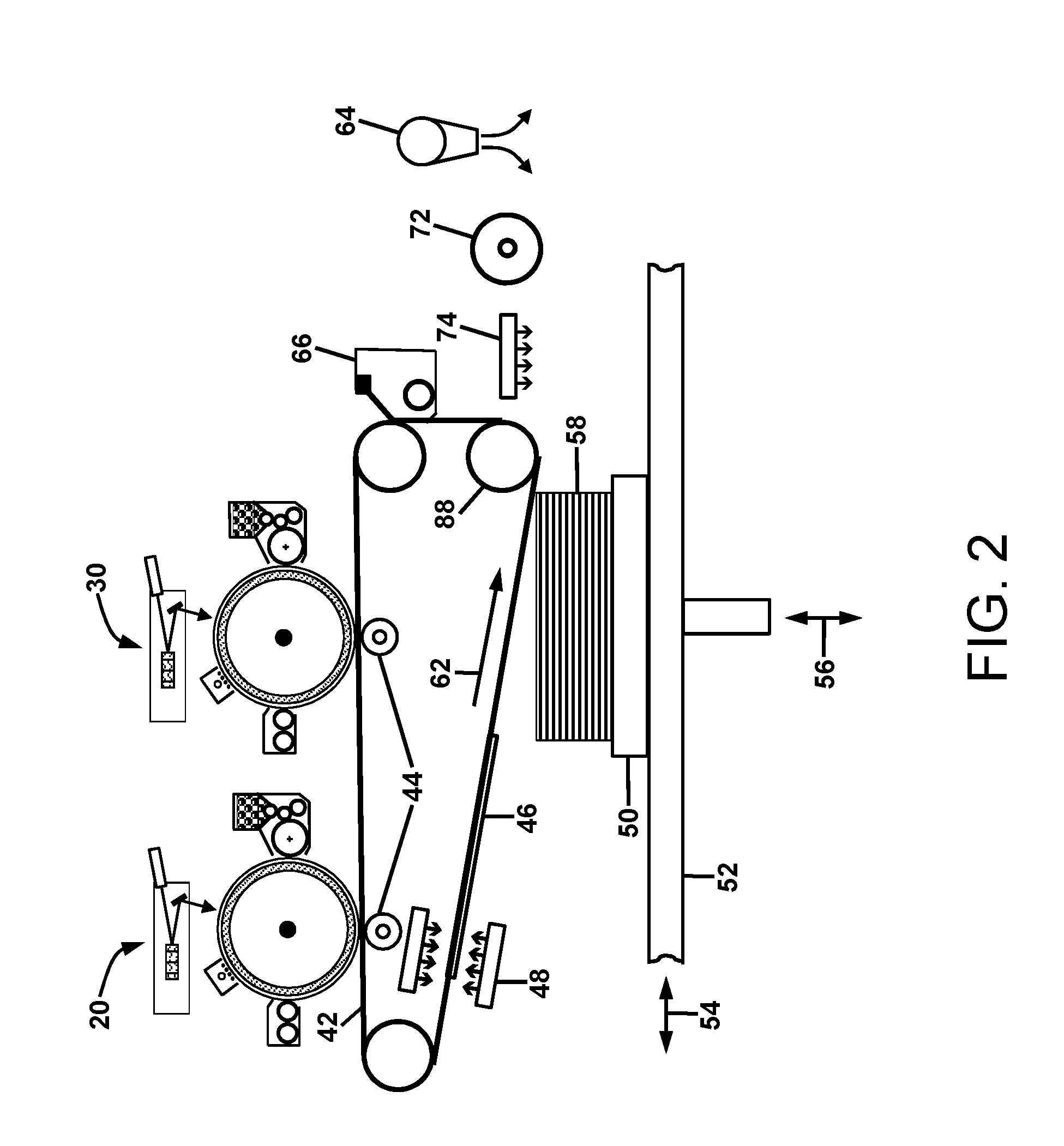

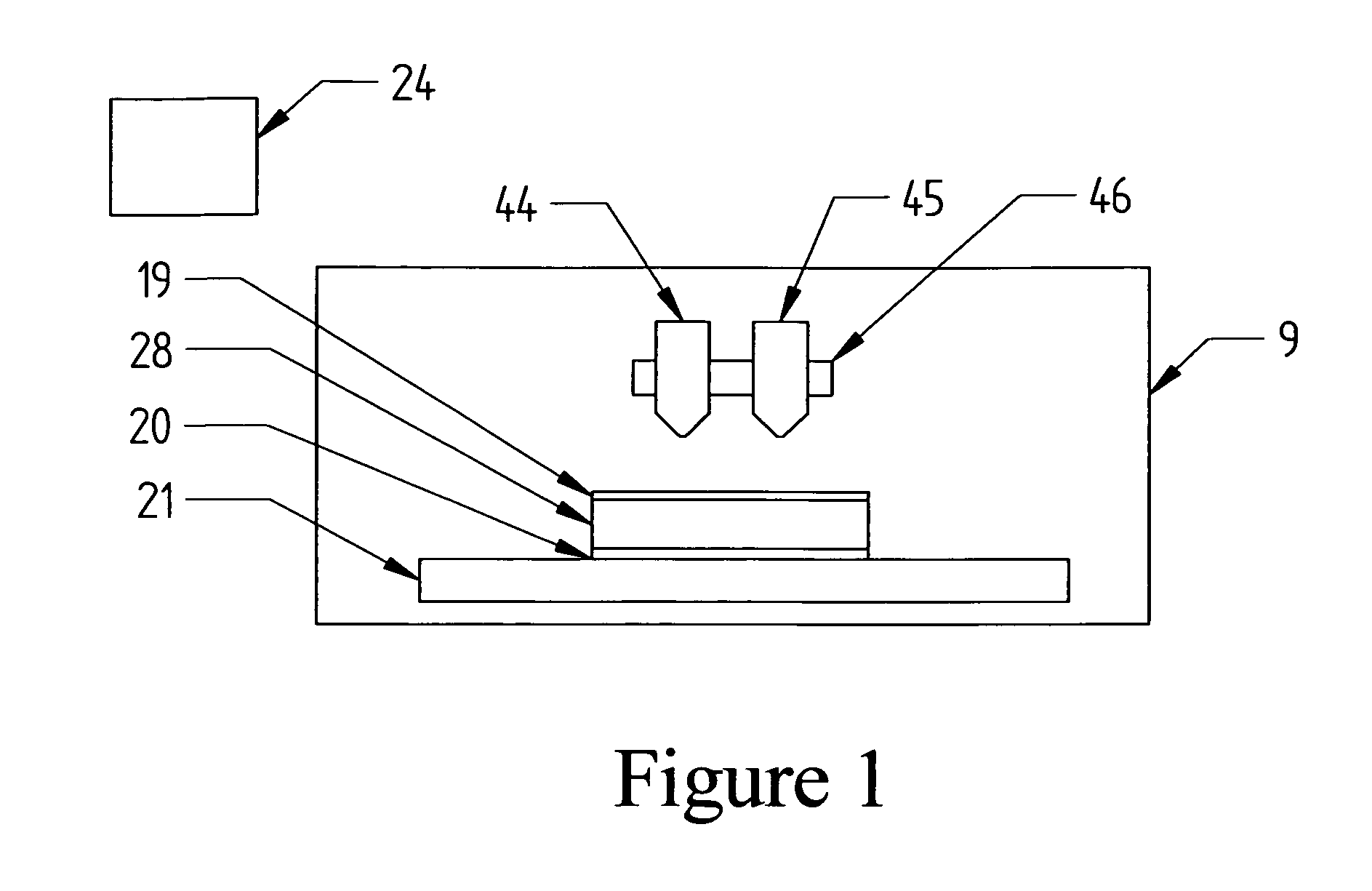

Fabrication of 3D objects via multiple build platforms

ActiveUS20160200084A1Shorten cycle timeImprove productivityMechanical working/deformationManufacturing driving meansProduction rateMultiple platform

A method is disclosed for improving the productivity of digitally fabricated 3D objects with the same or different shape and material composition. The improved productivity is enabled by the incorporation of multiple build platforms and multiple objects per build platform within a 3D object fabrication apparatus. Some 3D manufacturing processes such as those based on electrophotography require a wait time to condition the build object before the next layer of build and support material can be applied. Under these fabrication conditions, the utilization of multiple build platforms in the 3D object manufacturing process effectively minimizes the wait time between layer deposition so that the productivity for fabricating 3D objects is improved. Furthermore, the incorporation of an additional adjacent set of multiple platforms enables rapid changeover when the fabrication of one set of 3D objects is completed on an adjacent set of build platforms.

Owner:XACTIV

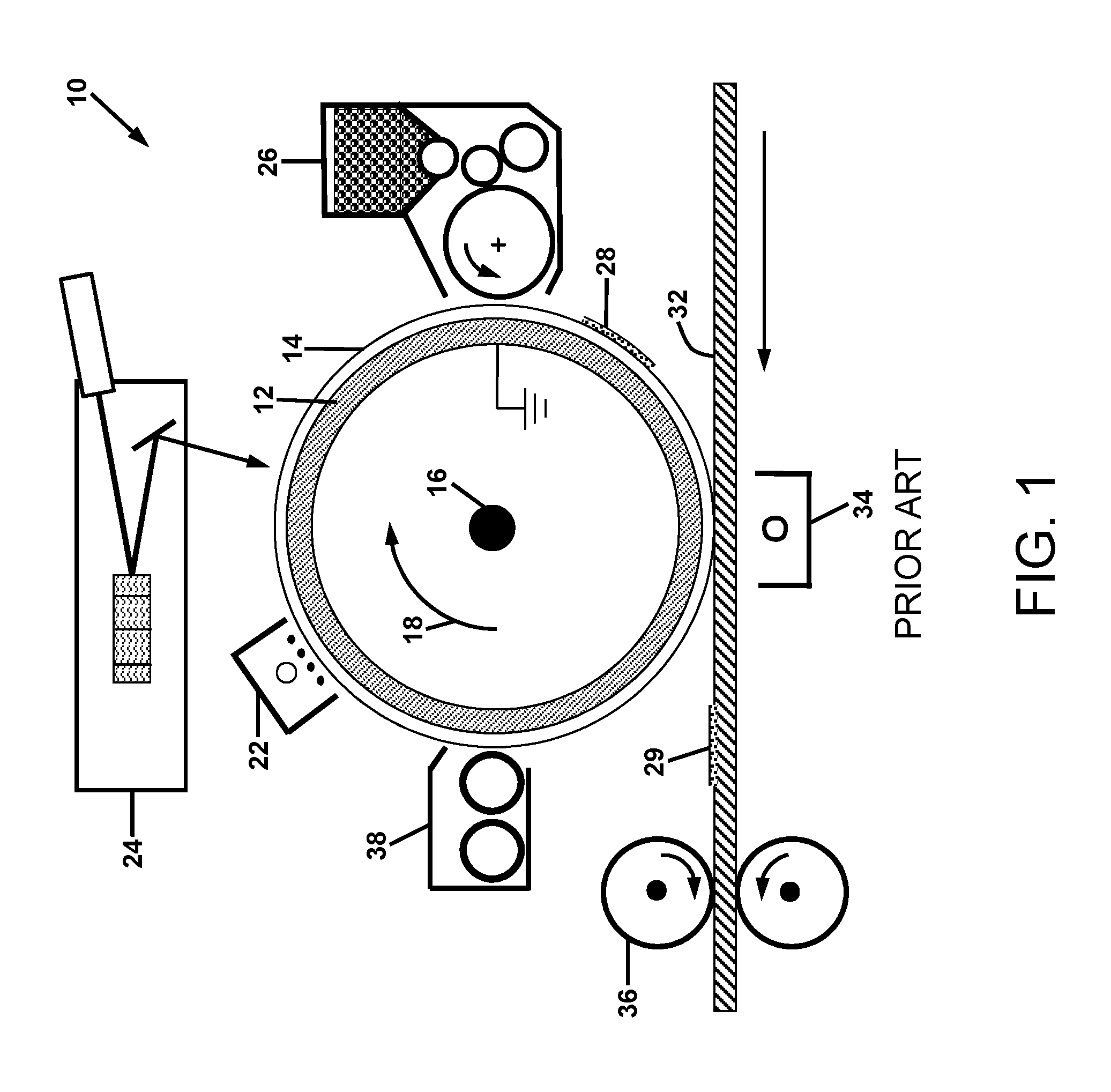

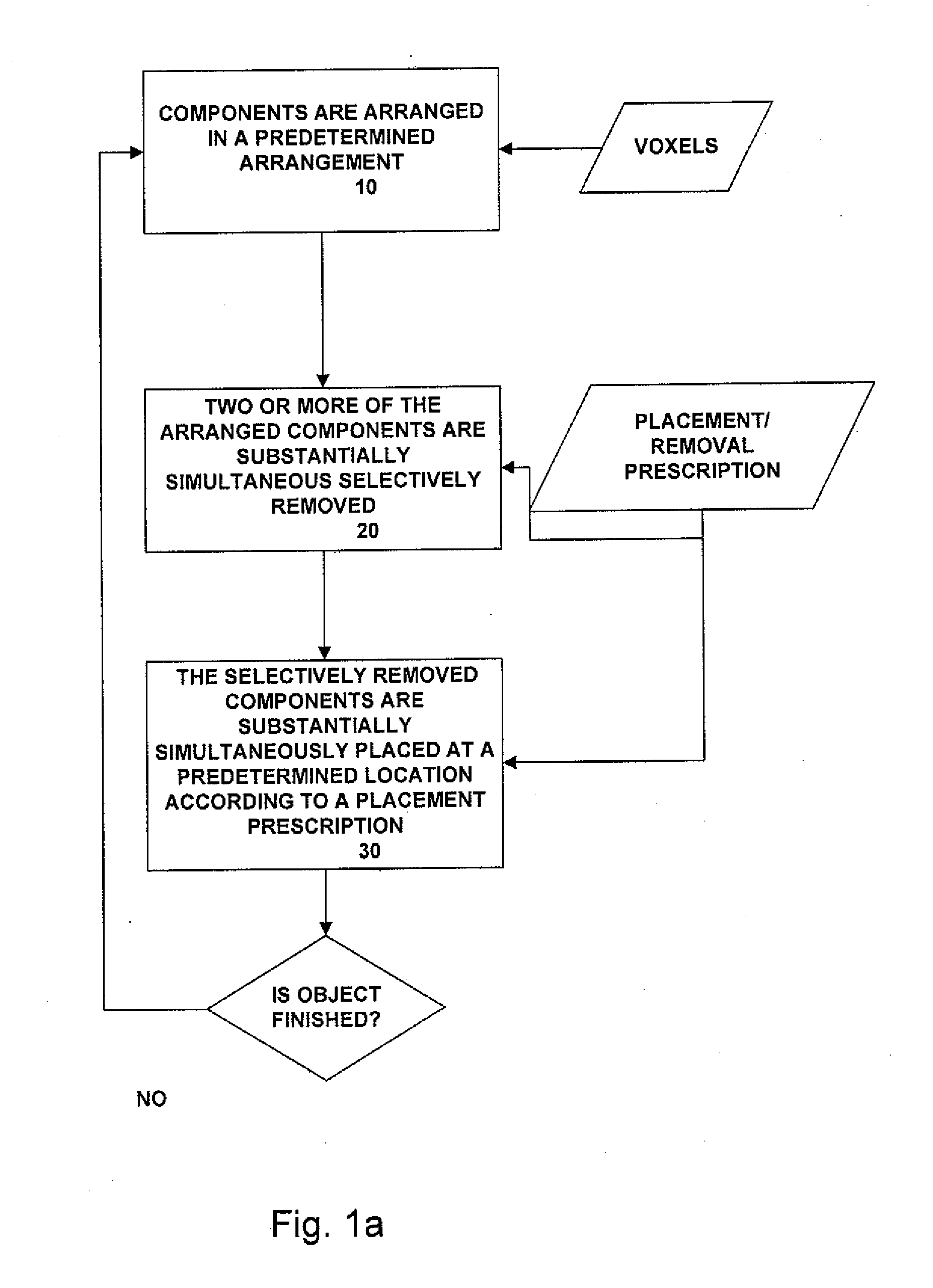

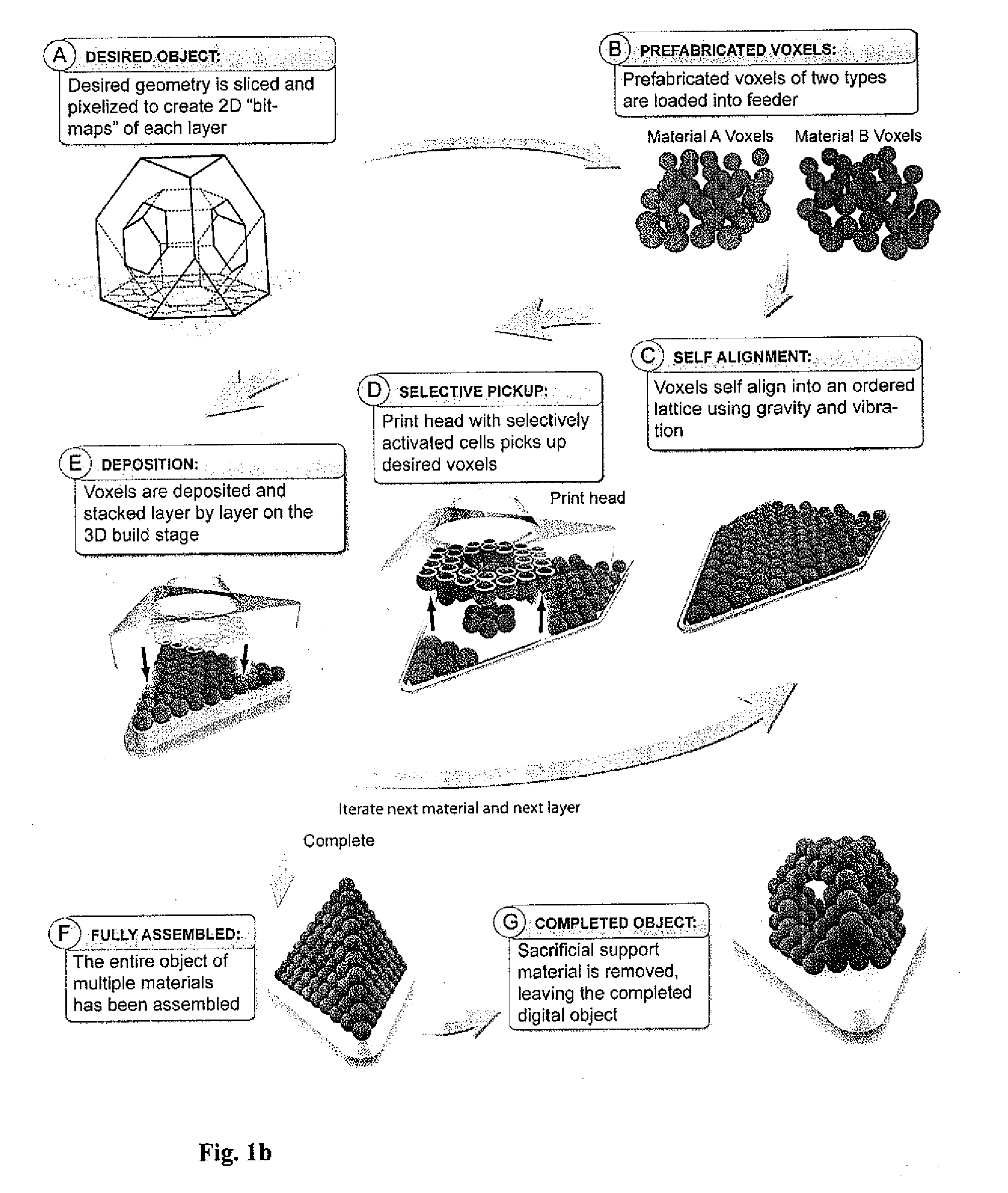

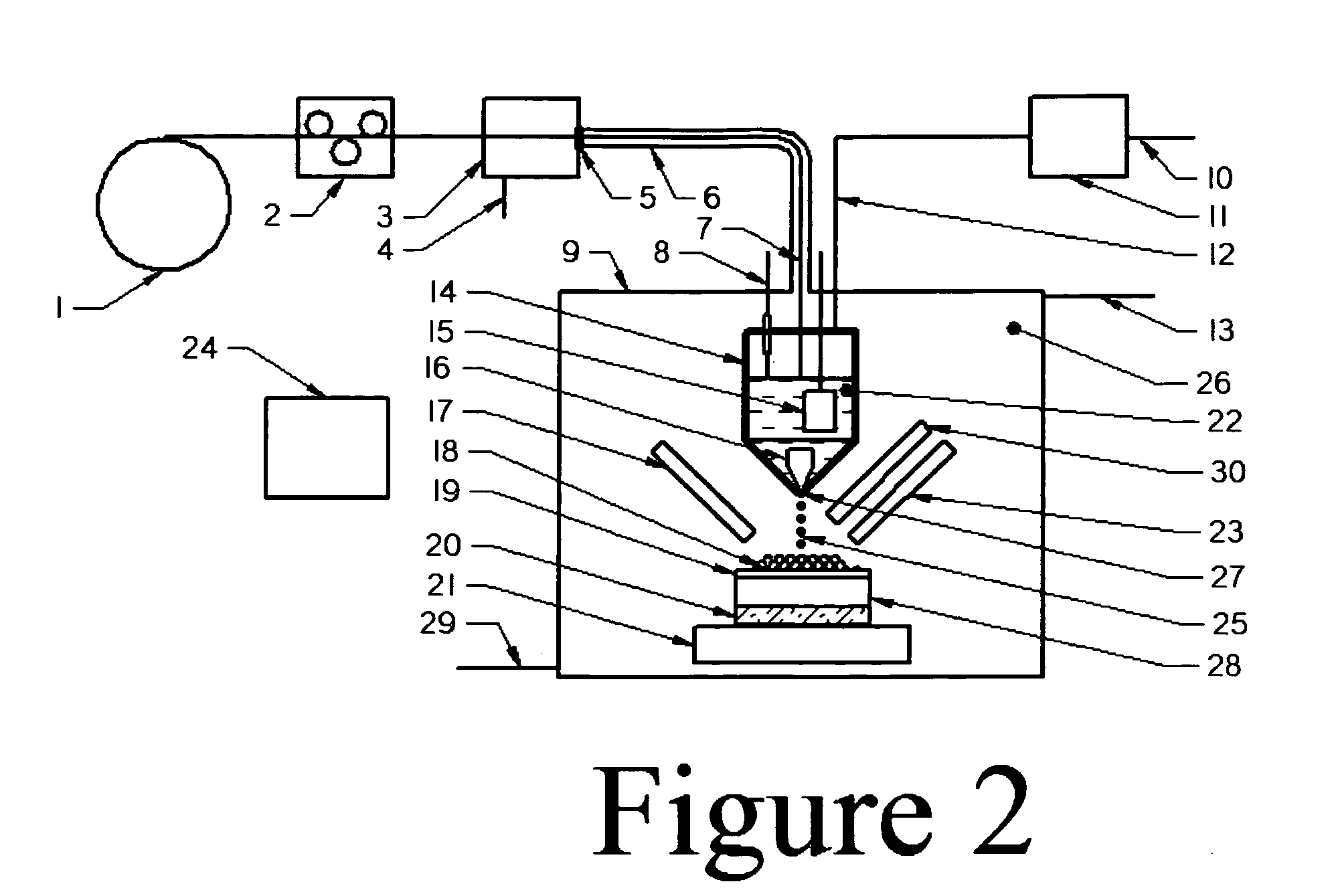

Apparatus and methods for digital manufacturing

ActiveUS20110123794A1Liquid surface applicatorsMechanical working/deformationEngineeringDigital manufacturing

A method for manufacturing objects / materials includes selectively arranging the predetermined components in a staging area, substantially simultaneously selectively removing two or more of the selectively arranged predetermined components according to a predetermined removal plan and substantially simultaneously placing the selectively removed components, the removed components being substantially simultaneously placed at a predetermined location. A system for practicing the method includes a supply of the predetermined components, an arranging subsystem receiving the predetermined components and arranging the predetermined components according to a predetermined arrangement, a selective removal subsystem for selectively removing at least two of the selectively arranged predetermined components, the selectively removing occurring substantially simultaneously and according to a predetermined removal prescription, and a placement subsystem for substantially simultaneously placing the selectively removed components at a predetermined location.

