Method for positioning and detecting QFP (Quad Flat Package) chip

A positioning detection and chip technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of QFP chip position detection and pin analysis difficulties, low efficiency, and unsatisfactory practical application requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

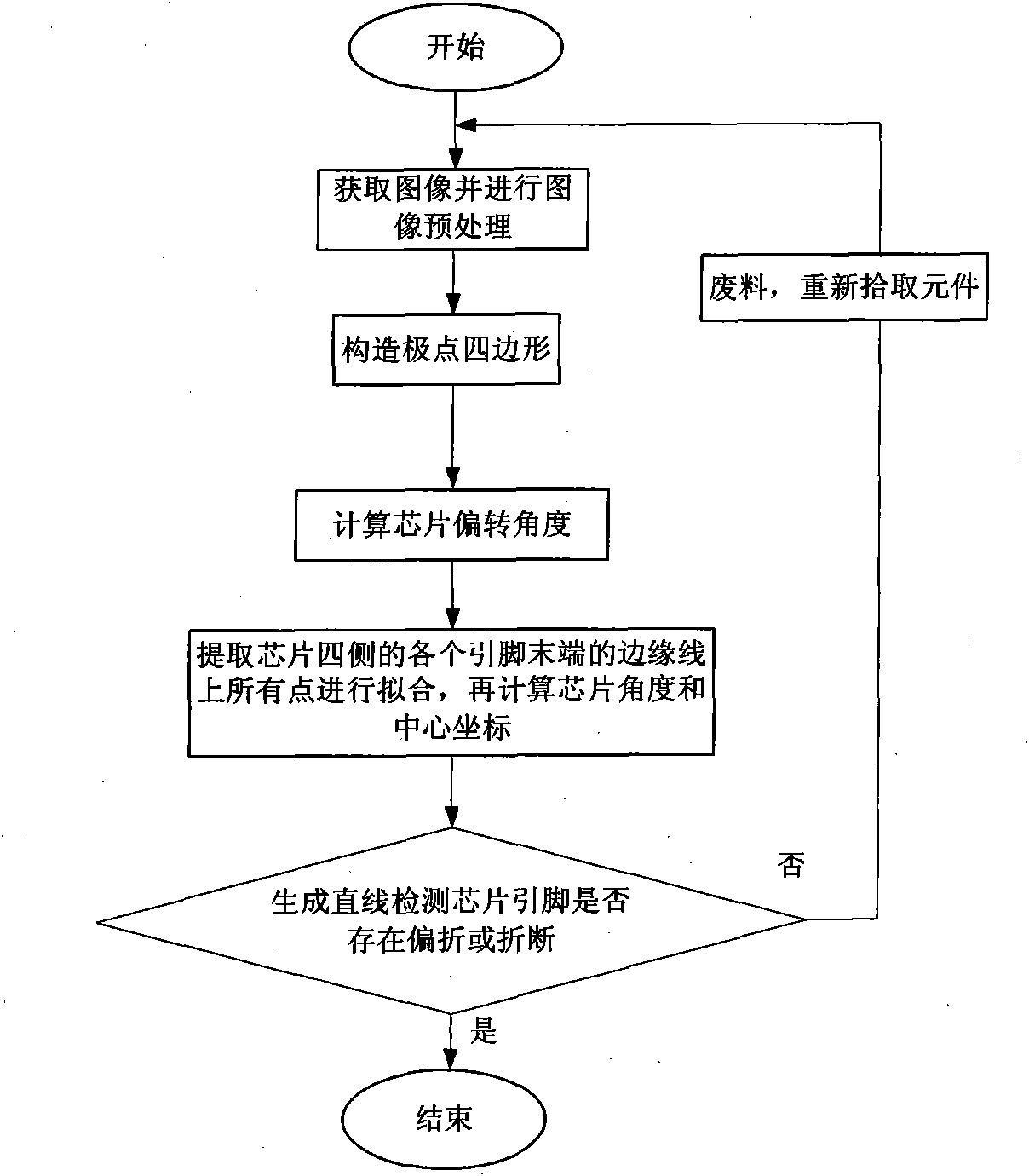

[0039] A positioning detection method for a QFP chip, the steps of which include:

[0040] a. Step 1 is the image acquisition and image preprocessing of the QFP chip:

