Method and device for compensating for errors of synchronous rotating shafts of numerical control gear shaping machine

A technology of synchronous rotation and compensation method, applied in the direction of gear tooth manufacturing device, gear cutting machine, gear tooth, etc., can solve the problems of different inertia, error, high cost, reduce transmission chain error, improve machining accuracy, and compensate transmission chain error. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

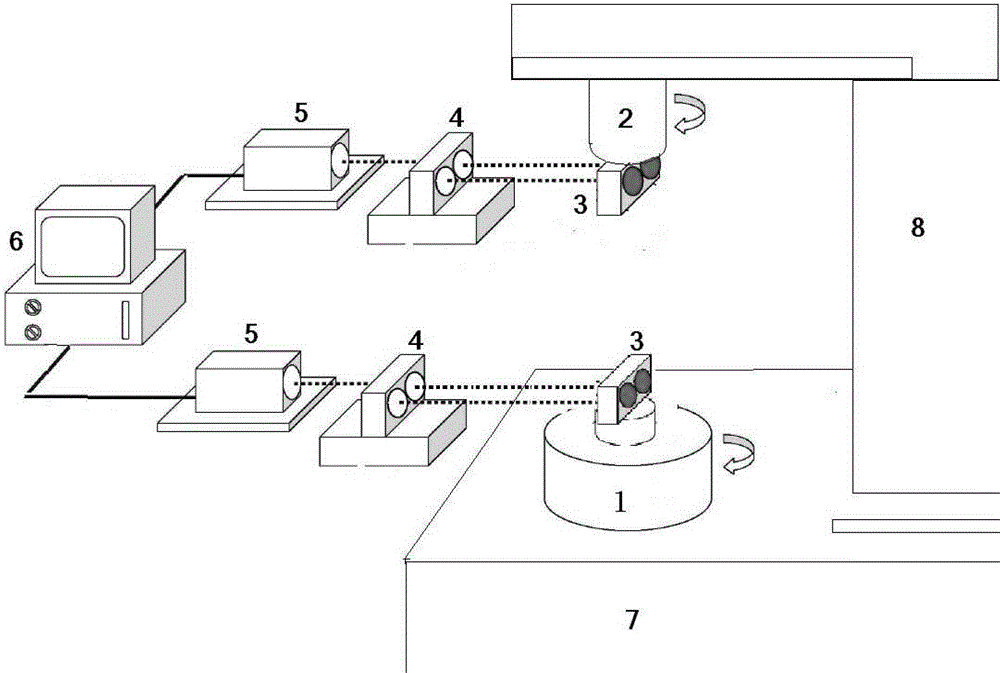

[0036] see figure 1 , using a laser interferometer measurement device used in the error compensation method of the synchronous rotation axis of the CNC gear shaping machine. It includes two sets of laser interferometer measurement systems. 1 The mirror 3 on the rotating spindle C, the workbench 1 is installed on the base 7 of the CNC gear shaping machine, the mirror 3 cooperates with the interference mirror 4, the laser 5 cooperates with the interference mirror 4, and the computer 6 communicates with the Laser 5 is connected.

[0037] Further, the emitting and receiving components of the second group of laser interferometers include a reflector 3 installed on the rotating spindle B of the tool rest 2, and the tool rest 2 is installed on the CNC gear shaping machine body 8, and the reflector 3 and The interference mirror 4 cooperates, the laser 5 cooperates with the interference mirror 4, and the computer 6 is connected with the laser 5 through a signal line.

[0038]Further,...

Embodiment 2

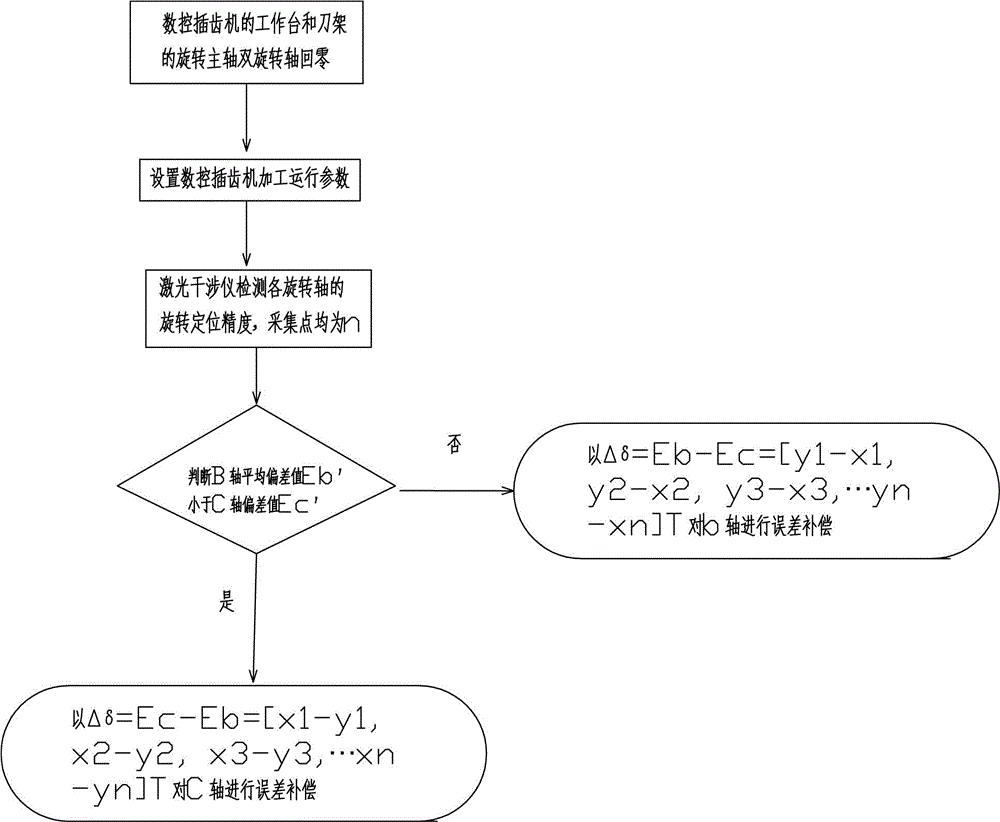

[0040] see figure 2 , a method for compensating an error of a synchronous rotating shaft of a numerically controlled gear shaping machine, comprising the following steps:

[0041] The first step is to install the transmitting and receiving components of the first group of laser interferometers on the rotating spindle of the worktable 1, and install the transmitting and receiving components of the second group of laser interferometers on the rotating spindle of the tool post 2; the two groups of components share A set of control system can perform preliminary measurement and adjustment on the positioning accuracy and repeat positioning accuracy of the rotary axis of the worktable 1 and the tool post 2 separately or simultaneously, so as to ensure that the positioning accuracy and repeat positioning accuracy of the two rotating synchronous axes reach the lowest machining accuracy Requirements above; then use the first group of laser interferometers to measure the positioning ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com