Owner:CORNELL UNIVERSITY

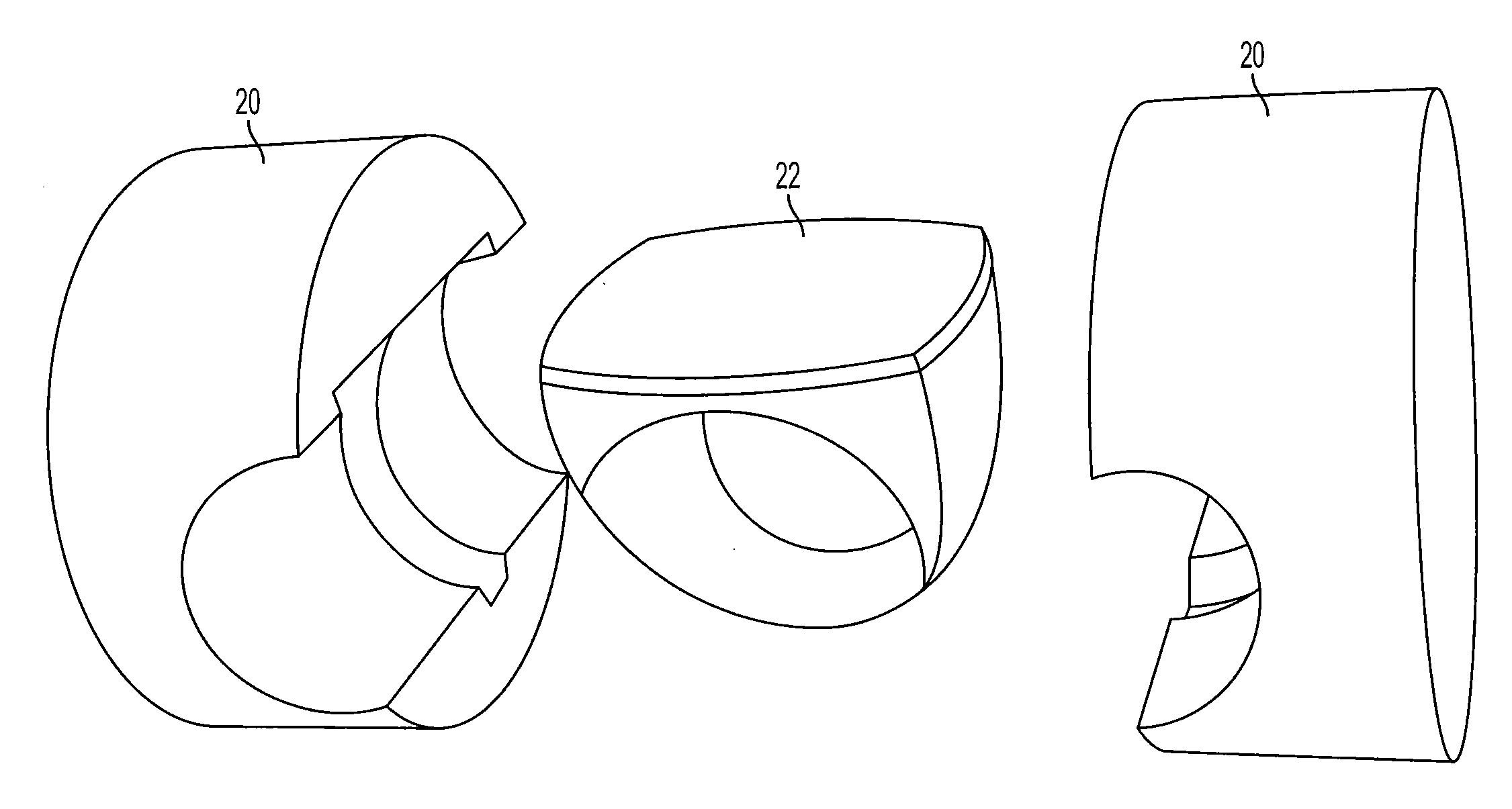

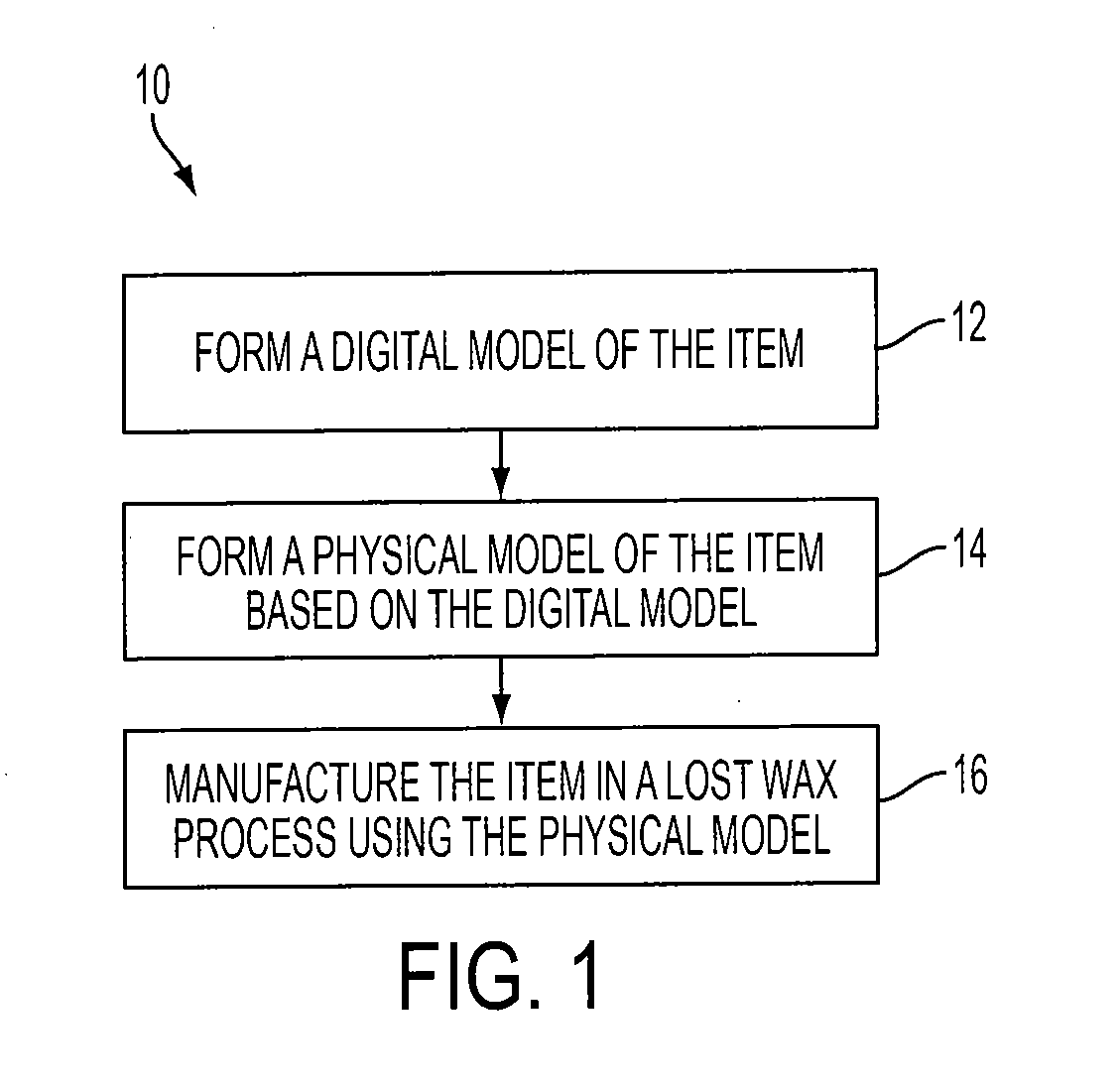

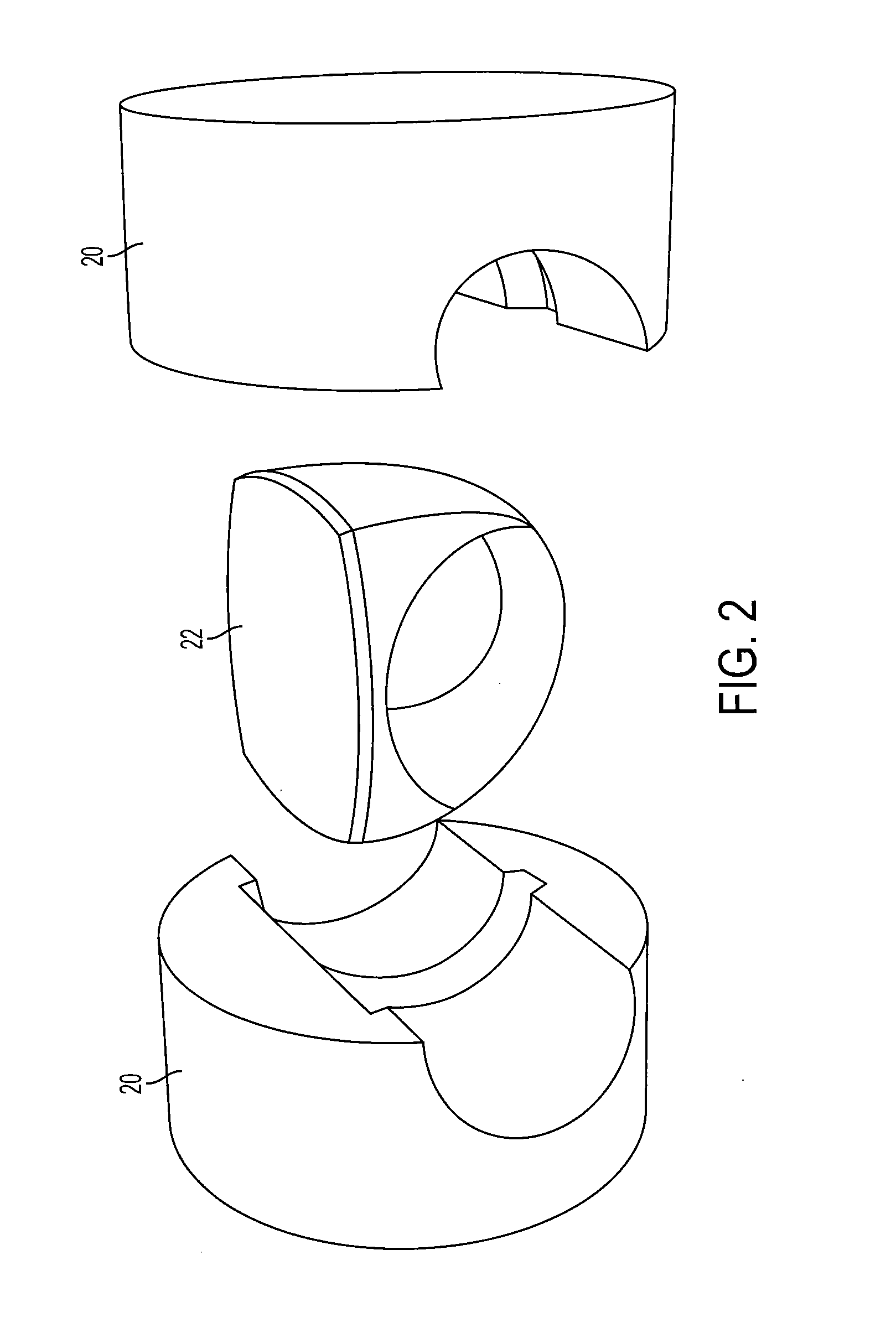

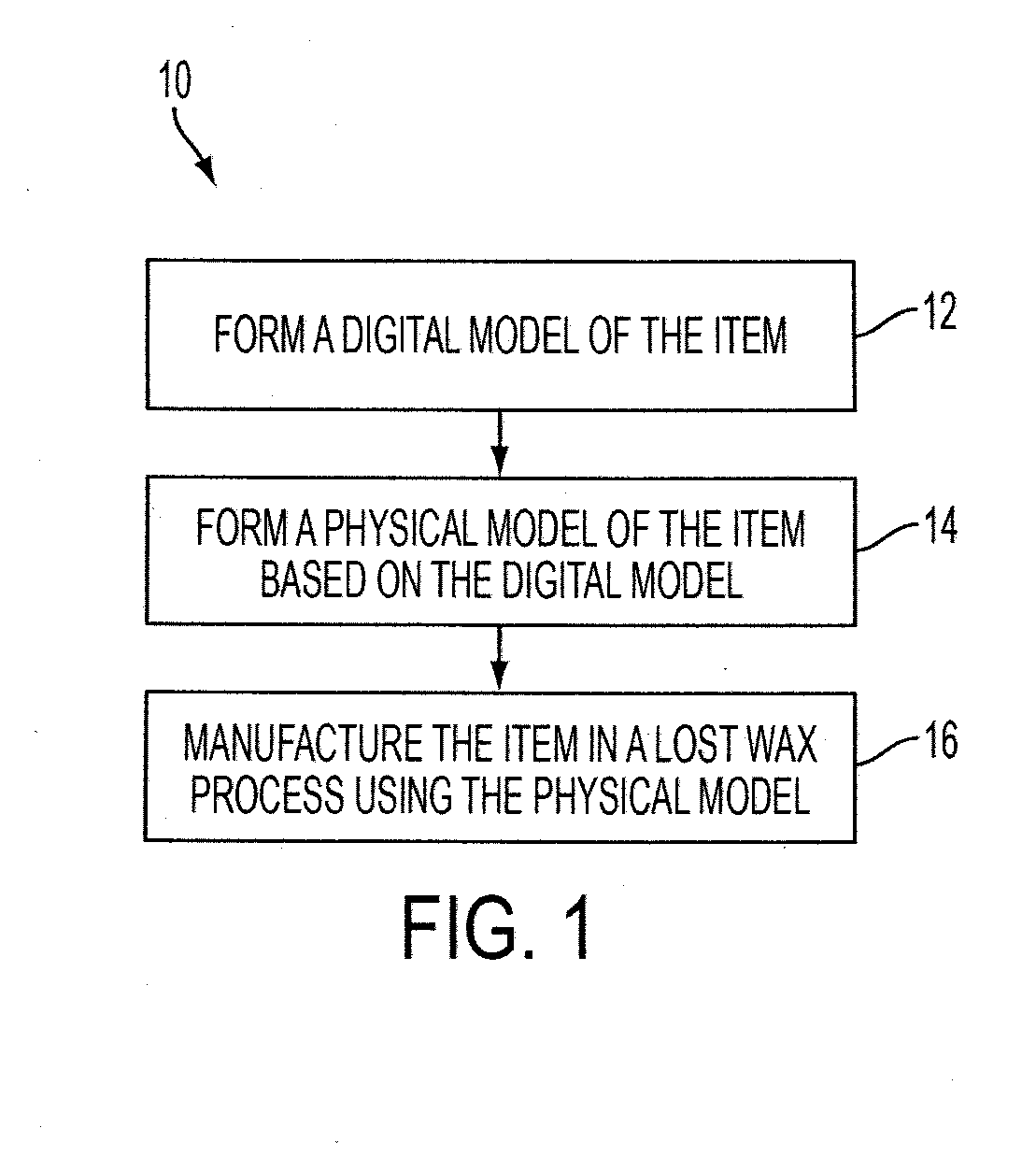

Method for digital manufacturing of jewelry items

In various embodiments, digital manufacturing of jewelry items is provided, including a physical process and software automation for implementing the physical process. Further, models formed during the process, as well as the resultant jewelry items, are provided. In some embodiments, the method comprises forming a digital model of the jewelry item, forming a physical model of the jewelry item based on the digital model, and manufacturing the jewelry item in a lost wax process using the physical model.

Owner:JOSTENS INC

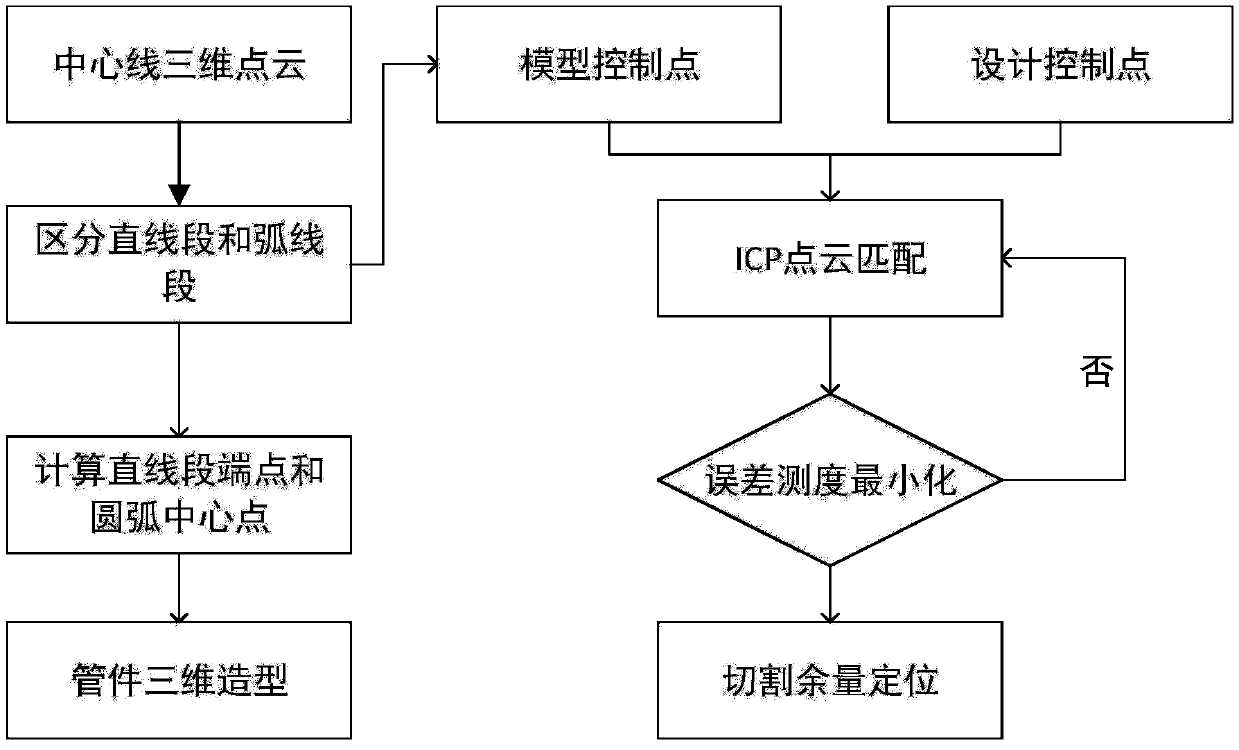

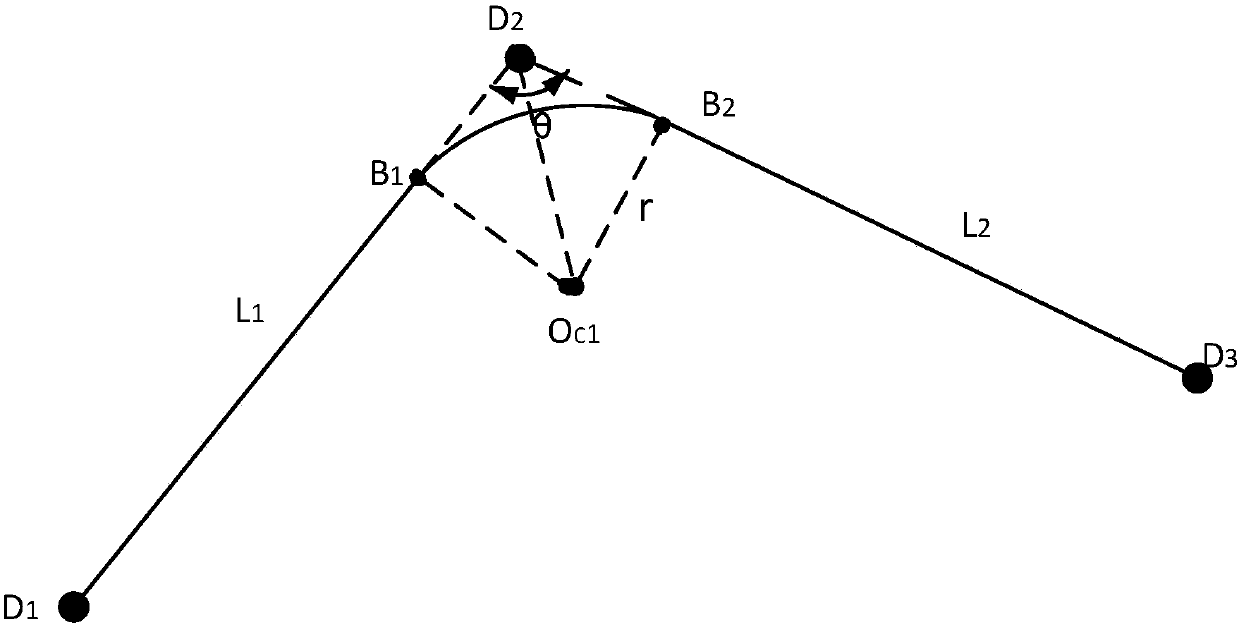

Bend pipe measuring and allowance locating method facing digital manufacture

ActiveCN108074277ARealize 3D reconstructionRealization of self-seeking cuttingImage enhancementImage analysisMatch algorithmsMultiple sensor

The invention relates to a bend pipe measuring and allowance locating method facing digital manufacture. The method comprises the following steps that multiple sensors are calibrated globally by meansof a laser tracker and a target, and coordinate systems of the sensors are unified into a global coordinate system; the sensors collect bend-pipe images and carry out edge detection and morphologicalrefinement to obtain a center line of the bend pipe in a strictly synchronous way, and 3D reconstruction of the center line is carried out in a bidirectional polar line matching algorithm; the centerline is dispersed into space point cloud, a control point, straightway end points and an arc center point of an arc segment are calculated, and 3D molding is carried out by taking the center line asa guiding line; and a design model matches a measurement model via a nearest point iteration method, the allowance position is calculated. Thus, self-locating cutting and welding of the bend pipe is realized, and the digital manufacturing process of the bend pipe is accelerated.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

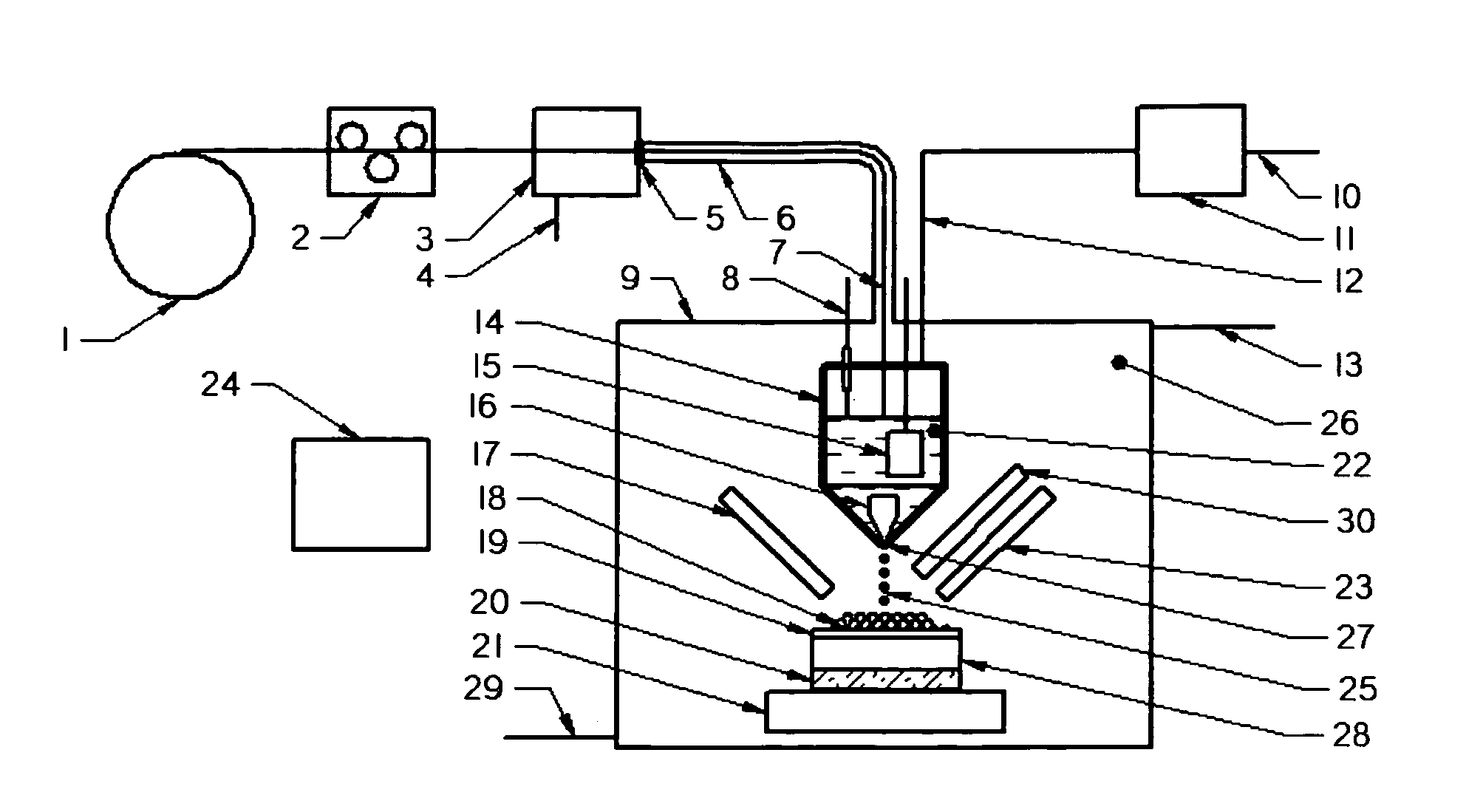

Liquid Metal Digital Manufacturing System

InactiveUS20130287934A1Reduce oxideReduce other contaminationAdditive manufacturing apparatusVacuum evaporation coatingProduction rateMelting tank

A process and apparatus for the production of metal parts by layered manufacturing starting from wire raw material comprising of the steps of; descaling of the wire; creating and maintaining a melt pool of the metal in a melt chamber; expelling controlled amounts of melt from the melt chamber in predetermined layer patterns, which solidify to form a desired object; managing the solidification parameters to achieve the deposit cross sections desired and depositing a removable support material to assist in maintaining the geometry of the desired metal deposit. Said apparatus is capable of higher production rate than other metal layered manufacturing systems available commercially and can be used for any metal alloy or non-metal material that can be supplied in wire form and that is within the melt capacity of this invention.

Owner:RAMSUNDAR PALLANT SATNARINE

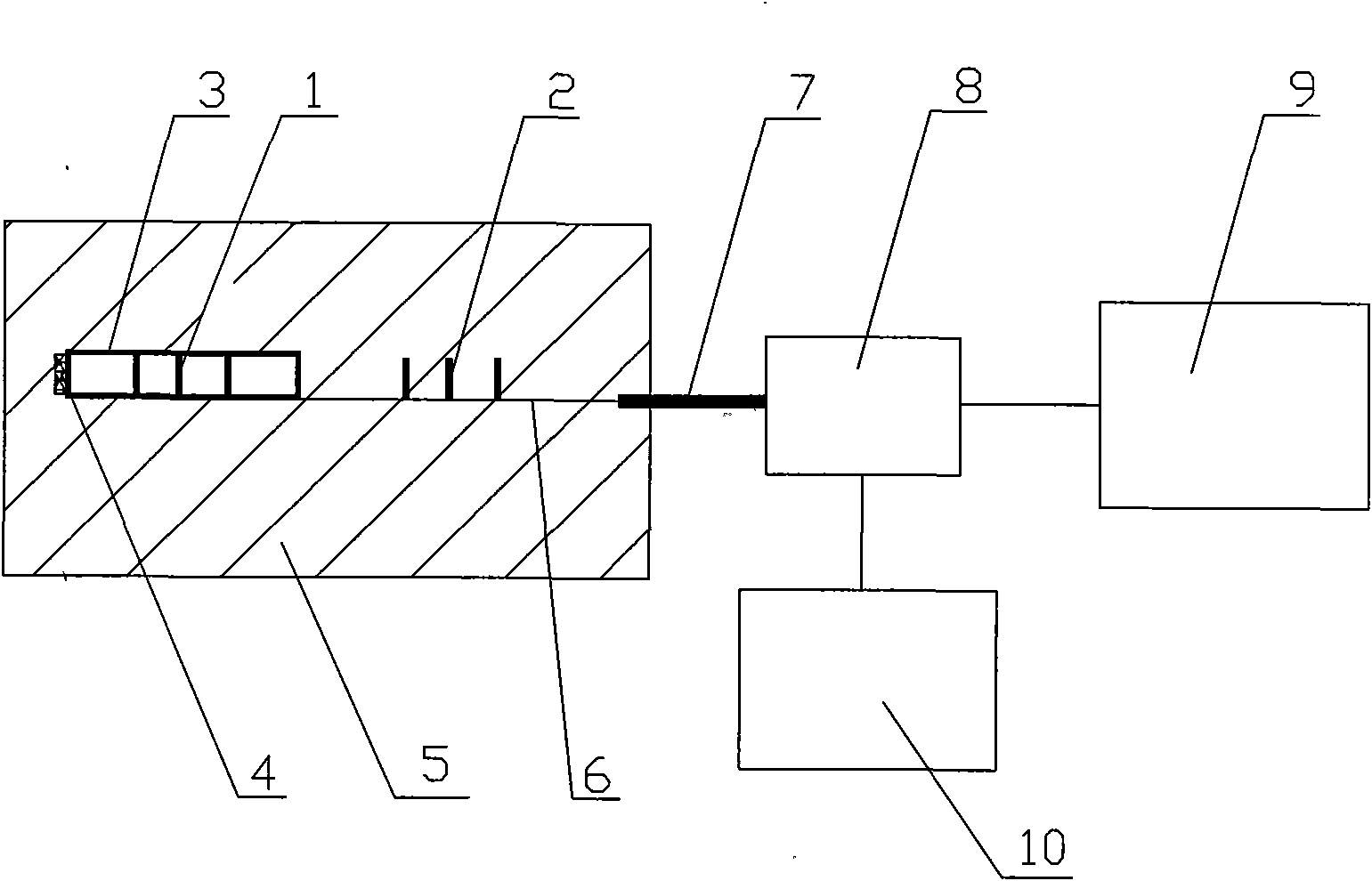

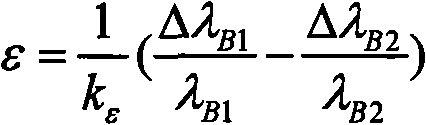

Fiber grating monitoring method for curing residual strain of composite materials

InactiveCN101571491ALittle effect on mechanical propertiesRealize online monitoringMaterial analysis by optical meansUsing optical meansFiberResidual strain

The invention provides a fiber grating monitoring method for the curing residual strain of composite materials. The method comprises the following steps: (1) manufacturing a sensor string comprising grating temperature sensors and grating temperature strain sensors; (2) embedding fiber grating sensors in to-be-monitored parts of a composite material in the process of layering the composite material; (3) reasonably selecting a molding process for the composite material, such as hot-pressing reactor, compression molding and the like; (4) cooling the composite material to room temperature after curing molding is performed and using a grating demodulation instrument to monitor the wavelength value of the highest reflection peak of a reflection spectrum of a fiber grating; and (5) utilizing epsilon=1 / k epsilon((delta lambda B1 / lambda B1)-(Delta lambda B2 / lambda B2)) to calculate the curing residual strain of the composite material. The method can realize the measurement of the residual strain of key parts of the structure of the composite material on the premise of not destroying the structure, and has the advantages of stable reliable measured values and good repeatability; in addition, the embedded grating can continue to play a role in monitoring the structure health of the composite material. The method organically combines the digital manufacturing and the health monitoring of the composite material, thereby realizing the on-line monitoring for the manufacturing process of the composite material.