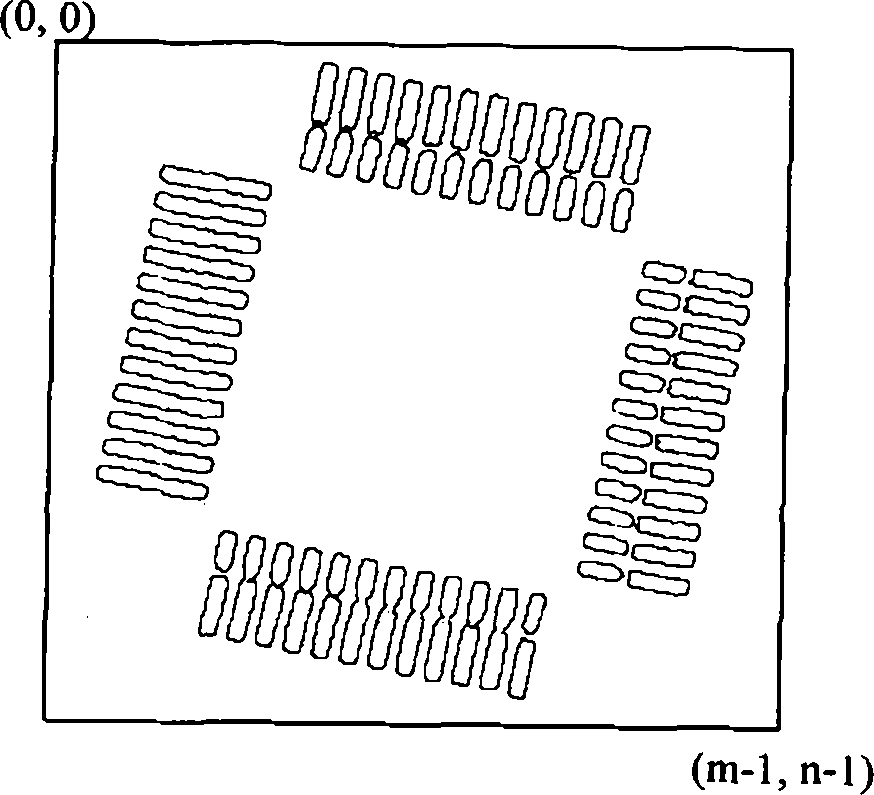

[0041] Use a high-speed camera and an image acquisition card to collect the image of the QFP chip, and send the collected image of the QFP chip to the computer for image preprocessing to obtain the image of the QFP chip after image preprocessing (m×n), where the image preprocessing Processing includes filtering, threshold segmentation and contour enhancement of QFP chips;

[0042] b. Step 2 is to construct a pole quadrilateral:

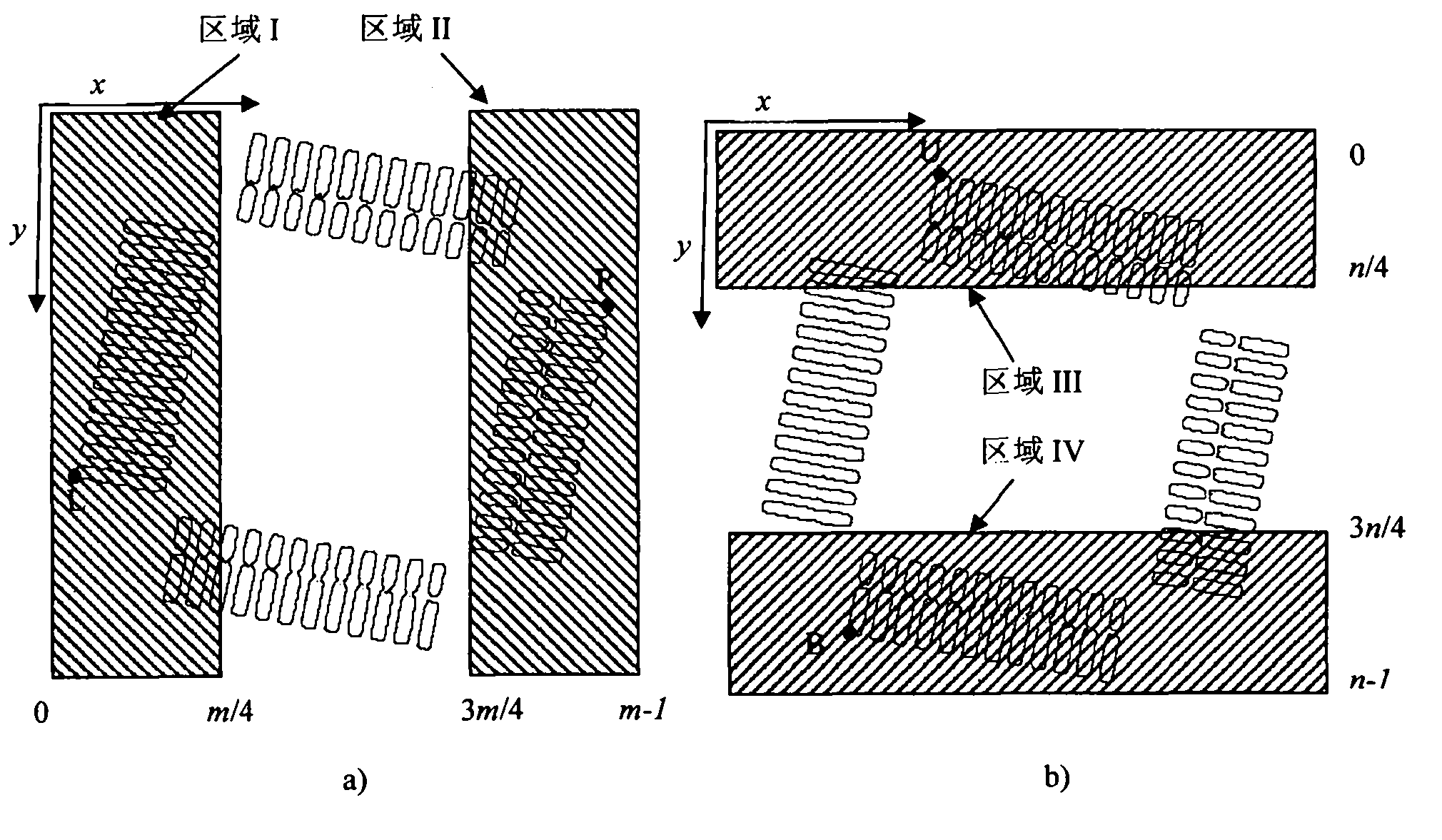

[0043] Divide the image (m×n) of the QFP chip after image preprocessing in step 1 into regions, that is, according to the x coordinate, it is divided into the left region [0, m / 4] and the right region [3m / 4, m-1 ], divided into the upper area [0, n / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com