Digital control manufacturing device for abrasive wheel

A technology for manufacturing device and grinding wheel, applied in the field of grinding wheel numerical control manufacturing device, can solve the problems of low exposure height of abrasive grains, complex production process, weak holding force, etc., achieve sufficient curing strength, high technical content, reduce grinding Effects of heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

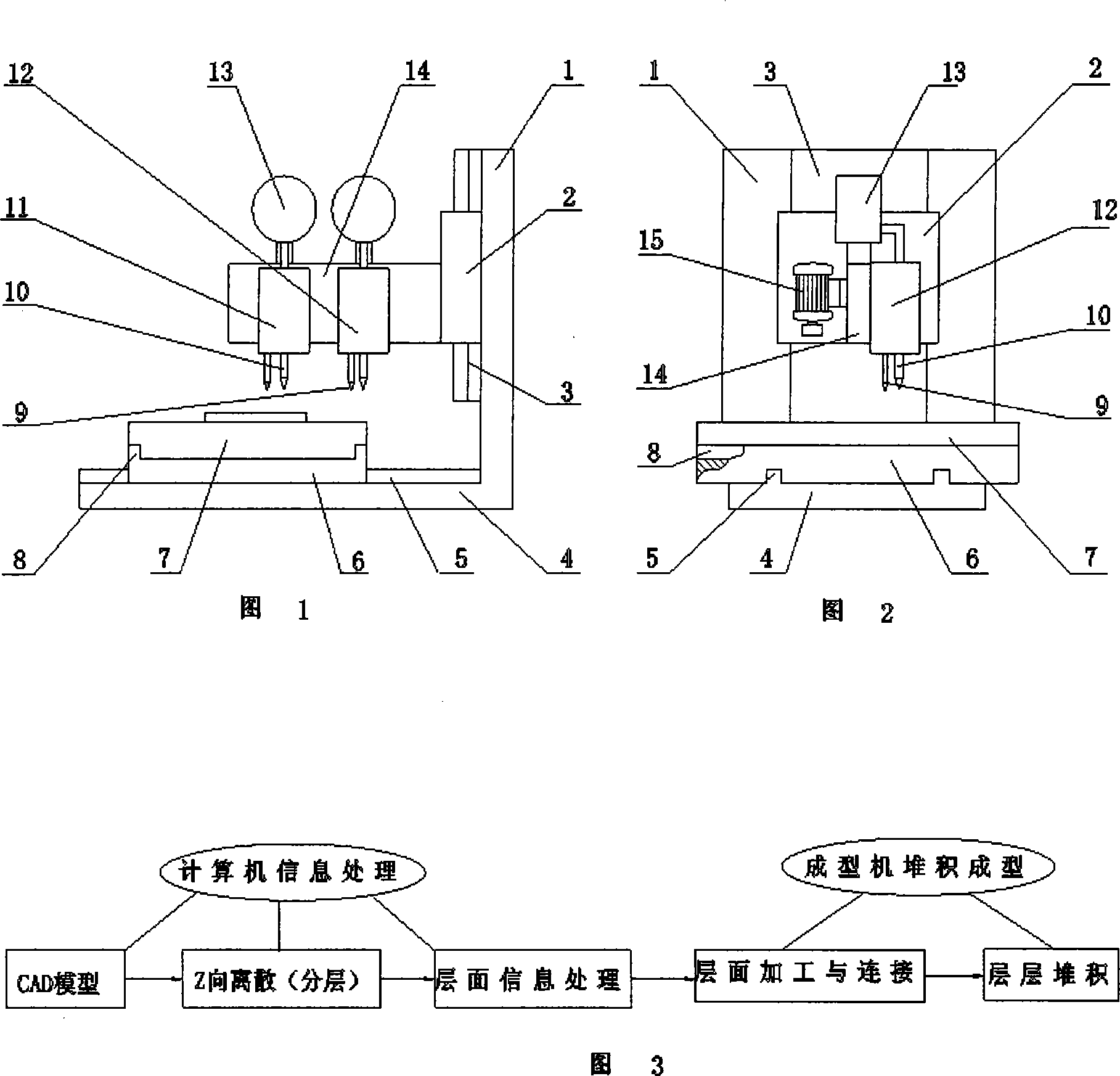

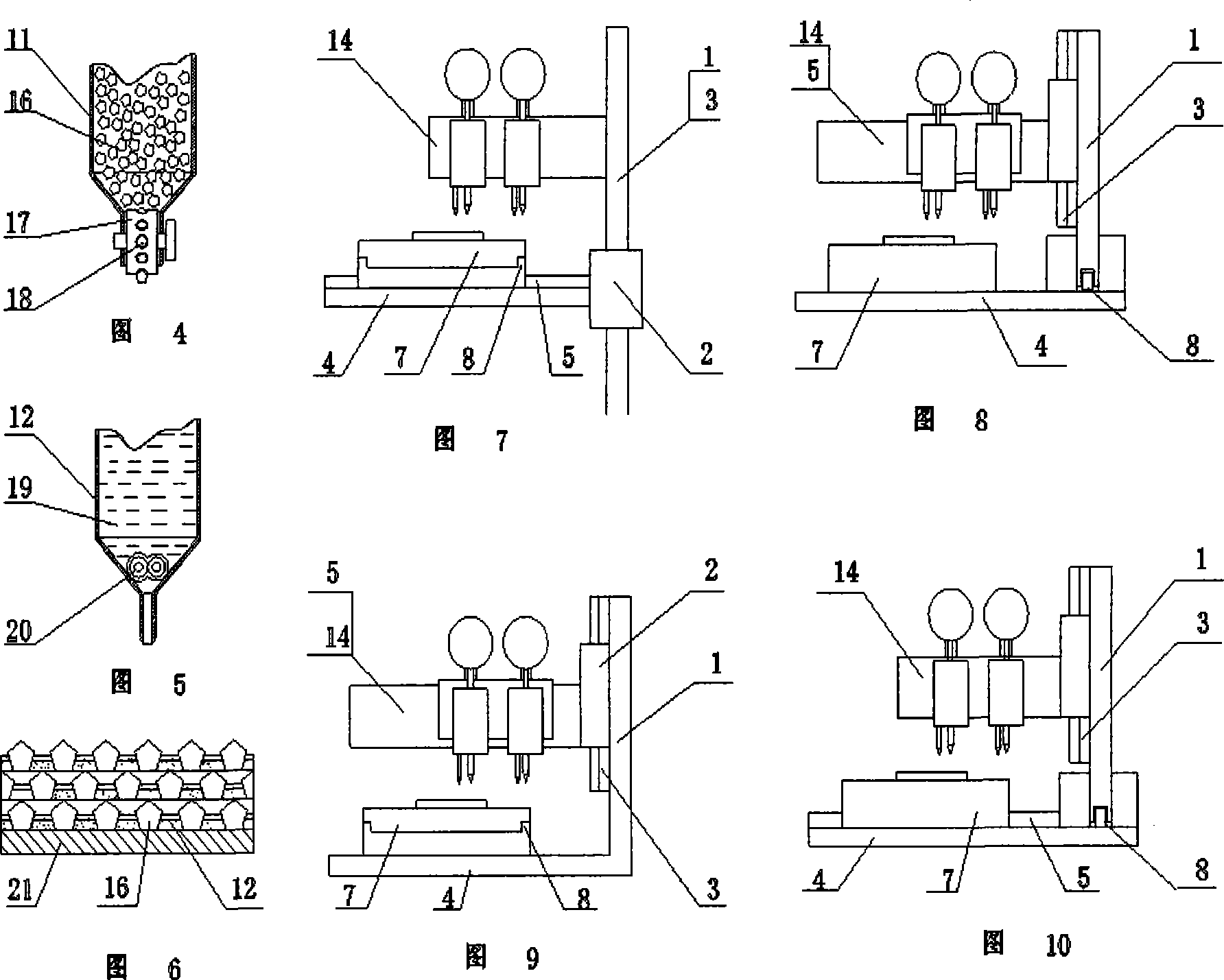

[0025] The general idea of the invention is to solve the problem of positioning and curing of abrasive grains of the grinding wheel by adopting computer numerical control technology and laser sintering technology. In order to achieve this goal, a mechanical device consisting of a platform carrying workpieces, an operating part opposite to the platform, a slideway for relative movement between the platform and the operating part, and a dragging part is used. The concrete form of this device can be various, only enumerates six kinds of embodiments below:

[0026] The first embodiment: as shown in Figures 1 and 2, the frame of this grinding wheel numerical control manufacturing device is composed of an upright vertical back 1 and a flat machine platform 4, and a vertical slideway 3 is provided in front of the vertical back 1 , the vertical slideway 3 lifts a plate-shaped assembly frame 14 through the slider 2, and the assembly frame 14 is equipped with two laser generators 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com