Owner:SHENYANG INST OF AERONAUTICAL ENG +1

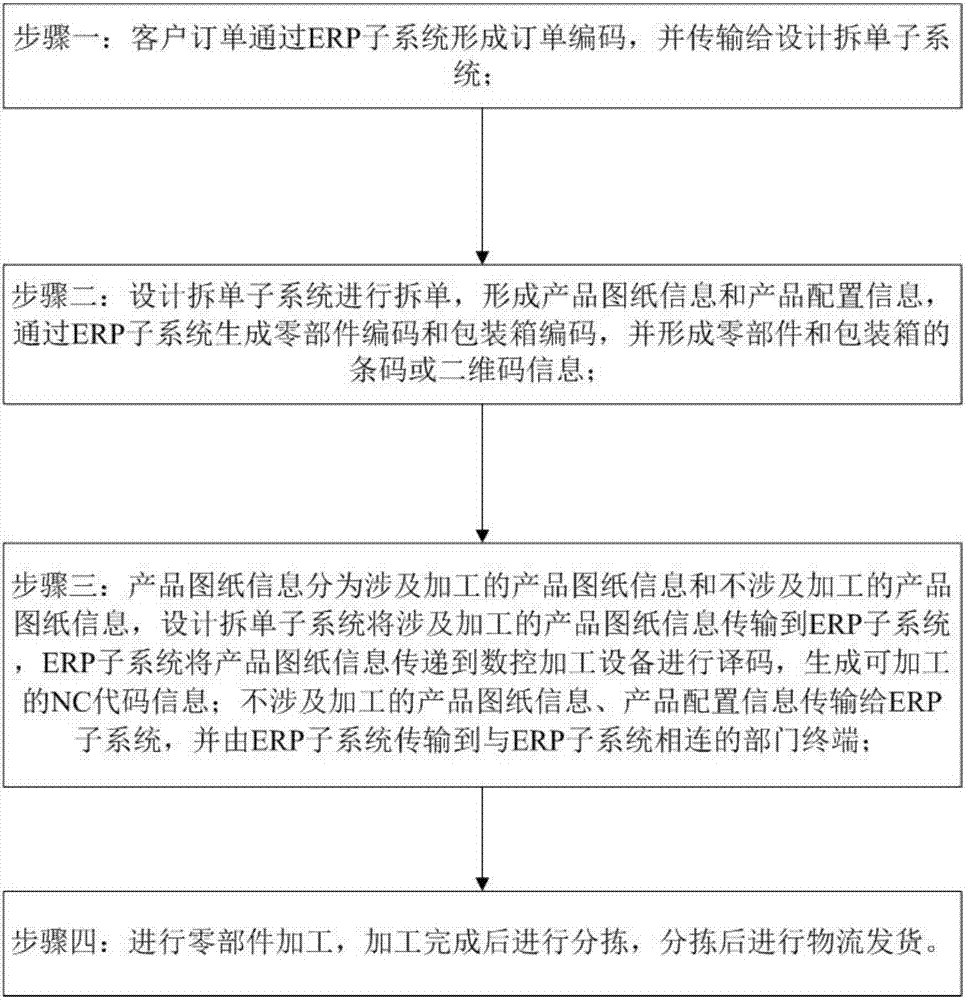

Large-scale customized furniture digital manufacturing information flow circulation method

InactiveCN107967654AImprove circulation efficiencyData processing applicationsAutomatic testing and analysing marked record carriersNumerical controlMass customization

The invention discloses a large-scale customized furniture digital manufacturing information flow circulation method. An order code is formed through an ERP subsystem for a client order and is transmitted to a design order analyzing subsystem; the design order analyzing subsystem is used for analyzing the order code to acquire the product drawing information and the product configuration information, a part code and a packing case code are generated through the ERP subsystem, and bar codes or the two-dimensional code information of a part and a packing case are generated; the product drawing information comprises the product drawing information related to processing and the product drawing information not related to processing, the product drawing information is transmitted by the ERP subsystem to numerical control processing equipment for decoding, and the NC code information which can be processed is generated; the information is further transmitted through the ERP subsystem to a department terminal connected with the ERP subsystem, and part processing is carried out. The method is advantaged in that circulation efficiency of the customized furniture information in the manufacturer product processing process is improved.

Owner:NANJING FORESTRY UNIV

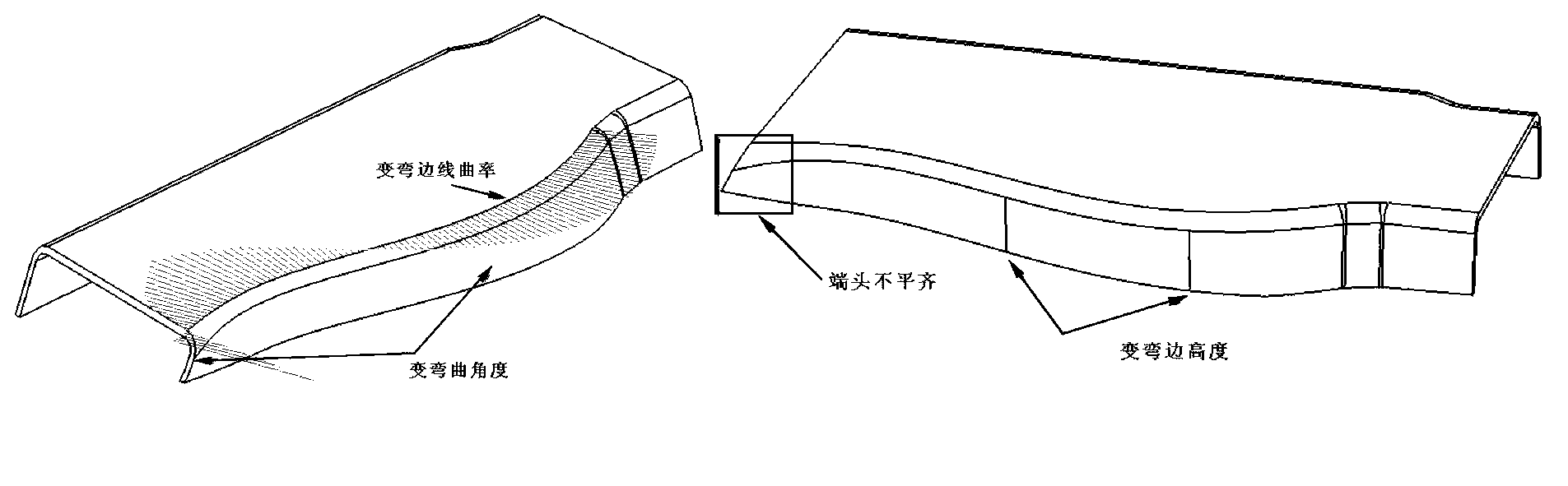

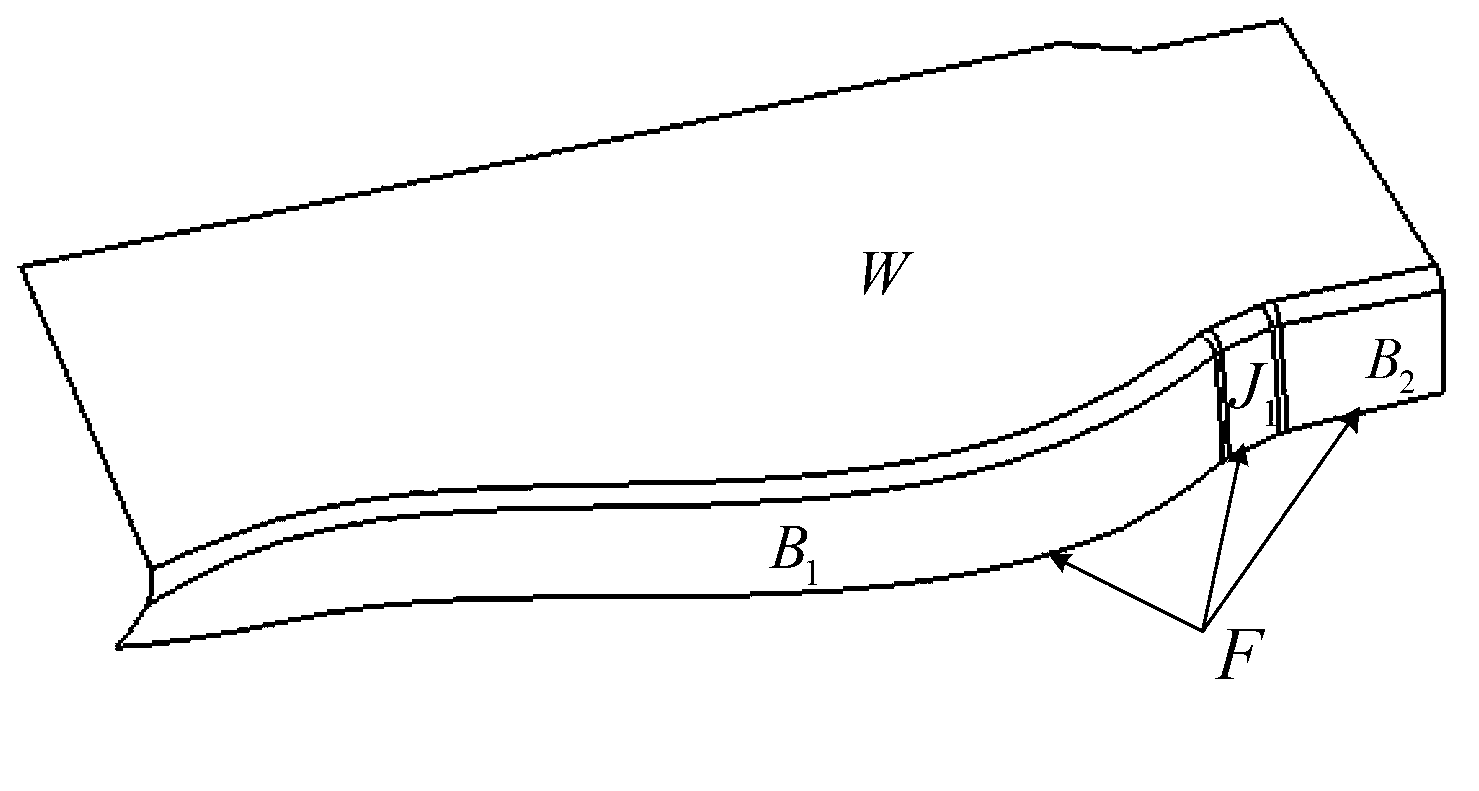

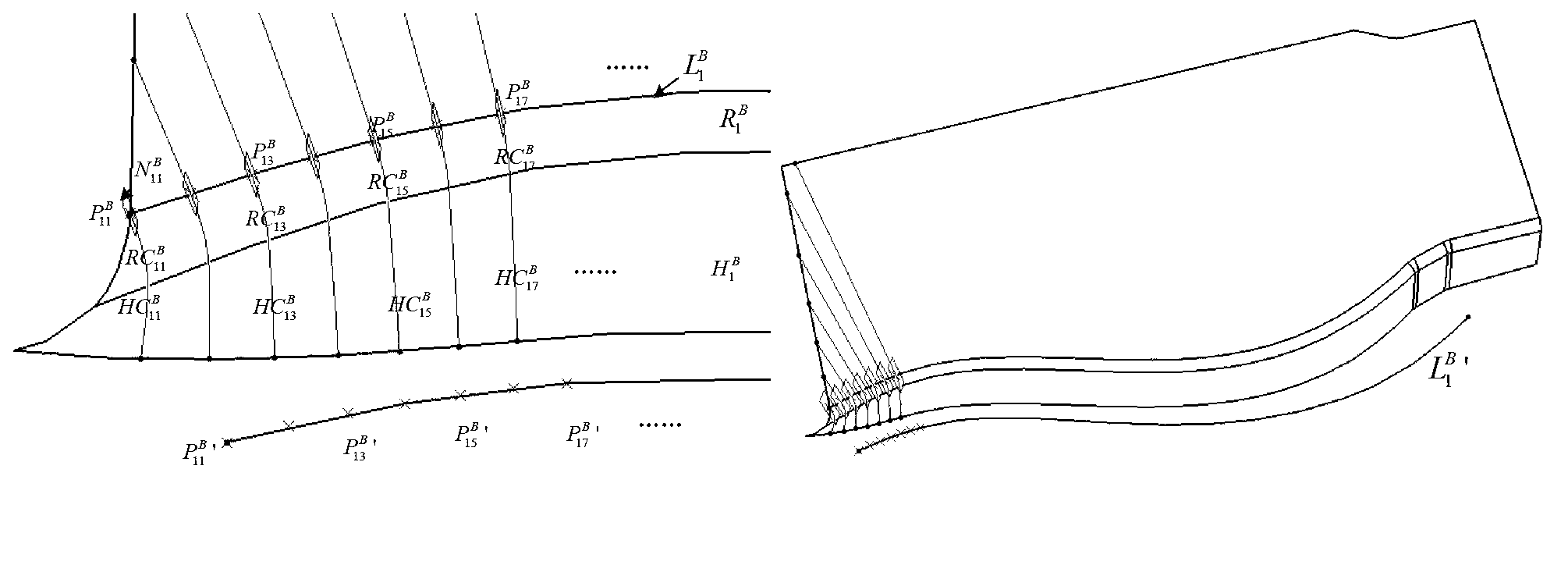

Unfolding method for complex flange of frame rib sheet metal part

ActiveCN103008497ASolve unrolled puzzlesAircraft componentsStructural engineeringDigital manufacturing

The invention relates to an unfolding method for a complex flange of a frame rib sheet metal part and belongs to the technical field of aircraft manufacturing. A digital manufacturing technology is adopted for dividing the flange of the frame rib sheet metal part into a bent area and a sunken area, respectively unfolding and then jointing and shearing, so that an unfolded outline of the flange is obtained. The unfolding problem of the frame rib sheet metal part with the complex flange is solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

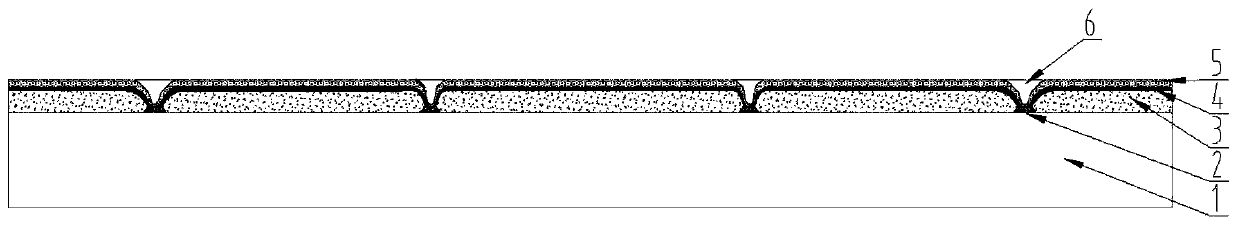

Ceramic product with digital process manufacturing mold effect texture and manufacturing method of ceramic product

The invention relates to a ceramic product with a digital process manufacturing mold effect texture. The ceramic product has a three-dimensional concave and convex mold effect texture on the surface,the mold effect texture is made in a digital process mode, and the mold effect texture is formed by forming a texture pattern of a sinking depth of 0.5-3mm in the surface of a glaze layer including apattern layer of a product. According to the ceramic product provided by the invention and the manufacturing method of the ceramic product a conventional physical mold is replaced by the mold effect texture which is made by using a novel digital process and has a controllable sinking depth of 0.5-3mm, digital designing output is directly implemented, the texture can be achieved without changing pressing molds, directions modern environment protection and automatic intelligent manufacturing can be well met, in addition, defects of surface three-dimensional feelings and sharpness of a conventional texture mold can be well solved, the mold effect can be good in three-dimensional feeling, reality and tough feeling, and the digital manufacturing process can be easy to use.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +2

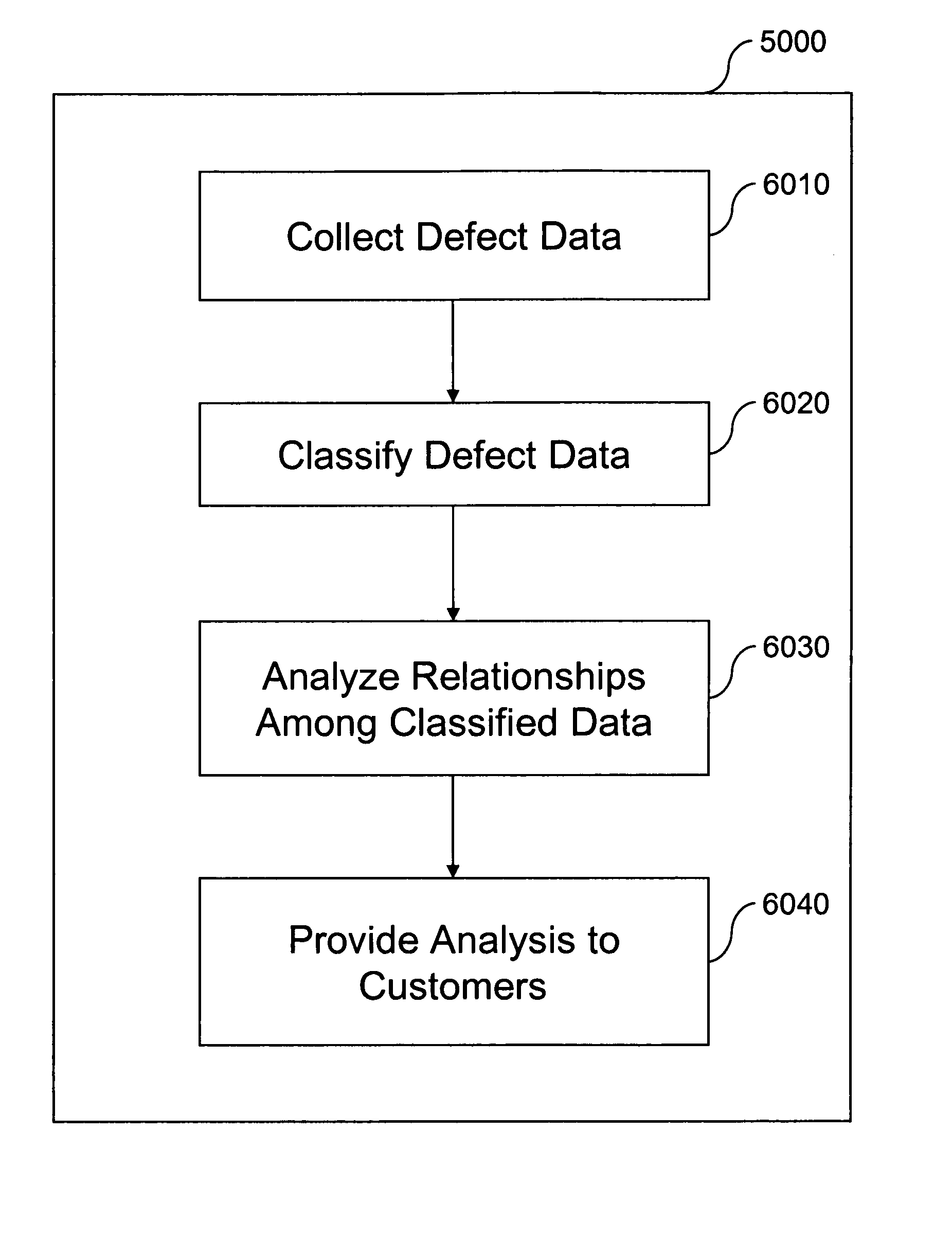

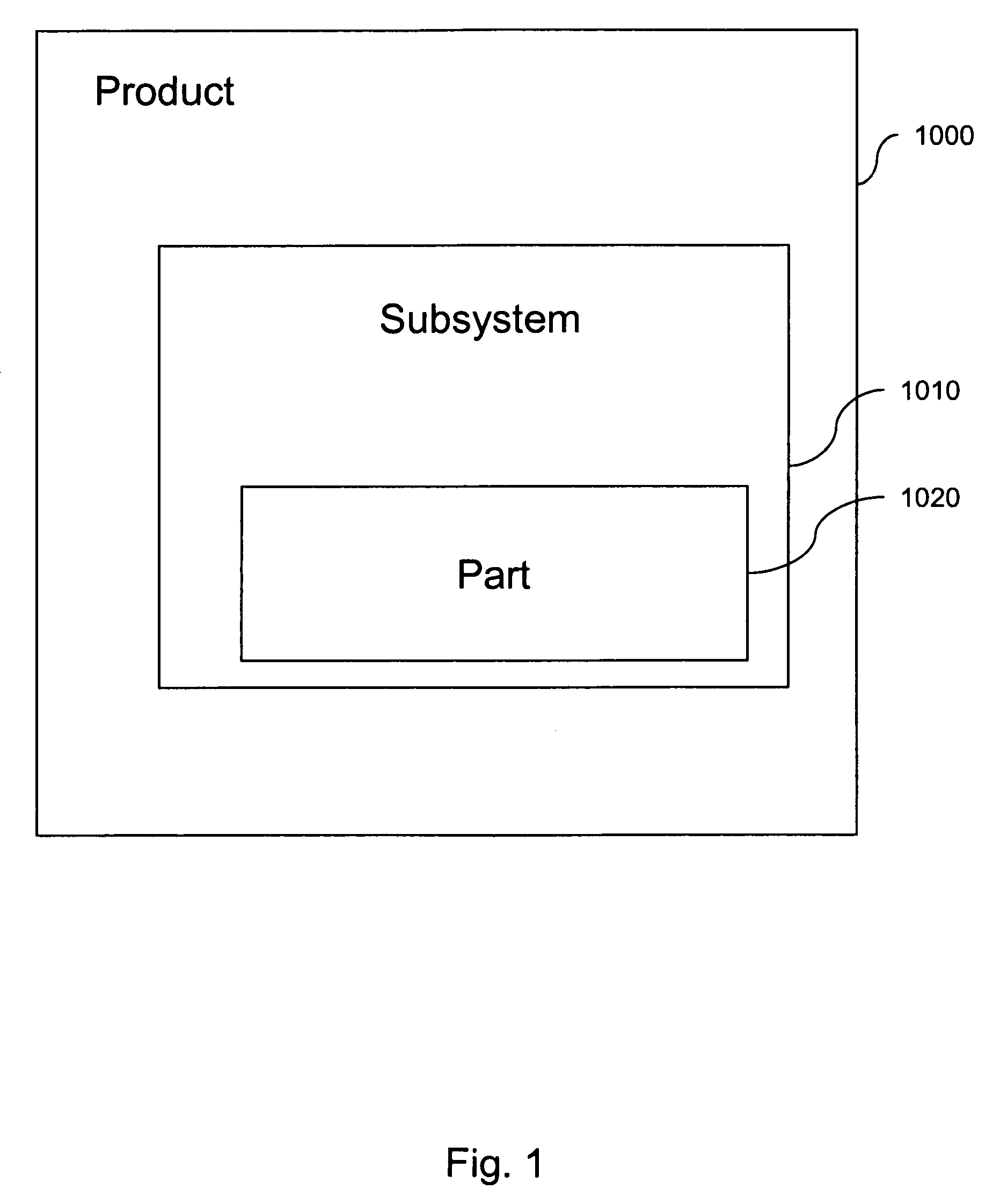

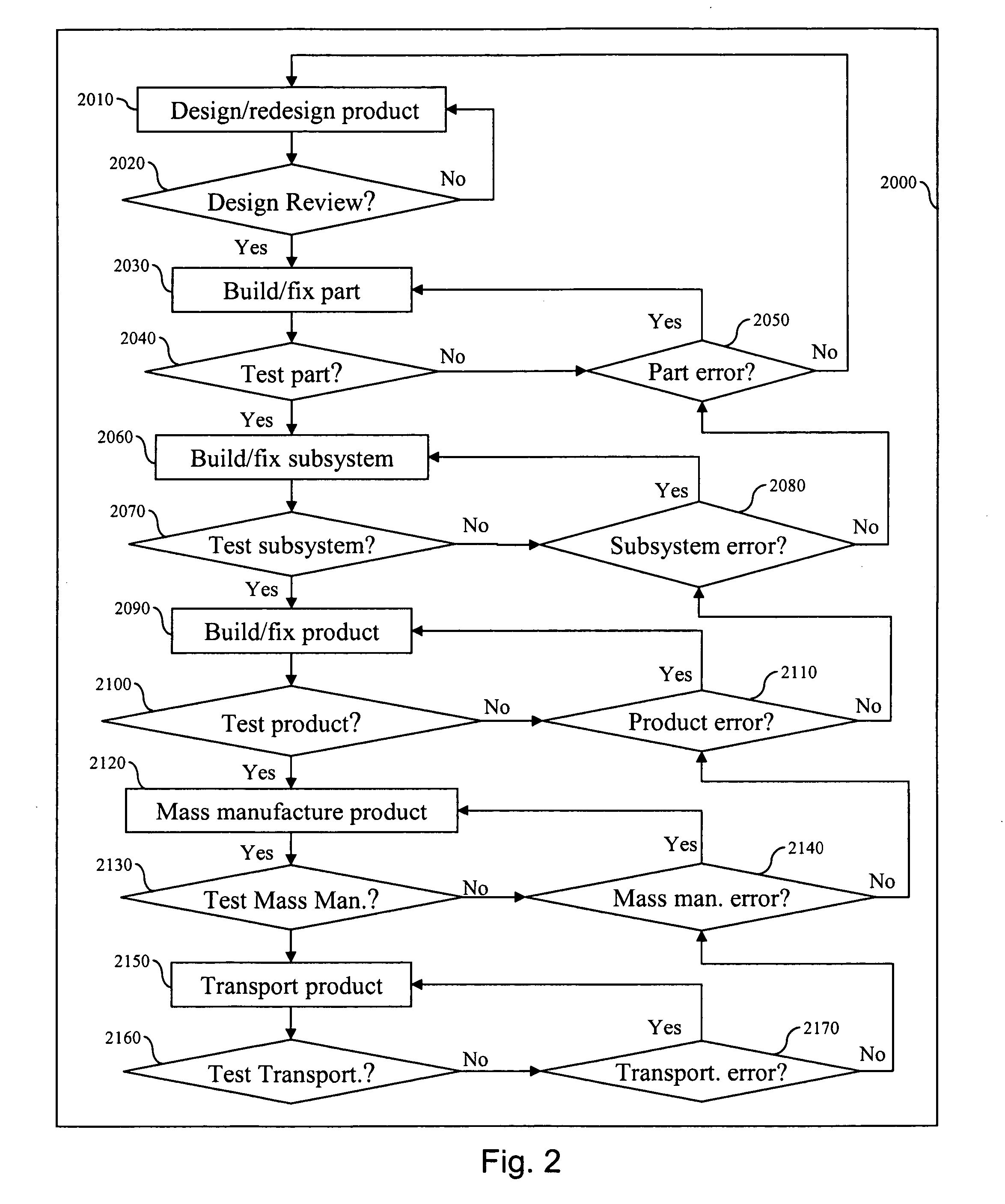

Method to improve requirements, design manufacturing, and transportation in mass manufacturing industries through analysis of defect data

Owner:GLOBALFOUNDRIES INC

CAD/CAM digital manufacturing method for bracket movable denture

ActiveCN109223218AQuality improvementReduce manual dependenceArtificial teethDenturesDigital manufacturing

Owner:邢浩

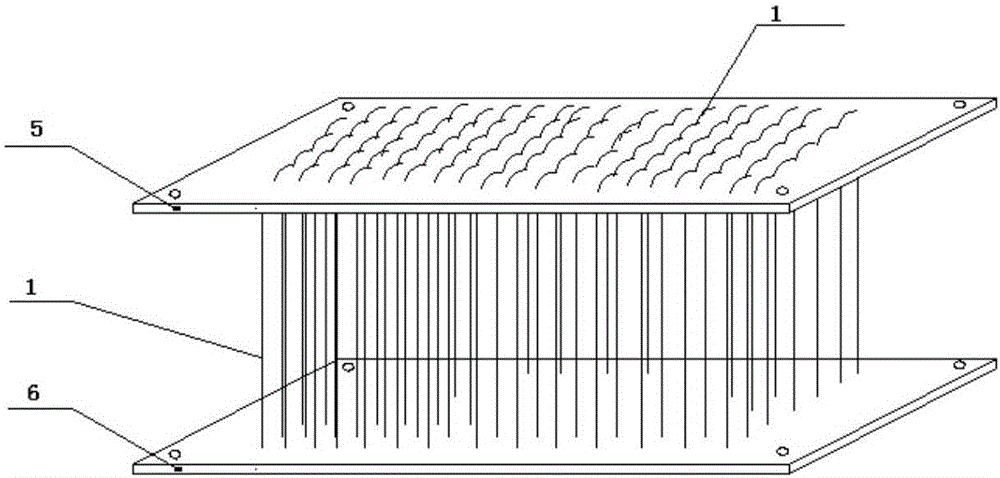

Digital manufacturing method for light permeable concrete

ActiveCN105946108AQuick layoutPrecise and diverse layoutCeramic shaping apparatusBuilding componentsNumerical controlFiber

The invention discloses a digital manufacturing method for light permeable concrete. The method comprises the following steps that the density, array modes and patterns of optical fibers are designed through computer aided software; light guiding fibers are fixed to two optical fiber substrates in a penetrating-inserting mode through a braiding mechanism and a wire drawing mechanism, and different arrangement modes and separation distances of the optical fibers are achieved through stepping displacement of the two assembled optical fiber substrates; the optical fibers in certain lengths are reserved, the upper optical fiber substrate and the lower optical fiber substrate are separated after optical fiber arrangement is completed, and the near optical fibers are bonded into bundles through a binder so as to improve the mechanical strength of the optical fibers and protect the surfaces of the optical fibers; and the optical fiber substrates with the optical fibers arranged in advance are placed in a mold for concrete pouring and forming, and then cured to the demolding period, and the optical fiber substrates and the superfluous optical fibers are ground to obtain the light permeable concrete. The computer numerical control technology is firstly adopted for the optical fiber arrangement process of the light permeable concrete, and automatic rapid production of the light permeable concrete can be achieved.

Owner:WUHAN UNIV OF TECH

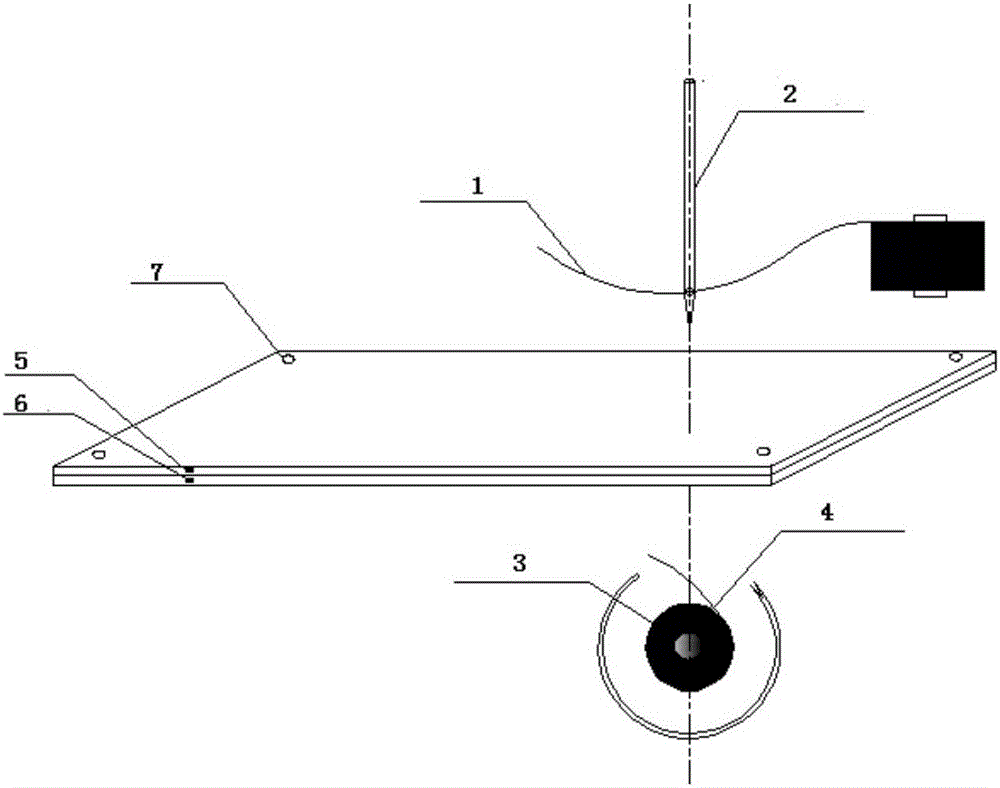

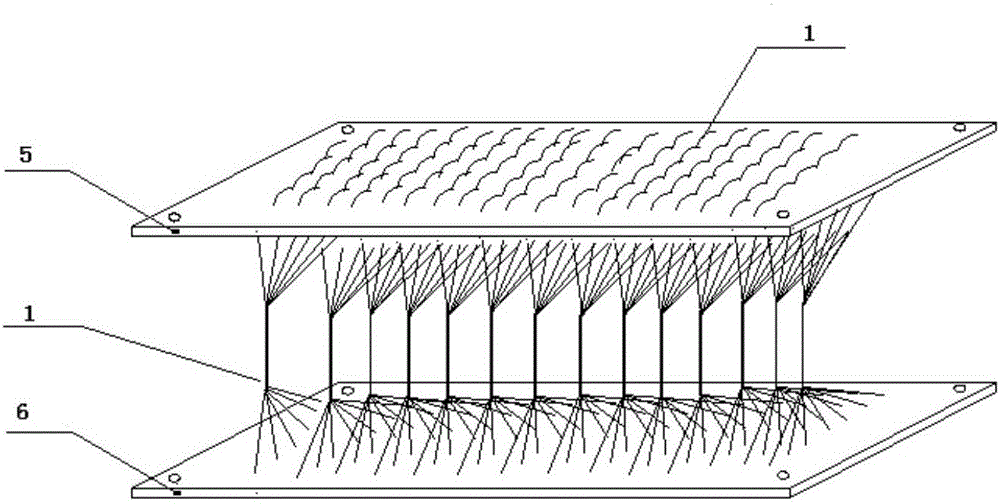

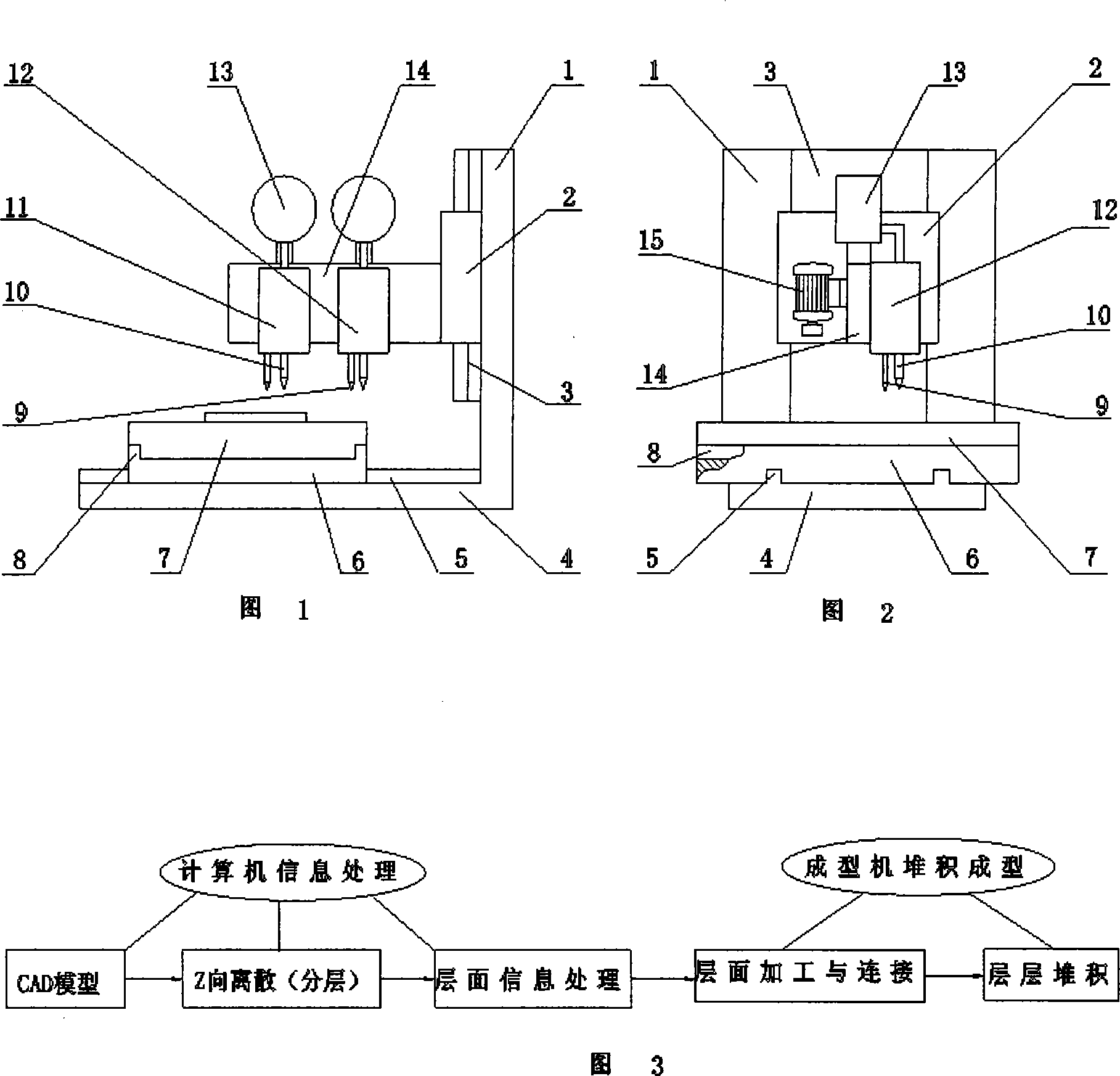

Digital control manufacturing device for abrasive wheel

InactiveCN101186031AAccurate locationHigh technical contentGrinding devicesMechanical equipmentDigital manufacturing

The invention relates to a mechanical equipment, namely a grinding wheel layered digital manufacturing device. The invention is characterized in that the device consists of a mechanical part and a computer control part. The mechanical part consists of a platform 7 used for bearing a work piece, an operation part and a slide way used for movement of the platform 7 or the operation part, etc. The operation part comprises a raw material box used for feeding raw materials to the platform 7 and a laser generator 13 used for sintering and forming the raw materials. When in work, various technical parameters are transmitted into the computer control system ahead, and then under the control of a computer program, the grinding wheel raw materials are layered and put on the platform and are sintered into shape by a laser. The granule position of the grinding material of the grinding wheel manufactured by the device is accurate, and the protruding height can be controlled. The scraps-containing room is proper and the solidified strength is enough, and the later finishing can be avoided and the shape can be randomly selected. The manufacturing cost is low and the service life is long. The grinding heat loss can be largely reduced by the device and the device can meet high processing accuracy and high manufacturing efficiency requirement. The invention provides suitable equipment for realizing the digital manufacturing of the grinding wheel.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

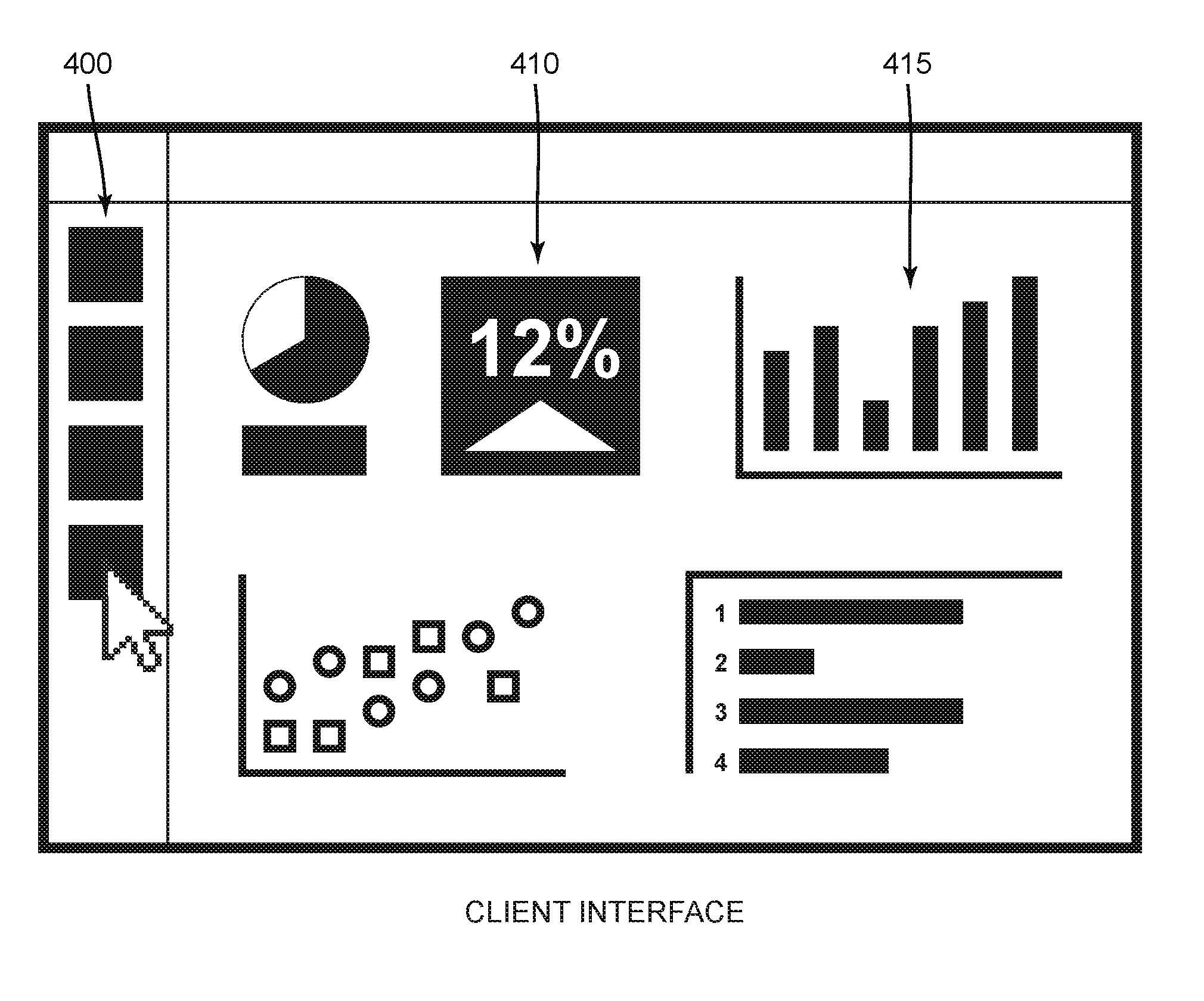

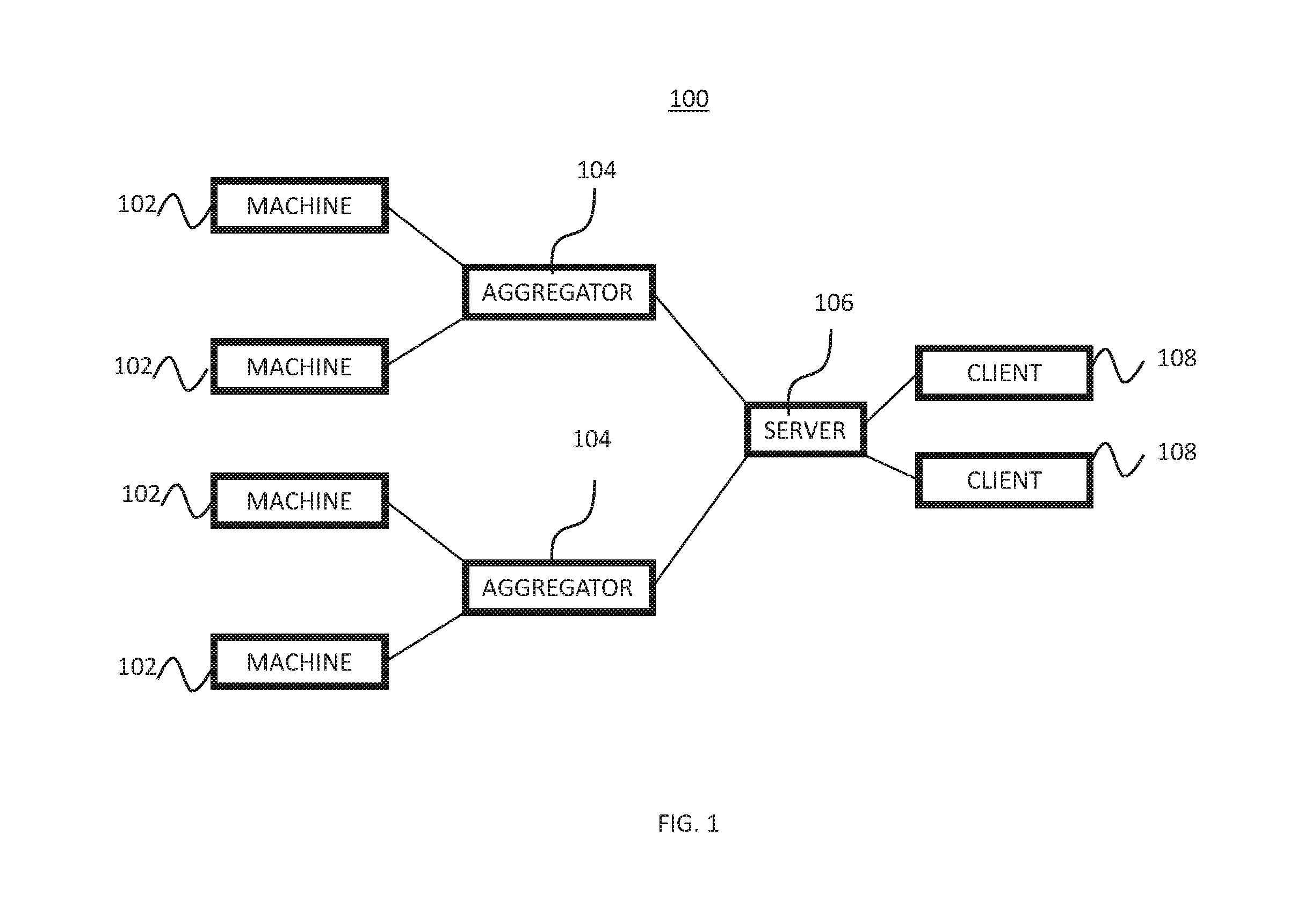

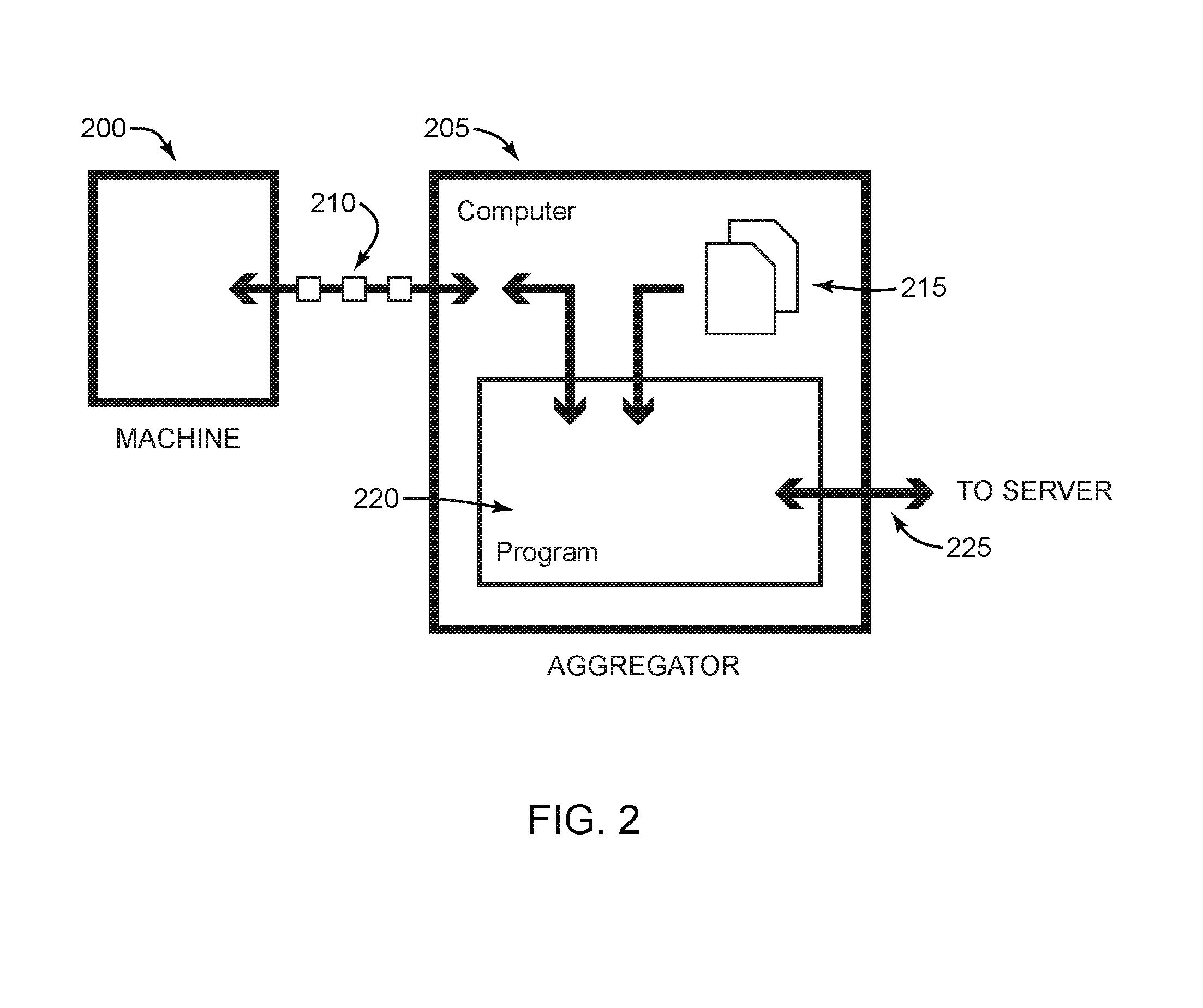

Data aggregation and analytics for digital manufacturing

InactiveUS20160328808A1Increase productivityImprove automationDigital data information retrievalResourcesData aggregatorDigital manufacturing

Systems and methods for aggregating and analyzing digital manufacturing data are disclosed. An aggregator can collect output data generated a number of digital manufacturing machines. The output data can be filtered and transmitted to a server for storage in a database. One or more clients can access the data in the database via an API.

Owner:KEMEERA INC

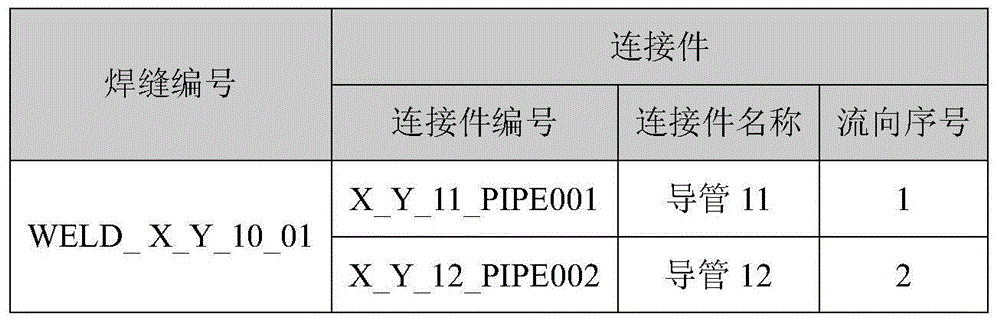

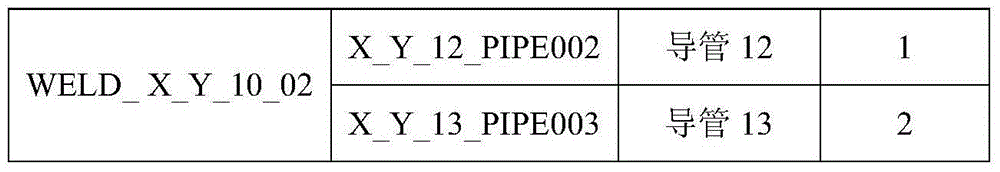

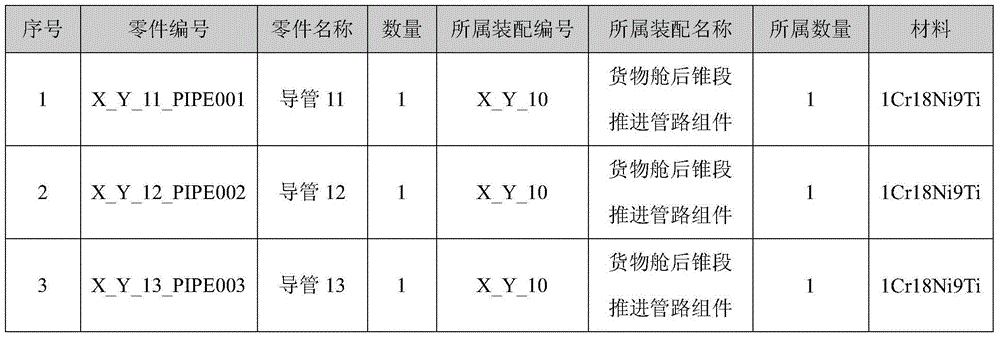

Pipeline welding line information extraction method based on three-dimensional design model

ActiveCN104933242AImprove preparation efficiencyGuaranteed accuracySpecial data processing applicationsMatingDigital manufacturing

The invention relates to a pipeline welding line information extraction method based on a three-dimensional design model, and belongs to the technical field of digital manufacturing. The three-dimensional design model information of a pipeline assembly is directly utilized, and a welding line list and a pipeline assembly mating table are automatically extracted, so that the accuracy of welding line information is ensured; the compiling efficiency of a pipeline welding process is increased effectively; and welding of pipelines is realized.

Owner:BEIJING SATELLITE MFG FACTORY

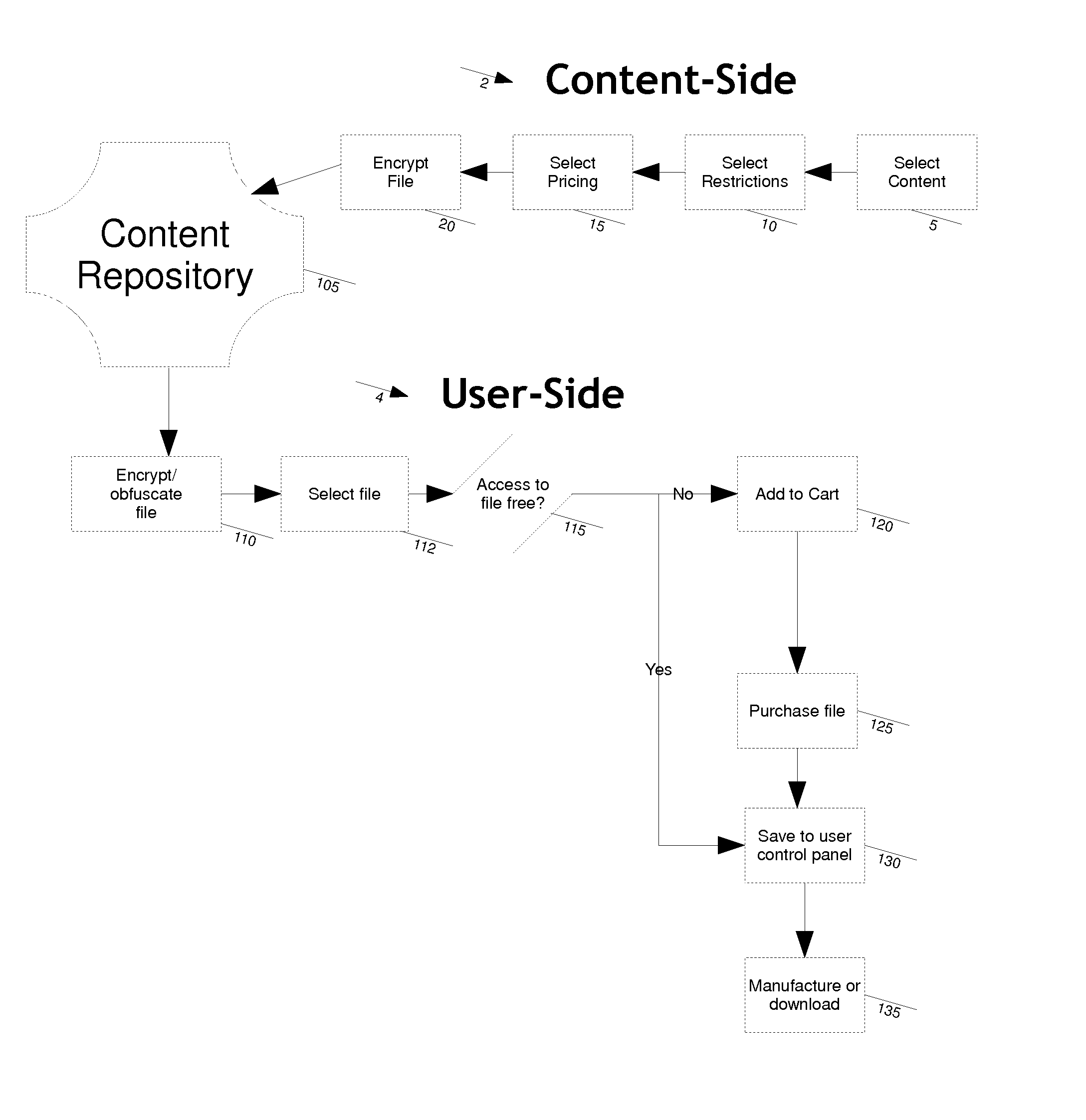

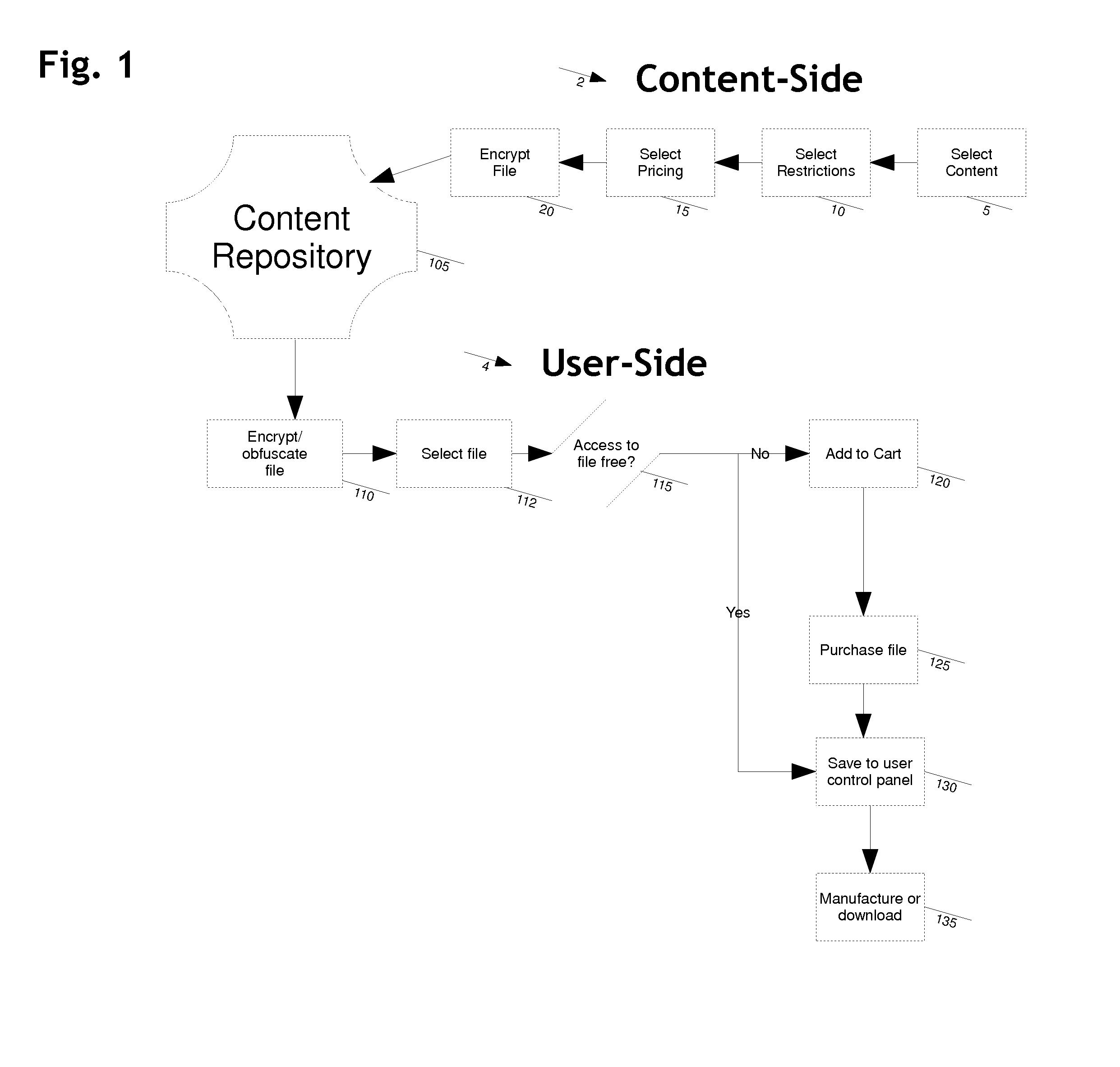

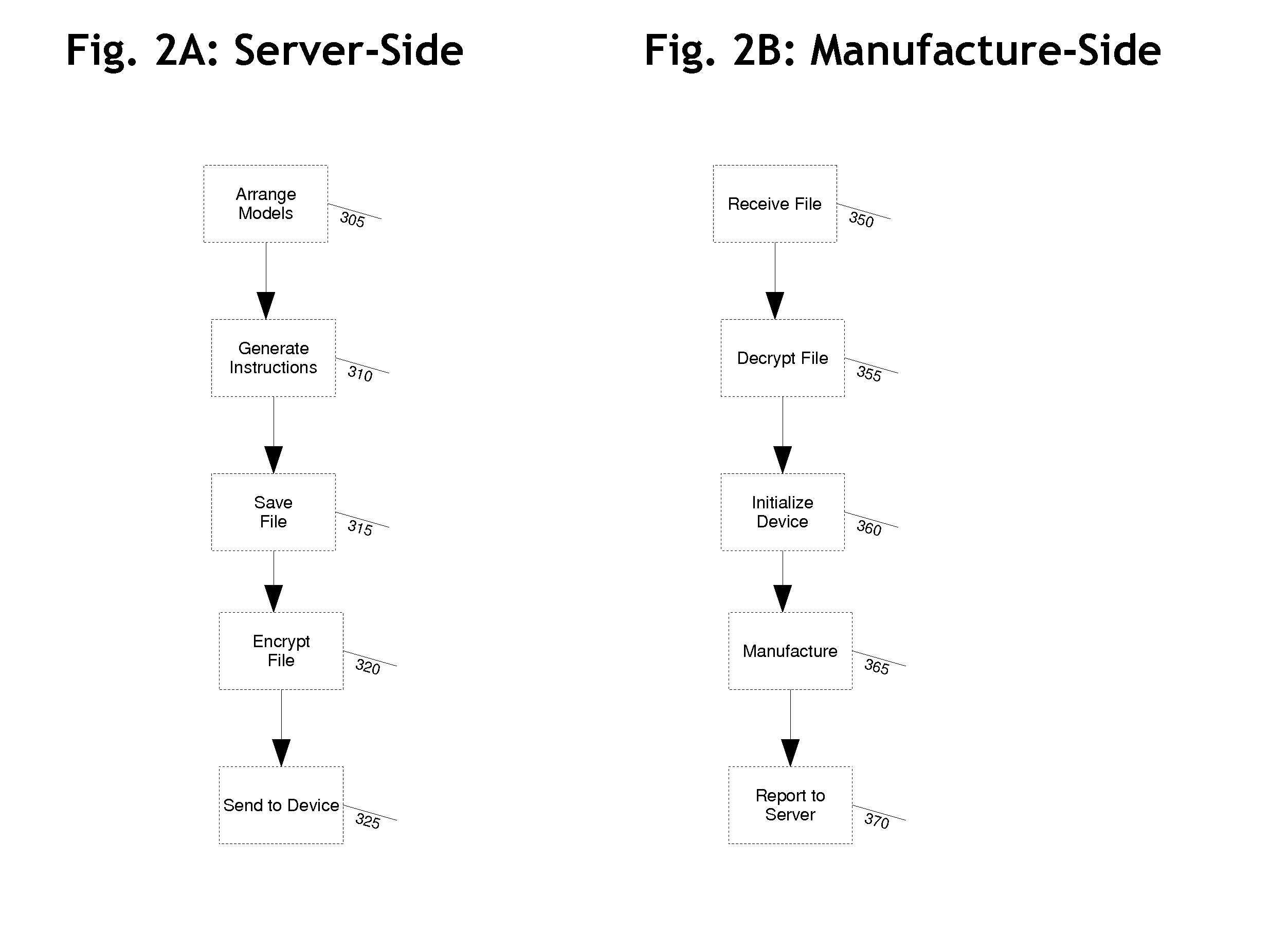

Security in Digital Manufacturing Systems

InactiveUS20140337985A1Digital data processing detailsAnalogue secracy/subscription systemsObfuscationDigital manufacturing

A system for digital manufacturing is described. A content repository includes digital manufacturing source files that have model information, pricing information, and rights information. A viewport for viewing a visual rendering of the digital manufacturing source file is included along with an obfuscation engine for obfuscating the digital manufacturing source file at the content repository and de-obfuscating the digital manufacturing source file at the viewport. Also included is a selection engine for choosing the digital manufacturing source file for digital manufacturing.

Owner:MUYSHONDT JORGE ENRIQUE

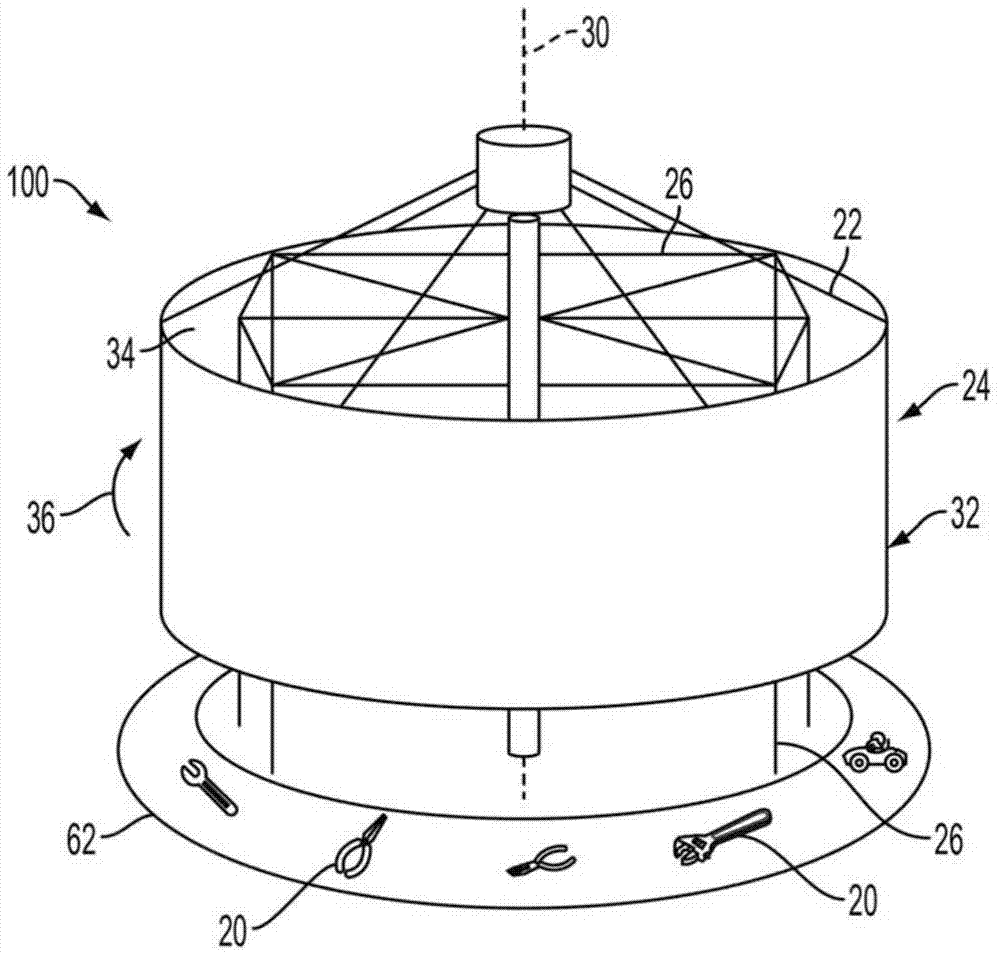

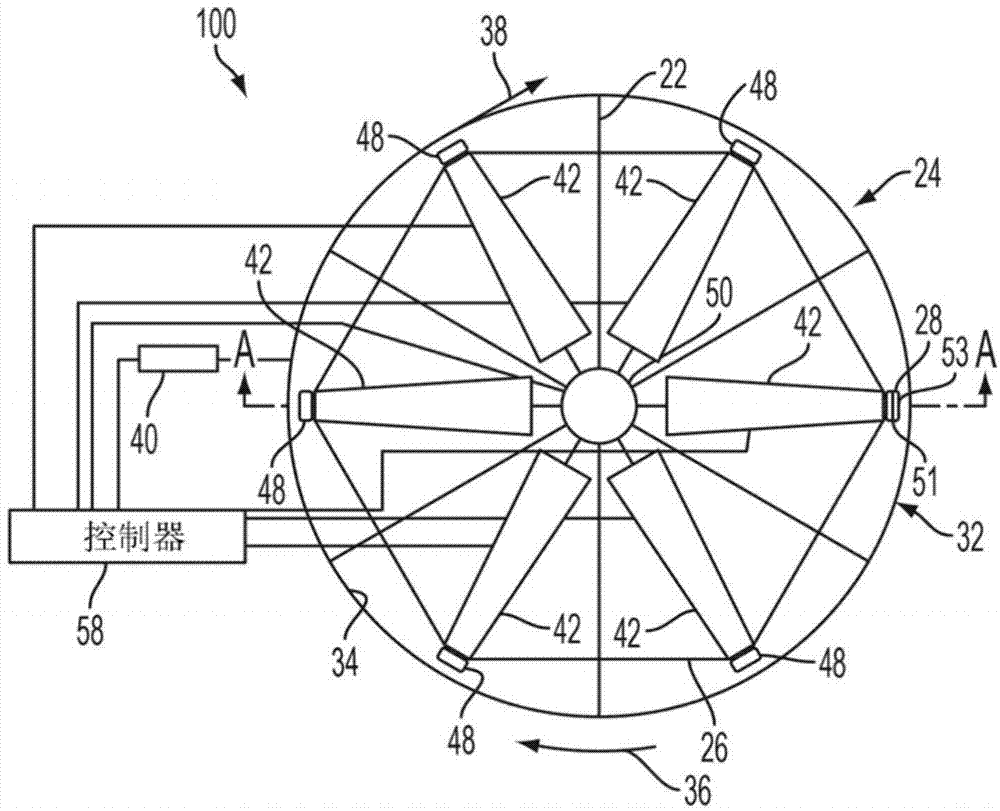

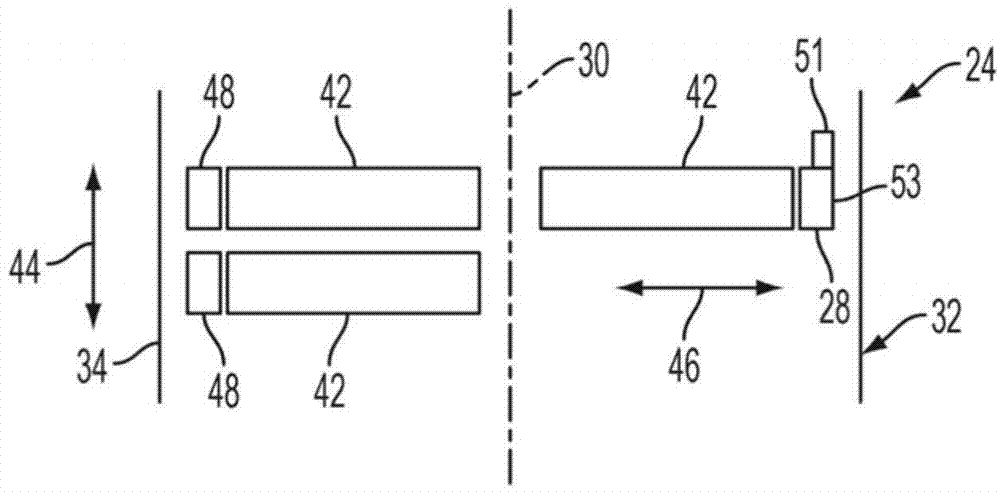

Digital Manufacturing System For Printing Three-Dimensional Objects On A Rotating Surface

ActiveCN104275800AIncreasing energy efficiency3D object support structuresImage resolutionDigital manufacturing

A printer forms a three-dimensional object on a rotating substrate. The printer includes a first driver to rotate the substrate past at least one printhead at a predetermined velocity and a controller to operate the printhead to eject material onto the substrate to form the object. A second driver is operated to move the position of the printhead perpendicular to the substrate to maintain a predetermined gap between the printhead and the layer of material most distant from the substrate. The second driver is further operable to move the position of the printhead parallel to the substrate to adjust a resolution of the ejected material. The controller interpolates an alternating signal generated from a position encoder to adjust the operation of the printhead based on the rotational position and velocity of the substrate.

Owner:XEROX CORP

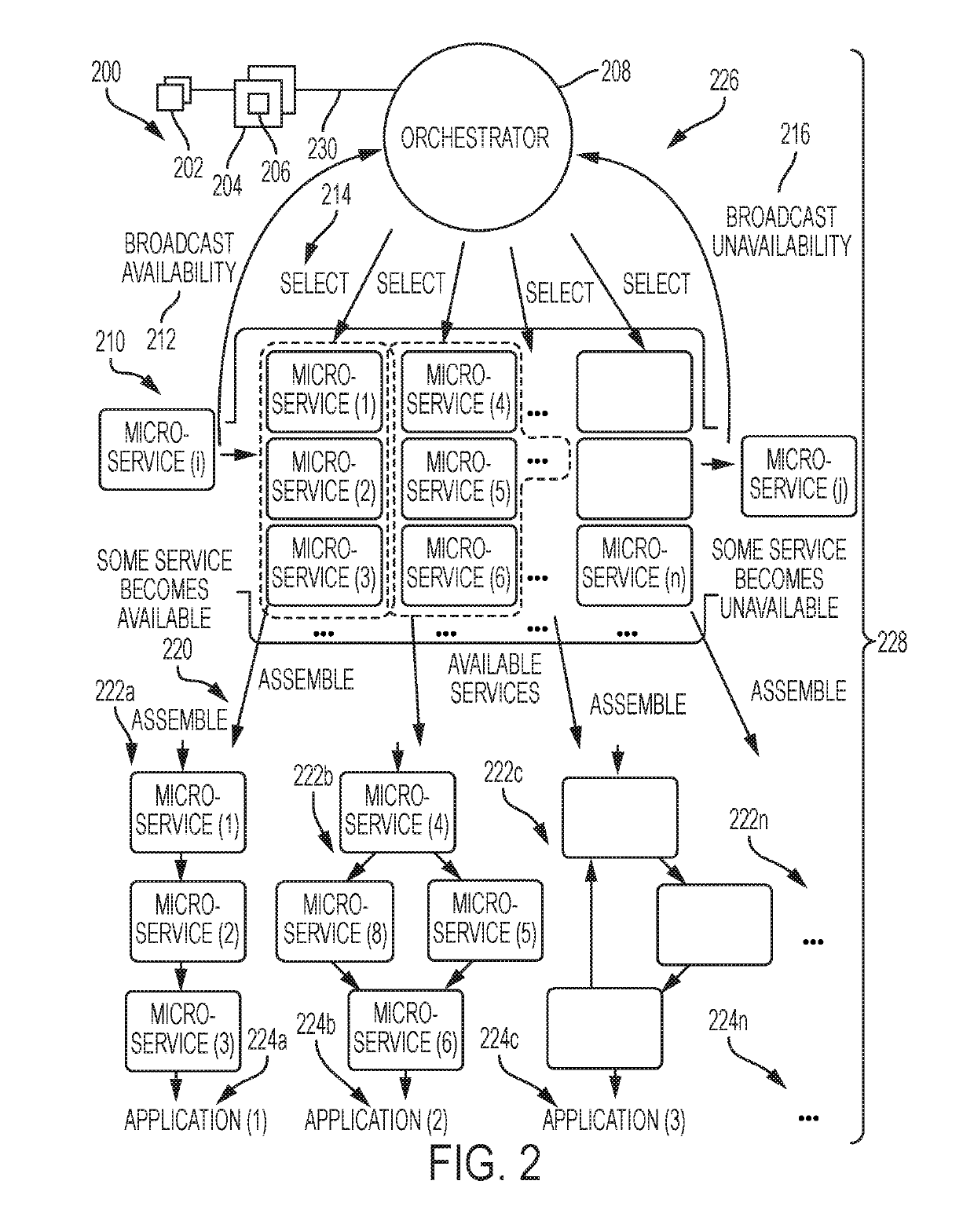

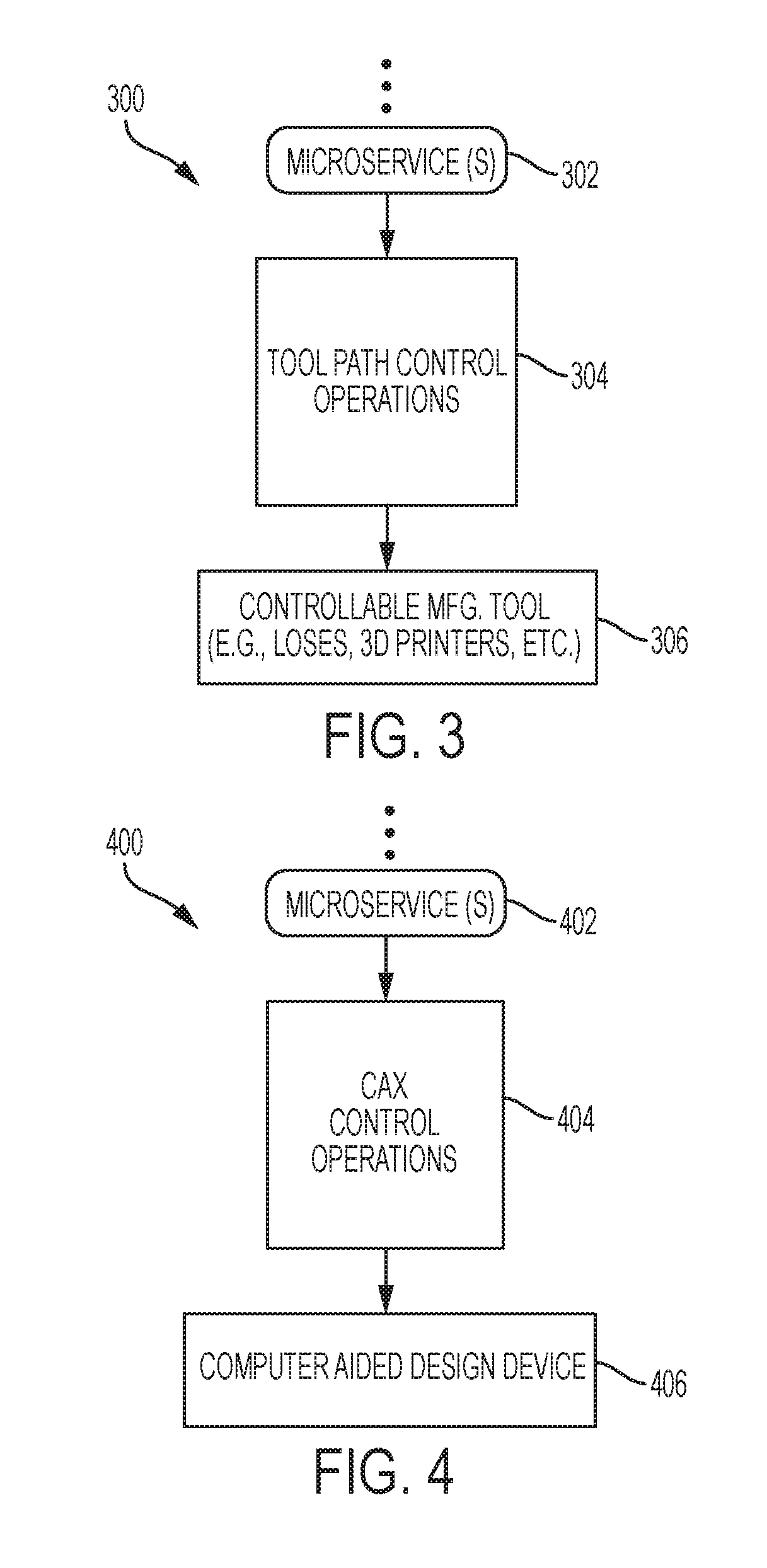

Composing Microservices through Workflows for Applications in Engineering Design and Manufacturing

An approach to architecting engineering design and digital manufacturing software systems by orchestrating several independently deployable, limited in scope, small software components (i.e., microservices). Interactions between these components are composed via first-order descriptions of workflows, allowing the construction of flexible, scalable, resilient systems.

Owner:PALO ALTO RES CENT INC

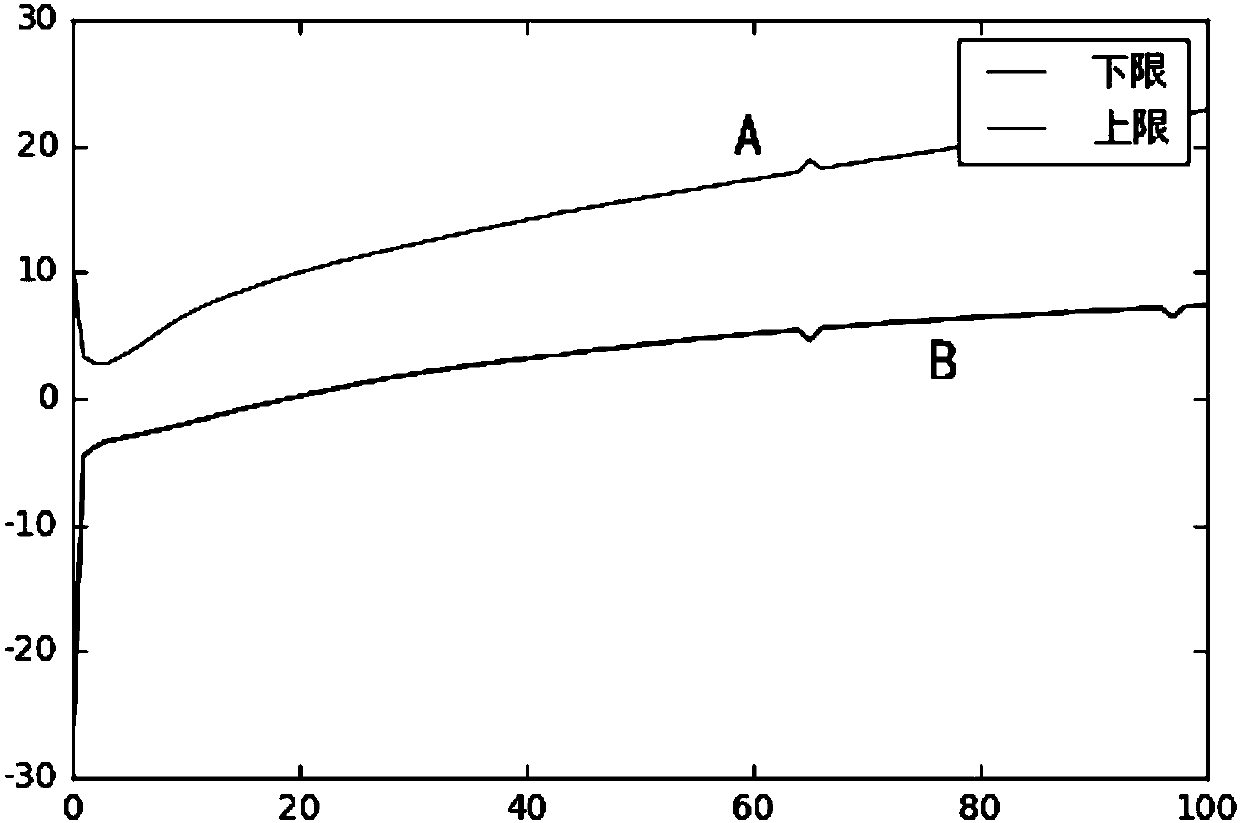

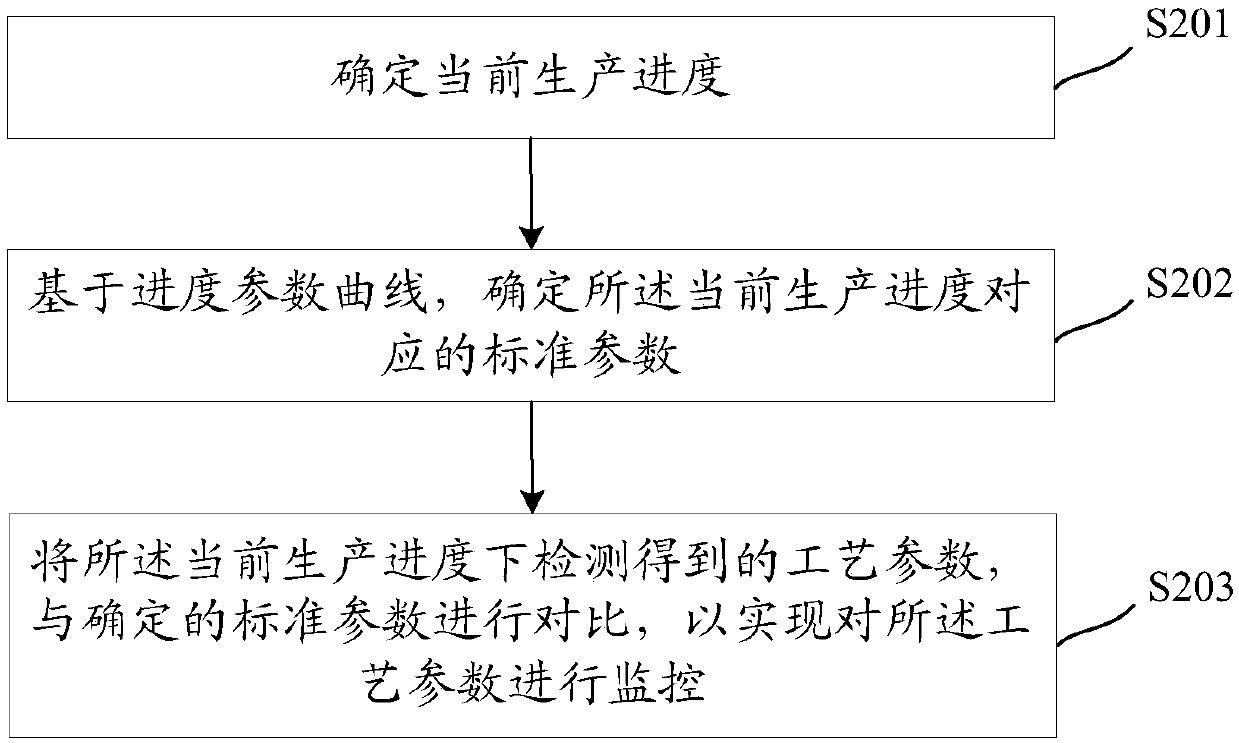

Monitoring method and device for parameters in industrial manufacturing

InactiveCN109753027AImprove monitoring accuracyTotal factory controlProgramme total factory controlProduction scheduleProcess equipment

The embodiment of the invention discloses a monitoring method for parameters in industrial manufacturing. When process parameters in an industrially manufactured batch are monitored, standard parameters used for monitoring the process parameters can be determined from a progress parameter curve according to the current production schedule of the batch in industrial manufacturing, in the process ofmonitoring the process parameters in the batch, the standard parameters corresponding to different production schedules can be used for monitoring as progressing of the production schedules, due to the fact that the standard parameters corresponding to a production schedule can reflect the normal range of the process parameters in the production schedule, through a mode of monitoring through thestandard parameters in the progress parameter curve, the difference of the process parameters in the different production schedules can be taken into account, and the monitoring accuracy is improved.The embodiments of the invention further disclose a parameter monitoring device in industrial manufacturing, process equipment, a correlated storage medium, computer program products and the like.

Owner:ALIBABA GRP HLDG LTD

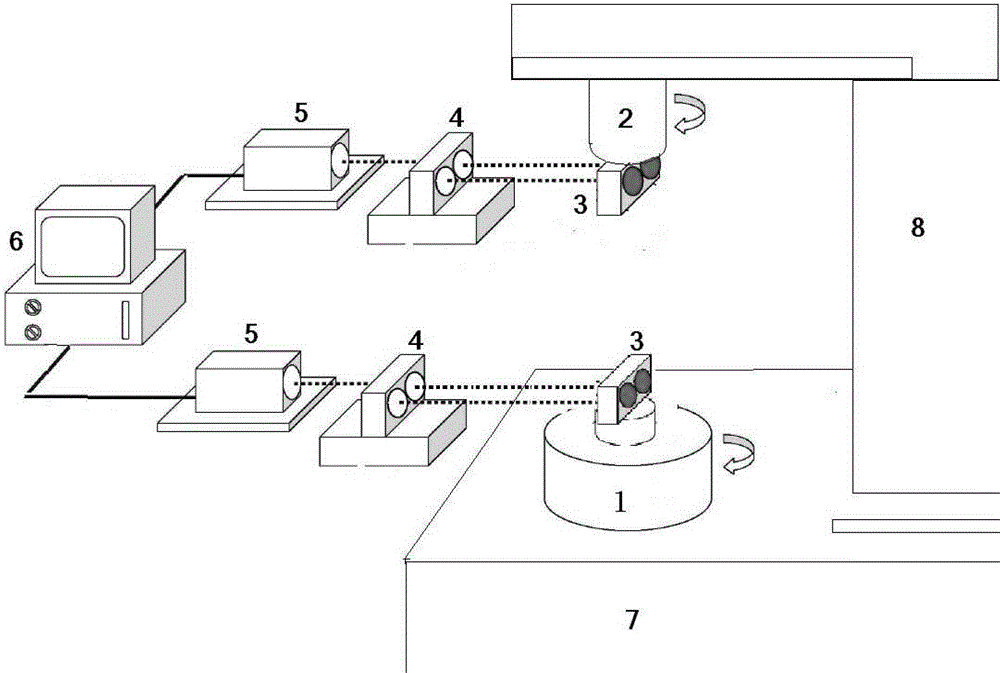

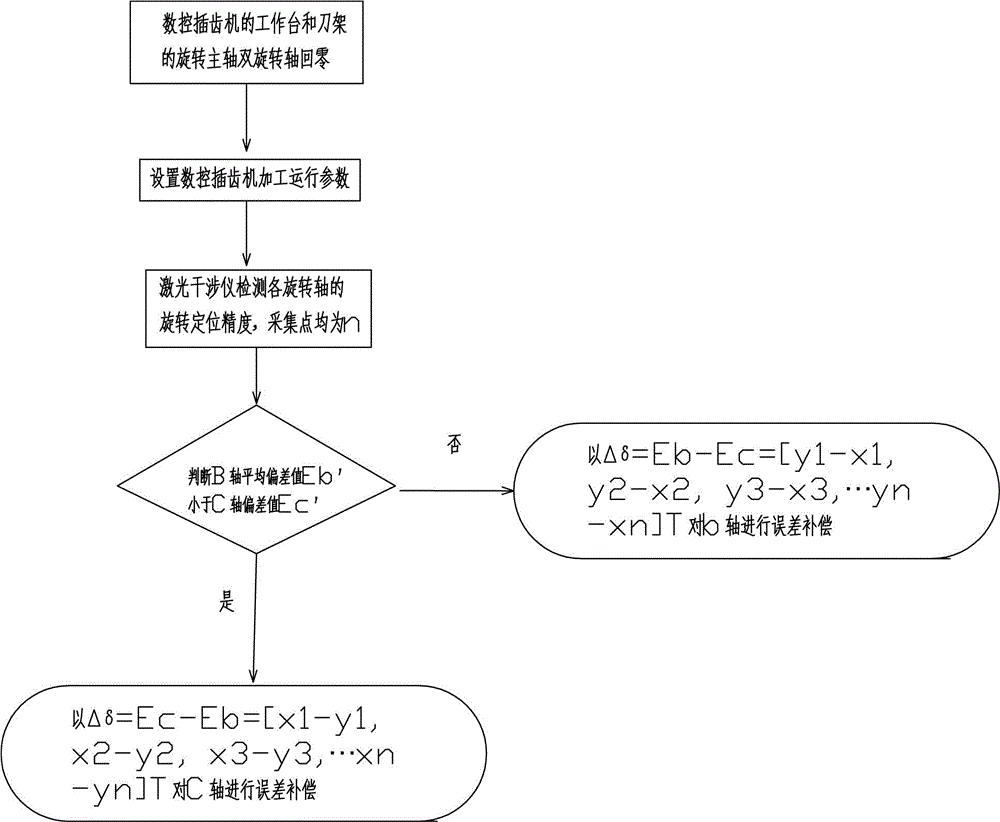

Method and device for compensating for errors of synchronous rotating shafts of numerical control gear shaping machine

InactiveCN105215479AGuaranteed positioning accuracyGuaranteed repeat positioning accuracyGear-cutting machinesGear teethNumerical controlManufacturing technology

The invention relates to a method for compensating for errors of synchronous rotating shafts of a numerical control gear shaping machine, belongs to the technical field of gear machining and manufacturing, and relates to a high-precision gear digital manufacturing technology, in particular to a method for improving the gear machining accuracy through compensation for errors of synchronous shafts of a gear manufacturing machine tool. A moving workbench and a rotating shaft of a tool rest are measured at the same time through two laser interferometer measuring assemblies, a measuring system obtains movement data of the double synchronous shafts at the same time, and then data processing and error compensation are conducted, so that the machining accuracy of gears is improved.

Owner:HUBEI THREE GORGES POLYTECHNIC

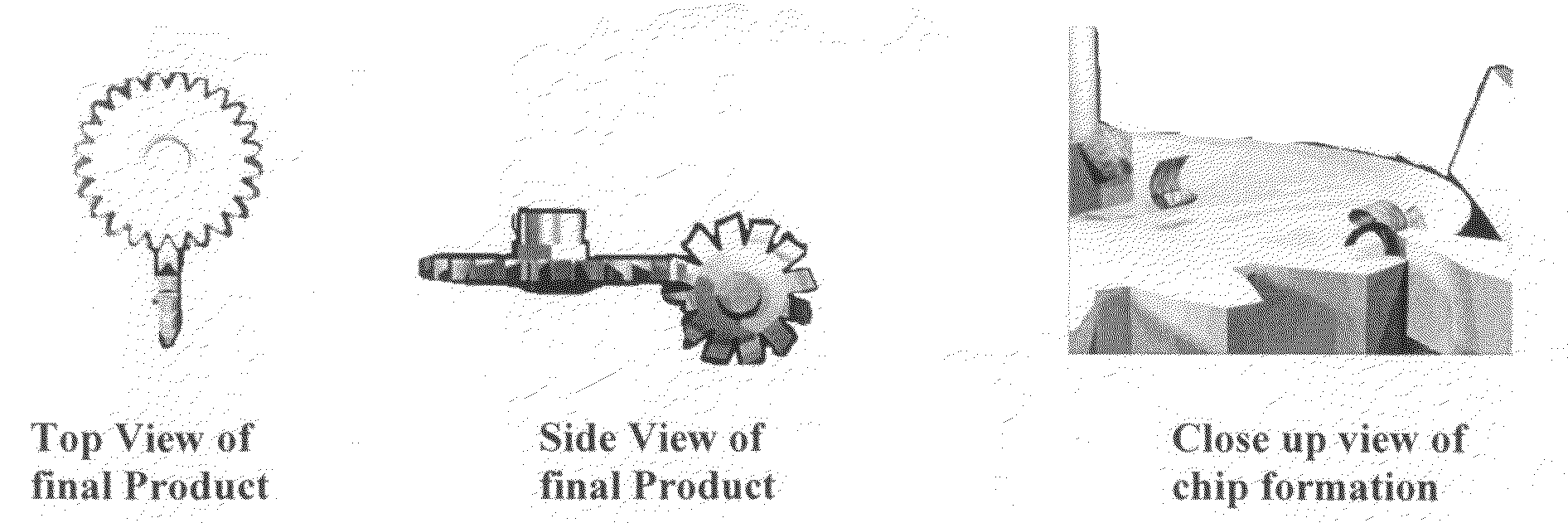

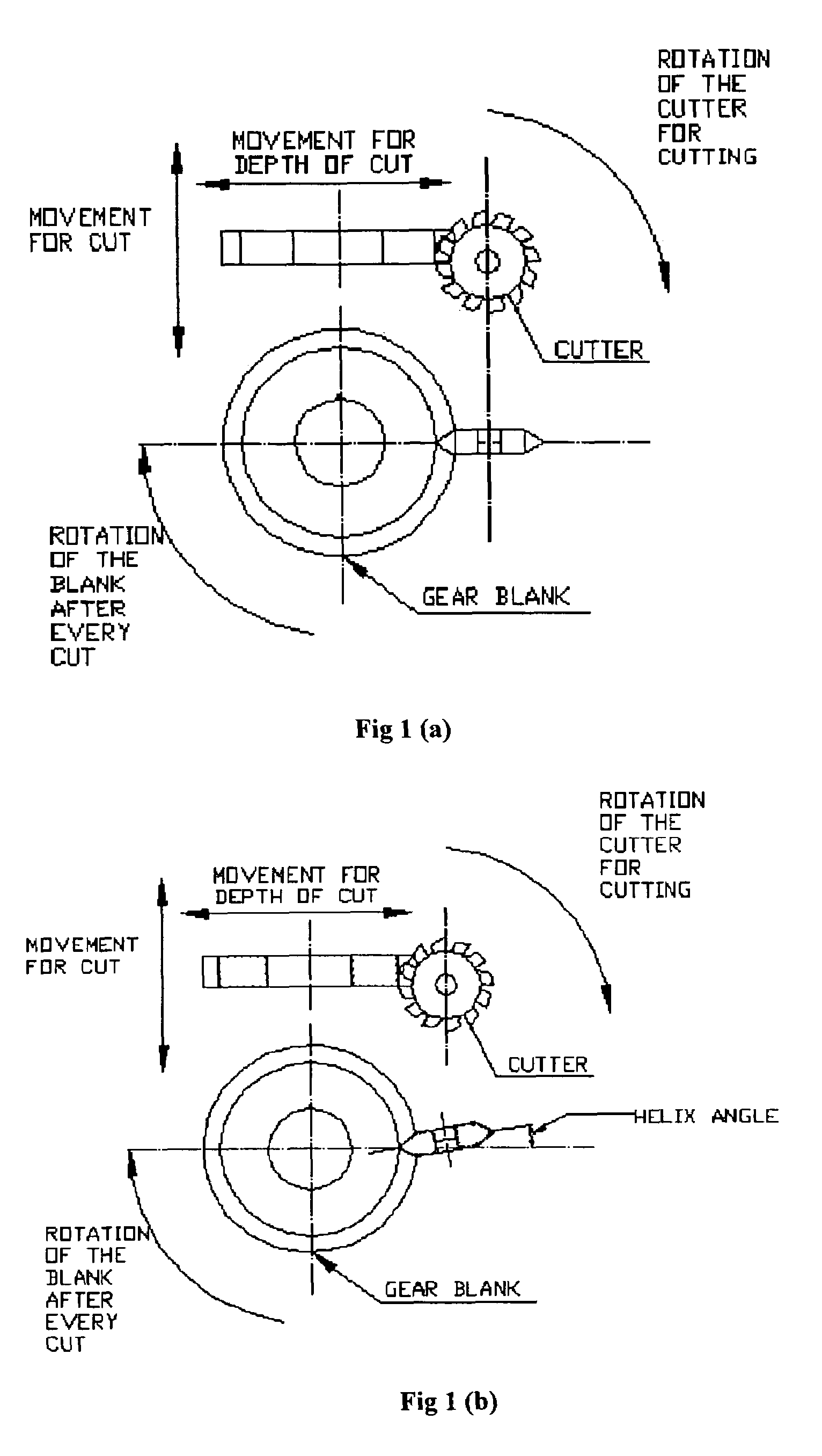

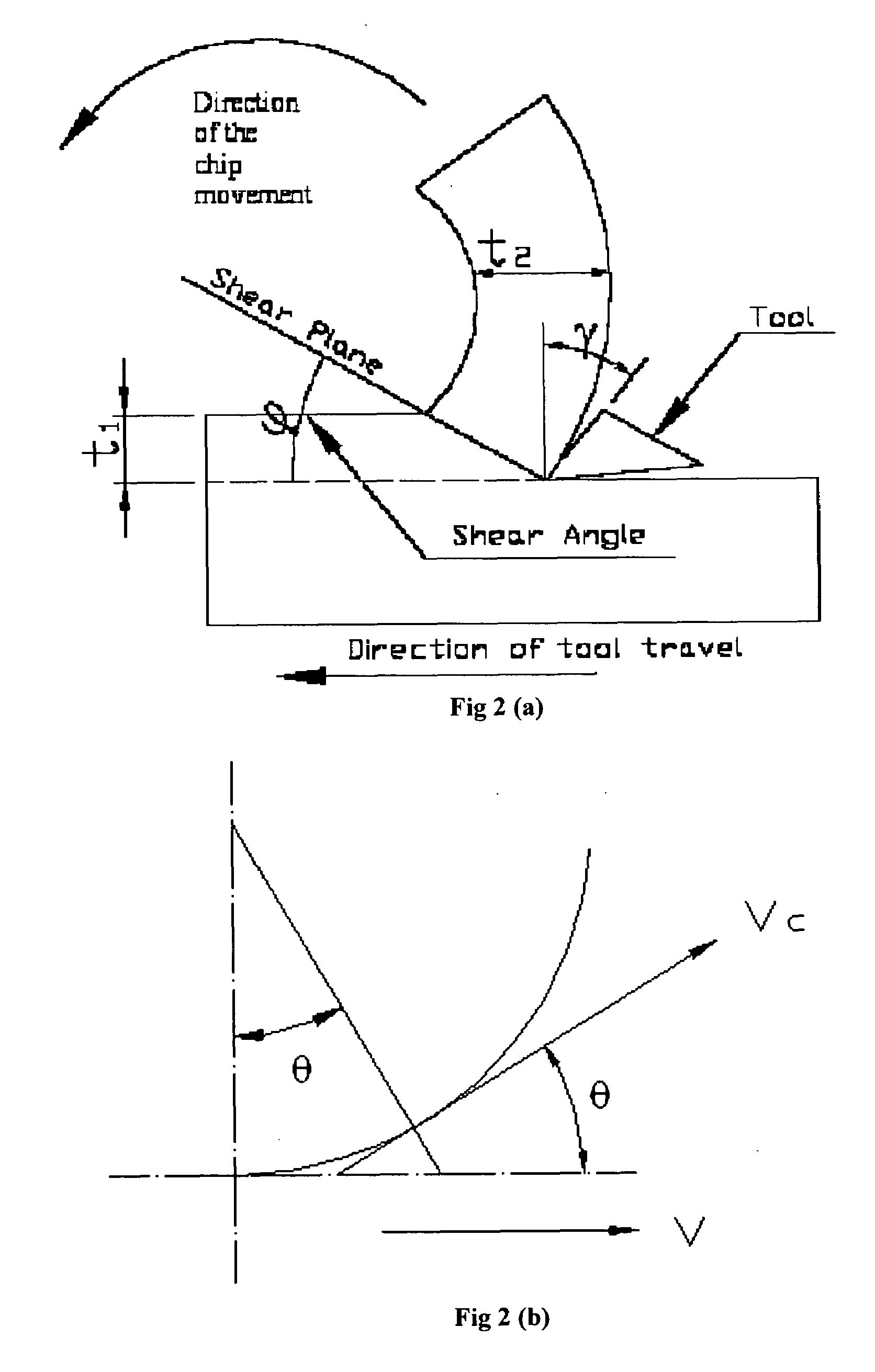

Virtual manufacturing of transmission elements

A software structure which when adapted in an apparatus is capable of virtual manufacturing of transmission elements for example gear means with chip formation, the software structure comprising a start module for loading the source file in a main editor-file that contains the computer program, an input module for providing input parameters that are essential for the configuration of a product and a cutting tool, a product design module for evolving the parameters for the manufacturing of the product; and a virtual manufacturing module having at least three sub-modules one each for tool generation, visualisation of machining operation, and disassembly of the product from the machine bed.

Owner:IONSENSE +1

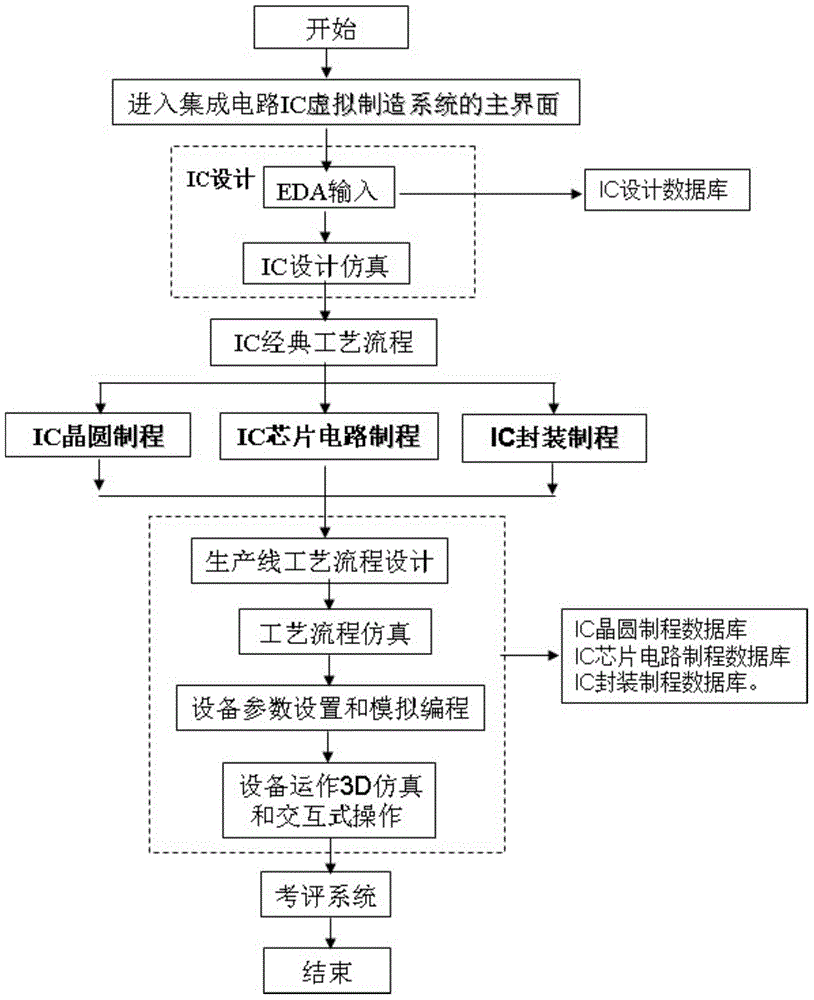

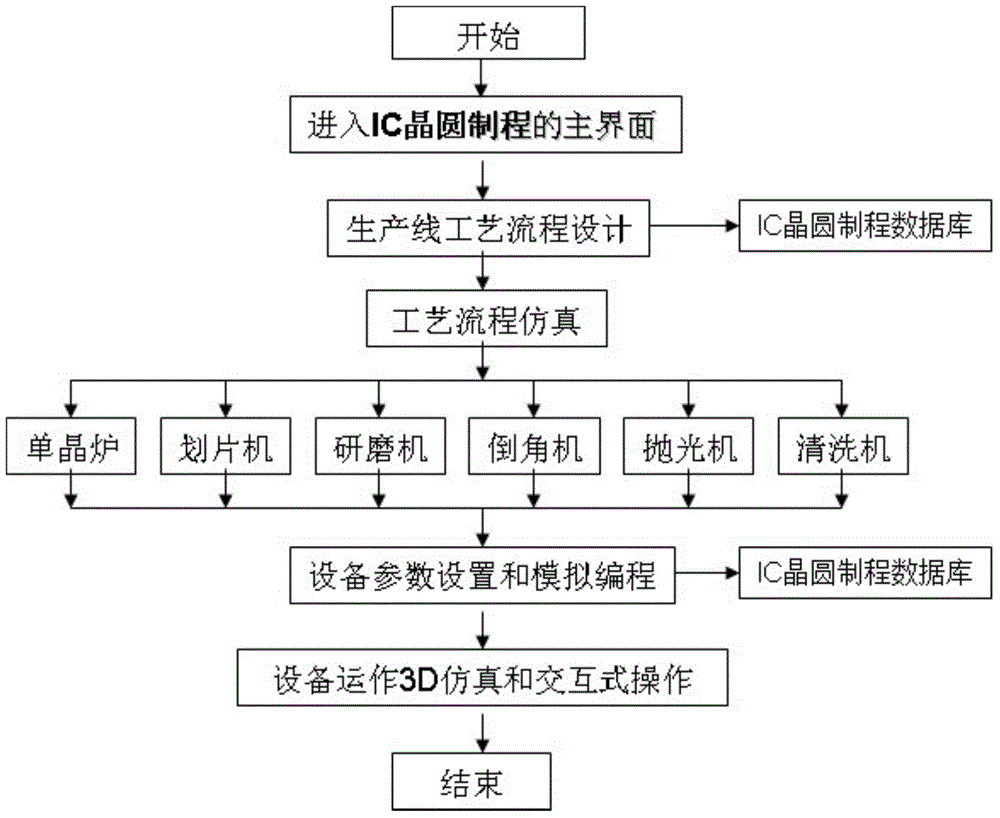

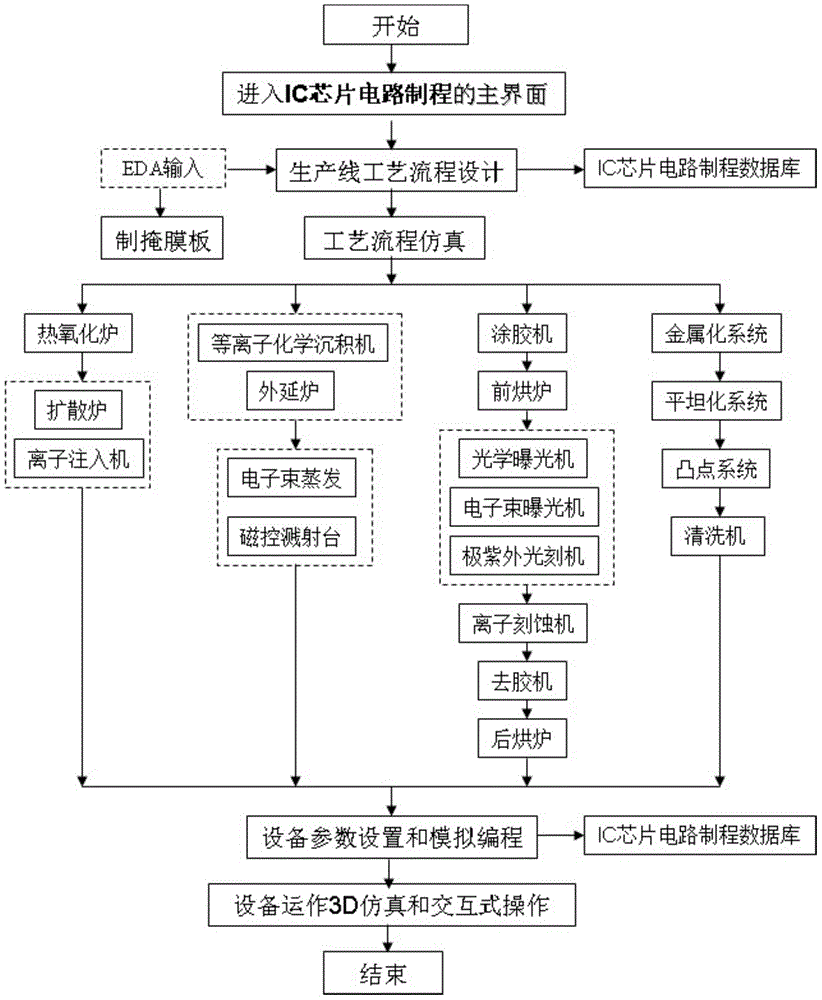

IC (integrated circuit) virtual manufacturing system and implementing method thereof

InactiveCN104657560AImprove technical levelShort development cycleSpecial data processing applicationsIntegrated circuit layoutDigital manufacturing

The invention relates to an IC (integrated circuit) virtual manufacturing system and an implementing method thereof. The implementing method comprises the following steps of according to an EDA (electronic design automation) design document, designing the technological process of an IC production line, wherein the IC production line comprises an IC wafer manufacturing process, an IC chip circuit manufacturing process and an IC packaging manufacturing process; displaying the technological process of the IC production line in a 3D (three-dimensional) cartoon way; performing the parameter setting and programming simulating on key equipment of the IC production line, and inputting the data into a database; automatically performing the mechanism working process 3D simulating and interactive operation on the key equipment of the IC production line by an object orienting technique and a Unity technique under the VC++6.0 environment. The implementing method has the advantages that the intuitive reference is provided for the data modifying of the technological design of the IC production line and the key equipment within the shortest period, so as to realize the purposes of short development cycle, low cost and high production efficiency; the training, examination and technical qualification certifying examination can be performed on IC technicians and engineers.

Owner:CHANGZHOU AUTOSMT INFORMATION TECH

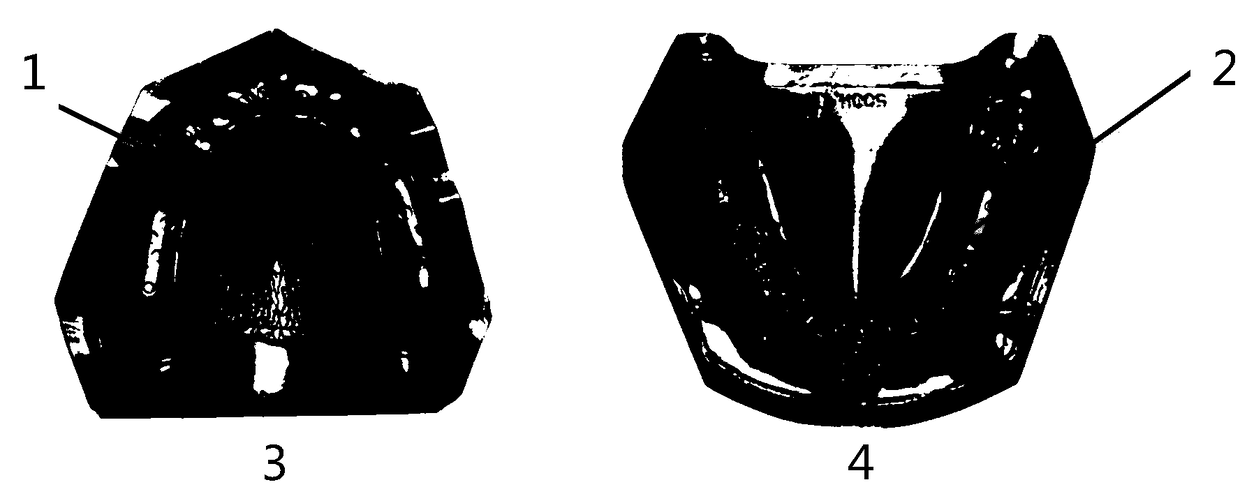

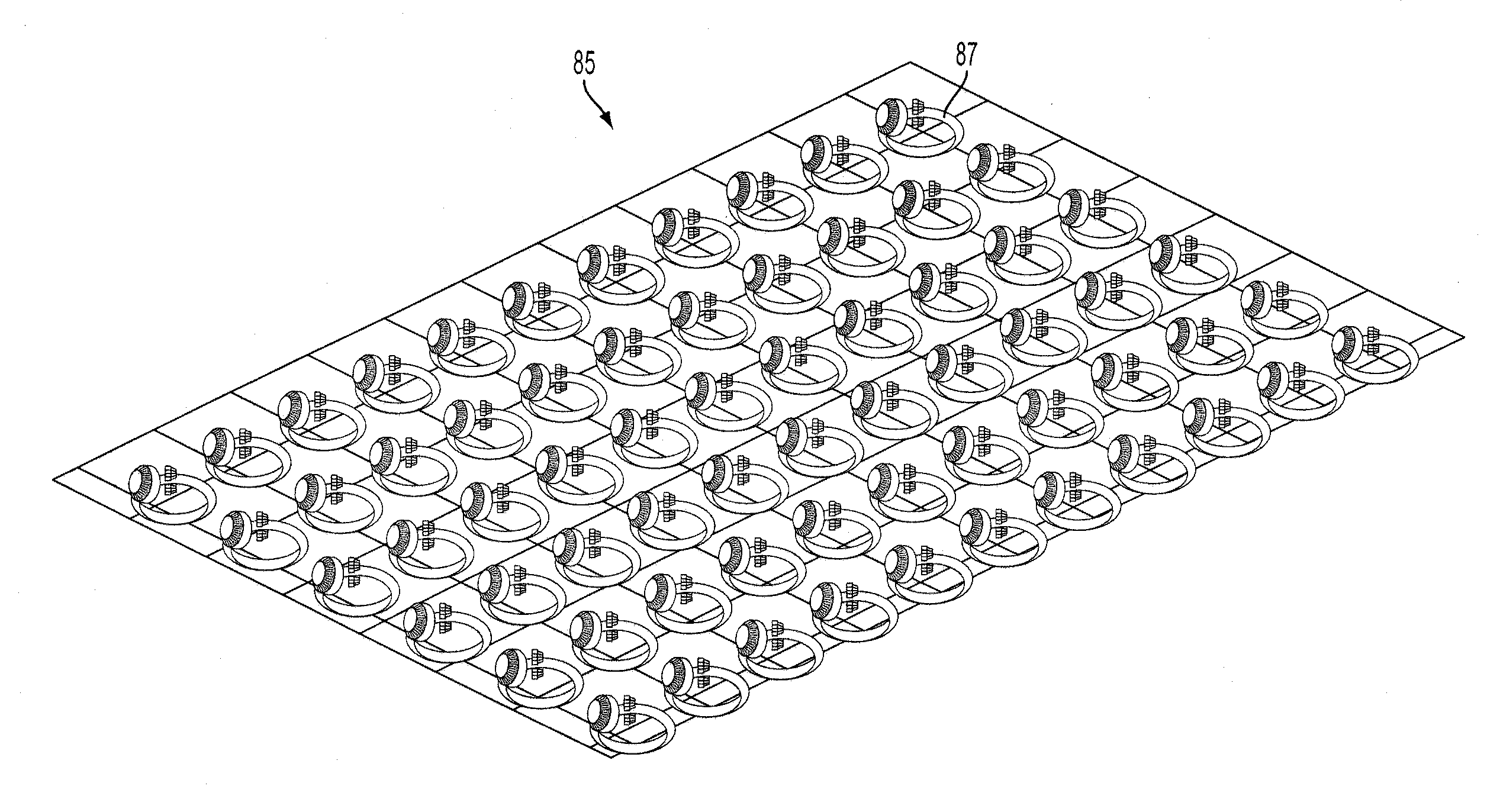

Method for digital manufacturing of jewelry items

A method for digital manufacturing of a jewelry item includes printing a three-dimensional wax model on a substrate and printing a three-dimensional sprue, the sprue being adapted to support the wax model. A fixture for handling wax models includes a platform, a plurality of holders, a plurality of standoffs, and a tie. A method of manufacturing a jewelry item, comprises forming a first wax model for a portion of a jewelry item, forming a second wax model for a portion of a jewelry item using a rapid prototyping process, and performing one or more lost wax processes with the first and second portion to create the jewelry item.

Owner:JOSTENS INC

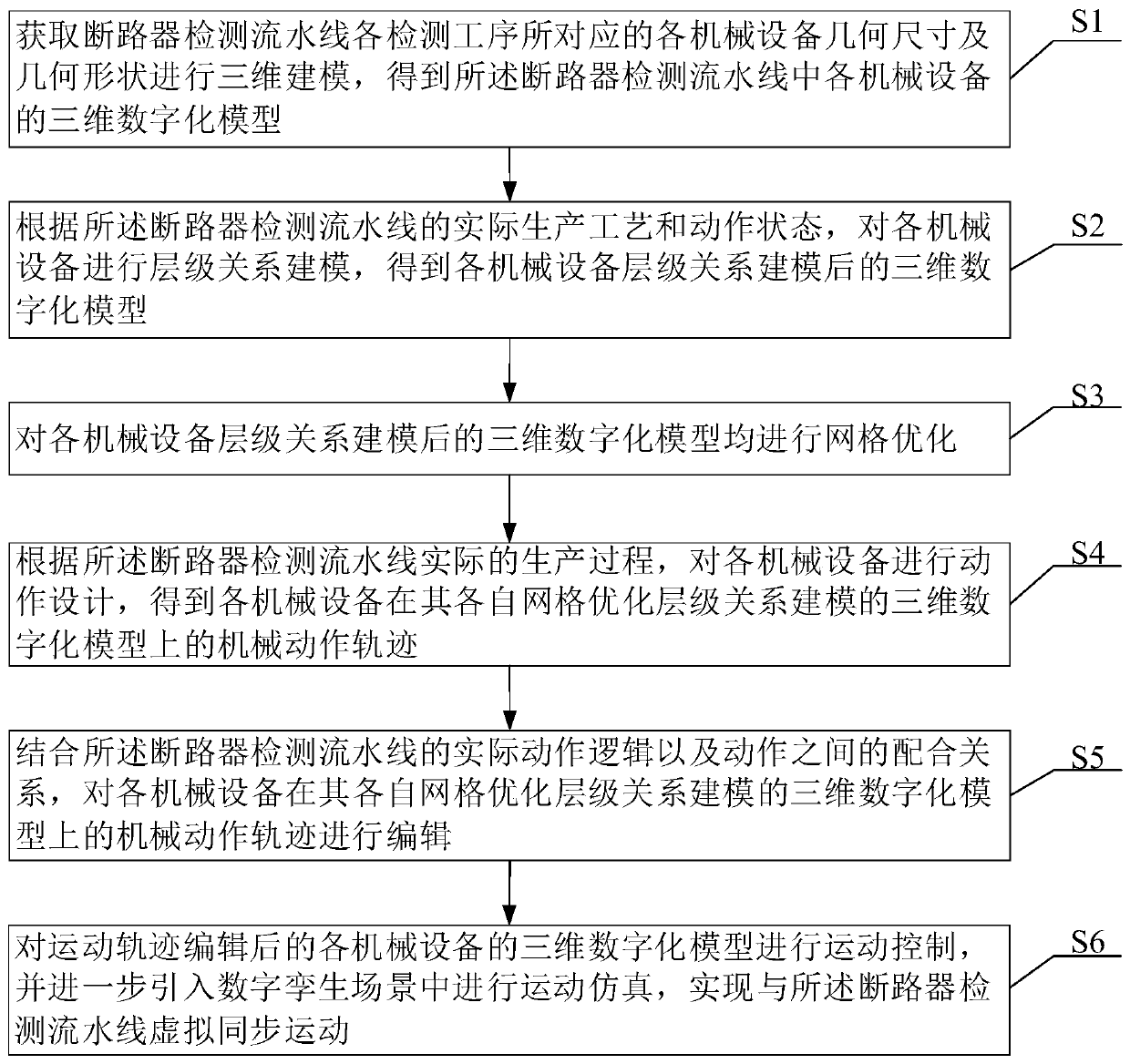

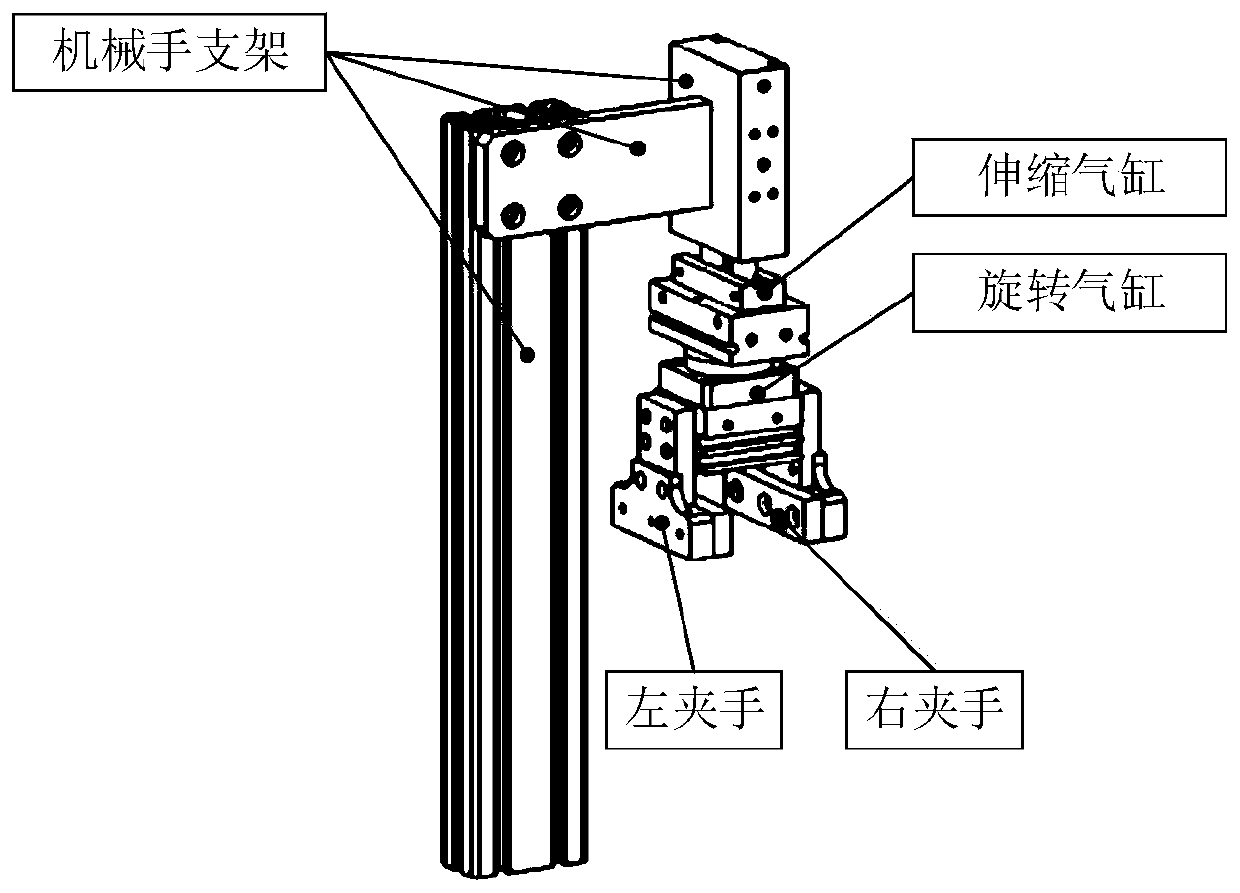

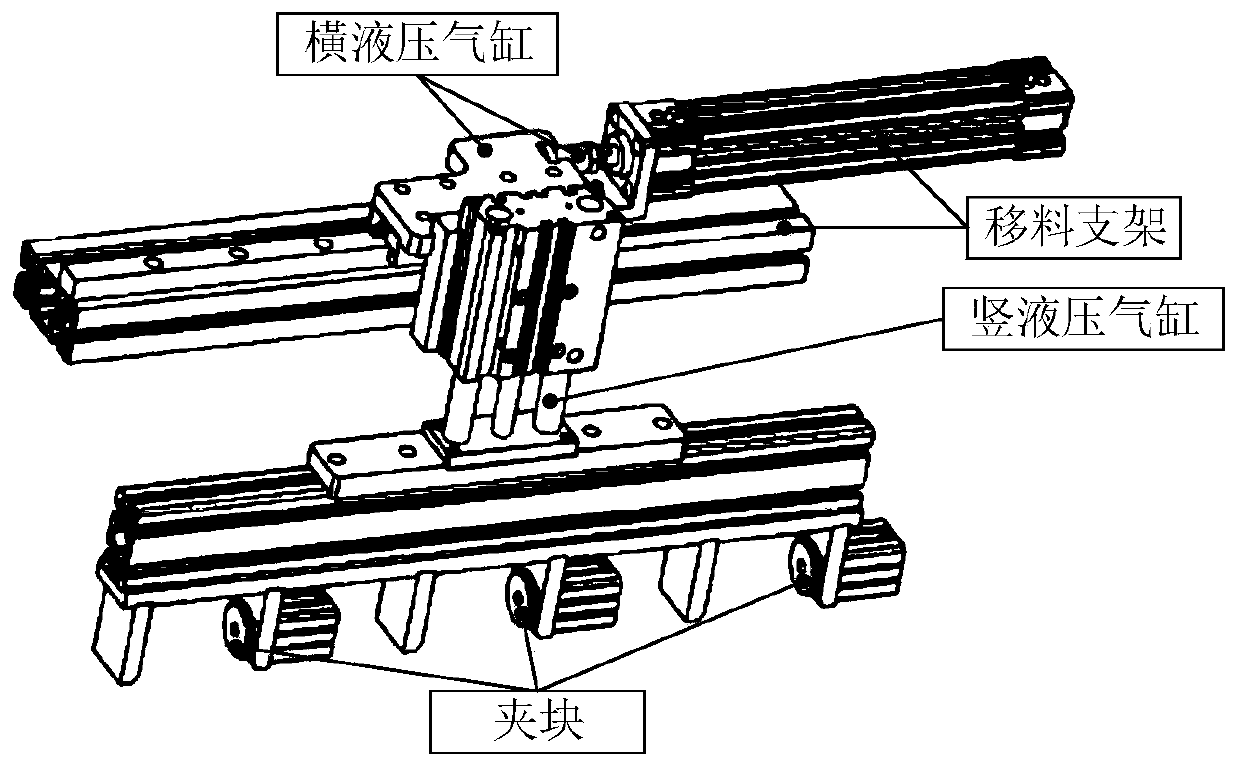

Method for realizing digital twin modeling of automatic circuit breaker detection assembly line

ActiveCN110866313ARealize centralized management of production dataRealize remote visual operationGeometric CADProgramme controlDigital manufacturingAssembly line

The invention provides a method for realizing digital twin modeling of an automatic circuit breaker detection assembly line. The method comprises the following steps: obtaining a three-dimensional digital model of each mechanical device in the circuit breaker detection assembly line; carrying out hierarchical relationship modeling according to an actual production process and an action state; performing grid optimization on the model; according to an actual production process, performing action design on each mechanical device to obtain a mechanical action track of the model; editing the mechanical action track of the model in combination with the actual action logic and the matching relationship between the actions; and introducing motion control, carrying out motion simulation in a digital twin scene, and realizing virtual synchronous motion with a real circuit breaker detection assembly line. According to the method, through information fusion and interaction between real physical equipment of the detection assembly line and the digital twinning model, centralized management of assembly line production data is realized, and remote visual operation, management and maintenance canbe carried out on the detection assembly line, and a basic platform is provided for digital manufacturing of miniature circuit breakers.

Owner:WENZHOU UNIV

Composite material skin digital manufacture method

InactiveCN105880918APrecise positioningAvoid repetitionManufacturing technologyDigital manufacturing

The invention belongs to the composite material skin manufacturing technology, in particular to a composite material skin digital interchange coordination manufacturing method. In the present invention, after the skin of the forming mold is solidified and before demolding, the skin is in the best shape, and the digital drilling template is used to directly drill the positioning holes for the process ears of the skin on the mold, so as to drill holes for the subsequent trimming of the skin and The assembly provides the processing reference and assembly reference, and then performs skin positioning, trimming and drilling, skin assembly positioning, and then cuts off the process lugs, and finally performs skin riveting assembly. The composite material skin digital manufacturing method of the present invention can accurately locate in one step during the skin shifting process, avoid repetition, greatly save clamping time, and because it directly cuts to the clean edge, no on-site marking is required, and the installation accuracy is high. In addition, only the craft lugs need to be polished off at the riveting site, the grinding workload is small, the amount of dust is greatly reduced, and the production and use interchangeability in the skin manufacturing process is realized.

Owner:HARBIN

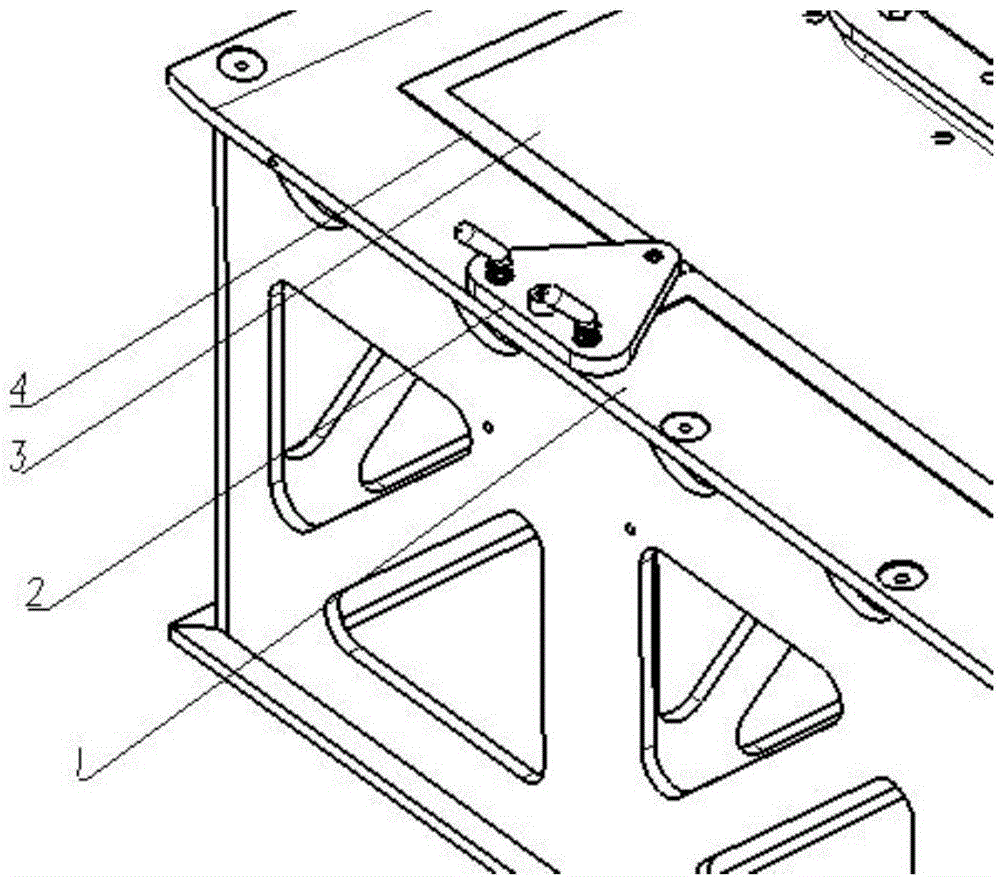

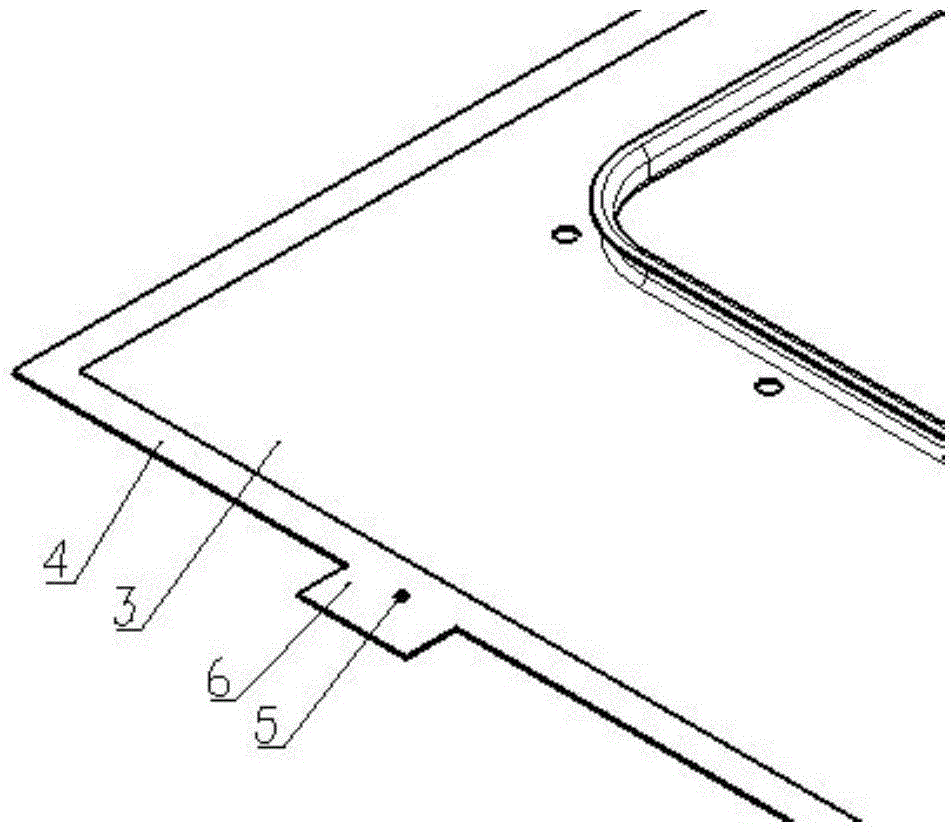

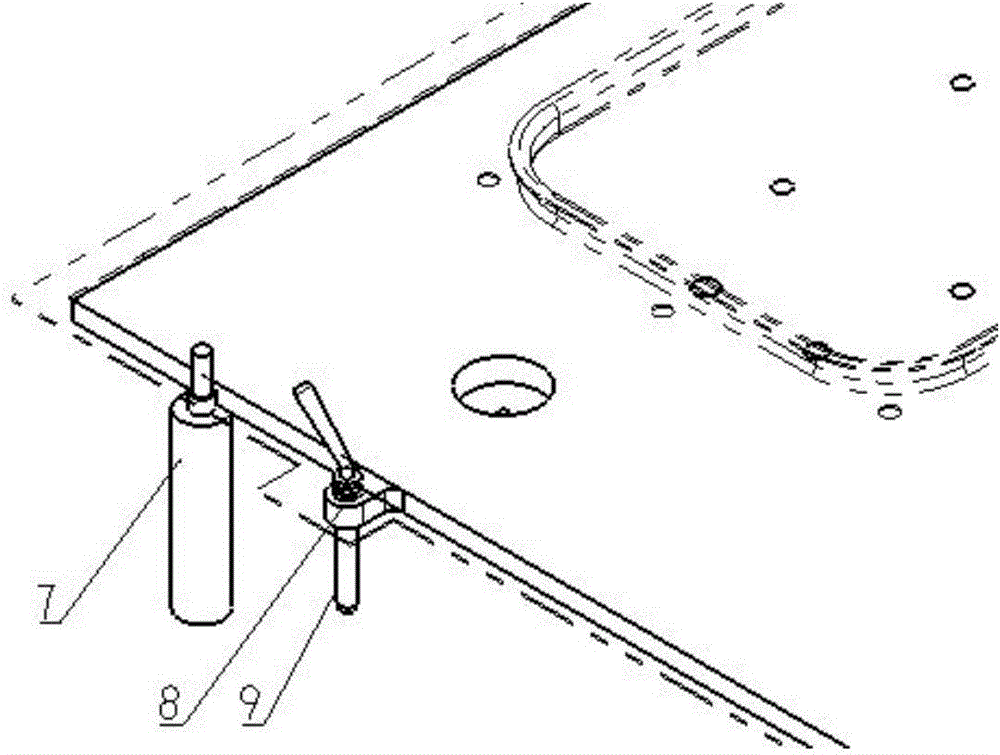

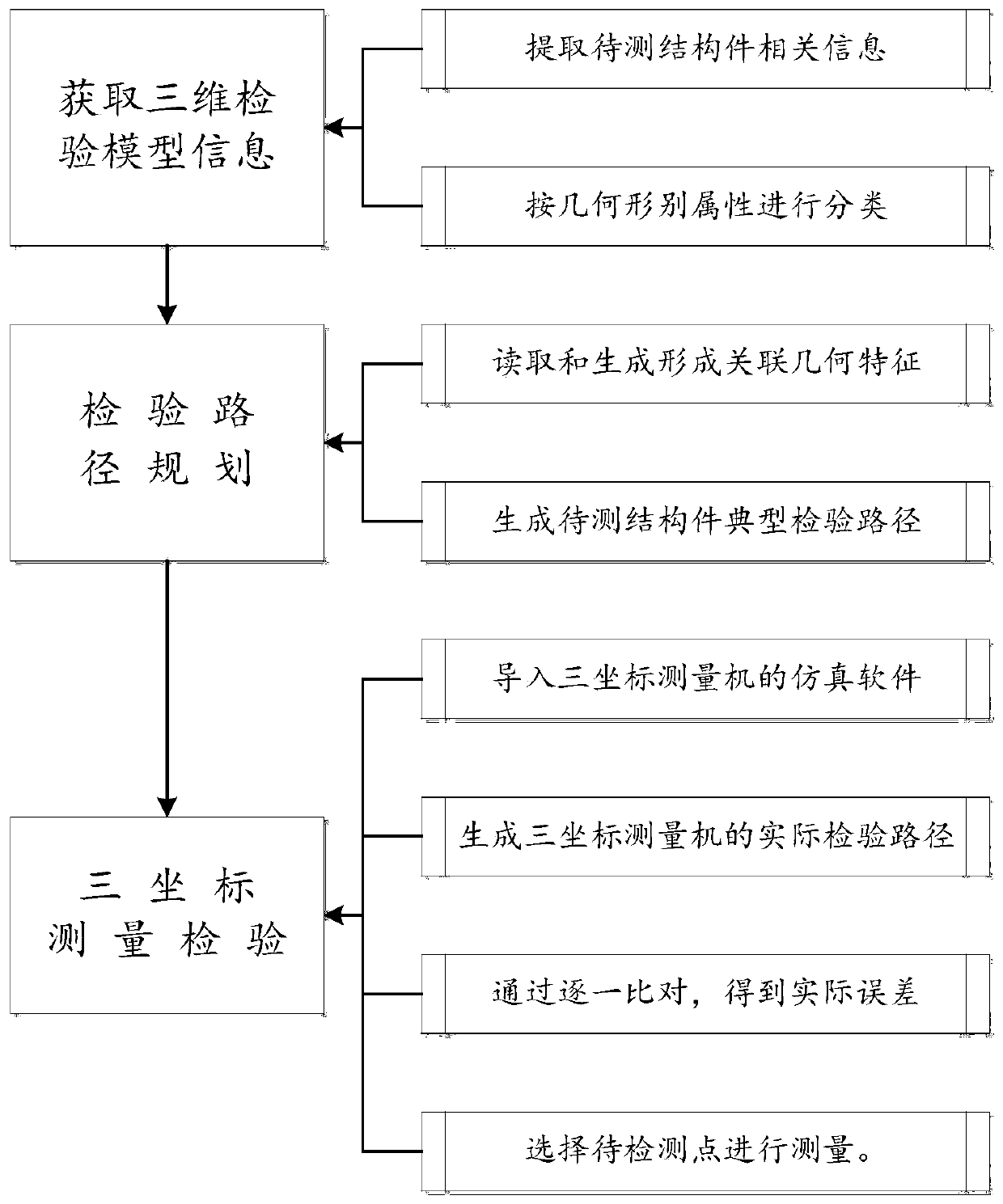

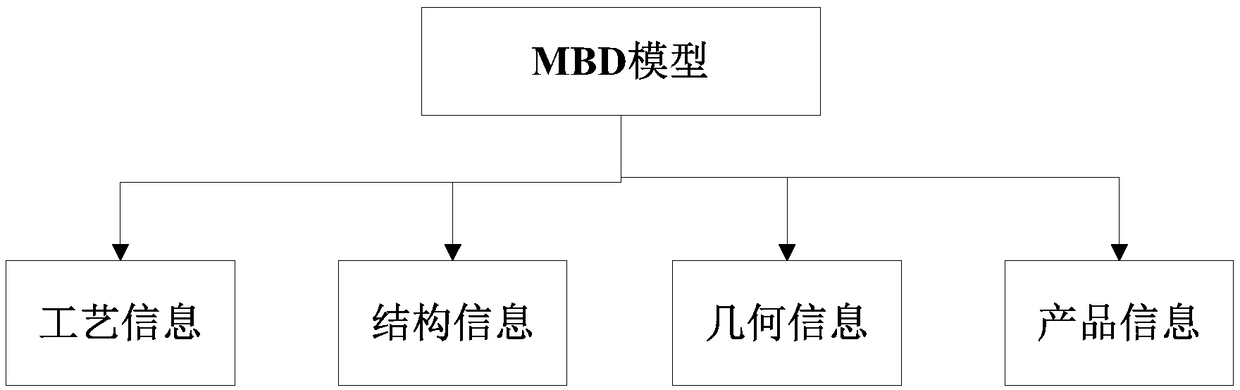

MBD-based aviation complex structural member inspection method

PendingCN111027134AGuaranteed accuracyImprove inspection efficiencyGeometric CADAviationProduct inspection

The invention belongs to the field of aircraft digital manufacturing, and relates to an MBD-based aviation complex structural member inspection method, which comprises the following steps: step 1, acquiring three-dimensional inspection model information; step 2, planning and inspection path; and step 3, three-coordinate measurement and inspection. According to the invention, a software secondary development technology is used; a computer identification technology is adopted to replace manual inspection in the inspection process, three-dimensional labeling information and associated geometricalinformation of a part are directly detected through feature identification of a three-dimensional model by software, geometrical features to be detected and detailed geometrical information of the geometrical features to be detected are obtained, and then a measurement program is generated through detection planning to complete product inspection.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

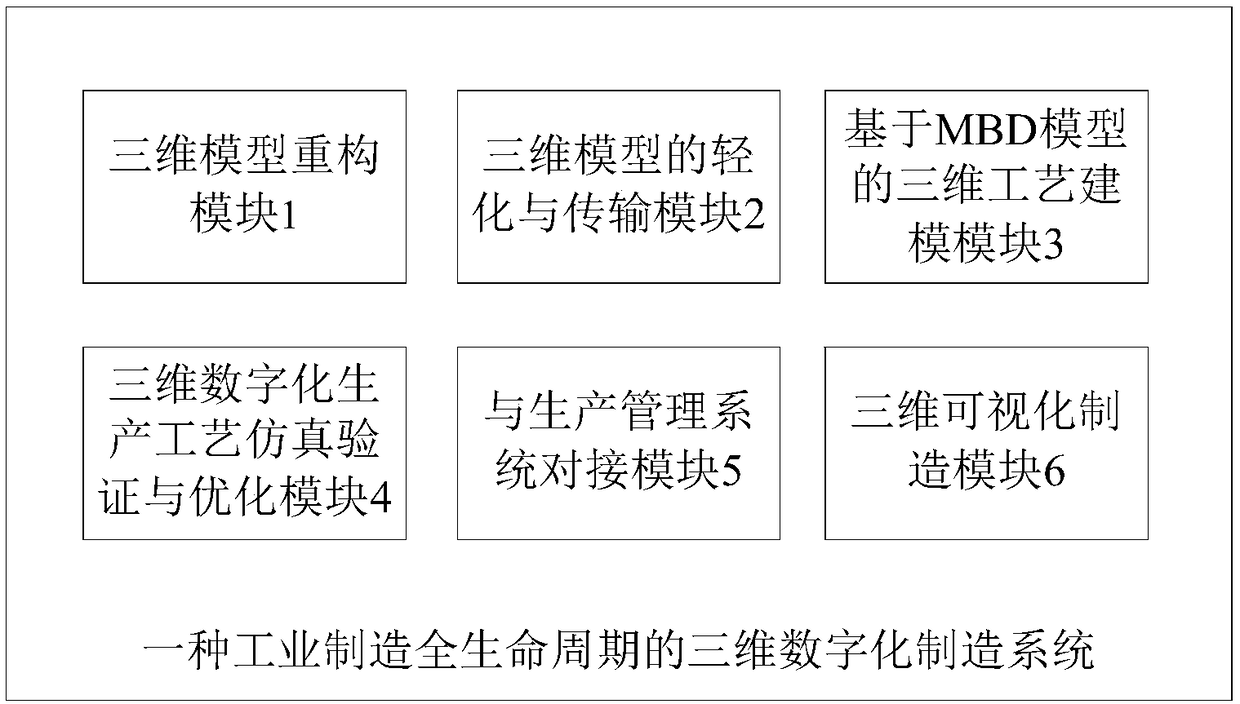

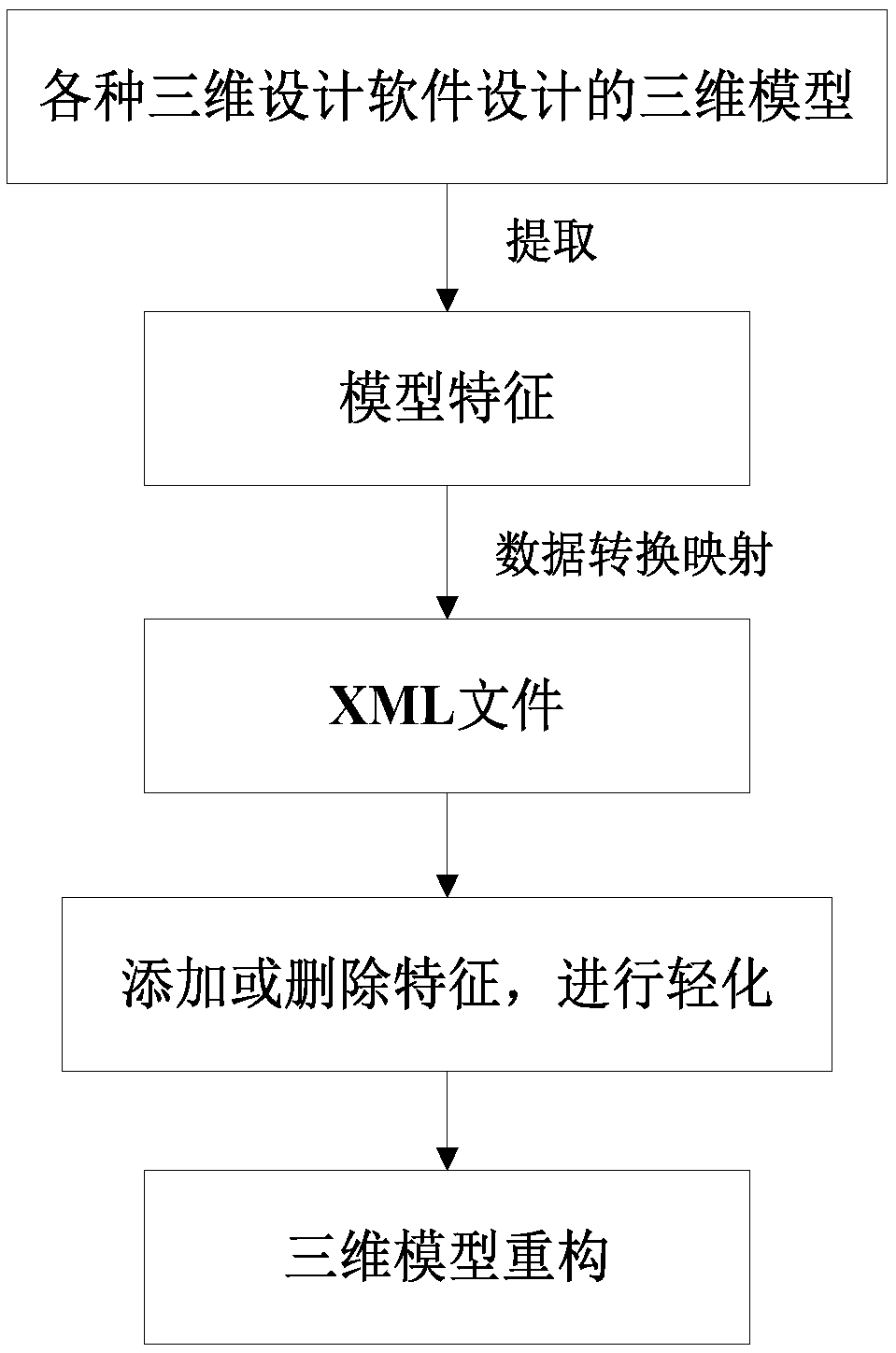

Three-dimensional digitized manufacturing system for whole life cycle of industrial manufacturing and realization method thereof

ActiveCN109325736ASolve the problem of information gapDesign optimisation/simulationOffice automationComputer moduleDigital manufacturing

The invention discloses a three-dimensional digitized manufacturing system for the whole life cycle of industrial manufacturing. The three-dimensional digitized manufacturing system includes a three-dimensional model reconstruction module, a three-dimensional model lightening and transmission module, a three-dimensional process modeling module based on an MBD model, a three-dimensional digital production process simulation verification and optimization module, a docking module with a production management system and a three-dimensional visual manufacturing module. The invention also disclosesa three-dimensional digitized manufacturing realization method for the whole life cycle of industrial manufacturing, comprising the S1-S6 steps of 1 transforming the format, extracting and classifying, and reconstructing the three-dimensional model; 2 classifying, extracting and compressing various types of attributes; S3 reconstructing the MBD model; S4 carrying out virtual simulation and verification; 5 conveying the processing information and requirement; S6 carrying out the three-dimensional real-time visual control. The system and the method of the invention realize the heterogeneous coordination, interconnection, real-time control and three-dimensional visual management of each system in the whole production process from product design to production and manufacture.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

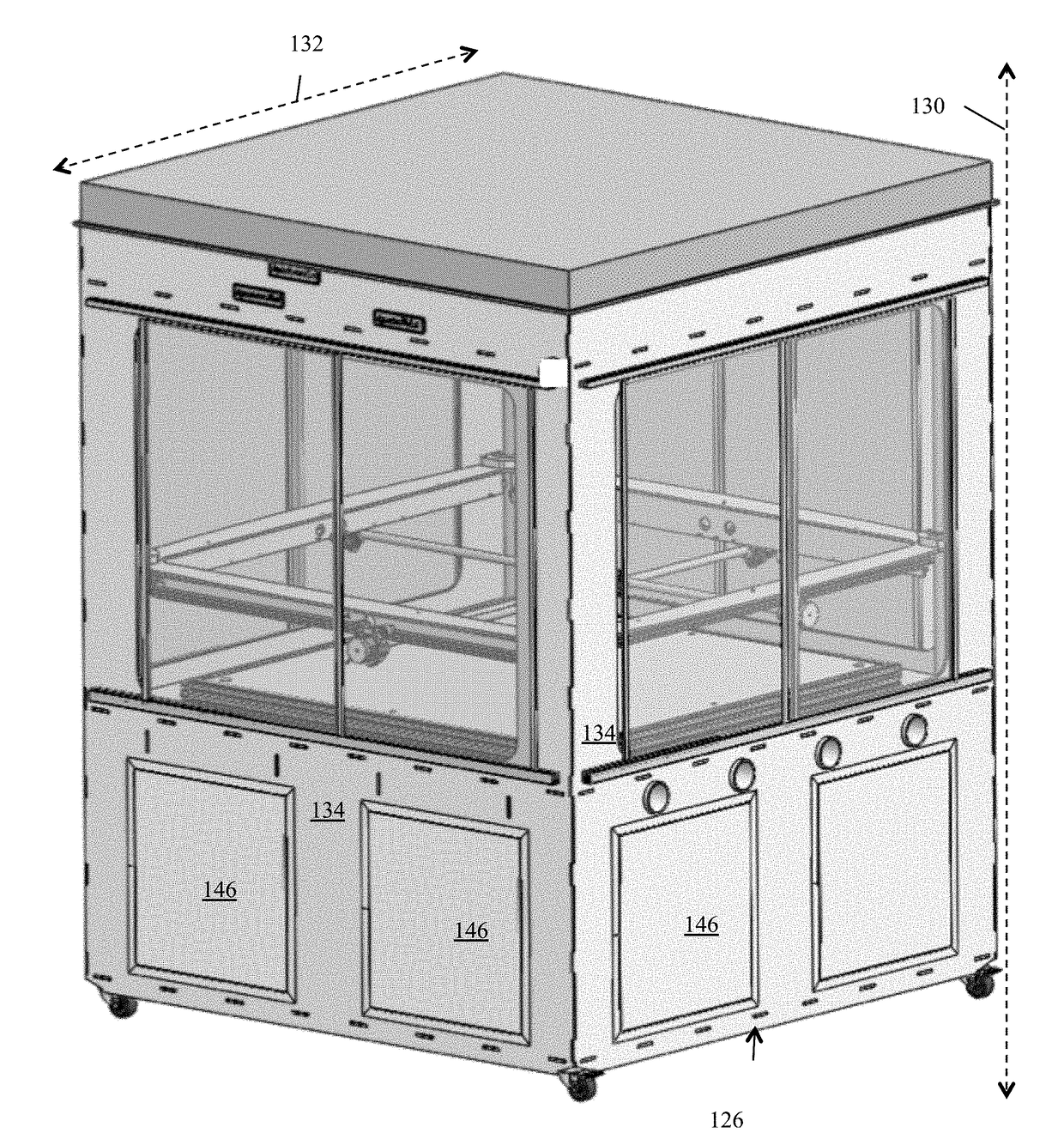

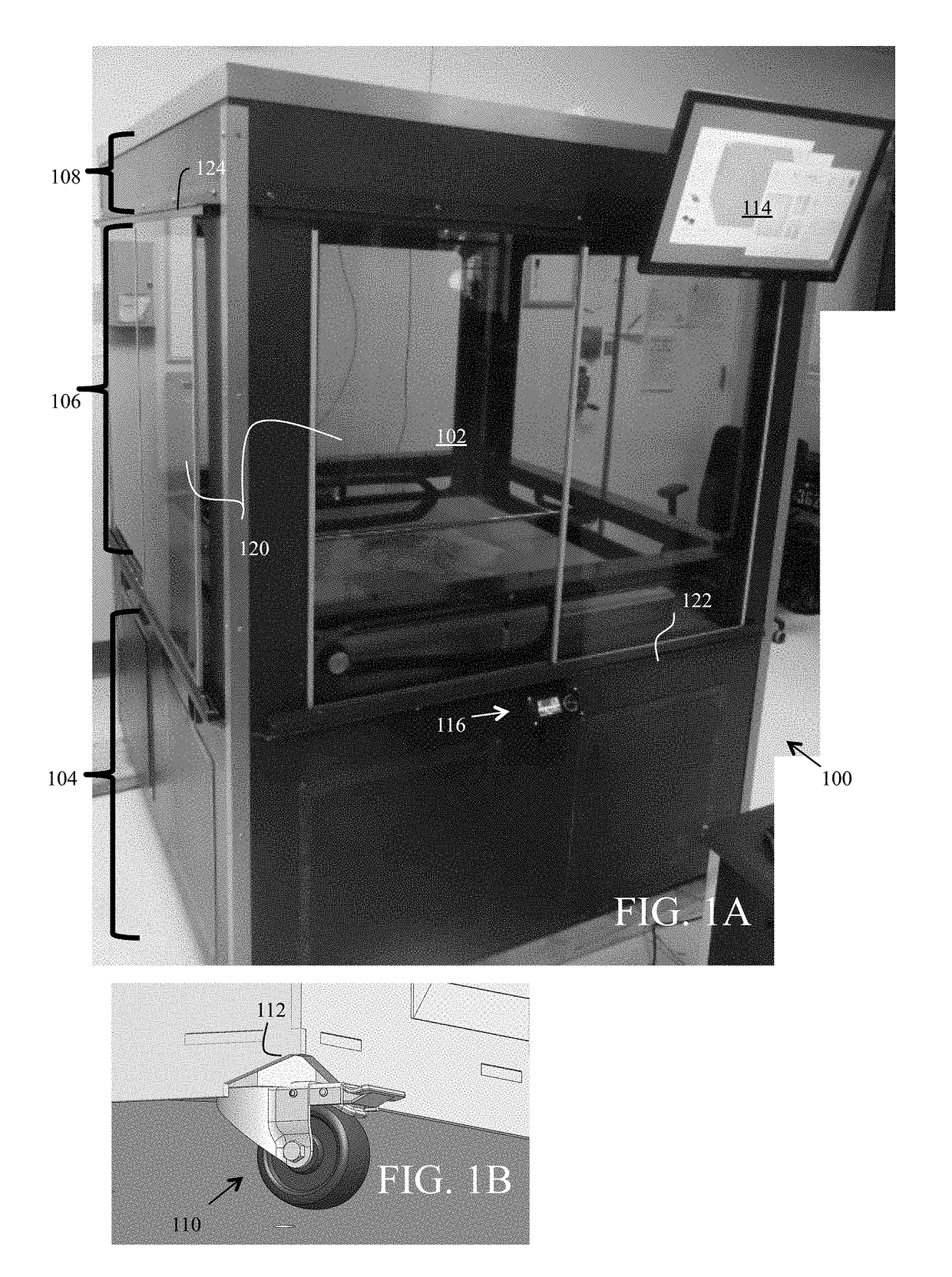

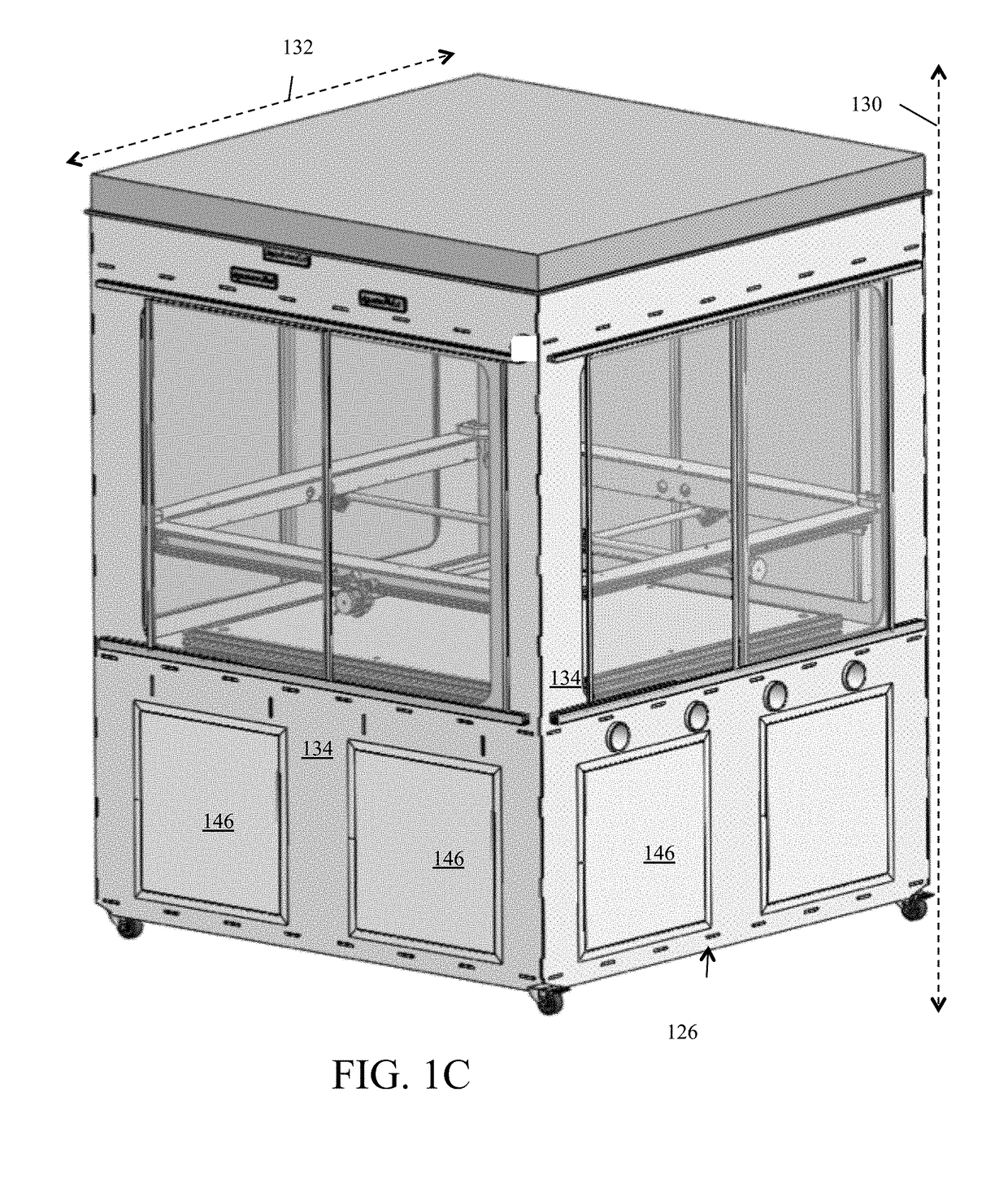

Apparatus and method for fabrication of three dimensional objects

ActiveUS20170313049A1Manufacturing platforms/substratesManufacturing heating elementsDigital manufacturingComputer science

Owner:SYNCRONETICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com